Acetabulum parastyle and posterior column united steel plate

A technology of anterior and posterior columns and steel plates, applied in the direction of outer plates, internal bone synthesis, fixers, etc., can solve problems such as increased infection rates, excessive bleeding, and redisplacement of fracture fragments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

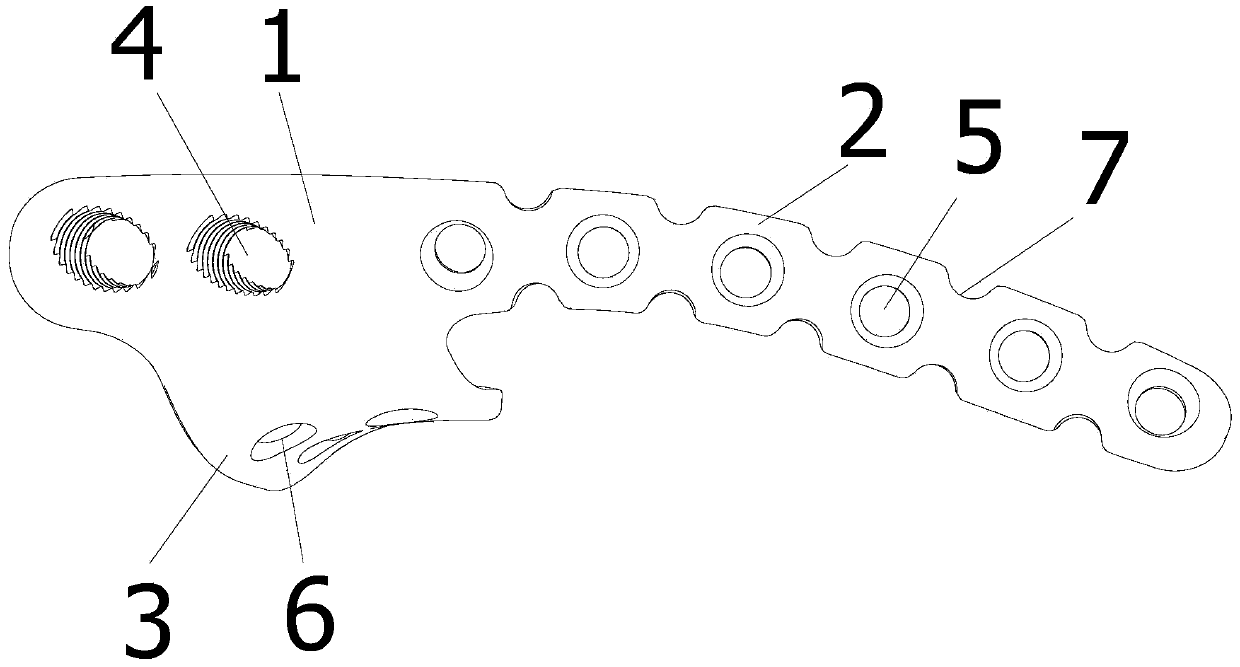

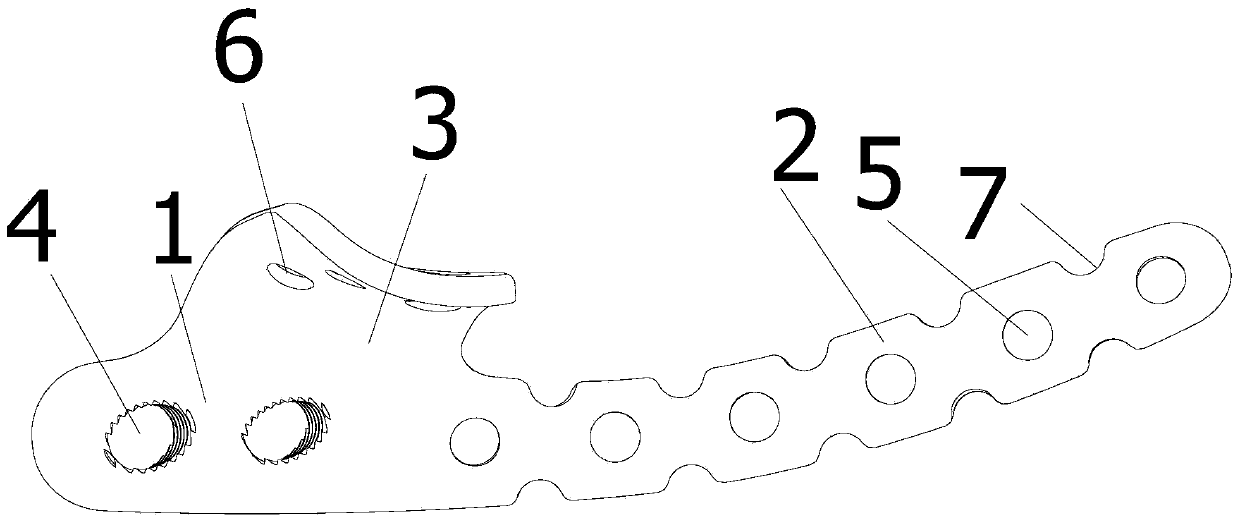

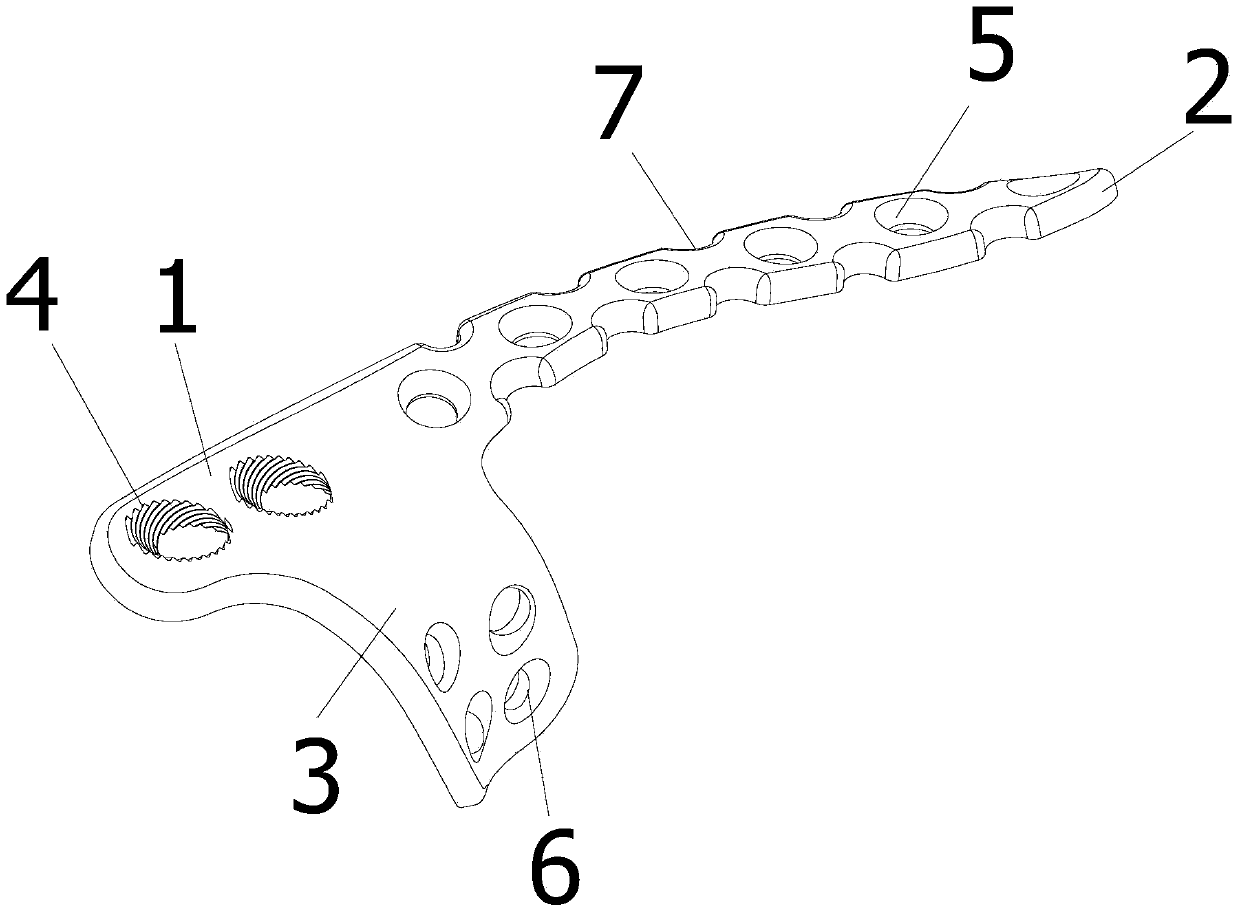

[0026] Such as Figure 1 to Figure 4 The combined plate of the anterior and posterior columns of the acetabulum shown is composed of the main plate 1, the anterior column plate 2 and the baffle plate 3, wherein,

[0027] The main board 1 is provided with two threaded holes 4 connected to the rear column locking screw sleeve 14, the threaded holes 4 are arranged along the arcuate edge 12 from the proximal arcuate edge surface 9 of the iliac fossa, and each threaded hole 4 the axis is vertical;

[0028] The baffle plate 3 is formed by one side of the main board 1 bending downwards and extending to the square area 11 above the ischial spine 15, and the curved surface formed by the lower surfaces of the two is compatible with the corresponding arcuate edge surface 9 of the iliac fossa. The surface of a segment of the arcuate edge 12 from the front edge of the sacroiliac j...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com