Patents

Literature

577results about How to "Improve the compaction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

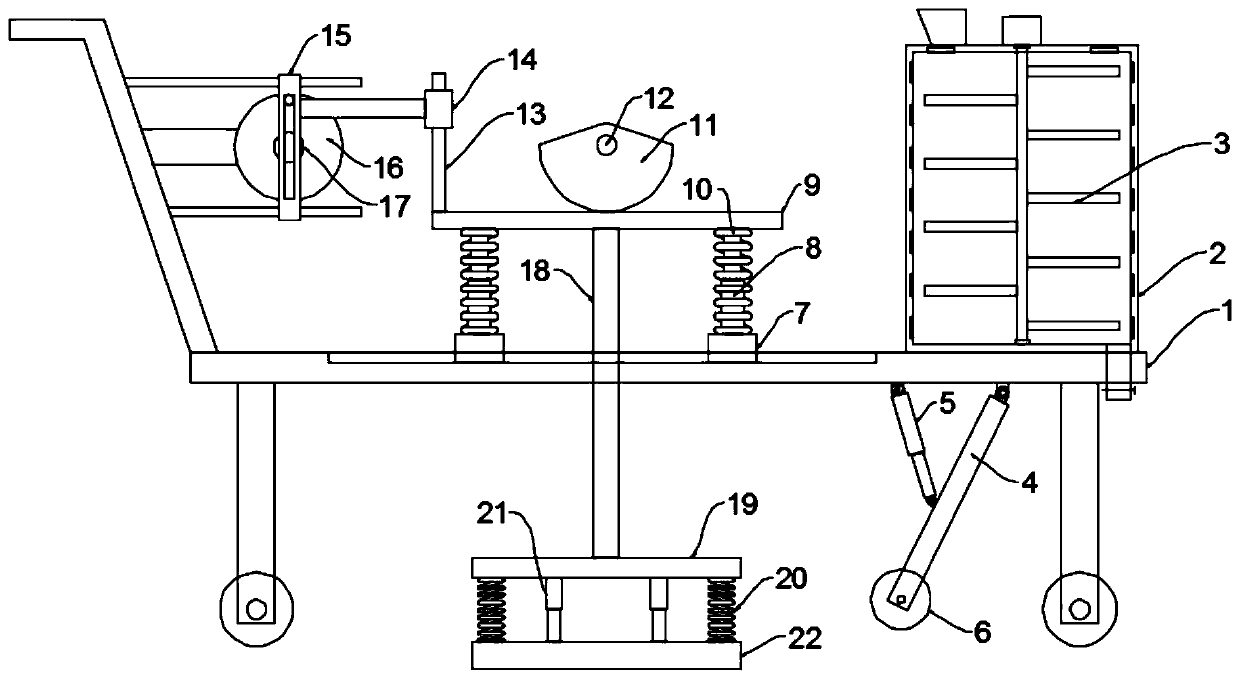

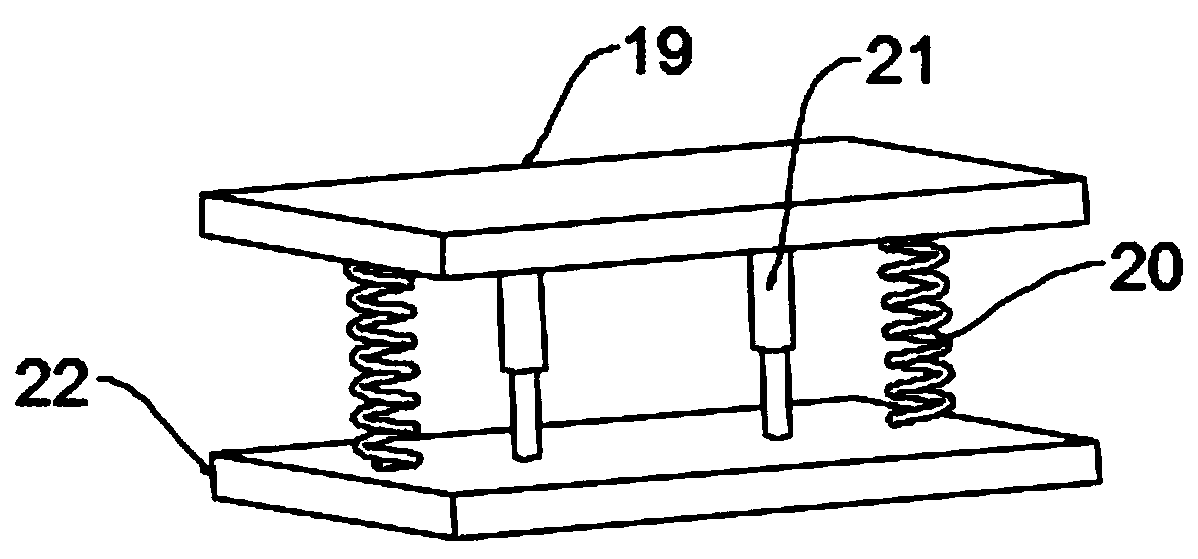

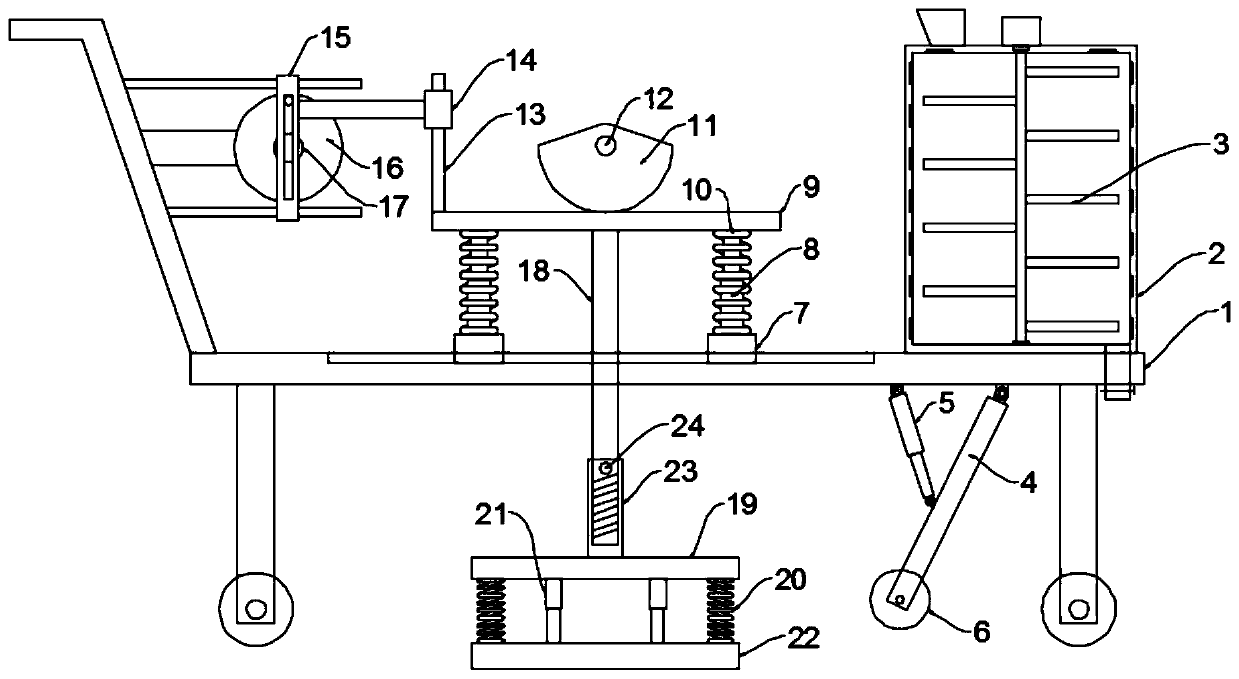

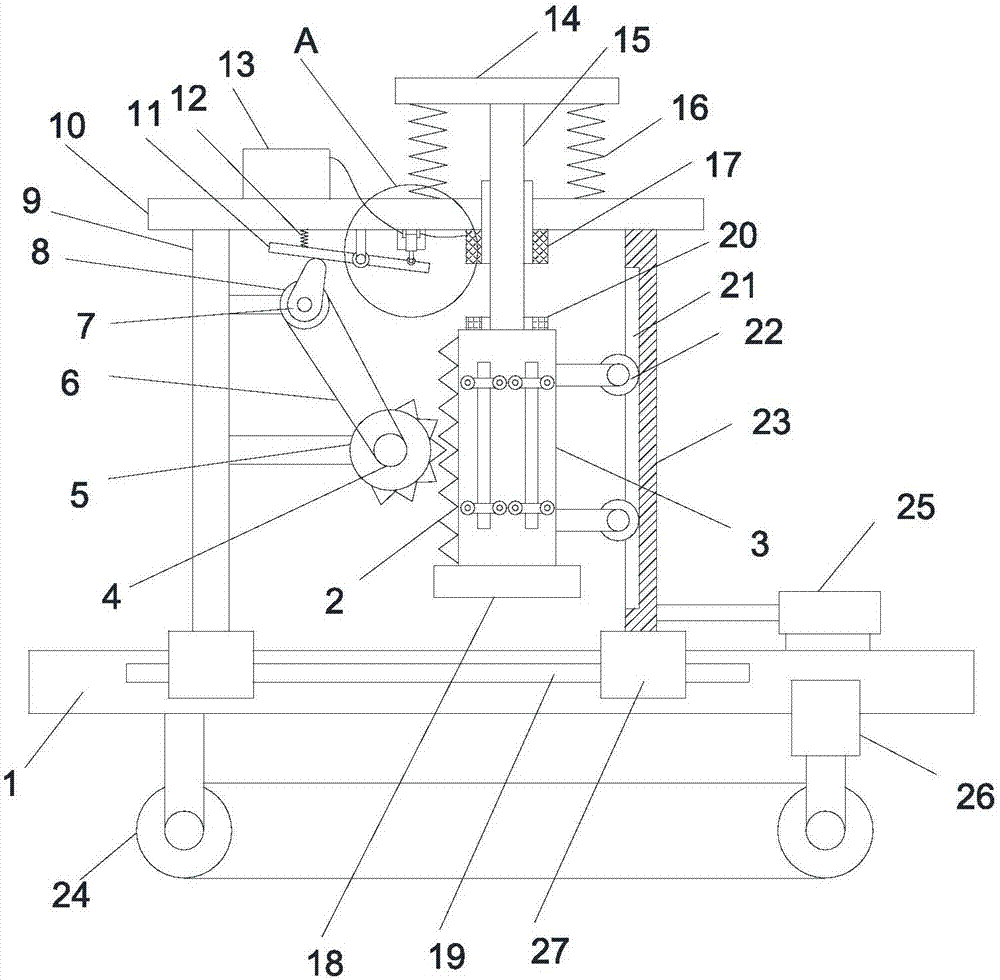

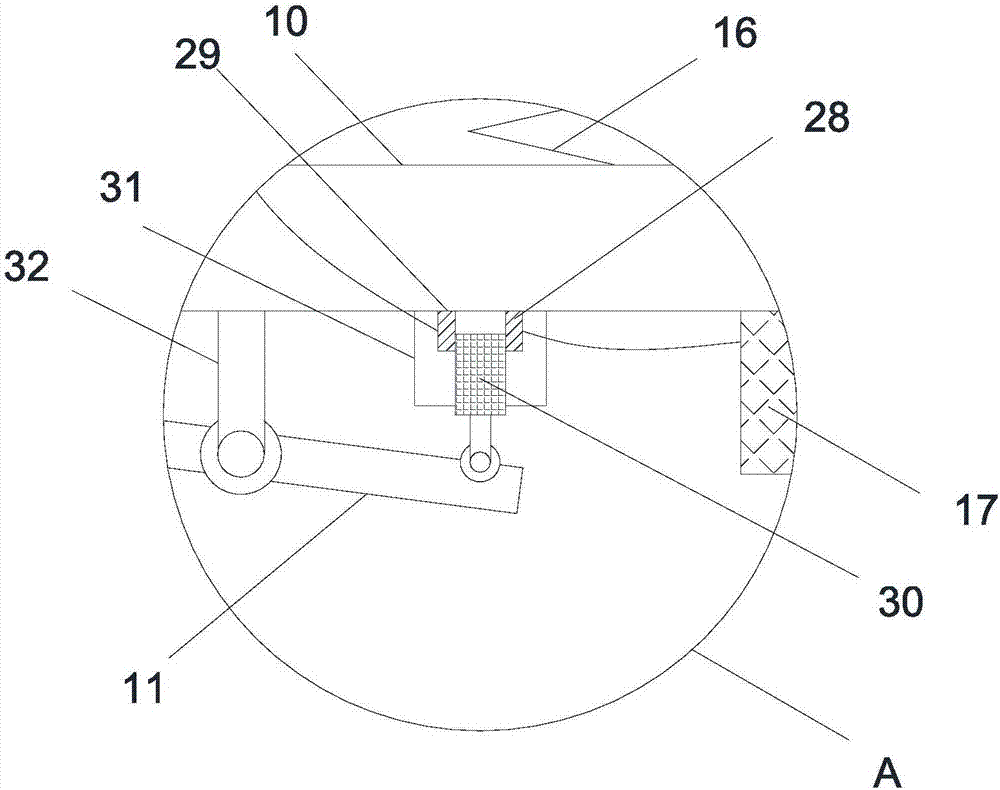

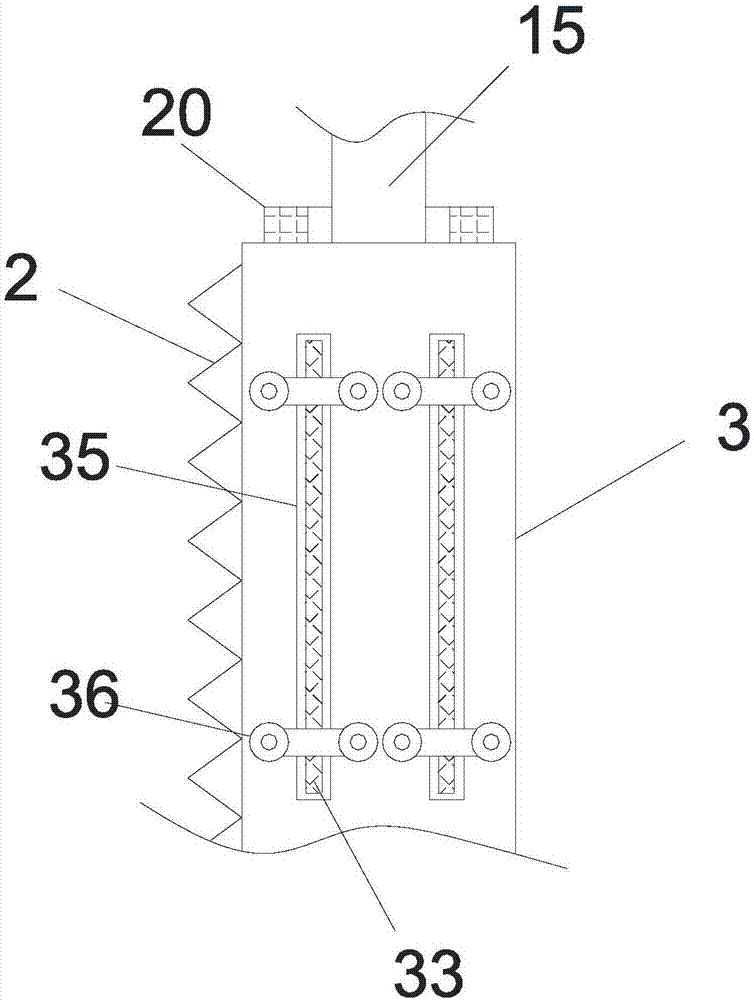

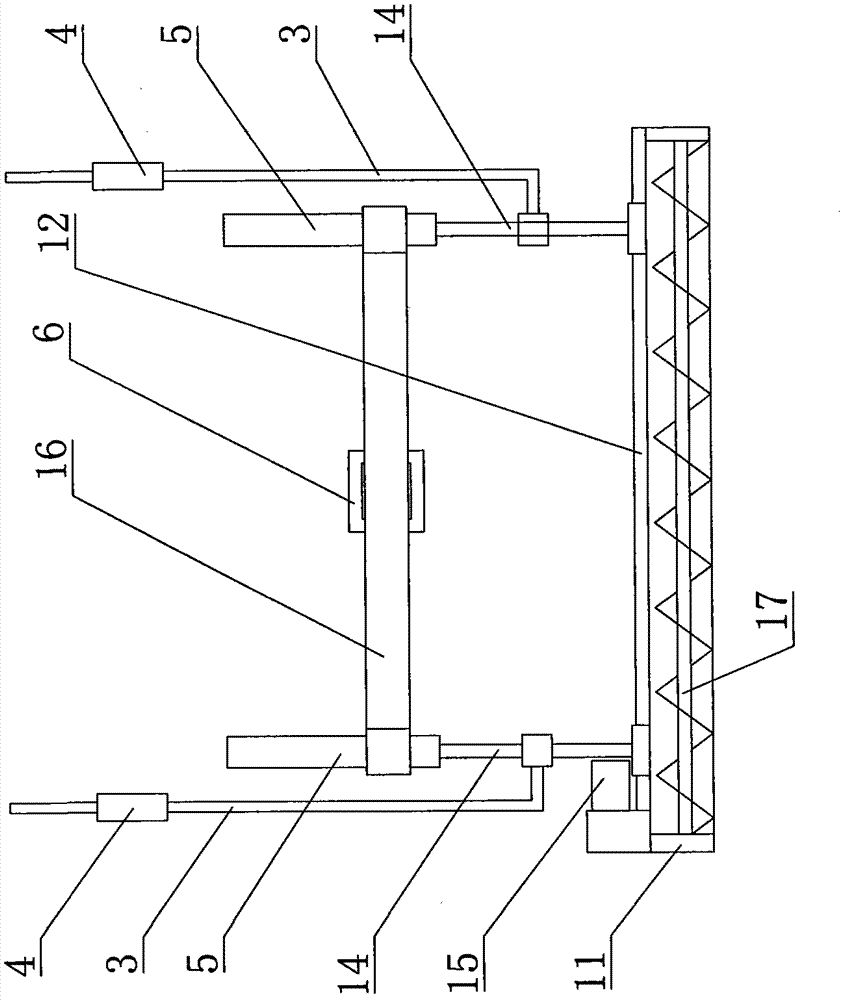

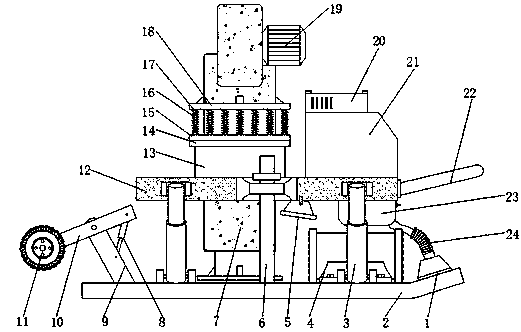

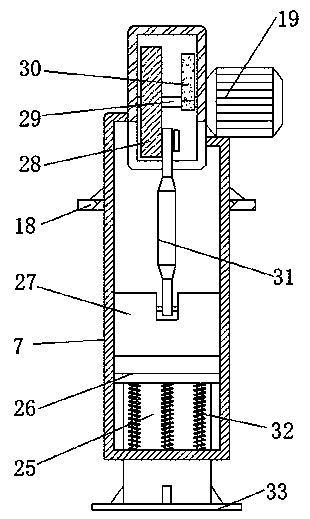

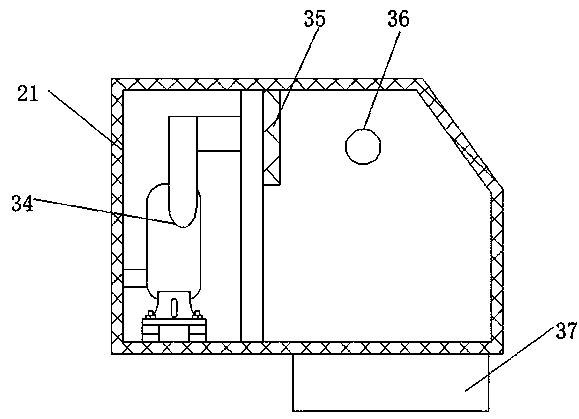

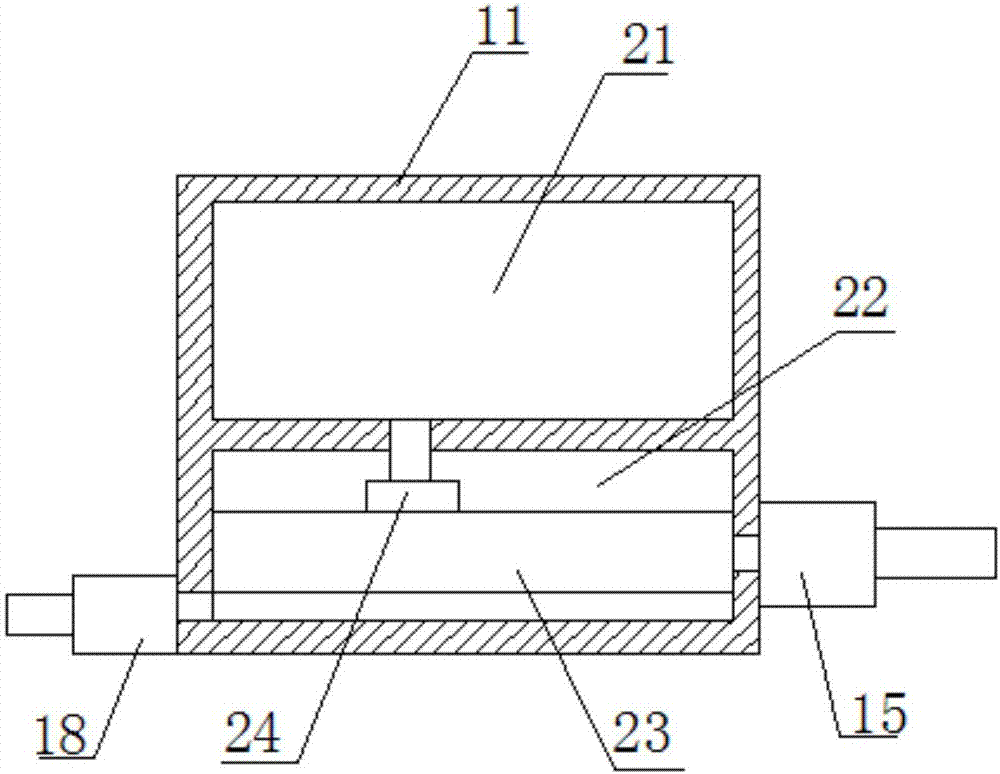

Road asphalt paving and compacting device

PendingCN111236004AAdjustable distanceAdjust leveling thicknessRoads maintainenceReciprocating motionArchitectural engineering

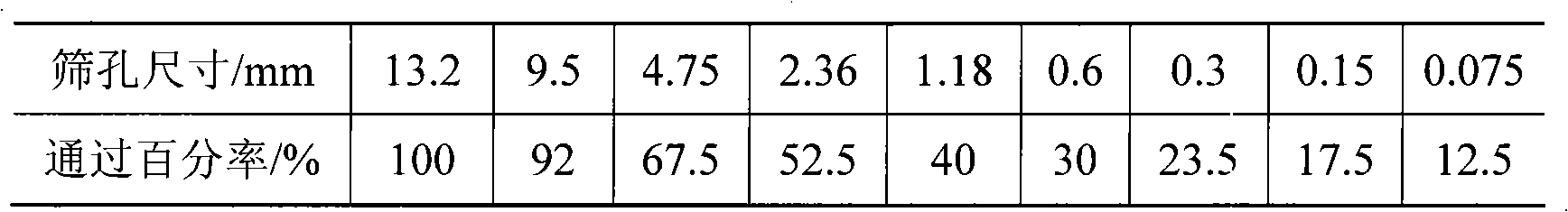

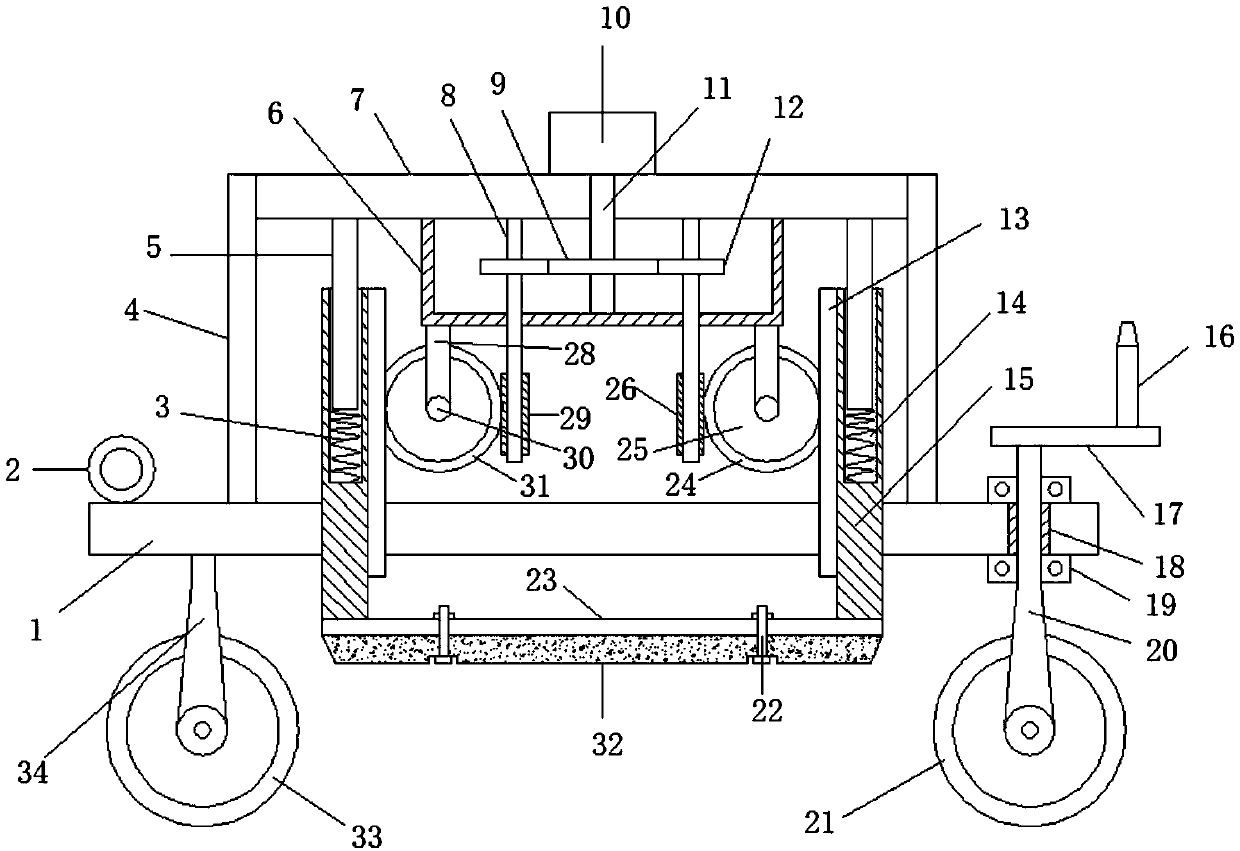

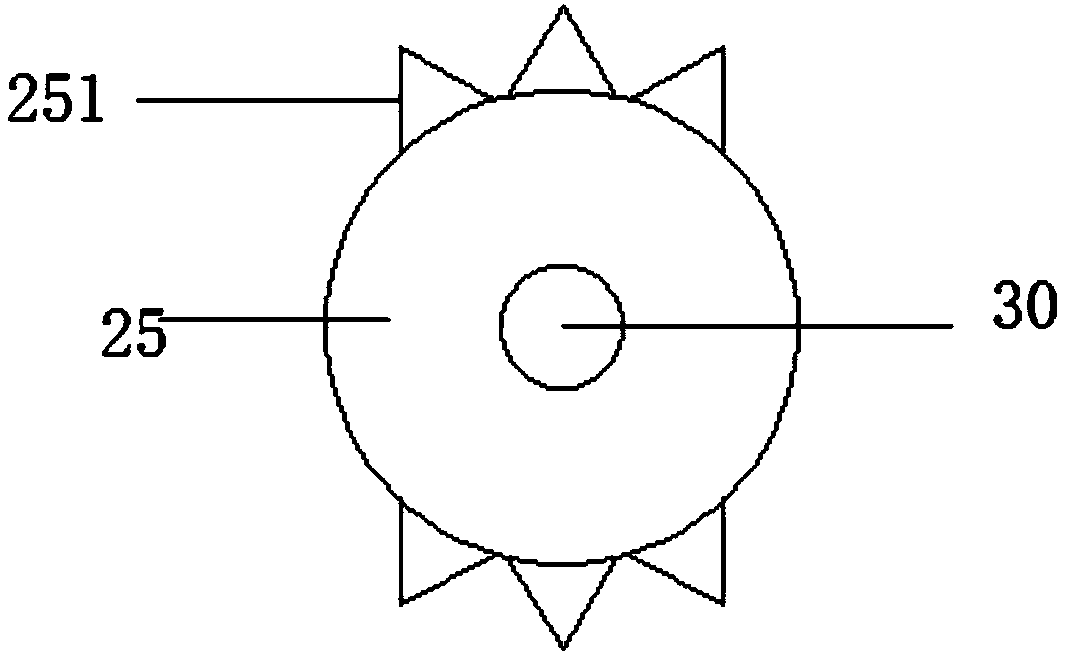

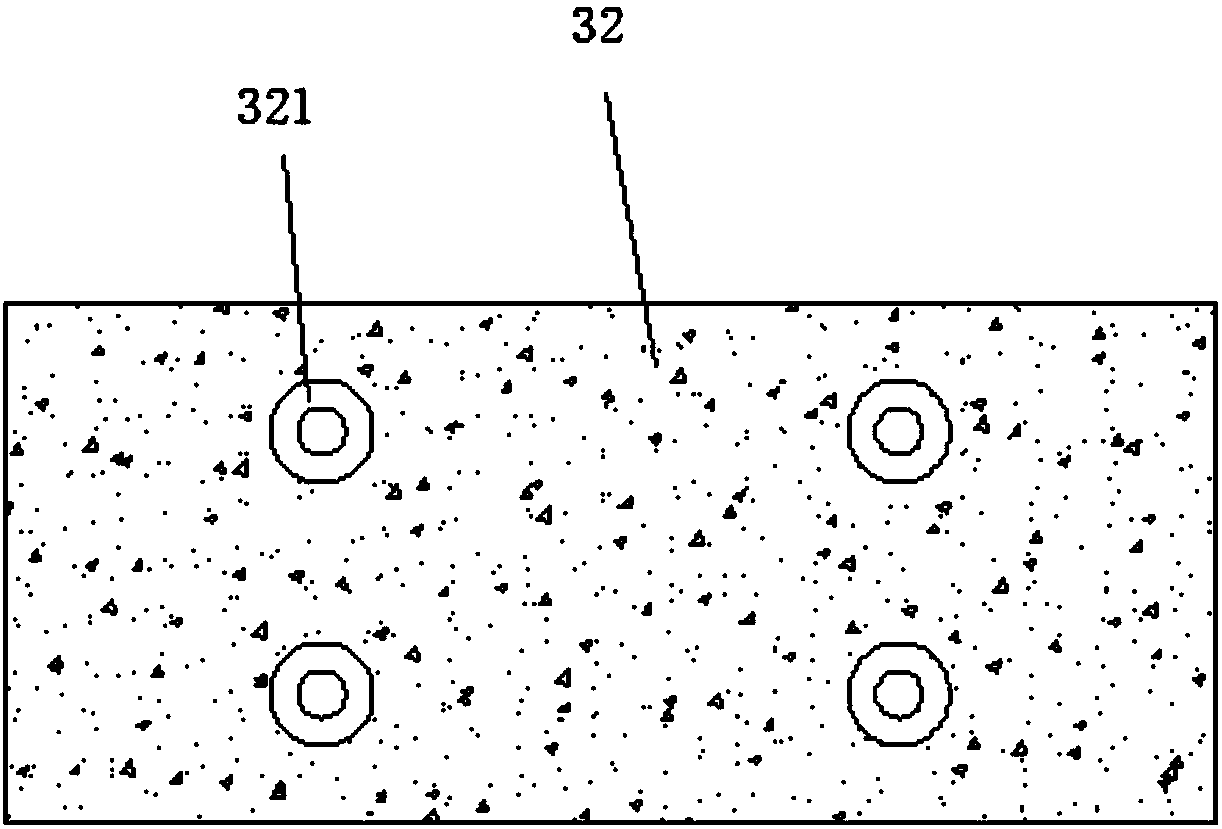

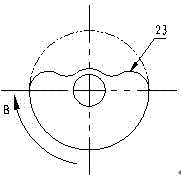

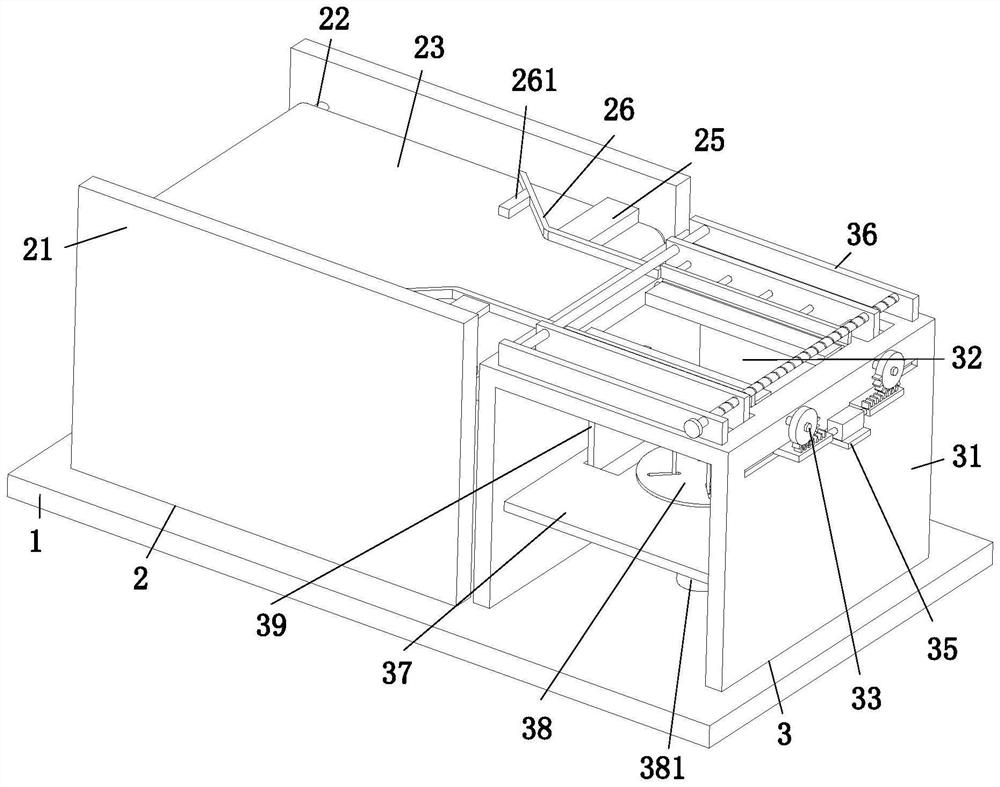

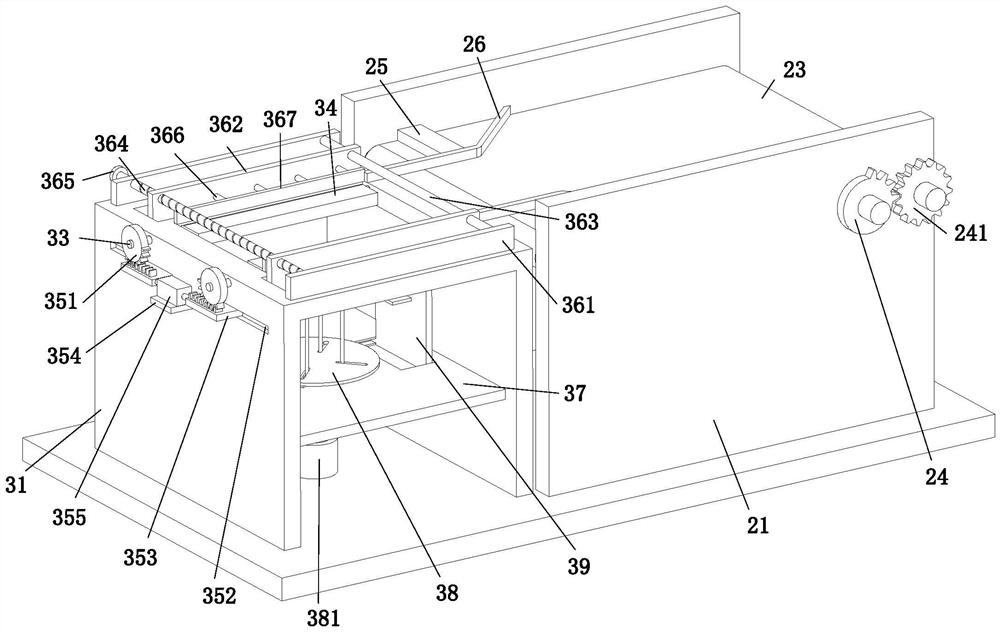

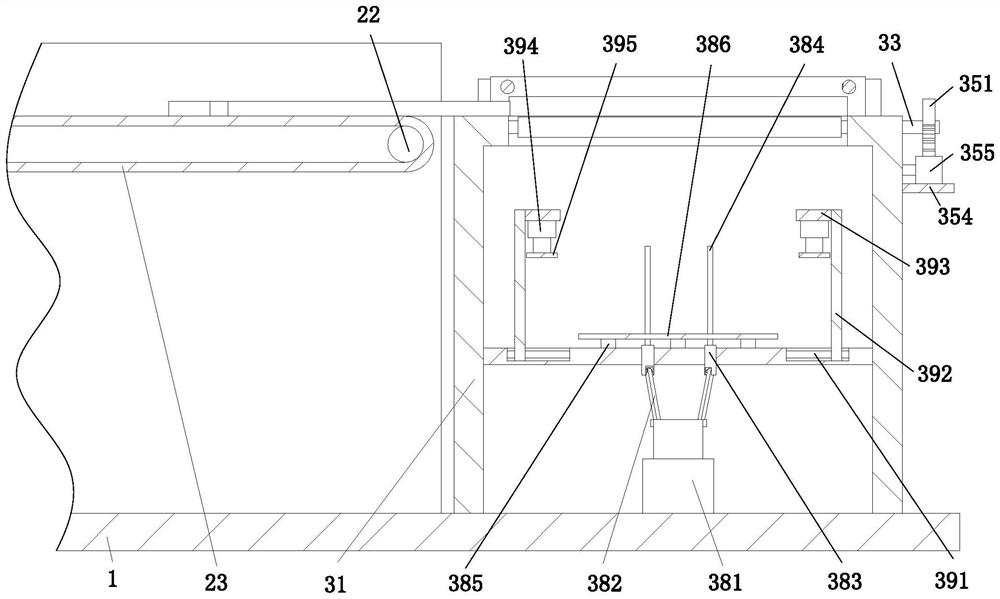

The invention discloses a road asphalt paving and compacting device. The device comprises a cart and a laying unit, the laying unit is installed on the cart. The laying unit comprises a heating box used for heating asphalt and a leveling roller used for leveling the asphalt. The road asphalt paving and compacting device further comprises a compacting unit, the compaction unit comprises a pressingplate and a driving assembly used for driving the pressing plate to move. The driving assembly comprises a fan-shaped cam, a driving plate, a driving mechanism used for driving the driving plate to reciprocate left and right, a first telescopic rod, a first spring, a mounting base, a connecting rod and a connecting plate. According to the device, the laying unit is arranged, and the electric pushrod extends or contracts, so that the leveling roller can be driven to rotate through the mounting rod, the distance between the leveling roller and the ground is adjusted, and the effect of adjustingthe leveling thickness is achieved; and the compaction unit is arranged, the pressing plate reciprocates left and right while keeping pressure on asphalt, the compaction area is increased, the compaction effect is better, and the working efficiency is improved.

Owner:陈嘉宇

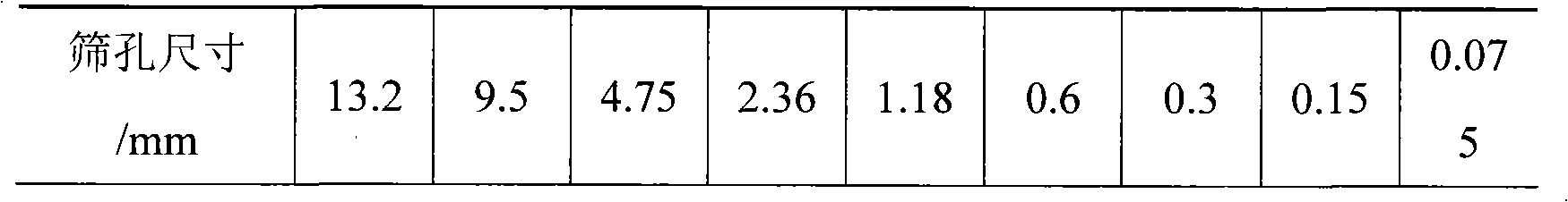

Asphalt mixture for rapid repair of hot-mix-cold-laid pavement

InactiveCN101353481AHigh porosityImprove the compaction effectIn situ pavingsBuilding insulationsDiluentMaterials science

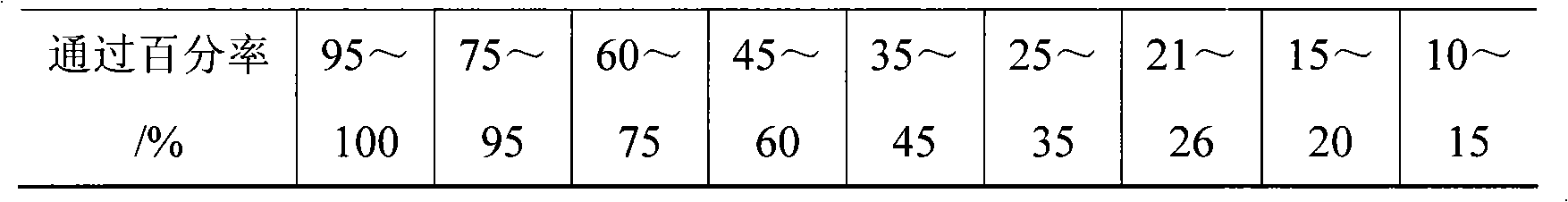

The invention relates to a road restoration asphalt mixture, and discloses a hot-mixing cold-paving road restoration asphalt mixture which comprises modified asphalt, additives and aggregates, wherein, the additives include a diluent, petroleum resin and an anti-stripping agent, the aggregates include coarse aggregate, fine aggregate and mineral powder. While preparing liquid asphalt, using the weight of the modified asphalt as reference, the weight proportion of the diluent is 14 percent to 22 percent, the weight proportion of the petroleum resin is 1.8 to 2.2 percent and the weight proportion of the anti-stripping agent is 0.4 to 0.6 percent. The asphalt mixture of the invention has strong comprehensiveness, performs excellently in poriness, compactibility, initial strength, workability, the strength of formed mixture, anti-water damage property and storage property, can be mixed easily and operated conveniently and is suitable for practical application and generalization.

Owner:TONGJI UNIV

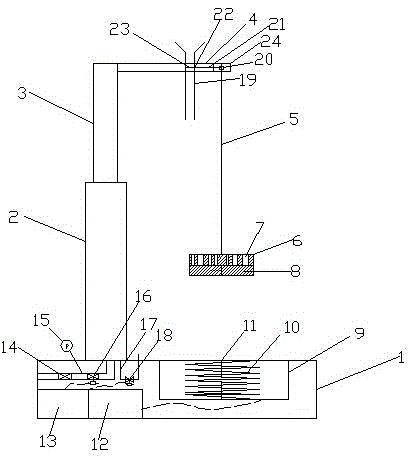

Asphalt paving device for building construction

The invention discloses an asphalt paving device for building construction, including a fixed bottom plate, wherein a control box is fixed on the top outer wall of the fixed bottom plate through bolts, and a processor is fixed on one side inner wall of the control box by bolts, four first hydraulic cylinders are fixed on the top outer wall of the fixed bottom plate by bolts, and a mounting plate is fixed on the top of the first hydraulic cylinder by bolts, and a heat dissipation hole is arranged on the top of the mounting plate. The invention can stir and scrape the raw materials in the material box body to scrape the inner wall of the animal material box body, preventing the raw material from agglomerating and adhering to the inner wall of the material box body, The height of the mountingplate can be adjusted according to different requirements, so as to adjust the height of the tripod and the rake teeth, better spread the asphalt, collect excess asphalt for reuse, avoid waste, placeheavy blocks of different weights according to different requirements, compact the asphalt, and improve the paving effect.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

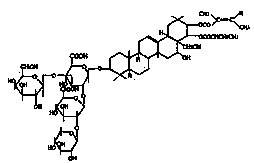

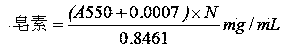

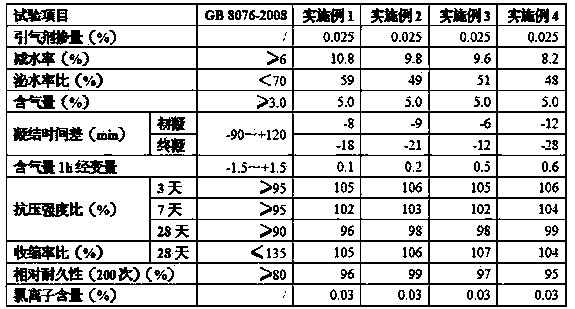

Sasanqua saponin concrete air entraining agent and preparation method thereof

The invention provides a sasanqua saponin concrete air entraining agent and a preparation method thereof. The air entraining agent is characterized by containing sasanqua saponin therein. The preparation method is characterized by extracting sasanqua as a raw material at normal temperature by hydrophilic solvent water solution, and filtering; removing large-molecule impurities from the filtrate by membrane separation under pressure, removing small-molecule impurities by membrane separation, concentrating to be concentrate with Baume degree of not lower than 10Be (60 DEG C), and spray-drying to form solid formulation; or adding a modifying agent to prepare the air entraining agent in liquid formulation. The idea is novel, the raw materials are abundant, the production efficiency is high, the energy consumption in the production is low, the production cost is low, the preparation method is simple in process, green and environment-friendly and is convenient to implement; when the air entraining agent is used in concrete engineering, the dosage of the air entraining agent is low, the air production rate is high, the aperture of the entrained air bubbles is small and the distance among the entrained air bubbles is small, and the air holes of the concrete are more even, more compact and non-communicated, therefore, the sasanqua saponin concrete air entraining agent is valuable for popularizing.

Owner:FUZHOU UNIV

Composite material, high-frequency circuit baseboard made therefrom and production method thereof

ActiveUS20140057094A1Excellent dielectric propertiesLow dielectric constantPorous dielectricsPlastic/resin/waxes insulatorsEmulsionDielectric loss

Disclosed is a composite material, a high-frequency circuit baseboard made therefrom and a production method thereof. The composite material comprises: a dispersed emulsion of fluoropolymer with a low dielectric loss; a porous, expanded polytetrafluoroethylene film;and a powdery packing. The high-frequency circuit baseboard made from the composite material comprises: several laminated sheets of prepreg made from the composite material, and copper foils pressed over the two sides thereof. The baseboard uses a porous ePTFE film with an excellent dielectric property as a carrier material, which can lower the dielectric constant and dielectric loss angle tangent of the composite material and high-frequency circuit baseboard; due to good flatness and uniformity of the porous ePTFE film, the dielectric constant of the high-frequency circuit baseboard and prepreg made by using the film as the carrier material is isotropic in both X and Y directions; and the thickness of the prepreg made from the composite material can be regulated by employing porous ePTFE films with a different thickness, which avoids the cracking problem caused by using a thick film produced by casting.

Owner:GUANGDONG SHENGYI SCI TECH

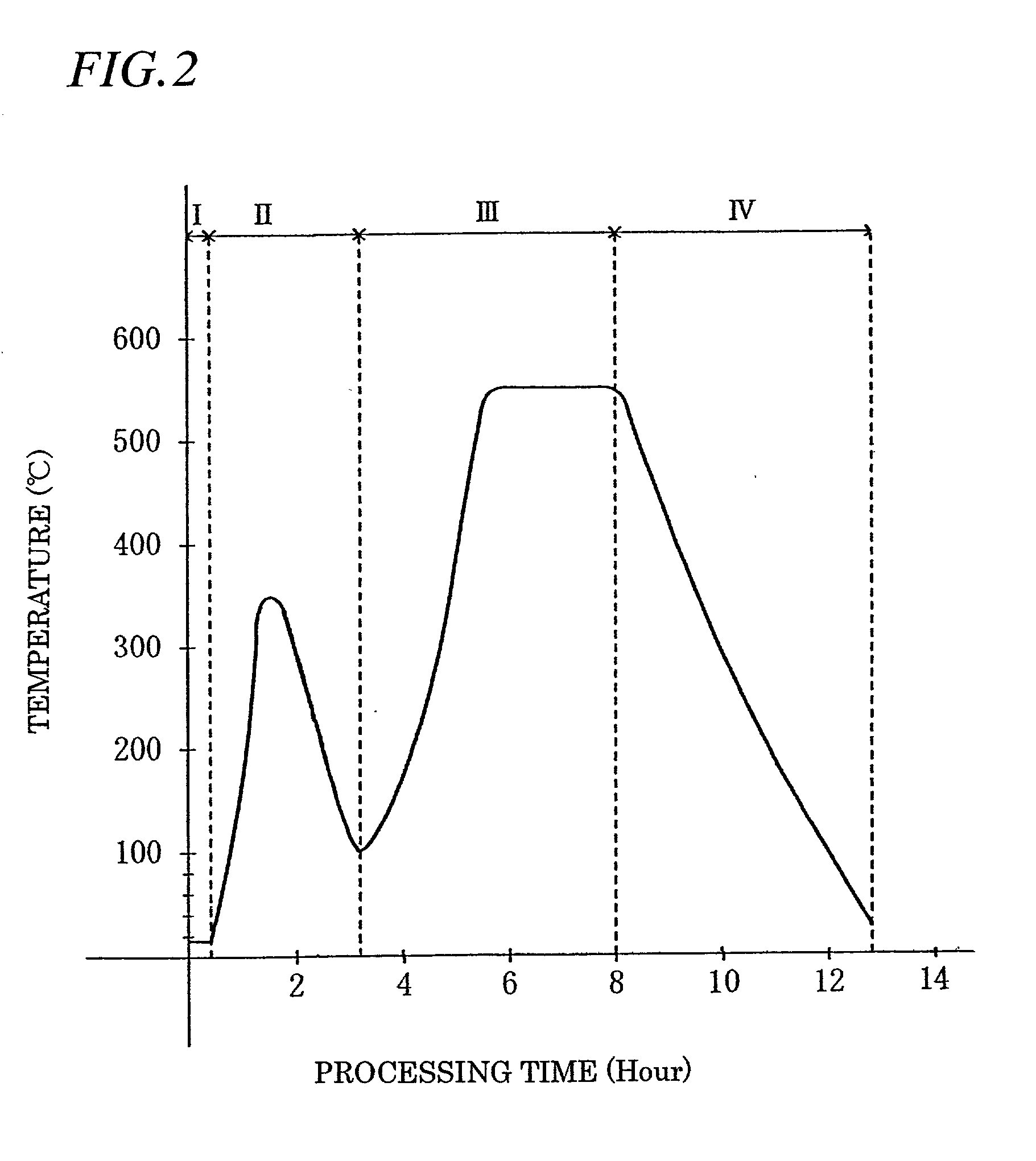

Rare earth magnet and method for producing the magnet

InactiveUS20020129874A1Improve the compaction effectReduce volume fractionTransportation and packagingMetal-working apparatusRare-earth magnetVolume fraction

Owner:HITACHI METALS LTD

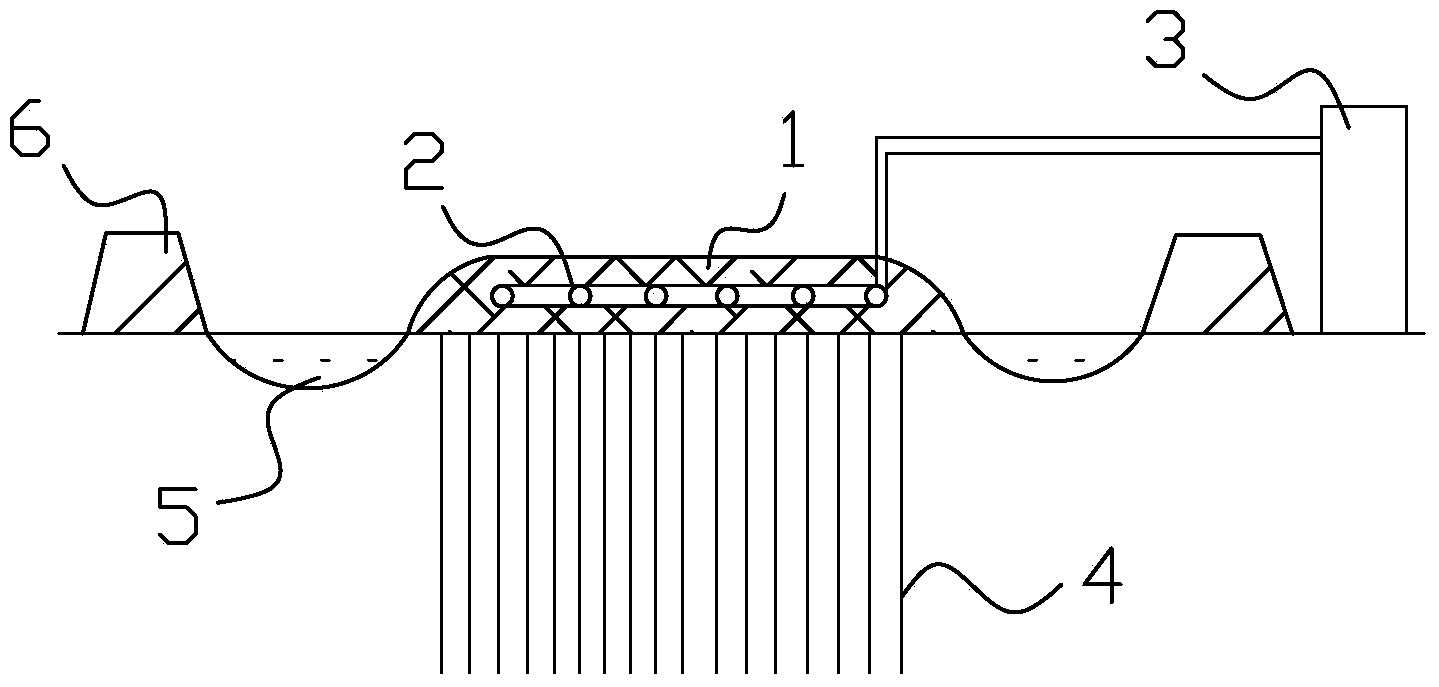

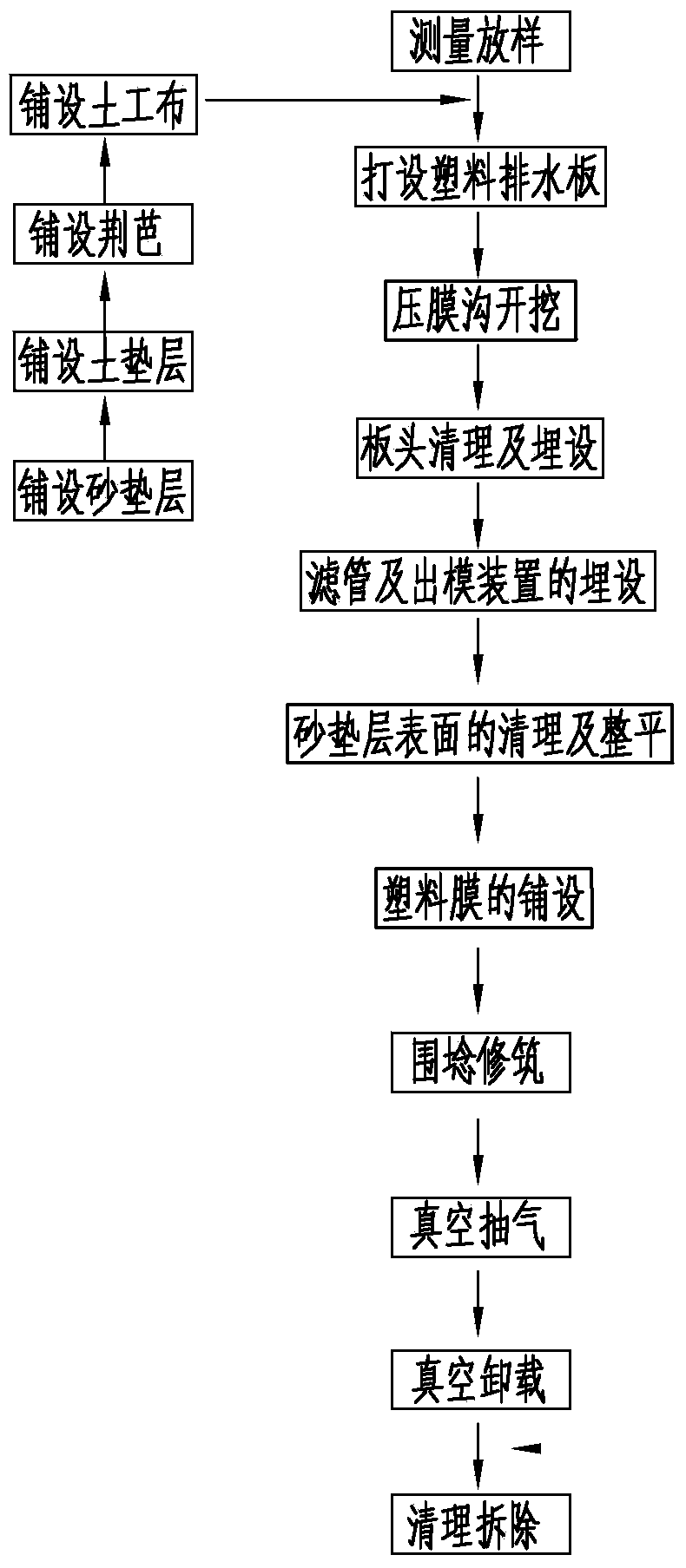

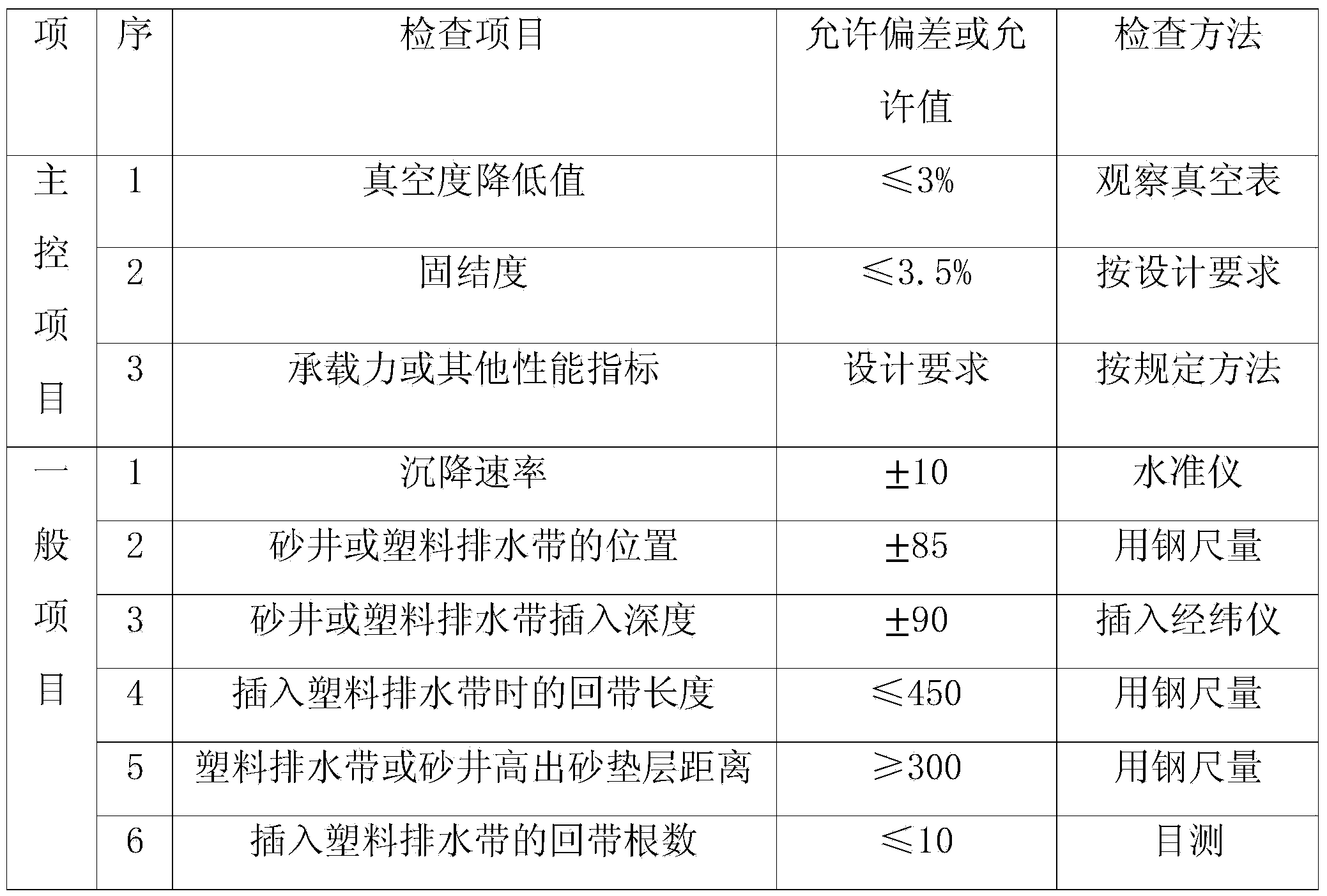

Vacuum preloading foundation treatment construction method

ActiveCN103643672AIncrease stiffnessImprove stabilitySoil preservationVacuum pumpingArchitectural engineering

The invention discloses a vacuum preloading foundation treatment construction method. The method includes the first step of conducting survey staking out, the second step of laying geotechnical cloth, the third step of laying vitex fences, the fourth steps of laying a soil cushion layer, the fifth step of laying a sand cushion layer, the sixth step of arranging a plastic drain plate in a striking mode, the seventh step of excavating a pressed film ditch, the eighth step of cleaning and embedding a plate head, the ninth step of embedding filter tubes and a film outlet device, the tenth step of cleaning and leveling the surface of the sand cushion layer, the eleventh step of laying a plastic film, the twelfth step of constructing a dam, the thirteenth step of vacuum air exhaust, the fourteenth step of vacuum unloading, and the fifteenth step of conducting cleaning and disassembly. According to the method, the strength and the rigidity of a foundation are improved, the reinforcing speed is high, the densification effect is good, the strength increase rate is high, the density of the foundation is improved, the foundation is made to be more stable, and the settling volume of the foundation is reduced. Vacuum is generated through air exhaust, the pore water pressure is effectively reduced, negative excess pore water pressure is generated to increase the effective stress of a soil body, reinforcing is conducted through the pore water pressure so that sphere effective stress increment can be generated, and the construction speed is effectively increased.

Owner:ZHEJIANG JIANGNANCHUN CONSTR GRP

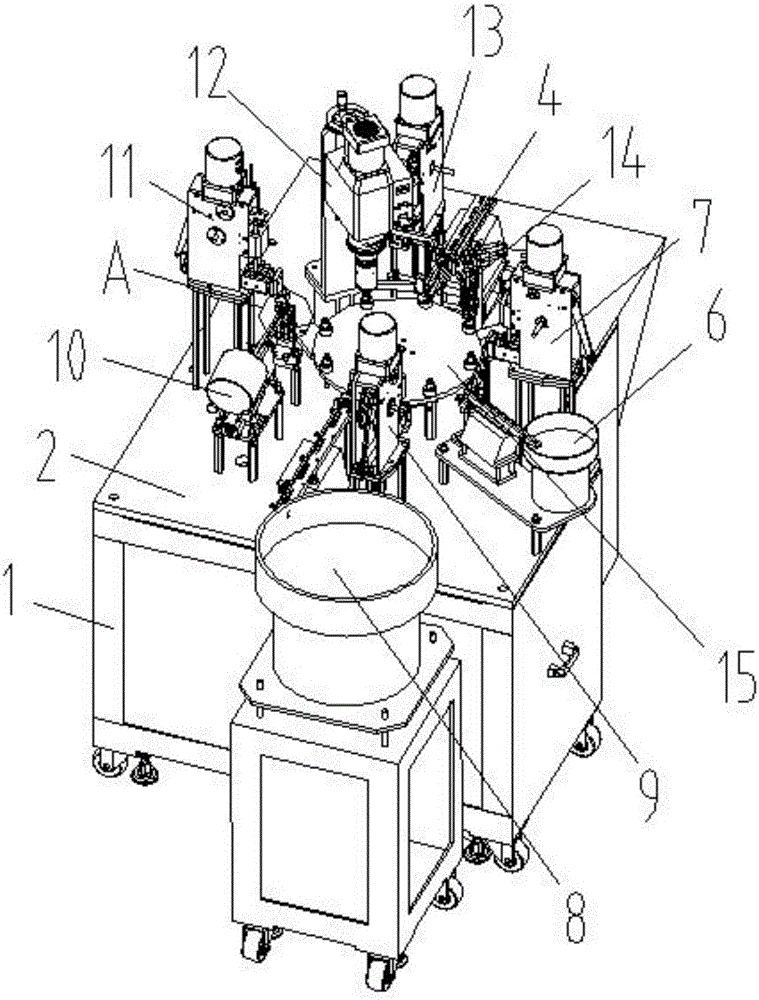

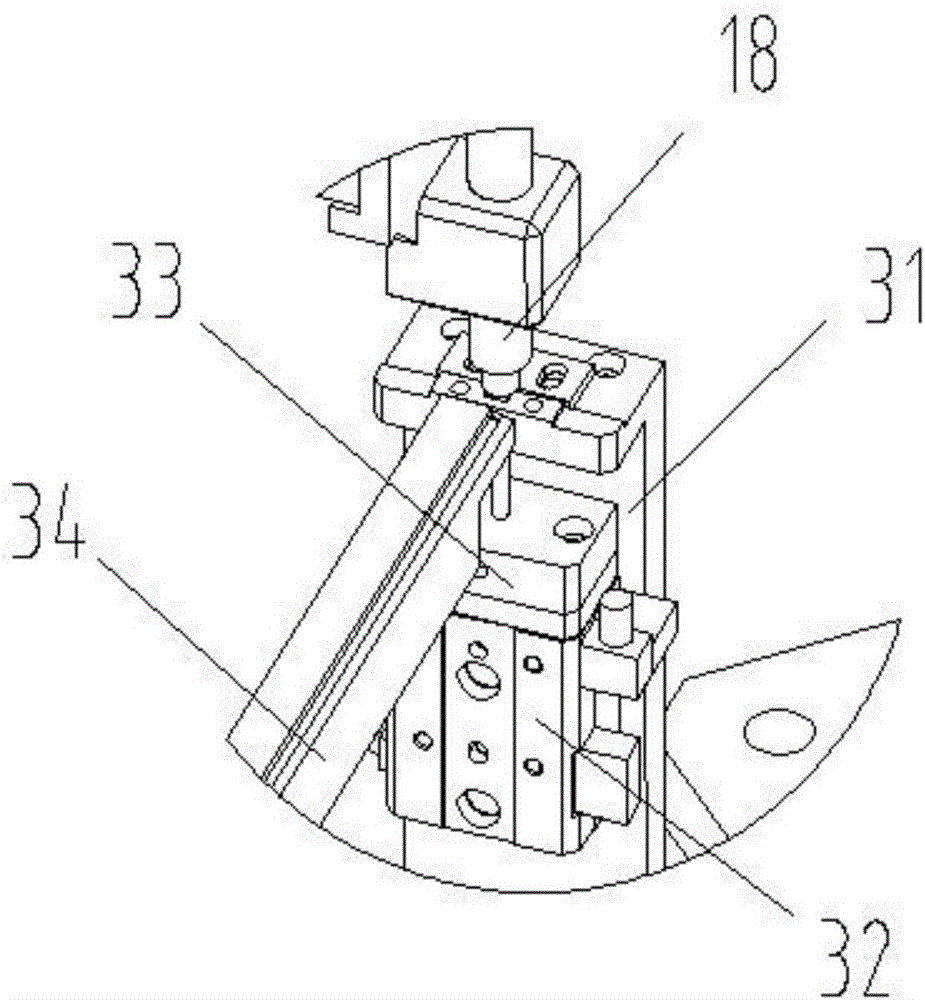

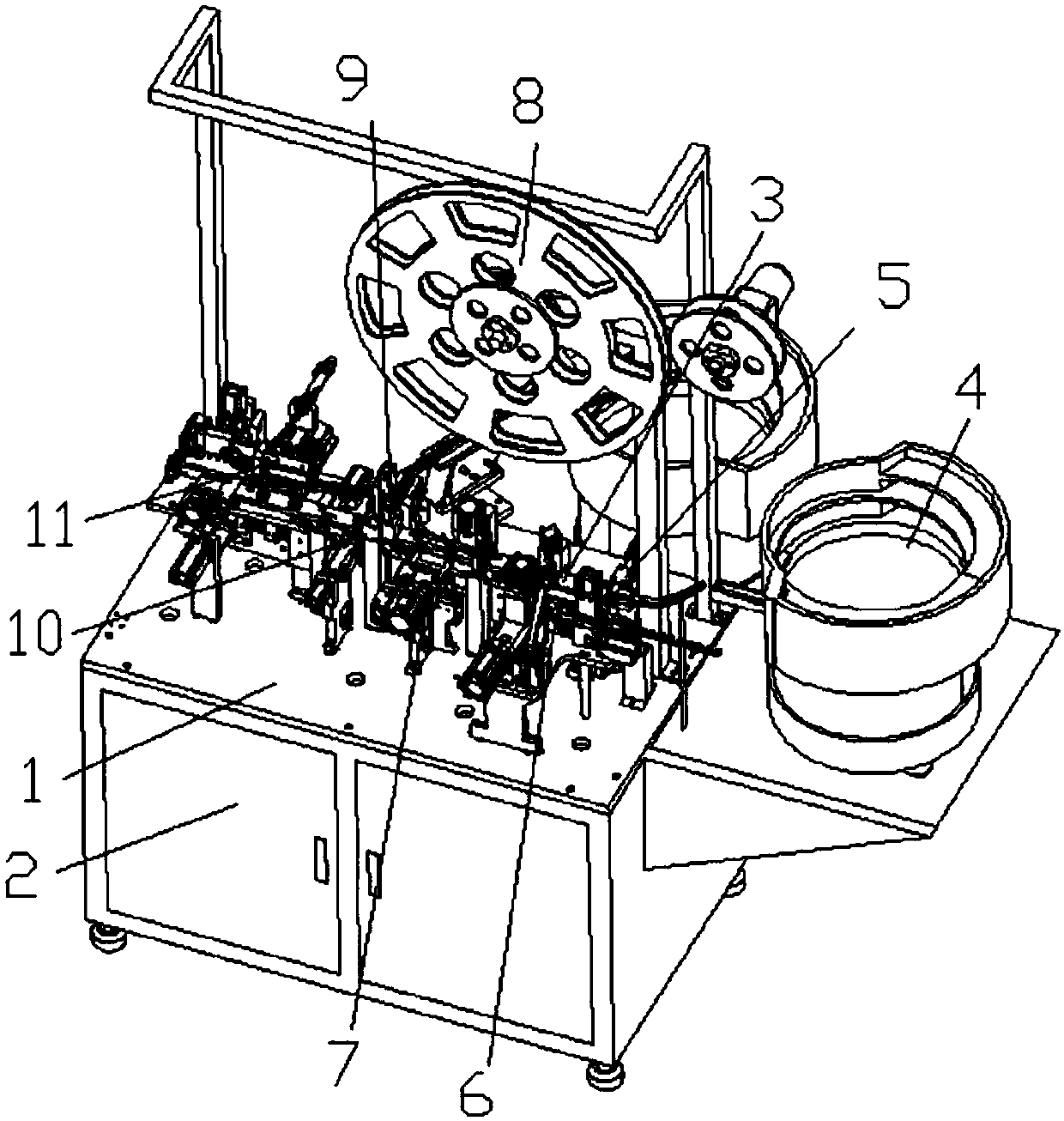

Automatic shaft sleeve assembly machine

InactiveCN106514197AImprove installation efficiencyRealize integrated automatic continuous operationMetal working apparatusDistribution controlEngineering

The invention relates to an automatic shaft sleeve assembly machine which comprises a rack and a power distribution control cabinet. The rack is provided with a shaft sleeve mounting rotary disc which is connected to a shaft sleeve mounting motor and uniformly provided with loading holes matched with shafts. A shaft feeding device, a shaft sleeve feeding device, a screw feeding device, a shaft sleeve pressing device and a shaft sleeve discharging device which are matched with the loading holes and connected to the power distribution control cabinet are sequentially arranged outside the shaft sleeve mounting rotary disc. According to the automatic shaft sleeve assembly machine, the shaft sleeve mounting rotary disc is arranged and uniformly provided with the loading holes matched with the shafts, the shaft feeding device, the shaft sleeve feeding device, the screw feeding device, the shaft sleeve pressing device and the shaft sleeve discharging device are sequentially arranged outside the shaft sleeve mounting rotary disc, integrated automatic continuous operation of shaft sleeves and screws is achieved, the shaft sleeve mounting efficiency is greatly improved, and meanwhile, the equipment utilization rate is increased.

Owner:柳州市凯仕达汽车配件有限公司

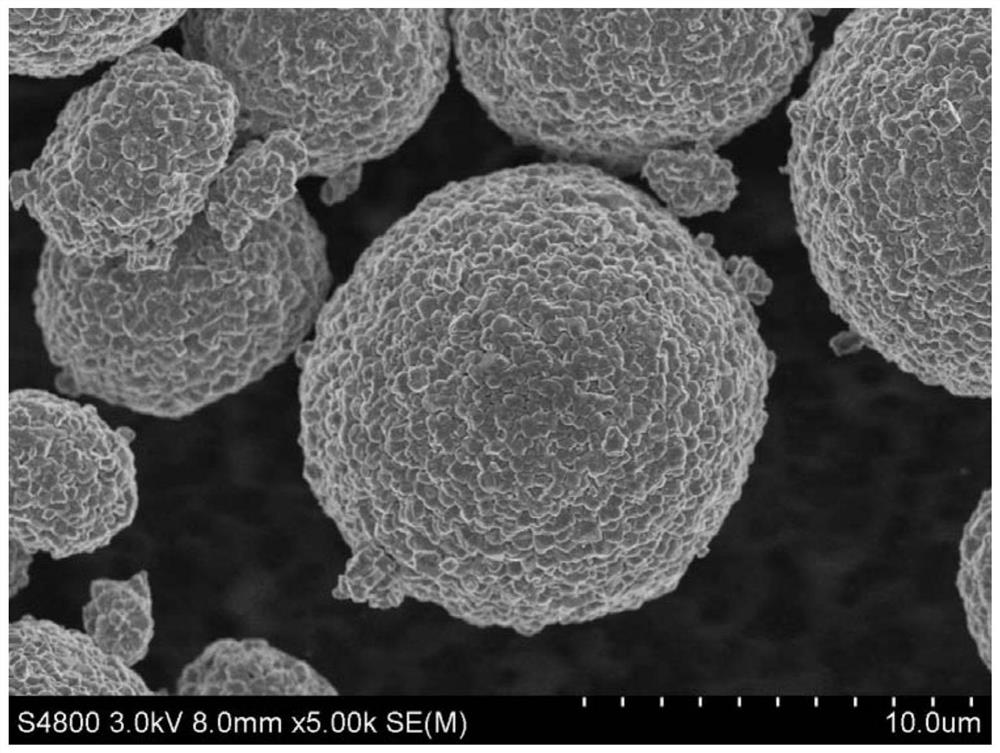

Pharmaceutical superdisintegrant

InactiveUS20020068084A1Allow useImprove the compaction effectPowder deliveryPill deliveryCelluloseParticulates

Superdisintegrants which provide improved compressibility compared to prior art superdisintegrants and which does not negatively impact the compressibility of formulations which include high-dose drugs, and methods for obtaining the same are disclosed. The superdisintegrants include a particulate agglomerate of coprocessed starch or cellulose and a sufficient amount of an augmenting agent to increase the compactibility of the superdisintegrant. The augmented superdisintegrant provides a fast disintegration of a solid dosage form when incorporated in sufficient quantity therein, without untowardly affecting the compactibility of the solid dosage form (relative to the solid dosage form without the superdisintegrant).

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

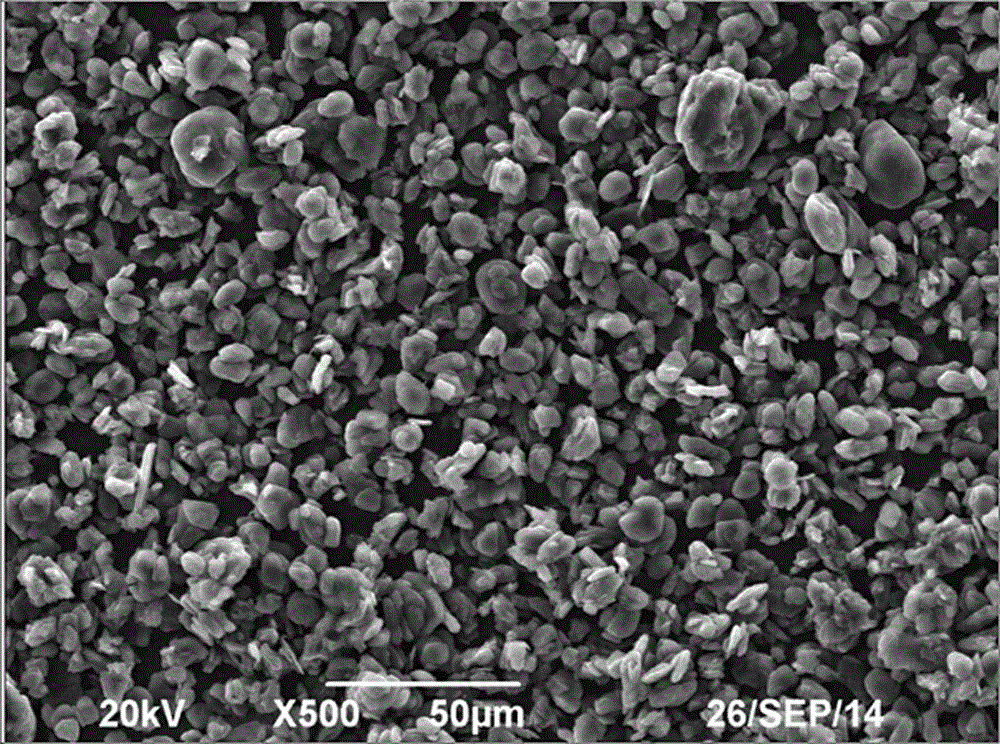

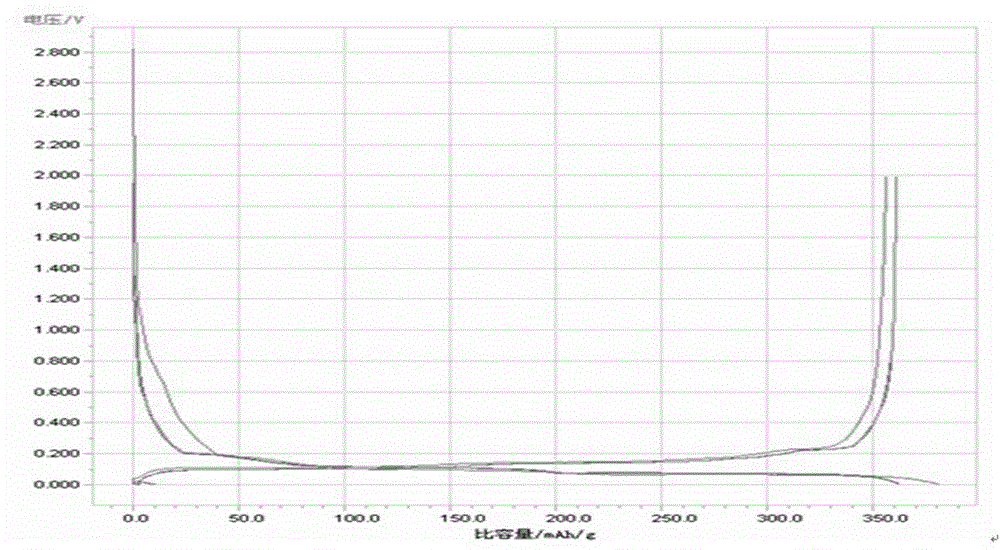

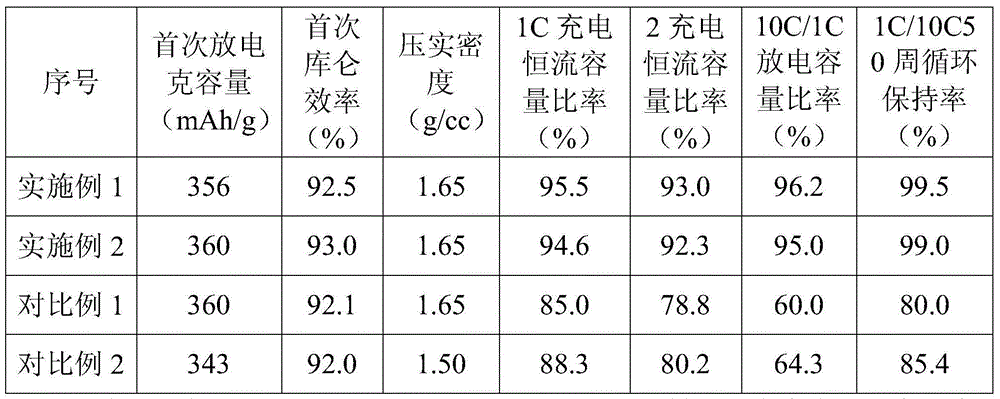

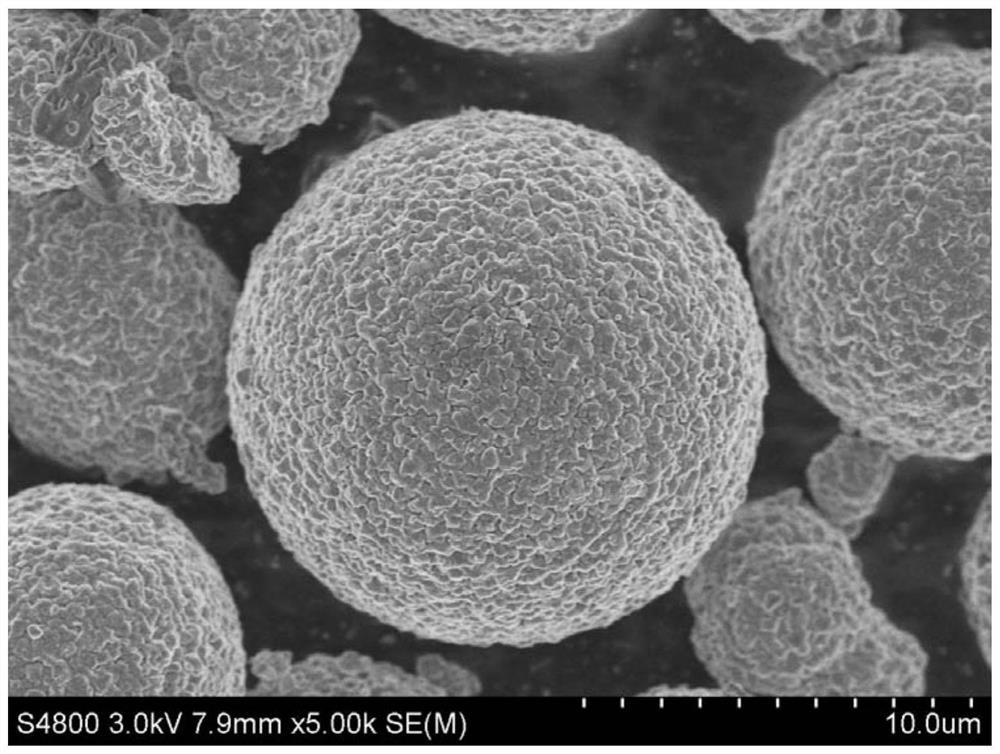

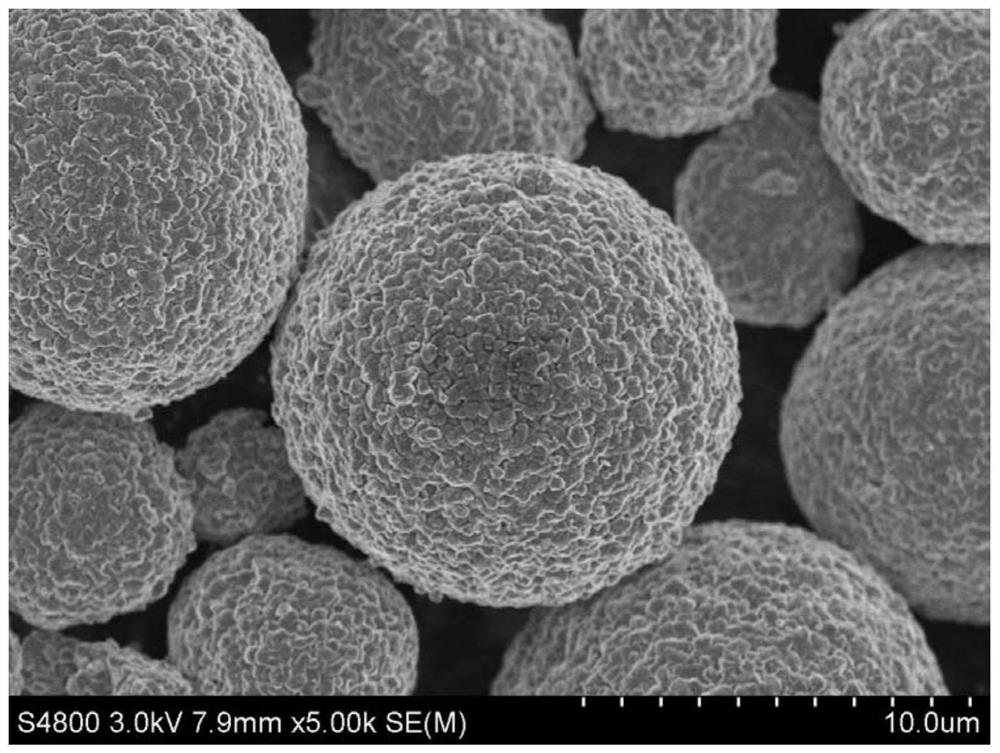

Composite graphite cathode material and preparation method thereof

ActiveCN104609400AImprove cycle performanceGood high current charge and discharge performanceCell electrodesCarbonizationGraphite particle

The invention discloses a composite graphite cathode material and a preparation method thereof. The composite graphite cathode material comprises graphite particles a and b, wherein the graphite particles a are secondary artificial graphite particles formed by granulating, coating and bonding oil-based petroleum coke; the graphite particles b are secondary composite graphite particles, adopting core-shell structures, formed by removing impurities from small-particle diameter natural graphite balls, and spherodizing, coating and bonding the small-particle diameter natural graphite balls; the composite graphite material is prepared by mixing the graphite particles a and b, adding a binding agent, coating, bonding and performing high temperature carbonization. By compounding the two secondary graphite particles with different characteristics to prepare the composite graphite material, the capacity of graphite is improved and the problems that the graphite is poor in rate capability, poor in high-current charge and discharge performance, poor in compacting performance are solved.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Dead weight type compaction device for road repairing of municipal construction

The invention discloses a dead weight type compaction device for road repairing of municipal construction. The dead weight type compaction device comprises a supporting plate, wherein supporting frames are respectively mounted on two sides of the upper end of the supporting plate; a crossbeam is mounted at the upper end of the supporting frame; a driving motor is mounted at the middle part of theupper end of the crossbeam; a driving shaft is mounted at the lower end of the driving motor; a driving gear is mounted in the middle part of the driving shaft; a rotating gear is meshed with each oftwo ends of the driving gear; a rotating shaft is mounted in the middle part of each rotating gear; a first worm is mounted at the lower end of a left side rotating shaft, and a first worm wheel is meshed with the left end of the first worm; a second worm is mounted at the lower end of a right side rotating shaft, and a second worm wheel is meshed with the right end of the second worm; fixing shafts are respectively mounted in the middle part of the first worm wheel and the middle part of the second worm wheel; a meshing gear is mounted at the middle part of the front end of each fixing shaft;and a lifting rack is meshed with the outer side of each meshing gear. According to the dead weight type compaction device disclosed by the invention, the up-and-down reciprocating movement of a compaction plate is realized, so that the compaction effect to road surfaces is realized by the gravity of the compaction plate, and the compaction requirements for different road surfaces are also met.

Owner:SHENZHEN SHENGXIANG INTPROP CO LTD

Pharmaceutical superdisintegrant

InactiveUS6660303B2Improve the compaction effectImprove ductilityPowder deliveryPill deliveryCelluloseParticulates

Superdisintegrants which provide improved compressibility compared to prior art superdisintegrants and which does not negatively impact the compressibility of formulations which include high-dose drugs, and methods for obtaining the same are disclosed. The superdisintegrants include a particulate agglomerate of coprocessed starch or cellulose and a sufficient amount of an augmenting agent to increase the compactibility of the superdisintegrant. The augmented superdisintegrant provides a fast disintegration of a solid dosage form when incorporated in sufficient quantity therein, without untowardly affecting the compactibility of the solid dosage form (relative to the solid dosage form without the superdisintegrant).

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

Movable type foundation earth fast ramming device used for civil engineering

The invention discloses a movable type foundation earth fast ramming device used for civil engineering. The device comprises a device table, connecting supports, supporting frames, a lead screw, a manual rocking wheel, a slide plate, slide rails, a drive motor, a round roller, an eccentric wheel and a ramming head. The lead screw is rotationally mounted between the connecting supports located on the two sides. An output shaft of the drive motor is fixedly connected with the round roller. The eccentric wheel is further fixedly mounted on a rotary shaft. The ramming head is fixedly mounted at the lower end of a slide bar. By manually rocking the rocking wheel, accordingly the distance between the ramming head and a to-be-rammed foundation is adjusted through cooperation of the lead screw, a left slide sleeve and a right slide sleeve, operation is stable and reliable, distance adjustment can be stopped immediately after manual rocking is stopped, the adjustment precision of the distance between the ramming head and the to-be-rammed foundation is improved, and the earth ramming effect is improved; through rotation of the drive motor, the ramming head moves up and down periodically so as to ram the foundation; and compared with manual ramming, time and labor are saved, meanwhile, the ramming effect is better, and the efficiency is higher.

Owner:王连军

Positive electrode material, preparation method thereof and lithium ion battery

PendingCN111916687AImprove performanceHigh crystallinitySecondary cellsPositive electrodesElectrical batteryManganese

The invention provides a positive electrode material, a preparation method thereof and a lithium ion battery. The positive electrode material comprises a base material and a coating layer coating thebase material, the base material comprises boron-tungsten co-doped lithium nickel cobalt manganese aluminate, and the coating layer comprises a lithium salt coating layer containing yttrium and zirconium. The preparation method comprises the following steps of (1) preparing a nickel-cobalt-manganese-aluminum precursor; (2) preparing the boron-tungsten co-doped nickel-cobalt-manganese-lithium aluminate; (3) preparing a coating layer material; and (4) preparing the positive electrode material from the boron-tungsten co-doped nickel-cobalt-manganese-lithium aluminate and the coating layer material. The particles of the positive electrode material provided by the invention are secondary particles, and the positive electrode material is uniform in particle distribution, good in fluidity and good in compaction performance, and has excellent first discharge capacity, rate capability and cycle performance.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

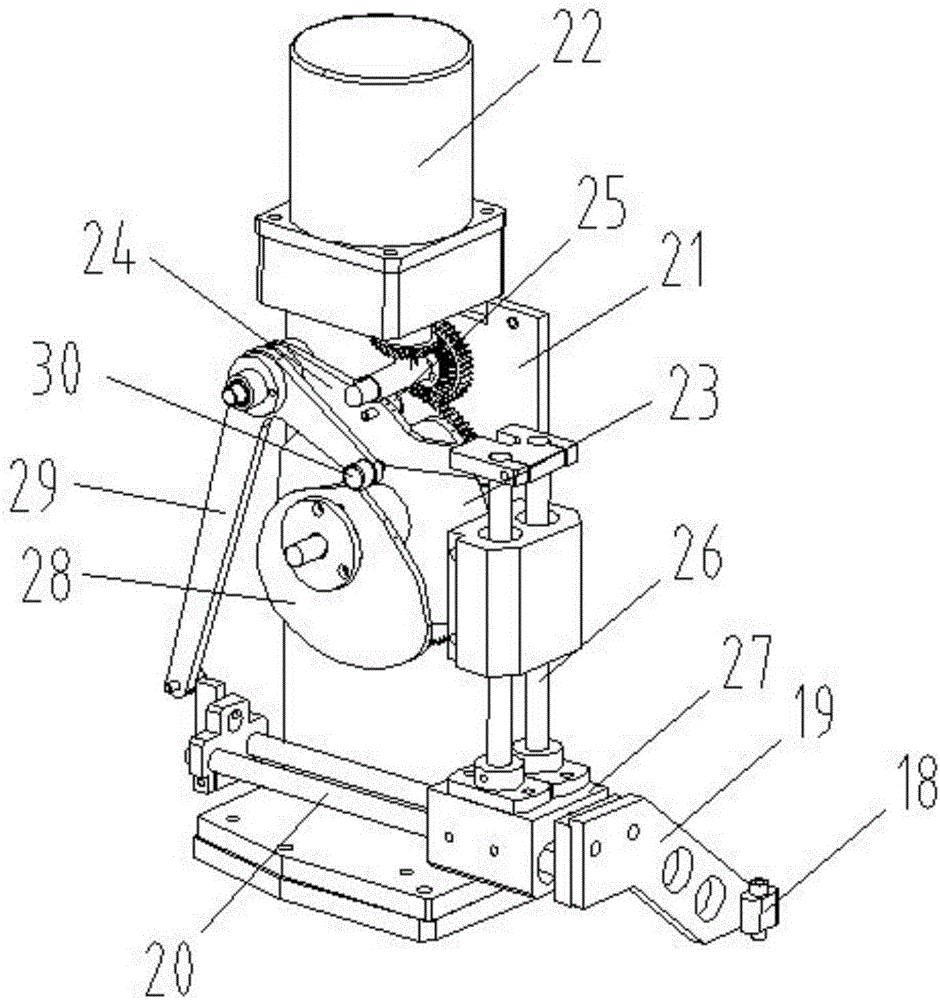

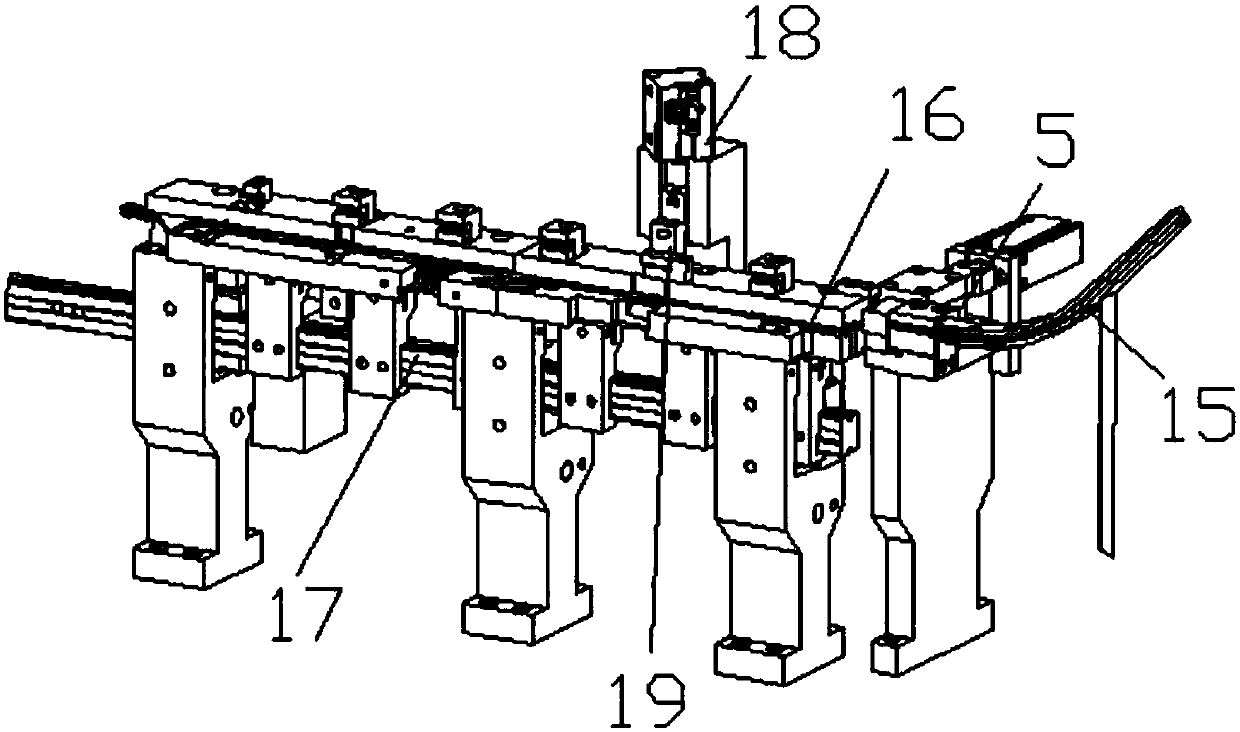

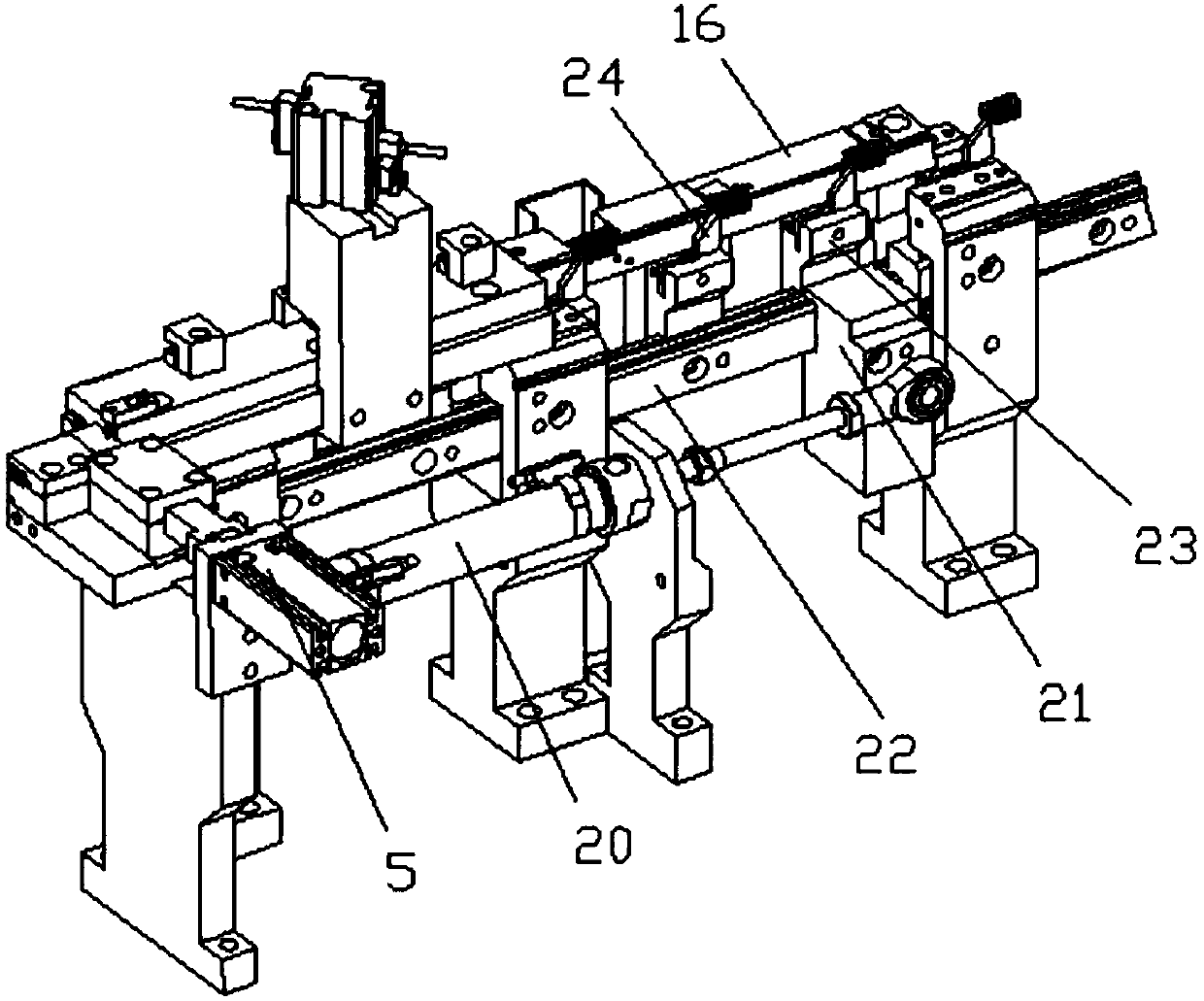

Automatic assembling machine for connector

ActiveCN107553085AAccurate jackingRealize automated assemblyOther manufacturing equipments/toolsMetal working apparatusMechanical engineering

The invention relates to an automatic assembling machine for a connector. A rack is provided with a rubber core conveying device and a shell conveying groove; a shell feeding device is arranged on theupper portion of the shell conveying groove, a shell material feeding device is matched with the right side of the shell conveying groove, and a rubber core ejecting-in port is formed in the front side of the shell conveying groove and is matched with a rubber core ejecting-in device; the shell material feeding device is connected with a shell vibration material feeding disk through a shell material feeding groove; the shell feeding device comprises a shell feeding lifting cylinder which is connected with a shell reciprocating feeding pull rod; the shell reciprocating feeding pull rod is connected with a shell feeding block; and feeding grooves matched with the left and right length of the shell are uniformly formed in the lower portion of the shell feeding block. According to the automatic assembling machine for the connector, by means of the shell feeding device in fixed distance feeding guarantees the fixed distance feeding of a shell, the fixed rubber core ejecting-in port is formed in the shell conveying groove, it is guaranteed that a rubber core is accurately ejected in from the rubber core ejecting-in port, automatic assembling of the connector rubber core and the shell isachieved, meanwhile the positioning and assembling structure is simplified, and the work efficiency is improved.

Owner:TONGXIANG YAORUN ELECTRONICS

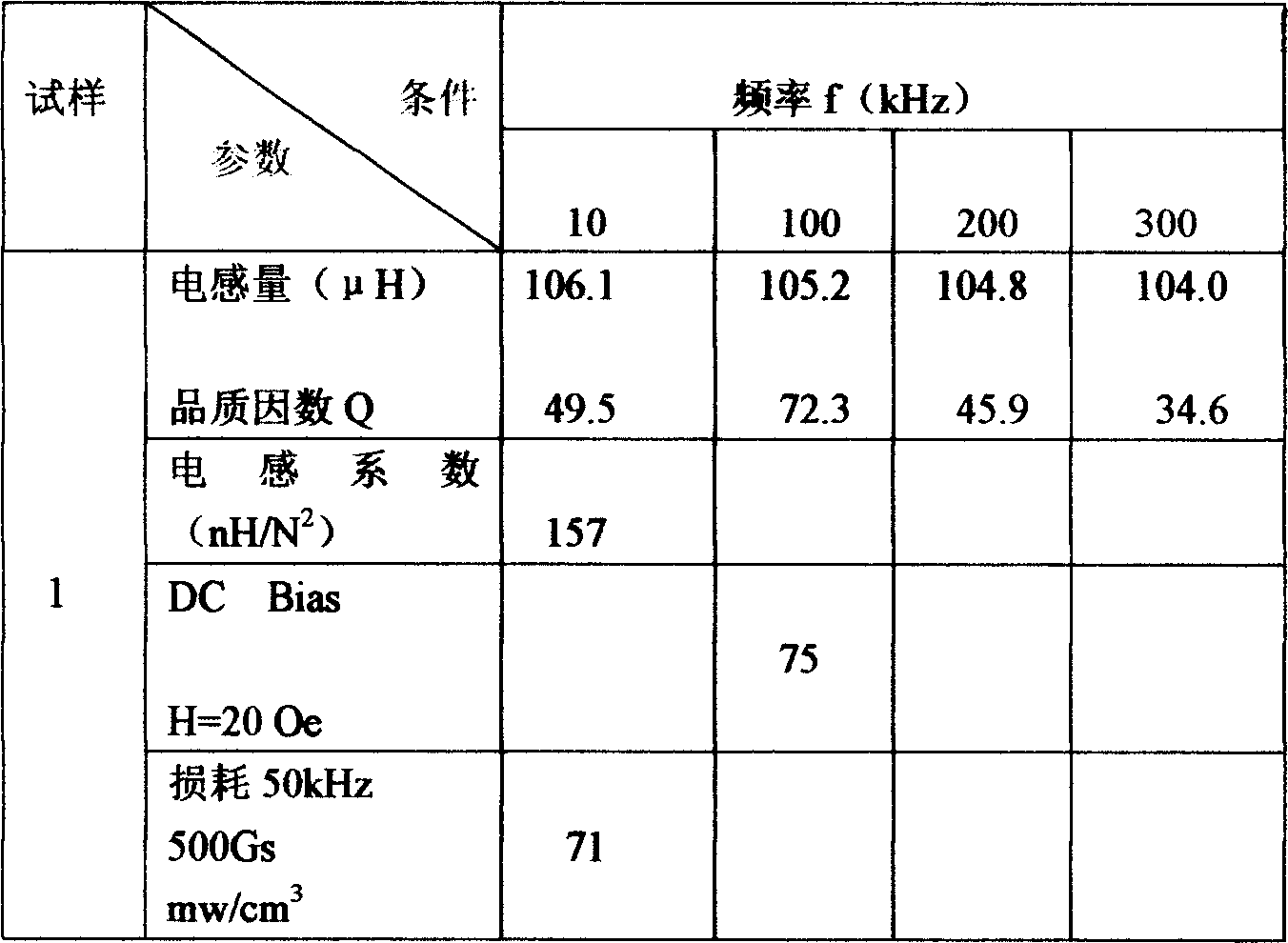

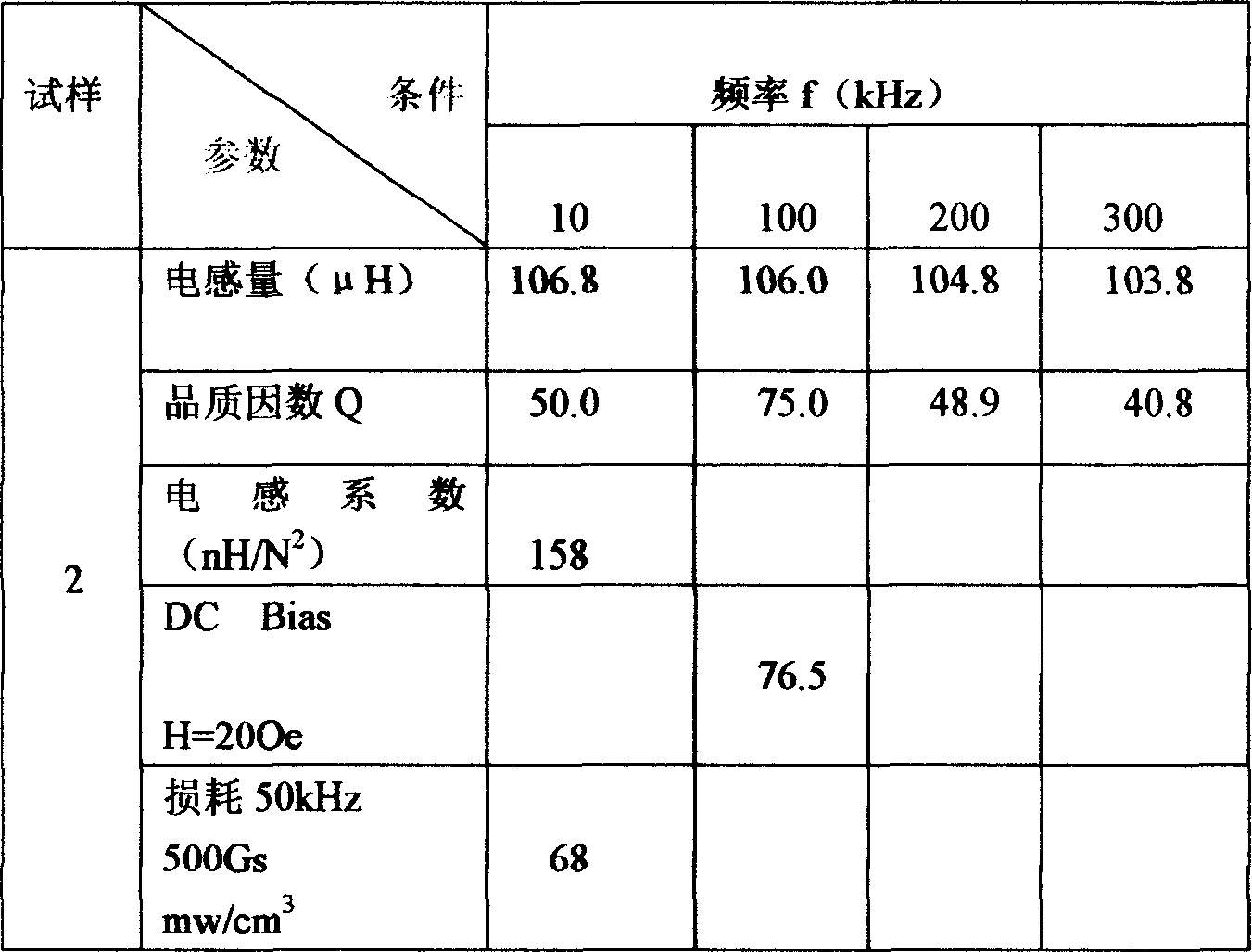

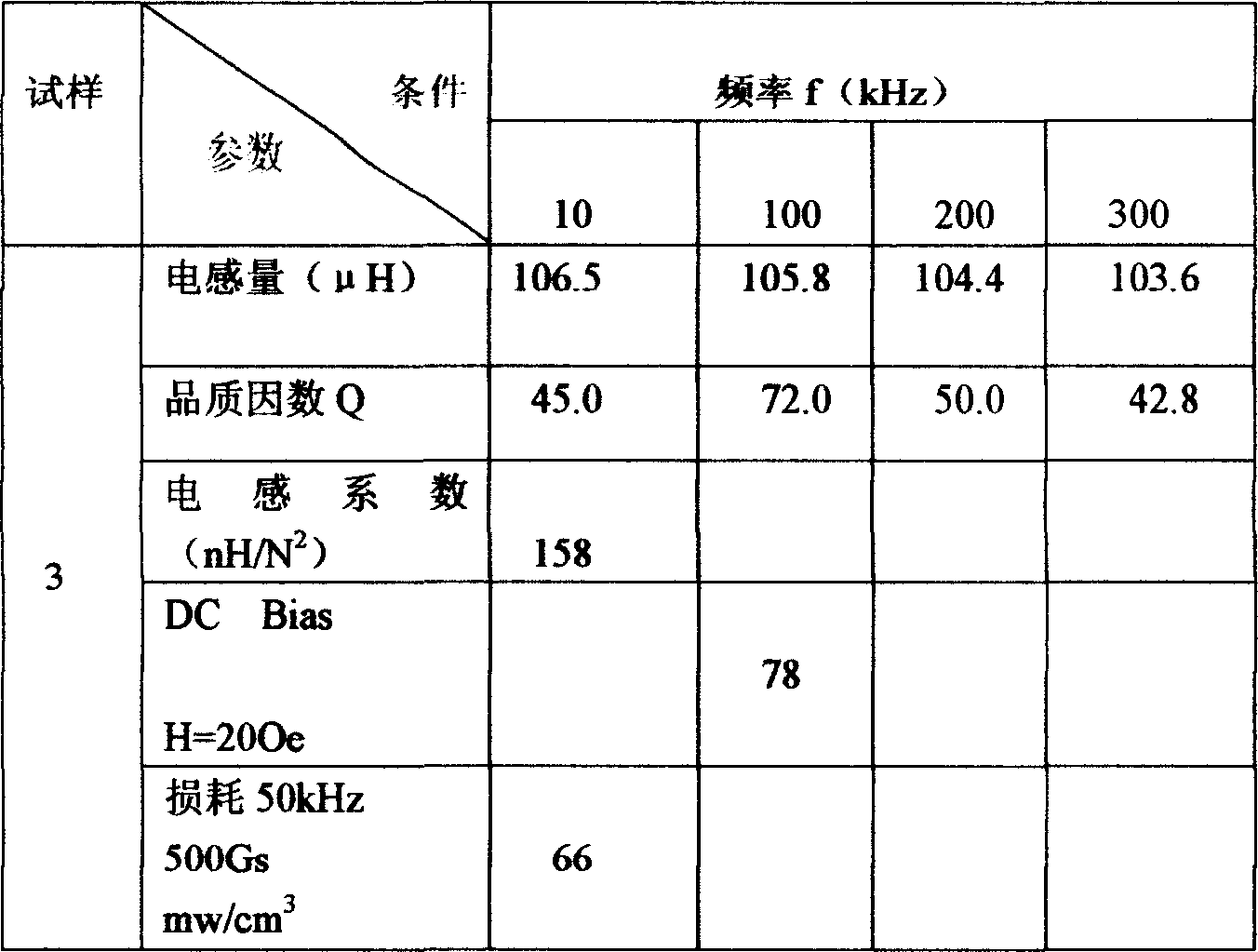

Method for manufacturing powder used for pressing and manufacturing Fe-Si-Al magnetic core

InactiveCN1967737AGood formabilityImprove the compaction effectInorganic material magnetismManganeseTitanium

The invention relates to a method for producing iron silicon aluminum magnetic powder, wherein it comprises that: using vacuum sensitive furnace to smelt, adding some manganese, titanium, to prepare the iron silicon aluminum alloy casting block; using mechanical method to break block into powder lower than 120 deals, removing stress and reducing. Since it adds manganese and titanium into alloy, the saturated magnetic density can reach 11000-11500Gs, the correct force is lower than 160A / m; and it uses mechanical breaking method to make the powder into polygons, to be molded in low pressure. The inventive magnetic powder has low magnetic consumption and better direct-current bias magnetic field (DC Bias). And via different diameters and formulas, it can produce the iron silicon aluminum magnetic powder whose effective magnetic conductivity is mue=60, mue=75, mue=90, and mue=125.

Owner:武汉欣达磁性材料有限公司

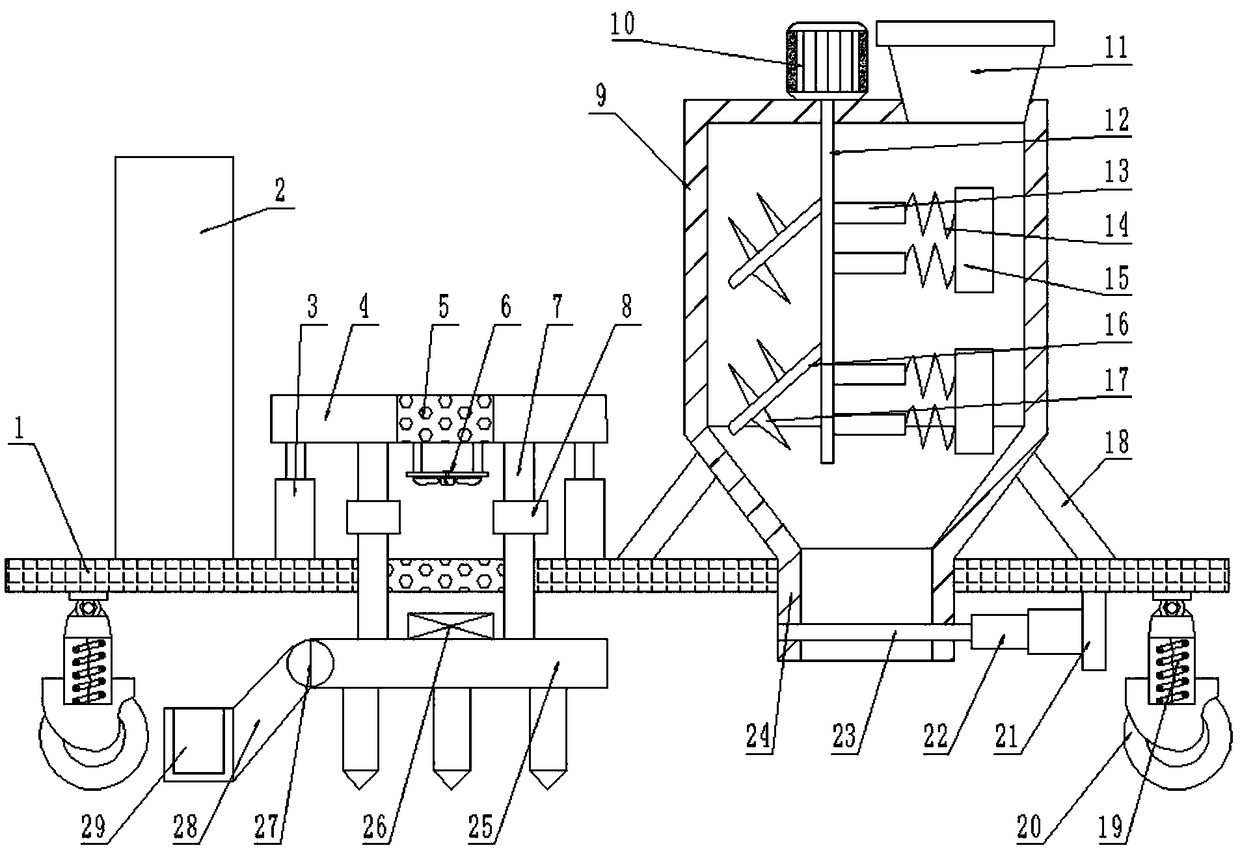

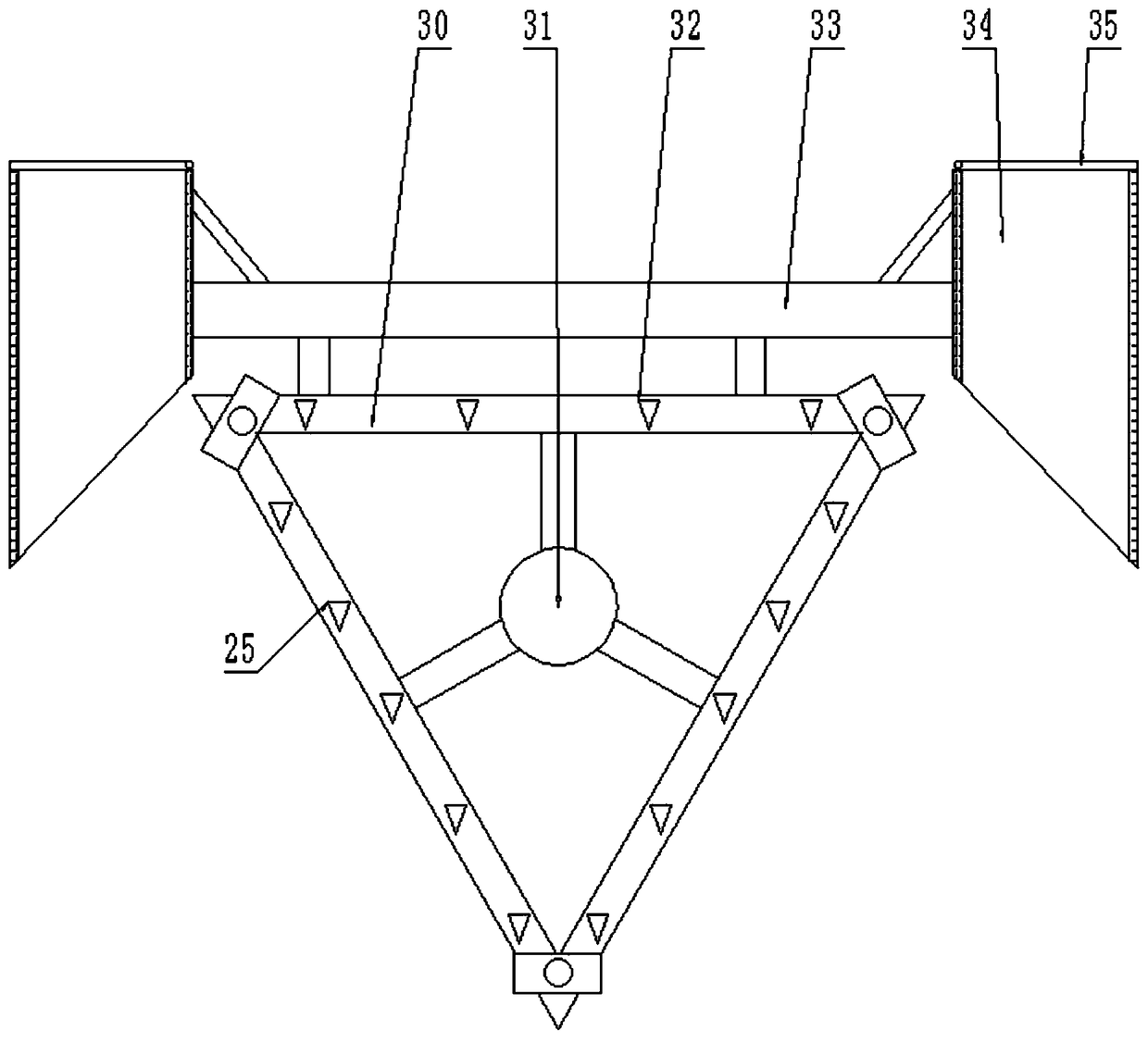

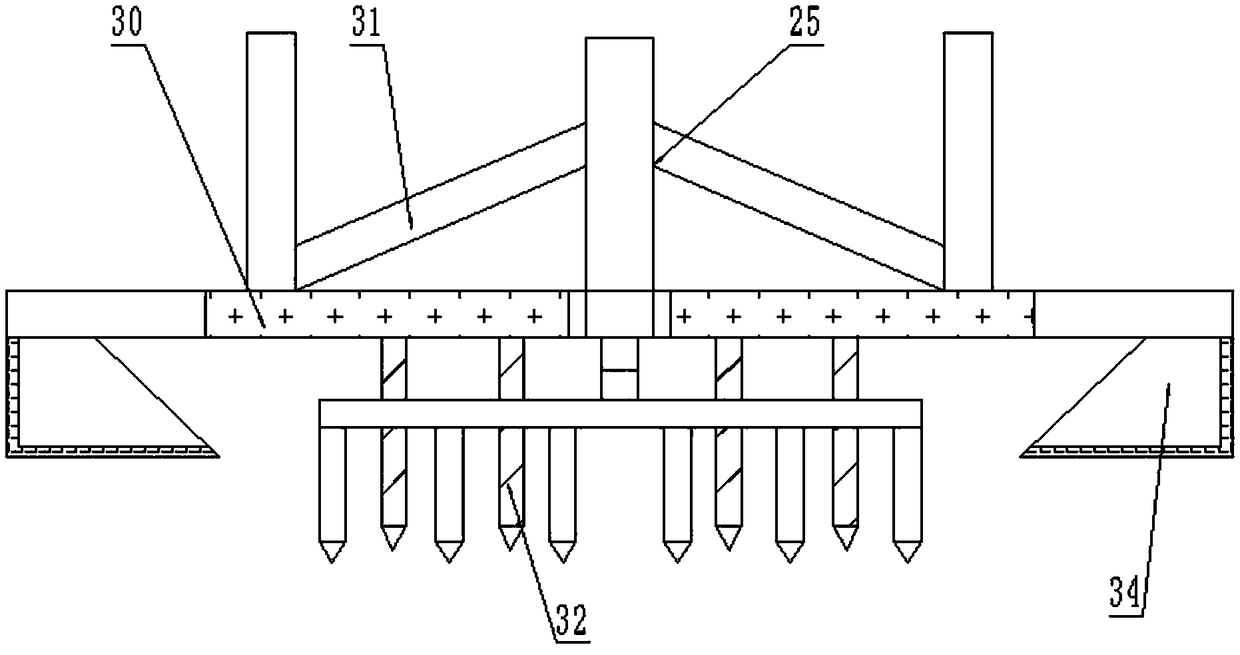

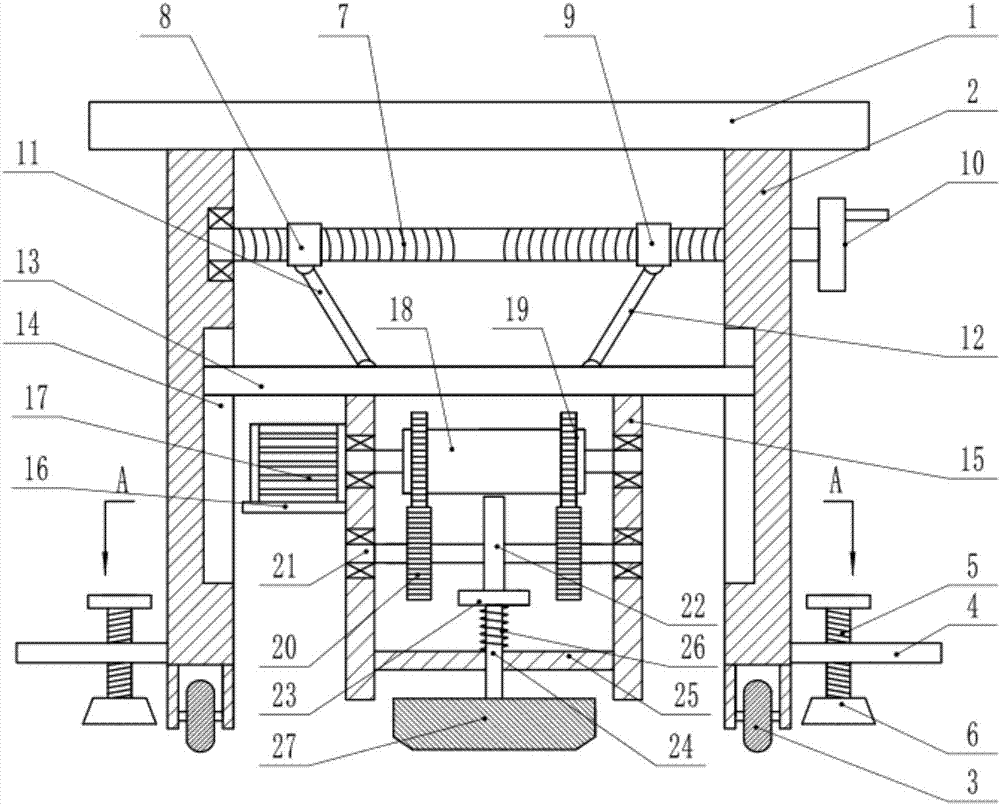

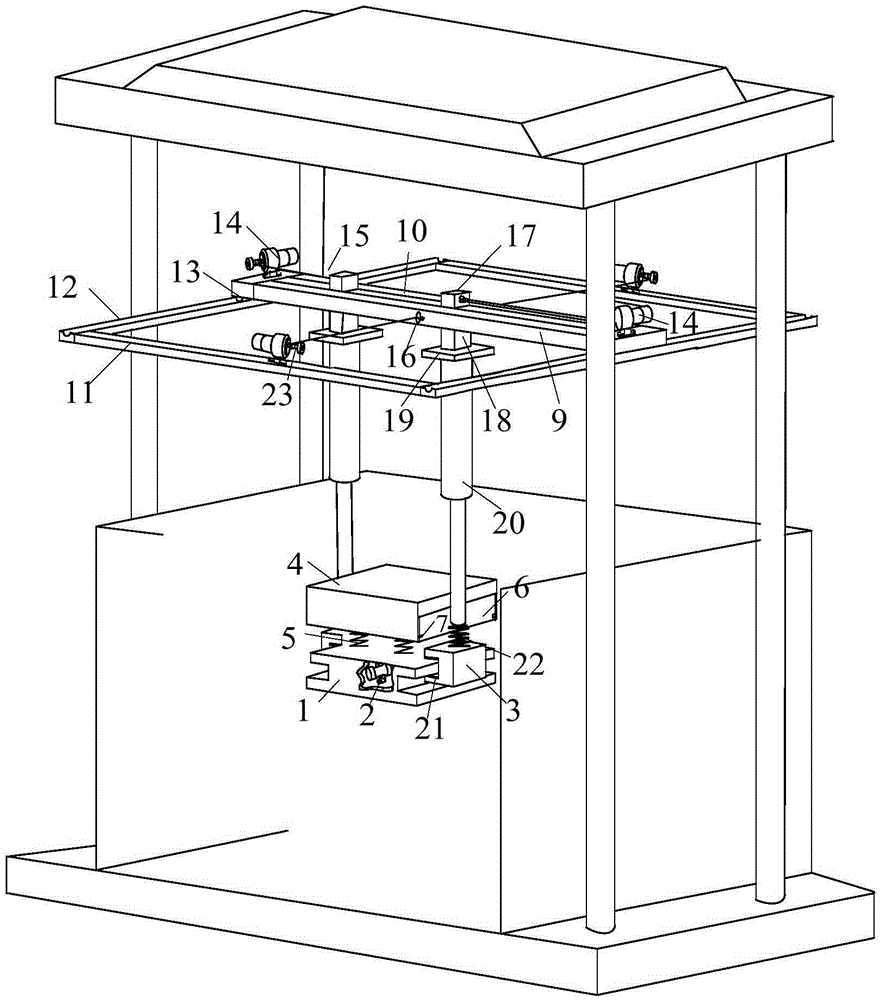

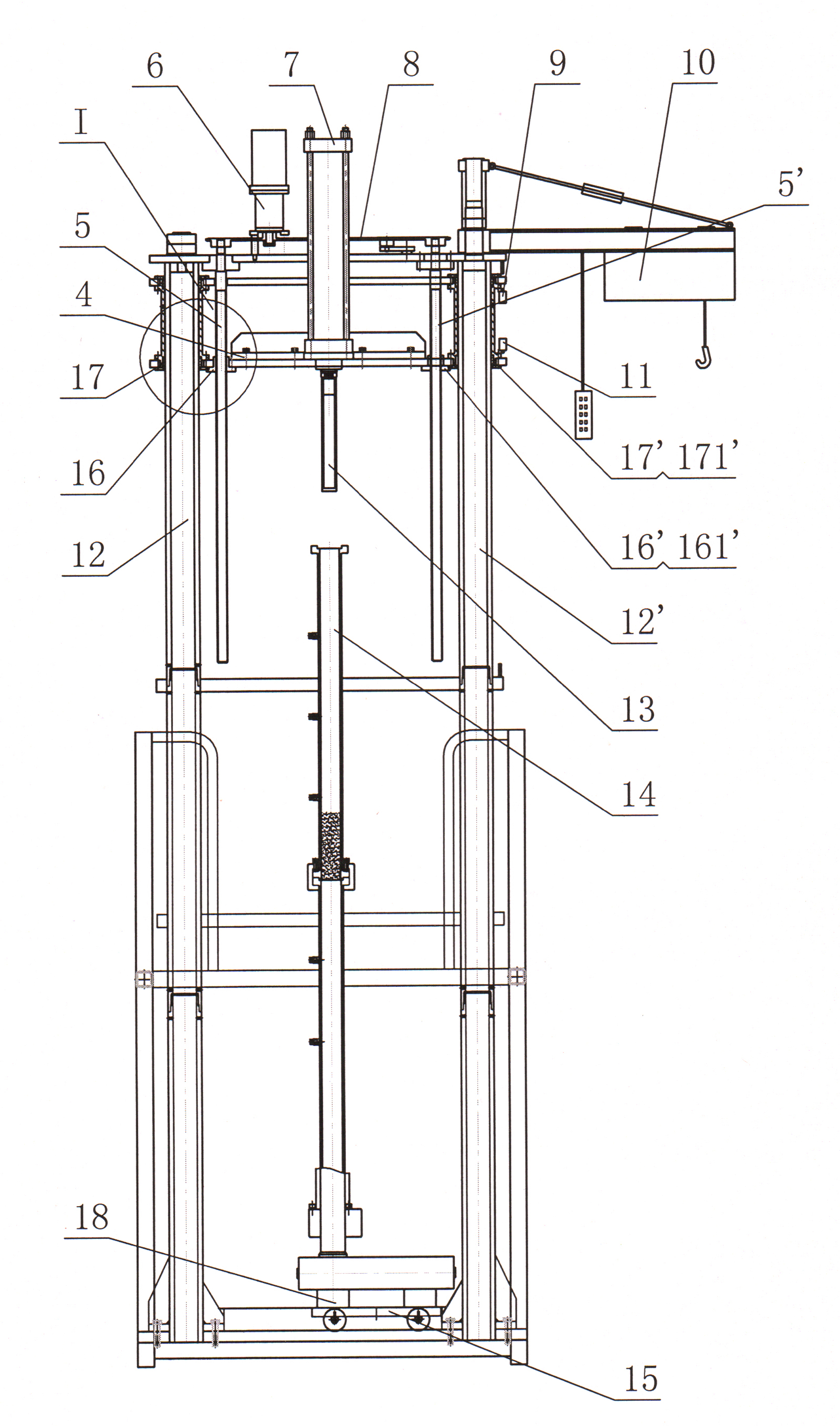

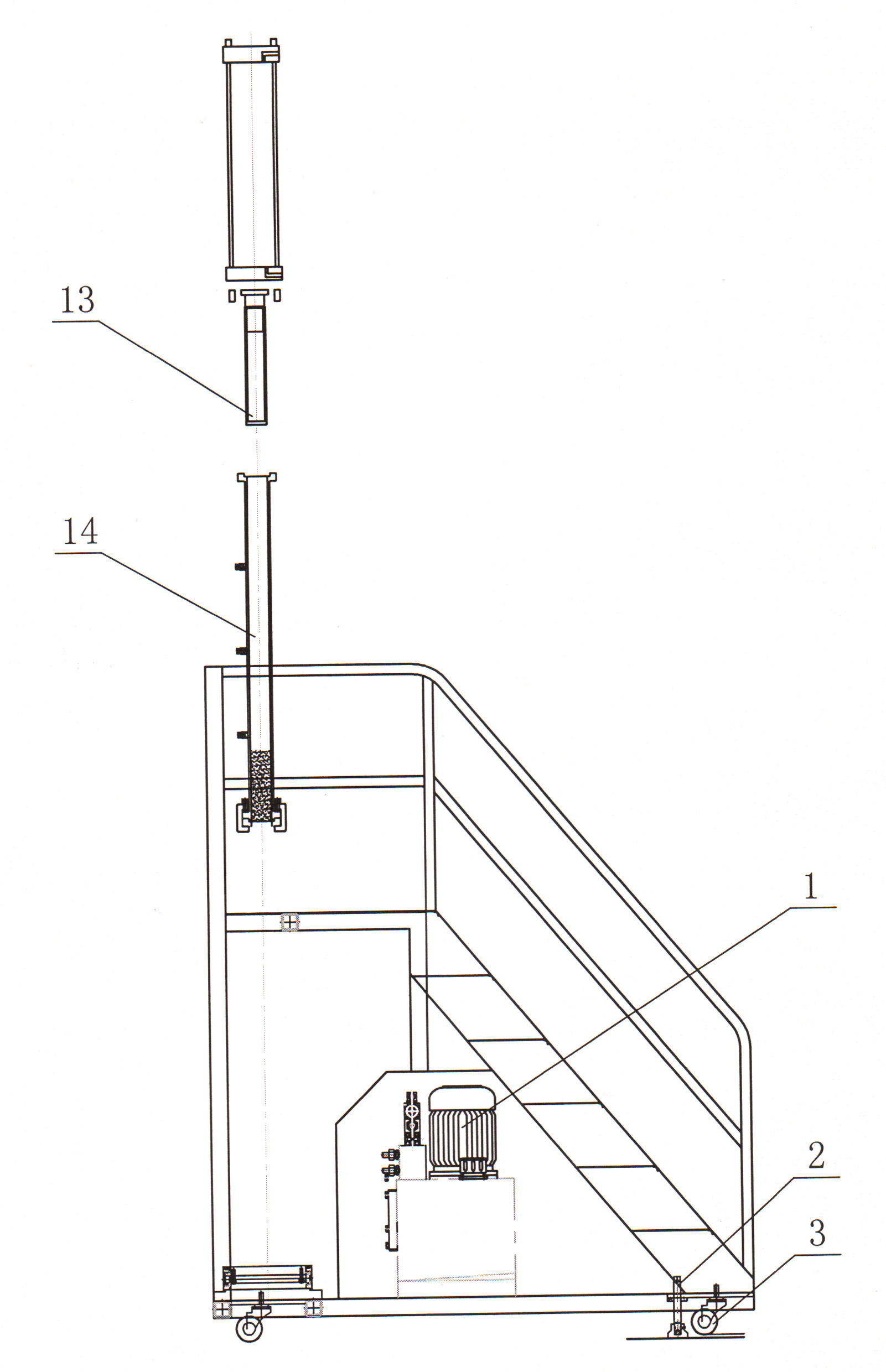

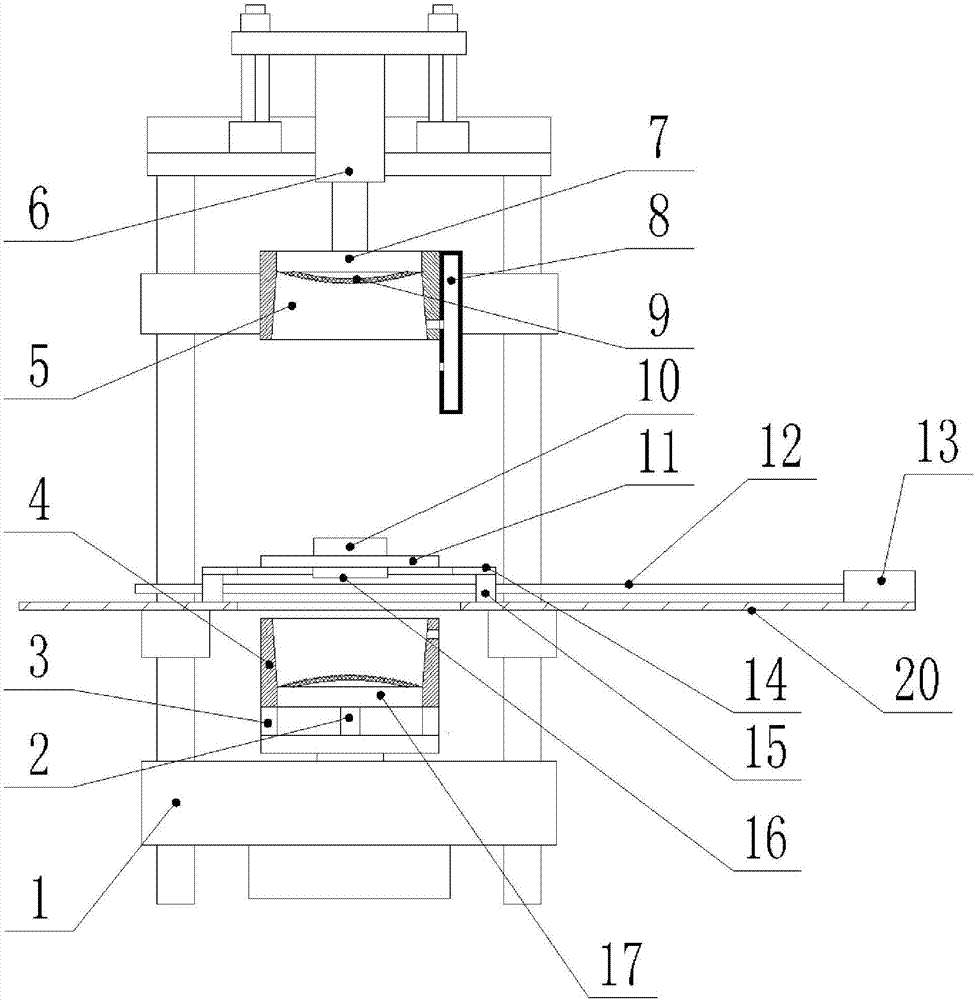

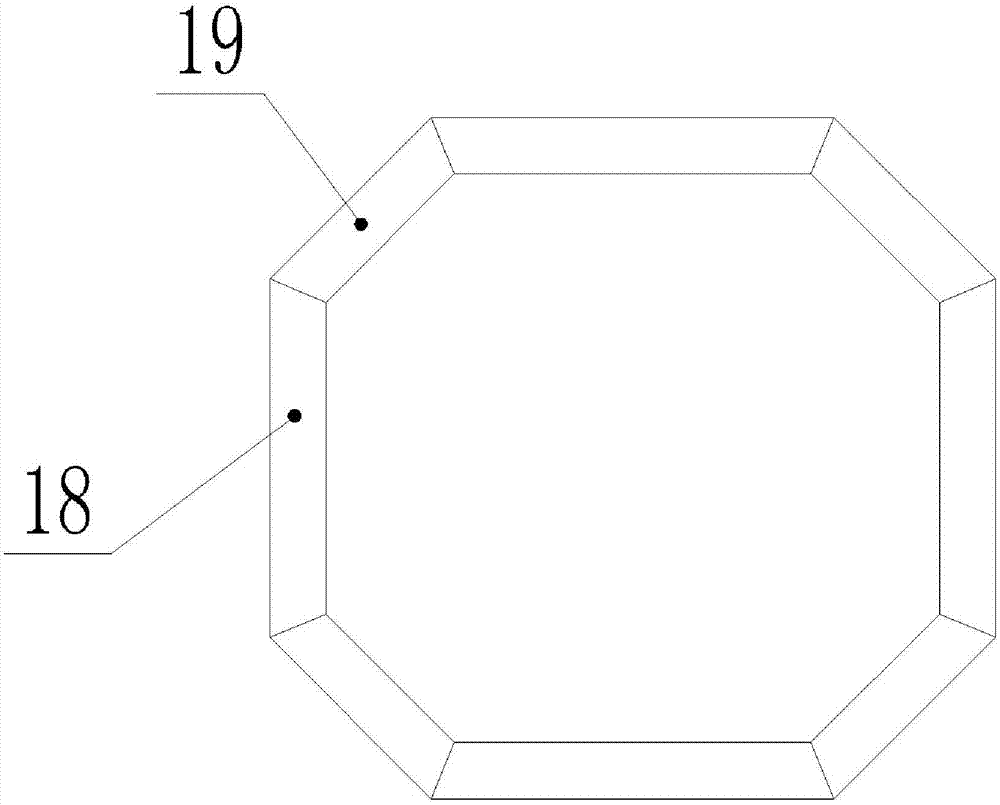

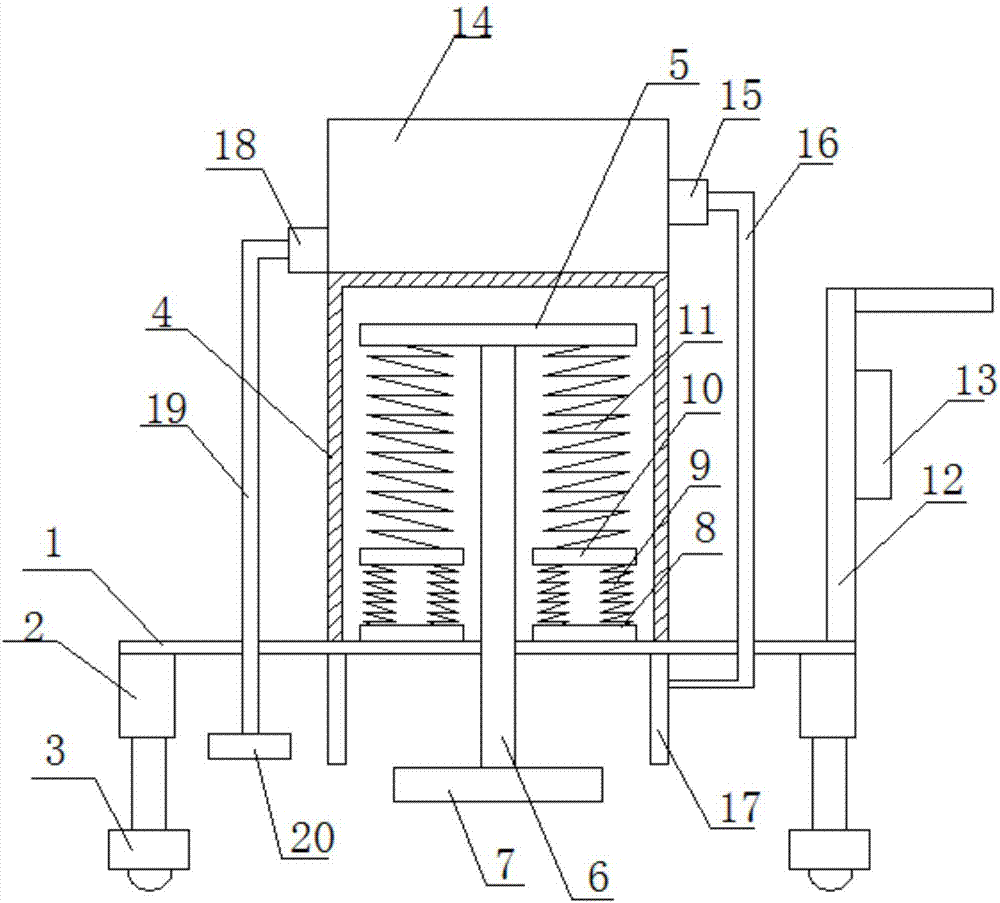

Automatic material spreading device for similar material simulation test, and use method of automatic material spreading device

ActiveCN105353093ASimple structureFlexible handlingMaterial analysisHydraulic cylinderUltimate tensile strength

The invention discloses an automatic material spreading device for a similar material simulation test, and a use method of the automatic material spreading device. The automatic material spreading device integrates a material accommodating box and a vibration device; a vibrating motor is used as a vibration source for realizing material spreading and tamping vibration; an auxiliary extrusion for force application is carried out through a hydraulic cylinder according to conditions to ensure that requirements on the flatness and the consistence of a simulation rock formation can be met in a similar material model production process. Compared with the prior art, the automatic material spreading device is simple in structure, flexible in control, high in maneuverability and production efficiency, low in labor intensity, excellent in material spreading and tamping effect, and the like; the forming speed and quality of the similar material model can be greatly improved, and the consistency of the similarity ratio of thickness to strength of the formed simulation rock formation is greatly improved; in addition, the automatic material spreading device has the benefits of being low in manufacturing cost, convenient to assemble and disassemble, low in maintenance and repair cost, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

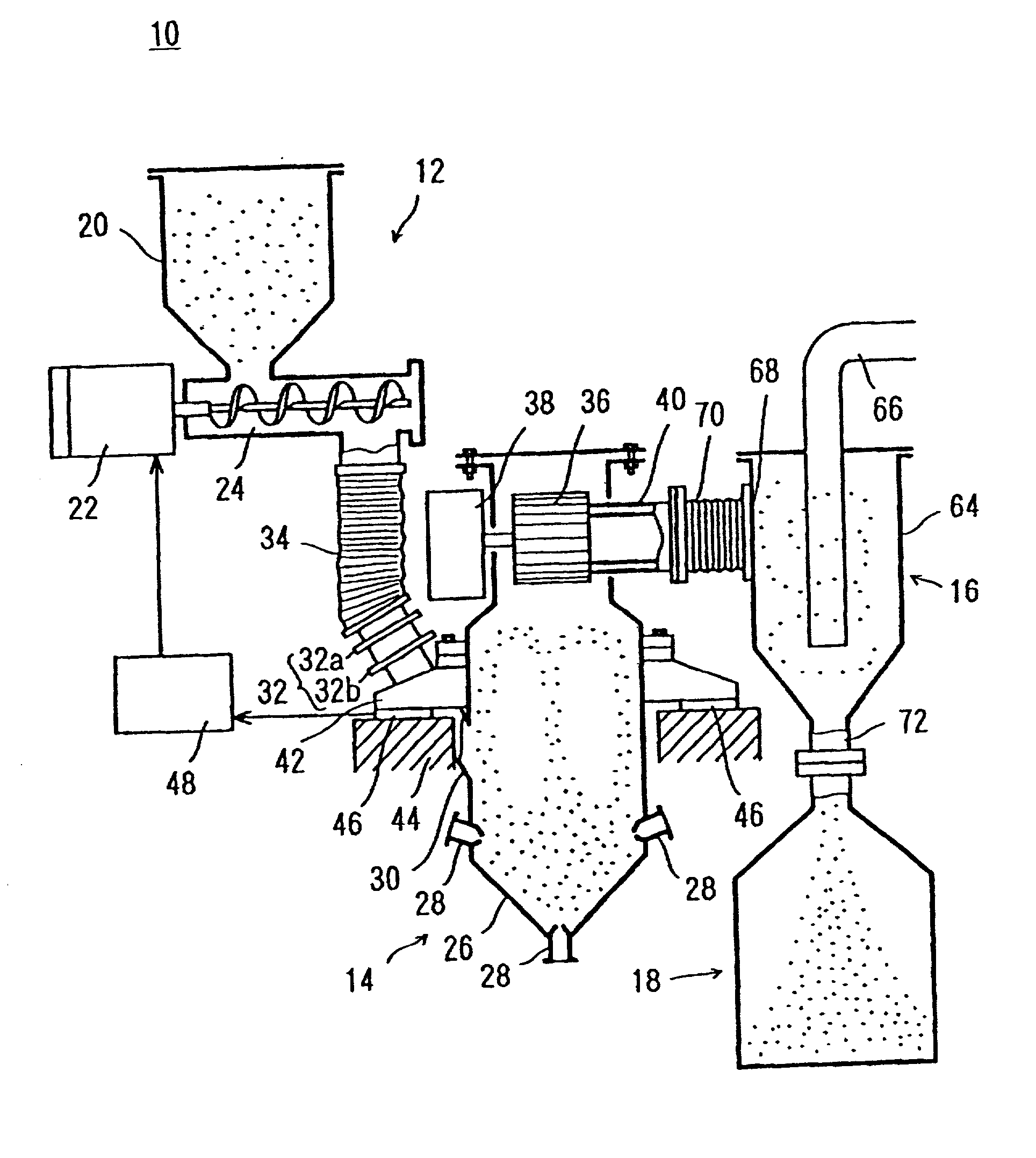

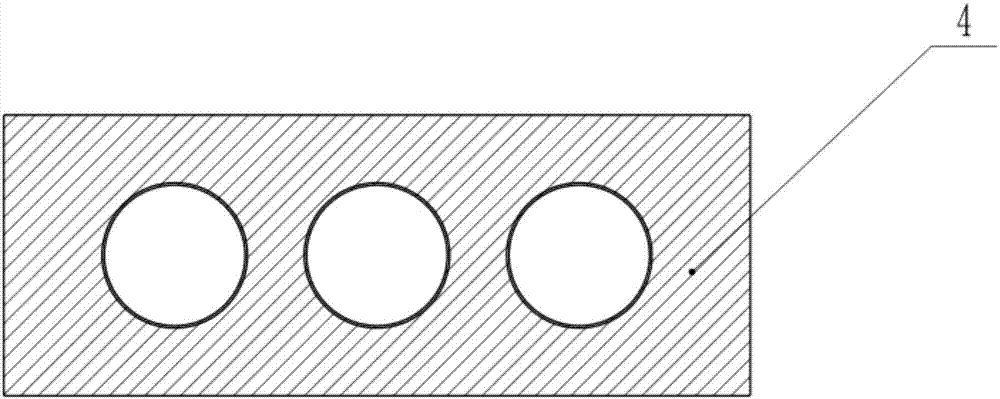

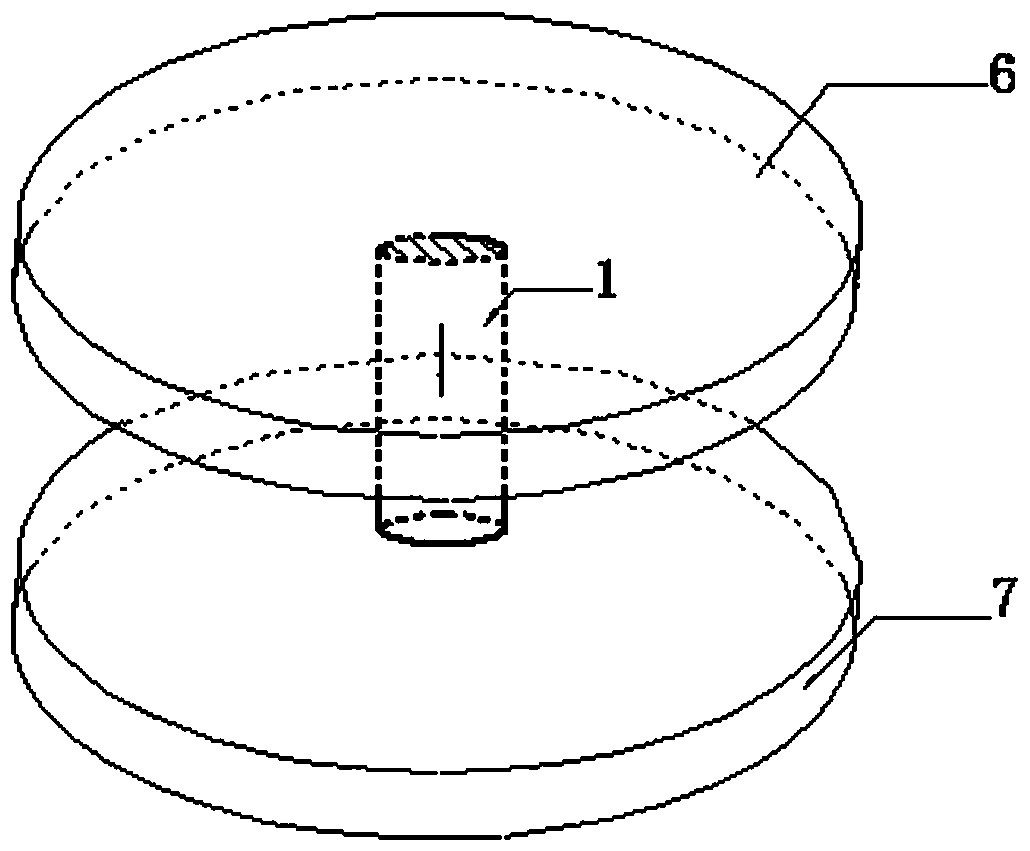

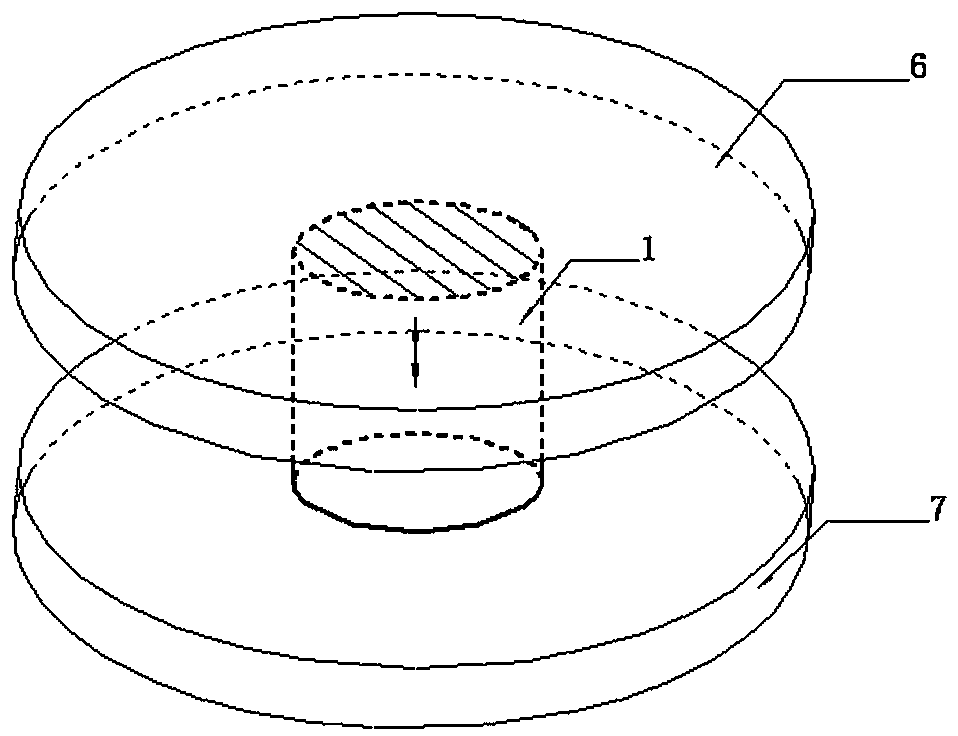

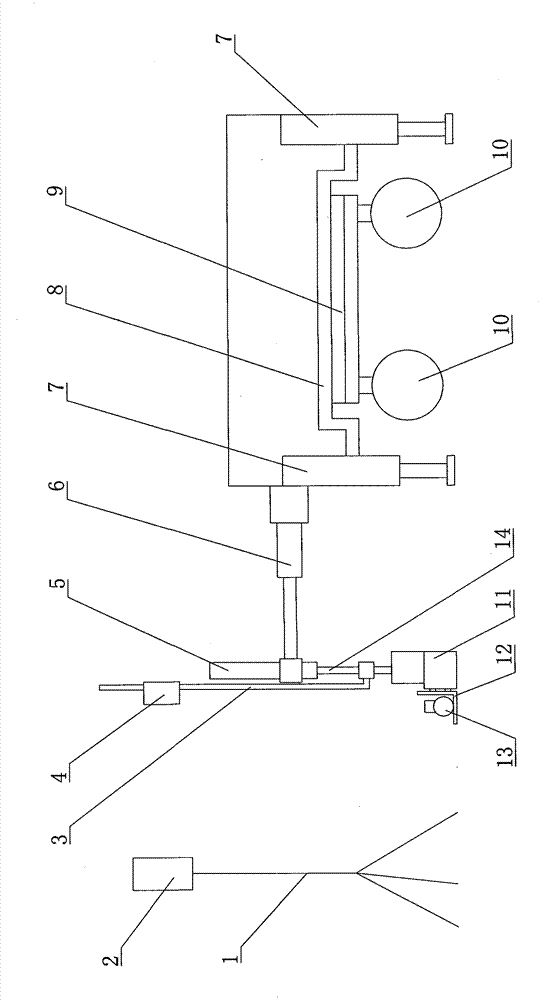

Sand-packed model pipe full-automatic compacting device

InactiveCN105464653AReduce labor intensityImprove work efficiencyConstructionsBorehole/well accessoriesHydraulic cylinderMagnetic poles

The invention discloses a sand-packed model pipe full-automatic compacting device. The sand-packed model pipe full-automatic compacting device comprises a pedestal, a hydraulic cylinder, a hydraulic push rod, a connecting rod, a straight rod and a compacting block. The upper end of the hydraulic cylinder is provided with the hydraulic push rod, the connecting rod is horizontally vertical to the hydraulic push rod, the end of the connecting rod is fixedly connected with an automatic sand-pack tunnel, the interior of the pedestal is provided with an electromagnet, an electromagnet pulse controller, a hydraulic control circuit board, a hydraulic input pipe and a hydraulic output pipe, and the hydraulic input pipe and the hydraulic output pipe are arranged under the hydraulic cylinder and are connected with the hydraulic cylinder. The and-packed model pipe full-automatic compacting device is advantaged in that the pulse controller is used for controlling two poles of the electromagnet to change; when the upward magnetic pole of the electromagnet is opposite to the downward magnetic pole of the compacting block, the compacting block is attracted downwards through a principle that unlike poles attract each other to carry out a compacting process; when the upward magnetic pole of the electromagnet is the same as the downward magnetic pole of the compacting block, the compacting block is pushed up through a principle that two like magnetic poles repel each other; and the sand-packed model pipe full-automatic compacting device replaces manual compacting operation, the labor intensity is reduced, and the work efficiency is improved.

Owner:QIDONG JOYSON TOYS CO LTD

Ground compacting device for construction

The invention discloses a ground tamping device for building construction, which includes a bearing platform. The left vertical plate and the right vertical plate are fixedly installed by welding vertically, the horizontal plate is fixedly installed on the top of the left vertical plate and the right vertical plate, and the electromagnet is fixedly installed on the bottom of the horizontal plate, and the vertical sliding type runs through the horizontal plate with a slide bar , the slide bar passes through the electromagnet, and the top of the slide bar is provided with a top plate; several slots are longitudinally opened in the stamping cylinder, and the slots are extended to the center of the stamping cylinder, and a weight-increasing steel plate is detachably inserted into the slot; the present invention The structure is ingenious and the operation is convenient. The elastic potential energy of the return spring and the accumulation of the gravitational potential energy of the stamping cylinder are realized through the adsorption of the electromagnet and the iron block. The separation of the electromagnet and the iron block realizes the tamping effect of the rammed earth plate on the ground, and the tamping action can be automatic. Complete, high degree of automation.

Owner:杨燕萍

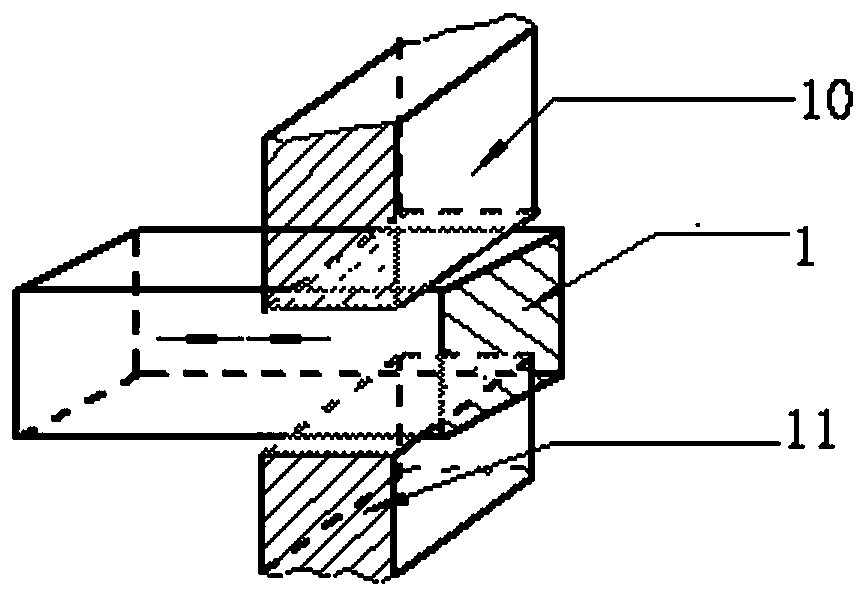

Forging method capable of efficiently, integrally and uniformly compacting deformation

InactiveCN108465762AImprove forgeabilityImprove forging efficiencyMetal-working apparatusIngotDeformation Problem

The invention relates to a forging method capable of efficiently, integrally and uniformly compacting deformation, and the forging method can uniformly refine compacting deformation and the structureof a large forged piece product. The forging method is characterized in that special upper and lower wide plates are adopted for upsetting and forging a forged piece, so that forging main deformationis completed; then, finishing forming is performed on upper and lower anvils; a special wide plate is utilized for integrally forging, so that forging permeability is greatly improved, and the problemthat forging deformation is uneven at positions such as each hammer head, and a joint of the hammer heads during upper and lower anvil forging is also overcome, and therefore, the inner part of the forged piece is forged thoroughly and compacted, and a uniform fine grain structure is obtained; upset electroslag ingots are mainly deformed on upper and lower wide plates, and integral once formationis performed until design dimensions at every pass in a wide plate forging process, and reduction is controlled to be 25%-40%; the electroslag ingots are integrally forged until deformed to the designed dimensions between upper and lower flat plates after being turned over by 90 degrees, and 700mm-wide upper and lower nails are adopted for forging and forming so as to conveniently erecting angles, so that the uneven forging deformation problem of the hammer head during main deformation is avoided, forging permeability is improved, anvil replacing times are reduced, forging time is saved by about 1 / 2, forging production efficiency is improved, production cost is reduced, and product quality stability is high.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

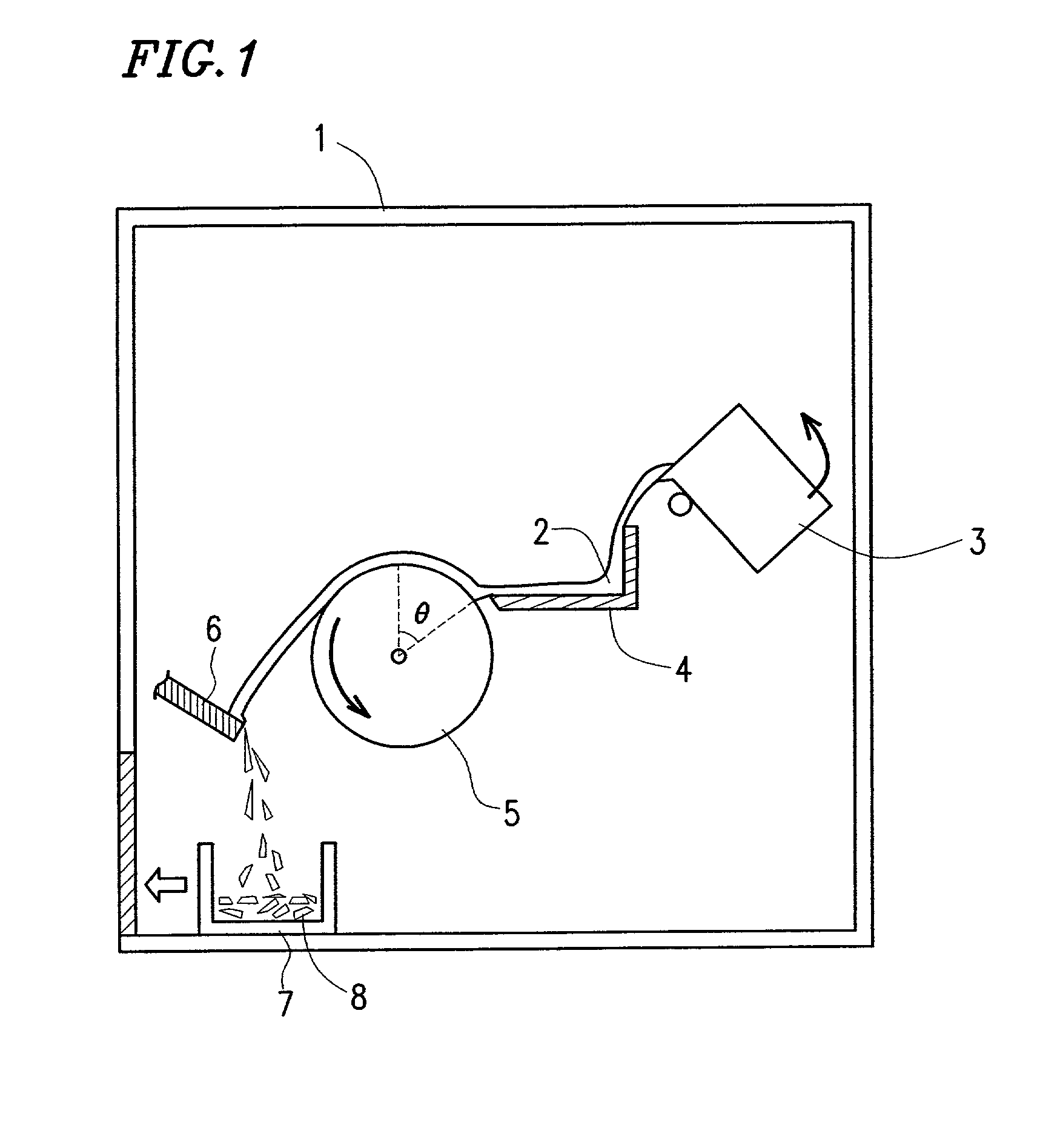

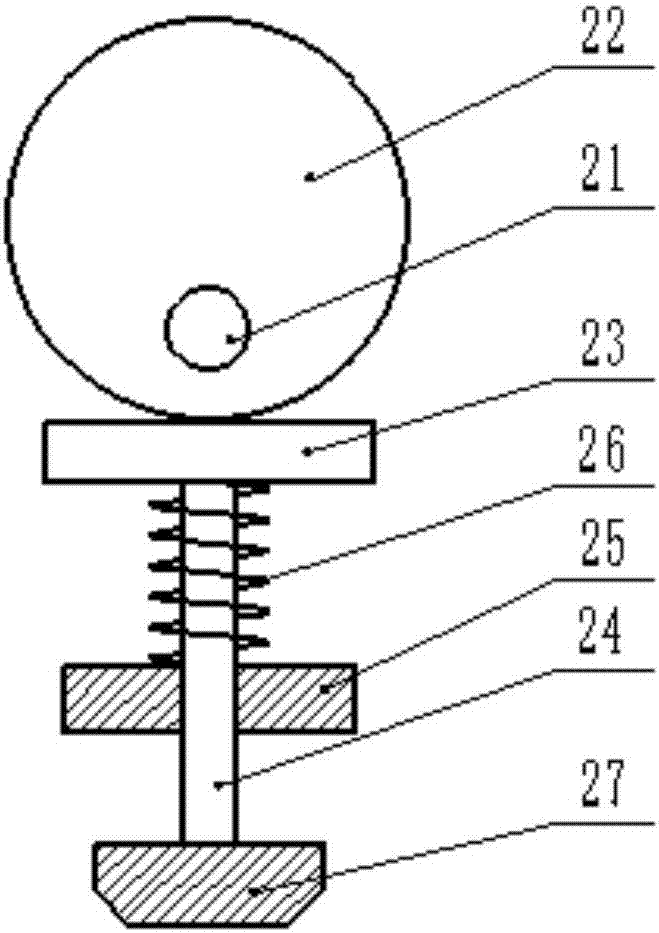

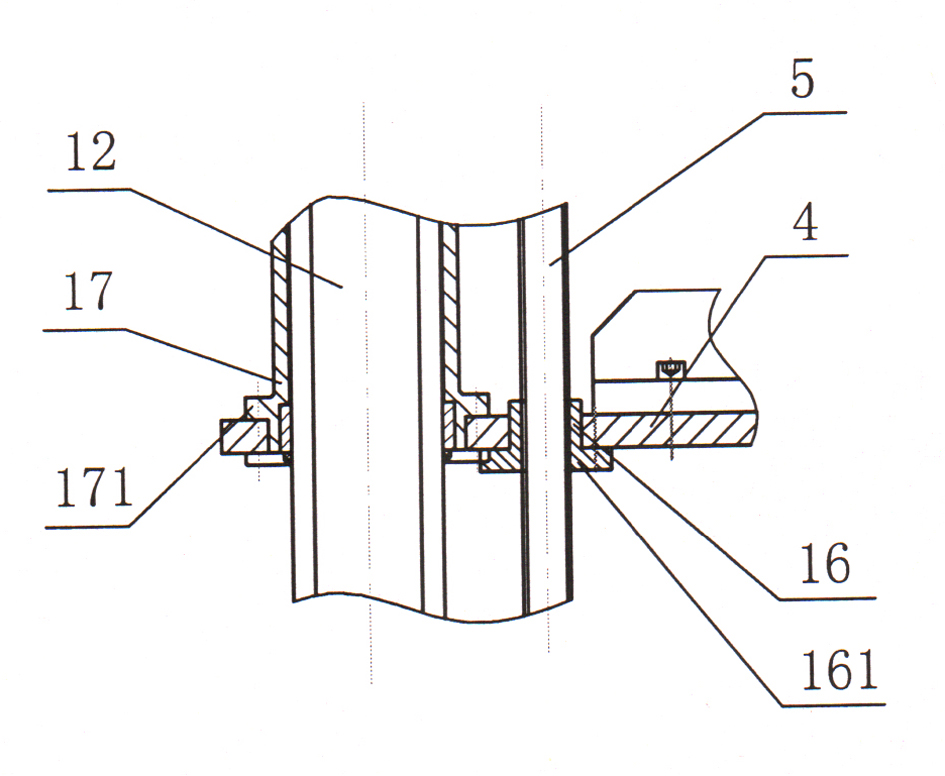

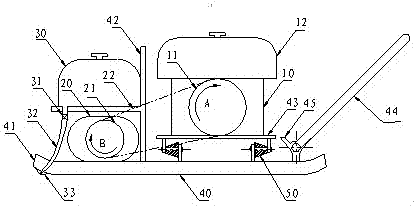

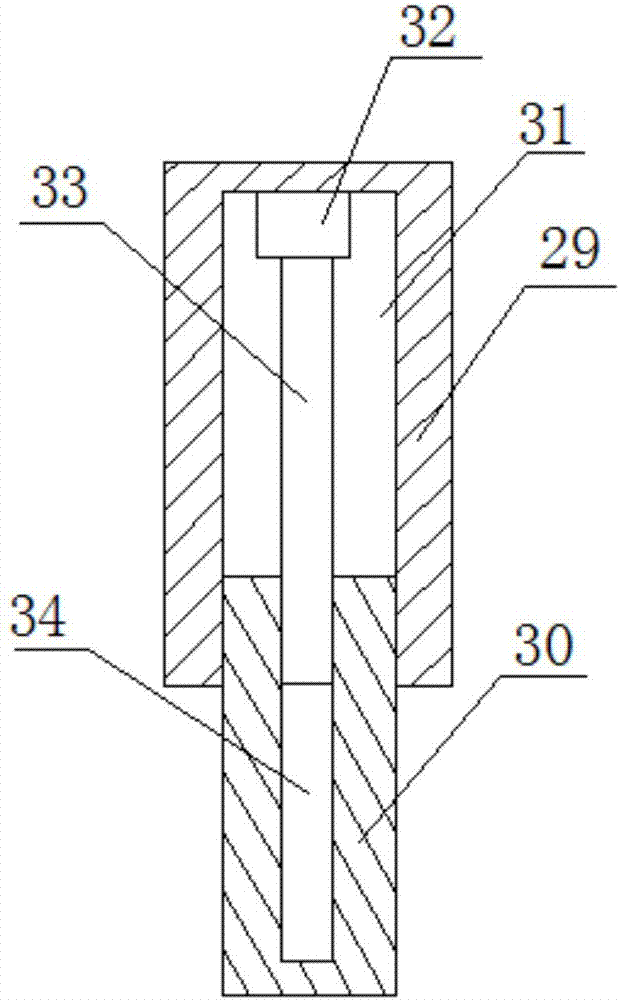

Automatic sand pack tube model compaction device for physical simulation

InactiveCN102022114APlay a guiding roleEven by forceBorehole/well accessoriesHydraulic cylinderEngineering

The invention relates to an automatic sand pack tube model compaction device for physical simulation, mainly solving the problem of poor compaction effect caused by small manual sand pack stress and uneven stress in the existing manufacturing process of the sand pack tube model. The device is characterized in that a slider in sliding fit with a slide guide bar is arranged at the external of the slide guide bar, the external of the slider is provided with a boss B, a transmission screw rod is engaged with a gear arranged at the external of the transmission screw rod, and the external of the gear is provided with a boss A. The slider and the gear both pass through a horizontal support beam and are respectively connected with the support beam through the boss B and the boss A. The middle of the support beam is fixedly connected with a hydraulic cylinder vertical to the support beam, and the hydraulic cylinder and a hydraulic pushrod arranged below the hydraulic cylinder are vertically aligned with the sand pack tube. By using the compaction device, manual compaction is replaced by machinery compaction of a hydraulic cylinder plunger, therefore, the compaction device has the characteristics of reduced labor intensity of the workers, even stress on the sand pack tube, and good compaction effect.

Owner:DAQING OILFIELD CO LTD

Concrete laser leveling machine

InactiveCN103758351AEasy to operateImprove the leveling effectBuilding material handlingComputer control systemLeveling effect

The invention provides a concrete laser leveling machine which comprises a frame, a laser system and a computer control system. The laser system and the computer control system coordinate to form a horizontal-detection control loop, and a high-precision horizontal detection and control method is created. The concrete laser leveling machine has the advantages that the machine is convenient to operate, good in leveling effect, good in concrete ground tamping effect, low in high-low error, and efficient in floor operation; the machine can be operated through remote control, an operator can observe the machine operation and ground conditions favorably, and operation efficiency can be increased, and operation effect can be guaranteed; the concrete machine can rotate 360 degrees without moving the body of the machine, leveling operations can be performed in narrow and limited spaces, and the machine is wide in work application range.

Owner:于海

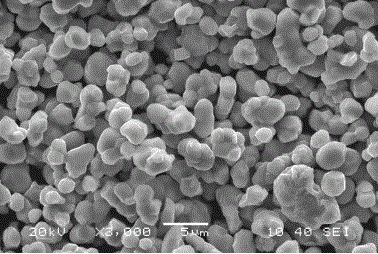

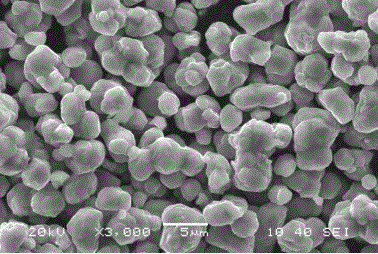

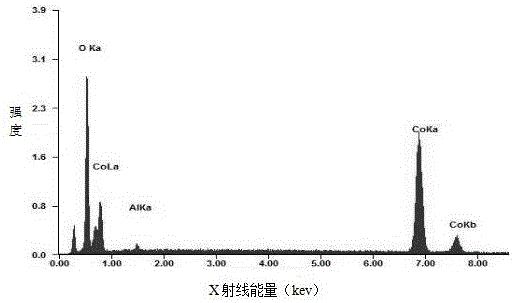

High-temperature rate type lithium cobalt oxide anode material and preparation method thereof

ActiveCN105826553AShort de-embedding pathUniform particle distributionCell electrodesCobalt compoundsPhysical chemistryMaterials science

The invention discloses a high-temperature rate type lithium cobalt oxide anode material .The anode material is formed by doping lithium cobalt oxide with metallic elements M .The molecular formula of the anode material is LirCo(1-x)MxO2, wherein 1.00<=1<=1.10, 0.002<=x<=0.005, and the metallic elements M include at least one of Al, Y and Mg .The surface morphology of the lithium cobalt oxide anode material is in a highly agglomerated state that primary particles are closely fused, particle distribution is uniform, fluidity is good, the compaction performance is good, and the rate performance can be improved; the morphology is well kept in the finished lithium cobalt oxide anode material according to the characteristic that the metal elements are uniformly distributed, so that the structural stability of lithium cobalt oxide in the charging and discharging process is improved, the rate discharge performance is improved, the material can adapt to an environment at higher temperature, and therefore the lithium cobalt oxide anode material can have good rate performance in both a normal temperature environment and the high-temperature environment .The invention further provides a preparation method of the high-temperature rate type lithium cobalt oxide anode material .By means of the method, steps are simple and easy to implement, operation is convenient, and cost is low.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

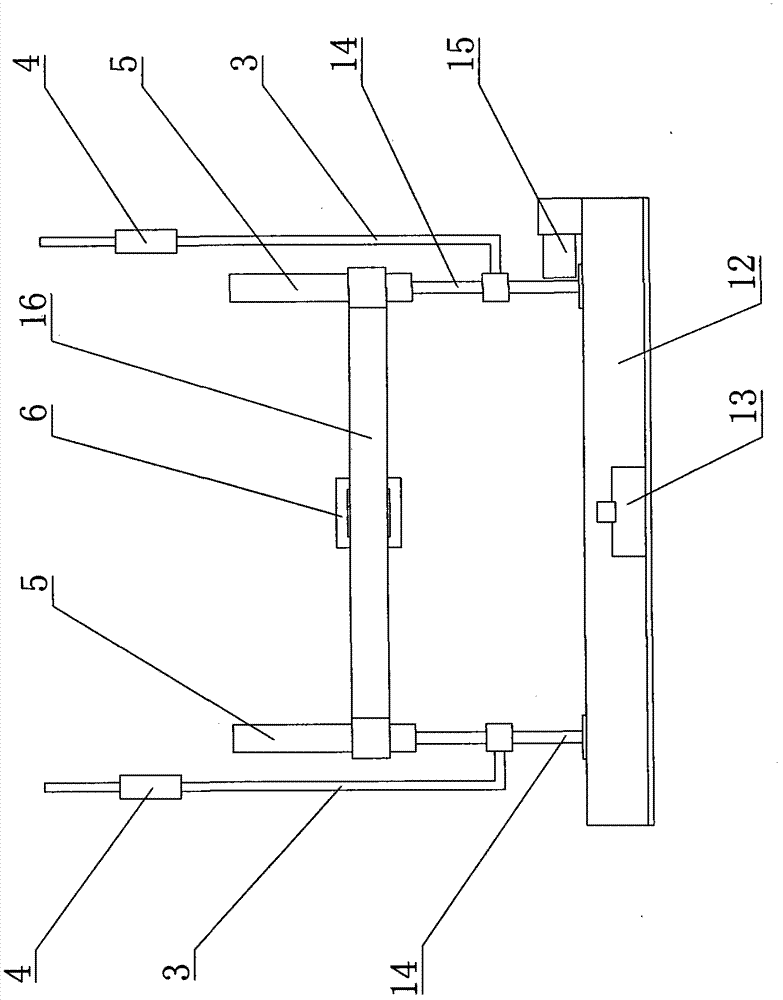

Efficient horizontal parting type removable flask molding machine and molding method thereof

ActiveCN107321933AImprove compaction uniformityGood molding effectMoulding machinesMould controlling devicesMolding machineSand blasting

The invention relates to an efficient horizontal parting type removable flask molding machine and a molding method thereof. A lower molding flask module is arranged on a rack and comprises a lower enclosing frame. A lower push plate is slidably arranged in the lower enclosing frame. The lower enclosing frame is connected with a first driving device. The lower push plate is connected with a second driving device. The efficient horizontal parting type removable flask molding machine further comprises an upper molding flask module. The upper molding flask module comprises an upper enclosing frame fixed to the rack. An upper push plate is slidably arranged in the upper enclosing frame and connected with a third driving device. The efficient horizontal parting type removable flask molding machine further comprises a sand blasting nozzle seat fixedly connected with the upper enclosing frame, and the sand blasting nozzle seat is connected with a pressure sand blasting system. The upper enclosing frame and the lower enclosing frame are provided with sand inlet channels communicating with the pressure sand blasting system correspondingly. Attaching air bags are arranged on the lower surface of the upper push plate, and the upper surface of the lower push plate correspondingly; pressure sensors are arranged on the surfaces of the attaching air bags; and the upper enclosing frame and the lower enclosing frame are internally provided with limit switches correspondingly. The influences of gas in a molding flask on sand blasting and compaction are avoided, the uniformity of molding sand compaction is high, and the size, shape and precision of a poured casting are well ensured.

Owner:湖北腾越机械制造有限公司

Portable plate tamper

InactiveCN102561157ACompact structureImprove the effectRoads maintainenceEngineeringVibration damper

The invention relates to a portable plate tamper comprising a power device, a vibration generator, a watering device, a plate tamper body and a vibration damper, wherein the plate tamper body is provided with a smooth bottom surface, the power device; the vibration generator, the watering device and the vibration damper are arranged on the plate tamper body; the vibration generator comprises an eccentric vibration generating body, the vibration generating body rotates to drive the plate tamper to vibrate up and down; the watering device is arranged at the advancing front end of the plate tamper; and the vibration damper comprises at least one vibration damping body which is an elastic piece, the vibration damper is fixed on the plate tamper body, and the power device is arranged above the vibration damper. The portable plate tamper disclosed by the invention has a compact structure; the eccentric vibration generating body rotates to drive the whole plate tamper to vibrate up and down so that a pavement is tamped. The plate tamper is further provided with the watering device and the vibration damper so that not only further the effect of pavement tamping is improved and simultaneously the service life of the plate tamper is prolonged.

Owner:ANHUI SANJING ENG MACHINE

Three-phase transformer iron core silicon steel sheet stacking equipment

PendingCN114156078AGuaranteed uniformityQuick compressionInductances/transformers/magnets manufactureTransformerWorkbench

The invention relates to three-phase transformer iron core silicon steel sheet stacking equipment which comprises a workbench, a conveying device and a moving device. The conveying device and the moving device are sequentially arranged on the upper end face of the workbench from left to right; and the moving device comprises a C-shaped plate, a first rectangular through groove, a rotating rod, a round head plate, a moving frame, a limiting frame, a horizontal plate, a clamping frame and an extrusion frame. The transformer iron core silicon steel sheets do not need to be manually stacked one by one, and the problems that operation is tedious and labor force is increased due to traditional manual stacking are solved; according to the transformer iron core silicon steel sheet arranging and limiting device, stacked transformer iron core silicon steel sheets can be rapidly arranged and limited, so that the uniformity of the stacked transformer iron core silicon steel sheets is guaranteed, the stacked transformer iron core silicon steel sheets can be rapidly pressed, and the pressing effect is improved.

Owner:邵雅哥

A tamping apparatus for road engineering

The invention belongs to the technical field of tamping apparatuses, in particular to a tamping apparatus for road engineering. Aiming to solve problems that local cavities in the road surface, uneventamping, a lot of dust during work and inconvenient movement are likely to occur, the invention proposes the following scheme: the tamping apparatus comprises a bottom plate and a mounting rack; theouter walls on both sides of the top end of the bottom plate are fixed by bolts with vertically arranged positioning posts; the outer wall of one side of the top end of the bottom plate is fixed witha vibration motor by bolts; the side walls of the two positioning posts are sleeved with connecting sleeves; and the two connecting sleeves are respectively fixed by bolts at intermediate positions onthe outer walls of the two sides of the mounting rack; and shock absorbing rods are hinged at positions, close to four corner portions, of the outer wall of the two sides of the mounting rack. The tamping apparatus of the invention can realize graded tamping, improve the tamping effect, make the tamping more uniform, avoid the local cavity phenomenon, collect dust, reduce the amount of dust in the working process and improve the working environment.

Owner:明磊建设集团有限公司

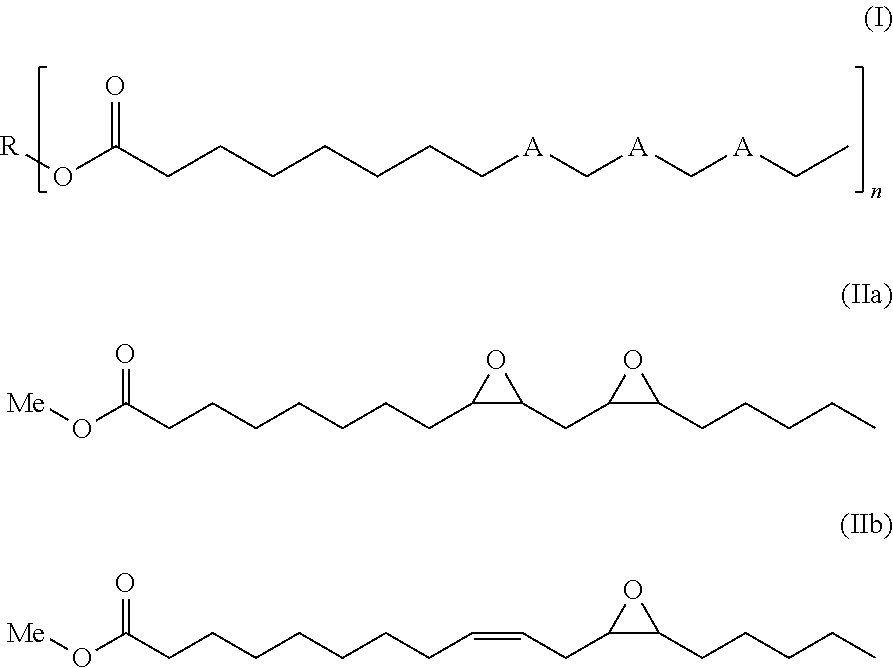

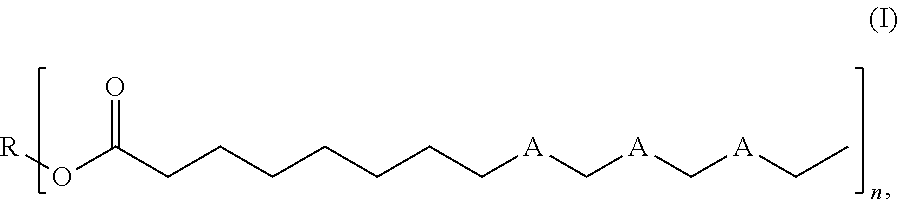

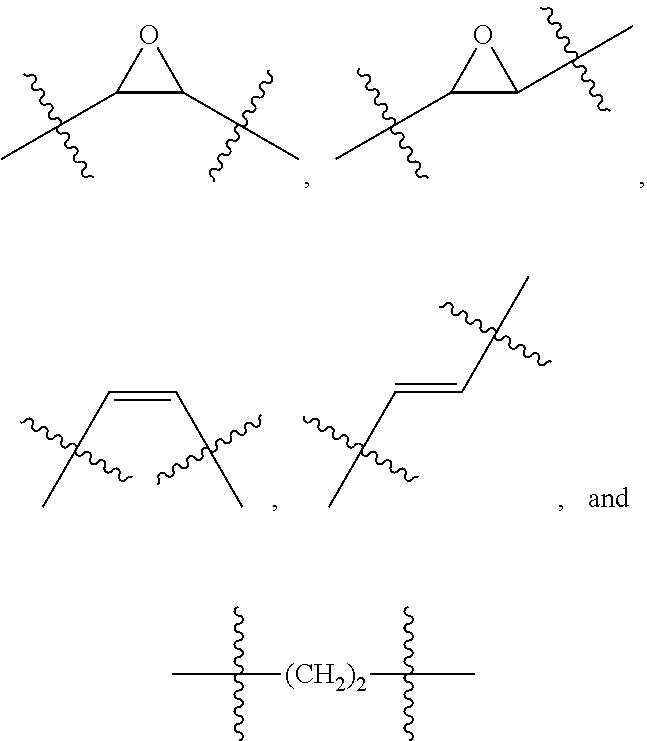

Improved asphalt products and materials and methods of producing them

ActiveUS20170283615A1Reduce mixing and compaction temperatureEmission reductionOrganic chemistryClimate change adaptationPolymer sciencePolymer modified

The present invention relates to a method of producing an improved asphalt. The method involves providing an asphalt and providing a compound of formula (I), as described herein. The asphalt is mixed with the compound of formula (I) under conditions effective to produce an improved asphalt. Also disclosed are an asphalt product and a method of making asphalt material. The invention further discloses a method of producing an improved asphalt comprising providing a polymer modified asphalt and providing a compound of formula (IIa) or formula (II). The polymer modified asphalt is mixed with the compound of formula (IIa) or formula (IIb) under conditions effective to produce an improved asphalt, which is yet another aspect of the present invention.

Owner:IOWA STATE UNIV RES FOUND

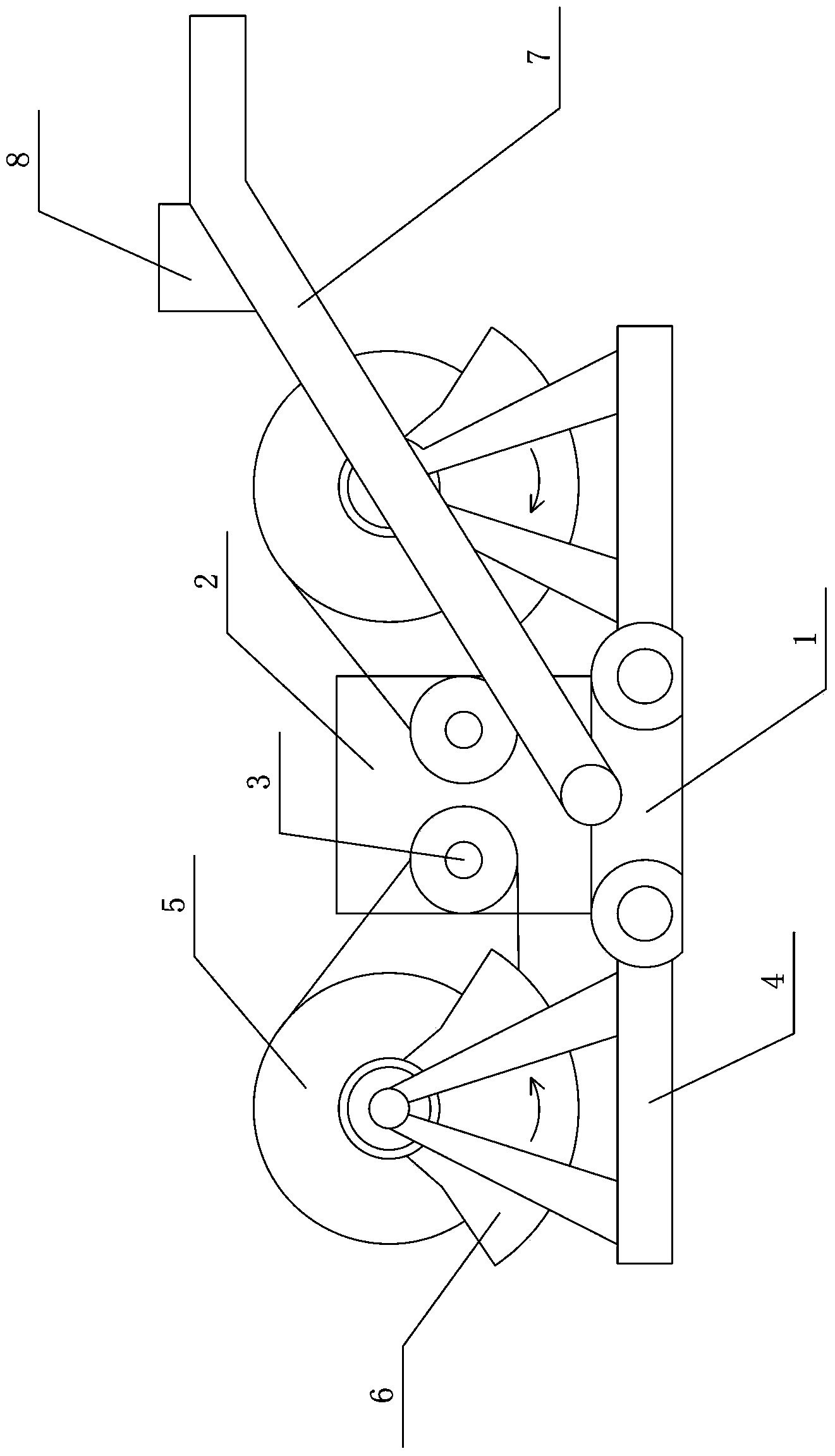

Novel double-wheel type flat ground rammer compactor

InactiveCN104141296ASimple structureGood compaction effectRoads maintainenceSoil preservationElectric machineMechanical equipment

The invention relates to a novel double-wheel type flat ground rammer compactor, in particular to the technical field of mechanical equipment. A motor case (2) is arranged on a chassis base (1), a motor set (3) is arranged inside the motor case (2), the two sides of the chassis base (1) are connected with compaction steel plates (4) through a movable bearing, round rotating wheels (5) are arranged on the compaction steel plates (4), eccentric arc-shaped wheels (6) are arranged on the outer sides of the round rotating wheels (5), the round rotating wheels (5) are connected with the motor set (3) through belt wheels, a handle (7) is connected to the middle of the chassis base (1), and a control switch (8) is arranged on the handle (7). The rammer compactor is simple in structure, a double-face compaction structure is adopted, and therefore the compaction effect is more obvious, the compaction efficiency is improved, and time is saved.

Owner:KUNSHAN RUIHENGFENG TECH CONSULTING

Ramming machine for dustproof building construction

The invention discloses a ramming machine for dustproof building construction. The ramming machine comprises an underframe, an extensible device is arranged at each of four corners on the lower side of the underframe, a universal wheel is arranged at the lower end of each extensible device, each extensible device comprises a supporting rod and an extensible rod, a cavity is arranged on each supporting rod, a motor is arranged inside each cavity, a threaded rod is arranged at an output end of each motor, a threaded cavity is formed in each threaded rod, each threaded rod and the corresponding threaded cavity are in threaded connection, a ramming box is arranged on the upper side of the underframe, a dust suction box is arranged at the upper end of the ramming box, a dust suction cavity anda water cavity are arranged inside the dust suction box, a fan is arranged at the right end of the dust suction cavity, a dust suction pipe is arranged on the fan, a dust suction cover positioned on the outer side of a ramming hammer is arranged on the lower side of the underframe, the dust suction pipe is connected with the dust suction cover, a first water pump is arranged on the left side of the dust suction cavity, a water delivery pipe is arranged on the first water pump, and a spraying nozzle positioned on the lower side of the underframe is arranged at the lower end of the water delivery pipe.The ramming machine is simple in structure, convenient to use, good in dust suction effect and long in service period and service life.

Owner:王新念

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com