Destructive distillation method and device for brown coal

A technology for dry distillation and lignite, which is used in special forms of dry distillation, combined direct and indirect heating for dry distillation, and gas dust removal. The effect of low ash content, high gas calorific value and low dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

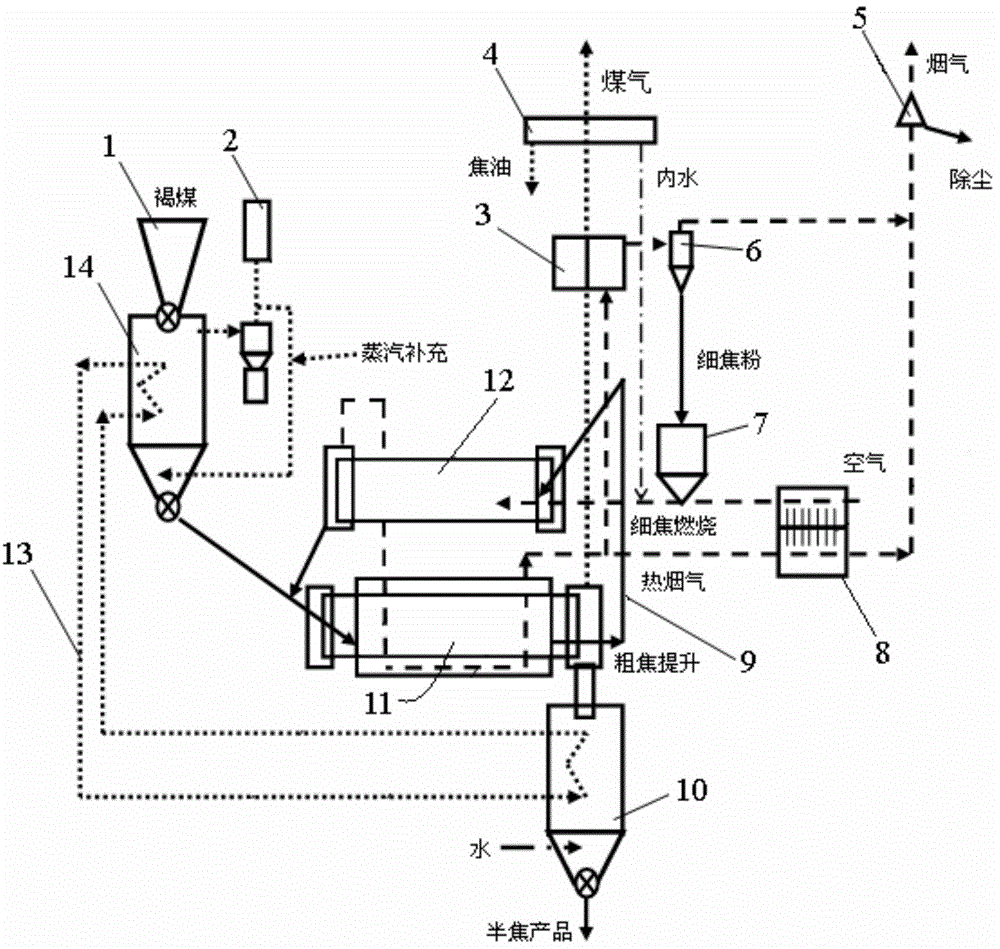

[0043] refer to figure 1 , the device of this embodiment comprises: drying furnace 14, dry distillation furnace 11, coke oven 12, feed bin 1, condenser 2, gas cooling purifier 4, bag filter 5, cyclone dust collector 6, fine coke powder bin 7, Air-flue gas heat exchange device 8 , semi-coke lifting device 9 , semi-coke cooling device 10 , steam coil 13 and coal gas particle dust removal device 3 .

[0044] Wherein the carbonization furnace 11 is located on the first floor of the production building, and the drying furnace 14 and the coke oven 12 are located on the second floor; coke.

[0045] The coal gas produced in the dry distillation process is dedusted by the intermittent particle dust collector, and the final semi-coke product is recovered after being cooled by the semi-coke cooling device 10 .

[0046] The specific dry distillation process is as follows:

[0047] Raw coal is lignite with particles smaller than 30mm.

[0048] The drying furnace 14 is a steam fluidized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com