Patents

Literature

187 results about "Surface mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface mining, including strip mining, open-pit mining and mountaintop removal mining, is a broad category of mining in which soil and rock overlying the mineral deposit (the overburden) are removed, in contrast to underground mining, in which the overlying rock is left in place, and the mineral is removed through shafts or tunnels.

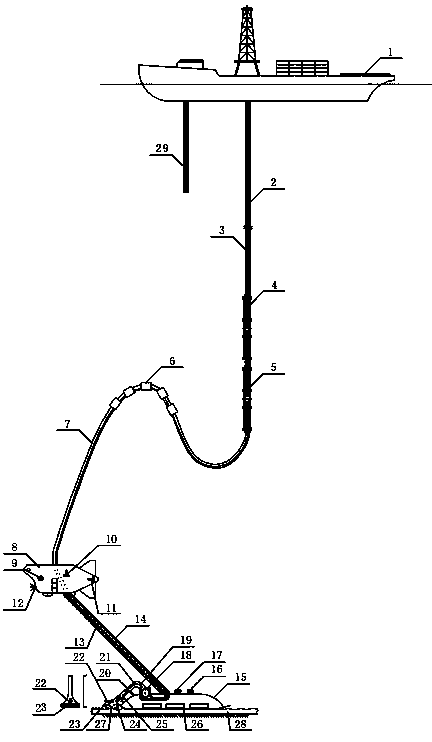

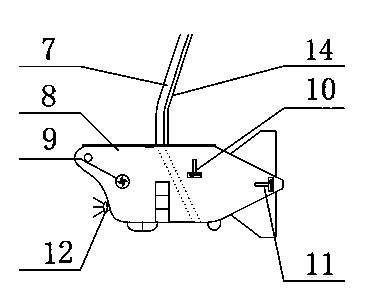

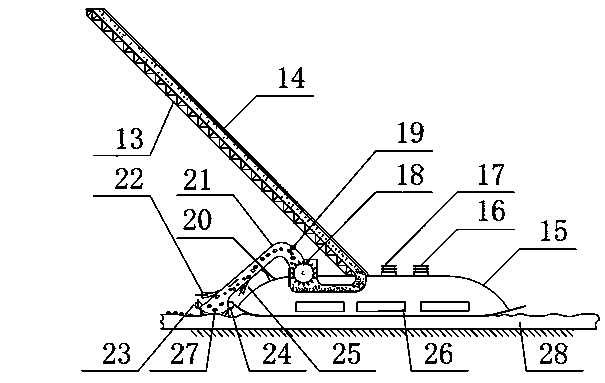

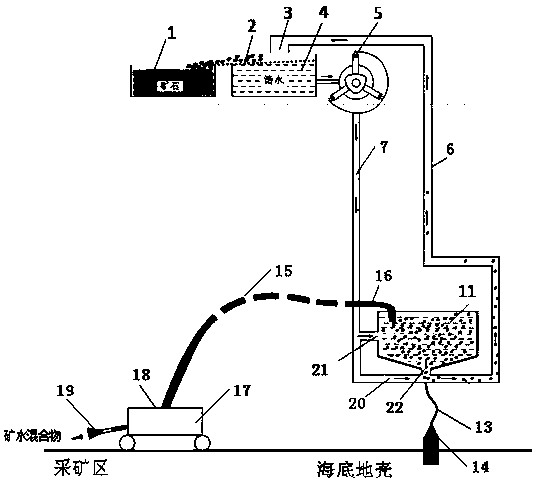

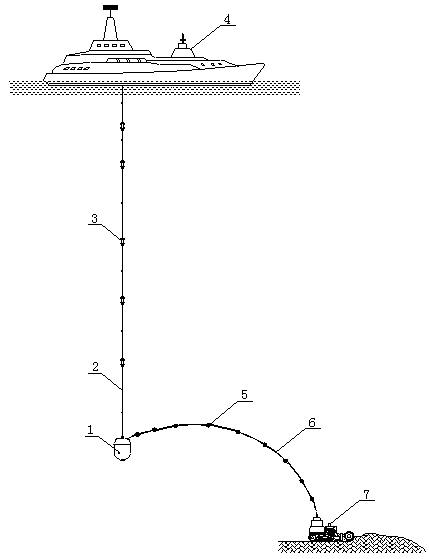

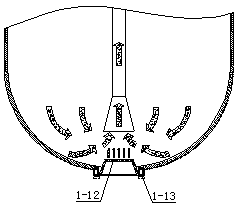

Oceanic mineral resource exploitation device and exploitation method

InactiveCN103628881AReduce disturbanceImprove reliabilityMineral miningFluid removalTerrainElectricity

The invention discloses an oceanic mineral resource exploitation device and exploitation method and aims to overcome the technological difficulty of the existing submarine mining vehicle and the pipeline waterpower lifting exploitation system. The exploitation device comprises a water surface mining vessel, a lifting pipe, a lifting electric pump station, a hose, a mineral crushing mechanism and a mining mechanism, wherein a plurality of perturbance jet flow nozzles, a plurality of ascending jet flow nozzles and a flow guide pipe are mounted on the mining mechanism; the flow guide pipe is communicated with the feeding hole of the mineral crushing mechanism; the lifting pipe, the lifting electric pump station, the hose and the mineral crushing mechanism are sequentially connected with the flow guide pipe in series to form an ore pulp lifting passage; the hose is fixed onto an ROV; the ROV is connected with the mining mechanism through a connecting device. The oceanic mineral resource exploitation device is not limited by the complicated terrain and gradient at the bottom of the sea, avoids the slipping and sinking of the underpan of the submarine mining vehicle on a settled layer, greatly reduces the disturbance of mineral mining to bottom sediments, and also solves the problem that the terrain clearance of the mining mechanism is difficult to control.

Owner:HUNAN UNIV

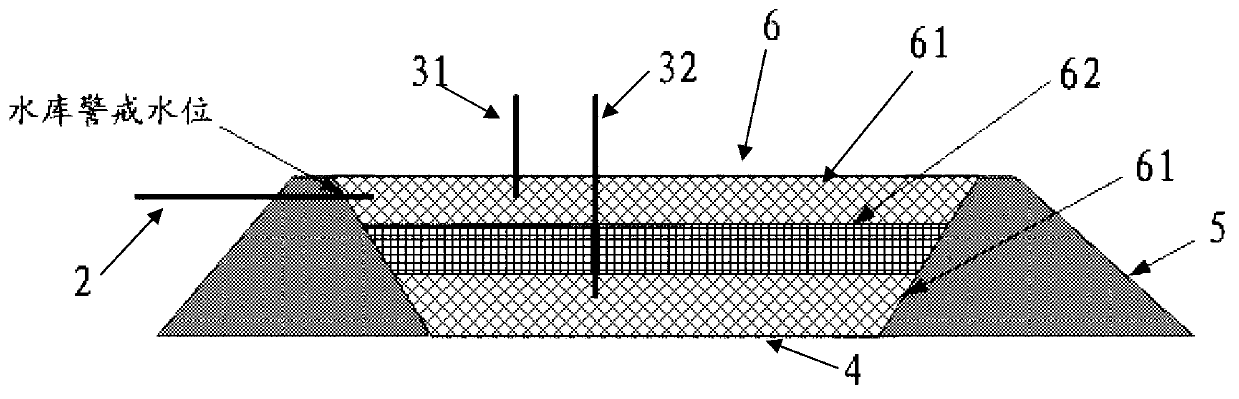

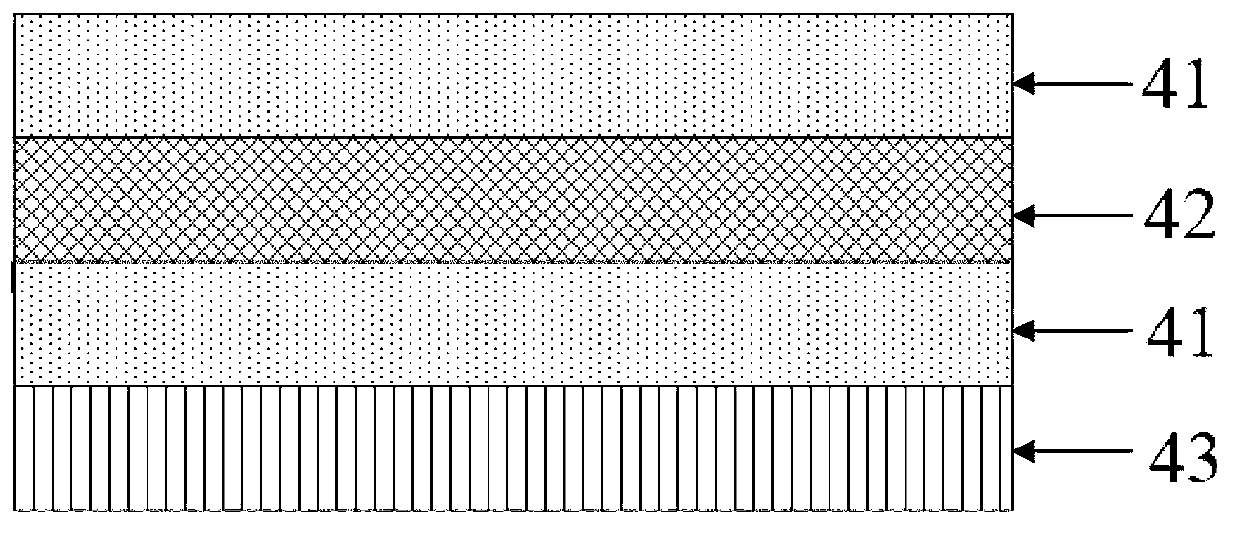

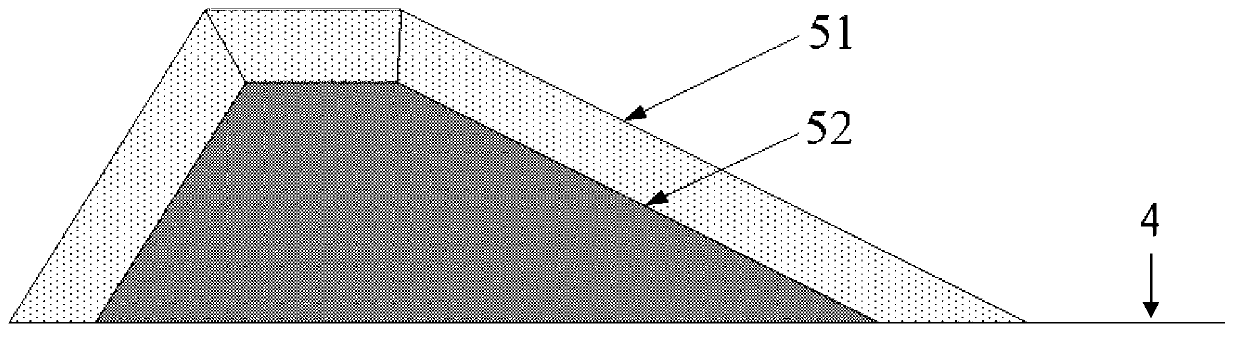

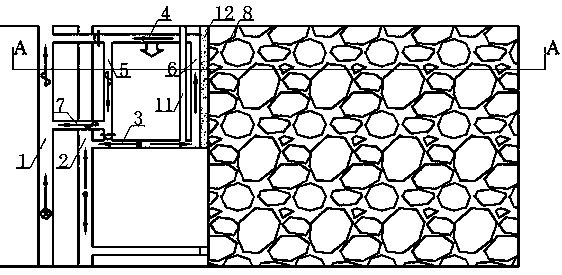

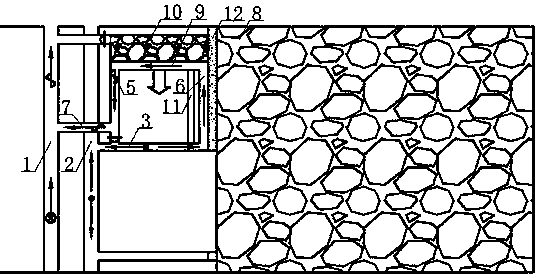

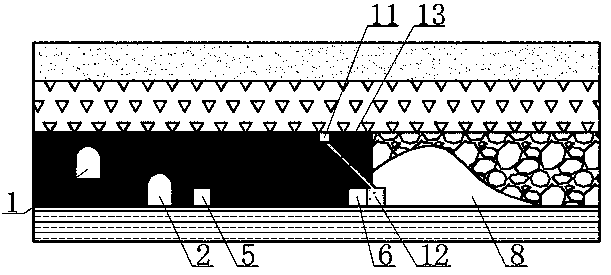

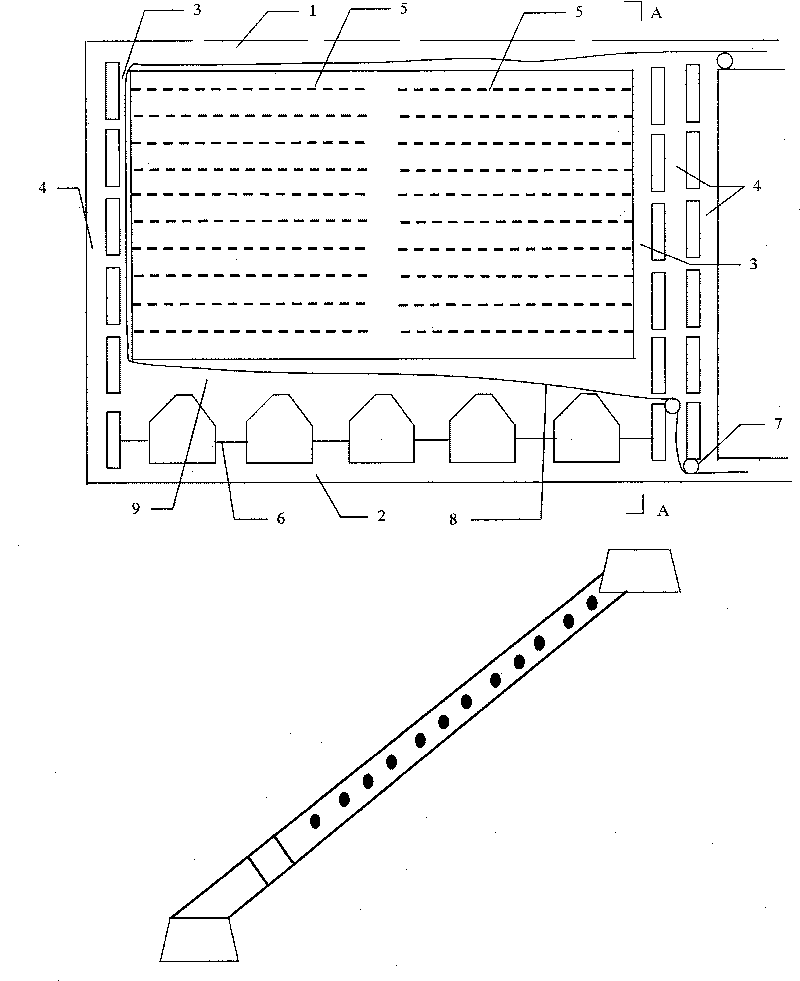

Distributed underground reservoir and construction method thereof

ActiveCN102767302AReduce occupancyReduce evaporationProtective foundationLoose filtering material filtersWater resourcesEvaporation

The invention provides a distributed underground reservoir suitable for storing underground water in open mining areas. The distributed underground reservoir comprises a plurality of reservoir bodies located underground, recharge water pipelines and connecting pipelines. Each reservoir body comprises a reservoir bottom, a dam and reservoir fillers, and the reservoir fillers fully fill a semi-closed area enclosed by each reservoir bottom and each dam. The lower ends of the recharge water pipelines are positioned in the reservoir fillers, and the upper ends of the recharge water pipelines extend above the ground. Besides, the reservoir bodies are communicated with one another by the connecting pipelines penetrating through the dams. The invention further provides a construction method of the distributed underground reservoir. The distributed underground reservoir can contain underground water outflowing during mining, occupancy of the ground and evaporation of moisture are reduced, stored superfluous water among the reservoir bodies can be automatically distributed, and storage of water resources in other places during stripping of an open pit mine is achieved by the aid of the recharge water pipelines so that water resources are protected.

Owner:CHINA SHENHUA ENERGY CO LTD +1

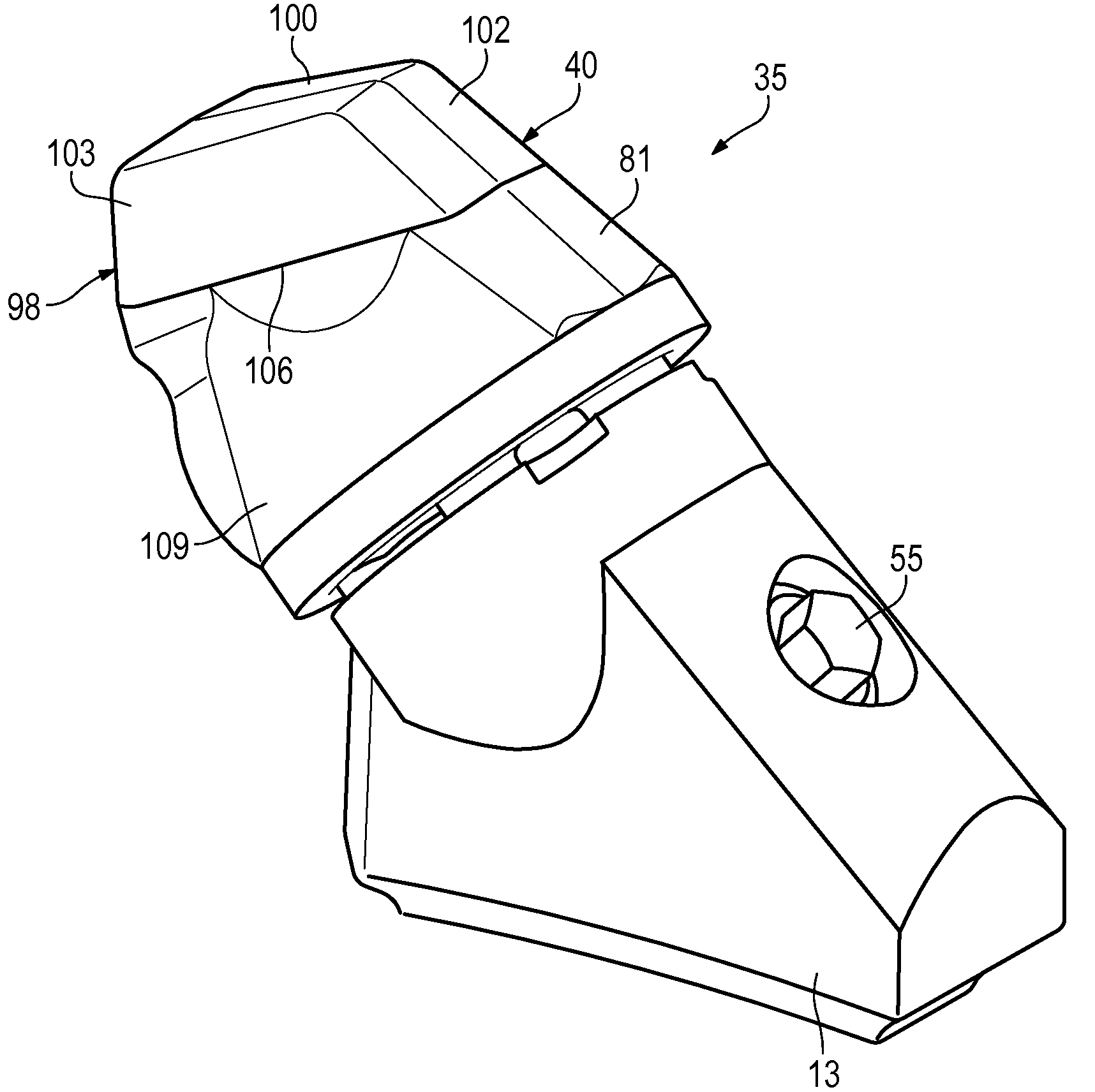

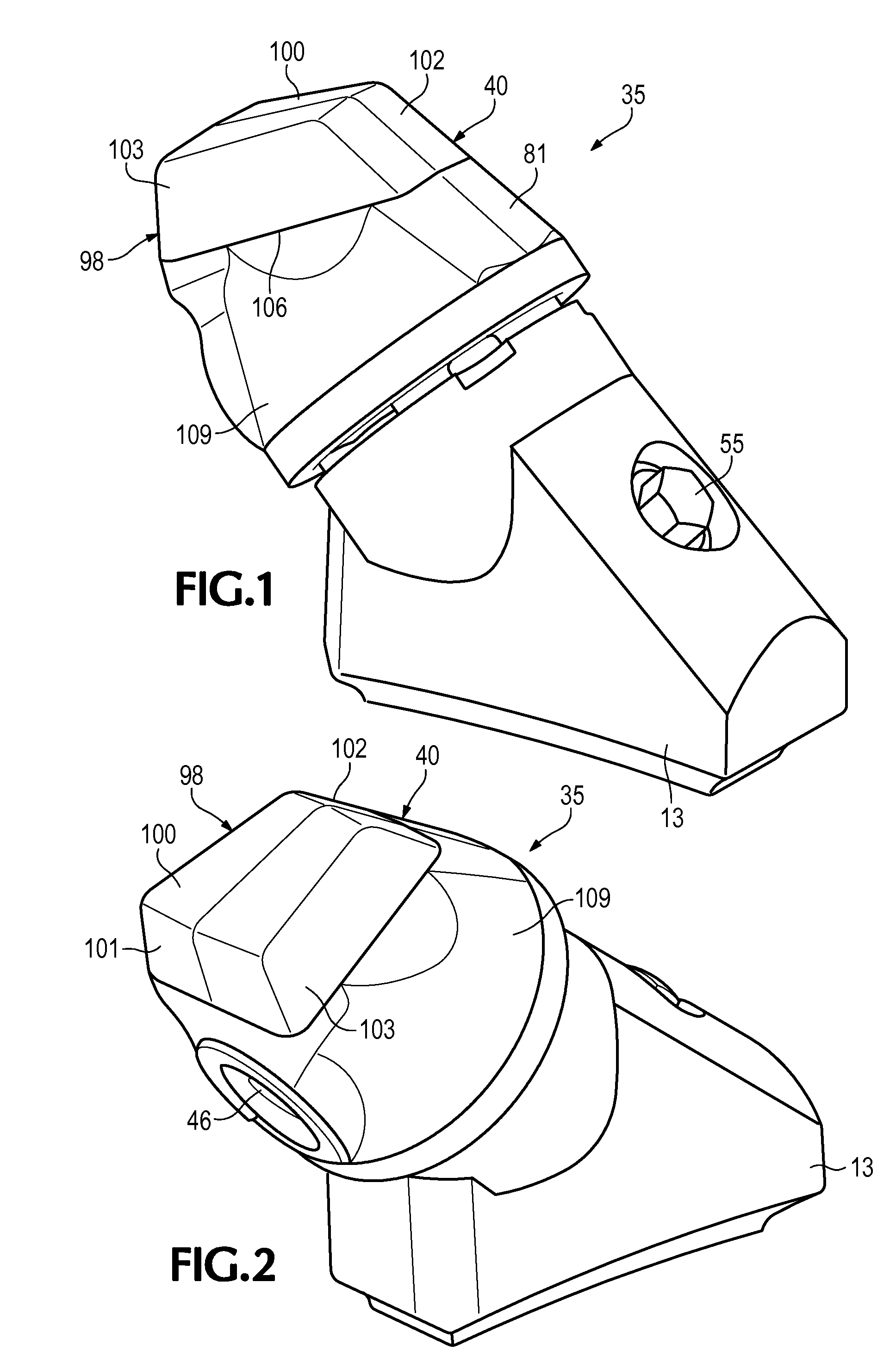

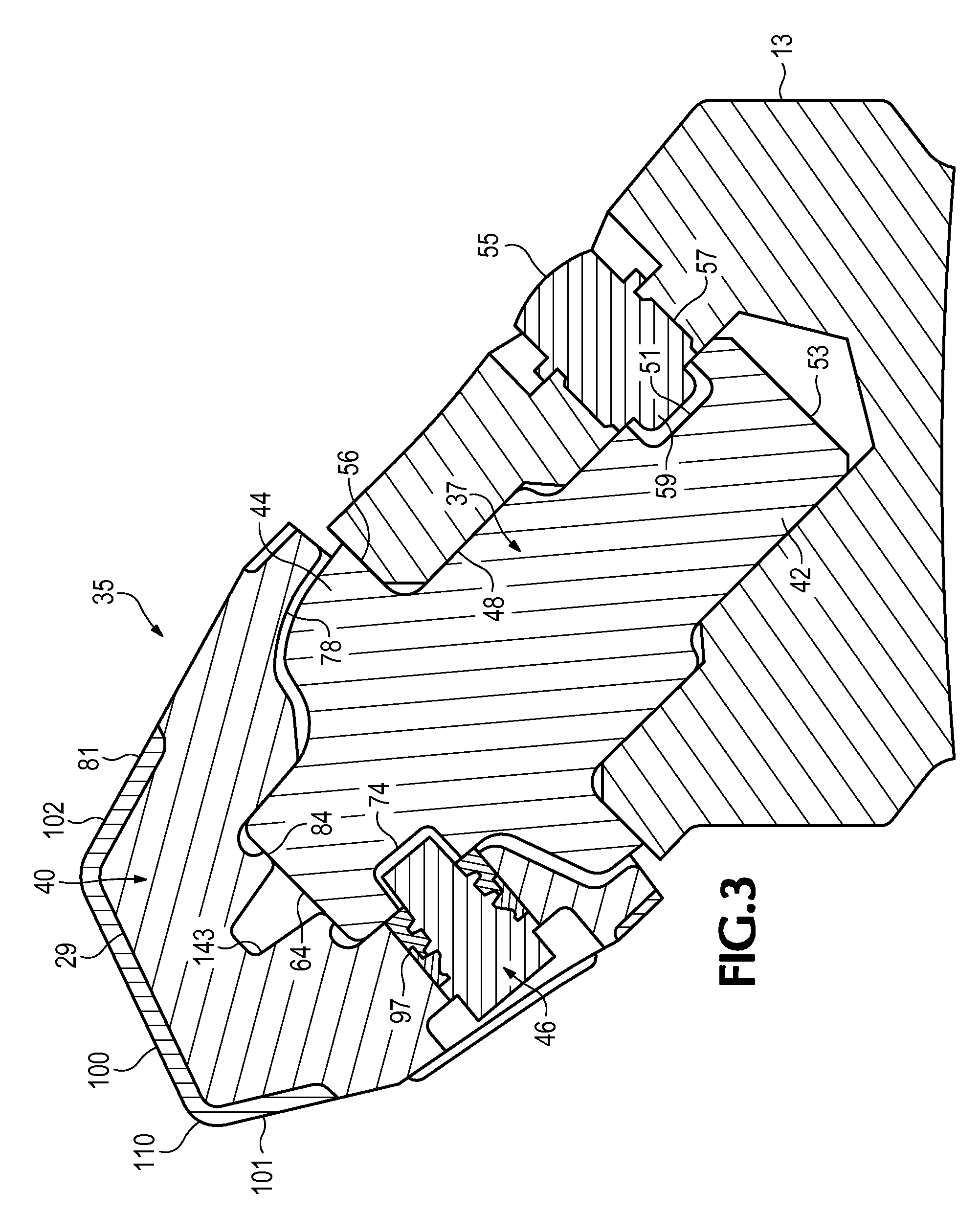

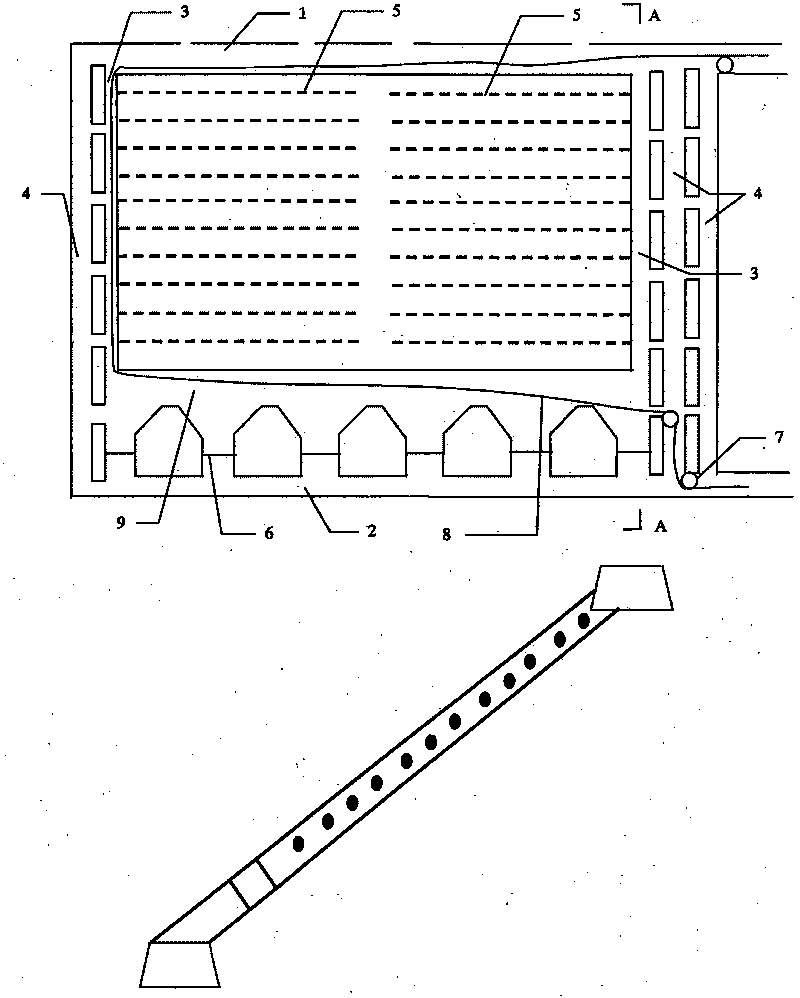

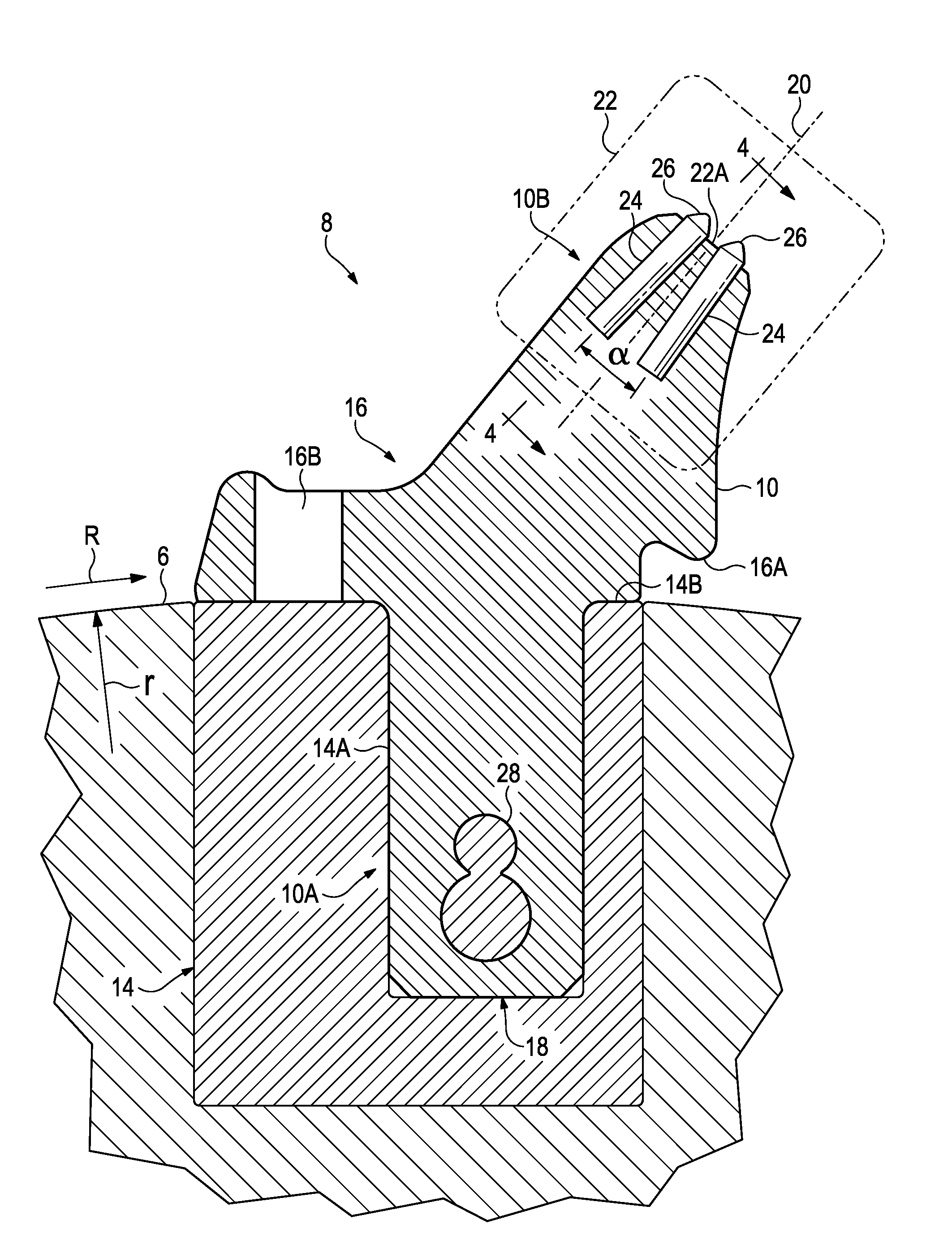

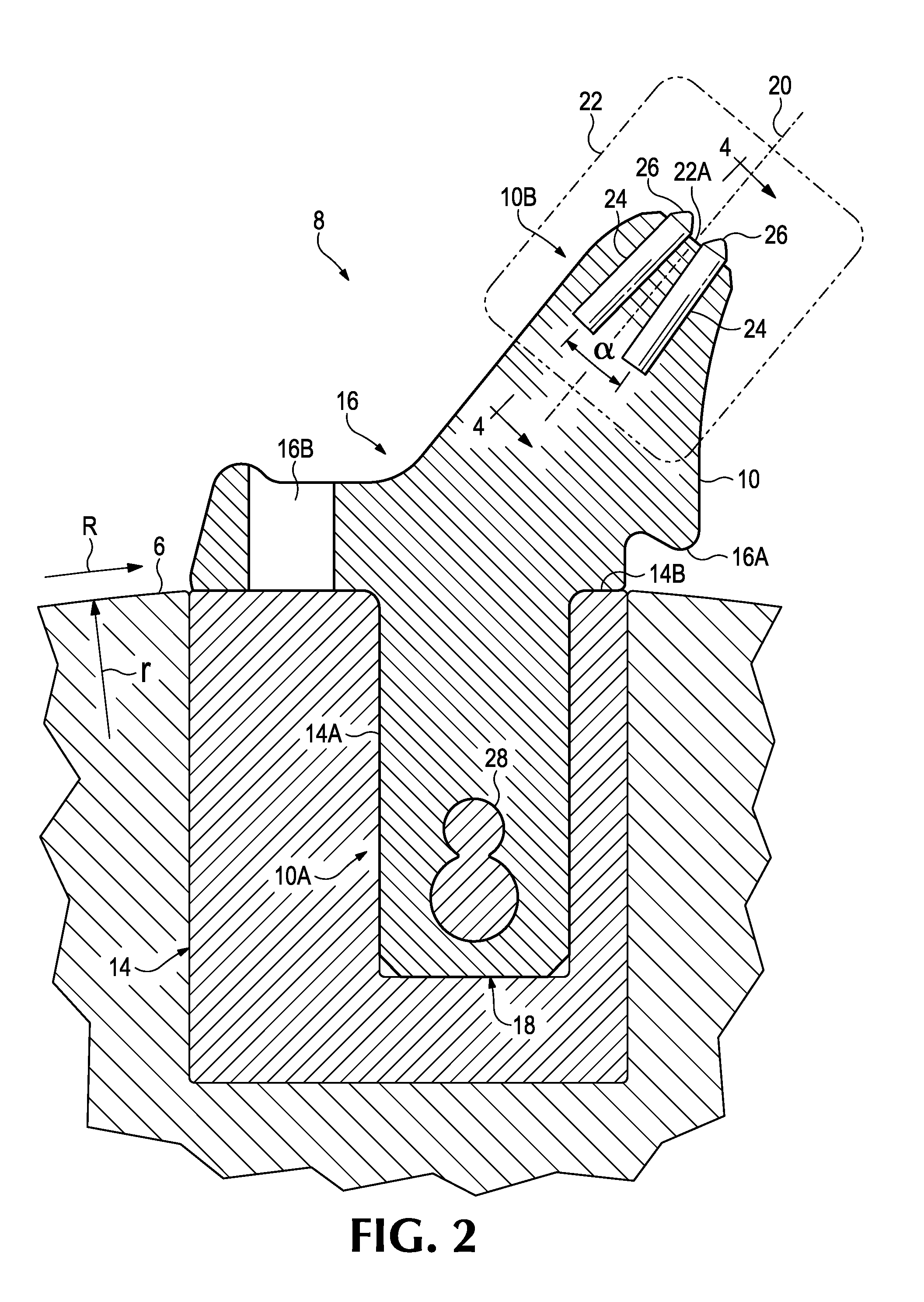

Tip for an earth working roll

ActiveUS20090174252A1Reduce wearReduced service lifeDisloding machinesUnderground miningWork rollCrusher

A tip for use on an earth working roll for mining, construction and public works machines such as crushers, surface miners, milling machines and the like includes a working end provided with side relief to reduce drag and wearing, require less power to drive the rolls, and lengthen the usable life of the tip. The working end can also have a generally flat front surface to improve the yield in a crushing or other similar operation. The tip includes a base and a wear cap releasably secured together by a retainer.

Owner:ESCO GRP LLC

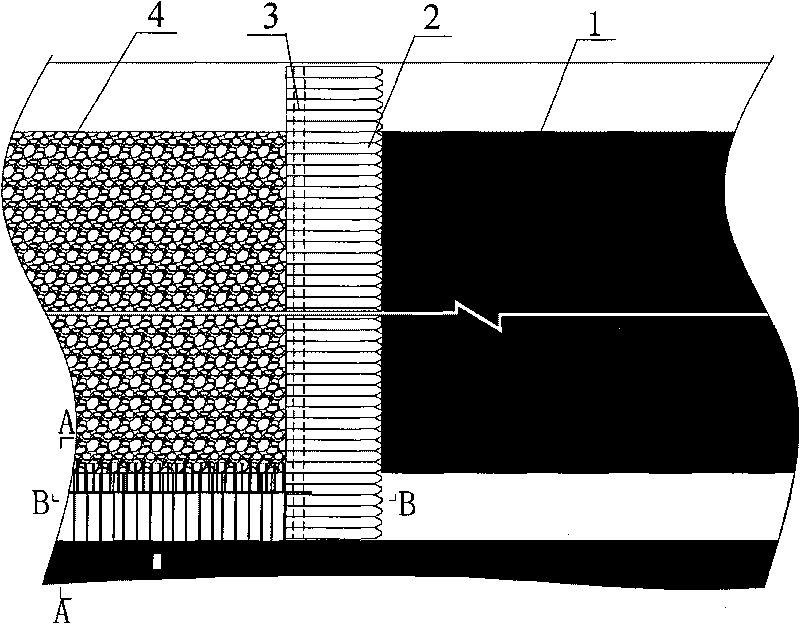

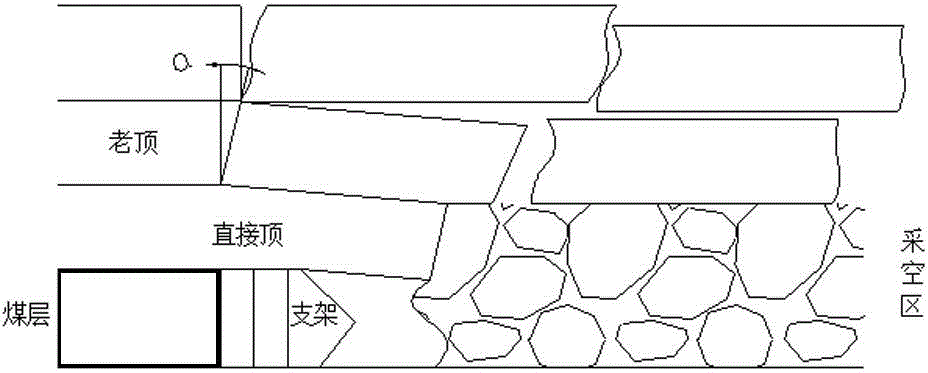

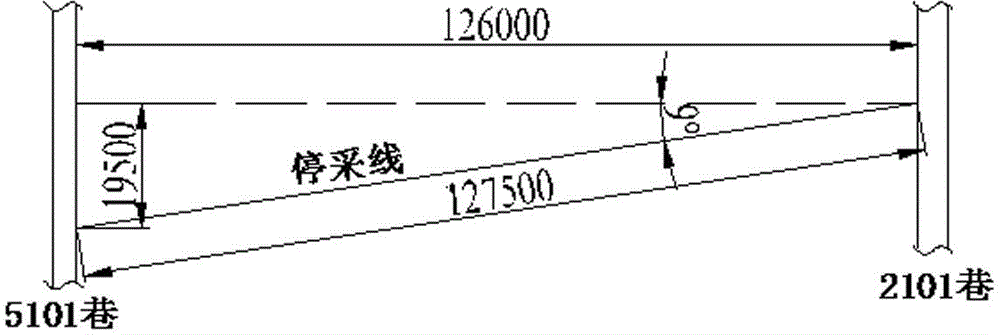

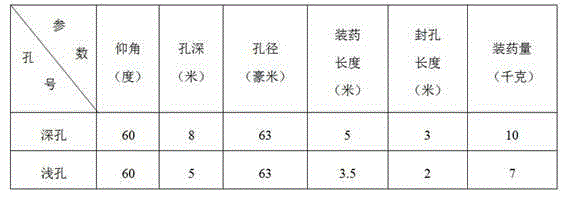

Method for second mining mining-stopping line coal column in super thick coal layer

ActiveCN107313778ARecovery is safe and reliableAvoid safety accidentsUnderground miningSurface miningEconomic benefitsEngineering

The invention discloses a method for second mining a mining-stopping line coal column in a super thick coal layer. The method comprises the following steps that (1), positions of a coal column second mining working surface transporting gate trough and a rail gate trough are stimulated; (2) comprehensive probing is conducted on an original working surface goaf area where the super thick coal layer mining-stopping line coal column is located, and potential safety hazard is removed; (3) a roadway in the propelling direction of the coal column second mining working surface is dug at the upper part of the super thick coal layer, and the roadway is filled; (4) a coal column second mining working surface mining returning roadway and a affiliated oblique roadway are dug, so that the coal column second mining working surface mining returning roadway and the affiliated oblique roadway form a completed producing system, and the coal column second mining working surface is arranged; (5) a bottom plate of the roadway is drilled from top to bottom for using as a filled pipeline; (6) filling paste is prepared, the filling paste is evenly injected into one side, close to the original working surface goaf area, of the transporting gate trough along the filled pipeline; and (7) comprehensive mining is conducted on the coal column second mining working surface. According to the method for second mining the mining-stopping line coal column in the super thick coal layer, the compressed coal amount is reduced, waste of coal resources is avoided, the economic benefits of enterprises are improved, and the service life of mines and mining areas is prolonged.

Owner:TAIYUAN UNIV OF TECH

Method for mining coal of steeply inclined thin seam

InactiveCN101737047ALow costEasy dischargeUnderground miningBlastingMining engineeringEconomic benefits

The invention provides a method for mining coal of a steeply inclined thin seam on the basis of learning from a long-hole blasting coal mining method and a wire saw coal mining method, which is a long-hole blasting and wire saw coal mining method and relates to underground coal mining. The method comprises the following steps: long boreholes are arranged in a direction which is parallel to the cross pitch of the coal seam for coal blasting; after finishing blasting a work surface, making the coal slip out from a section coal bin and loading the coal for outward transport through a haulage drift; and when blasting to the vicinity of a tailgate through the long boreholes, stopping the blasting and utilizing a wire saw to mine remaining coal. The method has the advantages of no work surface support, rational tunnel arrangement, simple ventilation management, the capacity of realizing unmanned work surface mining, low cost, strong security, high coal mining rate, low worker labor intensity, good social and economic benefits and the like.

Owner:孙广义 +2

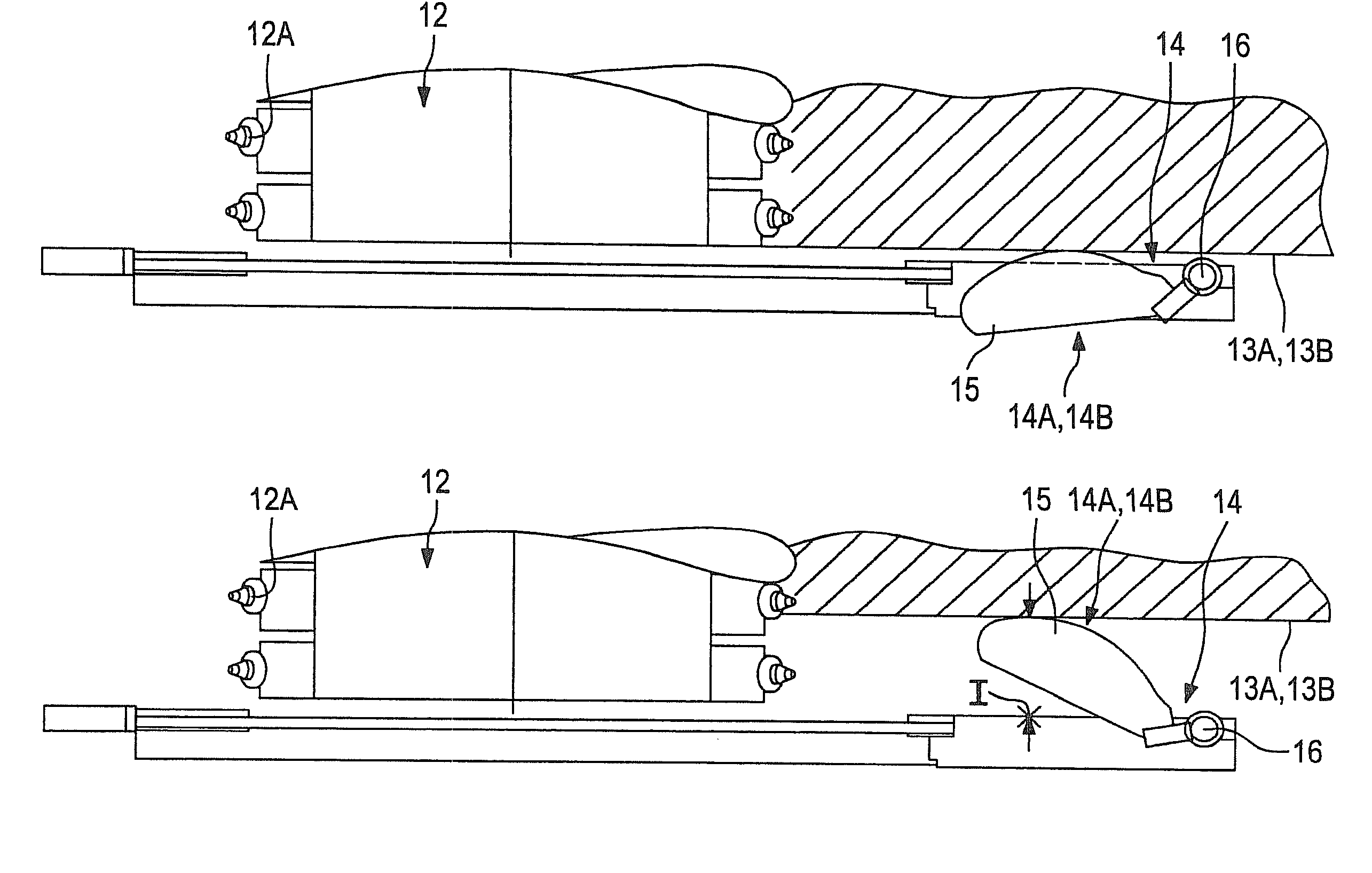

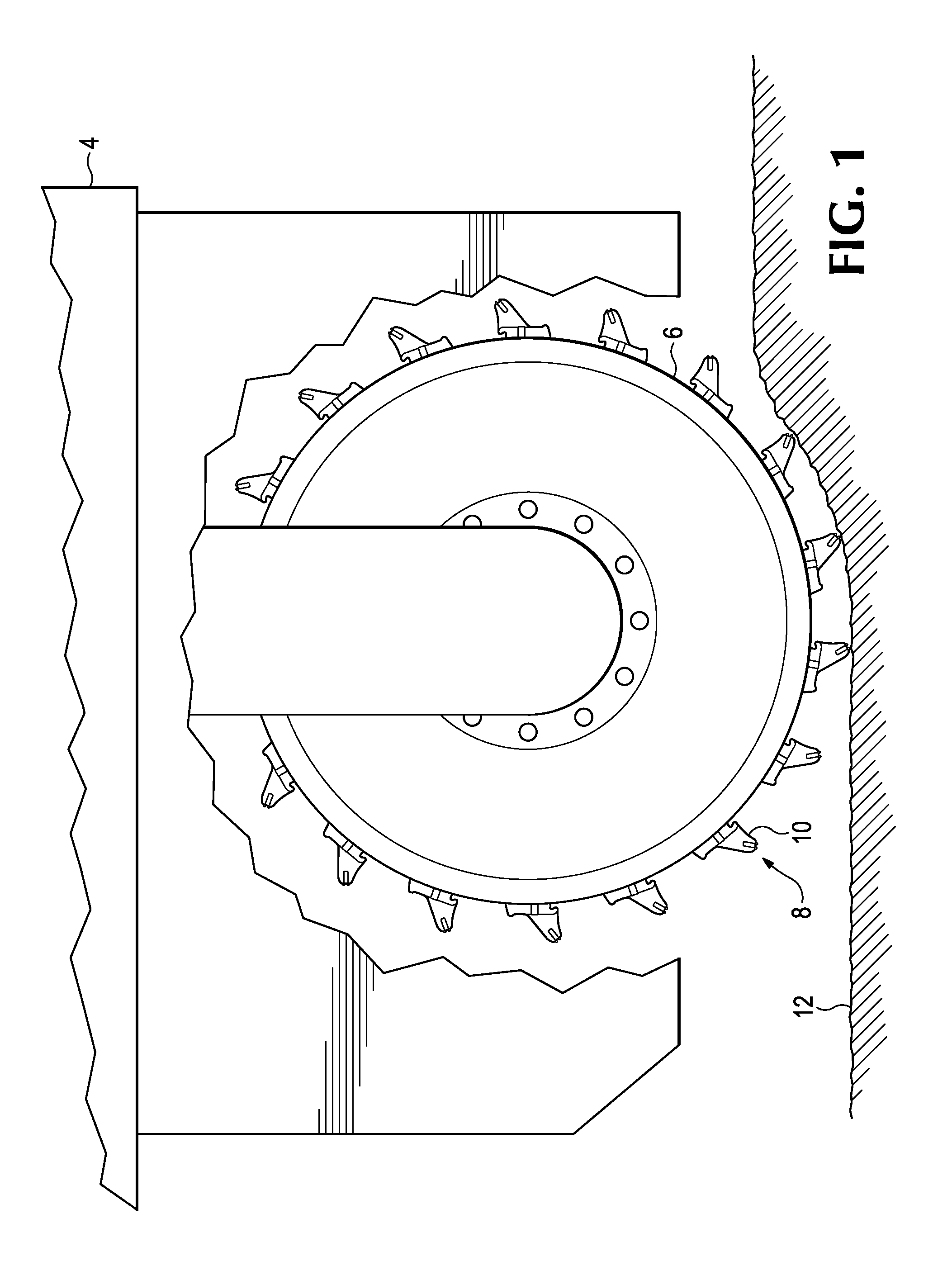

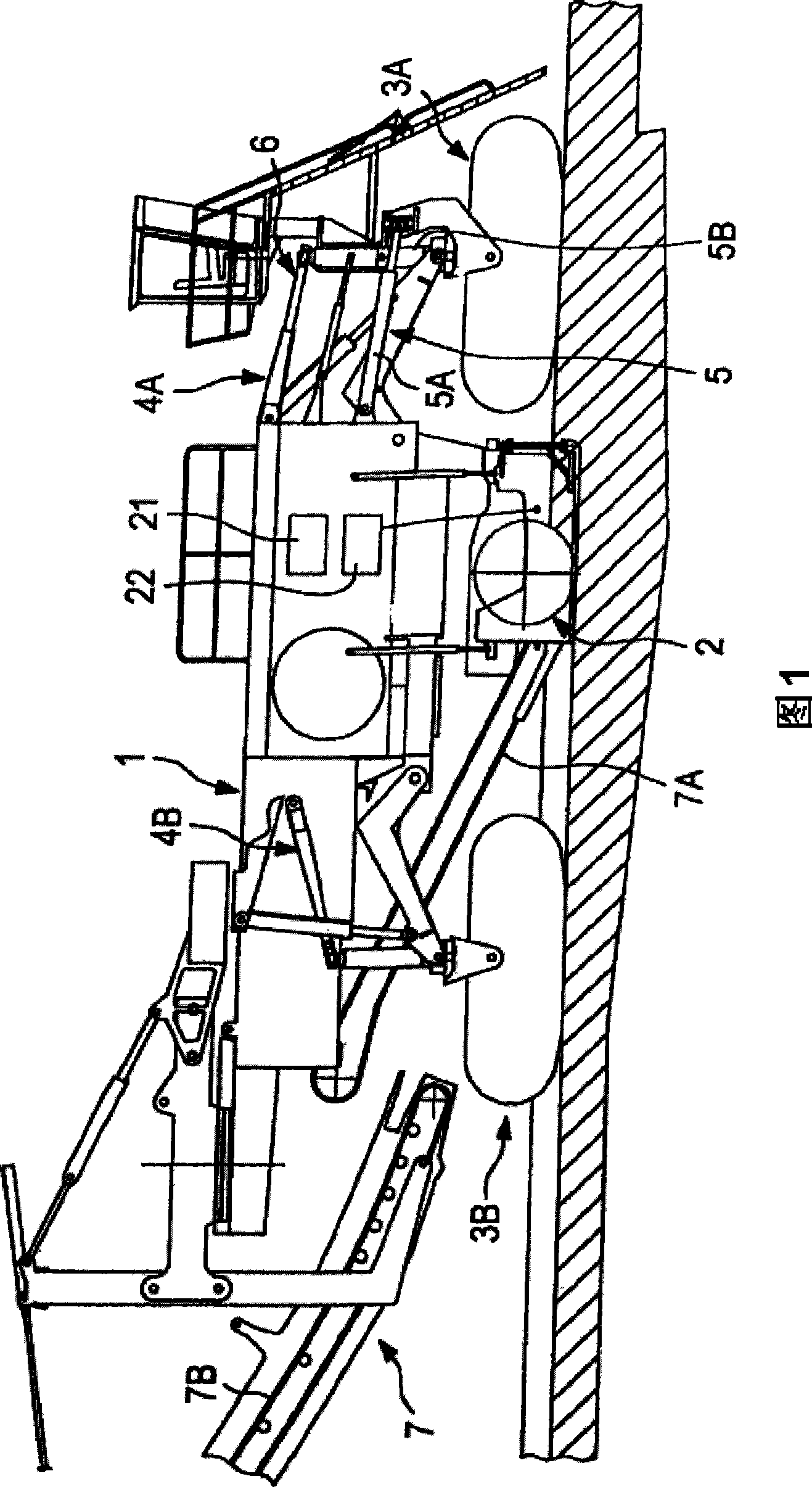

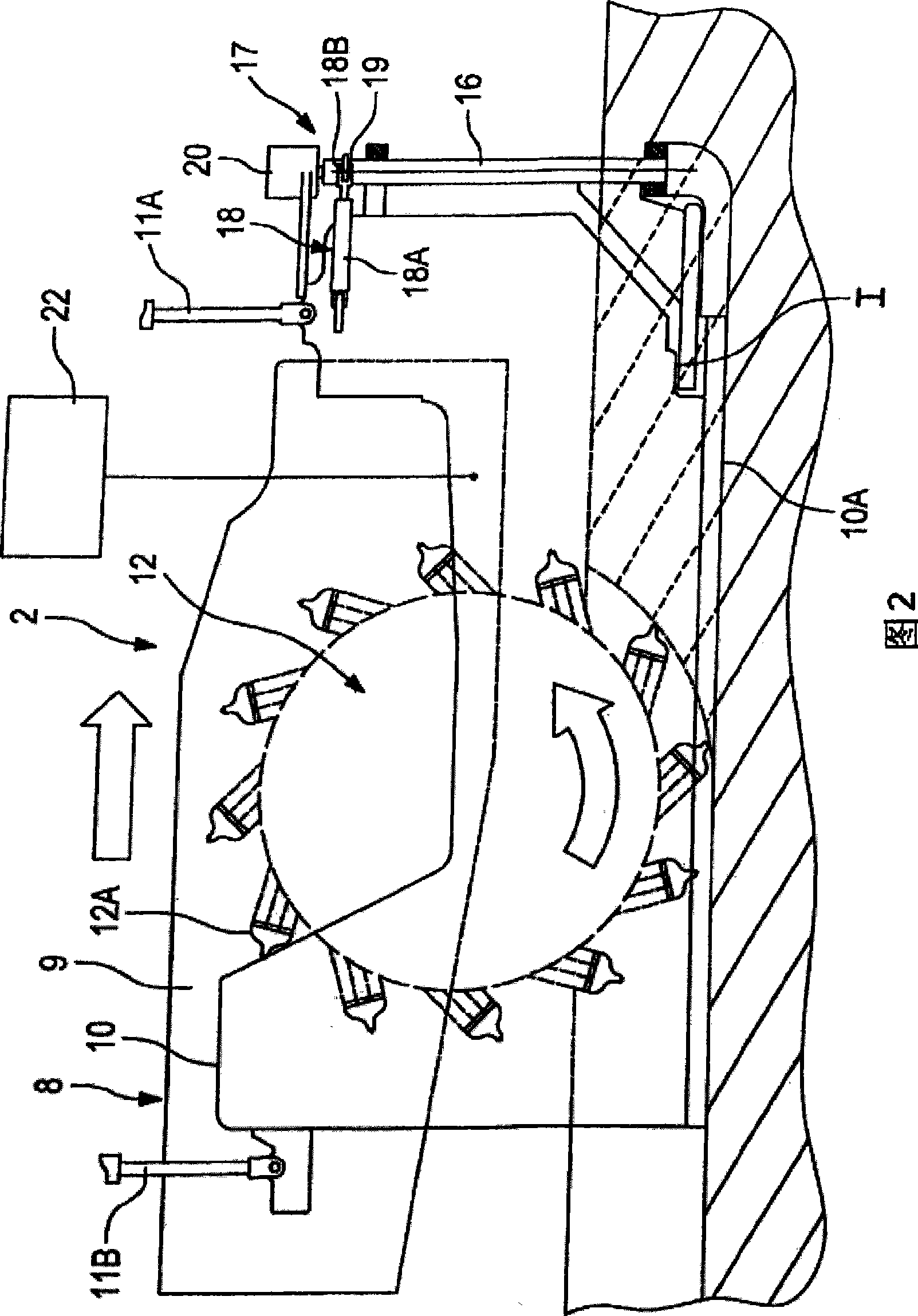

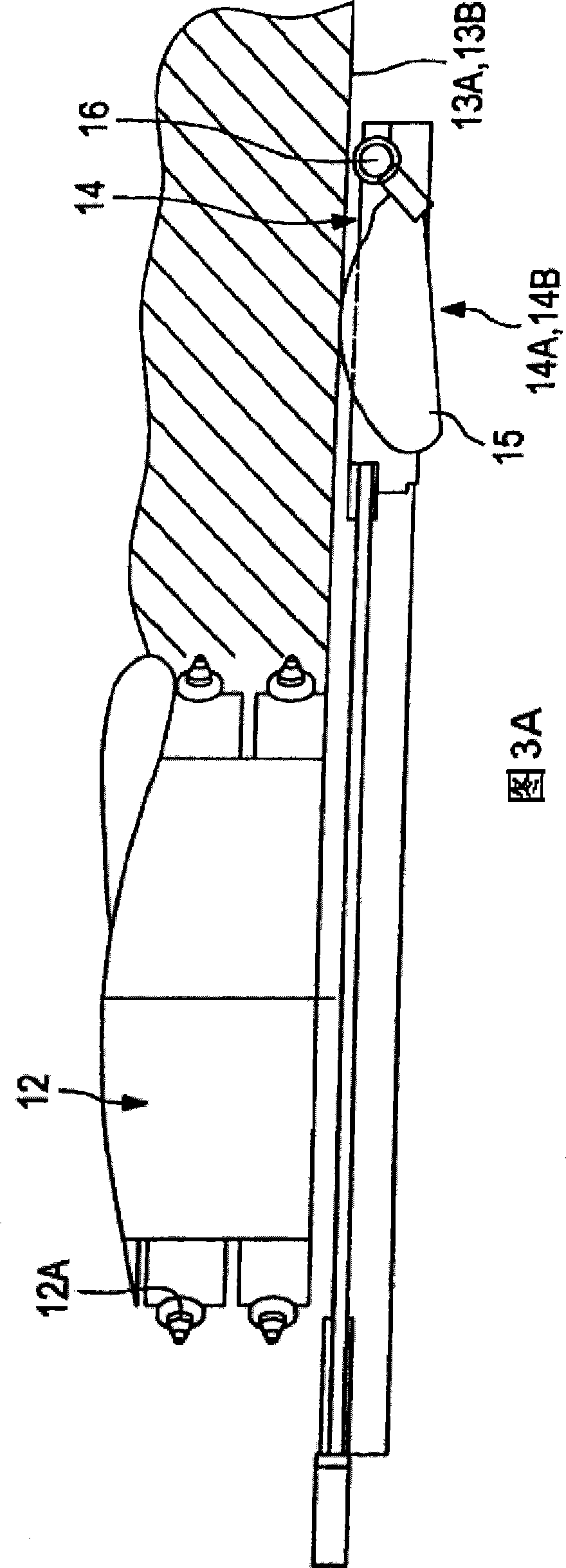

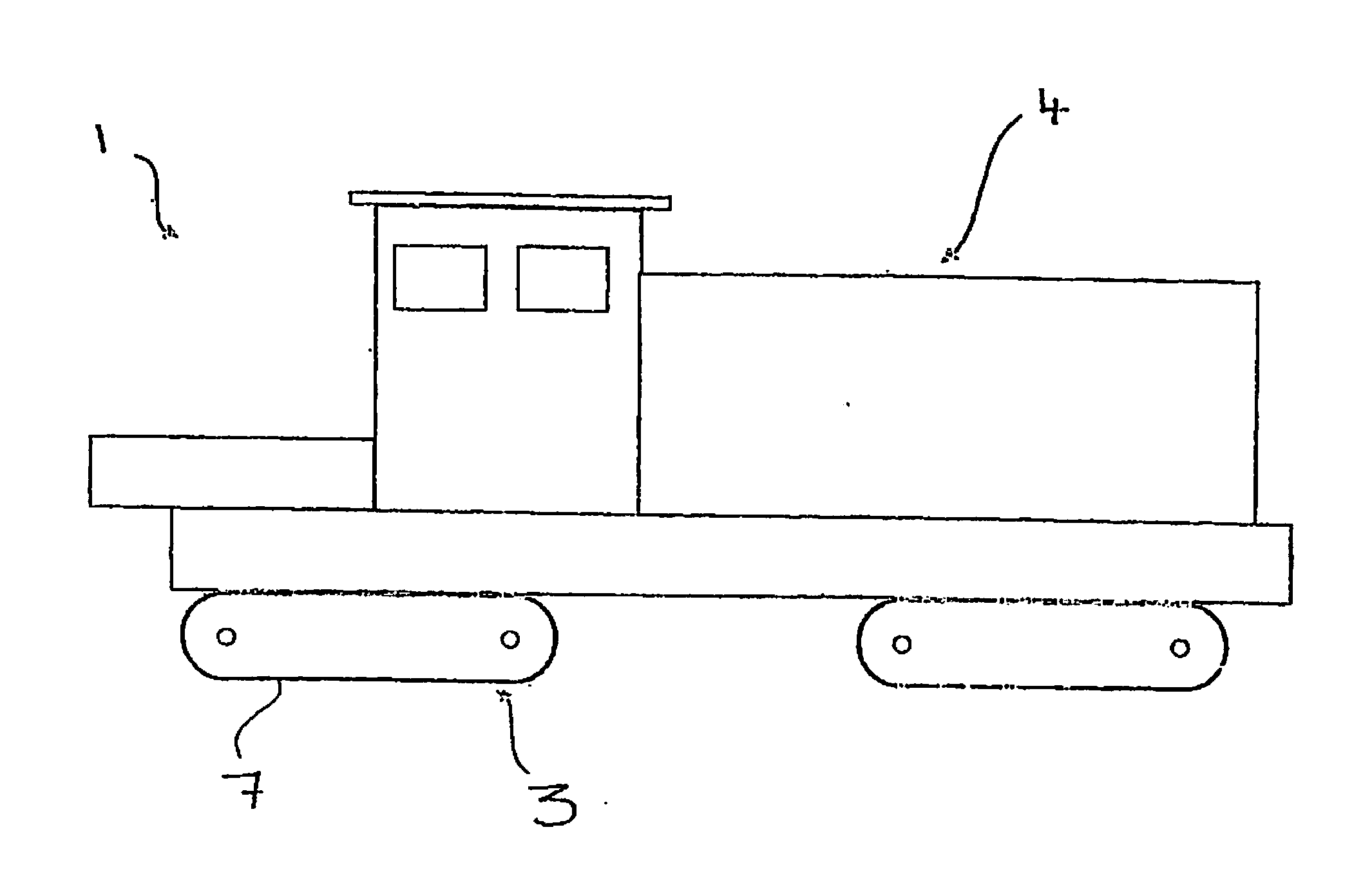

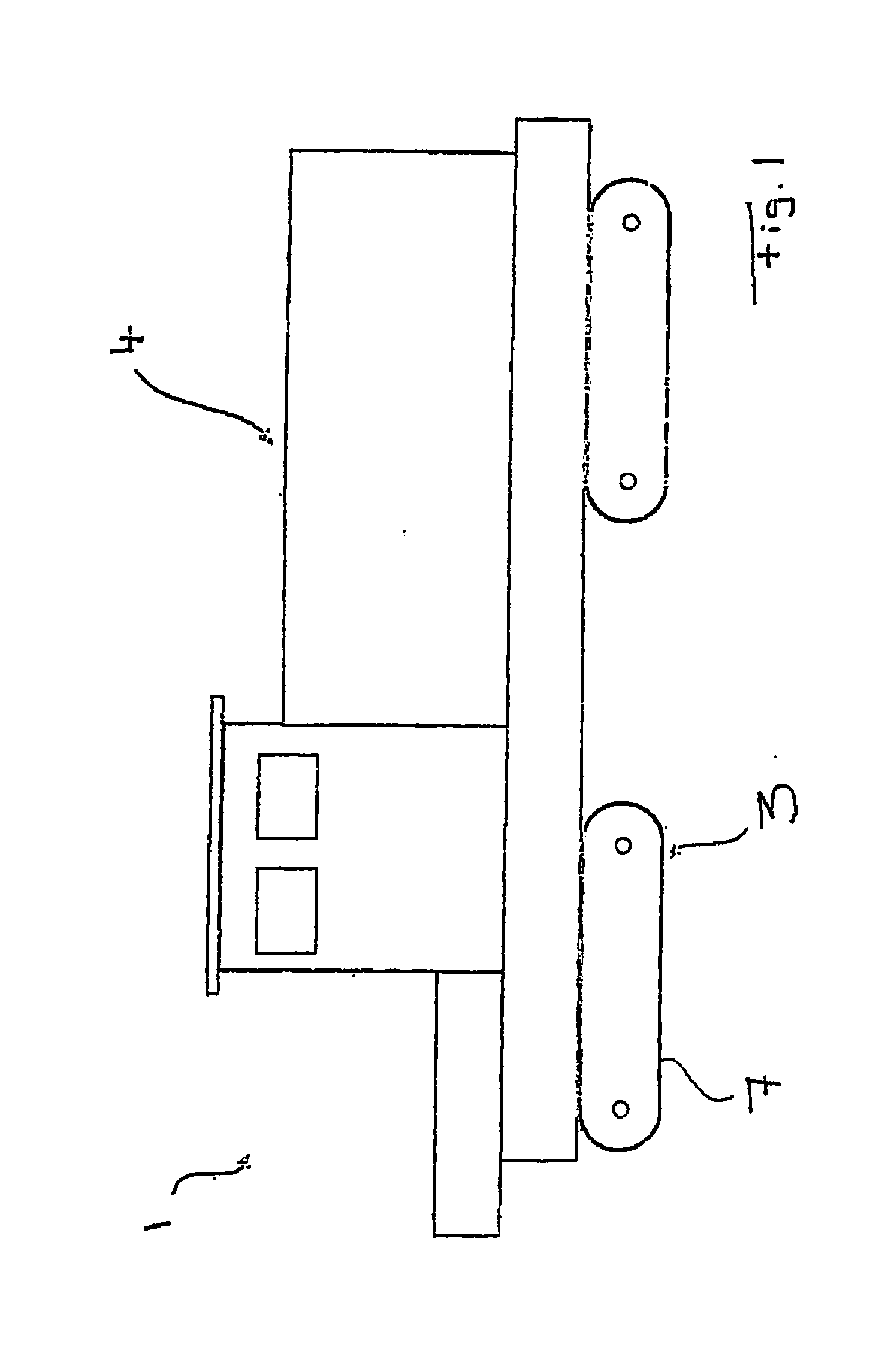

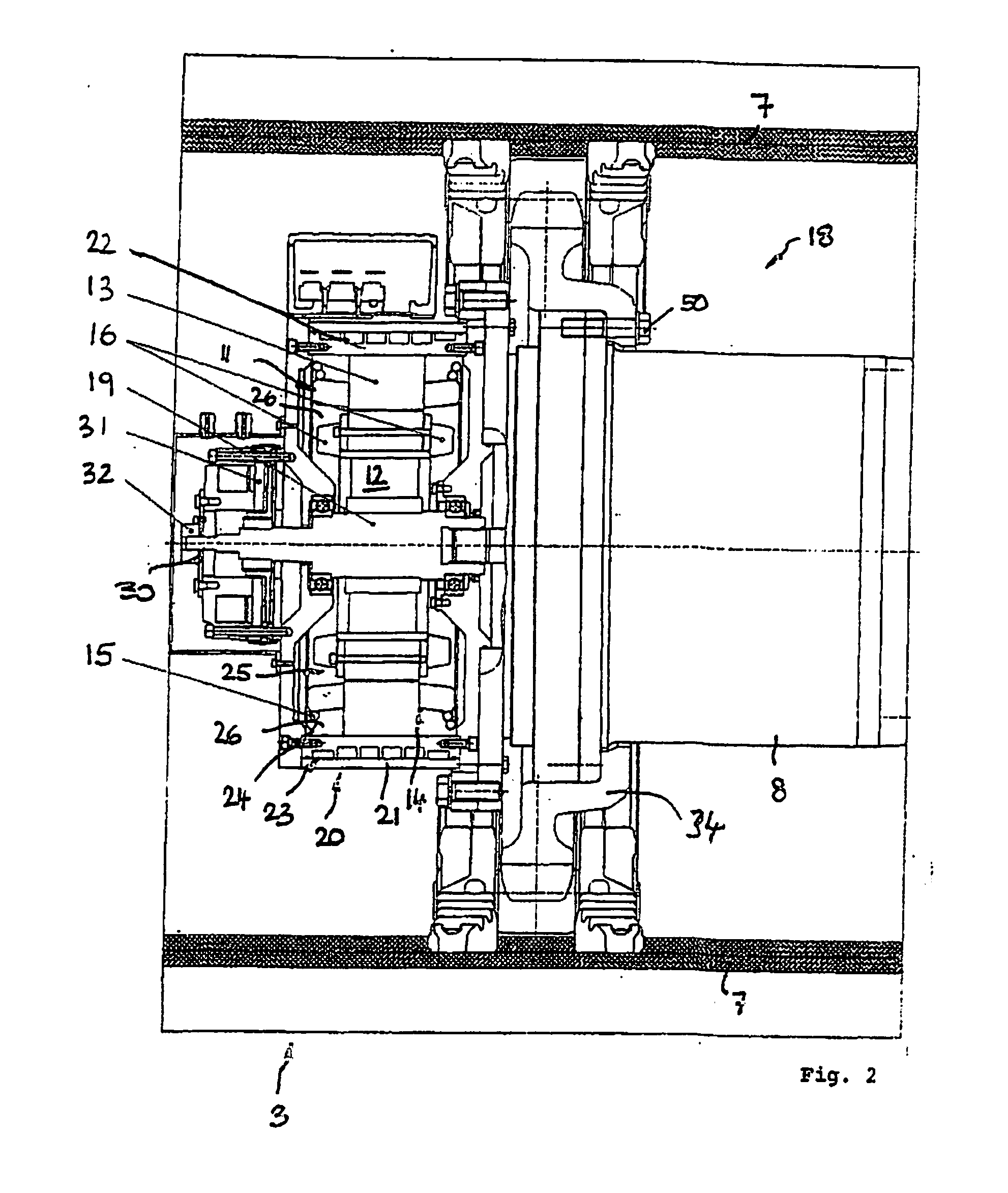

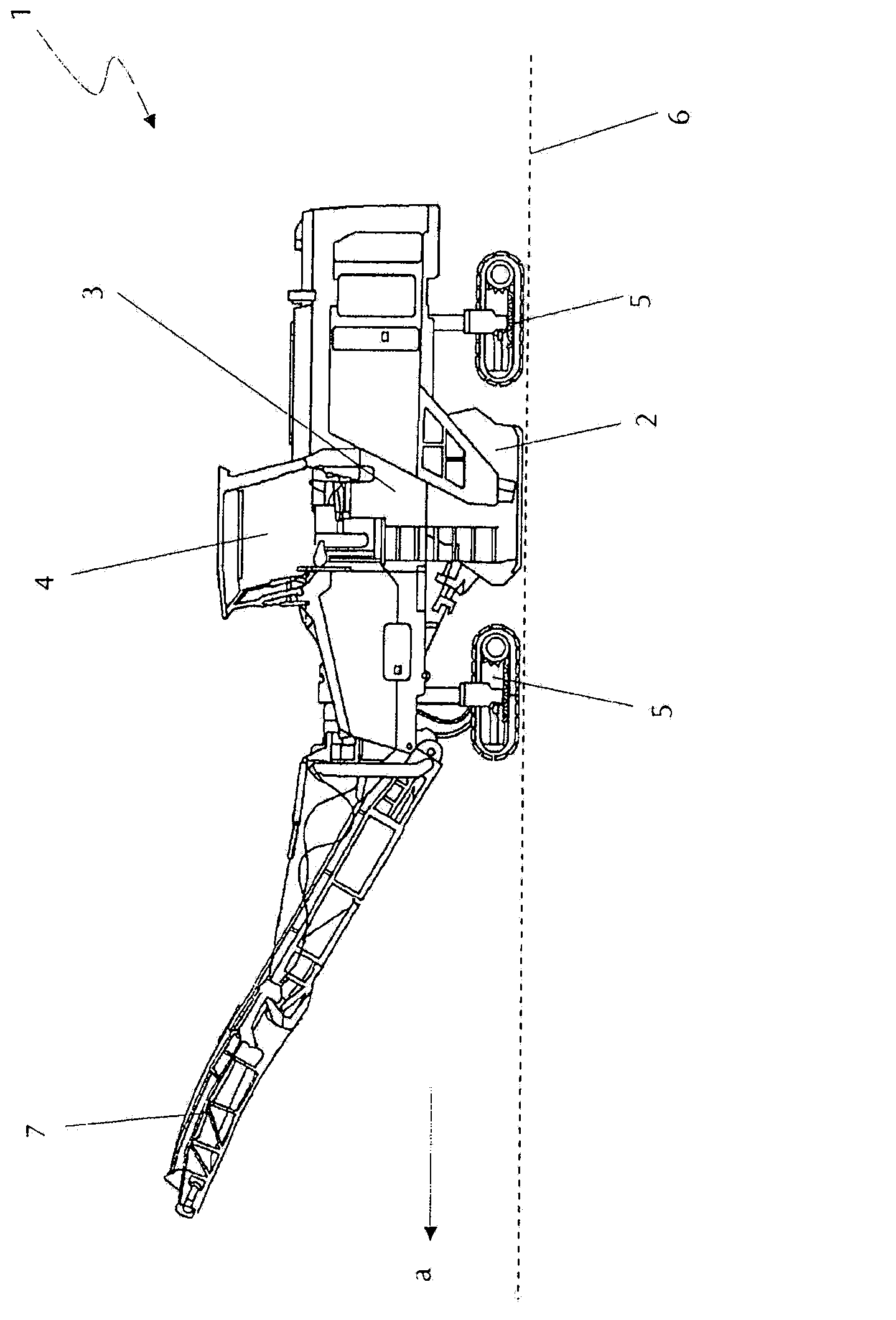

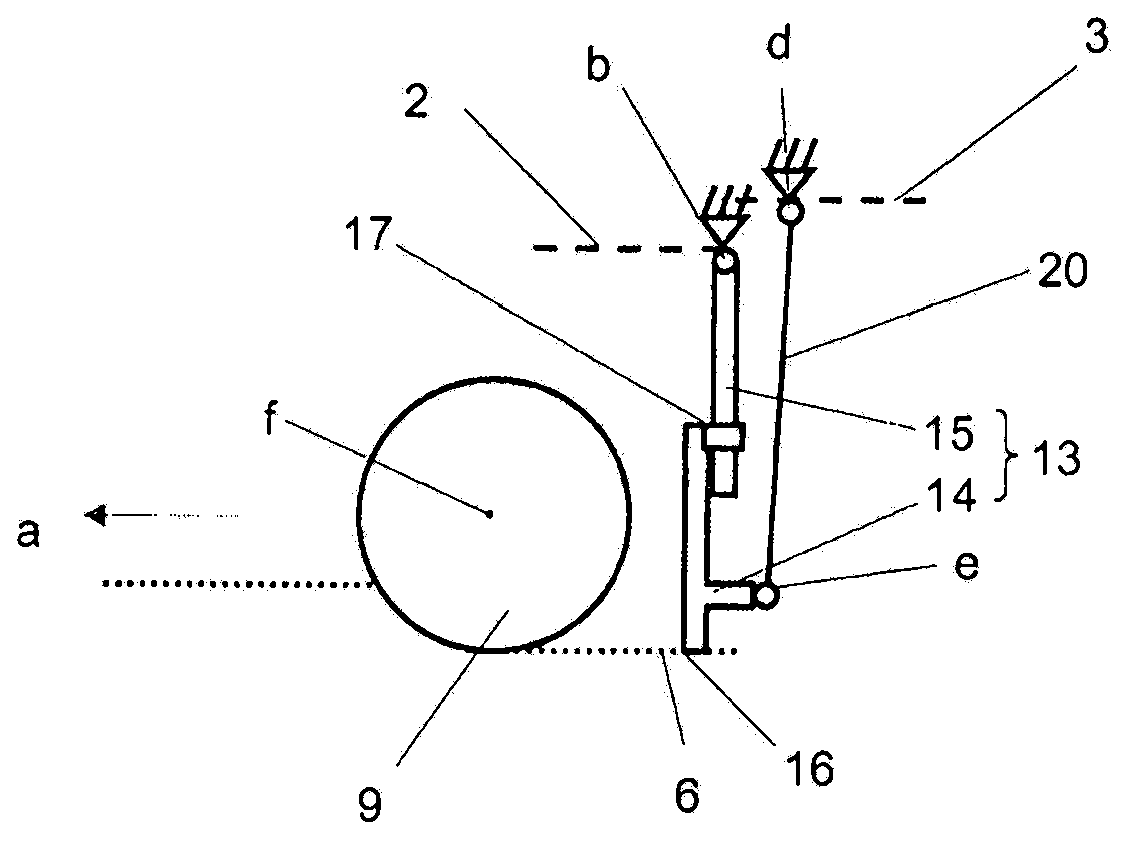

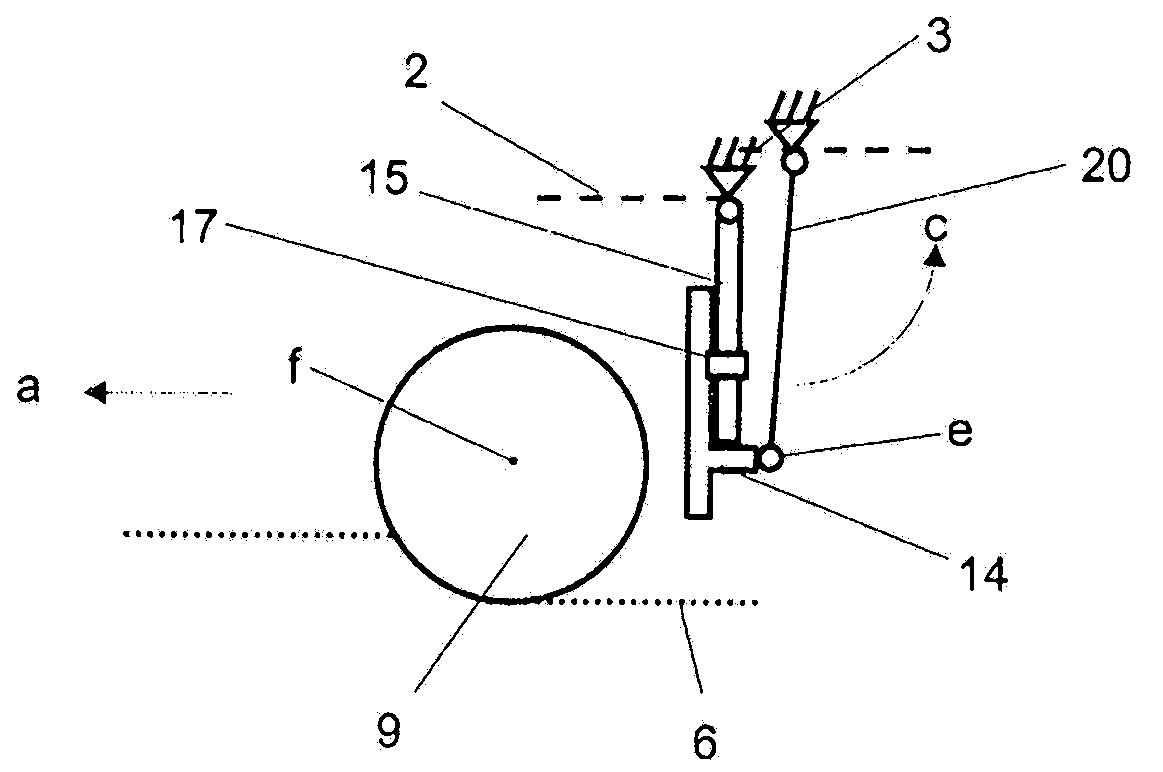

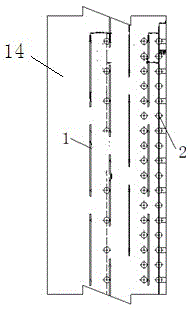

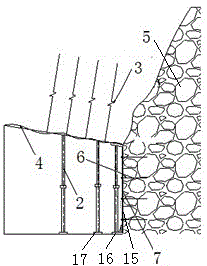

Road-milling machine or machine for working deposits

The invention relates to a road-milling machine or machine for working deposits, such as deposits of coal, ores, minerals, etc. by surface mining. The machine according to the invention has an arrangement 14 for detecting the path followed by a milled edge 13 of a milled strip, with the arrangement for detecting the path followed by the milled edge having means 14 for measuring the distance between at least one reference point I on the machine and the milled edge. The means 14 for detecting the path followed by the milled edge co-operate with the arrangement 6 for steering the track-laying units 3A, 3B in such a way that the machine follows the path followed by the milled edge. The distance between the at least one reference point on the machine and the milled edge can be set in such a way that milled strips situated alongside one another are exactly aligned relative to one another.

Owner:WIRTGEN GMBH

Pick For Earthworking Machine

A pick to be used on an earth working roll for mining, construction and public works machines such as crushers, surface miners, milling machines and the like. The pick includes a working end with holes that extend into the pick and inserts are received into the holes. The inserts during operation impact and fracture a consolidated material to separate the material. Impacting the material generates heat in the pick at the working end of the pick which must be dissipated and attenuated to limit thermal fatigue in the inserts that occurs at high temperatures. The inserts in the working end are configured to dissipate the generated thermal energy from the inserts to the body of the pick.

Owner:ESCO HYDRA UK

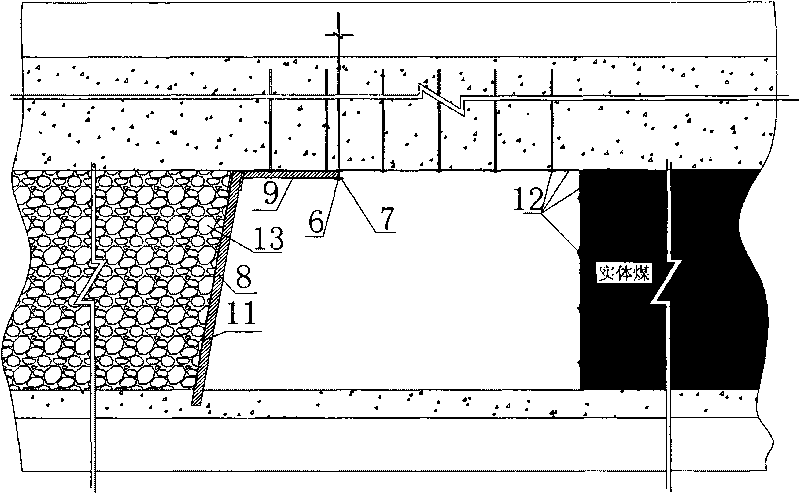

Gob-side entry retaining method of a solid filling coal mining half-section one-leg shed

InactiveCN101761338AAvoid lostImprove recovery rateUnderground miningSurface miningSolid massMining engineering

The invention relates to a gob-side entry retaining method of a solid filling coal mining half-section one-leg shed, which comprises the steps of supporting the coal side and the top plate of a roadway entity, filling a gob with a coal mining filling hydraulic support and a fill mining conveyor behind a filling coal mining working surface, and then fixing a row of H-shaped steel with an anchor rod and an anchor rope at the 1 / 3 point of the distance from an end top plate of the working surface to the gob; with the forward movement of one pace of the coal mining filling hydraulic support, a metal net is paved and side-wall I-beams are bridged firstly on the outer side of the gob; simultaneously, a metal net is paved within 1 / 3 of the distance from the top plate to the gob, and then a stull I-beam is bridged so as to form a reverse L-shaped one-leg shed steel structure support body; and with the forward movement of the coal mining filling hydraulic support, the side wall I-beams are connected and fixed via steel bars, and one-leg shed steel structure support bodies are connected into sheets which are matched with the support of the coal side and the top plate of a roadway entity to realize the gob-side entry retaining of a filling mining work surface mining roadway. The method is simple, has high support strength and low cost, is implemented easily and has high efficiency.

Owner:CHINA UNIV OF MINING & TECH

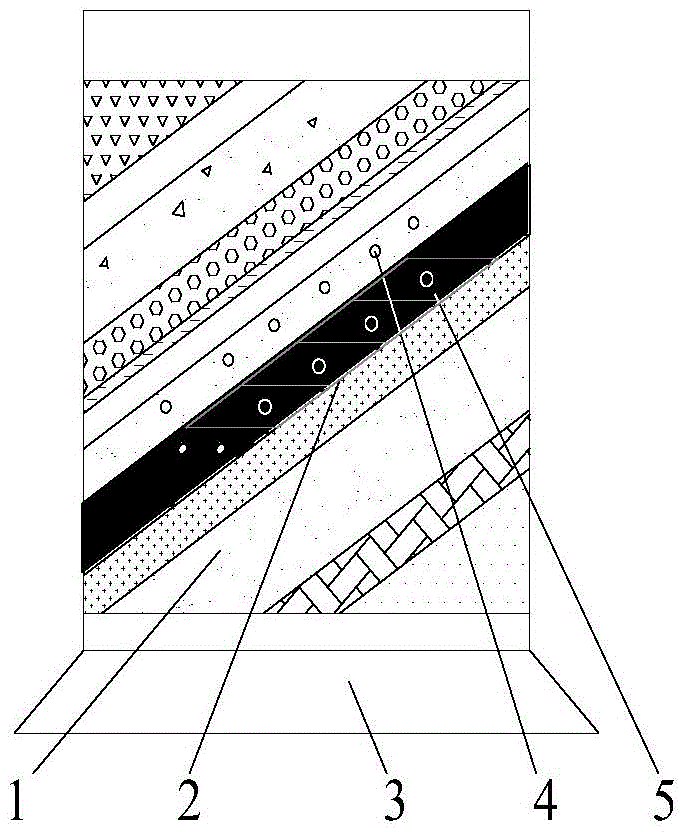

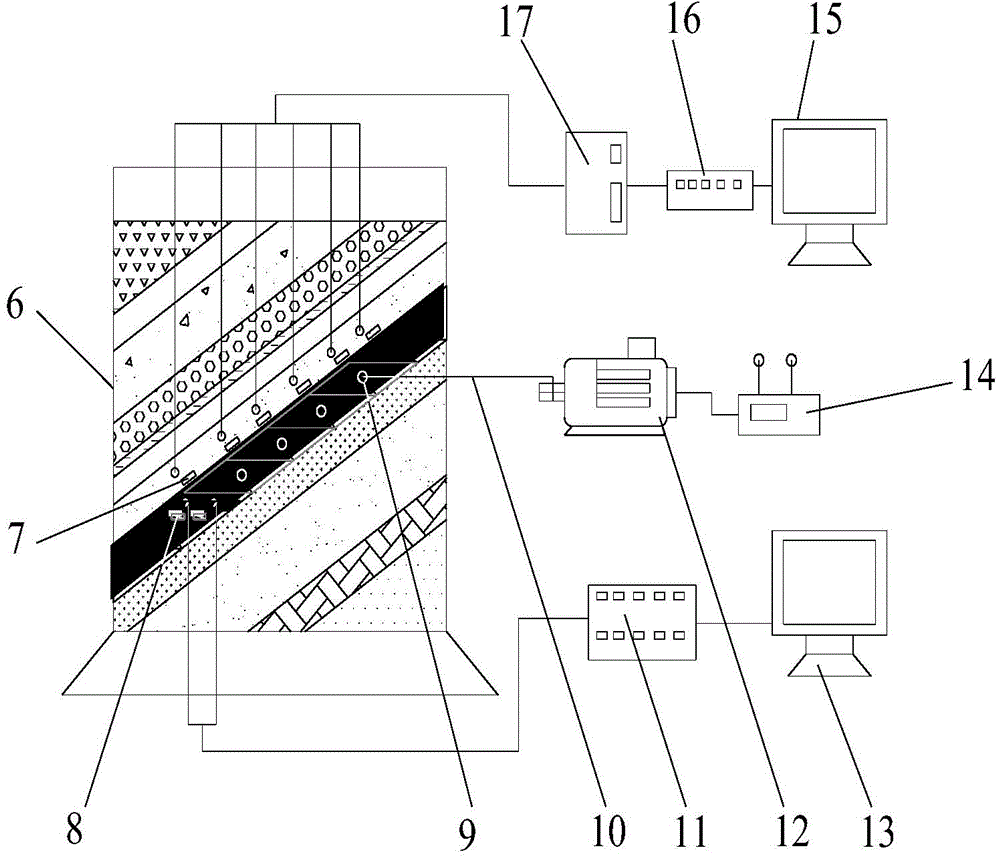

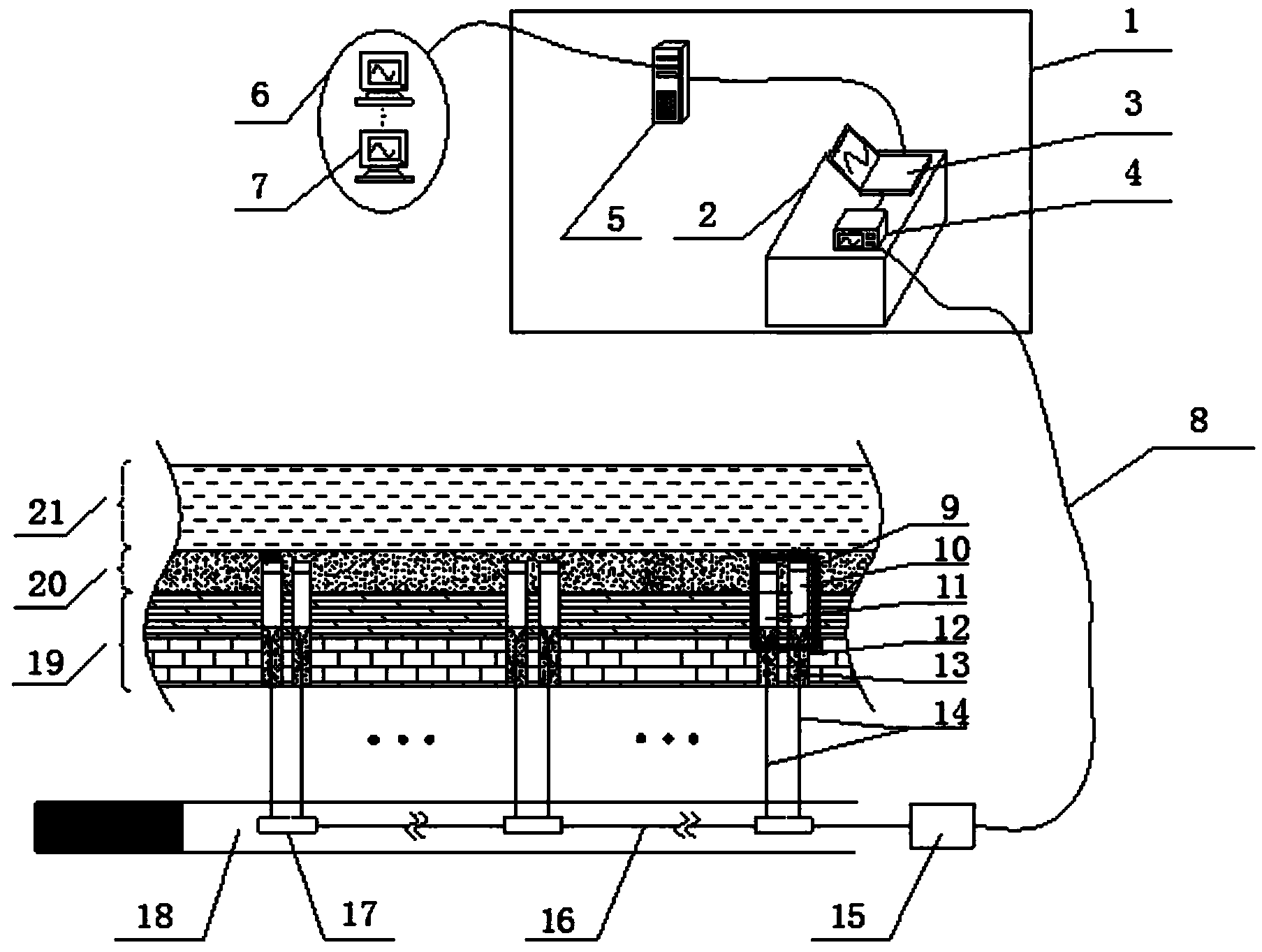

Heavy-pitch ultra-thick coalbed fully-mechanized caving mining three-dimensional similar material simulation test bed

ActiveCN104931674AHelp with simulationHelpful for analysisEarth material testingTechnological systemThree-dimensional space

The invention discloses a heavy-pitch ultra-thick coalbed fully-mechanized caving mining three-dimensional similar material simulation test bed, which solves the problems in the prior art that the two-dimensional similar material for heavy-pitch ultra-thick coalbed is poor in similarity and accuracy. The test bed comprises a test box body, a coalbed mining simulation system, an acoustic transmitting and monitoring system and a stress monitoring system, the coalbed mining simulation system comprises a peristaltic motor and a controller, the peristaltic motor is connected with a metal lock ring on the tail part of a cylindrical medium simulation material in a test box body, a parallelogram jack is respectively formed in a left baffle plate and a right baffle plate of the test box body. By adopting the heavy-pitch ultra-thick coalbed fully-mechanized caving mining three-dimensional similar material simulation test bed, the simulation in a three-dimensional space form can be carried out and is closer to the real situation of the engineering, the moving rule of a overlying strata in the heavy-pitch ultra-thick coalbed fully-mechanized caving mining process, the pressure release rule of a coalbed soleplate and the surface mining settlement rule can be obtained, and theoretical support can be provided for establishing a heavy-pitch ultra-thick coalbed fully-mechanized caving mining technical system.

Owner:SHANDONG UNIV OF SCI & TECH

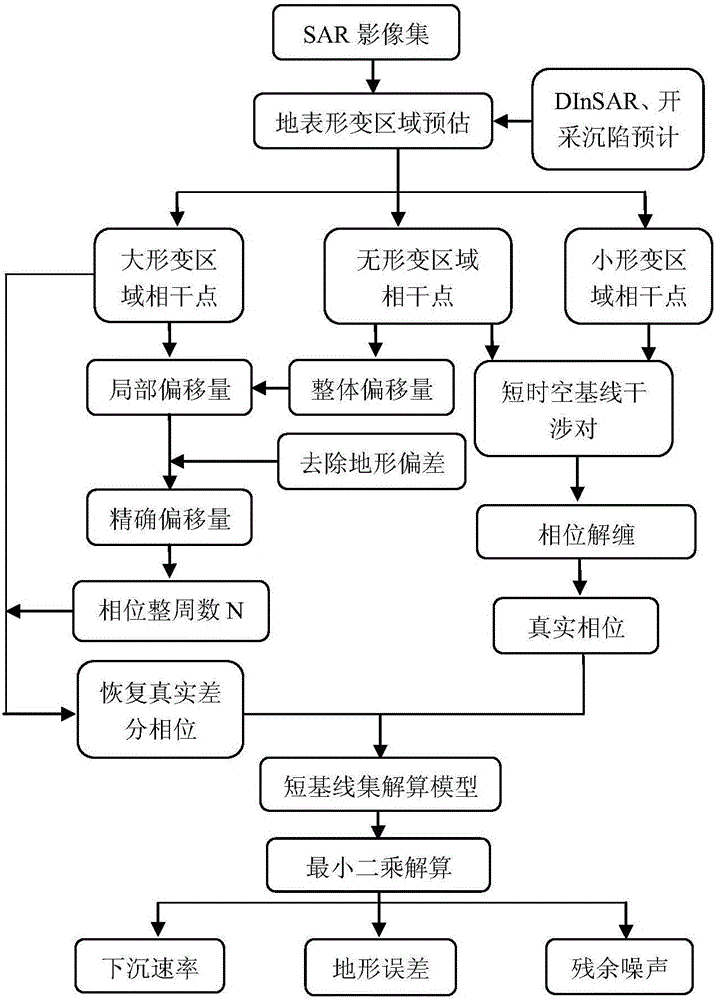

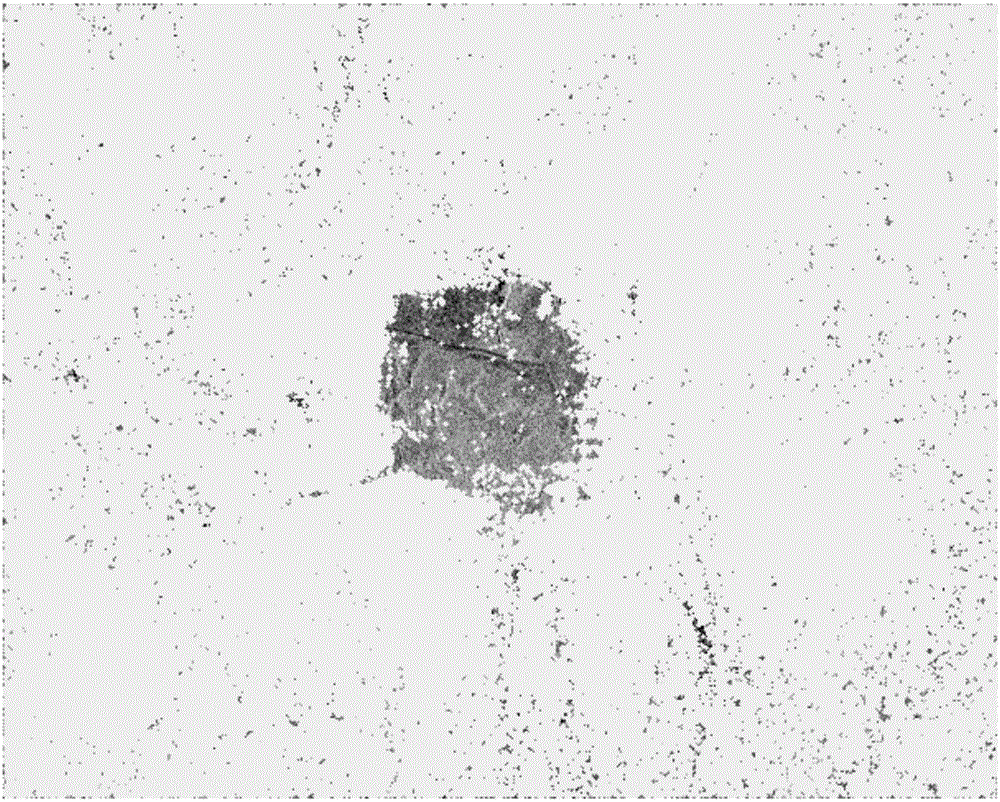

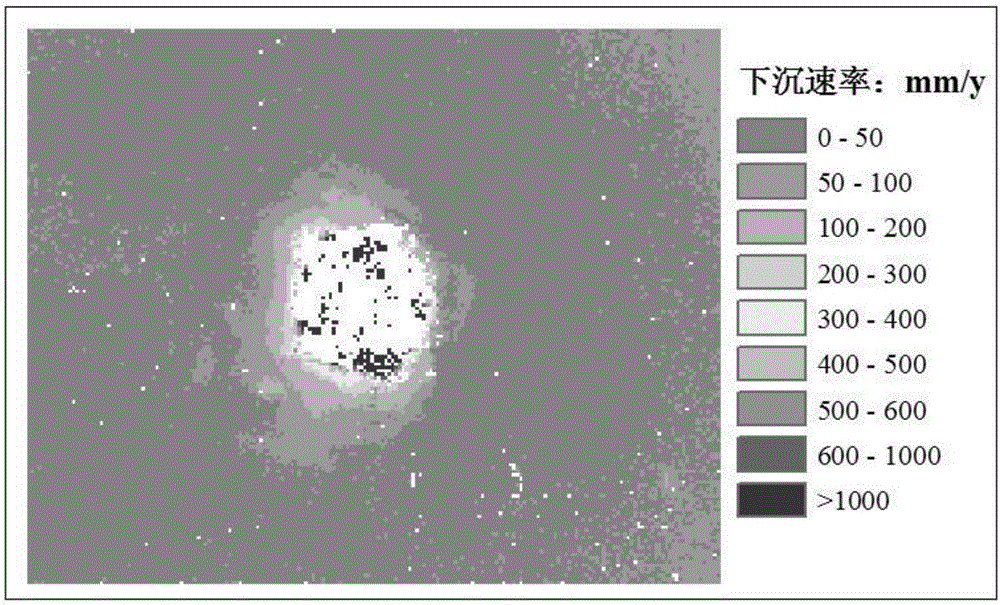

Mining area surface deformation resolving method through fusion of pixel element offset tracking and short baseline set

ActiveCN106066478ASolve the problem that the terrain error cannot be solved effectivelyImprove monitoring accuracyRadio wave reradiation/reflectionDifferential phaseLarge deformation

The invention provides a mining area surface deformation resolving method through fusion of pixel element offset tracking and a short baseline set, and is suitable for the research of surface mining area surface deformation. The method comprises the steps that a mining area surface deformation area is pre-estimated; high-coherence points in coherence images on time sequences are selected; the number N of integer phase cycles of the high-coherence points of a large-deformation area is recovered by utilizing a time sequence offset tracking algorithm; the high-coherence points of the large-deformation area and a small-deformation area are combined to establish a short baseline set resolving model; and resolving of mining area surface elevation error and deformation rate is performed. The method is high in monitoring precision, large in range, simple in implementation operation process and low in cost so that the problem that the conventional time sequence InSAR method cannot correctly acquire surface settlement under large mining area deformation gradient can be overcome, the problem that the time sequence pixel element offset tracking algorithm based on SAR amplitude information and the short baseline set technology based on differential phase are difficult to combine to resolve the surface deformation rate and the elevation error can also be solved, and thus the method has wide practicality.

Owner:CHINA UNIV OF MINING & TECH

Safety recovery method of island working surface under complicated condition

ActiveCN104453899ADoes not affect normal recoveryNormal recovery guaranteeUnderground miningSurface miningRecovery methodPlate pressure

The invention relates to a safety recovery method of an island working surface under a complicated condition. An innovated manner of pre-discharging before mining and mining while discharging is adopted, and normal recovery of the working surface is not influenced by deposited water of a goaf. Other relative rock burst prevention and treatment methods including drilling and pressure relief, bottom plate pressure relief and blasting, coal seam water injection and the like are adopted by rock burst prevention and treatment, so that the accuracy degree of predication is improved, the possibility of rock burst is reduced and guarantees are provided for the normal recovery of the working surface. A working surface mining stopping position is comprehensively determined by adopting a manner of combining adjusting slope of tail mining of the working surface and avoiding a periodic pressure position, the length of the working surface is in a cutting range of a coal mining machine and the two ends of the working surface avoid the periodic pressure position, and the middle part of the working surface does not avoid the periodic pressure position.

Owner:DATONG COAL MINE GRP

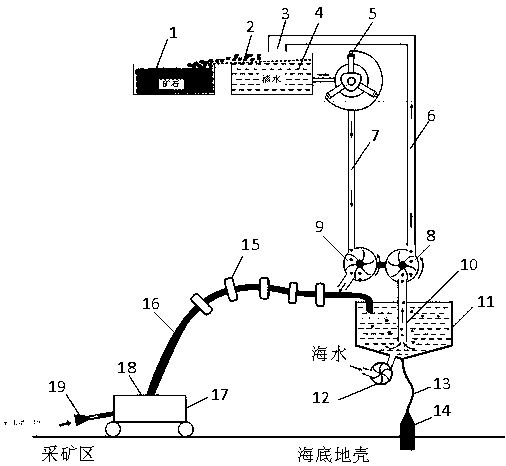

Novel lifting system for deep-sea mining

The invention relates to a novel lifting system for dee-sea mining. The novel lifting system comprises a mining mechanism, a mine water lifting mechanism and a mine water separating mechanism; the mining mechanism comprises a mining cart which is arranged on the sea floor, a mining cart ore absorbing port is arranged on the front part of the mining cart, and a mining cart ore conveying pump is arranged on the rear part of the mining cart ore absorbing port; the mine water lifting mechanism comprises a high-pressure water feeding pump, a lifting main pipe, a water feeding pipe and a middle bin;the middle bin is connected with a fixed pile which is arranged on the sea floor bottom crust through a middle bin sea floor fixing cable rope, the middle bin is connected with the mining cart through a hose, and a floating body is arranged on the hose; the mine water separating mechanism comprises an ore storage tank, a mine water separating mechanism body and a clean water tank which are arranged on a sea surface mining vessel; and the ore storage tank is connected with the clean water tank through the mine water separating mechanism body. The novel lifting system for deep-sea mining has the advantages that hydraulic power is used for lifting, waste water lifted to the water surface can be fed back to the sea floor, meanwhile, a lifting pump on the sea floor can be driven to lift ore through the waste water, and the environment of the mining sea surface is protected.

Owner:JIANGSU UNIV OF SCI & TECH +1

A high-efficiency, safe and environmentally-friendly mining method for irregular strip-shaped distribution of poor and shallow buried seams

InactiveCN102278115AIncrease production capacityEasy to manageMaterial fill-upOpen-pit miningEcological environmentLand resources

The invention discloses a high-efficiency, safe and environment-friendly mining method for irregular strip-shaped thin and shallow buried mine seams. The mining method adopts the method of arranging mining pits along the direction of the mine seam, and Stripping and mining by step-by-step open-air step blasting in sequence, drilling, blasting and transportation are arranged in steps. The drilling, blasting, and transportation operations have high production efficiency and are safer than other mining methods. The stripped waste rock is backfilled to the first mining area. The mined-out area of the section saves land resources, protects the natural environment, saves transportation costs, reduces comprehensive mining costs, reduces energy consumption, and reduces waste rock discharge. The invention solves the problems of backward mining planning, low production efficiency, unsafe production, valuable land occupied by dumps, environmental pollution by dumps, high transportation energy consumption, high mining costs and living environment caused by mining in traditional open-pit mining projects. and environmental pollution and other technical issues.

Owner:汉通控股集团有限公司

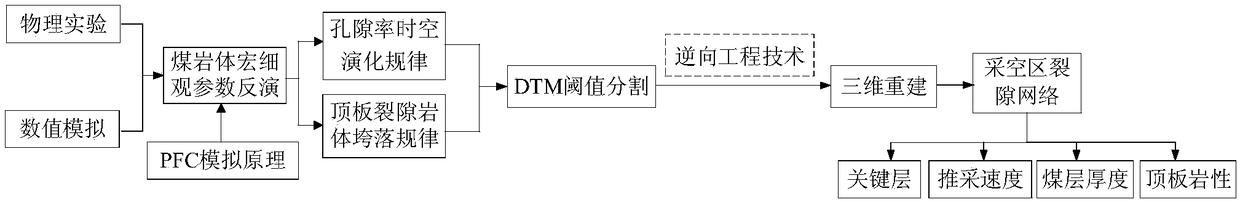

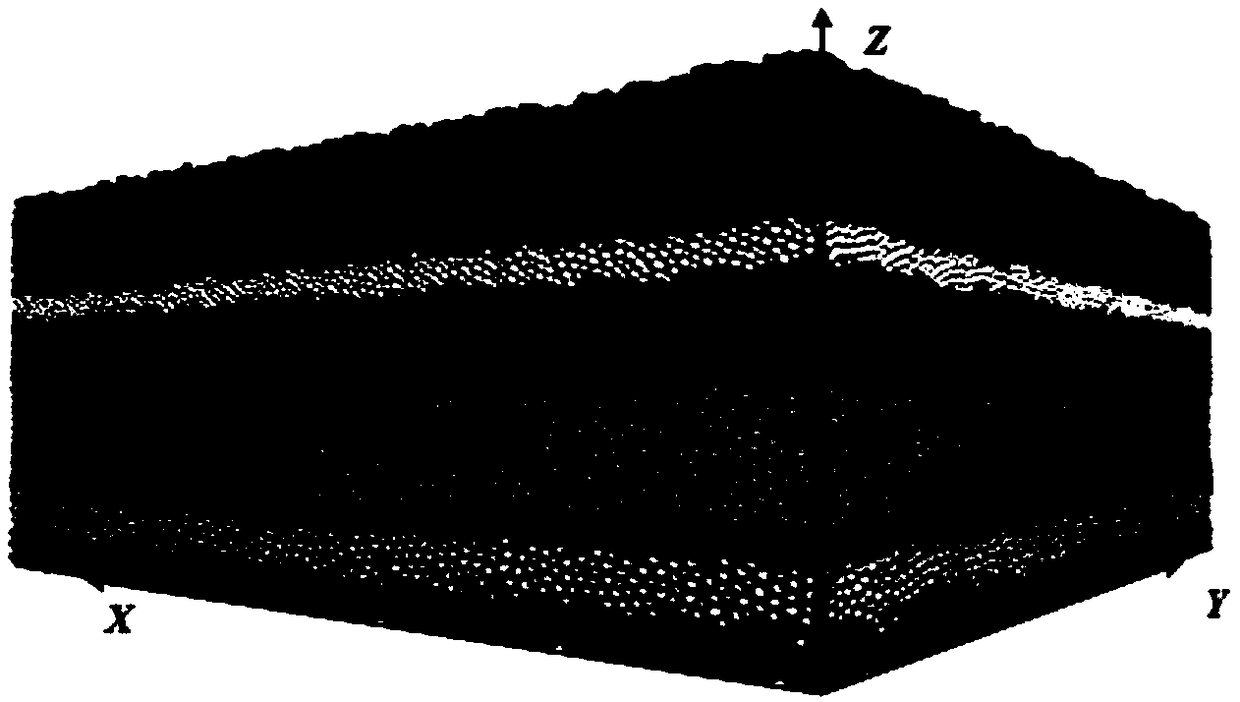

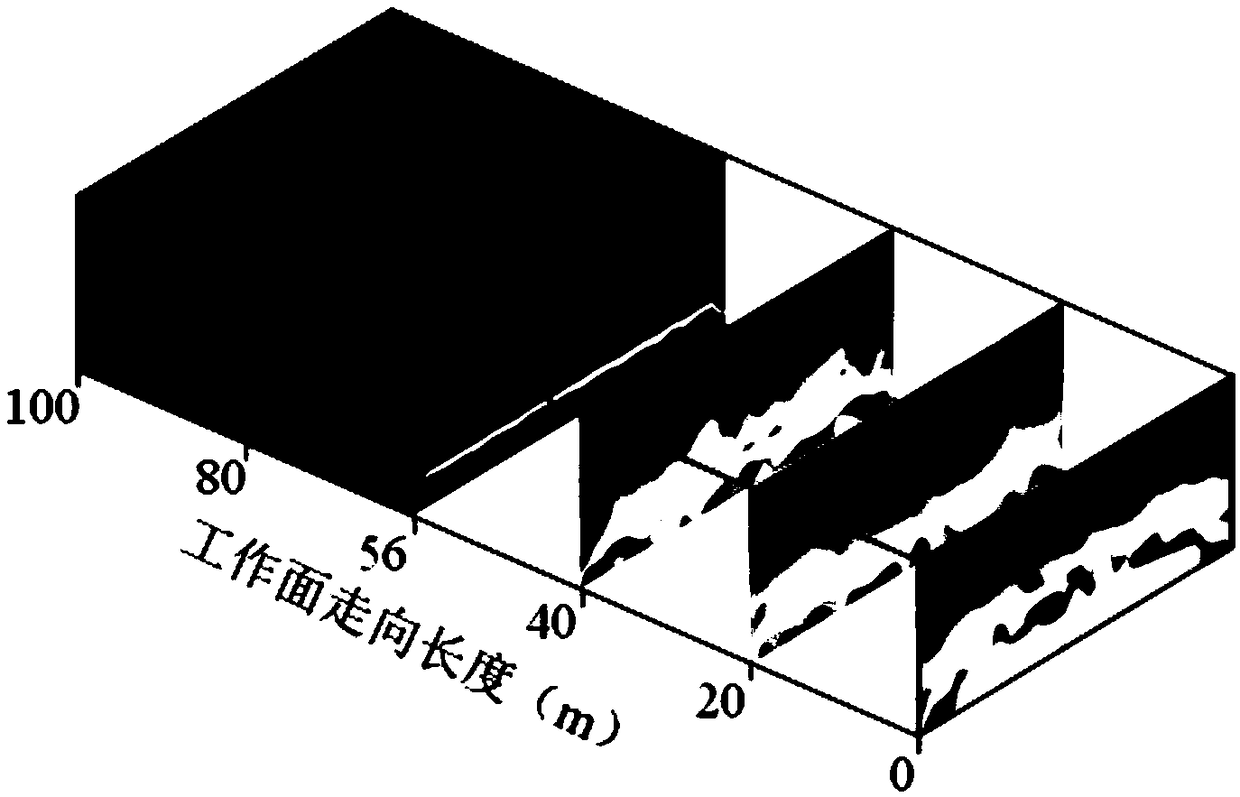

Overburden strata mining-induced fracture network model construction method

ActiveCN108763650ARealize dynamic analysisDesign optimisation/simulationImage data processingPorosityImaging processing

The invention discloses an overburden strata mining-induced fracture network model construction method. The method comprises the following steps of: constructing a working surface mining model throughgrain flow numerical simulation software, and simulating a real working surface mining process by adoption of a distributed mining method; obtaining a collapse form and a porosity spatial-temporal distribution evolution law in the model in each mining period; and obtaining a porosity result by combining an image processing technology, real investigation of porosity in gobs in local point positionareas and PFC3D simulation, extracting rocks and fracture spaces of a two-dimensional image, and extracting gob fracture network distribution information on the basis of a three-dimensional reconstruction technology so as to establish an overburden strata mining-induced fracture network model. Through the method, dynamic representation of distribution processes of real fracture networks in miningprocesses can be rapidly realized on the basis of quantitative representation of macro-micro parameters of coal and rock masses.

Owner:XIANGTAN UNIV

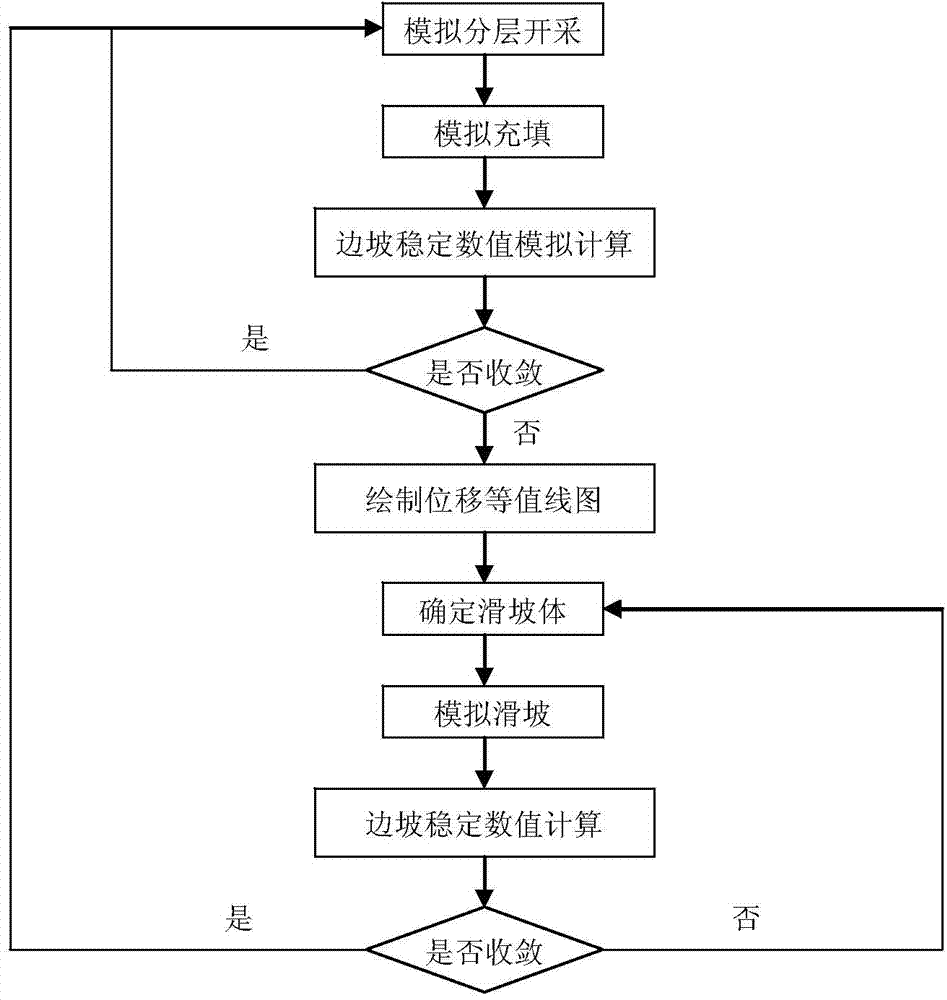

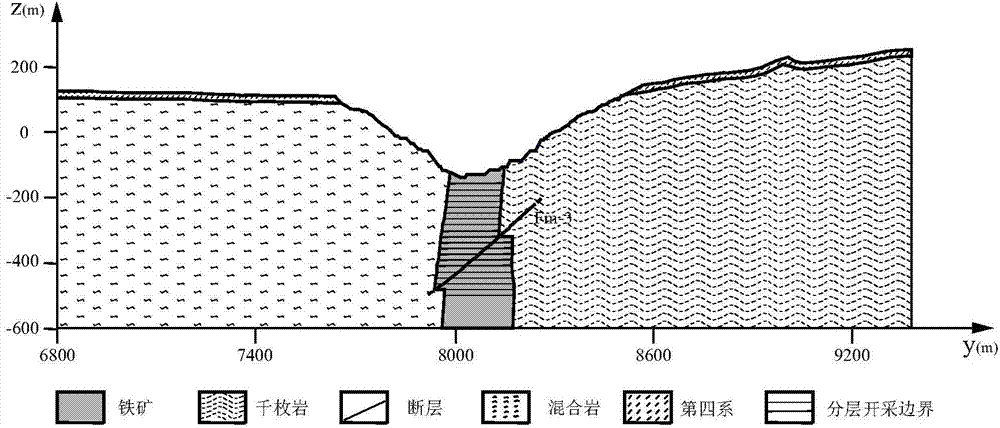

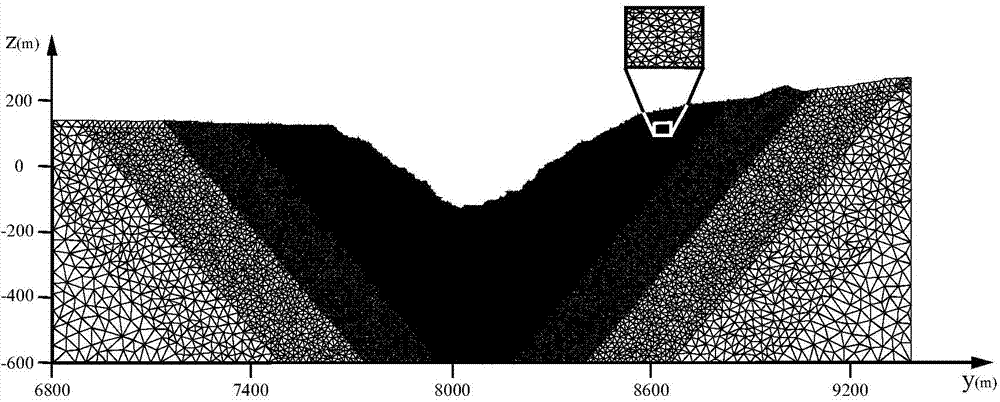

Method for predicating mine pit slope deformation destroy induced by conversion from surface mining to underground mining

The invention relates to a method for predicating mine pit slope deformation destroy induced by conversion from surface mining to underground mining. The method is characterized in that numerical simulation analysis software FLAC<3D> is adopted, a slope numerical analysis mode is built, the simulation processes of layer mining, numerical calculation and land sliding are cyclically used, the continuously generated processes of stabilization, stability losing, land sliding and re-stabilization of the mine pit slope in the mining process are simulated, and further, the slope deformation destroy rule in the underground mining process is obtained. The method has the advantages that the influence degree of the mining on neighboring buildings and facilities is judged according to the mine pit slope destroy predication result, basis is provided for determining the removal range and the removal time, and in addition, reference is provided for reasonably laying out ground facilities to be built in the aspects of production, office, life and the like.

Owner:ANSTEEL GRP MINING CO LTD

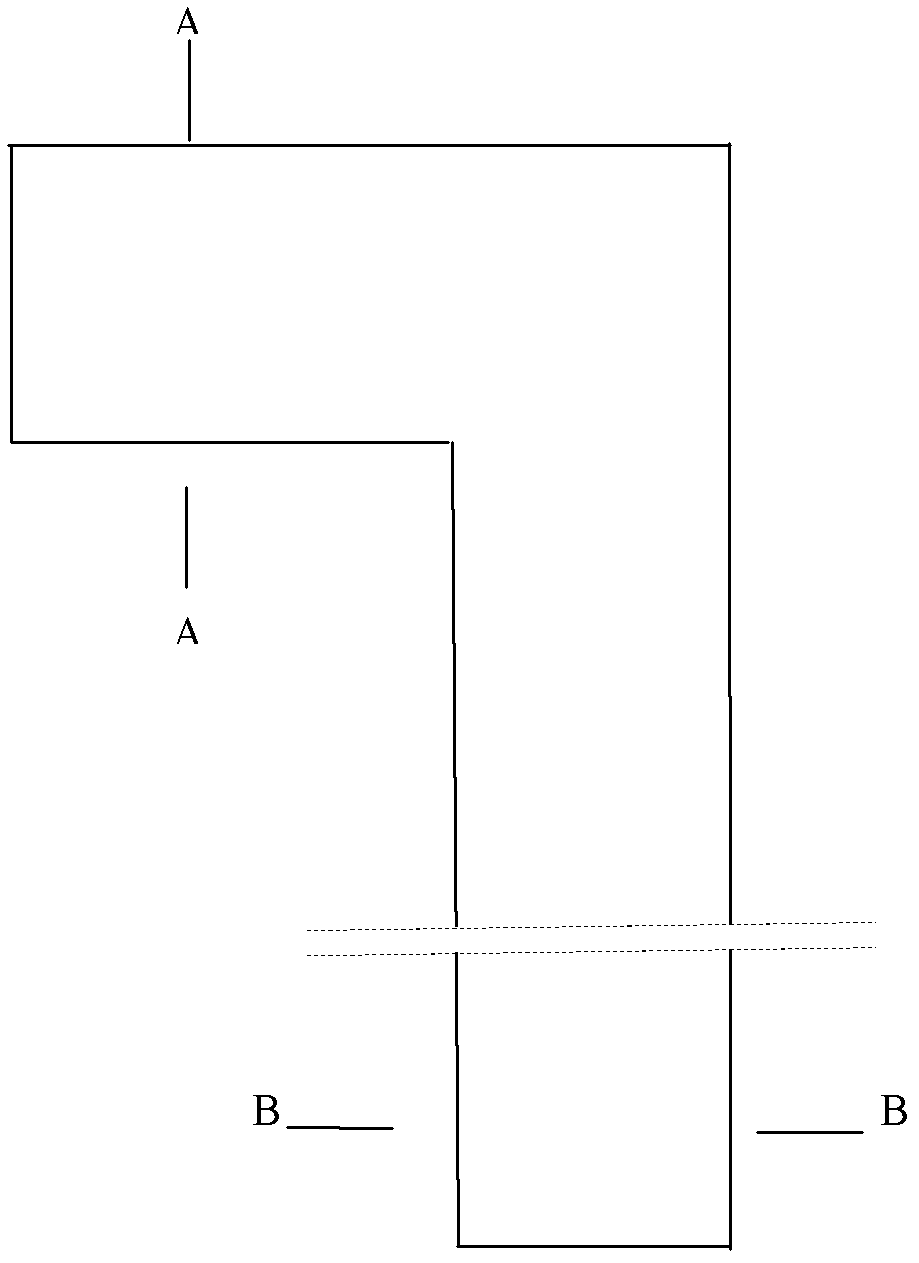

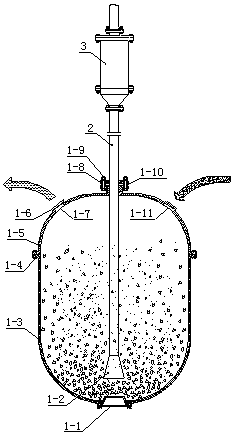

Deep-sea ore transport system relay warehouse

InactiveCN108194085ASolve the problem of clogged orificeImprove mining efficiencyMineral miningTransport systemDual action

The invention discloses a deep-sea ore transport system relay warehouse. The deep-sea ore transport system relay warehouse comprises an upper warehouse body, a lower warehouse body, a warehouse connection bolt assembly, a fluidic generator, and a fluidic generator connecting bolts. Polymetallic nodules reserved under the sea are collected by an ocean mining machine and are transported to the relaywarehouse by an ore pulp conveyor hose after mud removal and crushing; and a lifting rigid pipe connected with a pulp pump is directly inserted into the bottom end of the relay warehouse, the position, close to the bottom end of the relay warehouse, of the lifting rigid pipe is provided with a bell-shaped suction inlet, and the fluidic generator is arranged on the relay warehouse under the bell-shaped suction inlet. When the pulp pump works, the bottom end of the bell-shaped suction inlet generates upward water jet due to negative pressure, and ore particles deposited at the bottom of the relay warehouse are sucked into the lifting rigid pipe under the dual action of the suction of the pulp pump and the jet flow water hammer and are transported by a pipeline to a surface mining ship. Thedeep-sea ore transport system relay warehouse is simple in structure and convenient to use, and effectively solves the problem that a pipe outlet is plugged due to that fact that a deep-sea ore transport system is prone to depositing materials at the suction inlet of the lifting rigid pipe.

Owner:CENT SOUTH UNIV

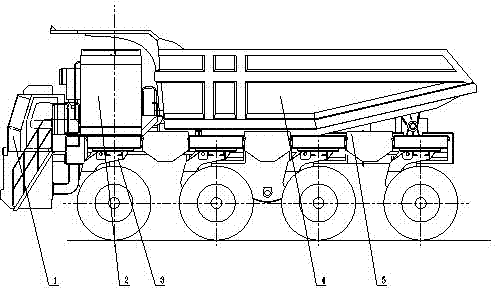

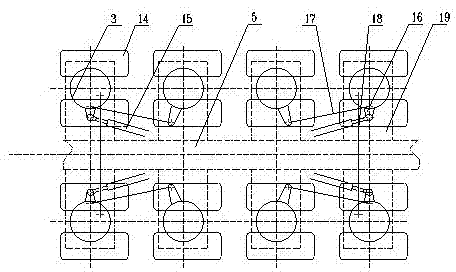

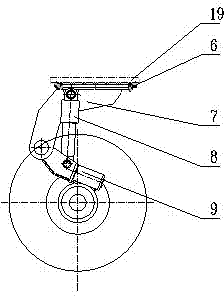

Mining multi-shaft dump truck

ActiveCN102529781AReduced minimum turning radiusImprove passabilitySteering linkagesUnderstructuresVehicle frameTruck

The invention relates to a mining dump truck which is mainly suitable for large surface mining transportation. A running gear of the mining dump truck comprises a truck frame and a plurality of hydraulic suspensions; every two hydraulic suspensions form a shaft line; the running gear at least comprises two shaft lines; the truck frame is an intermediate box beam structure; wing beams are extendedfrom the two sides of the intermediate box beam; each hydraulic suspension comprises a rotary bearing, a rotary frame, a swinging arm, a suspension cylinder, an oscillating shaft and wheels; wherein the upper end of the rotary frame is arranged on the lower plane of each wing beam of the truck frame by the rotary bearing; the upper end of the rotary frame is movably connected with the swinging arm by pins; one end of the suspension cylinder is hinged at the lower part of the rotary frame; the other end of the suspension cylinder is hinged at the middle part of the swinging arm; the front end of the swinging arm is a cylindrical pin shaft; the oscillating shaft is sleeved on the cylindrical pin at the front end of the swinging arm; and the wheels are arranged at the two ends of the oscillating shaft. According to the mining dump truck, the safety of the mining dump truck is improved, the minimal turning radius of a vehicle is also reduced at the same time, the throughput capacity, the maneuverability and the off-road performance of the mining truck are improved, and the cost of use and maintenance is reduced.

Owner:AEROSPACE HEAVY IND

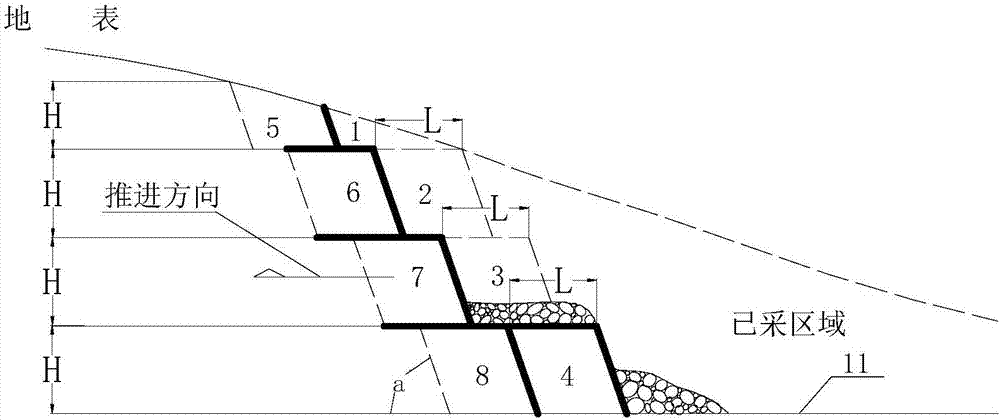

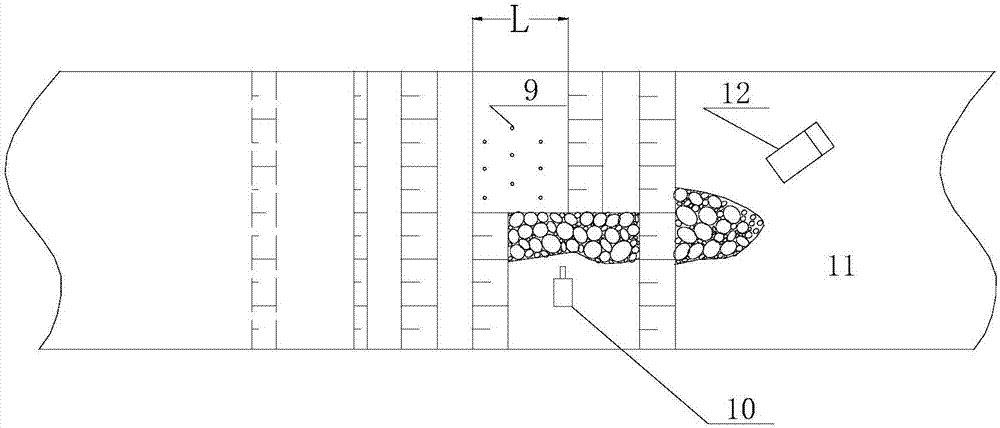

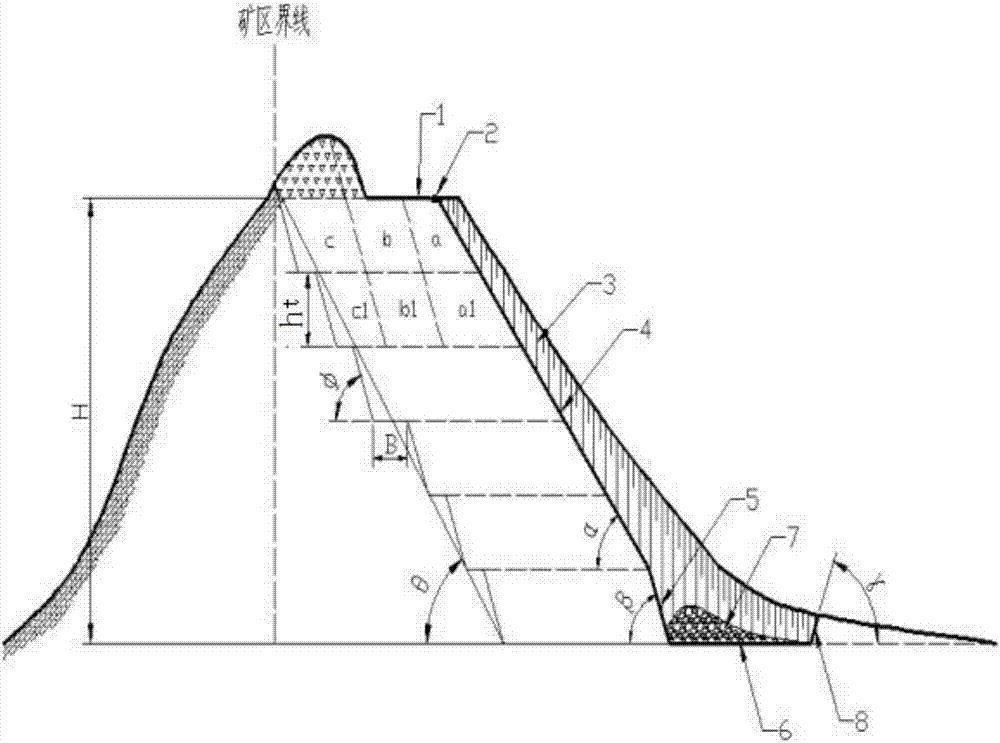

Novel open-pit mining method suitable for steep slope topography

InactiveCN106869936ASimple processSolve difficult construction problemsOpen-pit miningOpen-pit miningSteep slope

The invention discloses a new open-pit mining method suitable for steep slope terrain. The steep slope terrain is divided into 2 to 4 steps, the stripping operation surface is arranged along the strike, and a vertical strip L is divided every 14 to 16m in the vertical strike direction. , the step height H is not greater than 1.5 times the maximum excavation height of the hydraulic excavator (10), and the width of the bottom loading platform (11) is greater than 18m, so as to meet the operation requirements of the mine transport vehicle (12), implement single-step operation, blasting operation Finally, the hydraulic excavator (10) is used for mining from top to bottom, from outside to inside, and gradually advances to the final side. The ore is unloaded to the bottom by the hydraulic excavator (10) from top to bottom, from inside to outside The loading platform (11) is transported out through the mining transport vehicle (12). The invention has the advantages of simple process, easy-to-obtain equipment, safety and feasibility, and effectively solves the problems of large steep slope terrain, impossibility to build transportation roads, and difficult construction when conventional step mining is adopted.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

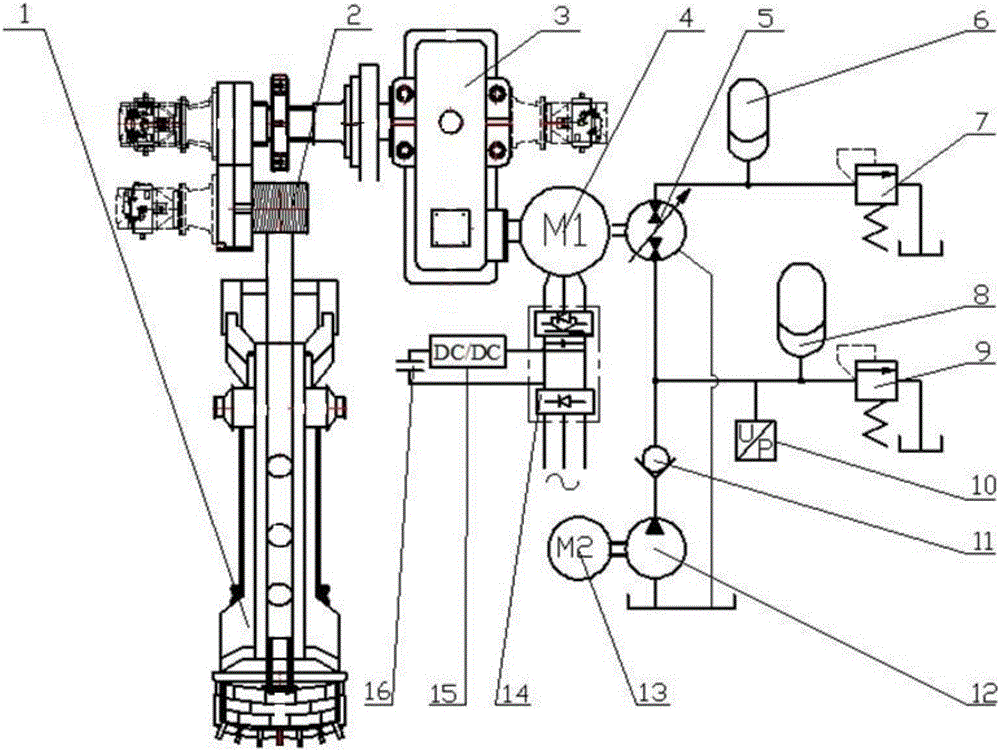

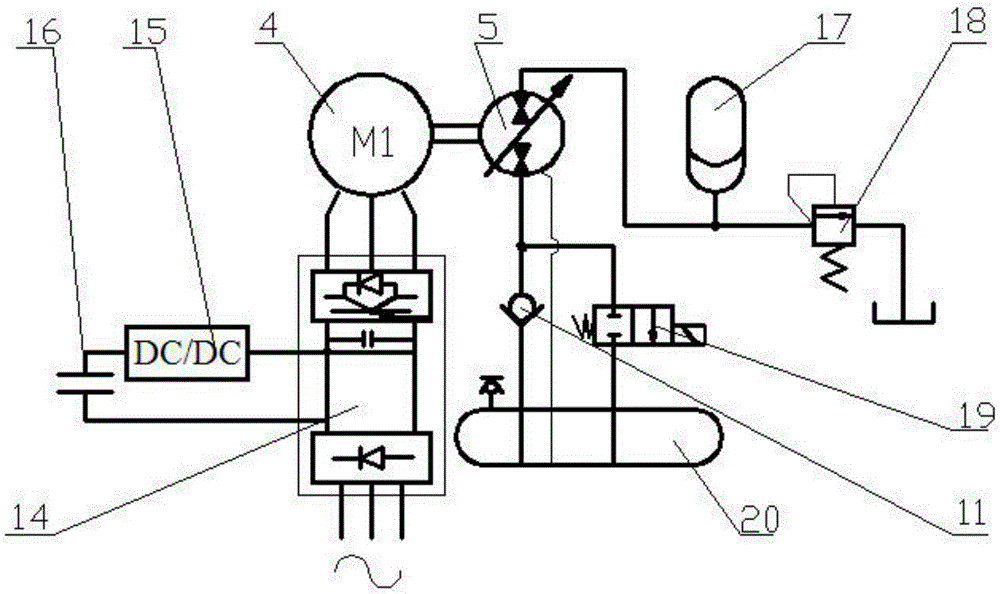

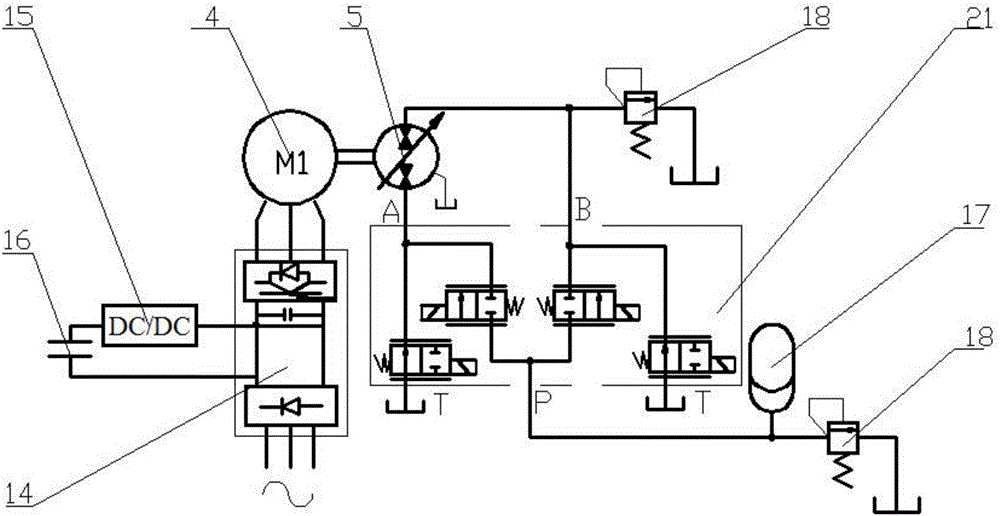

Electro-hydraulic hybrid driven electric shovel hoisting system

InactiveCN106761760AHigh working reliabilityImprove job stabilityOpen-pit miningCapacitanceReduction drive

The invention provides an electro-hydraulic hybrid driven electric shovel hoisting system and belongs to the field of large equipment for surface mining. The electro-hydraulic hybrid driven electric shovel hoisting system comprises a dipper, a hoisting drum, a speed reducer, a hoisting motor, a hydraulic pump / motor, accumulator groups, an overflow valve, a frequency converter, a DC / DC converter and a super-capacitor group, wherein the DC / DC converter is connected onto a DC bus of the frequency converter and connected with the super-capacitor group; the hydraulic pump / motor is arranged at an output end of any drive shaft between the speed reducer and the hoisting motor, and an oil port of the hydraulic pump / motor is connected with the corresponding accumulator group. According to the electro-hydraulic hybrid driven electric shovel hoisting system, electric energy produced by the hoisting motor during falling of the electric shovel dipper can be stored in the super-capacitor group, so that peak current of an electric shovel motor is reduced, and the working stability of the electric shovel motor is improved. Meanwhile, gravitational potential energy of the electric shovel dipper during falling is converted into hydraulic energy which is stored in the accumulator groups, the energy is used effectively during dipper hoisting to assist motor working, installed power of the electric shovel hoisting motor is reduced, and the working efficiency of the electric shovel is increased.

Owner:TAIYUAN UNIV OF TECH

Coal mine top plate aquiclude stability monitoring system based on fiber Bragg grating and monitoring method

Disclosed is a coal mine top plate aquiclude stability monitoring system based on a fiber Bragg grating. A measurement station is arranged on a work surface mining roadway, a vertical top plate drilling hole is drilled in a top plate of the work surface mining roadway to an aquiclude, a fiber Bragg grating pressure sensor is arranged at the top end of the drilling hole, a fiber Bragg grating top plate bed separation instrument is installed at the height position of the drilling hole between the aquiclude and a rock stratum below, and an optical fiber connector is led out of the drilling hole and connected with an optical fiber tail fiber, thereby being connected with an optical fiber splitter. The optical fiber connector is connected with an optical fiber terminal box through a communication optical fiber and connected to an optical fiber interrogator of a ground control chamber through a mining optical cable, signals are transmitted to a monitoring server after demodulation and are processed through the monitoring server, and the data processing result is shared with a client side through a mine local area network. The stability conditions of the aquiclude are monitored in real time through a computer display, and an alarm is given timely when the stress is near the bearing upper limit of the aquiclude and separation occurs between the aquiclude and the overlying strata blow.

Owner:CHINA UNIV OF MINING & TECH

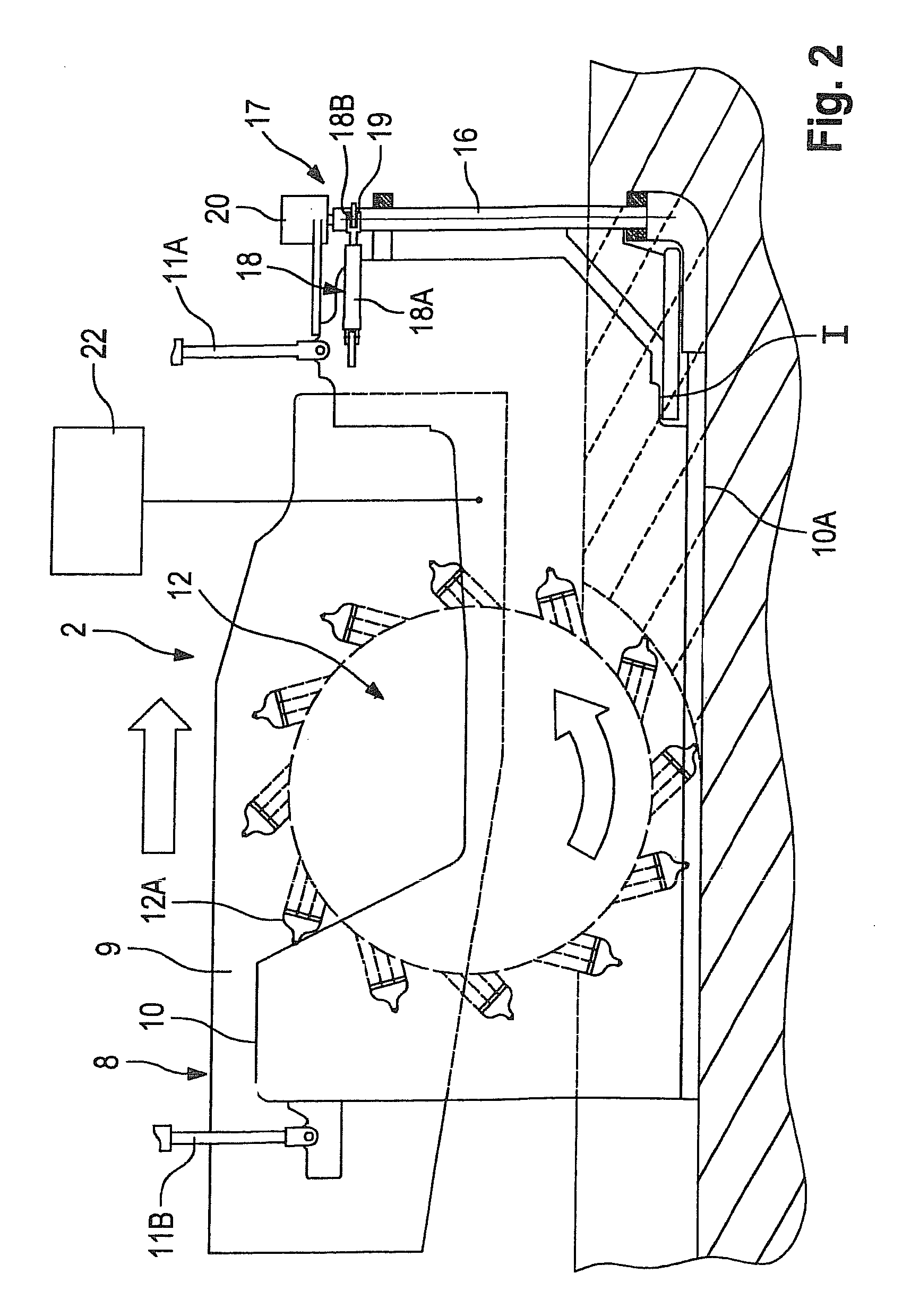

Road milling machine or machine for exploiting deposits

The invention relates to a road-milling machine or machine for working deposits, such as deposits of coal, ores, minerals, etc. by surface mining. The machine according to the invention has an arrangement 14 for detecting the path followed by a milled edge 13 of a milled strip, with the arrangement for detecting the path followed by the milled edge having means 14 for measuring the distance between at least one reference point I on the machine and the milled edge. The means 14 for detecting the path followed by the milled edge co-operate with the arrangement 6 for steering the track-laying units 3A, 3B in such a way that the machine follows the path followed by the milled edge. The distance between the at least one reference point on the machine and the milled edge can be set in such a way that milled strips situated alongside one another are exactly aligned relative to one another.

Owner:WIRTGEN GMBH

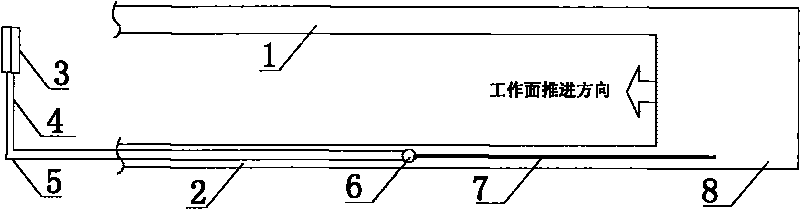

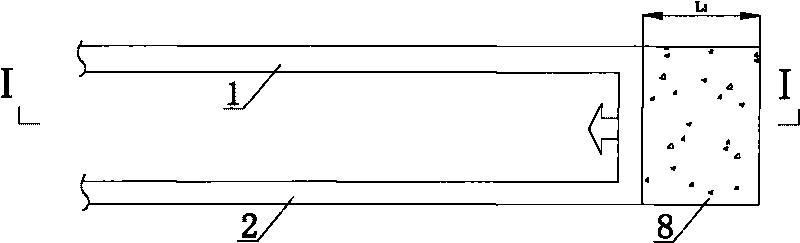

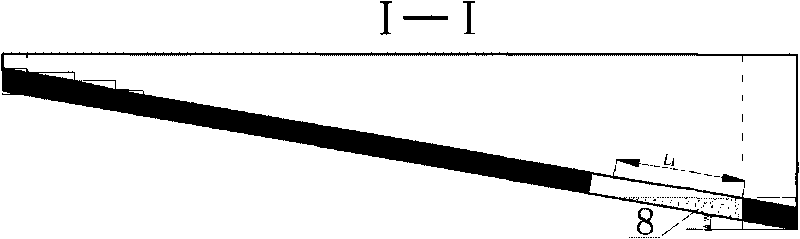

Goaf open-type packing method

InactiveCN101701527ASolve the low filling rateAddress process complexityMaterial fill-upEngineeringSlurry

The invention discloses a goaf open-type packing method, comprising the following steps: firstly filling the goaf of initial prefilling top plate span L1 from an open-off cut, stopping filling until the filled high-water material seriflux is contacted with the top plate of the goaf, filling constantly along with forward propulsion of coal mining working face, finishing filling the underfilling area of the initial prefilling top plate span L1 and goaf within the range of top plate span L2; after work surface mining finishes, constructing a plugging wall in work surface conveying inclined alleys and track inclined alleys to tight goaf, filling the underfilling area of ending prefilling top plate span L3 and metaphase prefilling top plate span L2, thereby finishing goaf filling in the last stage, wherein the solidified filling body has the function of supporting the top plate of goafs. The method of the invention is suitable for inclined mining working face of which the coal seam dip angle is more than 12 degrees, and has good filling density; and filling does not influence coal mining, the filling method is simple and has low primary investment and wide practicability, and the primary input of the filling system can be reduced by 90% to 97%.

Owner:JIZHONG ENERGY HANDAN MINING GROUP +1

Internal discharge method during anticline passing period of open-cast mining

ActiveCN105507905ADecrease the inclinationReduce the distance of soil dischargeUnderground miningSurface miningMarine engineeringTruck

The invention relates to an internal discharge method during anticline passing period of open-cast mining. After a working slope enters an anticline region, an L-shaped operating line is arranged, an original stope operating line is arranged on one side of the L-shaped operating line, the other side of the original stope operating line is obliquely arranged along an ore body baseplate, and propulsion from one end slope to the opposite end slope of a stope is carried out. Meanwhile, an internal waste dump is obliquely arranged along the ore body after being rotated in the propulsion direction and follows up the side, arranged in the inclination direction, of the L-shaped operating line to form a new internal waste dump. According to the internal discharge method, based on the situation that the operating line is transversely arranged during the anticline passing period, the dip angle of the base of the internal waste dump is reduced, internal discharge of stripped materials is realized by fully utilizing the internal waste dump space. The internal discharge method can effectively reduce the land area occupied by external discharge, meanwhile, reduces the dumping transport distance of a truck and lowers the mine production cost.

Owner:CINF ENG CO LTD

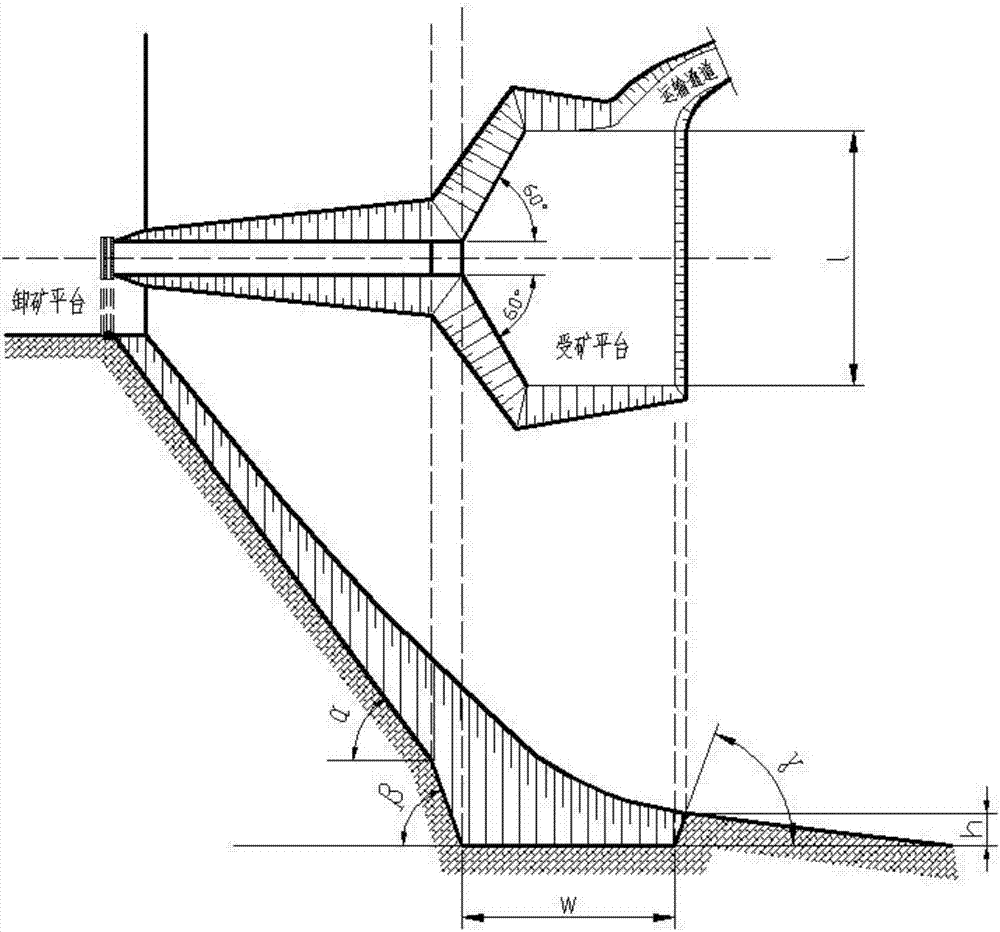

Chute for storing ore in opencast quarry and mining method of opencast quarry

InactiveCN107503751AOvercoming the need for secondary transportOvercome costsOpen-pit miningTerrainEconomic benefits

The invention provides a chute for storing ore in an opencast quarry and a mining method of the opencast quarry. The advantages of stepped mining and layered mining in safety and economy are fully absorbed, an opencast mining method for unified management of ore rock humping through the chute by use of natural dip angles and height difference of hillsides is formed, and the technical problem that safe uphill transportation roads are difficult to build when bamboo shoot type isolated peak ore deposits are mined in the stepped manner is solved. Original terrains are fully used, and the safe production requirement can be met while the best economic benefit is obtained; the defect of increase of the production cost due to the fact that ore retained on rock drilling platforms partially after blasting each time needs to be transported secondarily when the bamboo shoot type isolated peak ore deposits are mined in the layered mining manner is overcome.

Owner:GUANGXI UNIV

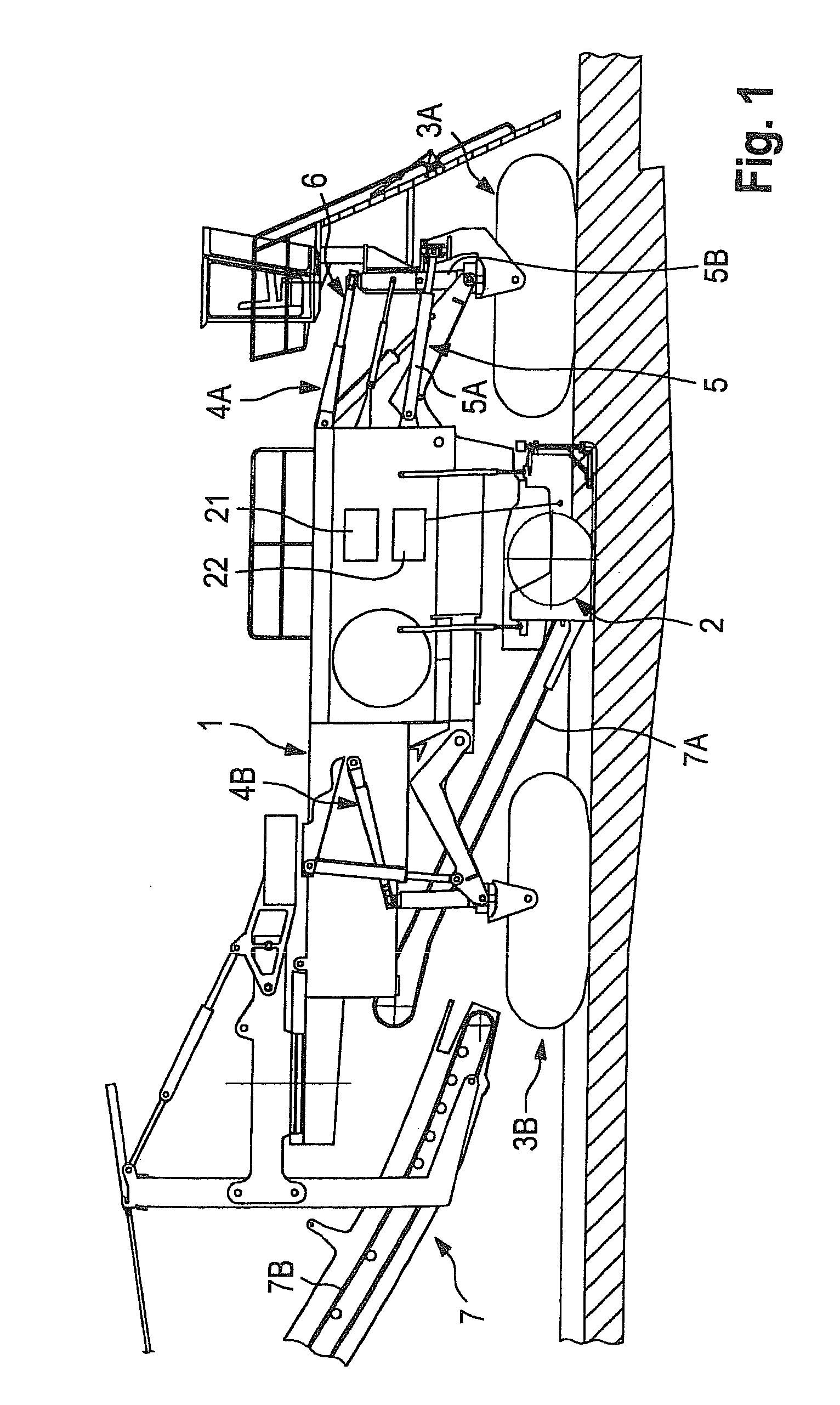

Electric Tracklaying Gear and Use Thereof for a Self-Propelled Working Machine

ActiveUS20120097462A1Reduce heat loadIncreased dust loadElectric propulsion mountingElectric machinesEngineeringCooling fluid

The present invention relates to an electric tracklaying gear and the use thereof for a self-propelled working machine, preferably for a construction or earth-moving machine or a surface mining machine such as Surface Miner, which includes an endlessly circulating track chain which can be driven by a crawler drive that is arranged inside the path of circulation of the track chain. It is proposed to associate a cooling device with a closed fluid cooling circuit to the electric motor of the crawler drive arranged in the interior of the path of circulation of the track chain. Due to the high thermal capacity of a suitable cooling fluid such as oil or water-glycol mixture small volumetric flow rates in the fluid cooling circuit and hence small conduit cross-sections are sufficient. On the other hand, due to the closed formation of the fluid cooling circuit any dust input into the crawler drive and also any generation of dust by exhaust air can be avoided.

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

Scraping device of ground scarifier, ground scarifier, and method for controlling scraping device

ActiveCN103510455AIncreased functional reliabilityOvercoming retentionRoads maintainenceRoad surfaceEngineering

The invention relates to a scraping device used for a ground scarifier which has a scarifying roller. The scraping device is disposed behind the scarifying roller in a working direction of the ground scarifier. The scraping device comprises a scraping plate which has an upper plate (15) that can rotate and a lower plate that is movably supported on the upper plate. The invention also relates to a ground scarifier with such a scraping device, especially a road scarifier or a surface mining machine, and a method for controlling the scraping device of the ground scarifier.

Owner:BOMAG

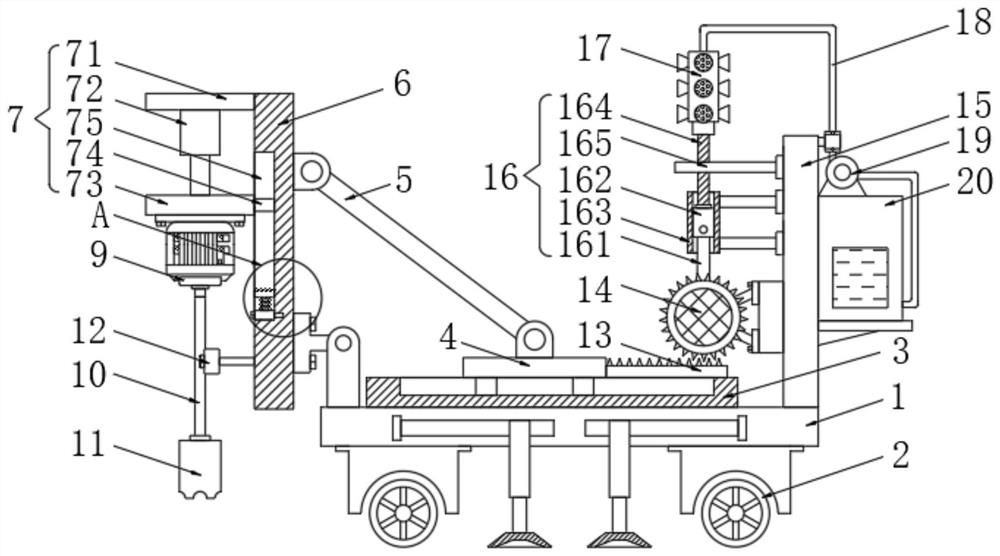

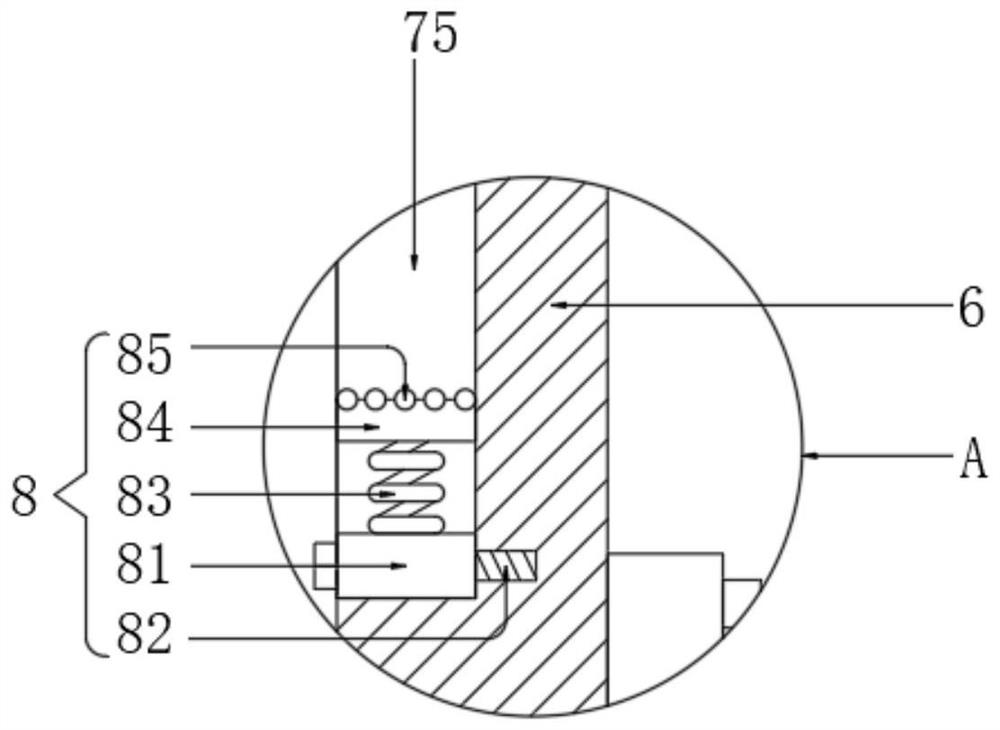

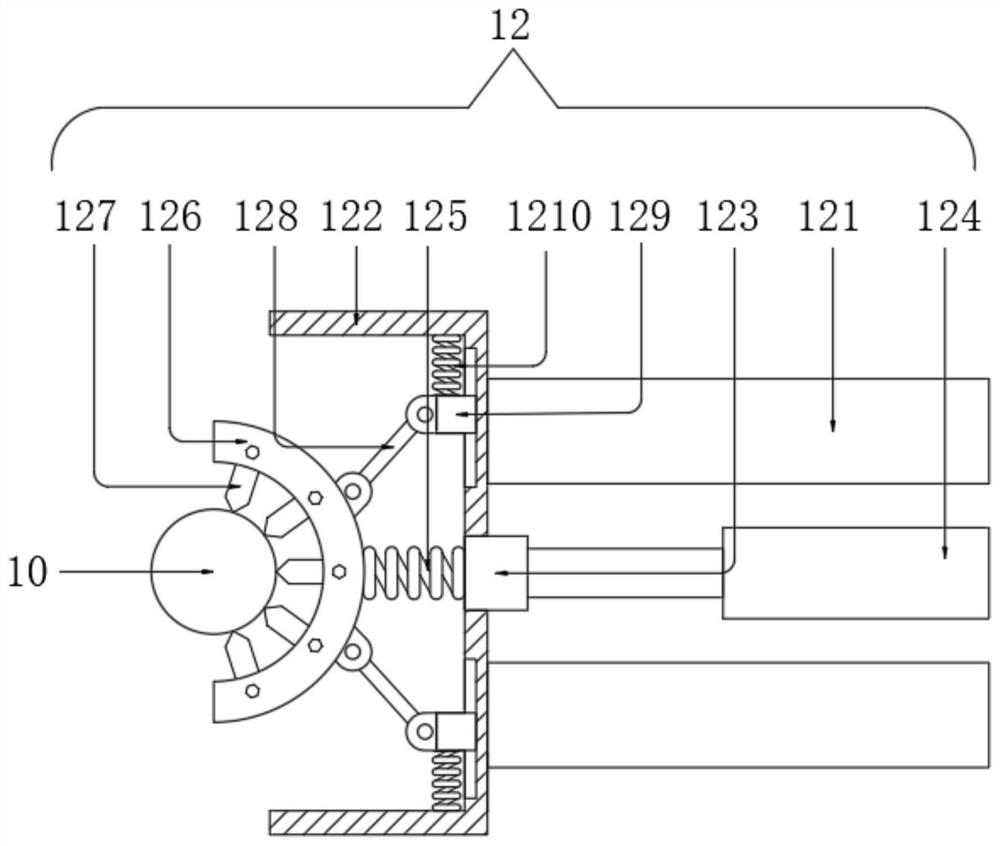

Stope drilling device and method for open-pit mining

InactiveCN111980708AStable drilling workWon't hitEarth drilling toolsConstructionsHydraulic cylinderMining engineering

The invention discloses a stope drilling device and method for open-pit mining in the technical field of stope open-pit mining. The stope drilling device comprises a transport vehicle body; wheels areinstalled on the periphery of the bottom of the transport vehicle body, a fixed plate is fixedly connected with the top of the transport vehicle body, and a movable plate is installed on the top of the fixed plate in a sliding mode; the top of the movable plate is hinged to one end of a pull rod, and the other end of the pull rod is hinged to a fixed beam; the bottom of the right side of the fixed beam is hinged to the transport vehicle body through a hinge part; and a height adjusting assembly is installed on the left side of the fixed beam. A hydraulic cylinder continues to drive a drill rod to move upwards, and a drilling motor drives the drill rod to rotate, so that a mud scraping rod can scrape off mud attached to the drill rod; and a reset spring enables a movable block to drive a connecting rod to extrude a push plate through the elasticity of the reset spring, moreover, the push plate is extruded through the elasticity of a stress spring, so that the mud scraping rod is more tightly attached to the drill rod, and the mud scraping effect is better.

Owner:韦秀妃

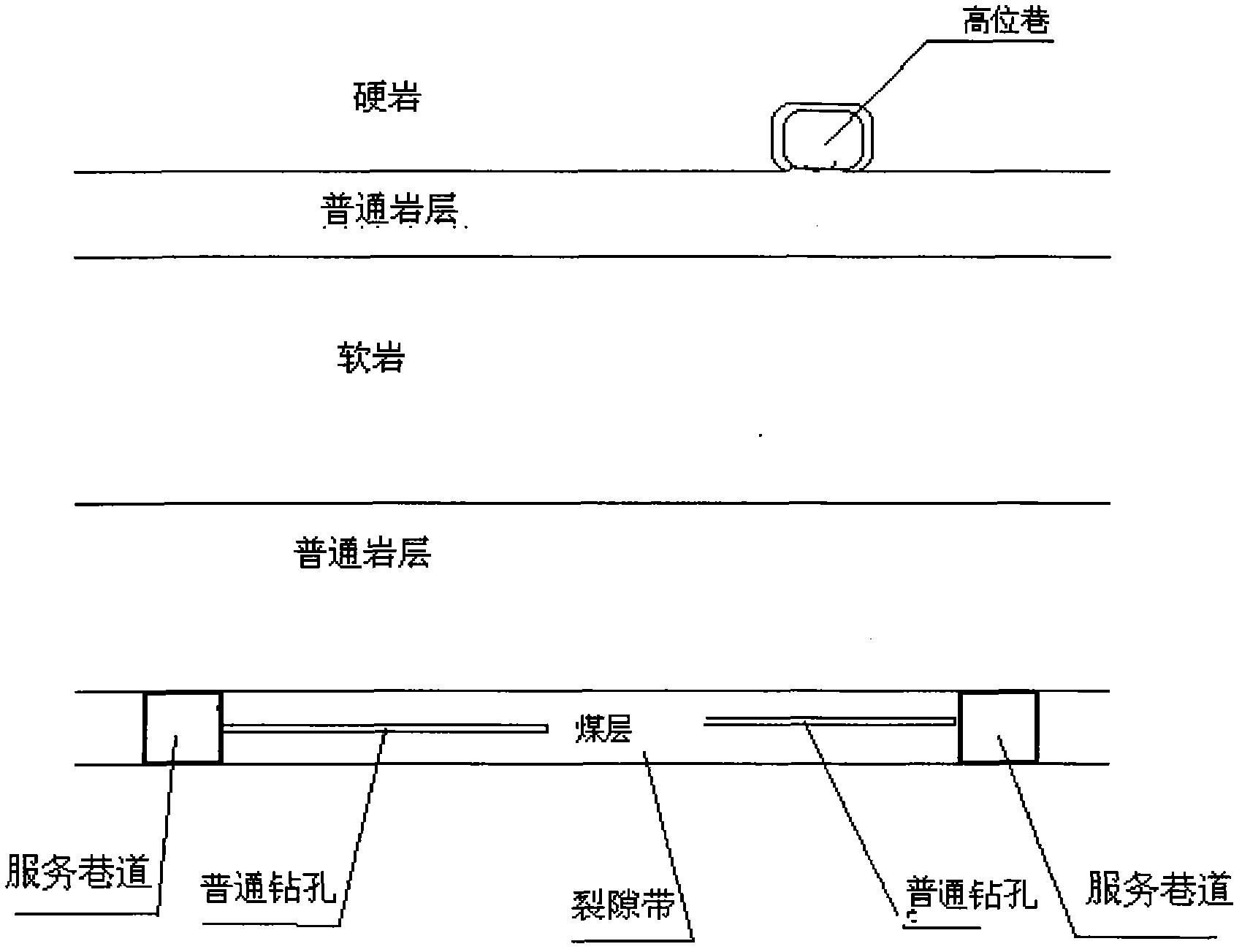

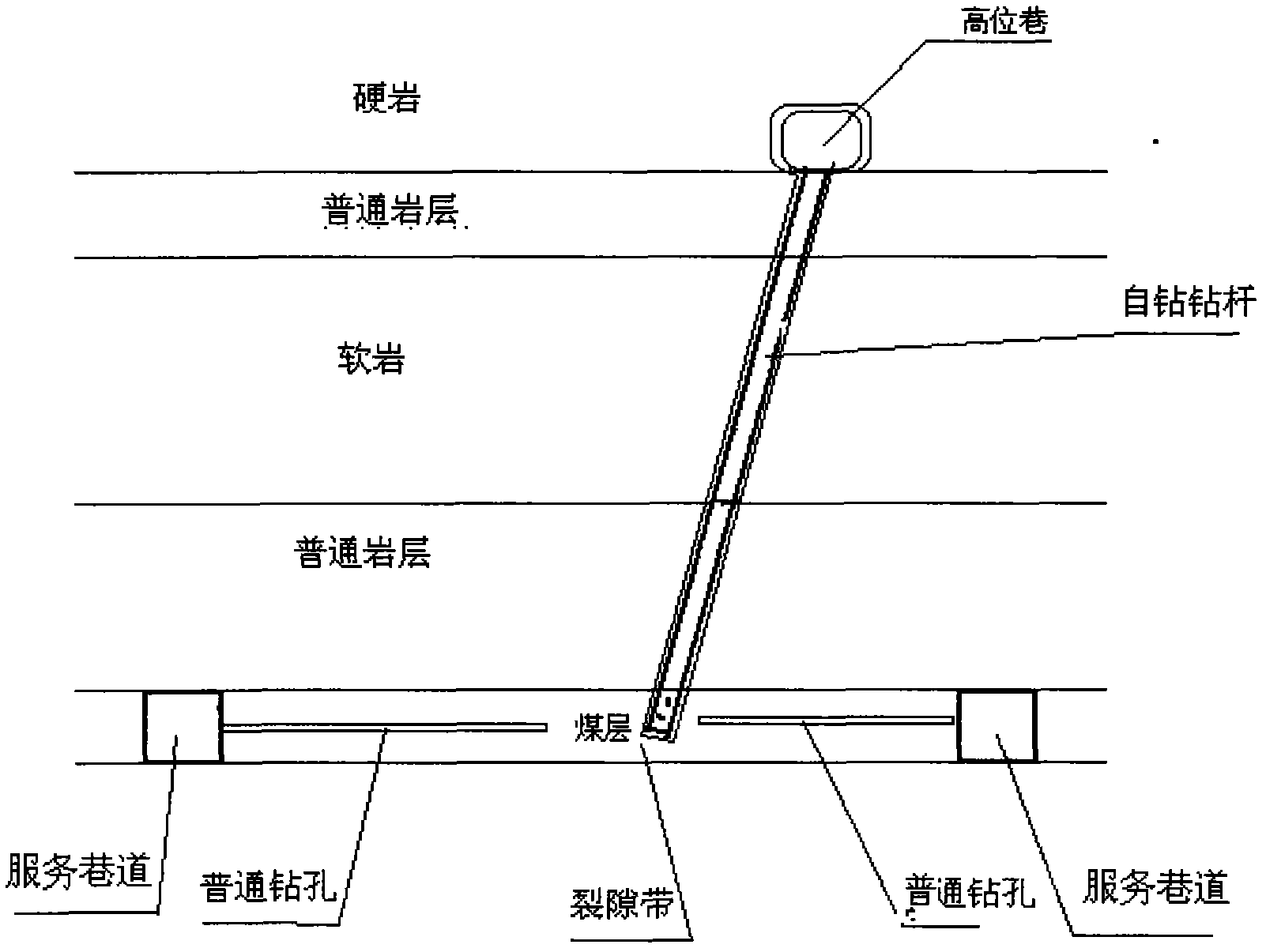

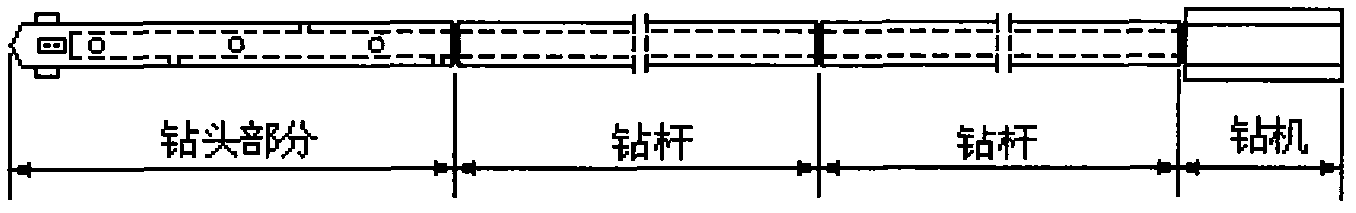

Method for gas drainage from high-position roadway coal seam containing shielded soft rock

The invention discloses a method for gas drainage from a high-position roadway coal seam containing shielded soft rock. According to the method, before the coal seam is mined, a roadway is developed in a hard rock formation of the coal seam roof and is called a high-position roadway for short as being designed at the coal seam roof part. The well-developed roadway can be used for ensuring the stability of surrounding rock and enhancing the temporary support; then during the working surface mining, holes are drilled in the coal seam in the roadway of a working surface, and preliminary gas drainage is carried out; and finally, at the same time of the preliminary gas drainage, holes are drilled in the coal seam in the high-position roadway, self-drilling drill rods with a hollow structure are adopted in the drilling, small holes are processed in the sections where the self-drilling drill rods enter the coal seam, the self-drilling drill rods are kept in the drilling holes of the coal seam after drilling in the coal seam, and the gas drainage can be continuously carried out through the self-drilling drill rods. According to the method, the drainage is carried out in the high-position roadway, the characteristic of upward flow of gas is fit, and thus the drainage is convenient to realize. The hollow drill rods with holes are used for the drainage, the drilling holes can be prevented from being sealed by the shielded soft rock and further a good drainage effect is realized.

Owner:SHANDONG UNIV OF SCI & TECH

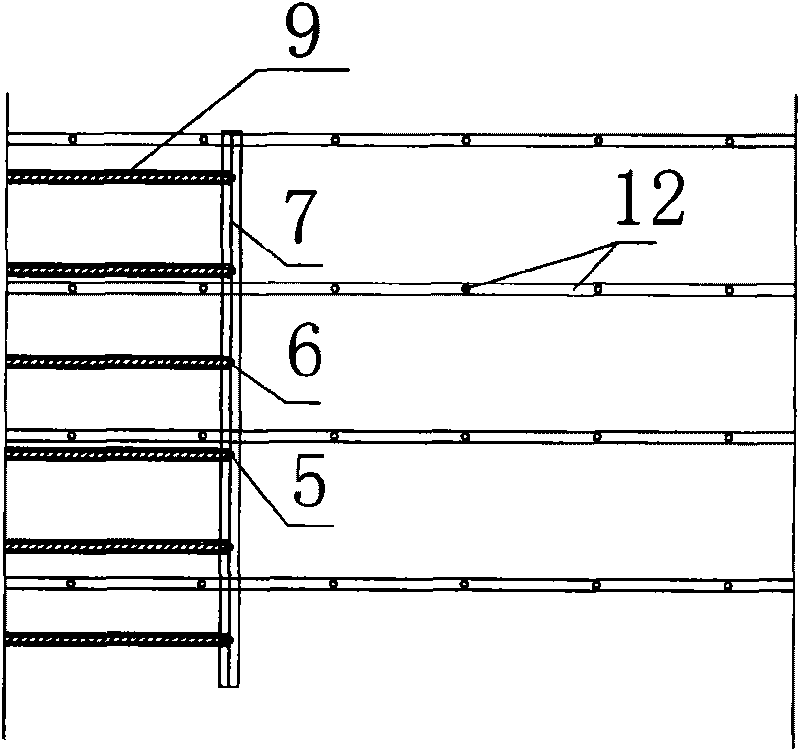

Medium-thickness coal seam gob-side entry retaining method and support system

ActiveCN105003288AImprove stabilitySimple construction processAnchoring boltsSupporting systemEngineering

The invention relates to a medium-thickness coal seam gob-side entry retaining method and support system. The support system comprises an entry retaining roadway, four channel-steel anchor cable supports, three hydraulic props, a steel wire mesh, a pre-buried sidewall anchor rod, a linear articulated top beam, a crossed articulated top beam, iron shoes and Pi type steel. The hydraulic props and the top beam are connected into a whole and iron shoes are worn at the bottoms of the hydraulic props. The gob-side entry retaining method comprises the following steps:(1), constructing four channel-steel anchor cables for reinforcing supporting along the roadway and arranging the channel-steel anchor cables in a stepping manner; (2), constructing a top anchor rod outside an advance support of a working surface along with working surface mining in advance and mounting the steel wire mesh along the roadway in a hanging manner; pre-burying the sidewall anchor rod along with mining and hanging an anti-tear steel wire mesh along the roadway; (3), at the gob-side entry retaining section inside a working surface mining line, adopting telescopic hydraulic props for supporting. According to the invention, a support body on one side of the roadway is constructed by using rock collapsed from the roof, so that the construction is simple, the cost is low and high safety is realized. The hydraulic props, iron shoes, Pi type steel, cross articulated top beam and the steel wire meshes are combined for supporting, so that the stability of the support system is improved.

Owner:河北充填采矿技术有限公司

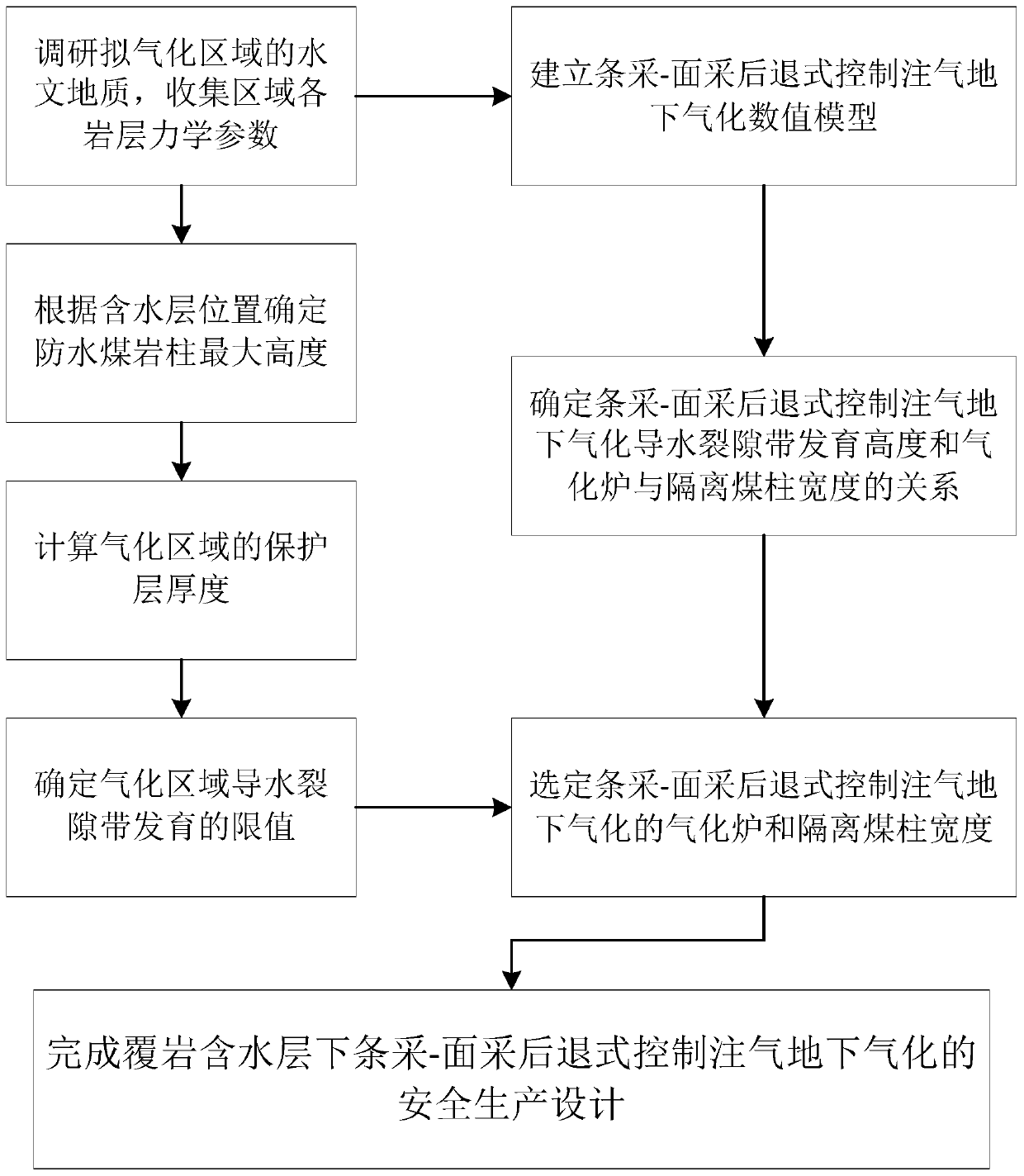

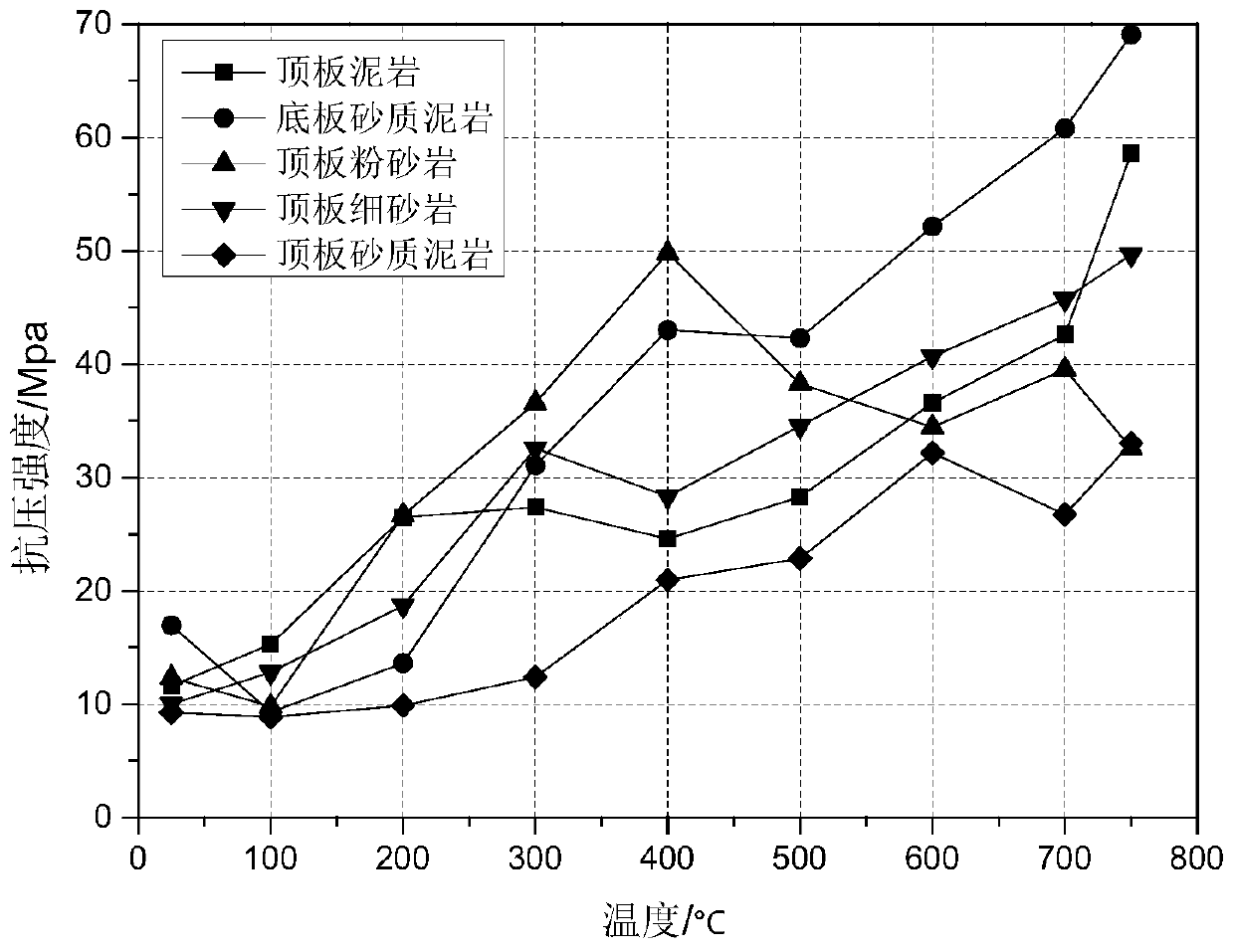

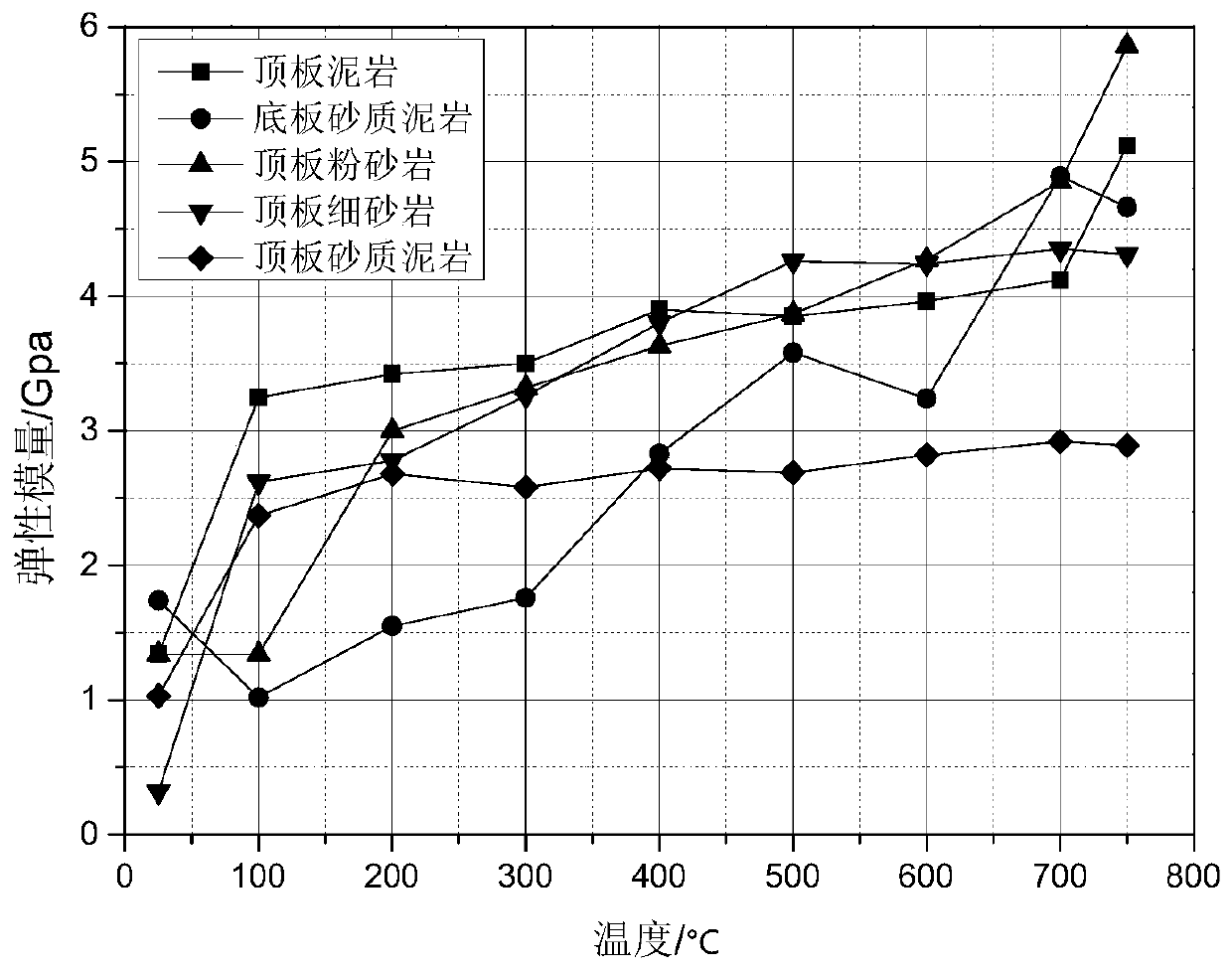

Overlying strata aquifer-oriented isolation coal pillar and gasification furnace width design method for underground gasification

ActiveCN110991042ASimple stepsReduce computationGeometric CADDesign optimisation/simulationMining engineeringWater flow

The invention discloses an overlying strata aquifer-oriented isolation coal pillar and gasification furnace width design method for underground gasification. The method is suitable for underground gasification coal mining design under an overlying strata aquifer. The method includes the following steps that: the maximum height of a waterproof coal-rock pillar is determined according to the position of the aquifer; the thickness of the protective layer of a to-be-gasified area is calculated, and the limit value of the water flowing fractured zone development of the to-be-gasified area is determined; a strip-surface mining retreating type control gas injection underground gasification numerical model is established, and a relationship between strip-surface mining retreating type control gasinjection underground gasification water flowing fractured zone development height and gasification furnace and isolation coal pillar width is determined; and on the basis of the relationship betweenthe water flowing fractured zone development height and the gasification furnace and isolation coal pillar width, the gasification furnace and isolation coal pillar width for strip-surface mining retreating type control gas injection underground gasification is selected; and therefore, safety production design for the strip-surface mining retreating type control gas injection underground gasification of the overlying strata aquifer is completed. The steps of the method are simple. Optimal gasification production benefits can be guaranteed on the premise that the stability of the overlying aquifer and underground gasification safety production are guaranteed.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com