Patents

Literature

66 results about "Acetabular bone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

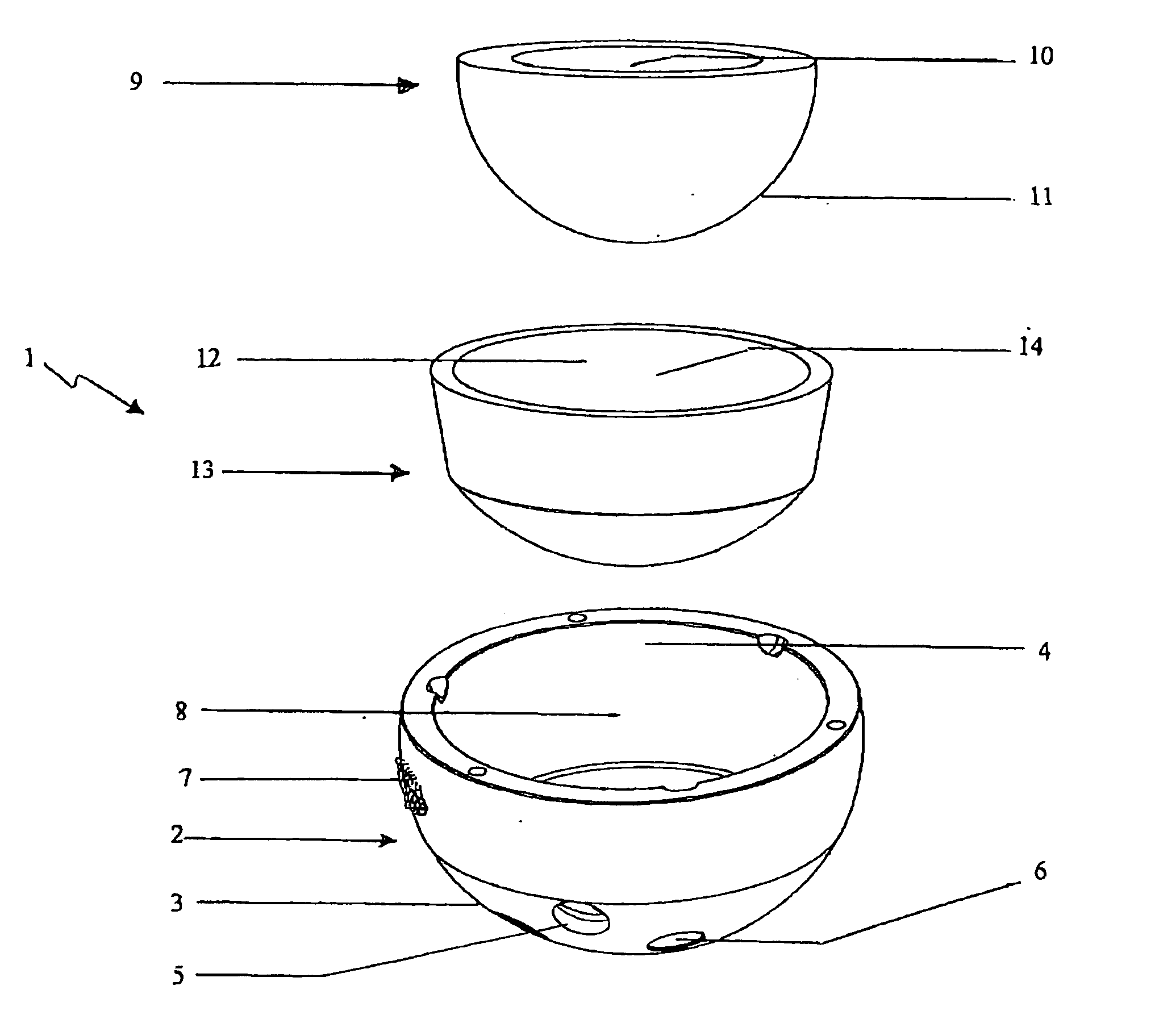

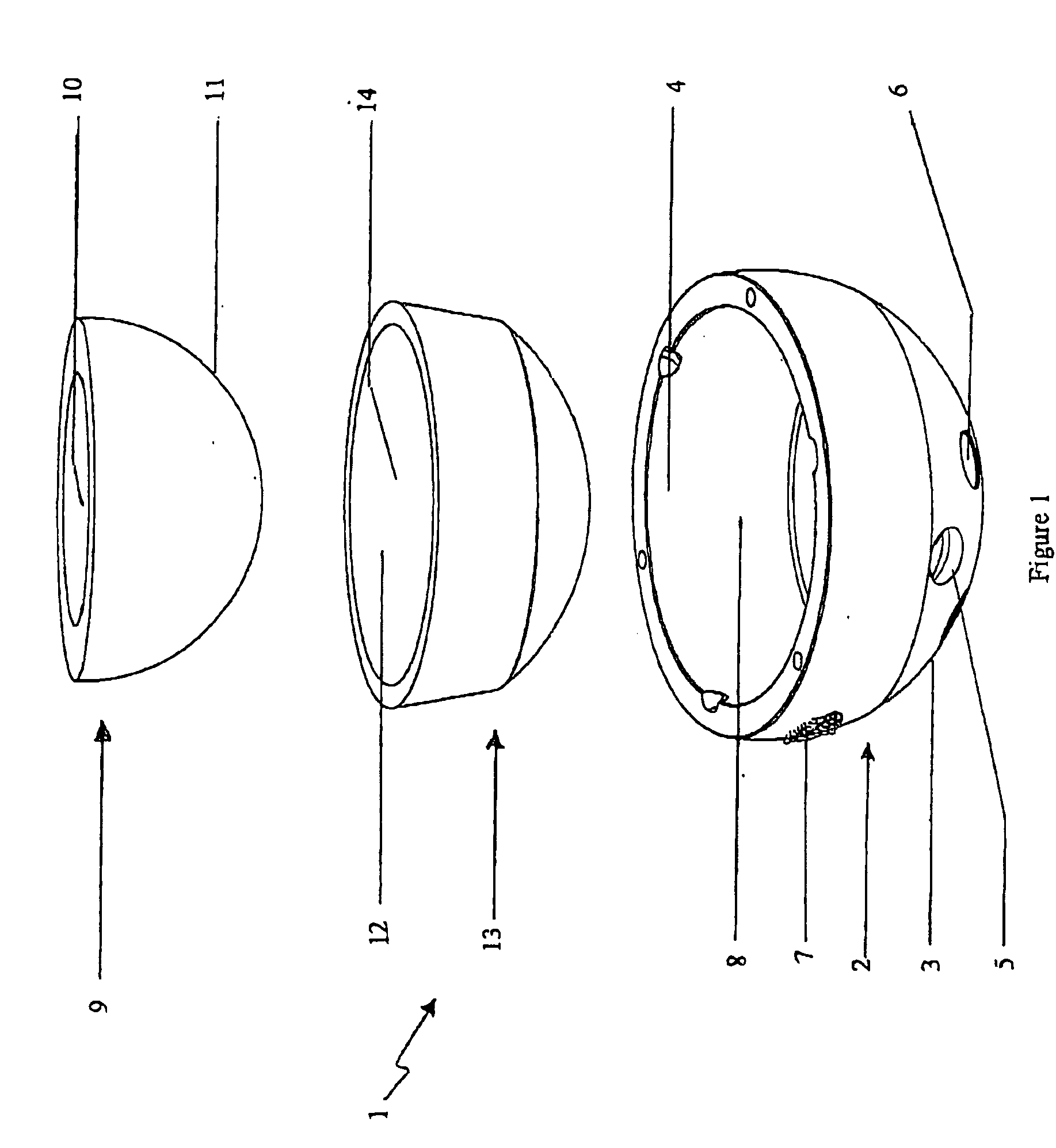

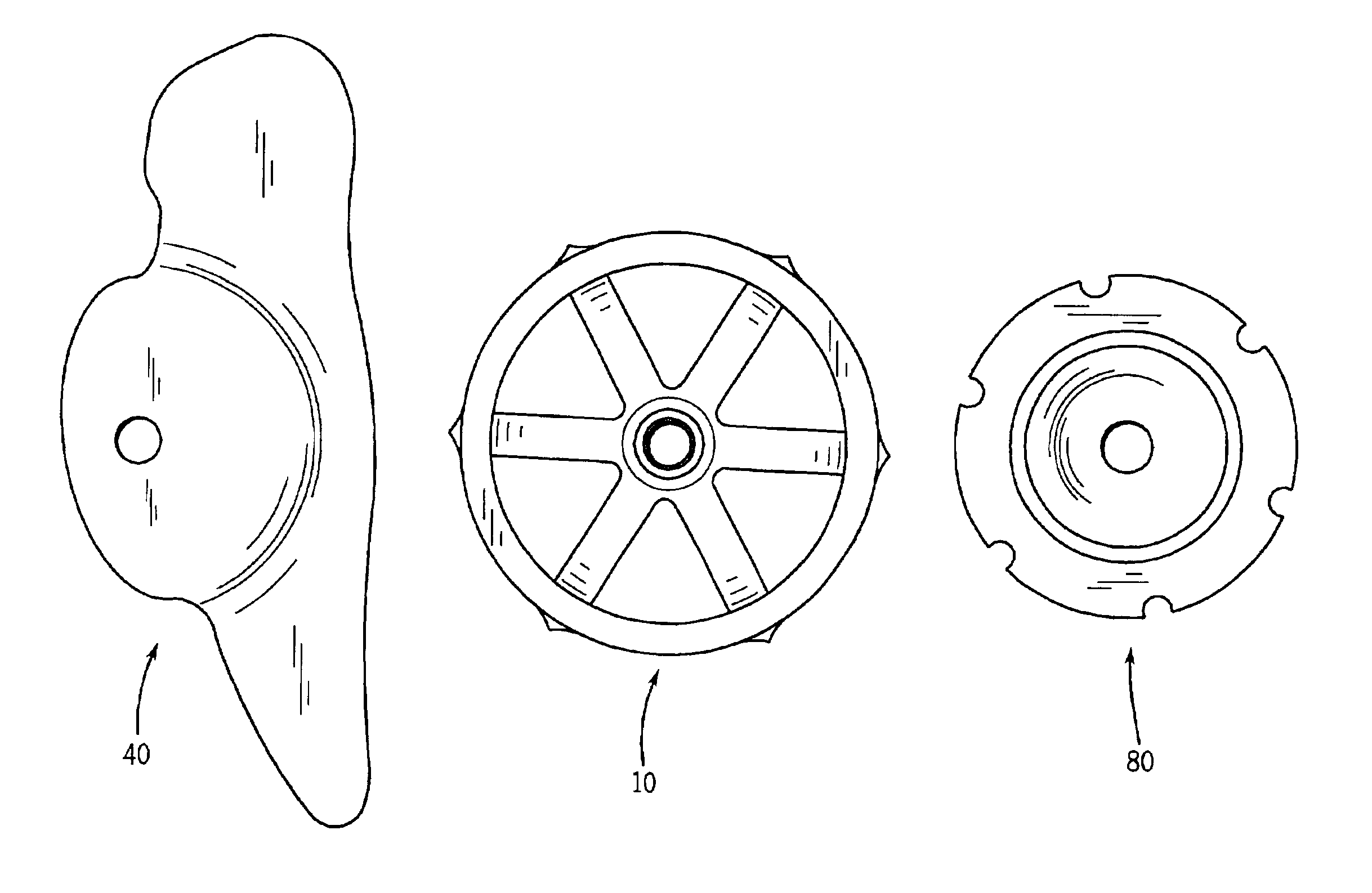

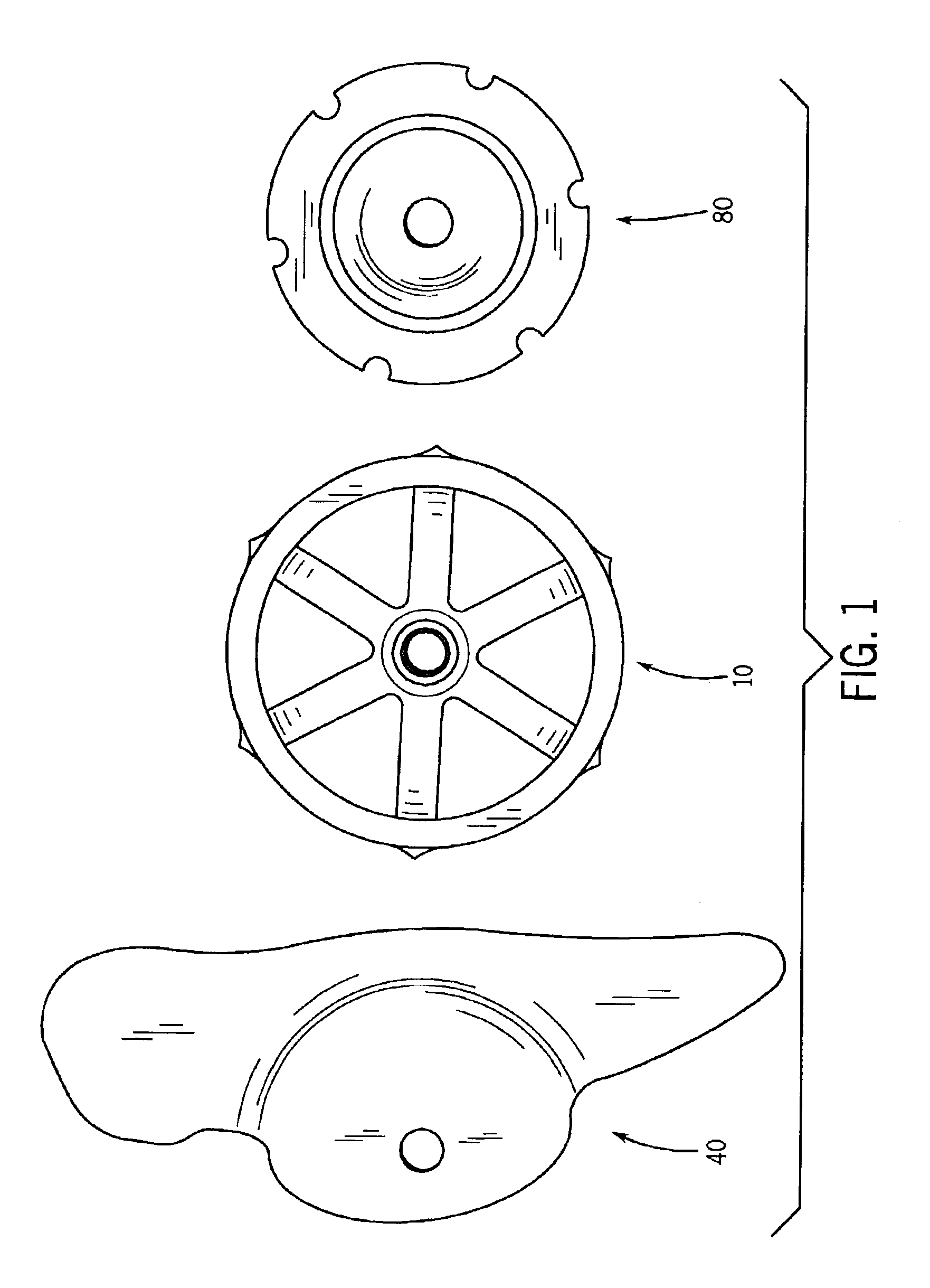

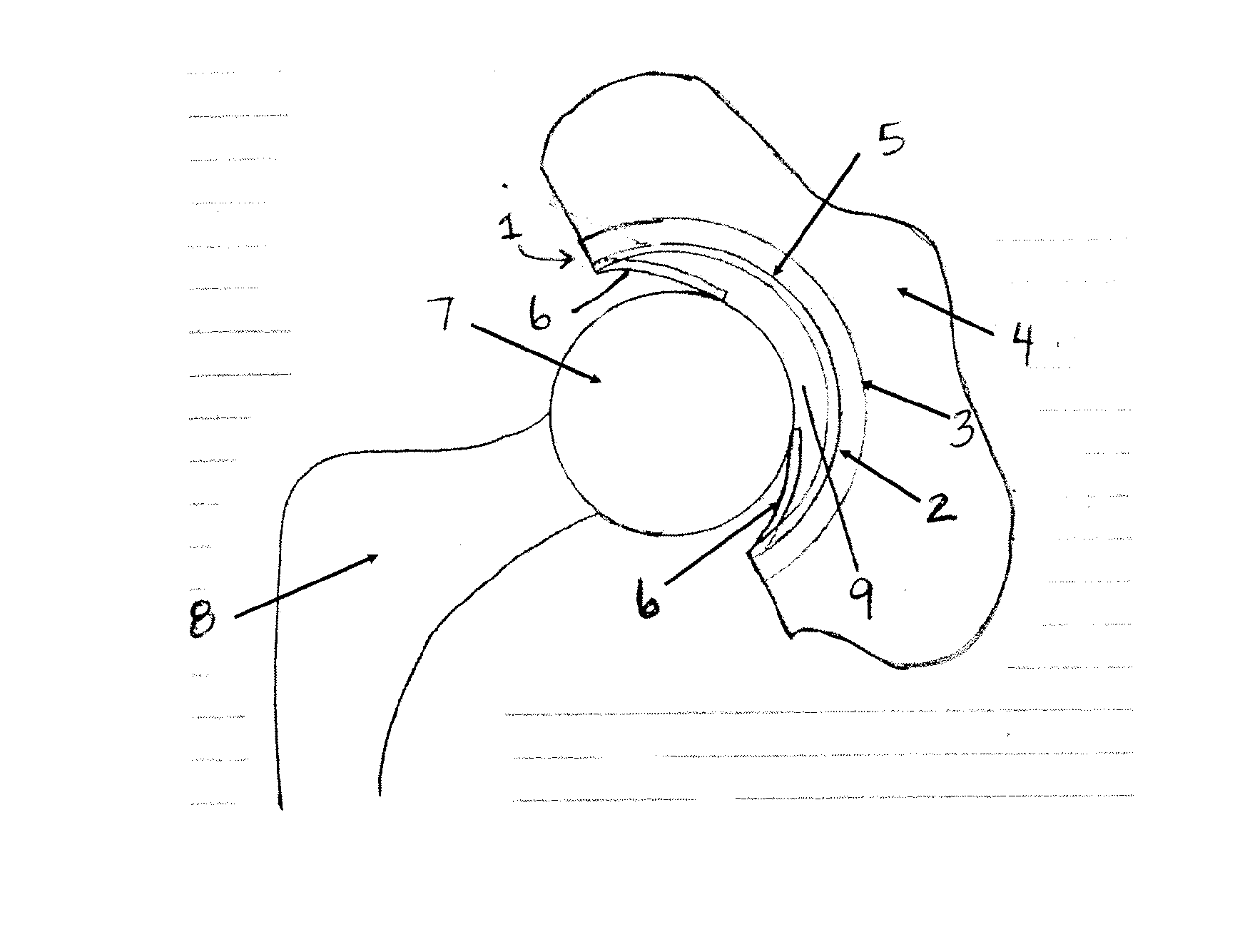

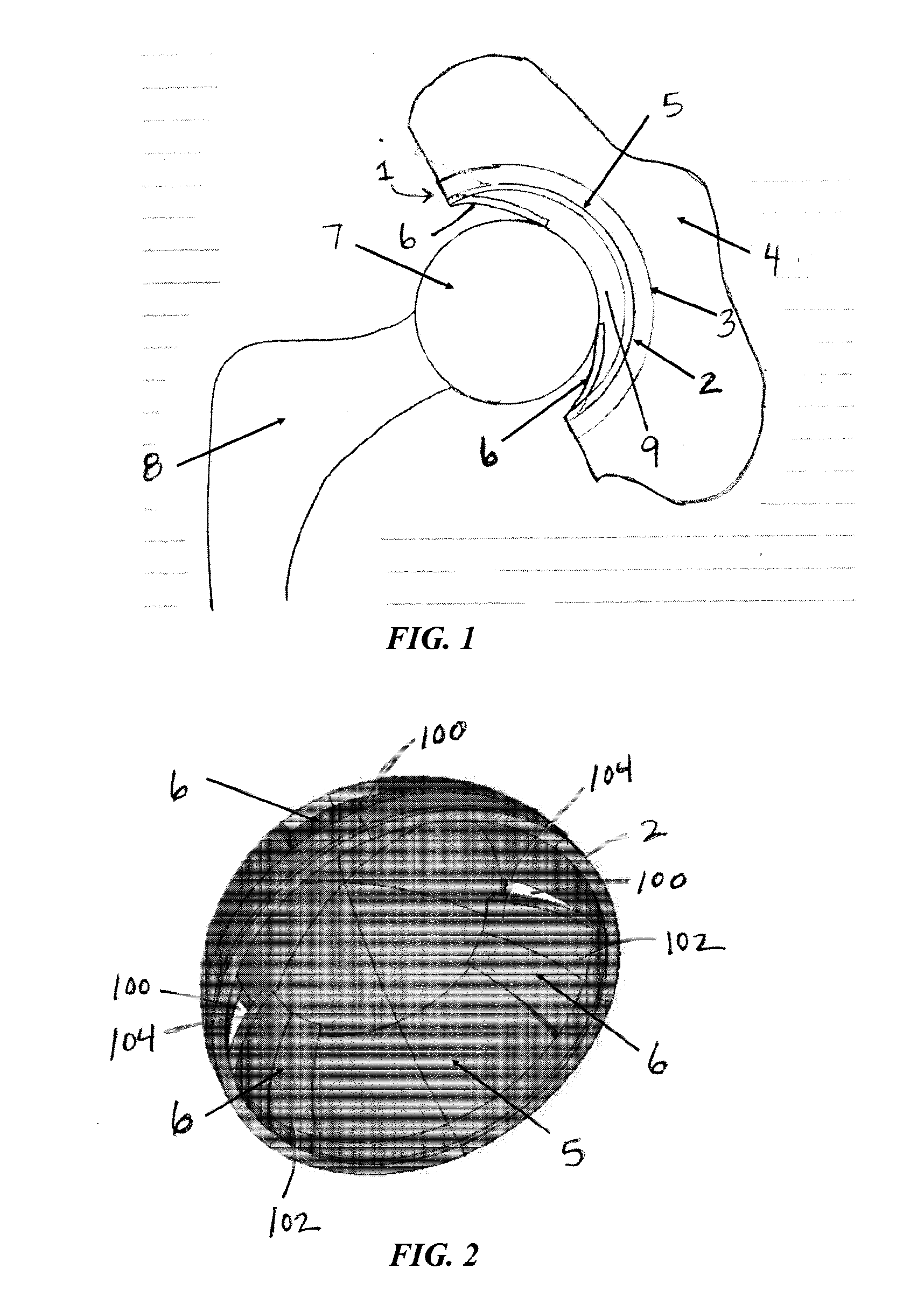

Acetabular prosthesis assembly

InactiveUS20050071015A1Reduce wearEliminate wear and tearJoint implantsFemoral headsRight femoral headEngineering

An acetabular prosthesis assembly (1) comprising an acetabular cup (3) with a generally convex outer surface for engaging acetabular bone and a generally concave inner surface, an insert (10) capable of insertion in the cup (3) for receiving a femoral head component, wherein a wear liner (13) is disposed between the cup (3) and the insert (10), the liner (13) providing a wear inhibiting surface (4a).

Owner:PORTLAND ORTHOPAEDICS

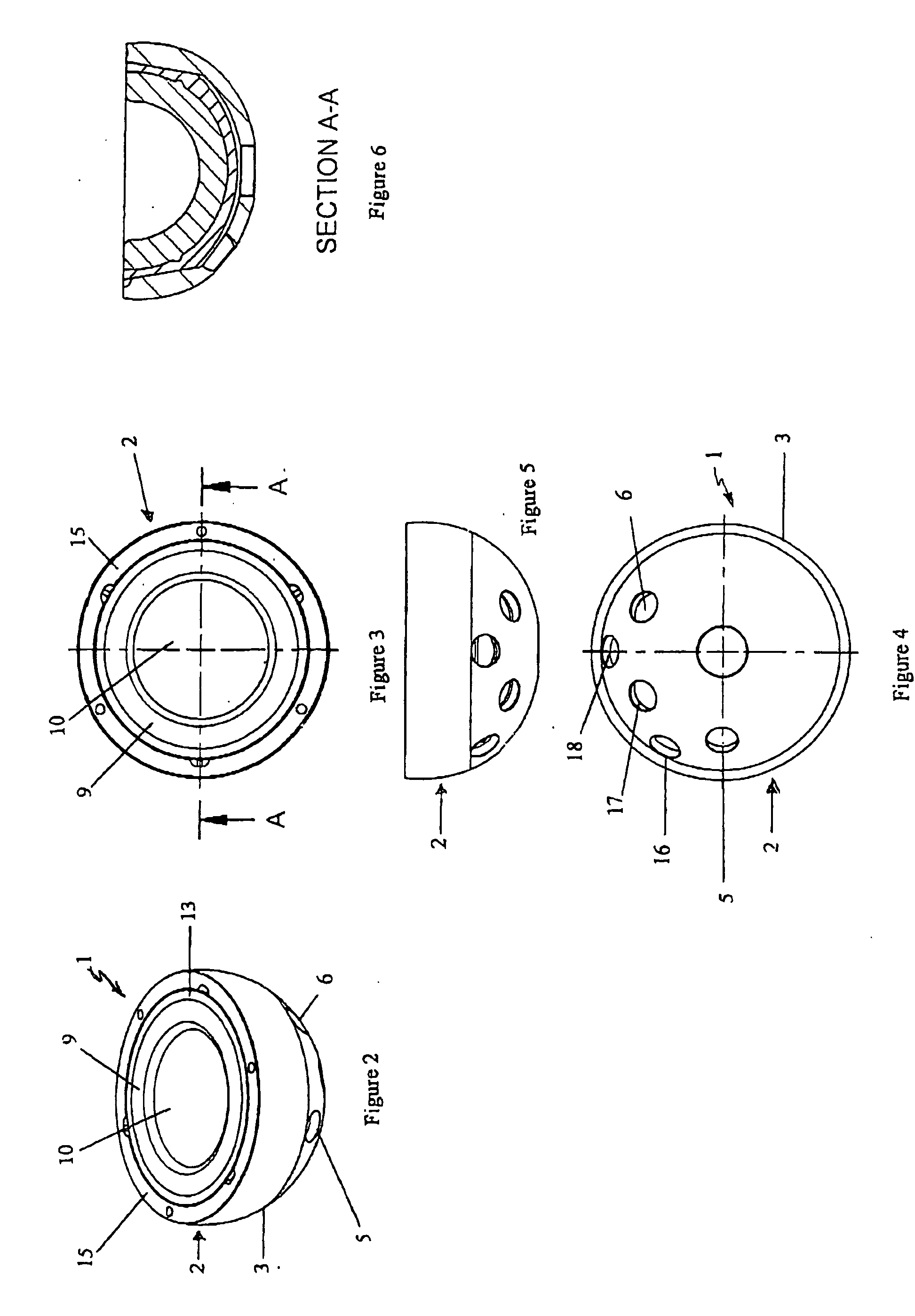

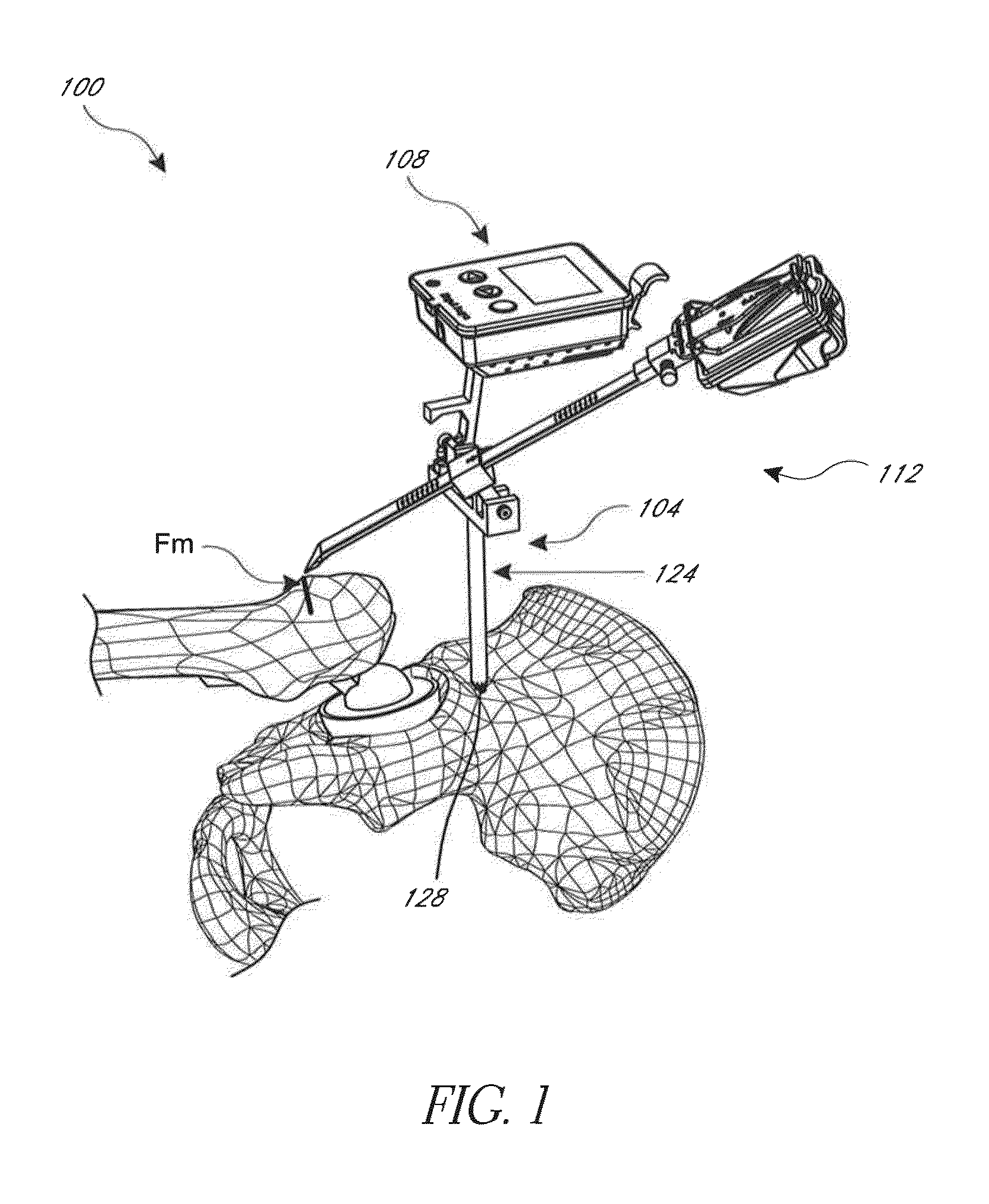

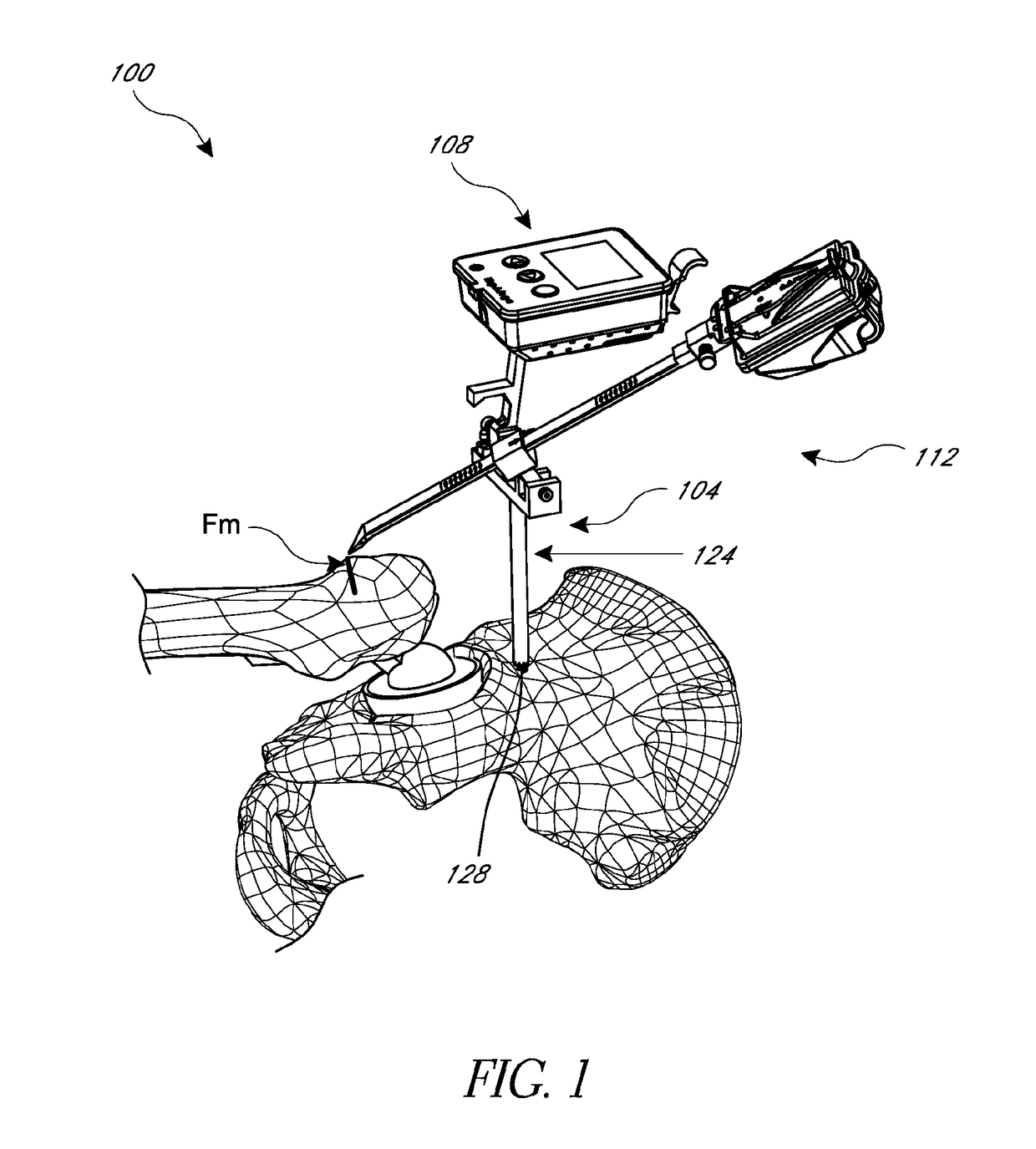

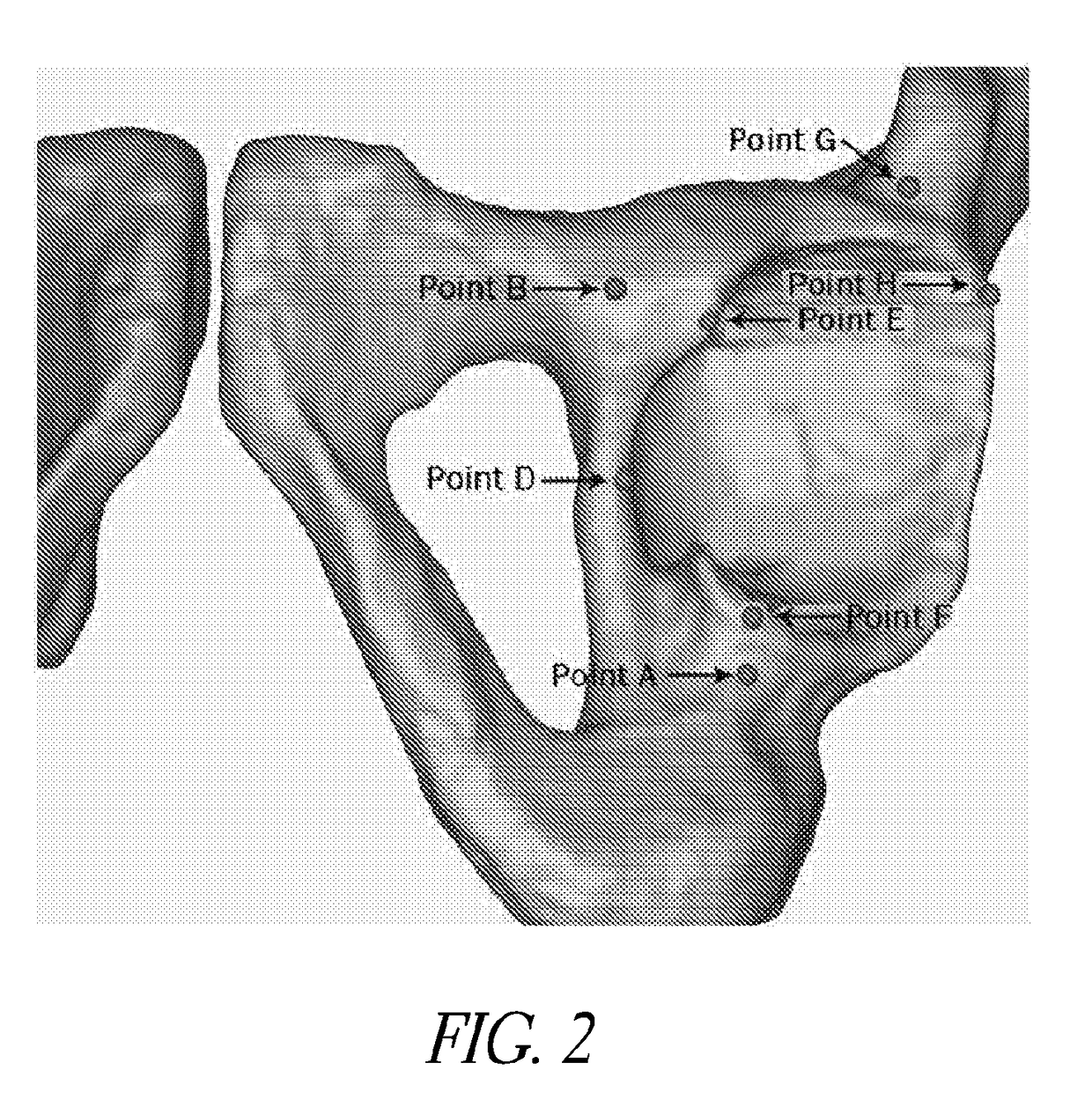

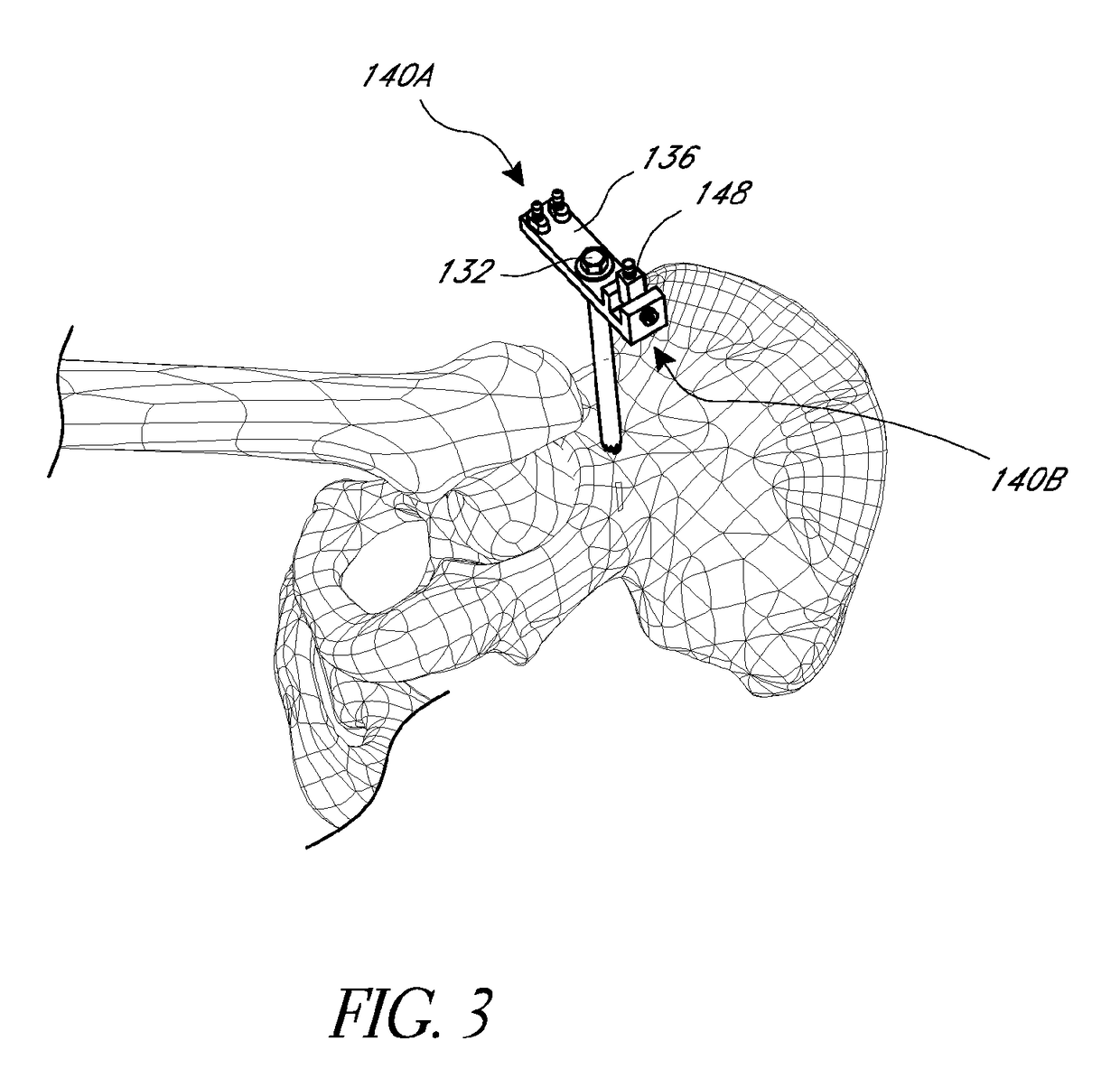

Hip replacement navigation system and method

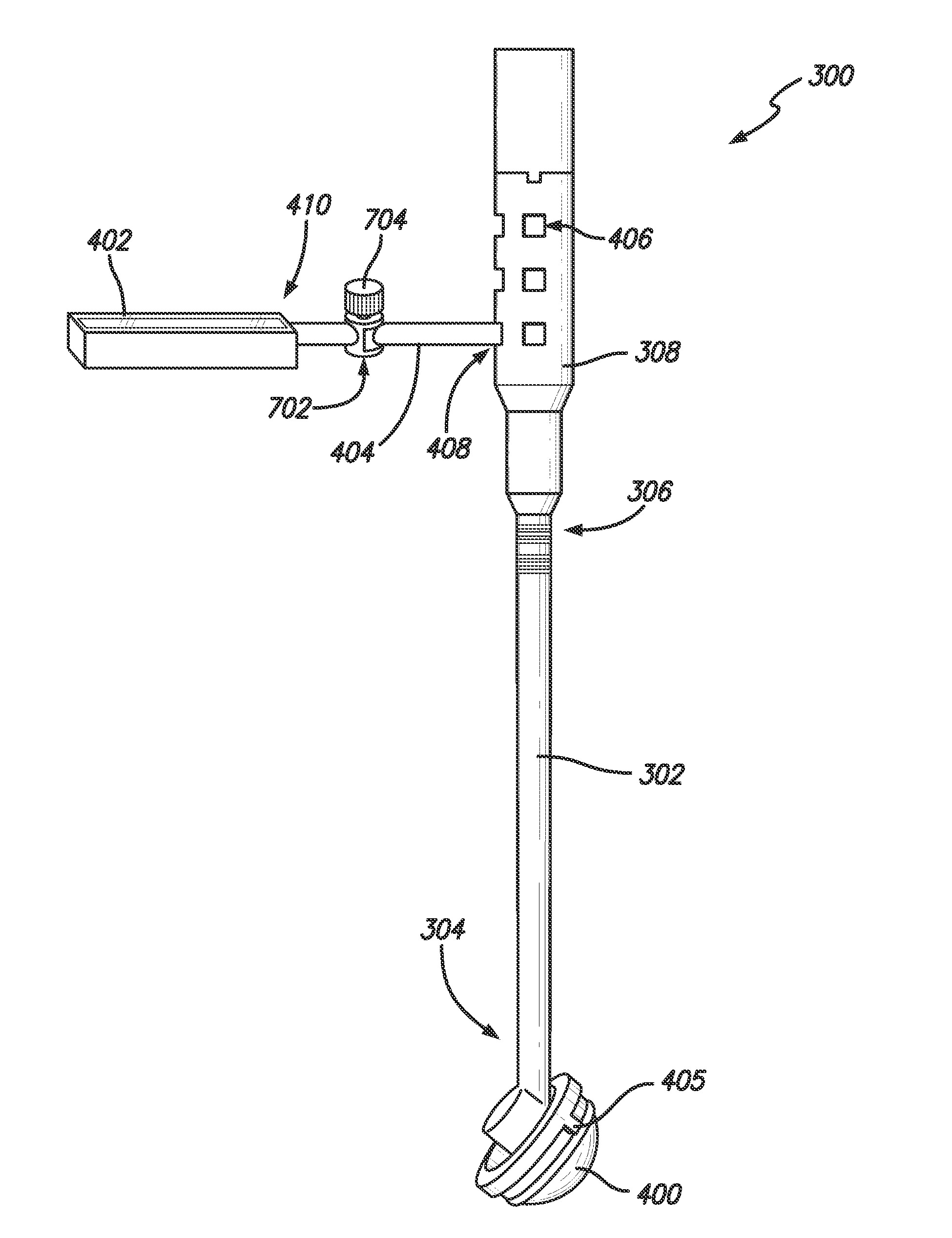

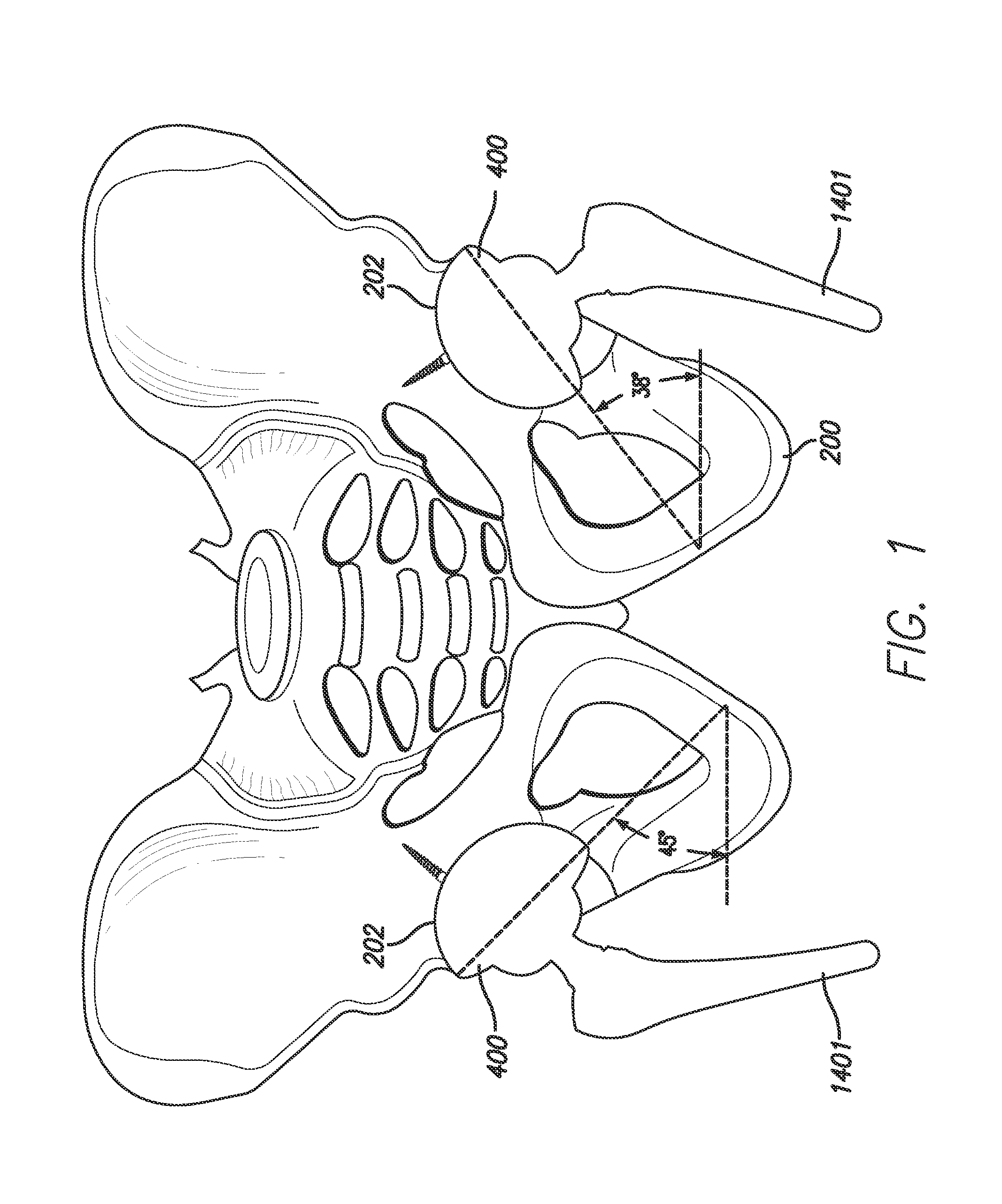

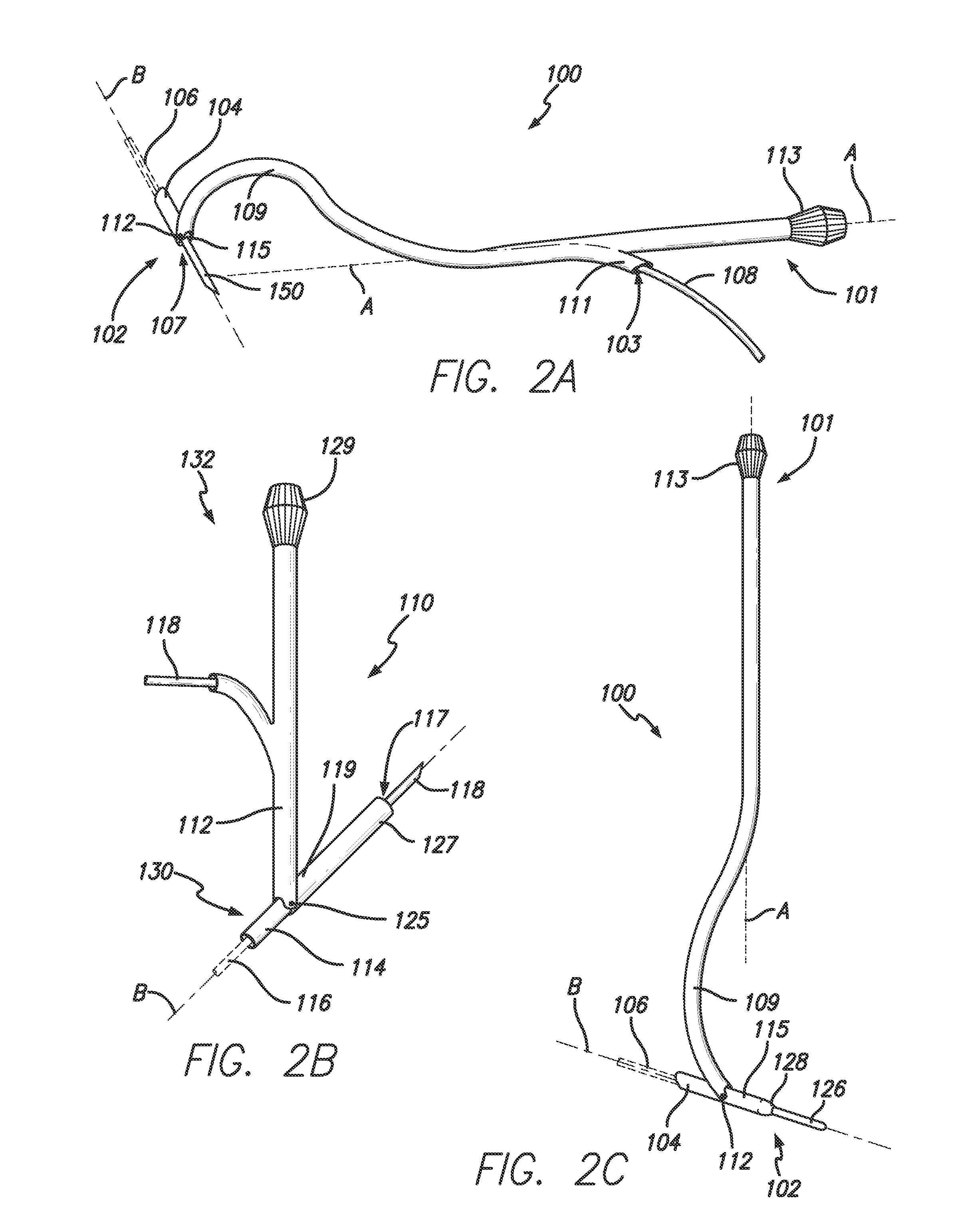

ActiveUS20160242934A1Eliminate errorsDiagnosticsSurgical navigation systemsAnatomical landmarkAcetabular bone

A hip joint navigation system is provided that includes a base having at least one channel disposed therethrough for receiving a pin for mounting the base to the pelvis. A mount feature is disposed on a top surface. A registration jig is configured to couple with the base and to engage anatomical landmarks. In some aspects, a patient specific jig system for hip replacement is provided including an engagement surface formed to closely mate to acetabular bone contours of a specific patient and a registration feature configured to be in a pre-determined orientation relative to an acetabulum the patient when the jig is coupled with acetabular bone contours of the specific patient. In other aspects, methods of using the systems are provided.

Owner:ORTHALIGN

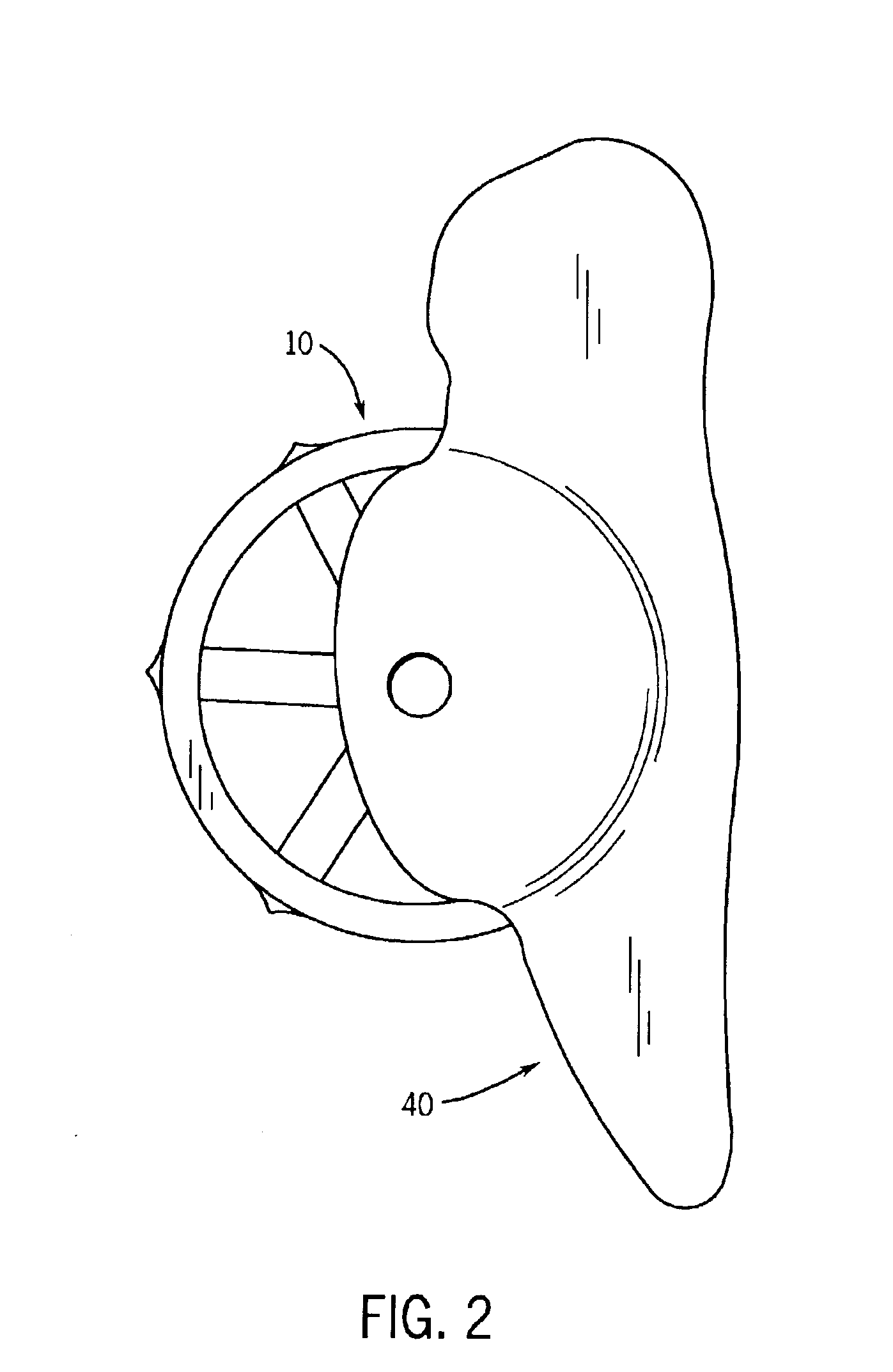

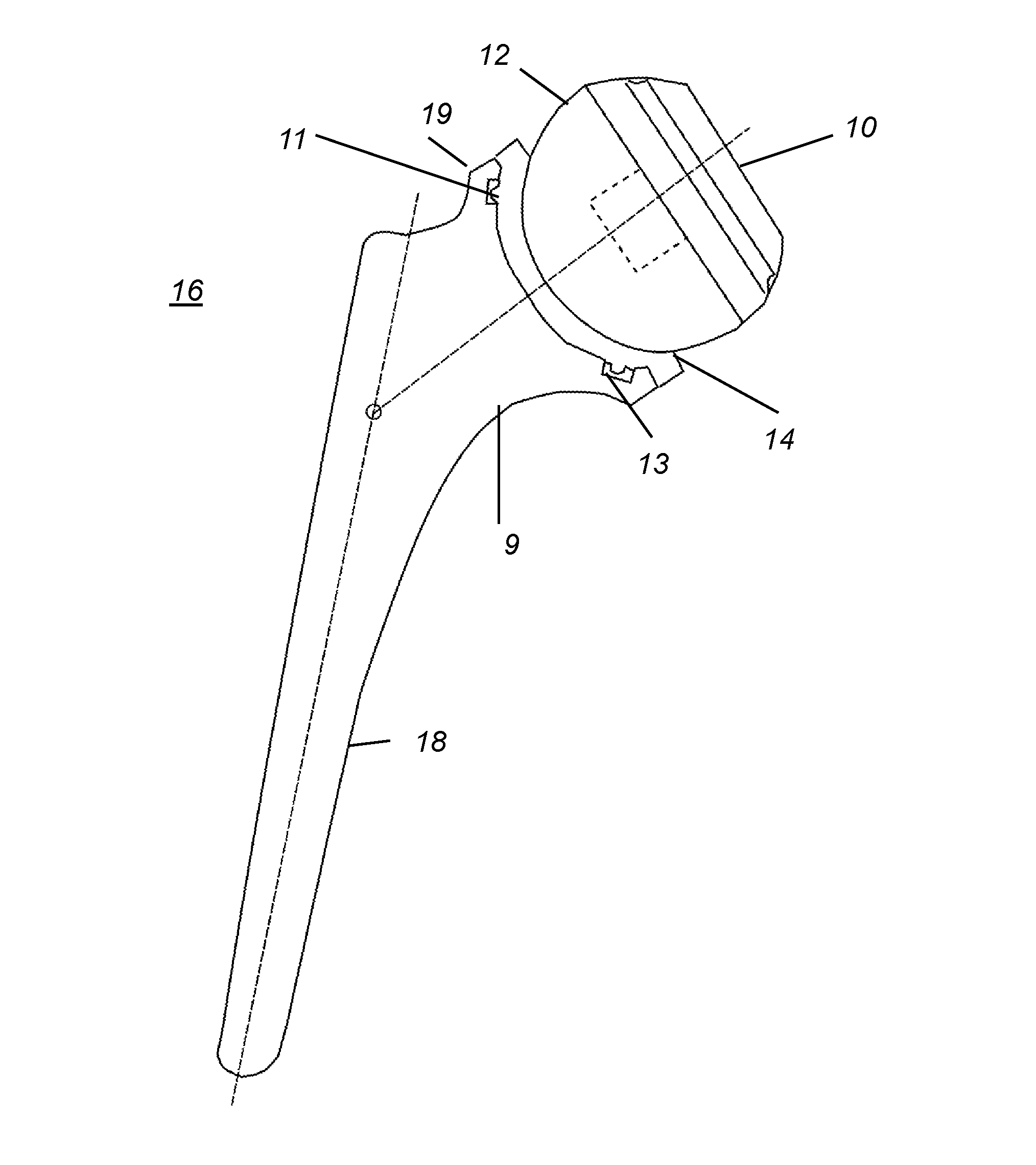

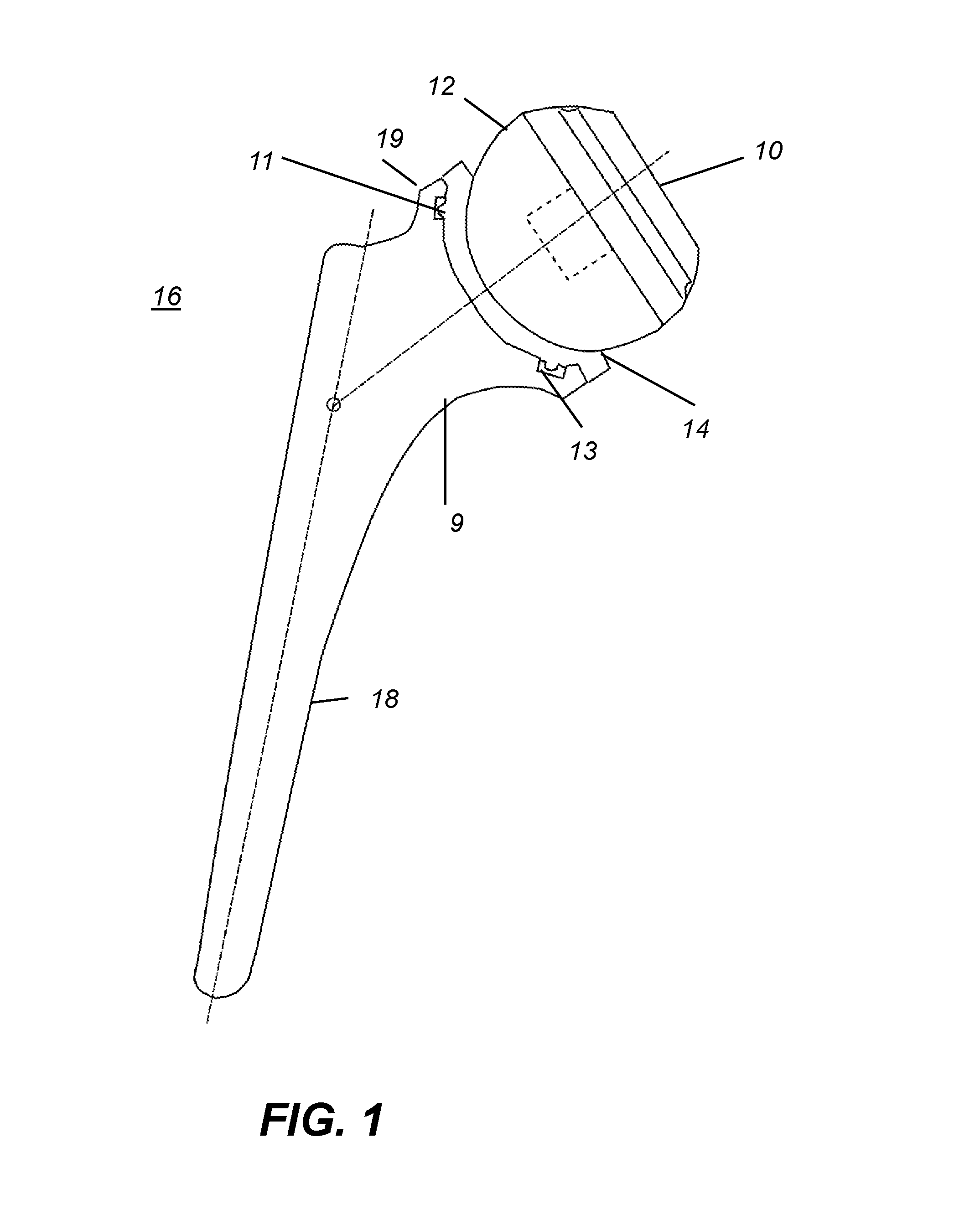

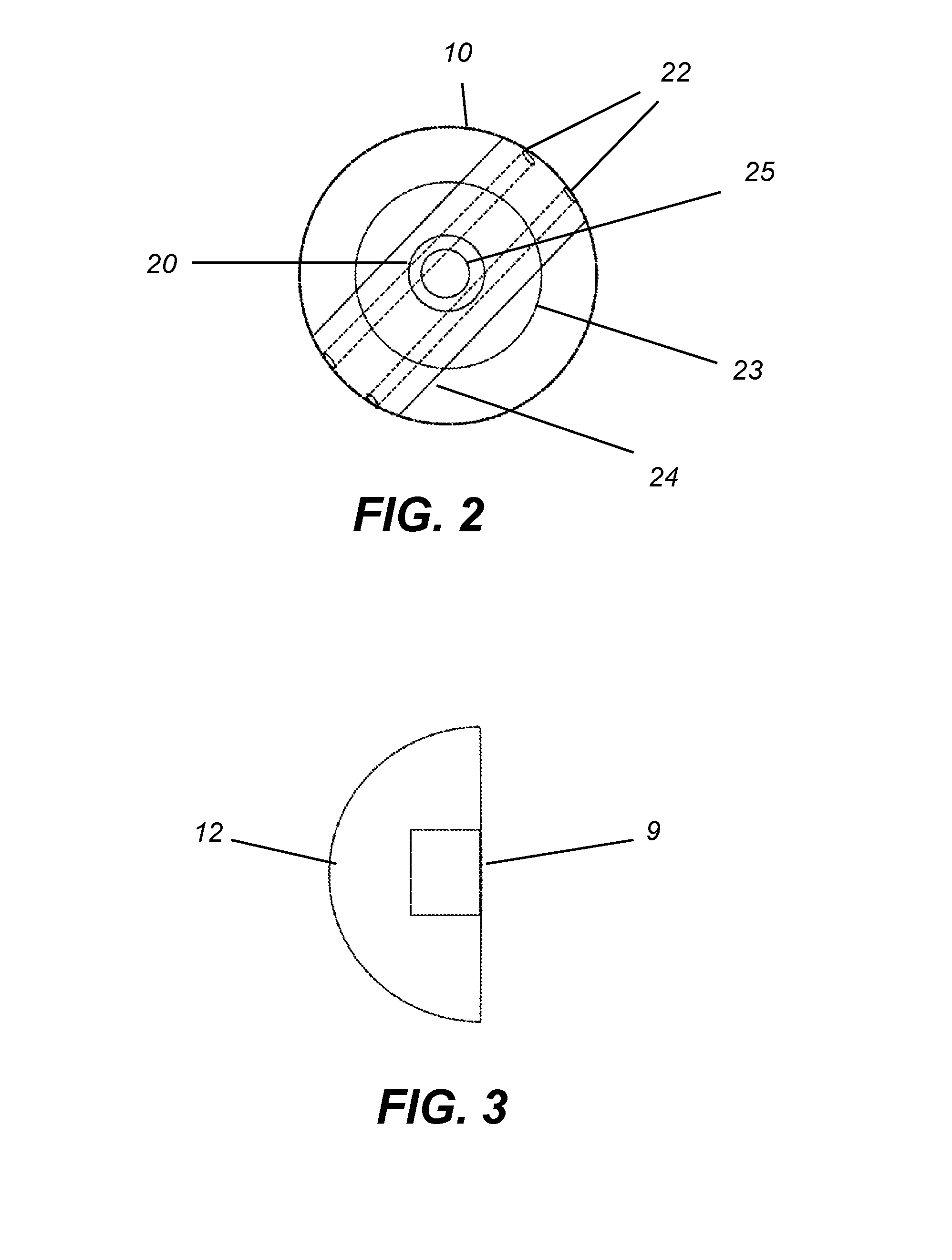

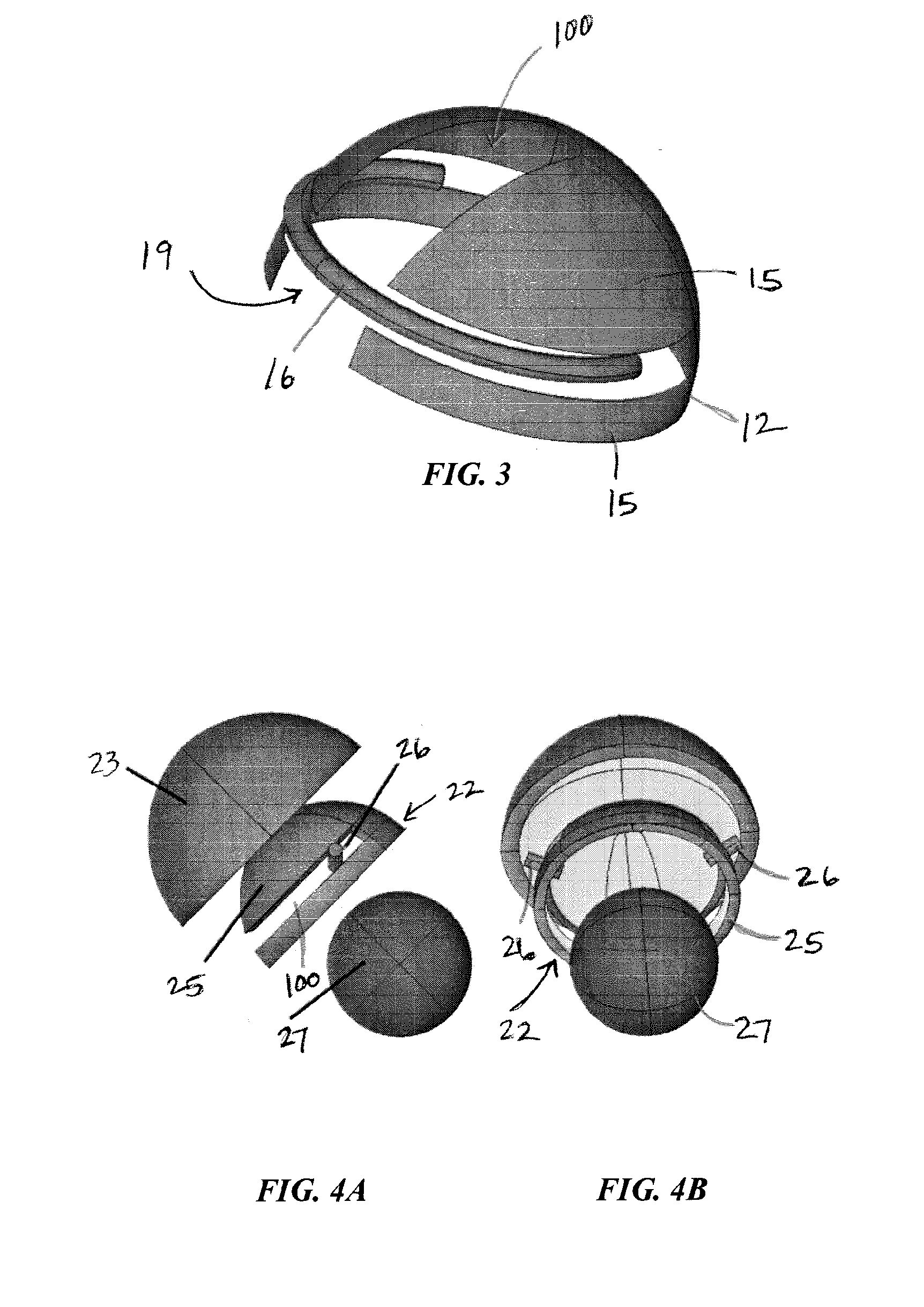

Modular acetabular anti-protrusio cage and porous ingrowth cup combination

InactiveUS6908486B2Maximum flexibilityInternal osteosythesisJoint implantsAcetabular componentRight femoral head

A modular acetabular anti-protrusio cage and acetabular cup combination includes an acetabular cup having a bone ingrowth-promoting surface and a shaped anti-protrusio cage having one or more fixation flanges. The acetabular cup is attached to acetabular bone, and the anti-protrusio cage is thereafter mounted to the inner surface of the acetabular cup. Alternatively, the anti-protrusio cage can be mounted to the inner surface of the acetabular cup before the acetabular cup is attached to acetabular bone. The flanges of the anti-protrusio cage are joined to the ilium, ischium and / or pubis to secure the acetabular cup and the anti-protrusio cage to the hip bone and to distribute forces away from the medial wall of the acetabulum. After the cup and the cage are mounted in the patient, a bearing insert is secured within the interior of the anti-protrusio cage, and a prosthetic femoral head is positioned in the bearing insert.

Owner:ZIMMER INC

Hip replacement navigation system and method

A hip joint navigation system is provided that includes a base having at least one channel disposed therethrough for receiving a pin for mounting the base to the pelvis. A mount feature is disposed on a top surface. A registration jig is configured to couple with the base and to engage anatomical landmarks. In some aspects, a patient specific jig system for hip replacement is provided including an engagement surface formed to closely mate to acetabular bone contours of a specific patient and a registration feature configured to be in a pre-determined orientation relative to an acetabulum of the patient when the jig is coupled with acetabular bone contours of the specific patient. In other aspects, methods of using the systems are provided.

Owner:ORTHALIGN

Hip replacement navigation system and method

A hip joint navigation system is provided that includes a base having at least one channel disposed therethrough for receiving a pin for mounting the base to the pelvis. A mount feature is disposed on a top surface. A registration jig is configured to couple with the base and to engage anatomical landmarks. In some aspects, a patient specific jig system for hip replacement is provided including an engagement surface formed to closely mate to acetabular bone contours of a specific patient and a registration feature configured to be in a pre-determined orientation relative to an acetabulum the patient when the jig is coupled with acetabular bone contours of the specific patient. In other aspects, methods of using the systems are provided.

Owner:ORTHALIGN

Precise femoral component positioning for hip replacement surgery

InactiveUS20130053904A1Precise alignmentPrecise positioningIncision instrumentsDiagnosticsHip joint replacement operationAcetabular component

A method for accurately positioning the acetabular cup in a minimally invasive total hip arthroplasty (THA), comprising the steps of (a) placing the cup in roughly the correct position in the acetabulum using a acetabular component placement tool, (b) taking a first abduction reading and a first anteversion reading using a gyroscopic positioning unit aligned with the acetabular component placement tool, (c) taking an image of at least a portion of the cup using a radiography unit, (d) using the image to determine the actual orientation of the cup and required position of the cup to properly orient the acetabular component, (e) incrementally altering the position of the cup by using a striking tool, (f) taking new abduction and anteversion readings using the gyroscopic unit to determine the relative movement of the cup caused by the tapping, and (g) repeating any of the steps as necessary.

Owner:CRESCENT H TRUST

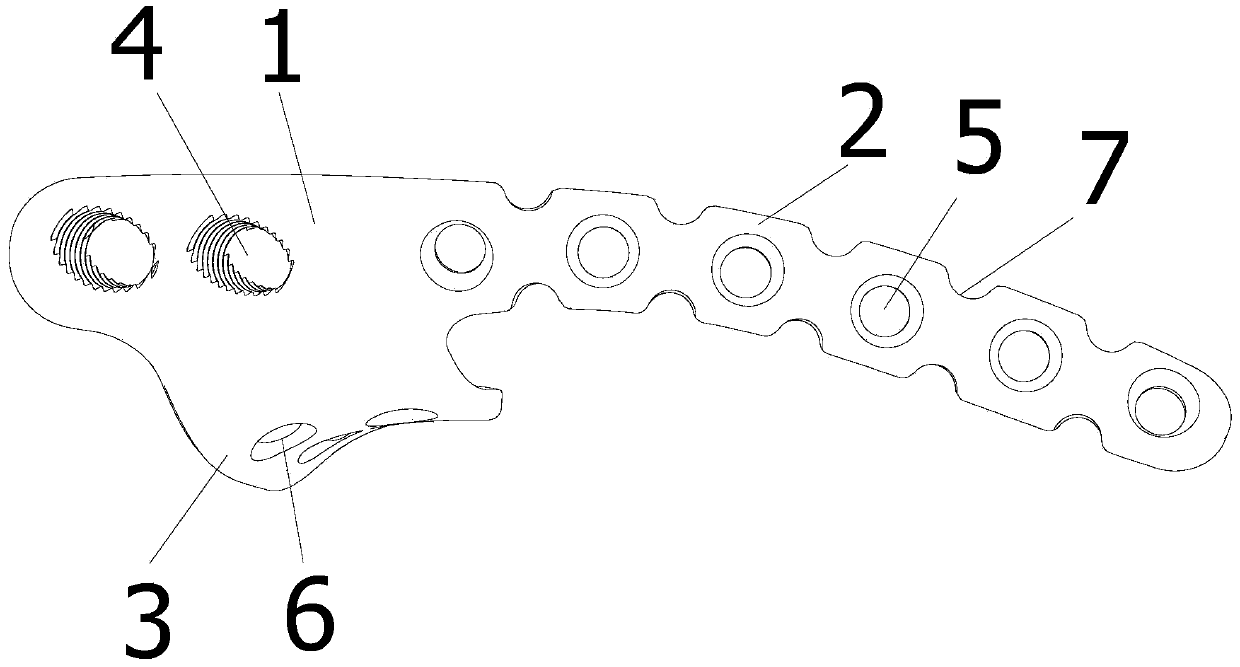

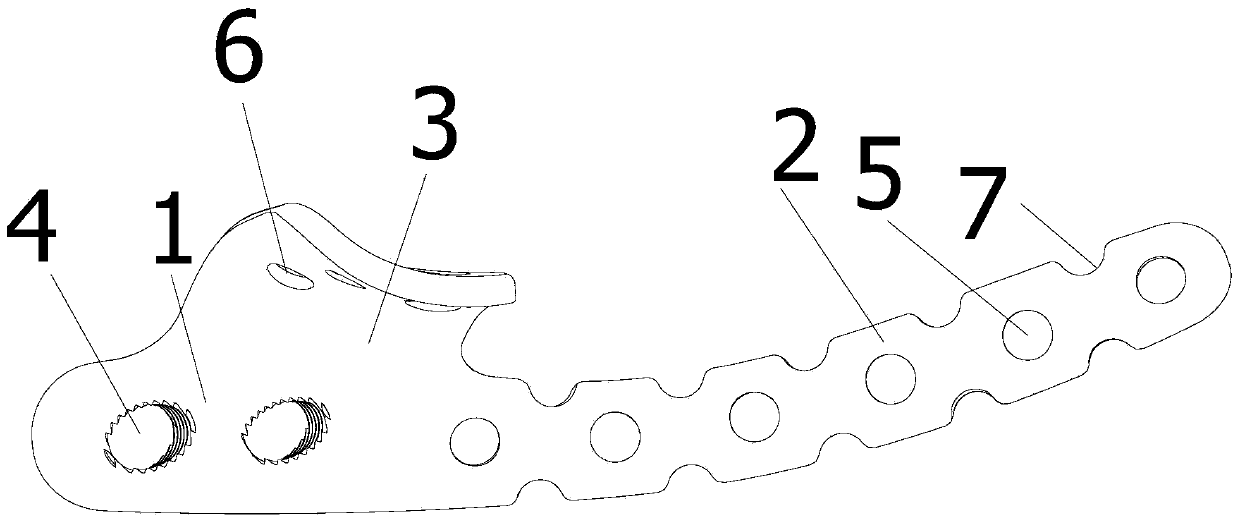

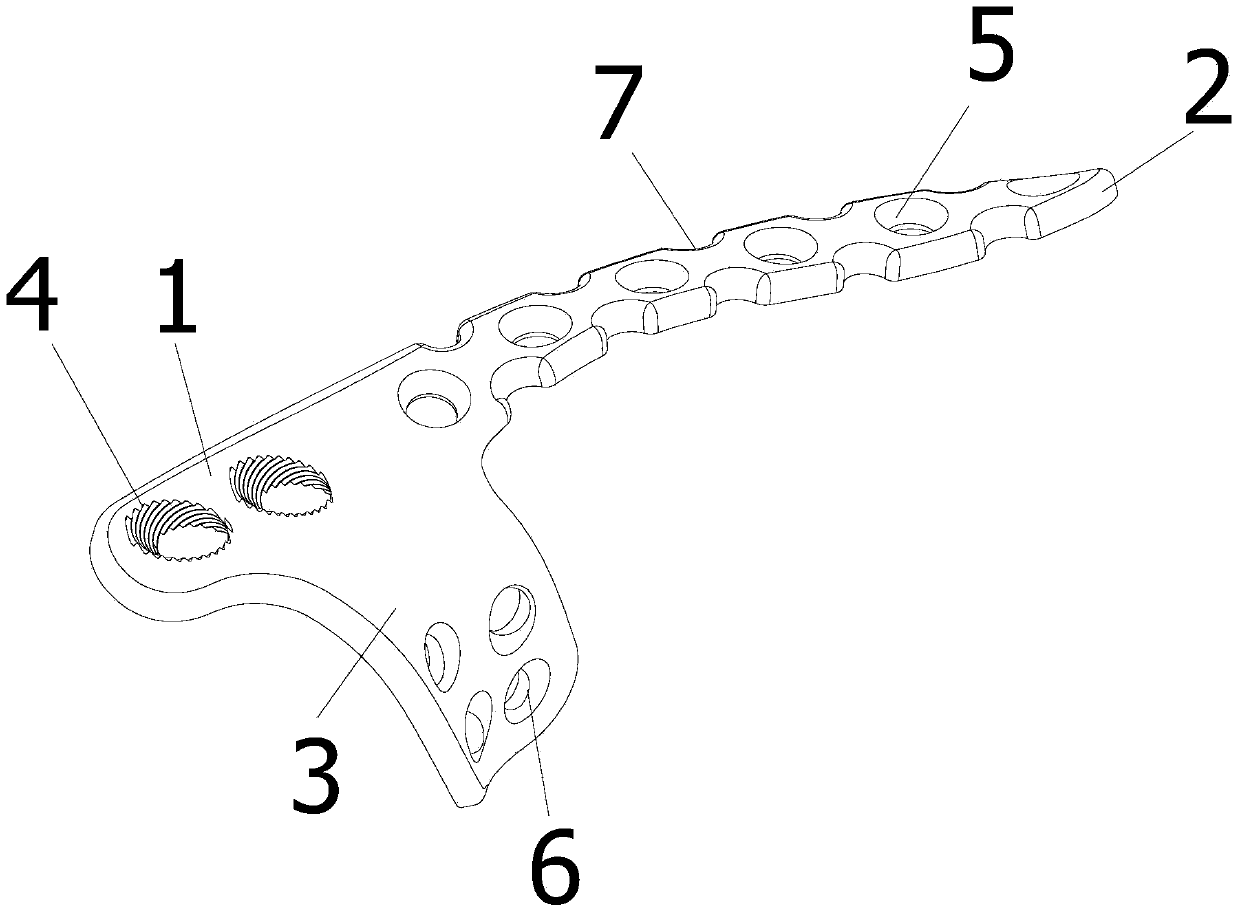

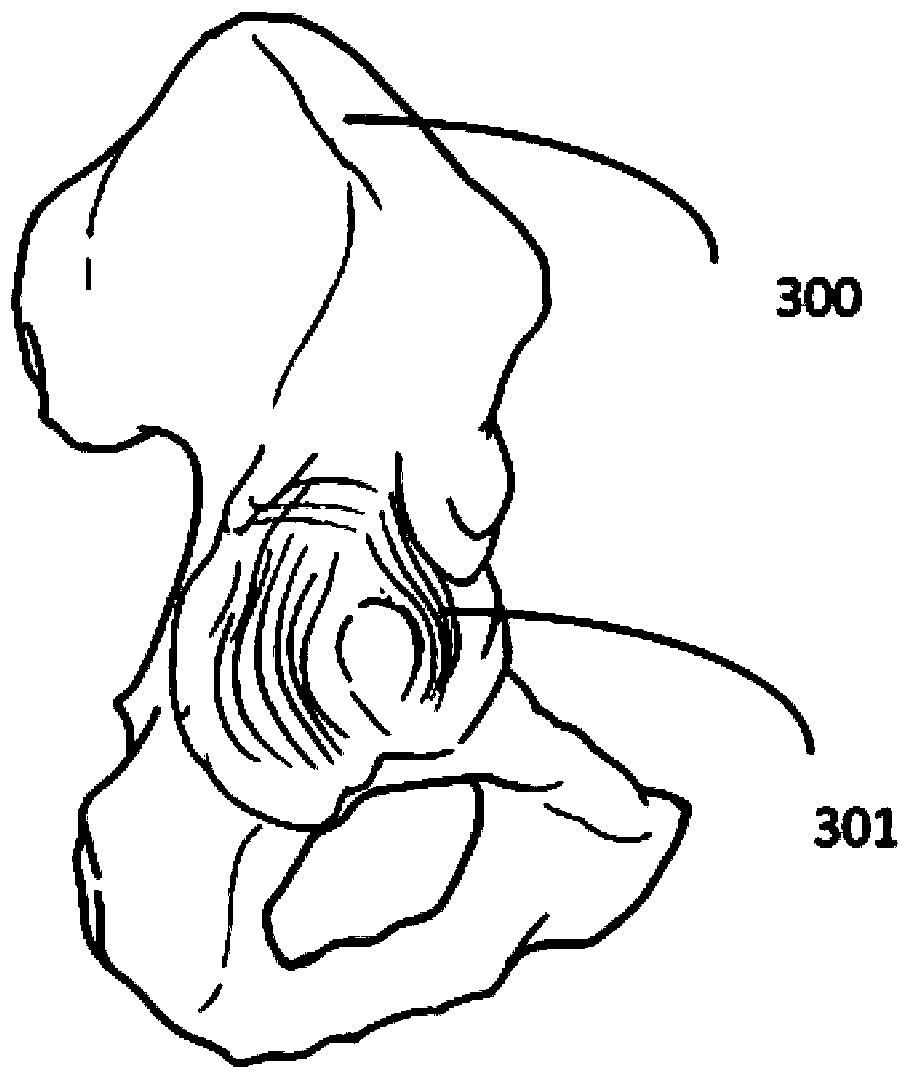

Acetabulum parastyle and posterior column united steel plate

The invention discloses an acetabulum parastyle and posterior column united steel plate. The united steel plate is composed of a main plate, a parastyle steel plate and a baffle which are connected into a whole. At least two threaded holes are formed in the main plate and are arranged along the bow-shaped edge from the proximately-bow-shaped edge face of the fossa iliaca. The axis of each threaded hole is vertical. One side of the main plate is bent downwards and extends to the square area above the ischial spine to form the baffle. The curved surface formed by the lower surface of the baffle and the lower surface of the main plate is matched with the curved surface formed by the corresponding proximately-bow-shaped edge face of the fossa iliaca, the surface of a bow-shaped edge from the front edge of the sacroiliac joint and the surface of the square area above the ischial spine of the acetabulum bone. A plurality of fixed screw holes are formed in the baffle. The parastyle steel plate extends to the ramus superior ossis pubis from one end of the main plate along the surface of the proximately-bow-shaped edge face of the fossa iliaca. A parastyle fixing screw hole is formed in the parastyle steel plate. The bone fracture plate is easy and convenient to operate, high in safety, small in operation wound, and capable of being used for simultaneously drawing in fractured acetabulums of the parastyle and the posterior column.

Owner:王钢

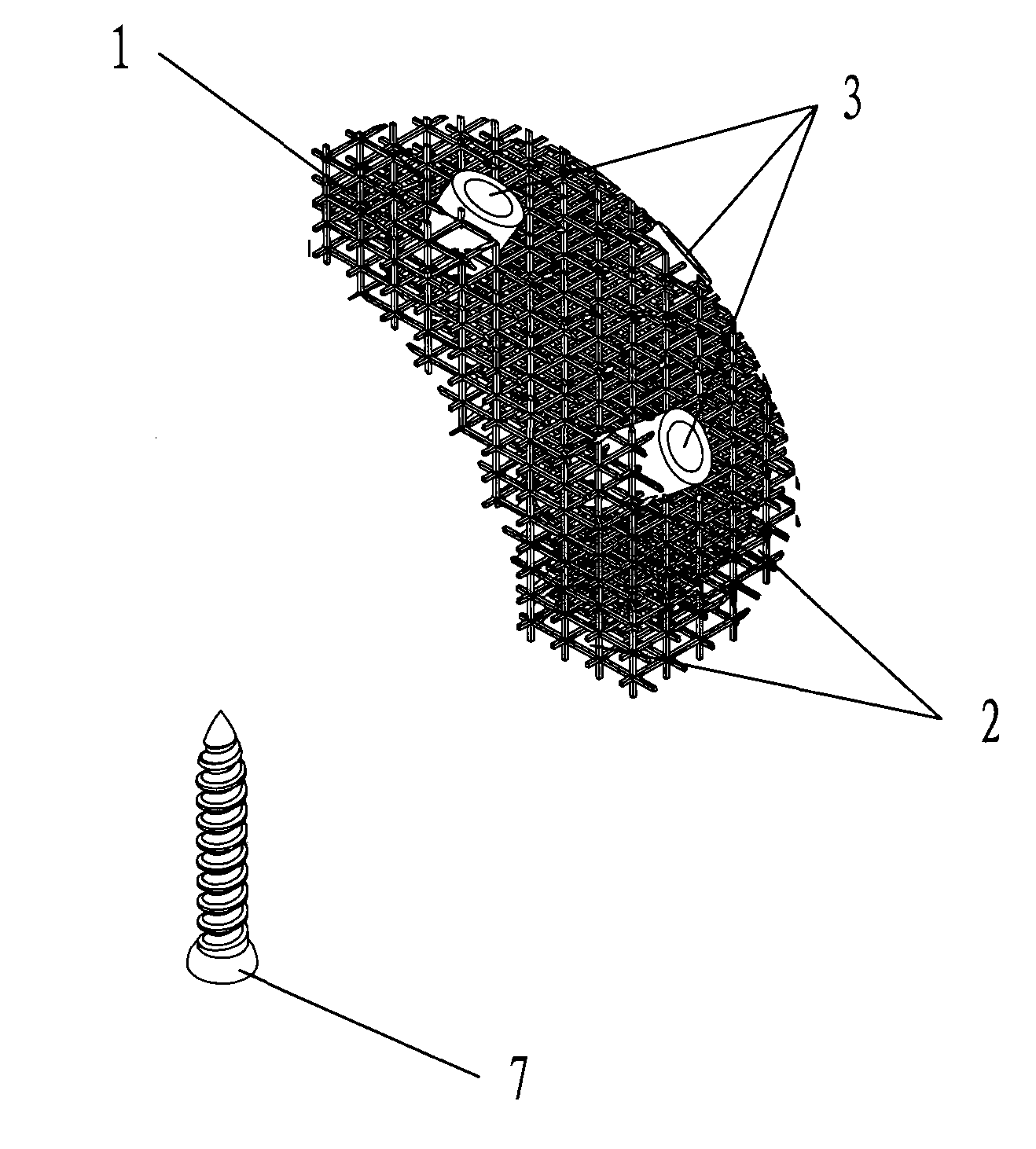

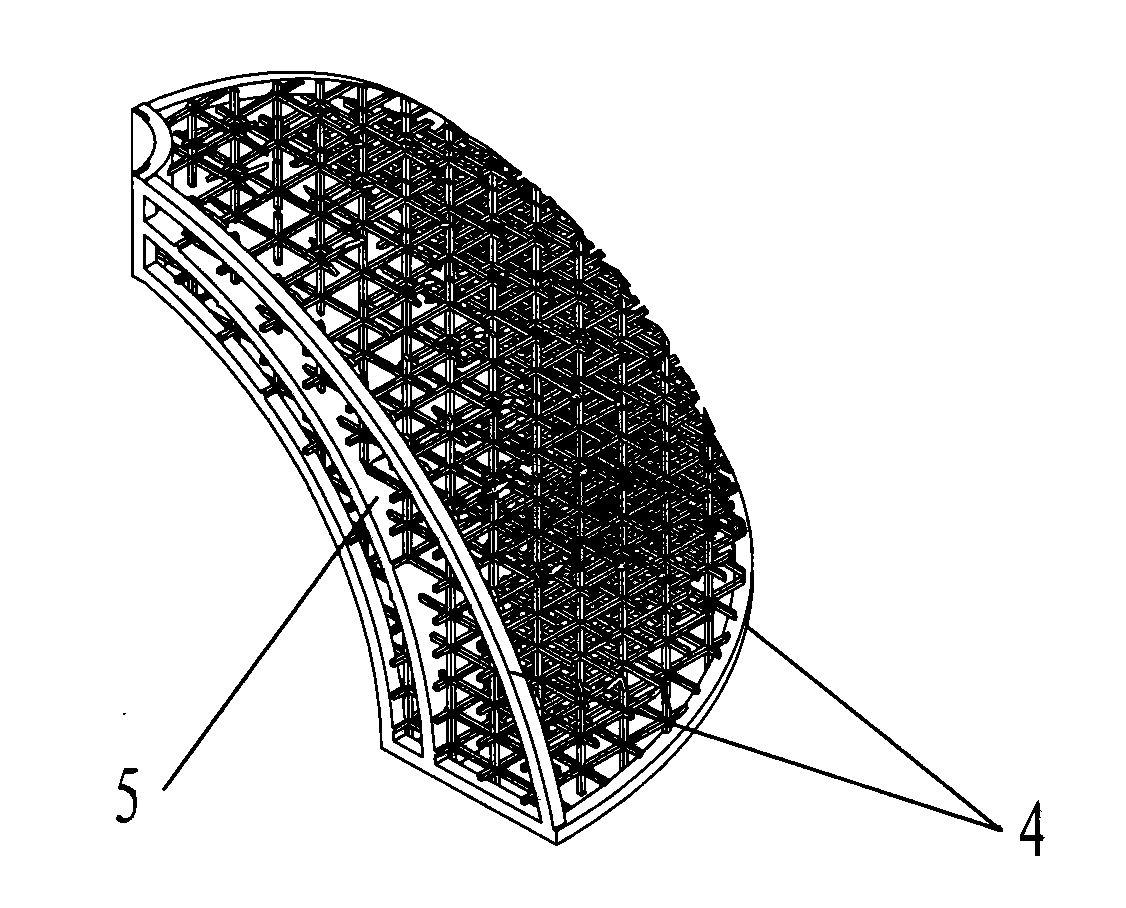

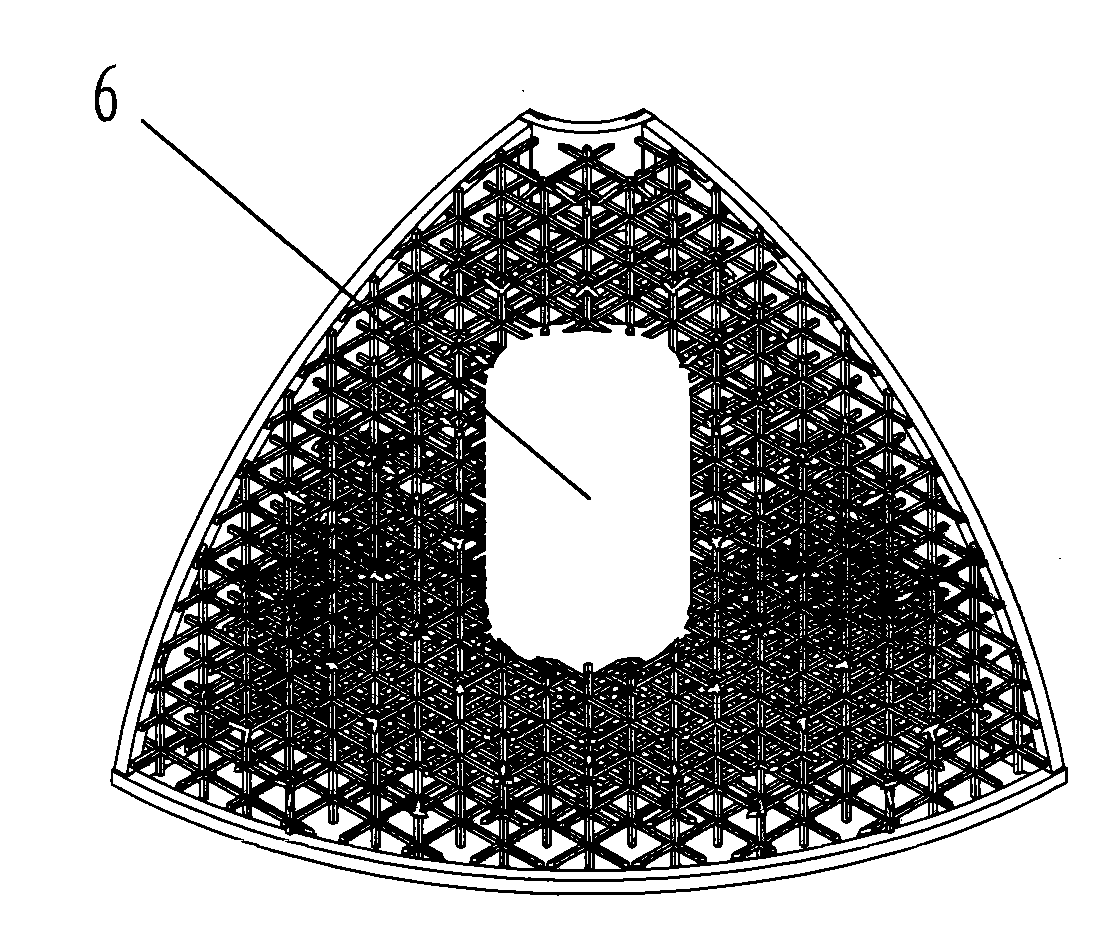

Acetabular bone deformity filler

InactiveCN102113924APromote ingrowthPrevent long-term looseningJoint implantsAcetabular cupsHydroxyapatite coatingMedicine

The invention relates to an acetabular bone deformity filler which comprises a bone deformity filler, a screw hole, reinforcing ribs and a reinforcing plate and is made into a three-dimensional porous dictyosome structure by adopting medical metals or biological ceramics. The surface and the interior of the three-dimensional porous dictyosome are provided with a plurality of mutually communicated pore canals, the acetabular bone deformity filler is provided with a screw hole in a suitable position and also provided with a bone-planting hole for containing bone-planting particles or bone meal in a suitable position, all or partial surface of the acetabular bone deformity filler is provided with a hydroxyapatite coating, and the acetabular bone deformity filler can be effectively prevented from loosening for a long time when external osseous tissue permeates and grows in the three-dimensional porous dictyosome and melts and grows with the bone-planting particles or the bone meal filled in the bone-planting hole into a whole after operational planting.

Owner:BEIJING AKEC MEDICAL

Reverse total hip replacement

ActiveUS20170035571A1Less forceOptimal trajectoryJoint implantsFemoral headsAcetabular componentProsthesis Implantation

A reverse total hip prosthesis is characterized by a femoral cup component and an acetabular ball component and is used for reconstruction of a hip joint. The prosthesis reverses the mechanics across the joint medializing the center of rotation, preventing dislocation in a posterior direction. Both ball and socket portions of the components lie outside of bone enabling larger sizing of the femoral and acetabular components improving stability, regardless of the size of the patient's anatomy. A method for reverse hip prosthesis implantation eliminates reaming through the base of the acetabulum preserving acetabular bone stock.

Owner:LOFFREDO NICHOLAS JOHN

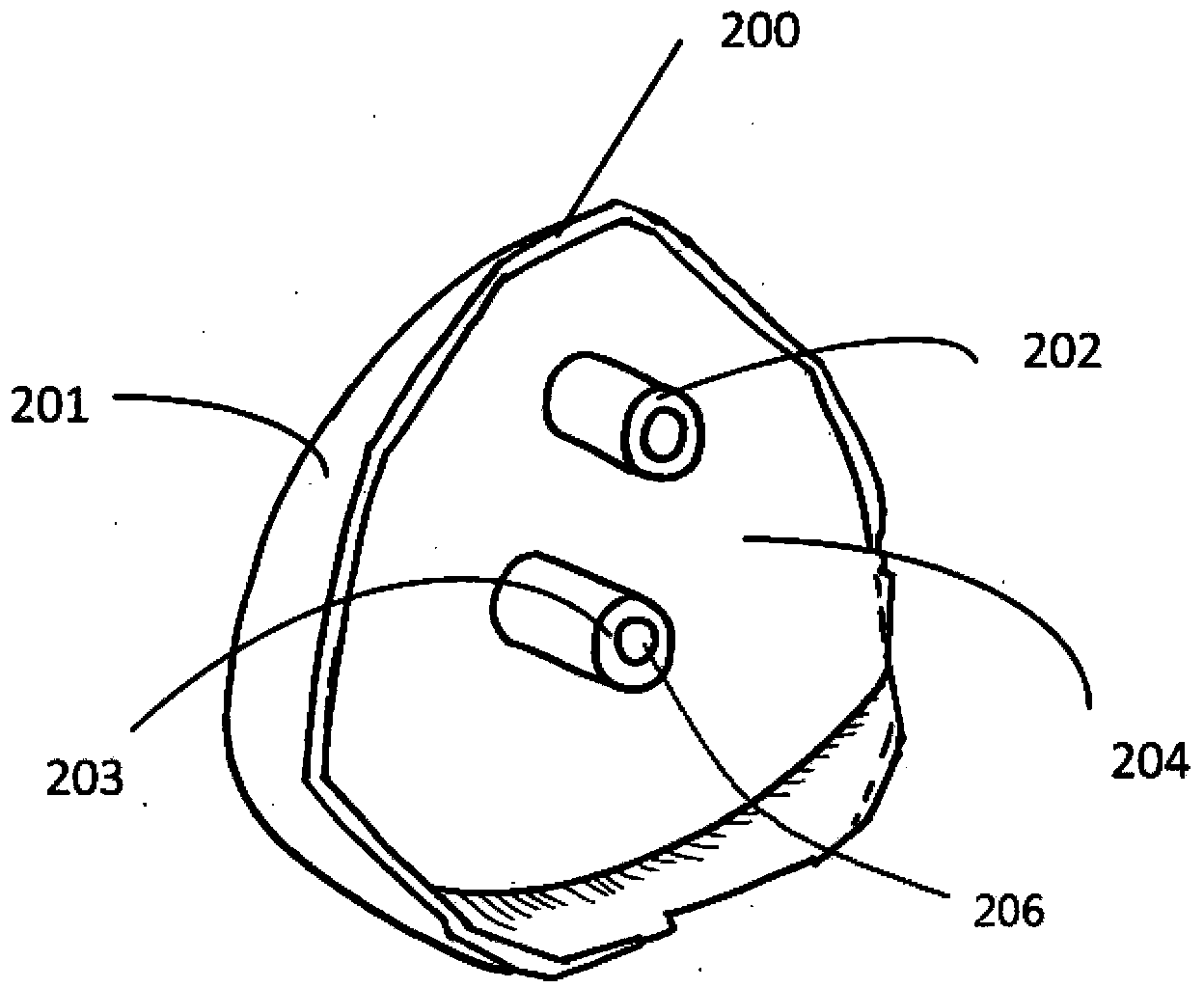

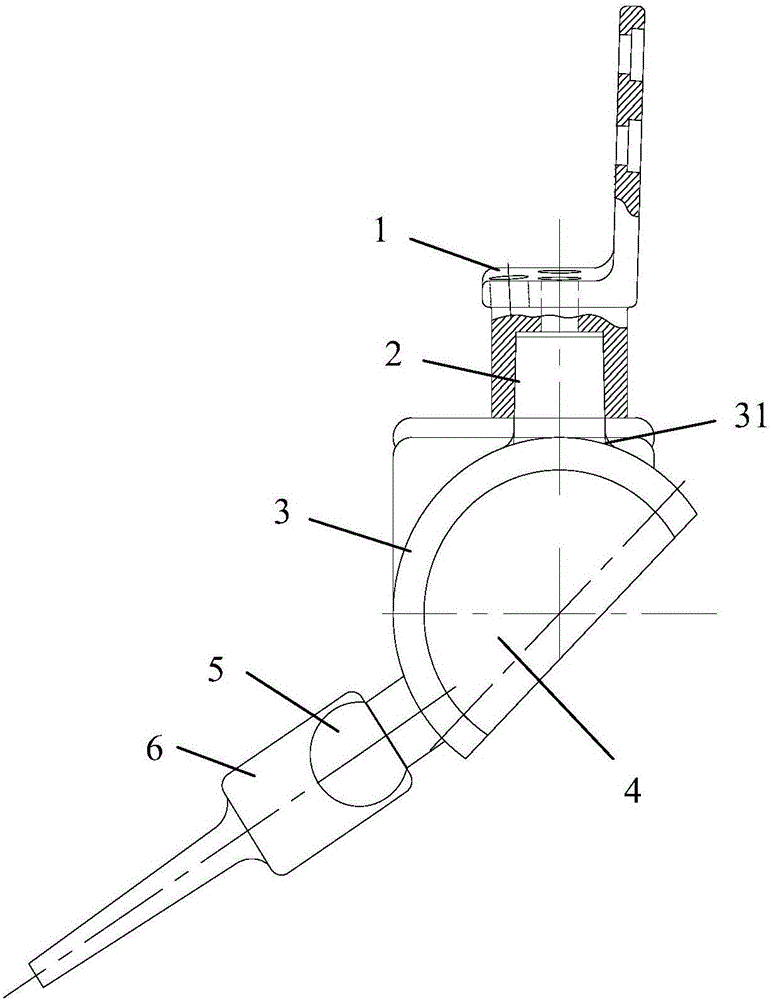

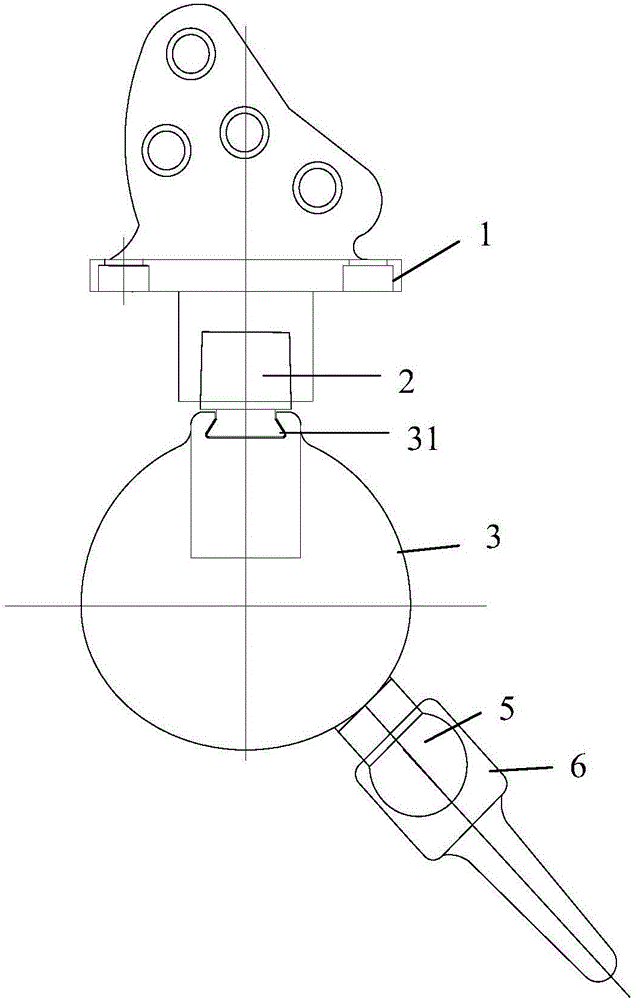

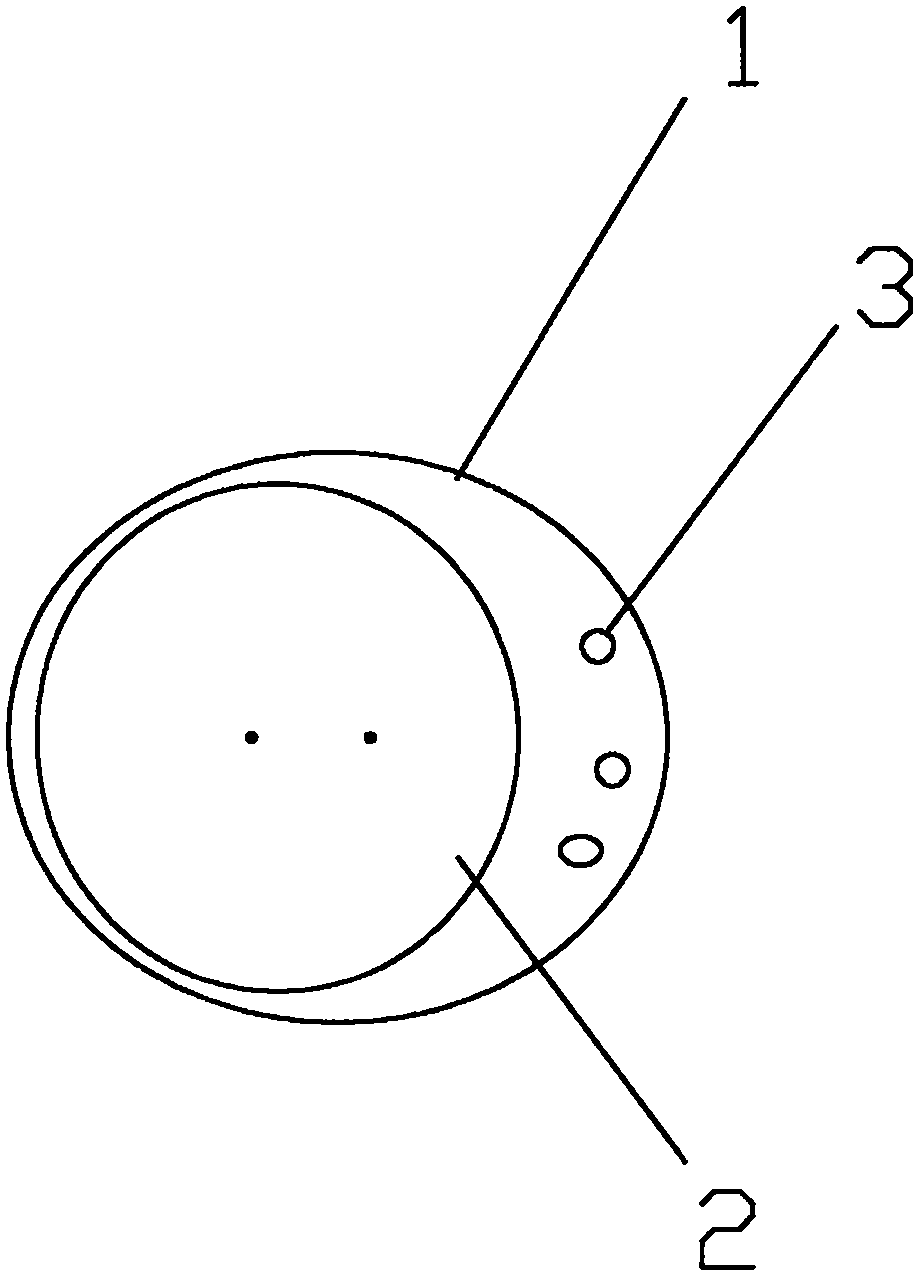

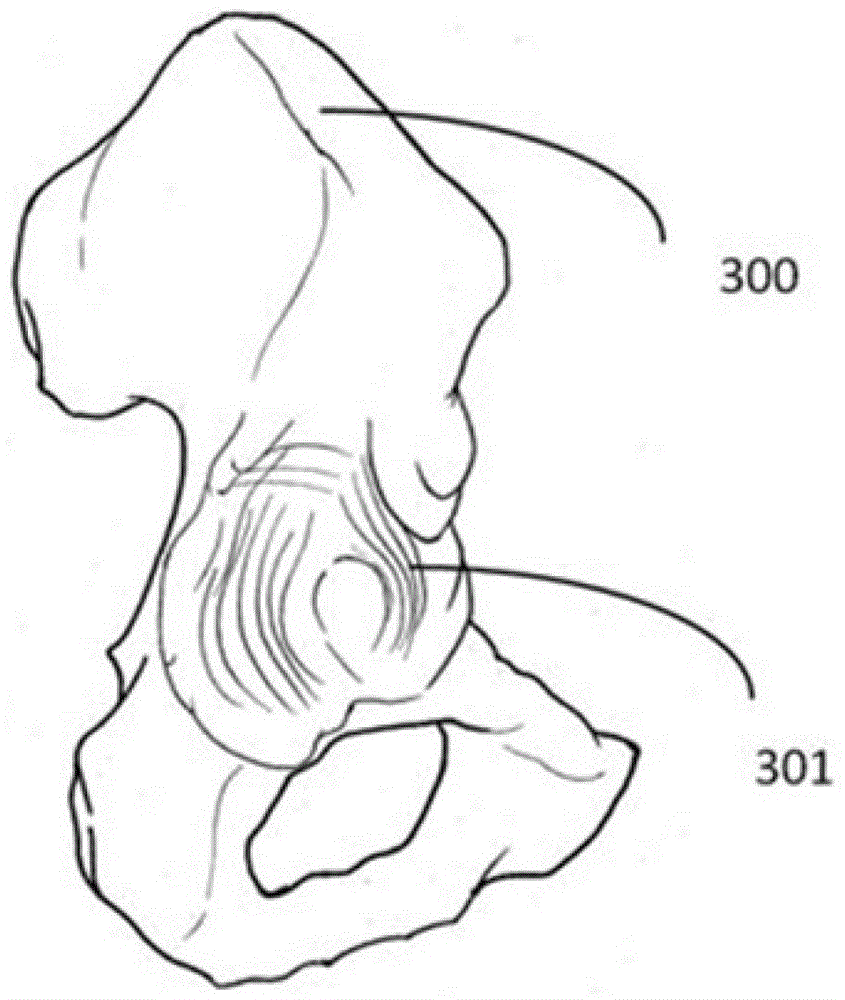

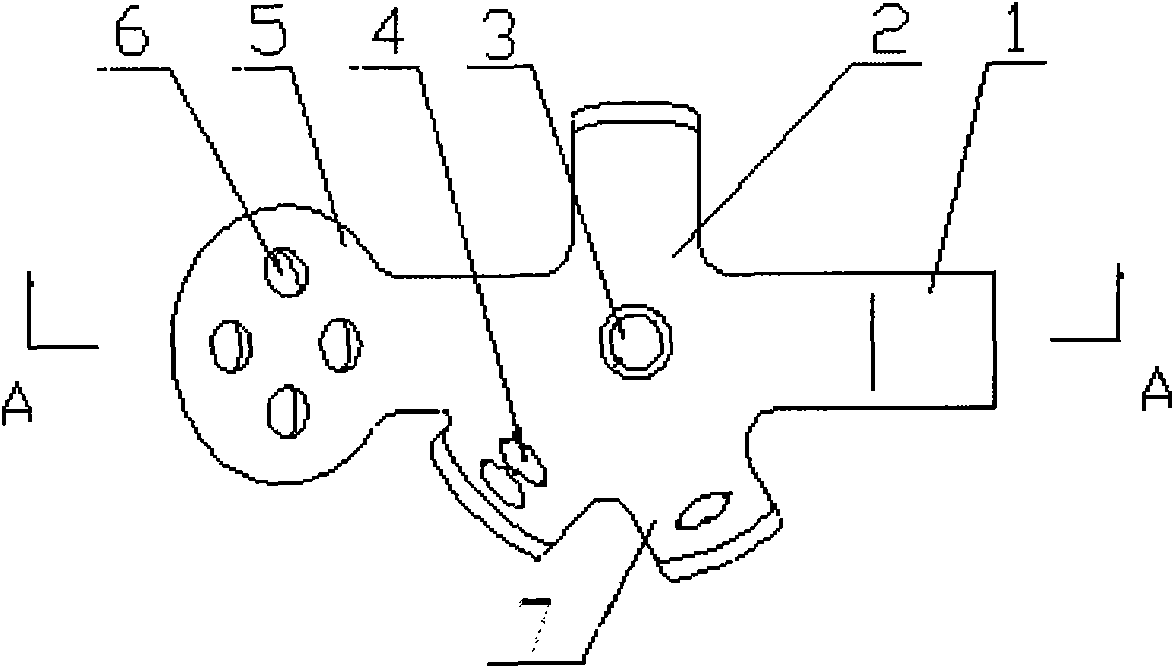

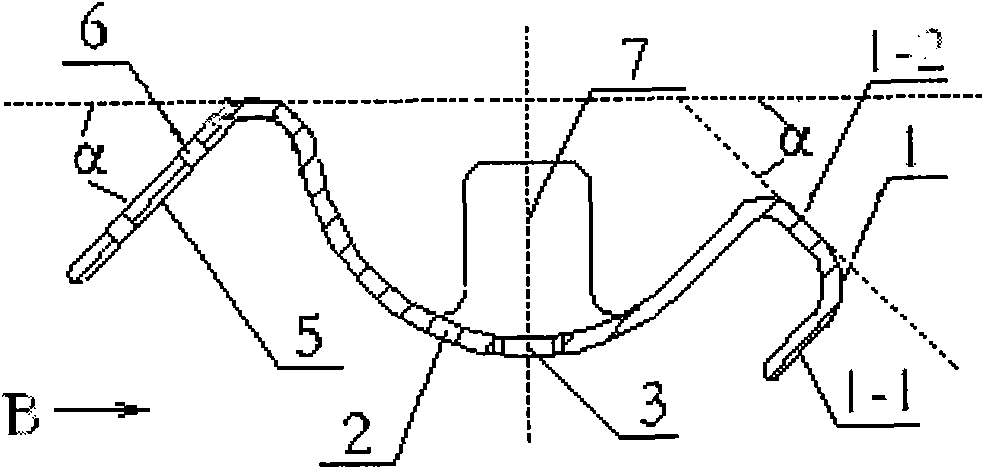

Customized hip joint surgical positioning device based on medical images and matched prosthesis

ActiveCN104337572AHigh precisionEfficient resectionDiagnosticsSurgeryAcetabular boneAcetabulum prosthesis

The invention discloses a customized hip joint surgical positioning device based on medical images, a matched prosthesis and a positioning method. An eccentric positioning hole for positioning a short eccentric handle is formed in the acetabulum according to preoperative planning, meanwhile effectively cutting off damaged acetabular bone in the acetabulum based on a drilling nail corresponding to the central axis of an acetabulum prosthesis and achieving effectiveness and accuracy of the transplantation position of the acetabulum prosthesis. The positioning accuracy in operation is improved, the usage cost is reduced, meanwhile surgeons are not required to be trained specially, the prosthesis is simple and convenient to operate and install, a three-dimensional coordinate position of the prosthesis during installation is determined, the time for required calibration in operation is shortened, and operation efficiency is improved. The peripheral positioning of the acetabulum prosthesis is achieved and high-accuracy installation of the acetabulum prosthesis is ensured when the short eccentric handle is arranged on the acetabulum prosthesis and installed in the acetabulum.

Owner:SHANGHAI XINJIAN MEDICAL TECH

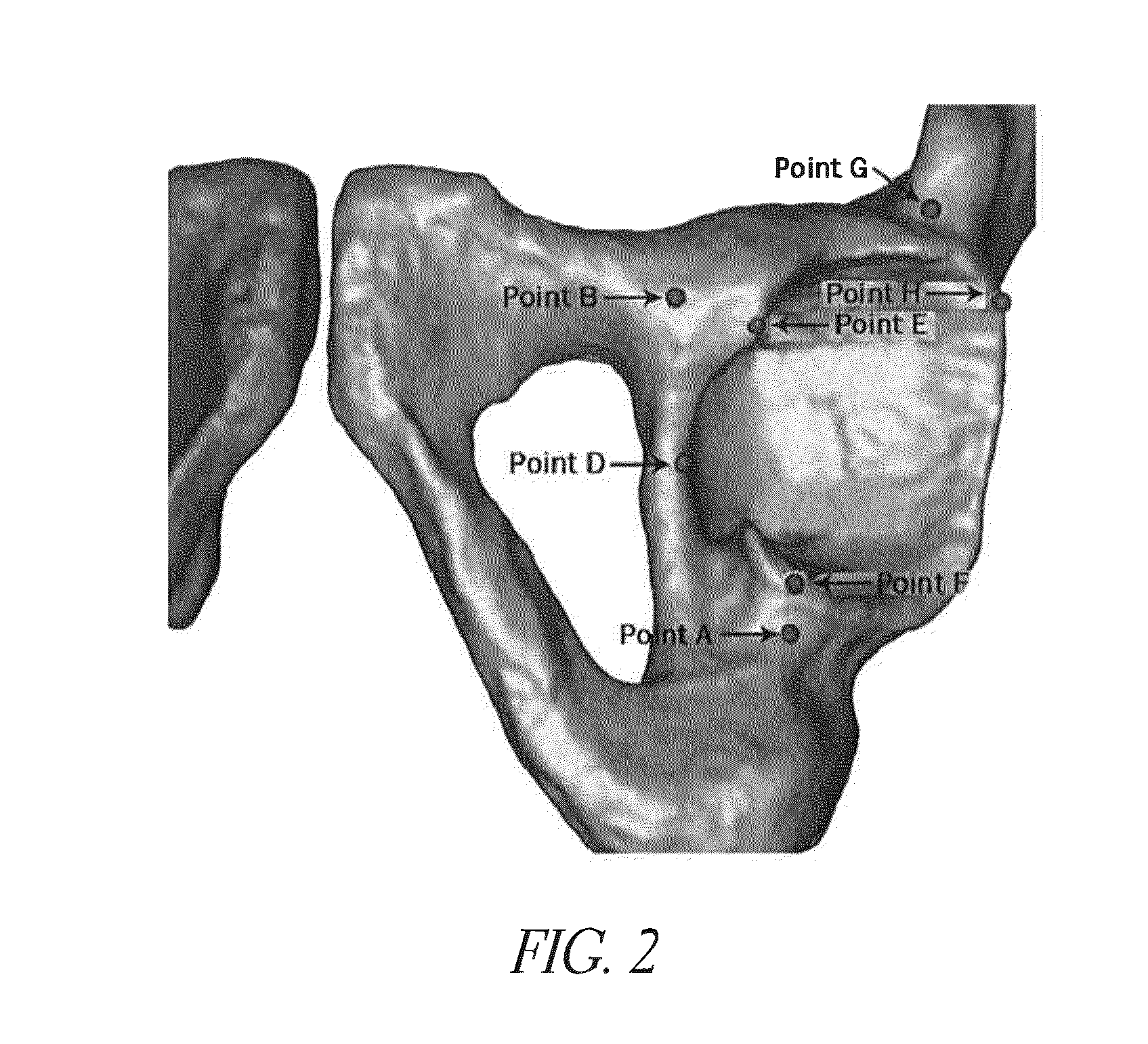

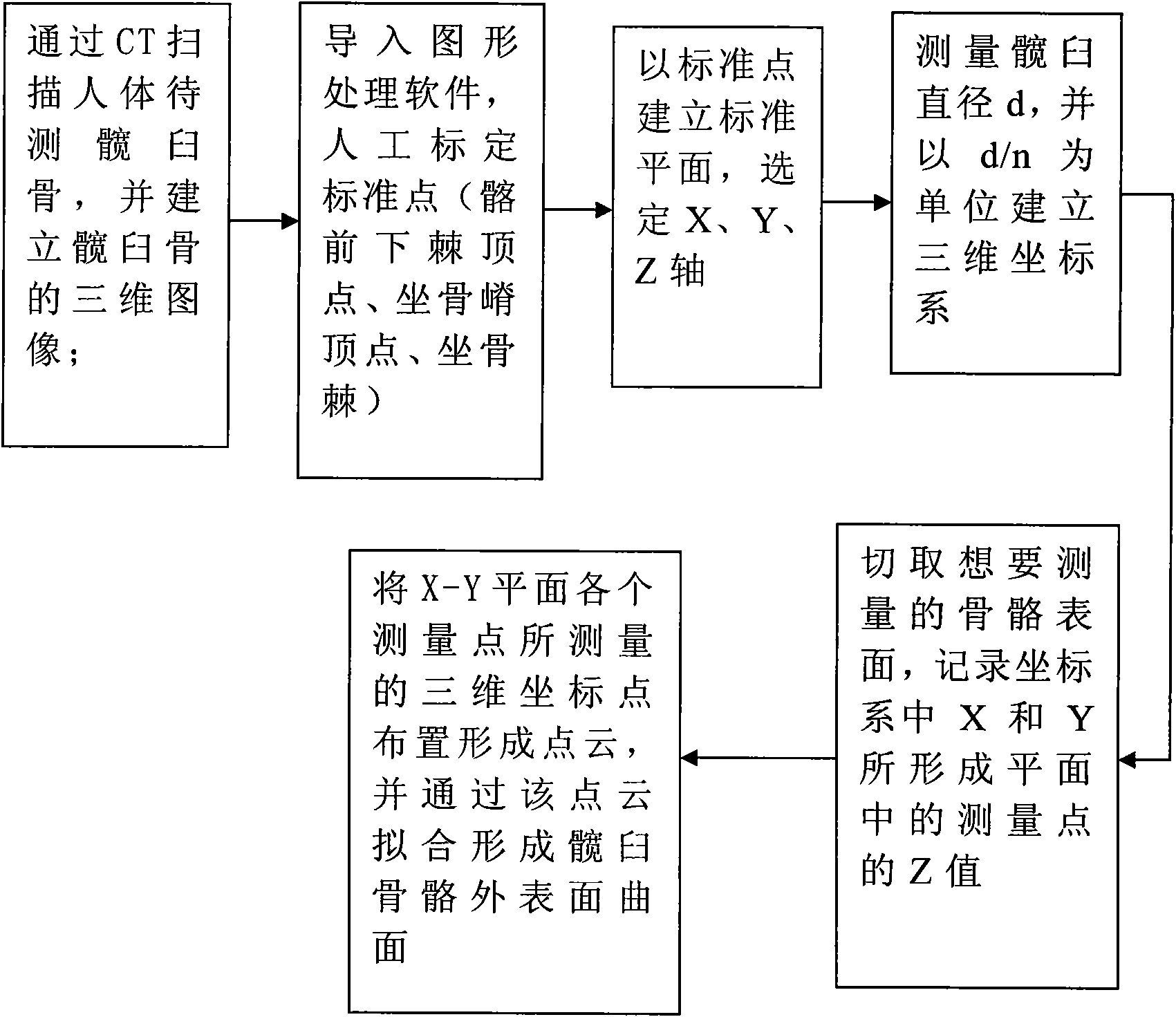

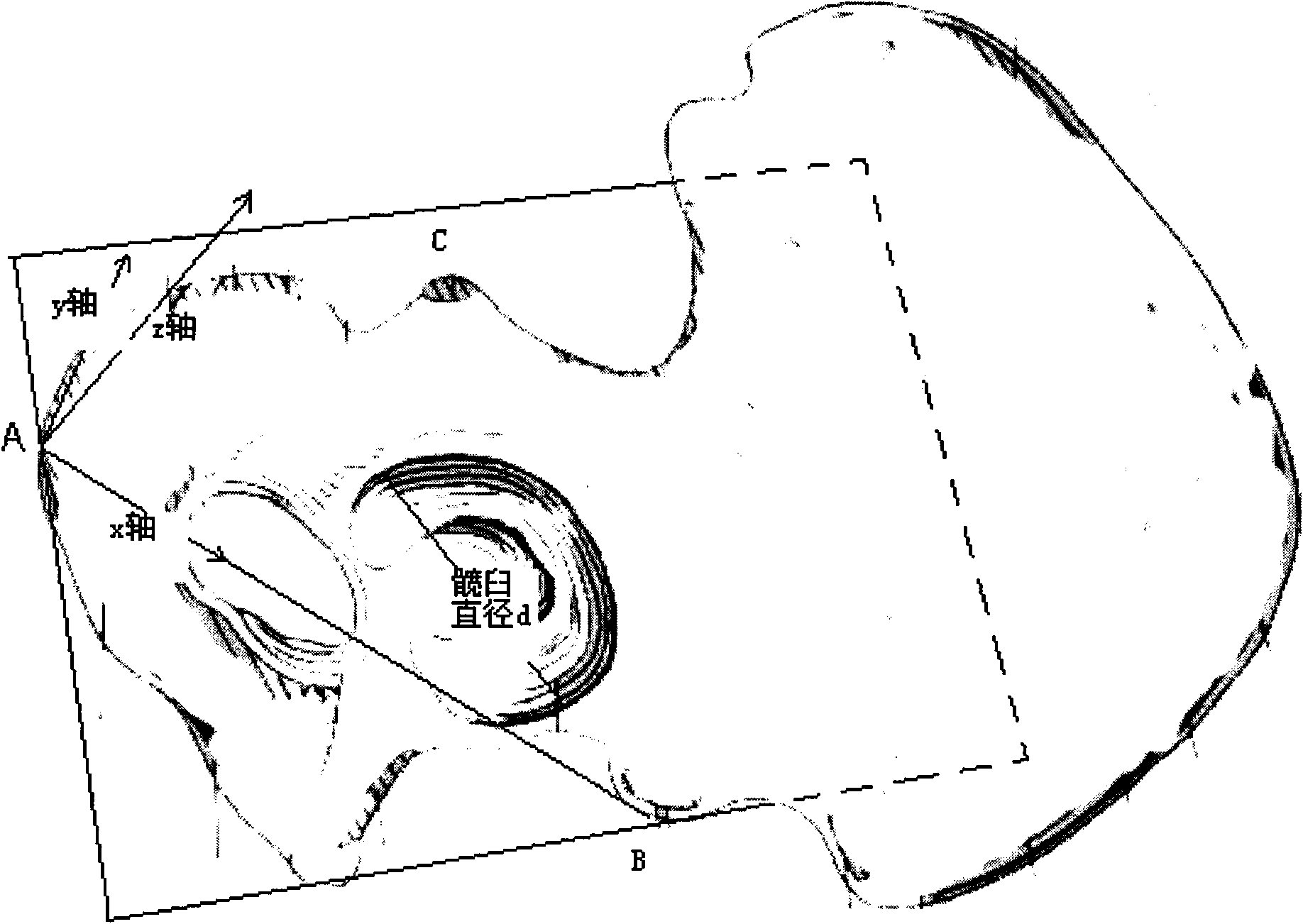

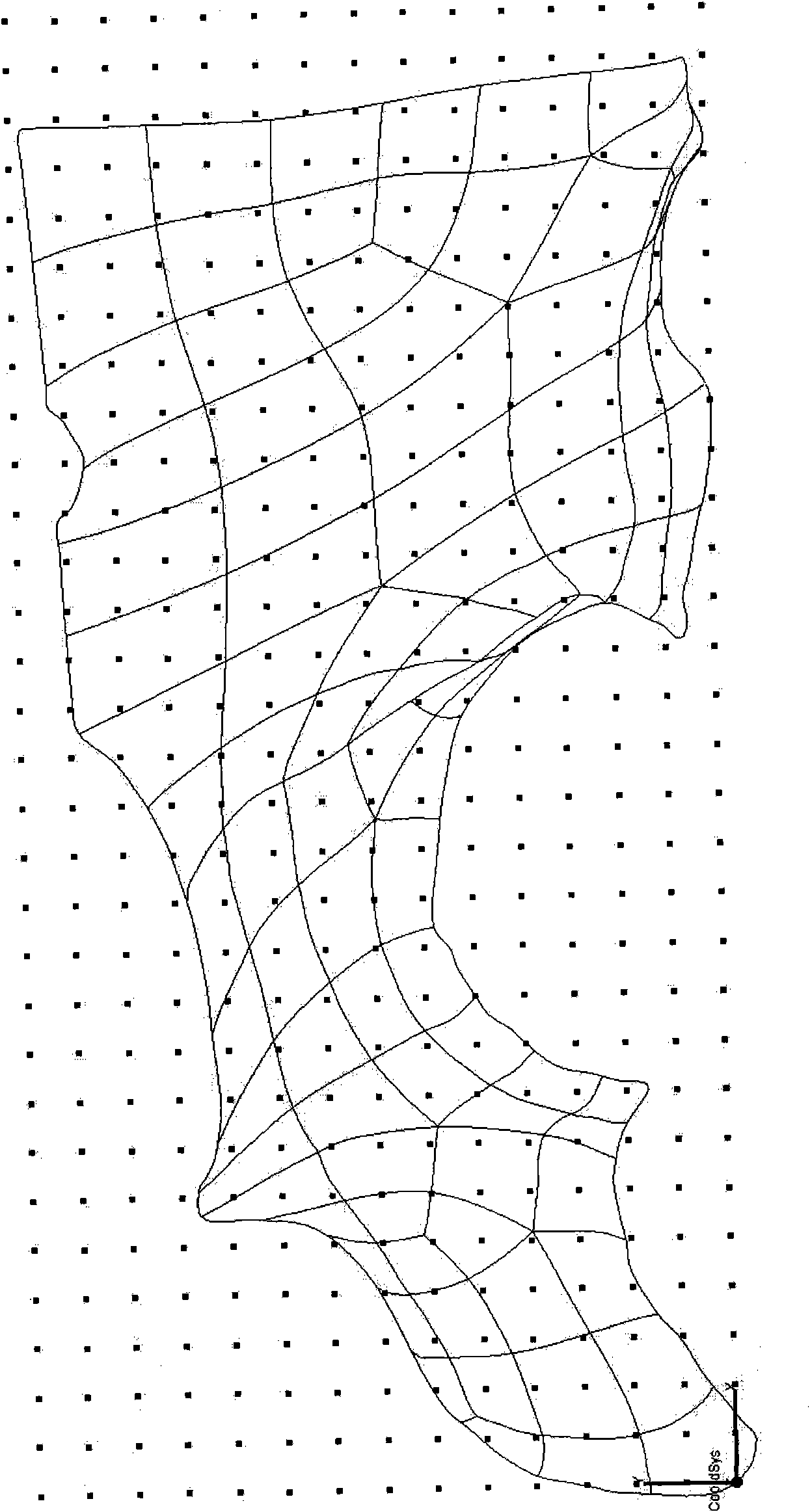

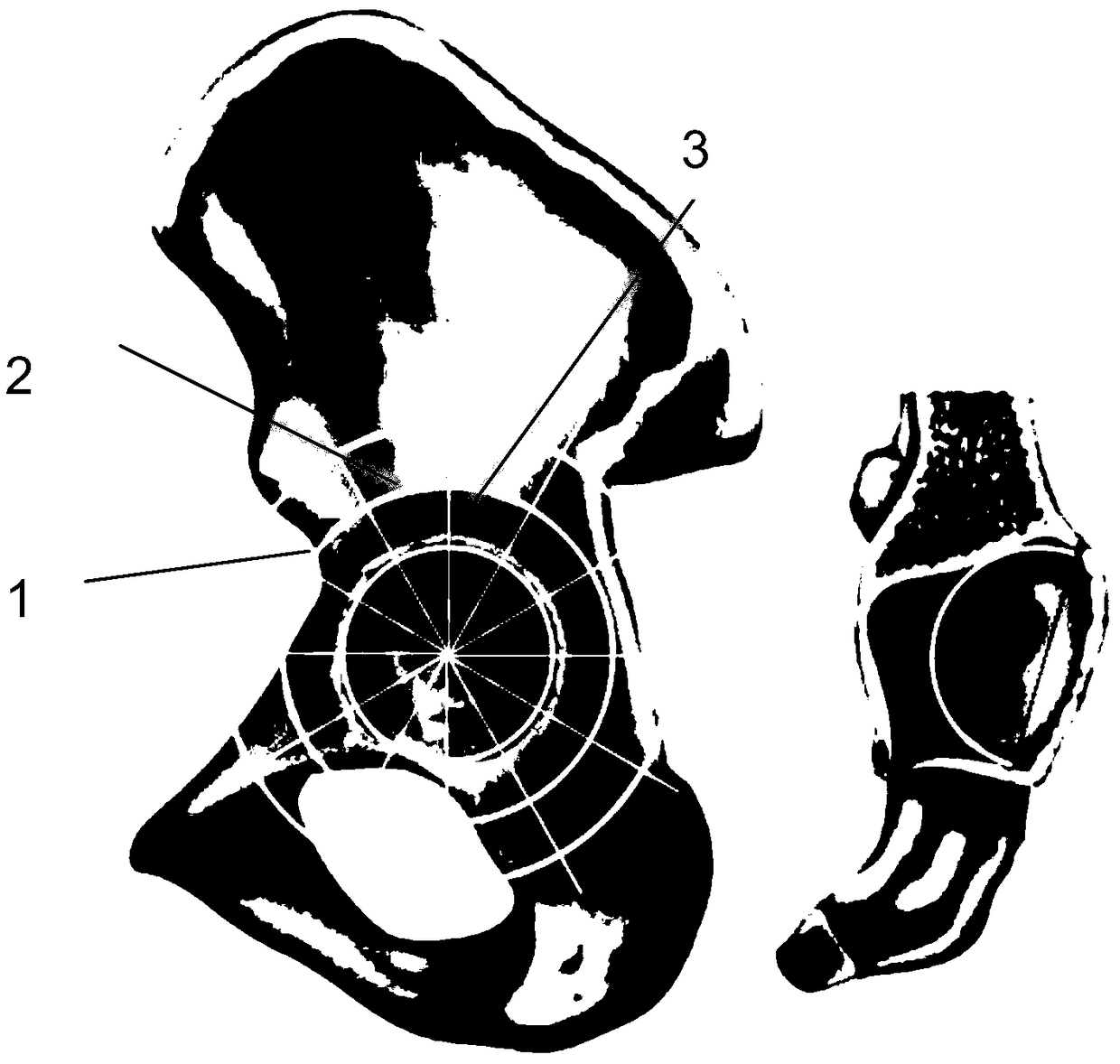

Measuring method of acetabular bones of human bodies

ActiveCN101579240ALow costScale upComputerised tomographsTomographyAcetabular componentSize difference

The invention provides a measuring method of acetabular bones of human bodies, which not only realizes anthropometry through CT scanning and imaging technology, but also standardizes the measured data of the acetabular bones with the diameter d of acetabulum as the basis of unit standardization. The acetabular bones of human bodies probably differ in sizes but the basic proportion of the acetabular bones is consistent, therefore, the method applies the point and standardizes the measured data of the acetabular bones with the diameter d of acetabulum as the basis of unit standardization, thereby eliminating comparison difficulty caused by size difference of each bone and providing convenience for comparison and analysis between acetabular bones.

Owner:唐佩福 +2

An artificial hip joint replacement system

The present invention relates to an artificial hip joint replacement system. The system includes an acetabulum portion comprising a cup suitable to be received by a subject's acetabular bone. The cup includes a rigid portion and an elastic portion attached to the rigid portion. Also included in the system is a ball received within the cup and in contact with the elastic portion and a femoral stem attached to the ball. The elastic portion is positioned to cause expansion and contraction of a space between the ball and the rigid portion of the cup so they are further apart from one another during periods of low mechanical loads.

Owner:CORNELL UNIVERSITY +1

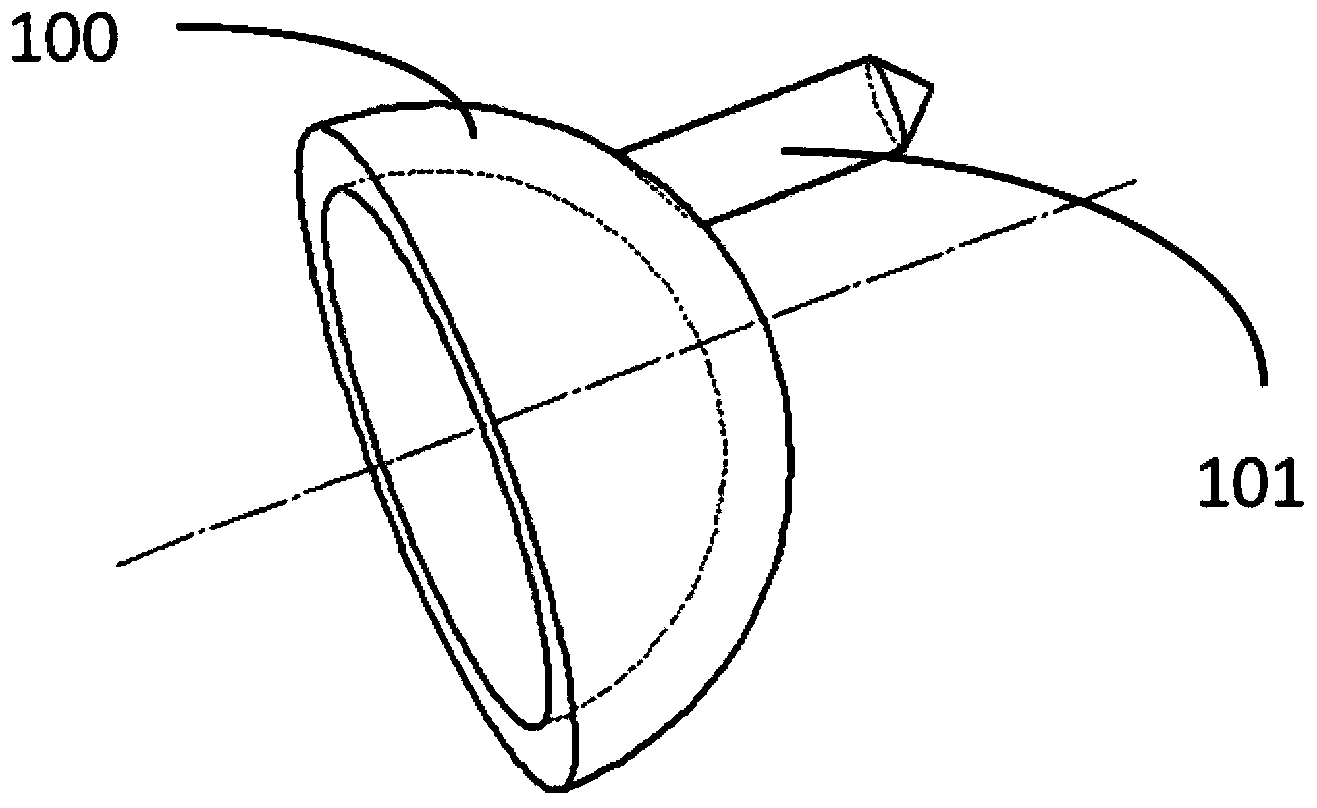

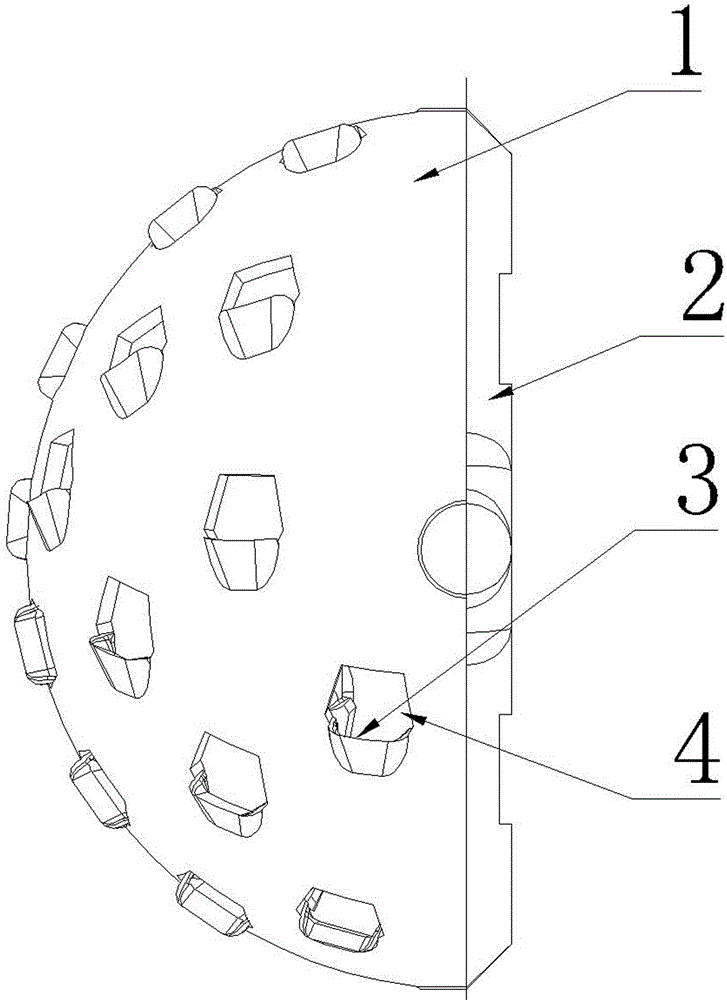

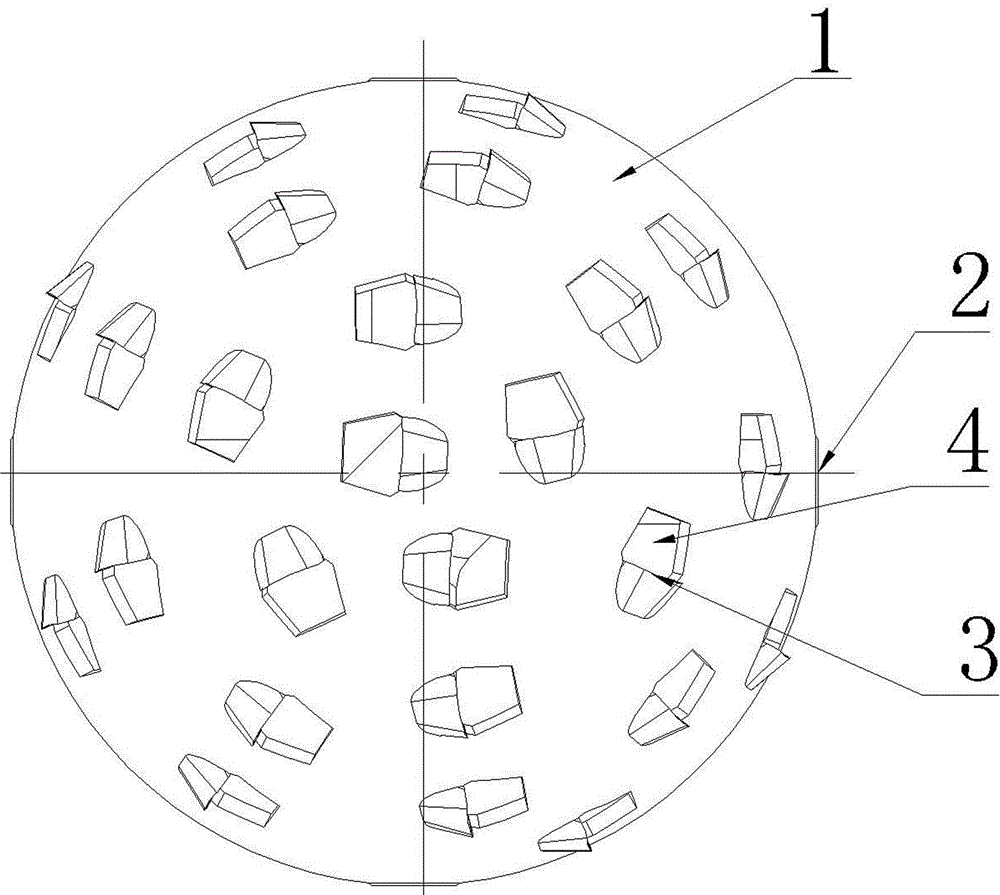

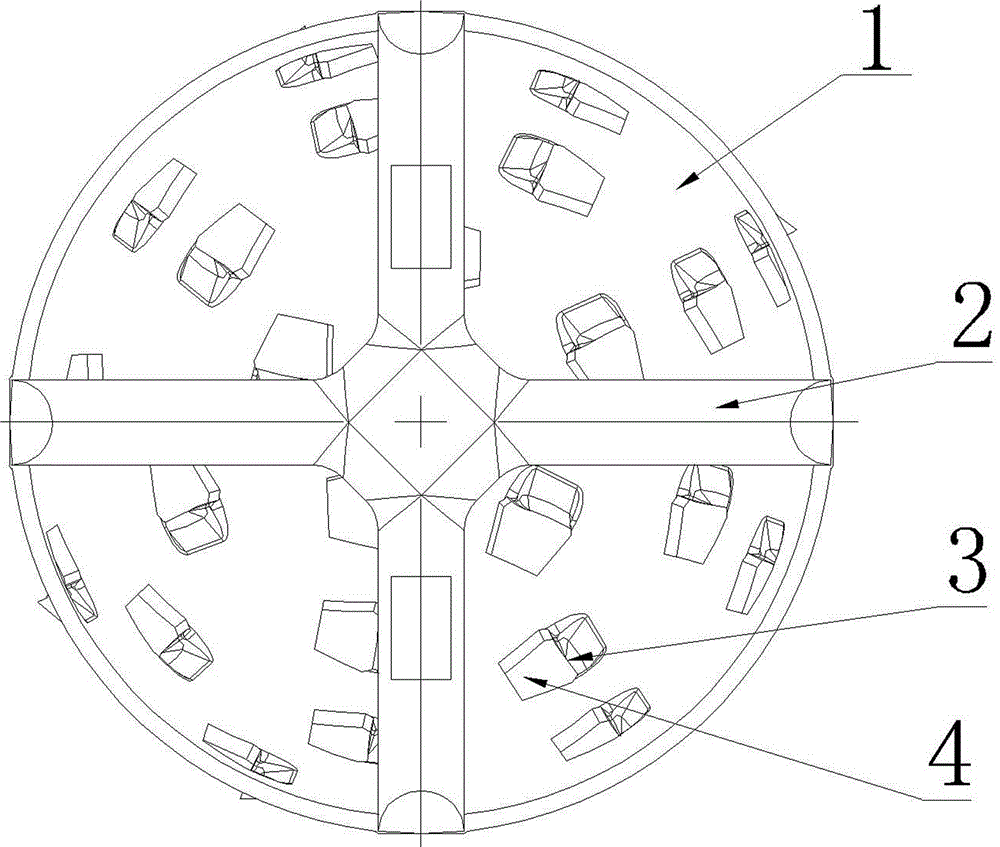

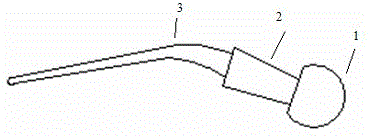

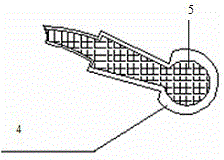

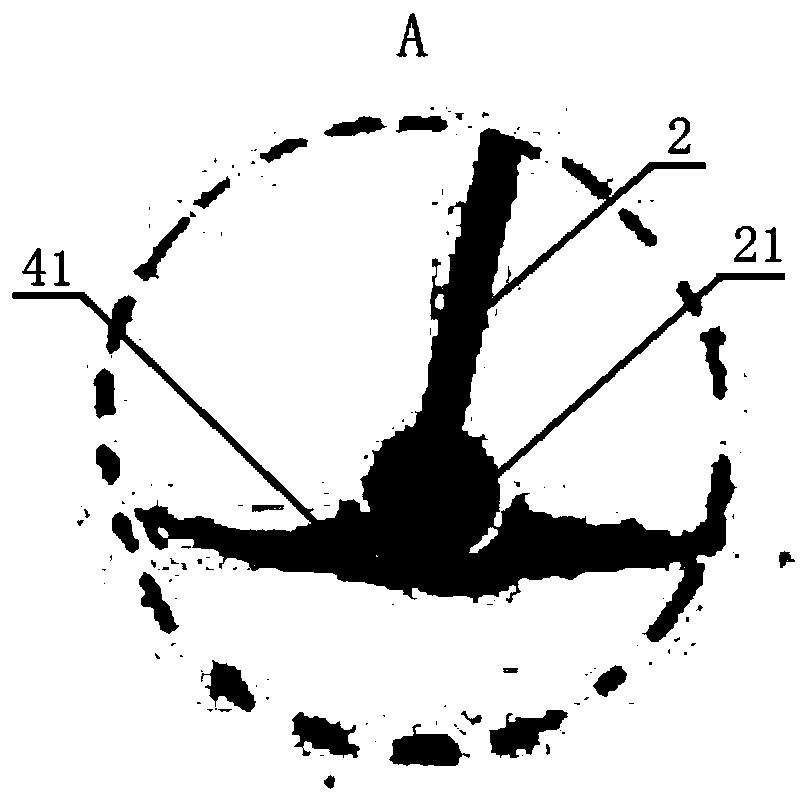

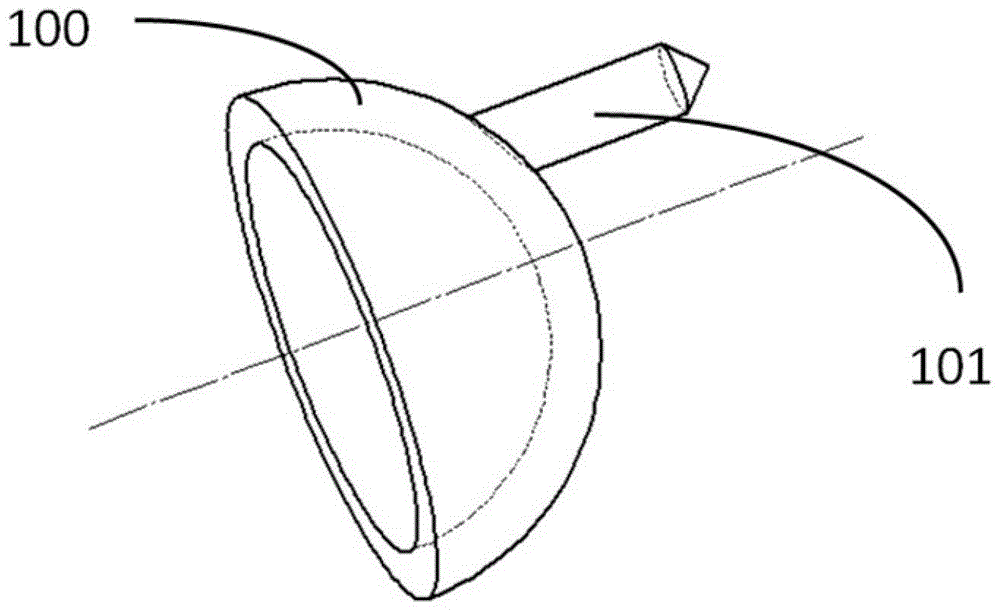

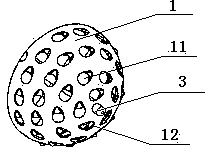

Acetabular bone file

The invention relates to an acetabular bone file which is suitable for a bone joint replacement surgery. Under the driving a power tool, a physical acetabular bone is filed to form an accurate predicated shape (semi-spherical shape or frustum shape), so that an acetabular bone planted object is convenient to plant. The acetabular bone file is composed of a cutting main body and a rapid replacement part, wherein the rapid replacement part is fixedly connected with the cutting main body; the cutting main body is a dome-shaped thin shell; a plurality of convex cutting edges are irregularly distributed on the outer surface of the thin shell; each cutting edge is provided with a scrap containing hole; the length direction of each scrap containing hole is vertical to the corresponding cutting edge; the cutting edge parts are parallel to the outer surface of the dome-shaped thin shell. The plurality of convex cutting edges are distributed at all parts of the predicated formed shape. The lengths of one part of the cutting edges parallel to the outer surface of the dome-shaped thin shell is not less than 0.5mm. The wall thickness of the cutting main body is not more than 3mm. The rapid replacement part is a cross-shaped bracket or in a disc shape with holes.

Owner:常州玛斯特精密工具有限公司

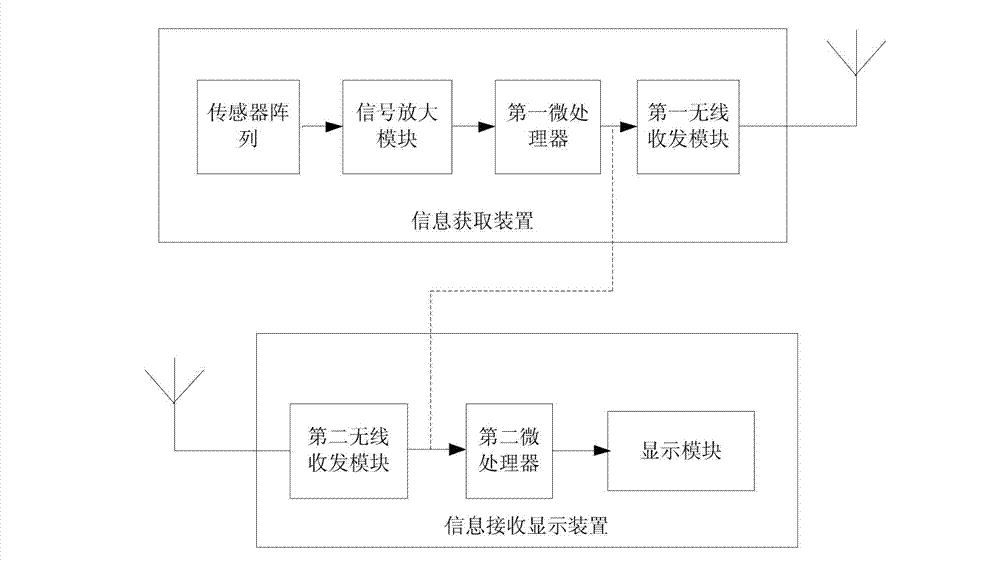

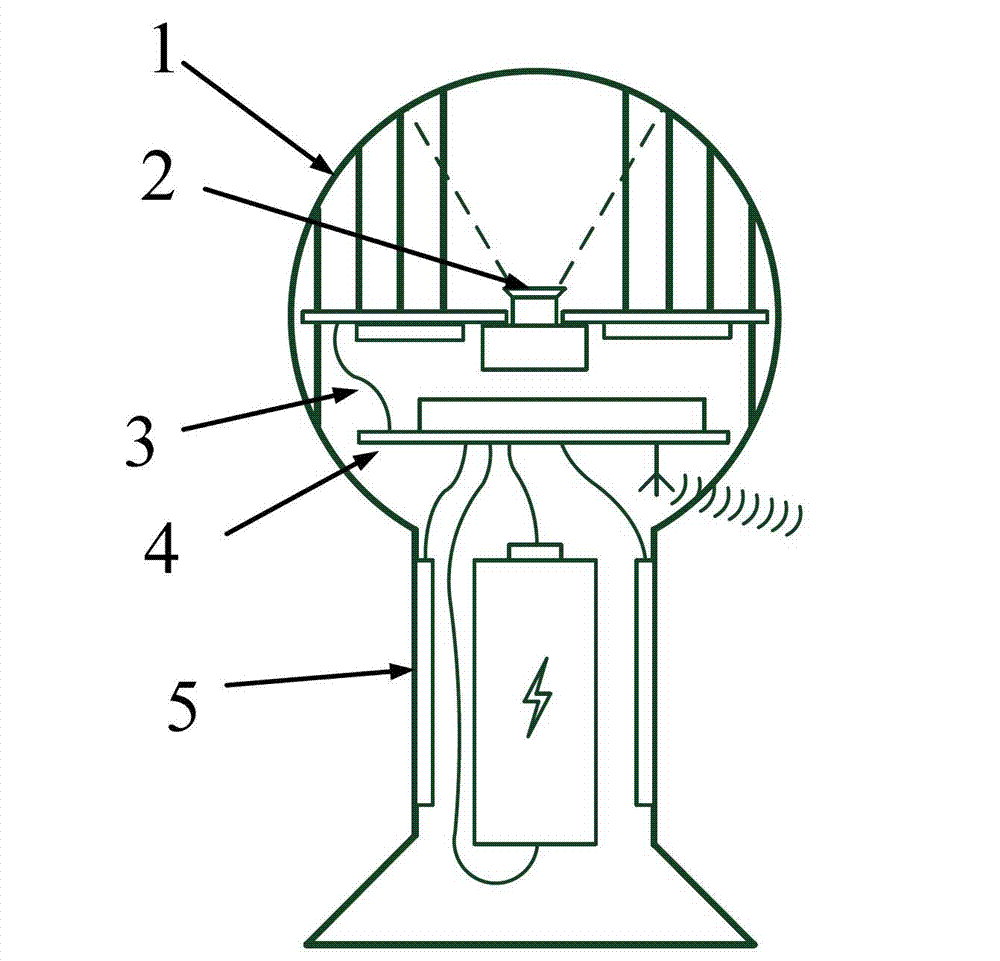

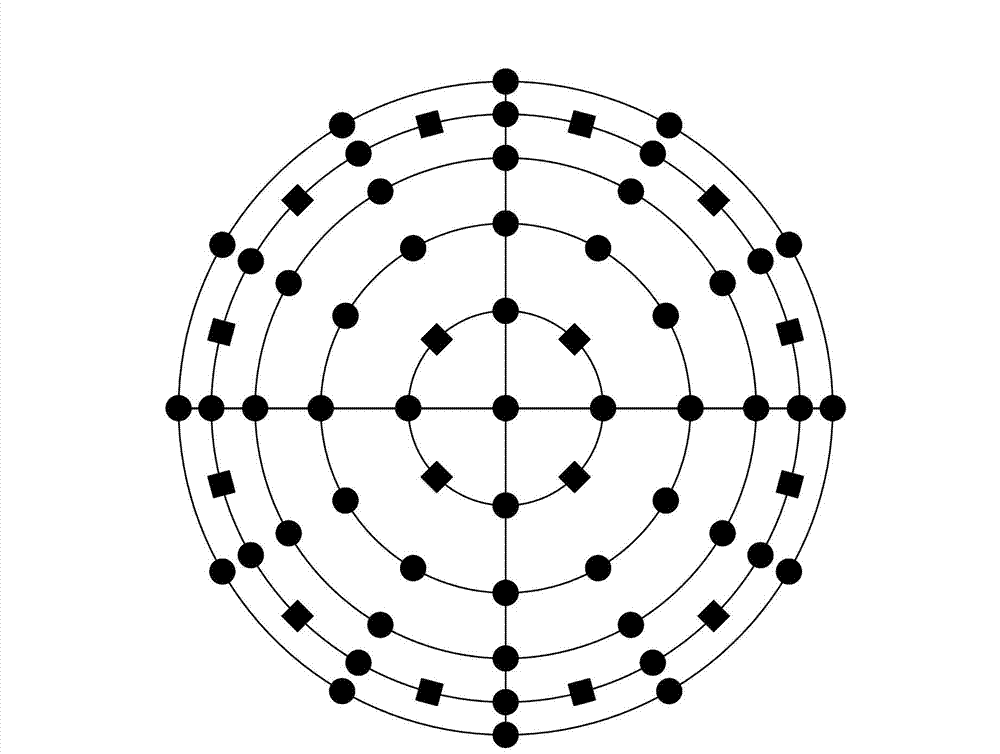

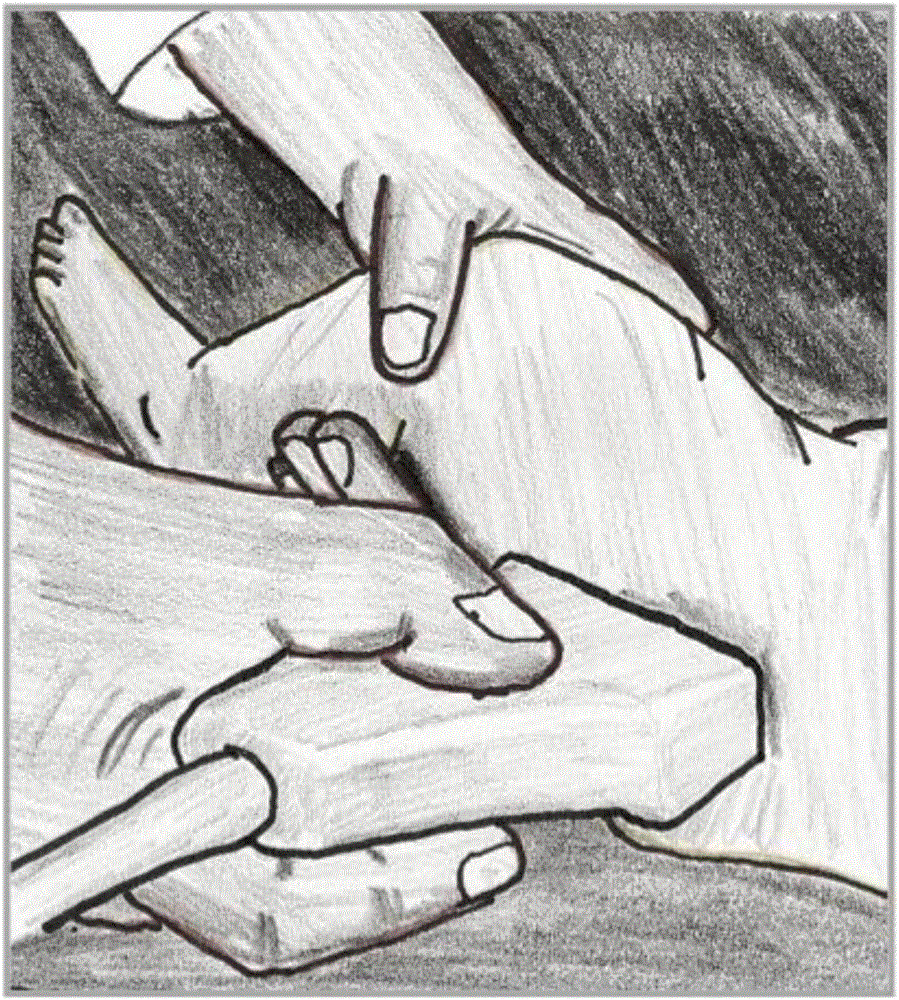

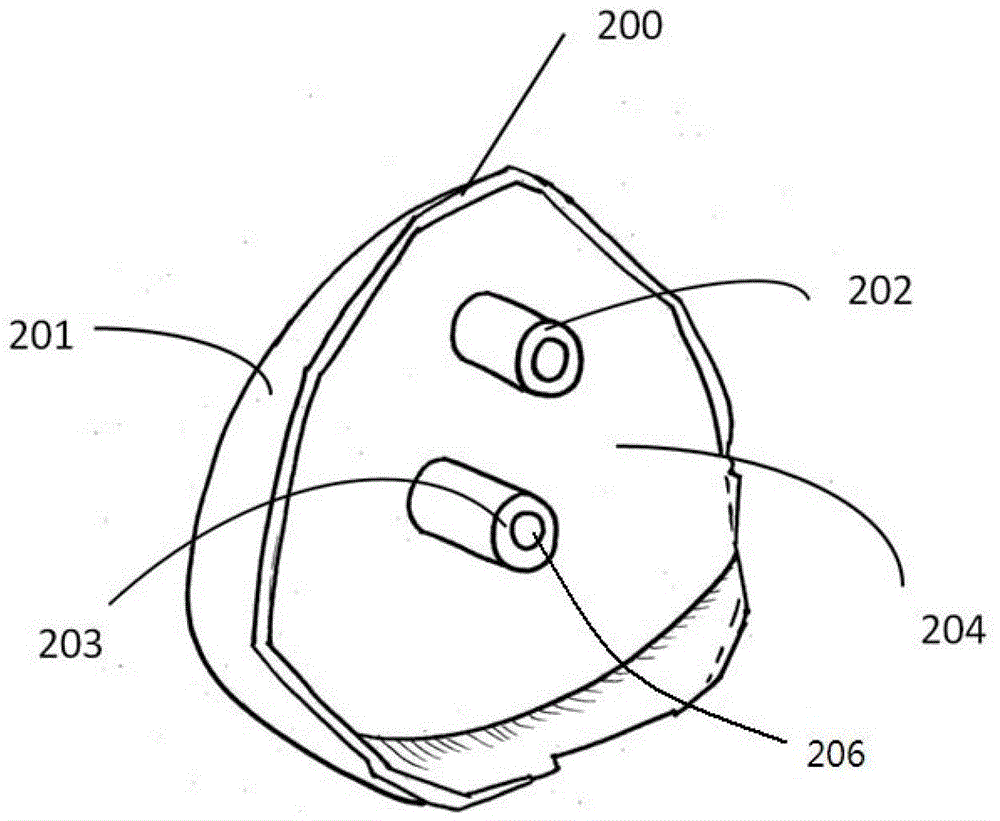

Method and system for acquiring postures of acetabular bone and femoral head in novel hip arthroplasty

ActiveCN102885626AImprove surgical efficiencyImprove the curative effect of surgeryEndoradiosondesSensorsAcetabular componentSensor array

The invention discloses a method and a system for acquiring posture of an acetabular bone and a femoral head in novel hip arthroplasty. The method comprises the following steps of: setting pressure sensors and / or touch sensors and an image sensor on a femoral head false test mould to form a sensor array; acquiring the contact and stress condition and position information of the femoral head false test mould and acetabular bone by the sensor array, and sending a signal; and receiving the signal by a receiving end, and displaying the received signal on a display module, so as to acquire the analogue postures of the acetabular bone and the femoral head. The system comprises the sensor array, a necessary external circuit and a signal receiving and displaying device for receiving and displaying the signal emitted by the external circuit. According to the invention, the existing posture of the femoral head false body can be accurately simulated during the hip arthroplasty, so that a doctor can intuitively see the position and movement status of the femoral head false body during the hip arthroplasty, and further, the success rate and the surgical treatment of the hip arthroplasty can be greatly improved.

Owner:TSINGHUA UNIV

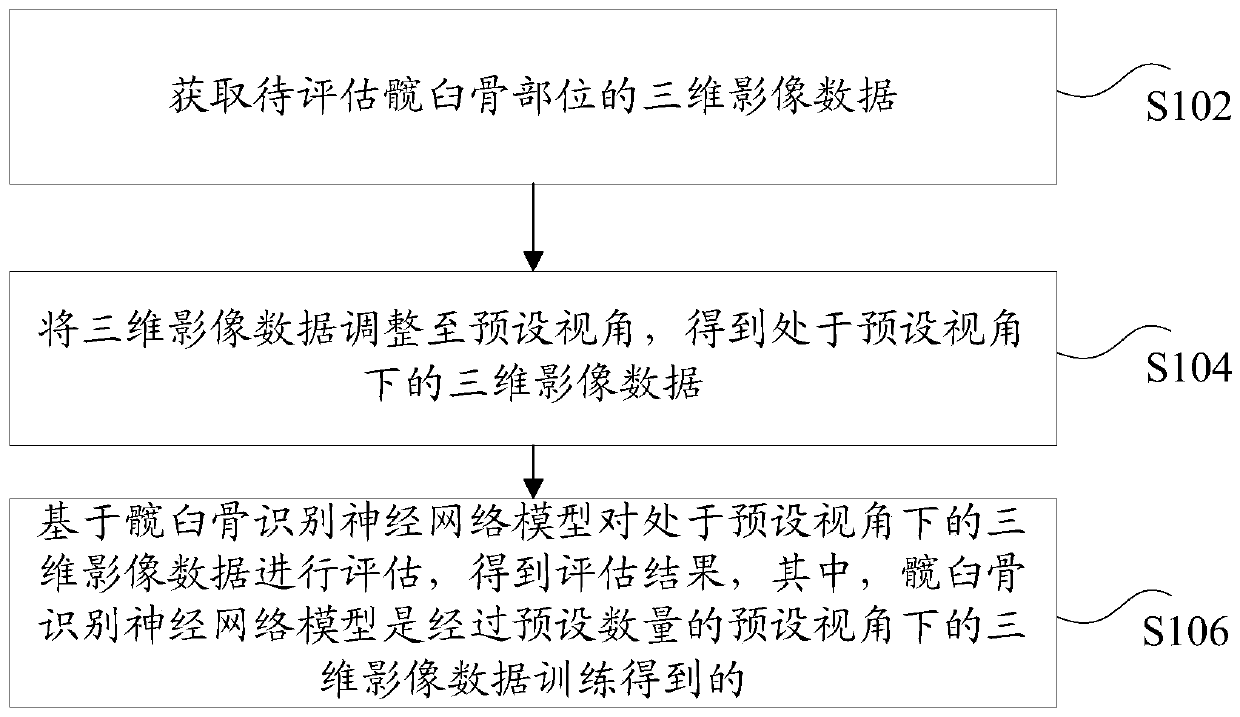

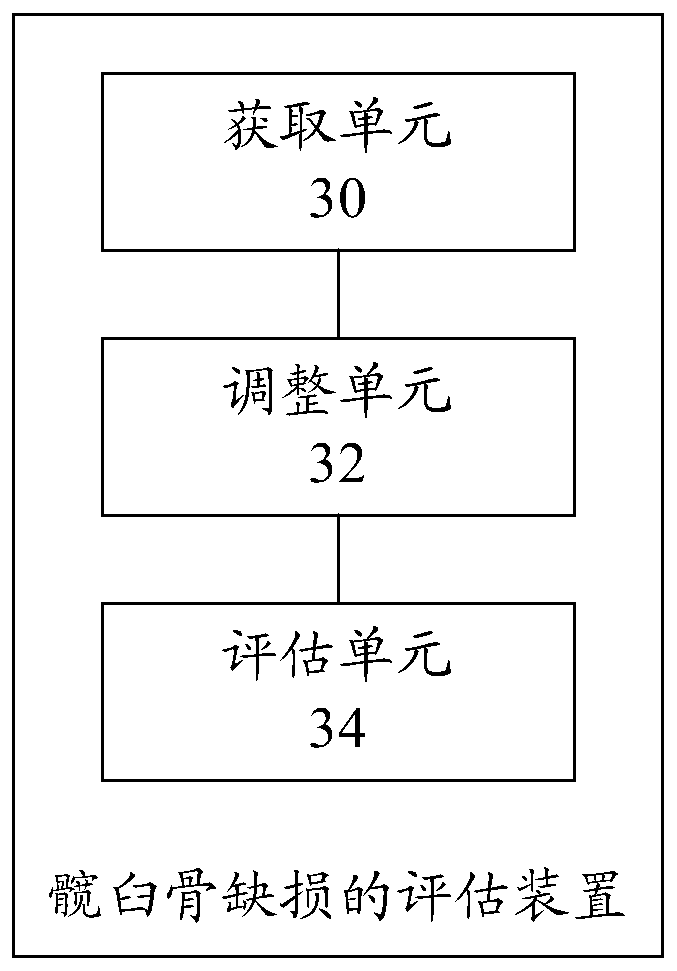

Acetabulum bone defect assessment method and device, storage medium and processor

InactiveCN109727236AImprove assessment accuracyFix technical issues with lower accuracyImage analysisNeural learning methodsEvaluation resultX-ray

The invention discloses an acetabular bone defect assessment method and device, a storage medium and a processor. The method comprises the following steps: acquiring three-dimensional image data of ato-be-evaluated acetabular bone part; Adjusting the three-dimensional image data to a preset visual angle to obtain three-dimensional image data under the preset visual angle; And based on the acetabulum bone recognition neural network model, evaluating the three-dimensional image data under a preset visual angle to obtain an evaluation result. The technical problem that in the prior art, X-rays are adopted for evaluating acetabular bone defects, and consequently the evaluation result is low in accuracy is solved.

Owner:BEIJING AKEC MEDICAL

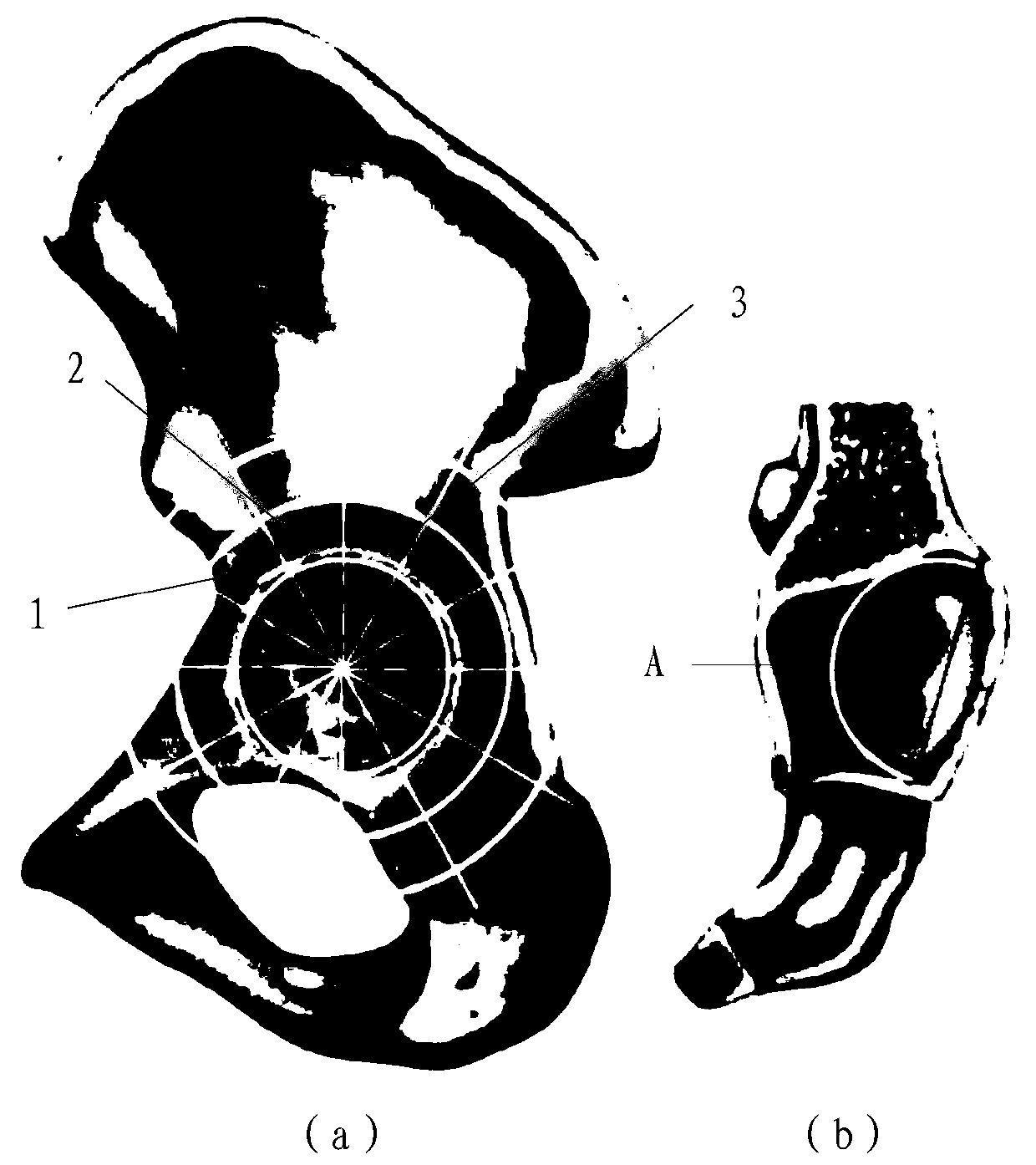

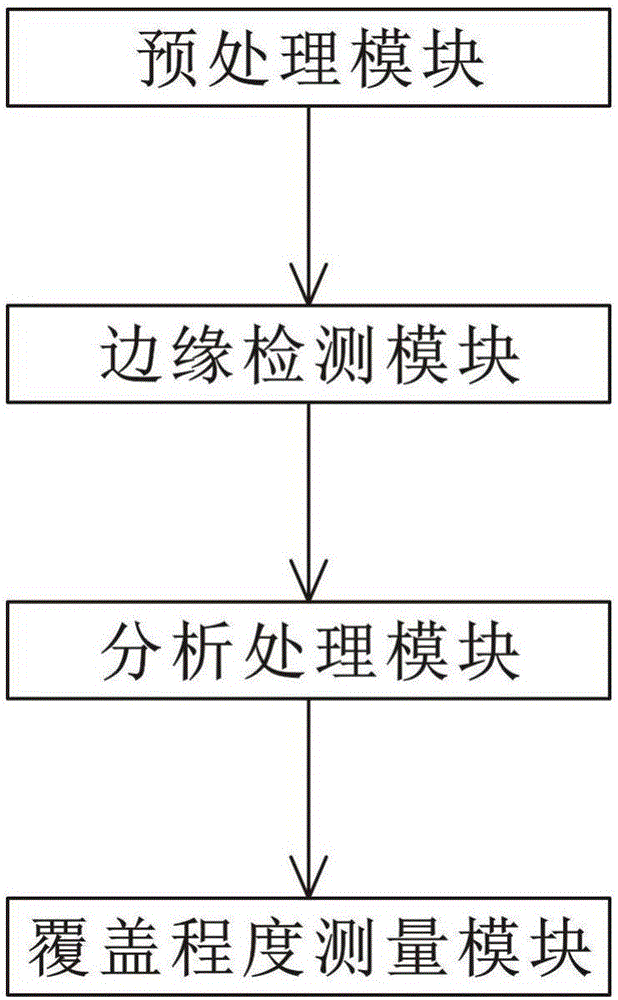

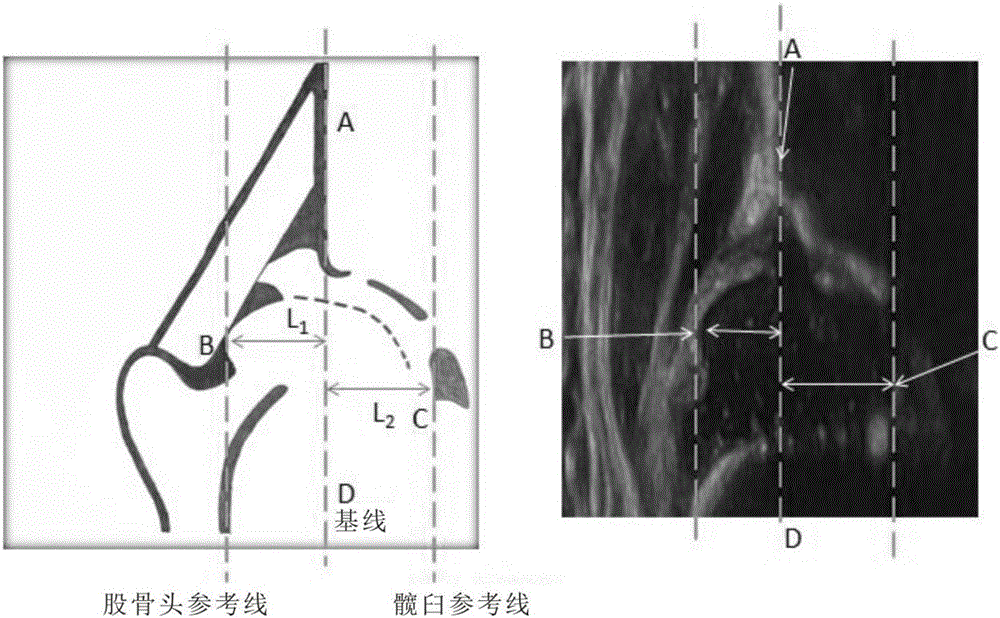

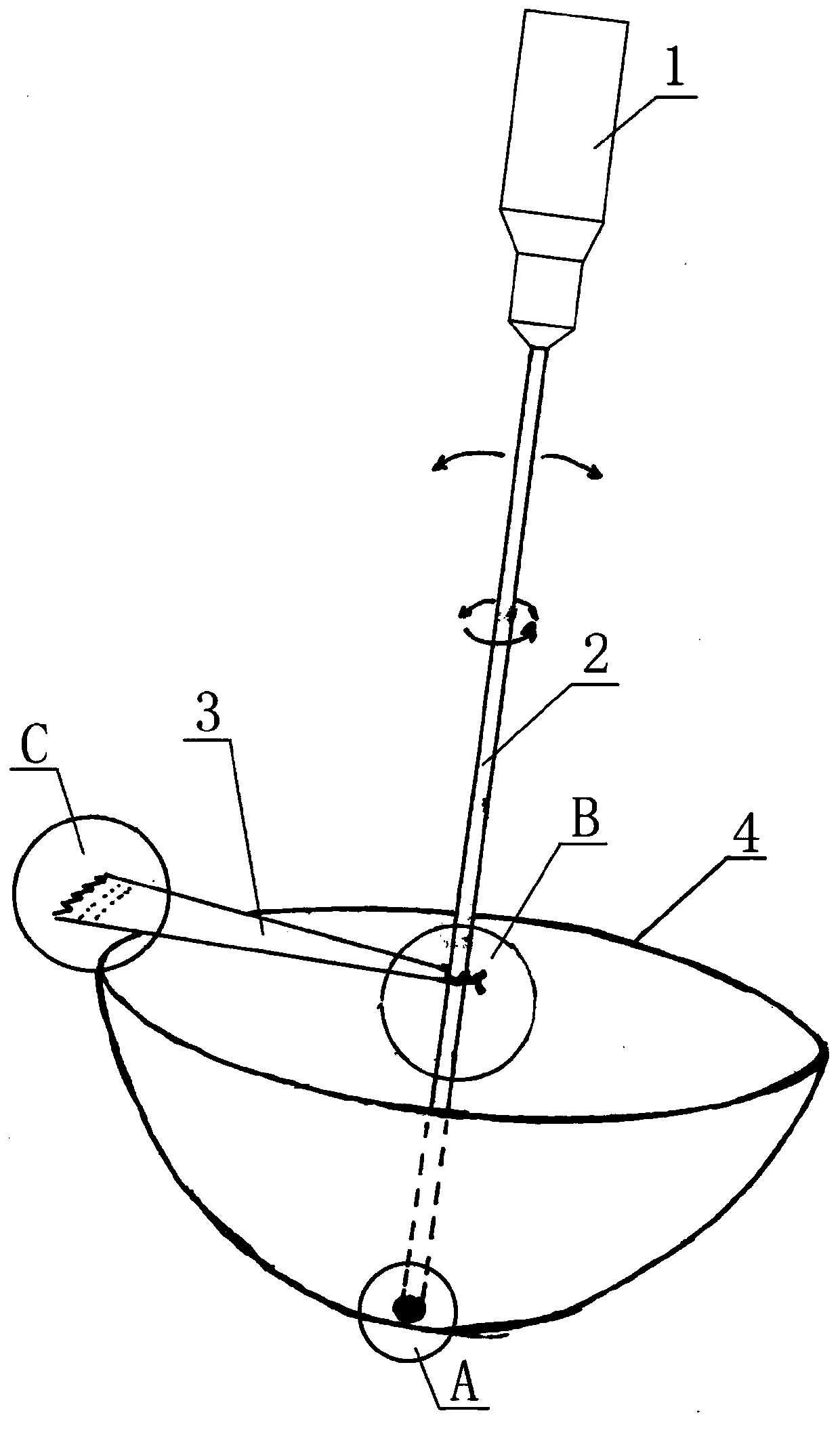

Measurement system and method of acetabular bone coverage degree based on ultrasonic image

PendingCN106667525ALow proficiencyLower requirementInfrasonic diagnosticsSonic diagnosticsRight femoral headIliac bone

The invention discloses a measurement system of an acetabular bone coverage degree based on an ultrasonic image. The measurement system comprises a pre-processing module, an edge detection module, an analysis processing module and a coverage degree measurement module. A measurement method comprises the following steps: S1, carrying out detail enhancement processing; S2, carrying out outline completion processing; S3, carrying out image analysis processing; and S4, measuring a coverage ratio. According to the measurement system and the measurement method, the obtained ultrasonic image is subjected to the detail enhancement processing and the outline completion processing; then an iliac bone A, a round outermost side edge point B of a femoral head, an outermost edge point C of an inner side of an acetabular bone, a base line D, a femoral head reference line and an acetabular bone reference line are determined; and finally, the acetabular bone coverage ratio R is calculated by utilizing a vertical distance L1 between the round outermost side edge point B of the femoral head and the base line D, and a vertical distance L2 between the outermost edge point C of the inner side of the acetabular bone and the base line D. The measurement system and the measurement method have relatively low requirements on the skill level of an operation way and the definition of the image, so that the measurement speed is relatively high and errors are not easy to occur.

Owner:CHENGDU YOUTU TECH

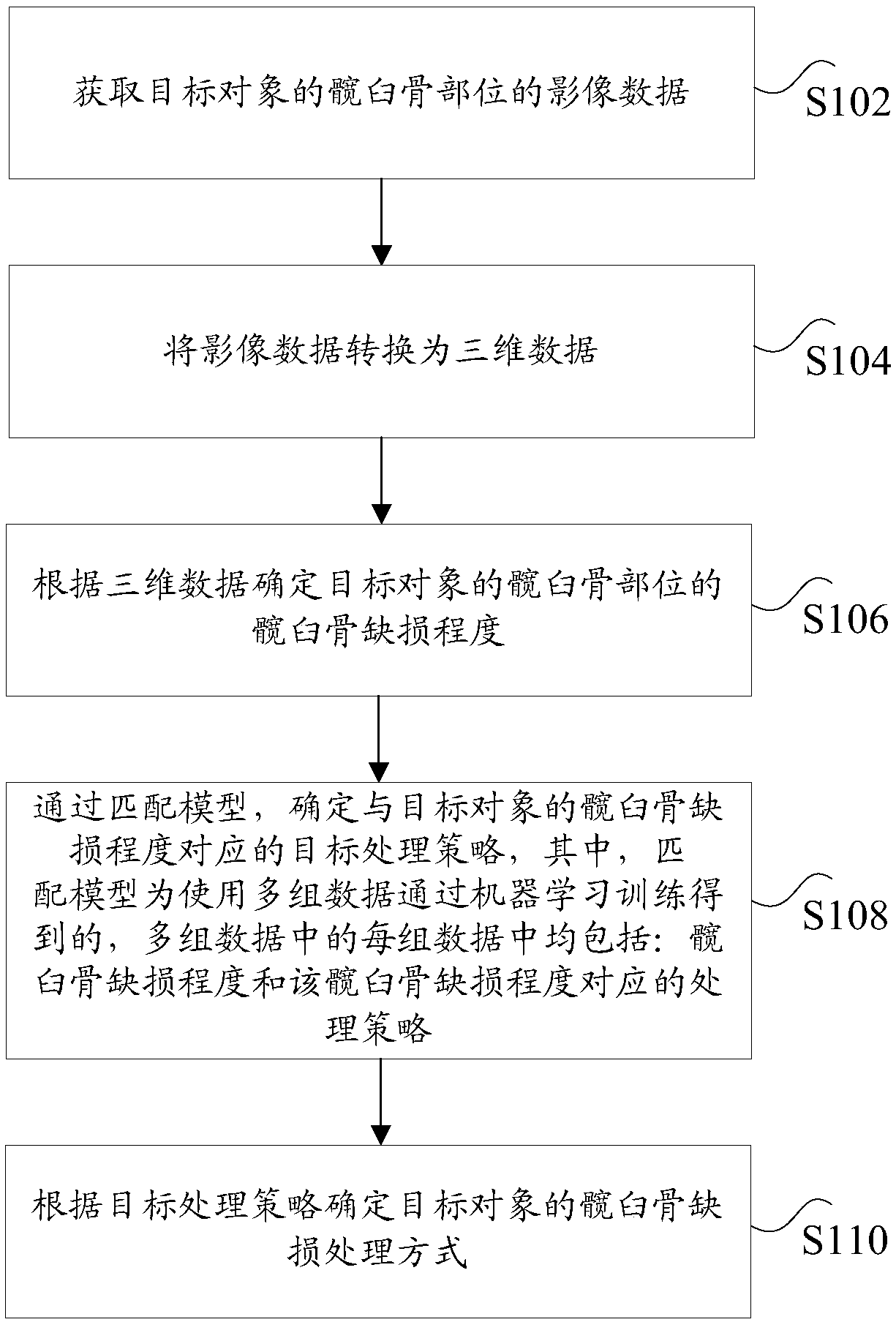

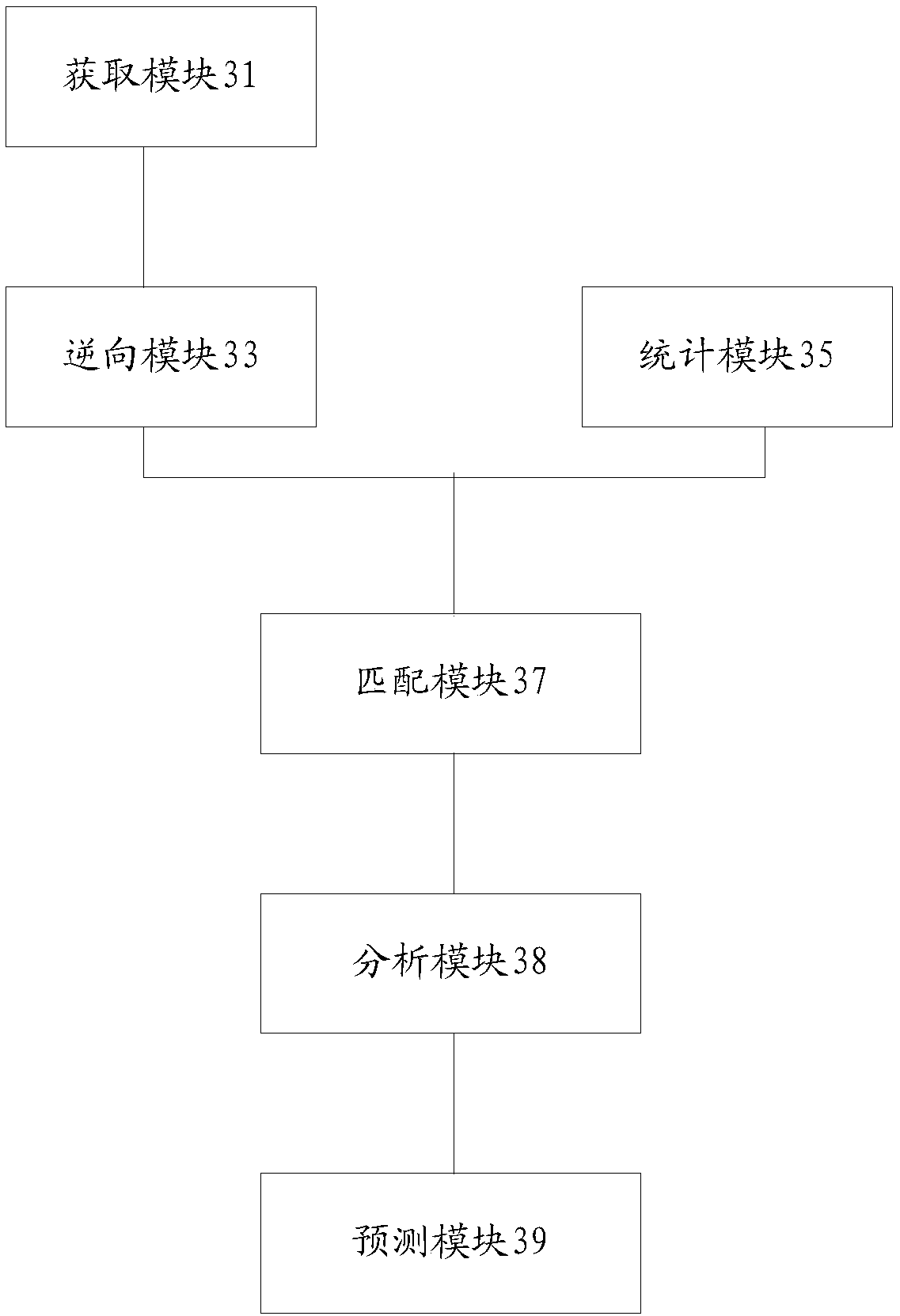

Method and device for determining treatment mode of acetabular bone defect

ActiveCN109124836AImprove reliabilityFix technical issues with lower reliabilityJoint implantsAcetabular cupsAcetabular boneTreatment strategy

The invention discloses a method and a device for determining an acetabular bone defect treatment mode. The method comprises the following steps: acquiring image data of acetabular bone part of a target object; converting image data into three-dimensional data; determining the acetabular bone defect degree of the target object according to the three-dimensional data. The target processing strategycorresponding to the acetabular bone defect degree of the target object is determined by a matching model, wherein, the matching model is obtained by machine learning training using a plurality of groups of data, and each group of data in the plurality of groups includes: a processing strategy corresponding to the acetabular bone defect degree and the acetabular bone defect degree. According to the target treatment strategy, the treatment of acetabular bone defect of the target object was determined. The invention solves the technical problems that the acetabular bone loss operation is mainlyperformed according to the subjective experience and the reliability is low in the related art.

Owner:BEIJING YIDIANLINGDONG TECH CO LTD

Artificial hip joint and manufacturing method thereof

InactiveCN104546226AAvoid disadvantagesAffect healthJoint implantsAcetabular cupsAcetabular boneWear resistant

The invention relates to medical rehabilitation instruments, and in particular, to an artificial hip joint. According to the scheme, the artificial hip joint comprises an acetabular bone, a thighbone and a joint handle; the acetabular bone is composed of an inner acetabular bone layer and an outer acetabular bone layer, and the inner acetabular bone layer is wrapped by the outer acetabular bone layer; and the outer acetabular bone layer is a wear-resistant material layer, and the inner acetabular bone layer is a metal material layer. According to the artificial hip joint, a structure of an existing artificial hip joint is improved, and the structure that the inner layer is wrapped by the outer layer is adopted. In addition, the outer layer is made of quartz material, diamond material, ceramic material or zirconium oxide material, and the inner layer is the metal material layer. By means of the artificial hip joint, the cost is not increased, and the defects of existing products made of single material such as alloy material or metal material are effectively overcome. Compared with existing products made of metal material, the artificial hip joint provided by the invention achieves composite material functions. The outer layer is the wear-resistant material layer, and the inner layer is the metal material layer, so that the wear-resistant characteristic is achieved; and toxic metallic elements are prevented from influencing the health of the human body.

Owner:ZHEJIANG YIHUO TECH

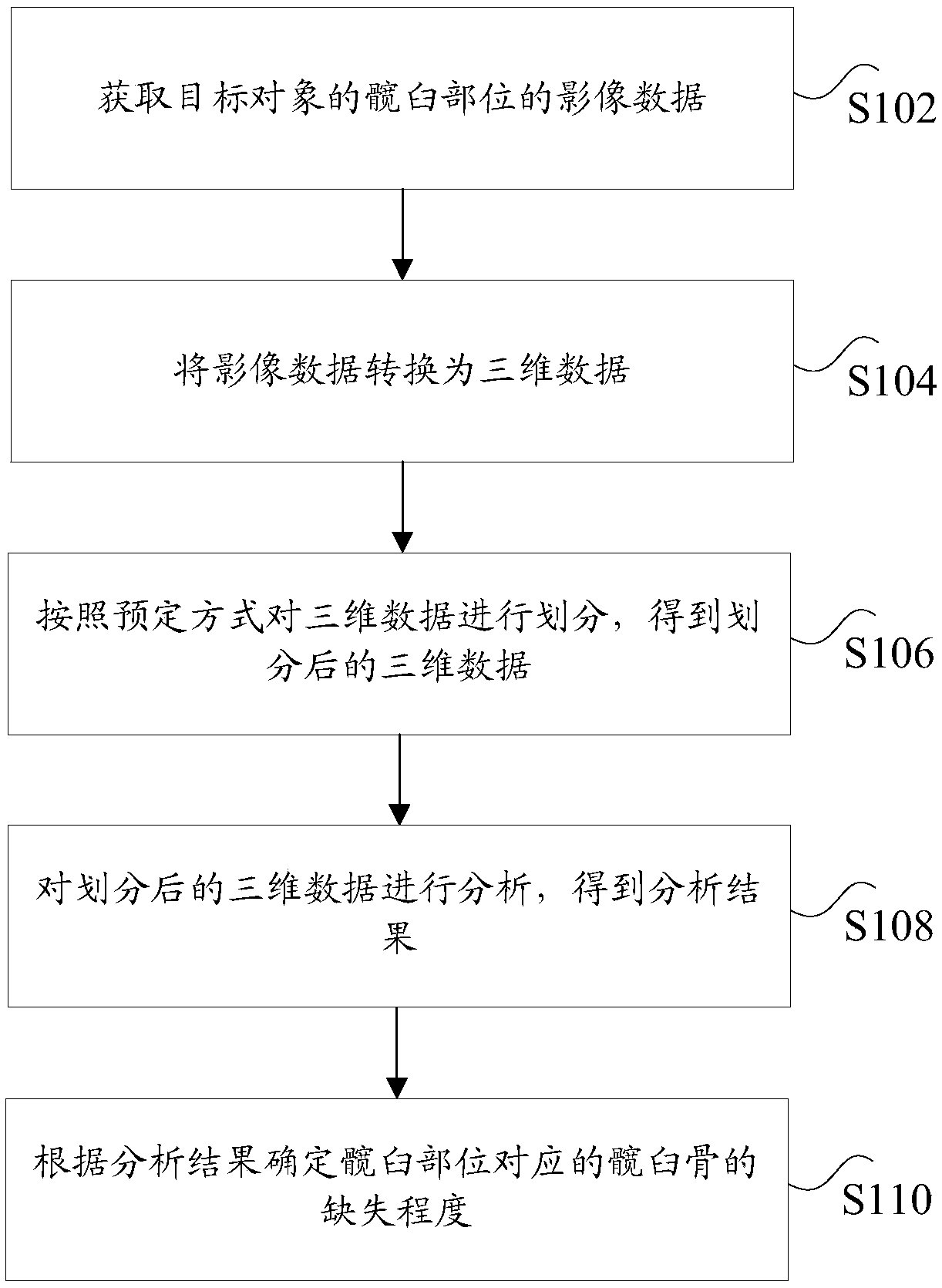

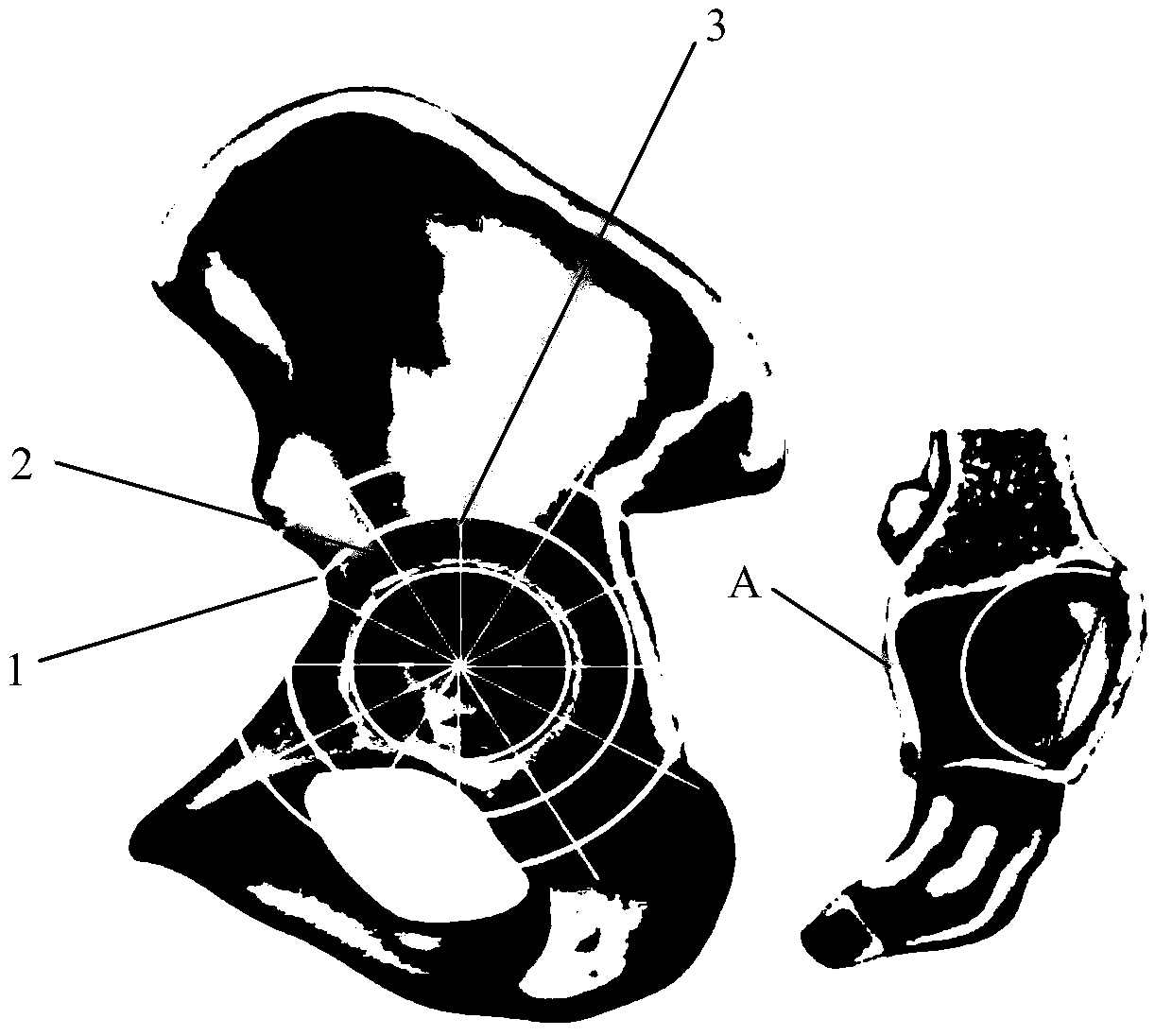

Method and device for determining degree of acetabular bone defect

ActiveCN109106481AFix technical issues with lower accuracyImprove accuracyJoint implantsAcetabular cupsEvaluation resultJoint revision

The invention discloses a method and a device for determining the degree of acetabular bone defect. The method comprises the following steps: obtaining image data of acetabular part of a target object; converting image data into three-dimensional data; dividing the three-dimensional data according to a predetermined mode to obtain the divided three-dimensional data; analyzing the divided three-dimensional data and get the analysis result, and determining the degree of acetabular bone loss corresponding to the acetabular site according to the results of the analysis. The invention solves the technical problem in the related art that the accuracy of the evaluation result obtained by the evaluation method for the acetabular bone defect in the hip joint revision operation is low.

Owner:BEIJING AKEC MEDICAL

Acetabulum prosthesis

ActiveCN105078618AEasy to fixWide range of motion anglesJoint implantsAcetabular cupsRight femoral headFemoral stem

The invention discloses an acetabulum prosthesis, which is used to replace bone tumor in an acetabulum, and comprises an inner liner (4) which is sleeved outside a ball head of a femoral head, an acetabulum cup (3) is sleeved outside the inner liner (4), the inner liner (4) can rotate between a ball head of a femoral stem and the acetabulum cup (3), and the size of an opening of the acetabulum cup (3) is adjusted to prevent the acetabulum prosthesis from dislocating. The acetabulum prosthesis can be combined with an acetabular bone which is arranged in a patient body, is more firm to fix, is large in activity angle range, and is prevented from dislocating. The acetabulum prosthesis can be assembled at random according to situations of different patients, and meets the demands of different patients. The acetabulum prosthesis can protect limbs for patients, meets the demands of different positions of osteotomy in acetabulum surgery of hip joints, is identified with an original acetabulum position of in a patient body and an angle physical line, and can effectively and reliably rebuild functions of bodies.

Owner:河北春立航诺新材料科技有限公司

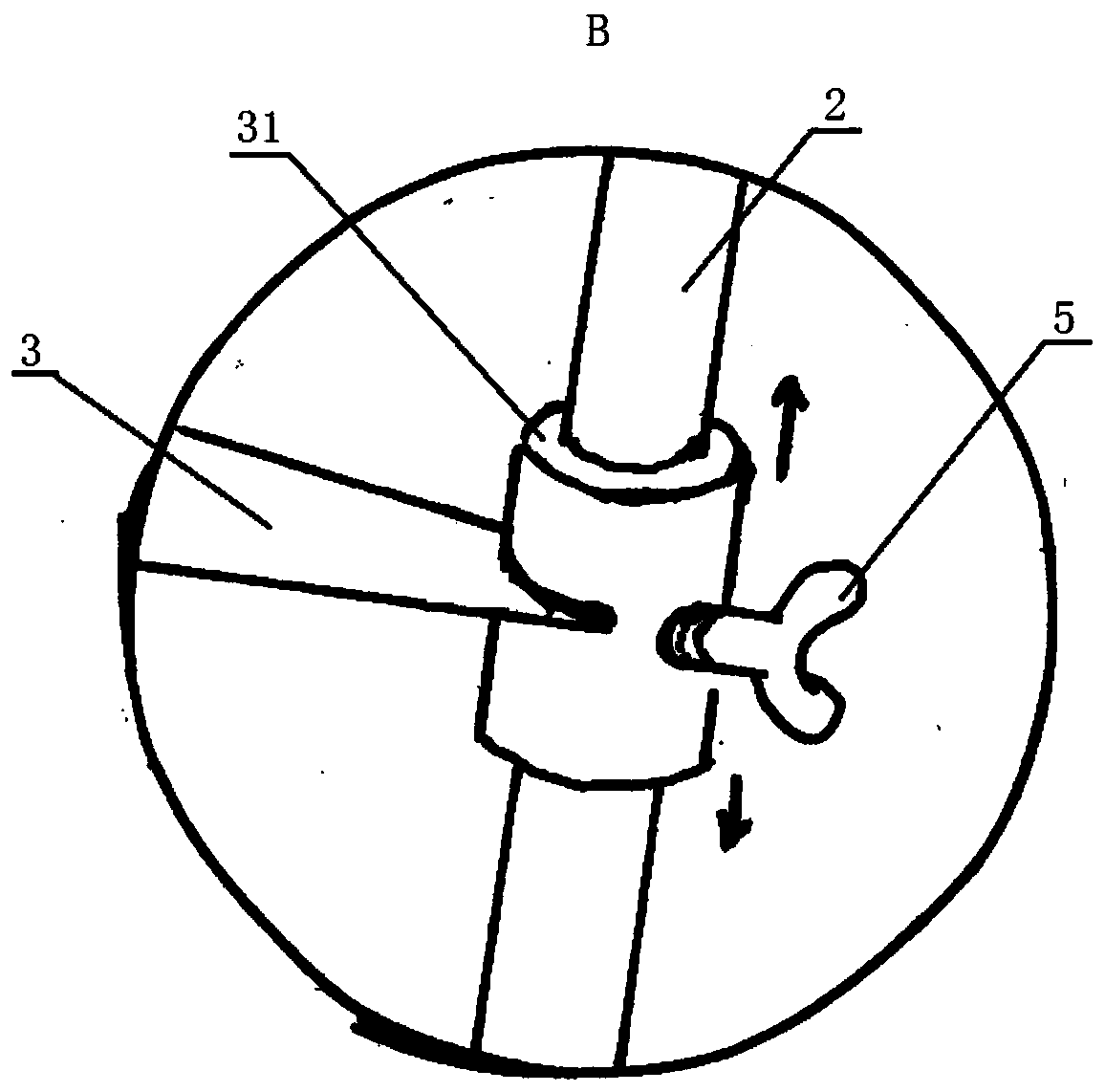

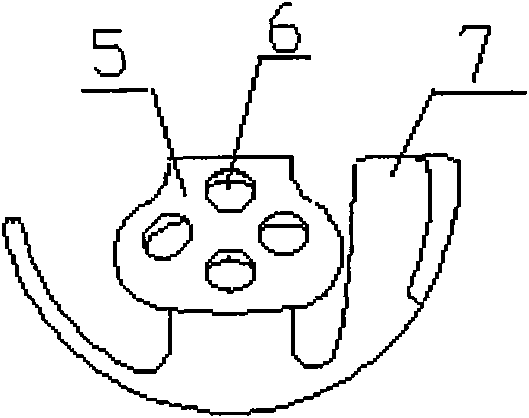

Electric acetabular osteophyte excider

PendingCN111227903AStable working positionGuaranteed flatnessExcision instrumentsDeep IncisionEngineering

The invention discloses an electric acetabular osteophyte excider. The electric acetabular osteophyte excider comprises a driver, a working rod, a saw blade and an attaching cup, wherein a positioninggroove is arranged in the attaching cup; the lower end of the working rod is inserted into the positioning groove for positioning; the working rod is fixed to the driver; the saw blade is arranged onthe working rod in a sleeving mode and can move on the working rod; the saw blade is locked and positioned through a locking device; the lower end surface of the saw blade is attached to the upper end surface of the attaching cup; the driver drives the working rod to rotate in a reciprocating mode; and the working rod drives the saw blade to swing back and forth to cut osteophyte. The electric acetabular osteophyte excider provided by the invention can guarantee that an incision is flat and smooth, can effectively avoid too large and too deep incision, guarantees excessive incision from generation, and does not need grooving in the using process.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

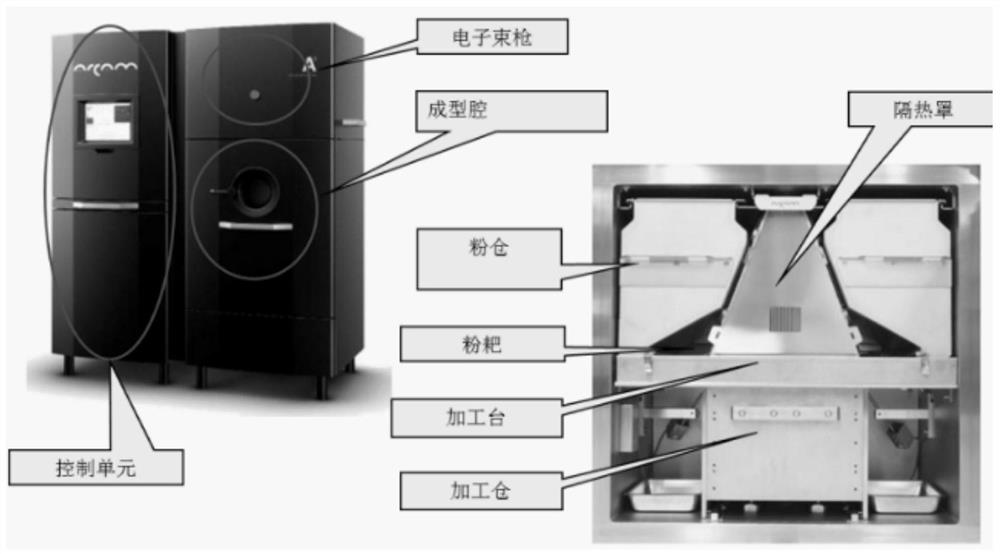

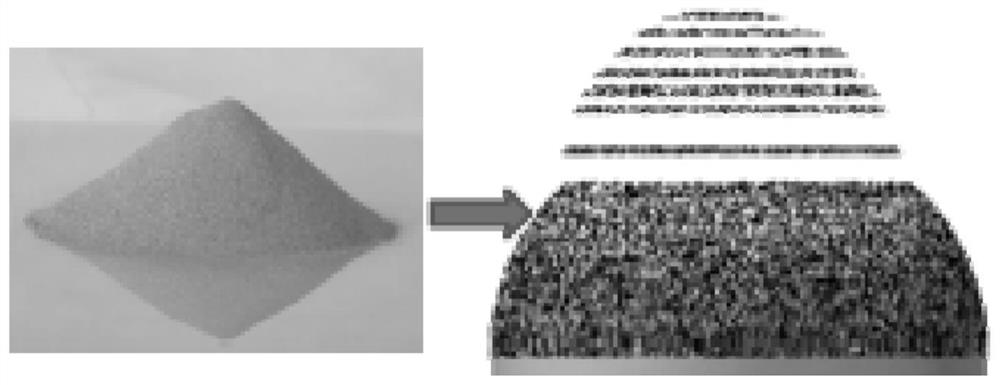

Acetabular bone defect reconstruction method based on 3D printing

InactiveCN114259327AEfficient reconstructionGood biological propertiesAdditive manufacturing apparatusArtificial cell constructsTitanium metalDefect reconstruction

The invention discloses a 3D printing-based acetabular bone defect reconstruction method. The method comprises the following steps: S1, preparing and representing a titanium metal implant subjected to electron beam melting 3D printing, and detecting cell compatibility; s2, in-vitro characterization of biological characteristics of the titanium metal implant subjected to electron beam melting 3D printing; s3, in-vivo characterization of biological characteristics of the titanium metal implant subjected to electron beam melting 3D printing; and S4, clinical research of the titanium metal implant subjected to electron beam melting 3D printing. According to the scheme, based on CT three-dimensional reconstruction of the acetabular bone defect form, a digital cushion block filler model is established by means of computer-aided design (CAD), and a personalized metal cushion block implant with good biological characteristics is manufactured by means of an electron beam melting (EMB) 3D printing technology, so that effective reconstruction of the acetabular bone defect is achieved, and the acetabular bone defect is effectively reconstructed. Therefore, a new solution is provided for the bone defect problem in the hip joint revision.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

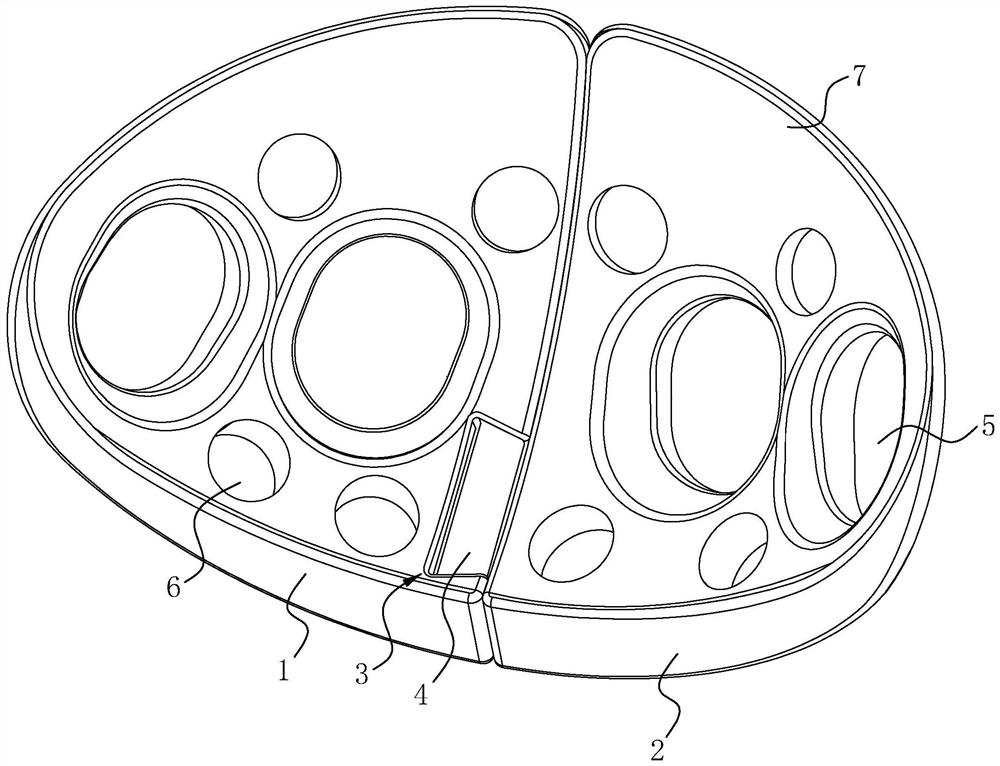

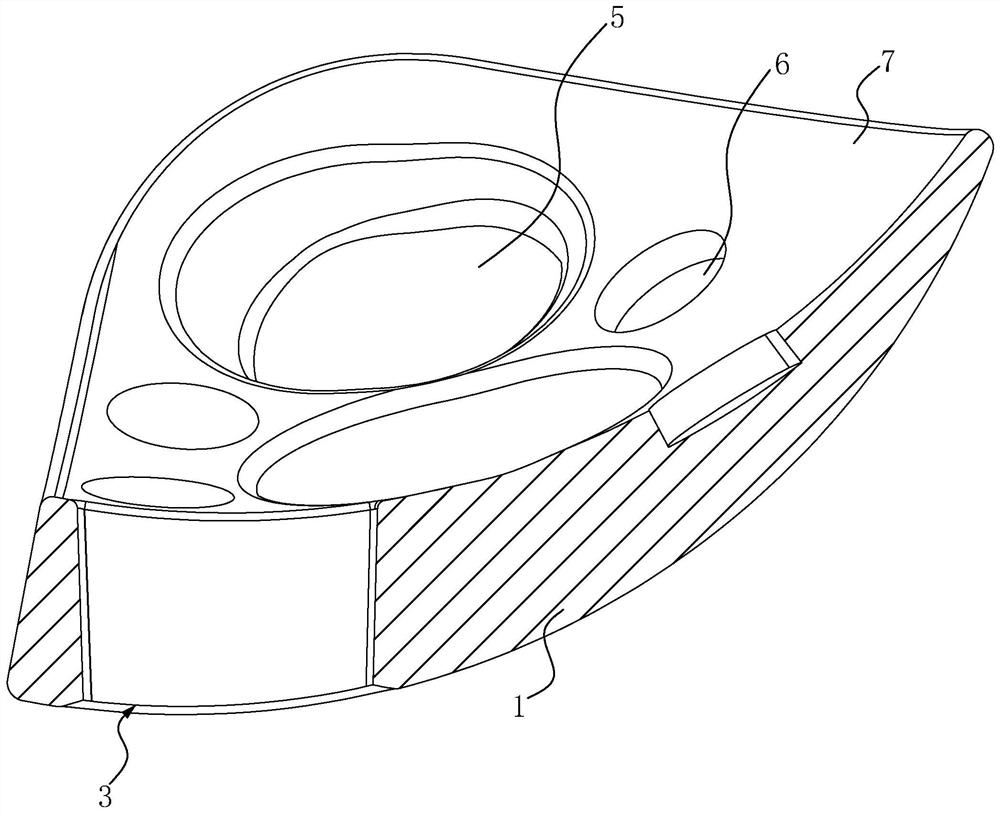

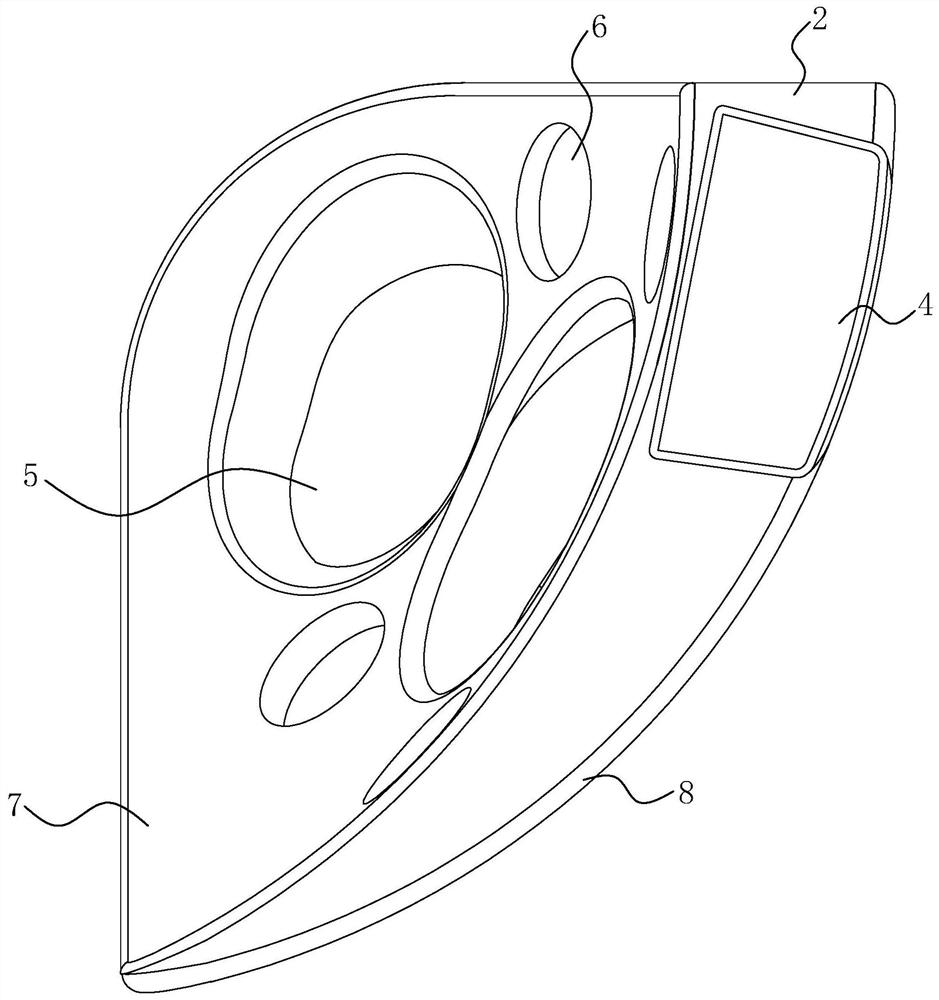

Cushion block for rebuilding and reconstructing acetabular bone and fixing structure of cushion block and acetabular cup prosthesis

PendingCN113855338APromote repairPromote reconstructionJoint implantsCoatingsProsthesisAcetabular bone

The invention relates to the field of medical instruments, in particular to a cushion block for rebuilding and reconstructing an acetabular bone and a fixing structure of the cushion block and an acetabular cup prosthesis. The cushion block is located between the acetabular cup prosthesis and the acetabular bone and connected with the acetabular cup prosthesis and the acetabular bone; the cushion block comprises a first component and a second component which is the same as or different from the first component in radius and shape, the first component is movably connected with the second component, and the shape of the first component and the shape of the second component are matched with the defect position of the acetabular bone after the first component and the second component are connected. The first part and the second part which are the same or different in radius and shape are movably connected, the shape formed by combining the first part and the second part is matched with the shape of the defect position of the acetabular bone, and therefore the defect position of the acetabular bone can be better repaired, the first part and the second part are suitable for acetabular bone defects of different shapes, and the acetabular bone defect repairing effect is better. The acetabular bone is better reconstructed and fixed, subsequent fixation of the acetabular cup prosthesis is facilitated, and the effect of operation flexibility is improved through the split structure of the cushion block.

Owner:长沙市第三医院

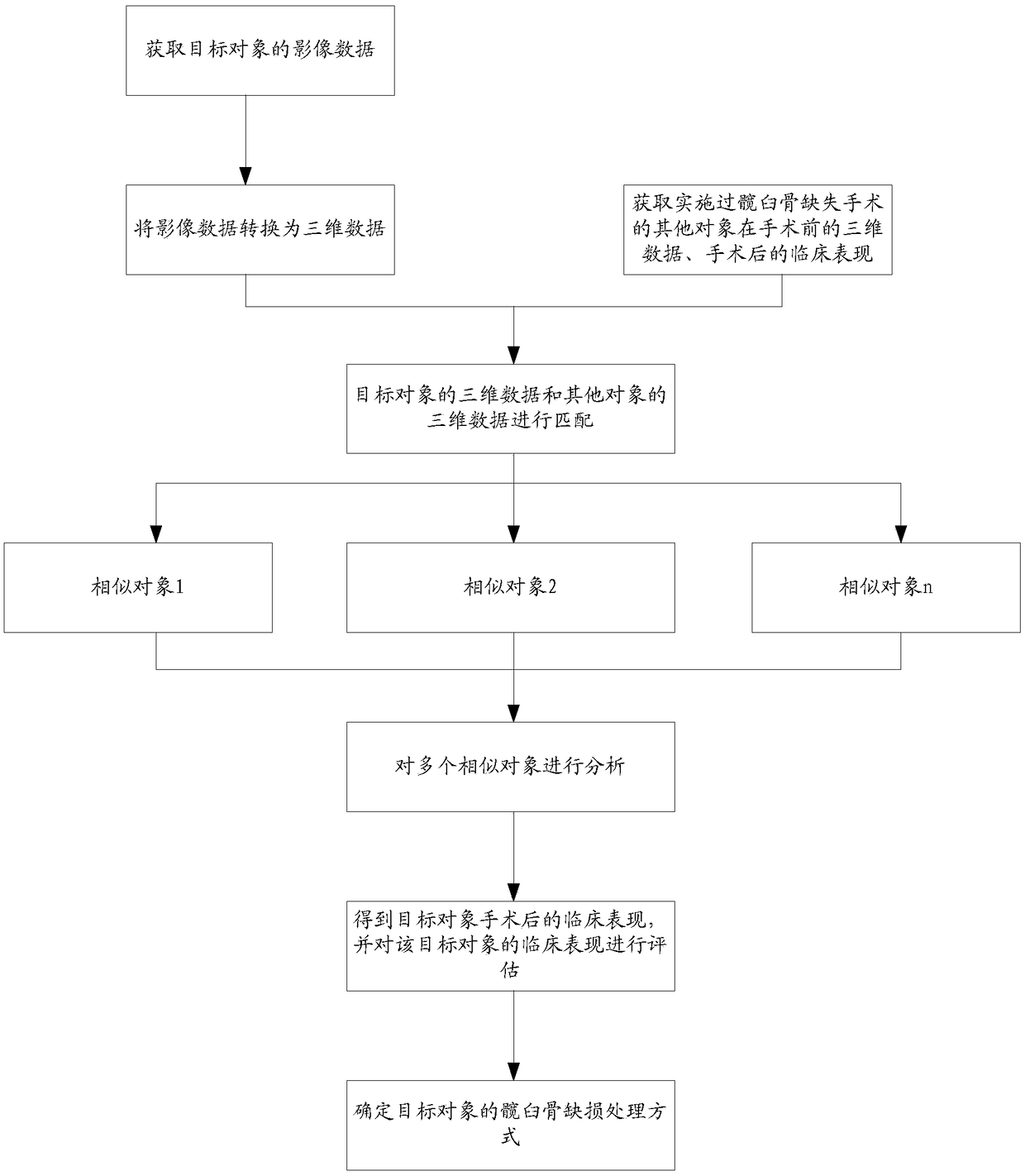

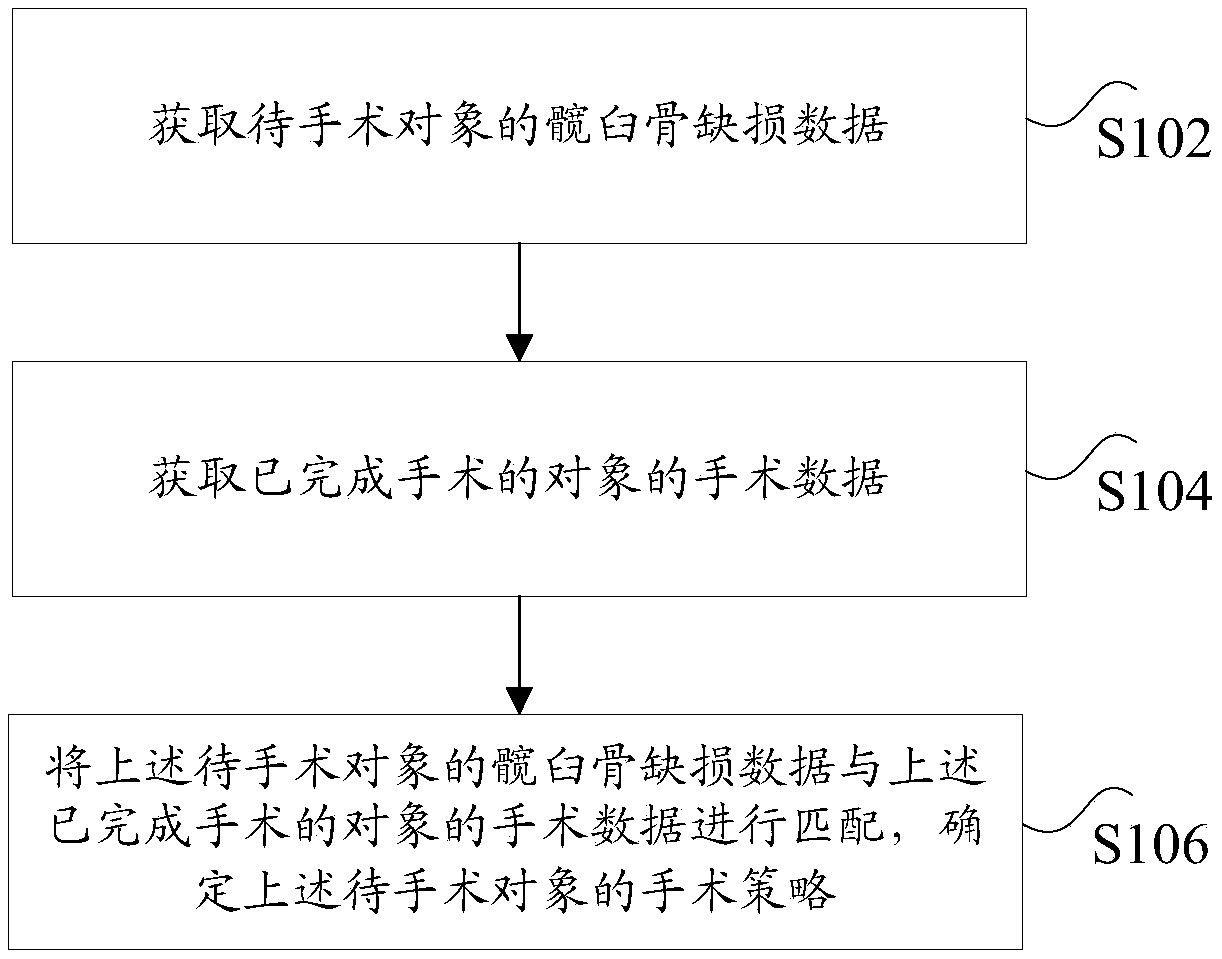

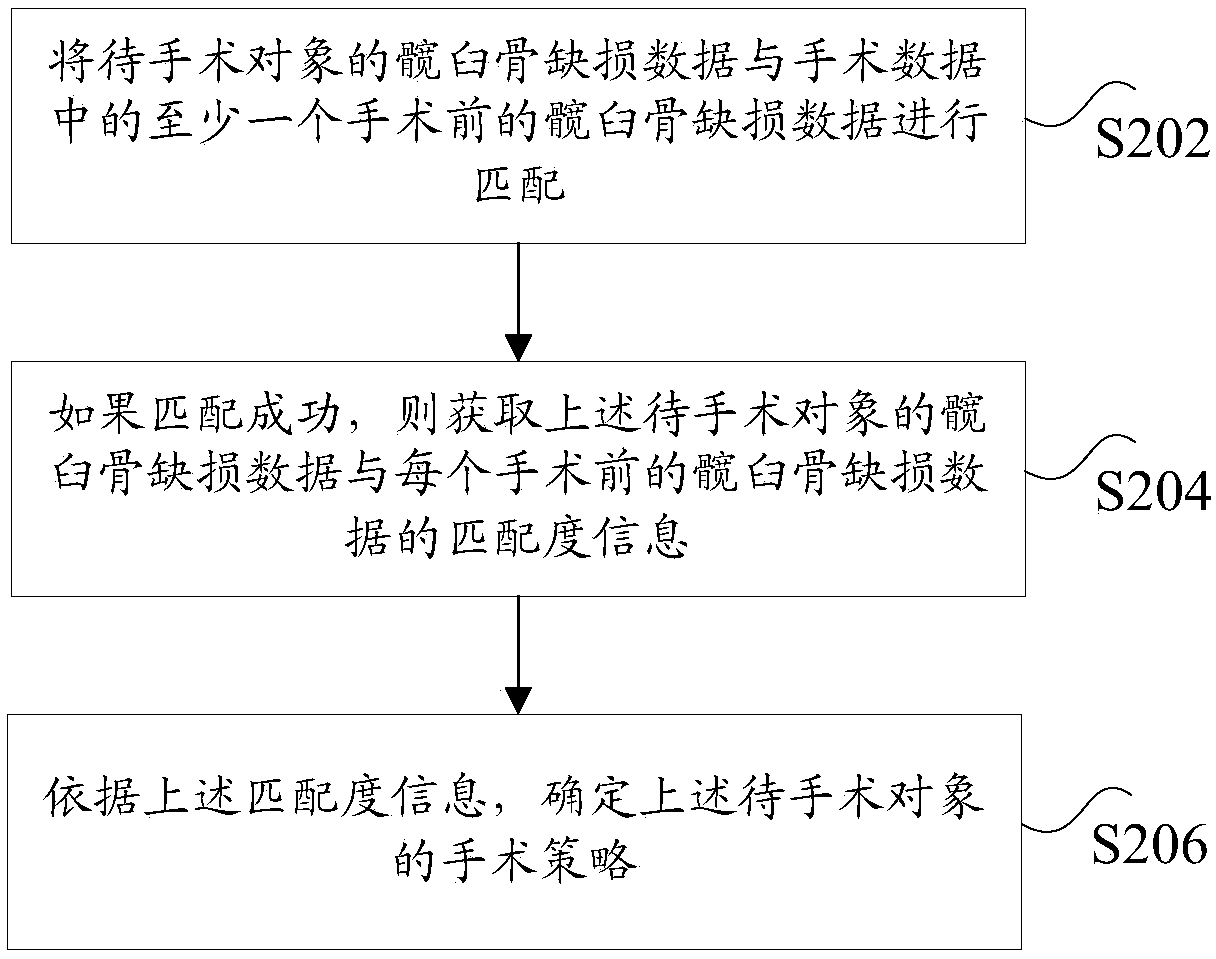

Method and devices for determining surgical strategy, storage medium and processor

InactiveCN109259861AIncrease success rateComputer-aided planning/modellingJoint revisionPostoperative recovery

The invention discloses a method and a device for determining a surgical strategy, a storage medium and a processor. The method comprises the following steps: acquiring acetabular bone defective dataof an object to be operated; acquiring surgical data of a subject having completed an operation, wherein the surgical data includes at least one of acetabular bone defect data before the operation, postoperative recovery data corresponding to the acetabular bone defective data before the operation, and surgical strategy corresponding to the acetabular bone defective data before the operation; theacetabular bone defective data of the object to be operated is matched with the surgical data of the object that has completed the operation to determine the surgical strategy of the object to be operated. The invention solves the technical problem in the prior art that the surgical strategy of the hip joint revision surgery patient cannot be determined by the technical means.

Owner:BEIJING AKEC MEDICAL

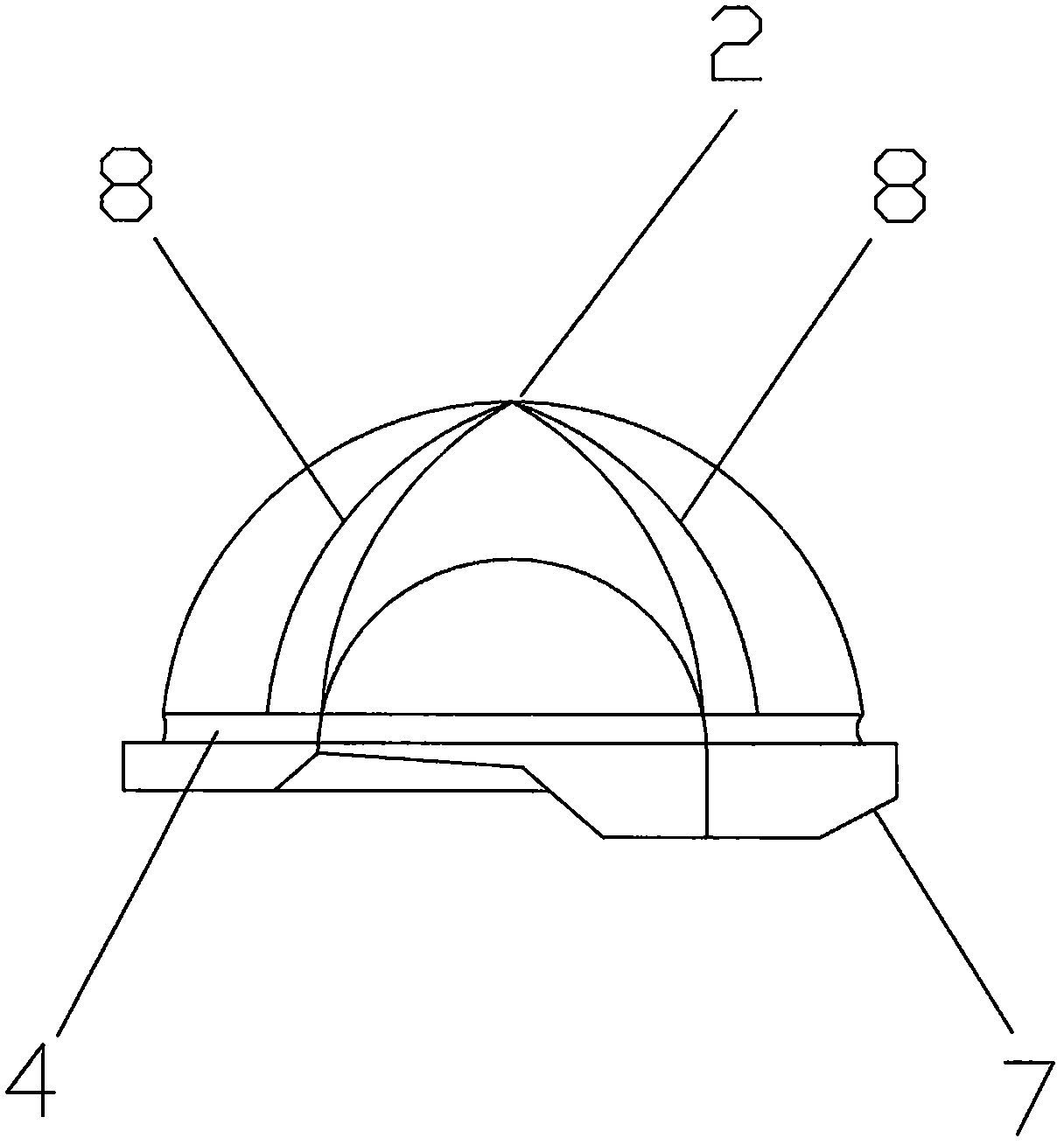

Winged eccentric acetabular cup prosthesis

PendingCN108969151AAvoid problems with the touch interfaceAvoid the disadvantages of moving upJoint implantsAcetabular cupsAcetabular notchProsthesis

The invention relates to the technical field of hip joint repairing surgery, in particular to a winged eccentric acetabular cup prosthesis. The winged eccentric acetabular cup prosthesis comprises anouter acetabular cup and an inner acetabular cup and is characterized in that the outer acetabular cup has a semispherical outer surface, and the semispherical outer surface of the outer acetabular cup is provided with three wings; the inner acetabular cup is provided with a semispherical inner cavity, and the sphere center of the semispherical inner cavity and the sphere center of the semispherical outer surface are staggered from each other; a plurality of limit mechanisms are evenly distributed at the edge of the inner wall of the outer acetabular cup, and a plurality of positioning mechanisms are evenly distributed at the edge of the outer wall of the inner acetabular cup. The winged eccentric acetabular cup prosthesis has the advantages that acetabular bone defect repairing is prevented from using traditional methods such as padding and bone grafting, the contact interface problem between a pad and an acetabular cup is avoided, the absorption problem of bone grafting is solved, complete contact between a host bone and the surface of the acetabular cup is achieved, the contact area and bone growth area of the prosthesis and the host bone, and the three wings increases the contact area of the acetabular cup and the host bone to a large extent and guarantees the initial stability of the acetabular cup.

Owner:肖建林

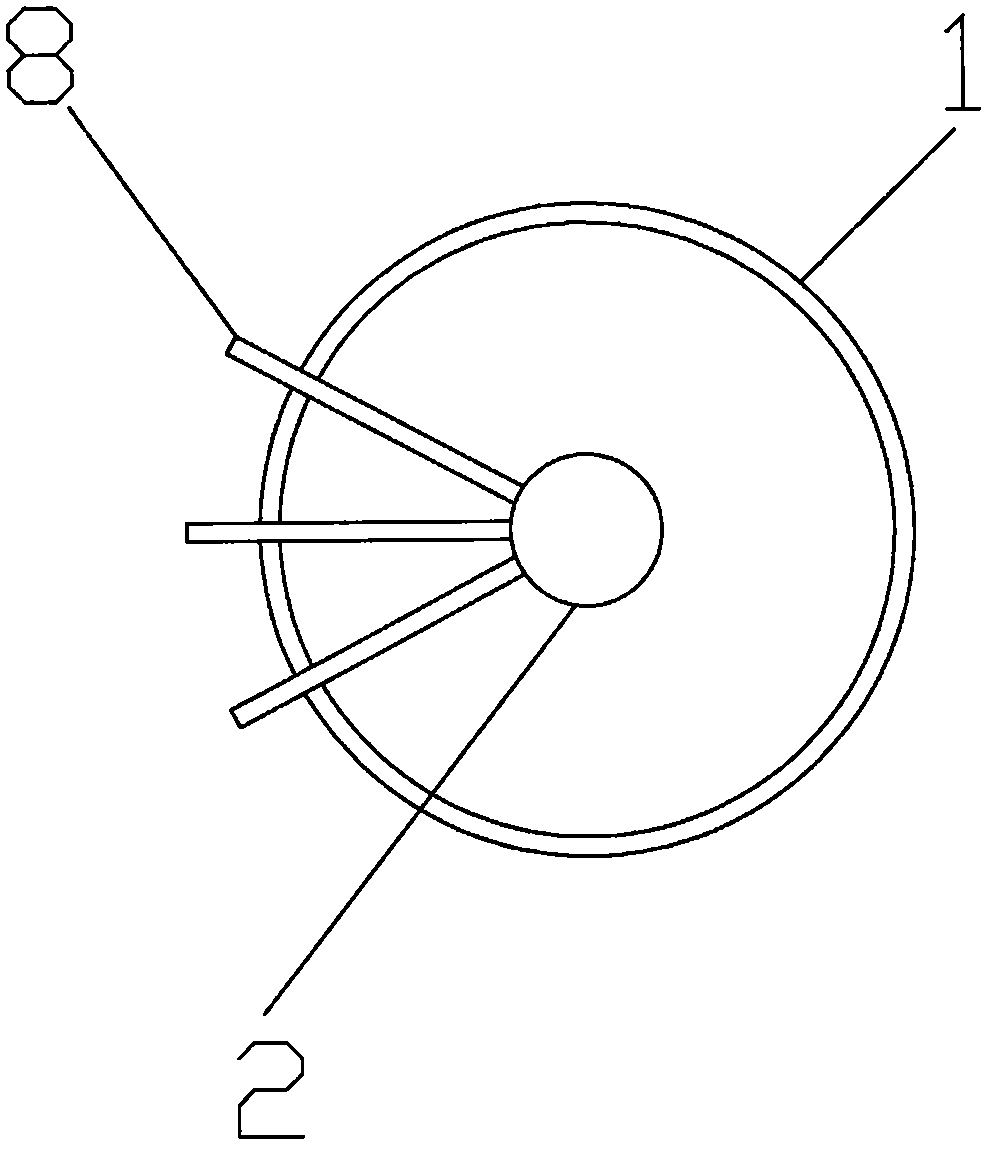

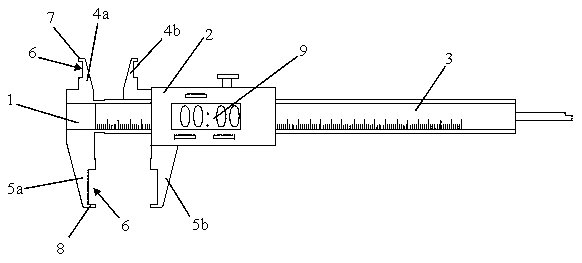

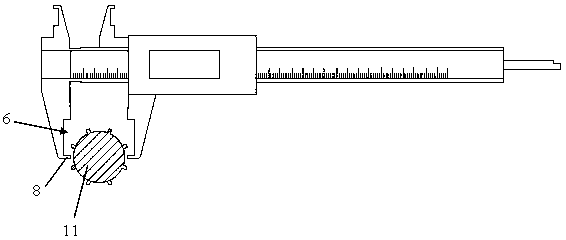

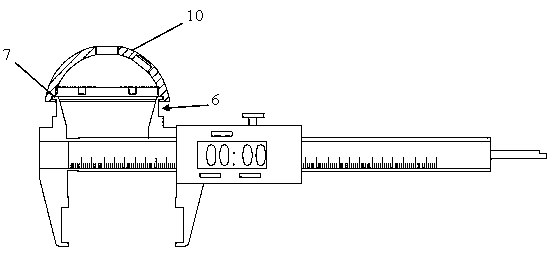

Device for measuring bottom diameters of acetabular bone outer cup groove and joint handle body

PendingCN109443161AAccurately get measurement dataIncrease productivityMechanical diameter measurementsEngineeringAcetabular bone

The invention provides a device for measuring bottom diameters of an acetabular bone outer cup groove and joint handle body. The two outer edges, back onto each other, of a first measuring claw is a first measuring end, the outer ends of a first main measuring claw and first sub measuring claw are provided with concave notches respectively, and therefore outer measuring heads of the first measuring end are formed on the first main measuring claw and first sub measuring claw; the two inner edges, opposite to each other, of a second measuring claw is a second measuring end, the inner ends of a second main measuring claw and second sub measuring claw are provided with concave notches respectively, and therefore inner measuring heads of the second measuring end are formed on the second main measuring claw and second sub measuring claw. The outer measuring heads of the first measuring end and the inner measuring heads of the second measuring end are kept away from measurement interference parts respectively, thereby accurately obtaining measurement data of the corresponding part and improving the production efficiency.

Owner:TIANJIN ZHENGTIAN MEDICAL INSTR CO LTD

Customized positioning device for hip joint surgery and supporting prosthesis based on medical images

ActiveCN104337572BHigh precisionEfficient resectionJoint implantsAcetabular cupsAcetabular boneAcetabulum prosthesis

Owner:SHANGHAI XINJIAN MEDICAL TECH

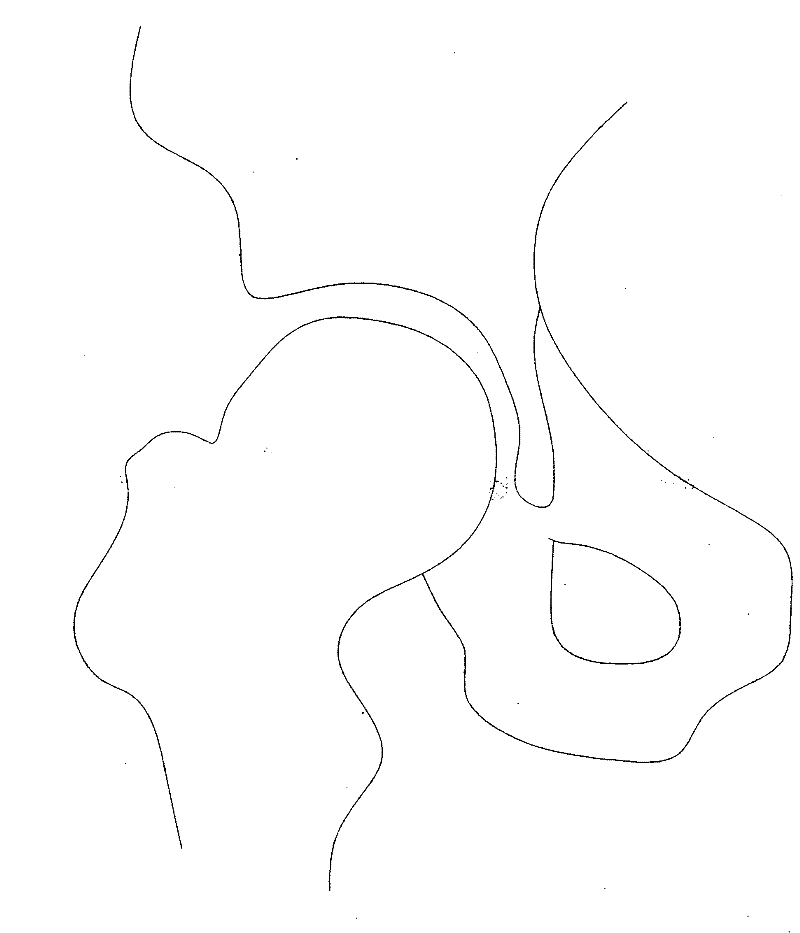

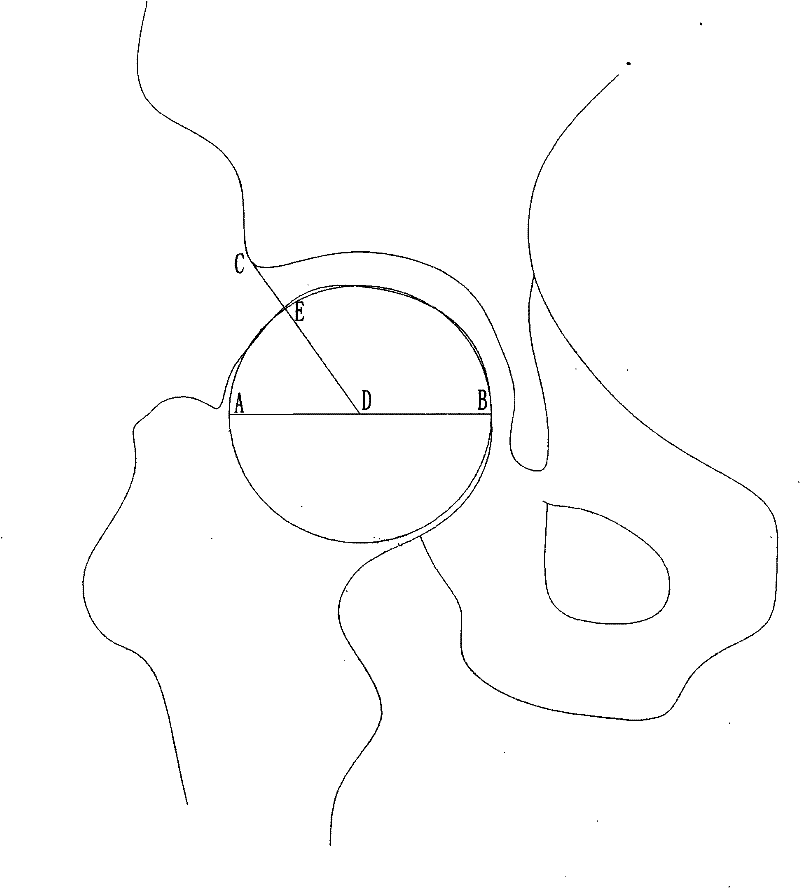

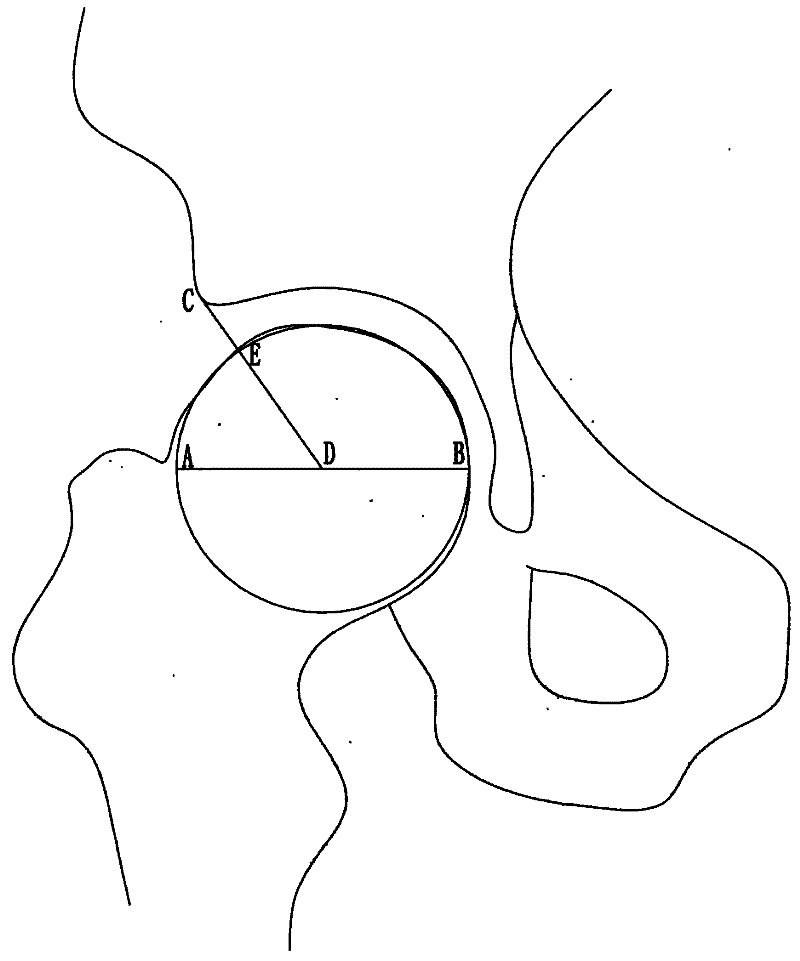

Measuring method of median load-bearing arc angle of hip joint

InactiveCN102258382AReduce dislocationEasy to dislocateComputerised tomographsTomographyRight femoral headFemoral neck

The invention discloses a method for measuring a hip joint by using a multi-row spiral CT (Computerized Tomography) three dimensional reconstruction technology, and particularly discloses a method for measuring a midst load bearing arc angle of a hip joint. The method comprises the following steps of: (1) arranging a target to be measured; (2) performing CT scanning and three-dimensional reconstruction; and (3) acquiring a definition line of the midst load bearing arc angle, adjusting a three-dimensional image of the hip joint to a side position image, removing a front side image of the entire hip joint by cutting along the middle axis of a femoral neck, adjusting the three-dimensional image of the hip joint to a positive position image, drawing a circle by fitting a femoral head joint surface, making a horizontal diameter by passing through a circle center point and connecting an outer edge point of an acetabular bone with the circle center point, wherein intersection points between the horizontal diameter and the circuit are points A and B, the point B is an inner side intersection point; an intersection point between the connecting line and the circuit is a point E, and an included angle between radiuses ED and BD is the resolved midst load bearing arc angle of the hip joint. According to the method for measuring the midst load bearing arc angle of the hip joint, the technical defects of load bearing measuring middle parameters in the prior art are overcome, and easy measurement of load bearing stable form parameters of the hip joint is realized.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Acetabulum reconstruction bracket for revision of total hip arthroplasty

InactiveCN101836906AGenerous size designPrevent movementJoint implantsAcetabular cupsAcetabular boneCotyloid Cavity

The invention provides an acetabulum reconstruction bracket for revision of total hip arthroplasty, which is characterized in that: an upper side wing, a bracket main body and a lower wing hook are connected integrally in turn. The upper side wing, bladed side wings arranged at the periphery of the bracket main body and the lower wing hook bend towards the same side and are cup-shaped; the other end of the lower wing hook bends towards the back side of the bracket main body in an inverted U shape; the round end part of the upper side wing bends towards the cup bottom direction of the cup-shaped bracket main body; and the surface of the round end part of the upper side wing is provided with an inclined hole. The bracket has high initial stability, firm supporting function, easy installation, capability of preventing transplanted bone tissue from moving and intensifying bone mass in a bone bed after revision and particular suitability for the situation of wide range acetabular bone defect.

Owner:THYTEC SHANGHAI

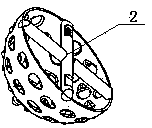

Acetabular bone file with rotating shaft positioning function

InactiveCN103750880AChanging the way of acetabular reamingGood curative effectSurgeryCurative effectAcetabular bone

The invention relates to the technical field of medical instruments, in particular to an acetabular bone file with a rotating shaft positioning function. The acetabular bone file comprises an acetabular bone file body, a supporting rack and a rotating shaft, wherein the acetabular bone file body is a semi-spherical cover; a plurality of holes are formed in the acetabular bone file body; a cutting edge is arranged on the side of each hole; the supporting rack is fixed on the bottom of the acetabular bone file body; and the rotating shaft is fixed on the top of the acetabular bone file body. The acetabular bone file is used with a rotating axis positioner; the existing acetabular bone filing mode can be changed; and a curative effect is improved.

Owner:王禹基 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com