Modified silica sol, and preparation method and application thereof

A silica sol and modification technology, which is applied in dyeing organosilicon compound treatment, fibrous filler, coating, etc., can solve the problems of inability to form uniform inorganic/organic composite materials, limit the application of silica sol, and easy agglomeration of silica sol. Achieve the effect of excellent hydrophilic performance, improved compatibility and enhanced hydrophilic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

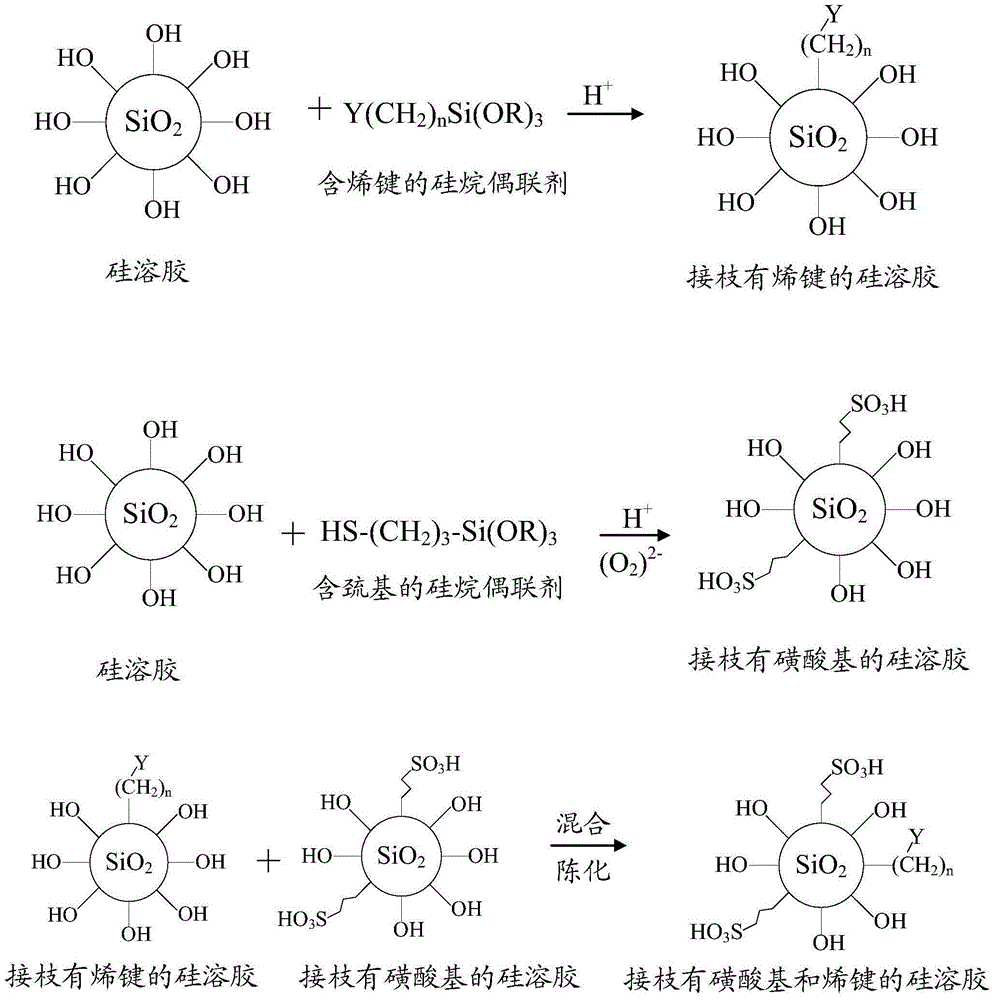

[0035] The invention provides a kind of preparation method of modified silica sol, comprises the following steps:

[0036] S100: preparing silica sol grafted with ethylenic bonds.

[0037] Preferably, as a possible embodiment, the preparation of the silica sol grafted with ethylenic bonds comprises the following steps:

[0038] S110, taking a certain amount of silica sol for activation treatment.

[0039] Since the silica sol is prone to agglomeration when standing still, preferably, before use, the silica sol needs to be activated to disperse the particles in the silica sol uniformly, so as to increase the uniformity of the subsequent reaction. As a possible implementation manner, the silica sol is activated in ultrasonic waves for 10 minutes to 60 minutes. In addition, other ways can also be used for activation, for example, the silica sol can be activated by heating or high-speed stirring.

[0040] It should be noted that the silica sol described in this step refers to u...

Embodiment 1

[0078] 1. Activate the silica sol by ultrasonic waves for 30 minutes, wherein the solid content of the silica sol is 5wt%, and the particle size of the silica particles in the silica sol is 5nm;

[0079] 2. Take the partially activated silica sol in step 1, adjust its pH value to 2.5 with acetic acid and stir under a nitrogen atmosphere, and add γ-(methacryloyloxy)propyltrimethoxysilane dropwise while stirring, The dropping time is 30min, wherein, the mass fraction ratio of the added γ-(methacryloyloxy)propyltrimethoxysilane to the solid content of the silica sol taken is 0.5:1; Stirring under a nitrogen atmosphere for 1 h, and then aging for 12 h at room temperature to obtain a silica sol grafted with ethylenic bonds;

[0080] 3. Take the partially activated silica sol in step 1, adjust its pH value to 3 with acetic acid and stir it under a nitrogen atmosphere, add γ-mercaptopropyltriethoxysilane dropwise while stirring, and the dropping time is 30 minutes , wherein, the mas...

Embodiment 2

[0084] 1. Activate the silica sol by ultrasonic waves for 20 minutes, wherein the solid content of the silica sol is 10wt%, and the particle size of the silica particles in the silica sol is 10nm;

[0085] 2. Take the partially activated silica sol in step 1, adjust its pH value to 3 with hydrochloric acid and stir under an argon atmosphere, and add γ-methacryloxypropyltriethoxysilane dropwise while stirring , the dropping time is 40min, wherein, the mass fraction ratio of the added γ-methacryloxypropyltriethoxysilane to the solid content of the silica sol is 0.8:1; Stirring under argon atmosphere for 3h, then aging at room temperature for 16h, to obtain silica sol grafted with ethylenic bonds;

[0086] 3. Take the partially activated silica sol in step 1, adjust its pH value to 4 with hydrochloric acid and stir it under an argon atmosphere, add γ-mercaptopropyltrimethoxysilane dropwise while stirring, and the dropping time is 40 minutes , wherein, the mass fraction ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com