Dehydrator for fabrics and cheeses

A dehydration machine and bobbin technology, which is applied in the processing of textile materials, textile processing machine accessories, textiles and papermaking, etc., can solve the problem of not being able to automatically control the dehydration time, and achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

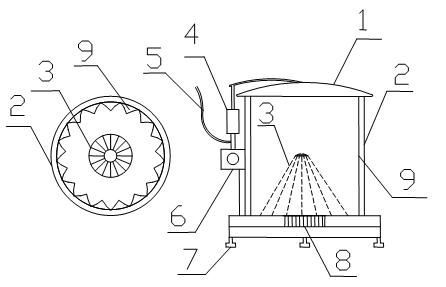

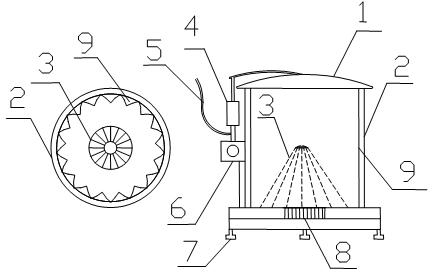

[0008] Such as figure 1 As shown, a dehydrator for fabrics and cheeses includes a pneumatic cover 1, a dehydrator cylinder composed of an inner wall 9 and an outer wall 2, a base 7 arranged at the bottom of the dehydrator cylinder, a pneumatic pump 4, a pneumatic switch 6, Motor 8 and control cabinet, tumbler 3 is set in the cylinder of the dehydrator, air pipe 5 and pneumatic switch 6 are arranged at one end of the pneumatic pump 4, and the other end of the pneumatic pump 4 enters the cylinder of the dehydrator through the pneumatic cover 1.

[0009] 1. The intelligent control of the dehydration machine is realized through the time relay installed in the control cabinet 10 and the start-up switching valve. A certain dehydration time and dehydration intensity can be input into the control cabinet. After reaching a certain time, the time relay sends instructions to the motor 8. Realize automatic shutdown, and the alarm device will sound.

[0010] 2. The switching valve can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com