Patents

Literature

56 results about "Thermal pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

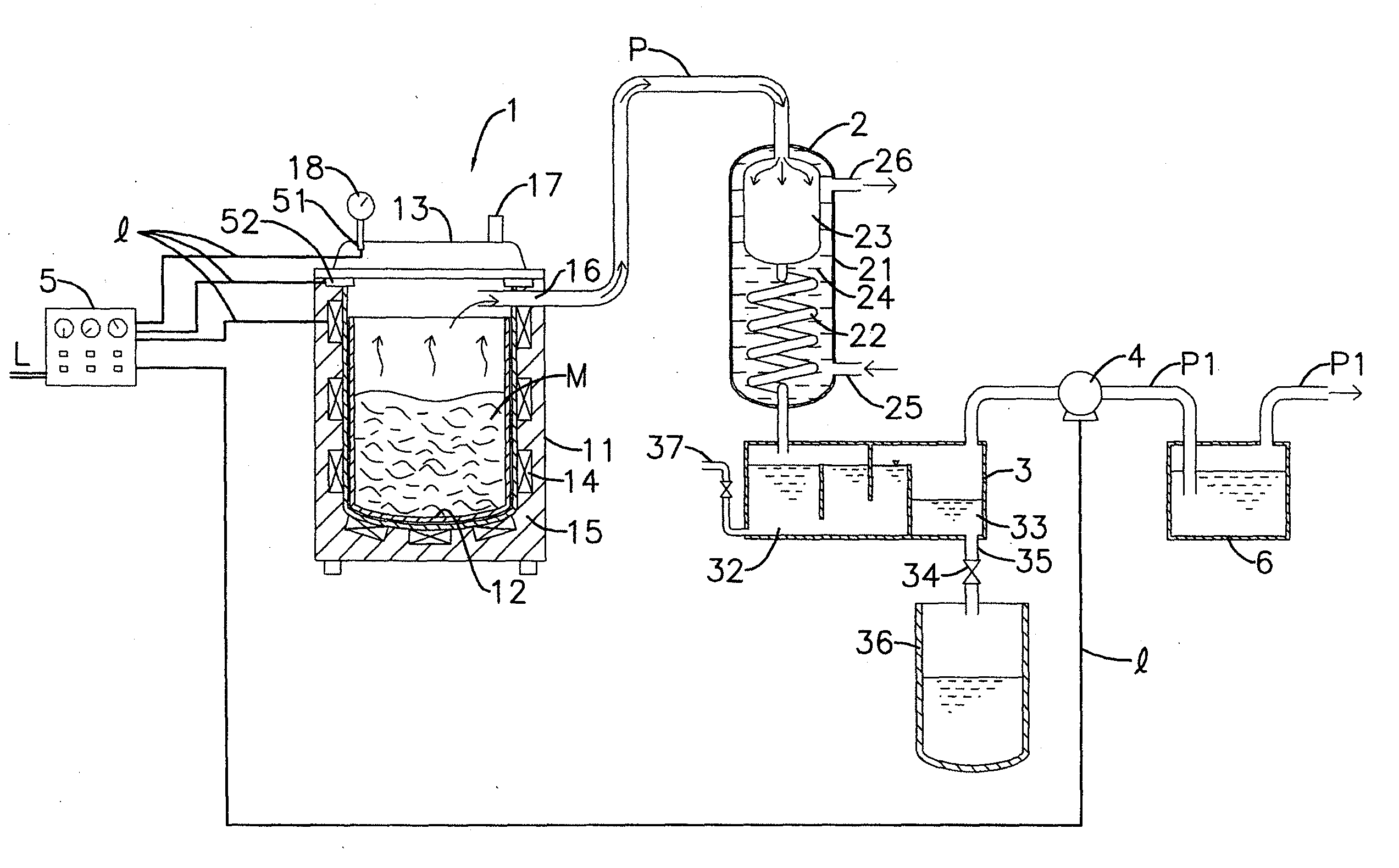

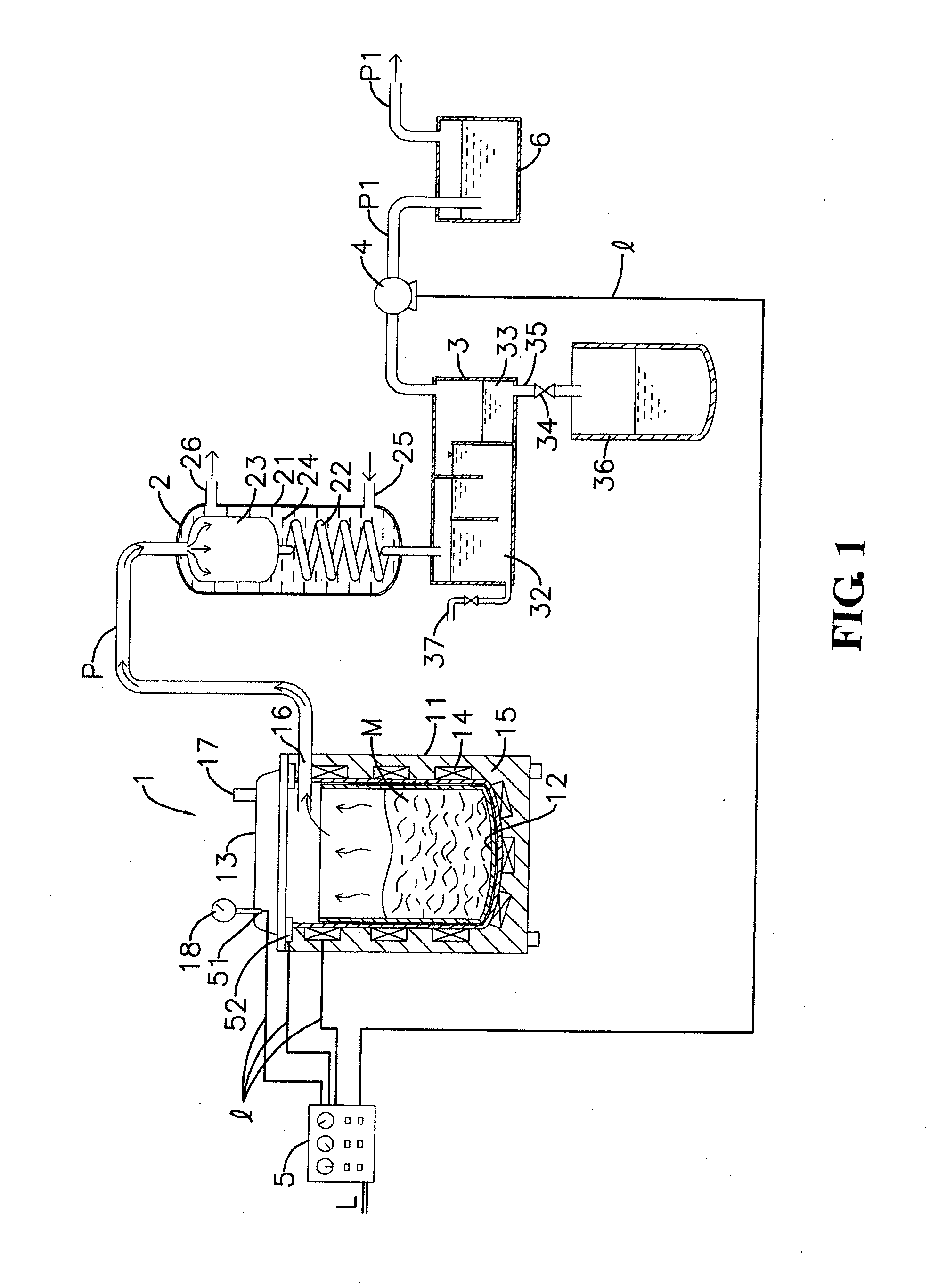

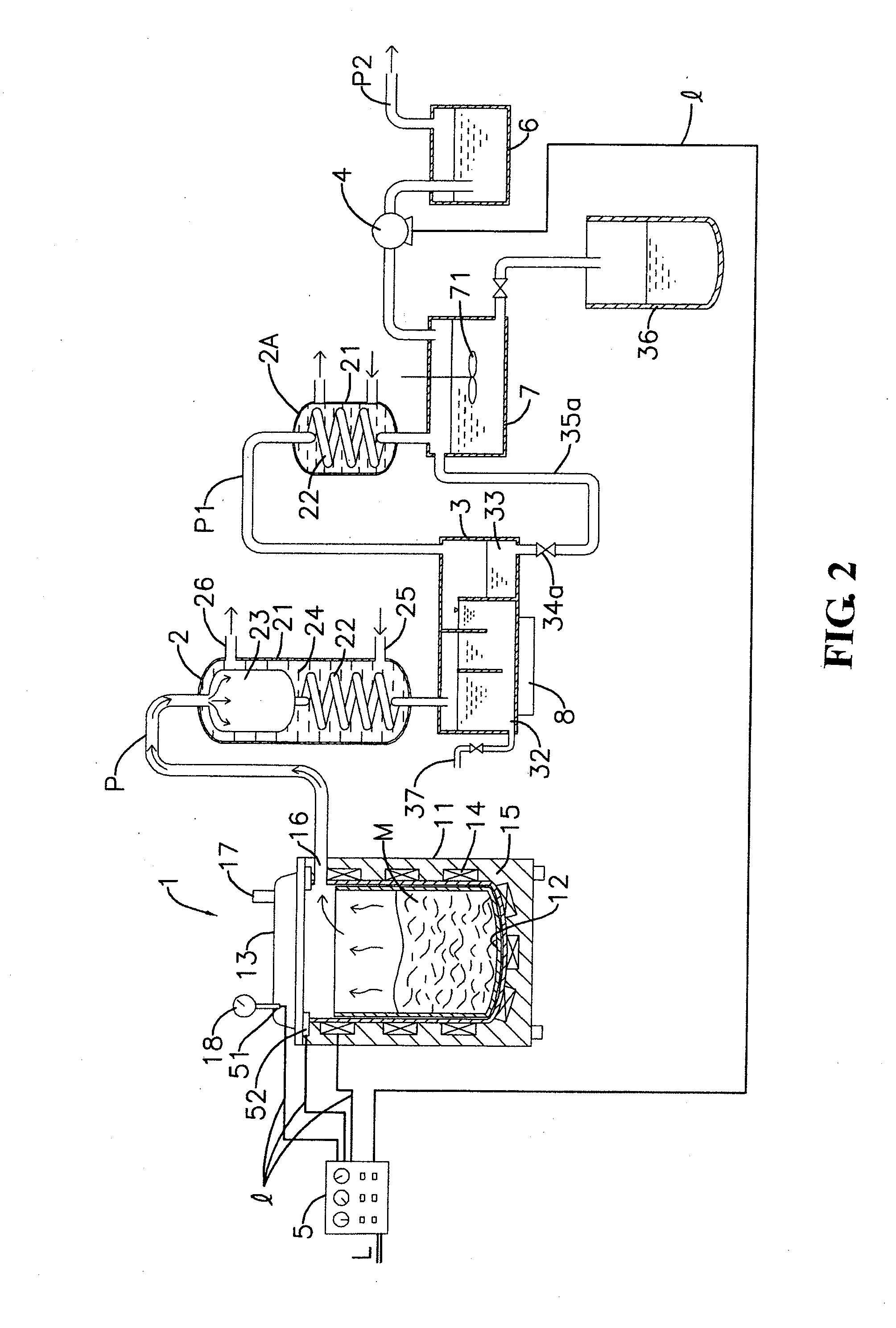

Method of extracting essential oil from biomass wastes and a device thereof

InactiveUS20110034712A1Reduce processing timeQuality improvementRetortsLiquid hydrocarbon mixture productionEngineeringOxygen

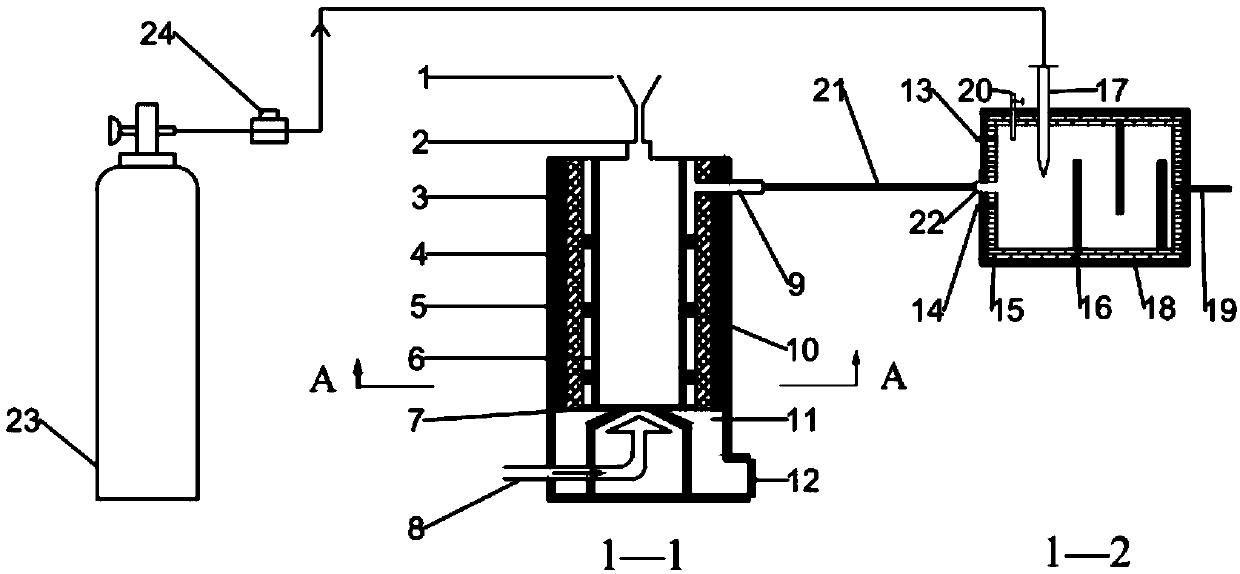

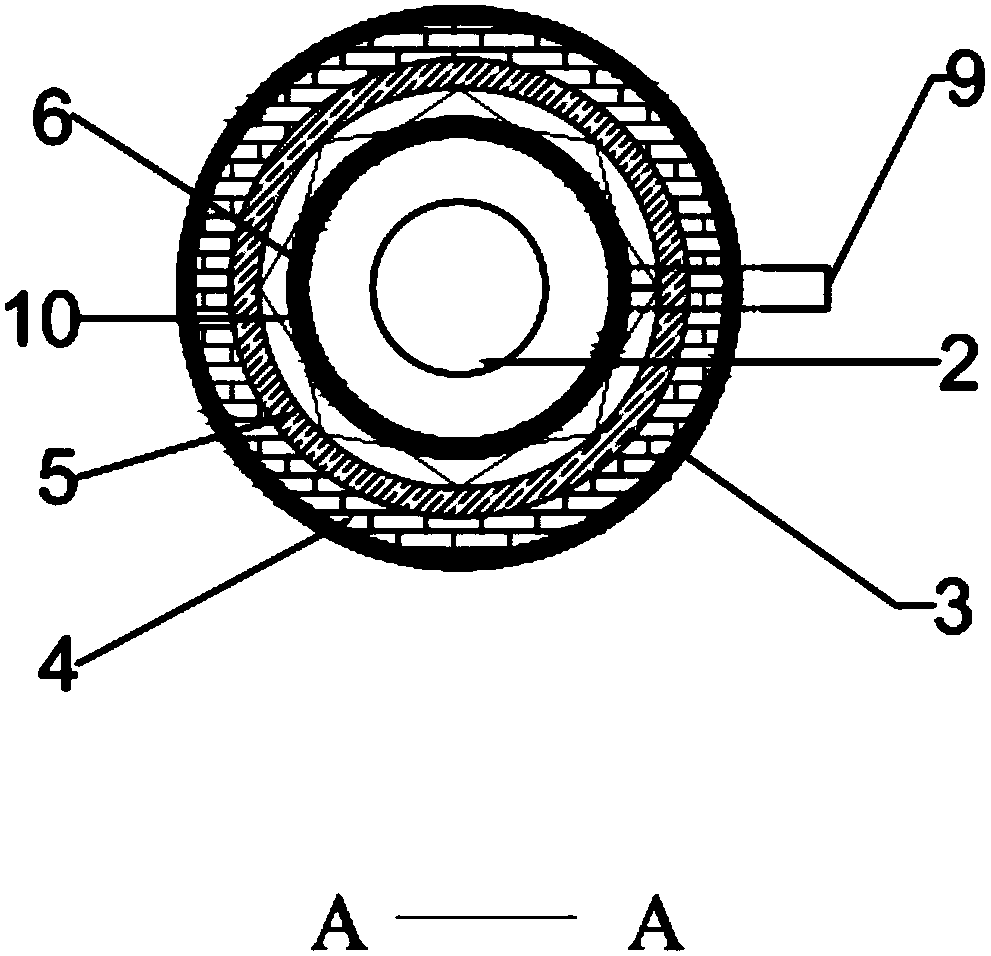

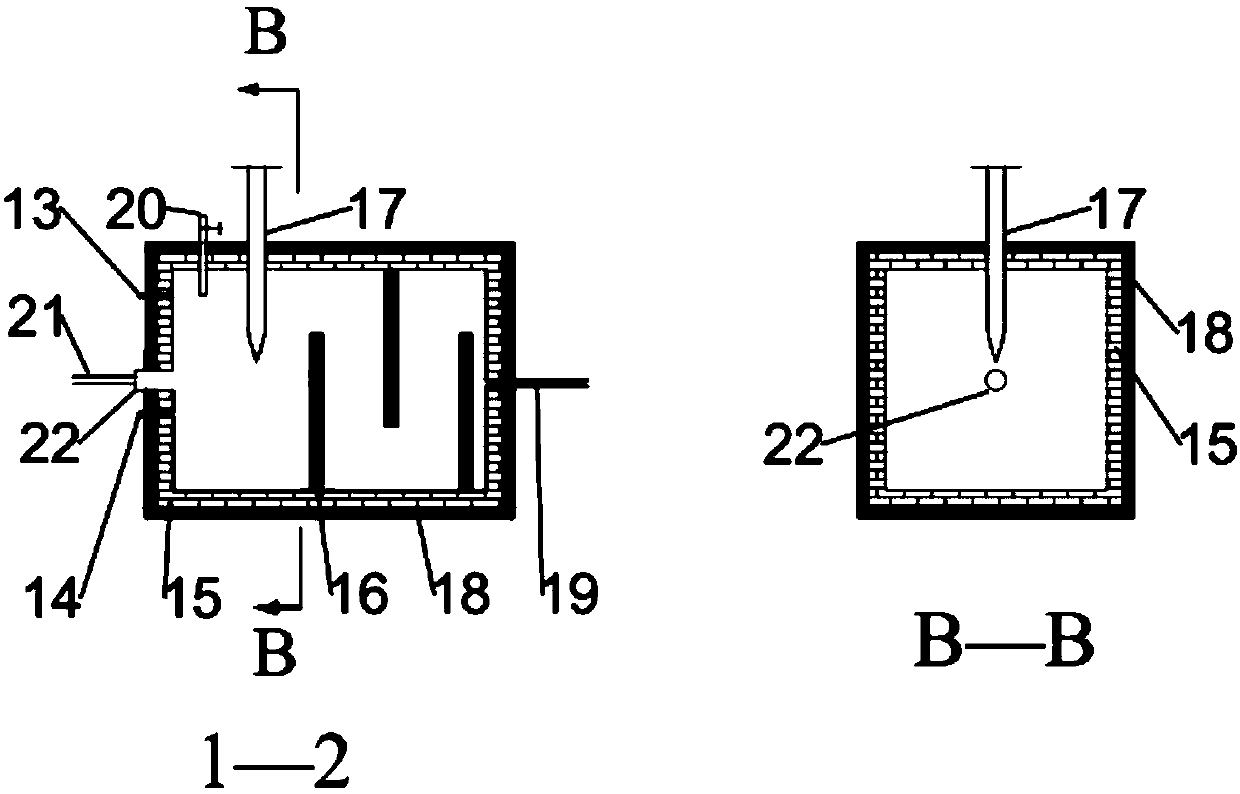

A method of extracting essential oil from biomass wastes puts biomass wastes, such as wood residuals, wood chips or other plants, in an air-tight oxygen-free reaction vessel to be heated up indirectly, for conducting a thermal pyrolysis cracking reaction (i.e. dry distillation); and guides volatile gas which is distilled when the processed wastes disintegrate, into a condenser to be condensed as liquid which is then separated into water and oil through an oil-water separation tank. Whereas, non-liquefied gas is discharged outside after deodorizing, and residuals in the reaction vessel are processed with high-temperature dry distillation once to become activated carbons. In processing, temperature and pressure in the reaction vessel are controlled in multiple phases, along with using a suction pump of a changeable speed and a changeable flow rate to suck out air in high speed in phases, to keep internal pressure of the reaction vessel at a low pressure condition, thereby shortening a processing time and acquiring high quality essential oil and activated carbons as by-products.The present invention also includes a system device to implement this method. In the oil-water separation tank of this device, an ultrasonic generator is provided to re-disintegrate tars, which improves quality of the oil products.

Owner:LIN WEI CHIH

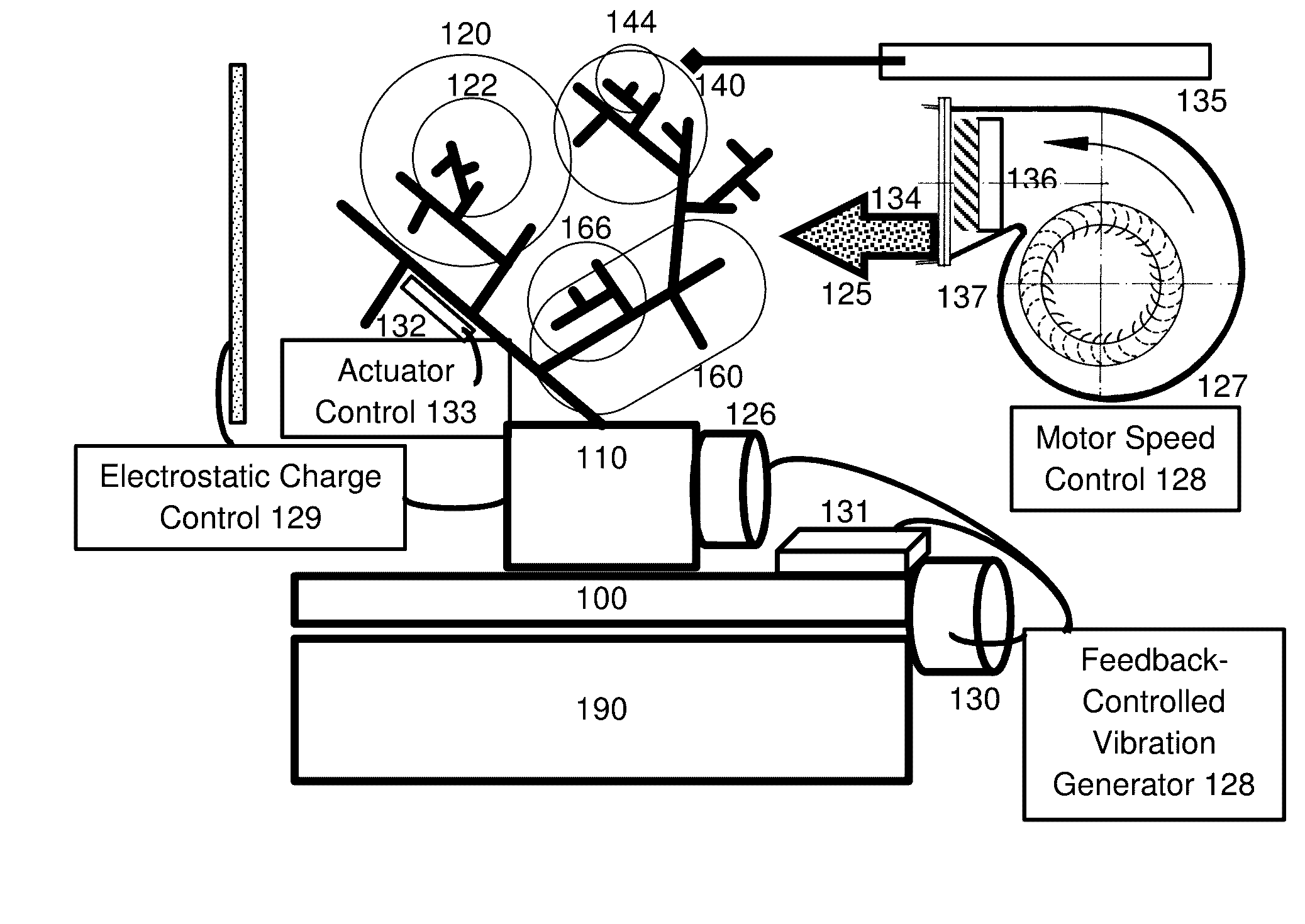

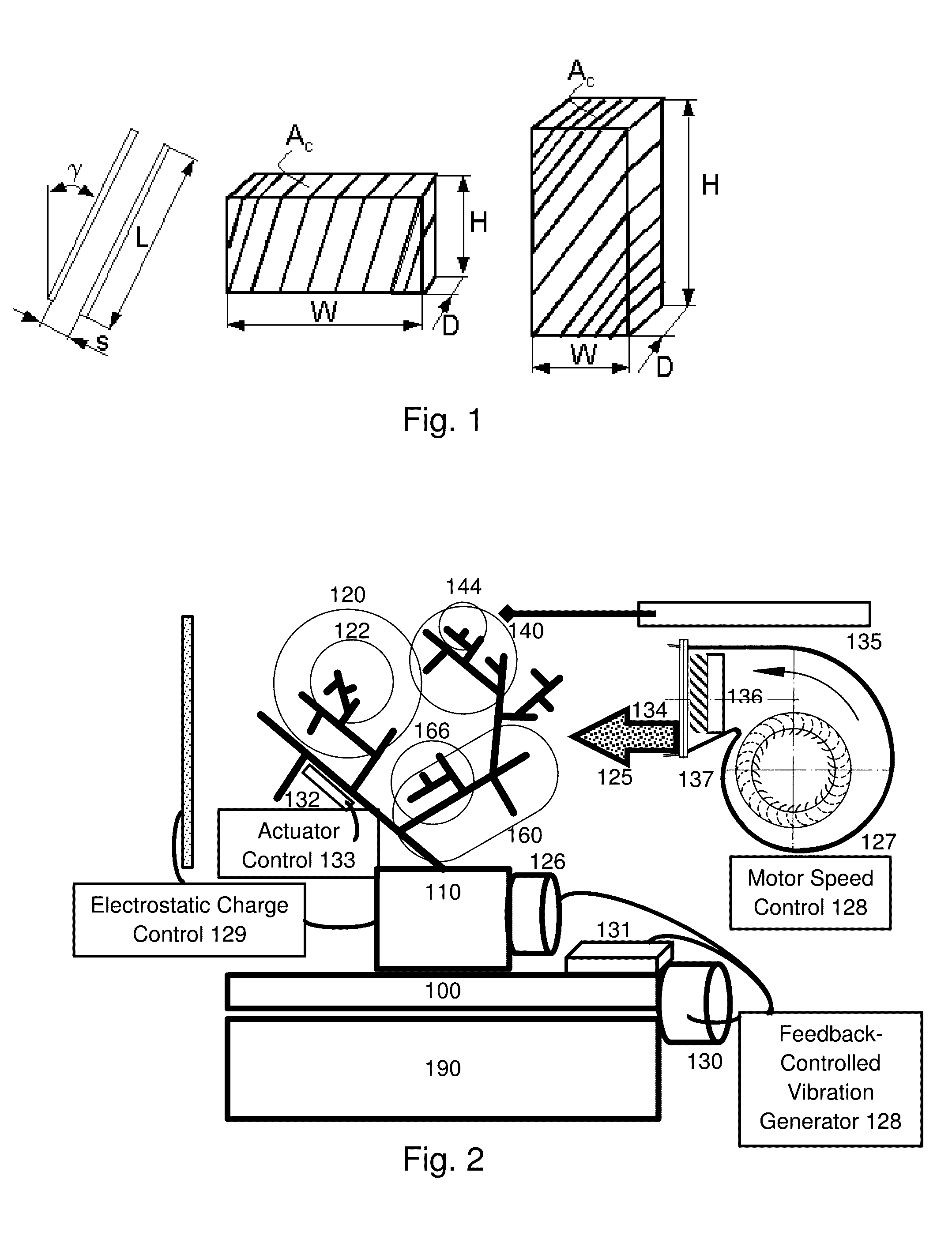

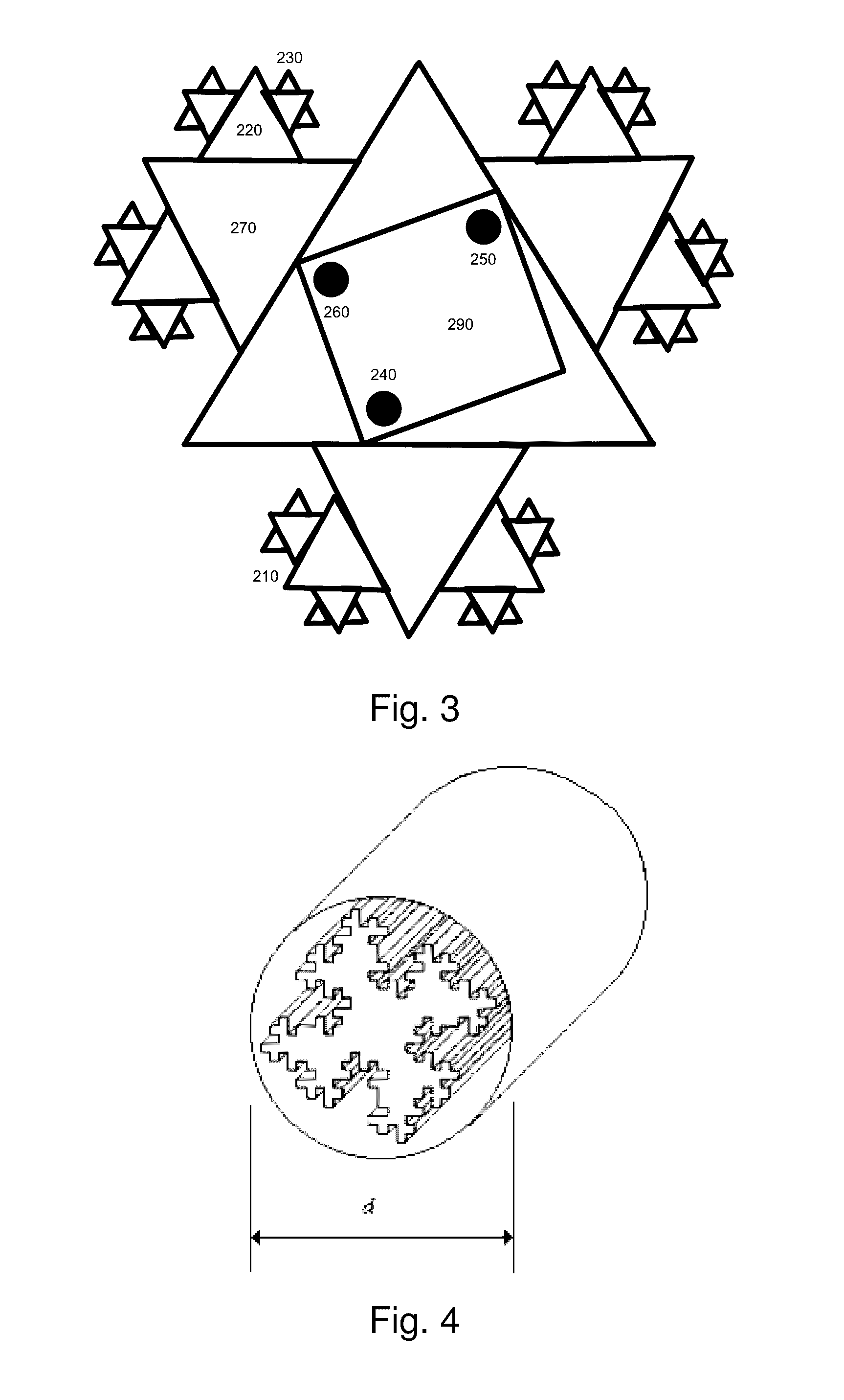

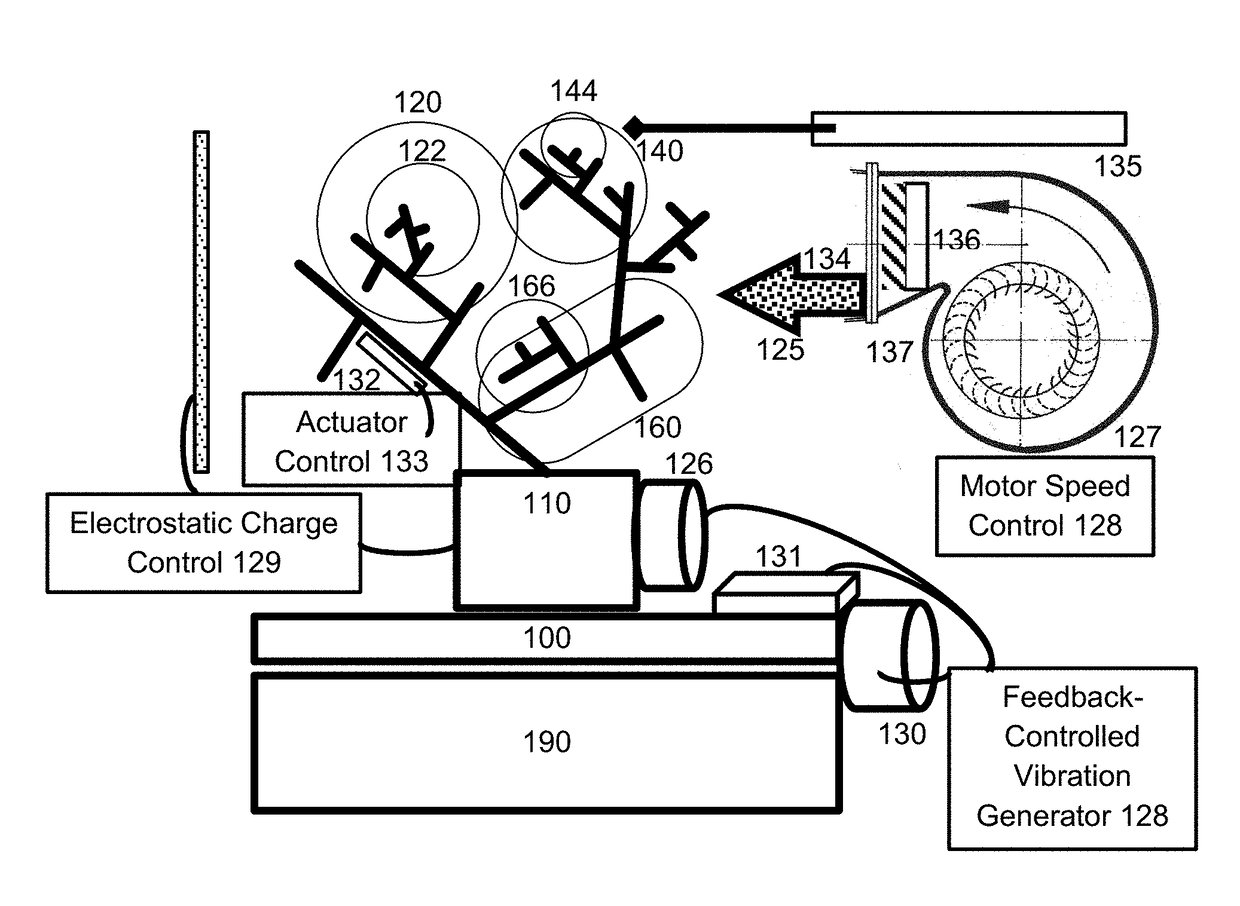

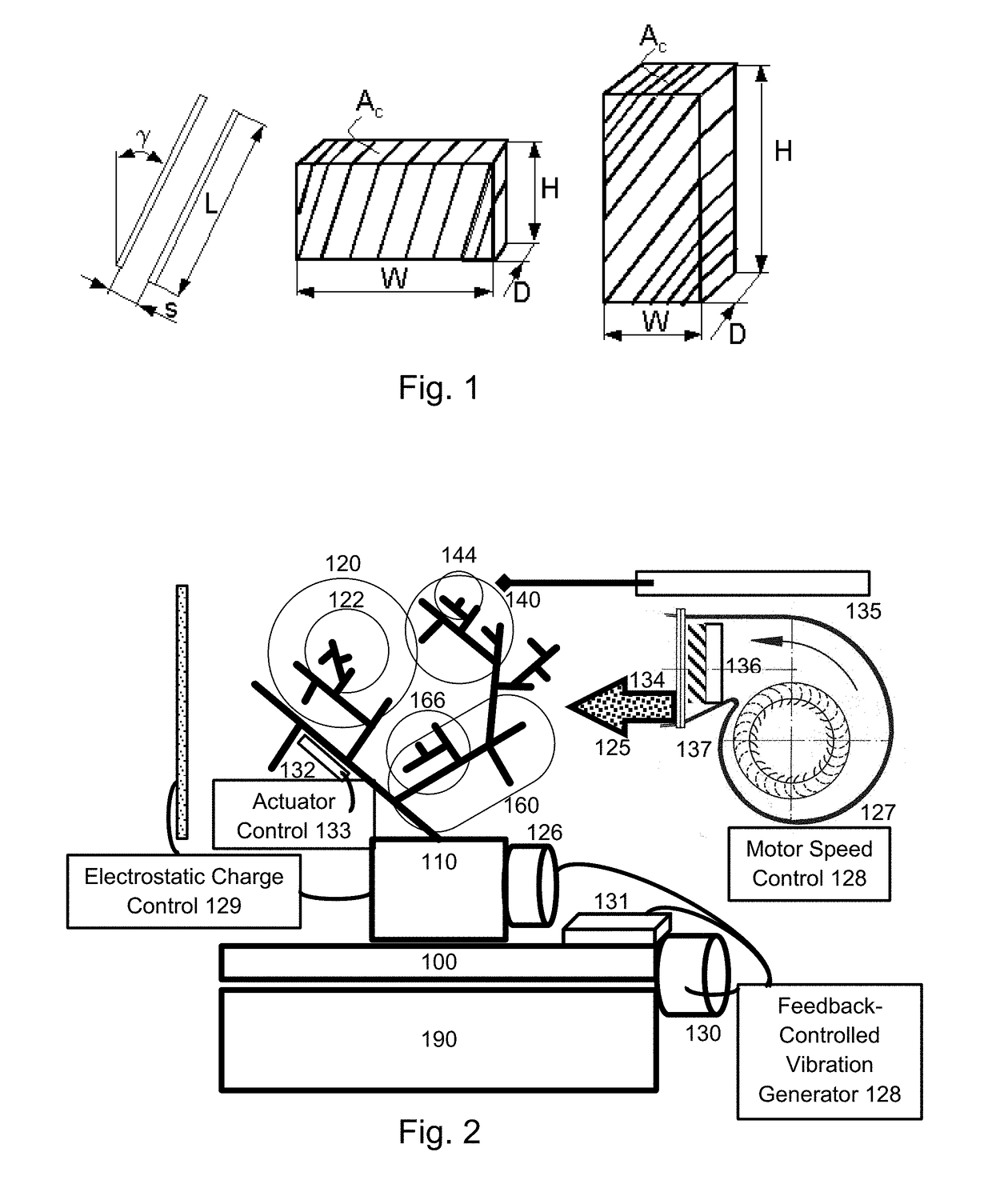

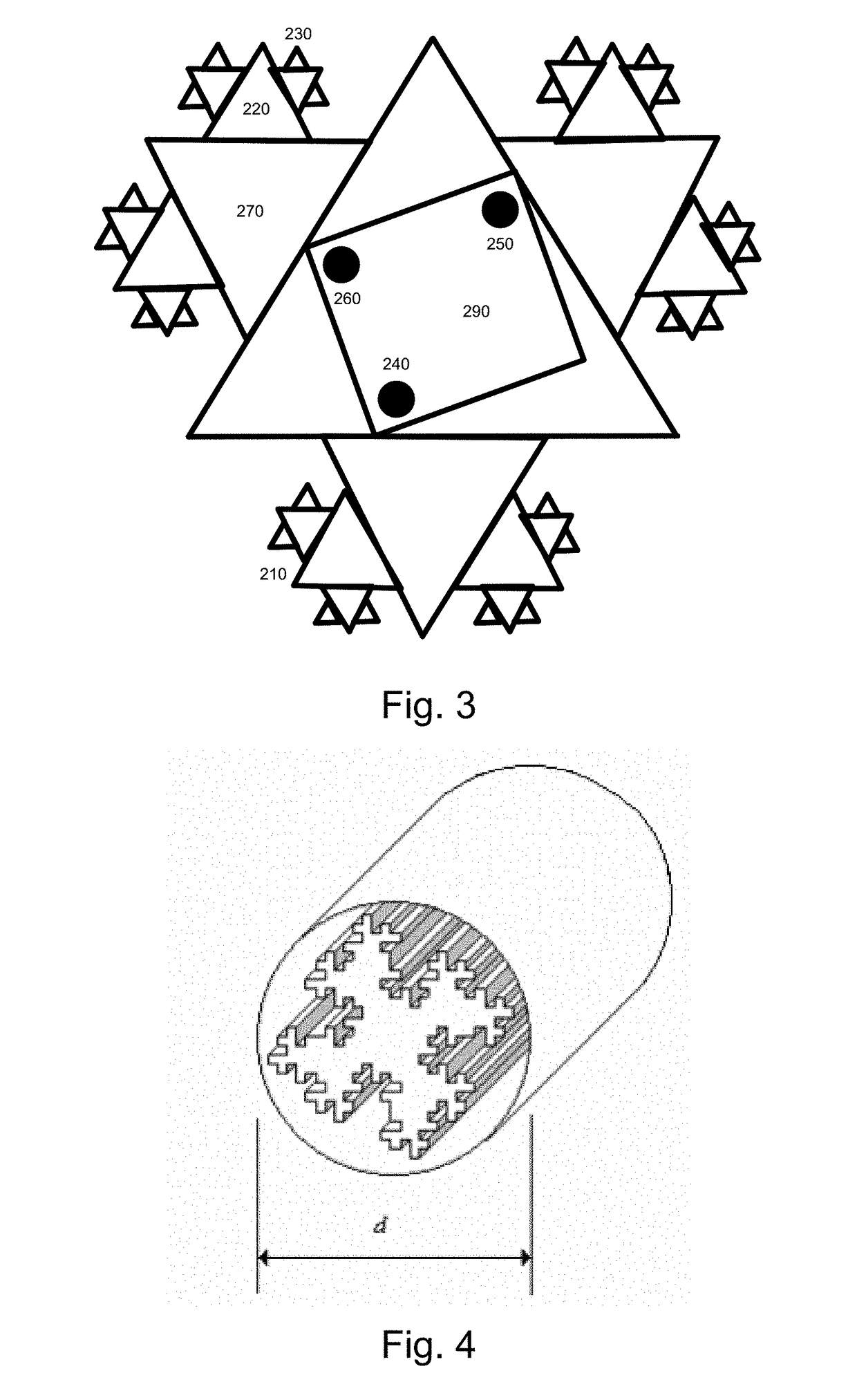

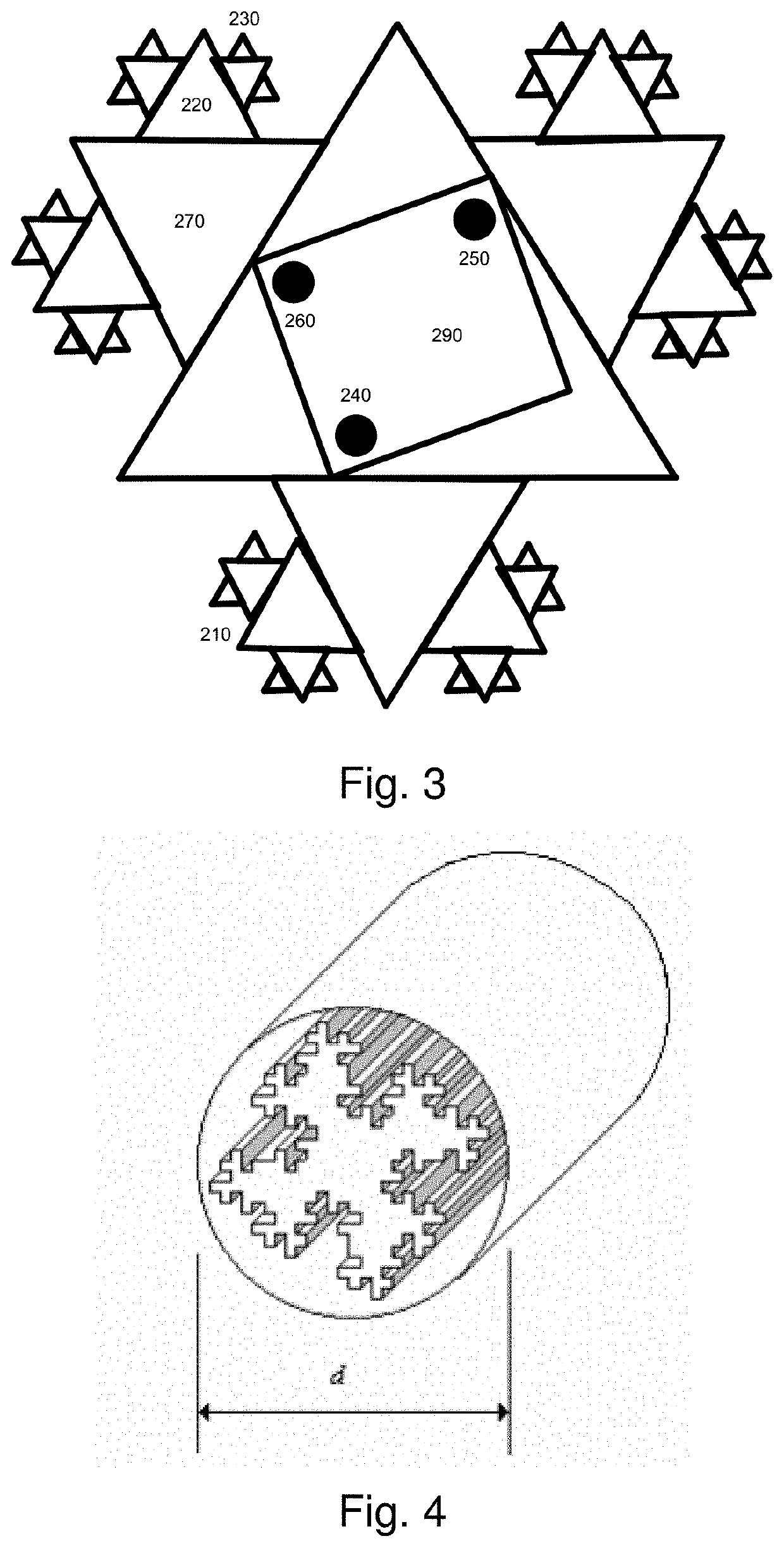

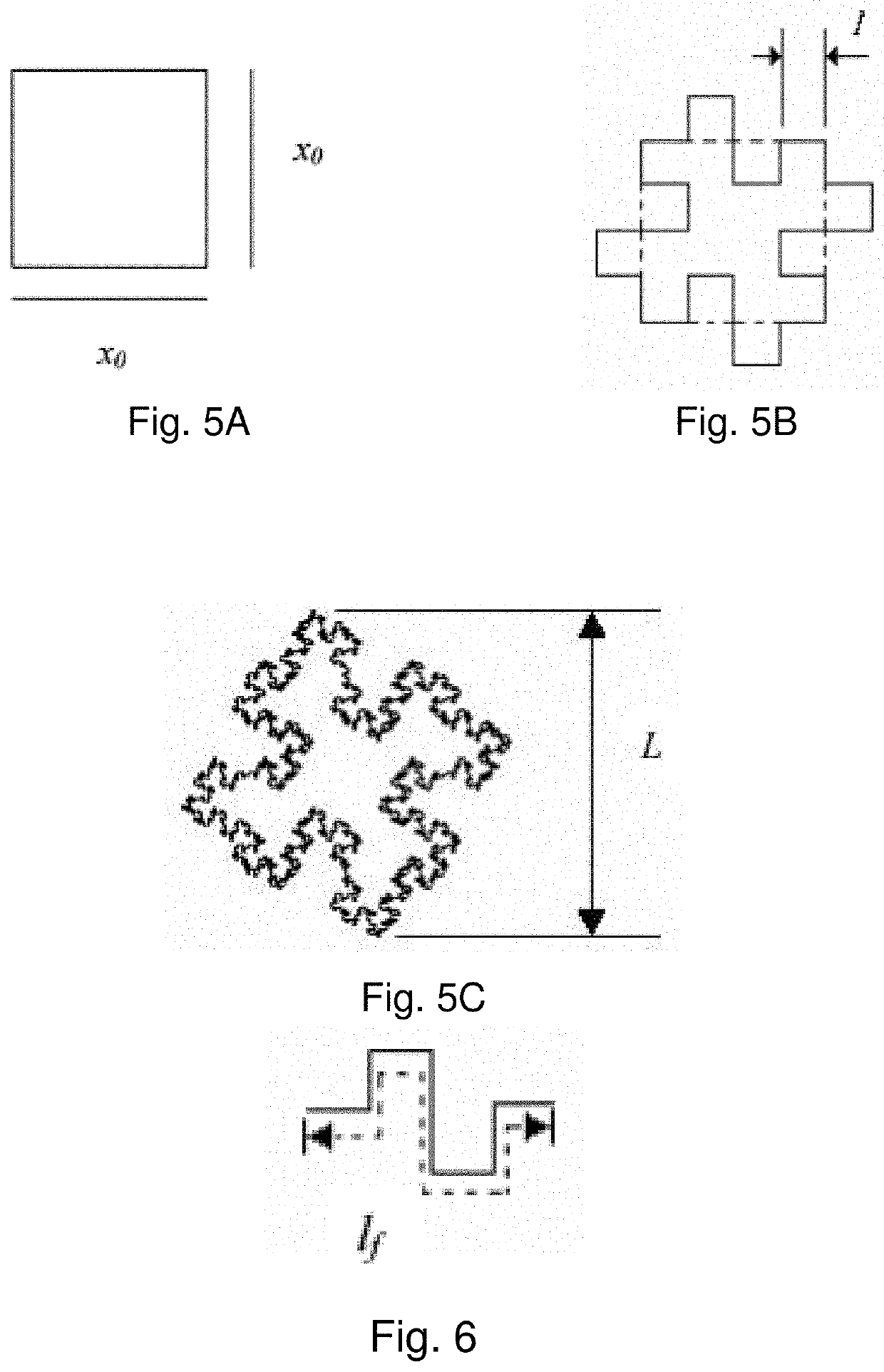

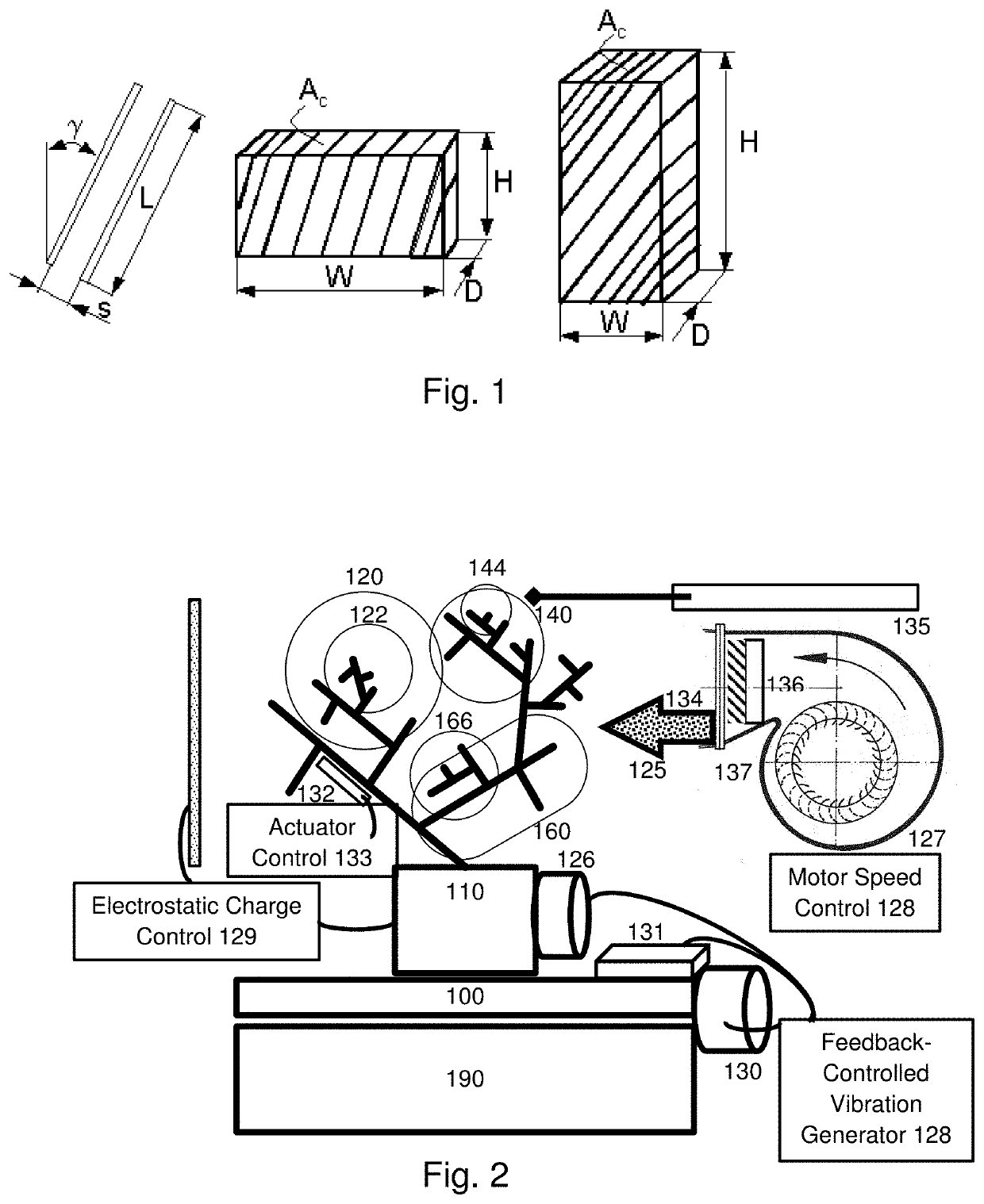

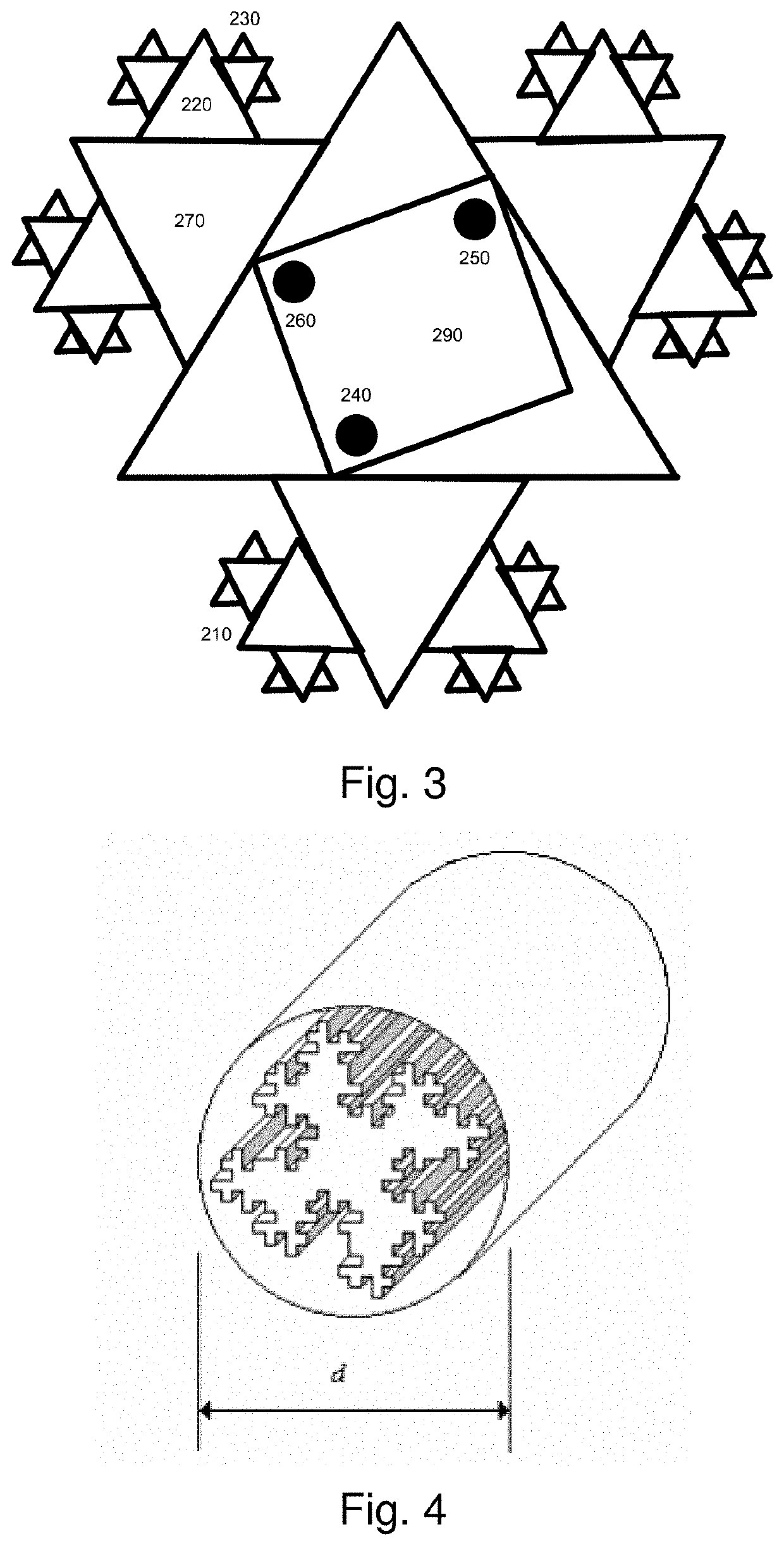

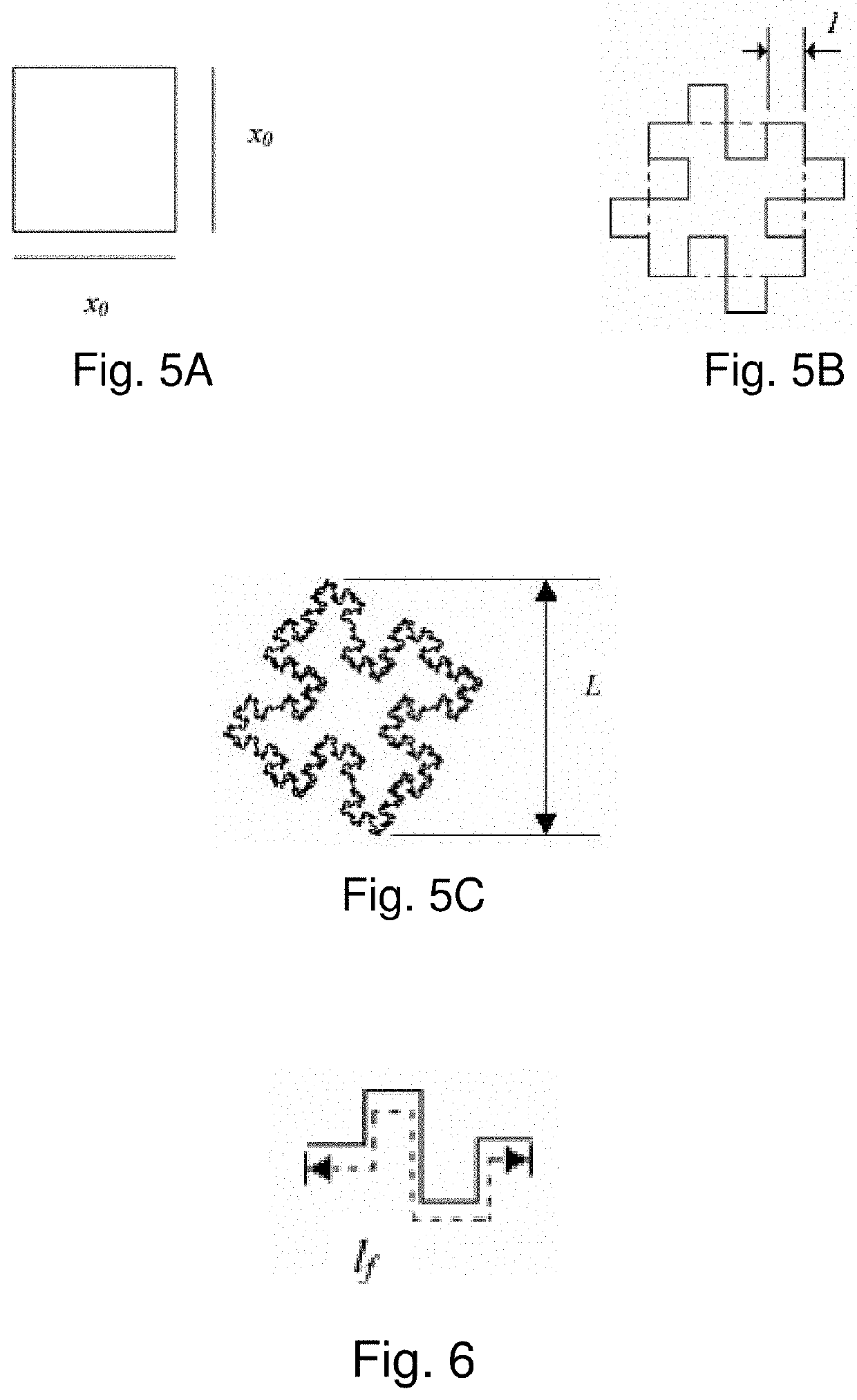

System and method for maintaining efficiency of a fractal heat sink

ActiveUS20160320149A1Large specific surface areaSmall surface areaHeat exhanger finsIndirect heat exchangersEngineeringHeat transfer fluid

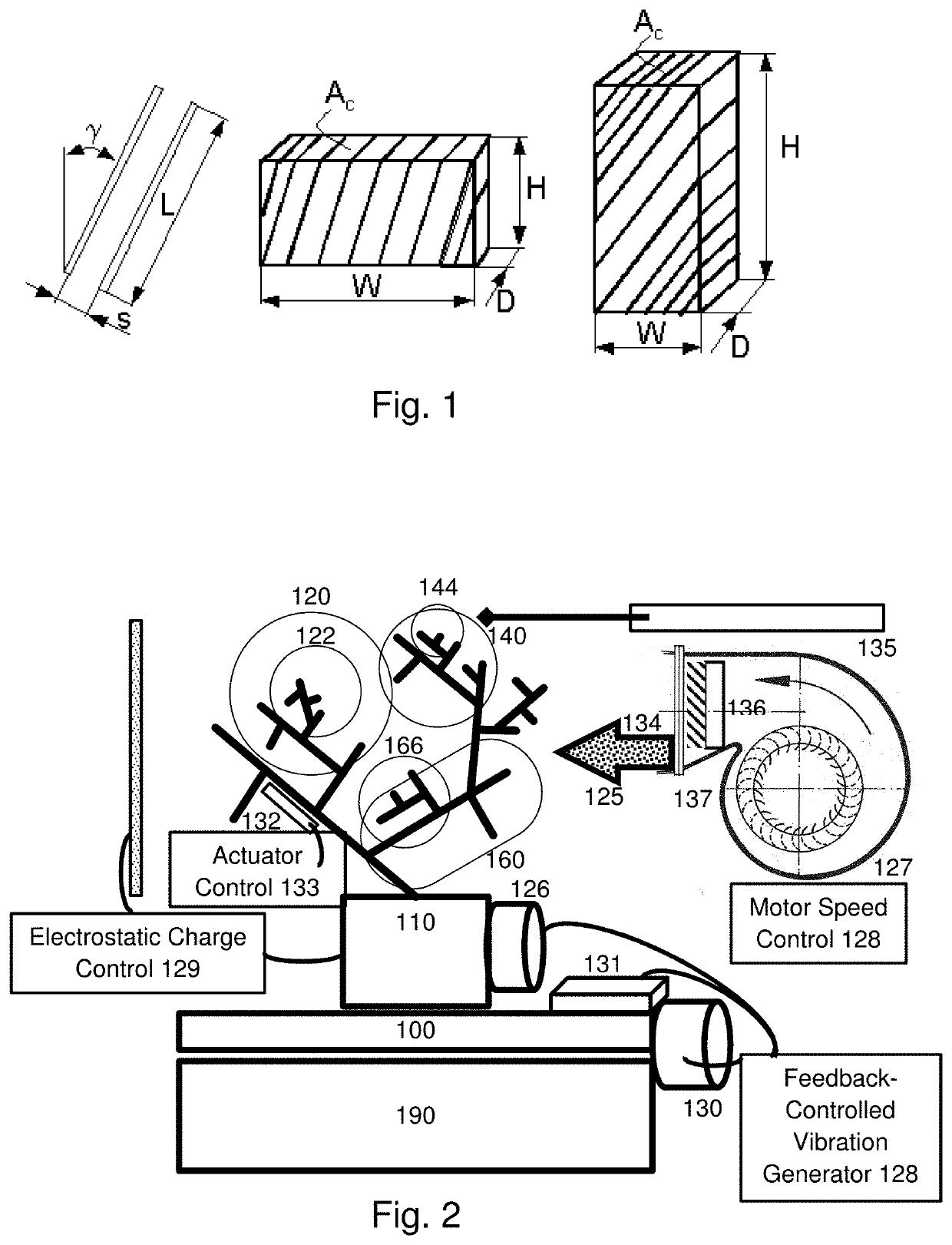

A heatsink comprising a heat exchange device having a plurality of heat exchange elements each having a surface boundary with respect to a heat transfer fluid, having successive elements or regions having varying size scales. According to one embodiment, an accumulation of dust or particles on a surface of the heatsink is reduced by a removal mechanism. The mechanism can be thermal pyrolysis, vibration, blowing, etc. In the case of vibration, adverse effects on the system to be cooled may be minimized by an active or passive vibration suppression system.

Owner:FRACTAL HEATSINK TECH

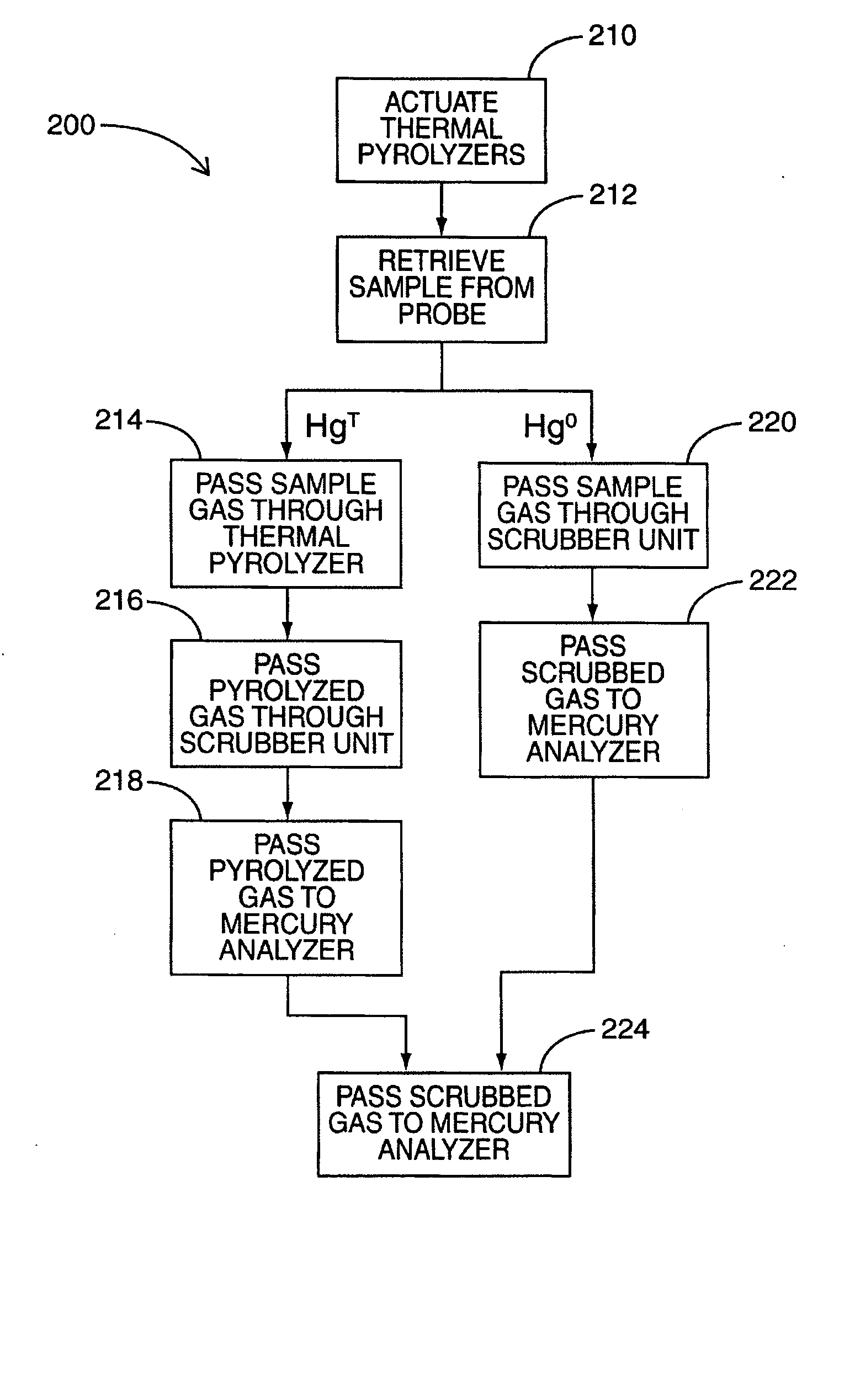

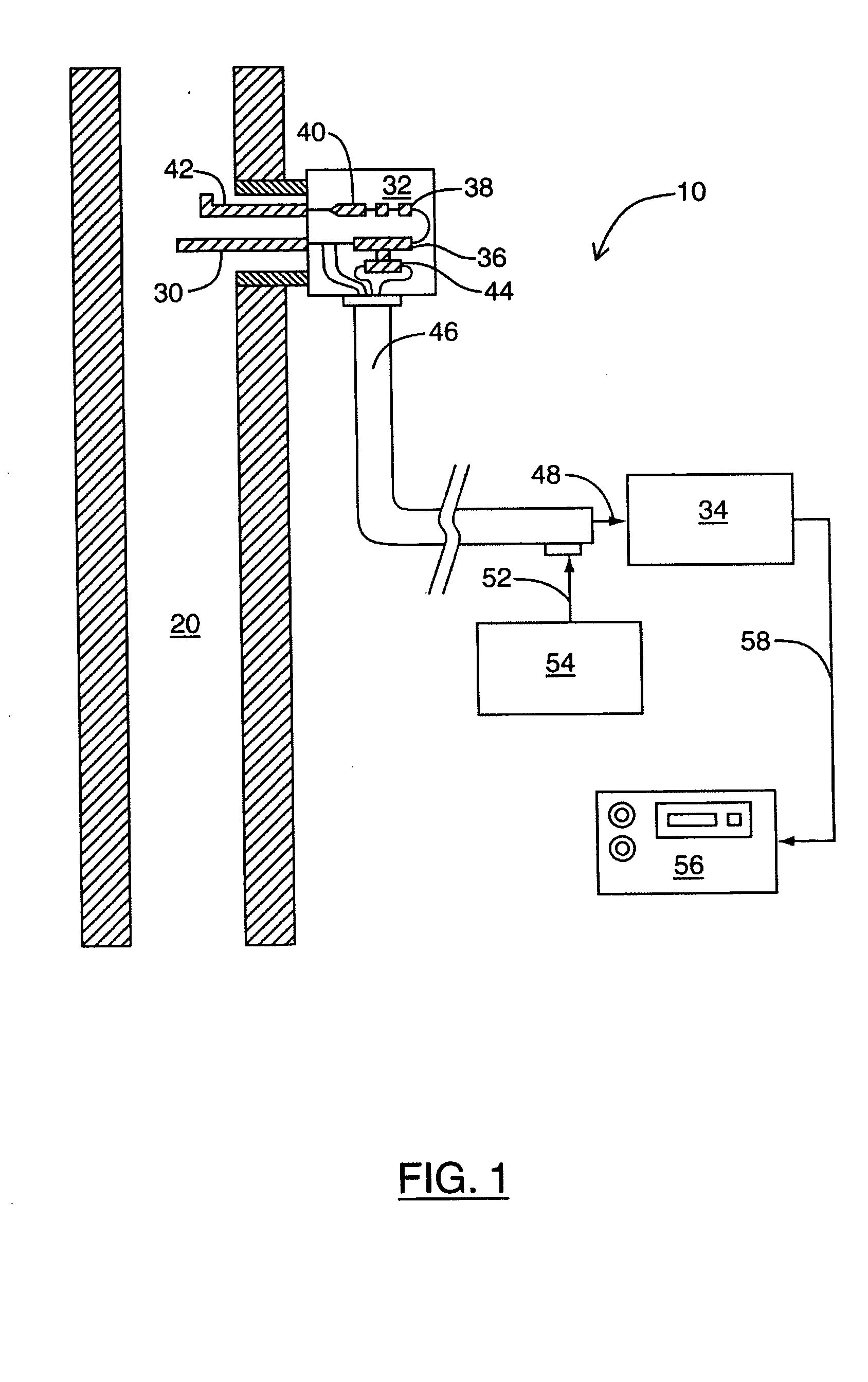

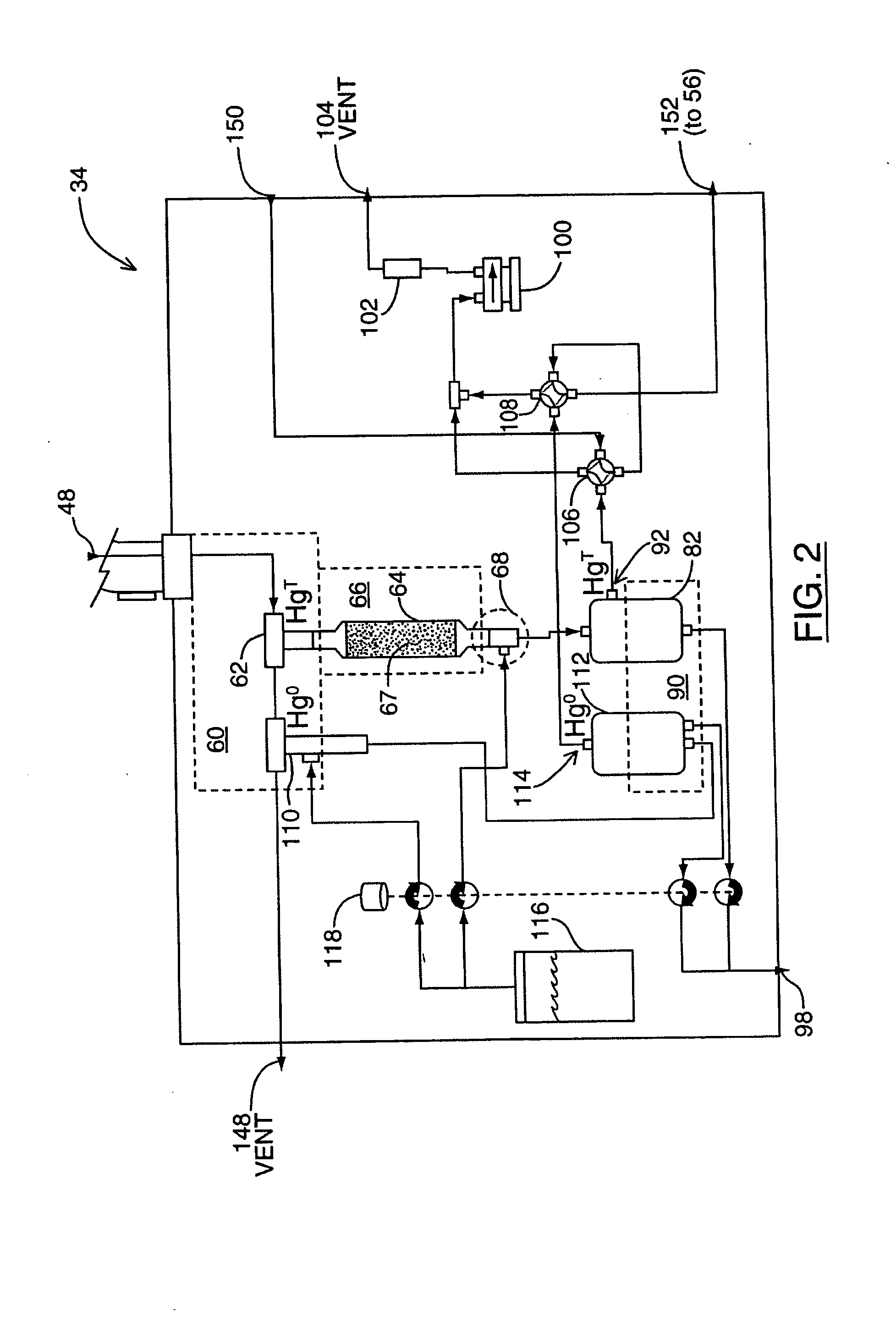

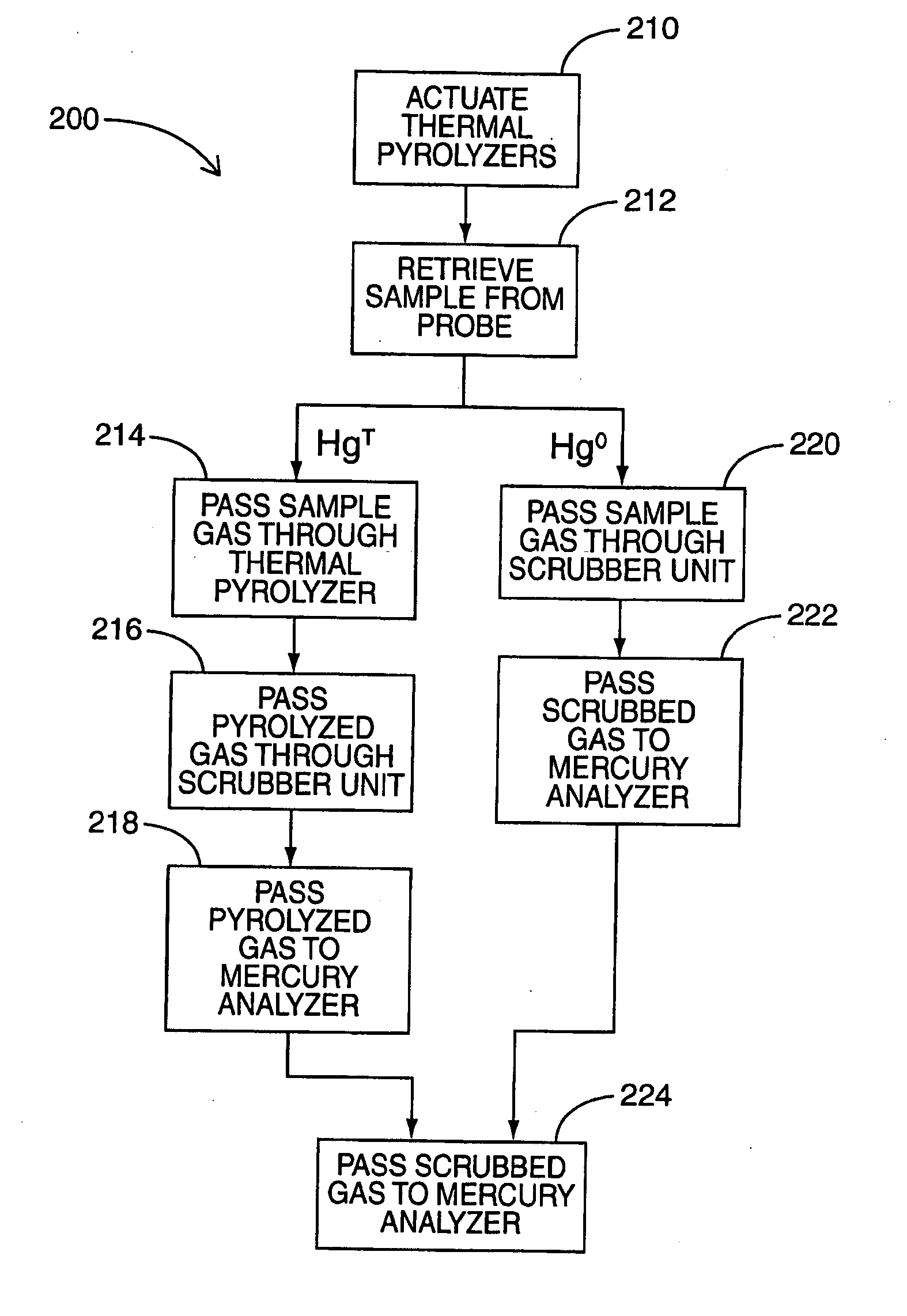

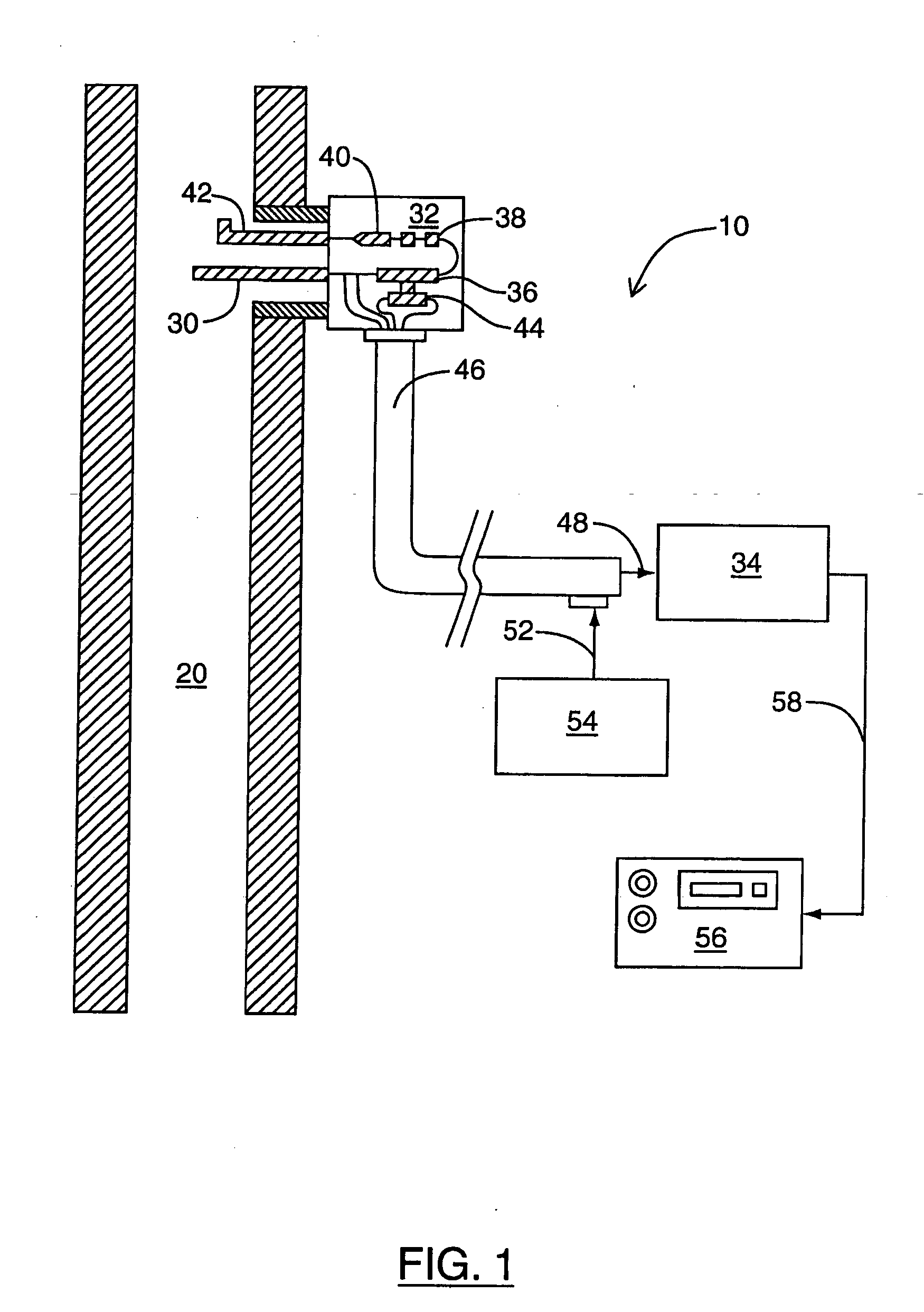

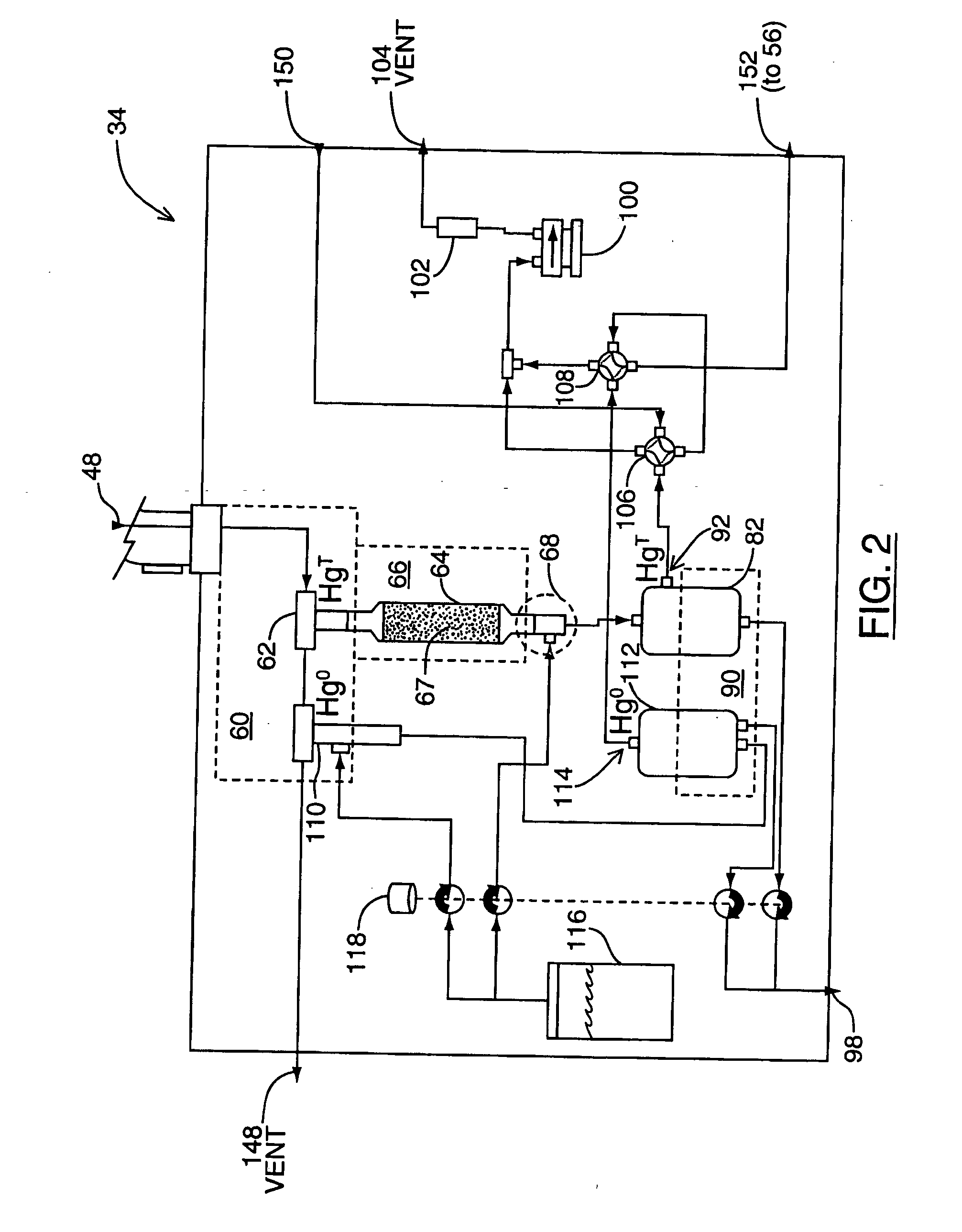

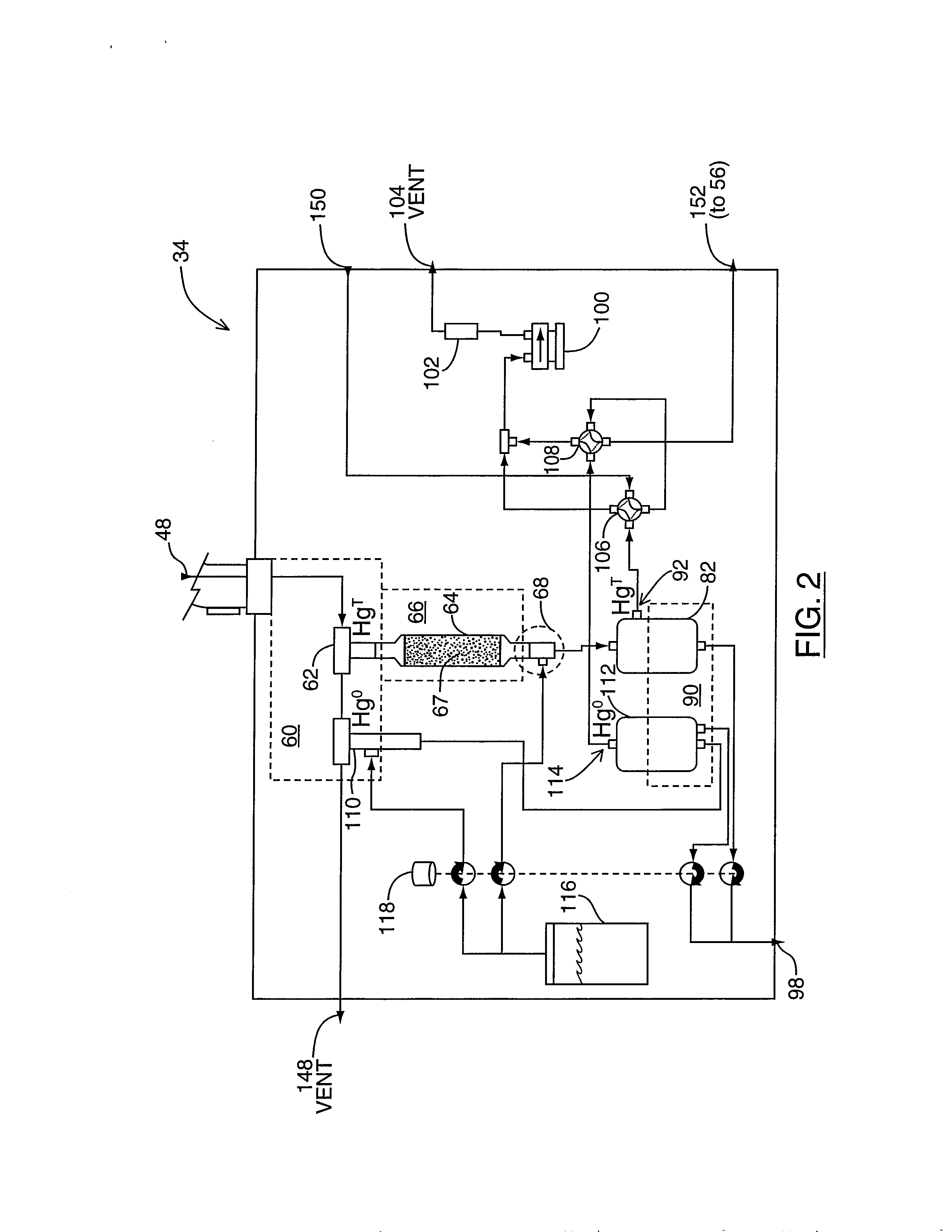

Conditioning system and method for use in the measurement of mercury in gaseous emissions

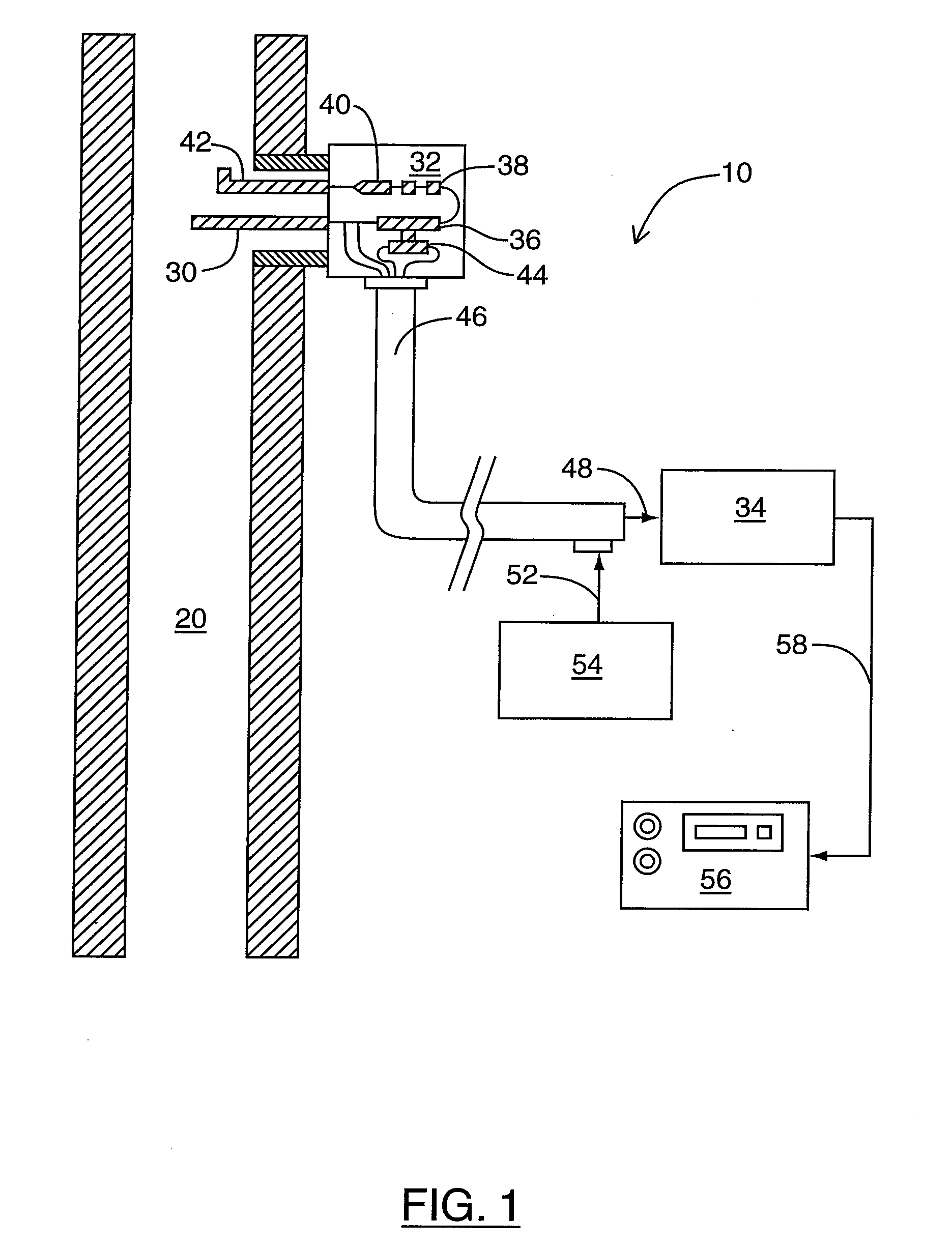

ActiveUS20050061110A1Avoid reorganizationReduced form requirementsGas treatmentSamplingBoron nitrideSilicon boride

Embodiments of the invention relate generally to systems used to measure mercury in gaseous emissions. In one aspect, the invention is directed to the use of silicon carbide as material for a thermal pyrolysis unit. In another aspect, at least one of silicon nitride, silicon boride, and / or boron nitride is used as material for a thermal pyrolysis unit. In another aspect, the invention is directed to an improved pyrolyzer design, in which a thermal pyrolysis unit comprises a tailpiece that allows water to be injected at the heated exit of the thermal pyrolysis unit. In another aspect, the invention is directed to the use of a coalescing filter in a scrubbing unit. In another aspect, the invention is directed to the use of a hydrophobic filter element in a scrubbing unit. One or more of these elements may be used in a conditioning module of a continuous emissions monitoring system, for example.

Owner:TEKRAN INSTR CORPORTION

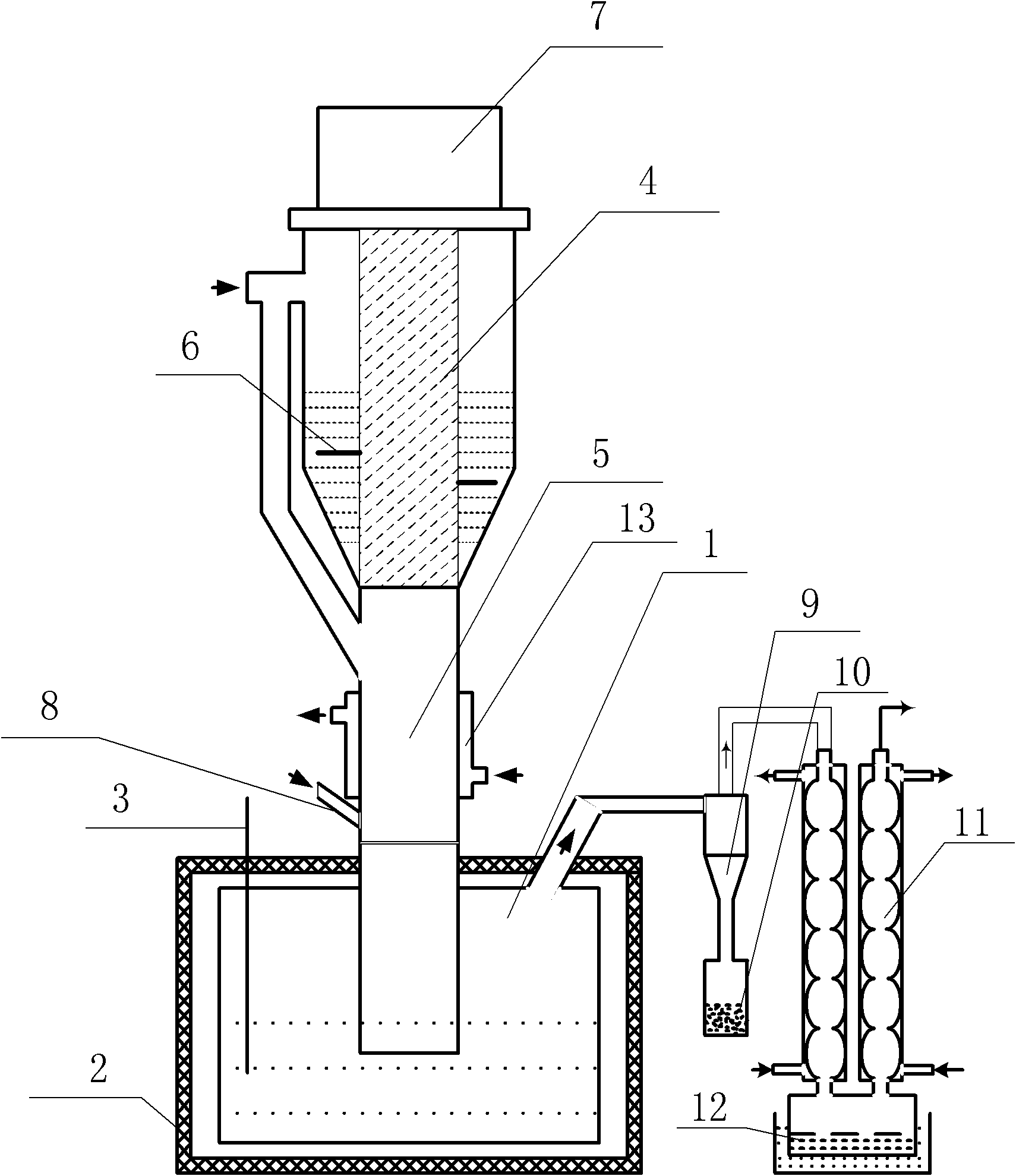

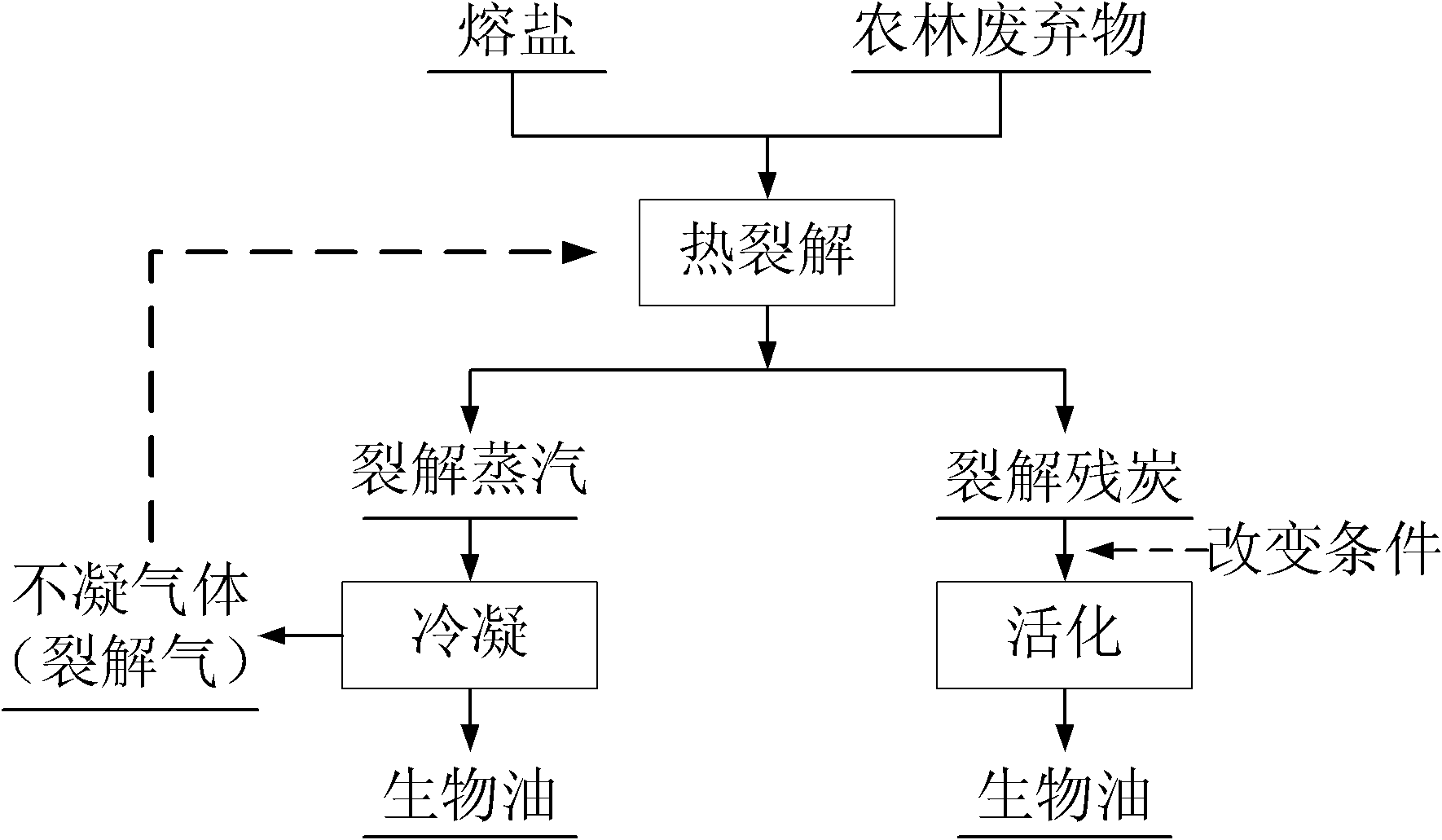

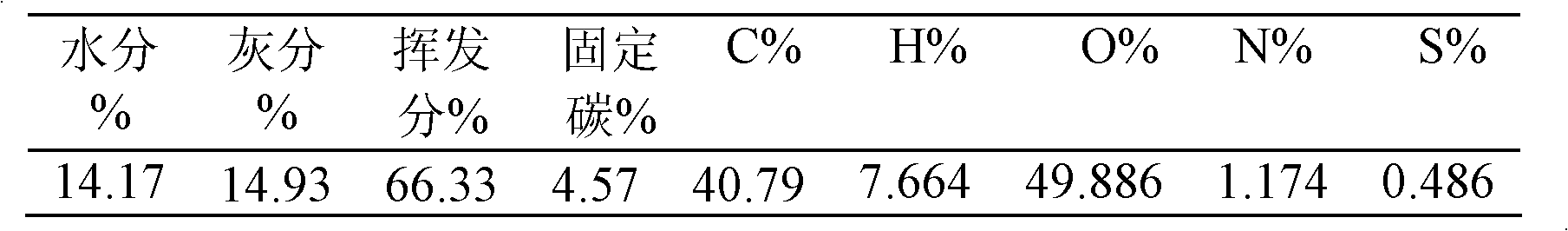

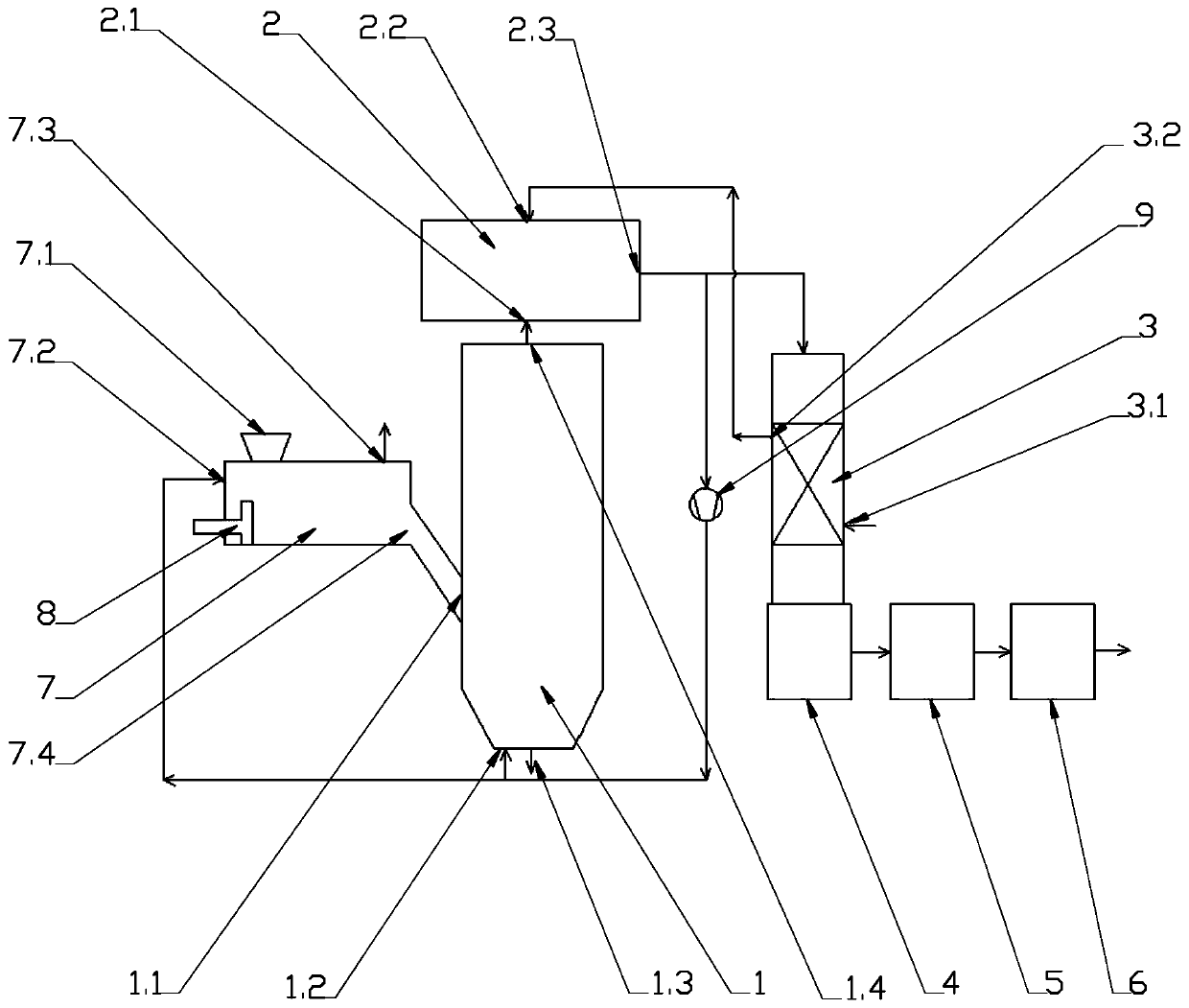

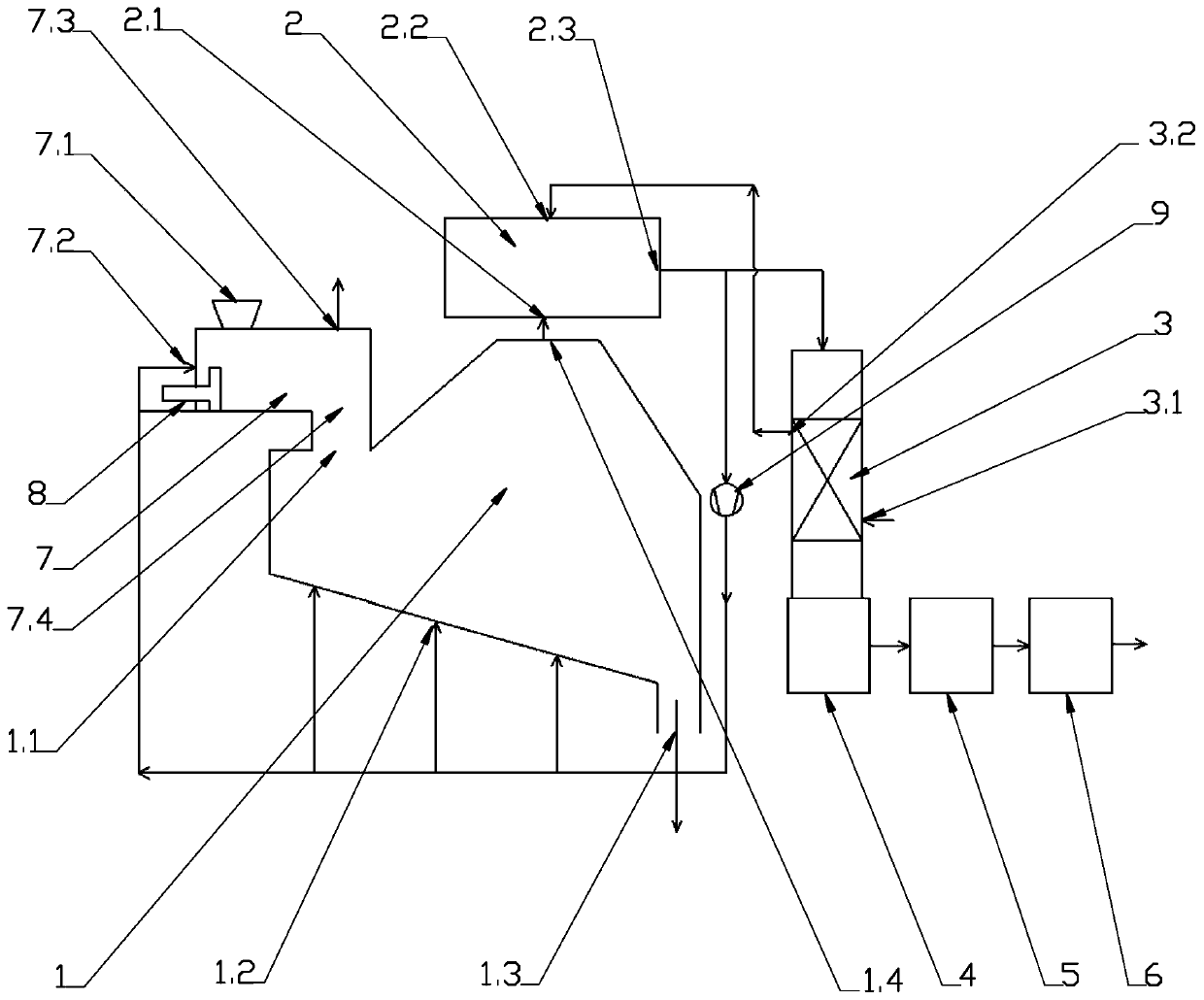

Process for co-producing bio-oil and biological carbon by utilizing crop straws and special device

InactiveCN101875845AReduce pollutionEasy to operateDirect heating destructive distillationBiofuelsLiquid productAlkaline earth metal

The invention relates to a process for co-producing bio-oil and biological carbon by utilizing crop straws, comprising the following steps of: firstly, selecting alkali earth metal halides or alkali as molten salts, and putting the molten salts into a molten salt thermal pyrolysis reactor; secondly, opening an electrothermal furnace of the molten salt thermal pyrolysis reactor; thirdly, sending the crop straws into the molten salt thermal pyrolysis reactor; fourthly, obtaining a liquid product, i.e. the bio-oil by condensing a steam part generated by thermal pyrolysis in the molten salt thermal pyrolysis reactor, wherein a non-condensation part is a gaseous product; fifthly, regulating the temperature of the molten salt thermal pyrolysis reactor to the activation temperature, and cooling the molten salt thermal pyrolysis reactor to the room temperature after activation is finished; and sixthly, taking out a solid product after activation, soaking the solid product by using 3mol / L hot hydrochloride, and obtaining a solid-state product, i.e. the biological carbon by soaking the solid product by hot distilled water. The invention also provides a special device for co-producing the bio-oil and the biological carbon by utilizing crop straws. The invention has simple components and lowers the production cost.

Owner:ZHEJIANG UNIV OF TECH +1

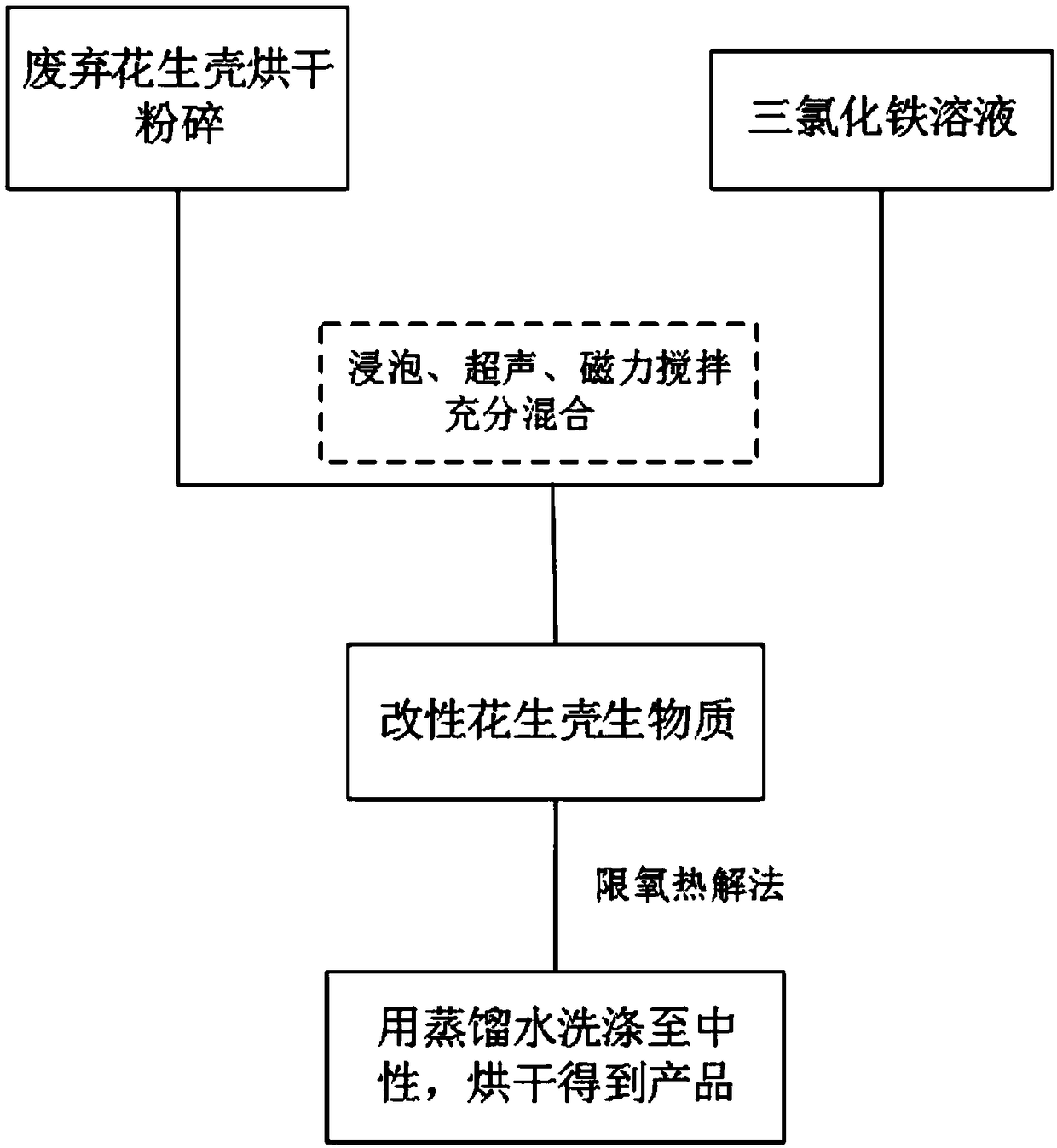

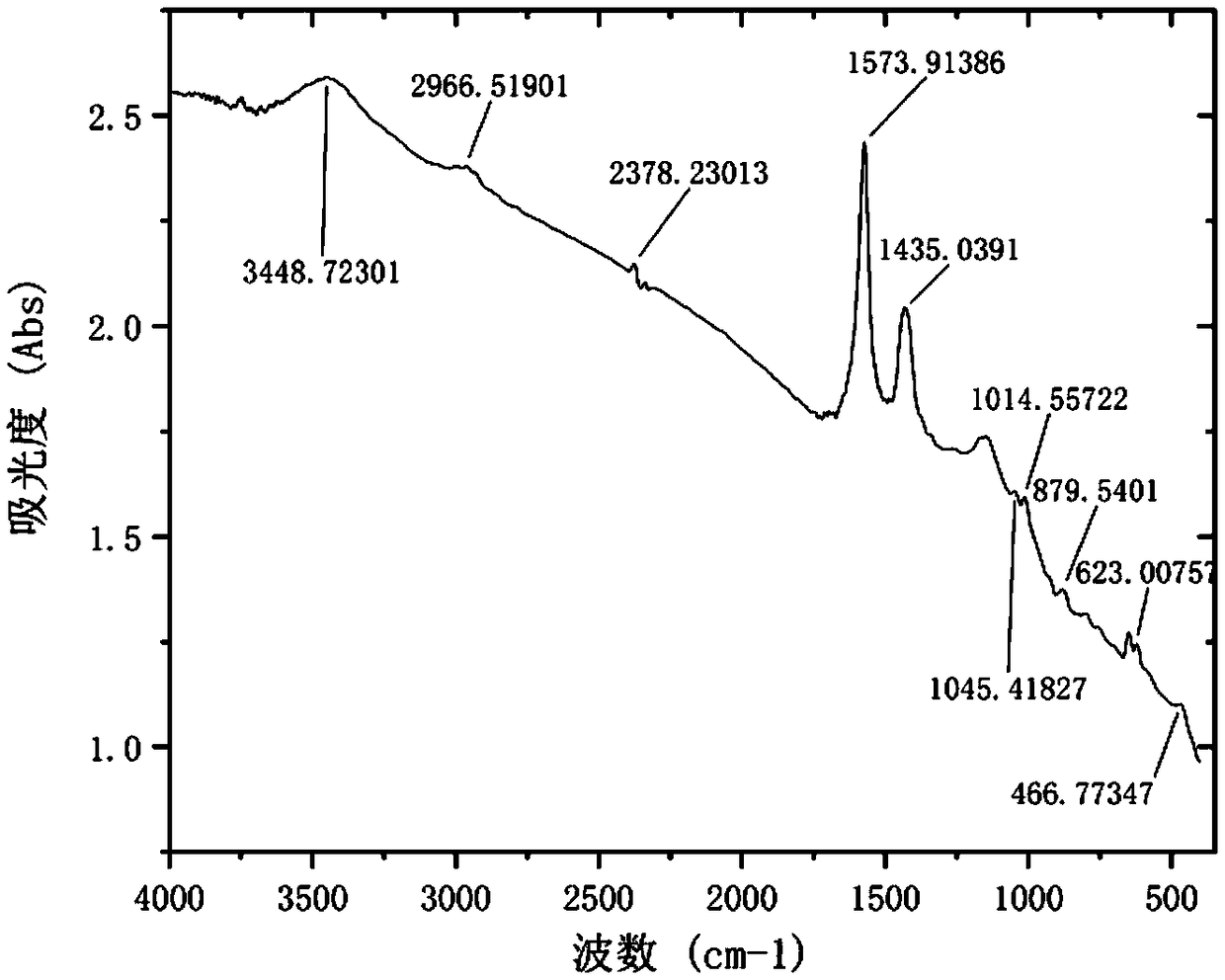

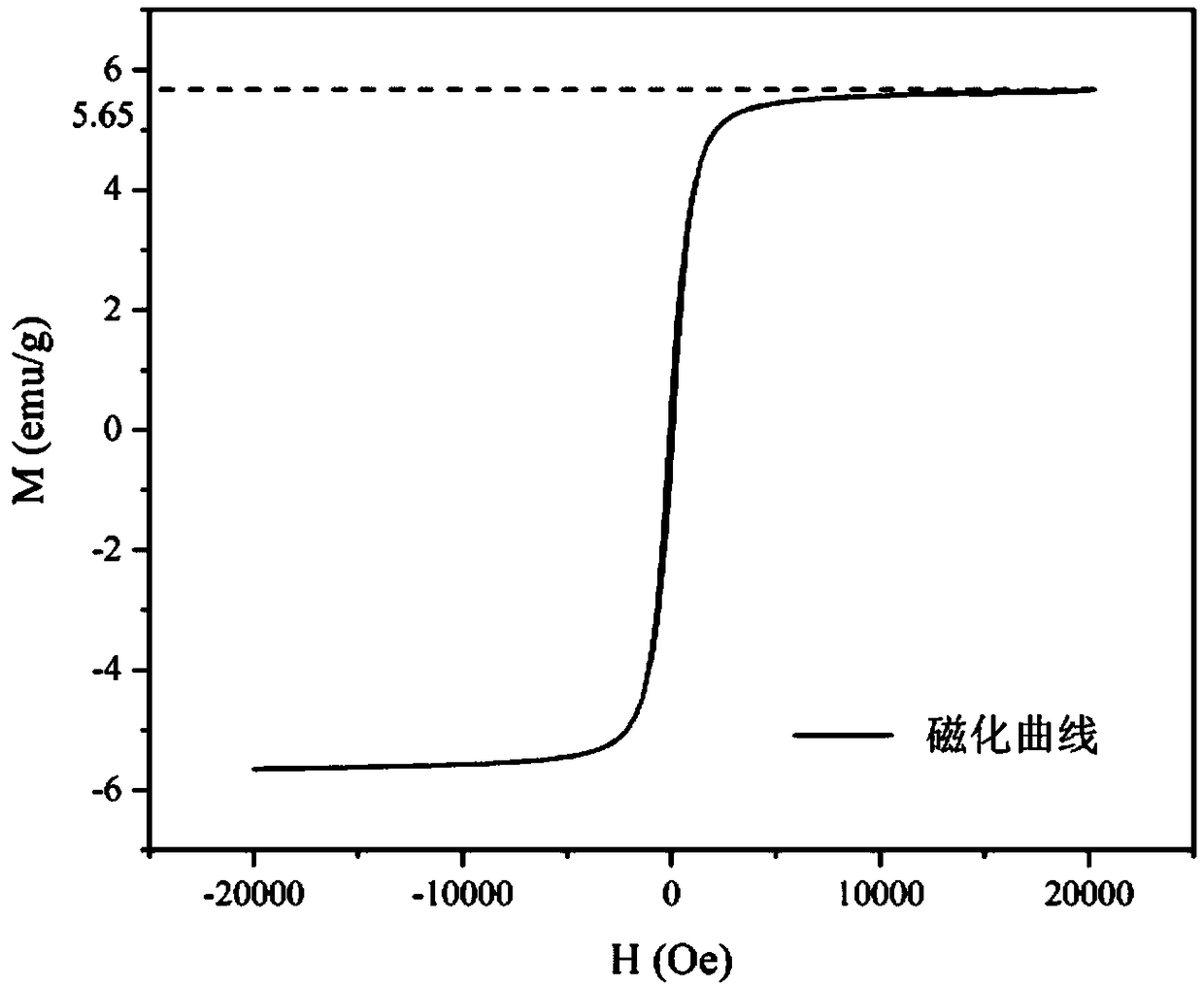

Iron modified peanut shell magnetic biochar as well as preparation method and application thereof

InactiveCN109499538ARealize recyclingAvoid secondary pollutionOther chemical processesWater contaminantsSorbentResource utilization

The invention belongs to the technical field of biochar materials and discloses iron modified peanut shell magnetic biochar as well as a preparation method and the application thereof. The preparationmethod comprises the following steps: taking peanut shells and ferric trichloride as raw materials, magnetizing by a method for soaking peanut shell biomass with a ferric trichloride solution, and performing oxygen limited thermal pyrolysis, so as to obtain the product. The iron modified peanut shell magnetic biochar is applied to an aqueous solution containing hexavalent chromium, the solution is overturned and oscillated at a room temperature, the iron modified magnetic biochar is separated from the solution after the reaction is completed, and aims of removing the hexavalent chromium in the water and separating and recovering the adsorbent are achieved. The method disclosed by the invention has the advantages of being low in cost, simple and convenient to operate, high in treatment efficiency and the like. Moreover, the adsorbent is wide in raw material source, the resource utilization of the biomass is realized, and the biochar has magnetism, is convenient to separate, recover andrecycle, does not cause secondary pollutions, and can be applied to treatment of industrial wastewater containing hexavalent chromium in electroplate factories, tannery factories, smelting plants andthe like.

Owner:TIANJIN UNIV

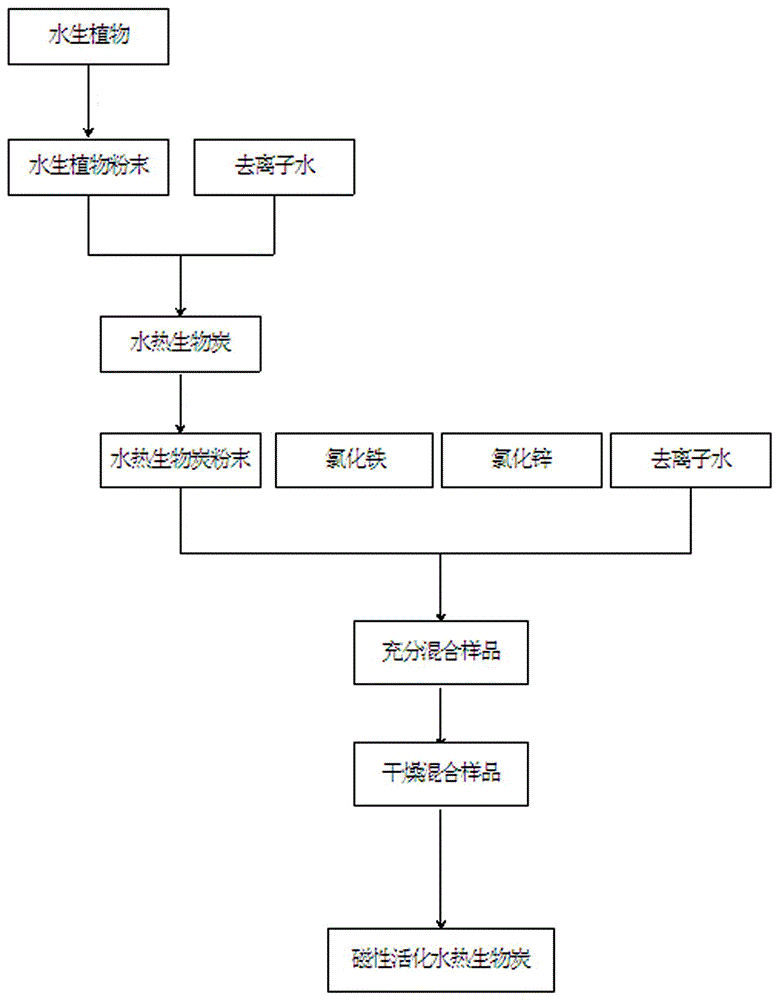

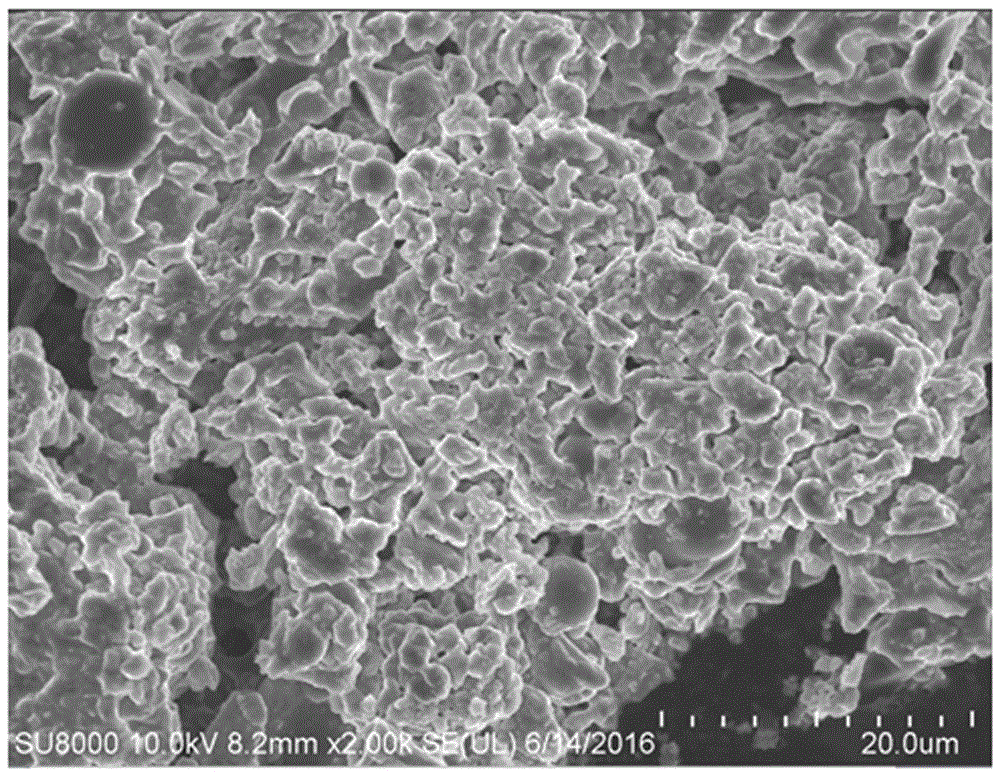

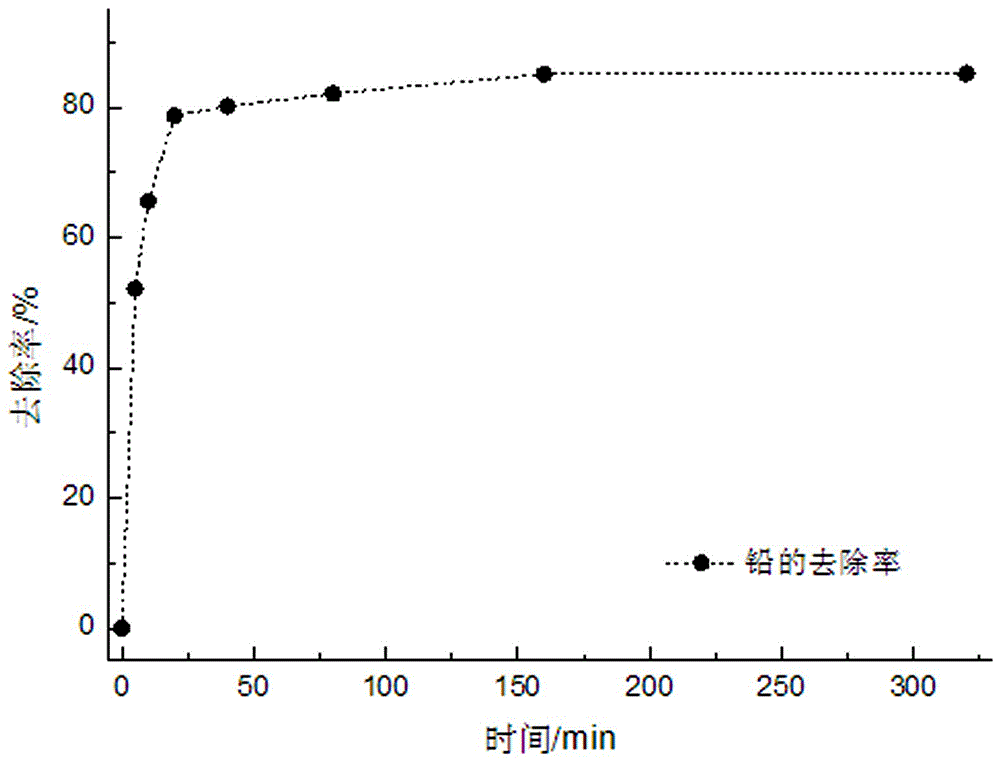

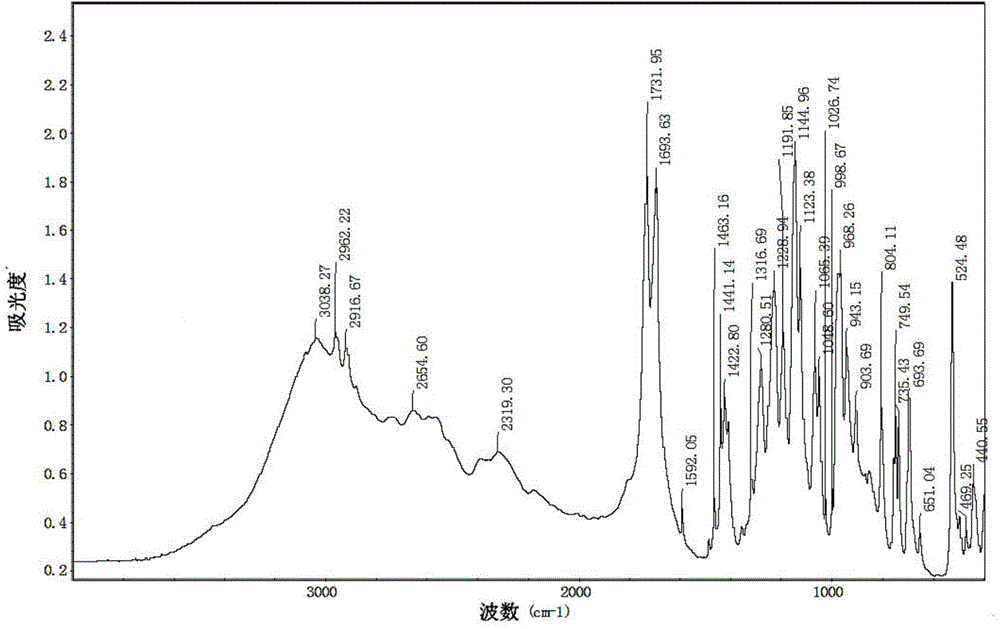

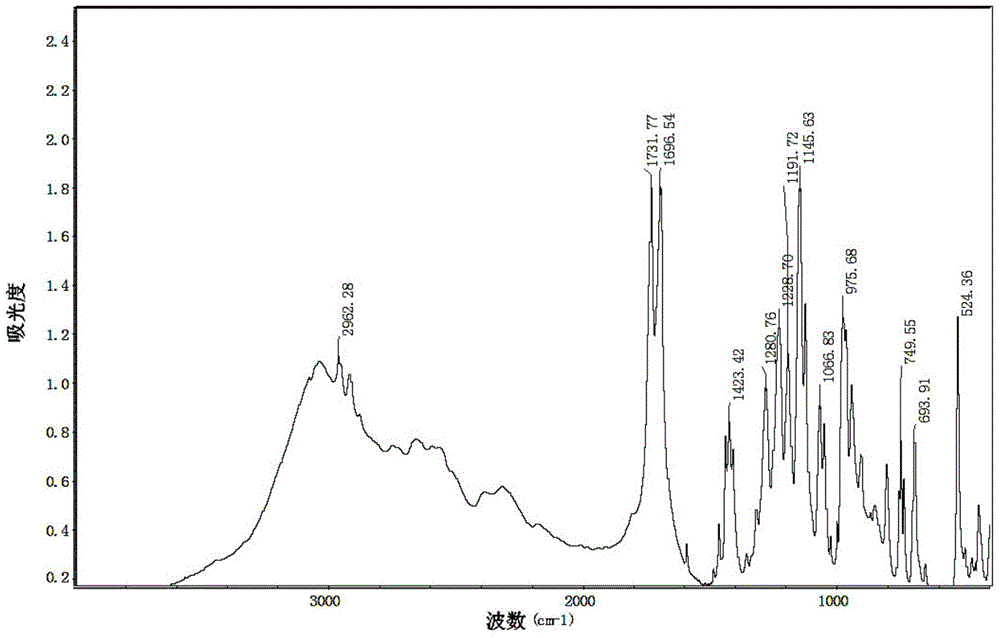

Preparation method and application of magnetically-activated hydrothermal biological carbon

InactiveCN106179216AHigh yieldLarge specific surface areaOther chemical processesWater contaminantsNitrogenNitrogen gas

The invention relates to a preparation method and application of magnetically-activated hydrothermal biological carbon. The preparation method comprises the following steps: performing hydrothermal reaction on aquatic plant powder and deionized water in a reaction kettle to prepare hydrothermal biological carbon; then fully mixing the hydrothermal biological carbon, FeCl3, ZnCl2 and the deionized water and drying; putting a dried mixed sample into a box-type atmosphere furnace, performing final thermal pyrolysis at a target temperature under the condition of nitrogen protection to prepare the magnetically-activated hydrothermal biological carbon. The magnetically-activated hydrothermal biological carbon material prepared by the method can effectively absorb and remove a large amount of heavy metals like lead and copper in a water body; the composite material prepared by the method can be added into soil in which the lead and the copper exceed the standard so as to reduce the bio-availability of the lead and the copper in the soil and achieve the purposes of resisting and controlling the heavy metals.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

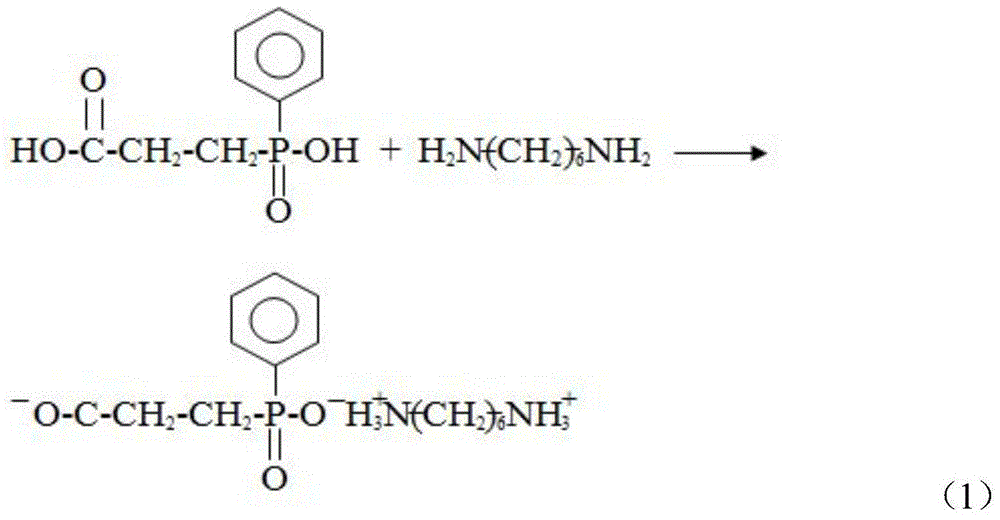

Halogen-free copolymer-type flame-retarding polyamide 66 and preparation method thereof

The invention discloses halogen-free copolymer-type flame-retarding polyamide 66 and a preparation method thereof and belongs to the technical field of flame-retarding polyamide 66 high-molecular materials. The method includes the steps of 1) preparing a flame retardant organic salt solution; 2) mixing hexanediamine and adipic acid in a polymerization kettle, and carrying out a pre-amidation reaction to prepare polyamide 66; 3) when the pre-amidation reaction is finished, reducing the pressure in the polymerization kettle to normal or negative pressure through flash pressure reduction, and adding the flame retardant organic salt solution to the polyamide 66 in the polymerization kettle, and performing after-polymerization reaction under a normal or negative pressure to prepare the halogen-free copolymer-type flame-retarding polyamide 66. The halogen-free copolymer-type flame-retarding polyamide 66 is not subjected to a thermal pyrolysis reaction in a remelting process during fiber forming and casting processes. The active component in the halogen-free copolymer-type flame-retarding polyamide 66 is phosphorus in a low content so that the flame-retarding efficiency is high.

Owner:LIAONING YINZHU CHEMTEX GROUP

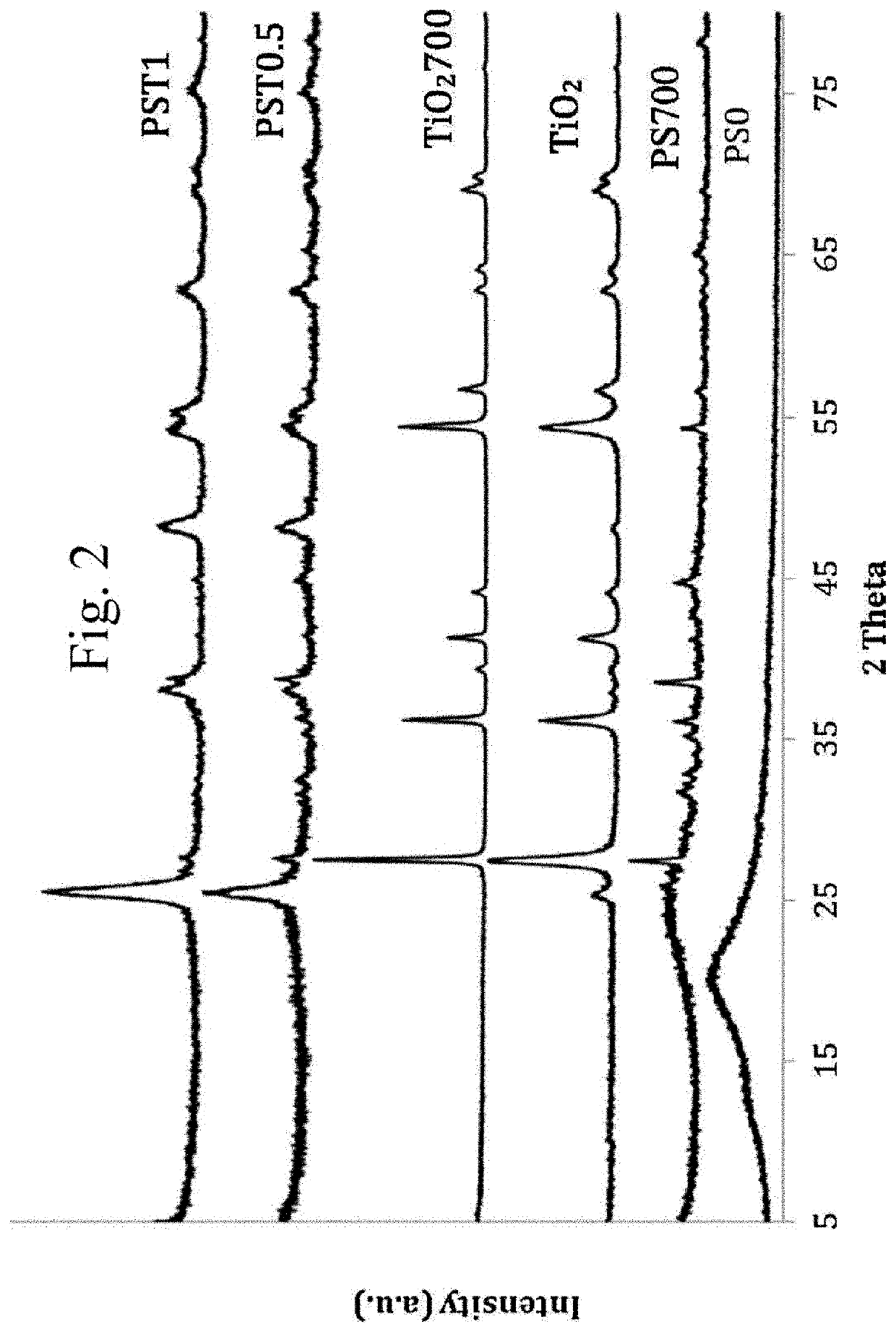

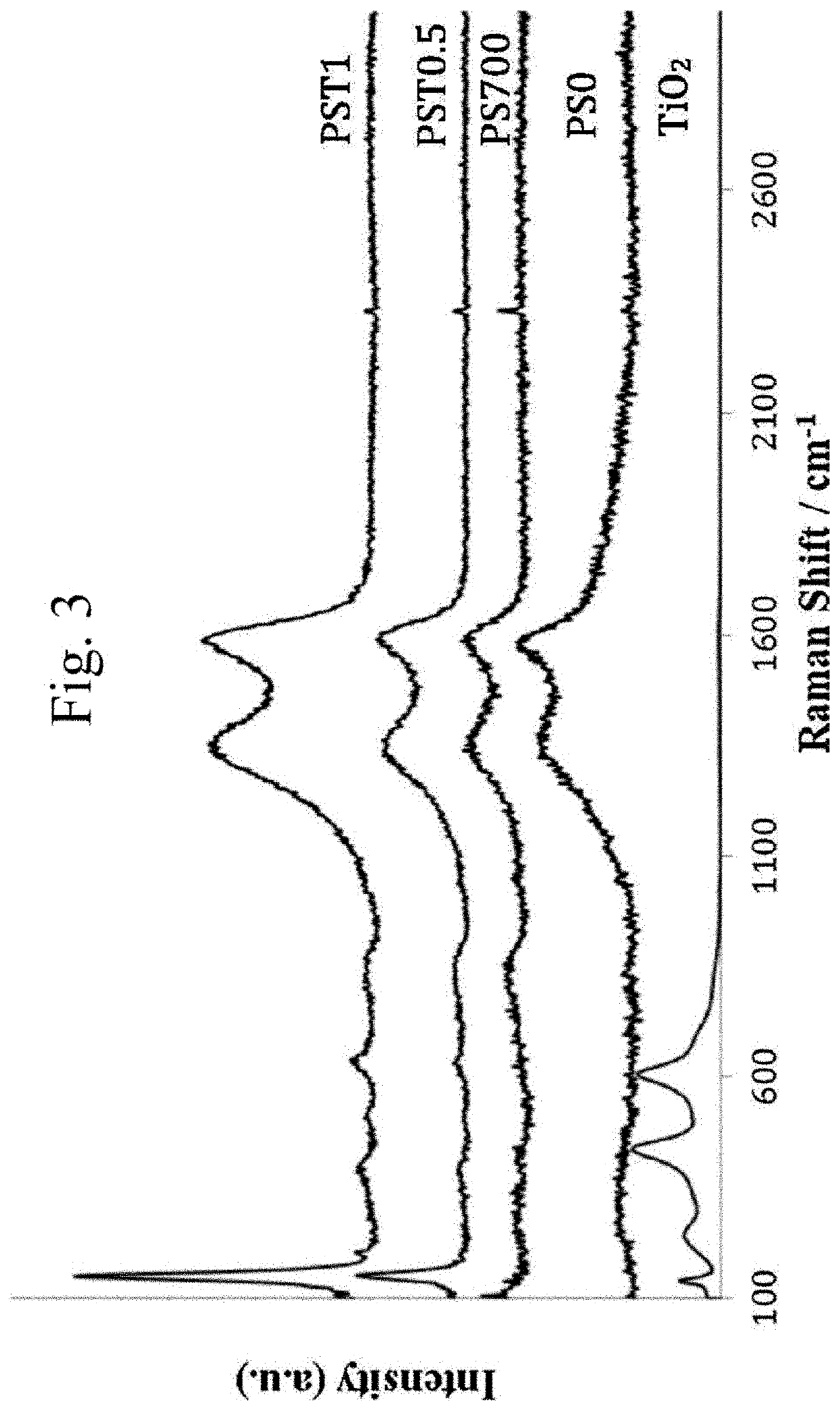

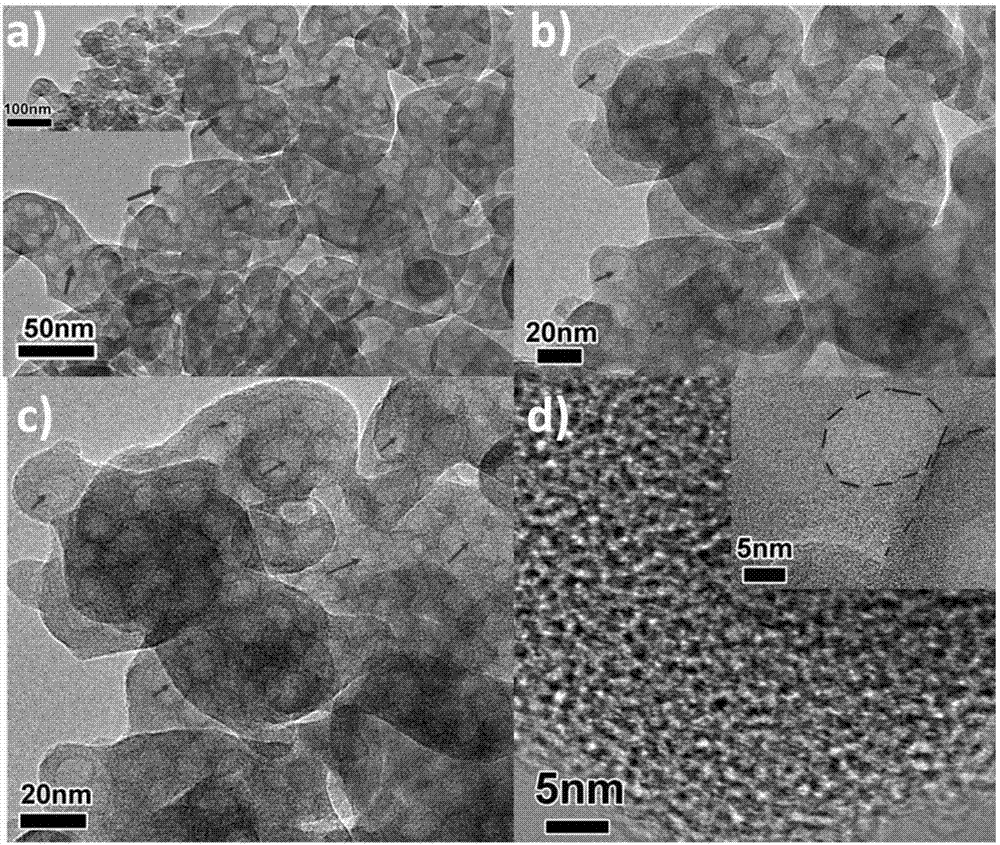

Titania-carbon dot-reduced graphene oxide composites, their make, and use

ActiveUS20200346187A1Extraordinary electrical propertiesEasy to transportWater/sewage treatment by irradiationWater treatment compoundsCatalytic pyrolysisPtru catalyst

Catalytic pyrolysis can upcycle waste, e.g., car bumpers, to carbon nanomaterials, preferably using synthetic TiO2 nanoparticles as catalyst during pyrolysis. Analysis of the carbon nanomaterials shows that, while RGO is produced from thermal pyrolysis of car bumper waste absent TiO2, RGO spotted with carbon dots is produced in presence of TiO2 catalyst. Rutile to anatase TiO2 phase transformation and carbon nanomaterial formation can simultaneously occur during the pyrolysis. Anatase to rutile transformation may occur while TiO2 absent the bumper material. Such TiO2-CD-RGO can be used, for example in photocatalytic degradation of organic compounds, such as methylene blue.

Owner:IMAM ABDULRAHRNAN BIN FAISAL UNIVERSITY

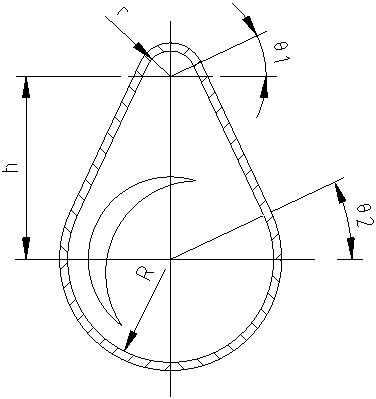

System and method for maintaining efficiency of a heat sink

ActiveUS20180017345A1Reduces narrow band acoustic resonanceEfficient heat transferHeat exhanger finsIndirect heat exchangersEngineeringHeat transfer fluid

A heatsink comprising a heat exchange device having a plurality of heat exchange elements each having a surface boundary with respect to a heat transfer fluid, having successive elements or regions having varying size scales. According to one embodiment, an accumulation of dust or particles on a surface of the heatsink is reduced by a removal mechanism. The mechanism can be thermal pyrolysis, vibration, blowing, etc. In the case of vibration, adverse effects on the system to be cooled may be minimized by an active or passive vibration suppression system.

Owner:FRACTAL HEATSINK TECH

Conditioning system and method for use in the measurement of mercury in gaseous emissions

ActiveUS20060042418A1Avoid reorganizationReduced form requirementsGas treatmentDispersed particle separationBoron nitrideSilicon oxide

Embodiments of the invention relate generally to systems used to measure mercury in gaseous emissions. In one aspect, the invention is directed to the use of an inert covalently bonded material selected from silicon carbide (SiC), silicon oxides (SiOn, n=1-2), silicon nitride (e.g. Si3N4), silicon boride (e.g. SiB6), boron nitride (e.g. BN) and mixtures thereof as material for a thermal pyrolysis unit. In another aspect, the invention is directed to an improved pyrolyzer design, in which a thermal pyrolysis unit comprises a tailpiece that allows water to be injected at the heated exit of the thermal pyrolysis unit. In another aspect, the invention is directed to the use of a coalescing filter in a scrubbing unit. In another aspect, the invention is directed to the use of a hydrophobic filter element in a scrubbing unit. One or more of these elements may be used in a conditioning module of a continuous emissions monitoring system, for example.

Owner:TEKRAN INSTR CORPORTION

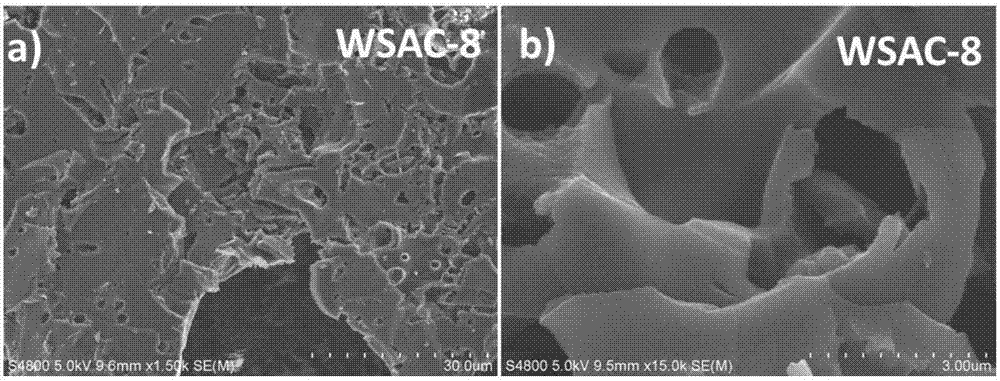

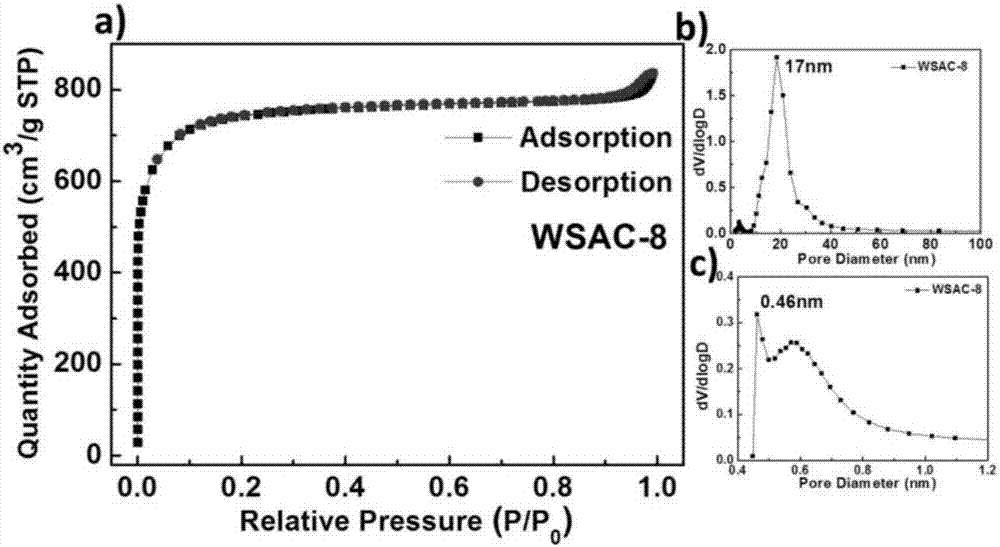

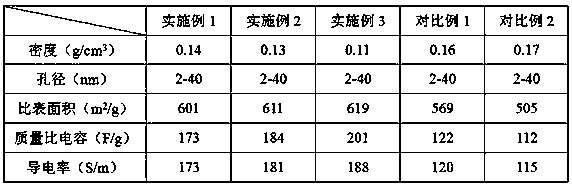

Biological porous carbon-based cathode material of lithium-sulphur battery and preparation method thereof

ActiveCN107151014AImprove electrochemical performanceHigh microporous contentCarbon compoundsAlkali metal sulfides/polysulfidesSulfurPorous carbon

The invention discloses a biological porous carbon-based cathode material of a lithium-sulphur battery. By taking a walnut shell as a biological carbon source, the walnut shell is subjected to thermal pyrolysis at a high temperature to obtain a bio-coke; and then activation reaction on the bio-coke is carried out by adopting KOH, so that microporous channels are effectively enriched and the mesopore size is adjusted. The obtained microporous bio-carbon material has extremely high specific surface and has a developed pore structure; after the material is supported with sulphur, excellent electrochemical performance and stability can be shown; moreover, the sources of the related raw materials are wide, the preparation process is simple, and the material is suitable for being popularized and applied.

Owner:WUHAN UNIV OF TECH

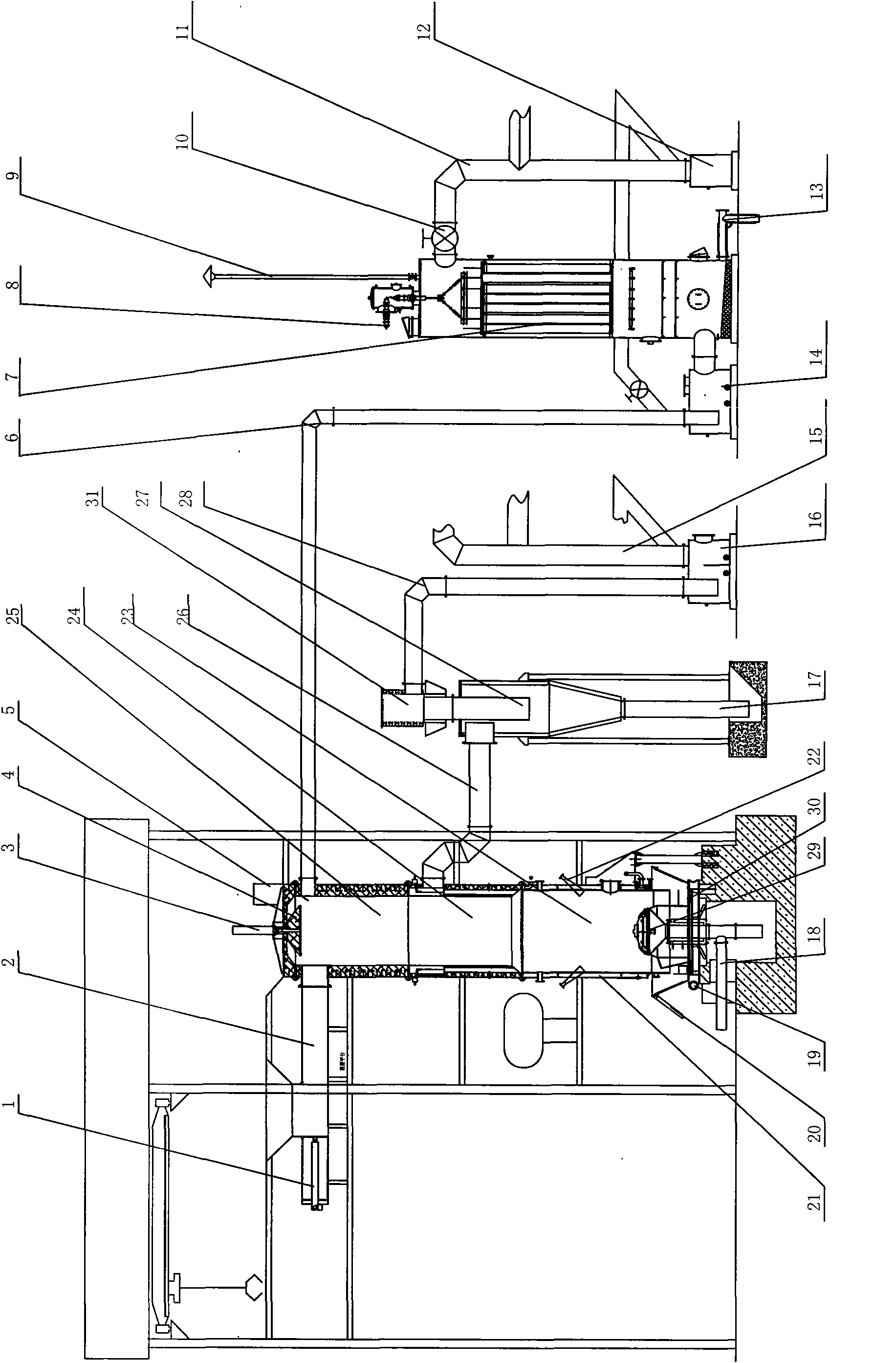

House refuse thermal pyrolysis device

InactiveCN102147114AWill not polluteNo humidityIncinerator apparatusHydraulic cylinderRefuse Disposals

The invention discloses a house refuse thermal pyrolysis device belonging to a refuse disposal device and comprises a feeding device, a refuse thermal pyrolysis device, a waste gas recovery device and an ash disposal device, wherein the feeding device comprises a feeding bin and a pushing cylinder arranged in the feeding bin, wherein the feeding bin is connected with a drying section of a digestion furnace; the refuse thermal pyrolysis device comprises the digestion furnace, the digestion furnace is divided into a drying section, a distilling section and a thermal pyrolysis section from top to bottom, the upper end of the drying section is provided with a compacting hydraulic cylinder and a hydraulic station, the lower end of the compacting hydraulic cylinder is connected with a compacting block, the drying section is connected with an upper gas outlet pipe and the distilling section is connected with a lower gas outlet pipe I; and the bottom of the thermal pyrolysis section is provided with the ash disposal device, the ash disposal device comprises a ventilation furnace wind grate, an ash tray and an ash removing hopper, the ash tray is connected with an ash tray transmission device, and the ventilation furnace wind grate is connected with a ventilating pipe. The invention has the advantages of low construction cost, no environment pollution and more thorough refuse disposal.

Owner:屈玉林

Method for extracting triterpenes from schisandra chinansis

ActiveCN101708215ANo pollution in the processAvoid pyrolysisAntiviralsImmunological disordersPollutionHigh heat

The invention relates to a method for extracting triterpenes from schisandra chinensis. The method comprises the steps of taking stems of the schisandra chinensis as main raw materials, firstly carrying out tissue breaking and cellulase and ultrasonic extraction for separating substances to be extracted from the raw materials, and then separating and extracting the triterpenes from the schisandra chinensis by utilizing the supercritical fluid extraction technology, selecting different composite entrainers and operation technological parameters and combining the high-speed countercurrent chromatography technology, thereby providing the effective method for separating and purifying the triterpenes from the schisandra chinensis. The method for extracting the triterpenes from the schisandra chinensis has the advantages of high extraction rate, simple operation process, low energy consumption, no pollution and high recovery rate, and can avoid the thermal pyrolysis of extracts at high temperature, protect the activity of physiological active substances and the like.

Owner:SANMARK CORP

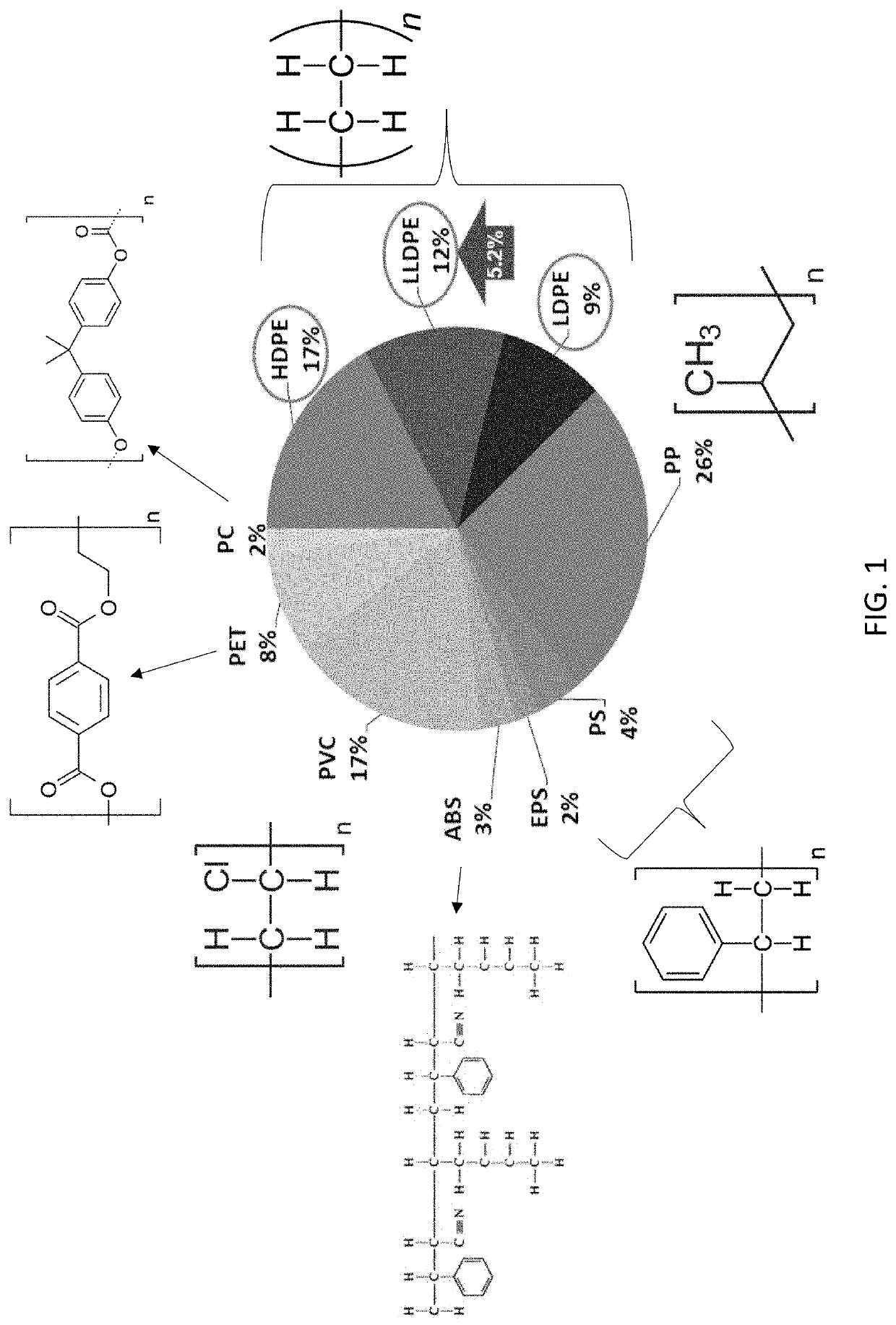

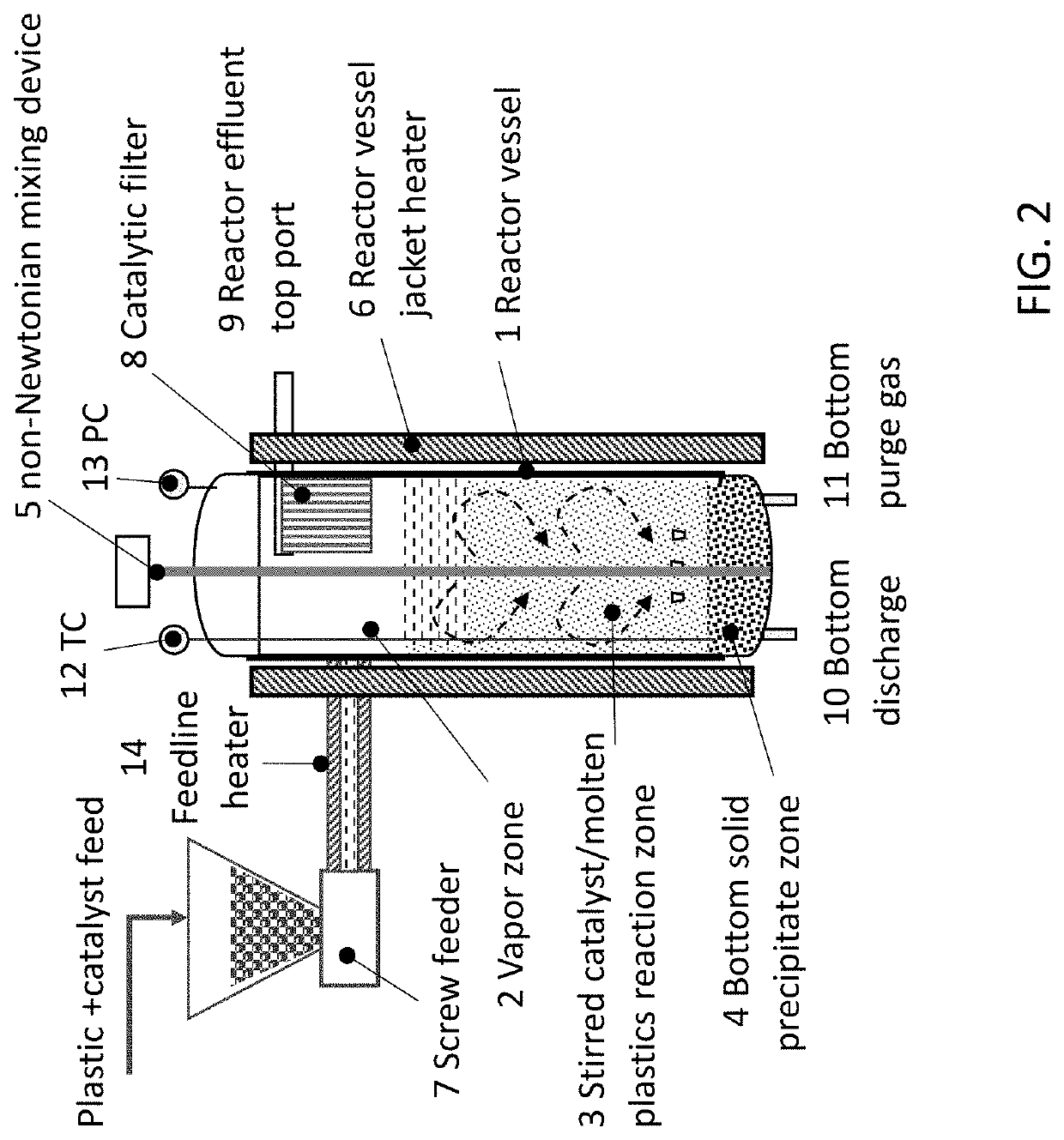

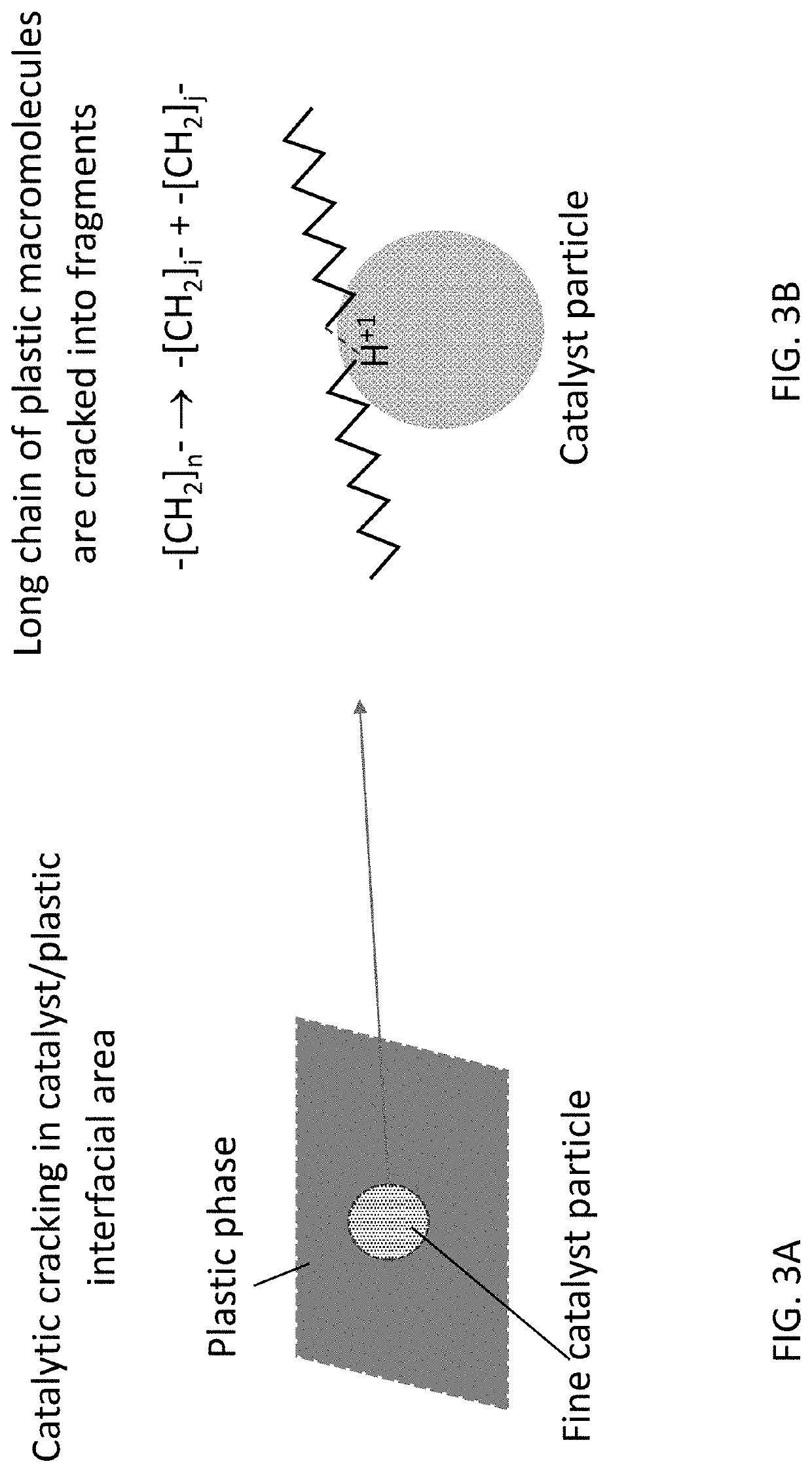

Catalytic Reactor Apparatus for Conversion of Plastics

ActiveUS20210071088A1Efficient heat transferMolecular sieve catalystsLiquid hydrocarbon mixture productionPtru catalystPlastic waste

Owner:MOLECULE WORKS INC

Method for producing tetrafluoroethylene by monochlorodifluoromethane thermal pyrolysis process

InactiveCN102516024AContinuous and stable productionSolve the disadvantages of unstable productionHalogenated hydrocarbon preparationTetrafluoroethyleneTube furnace

The invention discloses a method for producing tetrafluoroethylene by monochlorodifluoromethane thermal pyrolysis process, comprising the following steps of: quantifying HCFC-22 to be 1000-1200 kg / h and feeding in a high-nickel-alloy cracking reactor with a tubular furnace structure and capable of heating by using liquefied gas to crack; controlling the temperature of the cracking reactor to be between 800 to 900 DEG C and controlling the pressure thereof to be lower than 0.15 Mpa; quenching the cracked product via a quencher and then feeding in a hydrogen chloride absorber; adding 950-1100 L / h of water and 950-1100 L / h of alkaline to wash, and then feeding in a gas cabinet; freeze-dehydrating, drying and compressing, and then collecting a crude product in a crude product groove; and rectifying by a plurality of towers, and performing post-treatment and separating to obtain a tetrafluoroethylene product. The method disclosed by the invention is reasonable in process and simple in production, as well as is the most simple and ideal method for preparing tetrafluoroethylene.

Owner:TIANJIN TAIHENG GASES

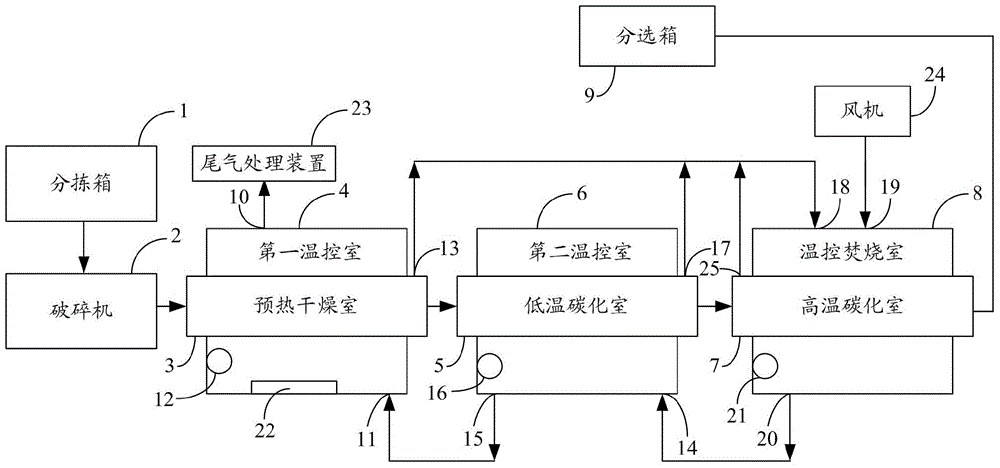

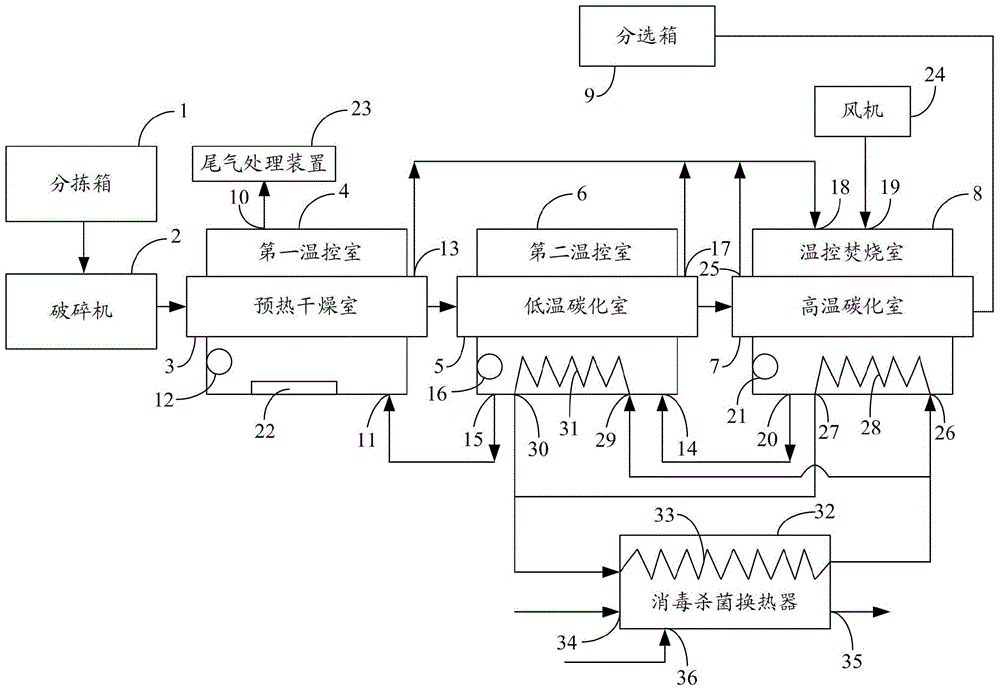

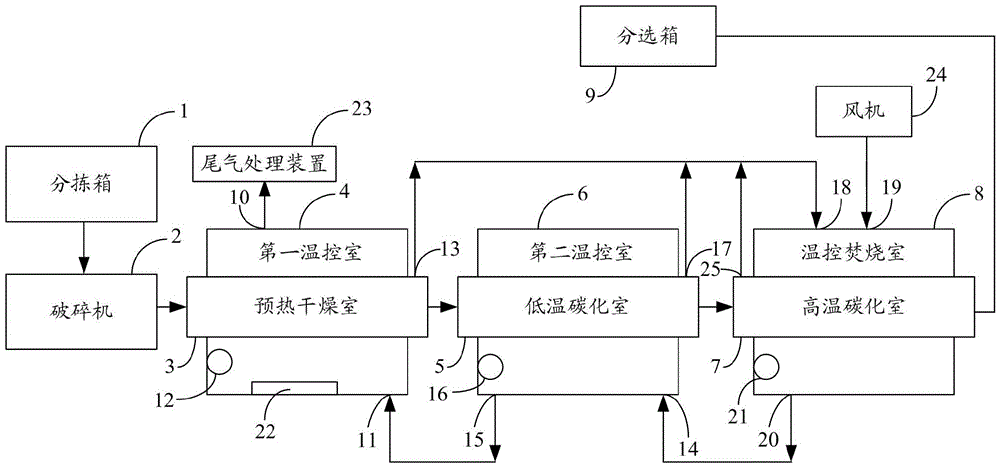

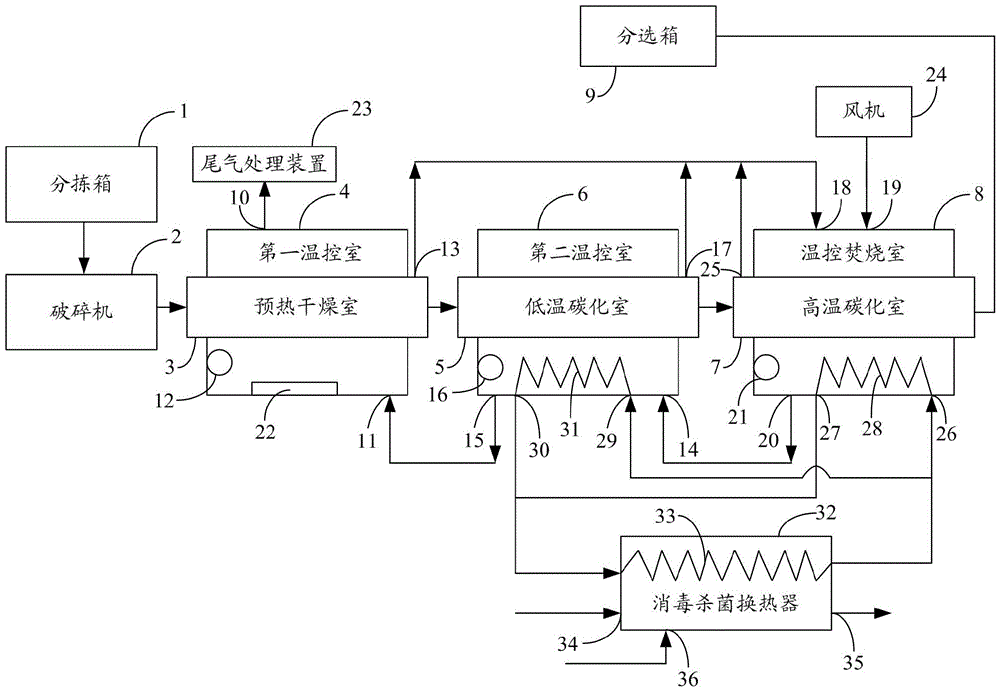

Medical waste disposal device and medical waste disposal method

InactiveCN104613482BRealize pyrolysis and gasificationReduce pollutionIncinerator apparatusTemperature controlMedical waste

Owner:SHANDONG HONGLI HEAT PUMP ENERGY

Medical waste treatment device and method

InactiveCN104613482ARealize pyrolysis and gasificationReduce pollutionIncinerator apparatusTemperature controlCarbonization

The invention relates to the technical field of medical waste treatment equipment and provides a medical waste treatment device and method. The medical waste treatment device comprises a sorting box used for performing preliminary sorting on medical waste. The sorting box is connected with a breaker which is connected with a preheating and drying chamber. The preheating and drying chamber is arranged in a first temperature control chamber and connected with a low-temperature carbonization chamber. The low-temperature carbonization chamber is arranged in a second temperature control chamber and connected with a high-temperature carbonization chamber. The high-temperature carbonization chamber is arranged in a temperature-control incineration chamber and connected with a separatory vessel. The preheating and drying chamber is used for performing preliminary preheating and drying on the medical waste. The low-temperature carbonization chamber is used for performing low-temperature carbonization on the medical waste, afterwards, the medical waste is subjected to high-temperature carbonization through the high-temperature carbonization chamber, and finally the cooled medical waste is separated through the separatory vessel. In this way, treatment on the medical waste is completed, thermal pyrolysis of the medical waste is achieved, the emissions of pollutants and pollution gas are reduced, the process of end gas purification is omitted, and environmental pollution is reduced.

Owner:SHANDONG HONGLI HEAT PUMP ENERGY

Device and method of solid waste thermal pyrolysis-plasma reforming

PendingCN109593535AEfficient removalNo secondary pollutionHydrogen separationHydrogen/synthetic gas productionPlasma technologyRefractory

The invention relates to a device and method of solid waste thermal pyrolysis-plasma reforming. The device comprises a pyrolyzing furnace and a plasma reforming device, wherein the gas outlet of the pyrolyzing furnace and the gas inlet of the plasma reforming device are connected through a gas guide pipe; a feed opening is formed in the top of the pyrolyzing furnace, and a gas outlet is formed inthe upper part of the side wall of the furnace body; a pyrolyzing furnace wall, a pyrolyzing furnace outer flame retarding material, a pyrolyzing furnace inner flame retarding material and a materialsteel cylinder are arranged on the side wall of the pyrolyzing furnace from outside to inside; the gas inlet of the plasma reforming device is positioned at the center of one side wall of the device,and the gas outlet is positioned at the center of the side wall opposite to the gas inlet; 1-4 plasma torches are distributed on plasma torque assembly points which are selected on other wall faces except the wall faces with the gas inlet and gas outlet; and by adopting the plasma technology, multiple compound pollutants in smoke can be can be efficiently removed, including gaseous pollutants, solid and liquid particles, and the reforming technology cannot generate secondary pollution. The device has small equipment size and simple operation.

Owner:TIANJIN UNIV

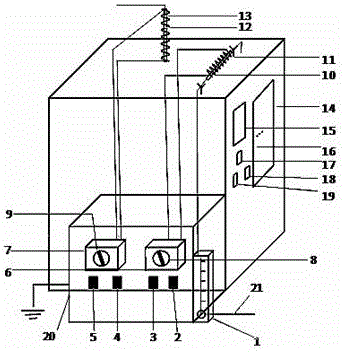

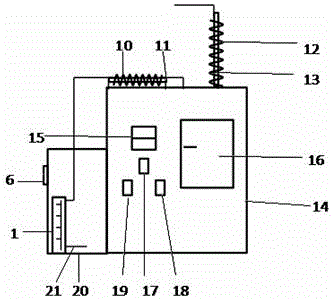

Thermal desorption-gas phase separation-thermal pyrolysis system based on phenylated derived organic mercury

ActiveCN106644664AEfficient determinationLow pricePreparing sample for investigationTemperature controlTenax

The invention discloses a thermal desorption-gas phase separation-thermal pyrolysis system based on phenylated derived organic mercury. The thermal desorption-gas phase separation-thermal pyrolysis system comprises a column box and a pressure-regulation and temperature-control switch box, wherein the pressure-regulation and temperature-control switch box is arranged at one end of the column box; the column box and the pressure-regulation and temperature-control switch box are provided with a thermal desorption assembly, a gas phase separation assembly, a thermal pyrolysis assembly and an assisting assembly; the thermal desorption assembly comprises a thermal desorption heating wire switch, a thermal desorption heating wire time control switch, a thermal desorption heating wire pressure regulator, a thermal analysis heating wire pressure regulator pressure-regulation knob, a thermal desorption heating wire and a Tenax adsorption pipe; the Tenax adsorption pipe is transversely mounted at the top of the column box; the thermal desorption heating wire is mounted at the outer part of the Tenax adsorption pipe. According to the thermal desorption-gas phase separation-thermal pyrolysis system disclosed by the invention, thermal desorption, gas phase separation and thermal pyrolysis parts are integrated, and methyl mercury and ethyl mercury in a sample can be effectively determined; compared with a traditional gas chromatograph, a programed temperature rising device has a smaller size, so that an experiment space is saved; meanwhile, programed temperature control can be realized, and temperature can be increased section by section.

Owner:OCEAN UNIV OF CHINA

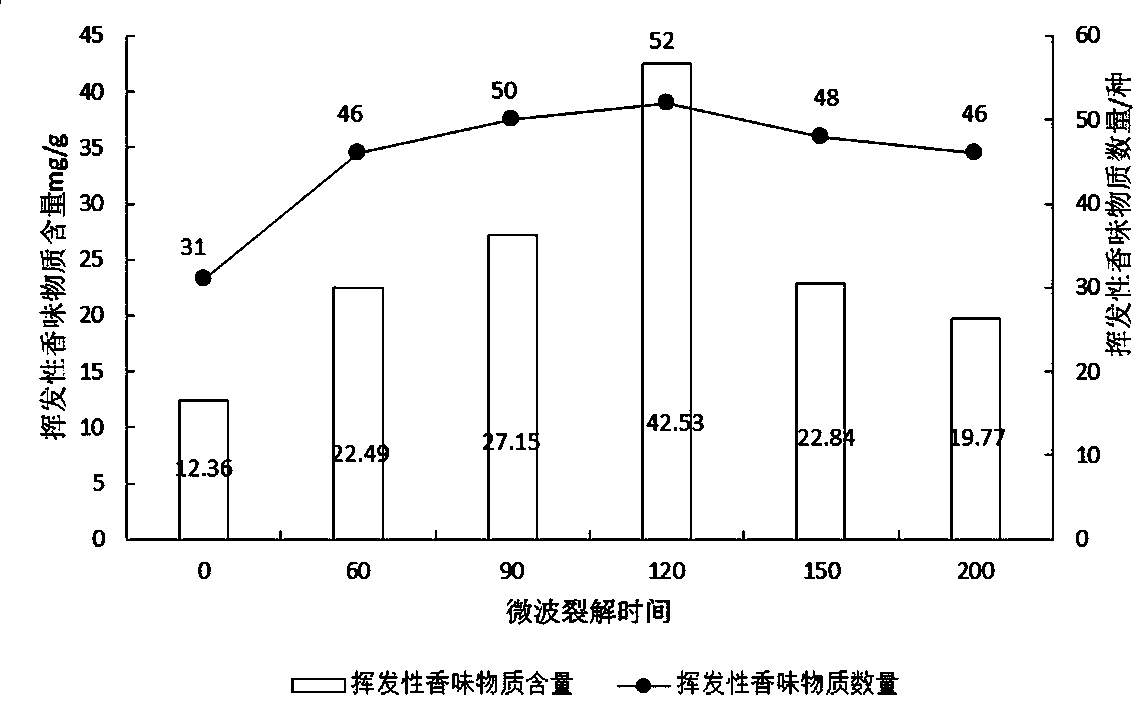

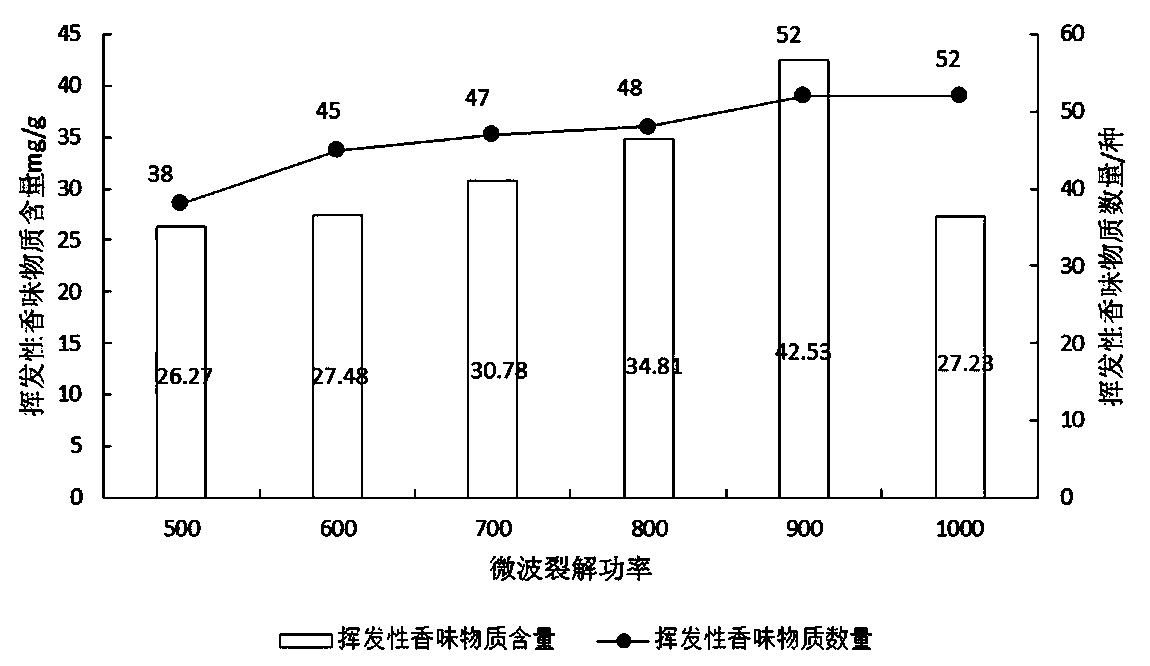

Electronic cigarette tar prepared from tobacco leaf concrete Maillard reaction products

The invention belongs to the technical field of novel tobacco products and particularly relates to electronic cigarette tar prepared from tobacco leaf concrete Maillard reaction products. According to the main technical ideas, tobacco leaves are subjected to concrete extraction firstly, then amino acid is added for Maillard reaction, finally, the Maillard reaction products are subjected to thermal pyrolysis, extraction is conducted to obtain the tobacco leaf concrete Maillard reaction pyrolysis products with different scent types and different fragrance characteristics, and thus the foundation is laid for improving the suction quality of an electronic cigarette. According to the electronic cigarette tar prepared from the tobacco leaf concrete Maillard reaction products, the fragrance quality of smoke of the electronic cigarette can be obviously improved, the baking fragrance and the smoke smoothness of the electronic cigarette are improved, dry sensation is reduced, thus the electronic cigarette has natural characteristic fragrance of flue-cured tobacco, thus the electronic cigarette is closer to a conventional cigarette in the prior art, and thus the electronic cigarette tar has good practical value.

Owner:CHINA TOBACCO HENAN IND

Strong turbulence combusting system for reducing CO and NOx

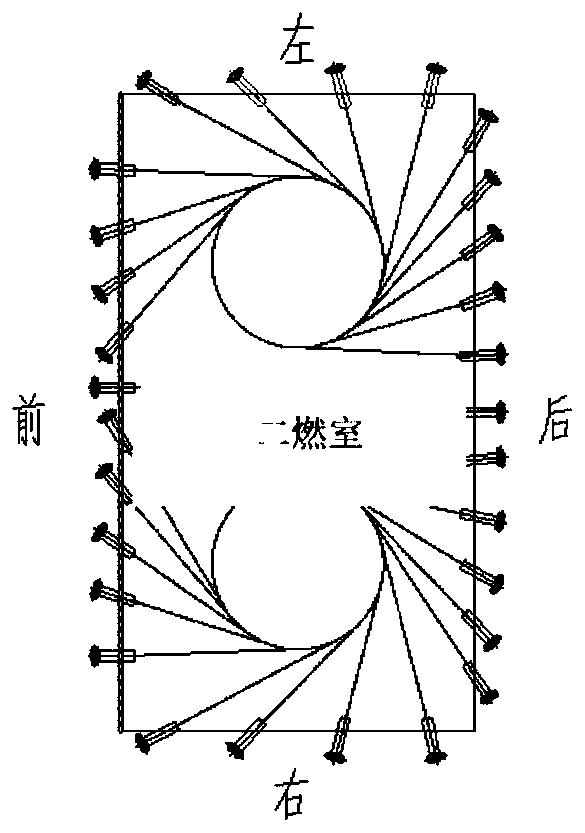

PendingCN110925774ASuppress generationReduce outlet oxygen contentIncinerator apparatusCombustion systemCombustion chamber

Owner:SHANGHAI SUS ENVIRONMENT

Conditioning system and method for use in the measurement of mercury in gaseous emissions

ActiveUS20090000484A1Avoid reorganizationReduced form requirementsCombination devicesGas treatmentProduct gasBoron nitride

Embodiments of the invention relate generally to systems used to measure mercury in gaseous emissions. In one aspect, the invention is directed to the use of silicon carbide as material for a thermal pyrolysis unit. In another aspect, at least one of silicon nitride, silicon boride, and / or boron nitride is used as material for a thermal pyrolysis unit. In another aspect, the invention is directed to an improved pyrolyzer design, in which a thermal pyrolysis unit comprises a tailpiece that allows water to be injected at the heated exit of the thermal pyrolysis unit. In another aspect, the invention is directed to the use of a coalescing filter in a scrubbing unit. In another aspect, the invention is directed to the use of a hydrophobic filter element in a scrubbing unit. One or more of these elements may be used in a conditioning module of a continuous emissions monitoring system, for example.

Owner:TEKRAN INSTR CORPORTION

Small-sized refuse disposal device

PendingCN109812815AImprove combustion effectSolve puzzles that cannot be fully exploitedIncinerator apparatusAir preheaterActivated carbon

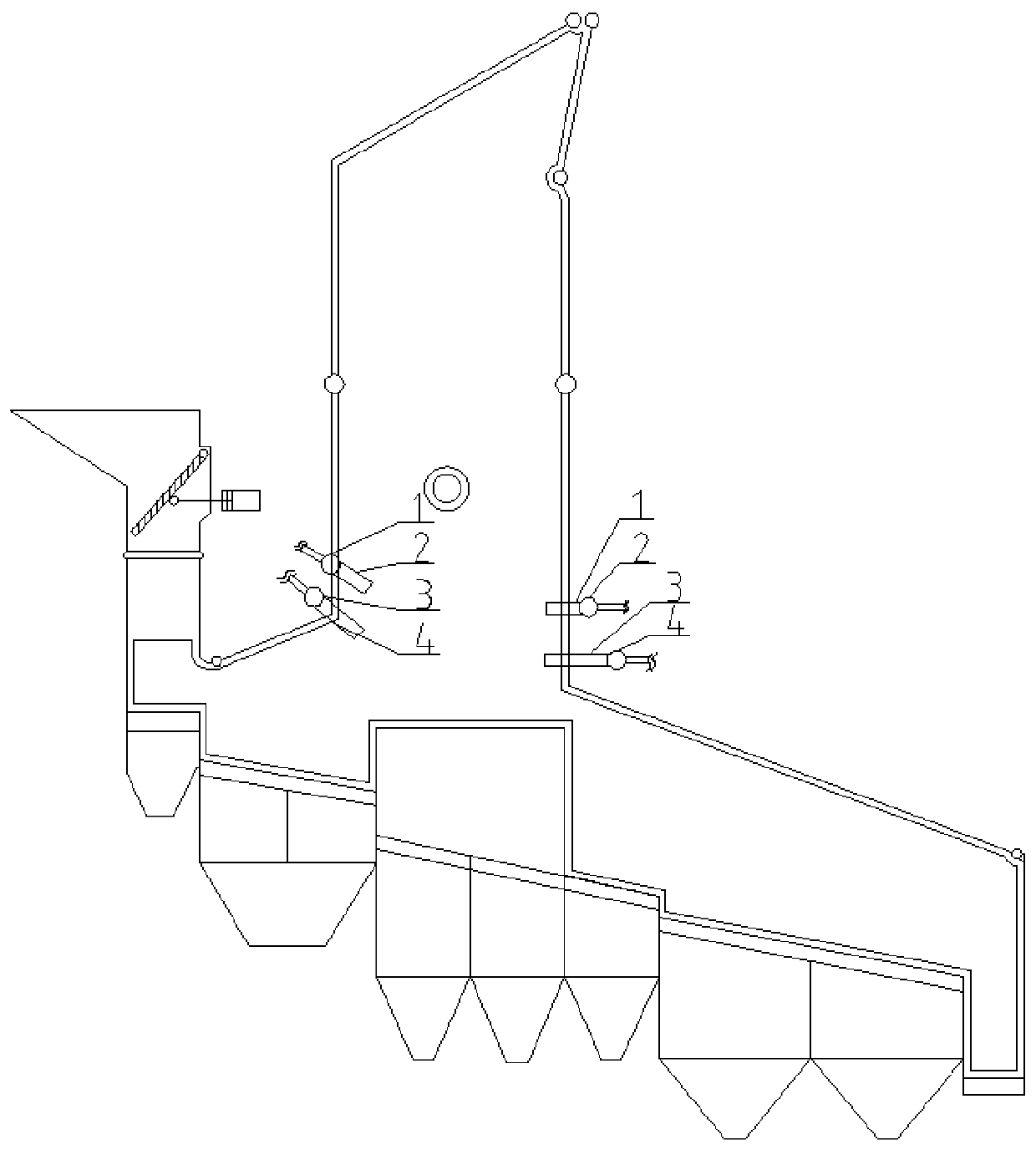

A small-sized refuse disposal device comprises a refuse thermal pyrolysis gasifier, a secondary combustion chamber, an air preheater, a semi-dry desulfurization system, an activated carbon spray system, a bag-type dust collector and a drying box. Air enters the air preheater from an inlet of the air preheater, and after being heated, the air enters the secondary combustion chamber from an air outlet of the air preheater through a pipeline. A part of high-temperature smoke of the secondary combustion chamber enters the refuse thermal pyrolysis gasifier through a pipeline from a high-temperaturesmoke outlet and enters the drying box through a high-temperature smoke inlet of the drying box to dry refuse. The other part of high-temperature smoke of the secondary combustion chamber enters theair preheater from the high-temperature smoke outlet through a pipeline to heat the air, and then the high-temperature smoke is sequentially processed by the semi-dry desulfurization system, the activated carbon spray system, the bag-type dust collector and the like and then discharged. Since no air is fed into the refuse thermal pyrolysis gasifier and generated combustible gas does not contain N2, the combustion effect of the secondary combustion chamber is optimized. Meanwhile, the refuse thermal pyrolysis gasifier, the drying box and the air preheater utilize heat of the smoke together, andtherefore the heat of the smoke is fully utilized.

Owner:SHENZHEN ENERGY ENVIRONMENT ENG

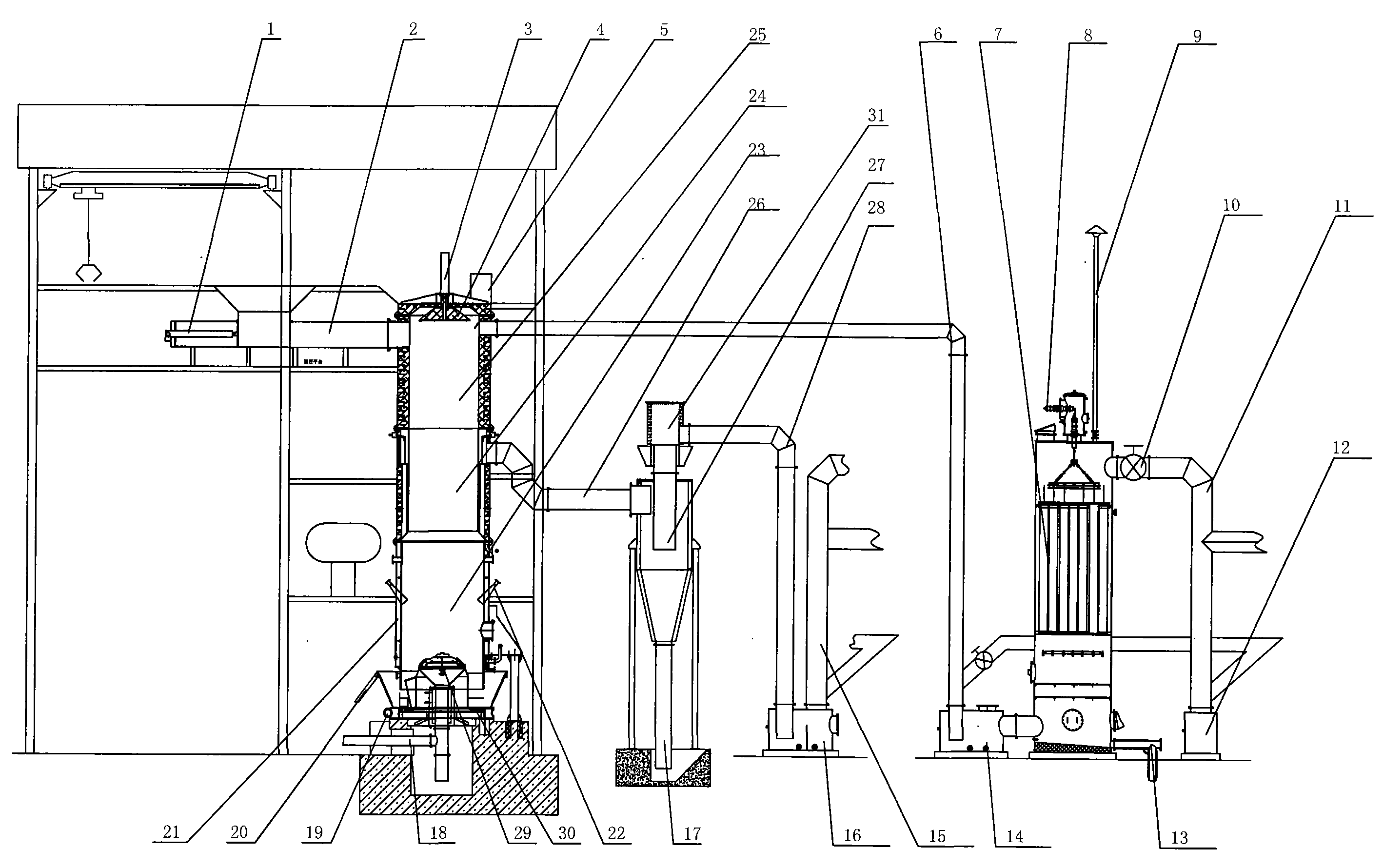

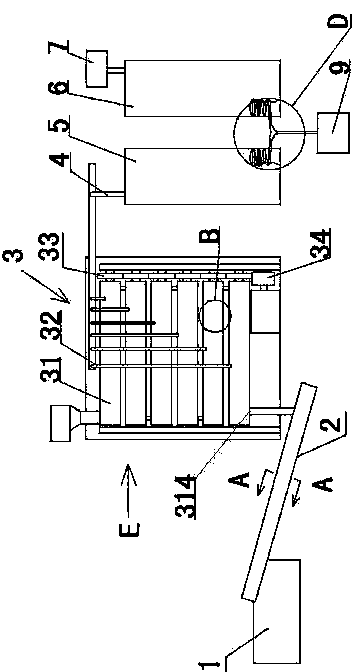

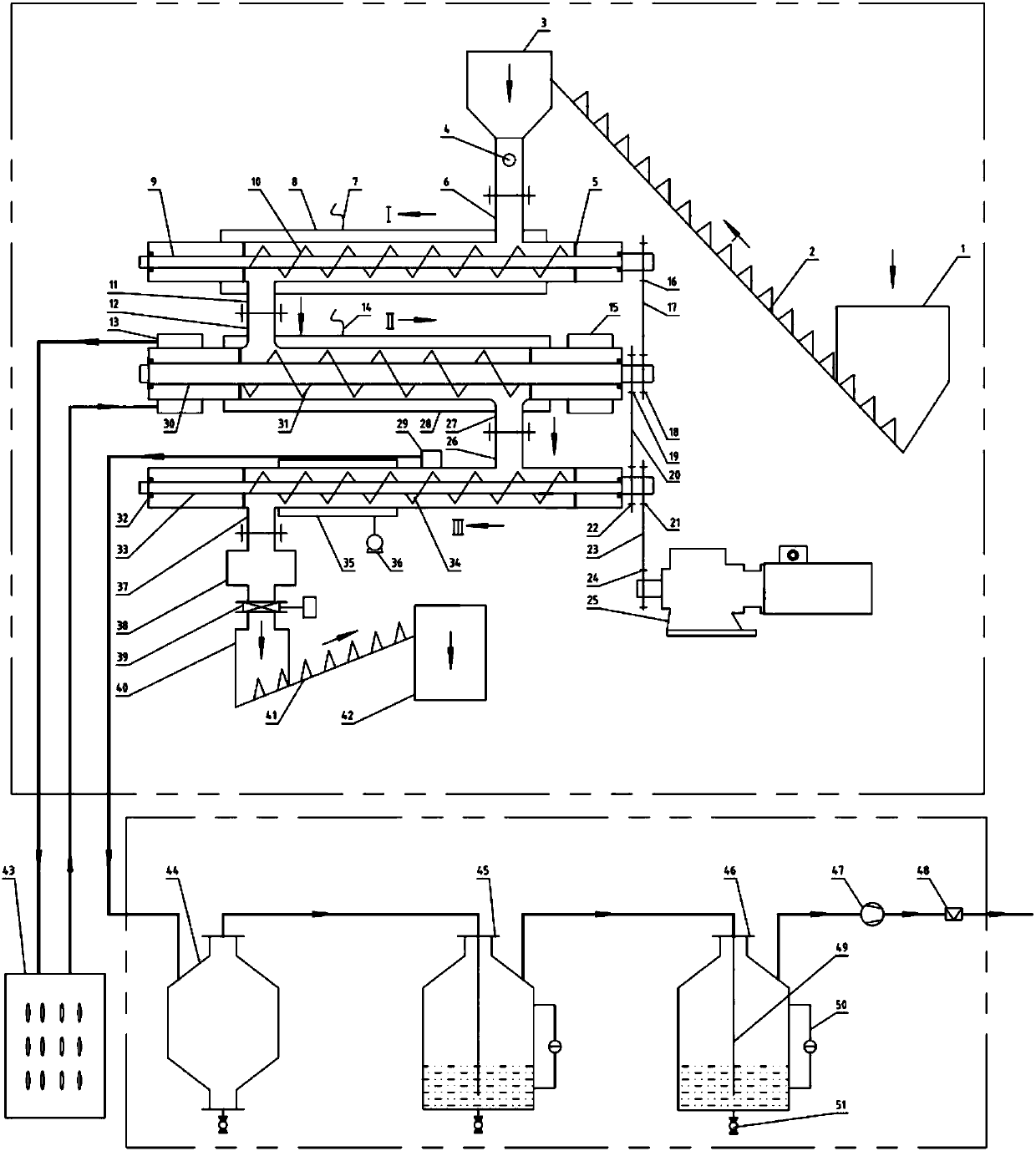

Method for extracting bio-oil through normal-pressure continuous thermal pyrolysis of straws and equipment used in same

InactiveCN103952170AEliminate potential safety hazardsReduce consumption costBiofuelsLiquid hydrocarbon mixture productionSlagEngineering

The invention provides a method for extracting bio-oil through normal-pressure continuous thermal pyrolysis of straws and equipment used in the same, solving the problem that carrier gases need to be used as fluidizing media to extract bio-oil from the straws at present, so that the power consumption is increased and certain potential safety hazards also exist. The method is characterized by drying and grinding the straws; carrying out thermal pyrolysis, wherein thermal pyrolysis equipment is formed by a plurality of screw feeders which are connected end to end and are arranged from top to bottom in a reciprocating manner, electrical heated tubes are laid on the surface of a pipeline of each screw feeder, and a pyrolysis gas pipeline is arranged at the upper part of a tube cavity of each screw feeder; condensing the generated pyrolysis gas, discharging oil and simultaneously discharging slag. The method and the equipment have the positive effects that the whole process is pressure-free, thus eliminating the potential safety hazards caused by pressure and simultaneously reducing the power consumption and operating cost caused by pressure; the whole process is energy-saving and environment-friendly.

Owner:LIAOYANG DINGLI TRADING +1

System and method for maintaining efficiency of a heat sink

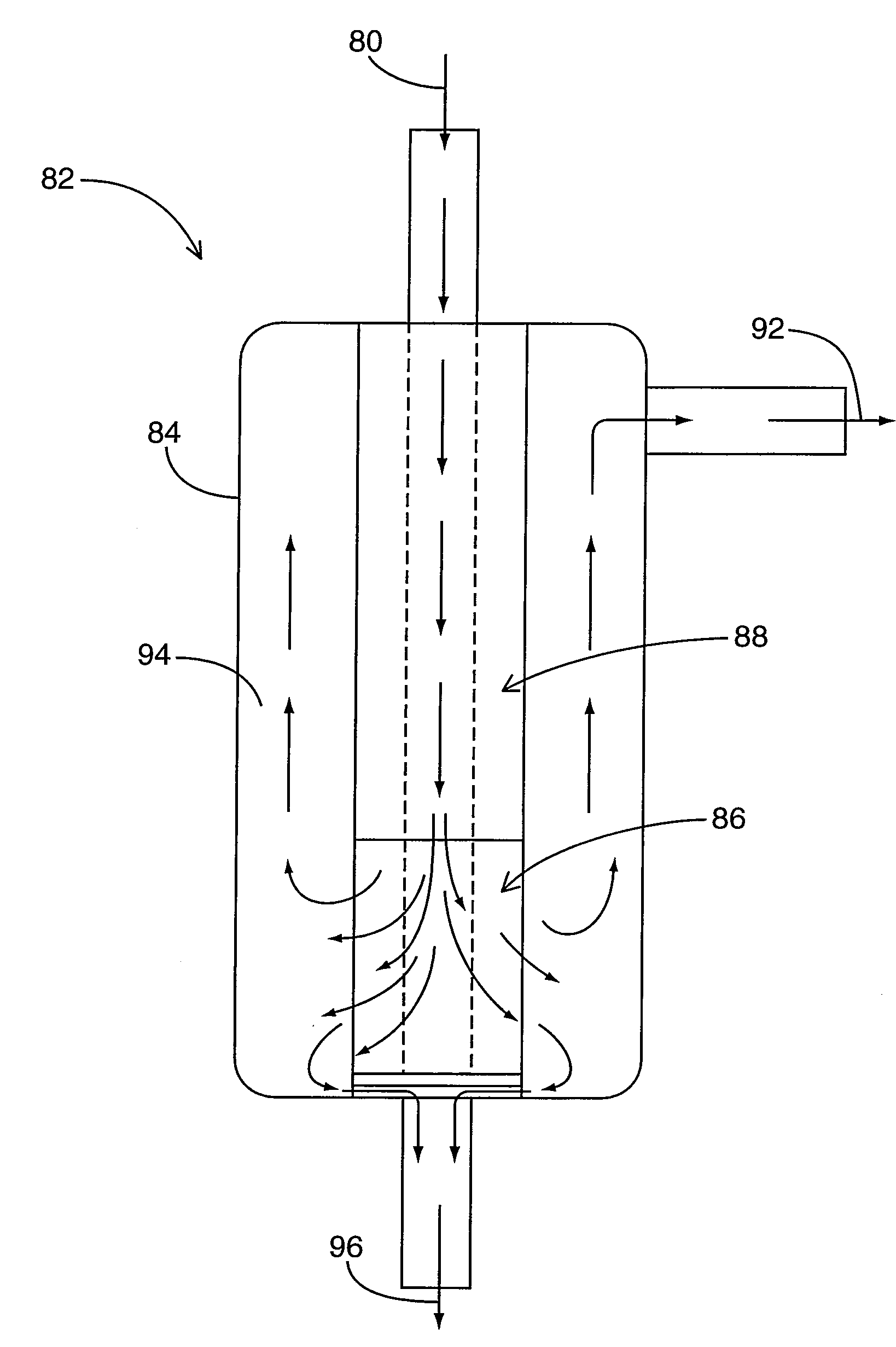

ActiveUS20210095932A1Large specific surface areaSmall surface areaIndirect heat exchangersHeat exhanger finsHeat transfer fluidHeat spreader

A heatsink comprising a heat exchange device having a plurality of heat exchange elements each having a surface boundary with respect to a heat transfer fluid, having successive elements or regions having varying size scales. According to one embodiment, an accumulation of dust or particles on a surface of the heatsink is reduced by a removal mechanism. The mechanism can be thermal pyrolysis, vibration, blowing, etc. In the case of vibration, adverse effects on the system to be cooled may be minimized by an active or passive vibration suppression system.

Owner:FRACTAL HEATSINK TECH

Spiral push type biomass continuous thermal pyrolysis multi-stage reaction device and method

InactiveCN107903925AShorten the lengthHigh yieldSpecial form destructive distillationGas purification by non-gaseous materials condensationBiomass carbonThree stage

The invention discloses a spiral push type biomass continuous thermal pyrolysis multi-stage reaction device and method. The device mainly comprises a biomass conveying unit, a biomass thermal pyrolysis multi-stage reactor unit, a biomass carbon conveying unit, and a thermal pyrolysis gas and bio-oil and pyroligneous liquor separation and collection unit, wherein a multi-stage reactor is of a three-stage structure, namely a biomass preheating unit, a biomass thermal pyrolysis unit and a biomass carbon conveying and thermal pyrolysis gas, pyroligneous liquor and bio-oil output unit. After preheating and thermal pyrolysis reactions, biomass carbon and a thermal pyrolysis gas are generated from biomass in the device, solid / gas separation (biomass carbon / fume) and oil / water separation (bio-oil / pyroligneous liquor) are achieved through the three-stage reactor, and finally biomass carbon, bio-oil, pyroligneous liquor and a clean combustion gas are finally produced, The device is simple in structural design, no nitrogen needs to be introduced, continuous production is achieved, coking can be reduced, and coke can be conveniently removed.

Owner:DALIAN MARITIME UNIVERSITY

Preparation method of n and s double-doped graphene-graphene nanoribbon aerogels

ActiveCN109003826BImprove conductivityAvoid gatheringHybrid capacitor electrodesGrapheneDoped grapheneFreeze-drying

The present invention relates to the technical field of electrode material preparation. Disclosed is a preparation method for an N / S-double doped graphene – graphene nanoribbon aerogel. The method comprises: first, mixing a graphene oxide nanoribbon with graphene oxide, adding deionized water, and performing uniform ultrasound to obtain the mixing solution; adding pyrrole and thiophene to the mixing solution, and performing one hydrothermal reaction to obtain a hydrogel; placing the obtained hydrogel into the KNO 3 solution, performing a second hydrothermal reaction, cooling to the room temperature, filtering, washing, and performing freeze drying; and performing thermal pyrolysis on the product obtained by freeze drying in an argon atmosphere to prepare the N / S-double doped graphene – graphene nanoribbon aerogel. According to the present invention, the graphene aerogel is doped with N / S. The N / S-double doping can further improve the reactivity and the conductivity of a carbon material. Compared with a single N- or S-doped material, more active sites are introduced to the N / S-double doped graphene aerogel to improve the electrochemical performance thereof, and the N / S-double doped graphene aerogel is expected to apply in the electrode material of a supercapacitor.

Owner:福建宸琦新材料科技有限公司

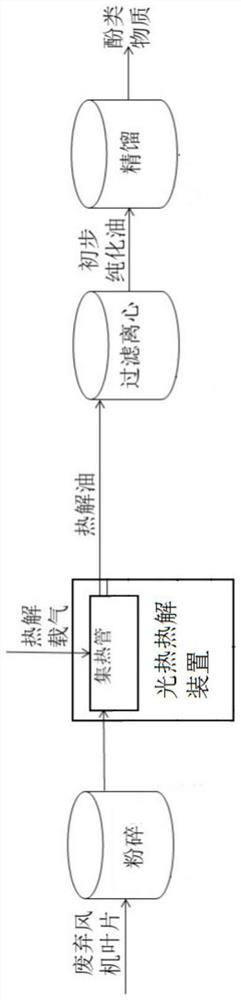

Method for preparing phenolic substances through photo-thermal pyrolysis of waste fan blades

InactiveCN113387776ARealize resource utilizationOrganic chemistryOrganic compound preparationWind drivenEngineering

The invention belongs to the field of waste fan blade treatment and resource utilization, and particularly relates to a method for preparing phenolic substances through photo-thermal pyrolysis of waste fan blades. The method for preparing the phenolic substances through photo-thermal pyrolysis of the waste fan blades comprises the steps of S1, smashing scrapped wind driven generator rotor blades to obtain smashed fan blades; S2, pyrolyzing the smashed fan blades in a photo-thermal pyrolysis device to obtain pyrolytic coke and pyrolytic oil; S3, removing part of impurities from the pyrolytic oil obtained in S2 through filtration and centrifugation to obtain preliminarily purified tar; and S4, rectifying the preliminarily purified tar to obtain three phenolic substances, namely, phenol, p-isopropyl phenol and 4-isopropenyl phenol. The method has the advantages that the waste fan blades are treated in a photo-thermal pyrolysis mode to prepare phenolic chemical raw materials, and resource utilization of the waste fan blades is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

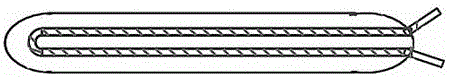

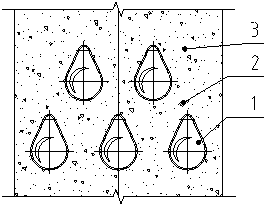

Radiant tube of quick pyrolyzing furnace without heat carriers

PendingCN107805517AReduce hindranceImprove Cloth EffectsIndirect heating destructive distillationSpecial form destructive distillationHeat carrierEngineering

The invention relates to a radiant tube of a fast pyrolysis furnace without a heat carrier, comprising a lower fan-shaped part, a connecting part and an upper fan-shaped part, wherein the radius R of the lower fan-shaped part is greater than the radius r of the upper fan-shaped part; A connecting portion is provided between the lower fan-shaped part and the upper fan-shaped part, so that the cross section of the radiant tube is drop-shaped; the central angle of the arc of the upper fan-shaped part is 180°‑2θ1, 10°≤θ1≤70 °; the central angle of the arc of the lower sector is 180°+θ2, 10°≤θ2≤70°. The reduced upper section of the radiant tube reduces the resistance of the radiant tube to the falling material, which can better increase the cloth effect and make the cloth more uniform.

Owner:SHENWU TECH GRP CO LTD

System and method for maintaining efficiency of a fractal heat sink

ActiveUS20210080189A1Large specific surface areaSmall surface areaHeat exhanger finsIndirect heat exchangersHeat transfer fluidHeat spreader

Owner:FRACTAL HEATSINK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com