Oxygen adding system and method for reactor iron removing

A reactor and oxygen technology, used in the field of hydrometallurgy, can solve the problems of uneven oxygen addition and blockage of the oxygen nozzle, and achieve the effects of high temperature, large steam volume, and continuous and stable production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

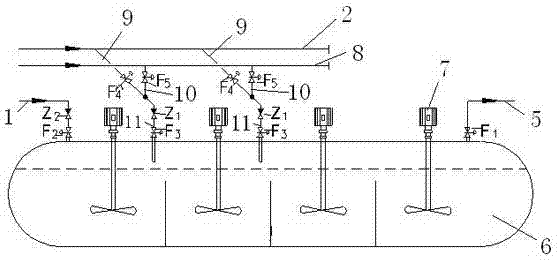

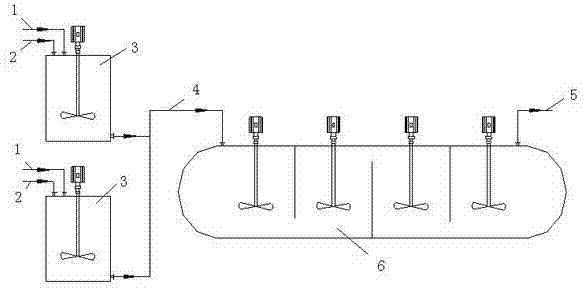

[0031] A kind of oxygen adding system that is used for reactor iron removal, comprises the reactor 6 that is provided with at least one stirring device 7, the liquid before iron removal that is connected at one end of reactor 6 adds pipe 1 and is connected at the other end of reactor 6 The liquid outflow pipe 5 after iron removal; also includes oxygen feed pipe 2, steam feed pipe 8 and a plurality of mixed gas feed pipes 11; the multiple mixed gas feed pipes 11 are evenly arranged on the top of the reactor 6, the mixing The upper end of the gas addition pipe 11 is located outside the reactor 6, and the lower end of the mixed gas addition pipe 11 is located inside the reactor 6, and is positioned above the liquid level; the oxygen addition pipe 2 is provided with a plurality of oxygen branch pipes 9, and the steam The feeding pipe 8 is provided with a plurality of steam branch pipes 10, and any oxygen branch pipe 9 communicates with a steam branch pipe 10 two by two, and then co...

Embodiment 2

[0034] A kind of oxygen addition method that is used for reactor deironing, uses the oxygen addition system described in embodiment 1, concrete steps are:

[0035] 1) Open the discharge valve F1 first, then open the feed valve F2, and pump the pre-deferrification liquid into the reactor 6 through the pre-deferrification liquid addition pipe 1;

[0036] 2) Open the oxygen regulating valve F4, open the steam regulating valve F5, introduce oxygen with a concentration of more than 98% and high-pressure steam at the same time, and enter the reactor 6 after the steam and oxygen are fully mixed, and control the temperature in the reactor to 190°C-210°C ℃, the total pressure is 1800KPa, and the oxygen partial pressure is 200KPa~300KPa;

[0037] 3) After the pre-iron removal liquid enters the reactor 6, under the conditions of step 2, iron precipitates into the slag as hematite, and the iron-removal liquid flows out through the iron-removal liquid outflow pipe 5. After the liquid afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com