Patents

Literature

2433 results about "Wall rock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wall rock is the rock that constitutes the wall of an area undergoing geologic activity. Examples are the rock along the neck of a volcano, on the edge of a pluton that is being emplaced, along a fault plane, enclosing a mineral deposit, or where a vein or dike is being emplaced.

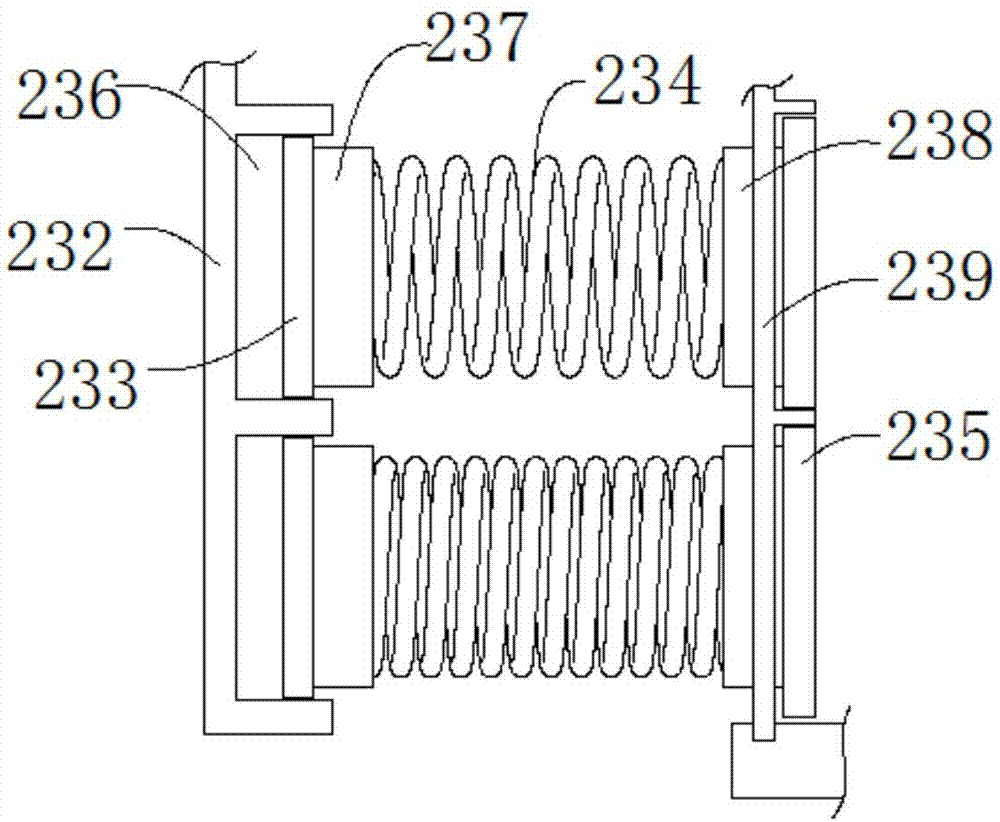

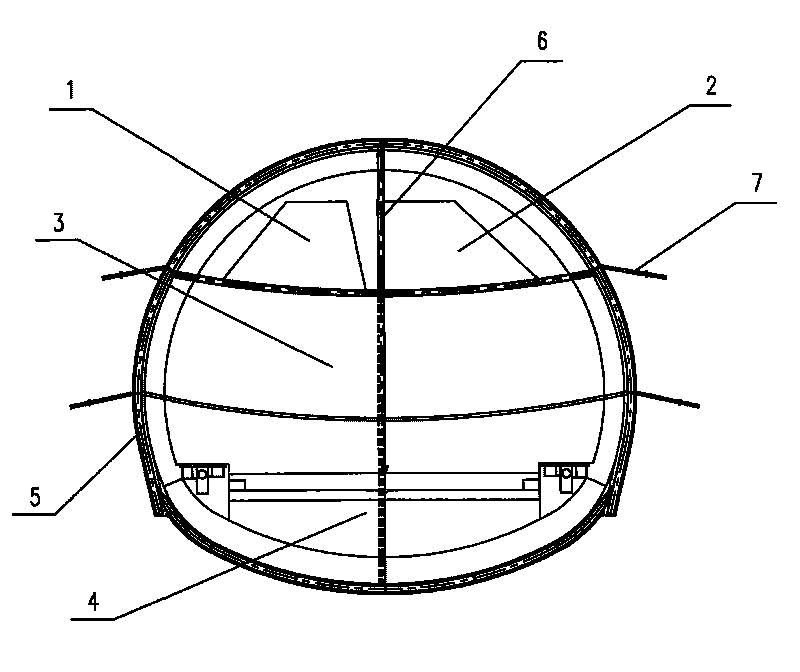

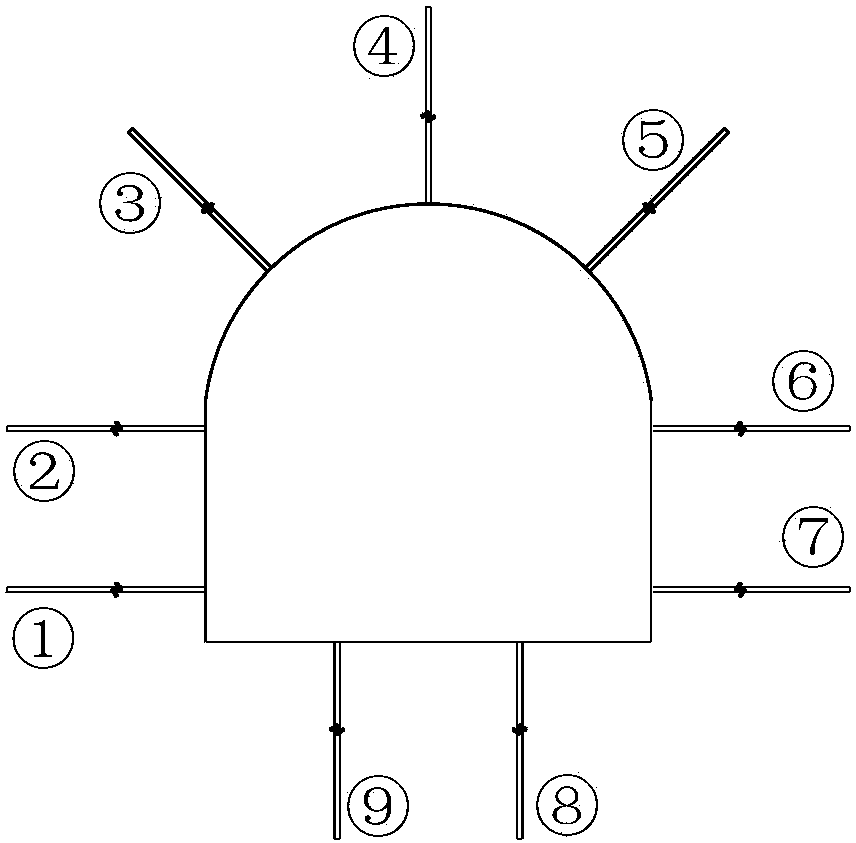

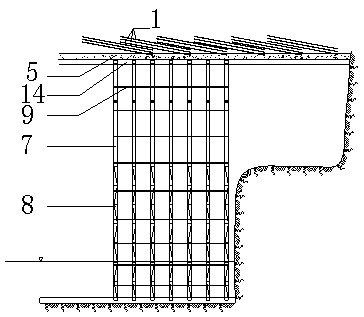

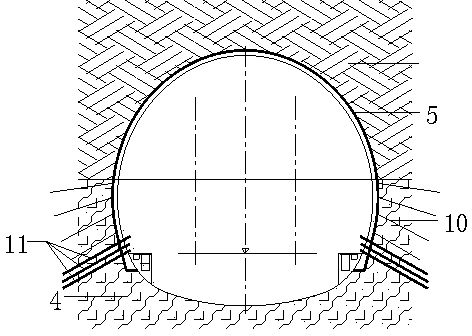

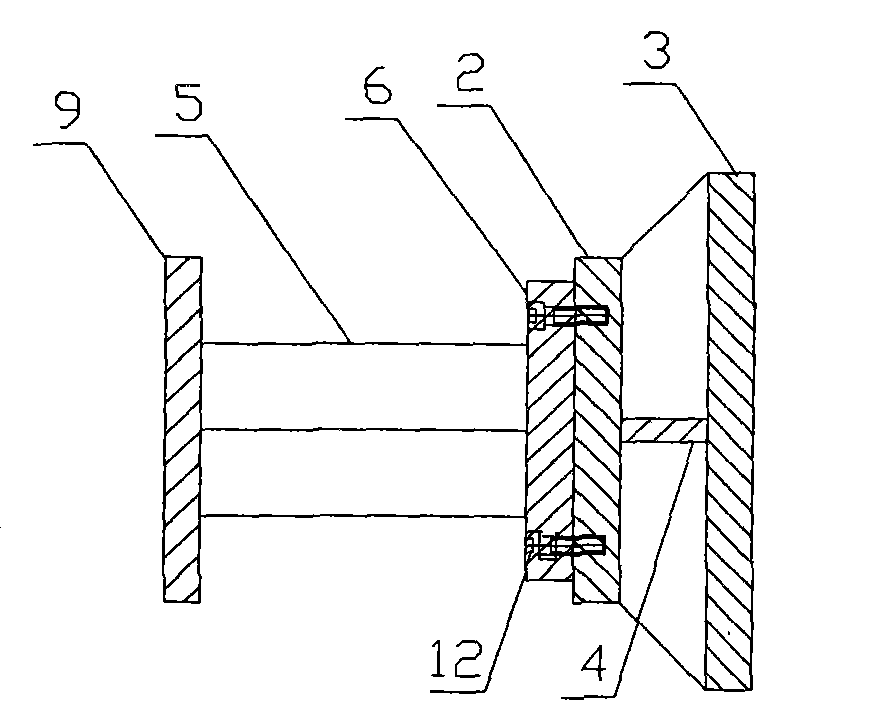

Composite support device of dynamic pressure softrock tunnel based on steel pipe concrete bracket

InactiveCN101725362AControl deformationSimple structureProps/chocksAnchoring boltsSupporting systemHardness

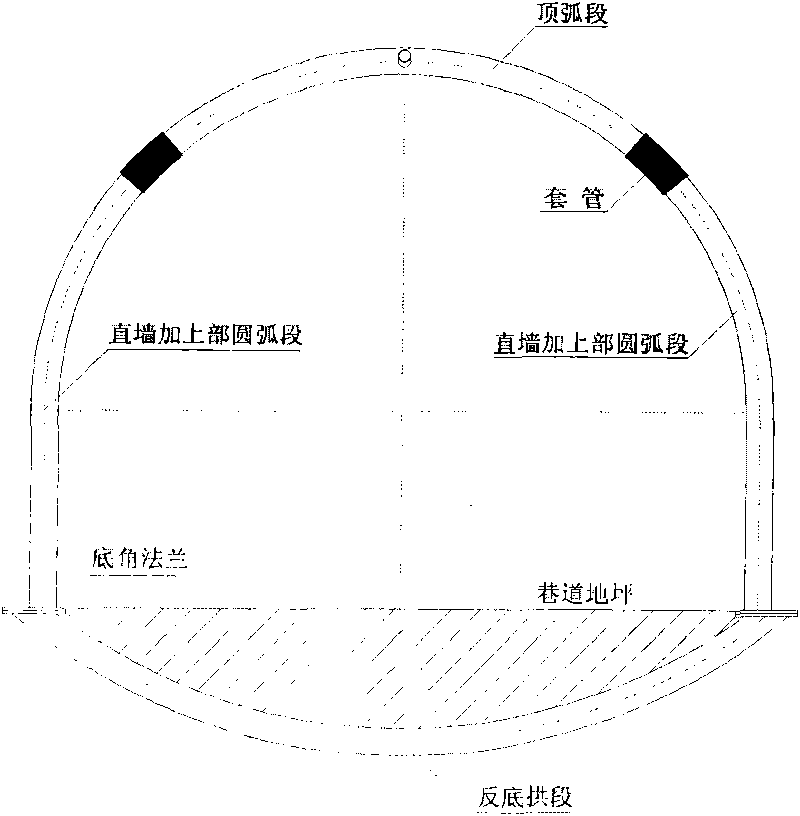

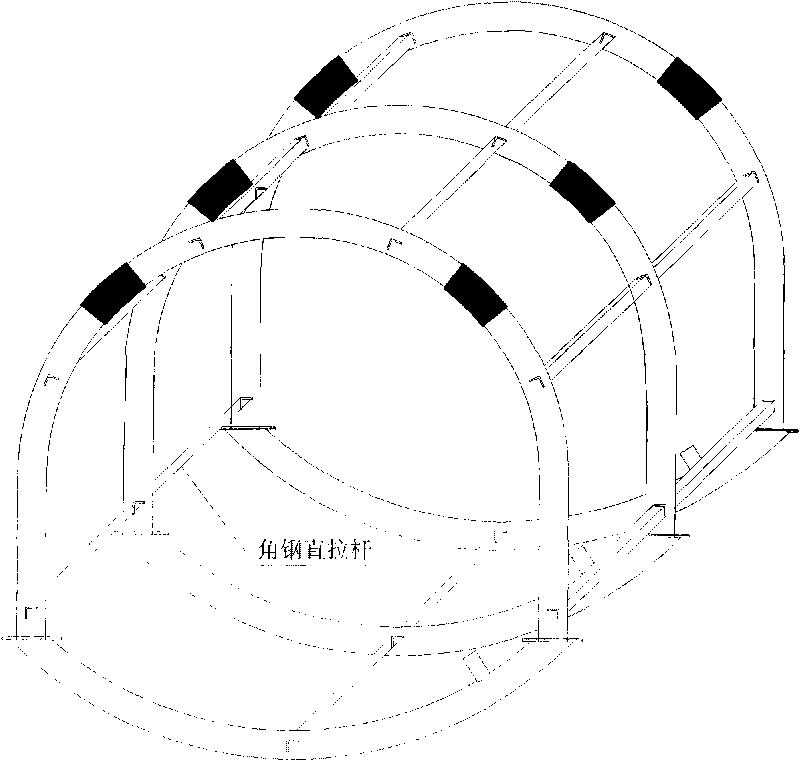

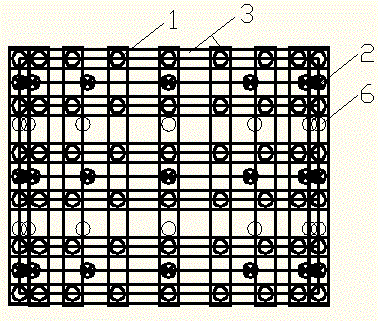

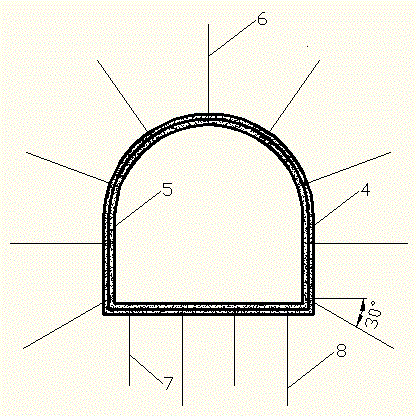

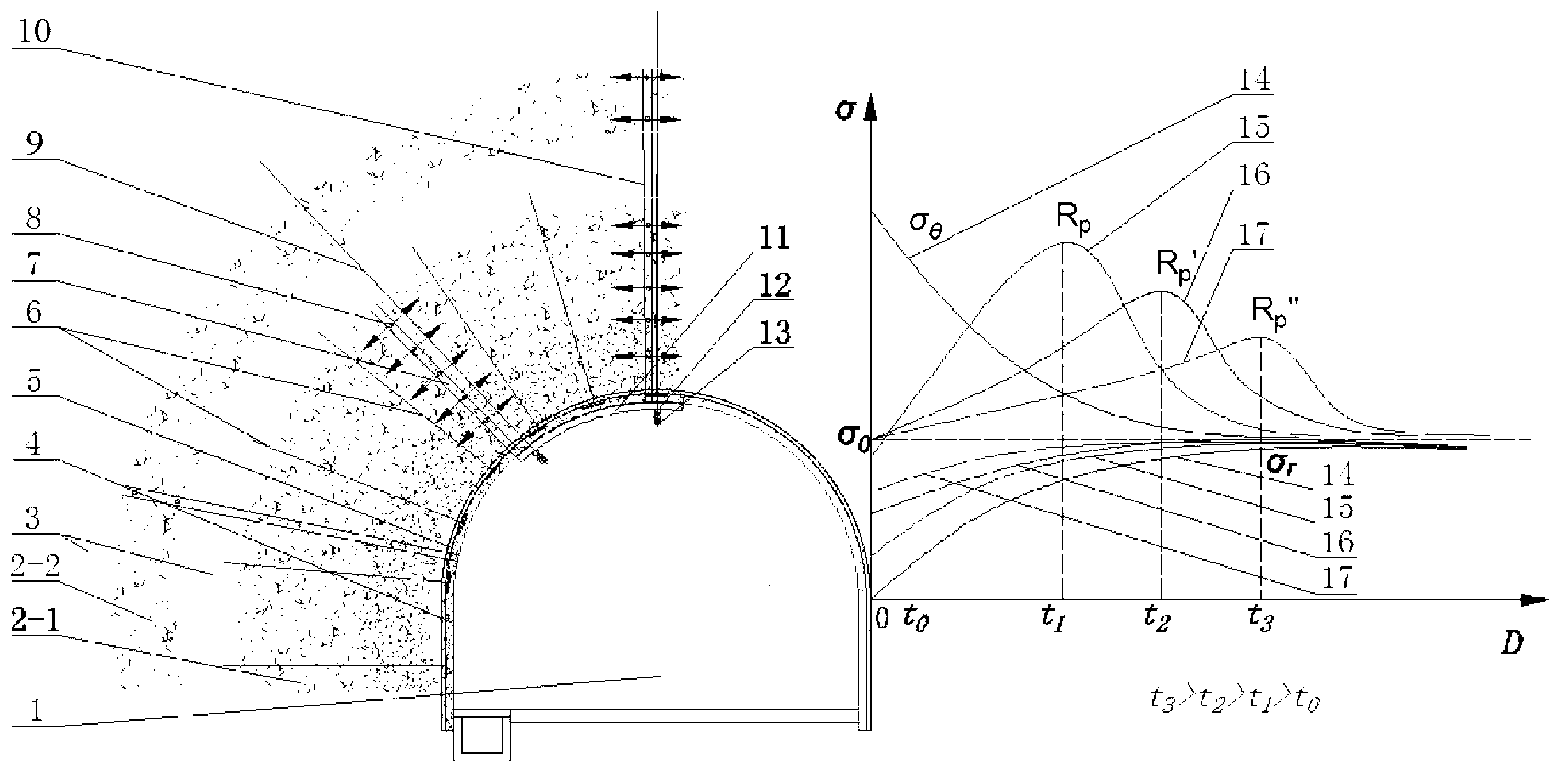

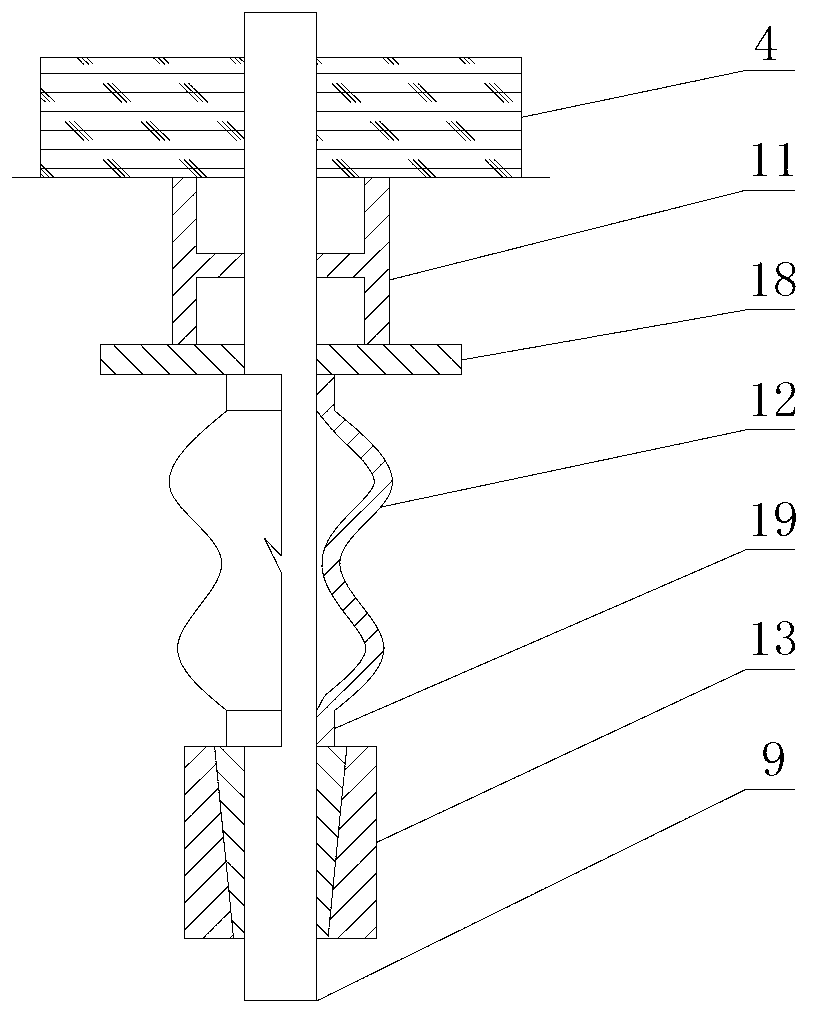

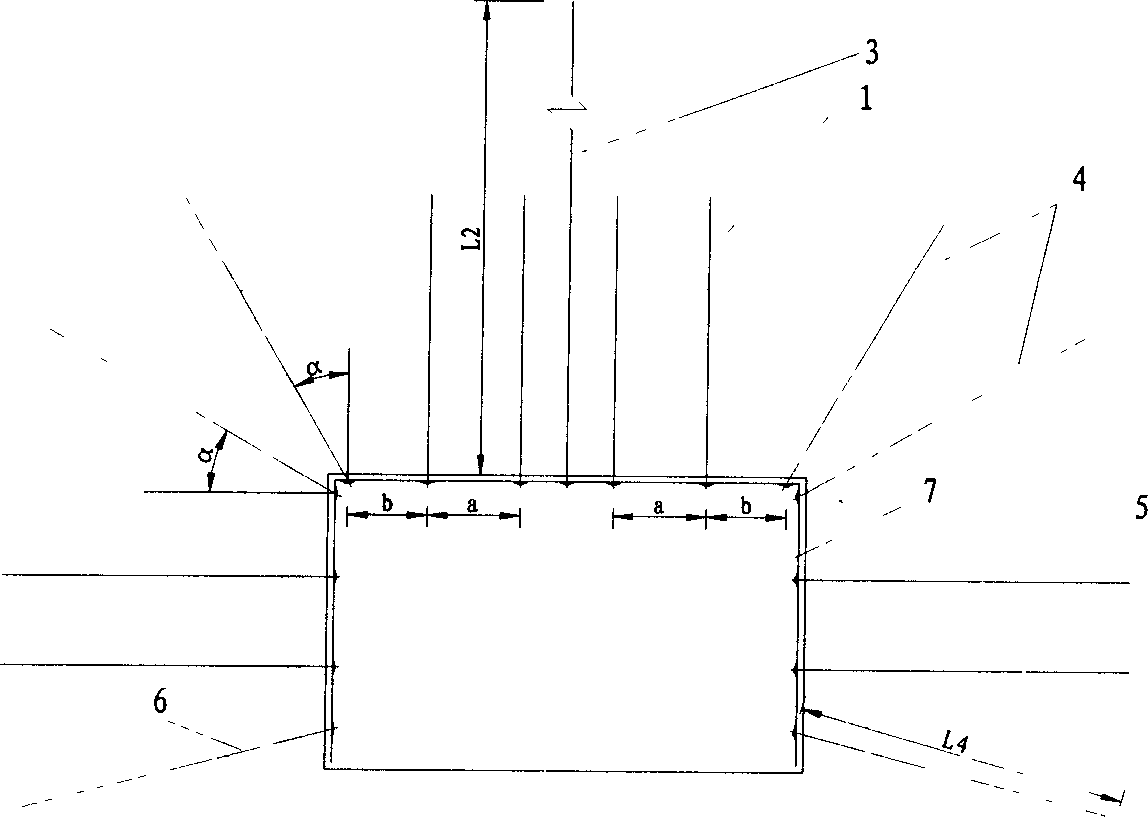

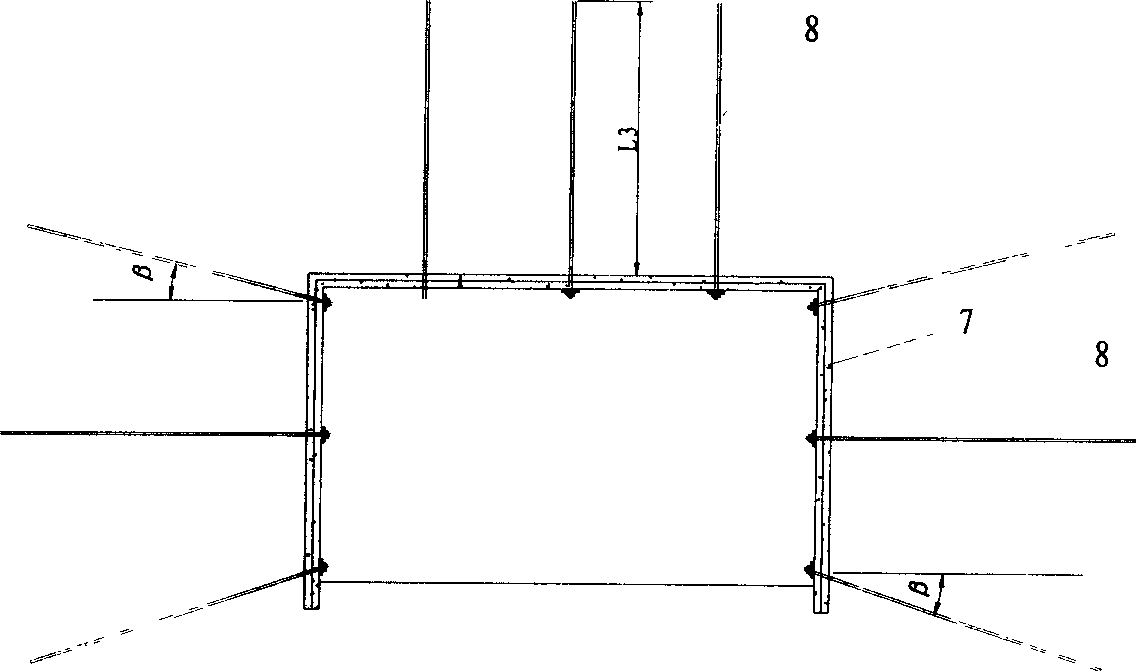

The invention relates to a composite support device of a dynamic pressure softrock tunnel based on a steel pipe concrete bracket, which comprises a steel pipe concrete bracket, wherein a flexible pressure sharing and releasing layer is arranged between the steel pipe concrete bracket and supported surrounding rock. The composite support device also comprises a surrounding rock grouting and reinforcing device, wherein the surrounding rock grouting and reinforcing device comprises a plurality of hollow surrounding rock grouting anchor rods, and the surrounding rock is grouted by the hollow anchor rods; after being injected with a concrete layer, the surrounding rock is covered by a flexible seal layer; and the steel pipe concrete bracket is provided with a vertical column shaped or Y-shaped or T-shaped high-strength steel pipe concrete strut. The high-strength steel pipe concrete bracket and the flexible pressure sharing and releasing layer are two necessary technologies; and the flexible seal layer, the surrounding rock grouting and reinforcement and the high-strength steel pipe concrete strut are three optional technologies. The flexible pressure sharing and releasing layer is combined with the steel pipe concrete bracket so that the whole support system combines hardness with softness, has simple structure, low cost and high support resistance and can effectively control the stability of large deformed tunnels of deep well softrock dynamic pressure, and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

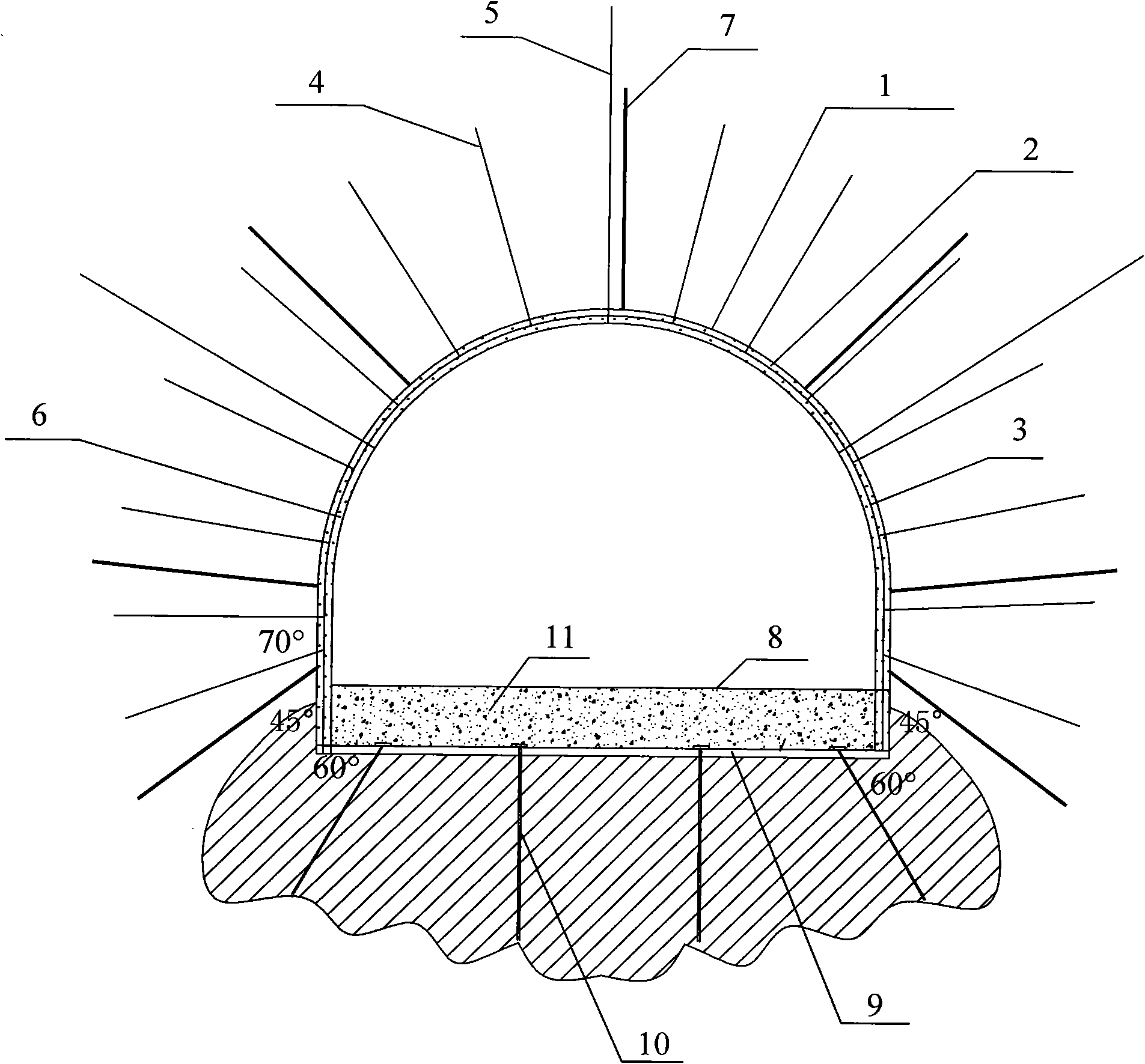

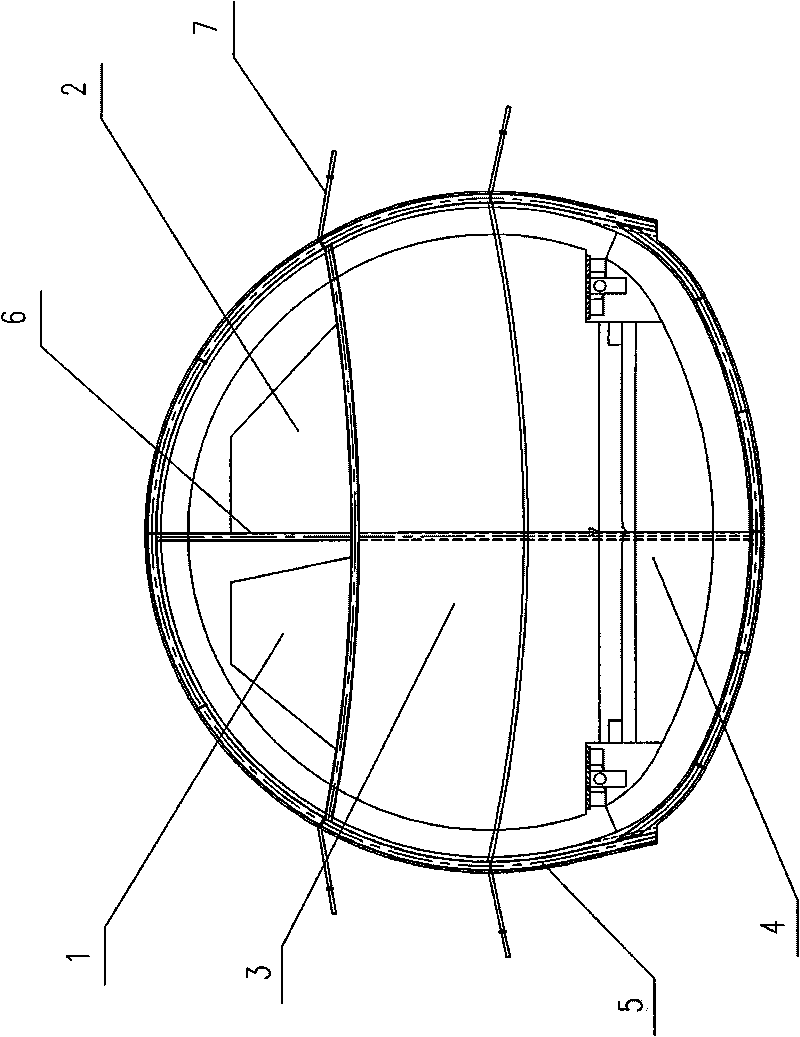

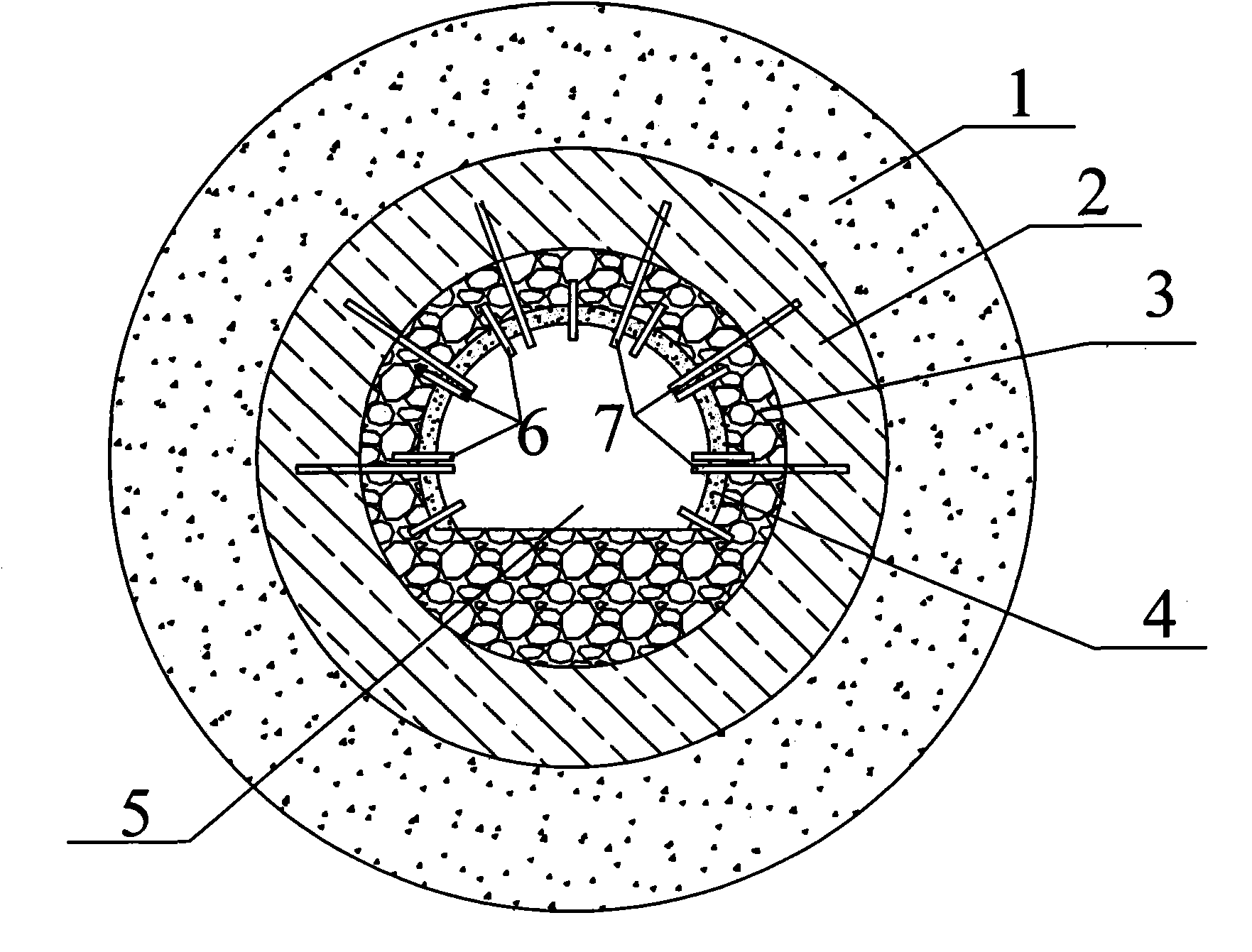

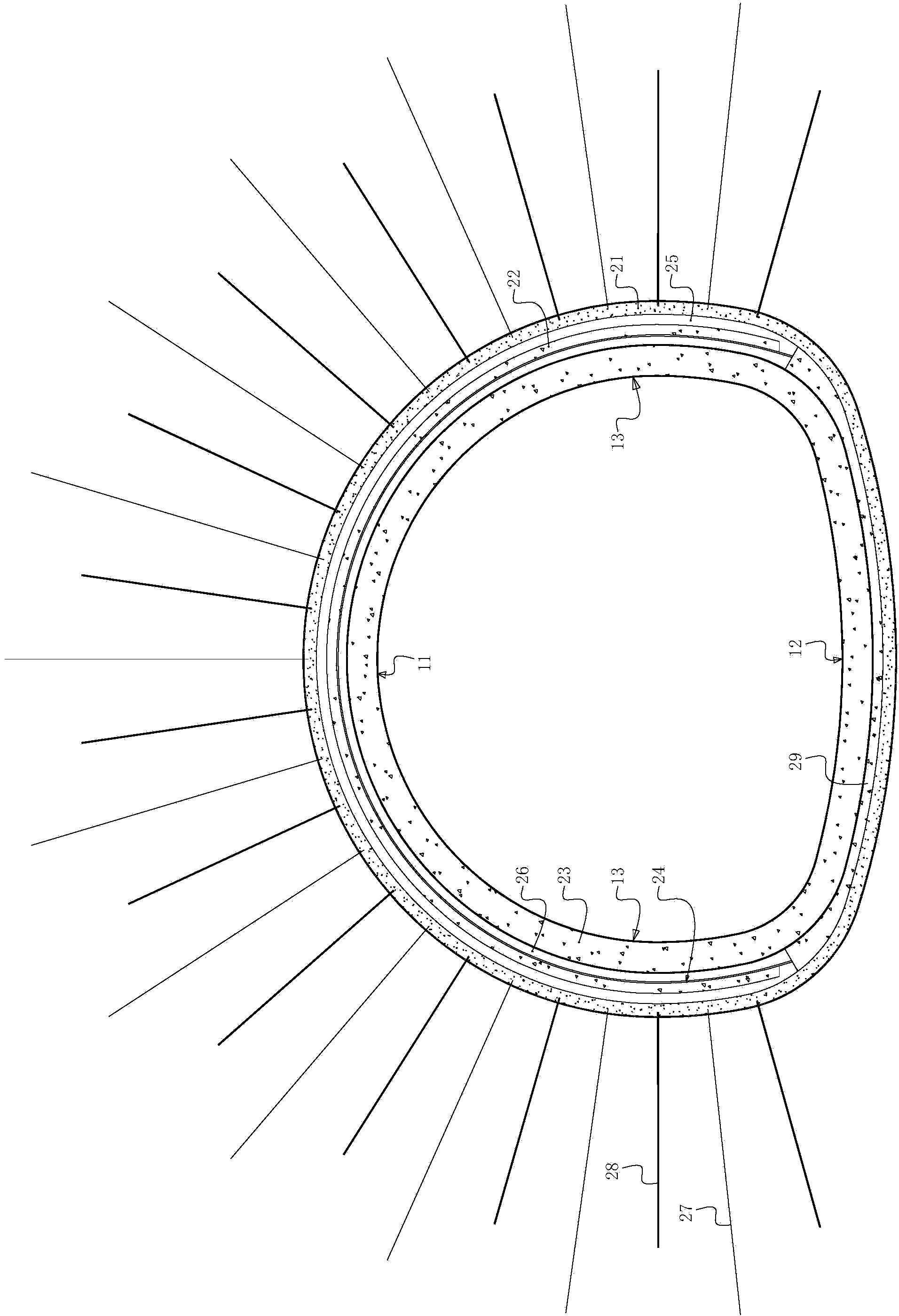

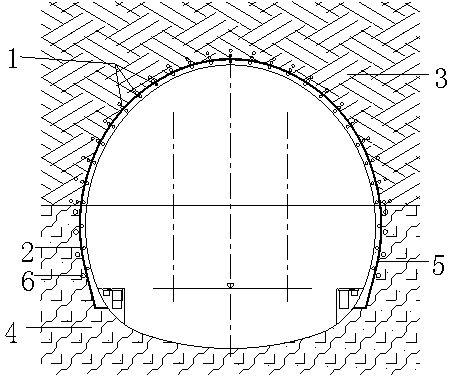

Total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for incompact and fractured soft-rock roadway

InactiveCN105178981AImprove support strengthWatch protection effect is goodUnderground chambersTunnel liningCouplingStructure of the Earth

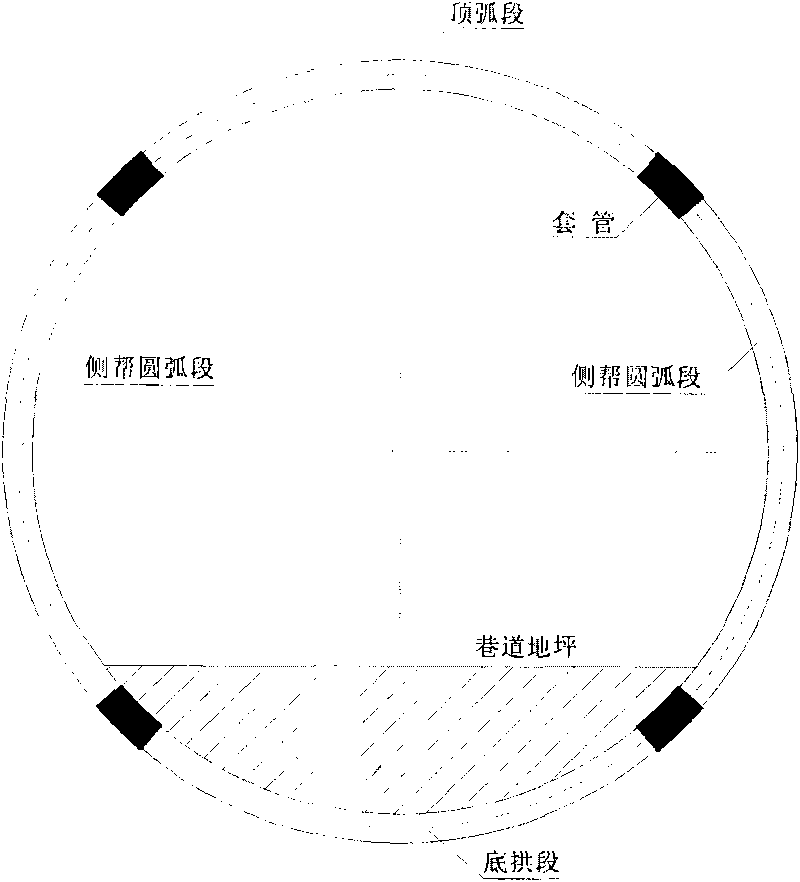

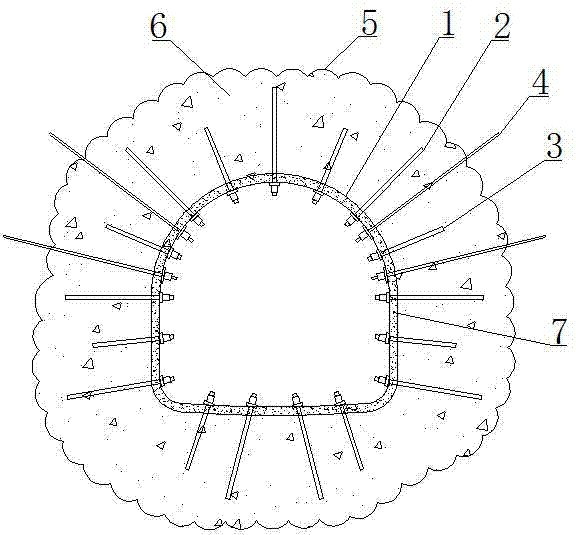

The invention relates to a total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for an incompact and fractured soft-rock roadway. On the basis of a multilayered cooperative supporting principle, a spraying net combined isolating arch, an anchor rod extruding reinforcing arch, a total-section closed type grouting reinforcing ring and a deep slurry diffusion reinforcing arch are respectively formed on surrounding rock of the roadway from shallow to deep finally, and are combined to form a multilayered effective combined arch by a suspension effect of a high-strength grouting anchor cable, advantages of yielding supporting, bolting-grouting supporting and deep-shallow coupling supporting are combined organically, bearing range, integrity and bearing capability of a supporting structure are improved obviously, a control effect on deformation characteristics of large deformation, high speed, long duration, wide destroying range, peripheral pressing, obvious floor heaves and the like of the surrounding rock of the incompact and fractured soft-rock roadway is excellent, and various deformations of the surrounding rock of the incompact and fractured soft-rock roadway are controlled effectively. The total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method is particularly suitable for a large-section incompact and fractured soft-rock roadway of a deep well, is simple in work procedures and low in cost, and has high field promotion and application value; and parallel operation can be realized.

Owner:CHINA UNIV OF MINING & TECH

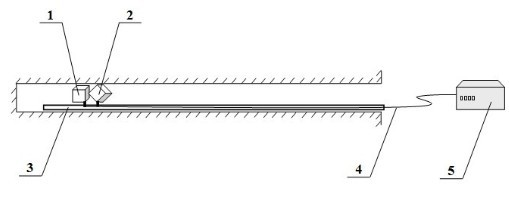

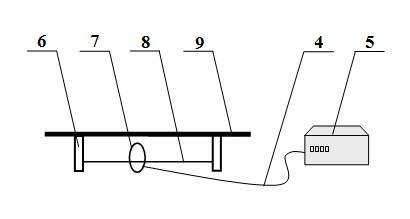

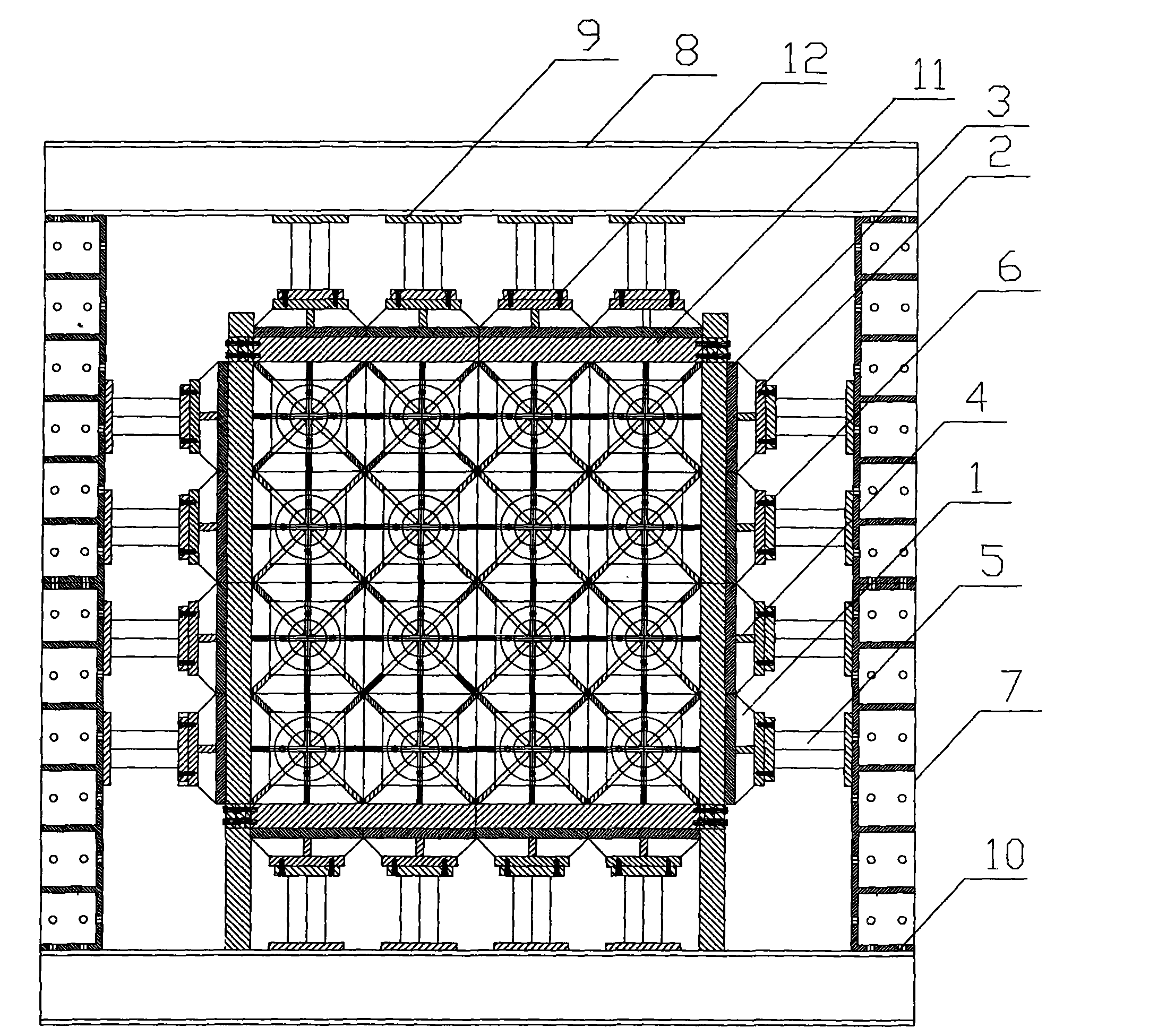

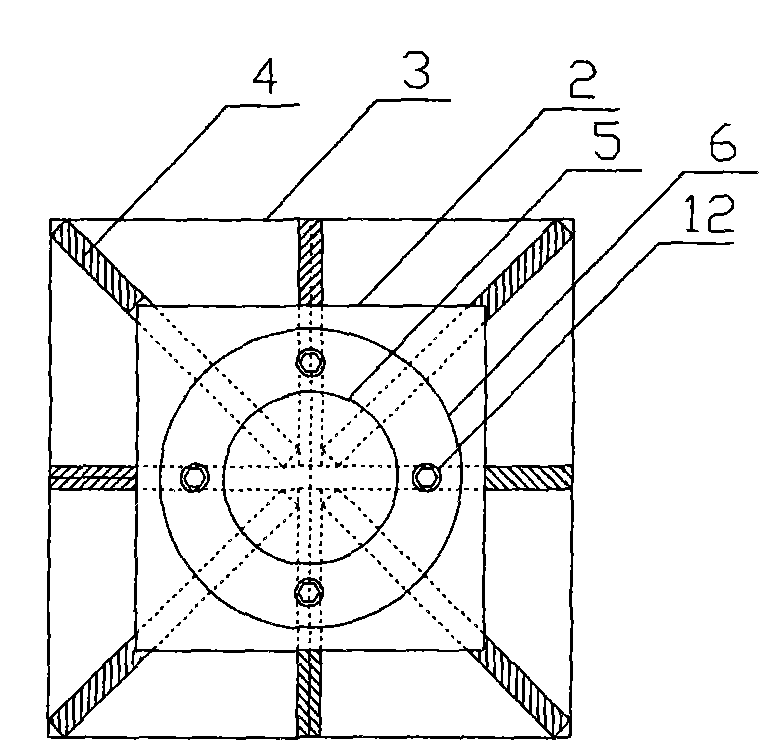

Roadway support mechanics simulation test system under dynamic-static combined loads and method of roadway support mechanics simulation test system

ActiveCN108007781AConsistent forceThe test result is accurateMaterial strength using tensile/compressive forcesControl systemMonitoring system

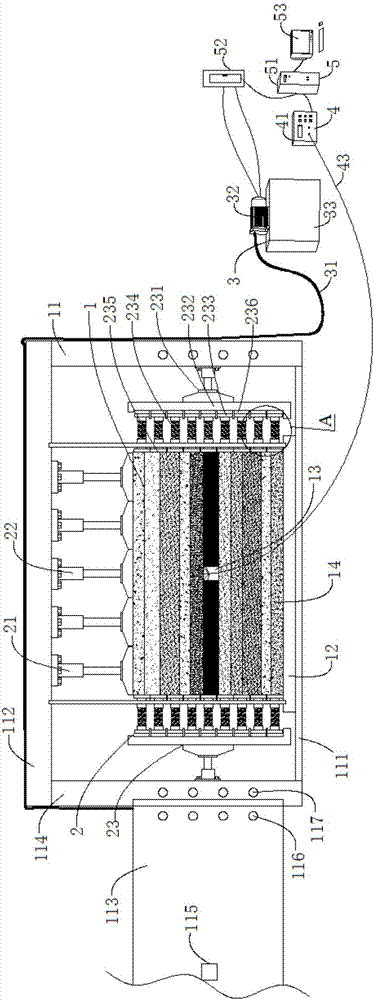

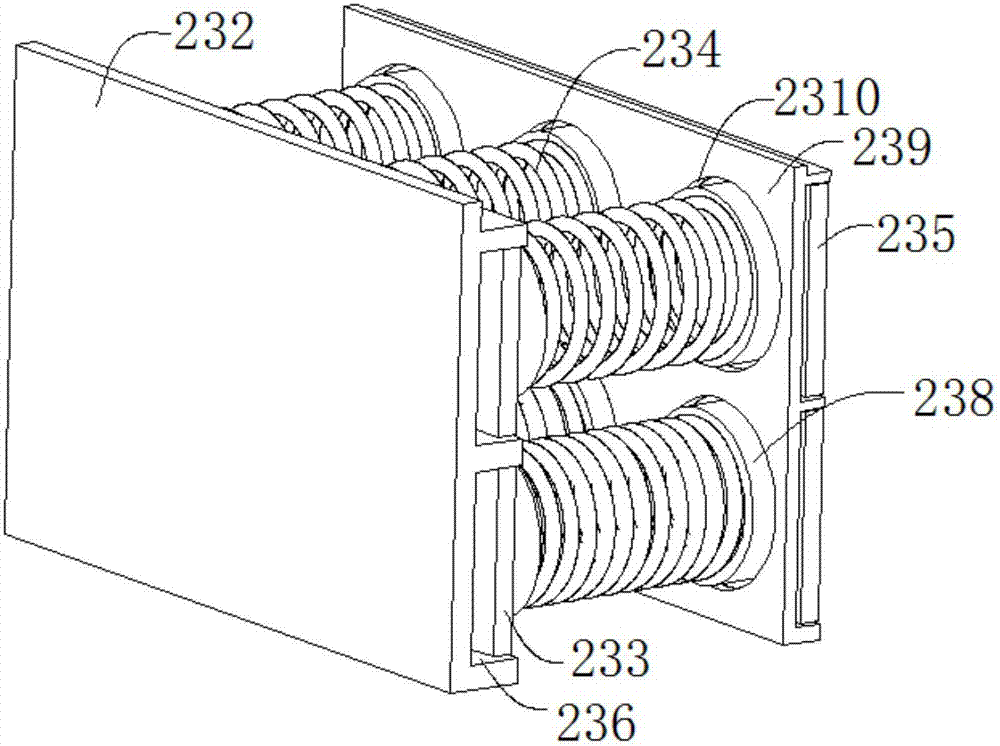

The invention discloses a roadway support mechanics simulation test system under dynamic-static combined loads and a method of the roadway support mechanics simulation test system. The system comprises a similar material laying system, a hydraulic loading system, a dynamical system, a monitoring system and a control system, wherein the similar material laying system comprises a connecting bracket,a laying platform and a reserved anchor rod model; the laying platform is placed in the connecting bracket; a coal rock similar layer is arranged on the laying platform; the coal rock similar layer is obtained by laying coal rock similar materials sequentially layer by layer; the reserved anchor rod model is arranged in the middle of the coal rock similar layer. According to the roadway support mechanics simulation test system, an adjustable static load and an adjustable dynamic load are simultaneously exerted on the coal rock similar layer, so that the force on a surrounding rock and a support of a roadway can be consistent with actual force; therefore, a test result is more accurate. Meanwhile, the roadway support mechanics simulation test system is simple in operation and is stable andreliable; therefore, the roadway support mechanics simulation test system has great significance in support designs of deep mines, tunnels and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Deep well tunnel cable anchor rigid-flexible coupling support and surrounding rock overall reinforced support method

InactiveCN101967984AImprove carrying capacityPrevent shear deformationUnderground chambersTunnel liningPre stressCoupling

Owner:ANHUI UNIV OF SCI & TECH

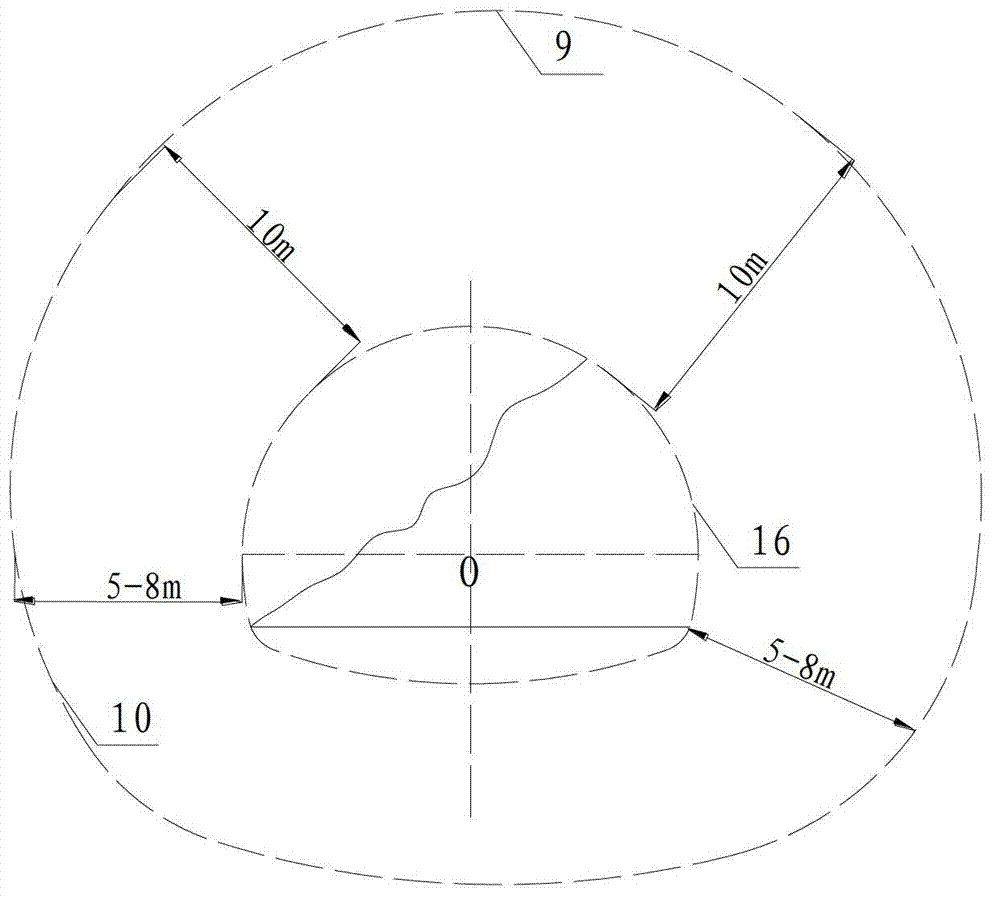

Excavation construction method of ultra-shallow buried uneven weathered stratum of tunnel

The invention relates to an excavation construction method of an ultra-shallow buried uneven weathered stratum of a tunnel. A segmented step method is used for construction, and a tunnel section is divided into a left side of an upper station, a right side of the upper station, a middle station and a lower station; each segment of step is sequentially constructed circularly, one-time excavation length of each segment of step is not larger than 30m preferably, and a middle partition wall is changed into a straight wall from the traditional curved wall at the left side of the upper station. Thus, for the uneven weathered stratum in the shallow buried area of wall rocks, the dynamic construction method using the segmented step method has little process interference, reduces the construction cost, has simple operation, safety, reliability, less temporary support, low fund investment and high construction speed, is suitable for large machinery for construction, and ensures that the whole construction process is in a safe, stable, high-quality and high-speed controllable state.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Strengthening and reinforcing method of high-ground-pressure soft rock laneway by hierarchical grouting

InactiveCN101864967AImprove the strengthening effectWill not blockUnderground chambersTunnel liningSlurryHigh pressure

The invention relates to a strengthening and reinforcing method of a high-ground-pressure soft rock laneway by hierarchical grouting. Aiming at the deformation damage and crack distribution rules of laneway wall rock of high-ground-pressure soft rock, a hierarchical grouting mode for a shallow layer and a deep layer is adopted to hierarchically and emphatically strengthen and reinforce the shallow layer and the deep layer by grouting. The method comprises the following steps of: firstly, carrying out shallow-hole low-pressure grouting to a laneway shallow-layer gap development zone and then carrying out deep-hole high-pressure grouting to deep rock bodies; constructing shallow-hole grouting with small grouting pressure so that grout is scarcely diffused into the deep part, and grouting passages, such as a deep gap of the deep part and the like, are well preserved without blockage; and adopting a double-component chemical grout malisan with easy dispersion and strong permeability in constructing deep-hole grouting to realize deep high-pressure grouting on the basis of a formed grout-stopping shielding shell formed by former-period shallow-hole grouting so that the distribution compactness and the dispersion evenness of the grout in the deep grouting are improved, and the strengthening effect of the deep grouting on the wall rock is effectively improved. The method is simple and easy to implement.

Owner:CHINA UNIV OF MINING & TECH

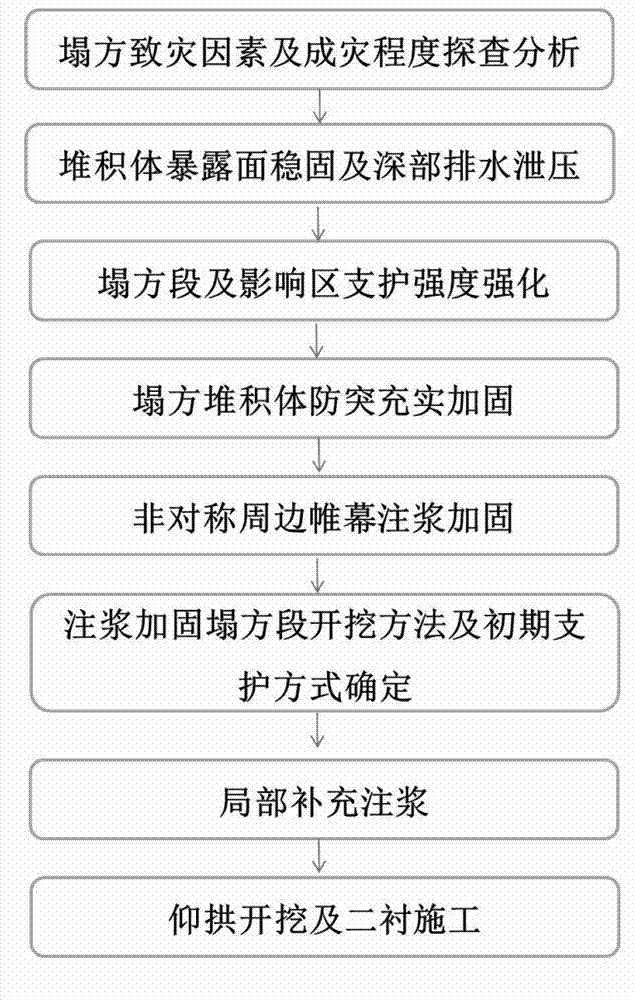

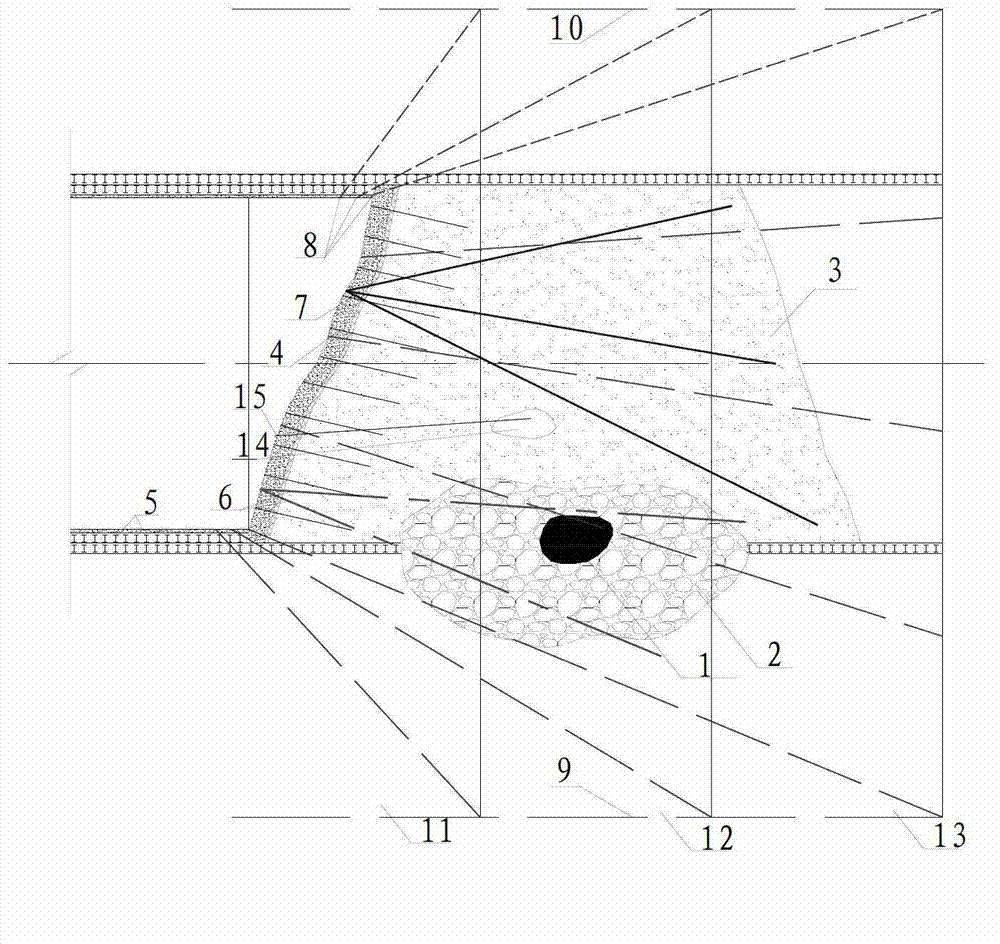

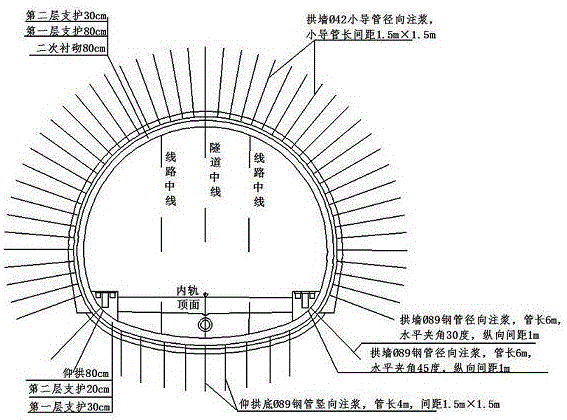

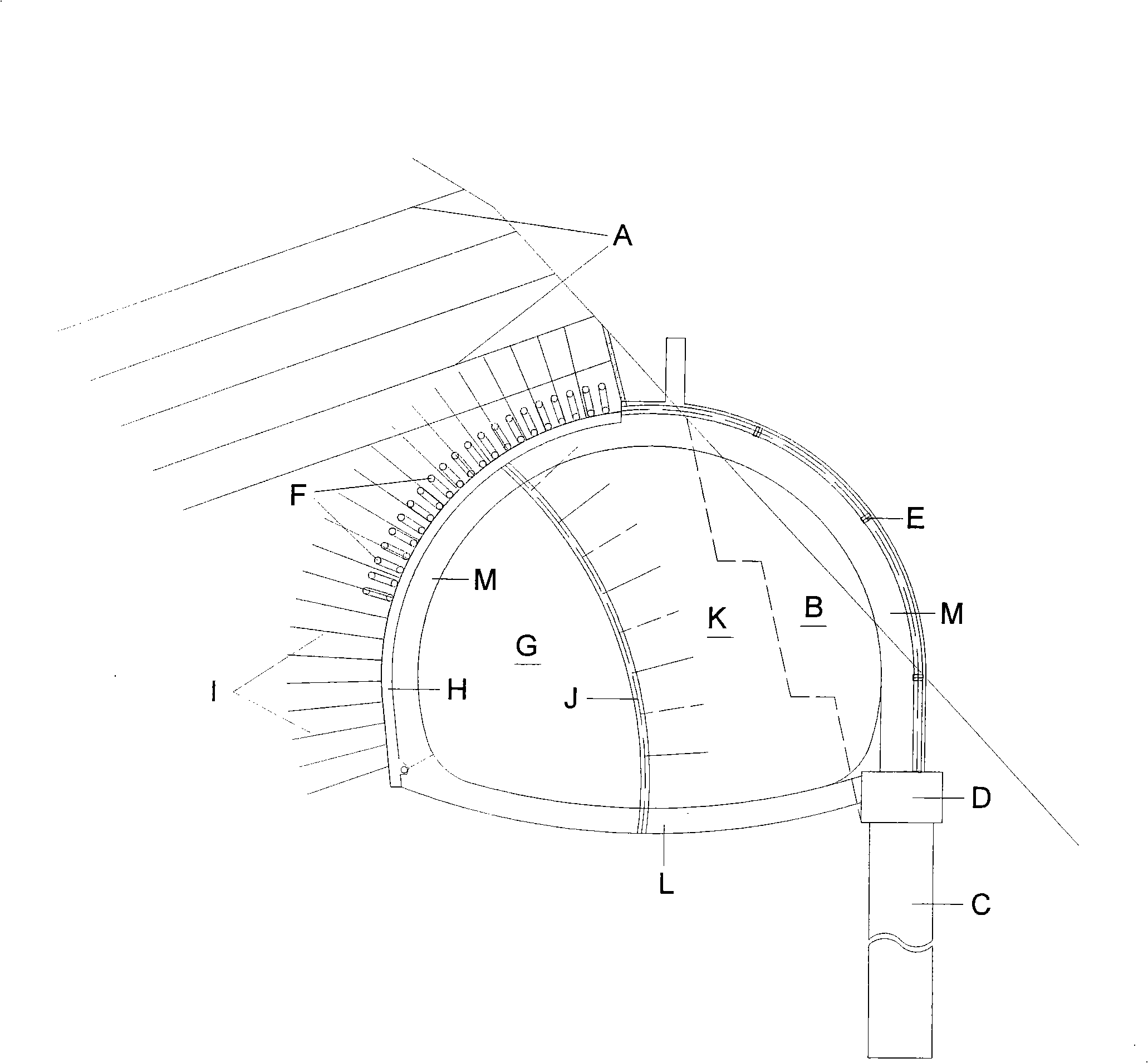

Control method of surrounding rocks in water-rich very-broken surrounding rock tunnel collapse sections

ActiveCN103089275AImprove stabilityEnsure stabilityUnderground chambersDrainageSocial benefitsRock tunnel

The invention relates to the field of tunnel engineering construction, in particular to a control method of surrounding rocks in water-rich very-broken surrounding rock tunnel collapse sections. According to the control method, problems in the existing methods that managing circle is long, reinforcing range and effect are bad, secondary geological disasters are triggered easily because of deformation and cracking of exceeding clearance limit of preliminary bracing and the like are solved. The method includes the following steps: searching and analyzing factors leading to collapse and disaster degree, stabilizing exposed face of an accumulation body and dewatering and decompressing deep parts, strengthening supporting intensity in the collapse sections and influencing areas, outburst prevention filling and strengthening the collapse accumulation body, grouting reinforcing asymmetrical peripheral curtains, confirming an excavating method in grouting reinforcing collapse sections and primary supporting patterns, replenishing grouting in parts, excavating inverted arches, and constructing second liners. The control method of surrounding rocks in water-rich very-broken surrounding rock tunnel collapse sections has the advantages that collapse disposing construction period of water-rich very-broken surrounding rock tunnels is shortened, reinforcing range and intensity of the surrounding rocks are guaranteed, grouting reinforcement is fully conducted on the surrounding rocks in direct collapse areas, deformation in the preliminary bracing is relieved, occurrence of the exceeding clearance limit and the secondary geological disasters is avoided, disposing quality of collapse accidents is improved effectively, and good social benefit and economical benefit are created.

Owner:SHANDONG UNIV

Construction method for soft rock deformation tunnel lining support dismantling-replacing arch

InactiveCN105781571AGuaranteed carrying capacityGuaranteed integrityUnderground chambersTunnel liningEngineeringLarge deformation

The invention provides a construction method for a soft rock deformation tunnel lining support dismantling-replacing arch. One-time whole section integral dismantling and replacing of a lining support is achieved. The construction method has the advantages that before dismantling and replacing, a lining which loses bearing capacity is subjected to grouting reinforcement treatment first, then a temporary cover arch is additionally arranged outside for reinforcement, and afterwards, the lining support is dismantled step by step, so that potential safety hazards caused by dismantling or removing of a temporary platform frame are avoided, and some security risks are avoided effectively. According to the construction method, the construction difficult problem of soft rock large deformation occurs during construction of a tunnel in special and complex geology is solved. Through the created novel construction method, the construction difficult problem of second lining cracking deformation needing remediation due to weak surrounding rock large deformation is solved. Through the construction method, safe, fast and economic treatment and remediation of the lining support and arch replacing construction are achieved, and the tunnel structure stability and construction safety are ensured effectively.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

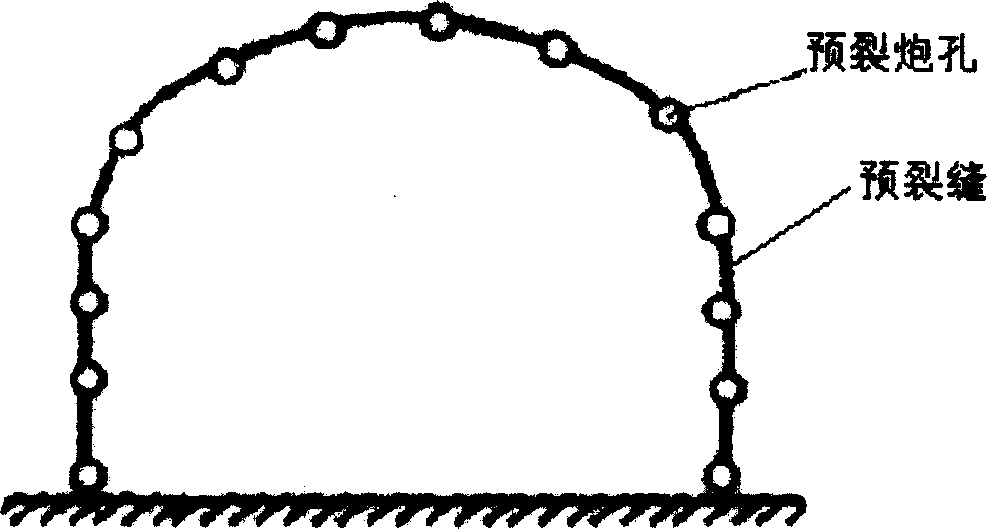

Rock lane digging method

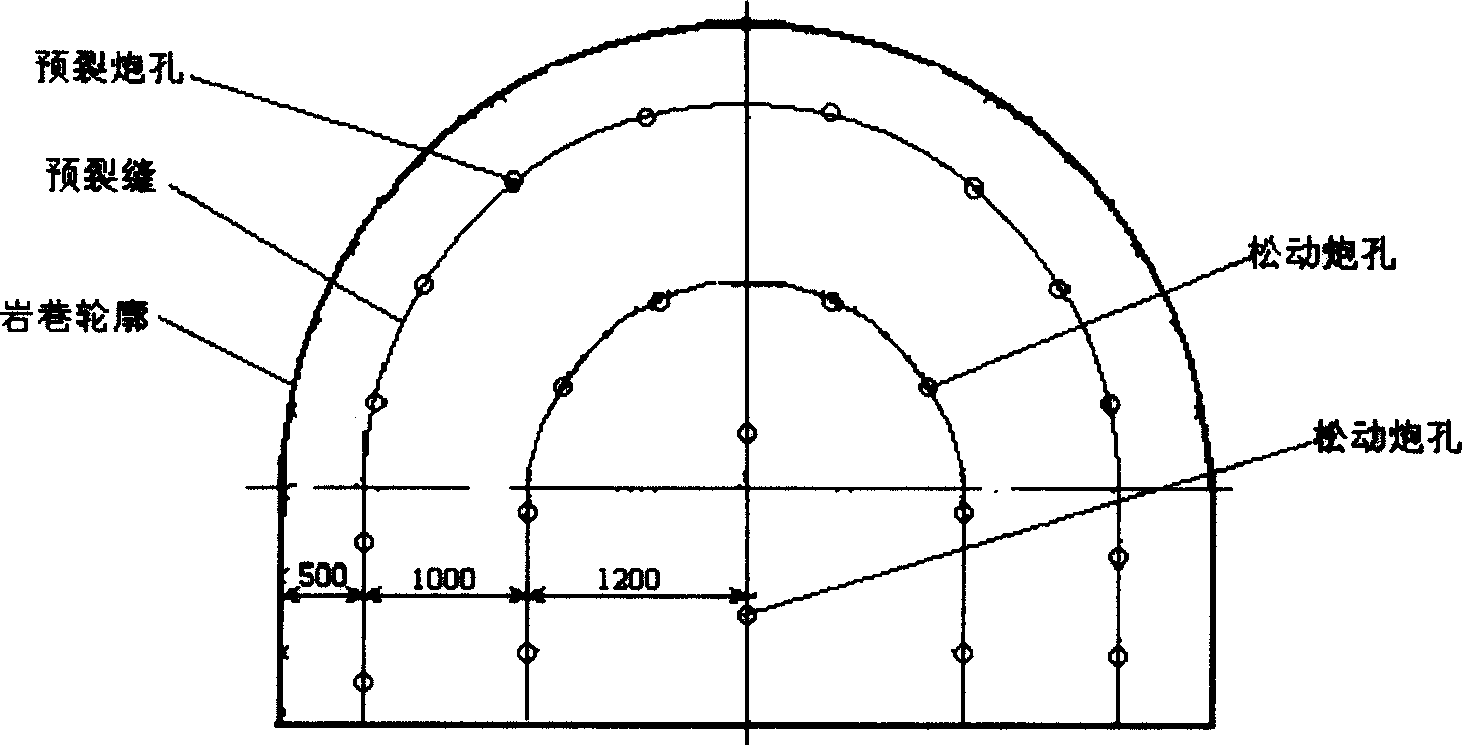

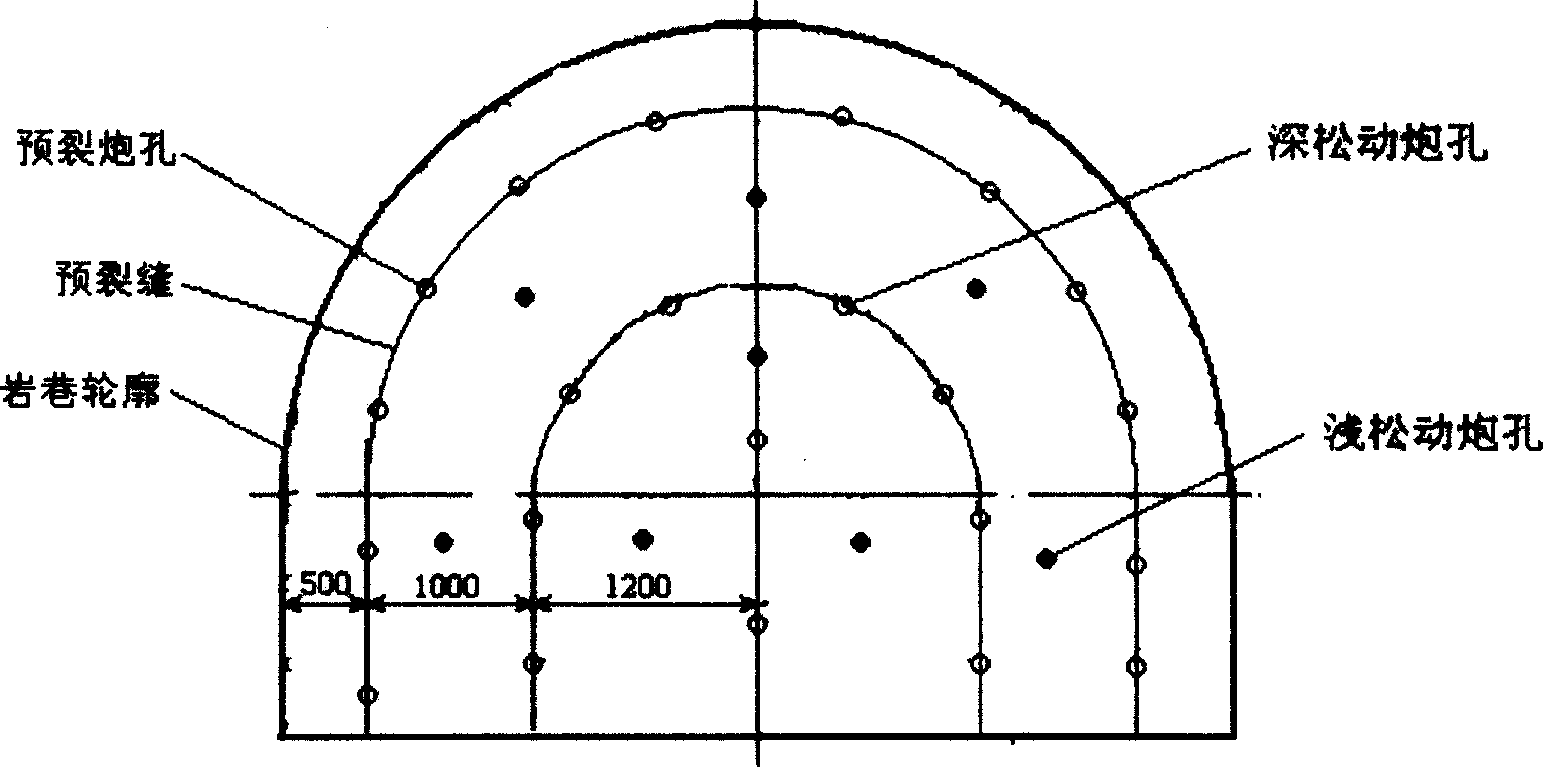

The invention discloses a rock gangway drifting method. Firstly, directional blasting technology is adopted, and presplitting cracks are arranged close to the periphery of a rock gangway through blasting. Secondly, loosening blasting technology is adopted to break rocks in the presplitting cracks; directional blasting and loosening blasting can be performed separately and also can be performed synchronously and initiated in sequence; the directional blasting is initiated before the loosening blasting. Finally, a rock gangway drifting machine is adopted to drill broken rocks. By adoption of combination of drifting of the drifting machine and controlled blastings, the invention has the advantages of great reduction of damage on surrounding rocks, increase of safety, improvement of drifting speed and reduction of cost, and is a rock gangway drifting method having the advantages of high efficiency, safety, low cost, good operating environment and low labor intensity. The invention is suitable for drifting various rock gangways and particularly suitable for drifting rock drifts with high hardness.

Owner:杨仁树

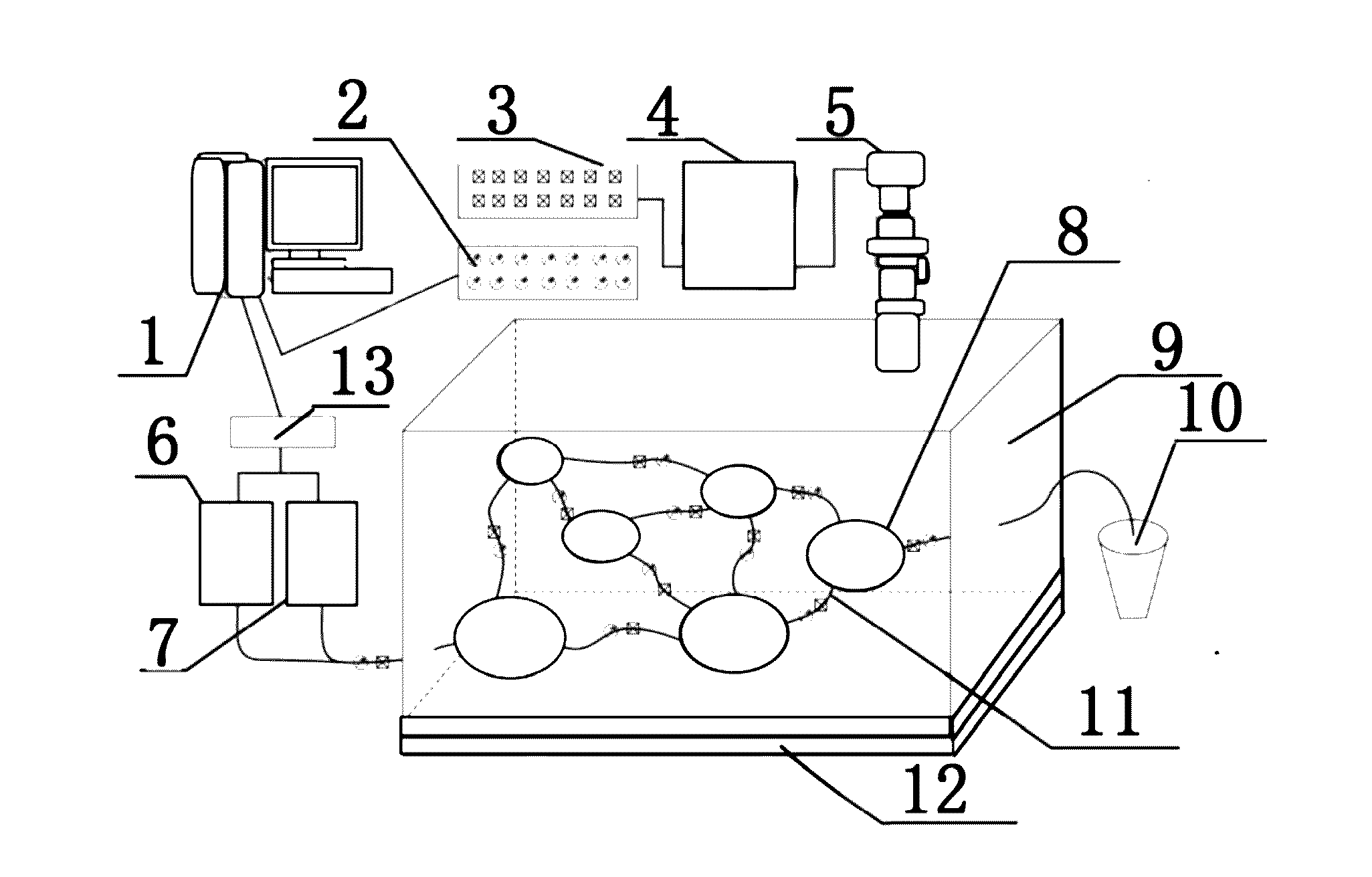

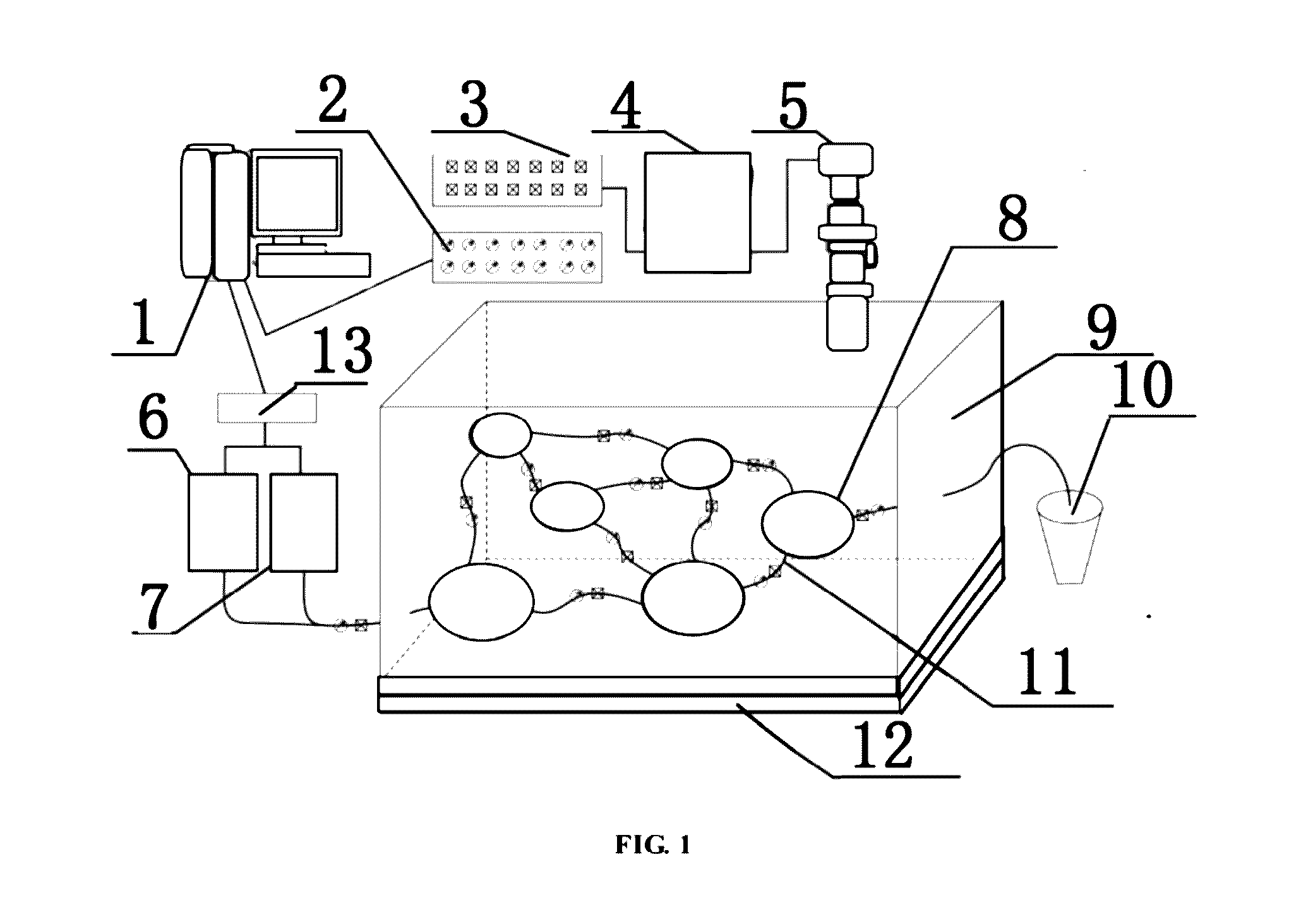

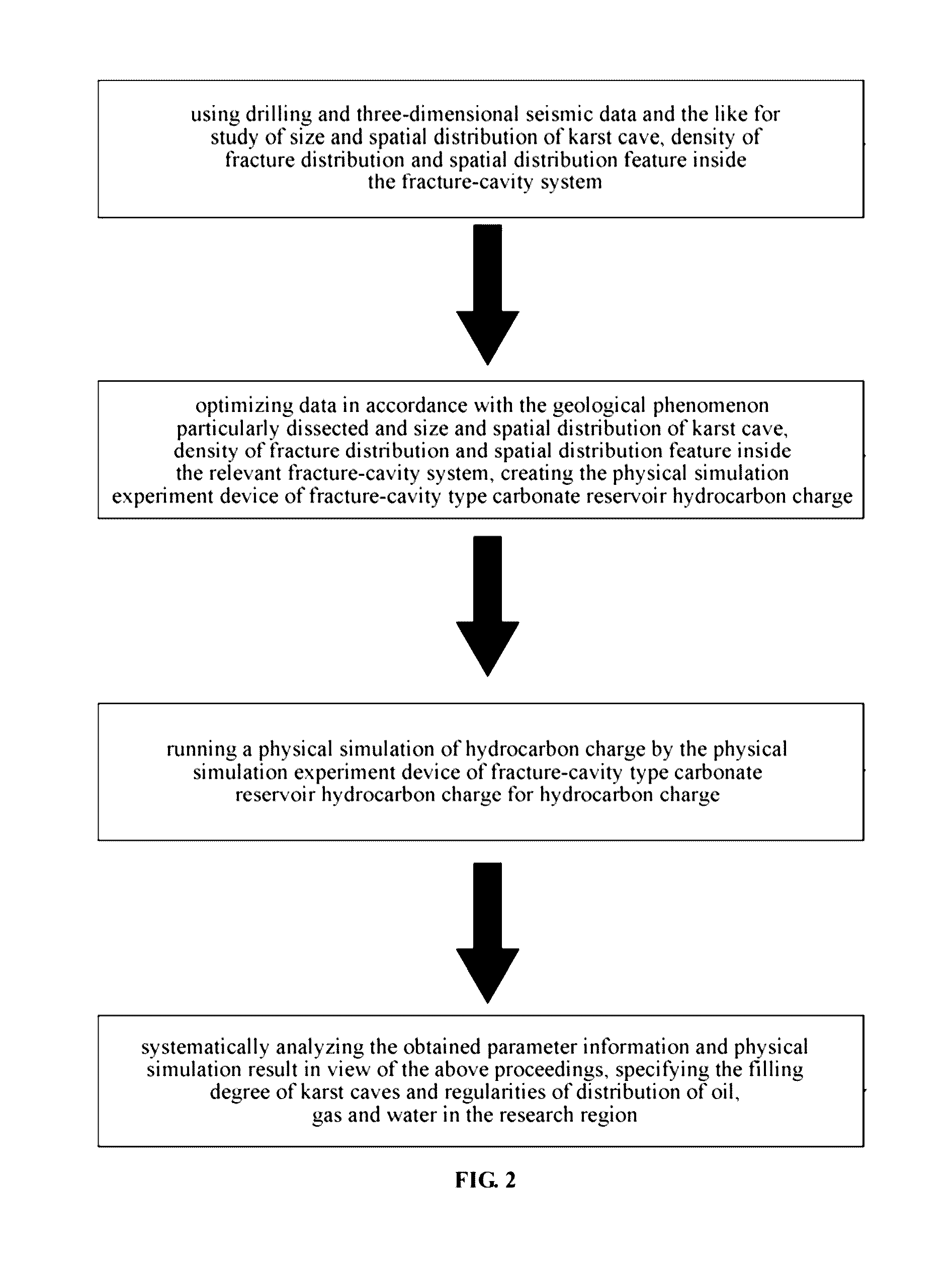

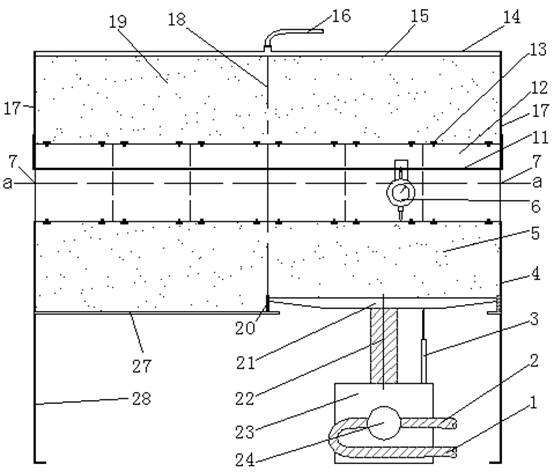

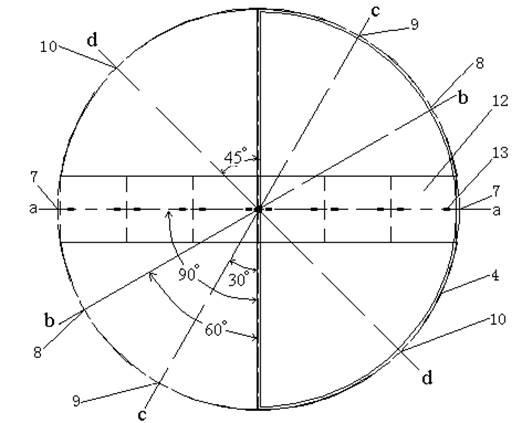

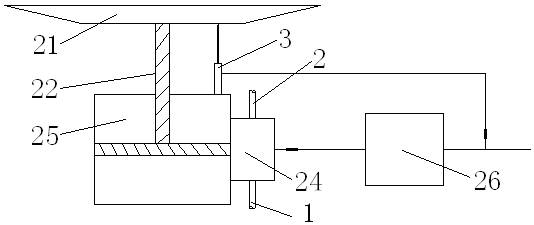

Physical simulation method and experiment device of fracture-cavity carbonate reservoir hydrocarbon charge

The present invention provides a physical simulation experiment device of fracture-cavity carbonate reservoir hydrocarbon charge. The experiment device comprises a fracture-cavity model, an experiment stand with windows, a wall rock and a camera monitoring system; the fracture-cavity model comprises simulation caves in different sizes and simulation fractures in different sizes; the simulation caves are connected to one another via the simulation fractures; the fracture-cavity model is arranged inside the experiment stand with windows, and the simulation caves of at least one side of the fracture-cavity model are visual through the windows of the experiment stand; a surrounding of the wall rock is arranged around the fracture-cavity model to simulate a formation of fracture-cavity carbonate reservoir; the camera monitoring system is used for measuring and adjusting changes in flow rate and pressure in a charge process, and recording an image of fracture and cave in the charge process displayed in the windows. The present invention further provides a physical simulation method of fracture-cavity carbonate reservoir hydrocarbon charge, which uses the above-mentioned experiment device. The present invention can obtain regularities of distribution of oil, gas and water through parameters such as karsts, fractures, density of cruel oil, and oil, gas and water distribution and the like.

Owner:PETROCHINA CO LTD

Physical model test device and method for ground fissure earth tunnel

InactiveCN101900642ASimple structureEasy to operateStructural/machines measurementSeismologySoil massSoil science

The invention discloses a physical model test device for ground fissure earth tunnels comprising a model box in a model device. A footwall soil mass and a hanging wall soil mass are symmetrically arranged by a vertical shaft in the model box, a simulation ground fissure is arranged between the footwall soil mass and the hanging wall soil mass, a fixed bottom plate is installed below the footwall soil mass, and a hanging wall soil mass supporting plate in a sedimentation device is installed below the hanging wall soil mass; an air pressure sac is arranged among an upper cover, the footwall soil mass and the hanging wall soil mass; a tunnel portal is horizontally arranged on the cylindrical side wall of the model box, the axial line of the tunnel portal is perpendicular to the vertical shaft of the model box, the tunnel portal is internally provided with a model tunnel lining structure, and various sensors are arranged. The invention also discloses a physical model test method for the ground fissure earth tunnels. Tests of various schemes, such as ground fissure trend variation, variations of wall rock soil mass stratum structures and mechanical properties, variations of lining structural forms, sections and rigidities, and the like are realized by utilizing the device. The device and the method of the invention are simple and have good accuracy.

Owner:XIAN UNIV OF TECH

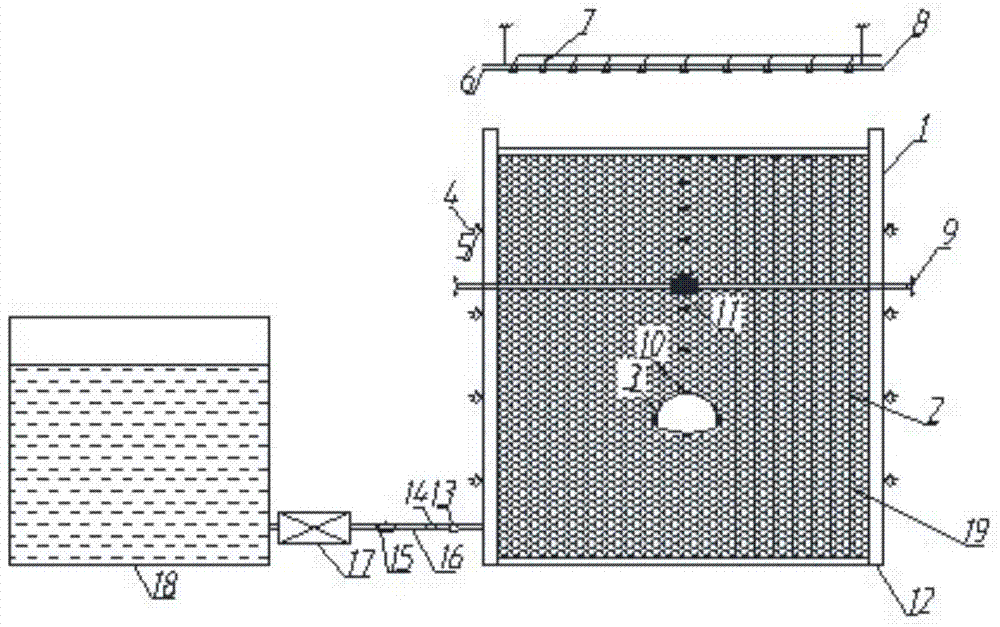

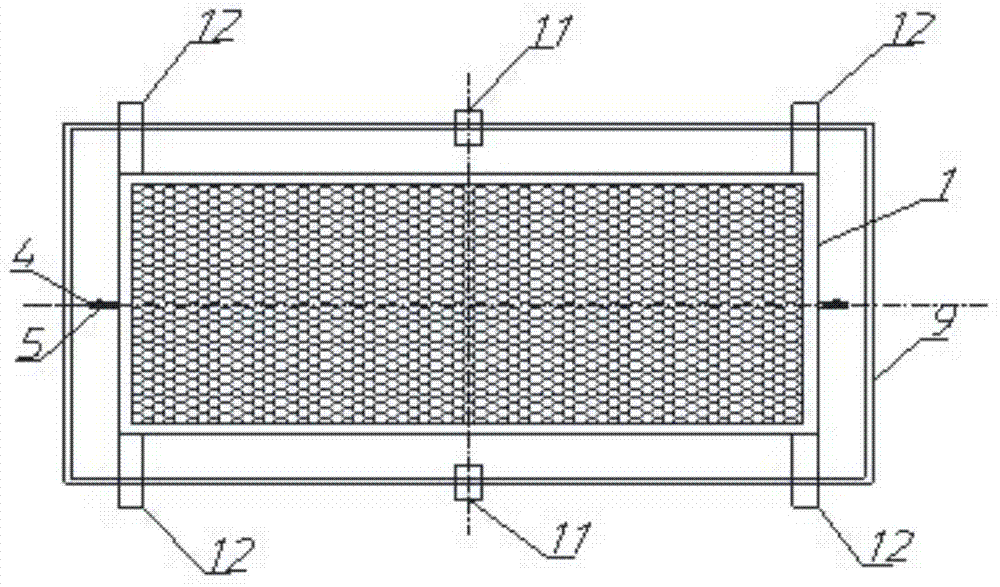

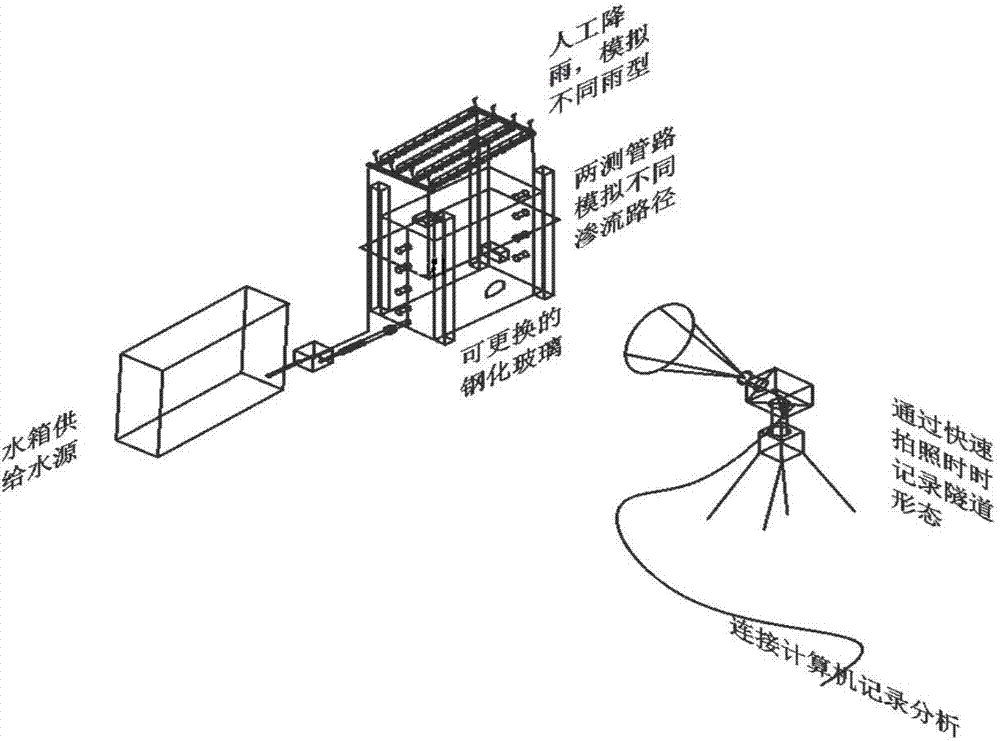

Testing device and method for simulating collapse of tunnel surrounding rock under conditions of rainfall and underground water seepage

ActiveCN104330533ARealize simulationAdjustable rainfallEducational modelsMaterial analysisPhysical fieldModel testing

The invention discloses a testing device and a testing device method for simulating collapse of tunnel surrounding rock under conditions of rainfall and underground water seepage. The testing device comprises a model testing box, a rainfall adjustable simulating system, an underground water seepage simulating system, an underground water supplying system, a water content testing system, a stress monitoring system, a digital radiography noncontact measuring system and an optical fiber bragg grating displacement monitoring system. By simulating a progressive failure process of tunnel weak broken surrounding rock under the action of seepage of surface water and underground water, mechanical behaviors of crushing the surrounding rock under different rainfall conditions and different underground water seepage path conditions are quantitatively researched. By obtaining multiple-physical field information in a tunnel surrounding rock collapse process, multi-information features in different evolutionary phases and internal links of information of all fields of the collapse are analyzed, a progressive failure process and fracture morphology and ranges of the tunnel weak broken surrounding rock under different factors are determined, and the effective basis is provided for disclosing a progressive failure principle and a dynamic pressure arch effect of the weak broken surrounding rock under conditions of rainfall and underground water seepage.

Owner:CHINA UNIV OF MINING & TECH

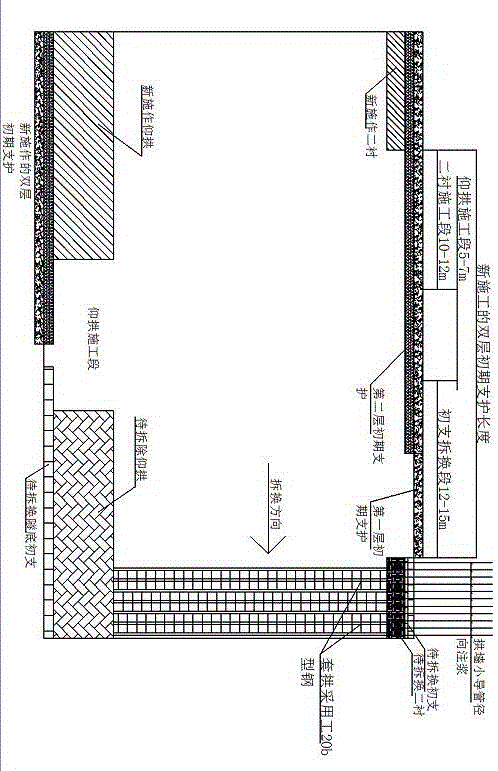

Construction method of pervious rib type arch beam tunnel

ActiveCN101324072AEasy constructionConstruction safetyArtificial islandsClimate change adaptationSupporting systemProcess safety

The invention discloses a through rib-typed arched girder tunnel construction method, comprising the steps as follows: before the excavation of the tunnel, the arch slope is reinforced by transverse pipe roof; the shaft excavation is carried out by a type of stepped excavation and reserving rock arch; after the wall rock deformation is basically stable, the internal side arch secondary lining, arch ground beam, the rock fall-proof retaining block, the rib-typed arched girder and the anti-collision wall are wholly constructed; the metering of each construction circulation excavation is 10-12m and the whole construction length is 6-8m. The invention is a set of whole construction method for the through rib-typed arched girder tunnel; the construction sequence and the supporting system are adaptable for the characteristics of the through rib-typed arched girder tunnel such as shallow burying, eccentric pressing and space forcing, effectively ensures the construction process safety and the stability of the tunnel structure, and provides a practically operatable construction technique for the generalization and application of the novel environmental-protective tunnel, namely, through rib-typed arched girder tunnel.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

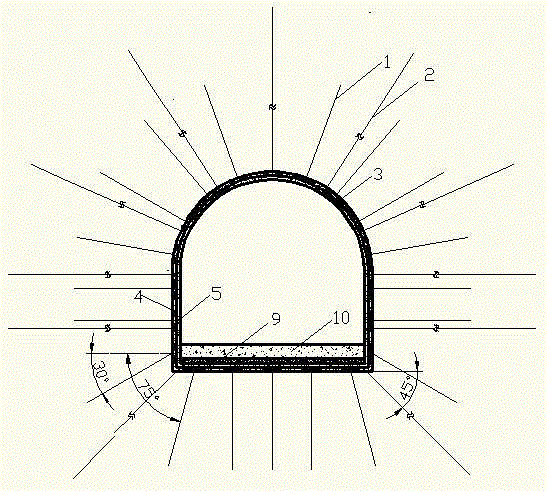

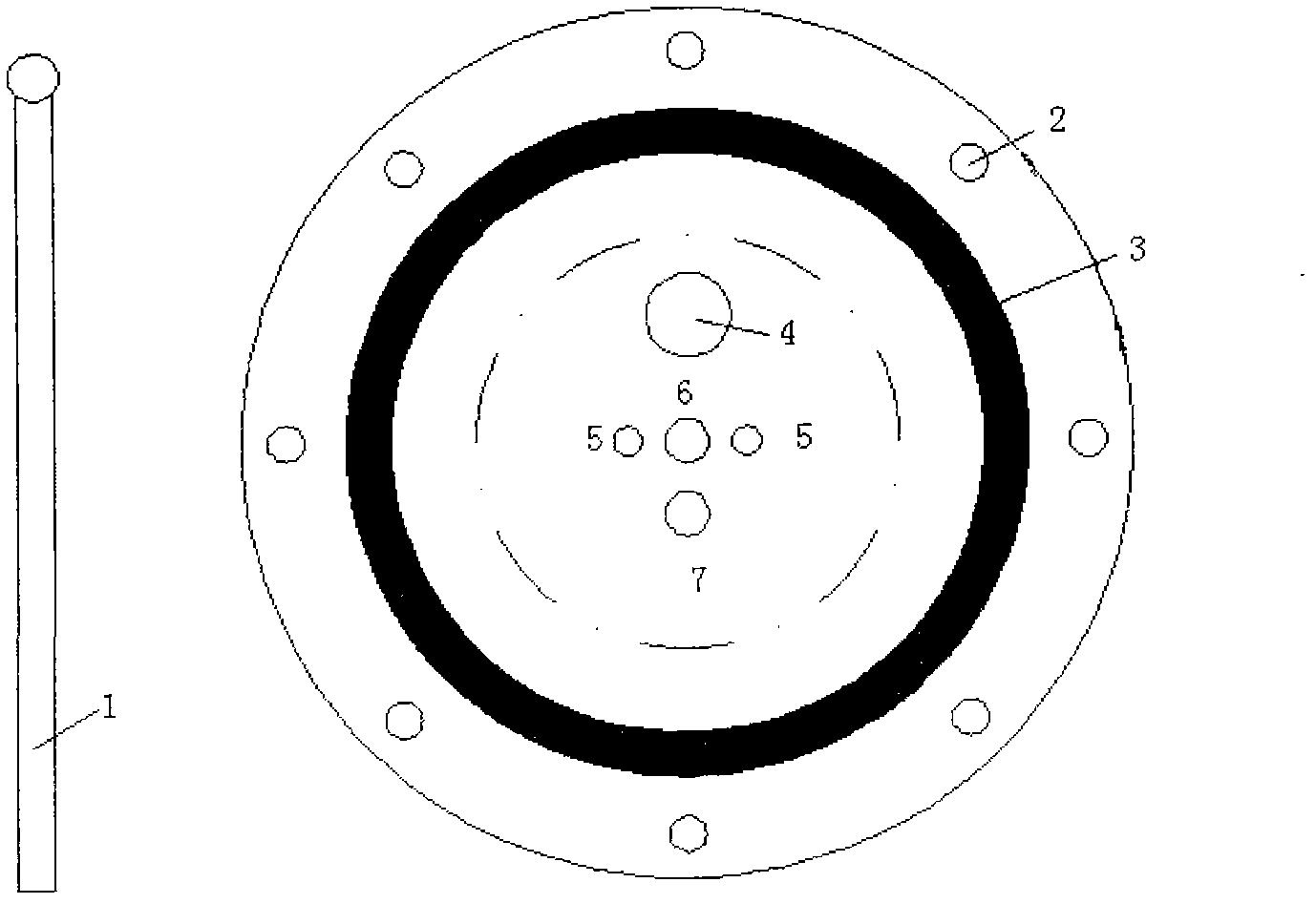

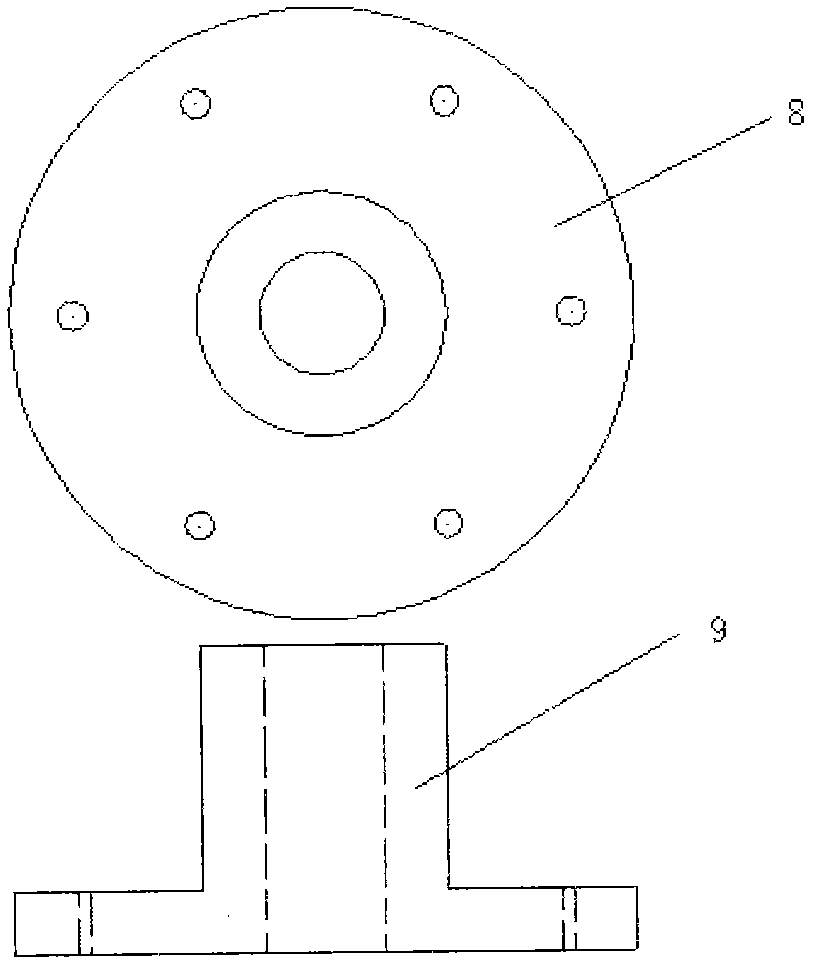

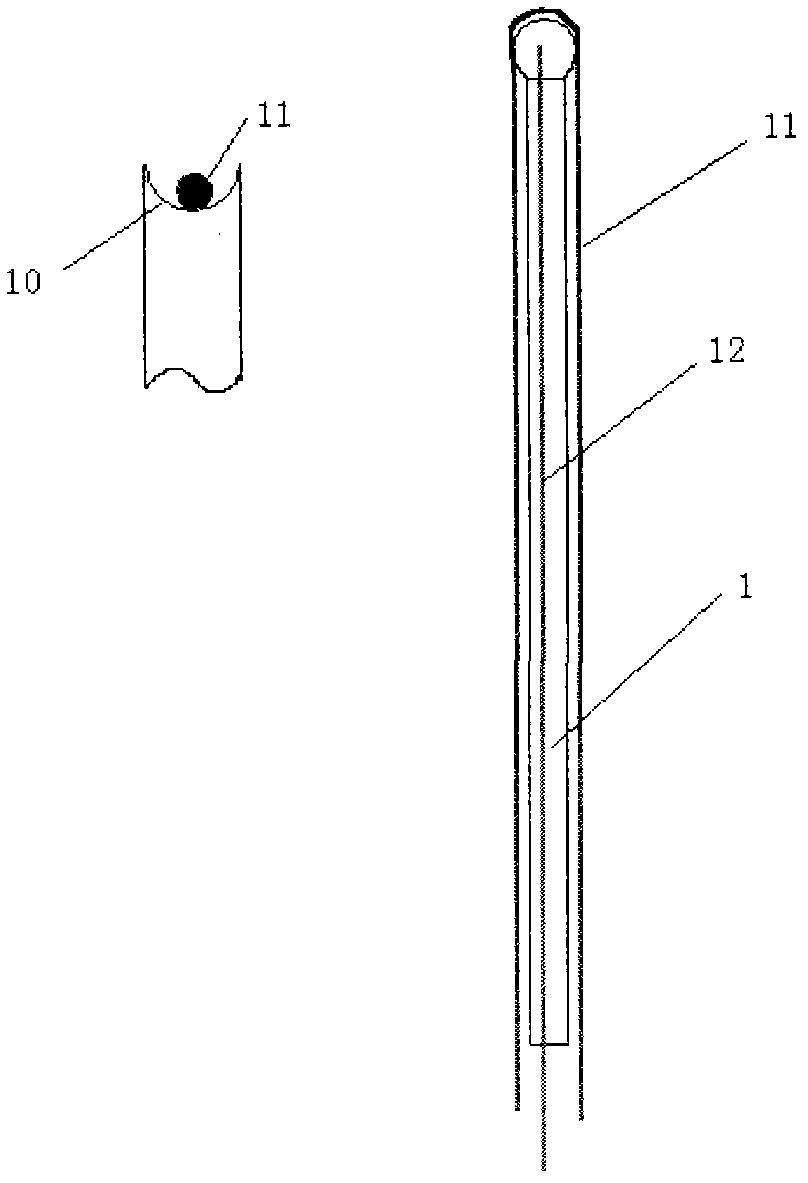

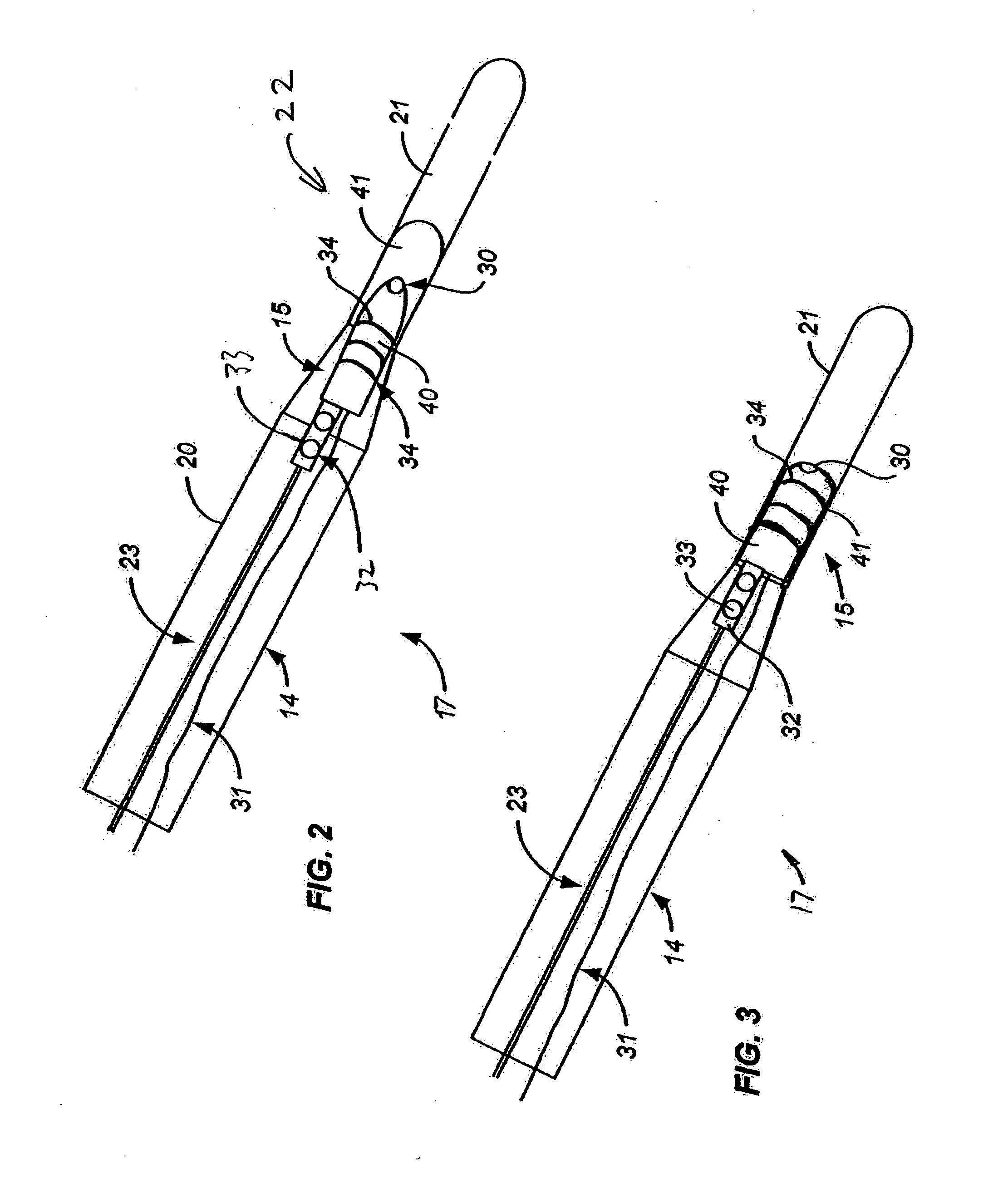

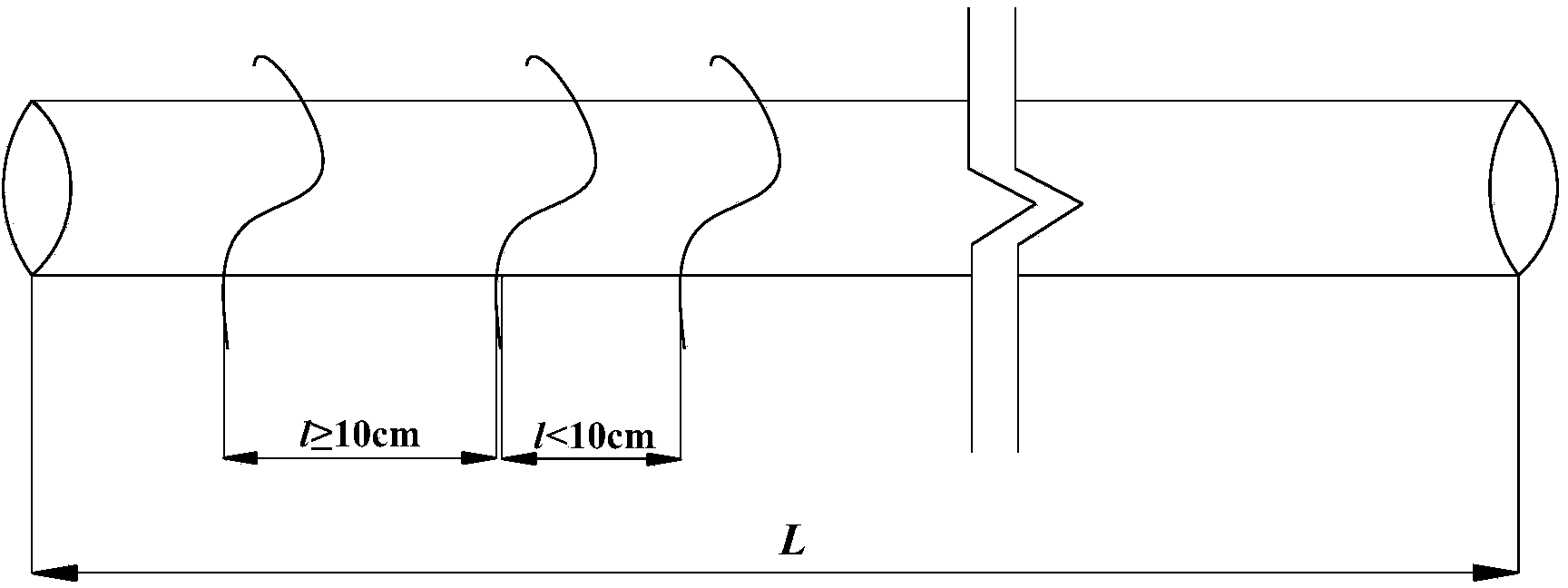

Tunnel surrounding rock radial stress strain distributed monitoring technology

The invention belongs to the technical field of geotechnical engineering monitoring, and relates to a distributed optical fiber sensing technology-based tunnel surrounding rock radial stress strain distributed monitoring technology. A distributed optical fiber sensor is conveyed to a hole bottom of a radial monitoring hole through a supporting rod member; the supporting rod member (1) and a grouting exhaust pipe (13) are plugged in the hole at a hole orifice through a hole orifice fixing system; a grouting hole (4) is connected to a grouting machine through a grouting pipe; a gap between the optical fiber sensor and a surrounding rock is filled by injecting grout which is matched with modulus of deformation of the surrounding rock into the hole, so that the optical fiber sensor and the surrounding rock cooperatively deform; the optical fiber sensor comprises a distributed optical fiber strain optical fiber sensor and a temperature optical fiber sensor; the distributed optical fiber sensor of each monitoring hole is connected in series to an optical fiber strain analyzer Brillouin optical time domain reflectormeter (BOTDR) by fusion welding; measurement and positioning functions ofBrillouin frequency shift on each point of an optical fiber are finished by measuring power of received Brillouin backscattered light; and strain distribution and temperature distribution in the radial direction in the surrounding rock can be obtained to evaluate and forecast the stability of the surrounding rock according to the linear relation between the Brillouin frequency shift and the strain as well as the temperature.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

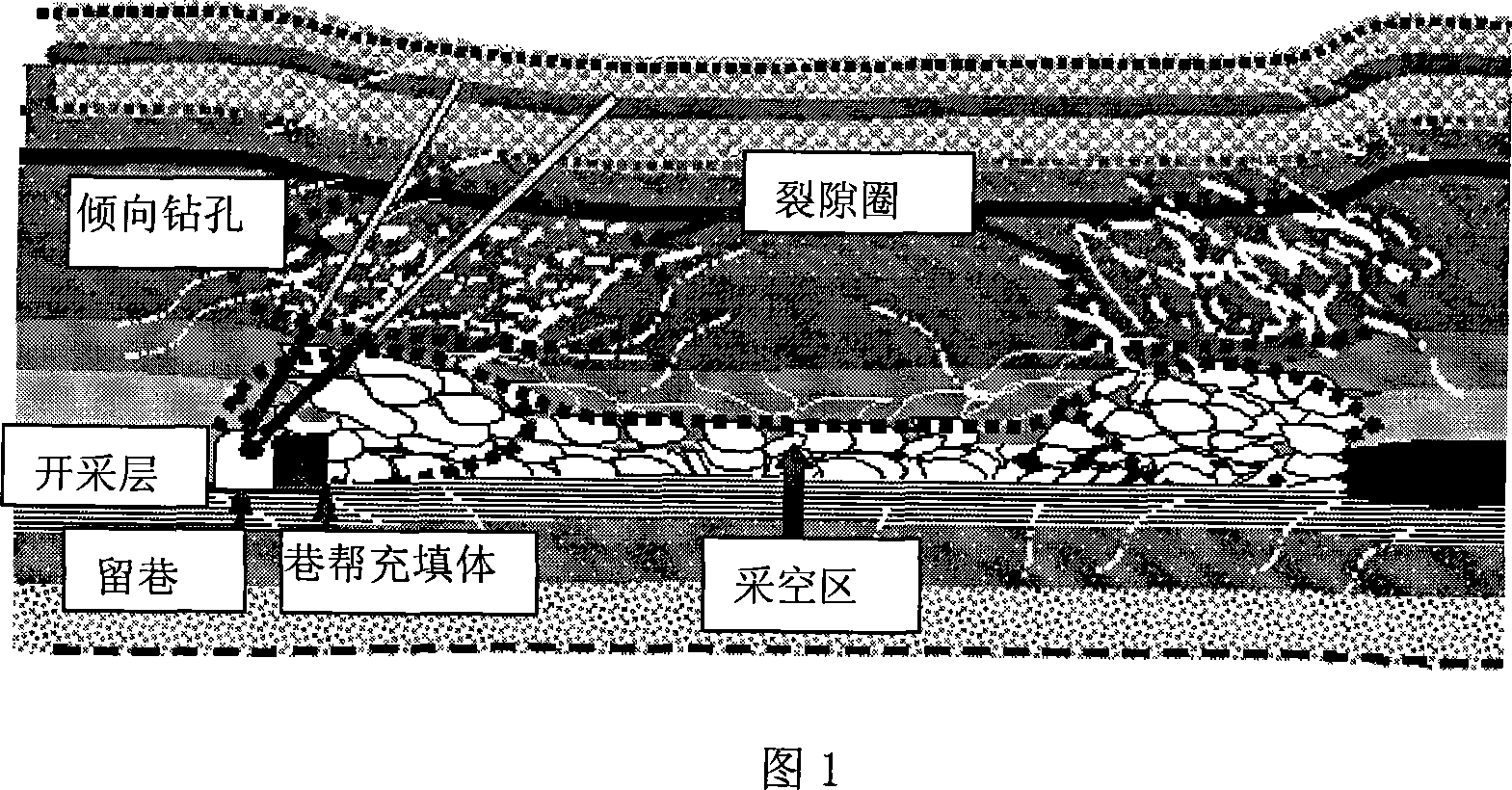

Method of support along spatially keeping lane

ActiveCN101117890ARelieve pressureMake sure not to breakMaterial fill-upProps/chocksSpontaneous combustionEngineering

A method for supporting and protecting gob roadway walls built along the gob road-way is characterized in that the filling bodies of gob roadway walls are built along the working surface at the side of the goaf to establish a supporting and protecting belt for gob roadway walls. The method can effectively control the roof delamination of a direct roof and can timely cut off the roof and the lower basic roof and also can fill out goaf with the falling recrement, thereby reducing the bending of the basic roof, and the loading of the inner supporting and protecting structure and the deformation of the wall rock of the gob roadway, as well as keeping the stability of the gob roadway, meanwhile, the method also can seal the goaf, prevent air leaking and spontaneous combustion of coal, and avoid harmful air coming into the working area.

Owner:HUAINAN MINING IND GRP +2

Bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock

The invention specifically discloses a bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock, and the method comprises the following steps of: (1) after the roadway is excavated, immediately shotting concrete to close the surrounding rock, employing a high-pretightening force overstrength anchor bolt for supporting in the first disintegration zone, and arranging a steel bar net on the inner wall of the roadway surrounding rock and shotting concrete again; (2) applying a pretightening force anchor cable on the top plate of the roadway surrounding rock such that the anchoring end of the anchor cable is located in the deep intact rock mass, arranging a steel I-beam closely to the surrounding rock, passing the anchor cable through the shotcrete, the steel I-beam and a yielding ring and fixing the anchor cable on the inner wall of the roadway surrounding rock by using an anchor cable lock, thereby realizing coupling and supporting of the anchor bolt and the anchor cable; and (3) according to the monitoring result of the zonal disintegration of the surrounding rock, performing the delayed anchor bolt support for about 20-30 days, and performing grouting reinforcement on each disintegration zone by virtue of long and short combined injection pipes or a hollow sectional spiral grouting anchor bolt. The bolting-grouting integrated support method is capable of effectively performing bolting-grouting integrated reinforcement on the disintegrated surrounding rock of the deep roadway and thereby obviously enhancing the stability of the roadway.

Owner:SHANDONG UNIV

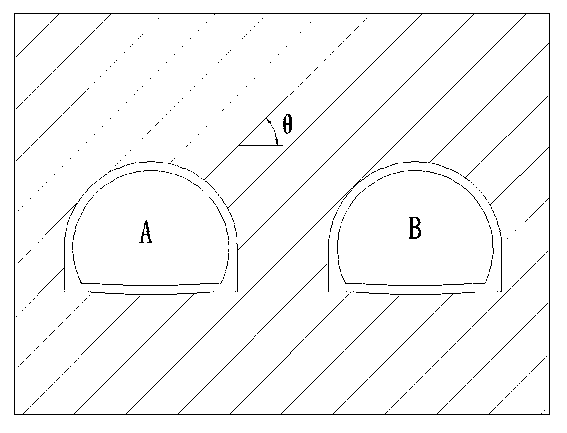

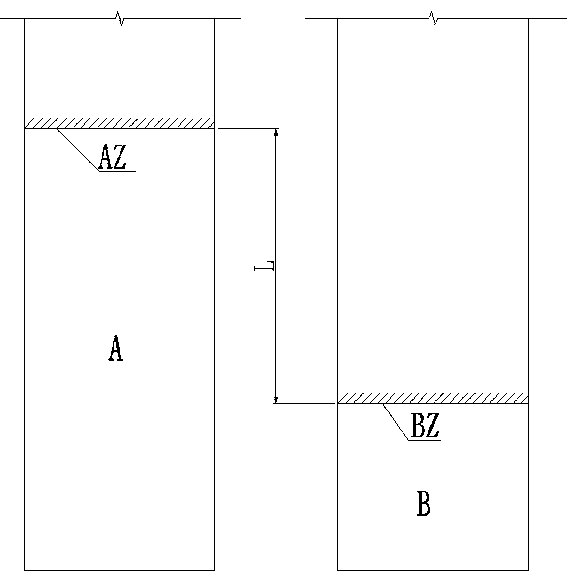

Damping blasting method for steep dip small crossing angle layered surrounding rock small-distance tunnel excavation

The invention provides a damping blasting method for steep dip small crossing angle layered surrounding rock small-distance tunnel excavation to solve the technical problem. The method comprises the following steps: dividing two small-distance parallel tunnels into a beforehand cavity and an afterwards cavity, wherein the beforehand cavity and the afterwards cavity are constructed in a staggered mode, dividing an excavated section of the tunnel into an upper bench excavating area, an upper bench excavating boundary, a lower bench excavating area and a lower bench excavating boundary; processing the upper bench excavating area by hole millisecond blasting excavating and processing the upper bench boundary by smooth blasting. After the upper bench excavating area is processed by excavating, the lower bench excavating area is processed by horizontal shallow hole blasting and the lower bench boundary is processed by smooth blasting. The damping blasting method for the steep dip small crossing angle layered surrounding rock small-distance tunnel excavation has the advantages that surrounding rock of the layered surrounding rock small-distance tunnel is prevented from losing balance during the blasting process or fissure of a blasting layer is prevented from being too deep to influence the stability of the tunnel, operating efficiency is improved and reinforce and maintain cost is reduced.

Owner:CHONGQING CONSTR ENG GRP +2

Three-connected-arch tunnel double-side cavity construction method for soft geological

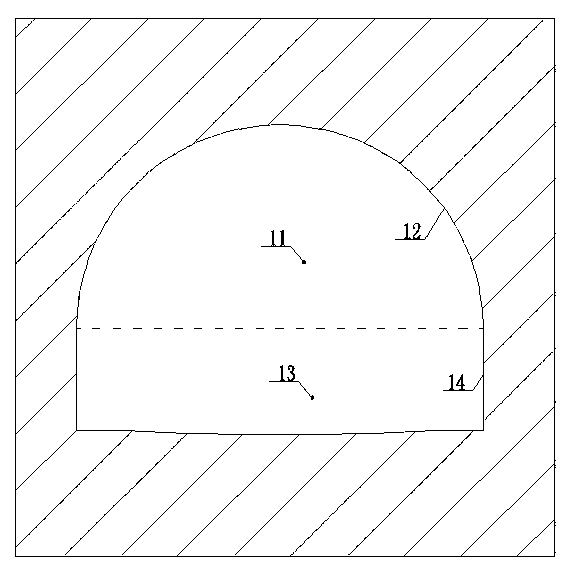

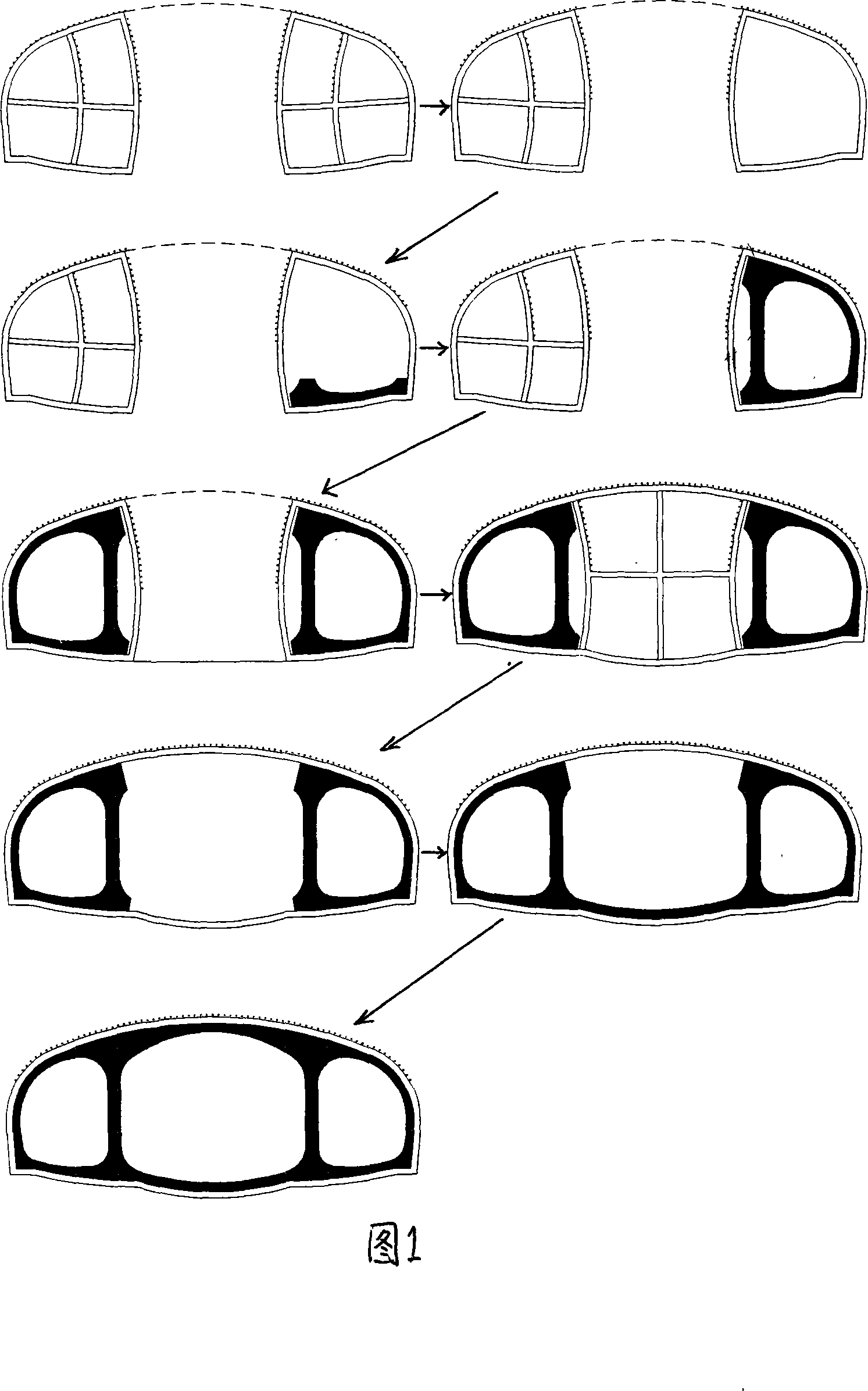

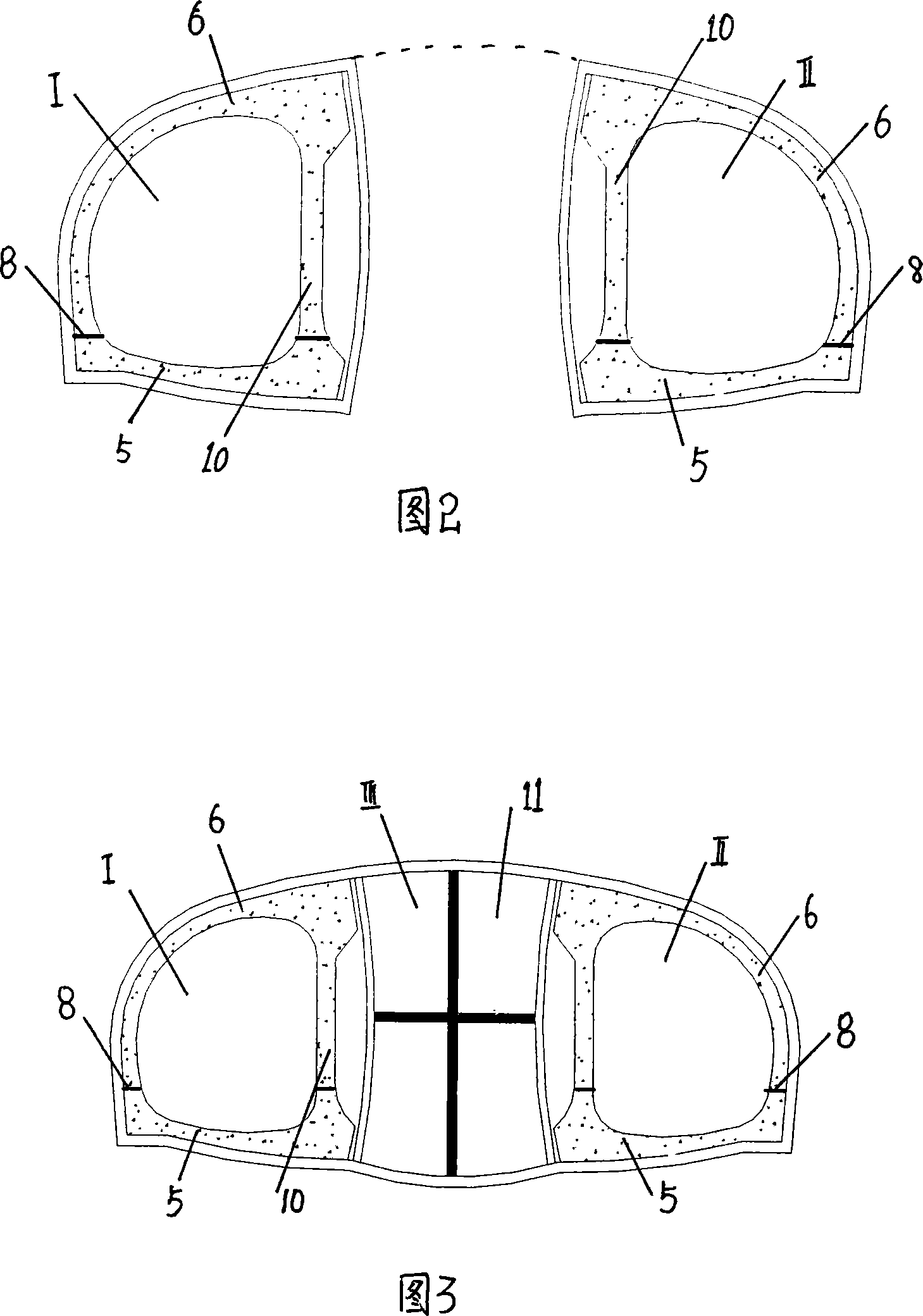

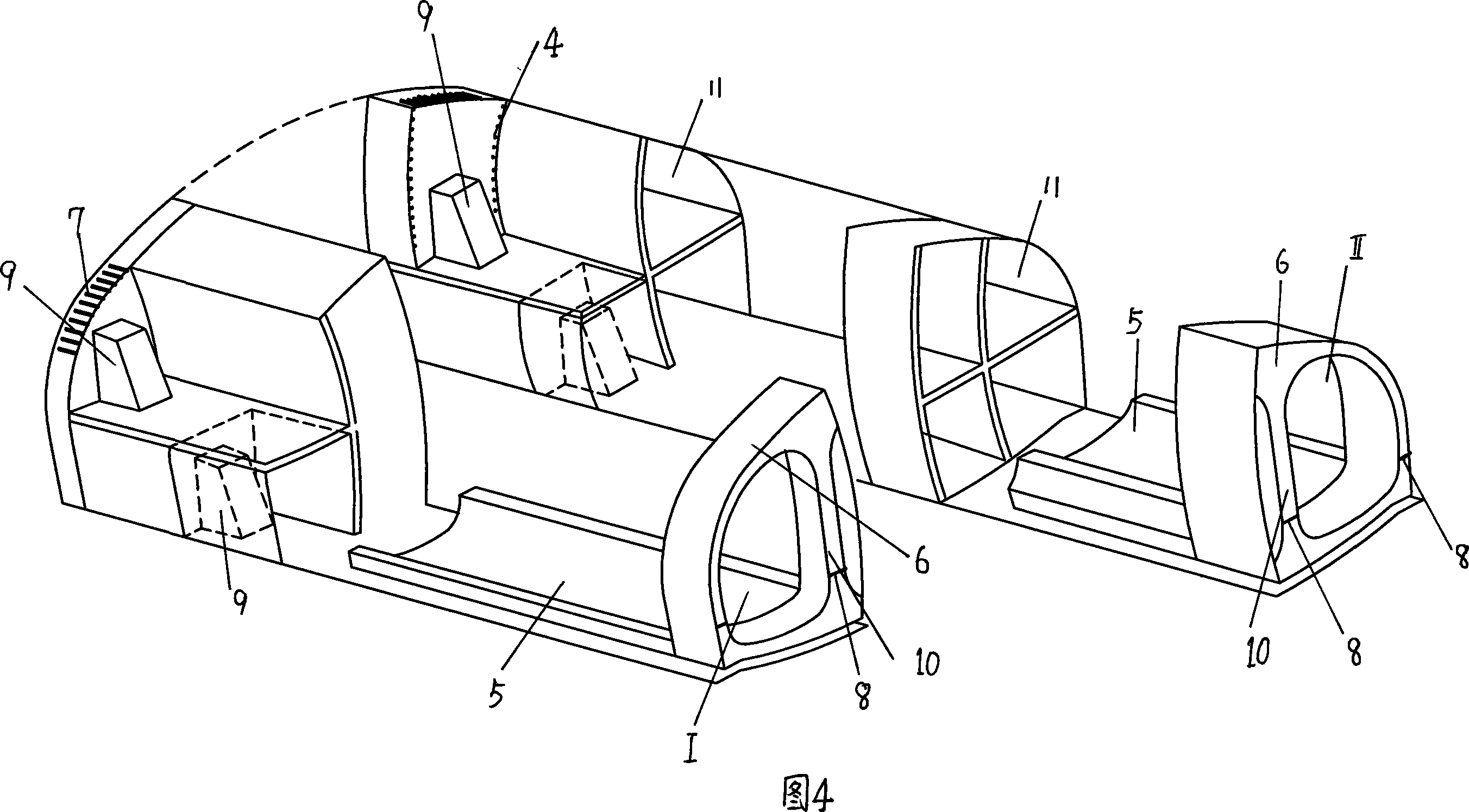

InactiveCN101196116AReasonable division of single excavation areaSuitable for manual excavationUnderground chambersTunnel liningEnvironment effectWall rock

The invention relates to the technical field for the engineering of large-section tunnel, in particular to an engineering method for the double lateral tunnel of a three-arc tunnel on soft and weak geological condition, which resolves the problem of longer duration for the exposure of wall rock, easy deformation of tunnel and poor waterproof effect in existing tunnel engineering method. The invention comprises: (1) excavation of lateral tunnel; (2) lining of later tunnel: first of all, dismantle the primary support of the whole section, then pour the arc invert secondary lining and arc section secondary lining with the construction joint being configured at the lower section of the middle wall for the lateral tunnel; (3) after the circular lining a left lateral tunnel I and a right lateral tunnel II on a same section, excavate and line a middle tunnel III. This method realizes simple equipment and convenient engineering; with the construction sequence of building the lateral tunnel and then the middle tunnel, the invention gives full play to the supporting function of the secondary lining of the middle wall, so as to reduce the load borne by the primary support of the arc section of middle tunnel and elevate the safety coefficient; the invention reduces the settlement and impact on peripheral environment, so as to ensure the stability and safety of the excavation working face; small number of construction joint and high working efficiency.

Owner:CHINA RAILWAY 12TH BUREAU GRP

Method and device for testing geo-stress in deep soft rock based on flow stress restoration principle

InactiveCN102628716AConvenient researchGet goodForce measurement by measuring frquency variationsTesting machinesObservation dataSlurry

The invention discloses a method and device for testing a geo-stress of a deep soft rock. The device comprises a connecting rod; two three-direction pressure boxes are adjacently fixed on the connecting rod; the three-direction pressure box is provided with three vertical working surfaces; a direction cosine of any two working faces among the two three-direction pressure boxes is not 1; a device for measuring a normal pressure stress is mounted on each working face of the two three-direction pressure boxes; and the device is connected with a reading instrument outside a drilling hole through a data wire. A geo-stress testing method comprises the following steps of: sending the two three-direction pressure boxes to a test point after drilling; grouting the drilling hole and sealing the drilling hole after the drilling hole is entirely filled; and after slurry is solidified, substituting six pressure data measured by the two three-direction pressure boxes into a geo-stress testing principle formula after the data is stable, so as to obtain the geo-stress at the test position. With the adoption of the method, a stress value inside surrounding rocks can be directly observed, and observation data can be obtained for a long time. Therefore, the method and device provided by the invention is good for researches of coal deep rock geo-stress and the stability of a surrounding rock.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

Tunnel supporting structure used for large deformation stratum and construction method of tunnel supporting structure

ActiveCN103527219ASolve support problemsGuaranteed stabilityUnderground chambersTunnel liningArchitectural engineeringLarge deformation

The invention relates to a tunnel supporting structure and a construction method of the tunnel supporting structure, and provides a tunnel supporting structure used for a large deformation stratum. An inner-layer primary support is arranged between a primary support and a secondary lining of the tunnel supporting structure. The construction method includes the steps that when deformation of the primary support reaches variable deformation, the inner-layer primary support is constructed, otherwise, the inner-layer primary support is not constructed, and the secondary lining is constructed according to the practical inner outline of the primary support or the inner-layer primary support. The primary support and the inner-layer primary support are matched, supporting to surrounding rock is initially flexible and then rigid and is initially released and then resisted, active adaptation to deformation of the surrounding rock is achieved, permanent supporting to the surrounding rock is achieved through a strong support formed by the primary support, the inner-layer primary support and the secondary lining, accordingly, the aim of supporting the large deformation stratum can be effectively achieved, and the stability and the safety performance during the running period of a tunnel can be guaranteed.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

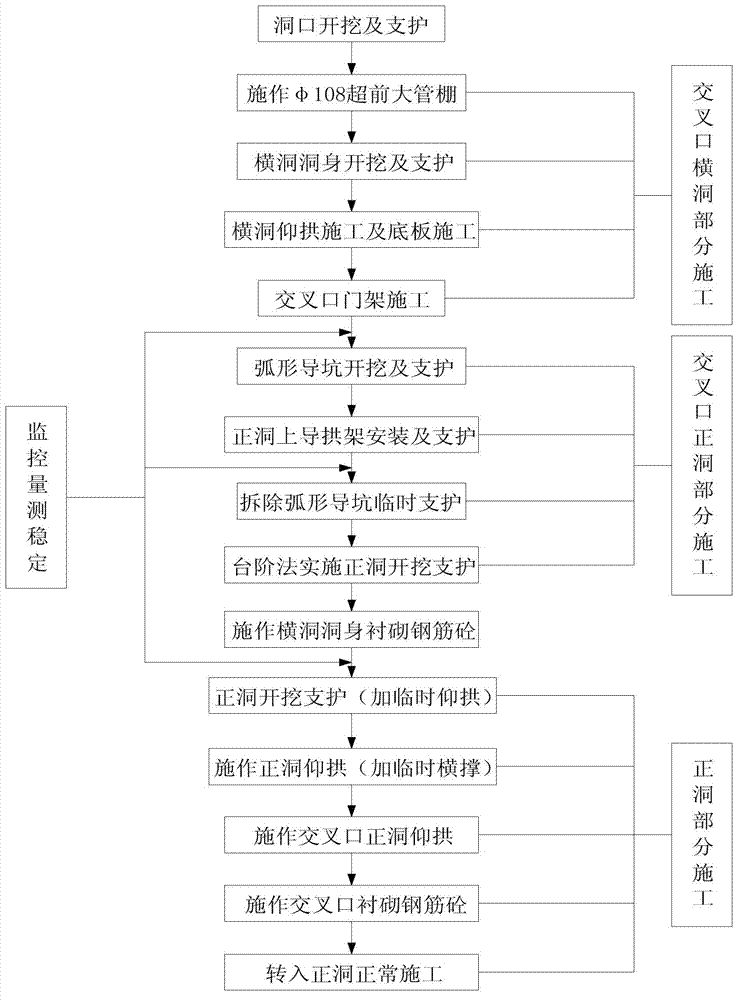

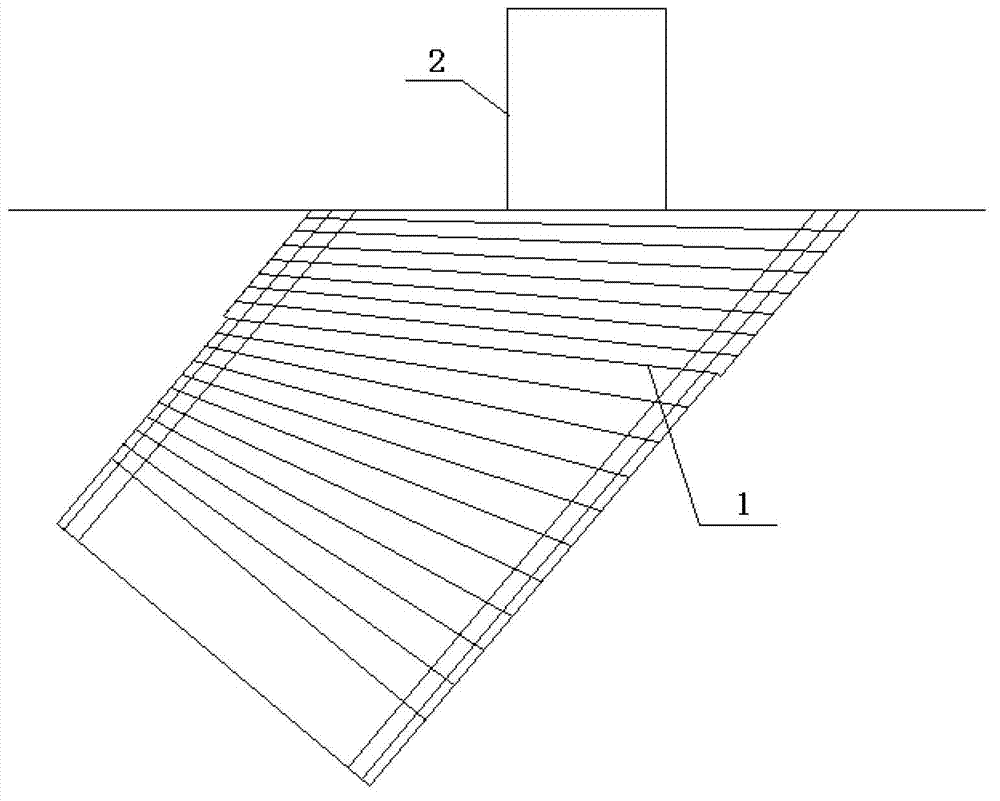

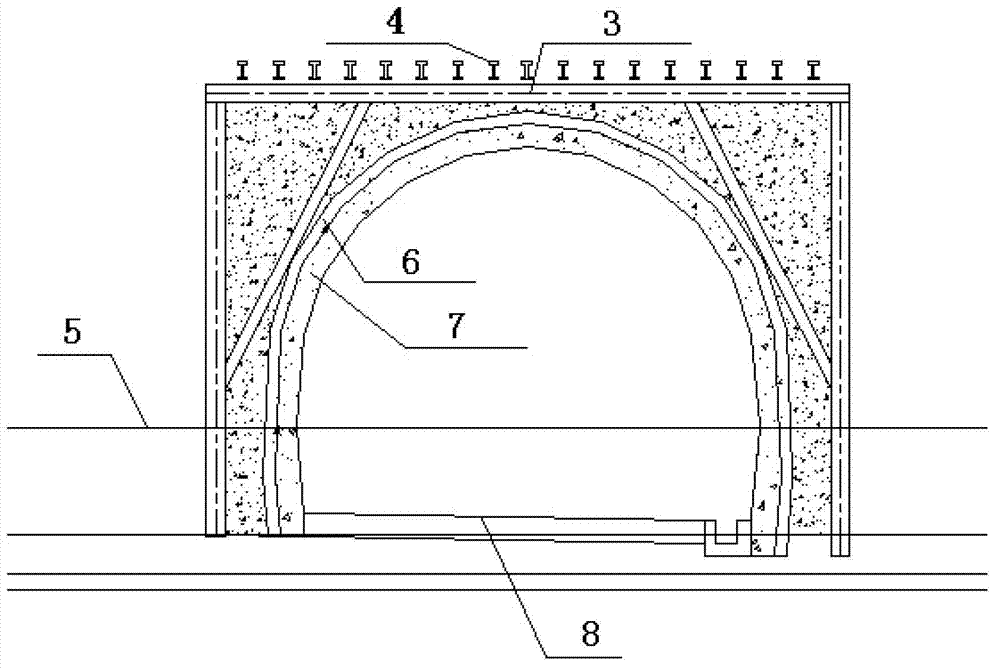

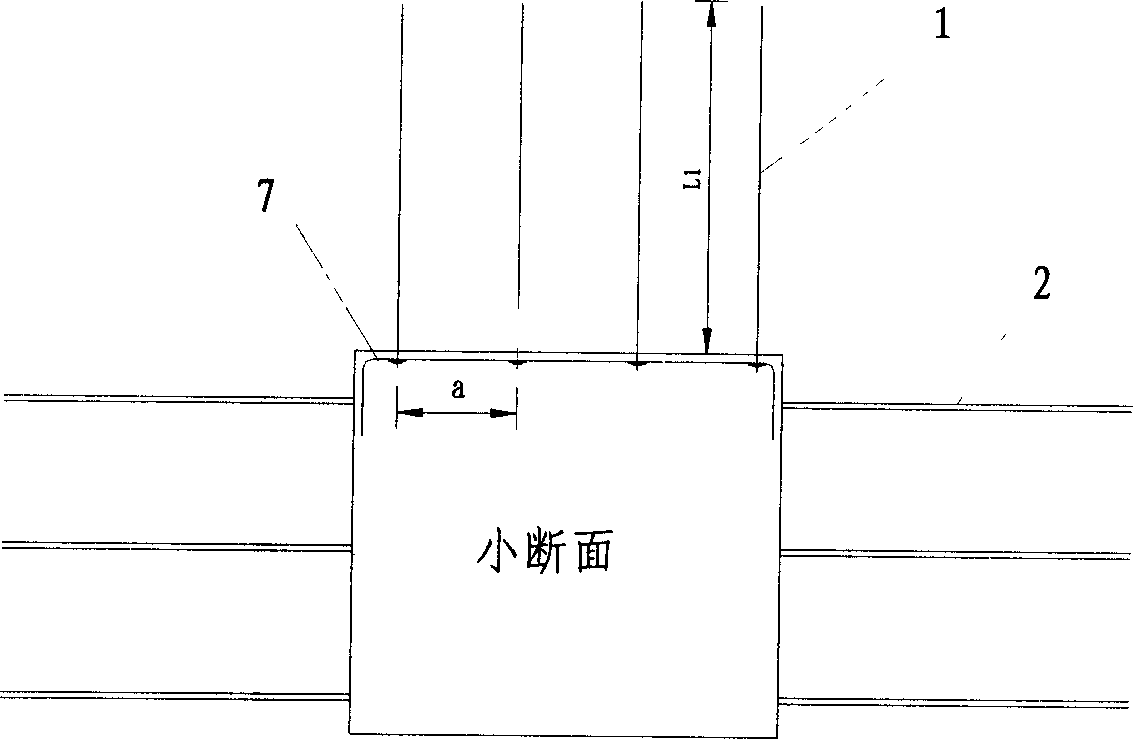

Weak surrounding rock, tunnel intersection and arc-shaped pilot tunnel construction method

InactiveCN103195432AAvoid safety hazardsImprove securityUnderground chambersTunnel liningReinforced concreteEngineering

The invention discloses a weak surrounding rock, tunnel intersection and arc-shaped pilot tunnel construction method. The method is characterized by consisting of the following steps: (1) excavating and supporting a mouth of a transverse hole; (2) constructing an advancing large pipe roof; (3) excavating and supporting a body of the transverse hole; (4) performing transverse hole inverted arch construction and bottom plate construction; (5) performing intersection door opening construction; (6) performing direct top brushing type excavation and supporting on an arc-shaped pilot tunnel; (7) mounting and supporting an upper guide arch frame of a front hole; (8) disassembling the temporary support of the arc-shaped pilot tunnel; (9) excavating and supporting the front hole by a step method; (10) constructing lining reinforced concrete on the body of the transverse hole; (11) excavating and supporting the front hole and adding a temporary inverted arch; (12) constructing a front hole inverted arch and adding a temporary cross brace; (13) constructing an inverted arch on the intersection front hole; (14) constructing lining reinforced concrete on the intersection; and (15) shifting to normal construction of the front hole. The arc-shaped pilot tunnel construction section is smaller than the front hole excavating section; the potential safety hazards of the arch change of the weak surrounding rock are avoided; the temporary work amount is small; the construction efficiency is high; the transverse hole at the intersection does not climb; and the stressed effect of the special-shaped arch frame of the front hole is good.

Owner:中铁二十二局集团第一工程有限公司 +1

Three-anchor coupling supporting method for high stress tunnel break wall rock

InactiveCN1693670AEffective control of deformationEffective damage controlAnchoring boltsProtective coversStress concentrationEngineering

This invention is a three-anchor-coupling supporting method for high stress tunnel break wall rock. Small section digging is used, roof deformation is controlled by reinforce the support of roof plate to lighten the stress concentration of two sides coal bodies. Pressure relief holes that allow wall rock to deform and damage are drilled on both sides to release the high stress in wall rack, then construction of big brush and consolidation is done. Roof and bottom angles are reinforced support in stress releasing course to effectively control deformation and damage of tunnel roof for stabilizing wall rock. bolt-spray supports anchor cable consolidation and anchor inject support in coal road and soft rock supporting is combined as one piece. Its coupled relation is fully exerted and the support problem of conforming complicated area and deep buried high stress cracking wall rack or soft tunnel. Its stability is strong, operability is strong, it is safe and reliable can meet the stability needs of roadway in complicated conditions.

Owner:CHINA UNIV OF MINING & TECH

Even-grouting structure of coal mine tunnel and construction technology thereof

InactiveCN103195442AChange cohesionChanging the internal friction angleUnderground chambersTunnel liningSlurryRock bolt

The invention discloses an even-grouting structure of a coal mine tunnel and a construction technology thereof. The even-grouting structure of the coal mine tunnel comprises a lane, wherein a concrete spraying layer is arranged on the inner wall of the lane, a grouting anchor rod for filling reinforcing slurry into surrounding rock so as to form a reinforcing assembly arch on the outer side of the lane is arranged in the surrounding rock of the lane, the inner end of the grouting anchor rod is communicated with a crack in the surrounding rock of the lane, the outer end of the grouting anchor rod protrudes out of the concrete spraying layer, grouting anchor cables are further arranged at the top of the lane and in the surrounding rock on two sides of the lane, one end of each grouting anchor cable is anchored in the surrounding rock, and the other end of the grouting anchor cable is anchored on the outer side of the concrete spraying layer. Slurry is filled in cracks in the surrounding rock of the lane for reinforcing, the grouting is performed according to the softness and broken degree and the crack development degree of the rock, and repeated reinforcing and cementing are performed, so that cohesion and inner friction angles of the surrounding rock can be fundamentally changed, the surrounding rock in a broken rock zone of the lane can be in a relatively homogeneous and stable state, and the reinforcing assembly arch even in stress is formed on the outer side of the lane.

Owner:PINGDINGSHAN TIANAN COAL MINING

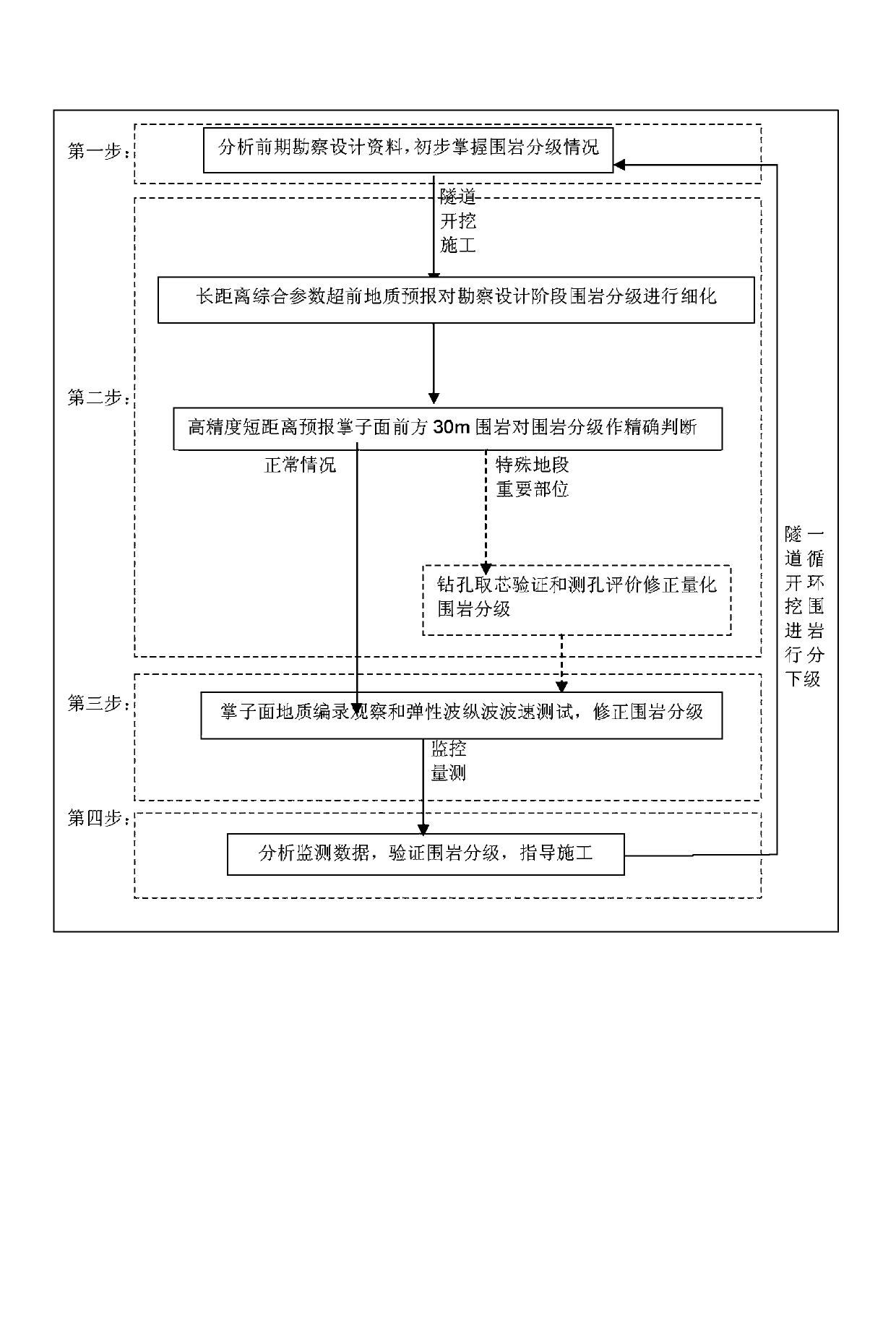

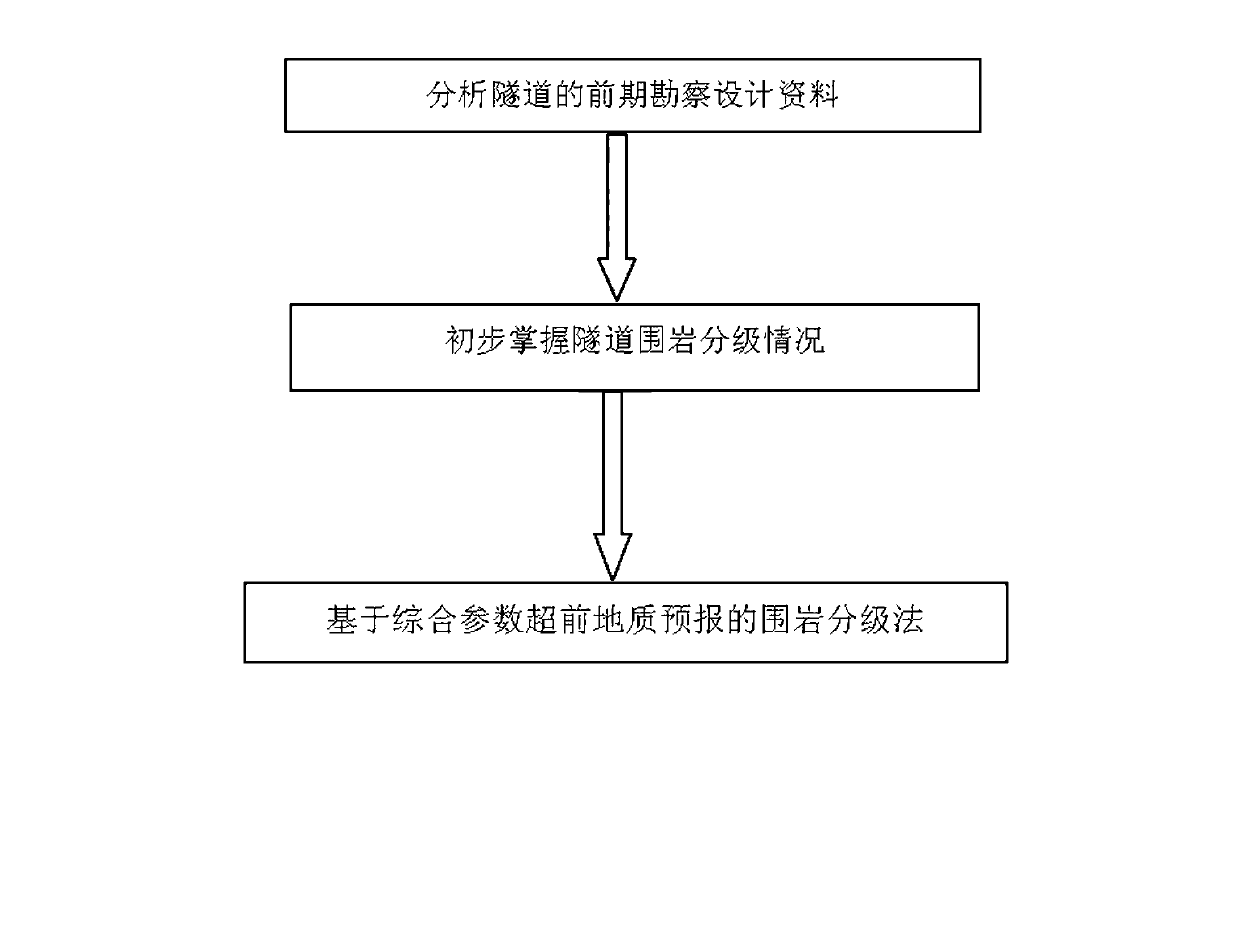

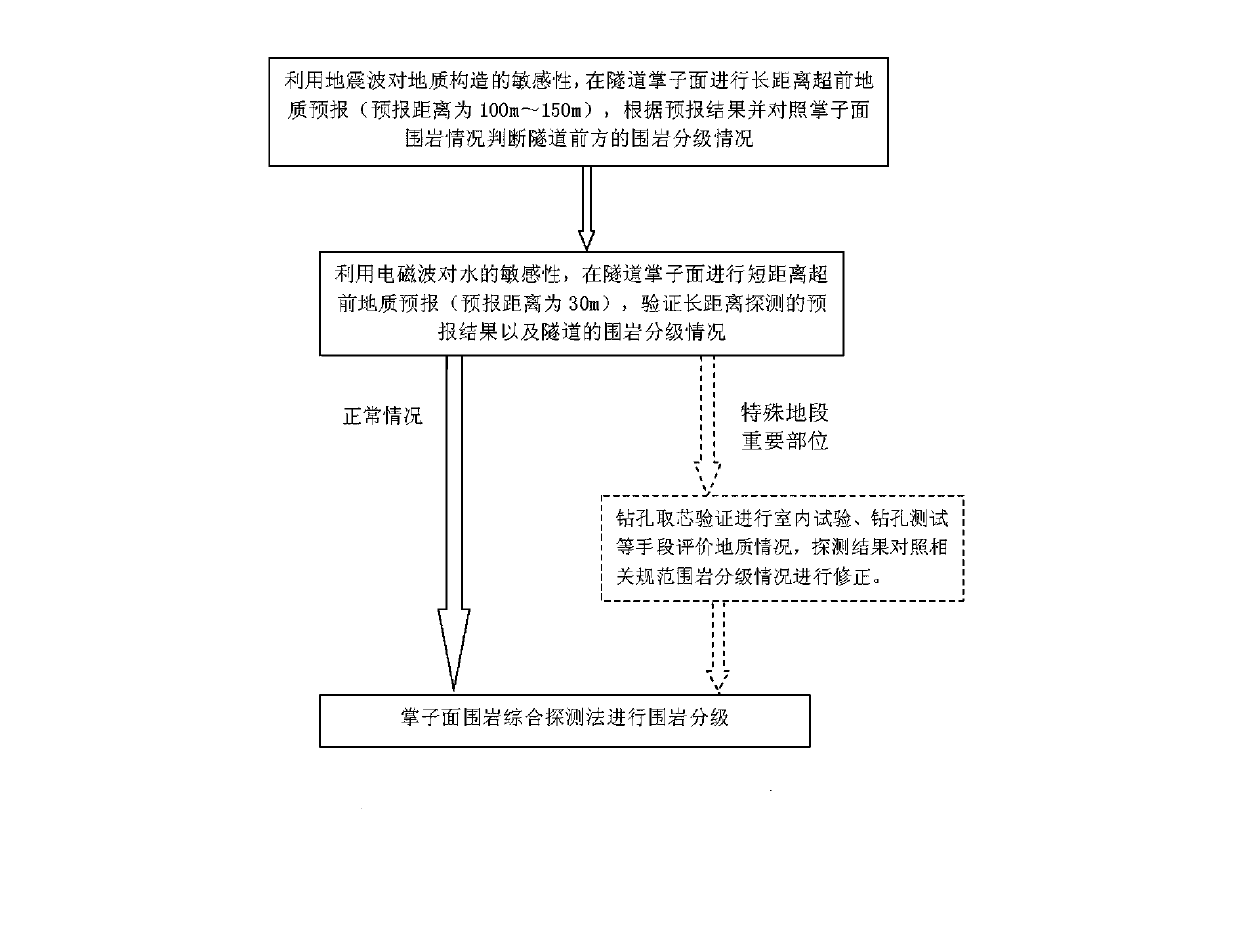

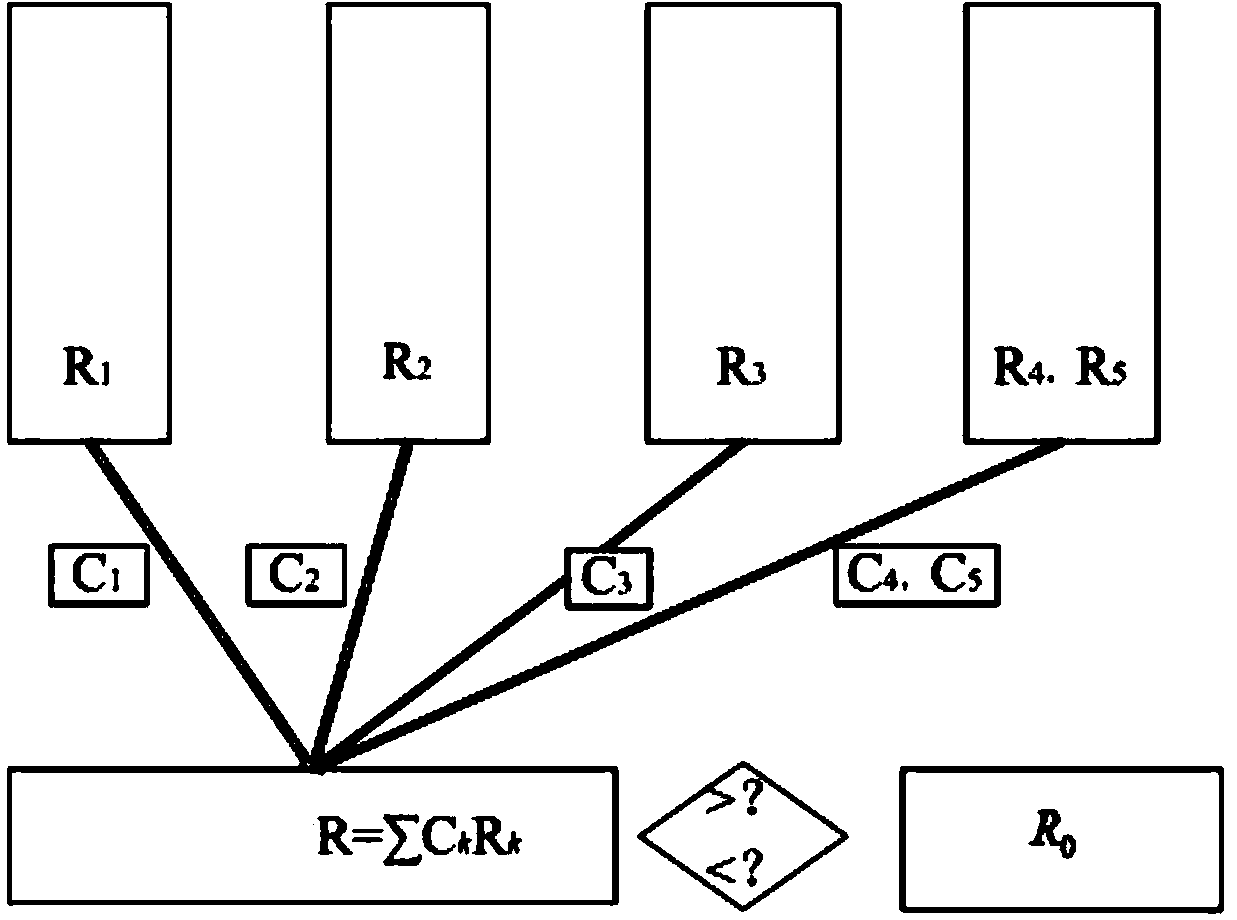

Tunnel excavation surrounding rock dynamic refined classification method based on integrated parameters

The invention discloses a tunnel excavation surrounding rock dynamic refined classification method based on integrated parameters. The method comprises the following steps of: analyzing tunnel prospective design data, preliminarily judging classification of tunnel surrounding rocks, performing integrated parameter advance geological forecasting exploration on excavation tunnel face surrounding rocks, and correcting classification of a tunnel face and front surrounding rocks according to a forecasting result; performing geological recording observation on tunnel face excavation surrounding rocks, performing elastic wave velocity testing, and further correcting classification of the surrounding rocks of the tunnel face according to observation data and elastic wave velocity testing data; and performing monitoring measurement according to each construction step, and correcting the obtained classification of the surrounding rocks of the tunnel face according to monitoring measurement data to finish a cycle of surrounding rock refined classification. The method has the advantages that on the basis of analyzing the prospective design data and determining classification of the surrounding rocks, tunnel surrounding rocks in a construction stage are subjected to dynamic integrated refined classification by integrated operation of integrated parameter advance geological forecasting, tunnel face surrounding rock integrated exploration and field monitoring data analysis, so the classification of the surrounding rocks is refined and accurate.

Owner:BEIJING MUNICIPAL ENG RES INST

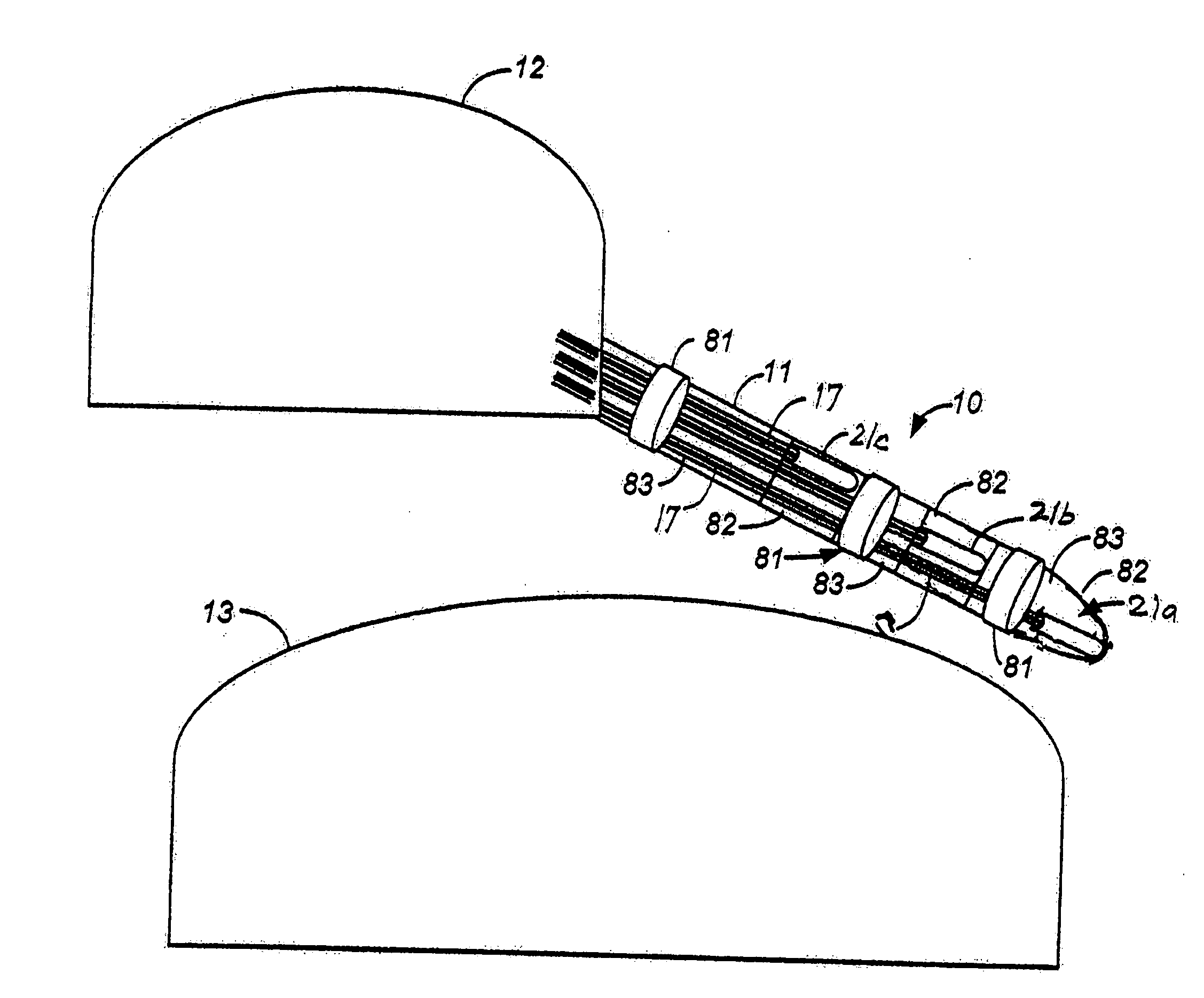

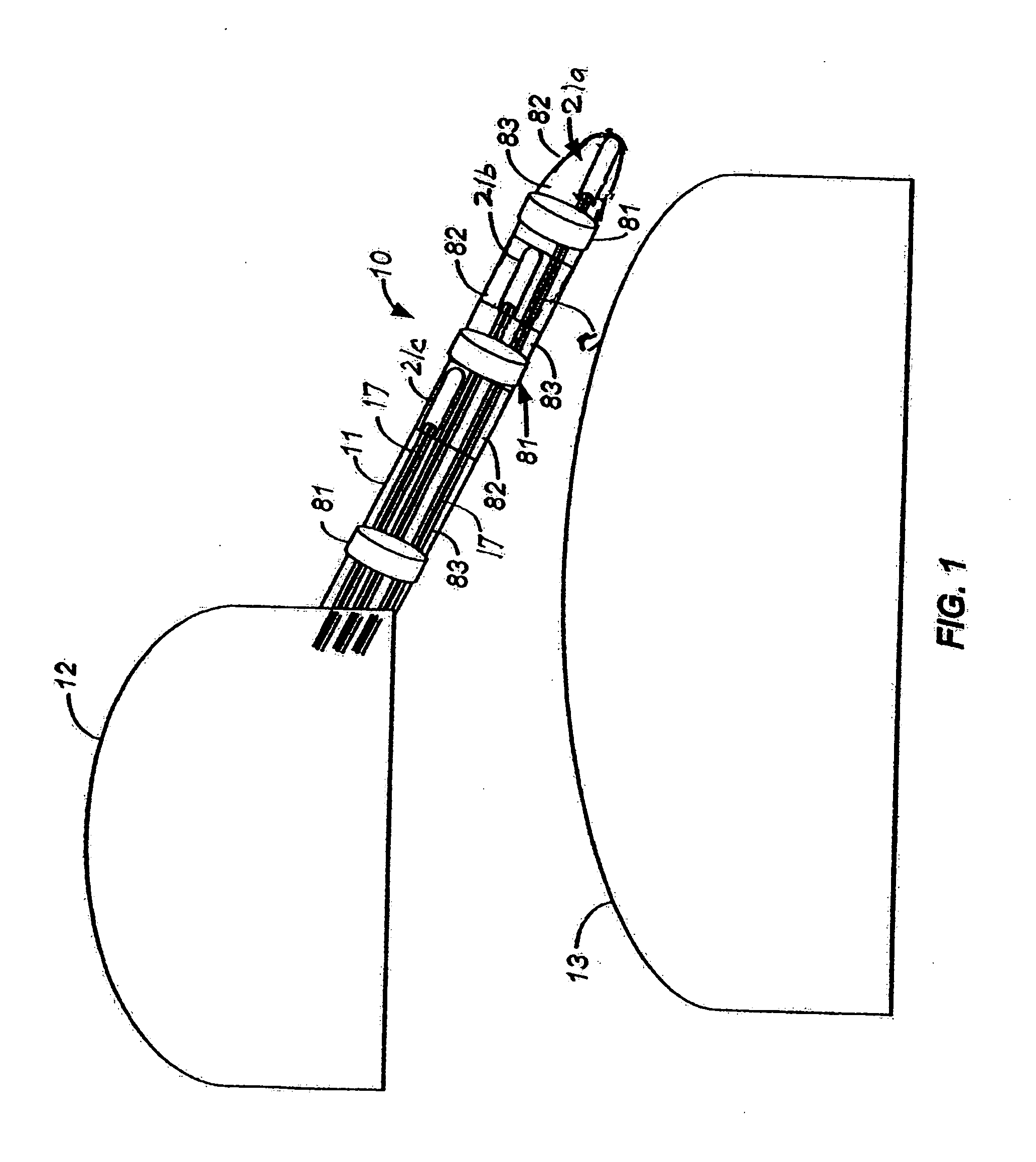

Systems and methods for installation, design and operation of groundwater monitoring systems in boreholes

Systems and methods for installation and operation of a groundwater monitoring system in a borehole of any angle using a coaxial gas displacement pump with a unique O-ring assembly that serves as a two-position valve for groundwater purging and sampling and also as a housing and sealing mechanism for isolating an optical pressure sensor. The optical sensor measures in-situ hydraulic pressure directly subjacent and adjacent to the surrounding rock fractures and sediment pores without hydraulic interferences from potentiometric equilibration lag time from recovery fluid pressure inside a borehole, in a zone above the optical sensor, or on the inside of a riser pipe that rises to the ground surface.

Owner:BESST +1

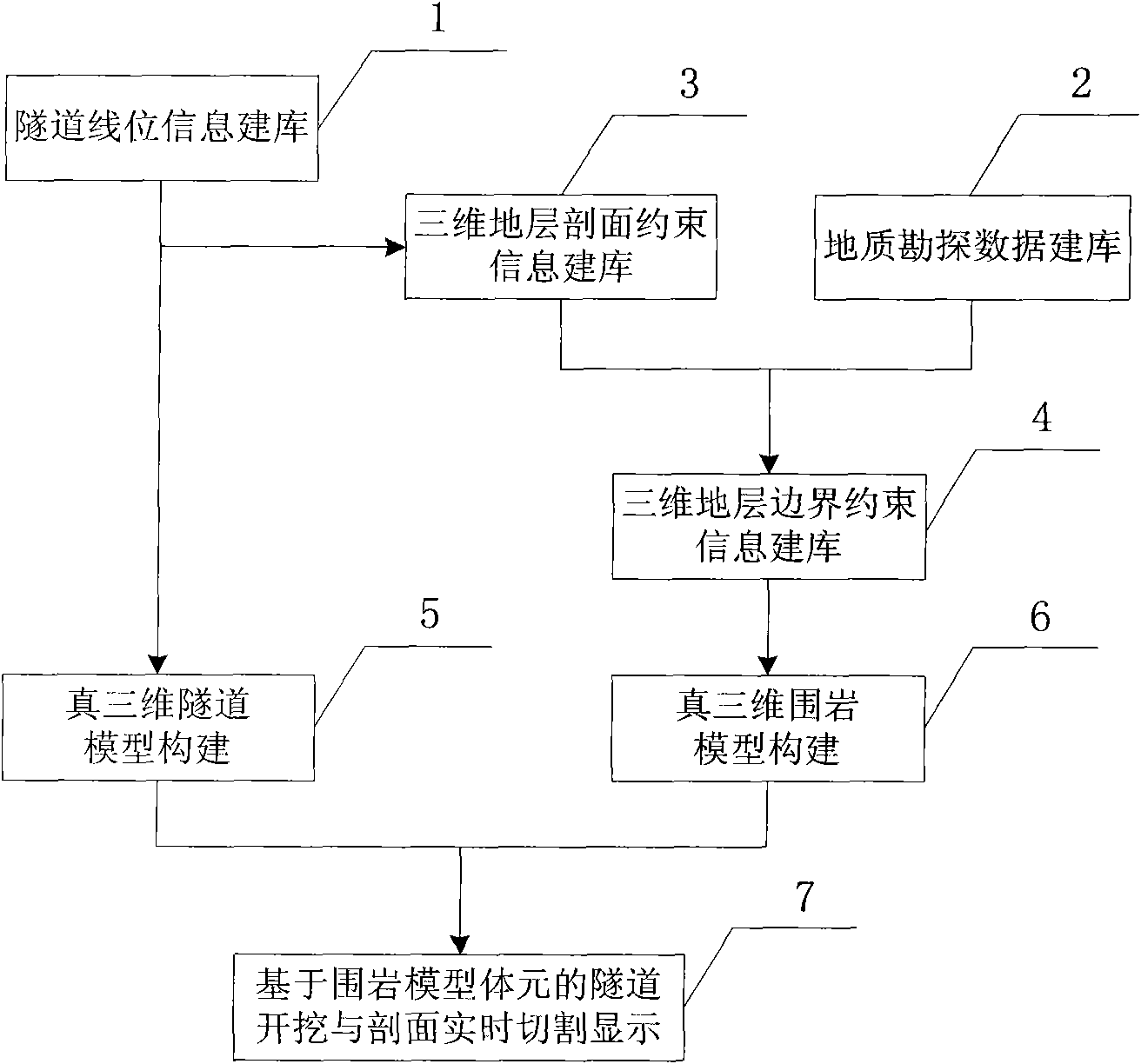

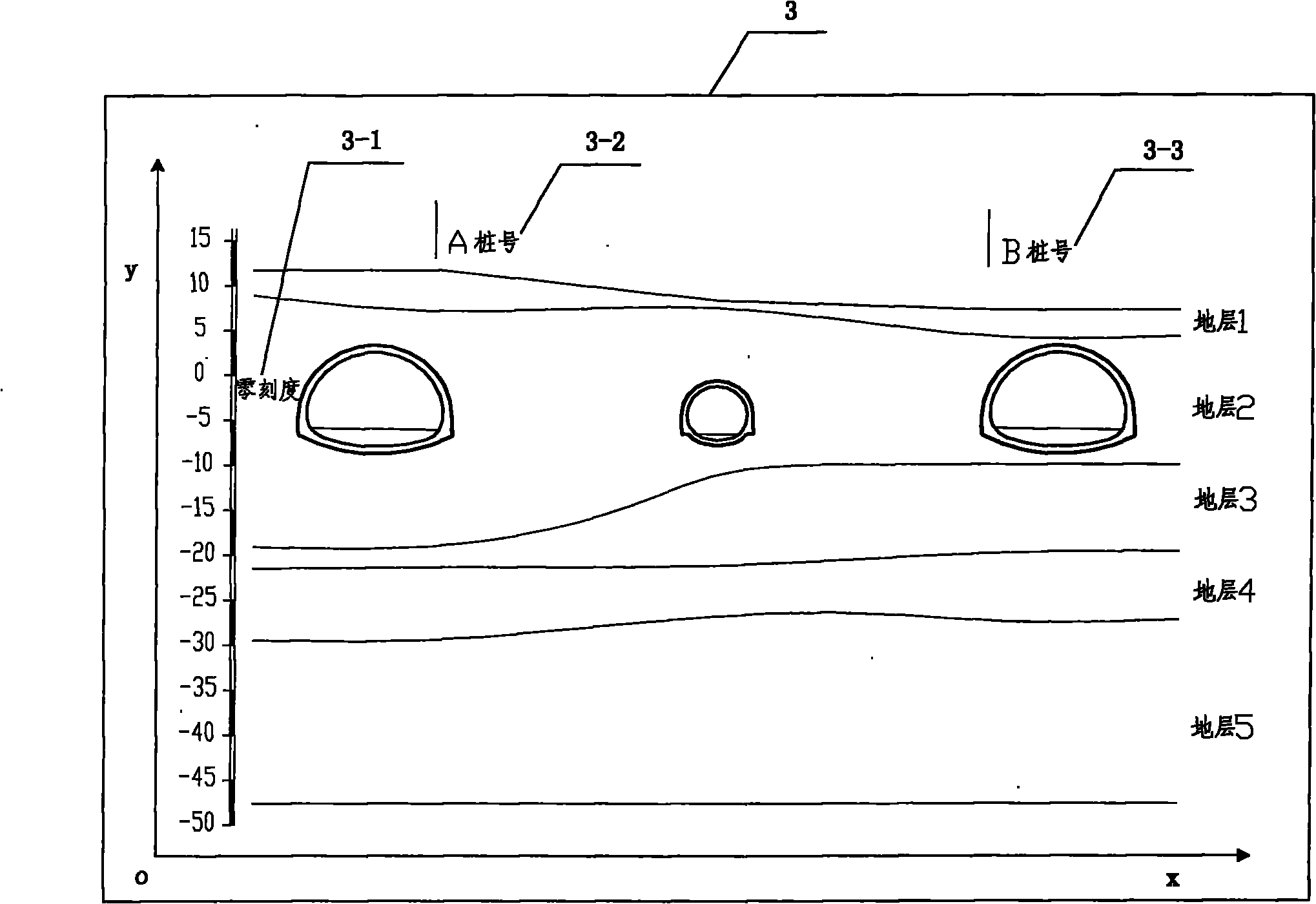

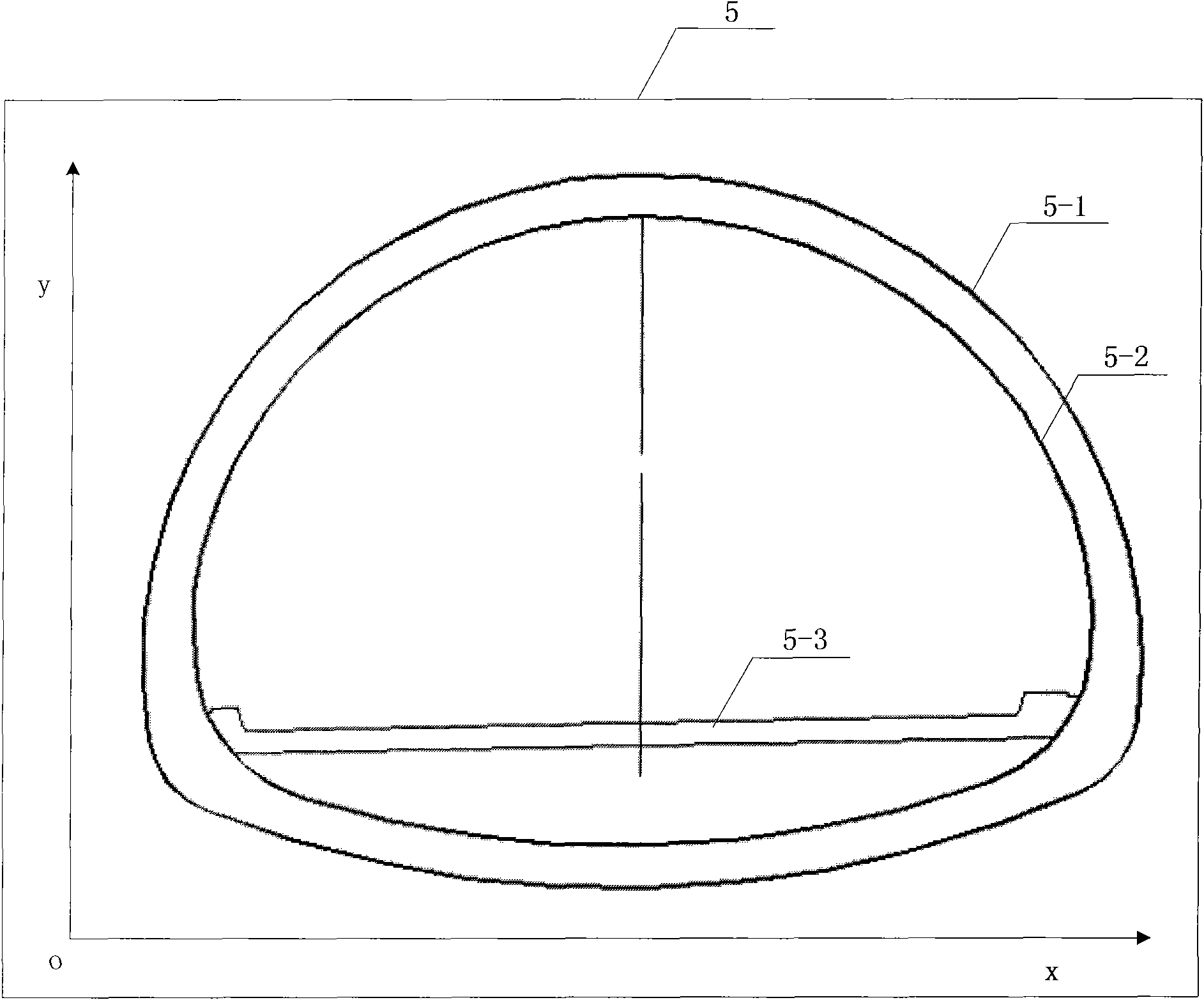

Method for fast establishing interactive tunnel and wall rock body three-dimensional models

ActiveCN101882171AFast refactoringOvercome time-consuming remodelingTunnelsSpecial data processing applicationsInformation repositoryClassical mechanics

The invention discloses a method for fast establishing interactive tunnel and wall rock body three-dimensional models, which comprises the following steps: A. tunnel line position information base establishment: collecting tunnel line position information and establishing a line position information base; B. geological exploration base establishment: carrying out standardized processing on hole drilling data obtained through geological exploration; C. three-dimensional stratigraphical profile constraint information base establishment: collecting three-dimensional stratigraphical profile constraint information; D. three-dimensional stratigraphical boundary constraint information base establishment: collecting self defined model establishing boundary; E. real three-dimensional tunnel model establishment: precisely establishing a tunnel three-dimensional model according to the information of tunnel line positions, the tunnel hole body outer cross section and the inner cross section; F. real three-dimensional wall rock model establishment: establishing a wall rock model according to the hole drilling and stratigraphical information; and G. tunnel digging and profile real-time cutting display based on the wall rack model body unit. The model establishing efficiency and precision of the tunnel simulation and digitalized design can be improved, the real-time cutting display of the tunnel passing through the wall rock and any vertical profile can be realized, and the fast reestablishment of the model can be realized.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

Comprehensive quantitative determination method for grouting reinforcement effect of underground engineering crushed surrounding rocks

ActiveCN104215748AAvoid breakingAvoid uncorable defectsEarth material testingStatistical analysisQuantitative determination

The invention discloses a comprehensive quantitative determination method for grouting reinforcement effect of underground engineering crushed surrounding rocks. The method is based on four technological detection meanings, and the four meanings comprise surrounding rock boring coring, detection by a ground penetrating radar, borehole inspection detection and in-situ strength detection on bored surrounding rock. By using the four detection meanings for respective statistics and analysis, the surrounding-rock boring coring enhancement rate, the damage area reinforcing enhancement rate, the crack closing enhancement rate, the strength parameter enhancement rate and other parameters before or after grouting are obtained. The grouting reinforcement effect is subjected to comprehensive quantitative analysis through a weight analysis method, and a quantitative evaluation index for the grouting reinforcement effect is established, and scientific reasonable evaluation is performed on the grouting reinforcement effect of the underground engineering crushed surrounding rock. The comprehensive quantitative determination method for the grouting reinforcement effect of underground engineering crushed surrounding rocks overcomes the disadvantages that a conventional technology for the grouting reinforcement effect of underground engineering crushed surrounding rocks is behindhand in detection meaning and single in evaluation method, cannot realize quantization and the like. The provided comprehensive quantitative determination method is advanced in detection meaning, relatively novel and relatively scientific compared with a conventional experiential qualitative analysis method.

Owner:SHANDONG UNIV +1

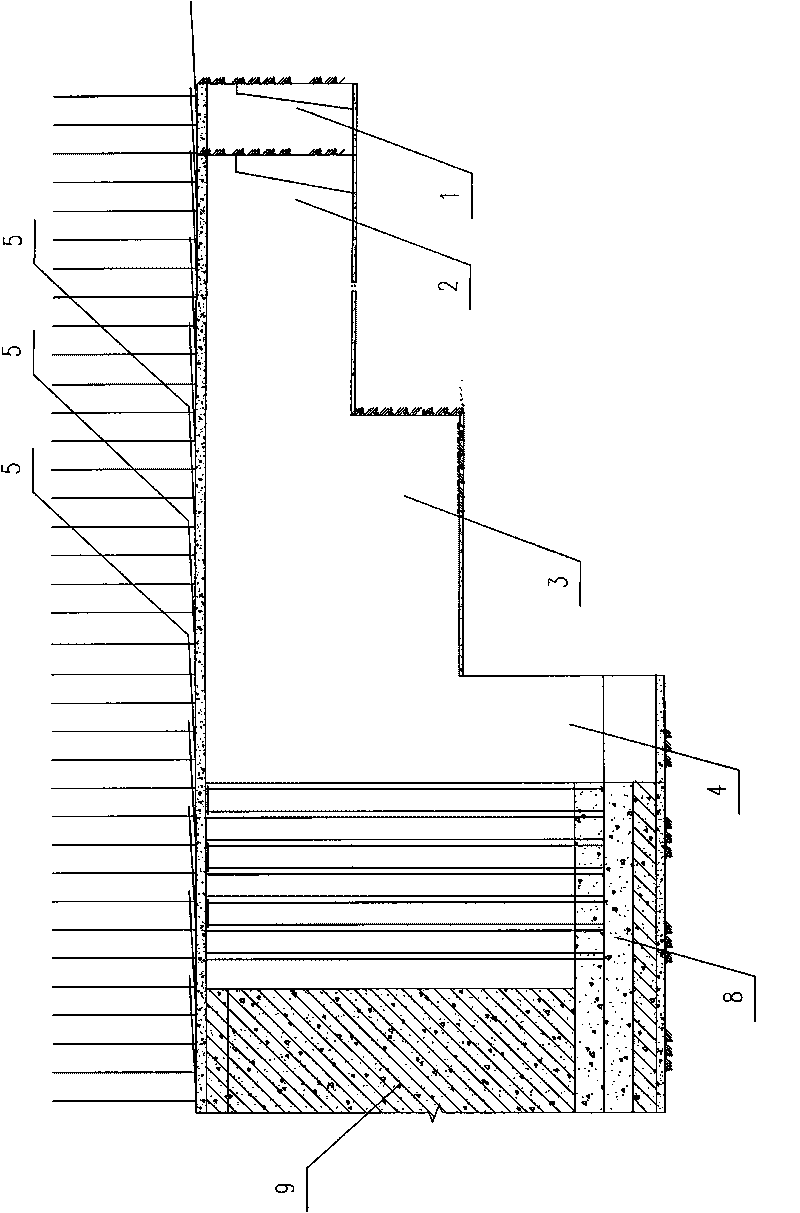

Preliminary bracing construction method for tunnel with surrounding rocks containing collapsible loess and soft rocks

InactiveCN103410527AEasy to operateEconomically reasonableUnderground chambersTunnel liningShotcreteMesh reinforcement

The invention discloses a preliminary bracing construction method for a tunnel with surrounding rocks containing collapsible loess and soft rocks. The method includes the following steps that a plurality of layers of advanced pipe sheds are arranged on a collapsible loess layer, and a single layer of advanced pipe shed is arranged on a soft rock layer; after the advanced pipe shed is set up, a working face is closed through sprayed concrete, a system anchor bolt is arranged on the soft rock layer, a foot locking small guide pipe is arranged at the arch springing position of the tunnel, and grouting is conducted on the rocks through permeation of the system anchor bolt and the foot locking small guide pipe; a pre-fabricated reinforcing mesh is paved on a concrete initial spraying layer formed by concrete initial spraying in a fluctuation mode, and a reinforcing mesh arranged at the collapsible loess layer is encrypted; a steel arch support is set on the collapsible loess layer, a reinforcing steel bar grid is set up at the soft rock layer, and the connecting position of the reinforcing steel bar grid and the steel arch support is welded; repeated spraying is conducted by adopting concrete spraying, and construction of tunnel preliminary bracing is finished. By means of the method, stress releasing and deformation coordination of two layers of surrounding rocks can be well controlled, operability is good, construction cost is low, and the safety is good.

Owner:CENT SOUTH UNIV

Device for testing model with three-dimensional gradient nonuniform loading structure

InactiveCN101539491ALoad bigLarge loading valueStructural/machines measurementNonlinear deformationModel testing

The invention relates to a device for testing a model with a three-dimensional gradient nonuniform loading structure, which comprises a table-shaped gradient nonuniform loading device and an opposite force loading device, wherein the opposite force loading device is connected with the table-shaped gradient nonuniform loading device which is arranged in the opposite force loading device; and a table-shaped gradient loading module of the table-shaped gradient nonuniform loading device is tightly attached to the surface of a testing model. Because the deep underground chamber engineering in the fields of hydroelectric power, traffics, power sources, resources and defense construction usually lies in three-dimensional loading states which are nonuniformly distributed in a gradient, the table-shaped gradient loading module is arranged on the surface of the model, thus the model testing device achieves the three-dimensional gradient nonuniform loading of an underground structure model and more truly discloses the nonlinear deformation characteristics and failure mechanisms of wall rocks of the deep underground chamber through the testing of the three-dimensional gradient nonuniform loading structure model so as to more reasonably evaluate the stability of the wall rocks of the underground chamber and take effective reinforcement measures, thereby having a quite important significance to guiding the design and the construction of the deep underground engineering and guaranteeing the safety of the deep underground engineering.

Owner:SHANDONG UNIV

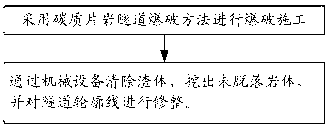

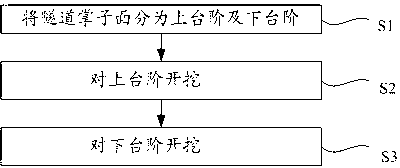

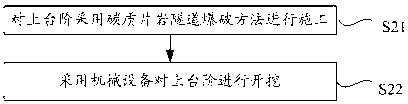

Carbonaceous schist tunnel blasting method and construction method

The invention discloses a carbonaceous schist tunnel blasting method and construction method. The carbonaceous schist tunnel construction method includes the steps of carrying out blasting in the carbonaceous schist tunnel blasting method, clearing away residues and digging out rock mass which does not fall off by using mechanical equipment, and revising a tunnel contour line. The carbonaceous schist tunnel blasting method includes the steps of dividing a tunnel face into a carbonaceous schist area and a none-carbonaceous schist area; arranging a plurality of blast holes in the tunnel face to form a hole pattern, wherein the density of the blast holes in the carbonaceous schist area is smaller than that of the blast holes in the none-carbonaceous schist area; filling explosives and detonators into the blast holes; connecting the detonators into a network; detonating the explosives according to a preset detonating sequence. The tunneling method of combining blasting and machinery is adopted, blasting is carried out first, rock does not need to be thrown out completely, and therefore disturbance and damage to surrounding rock are reduced; then the residues are cleared away and the rock mass which does not fall off is dug out by using the mechanical equipment, thus, tunneling efficiency can be improved, disturbance to the surrounding rock is little, and damage on the surrounding rock is reduced; in addition, the back break control effect is good, the tunneling effect is improved, and tunneling quality is high.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com