De-ironing device for dust extraction type chemical material

A technology of iron remover and materials, which is applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and appliances, etc. It can solve the problems of affecting the effect of iron removal, large impact force, damage to production equipment, etc., and achieves good iron removal effect and structure Simple, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

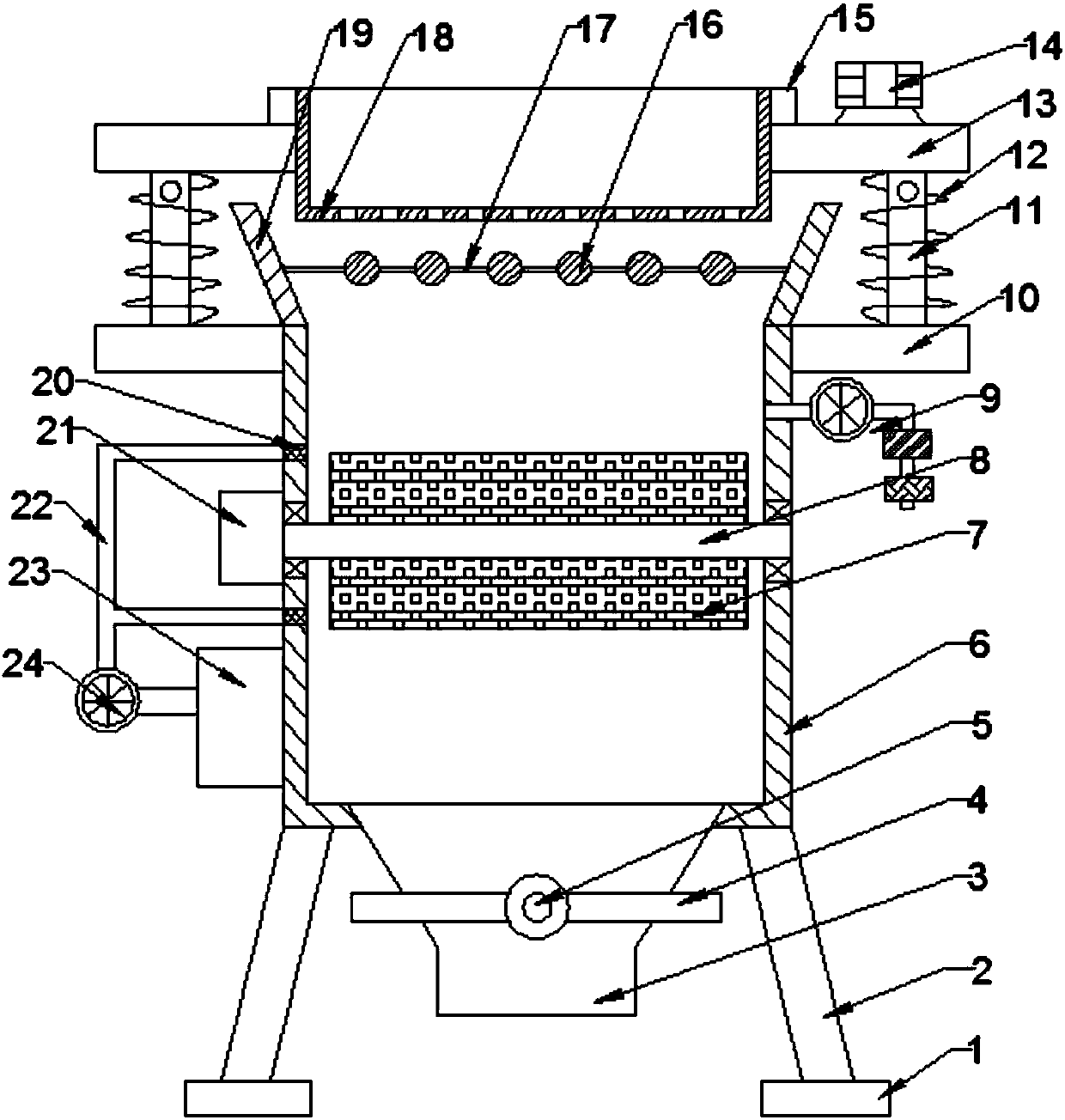

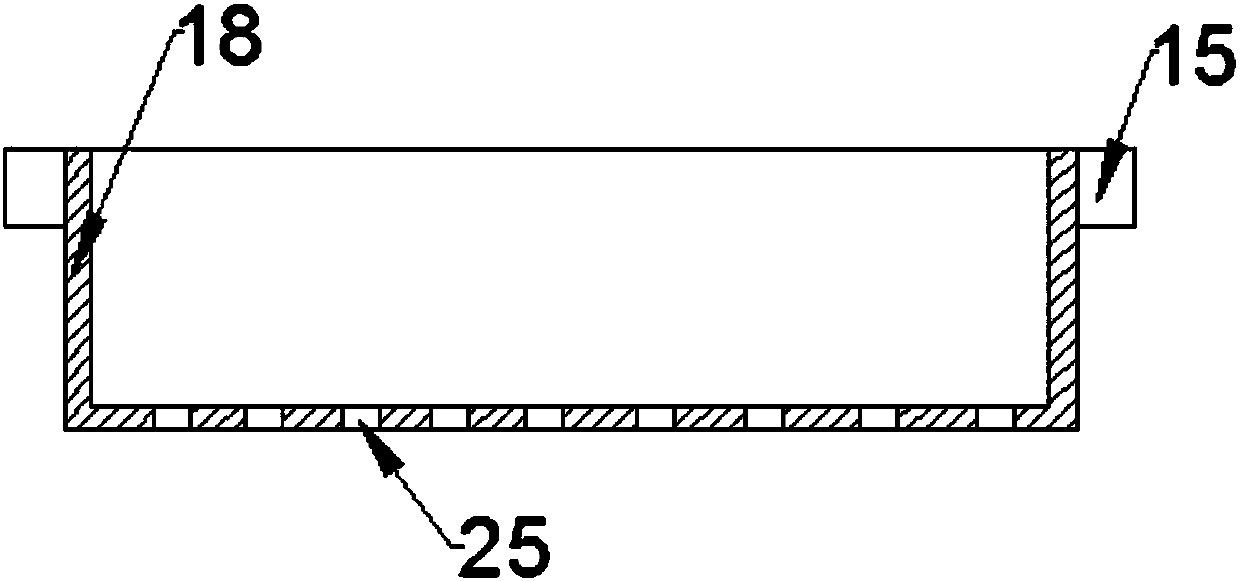

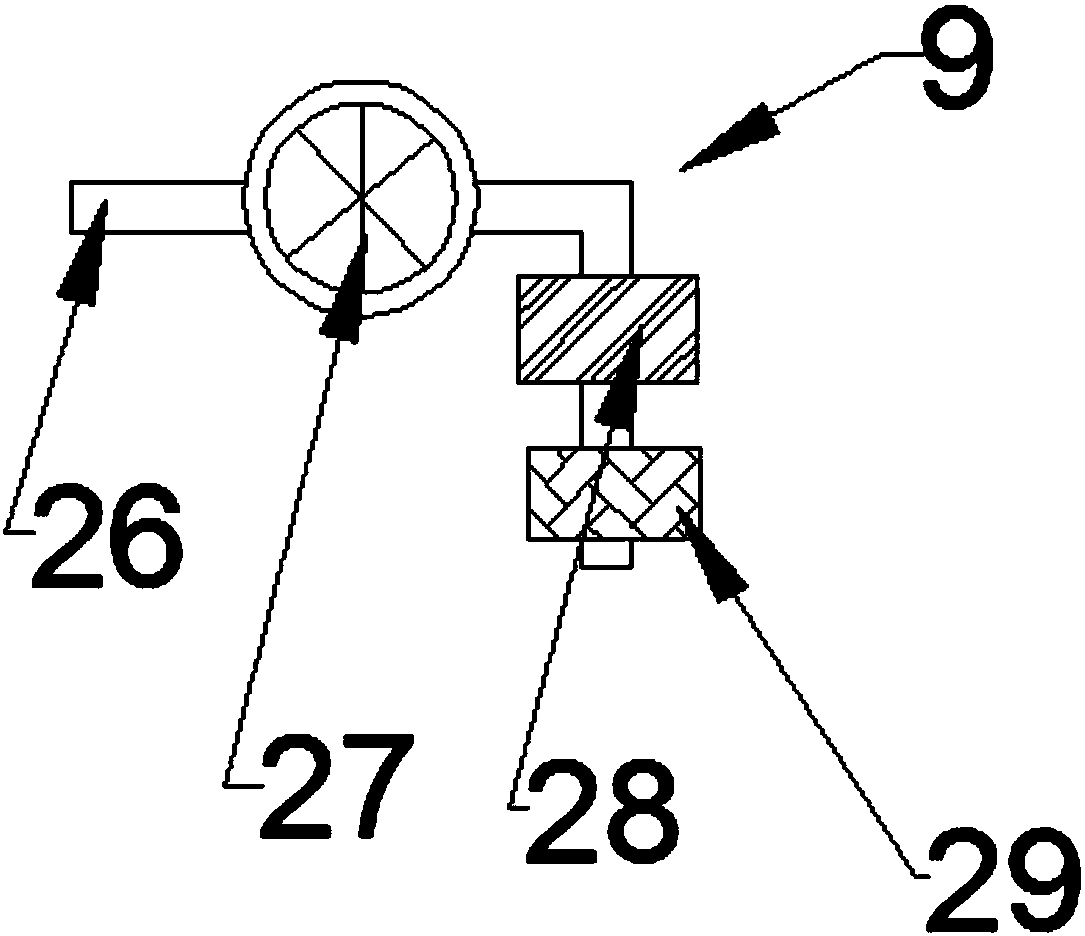

[0017] see Figure 1-3 , an iron remover for dust-removing chemical materials, including an iron removal device and a dust removal and drying device; Treatment box 6, permanent magnet 7, stirring shaft 8, support plate 10, connecting pillar 11, damping spring 12, vibrating plate 13, vibrating motor 14, supporting block 15, magnetic rod 16, connecting rod 17, vibrating screen 18, connection Hopper 19, drive motor 21 and feeding hole 25; said support frame 2 is welded and fixedly arranged on both sides below the processing box 6, and anchors 1 are fixedly arranged below the support frame 2; said support plate 10 is welded and fixedly arranged on Above the left and right sides of the processing box 6, the top of the support plate 10 is welded and fixedly provided with a connecting pillar 11, the surroundings of the connecting pillar 11 are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com