Layered and sequential grouting reinforcement treatment method for sunk vault of urban tunnel

A technology of grouting reinforcement and vaulting, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems affecting the normal operation of pipelines, grout coming out, tunnel collapse, etc., to ensure safety and stability, prevent further damage, Guarantee the effect of grouting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

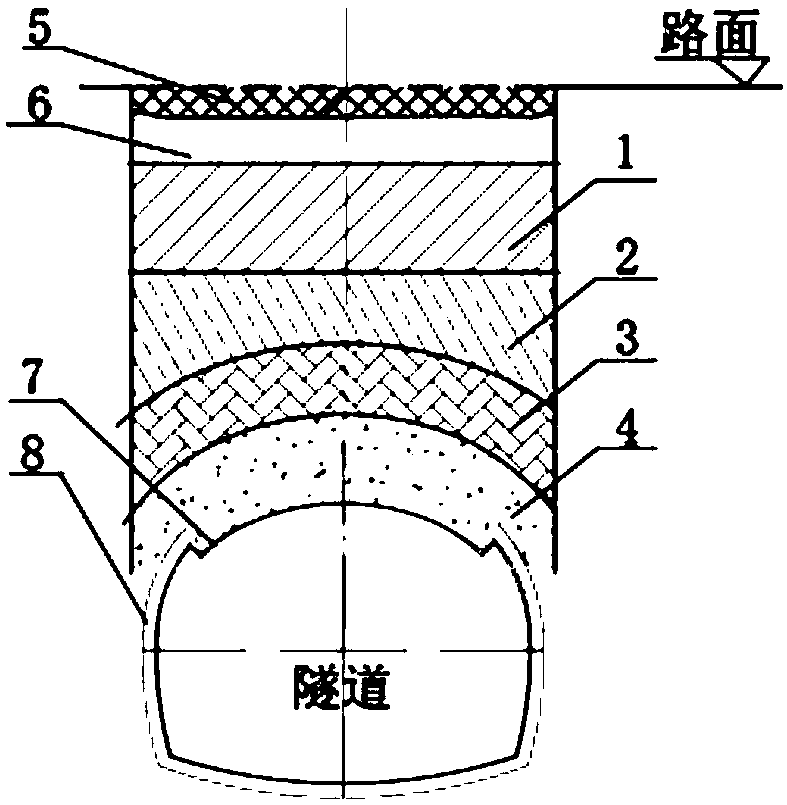

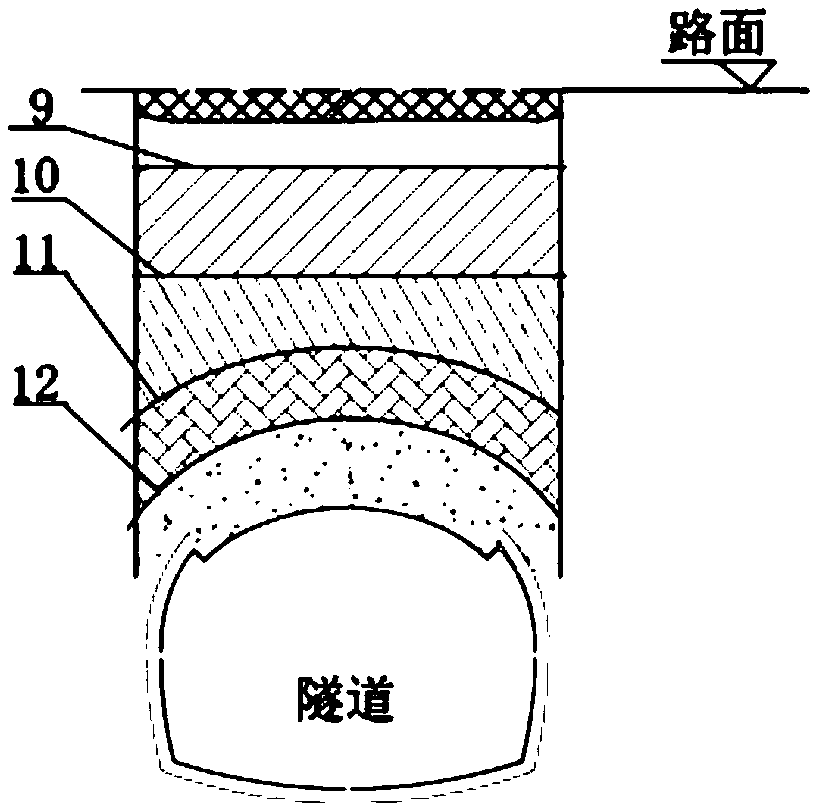

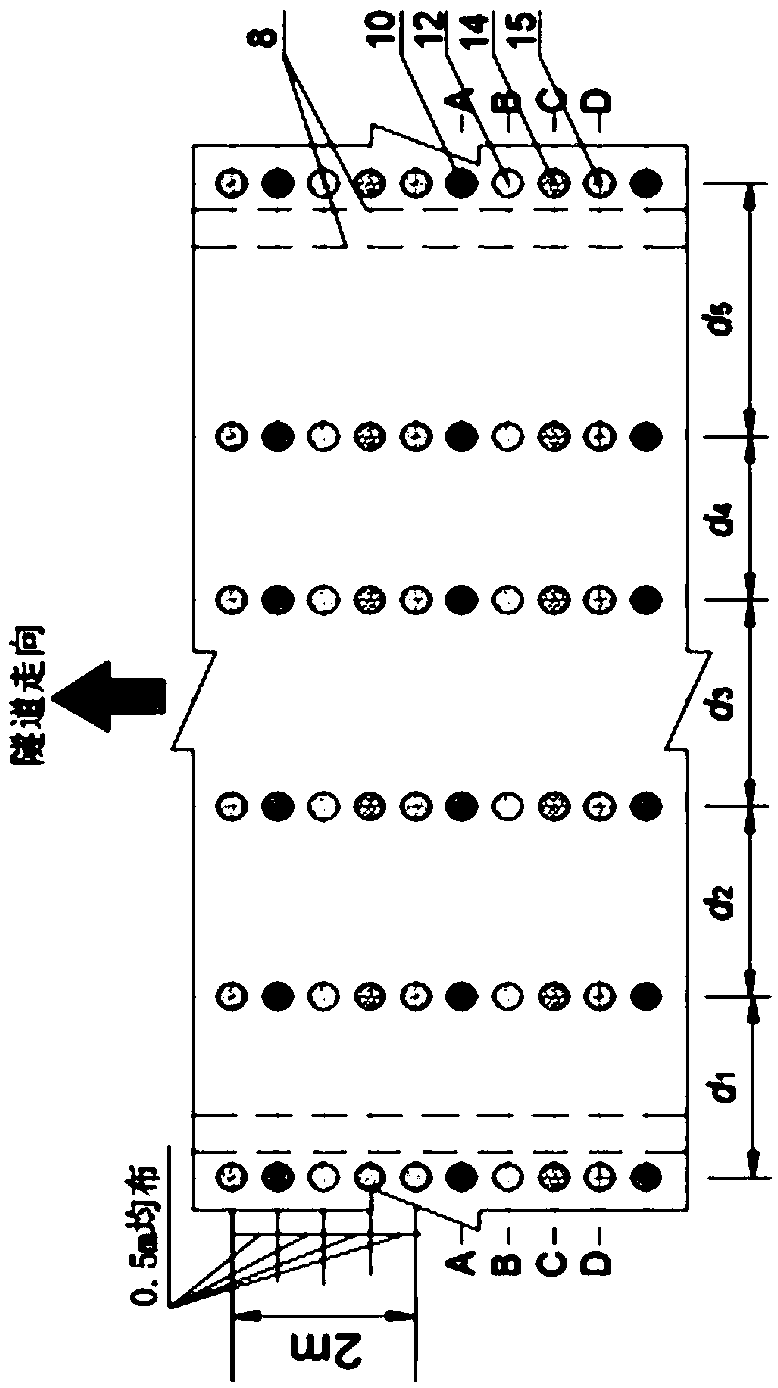

Method used

Image

Examples

Embodiment

[0116] The underground excavation section of the Yuhan Road underground road in the second phase of Jinan Shunhe Elevated South Extension Project is 2335 meters long, with a buried depth of 11m-20m and a road width of 32 meters. The traffic is heavy and the underground pipelines are dense. Under the road at the tunnel site is filled soil, and the Quaternary covering layer below the filled soil is collapsible loess, cohesive soil and gravel soil. The loess is in a plastic state, partially hard, with average strength, medium collapsibility, and rock quality. The grade is Ⅲ~Ⅳ.

[0117] At about 23:30 on June 12, 2017, when the face of the right line of the underground tunnel of the second phase of the south extension of the Shunhe Elevated Project was excavated to the YK2+702 mileage, the face of the face protruded, and the vault of the section YK2+692~702 Subsidence and subsidence of road surface. Immediately after the collapse occurred, backfill and backpressure were taken on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com