Electromagnetic stirring generating device, method and application of composite time-varying magnetic field

A generating device and electromagnetic stirring technology, applied in the field of steel continuous casting equipment, to achieve the effect of increasing fatigue performance and reducing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

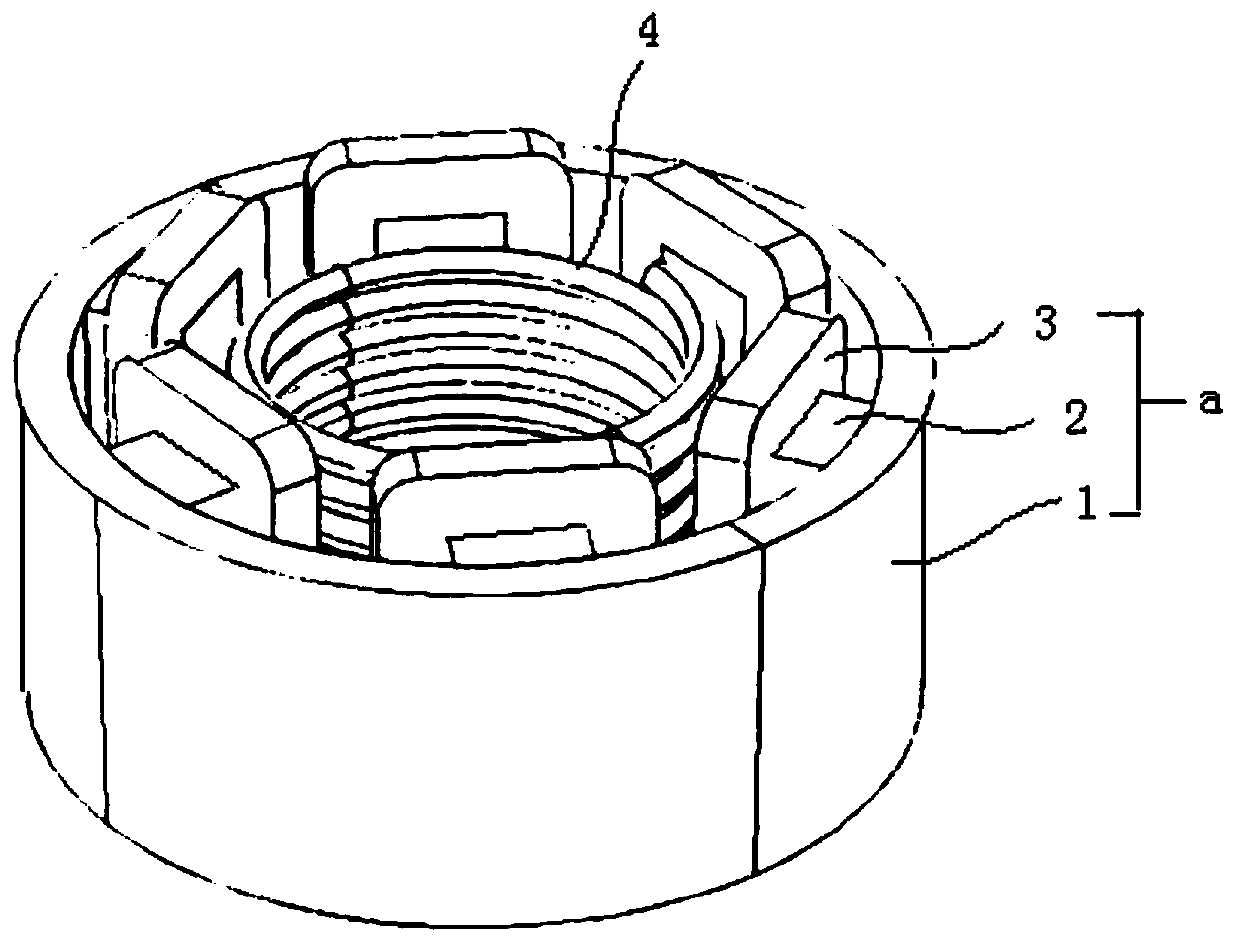

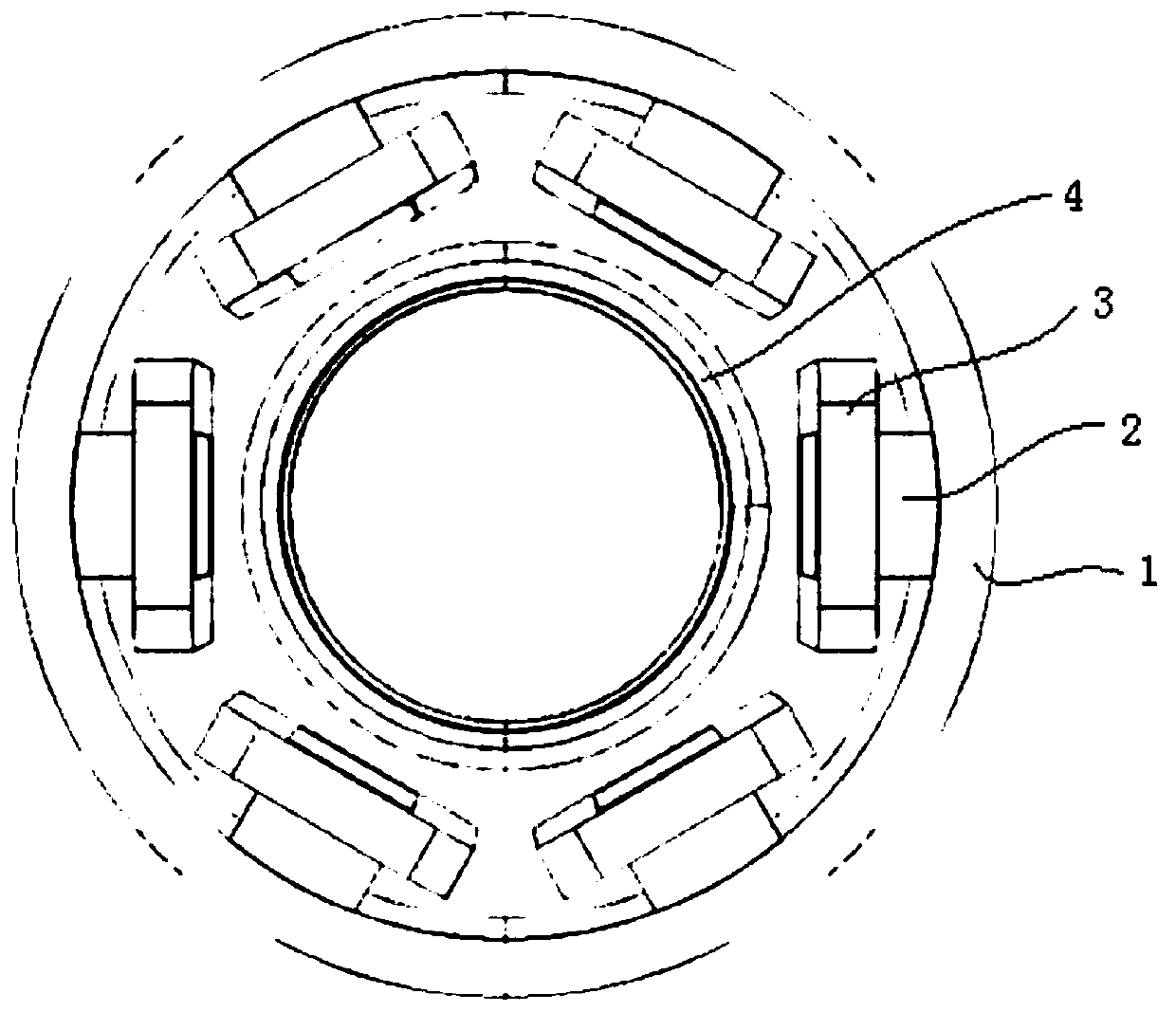

[0051] Device embodiment 1: The time-varying magnetic field generating device is combined with the rotating magnetic field electromagnetic stirring generating device a

[0052] see figure 1 and figure 2 , the time-varying magnetic field generating device is an annular time-varying magnetic field coil 4, placed in the rotating magnetic field electromagnetic stirring generating device a, the center of the annular time-varying magnetic field coil 4 is used for the billet to pass through, and the magnetic field acts on the billet, and the billet generates a corresponding Performance changes. When the two magnetic fields act on the melt at the same time, a current will be induced in the melt, and the current will interact with the magnetic field to generate electromagnetic force, which will lead to strong convection, so that the solute distribution and temperature distribution in the melt will be more uniform. Thereby reducing composition segregation and shrinkage porosity in th...

Embodiment 2

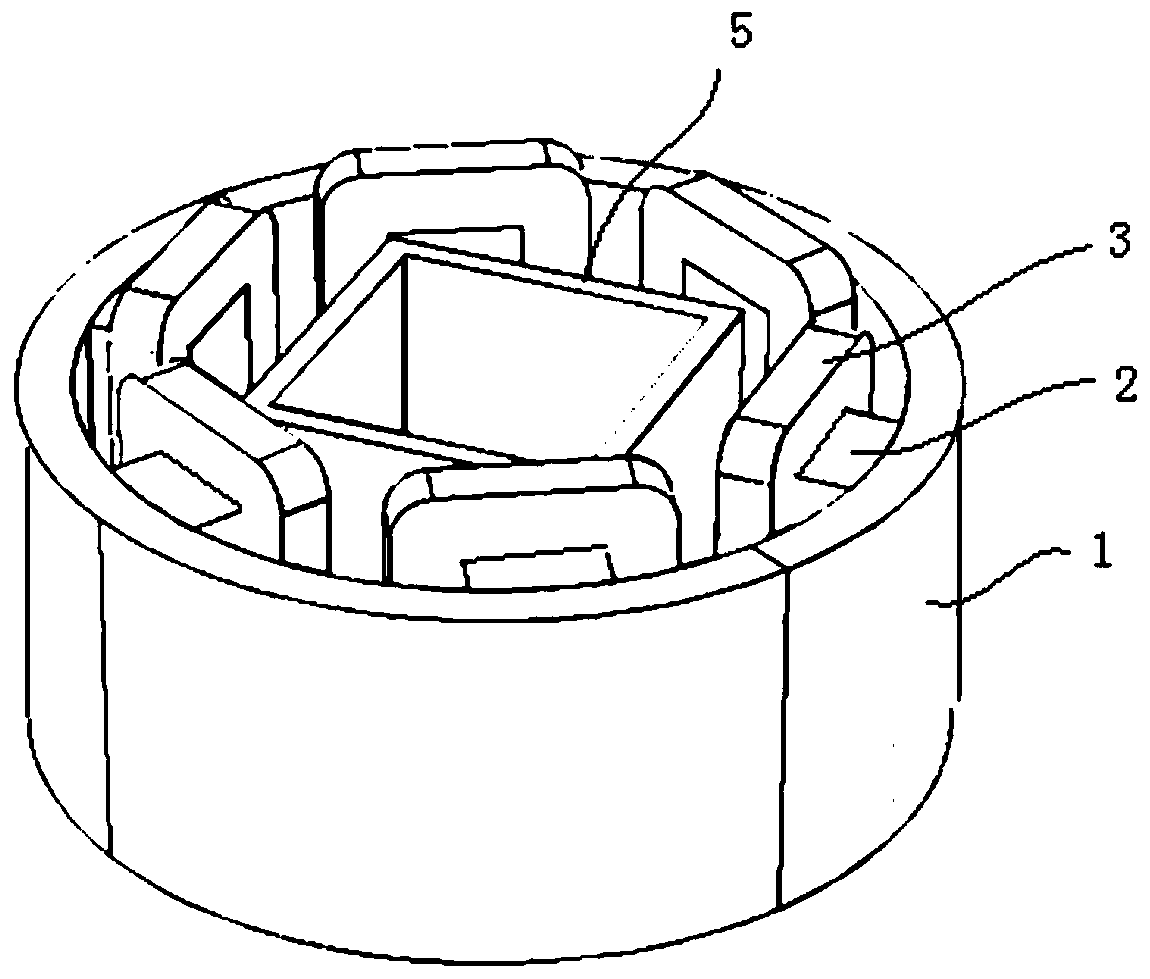

[0056] Device embodiment 2: The time-varying magnetic field generating device is combined with the traveling wave magnetic field electromagnetic stirring generating device b

[0057] see Figure 4 and Figure 5 , the figure takes the annular time-varying magnetic field coil 4 as an example to illustrate, showing that the time-varying magnetic field generating device is coaxially sleeved in the traveling wave magnetic field electromagnetic stirring generating device b.

[0058] The traveling wave magnetic field electromagnetic stirring generating device b includes annular yokes 1, and each annular yoke 1 is provided with more than four iron cores 2 and traveling wave magnetic field coils 6, and the traveling wave magnetic field coils 6 are evenly arranged on the circumference of the annular yoke 1. Inner side, each iron core 2 all comprises upper piece and lower piece, and one end of the upper piece of each iron core 2 is fixed with the upper surface of traveling wave magnetic...

Embodiment 3

[0060] Device embodiment 3: The time-varying magnetic field generating device is simultaneously combined with the rotating magnetic field electromagnetic stirring generating device a and the traveling wave magnetic field electromagnetic stirring generating device b

[0061] This embodiment has two implementation forms, one of which can be found in Figure 6 and Figure 7 , the rotating magnetic field electromagnetic stirring generating device a is set in the traveling wave magnetic field electromagnetic stirring generating device b, and the time-varying magnetic field generating device is placed in the rotating magnetic field electromagnetic stirring generating device a; another see Figure 8 and Figure 9 , the time-varying magnetic field generating device, the rotating magnetic field electromagnetic stirring generating device a and the traveling wave magnetic field electromagnetic stirring generating device b are coaxially sleeved, and from the inside to the outside are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com