Deep-sea ore transport system relay warehouse

A conveying system and ore technology, applied in mineral mining, special mining, earth drilling and mining, etc., can solve the problems of blocked nozzles and material accumulation, and achieve the effect of improving the problem of blocked nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

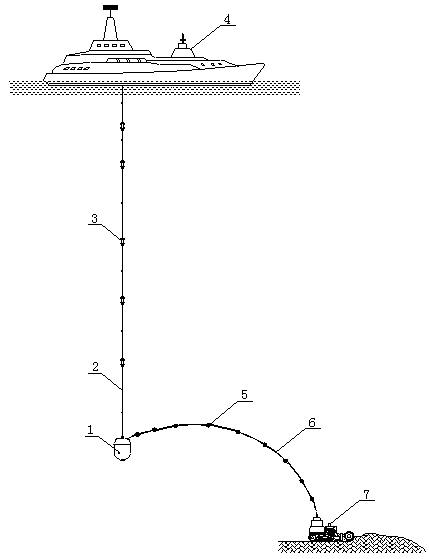

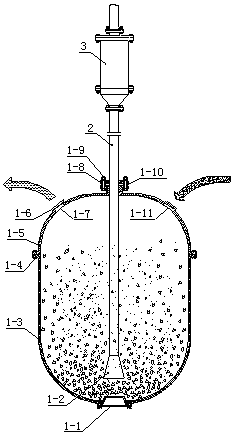

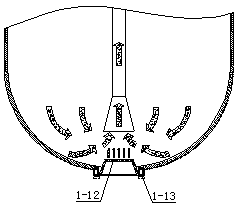

[0014] like Figure 1 to Figure 3 As shown, a deep-sea ore conveying system relay bin mainly includes an upper bin body 1-5, a lower bin body 1-3, a bin body connecting bolt assembly 1-4, a jet generator 1-1, and a jet generator connection Bolts 1-13 and ore filter cover 1-6, the deep-sea ore conveying system applicable thereto mainly consists of ore slurry conveying hose 6, buoyancy ball 5, ore slurry pump 3, lifting hard pipe 2, sea surface mining ship 4, relay warehouse 1 and ore collecting machine 7, etc.; the lifting hard pipe 2 is laid upward from the relay warehouse 1 to the mining ship 4 on the sea surface, and a number of slurry pumps 3 are installed on it. The slurry pump 3 provides power for the transportation of ore particles in the pipeline. In order to improve the pumping head and work efficiency of the conveying system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com