Acetabulum reconstruction bracket for revision of total hip arthroplasty

A hip joint and acetabular technology, applied in the field of acetabular reconstruction bracket, can solve the problems of narrow range of flexion and movement of saddle-shaped prosthesis, poor supporting effect of double-layer metal mesh, and unguaranteed initial stability, etc. Difficult, firm support, easy placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

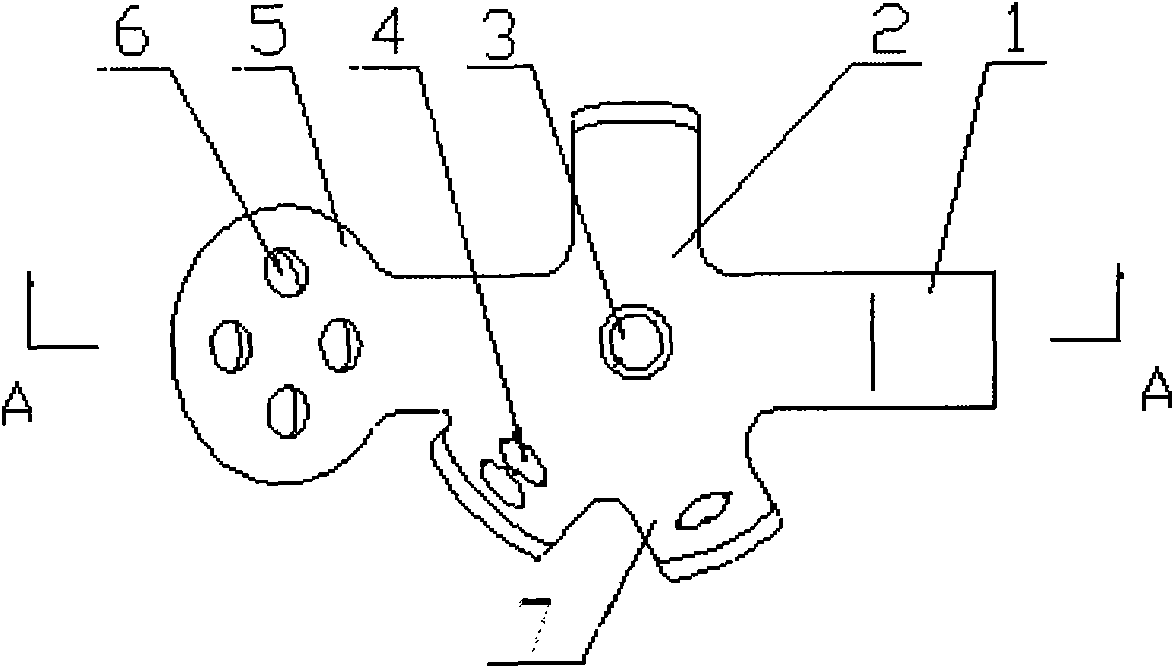

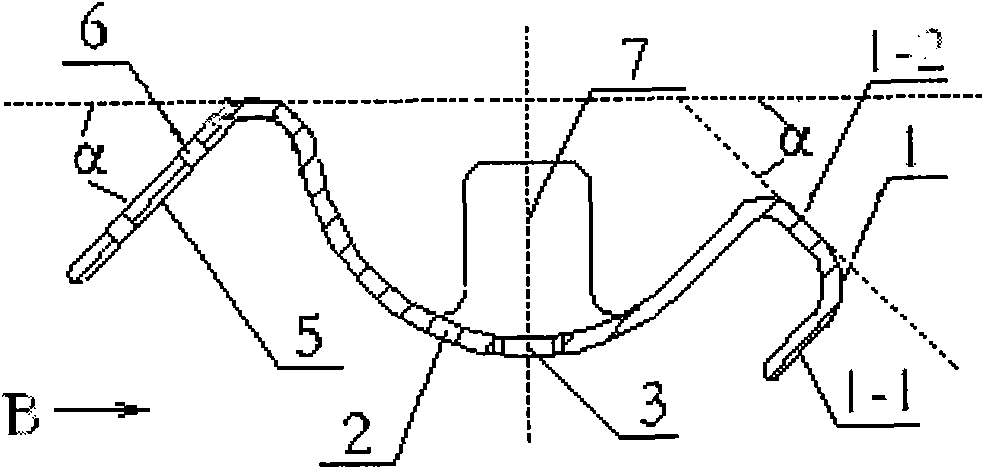

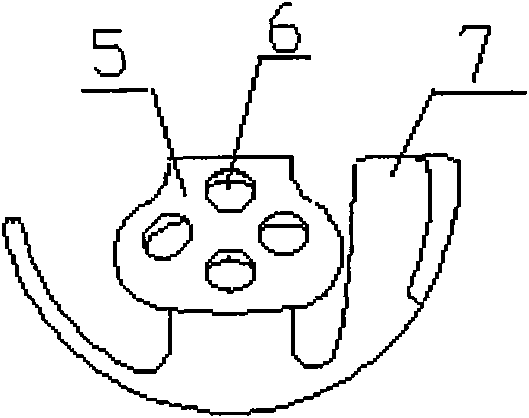

[0020] Figure 1 to Figure 3 It is a schematic diagram of the first embodiment of the present invention. It can be seen from the figure: an acetabular reconstruction stent for total hip arthroplasty, which is characterized in that the upper wing 5, the stent body 2, and the lower wing hook 1 are connected in sequence, so The upper side wing 5, the leaf-shaped side wing 7 provided around the bracket body 2, and the lower wing hook 1 are bent to the same side and are cup-shaped; the other end of the lower wing hook 1 faces the rear side of the bracket body 2 The curve is in a ∏ shape, and the round end of the upper wing 5 is bent toward the bottom of the cup-shaped bracket body 2; the surface of the round end of the upper wing 5 is provided with an oblique hole 6.

[0021] Such as figure 2 As shown, in the first embodiment, when the cup opening of the cup-shaped bracket body 2 is upward and perpendicular to the ground, the angle α between the center line of the upper side wing 5 a...

Embodiment 2

[0027] Figure 4 It is a schematic diagram of another structural form of the present invention. The second embodiment is basically the same as the first embodiment. Figure 4 versus figure 1 The structural difference is that the number of blade-shaped side wings 7 is 2, and the number of straight holes on each blade-shaped side wing 7 is 0, and the bending method is the same figure 2 .

[0028] During clinical operation, the lower wing 1 is hooked to the lower edge of the acetabulum to achieve rapid positioning; the cup-shaped stent body 2 is fitted with the acetabulum after bone grafting, and can pass through the threaded holes 3 and leaf-shaped wing at the bottom of the stent body 2 when necessary The straight hole 4 on 7 is connected with the acetabulum with screws to realize the reconstruction of the acetabulum; the oblique hole 6 on the upper wing 5 can be used to fix the whole cup-shaped stent body 2 with the connection of the screw and the iliac bone. The implanted prosthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com