Method for refining solidified structure of laser cladding layer by using alternating magnetic field and device thereof

An alternating magnetic field and laser cladding technology, applied in the field of laser processing, can solve the problems of uneven structure, laser cladding coating cracks, large temperature gradient of the cladding layer, etc. Install simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

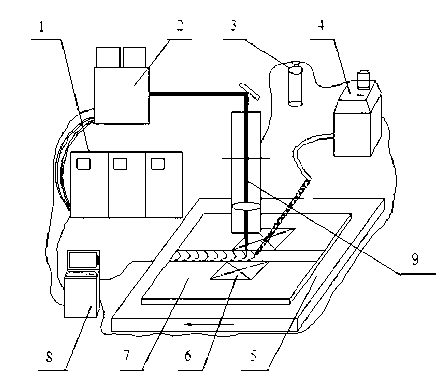

[0023] Such as figure 1 , a device for refining the solidified structure of the laser cladding layer with an alternating magnetic field, including a cooler 1, CO 2 Laser 2, argon protection device 3, synchronous powder feeder 4, fixture device 5, alternating magnetic field 6, cladding substrate 7, numerical control console 8, among which, cooler 1 and CO 2 Laser 2 connected, CO 2 The laser gun head 9 is set on the laser 2, the synchronous powder feeder 4 is connected to the argon gas protection device 3, the argon gas protection device 3 is connected to the laser gun head 9, and the synchronous powder feeder 4 passes through the protective gas nozzle 1 to the fixture device 5 The cladding matrix 7 sprays composite layer powder, the alternating magnetic field 6 is set under the cladding matrix 7, the numerical control console 8 and the cooler 1, CO 2 The laser 2, the synchronous powder feeder 4 and the fixture device 5 are connected together.

[0024] Firstly, the surface of...

Embodiment 2

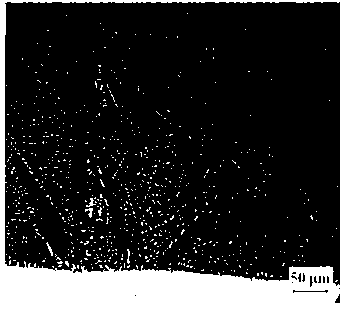

[0027] The method and device are the same as in Example 1, only the magnetic field current of the alternating magnetic field is 5A, and the magnetic field strength is 32.0mT. The longitudinal cross-sectional morphology of the obtained coating is shown in Figure 4 shown.

Embodiment 3

[0029] The method and device are the same as in Example 1, only the magnetic field current of the alternating magnetic field is 9A, and the magnetic field strength is 47.7mT. The longitudinal cross-sectional morphology of the obtained coating is shown in Figure 5 shown.

[0030] From image 3 It can be seen that the cladding layer is mainly composed of elongated columnar dendrites with different growth directions, and the top dendrites are small and developed, showing typical epitaxial columnar growth characteristics. From Figure 4 , 5 It can be clearly seen that the structure of the cladding layer changes from columnar dendrite to equiaxed grain, and the grain size is fine and evenly distributed.

[0031] Through the above comparative analysis, it can be concluded that compared with the coating without the action of alternating magnetic field, applying a certain intensity of alternating external magnetic field during the laser cladding process can make the dendrites dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com