Acetabular bone file with rotating shaft positioning function

A technology of acetabular rasping and rotating shaft, applied in the field of medical devices, can solve the problem of difficulty in coaxial burring, etc., and achieve the effect of improving curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

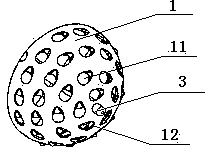

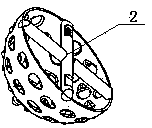

[0012] Such as figure 1 , 2 As shown, an acetabular file with positioning of the rotating shaft includes an acetabular file 1, a support frame 2 and a rotating shaft 3. The acetabular file 1 is a hemispherical cover with several holes 11 arranged on the side of the hole 11. There is a cutting edge 12, and the support frame 2 is fixed on the bottom of the acetabular file 1, which is a common acetabular file.

[0013] The acetabular file of the present invention is combined with the rotating shaft, and a short rod matching the hole drilled under the guidance of the rotating shaft is added to the center of the top of the ordinary acetabular file 1, that is, the rotating shaft 3, which can make the file rotate coaxially every time. . The top of the rotating shaft 3 is preferably hemispherical, which can facilitate the centering and rotation of the entire acetabular file. The cutting edge 12 can be an ordinary cutting edge, or preferably serrated. The serrated shape can improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com