Multifunctional dehydrator

A dewatering machine, multifunctional technology for liquid/gas/vapor removal with centrifugal force, textile material drum processing, textile material processing equipment configuration, etc., can solve the loss of short fibers, poor quality flax fibers, no rinsing or dyeing function and other problems to achieve good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

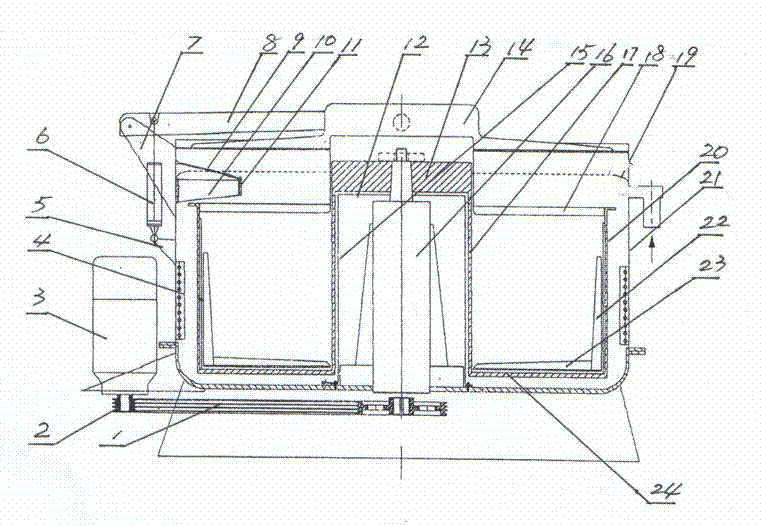

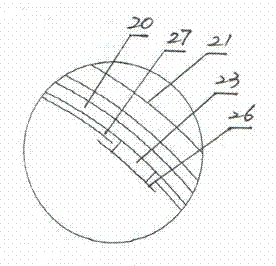

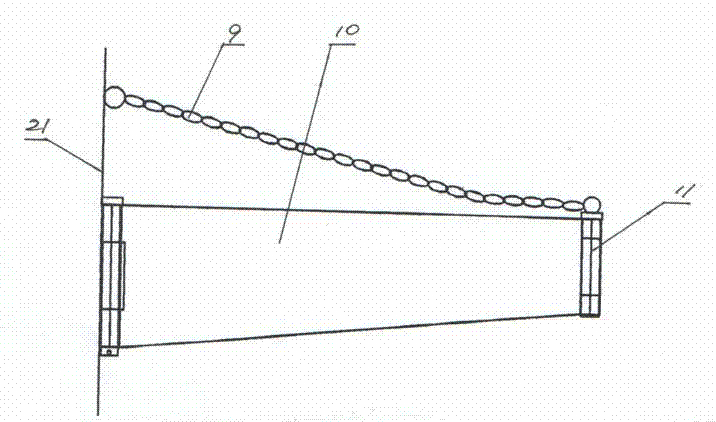

[0022] Such as figure 1 with figure 2 As shown, the multifunctional dehydrator of the present invention includes a cylinder body 21, the upper port portion of the cylinder body 21 is provided with a cylinder cover 14, and the cylinder cover 14 is provided with an activation arm 8, and the activation arm is fixed on the radial direction of the cylinder cover 14. The top of the cylinder cover 14. An upper pin seat 7 and a lower pin seat 5 are installed on the top of the outer surface of the cylinder wall of the cylinder body 21 and in the middle of the vertical direction, and the upper pin seat 7 and the extended end of the starting arm 8 are hinged together so that the cylinder cover 14 can be wound around the hinge. The pin shaft rotates, so that the opening and closing of the cylinder cover 14. A cylinder 6 is arranged between the lower pin seat 5 and the starting arm 8 , one end of the cylinder 6 is hinged on the lower pin seat 5 , and the other end is hinged on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com