A main and auxiliary two-stage stirring and mixing device for laundry tablet slurry

A technology of mixing and washing tablets, which is applied in the field of slurry mixing and mixing technology equipment, can solve the problems of low automation and working efficiency, low mixing and mixing efficiency, and high labor intensity, so as to improve mixing efficiency and high reliability of work , the effect of large operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

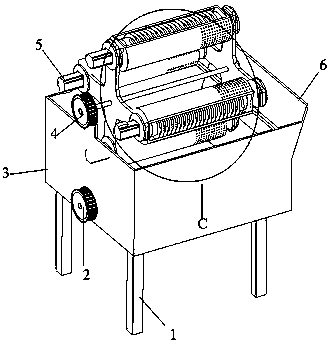

[0016] control figure 1 —3. The operator needs to check the connection of each component before work to avoid safety accidents during work, and then pour various components of the active ingredients of the laundry sheet into the material box 3, and add clean water, and the device has completed the preparation work.

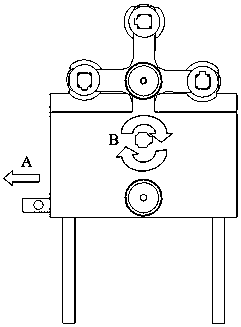

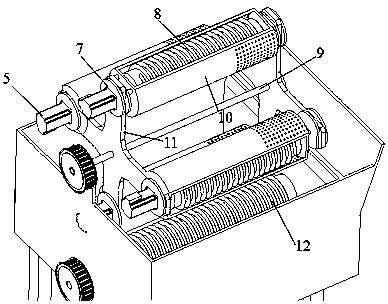

[0017] During work, under the action of external driving force, the main agitating shaft pulley 2 first moves, and the main agitating shaft pulley 2 drives the main agitating shaft 12 to move, and the main agitating shaft 12 will pour all kinds of active ingredients of the laundry tablets in the material box 3. The components are initially mixed with water, and then the stirring subgroup drives the pulley 4 to move, and the four-leaf rotating plate 11 starts to rotate. Since the double-sided rotating plate 7 rotates freely, the opening of the suspended cylindrical hopper 10 is always upward under the action of gravity, and the With the rotation of the four-leaf ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com