Patents

Literature

395results about "Liquid/gas/vapor removal by centrifugal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

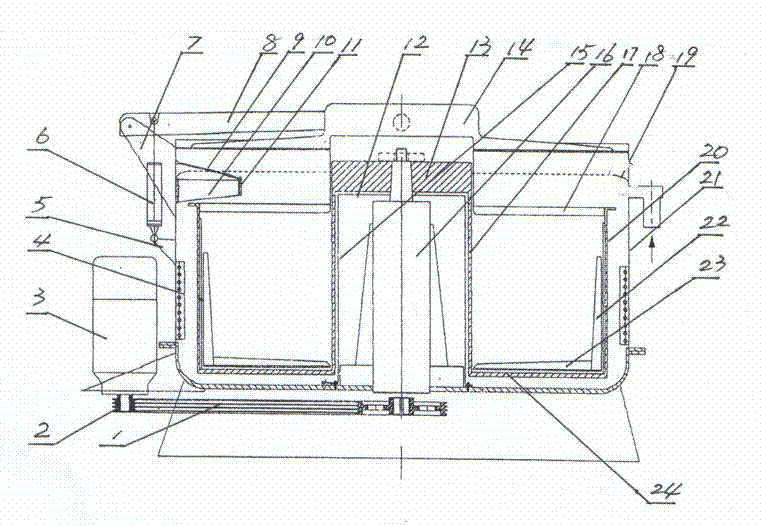

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

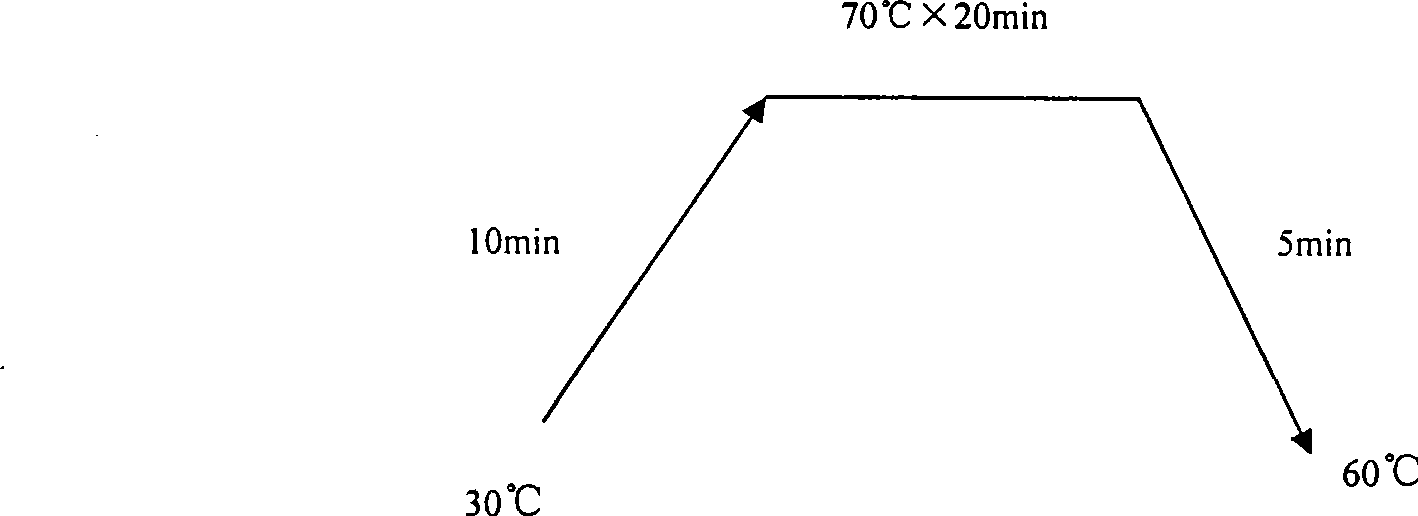

Koala velvet and production method thereof

InactiveCN101440552ASolve looseSolve the feelWarp knittingHeating/cooling textile fabricsFiberMaterials preparation

The invention discloses koala flock and a method for manufacturing the same. The koala flock is manufactured by taking 56 to 83dtex Shaoguang flat cross section fibers or semi-Shaoguang flat cross section fibers as koala flock face fibers, and 56 to 76dtex terylene FDY as bottom fibers, whereinthe 56 to 83dtex Shaoguang flat cross section fiber or semi-Shaoguang flat cross section fiber is 30 to 85 portions, and the 56 to 76dtex terylene FDY is 15 to 50 portions. The method comprises production processes of material preparation, weaving, thermal shaping, dyeing, treatment after dyeing, dewatering, colored cloth shaping, front face gigging, finished cloth shaping, combing, scalding, clipping and the like, and the flat fibers are used to replace the conventional circular fiber, so that the simulated koala flock with unique style is produced. The height of the koala flock is between 0.5 and 7mm, and the koala flock touches soft and smooth, and can be widely used in the production of flock toys, indoor flock slippers, blankets, knitting flock and the like, and can fully meet market demands.

Owner:ZHANGJIAGANG JINGDONG KNITTING PLUSH

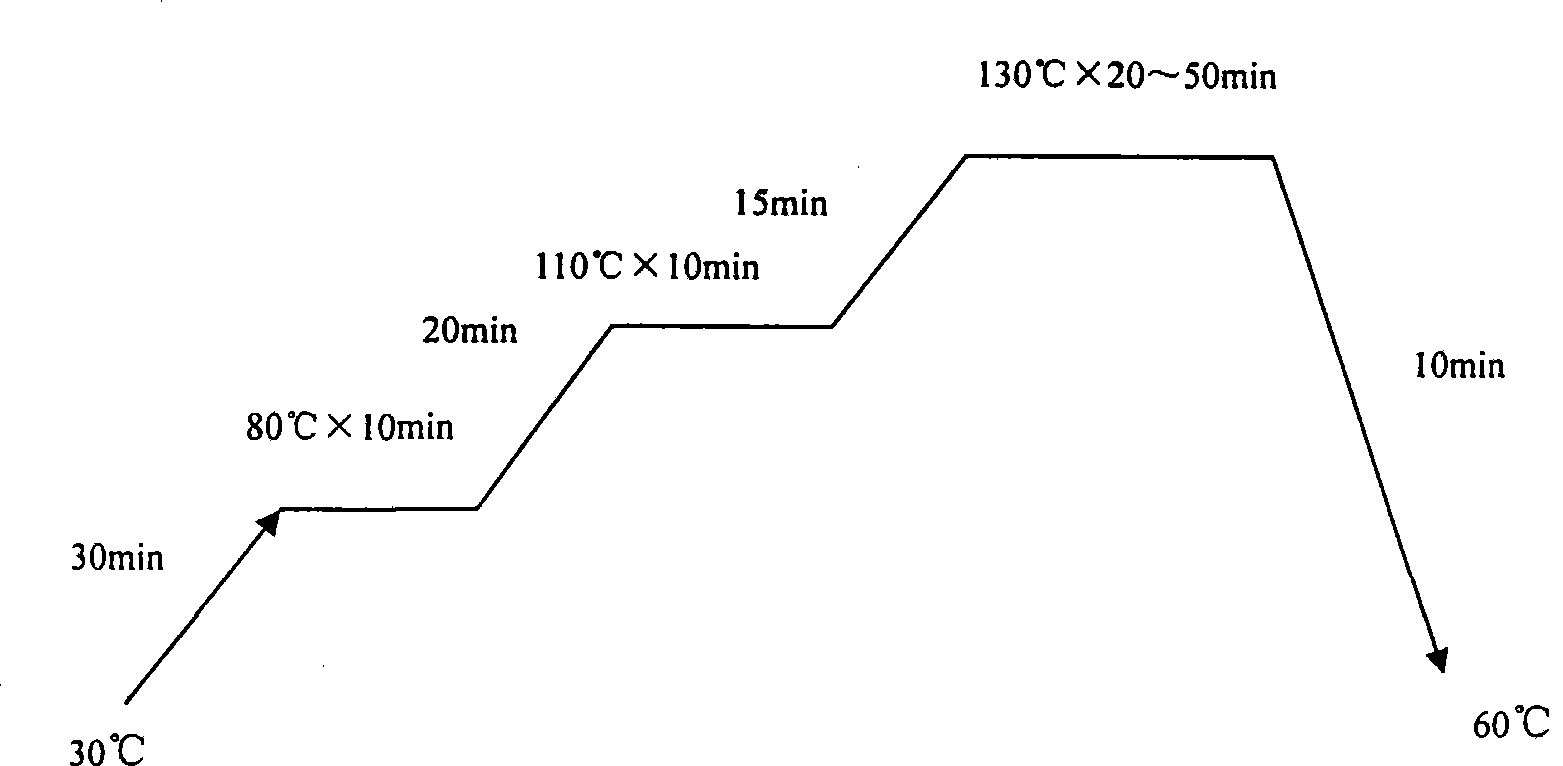

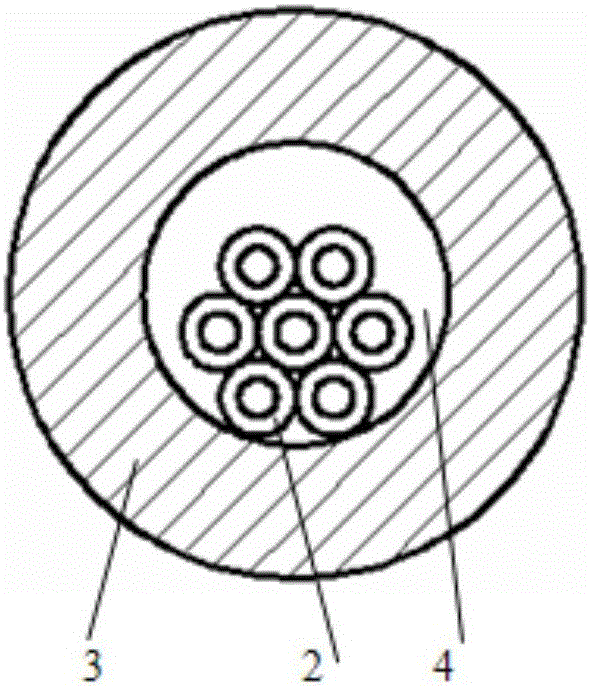

New dyeing process of polyester air-varying yarn

InactiveCN102277698AFully elasticFull moisture wickingLiquid/gas/vapor removal by centrifugal forceLiquid/gas/vapor yarns/filaments treatmentYarnTextile printer

The invention relates to the technical field of textile printing and dyeing and provides a novel dyeing process for polyester air textured yarns. By the process, a dyeing solution can fully penetrate yarns on the inner layer and the outer layer of a cheese during dyeing, so that the yarns of the cheese are free of inner and outer layer chromatic aberration. The novel dyeing process comprises a loose cheese winding procedure, a steaming and forming procedure, a second loose cheese winding procedure, a dyeing procedure, a post-arranging procedure and a dehydrating and drying procedure.

Owner:福建锦丰印染有限公司

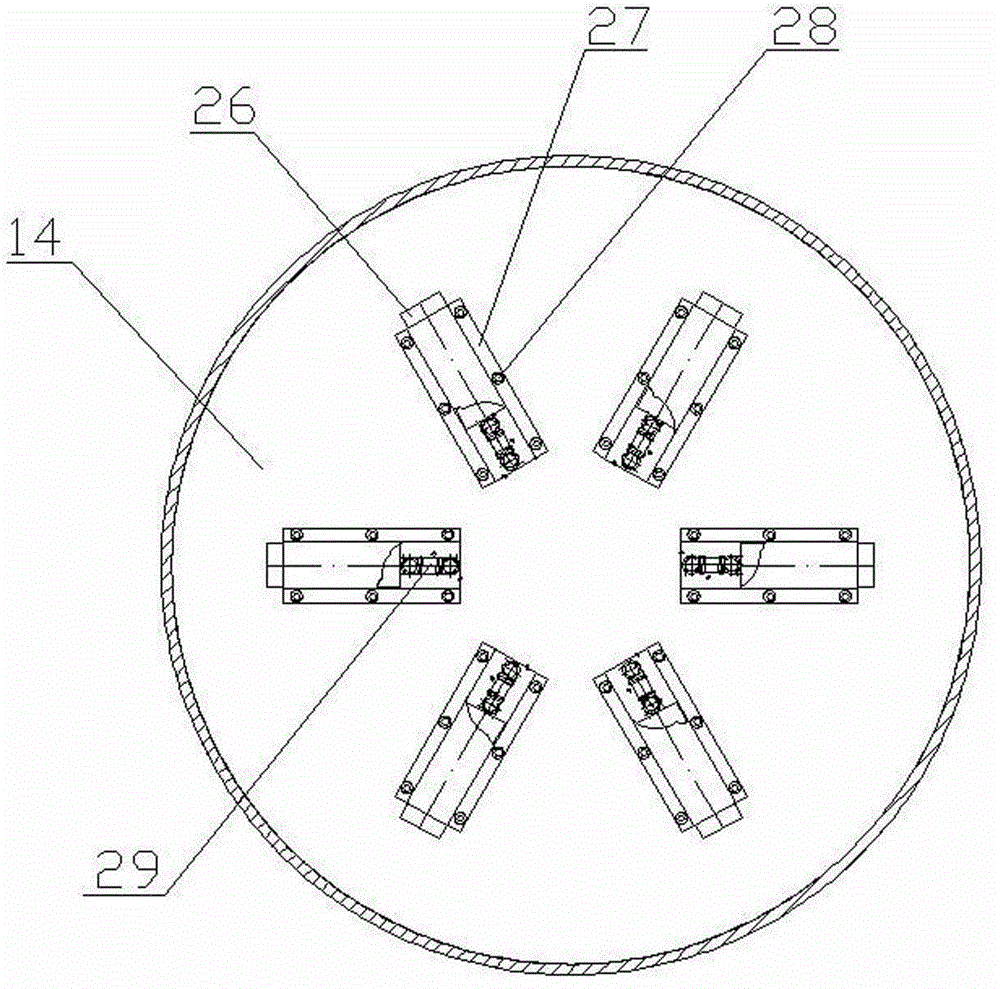

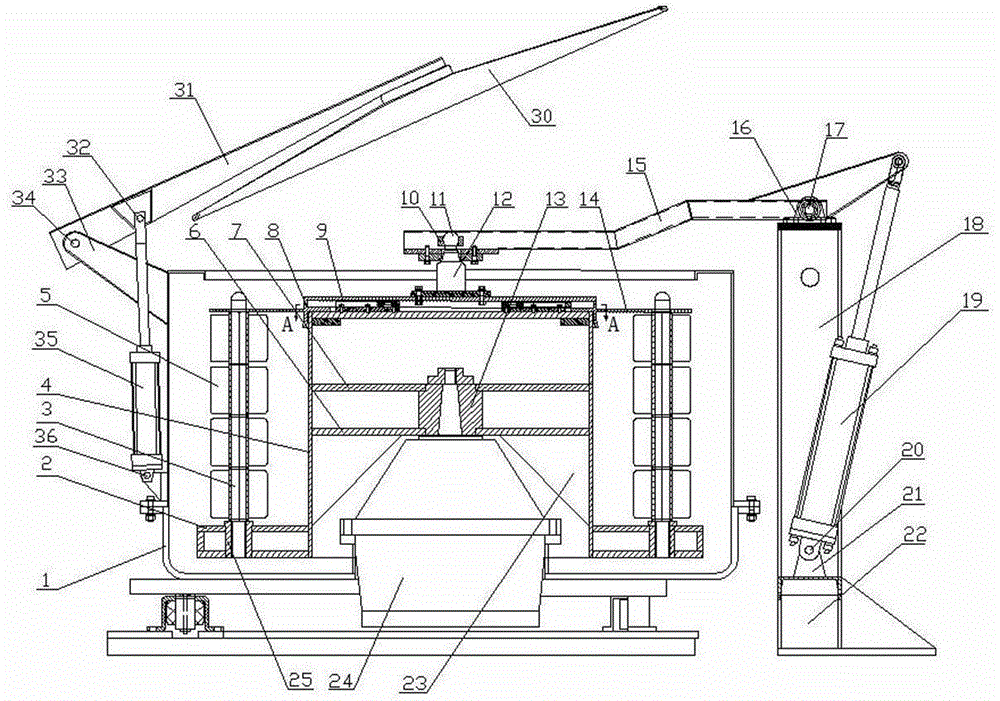

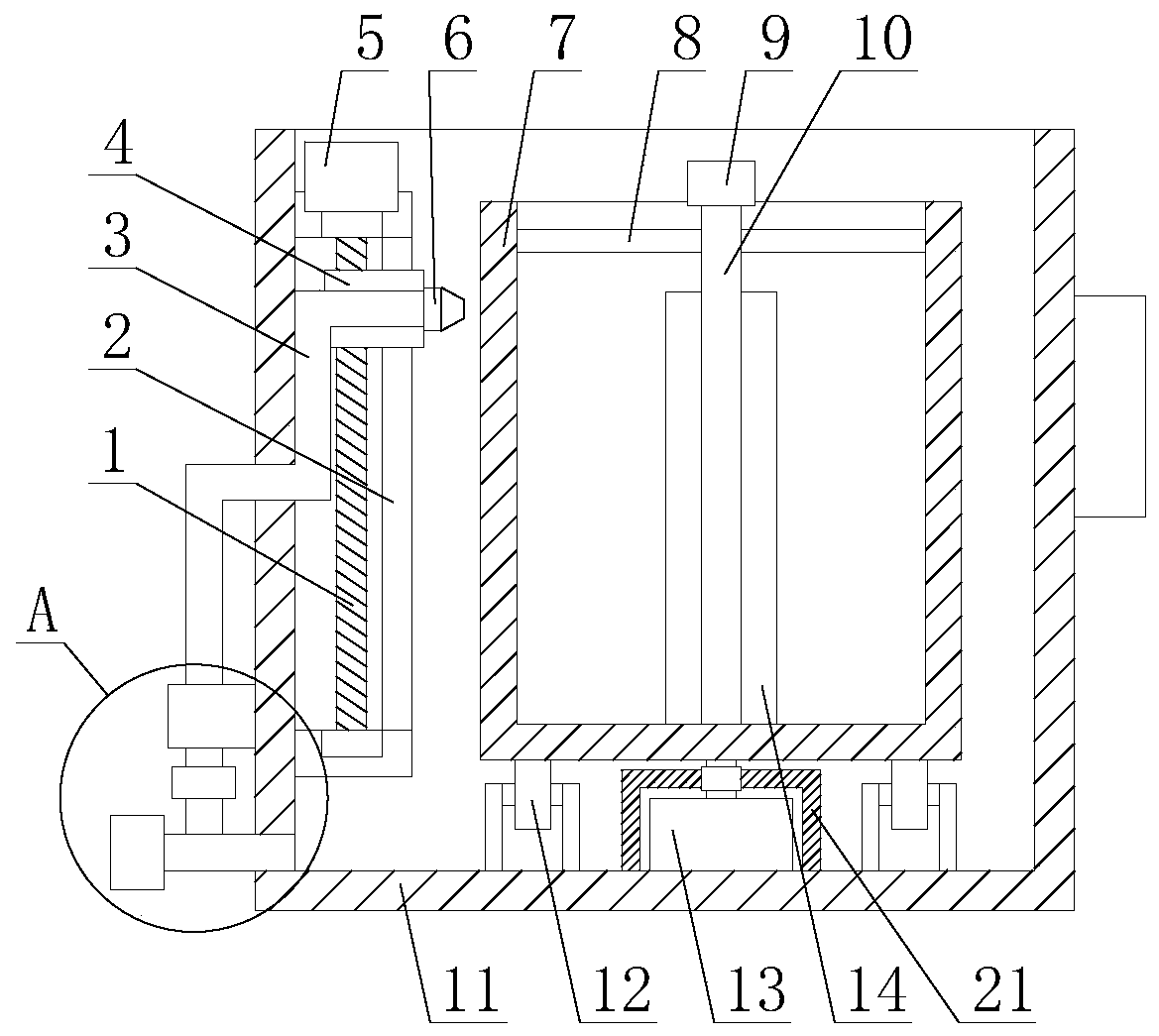

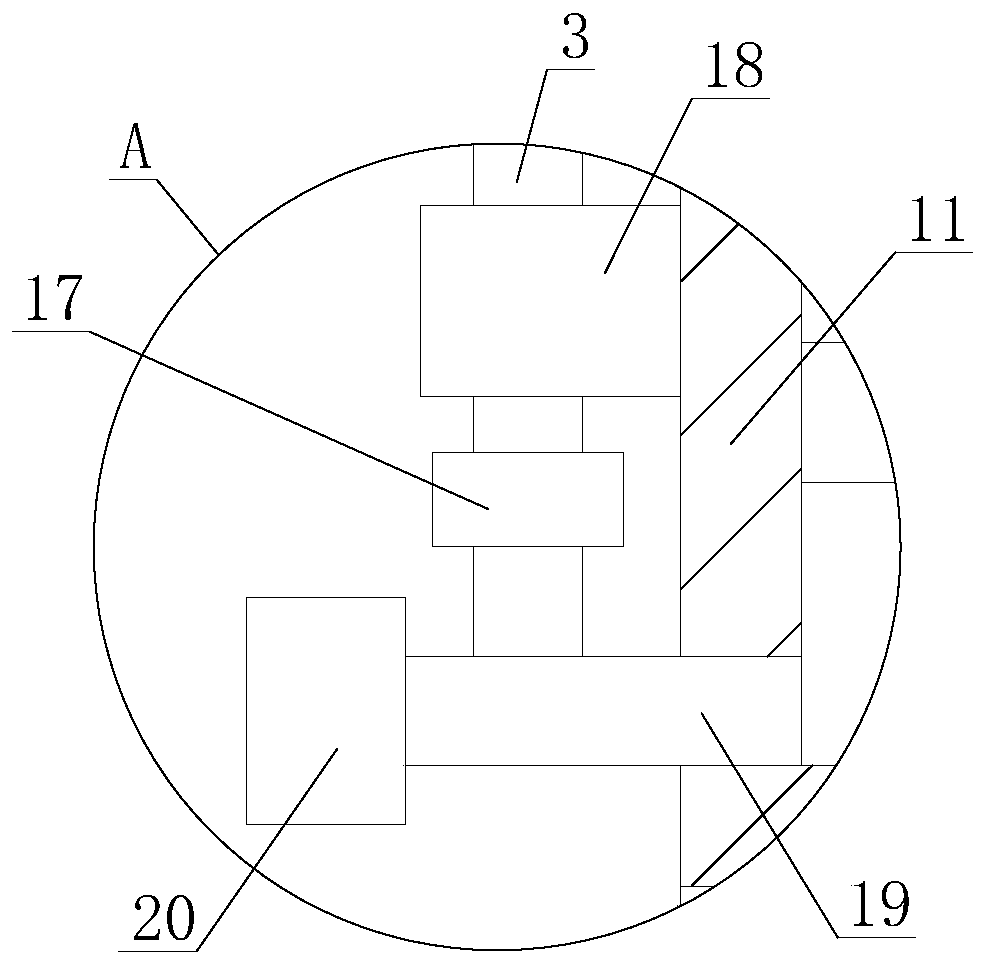

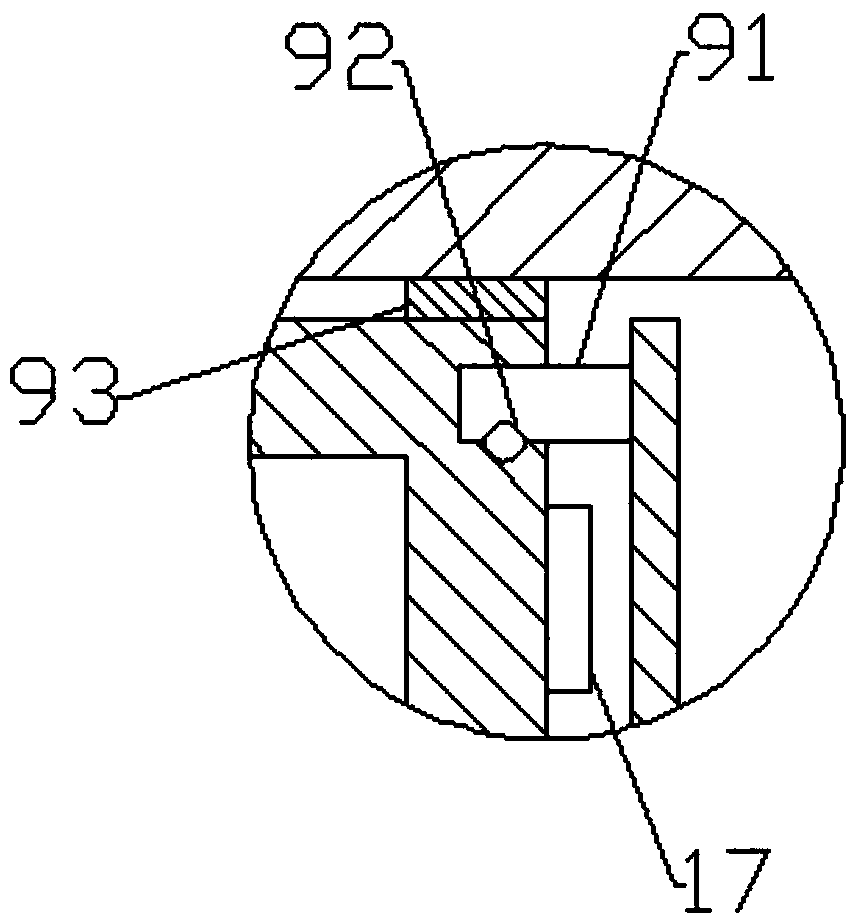

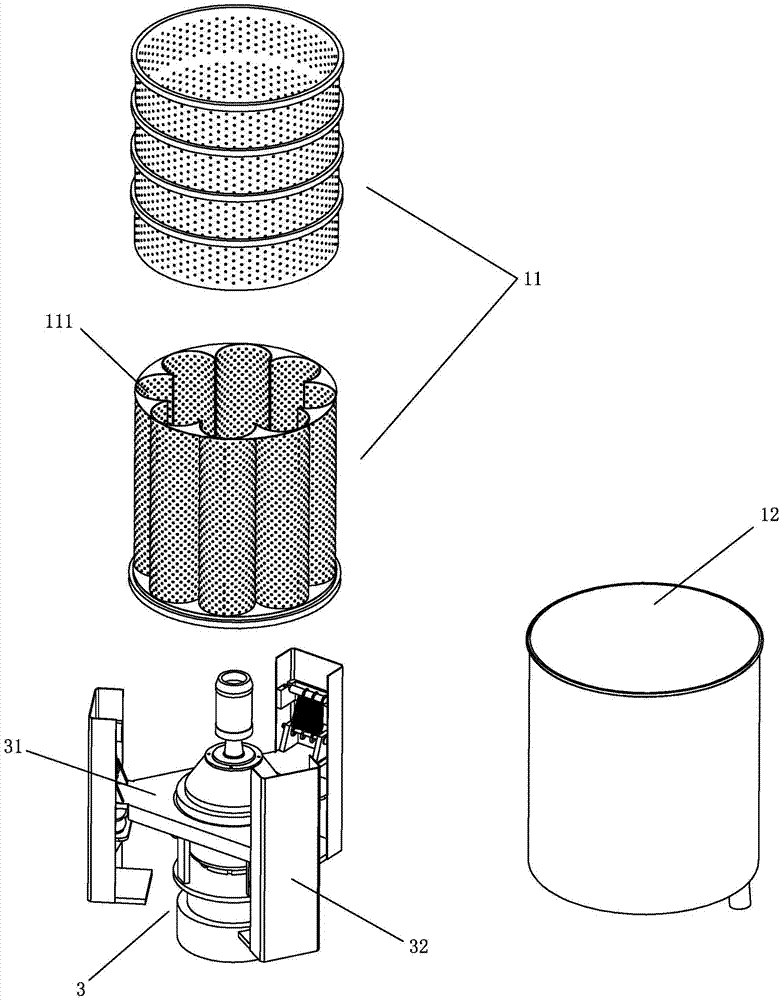

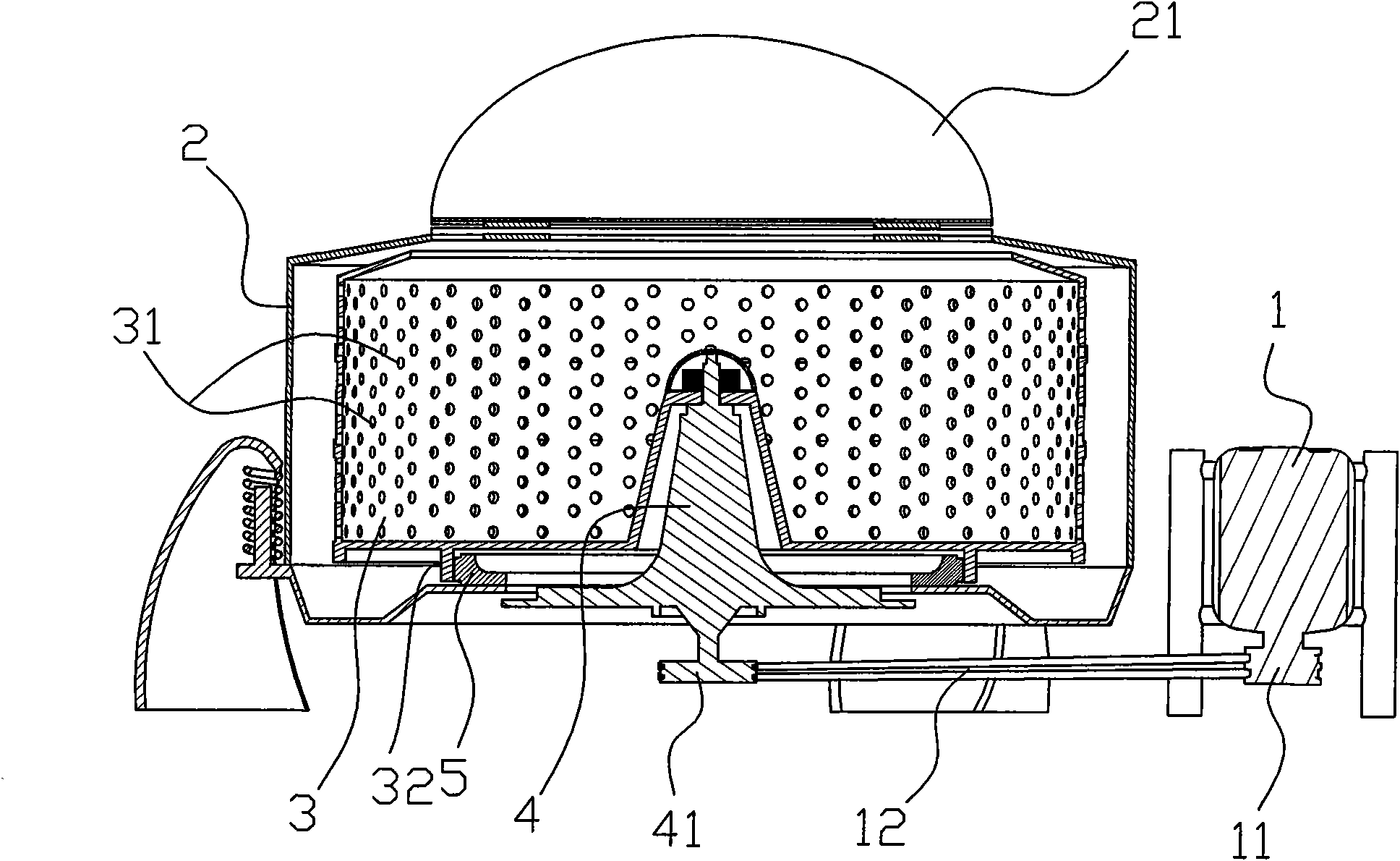

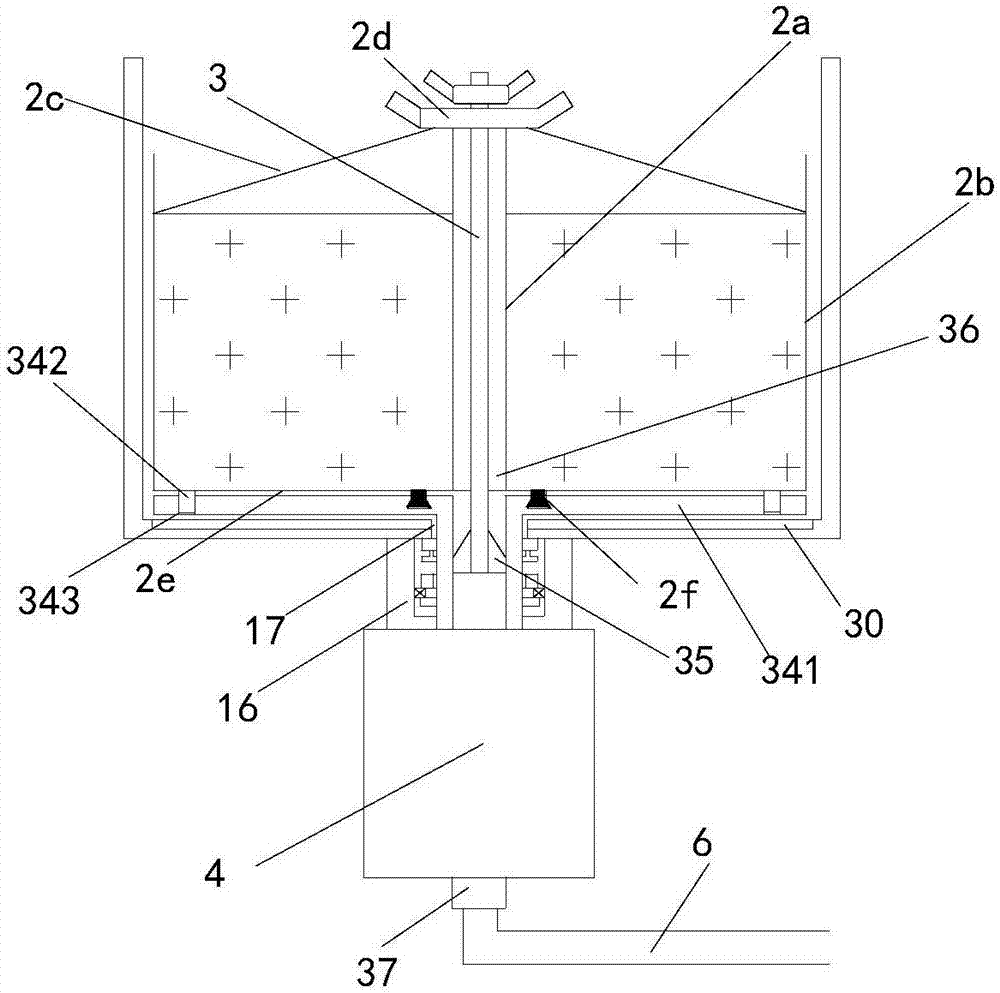

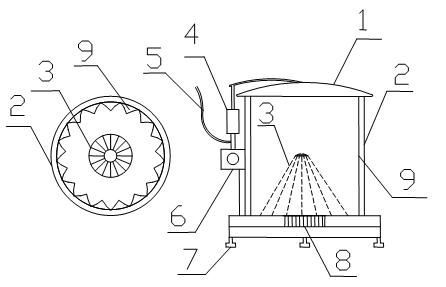

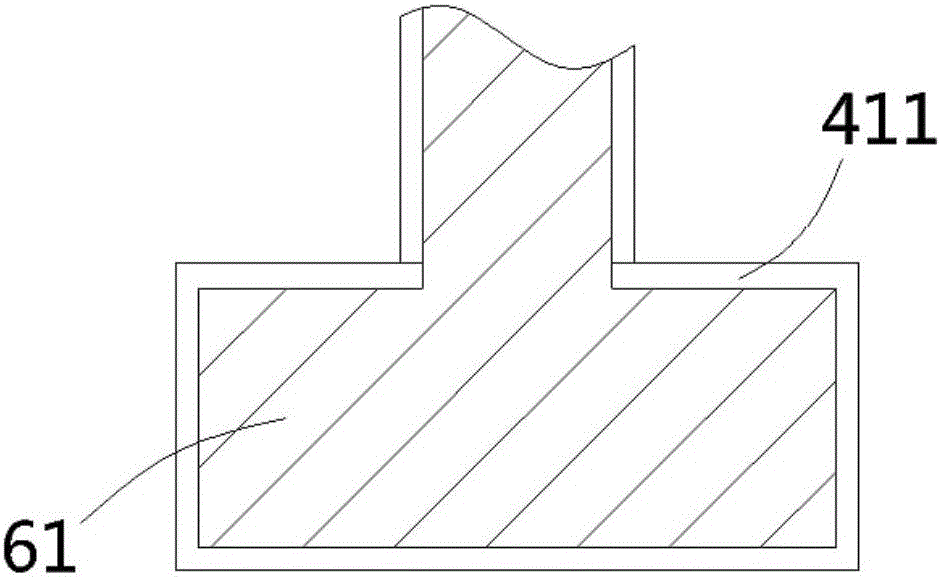

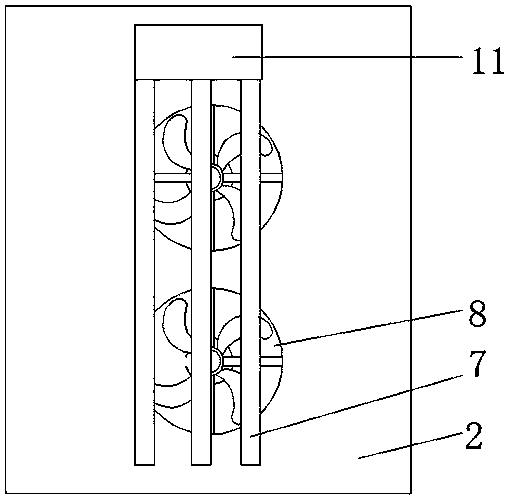

Rotating drum for cheese dewatering

ActiveCN104452151AReduce moisture contentRemove obstaclesLiquid/gas/vapor removal by centrifugal forceTextile treatment carriersYarnBobbin

The invention relates to a rotating drum for cheese dewatering. The rotating drum comprises a drum body, wherein a vertical cylinder is arranged in the drum body, a fixing plate is arranged approximately in the middle of an inner cavity of the vertical cylinder in the height direction, a motor is arranged below the fixing plate, and an output shaft of the motor is fixedly connected with the fixing plate. The rotating drum is characterized in that an annular disc is connected to the lower end of the vertical cylinder, vertical rod holes are evenly distributed in the circumference of the annular disc, a gland is arranged at the upper end of the vertical cylinder, the diameter of the gland is larger than the length of the line connecting the outer sides of two corresponding rod holes located on the same diameter line, rod holes are evenly distributed in the circumference of the gland and correspond to the rod holes in the annular disc, supporting rods are evenly distributed between the circumference of the annular disc and the circumference of the gland, and the upper ends and lower ends of the supporting rods stretch into the corresponding rod holes in the annular disc and the gland. When a dewaterer provided with the rotating drum is used for dewatering cheese, dewatering effect is good, energy consumption is low during later drying, production cost is low, the situations that cheese is pressed flat, yarns are bonded together and yarn breaking occurs during yarn rewinding can be avoided, and deformation of a bobbin is avoided. The rotating drum is suitable for dewatering after a yarn roll is dyed.

Owner:WUXI QIANZHOU YAODA MACHINERY FACTORY

Centrifugal dehydrator for textile

InactiveCN105040320AAvoid cloggingImprove isolationLiquid/gas/vapor removal by centrifugal forceNylon filterEngineering

The invention discloses a centrifugal dehydrator for a textile. The centrifugal dehydrator comprises a shell. An installation base is arranged at the bottom of the shell. An end cover is arranged on the upper portion of the shell. A rotating spindle is arranged at the center in the shell. A circle of dehydration baskets are arranged on the outer side of the rotating spindle. A drainage channel is arranged between the dehydration baskets and the inner wall of the shell. An upper pressing plate is arranged above the dehydration baskets. Nylon filter nets are suspended below the upper pressing plate. A direct current motor is arranged on one side of the shell. The direct current motor is connected with the rotating spindle. The direct current motor is provided with a sound insulating cover. The inner wall of the shell is provided with a waterproof sound-insulating cotton layer. Due to the fact that the waterproof sound insulating cotton layer is arranged on the inner wall of the shell, and the sound insulating cover is arranged on the direct current motor, the sound insulating effect is good; due to the fact that the nylon filter nets are arranged in the dehydration baskets, impurities on the textile are filtered out and stored, and dehydration holes in the dehydration baskets and the drainage channel are prevented from being blocked; the centrifugal dehydrator is simple in structure, convenient to use and wide in application prospect.

Owner:WUJIANG FUAILIANG TEXTILE

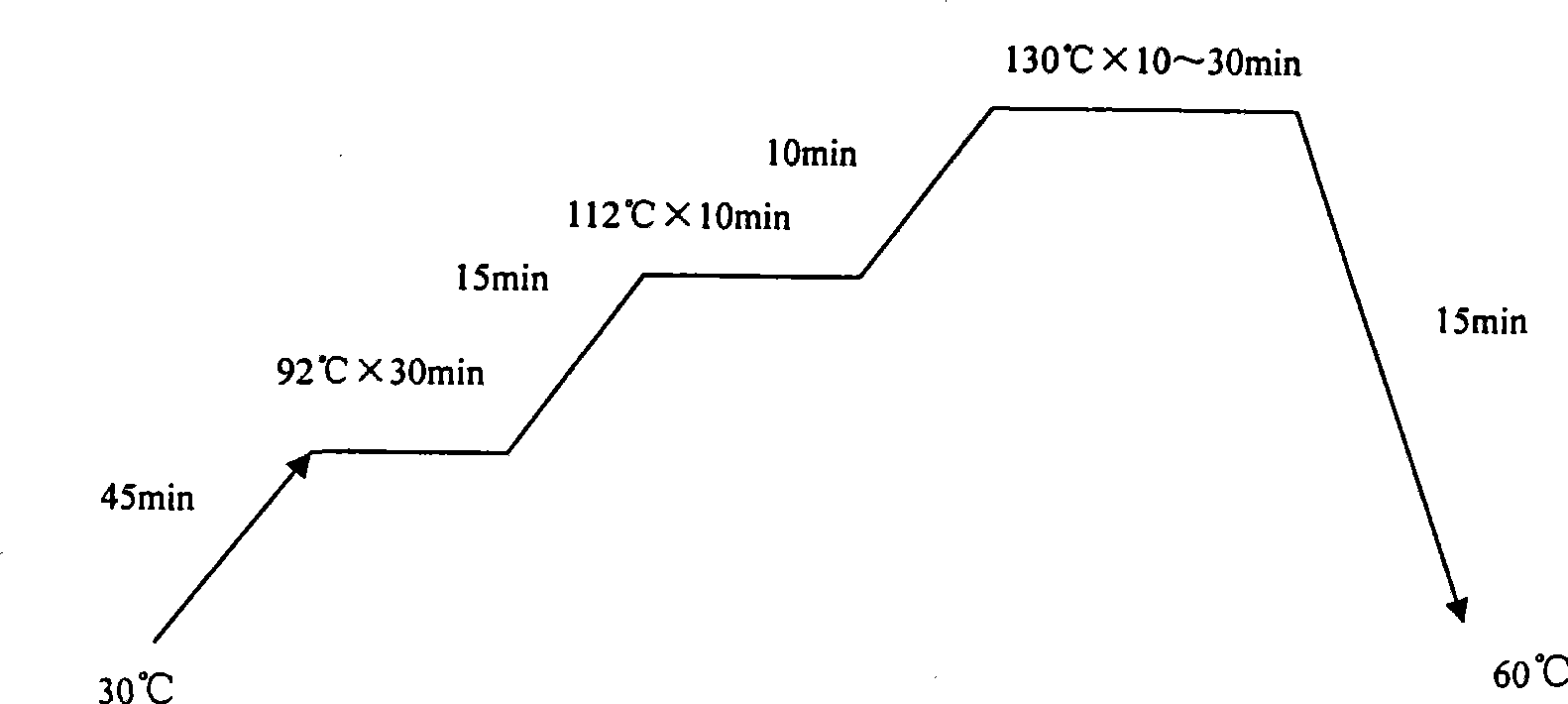

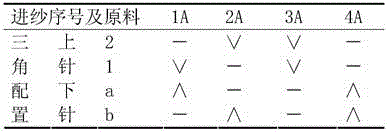

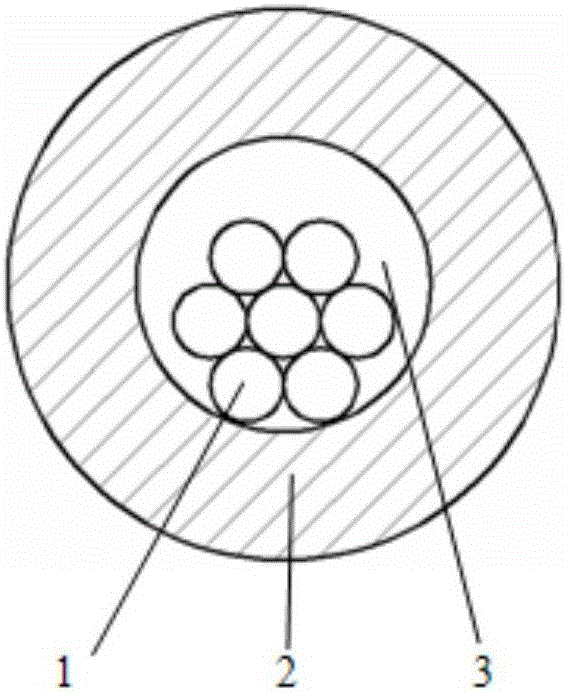

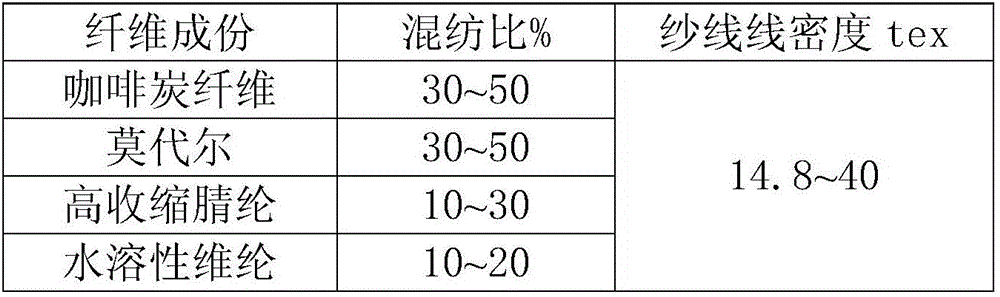

Production method of heat-accumulation and heating bulked double-layered-structure yarn warm-keeping knitted fabric

The invention discloses a production method of a heat-accumulation and heating bulked double-layered-structure yarn warm-keeping knitted fabric. The production method comprises the following steps: selecting fiber raw materials; a knitted fabric production process flow specifically comprising the following steps: skeining yarns and dissolving vinylon: preparing bobbin yarns, reeling and skeining, dissolving the vinylon and carrying out hot water bulking treatment, washing, drying, spooling, knitting and dyeing and finishing a knitted fabric; dissolving the vinylon from the fabric: preparing the bobbin yarns, knitting, dissolving the vinylon and carrying out the hot water bulking treatment, washing and dyeing and finishing the knitted fabric. The total structure of the used yarn is a bulked double-layered-structure hollow yarn; firstly, the yarns are spun, and four types of short fibers including heat-accumulation and heating fibers, regenerated cellulose fibers, water-soluble vinylon and high shrinkage acrylic fibers are blended into the yarns; secondly, vinylon dissolving and bulking are carried out and the four-in-one blended yarns are subjected to hot water treatment and the water-soluble vinylon is dissolved; meanwhile, the high shrinkage acrylic fibers have irreversible heat shrinkage and bulking effect is generated so that the axial length of the yarns is shortened; other fibers are bulked and crinkled and hollow parts are formed in the middles of the yarns, so that the double-layered-structure yarns are obtained.

Owner:IANGSU COLLEGE OF ENG & TECH

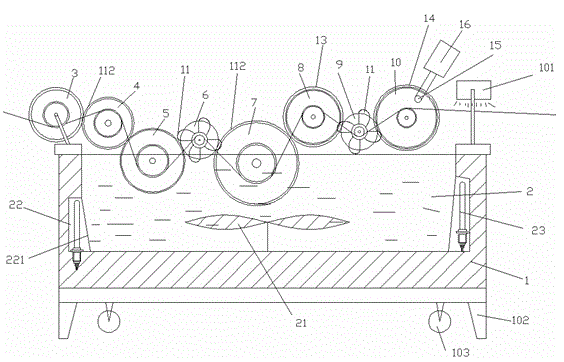

Yarn printing and dyeing device

ActiveCN104611862AUniform concentrationUniform temperatureLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsYarnIndustrial engineering

The invention discloses a yarn printing and dyeing device. The yarn printing and dyeing device comprises a printing and dyeing support and a printing and dyeing transmission mechanism. The printing and dyeing support is provided with a printing and dyeing pool. The printing and dyeing transmission mechanism is arranged above the printing and dyeing pool and comprises a motor axle, a main driving shaft, a first printing and dyeing shaft, a first air drying shaft, a second printing and dyeing shaft, a centrifugal shaft, a second air drying shaft and a steam guidance shaft, all of which are installed on the printing and dyeing pool through the support from left to right in sequence. According to the printing and dyeing device, printed and dyed yarn can be primarily air-dried through the first air drying shaft which is arranged behind the first printing and dyeing shaft and provided with a four-blade fan, and the effect is better when secondary printing and dyeing is carried out; the centrifugal shaft with a centrifugal cylinder is arranged behind the position where secondary printing and dyeing is conducted, the redundant dye pasted to the yarn can be thrown to the centrifugal cylinder through the centrifugal shaft under the action of centrifugal force, rapid air drying can be achieved through a fan on the second air drying shaft, and the air drying effect is good.

Owner:JIANGSU SHUANGYING TEXTILE TECH

Multifunctional dehydrator

InactiveCN102517823AQuality improvementEasy to separateTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsFiberEngineering

The invention relates to a multifunctional dehydrator, which comprises a cylinder. A cylinder cover is arranged at an upper opening of the cylinder. The bottom of the cylinder is provided with a center hole, and a spindle is arranged in the center hole. The lower end of the spindle extends out of the bottom of the cylinder, a power mechanism is arranged outside the cylinder, and the lower end of the spindle is connected with an output shaft of the power mechanism through a pulley and a transmission belt. A rotary cage is arranged in the cylinder, and a space is reserved between an inner cylinder of the rotary cage and the spindle while another space is reserved between an outer cylinder and the cylinder. A support board is connected to the upper end of the inner cylinder, and the upper end of the spindle is connected with the support board. An annular cage cover is arranged at the upper end of the rotary cage and is a meshed cage cover. The multifunctional dehydrator is characterized in that a sleeve for water proofing and heat insulation is arranged in the inner cylinder, and the lower end of the sleeve is hermetically connected with the bottom of the cylinder. A heater is arranged between the cylinder wall of the cylinder and the outer cylinder of the rotary cage. The dehydrator is multifunctional and used for treating linen fibers, quality of linen fiber products can be improved, and high loss of short staples is avoided. The multifunctional dehydrator is applicable to boiling, bleaching, washing and dehydrating of the linen fibers.

Owner:WUXI QIANZHOU YAODA MACHINERY FACTORY

Efficient centrifugal water extractor with cleaning function

InactiveCN110455042AGood energy saving effectImprove work efficiencyDrying solid materials without heatHollow article cleaningAir pumpPulp and paper industry

The invention relates to an efficient centrifugal water extractor with a cleaning function. The water extractor comprises a main body, a water extracting bucket, and a second motor; the water extracting bucket is arranged in the main body, the second motor is arranged on the inner wall of the bottom of the main body, the second motor is connected with the water extracting bucket, a cleaning mechanism and an extruding mechanism are further included, the cleaning mechanism comprises a sliding rod, a lifting block, a water pump, a driving assembly, a nozzle, a first pipeline, a second pipeline, avalve and two mounting plates, the extruding mechanism comprises a ventilation pipe, an air pump, and at least two air bags, and the driving assembly comprises a first motor and a screw. According tothe efficient centrifugal water extractor with the cleaning function, through the cleaning mechanism, the water extracting bucket can be cleaned, the probability that the water extracting bucket is blocked is reduced, the water extracting property of the water extracting bucket can be improved, through the extruding mechanism, cloth in the water extracting bucket can be extruded, the cloth waterextracting speed can be improved, and the work efficiency of the centrifugal water extractor can be improved.

Owner:李晓云

Dyeing and drying-integrated device

InactiveCN107794676AUniform dyeingReduce the hassle of moving to another deviceTextile treatment containersTextile treatment machine arrangementsWater dischargeElectric machinery

The invention disclose a dyeing and drying-integrated device for clothing. The device includes a shell, the upper end of the shell is provided with a cover, the cover is provided with a stirring box,the side of the stirring box is provided with a material charging pipe and a water charging pipe separately, the water charging pipe is provided with an electric controllable valve 1, the stirring boxis provided with a motor 1, and the main shaft of the motor 1 is provided with a rotating shaft 1; the shell is internally provided with an outer cylinder, the outer cylinder is provided with an ultrasonic generator and a controller, the bottom of the outer cylinder is provided with a water discharging pipe and multiple air discharging pipes, and the water discharging pipe is provided with an electric controllable valve 2; the bottom of the shell is provided with a thermal drying machine, a motor 2 and a motor 3, and the pipeline of the thermal drying machine is provided with an electric controllable valve 3; the outer cylinder is internally provided with a rotating cylinder, the upper end of the rotating cylinder is provided with a support ring, balls are arranged between the support ring and the outer cylinder, the bottom of the rotating cylinder is provided with a bearing 1, the bottom of the rotating cylinder and the main shaft of the motor 3 are both provided with gears, the mainshaft of the motor 2 is provided with a rotating shaft 2, and the joint of the rotating shaft 2 and the rotating cylinder is provided with a bearing 2. The automation degree of the device is high, sothat manual operation is reduced, and the economic benefit is improved.

Owner:FANCHANG QINGXIN WASHING CO LTD

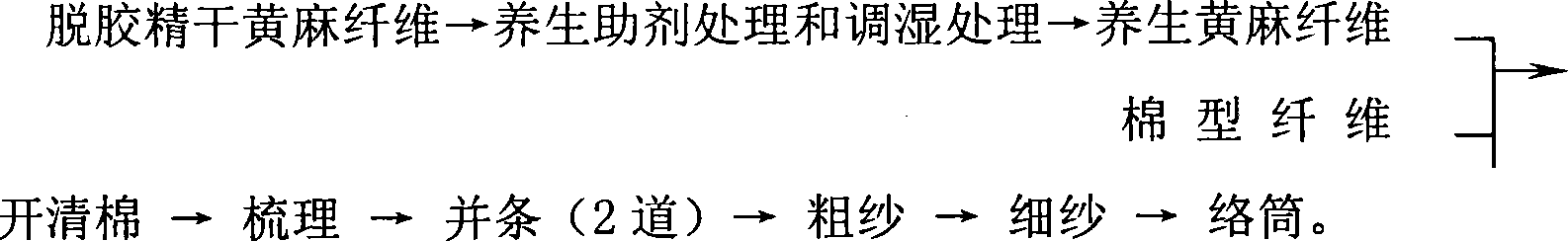

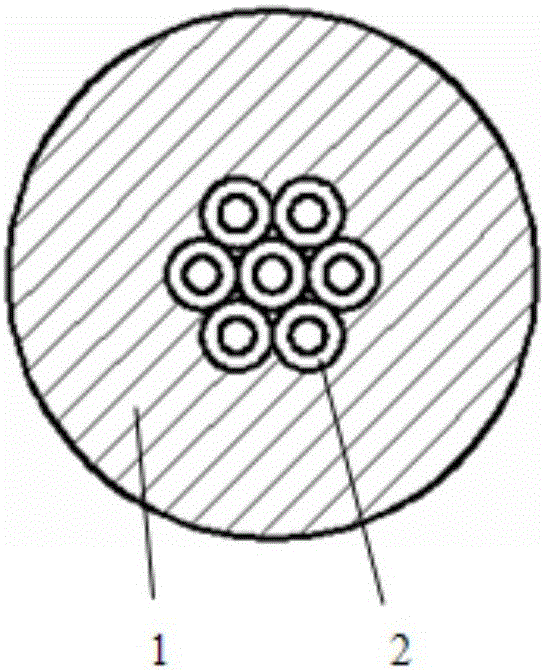

Health preserving jute blended yarn and preparation method thereof

InactiveCN101177810AReduce adverse effects of spinningRaise the ratioFibre treatmentLiquid/gas/vapor removal by centrifugal forceYarnEngineering

The invention pertains to the textile field and relates to a health jute blended yarns and a preparation method thereof, which is characterized in that the blending weight percentage of the health jute fiber and short-staple is 56 to 75: 44 to 25; through the treatment of health and conditioning of degumed and dried jute fibers and the improvement of spinning technique, the jute fibers generated stands a large proportion and the health jute blended yarns has smaller fineness, which can be used as clothes and home textile goods.

Owner:DONGHUA UNIV

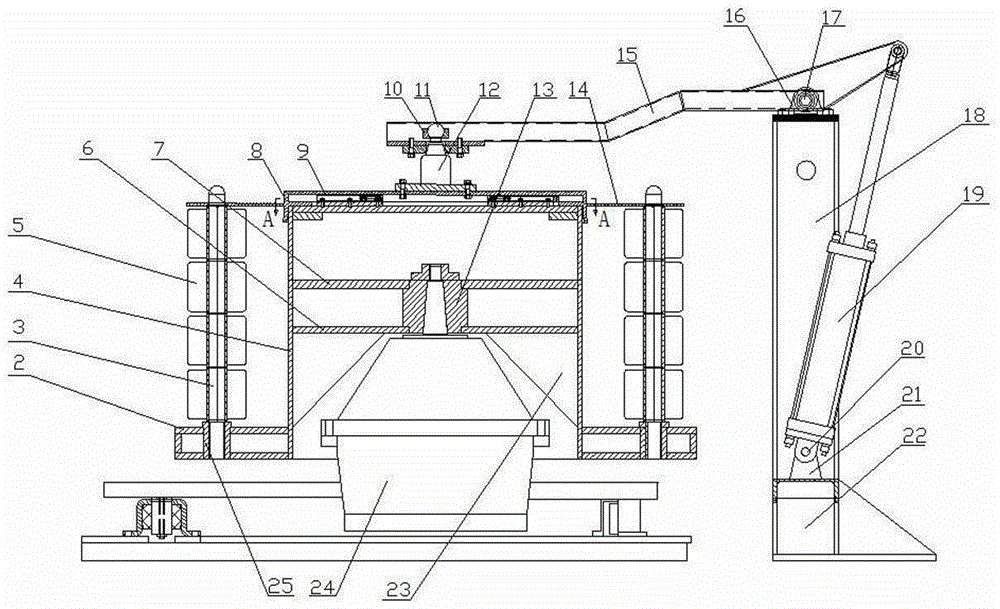

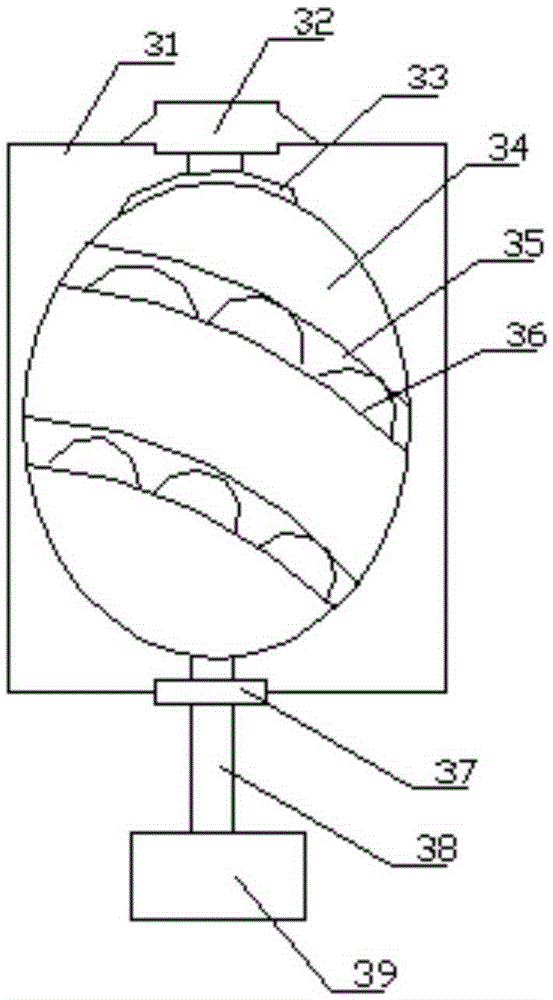

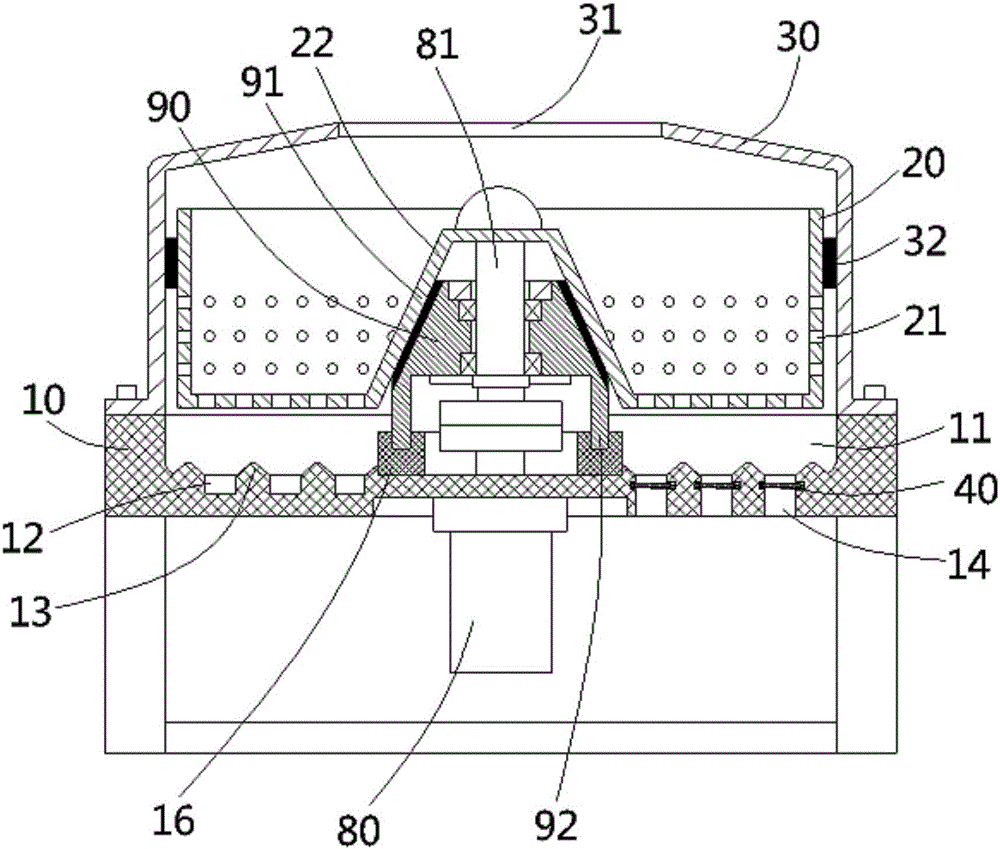

Cheese dewatering machine

InactiveCN105442223AAvoid displacementAvoid deformationLiquid/gas/vapor removal by centrifugal forceTextile treatment carriersYarnPulp and paper industry

The invention discloses a cheese dewatering machine which comprises dewatering barrels and hanging brackets. Each dewatering barrel comprises an inner container driven by a driving mechanism and an outer barrel which correspondingly contains the inner container, wherein the barrel wall of the inner container is provided with multiple grooves in a protruding mode in the internal radial direction and a plurality of through holes, and the grooves extend and contain cheese in a matched mode; the hanging brackets can be placed in the dewatering barrels and rotate along with the inner containers, and the hanging brackets are provided with cheese frames corresponding to the grooves. According to the cheese dewatering machine, shifting generated in the cheese dewatering process can be effectively prevented, yarn deformation is avoided, therefore, it is well guaranteed that yarn has the uniform tensile stress, and the forming quality of products is improved.

Owner:联合机器制造有限公司

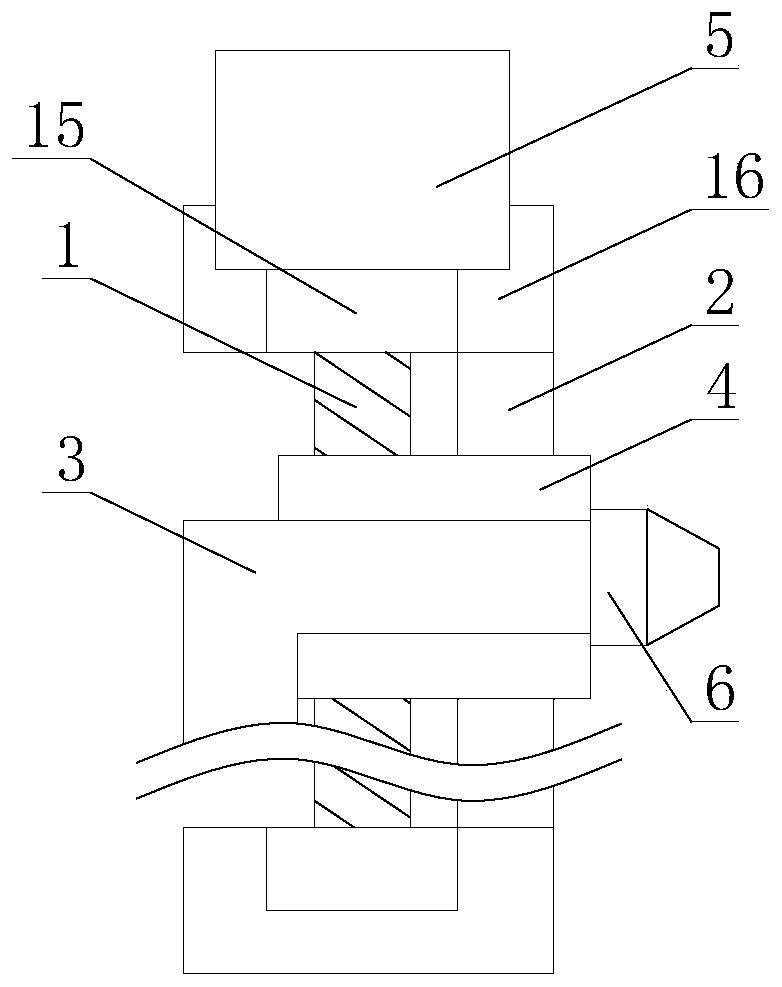

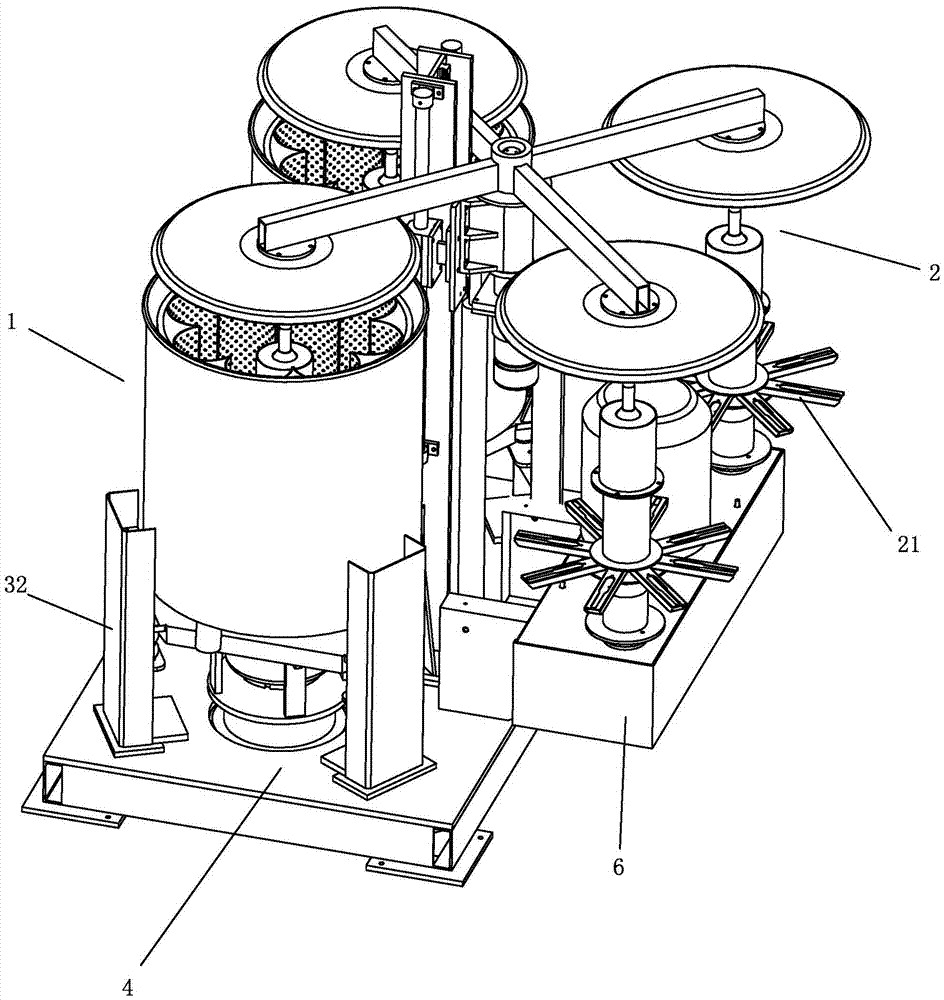

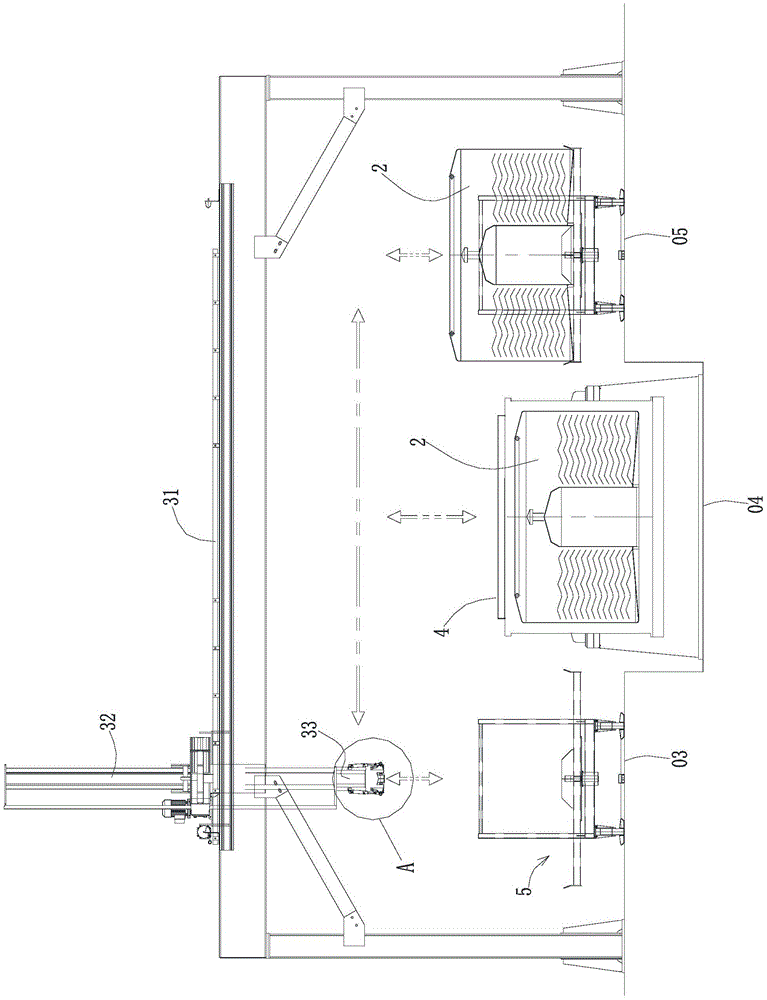

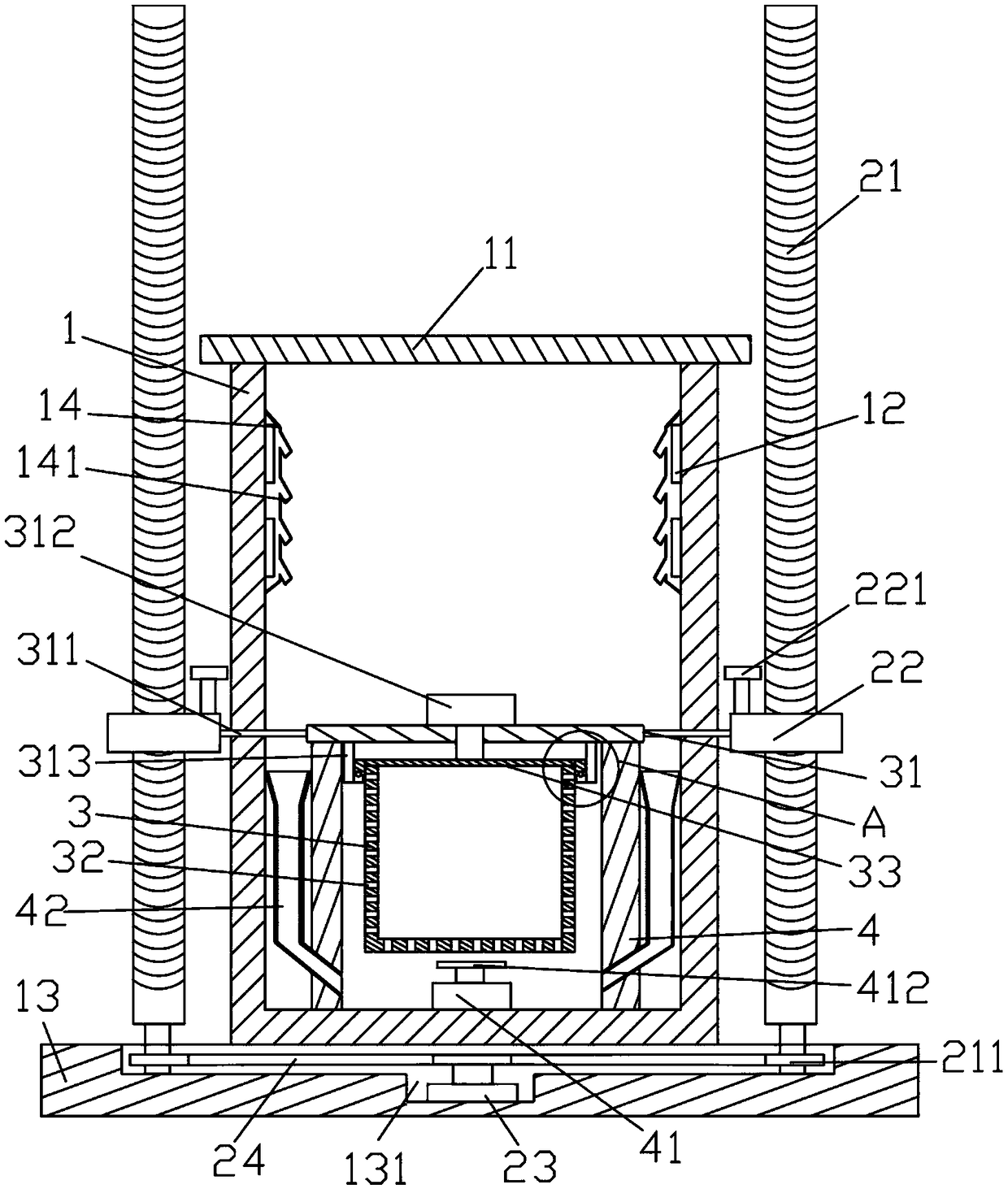

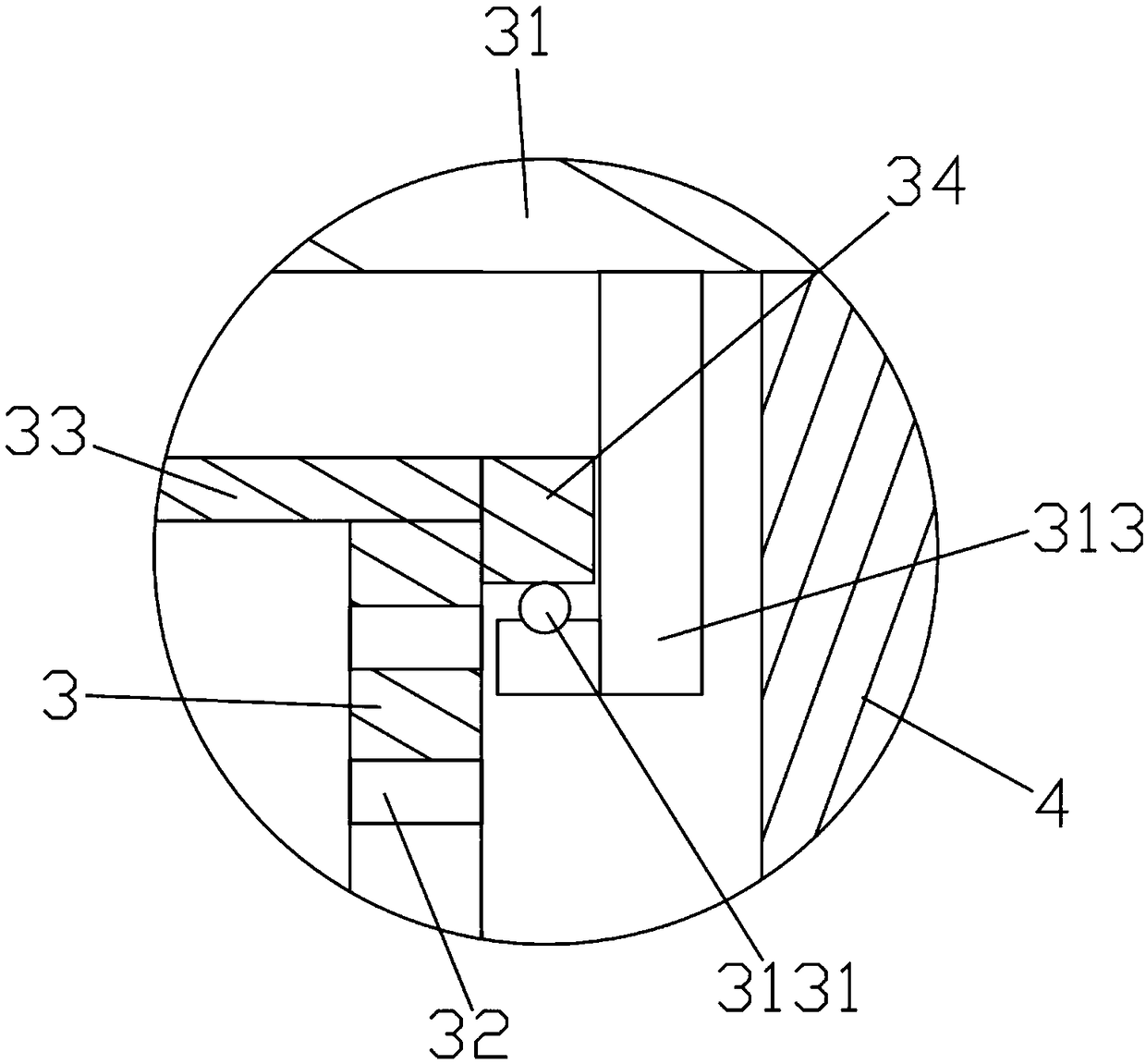

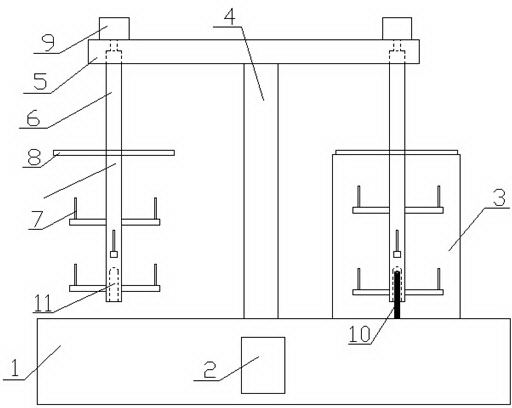

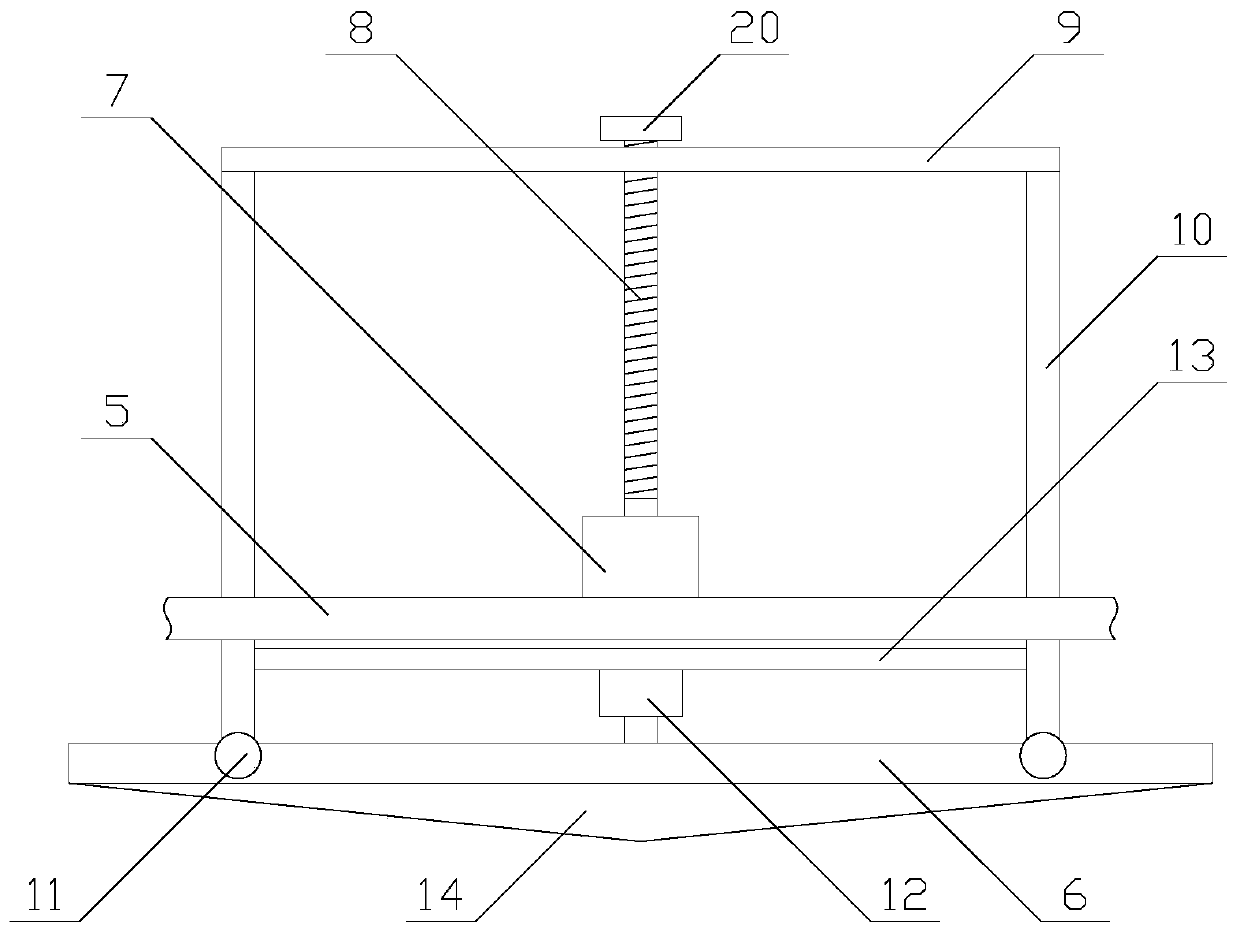

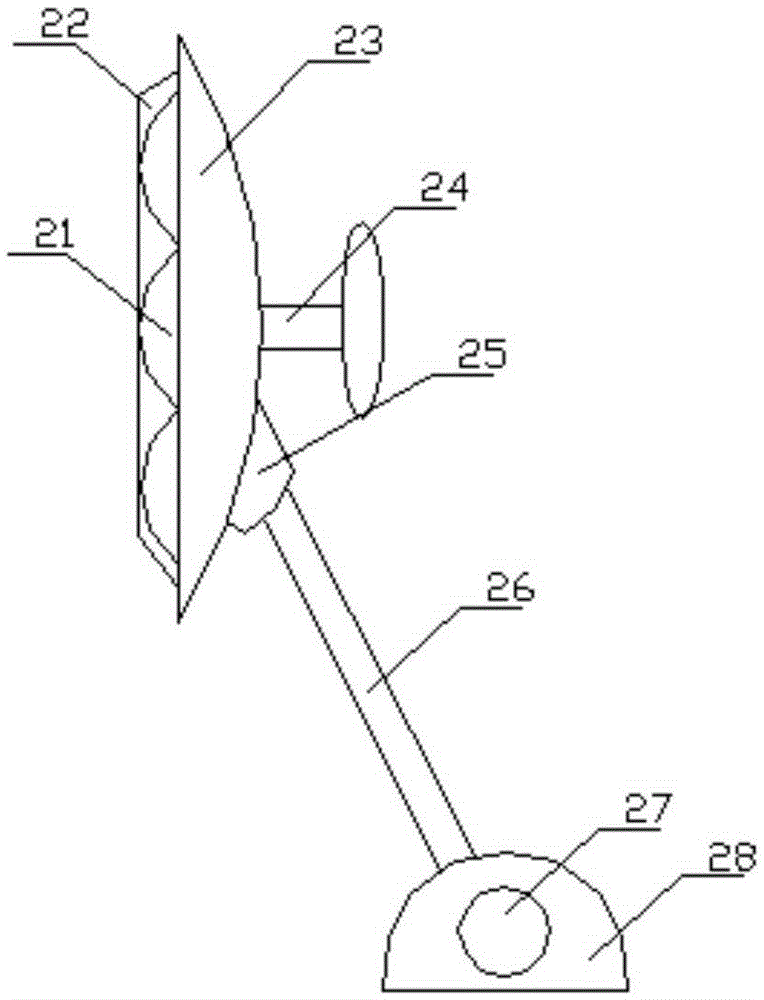

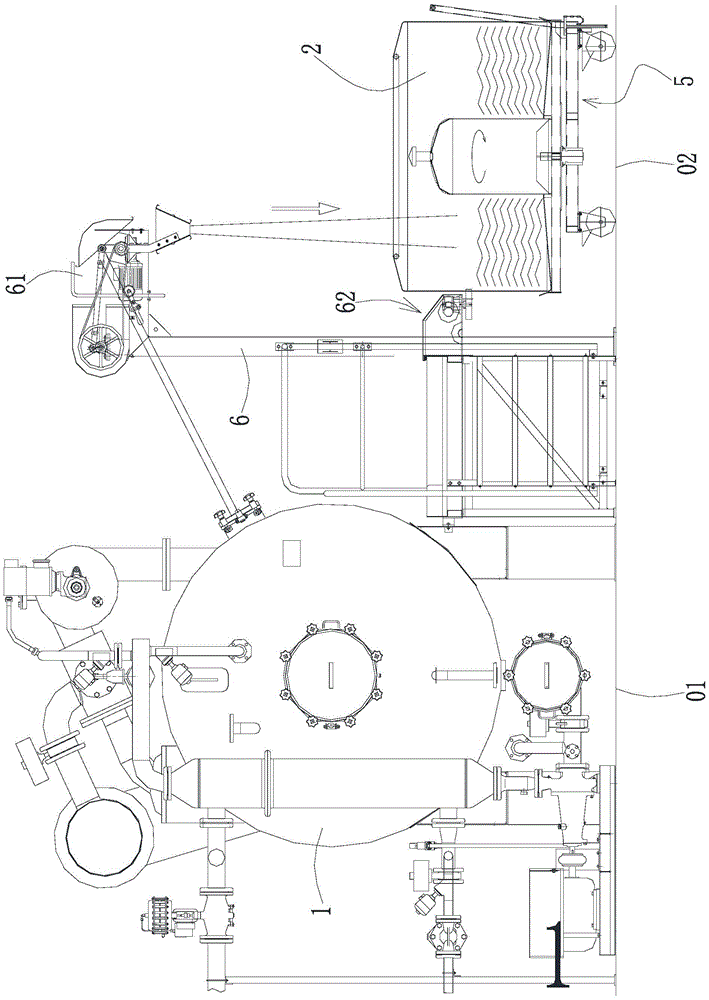

Inner cage conveying mechanical hand

The embodiment of the invention discloses an inner cage conveying mechanical hand. A connecting piece is arranged on an inner cage. The inner cage conveying mechanical hand is characterized by comprising a transverse guide rail, a longitudinal movement arm, and a clamping device arranged at the lower end of the longitudinal movement arm. The whole longitudinal movement arm can horizontally move leftwards and rightwards relative to the transverse guide rail. The longitudinal movement arm can drive the clamping device to move up and down. The clamping device comprises a body connected with the lower end of the longitudinal movement arm, a clamping head arranged at the lower end of the body and a clamping jaw pivoted to the clamping head. The clamping jaw can rotate relative to the clamping head so as to clamp or loosen the connecting piece on the inner cage. According to the inner cage conveying mechanism hand, the whole longitudinal movement arm can horizontally move leftwards and rightwards relative to the transverse guide rail, the longitudinal movement arm can drive the clamping device to move up and down, the clamping jaw of the clamping device can rotate relative to the clamping head to clamp or loosen the connecting piece of the inner cage, the structure is simple, and the inner cage conveying mechanical hand can be applied to a fabric centrifugal dewatering system to achieve inner cage clamping and conveying.

Owner:GAOWANLI TECH ZHONGSHAN CO LTD

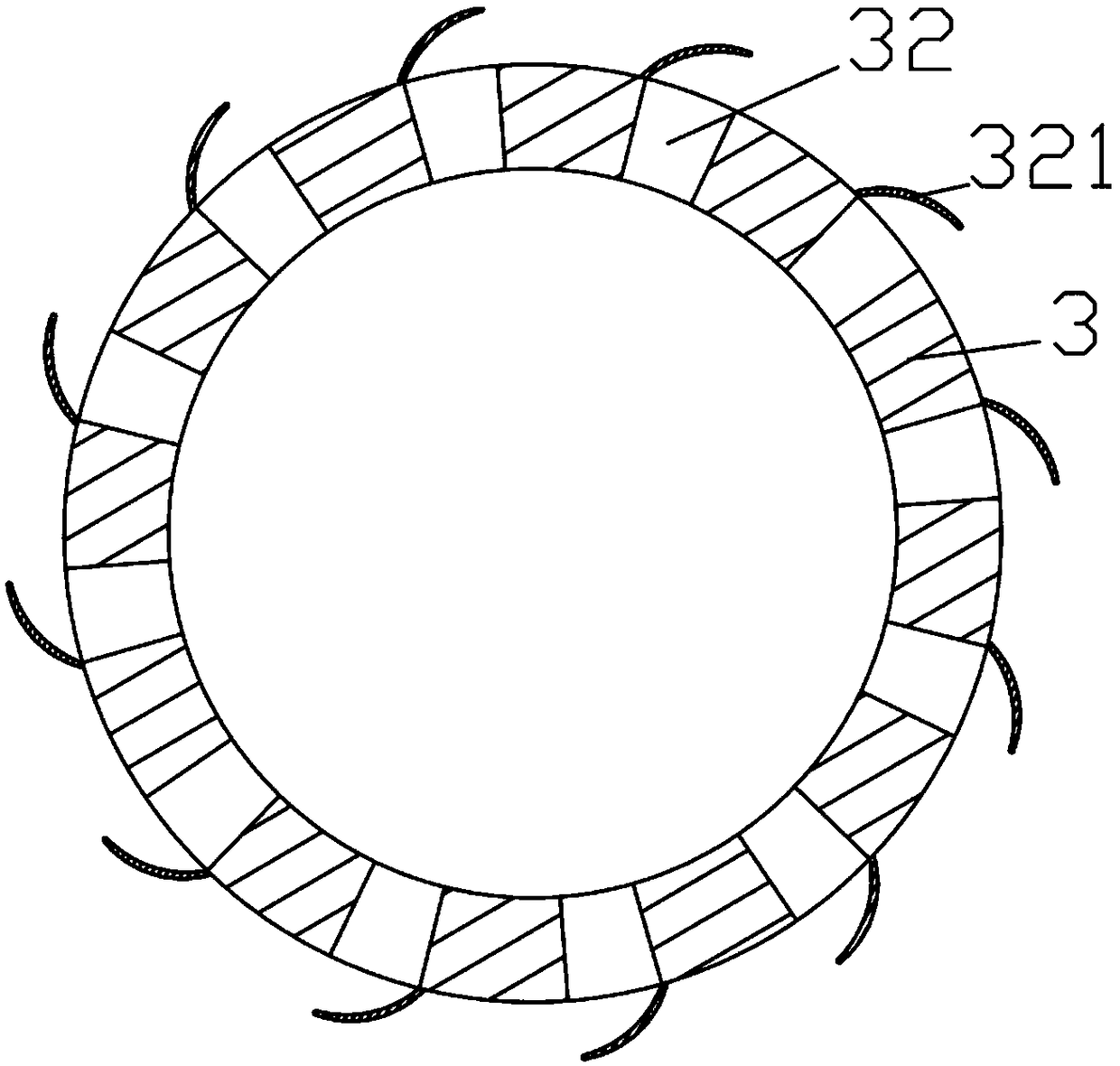

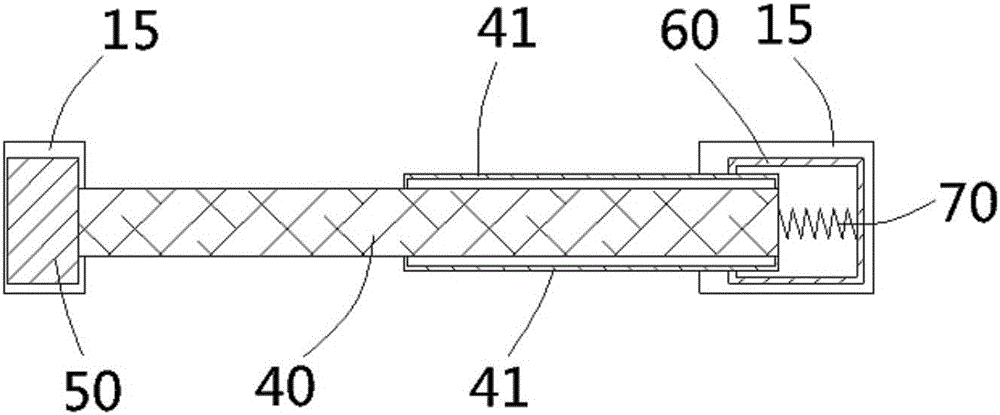

Dehydrator

InactiveCN101994221AExtended service lifeReduce loss rateTextile treatment machine partsLiquid/gas/vapor removal by centrifugal forceStopped workEngineering

The invention relates to a dehydrator. The dehydrator comprises a shell (2) and a rotating drum (3), wherein through holes (31) are distributed on the side face of the rotating drum (3); the lower surface of the bottom of the rotating drum (3) stretches downward to form a circular brake ring (32); a circular brake rail (5) which can be extended and retracted are arranged at the bottom of the shell (2); an annular brake pad (51) is tightly adhered and fixed on the outer side face of the circular brake rail (5); an oval rotating body (7) is movably embedded between the two ends of the circular brake rail (5); a spring (52) making the circular brake rail (5) retracted is connected to the two ends of the circular brake rail (5); and a vertical rotating shaft (71) of the oval rotating body (7)is connected with an electrical appliance controller. The dehydrator with the structure has the advantages that: data are input into the electrical appliance controller, the dehydrator can be automatically braked after a motor of the dehydrator stops working, and the rotating drum of the dehydrator is stopped; and the wastage rate of the annular brake pad is low, the service life of a brake is long, and the braking time is shorter due to the regulation reasonableness of the electrical appliance controller, so that dehydrating efficiency is higher.

Owner:华美线业有限公司

Production method of heat-accumulation and heating core-spun double-layered-structure yarn warm-keeping knitted fabric

ActiveCN106087218AIncrease warmthHigh hollownessWeft knittingHeating/cooling textile fabricsBobbinEngineering

The invention discloses a production method of a heat-accumulation and heating core-spun double-layered-structure yarn warm-keeping knitted fabric. The production method comprises the following steps: selecting fiber raw materials; a knitted fabric production process flow specifically comprising the following steps: skeining yarns and dissolving vinylon: preparing bobbin yarns, reeling and skeining, dissolving the vinylon, washing, drying, spooling, knitting and dyeing and finishing a knitted fabric; or dissolving the vinylon from the fabric: preparing the bobbin yarns, knitting, dissolving the vinylon, washing and dyeing and finishing the knitted fabric. The heat-accumulation and heating core-spun double-layered-structure yarn warm-keeping knitted fabric disclosed by the invention has a triple warm-keeping function of heat-accumulation and heating fibers, inner hollow parts of double-layered-structure yarns, double-rib air layer tissues and the like; if chemical fiber filaments have hollow parts, the warm-keeping woven fabric has a quadruple warm-keeping function of the heat-accumulation and heating fibers, the inner hollows parts of the double-layered-structure yarns, the hollow chemical fiber filaments, the double-rib air layer tissues and the like, so that the warm-keeping effect of the knitted fabric is extremely improved under the condition that the thickness is not increased.

Owner:IANGSU COLLEGE OF ENG & TECH

Device and method for cone yarn fixation aftertreatment

PendingCN106676792ASolve the technical problem that the liquid-carrying rate is higher than the liquid-carrying rate near the main shaft of the dehydratorEvenly charged rateLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor treatment of definite length materialsYarnPulp and paper industry

The invention relates to the technical field of reactive dyeing equipment, in particular to a device for cone yarn fixation aftertreatment. The device comprises a barrel body, a yarn barrel rotating shaft, a yarn barrel and a driving motor. The barrel body is divided into a dehydration chamber and a negative pressure chamber by a partition plate and provided with a water outlet communicated with the lower portion of the dehydration chamber. The yarn barrel rotating shaft is installed in the dehydration chamber, the driving motor is connected with the yarn barrel rotating shaft, the yarn barrel is tubular, through holes are evenly distributed in the outer circle surface of the yarn barrel, the yarn barrel is installed on the yarn barrel rotating shaft, the yarn barrel can be communicated with the negative pressure chamber through the yarn barrel rotating shaft, and the barrel body is provided with a negative pressure device interface communicated with the negative pressure chamber. The device for cone yarn fixation aftertreatment can make the liquid carrying rate of each part uniform after cone yarn fixation, and a fixation effect is improved.

Owner:SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD

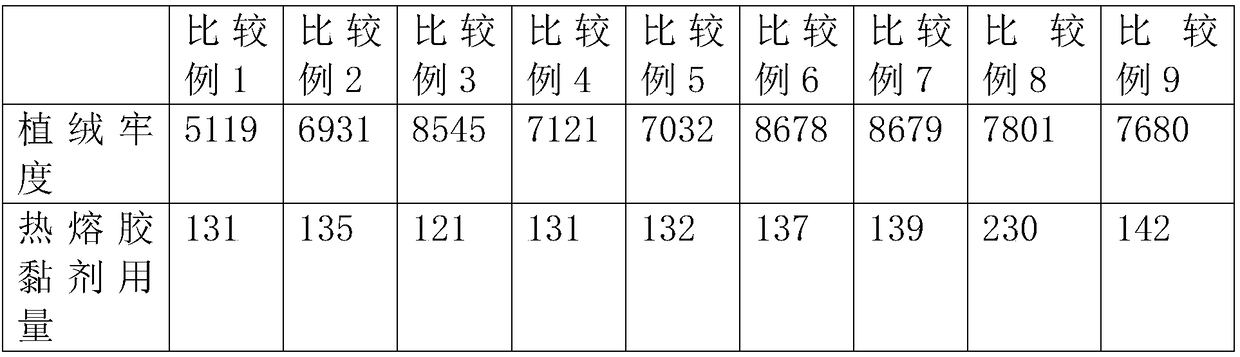

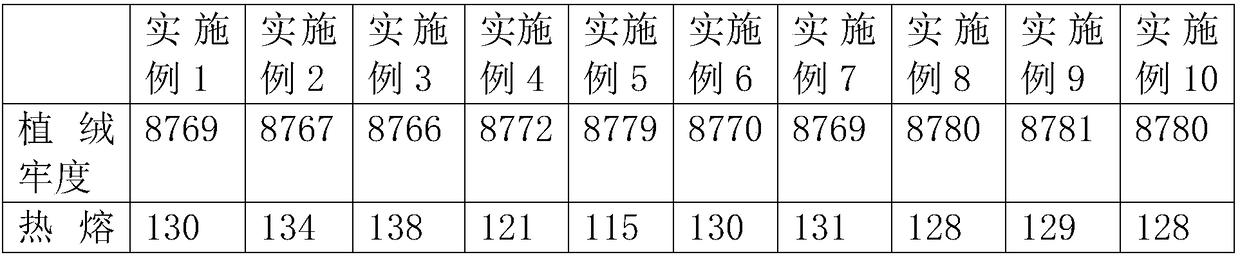

Flocking method of spunlace nonwoven fabric

ActiveCN109457503AImprove flocking fastnessNot easy to take off fleeceLiquid surface applicatorsNon-macromolecular adhesive additivesAdhesiveNonwoven fabric

The invention relates to the technical field of textile, and provides a flocking method for a spunlace nonwoven fabric, which aims at solving the problem of liability in removal of the flocks on the spunlace nonwoven fabric due to water washing. The flocking method specifically comprises the following steps of (1) applying of adhesive: applying the melted heat melt adhesive to the outer surface ofthe spunlace nonwoven fabric; (2) flocking: implanting the flocks to the surface of the spunlace nonwoven fabric by electrostatic charge, and arranging a heater in a flocking chamber; (3) dewatering:soaking the spunlace nonwoven flocked fabric after electrostatic flocking into water, and centrifugally dewatering; (4) drying: putting the spunlace nonwoven flocked fabric in step (3) into a dryer for drying, and finally coiling. The flocking method has the advantage that after water soaking and centrifugal dewatering, the un-firmly adhered flocks on the spunlace nonwoven fabric can be easily washed out, so as to improve the flocking firmness of the spunlace nonwoven flocked fabric, and avoid the liability in removal of the flocks on the spunlace nonwoven flocked fabric.

Owner:国源新材料(广州)有限公司

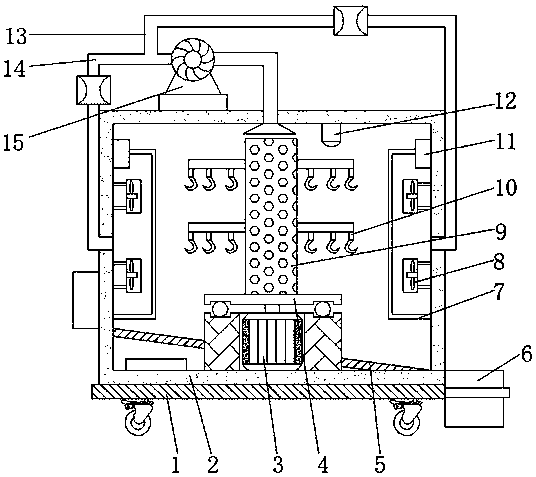

Cloth dyeing machine

ActiveCN108660646AQuick drying processAvoid wastingTextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forcePulp and paper industryTherapeutic effect

The invention discloses a cloth dyeing machine. The machine comprises a box, a dyeing cylinder arranged in the box and a base arranged at the bottom of the box, and a top cover detachably connected with the top of the box is arranged at the top of the box; the dyeing cylinder is arranged at the bottom of the box, a drying device is arranged above the dyeing cylinder, an automatic lifting device isarranged on the base and connected with a bearing plate, and a rotatable loading box is arranged below the bearing plate. According to the cloth dyeing machine, dyed cloth can be quickly dried, the drying treatment effect is improved, dyeing liquid during drying treatment can be recycled, the situation is avoided that a large amount of dyeing liquid is wasted, and the cloth dyeing machine is highin practicability and beneficial to environmental protection.

Owner:南通东晨服饰有限公司

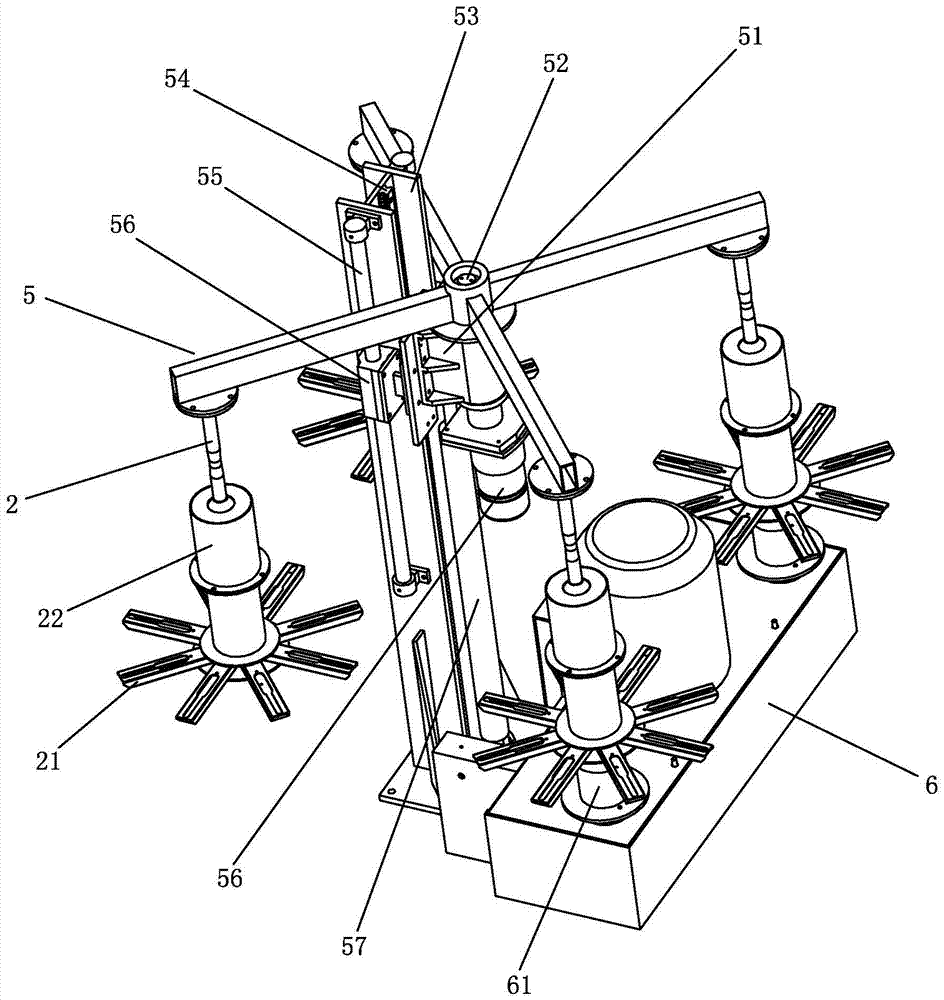

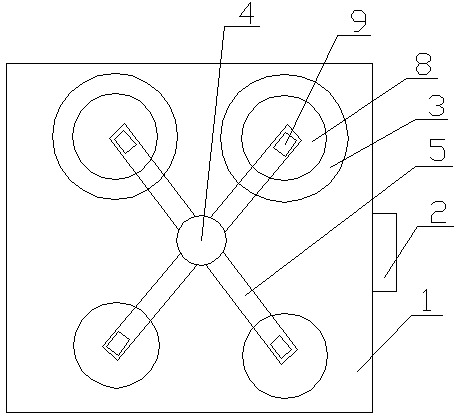

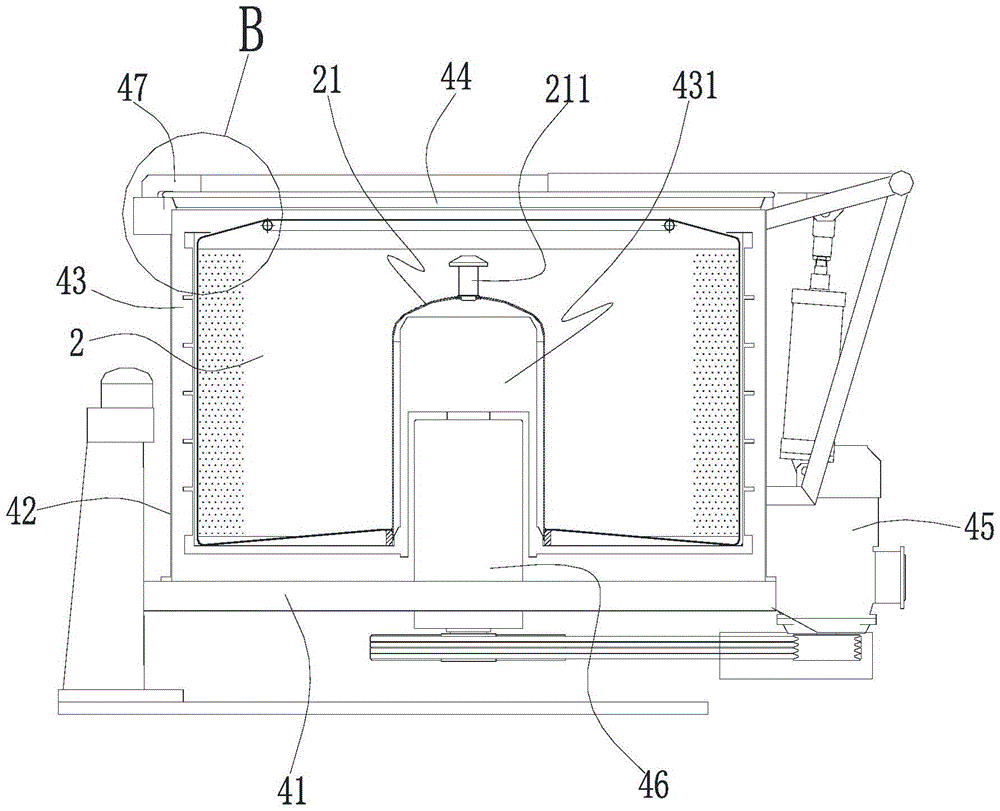

Textile centrifugal dewatering system

ActiveCN105506885ASimple processImprove dehydration efficiencyLiquid/gas/vapor removal by centrifugal forceEngineeringManipulator

The embodiment of the invention discloses a textile centrifugal dewatering system. The system at least comprises inner cages, a manipulator and a centrifugal machine, wherein the centrifugal machine is fixedly arranged at a centrifugal dewatering position; the inner cages can enter into the centrifugal machine at the centrifugal dewatering position from a to-be-dewatered position, and then enter into an after-processing position from the centrifugal machine at the centrifugal dewatering position; the manipulator can move among the to-be-dewatered position, the centrifugal dewatering position and the after-processing position, and is used for conveying the inner cages into the centrifugal machine at the centrifugal dewatering position and to the after-processing position sequentially from the to-be-dewatered position; the centrifugal machine is used for driving the inner cages to rotate in a circumferential direction so as to dehydrate water-containing textiles in the inner cages. According to the embodiment of the invention, in the whole process of centrifugal dewatering, the textiles are in the same inner cage all the way, a transfer basket or a textile conveynig frame is not needed, the textiles do not need to be conveyed in and out frequently, dehydration of one inner cage can be performed immediately after the dehydration of the front inner cage is finished, the process is simple, and the dehydration efficiency is enhanced greatly.

Owner:GAOWANLI TECH ZHONGSHAN CO LTD

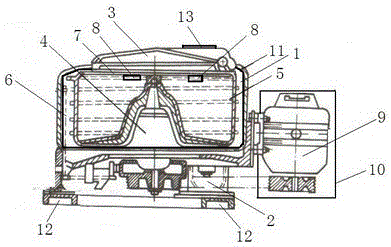

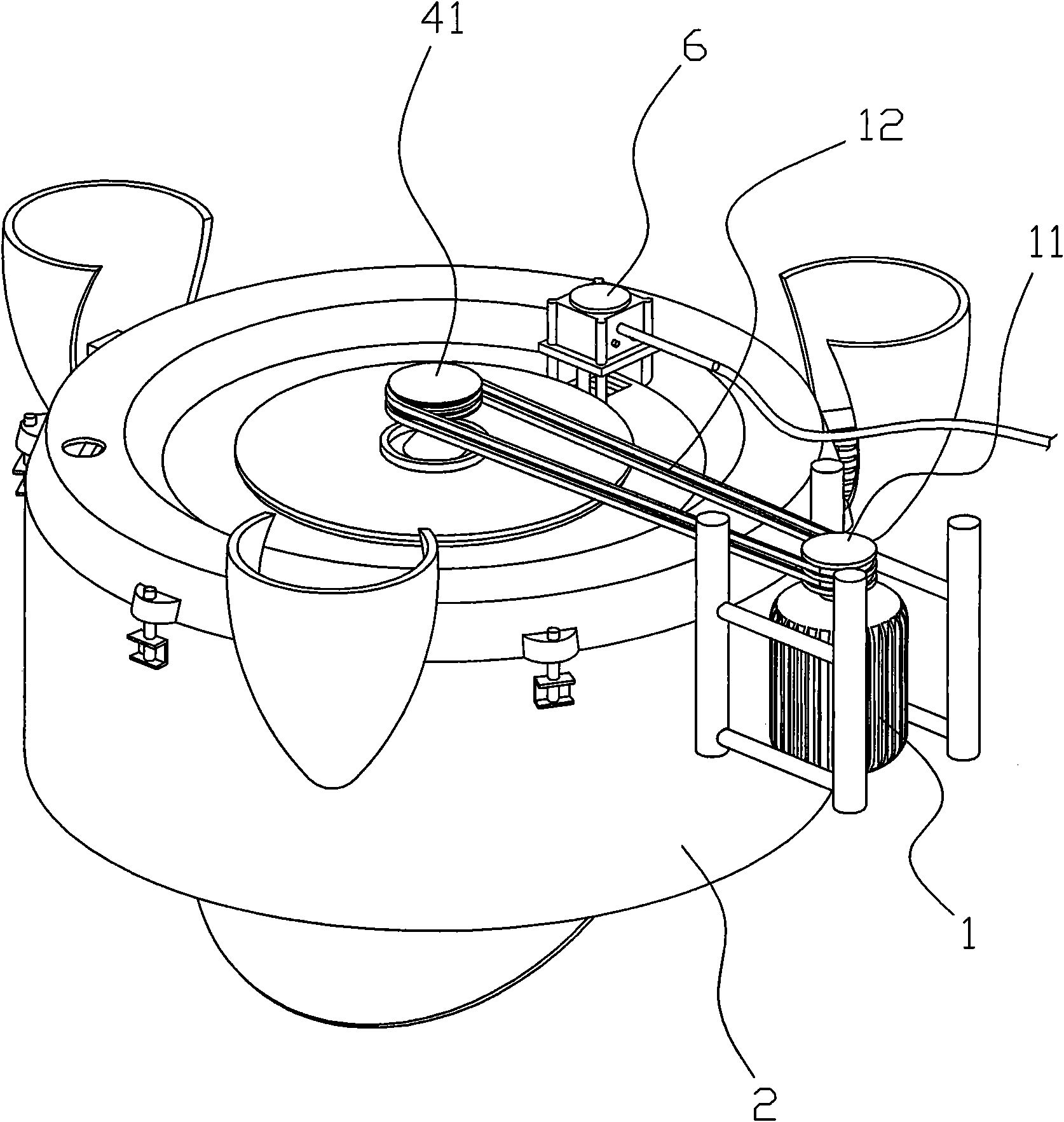

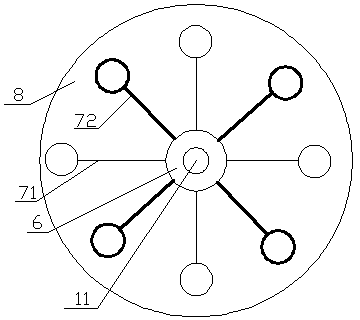

Dehydration device used after bobbin yarn is dyed and for production

ActiveCN104047138ARealize dehydration operationAvoid closeLiquid/gas/vapor removal by centrifugal forceYarnBobbin

The invention aims at providing a dehydration device used after bobbin yarn is dyed and for production. The dehydration device comprises a base, a control cabinet, dehydration barrels and a lifting rotary frame, wherein the control cabinet and the dehydration barrels are located on the base, and the lifting rotary frame is located on the base. At least four bobbin yarn frames are arranged on the lifting rotary frame through a support, and the number of the dehydration barrels is at least two. Each bobbin yarn frame comprises a center strut, bobbin yarn stringing columns and a barrel cover, the bobbin yarn stringing columns are arranged on the periphery of each center strut on multiple layers up and down, the bobbin yarn stringing columns on adjacent layers are arranged in a staggered mode, and the height of each bobbin yarn stringing column is 4 / 5 to 5 / 6 that of the bobbin yarn. The barrel covers are located above the corresponding bobbin yarn stringing columns, rotary motors are arranged on the support, the top ends of the center struts penetrate through the corresponding barrel covers and the support to be connected with rotary shafts of the rotary motors, fixing columns are arranged at the bottom portions of the dehydration barrels, and fixing holes matched with the fixing columns are formed in the end faces of the bottom portions of the center struts. Dehydration efficiency can be effectively improved, the dehydration effect is enhanced, and the bobbin yarn is more convenient to demount and mount.

Owner:WUHU FUCHUN DYEING & WEAVING

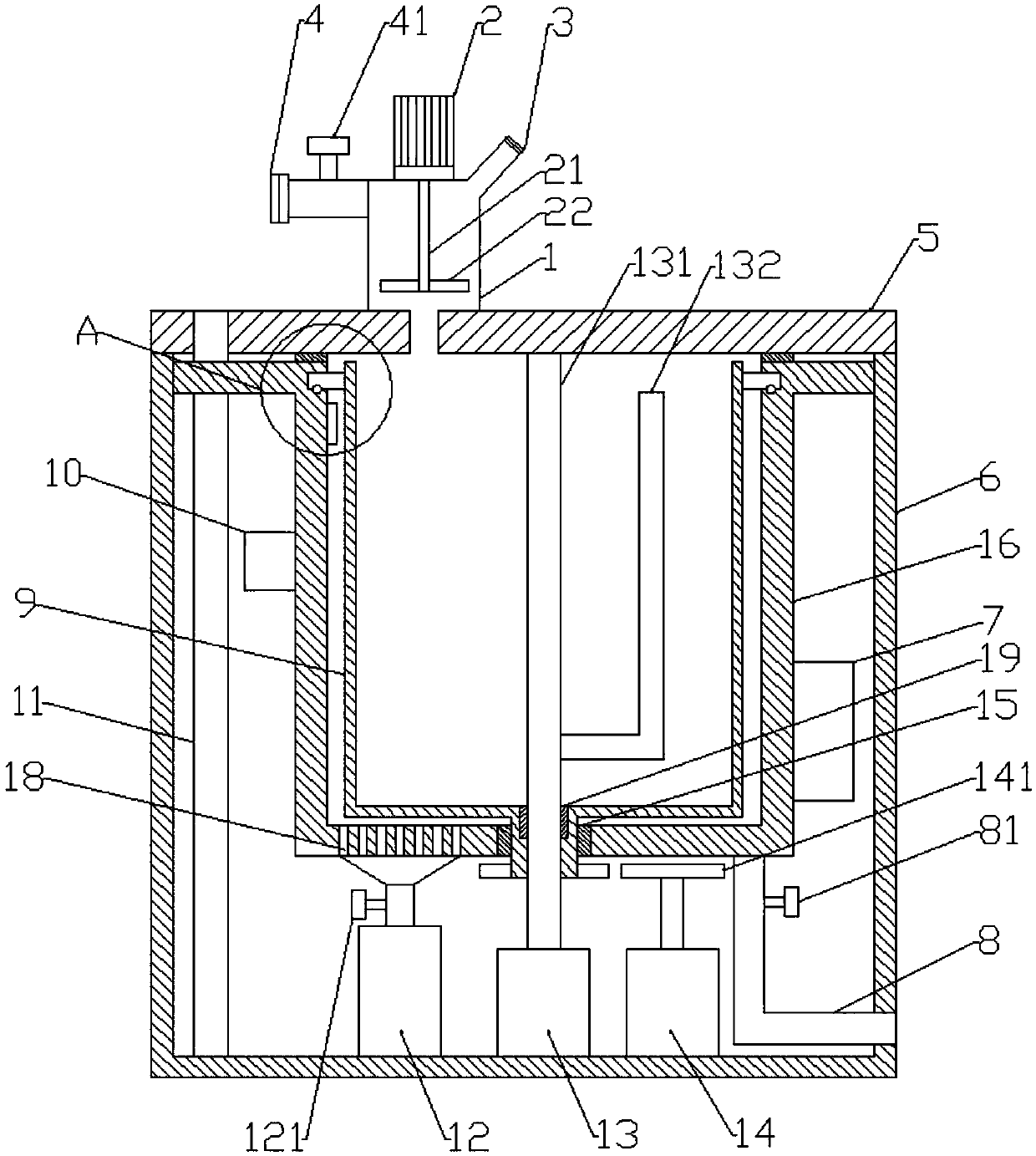

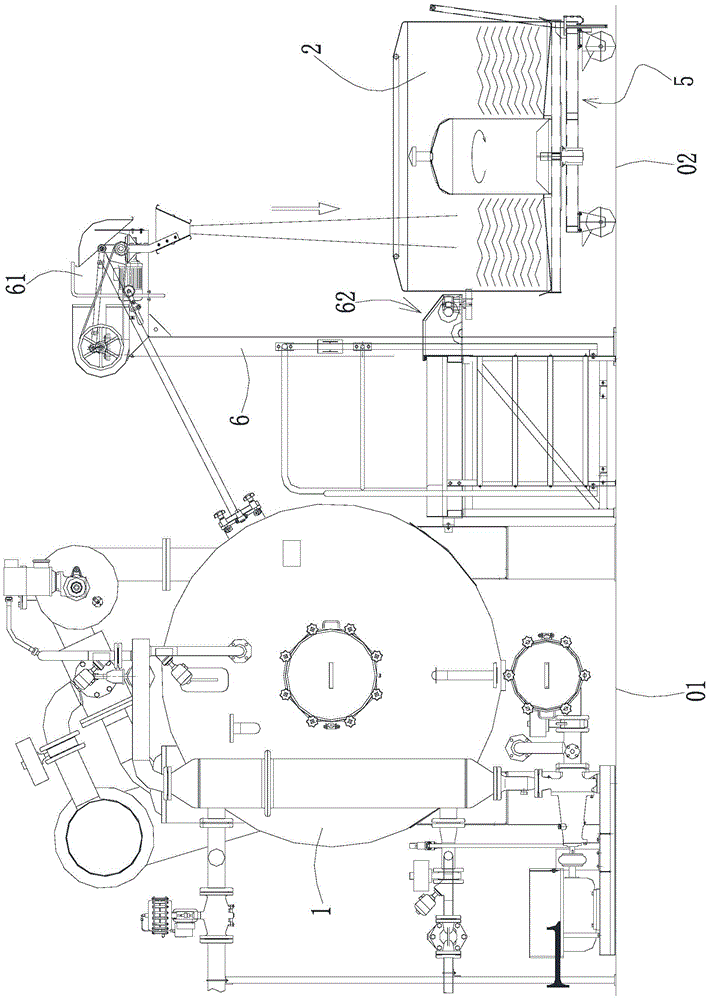

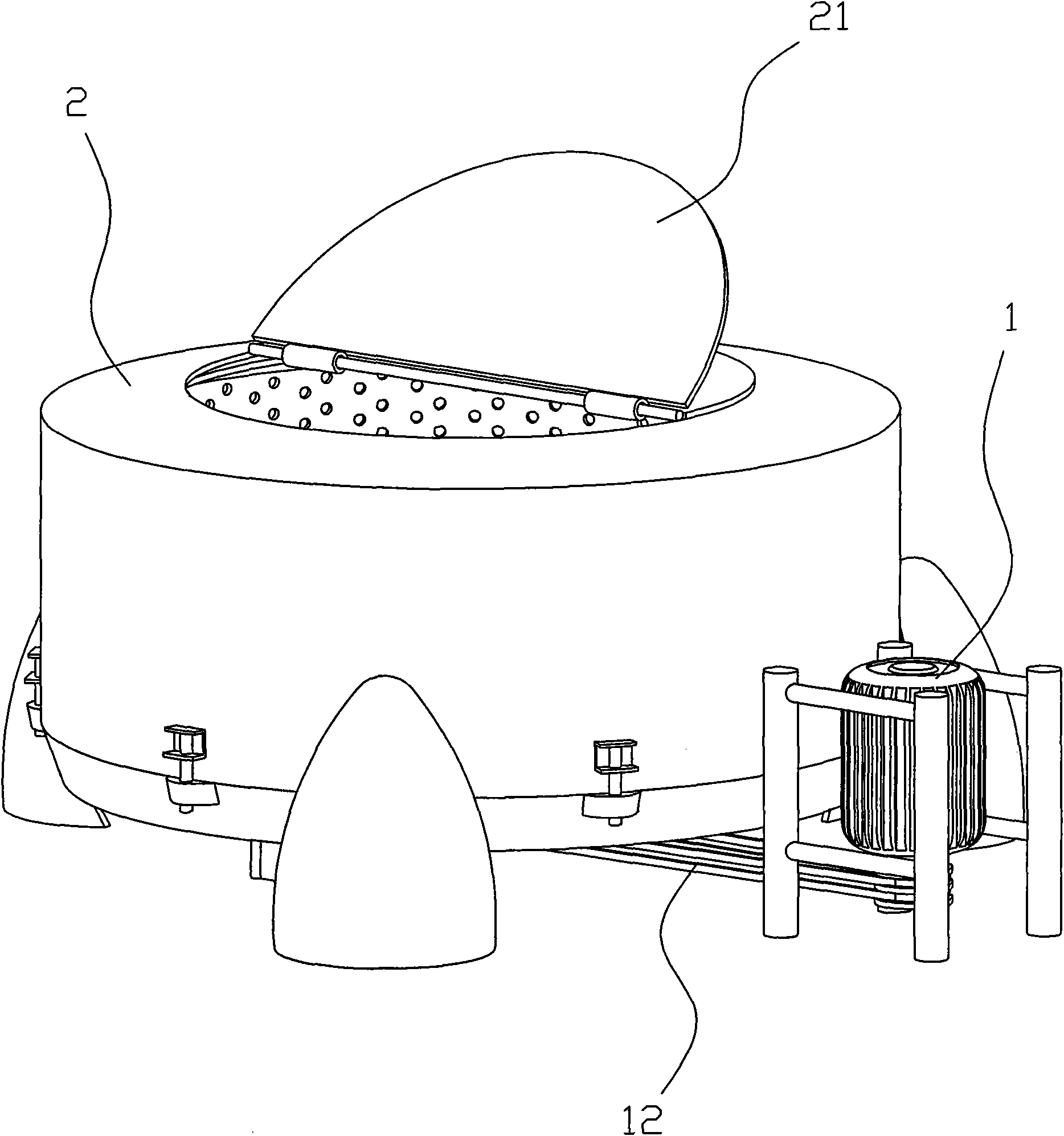

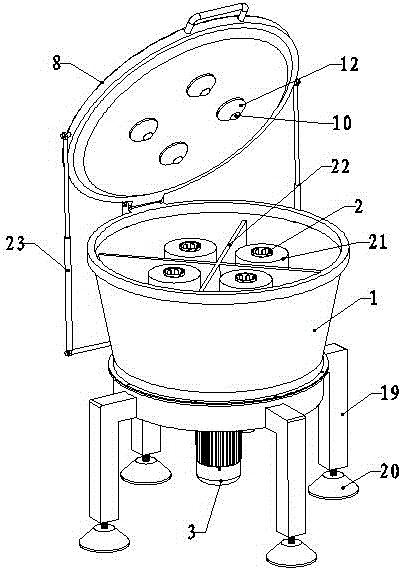

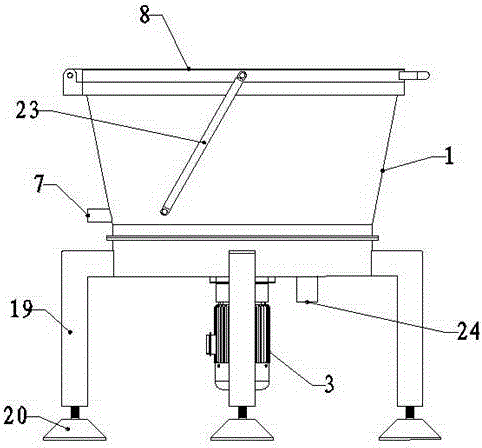

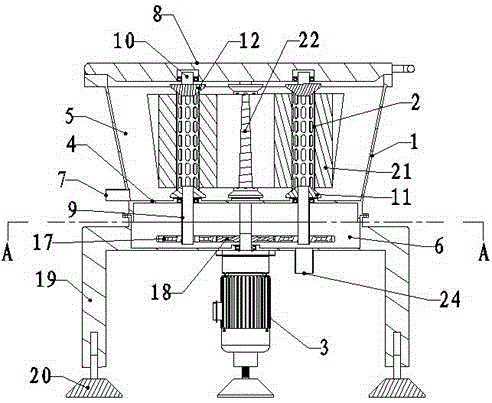

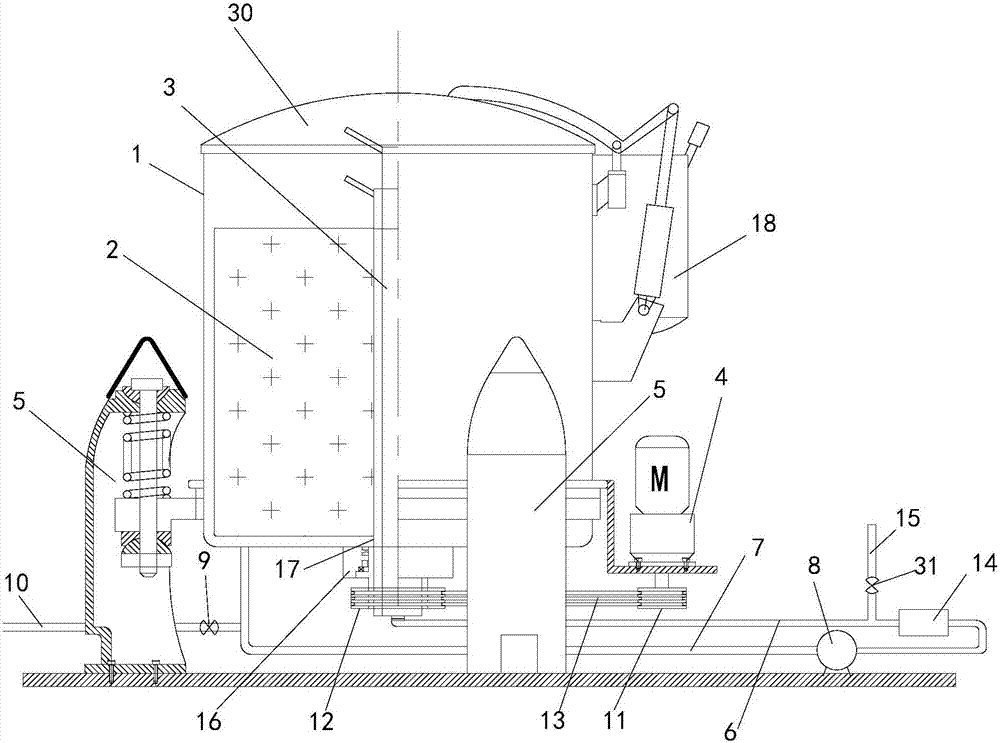

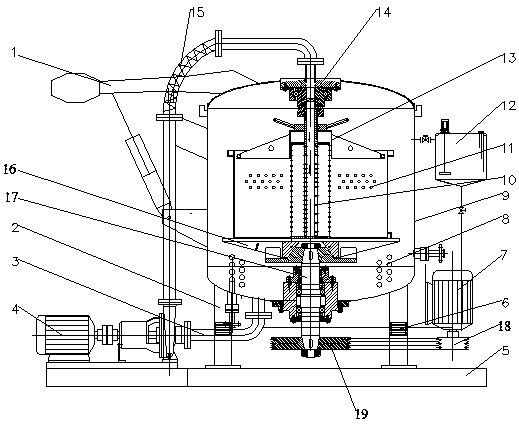

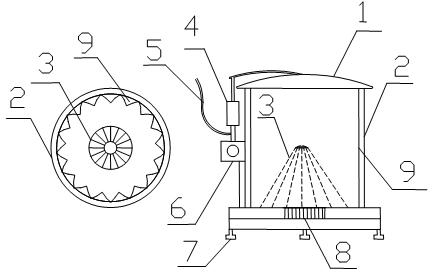

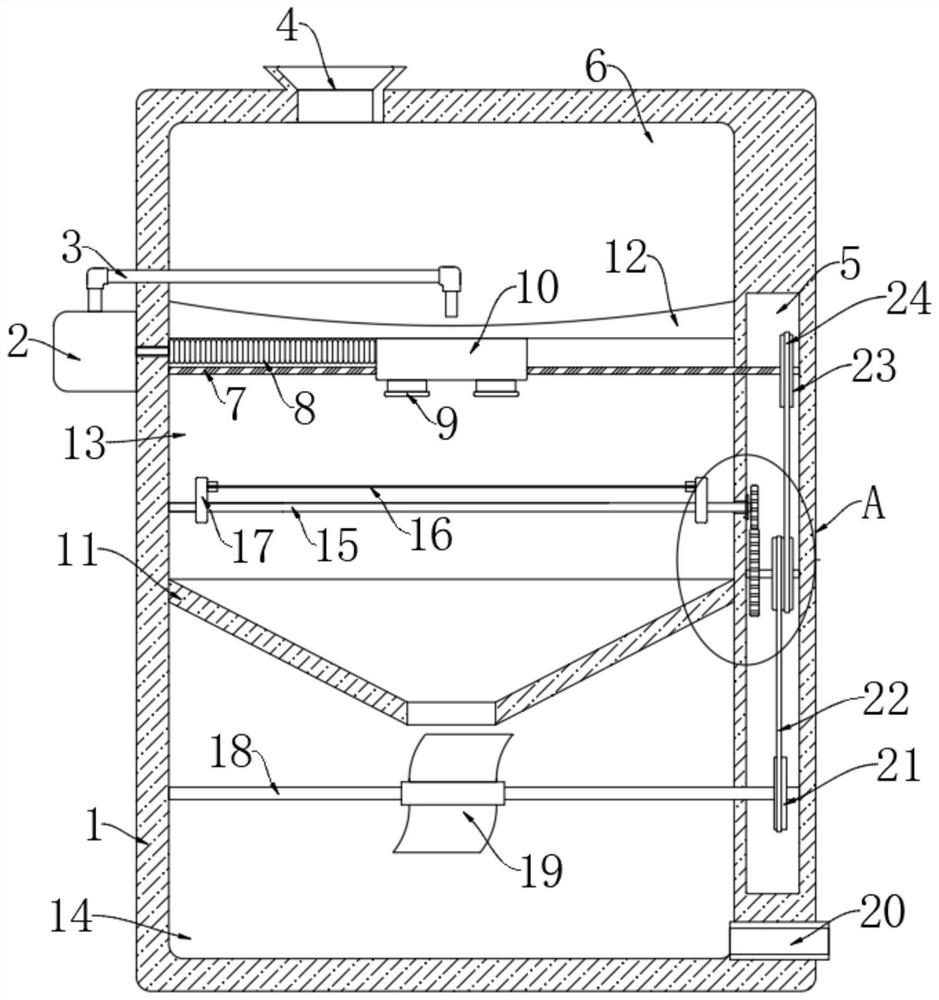

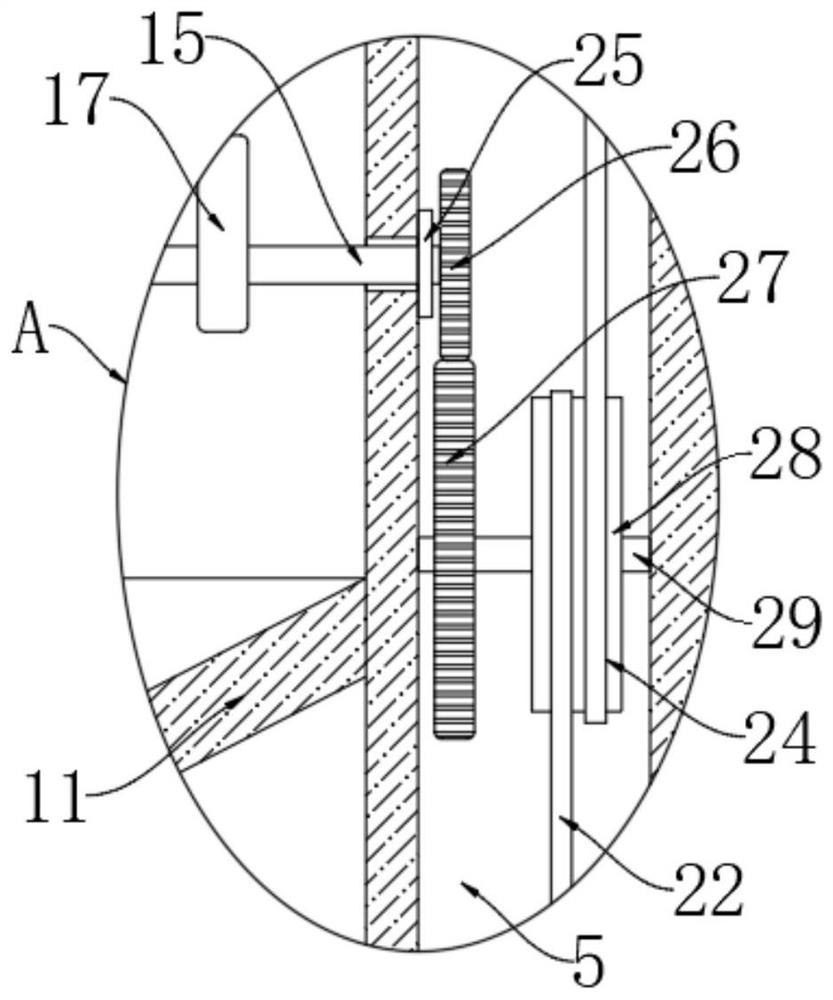

Loose fiber centrifugal dehydration dyeing device

PendingCN108004692AReduce residual dyeReduce chemicalsTextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forceFiberMaster cylinder

The invention relates to a loose fiber centrifugal dehydration dyeing device which comprises a main cylinder. A loose fiber cage is arranged in the main cylinder and comprises a central sleeve and anouter barrel, the central sleeve is arranged in the outer barrel, a plurality of small holes are formed in the central sleeve and the outer barrel, a central screw is arranged in the central sleeve, amotor is arranged outside the main cylinder, the central screw is fastened and connected with the loose fiber cage, a power output end of the motor is in transmission connection with the central screw and can drive the central screw to carry the loose fiber cage to rotate in the main cylinder, at least three suspension systems which are connected with the main cylinder are arranged on the peripheral side of the main cylinder, a water outlet end of a circulation washing and dyeing system is communicated with the central sleeve, and a water inlet end of the circulation washing and dyeing systemis communicated and connected with a drain opening of the main cylinder. The loose fiber centrifugal dehydration dyeing device has the advantages that loose fibers loaded in the loose fiber cage canbe centrifugally dehydrated by the loose fiber centrifugal dehydration dyeing device, accordingly, residual dye and chemicals in the loose fibers can be reduced to a great extent, the washing frequencies can be reduced, and water, power and the time can be saved; energy can be saved in operation procedures of the loose fiber centrifugal dehydration dyeing device, environments can be protected in the operation procedures of the loose fiber centrifugal dehydration dyeing device, and the dyeing quality can be greatly improved.

Owner:杭州鼎飞数控技术合伙企业(普通合伙)

High-efficiency processing equipment with high stability for cashmere dehydration

InactiveCN109763283APracticalImprove stabilityLiquid/gas/vapor removal by centrifugal forceAxial forceEngineering

The invention relates to high-efficiency processing equipment with high stability for cashmere dehydration. The equipment comprises a main body, a control panel, a dehydration cylinder and at least three brackets, wherein the control panel is arranged on the main body, and a water outlet hole is formed in the bottom of the main body; the brackets are arranged at the bottom of the main body; the dehydration cylinder is arranged in the main body; a driving device is arranged at the bottom of the main body and in transmission connection with the dehydration cylinder; an auxiliary mechanism and anadjusting mechanism are arranged on the main body. The high-efficiency processing equipment with high stability for cashmere dehydration extrudes moisture in cashmere through the auxiliary mechanism,so that dehydration efficiency is improved; moreover, uniformity of the cashmere in the dehydration cylinder is adjusted by the adjusting mechanism, intensified vibration and noise caused by larger axial force to the dehydration cylinder in the rotation process are avoided, and stability is improved.

Owner:GUANGZHOU SONGBIN ENG TECH CO LTD

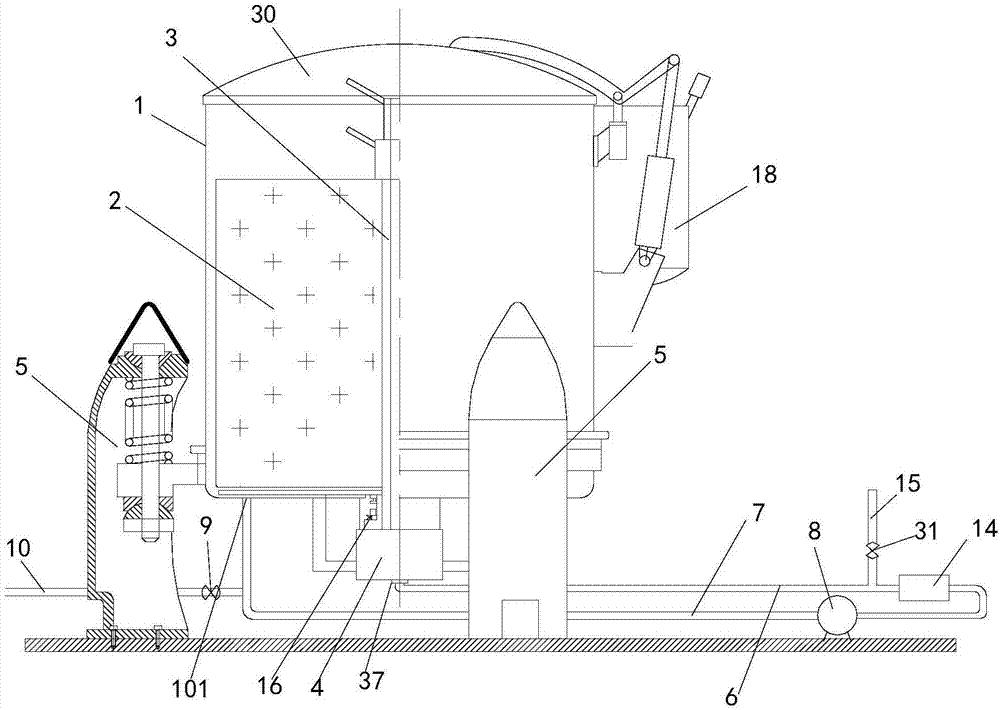

Environment-friendly energy-saving loose-wool dyeing and dehydrating all-in-one machine

ActiveCN108978070AOptimize the dyeing processSimple processSucessive textile treatmentsTextile treatment machine arrangementsFiberMaster cylinder

The invention discloses an environment-friendly energy-saving loose-wool dyeing and dehydrating all-in-one machine, and the machine comprises a pedestal. The pedestal is provided with a dye liquor circulating pump and a main cylinder body. The main cylinder body is fixed on the pedestal through a support connection system, and a dehydrating motor is connected below the main cylinder body. The interior of the main cylinder body is provided with a loose-wool cage and a dye liquor heating system. The main cylinder body is also provided with a charging system, and the top of the main cylinder bodyis provided with a dye liquor spraying nozzle. The all-in-one machine can optimize the water circulation, improve efficiency, reduce the waste of water resources, save water and energy, and reduce the number of water cleaning times. The all-in-one machine is better in stability and balance for the processing of loose fibers (more than 150kg). Dyeing equipment and dehydrating equipment are perfectly combined into the all-in-one machine, thereby shortening the technological process, reducing the labor intensity, reducing the equipment investment, alleviating the environment protection pressure,achieving the low-investment and high yield purpose, and maximizing the benefits.

Owner:ZHONGYUAN ENGINEERING COLLEGE

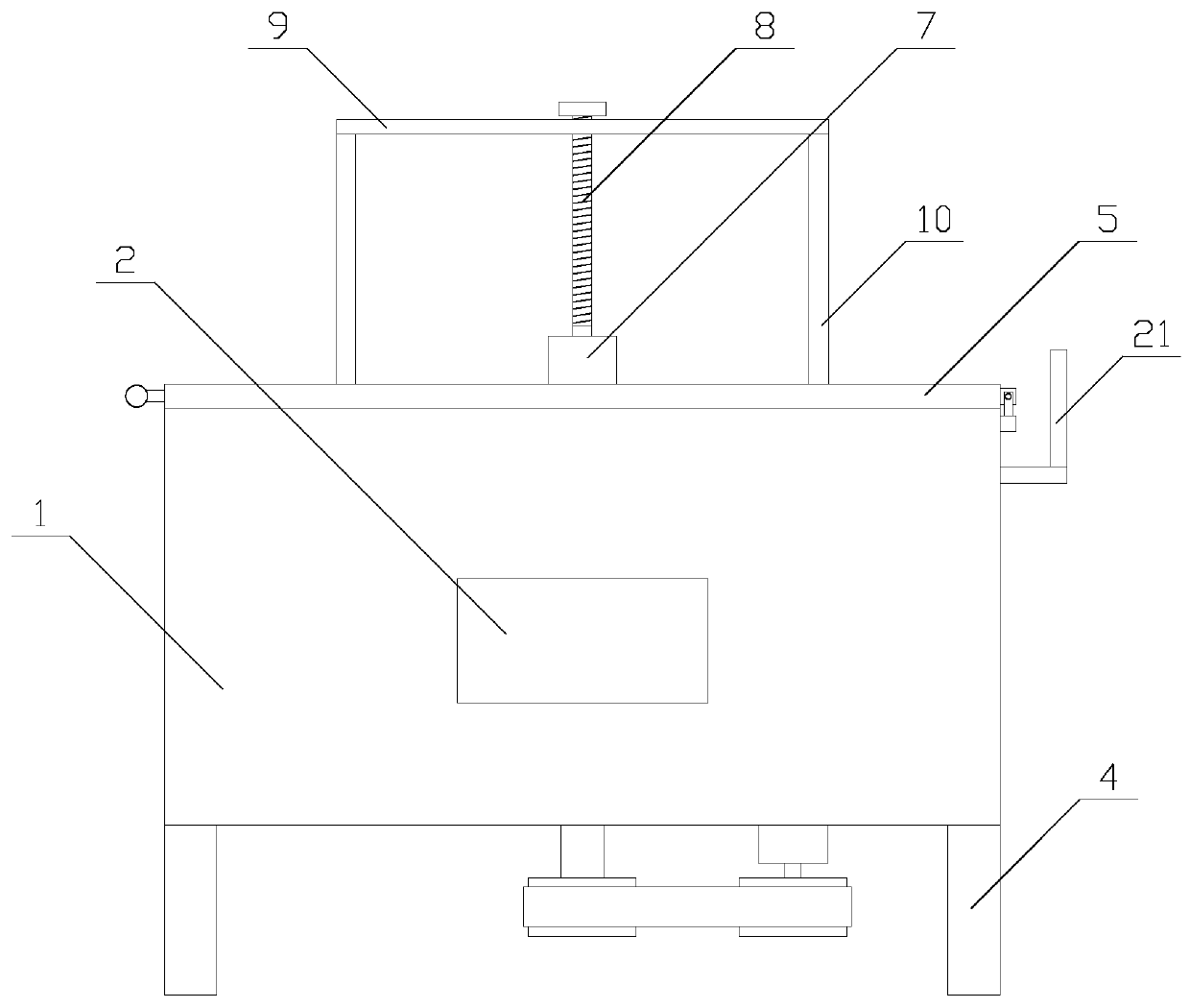

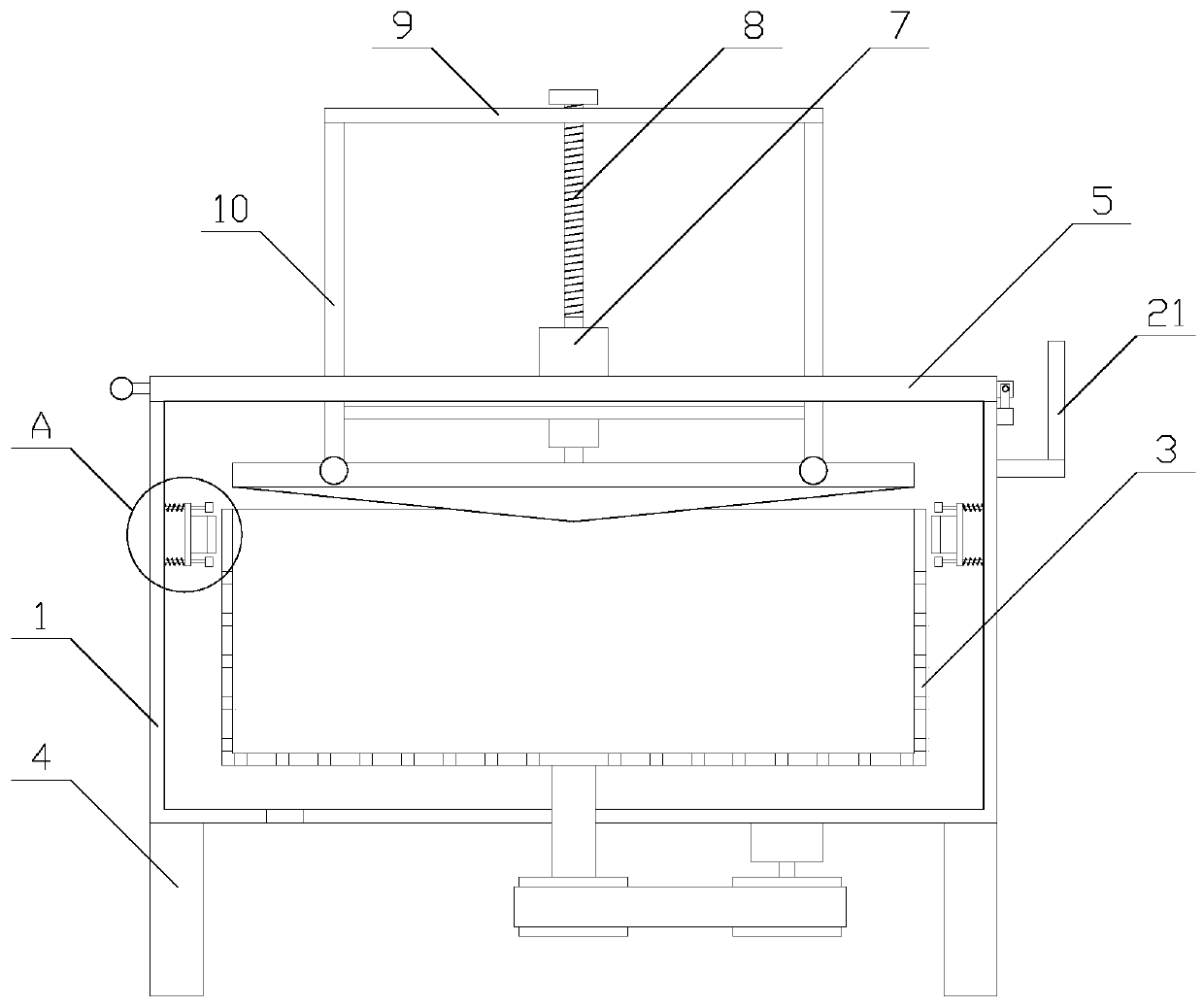

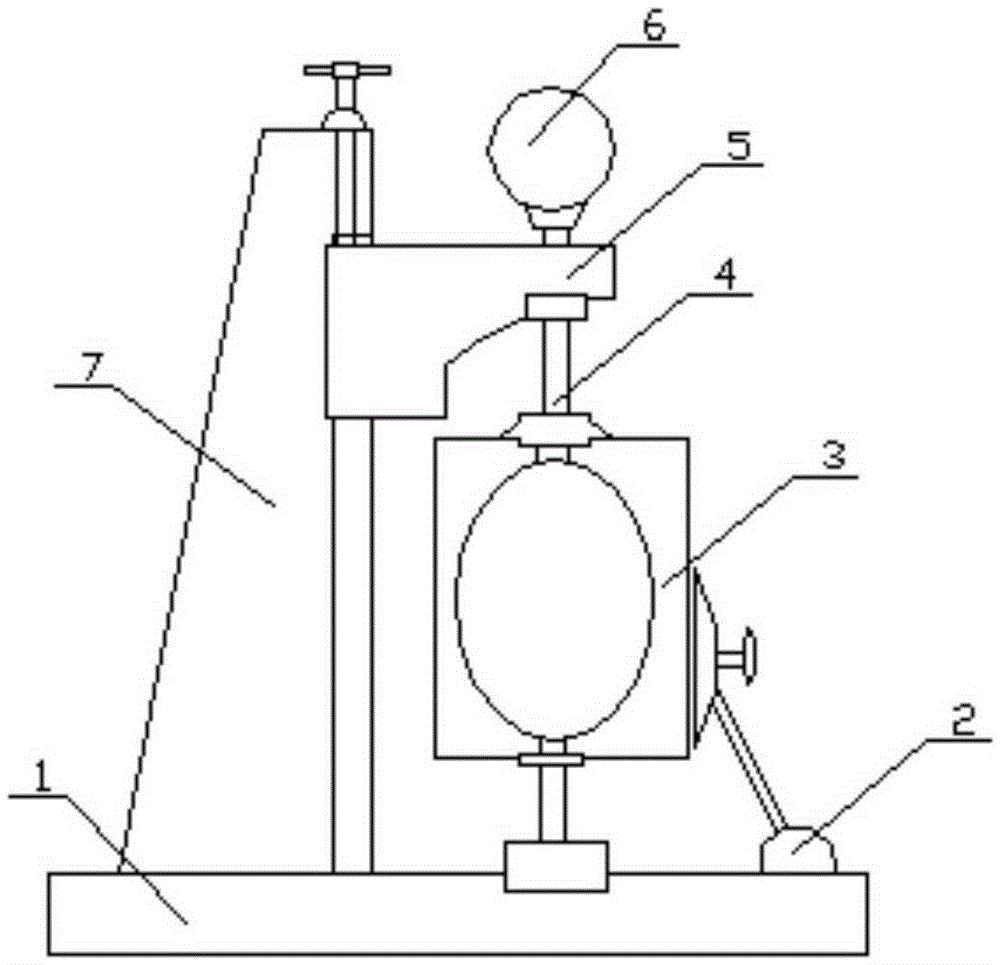

Drying equipment

ActiveCN105274756AEasy to operateEasy to adjustLiquid/gas/vapor removal by centrifugal forceDrive shaftEngineering

The present invention relates to the technical field of machinery equipment and particularly relates to drying euipment. The drying equipment comprises a bottom plate, a host machine frame arranged at one side of the upper end of the bottom plate, a lifting member, a driving shaft which goes through the lifting member, a driving component, a drying barrel and a pressing component. The drying barrel comprises a main barrel body, a first transmission seat, a driven shaft, a rotation chassis, a support ring, an inner rotation cylinder, a connection cover, a side plate and an extrusion block. The drying equipment has the advantages of easy operation, convenient adjustment, and high drying efficiency.

Owner:RUGAO LANTU KNITTING CLOTHING CO LTD

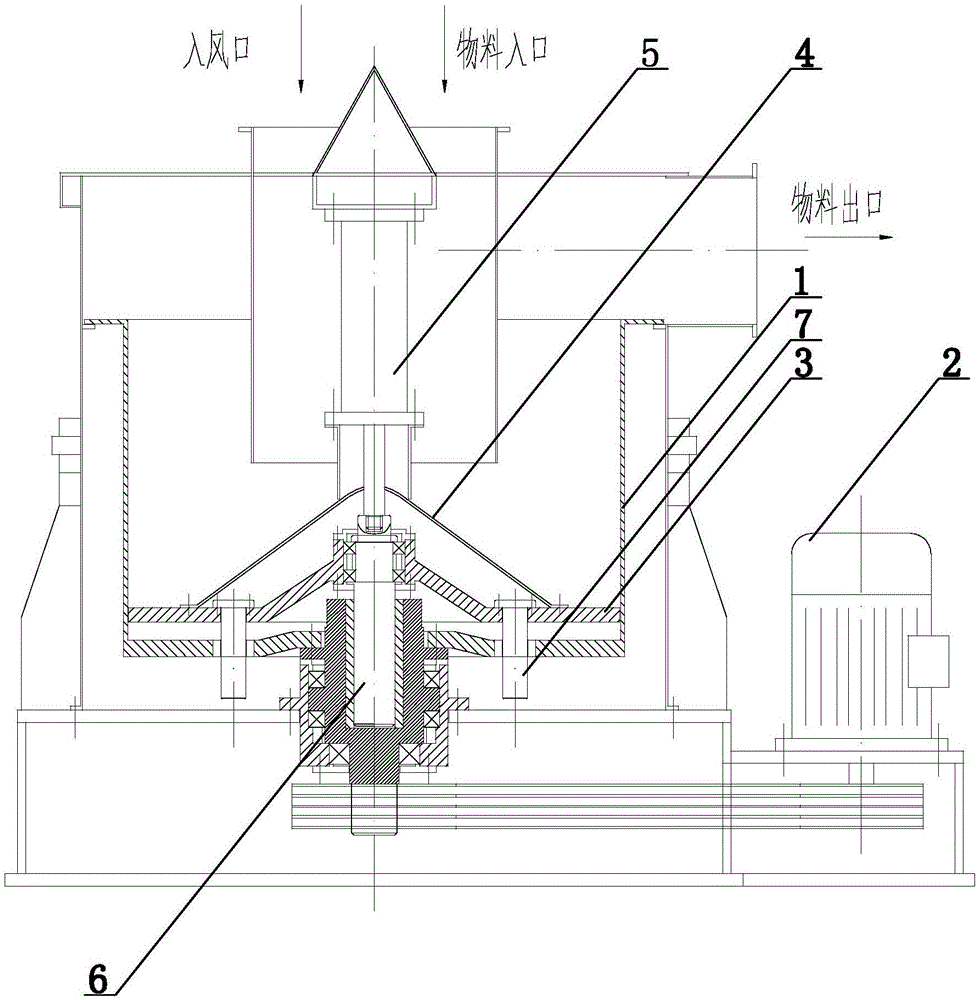

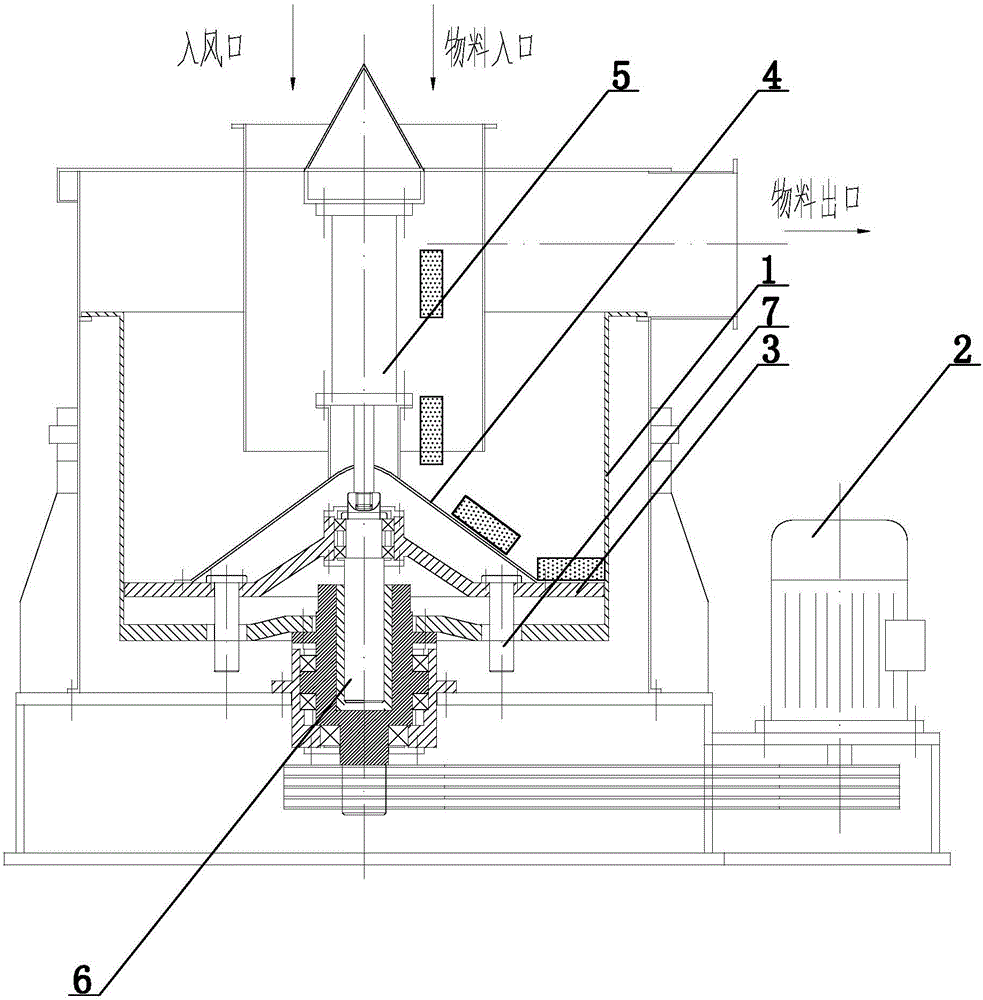

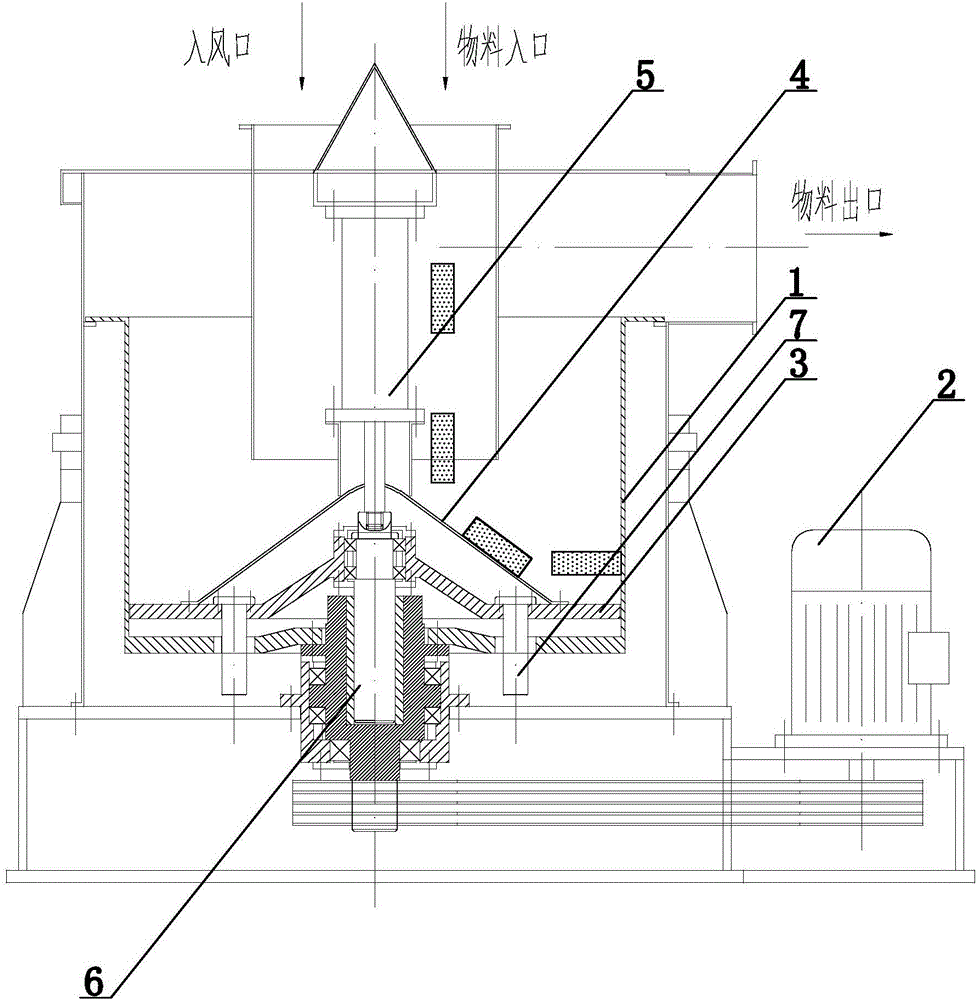

Dehydrator

The invention relates to a dehydrator and belongs to the technical field of material processing. The dehydrator comprises a drum, a material entry, a support plate and a material exit. The drum is driven by a motor, and the support plate is slidably mounted in the drum and may move up and down in the drum; material to be processed is fed into the drum by blowing air via the material entry and drops on the support plate, the motor drives the drum and the support plate to rotate together, the support plate moves up and down relative to the drum, and the material is moved up and is transferred out of the material exit. Being applied to fiber dehydration, drying and other steps, the dehydrator has the advantages of high dehydration speed, good drying uniformity, low energy consumption, low noise and the like.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

Dehydrator for fabrics and cheeses

ActiveCN102154795ADehydration time timing controlGuaranteed operational safetyTextile treatment machine partsLiquid/gas/vapor removal by centrifugal forceYarnCovering system

The invention discloses a dehydrator for fabrics and cheeses. The dehydrator comprises a pneumatic cover, a dehydrator cylinder body formed by inner walls and outer walls, bases arranged at the bottom of the dehydrator cylinder body, a pneumatic pump, a pneumatic switch, an electromotor and a control cabinet, wherein a rotating case is arranged in the dehydrator cylinder body; a gas pipe and the pneumatic switch are arranged at one end of the pneumatic pump; and the other end of the pneumatic pump enters into the dehydrator cylinder body through the pneumatic cover. The dehydrator has the following beneficial effects: an intelligent cover system is adopted; timing control of the dehydration time of the dehydrator is realized; the dehydrator can dehydrate the cheeses and the yarns; workersare not needed to watch the dehydrator for a long time; and the operation safety of the workers is ensured.

Owner:JIANGSU HUAJIA SILK

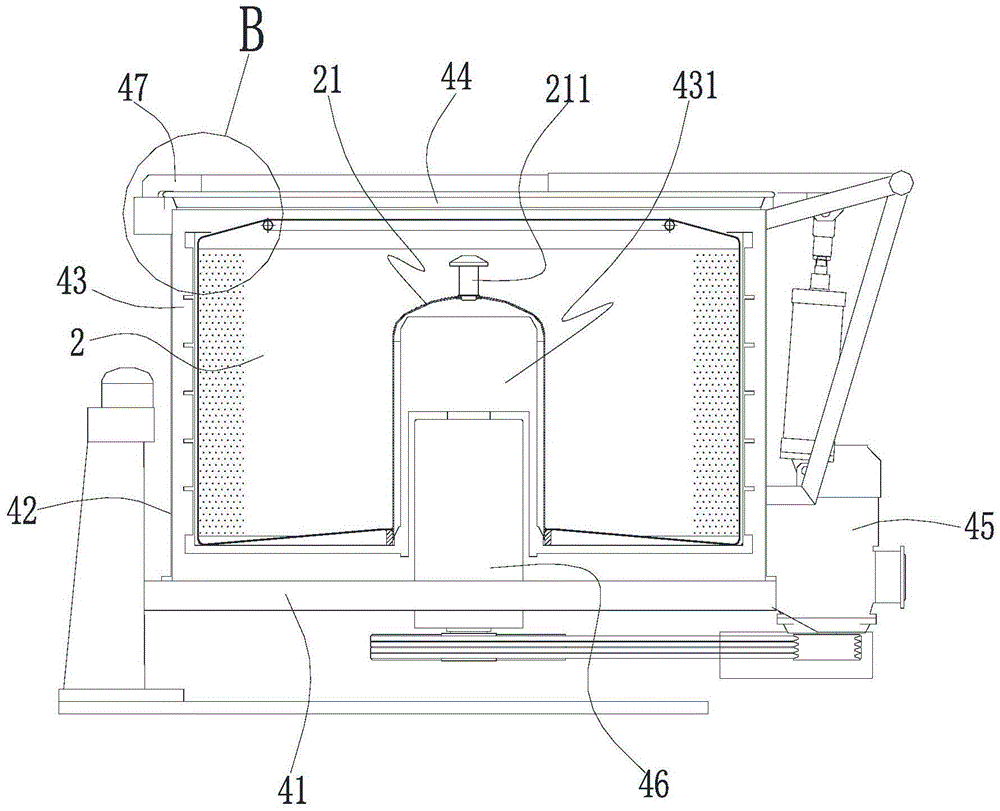

Fully-automatic dyeing and dehydrating system of fabric

ActiveCN105463741ATextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forceEngineeringFully automatic

The embodiment of the invention discloses a fully-automatic dyeing and dehydrating system of a fabric. The system comprises dyeing equipment, an inner cage, a mechanical arm and a centrifugal machine. The dyeing equipment is used for conducting dyeing treatment on the fabric; the inner cage can enter a station to be dehydrated from a cloth connection station, then enter the centrifugal machine on a centrifugal dehydrating station from the station to be dehydrated and then enter a posttreatment station from the interior of the centrifugal station on the centrifugal dehydrating station; the mechanical arm can move among the station to be dehydrated, the centrifugal dehydrating station and the posttreatment station; the centrifugal machine is used for driving the inner cage to conduct circumferential rotation so that water-containing fabric loaded in the inner cage can be dehydrated. According to the fully-automatic dyeing and dehydrating system, all the steps from output of the fabric out of the dyeing equipment to complement of dehydration treatment are conducted in the same cage, a transfer basket and a fabric conveying frame are not needed, the fabric does not need to be input and output frequently, after dehydrating treatment is completed in one inner cage, dehydrating treatment can be conducted on a next cage, the process is simple, and dehydrating efficiency is greatly improved.

Owner:GAOWANLI TECH ZHONGSHAN CO LTD

Printing and dyeing cloth dehydrator

InactiveCN105862296AEasy dischargeNot easy to depositTextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forcePulp and paper industryDehydration

The invention discloses a printing and dyeing cloth dehydrator. The printing and dyeing cloth dehydrator comprises a base, a groove is formed in the top face of the base, a dehydrating barrel is arranged on the groove, multiple water outlets are formed in the dehydrating barrel, and multiple annular draining grooves are formed in the inner wall of the bottom of the groove; a drain opening is formed in the inner wall of the bottom of each annular draining groove, a pair of inserting grooves is oppositely formed in the side wall opposite to the drain openings, inserting blocks are fixedly connected to one end of a filtering net, inserting sleeves are arranged at the other end of the filtering net, and the inserting blocks and the inserting sleeves are inserted into the corresponding inserting grooves respectively; a pair of connecting rods is formed in the top face and the bottom face of the filtering net, guide grooves are formed in the connecting rods, the upper ends and the lower ends of the inserting sleeves are sleeved with the corresponding guide grooves of the connecting rods, one end of the filtering net is sleeved with the inserting sleeves, and compression springs are fixedly connected between the end of the filtering net and the inner walls of the inserting sleeves. The printing and dyeing cloth dehydrator has the advantages that water is not accumulated in the groove of the base easily, dehydrating efficiency is improved, and water obtained through dehydration can be filtered.

Owner:超捷织造(深圳)有限公司

Energy-saving-type cloth cleaning system for spinning

ActiveCN112048851AComprehensive cleaningLow costTextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forceWater storageElectric drive

The invention discloses an energy-saving-type cloth cleaning system for spinning. The energy-saving-type cloth cleaning system comprises a box body and a spraying mechanism; a hollow cavity is formedin the box body, a bottom plate and a conical plate are sequentially arranged in the hollow cavity from top to bottom, the hollow cavity is divided into a water storage chamber, a treatment chamber and a water falling chamber through the bottom plate and the conical plate, the water storage chamber is located above the treatment chamber, and the water falling chamber is located below the treatmentchamber; a water inlet is formed in the inner top of the water storage chamber, a water outlet is formed in one side of the water falling chamber, a strip-shaped cavity is formed in the inner wall ofone side of the box body, and a sealing door is mounted on the front side of the box body; and the spraying mechanism comprises a reciprocating lead screw horizontally arranged in the treatment chamber, and the two ends of the reciprocating lead screw are rotationally connected with the inner walls of the two sides of the treatment chamber correspondingly. According to the system, only one electric driving device of a pump body is used, electric energy is consumed a little, gravitational potential energy generated when water falls down can be converted into kinetic energy and fully utilized,and the system conforms to the large trend of energy conservation.

Owner:HUZHOU YUEBIN INTELLIGENT TECH CO LTD

Efficient dryer for textile use

PendingCN108166194AIncrease the amount of dryingImprove drying efficiencyTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringCentrifugal force

The invention discloses an efficient dryer for textile use. The efficient dryer comprises a bottom plate. A box body is welded to the top of the bottom plate, a fixing block is welded to the center ofthe inner wall of the bottom of the box body, a fixing groove is formed in the top of the fixing block, a motor is embedded into the fixing groove, an adjusting disc is welded to the top of an outputshaft of the motor, the diameter of the adjusting disc is equal to that of the fixing block, a fixing column is welded to the center of the top of the adjusting disc, fixing rods distributed at equalintervals are welded to the outer wall of one side of the fixing column, and the fixing rods are parallel to the horizontal surface. Textiles can be driven to rotate, water on the textiles is removedby spinning through centrifugal force, the drying efficiency of the device is improved, the temperature in the device can be adjusted, air can be blown when the textiles rotate, air circulation is promoted, the drying efficiency of the device is improved again, hot air in a box body can be recycled, and energy is saved.

Owner:盐城融凡纺织制衣有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com