High-toughness full-degradable composite material

A composite material, fully degradable technology, applied in the field of high toughness fully degradable composite material and its preparation, can solve the problems of poor compatibility of matrix resin, strong hydrophilicity of plant fiber, etc., to expand the scope of application and improve the interface compatibility and the effect of interfacial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

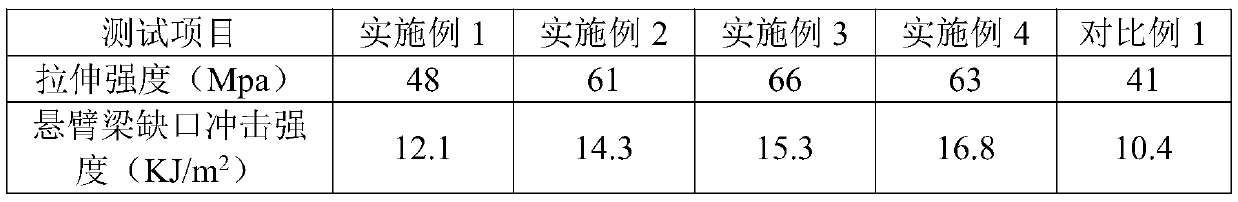

Examples

Embodiment 1

[0052] The composite material of the present embodiment is prepared by blending and preparing the following components in parts by weight: 100 parts of PLA; 10 parts of hydrophobic flax fiber; 1 part of polycaprolactone grafted maleic anhydride; 2 parts of stearic acid, and Prepare by following steps:

[0053] First, put the hydrophobic flax fiber, polycaprolactone grafted maleic anhydride, stearic acid into the low-speed mixer according to the proportion and mix for 2 minutes, then put the dried PLA into the low-speed mixer and mix for at least 3 minutes, among which the low-speed The rotating speed of mixer is 90-120 rev / min, obtains mixed material.

[0054] Secondly, put the mixture into a twin-screw extruder, set the extrusion temperature at 160-190°C, melt extrude and granulate to obtain slices of high-toughness fully degradable composite material.

[0055] The hydrophobic modification process of the hydrophobic flax fiber of the present embodiment comprises the steps: ...

Embodiment 2

[0062] The composite material of this embodiment is prepared by blending and preparing the following components by weight: 100 parts of PLA; 50 parts of modified palm fiber; 6 parts of polylactic acid grafted maleic anhydride; 3 parts of stearic acid, 1 part of KH570 . Among them, the modified palm fiber is obtained by sequentially hydrophobically modifying and coupling modifying the palm fiber, and then referring to the preparation process of the embodiment to obtain slices of high-toughness fully degradable composite materials.

[0063] Among them, the difference between the hydrophobic modification of the palm fiber in this example and Example 1 is that in this example, 30% KOH solution is used to weigh Na 2 SiO 3 , and configure a mass concentration of 30% Na 2 SiO 3 Solution, other is identical with embodiment 1, obtains hydrophobically modified palm fiber.

[0064] Wherein, the coupling modification process of the hydrophobically modified palm fiber of the present em...

Embodiment 3

[0069] The composite material of this embodiment is mainly prepared by blending and preparing the following components in parts by weight: 75 parts of PLA, 15 parts of PBAT, 10 parts of PCL, 30 parts of modified sisal fiber; 4 parts of polylactic acid grafted maleic anhydride ; 2 parts of stearic acid, 1 part of KH5701. Wherein, the modified sisal fiber is obtained by successively hydrophobic modification and coupling modification of the sisal fiber. The preparation process of this embodiment is the same as that of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com