Patents

Literature

73 results about "Flax fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flax (Linum usitatissimum L.) fibre is obtained from the stem of plants belonging to the family Linacea. The fibre is obtained from a blue flowered plant and woven into a fabric generally known as linen Flax is the designation given in English speaking countries to bast fibre from the plant Linum usitatissimum L. of the Linaceae family.

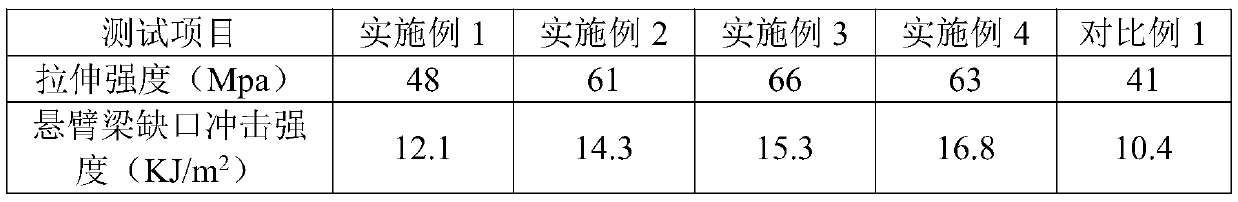

High-toughness full-degradable composite material

The invention provides a high-toughness full-degradable composite material, which is mainly prepared by blending the following components in parts by weight: 100 parts of biodegradable matrix resin; 1-60 parts of modified bio-based fiber; 1-8 parts of a compatilizer; 1-5 parts of a lubricant and 0-5 parts of a coupling agent; wherein the biodegradable matrix resin is one or a composition of more than two of PBAT, PCL, PLA, PBS, PBSA, PPC, PBST, PHB, PHA, PVA and PHBV, wherein the modified bio-based fiber comprises hydrophobic modification of the bio-based fiber or / and coupling modification ofthe bio-based fiber, the bio-based fiber is fibrilia, and the fibrilia is one or more of hemp fiber, flax fiber, sisal fiber and palm fiber. The modified plant fiber disclosed by the invention has a remarkable reinforcing and toughening effect on the bio-based matrix resin, and the interface compatibility and the interface bonding force of the modified plant fiber and the bio-based matrix resin are improved.

Owner:佰信(福建)新材料科技有限公司

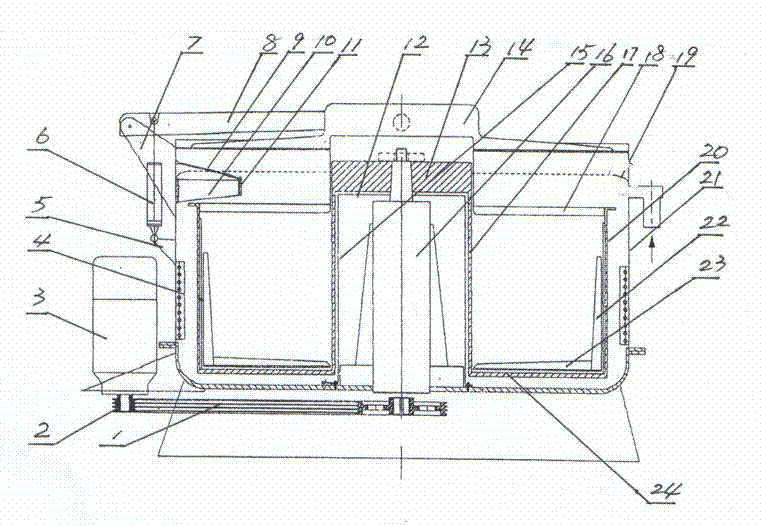

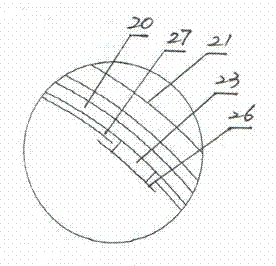

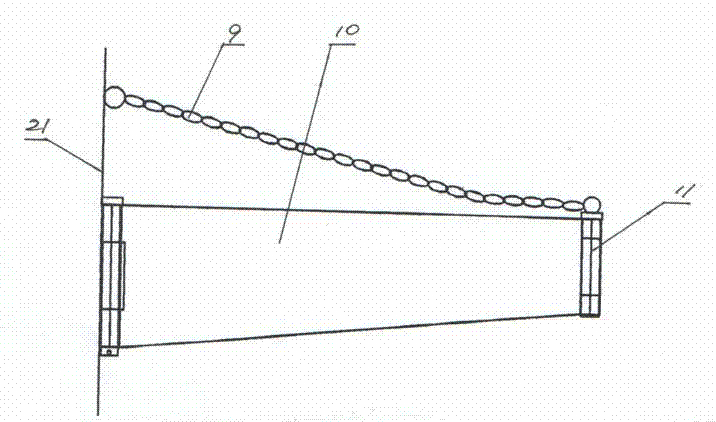

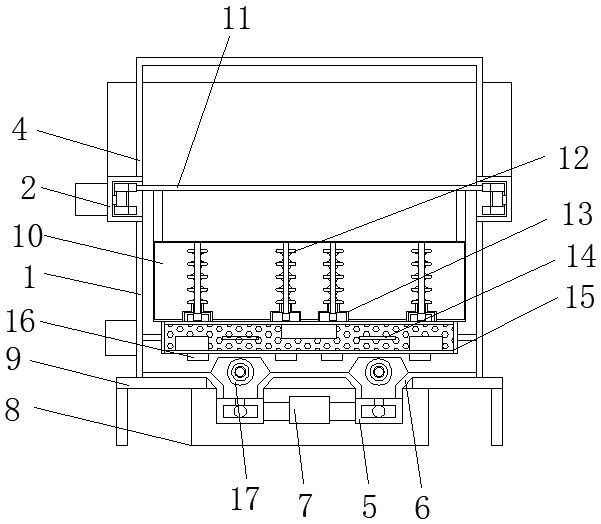

Multifunctional dehydrator

InactiveCN102517823AQuality improvementEasy to separateTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsFiberEngineering

The invention relates to a multifunctional dehydrator, which comprises a cylinder. A cylinder cover is arranged at an upper opening of the cylinder. The bottom of the cylinder is provided with a center hole, and a spindle is arranged in the center hole. The lower end of the spindle extends out of the bottom of the cylinder, a power mechanism is arranged outside the cylinder, and the lower end of the spindle is connected with an output shaft of the power mechanism through a pulley and a transmission belt. A rotary cage is arranged in the cylinder, and a space is reserved between an inner cylinder of the rotary cage and the spindle while another space is reserved between an outer cylinder and the cylinder. A support board is connected to the upper end of the inner cylinder, and the upper end of the spindle is connected with the support board. An annular cage cover is arranged at the upper end of the rotary cage and is a meshed cage cover. The multifunctional dehydrator is characterized in that a sleeve for water proofing and heat insulation is arranged in the inner cylinder, and the lower end of the sleeve is hermetically connected with the bottom of the cylinder. A heater is arranged between the cylinder wall of the cylinder and the outer cylinder of the rotary cage. The dehydrator is multifunctional and used for treating linen fibers, quality of linen fiber products can be improved, and high loss of short staples is avoided. The multifunctional dehydrator is applicable to boiling, bleaching, washing and dehydrating of the linen fibers.

Owner:WUXI QIANZHOU YAODA MACHINERY FACTORY

Complex enzyme generated by aspergillus niger and application thereof in boiling-off of flax roving

InactiveCN101805725ANo toxicityStrong pectinase activityHydrolasesBiochemical fibre treatmentYarnFiltration

The invention discloses a complex enzyme generated by aspergillus niger. The complex enzyme is prepared by taking aspergillus niger HYA4 with the preserving number of CGMCCNo.1897 as a strain through incline preservation and culture, solid fermentation and culture and leaching filtration and preparation, wherein a culture medium for the solid fermentation comprises bran, straw powder and ammonium sulfate; and the invention has the advantages that the used aspergillus niger HYA4 strain is at a food safety level and has no toxicity, large enzyme yield, complete enzyme system and more extensive culture condition. The cultured complex enzyme not only has very strong pectinase activity but also has very strong cellulase activity. The used complex enzyme can enhance the split degree of flax fibre, reduces nep and hair feather obviously, lowers the strength loss of yarn, also solves injuries caused by a chlorine bleach process to a worker and the environment thoroughly and has multiple advantages of saving water and electricity, reducing the treatment cost of sewage, lowering the production cost and the like.

Owner:QIQIHAR UNIVERSITY

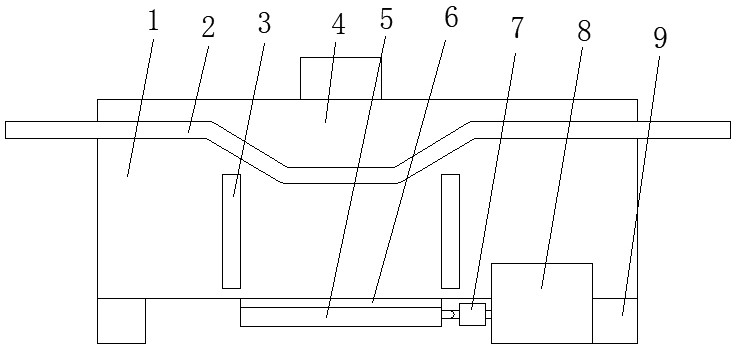

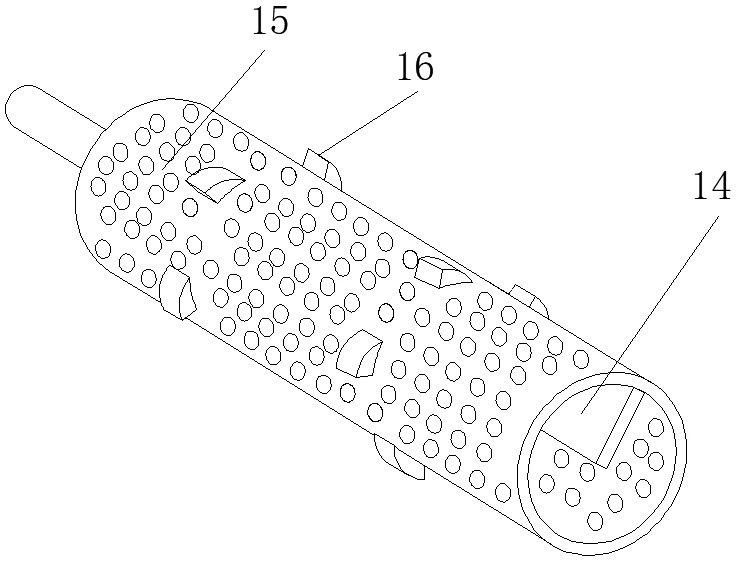

Linen fiber bleaching device for textile production

InactiveCN111826839AImprove bleaching efficiencyReduce lossTextile treatment machine arrangementsTextile treatment carriersFlax fibrePulp and paper industry

The invention discloses a linen fiber bleaching device for textile production and relates to the technical field of textile production. In order to solve the problem that the bleaching time is difficult to control and linen fibers are easy to damage when the linen fibers are soaked in a solution to be stirred, the linen fiber bleaching device specifically comprises a shell, a plurality of supporting frames are fixedly installed at the bottom of the shell, driving mechanisms are fixedly installed on the two sides of the top of the shell, a capping mechanism is fixedly installed between the topends of the two driving mechanisms, and bleaching sections extending downwards are arranged in the middle sections of the driving mechanisms. According to the linen fiber bleaching device for textileproduction, a bleaching solution is in contact with a heating mechanism when being sprayed out; the linen fibers are heated and cooked; the linen fiber bleaching efficiency is improved; the linen fibers are drained; a bleaching solution is recycled; the loss of the solution is reduced; the situation that the working environment is affected due to solution dripping is avoided; raw materials can becontinuously bleached due to the fact that the raw materials enter from one end and exit from the other end, and the linen fiber bleaching processing efficiency is improved.

Owner:宣城红妆美人床上用品有限公司

Flax fibre modifying method

InactiveCN1584183AImprove dyeing effectLoose arrangementPhysical treatmentFlax fibreMaterials science

This invention publishes the method of color flax fibre. A kind of character-change flax fibre: (1.) Put the flax fibre into 50-300g per L carbamide liquid. After endosmosis, put it out. (2) Heat the flax fibre in 300-400w micro-wave oven for 1-4 minutes. (3) Heat the flax fibre in the 600-hange the flax fibre. The color deepness can rise by 6%. (4) The flax fibre after character-change, the face will become coarse, it shows the face of some fibre molecule is cloven, and the face of other fibre molecule appears floss. So the fibre is a little loose, and it is dasy to be 800w imcro-wave oven for 0.5-3 minutes. The availability of the invention is: After character-c colored and character-change, the mechanics capability is not changed.

Owner:HEILONGJIANG UNIV

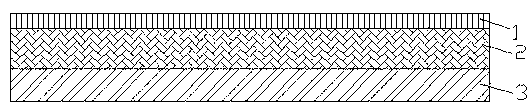

Waterproof anti-static fabric

InactiveCN102990993APrevent intrusionProtection securityLayered productsWoven fabricsFlax fibrePolymer science

The invention discloses a waterproof anti-static fabric. The fabric comprises a superficial waterproof layer, an anti-static layer under the waterproof layer and a moisture-absorbing permeable layer under the anti-static layer; the waterproof layer is structured by waterproof permeable films; the anti-static layer is structured by interweaving warps and wefts; the warps are formed by blending and weaving carbon fibers and linen fibers; the wefts are formed by blending and weaving polythiophene conductive fibers and viscose fibers; and the moisture-absorbing permeable layer is formed by weaving mercerized cotton fibers. The surface layer uses one-way waterproof permeable films from inside to outside; the inner moisture is released; the water is prevented from invading; the anti-static layer can prevent the generation of static electricity and protects the safety of human body; the inner layer is formed by weaving the mercerized cotton fibers; and the waterproof anti-static fabric can absorb moisture and breathe, is soft and comfortable and keeps human body surface dry, comfortable and clean.

Owner:常熟市东鑫经纬编织造有限公司

Method for producing pure flax woven or knitted fabrics spun with cotton flax

The invention discloses a method for producing pure flax woven or knitted fabrics spun with cotton flax. The method comprises the following steps: (1) taking the cotton flax and water-soluble polyvinyl alcohol fibers with the fineness of 1.5D38mm and fully mixing the cotton flax with the water-soluble polyvinyl alcohol fibers; (2) carrying out picking, carding, first drawing, second drawing, roving, spinning, automatic spooling and baling on the mixture to produce the woven or knitted fabrics; and (3) carrying out defibering on the woven or knitted fabrics, firstly weaving the woven or knitted fabrics into a woven or knitted cloth and then putting the woven or knitted cloth in the water at the temperature of 95-100 DEG C to be hydrolyzed to dissolve out the water-soluble polyvinyl alcohol fibers, thus producing the pure flax woven or knitted fabrics. The method has the following beneficial effects: the produced pure flax woven or knitted fabrics have good handfeel, broaden the application of the raw flax, provide a new flax spinning method and greatly improve the production efficiency of the following procedures.

Owner:TONGLING DELILAI SPINNING

Composite material containing renewable raw materials and method for the production thereof

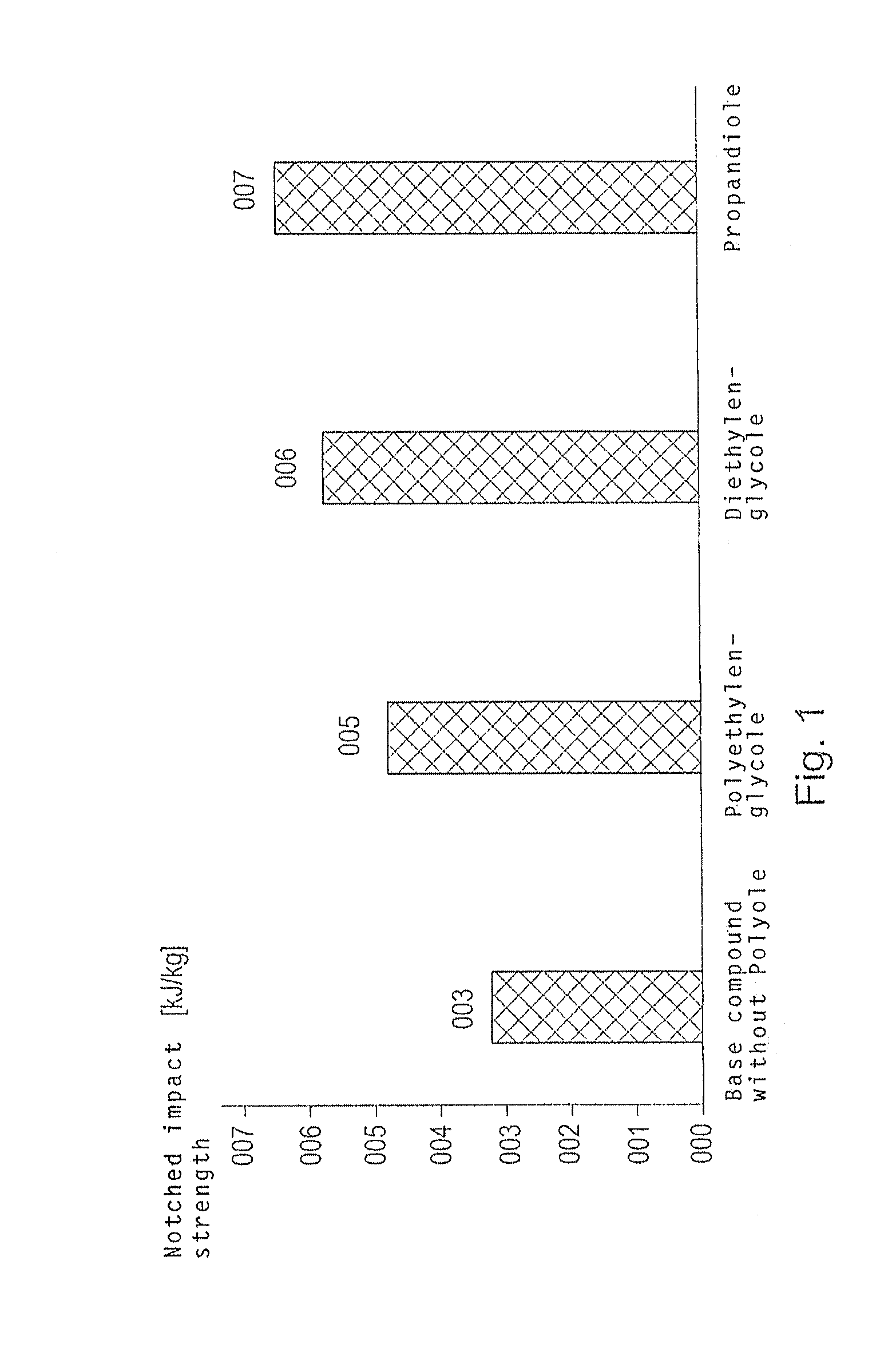

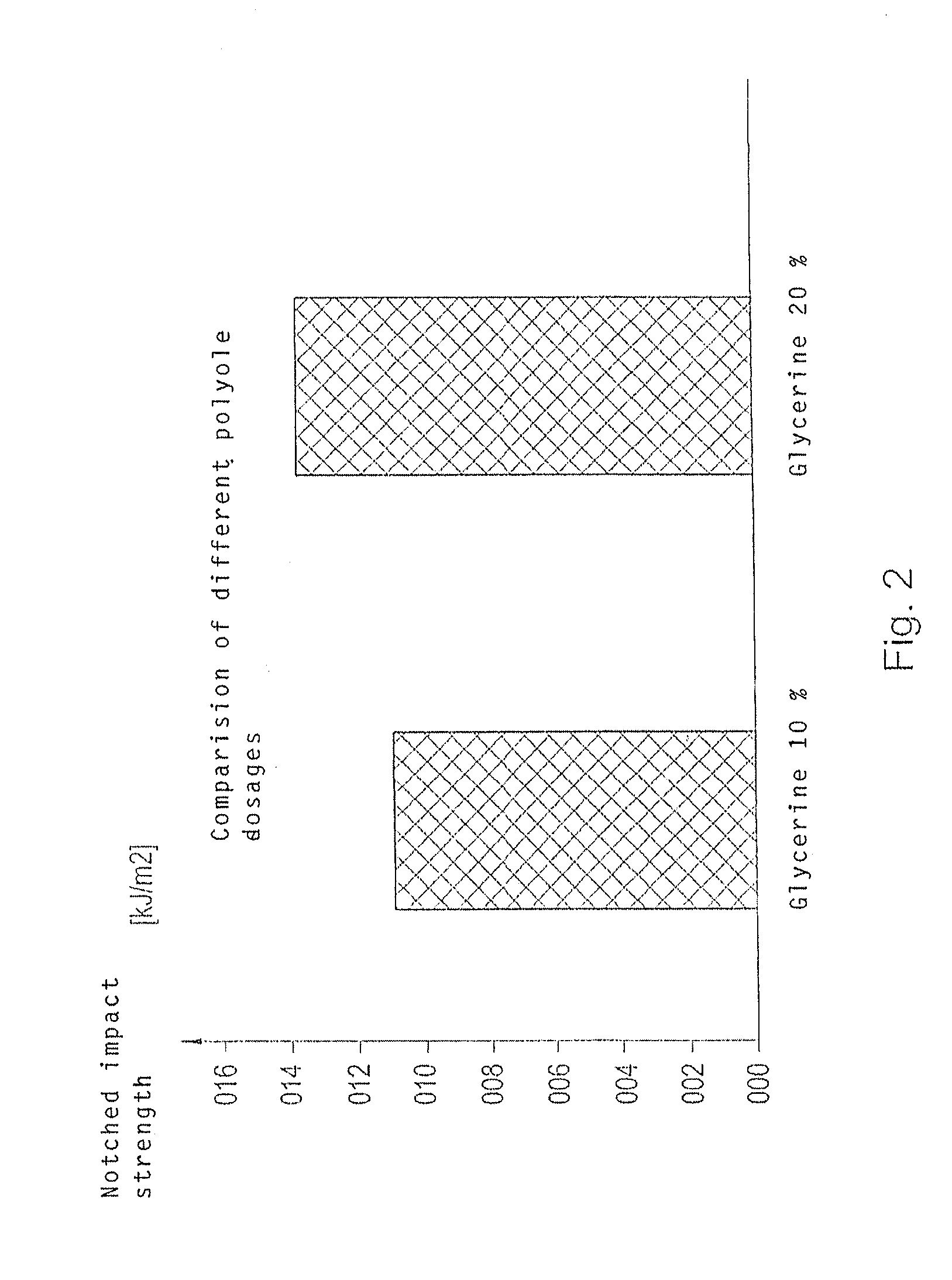

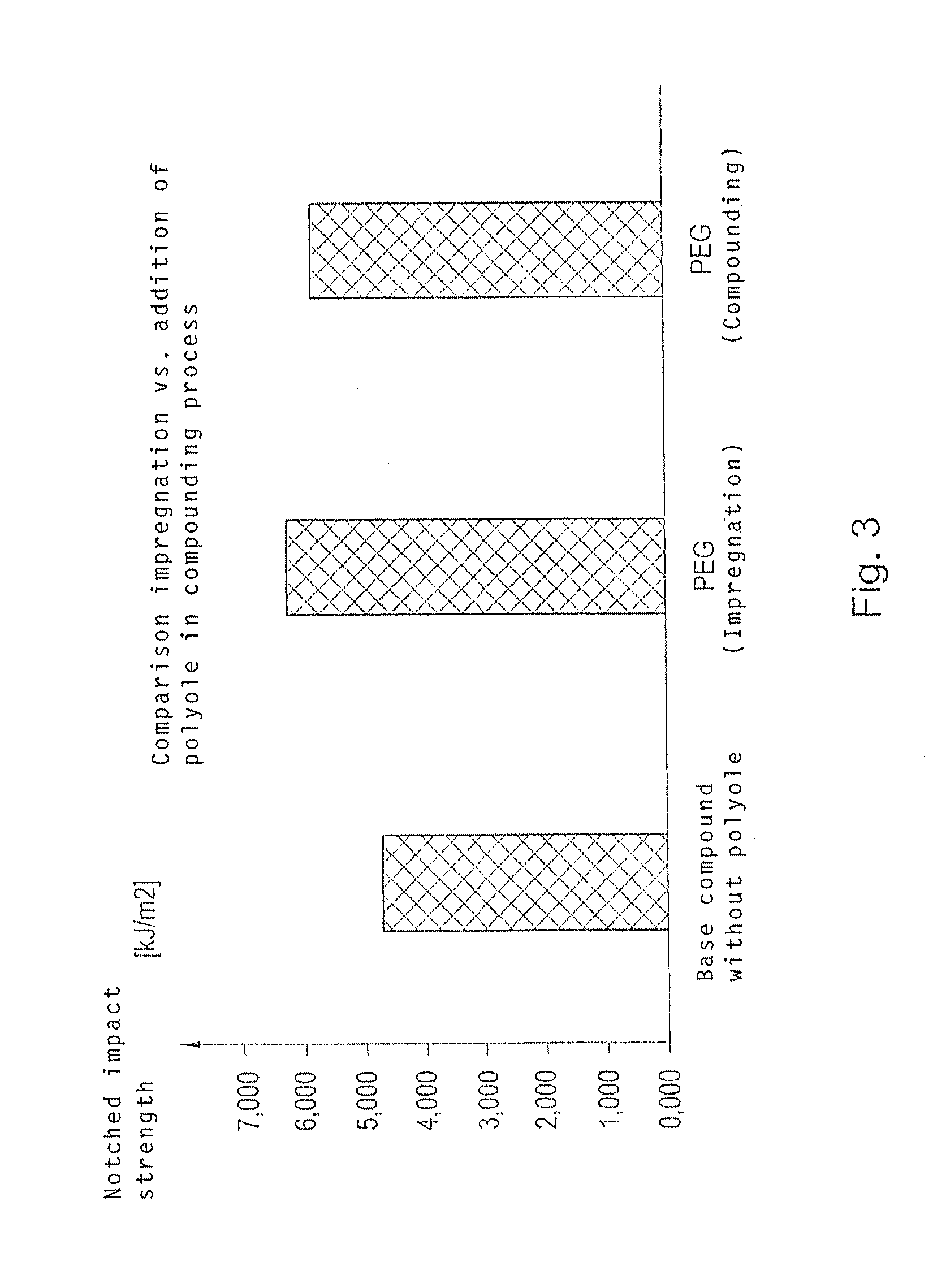

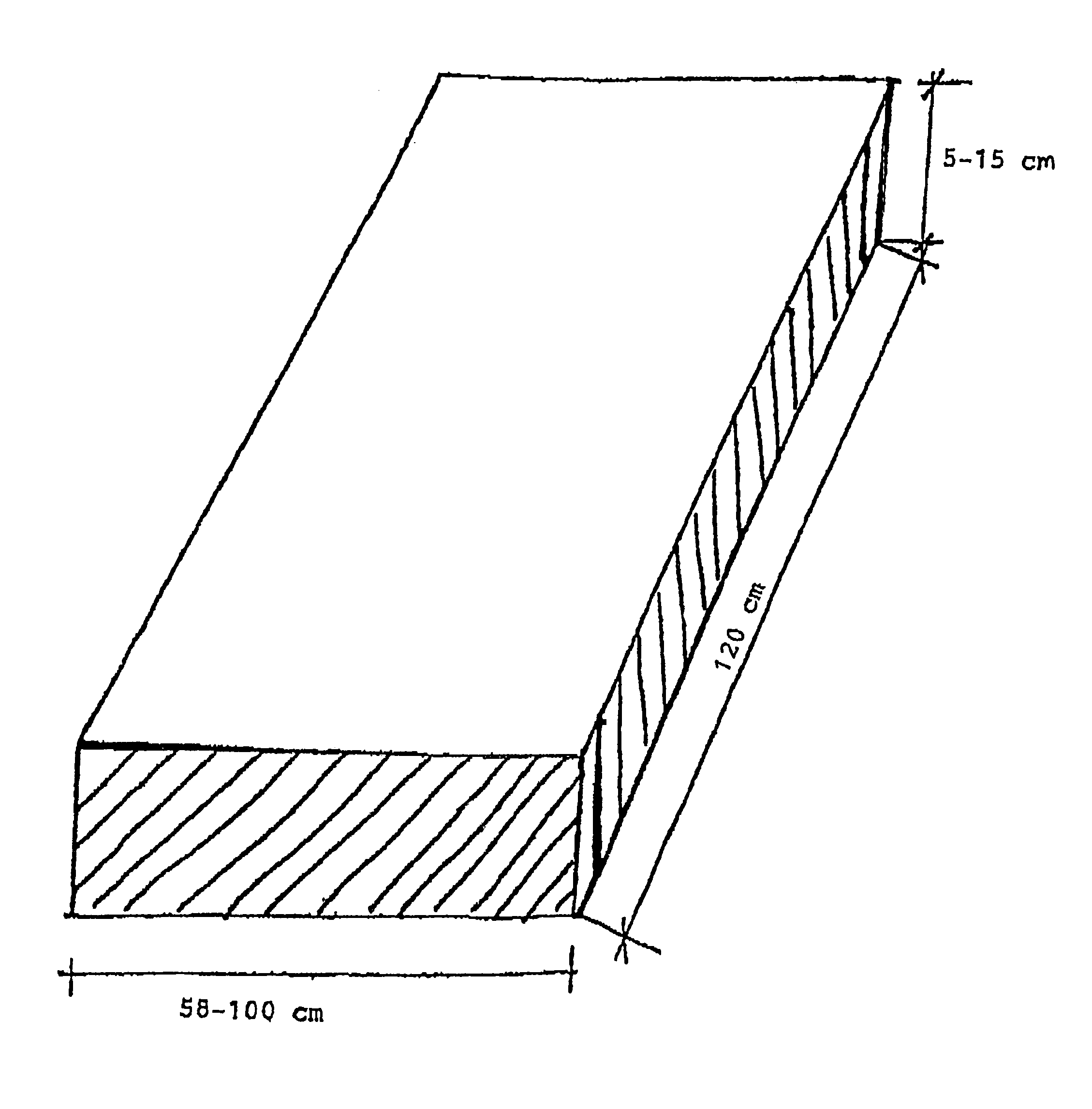

InactiveUS20150291784A1High impact strengthIncreased expansion and expandabilityWood treatment detailsFlax fibrePolymer science

A composite material made of a plastic base material with particles or fibres of renewable raw materials such as wood fibres, abaca, cellulose fibres, regenerated cellulose fibres, hemp fibres or flax fibres embedded therein and optionally a bonding agent, also contains a wetting agent selected from a polyethylene glycol with an average molecular weight of 90 to 40,000 and / or a polyvalent alcohol.

Owner:MONDI GROUP

Antibacterial folding fabric of radiation-proof clothes for pregnant women

InactiveCN103989276ANice appearanceImprove breathabilityProtective garmentSpecial outerwear garmentsFlax fibreYarn

The invention provides antibacterial folding fabric of radiation-proof clothes for pregnant women. The antibacterial folding fabric is composed of an inner radiation-proof fabric layer and an outer folding fabric layer. The radiation-proof fabric is made of blending yarns of nano-silver fibers, linen fibers and bamboo fibers, and the folding fabric is made of blending yarns of linen fibers and bamboo fibers. The antibacterial folding fabric of radiation-proof clothes for pregnant women has the following technical advantages that the fabric is formed by compounding the folding fabric and the radiation-proof fabric, so that the fabric has the radiation-proof function and the advantage of being attractive appearance, and the clothes made of the fabric has good breathability and is not prone to sticking to the body; the fabric has good antibacterial performance due to the linen fibers and the bamboo fibers.

Owner:NANTONG HUANYU SILK

Linen-fabric anticorrosive and antibacterial treatment process

The invention discloses a linen-fabric anticorrosive and antibacterial treatment process. The process specifically includes the steps of 1), selecting warp and weft materials including linen fibers, silkworm protein fibers, soft silk fibers and the rest of cotton fibers, boiling off linen fabric at normal pressure prior to cyclically washing the linen fabric with hot water and cold water and cleaning the same with the cold water; 2), performing immersion treatment on the linen fabric and then washing the same for 6-8 times; 3), treating the linen fabric in a solution containing sodium hydrogen sulfate and glacial acetic acid and then washing the linen fabric for 6-8 times; 4), immersing the linen fabric in a softening agent solution for treatment and drying. The linen-fabric anticorrosive and antibacterial treatment process is simple and easy to operate, safe, environment friendly and pollution free, and raw materials for treatment are easy to obtain; the linen fabric after treatment is good in anticorrosive and antibacterial performance, insect resisting and moth proofing and long in service life.

Owner:SUZHOU JIN YUAN OIL MACHINERY

Jute/flax/cotton blended yarn

A jute / linen / cotton blended yarn comprises three types of fiber of jute, linen and cotton and is characterized in that the weight of the linen fiber accounts for 10-40 percent by weight of the total weight of the jute, the linen and the cotton fiber. The fineness difference between the linen fiber and the jute fiber and the fineness difference between the linen fiber and the cotton fiber are both small. When being blended, the linen fiber of the blended yarn can be cohered with the jute fiber and can also be cohered with the cotton fiber, thereby enhancing the cohesion among different types of fiber; and the spun blended yarn has better breaking strength. The invention discloses the content range of the added linen fiber which can lead the breaking strength of the yarn to be more satisfactory during the blending of the jute fiber / cotton fiber with different weight percentages.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Environmentally friendly insulating material and method for manufacture thereof

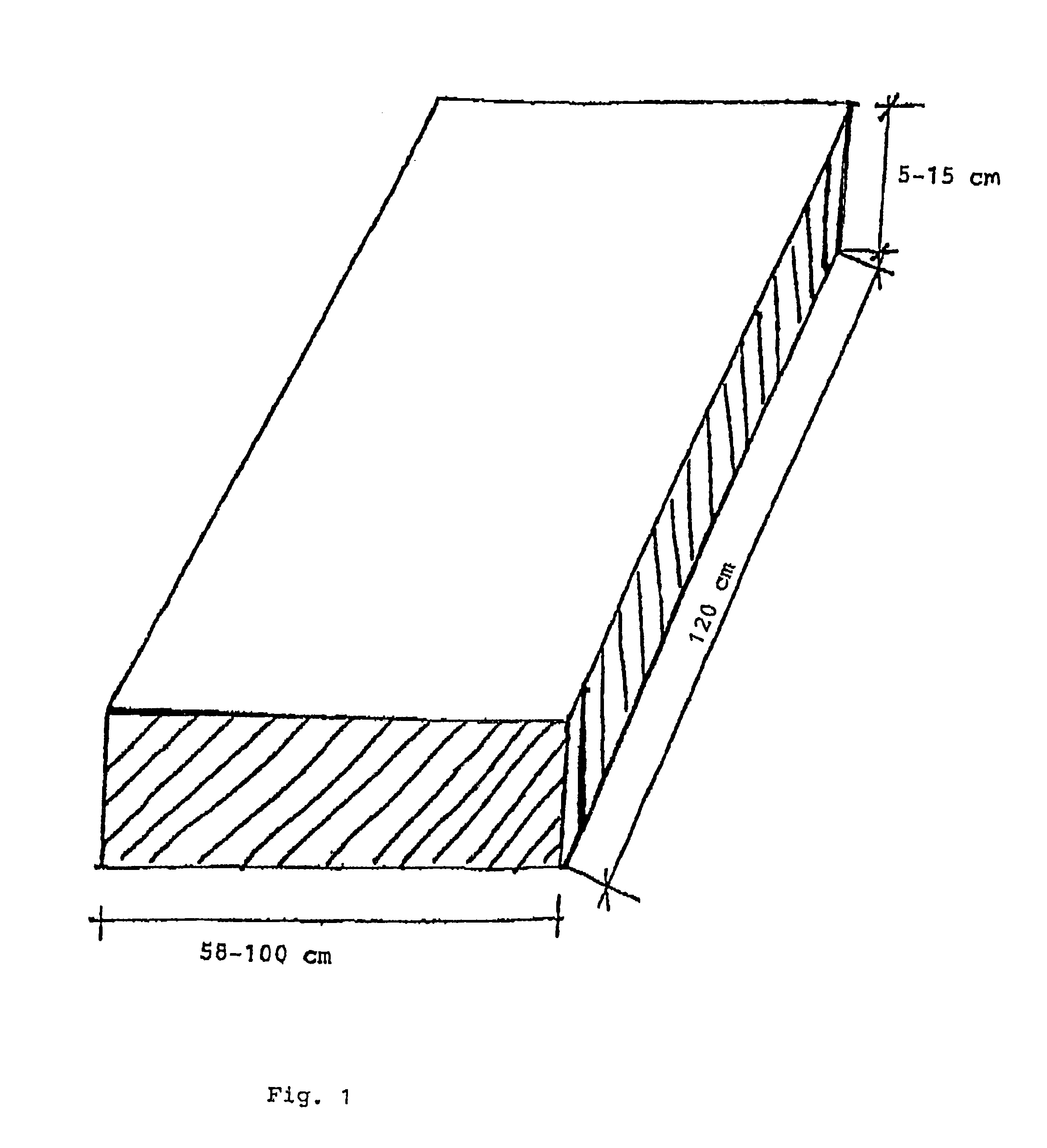

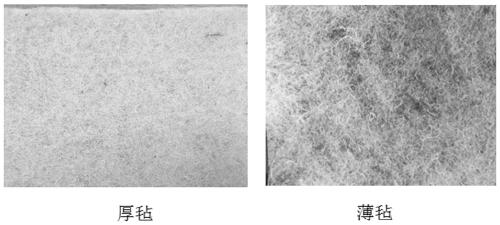

InactiveUS7014804B2Good flexibilityCheap and long and strongConstruction materialClimate change adaptationFlax fibrePolyester

This invention relates to an environmentally friendly insulating material, or more specifically an insulating mat for insulating buildings, houses etc. and a method for the manufacture thereof. The mat is non-allergenic and almost 100% recyclable, and is characterized in that it consists of fabric remnants which are shredded into shoddy, mixed with a fibrous polyester with a low melting point and flax fibres to form a homogeneous mass, which is then moulded into the desired shape and then heat-treated until the polyester fibres melt, bonding the fabric and flax fibres together.

Owner:JOHANSEN FRIDTJOV

Rapid qualitative filter paper and preparation method thereof

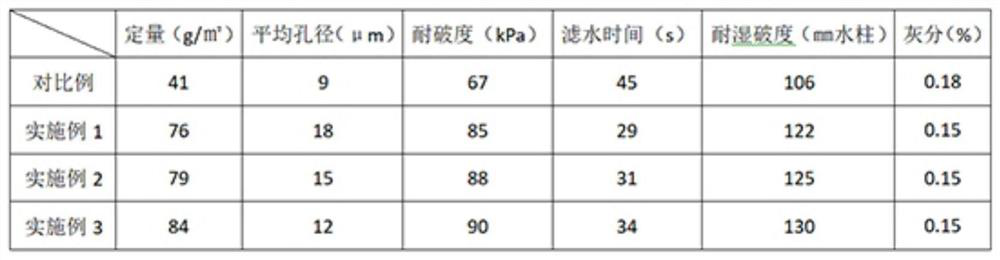

PendingCN113293648AHigh strengthImprove toughnessDryer sectionReinforcing agents additionFlax fibrePlant fibre

The invention relates to the technical field of filter materials, and discloses high-performance rapid qualitative filter paper and a preparation method thereof. The filter paper comprises 40-100 parts of mixed pulp of alkali-treated cotton linter pulp and alkali-treated cotton linter pulp; 40-100 parts of softwood pulp; 20-50 parts of mixed plant fiber; 2-5 parts of viscose fiber; 2-5 parts of a water-soluble phenolic resin; and 2-5 parts of polypropylene fiber. The mixed plant fibers comprise one or a combination of more of bamboo fibers, pineapple fibers, jute fibers, coconut fibers, psyllium fibers, straw fibers, linen fibers and Chinese alpine rush pulp. According to the invention, the high-performance rapid qualitative filter paper and the preparation method thereof have the beneficial effects that the high-performance rapid qualitative filter paper has high strength and good toughness, is not easy to damage in a suction filtration process, does not influence a final separation measurement result, and is convenient to use and environment-friendly.

Owner:杭州特种纸业有限公司

Rice seedling raising film

InactiveCN111296126AHigh light transmittanceImprove lighting conditionsClimate change adaptationGreenhouse cultivationFlax fibreSeedling

The invention discloses a rice seedling raising film, which is composed of the following components: linen fiber, hemp fiber, an adhesive and a pigment, and the pigment is a plant pigment. According to the rice seedling raising film, the plant pigment is added, the seedling raising film turns blue, the light transmittance is higher than that of a common film under the weak illumination condition and lower than that of the common film under the strong illumination condition, and therefore the optimal illumination condition can be guaranteed for rice seedlings, the plant pigment is harmless, andrice cannot be affected.

Owner:山东华农塑料制品有限公司

Linum usitatissimum planting method

InactiveCN107493947ASolve outputSolve quality problemsPlant cultivationCultivating equipmentsFlax fibreBiology

The invention relates to the technical field of flax planting, in particular to a planting method of flax, comprising the steps of selecting seeds, seed disinfection, drilling, fertilizing, weeding, harvesting and the like. Among them, timely harvesting is the key to ensure the high yield of flax and the quality of fiber. Harvest too early, then the flax fiber is not mature enough, the rate of hemp production is low, the strength is poor, and the harvest is too late, then the hemp stem is easy to dry, the fiber is thick and hard, the degree of splitting is low, and the fiber output is reduced. On the basis of seed disinfection, reasonable sowing and fertilization, and timely weeding, scientifically and accurately determine the harvest time and strictly control the progress of harvest, effectively solving the problems of low flax yield, low fiber quality, and poor strength in the past. The method of the invention is scientific and reasonable, the method is simple and effective, can significantly improve the flax output and fiber quality, and the flax fiber produced from the seed value has high maturity and soft fiber, and can meet the high requirements of the flax used for fiber in the market.

Owner:容县科学实验研究所

Special tool fabric capable of resisting static aggregation

ActiveCN113355787AGood electrical resistanceImprove performanceWoven fabricsVegetal fibresFlax fibreGraphene

The invention provides a special tool fabric capable of resisting static aggregation. The special tool fabric is characterized by comprising the following raw materials in parts by weight of 40-50 parts of linen fibers, 15-25 parts of bamboo fibers, 5-10 parts of an antistatic modifier, 3-6 parts of modified talcum powder and 1-5 parts of bentonite powder. The preparation method of the antistatic modifier is shown in the specification. The tool fabric is prepared from the linen fibers, the bamboo fibers and other raw materials, and the anti-static performance of the fabric is improved by adding the anti-static modifier, the modified talcum powder and the bentonite powder; and the antistatic modifier is modified by graphene and then is mixed with composite powder, and the antistatic performance of the antistatic modifier is improved through the assistance of nano zeolite powder.

Owner:YI HE STOCK

Production method of moisture-absorbing sweat-releasing breathable elastic knitted fabric

ActiveCN111020833AImprove moisture absorptionHigh moisture regainWeft knittingWarp knittingFlax fibrePolymer science

The invention relates to a production method of a moisture-absorbing sweat-releasing breathable elastic knitted fabric. Before linen fibers and other fibers are twisted together, dewaxing treatment iscarried out; removing natural oil wax on the outer surface of the linen fibers; hydromica and kaolinite powder are used for preparing a solution in the preparation process; adding CaO to the solution, soaking the linen fibers in the solution, performing clear water padding, and a hydromica coating layer is attached to the outer surface of the linen fibers; and hydromica has a relatively high moisture regain rate so that the moisture absorption function of the linen fibers can be obviously improved and the prepared fabric has a moisture absorption function. The added substances are free of toxic and side effects and suitable for supporting clothes, the wool fibers and the cotton fibers have good air permeability, the obtained fabric can have good perspiration and ventilation functions, andthe polyurethane fibers have good elasticity and thus the obtained fabric has good elasticity.

Owner:福建省新宏港纺织科技有限公司

Linen composite fiber and preparation method thereof

InactiveCN104313794AHigh tensile strengthGood wear resistance and pressure resistanceNon-woven fabricsAdhesivesTextile fiberFlax fibre

The invention relates to linen composite fiber and a preparation method thereof, and belongs to the technical field of production of textile fiber materials. The linen composite fiber comprises the following components in parts by weight: 5 to 95 parts of polyester fiber or three-dimensional hollow or hot-melt fiber and 5 to 95 parts of linen fiber. The preparation method comprises sieving, mixing, coiling, carding to form a net, thermal treatment, cooling and the like. The linen composite fiber has the advantages of high tensile strength and wearing and compression resistance, excellent water absorption, softness and uniformity and the like. The preparation method is simple in technology, lower in production cost and suitable for industrial production.

Owner:宋进清 +1

Low-speed qualitative filter paper and preparation method thereof

PendingCN113293649AHigh strengthImprove toughnessPulp beating methodsDryer sectionFlax fibrePlant fibre

The invention relates to the technical field of filter materials, and discloses slow qualitative filter paper and a preparation method thereof. The slow qualitative filter paper comprises 30-80 parts of mixed pulp of alkali-treated cotton linter pulp and alkali-treated cotton linter pulp; 40-80 parts of mixed pulp of softwood pulp and hardwood pulp; 20-50 parts of mixed plant fiber; 20-40 parts of viscose fiber; 2-5 parts of a water-soluble phenolic resin; and 2-5 parts of polypropylene fiber. The mixed plant fibers comprise one or a combination of more of bamboo fibers, pineapple fibers, jute fibers, coconut fibers, psyllium fibers, straw fibers, linen fibers and Chinese alpine rush pulp. According to the invention, the low-speed qualitative filter paper and the preparation method thereof have the beneficial effects that the low-speed qualitative filter paper has high strength and good toughness, is not easy to damage in a suction filtration process, does not influence a final separation measurement result, and is convenient to use and is environment-friendly.

Owner:杭州特种纸业有限公司

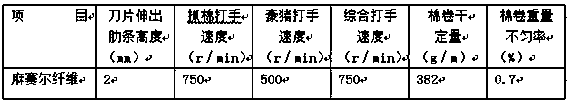

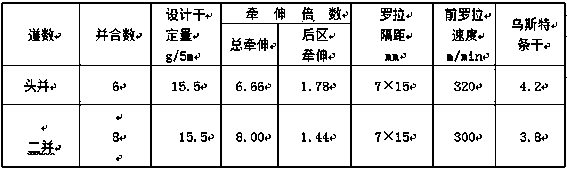

Processing technique for linen stretch fabric suitable for underwear

The invention discloses a processing technique for a linen stretch fabric suitable for underwear. The processing technique comprises the following specific steps: linen raw material processing, linen yarn production and linen fabric weaving, wherein the linen raw material process comprises: respectively spraying a softening agent on second rough linen raw materials in layers in two times, storing the sprayed linen raw materials, and removing impurities from the linen raw materials; the linen raw yarn production comprises: mixing processed linen fibers with functional fibers; the linen fabric weaving comprises a fore-spinning technique and a post-spinning technique, the fore-spinning technique is processed through a carding machine and a drawing frame, and the post-spinning technique is processed through a roving frame, a spinning frame and a winding machine. According to the processing technique for the linen stretch fabric suitable for the underwear, moisture absorption, perspiration and bacteriostasis effects of linen are retained, and meanwhile, advantages of functional-fiber fabrics are exerted to overcome a poor shaping performance disadvantage of the linen. Therefore, the produced linen stretch fabric is soft and comfortable without the rough feeling, and the underwear made by the produced linen stretch fabrics has effects of tight fitting, comfortableness, good shaping performance, moisture absorption, moisture transferring and bacteriostasis.

Owner:刘本志

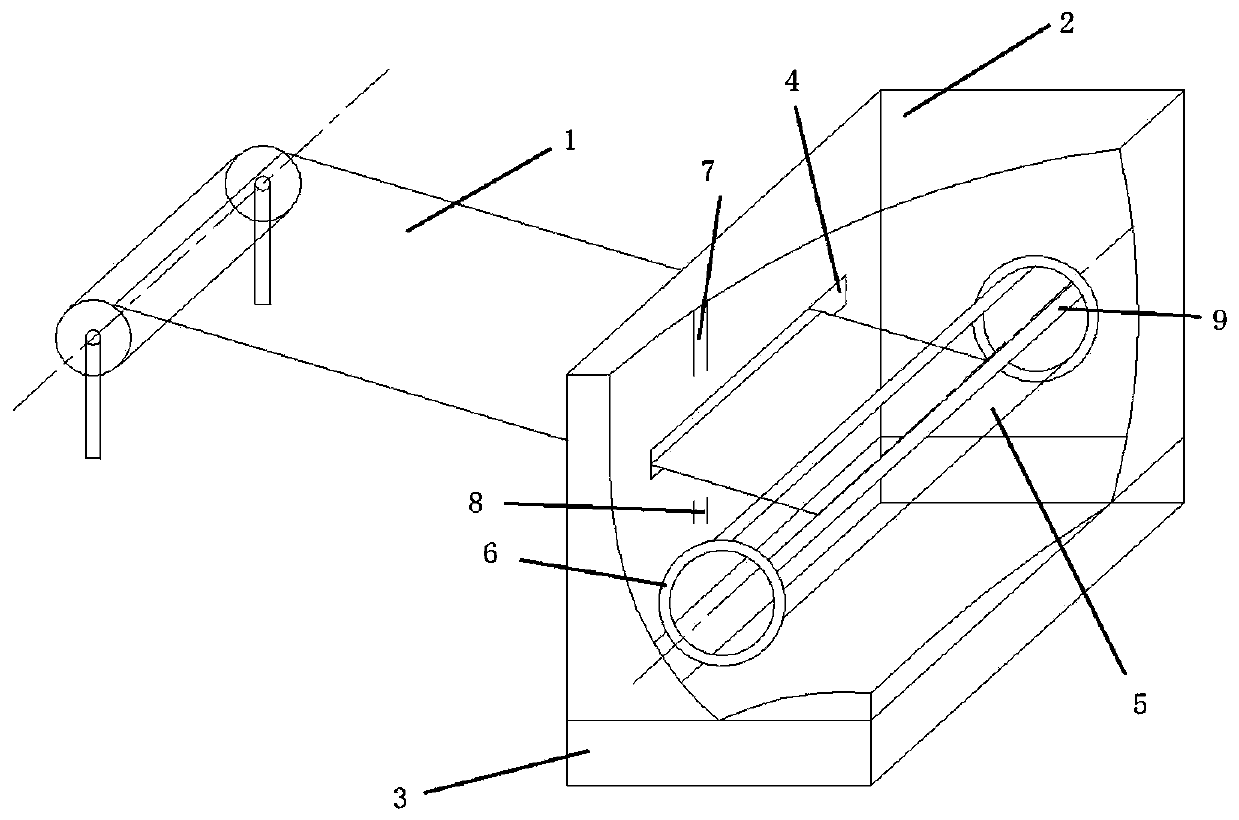

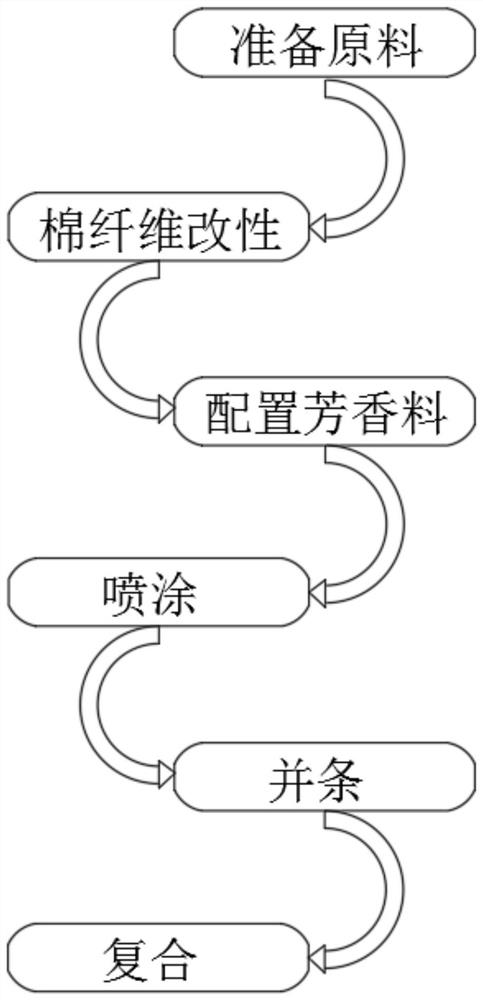

Composite spinning process of antibacterial aromatic yarn

PendingCN114457481AHigh cationic degreeImprove adsorption capacityYarnVegetal fibresActivated charcoal powderYarn

The invention relates to the technical field of composite spinning, and discloses a composite spinning process of antibacterial aromatic yarn, comprising the following steps: S1, preparing raw materials including 20-50 parts of cotton fiber, 15-35 parts of linen fiber and 5-20 parts of copper fiber; s2, cotton fiber modification: uniformly mixing polyallylamine, NaOH and a reaction medium to form a reaction solution, adding cotton fibers into the reaction solution, and washing the cotton fibers to be neutral after treatment to obtain cationic cotton fibers; s3, preparing an aromatic material: putting an aromatic agent, diatomite and activated carbon powder into a mixing tank, and mixing to obtain a mixed solution A for later use; the final composite spun yarn integrates the linen fibers, the cotton fibers and the copper fibers, the obtained composite spun yarn is high in strength and excellent in moisture absorption and air permeability, the antibacterial performance is improved by adding the copper fibers and the linen fibers, the aromatic and the cotton fibers can be bonded more firmly, and the durability of aroma is improved.

Owner:福建金浩盛纺织科技有限公司

Glass ceramic with high mechanical strength

A glass ceramic with high mechanical strength is prepared from the following raw materials in parts by weight: 6-9 parts of feldspar powder, 4-8 parts of potassium nitrate, 5-10 parts of potassium permanganate, 3-8 parts of zinc oxide, 5-11 parts of BaSO4, 5-8 parts of aluminum hydroxide, 2-6 parts of light stabilizer, 6-10 parts of hydroxyethyl cellulose, 3-8 parts of perlite, 4-10 parts of bamboo powder, 3-6 parts of filler, 5-9 parts of lead acetate, 1-5 parts of zirconium acetate, 6-8 parts of ceramsite powder, 3-9 parts of silica sand, 5-11 parts of coal gangue powder, 2-6 parts of silicon oxide, 1-5 parts of linen fiber and 4-10 parts of crosslinking modifier. The glass ceramic with high mechanical strength has the benefits of great mechanical strength, great chemical stability, uniform granules and great performance.

Owner:QINGDAO KELIKE INFORMATION TECH

Antibacterial blended fabric and preparation method thereof

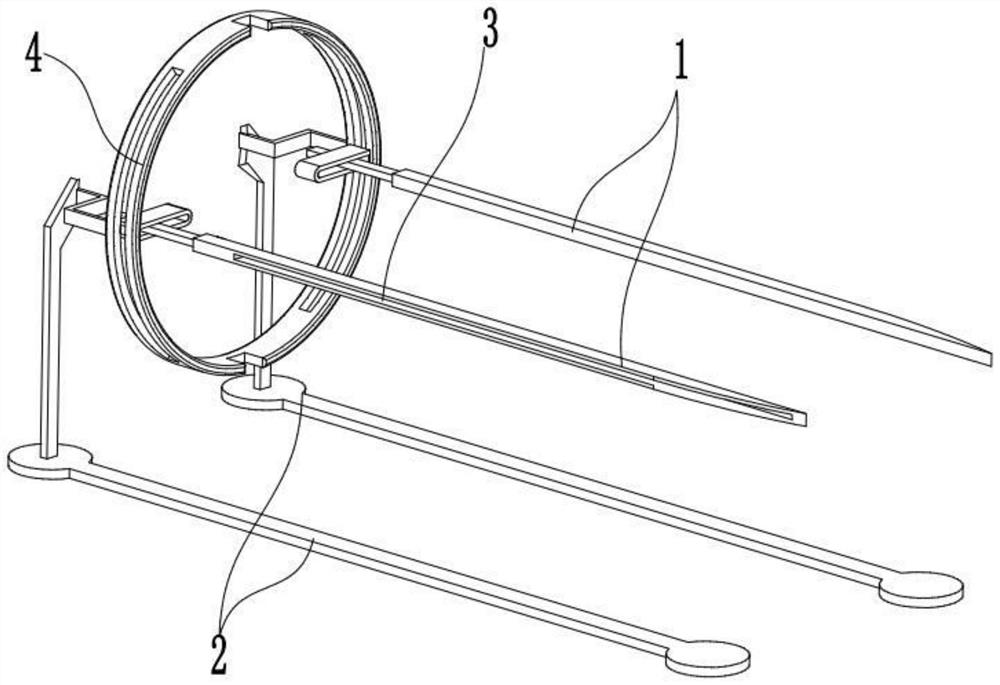

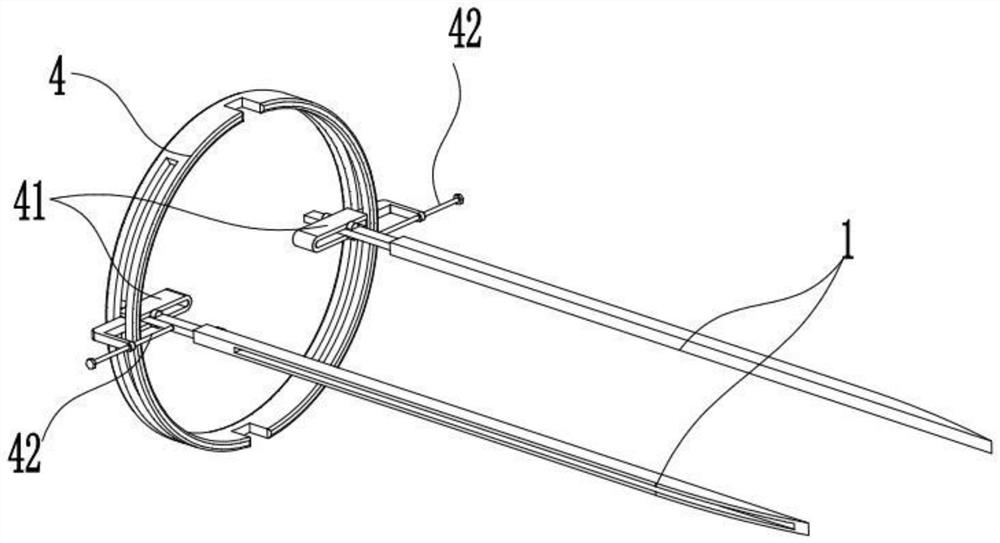

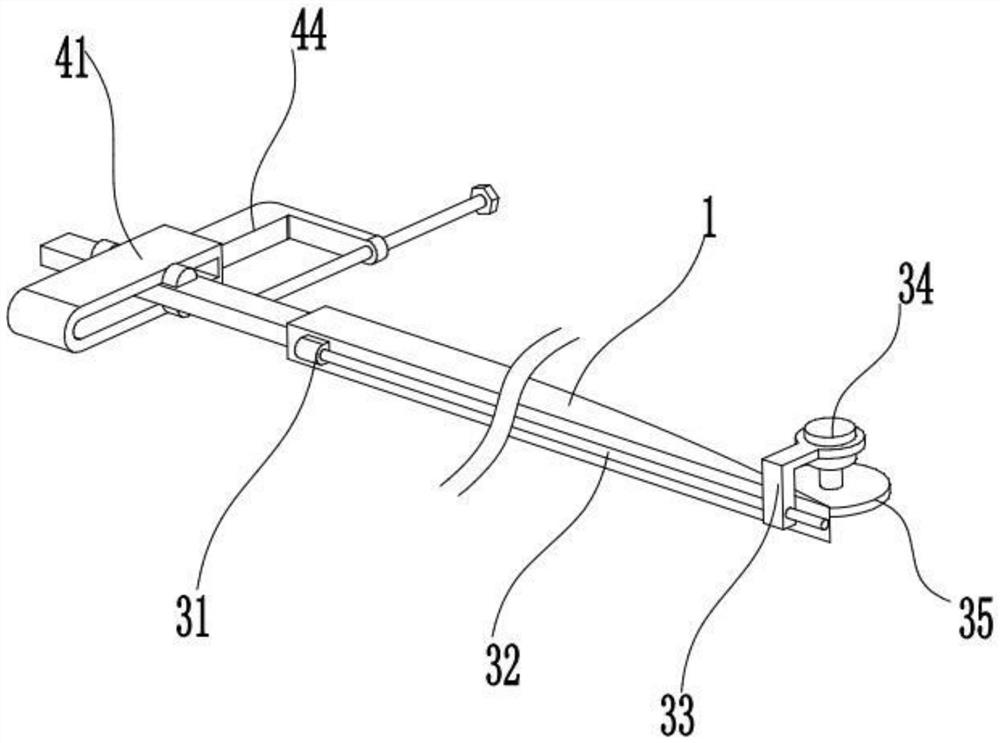

The invention relates to a preparation method of an antibacterial blended fabric, in particular to the antibacterial blended fabric and the preparation method thereof. The method comprises the following steps of s1, weighing raw materials in parts by weight, and then blending to obtain a fabric; s2, carrying out dip dyeing, cleaning, drying and sizing on the fabric, and obtaining the antibacterial blended fabric; and s3, winding the antibacterial blended fabric on a winding device, cutting a whole piece of fabric, and cutting one piece of fabric into a plurality of pieces of fabric at one time. The antibacterial blended fabric is prepared from the following raw materials in parts by weight: 5 to 12 parts of linen fiber, 25 to 40 parts of cotton fiber, 6 to 14 parts of viscose acetal fibers and 15 to 25 parts of bamboo fibers. The winding device used in the s3 comprises outer guide rods, supporting pieces and a ring seat, wherein the ring seat is arranged on the two supporting pieces; the two outer guide rods are symmetrically arranged on the ring seat; and the cloth is wound on the two outer guide rods, so that the cloth is unfolded to be in a horizontal state and is convenient to cut.

Owner:陈宝强

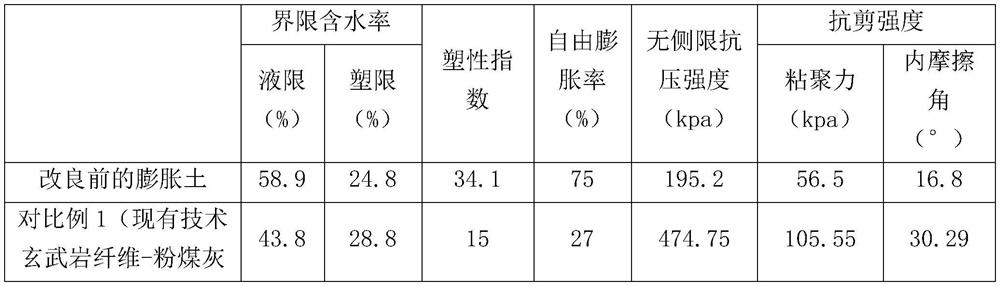

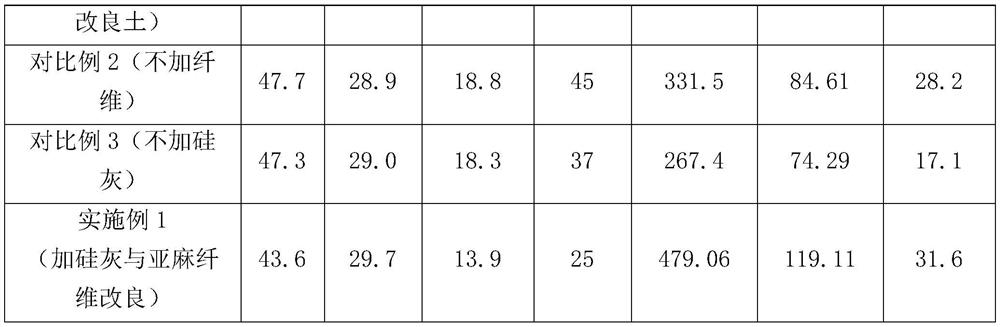

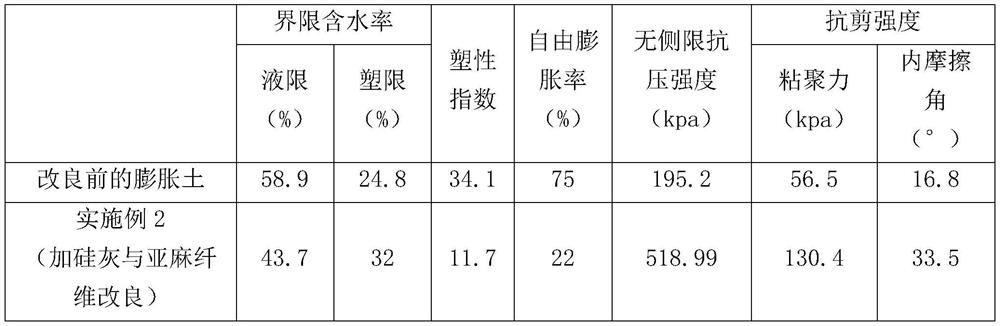

Improved expansive soil as well as preparation method, construction method and application thereof

PendingCN114108591ASmall expansion and contractionImproved particle size distributionRoadwaysSoil preservationFlax fibreSoil science

The invention relates to improved expansive soil and a preparation method, a construction method and application thereof.The improved expansive soil comprises, by mass, 8%-10% of silica fume, 1%-2% of linen fiber and 88%-91% of expansive soil of a soil body needing to be improved, and the improved expansive soil is formed by evenly mixing the silica fume, the linen fiber and the expansive soil. According to the invention, the expansive soil is improved by using the by-product silica fume in large-scale industrial smelting and the natural material linen fiber, so that the engineering cost is saved, and a new improvement method is developed for reducing engineering disasters caused by the expansive soil in combination with the application of the natural material linen fiber. In the improvement process, the linen fibers give full play to the advantage of softness, the fiber reinforcement effect, the reinforcement-soil interface interaction effect and the fiber caking effect are exerted in an embedded, bent and interwoven mode, creep deformation of the soil body in the deformation process is reduced, the strength of the expansive soil can be remarkably improved, meanwhile, the expansion and shrinkage performance of the expansive soil is reduced, and the expansive soil has the good application prospect. And the damage caused by expansion and shrinkage deformation is reduced.

Owner:NANJING UNIV OF INFORMATION SCI & TECH +1

Linen and viscose blended fabric and processing technology thereof

ActiveCN110144661AImprove the problem of poor comfortDemonstrate comfortDrafting machinesWoven fabricsEscherichia coliPolymer science

The invention relates to a linen and viscose blended fabric and a processing technology thereof. The fabric is formed by plain weave of warp and weft, and is characterized in that the warp is viscosefiber of 14.8 tex-9.8 tex, the weft comprise weft A and weft B, and the weft A is made of linen regenerated cellulose Jutecell of 14.8 tex-9.8 tex by self-made linen imitating equipment and technology, and has quality style characteristics of linen yarn; the weft B is blended yarn of 36 tex-19.5 tex prepared from linen fiber and viscose. The fabric has the advantage that the linen regenerated cellulose fiber is selected as a raw material, and the fiber is in a hollow cross-sectional shape similar to fibrilia, and is hygroscopic and quick-drying; the excellent antibacterial property of fibriliais retained, and the antibacterial rate to Escherichia coli and Staphylococcus aureus is higher than 90%; the yarn product with the quality style of the Jutecell linen-imitating yarn is made by self-made linen-imitating equipment and technology, has functions of fibrilia and style of dry linen lines.

Owner:RUGAO CITY DINGYAN TEXTILE

Triazine anti-ultraviolet blended yarn and production process thereof

The invention belongs to the technical field of novel spinning, and relates to a triazine anti-ultraviolet blended yarn. The blended yarn comprises the following components in parts by weight: 39-71 parts of cotton fibers, 9-20 parts of linen fibers and 20-41 parts of wool fibers. A production process of the blended yarn comprises the following steps that pre-treating and opening are carried out;a triazine ultraviolet absorber is sprayed on the cotton fibers and the linen fibers and then the cotton fibers and the linen fibers are taken out and aired to prepare cotton fibers and linen fibers with the triazine ultraviolet absorber on the surfaces; the prepared cotton fibers and linen fibers are subjected to a sandwich type lay-up mixing according to a blending ratio; an opening and cleaningprocess is carried out, wherein the cotton fibers and the linen fibers after lay-up mixing sequentially pass through a bale plucker, a cotton blending machine and a rolling machine to complete an opener process; a cotton carding process, a drawing process, a roving process and a spun yarn process are carried out to prepare roving; the wool fibers and the roving are blended to prepare the yarn. The prepared yarn has the relatively good anti-ultraviolet performance, is washable and has the good warmth retention property.

Owner:JIANGSU YUNFU FASHION CO LTD

Anti-radiation heat-insulation fabric and preparation method thereof

InactiveCN113512882AReduce pollutionImprove flame retardant performanceLight resistant fibresVegetal fibresPolymer sciencePtru catalyst

The invention discloses an anti-radiation heat-insulation fabric and a preparation method thereof. The anti-radiation heat-insulation fabric is prepared from a fabric and a modified polyurethane coating coated on the surface of the fabric; the fabric is formed by weaving linen fibers; the modified polyurethane coating is prepared from the following raw materials in parts by weight: 15-20 parts of isophorone diisocyanate, 30-40 parts of polycaprolactone diol, 3-4 parts of dimethylolpropionic acid, 0.5-1 part of a catalyst and 2-3 parts of trimethylolpropane; the modified polyurethane coating further comprises a flame retardant and an ultraviolet light absorber; the ultraviolet light absorber is prepared from resorcinol, trichlorotoluene and a solvent; the flame retardant is prepared from phenol, phosphorus oxychloride, a catalyst and anhydrous aluminum trichloride; and the solvent is toluene. On the basis of an original linen fiber fabric, the modified polyurethane coating is added on the linen fiber fabric through a padding process, and the added modified polyurethane coating can improve the mechanical strength and the anti-radiation performance of the product fabric.

Owner:东台市东驰服装有限公司

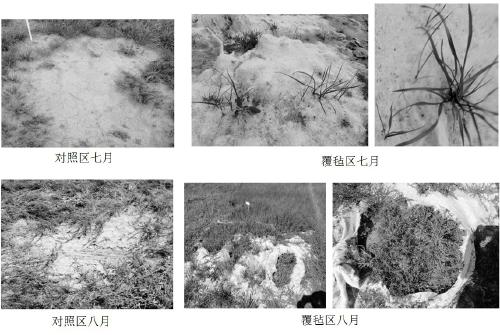

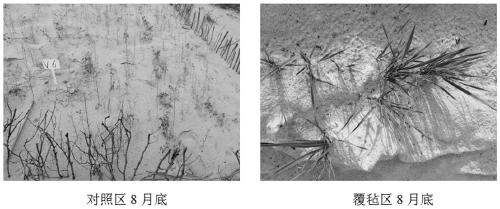

Biomass felt, preparation method thereof and application in grassland recovery

ActiveCN111501207AReduce investmentWide variety of sourcesHops/wine cultivationTurf growingGrasslandEdaphic

The invention provides biomass felt, a preparation method thereof and application in grassland recovery. The biomass felt is prepared from raw materials including, by weight, 65-75 parts of wool fiber, 15-25 parts of linen fiber, 5-15 parts of maize straw or polylactic acid fiber. The biomass felt is prepared through a needling molding non-woven technology. The application of the biomass felt in recovery of grassland in serious degeneration, salinization and desertification comprises the following steps that a, ploughing treatment is carried out on the grassland in serious degeneration and salinization to form ridges and furrows; b, selected gramineous forage grasses or legumes are reseeded; and c, after reseeding, the land is covered with the biomass felt, and then, the biomass felt is covered with a thin layer of soil and covered tightly. The biomass felt can retain soil moisture, reduce the temperature difference of desertified soil, the harm to plant seedlings from the high temperature is avoided, and the rate of emergence is high; and the biomass felt can be naturally degraded, environment pollution is avoided, and the soil nutrient can also be increased after degradation.

Owner:HEBEI UNIVERSITY +1

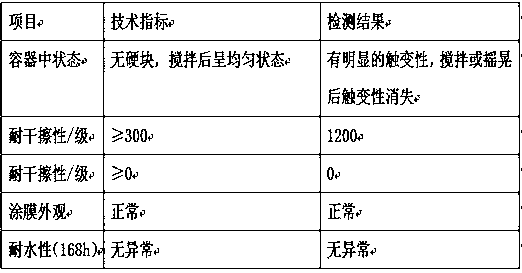

Building coating containing inorganic montmorillonite and production method

InactiveCN107815235AHighlight substantive featuresSignificant progressFireproof paintsPolyurea/polyurethane coatingsEmulsionDefoaming Agents

The invention discloses a building coating containing inorganic montmorillonite and a production method. The building coating containing the inorganic montmorillonite is prepared from the following raw materials: polyurethane, an emulsion, linen fiber, the inorganic montmorillonite, diatom ooze, water, a composite coupling agent, a preservative, a flatting agent and a defoaming agent. The buildingcoating provided by the invention is favorable in coalescence, air permeable in film, not easy to blister, particularly suitable for internal and external plastering, good in permeability and stain resistance, better in hardness, gloss, water resistance and chemical corrosion resistance, and not easy to peel or fall off.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com