Patents

Literature

1369results about "Textile treatment machine parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

FET-based sensor for detecting ionic material, ionic material detecting device using the FET-based sensor, and method of detecting ionic material using the FET-based sensor

ActiveUS7859029B2Reduce concentrationHigh sensitivityDrying solid materials without heatSolid-state devicesEngineeringElectric current

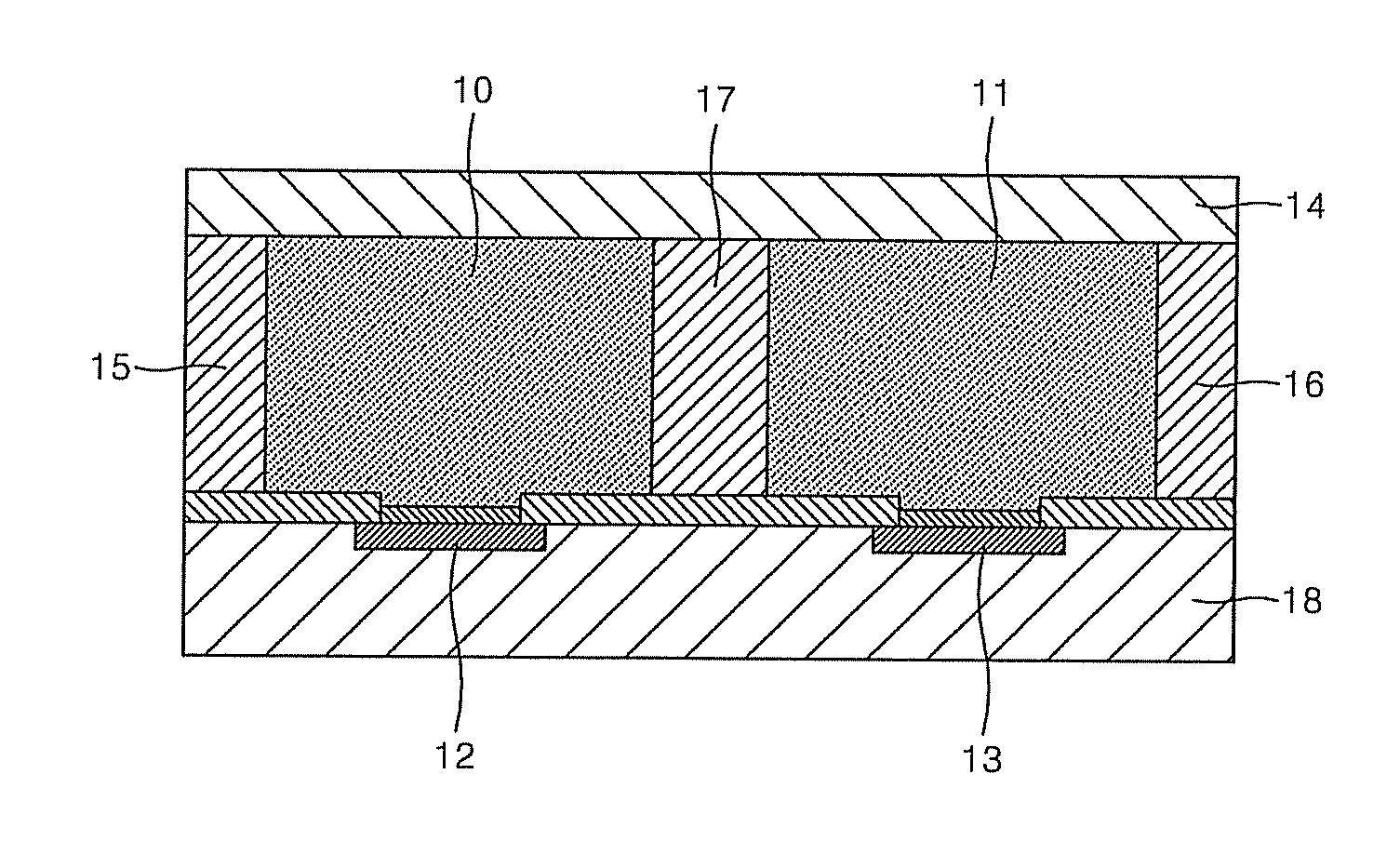

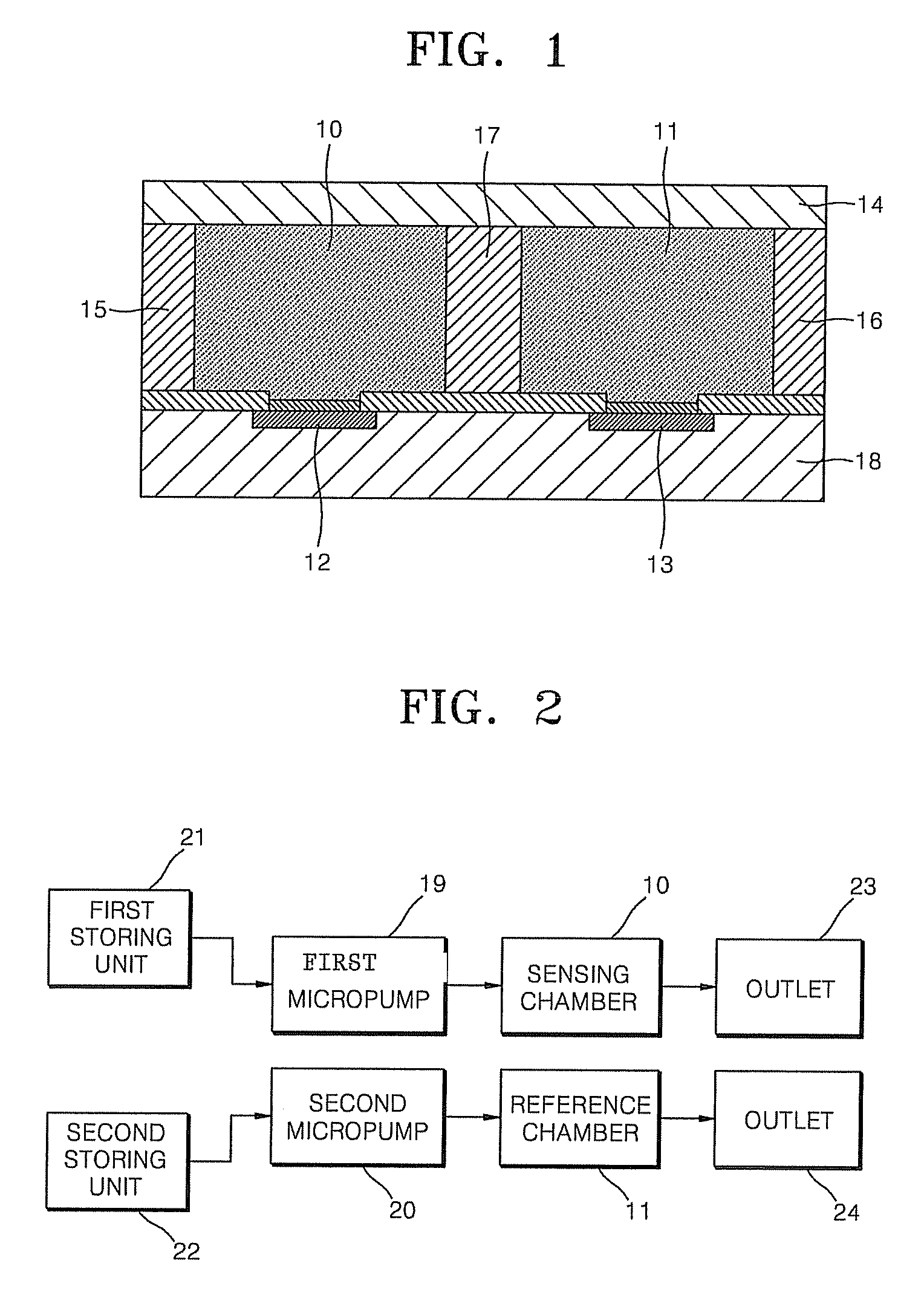

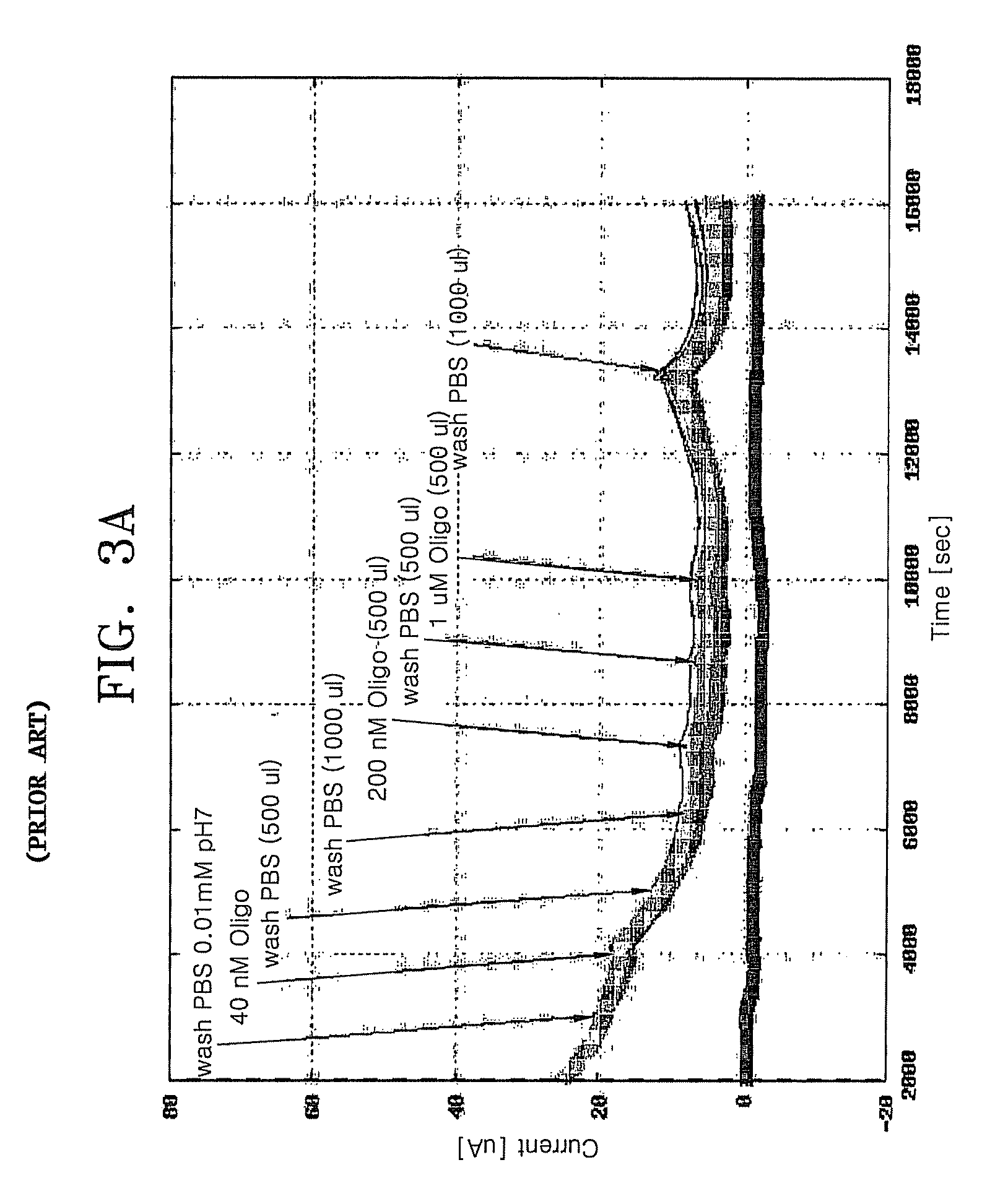

Provided are a FET-based sensor for detecting an ionic material, an ionic material detecting device including the FET-based sensor, and a method of detecting an ionic material using the FET-based sensor. The FET-based sensor includes: a sensing chamber including a reference electrode and a plurality of sensing FETs; and a reference chamber including a reference electrode and a plurality of reference FETs. The method includes: flowing a first solution into and out of the sensing chamber and the reference chamber of the FET-based sensor; flowing a second solution expected to contain an ionic material into and out of the sensing chamber while continuously flowing the first solution into and out of the reference chamber; measuring a current in a channel region between the source and drain of each of the sensing and reference FETs; and correcting the current of the sensing FETs.

Owner:SAMSUNG ELECTRONICS CO LTD

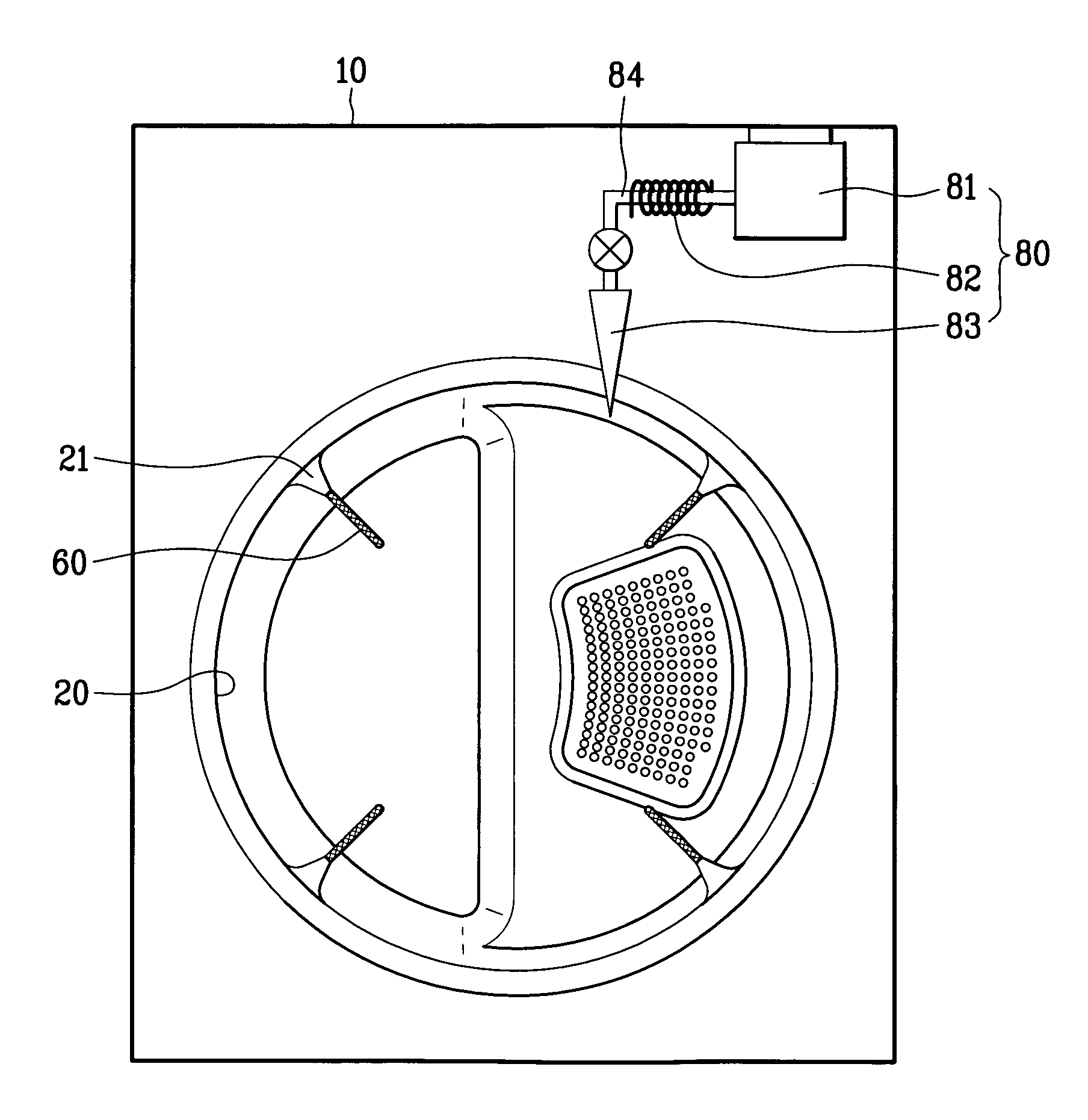

Washing machine

InactiveUS20090249840A1Improve rinsing efficiencyImprove washing efficiencyTextile treatment machine partsOther washing machinesWash waterEngineering

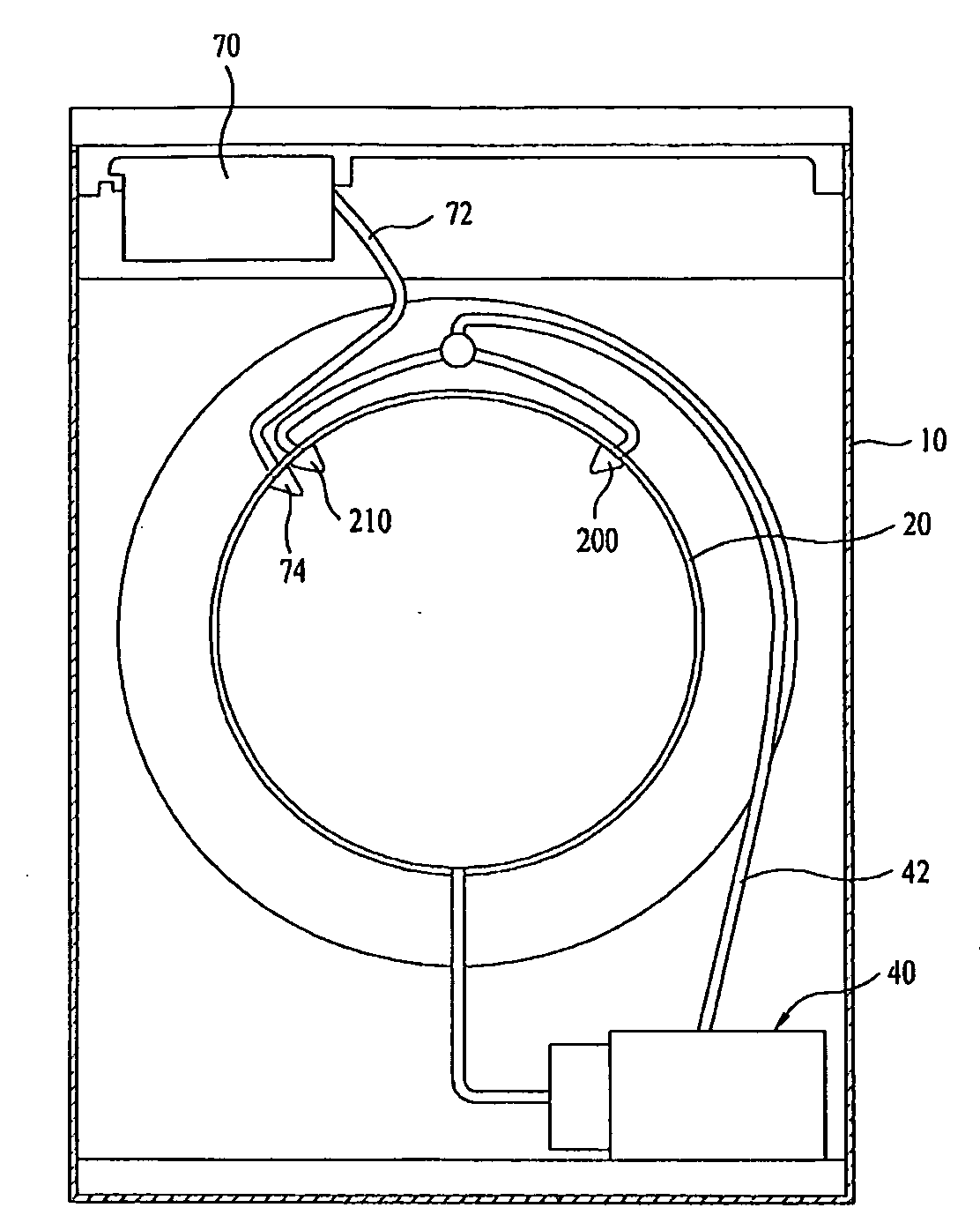

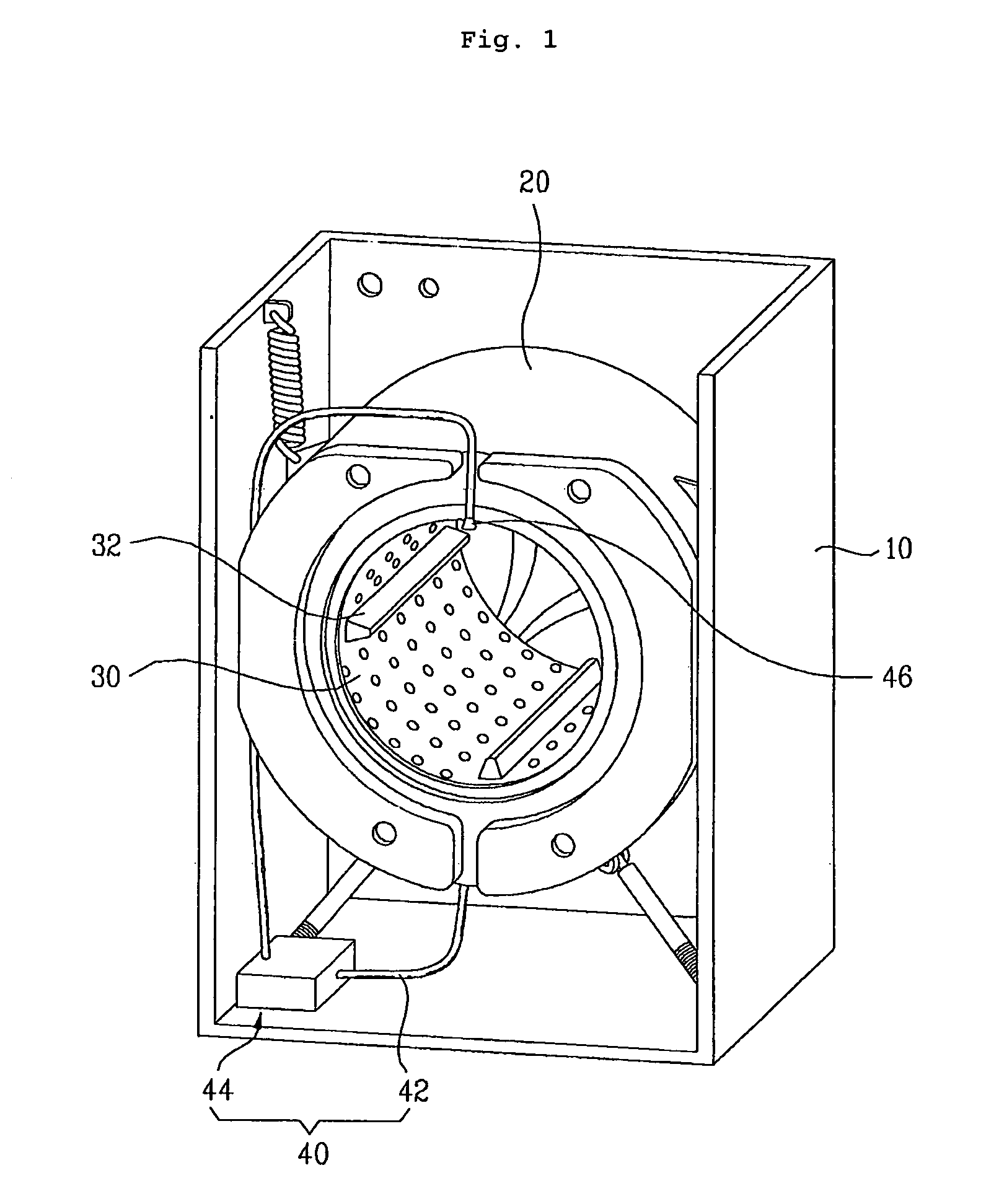

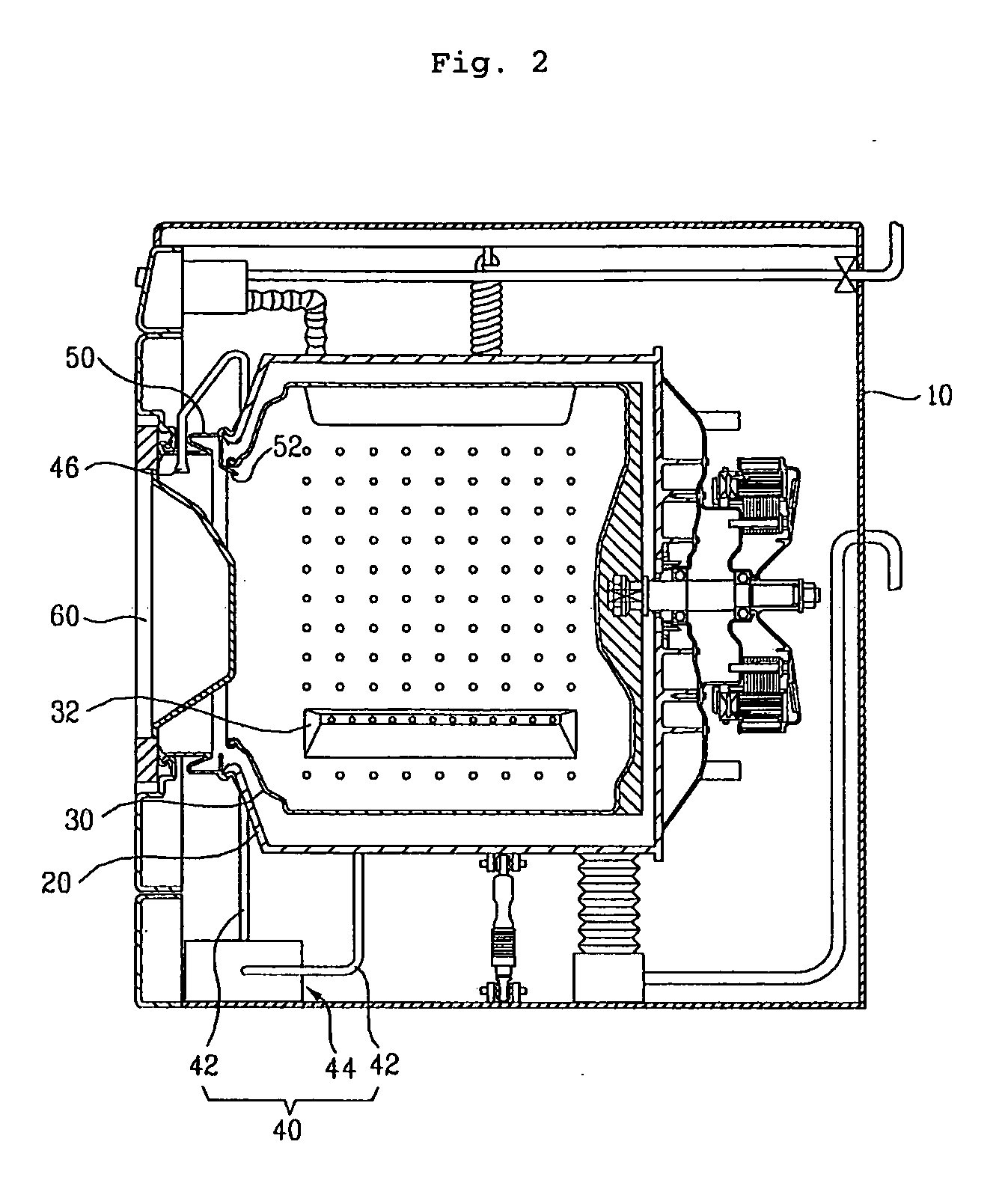

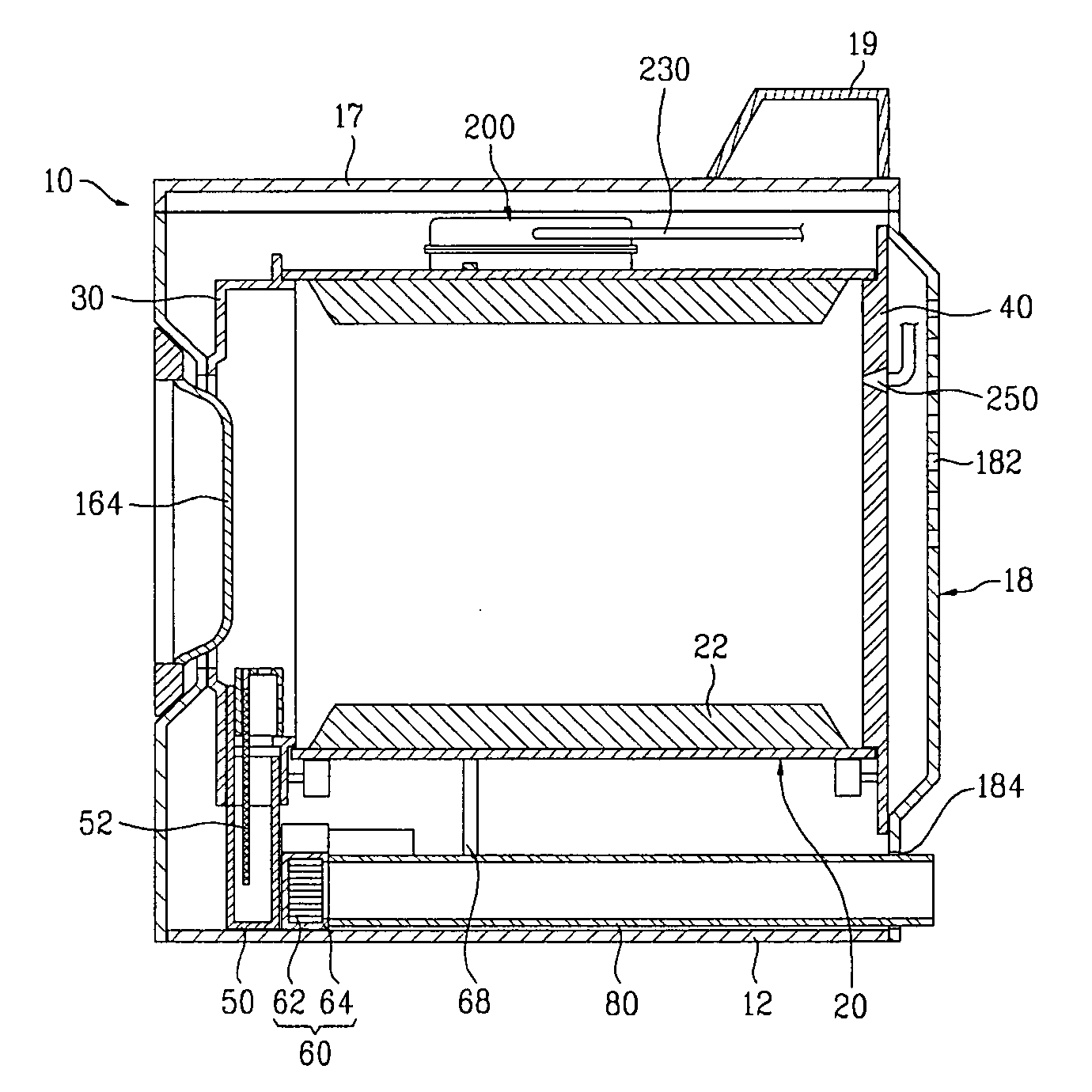

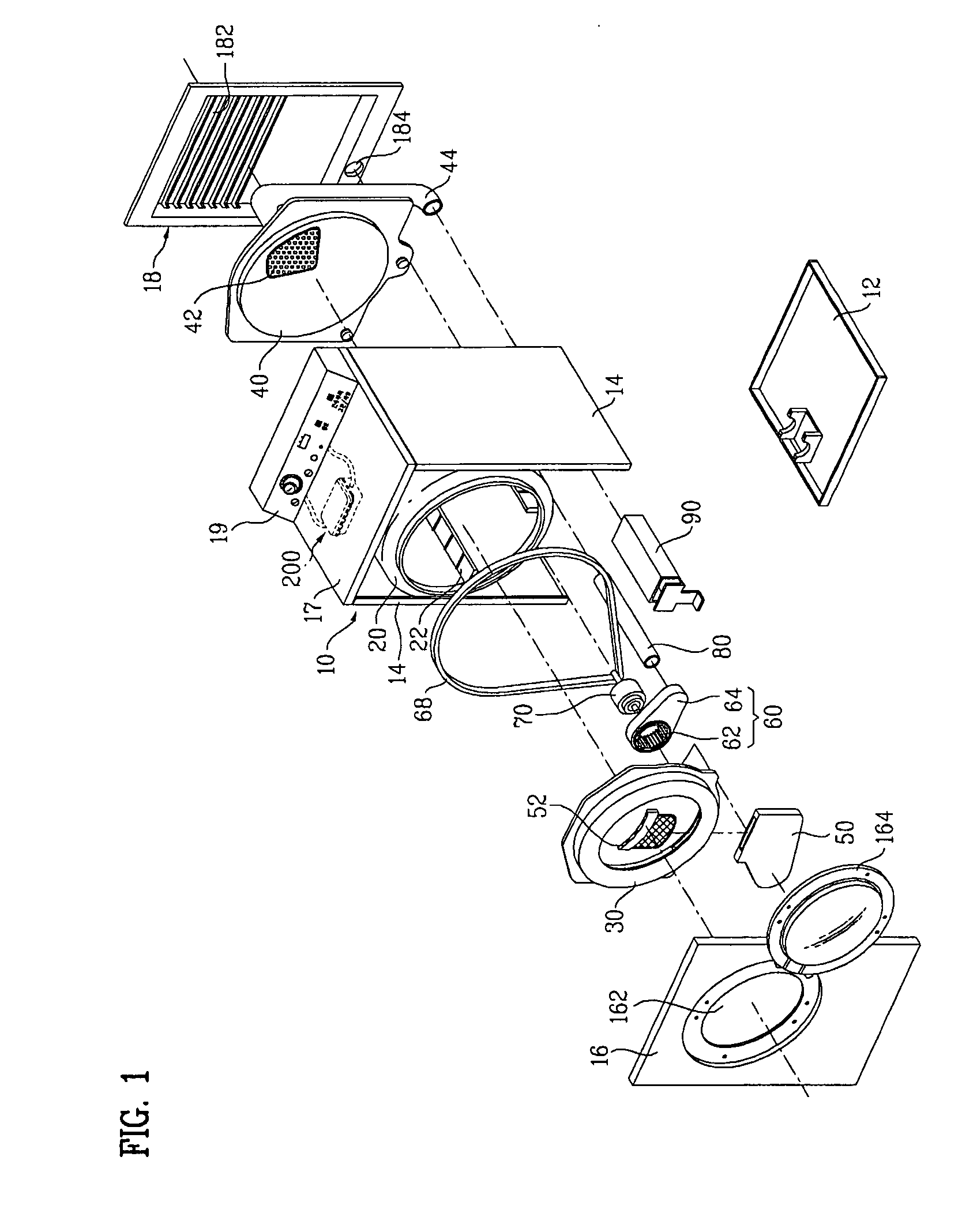

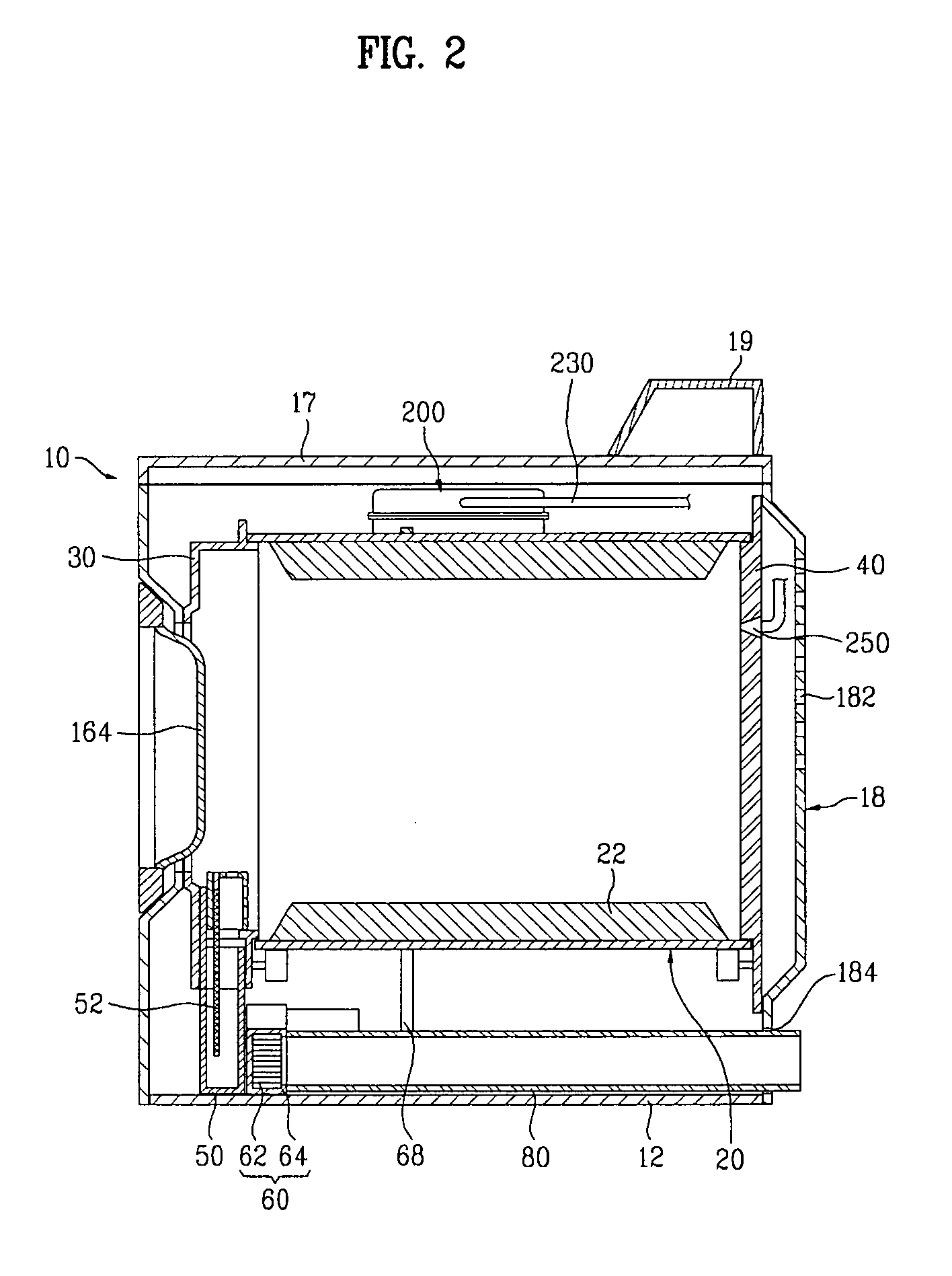

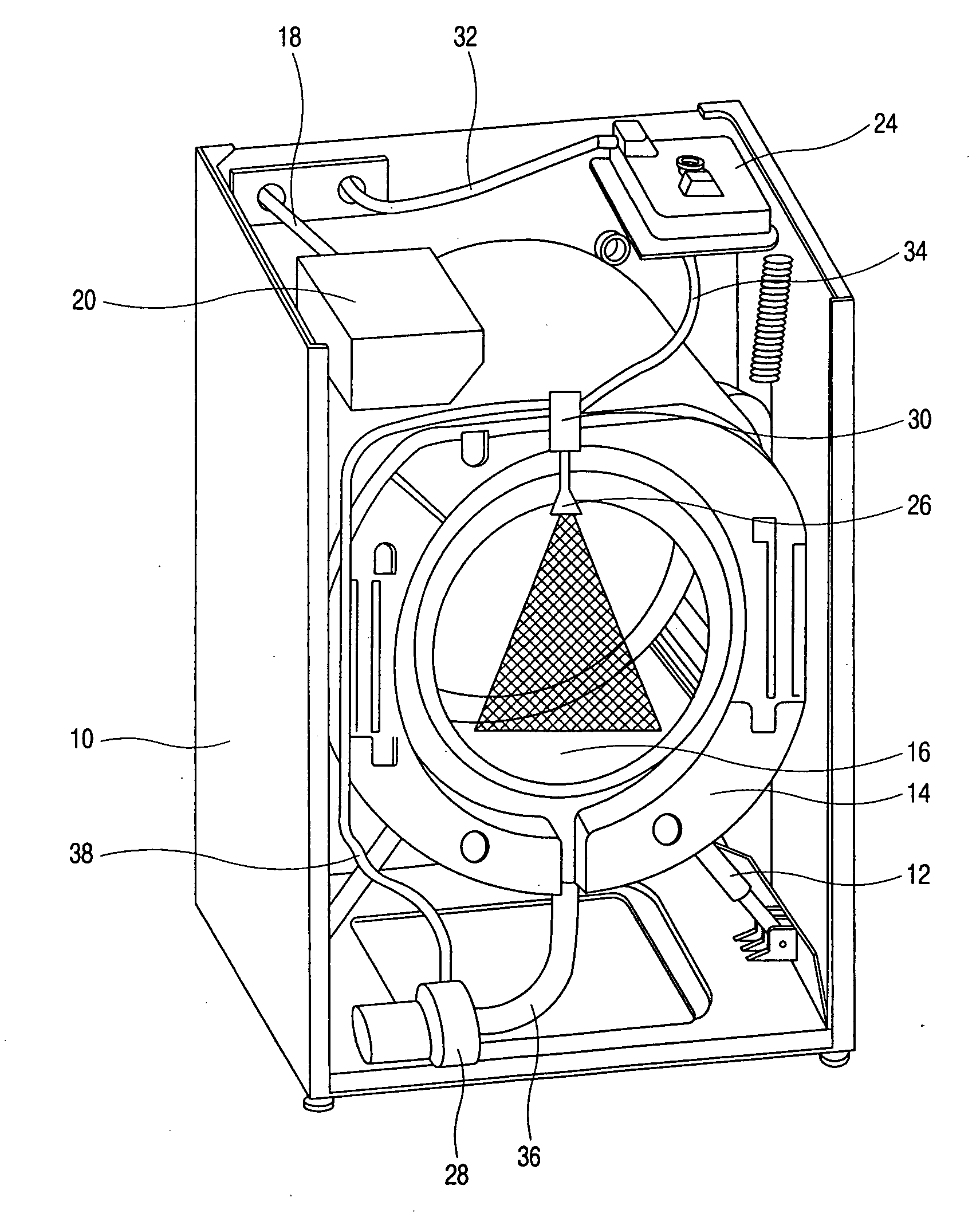

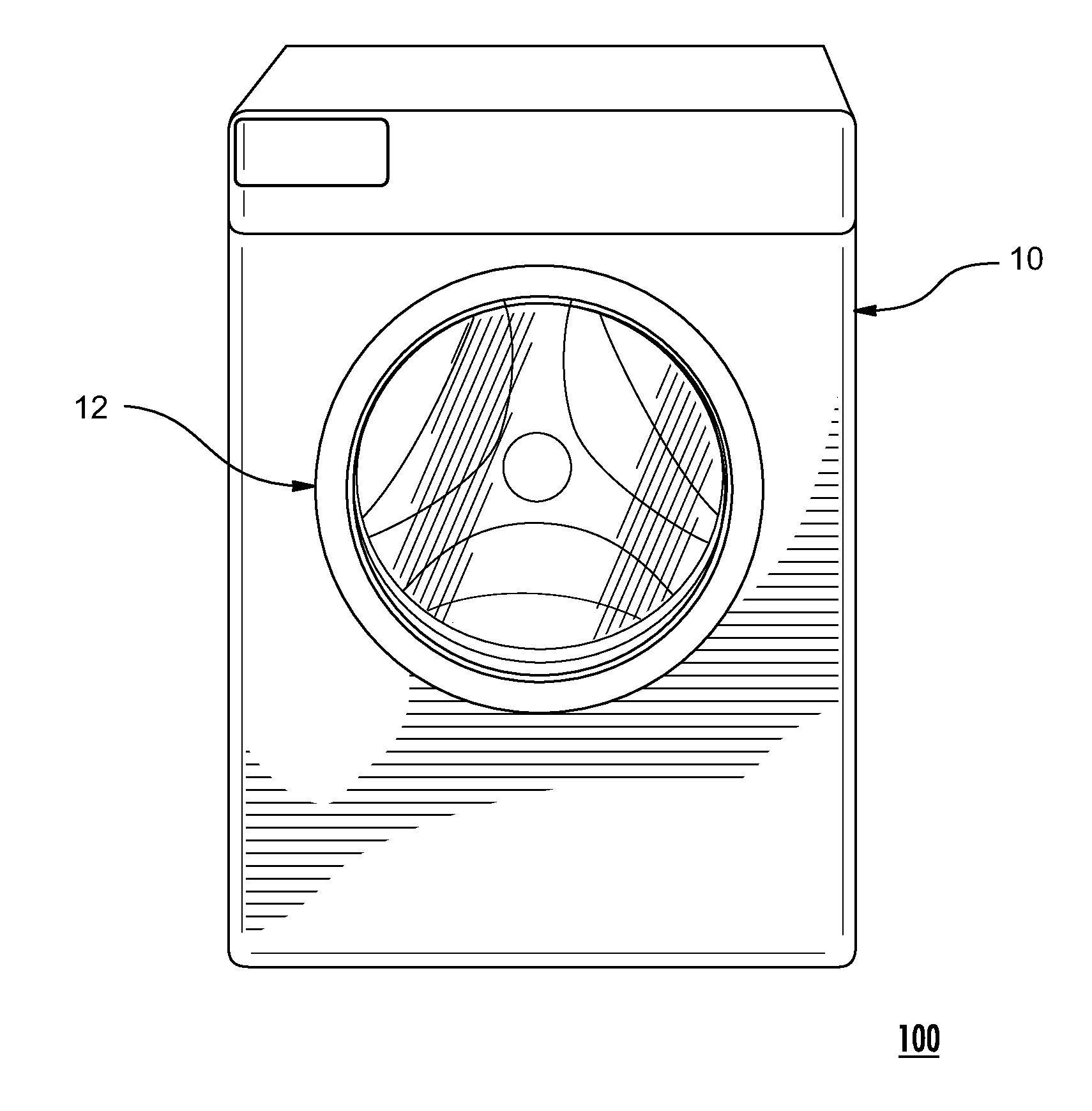

A washing machine includes a cabinet constituting the external appearance of the washing machine, a tub mounted in the cabinet for receiving wash water, a drum rotatably mounted in the tub for receiving laundry to be washed, a circulation unit for circulating wash water in the inner lower part of the tub through the upper part of the tub, and at least one circulation nozzle for spraying the wash water, supplied by the circulation unit, inwardly of the drum along a rotation axis of the drum in a longitudinal direction of the drum. According to the present invention, it is possible to improve washing or rinsing efficiency of the washing machine.

Owner:LG ELECTRONICS INC

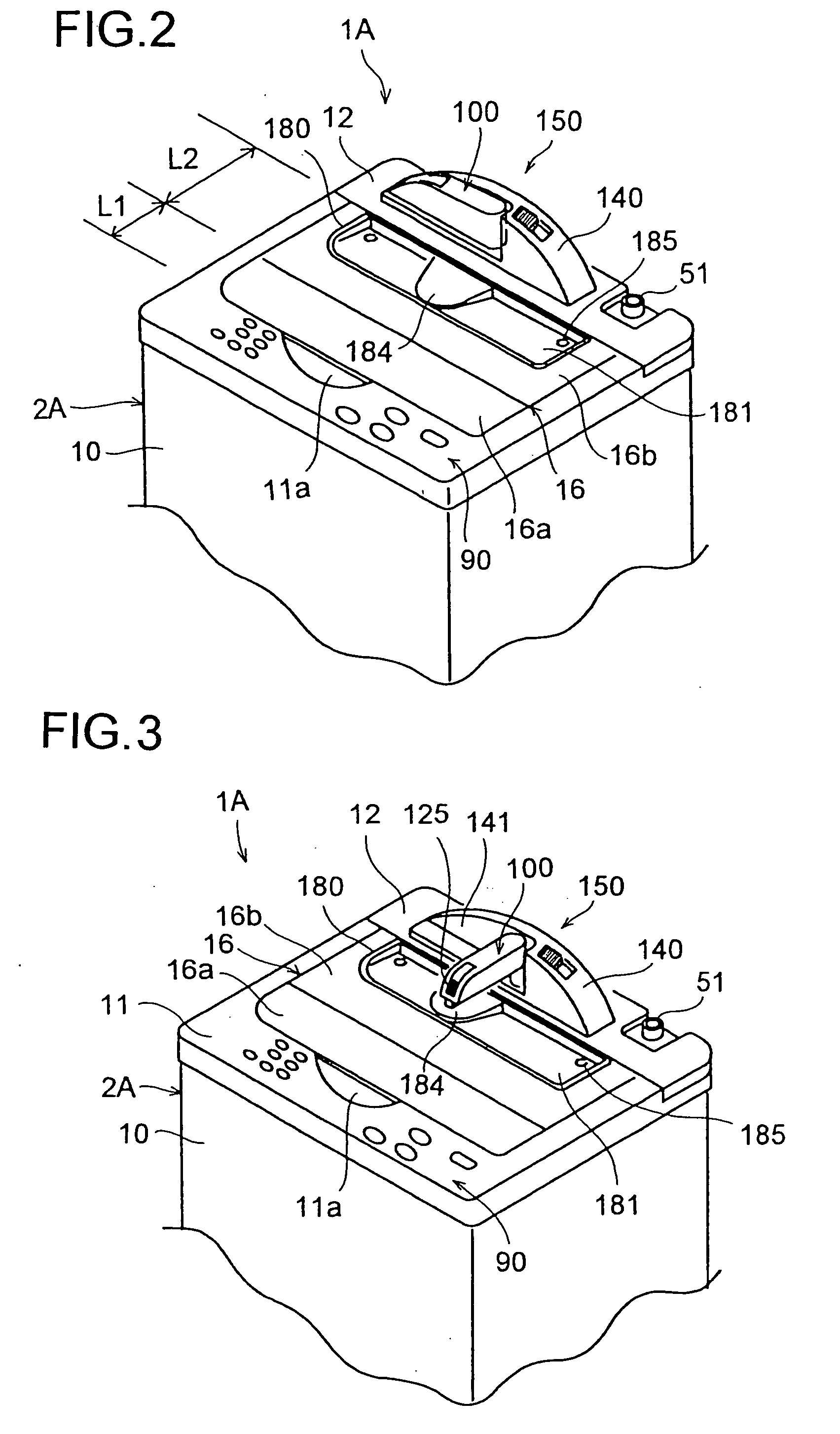

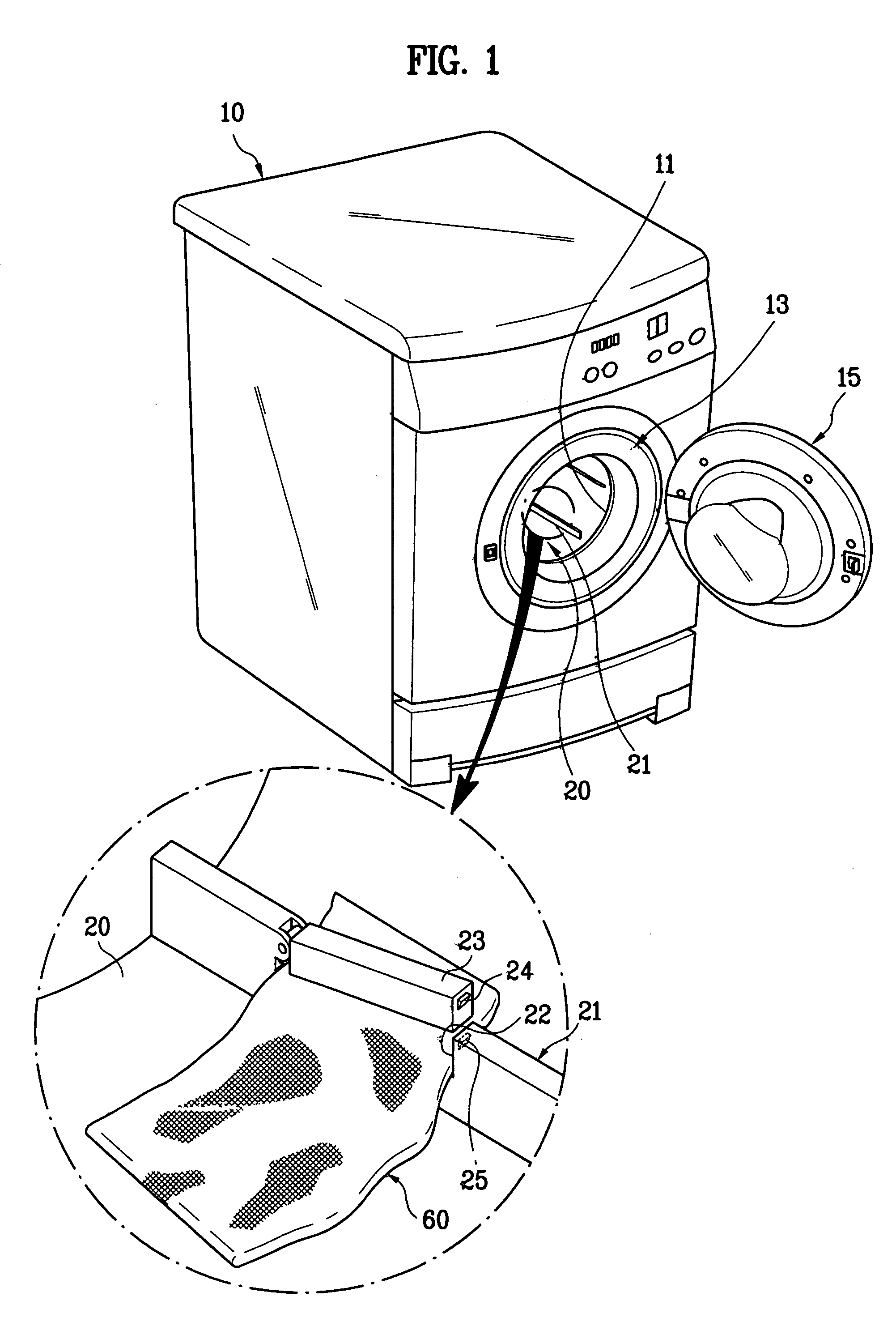

Washing machine

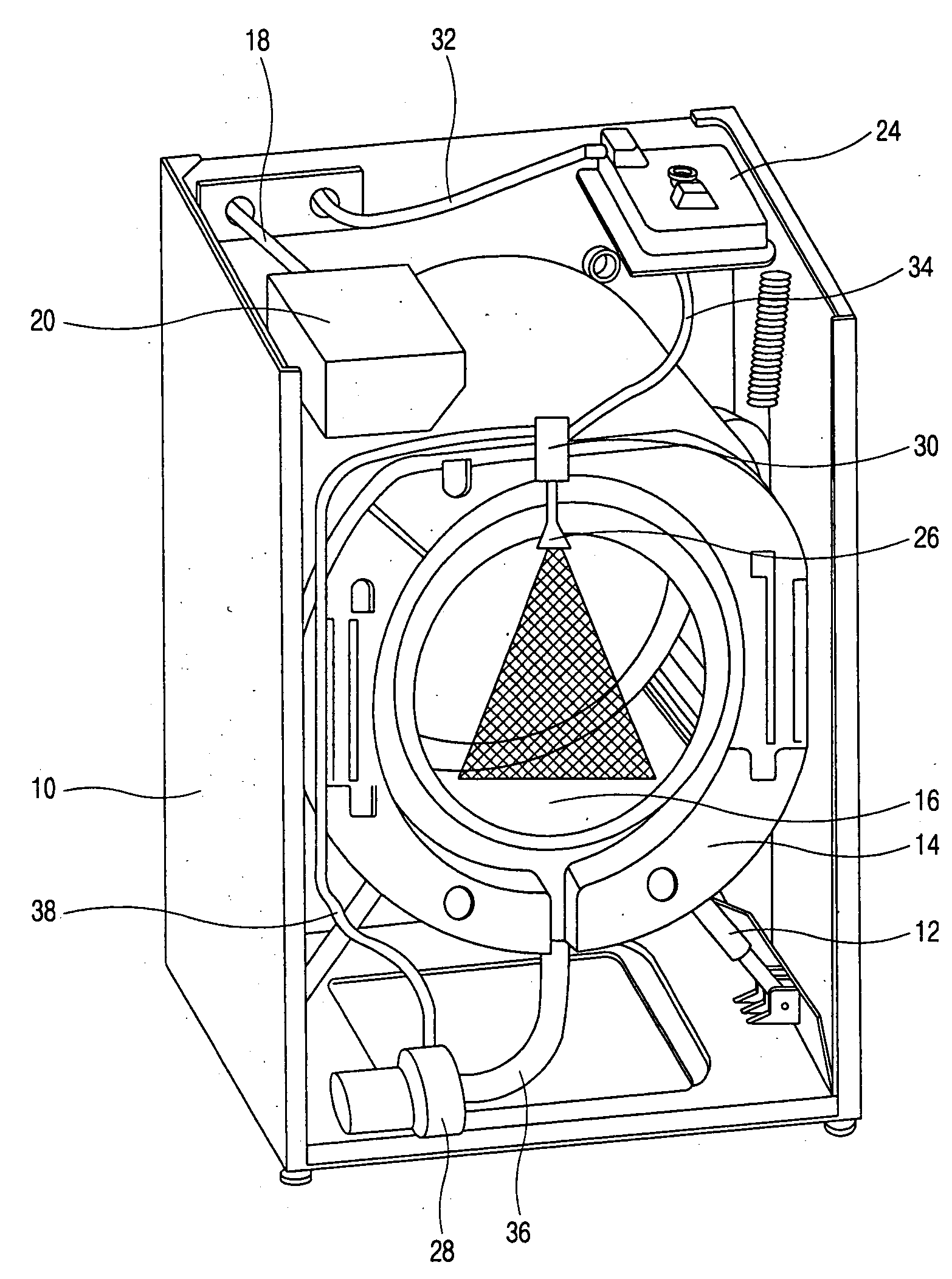

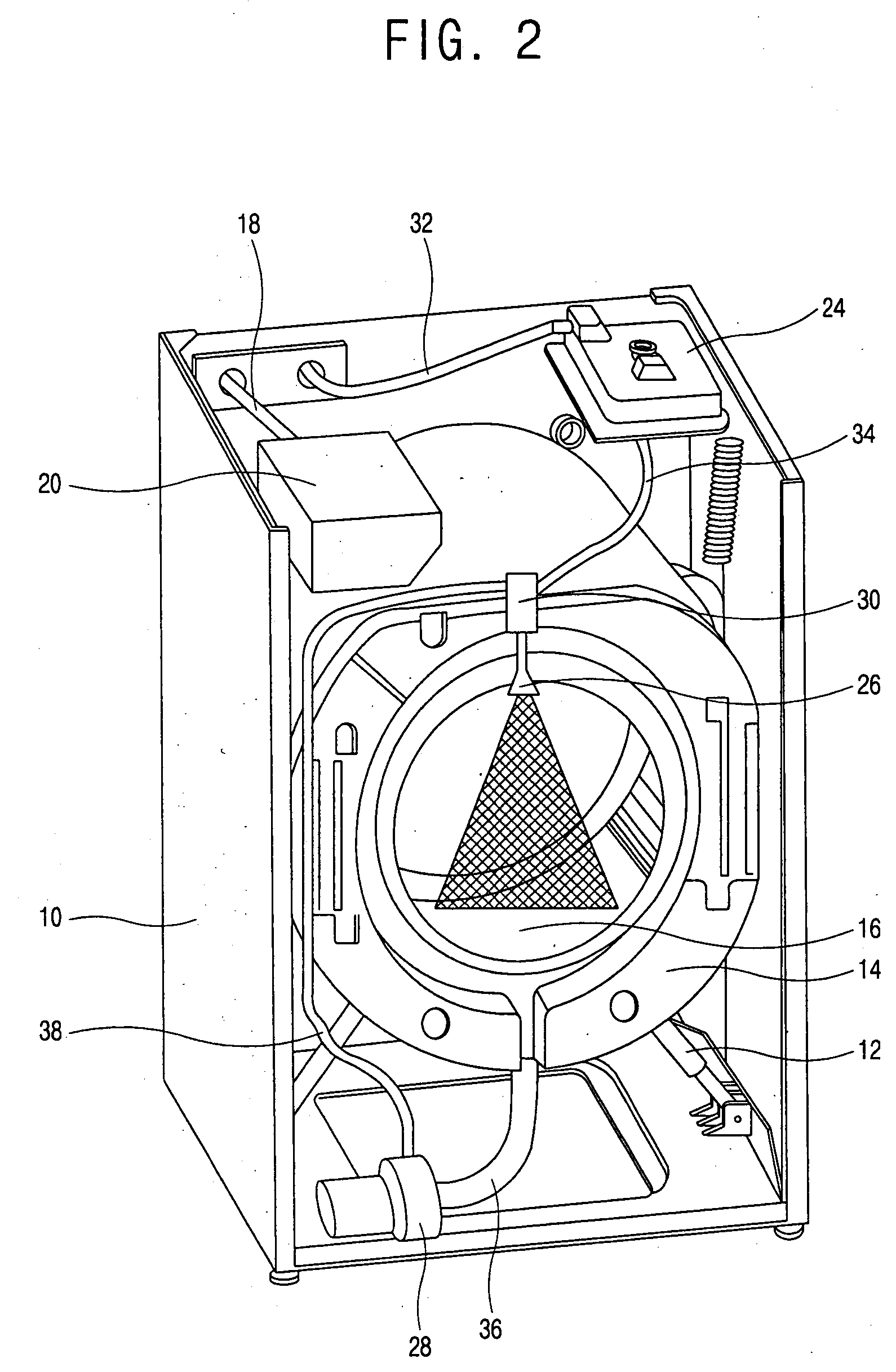

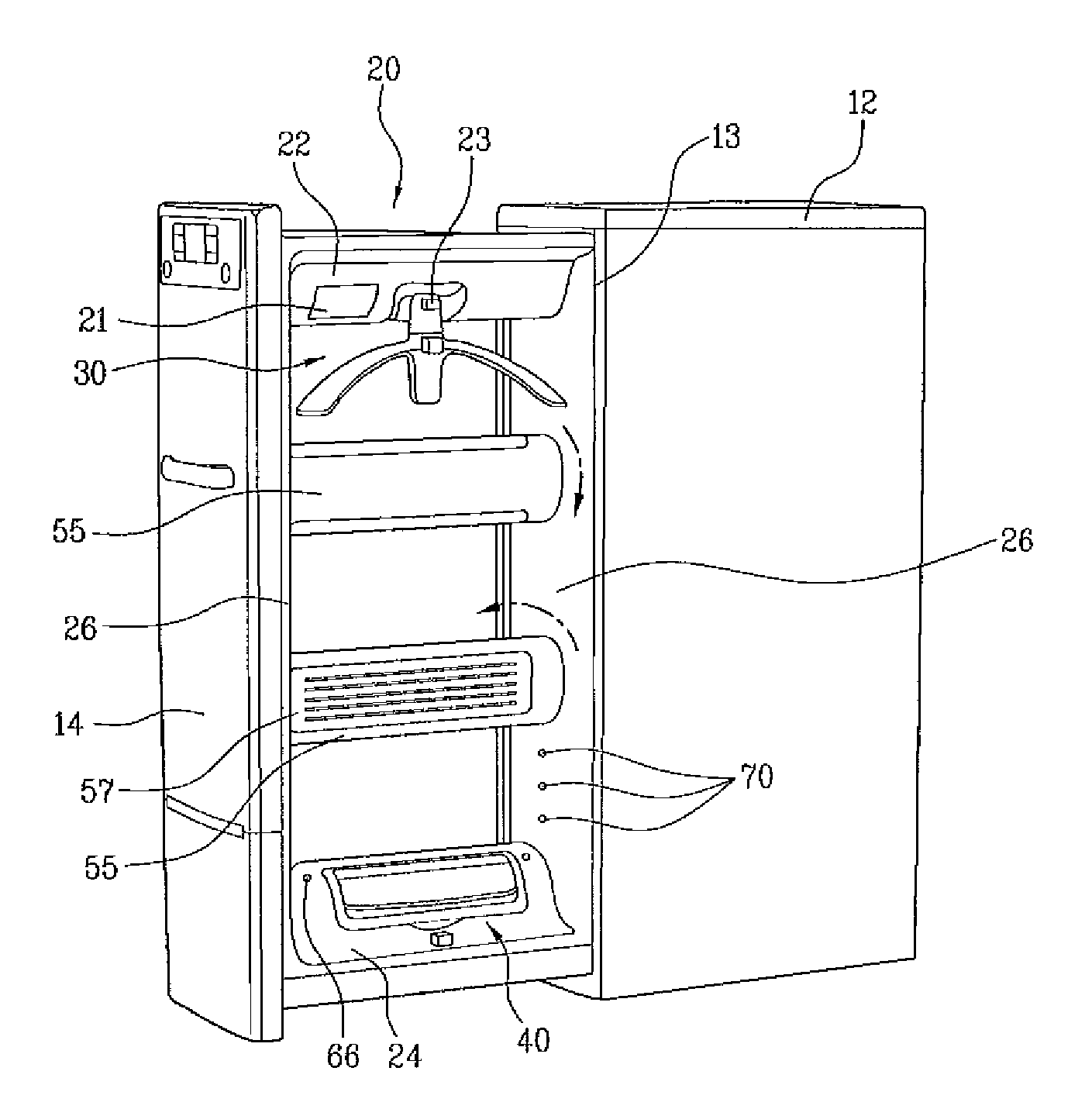

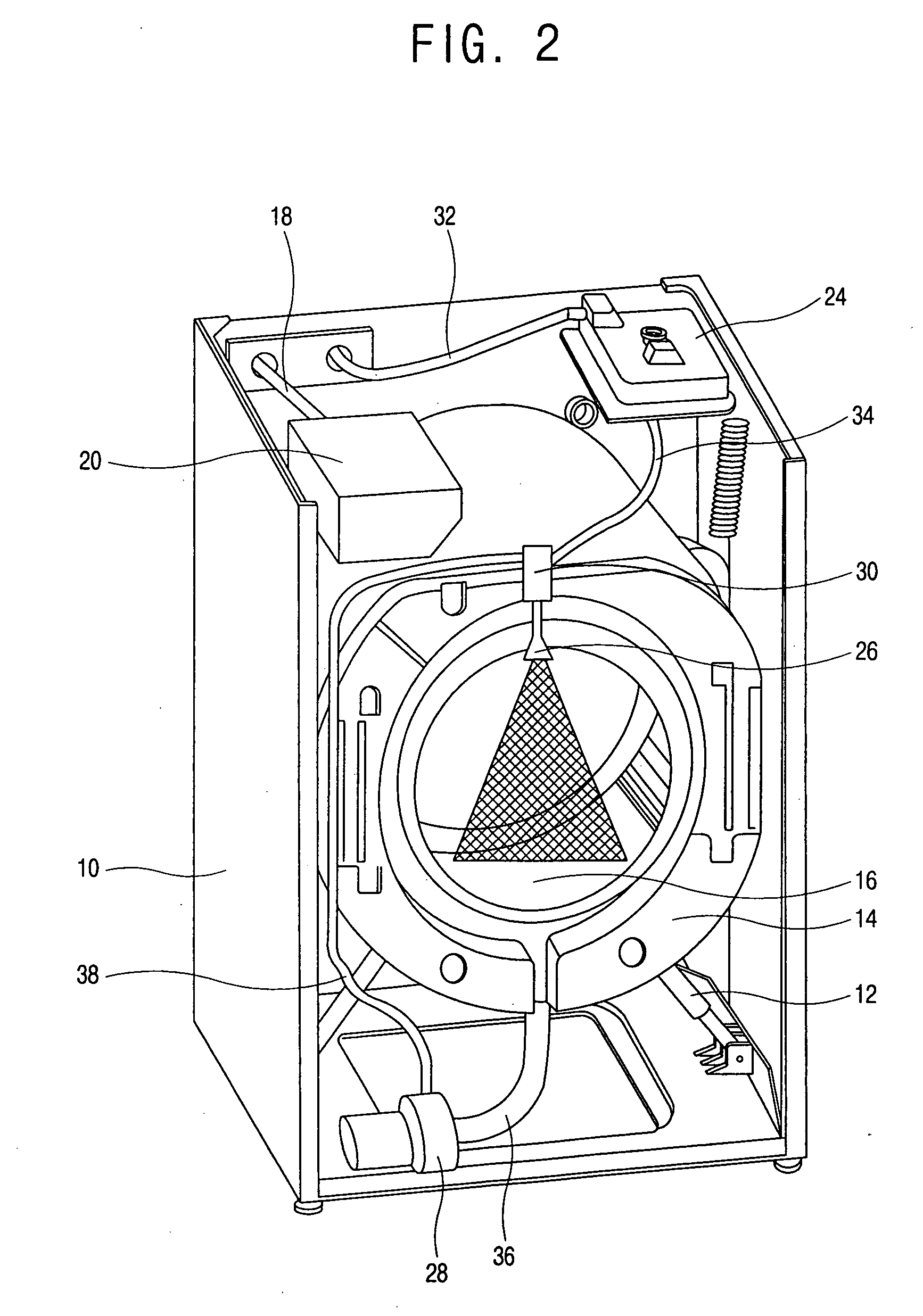

InactiveUS20050072194A1Without damaging laundryImprove washing effectTextile treatment machine partsOther washing machinesSupersonic wavesEngineering

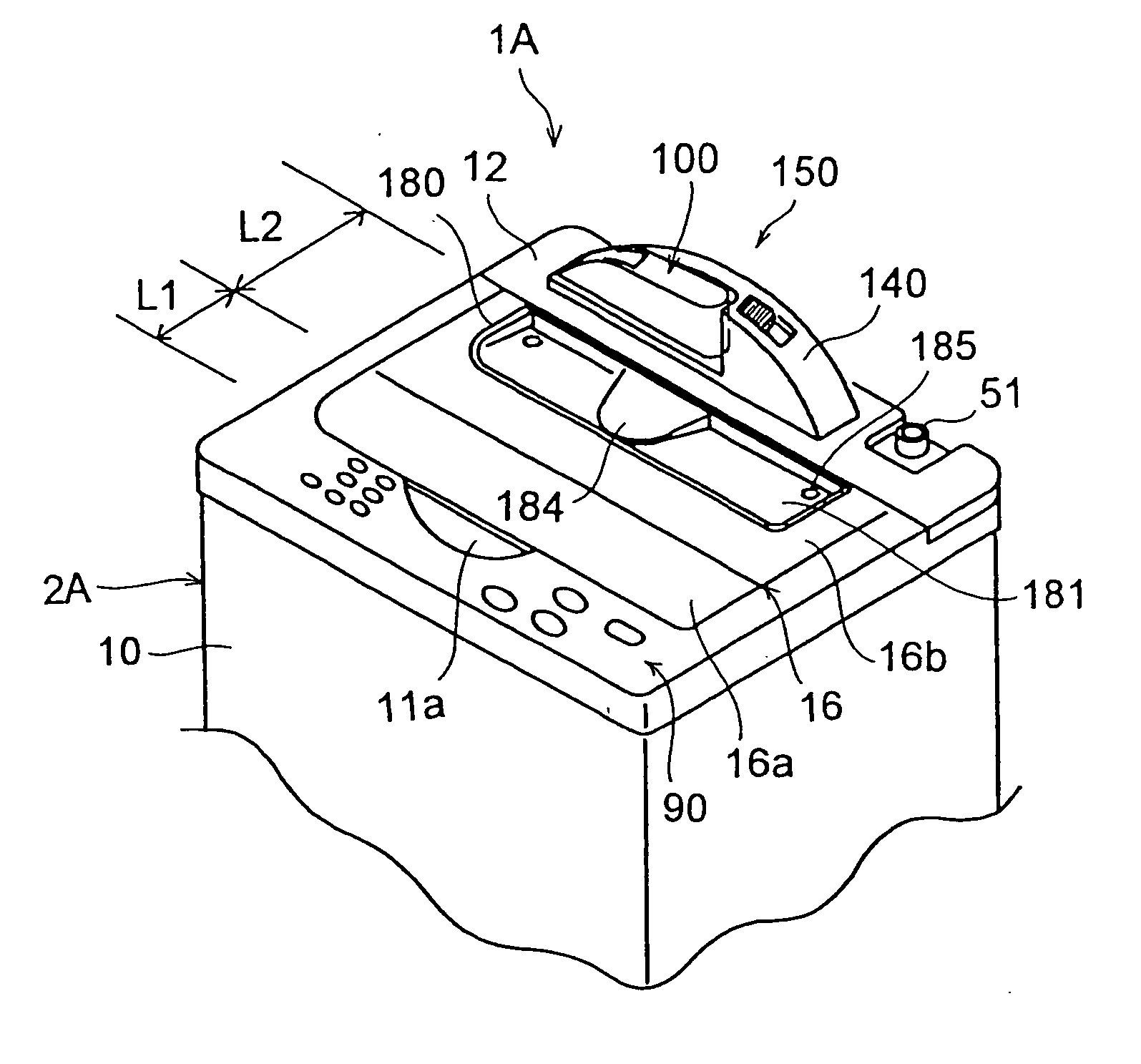

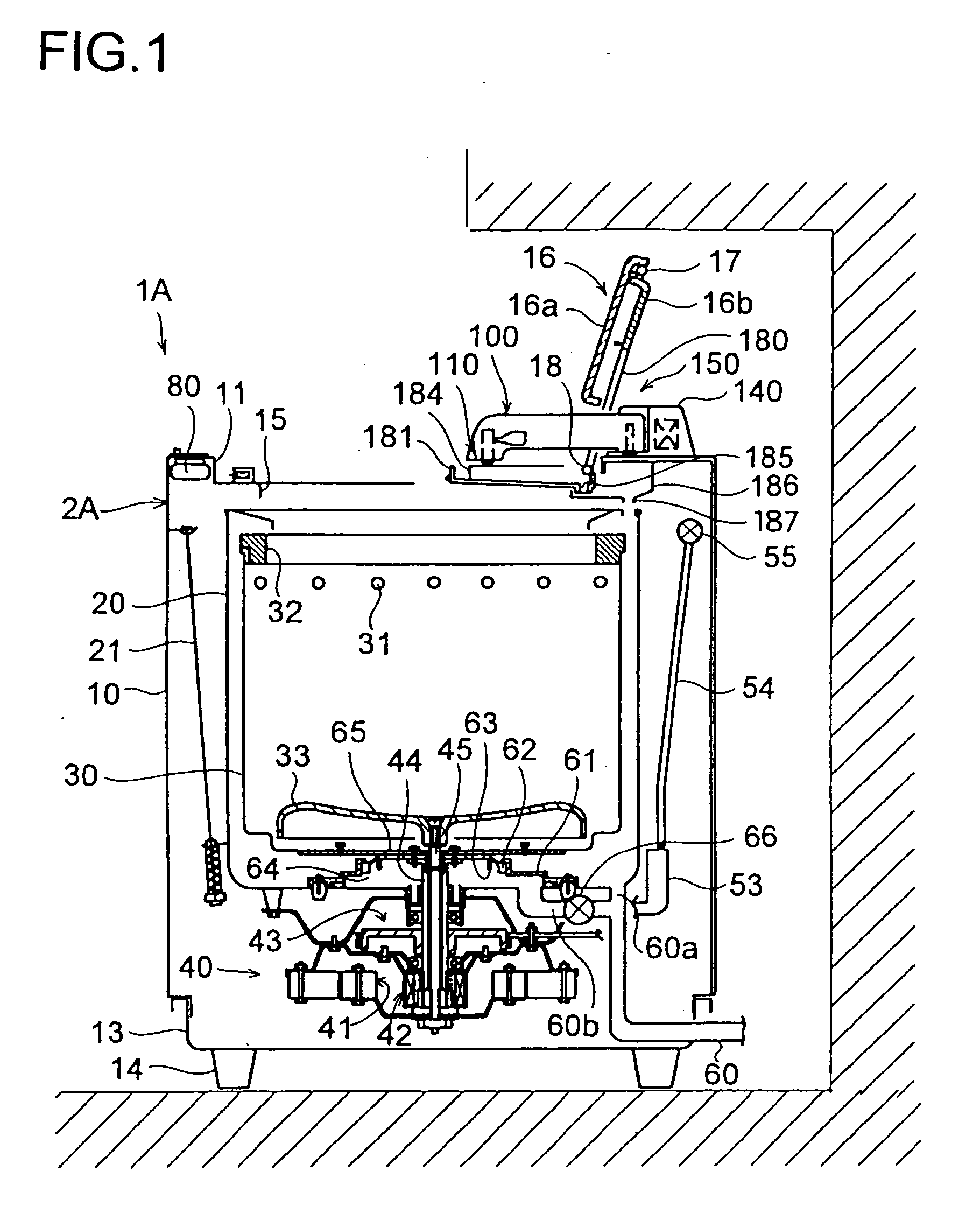

A washing machine has a partial washing apparatus fitted on an outer surface of a main unit having a washing tub housed therein. The partial washing apparatus is movable between an use position and a non-use position. When the partial washing apparatus is in the use position, its washing portion faces a laundry entrance from outside the main unit; when the partial washing apparatus is in the non-use position, its washing portion is retracted from the position in which it faces the laundry entrance. The washing portion achieves washing by using supersonic waves generated by a supersonic vibration device. The laundry entrance is covered with a lid composed of a front lid and a rear lid coupled together so as to be foldable in two. The rear lid has a gate opening formed therein to let the partial washing apparatus pass through. The gate opening is partially or completely closed by a tray for sustaining a piece of laundry. The tray has a drain outlet formed in its bottom surface, and the drain outlet is open toward or communicates with a drain path leading to outside the washing machine. When the partial washing apparatus is in the non-use position, the tray rotates together with the rear lid.

Owner:SHARP KK

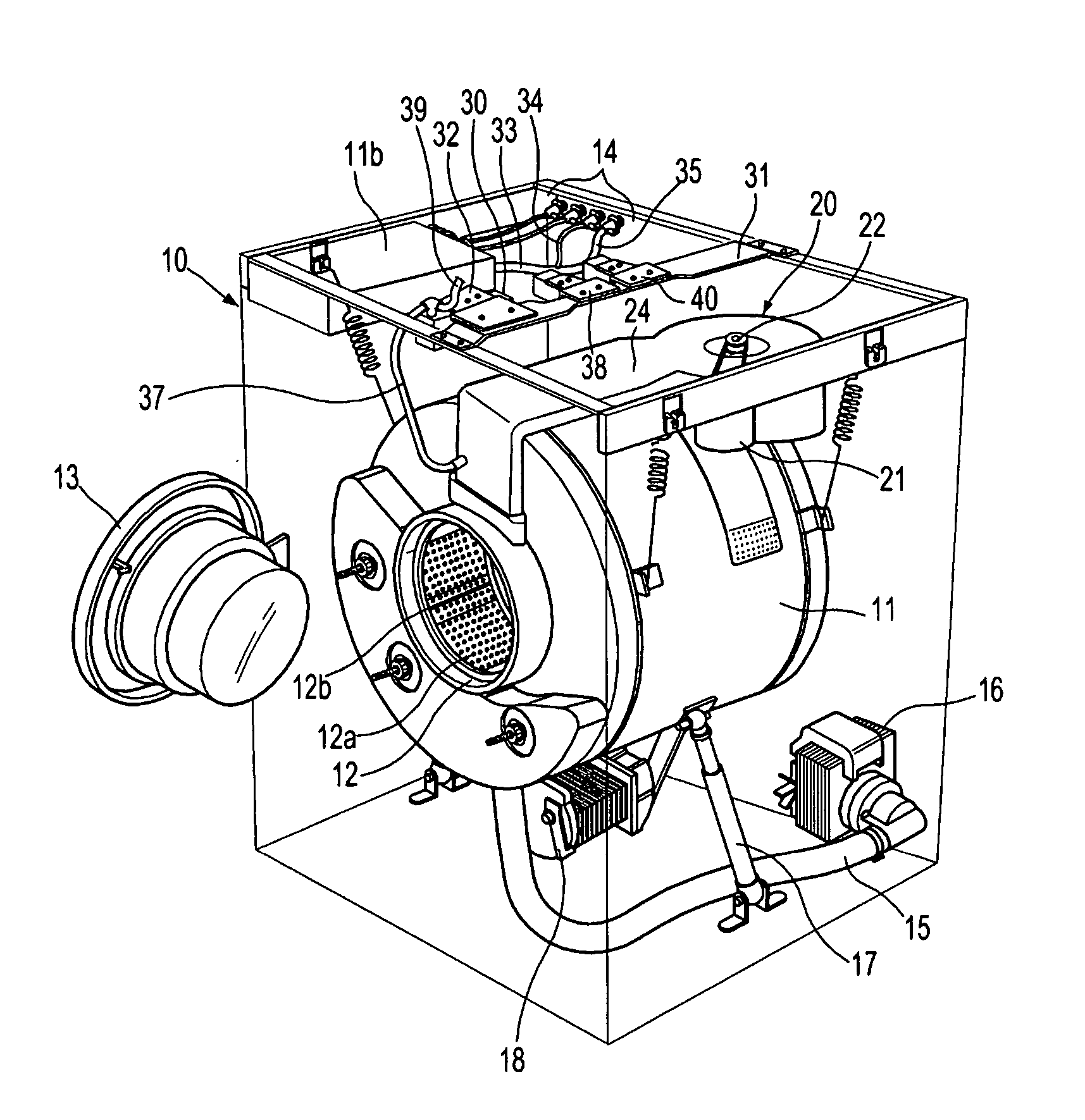

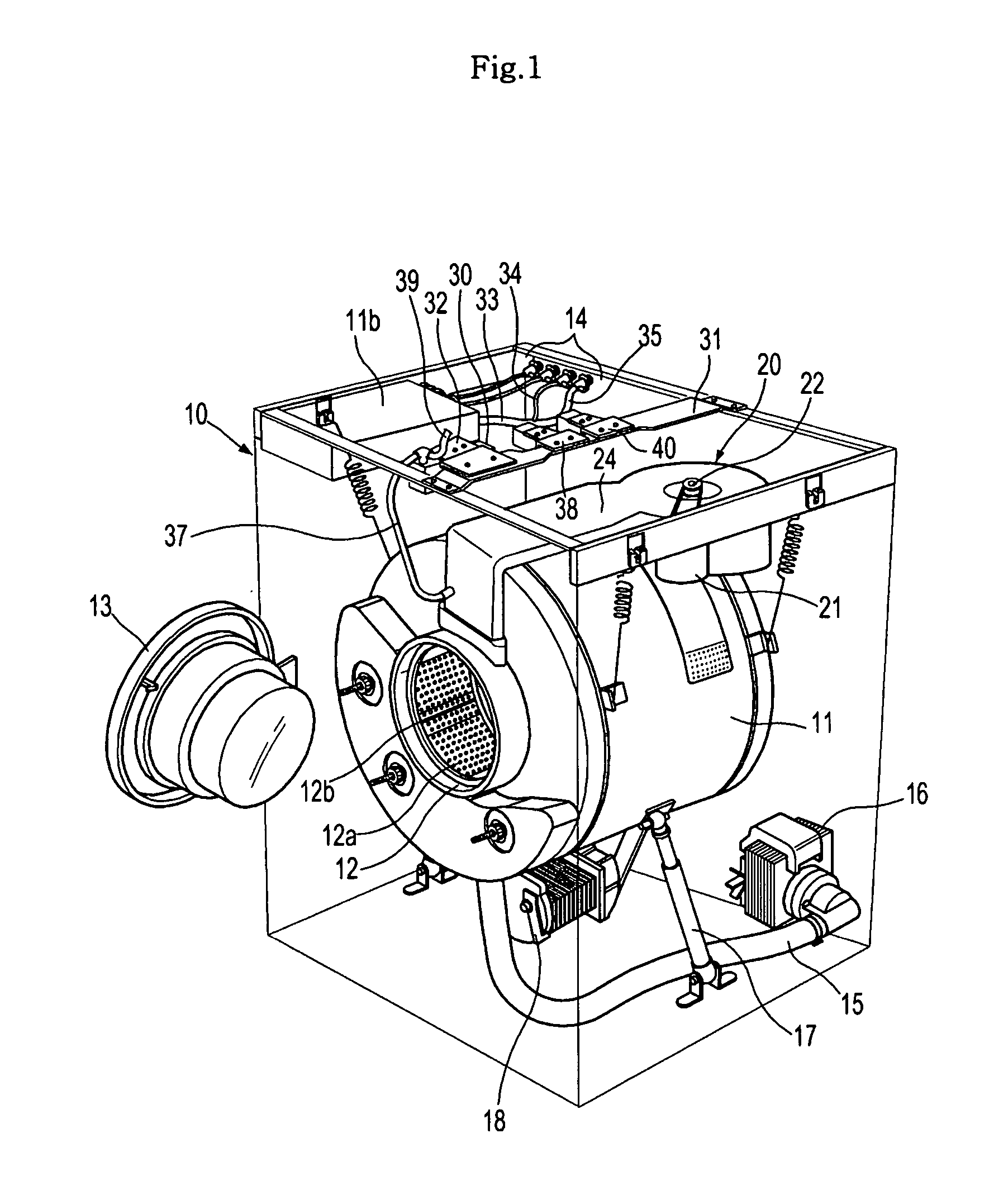

Dual mode laundry apparatus and method using the same

InactiveUS20050183208A1Dry-cleaning apparatusTextile treatment machine partsDual modeBiomedical engineering

An apparatus and a method for treating, cleaning or refreshing fabric articles. Specifically, the apparatus is dual mode apparatus capable of both washing and drying operations wherein a lipophilic fluid is used in at least one step of the fabric treatment process in the apparatus. A kit containing replaceable / consumable components is also provided.

Owner:THE PROCTER & GAMBLE COMPANY

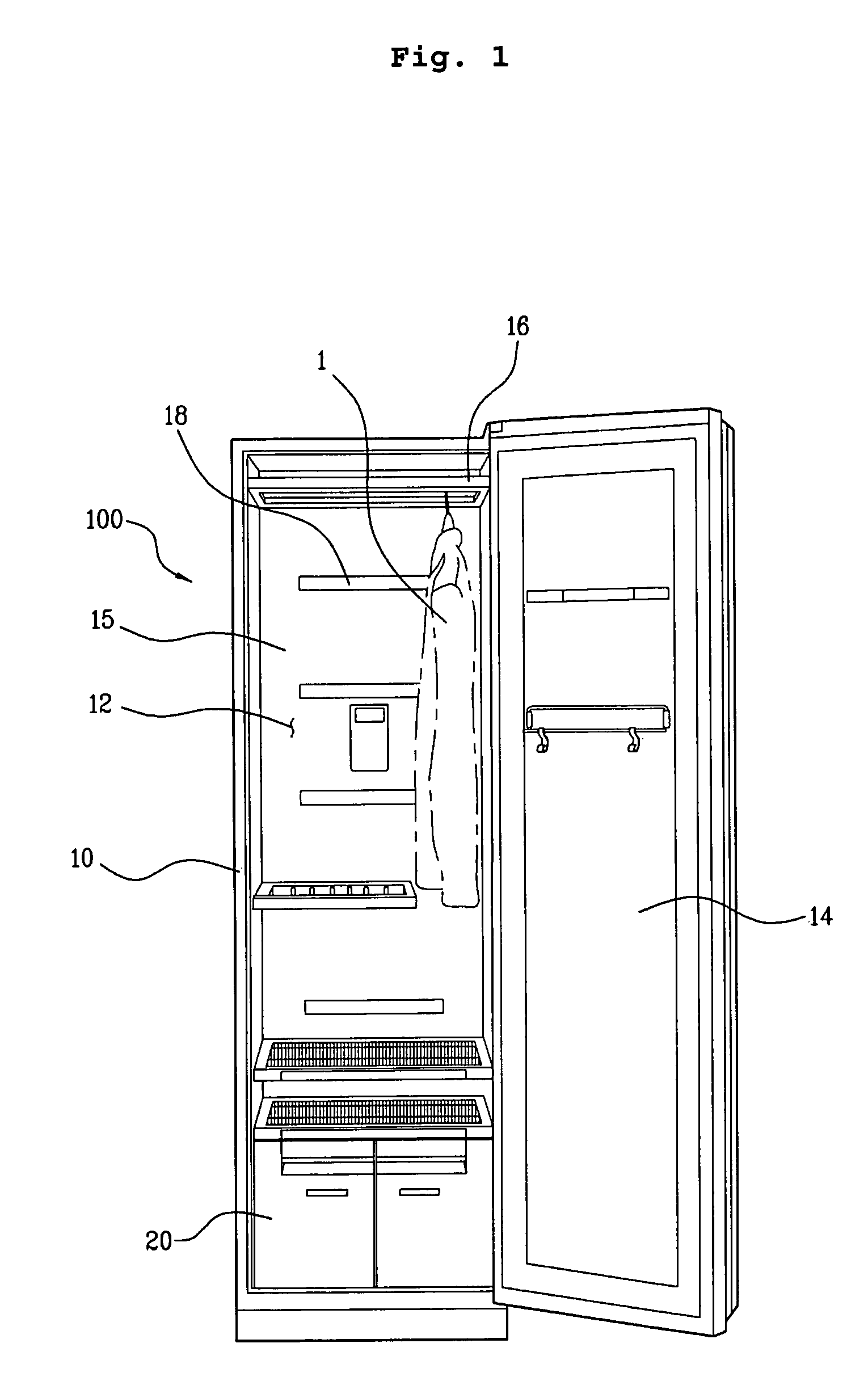

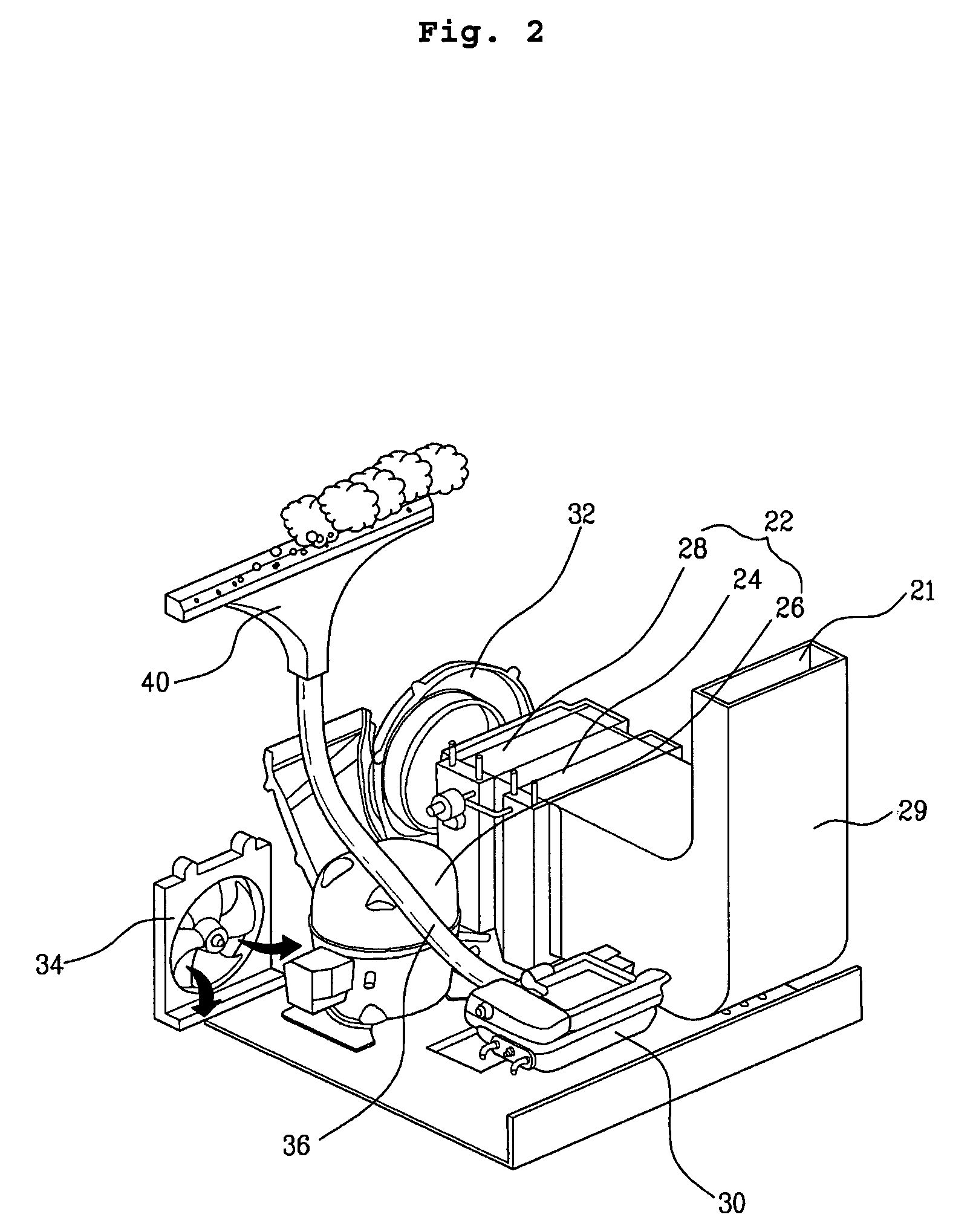

Garment refreshing apparatus and method

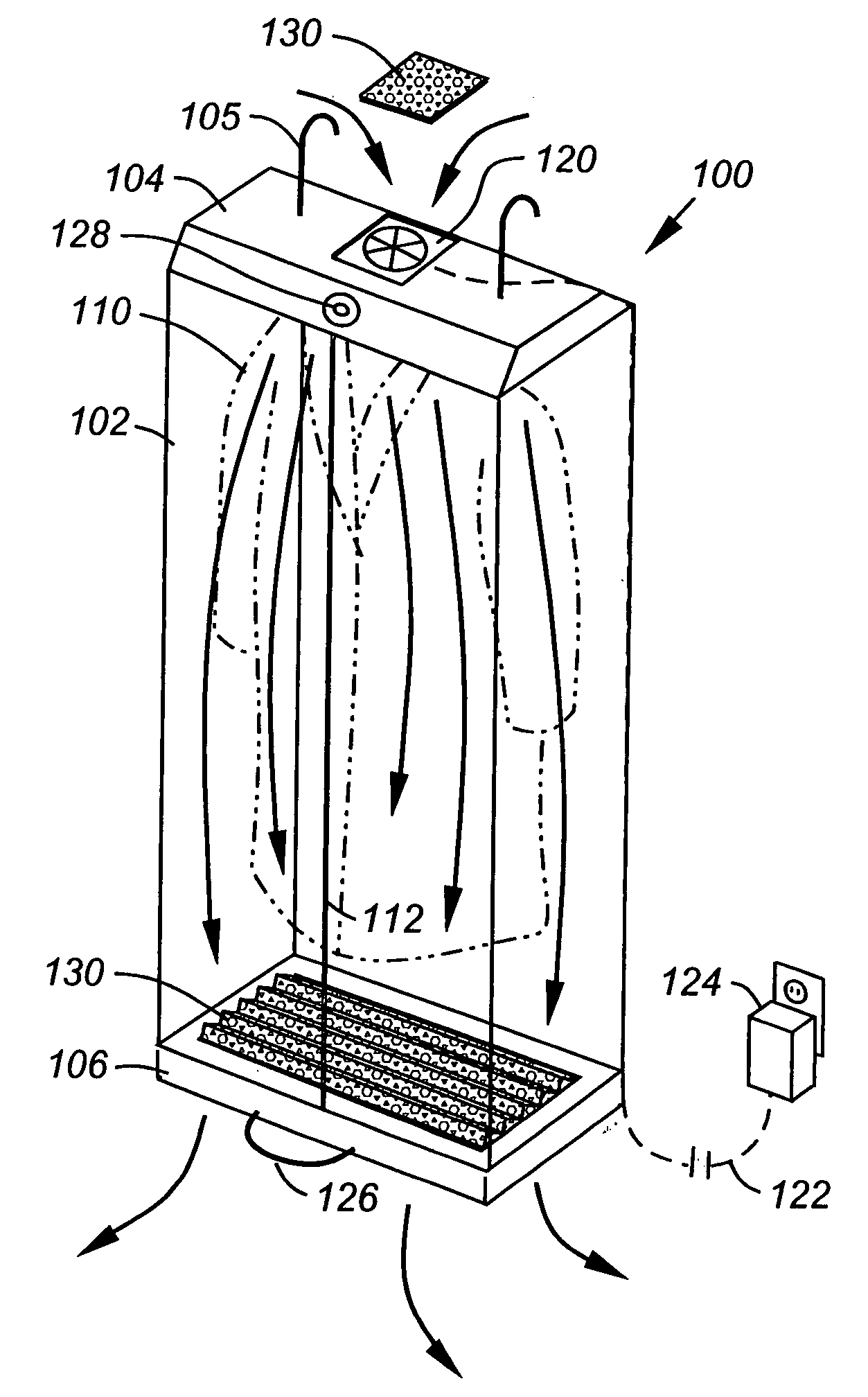

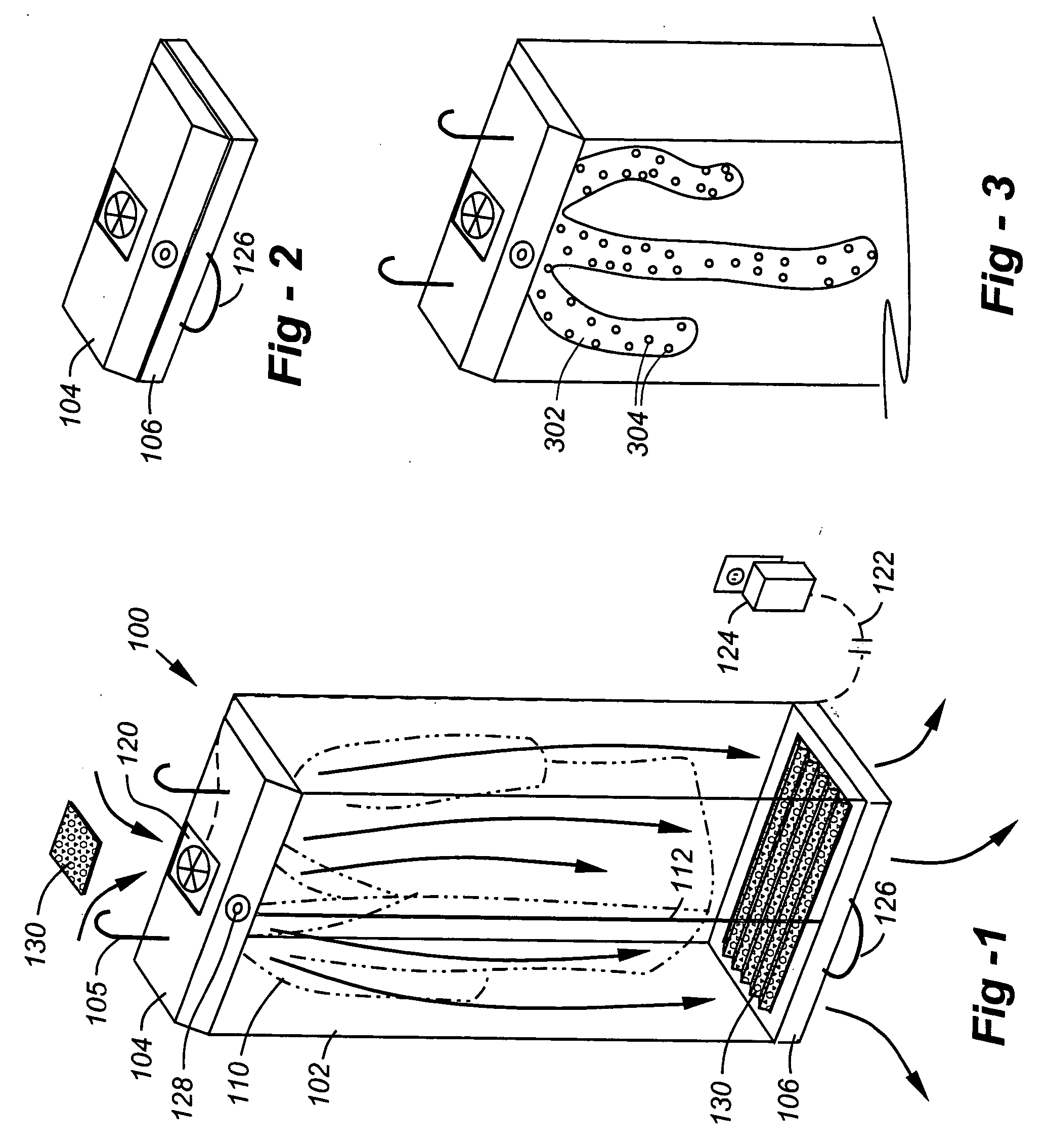

InactiveUS20050120757A1Easy to useHand rubbing apparatusTextile treatment machine partsLow voltageEngineering

A garment refreshing system includes an enclosure having a top, a bottom, a sidewall, an air inlet and an air outlet, and a hook or other element on the top to facilitate hanging in a closet or other location. An electrical fan at the air inlet is operative to bring air into the enclosure and past the clothing to the air outlet, and a filter supported at the air outlet for collecting odors removed from the clothing: The preferred configuration further includes a support within the enclosure to receive clothing on hangers, and the sidewall includes a closable opening to place clothing into, and remove clothing from the enclosure. The use of a low-voltage D.C. fan, such as a 12-VDC fan, facilitates use in a vehicle. As a further option, a material associated with the air inlet to introduce a deodorizer or fragrance into the enclosure. For example, an absorbent material may be provided to receive a deodorizer or fragrance in liquid form.

Owner:JACKSON W SHAUN

Washing apparatus

InactiveUS6898951B2Organic detergent compounding agentsDry-cleaning apparatusMechanical engineeringSurgery

Owner:THE PROCTER & GAMBLE COMPANY

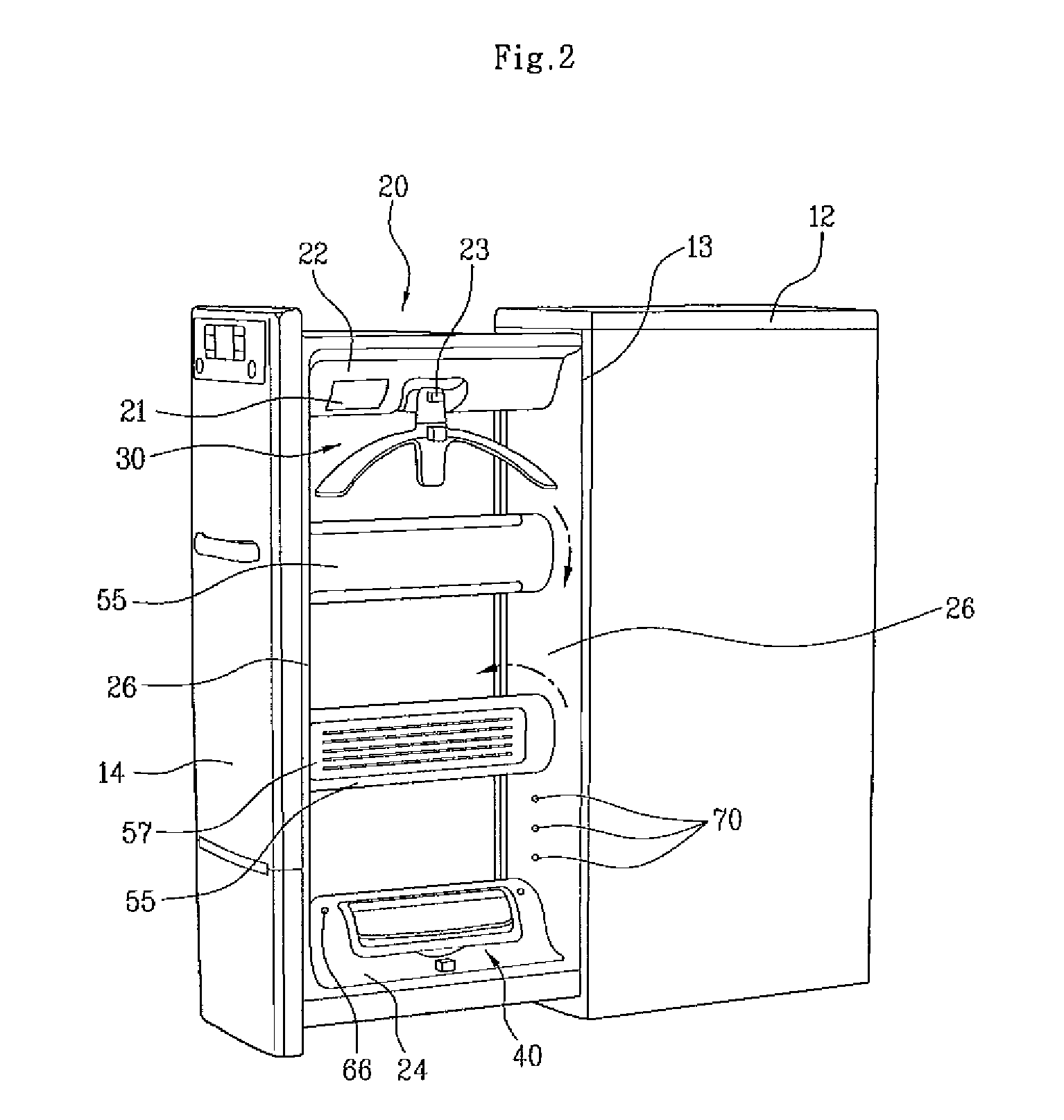

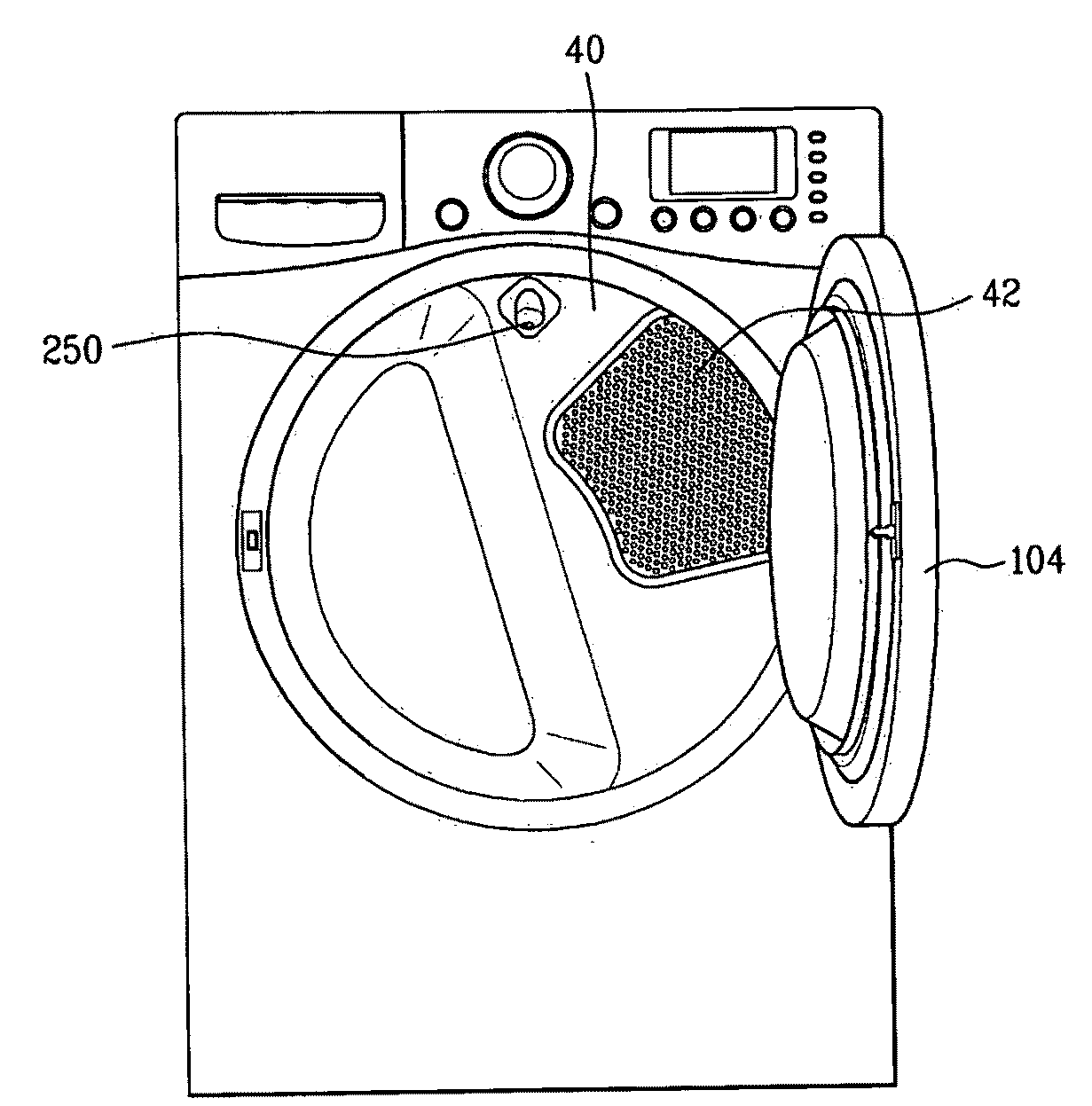

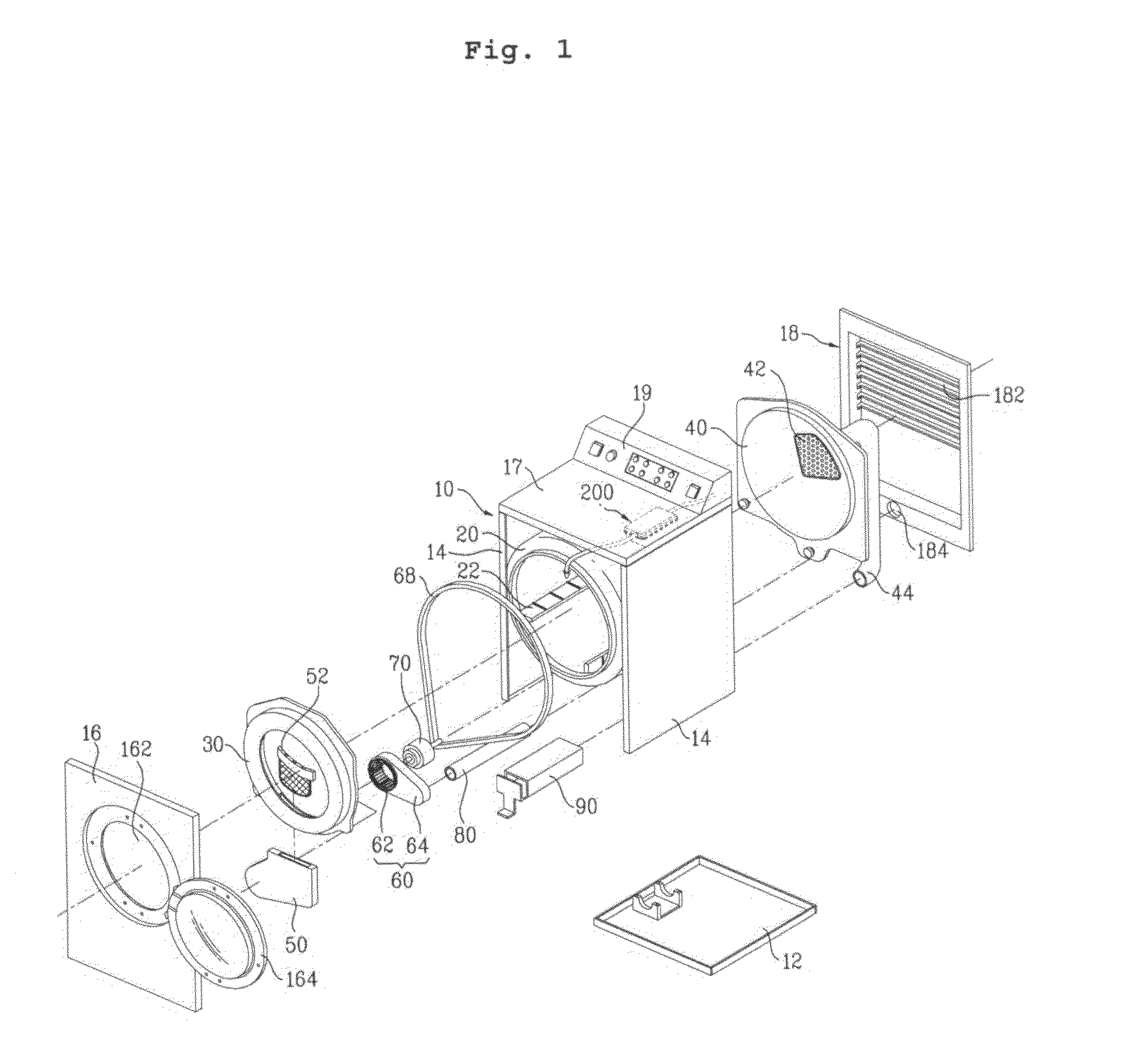

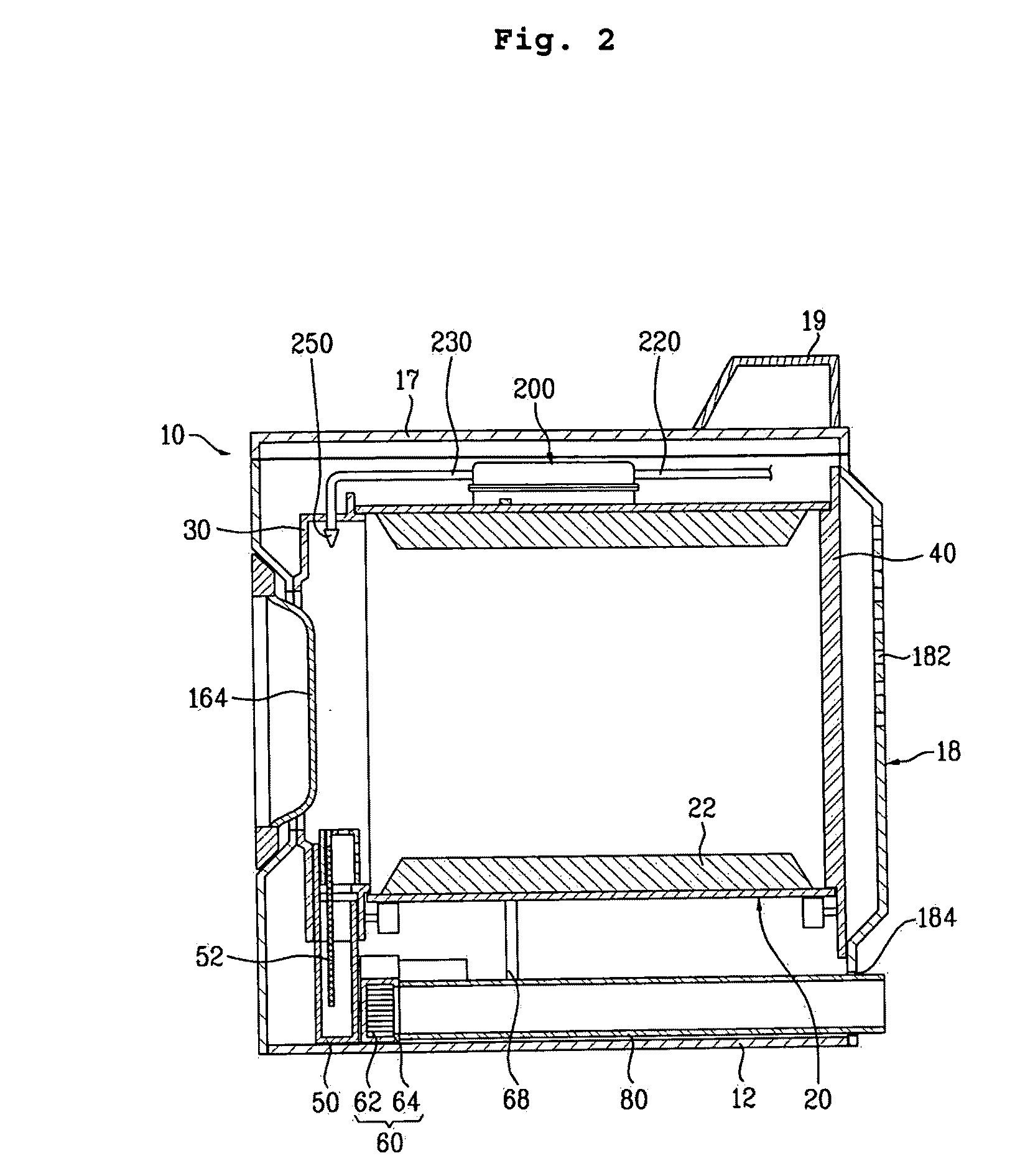

Washing machine

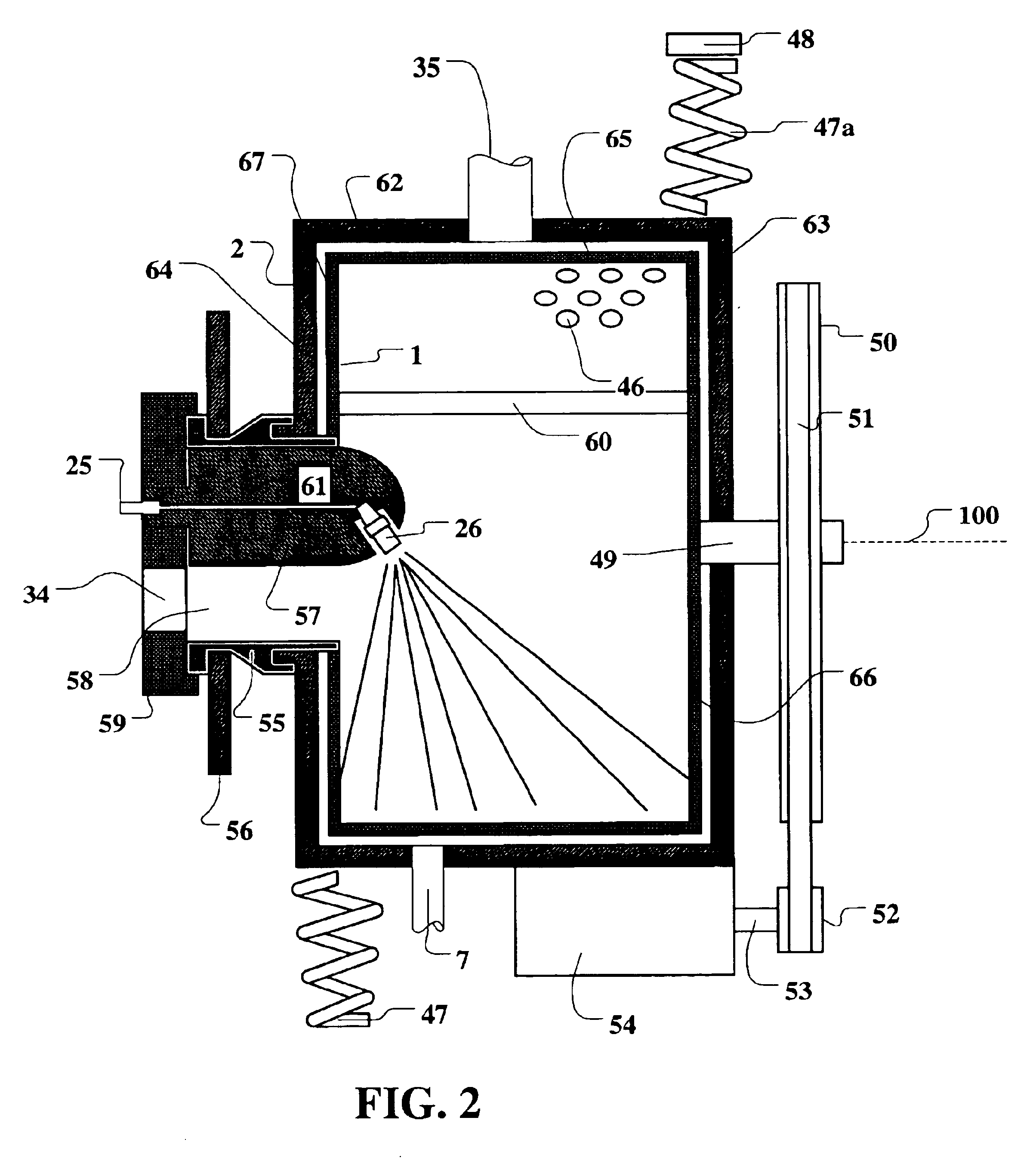

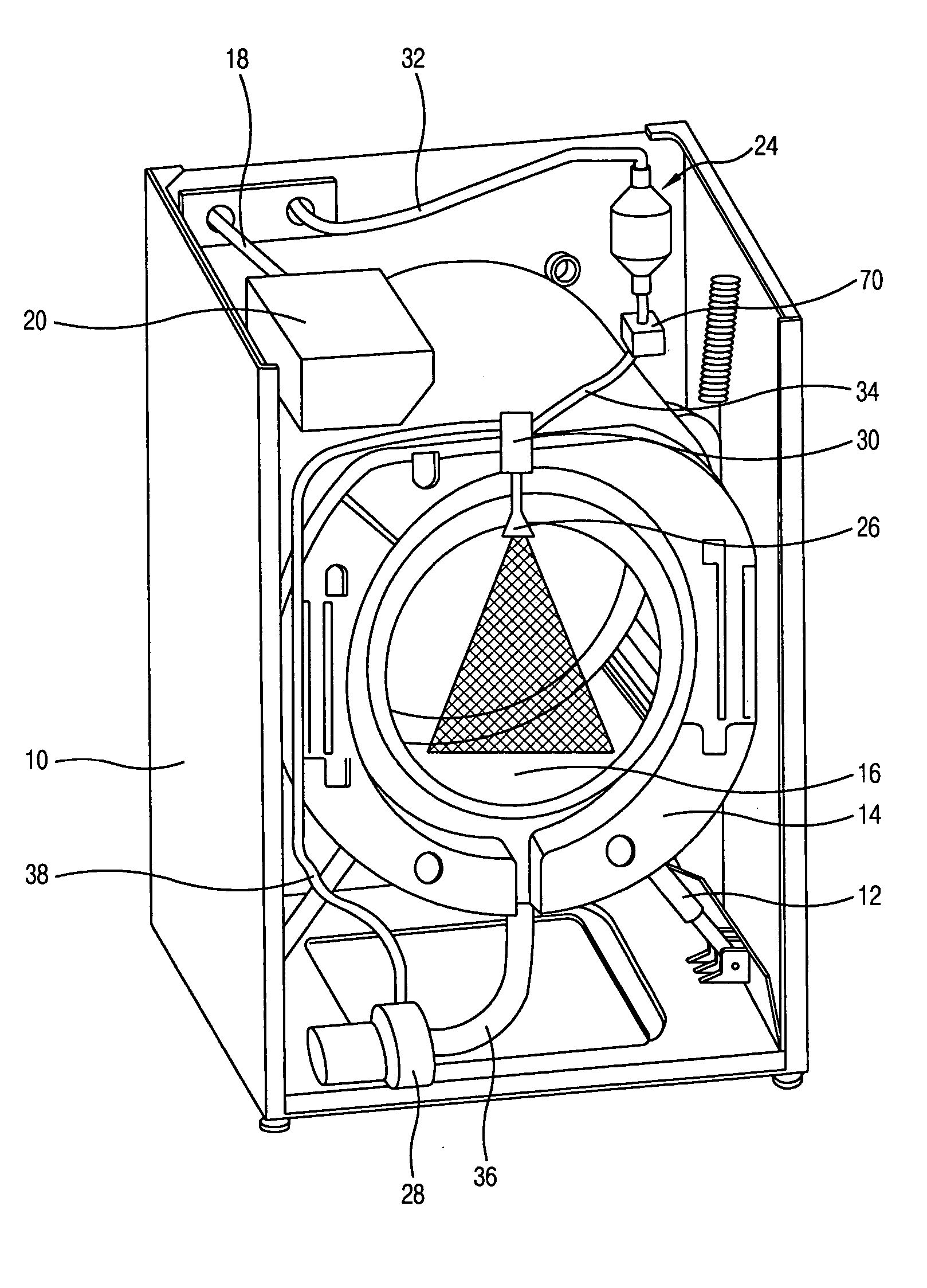

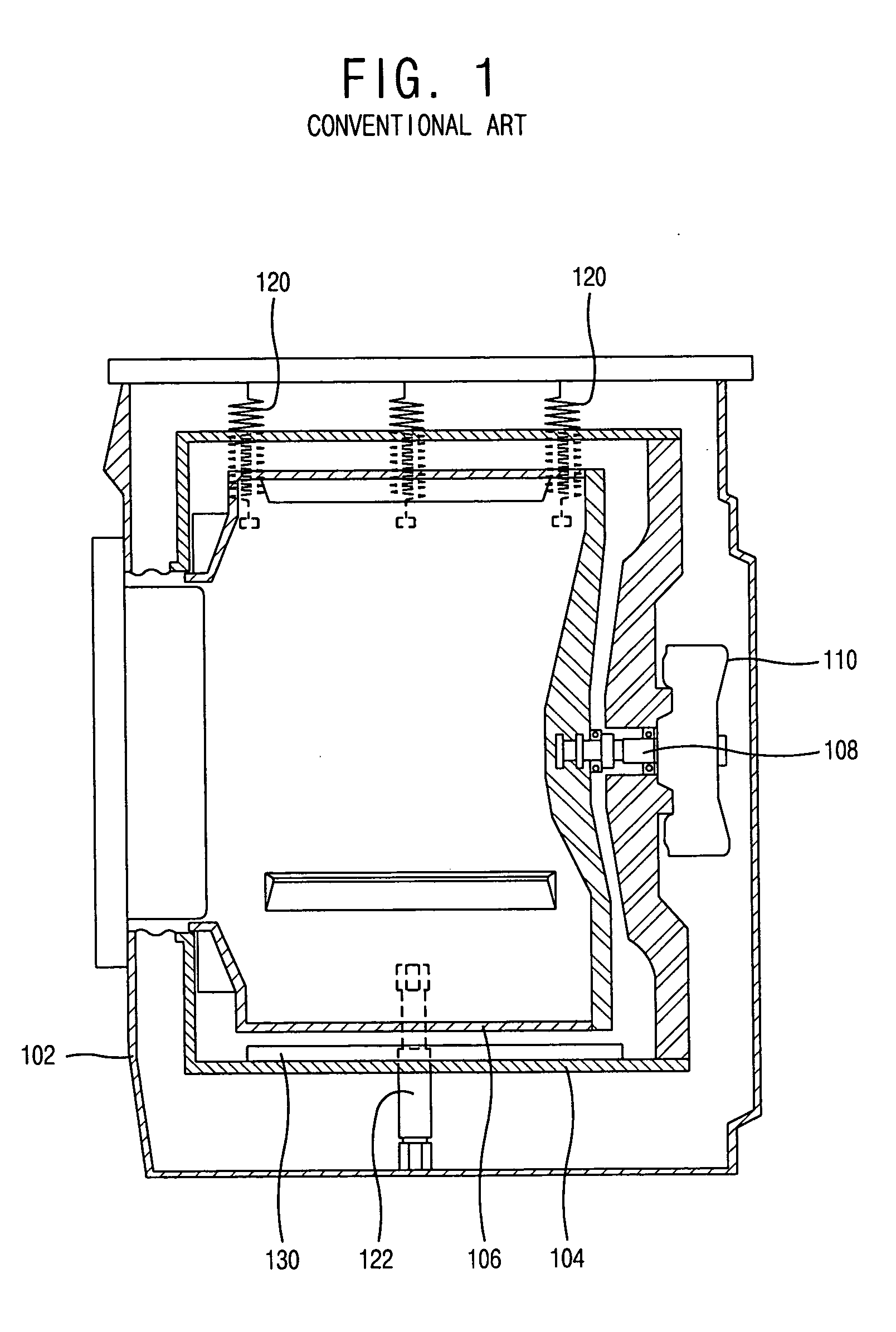

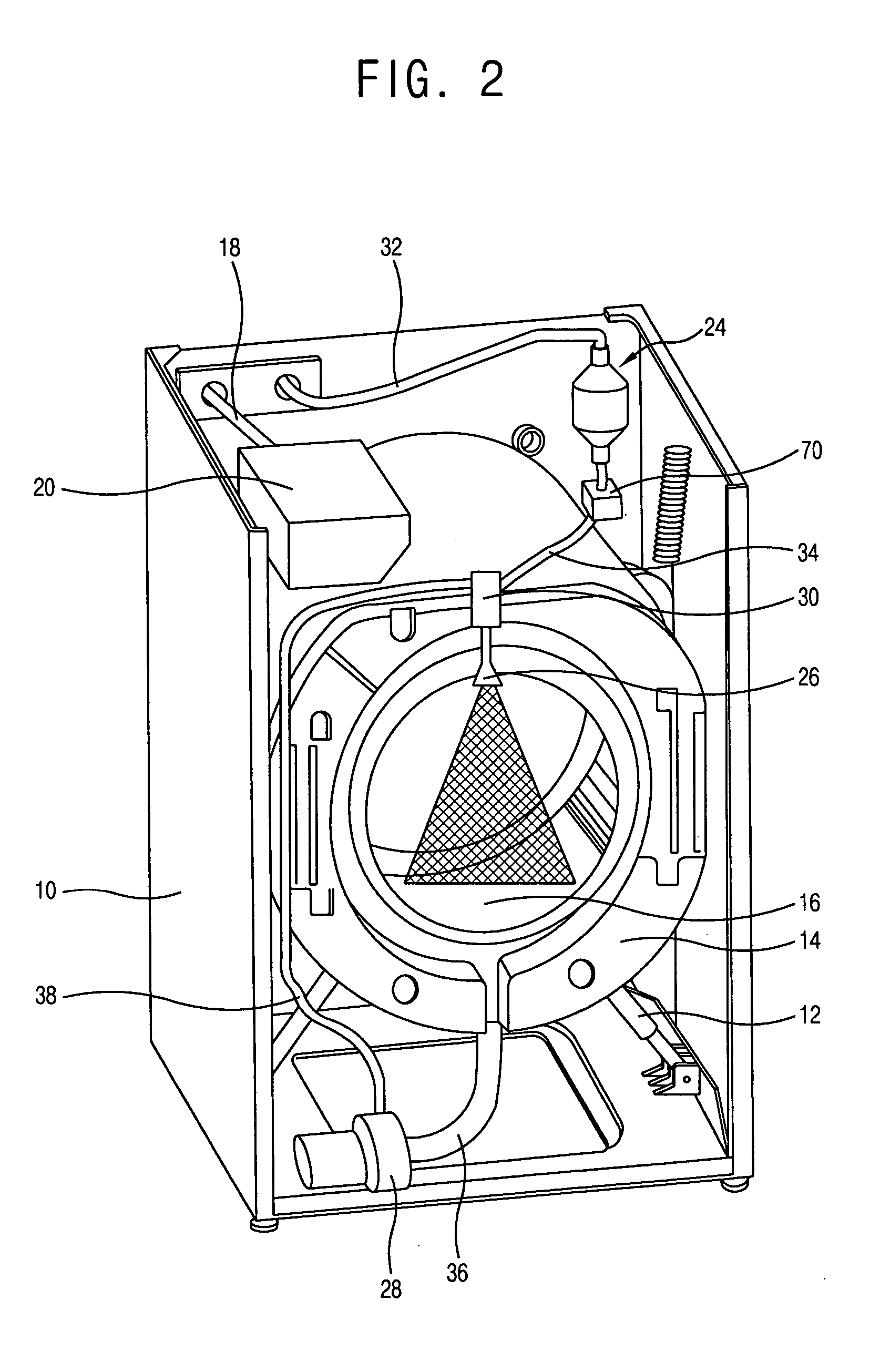

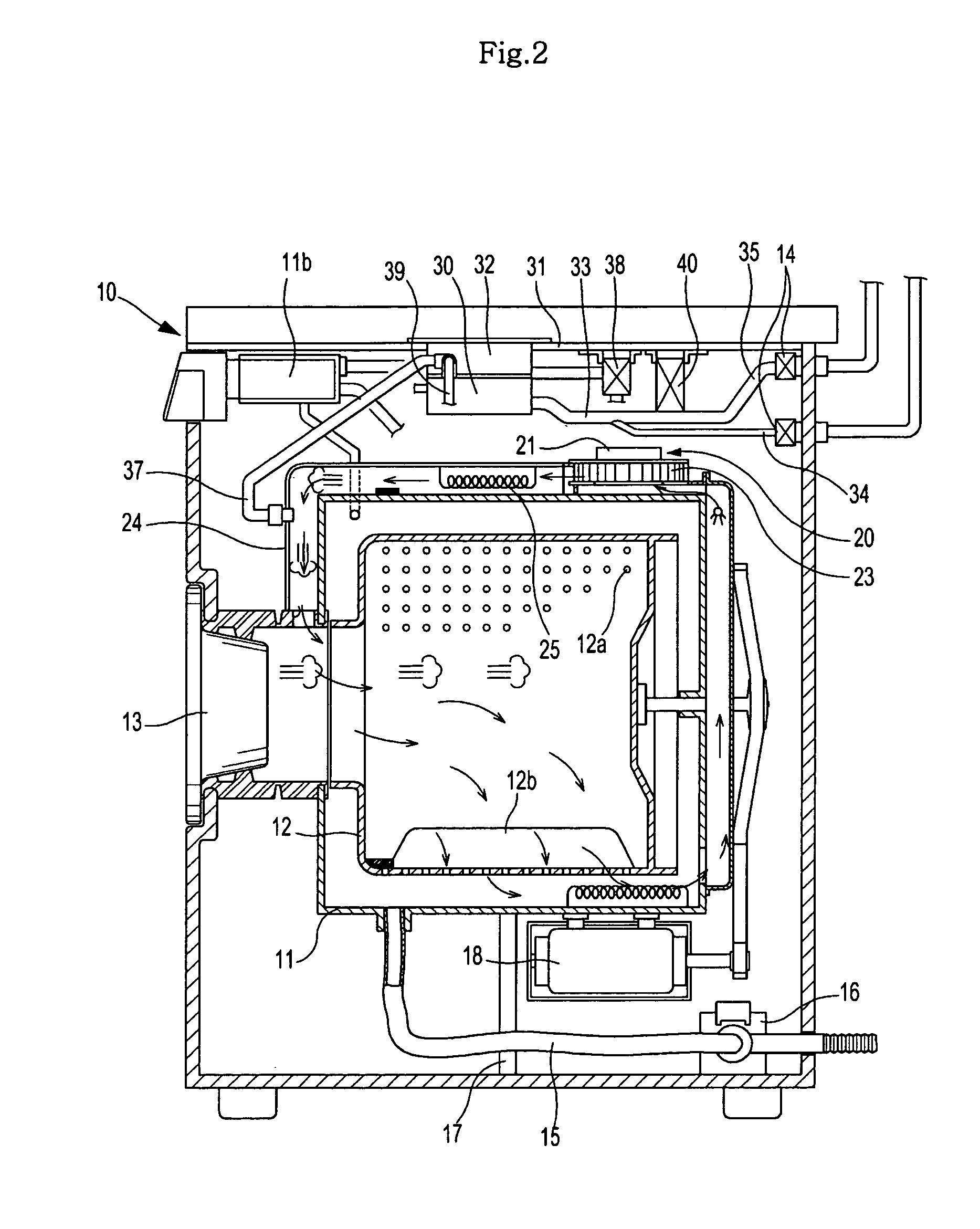

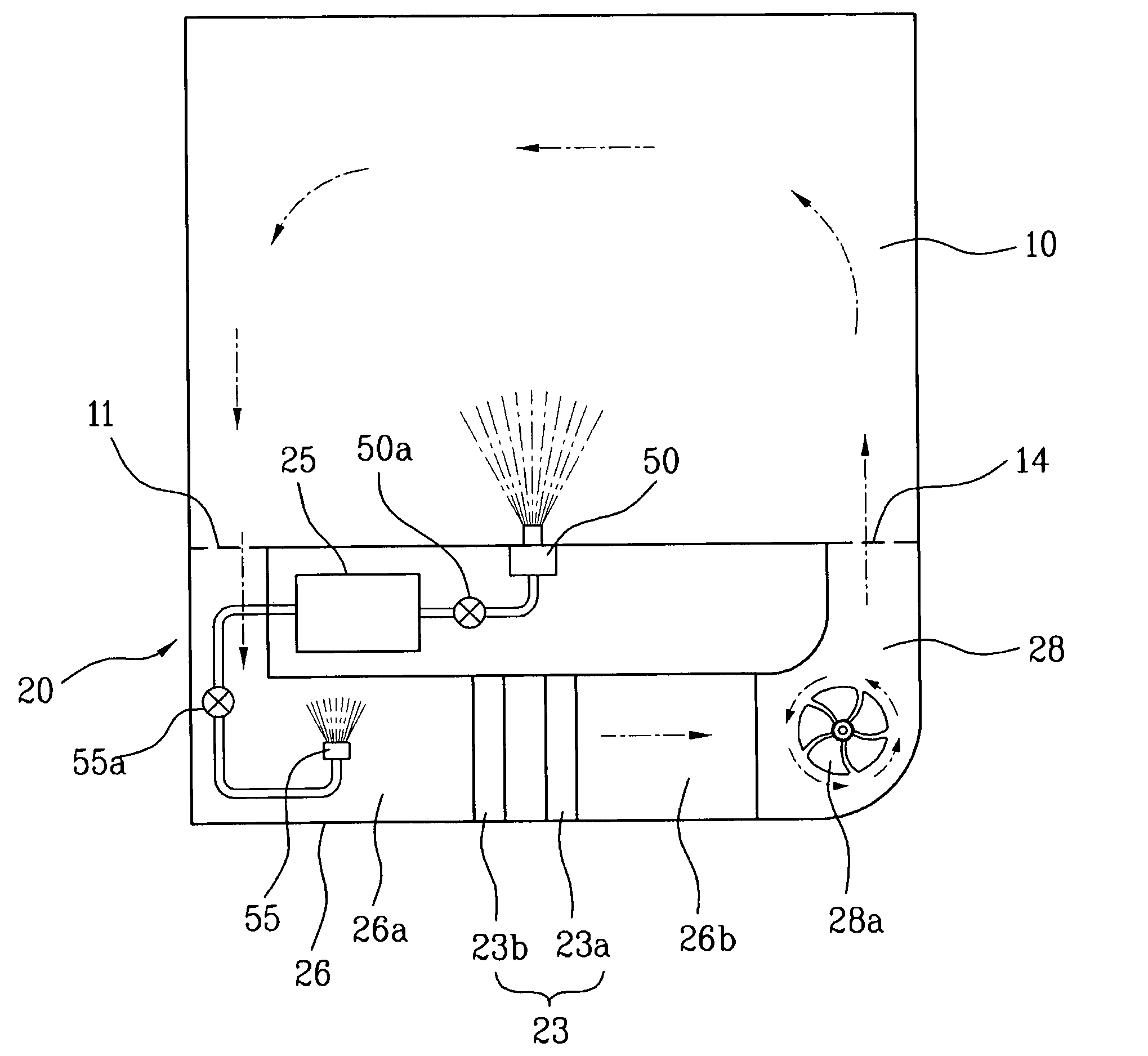

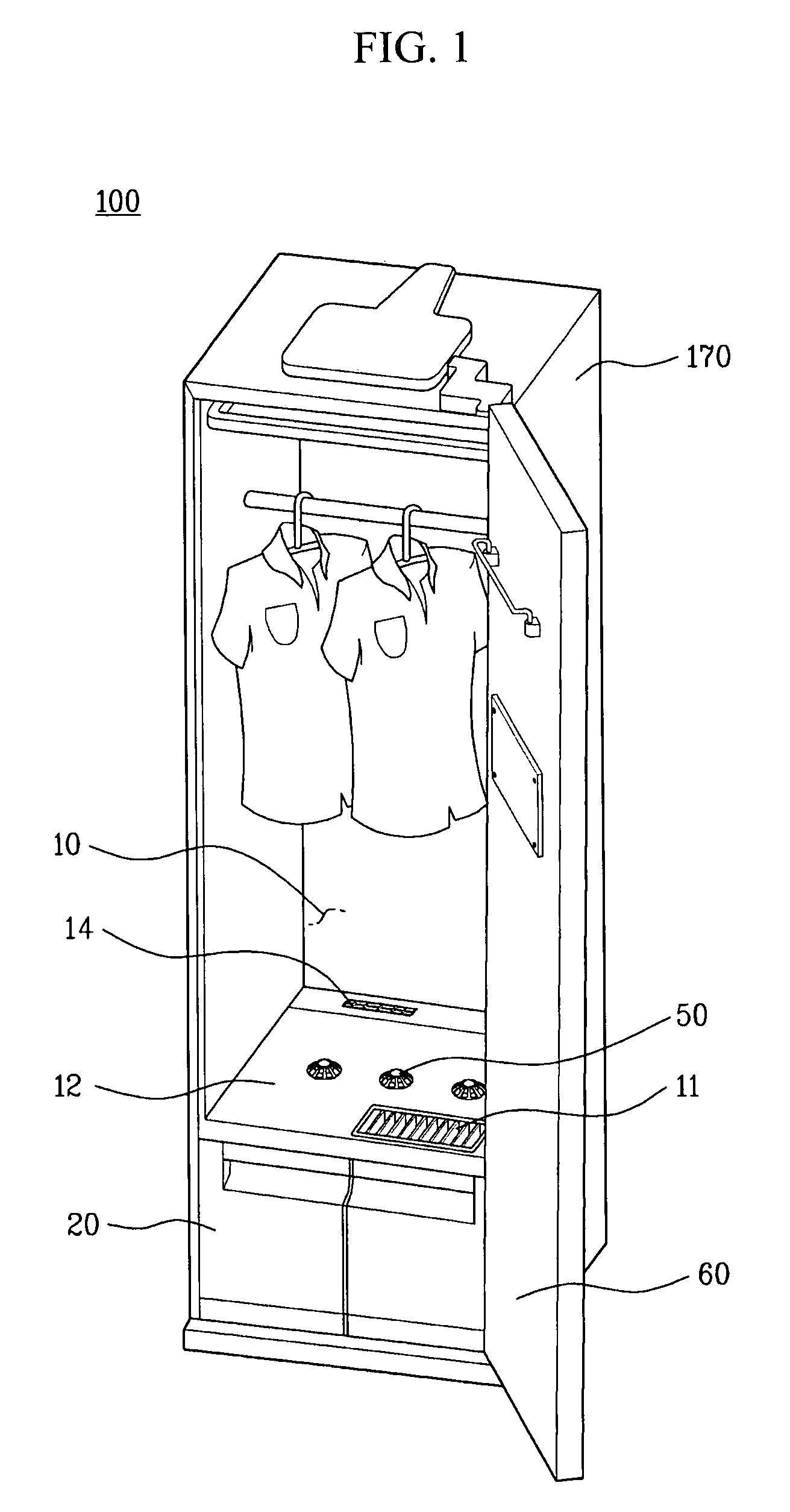

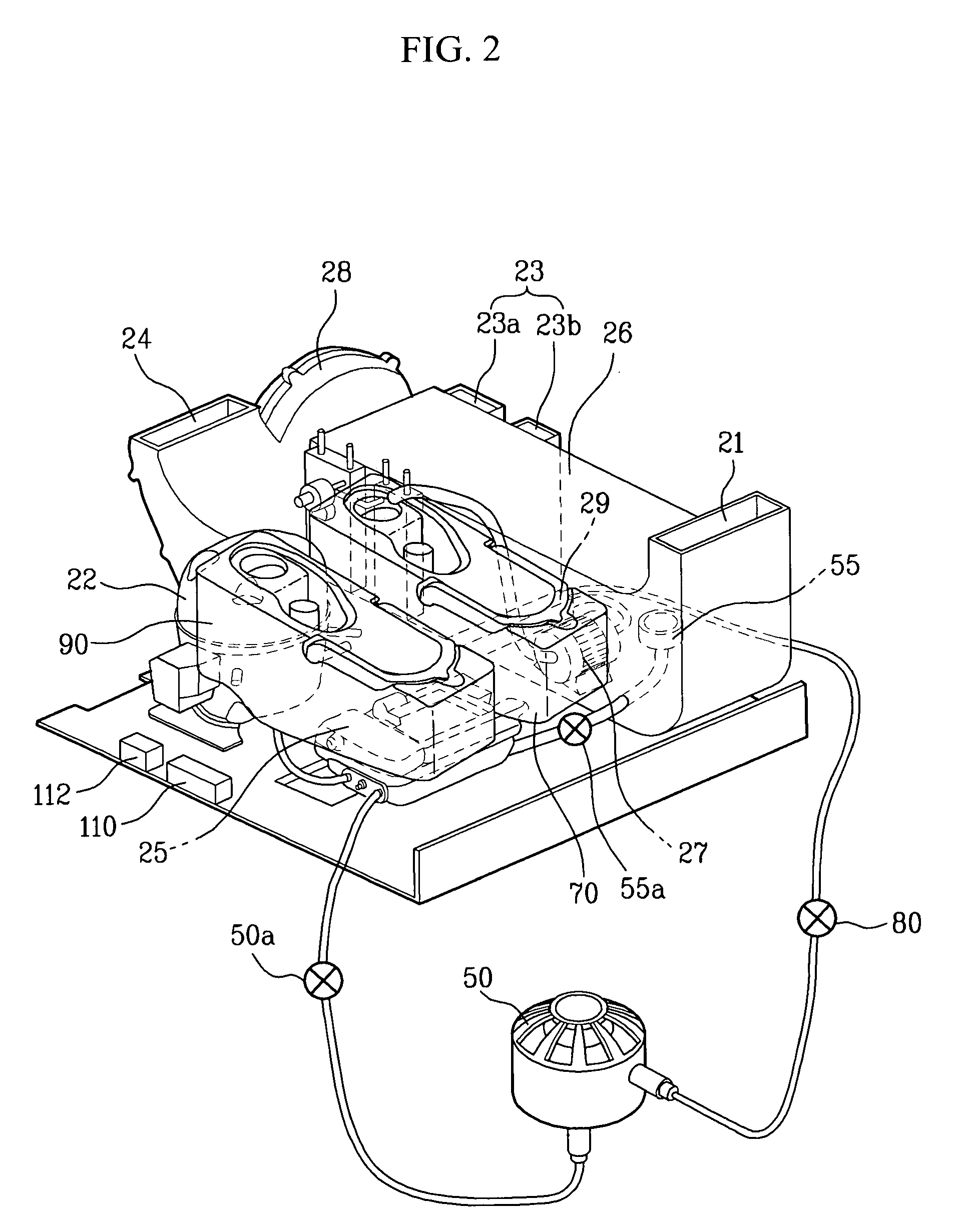

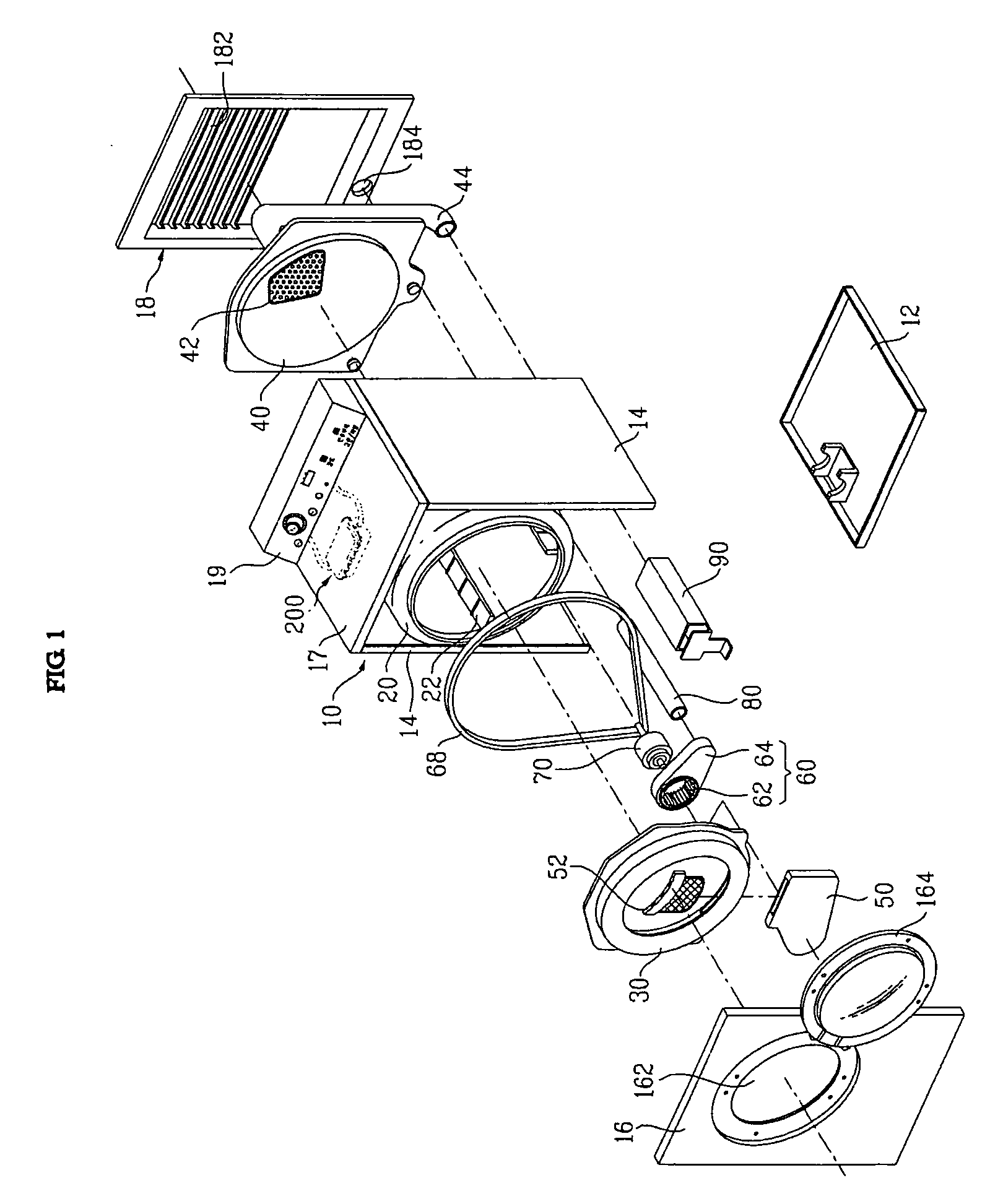

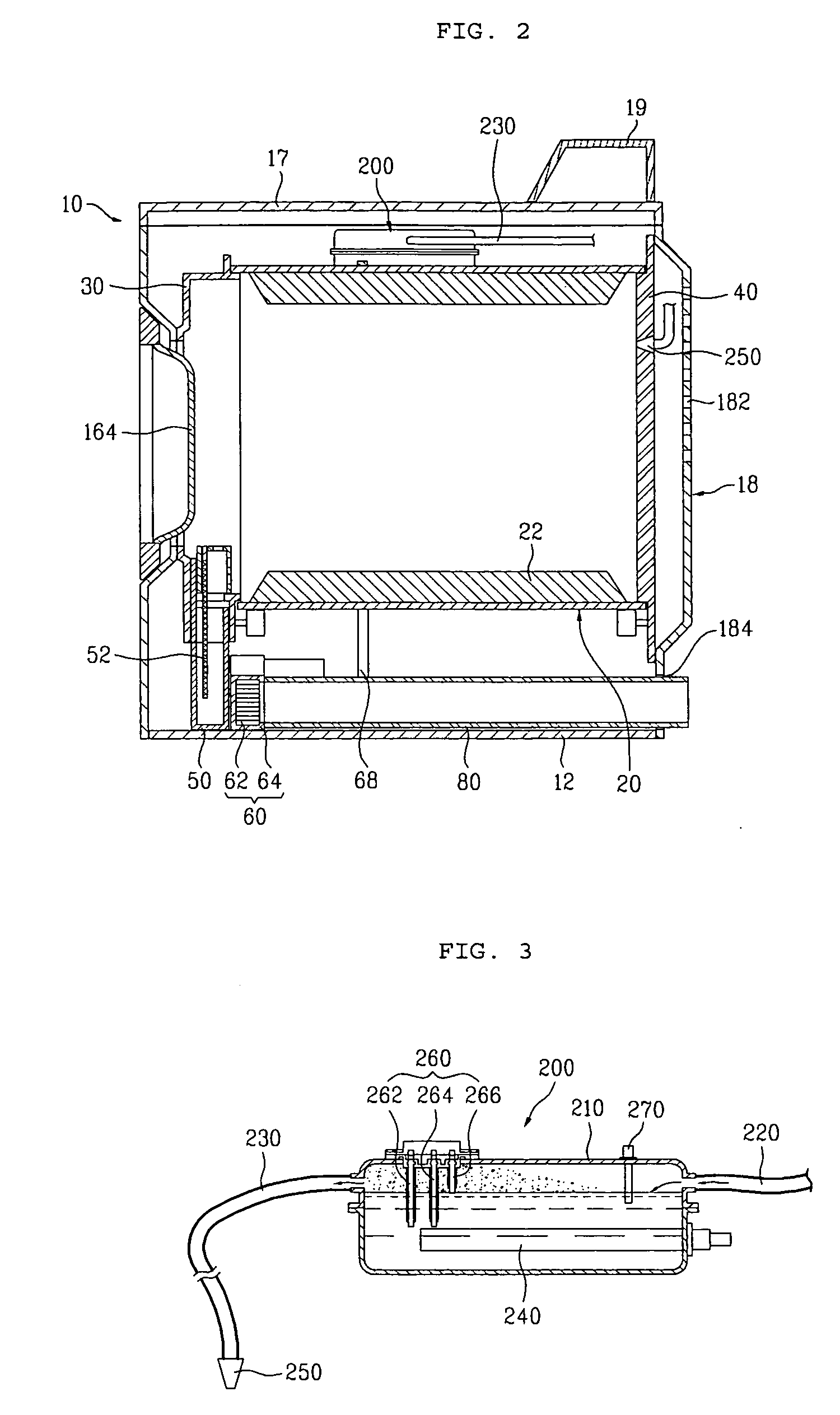

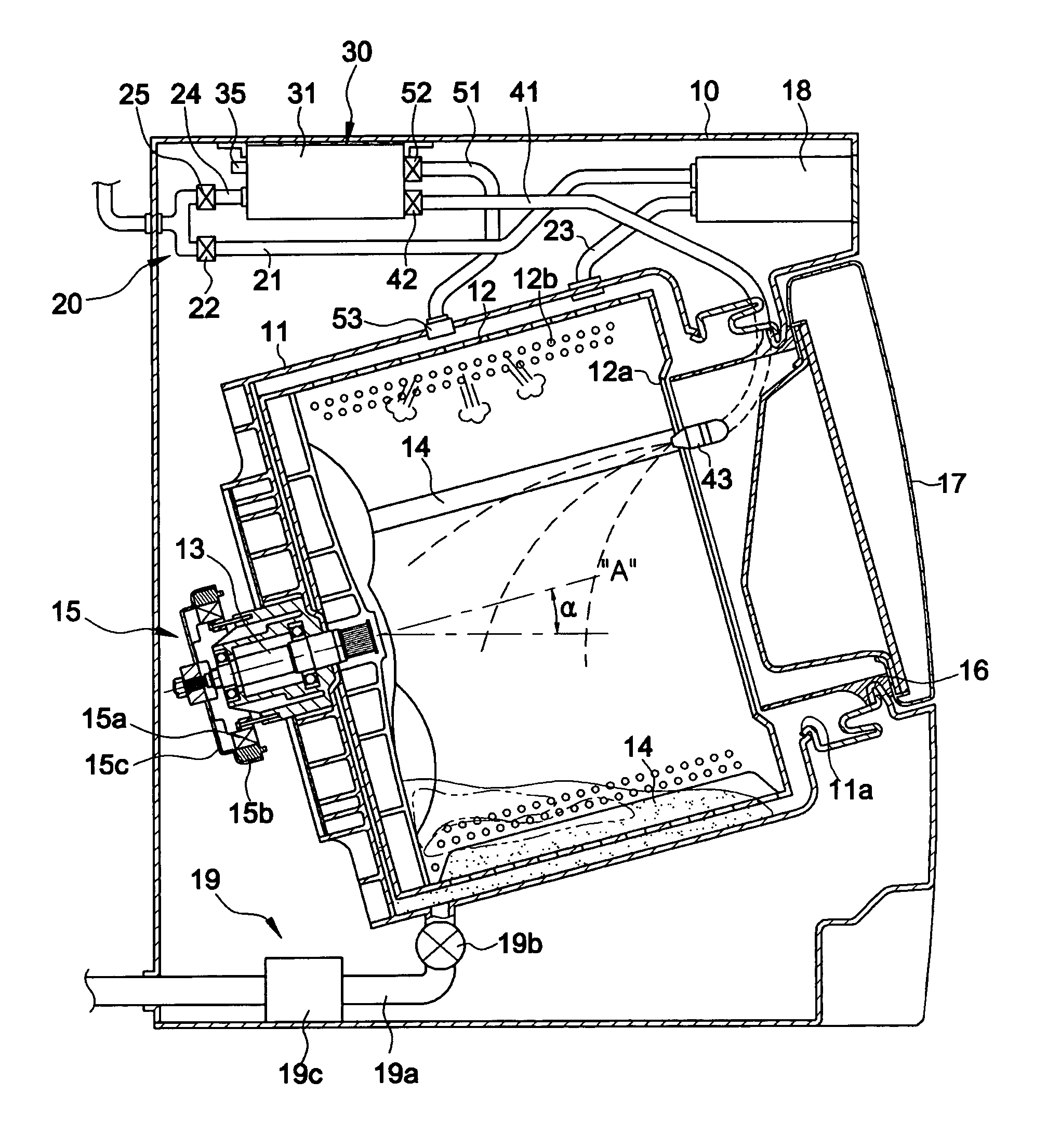

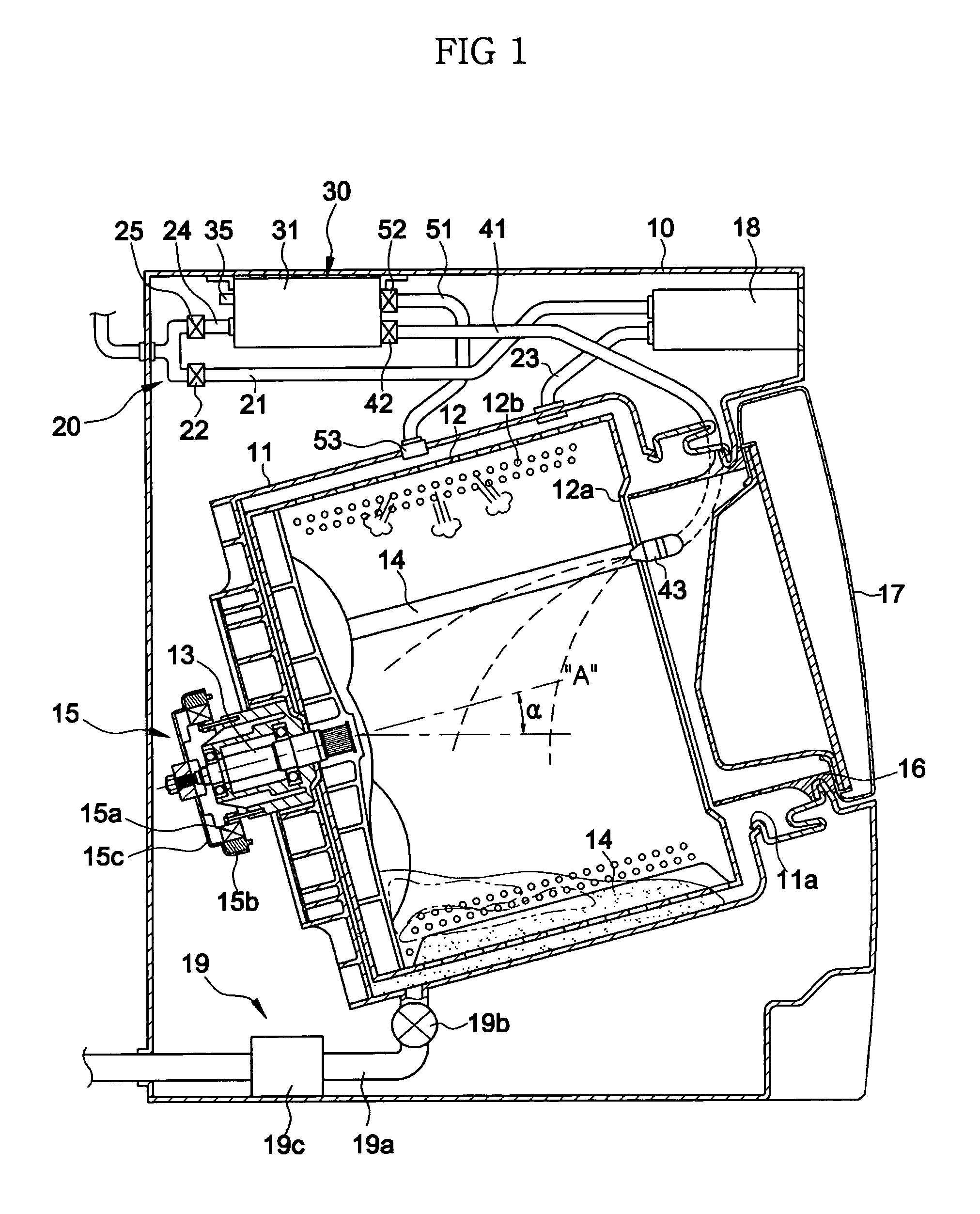

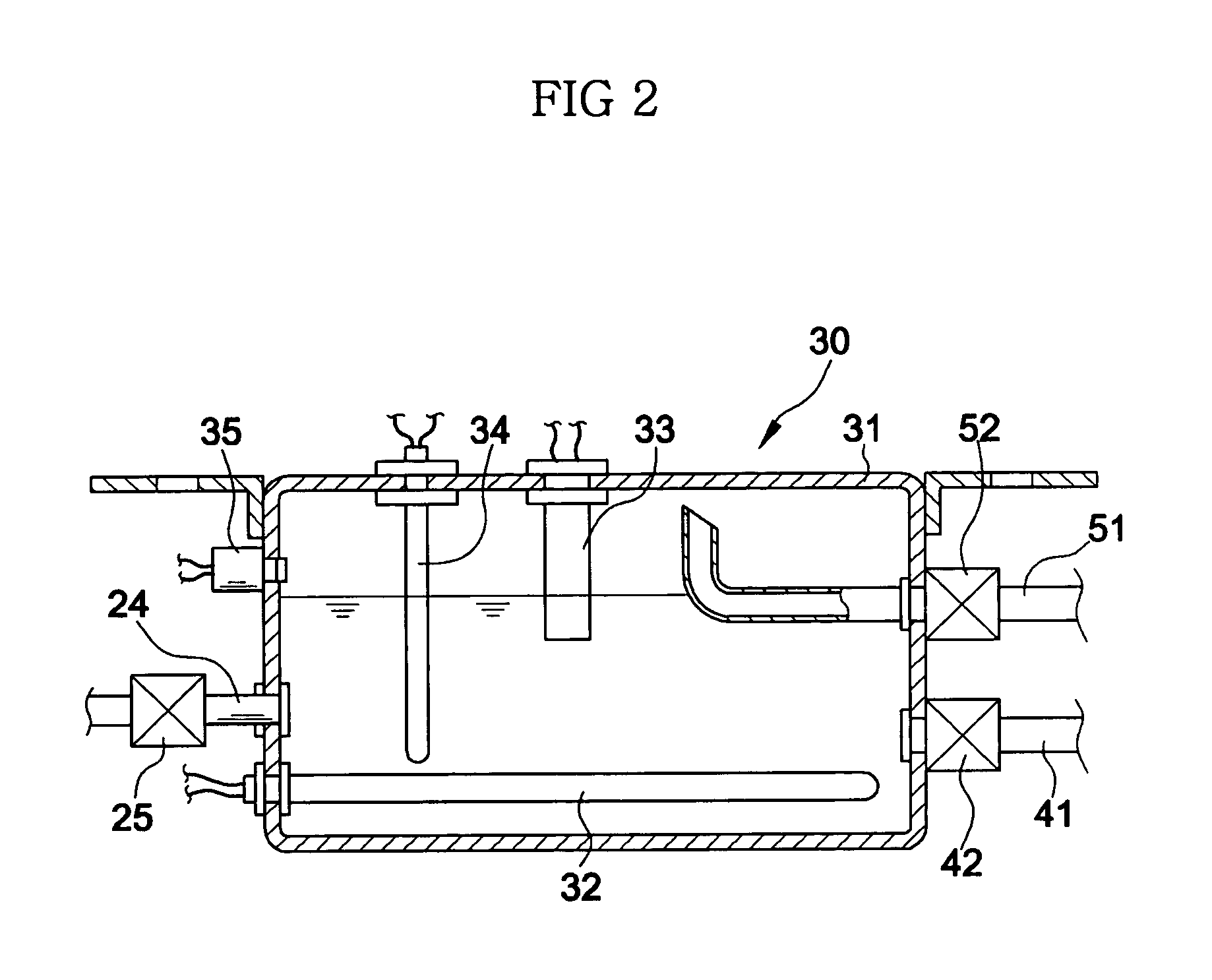

ActiveUS20050034488A1Small sizeReduce the amount of waterTextile treatment machine partsOther washing machinesManufacturing cost reductionWater discharge

A washing machine includes: a steam generator for generating steam; a circulation pump for pumping circulation water discharged from a tub and re-supplying it into a drum; a spray nozzle for spraying steam generated from the steam generator and the circulation water pumped from the circulation pump into the drum; and a back-current preventing branch unit connected to the steam generator by a steam supply line, connected to the circulation pump by a circulation line, and connected to the spray nozzle. With this structure, circulation water circulated by the circulation unit and steam generated from the steam generator are sprayed to the laundry through one spray nozzle, so that a system can be simplified and a fabrication cost can be reduced.

Owner:LG ELECTRONICS INC

Washing machine

InactiveUS20050034490A1Small sizeReduce the amount of waterSteam generation heating methodsTextile treatment machine partsEngineeringLaundry

A washing machine includes a tub disposed inside a cabinet, for storing water; a drum rotatably disposed inside the tub, for washing laundry; and a steam generating apparatus disposed at the cabinet, for generating steam supplied to the inside of the drum, by using high-frequency induction heating. Accordingly, by generating steam using high-frequency induction heating, a structure of the steam generating apparatus can be simplified, and performance of generating steam can be improved.

Owner:LG ELECTRONICS INC

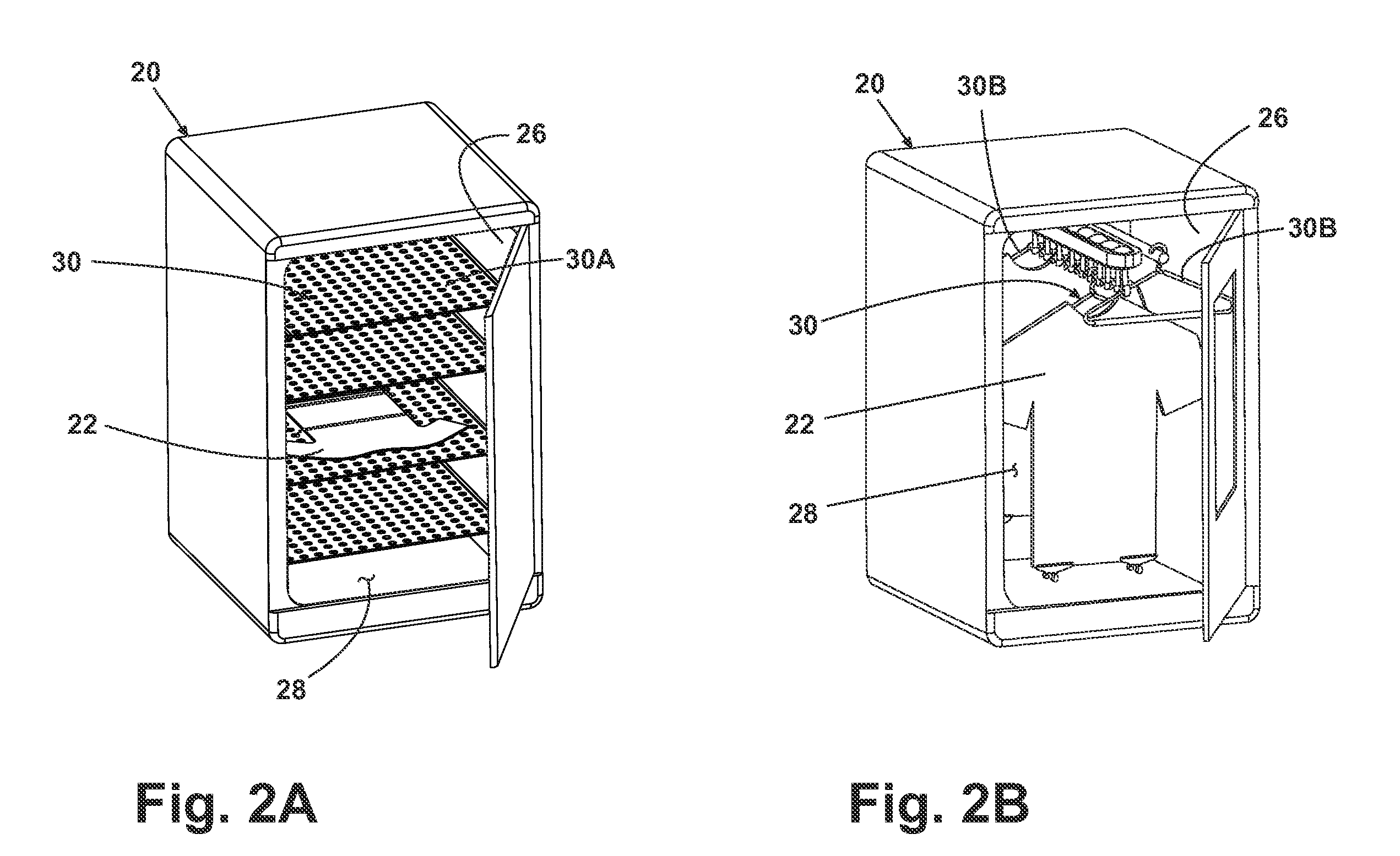

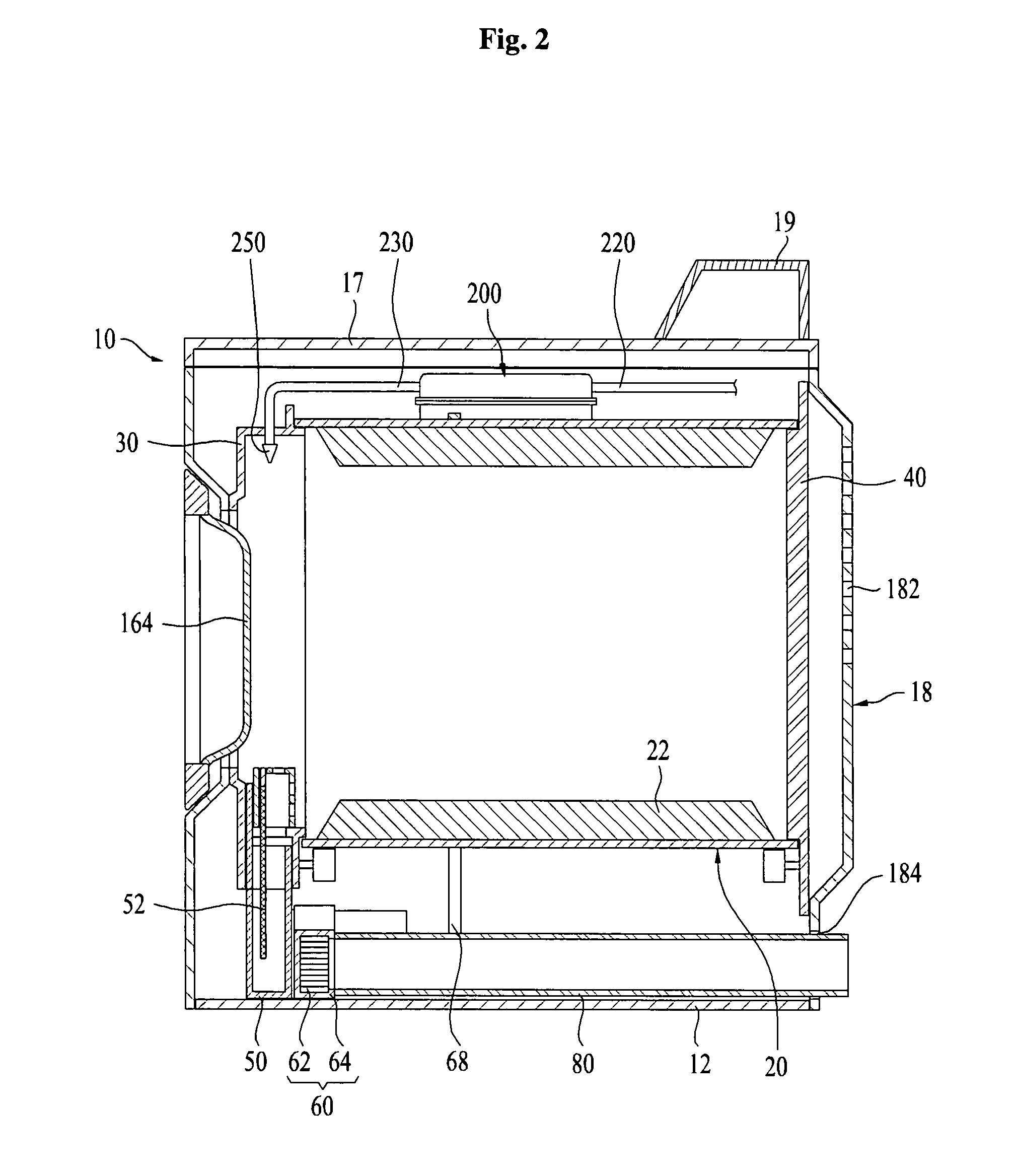

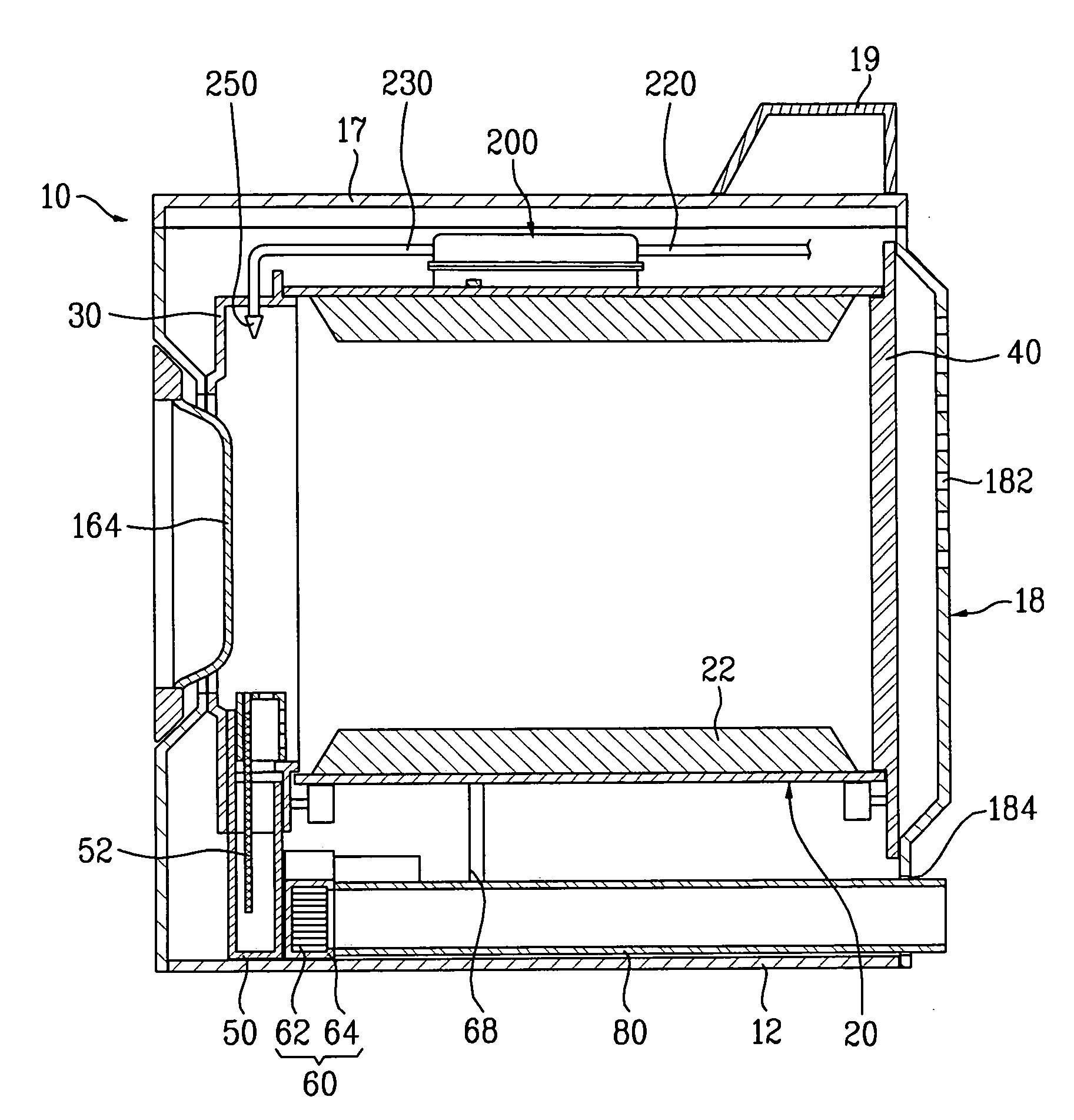

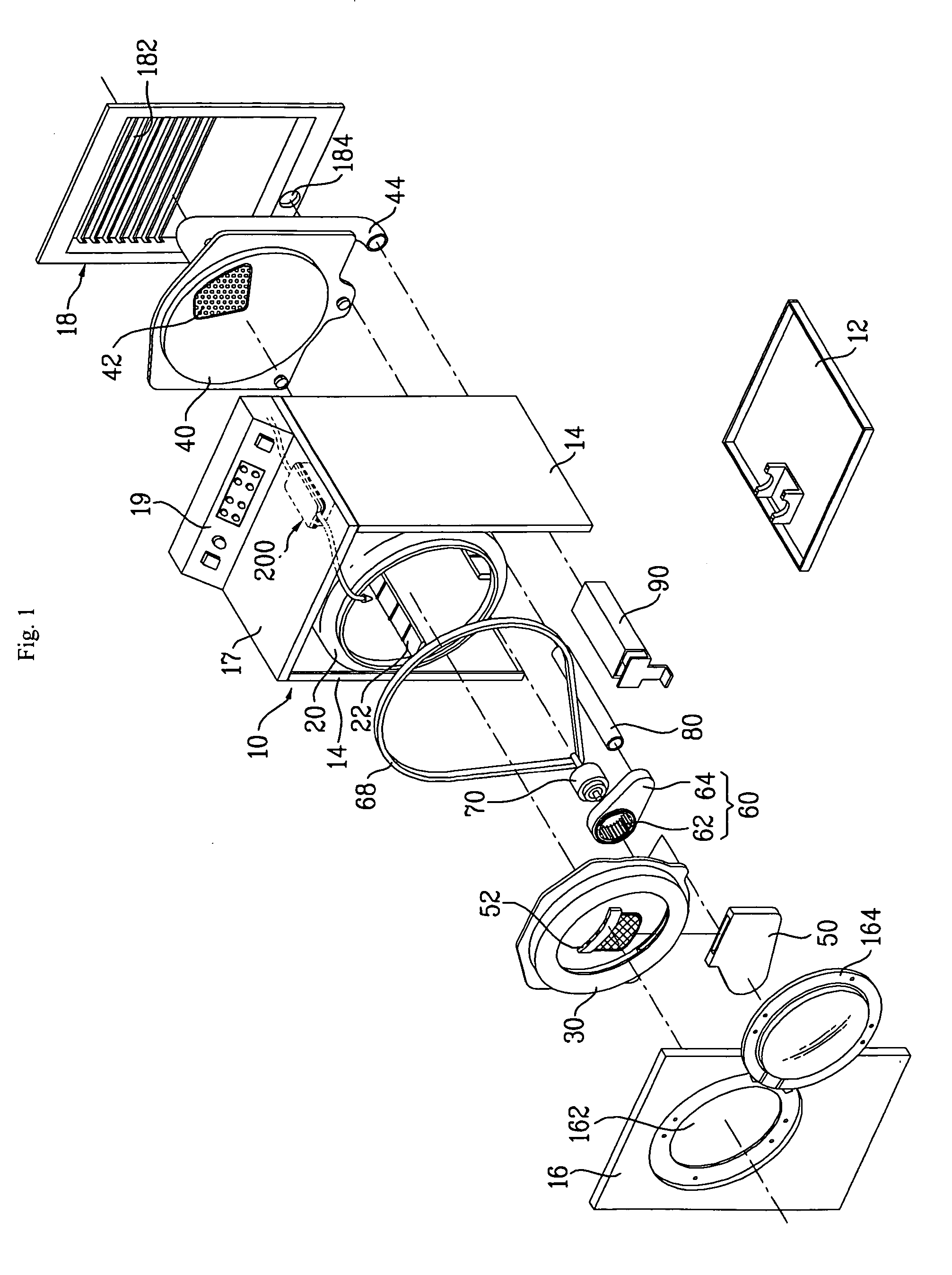

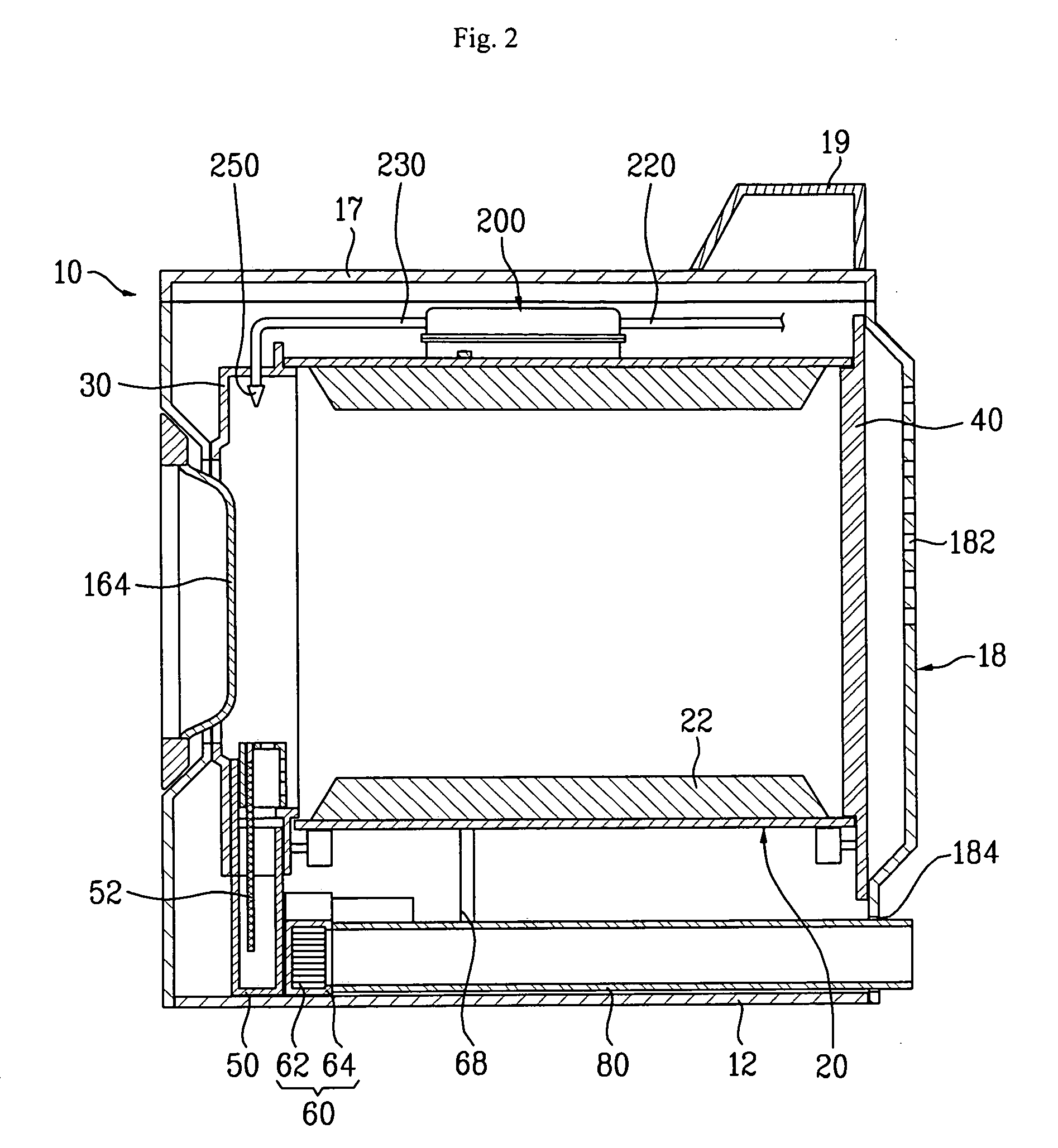

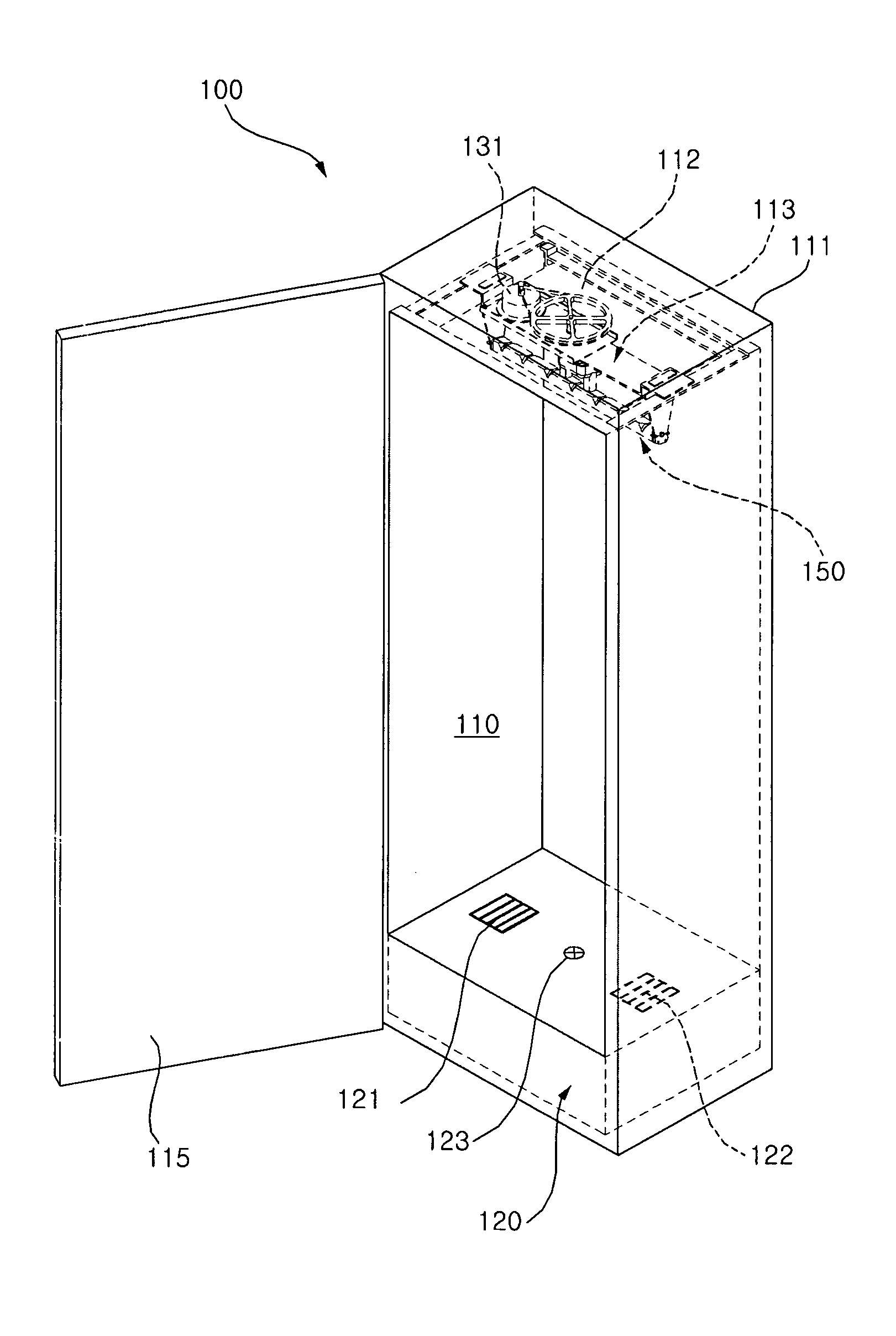

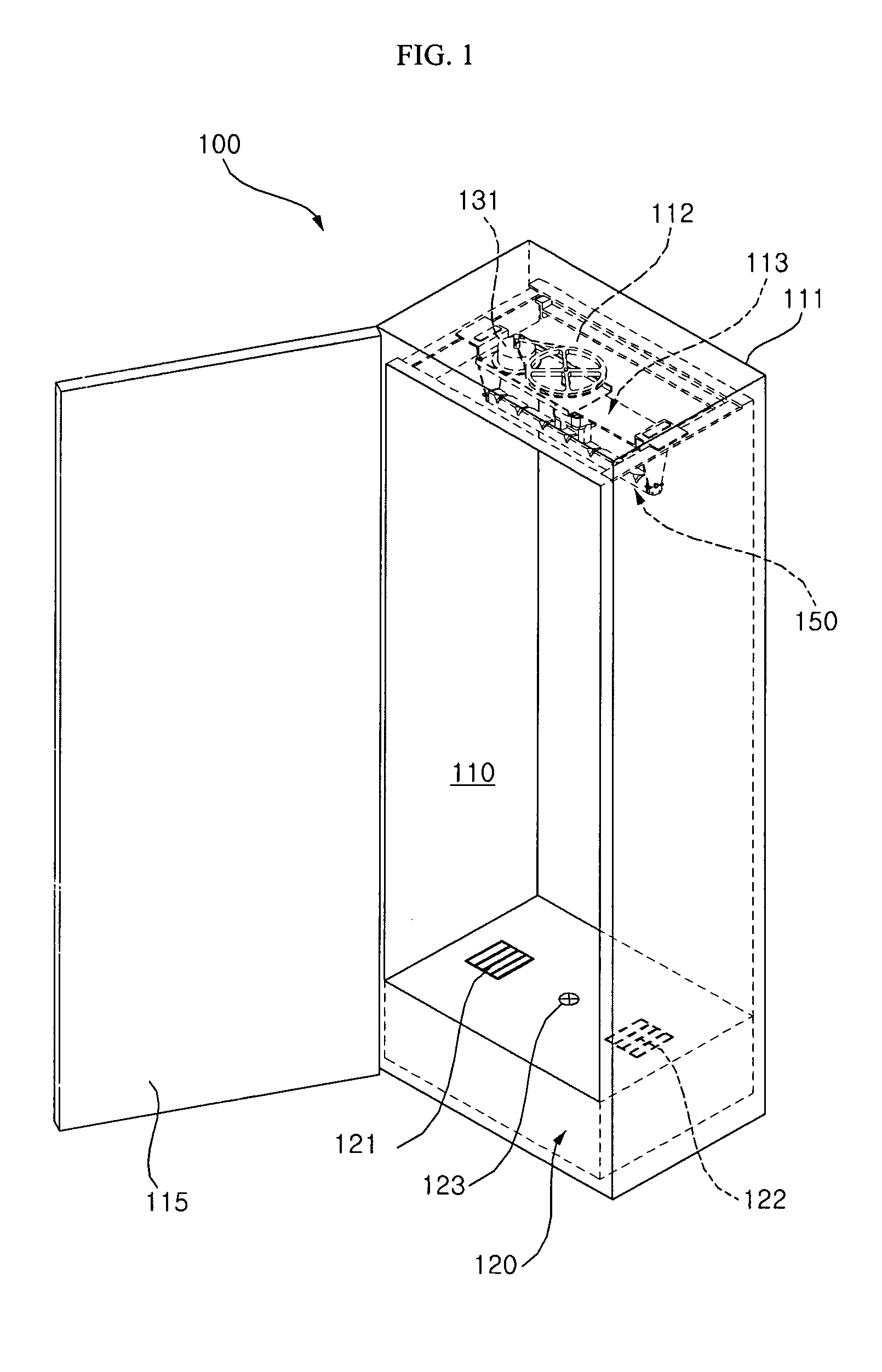

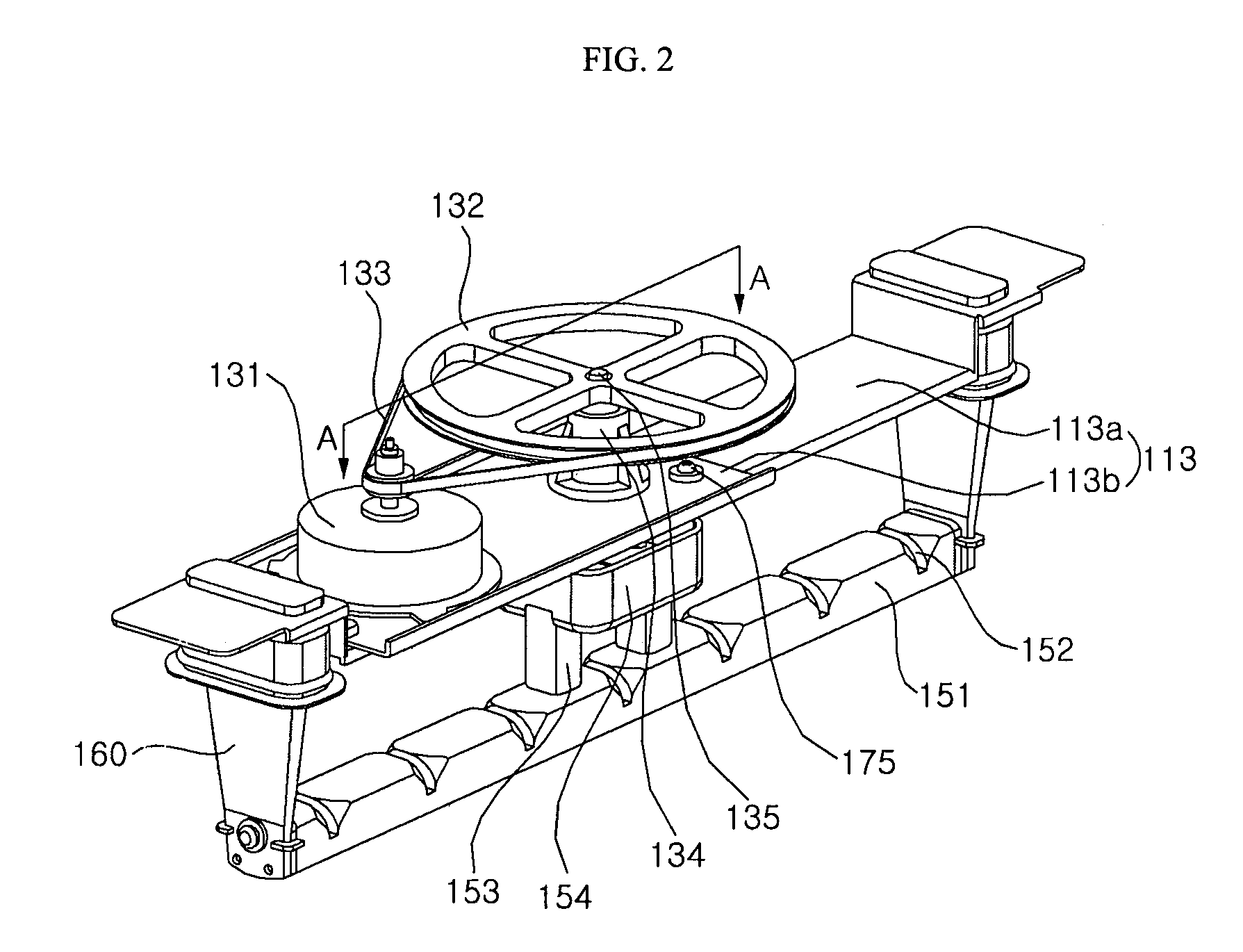

Supplemental clothes treating apparatus

InactiveUS20090126421A1Removing wrinkles of clothesTextile treatment machine partsOther washing machinesWaste management

Owner:LG ELECTRONICS INC

Modular fabric revitalizing system

InactiveUS20100018262A1Textile treatment machine partsOther washing machinesSoftware engineeringMechanical engineering

Owner:WHIRLPOOL CORP

Refresher and Machine for Washing or Drying with the Same

InactiveUS20080256989A1Improve satisfactionImprove convenienceTextile treatment machine partsOther washing machinesBiomedical engineering

Owner:LG ELECTRONICS INC

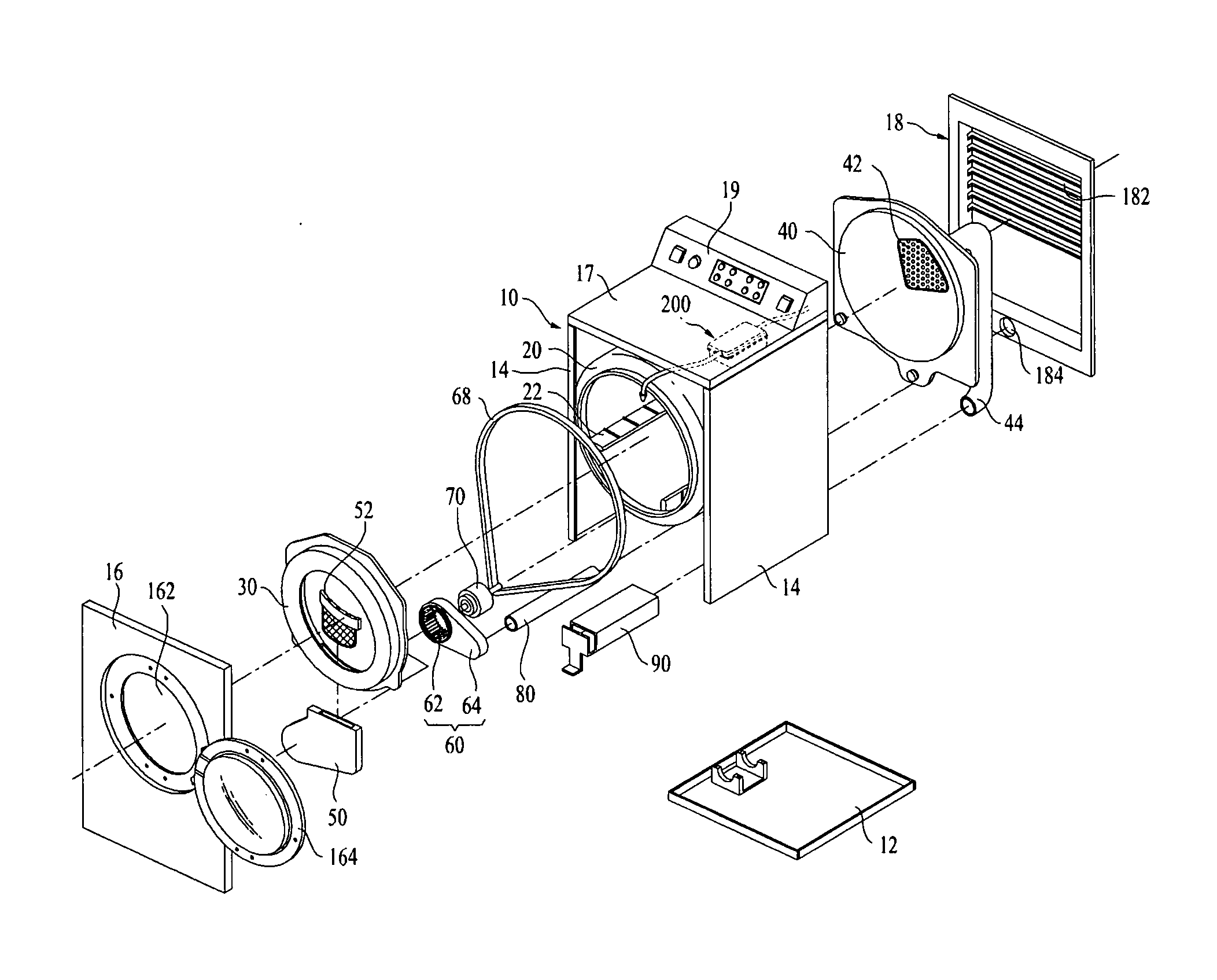

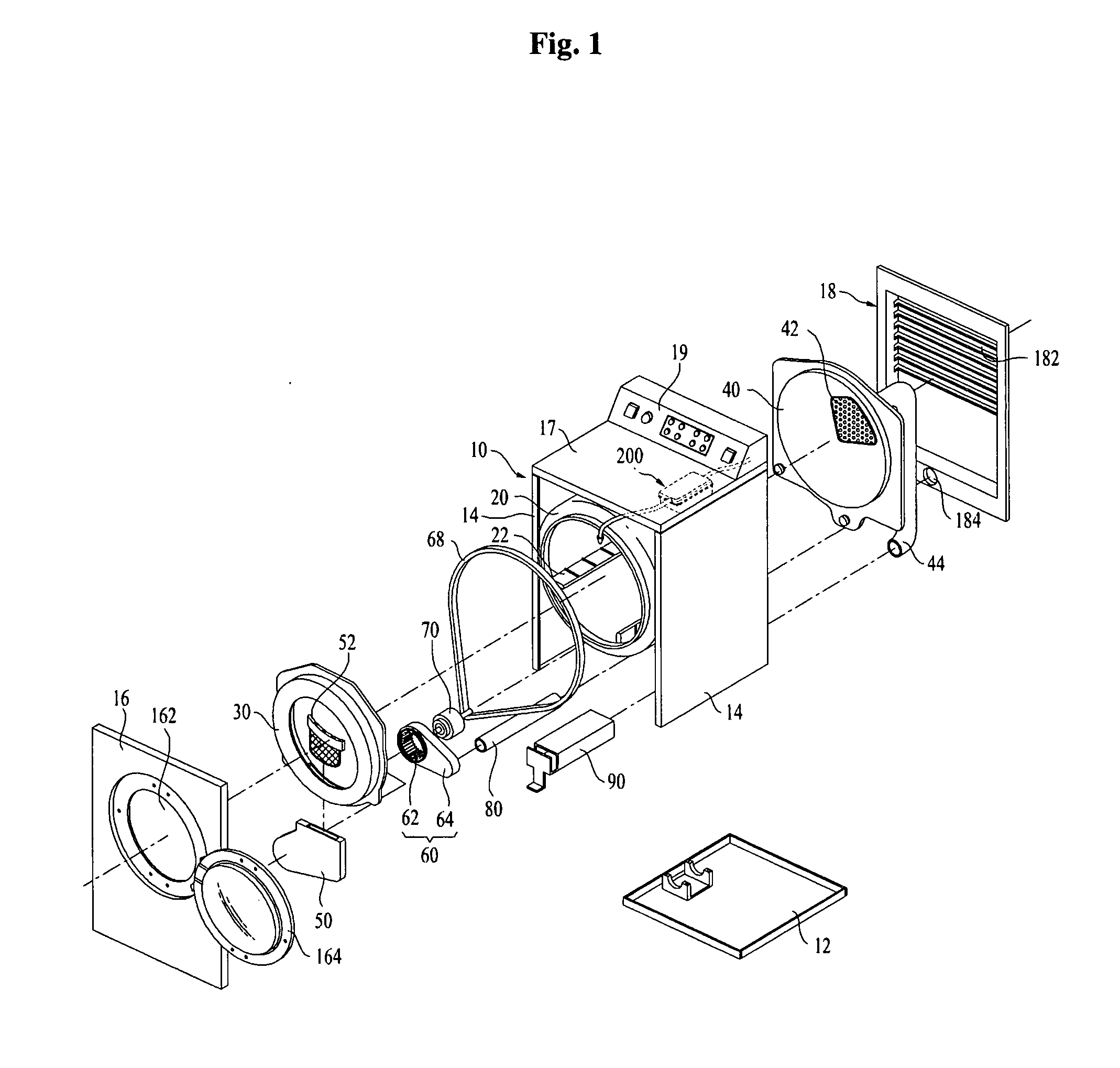

Dryer

ActiveUS20090113745A1Improve user convenienceEliminate wrinklesTextile treatment machine partsDrying gas arrangementsProcess engineeringSteam generation

A laundry machine, more particularly, a dryer is disclosed. A dryer includes a cabinet, a drum in which a drying object is held, a steam generation device to supply steam to the drum, a water supply device to supply water to the steam generation device in order to generate steam, an additive holding part in which an additive is held, and an additive supply device to supply the additive held in the additive holding part to the drum.

Owner:LG ELECTRONICS INC

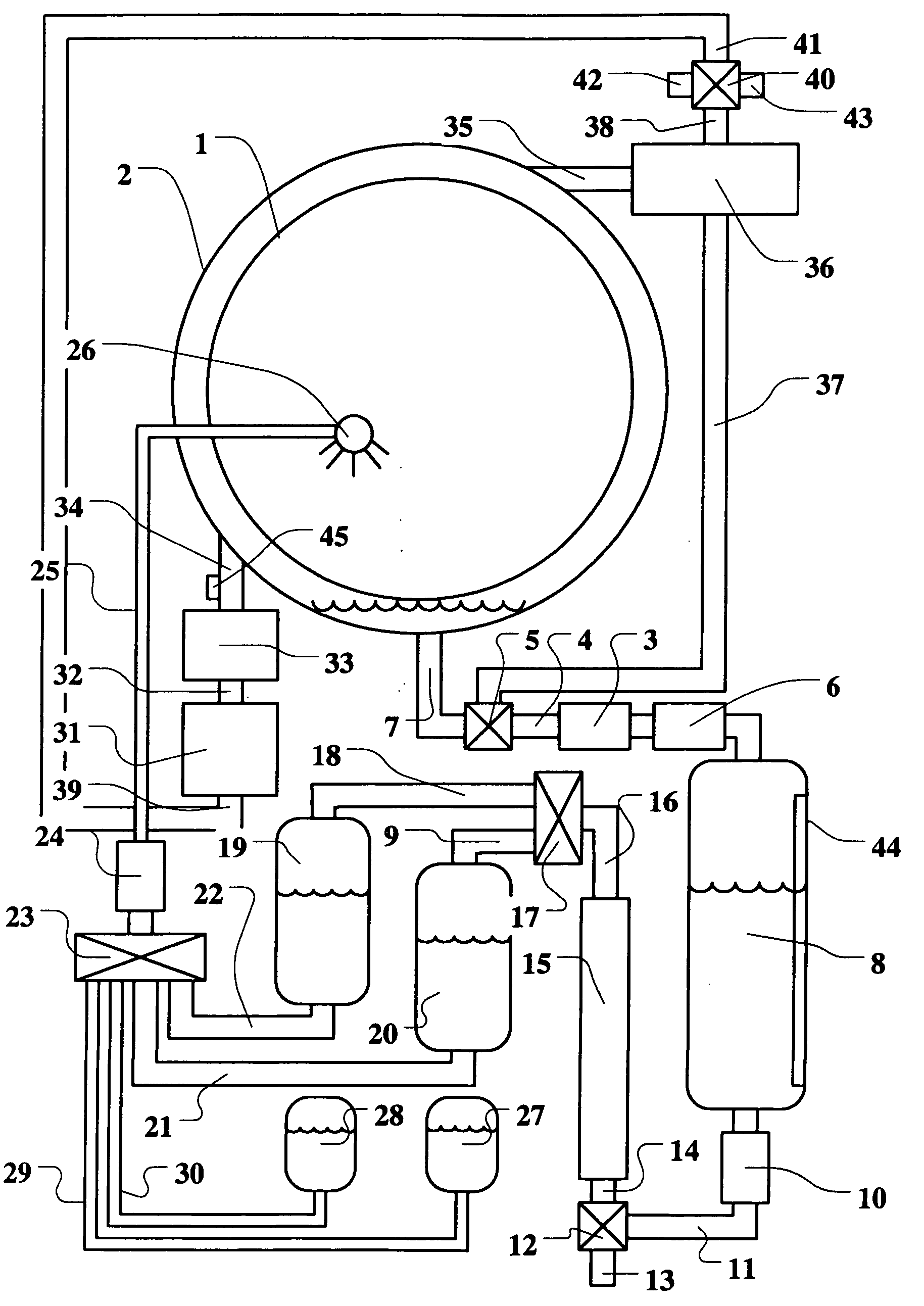

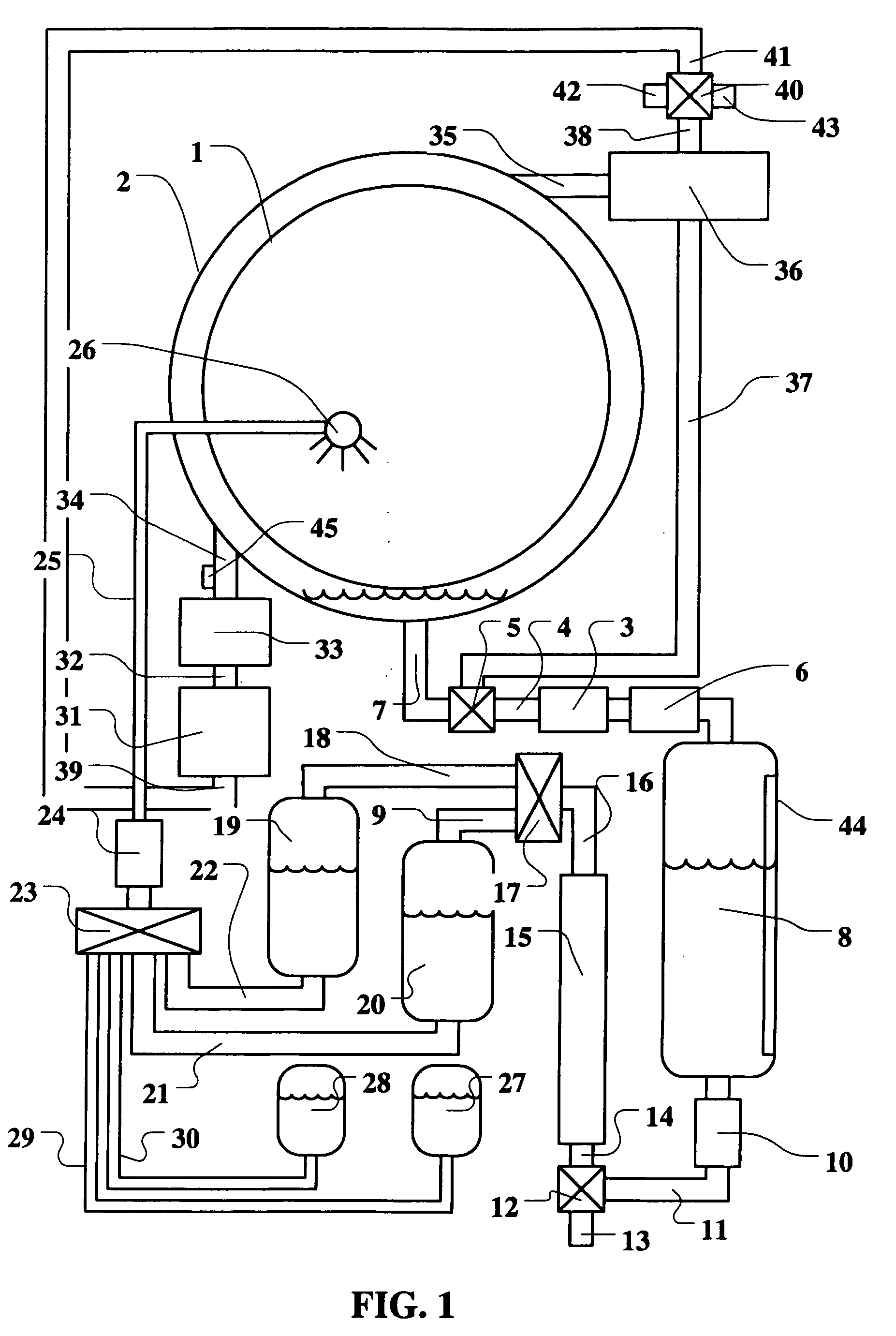

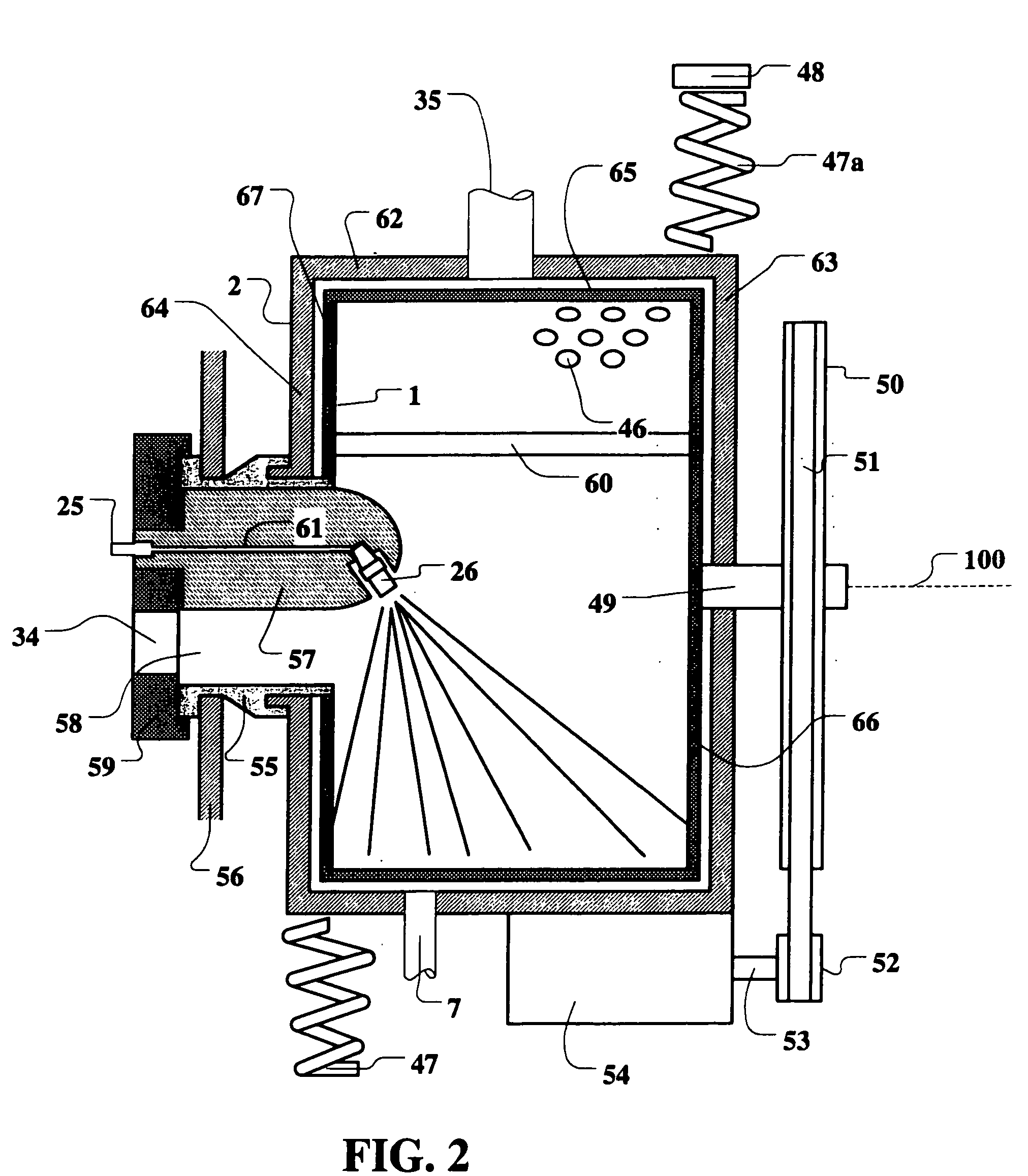

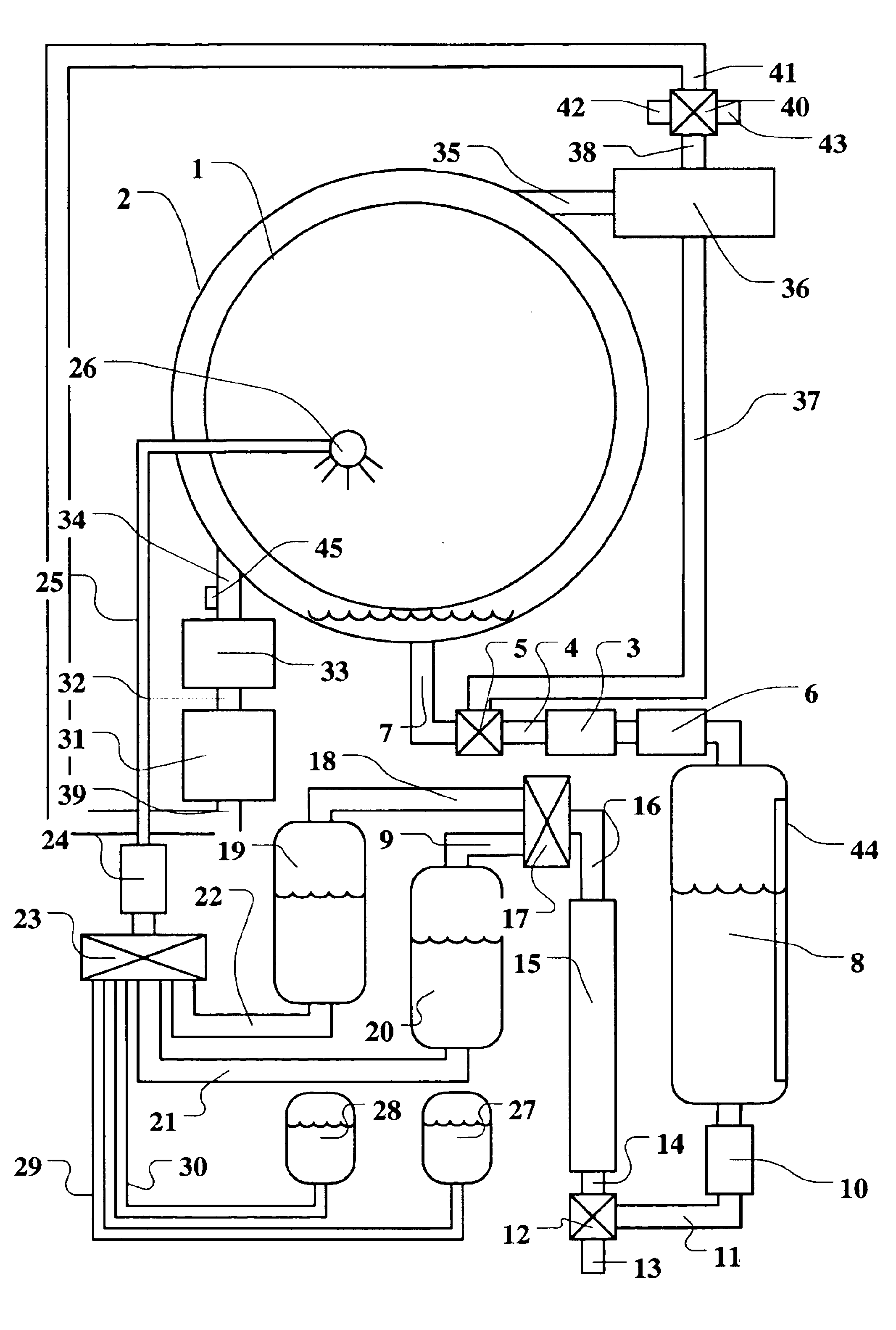

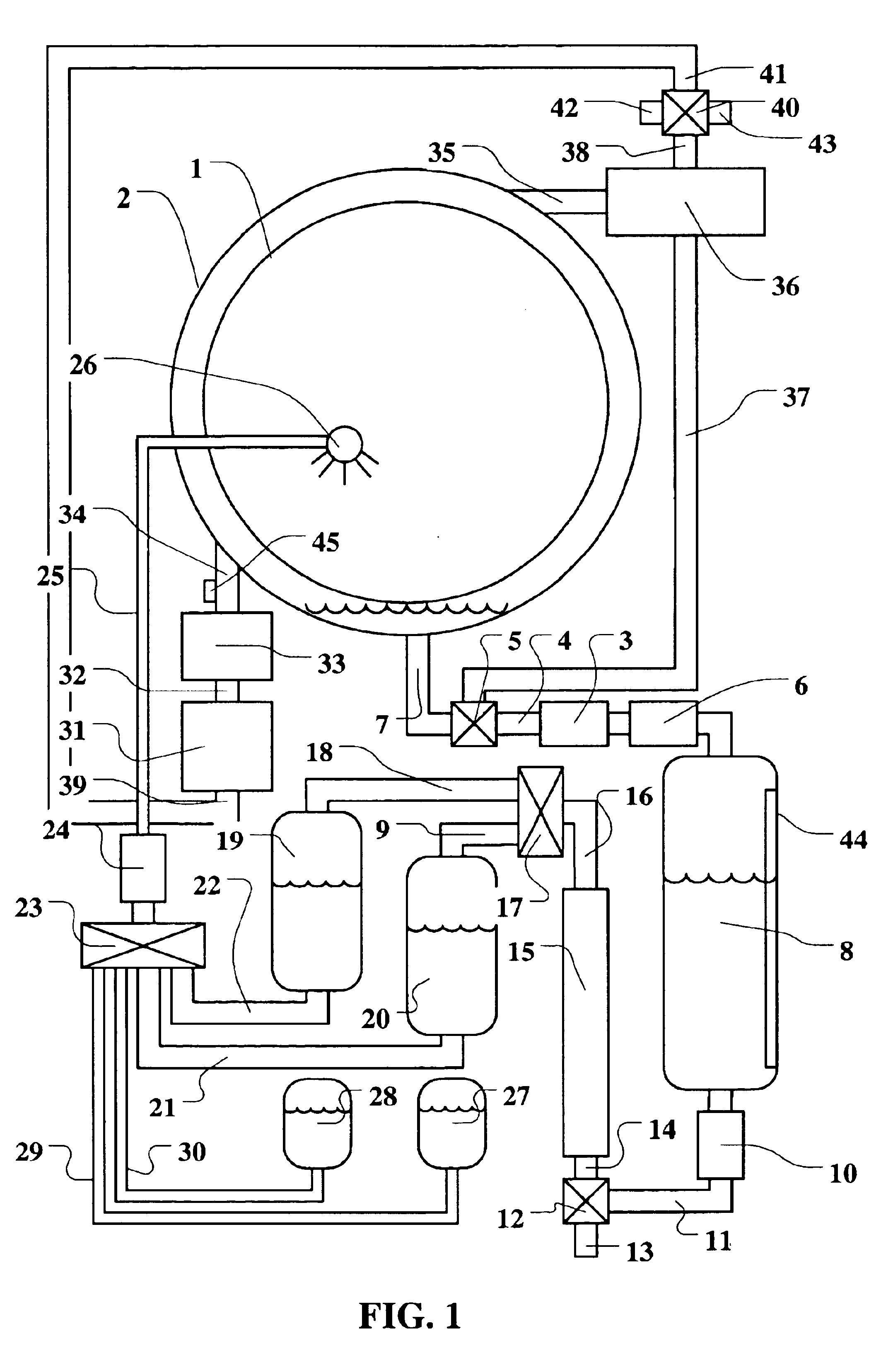

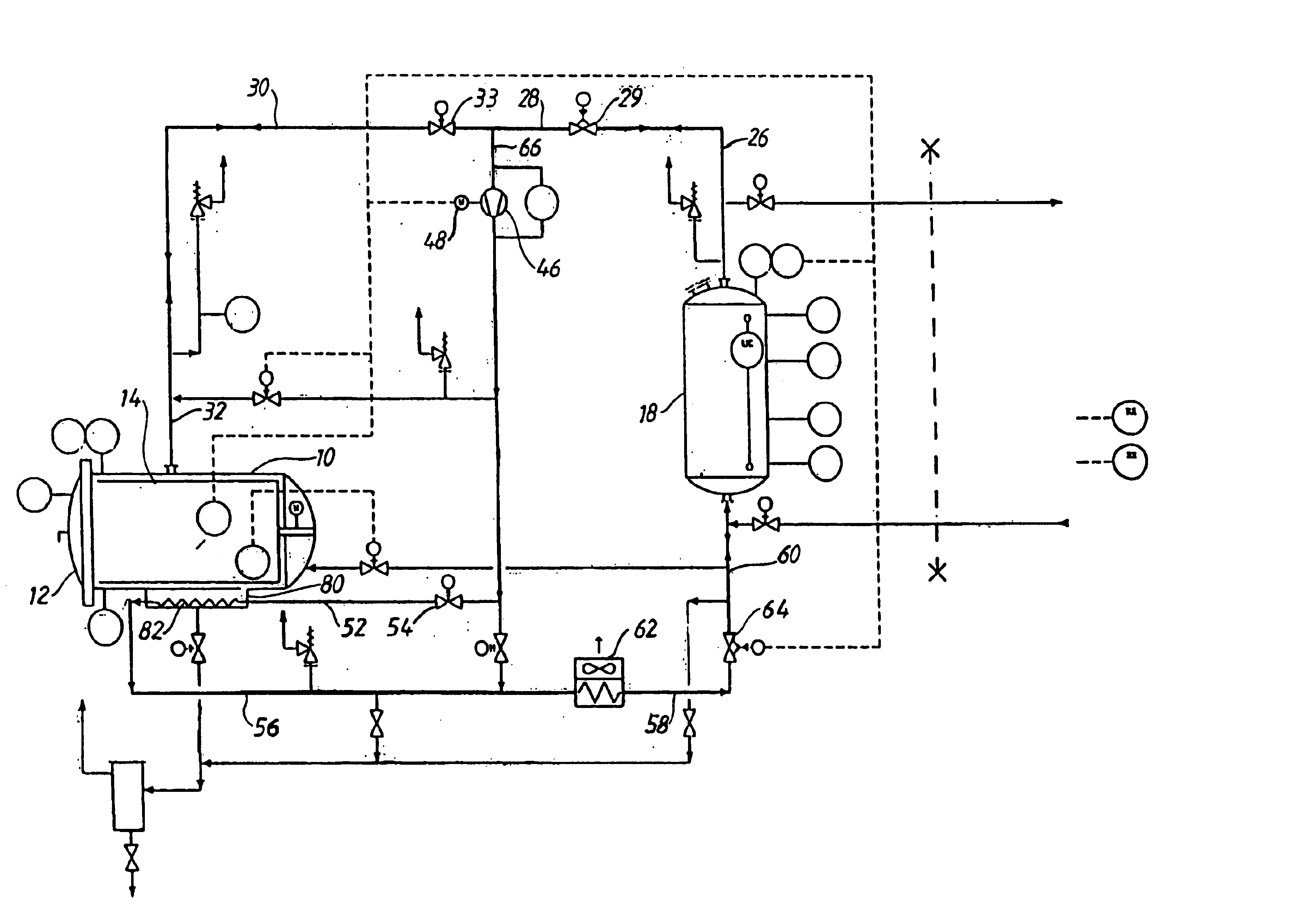

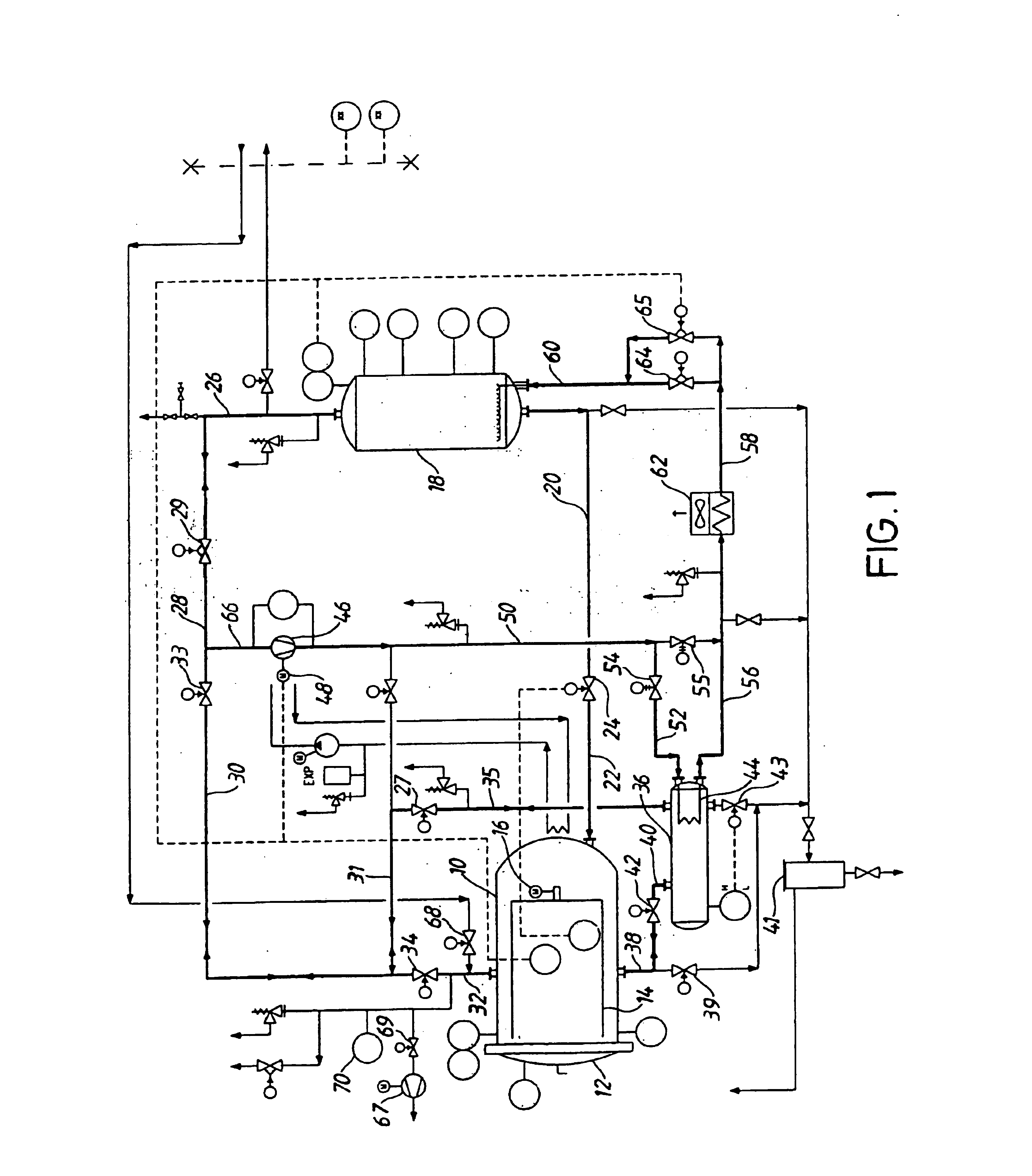

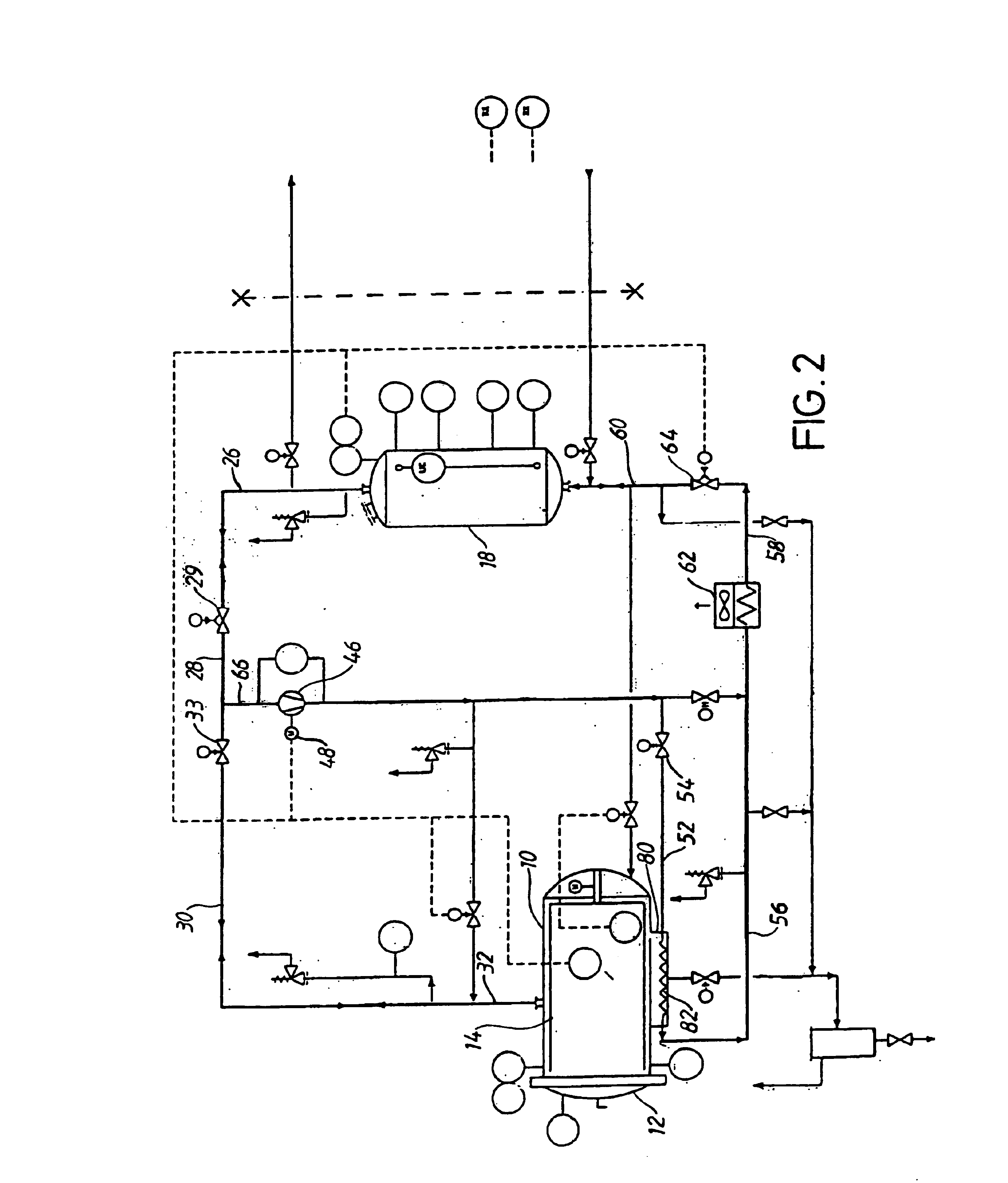

Apparatus for cleaning textiles with a densified liquid treatment gas

A device for cleaning textile articles with a densified liquid state treatment gas, comprising a treatment chamber (10), a supply tank (18) for densified treatment gas and an evaporator chamber (36), which spaces are connected to each other by way of suitable tubes to allow pressure balance between the different spaces, filling of the treatment chamber (10) with liquid state treatment gas from the supply tank (18), as well as drainage of liquid state treatment gas from the treatment chamber (10) to the evaporator chamber (36). Compressor means (46) are arranged which are organized partly to achieve essentially complete drainage of gaseous treatment gas from the treatment chamber (10), and partly constitute the driving means during one in the treatment process included distillation phase, where densified treatment gas in the evaporator chamber (36) is gasified and through condenser means (44) conveyed back to the supply tank (18). The condenser means are in heat conducting touch with the evaporator chamber (36), and form together with the compressor means (46) a heat pump, which alone furnish the necessary heat energy for evaporating the liquid in the evaporator chamber (36). In a modified embodiment the treatment chamber (10) is adapted so as to act also as an evaporation chamber.

Owner:AB ELECTROLUX

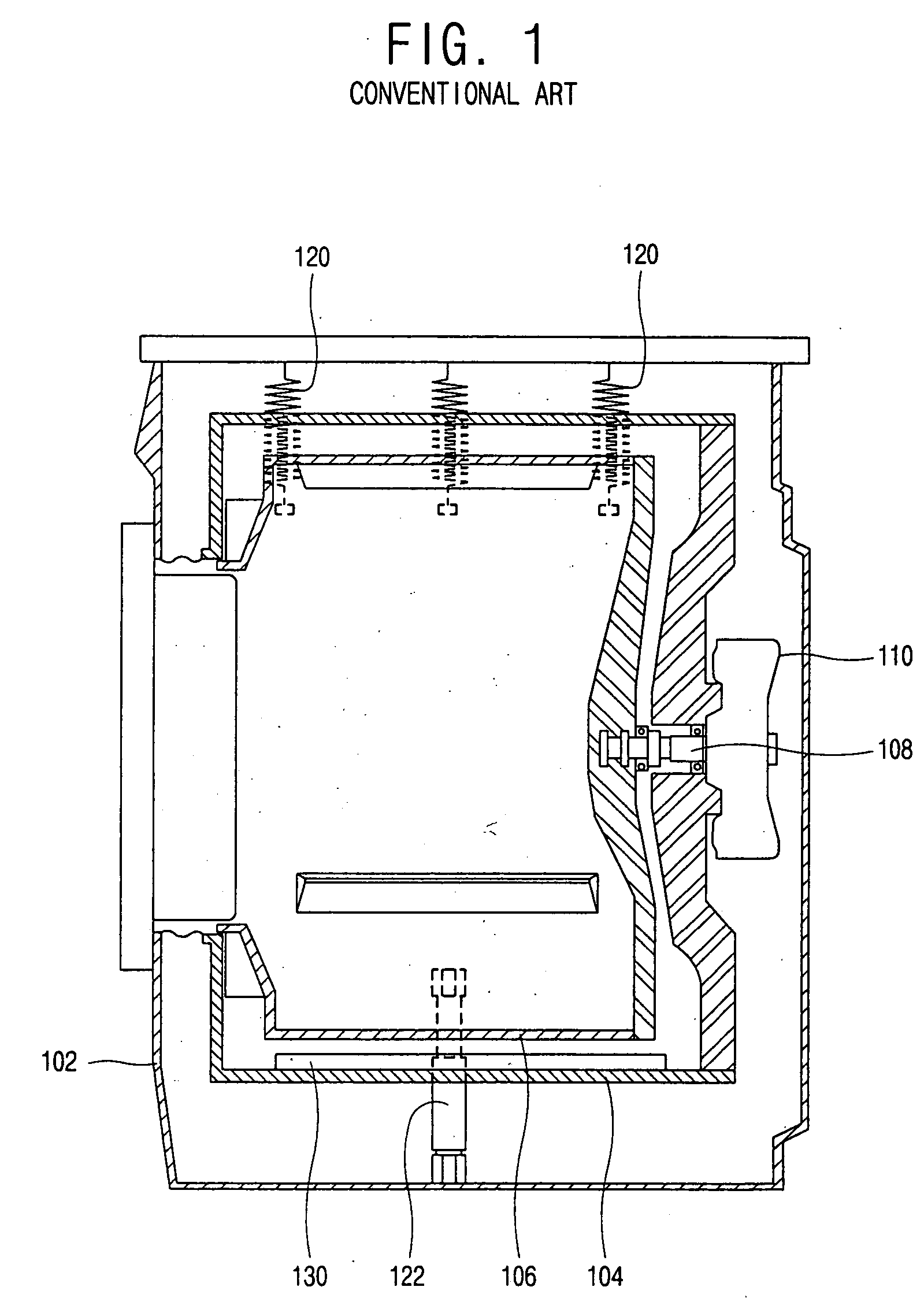

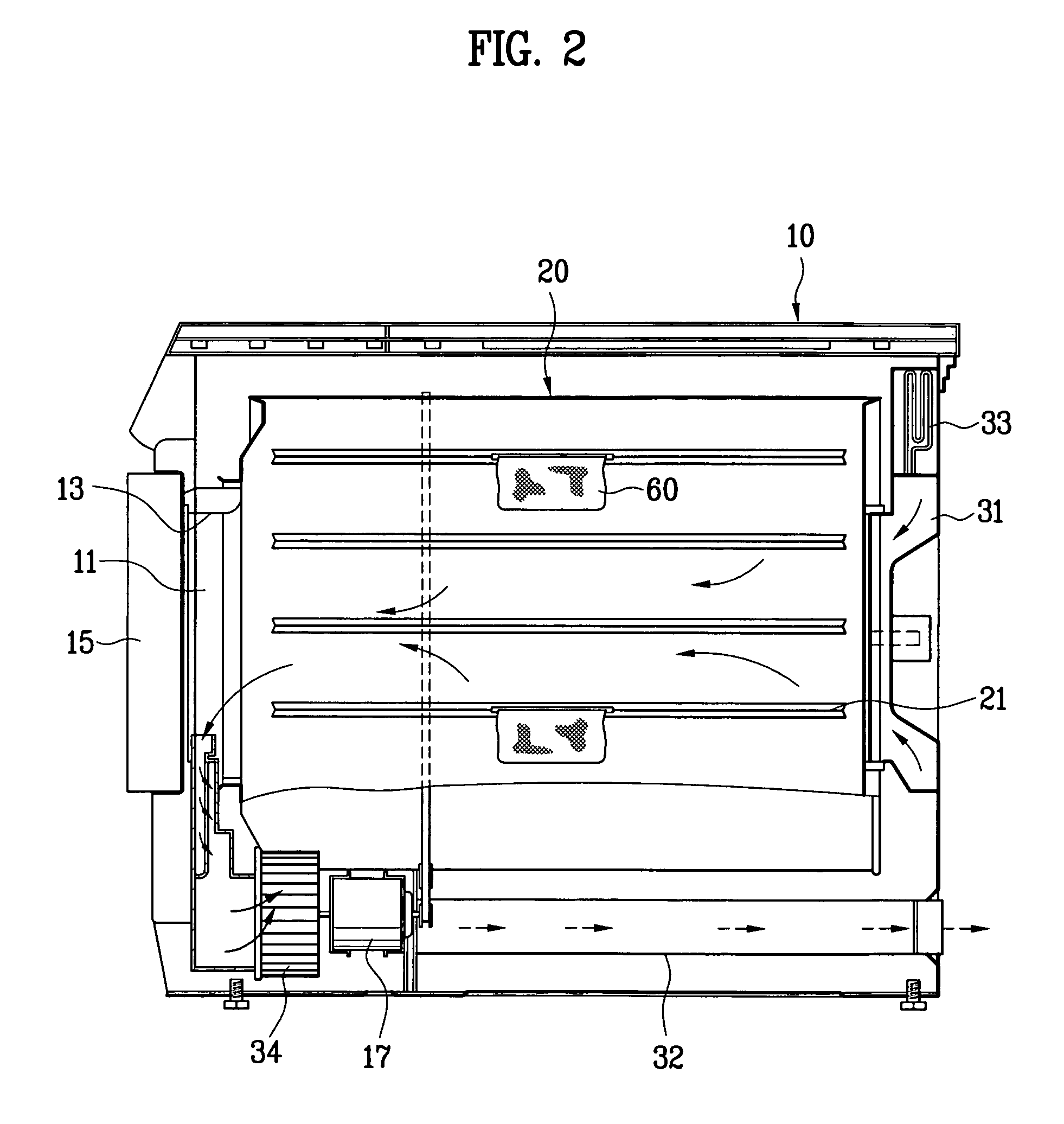

Drum washing machine

InactiveUS20070101773A1Eliminate scalingTextile treatment machine partsHollow article cleaningProcess engineeringVALVE PORT

A drum washing machine, in which scale deposited in a steam generating device installed for improving sterilizing and washing capacities is efficiently eliminated. The drum washing machine includes a housing; a tub for containing washing water; a drum rotatably installed in the tub; and a steam generating device installed in the housing for supplying steam for sterilizing laundry to the drum, wherein a scale eliminating unit is installed in a water supply channel of the steam generating device, and includes at least one protrusion formed on the inner circumferential surface of the water supply channel or a water supply valve and a pulsation circuit for controlling the flow rate and amount of the water. The scale eliminating unit forms turbulence in the steam generating device or supplies water having varied flow rate and amount to the steam generating device, thereby efficiently eliminating scale deposited in the steam generating device.

Owner:SAMSUNG ELECTRONICS CO LTD

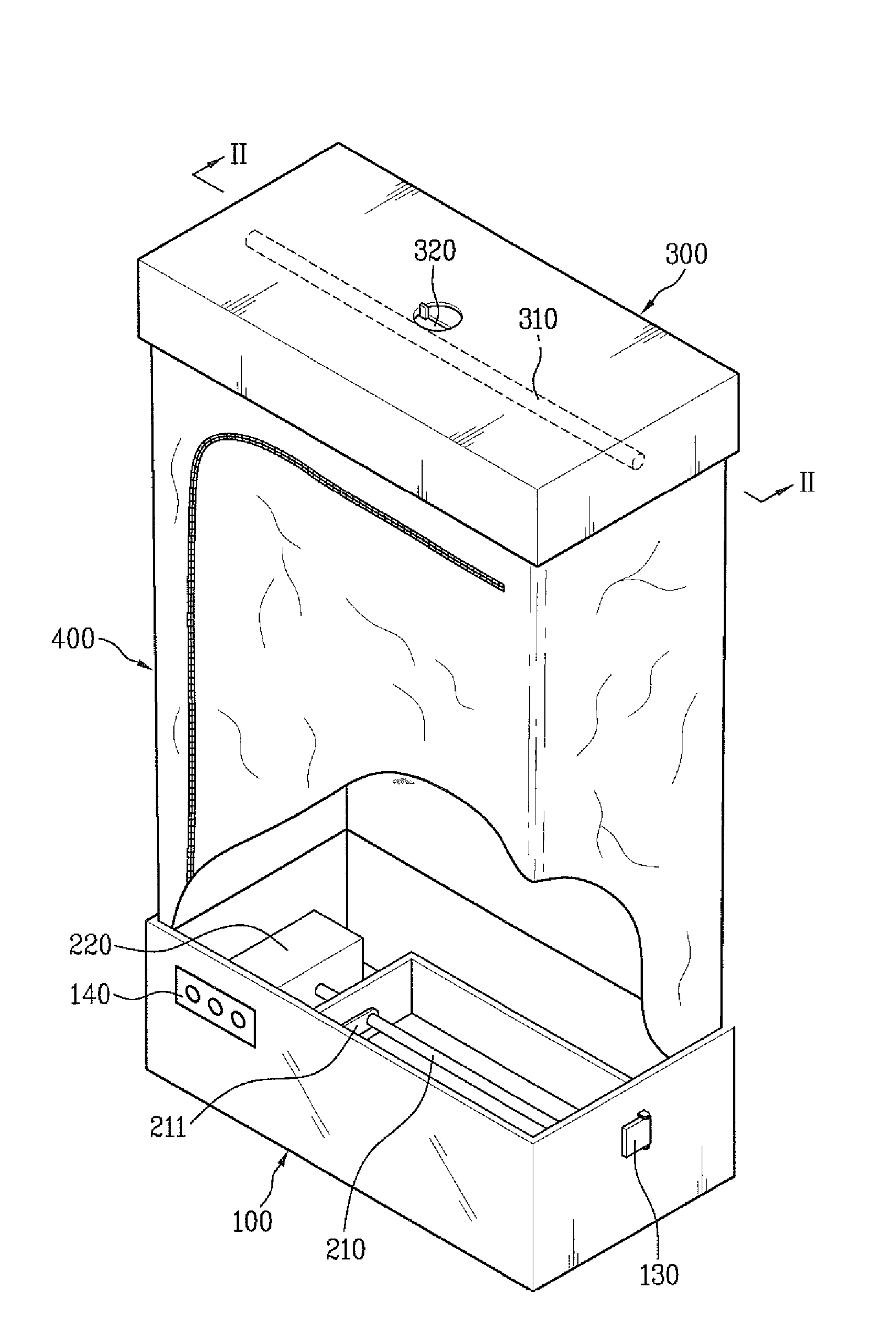

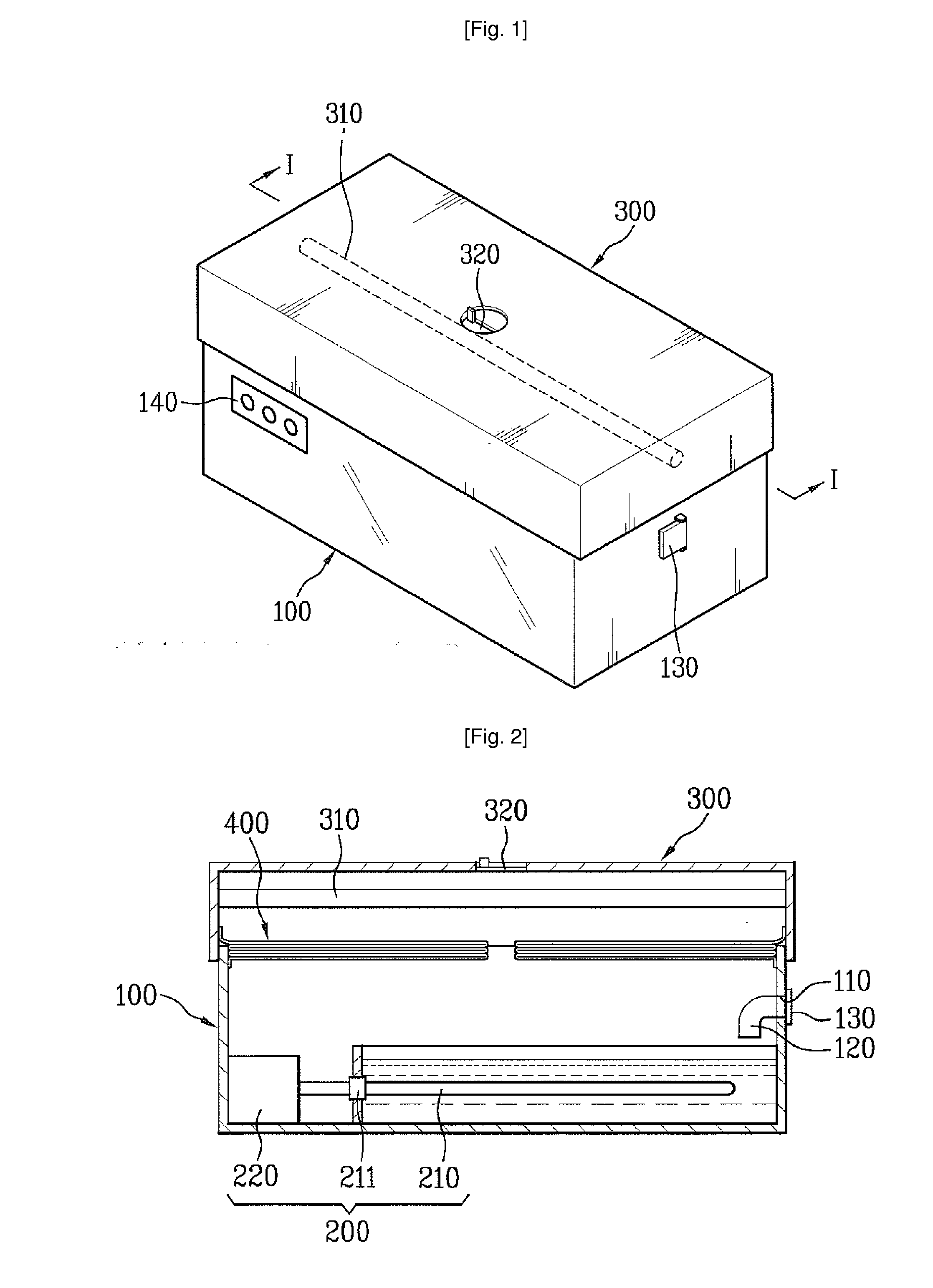

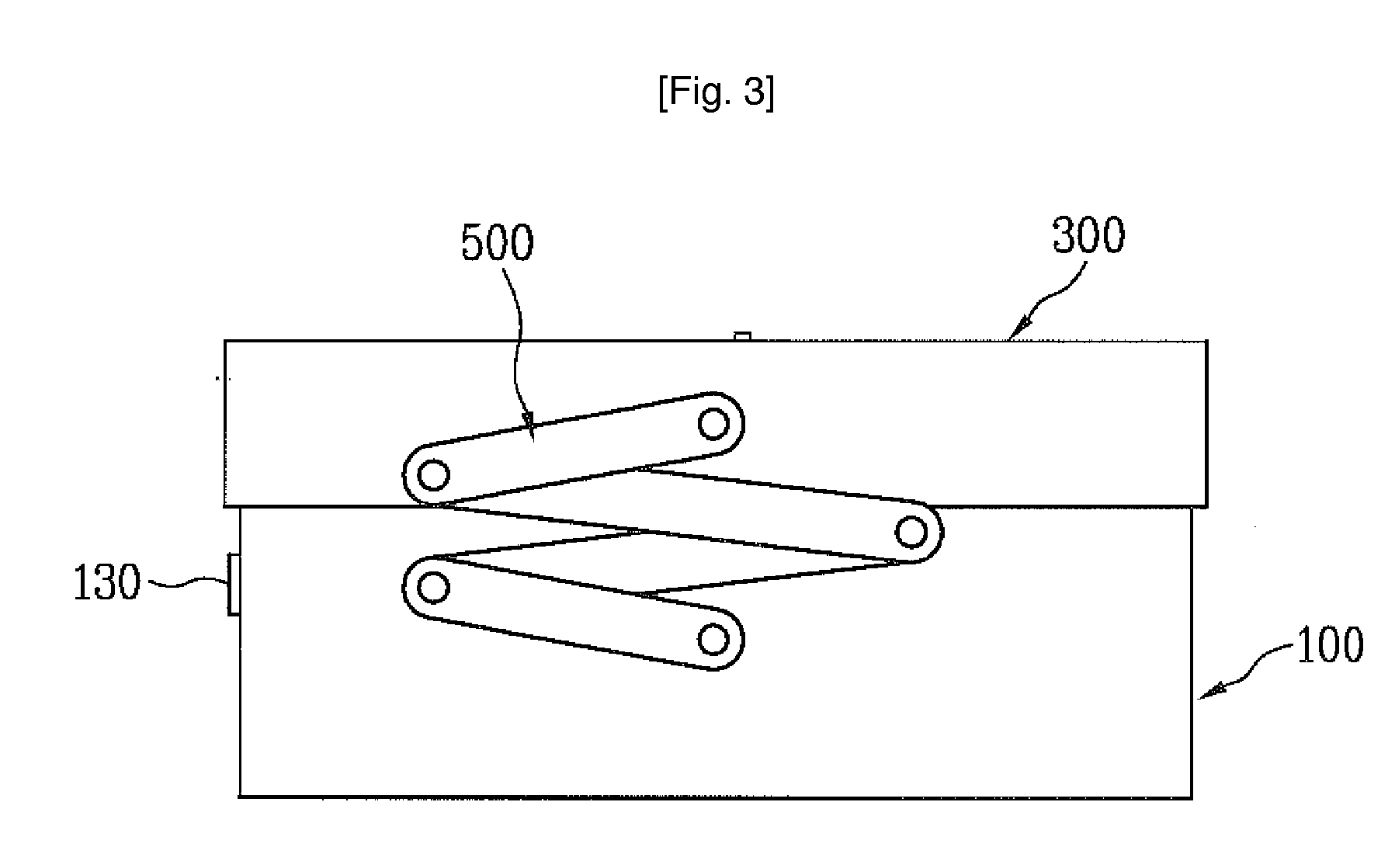

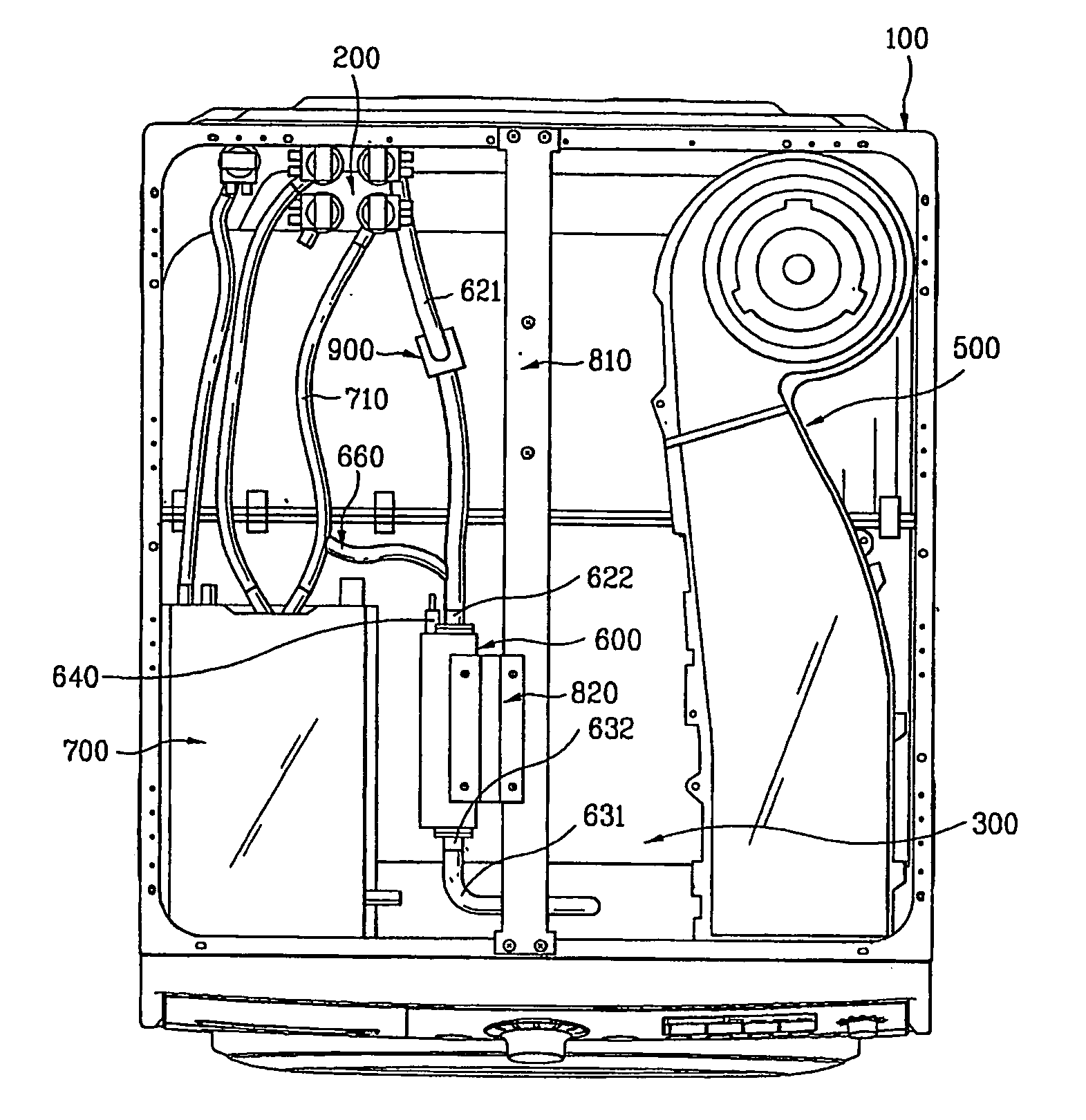

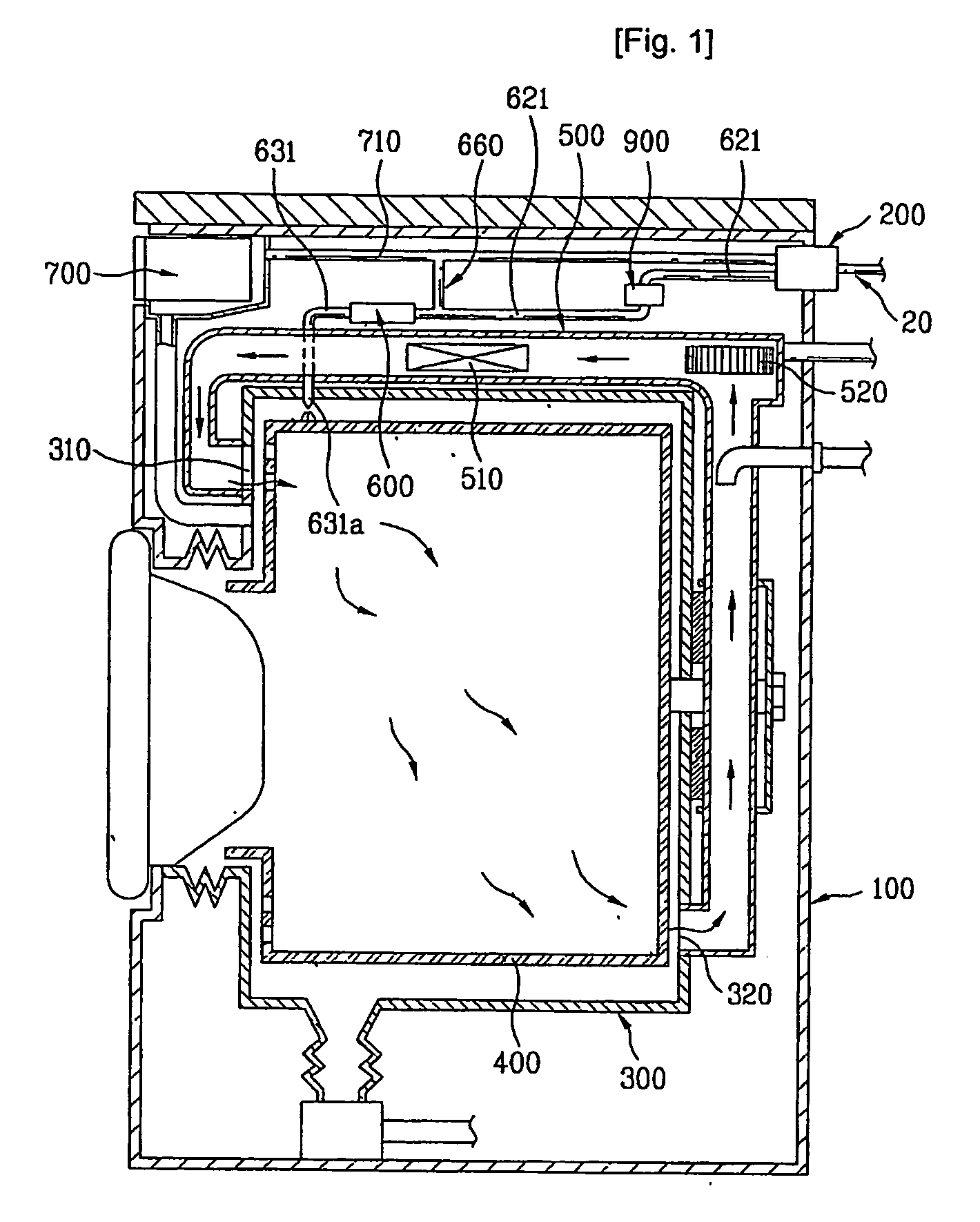

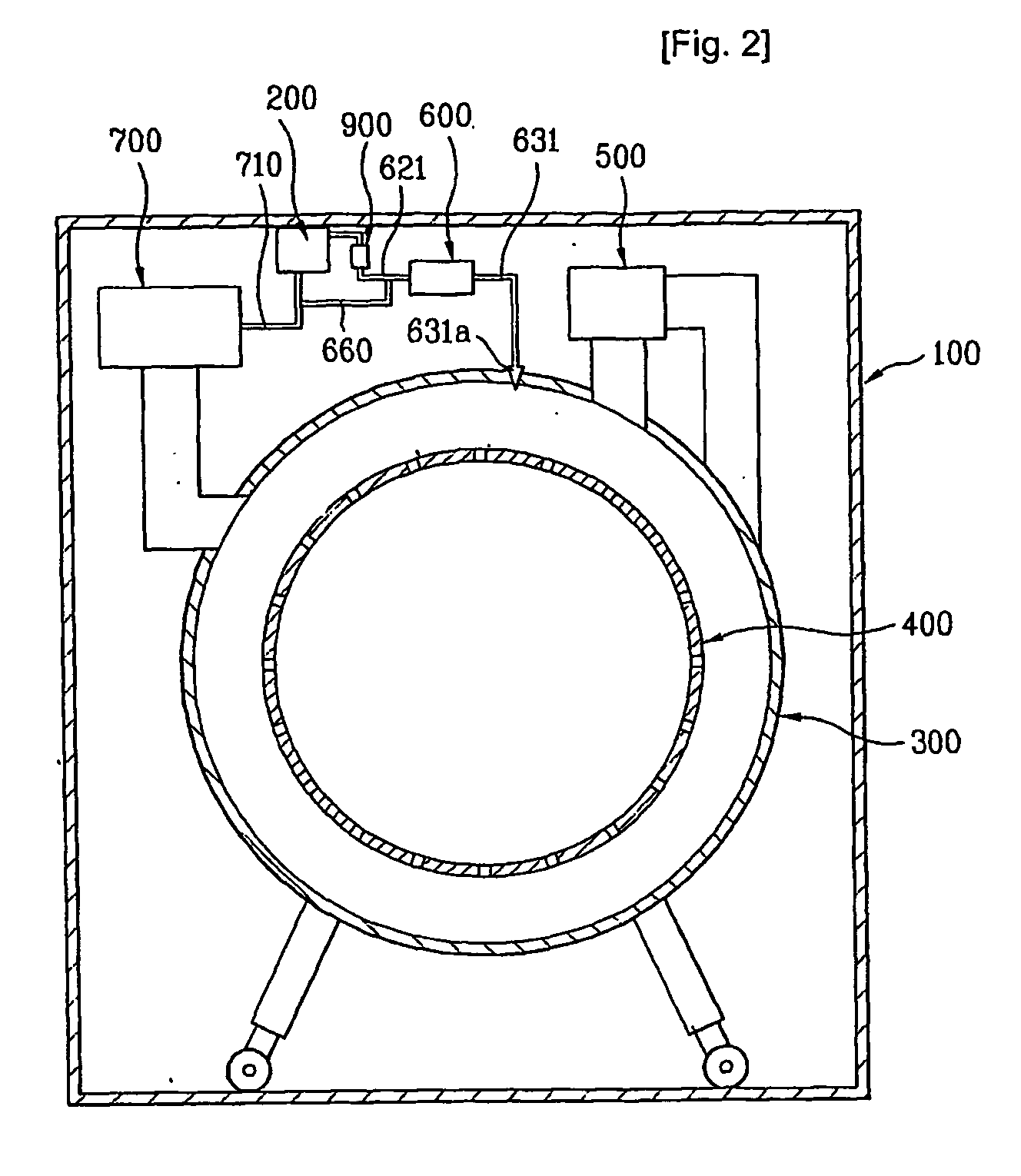

Laundry Machine

InactiveUS20080271500A1Improve washing efficiencyEconomizing in wash water in a washing cycleTextile treatment machine partsOther washing machinesProcess engineeringLaundry

A laundry machine is disclosed. A laundry machine includes a body (100) for defining an exterior, a water supply valve (200) provided in the body (100) and connected with an outer water supply device, a drum rotatably mounted within the body, at least one steam generator for supplying steam into the drum (600), and a water treatment apparatus (900) for treating water supplied to the steam generator (600). an object of the present invention is to provide a laundry machine which can perform washing and drying more quickly and efficiently as well as which has an effect of smoothing out wrinkles and sterilizing the laundry.

Owner:LG ELECTRONICS INC

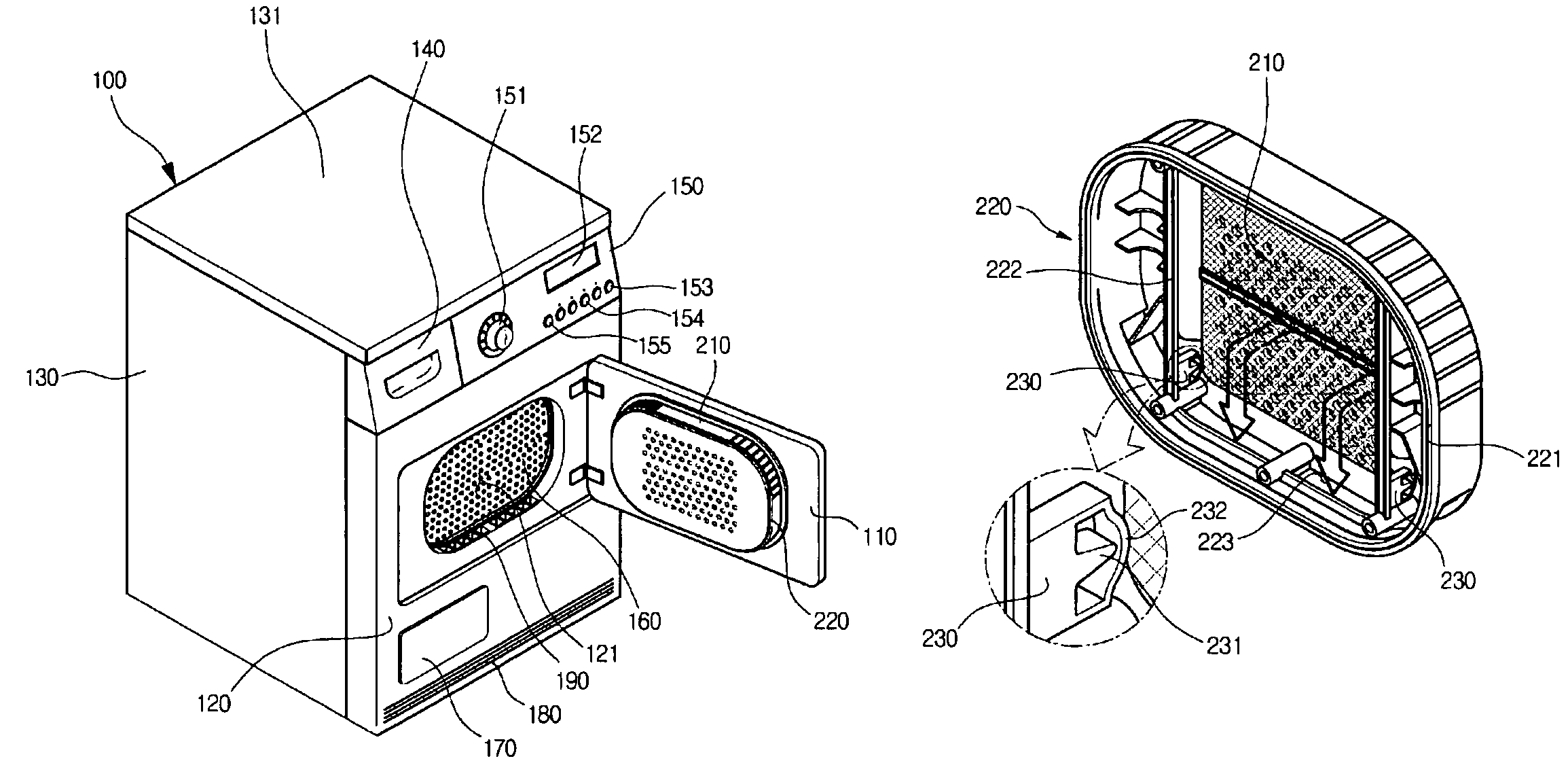

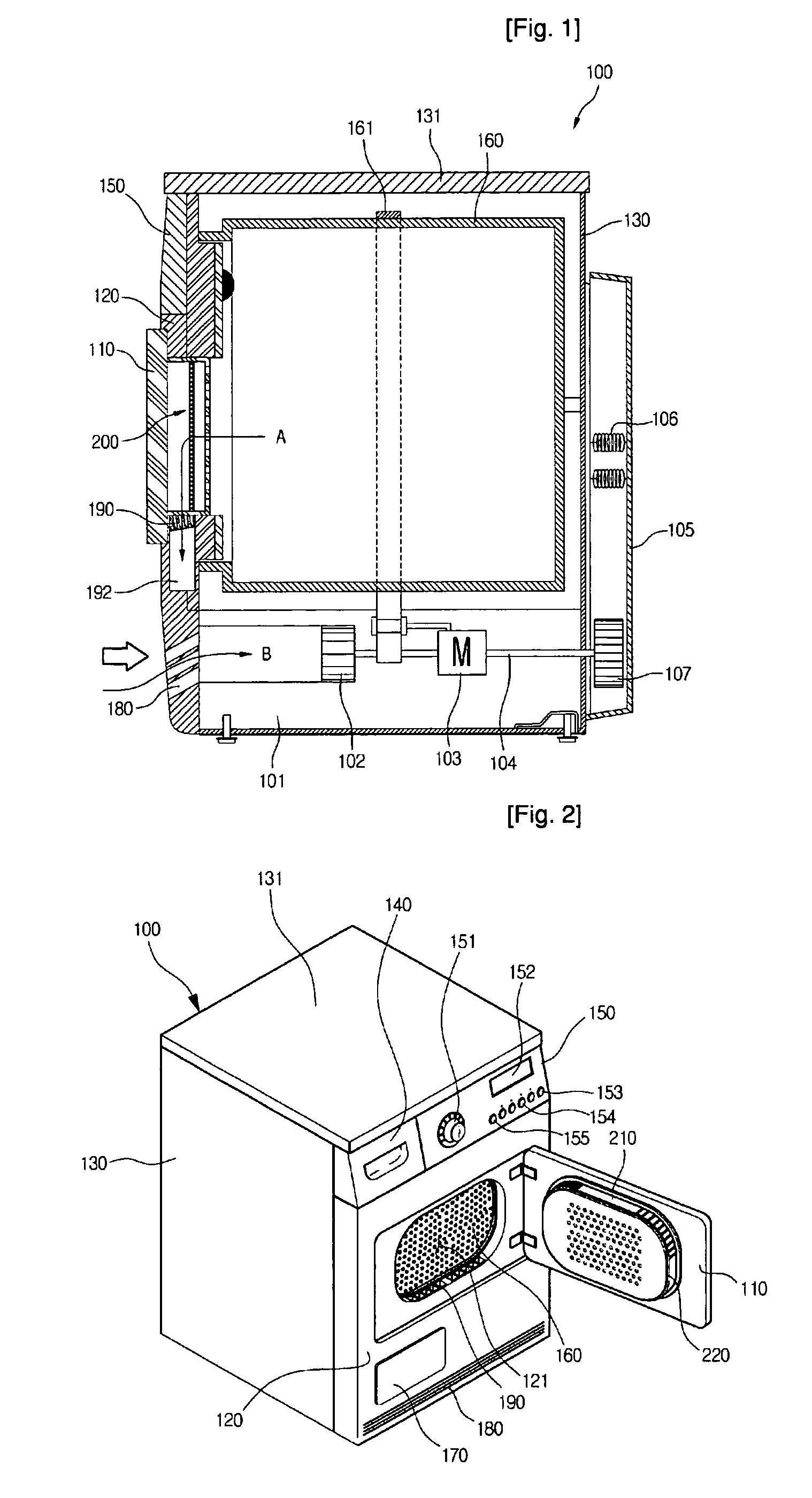

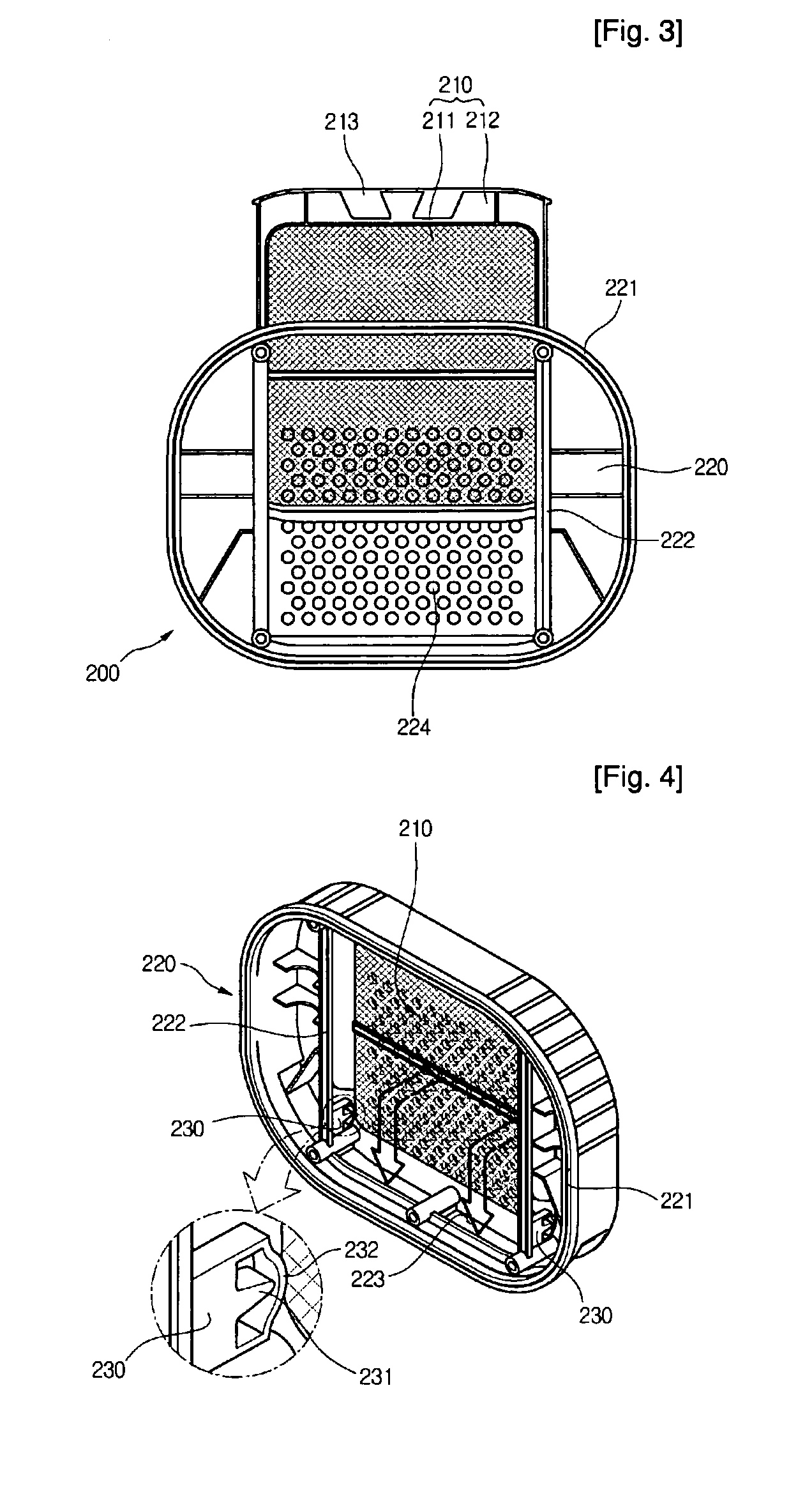

Lint filter assembly of laundry dryer

InactiveUS7644515B2Press firmlyAvoid accumulationTextile treatment machine partsDrying gas arrangementsEngineeringLaundry

Owner:LG ELECTRONICS INC

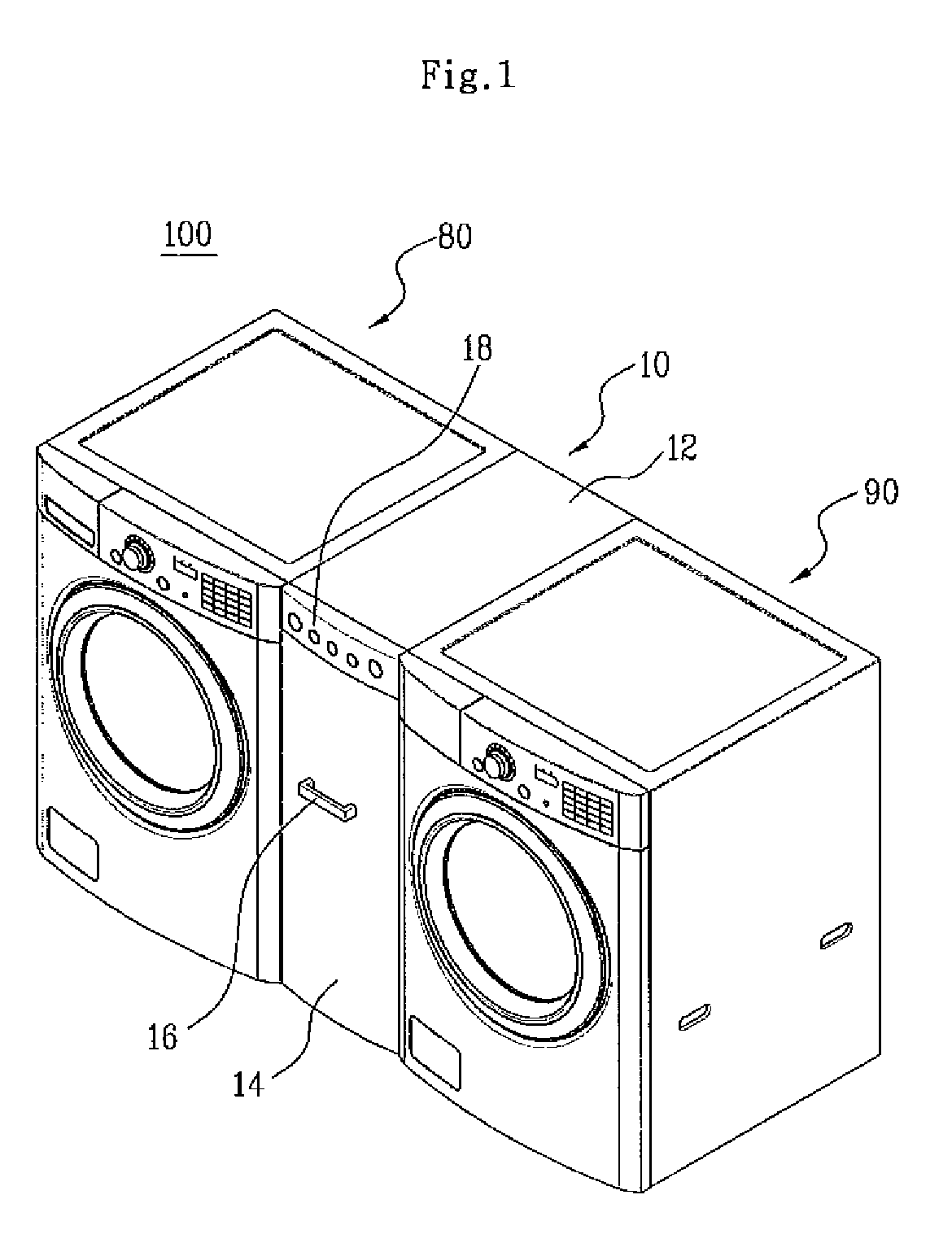

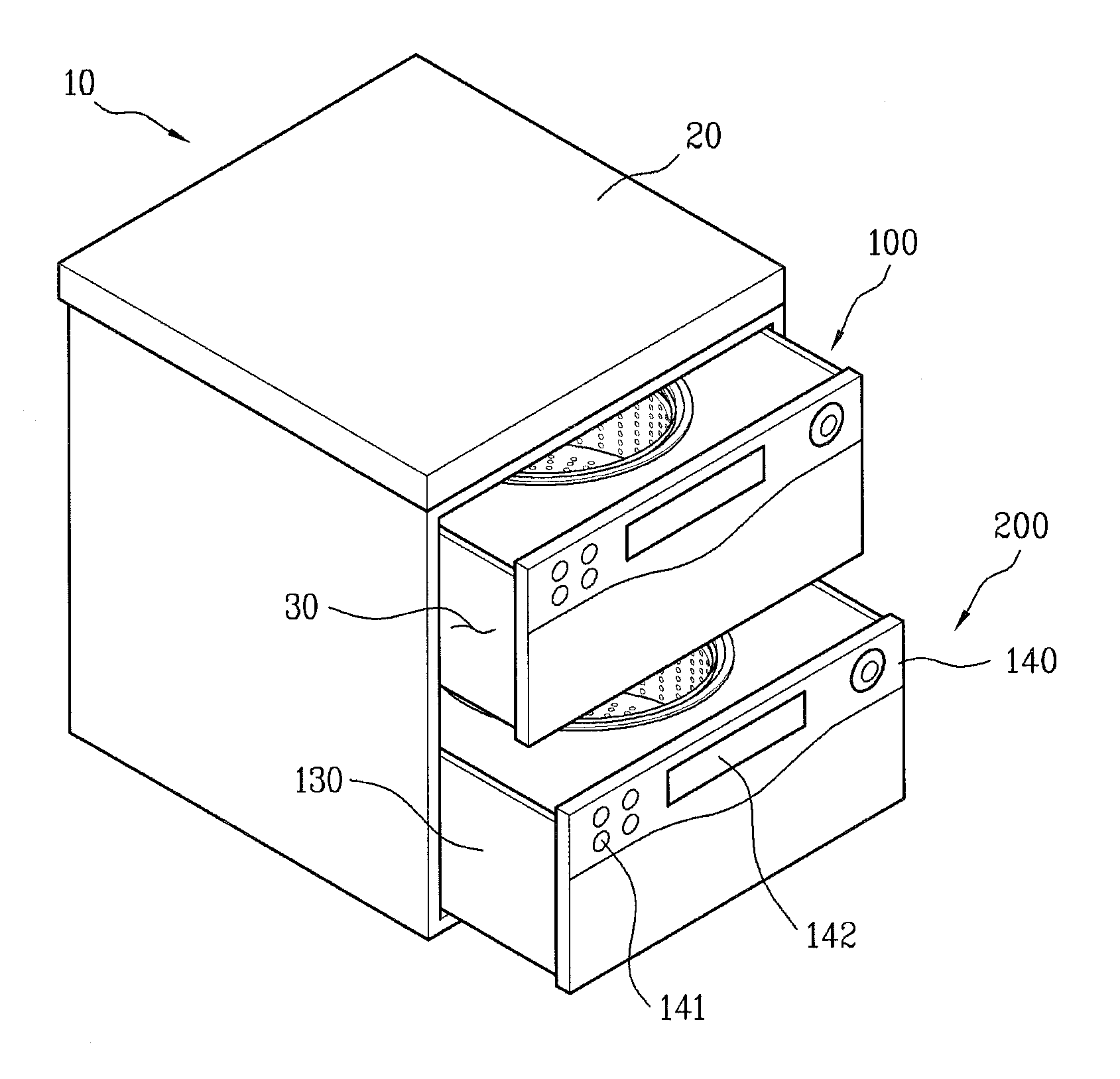

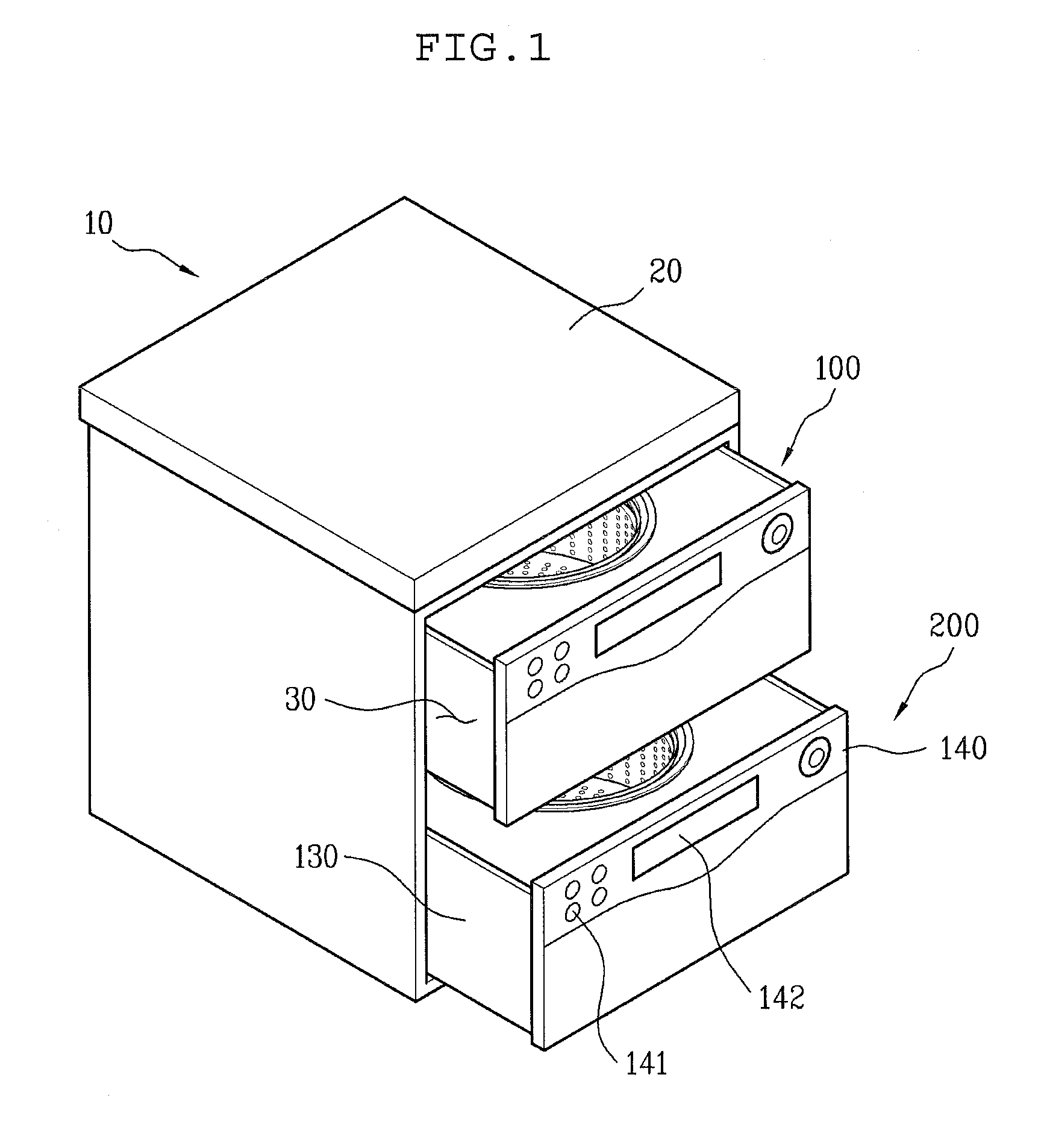

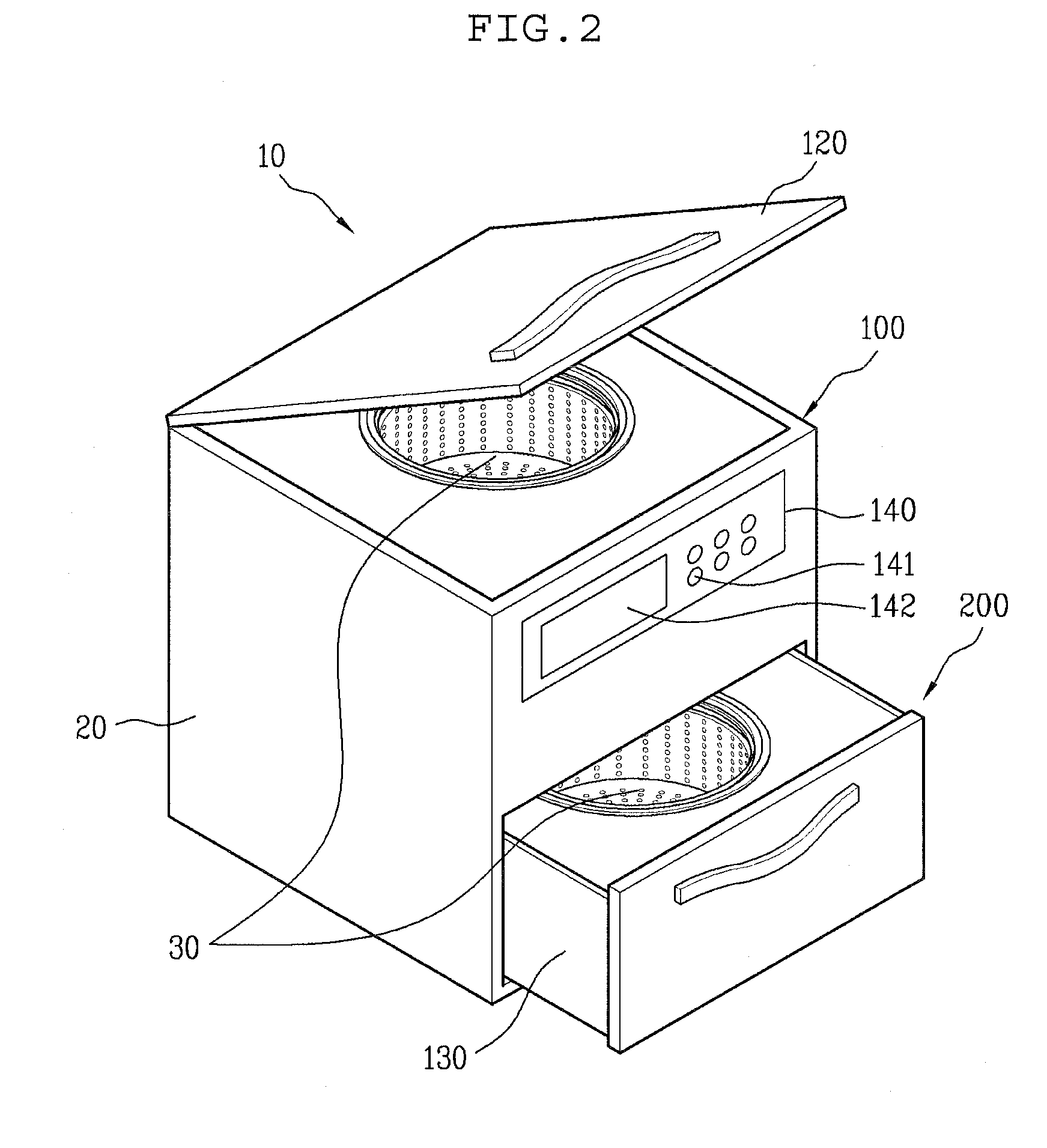

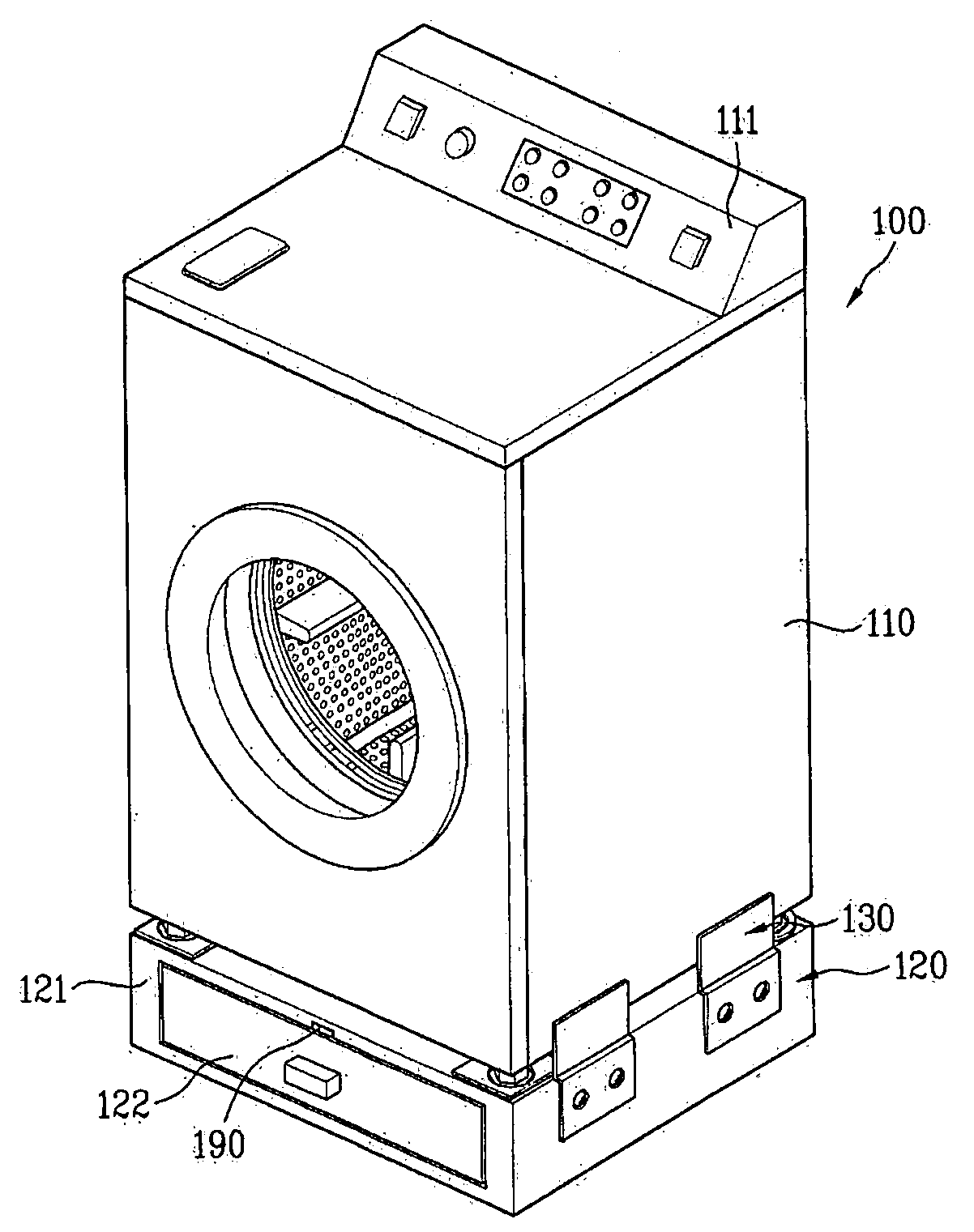

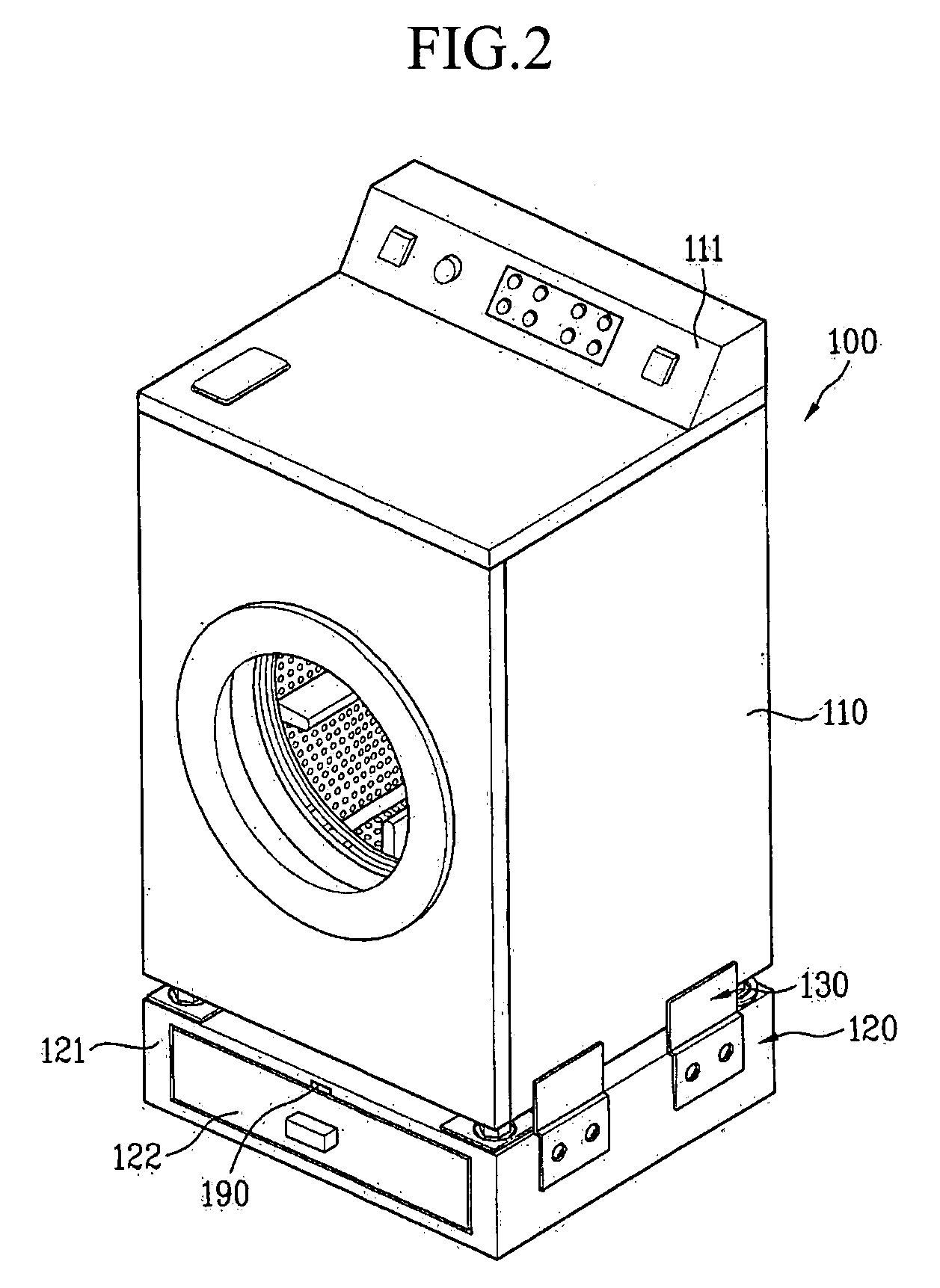

Multiple laundry machine

ActiveUS20090113945A1Eliminate the problemTextile treatment machine partsOther washing machinesLaundryEngineering

Owner:LG ELECTRONICS INC

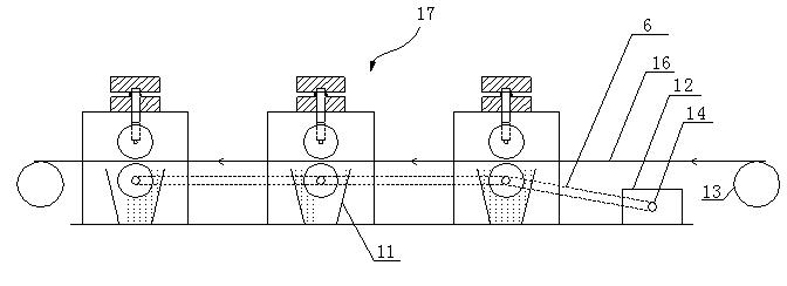

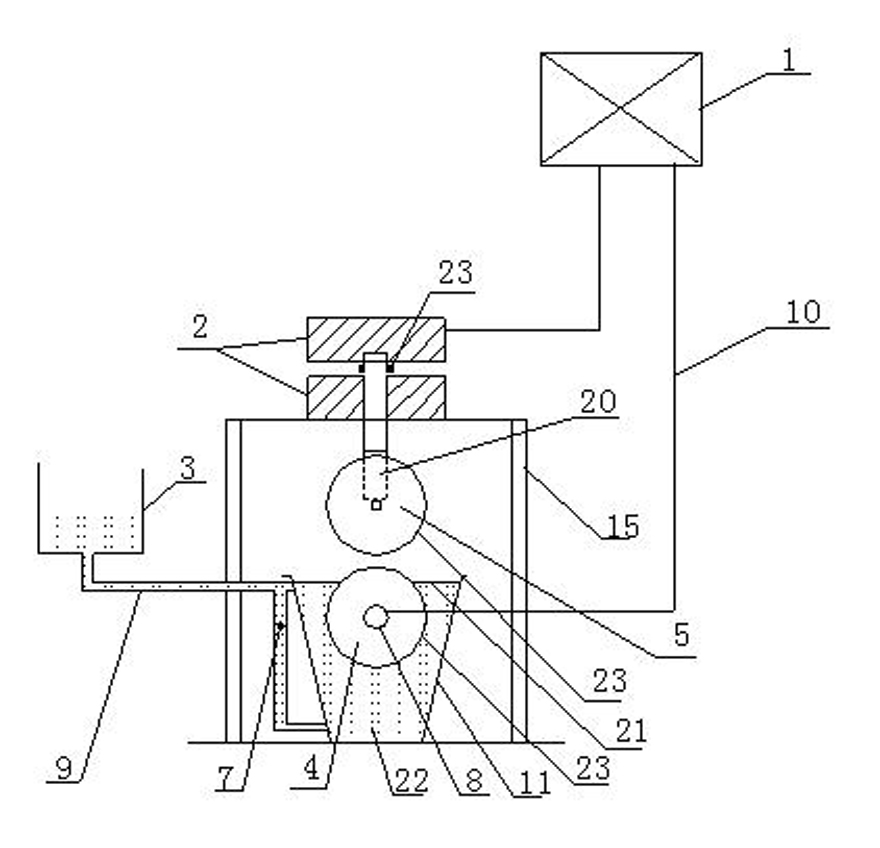

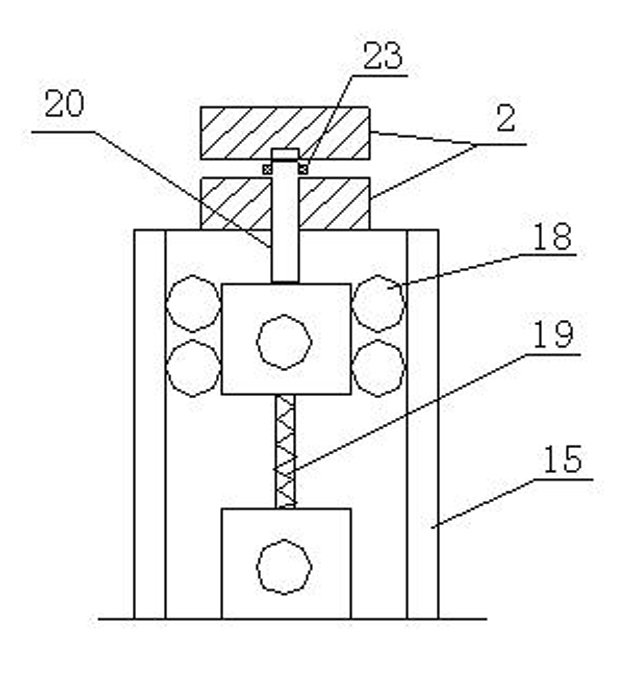

Device for producing space dye yarn

ActiveCN102021775AReduce in quantityReduce the number of rootsTextile treatment machine partsLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention relates to a device for producing space dye yarn, comprising at least one group of padders. A dye liquor slot for holding space dye liquor is arranged below each group of padders; the inside of the dye liquor slot is connected with a corresponding space dye liquor preparation bucket through a feed delivery pipe; each group of padders comprises a stand, a bottom roll and a top roll; at least part of outer wall surface of the bottom roll is soaked in the space dye liquor of the dye liquor slot; when the top roll is upwards lifted, the top roll and the bottom roll are separated, and the yarn passes through a gap between the top roll and the bottom roll; when the top roll is pressed downwards, the outer wall surface of the top roll and the outer wall surface of the bottom roll are appressed, the bottom roll drive the top roll to rotate to make the yarn pass through the rolling points of the top roll and the bottom roll, and the outer wall surface of the bottom roll adheres to the space dye liquor in the rotation to apply the space dye liquor to the yarn. By utilizing the device to carry out the space dye, the space dye liquor residual is little, and the space dye processing efficiency is high. The space dye process and a yarn grounding dye process can be also continuously finished at one time so that the space dye cost is reduced and the comprehensive benefit is good.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

Auxiliary dryer and complex laundry machine including the same

InactiveUS20080053166A1Avoid safety accidentsSave energyTextile treatment machine partsOther washing machinesEngineeringLaundry

An auxiliary dryer and a complex laundry machine are disclosed, by which a laundry machine having a relatively large size can be conveniently operated to save energy in a manner of handling a small laundry and the like without out driving the laundry machine. The present invention includes a body having a laundry accommodating part for accommodating a laundry therein, a hot air supplying means provided within the body to supply hot air to the laundry accommodating part, and a safety means for preventing a safety accident from being caused to a user by the hot air supplying means.

Owner:LG ELECTRONICS INC

Washing machine

ActiveUS20090120140A1Inhibition formationRemoving formedTextile treatment machine partsSpray nozzlesEngineeringAir heater

The present invention relates to a washing machine, and the washing machine includes a drum rotatably installed in a cabinet, an air heater for heating air, to supply hot air to the drum, a steam generator for generating steam, and supply the steam to the drum, and a water supply unit including a nozzle for spraying the steam generated by the steam generator to an interior of the drum, and a nozzle holder having a coupler at a rear surface of the nozzle holder, to separably mount the nozzle at a position adjacent to the drum.

Owner:LG ELECTRONICS INC

Cloth treating apparatus

Owner:LG ELECTRONICS INC

Laundry machine and method of controlling the same

ActiveUS20080141734A1Avoid creasesDrying solid materials without heatTextile treatment machine partsTime segmentEngineering

Laundry machine including a selectively rotatable drum, a pump for supplying water to a steam generator and controller for determining the pump of being out of order by using a time period required for supplying water to a preset water level of the steam generator or a current to the pump, thereby realizing product safety effectively.

Owner:LG ELECTRONICS INC

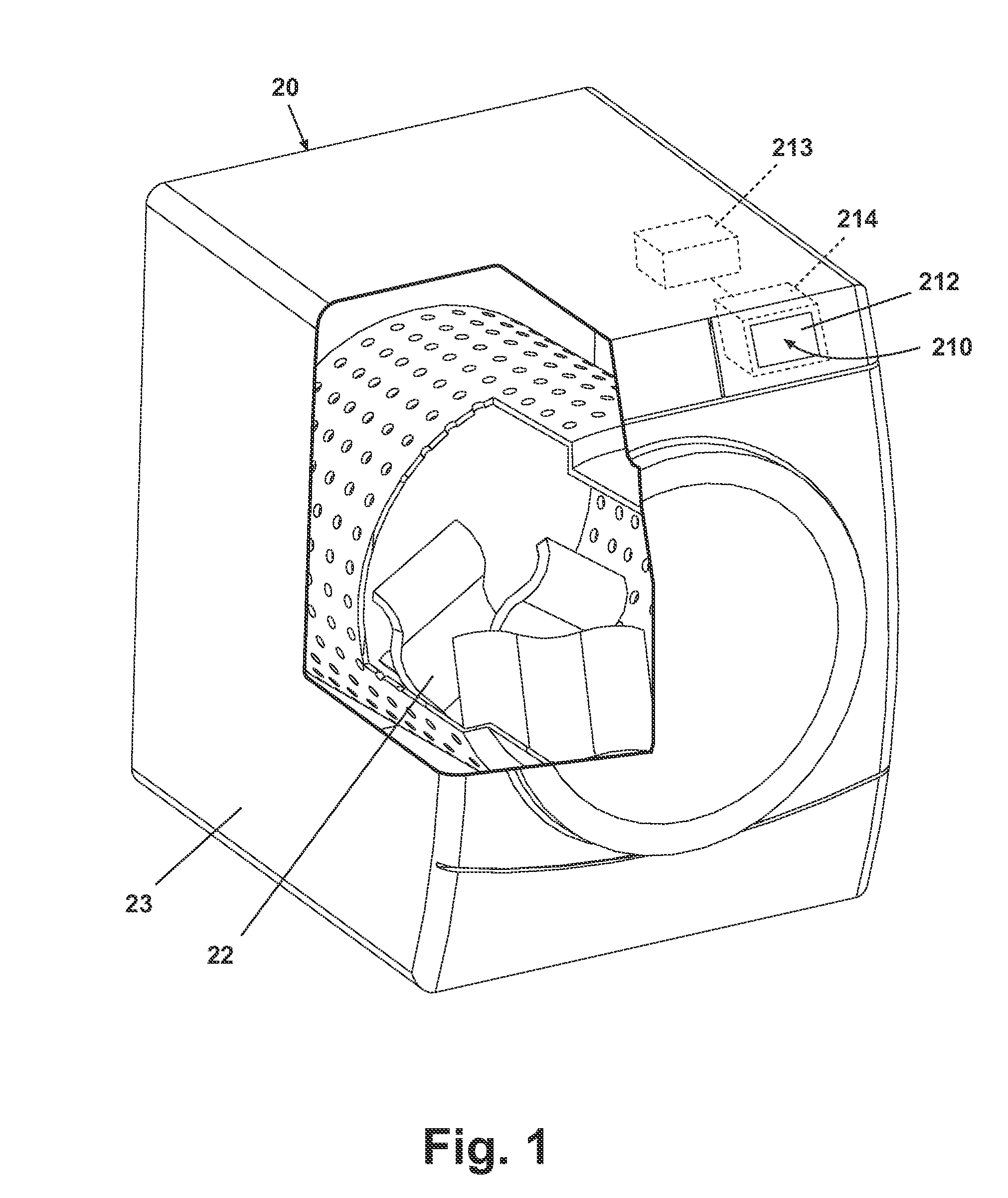

Controlling method of a dryer and a dryer with the same

ActiveUS20080313922A1Drying solid materials with heatTextile treatment machine partsProcess engineeringDrying time

A controlling method of a clothes dryer for detecting an amount of laundry and a clothes dryer with the same are disclosed. A controlling method includes drying laundry by supplying hot air to a drum, determining an amount of laundry based on a drying time, and supplying fine droplets of water and / or steam to the drum according to the determined amount of laundry.

Owner:LG ELECTRONICS INC

Laundry treating machine and control method of the same

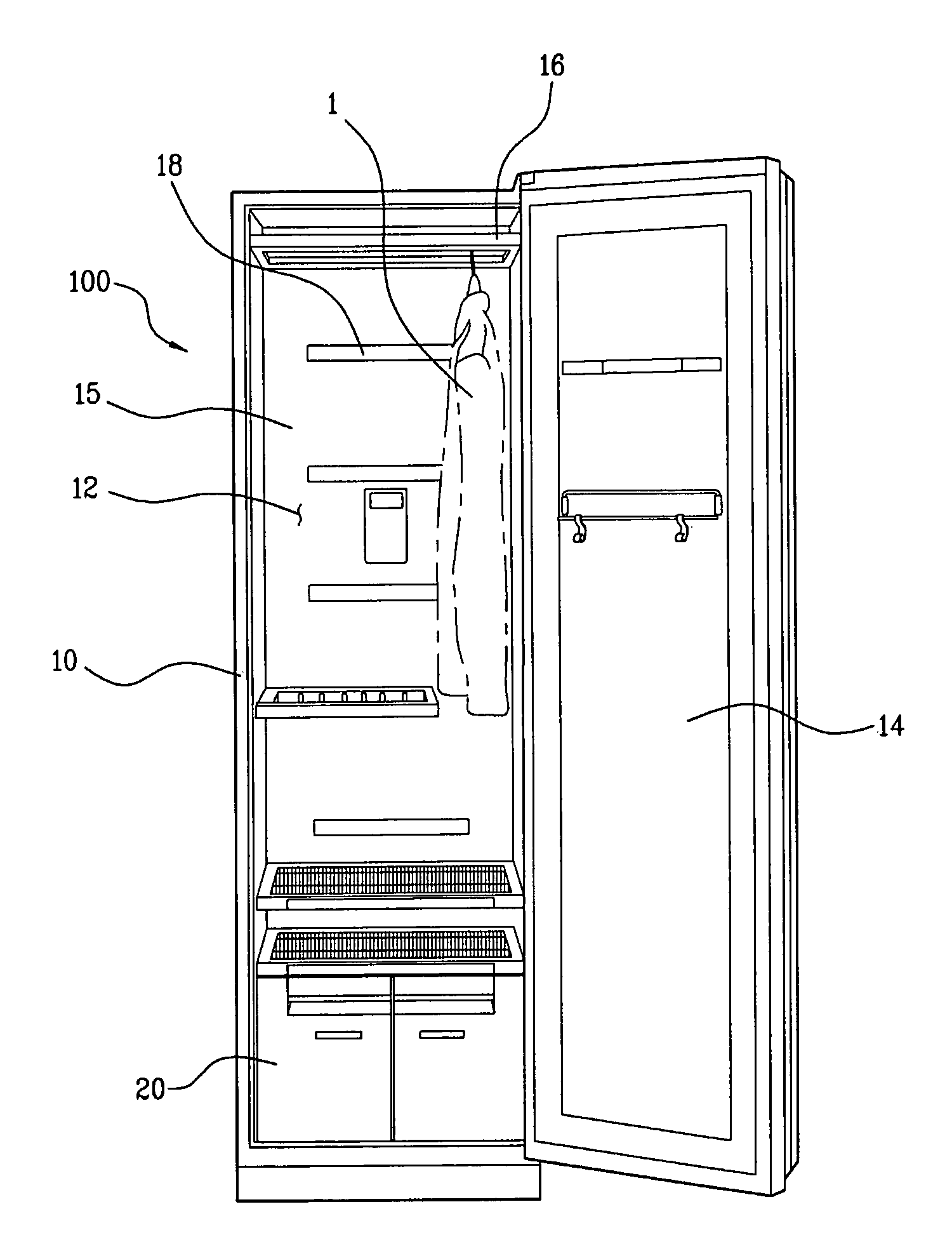

ActiveUS20090241269A1Drying using combination processesDrying solid materials with heatAfter treatmentEngineering

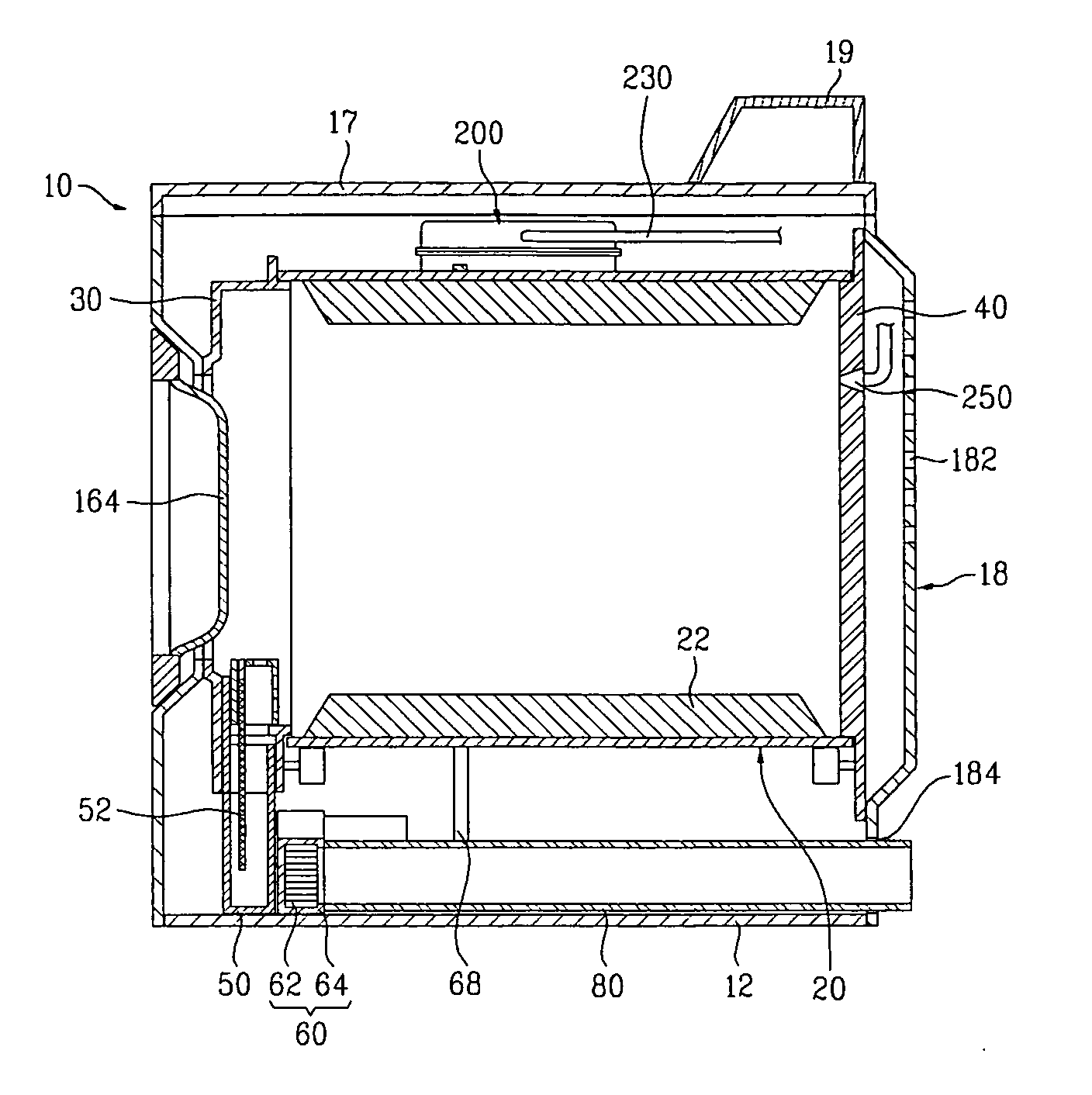

The present disclosure generally relates to a cloth treating apparatus, such as a laundry treating machine, and methods of control and operation which sanitize the machine. The laundry treating machine can include an accommodating space which supplies air and moisture in order to remove unpleasant odors, wrinkles, or dampness from the laundry. The laundry treating machine may further include a circulation duct to circulate, dehumidify, or heat air inside the accommodating space. Operation of the laundry treating machine can use steam-sanitizing to remove odors, moisture, bacteria from the accommodating space and circulation duct. Steam-sanitizing can be performed based on a user's selection or the occurrence of a condition, such as unloading of laundry from the accommodating space after treatment.

Owner:LG ELECTRONICS INC

Laundry treating apparatus

ActiveUS20090126423A1Improve ease of useEasy to addDrying solid materials with heatDrying solid materials without heatCold airProcess engineering

A laundry treating apparatus, particularly, a laundry treating apparatus using steam is disclosed. The laundry treating apparatus such as a washing machine, a dryer, a drying and washing machine is an apparatus which washes or dries articles such as clothes. The laundry treating apparatus includes an operation course including a drying process in which hot air is supplied into a drum adapted to accommodate articles to dry the articles and a cooling process in which cool air is supplied into the drum to cool the articles, wherein the operation course further includes a steam process in which steam is supplied into the drum, and the laundry treating apparatus includes a controller which controls a heater adapted to generate the steam such that an operation time point of the heater varies according to an amount of the articles. The laundry treating apparatus includes a drum adapted to accommodate articles, a control panel adapted to provide an interface with a user, and a controller to perform a steam process for supplying steam into the drum, wherein the controller controls a heater adapted to generate the steam to perform the steam process such that an operation time point of the heater varies according to an amount of the articles.

Owner:LG ELECTRONICS INC

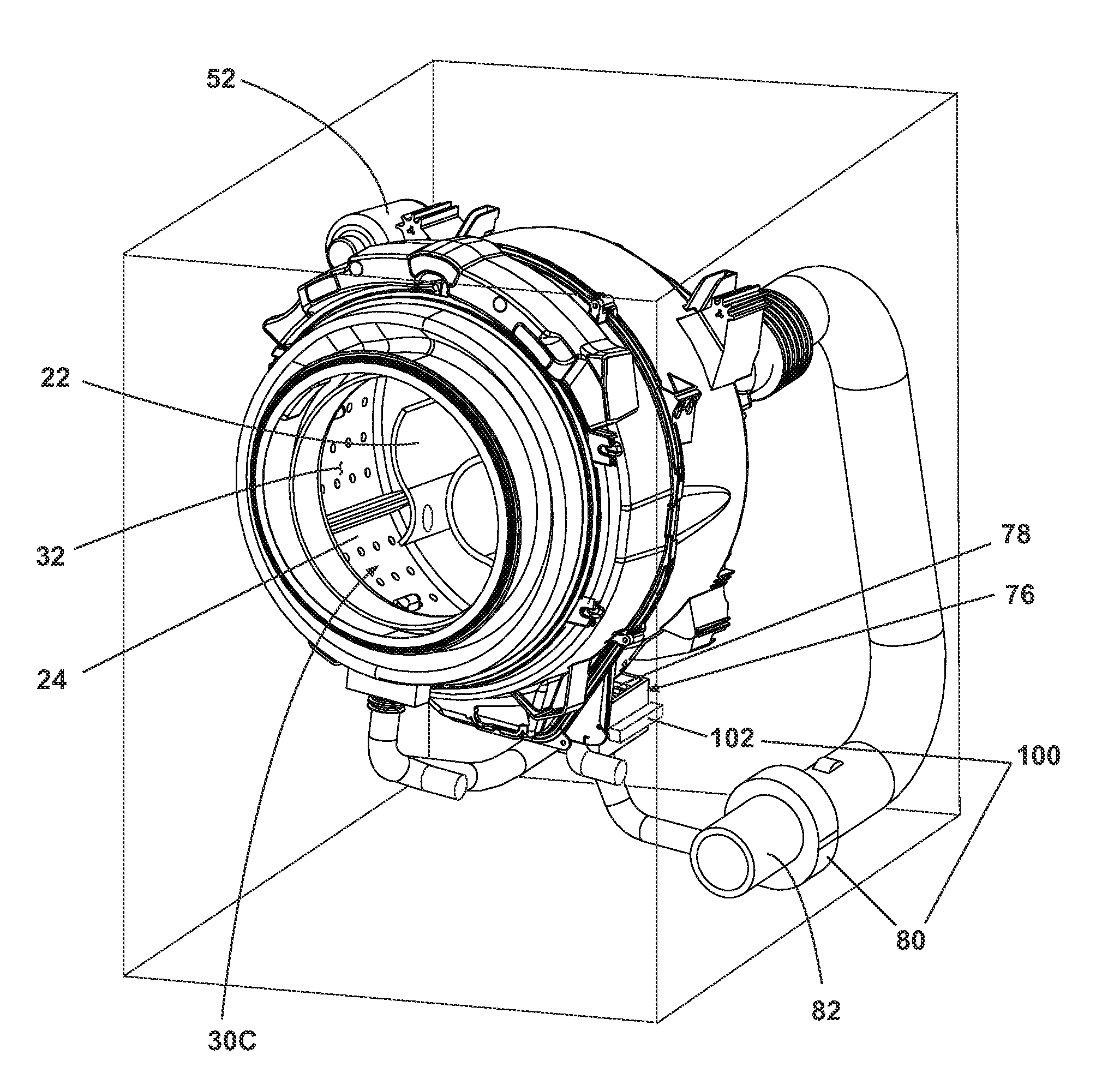

Washing machine

InactiveUS20080250824A1Reduce the amount requiredSmall sizeTextile treatment machine partsOther washing machinesManufacturing cost reductionWater discharge

A washing machine includes: a steam generator for generating steam; a circulation pump for pumping circulation water discharged from a tub and re-supplying it into a drum; a spray nozzle for spraying steam generated from the steam generator and the circulation water pumped from the circulation pump into the drum; and a back-current preventing branch unit connected to the steam generator by a steam supply line, connected to the circulation pump by a circulation line, and connected to the spray nozzle. With this structure, circulation water circulated by the circulation unit and steam generated from the steam generator are sprayed to the laundry through one spray nozzle, so that a system can be simplified and a fabrication cost can be reduced.

Owner:LG ELECTRONICS INC

Steam generator for domestic household appliance

InactiveUS20110197638A1Minimizing additional partReduce manufacturing costTextile treatment machine partsOther washing machinesEngineeringLiquid level sensor

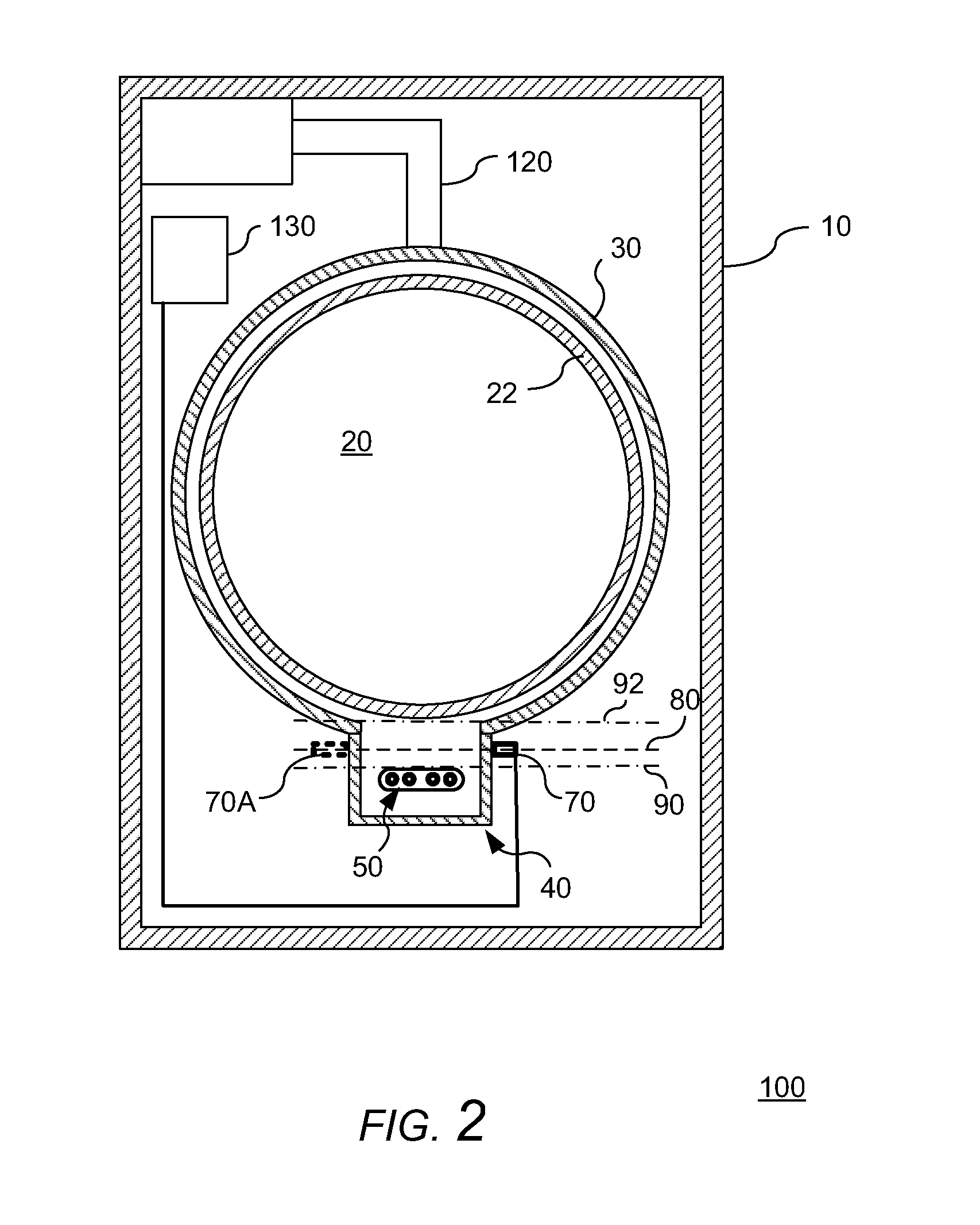

A household appliance includes a housing having a door formed in a front panel thereof for accessing an interior of the housing, a tub disposed inside the housing for containing a liquid, the tub having an inner surface and an outer surface, and a steam generator. The steam generator includes a heating element inside the tub, and a liquid level sensor on the outer surface of the tub, the liquid level sensor detecting a level of the liquid inside the tub, wherein the liquid level sensor includes a non-contacting sensor that detects the level of the liquid without directly contacting the liquid.

Owner:BSH HOME APPLIANCES CORP

Drum type washing machine with heater using steam and hot water

InactiveUS7404304B2Increase temperatureShorten washing timeTextile treatment machine partsOther washing machinesWash waterEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

Fabric treating apparatus

ActiveUS8505340B2Prevent air leakageTextile treatment machine partsOther washing machinesEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

Washing apparatus and control method thereof

ActiveUS7600402B2Prevent wettingOptimize quantityWringing machinesDry-cleaning apparatusEngineeringMechanical engineering

The present invention provides a washing apparatus and control method thereof, by which laundry can be dry-cleaned through the loaded configurations of the wet pad cloth, the filth transfer cloth, the steam providing unit, the fragrance spraying unit, and the detergent supplying unit using either the wet pad cloth or the filth transfer cloth or without using both of the wet pad cloth and the filth transfer cloth.

Owner:LG ELECTRONICS INC

Popular searches

Material analysis by electric/magnetic means Digital storage Liquid/gas/vapor removal by gas jets Semiconductor devices Current/voltage measurement Microbiological testing/measurement Drying machines with progressive movements Differential amplifiers Vibration treatment Dc-amplifiers with dc-coupled stages

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com