Patents

Literature

30results about How to "Increase flow strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

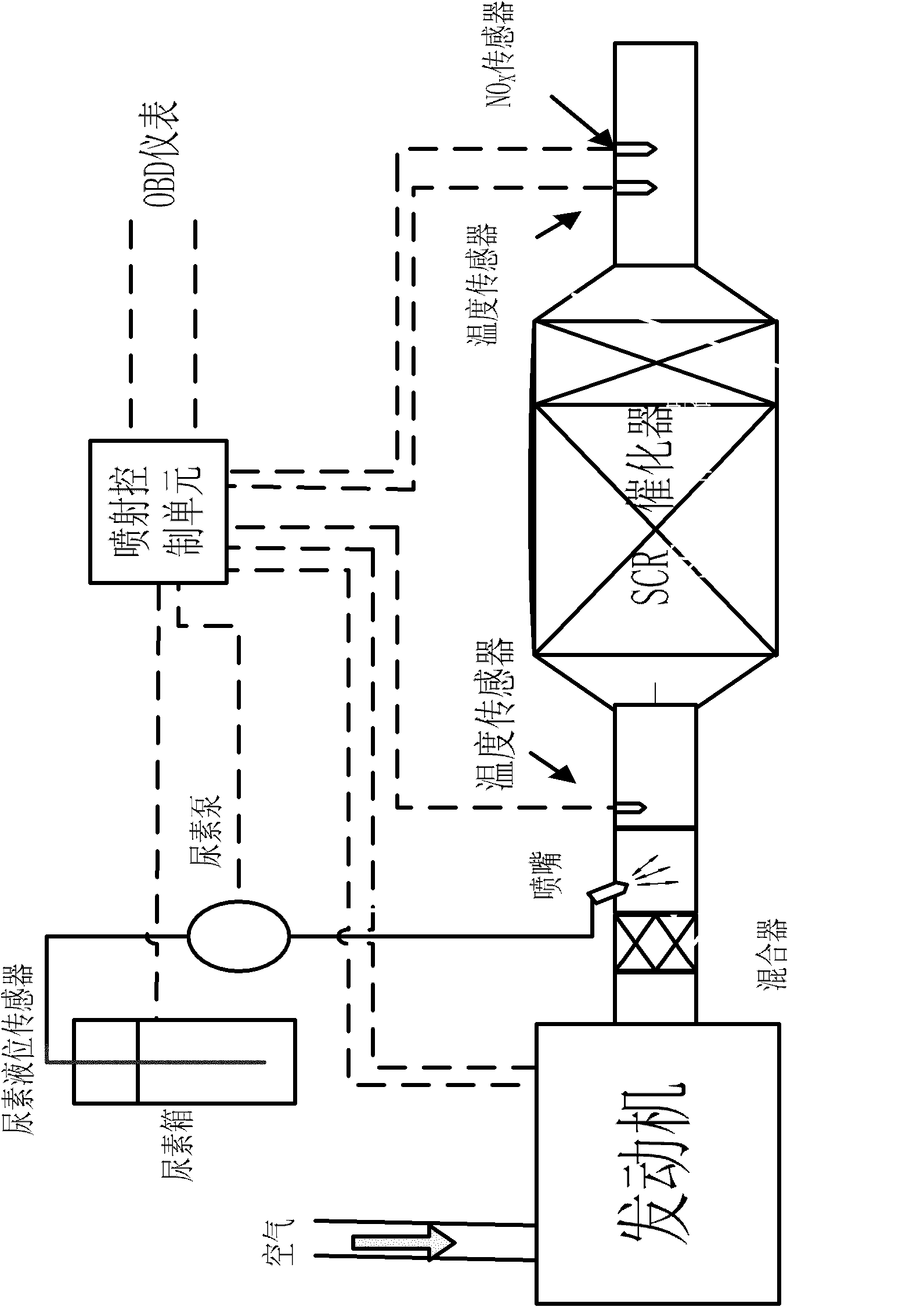

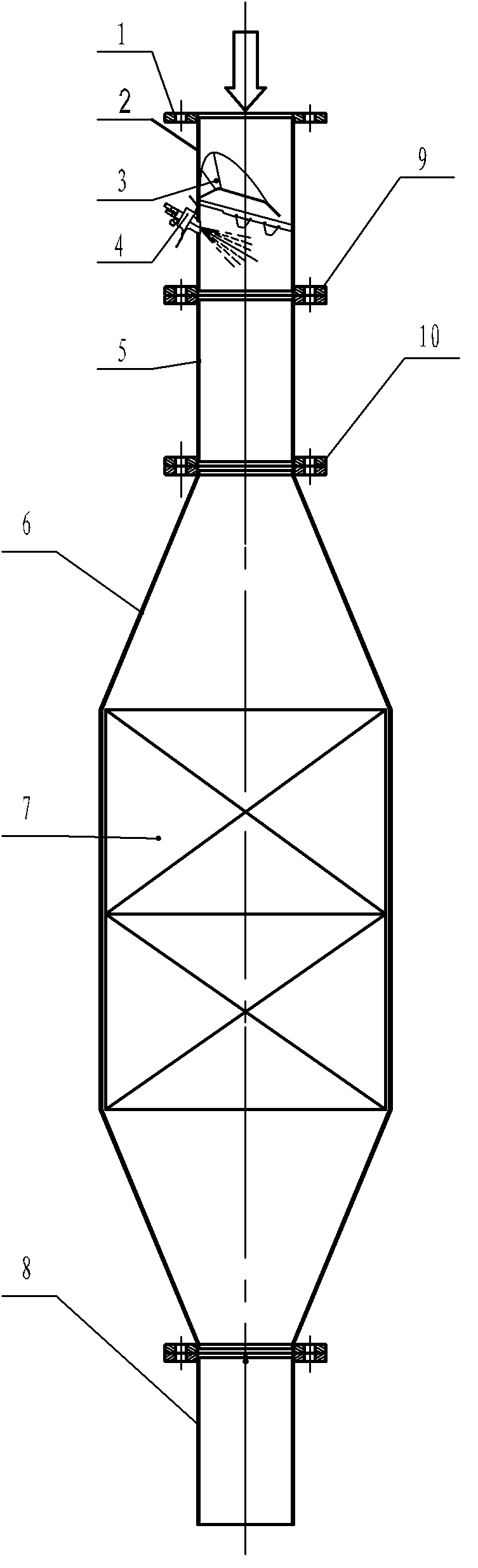

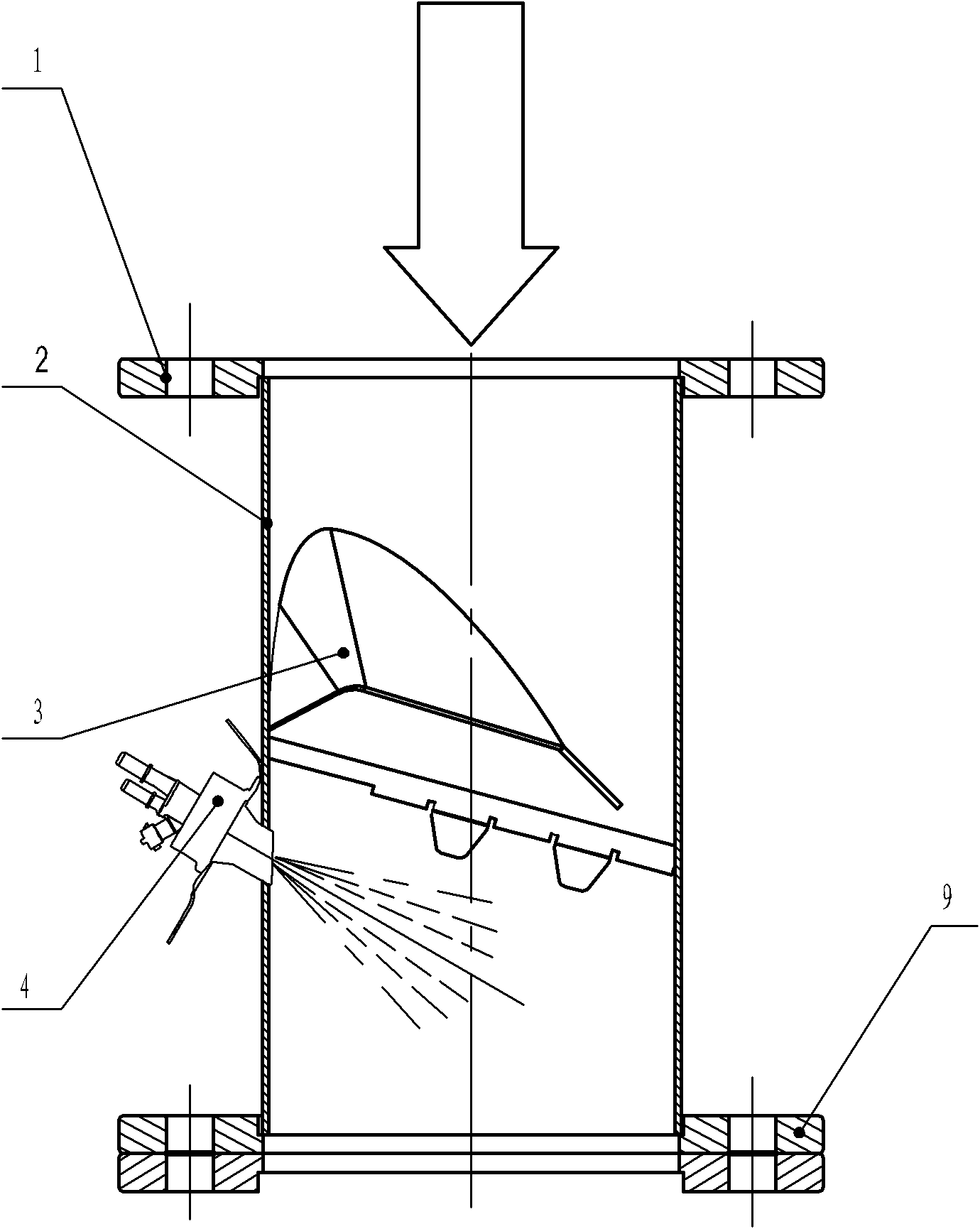

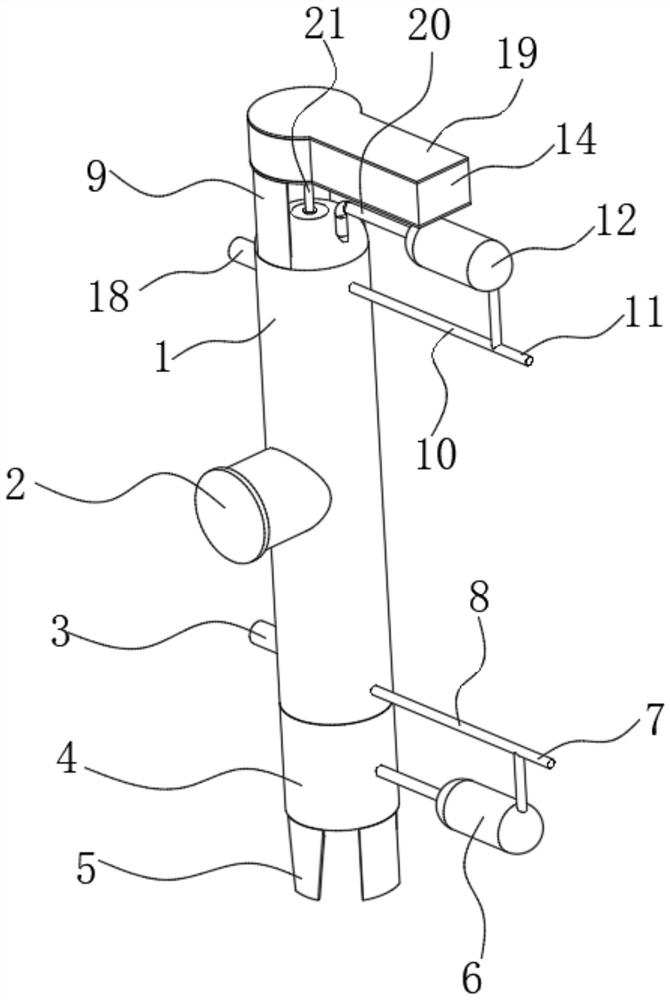

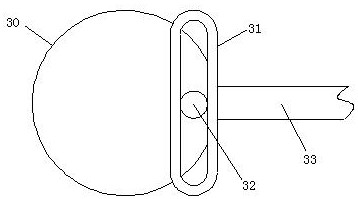

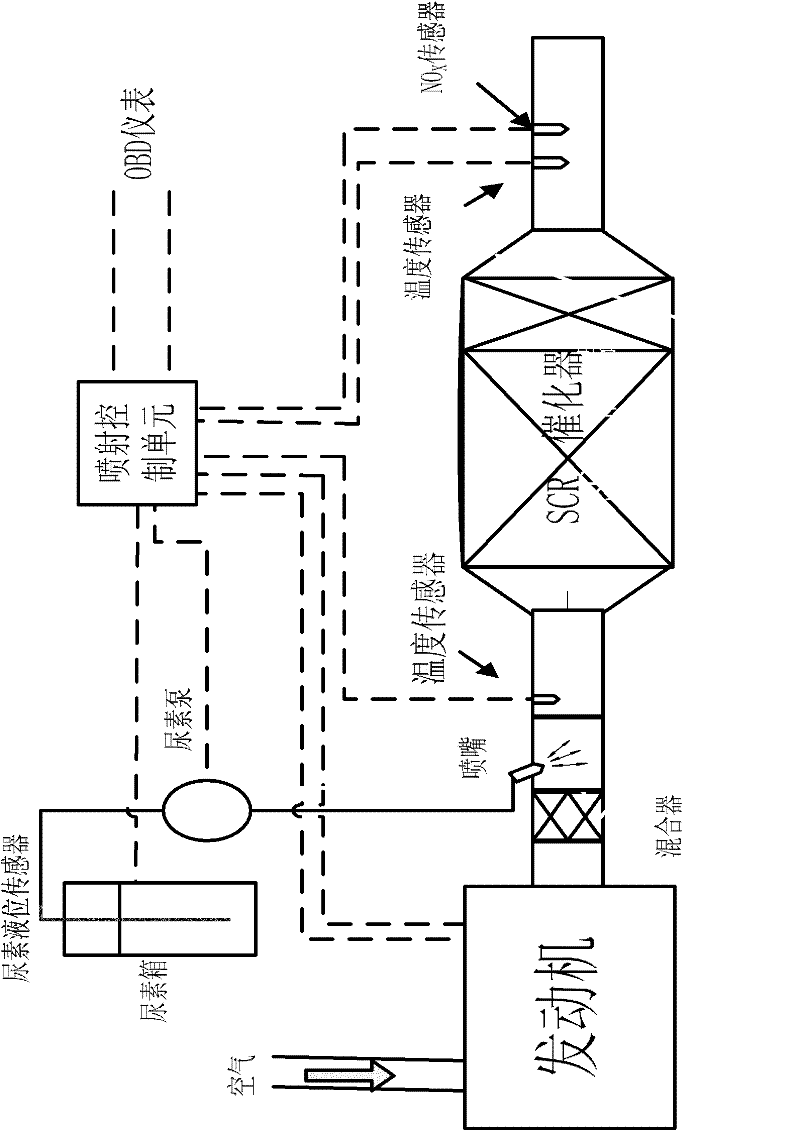

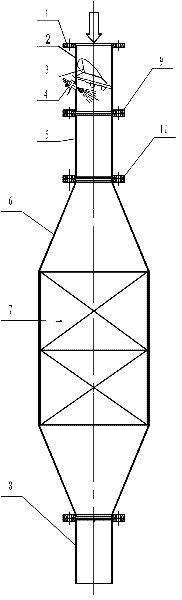

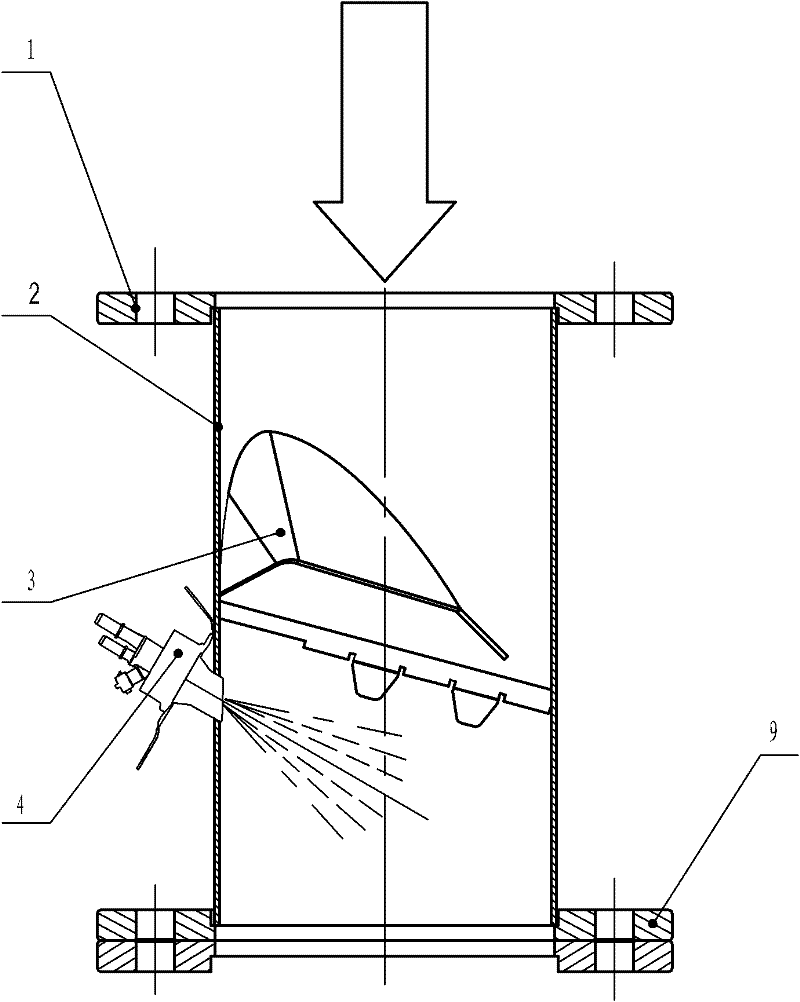

Hybrid unit of SCR (selective catalytic reduction) system for vehicle urea

ActiveCN102022165AReduce crystallizationWell mixedInternal combustion piston enginesExhaust apparatusUreaAqueous solution

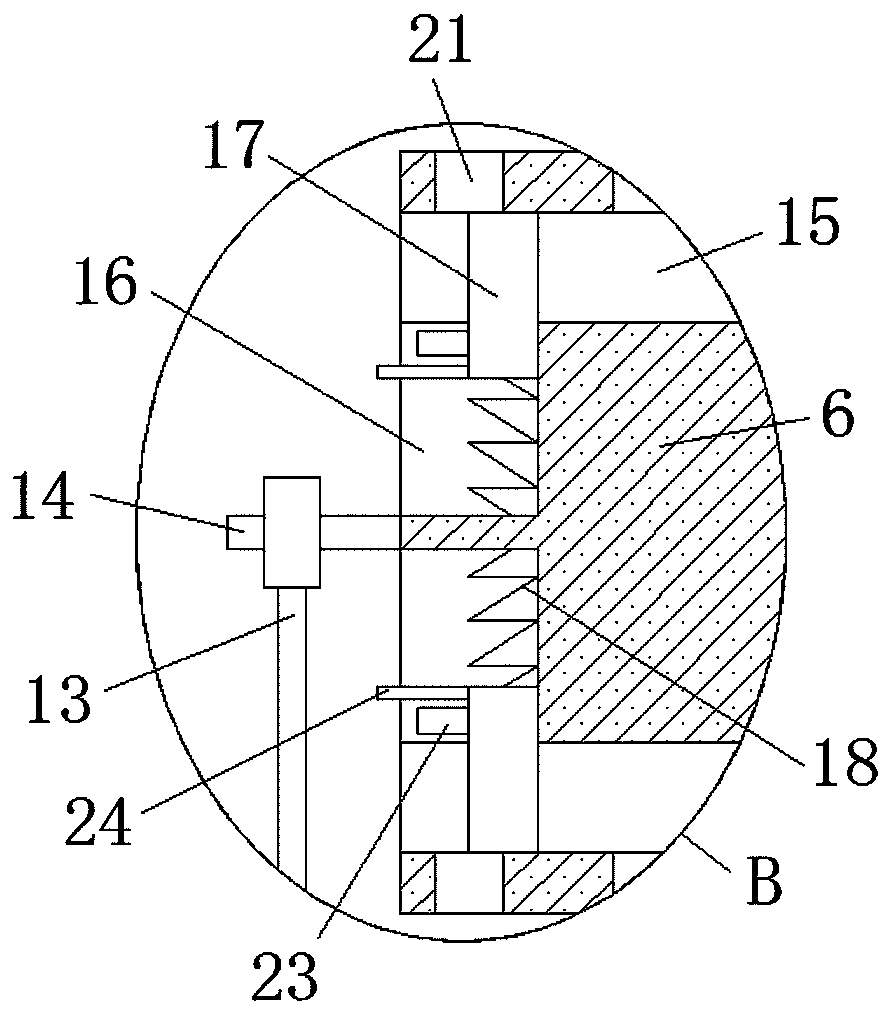

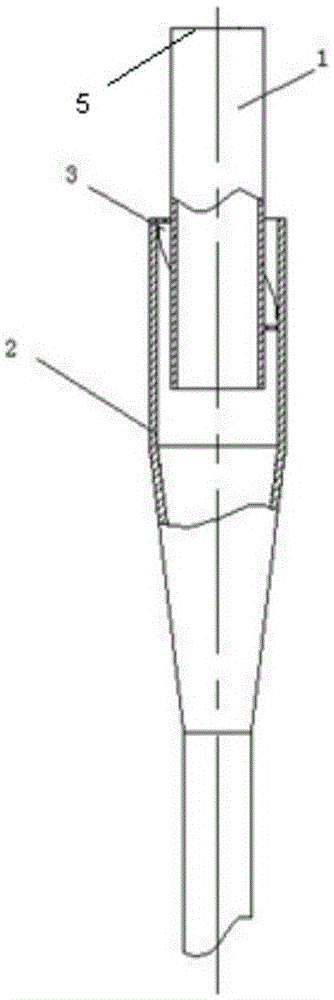

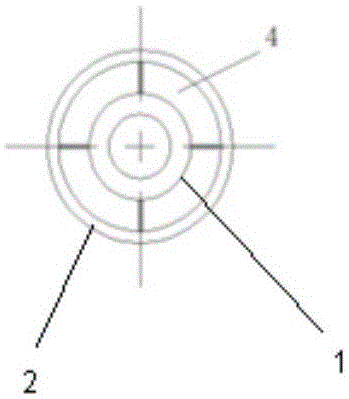

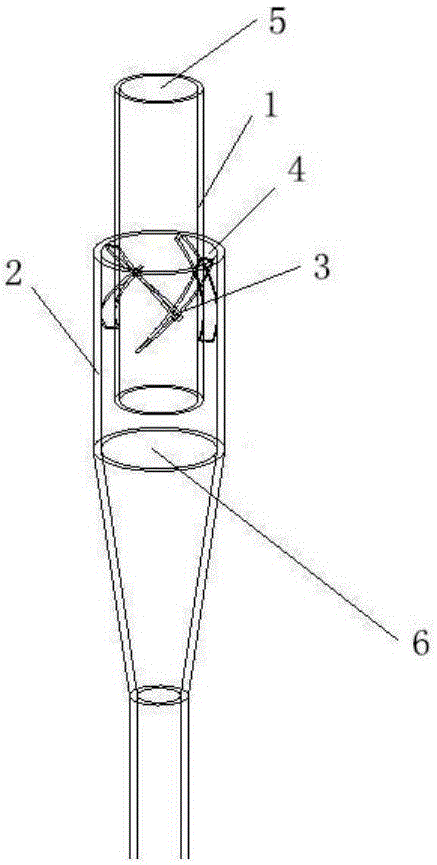

The invention discloses a hybrid unit of an SCR (selective catalytic reduction) system for vehicle urea, comprising a pipe body, a hybrid unit rib device and a nozzle, wherein the nozzle is aslant arranged on the wall surface of the pipe body; the hybrid unit rib device tightly abuts against the nozzle and is installed on the front end of the nozzle; the hybrid unit rib device comprises four ribs, the middle of the first rib and the second rib forms a fluid path similar to an atomizing pattern; the first rib and the second rib have certain gradient and twists towards the central area; the third rib has a baffle-shaped structure and is arranged near the pipe wall, the installation direction is vertical to the atomizing axis, and the third rib twists towards the wall surface; and the fourth rib is arranged along the atomizing axis direction and is composed of a group of blades alternately twisted left and right. The invention can bring the effect that a urea aqueous solution injected by the nozzle and tail gas are fully mixed before entering an SCR catalytic converter, thus reducing urea crystallization formed on the wall surface; and meanwhile, the hybrid unit has compact structure and is easy to process and install, and the effect of the hybrid unit is verified.

Owner:HANGZHOU YINLUN TECH CO LTD +1

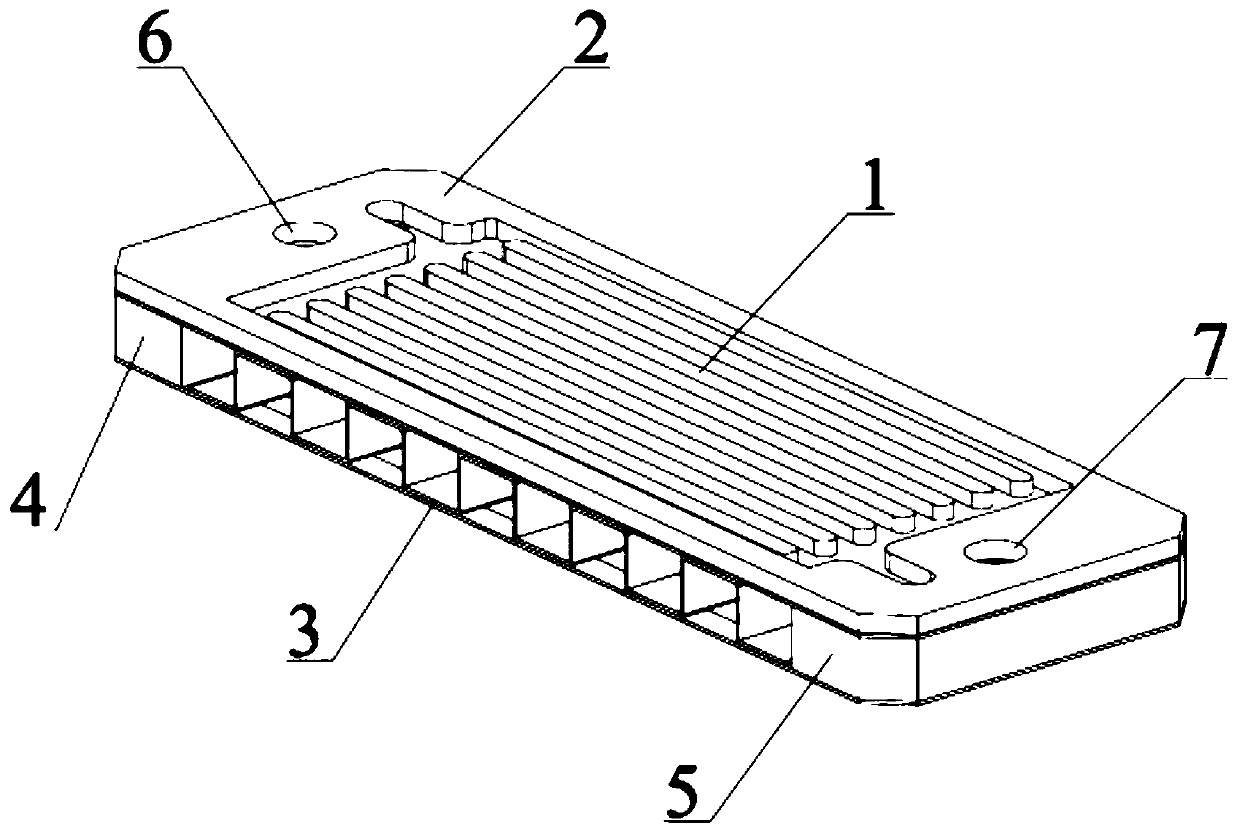

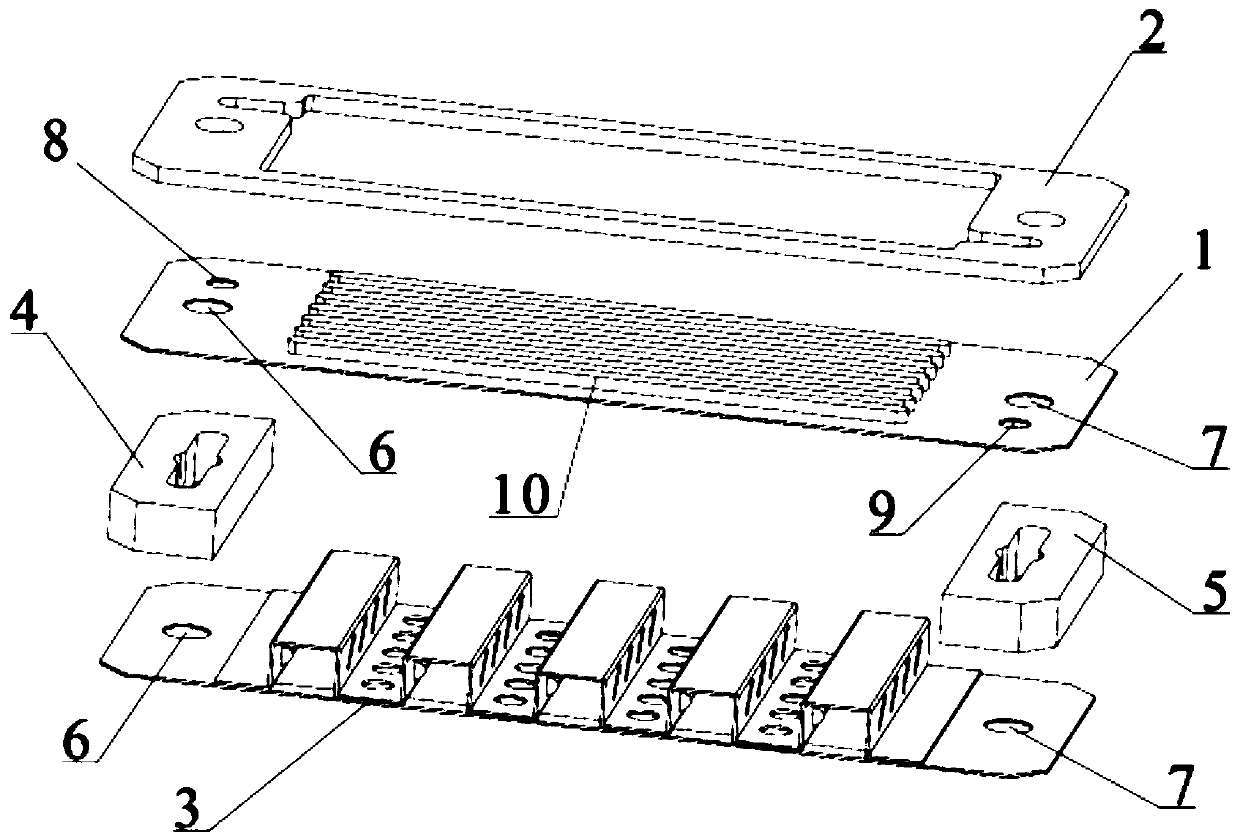

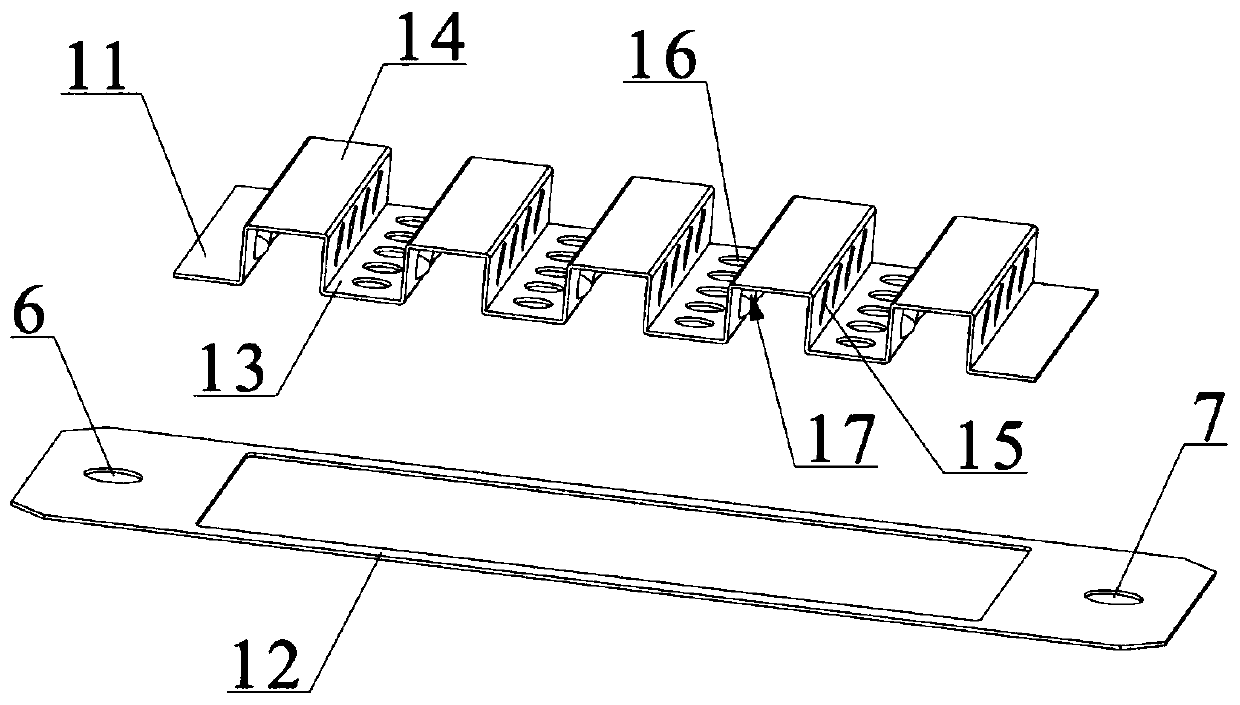

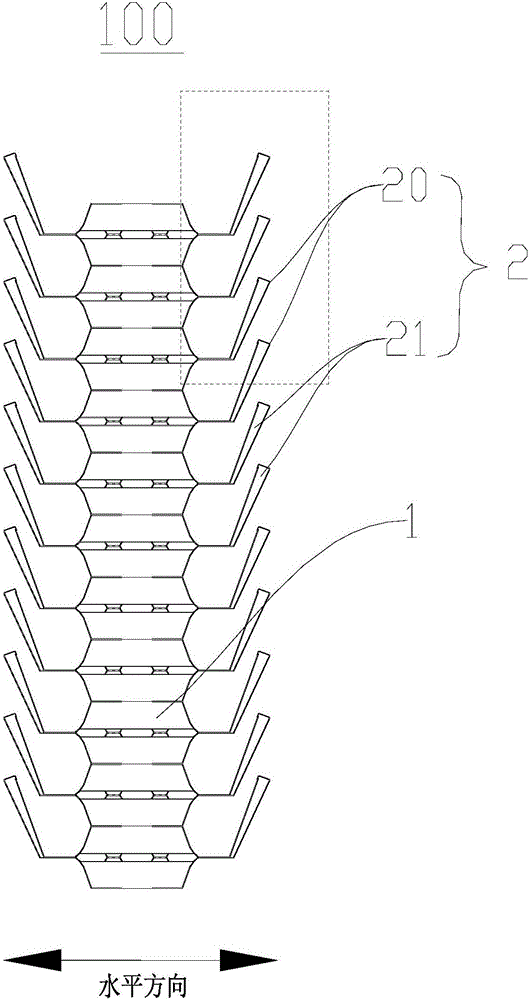

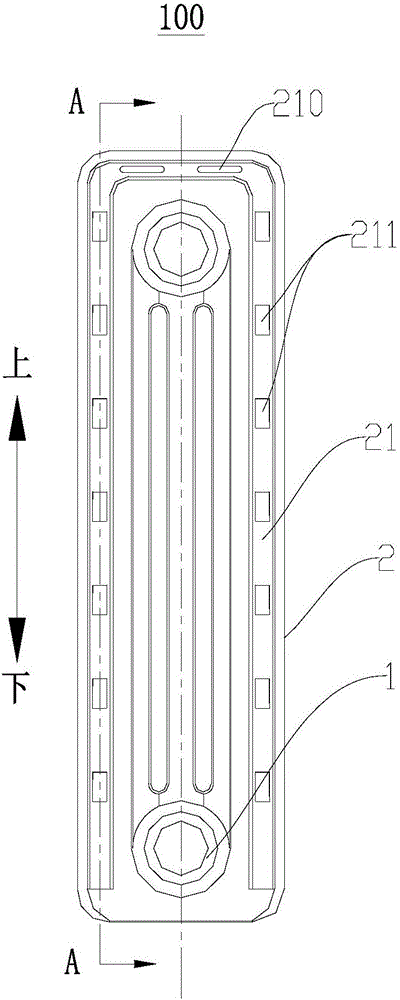

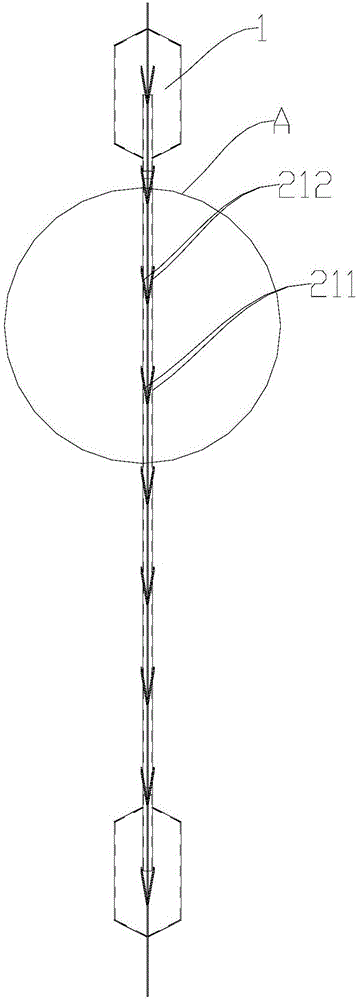

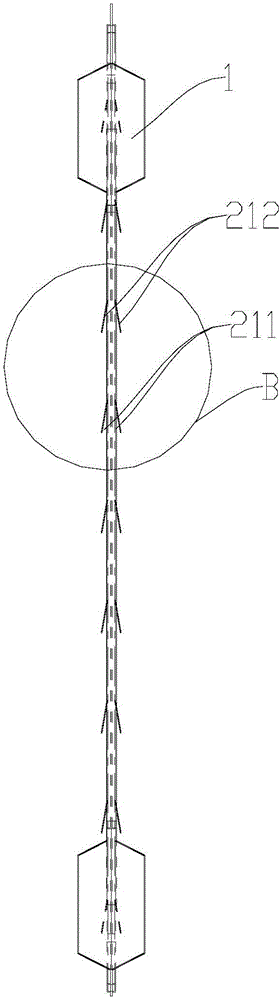

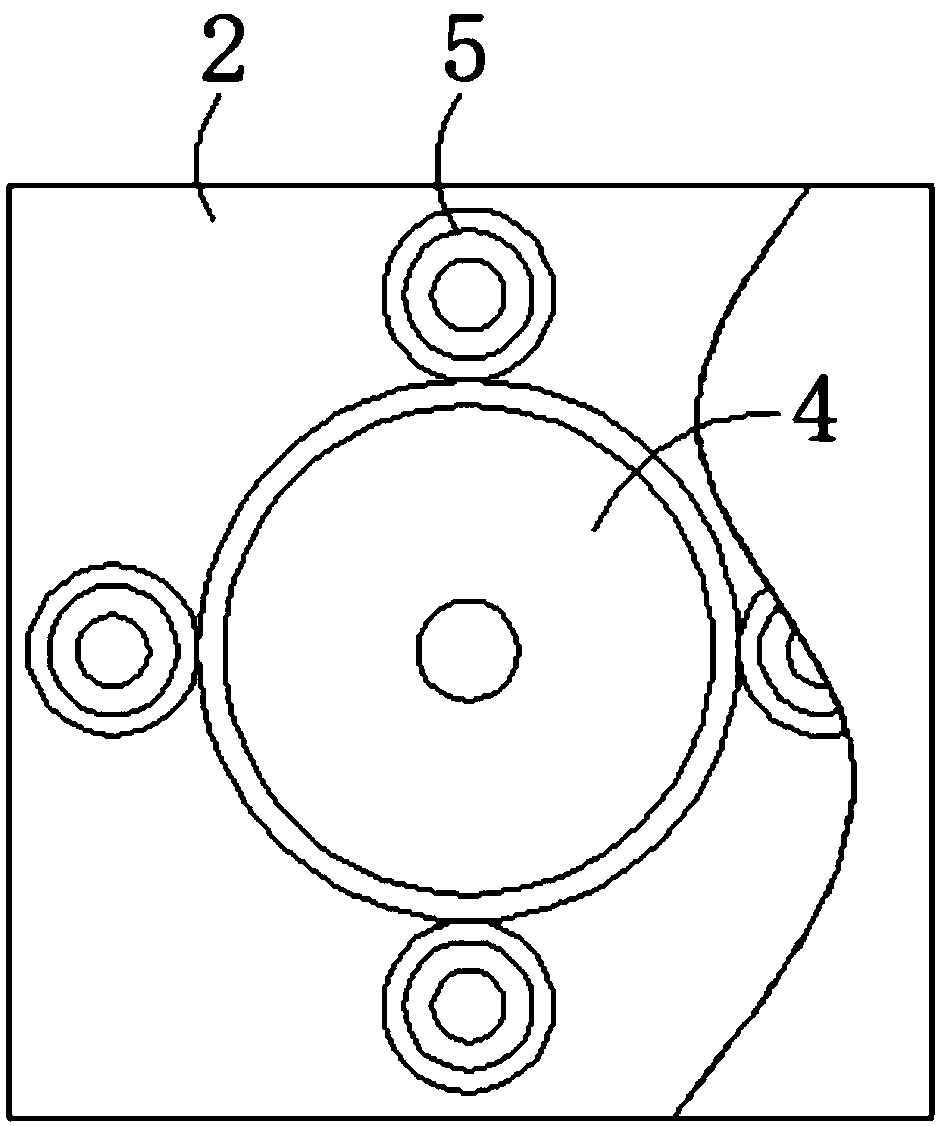

Fuel cell metal bipolar plate and manufacturing method thereof

PendingCN111554951AIncrease profitReduced Power RequirementsFinal product manufactureCollectors/separatorsGas passingEngineering

The invention relates to a fuel cell metal bipolar plate and a manufacturing method thereof, and belongs to the technical field of proton exchange membrane fuel cells. In the structure of the bipolarplate provided by the invention, the circular holes are distributed in the ridge of the cathode flow field, so the transmission of reaction gas and generated water under the ridge is facilitated, thedissipation of reaction heat at the ridge is also facilitated, the current density and the distribution uniformity thereof are improved, and meanwhile, the performance and the service life of a fuel cell are improved; inclined grids are evenly distributed on the two sides of the cathode flow field groove, so part of unreacted gas passing through the flow field ridge is forced to flow into the cathode flow field groove, the part of gas flowing into the cathode flow field groove plays a role in gas blocking, namely a backpressure role, on reaction gas originally flowing through the cathode flowfield groove, and the current density of the fuel cell can be improved.

Owner:南京攀峰赛奥能源科技有限公司

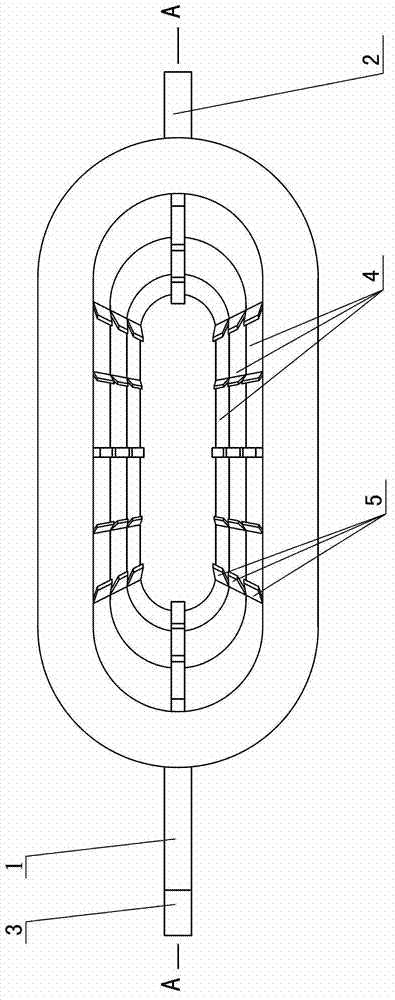

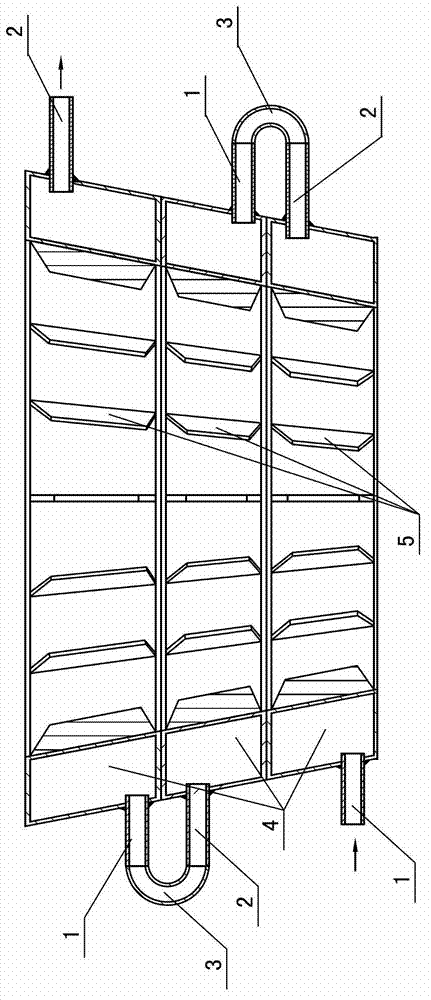

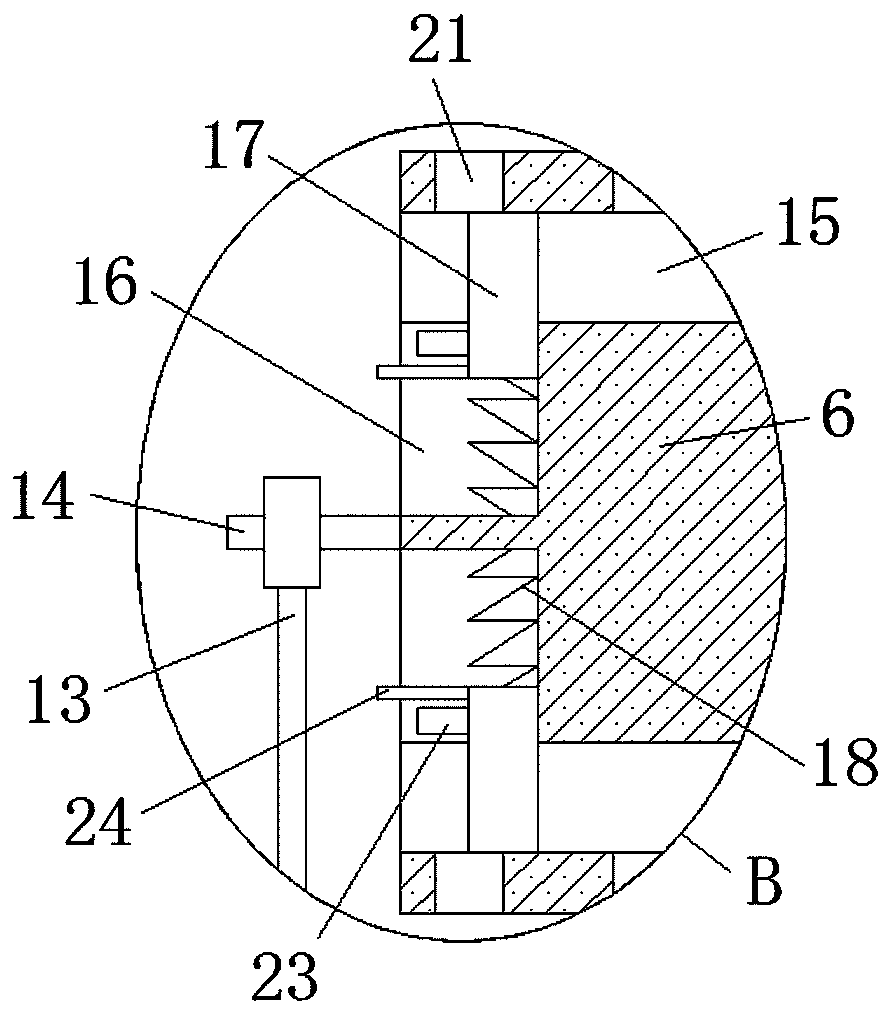

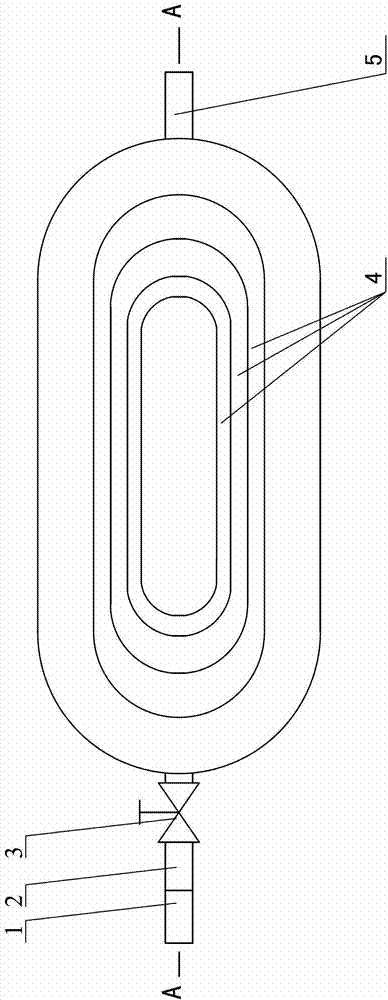

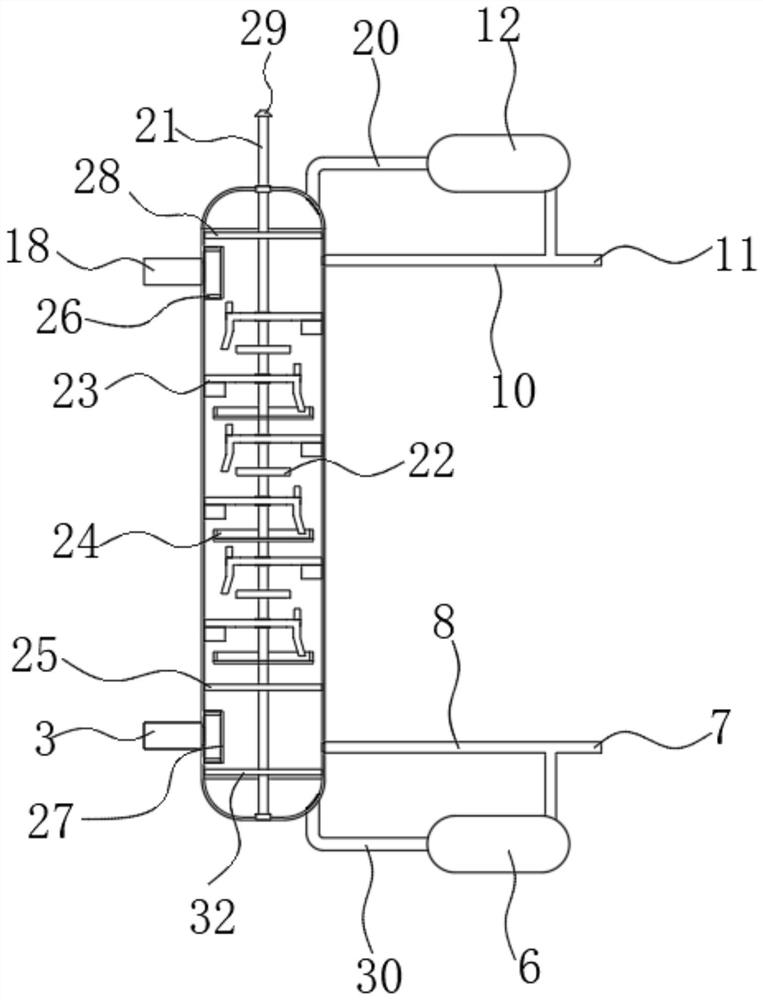

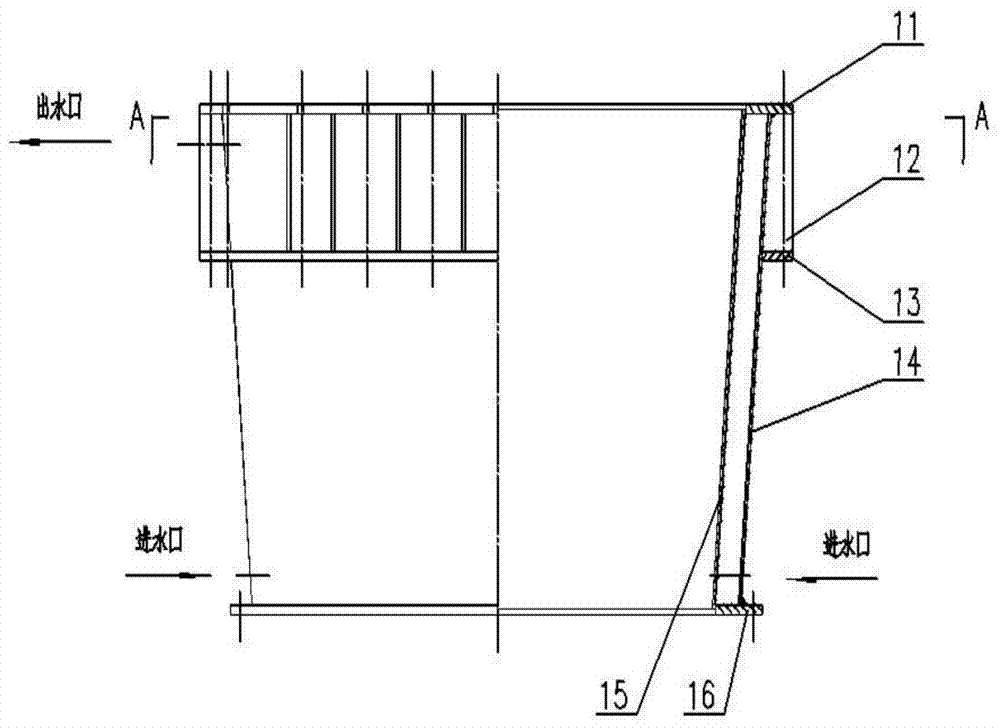

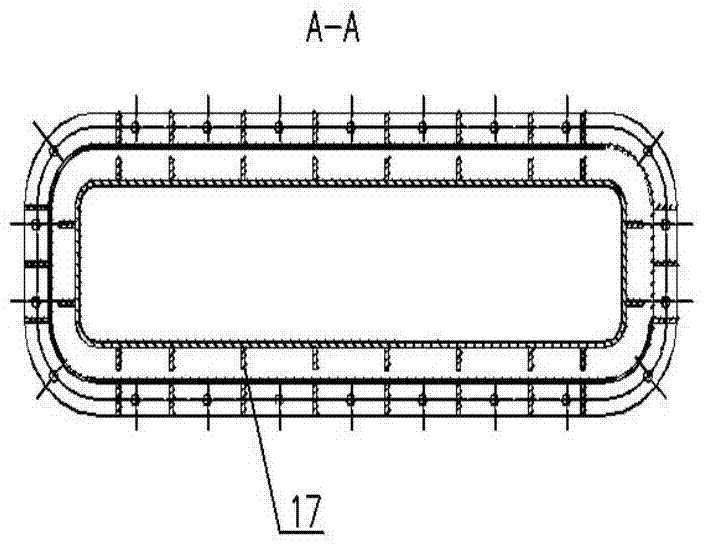

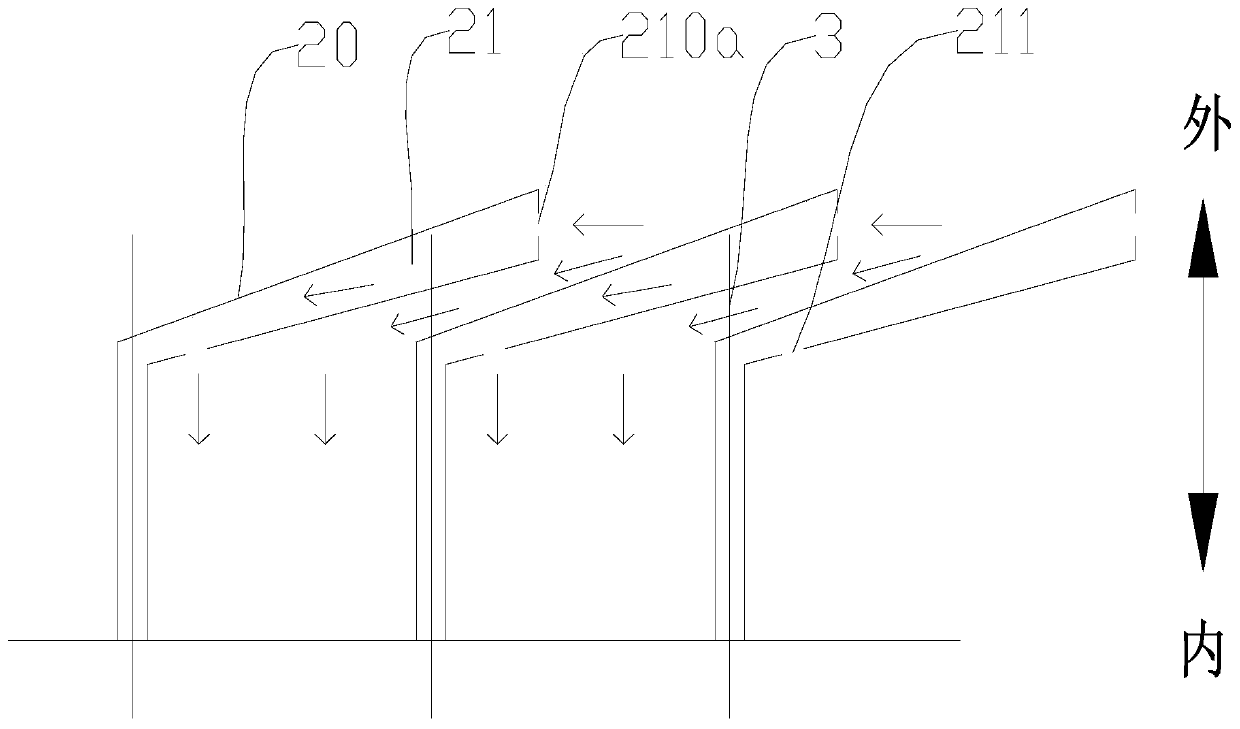

Pot-type calcinator multi-level series fin type cooling device for coke after high-temperature calcination

ActiveCN102774826AIncreased flow distanceHigh working reliabilityCarbon preparation/purificationWater jacketCalcination

The invention relates to a pot-type calcinator multi-level series fin type cooling device for coke after high-temperature calcination. The device comprises water inlet pipes, water outlet pipes and a plurality of annular cooling water sleeves and is characterized in that the plurality of cooling water sleeves are overlapped and fixedly connected, the outer wall of the inner side of each of the cooling water sleeves is provided with a plurality of fins, the fins on the cooling water sleeves are arranged into lines correspondingly, each line of the fins is located in the same vertical surface, the water inlet pipe and the water outlet pipe are correspondingly arranged at two ends of each of the cooling water sleeves, and except the water outlet pipe at the top cooling water sleeve and the water inlet pipe at the bottom cooling water sleeve, water inlet pipes and water outlet pipes of adjacent cooling water sleeves, which are located at the same end, are communicated through connecting pipes. The device has the advantages that the heat exchange area is large, coke cooling speed after the high-temperature calcination is fast, the discharge temperature is low, the working is reliable, and the like.

Owner:SHANDONG UNIV OF TECH

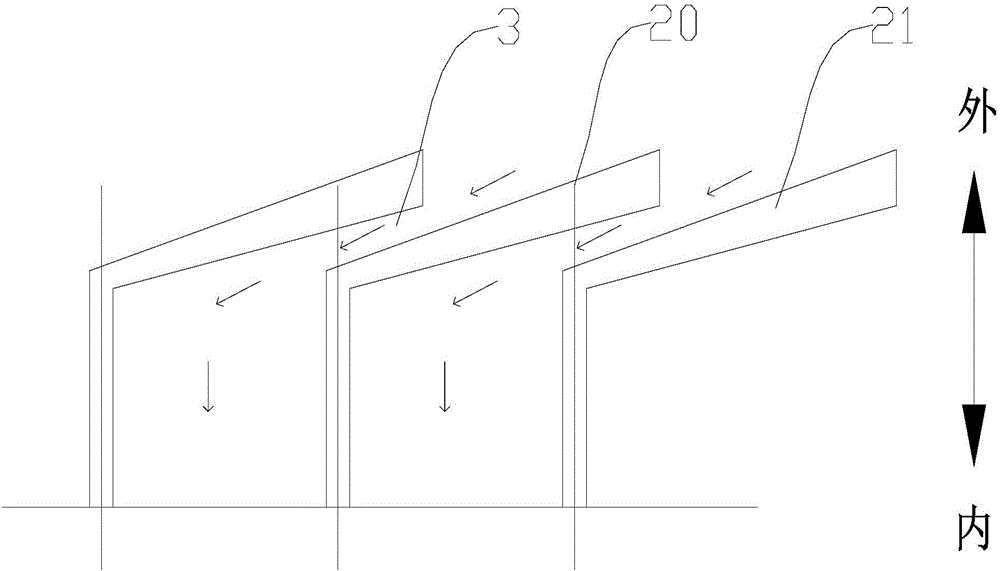

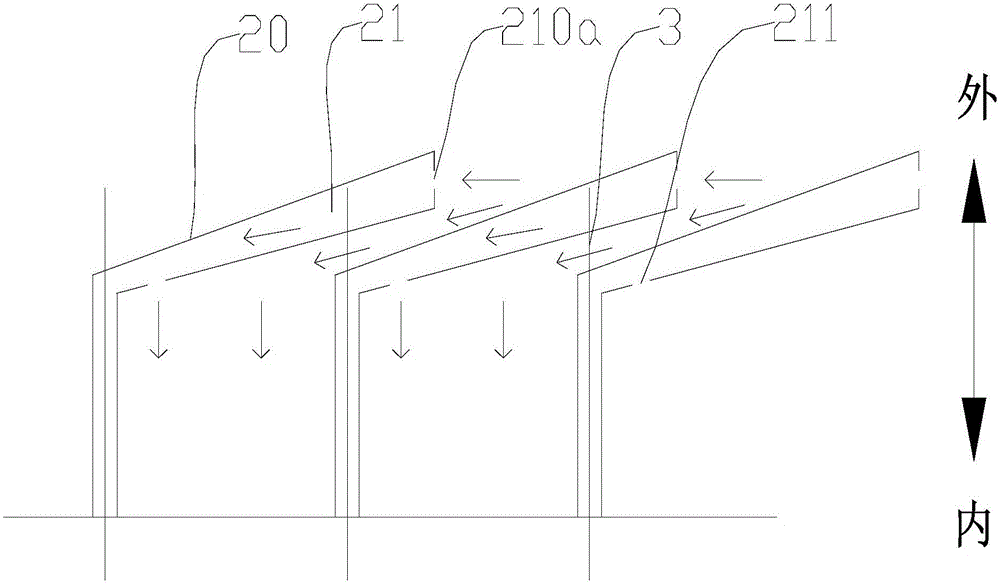

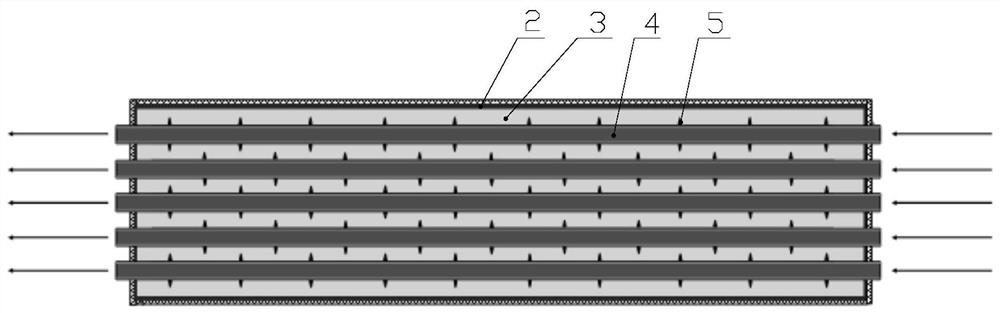

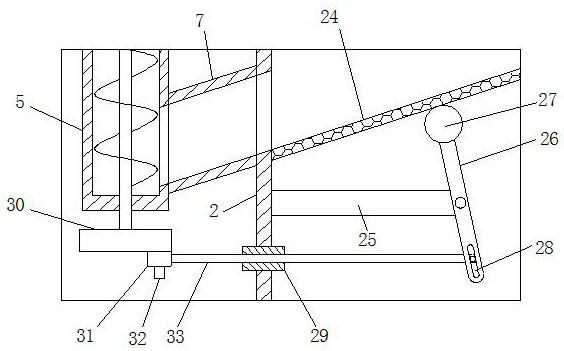

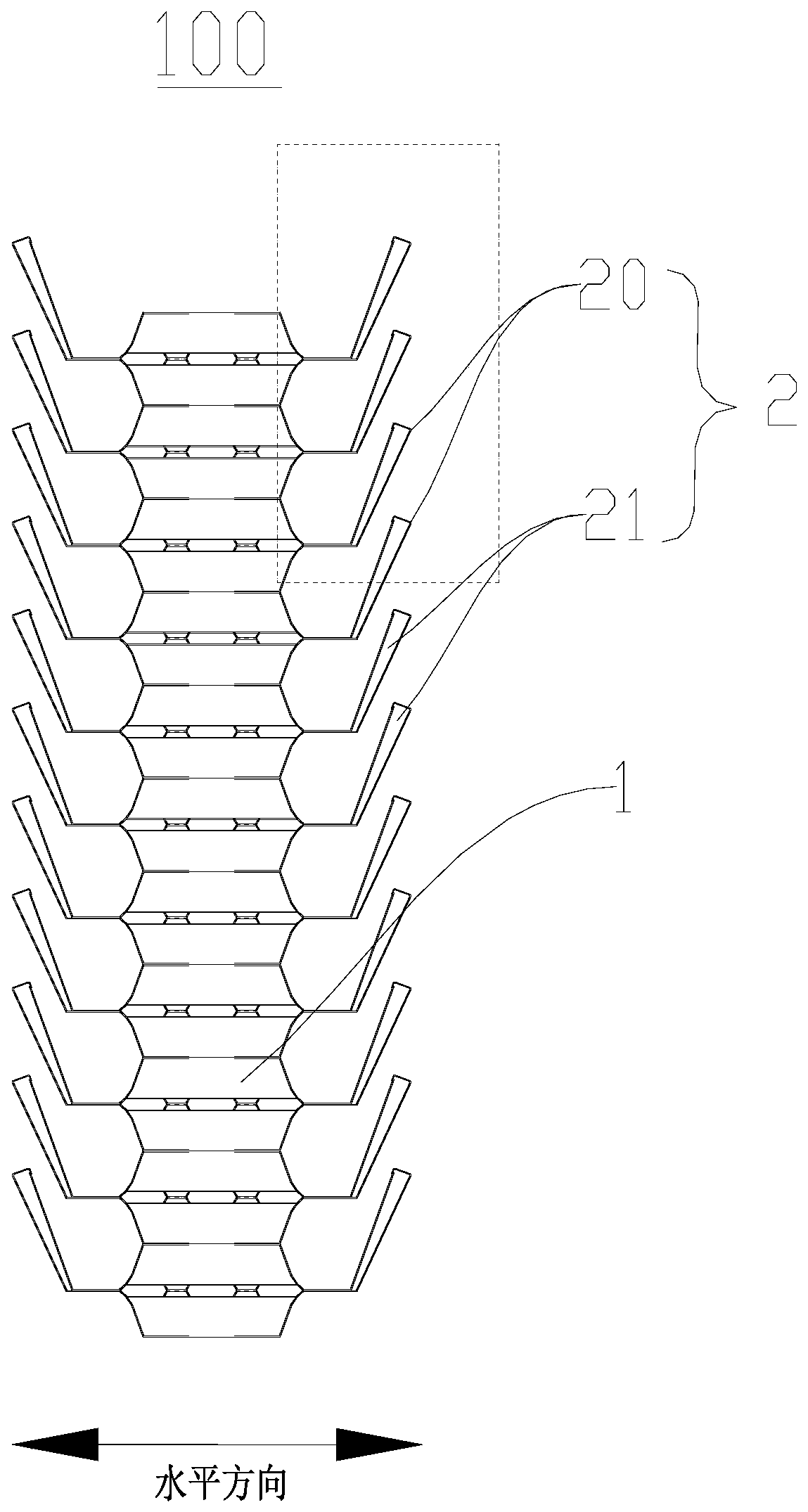

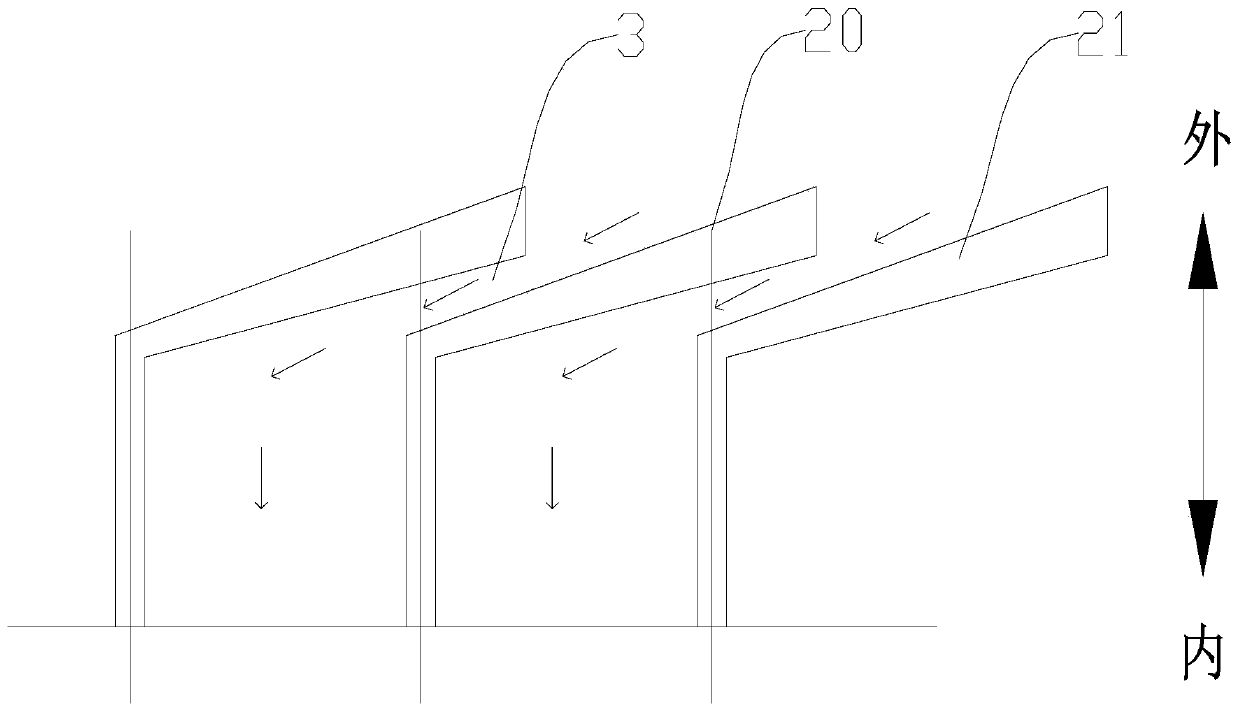

Heat exchanger of oil heater

ActiveCN106524786AImprove cooling effectIncrease flow strengthElectric heating systemStationary conduit assembliesEngineeringHeat sink

The invention discloses a heat exchanger of an oil heater. The heat exchanger comprises two oil pipes and multiple heat dissipation plates, wherein the two oil pipes are distributed vertically at an interval; and two ends of each heat dissipation plate are disposed on the two oil pipes respectively, an oil way channel communicating with the two oil pipes is disposed inside each heat dissipation plate, eat least one side edge of each heat dissipation plate is bent towards the other heat dissipation plate so as to form a bent part, bent parts with the same bending direction are disposed on the same side edge of at least two heat dissipation plates, and at least a part of one of the adjacent bent parts on the same side is located on the outer side of the other bent part so as to form an air flow channel. The heat exchanger of the oil heater disclosed by the invention has the advantages that flowing strength of air on the outer surface of the heat dissipation plates can be increased; the temperature on edges of the heat dissipation plates can be reduced; the heat dissipation capacity of the heat dissipation plates can be enhanced; and a user is prevented from being scalded during use of the heat exchanger of the oil heater.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

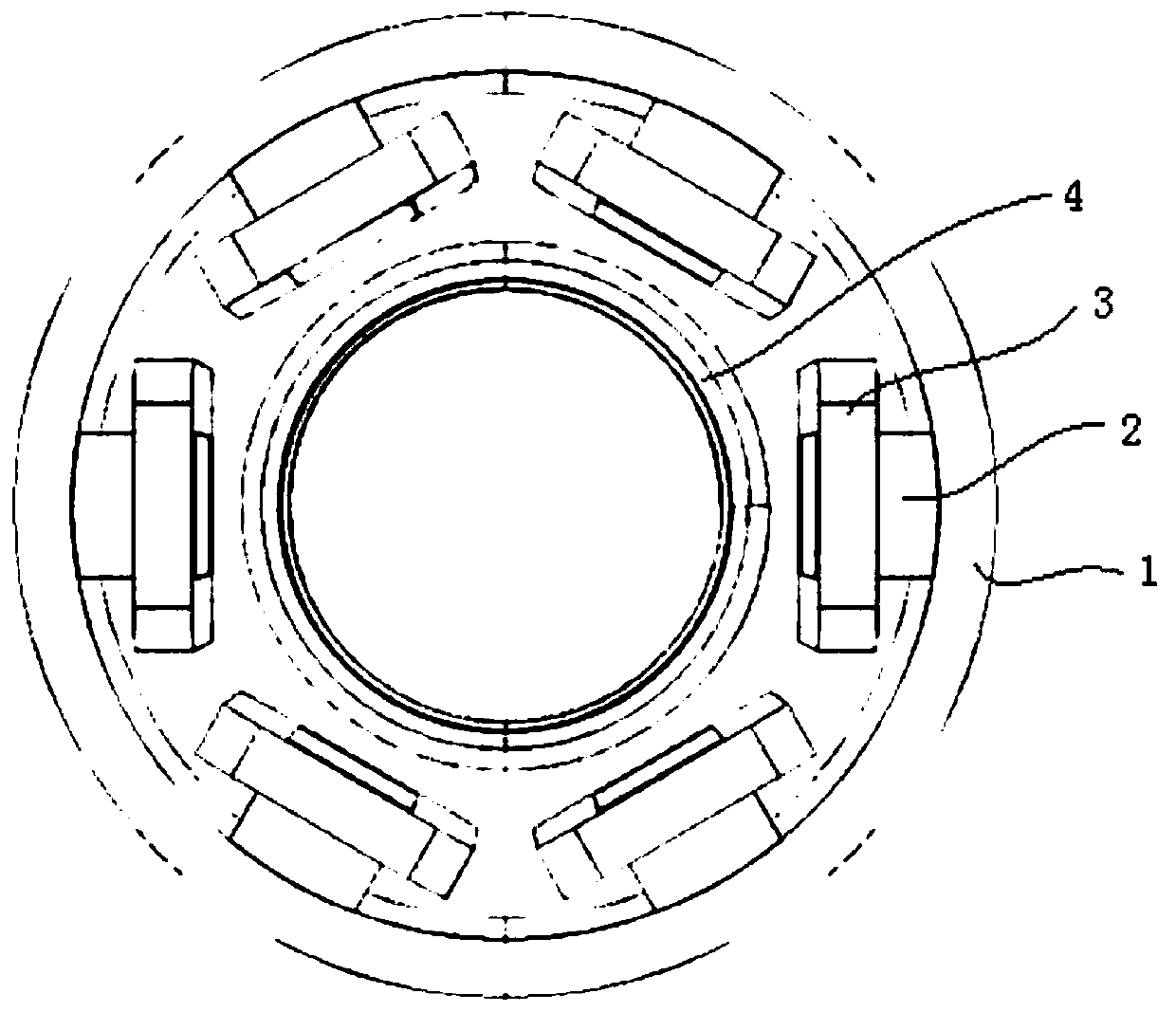

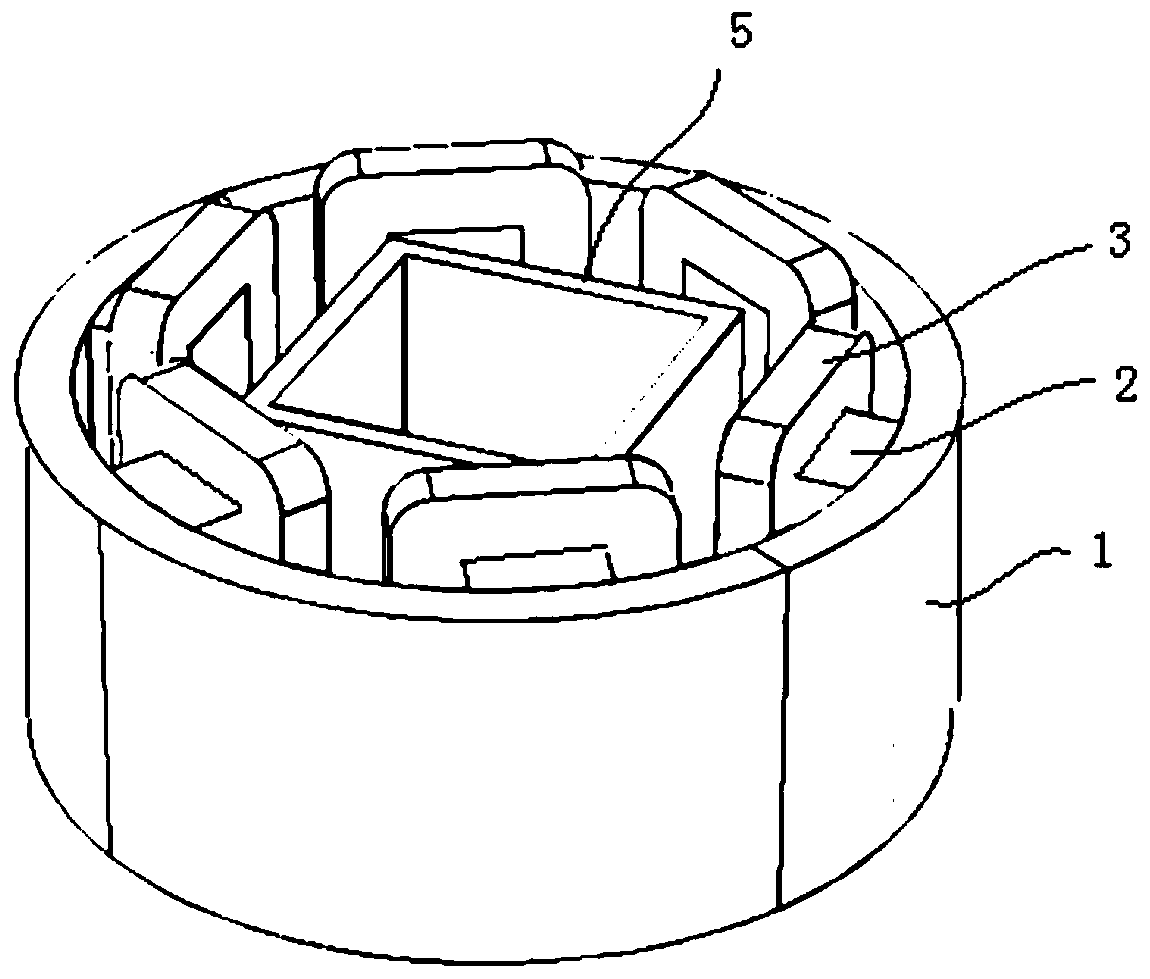

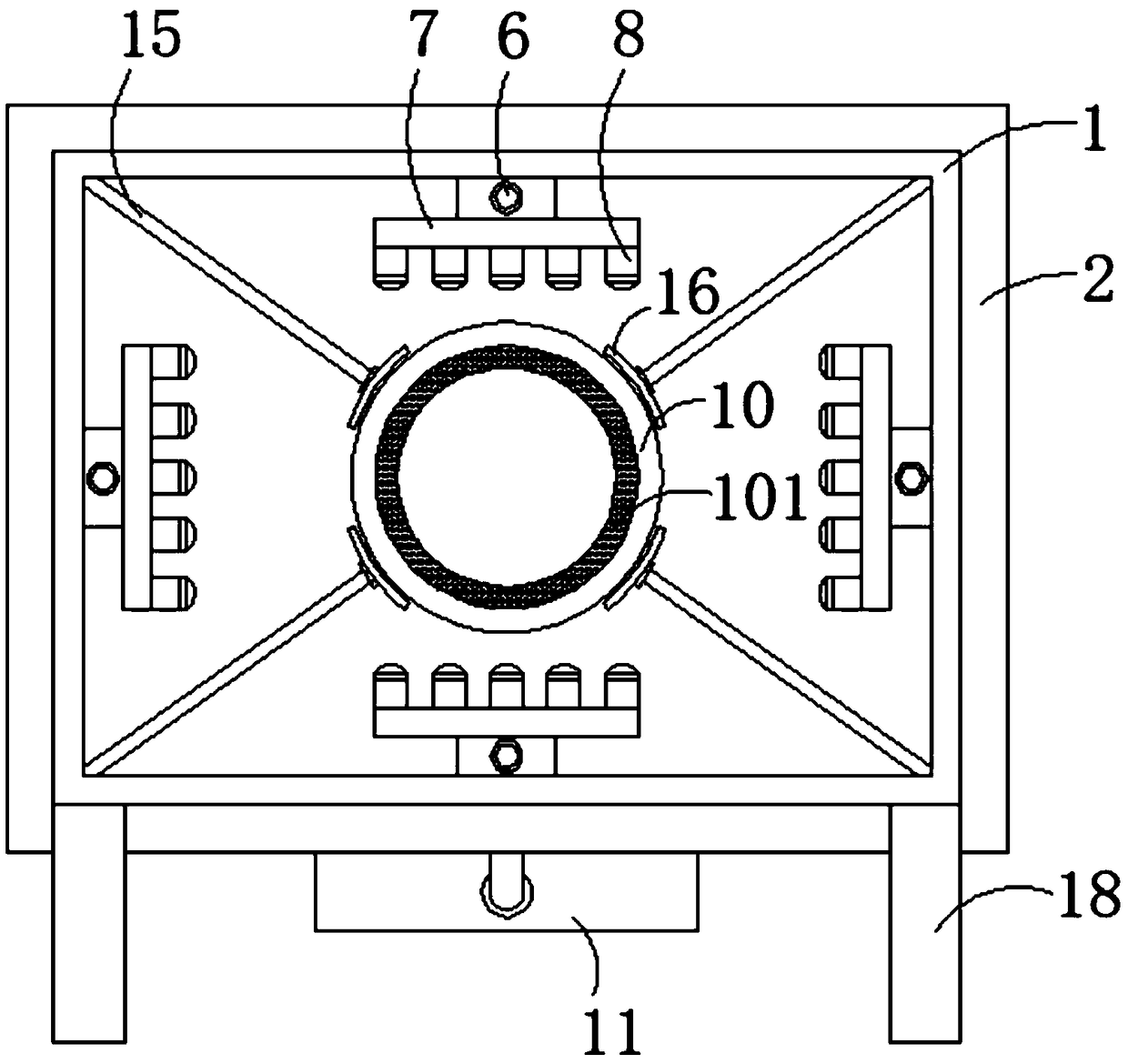

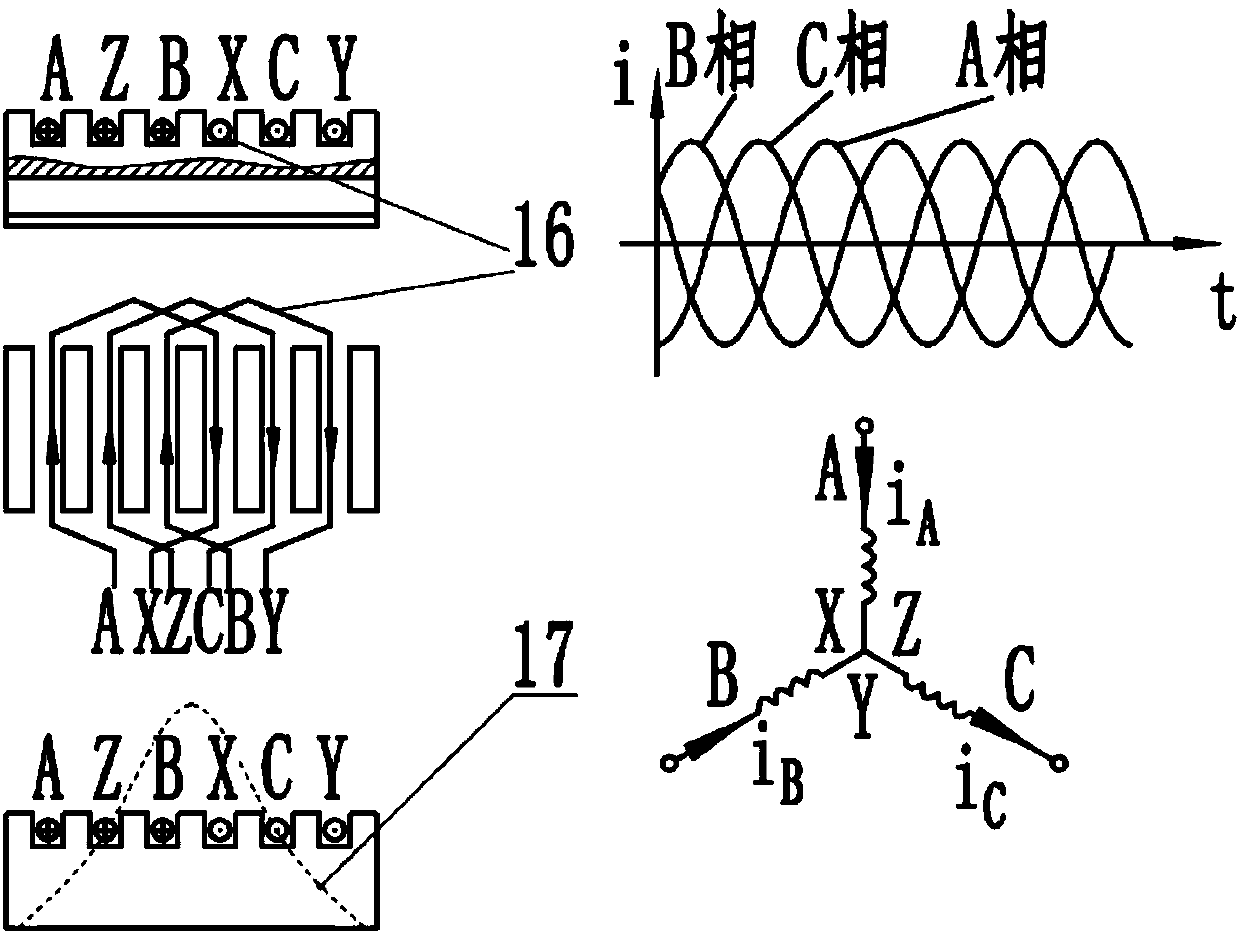

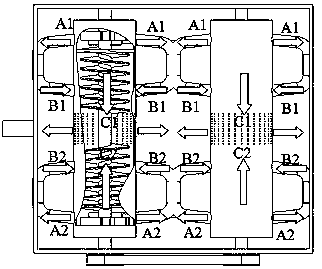

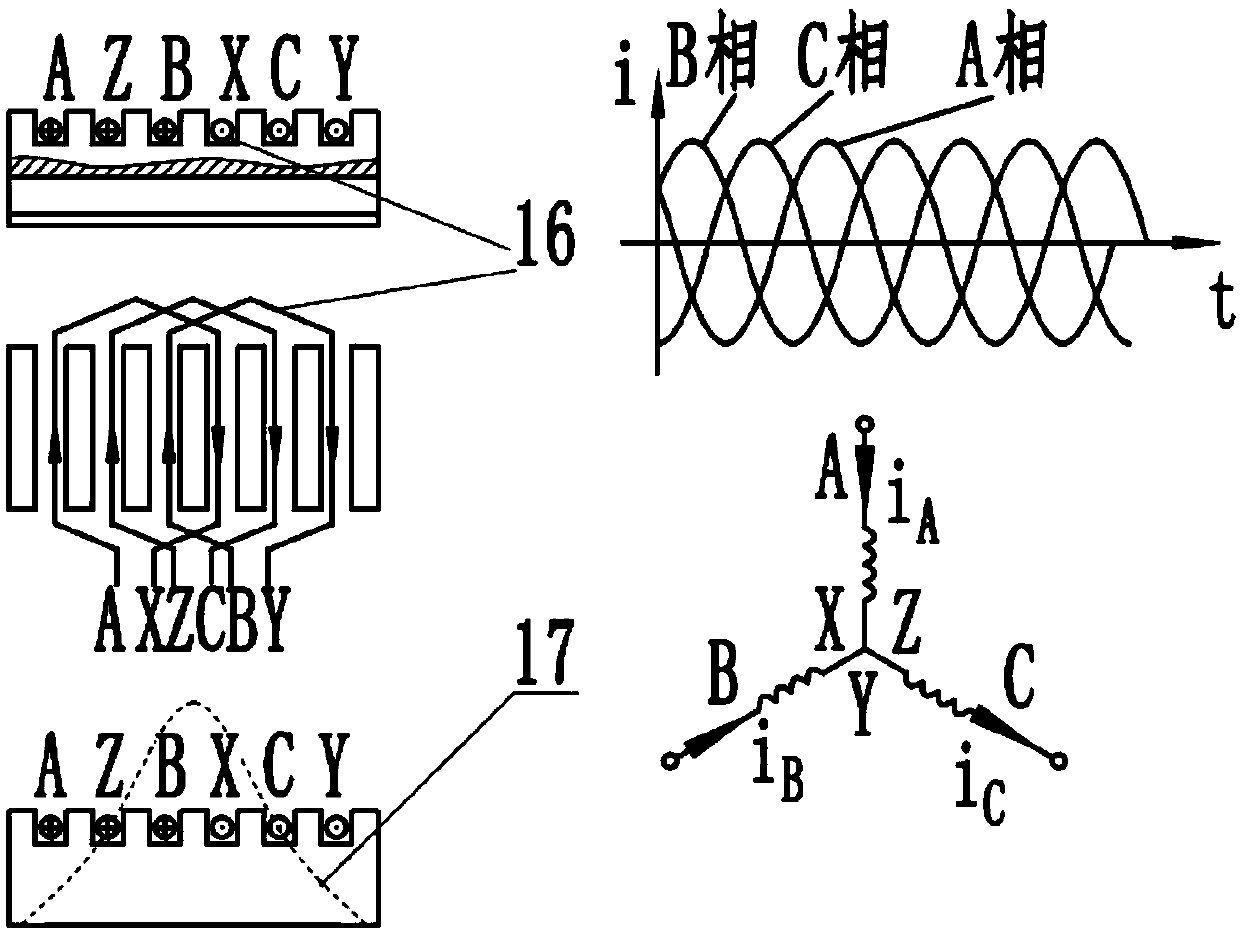

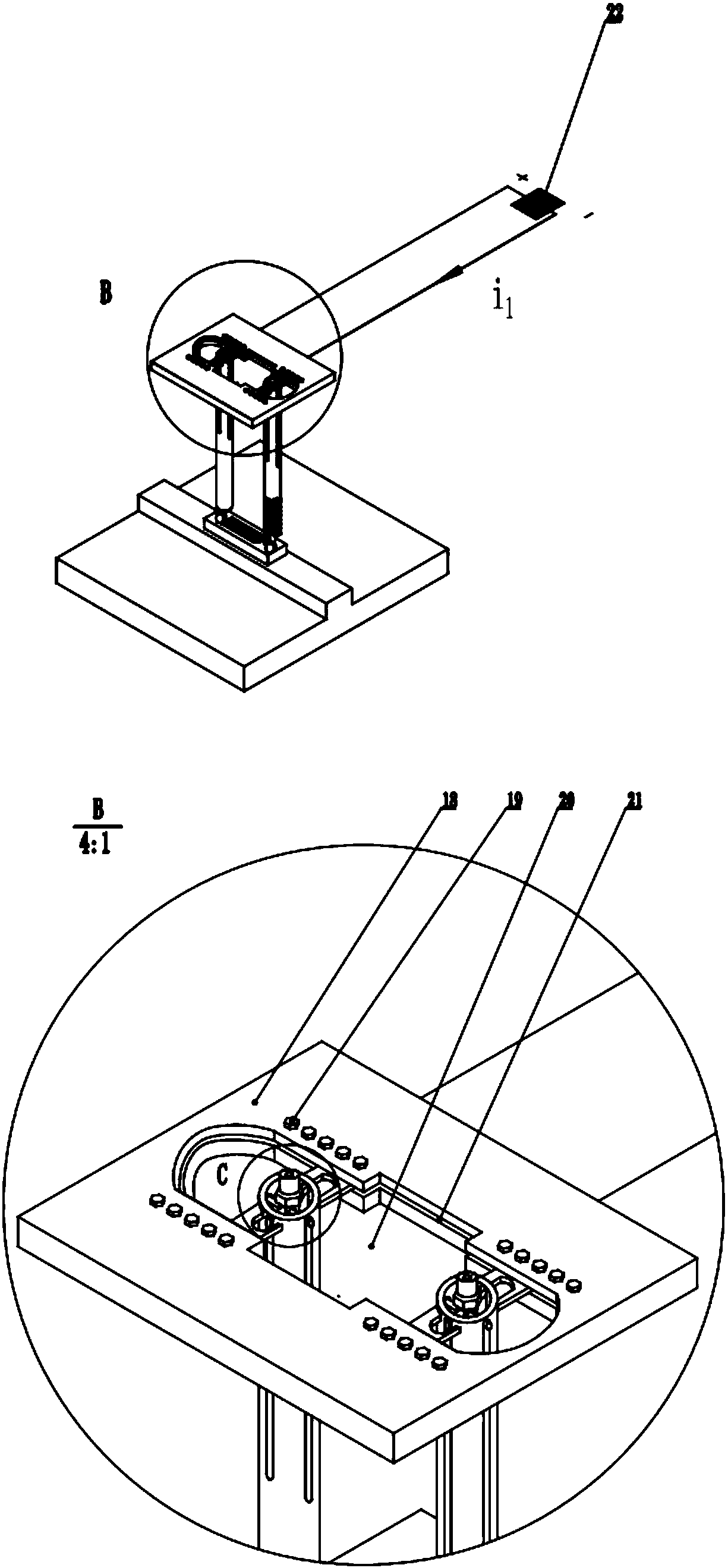

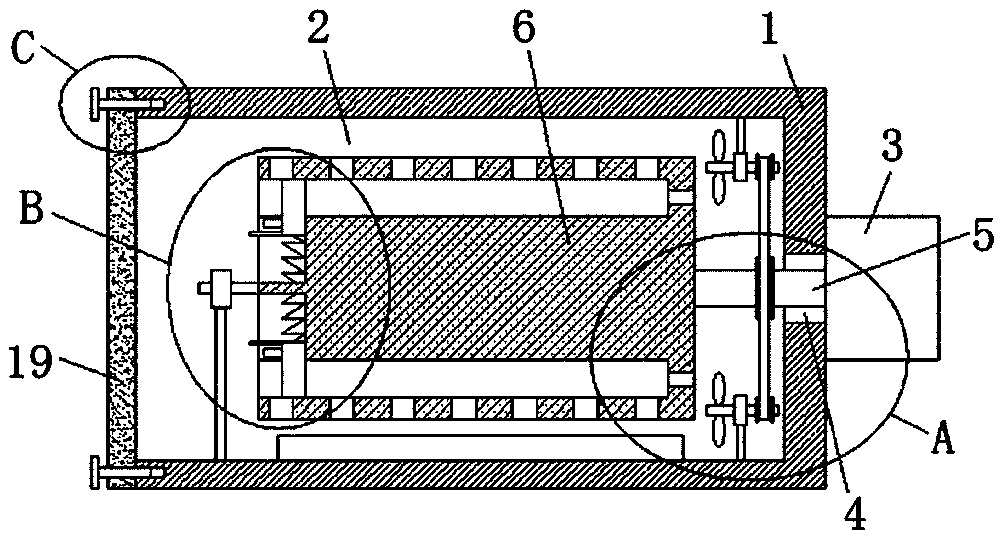

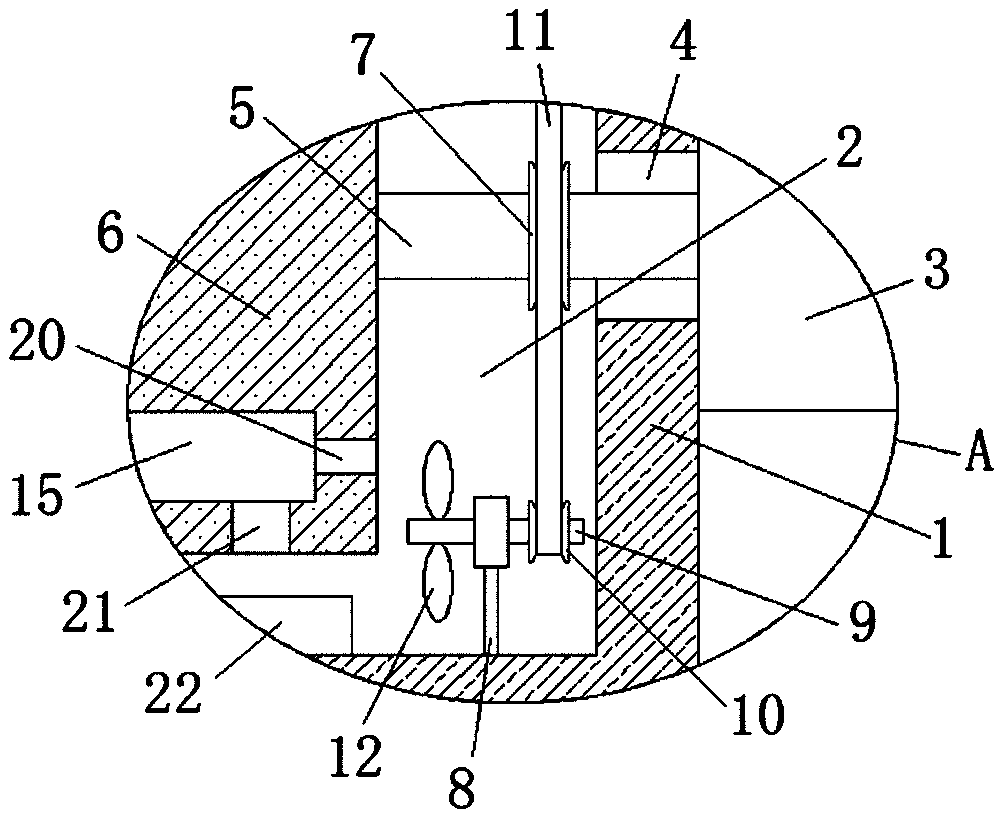

Electromagnetic stirring generating device, method and application of composite time-varying magnetic field

ActiveCN110252975AImprove fatigue performanceSmall mechanical propertiesPhysicsElectromagnetic stirring

The invention relates to an electromagnetic stirring generating device, method and application of a composite time-varying magnetic field. The device is a composite rotating magnetic field electromagnetic stirring generating device or a time-varying magnetic field generating device, or a traveling wave magnetic field electromagnetic stirring generating device. According to the method and the application, in the continuous casting, semi-continuous casting or die casting process, the electromagnetic stirring generating device of the composite time-varying magnetic field acts on a crystallizer for continuous casting or semi-continuous casting, a secondary cooling zone and any one position or multiple positions of the tail end or a riser in the mold casting production, liquid level and the like, so that the mechanical property of a casting blank is improved by improving the component segregation and the shrinkage porosity of the casting blank. Compared with the continuous casting or semi-continuous casting or die-casting production process, electromagnetic stirring or time-varying magnetic fields are independently applied, so that the shrinkage porosity and component segregation of the core of the casting blank are remarkably improved.

Owner:SHANGHAI UNIV

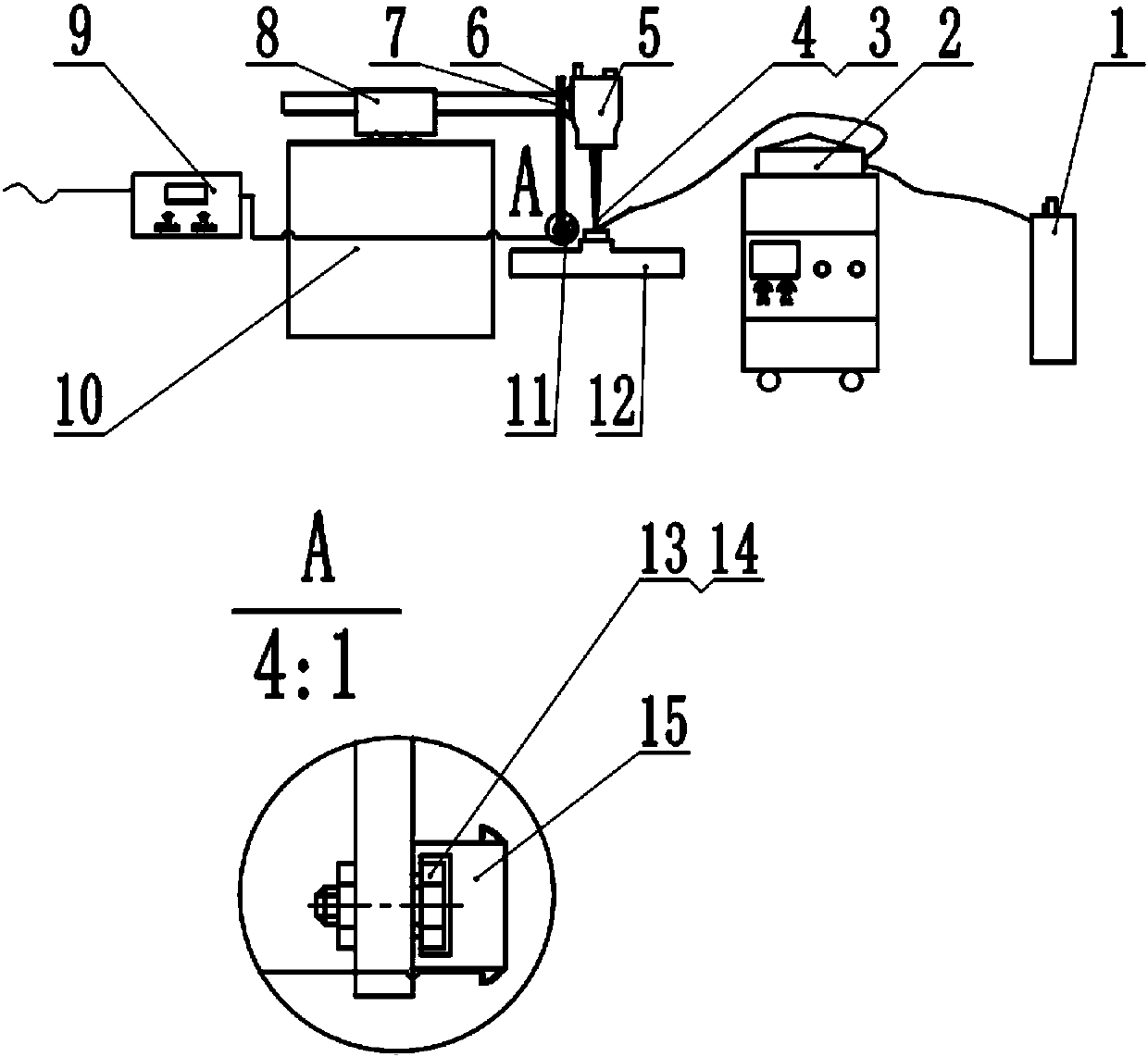

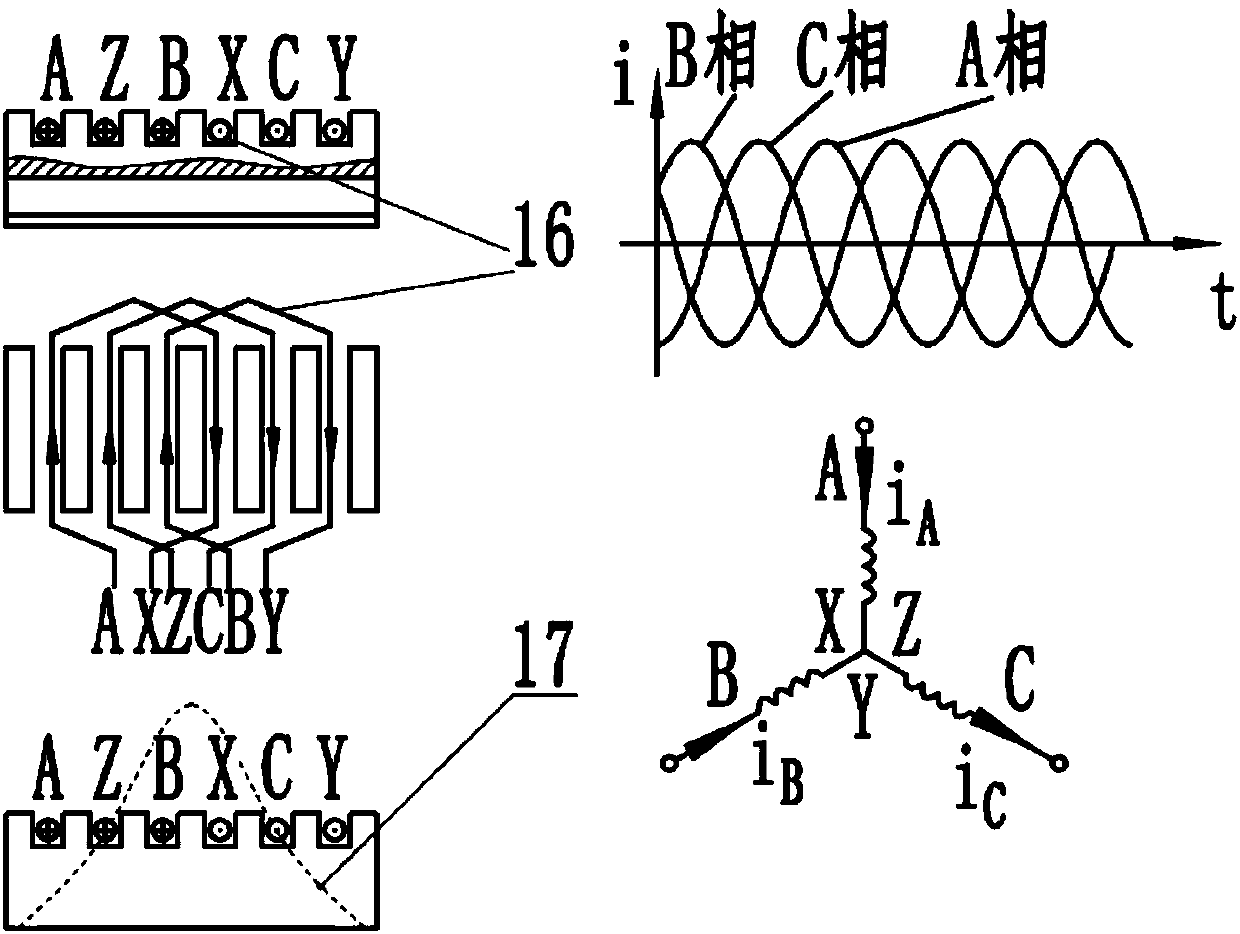

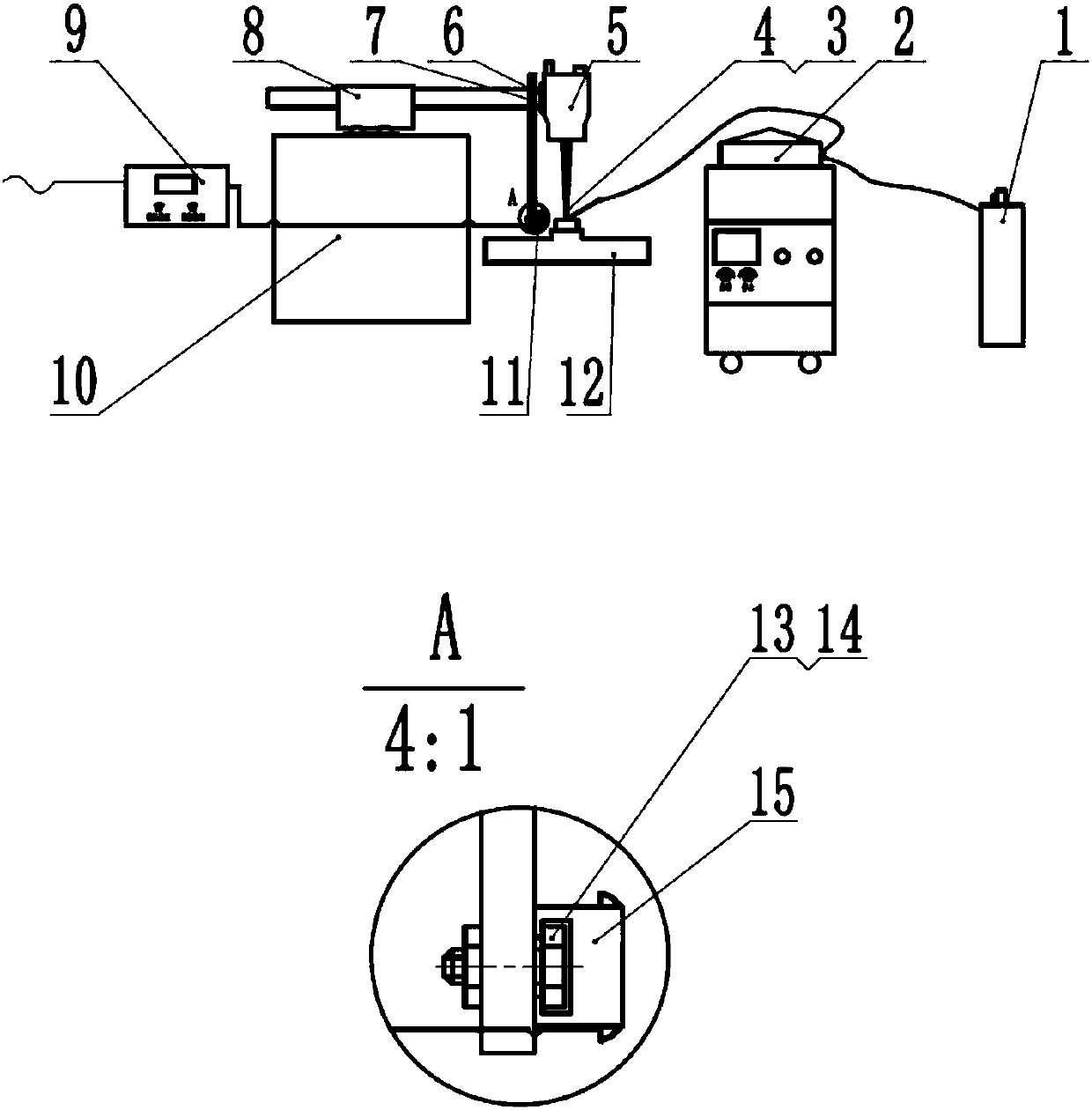

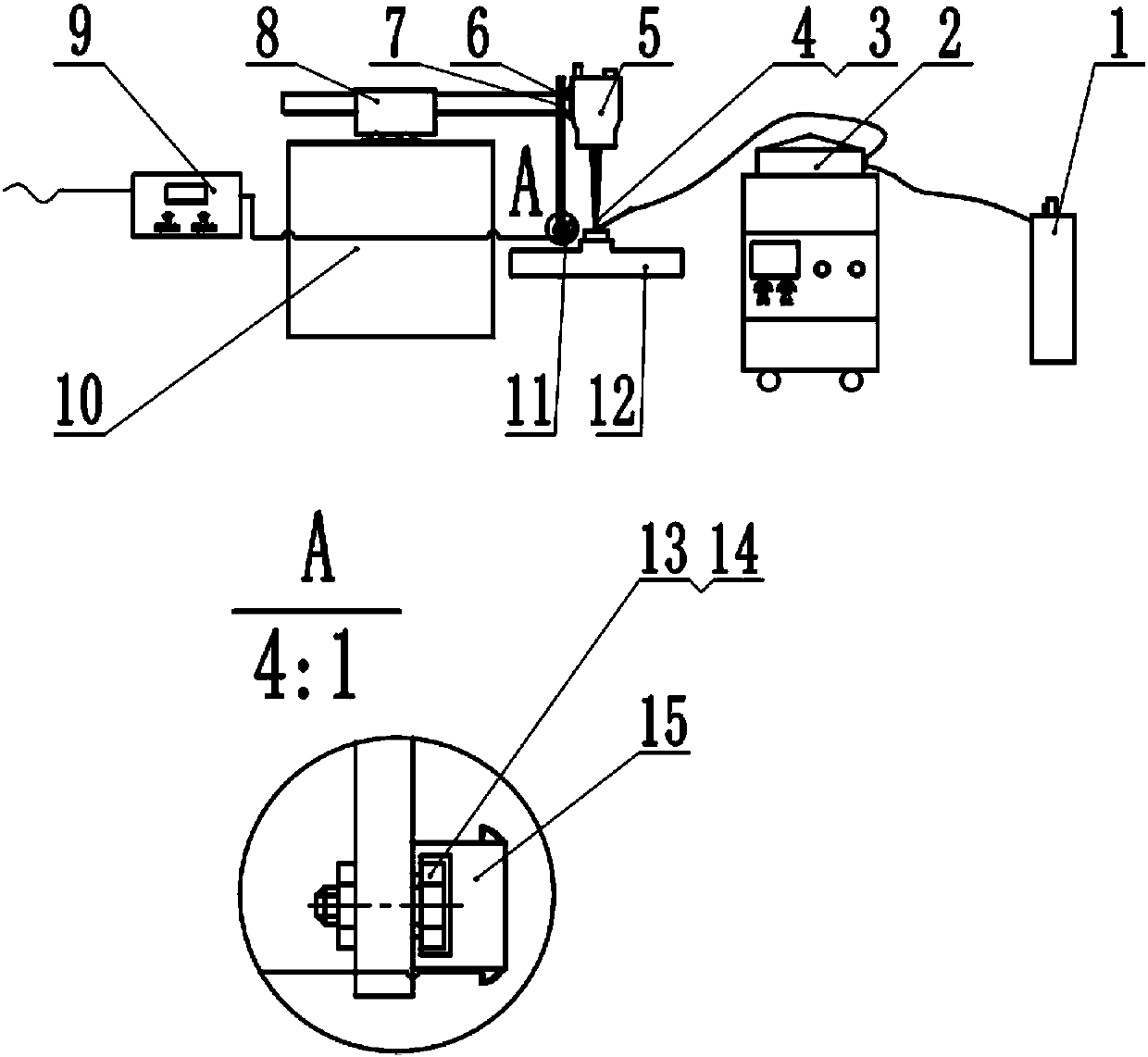

Pulse electric field-traveling wave magnetic field composite method for reducing cracks of cladding layer

PendingCN110527999AImprove chargeabilityImprove flushing effectMetallic material coating processesNumerical controlElectromagnetic shielding

The invention discloses a pulse electric field-traveling wave magnetic field composite method for reducing the cracks of a cladding layer. The devices used in the method comprise a laser cladding numerical control device, a traveling wave magnetic field device and a positive and negative pulsed electric field device. During the cladding process, a traveling wave magnetic field is applied to a molten pool, so that the charged quantity of the non-magnetic particles and the charged particles in the molten pool is increased under the action of impressed current, the liquid metal particles are remarkably enhanced in Lorentz force in an external follow-up traveling wave magnetic field, the stirring effect on a molten pool is enhanced, the effects of fluid scouring, crushing and the like on dendrites are increased, the grain size is reduced, the fine grain strengthening effect is obvious, the defects, such as air holes, inclusions, component segregation, etc., are reduced, and the crack generation probability of a cladding layer is reduced. The composite device effectively solves the problems that the non-magnetic and charged particles are subjected to small Lorentz force in an electromagnetic field, and the electromagnetic stirring effect of the magnetic field on the molten pool is small.

Owner:魏永强

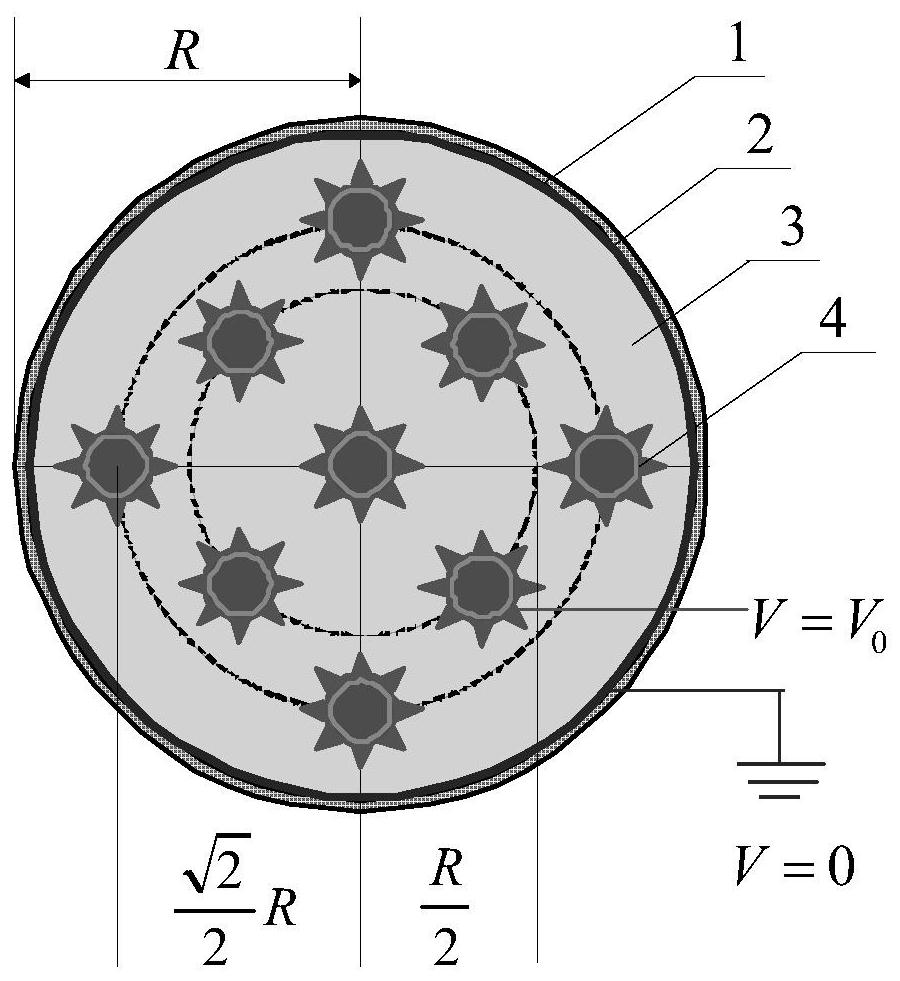

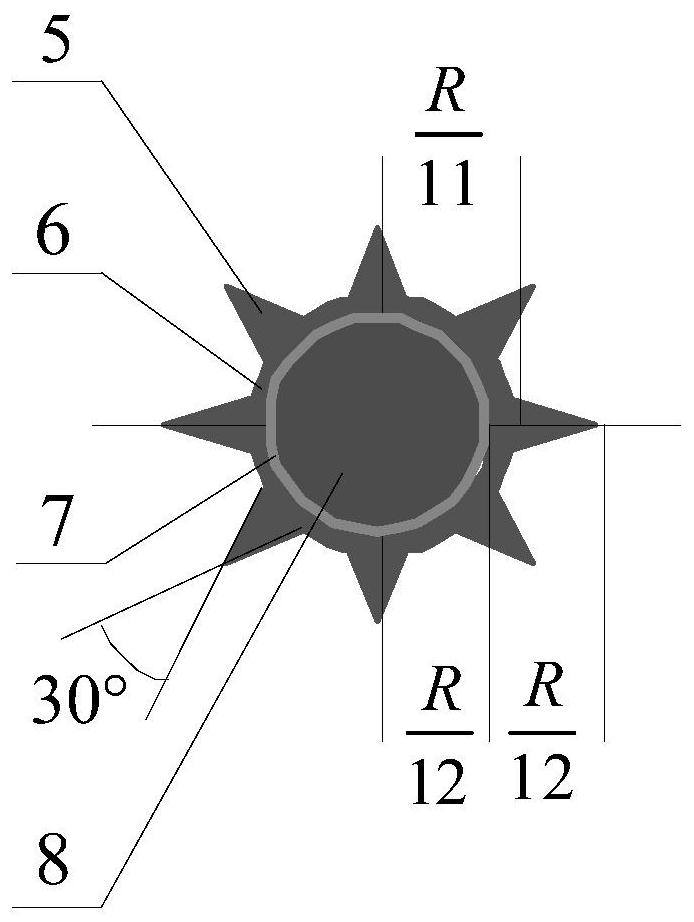

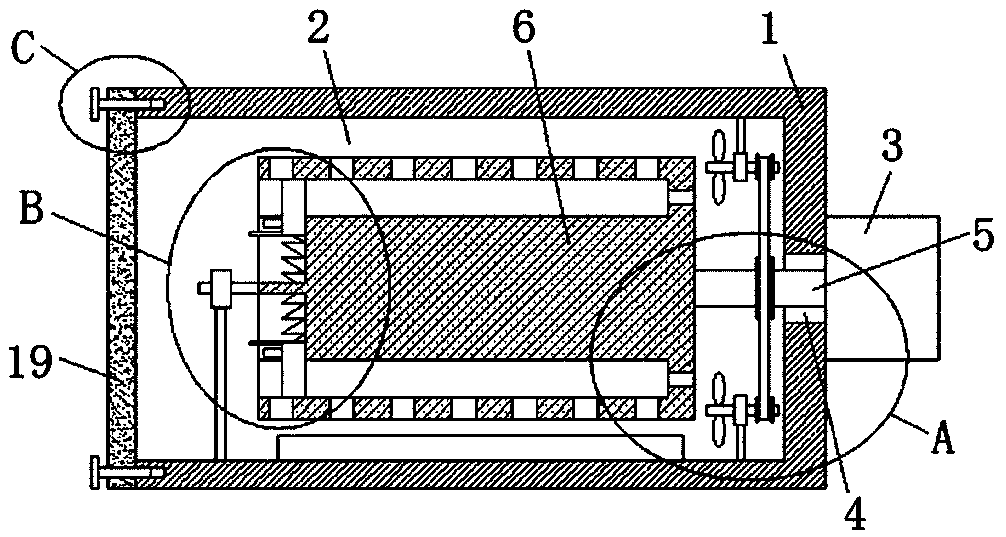

Shell-and-tube point discharge solid-liquid phase change enhanced heat transfer device based on electrofluid mechanics

InactiveCN112484537AReduce consumptionWeak currentHeat storage plantsStationary tubular conduit assembliesInsulation layerEnhanced heat transfer

The invention discloses a shell-and-tube point discharge solid-liquid phase change enhanced heat transfer device based on electrofluid mechanics and belongs to the technical field of solid-liquid phase change enhancement. The problem that the speed of the phase change process cannot be adjusted through an existing passive enhancing technology is solved. The shell-and-tube point discharge solid-liquid phase change enhanced heat transfer device comprises a metal outer pipe and a plurality of composite inner pipes arranged in the metal outer pipe; phase change materials are filled between the metal outer pipe and the composite inner pipes; the metal outer pipe is grounded; and a heat insulation layer is arranged on the outer wall of the metal outer pipe; each composite inner pipe comprises ametal inner pipe, a plurality of groups of fins arranged outside the metal inner pipe and an insulating layer arranged on the inner wall of the metal inner pipe; direct-current positive voltage is connected into the metal inner pipes; and a heat source circulates in the metal inner pipes. Compared with the existing passive enhancing technology, due to the fact that the electric heating convectionintensity in a flow field is directly affected by the potential difference between polar plates, the speed of the phase change process can be actively controlled by adjusting the input voltage of an anode plate. After an electric field is applied, the flow intensity can be remarkably enhanced, and a good phase change enhancing effect is obtained.

Owner:HARBIN INST OF TECH

Oil-filled heater

InactiveCN106369661AReduce the temperatureImprove cooling effectHeating fuelLighting and heating apparatusEngineeringHeat sink

The invention discloses an oil-filled heater. The oil-filled heater comprises two oil tubes and a plurality of cooling fins, wherein the two oil tubes are distributed vertically in a spaced mode; and the two ends of each cooling fin are arranged on the two oil tubes correspondingly, an oil channel communicating with the two oil tubes is formed in each cooling fin, and air chambers, a distance away from the corresponding oil channel, are formed in one or more side edges of each cooling fin; a top air outlet is formed in each air chamber, and air inlets are formed in all opposite side walls of the air chambers; and a guide plate used for guiding air into the corresponding air chamber is arranged in each air inlet. By adoption of the oil-filled heater, the cooling areas of the edges of the cooling fins can be enlarged, the flow intensity of air on the inner surfaces and the outer surfaces of the cooling fins is enhanced, the temperatures of the edges of the cooling fins are increased, the cooling capacity of the cooling fins is improved, and the danger that a user is scalded in the use process of the oil-filled heater is avoided.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

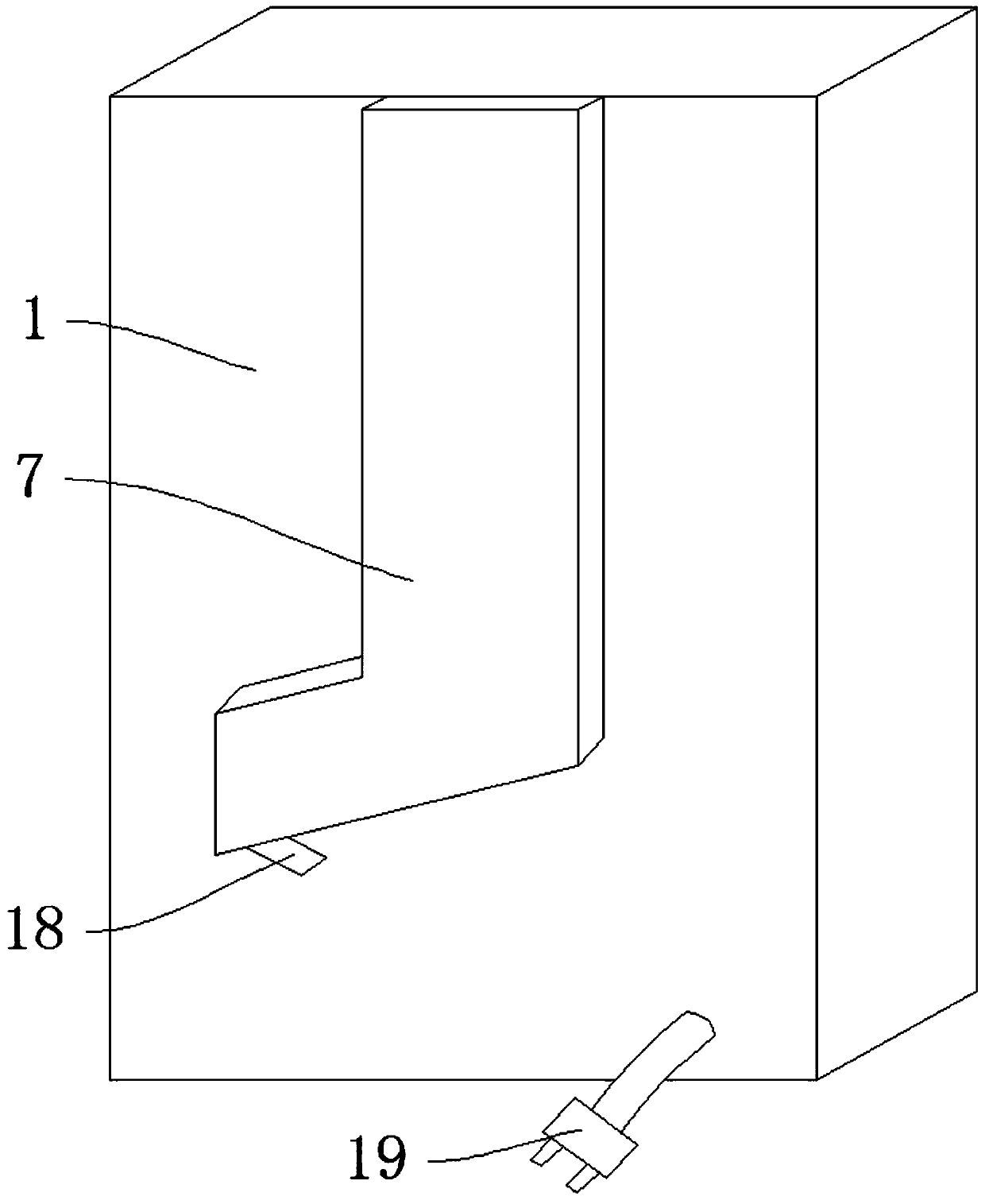

Assembly dust blowing device for aluminum alloy door and window

InactiveCN109201630AAvoid dirty cleaningBlow up effectivelyDispersed particle filtrationDirt cleaningBristleAlloy

The invention discloses an assembly dust blowing device for an aluminum alloy door and window. The assembly dust blowing device comprises a dust removal box, the outer wall of one side of the dust removal box is fixedly connected with a gear box through bolts, the outer wall of one side, away from the dust removal box, of the gear box is fixedly connected with a motor through bolts, one end of themotor is rotationally connected with a driving gear through a rotating shaft, and a driven gear is arranged in the gear box, and the driven gear is in meshed connection with the driving gear throughgear teeth, and a lead screw is welded on the outer wall of one side of the driven gear. The contact area between the aluminum alloy door and window and the air flow can be effectively improved through the reciprocating air flow, and the air flow intensity is improved, the dust and the bristles on the aluminum alloy door and window can be conveniently blown up more effectively, and the cleaning efficiency is improved; and on the other hand, full contact between the aluminum alloy door and window and the air flow can be guaranteed, all-directional cleaning can be guaranteed, and the problem that aluminum alloy door and window are not clean is avoided.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

Direct-current electric field-traveling wave magnetic field composite method for improving quality of cladding layer

PendingCN110527997AImprove chargeabilityImprove flushing effectMetallic material coating processesNumerical controlLiquid metal

The invention discloses a direct-current electric field-traveling wave magnetic field composite method for improving the quality of a cladding layer. The devices adopted by the method mainly comprisea laser cladding numerical control device, a traveling wave magnetic field device and a direct-current electric field device. According to the composite device, firstly, the direct-current power supply device is started before cladding until the cladding is completed, and secondly, a traveling wave magnetic field is applied to a molten pool during the cladding process, so that the charged quantityof non-magnetic particles and particles with less charges in the molten pool is increased under the action of impressed current. Furthermore, in an external follow-up traveling wave magnetic field, the Lorentz force borne by the liquid metal particles is remarkably enhanced, the stirring effect on a molten pool is enhanced, the effects of fluid scouring, crushing and the like on the dendrites areincreased, the grain size is reduced, the fine grain strengthening effect is obvious, the structure defects of a cladding layer are reduced, and the quality is improved. The composite device effectively solves the problems that the non-magnetic and charged particles are subjected to small Lorentz force in an electromagnetic field, and the electromagnetic stirring effect of the magnetic field on the molten pool is small.

Owner:魏永强

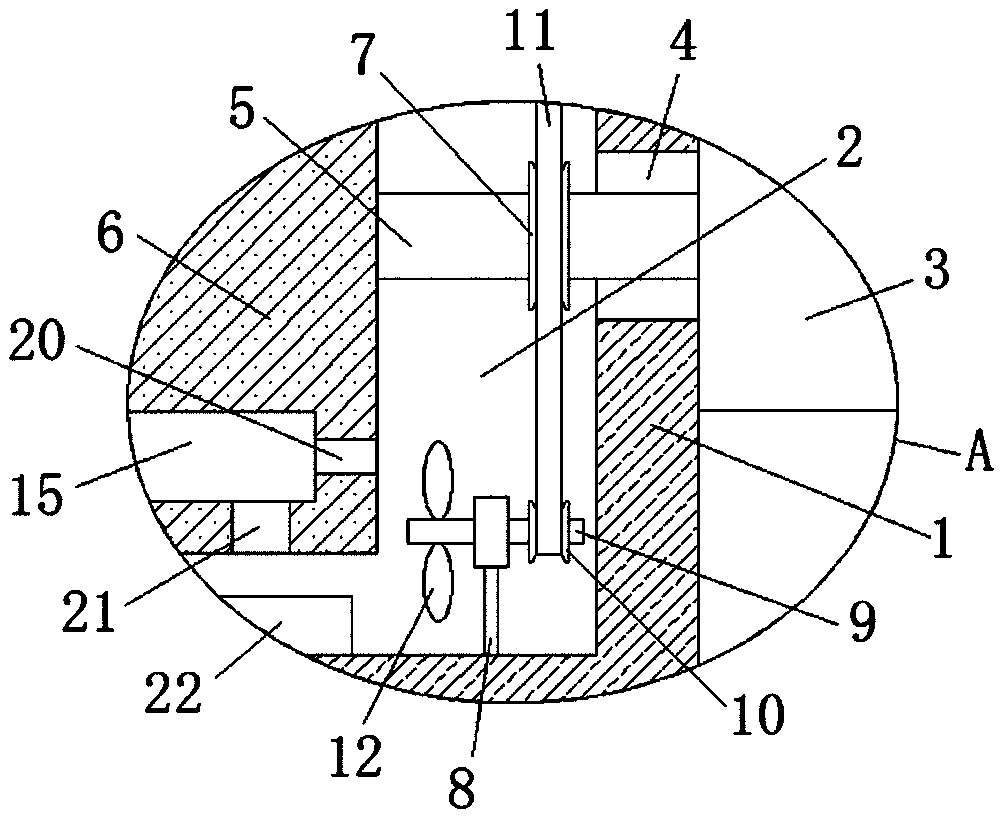

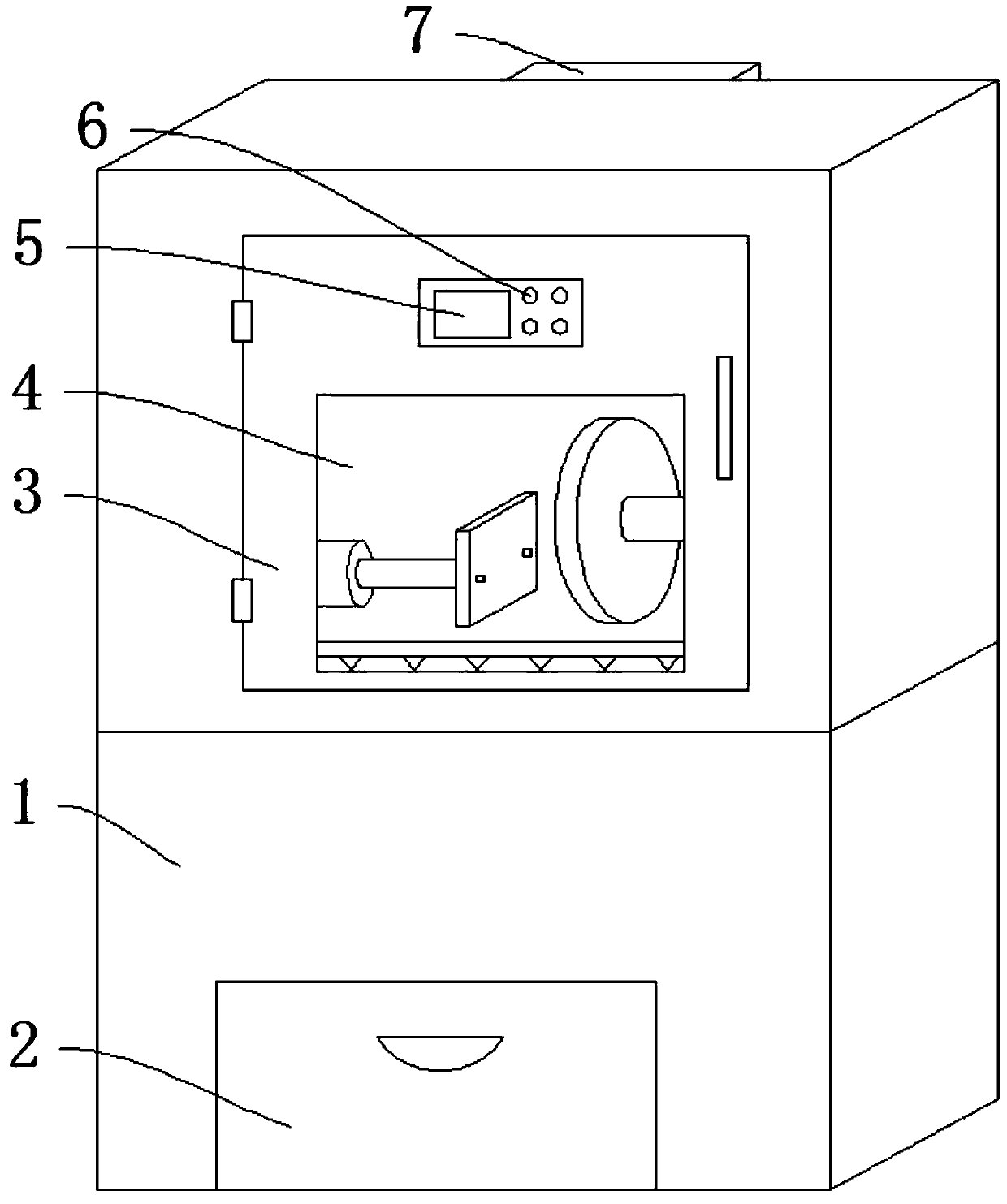

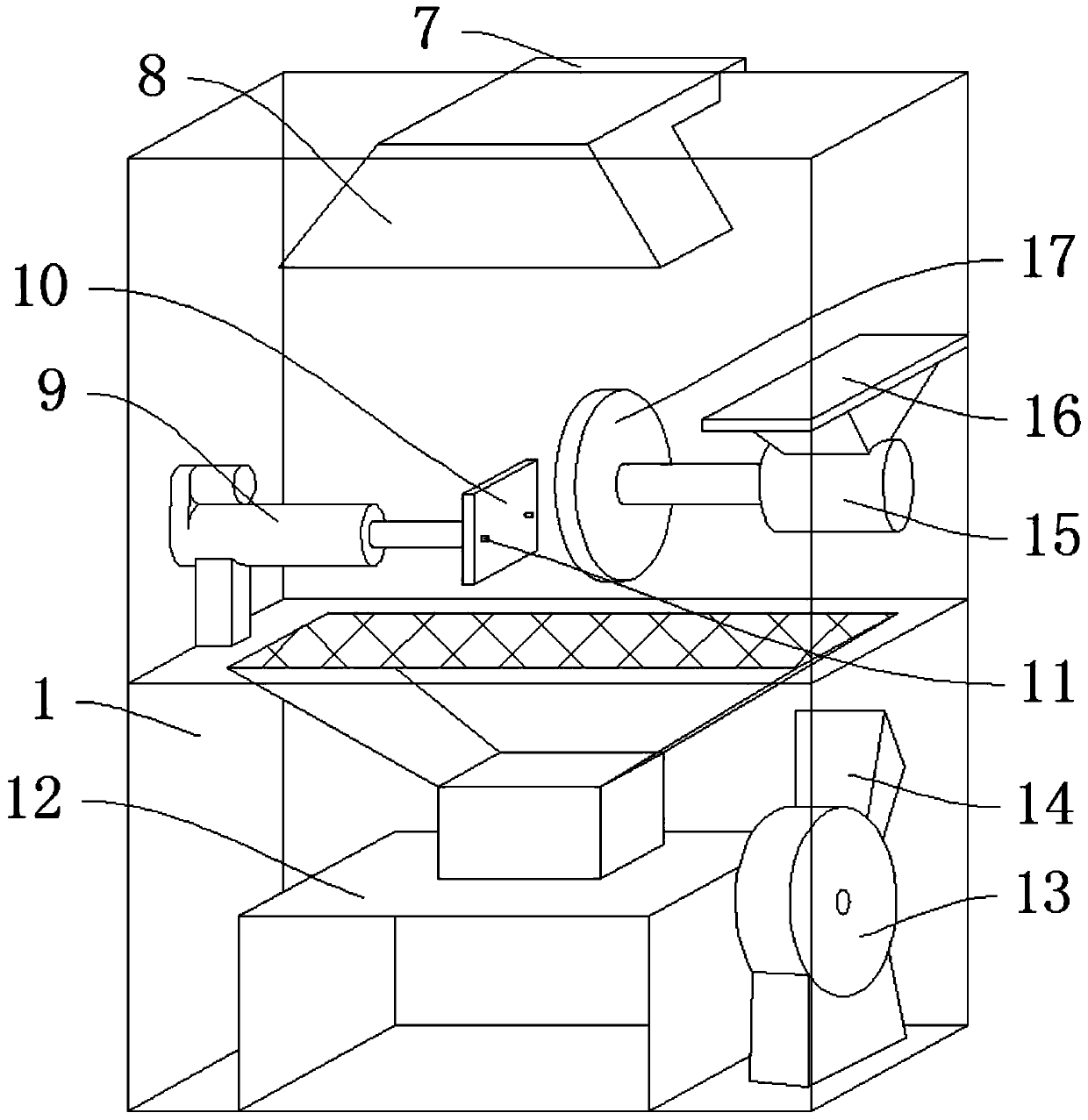

Graphite electrode heating device

ActiveCN109405559AReasonable designImprove practicalityElectric heating for furnacesGraphite electrodeEngineering

The invention discloses a graphite electrode heating device which comprises a box body and a motor arranged on one side of the box body. A groove is formed in one side of the box body, and a rotatinghole is formed in the inner wall of the side, close to the motor, of the groove. A rotating shaft is welded on an output shaft of the motor, one end of the rotating shaft penetrates through the rotating hole and extends into the groove, and a sleeve is welded on the end of the rotating shaft. A first belt pulley is fixedly sleeved on the outer side of the rotating shaft. Stand columns are welded on the inner wall of the top side and the inner wall of the bottom side of the groove, and circular columns are horizontally and rotationally arranged on the ends, close to each other, of the two standcolumns. Second belt pulleys are fixedly sleeved on the outer sides of the circular columns, and a same belt is arranged on the two second belt pulleys and the first belt pulley in a transmitting mode. The graphite electrode heating device has the advantages of reasonable design and high practicability and is convenient to drive a sleeve to rotate. Moreover, the flow intensity of air in the groove can be increased through a fan blade, so that a graphite electrode in an electrode placing slot can be fully in contact with the air in the groove, and the temperature rising rate of the graphite electrode is increased.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

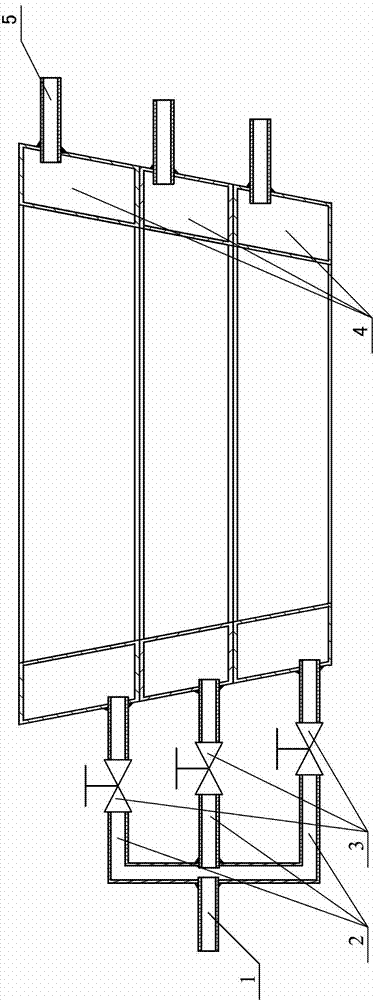

Multi-stage parallel cooling device for high-temperature calcined coke of pot-type calcining furnace

InactiveCN102774827AHigh working reliabilityLarge heat transfer temperature differenceCarbon preparation/purificationHandling discharged materialEngineeringWater jacket

The invention relates to a multi-stage parallel cooling device for high-temperature calcined coke of a pot-type calcining furnace. The multi-stage parallel cooling device comprises a water inlet system and annular water cooling sleeves, and is characterized in that a plurality of the water cooling sleeves are superposed and fixedly connected; the water inlet system comprises a water inlet header tube which is communicated with a water supply system and a plurality of water inlet branch tubes; a regulating valve is arranged on each water inlet branch tube; a water outlet tube is arranged on one end of each water cooling sleeve, and the other end of the water cooling sleeve is communicated with a water inlet branch tube; and the water outlet tube and the water inlet branch tube are arranged on the two ends of the water cooling sleeve. According to the multi-stage parallel cooling device, the high-temperature calcined coke provided by the invention has the advantages of quick cooling speed, controllable cooling water amount, low discharging temperature, high working reliability and the like.

Owner:SHANDONG UNIV OF TECH

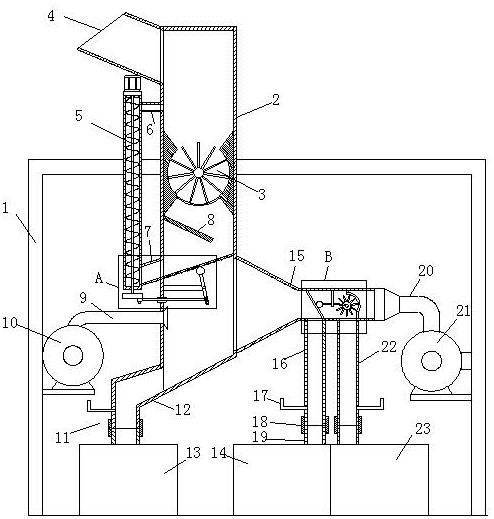

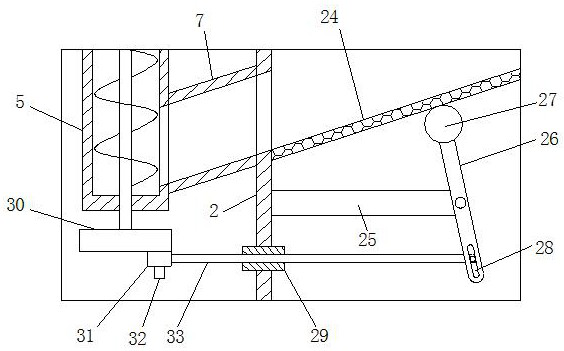

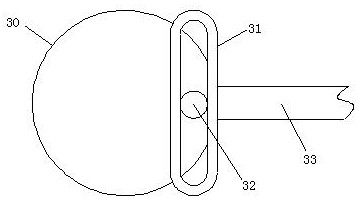

Surface treatment device for automobile brake pad manufacturing and use method of surface treatment device

The invention discloses a surface treatment device for automobile brake pad manufacturing and a use method of the surface treatment device. The surface treatment device for automobile brake pad manufacturing comprises a machine box, a dust collecting device and a filter plate, a front door is installed on the front of the machine box, a perspective window is arranged in the middle of the front door, a controller is installed above the perspective window, and the controller is connected with the front door in a bolt mode. A button is installed on the front of the controller, an air passing channel is installed at the rear of the machine box, a slag discharging plate is installed at the bottom of the air passing channel, a power cord is arranged below the air passing channel, an exhaust cover is installed at the top of the machine box, and the exhaust cover is in a conical table shape. According to the surface treatment device for automobile brake pad manufacturing and the use method ofthe surface treatment device, machinery is used for fixing brake pads to avoid handheld operation, the safety of an operator is increased, ground dust and slag are wholly sealed by using the machine box and collected by vacuum suction, and the harm of the dust and slag to a human body is reduced; and the one-way flow of the dust and slag is prompted by using gas circulation, the flow force of pushing the dust and slag is increased, the smoothness of dust and slag flow is improved, and the cleaning quality is ensured.

Owner:天津卓睿汽车配件制造有限公司

Electromagnetic stirring generating device, method and application of composite time-varying magnetic field

The invention relates to an electromagnetic stirring generation device, method and application of a composite time-varying magnetic field. The device is a time-varying magnetic field generating device, a composite rotating magnetic field electromagnetic stirring generating device and / or a traveling wave magnetic field electromagnetic stirring generating device; the method and application are In the process of continuous casting, semi-continuous casting or mold casting, the electromagnetic stirring generating device with composite time-varying magnetic field acts on any one or more of the crystallizer, secondary cooling zone and end of continuous casting or semi-continuous casting, or Riser, liquid level and other positions in die casting production, so as to improve the mechanical properties of the billet by improving the composition segregation and shrinkage porosity of the billet. Compared with the single application of electromagnetic stirring or time-varying magnetic field in the production process of continuous casting, semi-continuous casting or mold casting, the present invention can significantly improve the shrinkage cavity porosity and component segregation in the core of the billet.

Owner:SHANGHAI UNIV

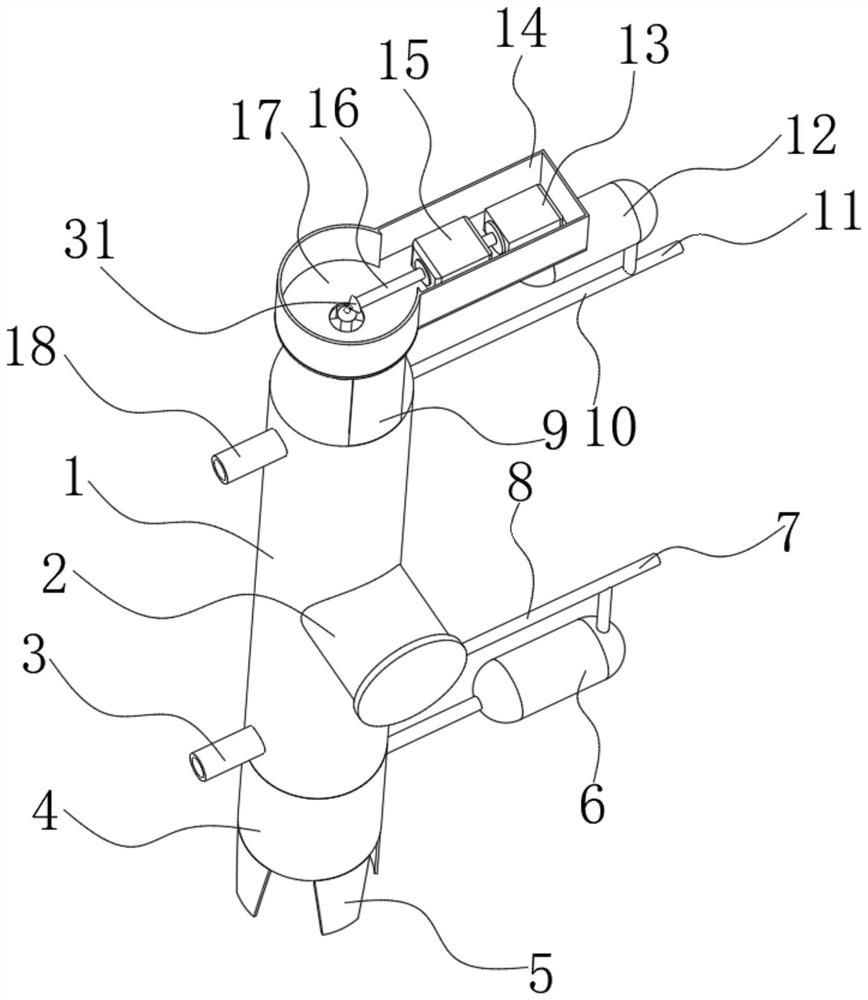

CO2 rectification separation and purification device with high purification rate

PendingCN113975842AIncrease flow strengthFull contact with each otherGas treatmentDispersed particle separationReboilerProcess engineering

The invention discloses a CO2 rectification separation and purification device with high purification rate, wherein the device comprises a rectification tower; the top of the rectification tower is communicated with an upper gas outlet pipe; one end, far away from the rectification tower,of the upper gas outlet pipe is communicated with a condenser, a liquid outlet of the condenser is communicated with an upper return pipe, and the liquid outlet of the condenser is communicated with an upper discharge pipe; and the bottom of the rectification tower is communicated with a lower liquid outlet pipe, one end, far away from the rectification tower, of the lower liquid outlet pipe is communicated with a reboiler, and an air outlet of the reboiler is communicated with a lower return pipe. When an arranged rotating shaft rotates, a rotary frame can be driven to rotate, heavy liquid in the rectification tower from top to bottom falls into the rotary frame, light gas from bottom to top blows open a small gas cap through a small vent hole, then the light gas makes contact with a heavy liquid, light substances and heavy substances in the rectification tower are mutually exchanged; and in addition, the light gas and the heavy liquid can be in full contact with each other through the rotating rotary frame, and the rectification effect is improved.

Owner:烟台冰轮环保科技有限公司

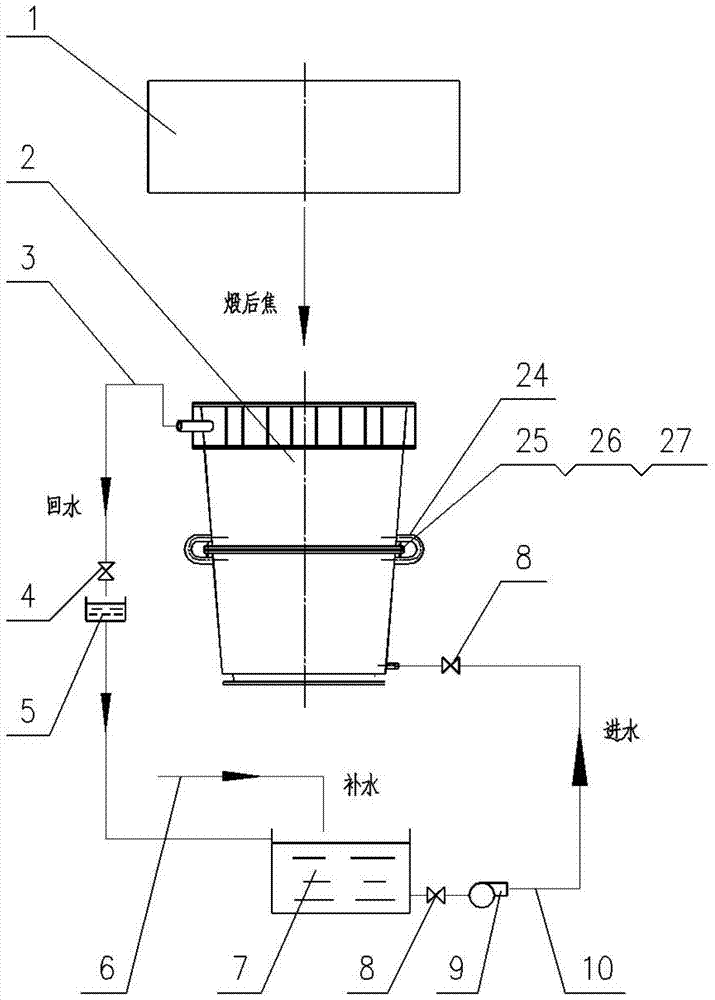

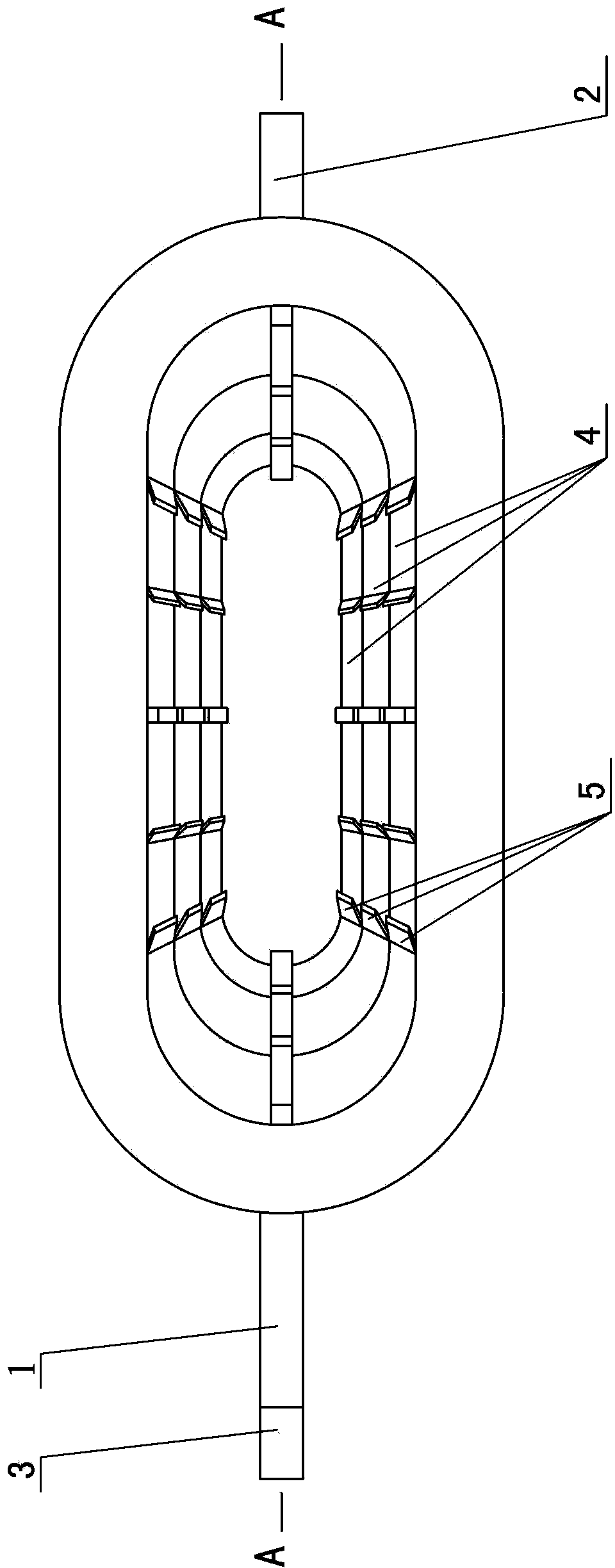

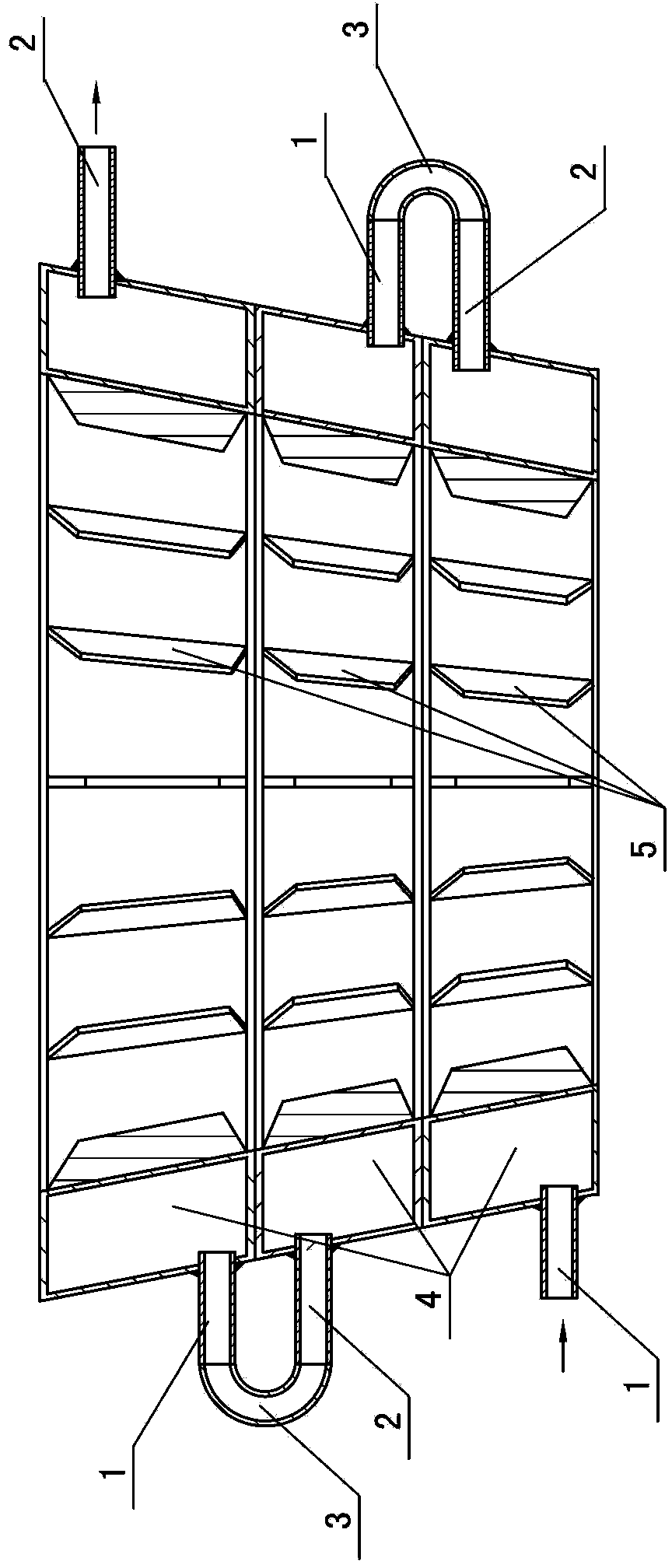

Tank calciner U-shaped open circulation cooling system and cooling method

ActiveCN104697342BPrevent vacuum zoneAvoid deformation and other phenomenaFurnace coolingAluminum anodeEngineering

The invention relates to the field of tank calciner cooling, specifically a U-shaped open circulation cooling system and cooling method for a tank calciner, and particularly relates to a tank furnace used in the carbon industry to produce anodes, cathodes, electrodes for aluminum and carbon graphitization materials. Cooling system and method for medium-forged coke. The system is equipped with a cooling water jacket, a U-shaped return pipe, a cup-shaped container, and a reservoir. The specific structure is as follows: the cooling water jacket and the reservoir are connected through a return channel, and a cup-shaped container is provided on the return channel. One end of the water channel is equipped with a U-shaped return pipe. One end of the U-shaped return pipe is connected to the water outlet of the cooling water jacket. The other end of the U-shaped return pipe leads into a cup-shaped container. The cup-shaped container is connected to the reservoir through the pipeline. The water reservoir is connected to the cooling water jacket through the water inlet pipe. The invention can solve the problems existing in the existing cooling system such as empty burning at the top of the water jacket, local overheating, easy welding, short service life, inability to monitor the return water system, and low cooling efficiency.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

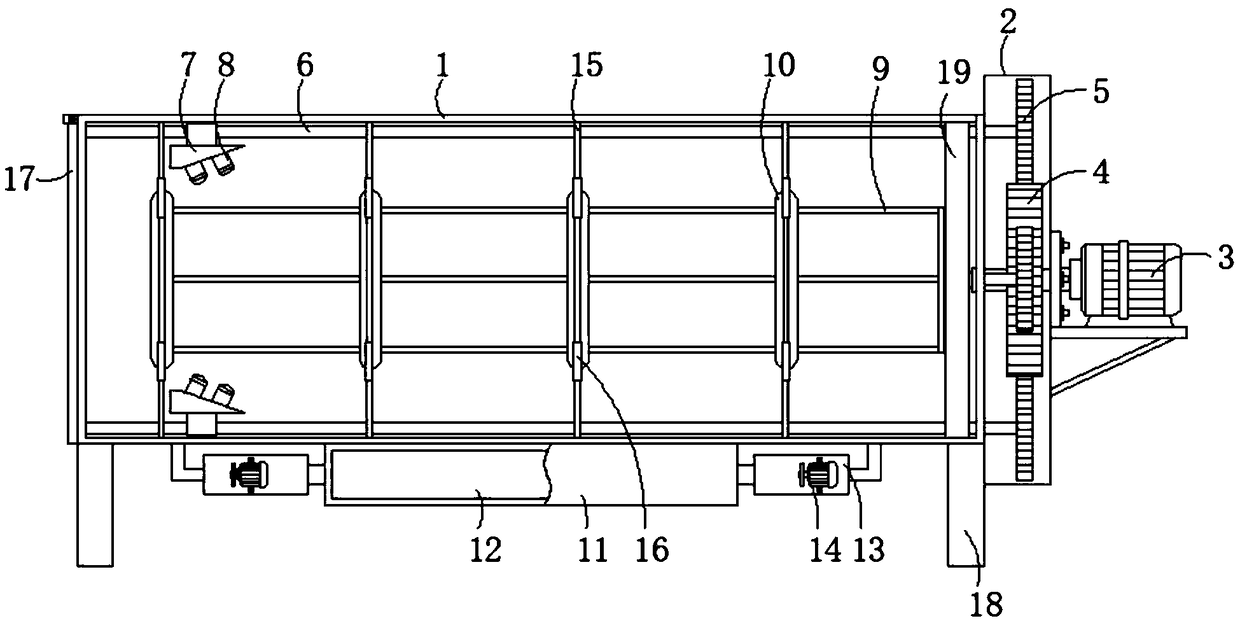

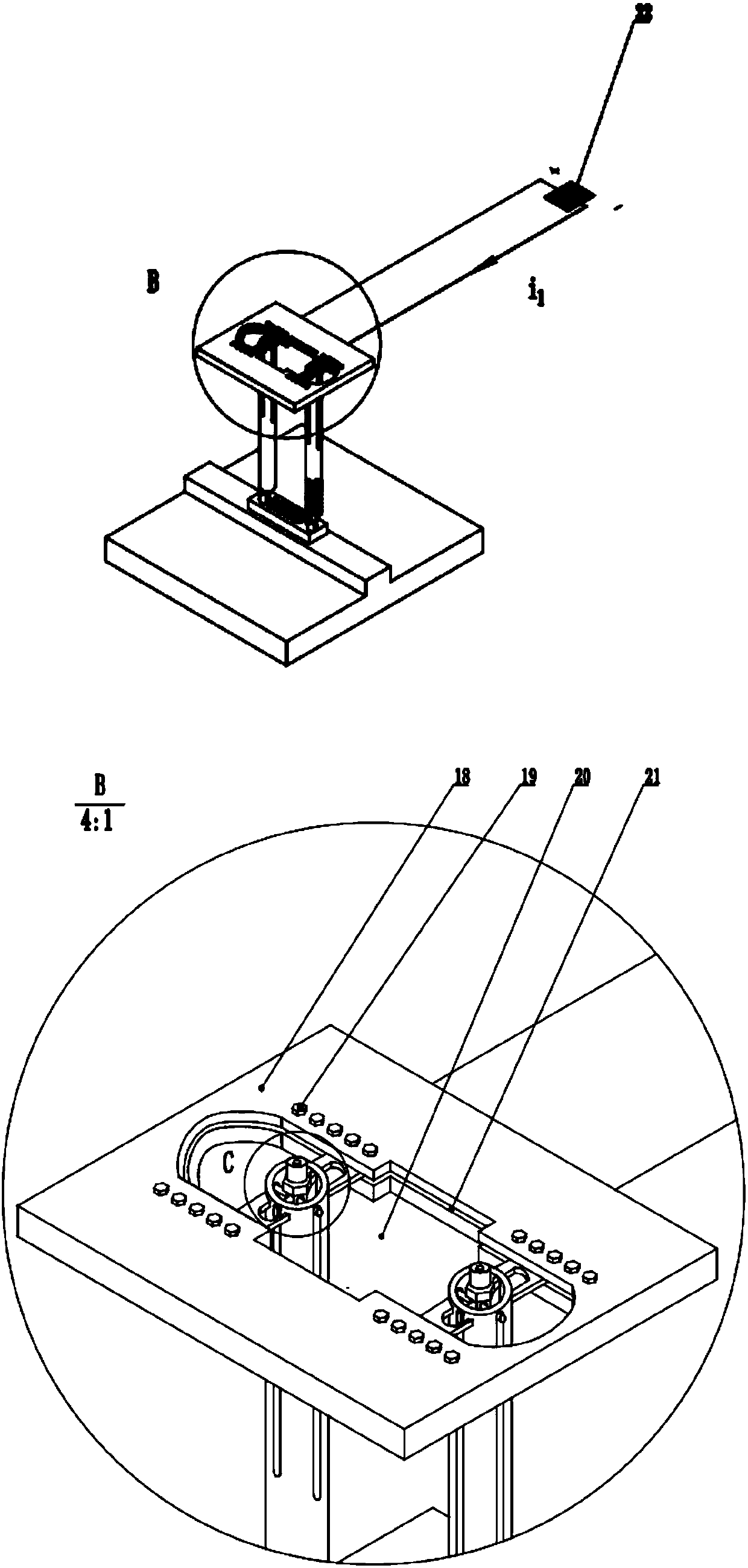

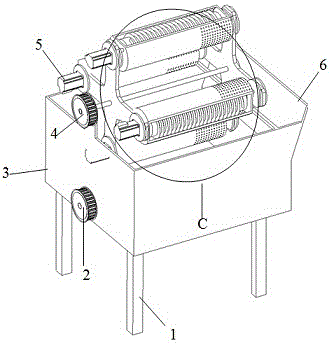

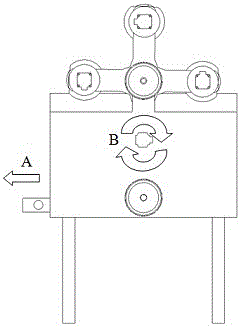

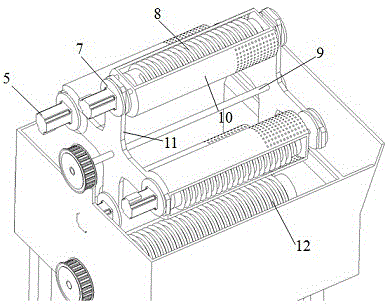

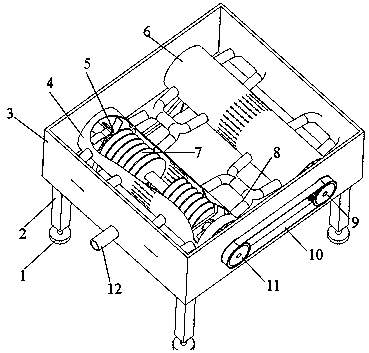

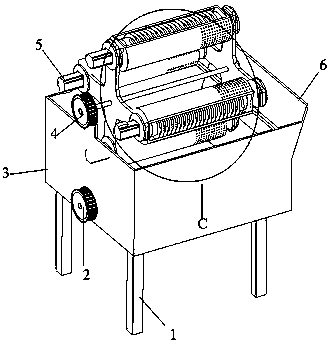

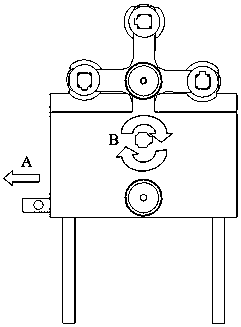

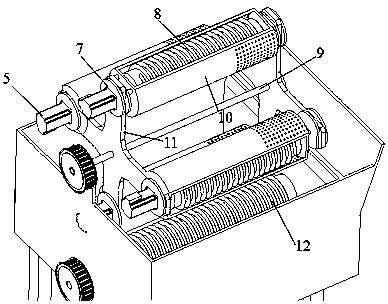

Laundry sheet slurry main-auxiliary two-stage stirring mixing apparatus

ActiveCN106237885ASimple structureLarge operating spaceRotary stirring mixersTransportation and packagingProduction lineMotor drive

The invention discloses a laundry sheet slurry main-auxiliary two-stage stirring mixing apparatus. According to the laundry sheet slurry main-auxiliary two-stage stirring mixing apparatus, various components of the effective components of a laundry sheet to be mixed are placed into a material box, a main stirring shaft belt wheel drives a stirring main shaft to rotate after the apparatus is started, the slurry forms anterior-posterior circulation through the main stirring shaft while a stirrer set drives the belt wheel to act, a four-blade rotation plate rotates, a suspending column material hopper is immersed into the slurry, the slurry is collected, the former suspending column material hopper leaves the liquid level of the material box and the next suspending column material hopper enters the slurry, a secondary stirring shaft motor drives a secondary stirring shaft to perform high speed rotation so as to stir the slurry of the suspending column material hopper, and the slurry overflows from the cavity on the other end of the suspending column material hopper and falls onto the other side of the main stirring shaft inside the material box. According to the present invention, with the laundry sheet slurry main-auxiliary two-stage stirring mixing apparatus, the problems of low efficiency, high labor intensity and low automation degree of the traditional laundry sheet slurry mixing equipment are solved while the automated production line is conveniently formed, and the advantages of simple operation and high stirring quality are provided.

Owner:河北匠心生物科技有限公司

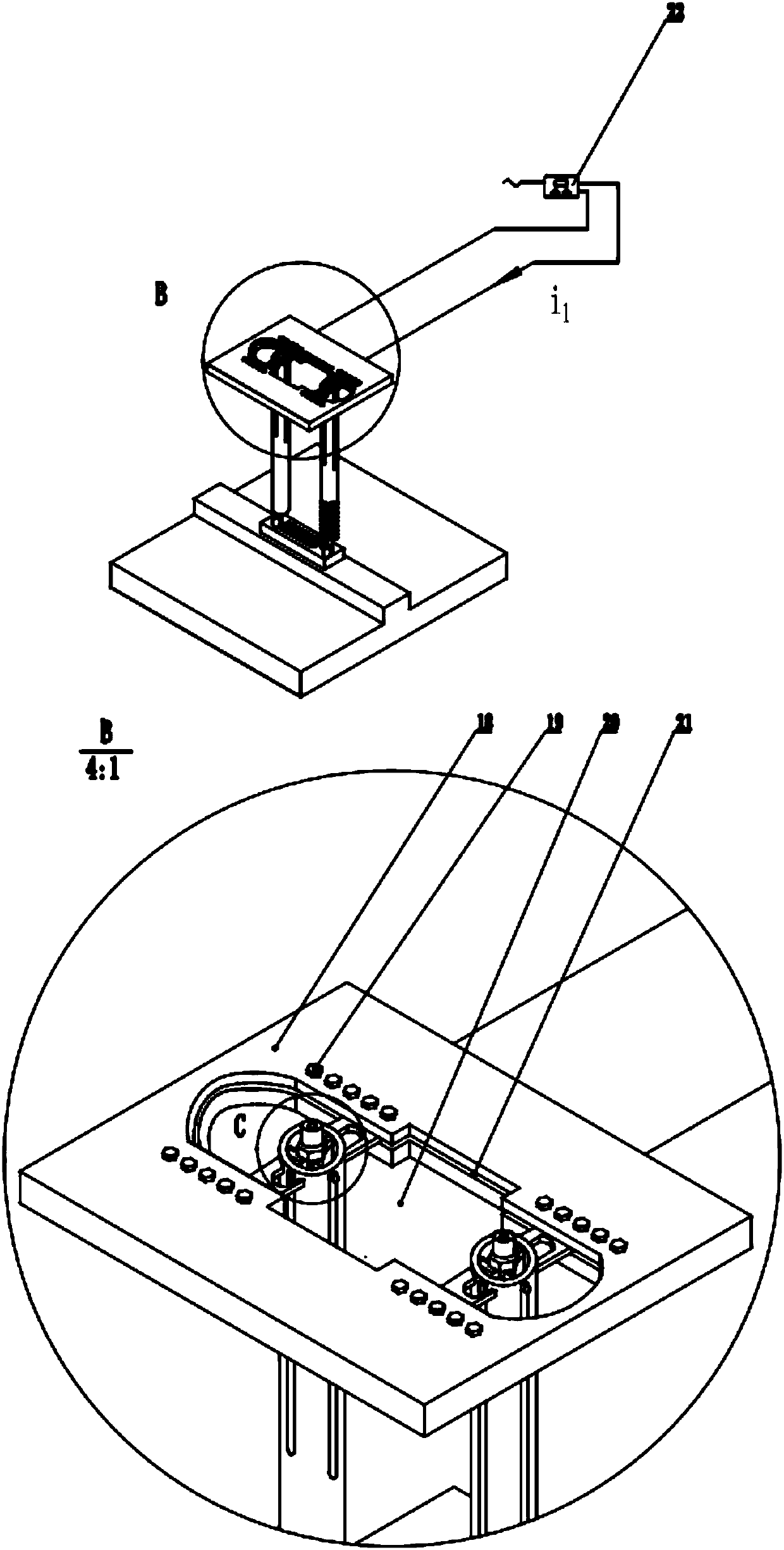

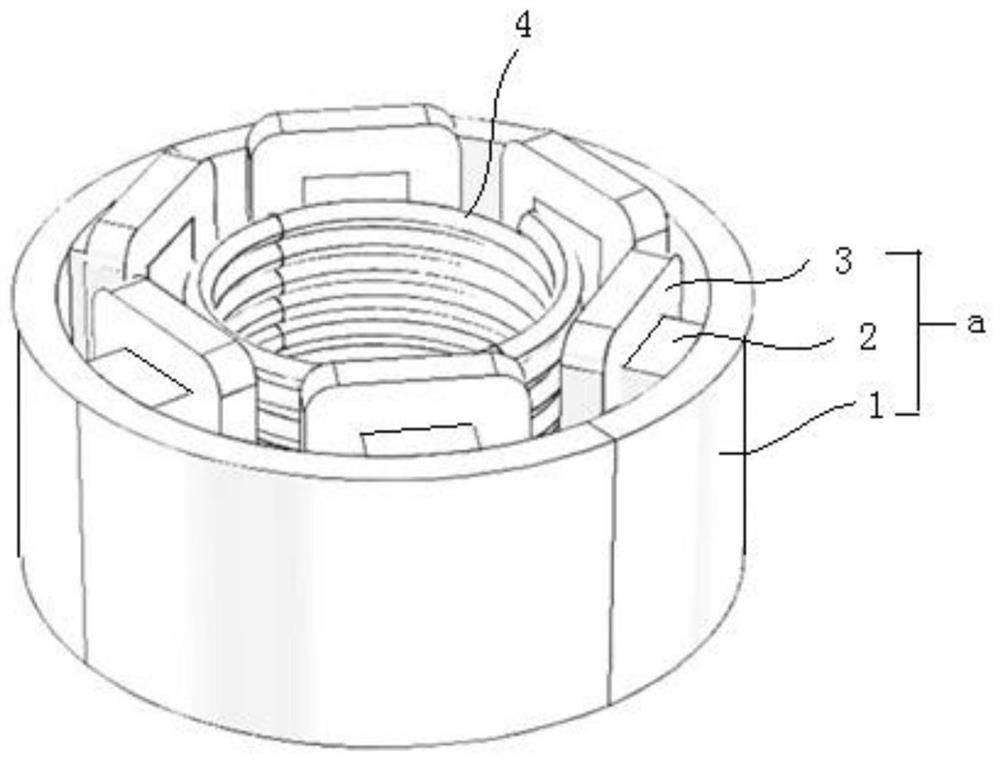

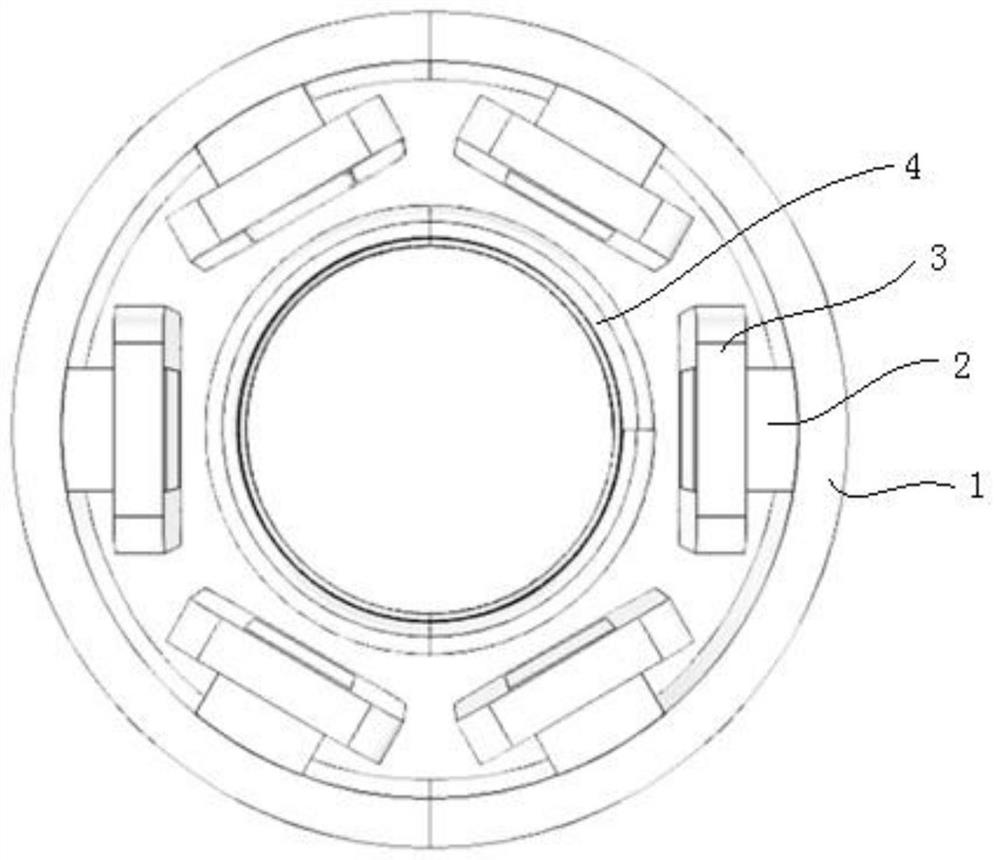

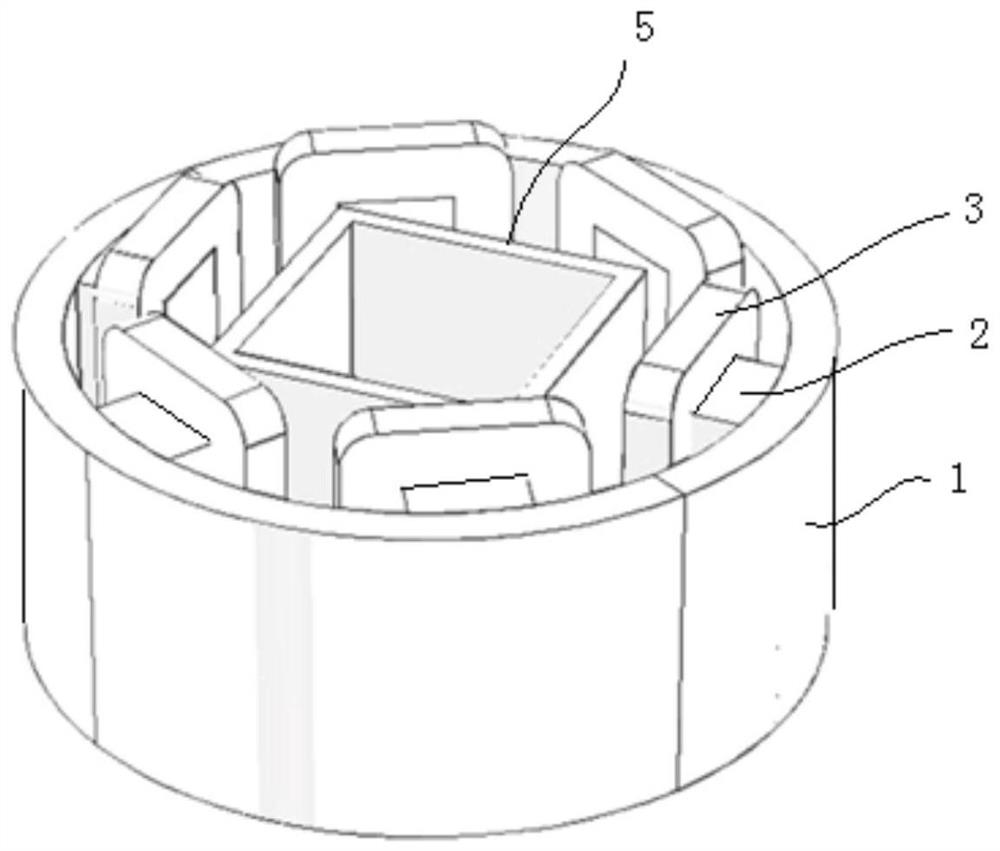

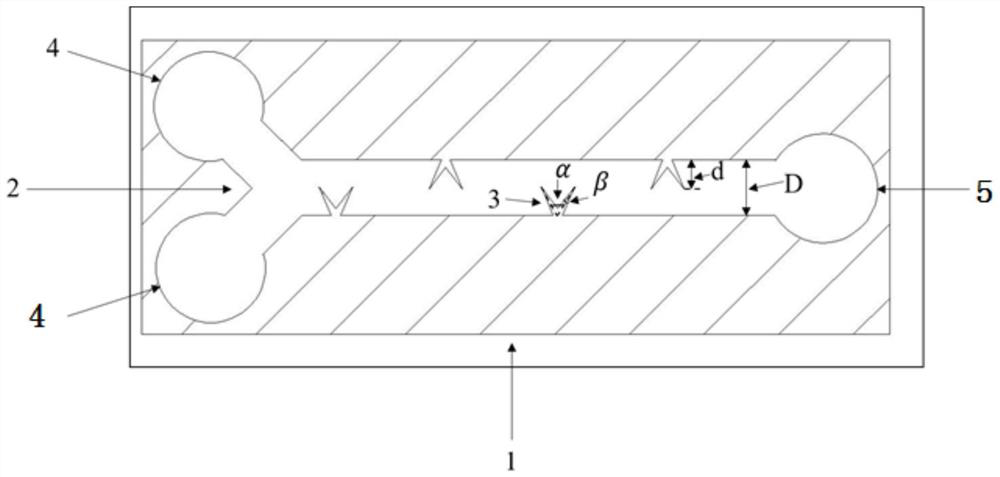

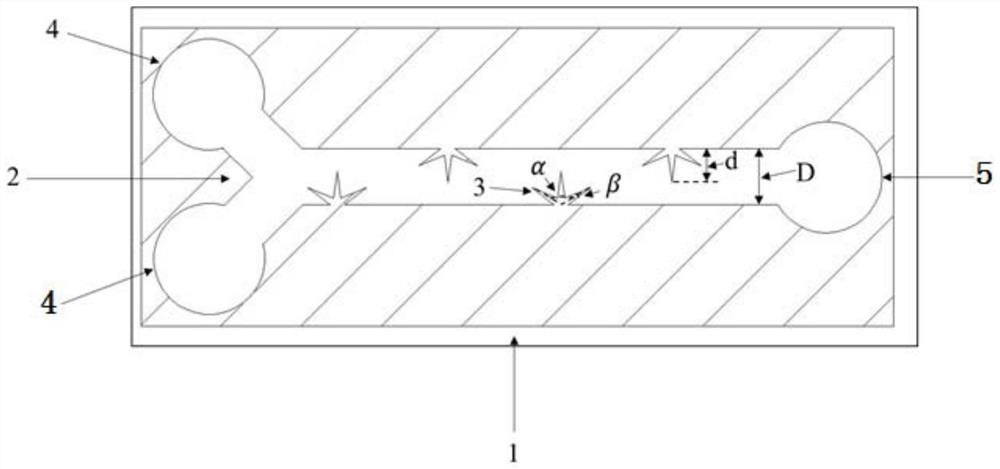

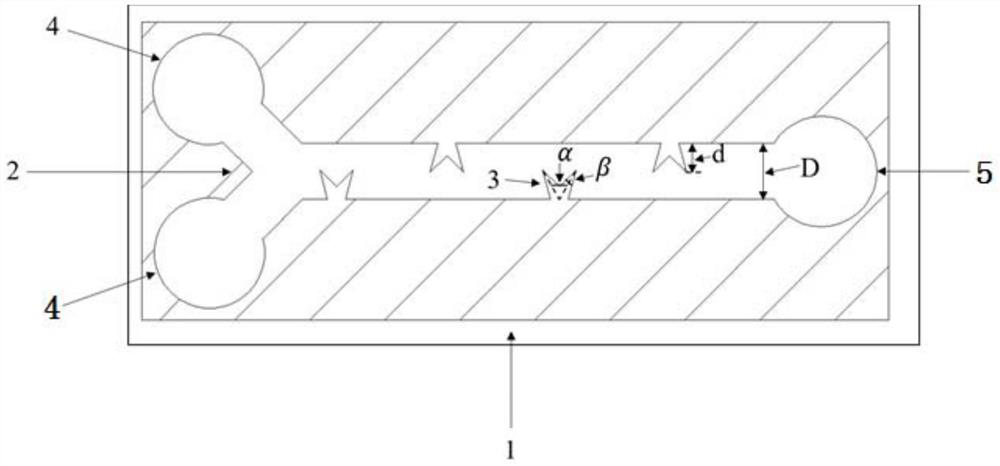

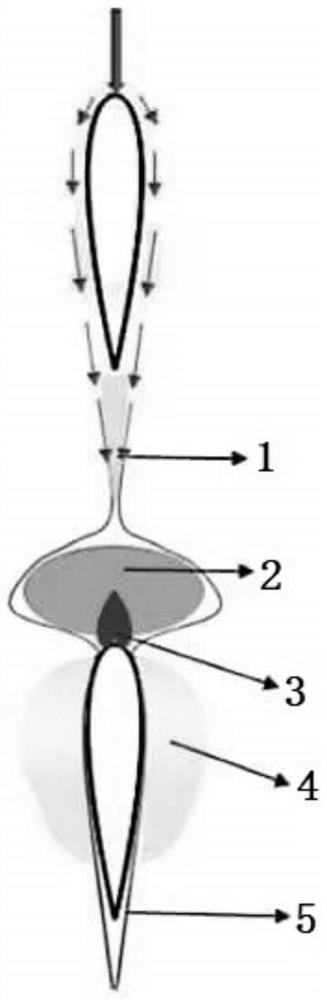

Micro-reaction channel structure, micro-reactor based on micro-reaction channel structure and nano material synthesis system

ActiveCN114259960AIncrease the degree of mixingReduce dosageZinc oxides/hydroxidesTransportation and packagingMicroreactorMaterial synthesis

The invention discloses a micro-reaction channel structure, a micro-reactor based on the micro-reaction channel structure and a nano-material synthesis system, and can overcome the defects that an existing micro-reactor is long in reaction distance, poor in operability and the like. The reaction mixing efficiency can be flexibly regulated and controlled; and based on the strong liquid mixing effect, a nano material synthesis system is constructed. According to the design working scheme, the micro-reaction channel structure comprises a micro-channel with the characteristic scale ranging from 0.005 mm to 2 mm, a certain number of spine structures are arranged on the inner wall or in the middle of the micro-channel, spines such as petals and roots in a flower gather together, and leaf tips are unfolded in the circumferential direction. The spines with the roots gathered together form a microstructure. According to the nano-material synthesis system constructed based on the micro-reaction channel, multiple chemical reagents needed for synthesizing the nano-material are completely mixed through the micro-reaction channel for multiple times, the mixed liquid is led to a target site where the nano-material needs to be synthesized, and the nano-material is formed after post-treatment such as heating and drying.

Owner:XI AN JIAOTONG UNIV

Laundry Tablet Slurry Vortex Channel Stirring and Mixing Device

InactiveCN106268418BSimple structureLarge operating spaceTransportation and packagingRotary stirring mixersLiquid waterSlurry

The invention discloses a stirring and mixing device for a laundry tablet slurry vortex flow channel. The operator pours each component of the active ingredients of the laundry tablet and liquid water into a material box, and then the device is started, and the blades and the pushing screw shaft are synchronized. Rotate, the slurry is sucked into extrusion barrel 1 and extrusion barrel 2 by the blades, flows to the pusher screw shaft through the transfer tube, and the slurry is stirred on the pusher screw shaft, and the formed axial thrust pushes the slurry To the middle of extruding barrel 1 and extruding barrel 2, the slurry from both ends converges at the center of extruding barrel 1 and extruding barrel 2 and flows from the opening in the middle of extruding barrel 1 and extruding barrel 2 When it overflows, the slurry goes through the vortex stirring channel, and repeats. The device solves the problems of low efficiency, high labor intensity and low degree of automation of traditional washing tablet active ingredient stirring and mixing equipment.

Owner:绍兴顶多纺织有限公司

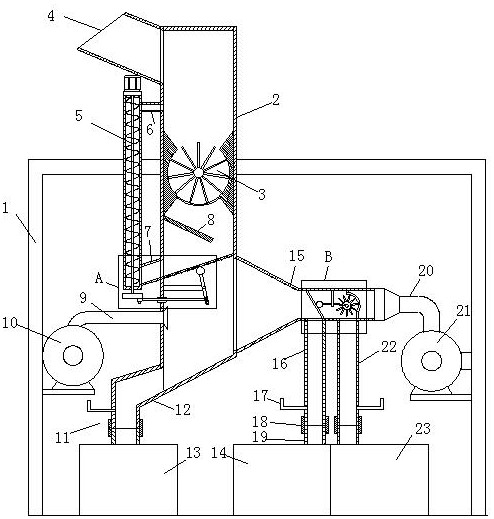

Fine waste glass powder slag recycling and smashing equipment

ActiveCN113559986AAchieve smashRealize screeningGlass recyclingGrain treatmentsSlagProcess engineering

The invention relates to the field of waste glass recycling equipment, in particular to fine waste glass powder slag recycling and smashing equipment which comprises a rack; a smashing cylinder used for smashing waste glass is fixed to the rack; crushing equipment is arranged in the smashing cylinder; a primary screening mechanism used for primarily screening the smashed waste glass is arranged on the side wall of the smashing cylinder; an air pipe II is fixed to the side wall of the lower end of the smashing cylinder; a second-stage screening mechanism and a third-stage screening mechanism which are used for secondary screening of the smashed glass screened by the primary screening mechanism are arranged in the air pipe II; the lower end of the smashing cylinder is fixed and communicated with a first discharging pipe corresponding to the primary screening mechanism; and a second discharging pipe and a third discharging pipe corresponding to the second-stage screening mechanism and the third-stage screening mechanism are fixed to and communicated with the air pipe II. According to the fine waste glass powder slag recycling and smashing equipment, smashing and screening of the glass powder slag are achieved, aqueous liquid is not needed, and the glass powder slag can be completely utilized.

Owner:HUNAN JUQIANG RENEWABLE RESOURCES SCI & TECH DEV CO LTD

Hybrid unit of SCR (selective catalytic reduction) system for vehicle urea

ActiveCN102022165BEvenly distributedReduce crystallizationInternal combustion piston enginesExhaust apparatusEngineeringAqueous solution

The invention discloses a hybrid unit of an SCR (selective catalytic reduction) system for vehicle urea, comprising a pipe body, a hybrid unit rib device and a nozzle, wherein the nozzle is aslant arranged on the wall surface of the pipe body; the hybrid unit rib device tightly abuts against the nozzle and is installed on the front end of the nozzle; the hybrid unit rib device comprises four ribs, the middle of the first rib and the second rib forms a fluid path similar to an atomizing pattern; the first rib and the second rib have certain gradient and twists towards the central area; the third rib has a baffle-shaped structure and is arranged near the pipe wall, the installation direction is vertical to the atomizing axis, and the third rib twists towards the wall surface; and the fourthrib is arranged along the atomizing axis direction and is composed of a group of blades alternately twisted left and right. The invention can bring the effect that a urea aqueous solution injected bythe nozzle and tail gas are fully mixed before entering an SCR catalytic converter, thus reducing urea crystallization formed on the wall surface; and meanwhile, the hybrid unit has compact structureand is easy to process and install, and the effect of the hybrid unit is verified.

Owner:HANGZHOU YINLUN TECH CO LTD +1

A fine waste glass powder slag recycling crushing equipment

ActiveCN113559986BAchieve smashRealize screeningGlass recyclingGrain treatmentsSlagProcess engineering

Owner:HUNAN JUQIANG RENEWABLE RESOURCES SCI & TECH DEV CO LTD

Seam-like welding-traveling wave-like magnetic field composite method for improving defects of cladding layer

PendingCN110527998AImprove chargeabilityIncrease flow strengthMetallic material coating processesLiquid metalNon magnetic

The invention discloses a seam-like welding-traveling wave magnetic field composite method for improving the defects of a cladding layer. The adopted devices mainly comprise a laser cladding numericalcontrol device, a traveling wave magnetic field device and a seam-like welding device. According to the present invention, firstly, the seam-like welding device is started before cladding until the power is continuously supplied for a period of time after cladding is completed, and secondly, a traveling wave magnetic field is applied to a molten pool during the cladding process, so that the charged quantity of non-magnetic particles and particles with small charged quantity in the molten pool is increased under the action of impressed current, in an external follow-up traveling wave magneticfield, the Lorentz force borne by the liquid metal particles is remarkably enhanced, then the stirring effect of a molten pool is enhanced, the number of crystal grains is increased, the fine grain strengthening is remarkable, the cladding layer structure defects are reduced, and the quality is improved. According to the method, the problems that the non-magnetic particles with small electric charge amount are subjected to small Lorentz force in the electromagnetic field, and the electromagnetic stirring effect of a magnetic field on a molten pool is small are effectively solved, and meanwhilethe defects that in the prior art, the refining effect is not remarkable only by enhancing the magnetic induction intensity of the magnetic field, and the pre-heating before melting and slow coolingdevices after melting are needed to be additionally arranged, are overcome.

Owner:魏永强

A graphite electrode heating device

ActiveCN109405559BPrevent disengagementIncrease temperatureElectric heating for furnacesGraphite electrodeEngineering

The invention discloses a graphite electrode heating device which comprises a box body and a motor arranged on one side of the box body. A groove is formed in one side of the box body, and a rotatinghole is formed in the inner wall of the side, close to the motor, of the groove. A rotating shaft is welded on an output shaft of the motor, one end of the rotating shaft penetrates through the rotating hole and extends into the groove, and a sleeve is welded on the end of the rotating shaft. A first belt pulley is fixedly sleeved on the outer side of the rotating shaft. Stand columns are welded on the inner wall of the top side and the inner wall of the bottom side of the groove, and circular columns are horizontally and rotationally arranged on the ends, close to each other, of the two standcolumns. Second belt pulleys are fixedly sleeved on the outer sides of the circular columns, and a same belt is arranged on the two second belt pulleys and the first belt pulley in a transmitting mode. The graphite electrode heating device has the advantages of reasonable design and high practicability and is convenient to drive a sleeve to rotate. Moreover, the flow intensity of air in the groove can be increased through a fan blade, so that a graphite electrode in an electrode placing slot can be fully in contact with the air in the groove, and the temperature rising rate of the graphite electrode is increased.

Owner:龙沃科技开发有限公司

Arc-top piston top, arc-top piston and combustion chamber

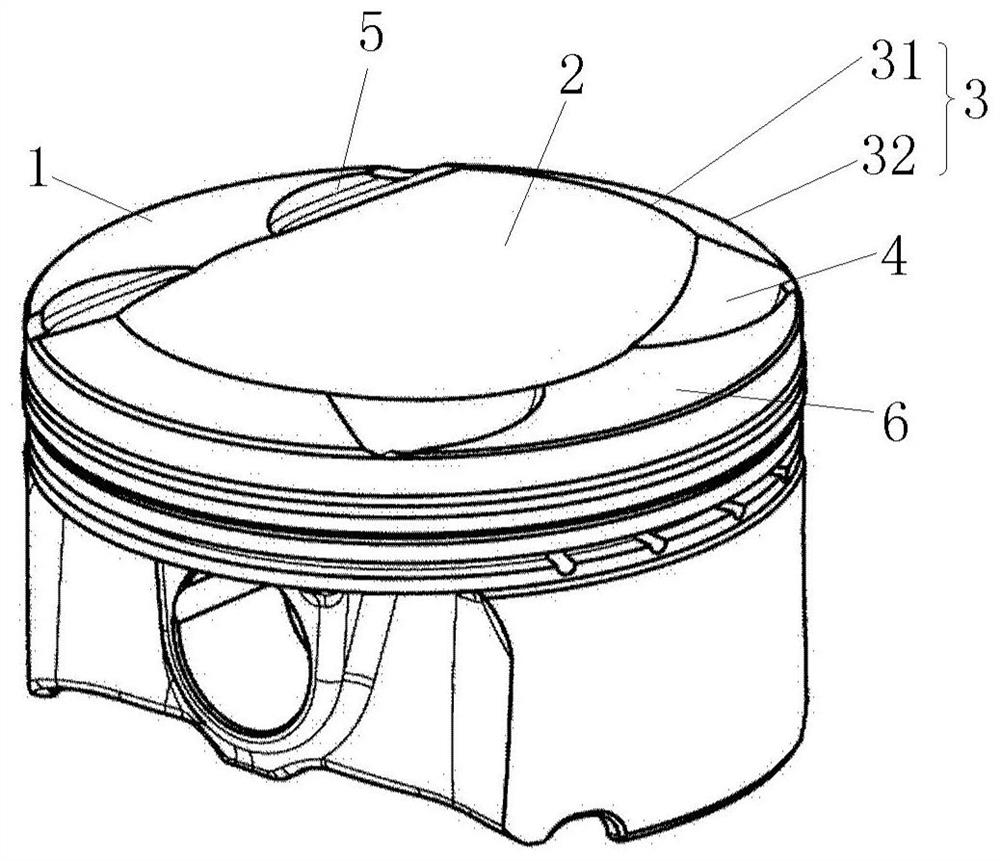

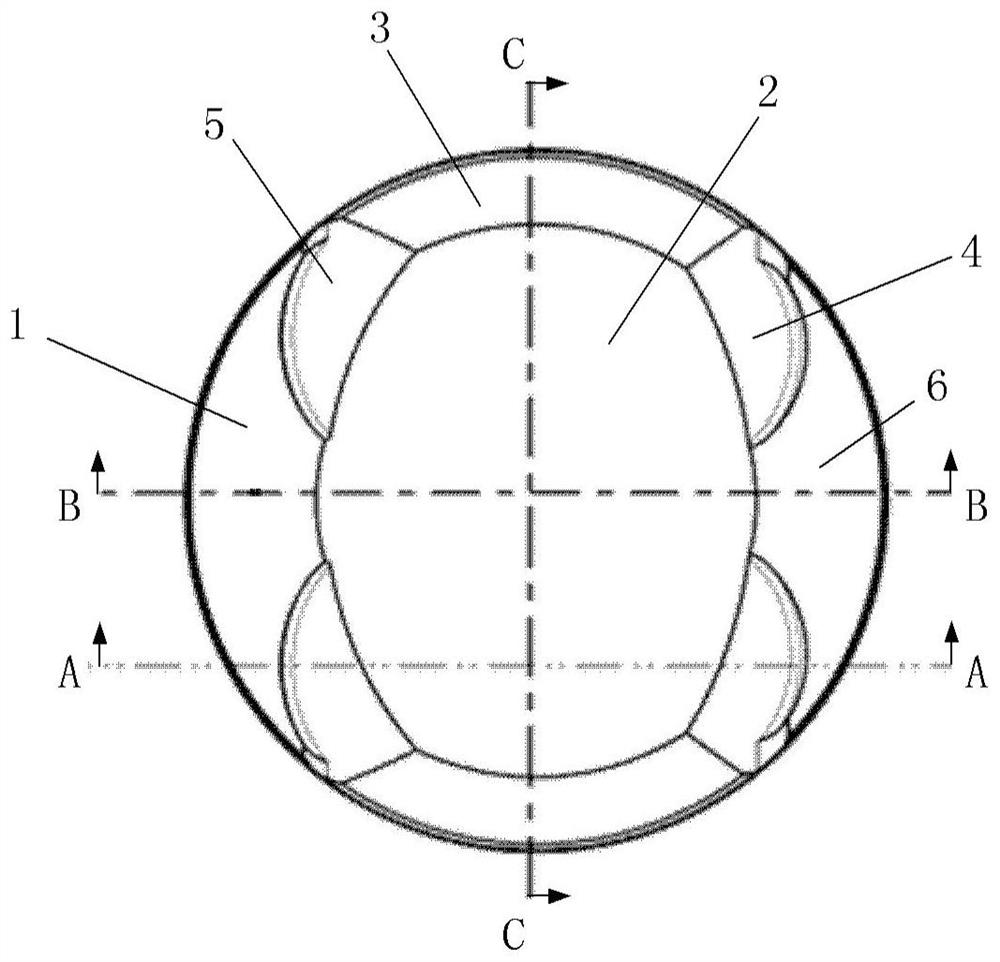

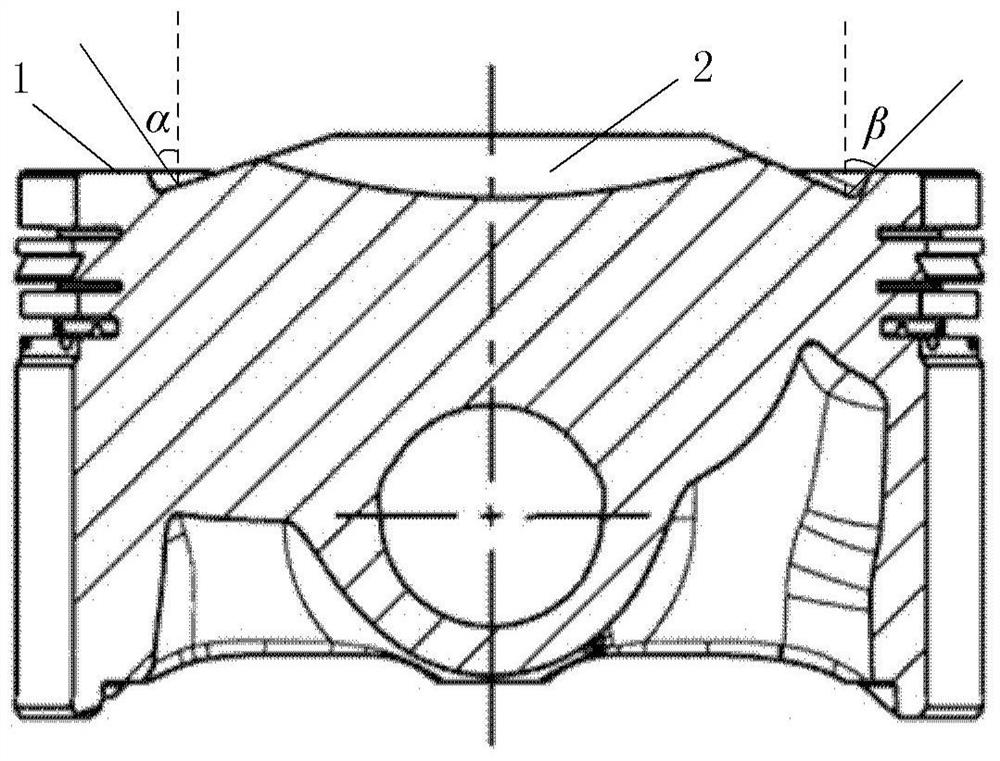

InactiveCN113404615AOptimize the airflow movement form in the cylinderIncrease air speedMachines/enginesPistonsPhysicsPiston

The invention provides an arc-top piston top, an arc-top piston and a combustion chamber. The arc-top piston top comprises an arc-shaped pit area and two conical surface protruding area; the arc-shaped pit area is a bowl-shaped pit and is located in the center of the arc-top piston top; the height of the first end of each conical surface protruding area is larger than that of the second end of each conical surface protruding area, the first ends of the conical surface protruding areas make contact with the outer edge of the arc-shaped pit area, and the second ends of the conical surface protruding areas extend to the edge of the arc-top piston top; the two conical surface protruding areas are located on the front side and the rear side of the arc-shaped pit area respectively, and the two conical surface protruding areas are symmetrically arranged relative to the arc-shaped pit area. The arc-top piston top can be applied to a large-cylinder-diameter and high-compression-ratio engine, the airflow movement speed in the air inlet stroke of the engine can be increased to a large extent, the compression stroke and the turbulence energy at the tail end are improved, and the knocking phenomenon of the large-cylinder-diameter and high-compression-ratio engine in the related technology is effectively avoided.

Owner:天津内燃机研究所(天津摩托车技术中心)

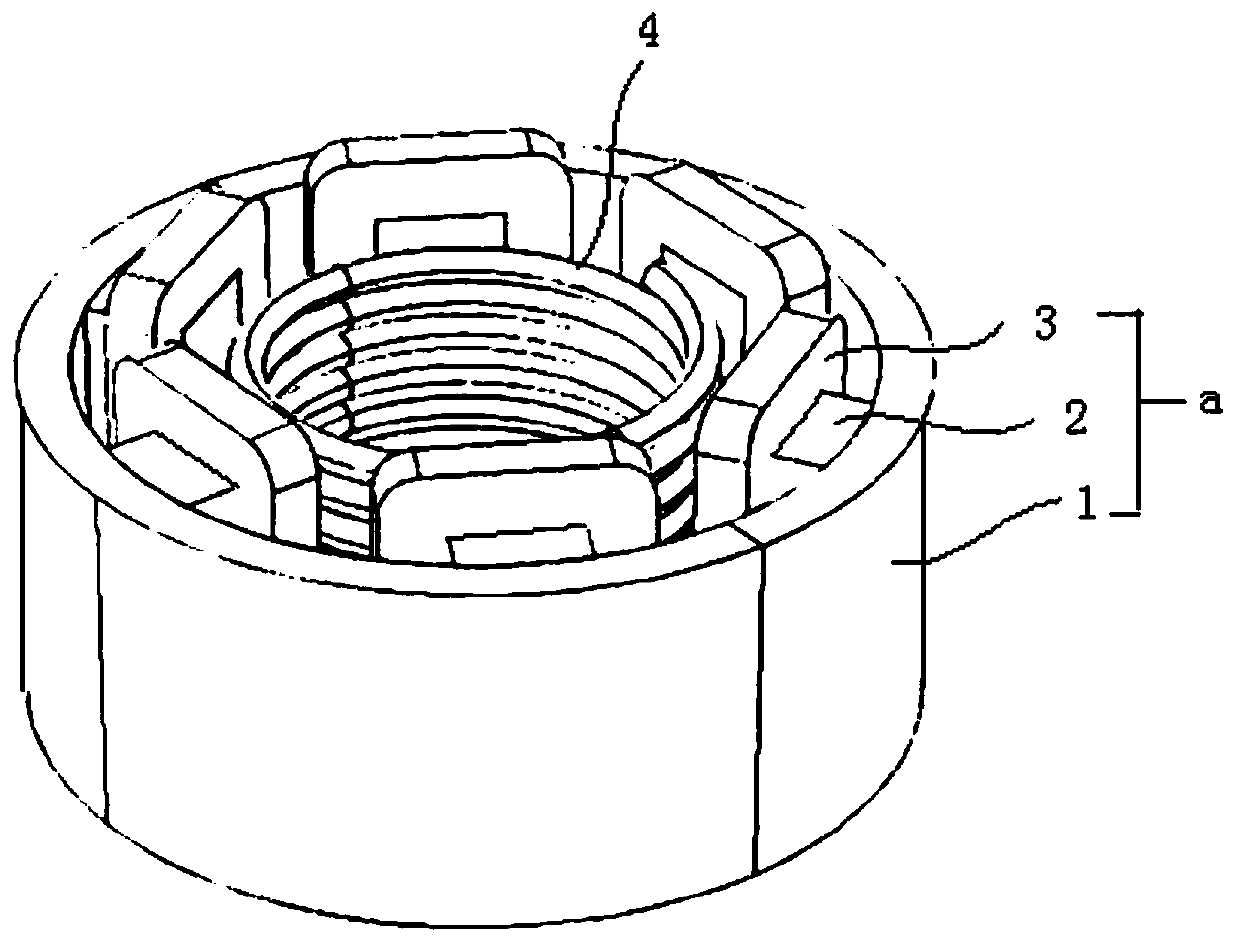

Strengthened micro cyclone separator and high-pressure separation device with same

InactiveCN105057126AIncrease the effective air intake areaImprove air intake efficiencyReversed direction vortexCycloneFriction loss

The invention discloses a strengthened micro cyclone separator and a high-pressure separation device with the separator. The strengthened micro cyclone separator comprises an outer pipe and an inner pipe. Part of the lower portion of the inner pipe enters the upper portion of the outer pipe. Guiding vanes are arranged between the inner pipe and the outer pipe. An opening between the outer pipe and the inner pipe is a cyclone separator inlet. The outer pipe and the inner pipe are connected through the guiding vanes. The 3-6 guiding vanes are in the spiral line type and are arranged in the circumferential direction of the outer wall of the inner pipe in the same direction and evenly distributed. According to the high-pressure separation device with the separator, a partition plate, the structure, the arrangement mode and the fixing method of the high-pressure cyclone separation device are designed at the same time. The efficient, energy-saving and long-period-running high-pressure separation device is established. Complete separation of gas, liquid and solid in gas, liquid and solid mixtures of the inlet is achieved, and the resistance loss is far smaller than the pressure loss of an existing conventional high-pressure separation device.

Owner:BEIJING YUANCHENG IND SAFETY TECH CO LTD

A main and auxiliary two-stage stirring and mixing device for laundry tablet slurry

ActiveCN106237885BSimple structureLarge operating spaceRotary stirring mixersTransportation and packagingMotor driveSlurry

The invention discloses a main and auxiliary two-stage stirring and mixing device for laundry tablet slurry. Each component of the active ingredients of the laundry tablet to be mixed is put into a material box. After the device is started, the main stirring shaft pulley drives the stirring main shaft to rotate, and the main stirring The shaft makes the slurry form a front-to-back cycle. At the same time, the stirring subgroup drives the pulley to move, the four-leaf rotary plate rotates, and the suspended cylindrical hopper is immersed in the slurry to collect the slurry. Then the previous suspended cylindrical hopper leaves the liquid surface of the material box, and the next one The suspended cylindrical hopper enters the slurry, and the secondary stirring shaft motor drives the secondary stirring shaft to rotate at a high speed to stir the slurry in the suspended cylindrical hopper. The slurry finally overflows from the hole at the other end of the suspended cylindrical hopper and falls into the material box at the other end of the main stirring shaft. side. This device solves the problems of low efficiency, high labor intensity and low degree of automation of traditional laundry tablet slurry mixing equipment, and at the same time facilitates the formation of an automatic production line, with the advantages of simple operation and high mixing quality.

Owner:河北匠心生物科技有限公司

Oil heat exchanger

ActiveCN106524786BImprove cooling effectIncrease flow strengthElectric heating systemSpace heating and ventilation detailsEngineeringHeat sink

The invention discloses a heat exchanger of an oil heater. The heat exchanger comprises two oil pipes and multiple heat dissipation plates, wherein the two oil pipes are distributed vertically at an interval; and two ends of each heat dissipation plate are disposed on the two oil pipes respectively, an oil way channel communicating with the two oil pipes is disposed inside each heat dissipation plate, eat least one side edge of each heat dissipation plate is bent towards the other heat dissipation plate so as to form a bent part, bent parts with the same bending direction are disposed on the same side edge of at least two heat dissipation plates, and at least a part of one of the adjacent bent parts on the same side is located on the outer side of the other bent part so as to form an air flow channel. The heat exchanger of the oil heater disclosed by the invention has the advantages that flowing strength of air on the outer surface of the heat dissipation plates can be increased; the temperature on edges of the heat dissipation plates can be reduced; the heat dissipation capacity of the heat dissipation plates can be enhanced; and a user is prevented from being scalded during use of the heat exchanger of the oil heater.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

Pot-type calcinator multi-level series fin type cooling device for coke after high-temperature calcination

ActiveCN102774826BIncreased flow distanceHigh working reliabilityCarbon preparation/purificationWater jacketCalcination

The invention relates to a pot-type calcinator multi-level series fin type cooling device for coke after high-temperature calcination. The device comprises water inlet pipes, water outlet pipes and a plurality of annular cooling water sleeves and is characterized in that the plurality of cooling water sleeves are overlapped and fixedly connected, the outer wall of the inner side of each of the cooling water sleeves is provided with a plurality of fins, the fins on the cooling water sleeves are arranged into lines correspondingly, each line of the fins is located in the same vertical surface, the water inlet pipe and the water outlet pipe are correspondingly arranged at two ends of each of the cooling water sleeves, and except the water outlet pipe at the top cooling water sleeve and the water inlet pipe at the bottom cooling water sleeve, water inlet pipes and water outlet pipes of adjacent cooling water sleeves, which are located at the same end, are communicated through connecting pipes. The device has the advantages that the heat exchange area is large, coke cooling speed after the high-temperature calcination is fast, the discharge temperature is low, the working is reliable, and the like.

Owner:SHANDONG UNIV OF TECH

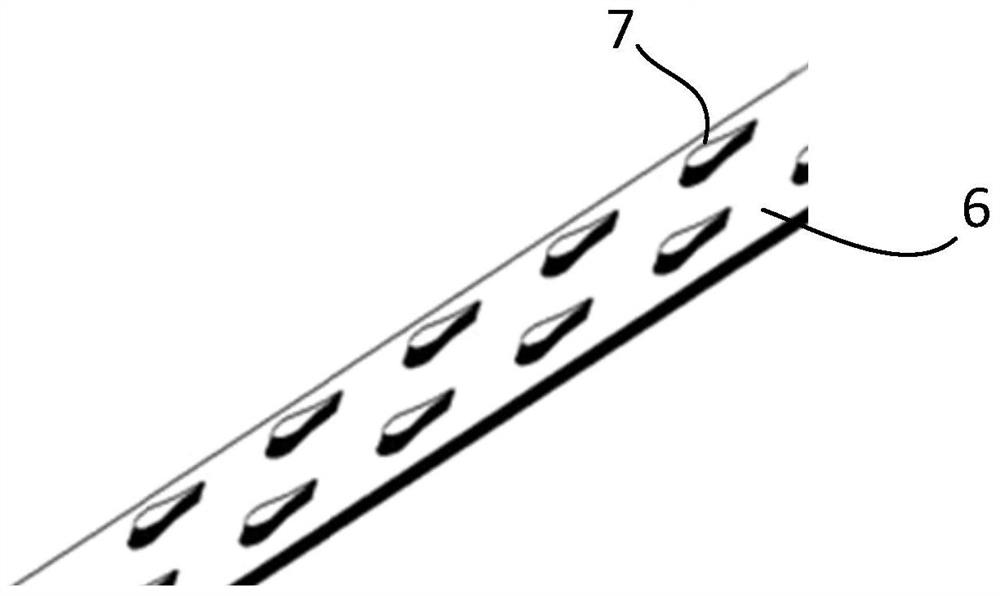

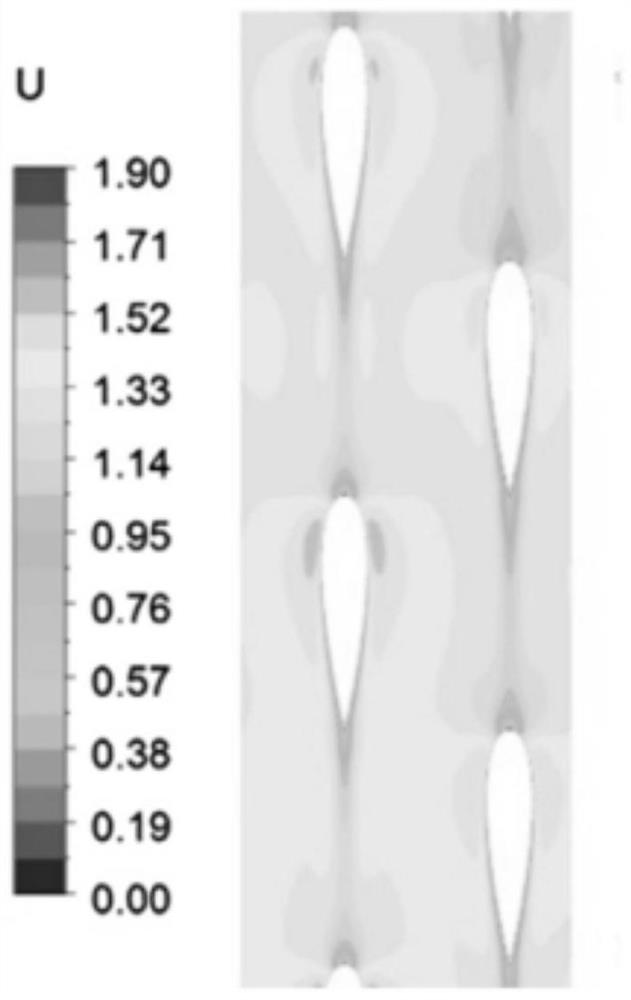

Wing-shaped structure, heat exchange plate, heat exchanger and heat exchange method

PendingCN114234704AIncrease flow strengthInhibition of nucleationChemical industryCorrosion preventionEngineeringHeat transfer efficiency

The invention provides a wing-shaped structure, a heat exchange plate, a heat exchanger and a heat exchange method, and belongs to the technical field of heat exchangers. The wing-shaped structure comprises a shell, at least one flow channel is formed in the shell in the axial direction, each flow channel comprises a plurality of communicated containing cavities, each containing cavity is divided into a plurality of sub containing cavities with different inner diameters, and the sub containing cavities with the different inner diameters are communicated through miniature discrete channels. The heat exchange plate comprises a base plate and a plurality of wing-shaped structures, and the wing-shaped structures are fixedly arranged on the base plate. The heat exchanger comprises the heat exchange plate. The heat exchange method comprises the steps that working fluid enters the sub-containing cavities from the micro discrete channels of the wing-shaped structures; the working fluid in the sub-containing cavity enters the next sub-containing cavity through the micro discrete channel again, and circulation is carried out; and the working fluid leaves the wing-shaped structure after passing through the last sub-accommodating cavity on the flow path. The heat exchanger has the advantage of being high in heat transfer efficiency, and deposition of scale substances can be reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com