Patents

Literature

7355results about How to "Avoid safety accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

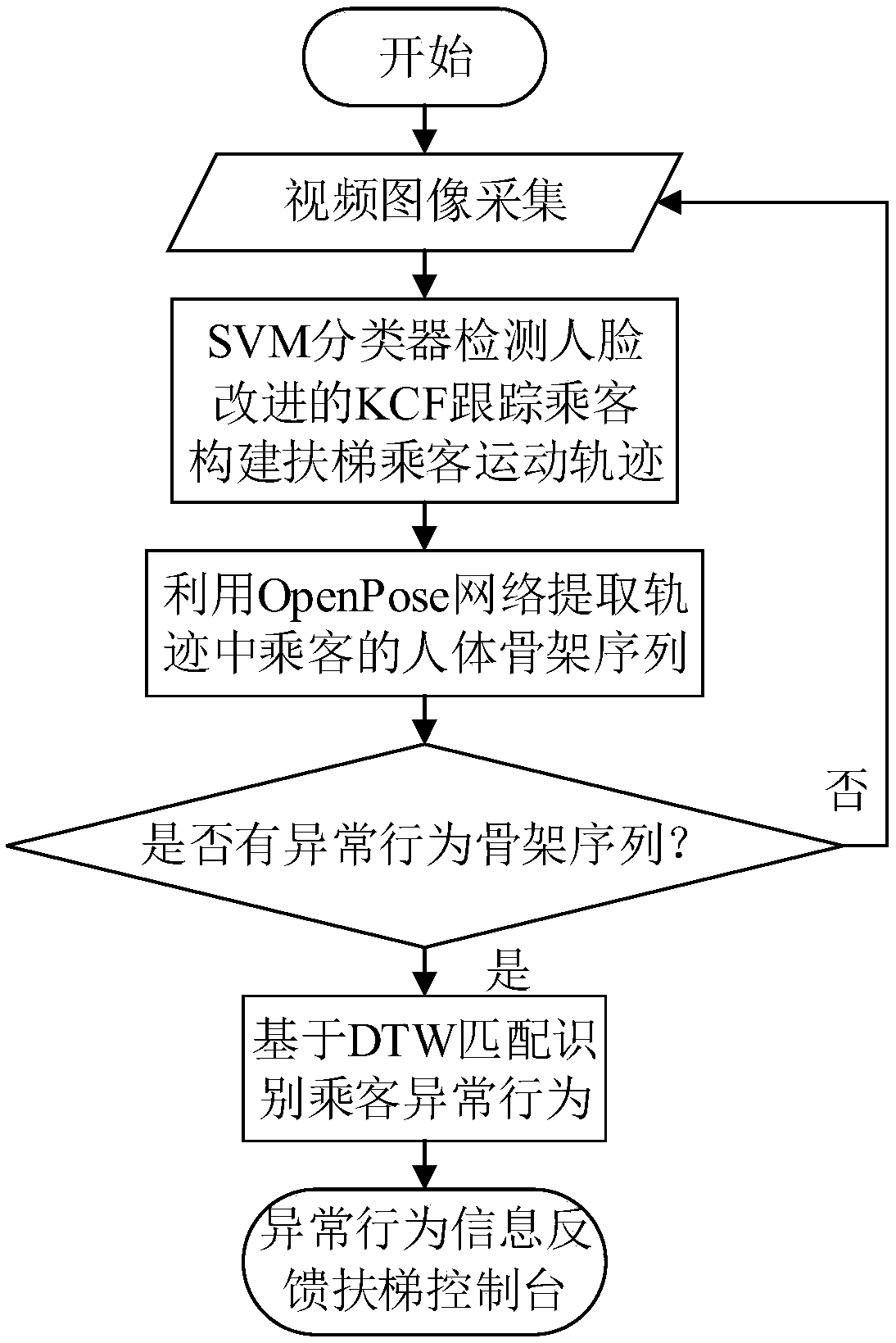

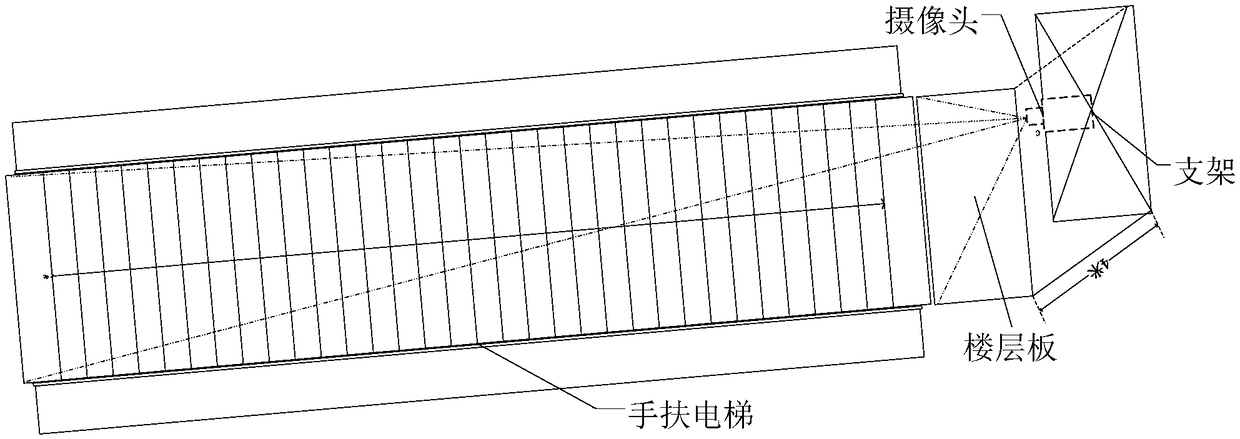

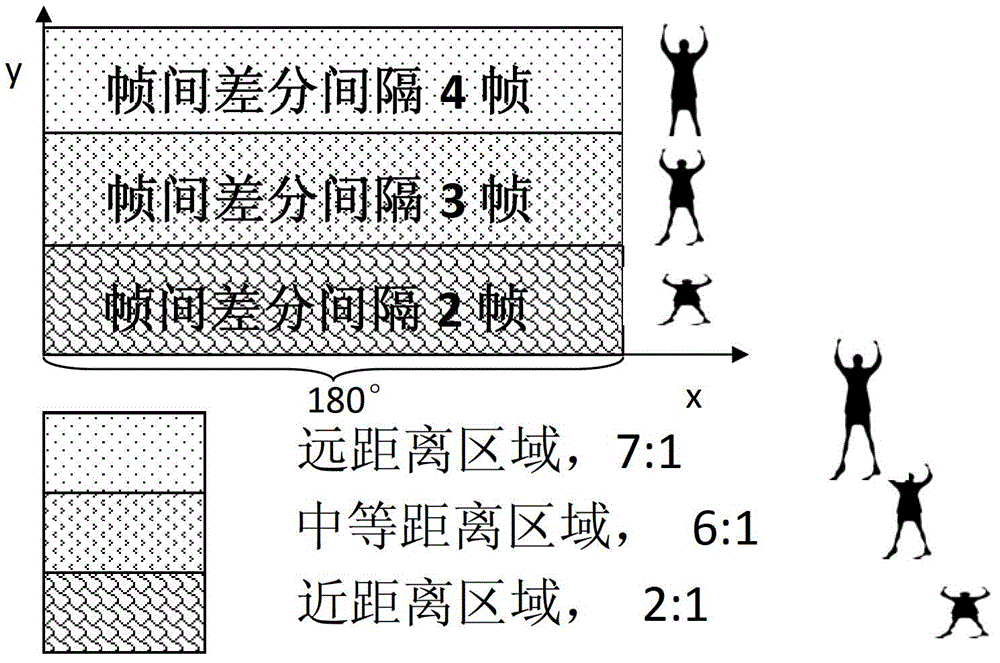

Passenger abnormal behavior recognition method based on human skeleton sequence

ActiveCN109460702AAccurate and stable buildAccurate and stable trajectoryImage enhancementImage analysisTemplate matchingAnomalous behavior

The invention discloses a passenger abnormal behavior identification method based on a human skeleton sequence, which comprises the following steps: 1) shooting an escalator area monitoring video image by a camera; 2) detecting that passenger face through the SVM and trac the passenger face with the KCF to obtain the passenger motion trajectory in the escalator; 3) extracting that human skeleton from the image by using the OpenPose depth learn network; 4) matching that human skeleton to the corresponding passenger trajectory to construct the human skeleton sequence of the passenger; 5) detecting that abnormal behavior skeleton sequence from the passenger human skeleton sequence through template match; 6) using DTW to match it with various abnormal behavior skeleton sequence template to identify abnormal behavior. That invention can accurately and real-time identify a plurality of abnormal behavior of passengers in the escalator base on human skeleton sequence, according to the abnormalbehavior type to control the operation situation of the escalator, and avoid the occurrence of safety accident.

Owner:SOUTH CHINA UNIV OF TECH +1

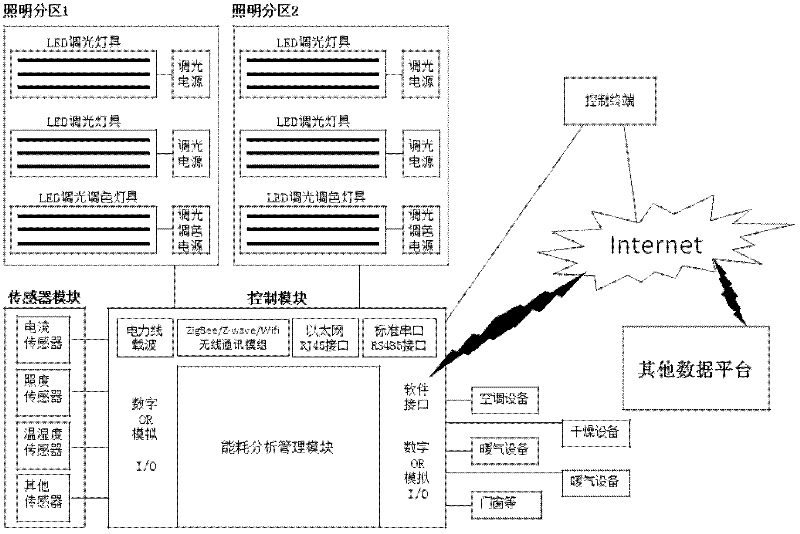

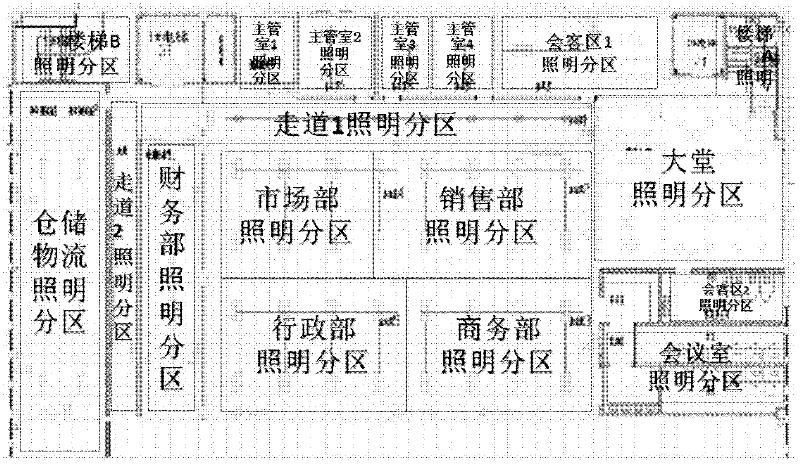

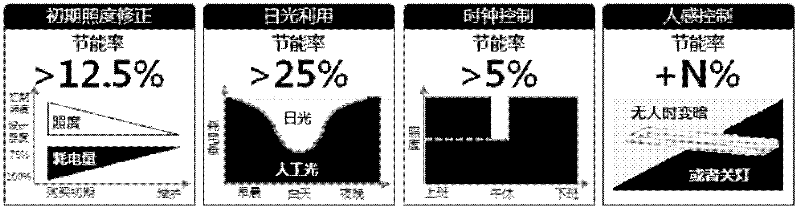

Intelligent environment monitoring system

InactiveCN102591277AReduce wasteLow costEnergy industryElectric light circuit arrangementIntelligent environmentIntelligent lighting

The invention discloses an intelligent environment monitoring system. The system comprises an LED lamp provided with a light-dimming or light-dimming and color-matching power supply, electric equipment, a sensor module, a control module and a control terminal. The system can automatically control the lightness of the lamp by sensing and measuring luminance / human body / objects so as to realize intelligent lighting control and reduce unnecessary energy waste; by measuring the environmental temperature / humidity, an air conditioner / heating equipment / air drying equipment / humidifying equipment can be automatically controlled; when the temperature / humidity is abnormal, the system automatically alarms to remind a manager by a short message / email so as to avoid safety accidents in the production and management. Meanwhile, the system can further monitor the use condition of energy sources in real time, provide an accurate energy consumption data report for a manager, and reduce the energy cost for the production and management.

Owner:得实半导体照明(江门)有限公司

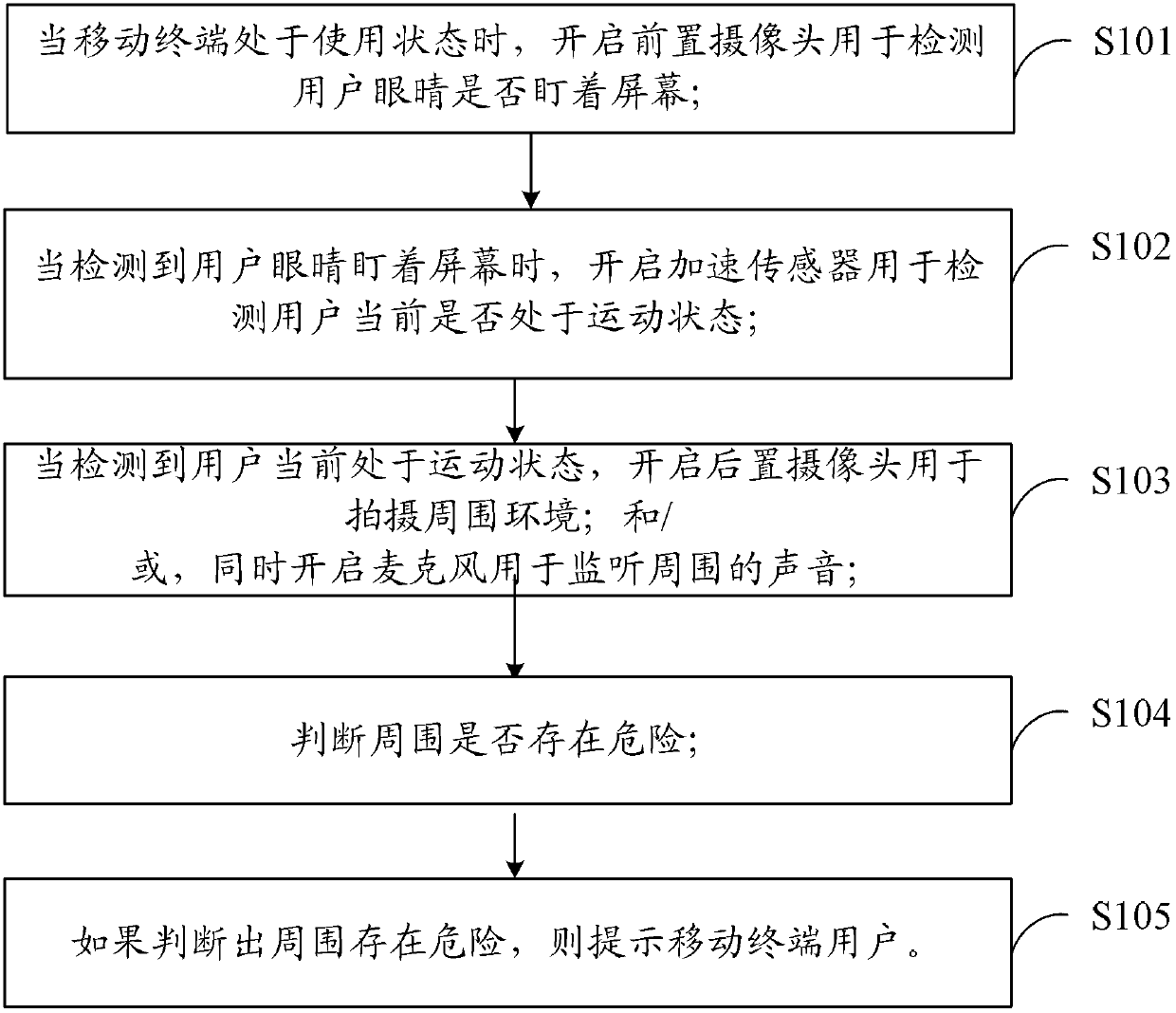

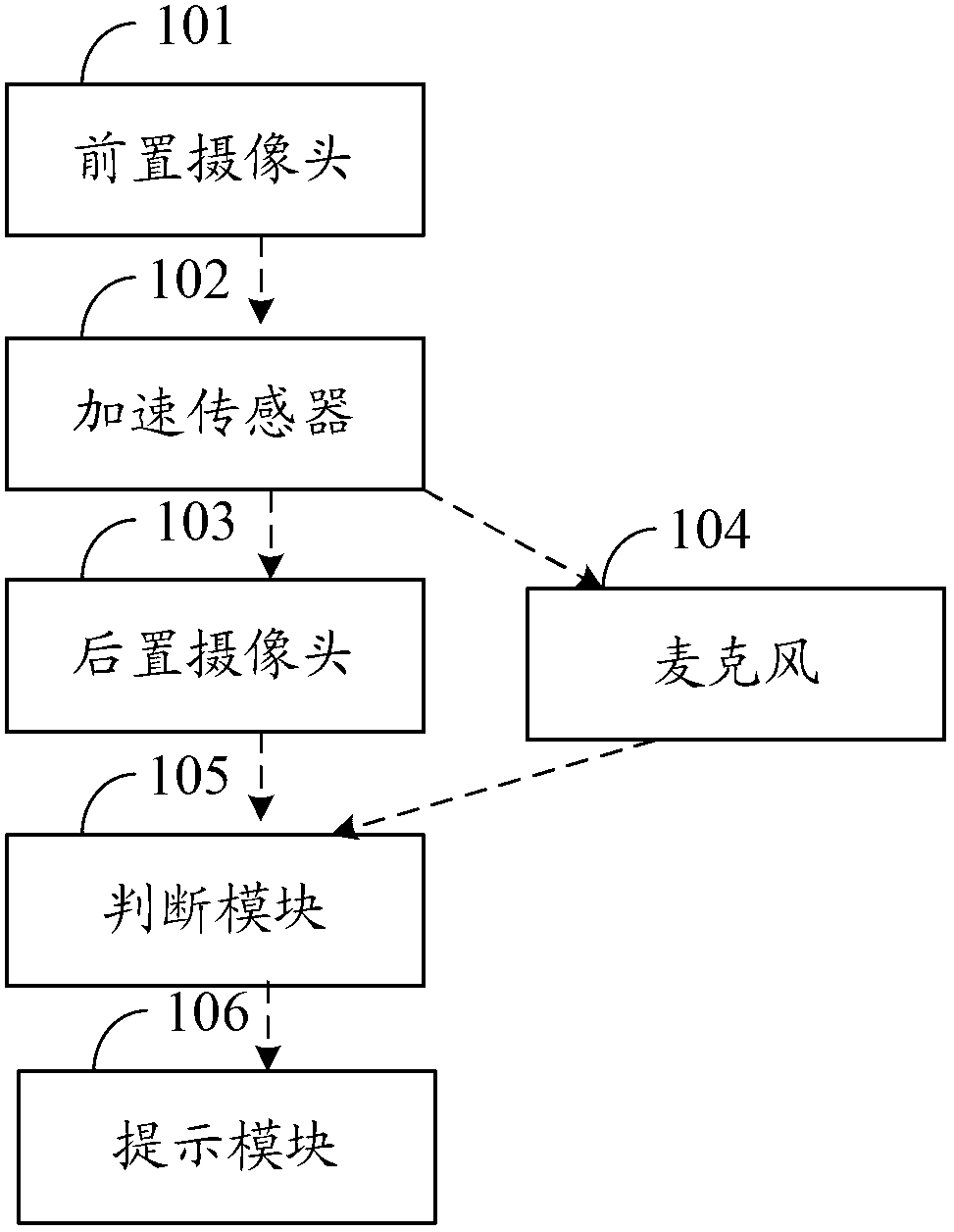

Safety pre-warning processing method, system and mobile terminal of reminding user of mobile terminal

The invention is applied to the field of mobile terminals and provides a safety pre-warning processing method, a system and a mobile terminal of reminding a user of the mobile terminal. The method comprises the following steps: opening a front-arranged camera head for detecting whether the user stares at a screen when the mobile terminal is in a utilization state; opening a speeding-up device for detecting whether the user is in a moving state when detecting the user stares at the screen; opening a back-arranged camera head for shooting surrounding environments when detecting that the user is in a moving state; and / or simultaneously opening a microphone for monitoring surrounding voice; judging whether dangers exist in the surrounding environments; and reminding the user of the mobile terminal if the dangers exist in the surrounding environments. By adoption of the safety pre-warning processing scheme, when the user checks the screen of mobile equipment in the moving state, the surrounding environments of the user can be detected, and safety pre-warming can be sent out, and therefore safety accidents are avoided.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

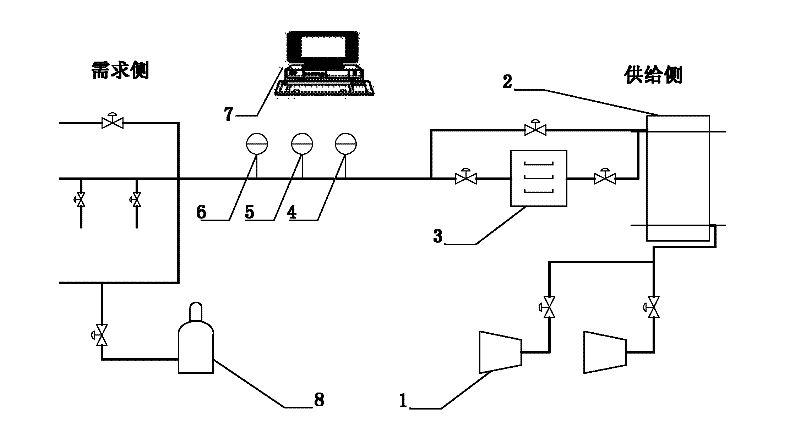

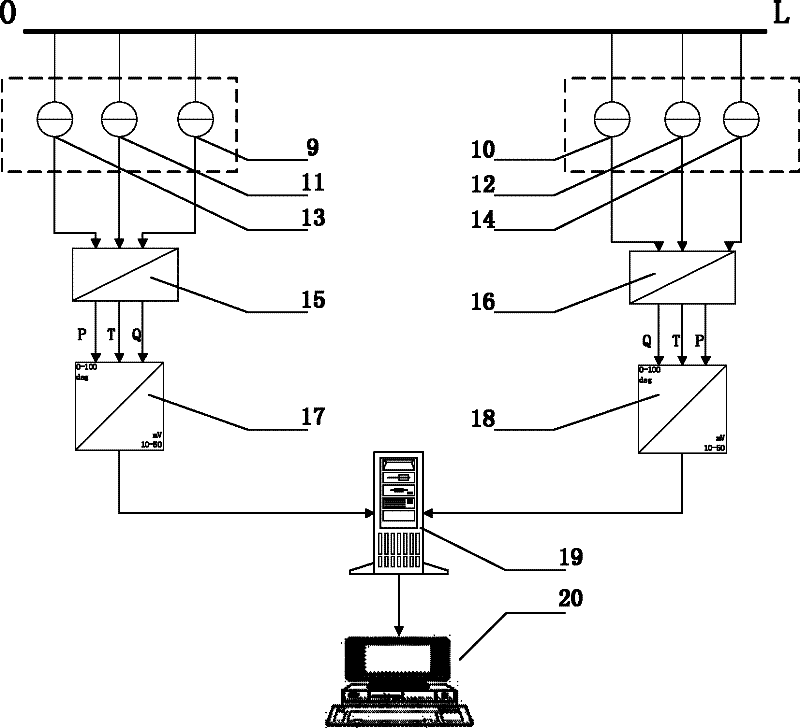

Method and device for intelligent diagnosis and location of leakage fault of fluid delivery pipeline

InactiveCN1435678APrevent overpressureAvoid wastingFluid-tightness measurementReal time analysisReal-time data

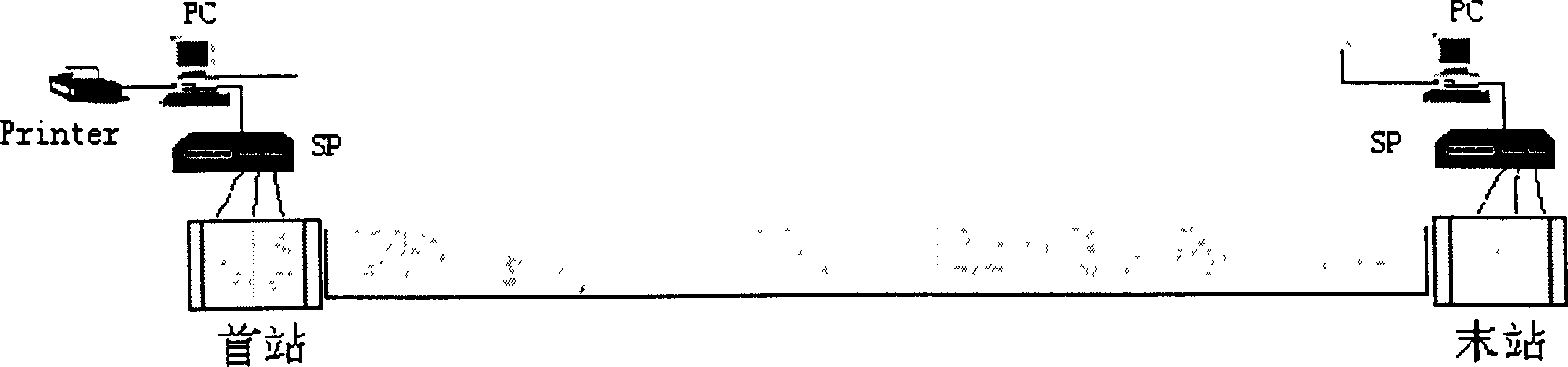

An intelligent device and method for diagnosing and positioning the leakage of fluid delivery pipeline are disclosed. Said method includes detecting leakage by delivery difference-pressure wave coupling method, and positioning by transient pressure wave locating method to calculate the leakage position. Its device is composed of the start and end stations to which the pressure flow and temp meters, upper-layer set and lower-layer set are mounted, communication network for real-time data exchange, and GPS correction system.

Owner:NORTHEASTERN UNIV

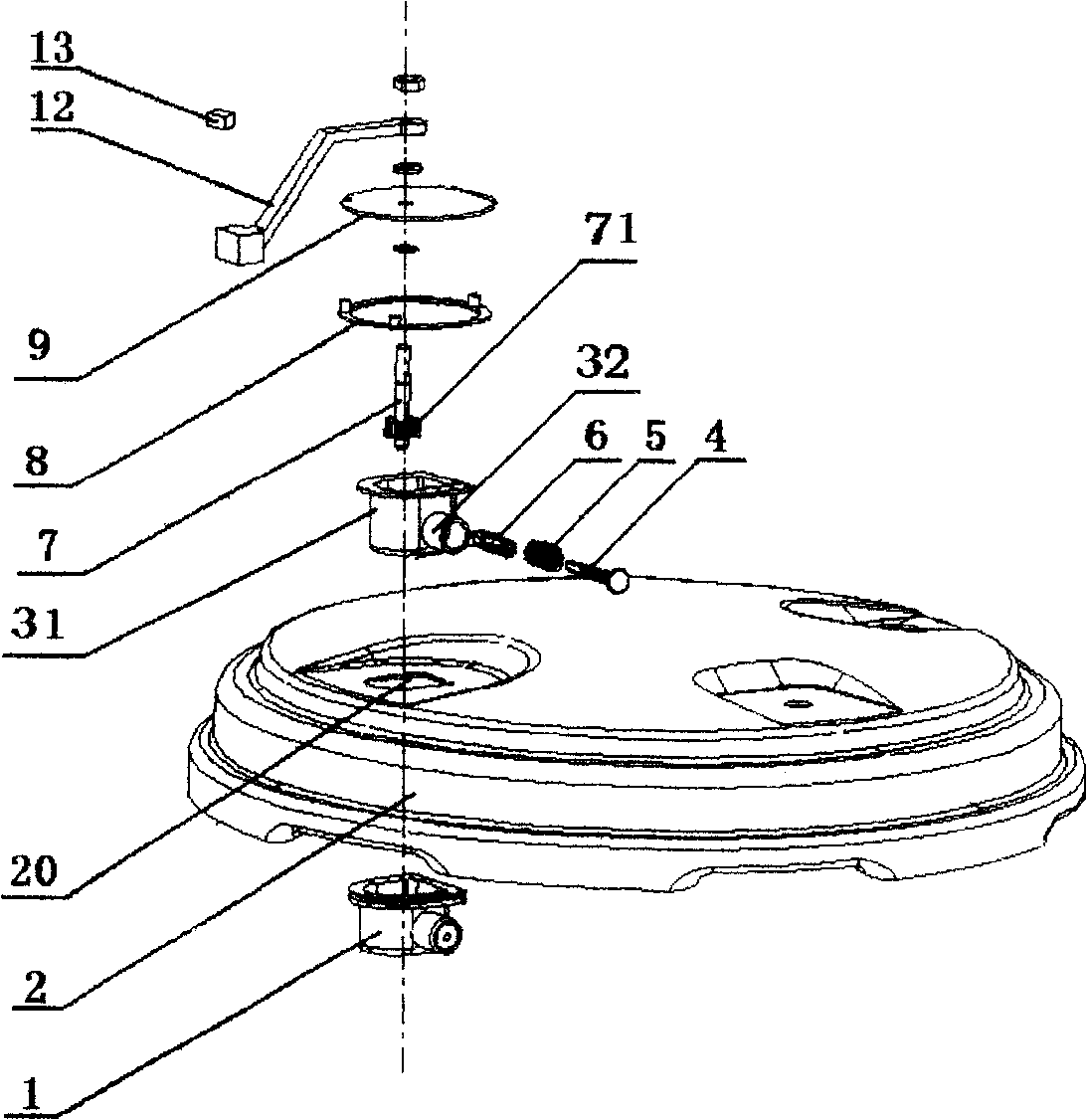

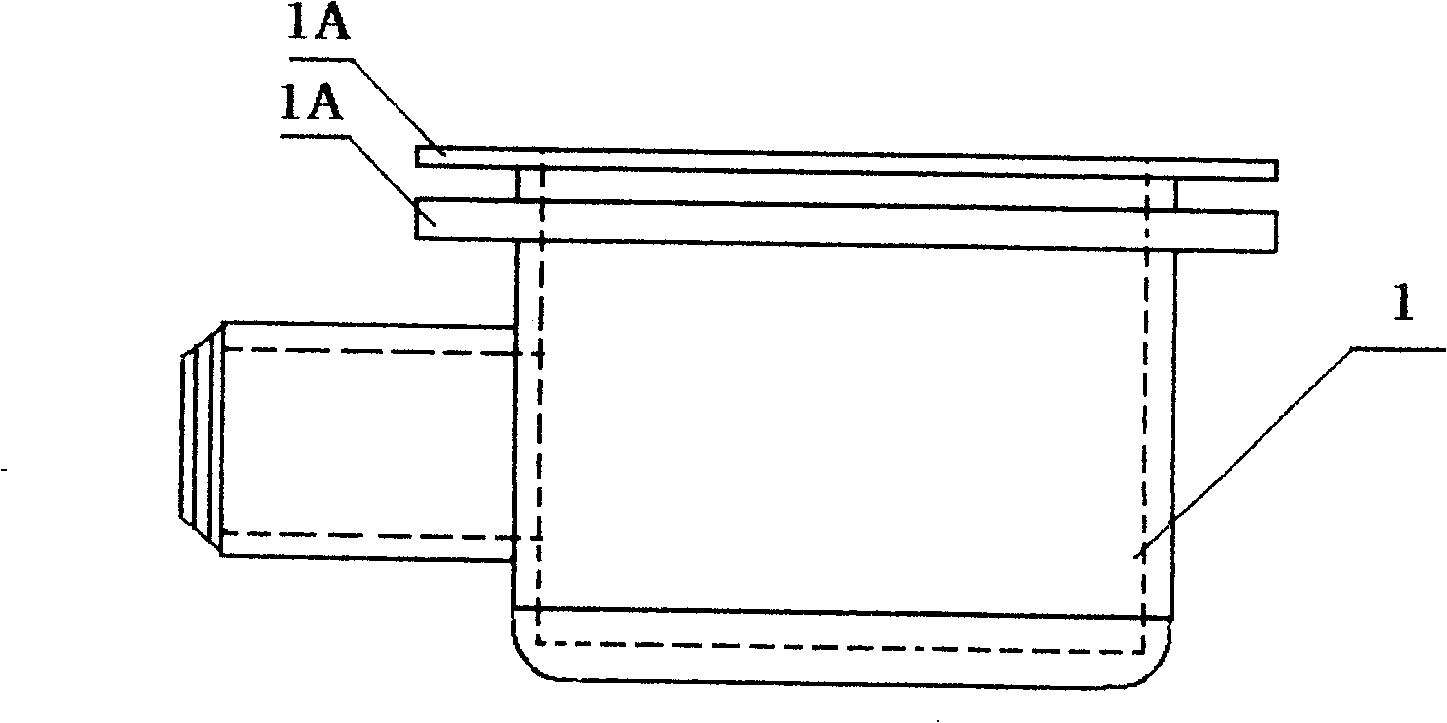

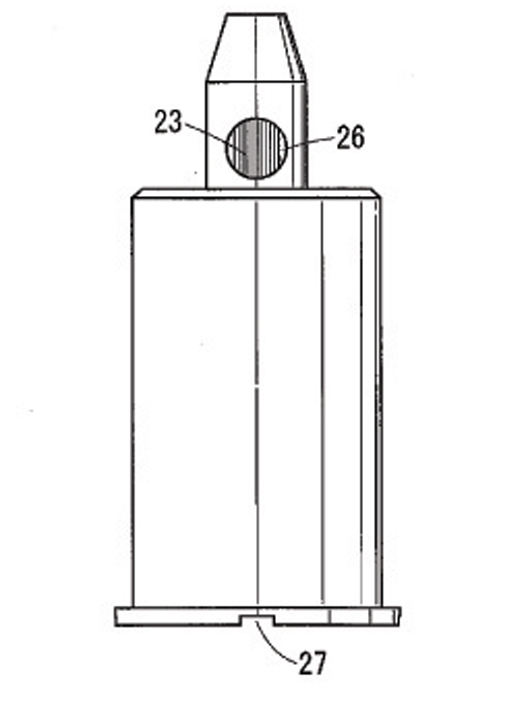

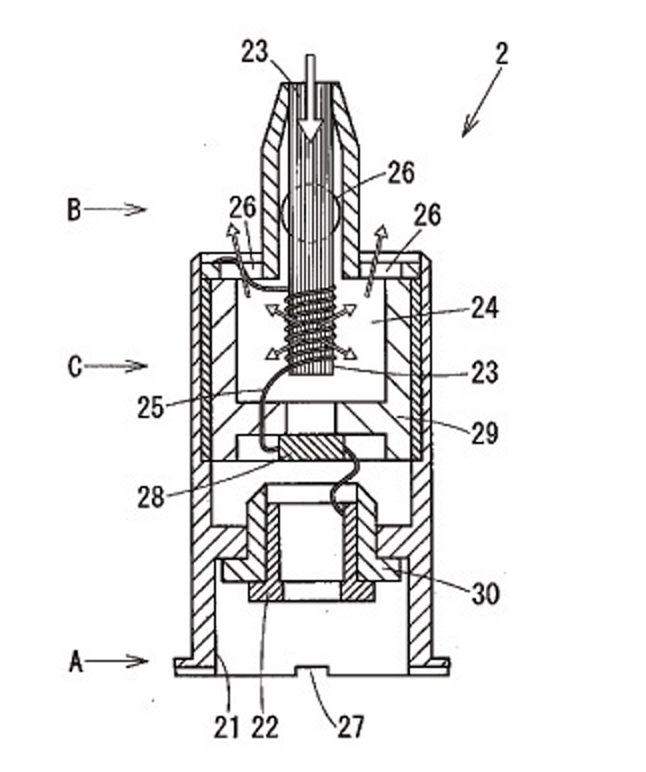

Electric pressure cooker pressure converting device

Owner:FOSHAN FUSHIBAO ELECTRICAL APPLIANCE TECH

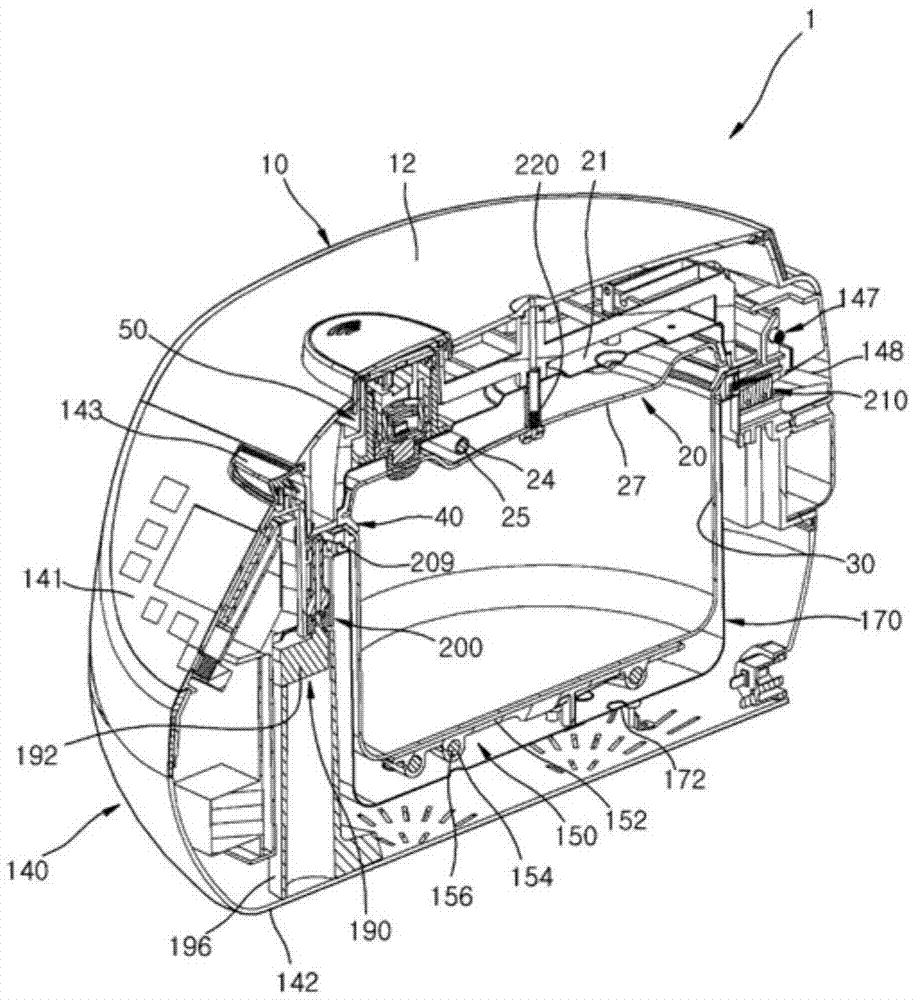

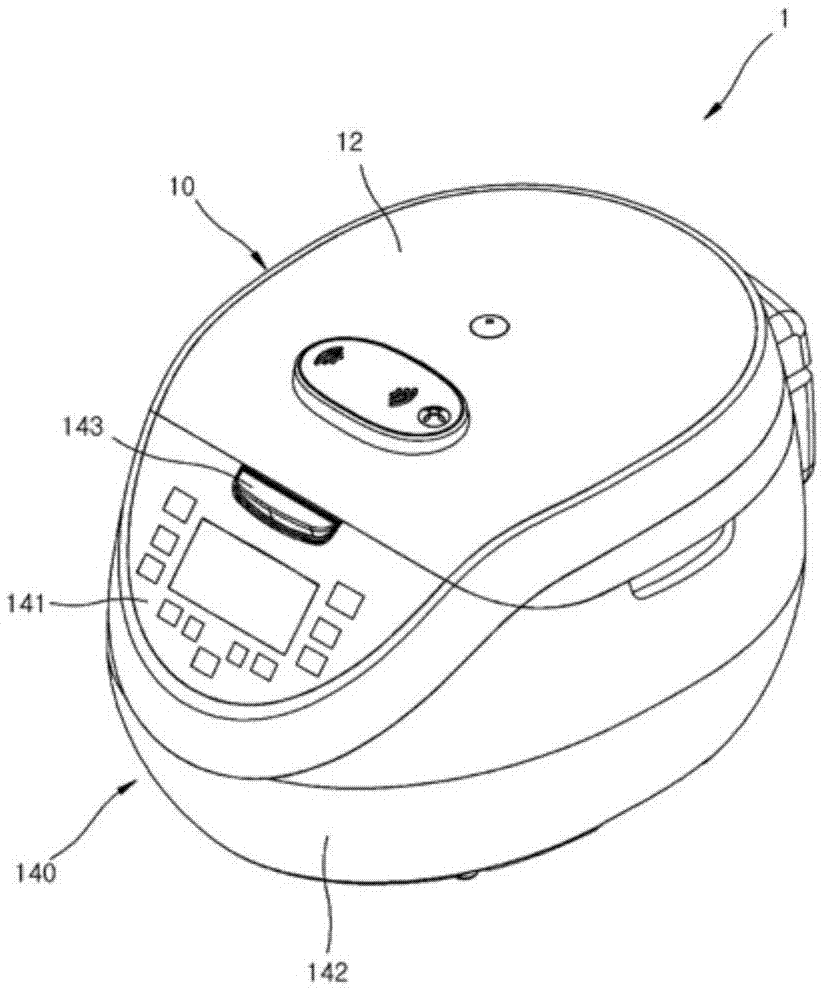

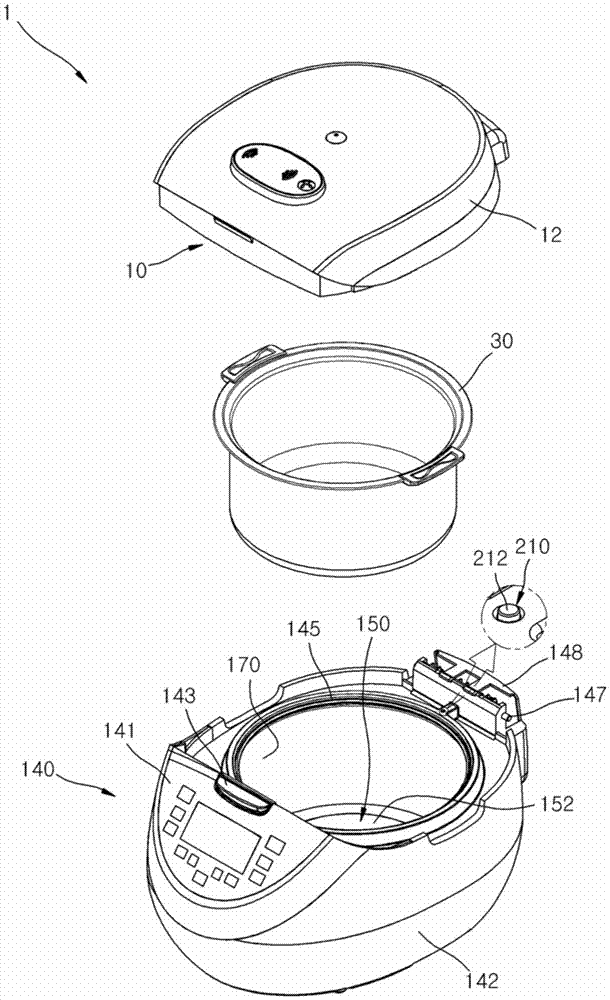

Electric rice cooker

InactiveCN105451610AImprove temperature uniformityPrevent corruptionPressure-cookersVessels with intergral heatingEngineeringCooker

An invention relating to an electric rice cooker is disclosed. The electric rice cooker according to an embodiment of the present invention comprises: an upper case part; an upper heater which is located on the lower side of the upper case part and downwardly emits heat; an inner container located on the lower side of the upper heater and containing an object to be cooked; an upper heat transfer plate located on the lower side of the upper heater while facing the inner container; a body constituting an outer shape of the electric rice cooker and having the inner container installed therein; and a vacuum packing part installed along the boundary of the upper heat transfer plate facing the inner container and blocking the flow of air moving between the upper heat transfer plate and the inner container.

Owner:金且植

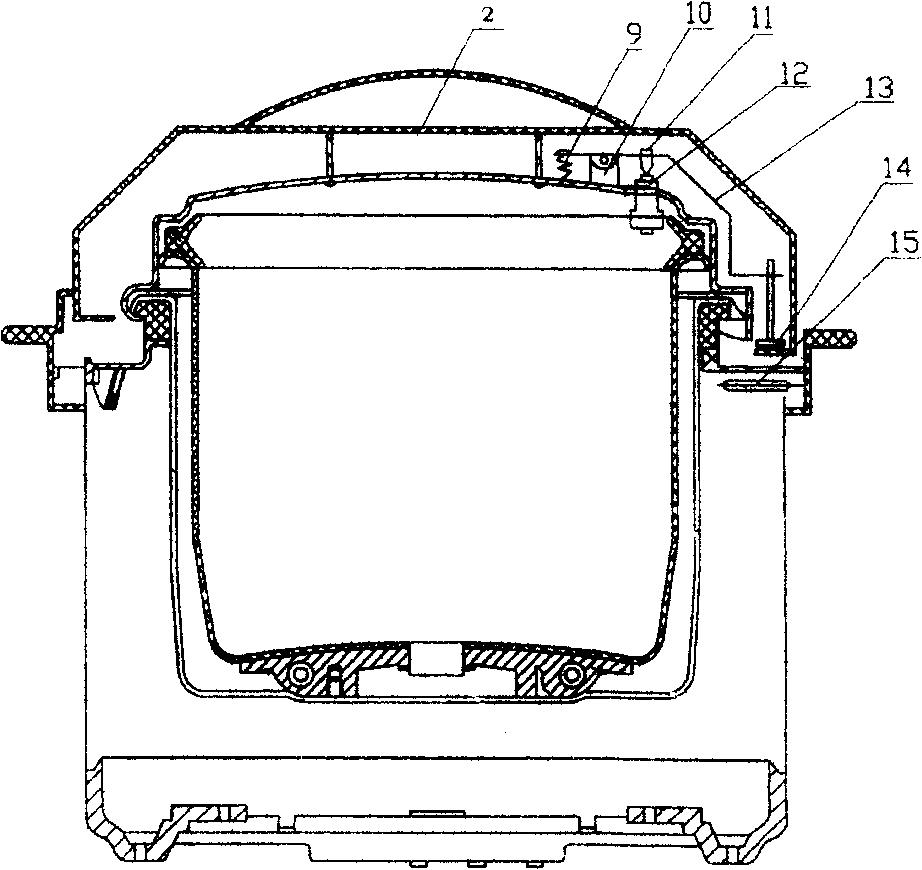

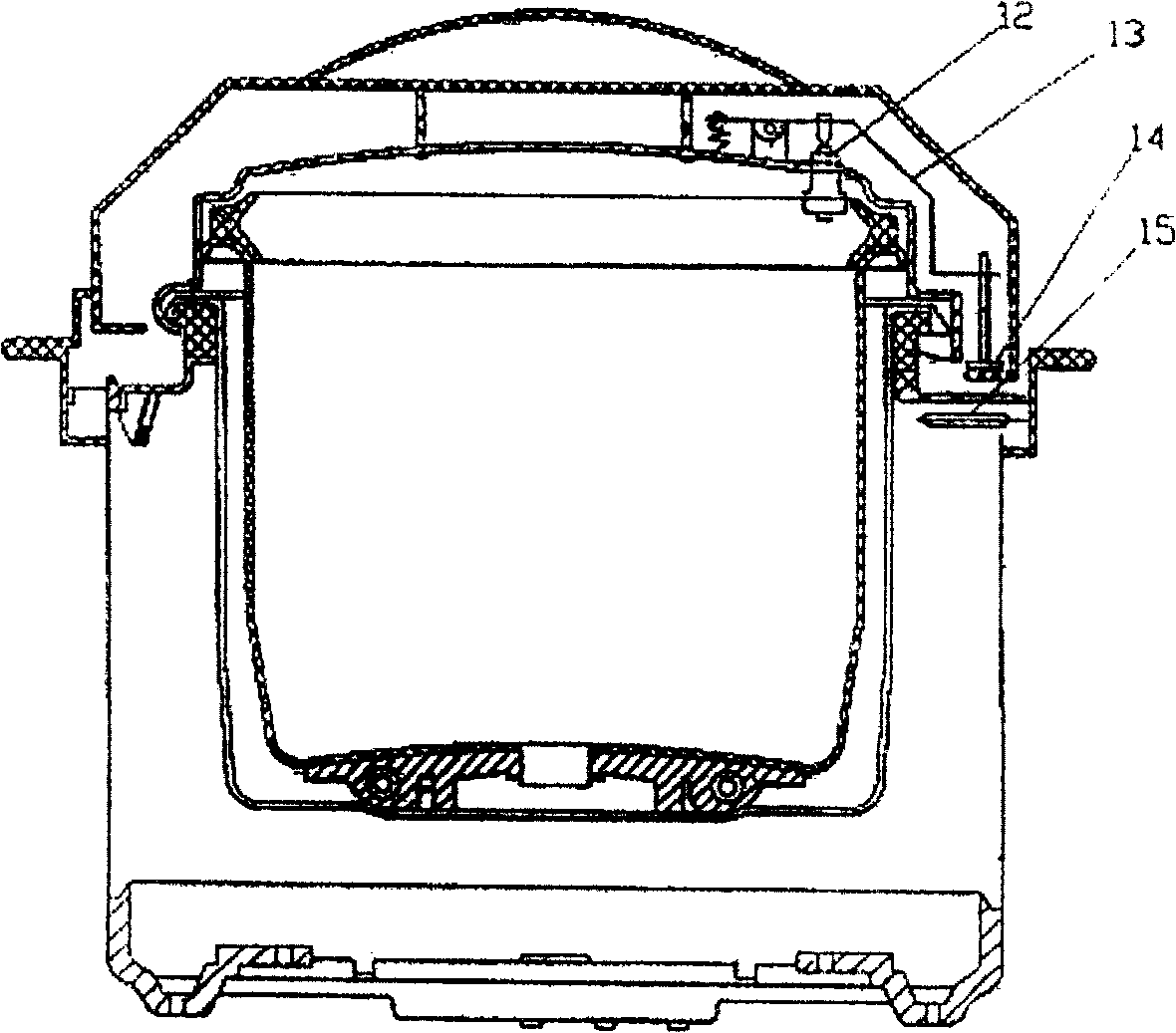

Electric pressure cooker

An electric pressure cooker is composed of a cooker body with control circuit and sensor on its top edge, and a cover with an elastic sealing sleeve and a pressure driver consisting of lining sleeve embedded in said elastic sealing sleeve, an axially moving piston and a rotary part driven by said piston and with fixed long arm and inductor.

Owner:FOSHAN FUSHIBAO ELECTRICAL APPLIANCE TECH

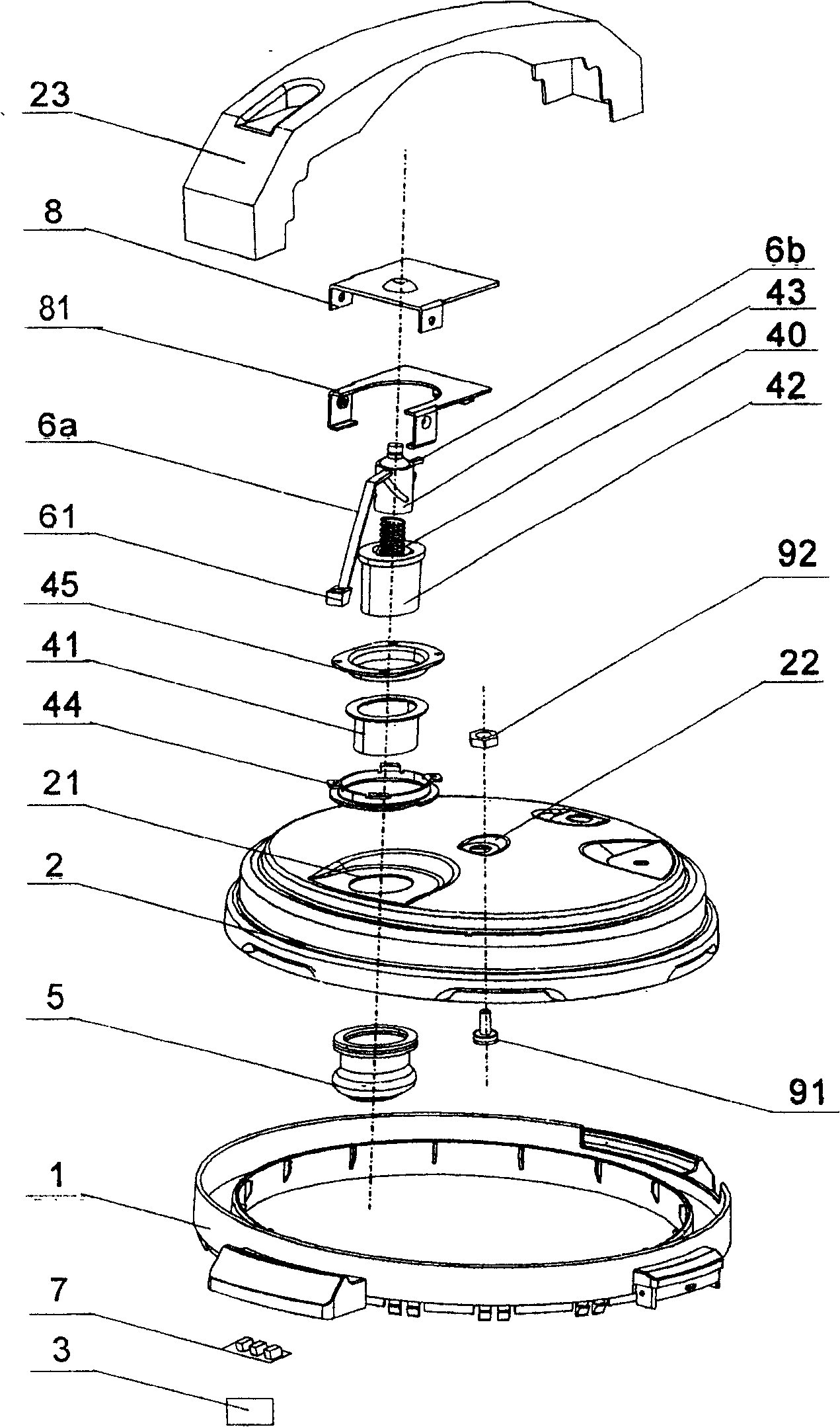

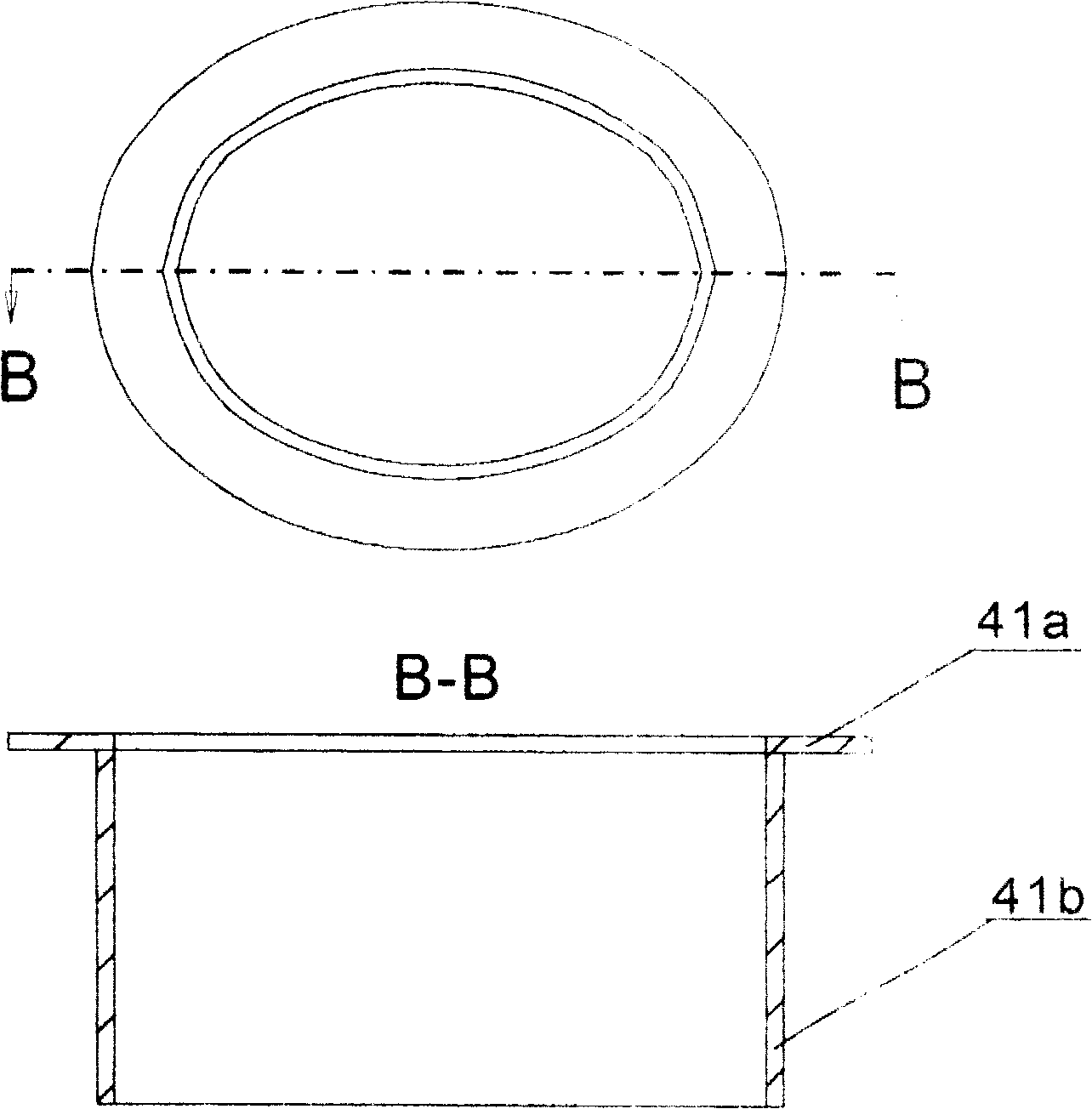

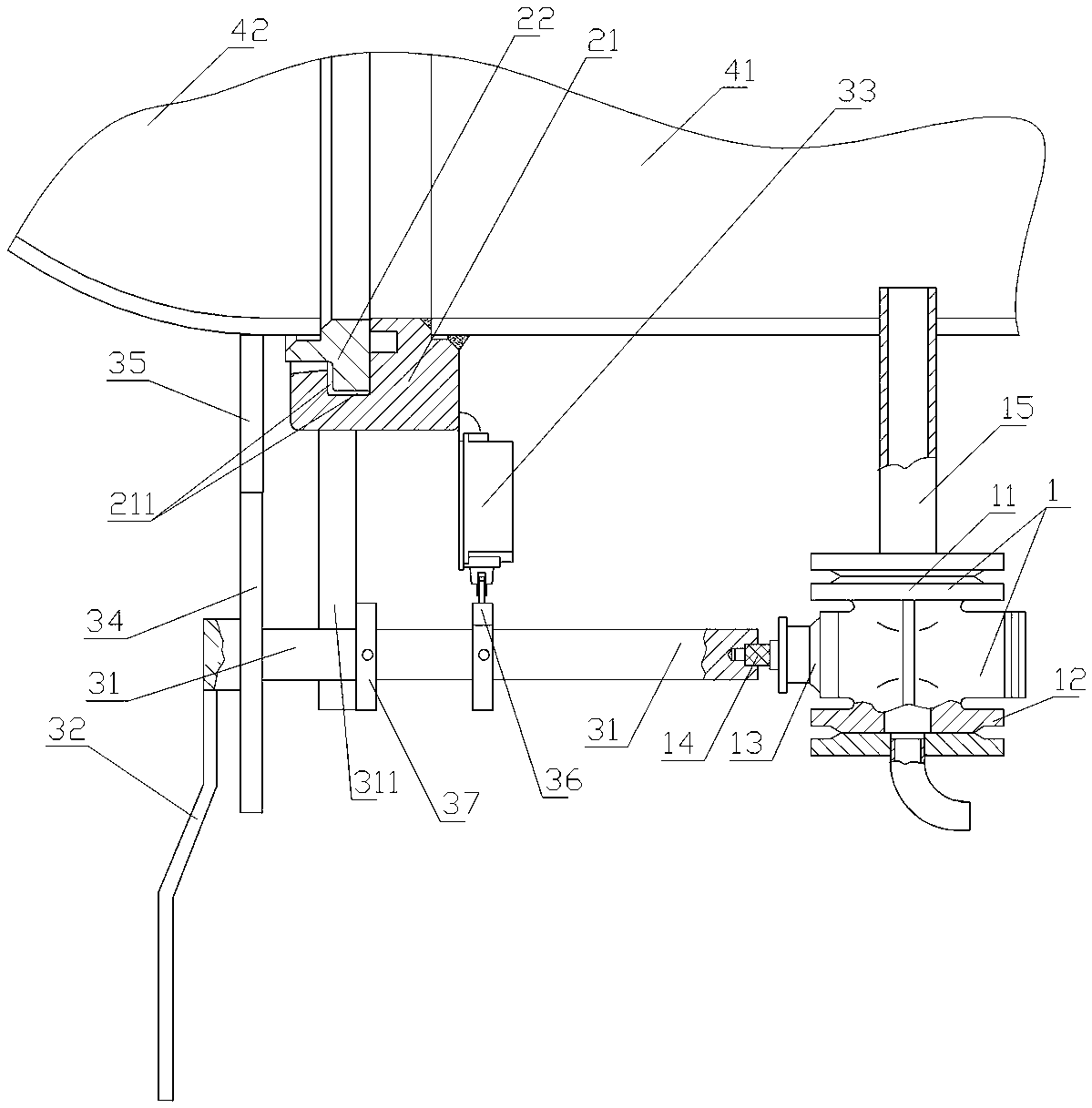

Still kettle door-opening safety interlocking structure

A still kettle door-opening safety interlocking structure includes a pressure release valve (1), a door lock mechanism and an interlocking mechanism. The pressure release valve (1) is installed on theouter side of a kettle body (41) of a still kettle, the interlocking mechanism includes a linkage rod (31), a handle (32), a travel switch (33) and a kettle door dragging mechanism. The linkage rod (31) is movably mounted on a lock catch (21) or the kettle body (41) through a linkage rod frame (311), one end of the linkage rod (31) is connected with the pressure release valve (1), the other end of the linkage rod (31) is connected with the handle (32), the travel switch (33) is mounted on the lock catch (21) or the kettle body (41), and the linkage rod (31) is further connected with the travel switch (33) through a cam (36). The linkage rod (31) is connected with the door lock mechanism through the kettle door dragging mechanism. The pressure release on a still kettle and the opening of akettle door can be performed consistently, the still kettle door-opening safety interlocking structure is convenient and quick, and the still kettle door-opening safety interlocking structure can avoid accidents caused by misoperation.

Owner:湖南长宏南雁锅炉修理安装有限公司

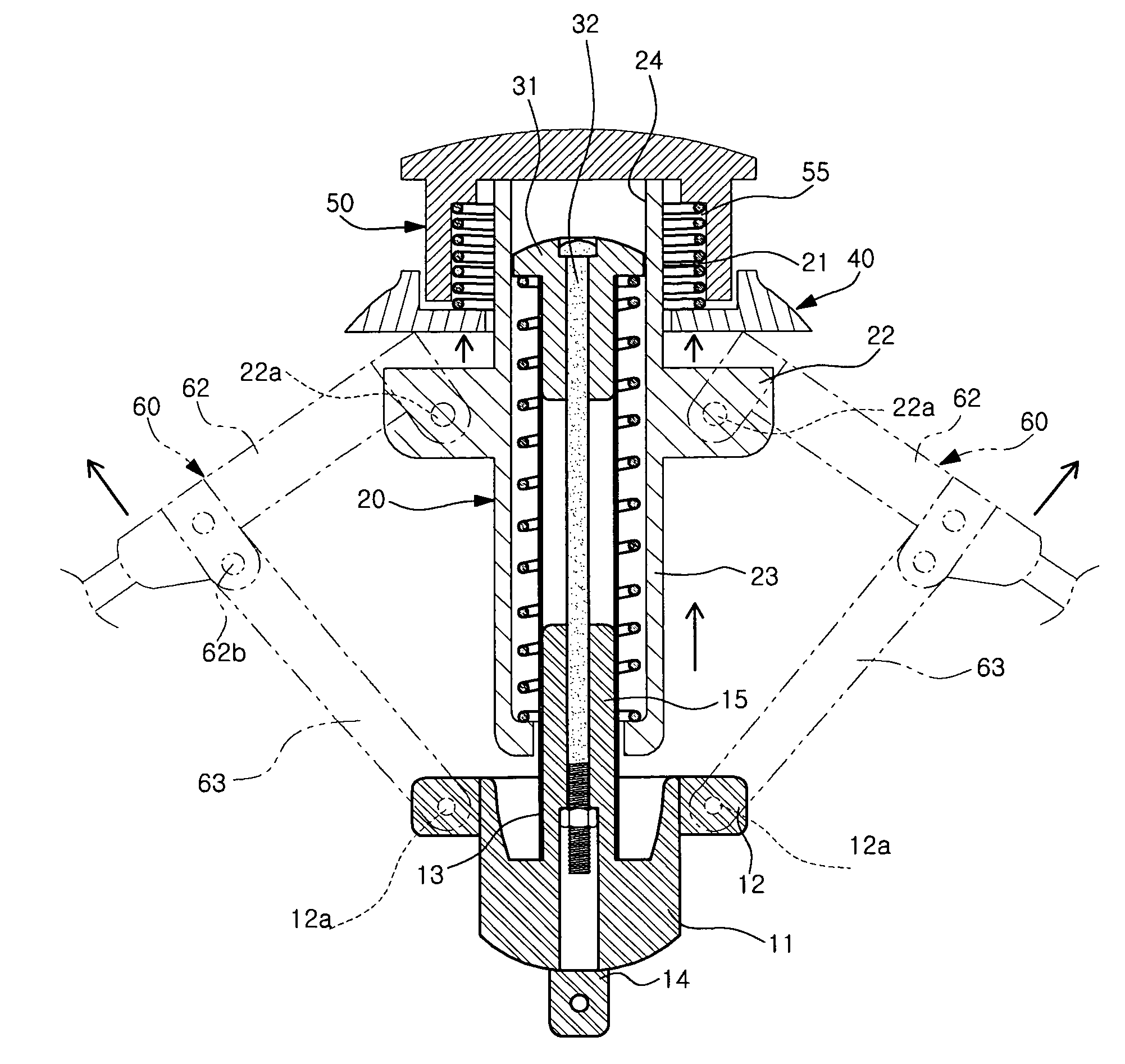

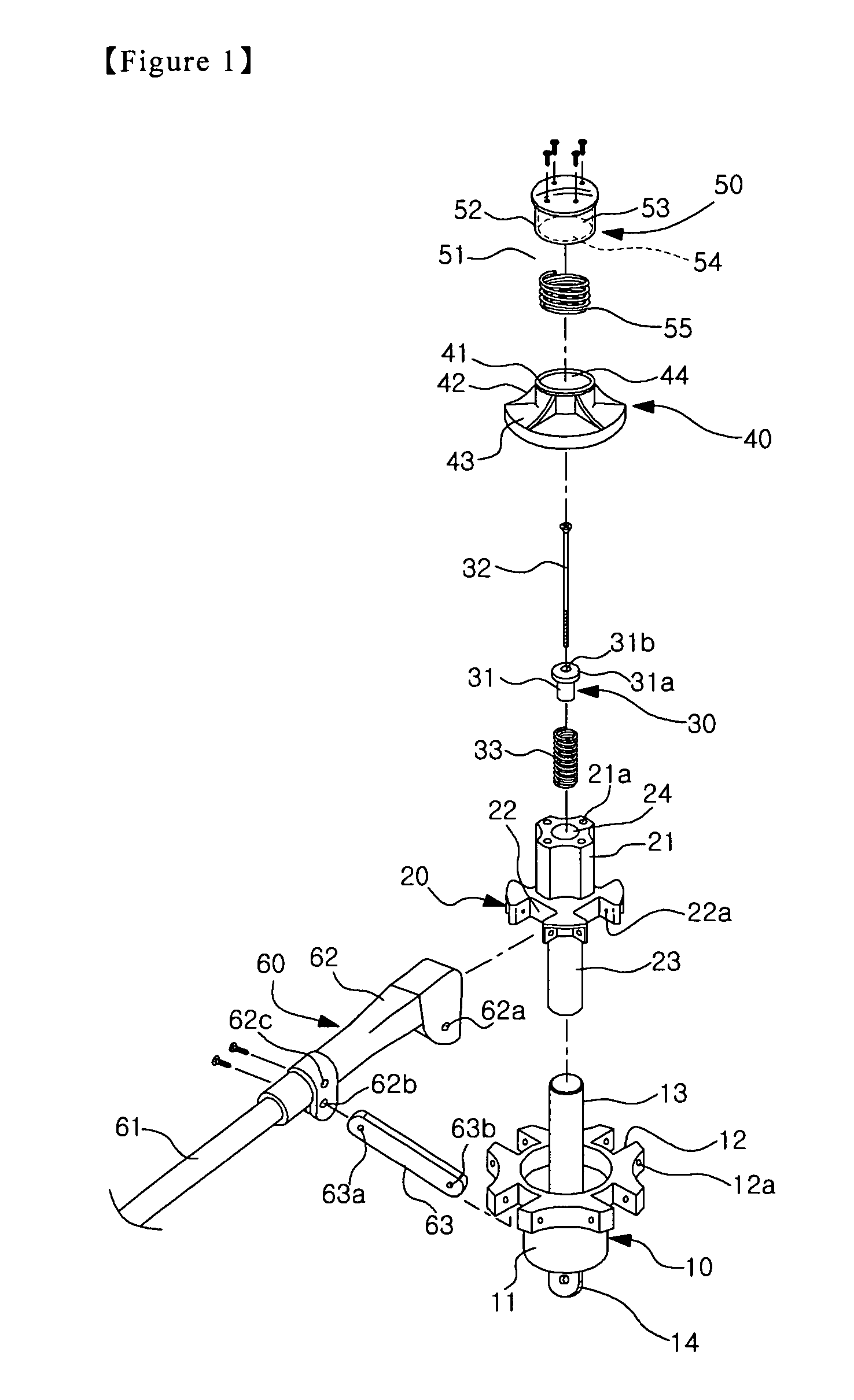

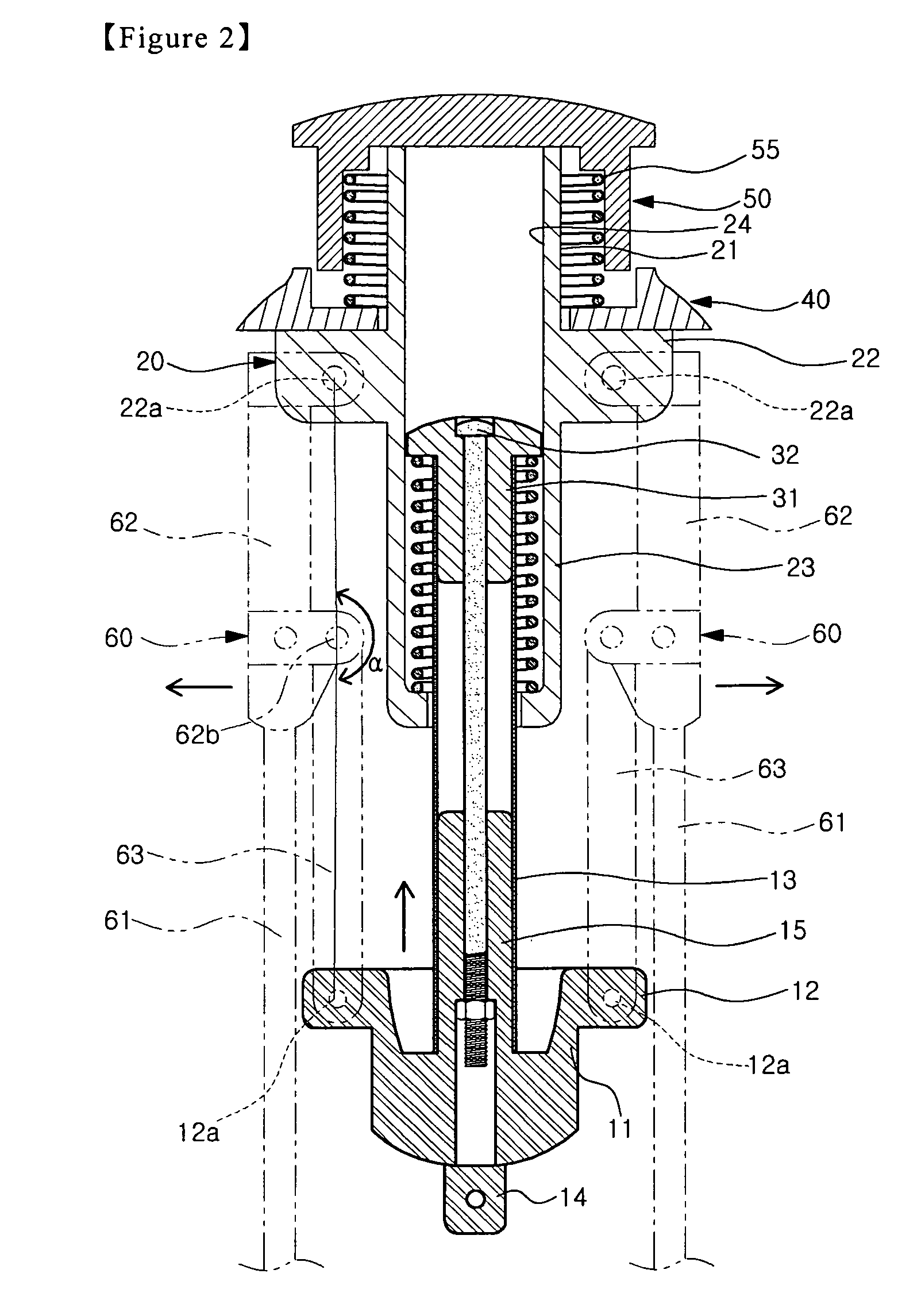

Frame assembly for canopy tent

The present invention discloses a frame assembly for a canopy tent. The frame assembly includes a housing unit with a through hole formed therein, a sliding unit joined to the through hole, a fixing unit immovably joined to this sliding unit, a cover unit joined to the top of the housing unit, a support unit fitted into the outer circumference of said cover unit, an upper connecting pole in which a connecting socket pivotly connected to a engage slot is formed in the upper portion, and a connecting unit one end of which is pivotly connected to the connecting socket and the other end of which is pivotly connected to the sliding unit. Such a present invention provides effects that it is easy to install the canopy tent and it is possible to prevent a finger from being caught during operation thereof and safety accidents due to collision when the fixing unit comes off.

Owner:HAM DONG HWAN

Dressing safety detection method for worker on working site of electric power facility

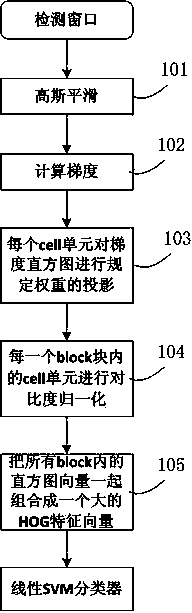

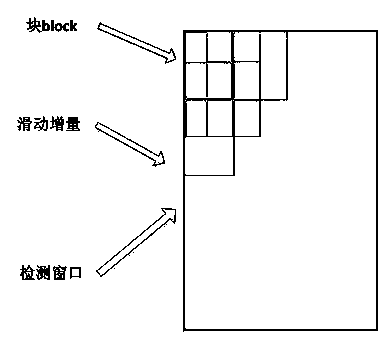

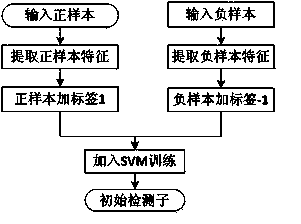

ActiveCN103745226AAvoid safety accidentsEliminate potential safety hazardsData processing applicationsCharacter and pattern recognitionTransformerHistogram of oriented gradients

The invention discloses a dressing safety detection method for a worker on a working site of an electric power facility. An SVM (support vector machine) classifier is trained based on HOG (histogram of oriented gradients) characteristics to identify the worker on the working site of the electric power facility and judge whether the worker is neatly dressed or not based on a worker identification result. The method comprises the following steps of detecting a worker target appearing on the working site of the electric power facility by training a HOG-characteristic-based classifier, and judging whether dressing and equipment of the worker target meet safety requirements on the working site or not based on the identified worker target, mainly comprising safety items such as whether a helmet is worn or not, whether safety clothes are completely worn (without exposed skin) or not and whether the worker on a pole transformer correctly wears a safety belt or not. According to the method, the dressing of the worker can be detected in advance before the worker enters the working site, and an additional worker for supervision is not required to be deployed; in addition, if the dressing of the worker is inconsistent with norms, the worker is early-warned and prompted, so that safety accidents caused by nonstandard dressing are avoided, and potential safety hazards are eliminated.

Owner:STATE GRID CORP OF CHINA +6

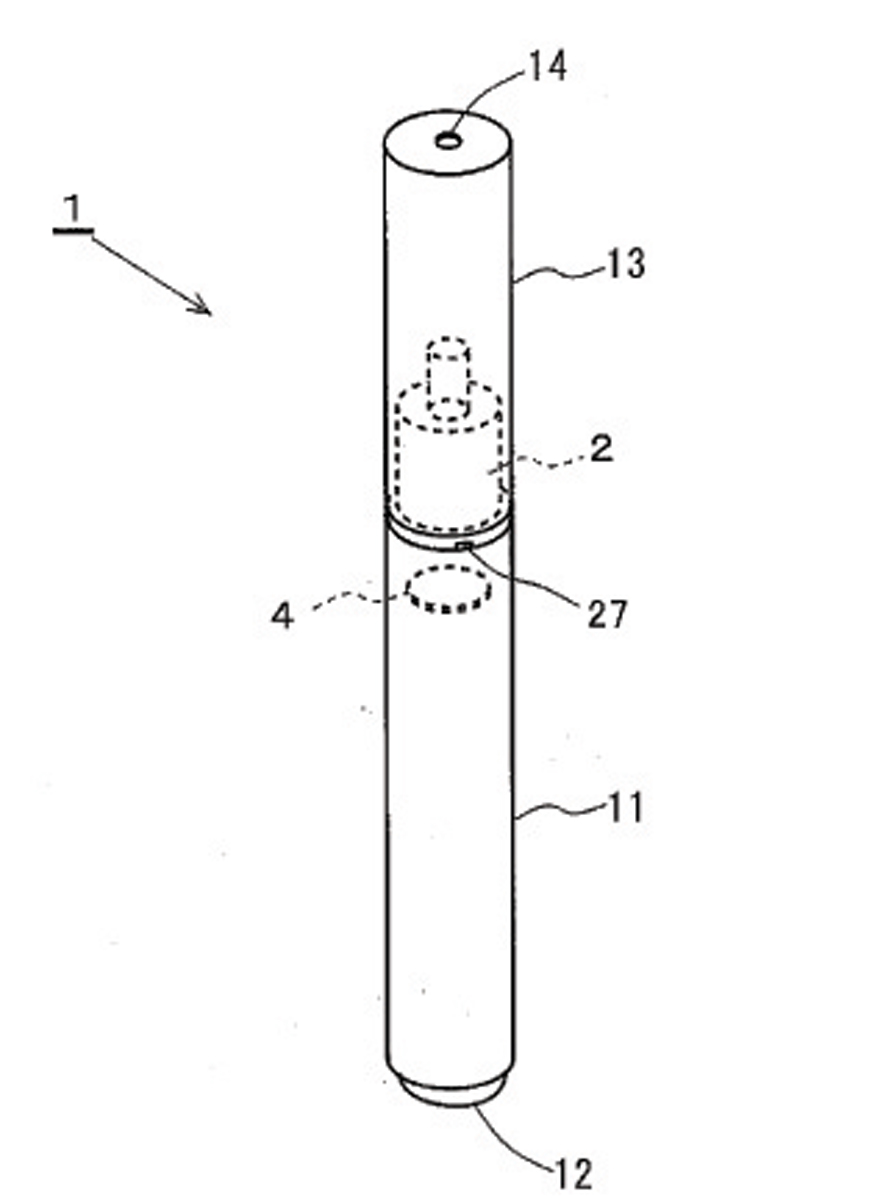

Atomizer for electronic smoking set

InactiveCN101986906AThorough atomizationAdd thermal safety deviceTobacco devicesGlass fiberEngineering

The invention discloses an atomizer for an electronic smoking set, which comprises an atomizer, wherein an oil suction device, a gasification device and a power supply device are arranged on the atomizer, through holes are arranged on a cover body and a pipe body of the oil suction device, glass fiber beams are arranged in the pipe body, the gasification device comprises a pipe type ceramic seat, a sealing cover for separating an inner cavity is arranged in the ceramic seat, through holes are arranged on the sealing cover, a heating chamber is formed between one side of the sealing cover and the cover body of the oil suction device, the glass fiber beams extending out of the cover body are accommodated in the heating chamber, heating wires are wound and arranged on the glass fiber beams at the place, a protecting device is arranged on the other side of the sealing cover positioned at outlets of the through holes, one end of the protecting device is connected with the heating wires, and the other end is connected with the power supply device. The traditional mode from nickel screen oil suction to glass fiber wire heating is changed, and the direct oil suction by the glass fiber wires is adopted, so that the atomization is more thorough. A temperature protecting device is added, when the temperature of the atomizer per se reaches 85 DEG C, a circuit can be automatically shut off, thus various safety accidents caused by high temperature can be prevented.

Owner:日本JBS株式会社

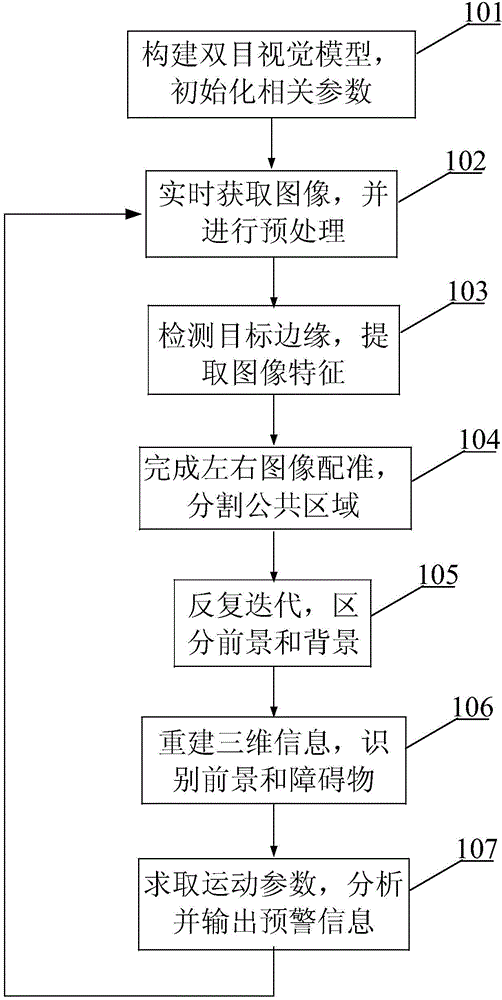

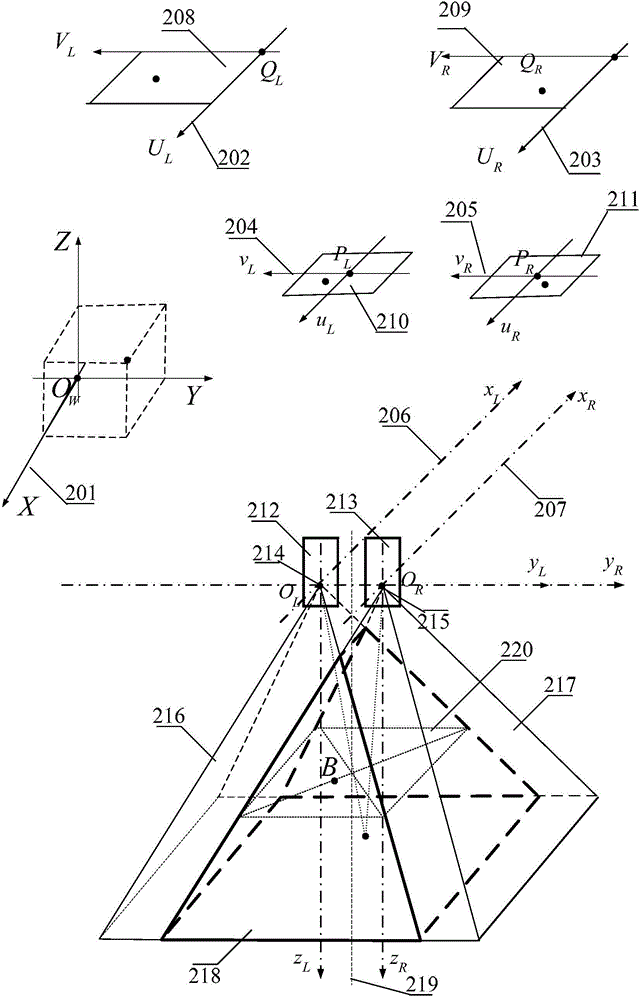

Crane barrier monitoring and prewarning method and system based on binocular vision

InactiveCN103559703ASolving the problem of collision preventionIncrease the level of automationImage analysis3D modellingQuality controlMotion parameter

The invention discloses a crane barrier monitoring and prewarning method and system based on binocular vision. The method includes the steps that a binocular vision model is established, and relevant parameters are initialized; images are acquired in real time and preprocessed; target edges are detected, and the characteristics of the images are extracted; the left images and the right images are registered, and a common area is segmented; iteration is repeatedly conducted, and foregrounds and backgrounds are distinguished; three-dimensional information is rebuilt, and the foregrounds and barriers are recognized; motion parameters are resolved, and prewarning information is analyzed and output. According to the crane barrier monitoring and prewarning method and system, a binocular vision system is adopted, the working environment of a crane is monitored in real time, the problem of preventing collision of the crane is effectively solved, and the system has the advantages of being high in efficiency, moderate in accuracy, simple in structure, low in cost, and very suitable for online, non-contact product detection and quality control on a manufacturing site.

Owner:CENT SOUTH UNIV

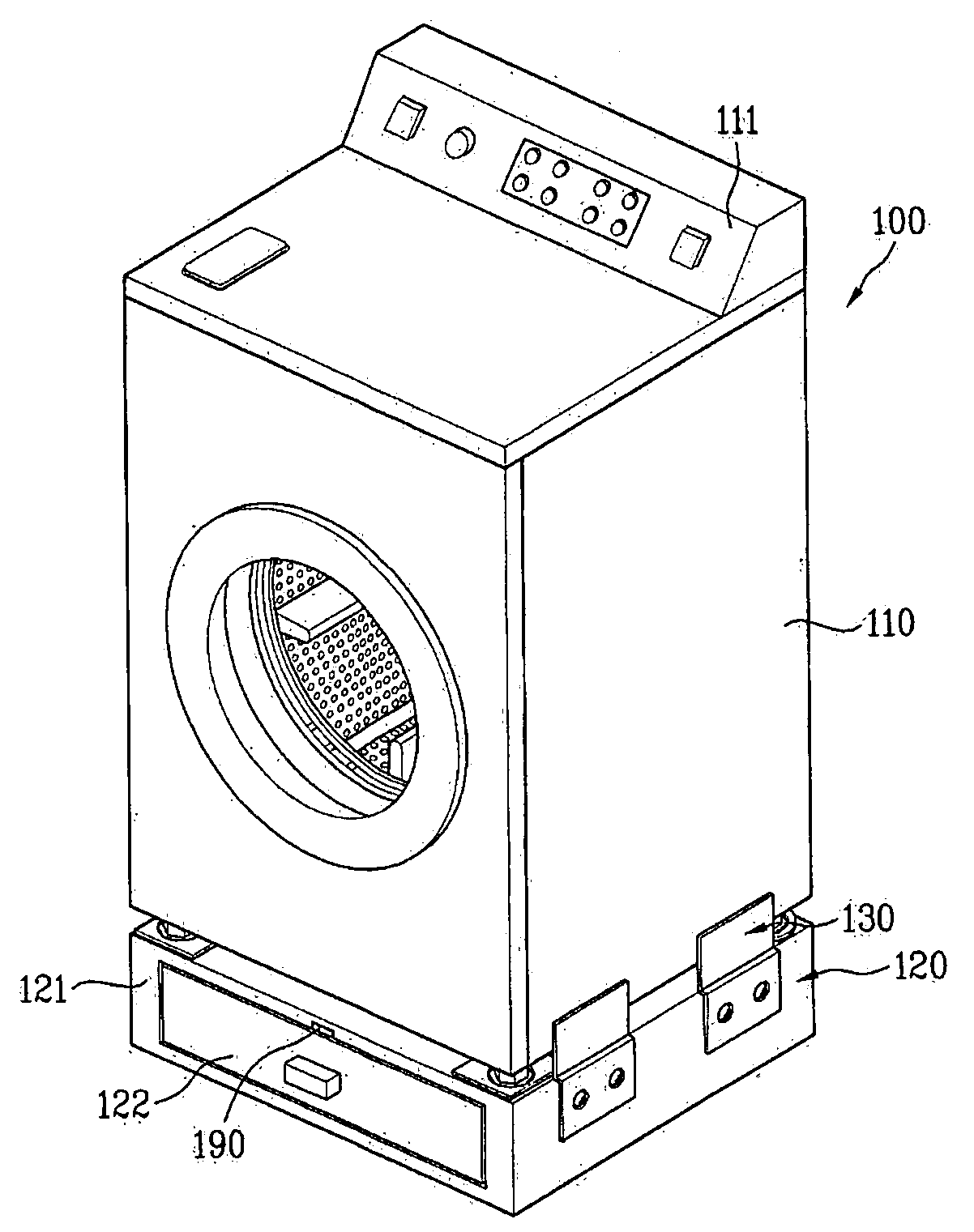

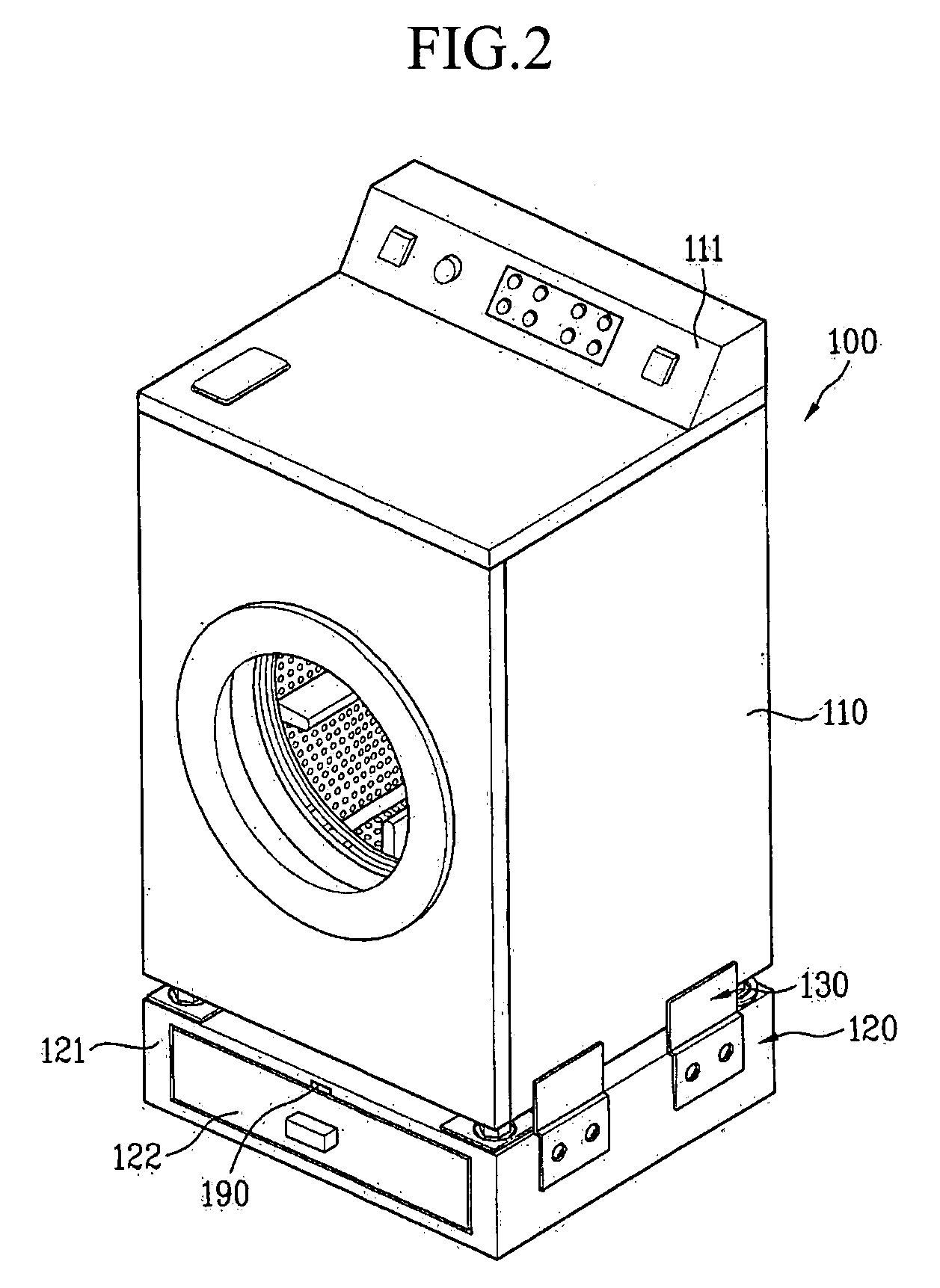

Auxiliary dryer and complex laundry machine including the same

InactiveUS20080053166A1Avoid safety accidentsSave energyTextile treatment machine partsOther washing machinesEngineeringLaundry

An auxiliary dryer and a complex laundry machine are disclosed, by which a laundry machine having a relatively large size can be conveniently operated to save energy in a manner of handling a small laundry and the like without out driving the laundry machine. The present invention includes a body having a laundry accommodating part for accommodating a laundry therein, a hot air supplying means provided within the body to supply hot air to the laundry accommodating part, and a safety means for preventing a safety accident from being caused to a user by the hot air supplying means.

Owner:LG ELECTRONICS INC

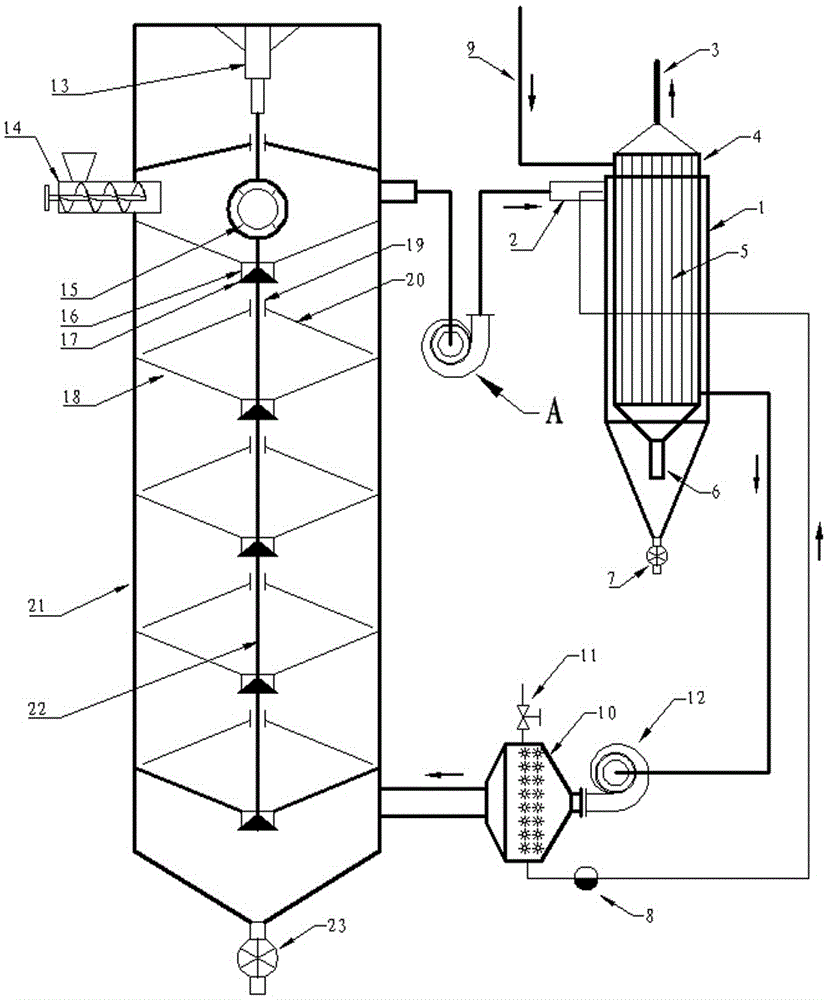

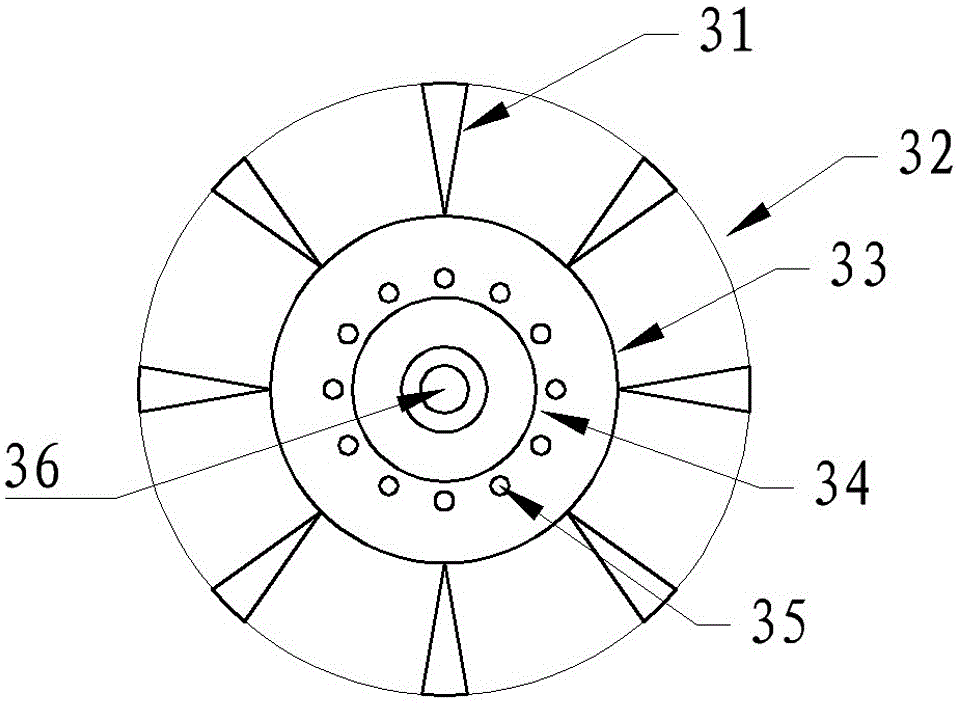

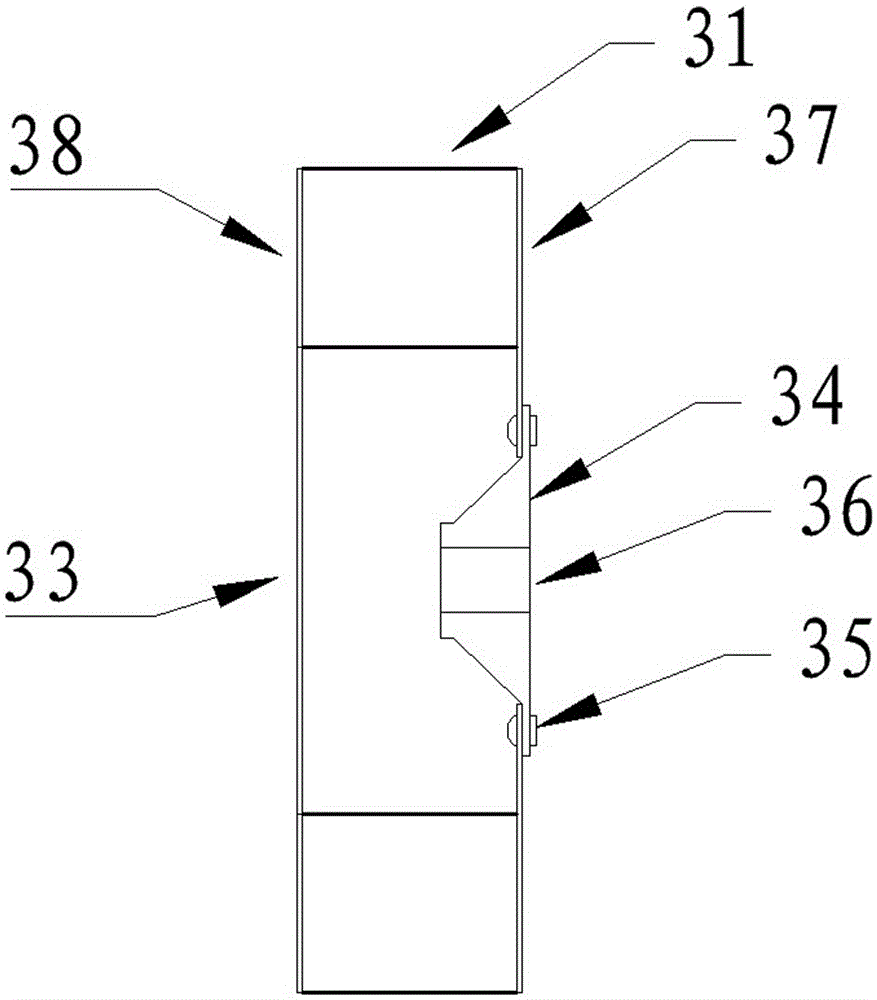

Hot-air drying machine capable of utilizing waste heat and achieving penetrating countercurrent fluidization

ActiveCN105021012AReduce equipment investmentImprove work efficiencyDrying gas arrangementsImpellerWhirlwind

The invention discloses a hot-air drying machine capable of utilizing waste heat and achieving penetrating countercurrent fluidization. The upper portion of a drying tower is connected with an induced draft fan, and the induced draft fan is connected with a cyclone dust removing waste heat efficient recoverer formed by a tube-type heat exchanger and a cyclone dust collector in an overlapped manner in the tangent direction and then is emptied; the air inlet end of the shell side of the tube-type heat exchanger is communicated with the atmosphere, and the air outlet end of the shell side of the tube-type heat exchanger is connected with the lower portion of the drying tower through an air blower and a steam finned heater; and an impeller of the induced draft fan is of a structure that blades are in a hollow and wedged shape, and the contour line of the appearance of the induced draft fan is an involute. According to the hot-air drying machine capable of utilizing the waste heat and achieving the penetrating countercurrent fluidization, creative integration is conducted on waste heat utilization and dust removal, the cyclone dust removing waste heat efficient recoverer is designed out, the equipment input is reduced, and the work efficiency is improved; and due to the fact that sieve mesh cone covers, sieve mesh cone discs, discharging tubes, a stretching vibration transmission shaft and conical plugs are arranged, penetrating, countercurrent, boiling and fluidization drying of materials are exquisitely and perfectly achieved, more energy is saved, the drying quality is higher, the power consumption of the induced draft fan is lower, and the application prospect is wider.

Owner:常州新舜干燥工程有限公司

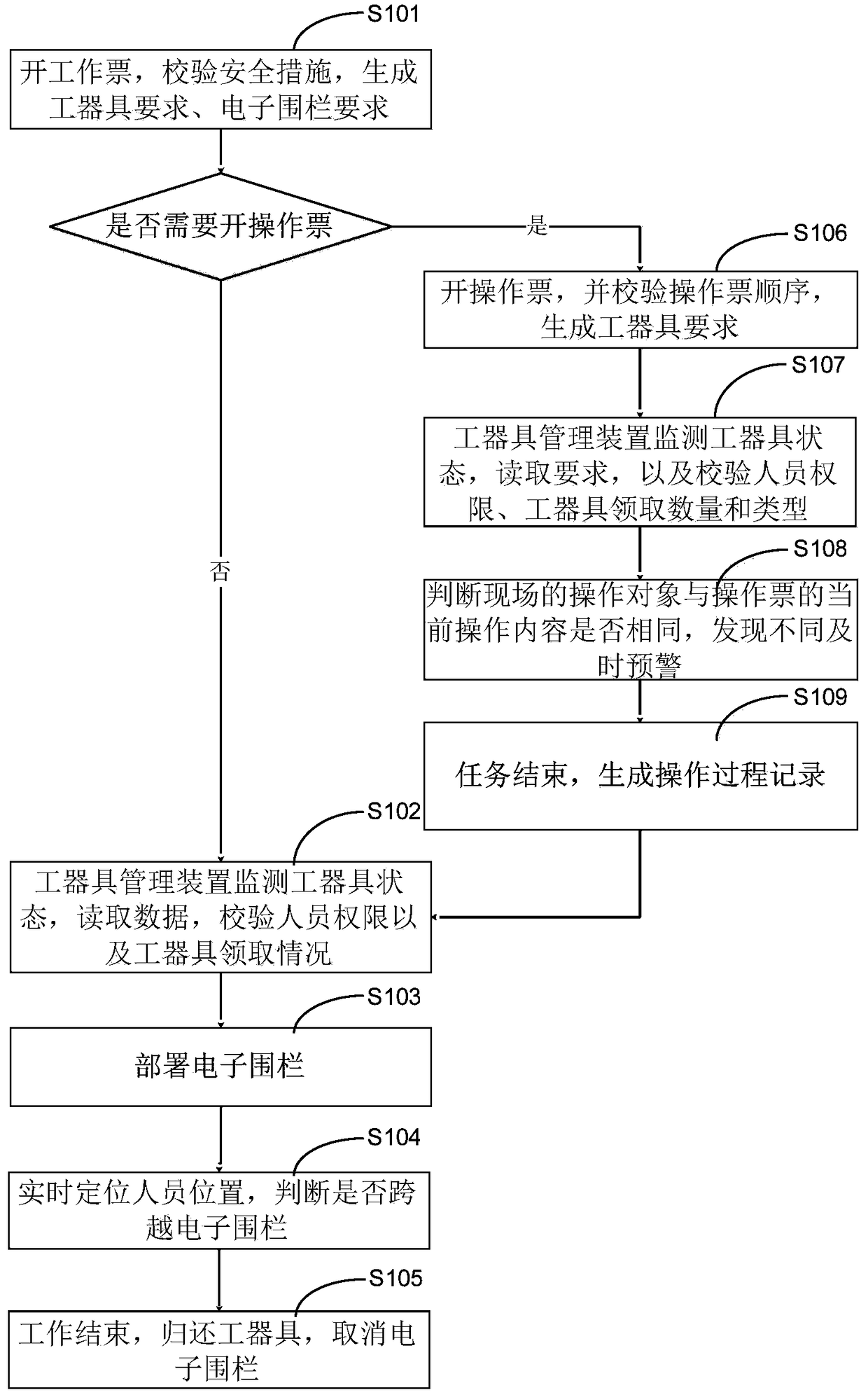

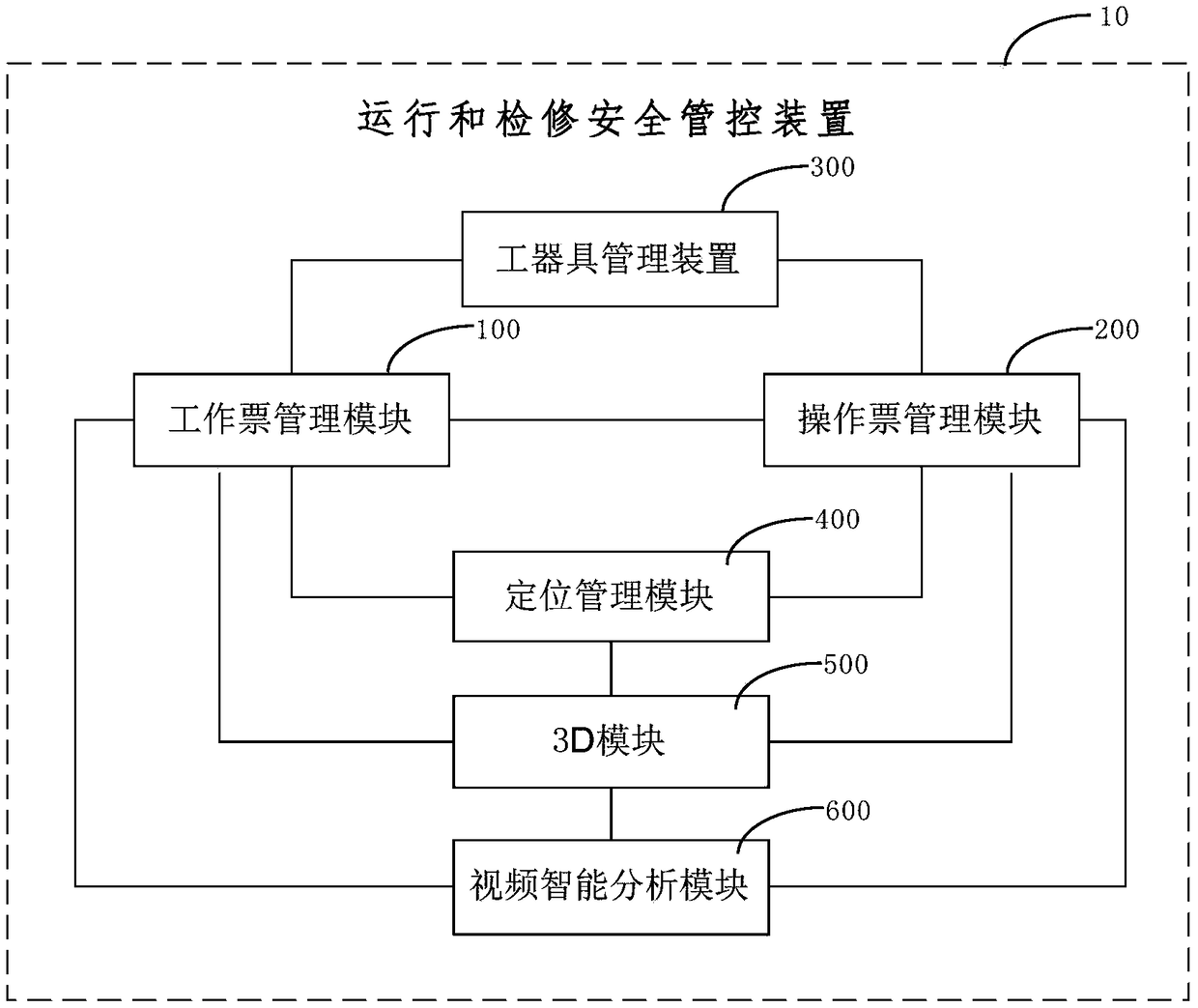

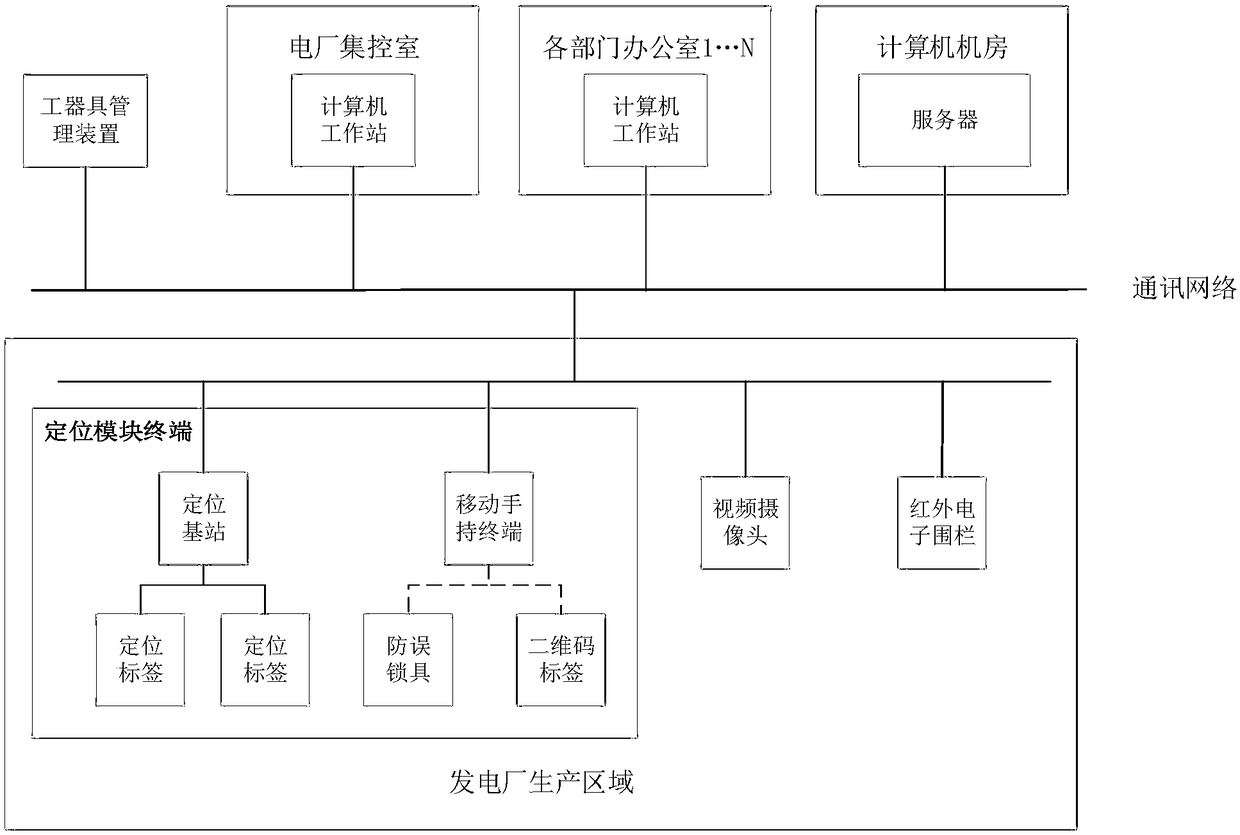

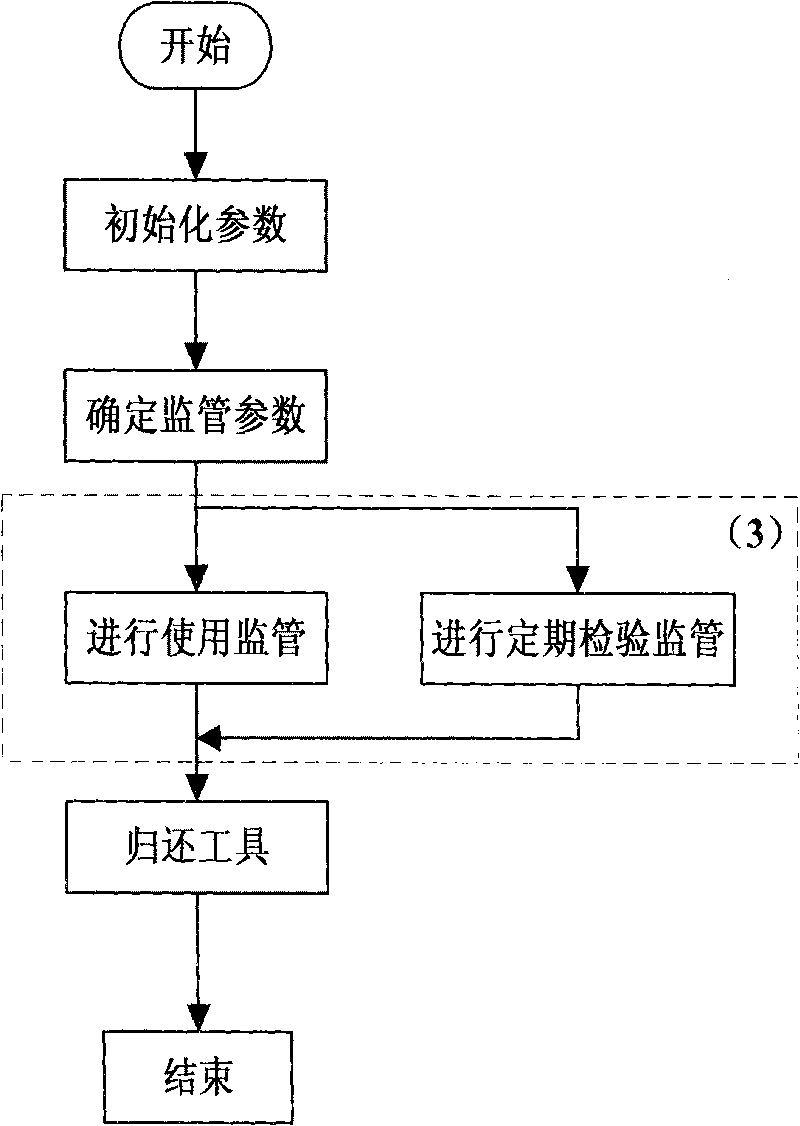

Operation and maintenance safety control device, system and method

ActiveCN108960554AComprehensive understanding of comprehensive dynamic informationReal-time grasp of production process risksResourcesSafety controlSecurity Measure

The present invention provides an operation and maintenance safety control device, system and method. A work ticket and an operation ticket of a main production task are taken as a main line. The total process control method from a billing source to execution ending comprises the following steps of: making out a work ticket, verifying a safety measure item, generating a tool requirement comprisingthe number, the type and the personnel access, and generating an electronic fence requirement comprising the deployment position, the range, the time and the personnel access; monitoring a safety tool state by a tool management device, reading the tool requirement, and verifying a tool receiving tool comprising the number, the type and the personnel access of the tool; deploying the electronic fence according to the electronic fence requirement; locating the personnel position in real time, determining the personnel access passing through the electronic fence, wherein alarm for prompting is performed if authorized officers pass through the electronic fence, or else, the alarm is not performed; finishing the work, and cancelling the electronic fence.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

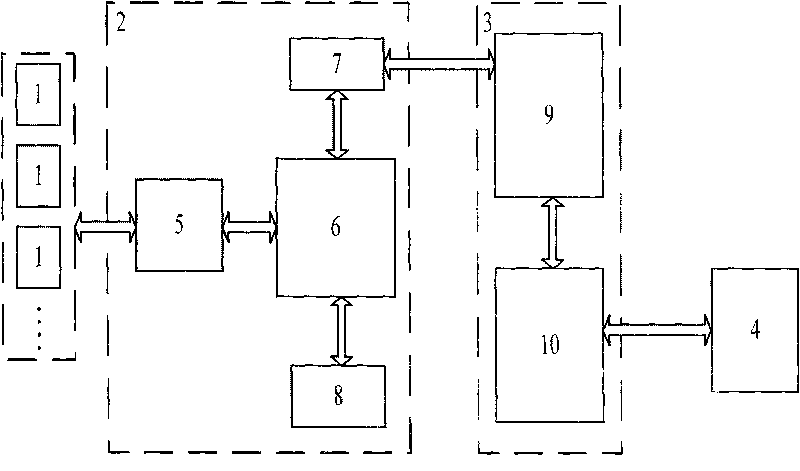

System and method thereof for online monitoring and managing security tools and instruments of transformer substation

InactiveCN101692587AImprove safety management levelEasy to operateData processing applicationsCircuit arrangementsTransformerElectric power system

The invention discloses a system and a method thereof for online monitoring and managing security tools and instruments of a transformer substation, which relate to the security equipment management of a power system. The system in the invention mainly comprises electronic tags, an electronic automatic identification device, a management centre server and a monitoring computer. The method in the invention utilizes the system in the invention to perform online monitoring and management through a program. The system and the method in the invention have the characteristics of ensuring the good technical conditions, sufficient quantity, standard use and automatic process management of the security tools and instruments, realizing remote online monitoring and management and having high management level and the like, and can be widely applied to the management over the security tools and instruments of the transformer substation, a distribution station, a power plant and the like of the power system, in particular to the management over the security tools and instruments of the transformer substations and the distribution stations which are unattended.

Owner:CHONGQING UNIV

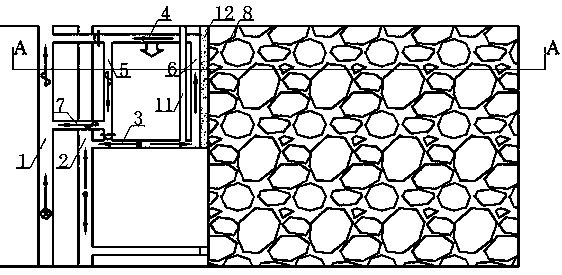

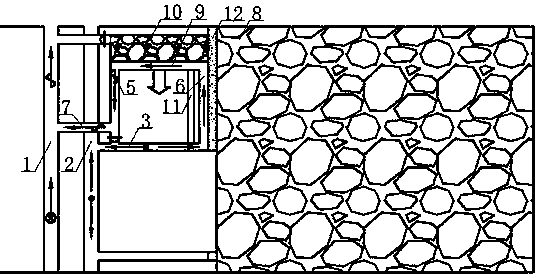

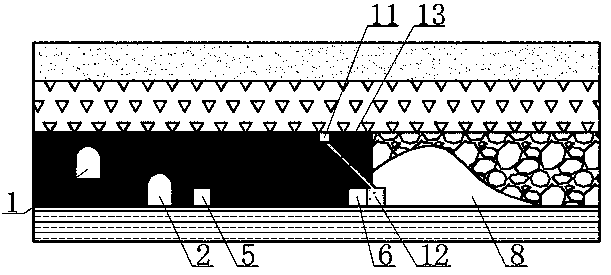

Method for second mining mining-stopping line coal column in super thick coal layer

ActiveCN107313778ARecovery is safe and reliableAvoid safety accidentsUnderground miningSurface miningEconomic benefitsEngineering

The invention discloses a method for second mining a mining-stopping line coal column in a super thick coal layer. The method comprises the following steps that (1), positions of a coal column second mining working surface transporting gate trough and a rail gate trough are stimulated; (2) comprehensive probing is conducted on an original working surface goaf area where the super thick coal layer mining-stopping line coal column is located, and potential safety hazard is removed; (3) a roadway in the propelling direction of the coal column second mining working surface is dug at the upper part of the super thick coal layer, and the roadway is filled; (4) a coal column second mining working surface mining returning roadway and a affiliated oblique roadway are dug, so that the coal column second mining working surface mining returning roadway and the affiliated oblique roadway form a completed producing system, and the coal column second mining working surface is arranged; (5) a bottom plate of the roadway is drilled from top to bottom for using as a filled pipeline; (6) filling paste is prepared, the filling paste is evenly injected into one side, close to the original working surface goaf area, of the transporting gate trough along the filled pipeline; and (7) comprehensive mining is conducted on the coal column second mining working surface. According to the method for second mining the mining-stopping line coal column in the super thick coal layer, the compressed coal amount is reduced, waste of coal resources is avoided, the economic benefits of enterprises are improved, and the service life of mines and mining areas is prolonged.

Owner:TAIYUAN UNIV OF TECH

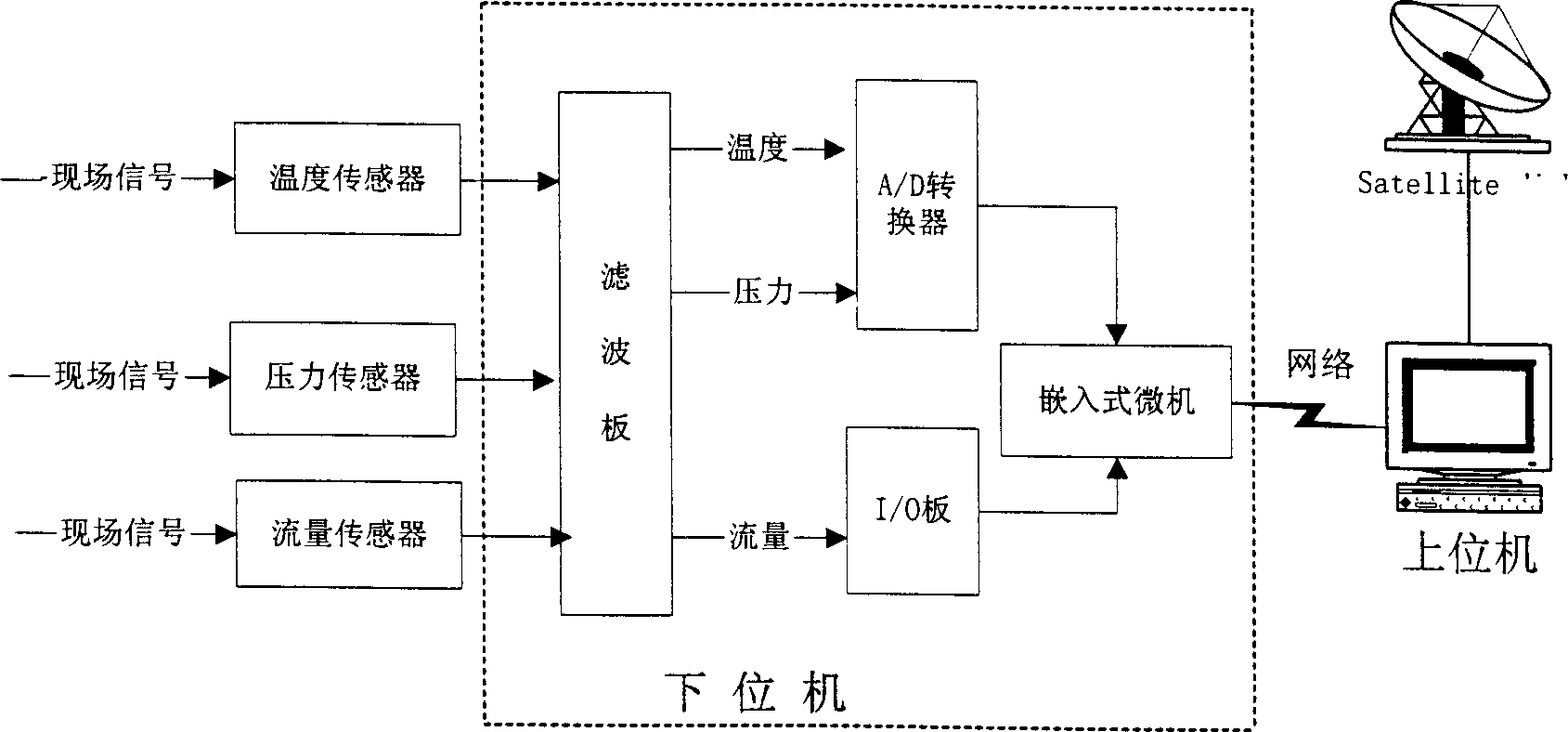

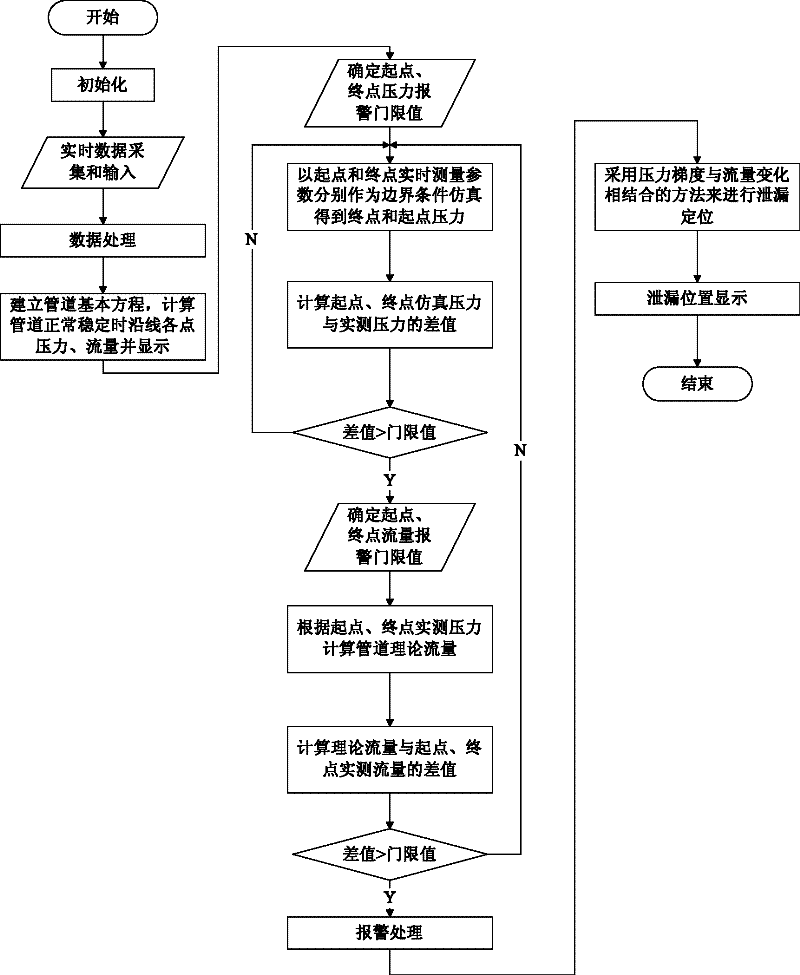

Compressed air system and intelligent pipe network leakage detecting method for same

ActiveCN102563362AHigh leak detection accuracyHigh sensitivityPipeline systemsFalse alarmTubular network

The invention relates to technology of fault diagnosis, and aims to provide a compressed air system and an intelligent pipe network leakage detecting method for the same. The intelligent pipe network leakage detecting method includes that signals of the pressure, the temperature and the flow of compressed air are acquired by a sensor mounted on a terminal delivery pipe network, and are transmitted to a low-pass filter circuit, received signals are coarsely filtered and are transmitted back to an upper computer by an A / D (analog / digital) conversion circuit via a lower computer, the upper computer obtains change relation of flow parameters along with time and the length of a pipeline according to actually measured data of a starting point and actually measured data of a finish point, and then a pipeline leakage detection function is realized by means of comparing theoretic output with actual output. The intelligent pipe network leakage detecting method adopting detection technology is high in leakage detection accuracy which is higher than 95 degrees, false alarm rate is lower than 3%, detection time is shorter than 55 seconds, sensitivity is high, and leakage quantity higher than 1.5% of delivery quantity of the pipeline can be detected. In addition, when the intelligent pipe network leakage detecting method is used for positioning a leakage point, precision is high, positioning precision error is lower than 1% of the total length of the pipeline, shutdown of a factory is avoided by means of online detection, and labor intensity of manual detection is reduced by means of online detection.

Owner:HANGZHOU ZETA TECH

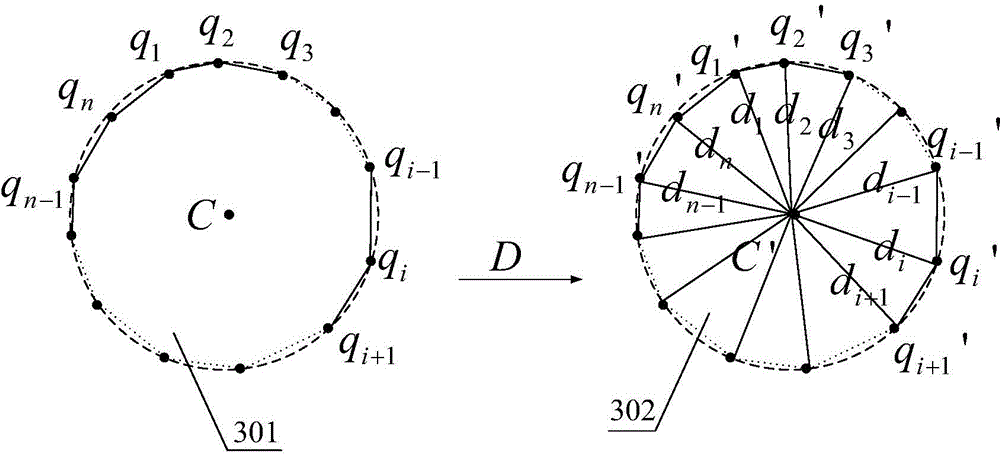

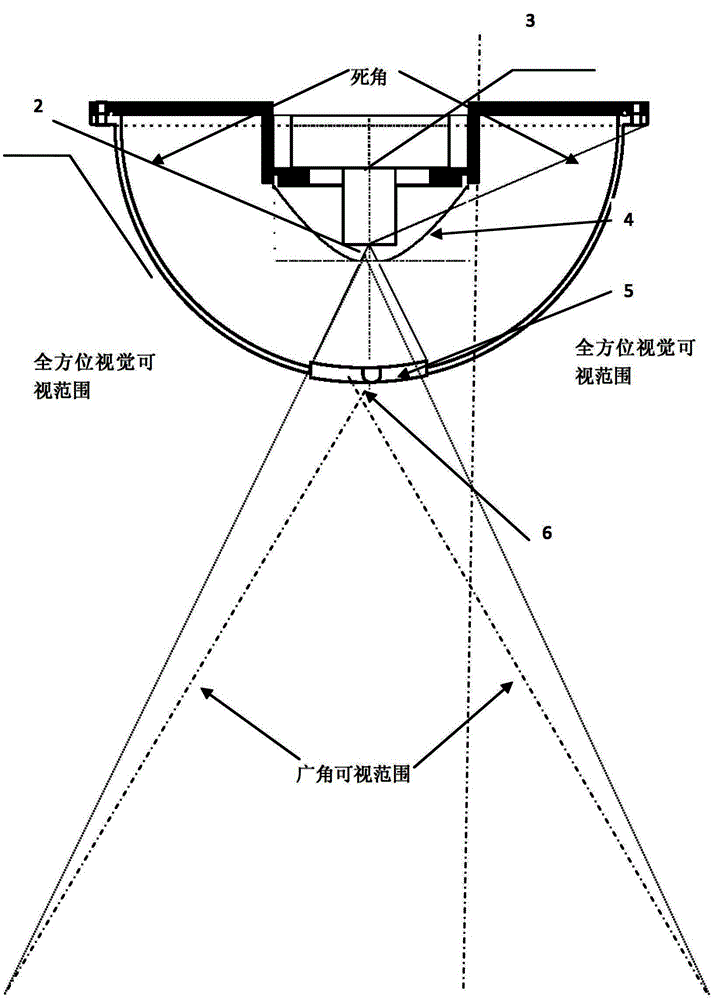

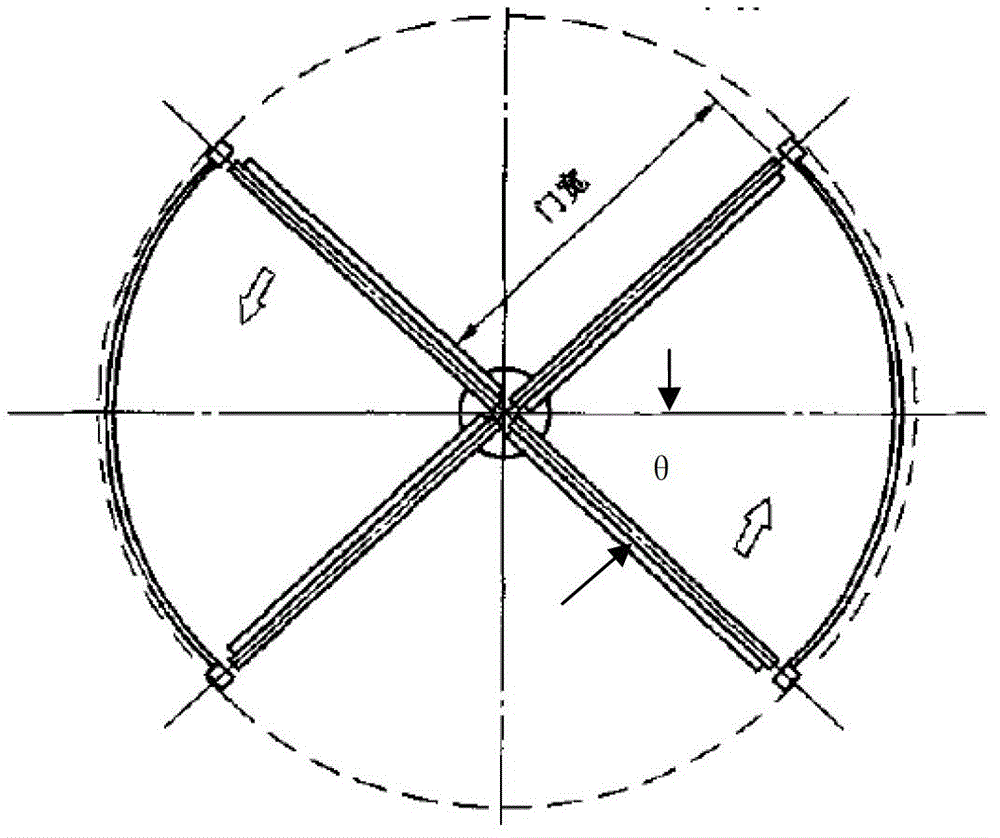

Omnidirectional computer vision-based safe and energy-saving control device for pedestrian automatic door

ActiveCN102747919AImprove the level of intelligent controlFriendly controlCharacter and pattern recognitionPower-operated mechanismAutomatic controlElectric machinery

The invention discloses an omnidirectional computer vision-based safe and energy-saving control device for a pedestrian automatic door. The control device comprises an omnidirectional vision sensor (ODVS) without dead corners, a microprocessor, a controller, a voice player and an automatic door, wherein the omnidirectional vision sensor is used for acquiring the video information of a full view around the automatic door and is provided with a network interface; the microprocessor is used for detecting the status of the automatic door and the behaviors of pedestrians; the controller is used for controlling the automatic door to be opened or closed or rotated; the voice player is used for performing a safety prompt; the automatic door is used for the pedestrians at the opening position of a building to pass; the ODVS is connected with the microprocessor through the network; the microprocessor is connected with the controller; the controller is used for controlling the action of an automatic door motor; the voice player is connected with the microprocessor through a voice interface; and the ODVS is arranged in the middle of the top part of the automatic door. The omnidirectional computer vision-based safe and energy-saving control device for the pedestrian automatic door automatically controls the automatic door to be opened through analyzing the behaviors of the pedestrians according to the behavioral intentions of the pedestrians. According to the behaviors of the pedestrians and the status of the automatic door, the safety accident that the pedestrians are rolled by the automatic door is avoided, and the goal that the safety control, the energy saving property control and the comfort control of the automatic door are highly fused is achieved.

Owner:ZHEJIANG UNIV OF TECH

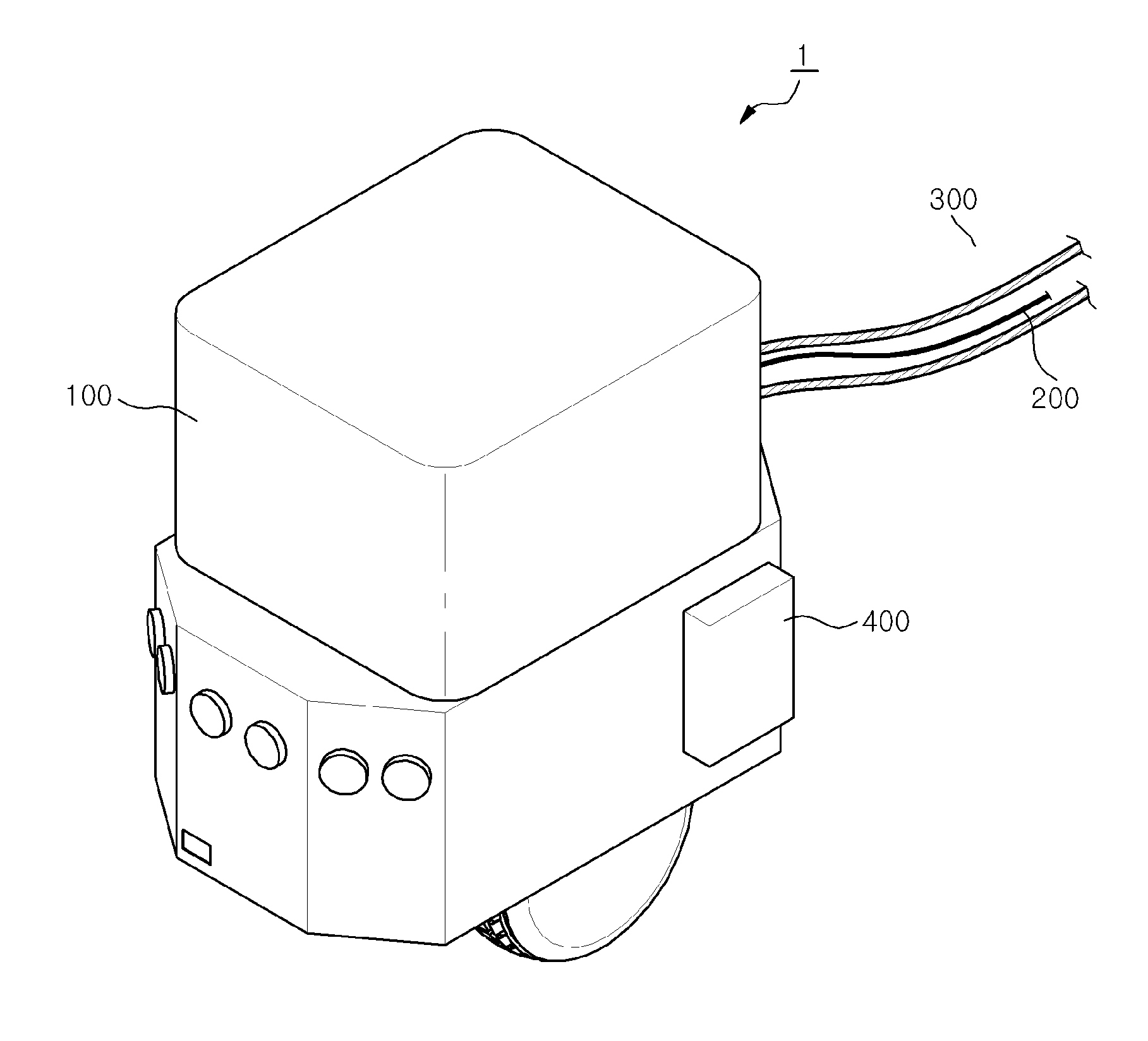

Mobile robot with returning mechanism

Owner:ELECTRONICS & TELECOMM RES INST

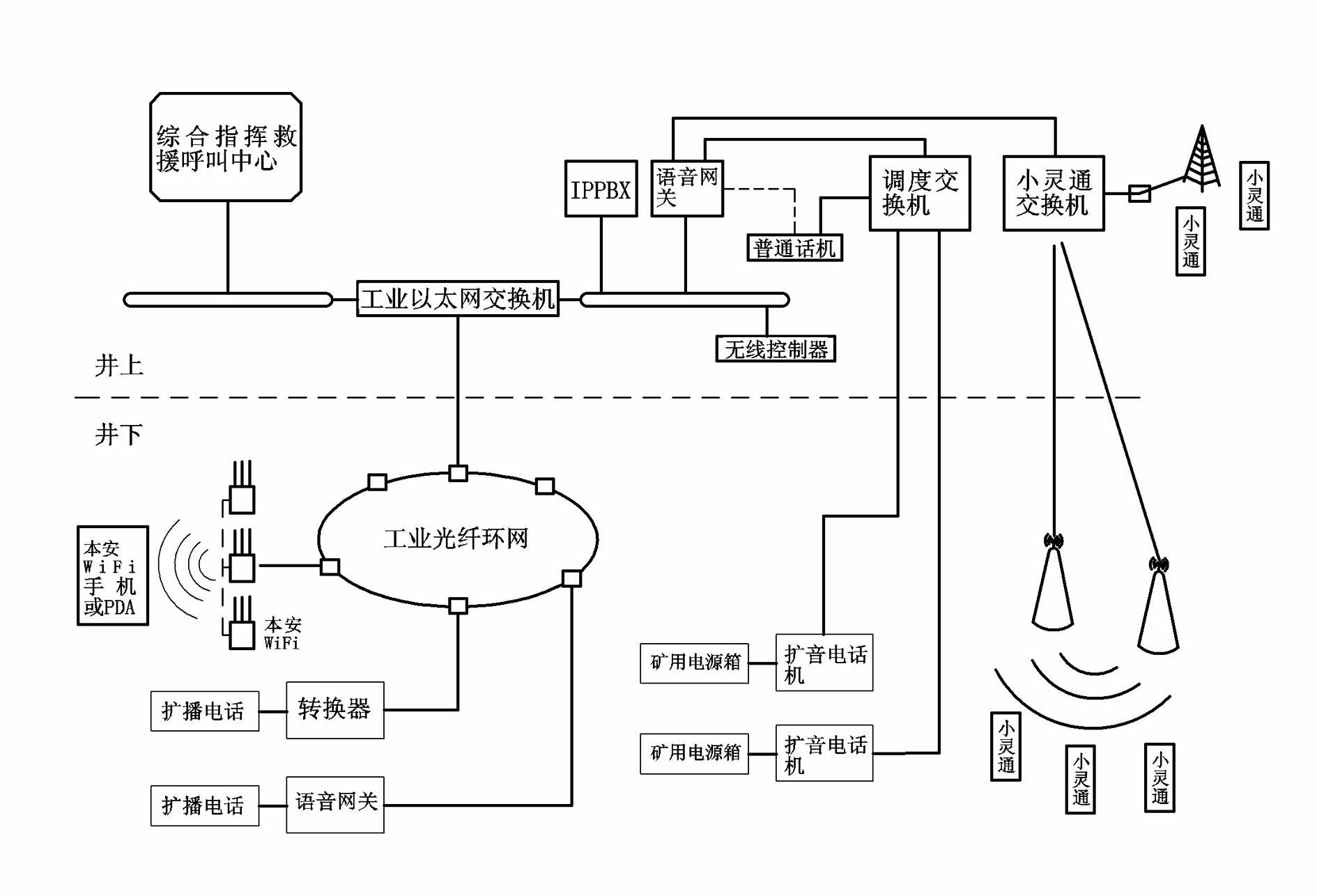

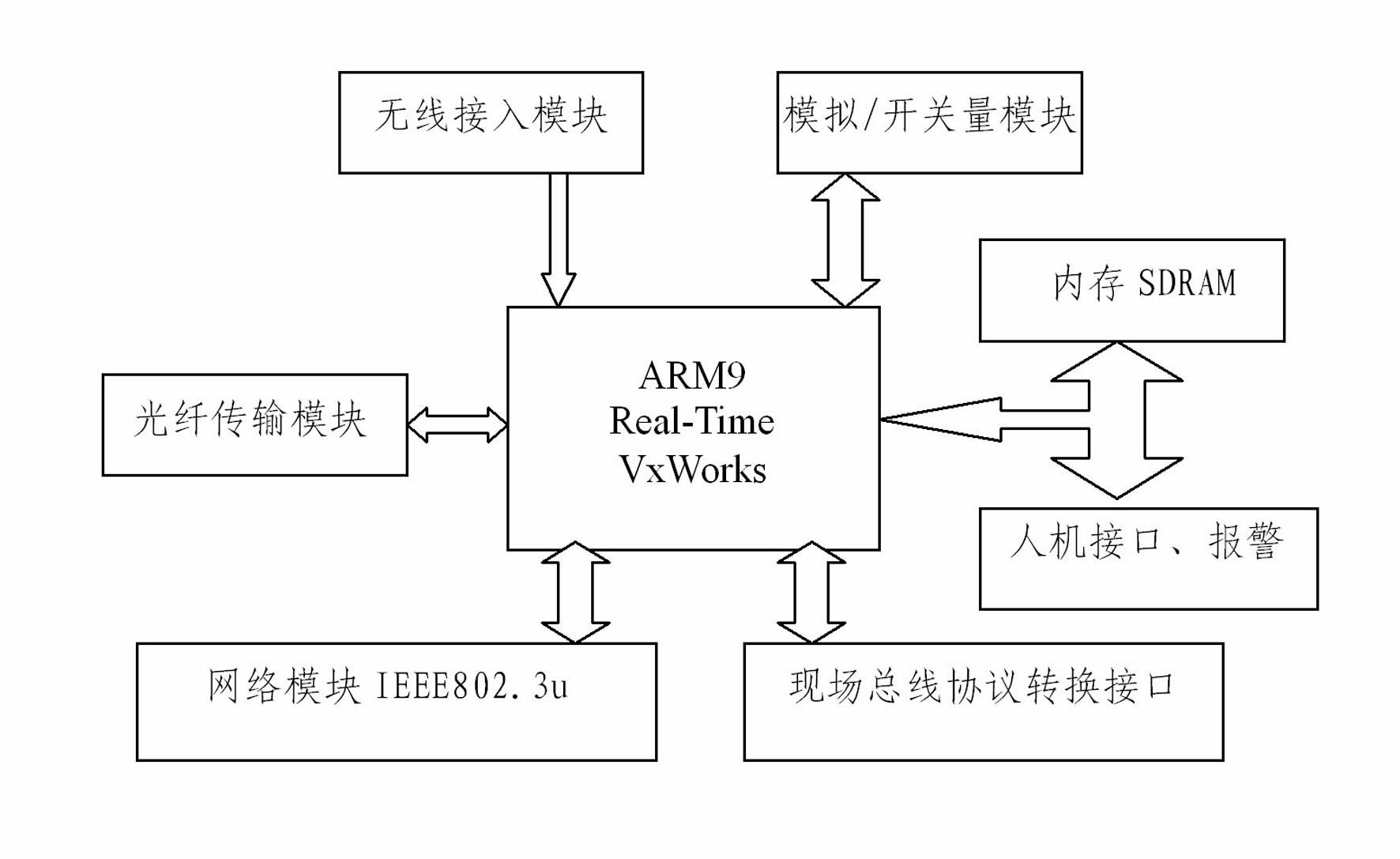

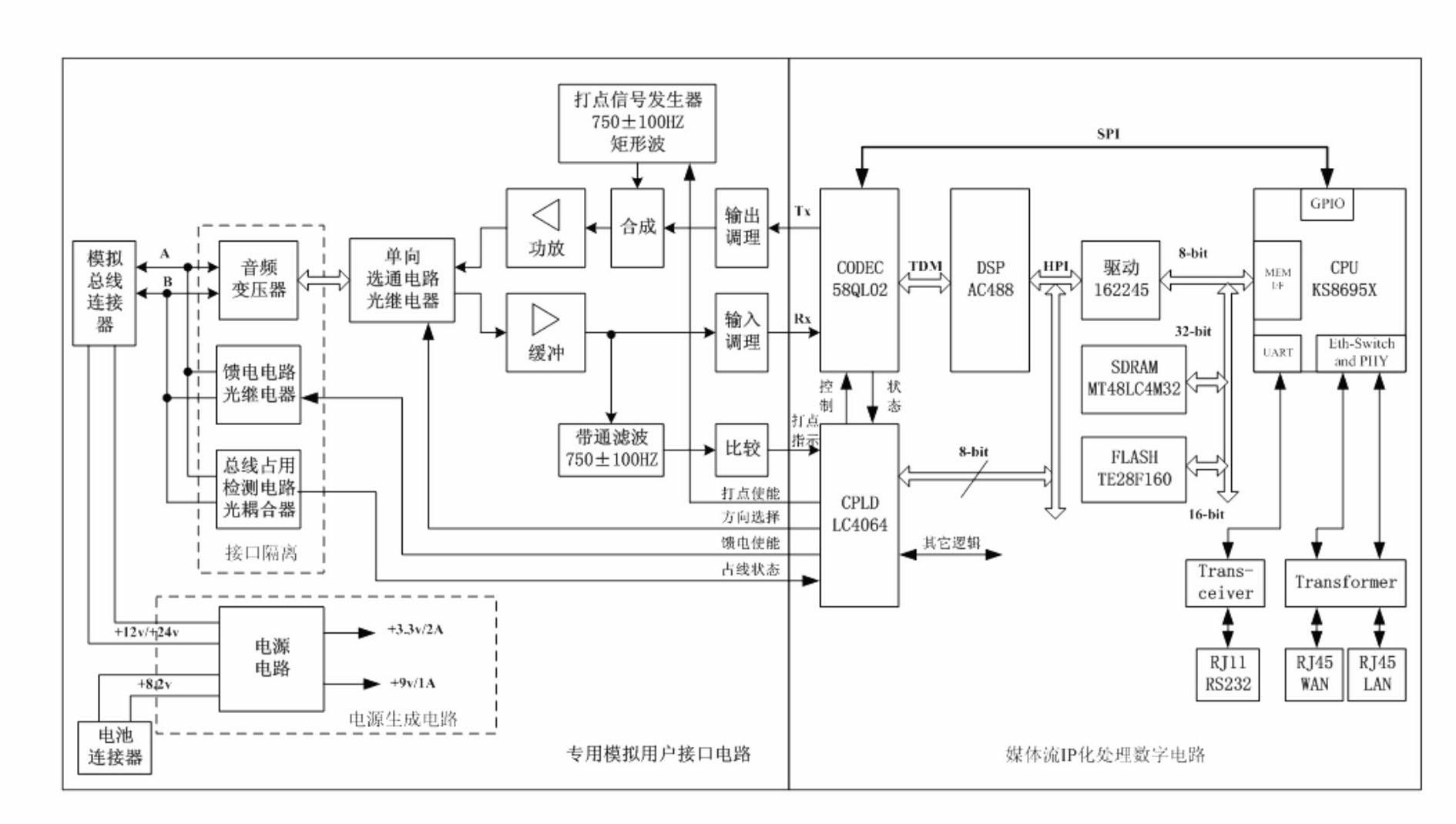

Mine emergency communication system

InactiveCN102427450ACommand in timeAvoid safety accidentsInterconnection arrangementsMining devicesConvertersTelephone switchboard

The invention relates to a mine communication system, in particular to an emergency communication support system of coal mines. The emergency communication support system comprises an integrated command rescue call center server, an IP (Internet Protocol) telephone switchboard and an voice gateway, which are interactively connected through Ethernet, wherein the voice gateway is simultaneously connected to a dispatching switchboard, an integrated IP voice access gateway for mine is adopted as the voice gateway, a 32-bit embedded microprocessor is adopted for the voice access gateway, a protocol conversion address of the microprocessor is connected with a system interface module, a serial port of the microprocessor is connected with a field bus protocol conversion module, the field bus protocol conversion module is connected with an underground dispatching amplified phone, an MAC (Media Access Control) address of the microprocessor is connected with a network module, and the microprocessor is connected with an Ethernet switchboard through the network module. The microprocessor is provided with a corresponding data interface for connecting an optical fiber transmission module, the microprocessor is accessed to an underground industrial optical fiber ring net through the optical fiber transmission module, and the underground loud-speaking phone is accessed to the underground industrial optical fiber ring net through a converter. According to the mine communication system disclosed by the invention, a difficult problem of the speed bottleneck in the wide-band network underground communication of a mine area is solved, and a way is paved for networking and informatizing of a mine monitoring system.

Owner:ZHENGZHOU SAIJIN ELECTRIC

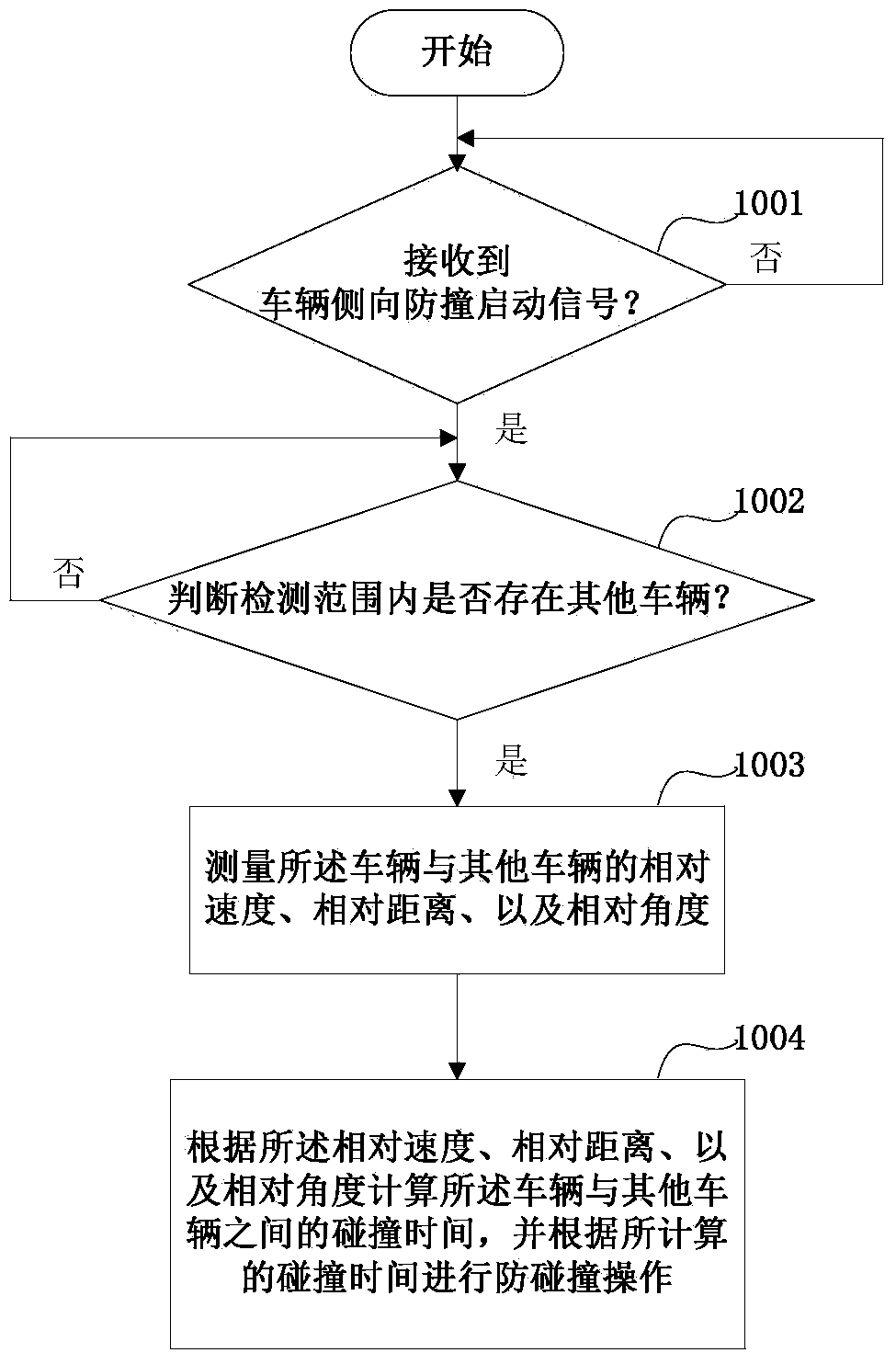

Vehicle lateral collision prevention method, device and system

ActiveCN103909926AImprove securityImprove intelligenceExternal condition input parametersEngineeringCollision prevention

The invention discloses a vehicle lateral collision prevention method, device and system. The method includes: receiving a vehicle side collision prevention start signal; when the vehicle side collision prevention start signal is received, judging whether other vehicles are in a detection range or not; when other vehicles are in the detection range, measuring relative speed, relative distance and relative angle of the vehicle relative to other vehicles; calculating collision time of the vehicle with other vehicles according to the relative speed, relative distance and relative angle, and performing collision prevention operations according to the calculated collision time. The vehicle lateral collision prevention method, device and system has the advantages that safety accidents can be prevented effectively, driving the vehicles is safer and more intelligent, and practical value is high.

Owner:GREAT WALL MOTOR CO LTD

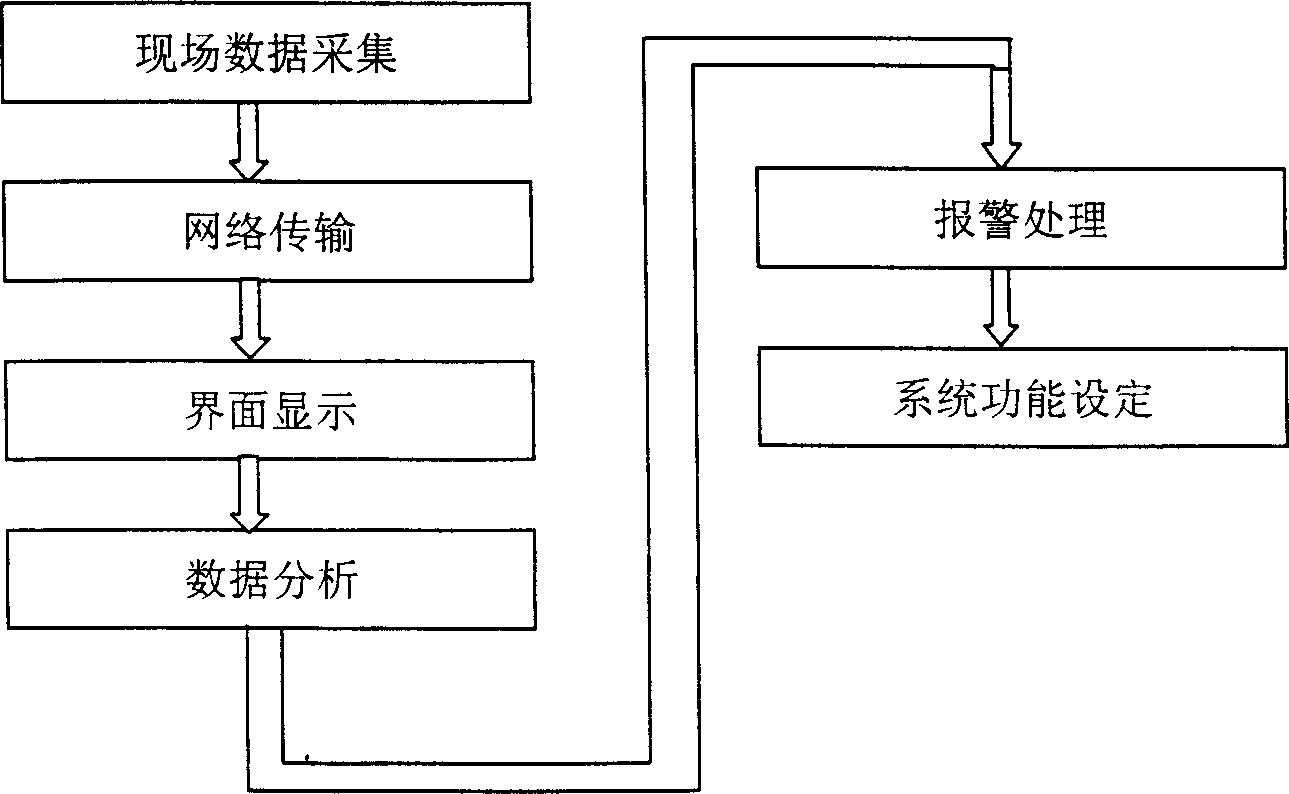

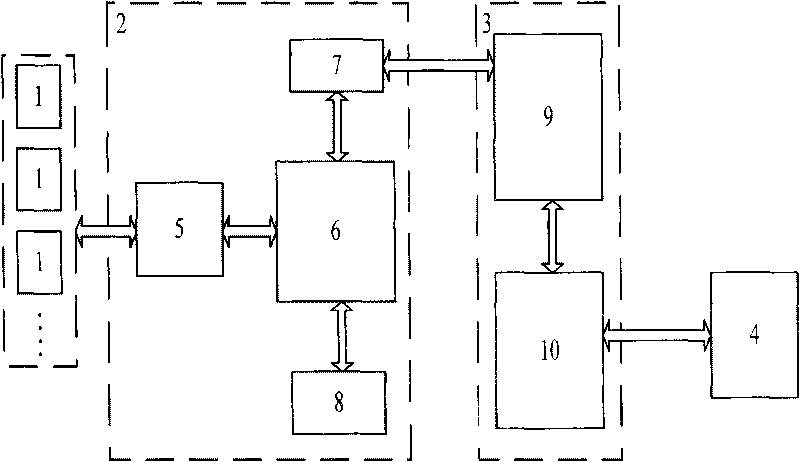

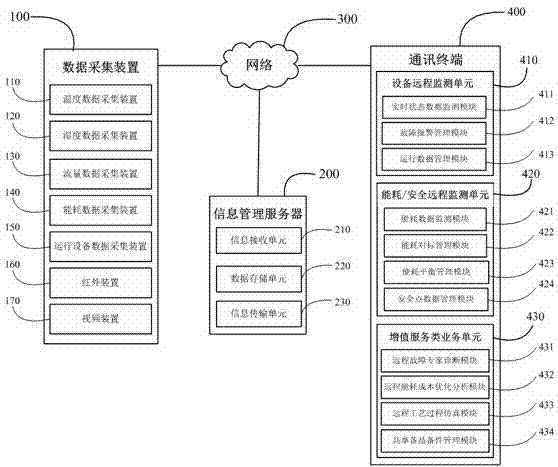

Remote monitoring and controlling system

InactiveCN103034213ATo achieve the effect of energy saving and emission reductionSimple processEnergy industryTotal factory controlMonitoring systemIndustrial equipment

The invention relates to a remote monitoring and controlling system, in particular to a remote monitoring system for industrial equipment. The remote monitoring and controlling system comprises a data collecting device, an information management server, a communication terminal and a network. The data collecting device is used for collecting data of the monitored equipment and transmitting the data to the information management server or the communication terminal. The information management server is used for receiving, storing and processing the data from the data collecting device and transmitting the data to the communication terminal. The communication terminal is used for receiving and displaying the data of the data collecting device and the data of the information management server. The network is used connecting the data collecting device, the information management server and the communication terminal. The remote monitoring and controlling system can not only carry out remote monitoring, failure warning, energy conservation statistics and data analysis to the industrial equipment, but also maintain, repair and preserve the industrial equipment.

Owner:WUHAN BEIDOU RUIHUA TECH

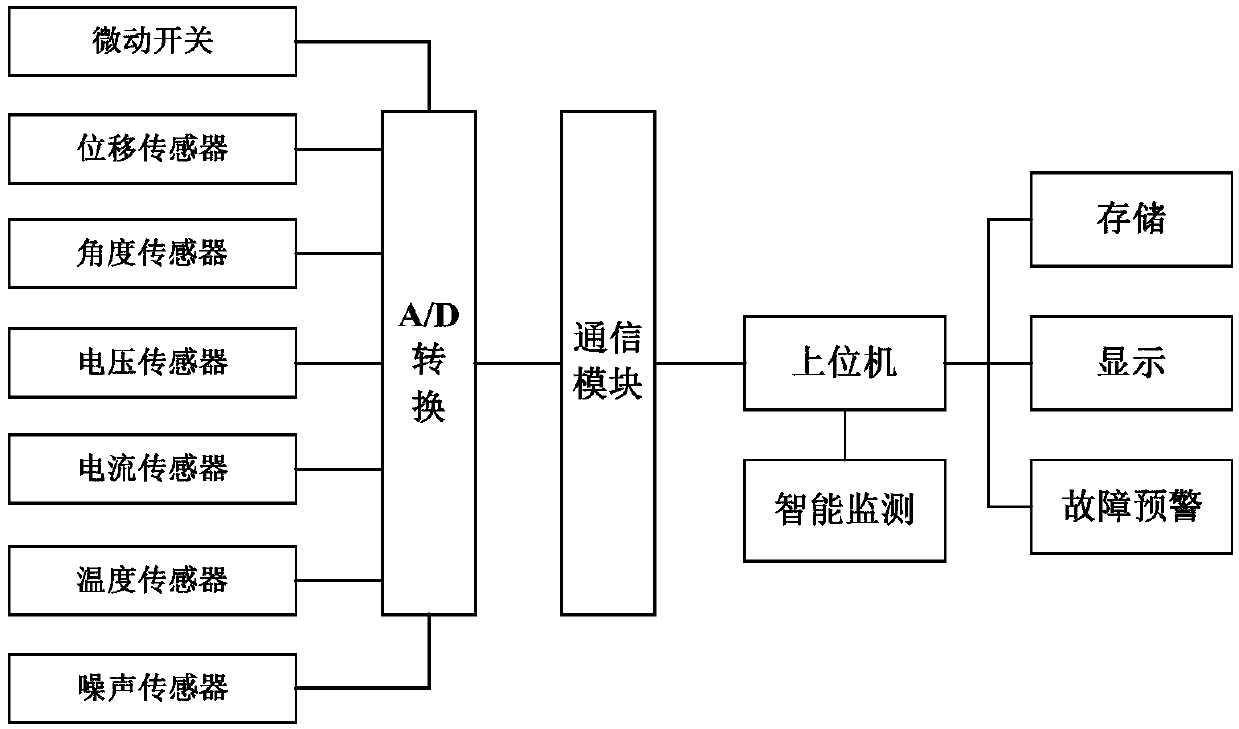

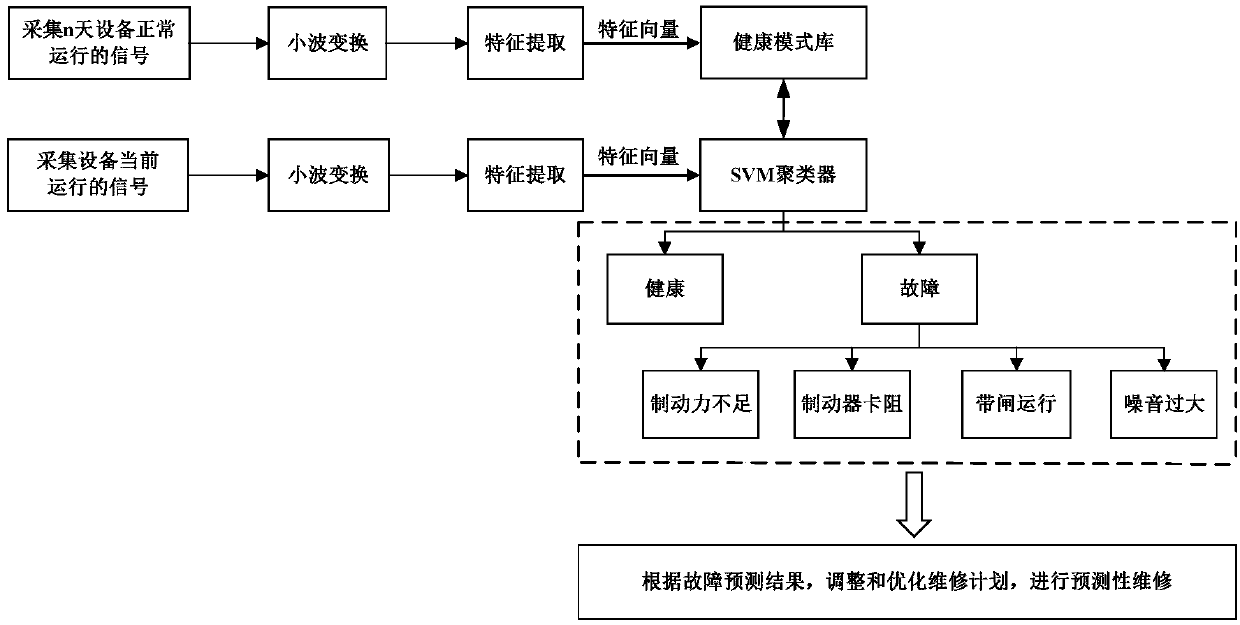

Intelligent monitoring and early warning method for elevator brake

PendingCN107814288AImprove the level of safety supervision and managementImprove the level of safe useBrake typesElevatorsMachinePredictive maintenance

The invention discloses an intelligent monitoring and early warning method for an elevator brake. The method comprises the following steps of 1, a hardware structure of an elevator brake intelligent monitoring and early warning system is built in an elevator machine room; 2, small sample monitoring data are collected, feature vectors of signals are decomposed, reconstructed and extracted through awavelet packet, and a health mode library is built; 3, the running state of the elevator brake is monitored in real time, and early warning is carried out on faults possibly occurring through an SVMclustering analysis algorithm; and 4, according to a fault prediction result, maintenance personnel of an elevator are guided to adjust and optimize the maintenance plan, predictive maintenance is carried out, the faults of the brake are eliminated in a sprouting state, and accidents are avoided. According to the intelligent monitoring and early warning method, key parameters like an elevator brake gap, the abrasion amount of a brake shoe, a brake distance, a brake coil voltage, a traction machine working current, brake temperature, noise are monitored in real time through a non-contact type measuring method, data mining and analysis are carried out on the large amount of monitoring data, so that fault hidden danger of the elevator brake is predicted in time, and safe operation of the elevator is guaranteed.

Owner:南京市特种设备安全监督检验研究院

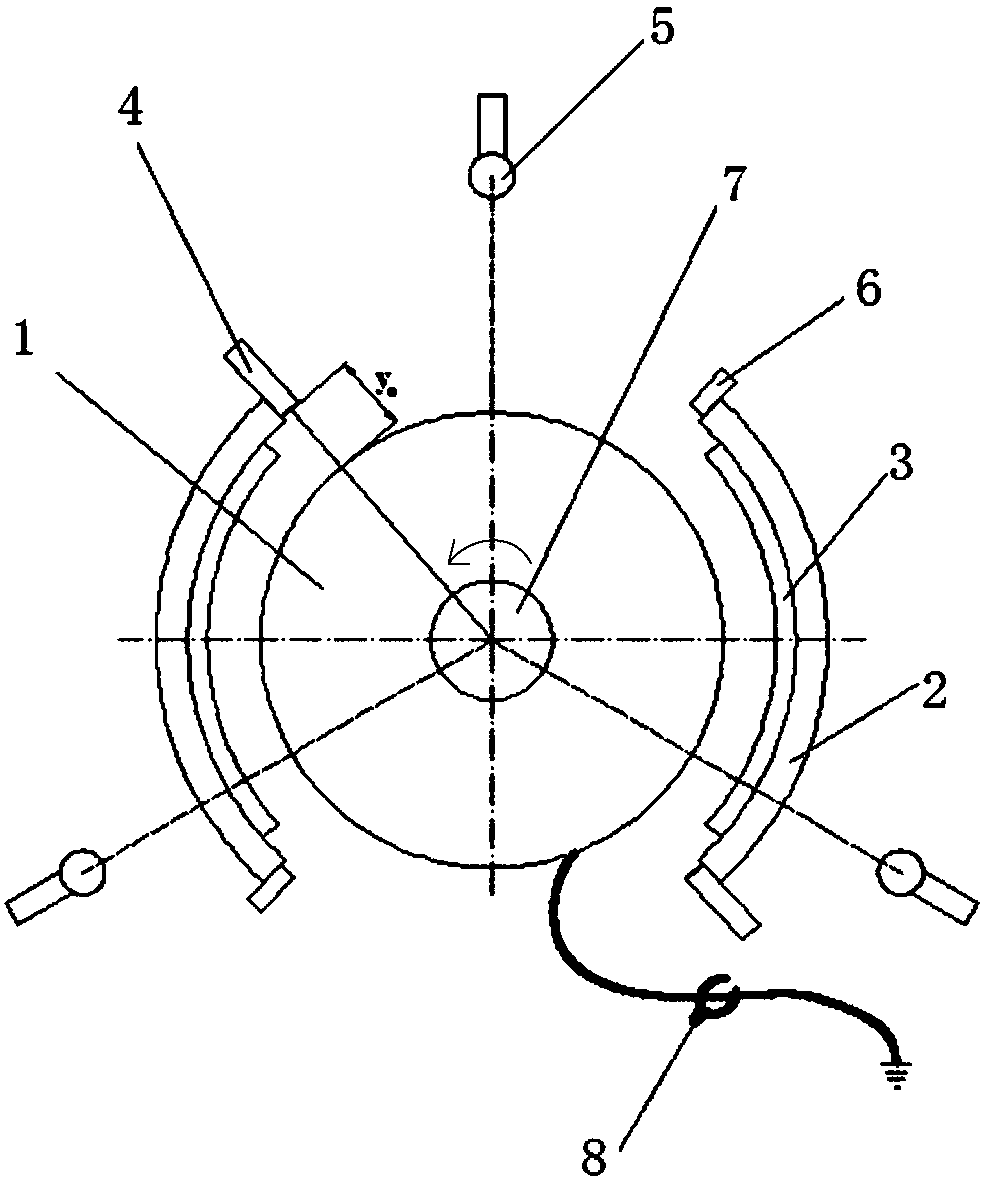

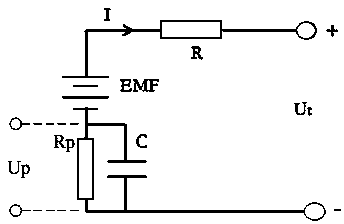

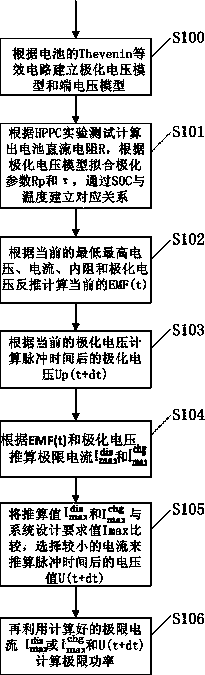

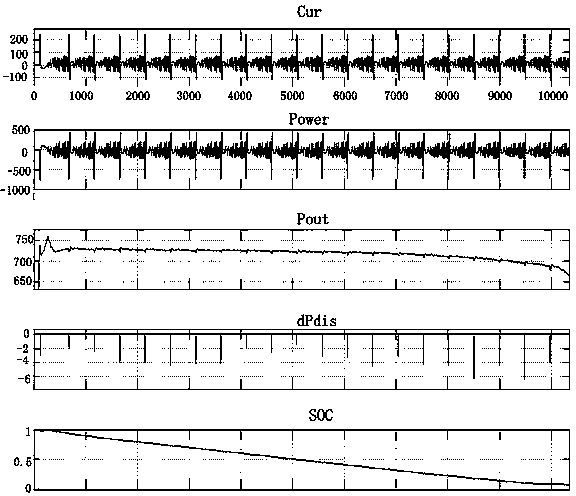

Model inverse dynamic algorithm for extreme power of power battery pack

ActiveCN104298793ASolve the problem that the valuation is affected by the accuracy of the SOCReduce estimation errorSpecial data processing applicationsSystems designTerminal voltage

The invention discloses a model inverse dynamic algorithm for the extreme power of a power battery pack, and aims to avoid the influence of the state of charge (SOC) accuracy of a battery on an extreme power estimated value due to calculation of the electrodynamic potential of the battery through a mathematical model. The model inverse dynamic algorithm comprises the following steps: establishing a polarization voltage model of a single battery and a terminal voltage model of the single battery by adopting a Thevenin equivalent circuit; computing the direct-current resistance R, polarization parameter Rp and tau of the battery according to an HPPC (Hybrid Pulse Power Characterization) experiment, and establishing a corresponding relation through the SOC and a temperature; computing current EMF(t) by using a current sampled voltage value U(t) and current I(t); computing a polarization voltage Up(t+dt) after pulse time according to Up(t); calculating extreme current according to EMF(t) and Up(t+dt); comparing the extreme current with a system design required value Imax, and selecting lower current for calculating a voltage value U(t+dt) after the pulse time; and computing extreme power and charging extreme power.

Owner:WANXIANG 123 CO LTD

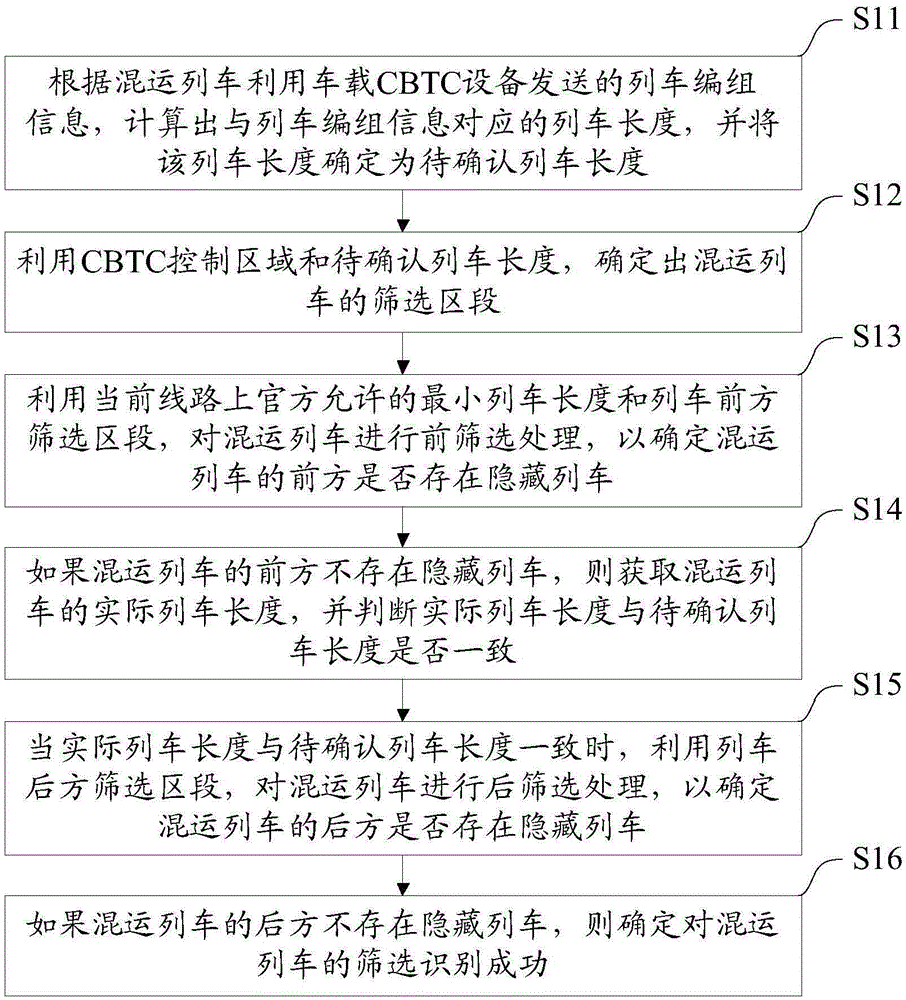

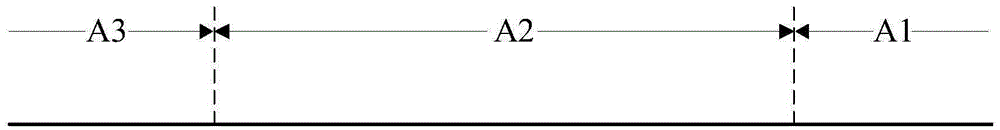

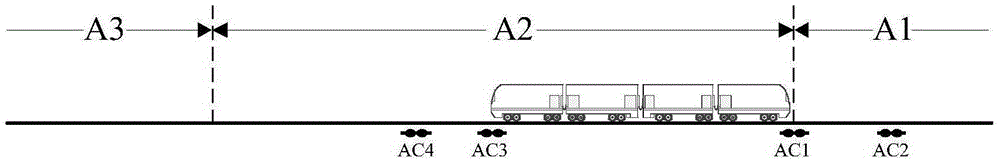

Multi-block mixed operation train screening recognition and mobile authorization method

ActiveCN105292184ASafe and effective screening and identificationAvoid safety accidentsVehicle route interaction devicesControl areaAuthorization

The invention discloses a multi-block mixed operation train screening recognition and mobile authorization method. The method comprises the steps of calculating corresponding train length according to train formation information, and determining the train length as train length to be confirmed; determining the screening zones of a mixed operation train according to a CBTC control area and the train length to be confirmed; conducting front screening on the mixed operation train by means of the minimum train length officially allowed on the current line and the front screening zone of the train; acquiring the actual train length of the mixed operation train and judging whether the actual train length is consistent with the train length to be confirmed if there is no hidden train in front; conducting rear screening on the mixed operation train by means of the rear screening zone of the train when actual train length is consistent with the train length to be confirmed. By the adoption of the method, safe and efficient screening recognition of the mixed operation train is achieved, and accidents caused by the probability of wrong train formation information are avoided.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

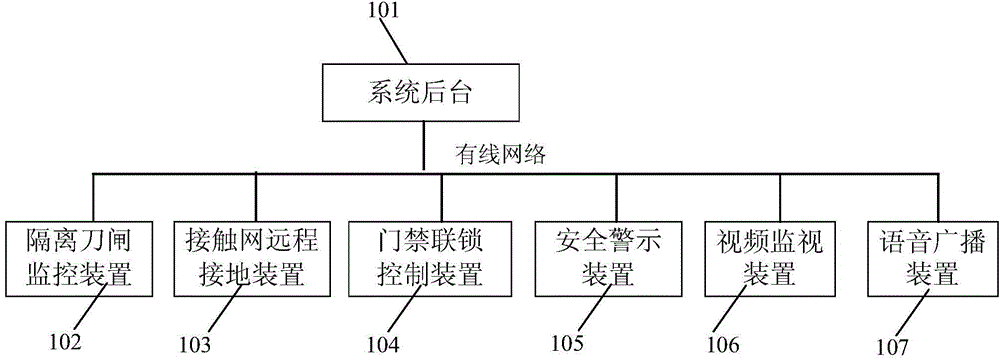

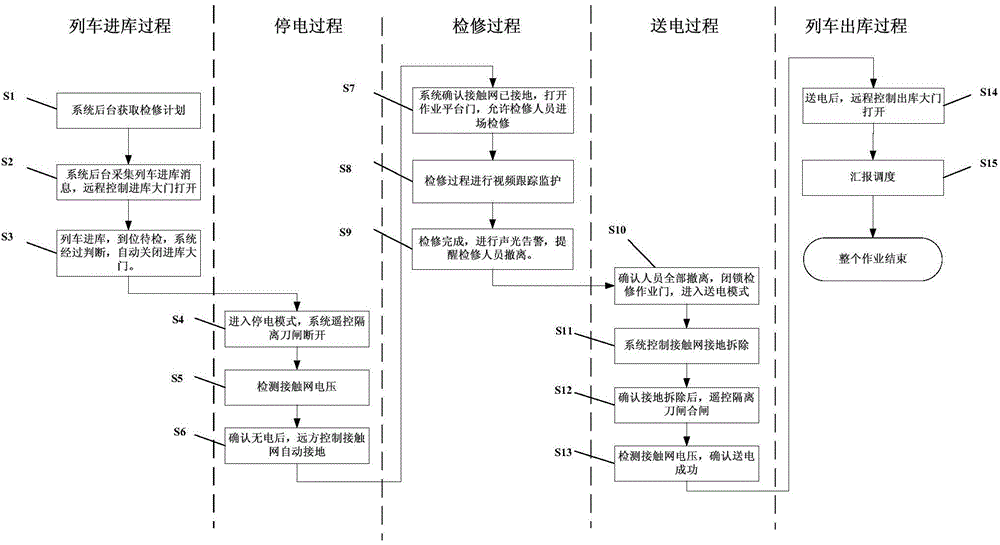

Full automatic vehicle-driving section safety management control system and method

ActiveCN104859687ATo achieve the overall requirements of safe productionMeet the overall requirements of safe productionRailway traffic control systemsVideo monitoringSocial benefits

The invention discloses a full automatic vehicle-driving section safety management control system and method, wherein the safety management control system comprises a system backstage, a separation isolator monitoring device, a contact line remote grounding device, a door control interlock control device, a safety warning device, a video monitoring device and an audio broadcasting device; a system backstage host computer is connected to each device through wired network; and the safety management control method comprises the process of a vehicle entering a garage, the process of contact line black out, the process of maintaining the vehicle, the process of the contact line supplying power and the process of the vehicle getting out of the garage. The control system provided herein has the beneficial effects that the operation of maintaining the vehicle-driving section is ensured to be safe and the operation process is regulated; the work efficiency is improved; the maintaining quality is ensured; the fault rate of the device is reduced, so the track transportation is safer and more reliable; and the economy benefit and social benefit are great.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

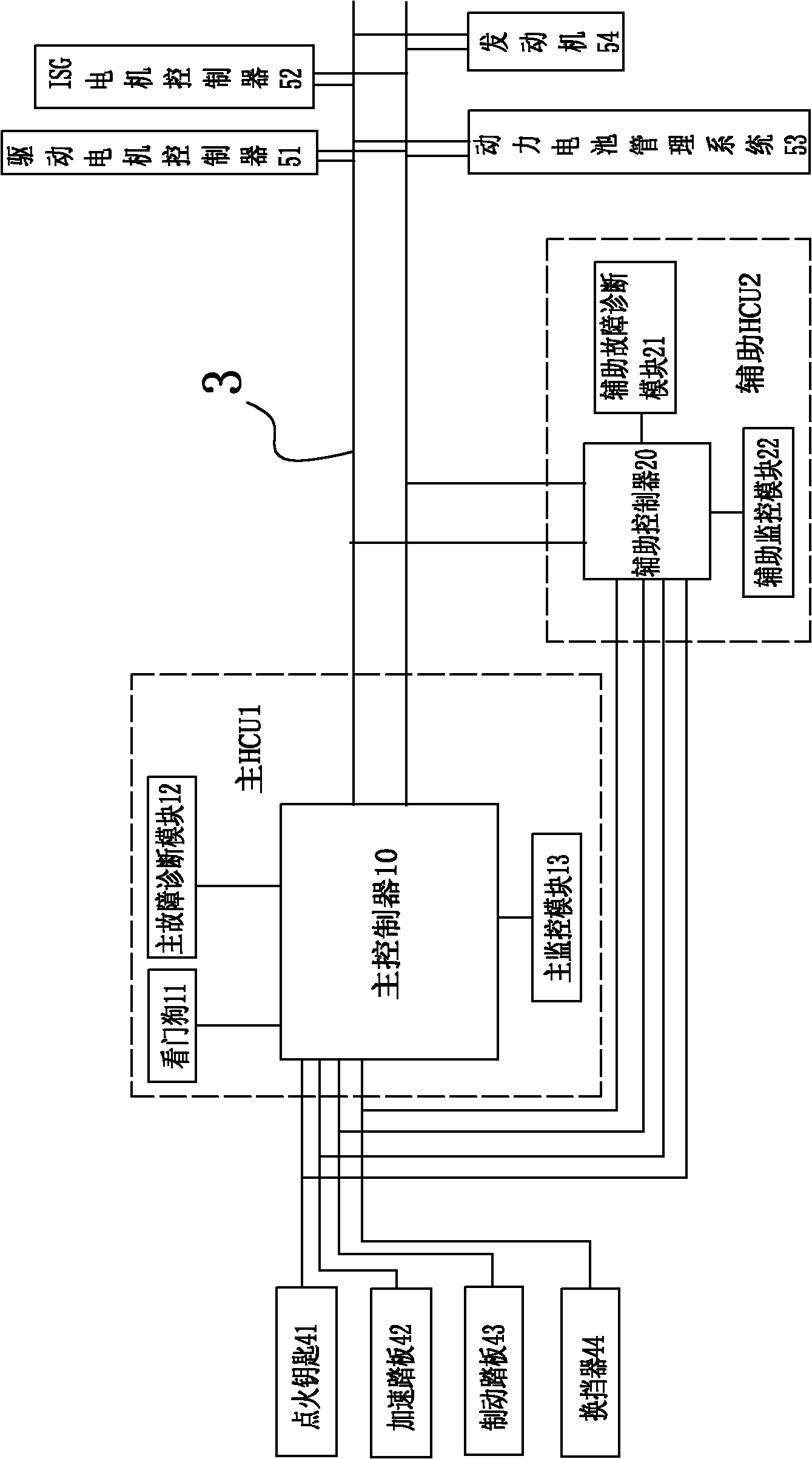

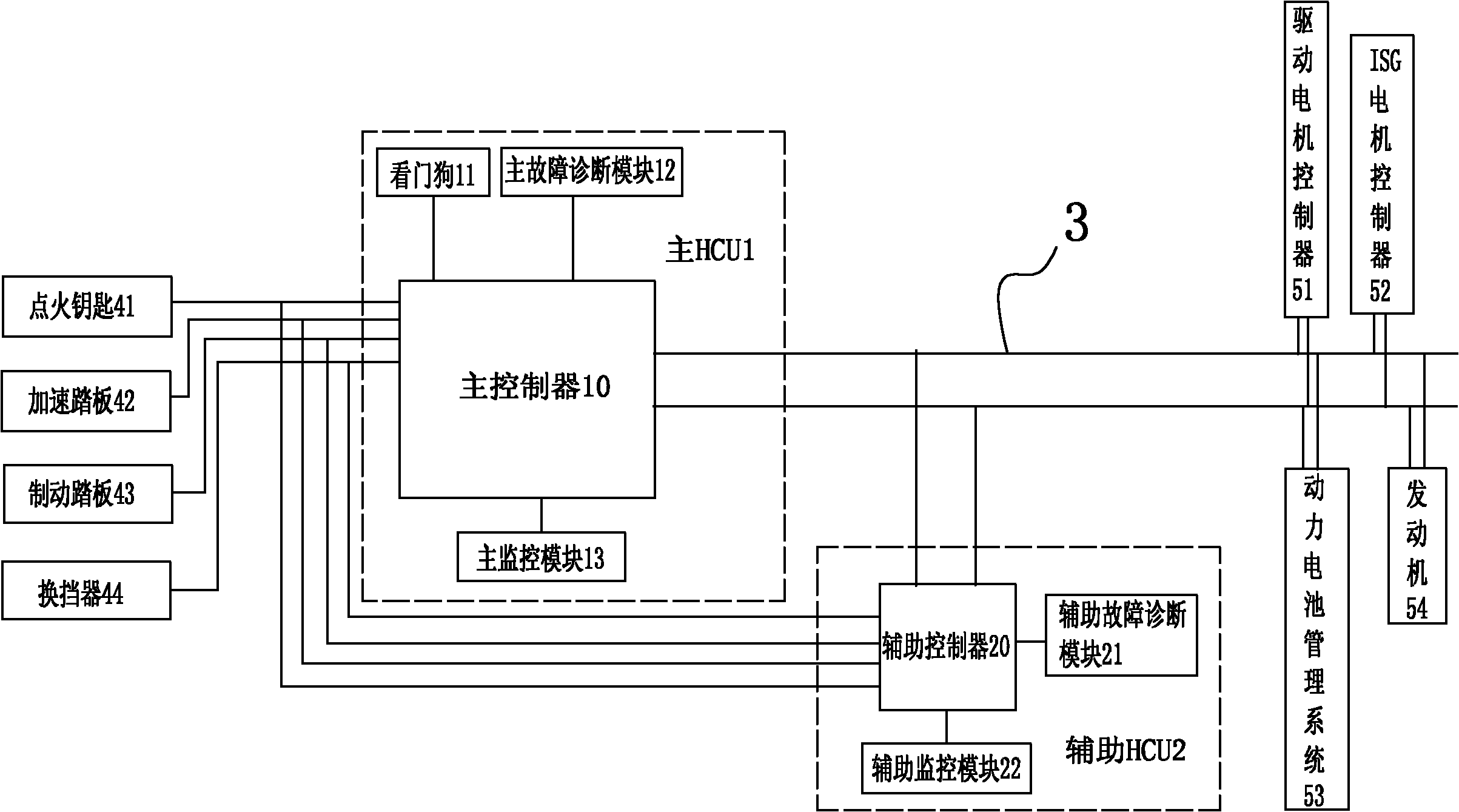

Double-HCU integrated control system of hybrid power vehicle

The invention provides an HCU (Hybrid Control Unit) integrated control system of a hybrid power vehicle, belonging to the technical field of hybrid power vehicles and solving the problems of poor economy and high cost of a multi-energy power assembly controller of the traditional hybrid power vehicle. The double HCU integrated control system of the hybrid power vehicle comprises a main HCU and an auxiliary HCU, wherein the main HCU and the auxiliary HCU are respectively linked with an operating mechanism, the main HCU is connected with an energy control mechanism through a CAN (Controller Area Network) bus, the auxiliary HCU is connected to the CAN bus and can receive a state signal of the main HCU, the main HCU can control the energy control mechanism according to an input signal of the operating mechanism, and the auxiliary HCU can replace the main HCU when receiving the state signal that the main HCU has a fault so as to control the energy control mechanism according to the input signal of the operating mechanism. The invention has the advantages of high reliability, high safety and the like.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

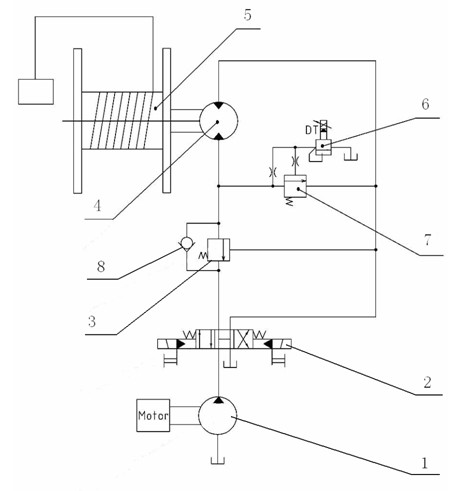

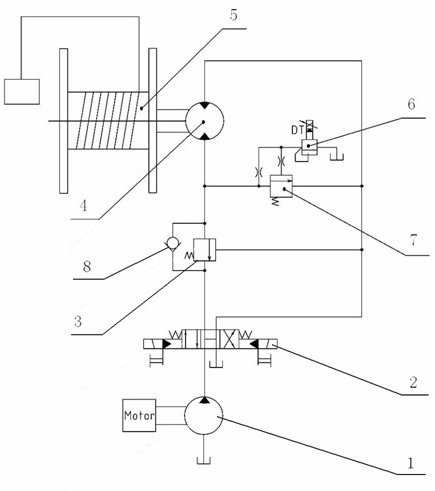

Stepless regulation constant tension device for hydraulic winch

ActiveCN102153027AAvoid safety accidentsMaintain system oil pressureWinding mechanismsFuel tankSafety valve

The invention discloses a stepless regulation constant tension device for a hydraulic winch, consisting of a power pump set, a reversing valve, a hydraulic motor, a winch, a one-way valve, a balance valve and a motor safety valve, wherein the power pump set is connected with an oil inlet of the reversing valve; a first oil exchange port of the reversing valve is connected with an oil return port of the balance valve; an oil inlet of the balance valve is connected with a rope folding side oil port of the hydraulic motor; a rope release side oil port of the hydraulic motor is connected with a second oil reversing port of the reversing valve; an oil outlet of the reversing valve is connected with an oil tank; a control port of the balance valve is connected with an oil path between the rope release side oil port of the hydraulic motor and the reversing valve; the one-way valve is connected between the oil inlet and the oil return port of the balance valve in parallel; the motor safety valve is connected between the rope folding side oil port and the rope release side oil port of the hydraulic motor in parallel; and the winch is connected with the hydraulic motor. The device achieves the function of keeping the tension of a steel wire rope constant when the hydraulic winch is positioned under various work conditions and can be used for carrying out remote on-line adjustment on theoutput capacity of the hydraulic winch. The stepless regulation constant tension device has the advantages of simple structure, low cost, convenience for use and high safety.

Owner:WUHAN MARINE MACHINERY PLANT

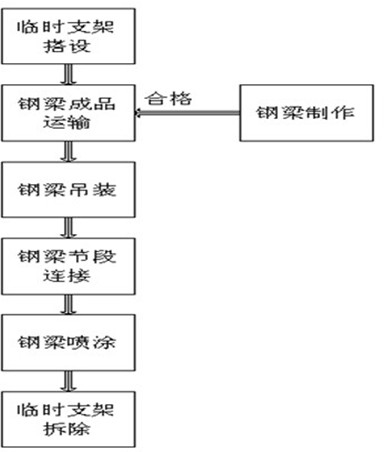

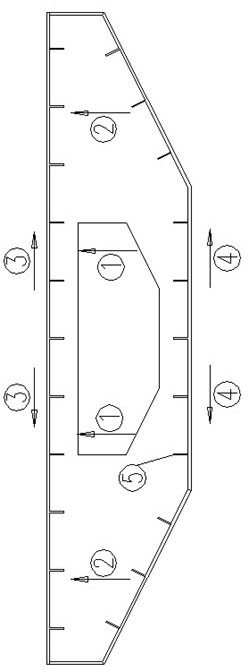

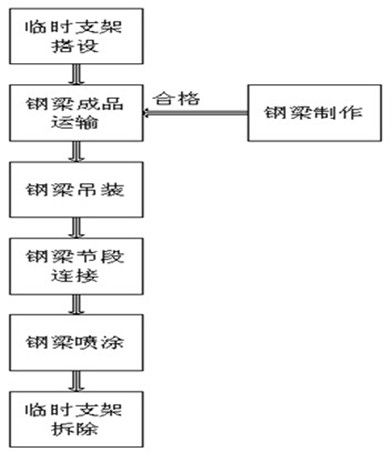

Method for installing abnormal-shape curve steel box girder

ActiveCN102433841AEnsure construction safetyAvoid safety accidentsBridge erection/assemblyAbnormal shapedWelding deformation

The invention discloses a method for installing an abnormal-shape curve steel box girder, belonging to the technical field of a longspan bridge. The method for installing the abnormal-shape curve steel box girder comprises the following steps of: 1. manufacturing each section of the steel box girder, pre-assembling, and detecting the lateral welding contraction amount; 2. erecting a temporary bracket, arranging a safety protection facility and a working platform on the temporary bracket, and setting a precamber of the top support of the temporary bracket; 3. measuring and positioning on a pier, hoisting the steel box girder above the working platform, controlling hoisting in position, and integrally measuring and regulating the installed steel box girder; 4. controlling the welding deformation of the steel box girder; and 5. regulating the local line of the steel box girder. The method for installing the abnormal-shape curve steel box girder, which is disclosed by the invention, is convenient to operate, is easy to implement, has the advantages of high construction efficiency, low cost and strong maneuverability, and can be suitable for installing the abnormal-shape curve steel box girder and is easy to popularize; and the installation and the line shape of the steel box girder can be better controlled, and the construction quality is guaranteed.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com