Hamburg type hemp fiber board and preparation method thereof

A Hamburg-style hemp and fiberboard technology, which is applied in the field of base materials, can solve the problems of uneven surface, uneven force, and non-environmental protection of interior parts, so as to reduce the probability of damp and moldy, no toxic substance emissions, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1: Preparation of Needle-Punched Nonwovens

[0037] Get 49kg of polypropylene fibers, 12kg of Korean-made 4080 fibers and 39kg of polyester fibers and mix them evenly, and make needle-punched non-woven fabrics after carding and laying;

[0038] Step two:

[0039] Take 25kg of brown silk and hemp fiber, 30kg of polyester fiber and 40kg of polypropylene fiber, mix them evenly, then comb and lay the net, and then compound the needle-punched non-woven fabric prepared in the first step on one side, after acupuncture, make one side It is a semi-finished composite base material of needle-punched non-woven fabric and hemp fiber felt on one side;

[0040] third step:

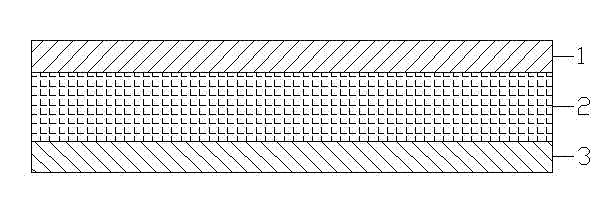

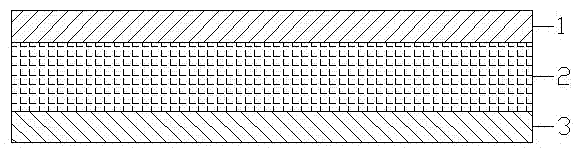

[0041] Take two semi-finished products of the composite base material obtained in the second step, put one side of the hemp fiber felt together, heat and press, and mold once to form a middle layer of hemp fiber felt layer, and the surface layer and the bottom layer are needle-punched non-woven fabric layer...

Embodiment 2

[0043] The difference between this embodiment and Example 1 is that the material ratio is different, that is: in the first step, 40kg of polypropylene fiber, 15kg of Korean 4080 fiber and 45kg of polyester fiber; in the second step, 30kg of brown silk and hemp fiber, polyester fiber Fiber 35 kg and polypropylene fiber 40kg.

Embodiment 3

[0045] The difference between this embodiment and Example 1 is that the material ratio is different, that is: in the first step, 60 kg of polypropylene fiber, 10 kg of Korean 4080 fiber and 30 kg of polyester fiber; in the second step, 10 kg of brown silk and hemp fiber, 10 kg of polyester fiber, 40 kg of fiber and 50 kg of polypropylene fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com