Automatic sand pack tube model compaction device for physical simulation

A technology of automatic compaction and physical simulation, applied in wellbore/well components, earthwork drilling, etc., can solve the problems of low artificial sand filling force, poor compaction effect, uneven force, etc., and achieve good compaction effect, The effect of uniform force and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

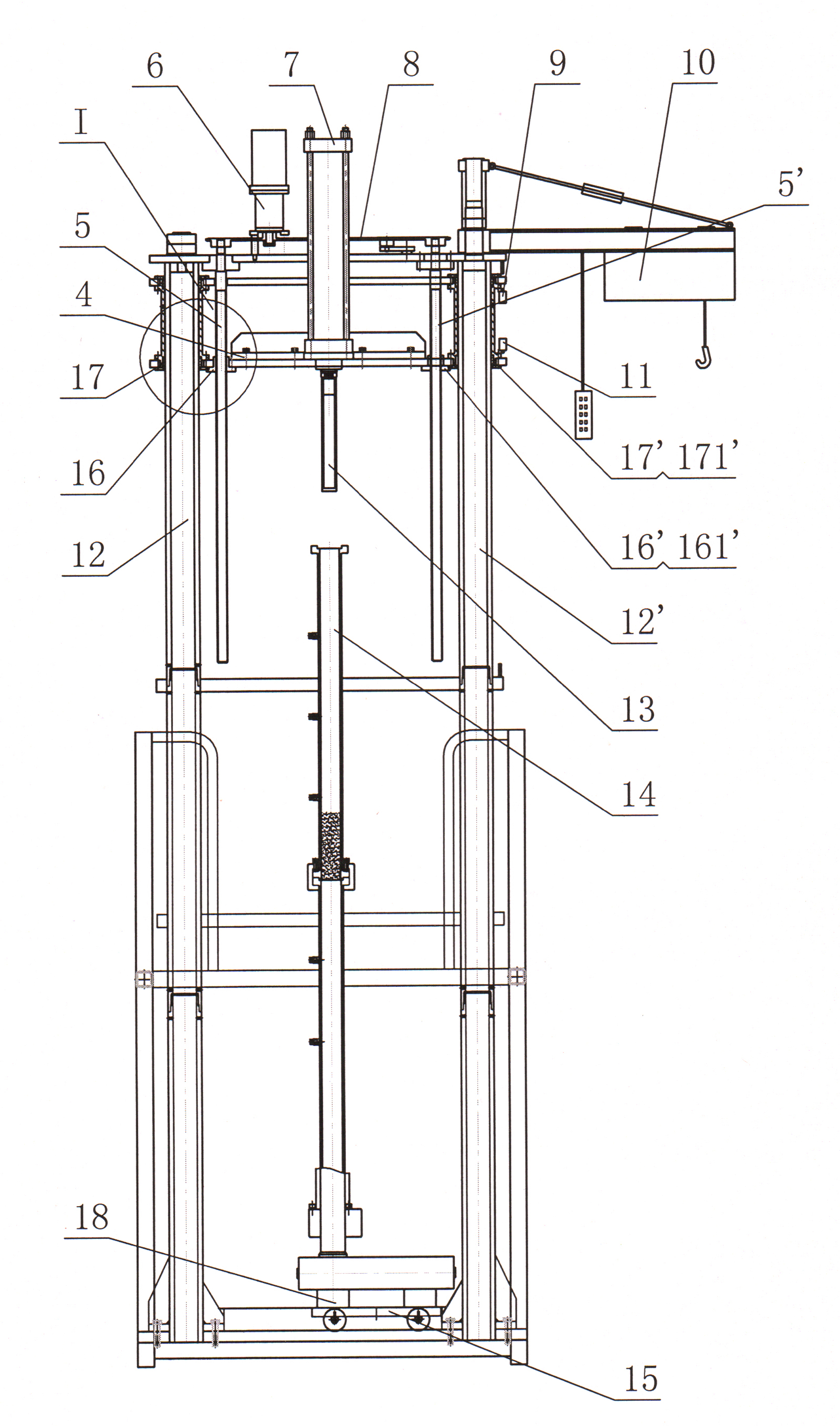

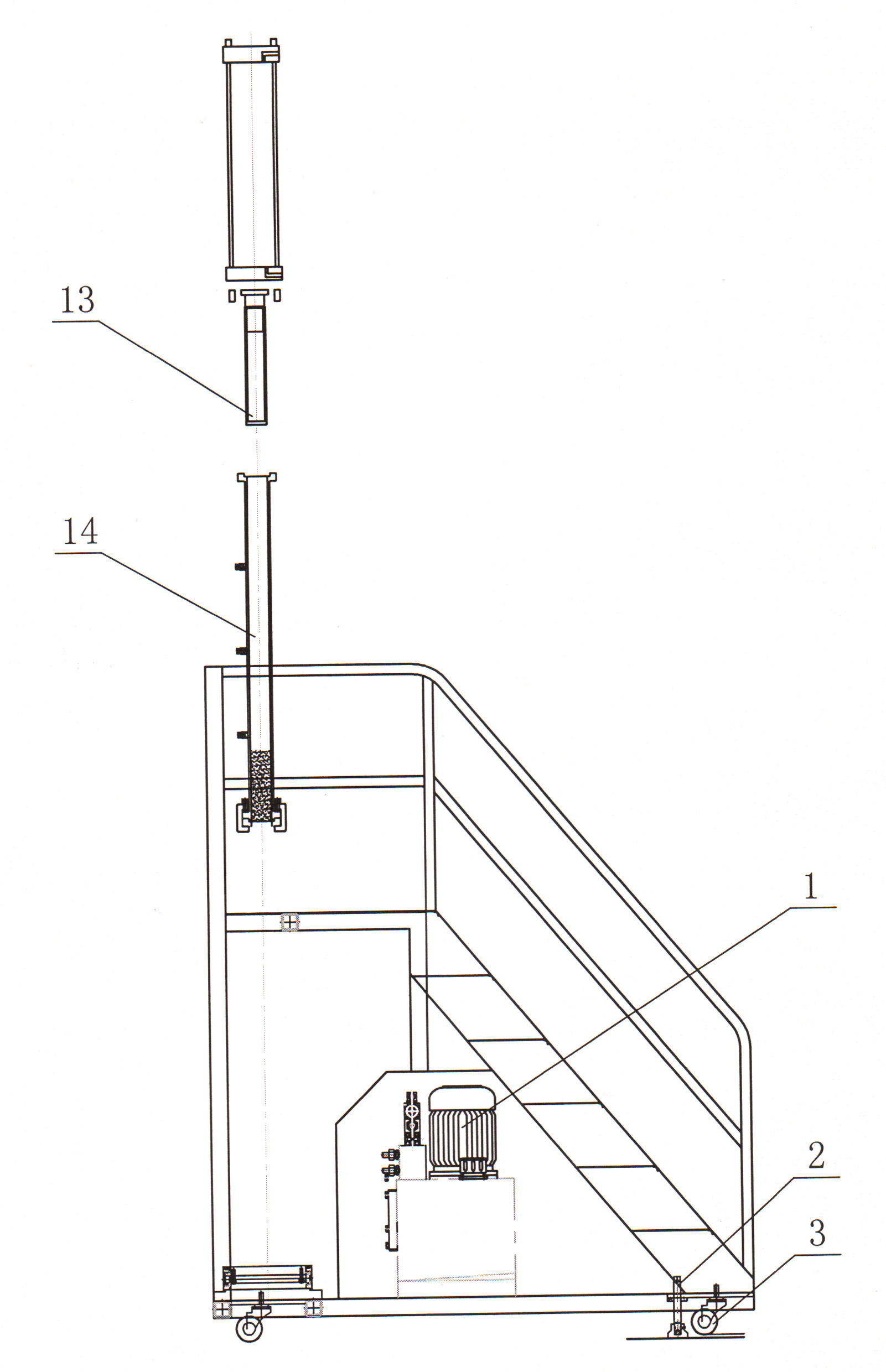

[0016] The present invention will be further described below in conjunction with accompanying drawing:

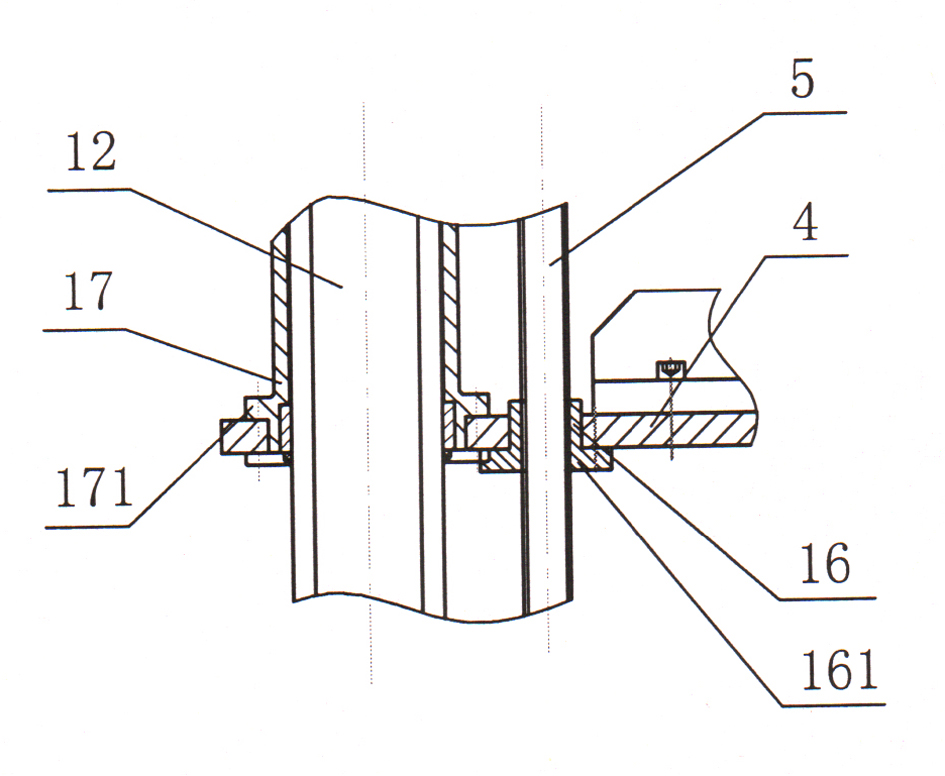

[0017] Depend on figure 1 combine figure 2 As shown, an automatic compaction device for a sand filling pipe model for physical simulation, including a left slideway guide rod 12, a right slideway guide rod 12', a left driving screw 5, a right driving screw 5', and a sand filling pipe 14 , the left drive screw 5 and the right drive screw 5' are connected to the reduction motor 6 through a chain 8, the left slider 17 is placed on the left slideway guide rod 12, and can slide on it, and the left slider There is a boss B171 on the outside of 17, and the left drive screw 5 meshes with the left gear 16 outside it, and there is a boss A161 on the left gear 16, and the left slider 17 is connected to the boss A161 of the left gear 16 through the boss B171 connect. The right slide block 17' is placed on the right slideway guide rod 12' and can slide on it, and the outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com