Patents

Literature

259results about How to "Consistent force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

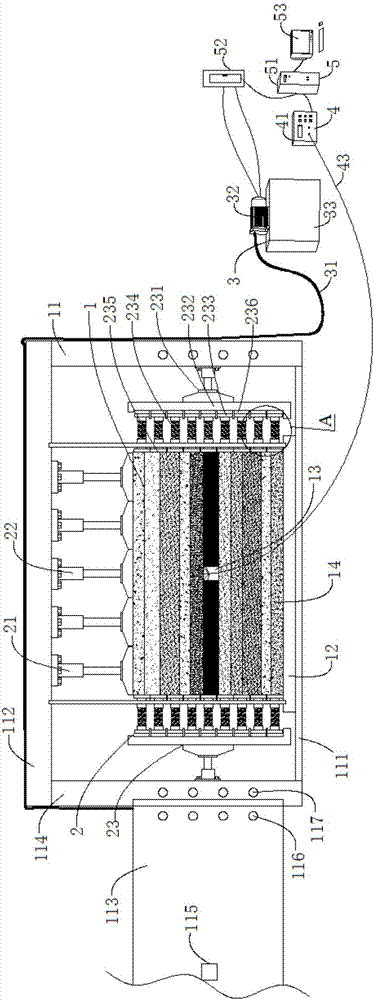

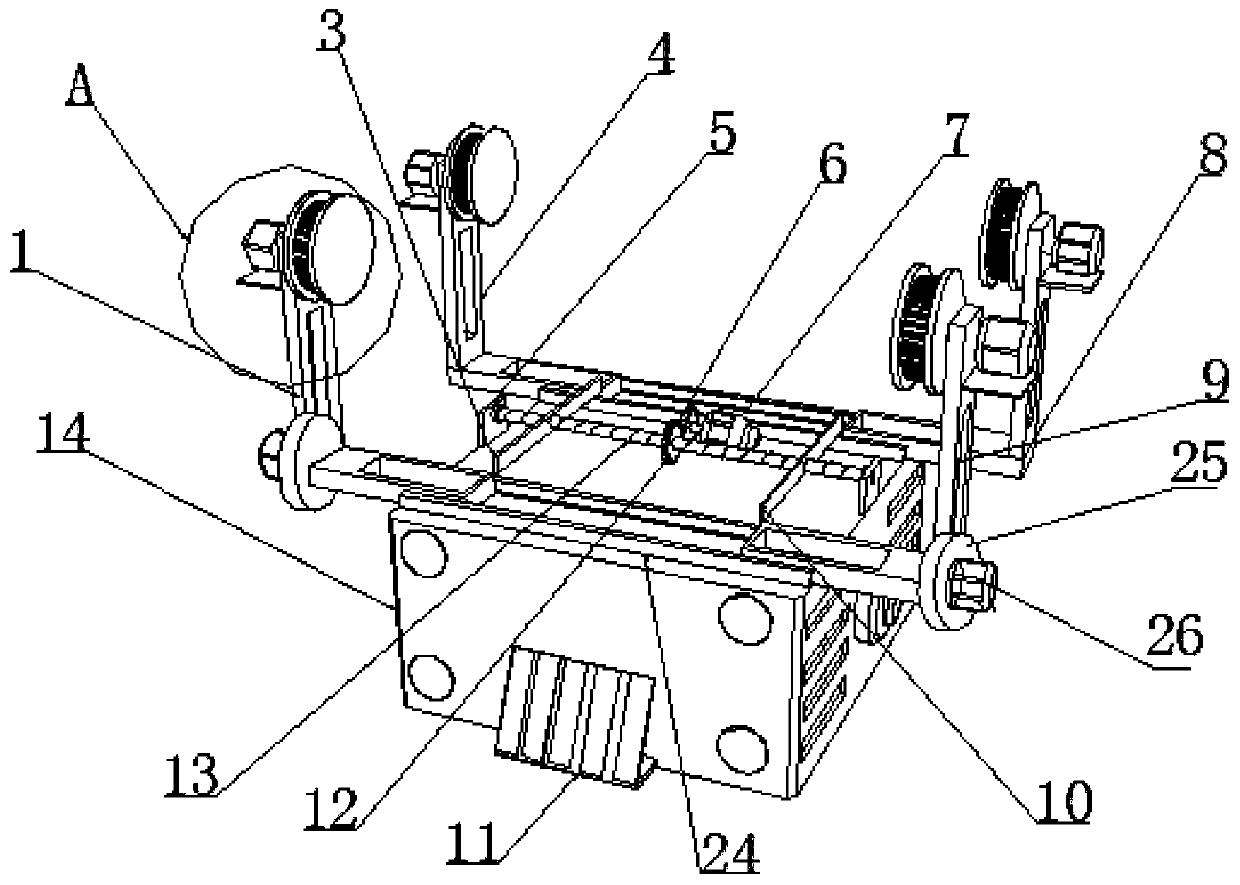

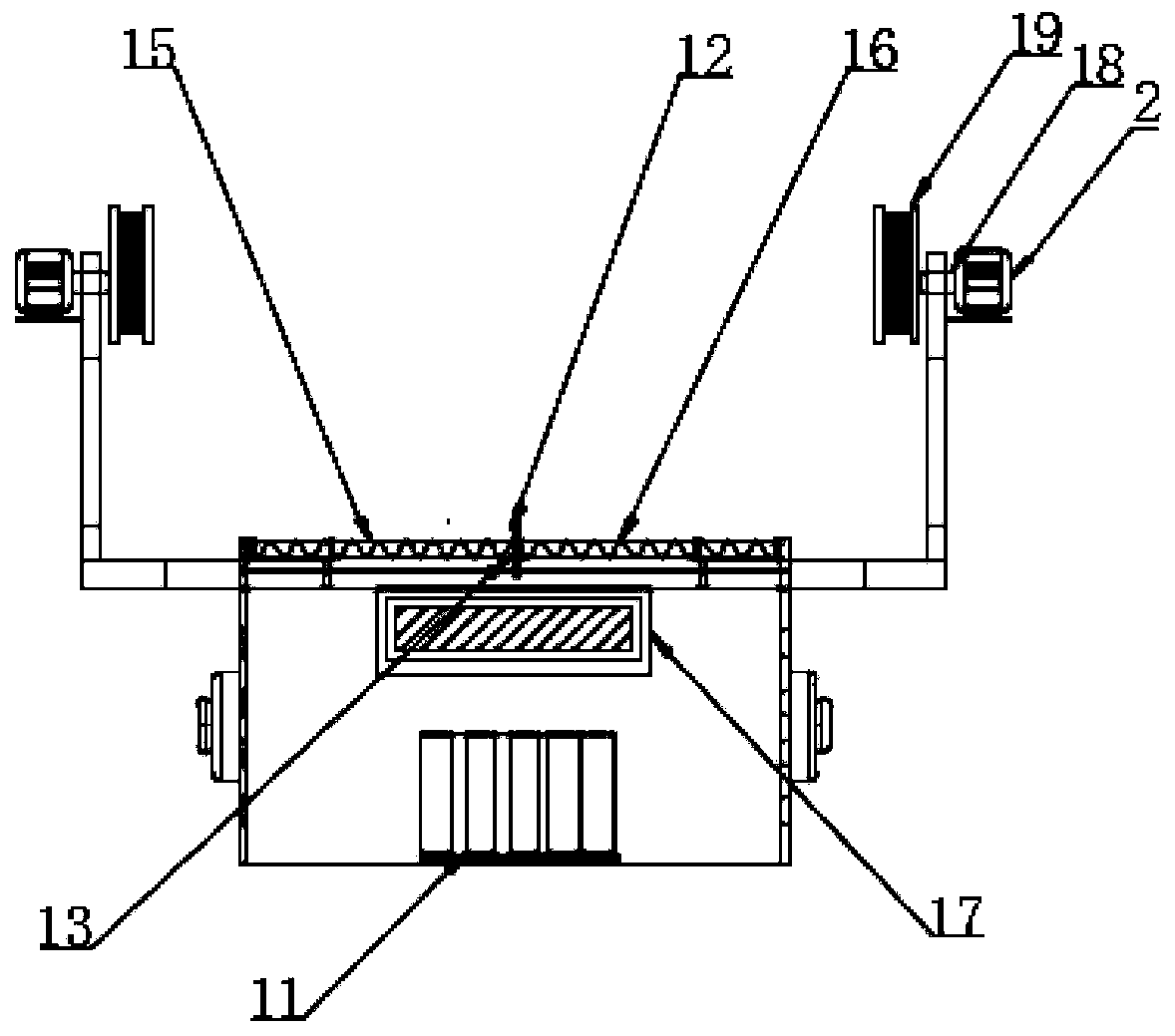

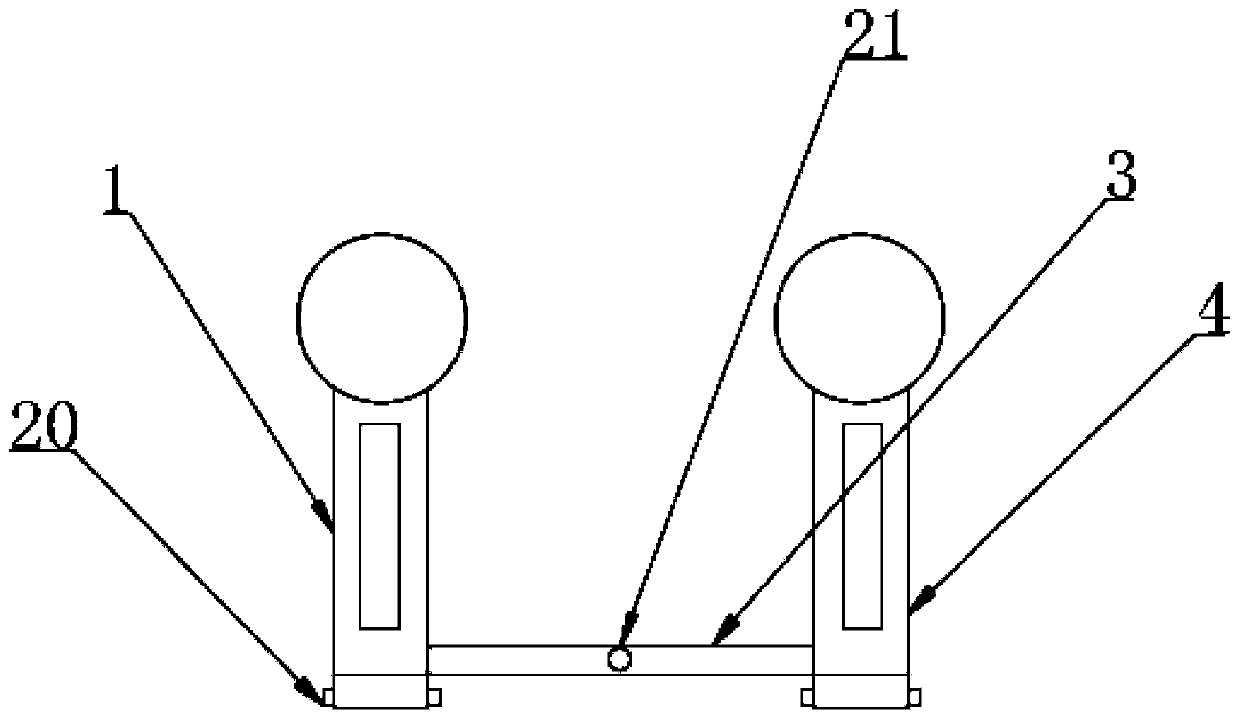

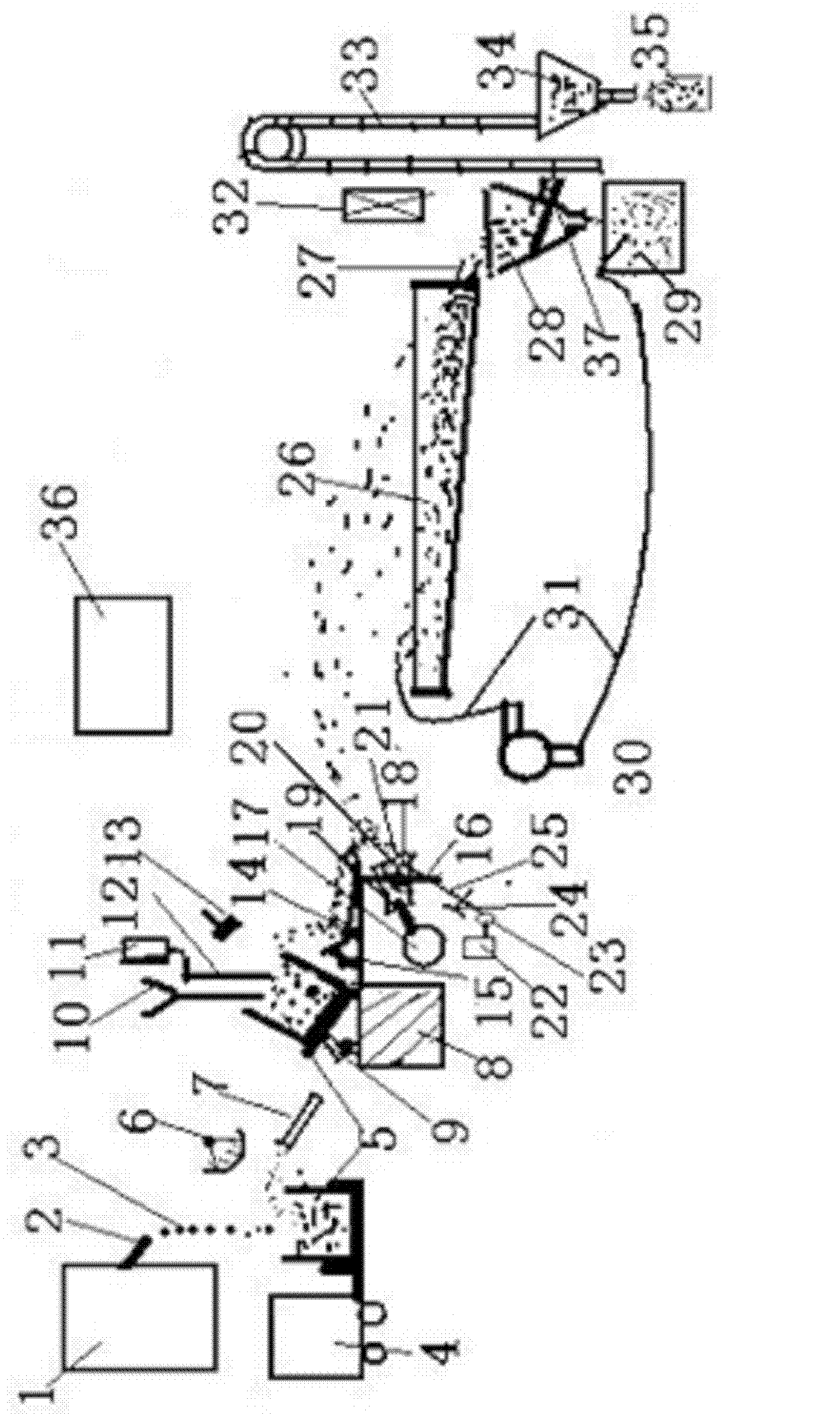

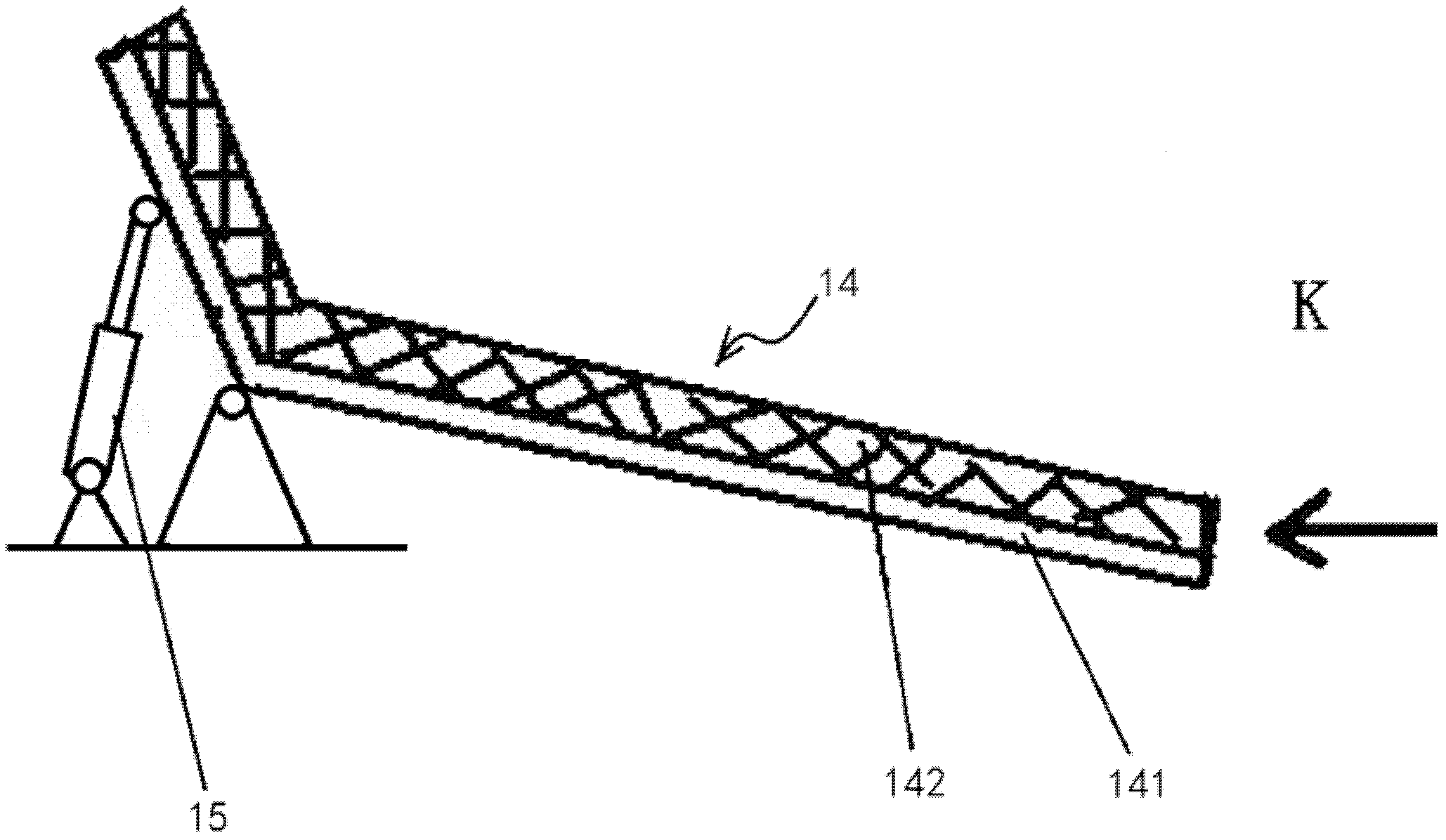

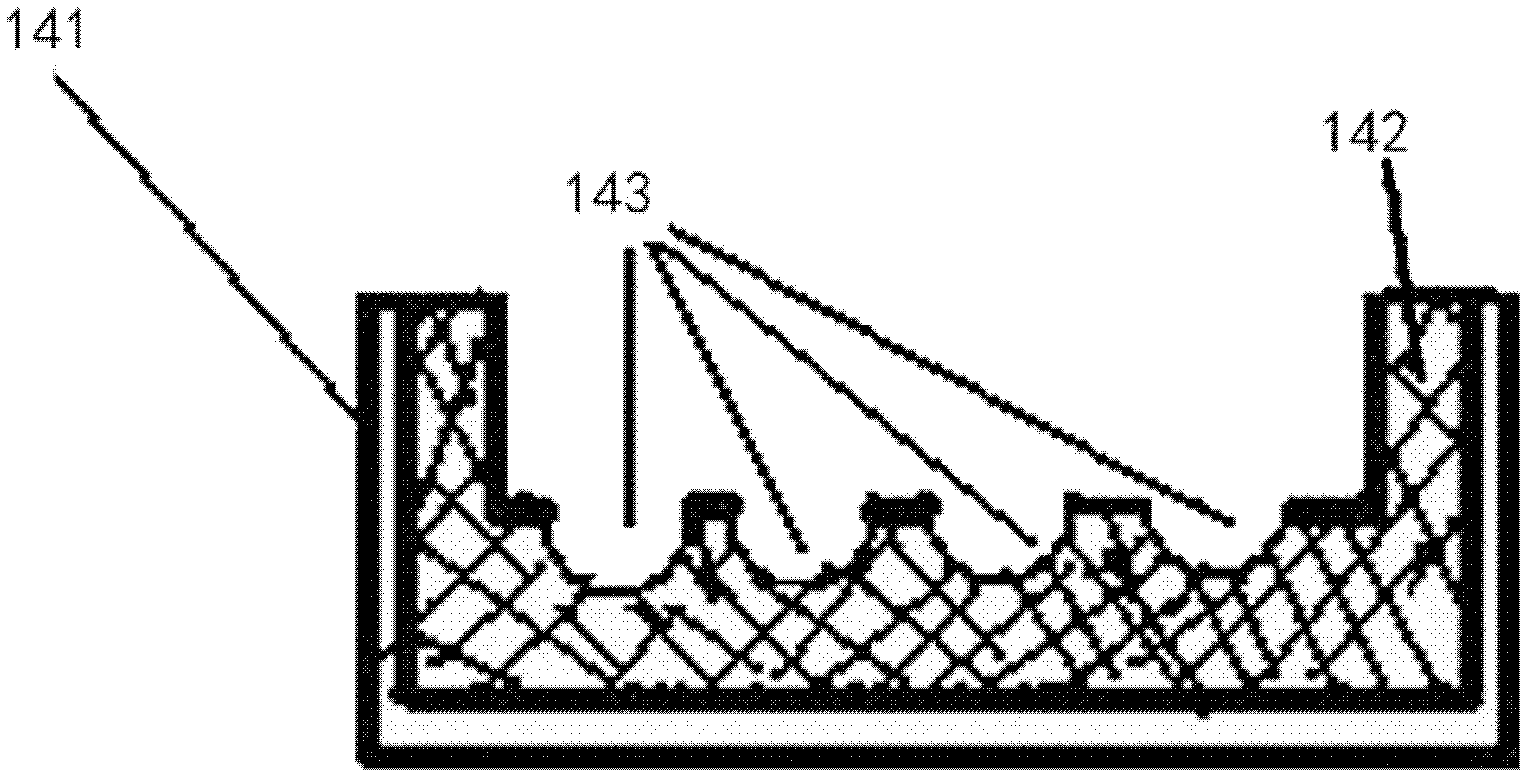

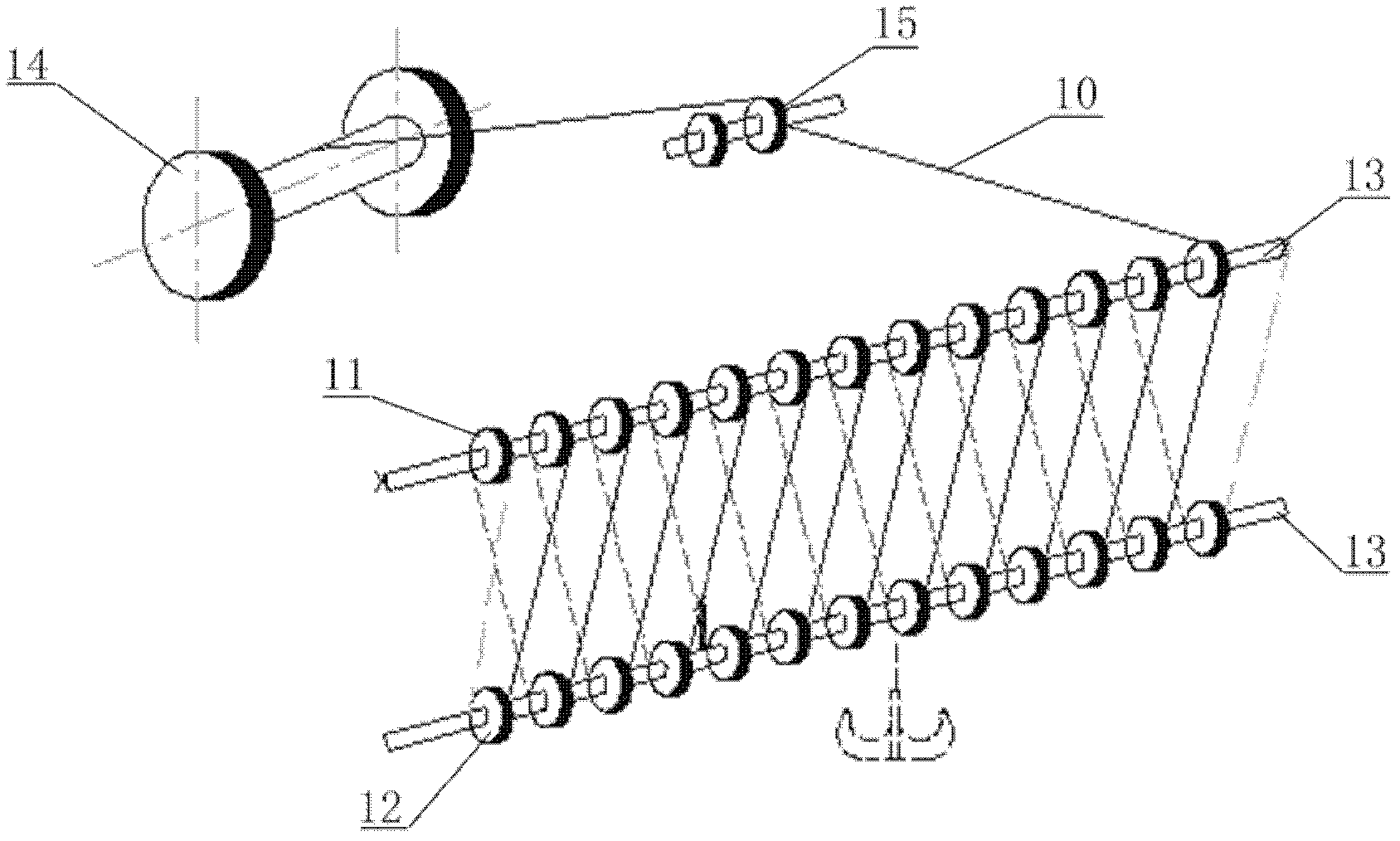

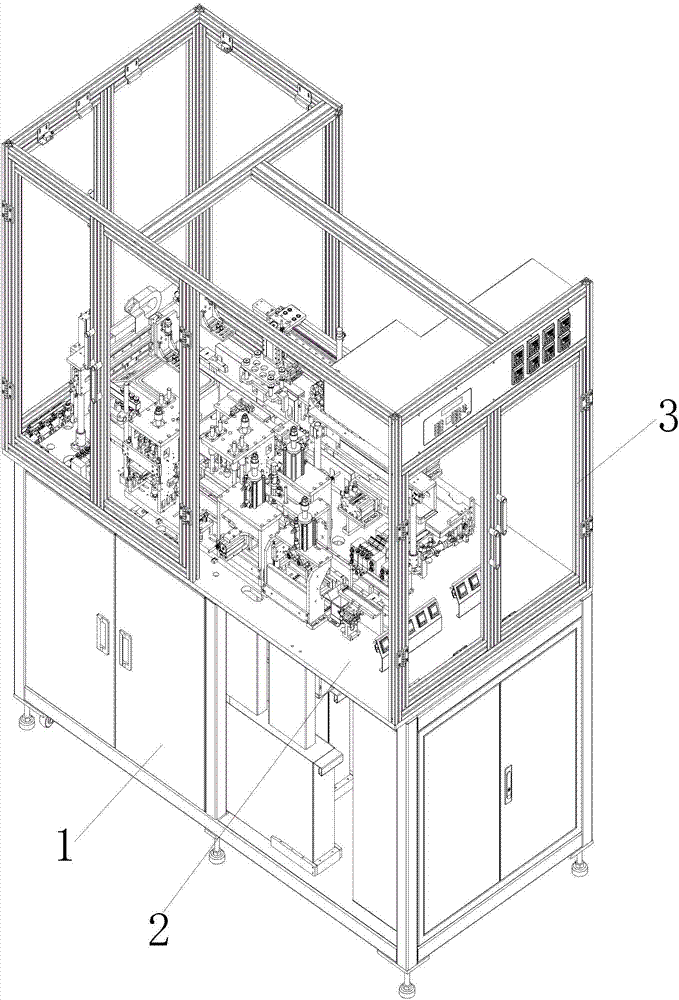

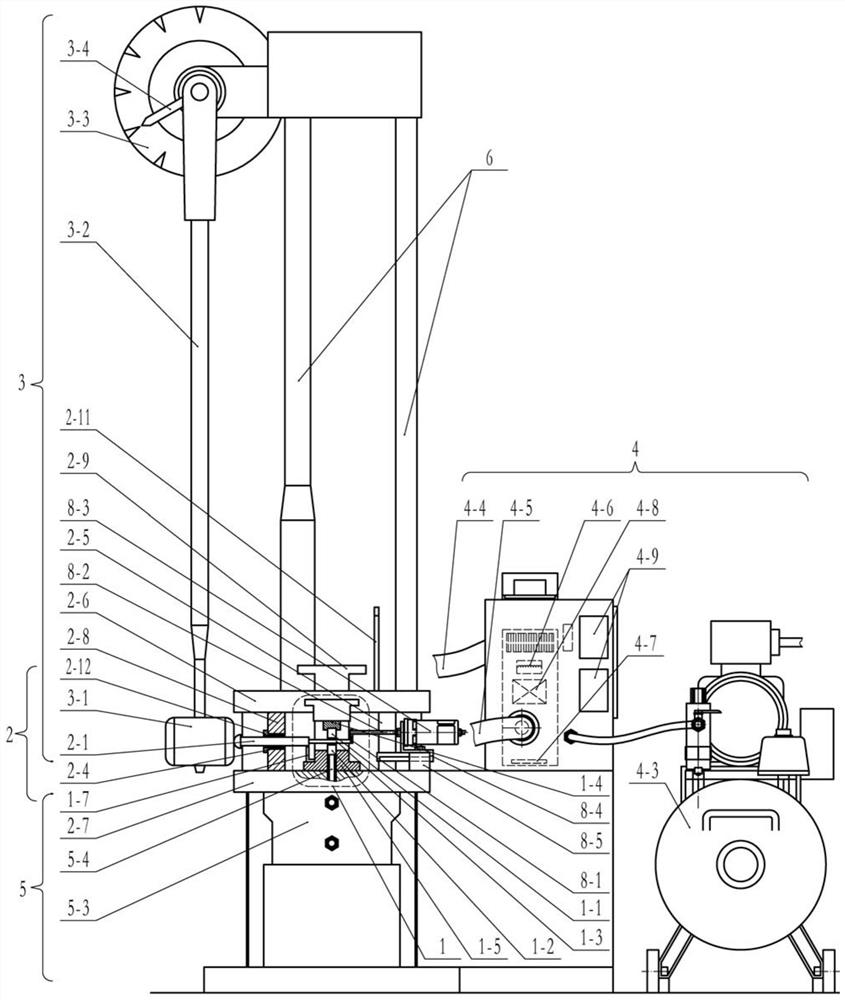

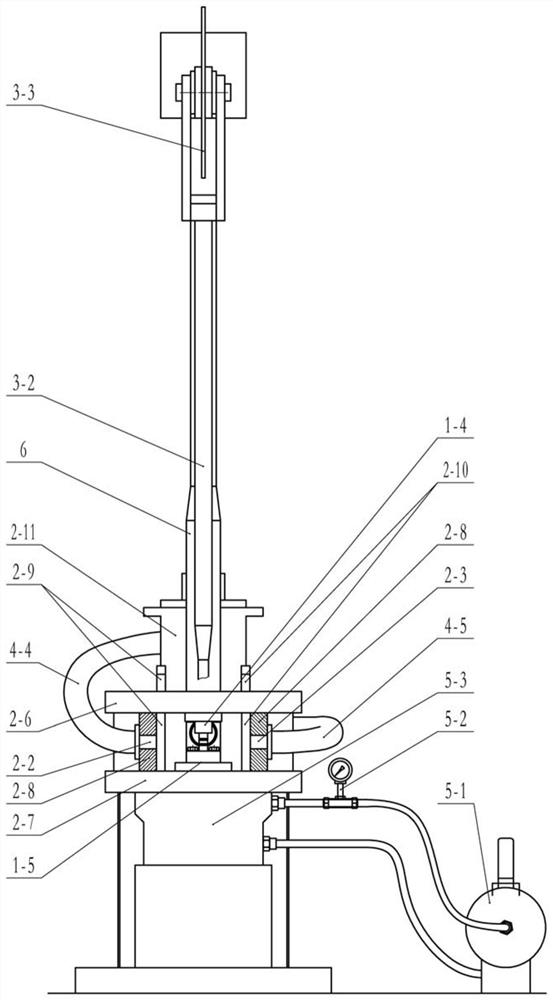

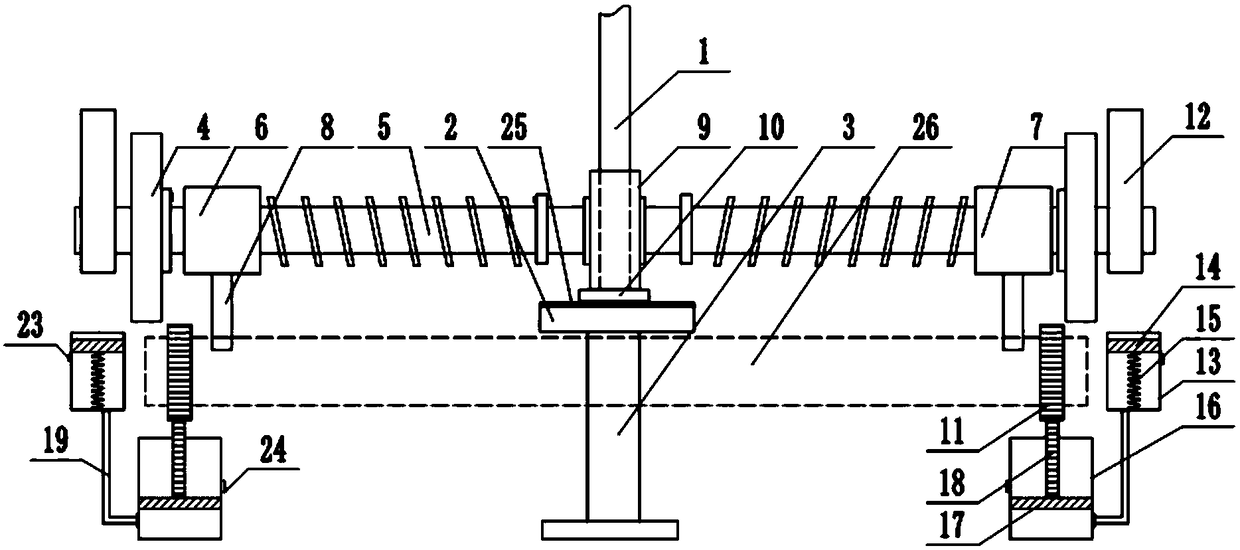

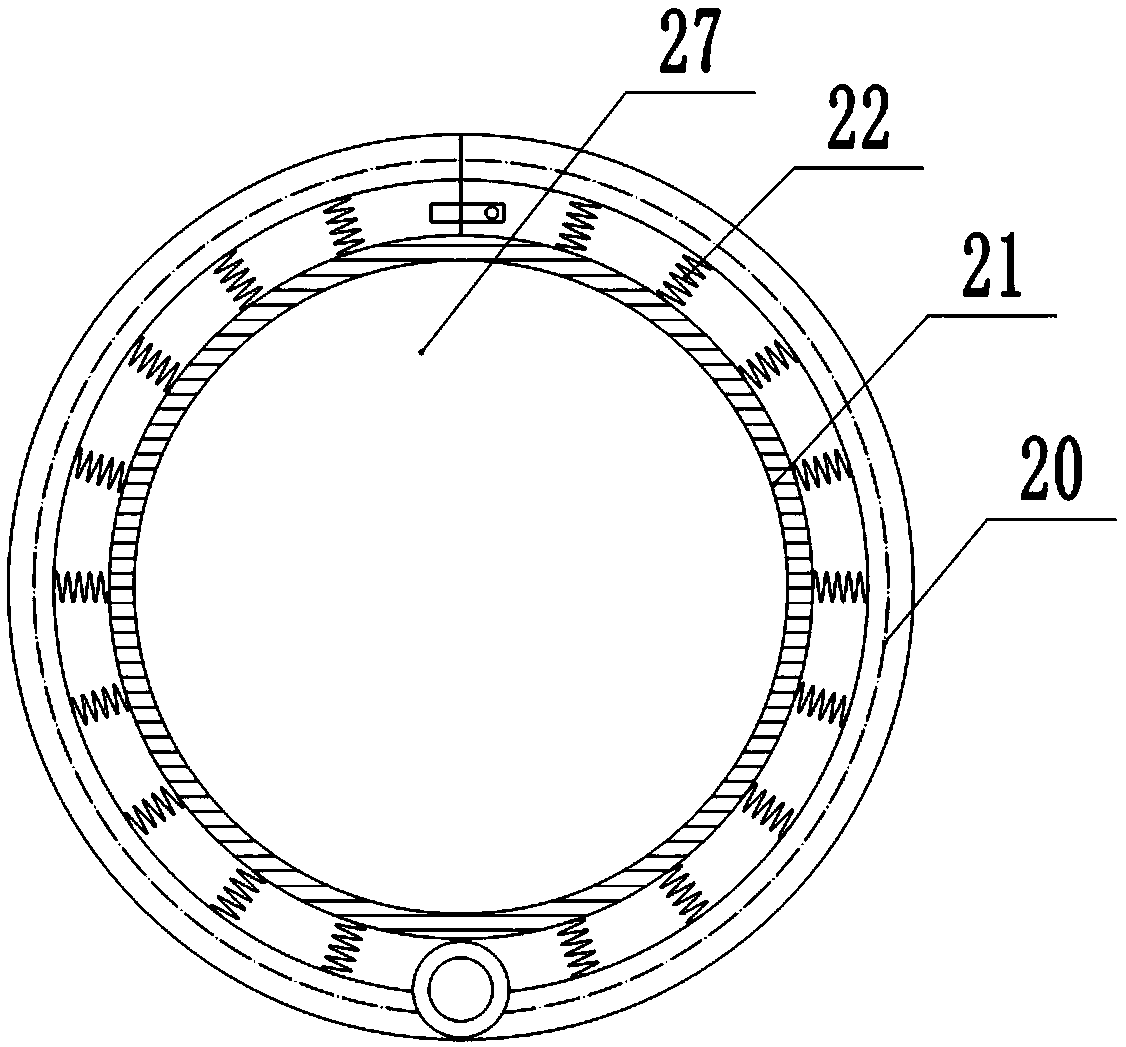

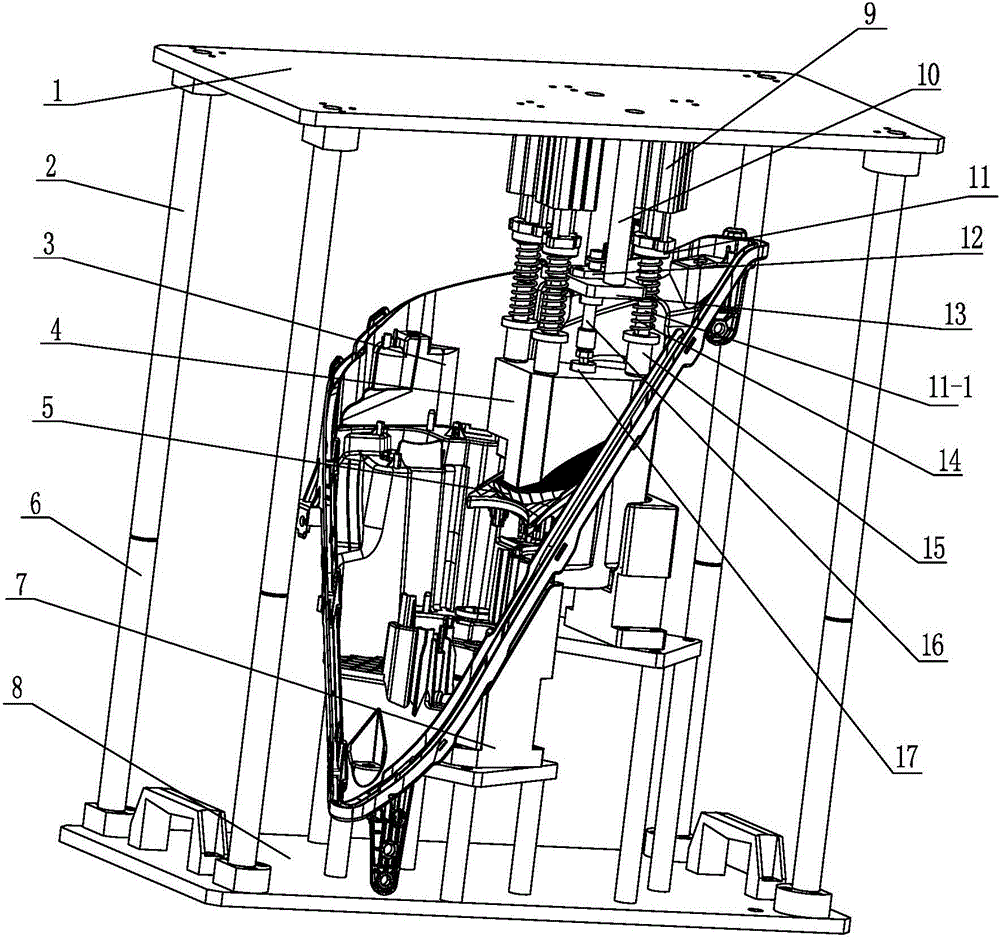

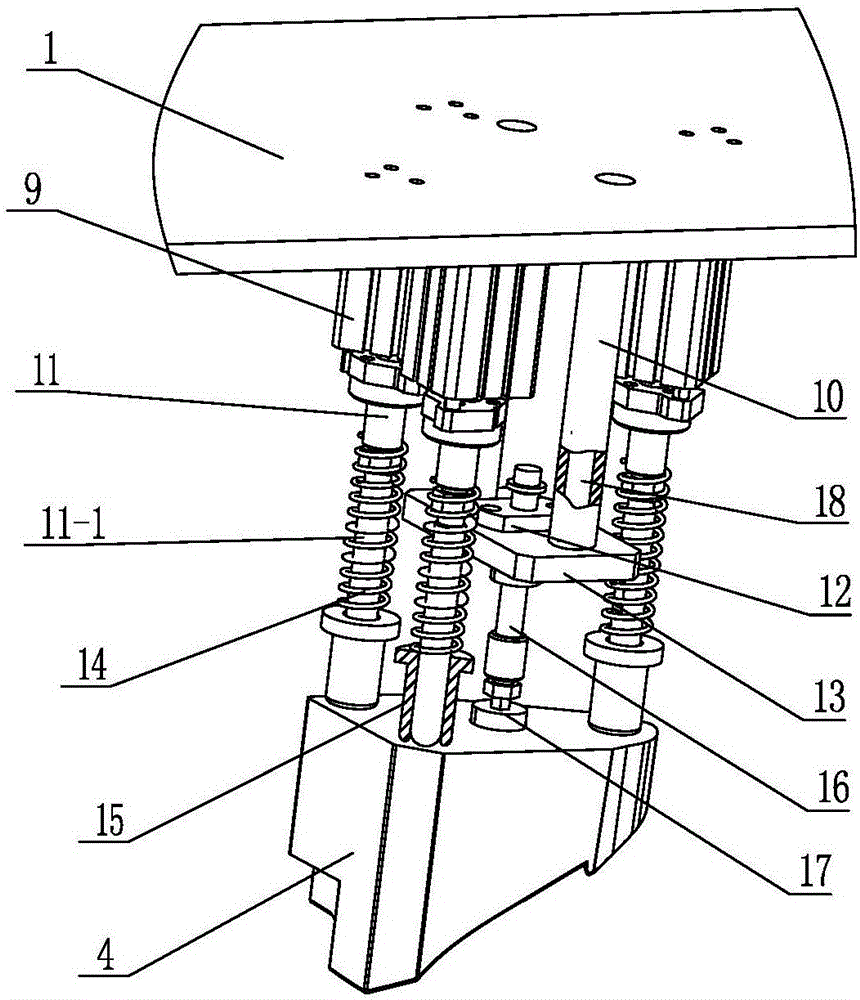

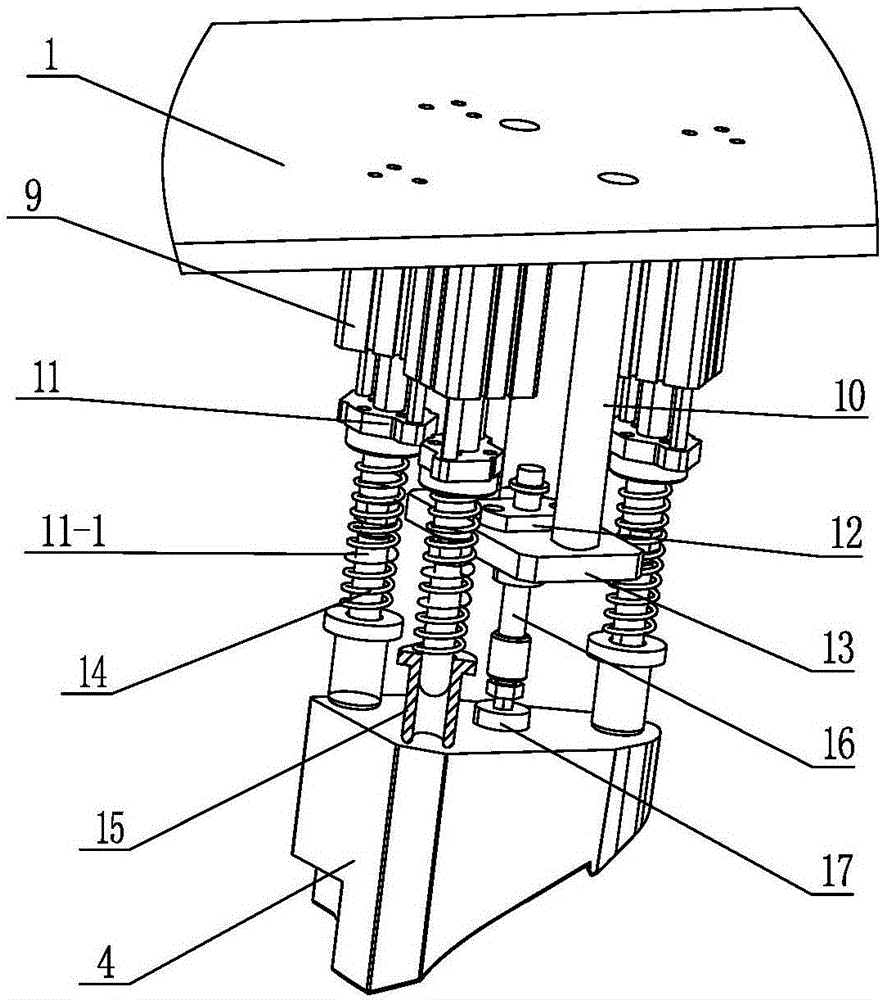

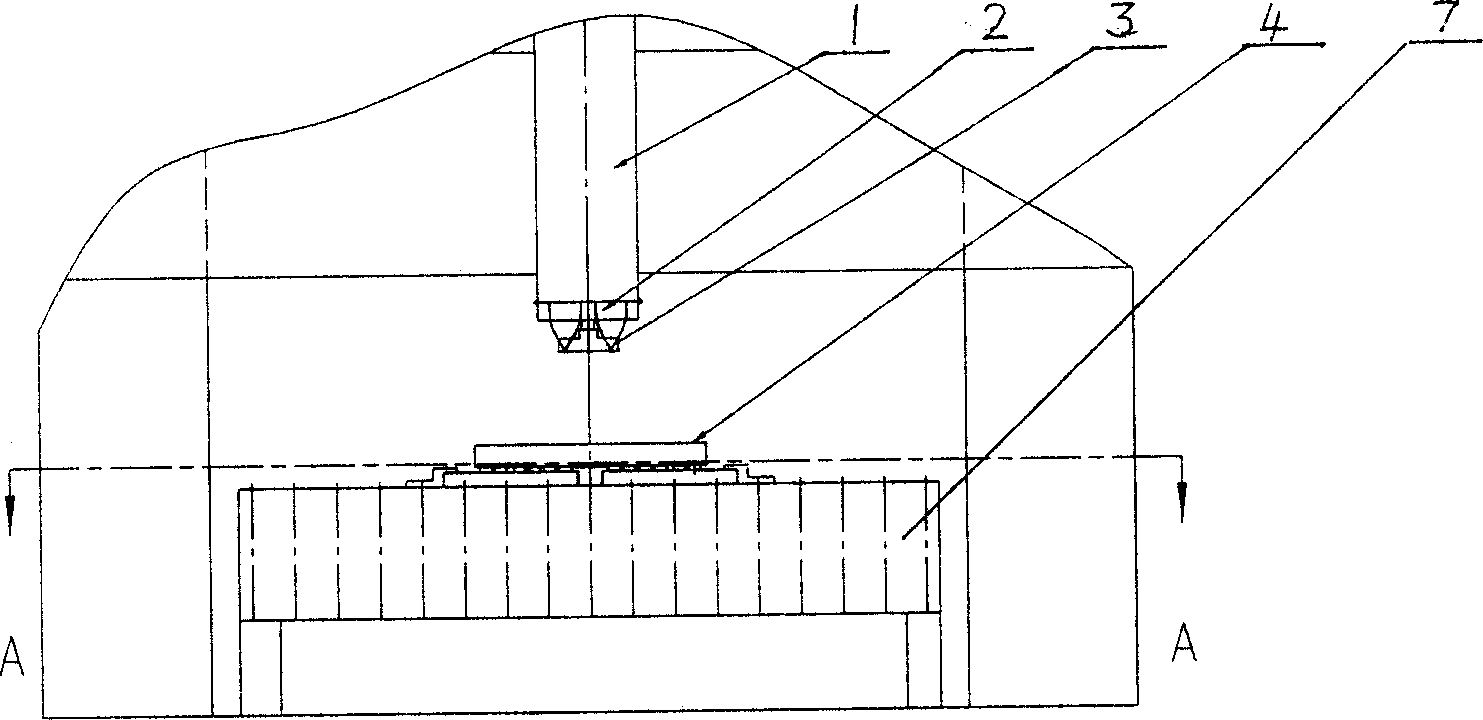

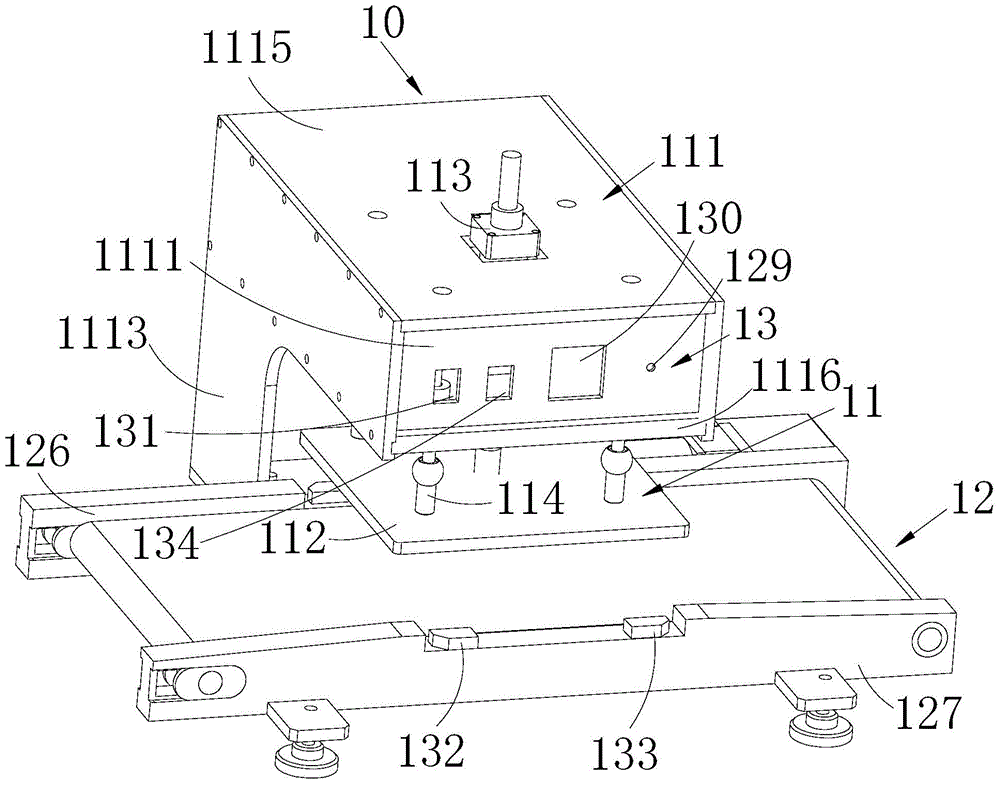

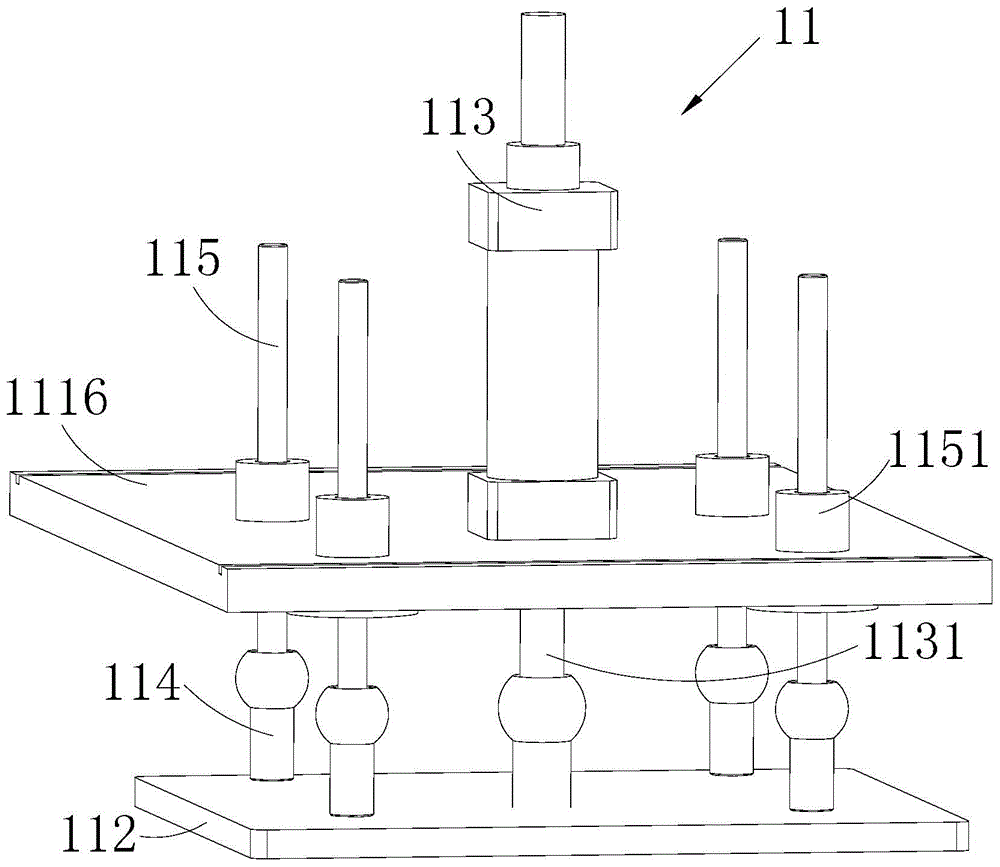

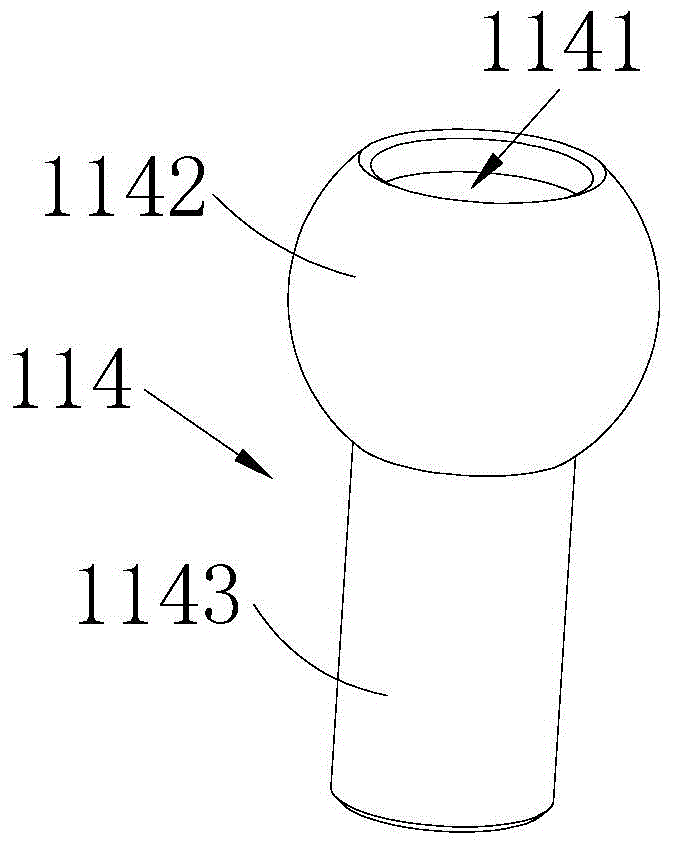

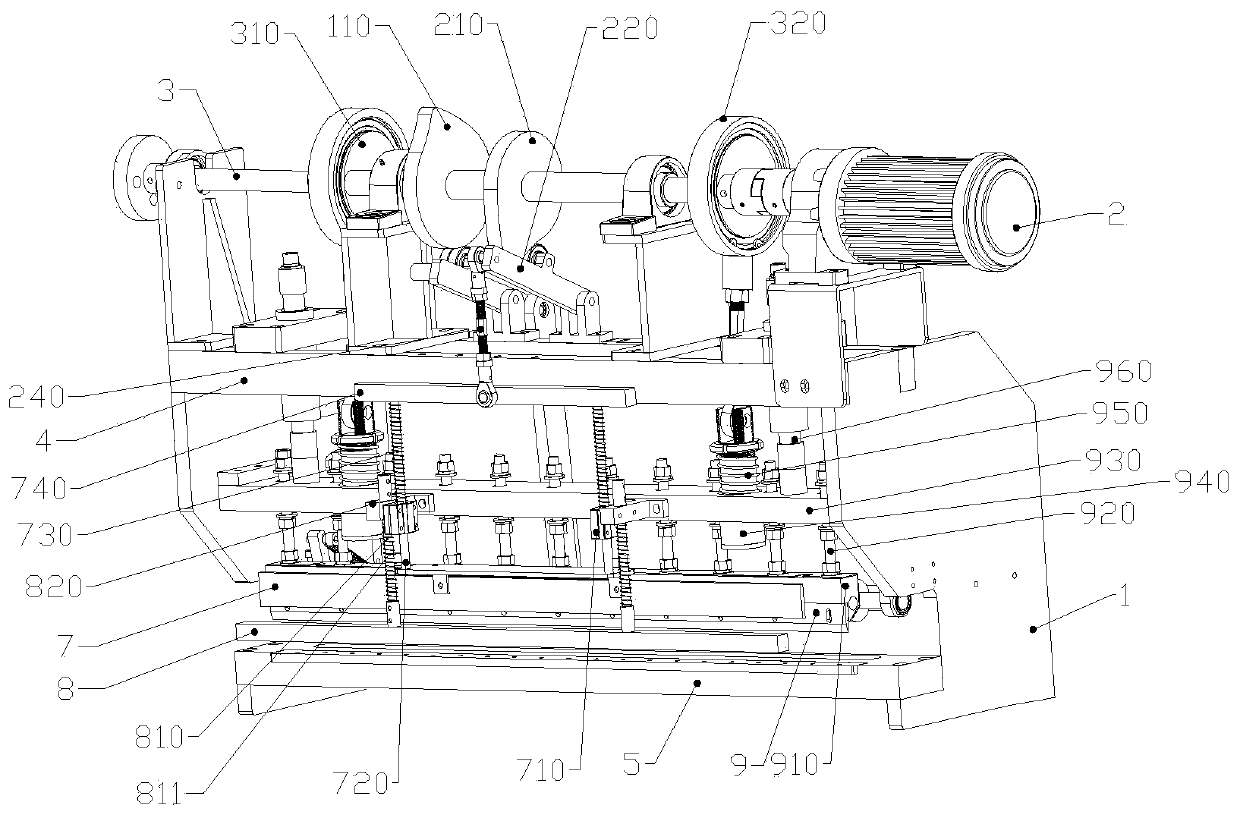

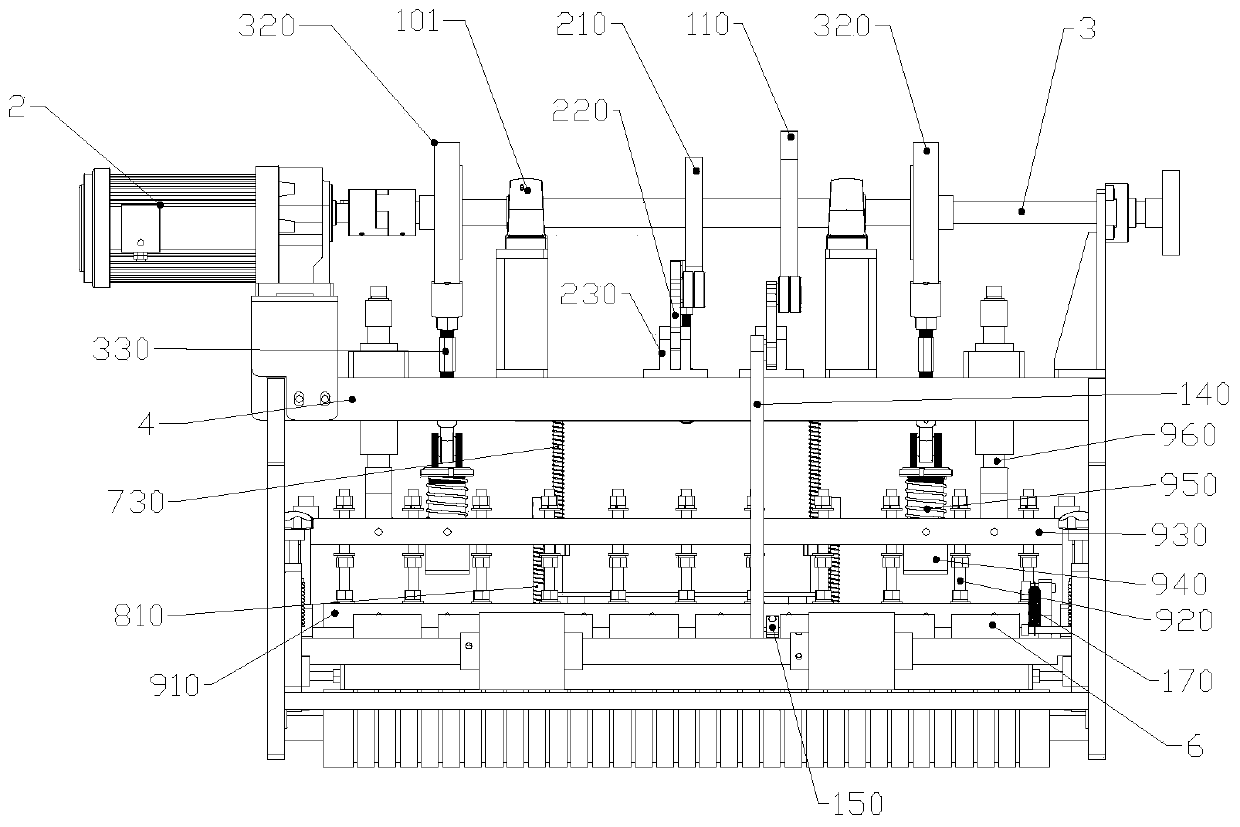

Roadway support mechanics simulation test system under dynamic-static combined loads and method of roadway support mechanics simulation test system

ActiveCN108007781AConsistent forceThe test result is accurateMaterial strength using tensile/compressive forcesControl systemMonitoring system

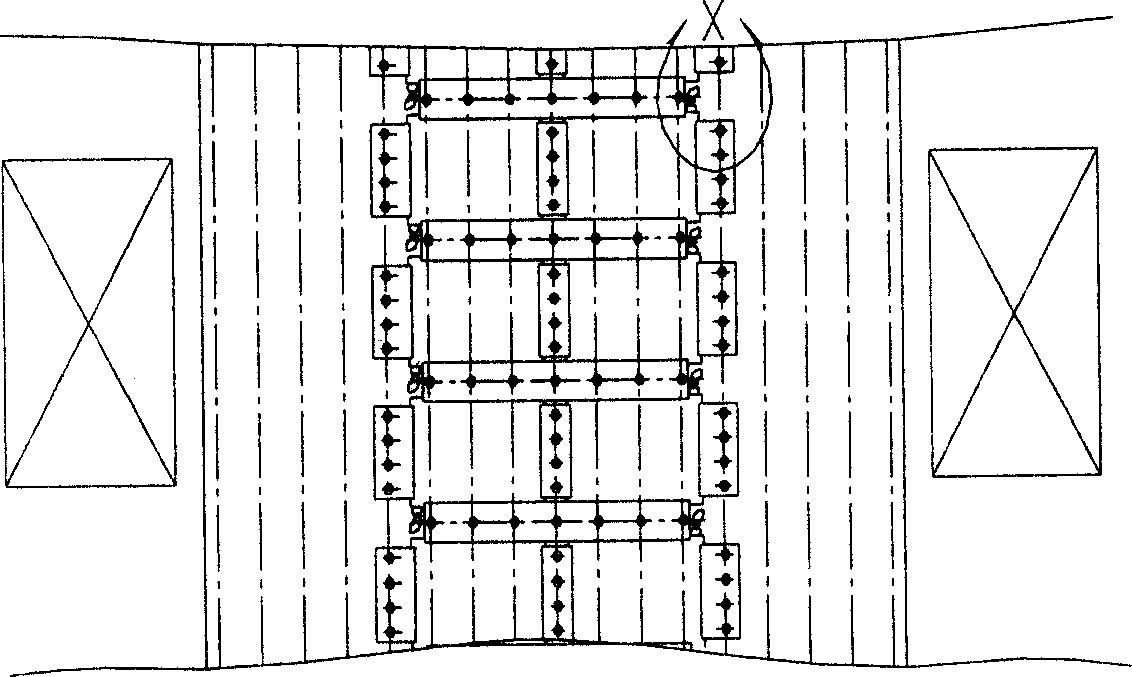

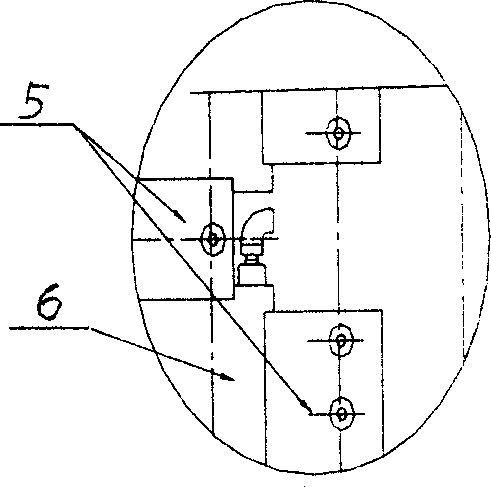

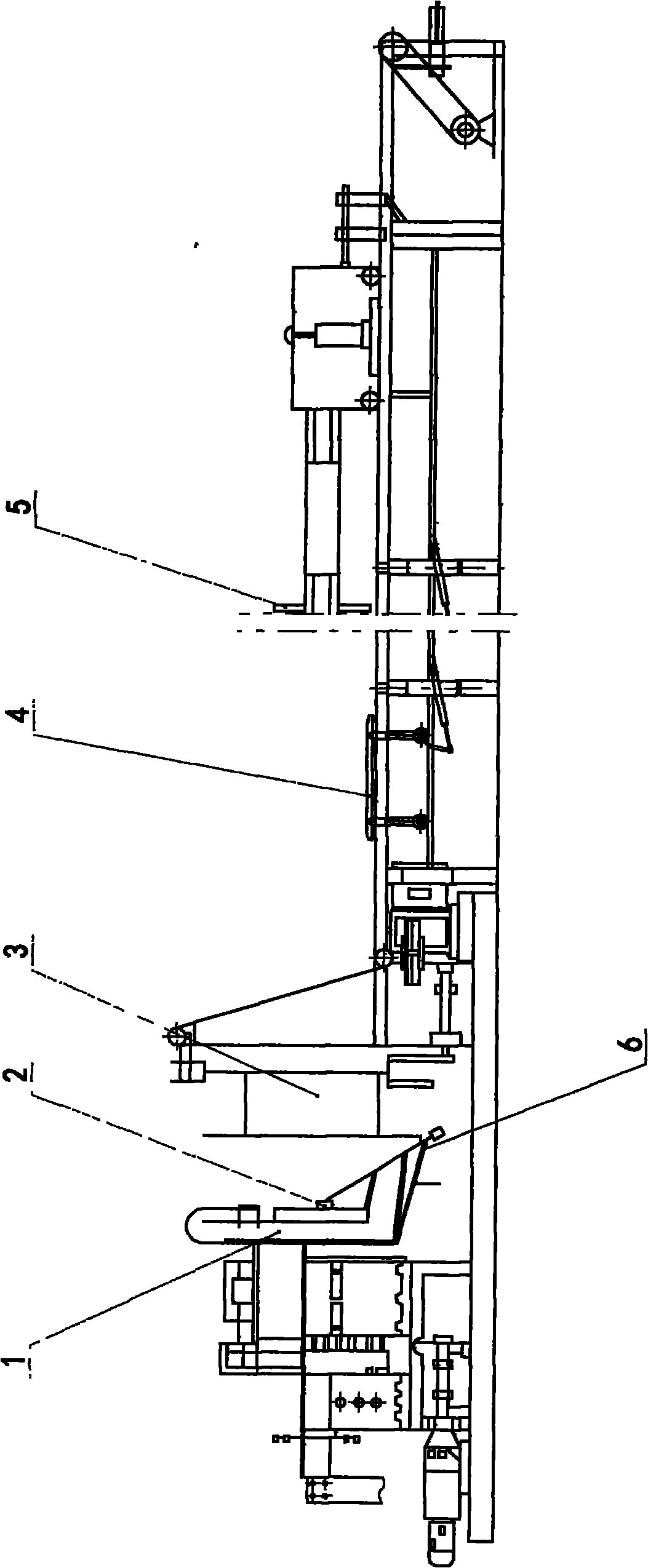

The invention discloses a roadway support mechanics simulation test system under dynamic-static combined loads and a method of the roadway support mechanics simulation test system. The system comprises a similar material laying system, a hydraulic loading system, a dynamical system, a monitoring system and a control system, wherein the similar material laying system comprises a connecting bracket,a laying platform and a reserved anchor rod model; the laying platform is placed in the connecting bracket; a coal rock similar layer is arranged on the laying platform; the coal rock similar layer is obtained by laying coal rock similar materials sequentially layer by layer; the reserved anchor rod model is arranged in the middle of the coal rock similar layer. According to the roadway support mechanics simulation test system, an adjustable static load and an adjustable dynamic load are simultaneously exerted on the coal rock similar layer, so that the force on a surrounding rock and a support of a roadway can be consistent with actual force; therefore, a test result is more accurate. Meanwhile, the roadway support mechanics simulation test system is simple in operation and is stable andreliable; therefore, the roadway support mechanics simulation test system has great significance in support designs of deep mines, tunnels and the like.

Owner:SHANDONG UNIV OF SCI & TECH

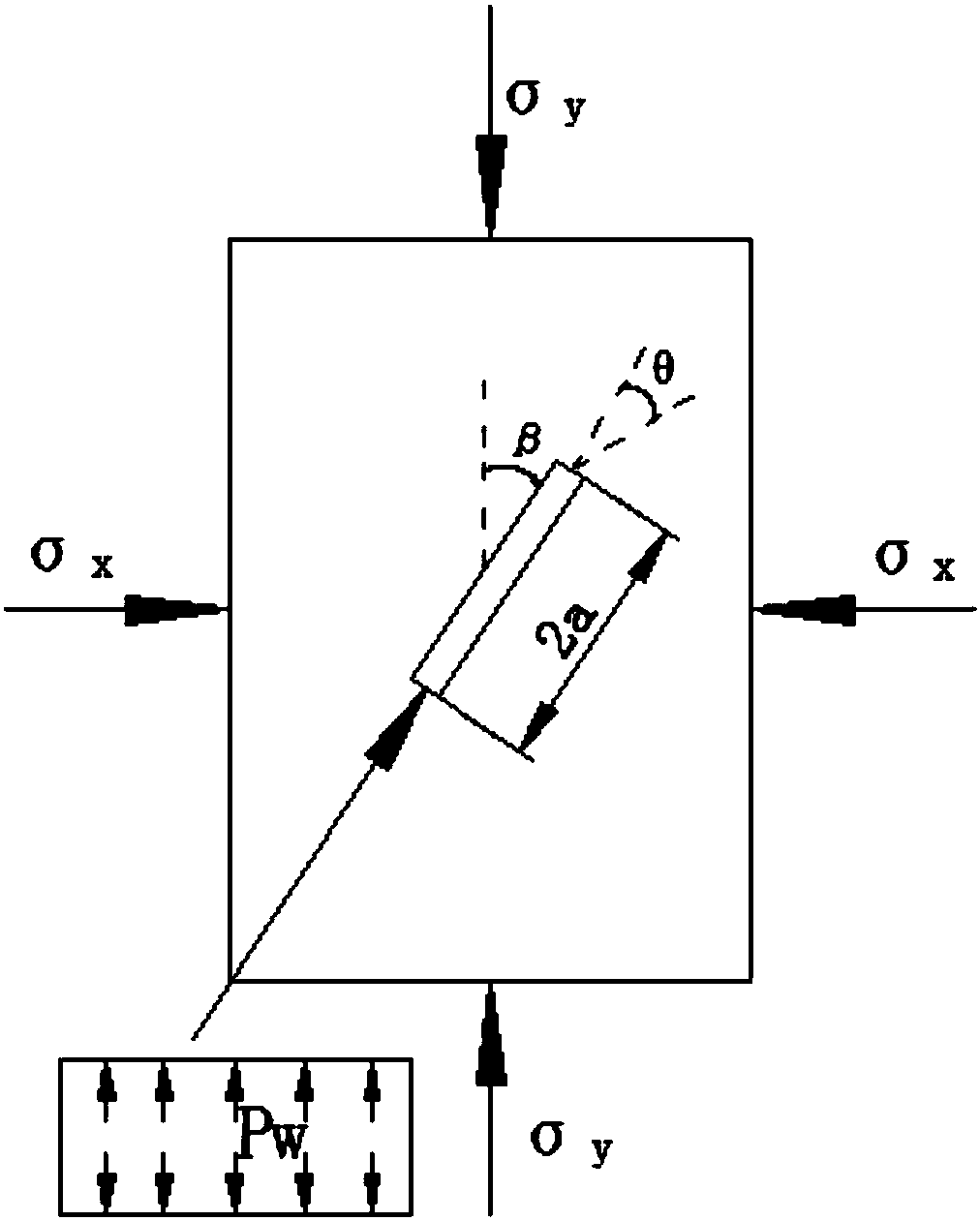

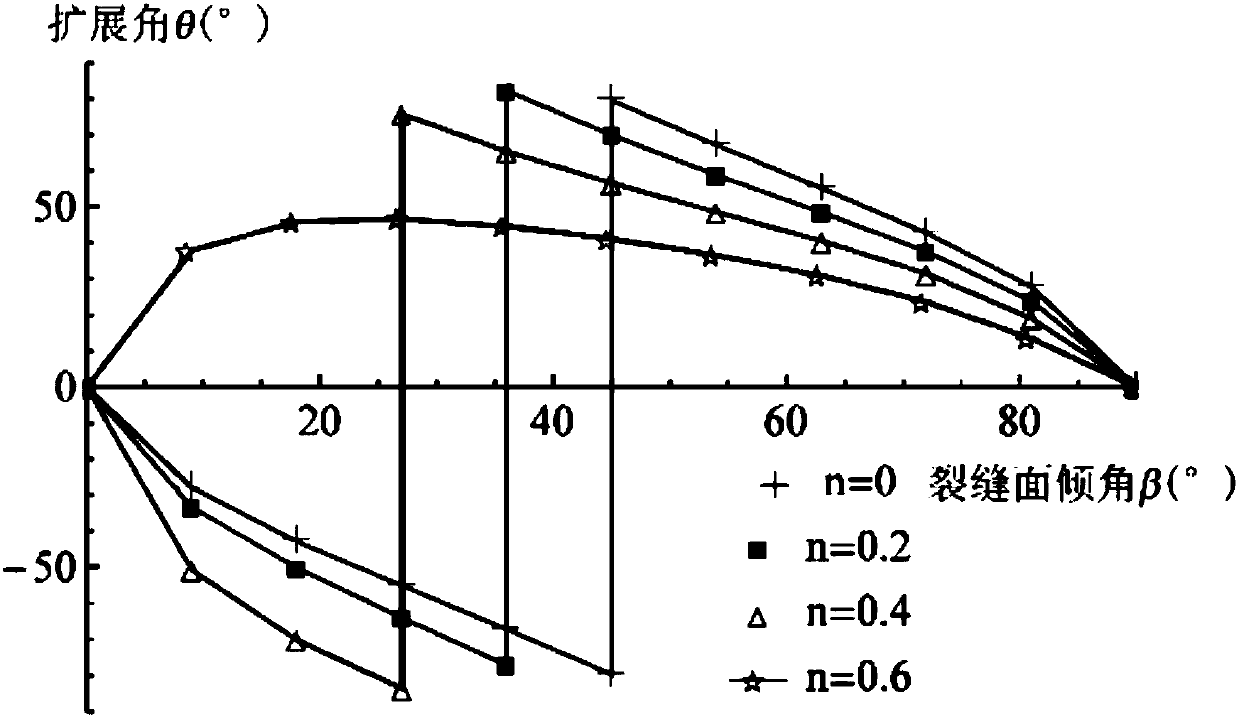

Shale hydraulic fracture propagation prediction method

ActiveCN108468538AGuaranteed accuracyHigh precisionFluid removalDesign optimisation/simulationFracture mechanicsStrain energy

The invention relates to the field of rock fracture prediction, in particular to a shale hydraulic fracture propagation prediction method. The method comprises the steps that 1, the normal direction,tangential stress and effect stress of an inclined fracture under the action of the external stress and water pressure are calculated; 2, a strain energy density function is obtained according to thetype of the fracture; 3, a strain energy density factor is obtained according to the strain energy density function; 4, the propagation direction and propagation angle of the fracture are judged according to a strain energy density criterion; 5, influences of stratification, natural fractures and the like on the propagation direction of hydraulic fractures are obtained through numerical simulation, so that fracture propagation under the effect of shale hydraulic pressure is predicted. The prediction method is based on fracture mechanics, a hydraulic condition factor is introduced, and the influences of different stratification directions on the propagation direction of the shale hydraulic fractures are obtained by researching the relation between the fracture propagation direction and themagnitude of the hydraulic pressure and utilizing an extended finite element method, so that accurate prediction of hydraulic fracture propagation is achieved, and higher prediction accuracy is obtained.

Owner:SOUTHWEST PETROLEUM UNIV

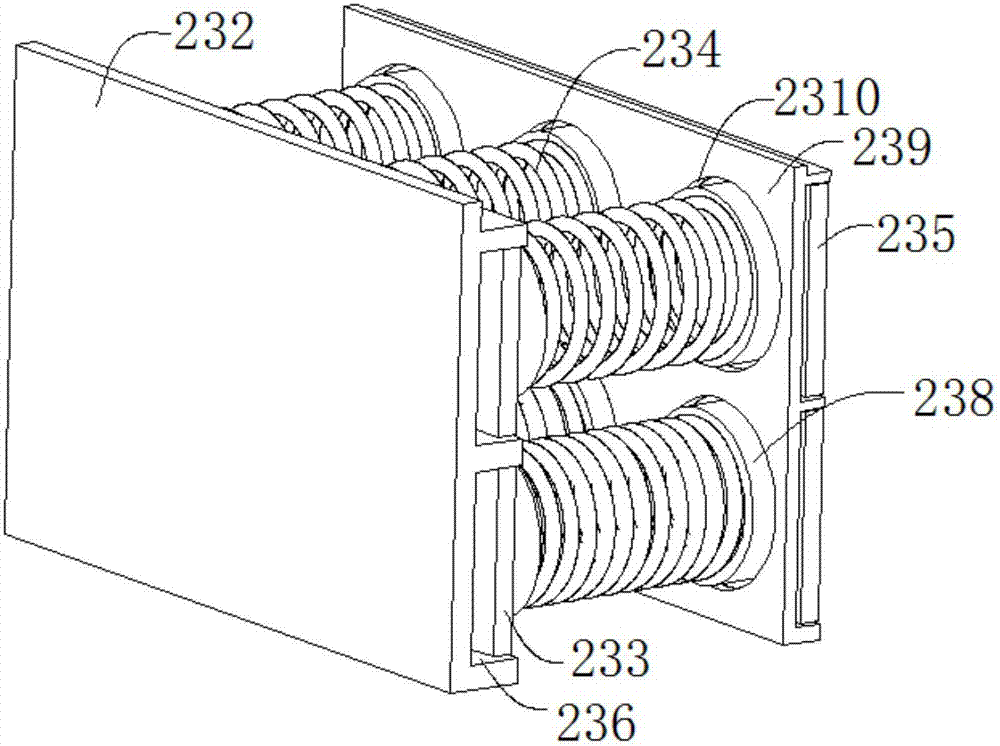

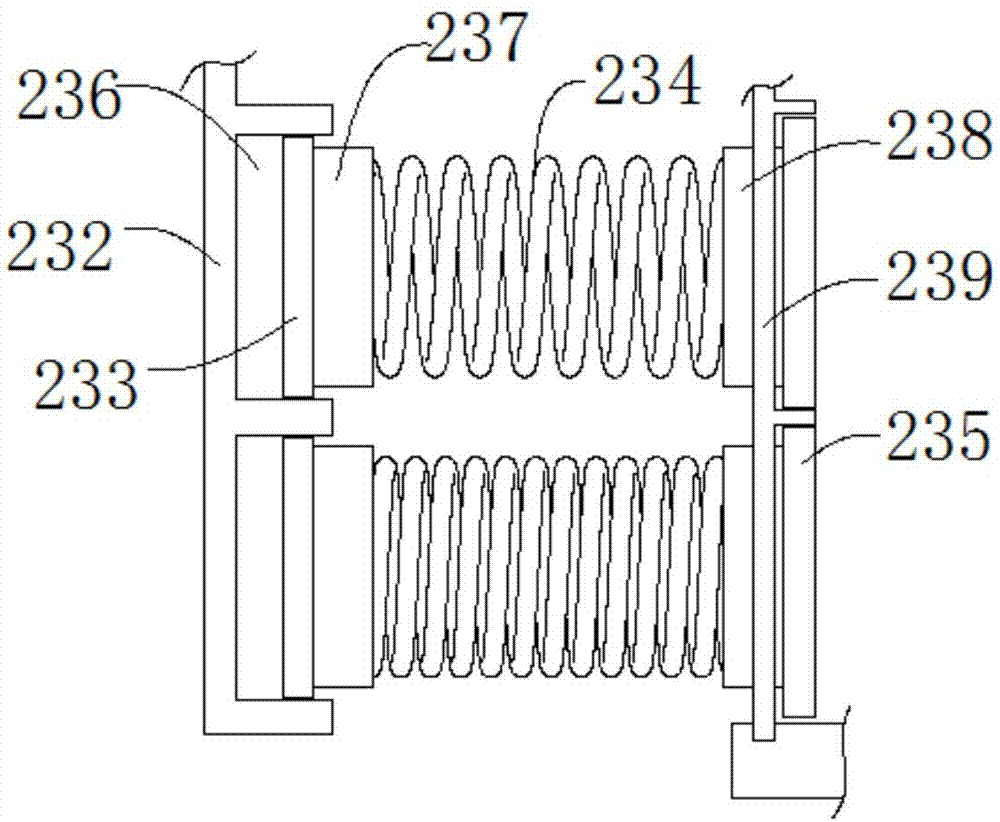

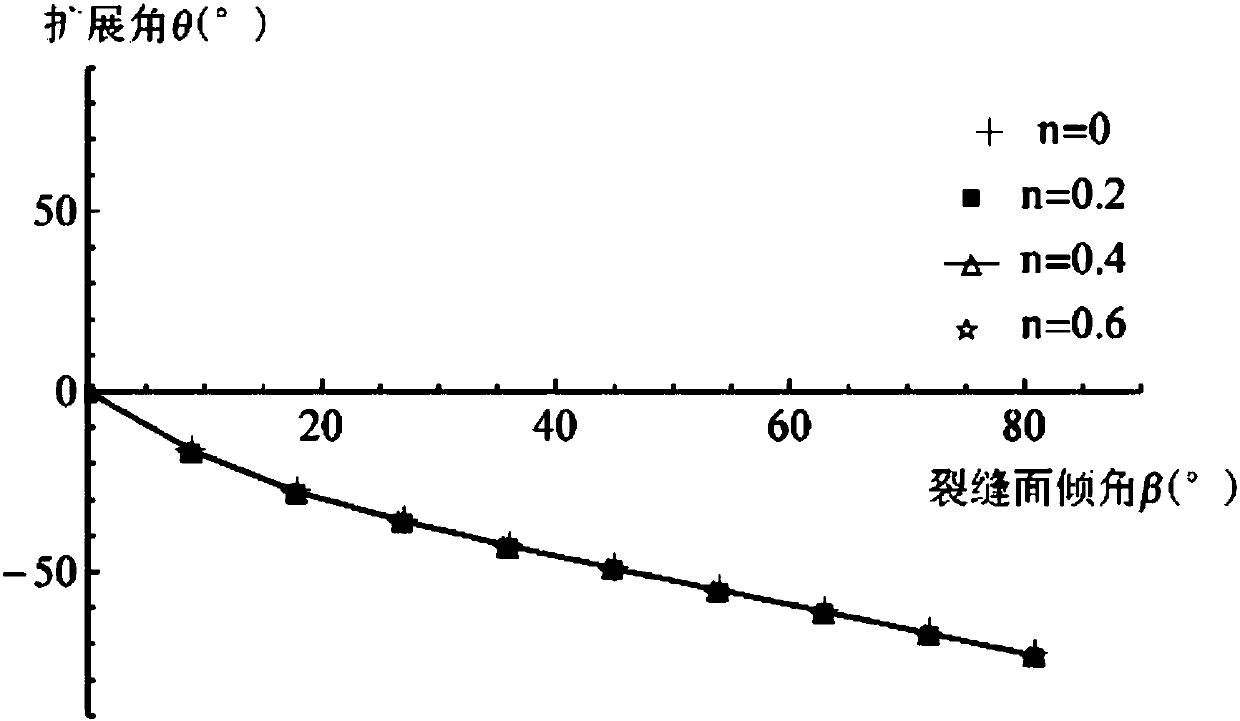

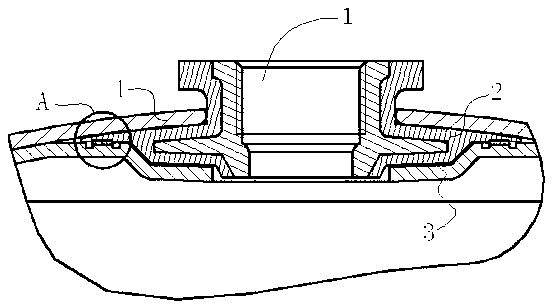

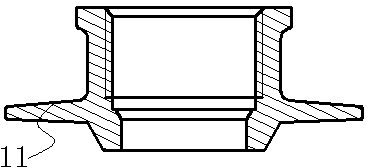

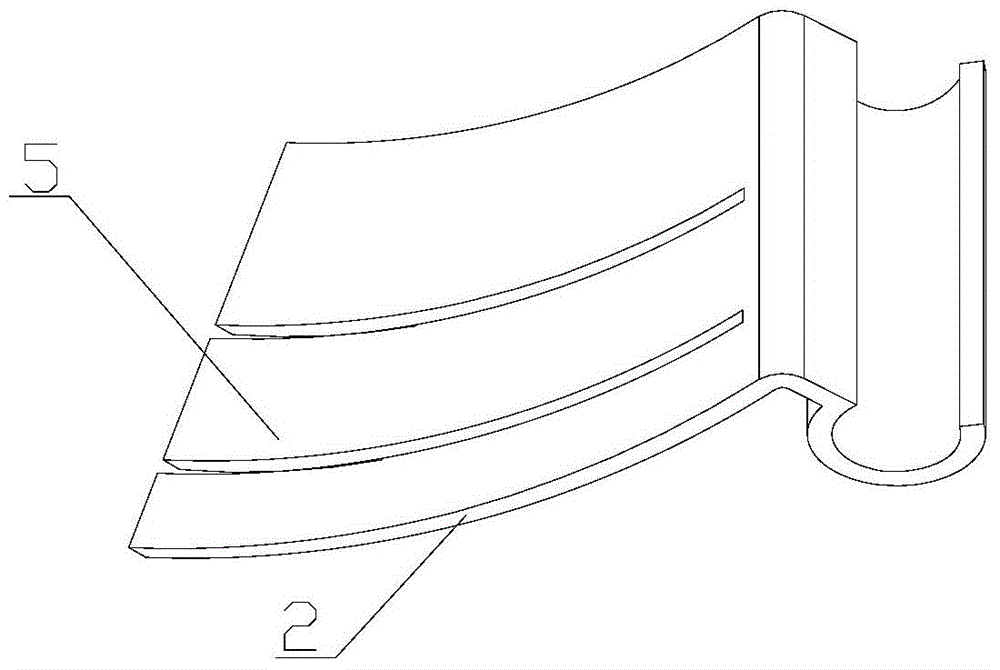

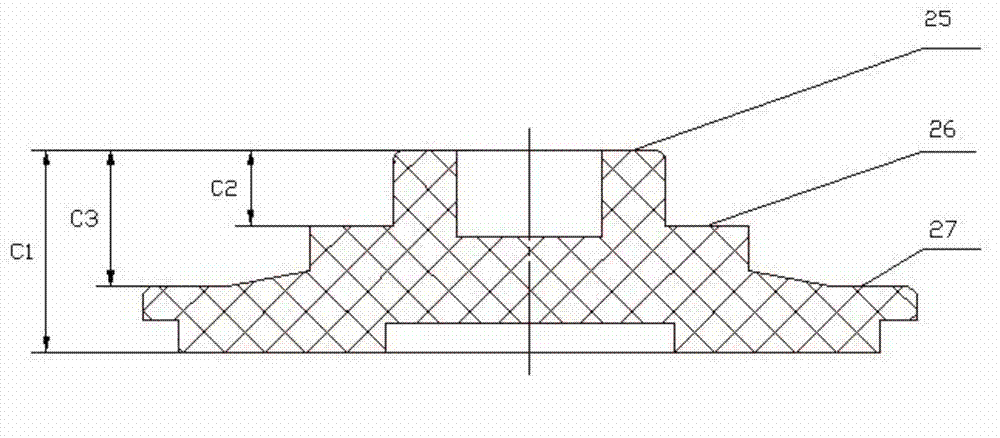

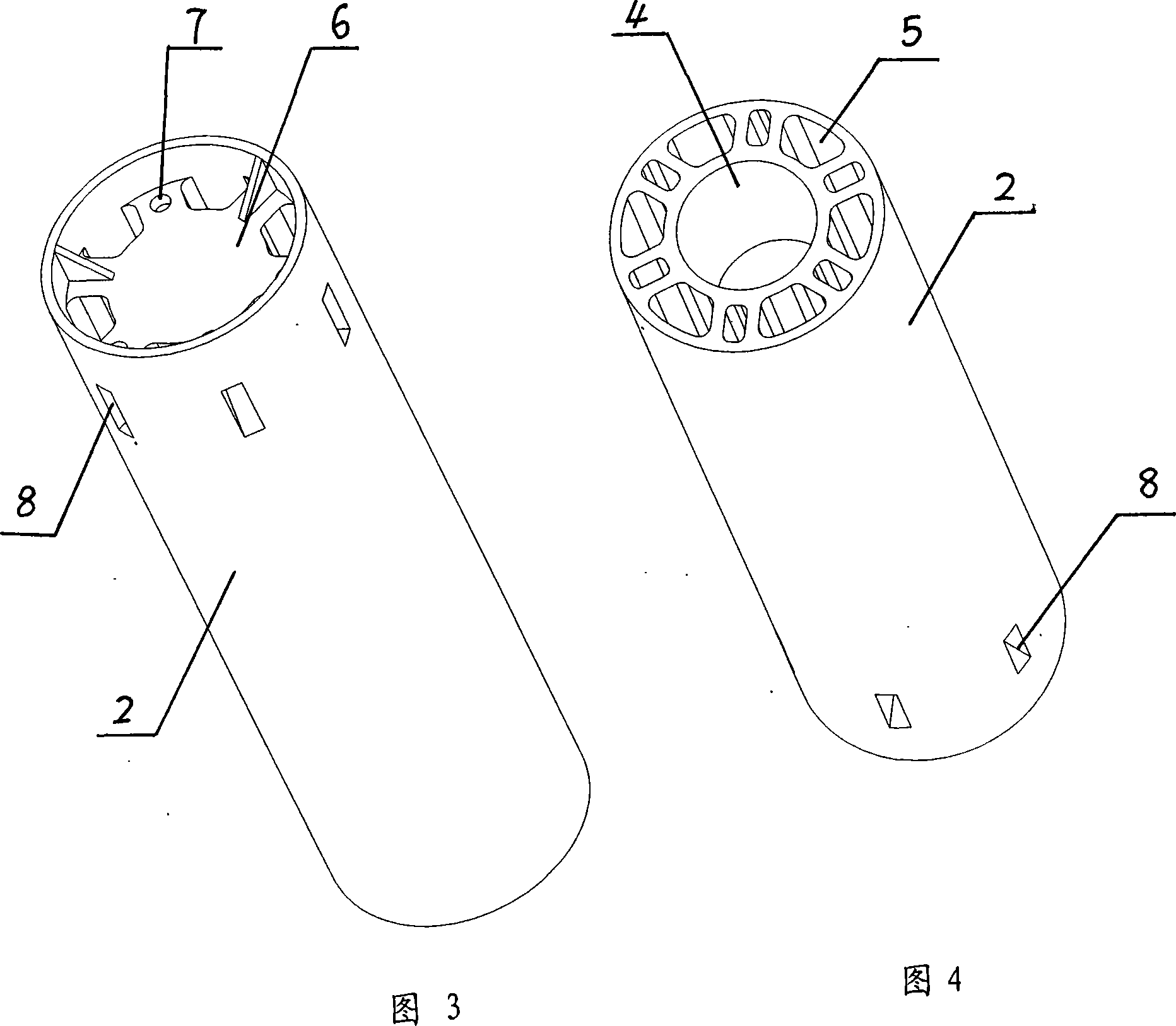

Plastic liner wound cylinder and manufacturing process

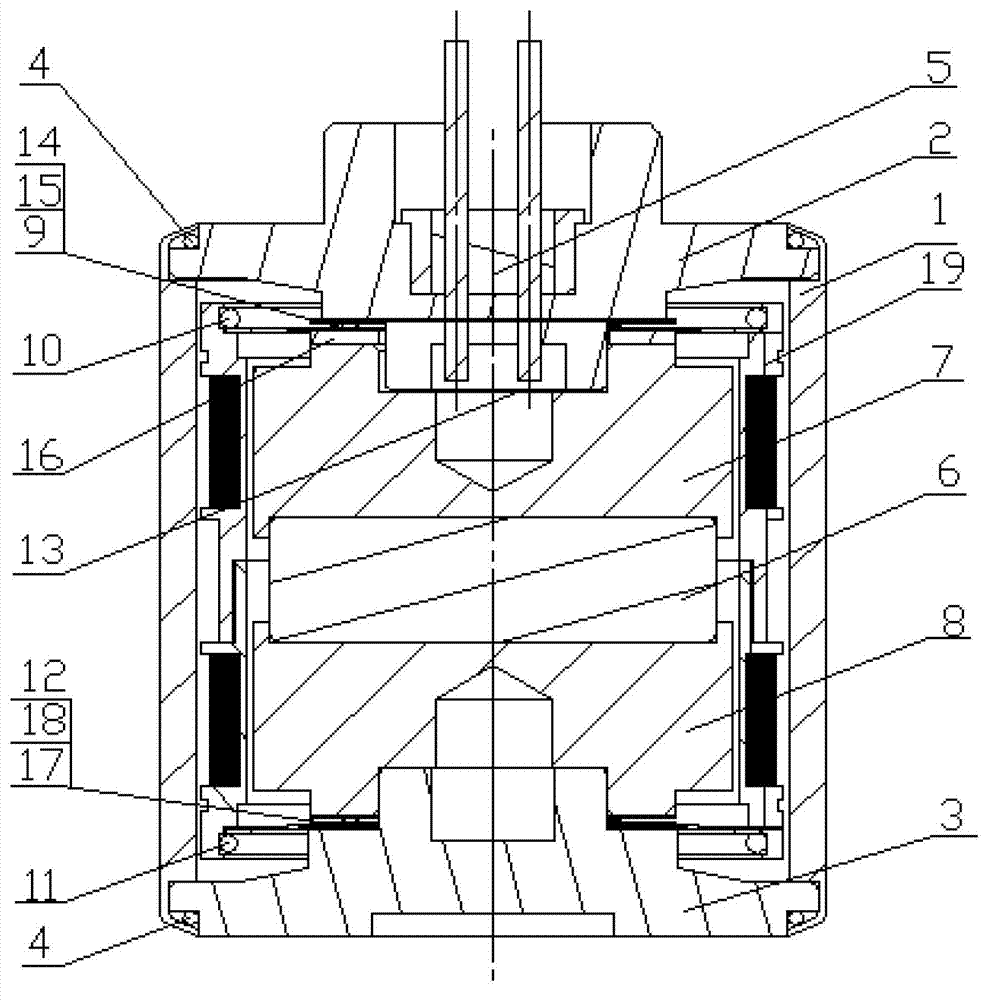

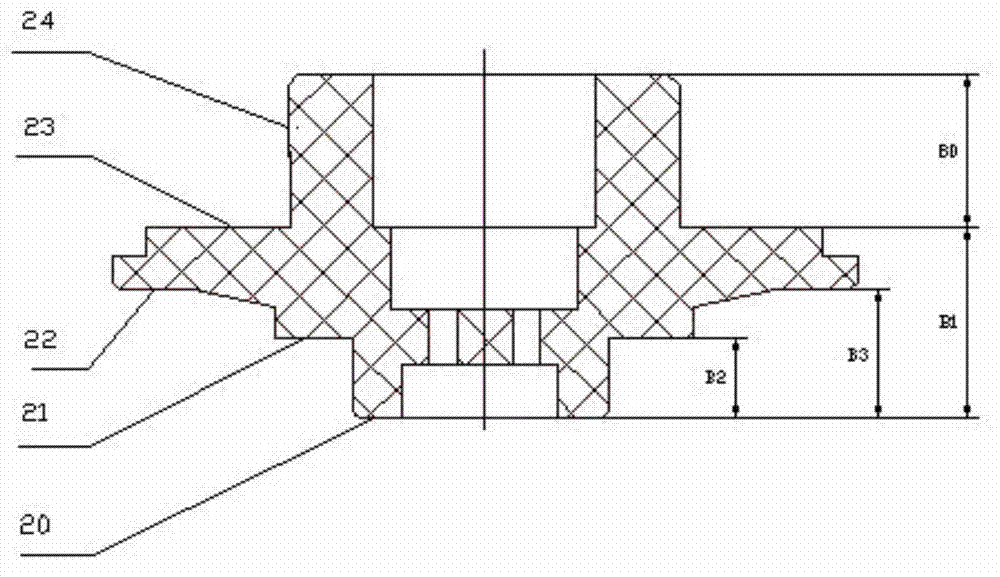

ActiveCN102840440AFew accessoriesNot easy to leakVessel mounting detailsPressure vesselsBlow moldingBottle

The invention relates to a plastic liner wound cylinder for liquefied petroleum gas, in particular to a plastic liner wound cylinder and a manufacturing process. The plastic liner wound cylinder comprises a metal bottle opening. An injection molding piece is arranged outside the metal bottle opening. The metal bottle opening and the injection molding piece are identical in vertical height. A circular bump is arranged outside the lower of the metal bottle opening. The upper surface of the circular bump is a downwards-inclined surface. The injection moulding piece is circular. The shape of the inner side of the circle is matched with that of the outer side of the metal bottle opening. The position of the injection molding piece, relative to the circular bump, is provided with an outer edge body. The upper surface of the outer edge body is a downwards-inclined surface. The thickness of the outer edge body is radially and gradually reduced to 3-20mm. An embedded ring is arranged on the lower surface of the outer edge body. Seal rings are arranged on both sides of the embedded ring. The outer side surface below the outer edge body of the injection molding piece is a blow molding plastic liner. A winding layer is arranged above the outer edge body. The winding layer is distributed at the outer side of the plastic liner to fasten the plastic liner and the metal bottle opening.

Owner:艾赛斯(杭州)复合材料有限公司

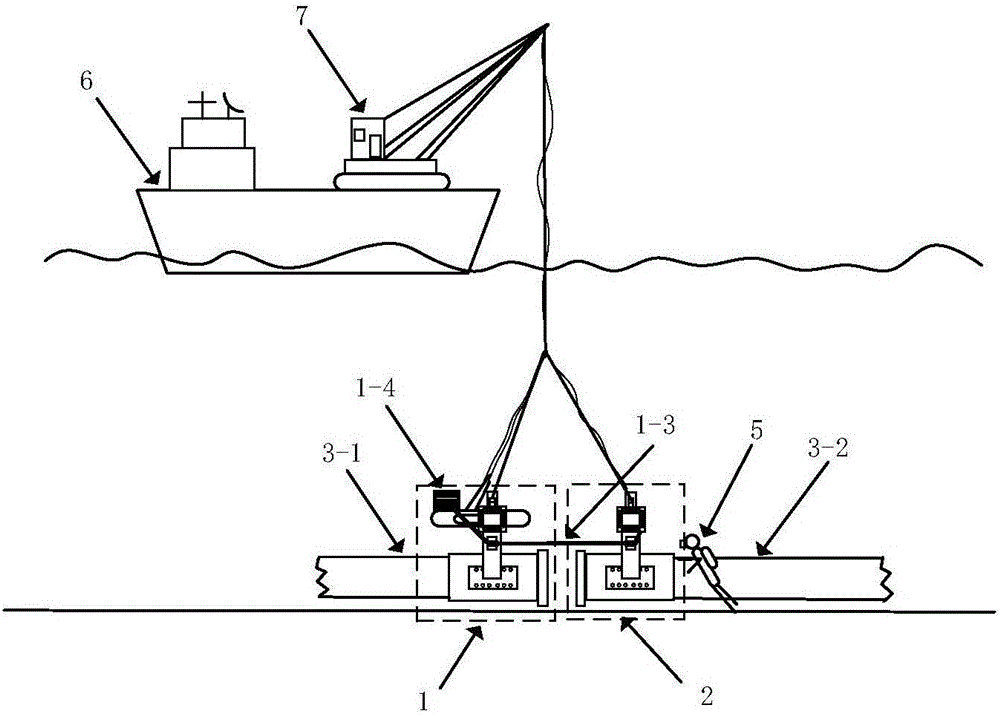

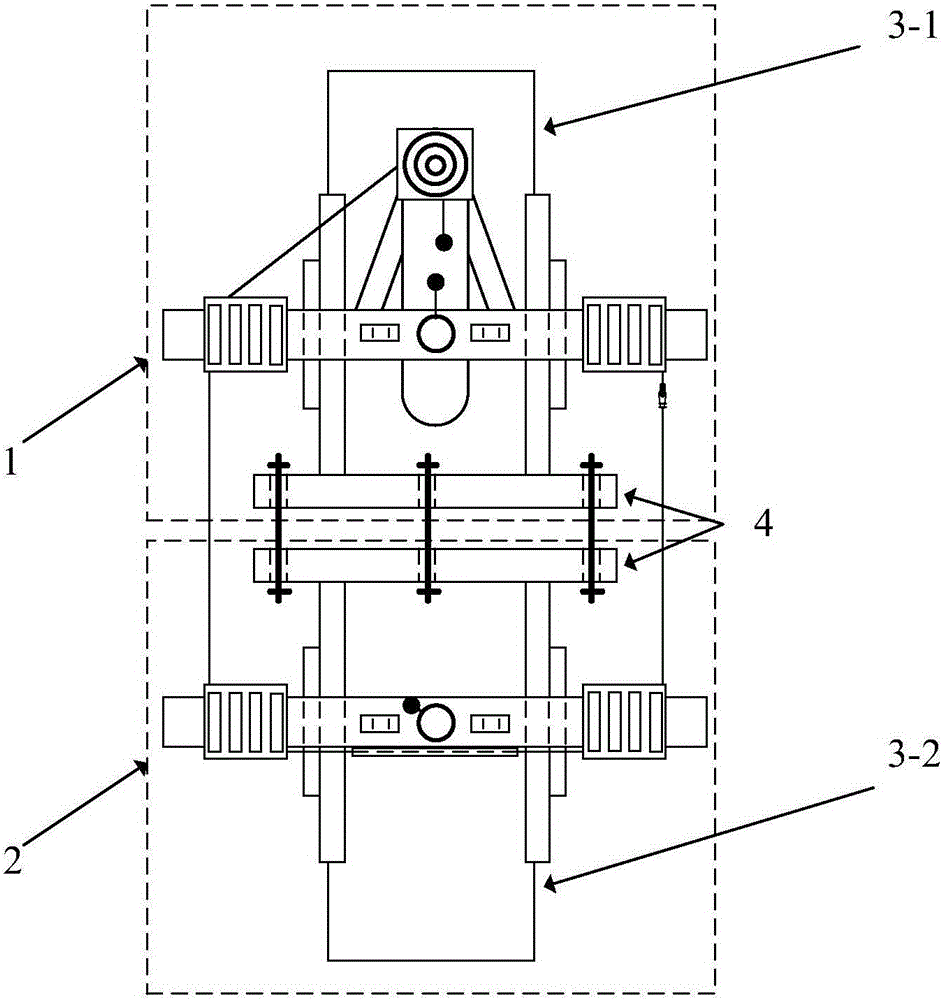

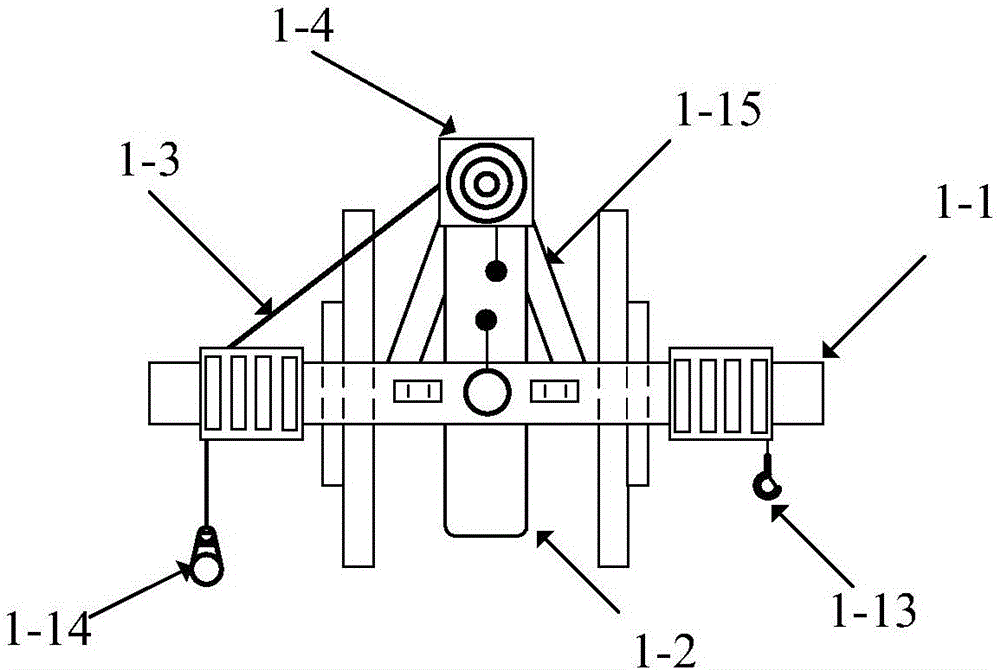

Submarine pipeline flange underwater abutting joint installation method

The invention discloses a submarine pipeline flange underwater abutting joint installation method. A main flange connecting device is installed on the abutting joint end of a submarine pipeline A, an auxiliary flange connecting device is installed on the abutting joint end of a submarine pipeline B, the submarine pipeline A to be butted and the submarine pipeline B to be butted are connected together through the main flange connecting device and the auxiliary flange connecting device, the negative influence of the marine condition on underwater flange connection can be removed, the influence of ship shake on the movement of the submarine pipeline A and the submarine pipeline B can be removed, underwater adjusting steps of a diver can be reduced, the diver can adjust the positions of the submarine pipeline A and the submarine pipeline B conveniently, the underwater operation difficulty degree of the diver can be reduced, the underwater operation time of the diver can be shortened, the case that flanges get close to each other in an aligned manner can be ensured, the force applied to a gasket of each flange is consistent, uniform deformation is generated, and the leakproofness of the flanges can be improved. The flange connection quality can be improved, the operating time of the support ship can be saved, the construction period of the whole fleet can be shortened, the working efficiency is improved, and the installation cost is saved.

Owner:CNOOC ENERGY TECH & SERVICES

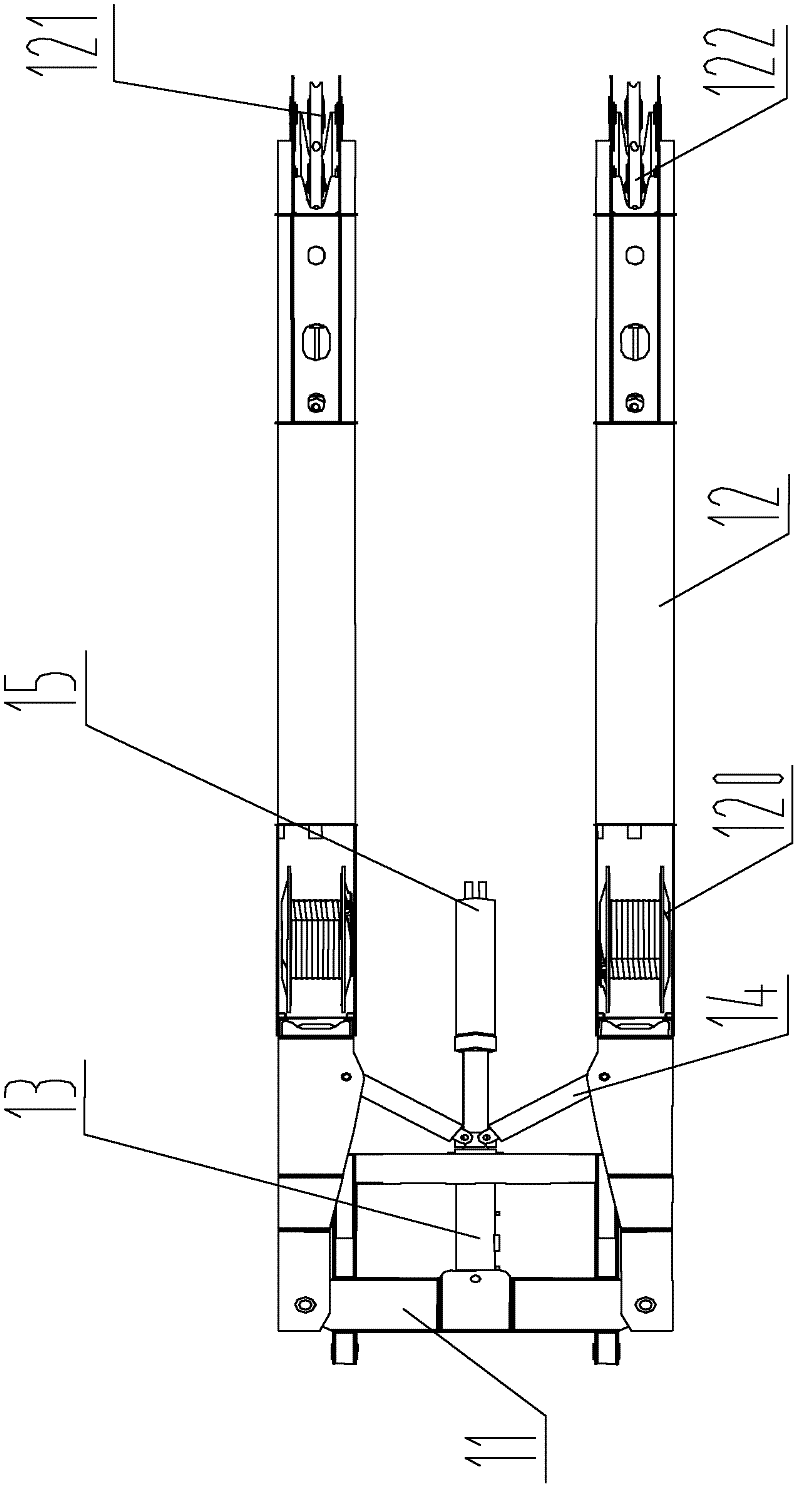

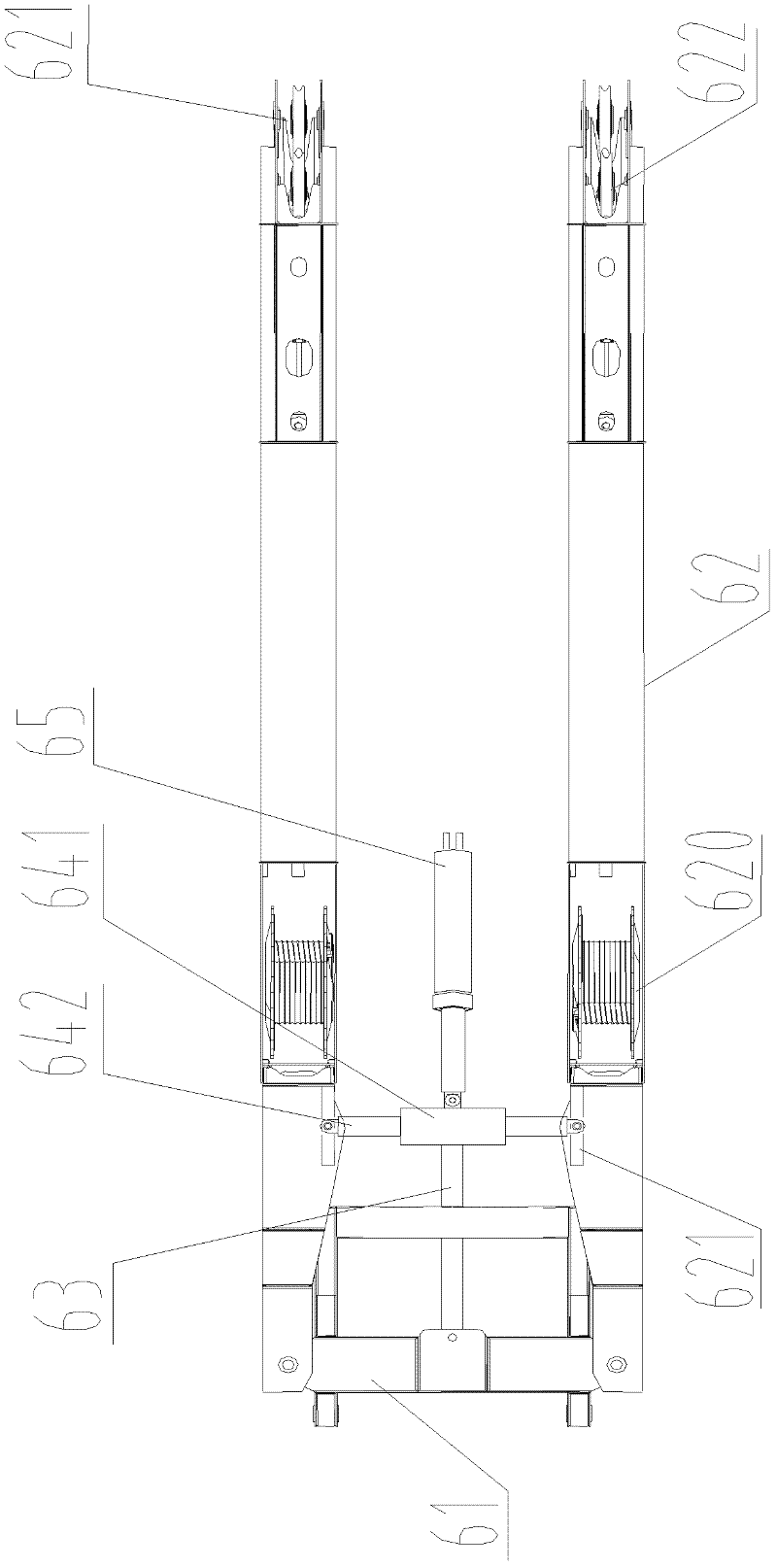

Four-mechanical-arm climbing type line patrol robot mechanical structure

ActiveCN110048338ARealize regulationEasy to controlBatteries circuit arrangementsElectric powerGobio gobio obtusirostrisMechanical engineering

The invention discloses a four-mechanical-arm climbing type line inspection robot mechanical structure. The distances between two opposite mechanical arms in a four-mechanical-arm group in the direction perpendicular to the extending direction of cables can be adjusted by a width adjusting mechanism, in this way, the distance adjustment between the two cables can be well adapted, and the cables are prevented from bearing too large tension or tensioning force; meanwhile, two mechanical arms in the four-mechanical-arm group are arranged in a swinging manner; therefore, the tightness support adjustment of the two mechanical arms on the cables can be realized through the swinging of the two mechanical arms; the stress of all line rollers is consistent; meanwhile, each line roller is provided with a width detection mechanism for detecting the widths of the two cables and a supporting detection mechanism for detecting the support force of the cables on the line roller. The controller can conduct feedback adjustment on the spatial positions of the four-mechanical-arm group according to the width detection mechanisms and the supporting detection mechanisms, automatic adjustment and controlover the robot are achieved, and the operation stability is guaranteed.

Owner:江苏东南测绘科技有限公司

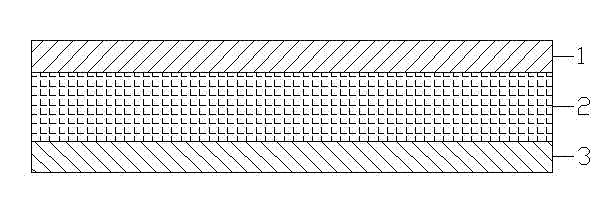

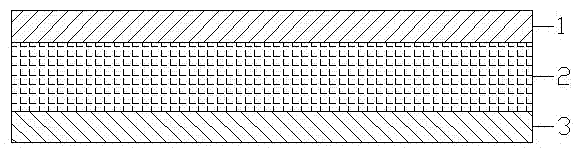

Hamburg type hemp fiber board and preparation method thereof

The invention relates to a hamburg type fibrilia plate and a preparation method thereof, and belongs to the technical field of automobile decoration fittings. The hamburg type fibrilia plate is characterized in that: the hamburg type fibrilia plate comprises three layers of a surface layer (1), a fibrilia felt layer (2) and a bottom layer (3). The surface layer (1) and bottom layer (3) are both needle-punched non-woven fabrics layers. Components of the needle-punched non-woven fabrics comprise, by mass, 40-60% of polypropylene fiber, 8-20% of 4080 fiber and 30-50% of polyester fiber. Components of the fibrilia felt comprise, by mass, 10-30% of palm fiber and the fibrilia, 30-40% of the polyester fiber and 40-50% of the polypropylene fiber. The preparation method comprises: 1, preparing the needle-punched non-woven fabrics; 2, preparing a composite substrate half finished product, wherein one side of the composite substrate half finished product is the needle-punched non-woven fabrics,the other side of the composite substrate half finished product is the fibrilia felt; 3, carrying out one-time mould-pressing to prepare the finished product. The prepared hamburg type fibrilia platehas characteristics of high strength, good stretching resistance, collapsing and deformation resistance, good flatness, low probability of moisten and mildewing, no toxicity and environmental protection.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

Steel slag ball production equipment and granulating system thereof

InactiveCN102690907AProlong the action timeFully oxidizedRecycling and recovery technologiesSlagAir compressor

The invention discloses steel slag ball production equipment and a granulating system thereof. The steel slag ball production equipment comprises the granulating system for spraying and cooling steel slag flowing out from a flowing groove by using high-pressure air water flow, wherein the granulating system comprises an air spraying mechanism and a cooling liquid spraying mechanism which are distributed up and down; the air spraying mechanism comprises an air compressor or a fan for supplying a high-pressure air source, and an air box for guiding air flow to be sprayed along a certain direction; the air box is provided with an air inlet and an air outlet; an air outlet of the air compressor or the fan is communicated with the air inlet of the air box through a pipeline; spraying panels are arranged at the front end of the air box; the spraying panels are provided with nozzles which are communicated with the air outlet of the air box; and more than two layers of spraying panels are arranged from top to bottom and each layer of spraying panel is horizontally provided with a plurality of nozzles in parallel. The granulating system of the steel slag ball production equipment adopts air and cooling liquid to commonly act on steel slag and the acting time in the air is long; the oxidization reaction is sufficient; the configuration of an organization is stable; and the granulating system can be used for grinding materials, building materials, water treatment, desulfurization agents and the like.

Owner:HENAN UNIV OF SCI & TECH

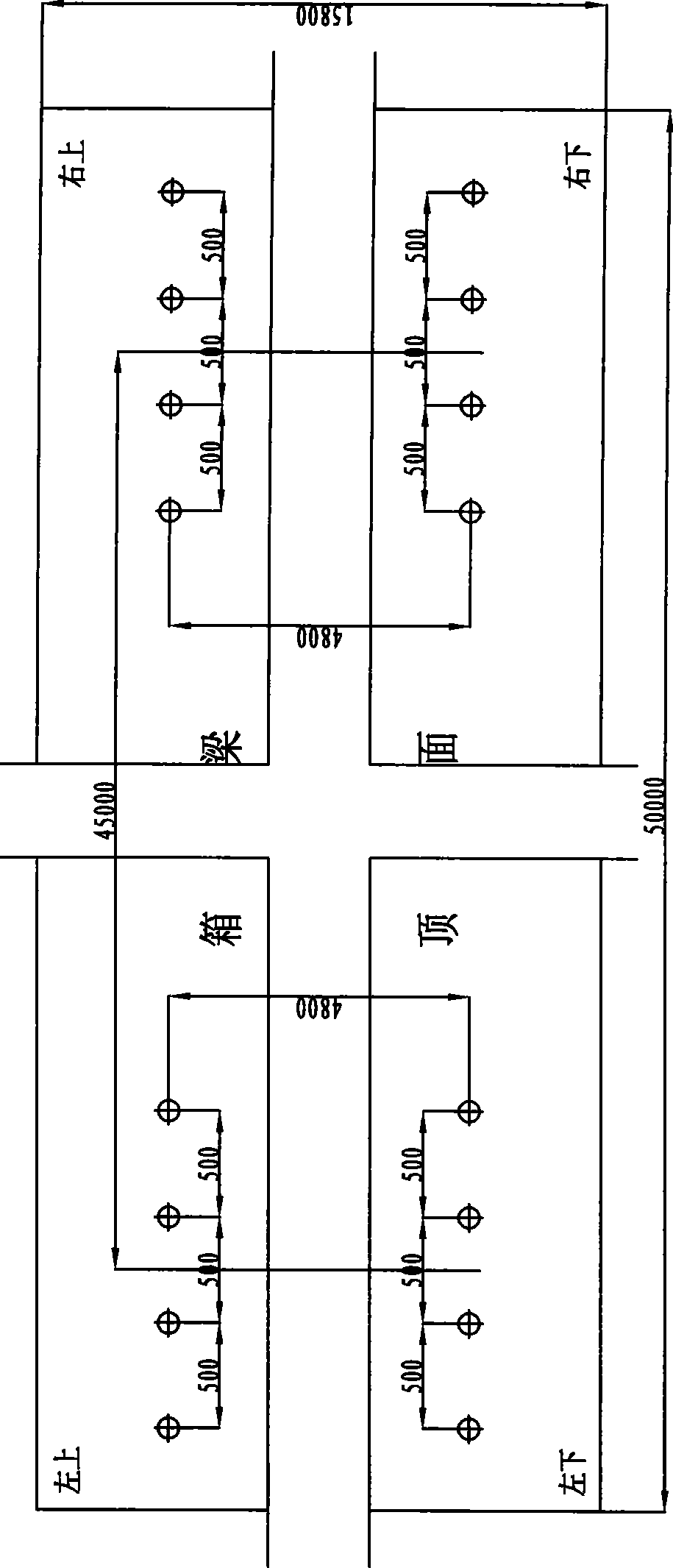

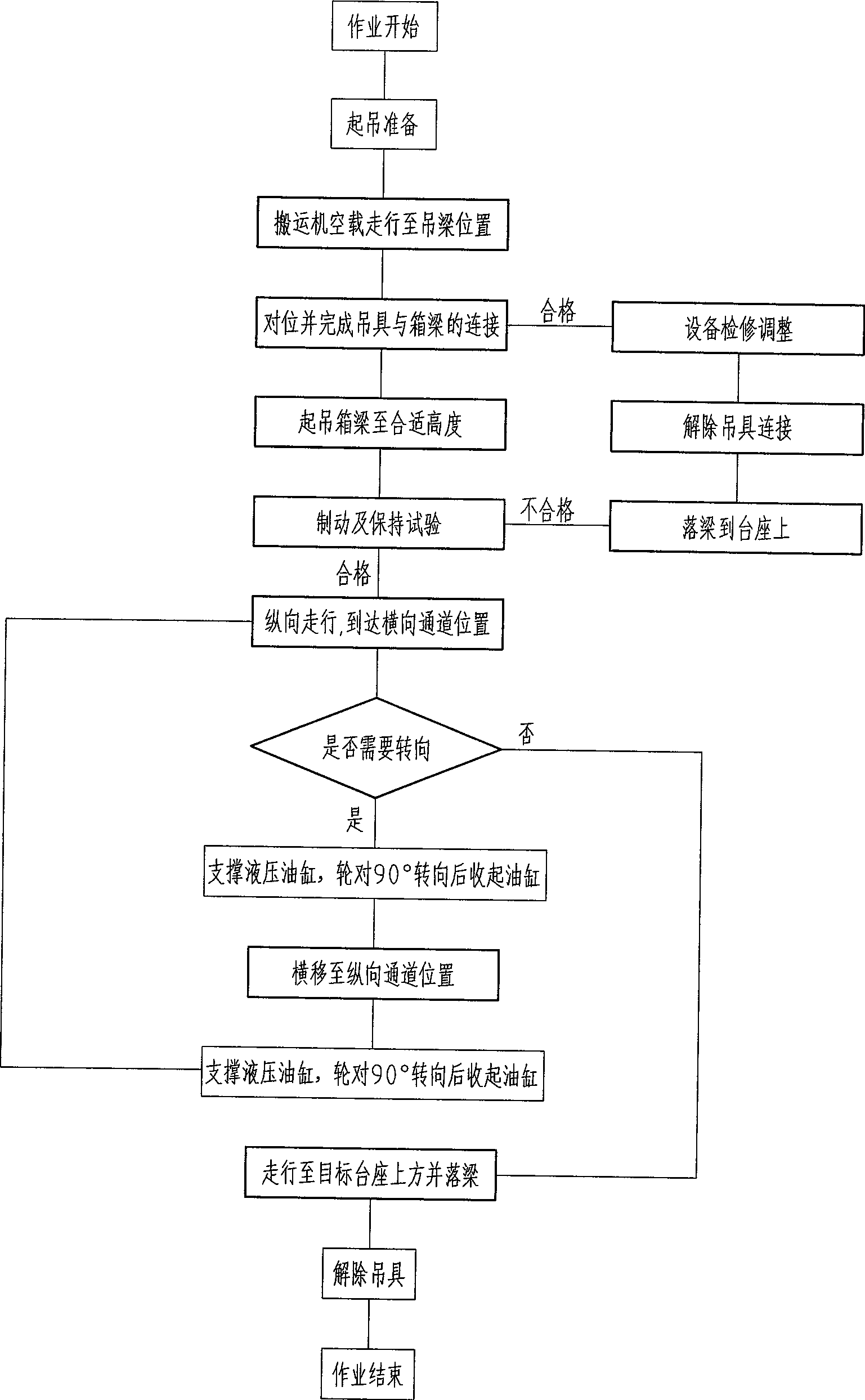

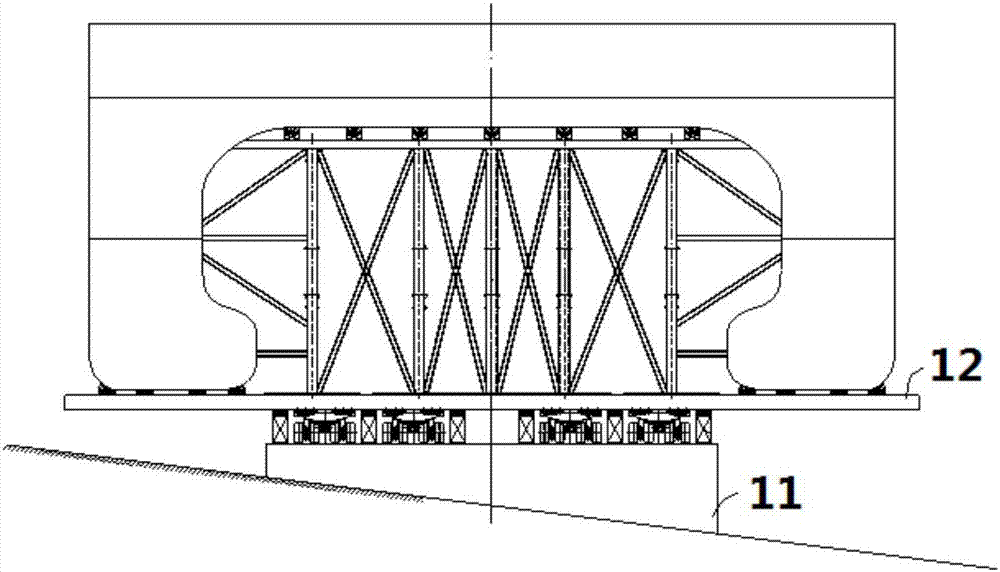

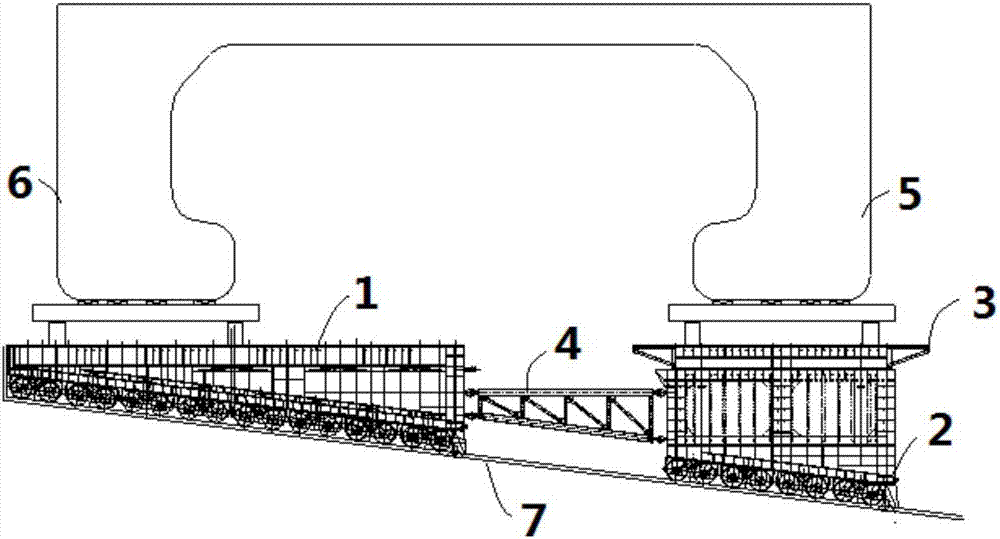

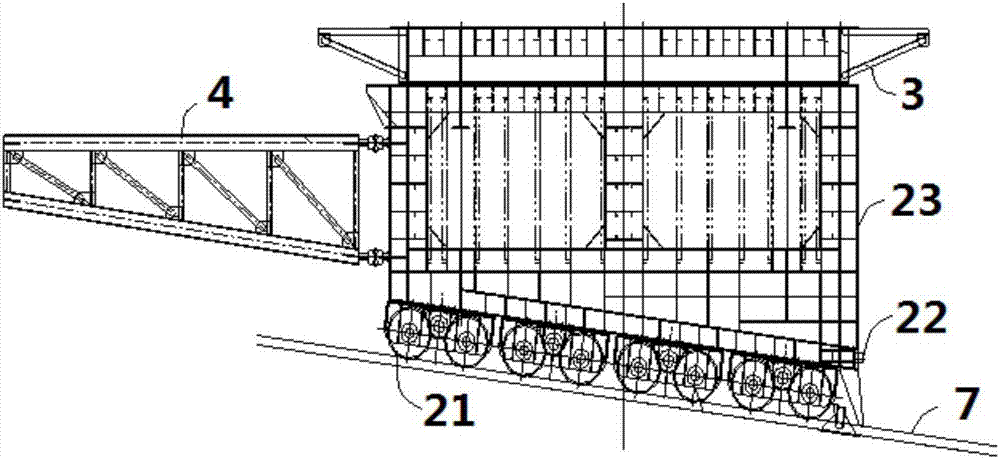

Construction method for carrying large box girder by tire type portal jib crane

ActiveCN101476287AImprove efficiencyGuaranteed normal displacementBridge erection/assemblyCross bridgeEngineering

The invention discloses a construction method for carrying large-scale box girder by tire type gantry crane, which comprises the following steps: 1): running empty wagons to collimating position: 2) lifting the beam; 3) running the double machine linked lifting beam longitudinally; 4) turning the wheel group by 90 degrees; 5) running the double machine linked lifting beam transversely; 6) placing the beam into the target position. The construction method of the invention for carrying large-scale whole hole prefabricated box girder in box girder fabrication yard is advanced, safe, reliable and efficient, and meets the requirement of large tonnage box girder prefabrication in the sea-crossing bridge tidal flat area in Hangzhou Bay.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

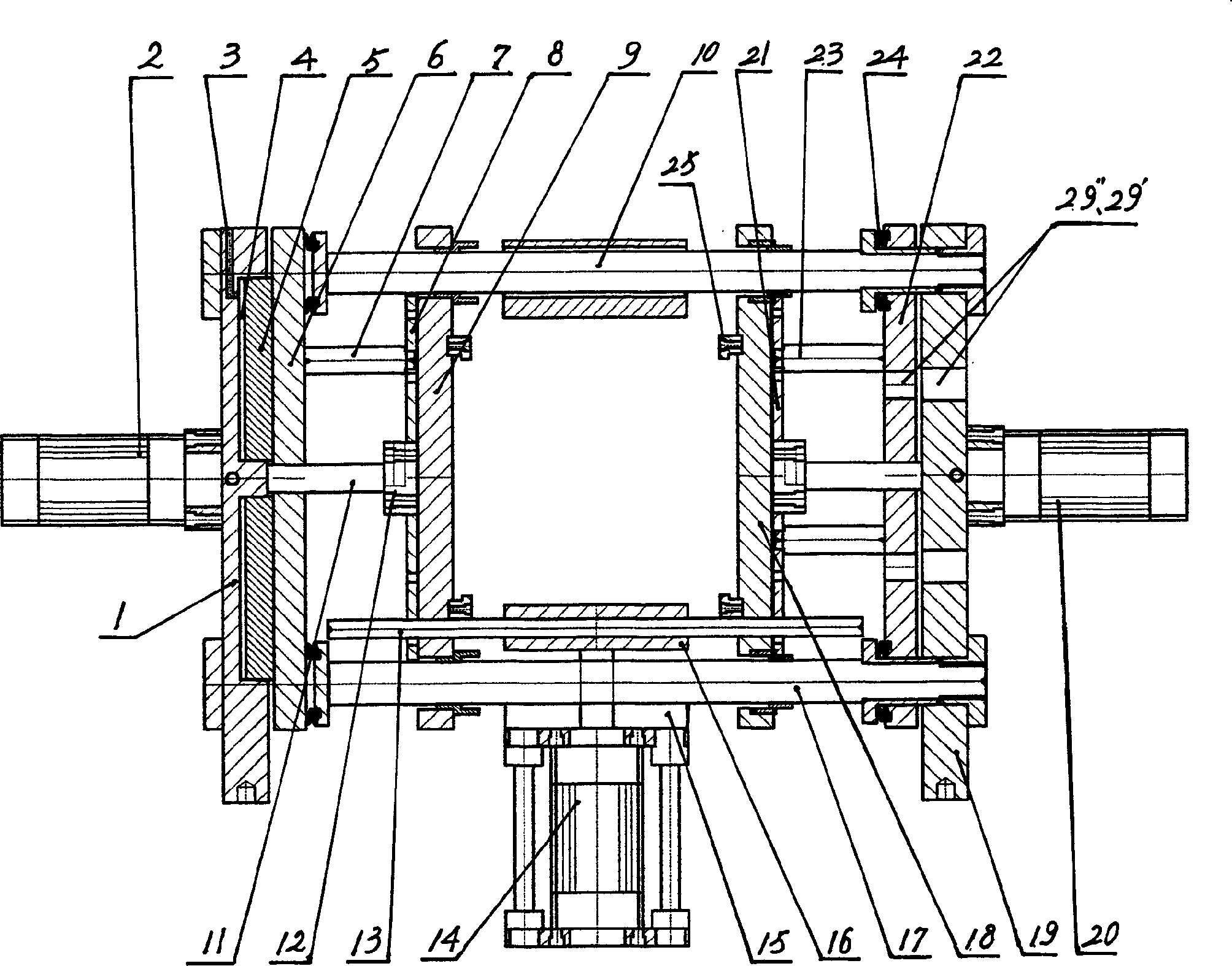

Mould clamping means for flastic bottle-blowing machine

The present invention relates to a mould-closing mechanism of plastic bottle-blowing machine. It comprises a fixed mould plate mounted on the machine frame, said fixed mould plate is connected with movable mould plate by means of upper and lower guide rods, on the fixed mould plate a cylinder for opening and closing mould is mounted, the piston rod of said cylinder is connected with movable mould plate. Its described fixed mould plate includes symmetrical two blocks of A and B, on said two blocks of fixed mould plates respectively are mounted mould-opening and closing cylinders of A and B, the piston rods of said two mould-opening and closing cylinders are respectively connected with movable mould plates of A and B. Besides, said invention also includes the components of upright column lifting fixing plate, top-moulding upright column, bottom mould cylinder, pressure piston and others.

Owner:蔡桂森

Wire-rope/pulley component and crane

ActiveCN102530757AExtended service lifeImprove safety and economyWinding mechanismsCranesEngineeringWire rope

The invention discloses a wire-rope / pulley component which comprises a first pulley block, a second pulley block and a wire rope passing through the first and the second pulley blocks, wherein the wire rope passes alternately through individual pulleys in the first and the second pulley blocks, and the head end and the tail end of the wire rope are positioned on the same side of a pulley shaft. The interference between the wire rope of the wire-rope / pulley component and a lifting hook side plate is eliminated, so that the service life of the wire rope is increased and thus the safety and economy are significantly improved. The invention also discloses a crane provided with the wire-rope / pulley component.

Owner:XUZHOU HEAVY MASCH CO LTD

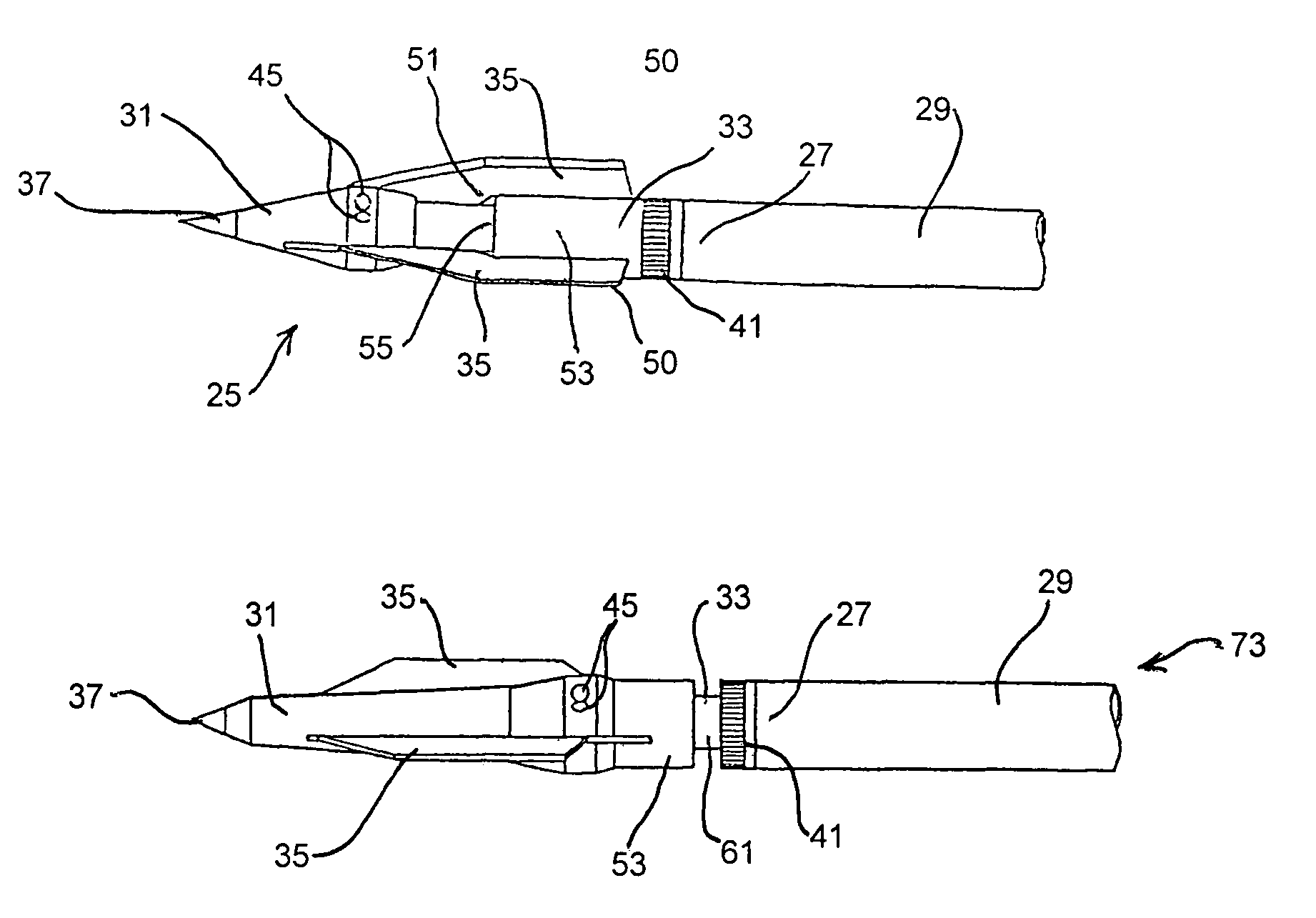

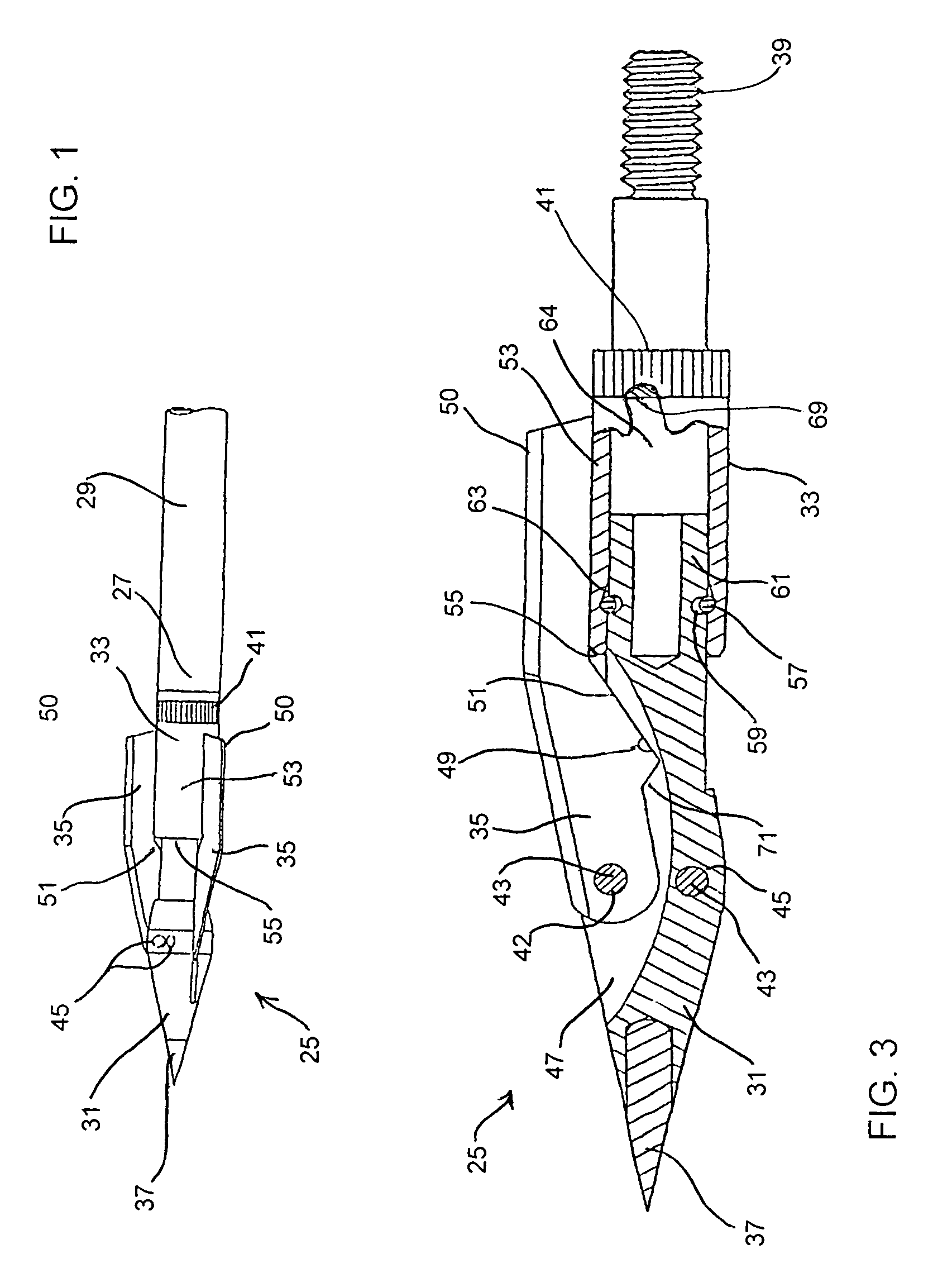

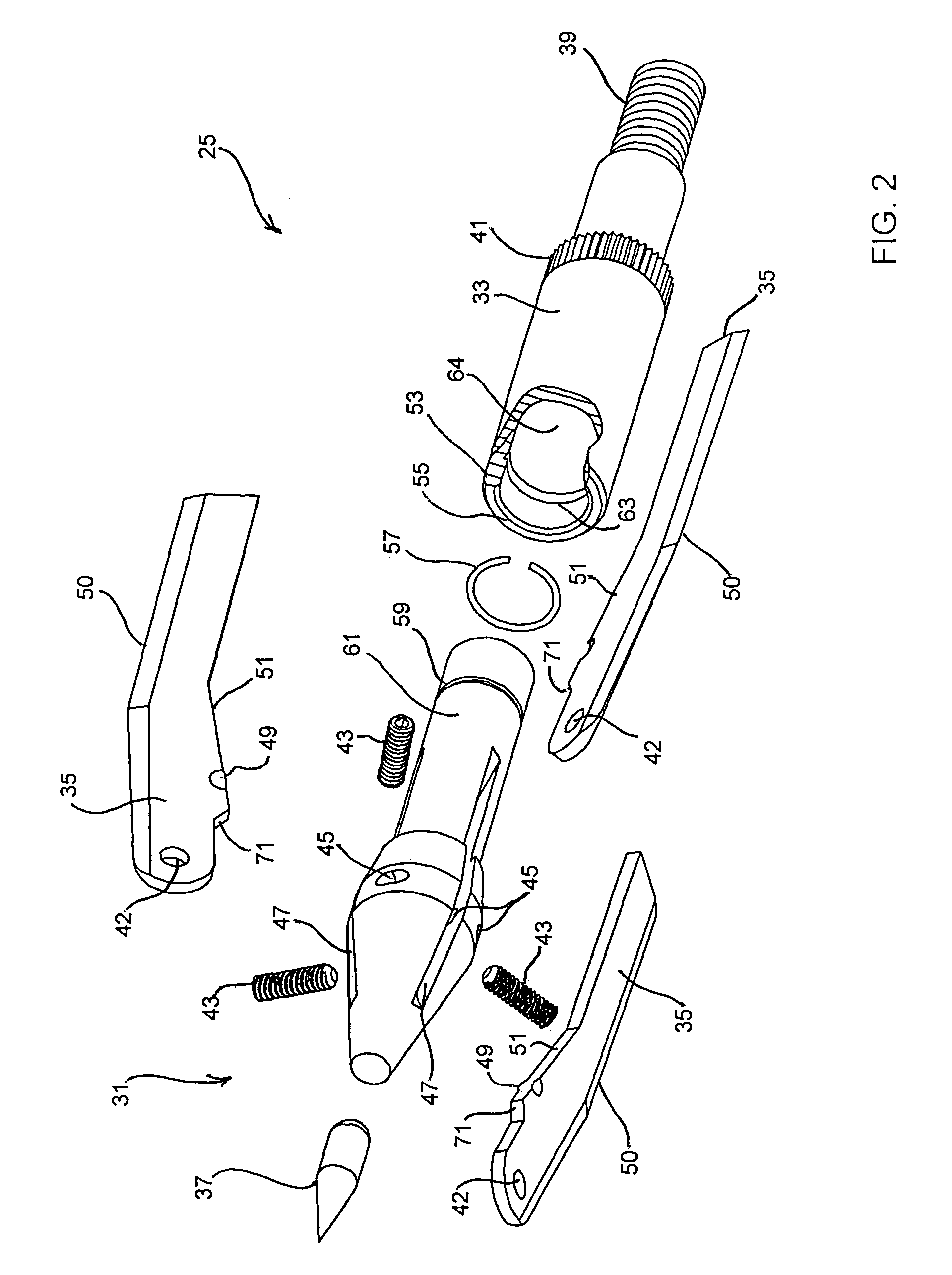

Highly efficient impact operative arrowheads

A target impact operative arrowhead mountable at an end of an arrow shaft is disclosed that includes an arrowhead body and blade actuator axially and rotationally movable relative to one another. The arrowhead body has blades pivotably mounted thereon, each of the blades having an actuation contact surface along an edge thereof, and the actuator has a blade contacting end. A spring ring retains assembly of the body and actuator, one of the arrowhead body and the actuator having an annular retention seat for mounting of the spring ring and the other of the arrowhead body and the actuator having an annular guide groove for receipt of the spring ring therealong thus accommodating relative axial travel of the spring ring.

Owner:ZEREN JOSEPH D

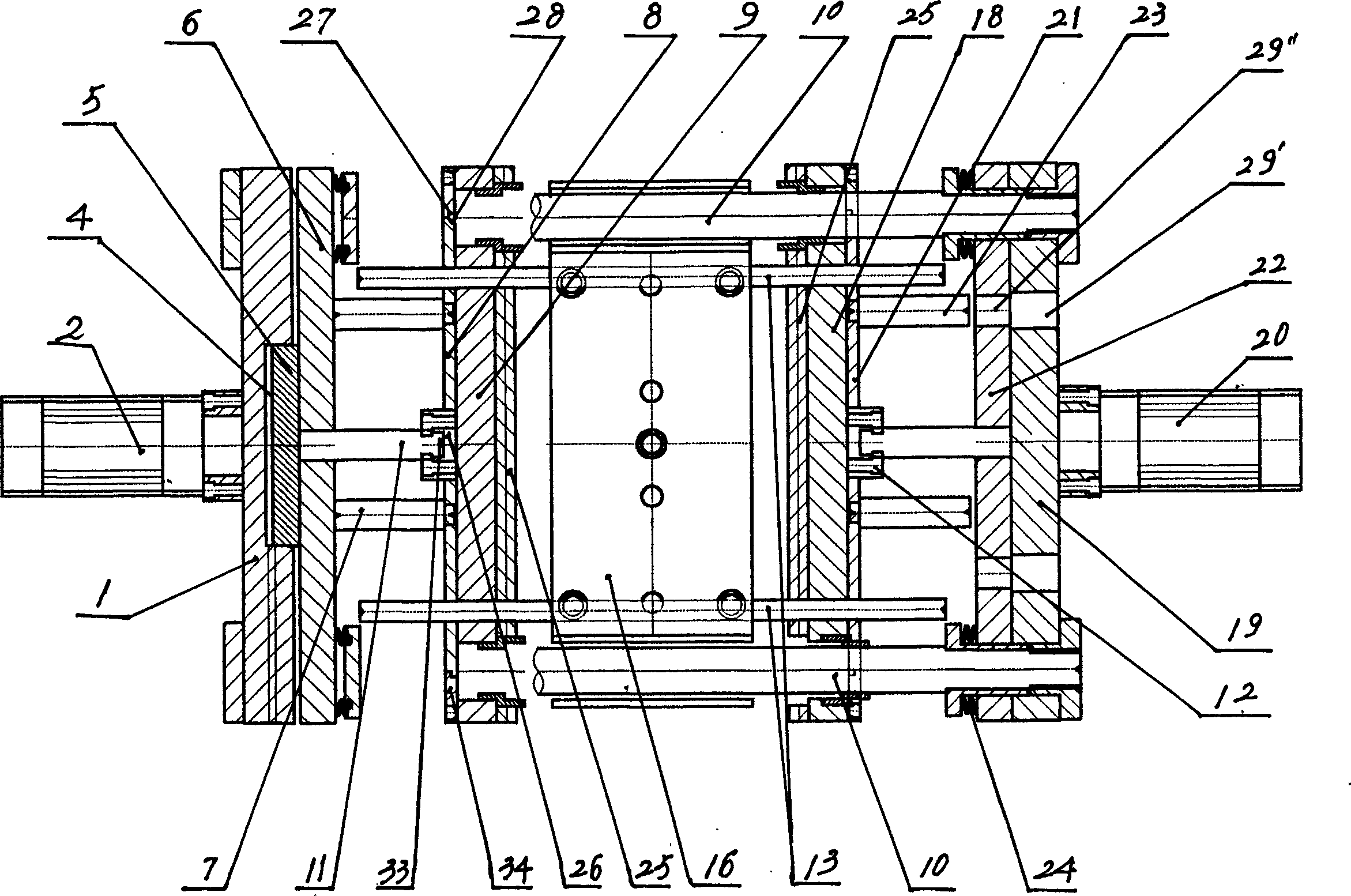

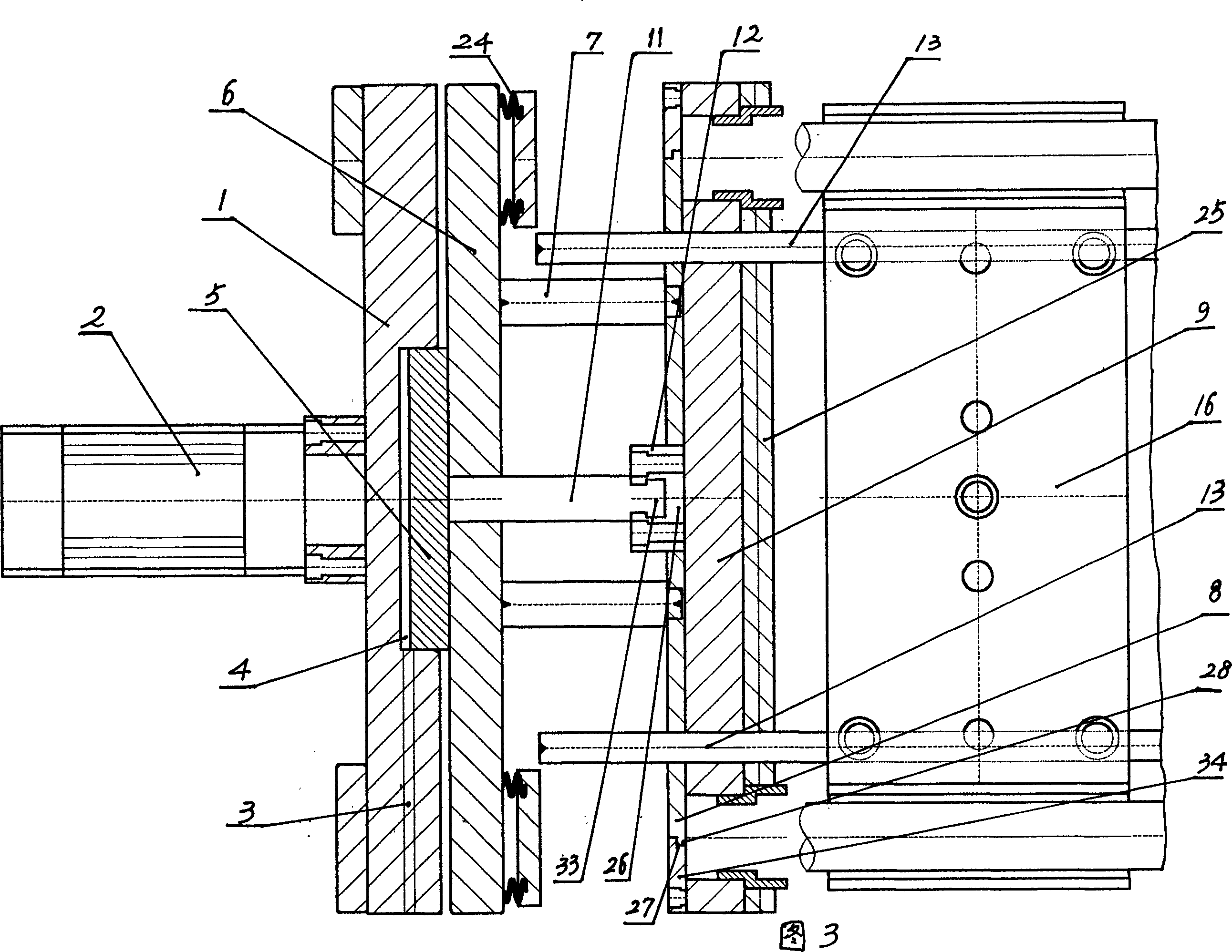

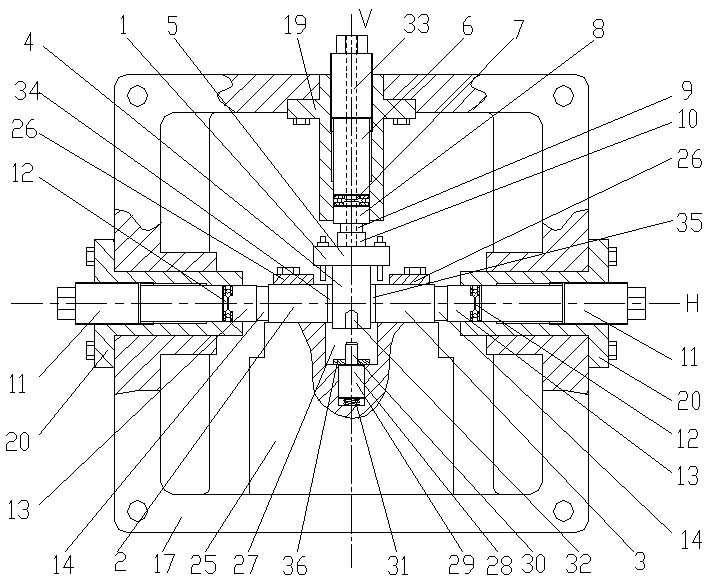

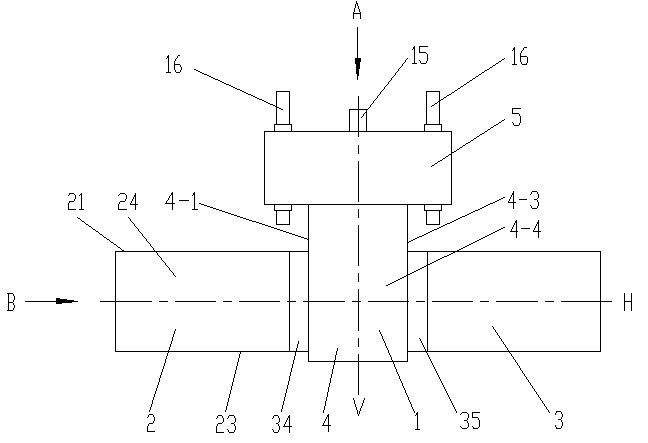

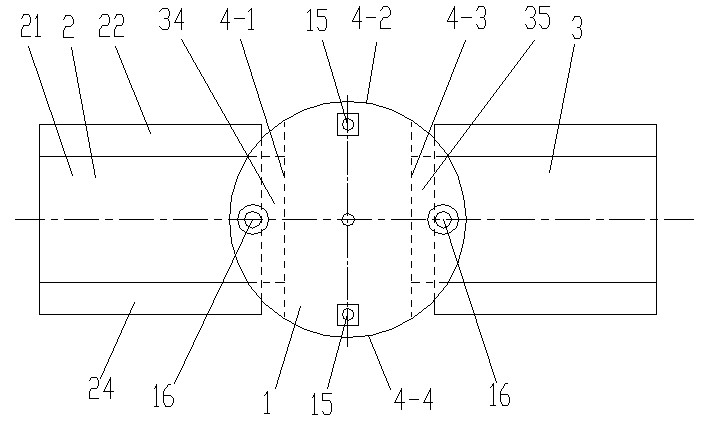

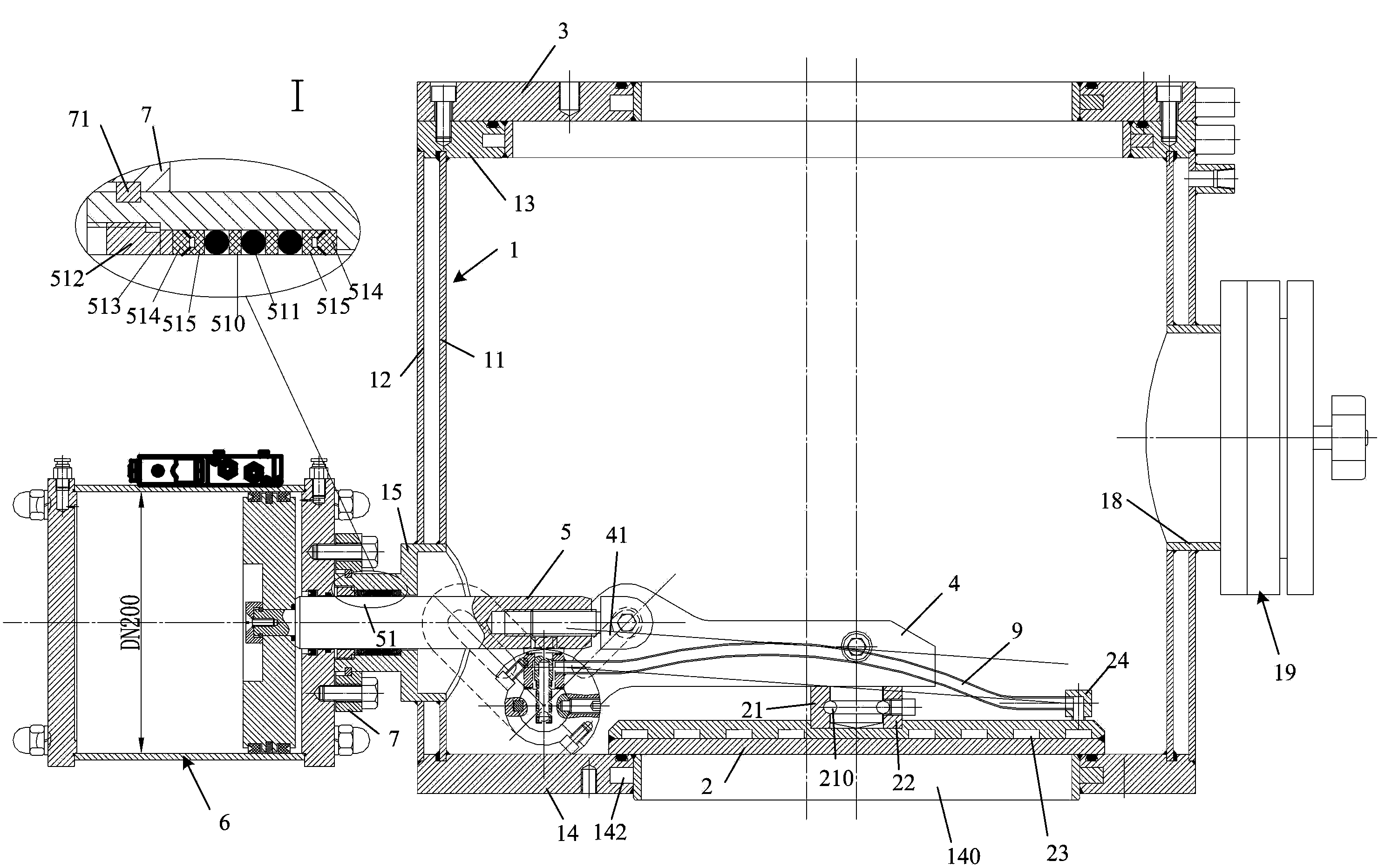

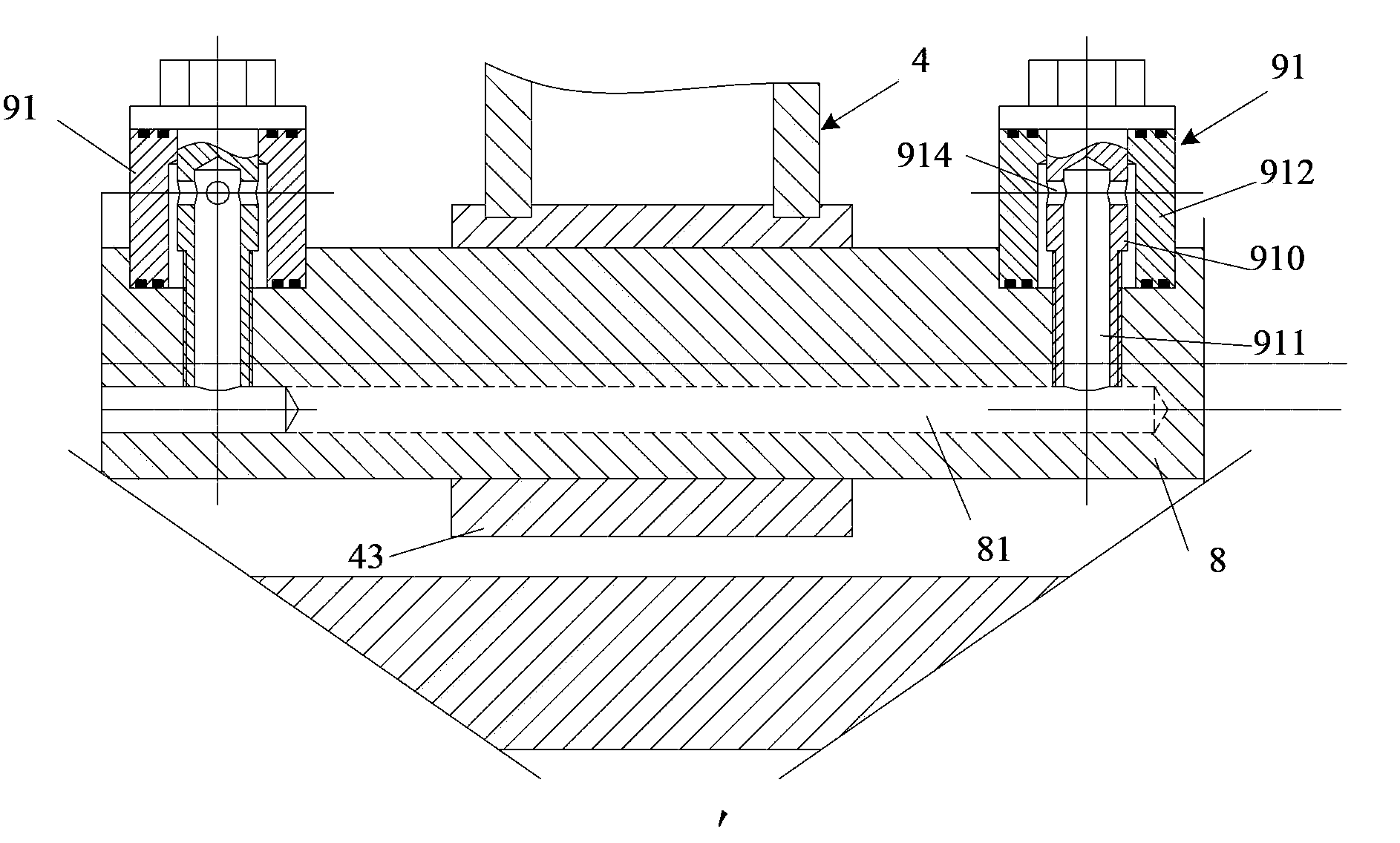

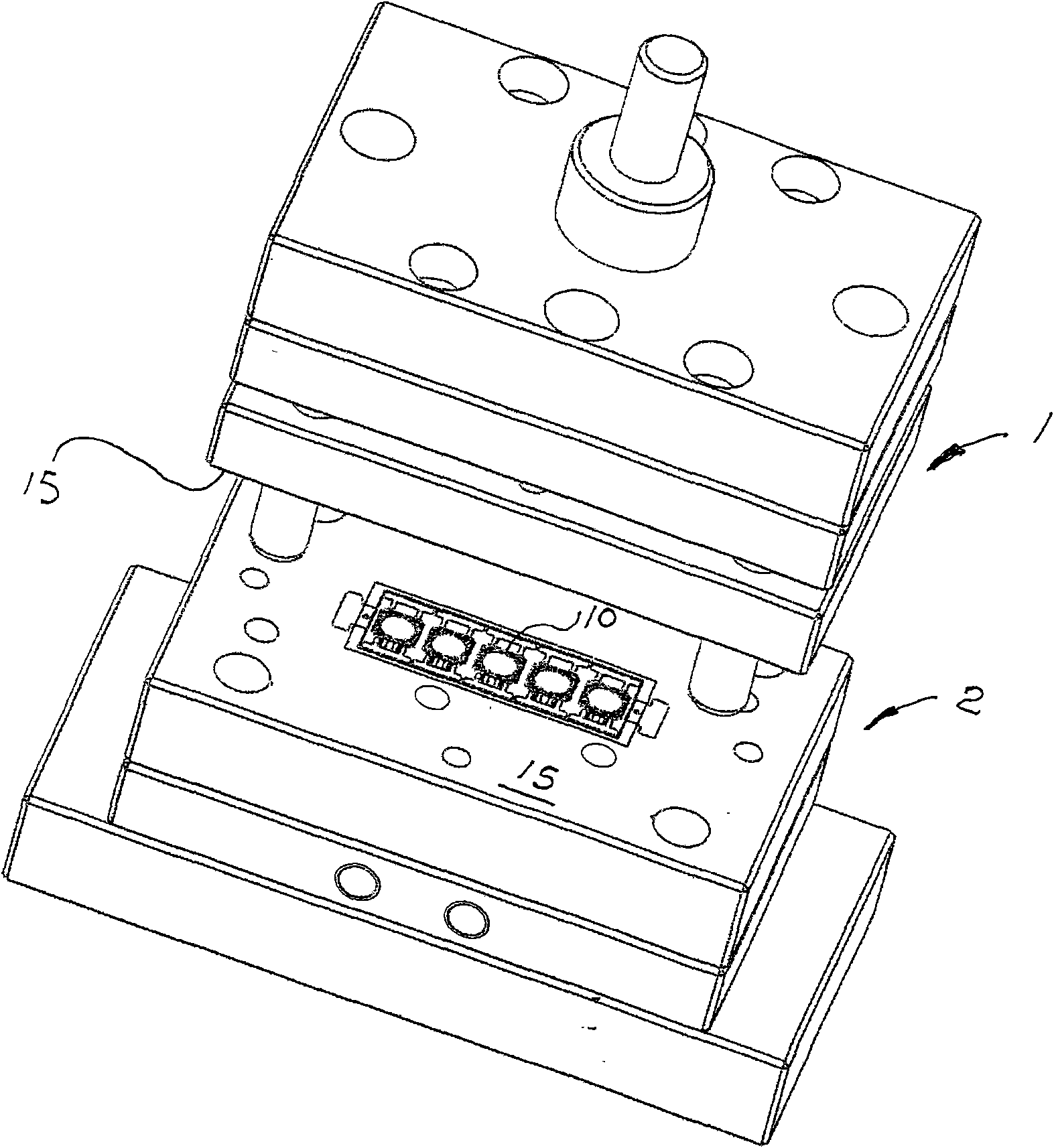

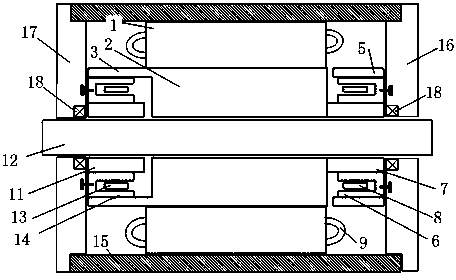

Tangential dynamic and static characteristic testing device of unit area faying surface

InactiveCN101915663AGuarantee the actual forceConsistent forceMachine part testingUsing electrical meansRelative displacementEngineering

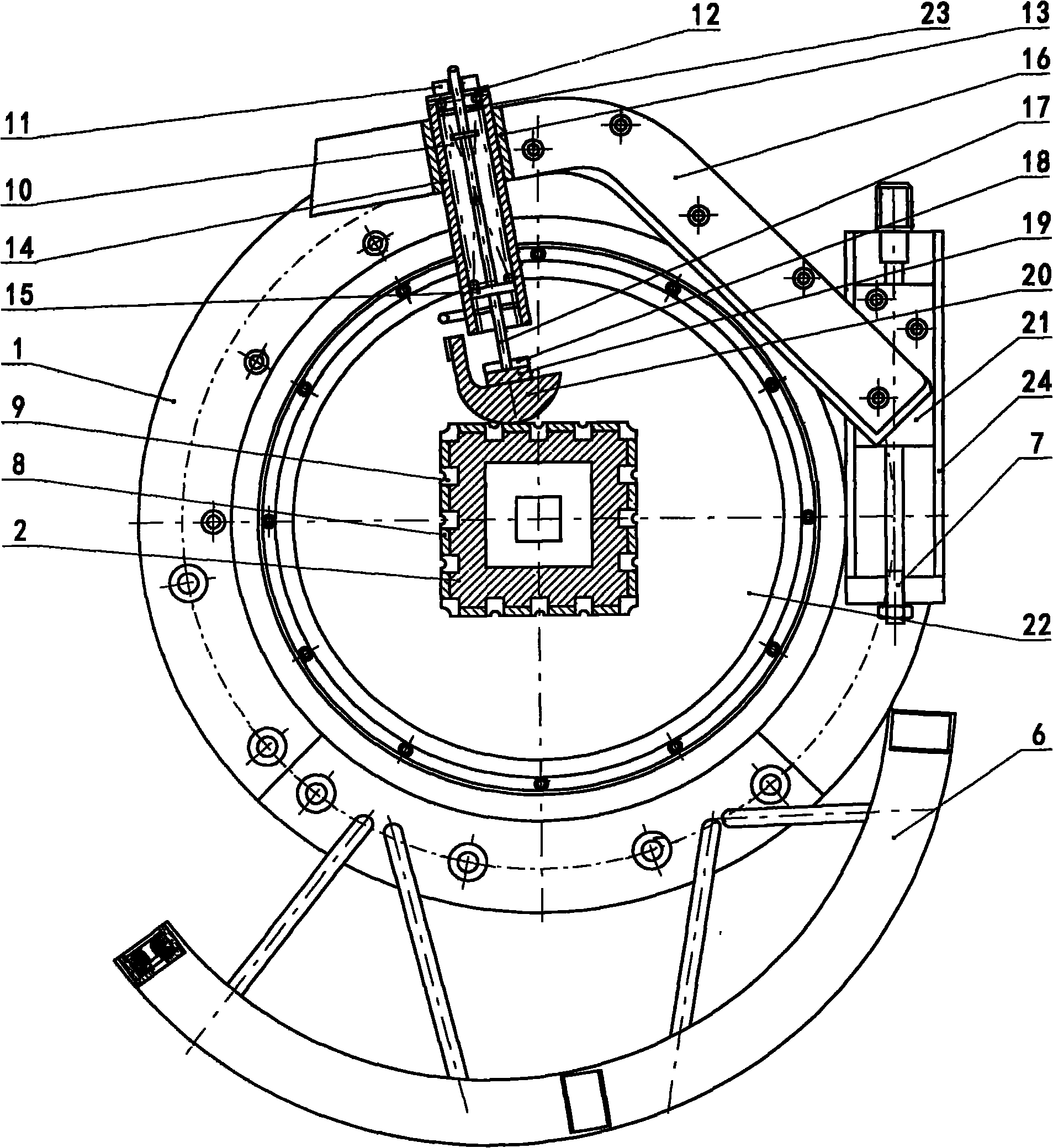

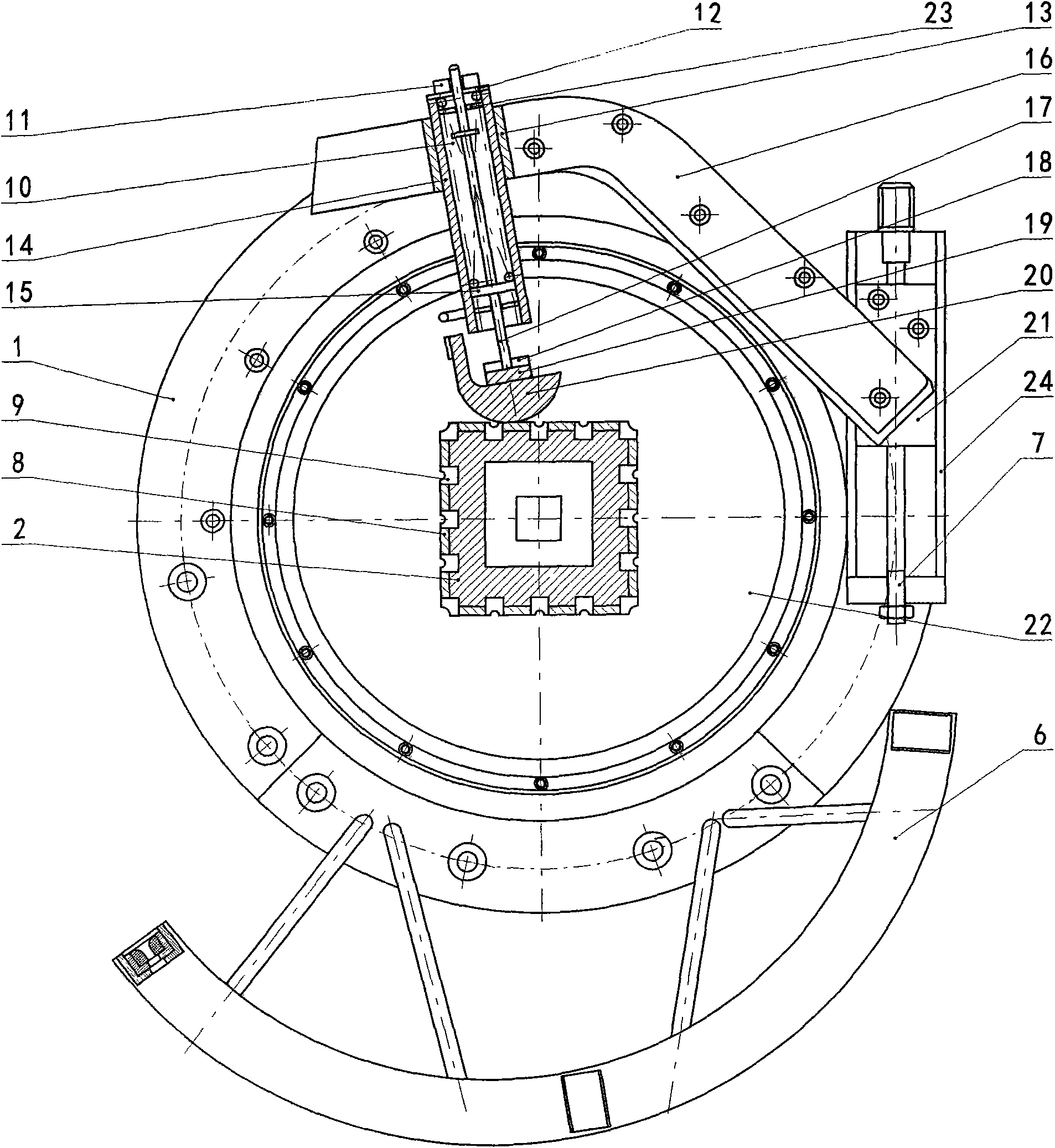

The invention provides a tangential dynamic and static characteristic testing device of a unit area faying surface, comprising a test-piece assembly, a set of tangential loading assemblies and two sets of normal loading assemblies, wherein the test-piece assembly comprises a middle test piece, a left test piece and a right piece; one end of the left test pipe is in surface contact with the side surface A through the round boss A arranged on the end surface of the left test piece; one end of the right test piece is in surface contact with the side surface of C through a round boss B arranged on the end surface of the left test piece; the tangential loading assemblies are arranged at the upper end of the middle test piece; and the two sets of normal loading assemblies are respectively arranged on the left test piece and the other end of the right test piece. The invention has the advantages that the dynamic force acted on the faying surface and the dynamic relative displacement of the faying surface can be directly acquired under the condition of different exciting frequencies and exciting amplitude values, and the introduction of other non-faying surface factors is furthest eliminated.

Owner:XIAN UNIV OF TECH

Flanging machine

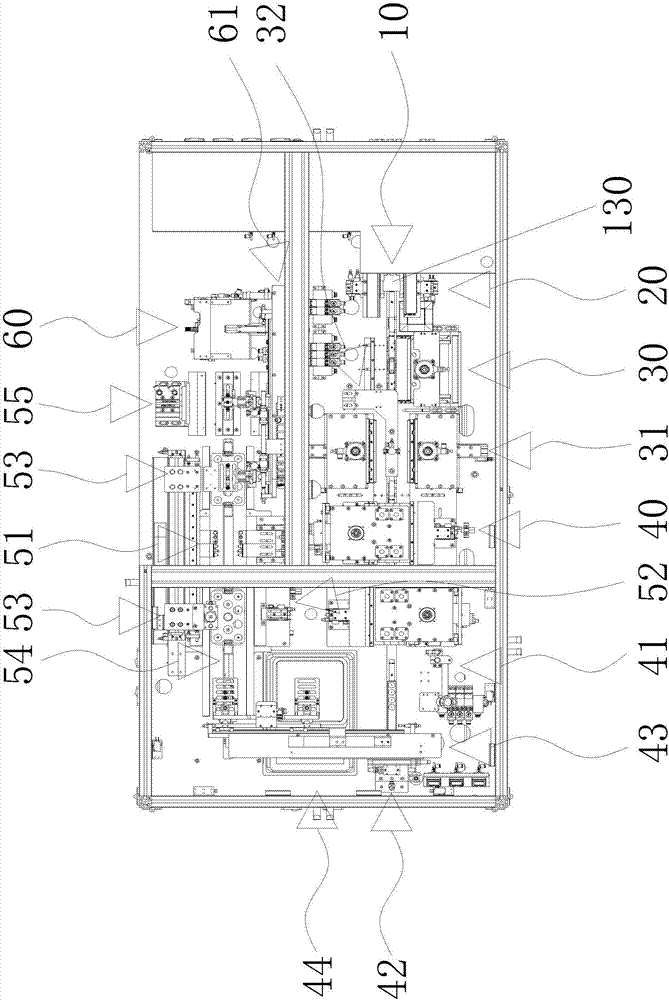

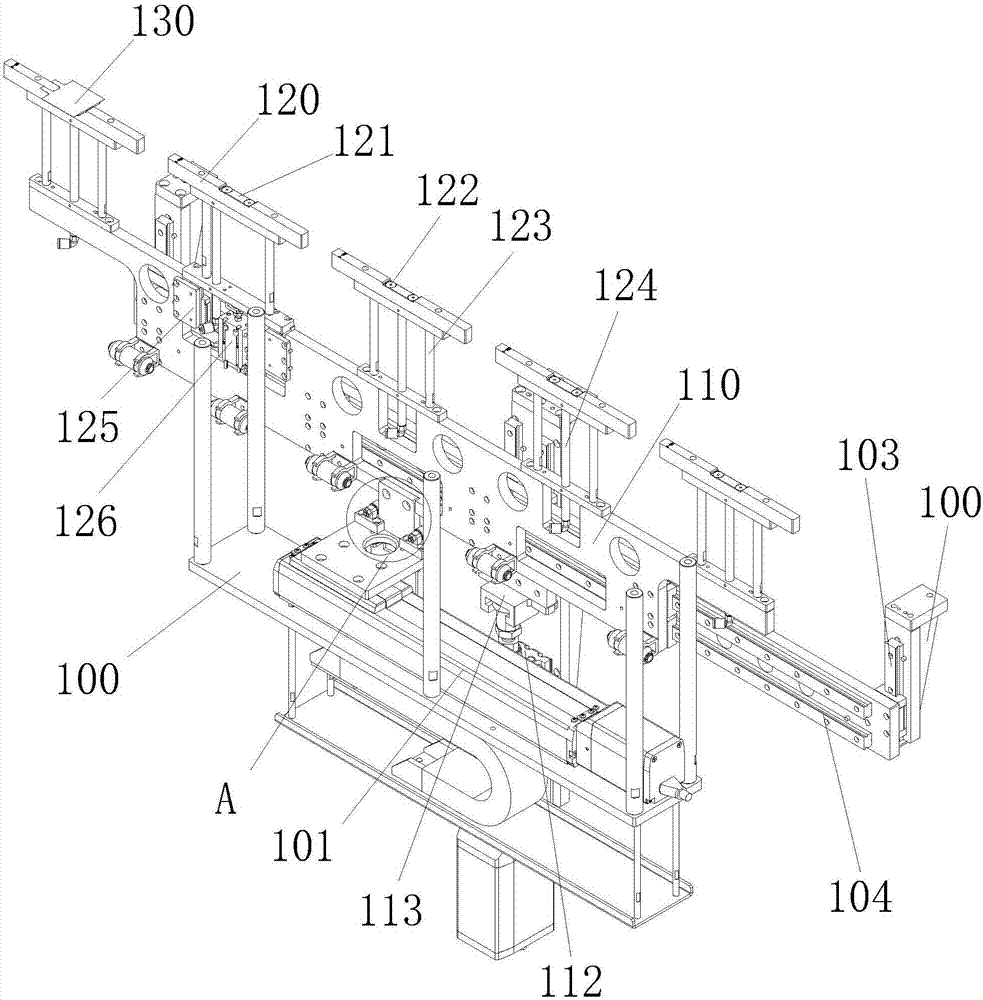

PendingCN107984733AStrong adsorptionFast deliveryFinal product manufactureElectrolyte accumulators manufactureEngineeringFlanging

The invention discloses a flanging machine. The flanging machine comprises a rack and a base arranged on the rack, wherein a trimming carrying and conveying mechanism, an alignment mechanism, a trimming mechanism and a flanging mechanism are arranged on the base; the trimming carrying and conveying mechanism is used for conveying a battery; the alignment mechanism is positioned on the two sides ofthe trimming carrying and conveying mechanism and is used for seeking the central line of the battery; the trimming mechanism is used for cutting a redundant laminating film; the flanging mechanism is used for bending the residual laminating film; an overturning mechanism used for overturning the battery is arranged in the position, following the flanging mechanism, on the base; a roll folding and carrying mechanism used for carrying the battery, a prepressing locating mechanism which is positioned on the two sides of the roll folding and carrying mechanism and is used for prepressing the laminating film and locating the battery, and a roll folding mechanism used for folding the laminating film through rolling are arranged in the position, following the overturning mechanism, on the base;and a hot pressing shaping mechanism used for leveling the laminating film is arranged in the position, following the roll folding mechanism, on the base. According to the flanging mechanism, trimming, flanging, code scanning, weighing, shaping and overturning can be automatically carried out on the battery, the automation degree is high, product specifications are uniform, the battery is not damaged, manpower is greatly saved, and quality is improved.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

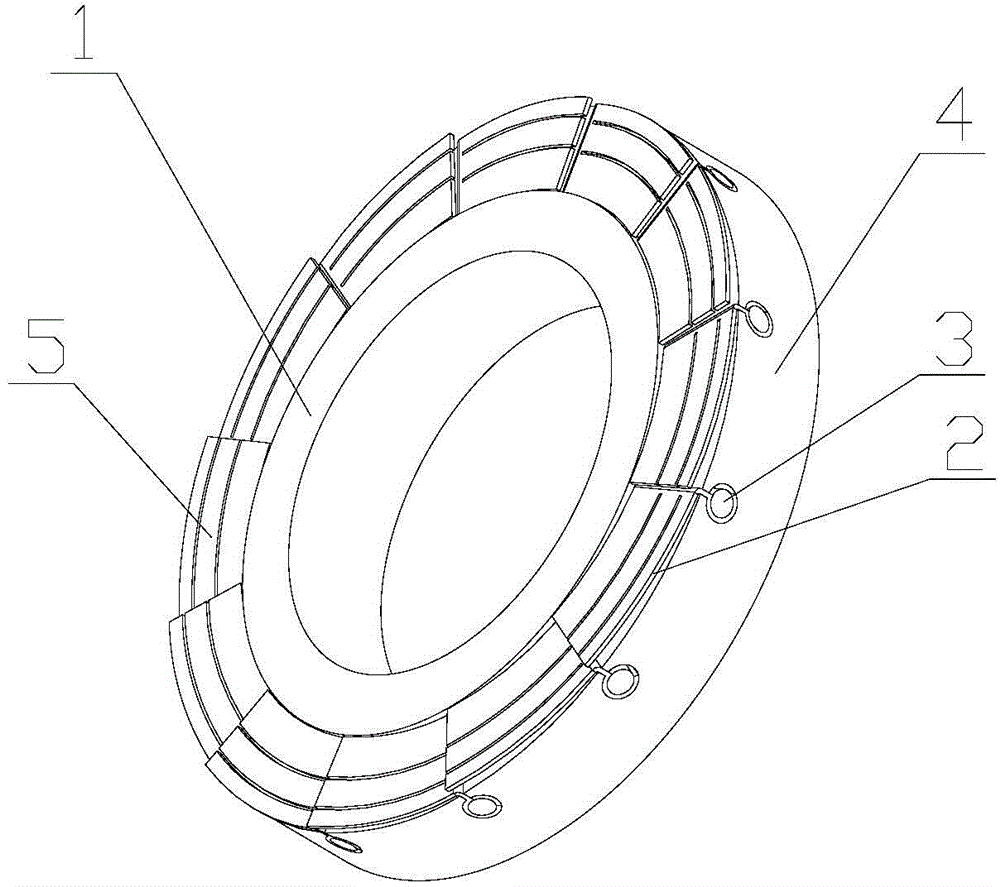

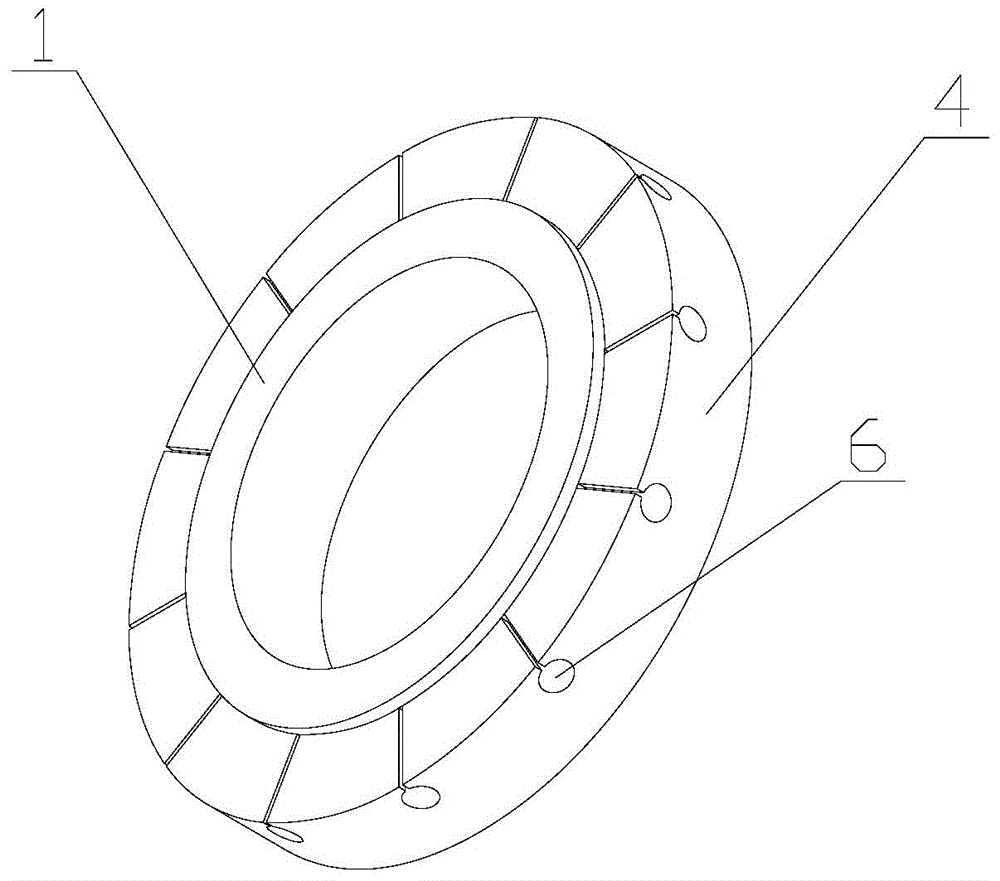

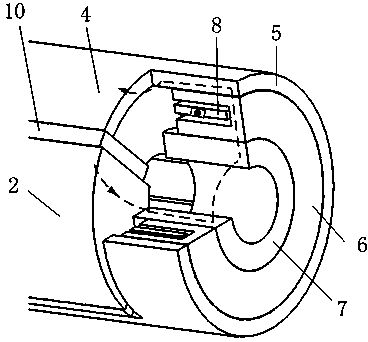

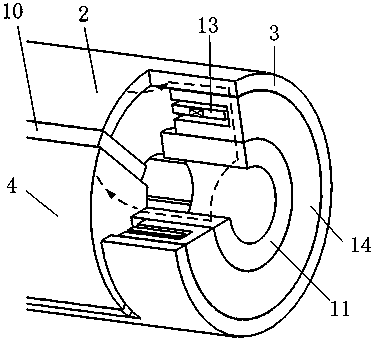

Gas film face seal structure for cantilever-type foils

The invention discloses a gas film face seal structure for cantilever-type foils. The gas film face seal structure comprises a dynamic ring and a static ring which are in gas film face seal; the seal face of at least one seal ring of the dynamic ring or the static ring is a cantilever-type foil face; the cantilever-type foil face comprises a circular ring-shaped ring body, a plurality of foils and dowels, wherein each foil is made of an elastic material; the inner side of the ring body is bulged to form a circular ring step; a seal dam is formed on the upper surface of the circular ring step; the foils are laid on the circular ring concave surface of the outer side of the seal dam end to end; the foils are evenly distributed along the circumference in a fan shape; one end of each foil is fixed to the ring body, and the other end of each foil is free; the free end of each of the foils is hung above the fixed end of the previous foil; the upper surface of the free end of each foil is flush with the plane of the seal dam and is higher than the upper surface of the fixed end; the peripheral directions from the fixed ends to the free ends of the foils are respectively consistent with the circumferential direction of airflow; each foil is divided into a plurality of small pieces along the radial direction from the free end to the fixed end, wherein the small pieces at the inner side are wider than the small pieces at the outer side. The gas film face seal structure disclosed by the invention has the characteristics that the stability is high, the abrasion is small, the service life is long, the reliability is high, high temperature can be resisted, the rotation speed is high, and the adaptivity is strong.

Owner:ZHEJIANG UNIV OF TECH

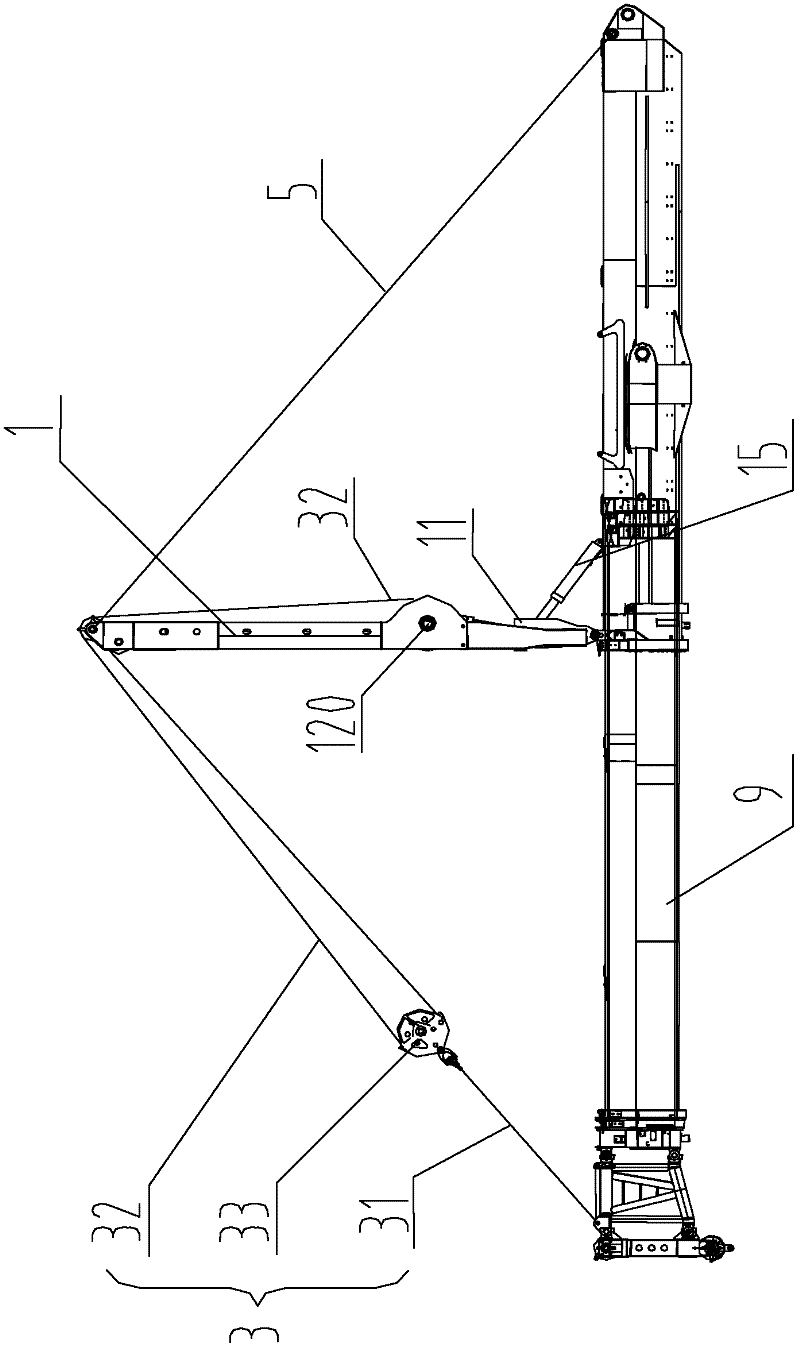

Crane and super-lifting device thereof

The invention provides a crane and a super-lifting device thereof. The super-lifting device comprises a super-lifting mast, a front tensioning mechanism and a rear tensioning mechanism, wherein the super-lifting mast comprises a base, rod parts and only one power mechanism; the base is fixed on a lifting arm of the crane; one end of each rod part is hinged with the base; the power mechanism is fixed on the base, and is hinged with the rod parts; the front tensioning mechanism is connected between the super-lifting mast and the head of the lifting arm; and the rear tensioning mechanism is connected between the super-lifting mast and the tail of the lifting arm. Only one power mechanism is arranged in the super-lifting device, and can be used for driving the two rod parts to unfold simultaneously, so that the two mast rod parts can be unfolded at the same time, and unfolding angles of the two mast rod parts are consistent; therefore, steel wire ropes matched with the two mast rod parts are consistently stressed; and an effect of controlling sidewise bending is achieved.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

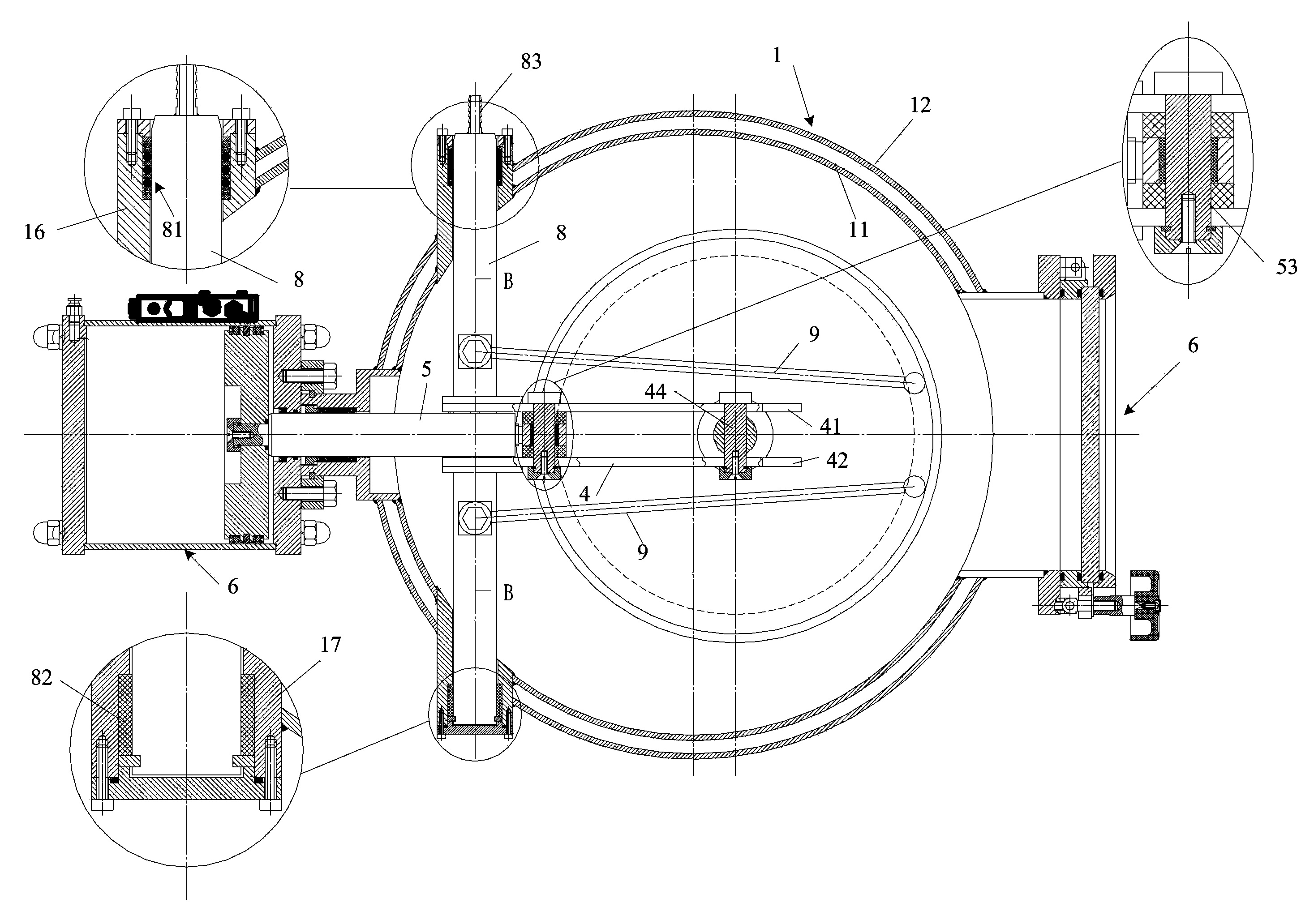

Water-cooling vacuum flap valve

ActiveCN103511715AImprove sealingImprove cooling effectOperating means/releasing devices for valvesValve members for heating/coolingAutomatic controlTransmitted power

The invention provides a water-cooling vacuum flap valve which has the advantages of being reliable in performance, convenient to use or maintain, capable of achieving automatic control or sufficient cooling, and the like. The water-cooling vacuum flap valve comprises a valve body, a valve plate and a valve deck, wherein the valve plate is used for sealing a valve port in the valve body. The water-cooling vacuum flap valve is characterized by further comprising a connecting rod mechanism and a linear driving device, wherein the connecting rod mechanism comprises a connecting rod, a supporting component, a rotation shaft and a supporting shaft, wherein the connecting rod is connected with a driving device to transmit power output by the driving device, the supporting component is connected with the rotation shaft in a rotary mode, the rotation shaft is fixed and supported by the valve body, the connecting rod is connected with the supporting component through the sliding matching of a pin shaft and a sliding hole, the supporting component is further connected with the supporting shaft in a rotary mode, and the supporting shaft is connected with a shaft sleeve on the valve plate.

Owner:费海鸿

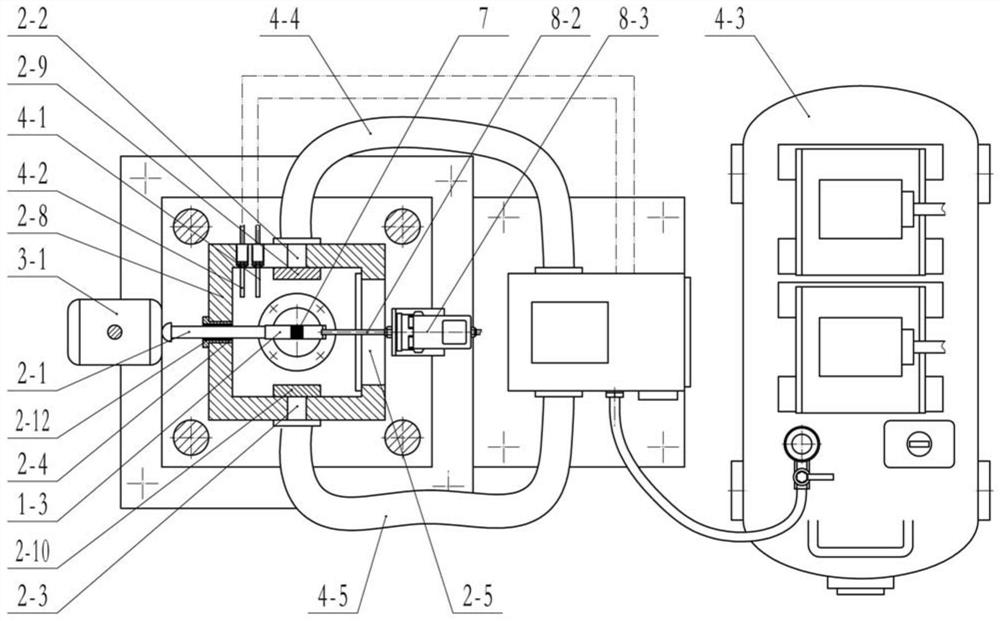

Device and method for testing friction sensitivity of explosives and powders

PendingCN111707607AEliminate distractionsAccurate locationUsing mechanical meansMaterial analysisFriction sensitivityExplosive Agents

The invention relates to the technical field of material performance testing, and provides a device and method for testing the friction sensitivity of explosives and powders. The testing device comprises a sample loading system, an explosion chamber, a pendulum bob mechanism, a temperature and humidity control system, a pressure loading system, and a rack. According to the invention, the influences of the temperature, humidity, speed and pressure are considered comprehensively, the influence of adverse factors of friction loss is reduced, the test control of temperature and humidity is increased, and the accuracy and controllability of speed are improved; and the influence of contact materials and surface roughness is also considered. More comprehensive and accurate friction sensitivity data can be obtained, and the influence of all parameters on friction safety in the actual explosive production and processing technology is reflected. The device and method are suitable for various explosive monomer semi-finished products, new components, new formulas, new types, medicaments, slurries and tablets. Friction sensitivity data obtained through the method can also be used for supporting and guiding mathematical model establishment, numerical calculation, analog simulation, new formulas, new equipment, new processes and other research and development work.

Owner:BEIJING UNIV OF CHEM TECH

Wood drilling device

InactiveCN108839128AAchieve axial drillingConsistent pitchStationary drilling machinesBark-zones/chip/dust/waste removalEngineeringSlide plate

The invention relates to a wood drilling device. The wood drilling device comprises a rack, a drilling mechanism and a driving mechanism; the rack is provided with a vertical sliding chute; the drilling mechanism comprises two supporting plates which are fixedly connected to the rack; a bidirectional screw is rotationally connected between the two supporting plates; the bidirectional screw is in threaded connection with a left-handed nut and a right-handed nut; the left-handed nut and the right-handed nut are each provided with a drill bit; the middle part of the bidirectional screw is coaxially sleeved with a sleeve block; the sleeve block is slidably connected inside the sliding chute; the driving mechanism comprises two clamping gears which are arranged oppositely; the clamping gears are positioned below the bidirectional screw; the two ends of the bidirectional screw are each fixedly connected with a cam; each air blowing box is arranged below the corresponding cam; each air blowing box is internally, hermetically and slidably connected with a sliding plate; each cam intermittently leans against the corresponding sliding plate; each cylinder body is arranged below the corresponding air blowing box; each cylinder body is internally, hermetically and slidably connected with a piston; the upper end of each piston is fixedly connected with a gear rack engaged with the corresponding clamping gear; and between each air blowing box and the corresponding cylinder body is provided with an air guide pipe in a communication manner. The wood drilling device can be used for drillingwood in both the axial direction and radial direction.

Owner:重庆木头木脑文化创意有限公司

Self-adaptive placing angle pressing device and pressing method thereof

ActiveCN106695301AConsistent forceConsistent pressing directionMetal working apparatusSelf adaptiveForce direction

The invention relates to a self-adaptive placing angle pressing device and a pressing method thereof. The self-adaptive placing angle pressing device comprises a clamping fixture on a base plate and a pressing block connected to an upper connection plate. At least two retractable driving pieces are connected to the upper connection plate of a pressing assembly, movable sides of all the driving pieces are connected with pushing rod bases, and the pushing rod bases are provided with pushing rods with ball surfaces at the bottoms; the pressing assembly comprises sleeves and springs, wherein the sleeves are installed at the lower portions of the pushing rods in a sleeving mode, and the springs are installed on the pushing rods in a sleeving mode; the two ends of the springs push the pushing rod bases and the sleeves, and the sleeves abut against the pressing block to provide pre-pressing force; and a bearing seat of an automatic adjusting piece is provided with a linear bearing, a guide shaft is installed in the linear bearing, a floating connector on the lower portion of the guide shaft is rotatably connected with the pressing block, and the height and the placing angle can be automatically adjusted when the pressing block makes contact with a workpiece. According to the self-adaptive placing angle pressing device, the structure is reasonable, automatic adjustment can be conducted according to the placing position of the workpiece, the force direction and the pressing direction of the workpiece are kept to be consistent, pre-pressing force can be provide for the workpiece needing to be pressed, and the assembling quality is improved.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST

Processing method for artificial board hot-press hot pressing board plane

InactiveCN1907612AReduce stress deformationConsistent forcePlywood pressesVeneer pressesPre treatmentEngineering

The invention relates to a method for processing the plane of artificial sheet thermal compressor, which uses national general digit-control crane boring-mill machine to bore and mill the plane to realize the high roughness and flatness, wherein said thermal compressed sheet is the pretreated mould steel, whose rigidity is HRC40, and the plane size of work-piece is large. The invention adjusts the accuracy of machine, adjusts the plane milling blade, and the work-piece is clamped via the electromagnetic absorb disc, via special parameters and digit-control program, using high-pressure air to cool it, to realize the high accuracy demand. The smoothness of inventive product can reach Ra0.4-Ra0.2, and flatness can reach 0.10.

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

High-resolution earthquake detector and manufacturing method thereof

ActiveCN102901980ASmall distortionReduce consistencySeismic signal receiversLow distortionImage resolution

The invention relates to a high-resolution earthquake detector and a manufacturing method thereof. With the adoption of a detector structure, an upper cover with a guide positioning part, a magnetic system consisting of upper and lower magnetic boots and magnetic steel, a spring-mass system consisting of a coil frame with a winding and a spring, a lower cover, and a shell are coaxial in an assembling process, so that the detector distortion can be effectively reduced. The matching condition ensures that inner and outer rings of upper and lower spring sheets are at a horizontal position after being assembled; the upper and the lower spring sheets are not additionally stressed by external force; and each part inside the detector with a sealed opening is compactly matched without release, so that the distortion of the detector can be reduced. The natural frequency of single spring can be directly detected, and the two springs with equal frequencies can be selected to be matched in pair, so as to ensure the consistency of the spring, and reduce the allowance range and the distortion. With the adoption of a method for directly testing the frequency, the natural frequency of the earthquake detector can be tested before the opening of the detector is sealed, so that the allowance range of the detector can be further reduced.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

Automatic foot pad pressing machine

ActiveCN104440031AConsistent deformationUniform downforceMetal working apparatusMechanical engineeringEngineering

The invention relates to the technical field of electronic product production equipment, and provides an automatic foot pad pressing machine. The automatic foot pad pressing machine comprises a pressing mechanism, a conveying mechanism and an electronic control module. The pressing mechanism comprises a support. A pressing plate and a driving component are arranged on the support. Guide rods are arranged on the support. The guide rods are connected with the pressing plate through knuckle bearings respectively. The knuckle bearings are sleeved with balance pressure springs. The conveying mechanism is adopted to convey foot pads to the position below the pressing plate, and the driving component drives the pressing plate to press the foot pads downwards under the control of the electronic control module. The balance pressure springs can automatically adjust deformation to adapt to the different foot pads whether the surfaces of the foot pads are planes or inclined faces. In this way, the automatic food pad pressing machine is simple in structure, easy to operate, convenient to maintain, stable in work, high in reliability, small in labor intensity and high in production efficiency, and the pressing-in effect of the foot pads and the product quality are ensured.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

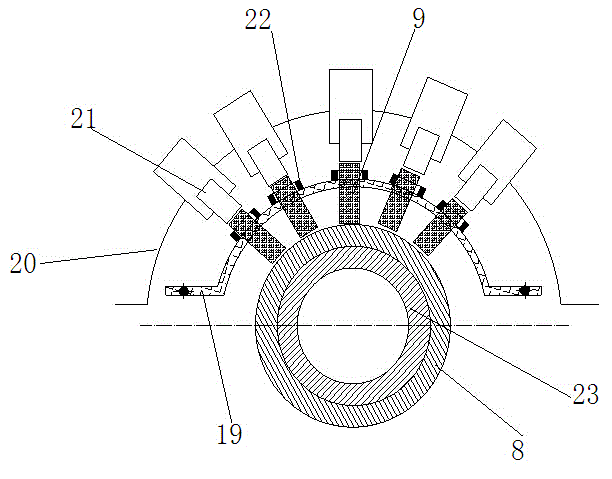

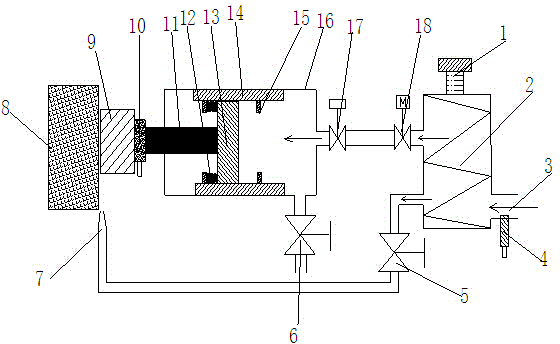

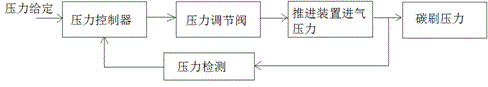

Generator carbon brush on-line automatic constant voltage regulation and sweeping device

ActiveCN106160356AConsistent forceTimely monitoring of wearManufacturing dynamo-electric machinesBrushControl theory

The invention relates to a generator carbon brush on-line automatic constant voltage regulation and sweeping device. The generator carbon brush on-line automatic constant voltage regulation and sweeping device is characterized by comprising a constant voltage device, a generator rotor, a carbon brush, a slip ring, a constant voltage device support and a carbon brush support; the slip ring is in rigid connection with the generator rotor; the carbon brush is fixed by the carbon brush support and a brush holder and is in contact with the slip ring; and the constant voltage device is fixed on the constant voltage device support. The generator carbon brush on-line automatic constant voltage regulation and sweeping device delicately use an air source pressure constancy to perform constant voltage compensation control on the carbon brush and introduces dried compressed air to constantly sweep the slip ring of a generator, which greatly prolongs the service life of the device; and the generator carbon brush on-line automatic constant voltage regulation and sweeping device uses on-line measurement of the pressure-sensing element to perform real-time monitoring on the wearing degree of the carbon brush and promptly reminds working staff of checking the thickness of the carbon brush. The generator carbon brush on-line automatic constant voltage regulation and sweeping device is simple in structure, delicate, easy in installation and easy to popularize.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

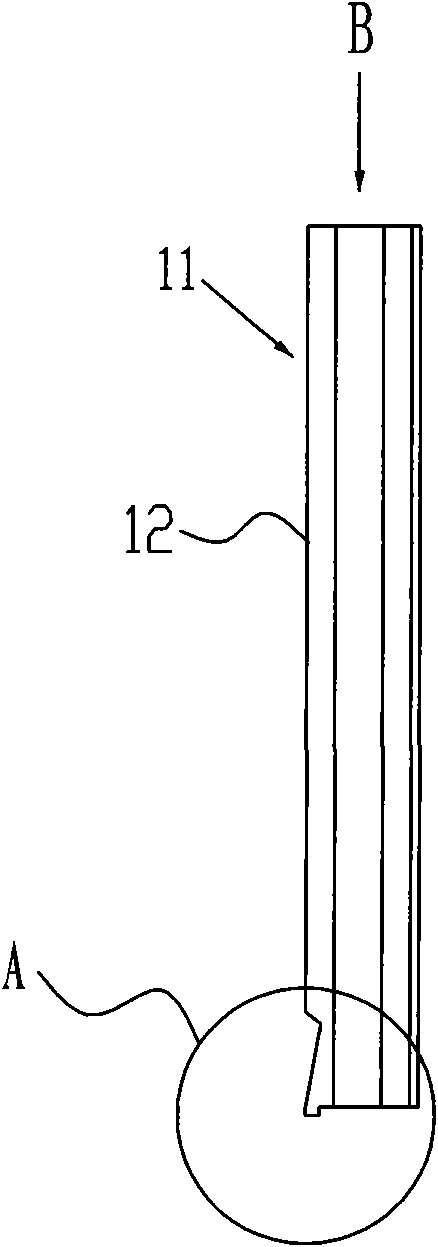

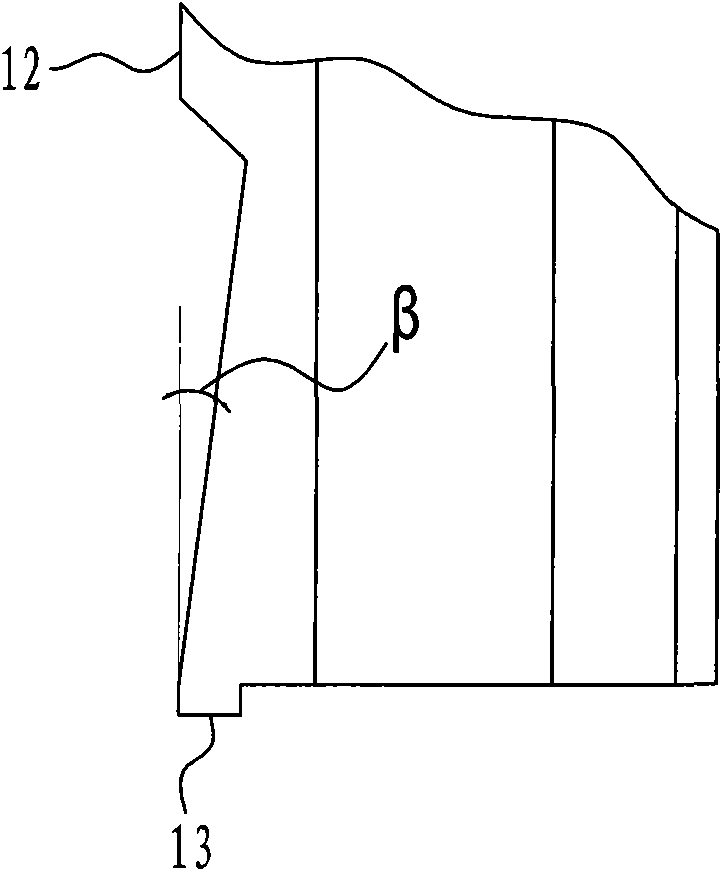

Ultra thin reed forming die

InactiveCN101569909AControl Geometric AccuracyControl Geometric ToleranceShaping toolsVertical planeStress point

The invention relates to an ultra thin reed forming die, comprising an upper die and a lower die which are connected and are provided with a plurality of upper cores and lower cores; the upper die and the lower die are provided with connected reed support positioning surfaces which are configured mutually and are vertical to the moving direction of the upper core and the lower core; the lower end of the front vertical plane of the upper core is provided with a springback angle beta which is inclined inwards along the moving direction; the bottom surface of the upper core is provided with a springback surface which is vertical to the moving direction; the upper end of the rear vertical plane of the lower core is provided with a prebending angle alpha which is inclined outwards along the moving direction; the rear vertical plane of the lower core and the front vertical plane of the upper core correspond; the cross section of the upper core is set as a section with arc rectangles at the front side and the rear side; and the springback angle beta and the springback surface are arranged at the front side of the arc section. The invention has the advantages of being capable of greatly improving geometric accuracy and geometric tolerance of the reed in the process of bending and pressing, and being capable of realizing the accordance of stress points and deformation amount of a plurality of reeds between the upper die and the lower die, thus being capable of greatly improving qualification rate of products and reducing the cost of products.

Owner:NINGBO JCT ELECTRONICS

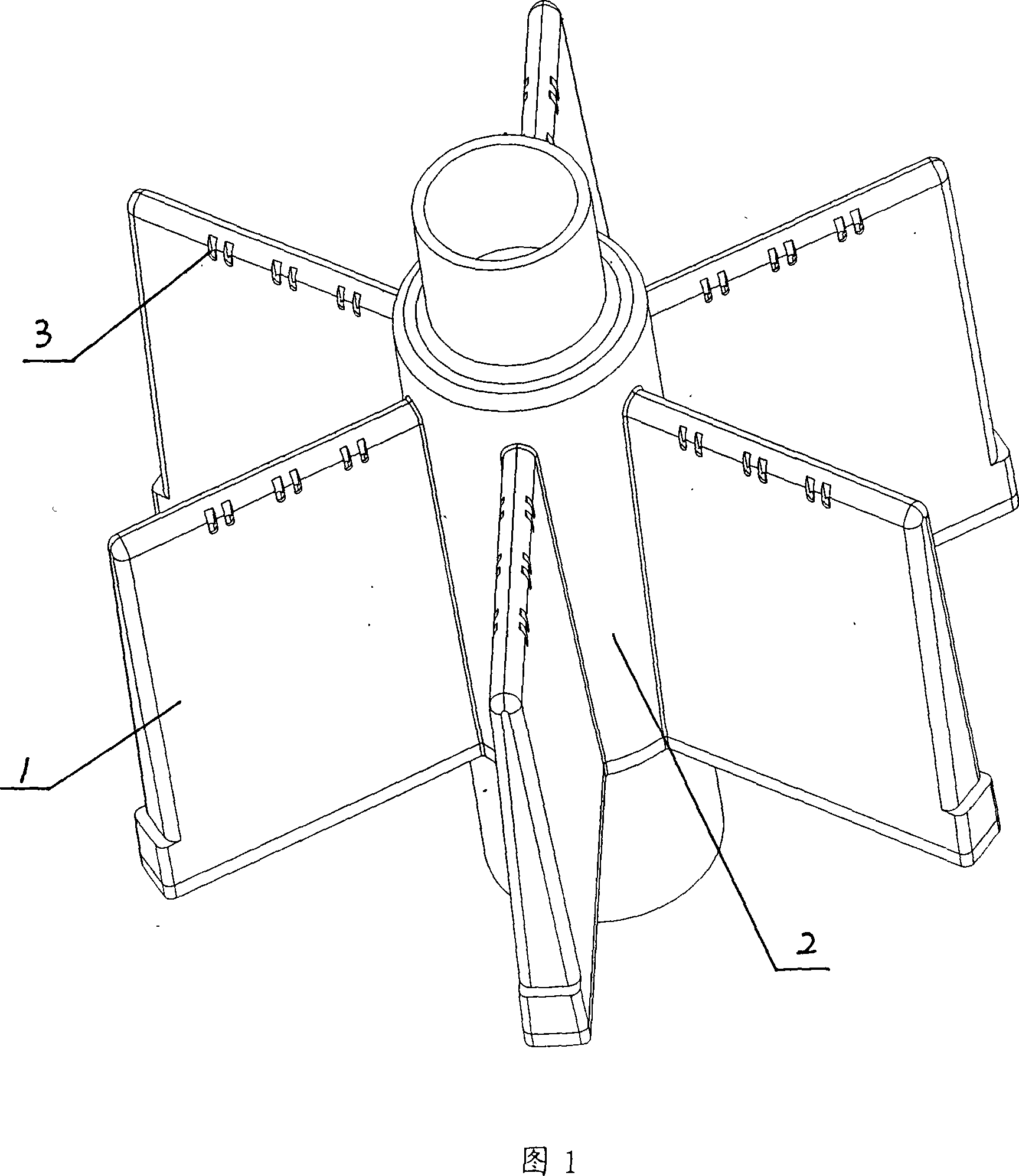

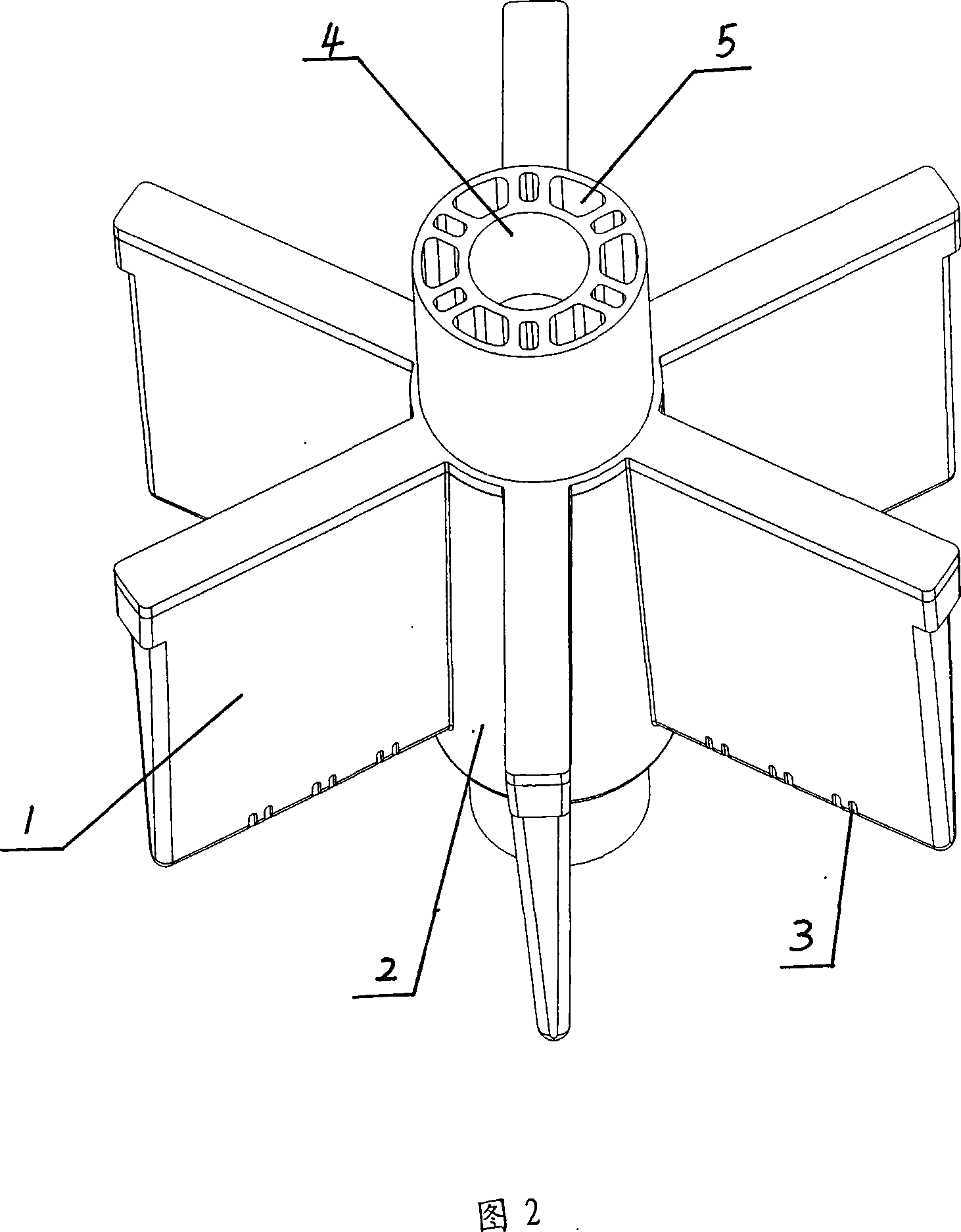

Aerating unit for film component

ActiveCN101139133AContinuous and stable useEvenly aeratedSustainable biological treatmentBiological water/sewage treatmentYarnWater collection

The present invention discloses an aeration device applied to membrane components and aims at providing an aeration device which is applied to membrane components so as to lead gas to form stable airflow in the inside of the components with a good membrane cleaning effect and can prolong the service life of membrane yarn and be able to carry through to produce water at two ends. The device includes an aeration body and an air collection chamber is arranged in the aeration body. The outside of the aeration body is connected with multiple closed air chambers communicated with the air collection chamber. Each air chamber is provided with multiple aeration holes. The upper part of the aeration body is provided with a water collection chamber and multiple outlet openings are arranged in the water collection chamber. The lower end of the aeration body is provided with multiple inlet openings. The aeration body is provided with a channel to communicate the inlet openings and outlet openings. The aeration device of the present invention leads gas to form continuous and stable airflow after entering the inside of the components so as to lead the up and down aeration of the membrane yarn to be uniform. The present invention has a good pollution removing and guarantees continuous and stable application of the components. And up and down arrangement of gas is uniform and the up and down force of the membrane yarn is consistent. The present invention has prolonged the service life of the membrane yarn.

Owner:TIANJIN MOTIMO MEMBRANE TECH

Rotor circuit double-ended excitation type hybrid excitation electrical machine

InactiveCN103780039ATake advantage ofEliminate the rotary rectifier partSynchronous machine detailsMagnetic circuit rotating partsMagnetoElectric generator

The invention discloses a rotor circuit double-ended excitation type hybrid excitation electrical machine comprising a housing. A stator composed of an armature core and an armature winding and a rotor composed of an N-pole magnet yoke, an N-pole shoe, an S-pole magnet yoke, an S-pole shoe, a permanent magnet magnetized in a tangential manner and a spindle are installed in the housing. Two ends in the axial direction are provided with an electric excitation device respectively. The main pole air-gap magnetic field of the electrical machine is generated by the permanent magnet and electric excitation devices collectively, brushless electric excitation can be realized through the excitation devices, so smooth adjustment can be performed on the main pole air-gap magnetic field in a certain range, when the electrical machine is used in an electromotor, the magnetic field is adjusted to make the electrical machine comprise a wide constant power region to realize weak magnetism speed raising, when the electrical machine is used as a generator, the voltage adjustment requirement can be satisfied through the design of structure parameters, compared with the prior art, advantages of short axial magnetic circuit, the magnetism-collected structure type permanent magnet, large air-gap magnetic field and high efficiency can be realized; additionally, the axial structure is symmetrical, the rotor weight is distributed evenly in the axial direction, stresses on left and right bearings are consistent; a magnetic bridge is located at the axial end, and the assembly is convenient.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

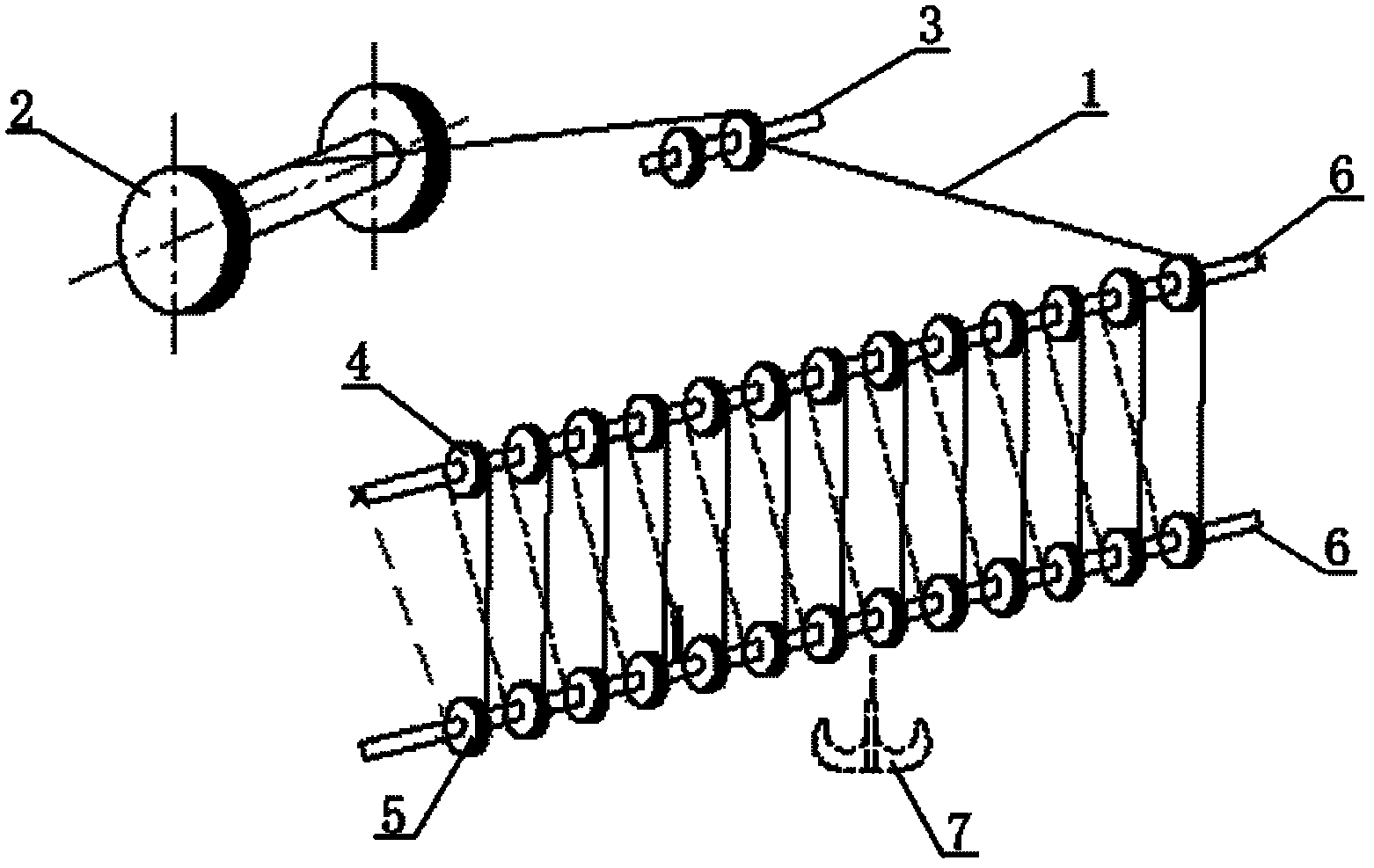

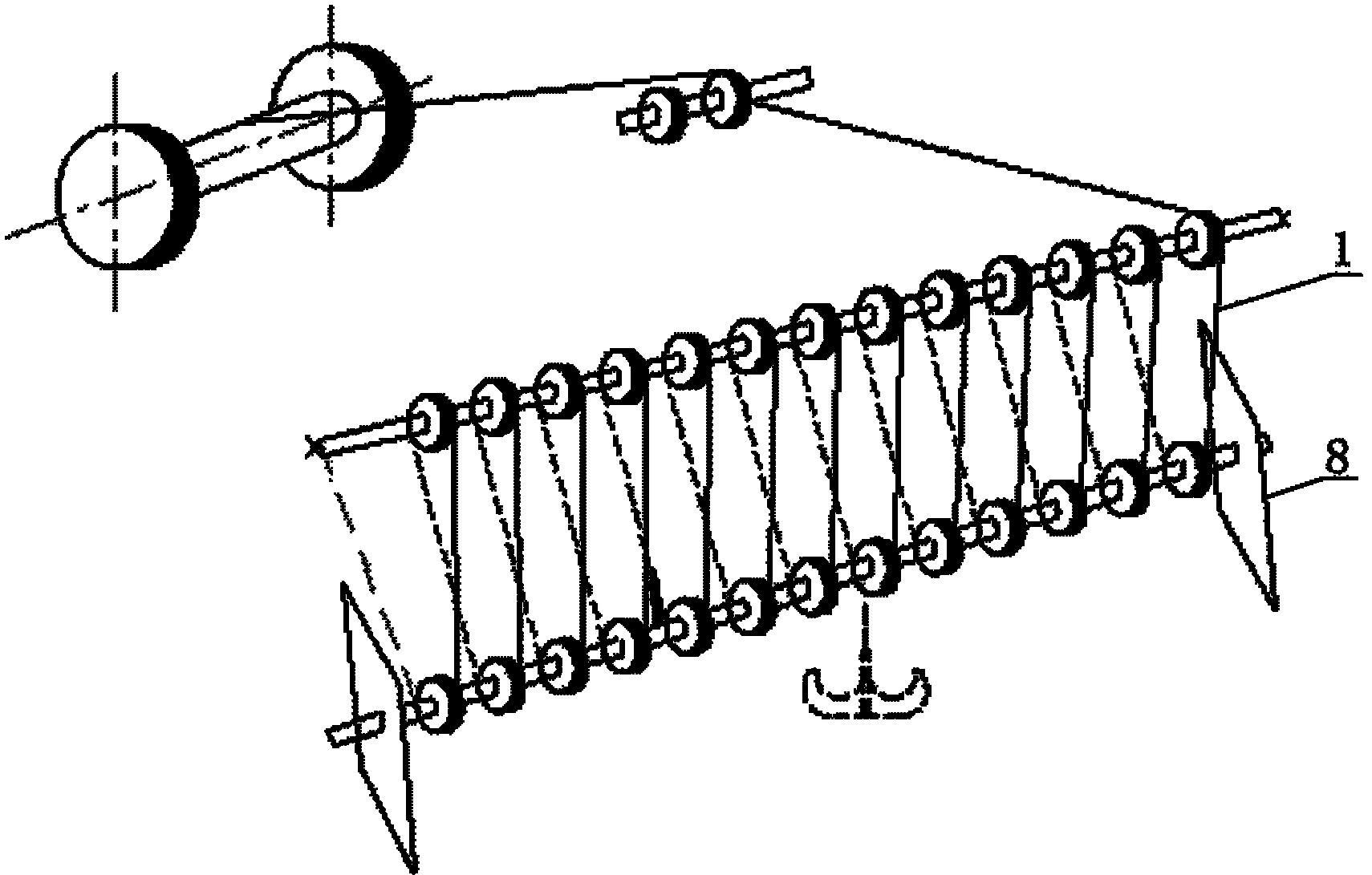

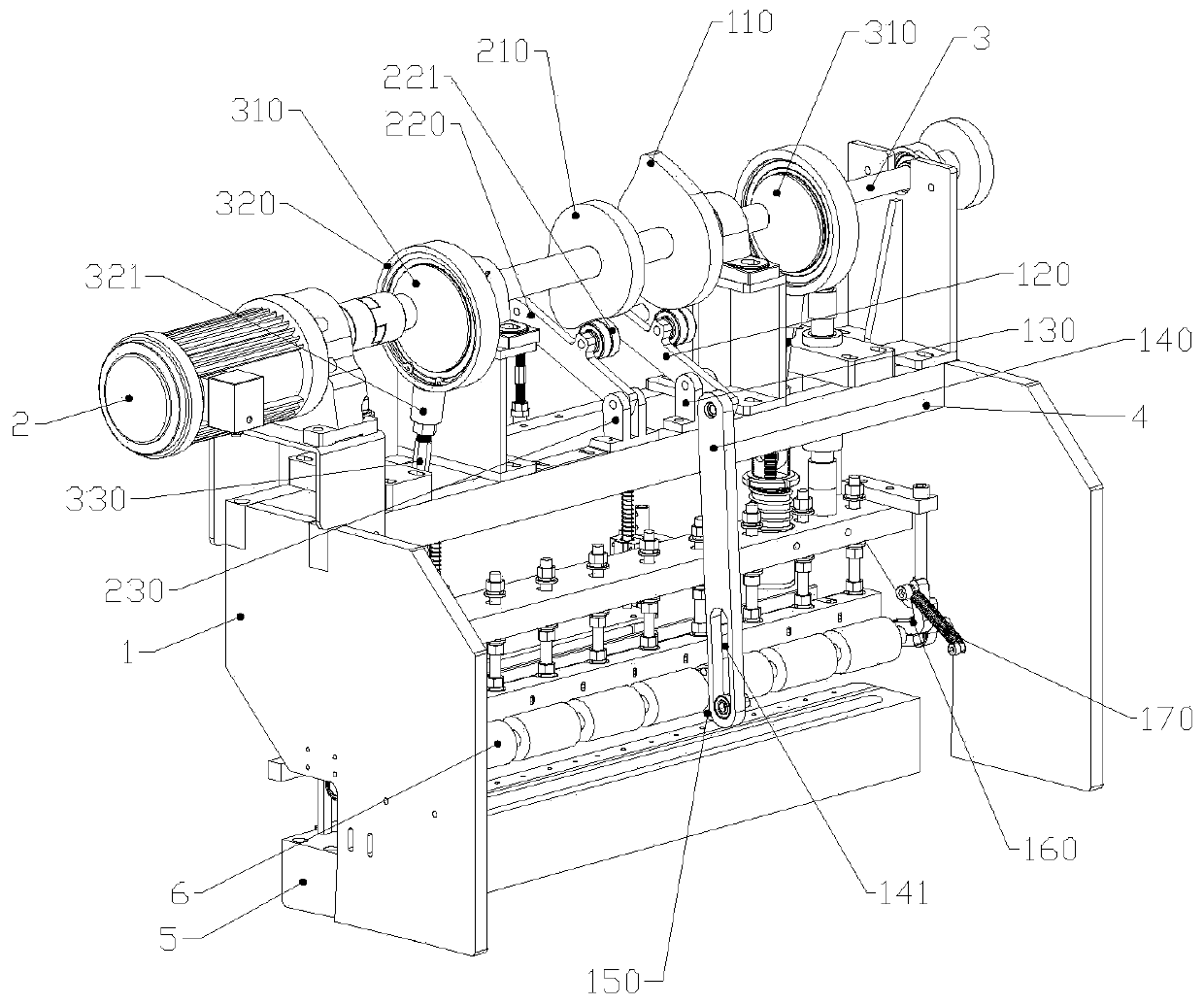

Processing method for reinforcing cage for pre-stressed concrete hollow square pipe pile

InactiveCN101817205AImprove welding qualitySmall loss of solder joint strengthShaping reinforcementsPre stressPre stressing

The invention discloses a processing method for a reinforcing cage for a pre-stressed concrete hollow square pipe pile, which comprises the following steps of: feeding a longitudinal rib and placing the longitudinal rib in a rib slot on a square fixed electrode; adjusting the elasticity of a spring in an elastic movable electrode so as to keep the acting force of an electrode body within the range from 12 to 16kg; driving an electrode wheel; driving the elastic movable electrode and a spiral annular rib winding mechanism to rotate around the square fixed electrode; driving the longitudinal rib to move horizontally by a longitudinal rib traction disk; driving an annular rib to spirally rotate around the square fixed electrode by the spiral annular rib winding mechanism, wherein the electrode body immediately follows the annular rib to finish the welding once the annular rib comes into contact with the longitudinal rib; keeping on rotating the electrode wheel and moving the longitudinal rib traction disk ceaselessly; repeating the process; and conveying the reinforcing cage through a reinforcing cage conveying mechanism until the reinforcing cage for the pre-stressed concrete hollow square pipe pile is finished. Owing to the adoption of the elastic movable electrode, the processing method ensures stable welding quality at the contact of the annular rib and the longitudinal rib, keeps the strength loss at the welding spot less than or equal to 5 percent and greatly improves the production efficiency.

Owner:凌德祥

Cropping device

PendingCN111360893AImprove cutting stabilitySimple structural designBag making operationsPaper-makingLinear motionDrive by wire

The invention belongs to the field of cropping equipment, and discloses a cropping device. At least two components of a cutter, a bag pressing piece, a bag twisting piece and a heat isolation piece are included. A rotary main shaft is arranged. A transmission structure for converting the rotation movement of the main shaft into the linear movement or for transmitting the rotation movement of the main shaft is arranged between the main shaft and at least two components. A rotary power source is adopted in the cropping device, a traditional air cylinder linear driving manner is replaced, the structure design can be optimized, the equipment size is reduced, and assembling and maintaining are convenient; and under the coaxial situation, the two ends of the cutter can act more easily, stress iskept consistent, and the cropping equipment has better action stability and can adapt to the occasion where the action speed is high.

Owner:WENZHOU KEWANG MACHINERY

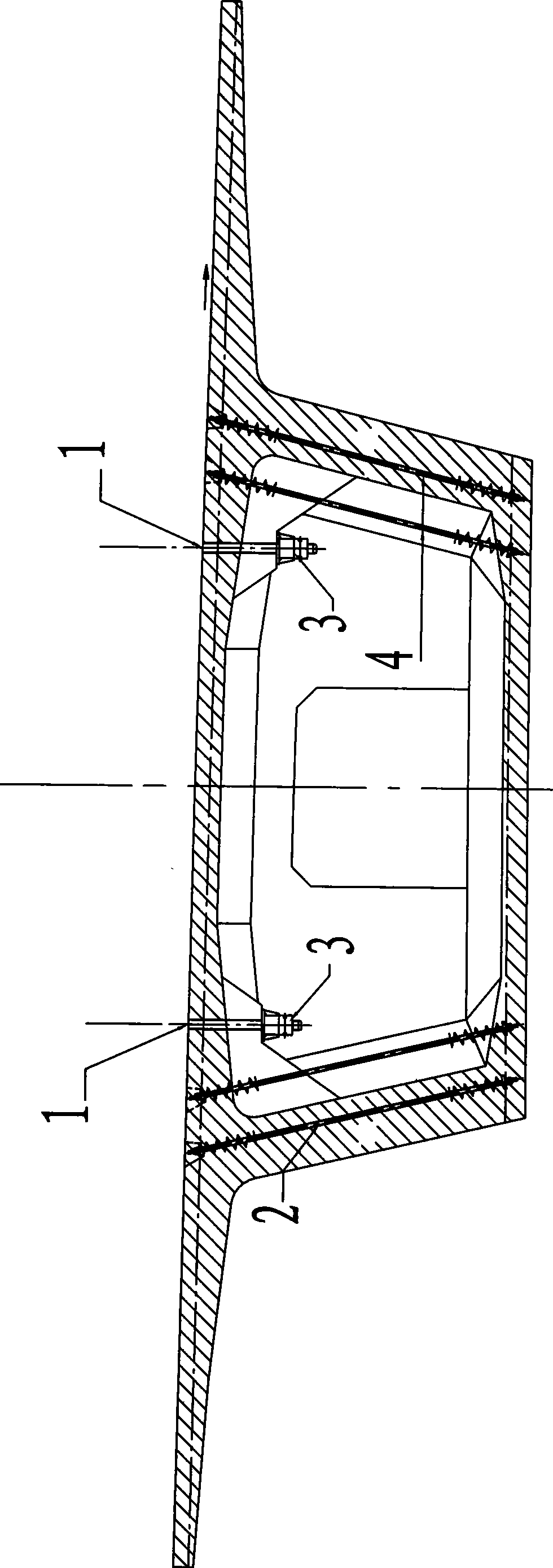

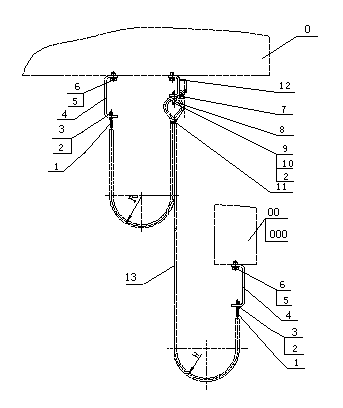

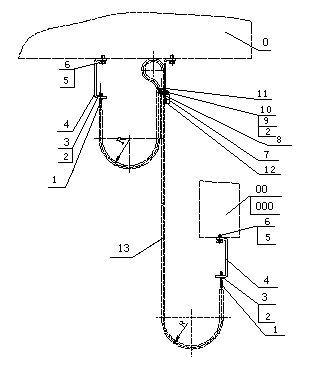

Suspension device of elevator trailing cable or compensating cable utilizing steel wire ropes as bearing parts

The invention discloses a suspension device of an elevator trailing cable or compensating cable utilizing steel wire ropes as bearing parts. The device is composed of threaded rope ends (1), nuts (2), locking pieces (3) and supports (4). The end portions of every bearing steel rope of a cable (13) are connected with the rope ends (1) in a pressing mode, the nuts (2) and the locking pieces (3) fix the rope ends onto the supports (4), and the nuts (2) are adjusted to enable the lengths of the bearing portions of the steel wires with the rope ends to be the same. The supports (4) at both ends are fixedly onto the bottom of a car (0) and the bottom of a counterweight (00) or the wall of a shaft (000). When secondary protection is needed, a suspension support (7), a clamping piece (8) and corresponding connection bolts are additionally arranged at the bottom of the car, and a section of freely overhung cable is arranged between the suspension support (7) and one of the supports (4). Further, the suspension (7) is provided with safety contacts (12), and when the cable snaps the clamping piece (8) or slides aside, the safety contacts can be cut off to enable an elevator to stop or to be unstartable.

Owner:宣城市安华机电设备有限公司

Twin-hull ship launching device and method

ActiveCN107140154AAvoids the problem of requiring specific configurations of inclined cradle structuresImprove stabilitySlipwaysMarine engineering

The invention belongs to the technical field of ships and discloses a twin-hull ship launching device and method. The twin-hull ship launching device comprises a main wedge type launching cradle and an auxiliary wedge type launching cradle; the main wedge type launching cradle is fixedly connected with the auxiliary wedge type launching cradle by a rigid connecting piece. The invention provides a device and a method for realizing stable and safe launching operation for an ultra-large twin-hull ship.

Owner:WUCHANG SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com