Patents

Literature

83 results about "Silicon boride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon borides (also known as boron silicides) are lightweight ceramic compounds formed between silicon and boron. Several stoichiometric silicon boride compounds, SiBₙ, have been reported: silicon triboride, SiB₃, silicon tetraboride, SiB₄, silicon hexaboride, SiB₆, as well as SiBₙ (n = 14, 15, 40, etc.). The n = 3 and n = 6 phases were reported as being co-produced together as a mixture for the first time by Henri Moissan and Alfred Stock in 1900 by briefly heating silicon and boron in a clay vessel. The tetraboride was first reported as being synthesized directly from the elements in 1960 by three independent groups: Carl Cline and Donald Sands; Ervin Colton; and Cyrill Brosset and Bengt Magnusson. It has been proposed that the triboride is a silicon-rich version of the tetraboride. Hence, the stoichiometry of either compound could be expressed as SiB4 - x where x = 0 or 1. All the silicon borides are black, crystalline materials of similar density: 2.52 and 2.47 g cm⁻³, respectively, for the n = 3(4) and 6 compounds. On the Mohs scale of mineral hardness, SiB4 - x and SiB₆ are intermediate between diamond (10) and ruby (9). The silicon borides may be grown from boron-saturated silicon in either the solid or liquid state.

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium, diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

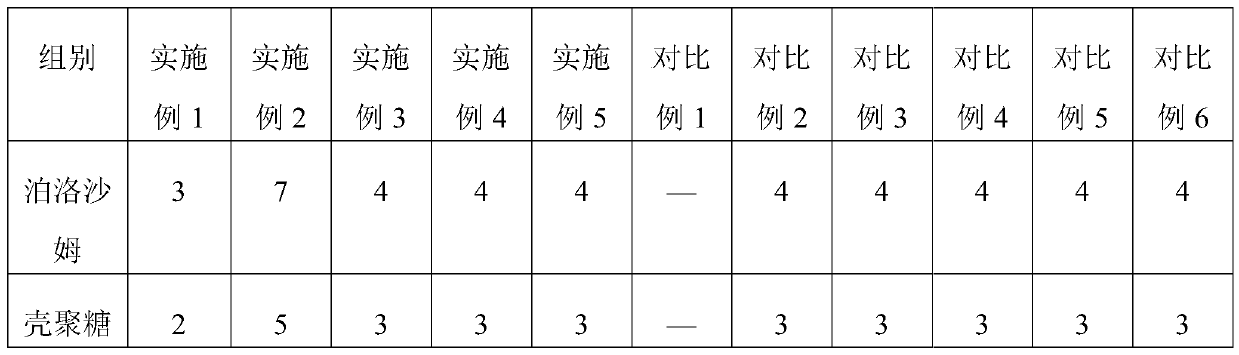

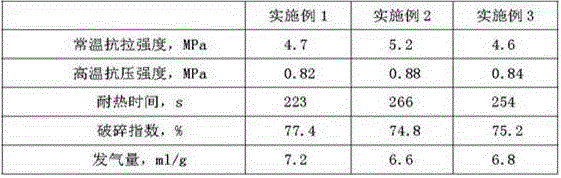

High-strength foundry casting sand and preparation method thereof

InactiveCN104801655AHigh strengthHigh tensile strengthFoundry mouldsFoundry coresFoundrySodium Bentonite

The invention discloses high-intensity foundry casting sand and a preparation method thereof. The high-intensity foundry casting sand comprises the following raw materials in parts by weight: 45 to 65 parts of quartz sand, 20 to 30 parts of desert sand, 15 to 20 parts of illite, 12 to 18 parts of calcium carbonate powder, 5 to 10 parts of silicon boride, 2 to 3 parts of 3-isocyanatopropyltriethoxysilane, 8 to 12 parts of modified bentonite, 5 to 10 parts of emery powder, 4 to 8 parts of shale ash, 5 to 10 parts of malthacite, 3 to 5 parts of sodium alginate, 6 to 9 parts of light calcined powder, 3 to 7 parts of carbon nanofiber, 4 to 6 parts of polyethylene imine, 2 to 3 parts of polyvinyl butyral, and a proper amount of water. Compared with the traditional casting sand, the casting sand provided by the invention is relatively high in wet compression strength and tensile strength, further is excellent in heat resistance, plasticity and air permeability, is easy for pattern drawing and modeling, has the effect of bearing various external forces and high temperature, can improve casting quality obviously, and avoids defect of air holes produced by castings.

Owner:江守仲

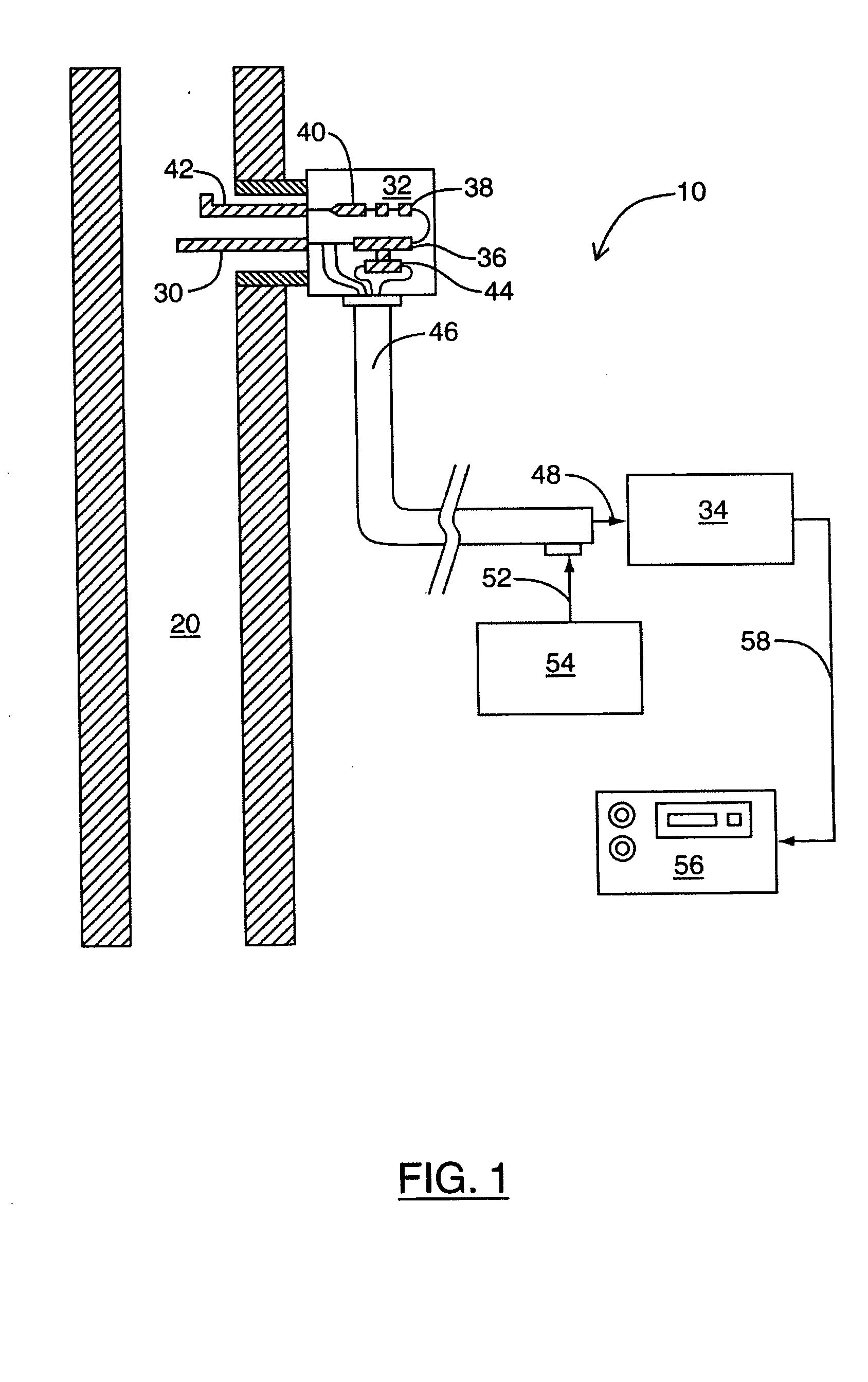

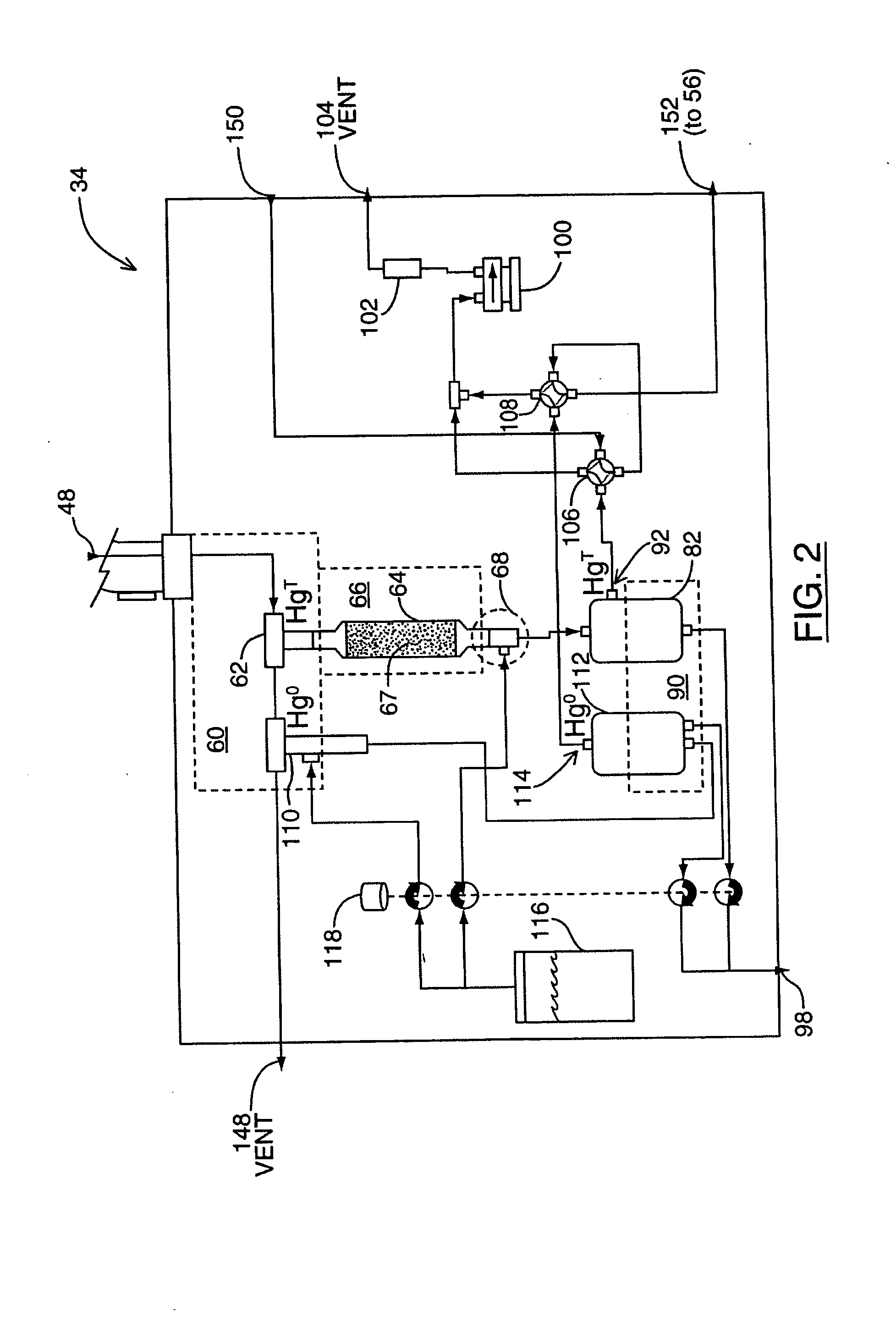

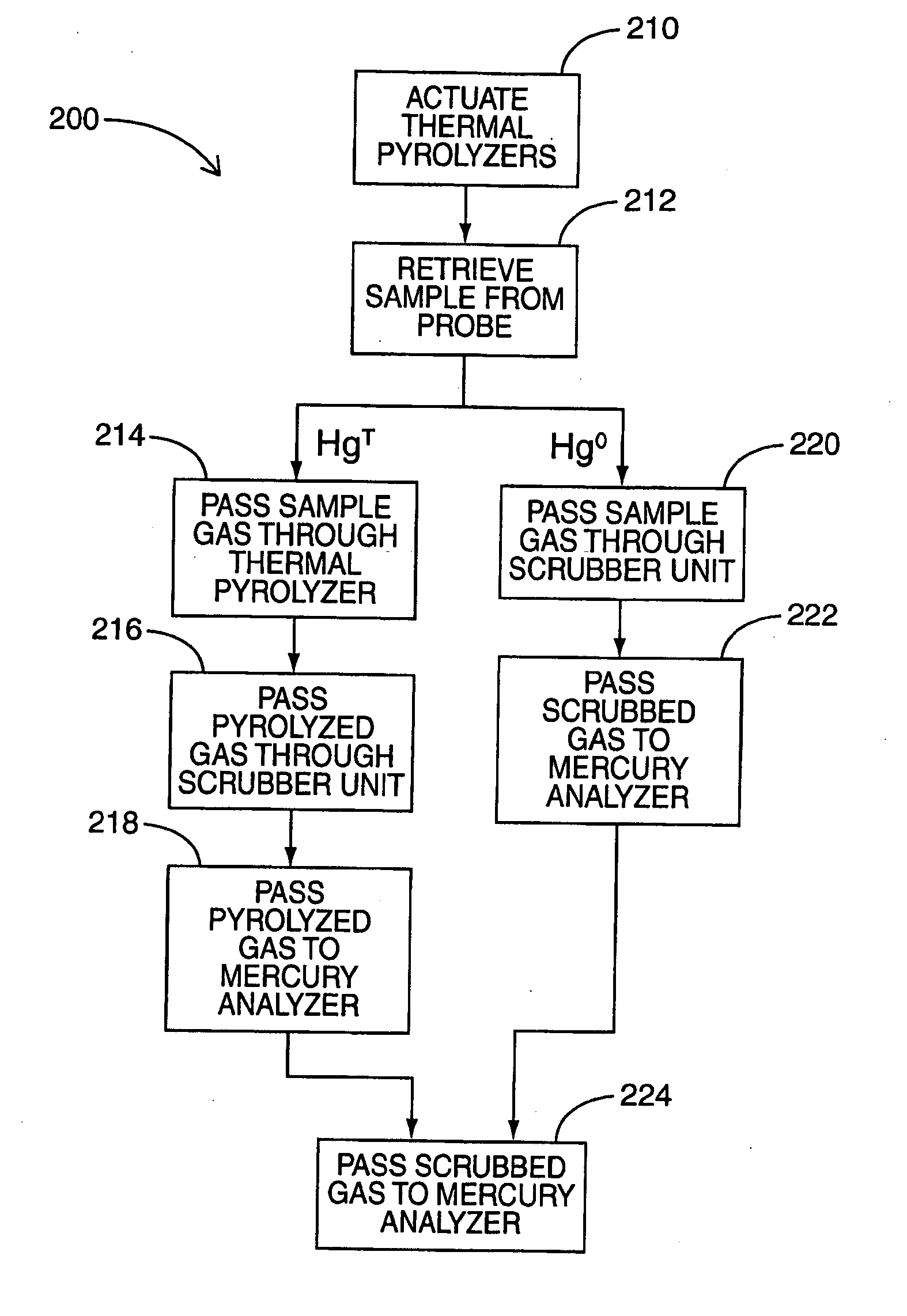

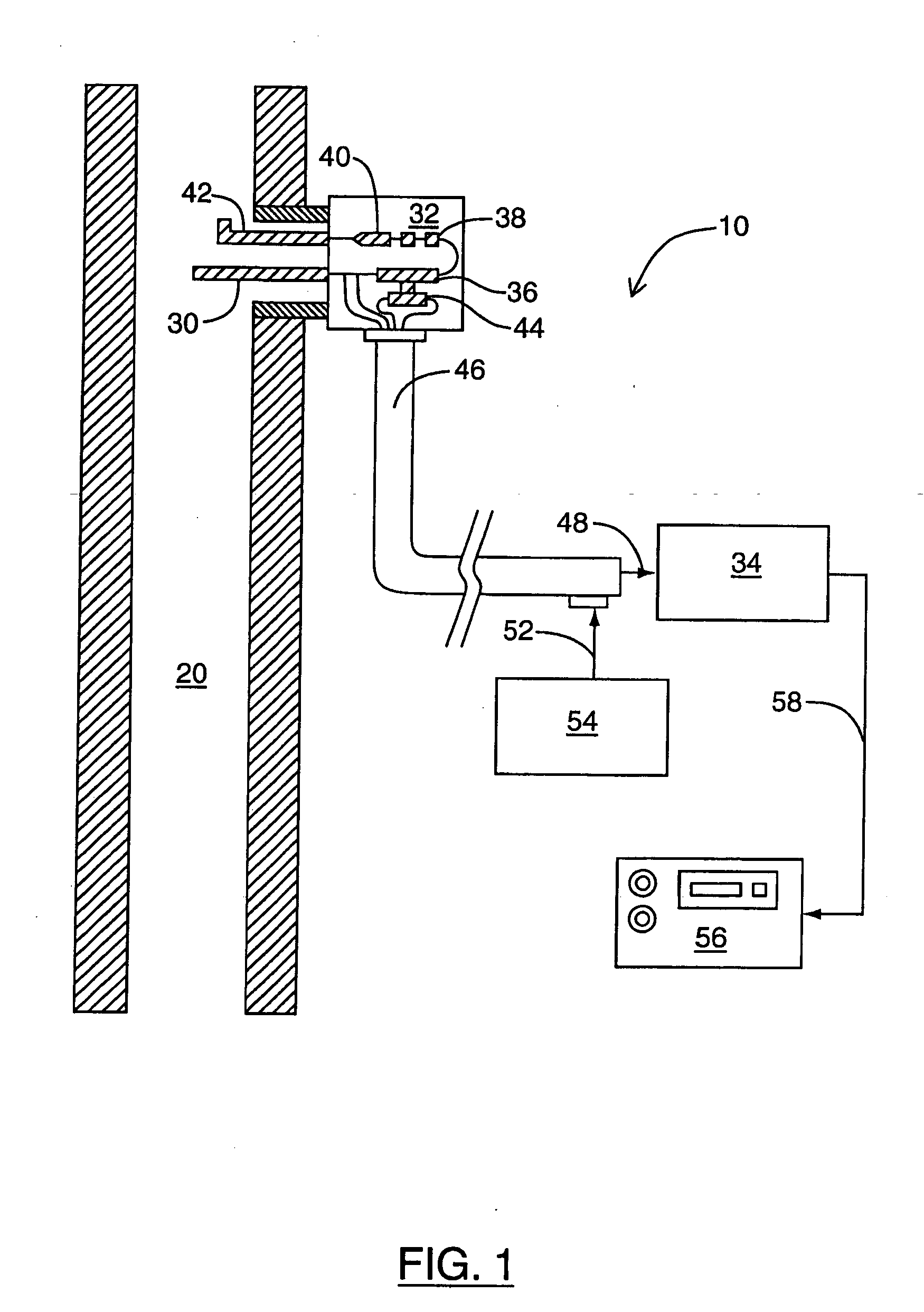

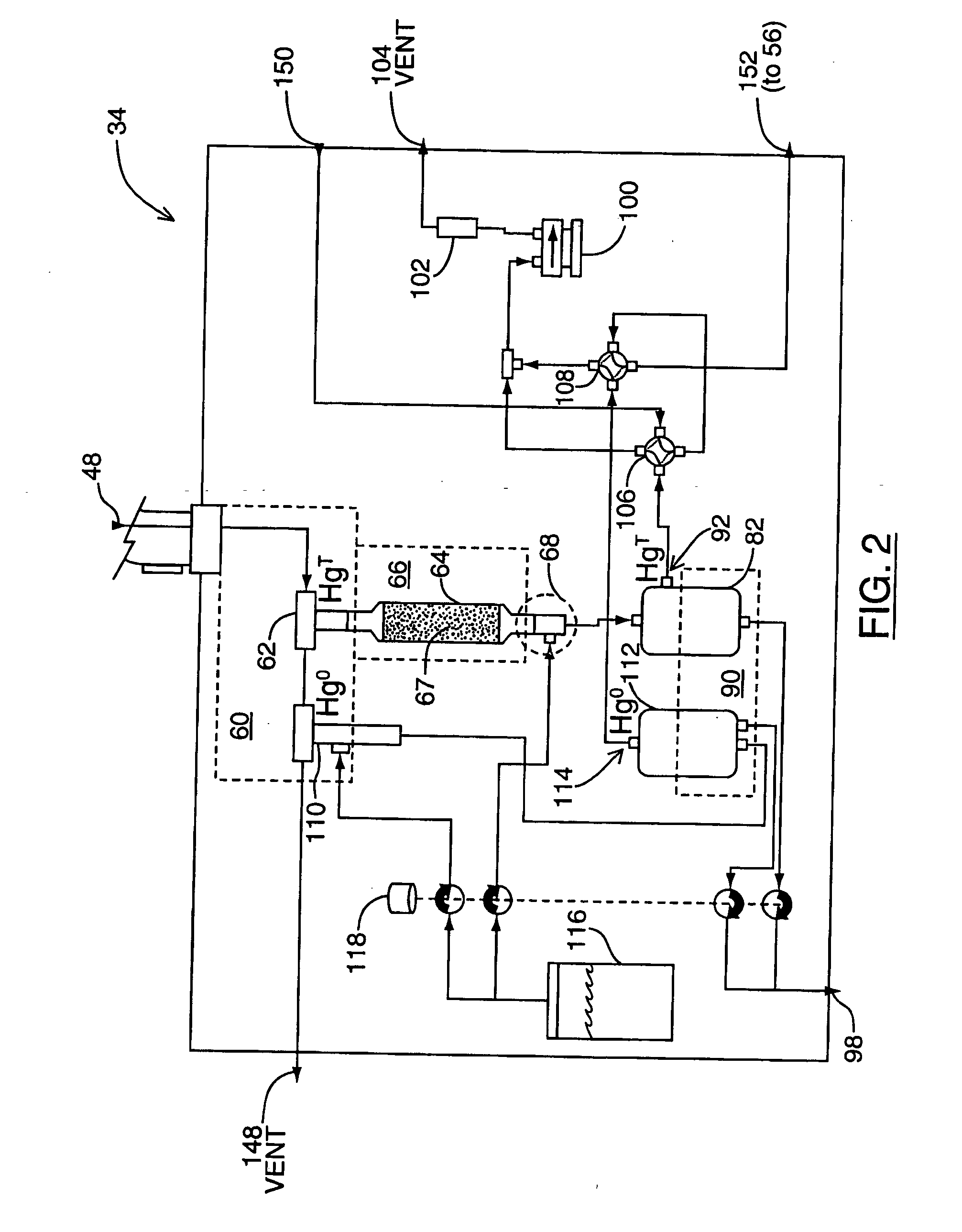

Conditioning system and method for use in the measurement of mercury in gaseous emissions

ActiveUS20050061110A1Avoid reorganizationReduced form requirementsGas treatmentSamplingBoron nitrideSilicon boride

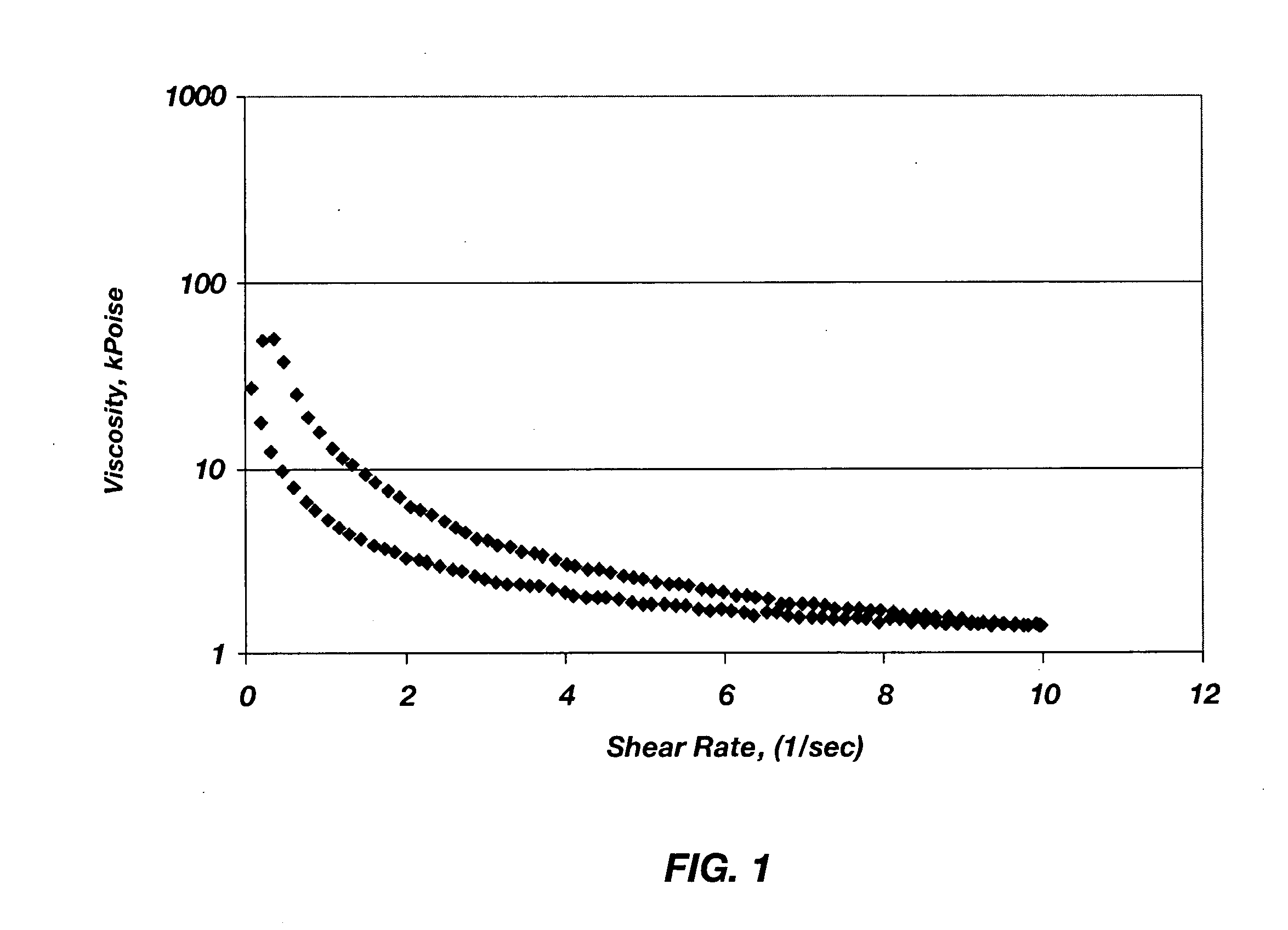

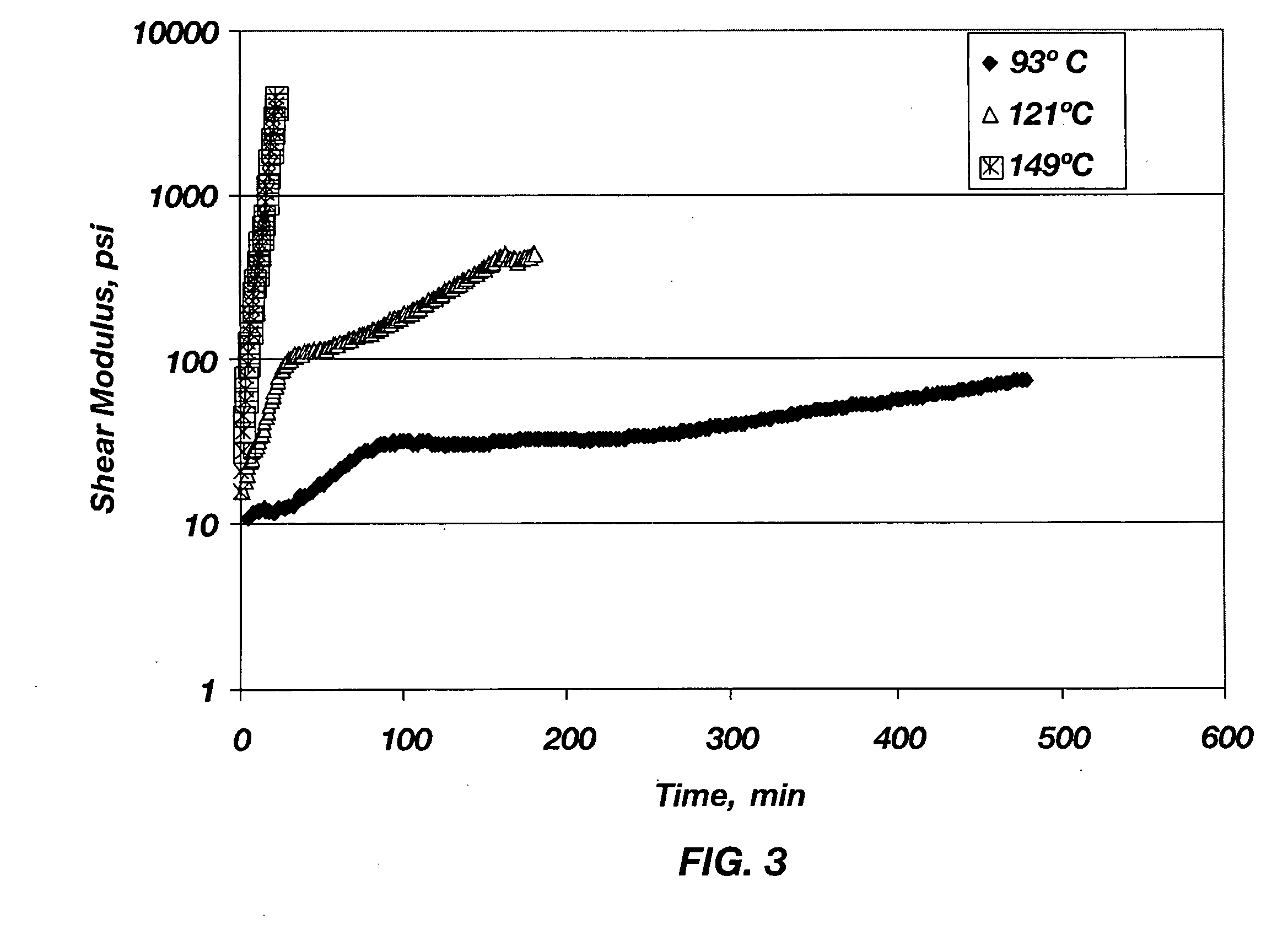

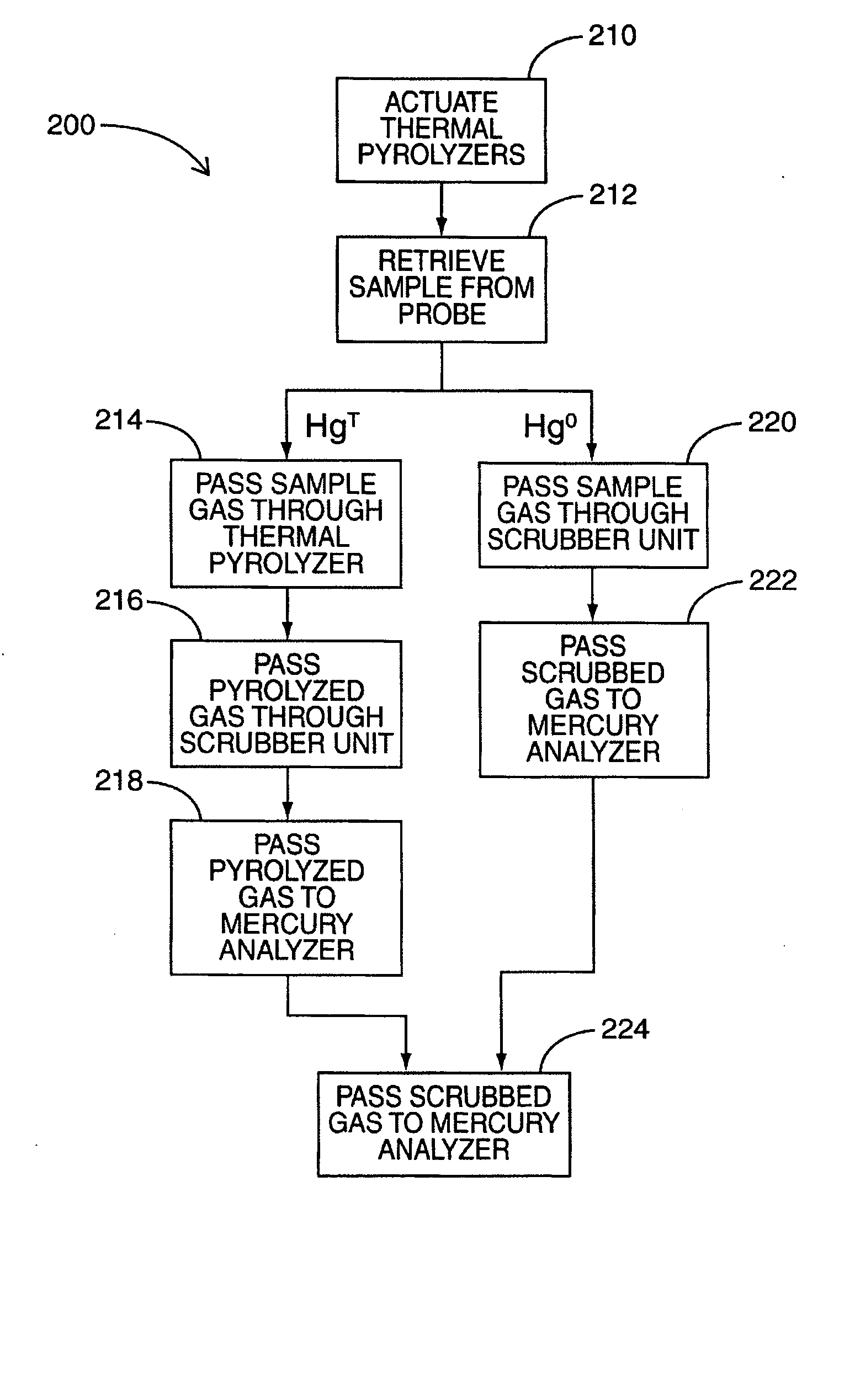

Embodiments of the invention relate generally to systems used to measure mercury in gaseous emissions. In one aspect, the invention is directed to the use of silicon carbide as material for a thermal pyrolysis unit. In another aspect, at least one of silicon nitride, silicon boride, and / or boron nitride is used as material for a thermal pyrolysis unit. In another aspect, the invention is directed to an improved pyrolyzer design, in which a thermal pyrolysis unit comprises a tailpiece that allows water to be injected at the heated exit of the thermal pyrolysis unit. In another aspect, the invention is directed to the use of a coalescing filter in a scrubbing unit. In another aspect, the invention is directed to the use of a hydrophobic filter element in a scrubbing unit. One or more of these elements may be used in a conditioning module of a continuous emissions monitoring system, for example.

Owner:TEKRAN INSTR CORPORTION

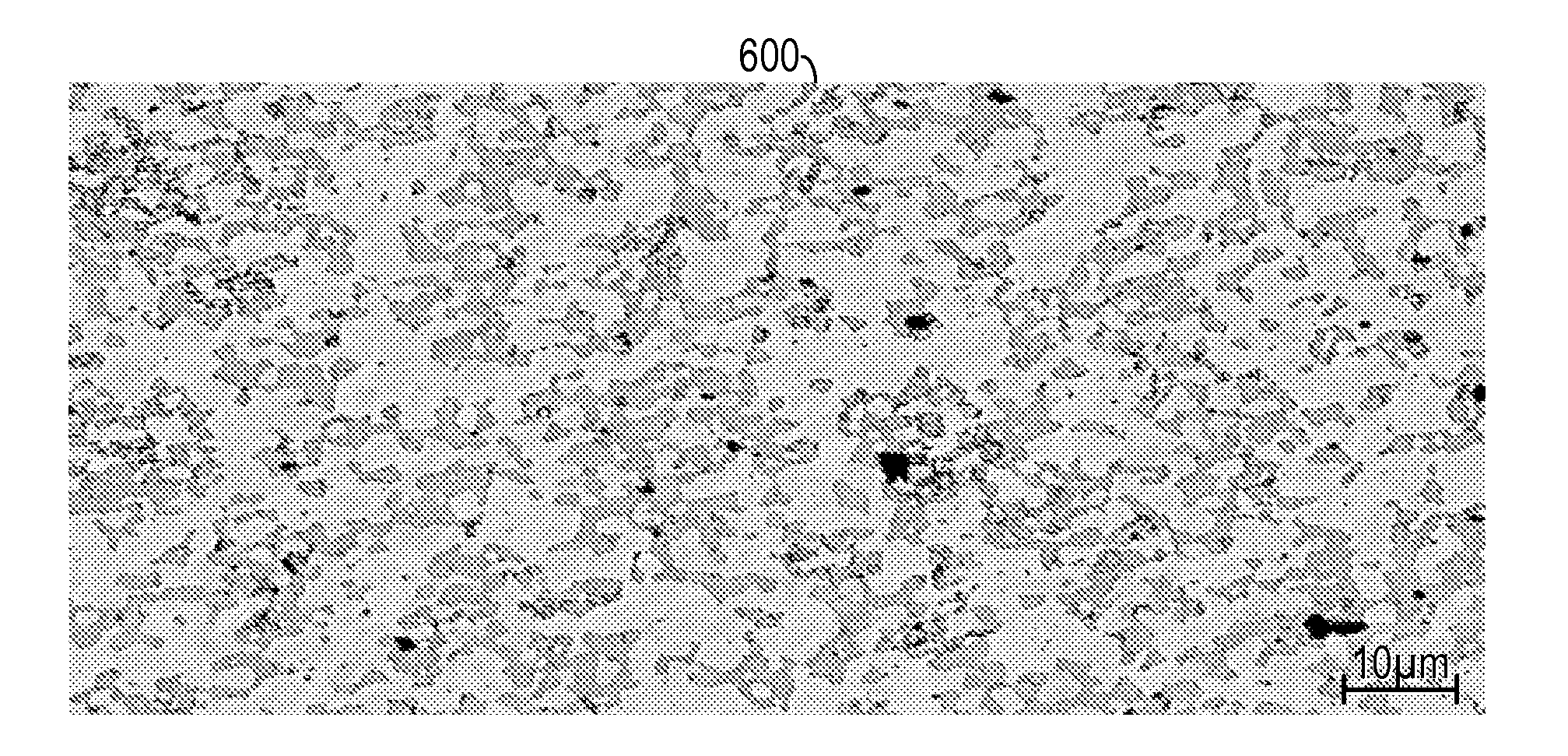

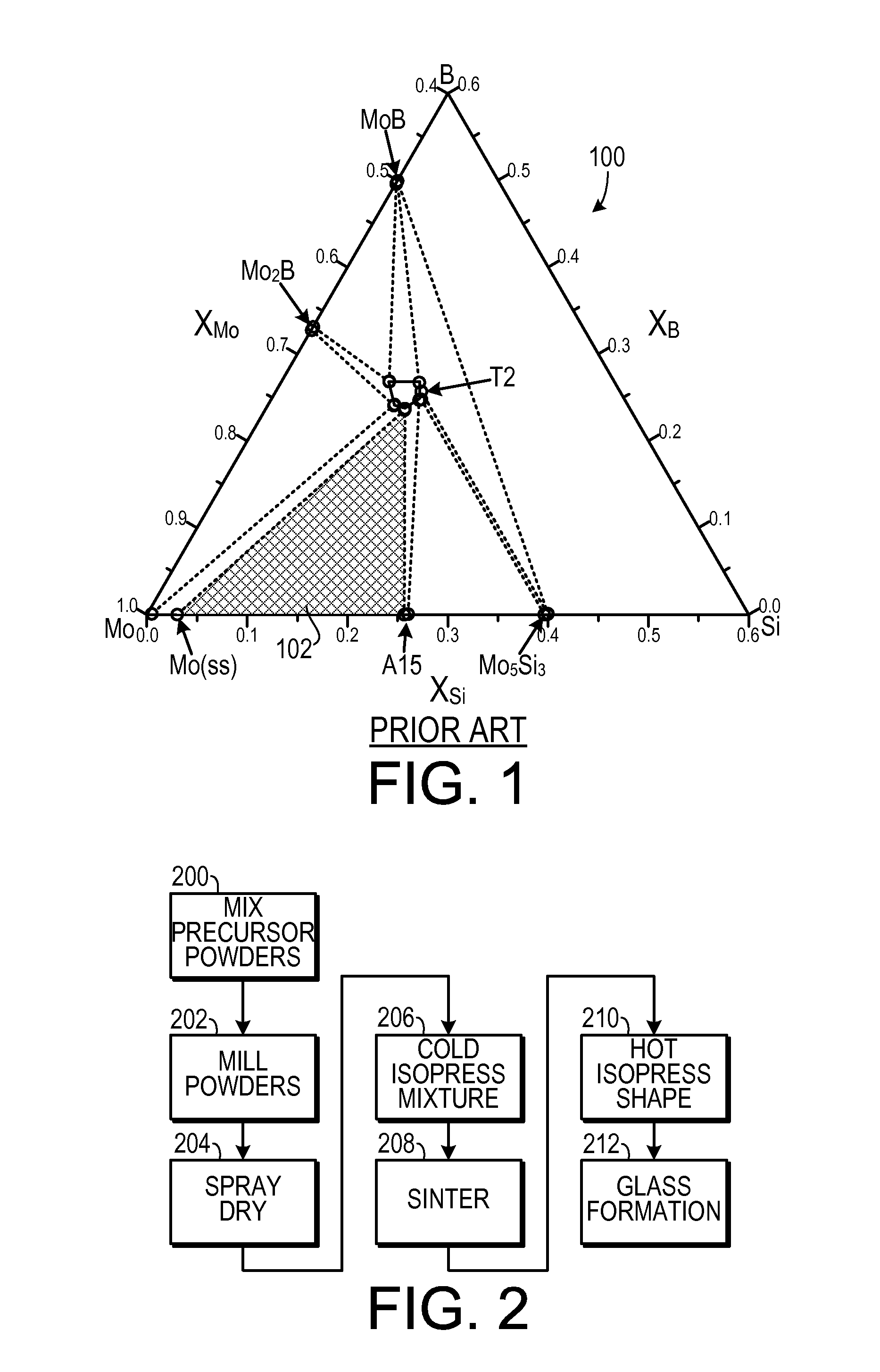

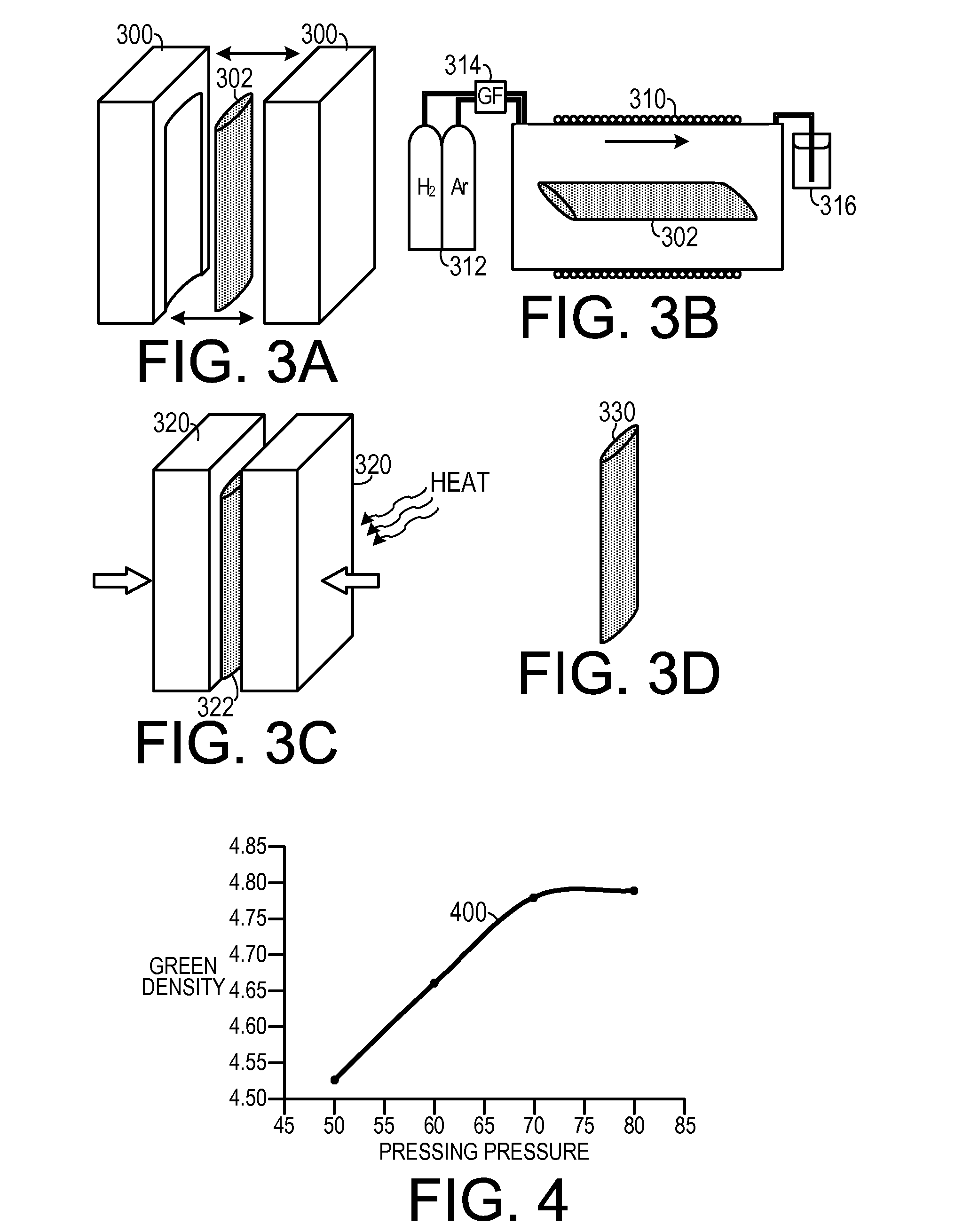

Intermetallic Composite Formation and Fabrication from Nitride-Metal Reactions

In a method of making a molybdenum, molybdenum silicide and molybdenum silicon boride composite material, a boron nitride powder, a silicon nitride powder and a molybdenum powder are mixed to form a composite precursor. The composite precursor is sintered in an atmosphere consisting essentially of hydrogen and argon to form a sintered material. The sintered material is hot isostatic pressed to form the composite material into a final shape.

Owner:GEORGIA TECH RES CORP

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

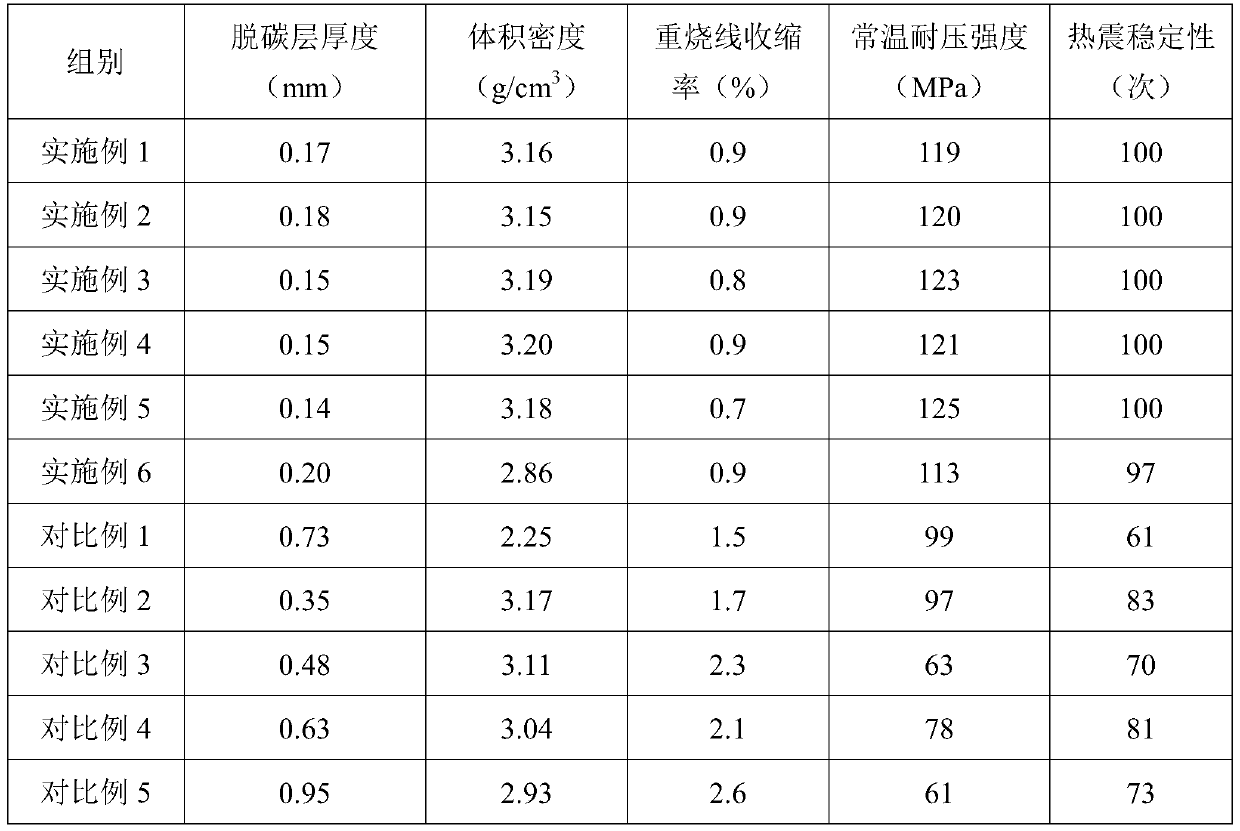

Special casting material of coal-injection duct

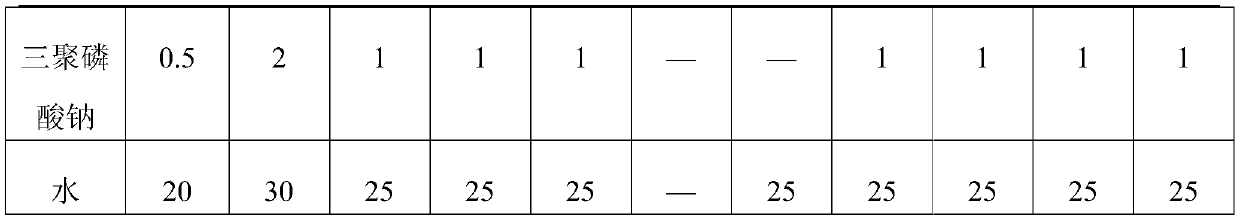

The invention discloses a special-purpose casting material of a coal-injection duct. The special-purpose casting material comprises the following components in percentage by weight: 5%-15% of silicon carbide, 15%-30% of andalusite, 10%-25% of corundum, 5%-15% of spinel powder, 15%-20% of silicon boride powder, 5%-10% of zirconite powder, 5%-10% of mullite powder, 5%-15% of aluminum oxide micro powder, 3%-8% of silicon micro powder, 2%-5% of pure calcium aluminate cement, as well as anti-explosion fiber and sodium hexametaphosphate which respectively account for 0.3% of the total weight of the components. The special casting material of the coal-injection duct disclosed by the invention has seismic stability, high temperature resistance, volume stability and abrasive resistance, has high strength, and can be used for improving the defects that the coal-injection duct is not wear-resisting and not thermal-spalling-resistant, so that the service life of a cement kiln coal-injection duct is prolonged to about 12-15 months from about 6-8 months at present.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

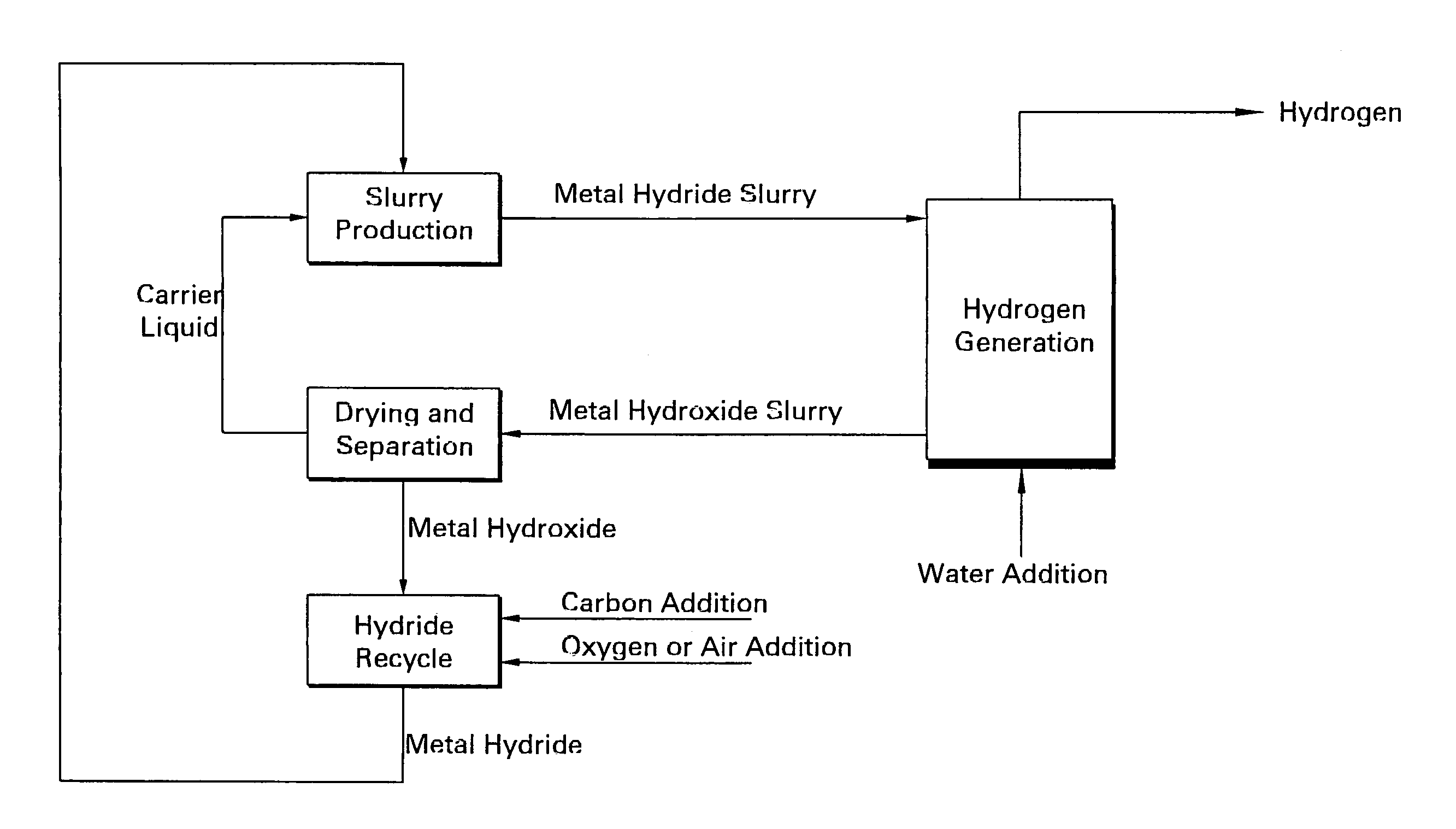

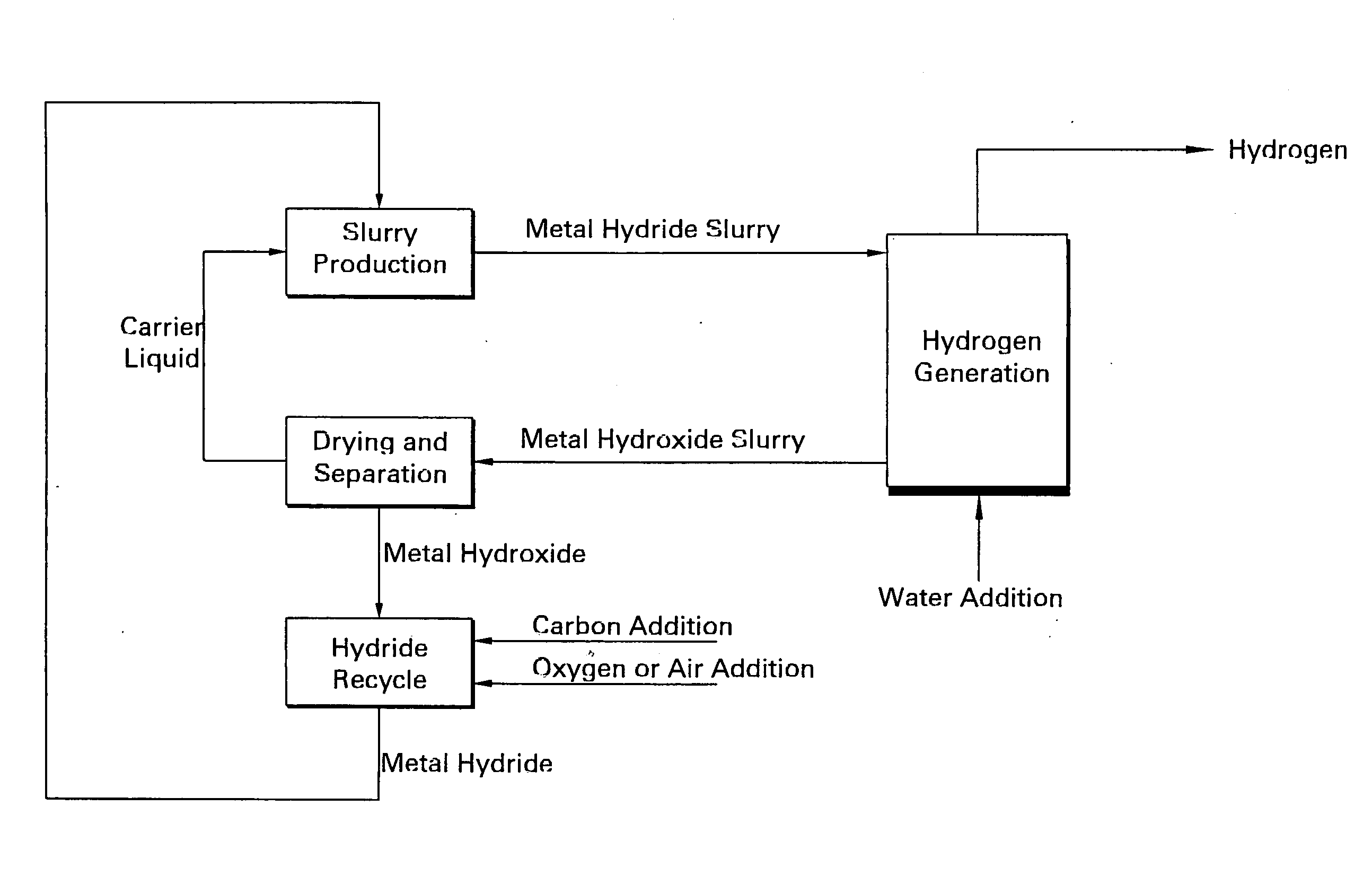

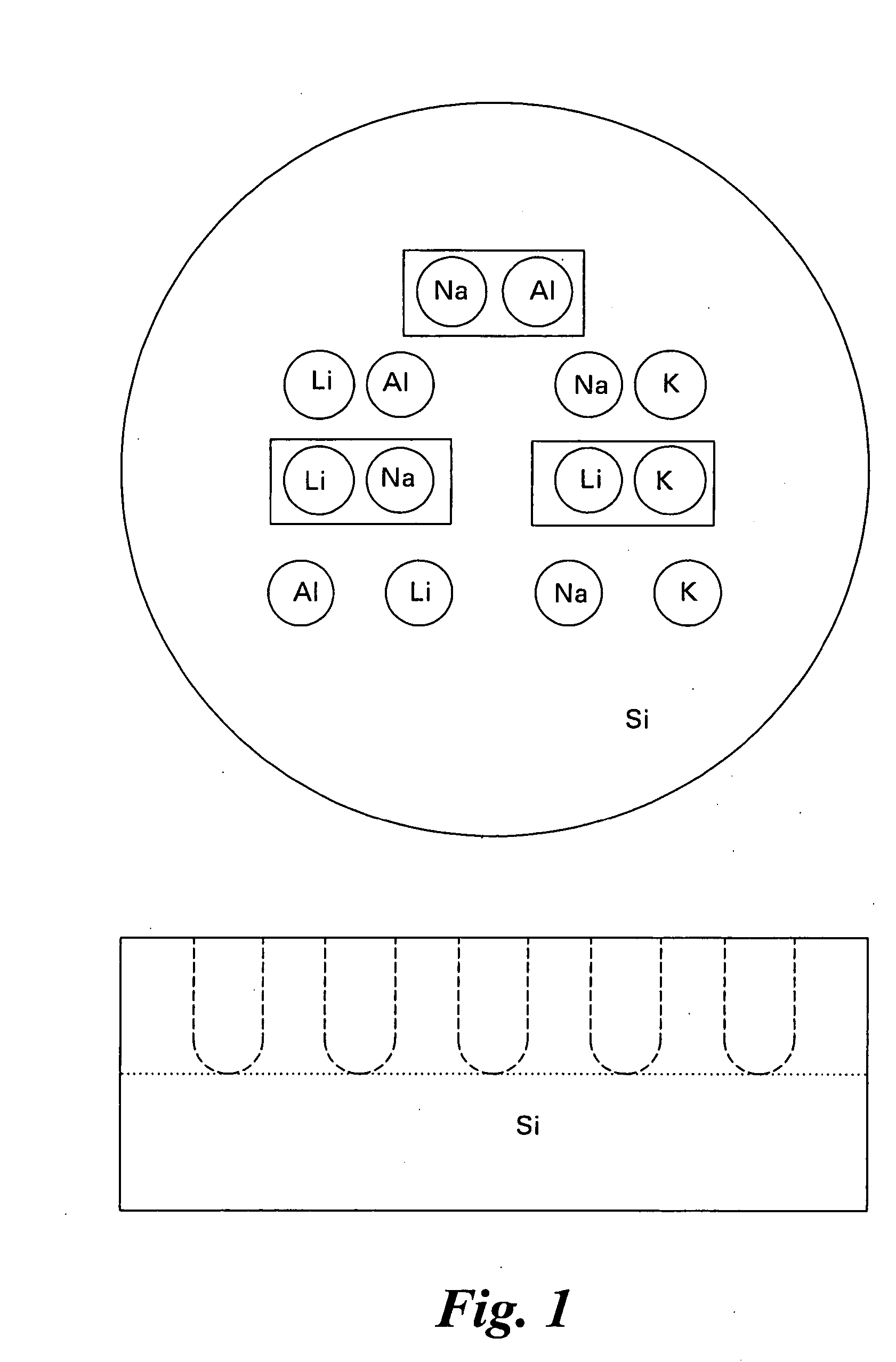

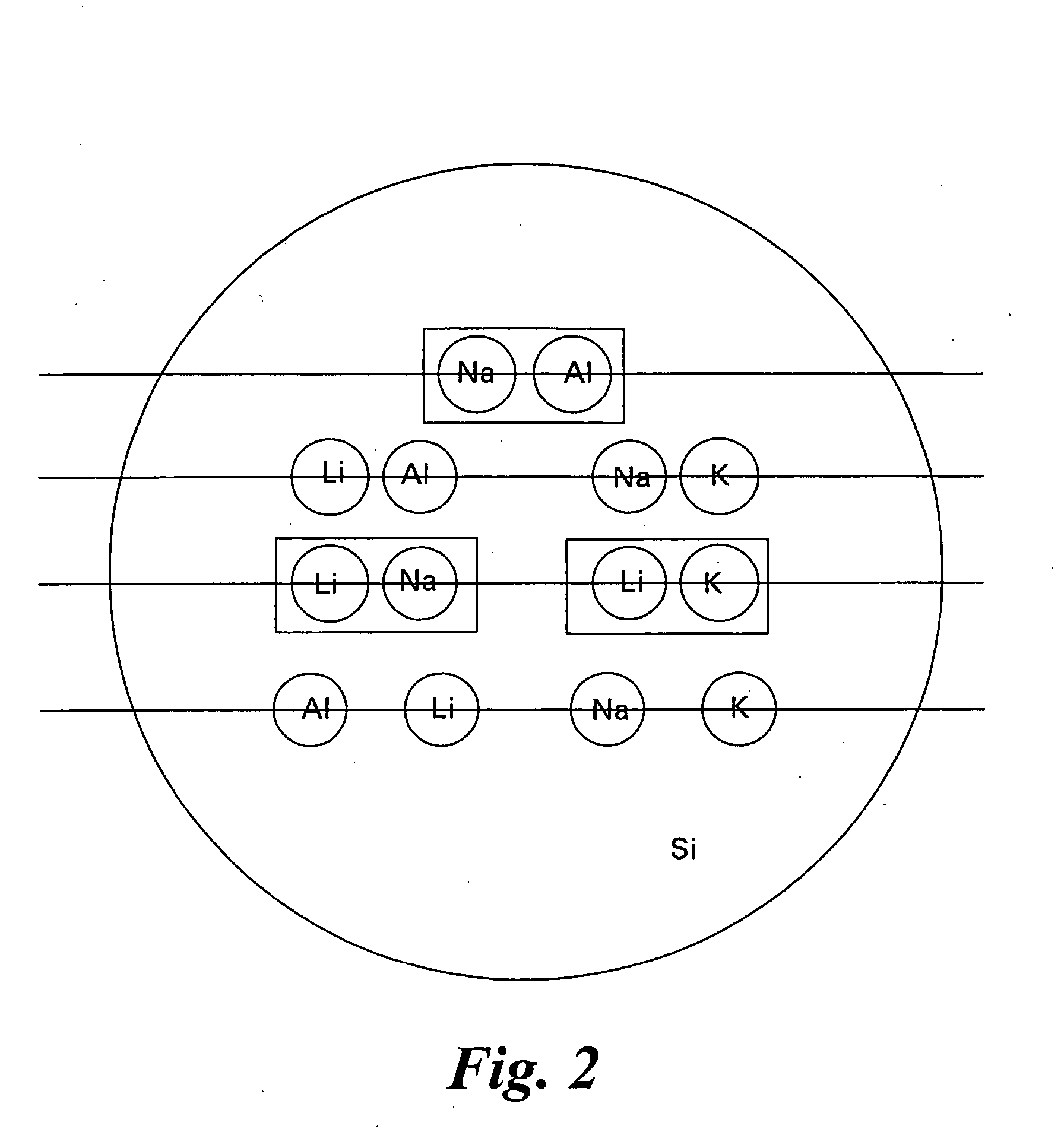

Hydrogen storage compositions and methods of manufacture thereof

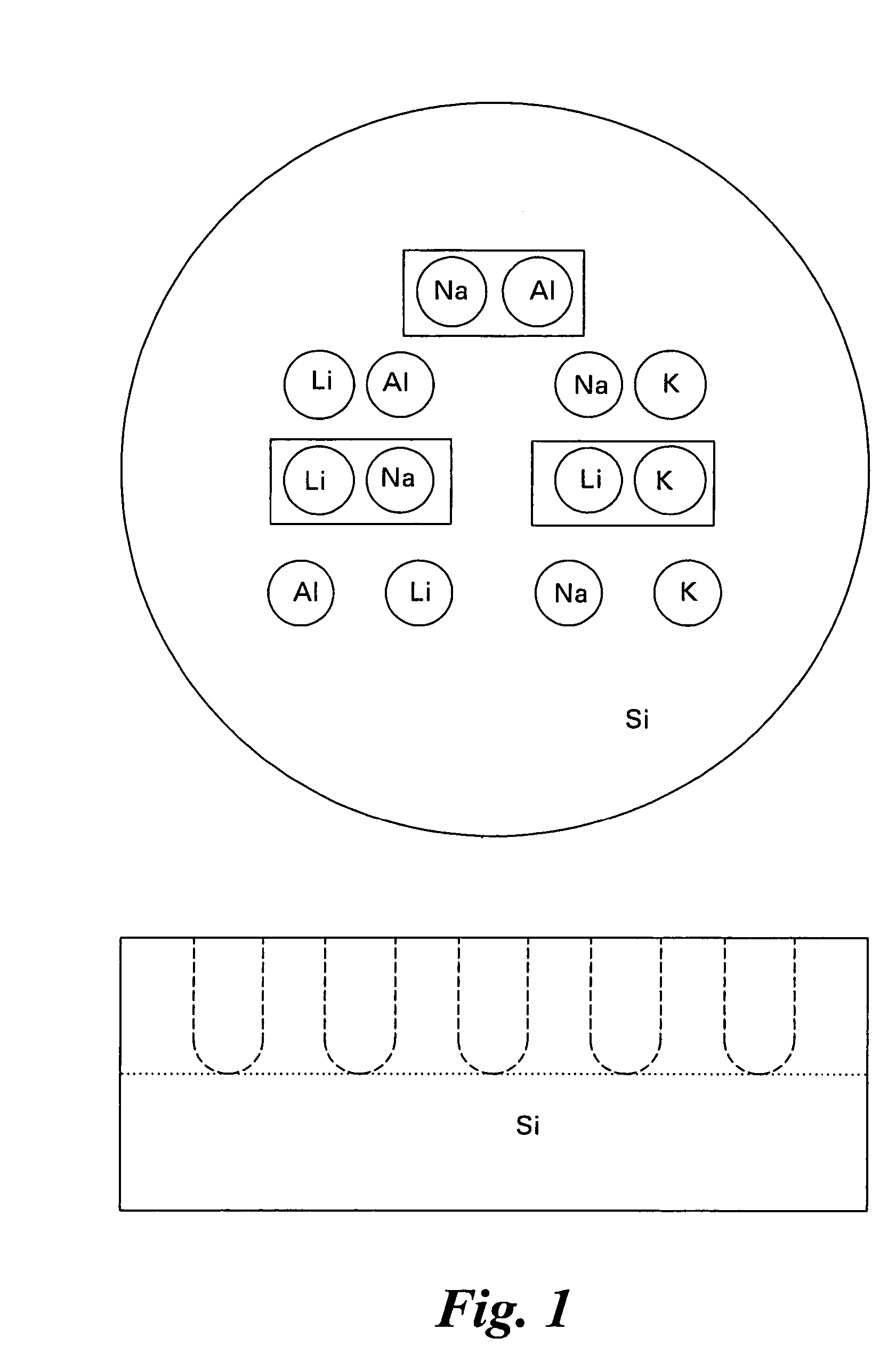

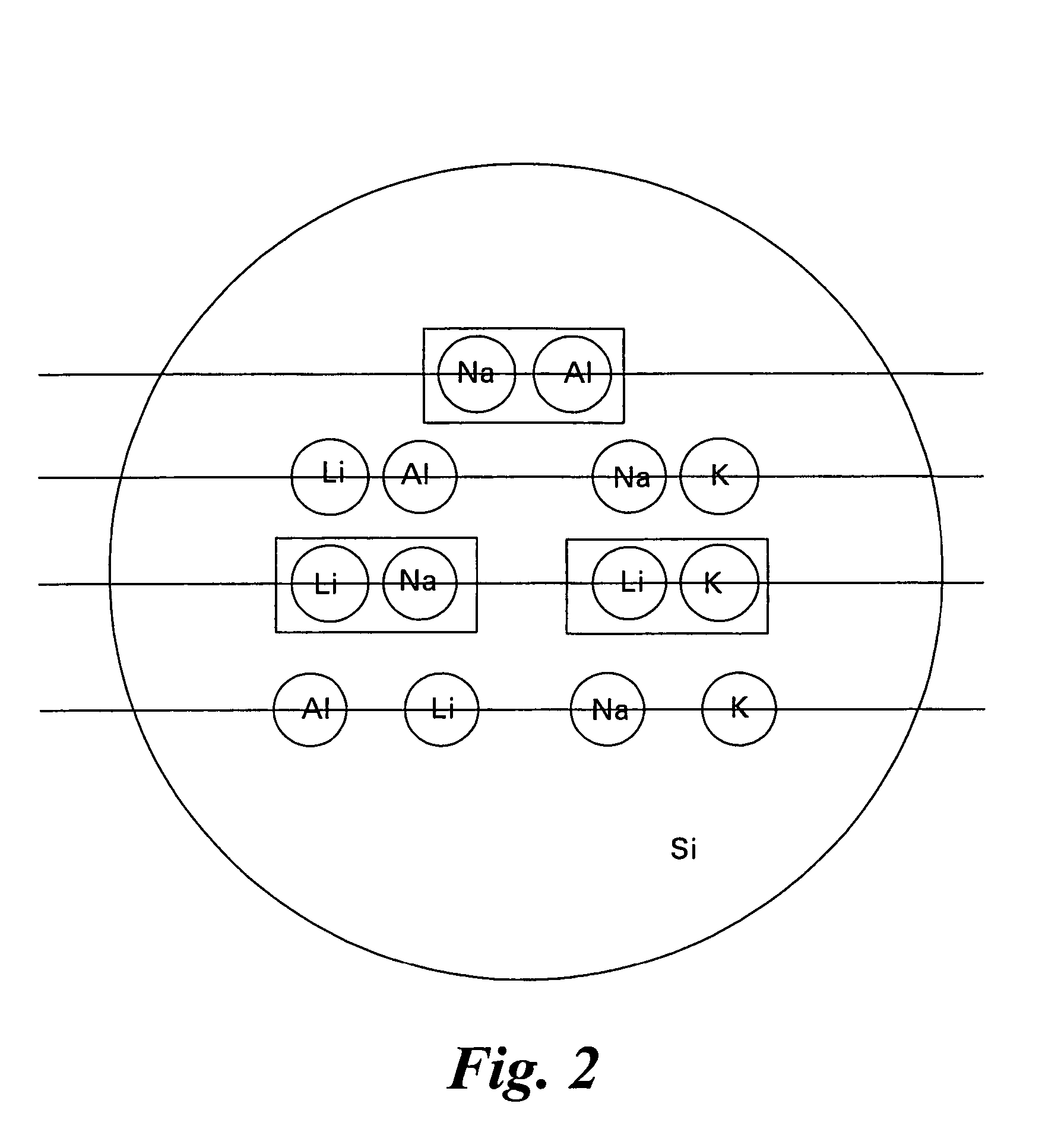

Disclosed herein is a method for making a combinatorial library comprising disposing on a substrate comprising silicon, silicon nitride, silicon carbide or silicon boride at least one reactant, wherein the reactants are lithium, magnesium, sodium, potassium, calcium, aluminum or a combination comprising at least one of the foregoing reactants; heat treating the substrate to create a diffusion multiple having at least two phases; contacting the diffusion multiple with hydrogen; detecting any absorption of hydrogen; and / or detecting any desorption of hydrogen.

Owner:GENERAL ELECTRIC CO

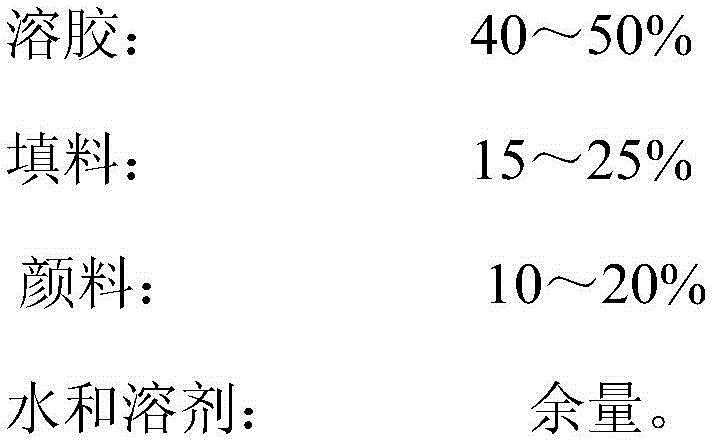

Ceramic membrane coating for interior decorative plate of urban rail transit vehicle

The invention relates to a ceramic membrane coating for an interior decorative plate of an urban rail transit vehicle. The ceramic membrane coating is characterized by comprising the following three raw material components in percentage by mass: 60-65 parts of a first component, 28-34% of a second component and the balance being a third component, wherein the first component is color paste, the second component comprises siloxane, and the third component is acid. The conventional ceramic membrane coating is of a double-coating structure comprising a base coating and a surface coating; generally speaking, the base coating has a color, mechanical performances and the like, and the surface coating has a using function, luster and the like. The coating disclosed by the invention is of a single-coating structure and not only has the functionality, but also has the luster and color; nanometer silicon boride has the characteristics of oxidation resistance, heat shock resistance, chemical erosion resistance and the like and particularly has the very high strength and stability under shock; and by using the ceramic membrane coating, the carriage matrix of a locomotive can be protected, the service cycle of the ceramic membrane coating can be prolonged, and the service life of the ceramic membrane coating can be prolonged.

Owner:SHANGHAI EXCILON NEW MATERIALS

Conditioning system and method for use in the measurement of mercury in gaseous emissions

ActiveUS20060042418A1Avoid reorganizationReduced form requirementsGas treatmentDispersed particle separationBoron nitrideSilicon oxide

Embodiments of the invention relate generally to systems used to measure mercury in gaseous emissions. In one aspect, the invention is directed to the use of an inert covalently bonded material selected from silicon carbide (SiC), silicon oxides (SiOn, n=1-2), silicon nitride (e.g. Si3N4), silicon boride (e.g. SiB6), boron nitride (e.g. BN) and mixtures thereof as material for a thermal pyrolysis unit. In another aspect, the invention is directed to an improved pyrolyzer design, in which a thermal pyrolysis unit comprises a tailpiece that allows water to be injected at the heated exit of the thermal pyrolysis unit. In another aspect, the invention is directed to the use of a coalescing filter in a scrubbing unit. In another aspect, the invention is directed to the use of a hydrophobic filter element in a scrubbing unit. One or more of these elements may be used in a conditioning module of a continuous emissions monitoring system, for example.

Owner:TEKRAN INSTR CORPORTION

Silicon carbide refractory material and preparation method thereof

The invention belongs to the technical field of refractory materials, and provides a silicon carbide refractory material and a preparation method thereof. The silicon carbide refractory material comprises, by weight, 25-40 parts of silicon carbide powder, 4-8 parts of silica fume , 1-5 parts of aluminum powder, 5-13 parts of titanium dioxide, 5-10 parts of zirconium oxide, 0.5-3 parts of polyhedral oligomeric silsesquioxane, 0.5-2 parts of molybdenum carbide, 0.5-2 parts of silicon boride, 0.5-1.5 parts of erbium acetate, 0.5-1.5 parts of ytterbium oxide, 1-3 parts of diamond and 3-5 parts ofbinding agent. The preparation method comprises the following steps: mixing the silicon carbide powder, the silica fume, the aluminum powder, the titanium dioxide and the zirconium oxide, grinding themixture to obtain first mixed powder, reacting the erbium acetate, the ytterbium oxide and the diamond to obtain second mixed powder, mixing the first mixed powder with the second mixed powder, mixing the obtained mixture with other components in the formula, and firing the obtained mixture to obtain the silicon carbide refractory material. By means of the technical scheme, the problems that in the prior art, a refractory material is poor in oxidation resistance and not high in strength are solved.

Owner:唐山市瑞兆碳化硅制品有限公司

Hydrogen storage compositions and methods of manufacture thereof

InactiveUS20050069489A1Sequential/parallel process reactionsFuel cell heat exchangeDesorptionPotassium

Disclosed herein is a method for making a combinatorial library comprising disposing on a substrate comprising silicon, silicon nitride, silicon carbide or silicon boride at least one reactant, wherein the reactants are lithium, magnesium, sodium, potassium, calcium, aluminum or a combination comprising at least one of the foregoing reactants; heat treating the substrate to create a diffusion multiple having at least two phases; contacting the diffusion multiple with hydrogen; detecting any absorption of hydrogen; and / or detecting any desorption of hydrogen.

Owner:GENERAL ELECTRIC CO

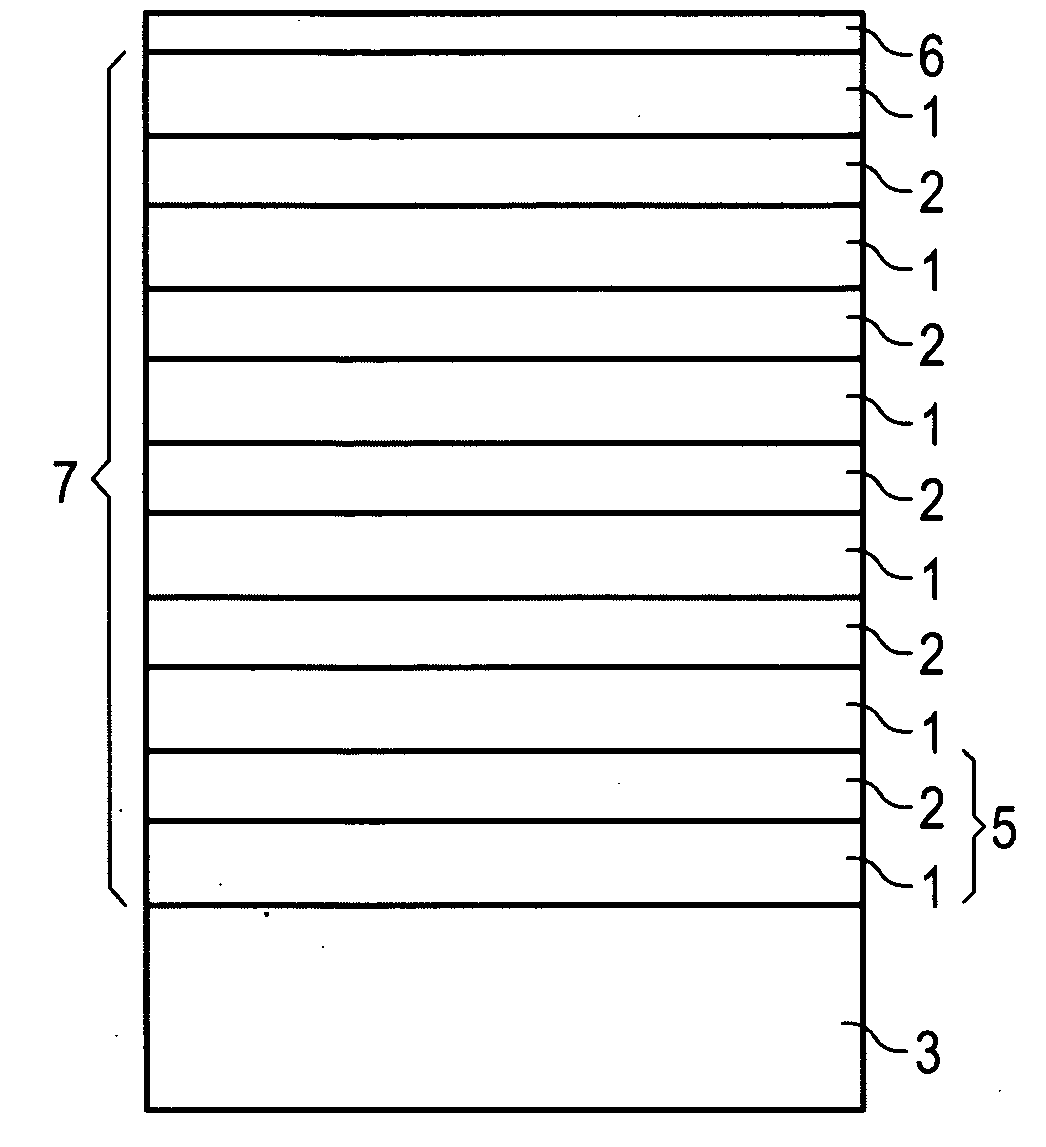

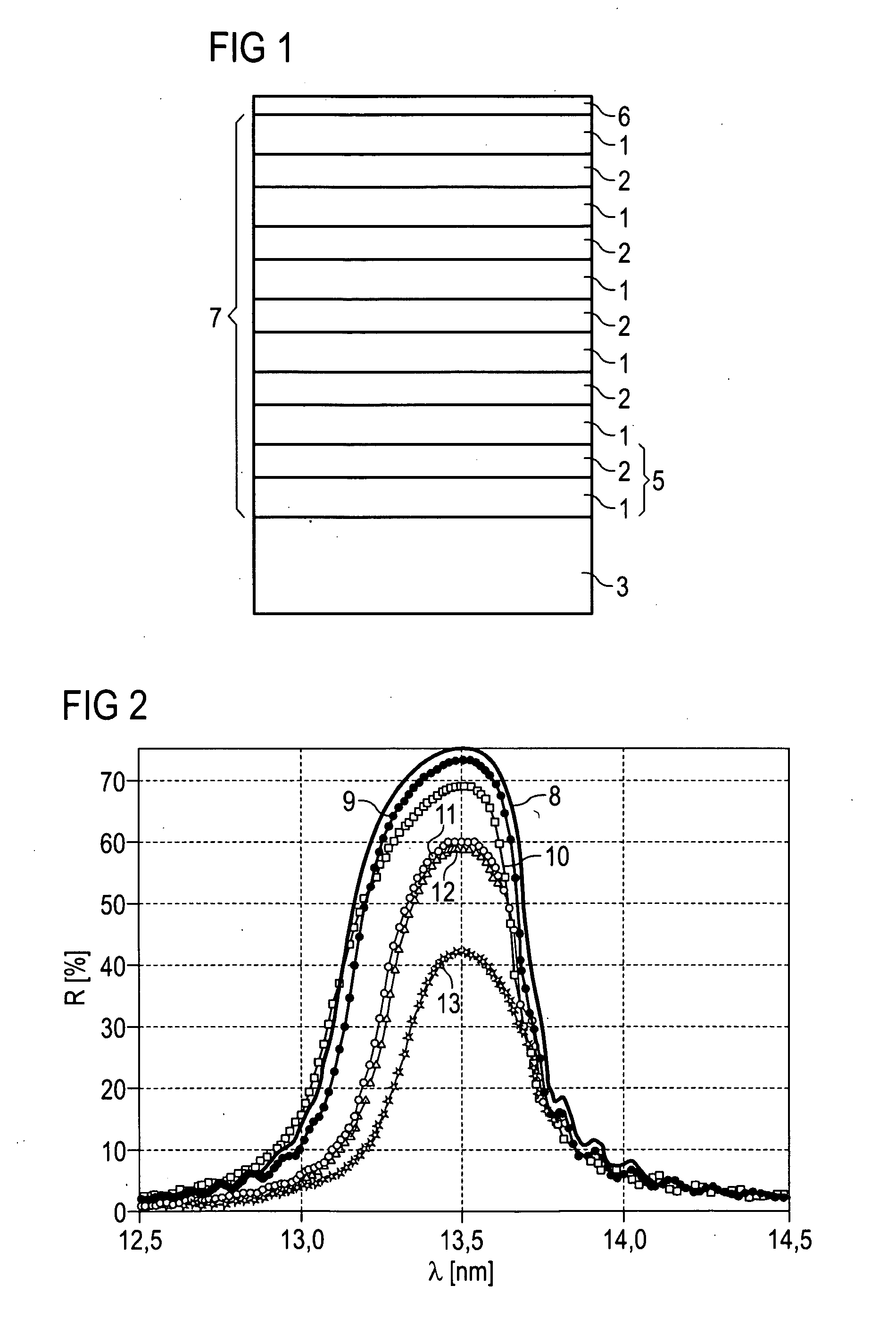

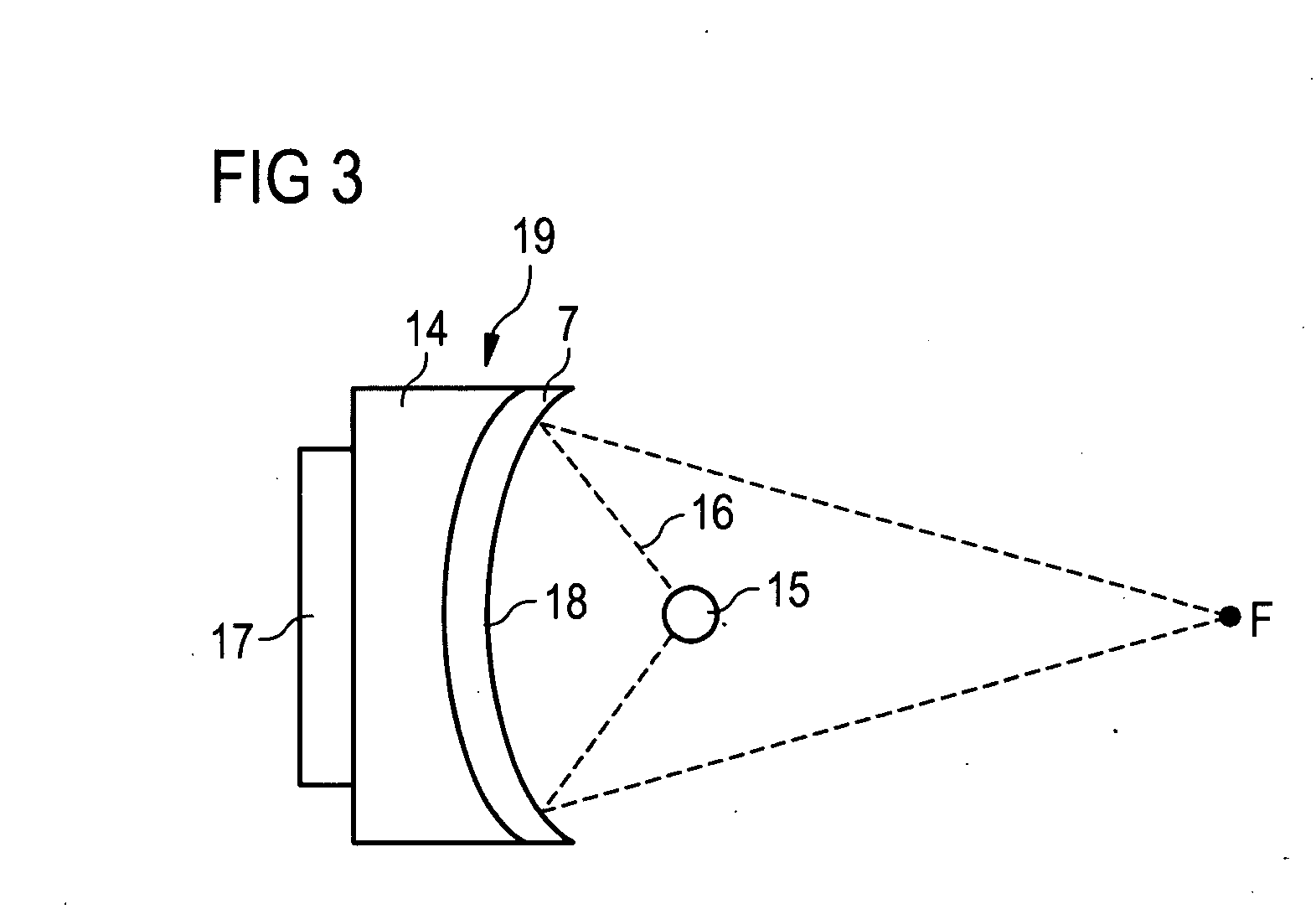

Thermally Stable Multilayer Mirror for the EUV Spectral Range

InactiveUS20090009858A1Improve thermal stabilityImprove long-term stabilityMirrorsNanoinformaticsComputational physicsSilicon boride

A multilayer mirror includes a layer sequence arranged on a substrate and a plurality of layer pairs. Each layer pair includes a first layer composed of a first material and a second layer composed of a second material. The first layers and the second layers each have a thickness of more than 2 nm, and the first material or the second material is a silicon boride or a molybdenum nitride.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

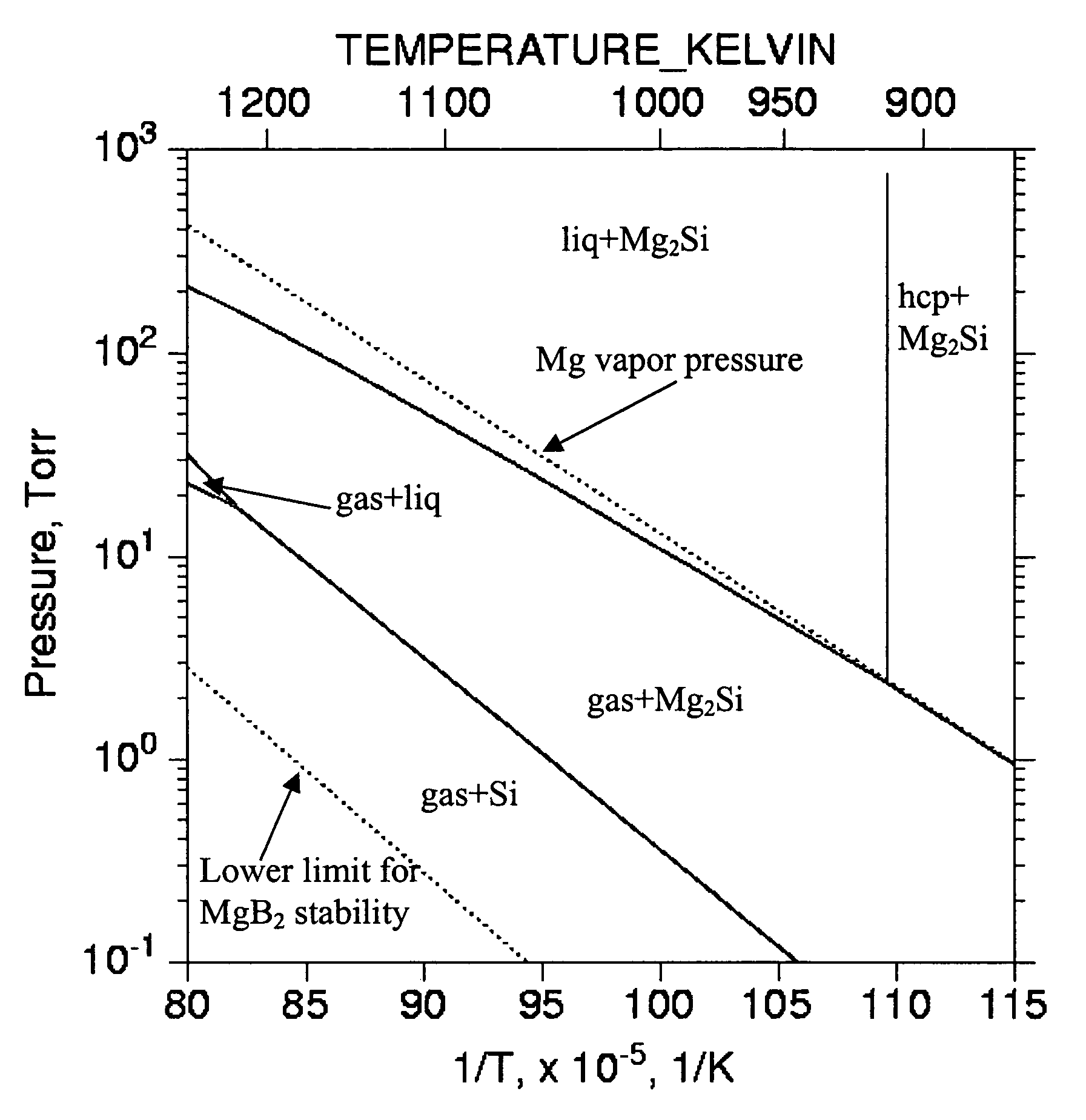

Boride thin films on silicon

InactiveUS7090889B2Minimize formationPromote formationSuperconductors/hyperconductorsVacuum evaporation coatingBorideGas phase

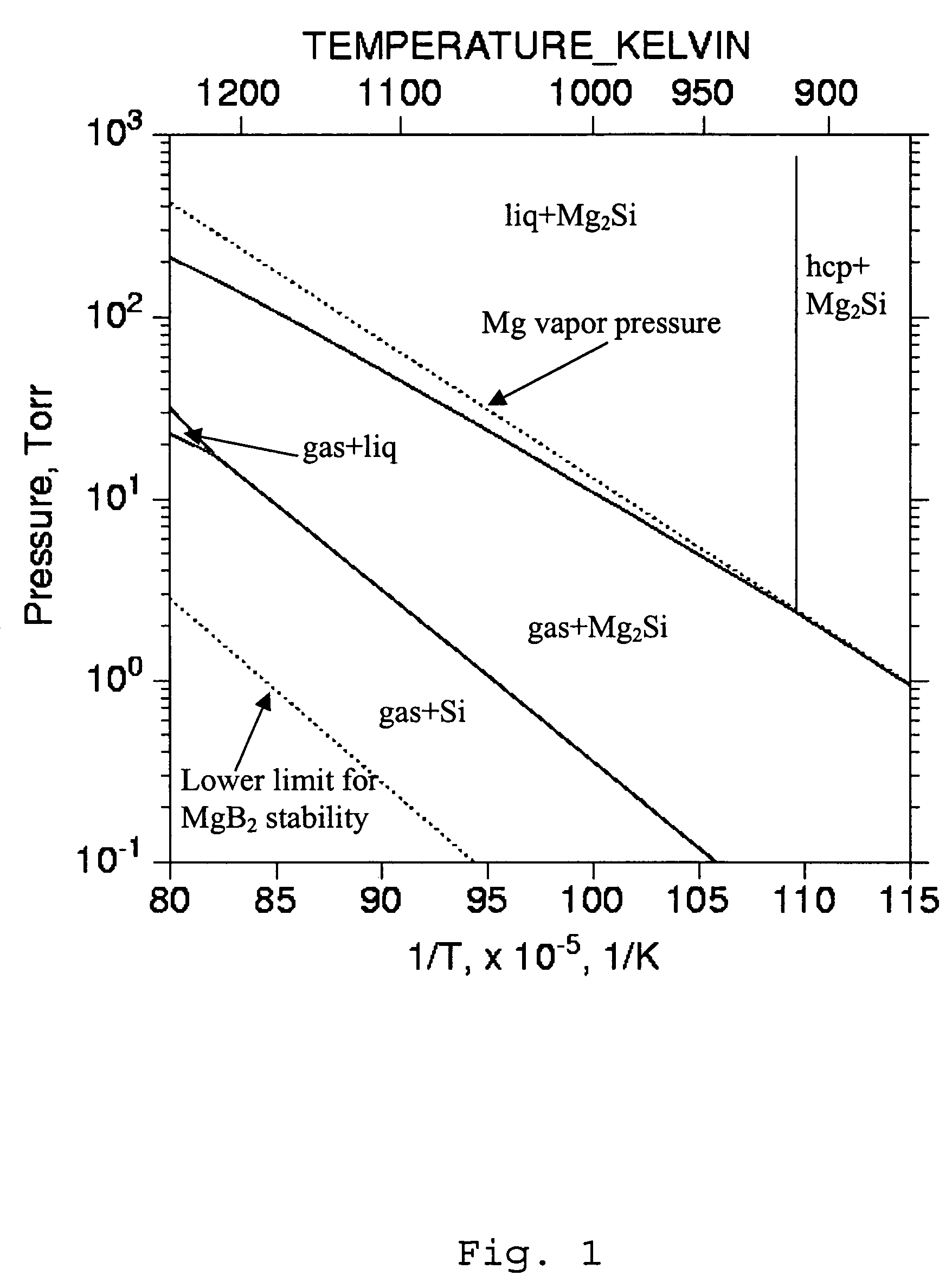

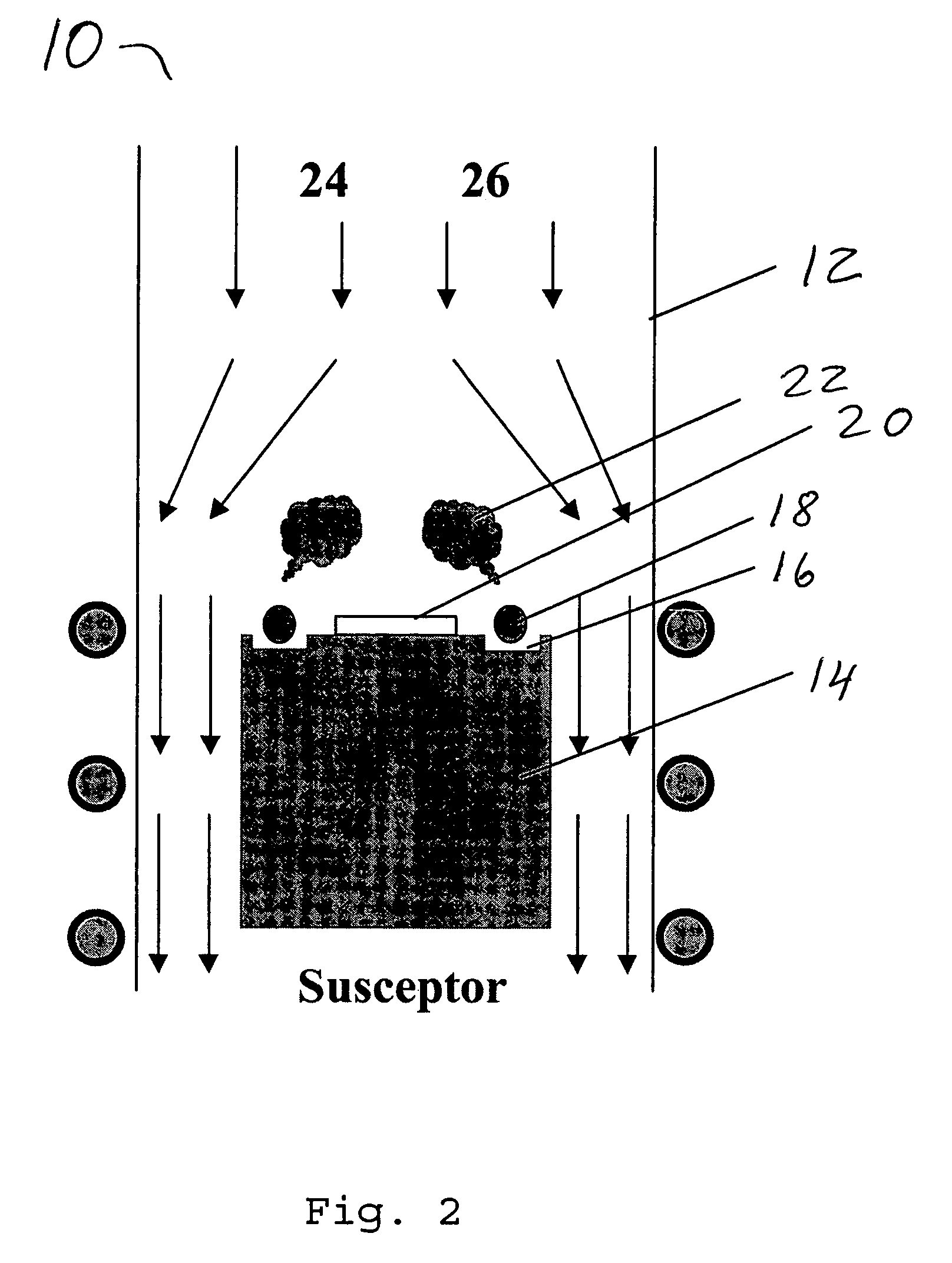

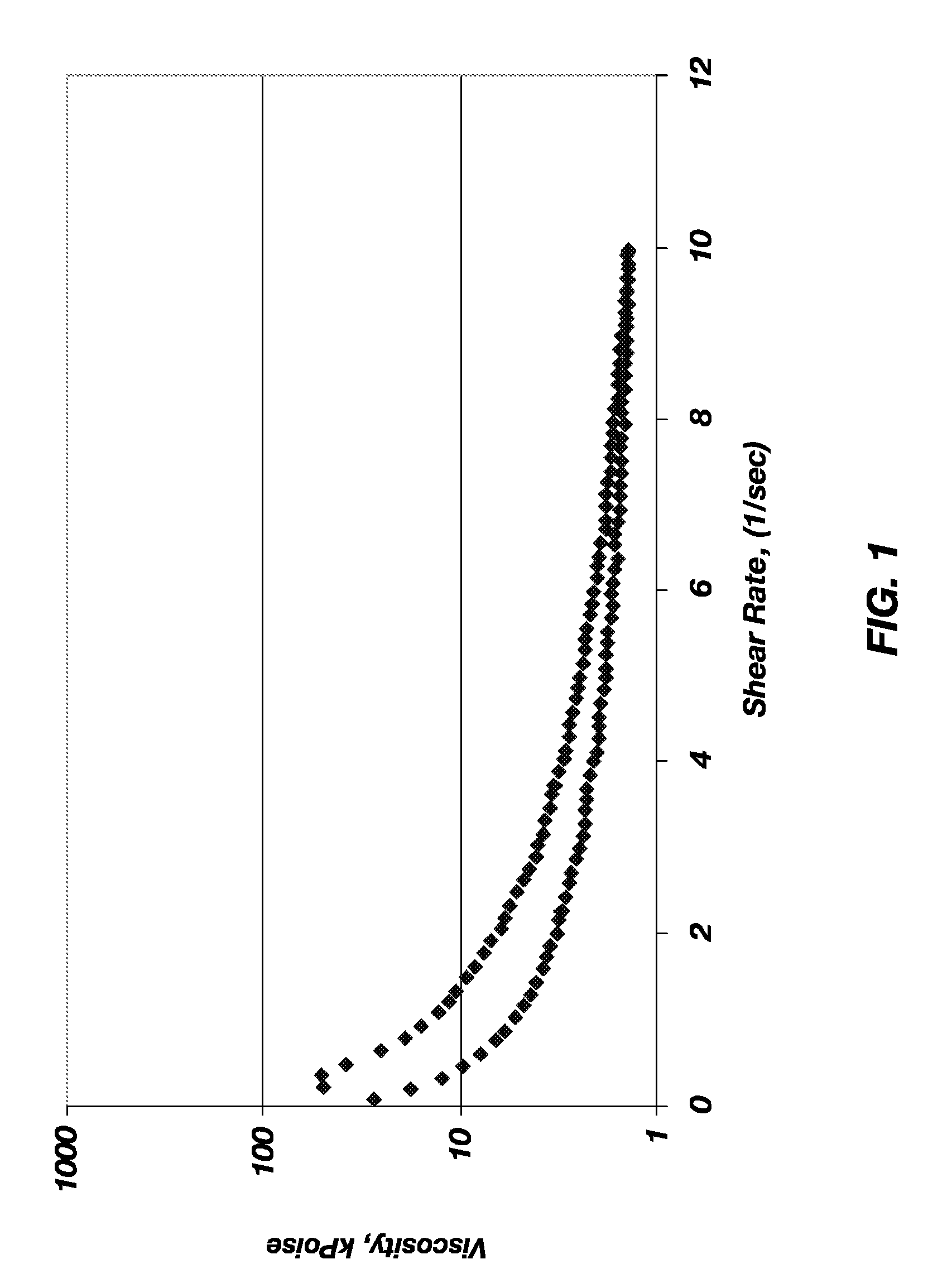

Boride thin films of conducting and superconducting materials are formed on silicon by a process which combines physical vapor deposition with chemical vapor deposition. Embodiments include forming boride films, such as magnesium diboride, on silicon substrates by physically generating magnesium vapor in a deposition chamber and introducing a boron containing precursor into the chamber which combines with the magnesium vapor to form a thin boride film on the silicon substrates.

Owner:PENN STATE RES FOUND

Far-infrared ceramic material and manufacturing method thereof

ActiveCN103664149AFar-infrared radiation band stabilityImprove radiation efficiencyInfraredFar infrared

The invention provides a far-infrared ceramic material and a manufacturing method thereof, and relates to the field of ceramic materials and the technical field of infrared rays. The manufacturing method comprises the steps as follows: step 1) material weighing and mixing: weighing raw materials in percentage by weight as follows: 75-90% of silicon dioxide, 6-13% of an oxide or salt of zirconium, 1-3% of an oxide or salt of neodymium, 1-3% of an oxide or salt of europium, 0-2% of an oxide or salt of chromium, 0-2.5% of an oxide or salt of cobalt and 0-3% of silicon boride, mixing and crushing the raw materials until the particle size is smaller than 5.0 mum, and preparing into a mixture; step 2) forming: forming the mixture to obtain a green body; step 3) sintering: putting the green body in a kiln for sintering at the temperature of 1160-1260 DEG C for 60-120 min to obtain the far-infrared ceramic material. The far-infrared ceramic material has the advantages of stable far-infrared radiation wave band, high radiation efficiency, high thermal stability and the like and can be better applied to frequent and rapid cooling and heating environments.

Owner:佛山中科产业技术研究院

Methods of repairing a substrate

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium boride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

Wear-resistant ecological environment-friendly lubricating oil and preparation method thereof

The invention discloses wear-resistant ecological environment-friendly lubricating oil. The wear-resistant ecological environment-friendly lubricating oil is characterized by comprising the followingcomponents in parts by weight: 50 to 60 parts of base oil, 10 to 20 parts of single-ended epoxy polyether modified amine-terminated hyperbranched polyester, 3 to 7 parts of single-ended hydroxypropylsilicone oil modified black phosphorus, 0.5 to 1.5 parts of silicon boride, 0.2 to 0.5 part of a coupling agent, 0.5 to 1.3 parts of a viscous agent, 0.2 to 0.6 part of a dispersing agent and 0.4 to 1part of an antioxidant. The invention also discloses a preparation method of the wear-resistant ecological environment-friendly lubricating oil. The wear-resistant ecological environment-friendly lubricating oil disclosed by the invention is good in lubricating effect, good in compression resistance and wear resistance, excellent in stability and safe and environment-friendly to use.

Owner:江苏智摩金属抗磨修复有限责任公司

Preparation method for fruit green ceramic handicraft

InactiveCN105906376AGood high and low temperature resistanceImprove flame retardant performanceBorideComing out

The invention discloses a preparation method for a fruit green ceramic handicraft. The preparation method comprises the following steps: weighing potassium dichromate, silicon-containing polycarbonate resin, calcium oxide, nanometer silicon boride, calcium boride, calcium carbonate, a fluorine-containing additive and AS resin in proportion, carrying out uniform mixing and levigation, then adding polypropylene fiber, carrying out uniform mixing, calcining the obtained mixture in a kiln, then crushing the calcined mixture, rinsing the crushed mixture until no yellow water comes out, then carrying out processing and levigation, placing the obtained powder into a double screw extruder for extrusion and granulation, carrying out crushing after granulation and then carrying out processing and levigation so as to obtain a colorant; weighing the colorant and lime glaze according to mass fractions, diluting the colorant, then sieving the colorant with a 250-mesh sieve, and sieving the lime glaze with a sieve with a size of 200 to 250 meshes so as to obtain a glaze; and glazing a ceramic handicraft having undergone briscuit firing and calcining the glazed ceramic handicraft in the kiln so as to obtain the fruit green ceramic handicraft. The glaze layer of the handicraft obtained in the invention is clear, transparent, uniform in color and good in glossiness, and has a bright and active color and excellent stability, wear resistance and corrosion resistance.

Owner:JINGDEZHEN CERAMIC INSTITUTE

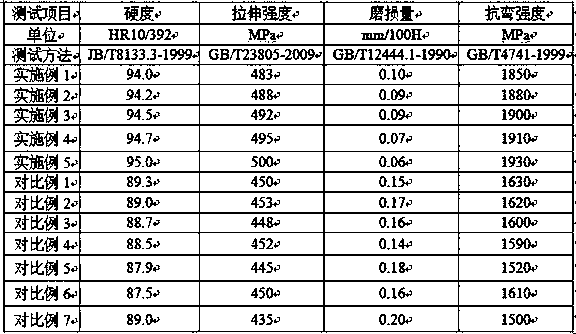

High-abrasion-resistance anti-scouring ceramic seal ring and preparation method thereof

InactiveCN106048363AImprove compactnessImprove adhesionPump componentsTransportation and packagingCrack resistanceCopper oxide

The invention discloses a high-abrasion-resistance anti-scouring ceramic seal ring. The ceramic seal ring is prepared from the following raw materials of, by weight, 80-90 parts of aluminum oxide, 3-5 parts of copper oxide, 5-10 parts of nickel iron powder FeNi80, 3-5 parts of silicon boride, 0.5-1 part of nanometer titanium dioxide P25, 0.1-0.2 part of nanosilica, 0.3-0.5 part of hydroxyethyl cellulose, 0.3-0.5 of sodium silicate, 0.15-0.25 part of titanate coupling agent TMC-201, 6-8 parts of sodium hydroxide, 0.05-0.1 part of polysorbate-80 and 0.1-0.2 part of alcohol-soluble phenolic resin. The ceramic seal ring is good in corrosion resistance, long in service life, and good in anti-scouring performance and has good stability and durability and high abrasion resistance, and the impact resistance and crack resistance are improved.

Owner:HEFEI ZHENGHAO MECHANICAL TECH

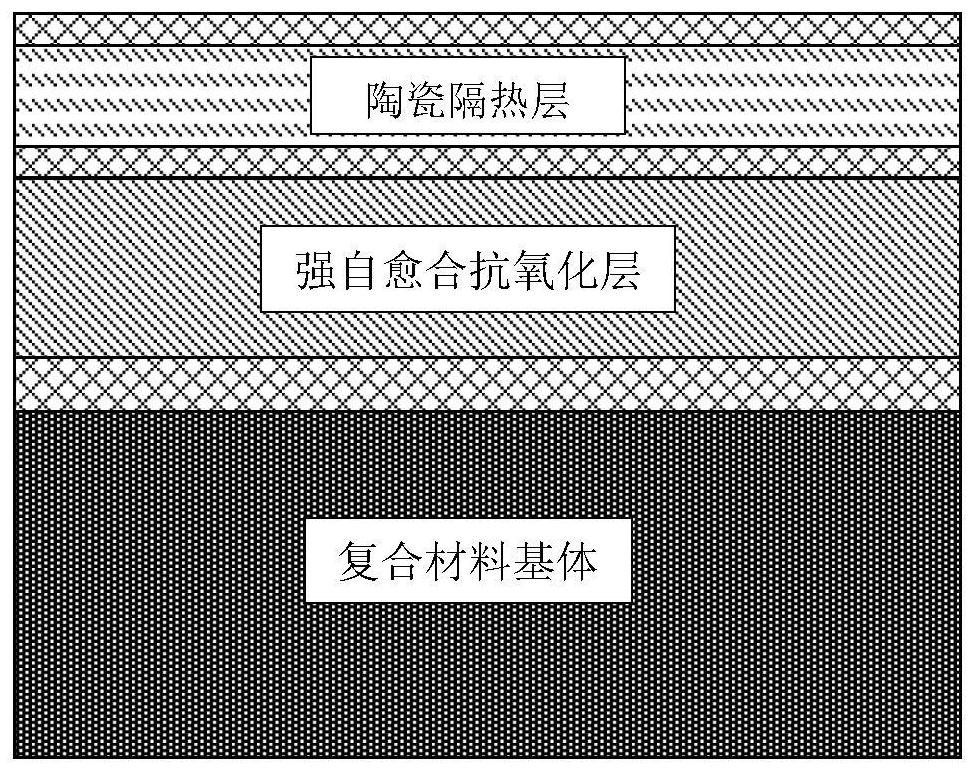

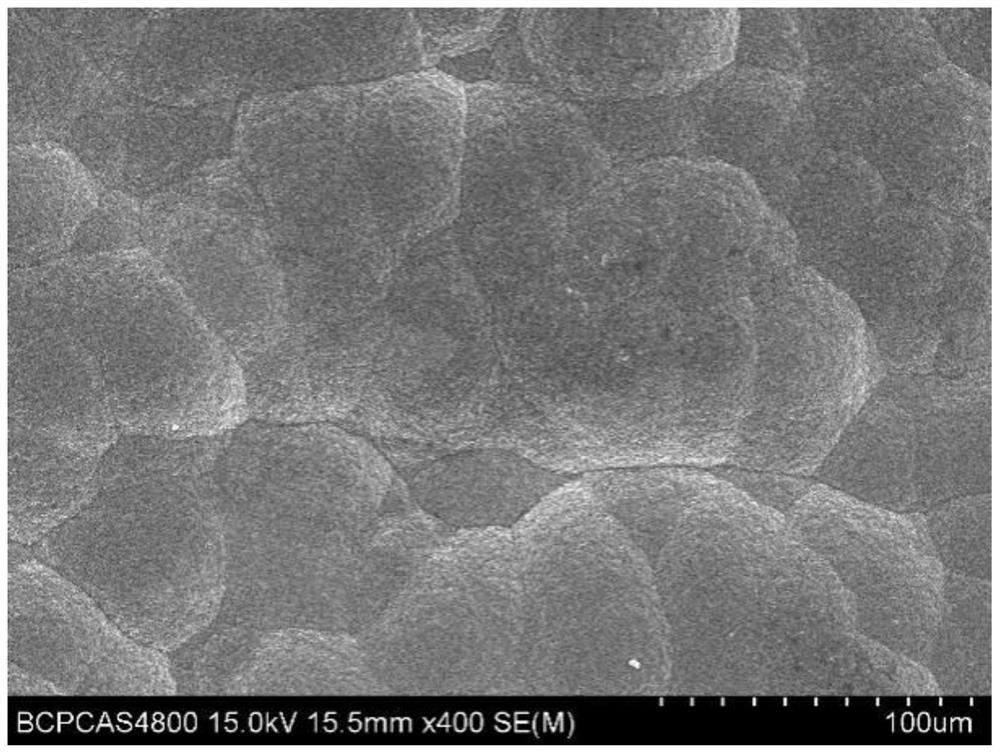

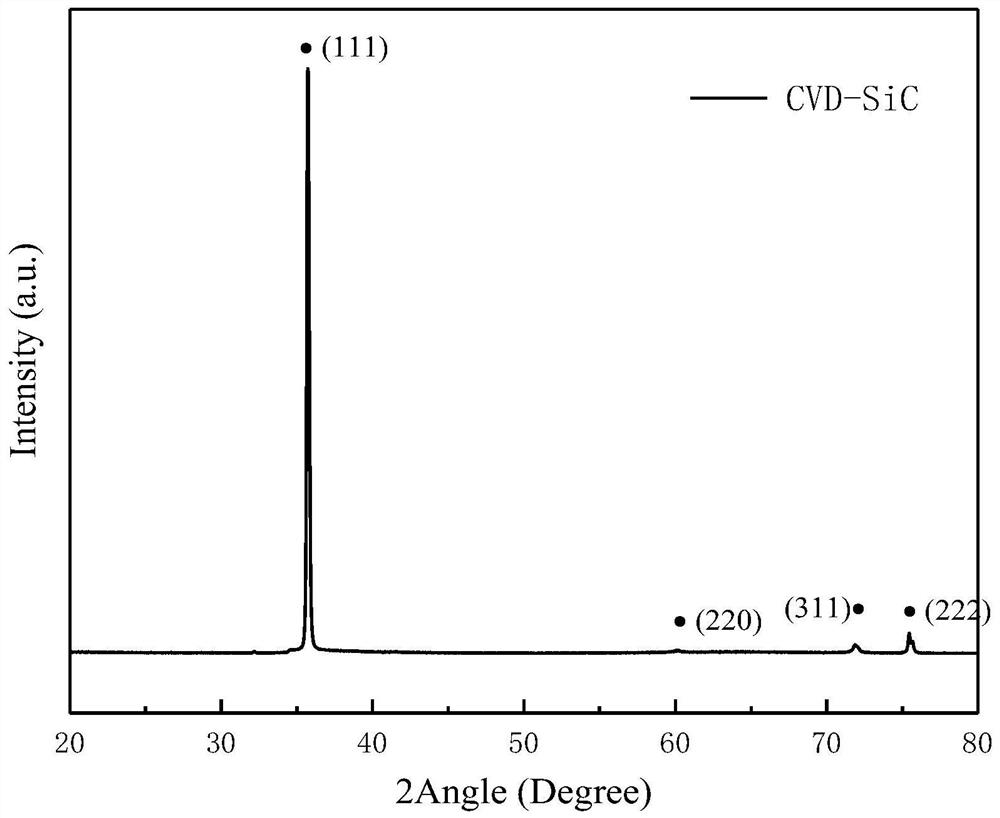

Multi-layer ceramic-based composite thermal protection coating as well as preparation method and application thereof

ActiveCN113800955ASmall difference in coefficient of thermal expansionInhibited DiffusionCosmonautic thermal protectionThermal insulationMullite

The invention provides a multi-layer ceramic-based composite thermal protection coating and a preparation method and an application thereof, and the multi-layer composite thermal protection coating is prepared by a combined process of preparing three layers by a chemical vapor deposition method and preparing two layers by a brushing sintering method, and the coating sequentially comprises a buffer layer, a high-strength self-healing anti-oxidation layer, a middle chemical barrier layer, a ceramic thermal insulation layer and a reinforced isolation layer from inside to outside. The inner buffer layer, the middle chemical barrier layer and the outer reinforced isolation layer are all made of chemical vapor deposition silicon carbide; the strong self-healing anti-oxidation layer of the secondary inner layer is made of silicon powder / zirconium silicide / silicon hexaboride multiphase ceramic; and the material of the ceramic thermal insulation layer on the secondary outer layer is silicon powder / lanthanum hexaboride / mullite / zirconium boride multiphase ceramic. The composite material has excellent thermal protection performance such as oxidation resistance, corrosion resistance and thermal shock resistance, the service life of the material under high-temperature chemical oxidation and corrosion conditions can be remarkably prolonged, and the ceramic-based or carbon-based composite material keeps stable comprehensive performance after being recycled for multiple weeks in the high-temperature environment of 1,500 K or above.

Owner:湖北瑞宇空天高新技术有限公司

Aluminium nitride-based multi-element nano-composite ceramic die material and preparation method thereof

The invention discloses an aluminium nitride-based multi-element nano-composite ceramic die material and a preparation method thereof. The material comprises the following raw materials in parts by weight: 60-80 parts of aluminium nitride, 10-20 parts of aluminium carbide, 15-25 parts of silicon boride, 2-6 parts of scandium oxide, 4-8 parts of neodymium oxide, 2-4 parts of chromium, 1-3 parts of tungsten and 1-3 parts of nickel, wherein nanoscale powder of all the materials is adopted; the grain size of aluminium nitride is 10-100 nanometers; the grain sizes of aluminium carbide and silicon boride are 1-10 nanometers; the grain sizes of the other raw materials are 1-100 nanometers. The preparation method is characterized by using aluminium nitride as the matrix, adding aluminium carbide and silicon boride as reinforcing phases, scandium oxide and neodymium oxide as stabilizing agents and chromium, tungsten and nickel as sintering aids and carrying out hot pressed sintering on the materials, thus preparing the material. A die has strong ageing and defect resistance, good comprehensive mechanical properties and excellent antifriction and wear resistance properties.

Owner:辽宁跨克石油装备有限公司

A kind of environment-friendly anti-wear hydraulic oil and its preparation process

ActiveCN104845711BGood dispersion and solubilityFully biodegradableLubricant compositionParaffin waxGlycerol

The invention discloses an environment-friendly anti-wear hydraulic oil, which comprises components A, B and C, component A includes components A and B, and its components include the following components: component A: component A: linseed oil, castor oil Sesame oil, sunflower oil; B component: sorbitan monopalmitate, triglyceride; B component: nano boride silicon, polyalkylene glycol, glycerol, isoparaffin, sulfurized fatty acid ester; Components: trimethylolpropane ester, polyacrylamide, calcium sulfonate, paraffin; the invention also discloses a preparation process of an environmentally friendly anti-wear hydraulic oil; the product of the invention is environmentally friendly, degradable, does not pollute the environment, and is also It can be recycled and reused, and the production process is simple and easy to operate, and the production cost is low.

Owner:SUZHOU TONGMING MACHINERY

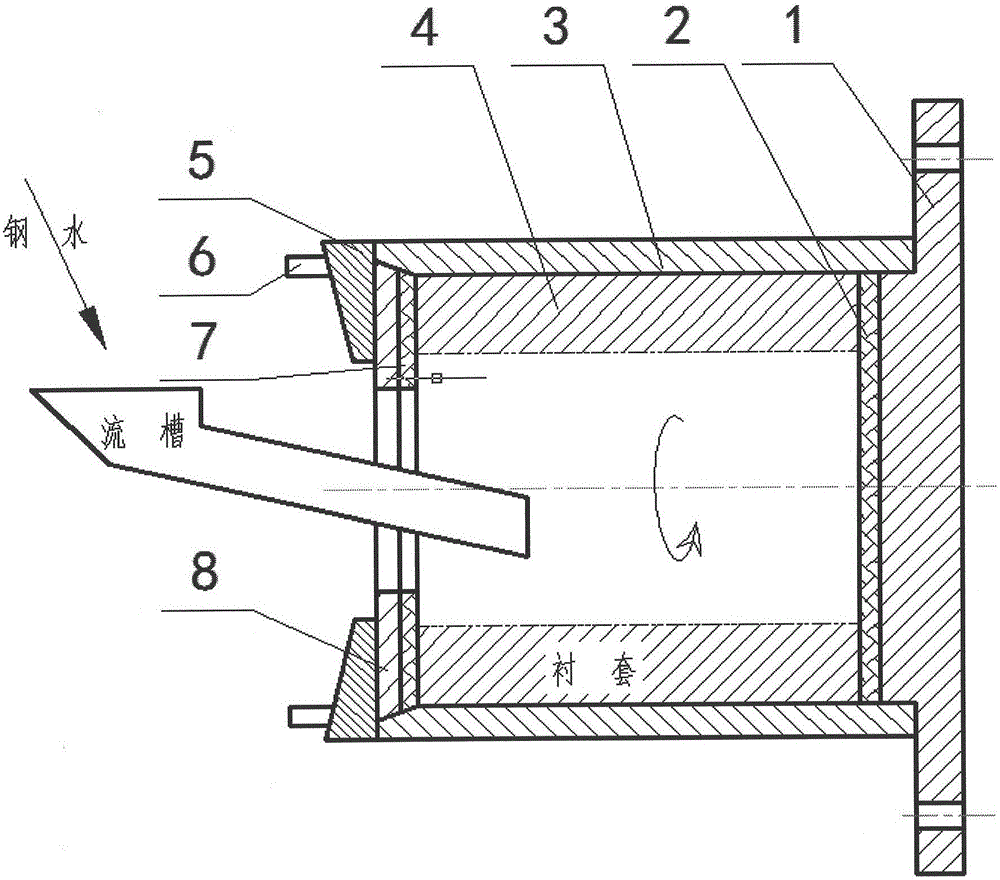

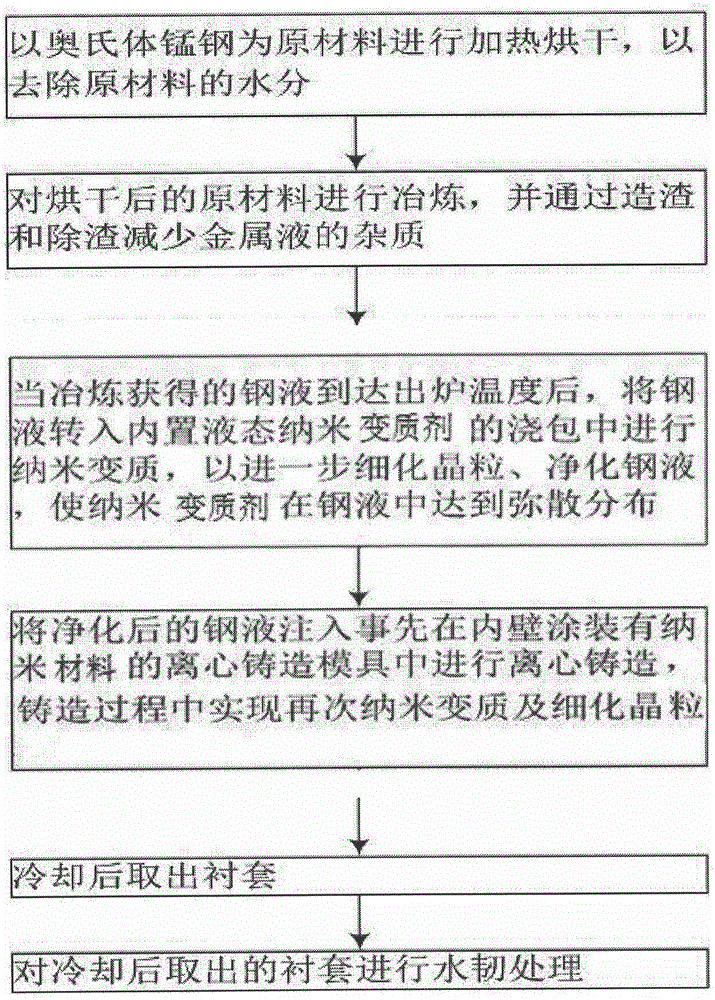

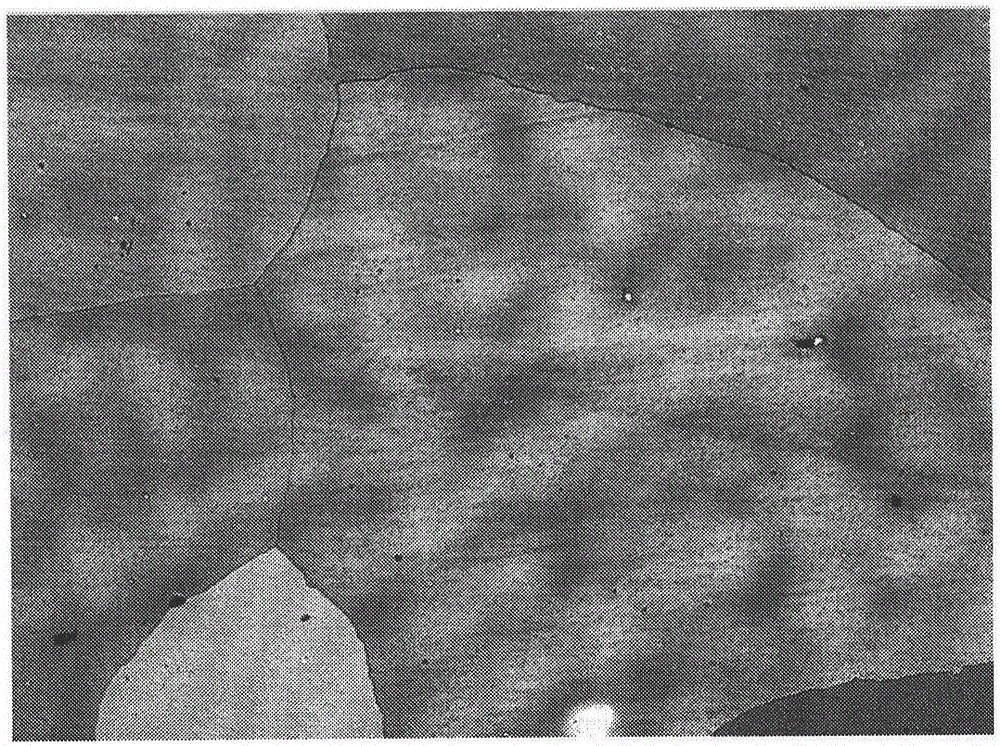

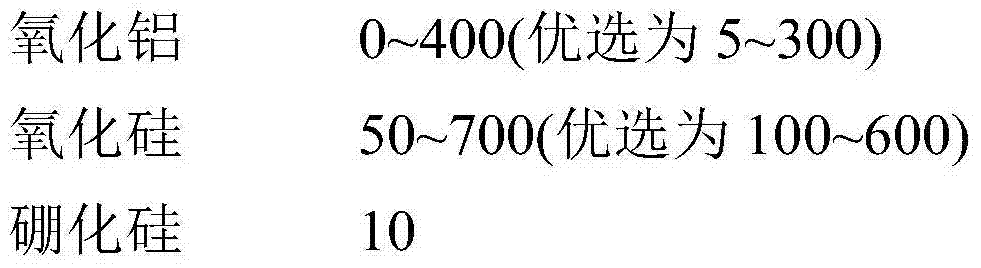

Bushing, preparation method and device of bushing

InactiveCN107177785AGrain refinementImprove mechanical propertiesShaftsBearing componentsBorideTitanium nitride

The invention provides a bushing, which is made of austenitic manganese steel as a base material into a cylindrical body, and a nano-modifying agent is uniformly dispersed in the base material, and the nano-material includes silicon nitride, titanium nitride, nitrogen At least one of aluminum oxide, silicon carbide, titanium carbide, boron carbide, zirconium carbide, silicon boride, zirconium boride and rare earth oxides, the content of the nano-modifier accounts for 0.01%-0.30% of the total weight of the bushing. The invention also provides a bushing preparation method and a bushing preparation device. By injecting nanomaterials into the liquid high manganese steel twice, the crystal grains are refined, and the metallographic structure of the high manganese steel and the mechanical properties of the bushing are greatly improved. By adding nano-materials, the grains of the metal structure are extremely refined, the molten steel is pure, the mechanical performance index is improved, and the wear resistance is better, so as to achieve the purpose of optimization modification.

Owner:青岛蓝鼎华昆耐磨钢有限公司

Impact-resistant fired clay hollow brick and preparation method thereof

InactiveCN105967711AStrong impact resistanceImprove mechanical propertiesCeramic materials productionClaywaresSteelmakingFiber

The invention discloses an impact-resistant fired clay hollow brick and a preparation method thereof. The brick of the invention is prepared from the following raw materials (by weight): 21-33 parts of sea sand, 10-15 parts of aluminium titanate fiber, 16-27 parts of construction waste residue, 12-20 parts of volcanic debris, 37-51 parts of attapulgite, 23-36 parts of salt slurry, 16-25 parts of water granulated slag, 22-38 parts of perlite, 11-17 parts of polyethyleneimine, 19-31 parts of old brick and tile powder, 5-10 parts of sodium tripolyphosphate, 14-22 parts of leucite, 9-18 parts of steelmaking slag, 15-25 parts of tuff, 10-15 parts of bamboo sawdust, 4-8 parts of silicon boride, 5-10 parts of coco coir, 6-13 parts of heavy calcium carbonate powder and a proper amount of water. The fired clay hollow brick prepared from the raw materials including sea sand, aluminium titanate fiber, silicon boride and the like has advantages of strong impact resistance, good mechanical property, high temperature resistance, ageing resistance, corrosion resistance and the like, is not easy to crack or destroy during using process, and has long service life.

Owner:安徽宏发节能设备有限公司

Boron-doped selective emitter and preparation method thereof, and boron-doped selective emitter battery

ActiveCN113035976AGuaranteed trapping effectImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationDopantElectrical battery

The invention discloses a preparation method of a boron-doped selective emitter, which comprises the following steps of preparing a heavily doped region and a lightly doped region on the surface of a textured silicon wafer, covering a layer of boron dopant on the surface of the silicon wafer, and enabling the coverage area of the boron dopant to be not smaller than the area of the heavily doped region, carrying out laser doping on the boron dopant in the heavily doped region to form silicon boride, then carrying out high-temperature propulsion on the silicon boride to form a heavily doped region, forming a lightly doped region on the surface of the silicon wafer, and preparing the boron-doped selective emitter. According to the method, the silicon boride is formed through laser doping, the silicon boride is propelled at high temperature to form the heavily-doped region, the used laser is low in power and friendly to the textured surface of the silicon wafer, and the heavily-doped region is prepared while the light trapping effect of the textured surface of the silicon wafer is guaranteed; An alkali liquor or acid liquor cleaning process is added after the laser doping process, so that the residual boron dopant and attached impurities on the surface of the silicon wafer are well removed, and the minority carrier lifetime of the silicon wafer is not reduced.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

High impact resistant ceramic ware and preparation method thereof

InactiveCN104961434AImprove mechanical propertiesImprove impact resistanceClaywaresSodium stearateSilicon boride

The invention discloses a high impact resistant ceramic ware and a preparation method thereof. The high impact resistant ceramic ware is prepared from the following raw materials by weight part: 25-37 of quartzite, 18-26 of germanite, 12-19 of garnet, 22-34 of nacrite, 8-16 of opal, 10-15 of attapulgite, 14-22 of silicon boride, 12-18 of barium molybdate, 10-15 of glass fiber, 4-8 of cobalt chromium tungsten alloy powder, 2-3 of sodium stearate, 4-6 of calcium gluconate, 6-9 of nano-antibacterial powder. The ceramic ware provided by the invention is added with boron silicon, cobalt chromium tungsten alloy powder, barium molybdate, glass fiber and other raw materials to enhance the mechanical properties and improve the impact resistance, and has very high hardness and good strength, so that the ceramic ware is not easy to break under external force impact, is durable, and can produce enormous economic benefits.

Owner:安徽省德邦瓷业有限公司

High-temperature infrared energy-saving coating based on boride ceramics and preparation method thereof

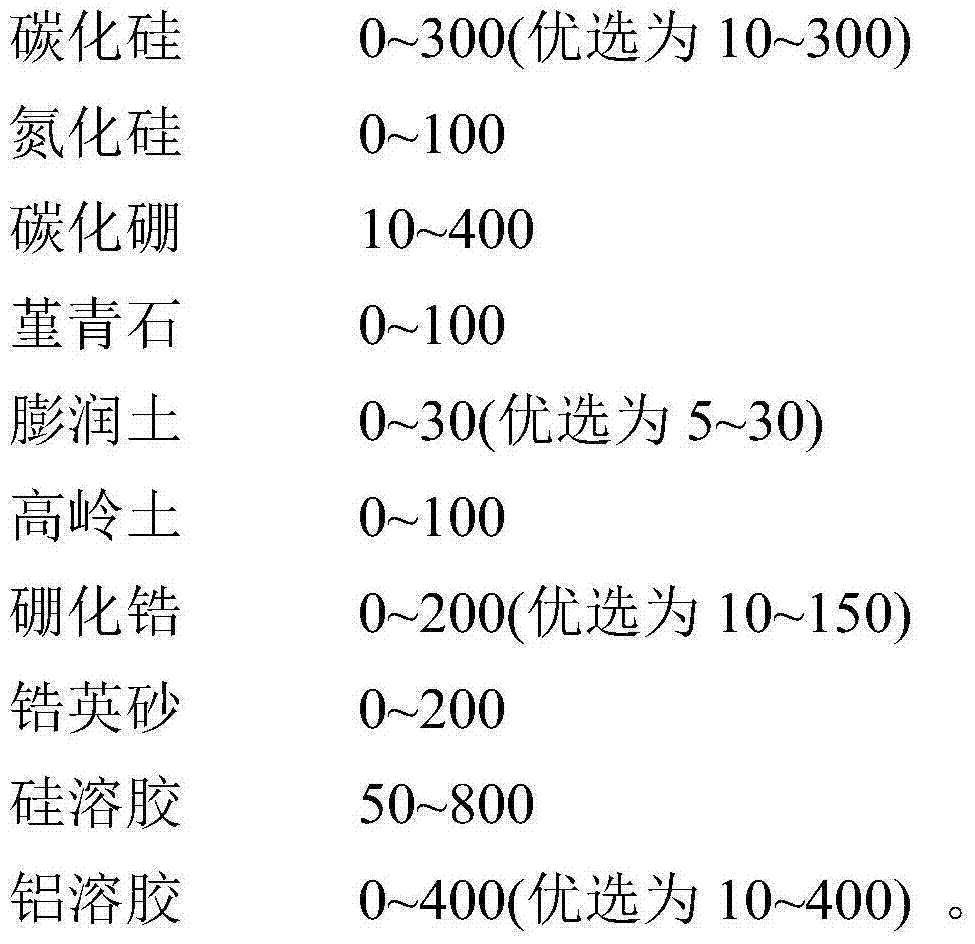

The invention belongs to energy-saving coating for high-temperature thermotechnical kiln equipment, and particularly relates to high-temperature infrared energy-saving coating based on high-emissivity boride ceramics. A preparation method of the high-temperature infrared energy-saving coating based on the high-emissivity boride ceramics comprises the following steps: mixing aluminium oxide, silicon oxide, silicon boride, silicon carbide, silicon nitride, boron carbide, cordierite, bentonite, kaolin, zirconium boride, zircon sand, silica sol and alumina sol, then putting in a dispersion grinding all-in-one machine, stirring at a high speed so as to prepare viscous suspension fluid, thus obtaining the high-temperature infrared energy-saving coating based on the boride ceramics. The high-temperature infrared energy-saving coating based on the high-emissivity boride ceramics can be stored for a long term and does not go bad. The high infrared emissivity of the high-temperature infrared energy-saving coating can be kept at the temperature of 1300 DEG C, the infrared emissivity of the high-temperature infrared energy-saving coating is 0.87-0.94 at a room temperature, the attenuation of the infrared emissivity of the high-temperature infrared energy-saving coating is less than 3% within two years, and the using amount of the high-temperature infrared energy-saving coating per unit area is little.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Silicon carbide powder and preparation method thereof

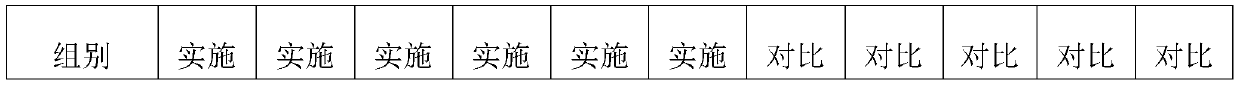

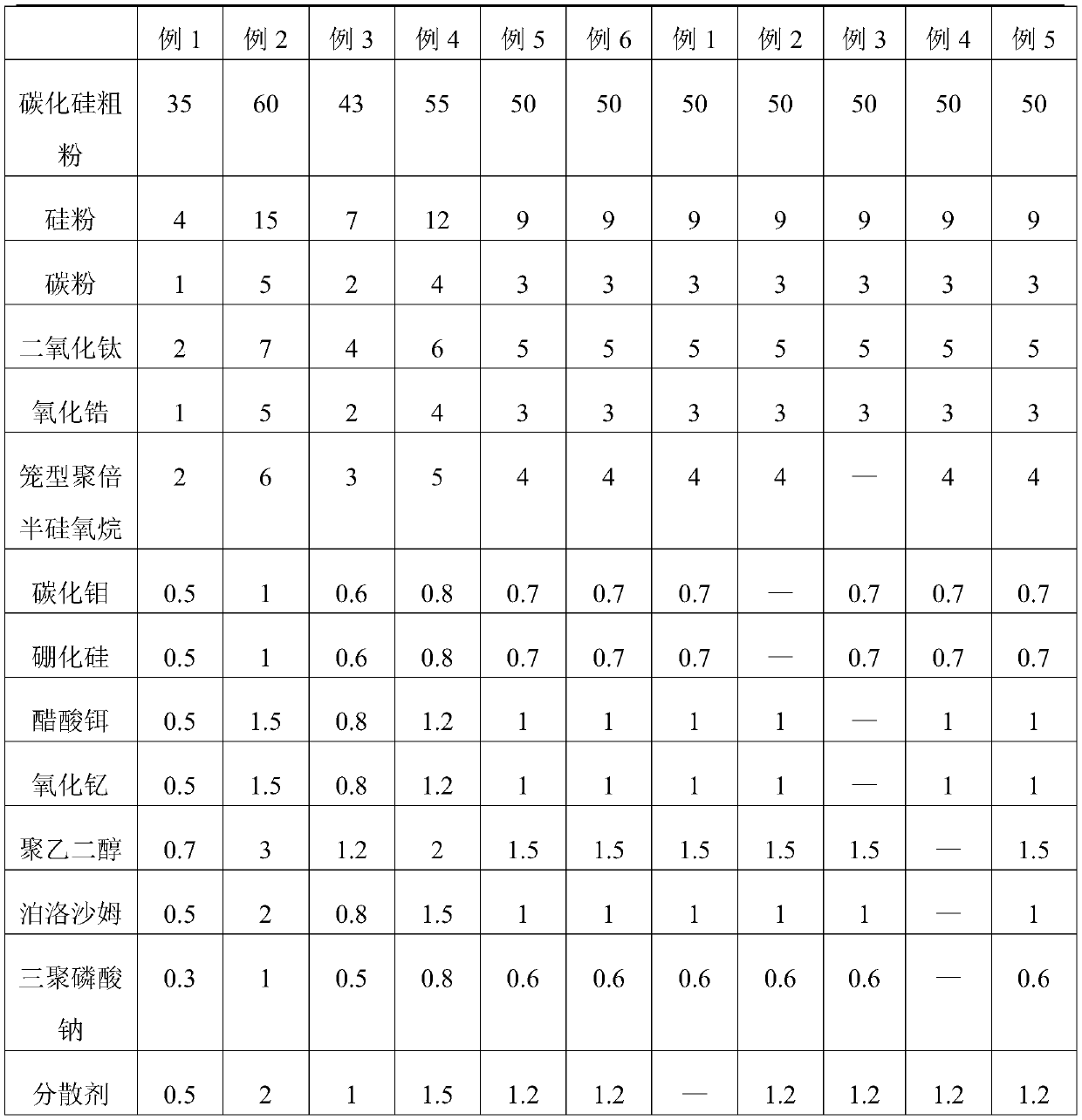

The invention belongs to the technical field of refractory materials, and provides silicon carbide powder and a preparation method thereof. The silicon carbide powder includes, by weight, 35-60 partsof silicon carbide coarse powder; 4-15 parts of silica fume, 1-5 parts of carbon powder, 2-7 parts of titanium dioxide, 1-5 parts of zirconium oxide, 2 to 6 parts of polyhedral oligomeric silsesquioxane, 0.5-1 part of molybdenum carbide, 0.5-1 part of silicon boride, 0.5-1.5 parts of erbium acetate, 0.5-1.5 parts of yttrium oxide, 0.7-3 parts of polyethylene glycol, 0.5-2 parts of poloxamer, 0.3-1part of sodium tripolyphosphate and 0.5-2 parts of a dispersing agent. In the preparation method, a step-by-step mixing and twice ball milling combined manner is adopted. Through the technical scheme, the problems of low strength and poor thermal shock stability of a silicon carbide plate caused by easy agglomeration when the silicon carbide plate is fired by the silicon carbide powder in the prior art are solved.

Owner:唐山市瑞兆碳化硅制品有限公司

Insulating heat-conducting rubber composite material and preparation method thereof

InactiveCN112646249AImprove production efficiencySimple processHeat-exchange elementsEpoxySilicon boride

The invention discloses an insulating heat-conducting rubber composite material which is prepared from the following components in parts by weight: 20-30 parts of amino-terminated hyperbranched polysiloxane HPSi-NH2, 50-70 parts of epoxy nitrile rubber, 15-25 parts of epichlorohydrin rubber, 5-8 parts of N, N', N''-tri-(tetra-(hexadecyl) melamine ethyl)-melamine, 4-7 parts of aluminum oxide nanotubes, 2-4 parts of silicon boride nano powder, 3-7 parts of silicon carbide fibers, 100-150 parts of inorganic filler and 3-5 parts of a negatively charged coupling agent. The invention also provides a preparation method of the insulating heat-conducting rubber composite material. The insulating heat-conducting rubber composite material is good in comprehensive performance and performance stability, remarkable in insulating and heat-conducting effect and good in mechanical property and aging resistance.

Owner:常明伟

Wear-resistant lining plate of bucket wheel machine hopper

PendingCN110358978ASimple preparation processEasy to operateFurnace typesProcess efficiency improvementWear resistantSilicon boride

The invention discloses a wear-resistant lining plate of a bucket wheel machine hopper and a manufacturing method thereof. The lining plate comprises the following components in percentage by weight:0.5-0.8% of C, 0.1-0.3% of Ge, 1.5%-2.0% of Mn, 0.05%-0.1% of Tc, 0.2%-0.5% of Cu, 0.4%-0.8% of Zr, 0.05%-0.08% of Ta, 0.01%-0.03% of Y, 0.02%-0.04% of Ho, 0.05%-0.1% of silicon boride, less than or equal to 0.03% of S, less than or equal to 0.03% of P, and the balance Fe. The manufactured wear-resistant lining plate has the advantages of higher hardness, wear resistance, impact toughness and fatigue strength, and can effectively improve the ball milling efficiency.

Owner:HUNAN CHANGZHONG MACHINERY

Furan resin laminating core sand for train component casting and preparing method of furan resin laminating core sand

InactiveCN106269025AImprove fire resistanceIncreased durabilityFoundry mouldsFoundry coresMonoglycerideDistillation

The invention discloses a furan resin laminating core sand for train component casting and a preparing method of the furan resin laminating core sand. The furan resin laminating core sand is prepared from, by weight, 140-160 parts of fused magnesite, 30-40 parts of chromite sand, 20-30 parts of ceramsite sand, 14-16 parts of glass pumice, 3-5 parts of furan resin, 0.5-0.7 part of molecular distillation monoglyceride, 2-4 parts of aluminophosphite, 3-5 parts of calcium stearate, 8-10 parts of spherical quartz powder, 3-5 parts of nanometer tungsten oxide, 5-7 parts of silicon boride and the like. According to the furan resin laminating core sand, the furan resin, the aluminophosphite, tri (4-hydroxyphenyl) methane glycidyl ether and triethylene tetramine are added for providing good caking property and solidification effect for the core sand, a resin curing agent prepared from toluenesulfonic acid and methyl sulfate is used for shortening resin hardening time, the concentration of formaldehyde in air in an operation area is reduced, and the health of workers is facilitated; under the joint effect of a furan resin binder and the curing agent, the strength of the self-hardening sand is improved; and in addition, as the addition of lubricating agents including the calcium stearate and the molecular distillation monoglyceride, the breathability of the core sand is improved, and the gas-forming amount is reduced.

Owner:江阴联华铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com