Stepless adjustable vibration generator of vibrating roller

A technology of exciters and road rollers, which is applied in roads, roads, road repairs, etc., can solve the problems of small amplitude selection range, and achieve the effect of less rolling times, good compaction effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

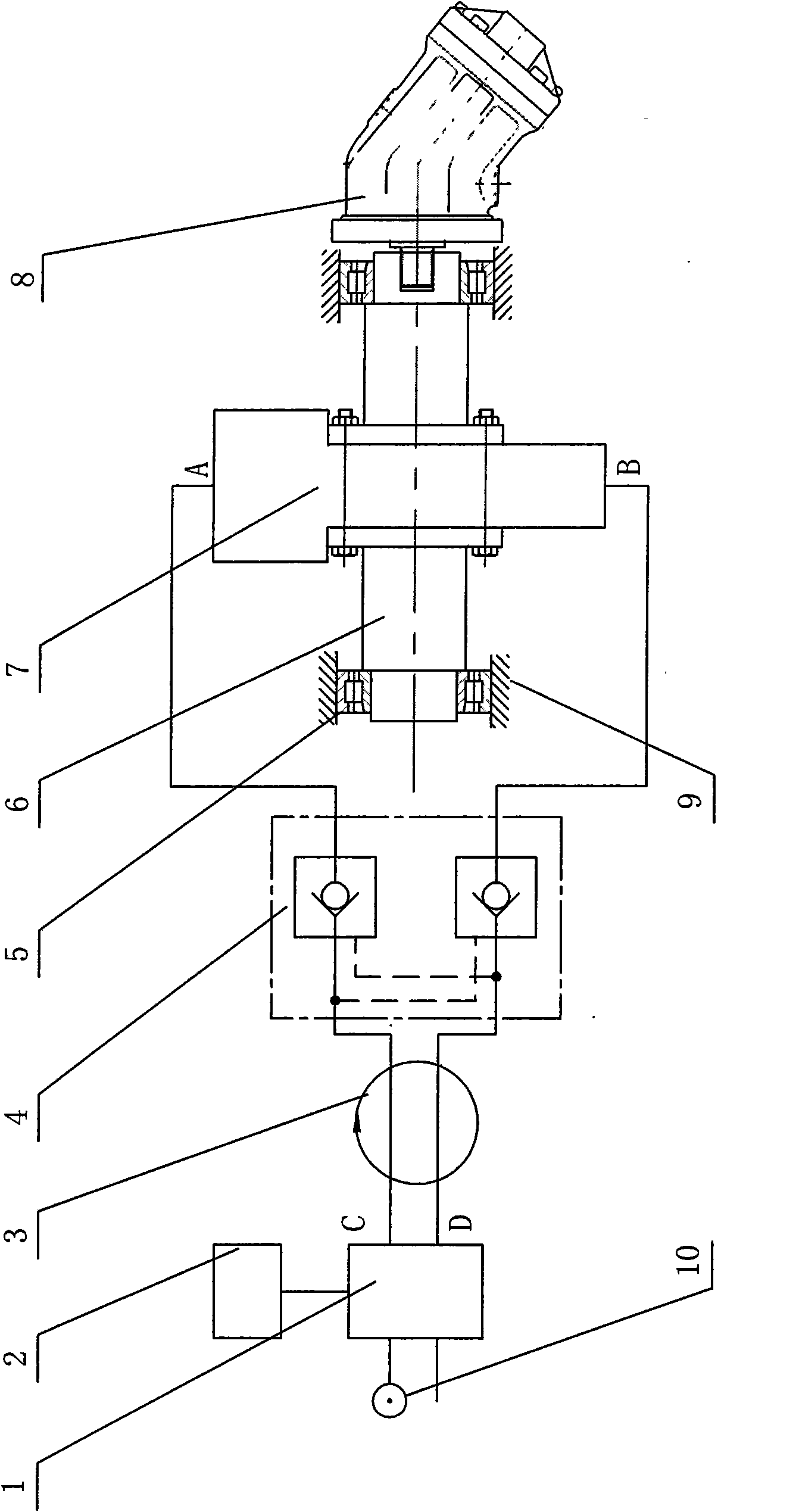

[0020] exist figure 1 , 2 Among them, the stepless adjustable exciter of the vibratory rolling roller in this embodiment is composed of a valve 1, a controller 2, a rotary joint 3, a hydraulic lock 4, a bearing 5, a rotating shaft 6, and a stepless adjustment exciter 7. .

[0021] The rotating shaft 6 is installed on the steel wheel 9 of the vibratory road roller, and a bearing 5 is installed between the rotating shaft 6 and the steel wheel 9 of the road roller, and a hydraulic motor 8 is fixedly connected to the end of the rotating shaft 6 with a coupling, and the rotating shaft 6 and Bearings 5 are installed between the hydraulic motors 8, and the hydraulic motors 8 communicate with the hydraulic pump 10 of the vibratory roller through pipelines. The rotation of the vibration exciter 7 is steplessly adjusted. The valve 1 communicates with the hydraulic pump 10 of the vibratory roller through a pipeline, and the hydraulic pump 10 of the vibratory roller provides a pressu...

Embodiment 2

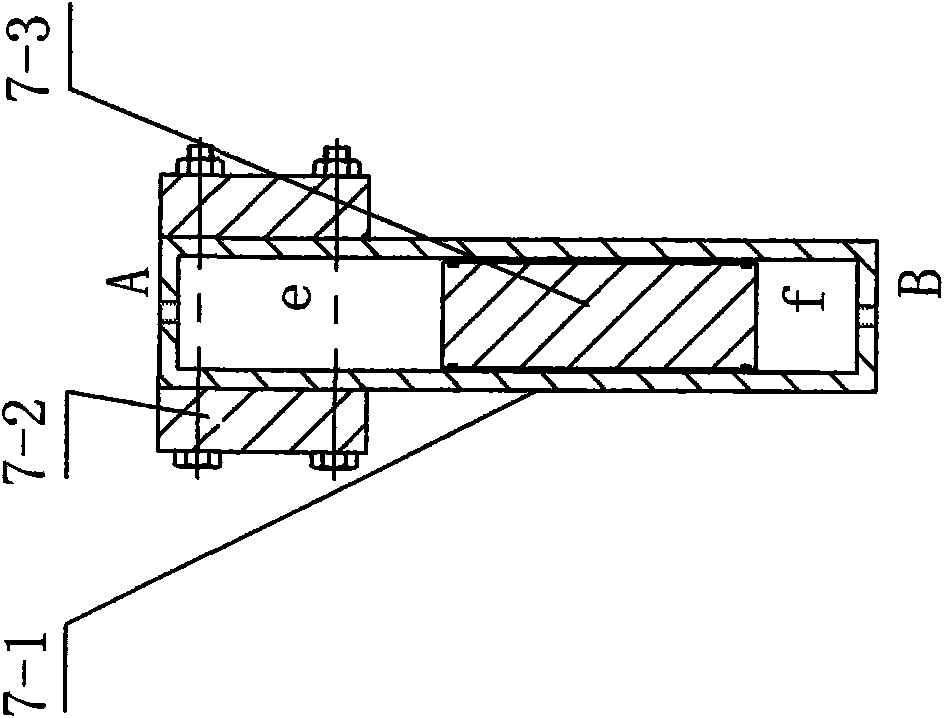

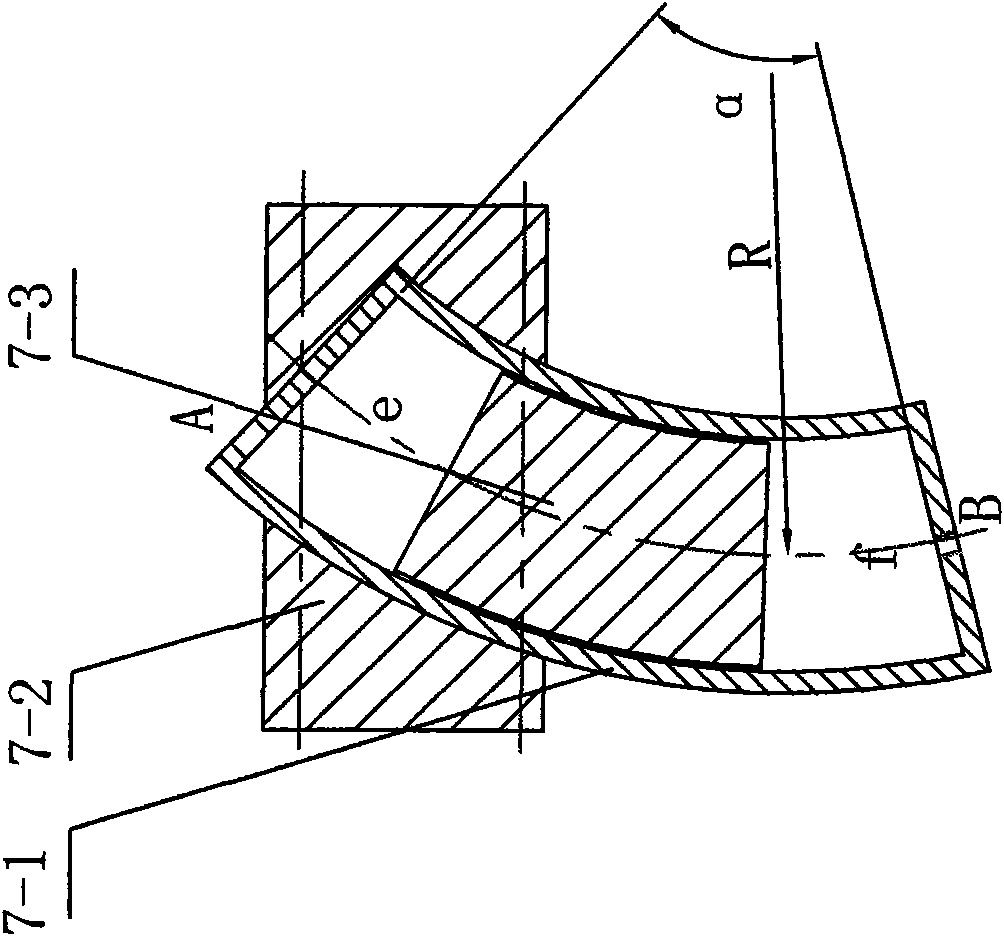

[0024] In this embodiment, the inner cavity of the exciter cylinder 7-1 of the steplessly adjustable vibrator 7 is a cylinder, and the cross section of the inner cavity of the exciter cylinder 7-1 is rectangular, and can also be a regular hexagon. , can also be circular or other shapes, a movable eccentric block 7-3 is installed in the cavity of the exciter cylinder 7-1, the shape of the movable eccentric block 7-3 is consistent with that of the cavity of the exciter cylinder 7-1 The shapes are the same, and the mass ratio of the movable eccentric block 7-3 to the fixed eccentric block 7-2 is 1:0.2. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0026] In this embodiment, the inner cavity of the exciter cylinder 7-1 of the steplessly adjustable vibrator 7 is a cylinder, and the cross section of the inner cavity of the exciter cylinder 7-1 is rectangular, and can also be a regular hexagon. , can also be circular or other shapes, a movable eccentric block 7-3 is installed in the cavity of the exciter cylinder 7-1, the shape of the movable eccentric block 7-3 is consistent with that of the cavity of the exciter cylinder 7-1 The shapes are the same, and the mass ratio of the movable eccentric block 7-3 to the fixed eccentric block 7-2 is 1:8. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com