Patents

Literature

465 results about "Palm fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

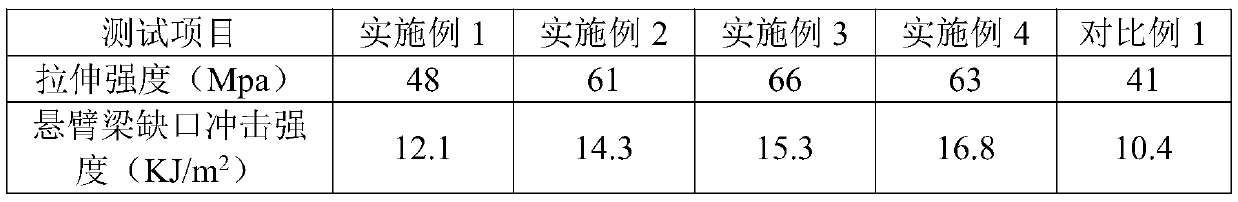

High-toughness full-degradable composite material

The invention provides a high-toughness full-degradable composite material, which is mainly prepared by blending the following components in parts by weight: 100 parts of biodegradable matrix resin; 1-60 parts of modified bio-based fiber; 1-8 parts of a compatilizer; 1-5 parts of a lubricant and 0-5 parts of a coupling agent; wherein the biodegradable matrix resin is one or a composition of more than two of PBAT, PCL, PLA, PBS, PBSA, PPC, PBST, PHB, PHA, PVA and PHBV, wherein the modified bio-based fiber comprises hydrophobic modification of the bio-based fiber or / and coupling modification ofthe bio-based fiber, the bio-based fiber is fibrilia, and the fibrilia is one or more of hemp fiber, flax fiber, sisal fiber and palm fiber. The modified plant fiber disclosed by the invention has a remarkable reinforcing and toughening effect on the bio-based matrix resin, and the interface compatibility and the interface bonding force of the modified plant fiber and the bio-based matrix resin are improved.

Owner:佰信(福建)新材料科技有限公司

Tourmaline-containing sheath-core composite fibers

ActiveCN104451940AHas antibacterial and antibacterial effectImprove itchingPhysical treatmentConjugated cellulose/protein artificial filamentsGlycerolSlurry

The invention relates to fibers, in particular to tourmaline-containing sheath-core composite fibers. The tourmaline-containing sheath-core composite fibers are prepared through the following steps: (1) tourmaline processing; (2) core layer material processing, that is, bast fibers and palm fibers after degumming processing are combed and cut into short bast fibers and short palm fibers, the short bast fibers and the short palm fibers are then soaked in a mixed manner in a lignocellulose aerogel solution for 15 to 20 minutes according to a formula, the short bast fibers and the short palm fibers after the mixed soaking are then taken out for draining, the short bast fibers and the short palm fibers after the draining are sent to an opener for opening and mixing, the short bast fibers and the short palm fibers after the opening and mixing pass through airflows and are arranged through a roller groove to form meshed semi-products with S-shaped section structures, and the meshed semi-products go through spunlace to form non-woven needled bast-palm fiber aerogel core layer materials; (3) sheath layer material processing, that is, a first pulp is prepared from processed tourmalines and ethylene glycol, phthalic acid and glycerol are used for esterification reaction, the first pulp, magnesium oxide and calcium hydroxide are added after the reaction for condensation polymerization, and polyester chip sheath layer materials are obtained through strip casting and sized dicing; (4) composite melt spinning for obtaining of the tourmaline-containing sheath-core composite fibers. The tourmaline-containing sheath-core composite fibers provided by the invention achieve the antibacterial and healthcare effects, high degree of comfort, as well as environment friendliness.

Owner:HEYE HEALTH TECH CO LTD

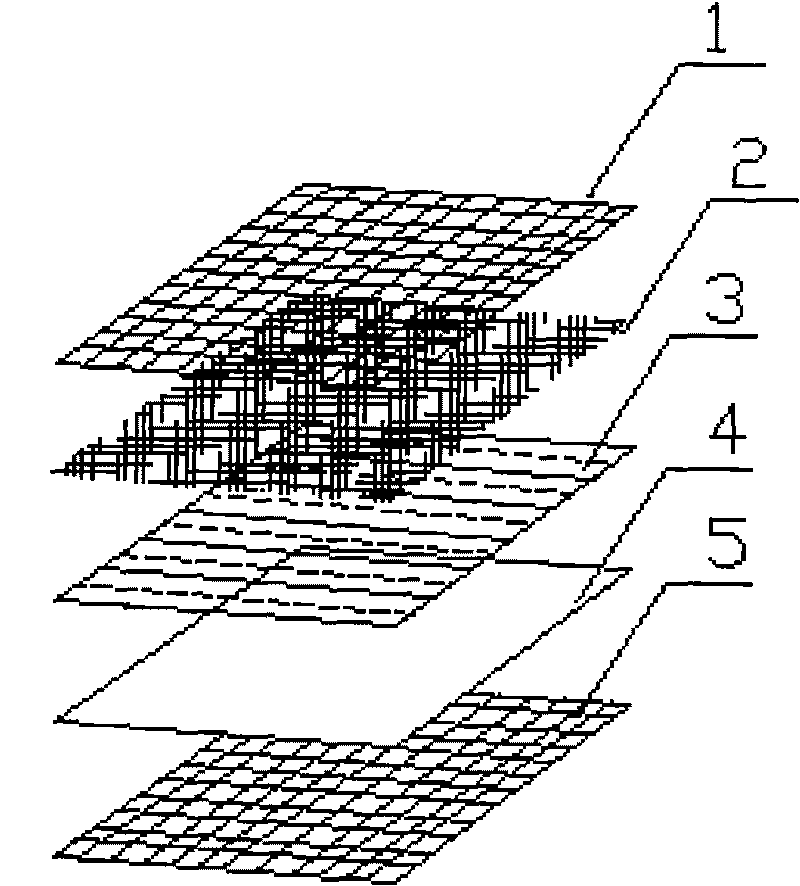

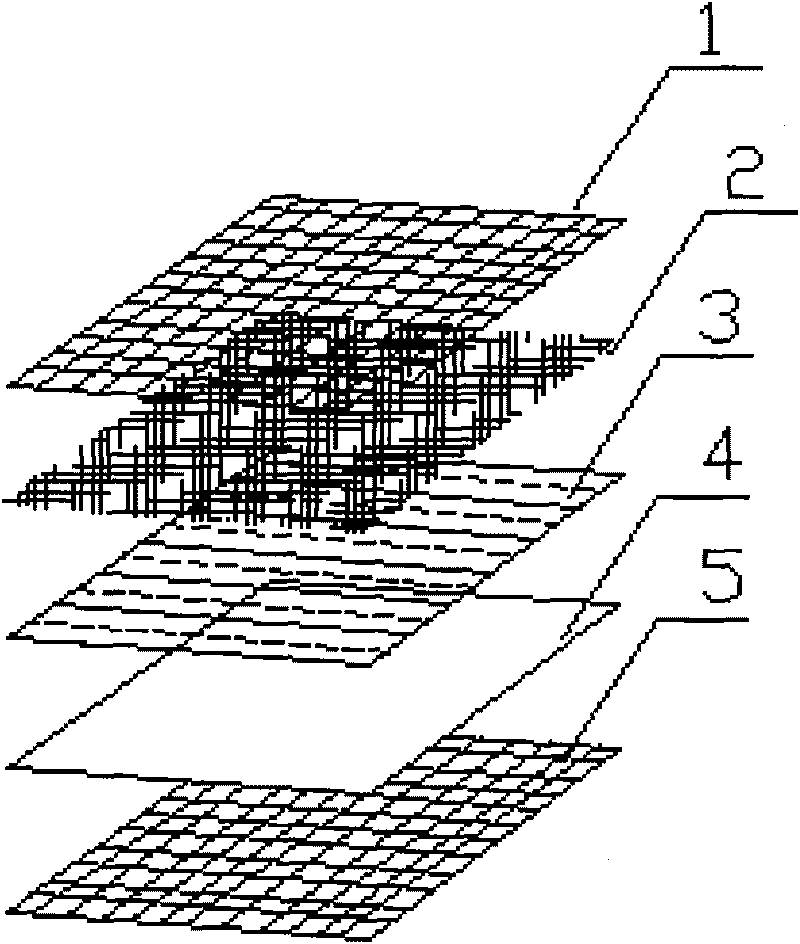

Grass blanket with soil

InactiveCN101692769AHigh strengthPlay a protective effectSeed arrangmentsHorticultureRevegetationOrganic layer

The invention provides a grass blanket with soil, which at least comprises an upper net, a fiber layer, an organic layer, a lining and a lower net, which are arranged in turn and are sewn together, wherein the organic layer is composed of nutrient soil, water-loss reducer and seeds. As the grass blanket is provided with the organic layer for providing an environment for seeds to grow and adopts straw, palm fibers and / or hemp which contain plant fibers as the fiber layer which is covered on the lining, the strength of the grass blanket is enhanced, the seeds and the nutrients are protected, and a plurality of nutrients for grown grasses can be provided after the composing materials of the fiber layer are degraded. The invention is applicable to the greening and vegetation recovery of deserts, mines and roadbeds, and has lower cost and stronger suitability.

Owner:康莱德国际环保植被(北京)有限公司

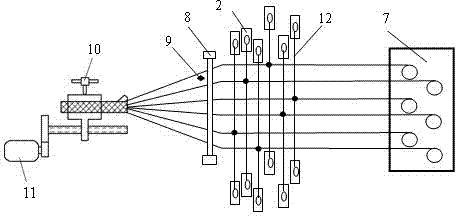

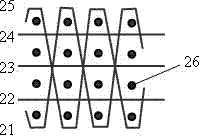

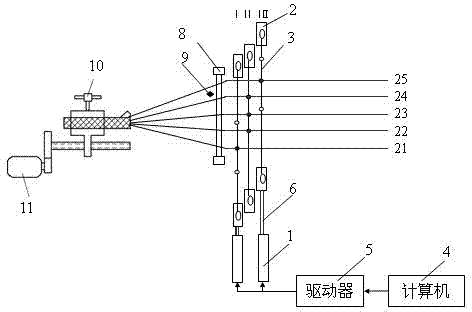

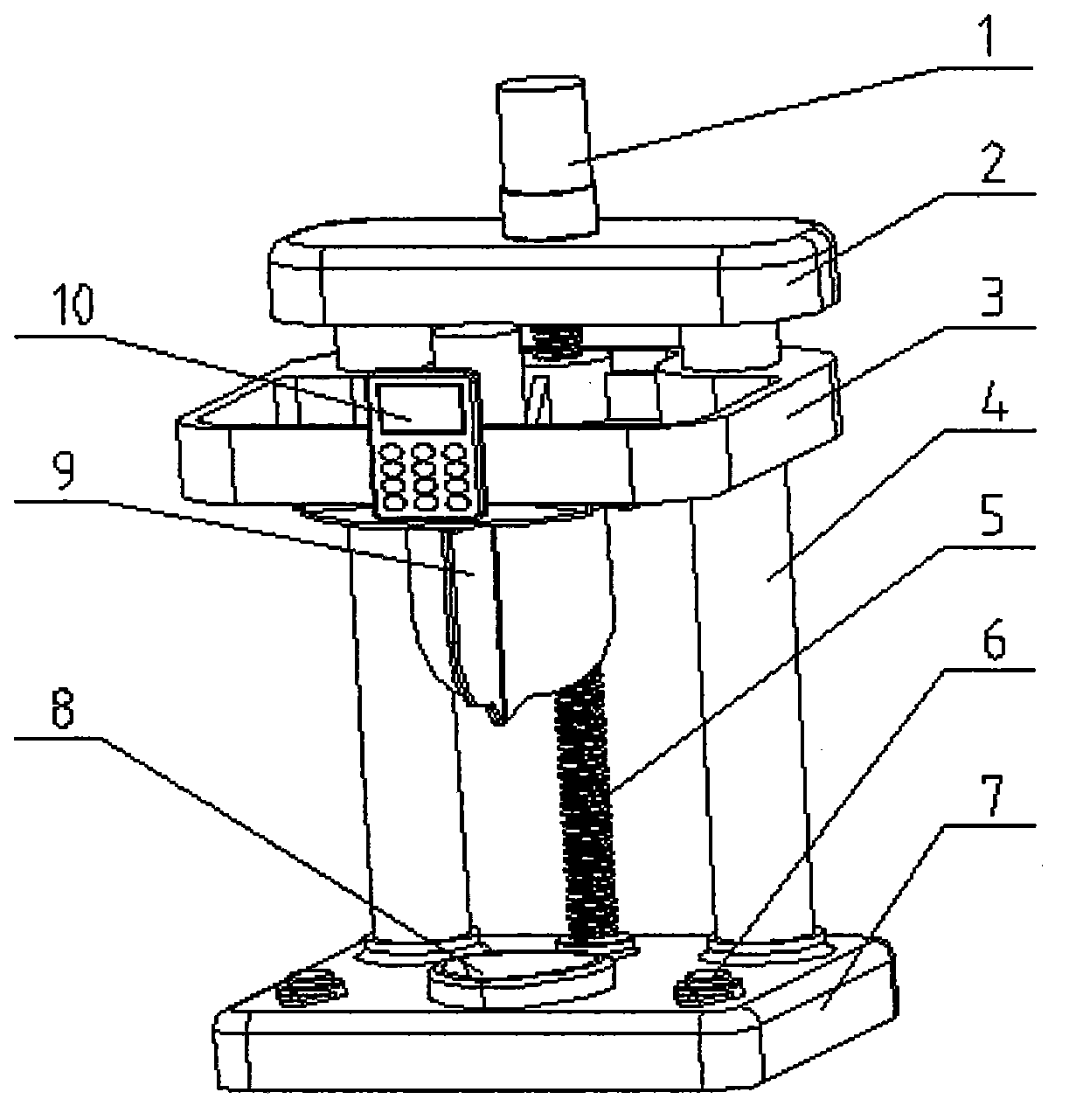

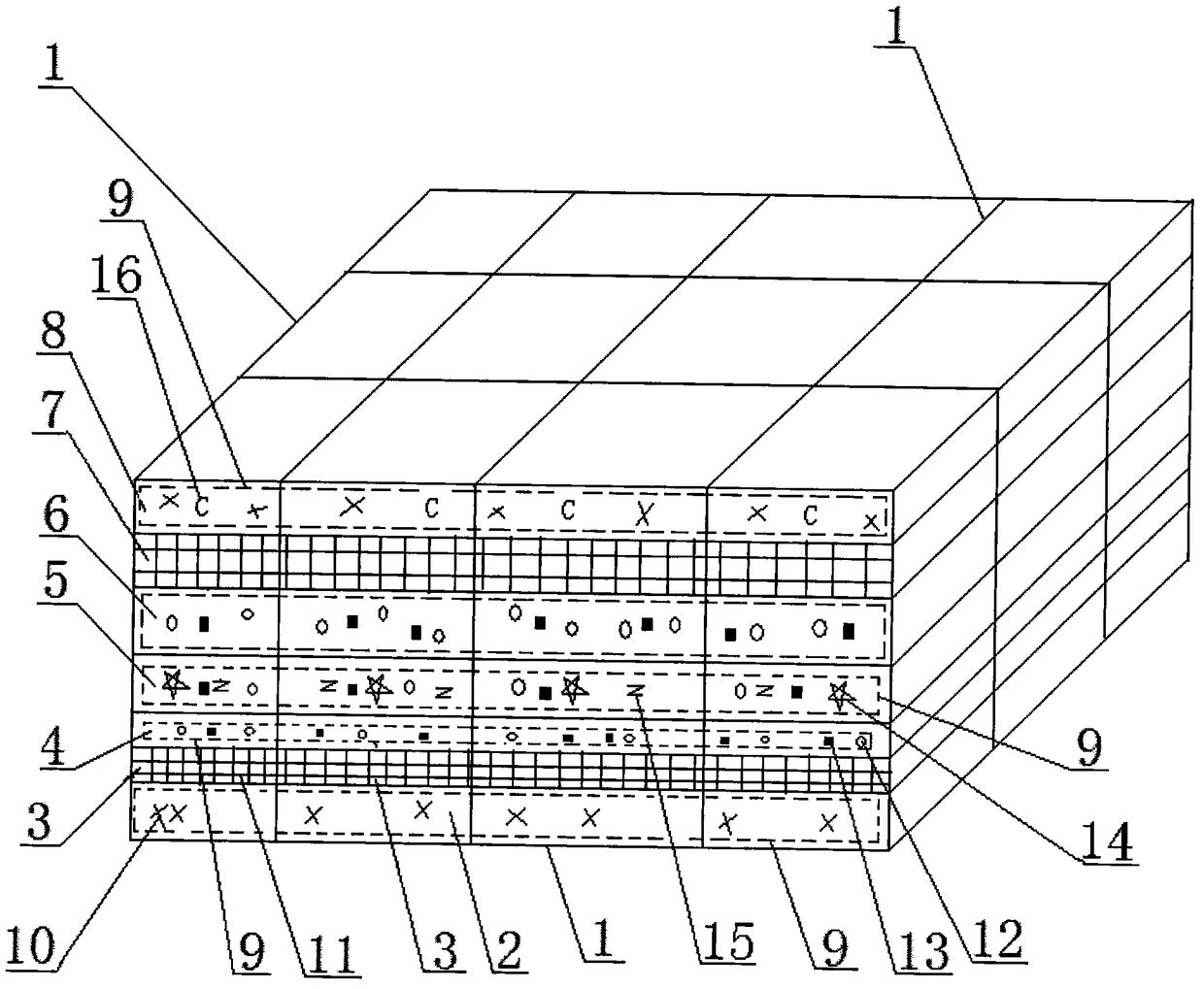

Opening device for stereo loom

InactiveCN102517741AReduce the number of pagesGood for weavingHealdsOther shedding mechanismYarnPalm fiber

The invention provides an opening device for a stereo loom. The opening device contains healed frames and is characterized in that at least one healed frame is connected with multi-hole palm fiber; at least one healed frame is connected with a push rod, which is connected with a servo electric cylinder; and the servo electric cylinder is connected with a driver, which is connected with a computer. By the adoption of the opening device, the number of heddles can be minimized and high-speed and digitalized control is carried out on the motion of the healed frames, thus greatly expanding types and specifications of fabrics and reducing abrasion of palm fiber to warp yarn.

Owner:DONGHUA UNIV

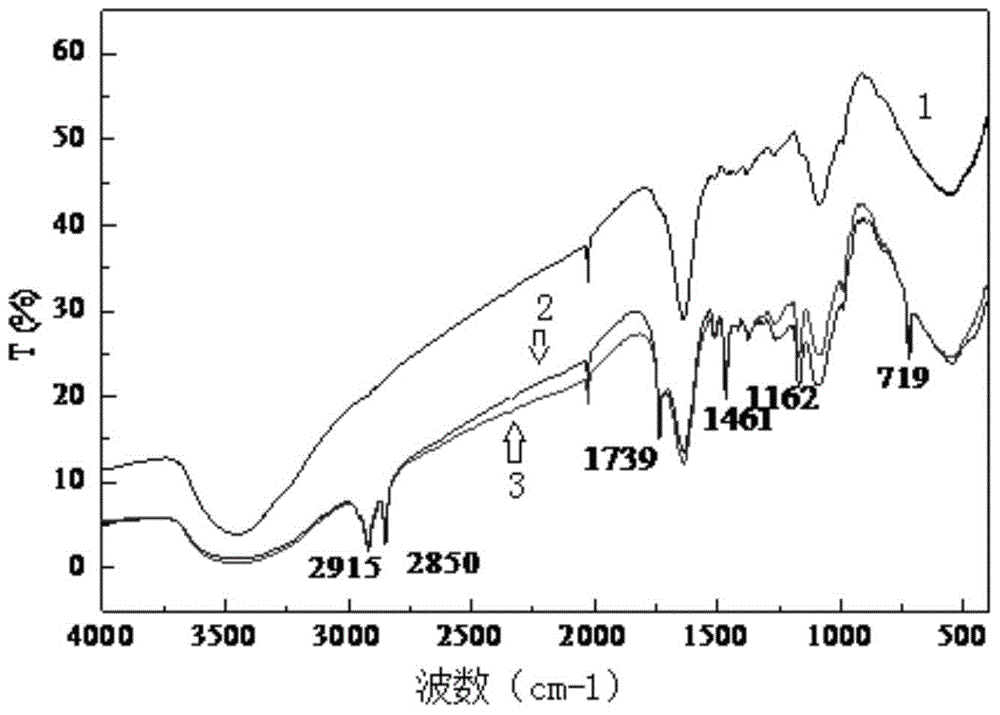

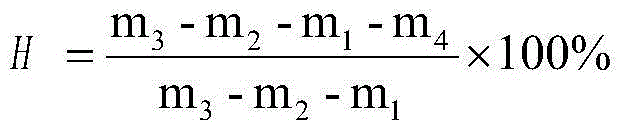

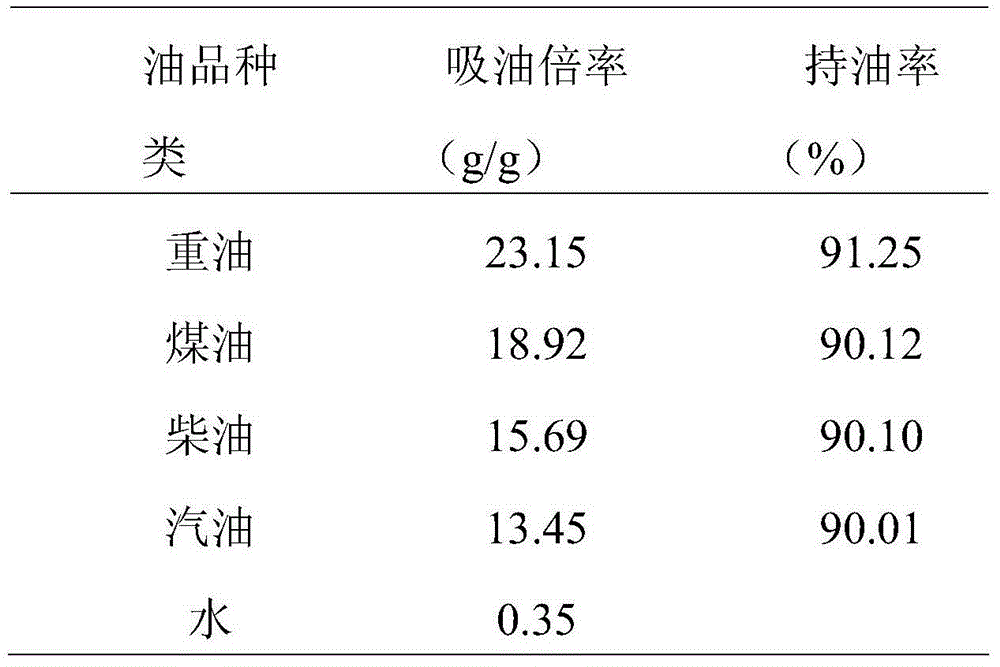

Preparation method of oil absorbing material by taking palm fiber as basic material

ActiveCN104624162ARich pore structureOptimized areaFatty/oily/floating substances removal devicesOther chemical processesParaffin waxChemical synthesis

The invention relates to a preparation method of an oil absorbing material, and the oil absorbing material is prepared by subjecting a basic material namely palm fibers to hydrophobic modification. The preparation method comprises the following steps: washing palm fibers, drying palm fibers, cutting the palm fibers into sections with a length of 0.5 to 5 cm; putting the palm fibers into a hydrophobic agent solution, soaking for 10 to 120 minutes at a temperature of 25 to 100 DEG C, taking out the palm fiber containing a hydrophobic agent, and quickly drying so as to obtain the modified oil absorbing material; wherein the hydrophobic agent is composed of paraffin, palm wax, or a mixture of paraffin and palm wax, the addition amount of the hydrophobic agent is 0.01 to 0.2 times of the weight of the palm fibers, the solvent is one or more of carbon tetrachloride, vinyl acetate, ethanol, and benzene, and the addition amount of the solvent is 20 to 800 times of the weight of the hydrophobic agent. Cheap and easily-available natural plant palm is taken as the raw material, the oil absorbing material is prepared by carrying out hydrophobic modification on the palm fibers, and compared with the oil absorbing materials prepared through chemical synthesis, the provided oil absorbing material has the advantages of low cost, biodegradability, and excellent oil absorbing performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Memory foam material containing natural fiber and application of memory foam material

The invention discloses a memory foam material containing a natural fiber and application of the memory foam material. The product comprises a memory foam material body, wherein the memory foam material body contains the natural fiber of which the content is 15-80 percents of the total volume of the memory foam material body. The natural fiber is one or more of bamboo fiber, hemp fiber, wood fiber, chitosan fiber, natural palm fiber and natural desiccated coconut. The natural fiber replaces the most of space occupied by air bubbles originally, so that the gas phase volume fraction of the foam body is reduced, and the thermal conductivity is increased; thus, the heat dissipation capacity and permeability of the product are greatly improved, and the problems of low thermal conductivity and poor heat dissipation of the traditional memory foam are solved. The higher the content of the natural fiber is, and the higher the heat dissipation capacity and permeability of the prepared memory foam are.

Owner:陈麒

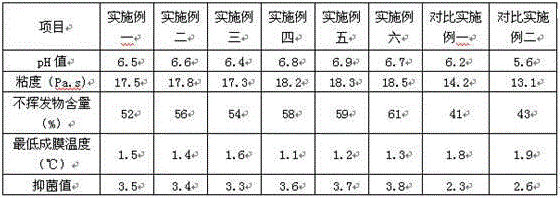

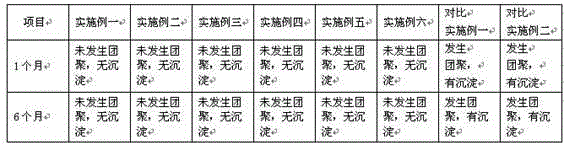

Multipolymer type waterproof sealant for construction

InactiveCN102994016ANon-toxic and environmentally friendlyExtended service lifeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesIsooctyl acrylatePolyester

The invention discloses a multipolymer type waterproof sealant for construction, wherein raw materials in a prescription based on ratio of part by weight are as follows: vinyl acetate, organic silicone monomer containing unsaturated double bonds, vinyl versatate, butyl acrylate, 2-ethylhexyl acrylate, acrylic acid and de-ionized water. The multipolymer type waterproof sealant has the advantages that the sealant can be used for coating surfaces of substances such as cement components, ceramics, glass, plywoods, shaving boards, palm fiber boards, bamboo slag boards, paper slag boards, composite boards, aluminum-plastic panels, polyvinyl chloride (PVC) boards, fireproof plates, metal, plastics, leather, rubber and the like and has the bonding strength that other waterproof materials cannot reach; the sealant has good stability and the shelf life at 5-35 DEG C. is more than 12 months; and the multipolymer type waterproof sealant for the construction has the advantages of no toxicity, no odor, no pollution, no corrosion, no combustion, no wiredrawing during coating and the like; and the problems of easy combustion, short shelf life, wiredrawing during coating, serious air pollution and the like during applications of solvent type materials, polyester type materials and the like are solved.

Owner:GUANGDONG BADESE CHEM

Method of mineralizing plant fiber and its applications

InactiveCN1833840AWith inorganic mineral materialsGood weather resistanceDomestic articlesFlat articlesCalcium silicateOxygen

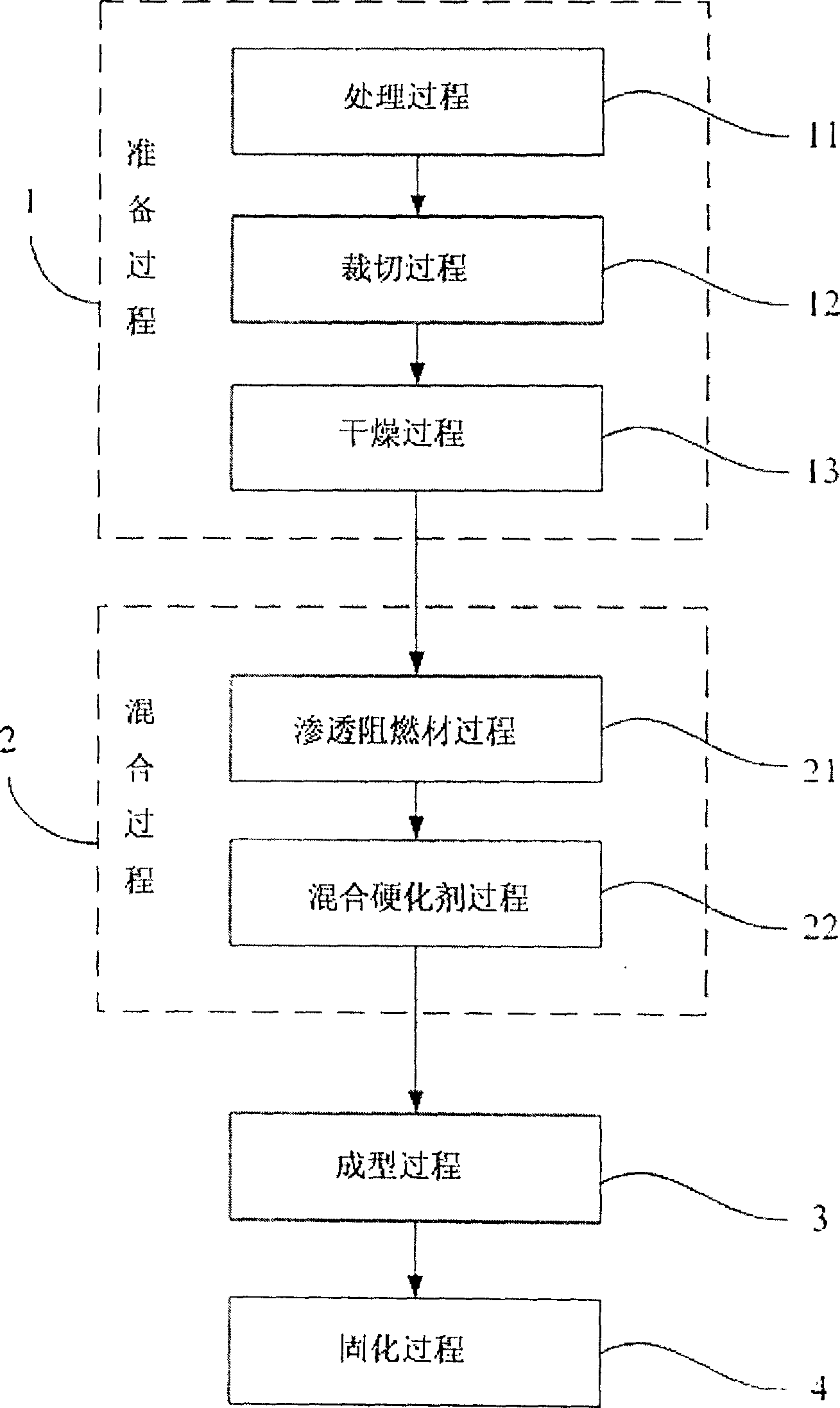

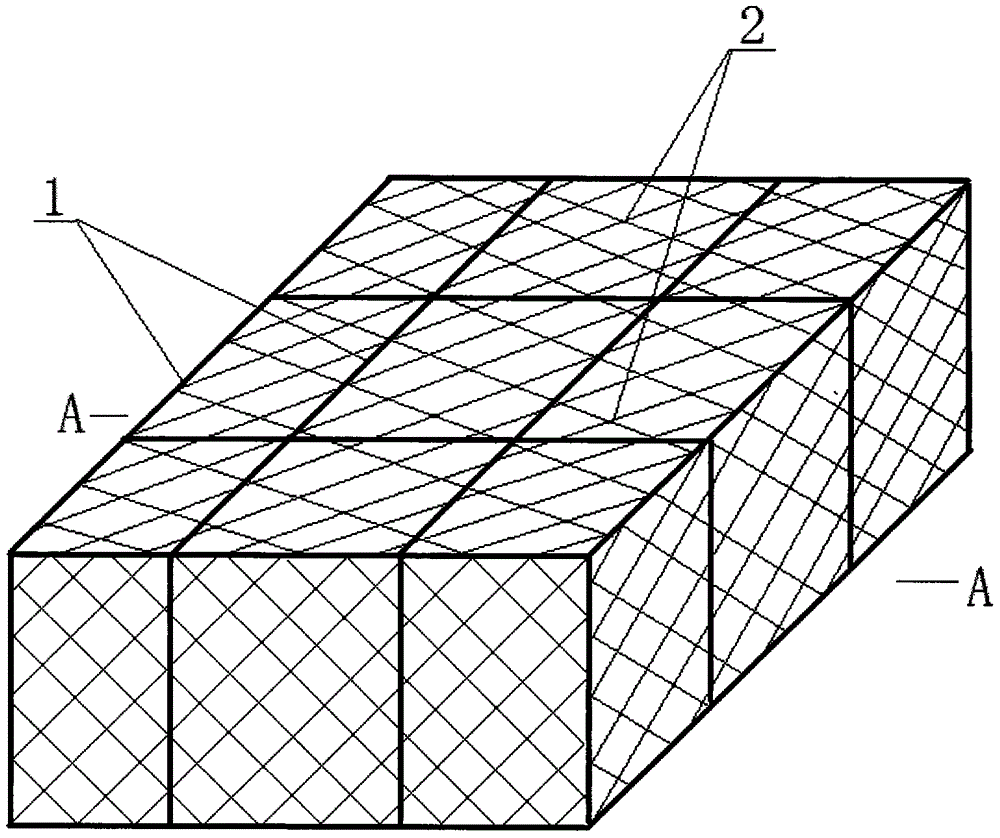

A method for mineralizing the plant fibers and using them to prepare building material includes such steps as preparing plant fibers from at least one of wood, palm fiber, coconut fiber, cotton stalk, bamboo, grass, nut shell and bean shell, preparing hardening agent by mixing solution with at least one of calcium carbonate, calcium chloride, calcium silicate, magnesium oxide, magnesium chloride, magnesium oxygen sulfate, zinc oxide, pearlite, carborundum and fluorspar, mixing it with said plant fibers, loading the mixture in mould, pressurizing, demoulding and solidifying.

Owner:孙辰豪

Quick mounting ecological module for slope rock body, and manufacturing method of quick mounting ecological module

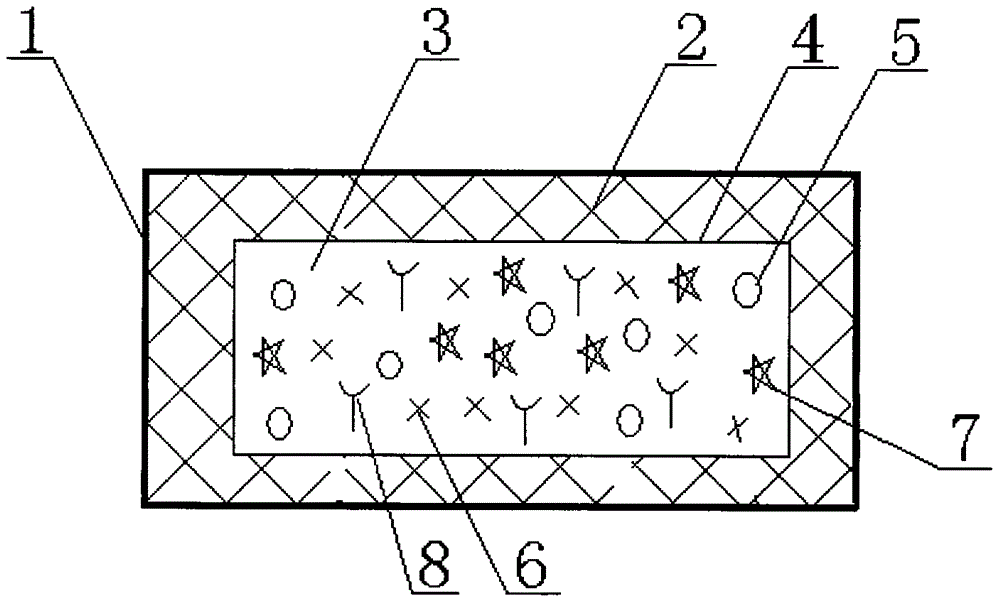

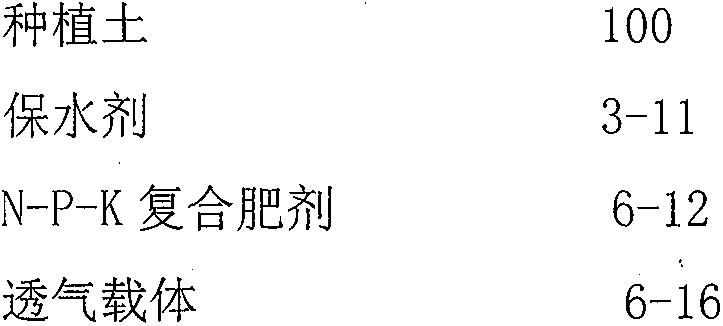

The invention relates to a quick mounting ecological module for a slope rock body, and a manufacturing method of the quick mounting ecological module. The quick mounting ecological module is suitable for quickly afforesting and repairing damaged mountain bodies and smooth surfaces of steep-slope rocks. The quick mounting ecological module consists of a stainless steel mesh cover, long palm fibers and a water retention type nutrition medium bag, wherein the water retention type nutrition medium bag is located at the middle position of the quick mounting ecological module for the slope rock body; the long palm fibers are used for coating the periphery of the water retention type nutrition medium bag; the stainless steel mesh cover is arranged at the outer parts of the long palm fibers; the water retention type nutrition medium bag is made by an external packing bag made of nylon; and media in the water retention type nutrition medium bag comprise planting soil, a water-retaining agent, an N-P-K compound fertilizing agent, and a ventilation carrier. The quick mounting ecological module provided by the invention is convenient to produce, appropriate in porosity, good in water retention properties, soft in soil and sufficient in fertility, so that the quick mounting ecological module facilitates the growing of coated green plants. The quick mounting ecological module provided by the invention is low in cost, wide in application range, and convenient to mount.

Owner:NANJING DAYUAN ECOLOGICAL CONSTR GRP

Intelligent mattress with massage and physiotherapy function

InactiveCN107157190APlay a relaxing roleImprove comfortElectrotherapyStuffed mattressesMassageEngineering

The invention relates to the technical field of intelligent mattresses, in particular to an intelligent mattress with massage and physiotherapy functions, comprising a bed board and a mattress substrate, the bottom surface of the bed board is provided with a coconut palm fiber cushion, and the coconut palm fiber cushion The bottom surface is provided with a hard cotton layer, the mattress substrate is installed on the bottom surface of the hard cotton layer, the upper surface of the hard cotton layer is embedded with a plurality of magnet blocks, and the upper surface of the coconut palm fiber cushion layer is opened There is a mounting groove, the inner bottom surface of the mounting groove is provided with two slide rails, the slide rails are provided with sliders, and the sliders slide along the surface of the slide rails, and a fixing plate is arranged between the two sliders. The interior of the installation groove is provided with an electric telescopic rod connected with the fixing plate. The invention is simple in structure and easy to use. It not only facilitates the reciprocating massage for the user, thereby improving the comfort of the massage, but also facilitates the user's adjustment and improves the simplicity of operation.

Owner:河南加特安物联网有限公司

Palm fiber-reinforced environment-friendly type brake pad and preparation method thereof

InactiveCN103436236AImprove integrityStrong porosityOther chemical processesFriction liningNatural fiberPalm fiber

The invention relates to a palm fiber-reinforced environment-friendly type brake pad and a preparation method thereof. The palm fiber-reinforced environment-friendly type brake pad comprises the components of natural palm reinforced fibers taken as a material framework, ceramic fibers, melamine modified phenolic resin, a friction performance conditioning agent and a filler; the parts by weight of the components are as follows: 25-35 parts of reinforced fibers, 10-15 parts of adhesive, 8-12 parts of friction performance conditioning agent and 35-45 parts of filler. After being pretreated, the natural palm fibers have multiple good performances of being long in fibers, tenacious in texture, high in elasticity and tensile strength, wear-resistant and the like, and belong to renewable resource. Under optimal process conditions, the prepared palm fiber-reinforced brake pad can stabilize and reduce the expansion of material and improve the braking performance; the palm fiber-reinforced environment-friendly type brake pad is good in chemical stability and heat fading performance, so that the surface of the brake pad is prevented from being corroded. A great deal of gaps exist among the palm fibers, and the palm fibers are internally hollow, so that the manufactured brake pad is high in porosity, reduces the brake noise and is an ideal environment-friendly type natural fiber-reinforced material.

Owner:李美凤

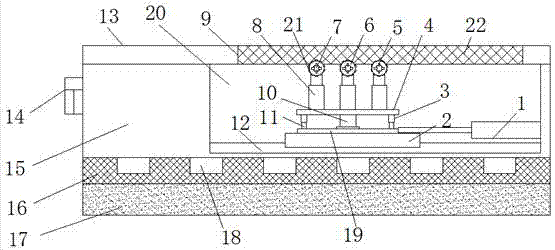

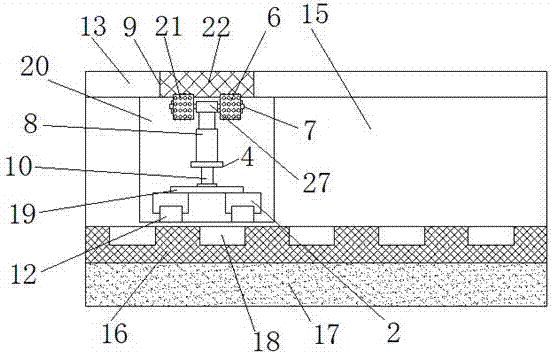

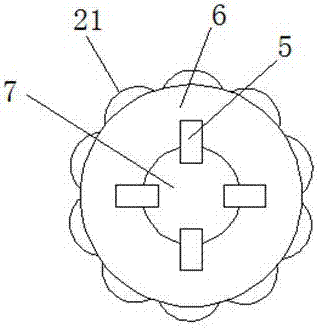

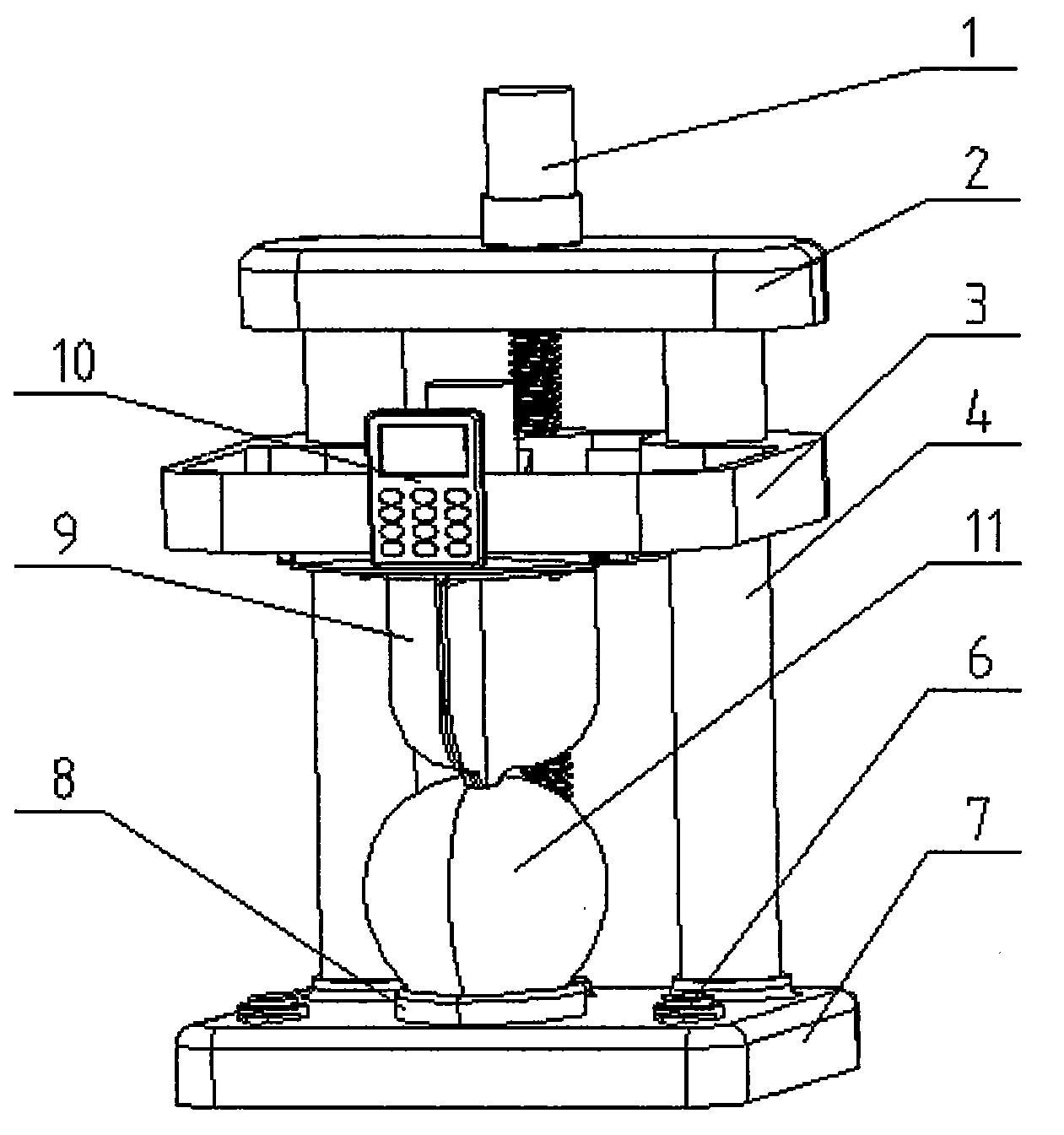

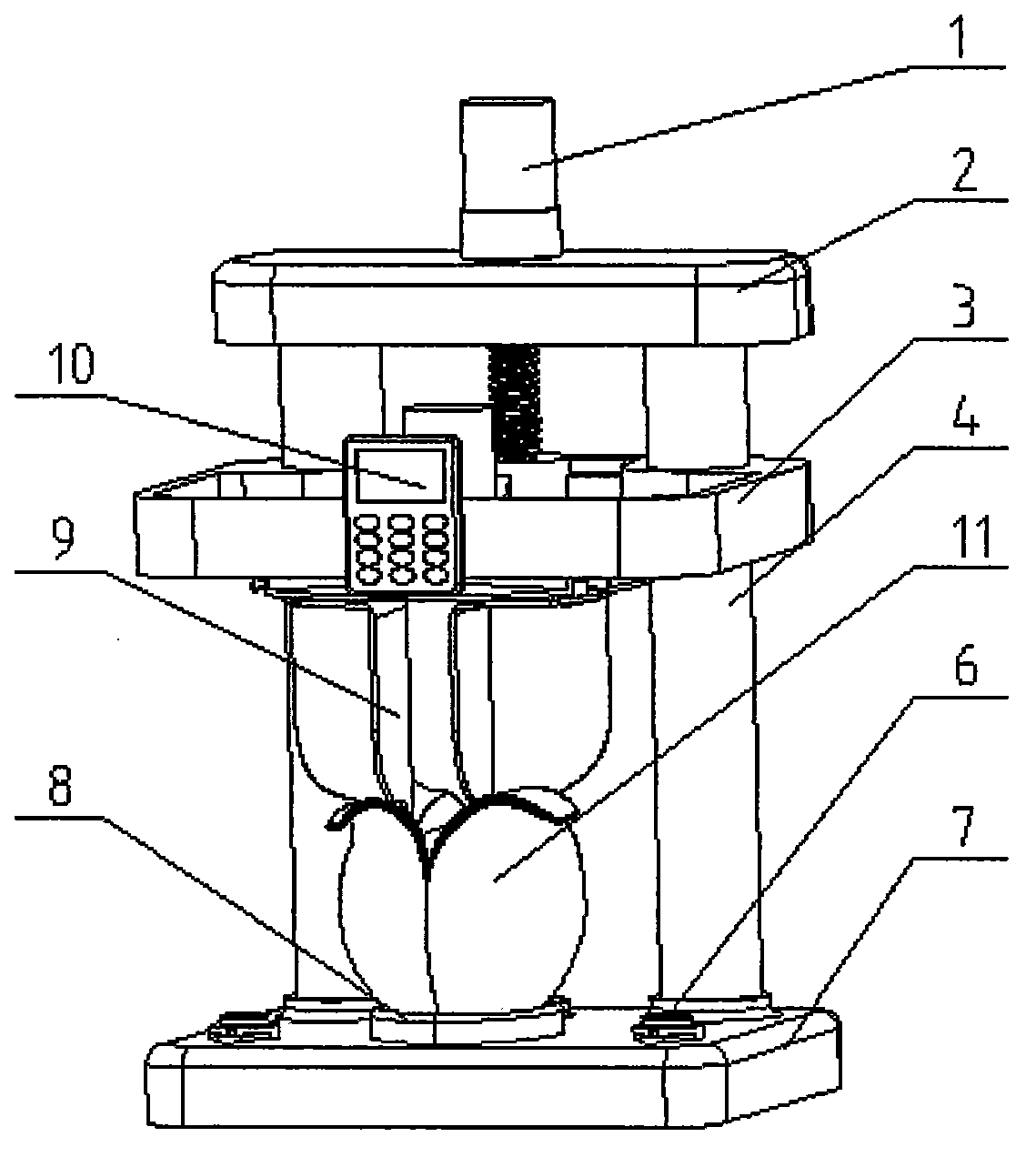

Coconut palm fiber peeling machine

InactiveCN104256859AImprove stripping efficiencyEasy to operateHuskingHullingPalm fiberMechanical engineering

The invention discloses a coconut palm fiber peeling machine. The coconut palm fiber peeling machine comprises a screw rod motor, a beam, a lifting platform, a stand pillar, a screw rod, press buttons, a bottom seat, a rubber seat, a turnover knife component and a controller, wherein the turnover knife component comprises a knife disk motor, a connection rod, a knife disk, a turnover knife, a rotator and a slide block. When a person uses the coconut palm fiber peeling machine to peel palm fibers of a coconut, the person only needs to right the coconut and place the coconut into the rubber seat, and simultaneously presses down the press buttons on two sides of the bottom seat, the palm fibers on the outer layer of the coconut can be peeled through united action of the lifting platform and the turnover knife component under control of the controller, and simultaneously the interior of the coconut can not be injured, and therefore the coconut palm fiber peeling machine is convenient to operate and greatly improves palm fiber peeling efficiency.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Magnesium oxysulfate wall plate and fabrication method thereof

The invention relates to a magnesium oxysulfate wall plate and a fabrication method of the magnesium oxysulfate wall plate. The magnesium oxysulfate wall plate comprises the following raw materials in parts by weight: 100 parts of magnesium oxide, 0.5-5 parts of a modifier, 100-130 parts of a magnesium sulfate solution, 2 parts of bamboo fiber, 3 parts of palm fiber, 10-30 parts of a filling and 1 part of a foaming agent. The fabrication method of the magnesium oxysulfate wall plate comprises the steps of putting the modifier into the magnesium sulfate solution, injecting into an agitator after agitation, putting the bamboo fiber and the palm fiber into the agitator for agitation, putting magnesium oxide in the agitator for agitation, allowing slurry agitated by the agitator to fall into a foam mixing machine, injecting the foaming agent subjected high-pressure foaming into the slurry, performing foam mixing to form uniform foaming slurry, injecting the foaming slurry into a special mold car via a distribution system, and performing foam expelling, fiber stroking, curing, female groove forming, core pulling and push plate mold stripping. The magnesium oxysulfate wall plate is high in structural strength, good in water resistance and stable in physical property.

Owner:江苏宝盛住宅工业有限公司

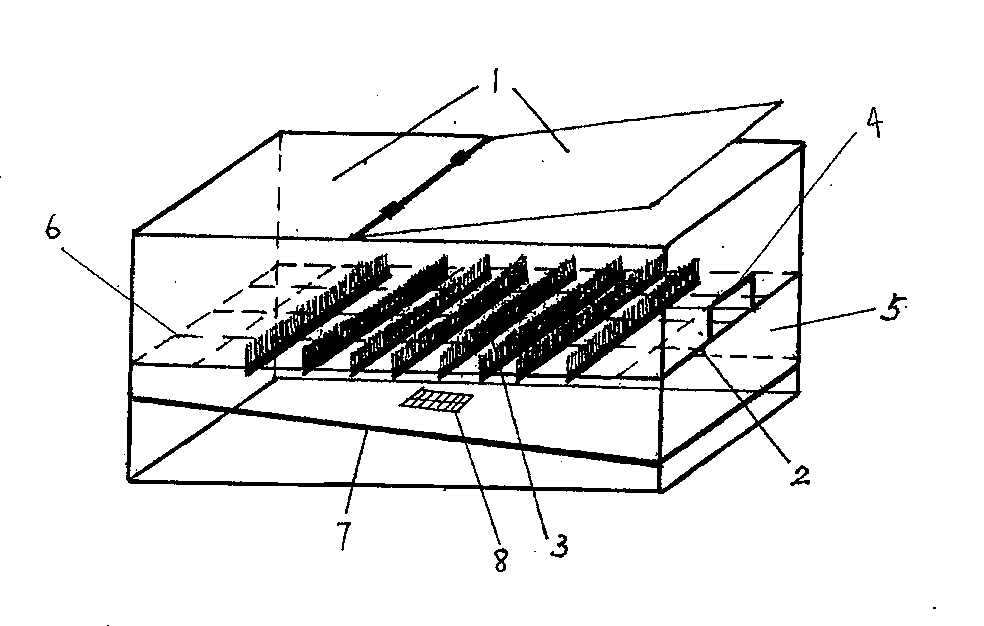

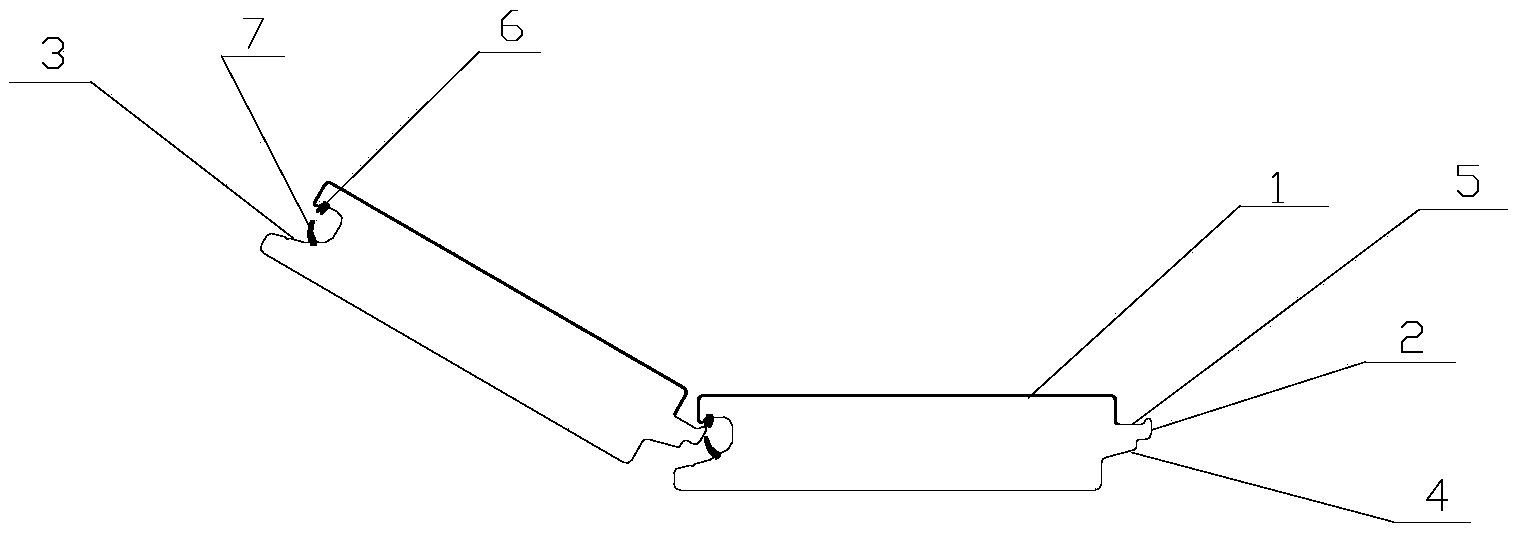

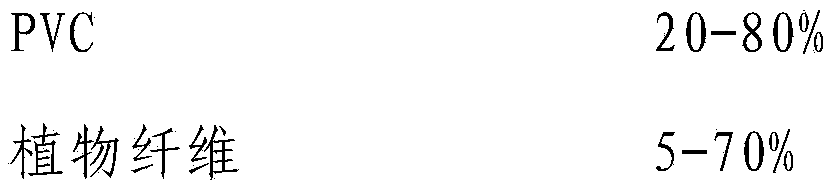

Continuous long fiber reinforced polyolefin plastic wood composite material and preparation method thereof

The invention relates to a plastic wood composite material and a preparation method and a co-extrusion die thereof, in particular to a continuous long fiber reinforced polyolefin plastic wood composite material and a preparation method thereof. The composite material consists of the following components in percentage by weight: 20 to 80 percent of polyolefin plastic, 0 to 80 percent of wood fiber, 0 to 80 percent of mineral filler, 0 to 10 percent of lubricating agent, 0 to 5 percent of antioxidant, 0 to 5 percent of ultraviolet absorbent, 0 to 10 percent of coupling agent, 0 to 10 percent of pigment and 0 to 30 percent of reinforcing fibers; the reinforcing fibers are surface modified or unmodified glass fibers, jute fibers or hemp palm fibers; and the reinforcing fibers are continuously extended along the length direction of the polyolefin plastic wood composite material, and the number of the reinforcing fibers is at least one beam. The reinforcing fibers are continuously extended and distributed in the polyolefin plastic wood profile; and when the plastic wood profile is forced during use, the continuous extended fibers can quickly transfer the local force to the whole profile so as to greatly improve the strength and the impact resistance of the plastic wood profile.

Owner:南京聚锋新材料有限公司 +1

Method for preparing coconut palm plate for mattress

InactiveCN102660842ANo glue smellNot susceptible to moisture and mildewStuffed mattressesSpring mattressesCold airPolyester

The invention discloses a method for preparing a coconut palm plate for a mattress. The method comprises the steps as follows: performing opening treatment on two-composition sheath-core fiber, coconut palm fiber and hollow polyester fiber; mixing the two-composition sheath-core fiber and coconut palm fiber to obtain a synthetic fiber A; mixing the two-composition sheath-core fiber and the hollow polyester fiber to obtain a synthetic fiber B; combing the synthetic fiber A and the synthetic fiber B; lapping; fusing the sheath of the two-composition sheath-core fiber by utilizing the hot air penetration technology together with the hollow polyester fiber and the coconut palm fiber; cooling and curing the sheath of the two-composition sheath-core fiber by utilizing the cold air penetration technology, and leading the fiber of the three layers to be bonded together to form a platy structure; and cutting into certain specification. The coconut palm plate for the mattress, prepared by adopting the preparation method, has the advantages of having no formaldehyde release and no glue smell, being not easy to moisture and mould, and being smooth in surface and uniform for thickness.

Owner:昆山吉美川纤维科技有限公司

Method for extracting fiber from oil palm fruit bundle and fiber obtained thereby

The invention discloses a method for extracting fiber yarns from palm fruit clusters of oil palm. The palm fruit clusters of the oil palm are cooked by steam with a temperature of between 100 and 200 DEG C for 0.5 to 1.5 hours, oil palm fruit pericarps are separated to obtain empty fruit clusters, then the empty fruit clusters are extruded and torn to obtain fiber blocks, the fiber blocks are washed and then are extruded to ensure that the water content of the fiber blocks is between 30 and 80 percent, then the selection is performed, the selected fiber blocks are subjected to silk fetching treatment to obtain the fiber yarns, and then the fiber yarns are dried, screened and bagged. The applicator aims at the requirement on an elastic material to process and select the fiber yarns in the palm fruit clusters so as to be suitable to process natural oil palm silk mattresses. Natural fiber yarns of the palm fruit clusters obtained by the method can substitute mountain palm fiber yarns to produce various natural palm mattresses, cushions, and products such as fiberboards and sound insulation boards for buildings and so on.

Owner:GUIZHOU DAZIRAN TECH

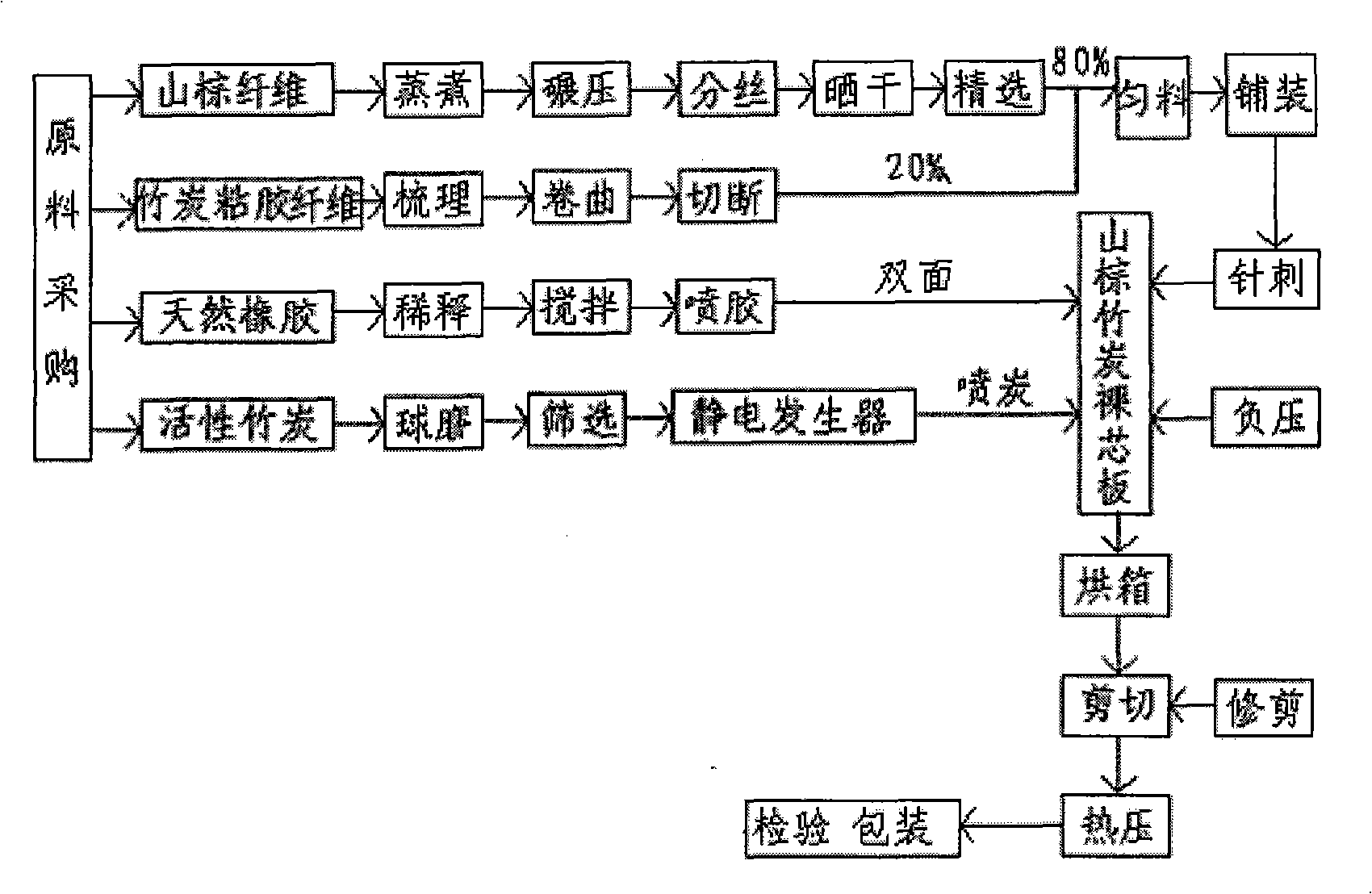

Method for manufacturing palm-bamboo charcoal mattress

InactiveCN101601542ARegulate dry humidityStay soft and comfortableStuffed mattressesSpring mattressesSocial benefitsEconomic benefits

The invention discloses a method for manufacturing a palm-bamboo charcoal mattress. Main raw materials comprise natural palm fibers, bamboo charcoal viscose, natural rubber latex and granular active bamboo charcoal. The raw materials are scientifically and reasonably combined, and the granular active bamboo charcoal is firmly combined with the palm fibers and the bamboo charcoal viscose by adopting innovative processes and equipments, so that the good efficacy of the active bamboo charcoal is fully exerted, and the defects of the mattress which is simply manufactured by the palm fibers and the bamboo charcoal mattress adopting natural cotton or artificial cotton fibers as attachment material are overcome. The method integrates multiple functions and efficacies in one mattress, provides a new variety for the functional mattress with high value-added, and has quite remarkable social benefit and economic benefit.

Owner:浙江晨峰模板有限公司

Novel bamboo palm fiber extraction process

The invention provides a process. The process comprises the following flows: original bamboo cutting off, mechanical chipping, green and yellow scraping off, mechanical hammering, scouring and loosening, mechanical fiber loosening and drying and cutting off. The process has the following beneficial effects: the thickness of the produced bamboo fibers is consistent with that of the palm fibers; the fiber content is much higher than the palm fiber content; the fiber has much better strength, water absorption and air permeability, flexibility and the like compared wtih the high-quality palm fiber; and the produced palm fiber can become the substitute of the coconut fibers.

Owner:李超

Antifreeze type ecological slope protection substrate

ActiveCN103510488AReasonable structureImprove frost resistanceCoastlines protectionOperabilityPlant growth

The invention belongs to the technical field of slope protection, and provides an antifreeze type ecological slope protection substrate which is formed by evenly mixing of plant growth soil, cement, humus, concrete afforesting additives, silica powder and palm fibers. The antifreeze type ecological slope protection substrate can create vegetation habitat which is reasonable in structure, good in hydraulic scour resistance and freezing resistance and high in fertilizer efficiency for bare rock slopes in a frigid region so as to restore damaged slope vegetation. Raw materials of the antifreeze type ecological slope protection substrate are low in price and convenient to use, and the antifreeze type ecological slope protection substrate is strong in technical operability and has broad application prospect.

Owner:CHINA THREE GORGES UNIV +2

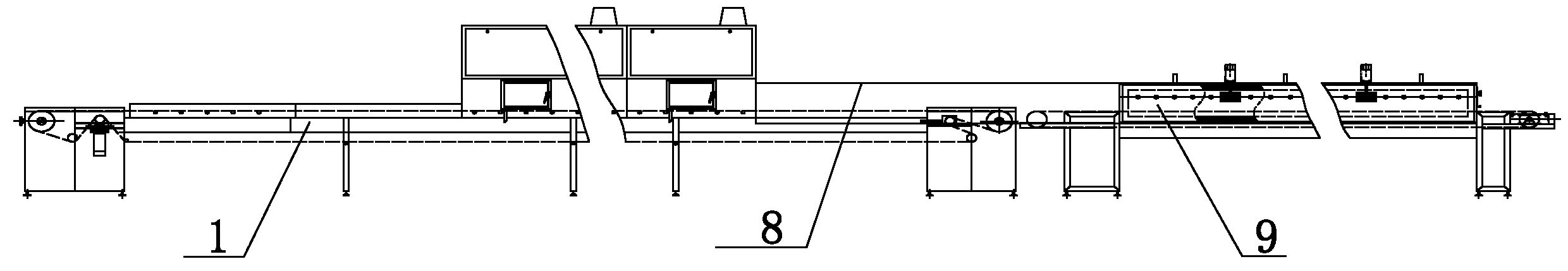

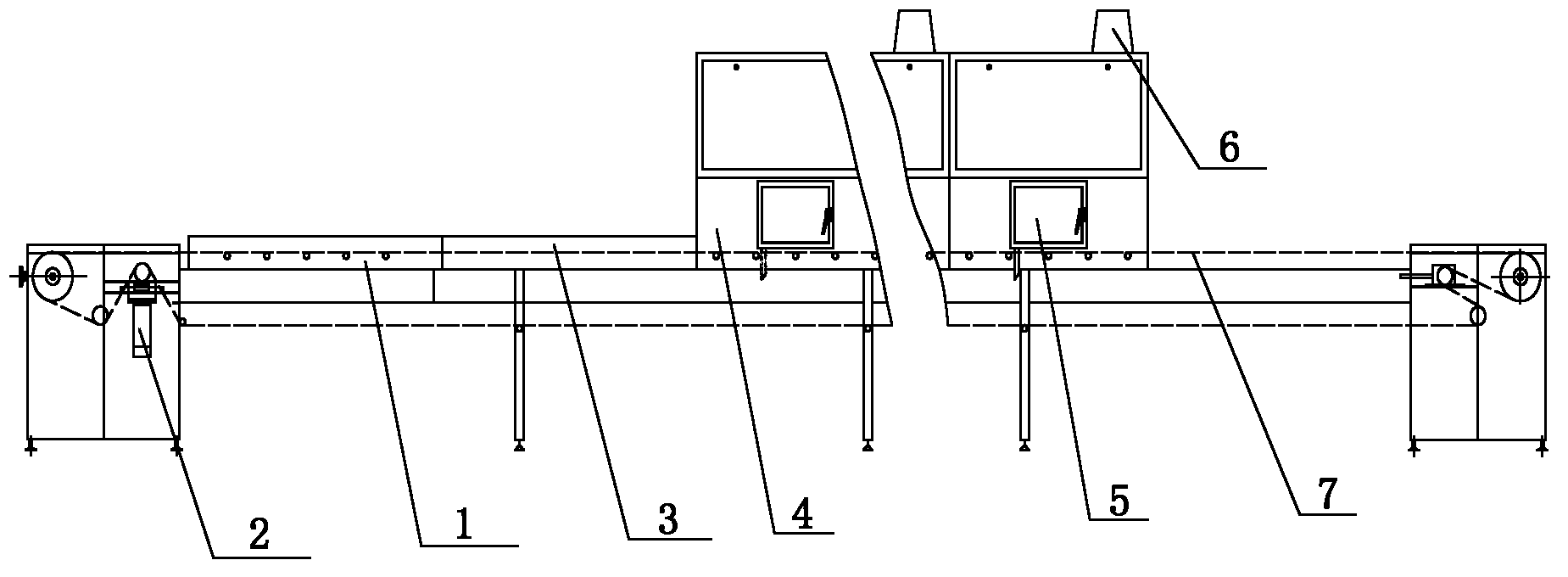

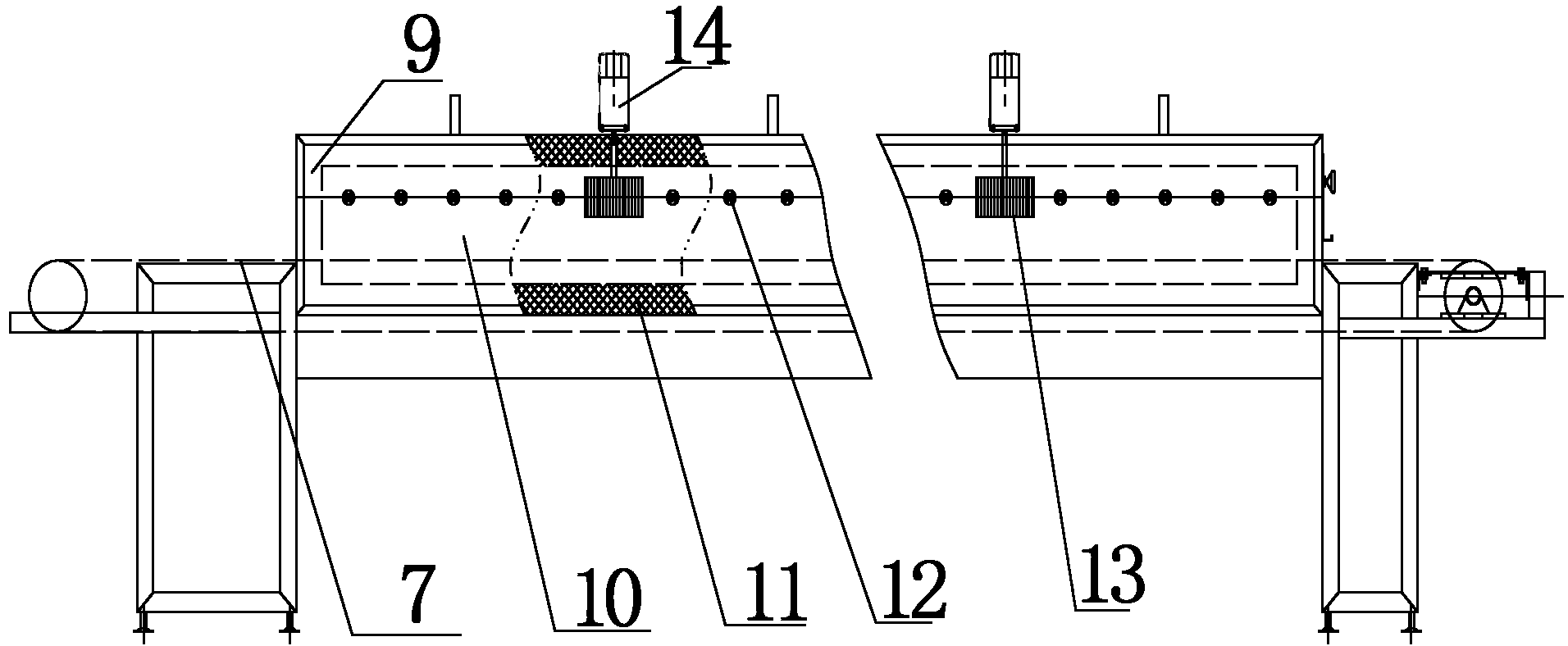

Microwave and far infrared vulcanization method and equipment

The invention discloses a microwave and far infrared vulcanization method which comprises the following steps: a to-be-vulcanized palm fiber material enters into a microwave vulcanization box on a microwave vulcanization machine to be subjected to primary vulcanization heating after being placed on a conveyor belt of the microwave vulcanization machine, the palm fiber material subjected to the primary vulcanization heating enters into a far infrared vulcanization box on a far infrared vulcanization machine to be subjected to secondary vulcanization heating; and after the secondary vulcanization heating, the finished product required is obtained. Compared with the vulcanization tank operation, the production is carried out on an assembly line, so that the vulcanization time of an article is shortened greatly, and the vulcanization efficiency of the article is improved; the whole vulcanization process is completed through microwave vulcanization operation and the far infrared vulcanization operation, so that the condition that the article is easy to burn due to over rapid microwave temperature rise under the once microwave vulcanization action is avoided, the safety performance is more reliable, and greater economic benefits are brought to enterprises.

Owner:GUIZHOU DAZIRAN TECH

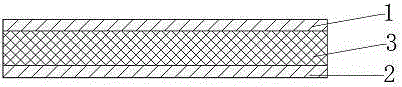

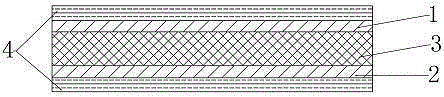

Natural fiber/polymer fibrous layer laminated automobile chair-back sheet material and production method

InactiveCN105235300AImprove breathabilityEffective bondingSynthetic resin layered productsLaminationWood fibrePalm fiber

A disclosed natural fiber / polymer fibrous layer laminated automobile chair-back sheet material comprises an integrated sheet material formed through lamination and combination of a first surface layer, a core layer and a second surface layer, the first surface layer and the second surface layer are non-woven fabrics, the core layer is a mixed fiber plate, the mixed fiber plate is prepared by compacting natural fiber and needle felt employing polymer fiber as the main composition, and the natural fiber is at least one selected from fibrilia, bamboo fiber, palm fiber and wood fiber. The invention also discloses a production method for the natural fiber / polymer fibrous layer laminated automobile chair-back sheet material. The automobile chair-back sheet material possesses the characteristics of being light in weight, small in density, excellent in breathability, and excellent in strength and toughness. By employing twice baking compaction and cold-press shaping processing in the production process, the sheet material density is improved.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

Coconut palm fiber elastic cushion

InactiveCN1579927AModerate elasticityUniform densityUpholstery manufactureNatural rubber adhesivesEngineeringPalm fiber

A stretch cushion is made of coir fiber. After steamed under a high pressure, carded by mechanism, sprayed glue (which is mixed by natural lactoprenes), dried, sulfuration and other processing technics, the cushion has a good air permeability, hydraulic permeability, and hygroscopicity. Also its processing technic is simple. It is warm in winter while cold in summer. With this character, it fits to make bed-cushion and seating cushion, and also it can be used as sound-proof, non-hygroscopic and packaging materials.

Owner:黄志平

Preparation technology of palm fiber

The invention discloses a preparation technology of a palm fiber; the preparation technology comprises the following steps: (1) acid dipping: putting a palm raw material into an acidic solution with the sulfuric acid concentration of 2-8 g / L, removing pigments on the surface of the fiber, and dissolving a part of pectin, wax and lignin impurities, wherein the acidic solution temperature during acid dipping is 40-60 DEG C and the time is 1-2 hours; (2) primary water washing; (3) primary alkali cooking: carrying out alkali cooking of a palm fiber after primary water washing, wherein the caustic soda amount during alkali cooking is 50-150 g / L, the time is 1.5-2 hours, and the temperature is controlled to be 90-140 DEG C; (4) secondary water washing; (5) chlorine bleaching; (6) pickling; (7) secondary alkali cooking; (8) tertiary water washing; (9) oxygen bleaching; (10) high temperature splitting; (11) quartus water washing; (12) vegetable oil addition and treatment; (13) finally, dehydration and drying treatment of the palm fiber after oil addition treatment. The prepared palm fiber has the advantages of soft hand feeling, high strength, strong moisture absorption and gas permeability, environmental protection, natural degradation and the like.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Efficient static raise-dust-free dust cleaning device of blackboard eraser

InactiveCN102909195AAdsorption removal rate increasedEasy to removeElectrostatic cleaningPalm fiberHigh pressure

The invention discloses an efficient static raise-dust-free dust cleaning device of a blackboard eraser. The efficient static raise-dust-free dust cleaning device comprises a sealing housing with a cover, a movable dedusting device and a dust storage box. A layer of metal filter screen is arranged in the movable dedusting device. A movable friction piece formed by palm fiber strands in a plurality of rows, fixing strips for fixing the palm fiber strands, sliders for connecting the fixing strips, and a movable handle connected with the sliders is arranged on the filter screen. The movable dedusting device is integrally horizontally arranged in the sealing housing. The distance between the palm fiber strands on the friction piece and the cover of housing is identical to the height of the blackboard eraser horizontally placed. As an improvement, an electrostatic dust absorption plate is obliquely arranged in the dust storage box and comprises a smooth panel, a high-voltage dust absorption plate and a sensing device, the high-voltage dust absorption plate is fixedly arranged under the panel, and the sensing device is arranged between the panel and the high-voltage dust absorption plate and is used for controlling an electrostatic high-voltage circuit. The efficient static raise-dust-free dust cleaning device has the advantage that removal rate of chalk dust can reach more than 90%, and the chalk dust is prevented from flying during dust cleaning process.

Owner:陈思思

Plastic-wood composite floor and preparation method thereof

ActiveCN103554751AIncreased surface oxidation resistanceImprove scratch resistanceFlooringPolyolefinOxidation resistant

The invention relates to a composite floor and a preparation method thereof and belongs to the technical field of materials. Plant fibers are distributed in a polyolefin plastic-wood section in a continuous extension manner, so that the plant fibers which are continuously extended can quickly transfer the local stress to the whole section when the plastic-wood section is stressed during an application process. Thus, the strength and the impact resistance of the plastic-wood section are substantially improved. In addition, coconut shell powder or palm fibers are adopted in the plant fibers, so that the environmental friendliness is good. The anti-oxidation degree of the surface of the plastic-wood composite is improved through co-extrusion of a surface material; and the scratch resistance and the abrasion resistance of the plastic-wood composite are improved at the same time. A PVC (Poly Vinyl Chloride) soft adhesive tape is coextruded at a buckling part of the plastic-wood composite, so that the excellent sealing effect is achieved.

Owner:南京聚锋新材料有限公司 +1

Compound ceramic filter element with good wearproof adsorbing property and preparation method of filter element

InactiveCN103831085AHigh strengthImprove wear resistanceOther chemical processesDispersed particle separationPolyvinyl alcoholPolyvinyl chloride

The invention discloses a compound ceramic filter element with a good wearproof adsorbing property. The compound ceramic filter element is characterized by being prepared from the following raw materials in parts by weight: 12-14 parts of kieselguhr, 9-11 parts of husk active carbon, 8-10 parts of cordierite, 2-3 parts of aluminum powder, 4-5 parts of silochrom, 10-12 parts of polyvinyl chloride powder, 1-2 parts of silicon carbide, 1-2 parts of ammonium molybdate, 3-4 parts of polyvinyl alcohol, 3-5 parts of palm fibers, 1-2 parts of silver nitrate, 5-7 parts of modifying coconut active charcoal, and the defined amount of water. The compound ceramic filter element provided by the invention has the advantages that the silicon carbide is added, so that the intensity and wearproof property of the filter element are improved; the palm fibers are added, so that the tenacity of the filter element is enhanced, meanwhile, the compound ceramic filter element has a porous property, and the filtering property is improved; the modifying coconut active charcoal is added, so that the gap structure is developed, the adsorbing property is good, the intensity is high, the regeneration is easy, and the compound ceramic filter element is economical and durable, is suitable for use in harsh environment and is capable of adsorbing hazardous gas and PM2.5 in the air.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Plant growing bed, seedling raising bed and cover soil material for seedling raising bed

The invention relates to a plant growing bed, seedling raising bed and cover soil material for seedling raising bed. The plant growing bed produced by mixing 100 pts.wt. of non-wood fibers composed of bamboo fibers having undergone expression processing to fibers and poaceous plant fibers from reed, straw, pampas grass, etc. with 30 to 70 pts.wt. of palm fibers having undergone crushing processing and 1 to 3 pts.wt. of vegetable starch, further adding thereto an appropriate amount of water enough to cause the starch to absorb the same and thereby generate viscosity; effecting agitation and kneading of the mixture; pressuring the kneading product so as to shape into an arbitrary thickness and configuration; and drying the shaped product. Further, there is provided a main body of seedling raising bed produced from bamboo fibers, poaceous plant fibers and palm fibers together with an intra-bed water retention antiseptic, and provided a cover soil material for seedling raising bed produced from a mixture of these components loaded with a small amount of soil.

Owner:飨庭利行

Formaldehyde-free adhesive and method for producing formaldehyde-free palm fiber mattress by using same

InactiveCN102618210ALow costSolve formaldehyde releaseStuffed mattressesProtein adhesivesCross-linkYarn

The invention discloses a formaldehyde-free adhesive and a method for producing a formaldehyde-free palm fiber mattress by using the formaldehyde-free adhesive. The formaldehyde-free adhesive is produced by using formaldehyde-free raw materials which are vegetable protein, a cross-linking agent, an auxiliary material and water. According to the method for producing the formaldehyde-free palm fiber mattress by using the formaldehyde-free adhesive, a palm fiber raw material is a natural coconut palm fiber yarn or a natural arenga engleri fiber yarn and is sequentially subjected to working procedures of felting, needling, glue spraying, drying, slicing, hot-pressing, side shearing and checking. The palm fiber mattress, the release amount of the free formaldehyde of which is far less than 0.050mg / m<2>.h (stated in QB1952.2-2004 spring soft mattress of upholstered furniture), can be produced according to the method. The free formaldehyde of the palm fiber mattress is only derived from the natural palm fiber, thereby the problem of formaldehyde release of the palm fiber mattress is fundamentally solved.

Owner:田志壮

Rapidly-assembled ecological planting module with variable bottom flexibility and preparation method of rapidly-assembled ecological planting module

ActiveCN108739256ASufficient room for growthEasy to produceGrowth substratesCulture mediaPorosityPlant roots

The invention relates to a rapidly-assembled ecological planting module with variable bottom flexibility for mountain restoration and a preparation method of the rapidly-assembled ecological plantingmodule, and is applicable to rapid greening and repairing of broken hills and smooth steep slope rocks. The rapidly-assembled ecological planting module with the variable bottom flexibility comprisesa stainless steel wire mesh, a soft attaching layer, a lower palm fiber protection layer, a lower water-retaining agent layer, a seed center layer, an upper water-retaining agent layer, an upper palmfiber protection layer and a soft surface layer. The rapidly-assembled ecological planting module is convenient to produce, suitable in porosity, good water and moisture preservation performance and rapid to mount, sufficient growth space of plant root systems can be ensured by the aid of buffering and adjusting actions of long palm fibers, surviving and growing of the plants are facilitated, andthe soft attaching layer can ensure that the module adapts to mountain slopes with different surfaces.

Owner:NANJING DAYUAN ECOLOGICAL CONSTR GRP

Plant fiber reinforced polylactic acid composite material and preparation method thereof

The invention discloses a plant fiber reinforced polylactic acid composite material and a preparation method thereof. The plant fiber reinforced polylactic acid composite material comprises the following components in parts by weight: 12 to 26 parts of sisal fiber, 8 to 16 parts of kapok fiber, 5 to 19 parts of linen fiber, 6 to 18 parts of kenaf fiber, 2 to 7 parts of cotton fiber, 3 to 11 parts of palm fiber, 2 to 13 parts of bamboo fiber, 3 to 9 parts of coconut fiber, 3 to 14 parts of silicon dioxide and 22 to 45 parts of polylactic acid. The plant fiber reinforced polylactic acid composite material has the following advantages: (1) the interfacial property of the plant fiber and the polylactic acid of the plant fiber reinforced biodegradable composite material is high; (2) the composite material has high tensile strength and elongation at break.

Owner:苏州奥宇包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com