Patents

Literature

279results about How to "Improve the effect of iron removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

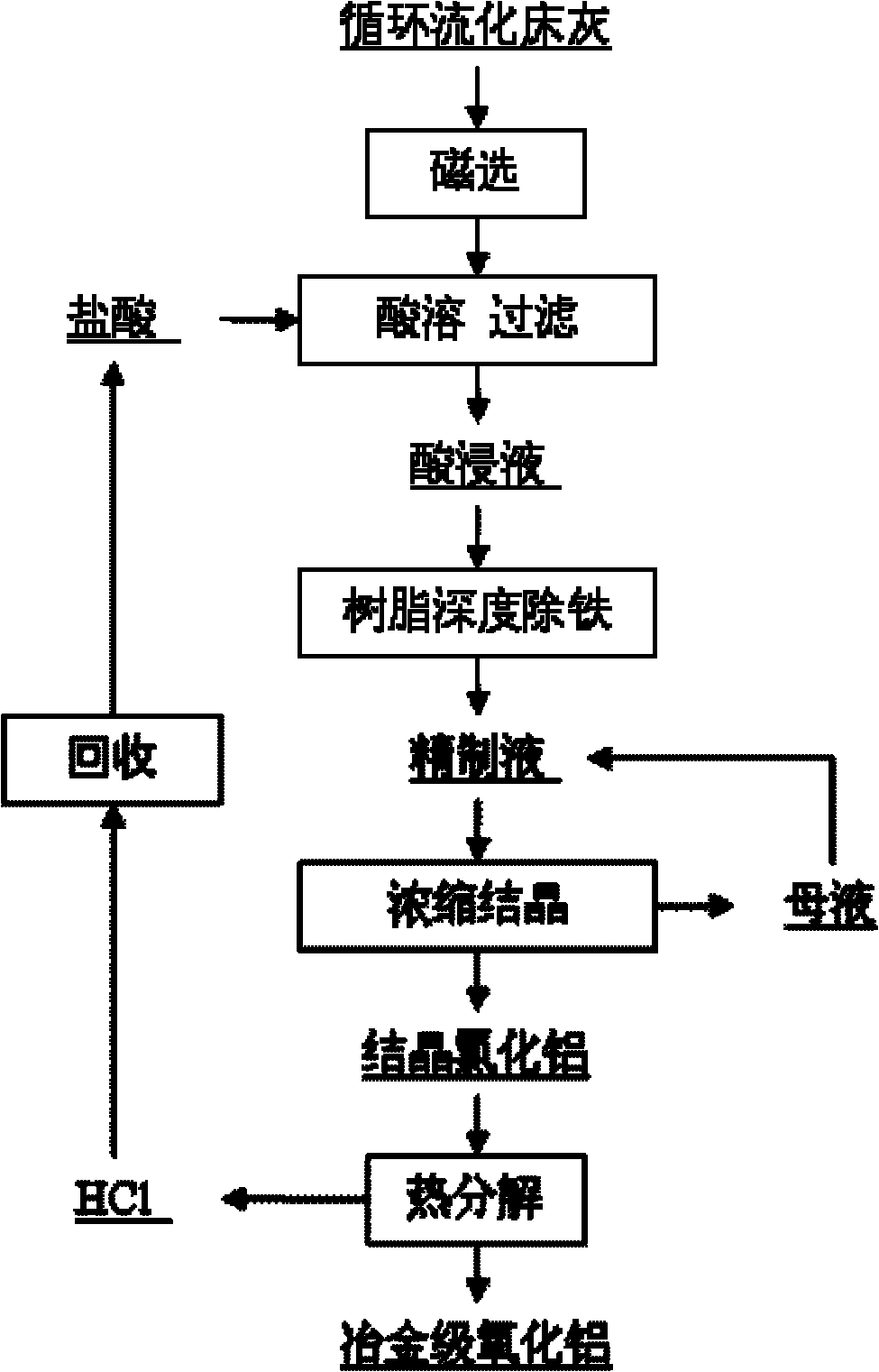

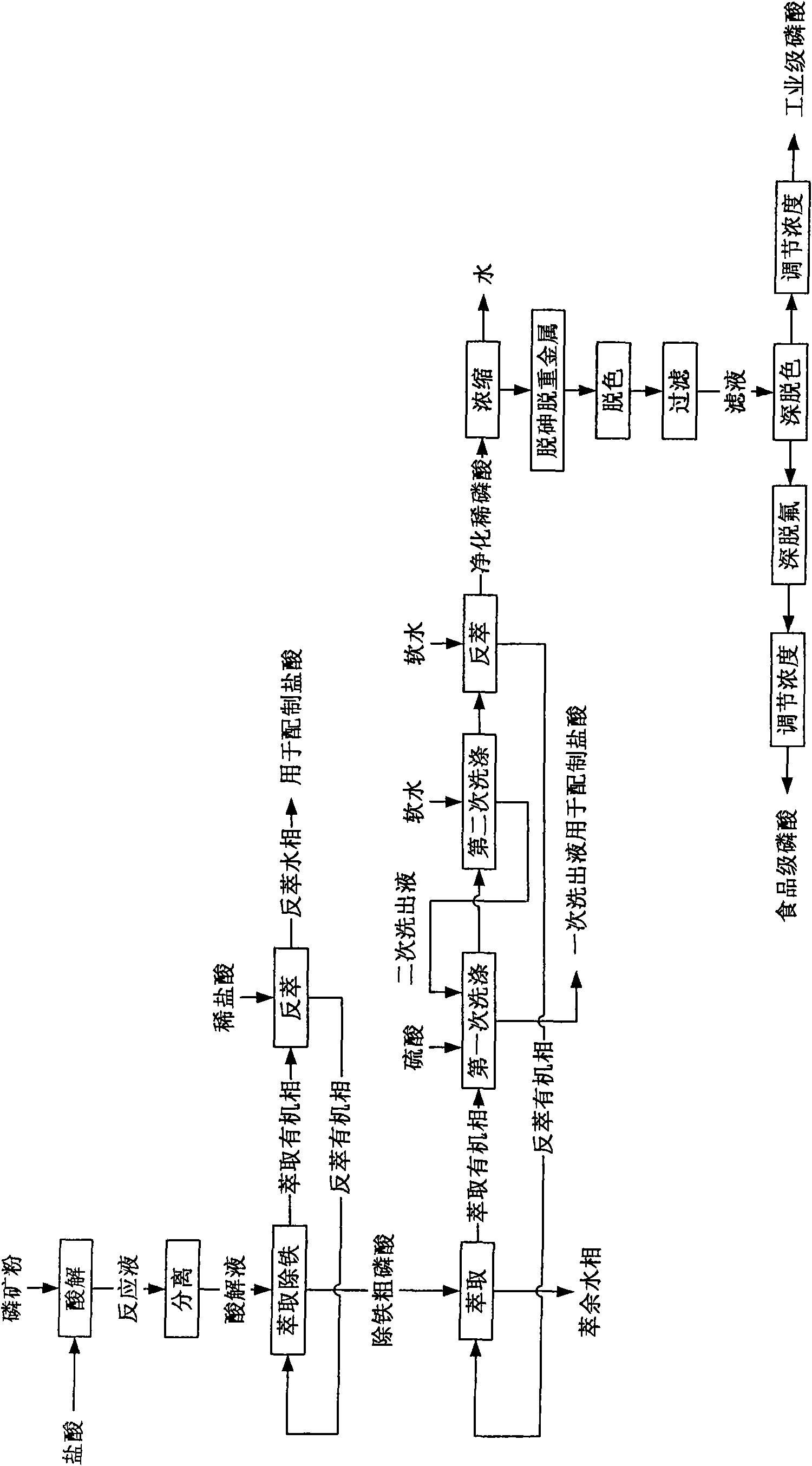

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

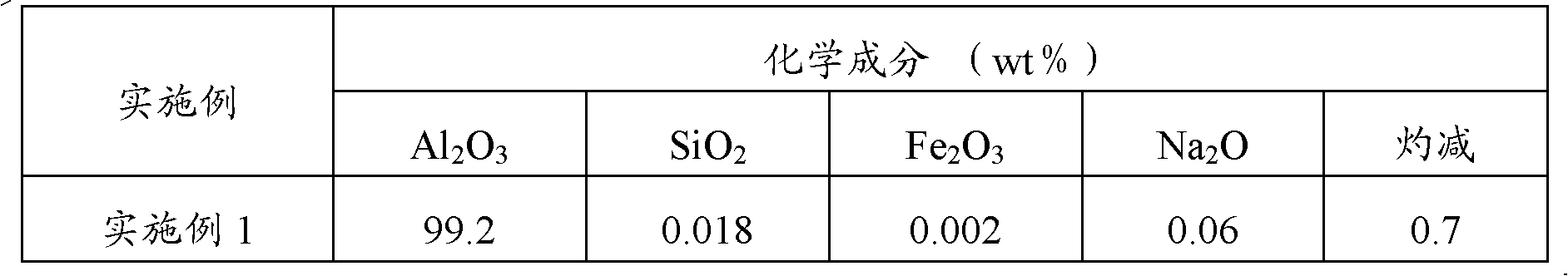

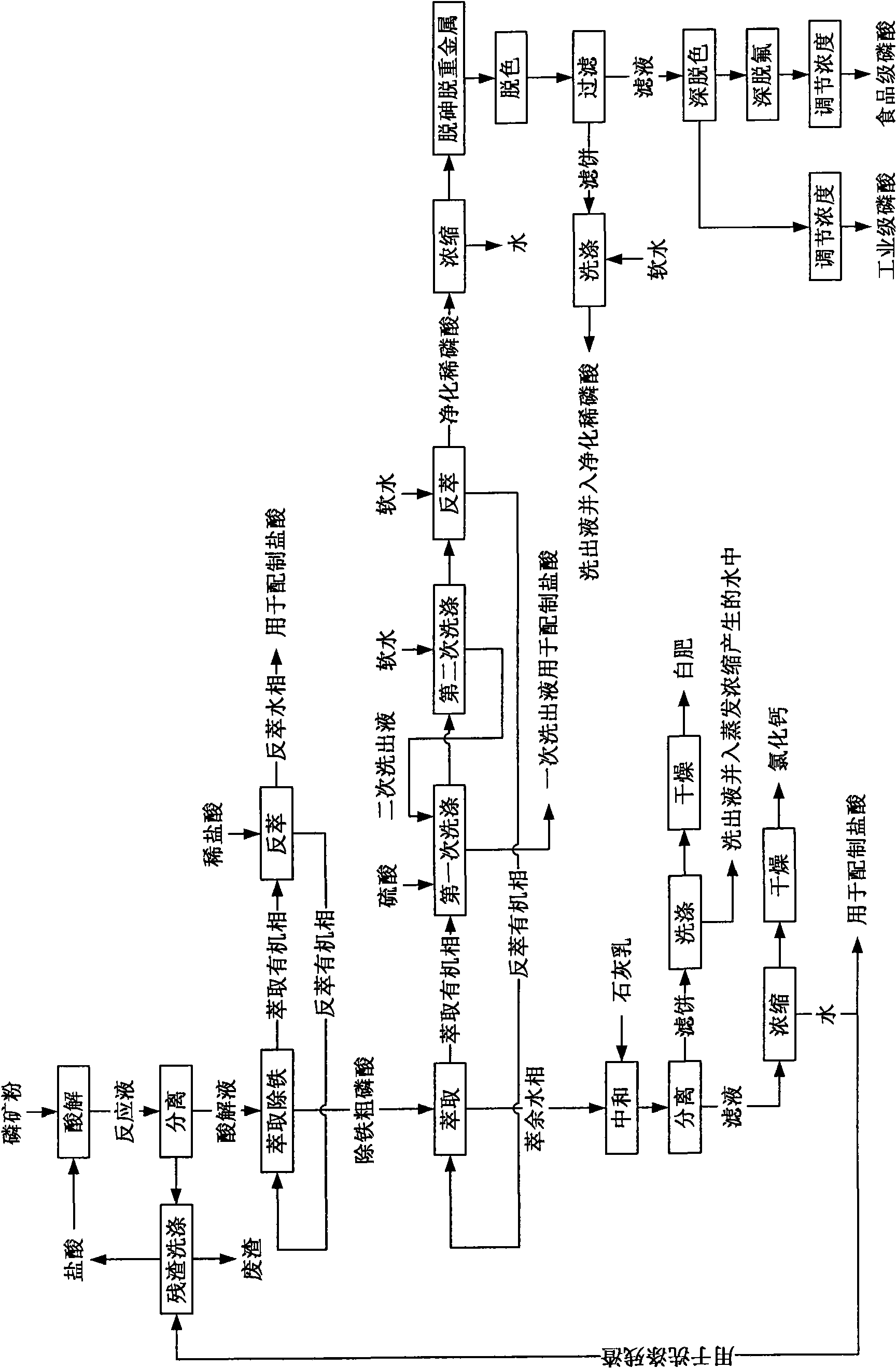

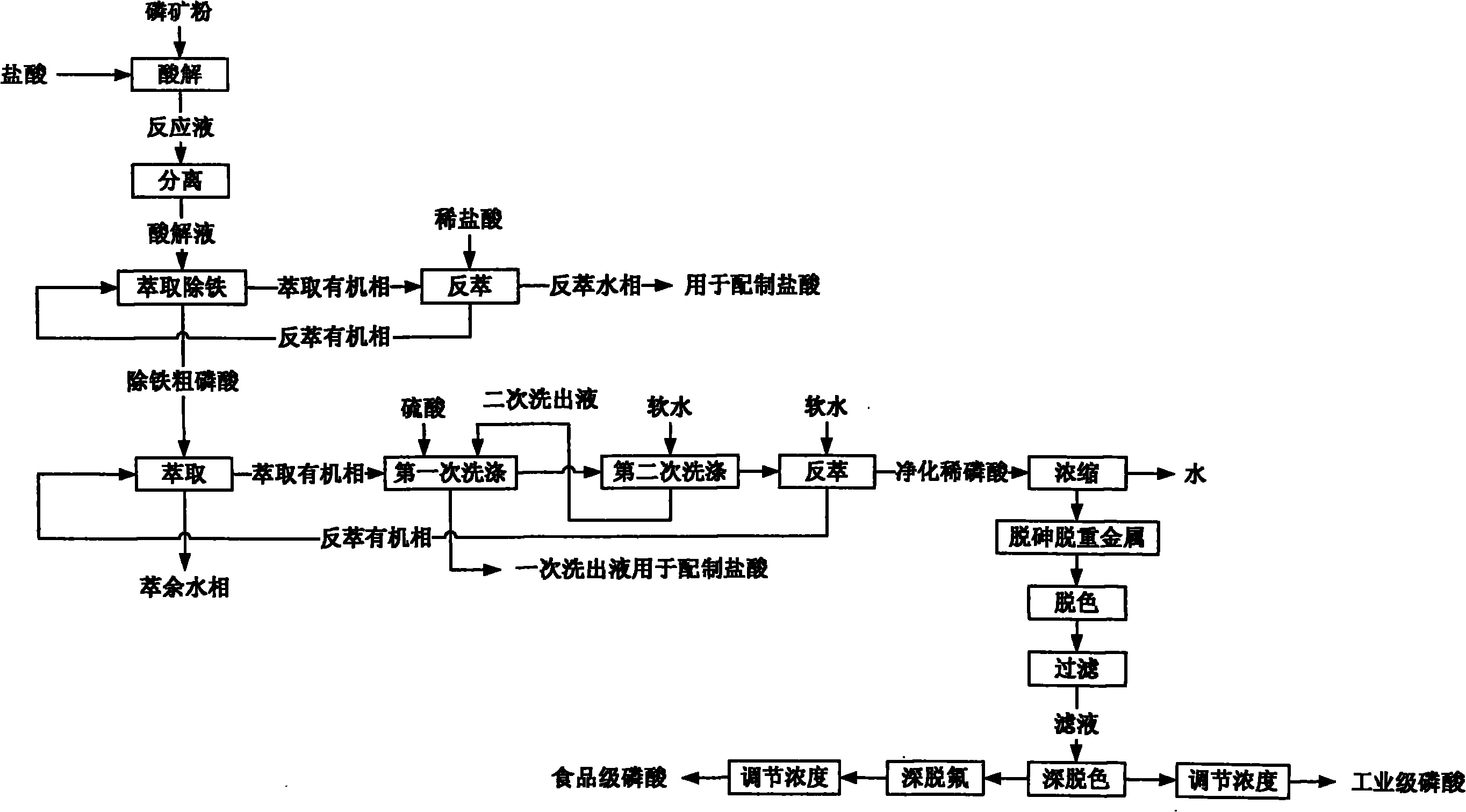

Method for preparing industrial grade and food grade phosphoric acid by decomposing low grade phosphate rocks with hydrochloric acid

The invention relates to a method for preparing industrial grade and food grade phosphoric acid by decomposing low grade phosphate rocks with hydrochloric acid. The method comprises the following processing steps: (1) decomposing phosphate rock powder with hydrochloric acid; (2) extracting to remove iron; (3) preparing dilute phosphoric acid; (4) preparing industrial grade phosphoric acid; and (5) preparing food grade phosphoric acid. Food grade phosphoric acid can be prepared only by adding deep defluorination process on the basis of the preparation steps of industrial grade phosphoric acid. The deep defluorination process adopts vacuum steam stripping process and the processing conditions are as follows: the vacuum degree is 0.075-0.090MPa, and the temperature is 95-110 DEG C. Industrial grade phosphoric acid prepared by the method of the invention meets the super grade or first-class product standards of GB / T 2091-2008; and food grade phosphoric acid meets the standards of GB 3149-2004.

Owner:SICHUAN UNIV

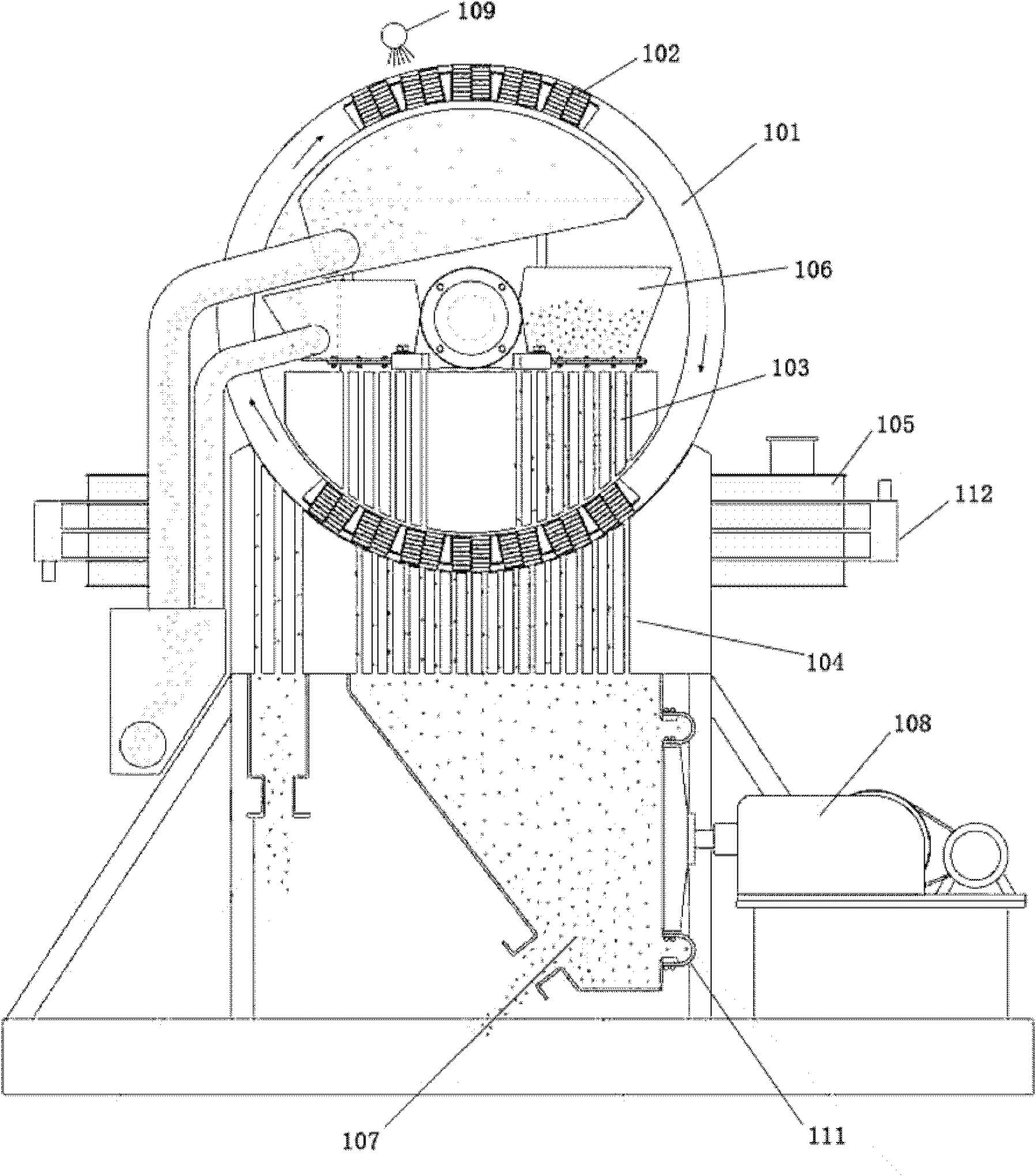

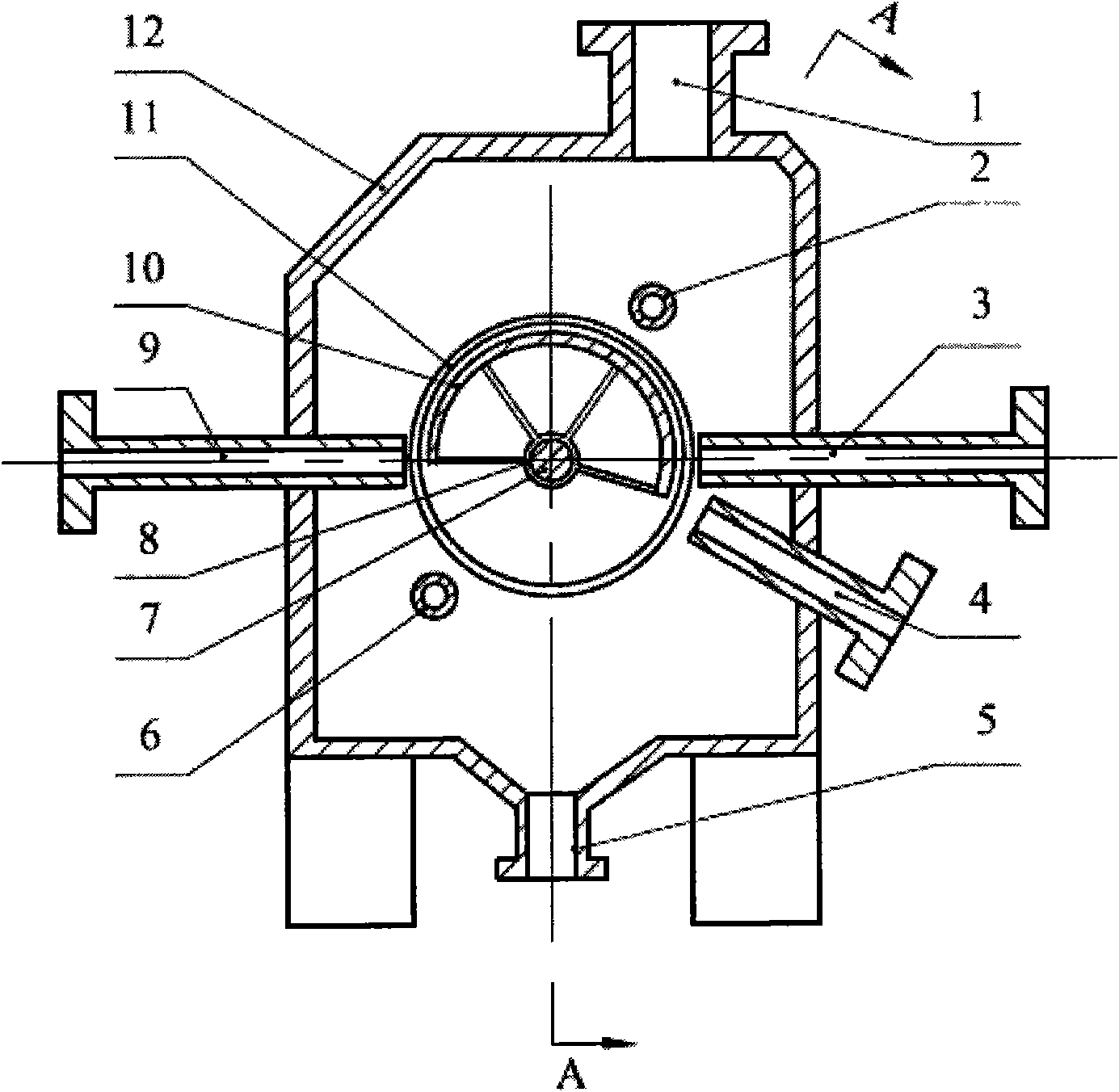

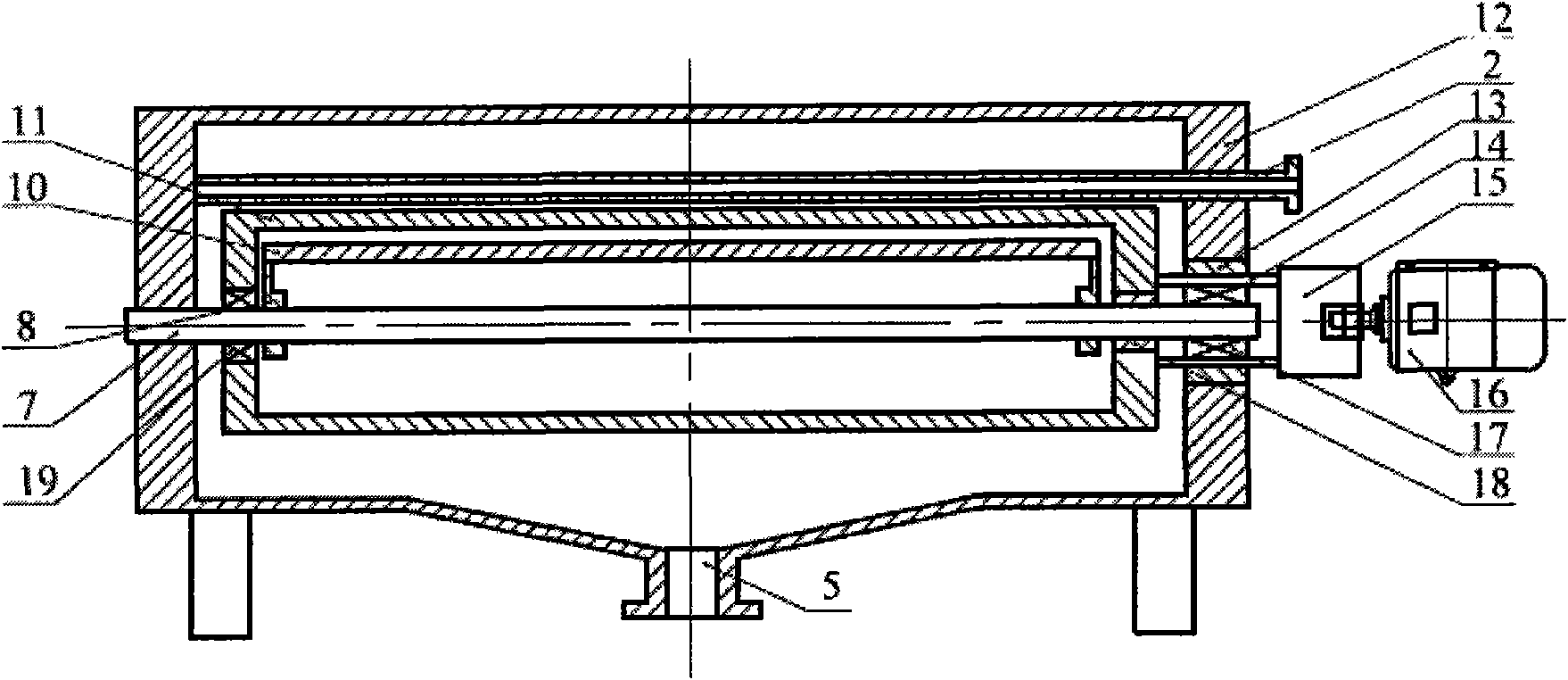

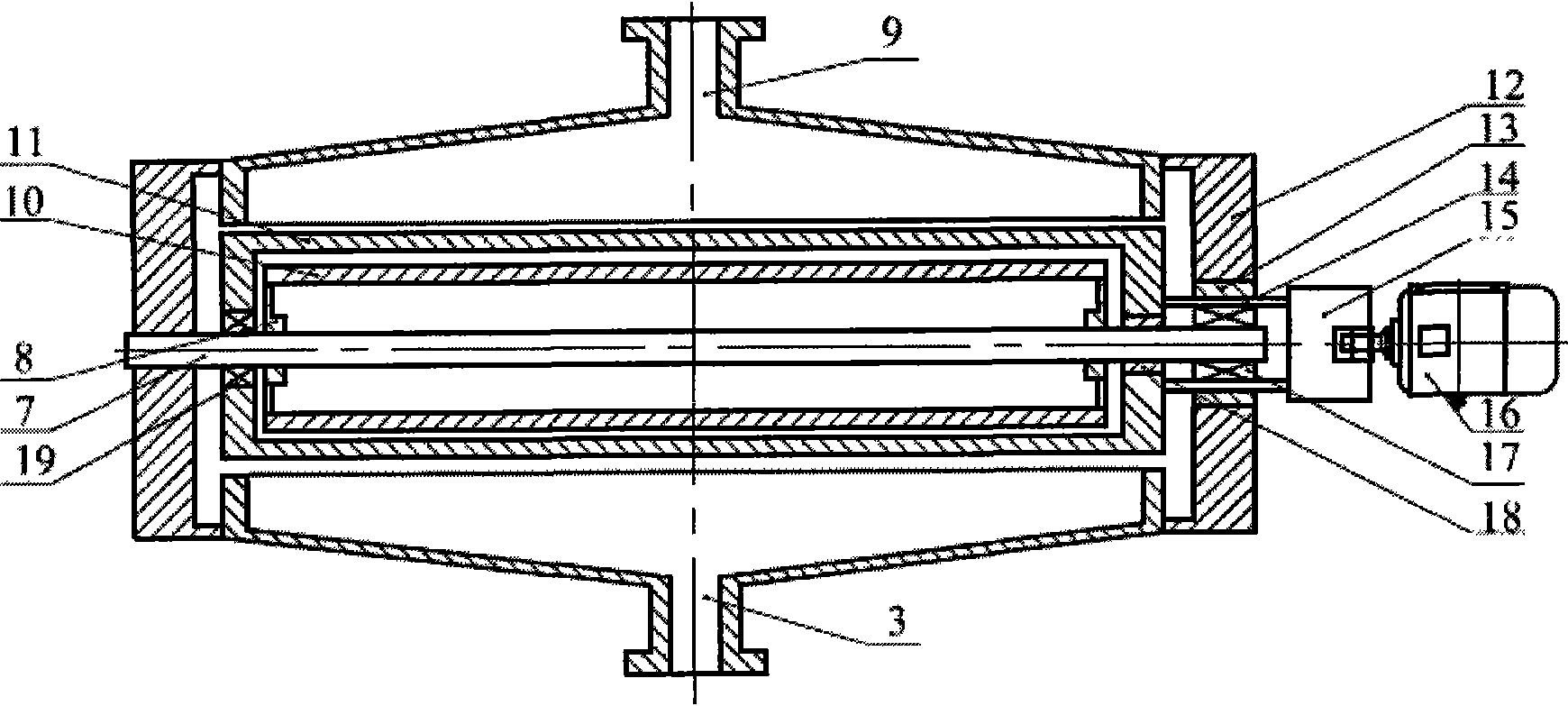

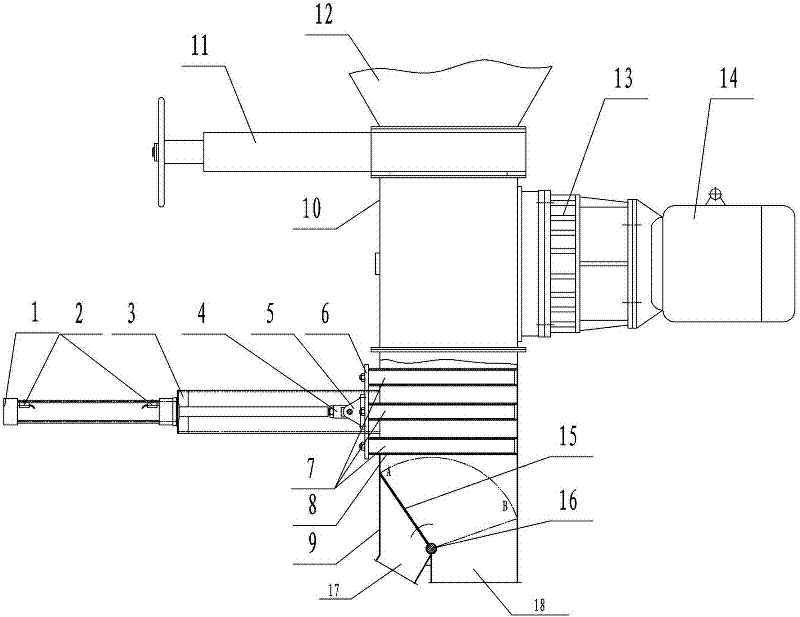

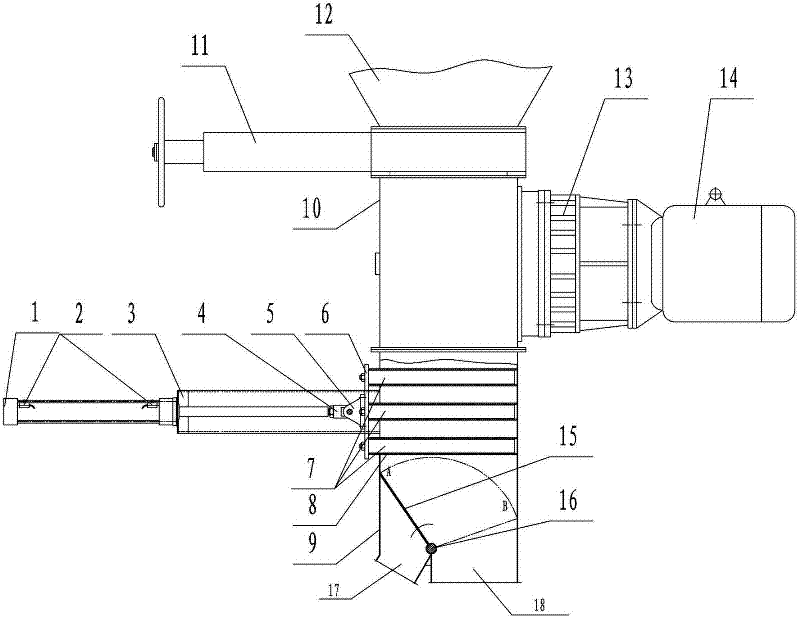

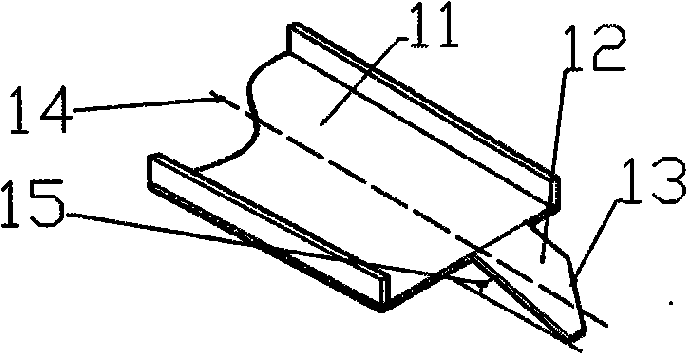

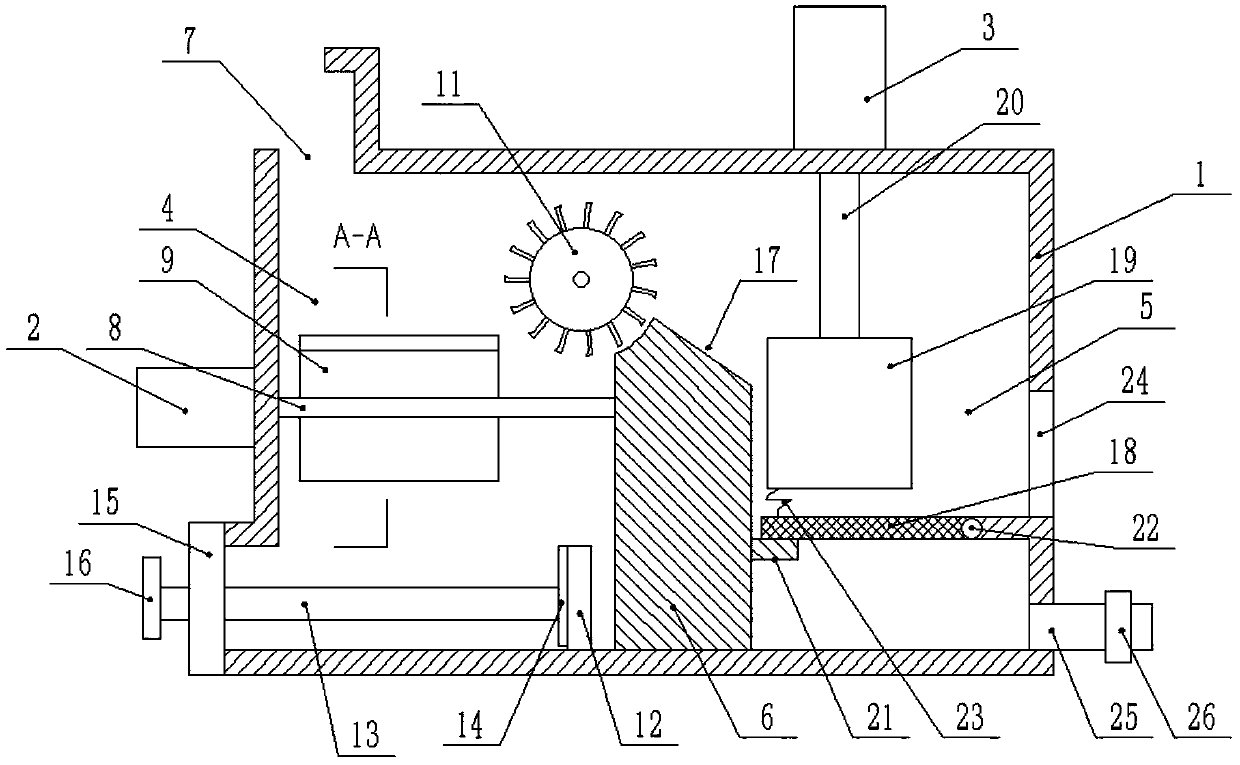

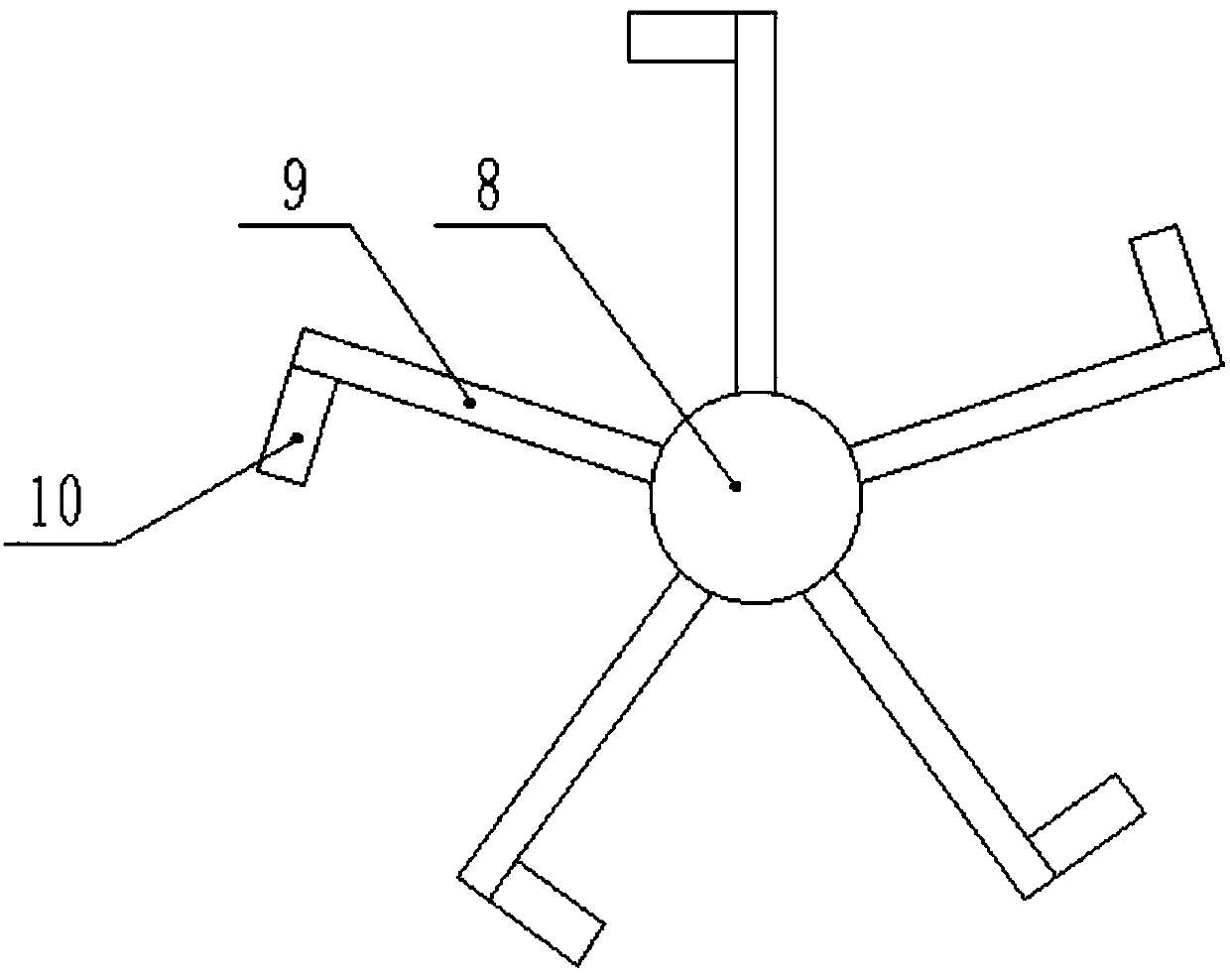

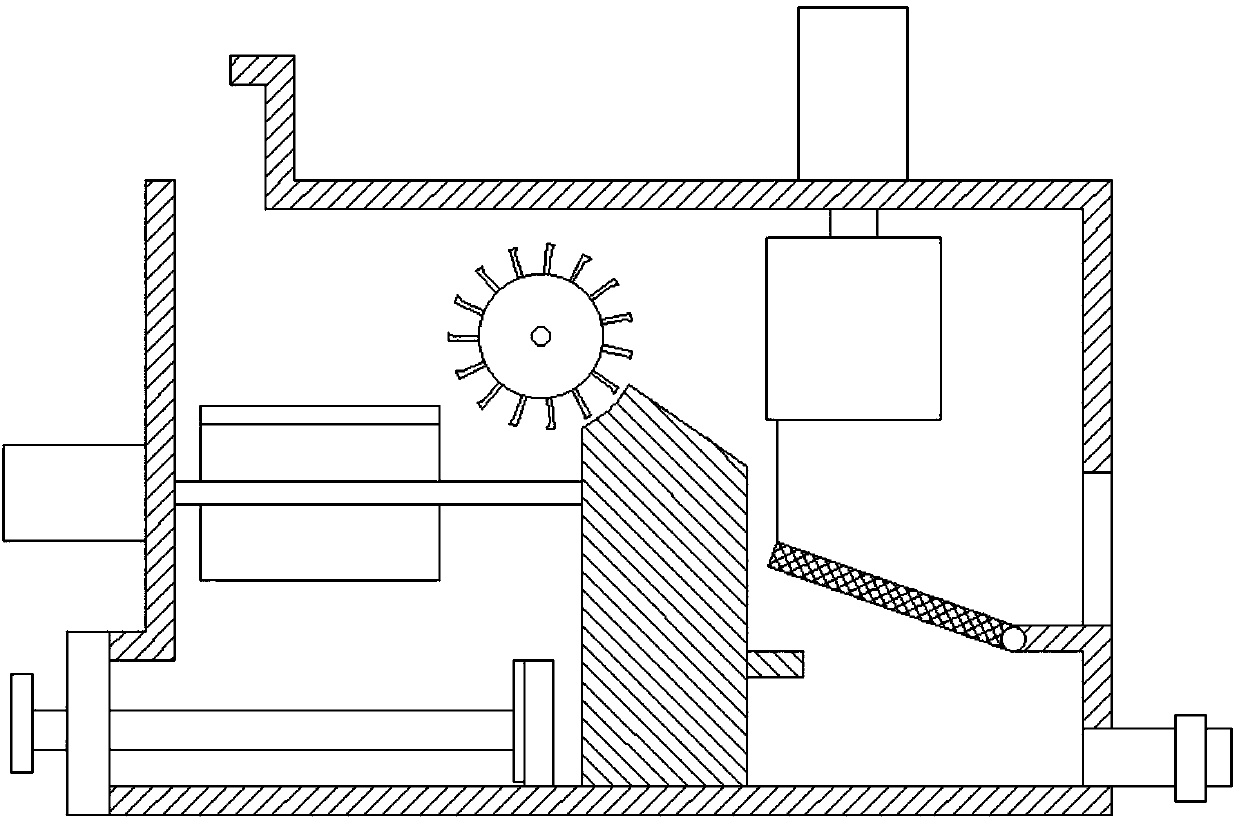

Micro powder dry-type magnetic separator

InactiveCN101596492AGood iron removal effectSolve sorting difficultiesMagnetic separationProcess efficiency improvementMagnetic separatorEngineering

The invention relates to a micro powder dry-type magnetic separator; the technical proposal is that: the two ends of a magnetic rotary drum (11) are respectively arranged on a fixing shaft (7) concentrically by a left end bearing (19) and a right end shaft liner (18), the right side of the magnetic rotary drum (11) is connected with a hollow shaft (14), a motor (16) is connected with the hollow shaft (14) by a speed reducer (15), a magnetic system (10) is concentrically arranged in the magnetic rotary drum (11), the upper right part and the bottom left part of the magnetic rotary drum (11) are respectively provided with one to two first air duct (2) and a second air duct (6) along the axial direction, a row of air outlet holes are uniformly opened on the first air duct (2) and the second air duct (6) towards to one side of the magnetic rotary drum (11), a sealing type machine shell (12) above the magnetic rotary drum (11) is provided with a tailings outlet (1), the sealing type machine shell (12) at the left side of the magnetic rotary drum (11) is provided with a first middling outlet (9), and the sealing type machine shell (12) at the bottom right part of the magnetic rotary drum (11) is provided with a second middling outlet (4). The micro powder dry-type magnetic separator has the characteristics of high separating purity of high recovery rate of magnetic products.

Owner:WUHAN UNIV OF SCI & TECH +1

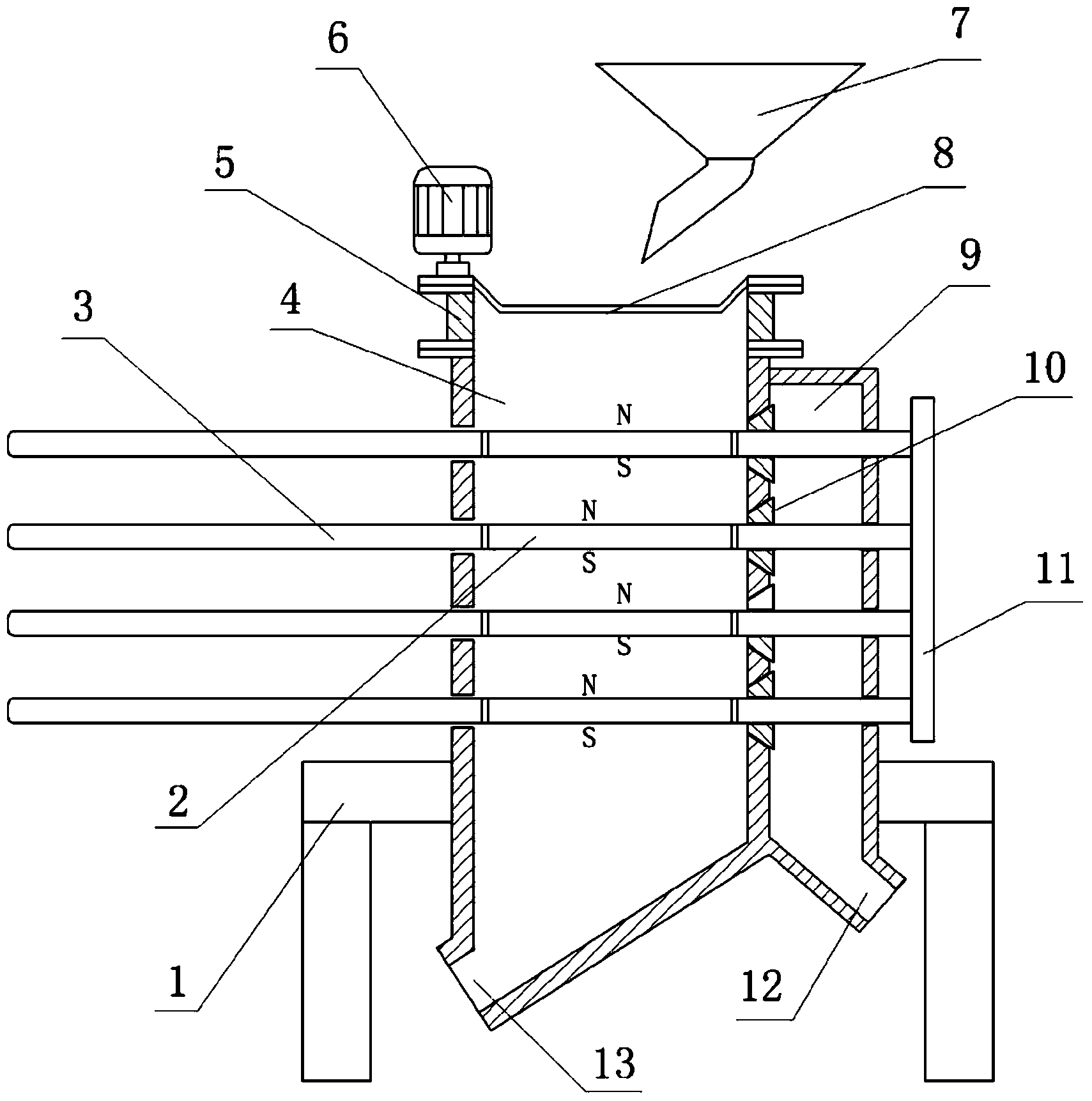

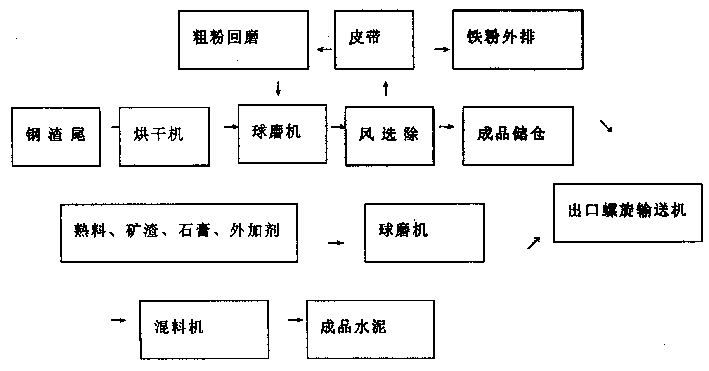

Technology for using steel dregs

InactiveCN1560283AIncrease added valueImprove the effect of iron removalRecycling and recovery technologiesSlagTubes types

The invention is a new environmental-protection using process of steel slags, crushing the slags by a multi-stage crushing system, and then adopting progressive iron magnetic separation system to make magnetic separation and screening process; drying the tail slags after eliminating the irons and transferring in a tube-type mill for powder milling; eliminating the irons from the fine powder by magnetic separation system, and separating the powder by a high-performance powder separator and a box-type dust cleaning device, and the separated fine powder is steel slag micropowder product, and the rough material is returned to the tube-type mill for milling fine, and the specific area of the product is greater than 450 sq m / kg. The mcropowder can act as a mixture of high-activity concrete of building material systems. Its advantages: the iron eliminating effect of the process is good and it can produce the steel slag micrpowder product, increasing the added-value of the product.

Owner:LAIWU IRON & STEEL GRP

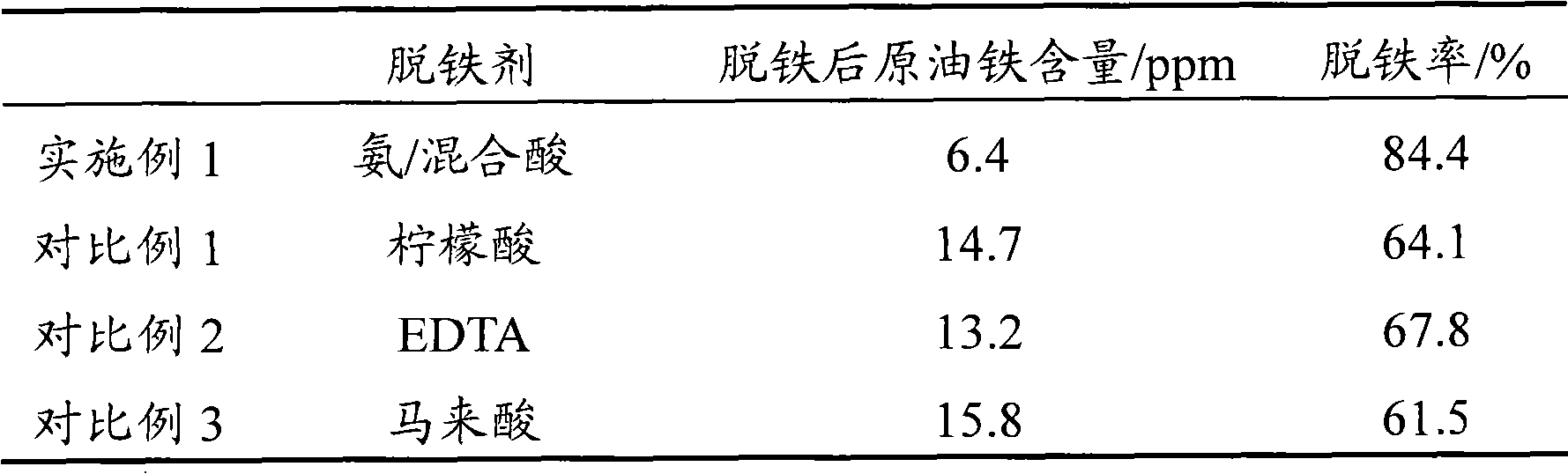

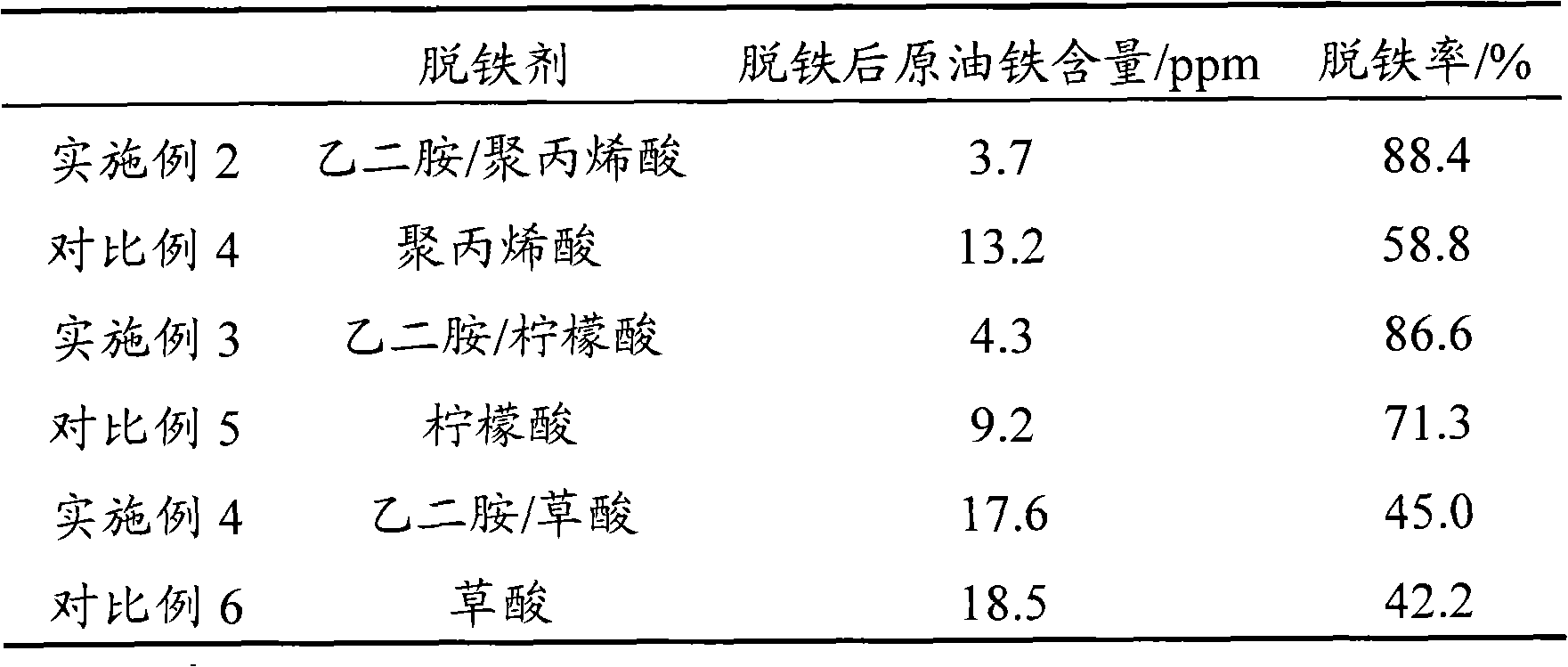

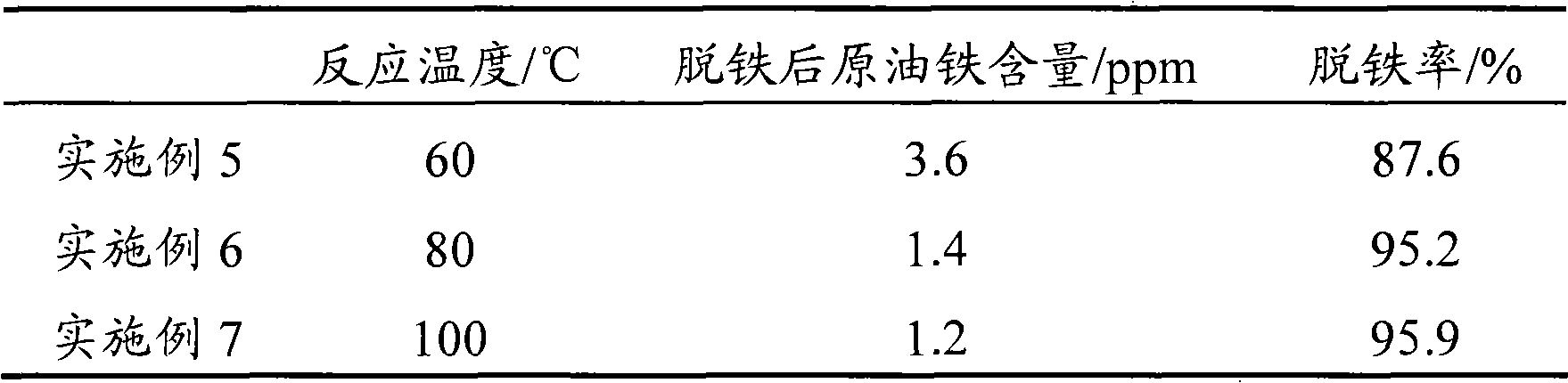

Deferrization method for hydrocarbons raw oil

ActiveCN101314728AStrong iron ion chelating abilityShort reaction timeHydrocarbon oils refiningAmmonium compoundsReaction temperature

The invention provides a method for removing iron from hydrocarbon feed oil, which comprises the following steps: (1) fully mixing iron-containing hydrocarbon feed oil with iron removing agent solution and reacting; and (2) separating oil-water mixture to remove the majority of iron in hydrocarbon feed oil. The iron removing agent contains a component A and a component B, wherein the component A is selected from one or more of C2 to C6 polycarboxylic acids, C2 to C8 hydroxycarboxylic acids and water-soluble maleic acid and acrylic acid polymer; and the component B is selected from one or more of ammonia, inorganic or organic ammonium compound, C2 to C8 linear alkyl-amines, cycloalkyl amines or alcohol amines, and polyethylene-polyamines with molecular weight of 100 to 5,000. The iron removing agent prepared from nitrogen-containing compound and organic acid by mixing has higher iron ion chelating ability and can achieve better iron removal effect in shorter reaction time and at lower reaction temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxidation continuous deferrization process for copper cobalt liquor

InactiveCN101117664AIncreased copper and cobalt contentPut into realizationProcess efficiency improvementAutomatic controlTurnover time

The present invention discloses an oxidation de-ironing method of copper cobalt solution. The iron removal of the copper cobalt ores lixivium adopts the interrupted de-ironing method, which can not realize the continuous input and output of material, thereby causing the long turnover time among the equipments, reducing the effective utilization rate of the equipments, at the same time increasing the production cost and the labor strength. The present invention makes a plurality of de-ironing tanks connect in series to form a multilevel continuous de-ironing system into which the copper cobalt solution containing iron is put continuously, the copper cobalt solution is performed with the oxidation treatment firstly to make ferrous iron in the solution to be oxidized completely into ferric iron, and then the copper cobalt solution carries out the multilevel continuous iron removal, and utilizes the pipeline port fall existing between the tanks to flow into the next tank from the last tank. Through adopting the present invention, the continuous input and output of the feed liquid is realized, the production continuity is good, the automatic control is realized completely, the labour force is reduced, the working intensity is lowered, and the production efficiency is high.

Owner:ZHEJIANG HUAYOU COBALT

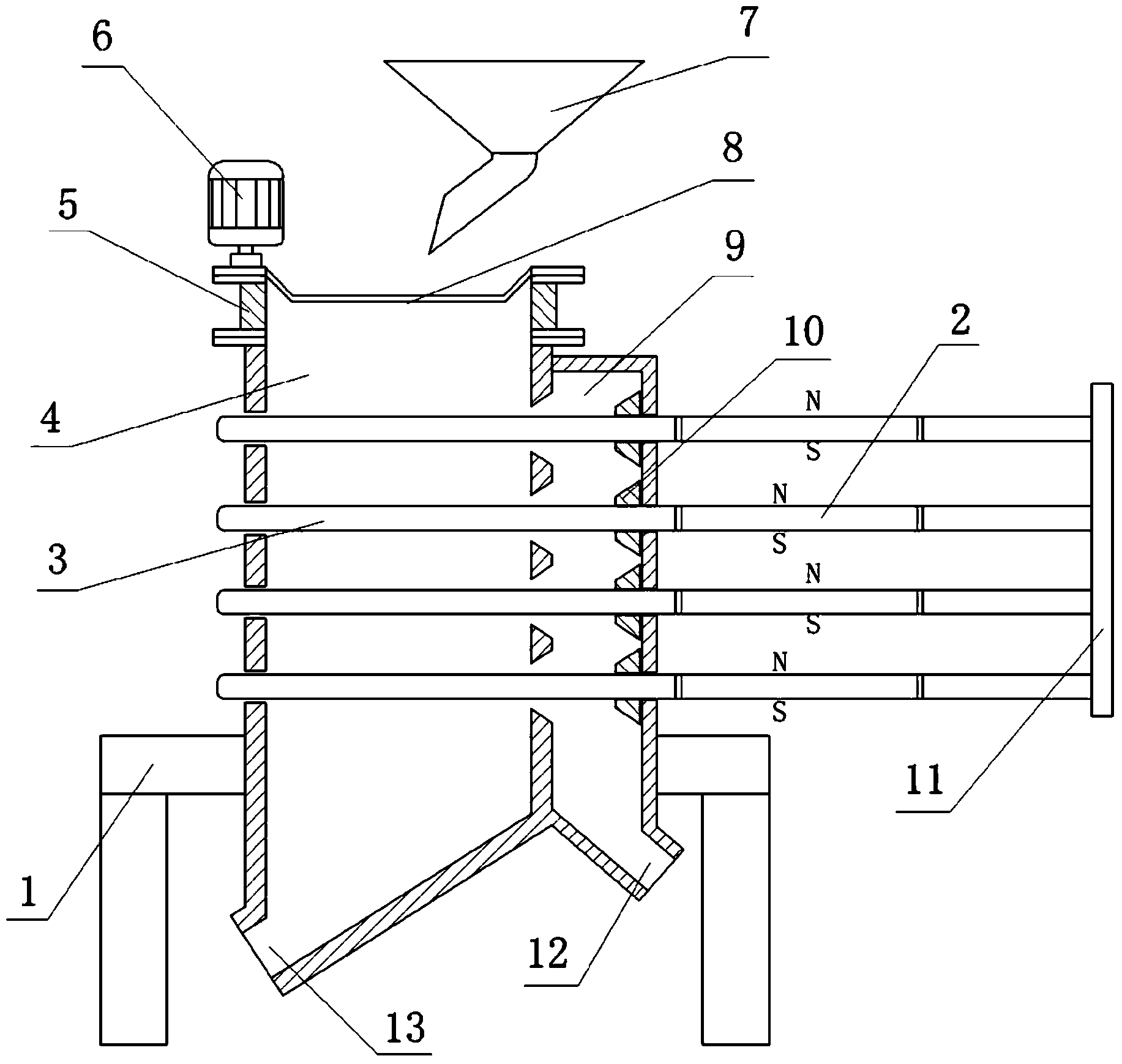

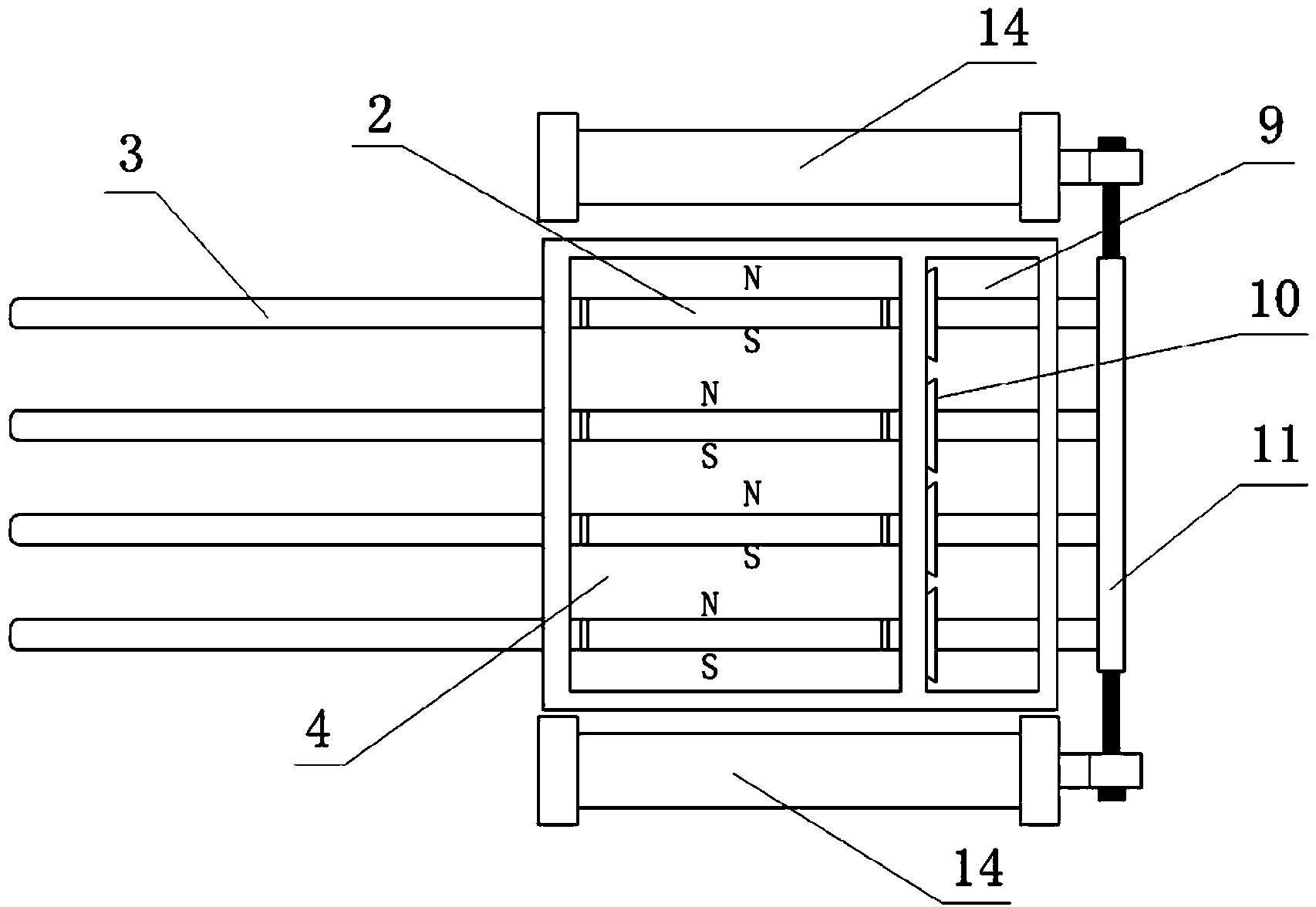

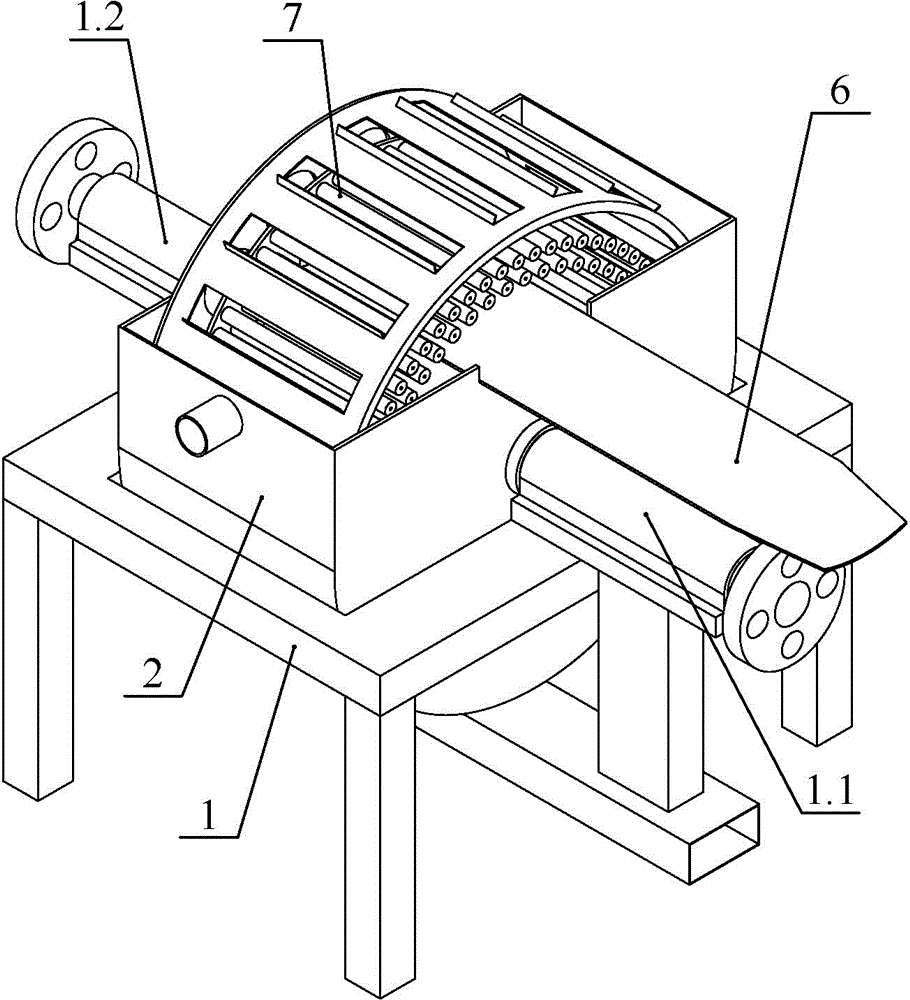

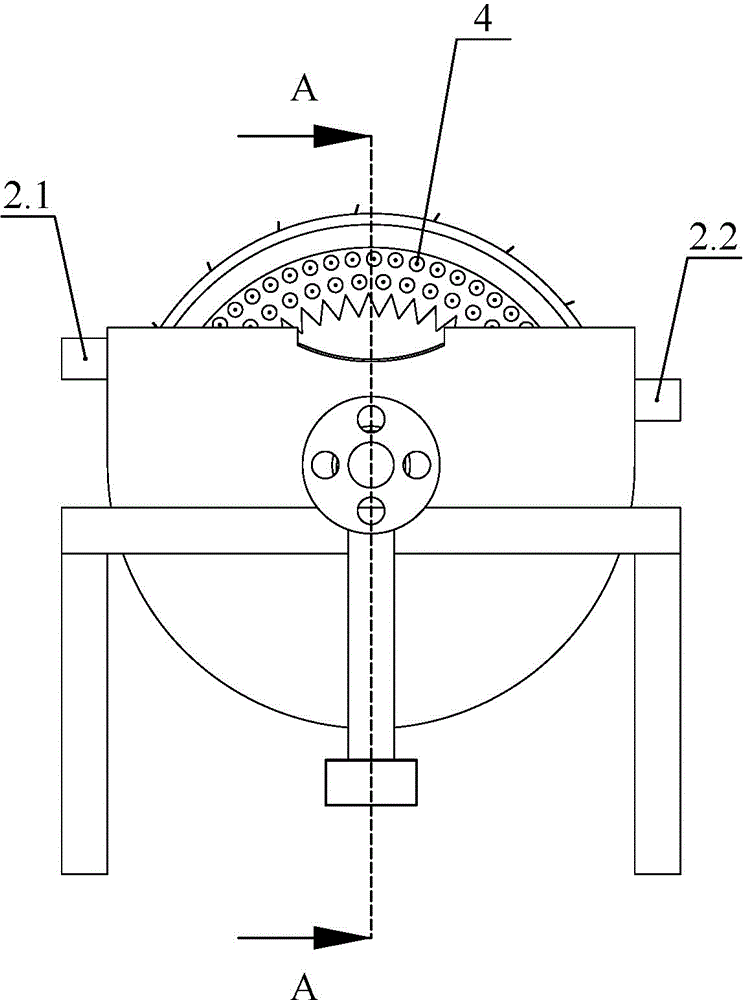

Permanent-magnetic type powder deironing machine

The invention relates to a permanent-magnetic type powder deironing machine. The permanent-magnetic type powder deironing machine comprises a rack, permanent magnet rods, a deironing box and a ferromagnetic slag collecting box, wherein the deironing box is arranged on the rack, a feeding hole is formed in the top end of the deironing box, a discharge hole is formed in the bottom of the deironing box, the permanent magnet rods are arranged on expansion links which transversely penetrate through the deironing box, the expansion links can slide transversely in the deironing box, when the expansion links slide transversely, the permanent magnet rods can be moved into or out of the deironing box, and wiper plugs are arranged on the expansion links and are used for scraping ferromagnetic substances attracted on the permanent magnet rods when the permanent magnet rods are moved out of the deironing box. According to the permanent-magnetic type powder deironing machine, the permanent magnet rods are arranged on the expansion links, the expansion links slide to enable the permanent magnet rods to move into and out of the deironing box, the expansion links are sleeved by the wiper plugs, a plurality of permanent magnet rods are distributed in an intersected manner, the deironing box is separated from the ferromagnetic slag collecting box, the deironing effect is good and the ferromagnetic substances can be removed conveniently and rapidly.

Owner:赵宽学

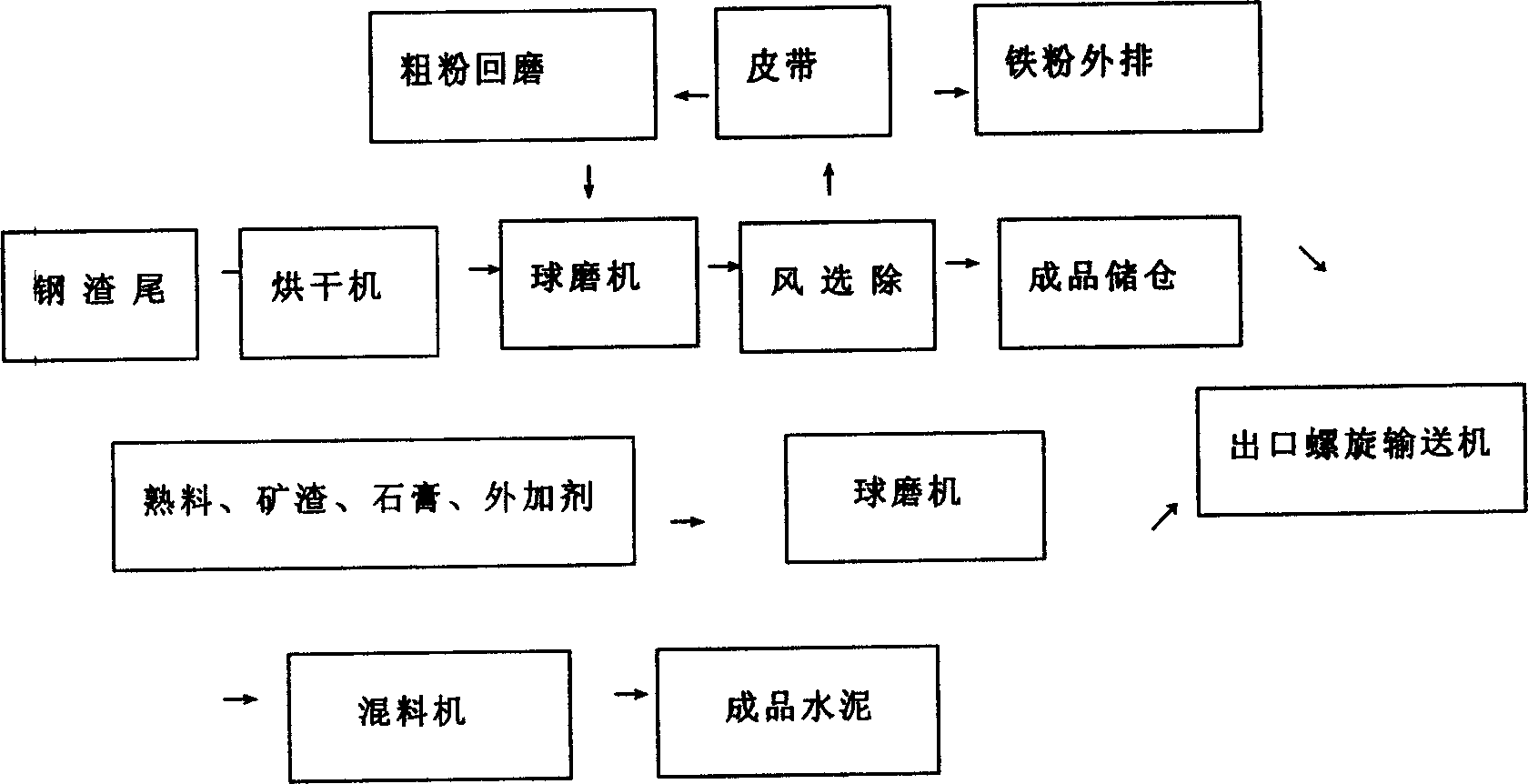

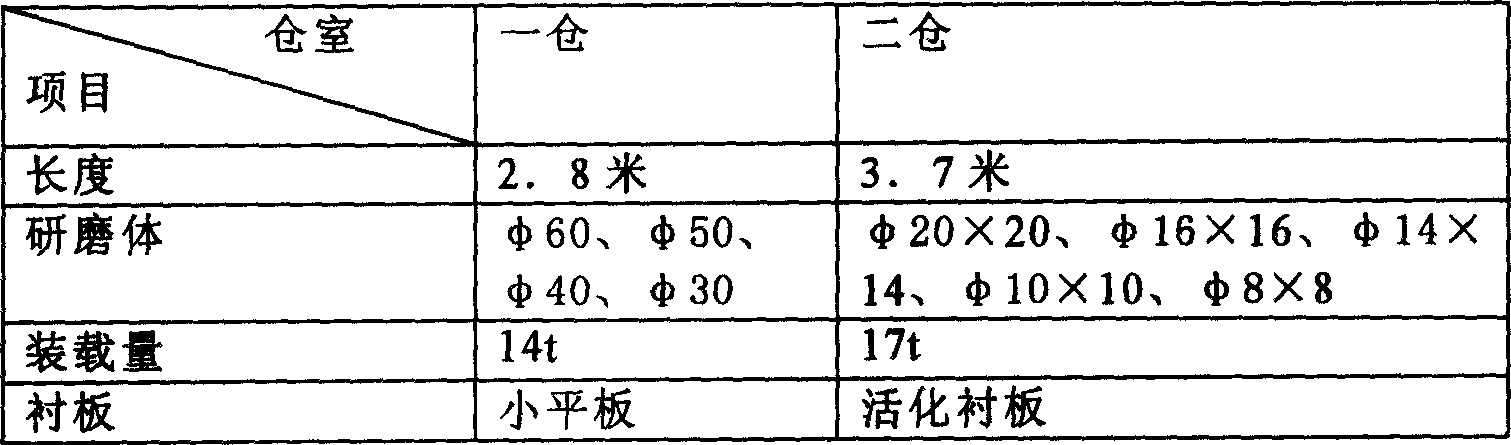

Deferrization process for steel scoria and application of steel scoria fine powder thereof

InactiveCN1566010ASolve technical problems such as low early strength and poor stabilitySimple processCement productionRecycling and recovery technologiesIron powderSlag

The invention discloses a deferrization process for steel slag and application of steel scoria fine powder thereof which comprises the steps of steel slag drying, fine grinding, air choosing, ferrum expelling, ferrum powder discharge, coarse powder returning for fine grinding, and mixing steel slag fine powder with semi-finished cement.

Owner:鞍钢集团水泥厂

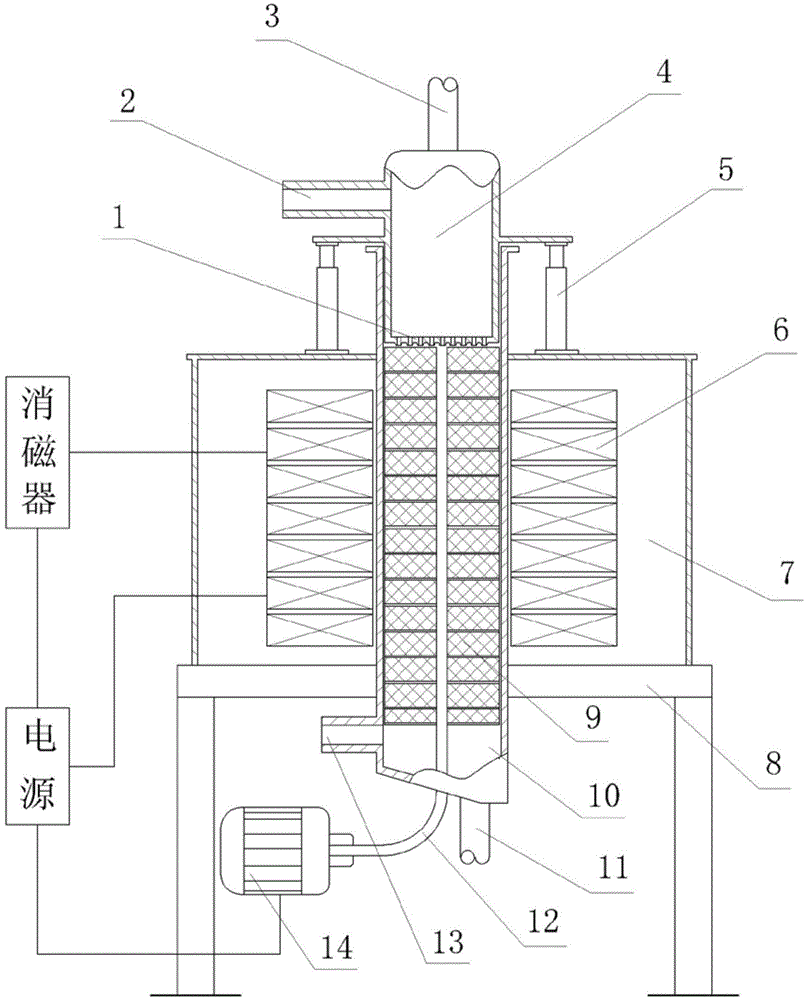

Electromagnetic iron-removing machine

ActiveCN104353549AWash thoroughlyEasy to cleanMagnetic separationCleaning processes and apparatusIron removalSlag

The invention discloses an electromagnetic iron-removing machine. The iron-removing machine comprises a rack, an inner barrel, a radiating tank, electromagnetic coils, a magnetic eraser and a power supply, wherein the inner barrel is installed on the rack, the electromagnetic coils are wound on the outside of the inner barrel, the lower end of the inner barrel is provided with a feed opening and a deslagging opening, and magnetically soft steel is filled in the inner barrel; a lifting bucket sleeves the upper end of the inner barrel, the top of the lifting bucket is provided with a discharge opening and a water inlet, a through hole is formed in the bottom of the lifting bucket, and the lifting bucket is capable of sliding up and down in the inner barrel; the magnetic eraser is capable of eliminating magnetism of magnetically soft steel and ferromagnetic slag absorbed on the magnetically soft steel when used for cleaning the magnetically soft steel, the electromagnetic coil is enclosed therein by the radiating tank, and a liquid is injected into the radiating tank to radiate the electromagnetic coil. Since the magnetically soft steel is adopted by the electromagnetic iron-removing machine as the magnetic medium, the lifting bucket is used for pressing the magnetically soft steel when the iron-removing machine is used for removing iron, and the lifting bucket is lifted to enable the magnetically soft steel to naturally fluffy while cleaning, and then cleaning is performed through a water spraying device and a vibrating device; the electromagnetic iron-removing machine is rapid and convenient to clean, and good in ferromagnetic slag removing effect.

Owner:佛山市高明星源机械有限公司

Hot-dip galvanizing process

The invention relates to a hot-dip galvanizing process, in particular to the hot-dip galvanizing process for galvanizing repeatedly, which comprises the following steps: 1) surface treatment; 2) acid cleaning; 3) activation of solvent; 4) drying; 5) treatment of liquid zinc; 6) galvanization; 7) repeated operation; 8) passivation; and 9) testing. In the invention, the method of adding a zinc-nickel alloy is adopted for the treatment of the liquid zinc, the effect is more obvious, and nickel can firstly react with silicon when iron is in contact with the zinc for generating an alloy element of a silicide, so as to eliminate adverse effects of the silicon; elements in the zinc-nickel alloy can react with the iron for generating low slag and surface slag respectively, and reducing the solubility of the iron, an excellent iron removing effect is achieved; and the appearance of a cast after treatment by the process steps is unchanged basically after one year of exposure, and the anti-corrosion capability is greatly improved. According to one year of follow-up services of a customer, the phenomena of blackening and variegation can be avoided during water and steam curing.

Owner:YUZHOU SHENYUN MACHINERY CO LTD

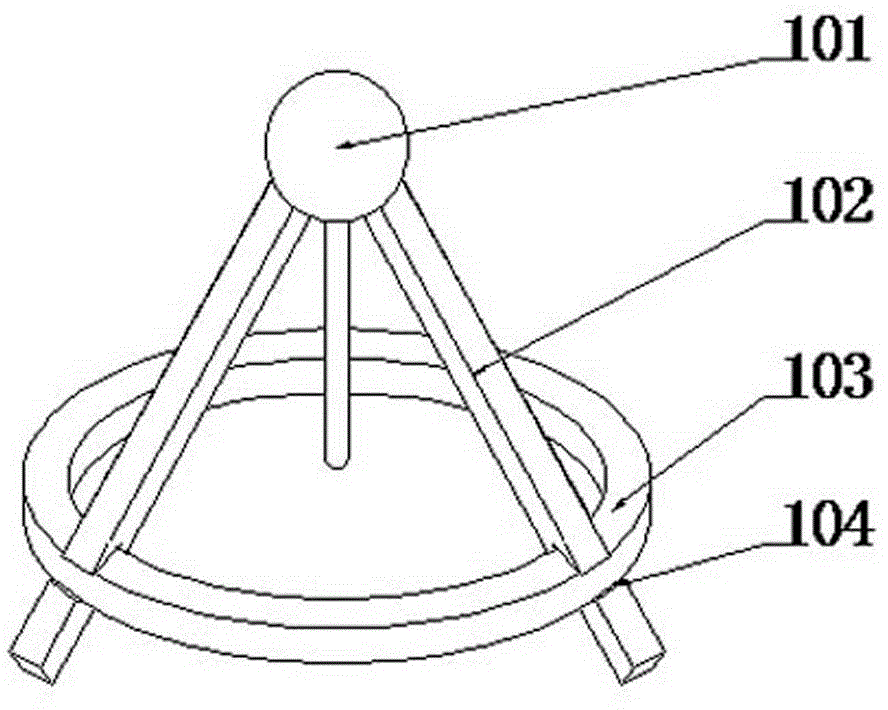

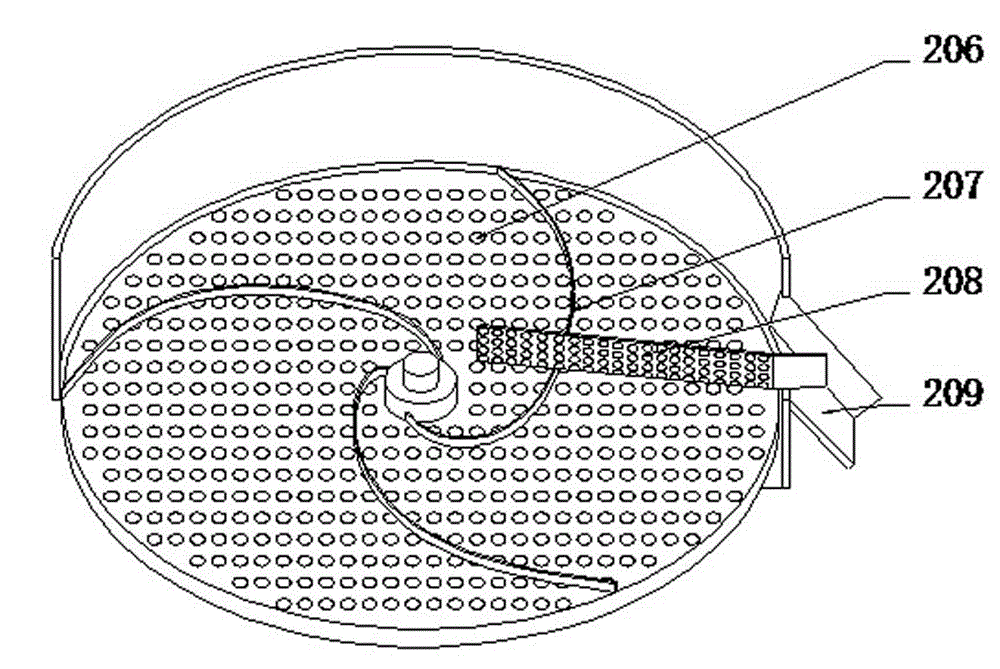

Rotary filtering apparatus of slurry

InactiveCN104959227AWill not pose a safety hazardSimple structureSievingScreeningIron removalMiniaturization

The invention discloses a rotary filtering apparatus of a slurry. The apparatus comprises an iron removal device and a filtering device, the iron removal device comprises a round ball, an annular magnet, supporting legs, and the round ball is movably connected with the supporting legs; the filtering apparatus comprises a filtering chamber, a feeding port, a fine material port and a coarse material port, and the lowest ends of the supporting legs are supported on the sidewall of the feeding port; a rotary sieve is arranged in the filtering chamber, the center position of the rotary sieve is provided with a rotating shaft, the rotating shaft is connected with a motor arranged at the bottom, the motor is arranged at the bottom of the filtering chamber, and a material outlet and the feeding port are arranged at the top of the filtering chamber; and a scraper plate is arranged on the half surface of the rotary sieve, and does not contact with the rotary sieve, and one end of the scraper plate outwardly extends to the upper portion of the coarse material port. The apparatus has the advantages of simple structure, use convenience, miniaturization, flexible and manoeuvrable production, good iron removal effect, low energy consumption and low cost, and is suitable for being used in small processing factories.

Owner:绥阳县华夏陶瓷有限责任公司

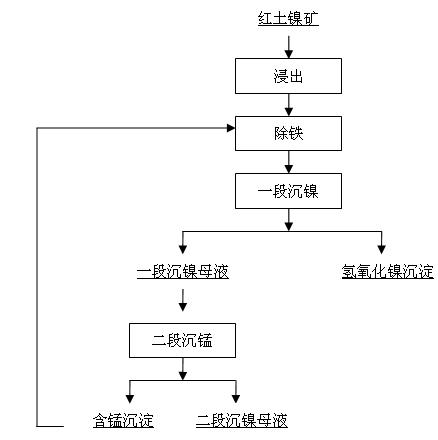

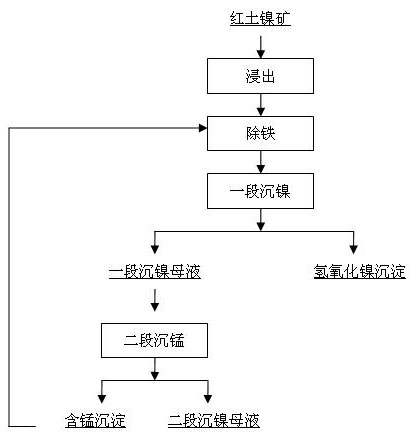

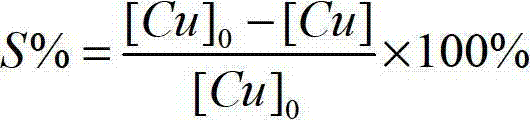

Method for removing iron in leaching liquid of lateritic nickel ore by oxidation

InactiveCN102061386ALow costImprove the effect of iron removalPregnant leach solutionMining engineering

The invention discloses a method for removing iron in leaching liquid of a lateritic nickel ore by oxidation. The method comprises the following steps of: regulating the pH value of the leaching liquid to 1.7-5.0 so as to precipitate Fe<3+> ions in the leaching liquid, and then regulating the pH value of the leaching liquid to 7.5-8.5 so as to convert Ni<2+>ions in the leaching liquid to Ni(OH)2 and precipitate and separate the Ni(OH)2. The method further comprises the following steps of: (1) regulating the pH value of nickel precipitant mother liquid to 8.6-10, converting Mn<2+> in the leaching liquid to Mn(OH)2 and precipitating the Mn(OH)2; (2) reacting the Mn(OH)2 in precipitates and oxygen to produce MnO2, using the precipitates containing the MnO2 as an oxidant, filling back to the leaching liquid, oxidizing Fe<2+> in the leaching liquid into Fe<3+> and regulating the pH value to precipitate Fe<3+>. In the method, the oxidant does not need to be additionally added, and the MnO2 produced by the self system is fully utilized as the oxidant, therefore, the cost can be reduced, the iron removing effect is great, and the content of the iron can be reduced below 0.025g / l.

Owner:广西银亿新材料有限公司

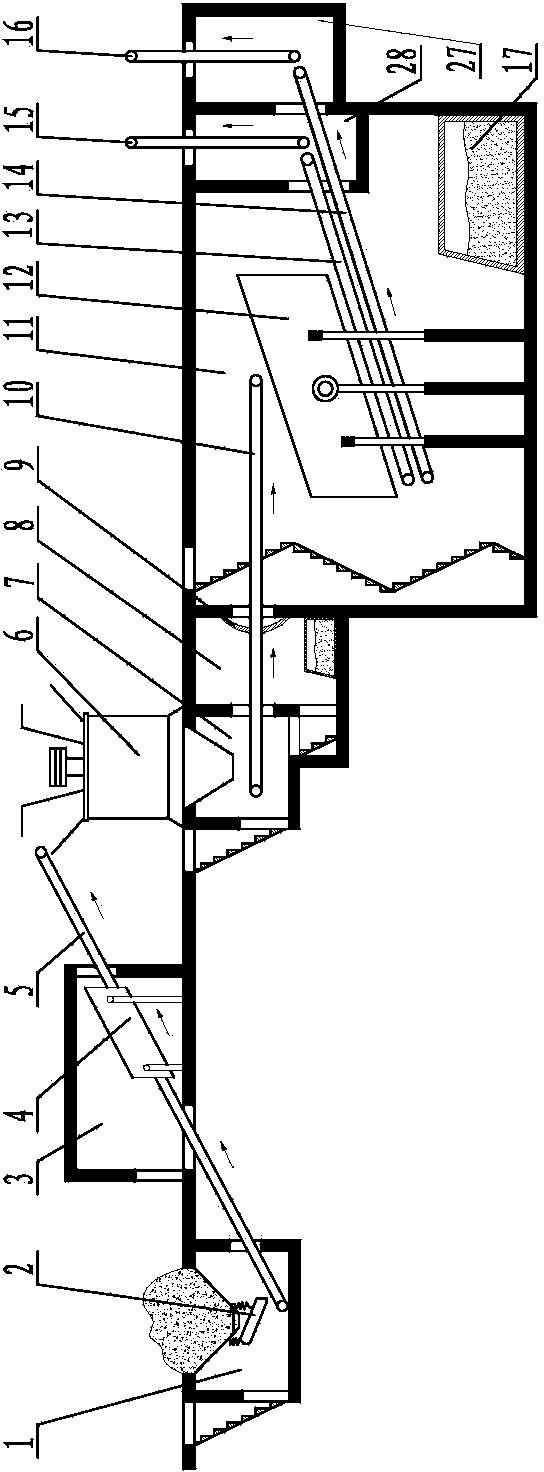

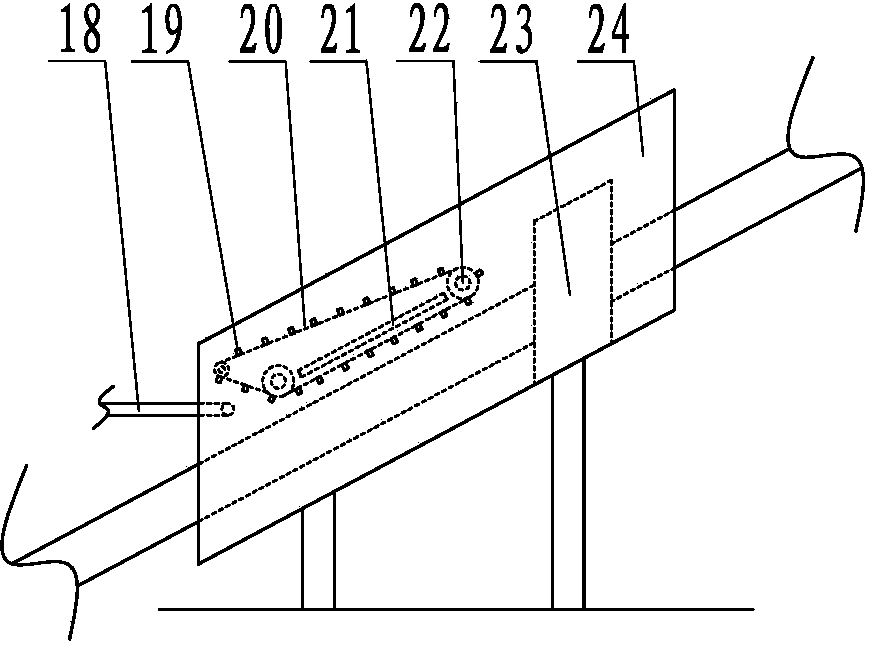

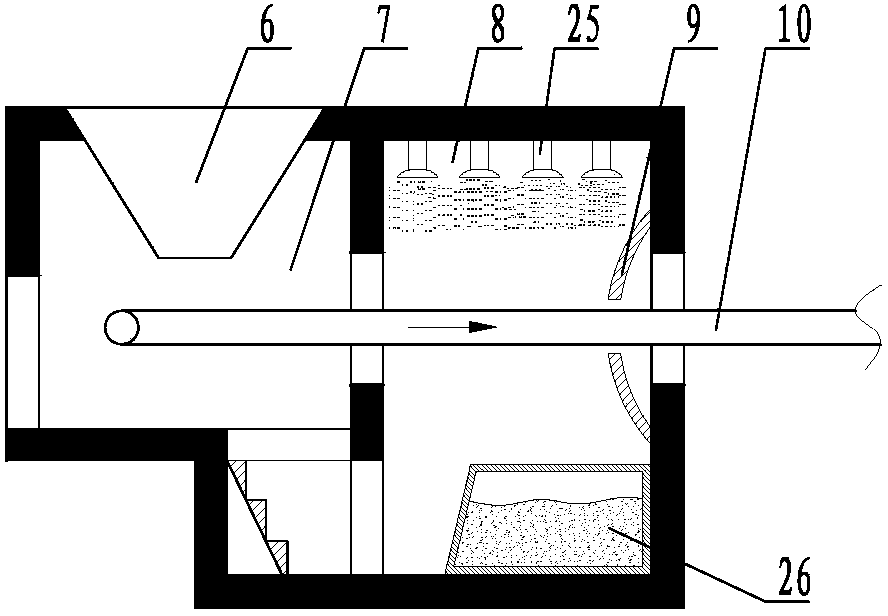

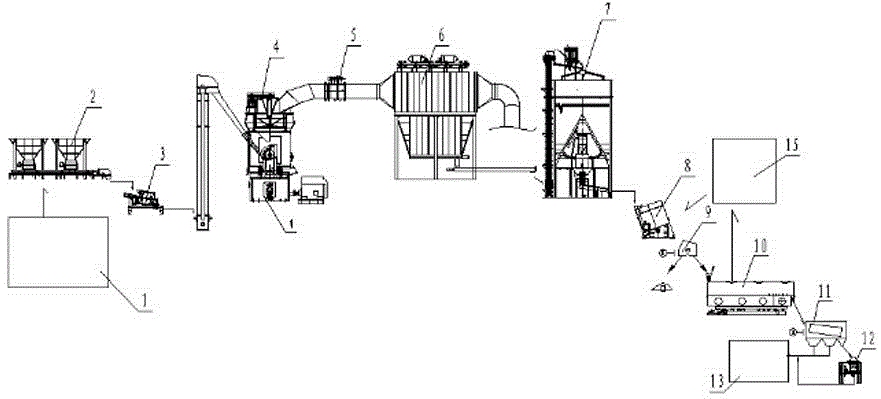

Technology and complete equipment for industrial sand making and building garbage processing

ActiveCN104384002AReduce energy consumptionLess investmentCombination devicesUsing liquid separation agentWork unitEnergy consumption

A technology and complete equipment for industrial sand making and building garbage processing are disclosed and belong to the field of processing of industrial sand making and building garbage processing. The complete equipment for industrial sand making and building garbage processing comprises a feeding settling zone, an iron removal zone, a fragmentation settling zone, a dust-removal settling zone and a vibration-screening settling zone, and the above five functional zones are in connection via a conveying belt; and the feeding settling zone, the fragmentation settling zone, the dust-removal settling zone and the vibration-screening settling zone are sunk under the ground. The complete equipment is capable of reducing the flowing dust pollution generated in production to a lowest level, and also the complete equipment does not need additionally adding large-scale environment-protection equipment for treating flowing dust, so that the energy consumption of the complete equipment in product is reduced, and also the investment on the complete equipment is substantially reduced. All working units of the complete equipment are reasonable matched, the production efficiency is high, energy is saved and environment is protected, and the complete equipment is in favor of practical application and technology popularization.

Owner:ZIBO DALI MINING MASCH CO LTD

Iron removing and whitening method for indianite

InactiveCN101844773AGood iron removal effectReduce dosageAluminium silicatesIron removalPhosphoric acid

The invention relates to an iron removing and whitening method for indianite. The iron removing and whitening method for the indianite is characterized by comprising the following steps: (1) preparing the following chemical reagents: (1) reducing agents, i.e. sodium bisulfite and zinc powder; and (2) a complexing agent, i.e. any one of oxalic acid, tartaric acid and phosphoric acid; (2) preparing size, i.e. preparing indianite size the concentration of which is between 15 and 20 wt% by adding water into crude ore of the indianite and using sulfuric acid solution the concentration of which is between 1.0 and 3.0mol / L to regulate a pH value to make the pH value is between 2 and 3 to obtain the indianite size the pH value of which is regulated; (3) performing a reduction reaction, i.e. adding the reducing agents into the indianite size the pH value of which is regulated, stirring the mixture to perform a reaction for 25 to 30 minutes and continuously regulating the pH value in the process of the stirring reaction to maintain the pH value between 2 and 3 to obtain the size subjected to the reduction reaction; and (4) adding the complexing agent into the size subjected to the reduction reaction, performing a reaction for 5 minutes, washing the reaction product and drying to obtain the indianite subjected to iron removal and whitening. The iron removing and whitening method is suitable for industrial production and has obvious effect.

Owner:YUNNAN BOSHANG GAOLING TECH

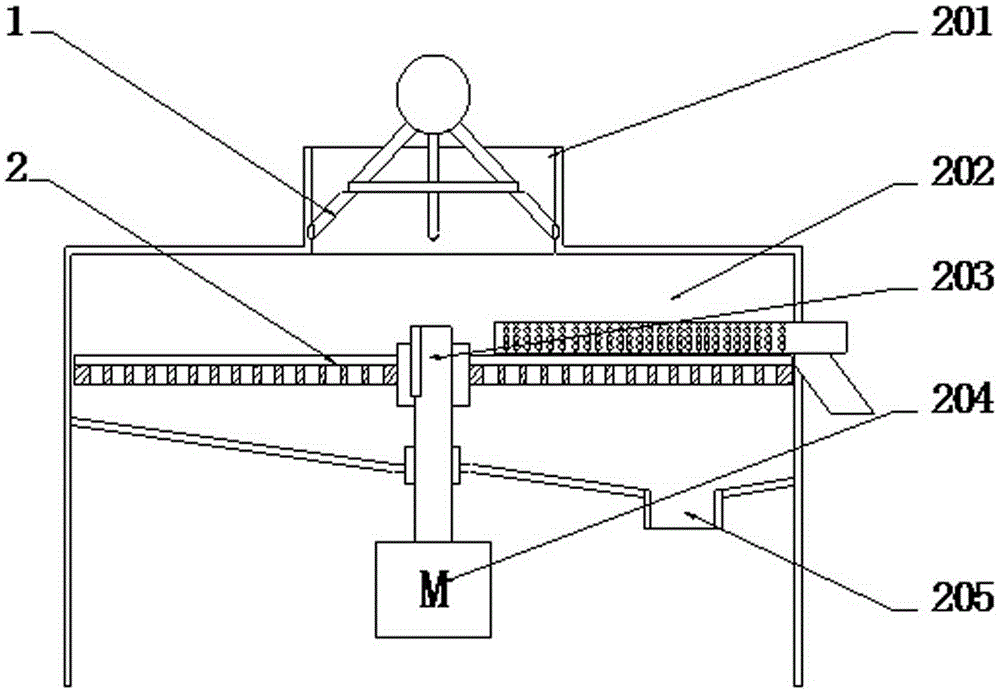

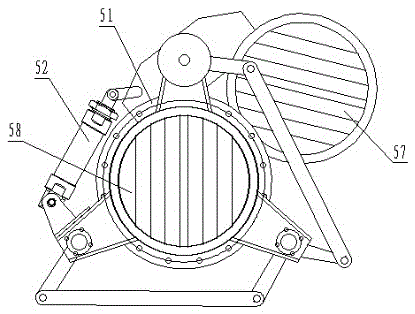

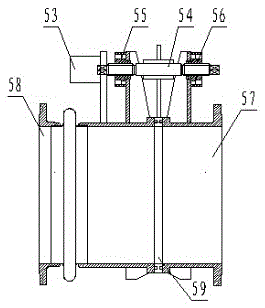

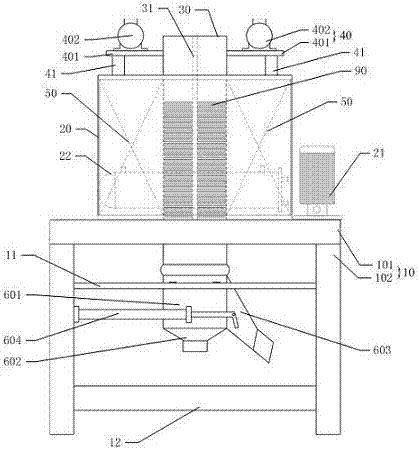

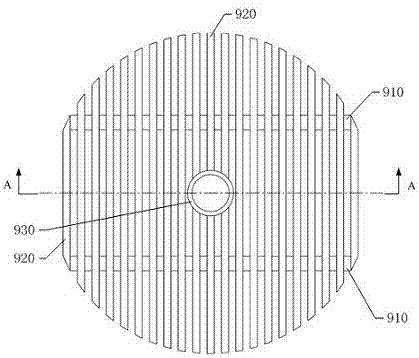

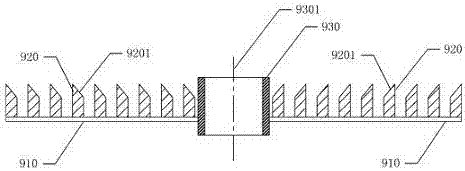

Apparatus for removing iron in powder

ActiveCN102441485AImprove the effect of iron removalReduce energy consumptionMagnetic separationEngineeringFlap valve

The invention relates to an apparatus for removing iron in powder. The apparatus comprises a feeding mechanism, a magnetic separation mechanism and a support; the magnetic separation mechanism comprises a box, at least a magnetic rod set, magnetic rod sleeves with an amount corresponding to the amount of magnetic rods, a magnetic rod set driving unit and a flap valve, wherein, the magnetic rod sleeves are transversely arranged at the middle and upper parts of the box, one end of every magnetic rod of the magnetic rod set is fixed by a connection board and is then connected with a power output terminal of the magnetic rod set driving unit, the other end of every magnetic rod passes through a corresponding magnetic rod sleeve, every magnetic rod slidely moves in its corresponding magnetic rod sleeve under the driving of the magnetic rod set driving unit, an iron discharging outlet and a material discharging outlet are arranged at the bottom of the box, and the flap valve is installed above the iron discharging outlet and the material discharging outlet. The apparatus has the following advantages: a good iron-moving effect, low energy consumption, low cost for operation and maintenance, particular suitability for fine removal of iron in a powder material, a simple structure, small occupation space, convenient fabrication, installation and maintenance, a low price and easy popularization and usage.

Owner:洛阳宜墨新材料有限公司

Ceramic raw material dry method granulation production line and production technology

InactiveCN105478056AImprove uniformityImprove pass rateSievingScreeningProduction lineFluidized bed drying

The invention relates to a ceramic raw material dry method granulation production line and a production technology. The production line orderly comprises a raw material field, a raw material bin, a grinding mechanism, a granulation mechanism, a drying mechanism and a screening mechanism. A mixer is arranged between a discharge outlet of the raw material bin and a feeding inlet of the grinding mechanism. A discharge outlet of the grinding mechanism is connected to a dust collector through a powder iron separator. An output end of the dust collector is connected to a powder homogenization mechanism. The powder iron separator is an iron separator with at least two rotary iron separation channels. A feeding end of a reciprocating type fluidized bed dryer is provided with a distributing device. The lower end of the distributing device is provided with an airlock. A ventilation partition plate is arranged in a blast chamber. The blast chamber is divided into a drying zone and a cooling zone through the ventilation partition plate. The screening mechanism is a rotary screen with a demountable screen. The production technology has a high one-step granulation qualified rate, a low production cost and good drying effects.

Owner:SHANDONG ECON ENERGY SAVING TECH

Method for preparing low-ferrum crystalline aluminium chloride from coal ash

The invention provides a method for preparing low-ferrum crystalline aluminium chloride from coal ash, which comprises the following steps of: 1, crushing the coal ash, and performing wet magnetic separation on the crushed coal ash to remove ferrum; 2, reacting the coal ash subjected to ferrum removal and hydrochloric acid to obtain pickle liquor; 3, concentrating the pickle liquor under a reduced pressure, cooling and crystallizing to obtain crystalline aluminium chloride slurry; and 4, performing solid-liquid separation on the crystalline aluminium chloride slurry, rinsing with leacheate, performing solid-liquid separation and drying to obtain low-ferrum crystalline aluminium chloride products. The method has the advantages of wide raw material source, low cost, simple operation step, easily controlled production process, stable product quality and the like. The ferrum (Fe) content of the crystalline aluminium chloride products prepared by the method of the invention is no more than 0.025 weight percent.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Magnetic shaker

InactiveCN101062487AStrong magnetic forceImprove sorting efficiencyMagnetic separationWet separationMagnetic bearingEngineering

The magnetic rocker comprises the bracket with bed head and surface which sets mineral and water supply grooves, magnetic bearing mechanism along the direction of the bed with magnetic system set on the magnetic bearing mechanism. The introduction of compound force field solves the serious issue of mixture, increasing selection efficiency, improving selection index. It meets special requirement for magnetic mineral and non-magnetic mineral separation and nonmetal equipment requirement except iron ones.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

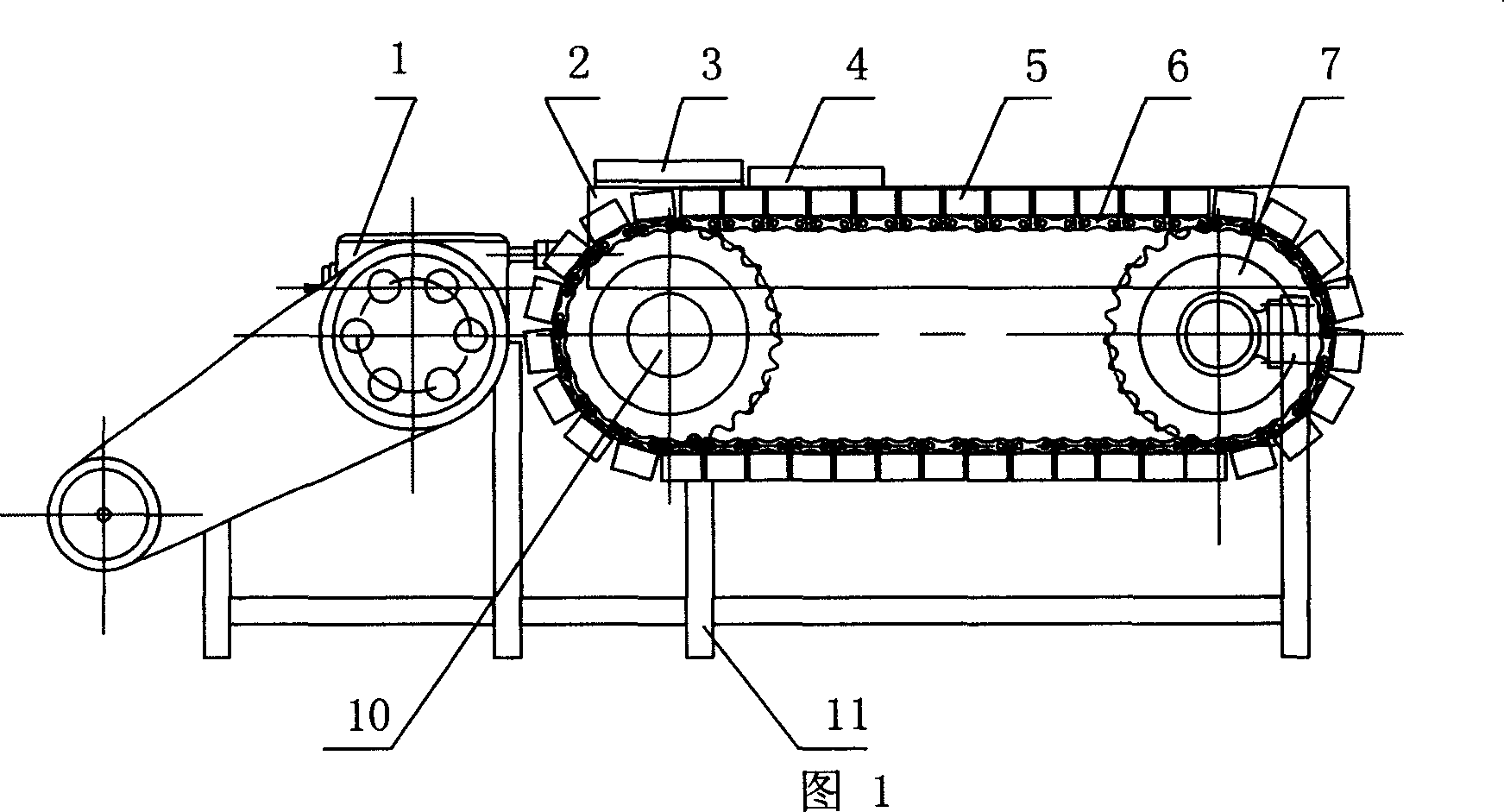

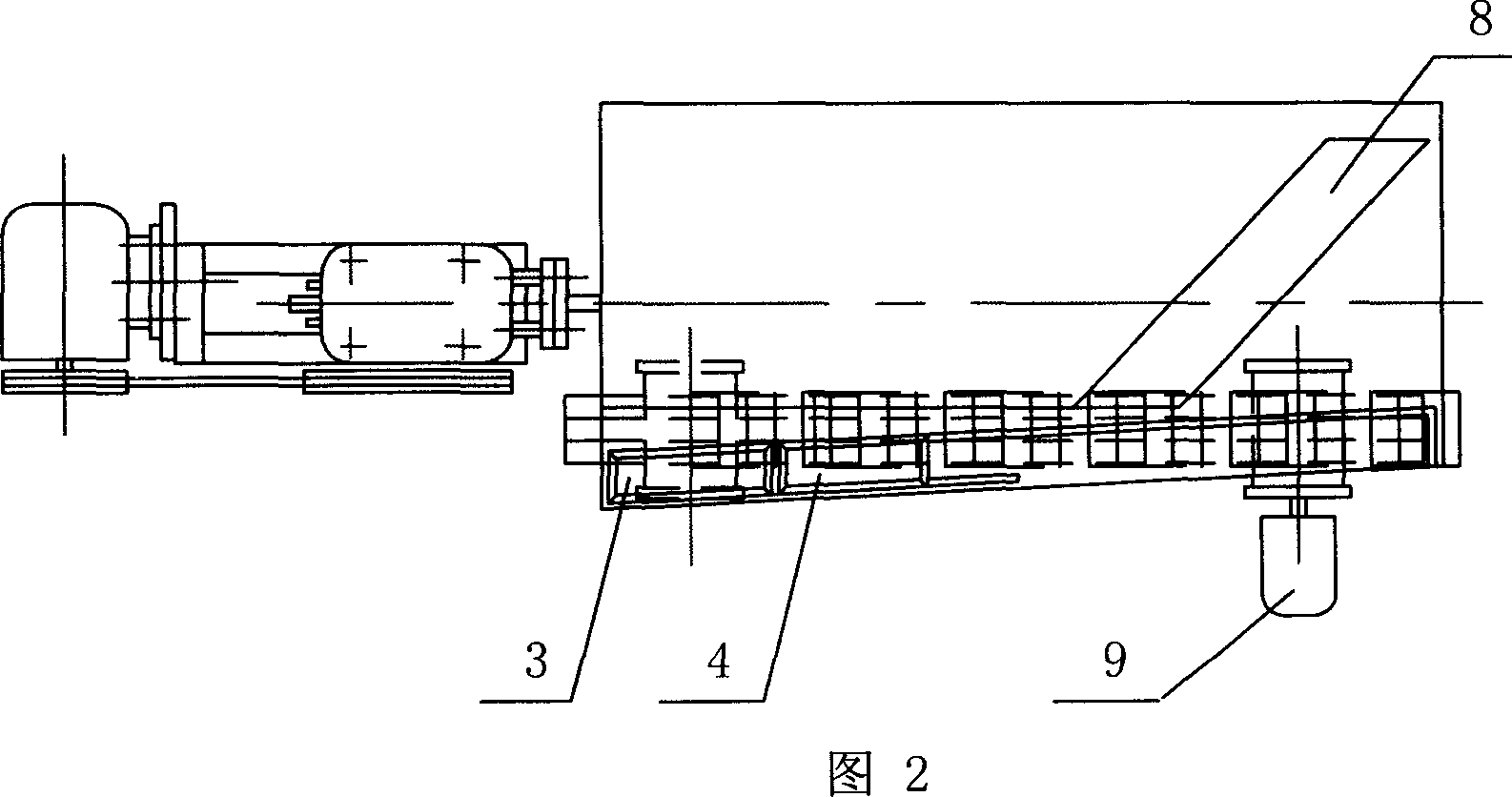

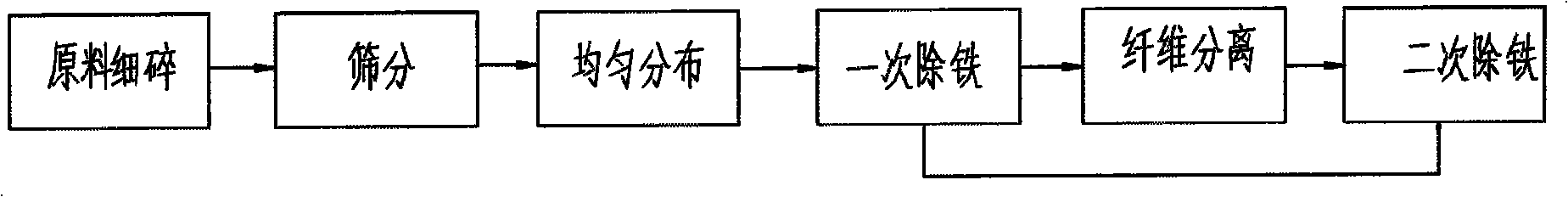

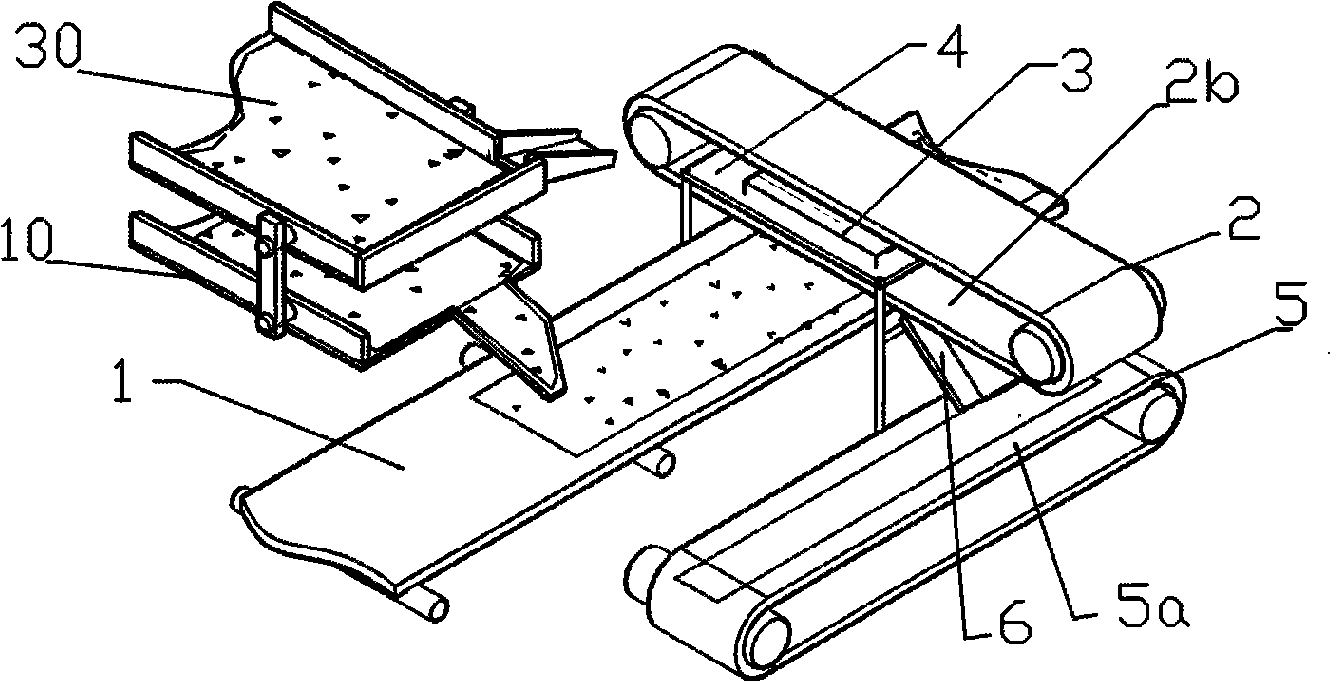

Deironing method for rubber powder and apparatus thereof

InactiveCN101407094AGood iron removal effectImprove the secondary iron removal effectSievingScreeningIron removalMagnet

The invention discloses a method and a device for removing iron in rubber powder. The method for removing iron is simple, simplifies rubber powder production process, and has a better iron removal effect. The device is simple in structure, convenient in installation and use, uniform in conveyed powder, and complete in iron removal. The method comprises the following steps: arranging iron removing devices in a process of conveying powder subjected to fine break and screen separation to a procedure; and arranging an equalizing device to equalize the powder before the powder is transmitted to the iron removing devices for iron removal. A first iron removal device comprises a conveyor belt a magnet arranged on a support and above the conveyor belt. A second iron removing device comprises a rolling shaft, an annular cylindrical magnet arranged on a roller of the rolling shaft and an equalizing plate arranged corresponding to the roller. A delivery hopper comprises a hopper body and an outward extending tongue plate connected with a material outlet end part of a bottom plate of the hopper body.

Owner:JIANGXI YAZHONG RUBBER

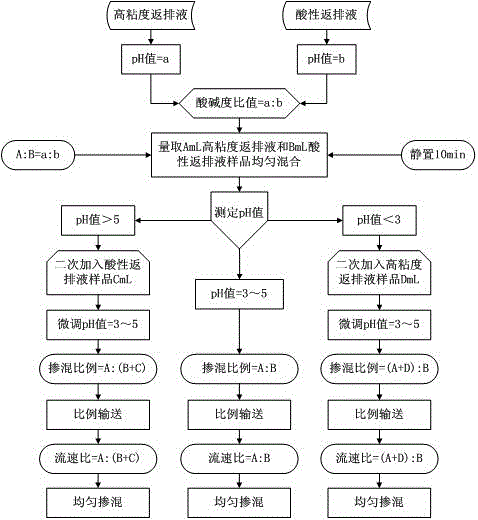

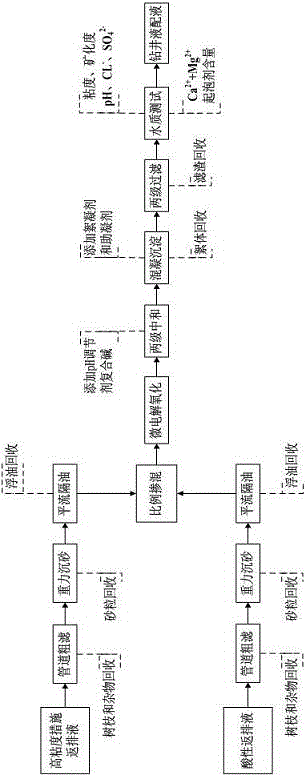

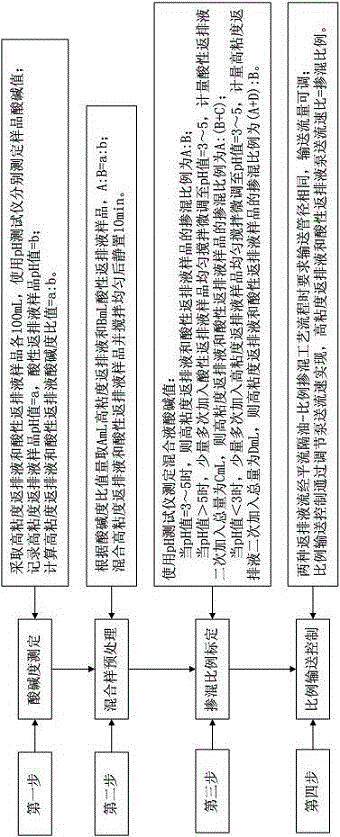

Method for treating oil field measure shaft backflow liquid to prepare rilling fluid

ActiveCN105967401AReduce manufacturing costLess corrosiveWaste water treatment from quariesWater treatment parameter controlFiltrationWater quality

The invention provides a method for treating oil field measure shaft backflow liquid to prepare rilling fluid. The method comprises the following steps of coarse pipeline filtration, gravitational sand setting, advectional oil separation, proportional mixing, micro-electrolytic oxidation, two-stage neutralization, coagulating filtration and water quality testing. The method achieves synchronous treatment of acidic backflow liquid and high-viscosity backflow liquid and is suitable for purification treatment of the backflow liquid produced in the operating measure process including old well fracturing, acidification, well washing and workover, and the viscosity, pH, mineralization degree, CL<->, SO4<2->, Ca<2+>+Mg<2+> and foaming agent content of treated water meet the requirements for drilling fluid preparation. An acidic electrolyte environment can enhance an electric field effect, accelerate the electric flocculation and oxidation reduction reaction, destroy a stable system of dispersoid in electrolyte, quickly make dispersoid ions precipitate or gather towards an electrode and accordingly improve the suspended-state or dispersoid-state pollutant removal efficiency in a solution.

Owner:PETROCHINA CO LTD

Preparation method of high-purity quartz sand

The invention discloses a preparation method of high-purity quartz sand, and belongs to the technical field of mineral refining, and the preparation method comprises the following steps: crushing: crushing quartz sand crude ore into quartz sand particles; ultrasonic scrubbing: performing ultrasonic scrubbing on quartz sand particles; magnetic separation: selecting high gradient magnetic separatorfor three times magnetic separation of quartz sand fine sand; acid leaching: performing microwave heating quartz sand after flotation, then stirring and soaking with a 10% oxalic acid solution; flotation: mixing the quartz sand after acid leaching with water and putting into a flotation machine, adjusting the pH value in three steps, and using different collectors for flotation at the same time; drying and bagging: drying in a vacuum drying oven, and vacuum bagging after cooling. The preparation process is simple, reasonable and efficient in design; iron impurities in the quartz sand can be removed by ultrasonic scrubbing, multiple magnetic separation, microwave heating and acid leaching and flotation; the iron impurities in the prepared high-purity quartz sand are reduced to below 0.35 mg / kg; and the product has stable quality and high efficiency, and is suitable for large-scale popularization and application.

Owner:SICHUAN QINGCHUAN HONGYUAN STONE IND

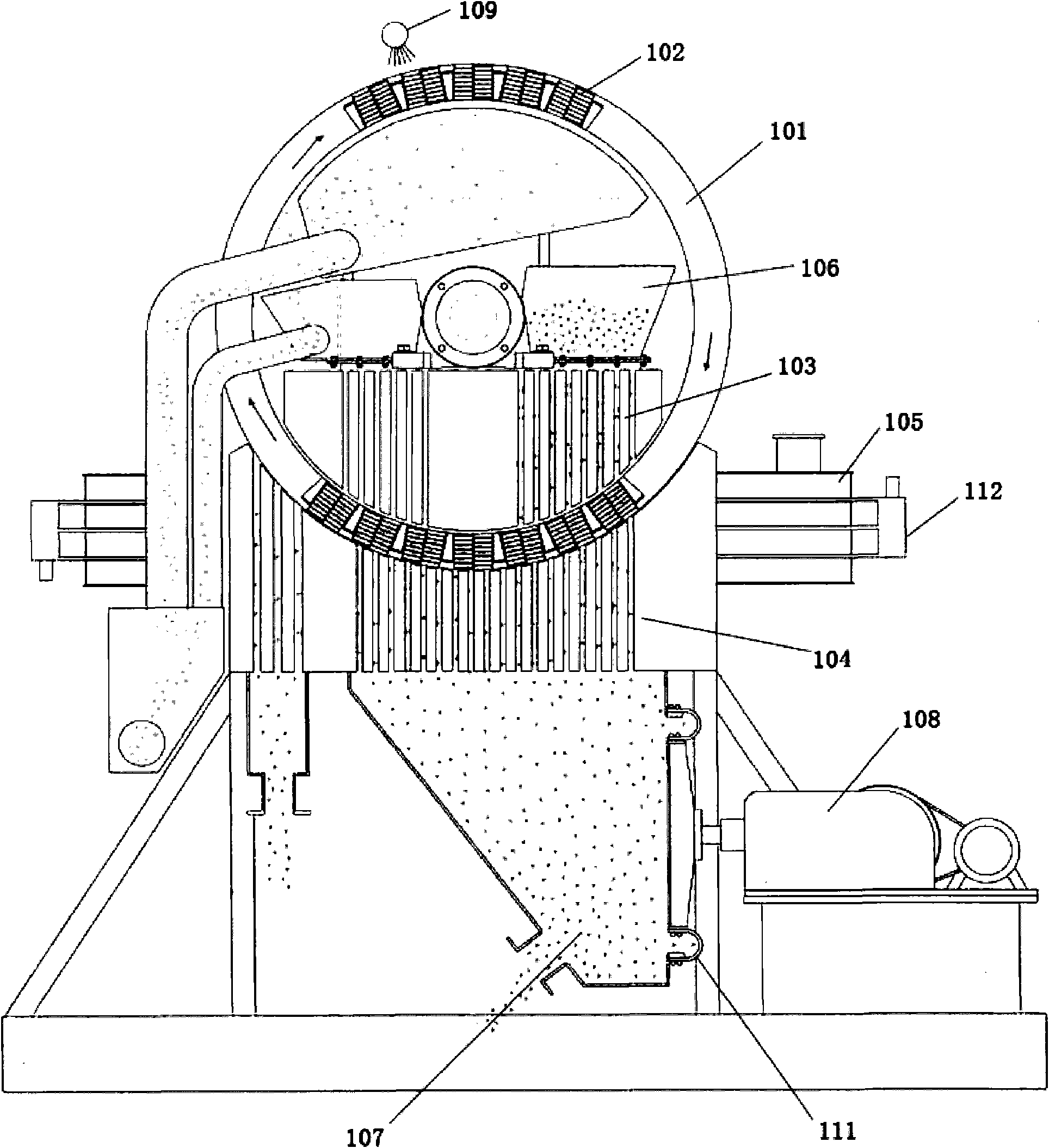

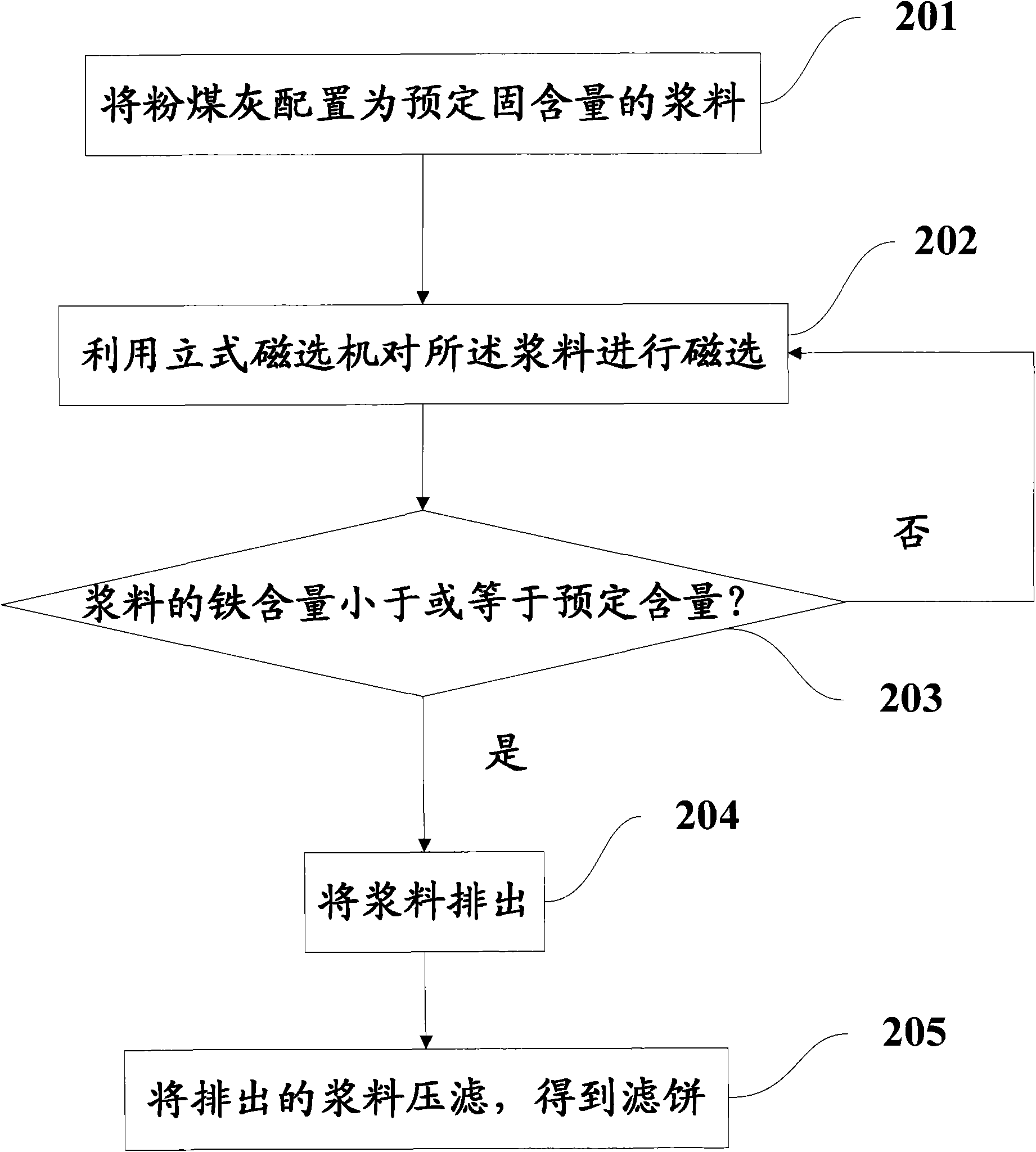

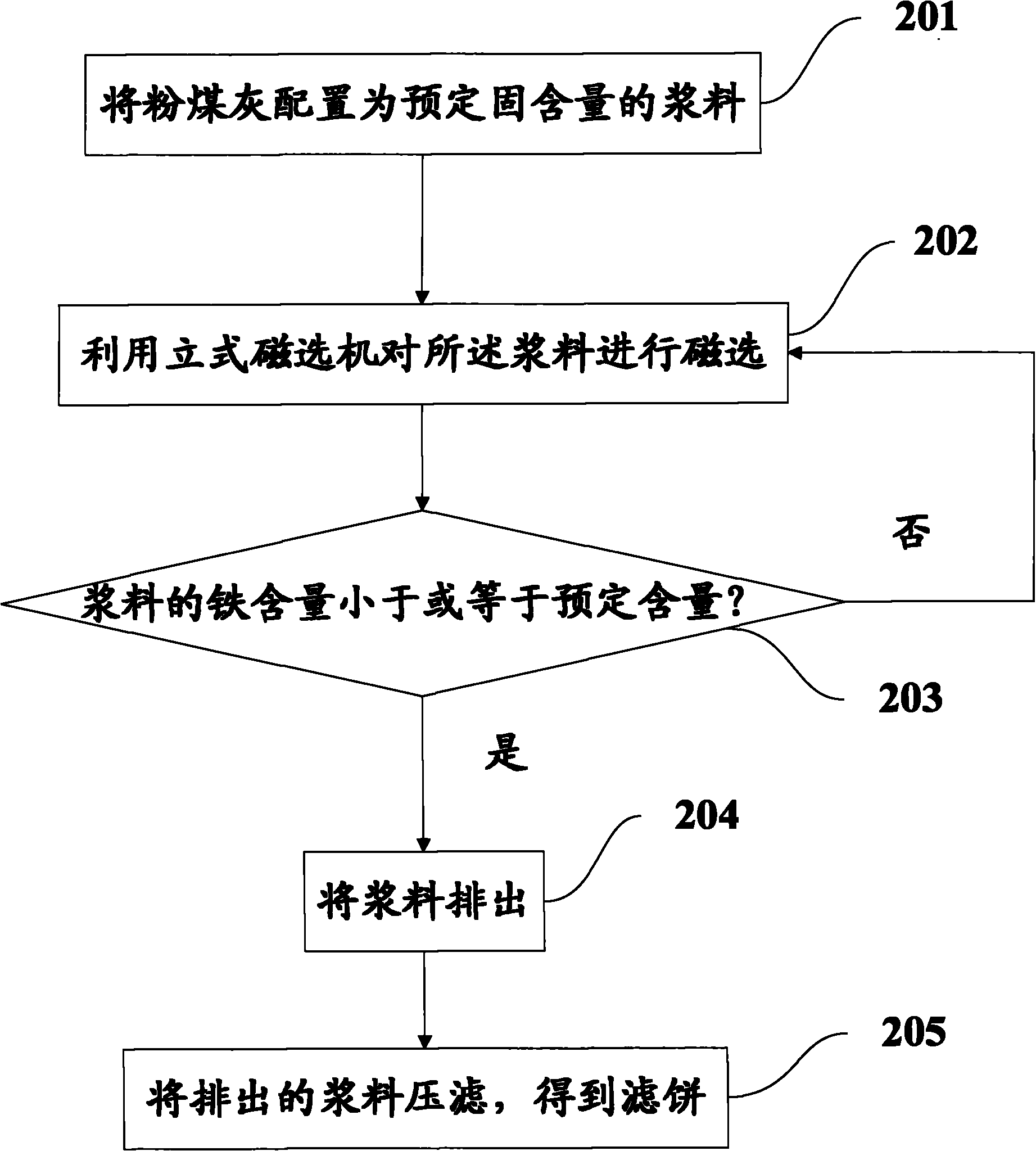

Method for magnetically separating and removing ion from fly ash

InactiveCN101869870ARemove completelyGood iron removal effectHigh gradient magnetic separatorsIon contentMagnetic separator

The invention discloses a method for magnetically separating and removing ion from fly ash, which comprises the following steps: configuring the fly ash into slurry with preset solid content; carrying out magnetic separation to the slurry with a vertical magnetic separator; detecting the ion content of the slurry after magnetic separation; when the iron content in the slurry is less than or equal to preset content, discharging the slurry; and when the iron content in the slurry is higher than the preset content, carrying out magnetic separation again to the slurry through the vertical magnetic separator. The method for magnetically separating and removing ion from fly ash can more thoroughly remove the ion impurity under the circumstance that the iron impurity content in the fly ash is low, and has significant iron removing effect.

Owner:CHINA SHENHUA ENERGY CO LTD +1

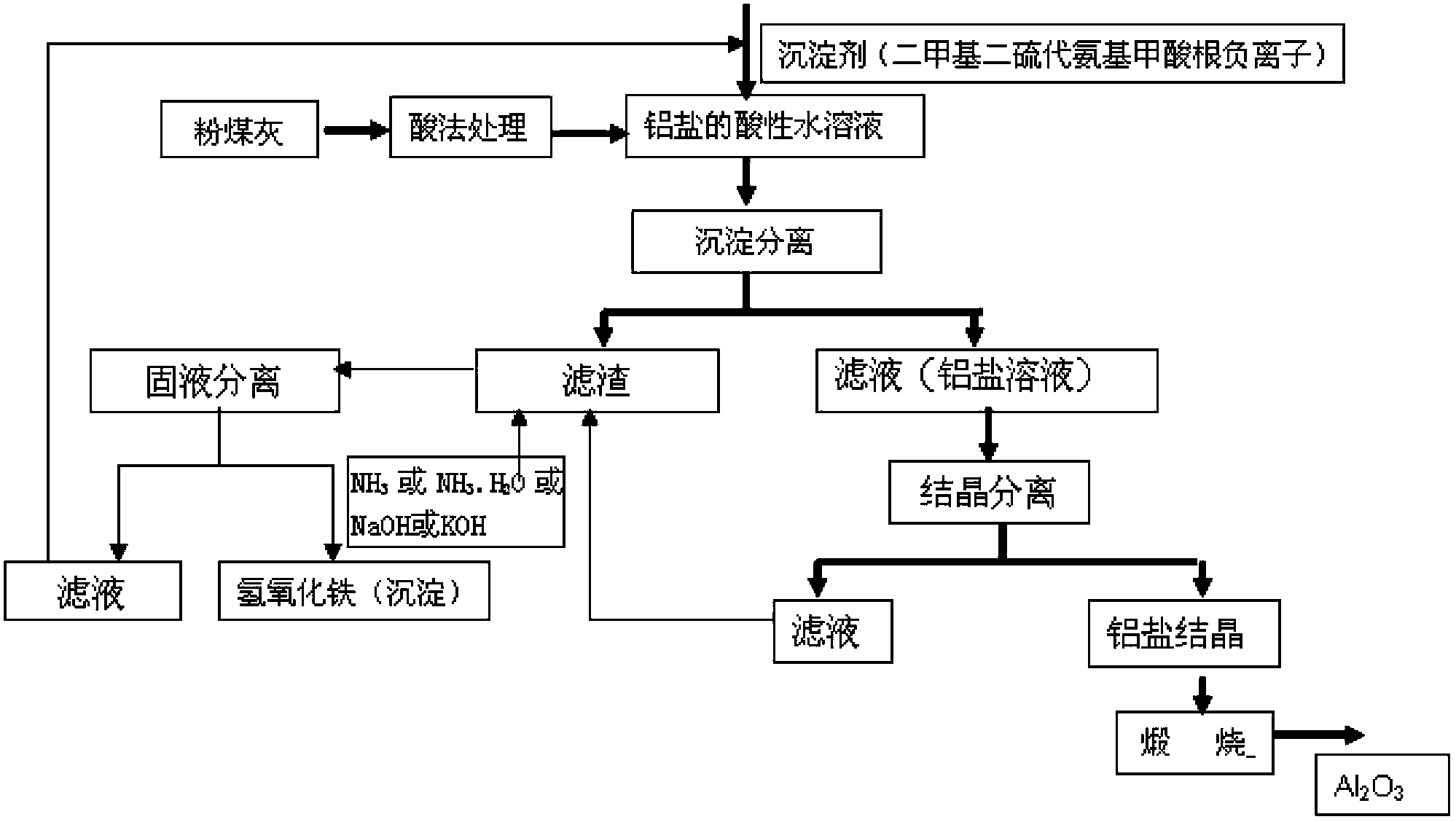

Impurity removing method in process of preparing alumina from fly ash by utilizing acid method

InactiveCN103449483ASolve the difficulty of removalFast precipitationSolid waste disposalAluminium oxides/hydroxidesChemistryAluminium salts

The invention relates to an impurity removing method in a process of preparing alumina from fly ash by utilizing an acid method. The method comprises following steps: by utilizing the characteristic that iron (III) dimethyldithiocarbamate does not precipitate in an alkaline environment condition, adjusting the pH value of the system to the alkaline range by adding ammonia water, ammonia gas, or sodium hydroxide to precipitate iron in the form of iron hydroxide, then subjecting the reaction liquid to a filtration separation treatment so as to obtain an aluminium salt solution without iron, crystallizing the aluminium salt solution without iron to precipitate, filtrating to separate so as to obtain aluminium salt crystals and filtration liquid, burning the aluminium salt crystals so as to obtain purified alumina. The method solves the technical problems of complicated technologies and difficult separation of impurities in the conventional acid method, and has the advantages of prominent iron-removing effect, simple technology, easy operation, and low technology cost.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Deironing water separation device used for garbage disposal

PendingCN107552232ASave time and effortSafe and convenient handlingMagnetic separationPressesLitterPush pull

The invention discloses a deironing water separation device used for garbage disposal. The device comprises a shell, a motor, a hydraulic drive device and a partition plate. The partition plate partitions the interior of the shell into a water separation cavity and a squeezing drainage cavity. The water separation cavity is filled with water, and a plurality of shifting plates are fixed to a stirring shaft; a scraping plate is horizontally arranged at the bottom of the water separation cavity in a sliding mode, and a magnet sheet is further fixedly mounted on the side wall of the scraping plate; and a shifting roller is mounted on the side, corresponding to the water separation cavity, of the top of the partition plate, a filter net is arranged in the squeezing drainage cavity, a pressingblock is fixed to the lower end of a connecting rod, and the free end of a push-pull rod is fixedly connected with a pull rope. According to the deironing water separation device provided by the invention, by filling the arranged water separation cavity with the water, iron in garbage is separated, the shifting plate can guarantee that the garbage makes full contact with the water, the iron is thoroughly separated, settled garbage is collected at the bottom and taken out conveniently and fast, time and labor are saved, the deironing effect is good, it is guaranteed that the light garbage doesnot contain iron, and garbage disposal is safer, more convenient and faster.

Owner:ZHENGZHOU UNIV

Copper sulfate de-ironing process

The invention provides a copper sulfate de-ironing process, which comprises the following steps that copper sulfate and distilled water are prepared into solution, insoluble impurities are removed through filtering, a certain number of oxidants are added, precipitants are slowly dropped after the full oxidation, the pH value of the solution is regulated to 3.0 to 4.0, the full hydrolysis is carried out at a certain temperature, and finally, the filtering is carried out. The depth de-ironing effect of controlling the iron content to be smaller than 1ppm and the copper loss rate to be smaller than 10 percent is reached by the method. In addition, the process has the advantages that the cost is low, the process is simple, sediments can be recovered and utilized, and the like.

Owner:GUANGZHOU SOLDERWELL ADVANCED MATERIALS

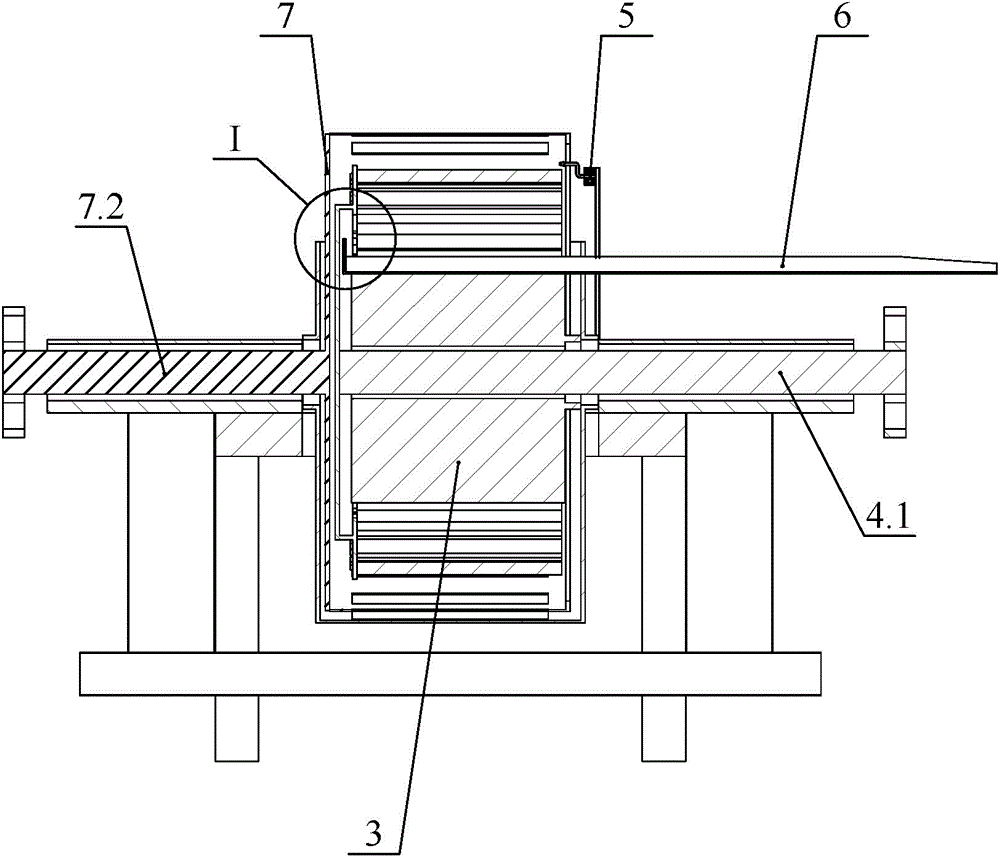

Method and device for deironing continuously in slurry in bi-twisting mode

InactiveCN103977888AGood iron absorption effectImprove slurry qualityMagnetic separationScrapEngineering

The invention discloses a method and device for deironing continuously in slurry in a bi-twisting mode, and belongs to the field of magnetically separating solids in slurry. Magnetic bars in magnetic bar groups are placed in a slurry barrel for adsorbing scrap iron in slurry, and then the scrap iron adsorbed on the magnetic bars is removed. The method and device for deironing continuously in slurry in a bi-twisting mode are characterized in that the magnetic bars in the magnetic bar groups are arranged horizontally; one part of the magnetic bars in the magnetic bar groups are positioned in the slurry, and the other part of the magnetic bars are all exposed out of the liquid level of the slurry; the magnetic bar groups rotate, so that the scrap iron adsorbed on the part of magnetic bars exposed out of the liquid level of the slurry is removed. The method and device for deironing continuously in slurry in a bi-twisting mode, which are provided by the invention, have the beneficial effects that the skillful design of a sandwiched wall cavity enables the slurry in the cavity to be in contact with the magnetic parts maximally, and the magnetic force is applied to the slurry uniformly, and a preferable deironing effect is obtained; the magnetic parts rotate continuously so that deironing is carried out uninterruptedly, and the deironing efficiency is improved greatly; the stability is extremely high, and the maintenance cost is extremely low.

Owner:钟娟英

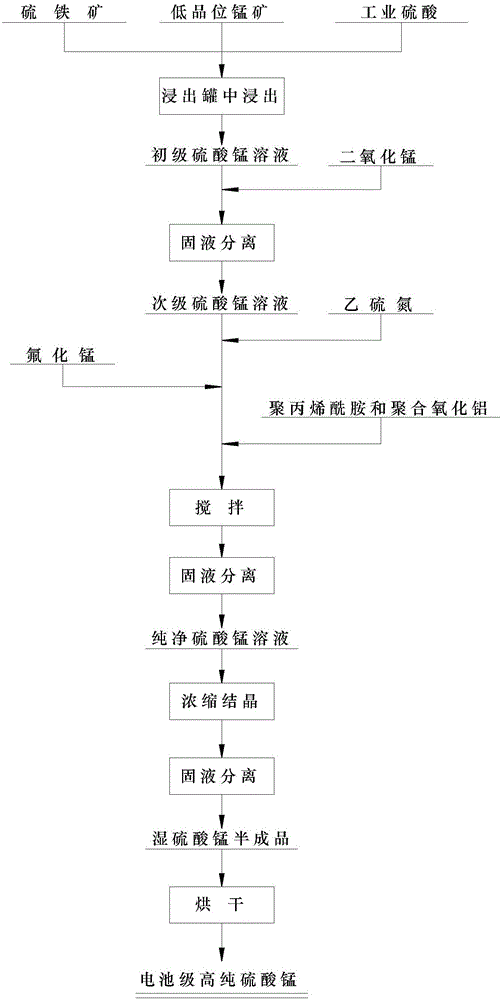

A method of preparing battery-grade high-purity manganese sulfate by utilizing low-grade manganese ore

The invention relates to a method of preparing battery-grade high-purity manganese sulfate by utilizing low-grade manganese ore. The method includes adding the low-grade manganese ore, pyrite and industrial sulfuric acid into a leaching tank, performing chemical leaching, performing solid liquid separation to obtain a primary manganese sulfate solution, then adding manganese dioxide into the primary manganese sulfate solution, adjusting the pH value of the solution, then performing solid liquid separation to obtain a secondary manganese sulfate solution, adding ethyl thiocarbamate, manganese fluoride, polyacrylamide and polyaluminum chloride into the secondary manganese sulfate solution, stirring the mixture for a certain period of time, performing solid liquid separation to obtain a purified manganese sulfate solution, adding the purified manganese sulfate solution into a crystallization kettle, performing concentration and crystallization, then performing solid liquid separation to obtain a wet manganese sulfate semi-finished product, and drying the wet manganese sulfate semi-finished product to obtain the battery-grade high-purity manganese sulfate. The method is simple in process and easy to operate. Addition of a large amount of agents is not needed in a preparing process. Secondary pollution to the environment is avoided and the production cost is low.

Owner:CENT SOUTH UNIV

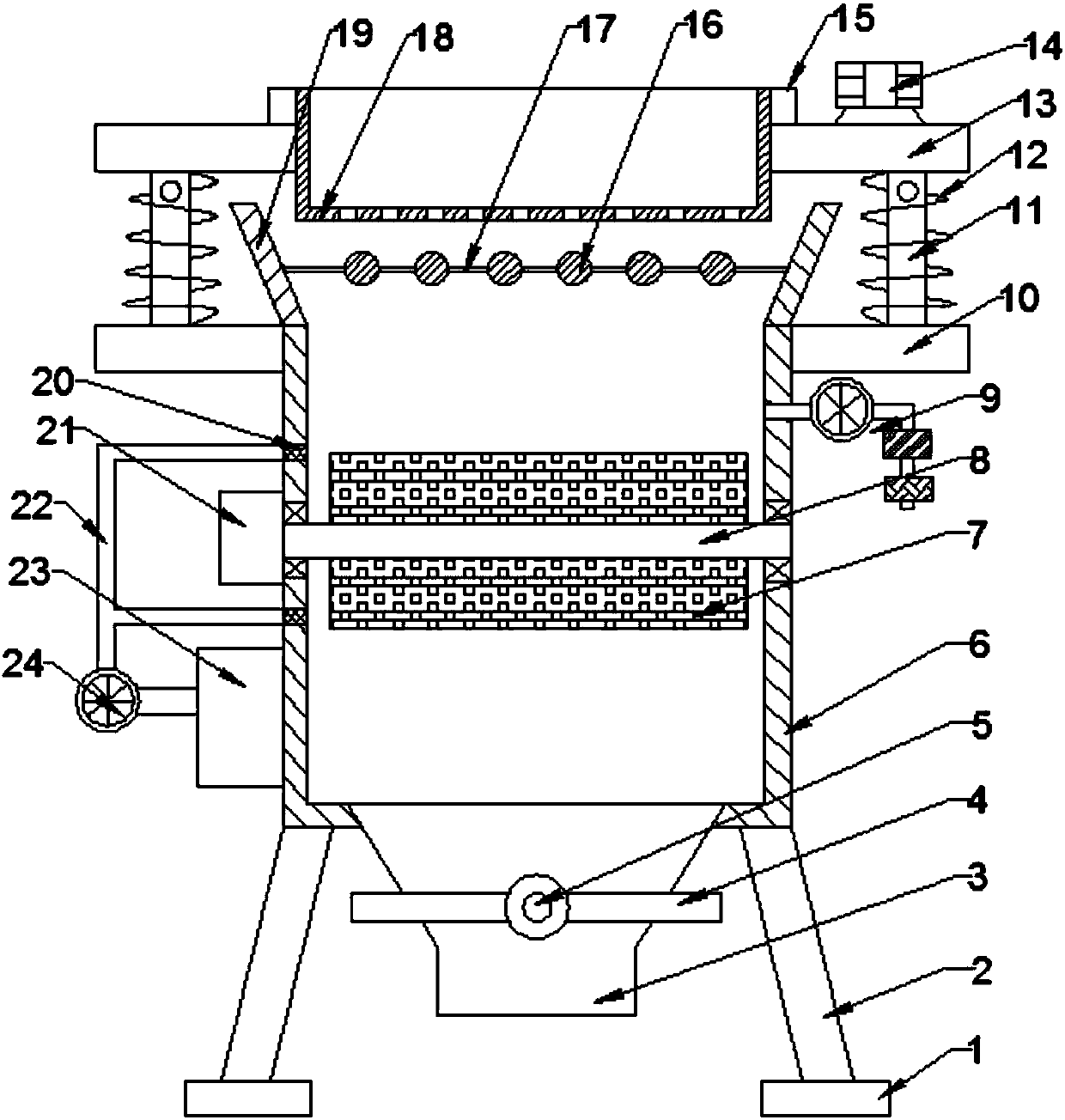

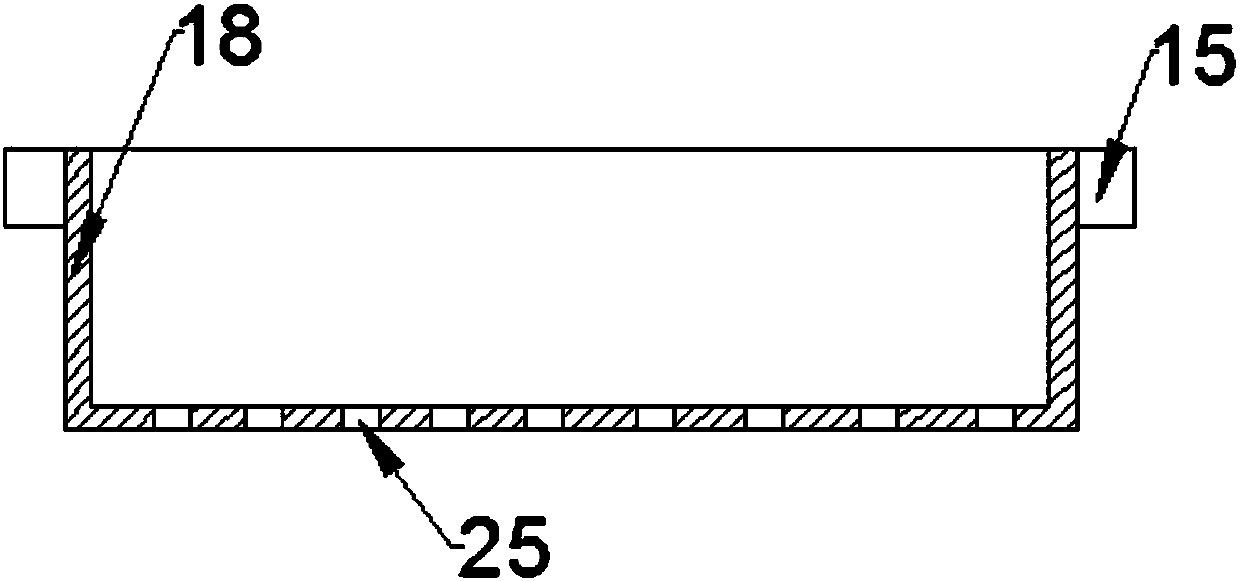

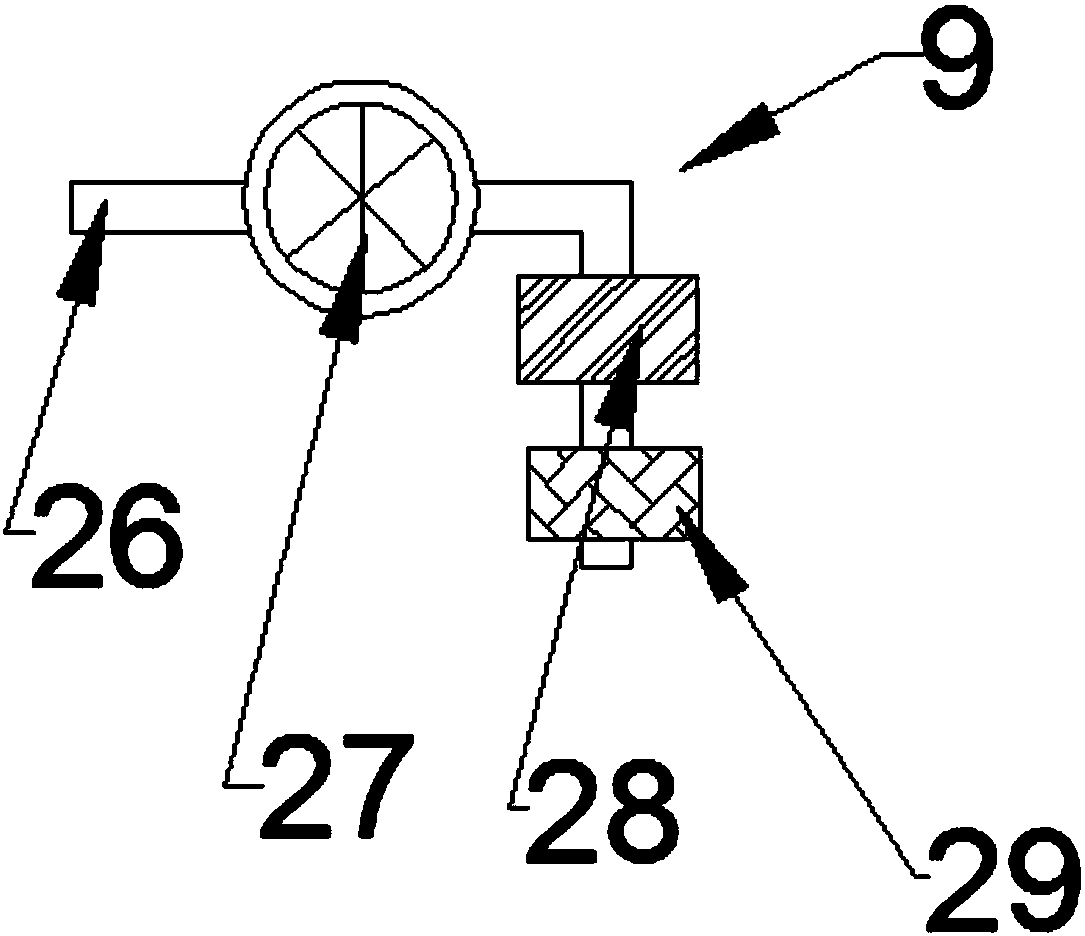

De-ironing device for dust extraction type chemical material

The invention discloses a dust-removing type iron remover for chemical materials, which comprises a de-iron device and a dust-removing and drying device; a connecting strut is fixedly arranged on the upper side of the support plate, shock-absorbing springs are arranged around the connecting strut, and The vibration plate is fixedly arranged by welding; the vibration motor is fixedly arranged on the upper right end of the vibration plate; the magnetic bar is equidistantly arranged in the receiving hopper through the connecting rod; the dust collection box is fixedly arranged under the left side of the processing box; The drying device is arranged on the upper right side of the processing box; the device of the present invention arranges the vibrating screen on the vibrating plate through the support blocks fixedly arranged at both ends, and has the functions of dispersing materials, extending soft blanking and contacting time of magnetic rods; A permanent magnet is fixed on the top of the stirring shaft, which has the function of stirring the material to facilitate dust removal and drying while further removing iron; the device has the characteristics of simple structure, strong practicability and good iron removal effect.

Owner:无锡威伟矿冶设备制造有限公司

Powder electromagnetic separator

InactiveCN107234001AQuick NestImprove processing efficiencyMagnetic separationIron powderMagnetic media

The invention discloses a powder electromagnetic separator, which comprises a bottom frame, an oil tank, a heat exchanger and an oil pump arranged on the bottom frame, an electromagnetic coil arranged in the oil tank, an iron removal cylinder vertically penetrating the oil tank, and an iron removal cylinder arranged in the oil removal tank. The vibration device on the side wall of the iron cylinder, and the unloading device arranged at the bottom of the iron removal cylinder; several pieces of magnetic nets are stacked in the inner cavity of the iron removal cylinder; the oil tank, oil pump and heat exchanger pass through the oil pipe Loop connections. The powder electromagnetic separator provided by the invention improves the iron removal efficiency and quality of the powder, and can effectively remove the heat generated by the electromagnetic coil during operation.

Owner:佛山市高明星诺机械设备有限公司

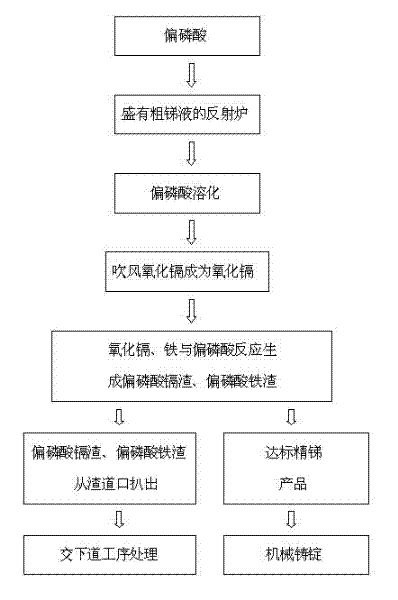

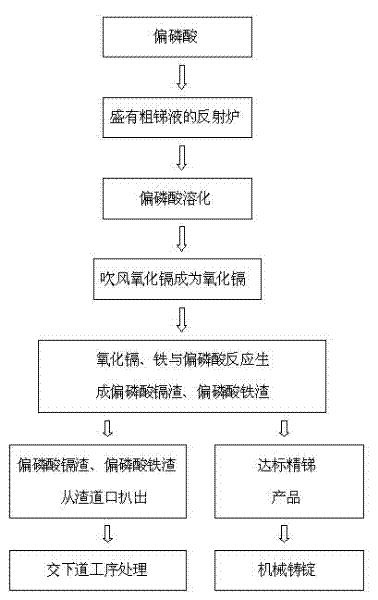

Method for removing cadmium and ferrum from crude antimony by using metaphosphoric acid

The invention discloses a method for removing cadmium and ferrum from crude antimony by using metaphosphoric acid. The method is carried out according to the following steps that: the metaphosphoric acid is added into a metallurgical furnace containing crude antimony liquid, and the furnace is continuously heated to melt the metaphosphoric acid, so that the metaphosphoric acid can cover on the surface of the antimony liquid; then, a blowing pipe is inserted into the antimony liquid to blow, the cadmium in the antimony liquid is oxidized into cadmium oxide, the temperature of the furnace is maintained, the continuous blowing is carried out, the cadmium oxide and the ferrum in the antimony liquid react with the metaphosphoric acid covering on the surface of the antimony liquid to produce cadmium metaphophate and ferrum metaphophate respectively, and the cadmium metaphophate and the ferrum metaphophate scarify with the metaphosphoric acid and float on the surface of the antimony liquid so as to realize the separation of the cadmium and the ferrum from antimony; and finally, the scum floating on the surface of the antimony liquid is removed. The method for removing the cadmium and the ferrum from the crude antimony, disclosed by the invention, belongs to an originate at home and abroad, the effect of cadmium and ferrum removal is good, the process flow is simple, the operation is convenient, the production cost is low, the pollution of environment cannot be generated, the production practicality is strong, considerable economic benefits are produced, and meanwhile, excellent environmental benefits are also brought.

Owner:HUNAN LOUDI HUAXING ANTIMONY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com