Patents

Literature

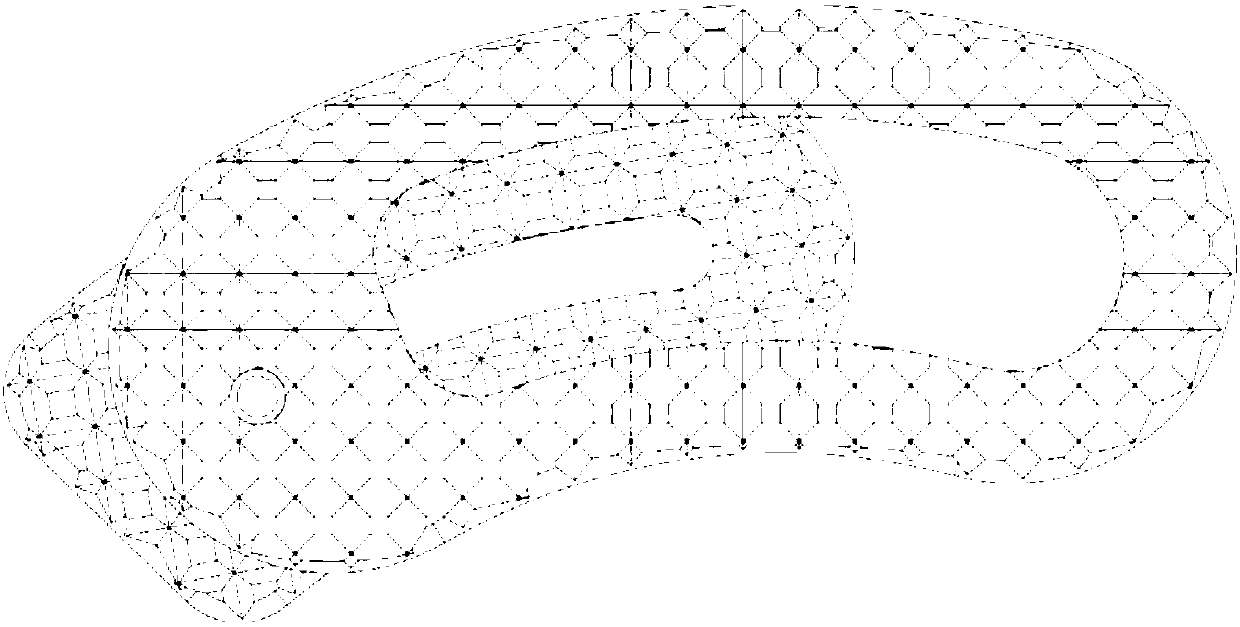

119results about How to "Improve initial stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

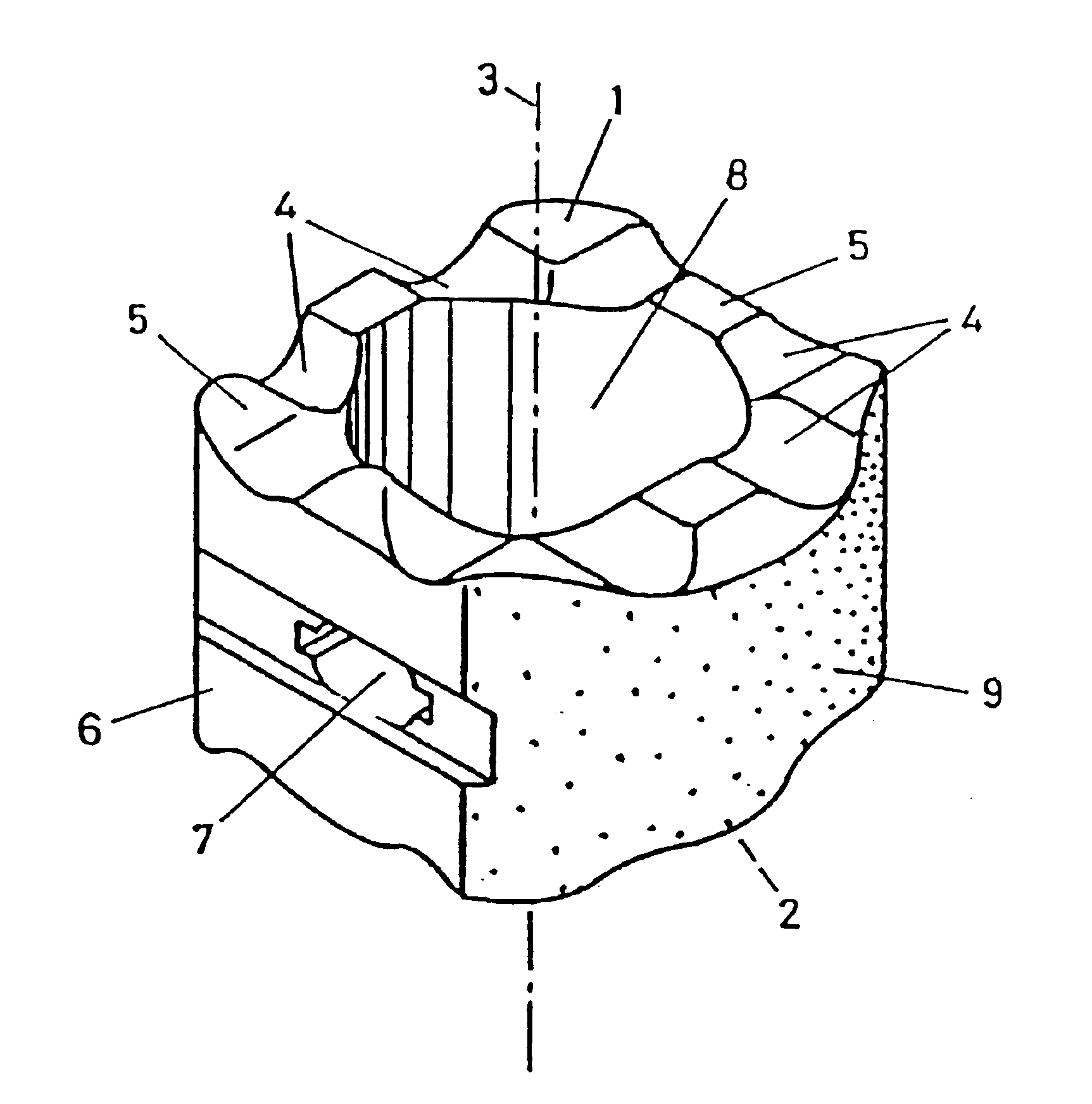

Intervertebral implant

InactiveUS6843805B2Increase contactFacilitate primary bone growthInternal osteosythesisBone implantIntervertebral diskBiomedical engineering

The present invention relates to an intervertebral implant for fusion of vertebrae. The implant has top and bottom surfaces configured and dimensioned to contact end plates of the vertebrae and a jacket forming a side surface of the implant and having a three-dimensional texture for promoting initial stability. The implant is made of a porous ceramic material. The implant according to this invention is characterized in that upon primary fusion during the resorption process, it equalizes the distance (corresponding to intervertebral disk height) between two vertebrae while providing adequate fusion and is resorbed by the body after a certain amount of time.

Owner:SYNTHES USA

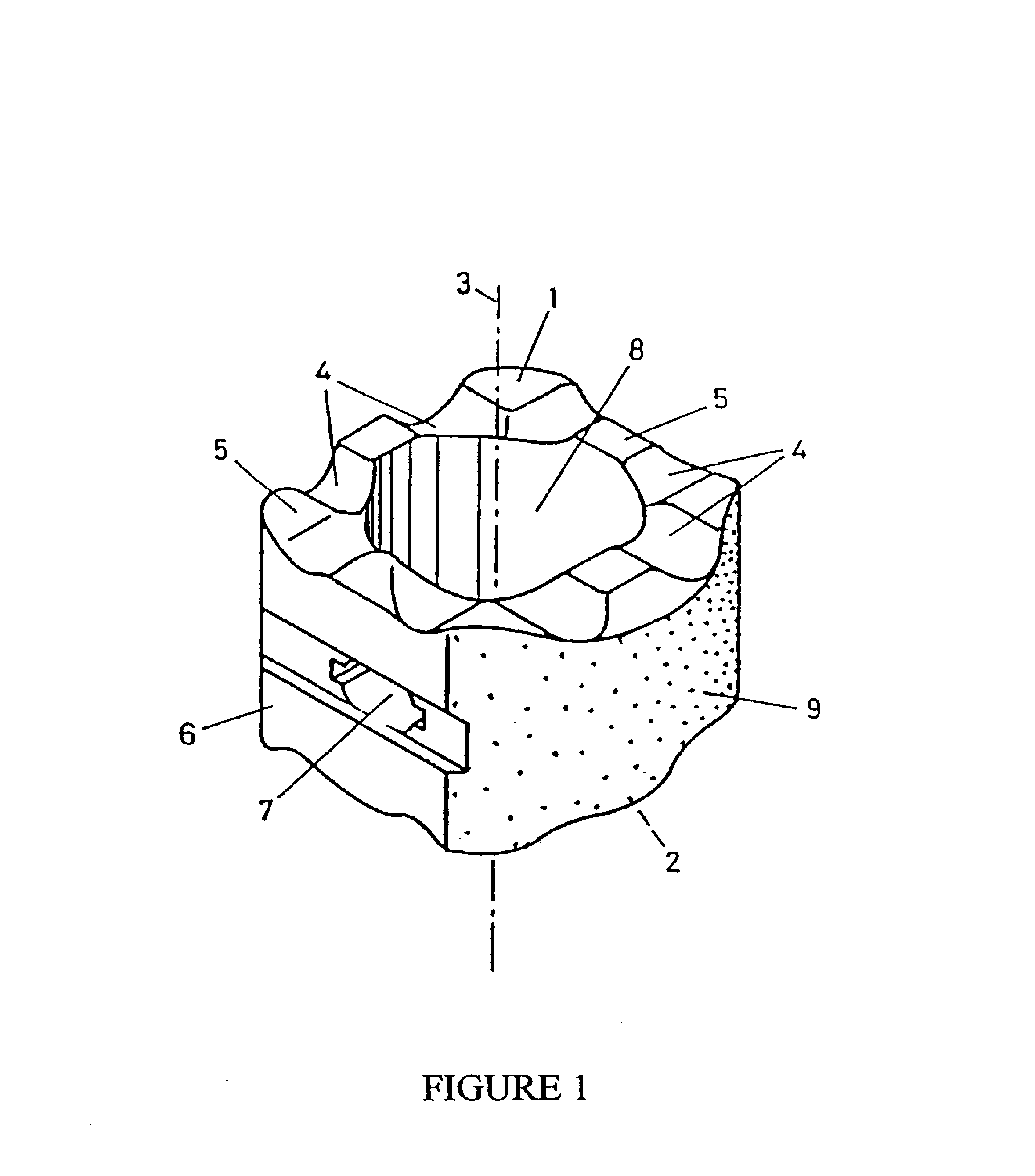

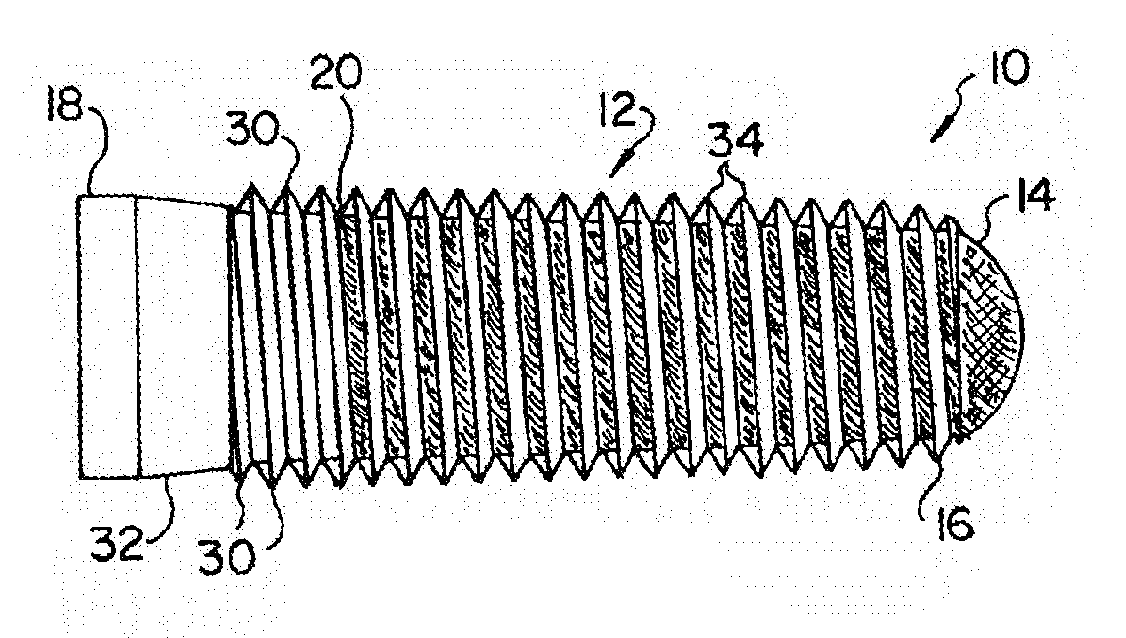

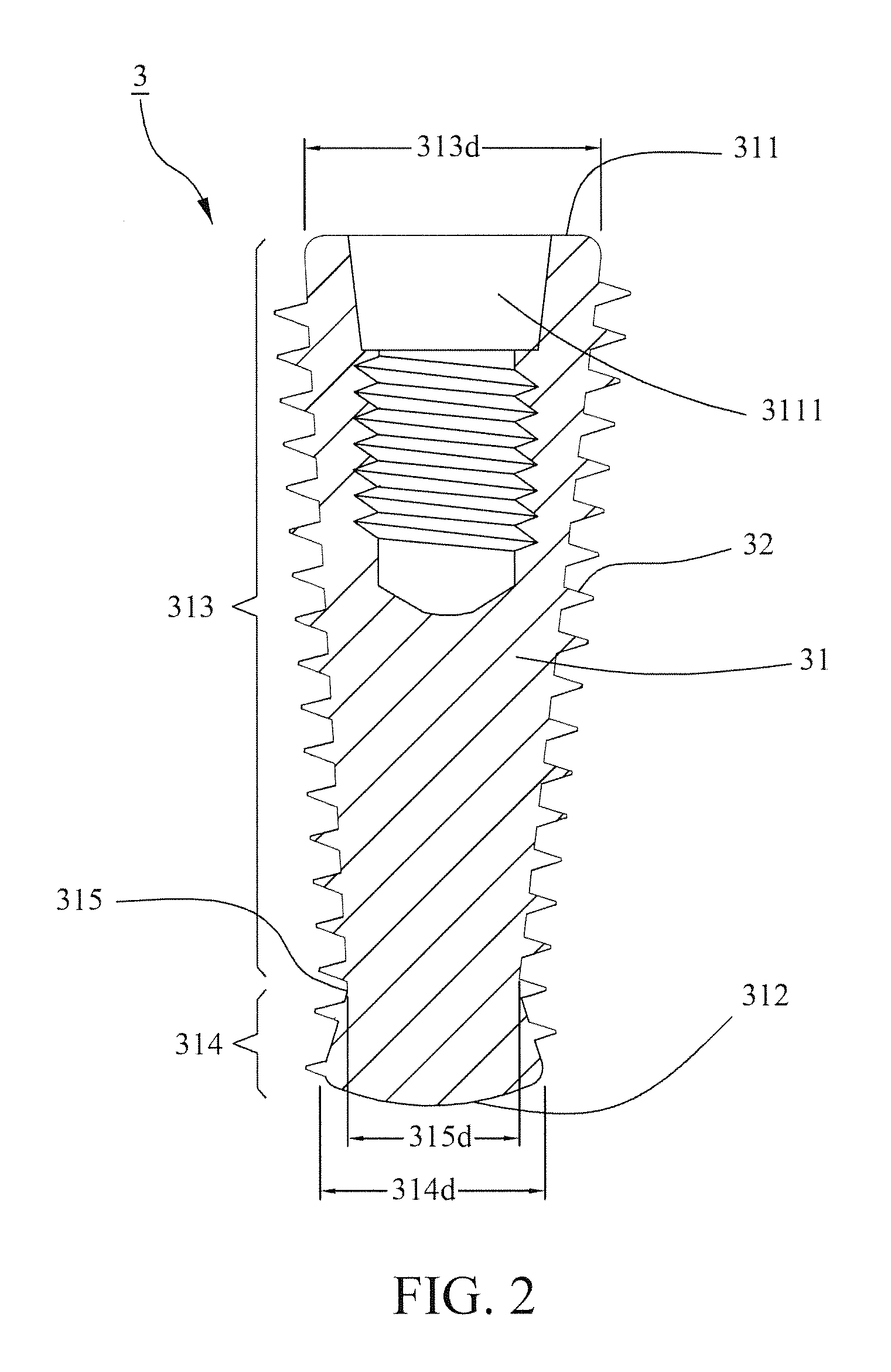

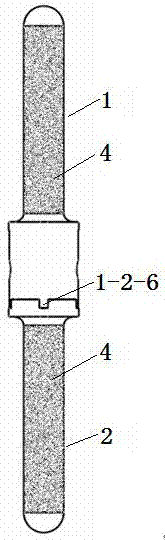

Porous implant with non-porous threads

InactiveUS20130022943A1Promote osseointegrationImprove short-term stabilityDental implantsPorous implantDental implant

A dental implant can comprise a shaft defining a longitudinal axis and having an apical end, a coronal end, and an exterior surface. A portion of the exterior surface can include a porous material. The dental implant can comprise at least one thread, including a non-porous material, having an interior surface and a bone-engaging surface. The interior surface can engage and wind around the exterior surface of the shaft and the bone-engaging surface can extend outwardly from the exterior surface of the shaft. The shaft can include one or more channels configured to communicate a flowable material, stored within the shaft, to the exterior surface. Each channel can include an opening at the exterior surface to release the flowable material. At least one channel can extend between a cavity of the shaft and the exterior surface and can optionally be angled toward the apical end.

Owner:ZIMMER DENTAL INC

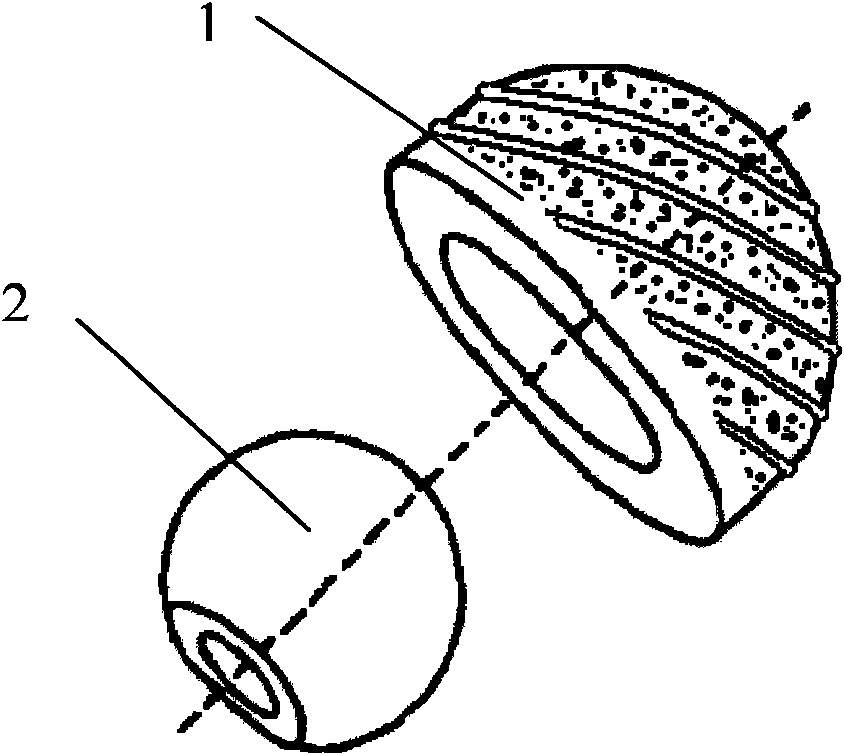

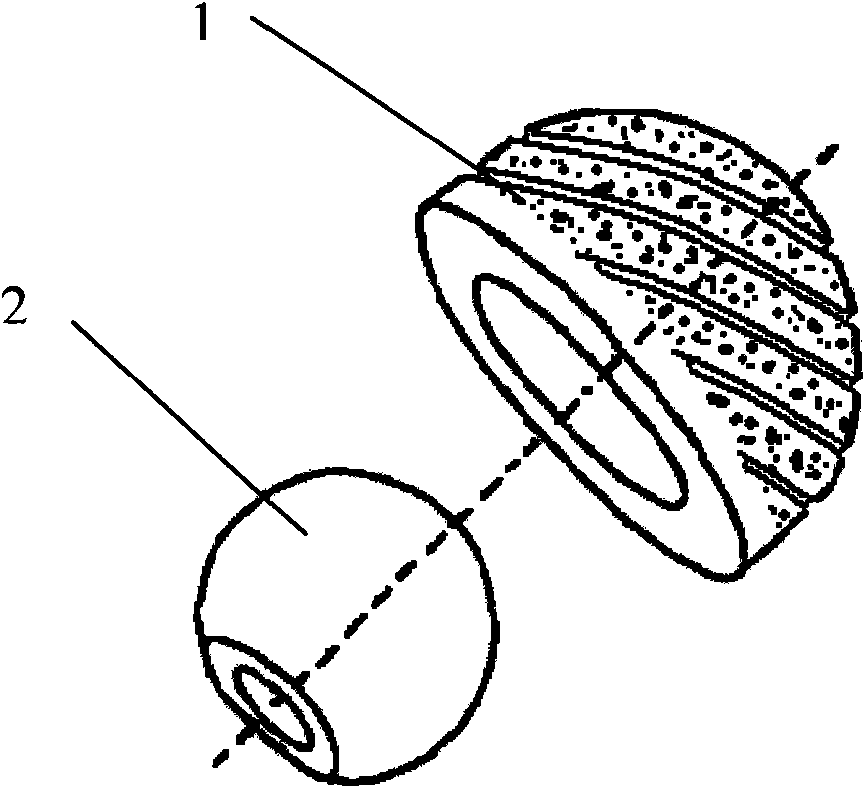

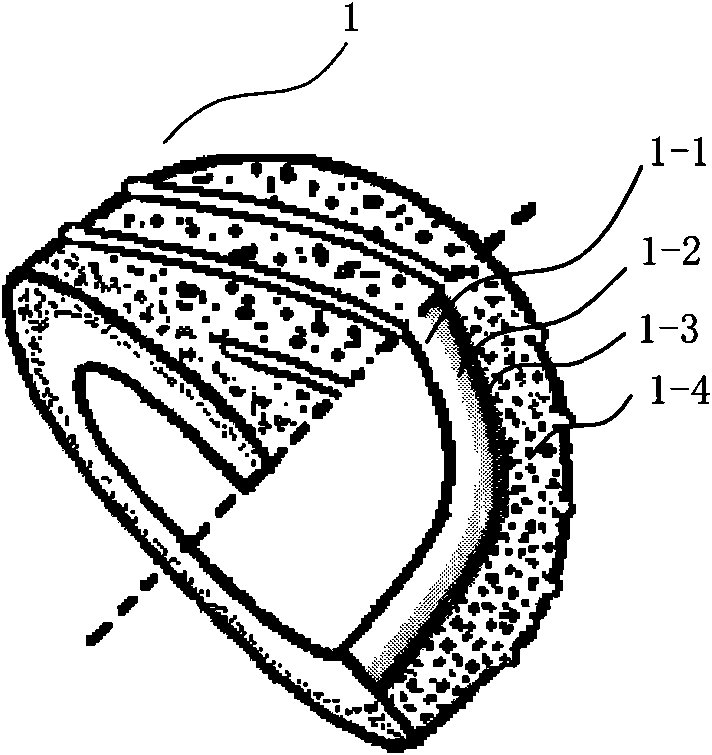

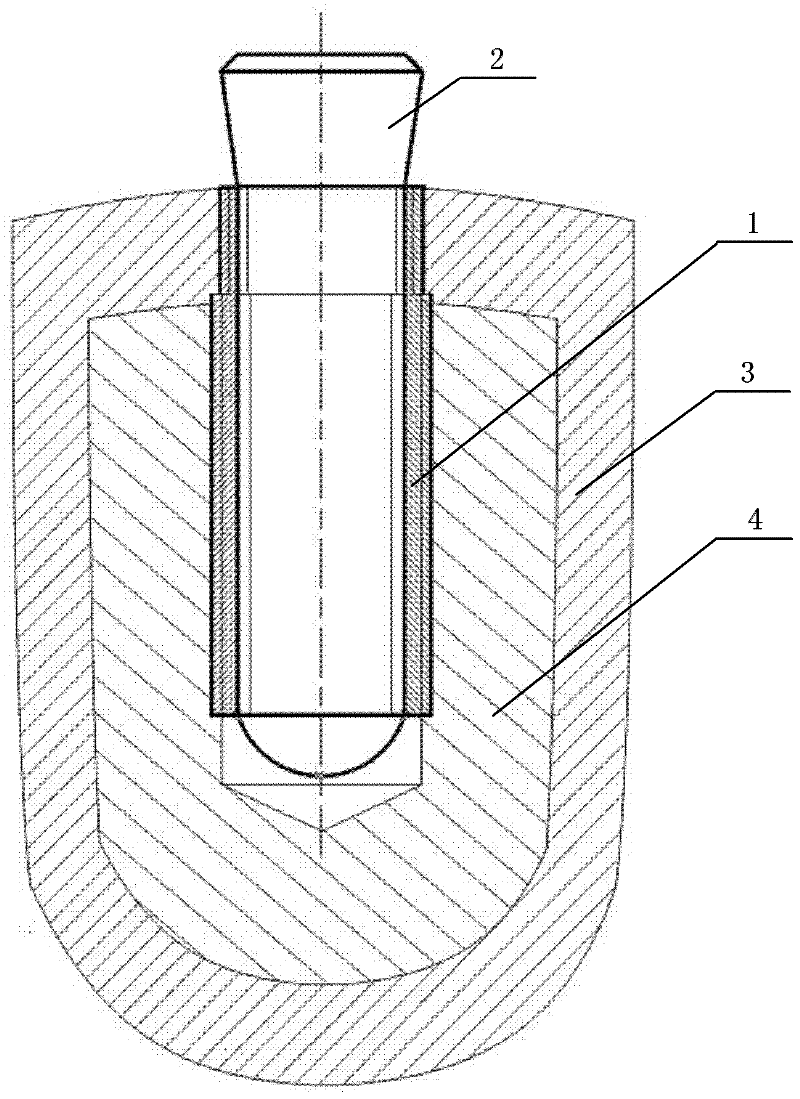

Artificial hip joint consisting of multilayer shell core composite structural components

The invention discloses an artificial hip joint consisting of multilayer shell core composite structural components. The artificial hip joint comprises an artificial acetabulum and an artificial thigh bone. The artificial hip joint is characterized in that: the artificial acetabulum has a multilayer shell core composite structure and consists of a ceramic acetabulum lining, a transition layer, a porous metal, a porous alloy or a porous toughened ceramic acetabulum shell; the artificial thigh bone has a multilayer shell core composite structure and consists of a ceramic spherical shell layer, a transition layer and a toughened ceramic inner core. The ceramic acetabulum lining and the spherical shell layer of the artificial thigh bone have high hardness, corrosion resistance and abrasion resistance; the artificial acetabulum shell layer and the inner core of the thigh bone have high toughness and impact resistance; and the transition layers are made of gradient composite materials between the materials for the shell layer and the inner core layer, and have the functions of increasing the bonding strength between the shell layer and the inner core layer, reducing the interface stressbetween the shell layer and the inner core layer and the like. The artificial hip joint has the characteristics of long service life, high reliability, high performance and the like.

Owner:SUZHOU DINGAN ELECTRONICS TECH

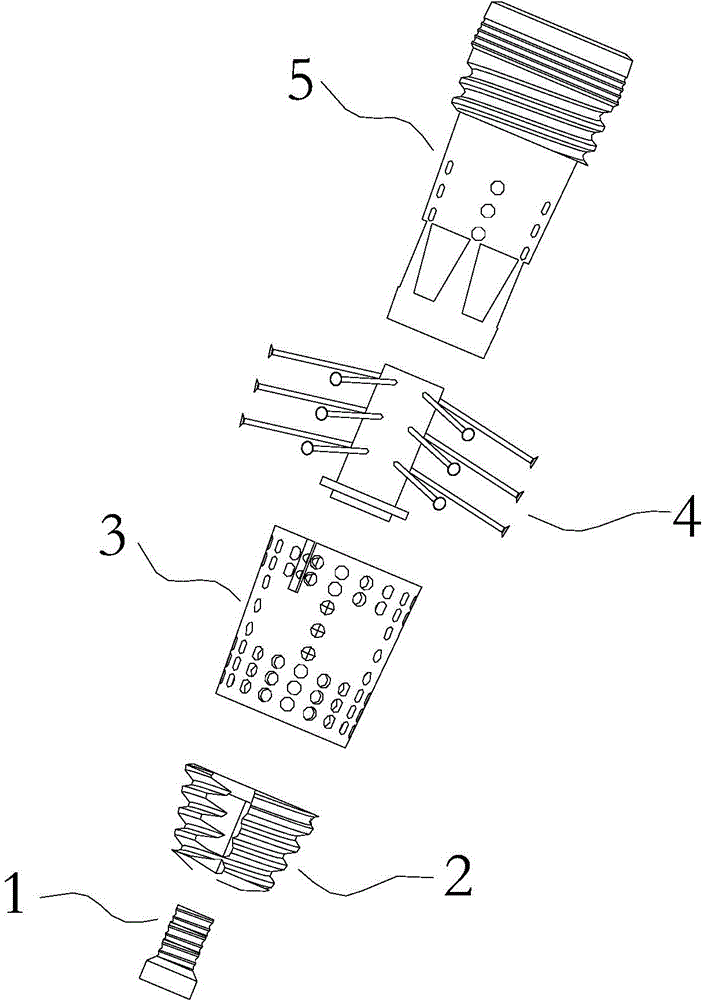

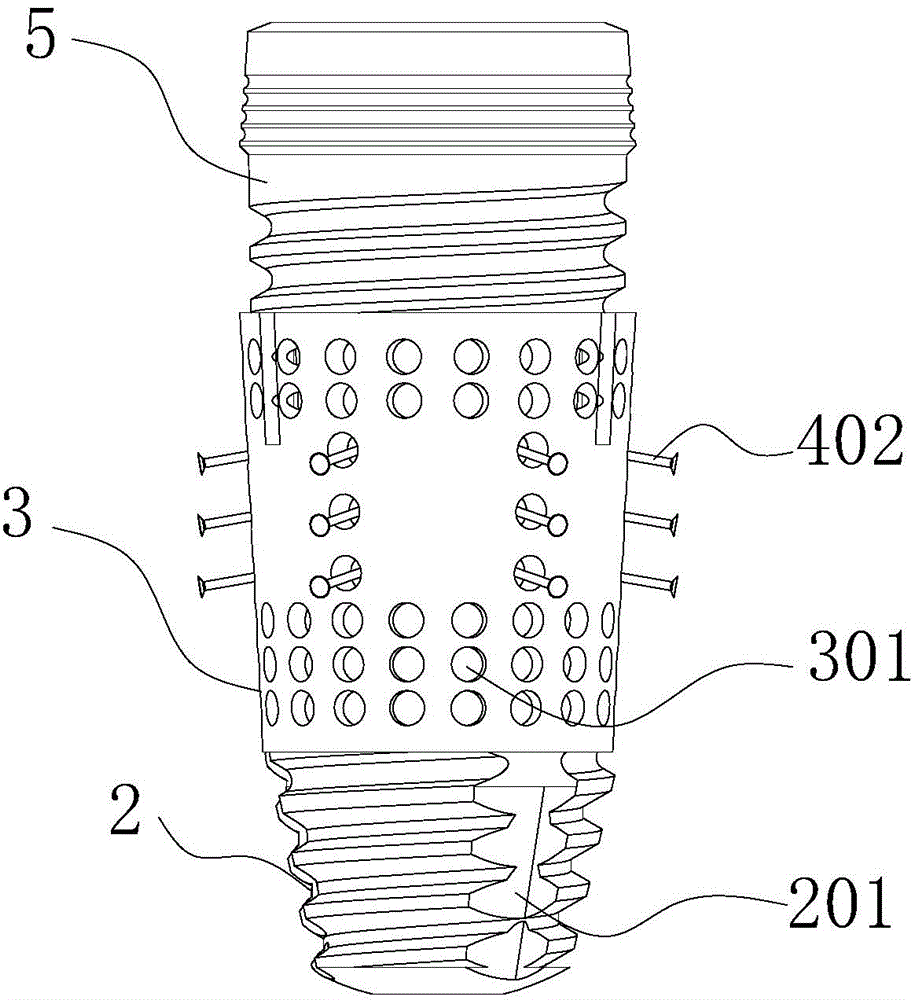

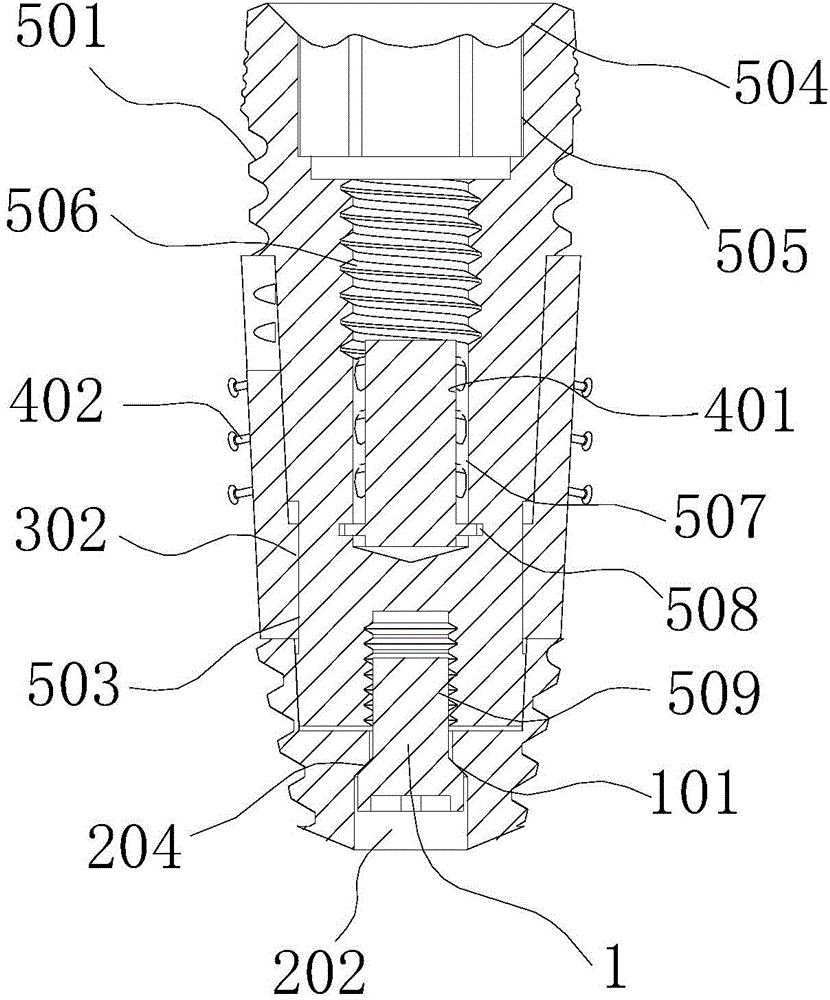

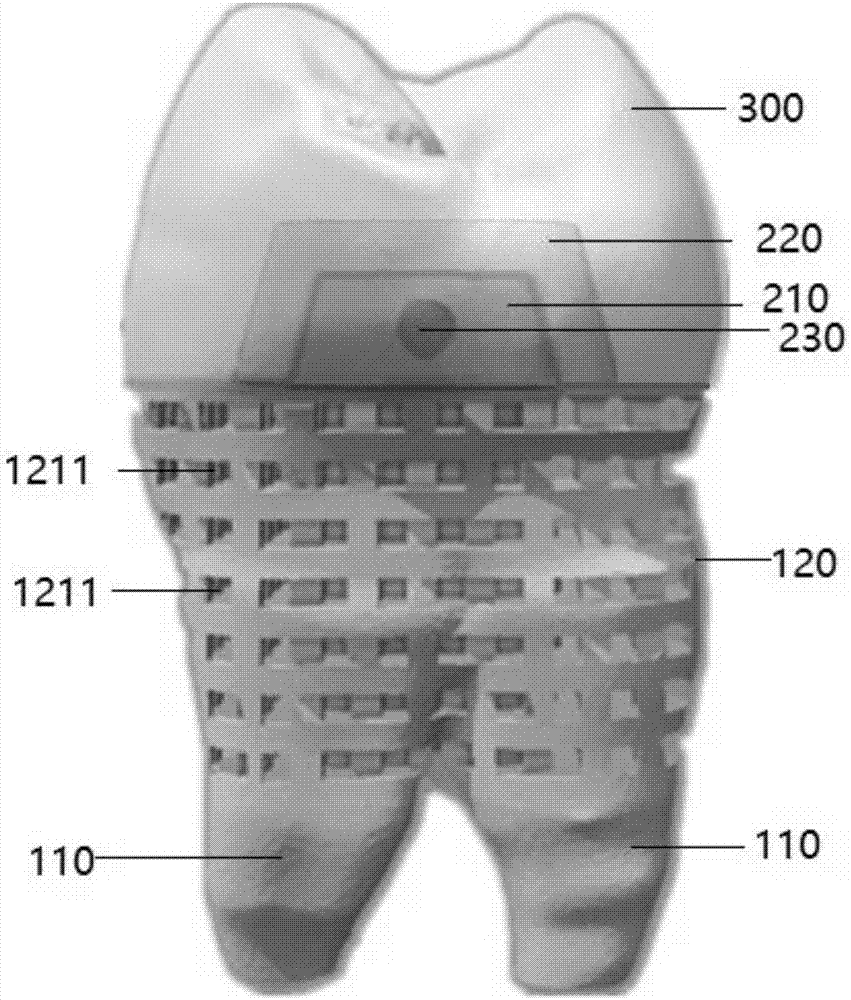

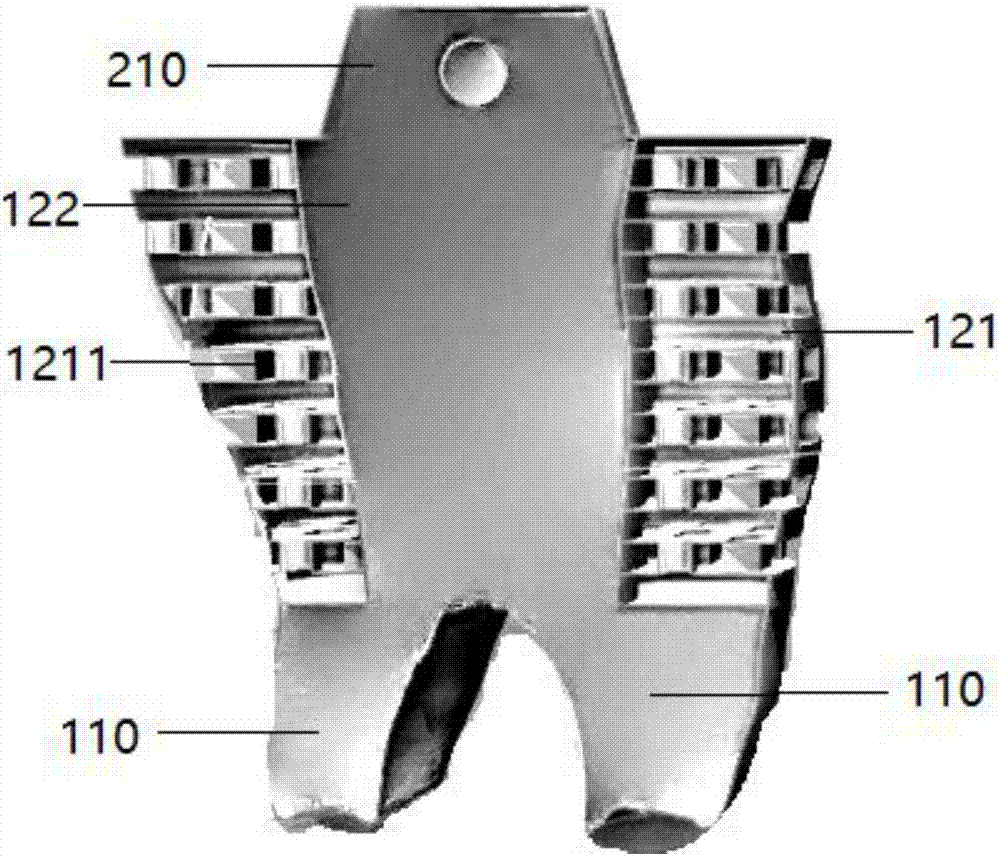

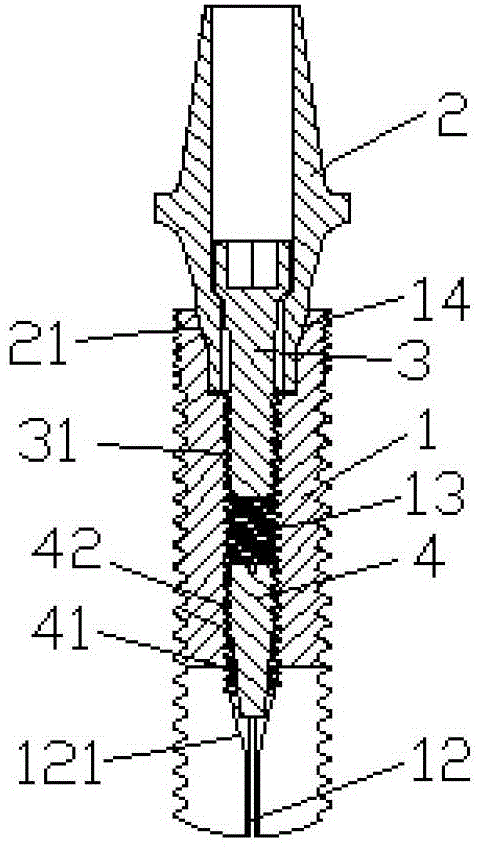

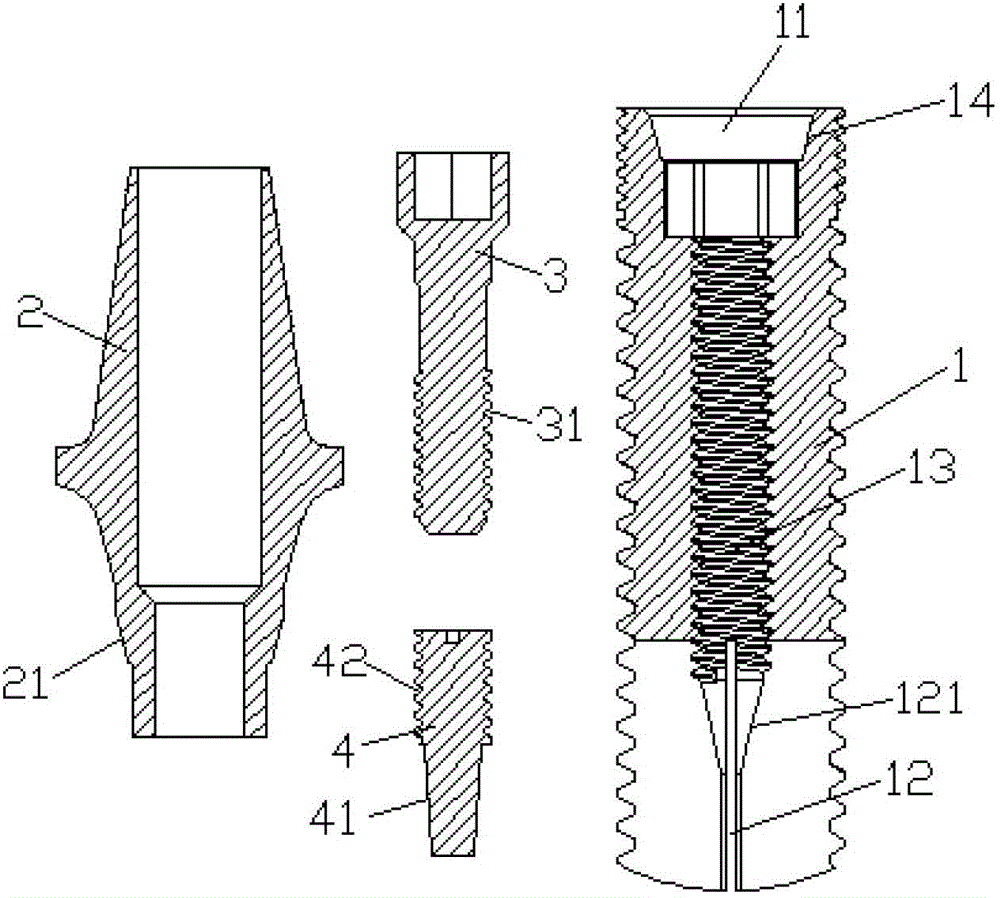

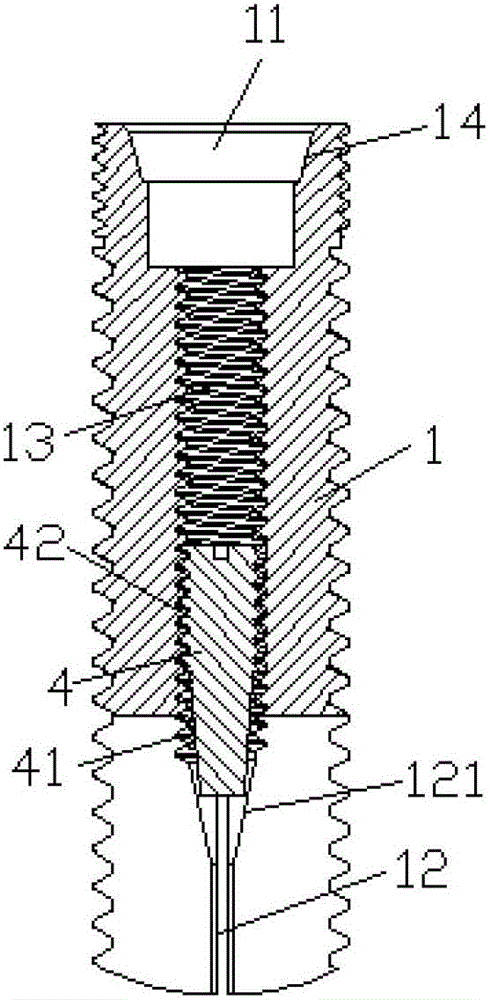

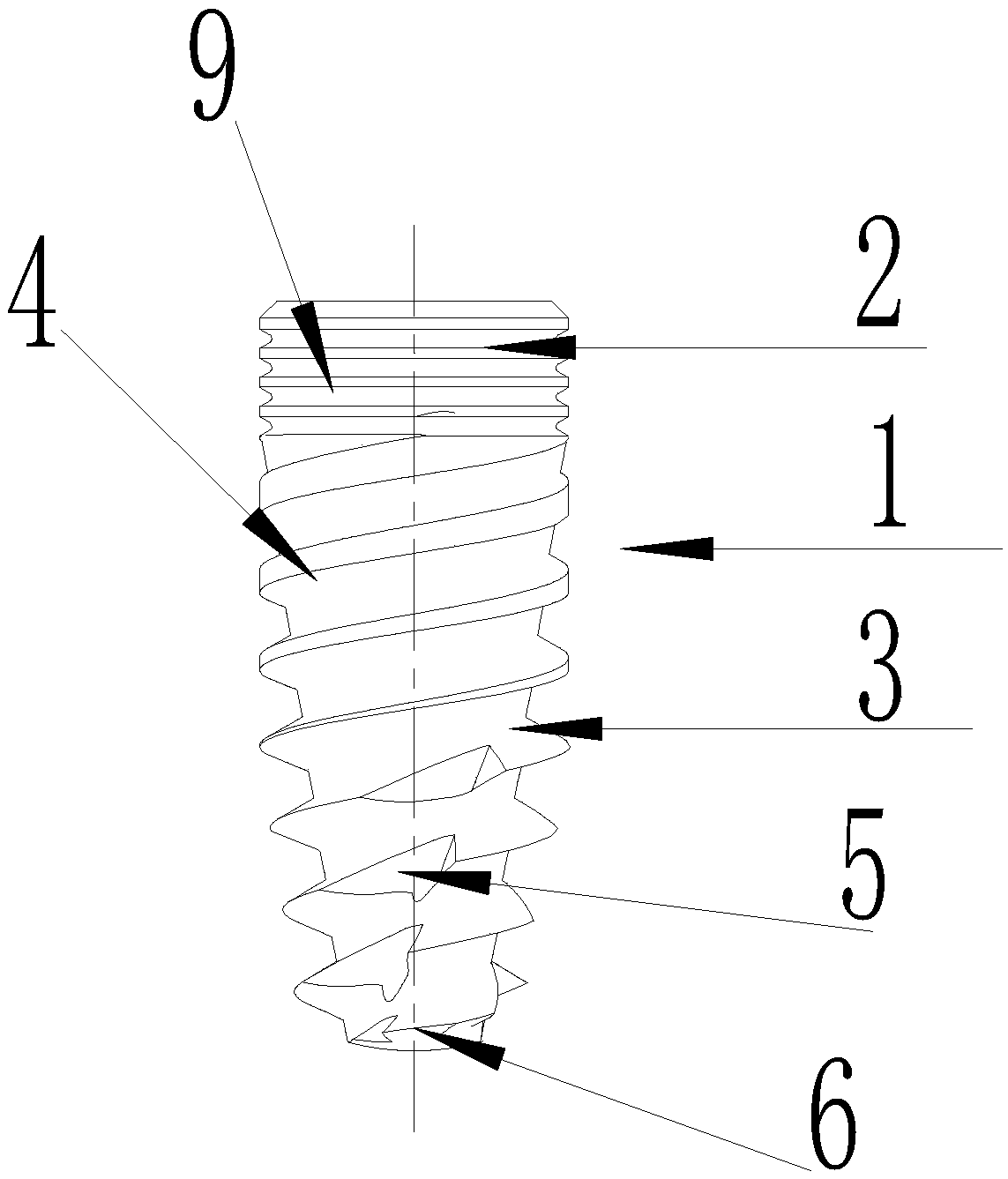

Dental implant of composite structure and manufacturing method of same

The invention provides a dental implant of a composite structure and a manufacturing method of the same. By adopting effective structural design, different materials and different manufacturing modes, the dental implant is divided into a fastening screw, a screw thread implanting section, a multi-hole implanting section, a tentacle supporting structure and an implant main body which are integrated to form a composite structure, and the dental implant has good strength, good bone combining capability and good initial stability. The thread implanting section, the fastening screw and the implant main body form a main frame of a composite implant, thus strength of the whole implant is guaranteed; meanwhile, the composite structure can be used for overcoming the defects caused by a single manufacturing mode, and the respective advantages of structural design, the manufacturing modes and materials are fully realized; a tentacle supporting structure made from a degradable material has the effects of well inducing osteogenesis and enhancing initial stability of the implant whole and can be applied to immediate implantation; elasticity modulus of the implant overall material is optimized by virtue of a porous structure of the outer layer, combination of bone growth and guiding in initial stage can be facilitated, and initial stability with osseointegration is also improved by the combined expanded-type structure.

Owner:广东健齿生物科技有限公司 +2

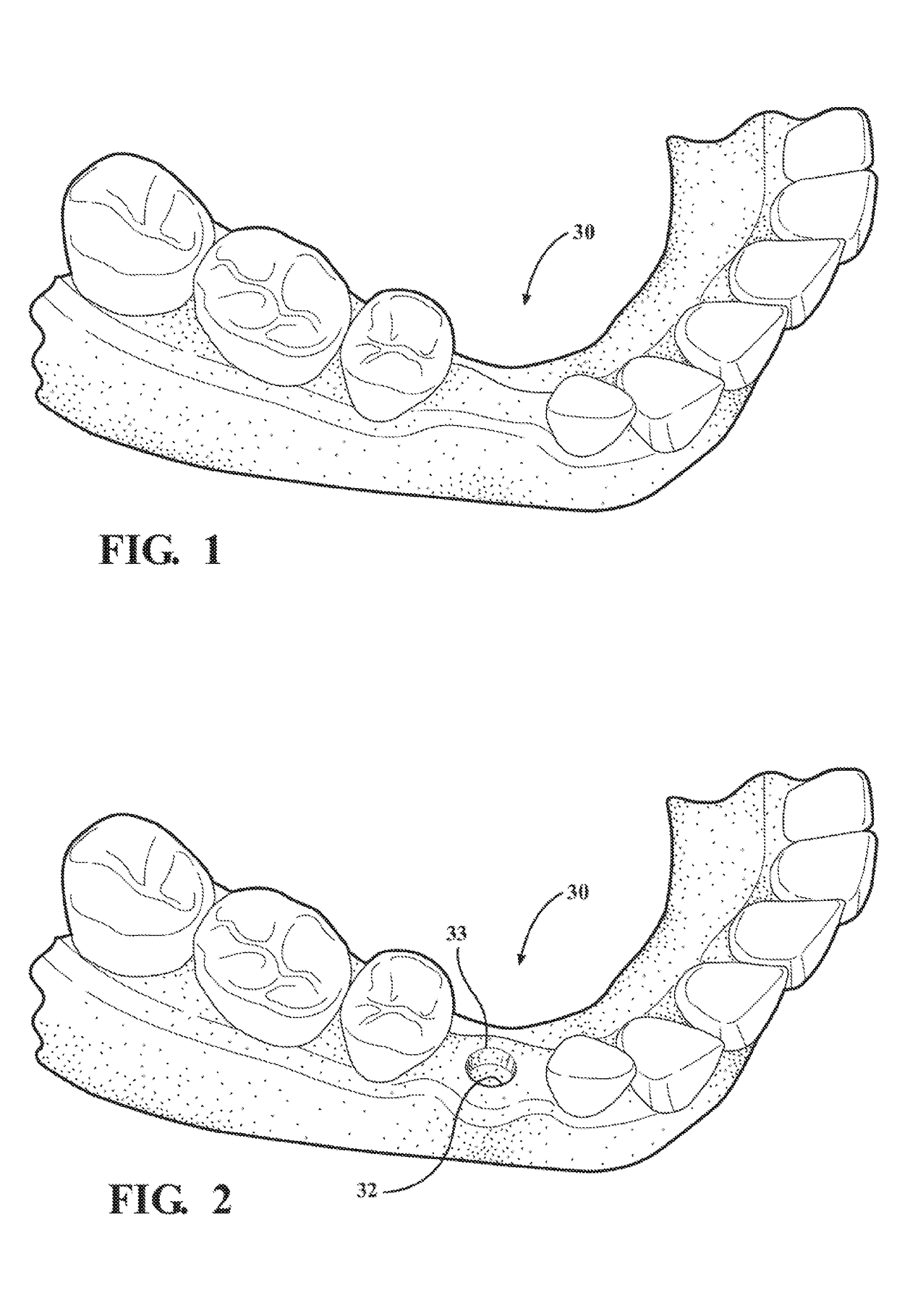

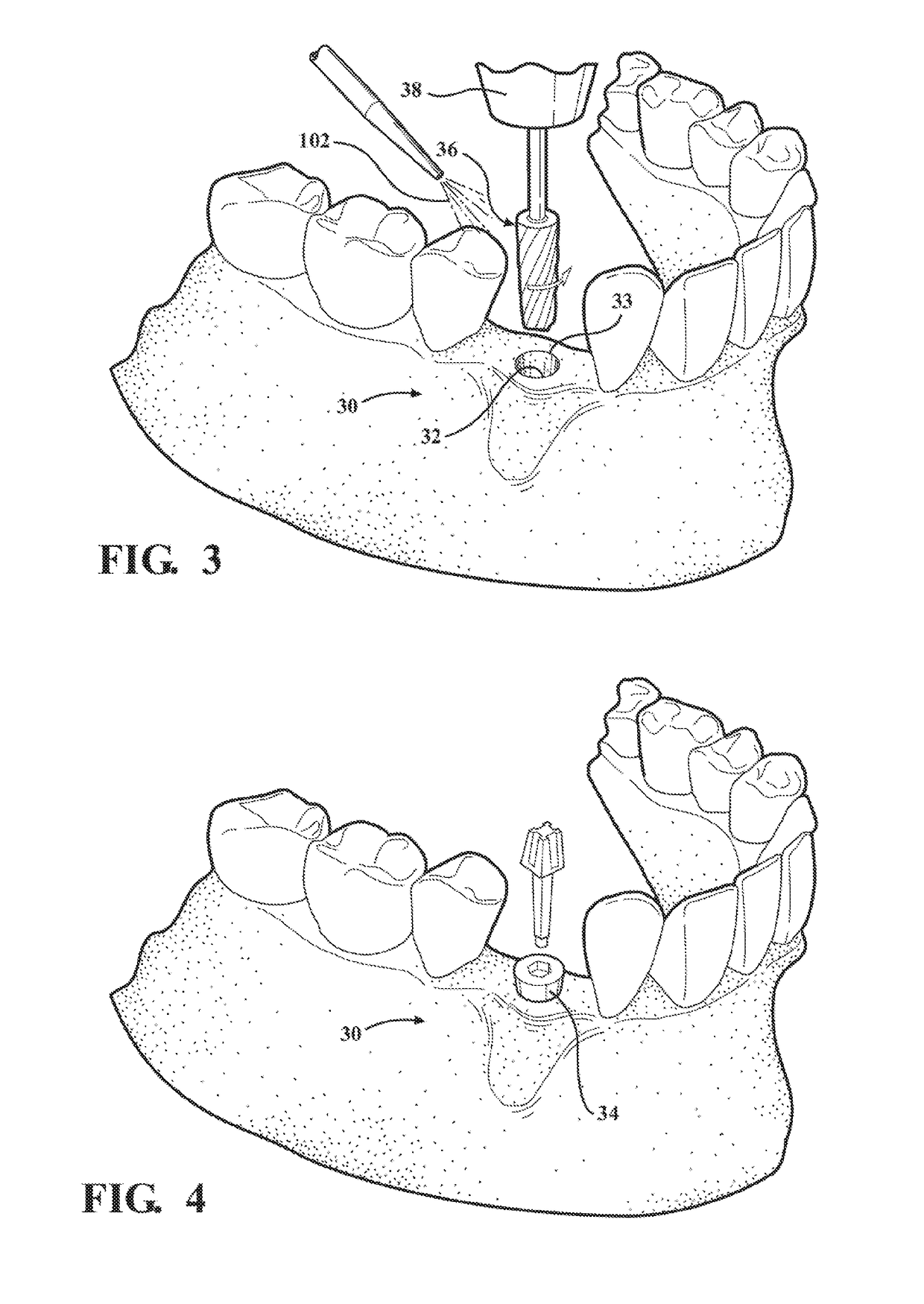

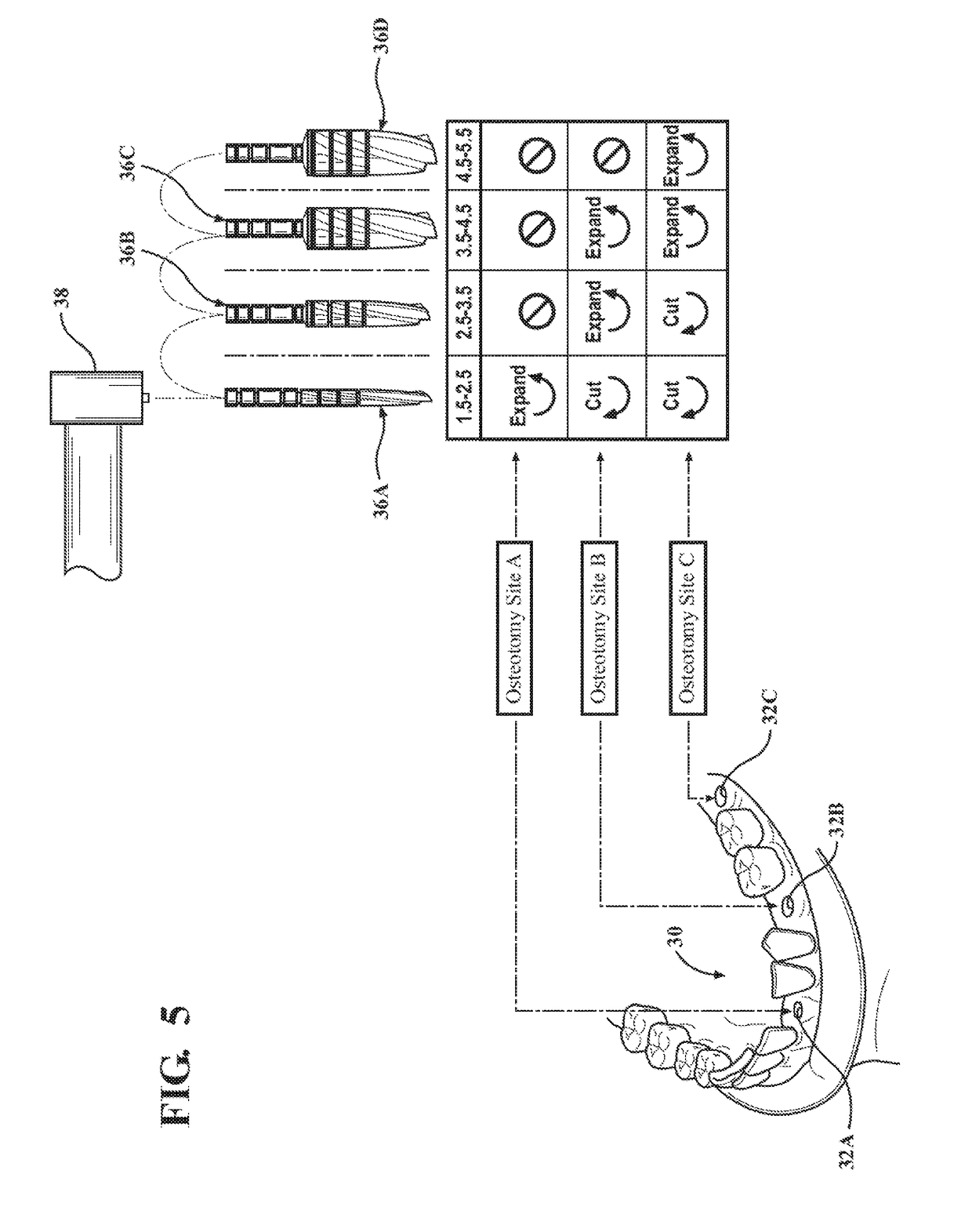

Autografting tool with enhanced flute profile and methods of use

ActiveUS20190029695A1Enlarge osteotomyImprove initial stabilityDental implantsDiagnosticsFluteHost material

Tools and methods for expanding a precursor hole in a host material to receive a fixture. The precursor hole is enlarged by a rotary tool having helical flutes and interposed lands. The flutes have a negative rake angle. The lands each have a working edge that cuts the host material when the tool is rotated in a cutting direction, and that condenses the host material when the tool is rotated in a densifying direction. The body of the rotary tool has a stopper section that plugs the hole when a certain depth is reached. When the tool is used with a copious wash of irrigating fluid at or below the necessary depth, hydraulic pressure builds inside the precursor hole. The hydraulic pressure can be advantageously exploited in cutting mode to autograft a slurry of host material particles into the sidewalls of the hole and create an incipient densifying crust.

Owner:HUWAIS IP HLDG

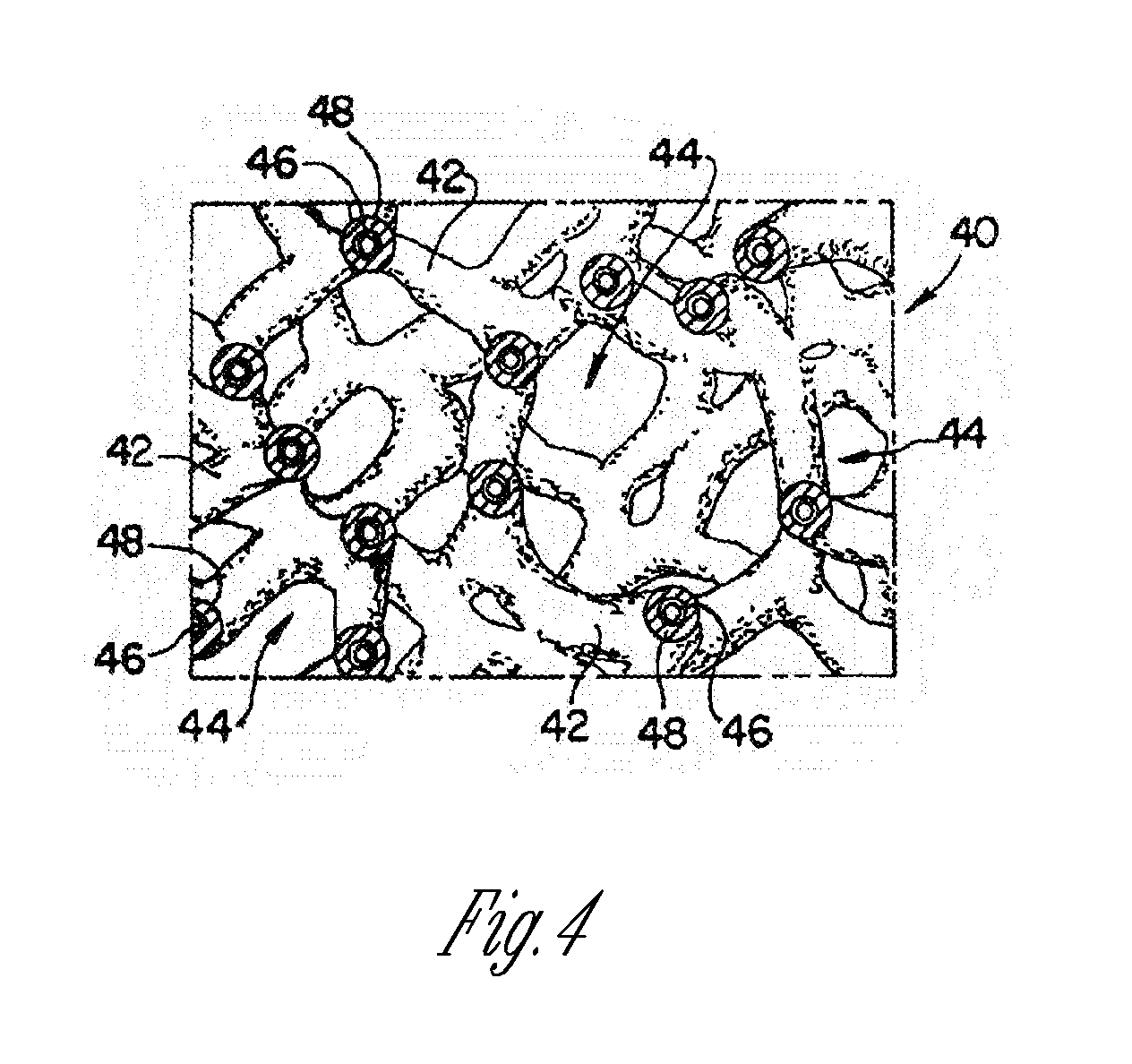

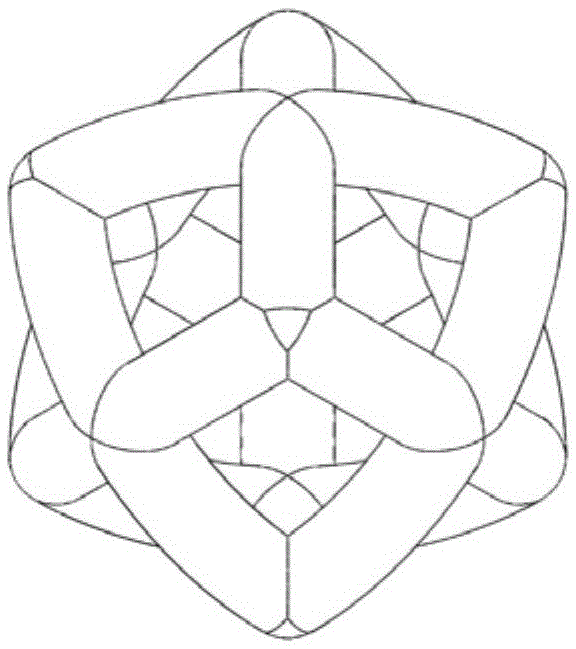

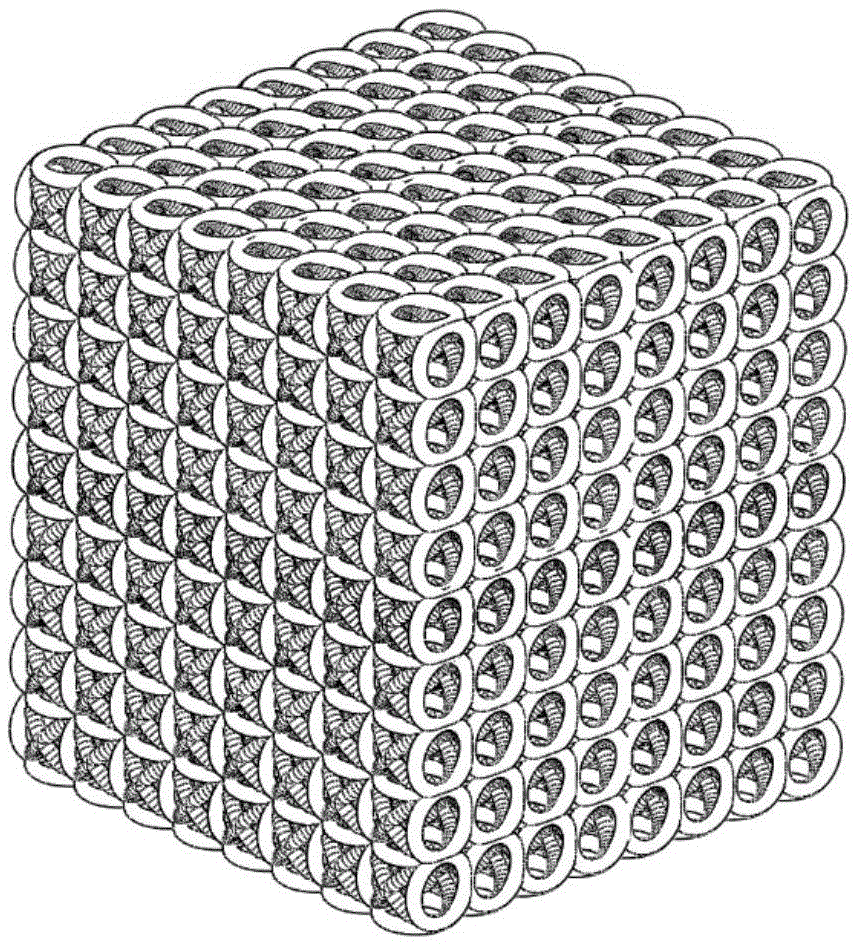

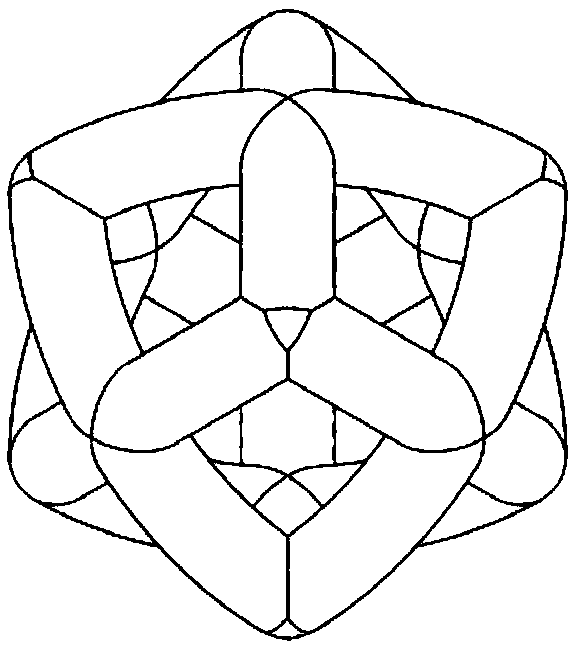

Preparation method of porous implant filled with O-intersecting lines units

InactiveCN105559947AThe preparation method is reliable and feasibleGreat potentialJoint implantsFemoral headsSand blastingPorous implant

The invention provides a preparation method of a porous implant filled with O-intersecting lines units. The preparation method comprises the following steps: drawing a three-dimensional model of the O-intersecting lines units, controlling the bore diameter, wall thickness and porosity of the three-dimensional model according to the given specific dimension so as to generate a unit structure cell body, carrying out array copying operation on the unit structure cell body, thus obtaining a space porous network body, introducing in a femoral three-dimensional surface model, scaling the model to reach the proportion actually needed, carrying out cutting and Boolean operation on the porous network body and the femoral three-dimensional surface, thus obtaining a porous main body part, drawing the femoral steam end and a bolt positioning hole part by utilizing three-dimensional modeling, combing the porous main body part to enable the porous main body part to form a single-output porous implant body, saving the single-output porous implant body into an output format file and transmitting the file to layering software, adding with a bottom surface support, printing the porous implant body by adopting a 3D printer, clearing a substrate plate, taking out the porous implant, carrying out sand blasting treatment on the porous implant, and packaging the porous implant. With the adoption of the preparation method, units which are regular and uniform and having no closure can be generated, and the stressing uniformity is guaranteed.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Anterior cervical interbody fusion cage

InactiveCN103300947AEnsure safe implantationPromote bone fusionInternal osteosythesisSpinal implantsSpinal cageGynecology

The invention discloses an anterior cervical interbody fusion cage which comprises a main body and a development needle arranged on the main body, wherein the main body is a hollow tetrahedron; the cross section of the hollow periphery of the tetrahedron is ladder-shaped; the cross section of the hollow inner circumference of the tetrahedron is square or rectangular; the main body comprises a front wall, a rear wall, a left side wall and a right side wall; and the front wall is connected with the rear wall through the left side wall and the right side wall. The shape of the main body confirms to the anatomic form of the cervical intervertebral disc of a normal human body; while the safe implantation is ensured, the main body can be in tight contact with end plates of an upper cervical vertebral body and a lower cervical vertebral body under the compression state to create a good condition for bone fusion; and the cross section of the hollow inner circumference of the main body is square or rectangular, so that the contact surface of the main body and the end plates of the cervical vertebral bodies is increased to the greatest extent, the bone implementation amount is increased, and the fusion is speeded up.

Owner:广州聚生生物科技有限公司

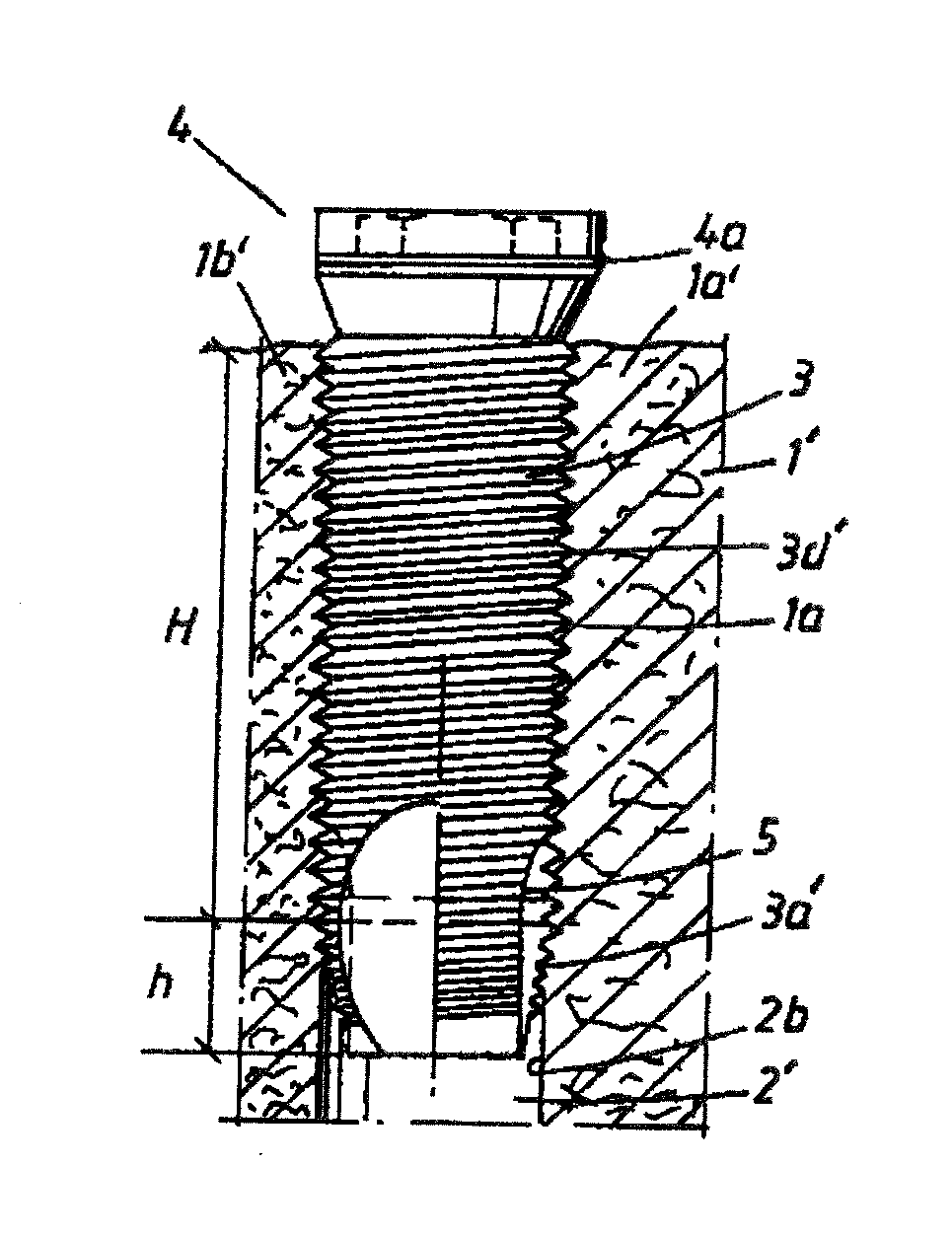

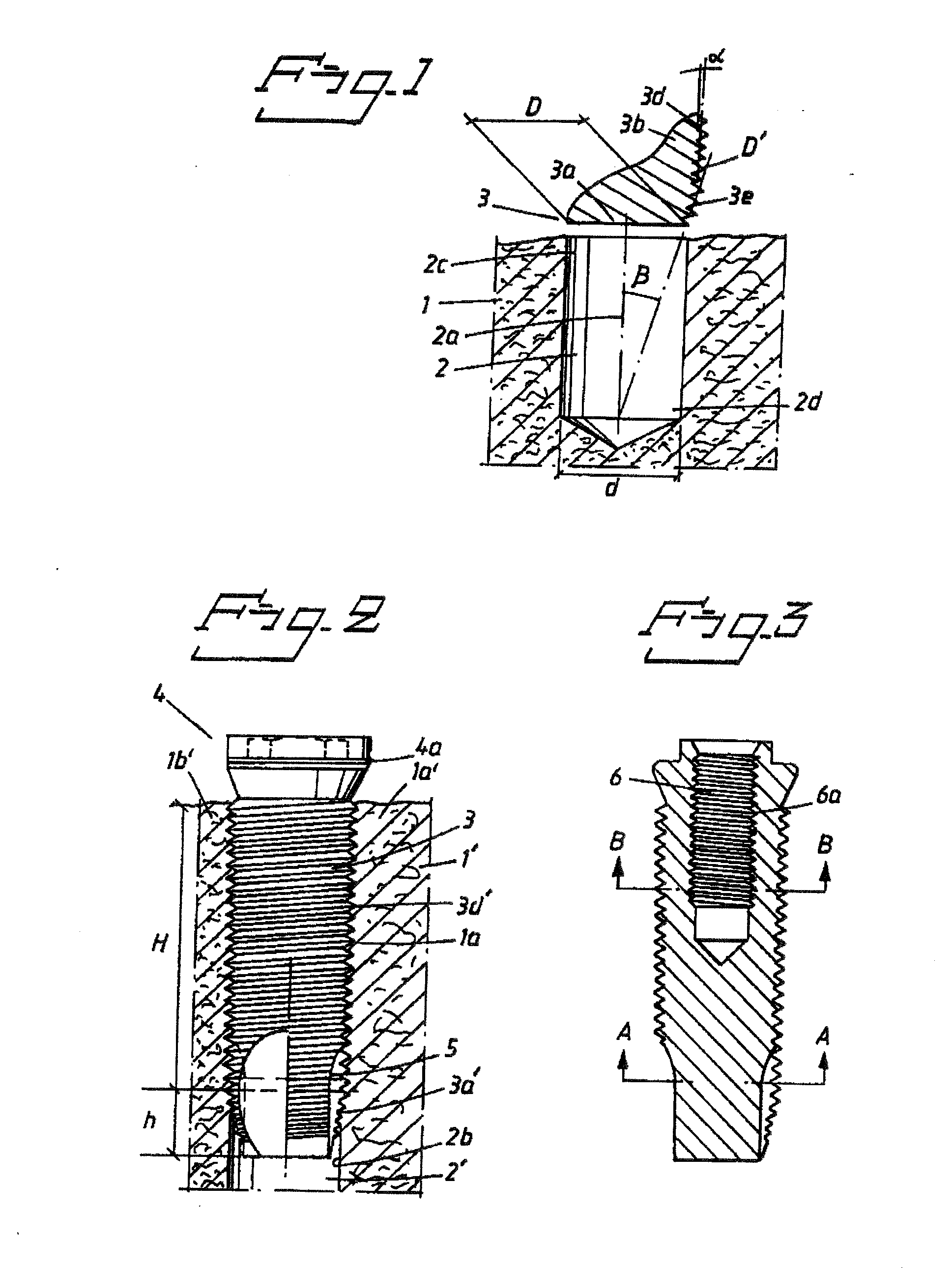

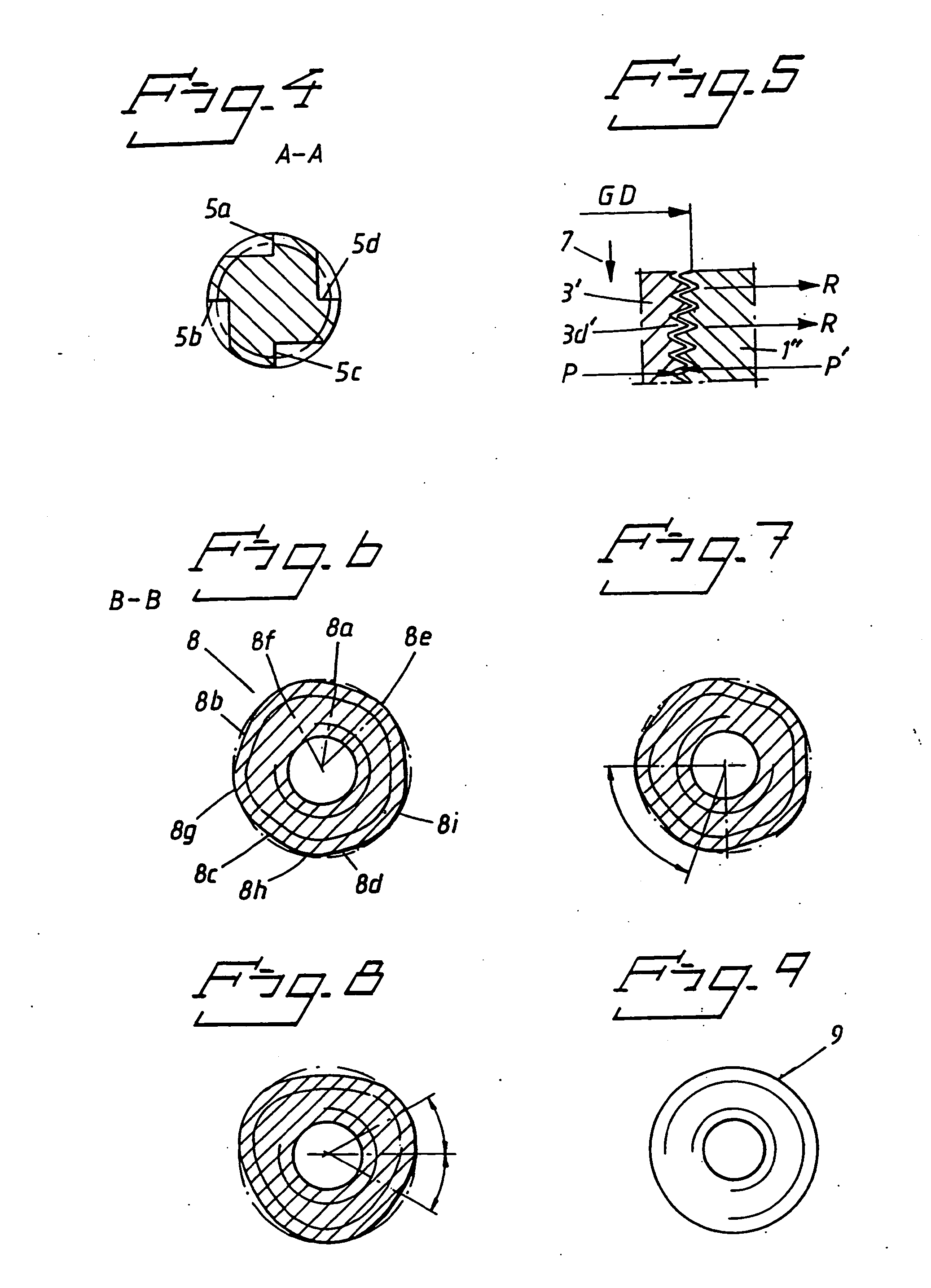

Arrangement for Obtaining Reliable Anchoring of a Threaded Implant in a Bone

InactiveUS20150044639A1Poor stabilityCut geometry of becomes badDental implantsBone implantBiomedical engineeringRotational stability

In an arrangement for obtaining reliable anchoring of a threaded implant in dentine, a hole is made in the bone substance. In the side wall of the hole it is possible to establish an internal threading which can cooperate with an external threading on the implant. The implant threading is arranged to force the bone substance out in essentially radial directions as a function of the extent to which the implant is screwed into the hole. The threading is arranged to effect greater forcing out of the bone substance at the outer parts of the hole than at the inner parts of the hole. The degree of forcing out is adapted in relation to the softness of the bone in order to achieve the reliable anchoring. Along at least part of the longitudinal direction of the implant, the implant threading can be given a non-circular configuration for the purpose of obtaining improved rotational stability in soft / weak bone.

Owner:NOBEL BIOCARE SERVICES AG

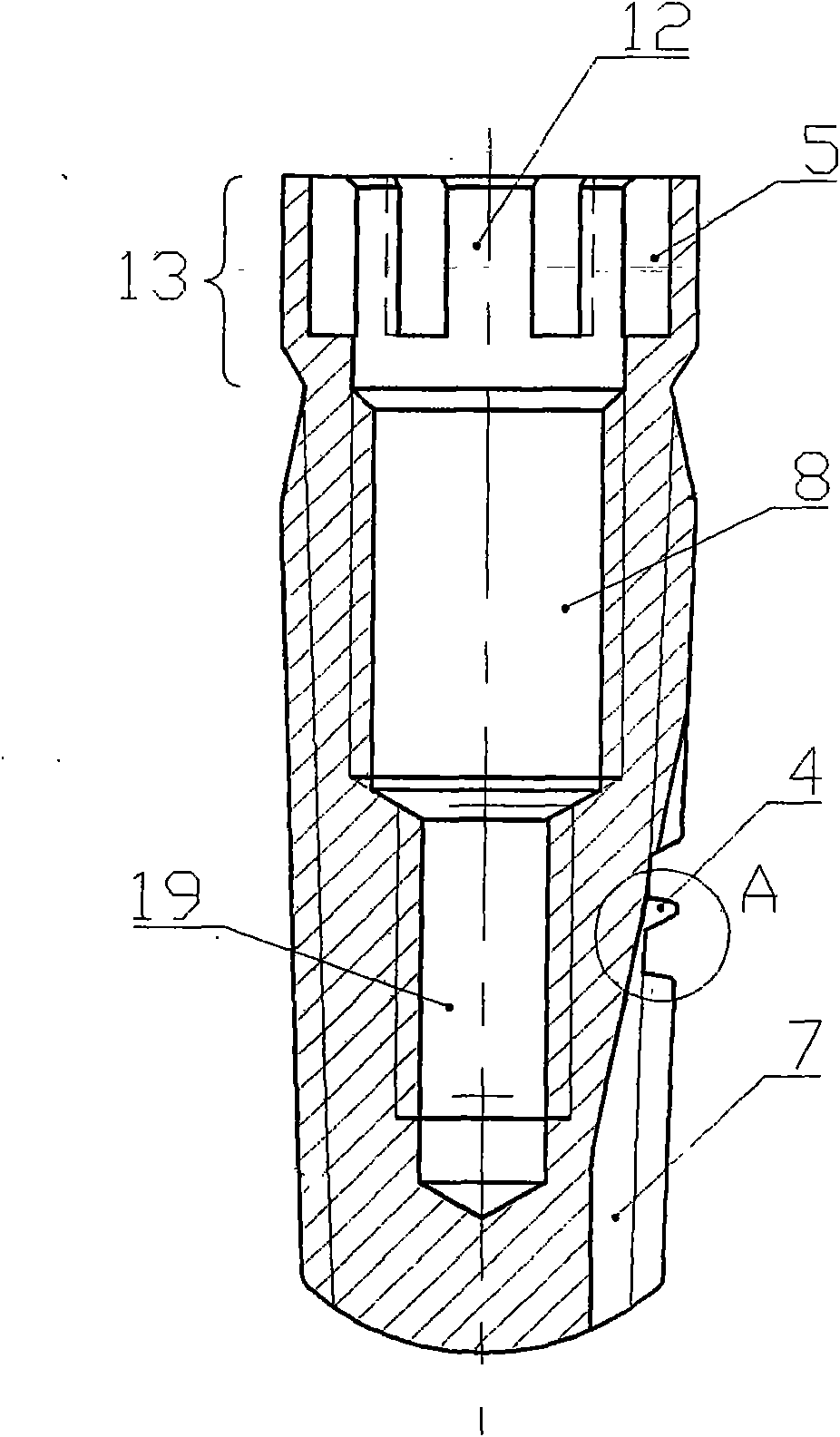

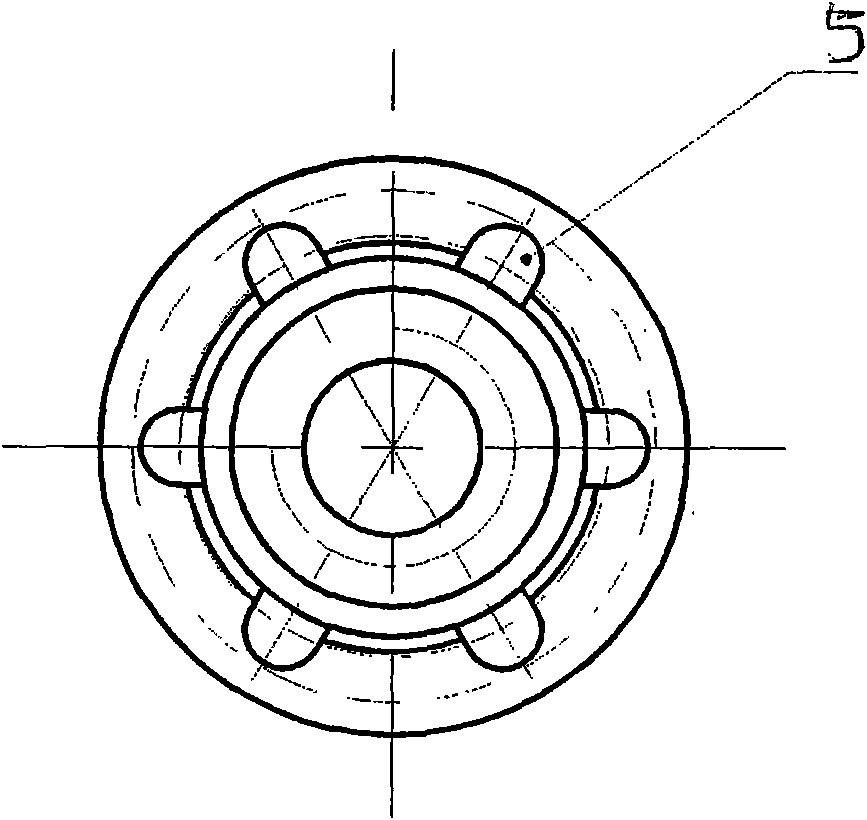

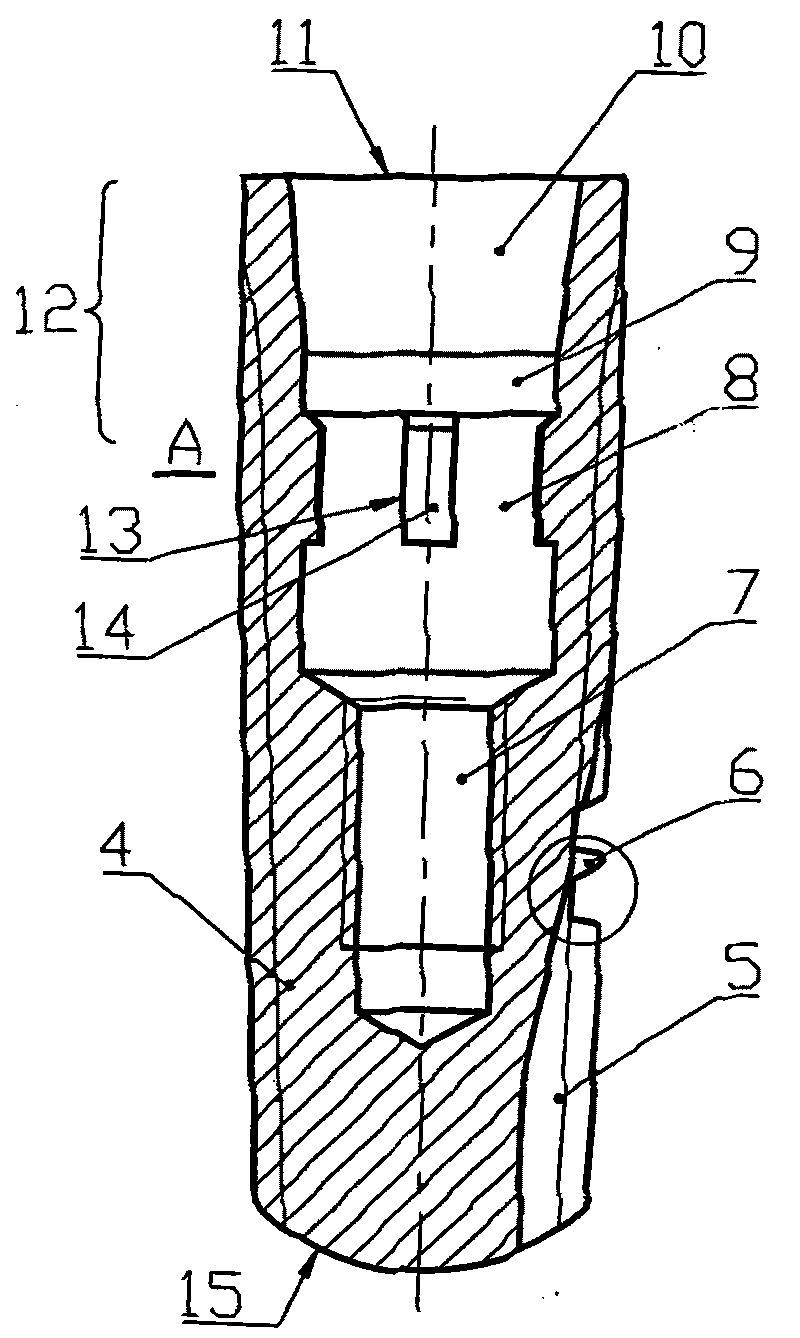

Bushing-type oral implanting device

InactiveCN101664342AEasy to operateImprove planting qualityDental implantsSurgical ManipulationOsseointegration

The invention relates to a defected-tooth implanting or restoring technology, in particular to a bushing-type oral implanting device which is characterized in that at least two grooves with openings on the upper ends are distributed on a cylindrical surface through which an implanting body is connected with a base station; the upper end of the base station is provided with lug bosses which are matched with the grooves; the combination length of the implanting body and a tubular connecting handle of the base station is nearly 1 / 2 or more of the length of the implanting body so that the implanting body can be embedded in shaped holes on the alveolar bone to shorten the operation time; the implanting body has good bone extruding effect, thus the early-stage stability and the later-stage osseointegration stability after the operation are improved, and the use effect after the healing is enhanced; the contact surface of the thread-type implanting body and the alveolar bone is enlarged, thusthe implanting body and the alveolar bone can be more firmly combined, and the implanting quality of the implanting body is improved; the base station and the implanting body are more tightly connected and are more firmly combined, thus the operation is more convenient; the bushing-type oral implanting device can be operated conveniently and can be well combined with the alveolar bone; the implanting body has good stability and can bear larger lateral force with little or no inclination; the base station and the implanting body can be adjusted in angle and can be connected in high precision;and the bushing-type oral implanting device can inhibit the bone resorption.

Owner:WEIHAI WEIGAO BIOTECH

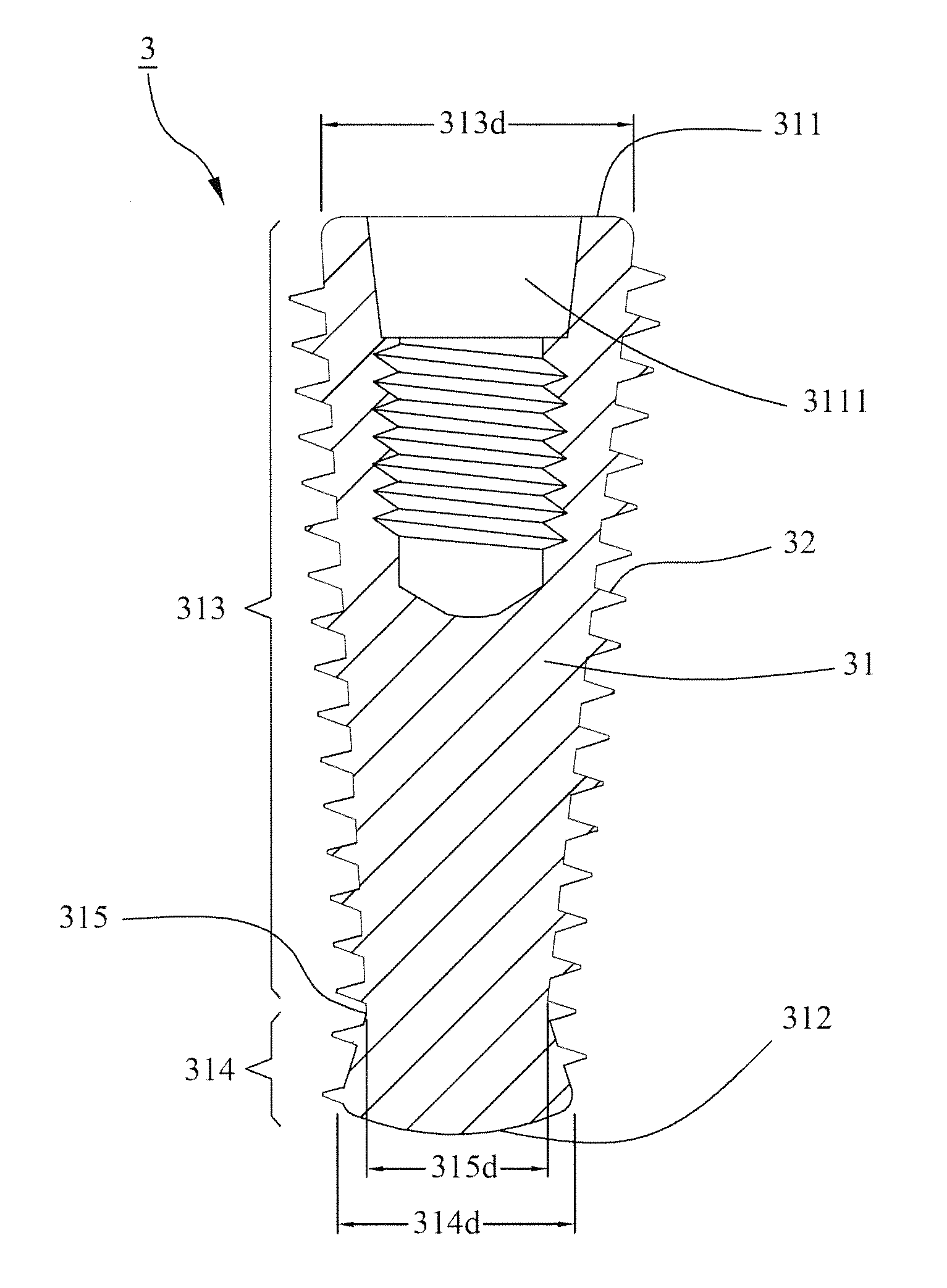

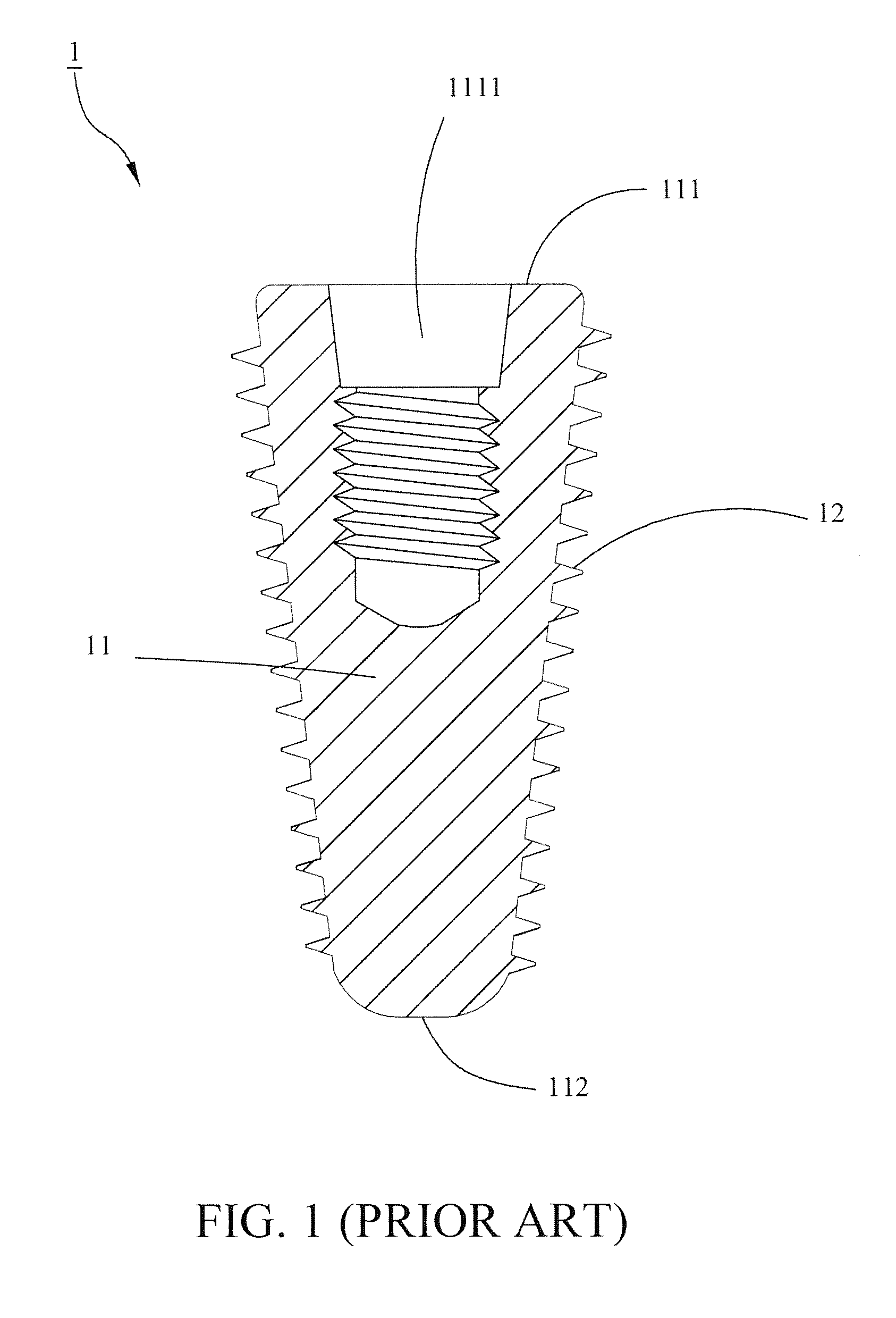

Dental implant with high combining stability

InactiveUS20150017605A1High combining stabilityImprove feelDental implantsBiomedical engineeringEngineering

A dental implant comprises a shank and a threaded section spirally disposed on the shank. The shank includes a first section extending from a first end toward a second end of the shank and a second section connecting the first section and extending to the second end. A shank diameter of a connecting part where the first and the second sections are connected is smaller than that of the second section, whereby the subject configuration increases an implant-fastening feel of dentists and an initial implanting stability efficiently while implanting the dental implant into an alveolar bone. When the dental implant is enclosed by a growth of the bone, the second section is firmly fixed by the bone to prevent the dental implant from loosening due to an inverse torque derived from the mastication and allow it to be firmly embedded in the bone to increase the combining stability.

Owner:TAIWAN SHAN YIN INT CO LTD

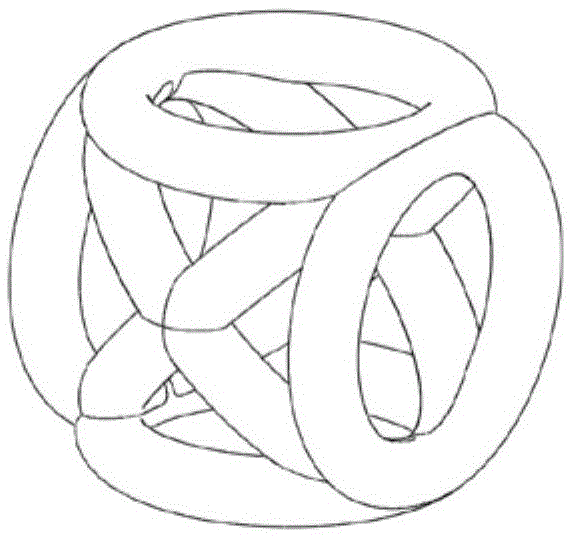

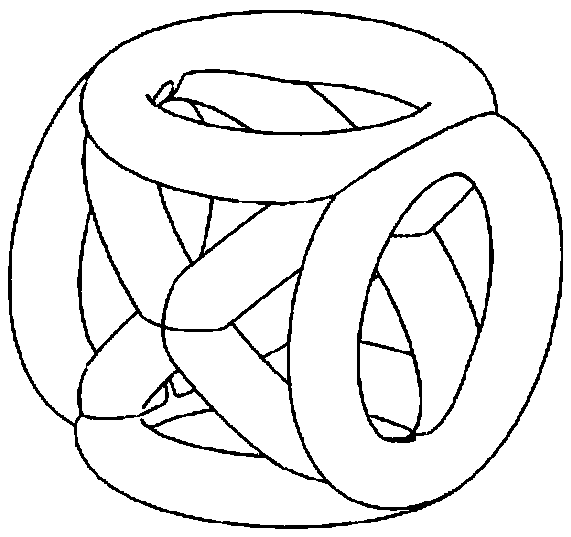

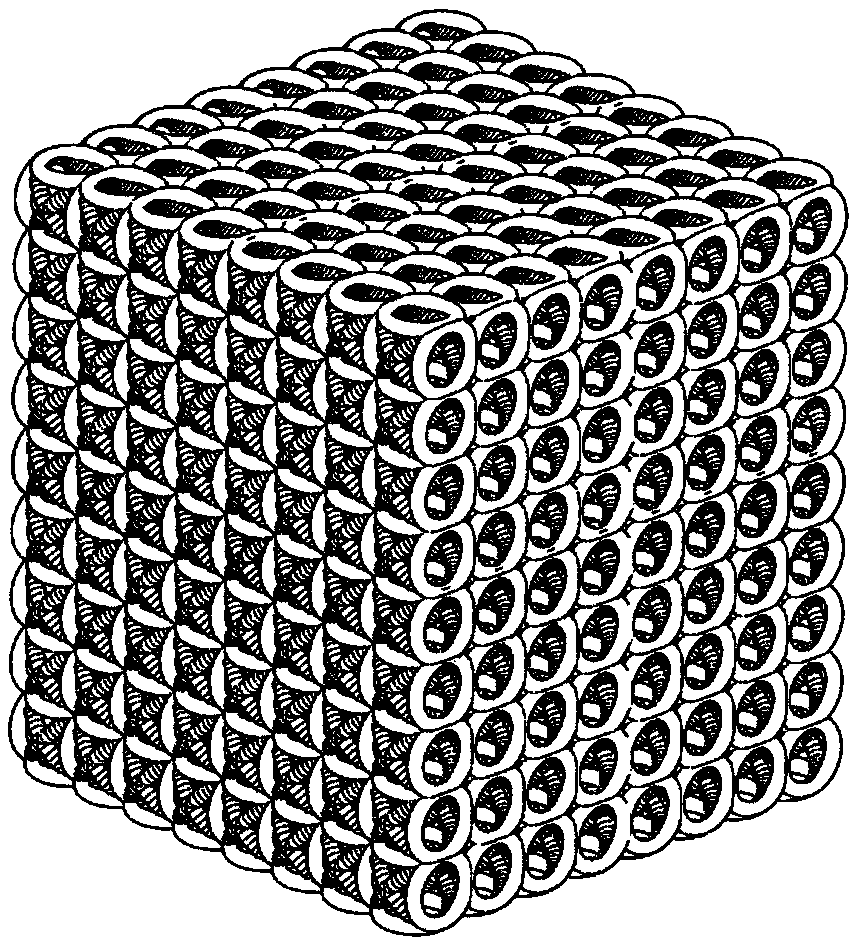

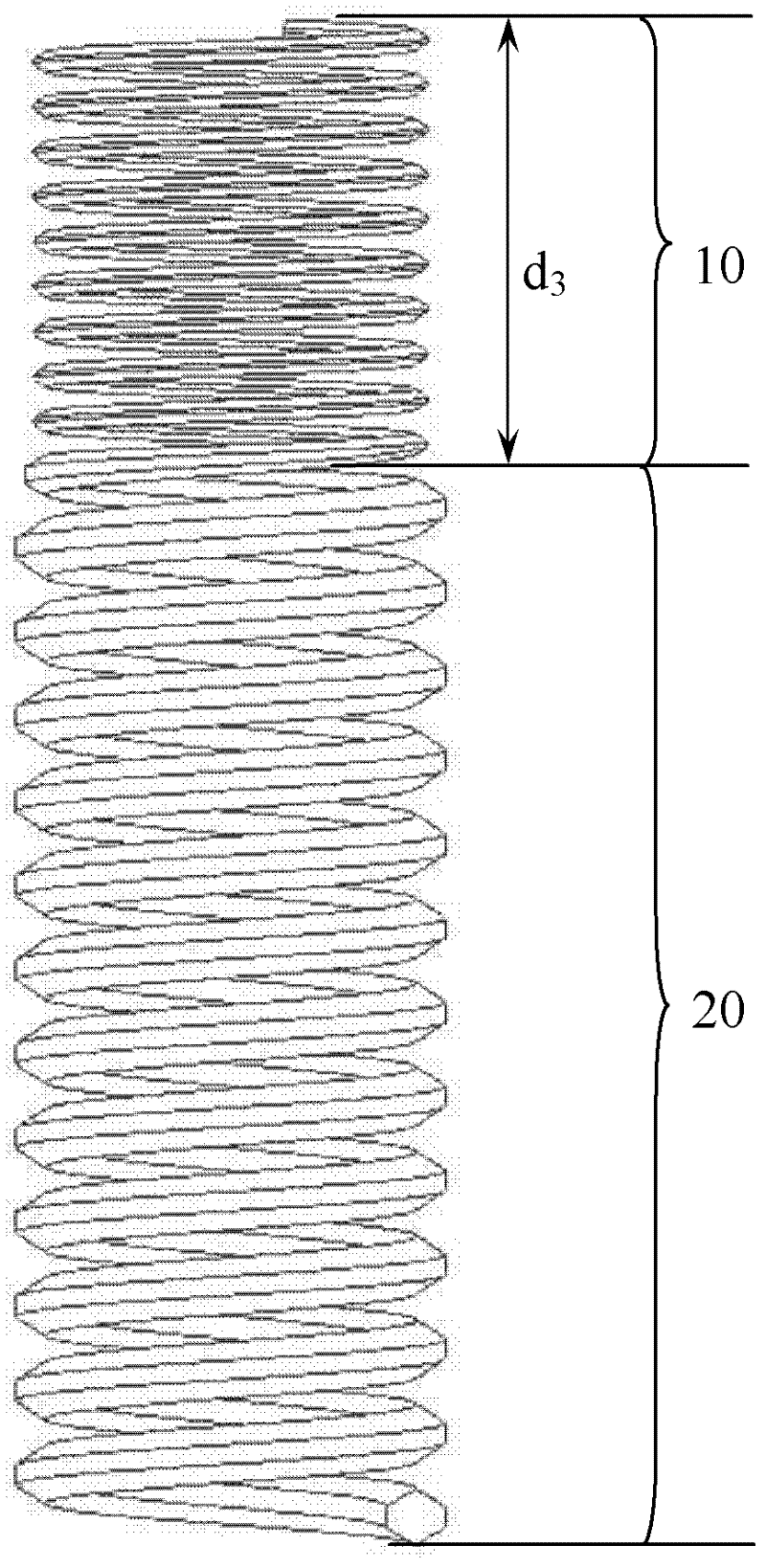

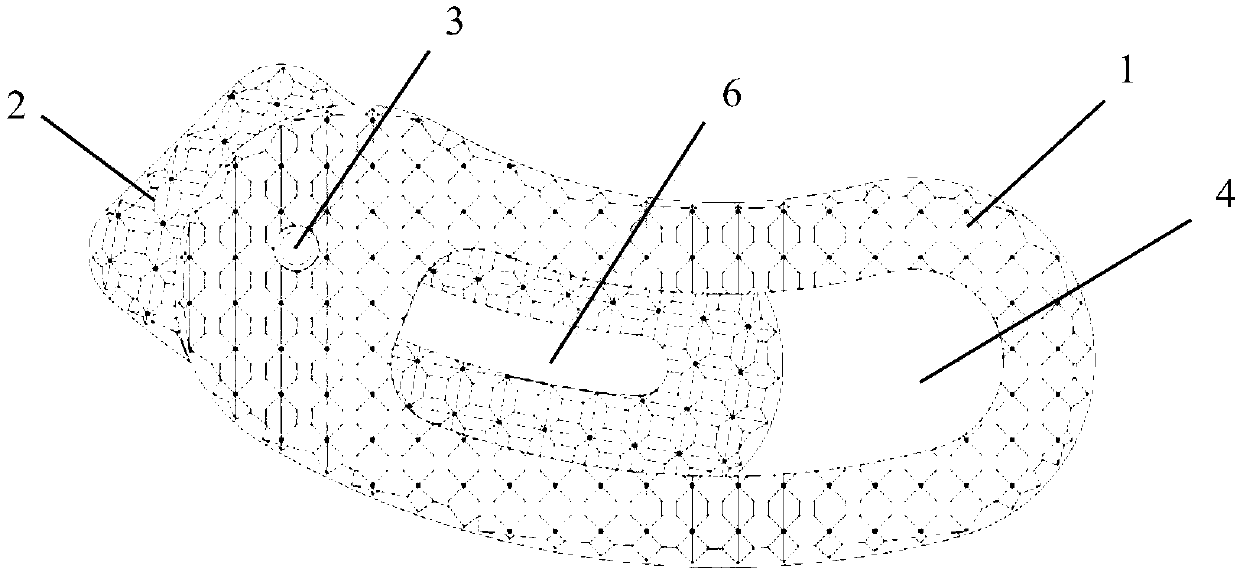

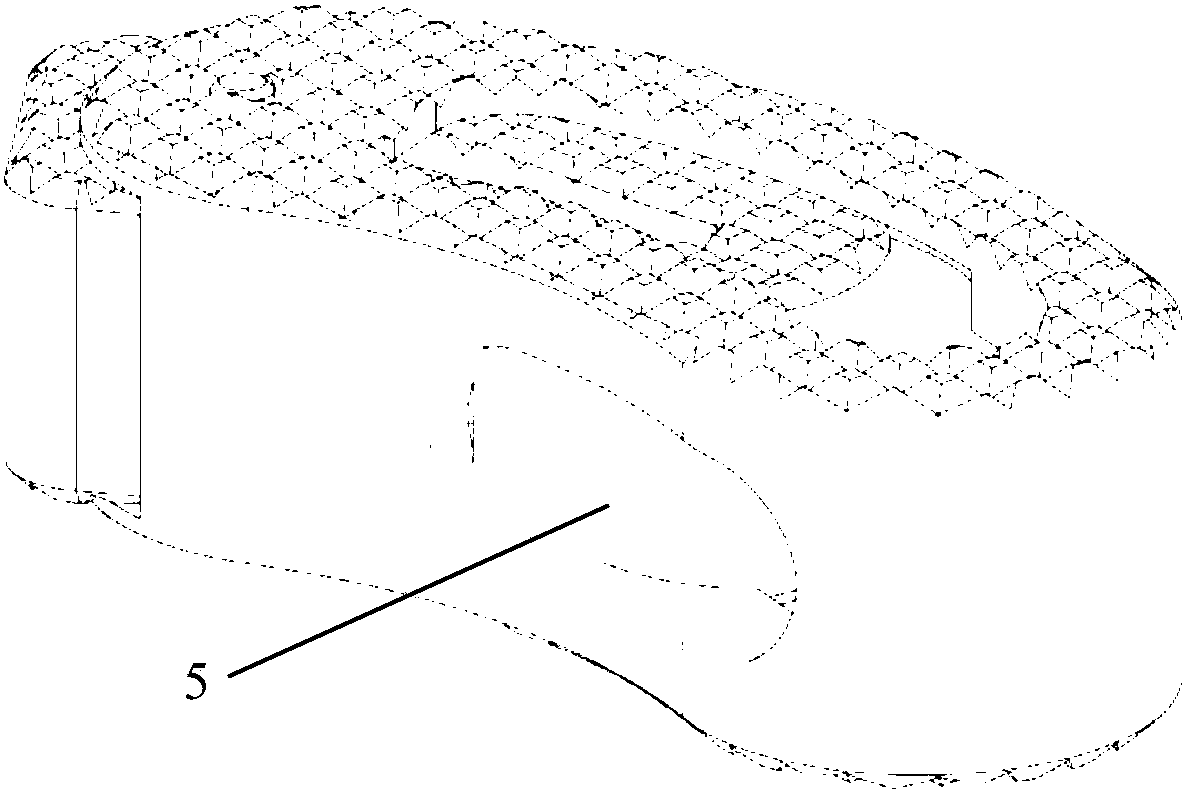

Porous implant filled with O-intersecting lines units

InactiveCN105496611AThe preparation method is reliable and feasibleGreat potentialJoint implantsTissue regenerationBone structureTissue fluid

A porous implant filled with O-intersecting lines units is mainly oriented to femoral stems and comprises a femoral stem end, a porous main body part and a screw positioning hole part, wherein the femoral stem end is used for positioning the porous implant, the screw positioning hole part is used for fixing the implant and a host, the porous main body part is a three-dimensional through porous network entity mainly formed by being filled with the O-intersecting lines units, the porous network entity comprises hollowed-out entities formed by scanning of O-intersecting lines unit cylinders penetrating through and crossing with one another in space, the hollowed-out entities are formed by pairwise perpendicular and linearly stacked O-intersecting lines unit cylinder surfaces, and the porous network entity has the pore diameter ranging from 400 mu m to 1,000 mu m, the unit wall thickness ranging from 80 mu m to 120 mu m and the porosity ranging from 55% to 85%. Thus, a porous network structure formed by stacking of the hollowed-out entities is close to a bone structure, has the high porosity, the high communication ratio and the larger surface contact area, is suitable for new bone ingrowth and circulation of nutrition tissue liquids and has the considerable clinical medical prospect.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

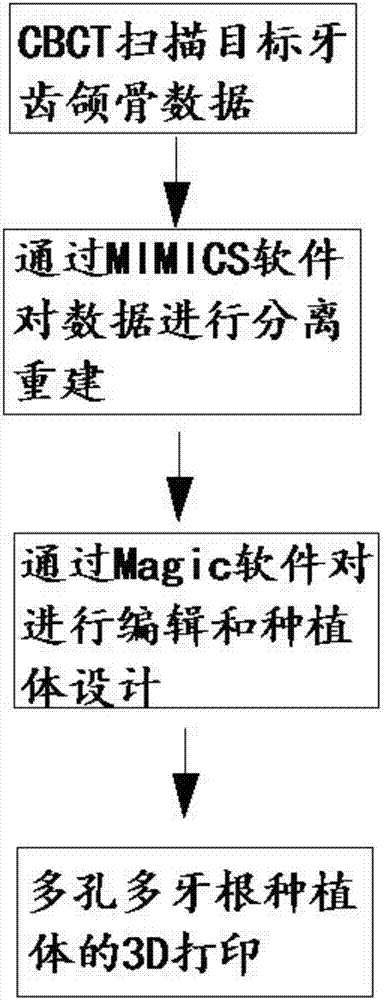

3D printing method of individualized porous-layer multi-tooth root implant

InactiveCN107485460AImprove stabilitySpeed up healingDental implantsAdditive manufacturing apparatusCorona dentisPorous layer

The invention discloses a 3D printing method of an individualized porous-layer multi-tooth root implant. The 3D printing method comprises the following steps of step one, scanning an object, and acquiring data; step two, aiming to a scanning region, using an MIMICS software to carry out separation and reconstruction on the data acquired in the step one to obtain a three-dimensional model of a tooth root, a tooth fossa, a corona dentis and a dentition region to be pulled out of the object; step three, utilizing a Magic software to edit the three-dimensional model in the step three, carrying out digital design on a root, an abutment and the corona dentis of the implant, and regulating printing parameters to obtain a model of the implant to be printed; and step four, copying the model of the implant to be printed in the step three into a 3D printer for printing to obtain the individualized porous-layer multi-tooth root implant. The method has the advantages of high manufacturing accuracy, shortening in planting treatment period, reduction in planting cost and improvement in stability of the tooth root implant.

Owner:SOUTHERN MEDICAL UNIVERSITY

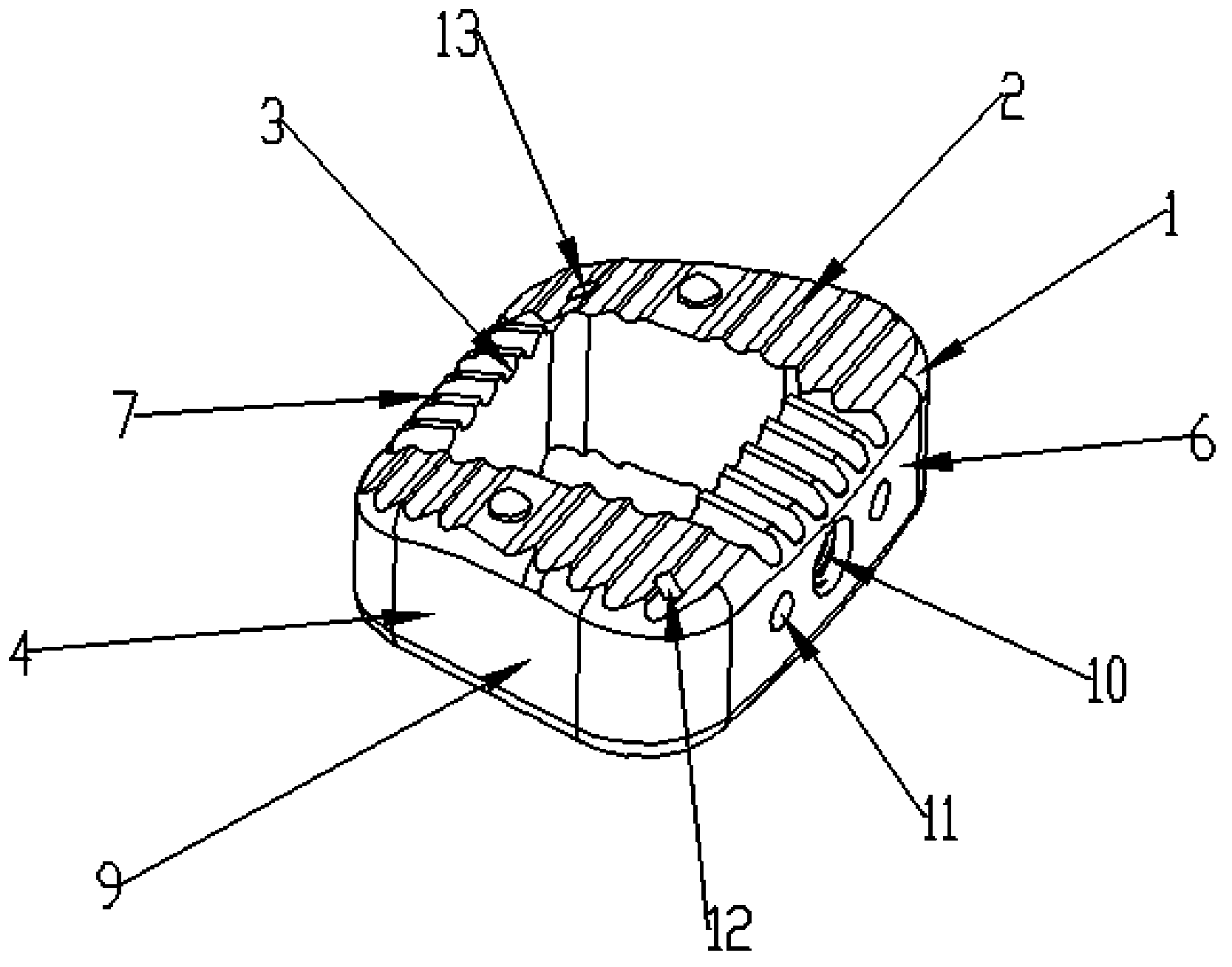

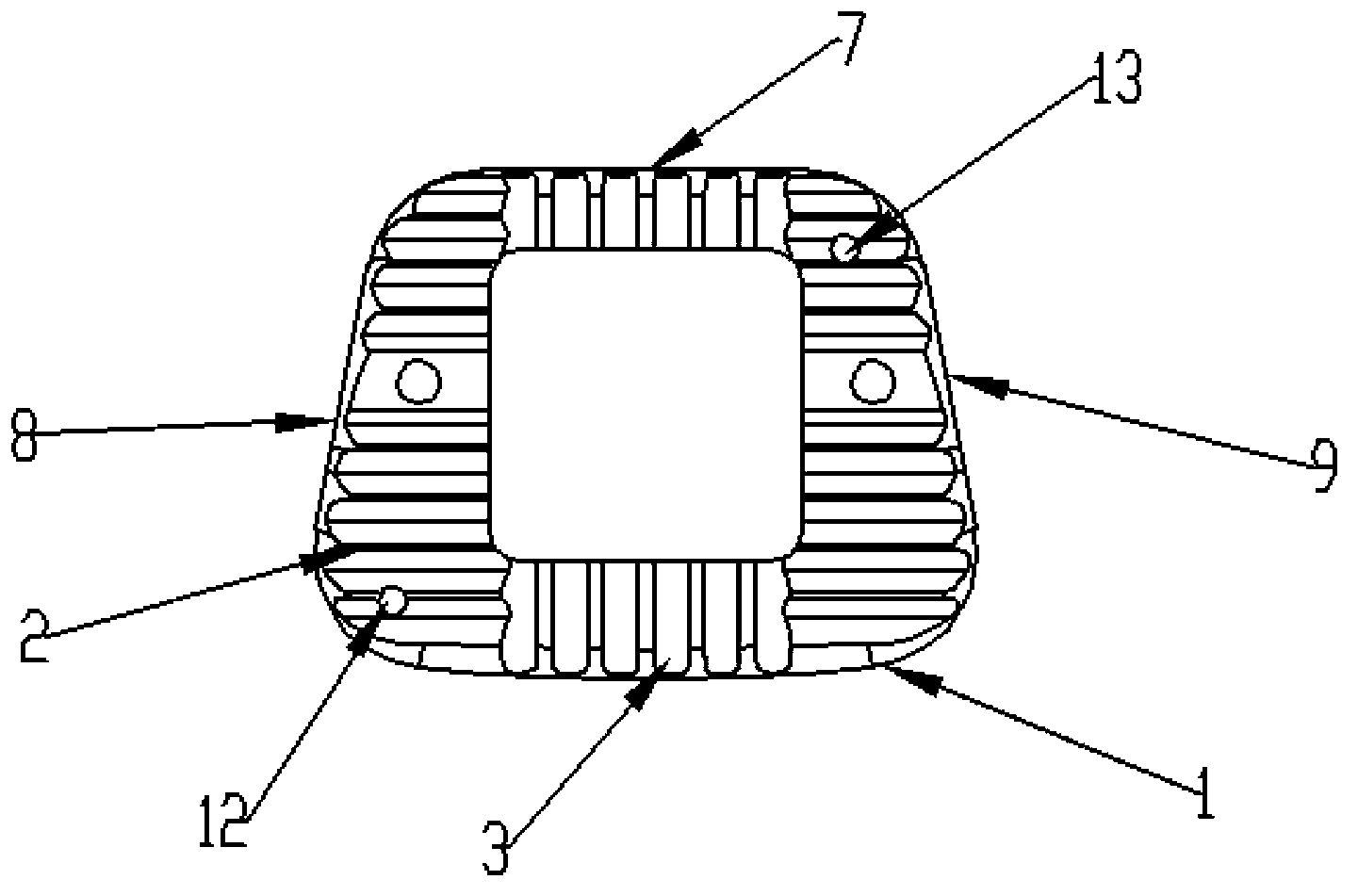

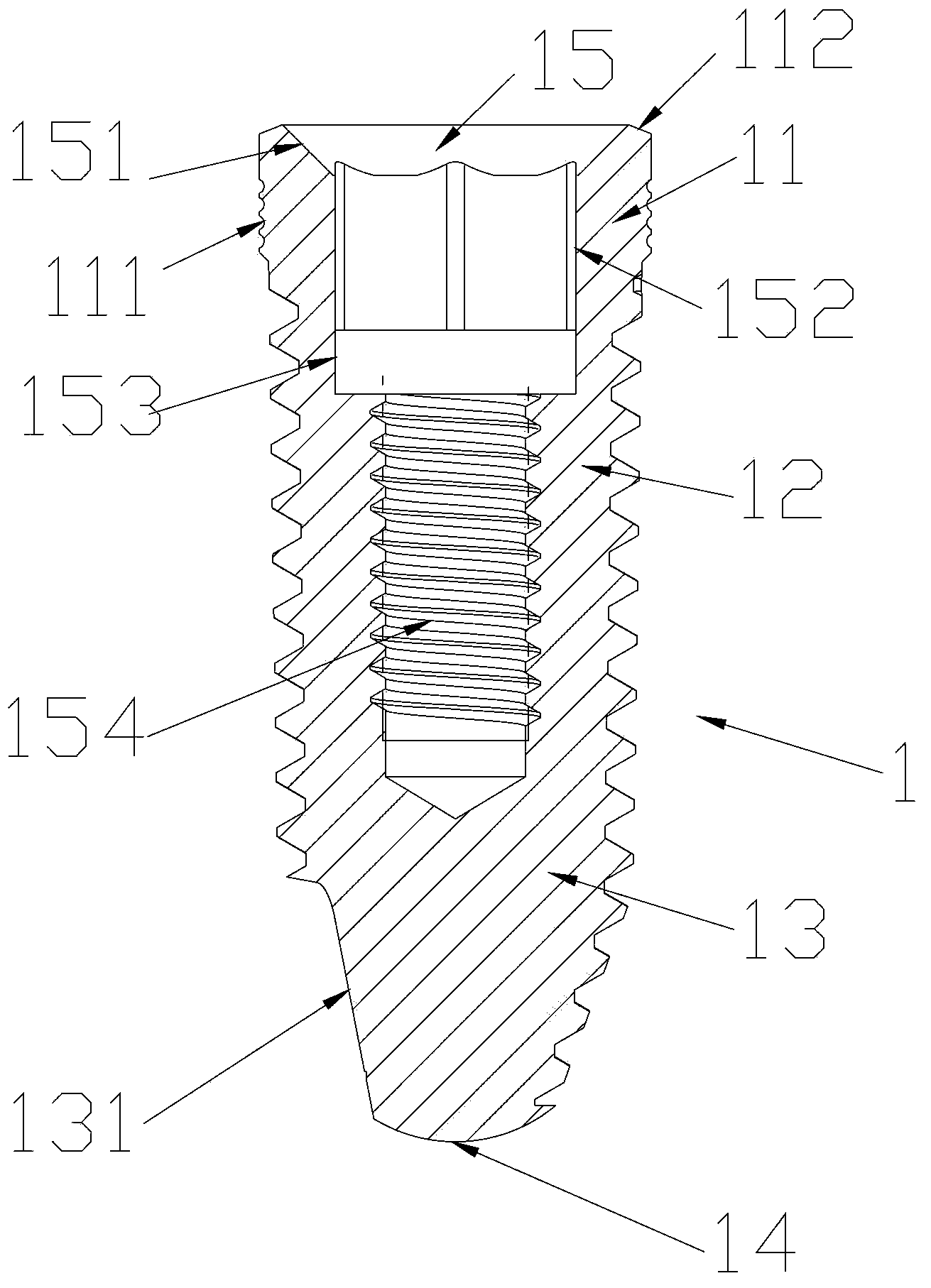

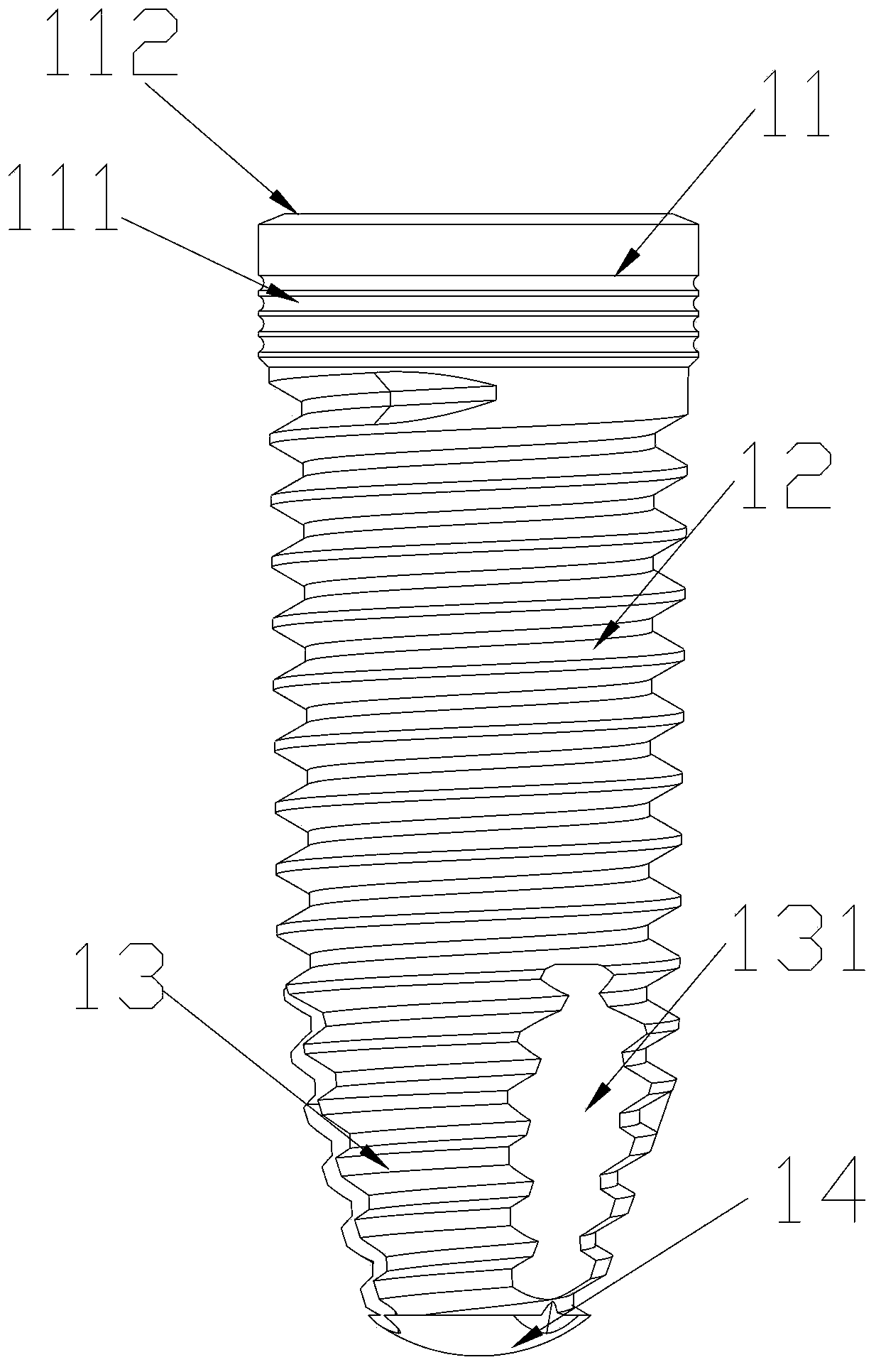

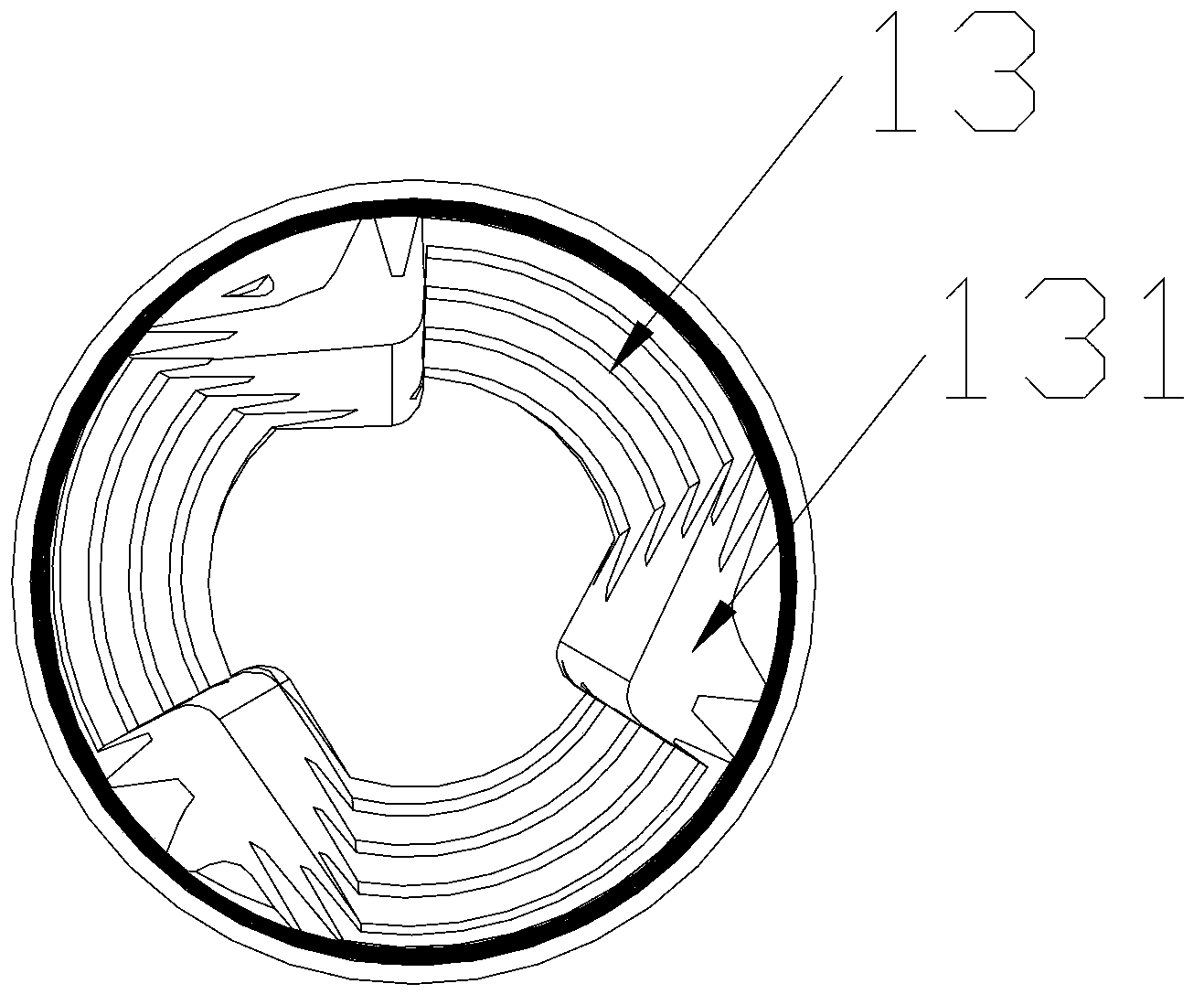

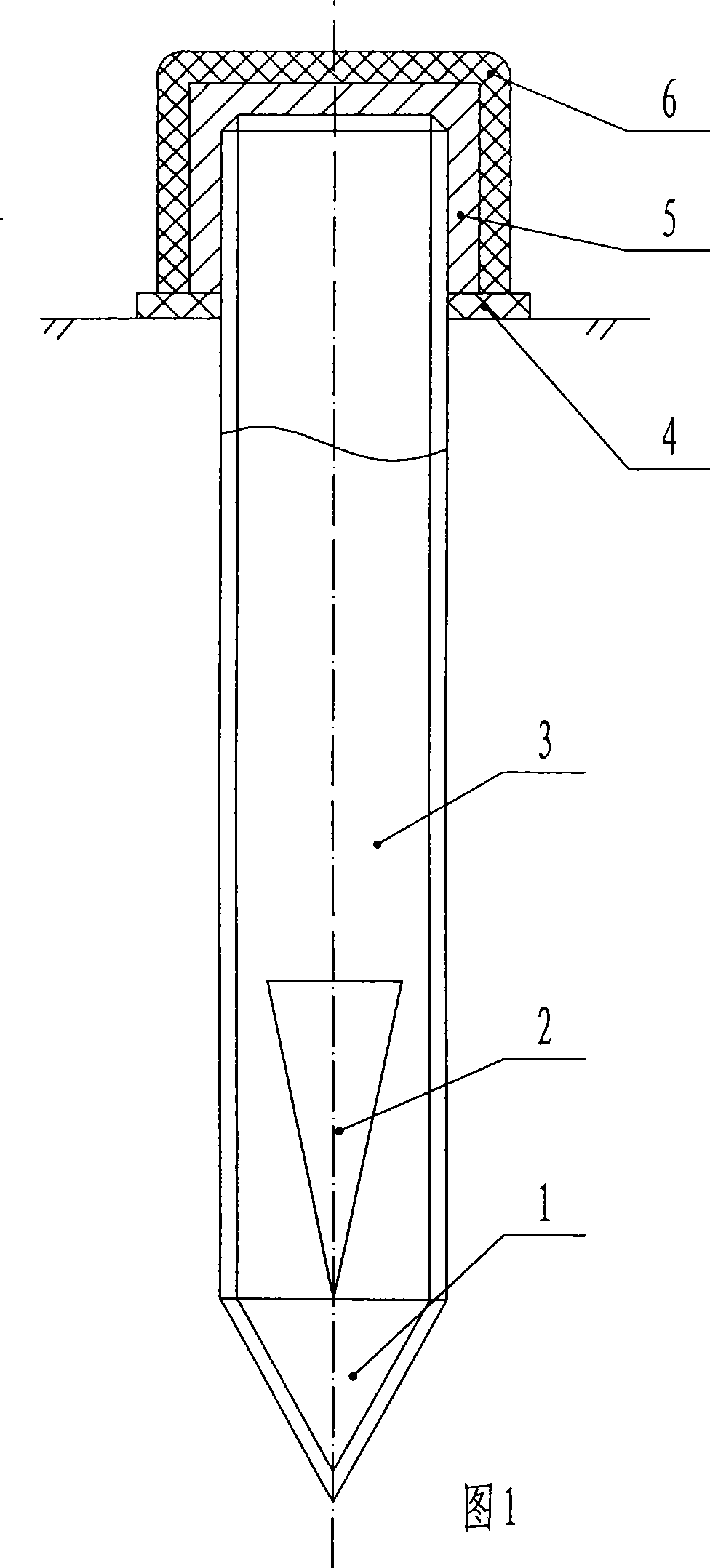

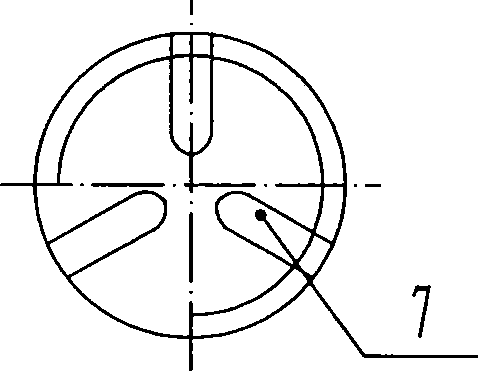

Self-tapping dental implant

InactiveCN104068941AImprove initial stabilityRealize the transfer functionDental implantsNeck partsDental implant

The invention provides a self-tapping dental implant. The self-tapping dental implant comprises a body, wherein the body is successively provided with a neck part, a body part, a root and a bottom from top to bottom in an adjoining manner; the neck part is a cylinder; the outer surface of the neck part is provided with a four-ring circular groove; the body part is a first tapered thread section; the root is a second tapered thread section; the thread tapers of the first tapered thread section and the second tapered thread section are different; three slant self-tapping cutting grooves are uniformly distributed in the periphery of the outer surface of the root; the bottom is a sphere; an open inner cavity is vertically formed in the radial middle part of the body; the inner cavity is successively provided with reverse tapered bores, regular polygon bores, cylindrical bores and inner threaded bores from top to bottom in an adjoining manner; the diameter of each cylindrical bore is the same as that of an inscribed circle of each regular polygon bore. The self-tapping dental implant has the function of platform transferring; due to the design of double tapers and arrangement of cutting grooves, implanting operation can be performed more easily, the initial stability of tooth implantation is improved, and the bone loss is reduced to the maximum extent. The matching of inner conical surfaces and the base station achieves the sealing effect to prevent micro leakage.

Owner:广东健齿生物科技有限公司

Positioning guiding device and positioning method thereof for acetabulum reaming and acetabular cup prosthesis implantation

ActiveUS20190380720A1Simple structureConveniently preparedJoint implantsComputer-aided planning/modellingProsthesis ImplantationCotyloid Cavity

The present invention has a simple structure which is convenient in preparation and easy to use. Moreover, in combination with three-dimensional preoperative analysis and rapid molding technology, the present invention has a high customized precision and clinical applicability, and is cost-effective. Based on the three-dimensional preoperative analysis and 3d printing model, the problems of high technical difficulty and cost of the customized accurate implantation of acetabular cup prosthesis in the total hip arthroplasty can be effectively solved, so that the learning curve of operator can be shortened. The present invention can realize the customized accurate implantation of acetabular cup prosthesis without fitting the positioning guiding module with the articular surface area, so that the assisted positioning and assisted reaming depth determination are realized without removing the guiding module when the acetabulum is being reamed, thus the accuracy of the assisted positioning can be guaranteed.

Owner:THE FIRST AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

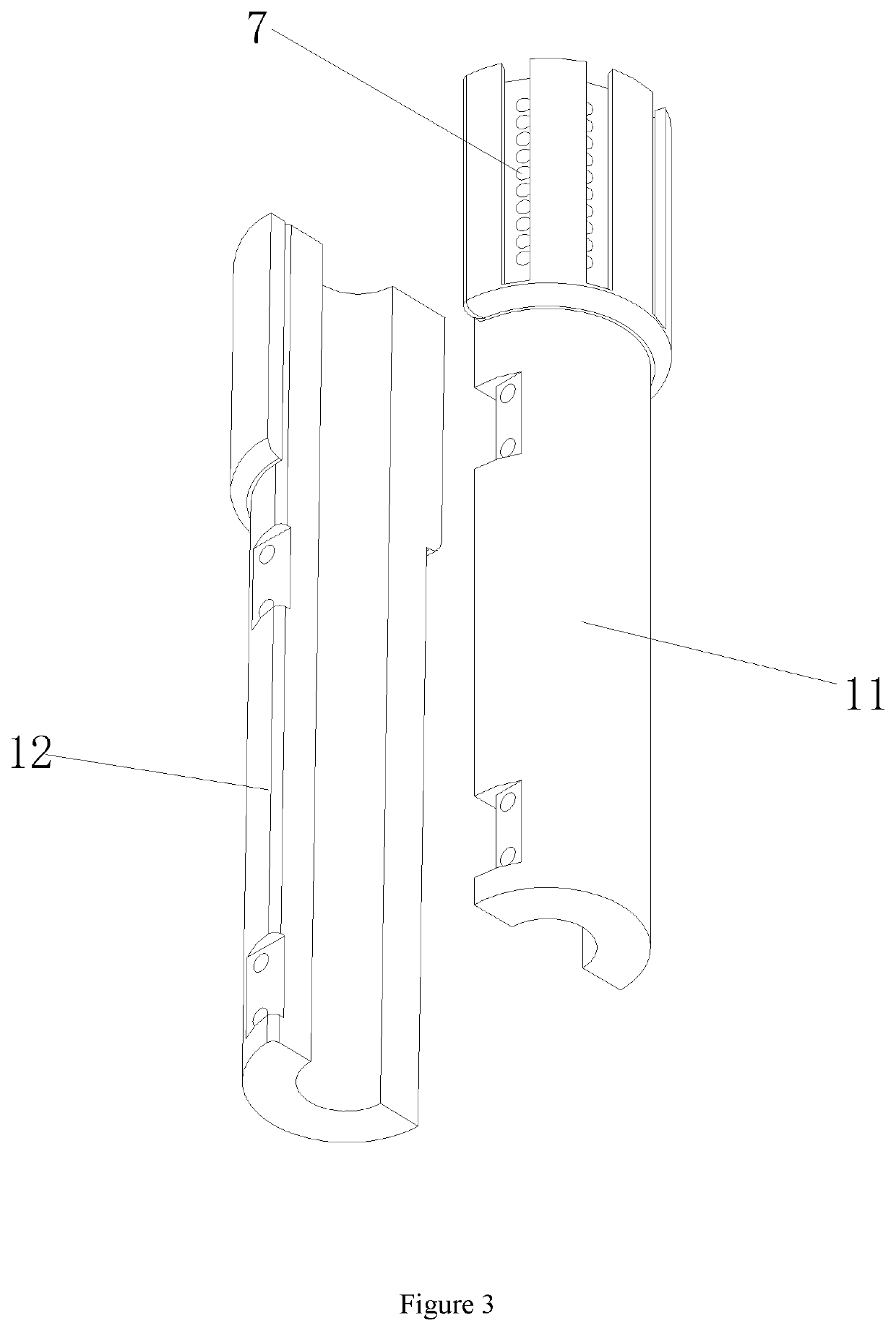

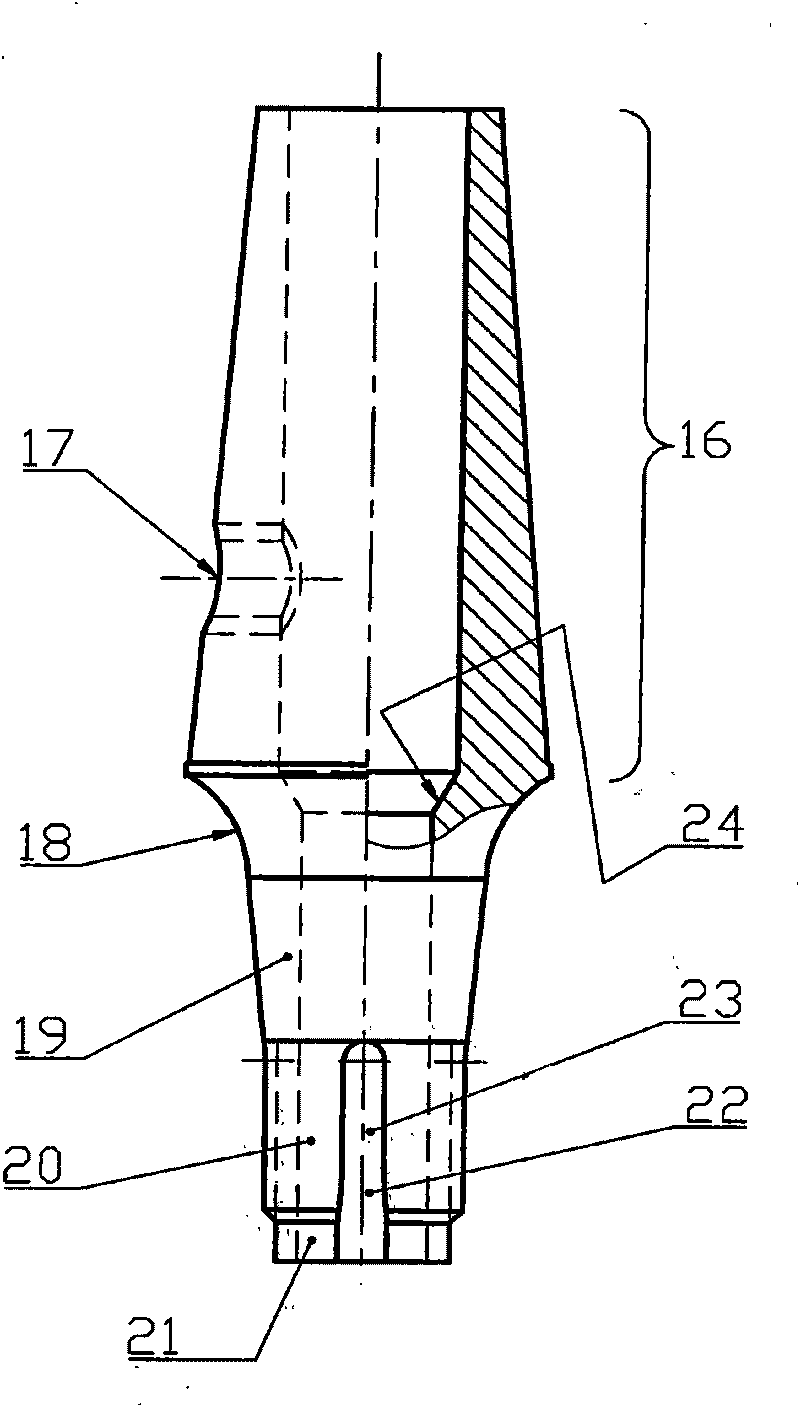

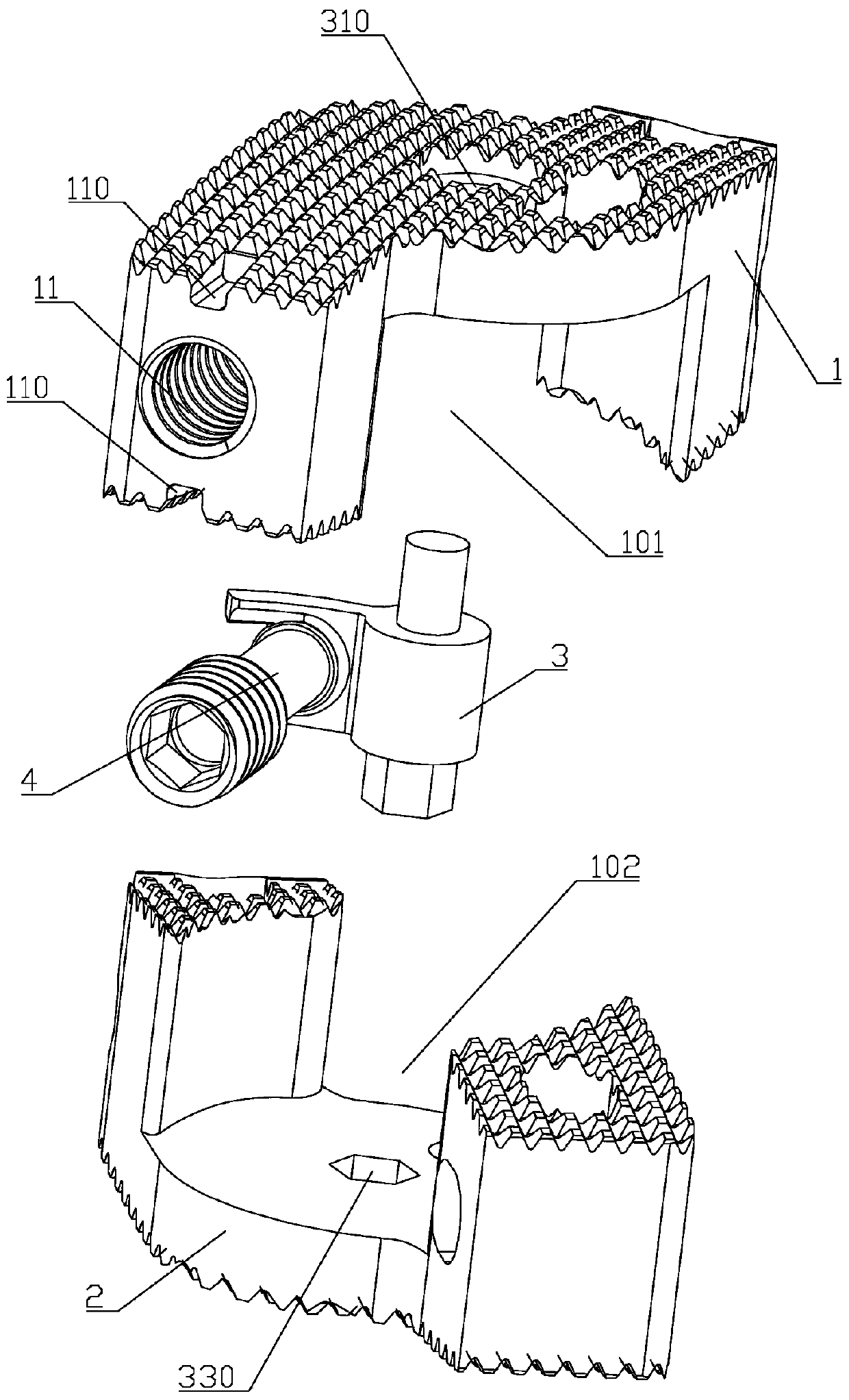

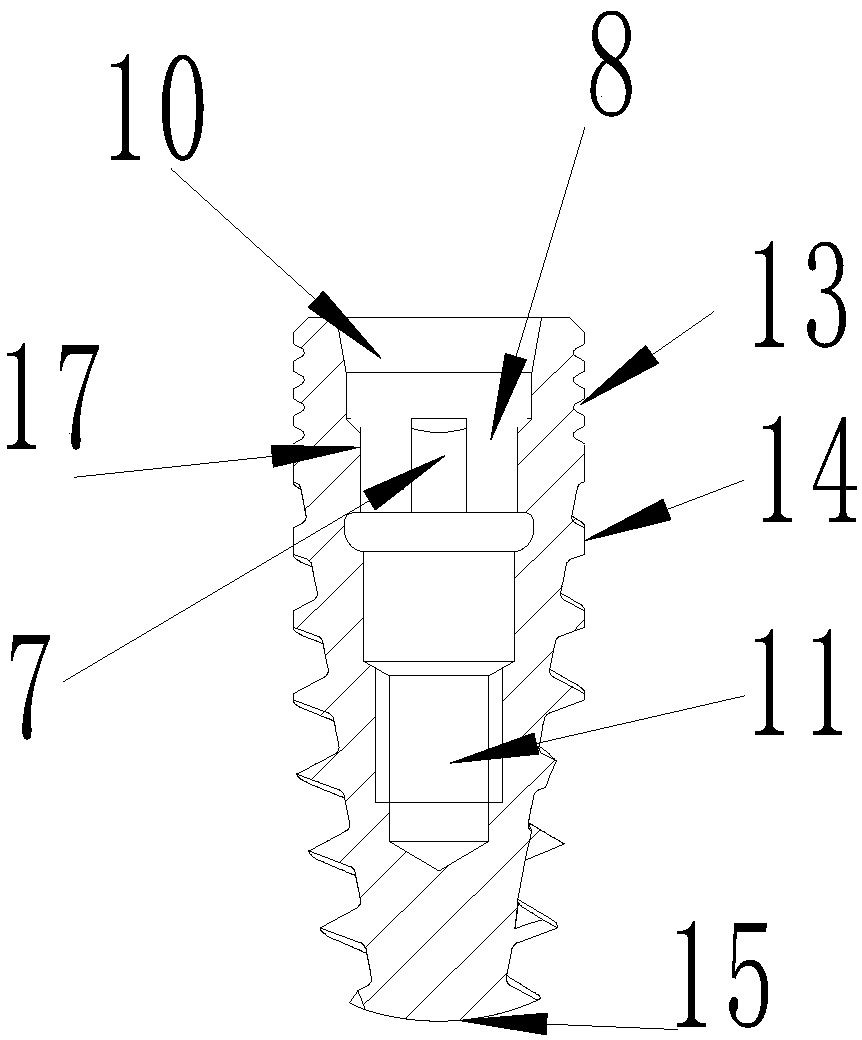

Two-section implant with spontaneous expansion function

InactiveCN104055590AImprove initial stabilityIncrease success rateDental implantsMissed toothTooth Supporting Structures

The invention discloses a two-section implant with a spontaneous expansion function. The two-section implant is applied to restoration of teeth in dental implanting surgeries. The two-section implant comprises an implant body, an abutment, a connecting screw and an expansion screw, wherein the implant body is connected with the abutment through the connecting screw and is provided with an opening and a notch groove; the expansion screw is screwed into the implant body from the opening, and a wedged slope is utilized for promoting the expansion of the notch groove to generate a tensile force so as to make fastened. The expansion screw with a thread and a taper is screwed into the implant body, and the wedged slope is utilized for promoting the expansion of the notch groove so as to generate the tensile force, so that a fastening effect is achieved, the early-stage stability of the dental implant is improved, and a missing tooth can be restored immediately; and when the appearance of the implant is in the shape of an imitation human tooth root, the damage on bones of patients can be more minimized to a greatest degree on the premise of ensuring the early-stage stability.

Owner:广东健齿生物科技有限公司

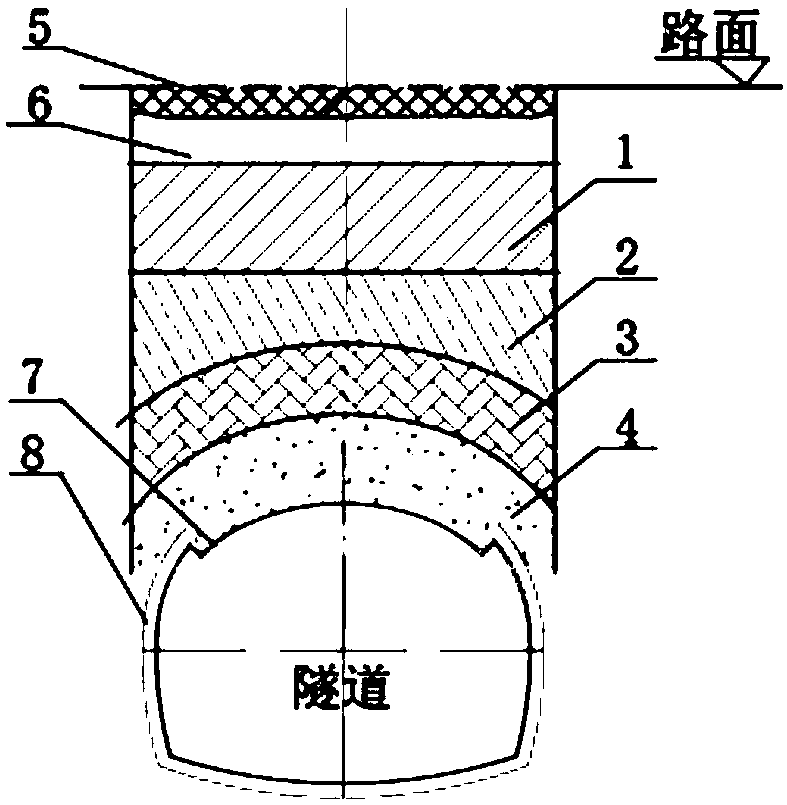

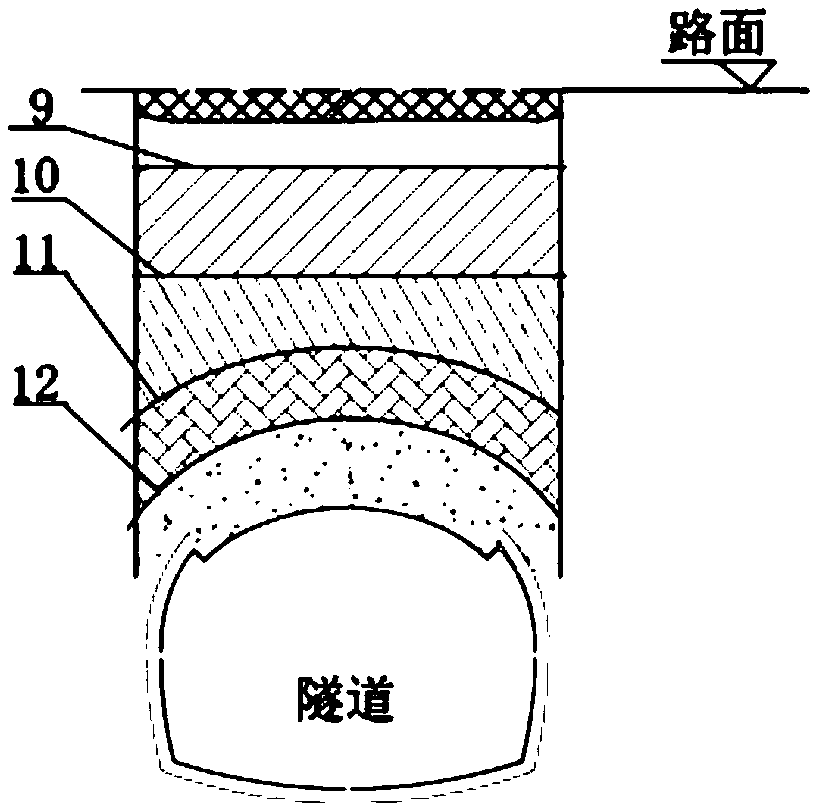

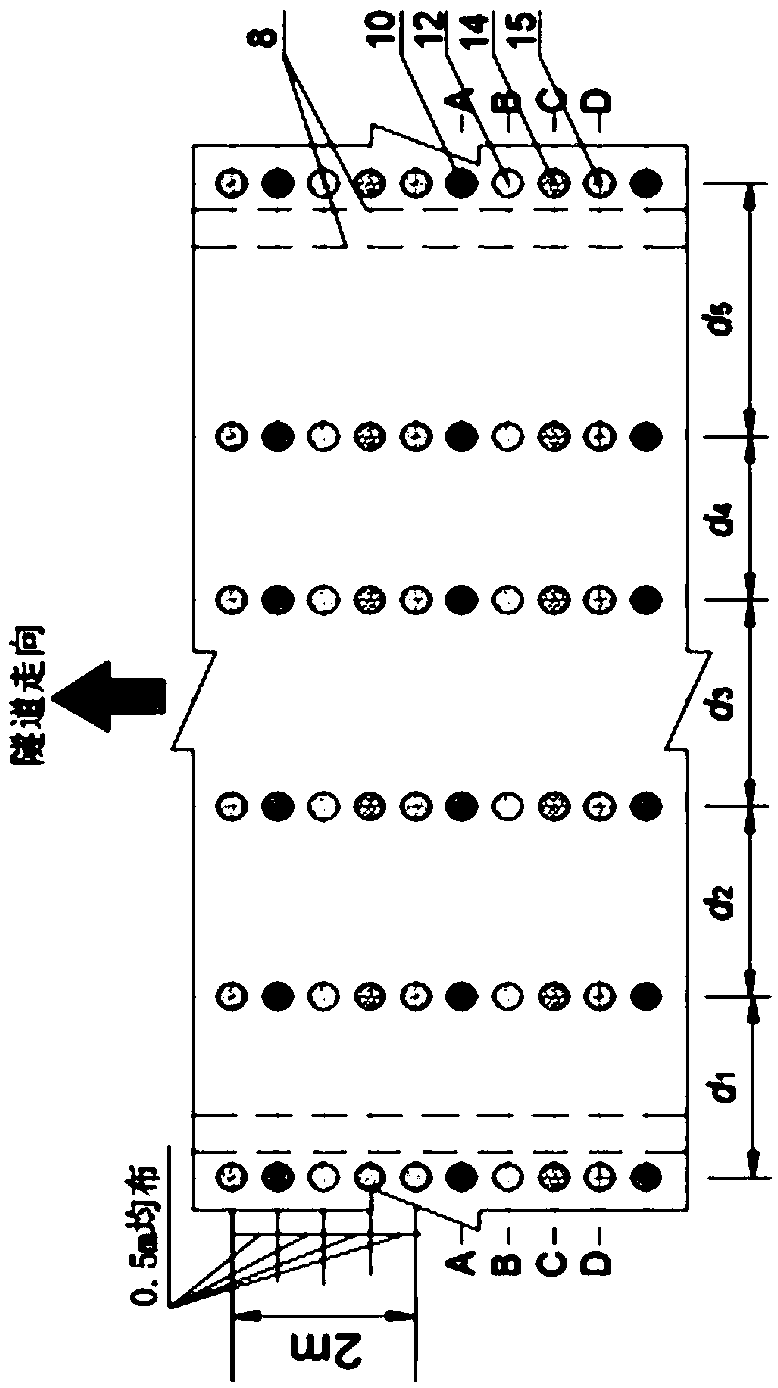

Layered and sequential grouting reinforcement treatment method for sunk vault of urban tunnel

ActiveCN108843345APrevent leakageGuaranteed diffusionUnderground chambersTunnel liningGeomorphologySlurry

The invention discloses a layered and sequential grouting reinforcement treatment method for the sunk vault of an urban tunnel. Through gaps between various pipelines under the ground, drilling is carried out on the ground in the range of a sunk area of the tunnel; through the drilling depths and the grouting-stop depths in holes in different positions, grouting is carried out in surrounding rockbelow the grouting-stop depths, specifically, the surrounding rock from the vault of the tunnel to the ground is divided into a shallow slurry-blocking layer, an intermediate reinforcement layer, a vault reinforcement layer and a vault grouting-stop layer, and grouting is carried out layer by layer in the sequence of the shallow slurry-blocking layer, the vault grouting-stop layer, the vault reinforcement layer and the intermediate reinforcement layer under different controllable slurry initial setting time and final grouting pressure, and overall system reinforcement of the upper formation ofthe tunnel is achieved.

Owner:SHANDONG UNIV

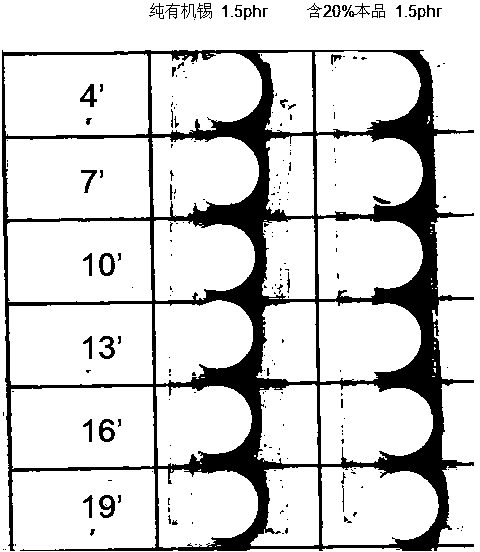

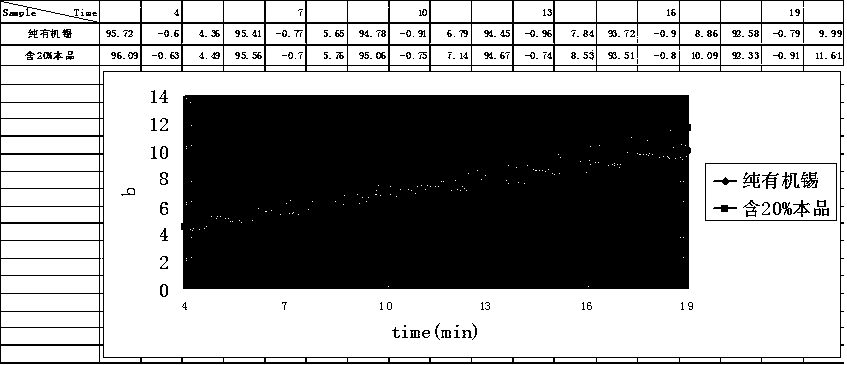

Hydrotalcite-tin maleate composite environmental protection stabilizer for PVC, and preparation method thereof

InactiveCN105295250APlay a role in thermal stabilityImprove heat resistancePolyesterPhosphorous acid

The present invention provides a hydrotalcite-tin maleate composite environmental protection stabilizer for PVC, wherein the hydrotalcite-tin maleate composite environmental protection stabilizer is prepared from the following raw materials by weight: 20-30 parts of modified magnesium aluminum hydrotalcite, 10-12 parts of tin maleate, 6-9 parts of lanthanum salicylate, 1-3 parts of triethyl phosphite, 3-6 parts of barium stearate, 2-4 parts of epoxidized soybean oil, 10-13 parts of poly(1,2-propylene glycol adipate), 2-3 parts of beta-diketone, 5-6 parts of isomaltitol, 2-3 parts of 2,4,6-tris(2'n-butoxyphenyl)-1,3,5-triazine, 1-3 parts of oxidized polyethylene wax, and 10-12 parts of celestine powder. According to the present invention, the PVC stabilizer has characteristics of good thermal stability, good processing performance, environmental protection, no toxicity, low cost, good plasticity and balance torque reducing during the PVC processing process, and low cost.

Owner:HWASU

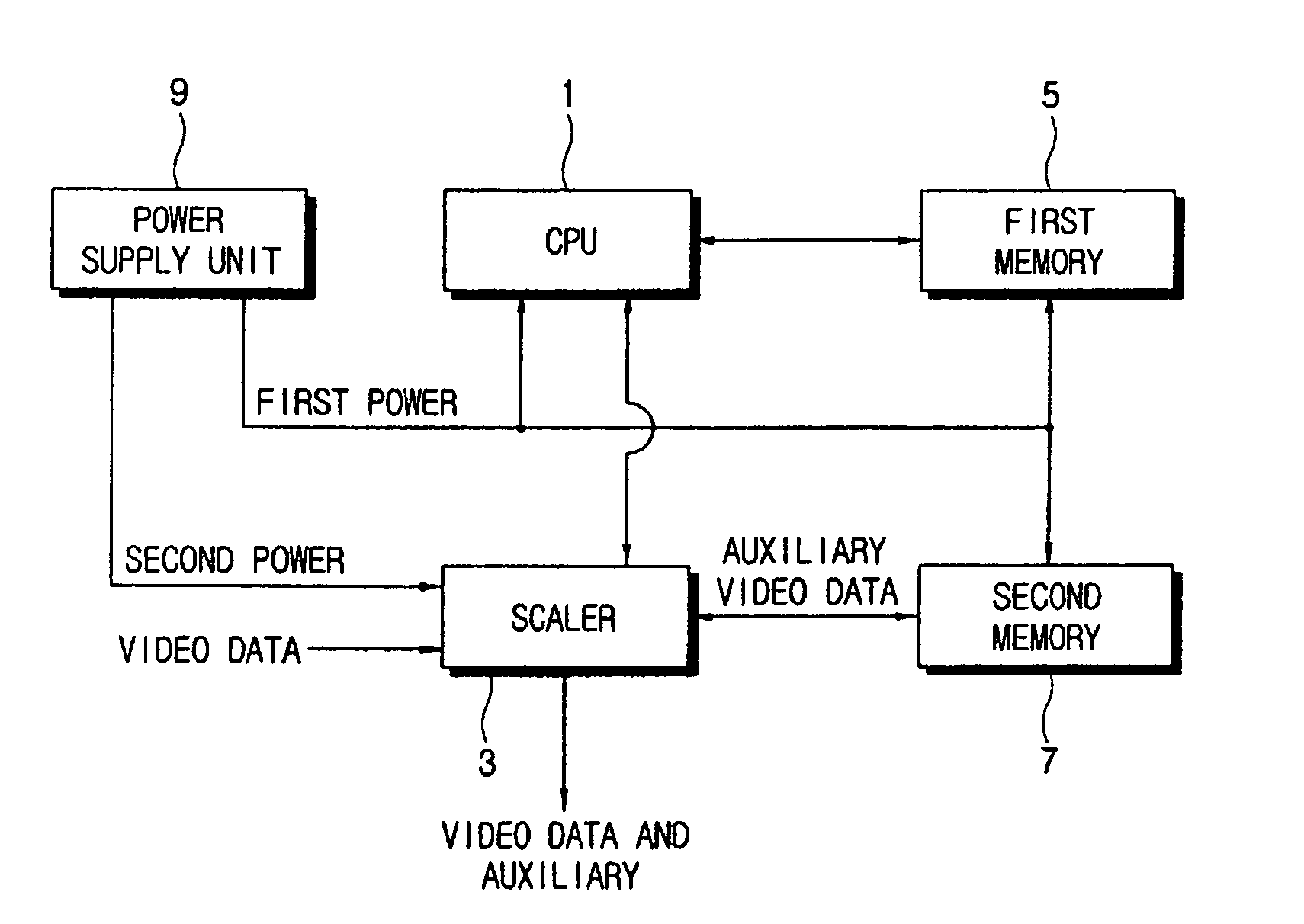

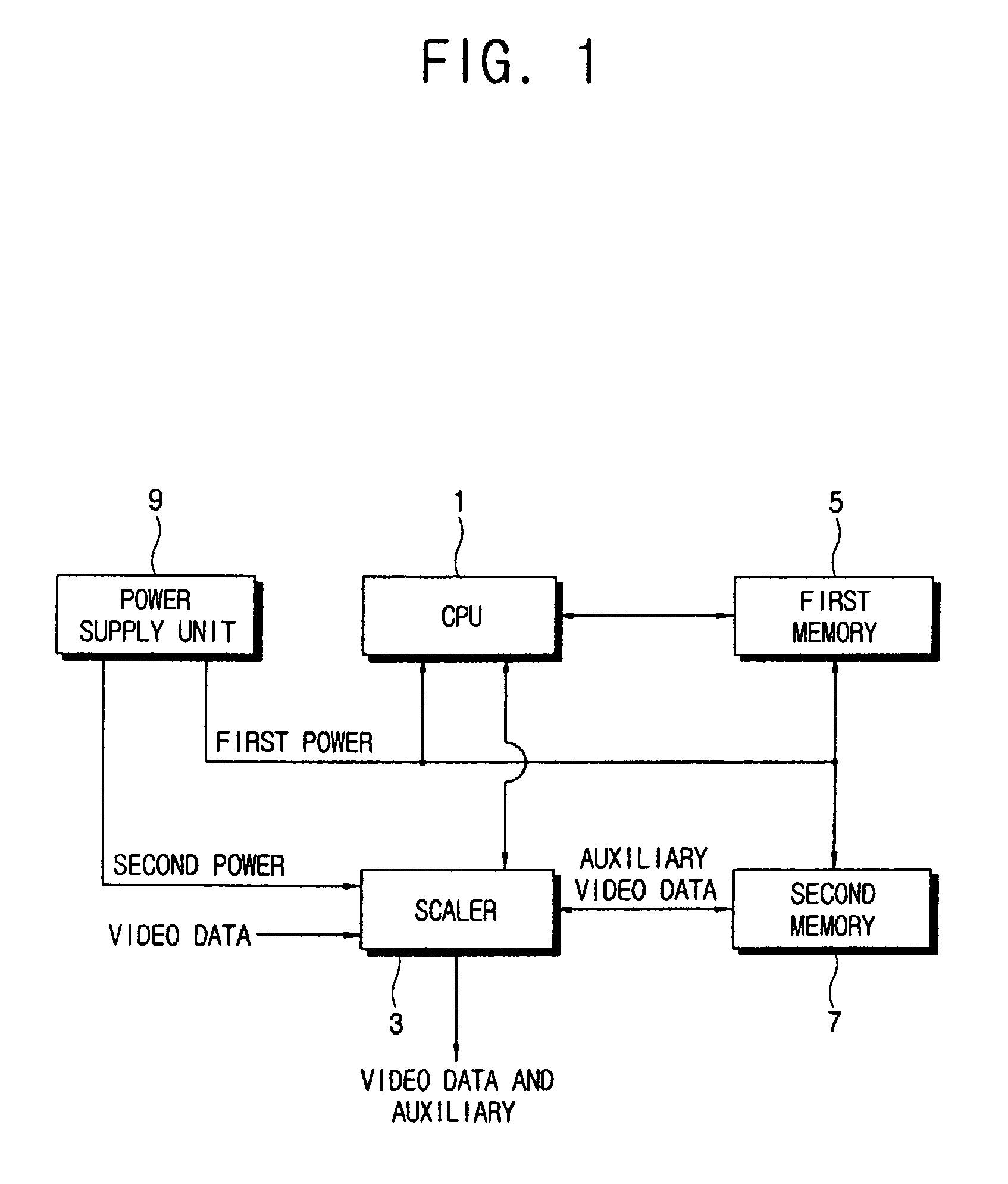

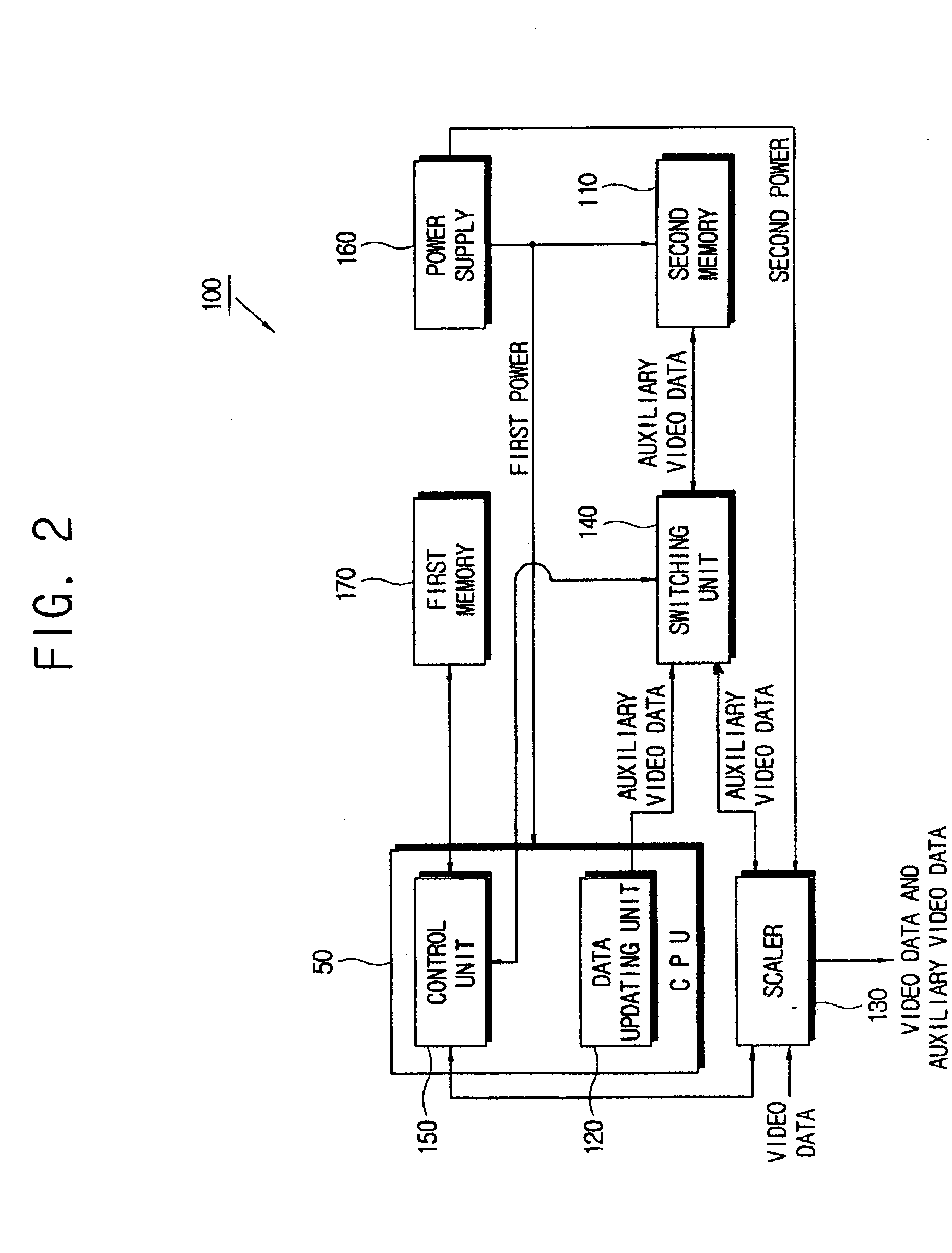

Video processing apparatus and data processing method

InactiveUS20060277587A1Improve loading speedImprove initial stabilityTelevision system detailsColor signal processing circuitsVideo processingProcessing element

A video processing apparatus includes a memory to store auxiliary video data therein; a data updating unit to transmit the auxiliary video data to be updated to the memory at a first transmission speed and update the auxiliary video data; a data processing unit having a second transmission speed which is slower than the first transmission speed, as a speed of data transmission to the memory, to read out the auxiliary video data stored in the memory and output it as overlapped with predetermined video data; a switching unit to connect either of the data updating unit or the data processing unit to the memory; and a control unit to control the switching unit so that the data updating unit is connected to the memory, when the data updating unit updates the auxiliary video data. Accordingly, the loading speed of the auxiliary video data can be enhanced.

Owner:SAMSUNG ELECTRONICS CO LTD

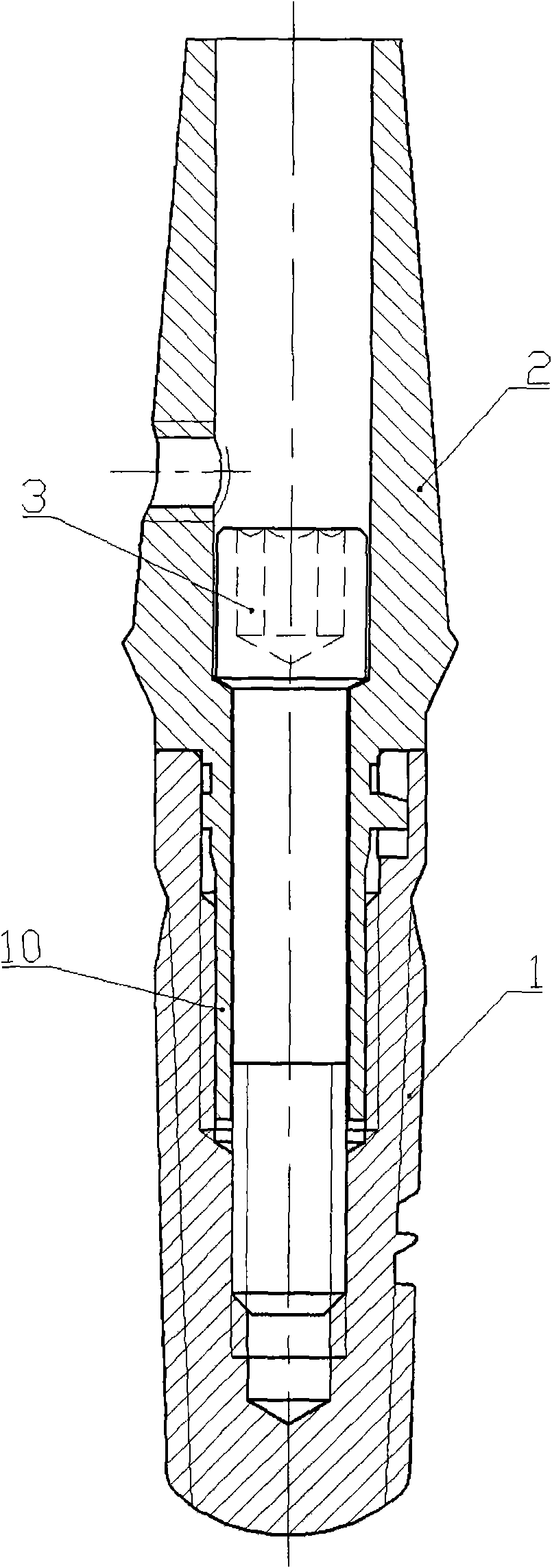

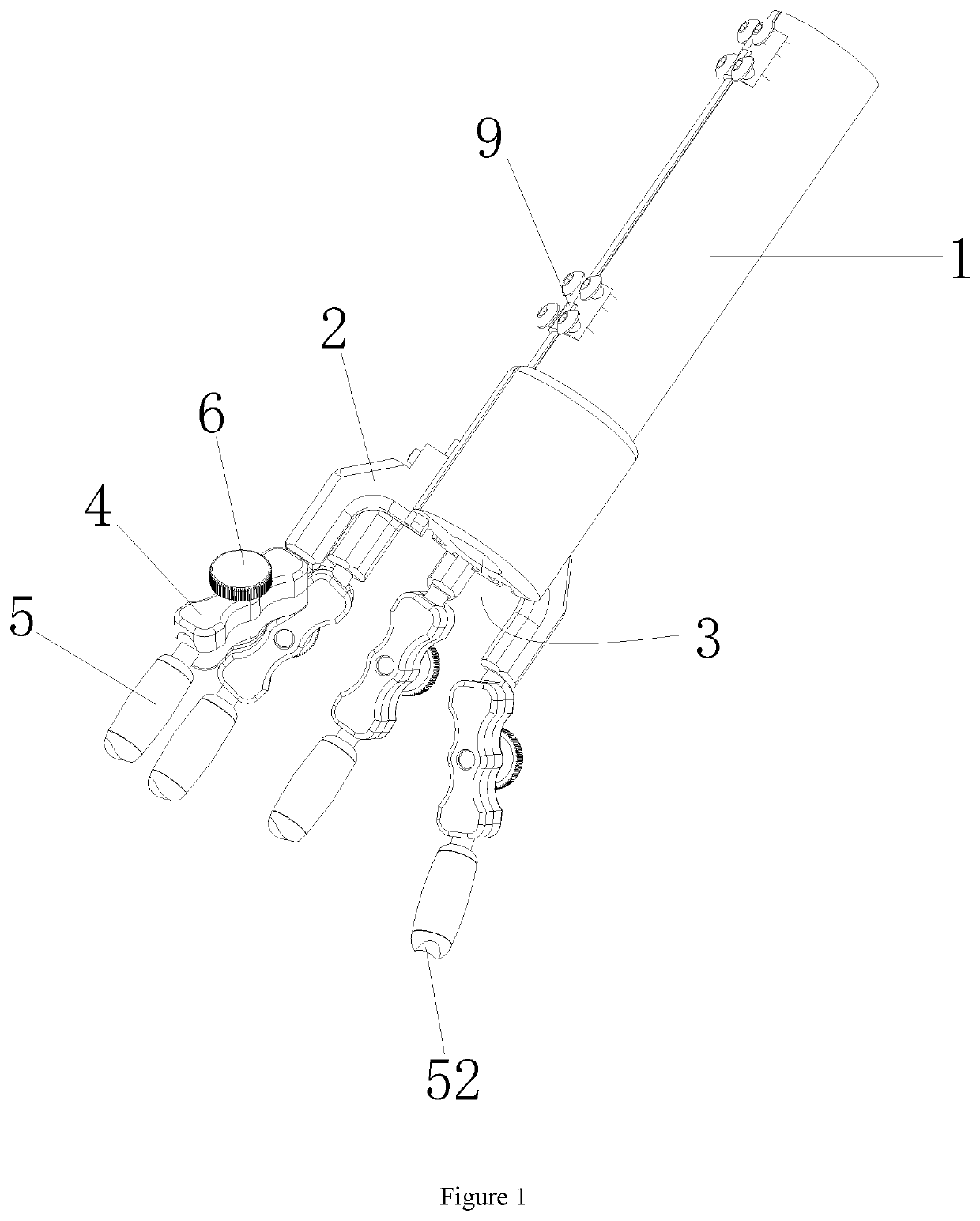

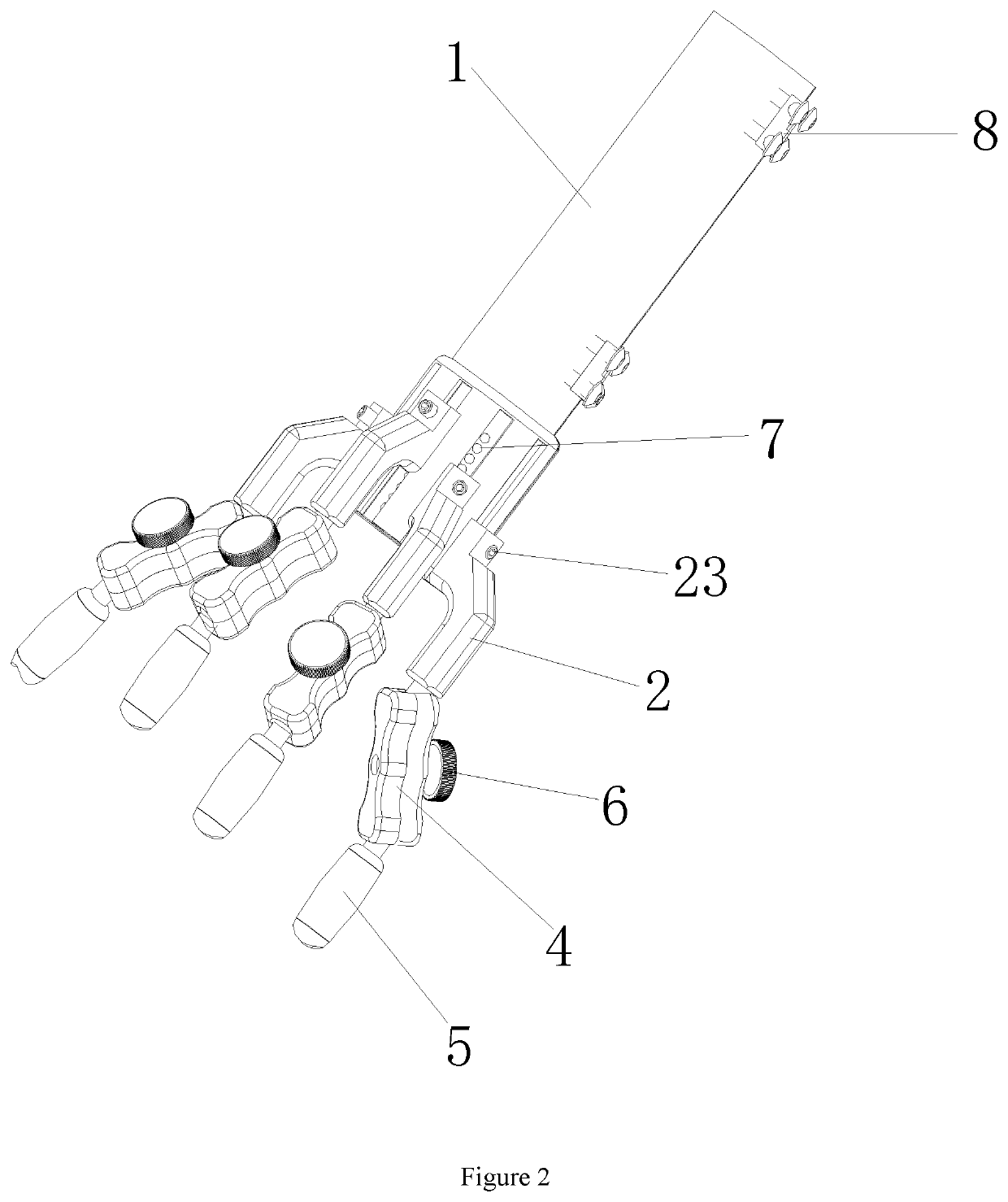

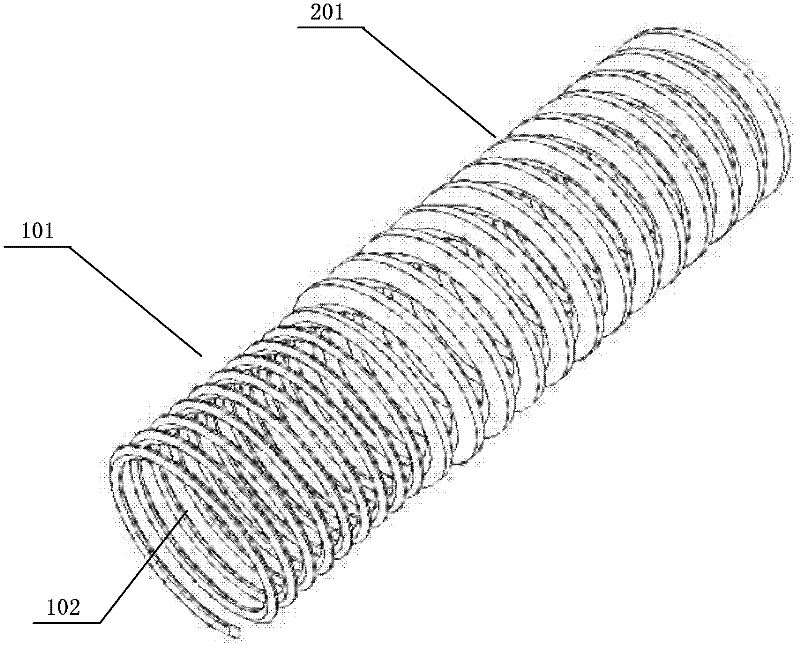

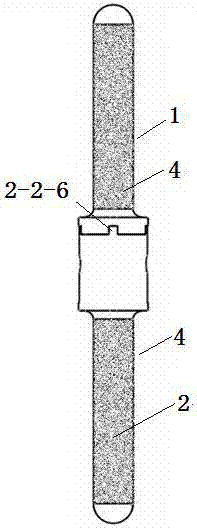

Oral implantation method for improving jaw bearing mode and screw implant

The invention discloses an oral implantation method for improving a jaw bearing mode and a screw implant. A spring-shaped screw with internal and external threads is made of pure titanium or titanium alloy with a diamond section; and the screw consists of a cortical bone section with fine threads and a cancellous bone section with coarse threads, and is arranged in a jaw spare hole in a compressed state, so that prestretching stress is formed in a bone tissue. A matrix is a cylindrical external thread main body, and is separated into a gum penetration section, a fine thread section, a coarse thread section and a guide section from top to bottom, and the center of the matrix is a composite cavity; external threads of the fine thread section and the coarse thread section are matched with internal threads of the cortical bone section and the cancellous bone section to form threaded connection; and the guide section is a one-third segment, and the bottom of the guide section is provided with a crossed groove. By the invention, the conventional integrated implant is optimized into a composite implant that the screw and the matrix are matched, the invention has the advantages of reliable connection and low possibility of loosening, the stress level of the alveolar ridge crest can be reduced, chewing impact can be relieved, and jaw damage and absorption can be effectively prevented.

Owner:BEIHANG UNIV

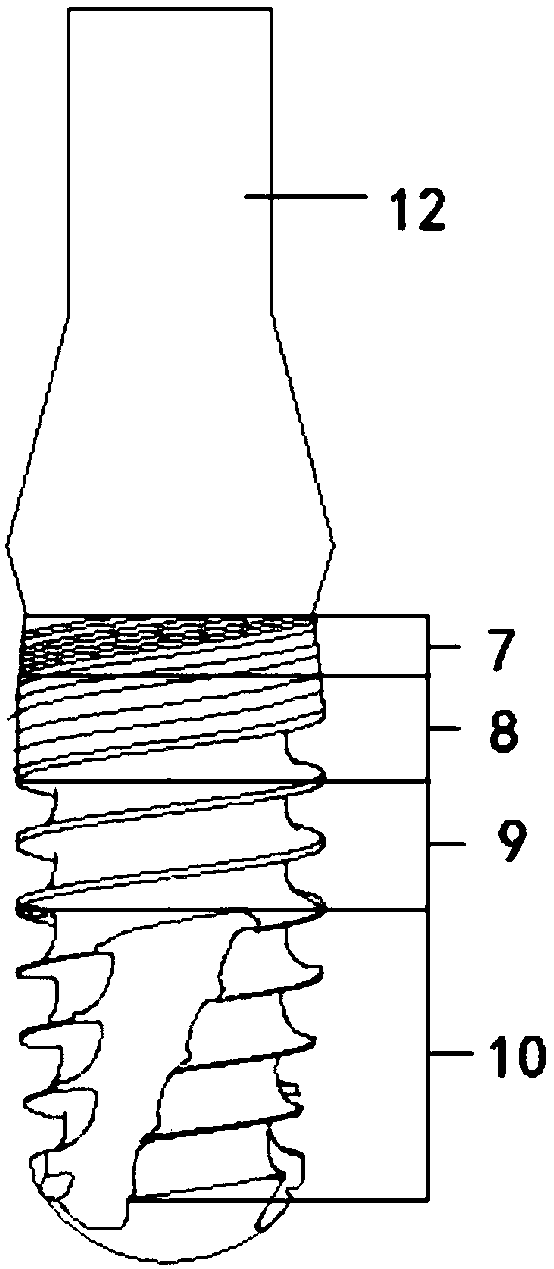

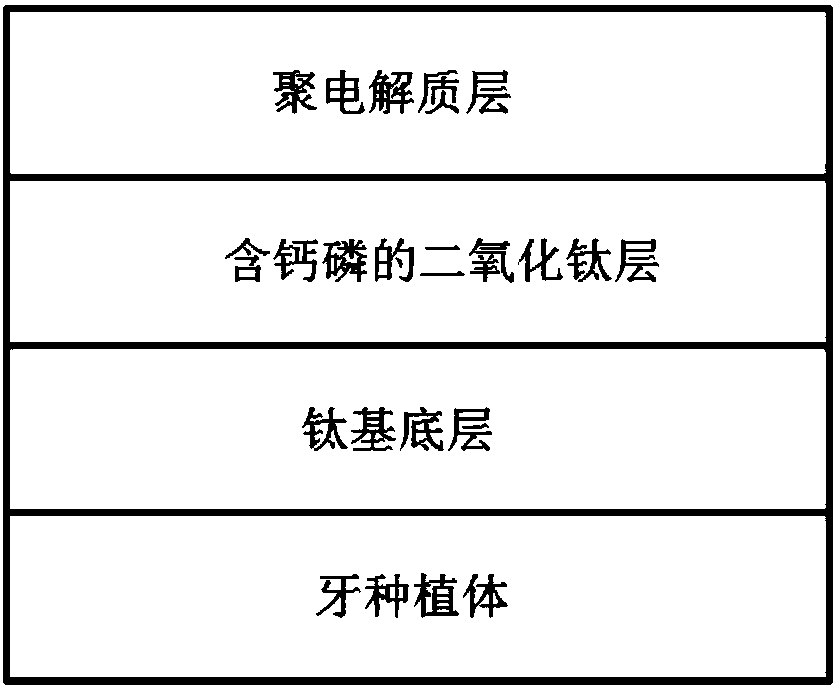

Implant with surface active coating

InactiveCN108144125AGood biocompatibilityIncrease free energyDental implantsSurface reaction electrolytic coatingBiomedical engineeringInitial stability

The invention discloses an implant with a surface active coating. Screw threads are arranged on an outer side wall of the implant, and are sequentially divided into a cortical bone decompression screwthread section, a cortical bone cutting screw thread section, a cancellous bone extruding screw thread section and a cancellous bone cutting screw thread section from top to bottom; screw pitches ofthe screw threads are increased from top to bottom; a self-tapping groove is formed in the cancellous bone cutting screw thread section; a screw thread is arranged in the implant; a titanium-based bottom layer is arranged on the surface of the implant; a titanium dioxide layer containing calcium phosphate is covered on the outer surface of the titanium-based bottom layer; a polyelectrolyte layer is covered on the outer surface of the titanium dioxide layer containing the calcium phosphate. According to the implant with the surface active coating provided by the invention, the implant is provided with the four different screw threads so as to produce different lateral pressures on a cortical bone and a cancellous bone when screwing into a jaw bone, so that the initial stability of the implant is facilitated, the superior initial stability is favorable for osseointegration, and the surface of the implant is endowed with a favorable antibacterial property through polylysine bacteriostasis.

Owner:DALIAN SANSHENG SCI & TECH DEV

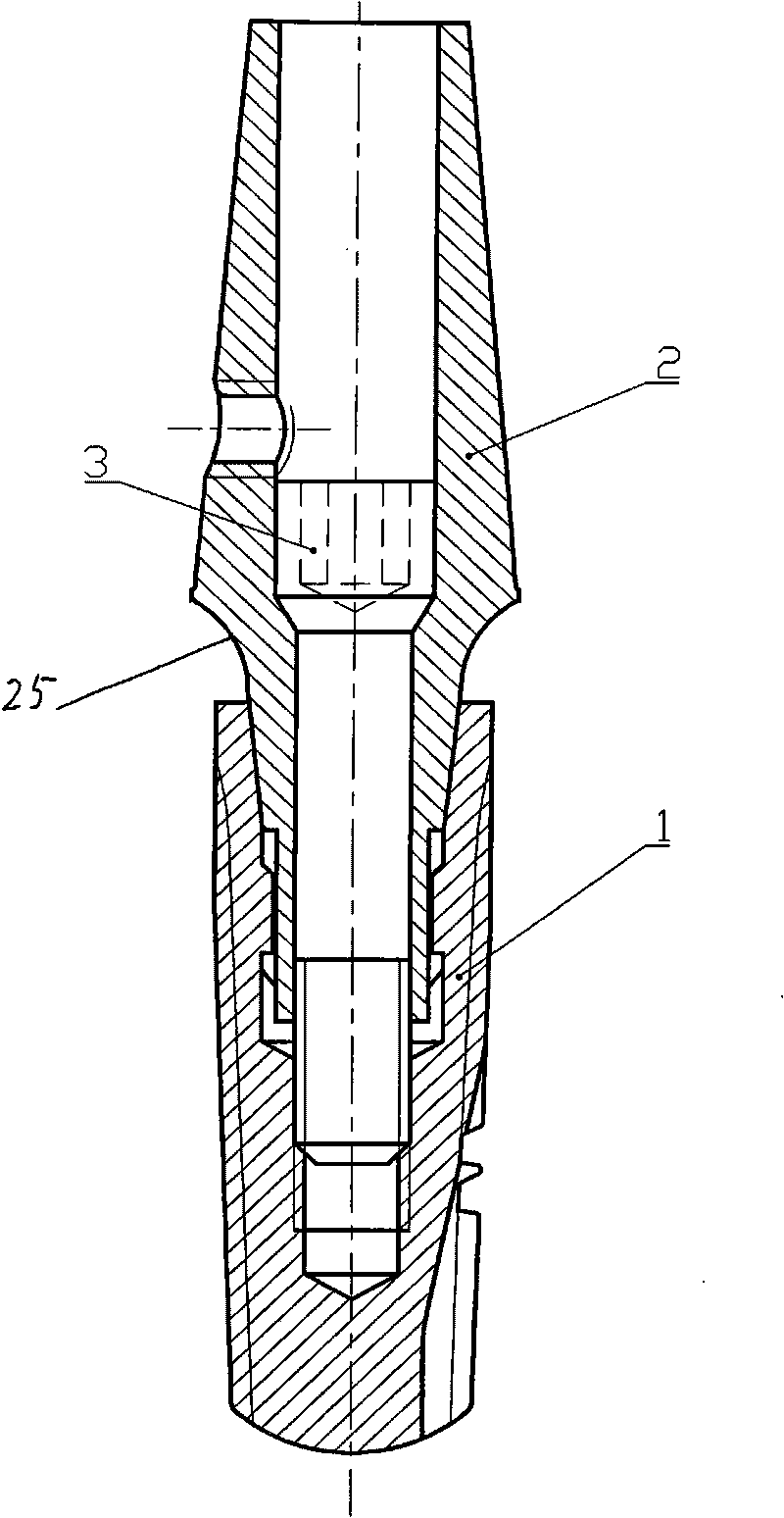

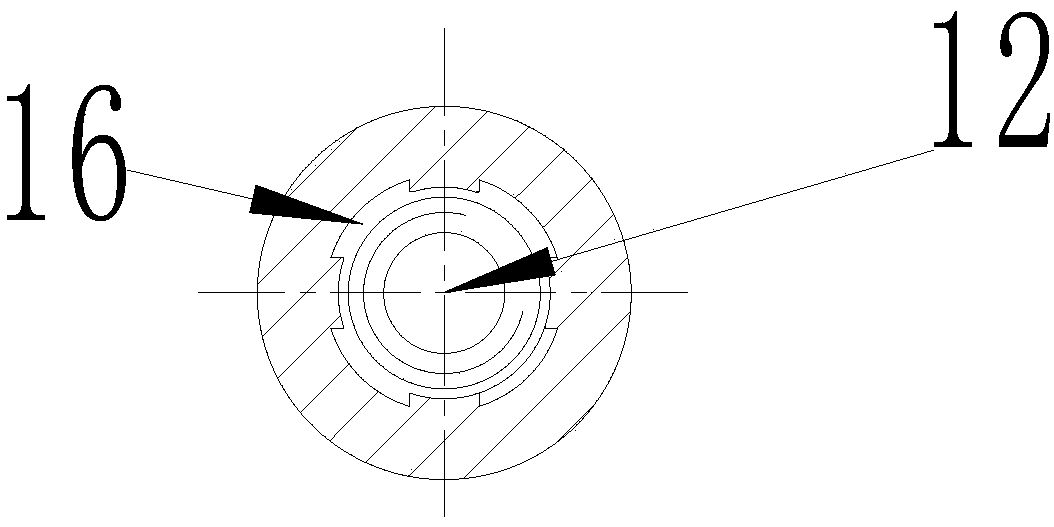

Oral implant with conical surface and rectangular key structure

InactiveCN101732097AEliminate frettingShorten operation timeDental implantsSurgical departmentBiomedical engineering

The invention relates to the field of dental repair technology, in particular to an oral implant with a conical surface and a rectangular key structure. The oral implant can be implanted in an alveolar bone in a surgery. The oral implant comprises an implant, and a base and a fastening bolt which are matched with the implant. The oral implant is characterized in that the implant consists of a cylindrical upper section part and a conical lower section part, wherein a conical hole is formed at the upper end of the interior of the implant, a cylindrical hole is formed at the middle section of the interior of the implant, a fastening screw hole is formed at the lower end of the interior of the implant, a cylindrical surface and the conical surface which are matched with the cylindrical hole and the conical hole are formed on the lower part of the base, and a key slot and a rectangular key which are matched with each other are formed on the cylindrical hole and the cylindrical surface respectively. The oral implant has the advantages of simple operation, short operation time, good initial stability after operation, good sealing property, high reliability, good base rotation resistance and platform conversion structure, bone absorption inhibition or removal and the like.

Owner:WEIHAI WEIGAO BIOTECH

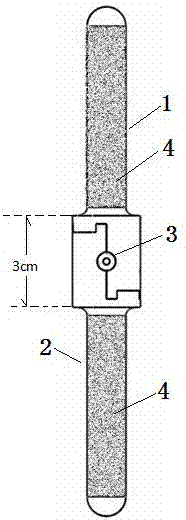

Artificial prosthesis of long bone diaphysis tenon and mortise structure

PendingCN107349032AImprove medium and long-term stabilityExtend your lifeFemurSkullNormal boneSurgical Manipulation

The invention relates to an artificial prosthesis of a long bone diaphysis tenon and mortise structure. A protruding face I and a rectangular protrusion I of a prosthesis proximal handle connecting part I are inserted into a strip-shaped groove II and a rectangular notch II of a prosthesis far-end handle connecting part II respectively, a protruding face II and a rectangular protrusion II of the prosthesis far-end handle connecting part are inserted into a strip-shaped groove I and a rectangular notch I of the prosthesis proximal handle connecting part I respectively, after a semicircular groove I of the prosthesis proximal handle connecting part I is in butt joint with a semicircular groove II of the prosthesis far-end handle connecting part II, a cylindrical counter bore is formed, tenon is inserted into the cylindrical counter bore formed in one end of the cylinder, and the tenon locks the connecting part I and the connecting part II together. Prosthesis fixation is firm and reliable, the operation is simple and convenient, the operation time is shortened, the operation effect and efficiency are improved, and operative complications are reduced. The artificial prosthesis can be widely applied to different defects of long bone diaphysis, the minimum osteotomy amount can reach 3.0 cm, and the maximum opportunity is provided for reserving normal bone tissue and joints as much as possible.

Owner:胡永成

Hydrotalcite composite environmental protection stabilizer for PVC, and preparation method thereof

InactiveCN105295242AImprove thermal stabilityPlay a role in thermal stabilityPhosphorous acidStearic acid

The present invention provides a hydrotalcite composite environmental protection stabilizer for PVC, wherein the hydrotalcite composite environmental protection stabilizer is prepared from the following raw materials by weight: 20-30 parts of modified magnesium aluminum hydrotalcite, 10-12 parts of octyl tin mercaptide, 6-9 parts of lanthanum laurate, 1-3 parts of triphenyl phosphite, 3-6 parts of zinc stearate, 2-4 parts of stearic acid, 2-4 parts of epoxidized soybean oil, 20-24 parts of diisononyl phthalate, 5-6 parts of carbitol, 2-3 parts of o-hydroxybenzophenone, and 10-15 parts of heavy calcium carbonate. According to the present invention, the PVC stabilizer has characteristics of good thermal stability, good processing performance, environmental protection, no toxicity, low cost, good plasticity and balance torque reducing during the PVC processing process, and low cost.

Owner:HWASU

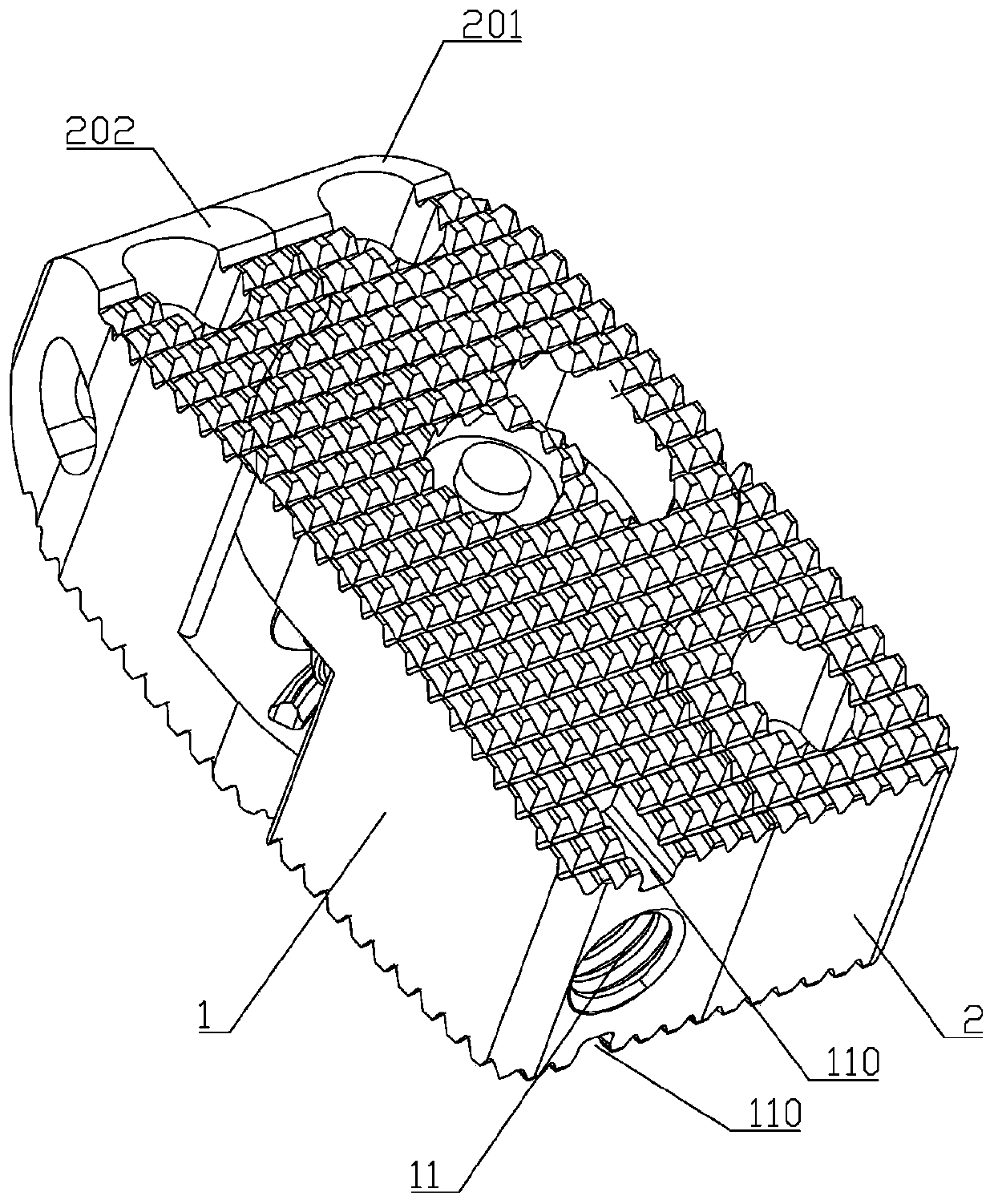

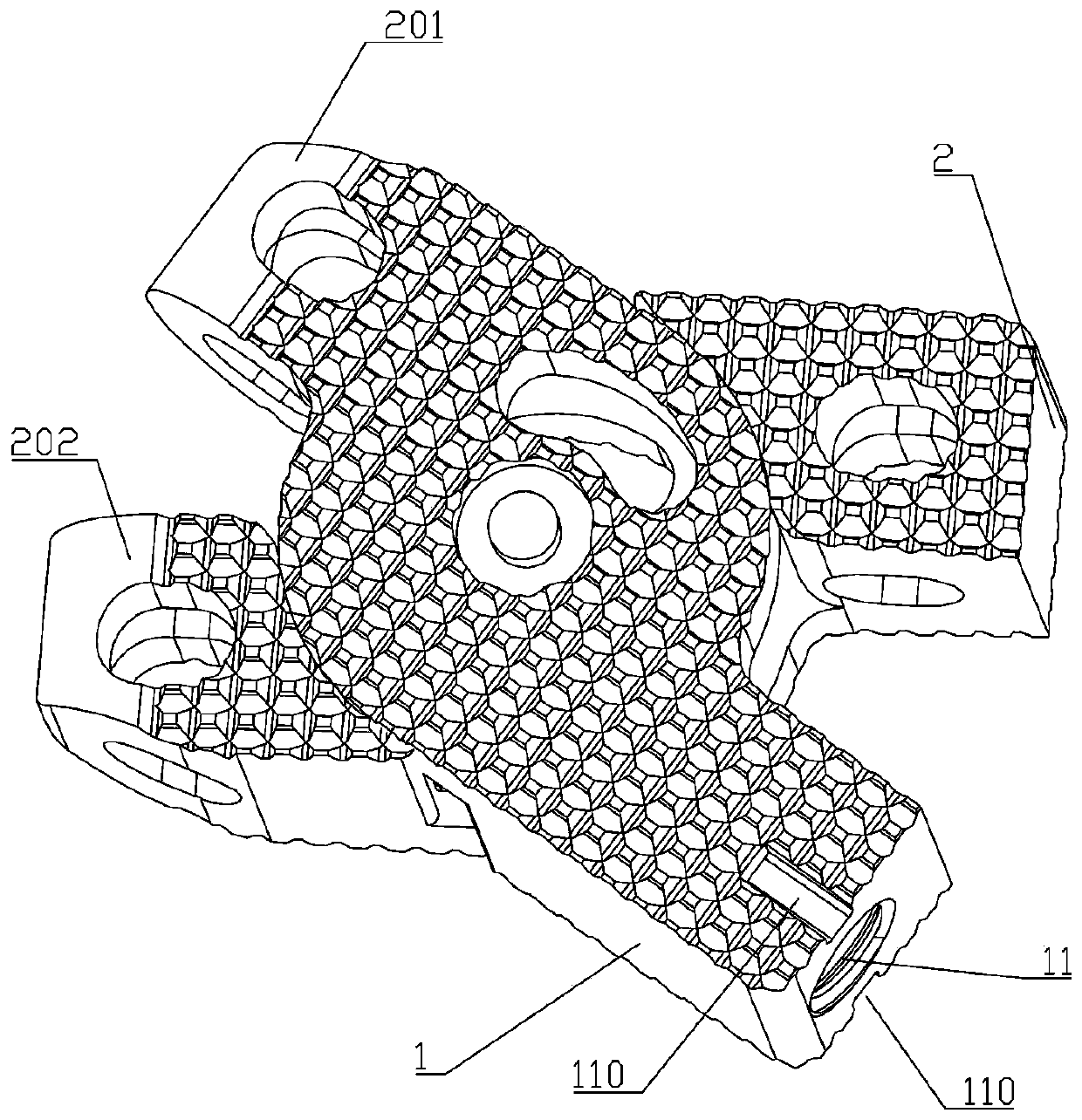

Rotary expansion type interbody fusion cage

ActiveCN110368146AReduce volumeThe implantation process is quick and easySpinal implantsSpinal cageEngineering

The invention belongs to the technical field of medical instruments and particularly relates to a rotary expansion type interbody fusion cage. The rotary expansion type interbody fusion cage comprisesan upper fusion cage body, a lower fusion cage body, a transmission body and a transmission screw, a first circular groove is formed in one end face, close to the lower fusion cage body, of the fusion cage, a second circular groove is formed in one end face, close to the upper fusion cage body, of the fusion cage, the upper fusion cage body and the lower fusion cage body are hinged in the shape of 'X' through the transmission body, the first circular groove and the second circular groove are combined to form a cavity for accommodating the transmission body and the transmission screw, the lower fusion cage body is fixedly connected with the lower end of the transmission body, the upper fusion cage body is rotatably connected with the upper end of the transmission body, a threaded hole matched with the transmission screw is formed in the upper fusion cage body, and the free end of the transmission screw is clamped onto the transmission body. The rotary expansion type interbody fusion cage has the advantage that problems of great trauma, serious pain and long recovery time after implantation of the single fusion cage, or complicated operation, long operation time and insufficient stability after implantation of multiple fusion cages in the prior art are solved.

Owner:ZHEJIANG CANWELL MEDICAL DEVICES CO LTD

Water soluble organic auxiliary heat stabilizer

InactiveCN103483720AImprove post-operation limitationsIncrease productivityZinc organic compoundsAlcoholStaging operation

The invention discloses a water soluble organic auxiliary heat stabilizer which is characterized in that a mercapto alcohol and a metal zinc oxide are used for synthesis to generate an organic metal complex as the stabilizer; the specific reaction steps are as follows: taking equivalent mercapto alcohol and zinc oxide into reaction at a temperature ranging from 60 to 120 DEG C for 120 minutes, washing by using a 5wt% sorbitol solution when the reactants are colorless and transparent, and filtering to obtain the organic metal complex as the stabilizer. The organic metal complex provided by the invention can be directly used as a PVC (Poly Vinyl Chloride) processing heat stabilizer, and meanwhile as an auxiliary heat stabilizer to improve the primary stability in the PVC processing course, and therefore, the later-stage operation limitation of the mainstream technology is improved and the production efficiency and use efficiency are greatly improved.

Owner:MATRIX HUAIAN CHEM CO LTD

Implant with bone absorption resistance

ActiveCN108742900ALess squeezeAchieving a coronal closed designDental implantsStress concentrationBone tissue

The invention discloses an implant with bone absorption resistance. The implant comprises a body and an implantation hole. The implantation hole is formed inside the body, a cone is positioned on thelower side of a straight neck, the straight neck is provided with a neck ring, the neck ring is provided with first threads, a spiral structure is arranged on a surface of the cone, second threads arearranged on the spiral structure, cutting grooves are formed in lower structures of the spiral structure, a root is arranged at the bottom of the cone, and a third thread is arranged on a surface ofthe root; the implantation hole comprises a first conical body implantation hole, a second conical body implantation hole, a padlock component hole and a fastening threaded hole which are sequentiallyformed in positions from the straight neck to the root, the padlock component hole is formed in four clamp teeth which are uniformly distributed, and a circular connector is arranged inside the clampteeth. The implant has the advantages that injury on surrounding tissues can be reduced, and stress concentration of the root and damage to bone tissues during implantation can be reduced.

Owner:JIANGSU TRAUSIM MEDICAL INSTR +1

Hydrotalcite and lanthanum ricinoleate composite environmental-protection stabilizer for PVC and preparation method thereof

The invention provides a hydrotalcite and lanthanum ricinoleate composite environmental-protection stabilizer for PVC. The hydrotalcite and lanthanum ricinoleate composite environmental-protection stabilizer for PVC is prepared from the following raw materials (by weight): 20-30 parts of modified Mg-Al hydrotalcite, 10-12 parts of tin dilaurate, 6-9 parts of lanthanum ricinoleate, 1-3 parts of triethyl phosphate, 3-6 parts of barium stearate, 2-4 parts of epoxidized soybean oil, 10-13 parts of propanediol sebacate polyester, 5-6 parts of zinc stearate, 2-4 parts of 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, 2-4 parts of ethylene bis-stearamide and 10-14 parts of potassium feldspar powder. The PVC stabilizer of the invention has good heat stability and processability, is environmentally-friendly, nontoxic and low-cost, has good plasticity during processing of PVC, can reduce balance torque and has good transparency.

Owner:HWASU

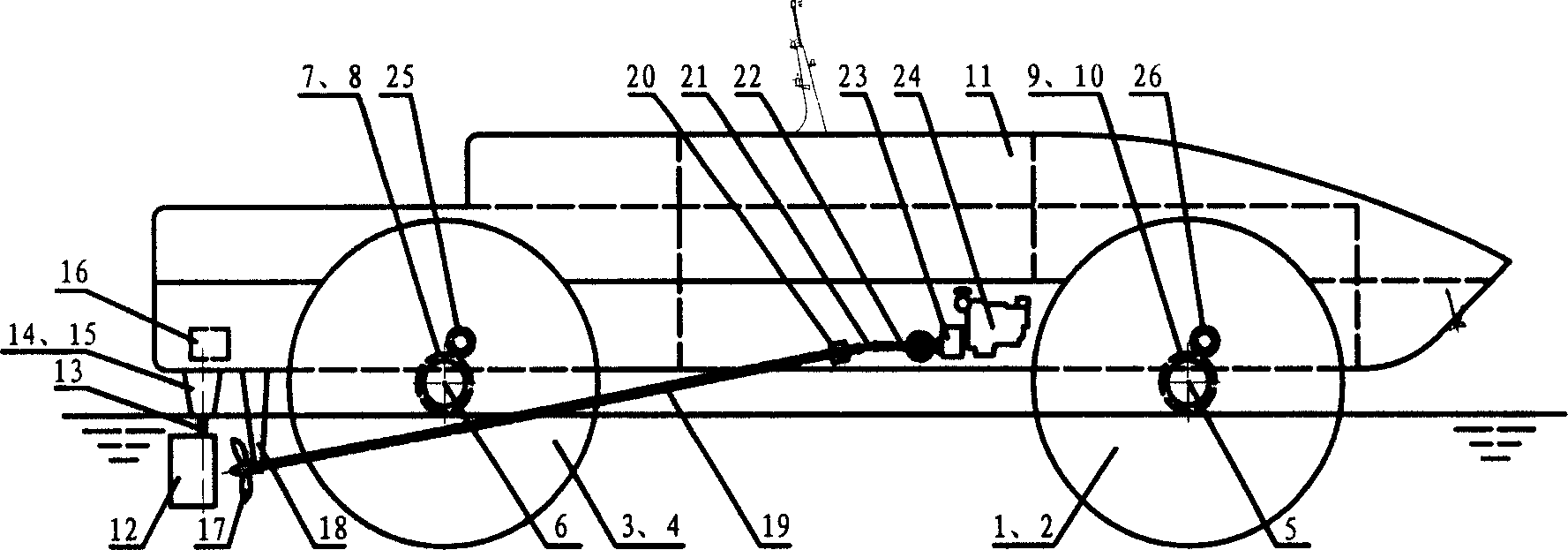

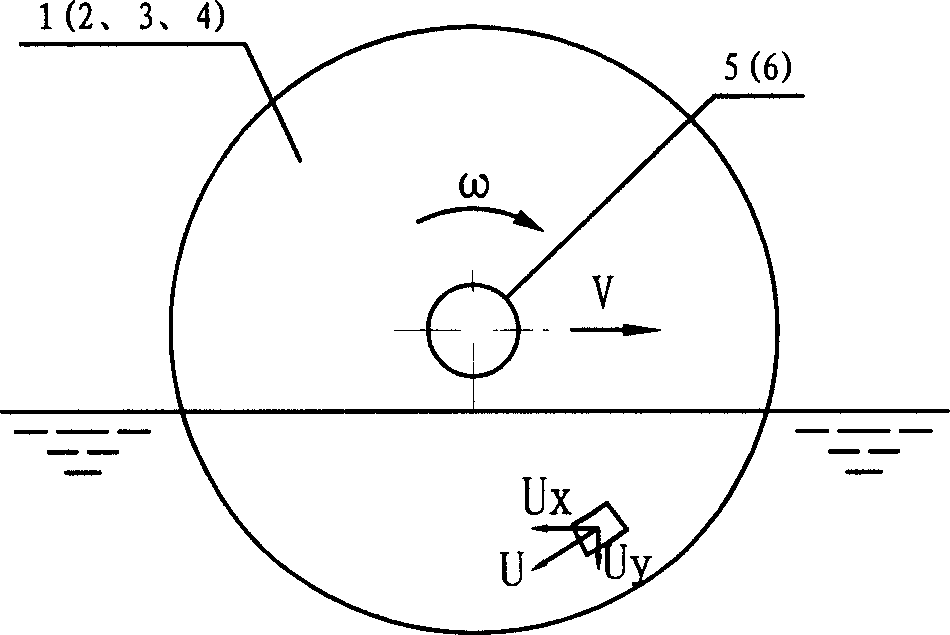

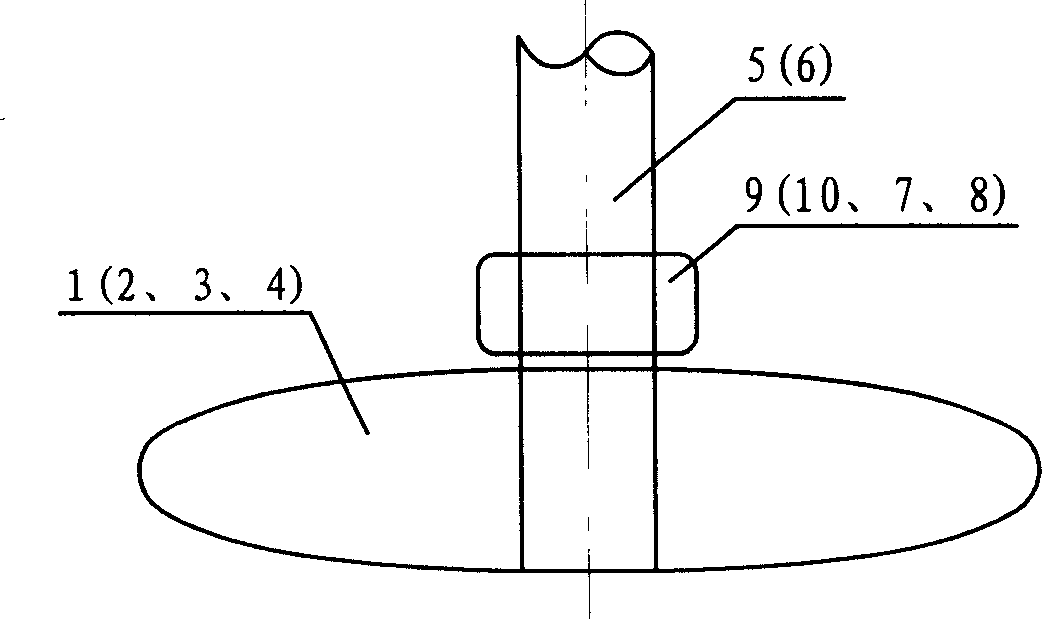

Wheel type ship shape

InactiveCN1586978ASave powerSave energyHydrodynamic/hydrostatic featuresSpecial purpose vesselsMarine engineeringVessel type

The wheel type ship as one kind of transportation facility includes right and left buoyancy wheels with small part soaked in water, right and left buoyancy wheel bearings, and ship body supported on the buoyancy wheel shafts to over water surface. The right and left buoyancy wheels capable of rotating freely are connected via the buoyancy wheel shafts to constitute buoyancy wheel combination, the ship body is connected to the buoyancy wheel shafts via the buoyancy wheel shaft bearings. The wheel type ship has reduced navigation resistance, raised wave resistance, raised stability, improved laying status and other excellent performance, and has excellent application foreground in high speed ship.

Owner:SHANGHAI JIAO TONG UNIV

Combined micro-implant anchorage

InactiveCN101438981AEasy to screw inNot easy to looseDental implantsOthrodonticsMedicineSilicon rubber

The invention belongs to a dental micro-implant anchorage and particularly relates to a combined micro-implant anchorage; the invention solves the problem that a head and a screwing part of the prior micro-implant anchorage can not be separated. The combined micro-implant anchorage comprises an anchorage body; the anchorage comprises the screwing part; the lower end of the screwing part is provided with a V-shaped slot; and the tip is provided with tapping screw thread. The combined micro-implant anchorage is characterized in that the upper end part of the screwing part is sheathed with a neck strap; the screwing part above the neck strap is connected with a cap body; and a silicon rubber case is sheathed outside the cap body. The invention has the beneficial effects the installation is convenient, the stability is high, and the combined micro-implant anchorage is good for soft tissue to be attached and closed and is good for changing and cleaning.

Owner:武秀萍

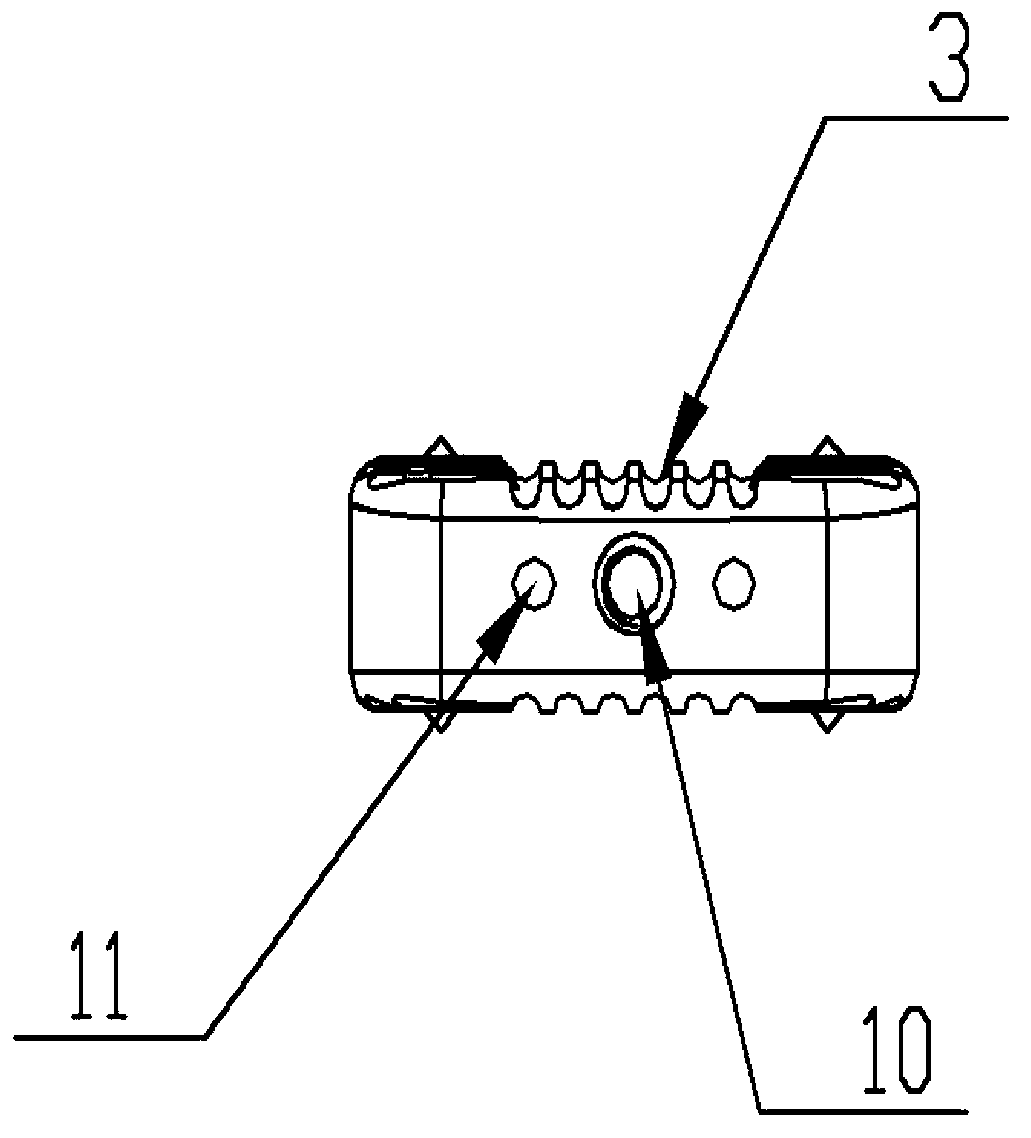

Lumbar vertebrae intervertebral fusion machine

PendingCN107773331AProtective structureExpand the main support areaSpinal implantsTransforaminal approachLumbar vertebrae

The invention discloses a horizontal-expansion lumbar vertebrae intervertebral fusion machine which can achieve minimally invasive implantation and relates to the field of medical apparatus and instruments. The fusion machine comprises a fusion machine body and a movable part, the movable part is arranged to slide along an inner cavity of the fusion machine body, a blocking part is fixedly arranged at one end of the fusion machine body, and the blocking part is arranged to prevent the movable part from being separated from the fusion machine body. The upper side surface and the lower side surface of the fusion machine body are provided with rough patterns. The inner cavity is provided with a first hole which runs through the inner cavity up and down and / or a second hole which runs throughthe inner cavity front and back. According to the lumbar vertebrae intervertebral fusion machine, the three-dimensional scale of the fusion machine is small before the fusion machine is spread, the fusion machine can be horizontally spread and expanded after the fusion machine is invasively implanted into the intervertebral gap through the intervertebral hole admission passage, the large bone grafting bed area can be provided, the main body supporting area that the fusion machine is in contact with an end plate is also greatly increased compared with a traditional fusion machine, the good initial stability can be achieved, the intervertebral fusion rate can be further improved, and the fusion machine helps to effectively lower sedimentation of the fusion machine.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com