Bushing, preparation method and device of bushing

A technology of bushing and nano-modifying agent is applied in the field of wear-resistant bushing and wear-resistant parts manufacturing, which can solve the problems of insufficient mechanical properties of high-manganese steel, complex raw material composition of high-manganese steel, easy formation of pores and inclusions, etc. Improved mechanical properties, improved mechanical properties, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be further described in detail below in conjunction with the drawings and specific embodiments.

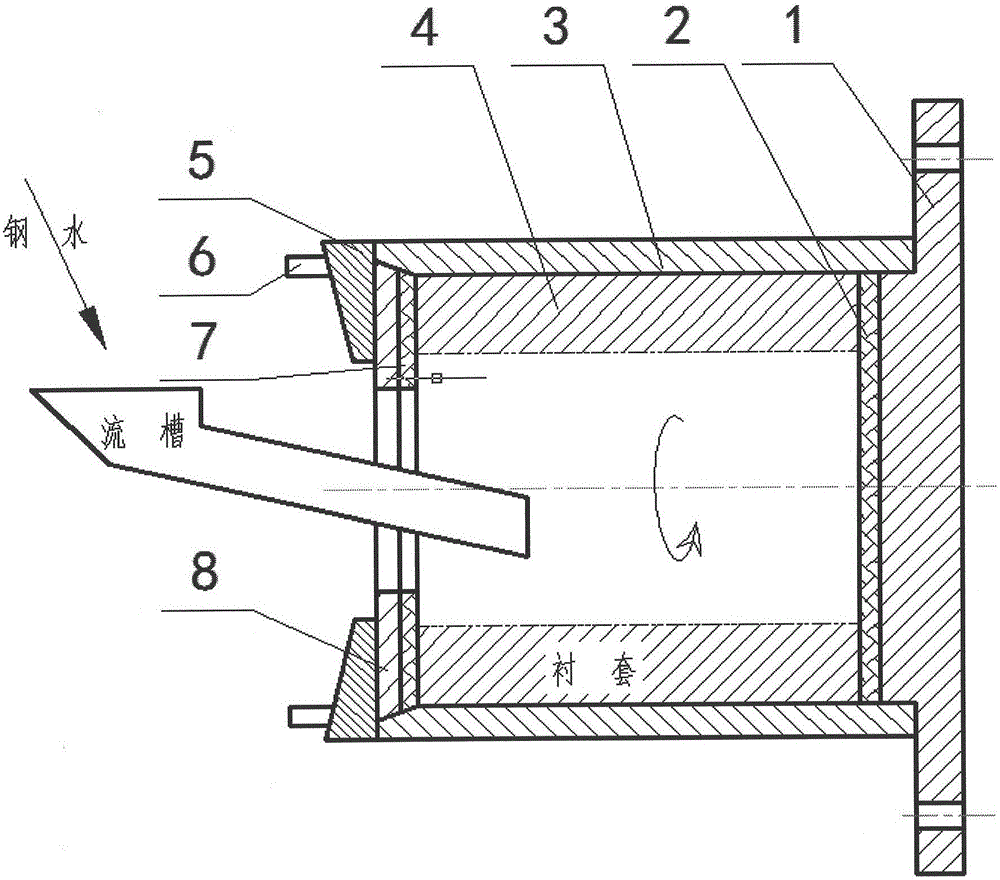

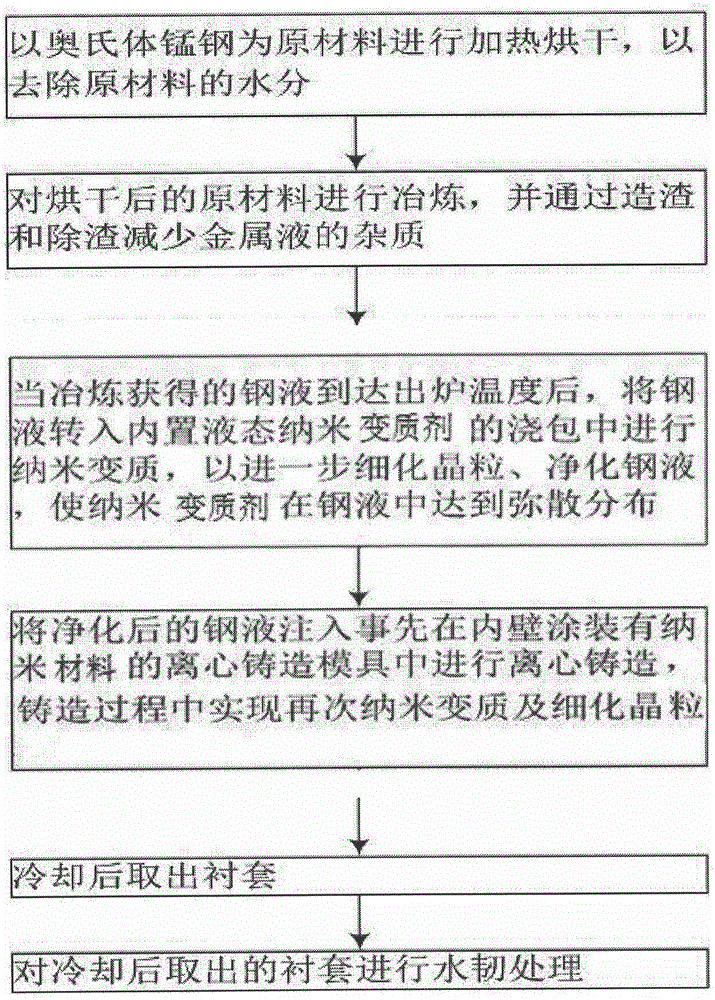

[0023] Such as figure 1 As shown, a bushing 4 of the present invention is made of a cylindrical body made of austenitic manganese steel as a base material, and a nano-modifier is uniformly dispersed and distributed in the base material. Wherein, the nanomaterial includes at least one of silicon nitride, titanium nitride, aluminum nitride, silicon carbide, titanium carbide, boron carbide, zirconium carbide, silicon boride, zirconium boride, and rare earth oxides. The content of the material accounts for 0.01%-0.30% of the total weight of the bushing; the content of the manganese alloy in the bushing 4 accounts for 6-18% of the total weight of the bushing 4 .

[0024] Such as figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com