Clamping spring feeding, pressing and mounting device of clutch master cylinder

A circlip and card feeding technology, which is applied in the field of clutch master cylinder circlip feeding and pressing device, can solve the problems of unstable feeding speed, high cost, low efficiency, etc., and achieve the effect of flexible action and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

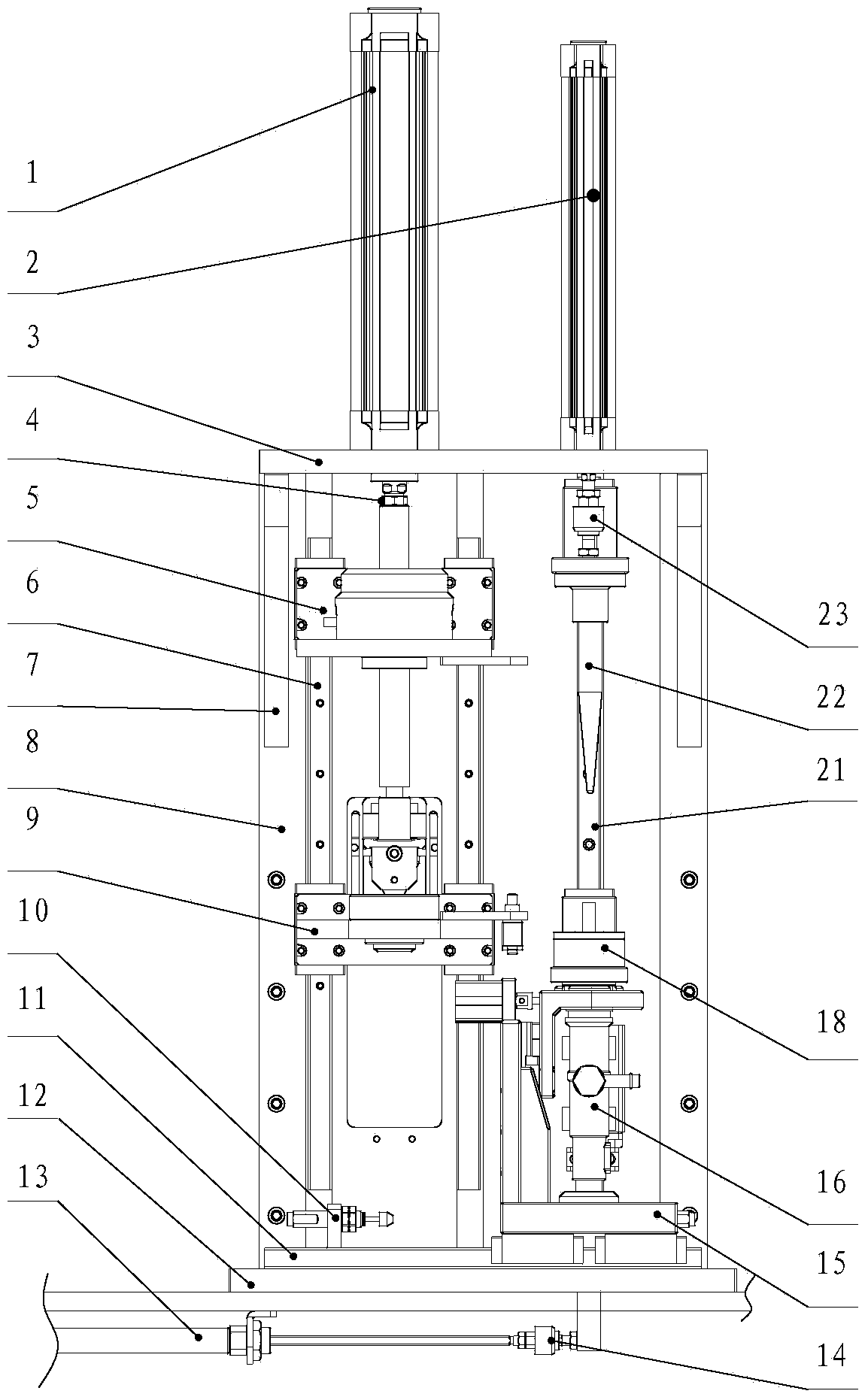

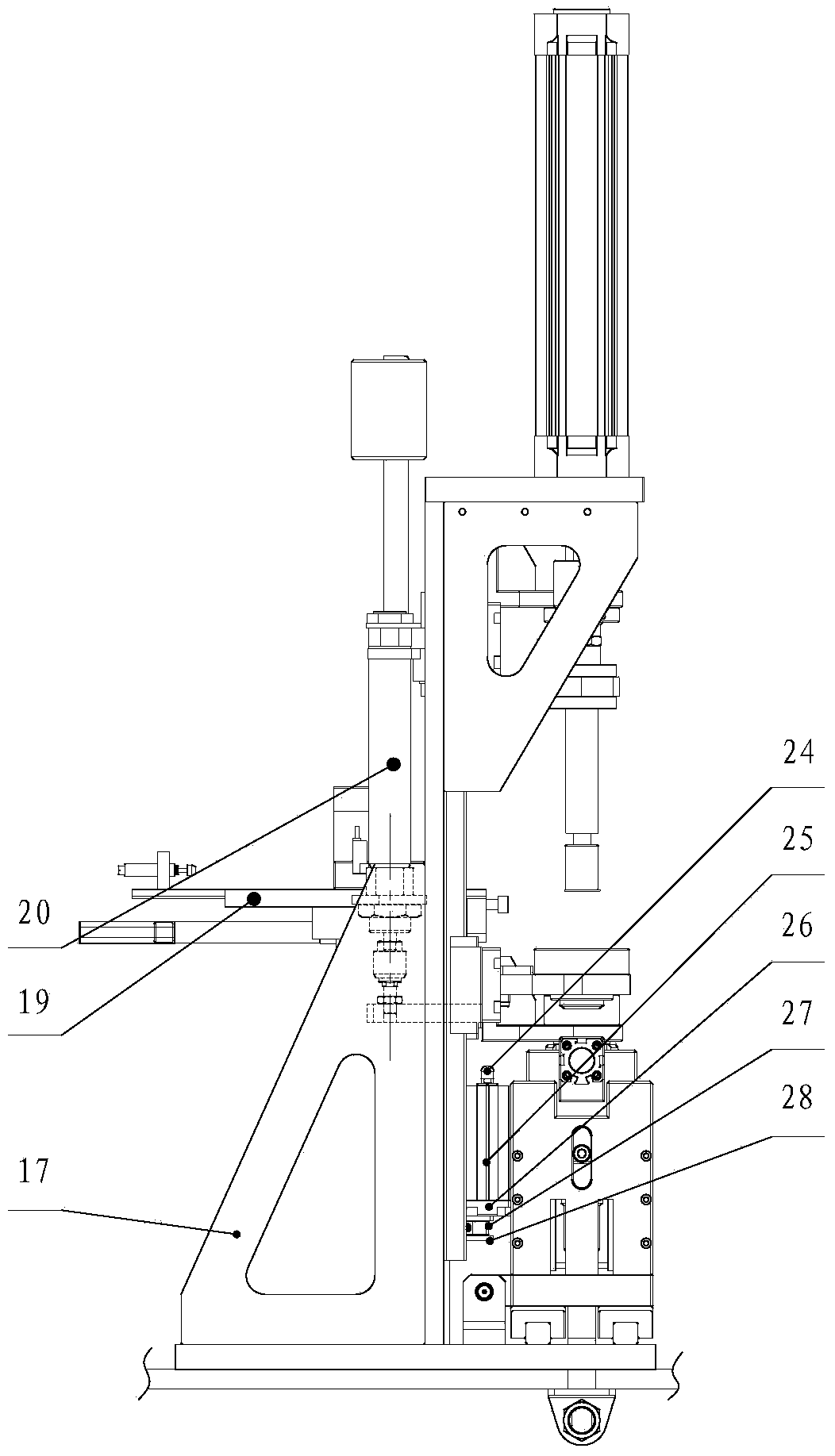

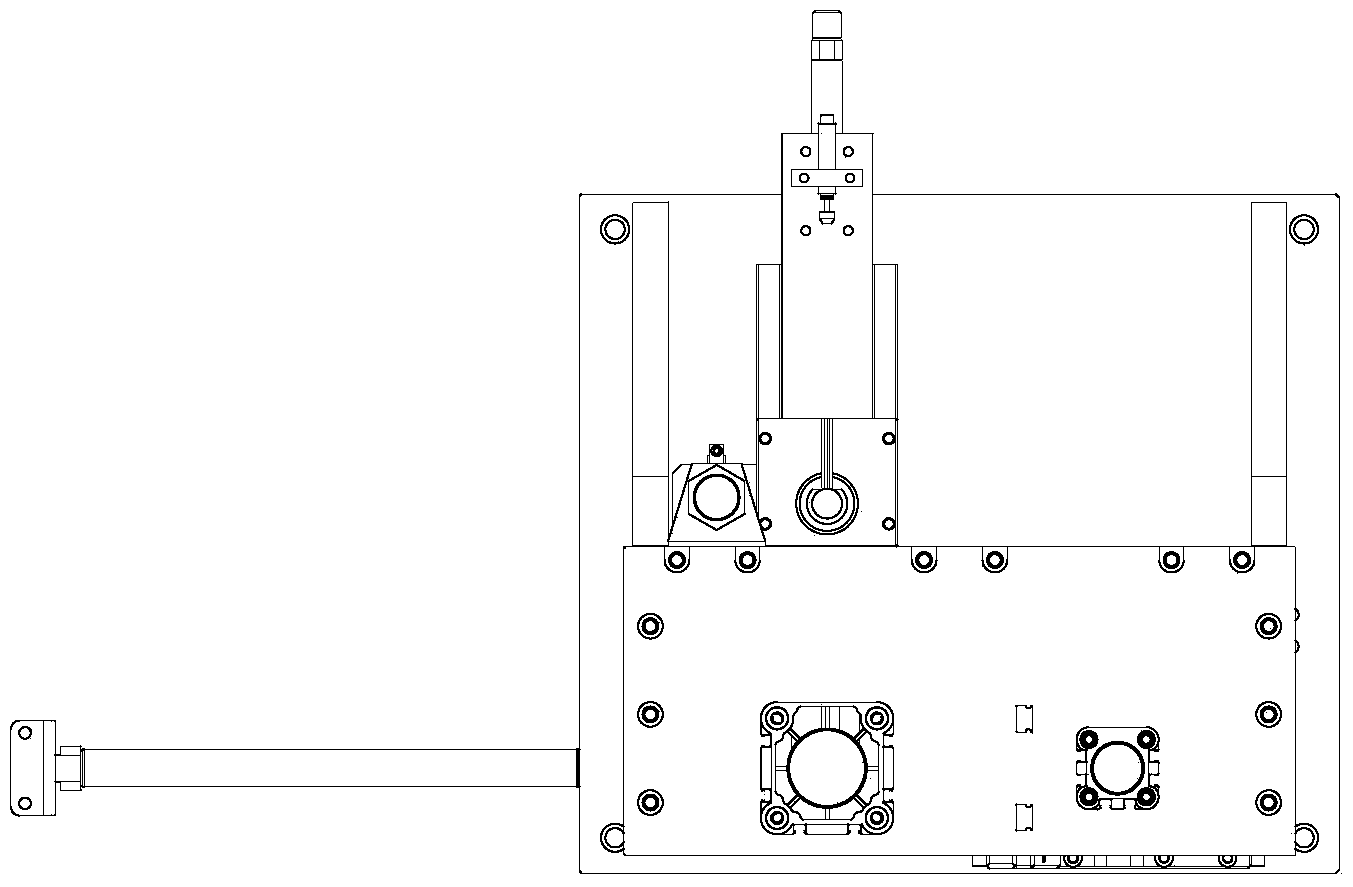

[0031] Further illustrate the present invention below in conjunction with accompanying drawing.

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a clutch master cylinder circlip feeding and pressing device mainly includes a positioning mechanism 15, a piston depressing mechanism 22, a piston grease coating mechanism 18, a circlip feeding mechanism 19, a circlip guiding mechanism 9 and a circlip depressing mechanism 5.

[0033] Such as Figure 5 As shown, the positioning mechanism includes an upper positioning sleeve 41, a lower positioning sleeve 31, a limit sleeve 35, a blocking cylinder 38, a limit push rod 40, a blocking cylinder connecting rod 39, a miniature linear guide rail 34, and a third floating joint connection Block 29, positioning mechanism base plate 30, positioning mechanism rib plate 32, positioning mechanism vertical plate 33, positioning seat 36 and blocking cylinder mounting frame 37;

[0034] One side of the positioning mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com