Patents

Literature

1205results about How to "Improve mix quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

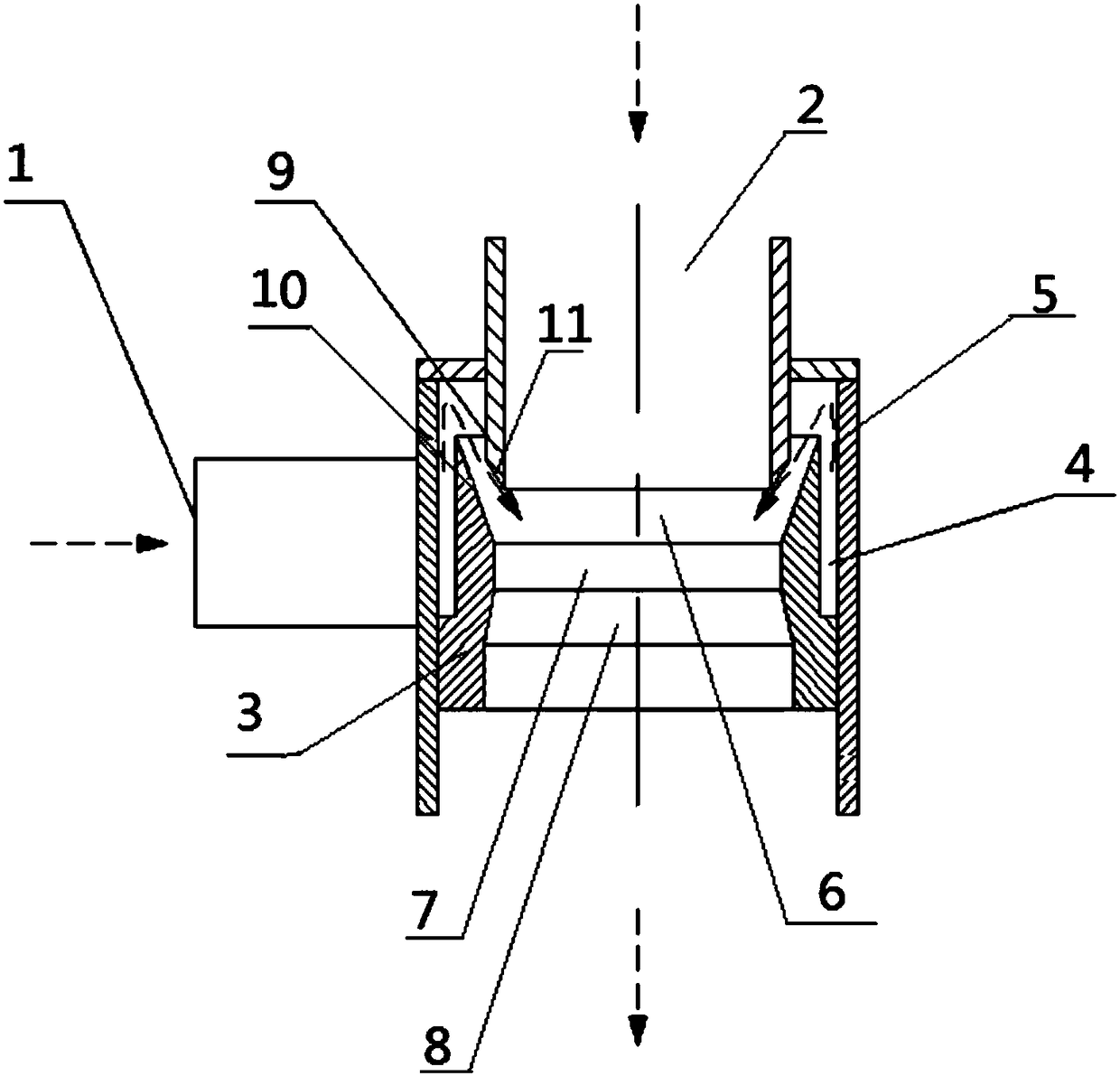

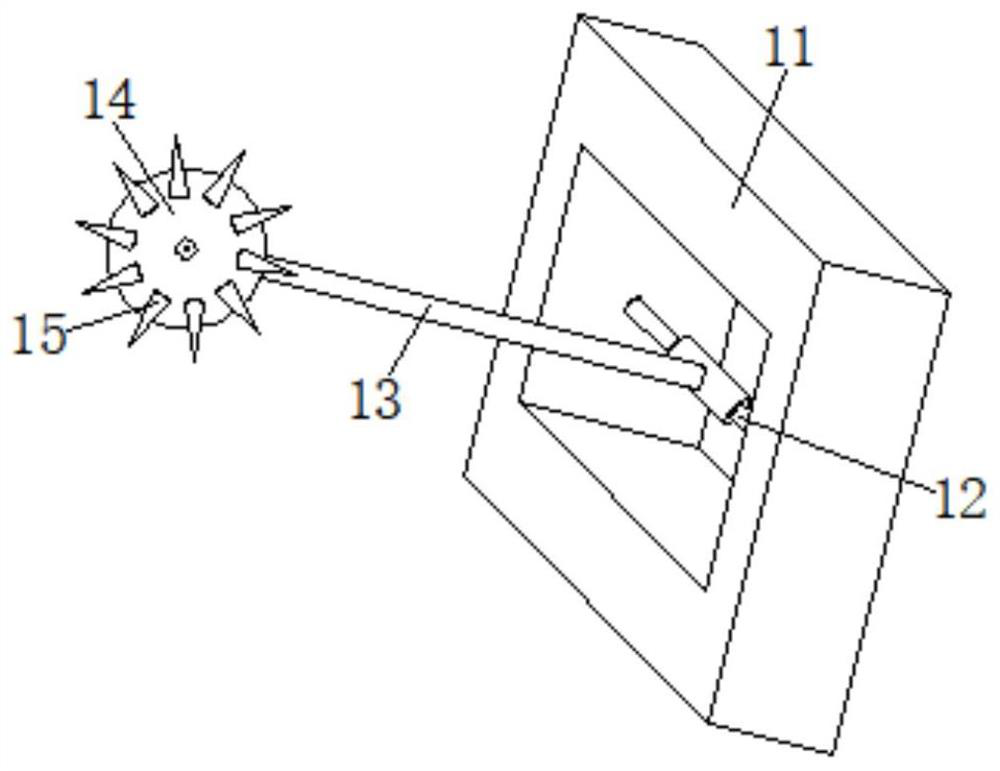

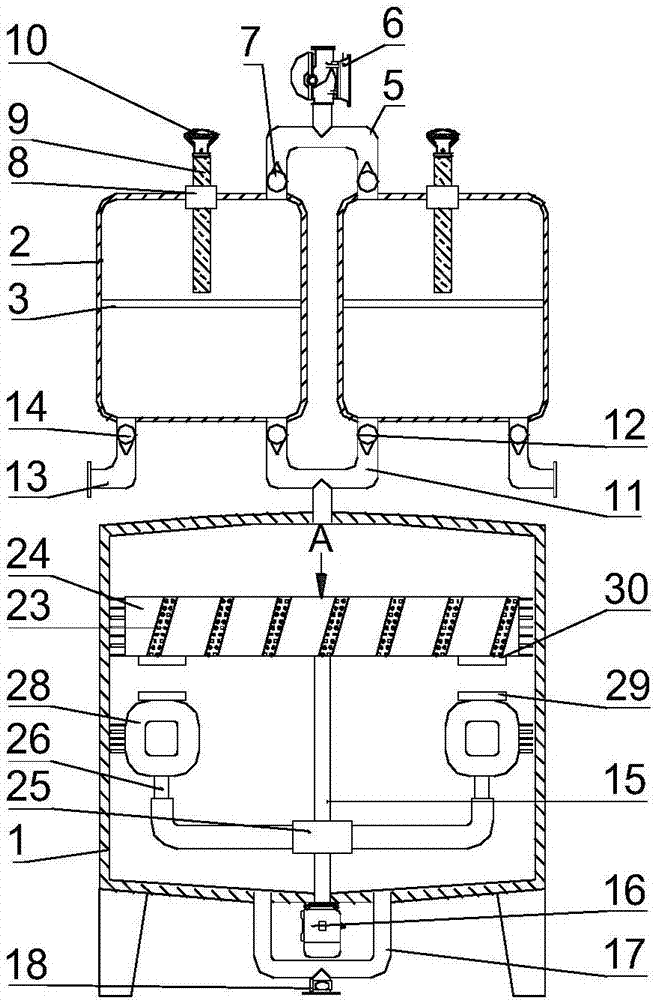

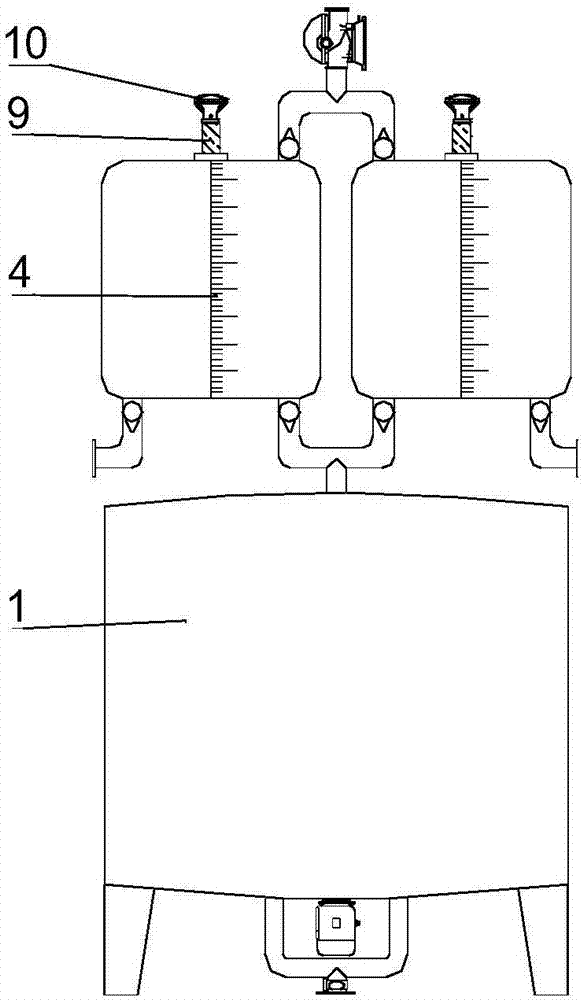

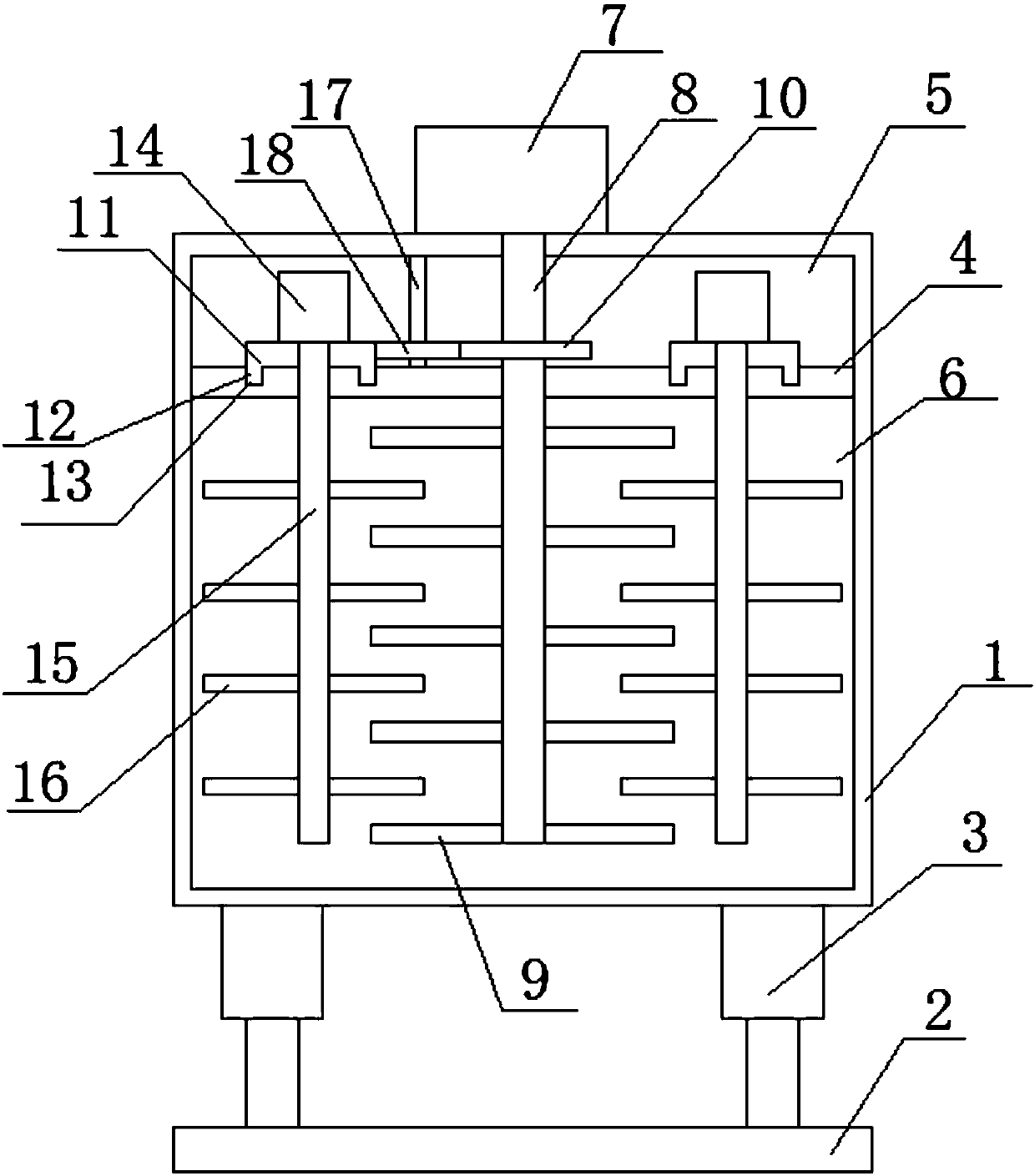

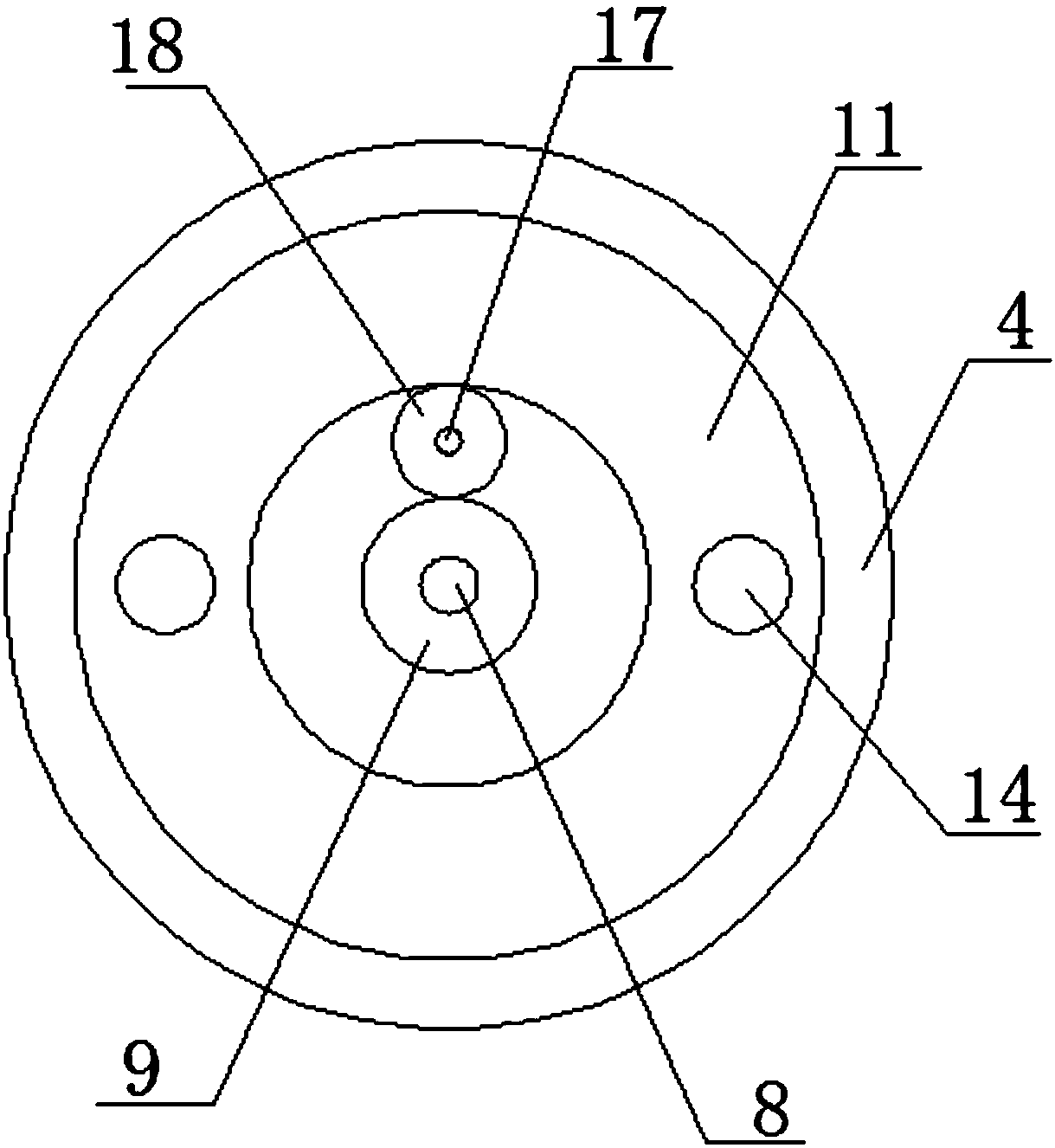

Fracturing base liquid mixer

PendingCN108371894AAchieve energy efficiency ratioCanto Efficiency RatioFlow mixersTransportation and packagingBusiness efficiencyFracture sites

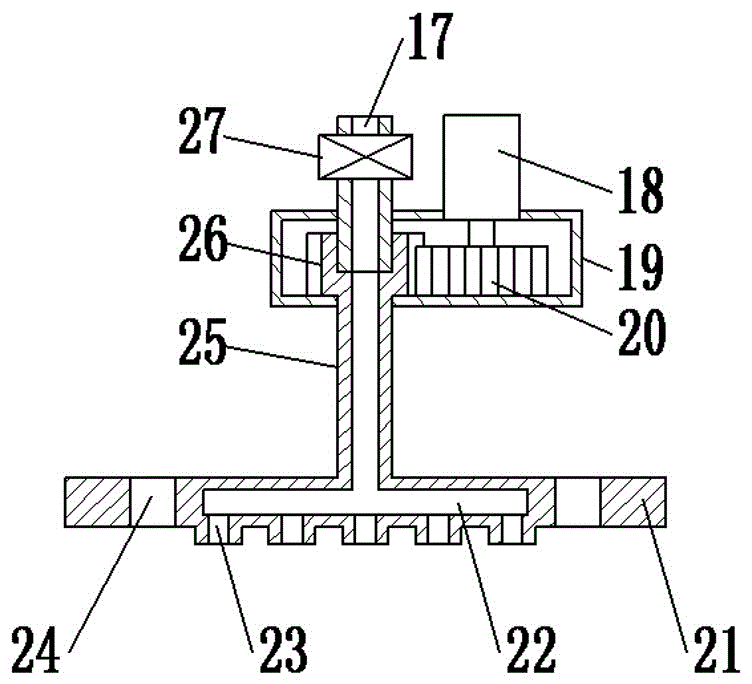

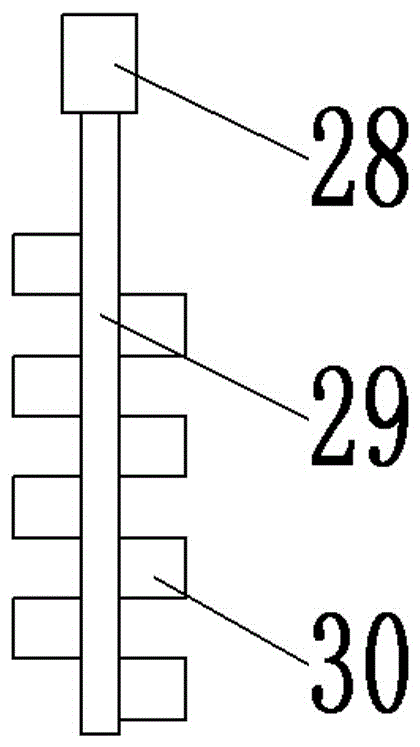

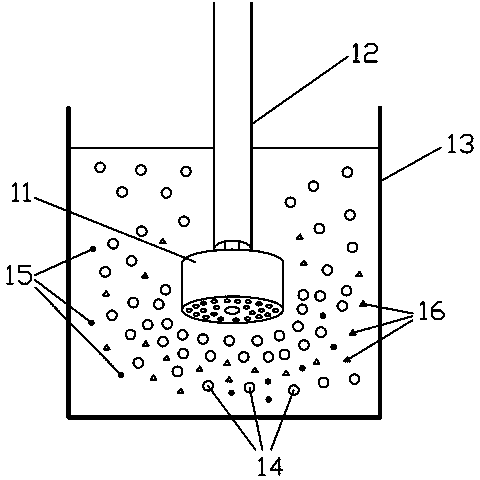

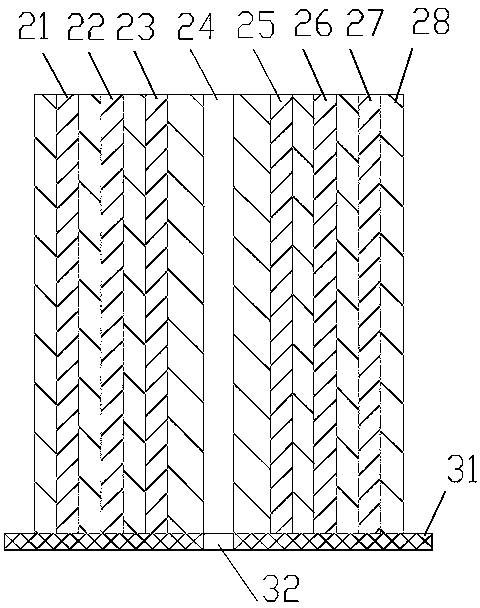

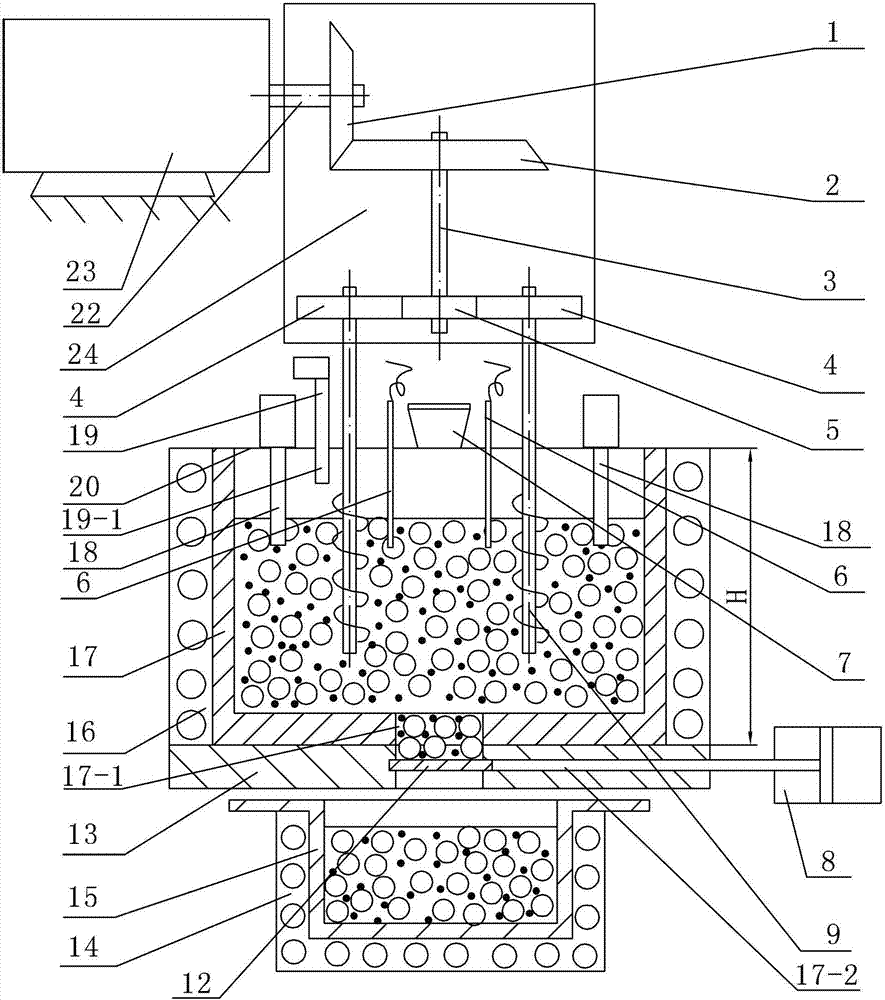

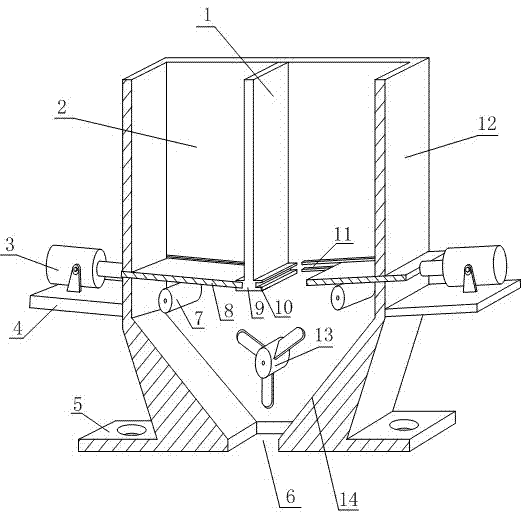

The invention relates to the technical field of water-powder mixing or liquid mixing equipment in the construction operations of oil and gas fields and particularly relates to a fracturing base liquidmixer used in a construction process of an oil field fracturing site. The fracturing base liquid mixer comprises a rotational flow premixing device which comprises a liquid inlet, a feeding hole, a connecting component and an annulus, wherein the feeding hole is vertically formed, the liquid inlet is horizontally formed, the side wall of the feeding hole is connected with a sleeve, the connectingcomponent is arranged in the sleeve, the annulus is formed by the connecting component and the side wall of the feeding hole and is communicated with the liquid inlet, an oblique side is arranged atthe lower end part of the side wall of the feeding hole, an oblique plane is arranged at the upper part of the connecting component, and the oblique plane and the oblique side form certain angles witha vertical plane and are 0-80 degrees; and a reduced section, a throat pipe and a dispersion pipe are sequentially arranged at the lower part of the feeding hole. The fracturing base liquid mixer canmeet the requirements on the fracturing base liquid during large-scale operations in a fracturing operation site, the blending and mixing efficiencies are improved, the mixing quality of guanidine gum liquid is improved, and the optimal energy efficiency ratio is realized.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

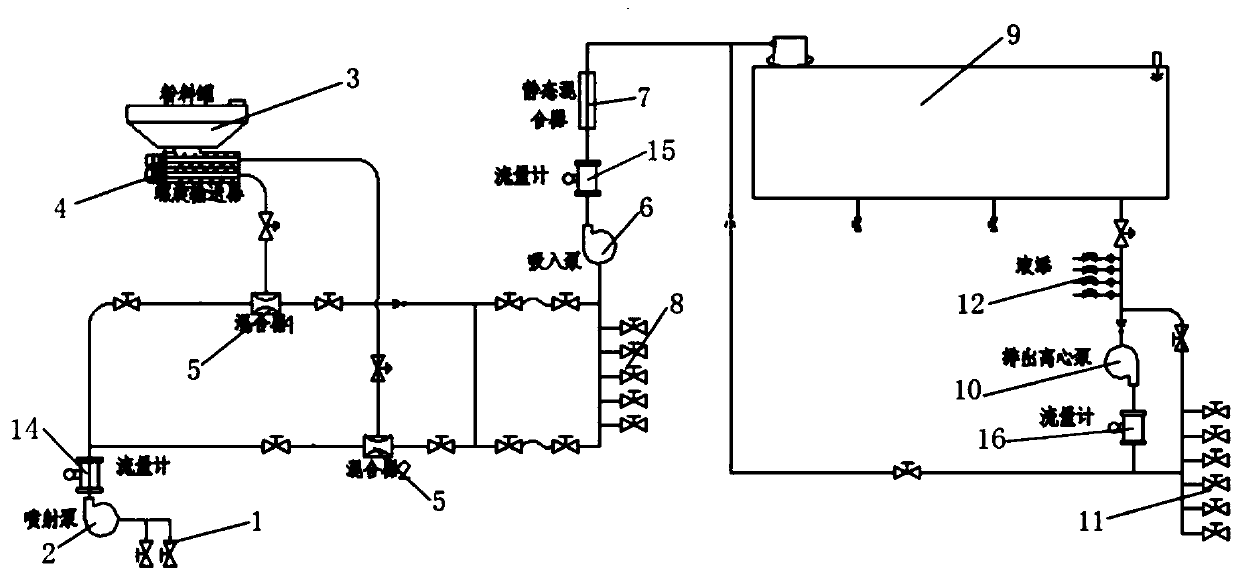

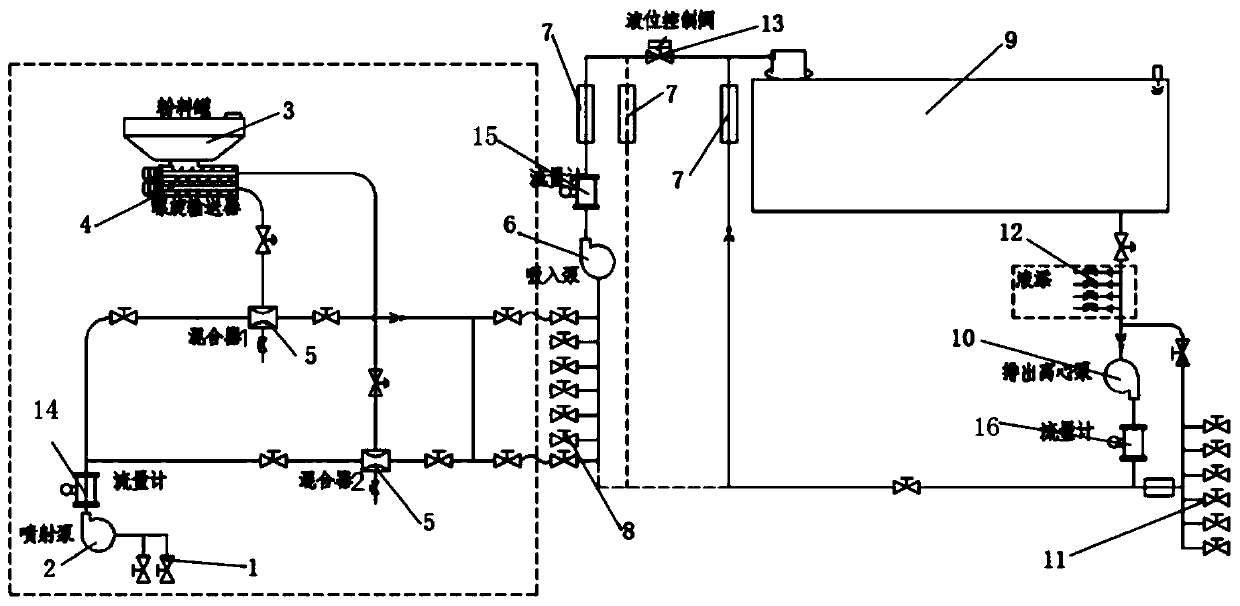

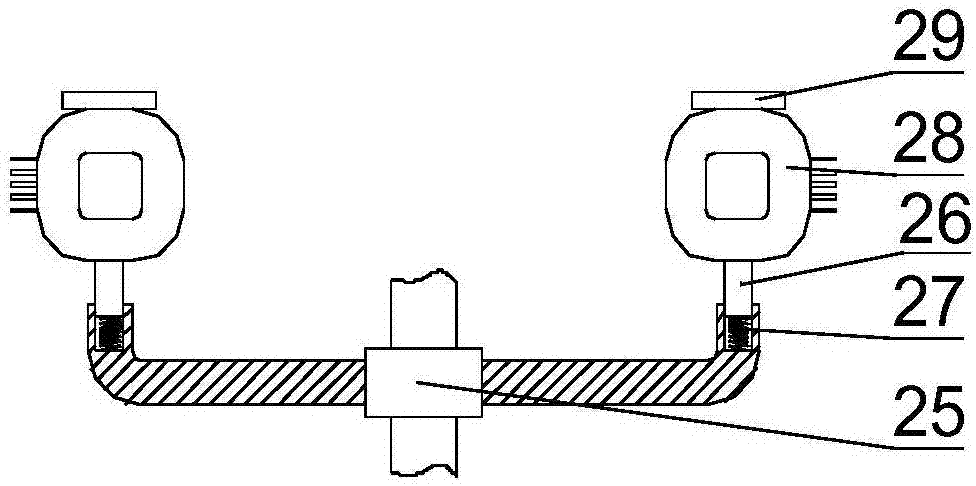

Mixing system

PendingCN110787667AImprove mix qualityImprove mixing efficiencyTransportation and packagingMixing methodsEngineeringStatic mixer

The invention discloses a mixing system. The mixing system comprises a mixing module and an output module, the mixing module comprises a first liquid inlet header, an injection pump, a powder tank anda mixer, the first liquid inlet header is connected with the injection pump, the injection pump is connected with the mixer, and the powder tank provides powder for the mixer; the output module comprises a second liquid inlet header, a suction pump, a second flowmeter, a static mixer, a mixing tank and a liquid discharge manifold, and the second liquid inlet header, the section pump, the second flowmeter, the static mixer, the mixing tank and the liquid discharge manifold are sequentially connected; an outlet of the mixer of the mixing module is connected with an inlet of the suction pump ofthe output module through a valve, and the mixing module and the output module can be used respectively or used in combination as a complete set. The mixing system has the beneficial effects that thesecond liquid inlet header and the static mixer are arranged, mixing with large discharge capacity and high quality can be completed with low energy consumption; and the mixing system is flexible in disassembly and assembly.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

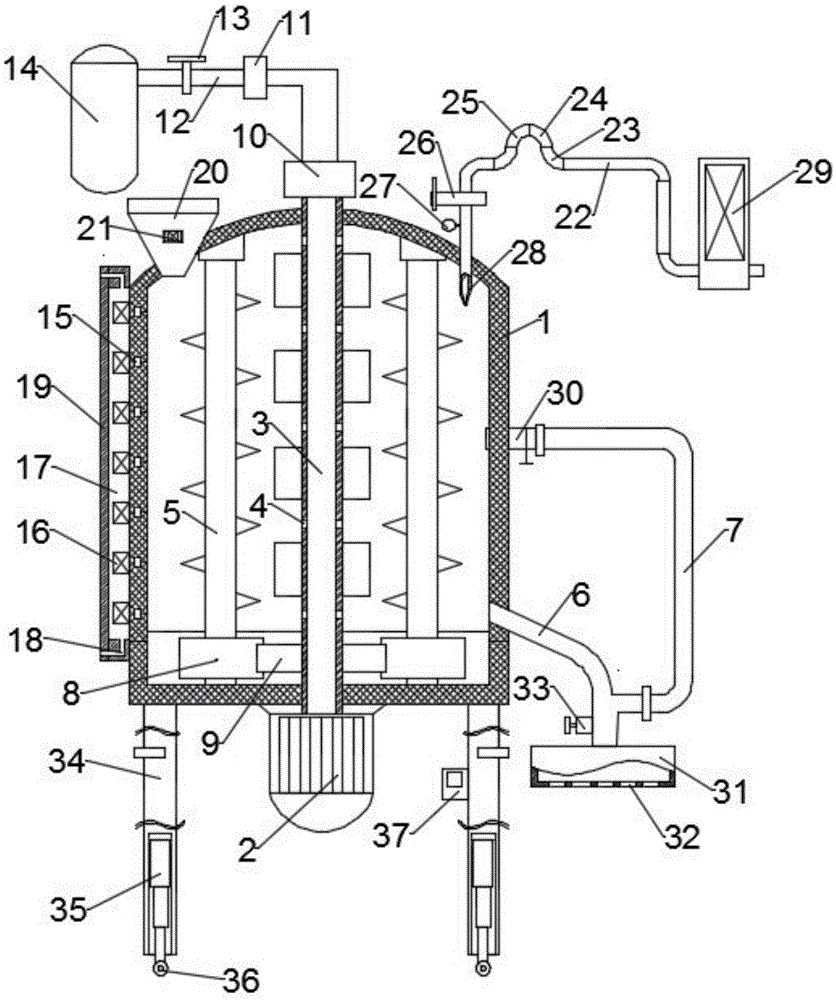

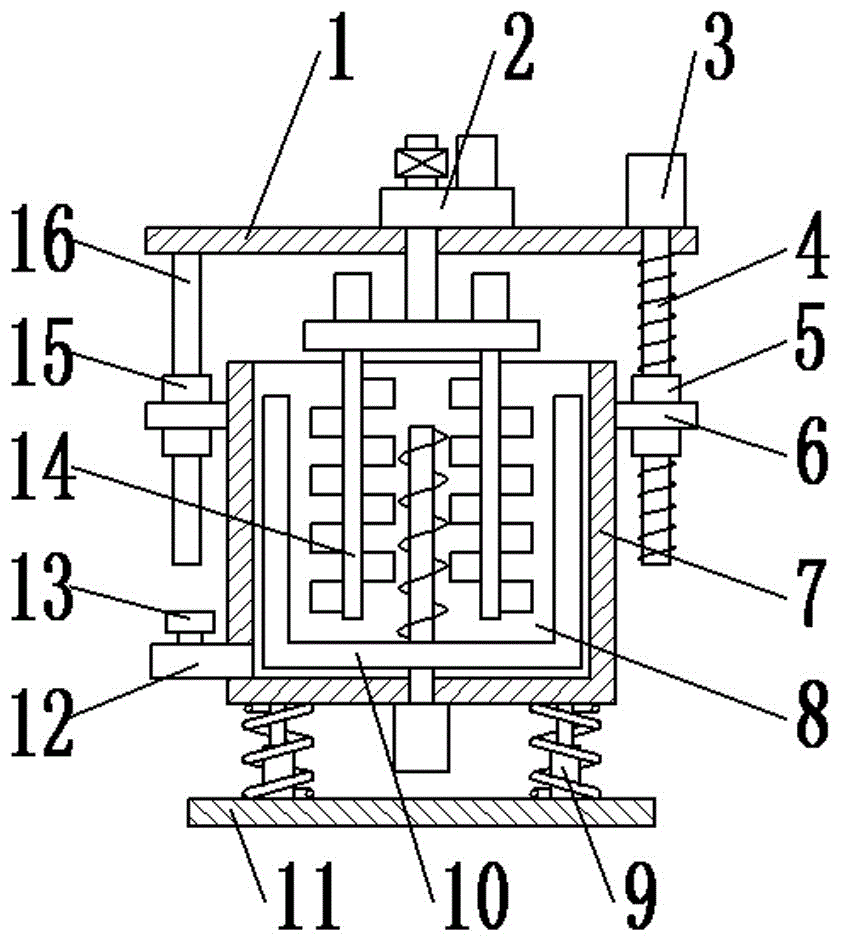

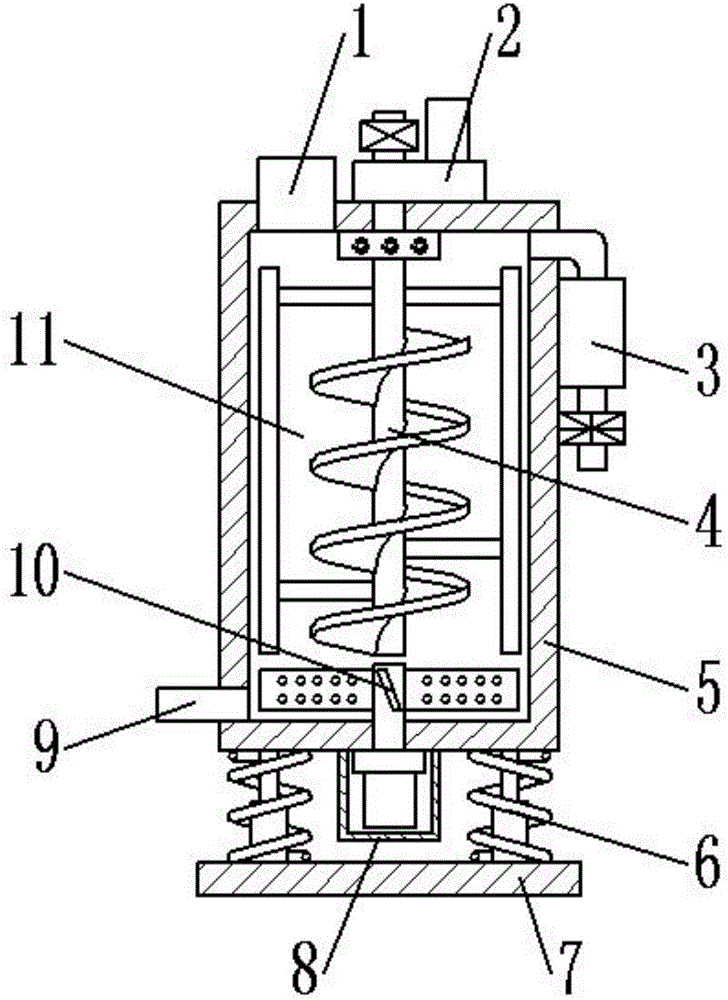

Temperature-controlled concrete stirring device

ActiveCN105643801AOvercome the problem of deviation in use effectImprove qualityDischarging apparatusMixing operation control apparatusTemperature controlStopped work

The invention discloses a temperature-controlled concrete stirring device comprising a stirring barrel body, wherein two sides of a first driving gear are meshed with second driven gears; the second driven gears are fixedly arranged on driven shafts; a plurality of temperature probes are arranged inside the left side wall of the stirring barrel body; a ceramic heating body is arranged inside a cavity; the bottom of the right side wall of the stirring barrel body is provided with a first discharging pipe; a second discharging pipe is connected with an auxiliary unloading hose; the top of the stirring barrel body is also provided with an additive introducing device; and a pipeline of a liquid control switch and an additive delivery pump is provided with a horizontal section pipeline, a first elbow pipeline, a second elbow pipeline and a third elbow pipeline. By using the temperature-controlled concrete stirring device, the temperature of inside concrete can be controlled, the automatic and quantitative addition of water is realized, the problem of deviation caused by different heights is overcome, and the retention phenomenon cannot be generated after the additive delivery pump stops working.

Owner:河南国龙矿业建设有限公司

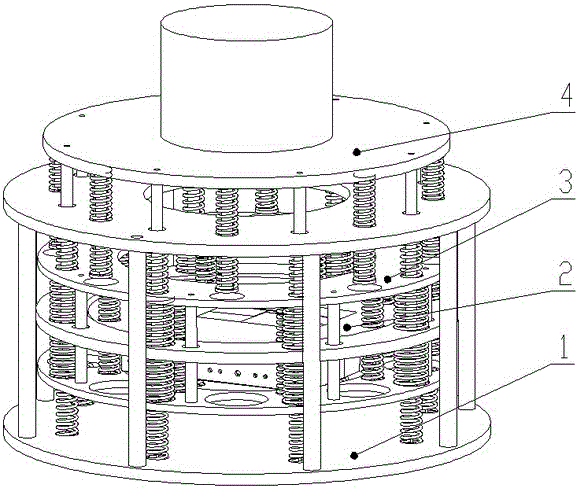

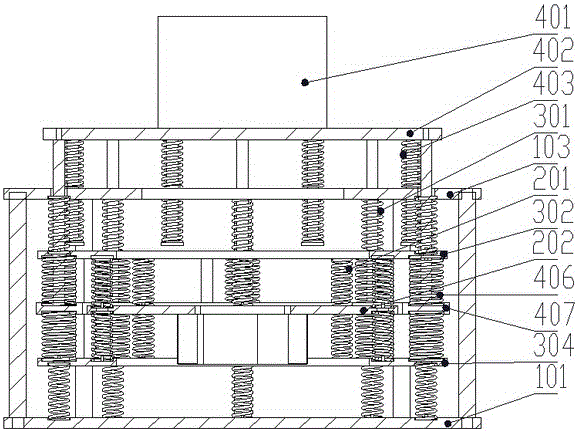

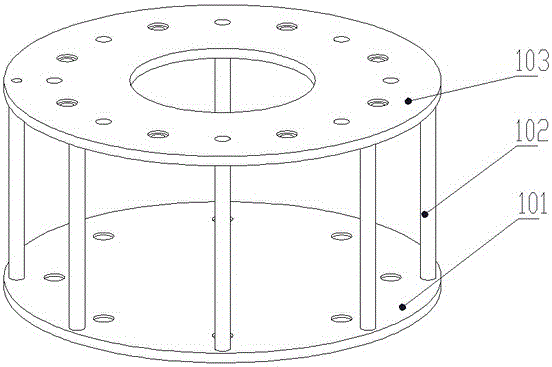

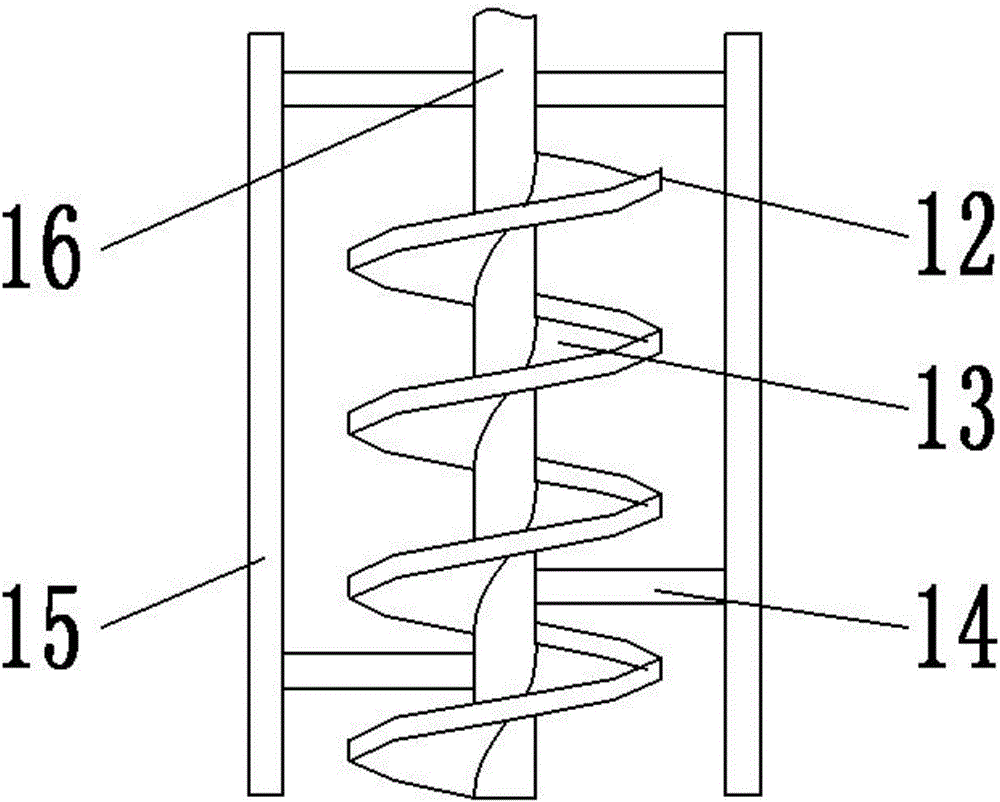

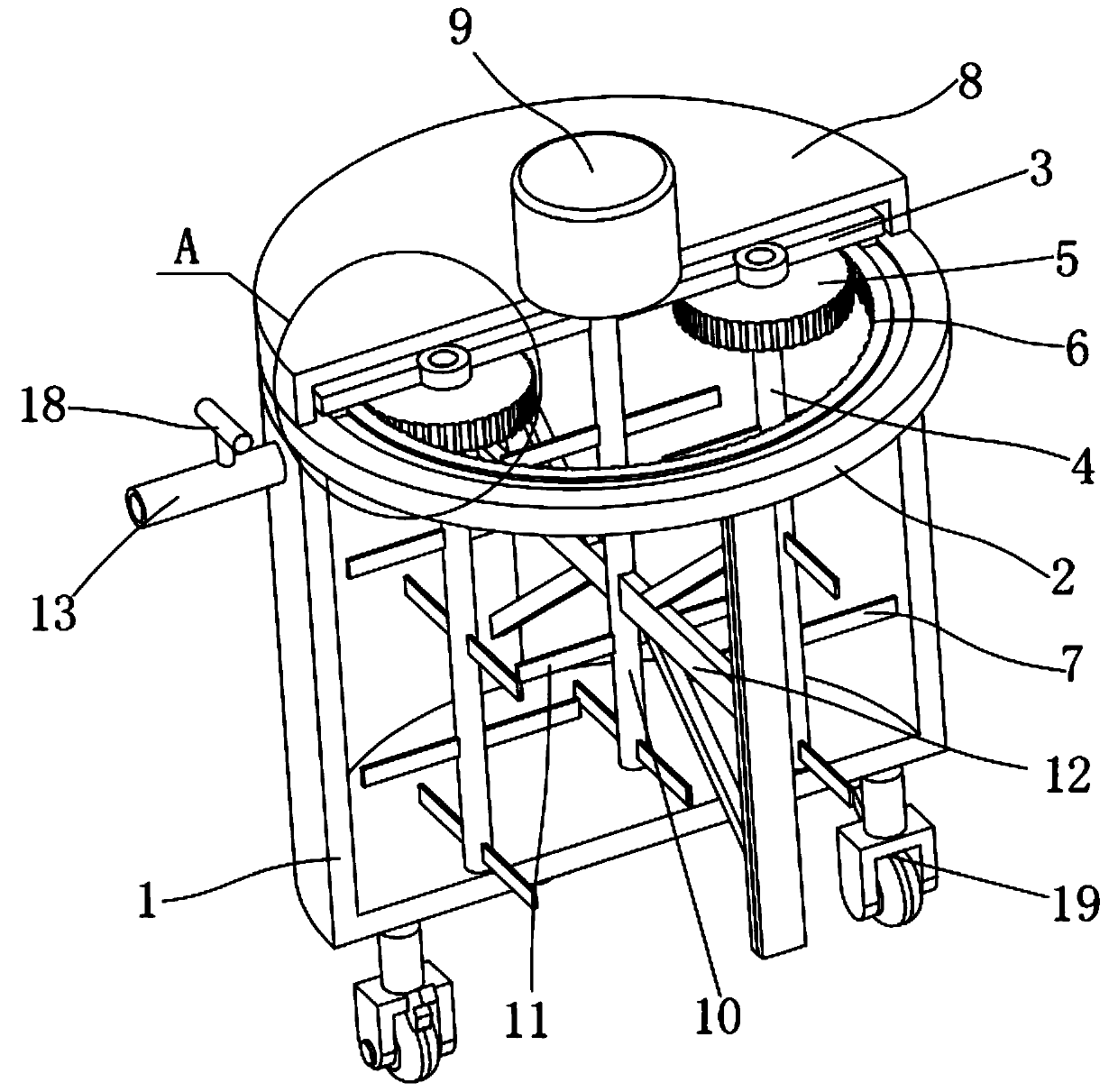

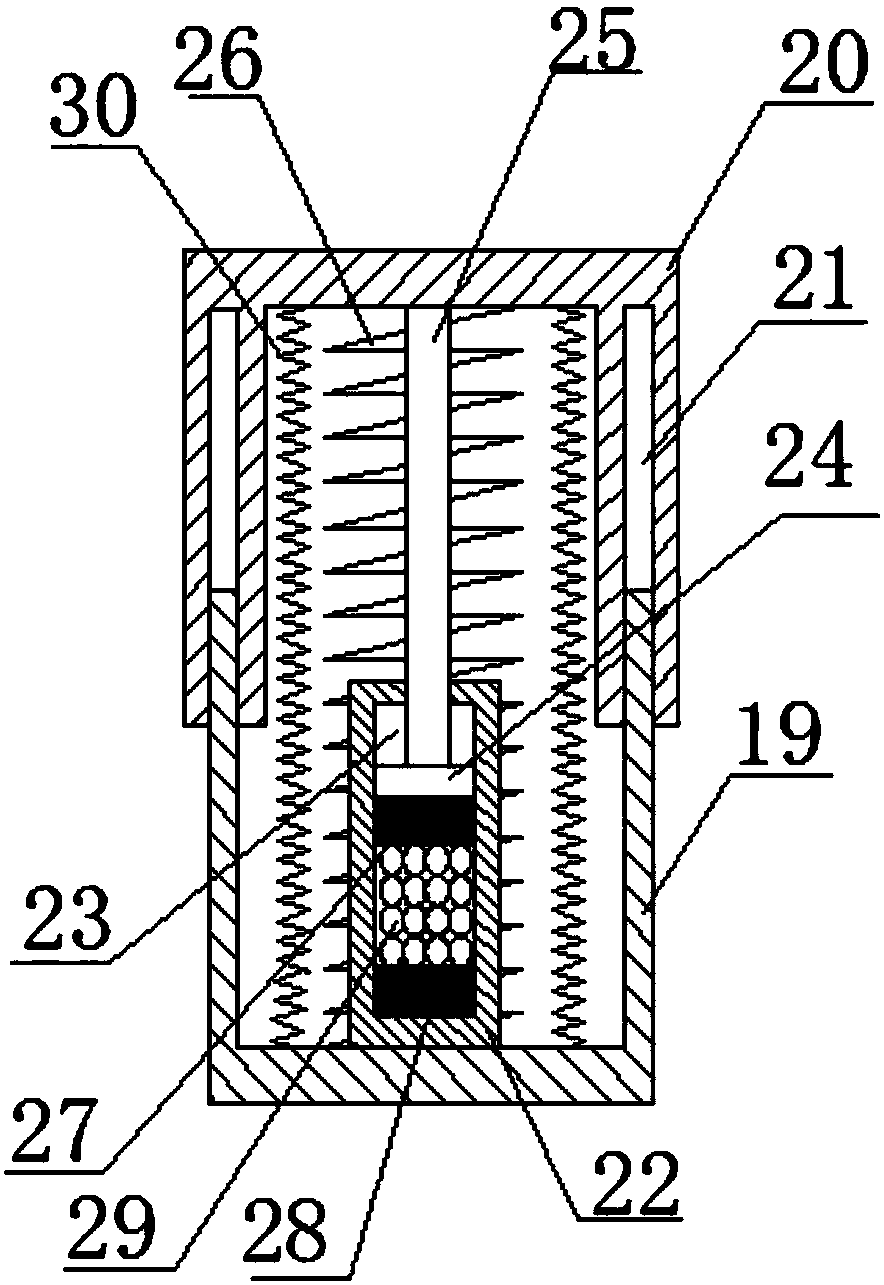

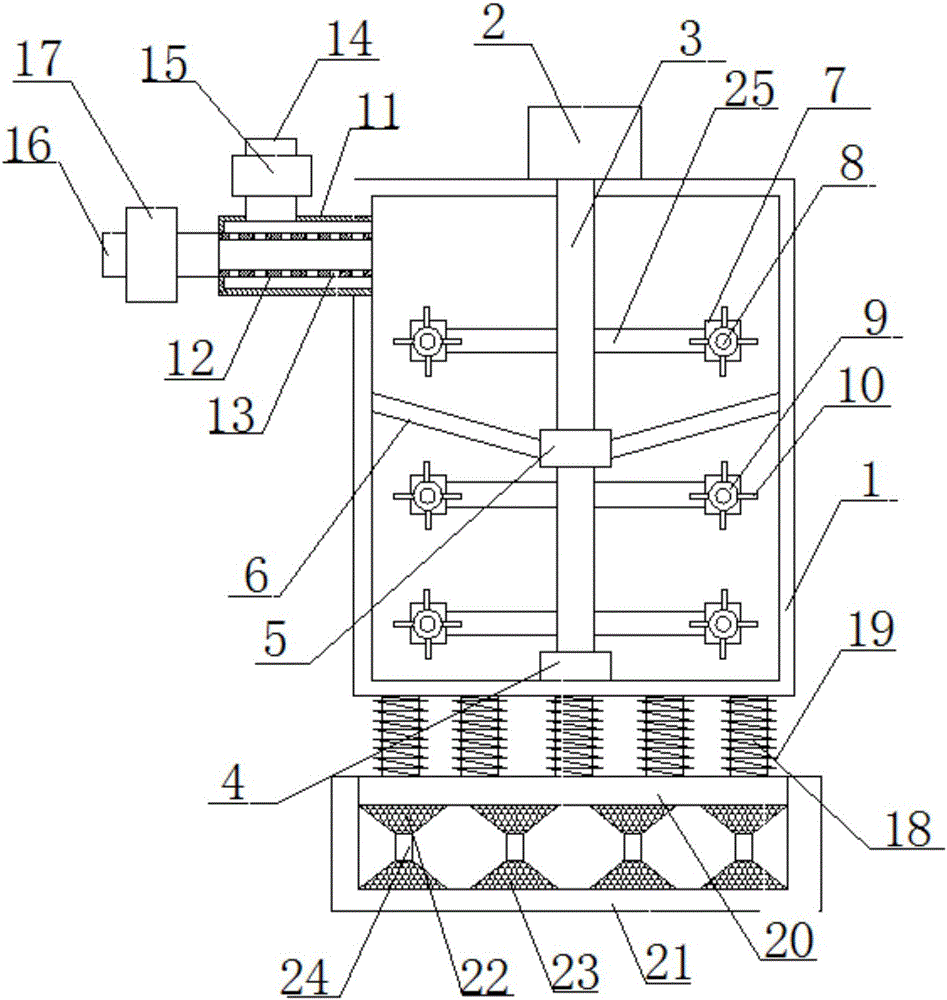

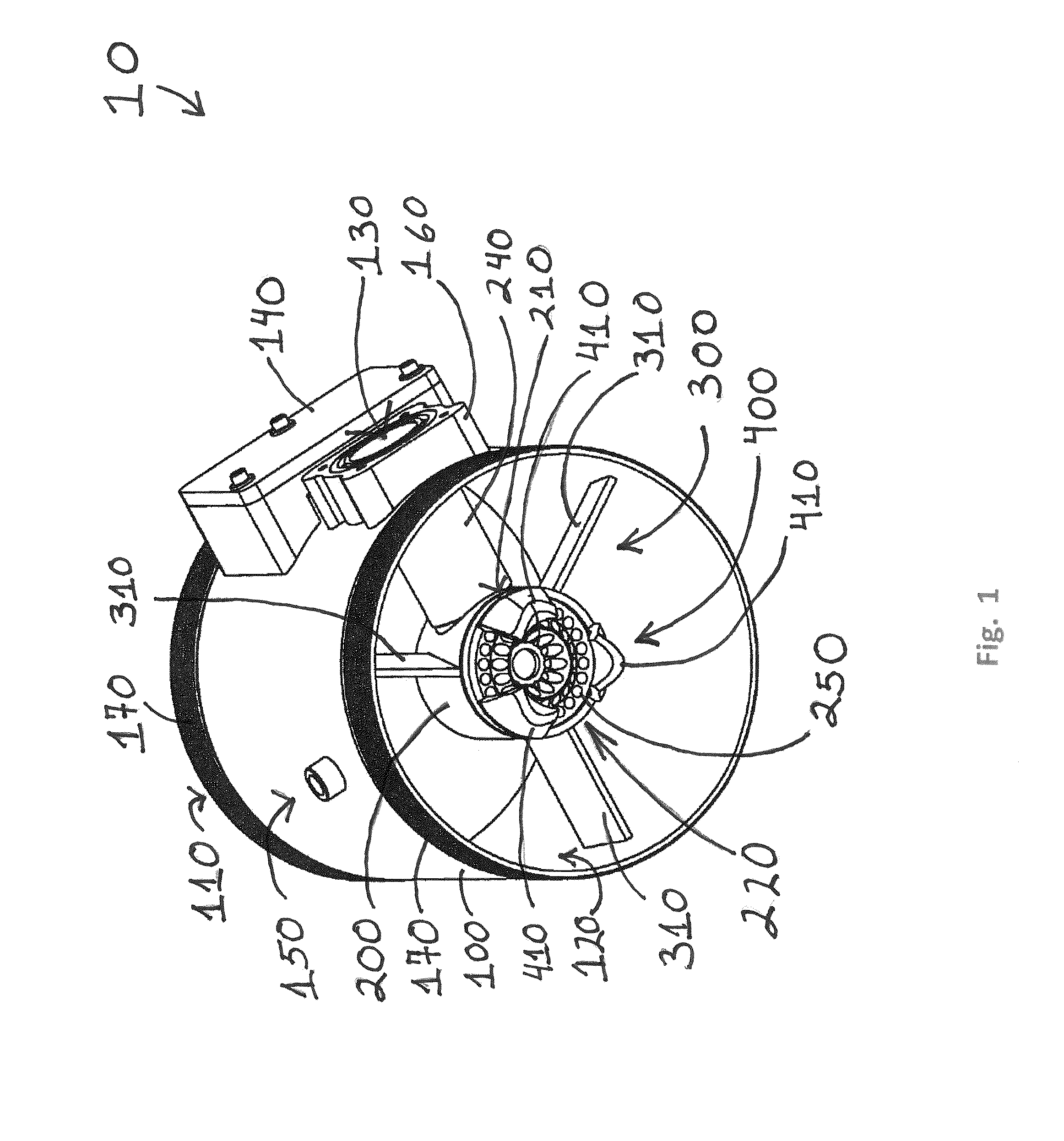

Sound wave mixing device based on three-freedom-degree resonance system

ActiveCN106000198AWide applicabilityImprove mix qualityShaking/oscillating/vibrating mixersTransportation and packagingEngineeringAcoustic wave

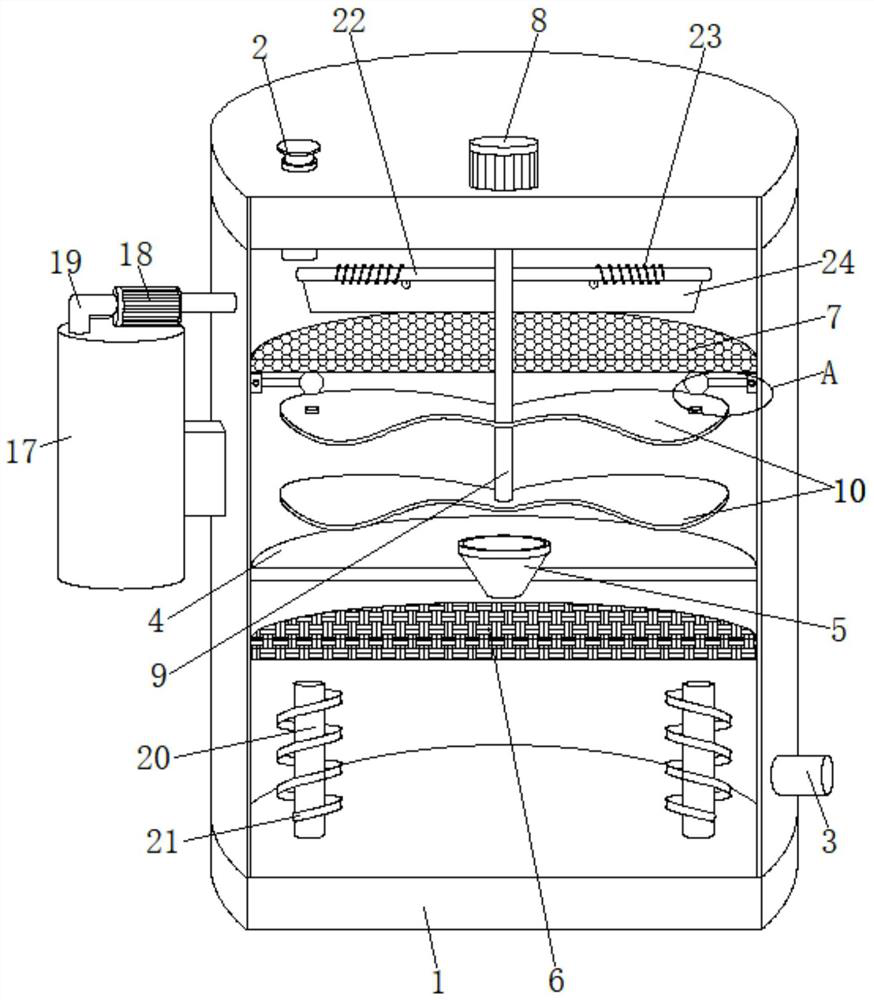

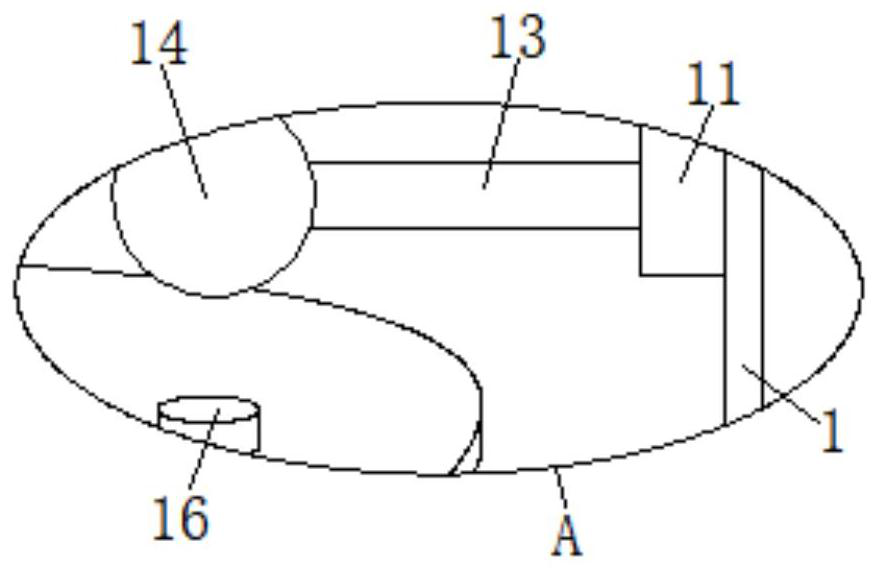

A sound wave mixing device based on a three-freedom-degree resonance system comprises a rack, a shock excitation unit, a counteraction unit and a load unit. The counteraction unit is located in the middle of the rack and is connected with an upper plate and a lower plate of the rack through second springs; the shock excitation unit is located in the counteraction unit and connected with an upper plate and a lower plate of the counteraction unit through first springs; the load unit is located between the rack and the counteraction unit and connected with the rack and the counteraction unit through third springs and fourth springs respectively. A mixing container can be fixed on the load unit or the counteraction unit, or two mixing containers are fixed on the load unit and the counteraction unit at the same time. Sound wave energy is generated with the resonance principle, vortexes are generated in mixed materials by the sound wave energy so that the materials can be mixed fast and efficiently, no paddle is arranged in the mixing container, the mixing process is safer, liquid-liquid, liquid-solid, gas-liquid and solid-solid systems can be mixed, and the sound wave mixing device is particularly suitable for mixing hazardous materials and is high in applicability.

Owner:HUBEI HANGPENG CHEM POWER TECH

Convenient-to-clean material mixing device with adjustable stirring range

InactiveCN106732025AImprove stabilityStir wellRotary stirring mixersTransportation and packagingEngineeringScraper site

Owner:卿琦

Preparation method of light metal alloy semi-solid slurry

The invention discloses a preparation method of light metal alloy semi-solid slurry. According to the method, a solidified metal solution I placed in a rod head is taken as a crystal nucleus formation, and the rod head is placed in a metal solution II, so that the metal solution I is dissolved to form crystal nucleuses; meanwhile, the rod head is rotated, and an inert gas is blown in, so that the metal solution II can be mixed uniformly and efficiently, and the mixing uniformity of the semi-solid slurry is guaranteed. According to the method, the solid metal solution I is re-melted to be used as the crystal nucleuses formed in the metal solution II, so that the operation method is convenient, the crystal nucleuses can be uniformly distributed in the semi-solid slurry, and the mixing efficiency and the quality of the semi-solid slurry are improved; other impurities cannot be introduced into the semi-solid slurry, so that the quality and the cleanliness of the semi-solid slurry are guaranteed; the metal solution I in the rod head is melted by the aid of heat dissipated by solidification of the metal solution II, and raw metal materials are only required to be melted once, so that the energy consumption is saved, and the production cost is reduced.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL +1

Gas turbine burner

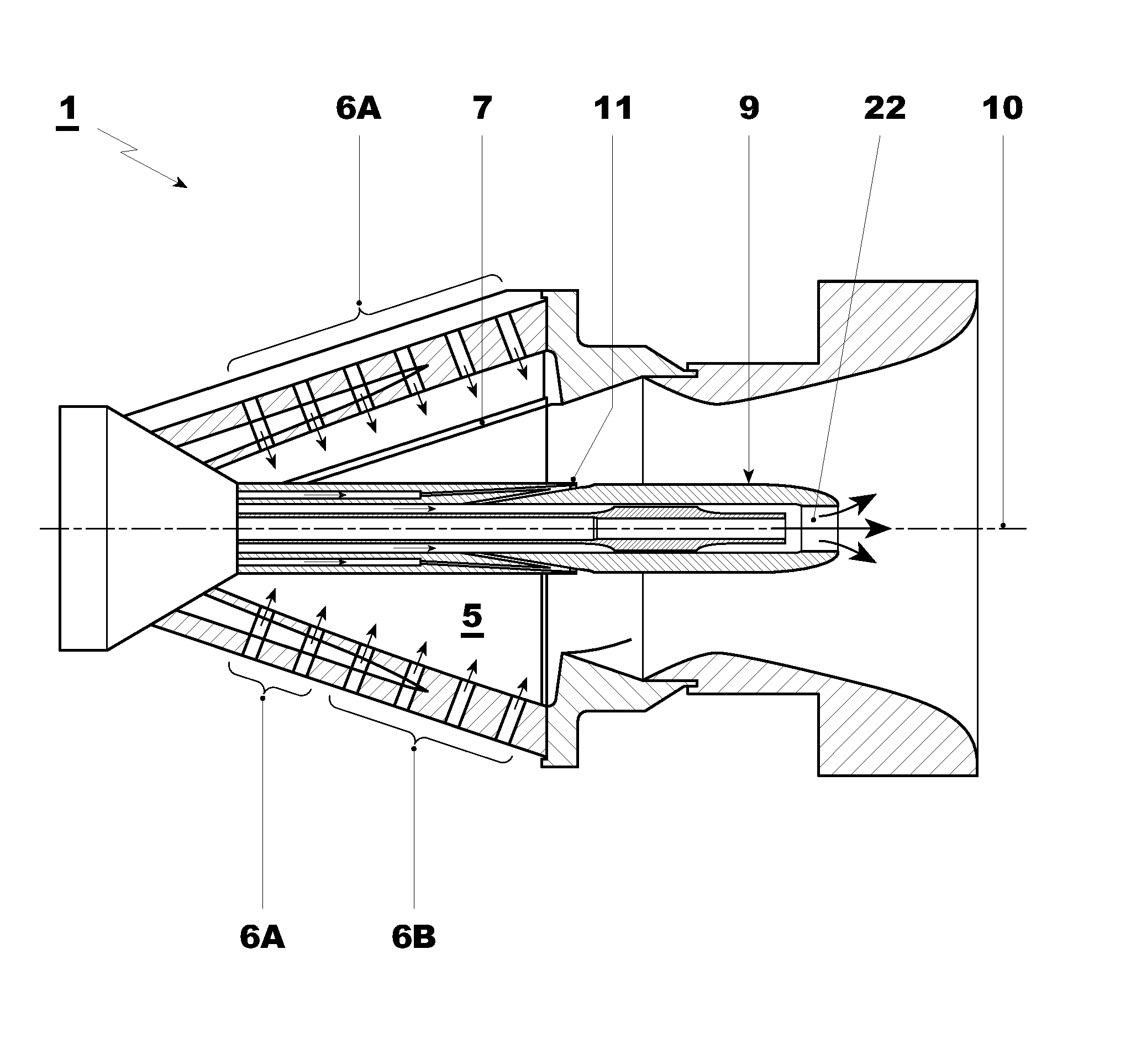

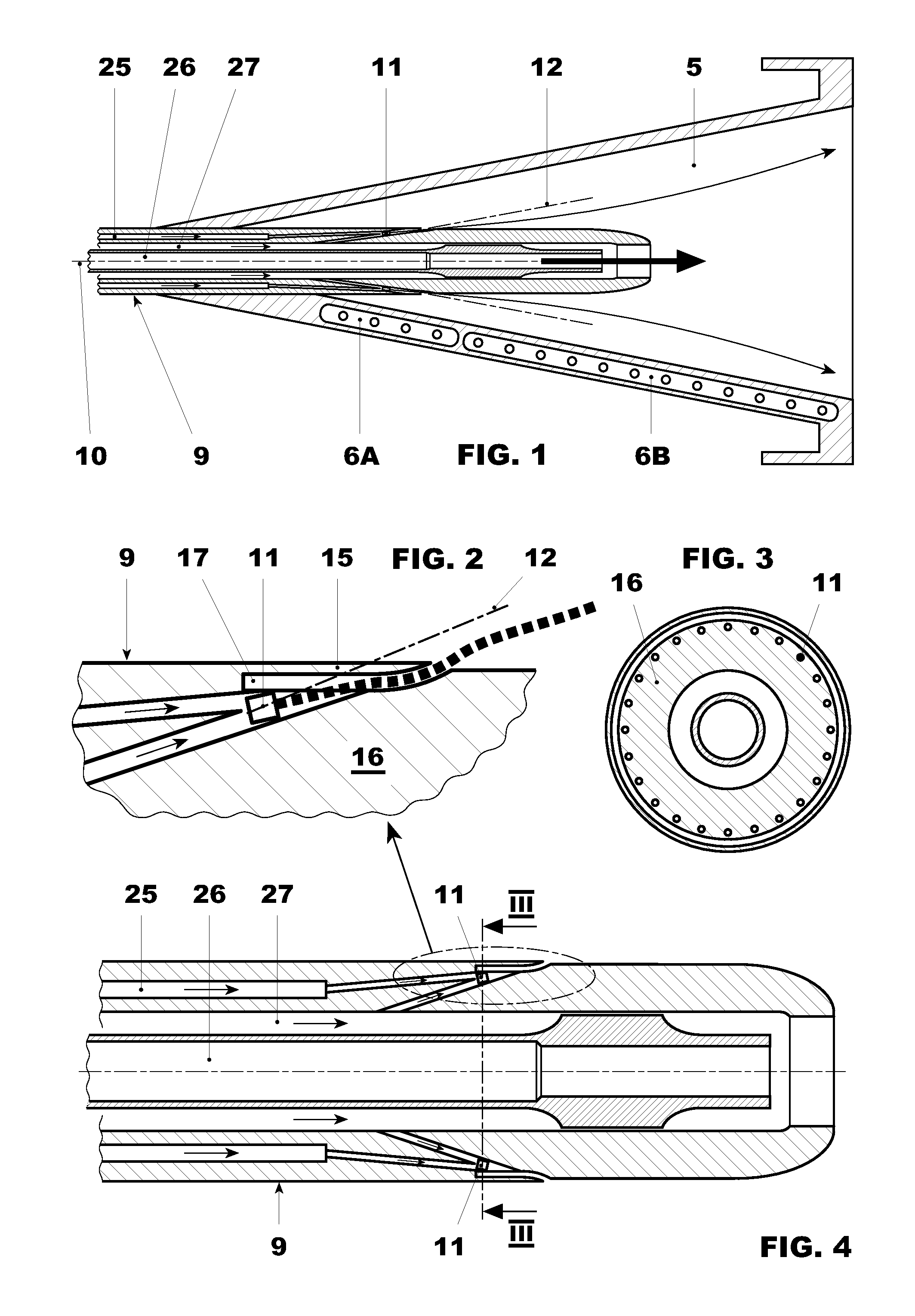

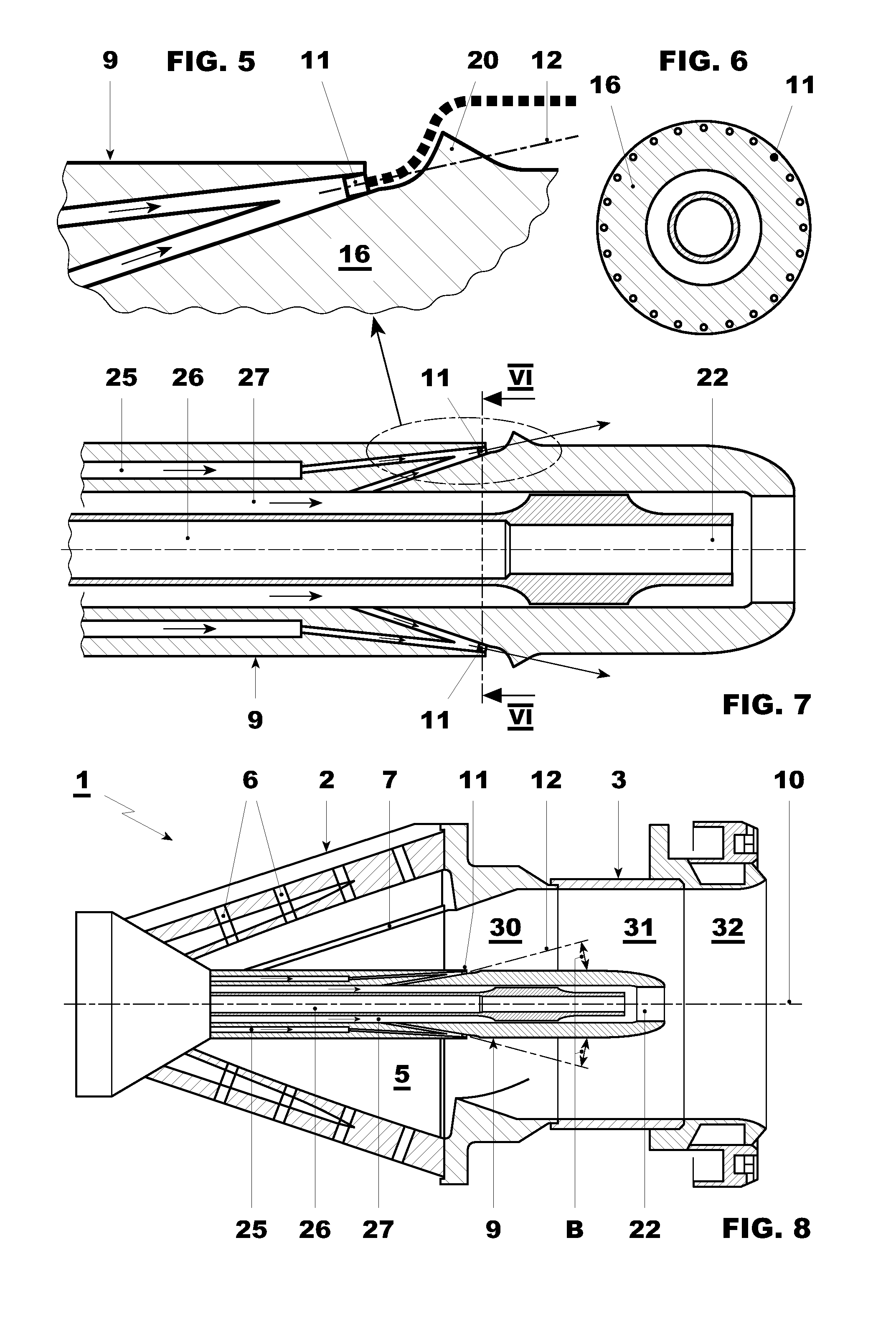

ActiveUS20100175382A1Pulsation and NOx emission be reducedImprove mixing qualityContinuous combustion chamberTurbine/propulsion fuel supply systemsGas turbinesNozzle

The burner (1) of a gas turbine includes a swirl generator (2) and, downstream of it, a mixing tube (3). The swirl generator (2) is defined by at least two walls facing one another to define a conical swirl chamber (5) and is provided with nozzles (6) arranged to inject a fuel and apertures (7) arranged to feed an oxidiser into the swirl chamber (5). The burner (1) includes a lance (9) which extends along a longitudinal axis of the swirl generator (2) and is provided with side nozzles (11) for ejecting a fuel within the burner (1). The side nozzles (11) have their axes (12) inclined with respect to the axis of the lance (9) and can be positioned along the axis of the burner.

Owner:ANSALDO ENERGIA SWITZERLAND AG

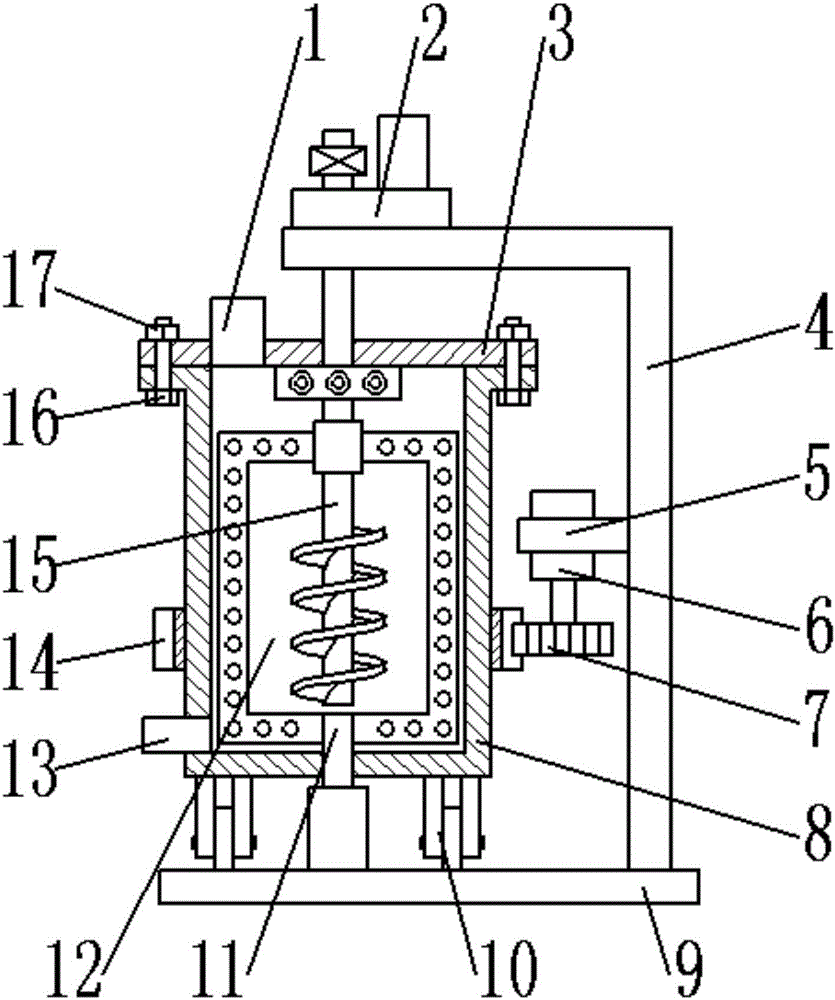

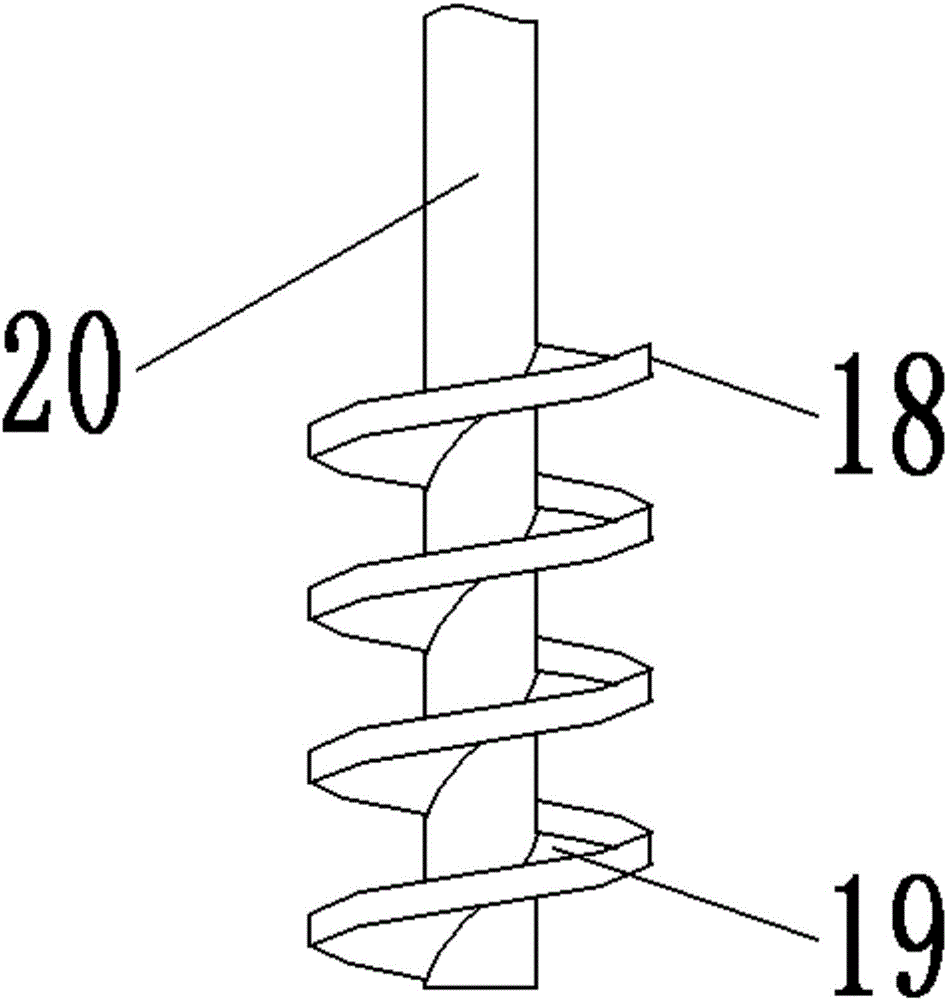

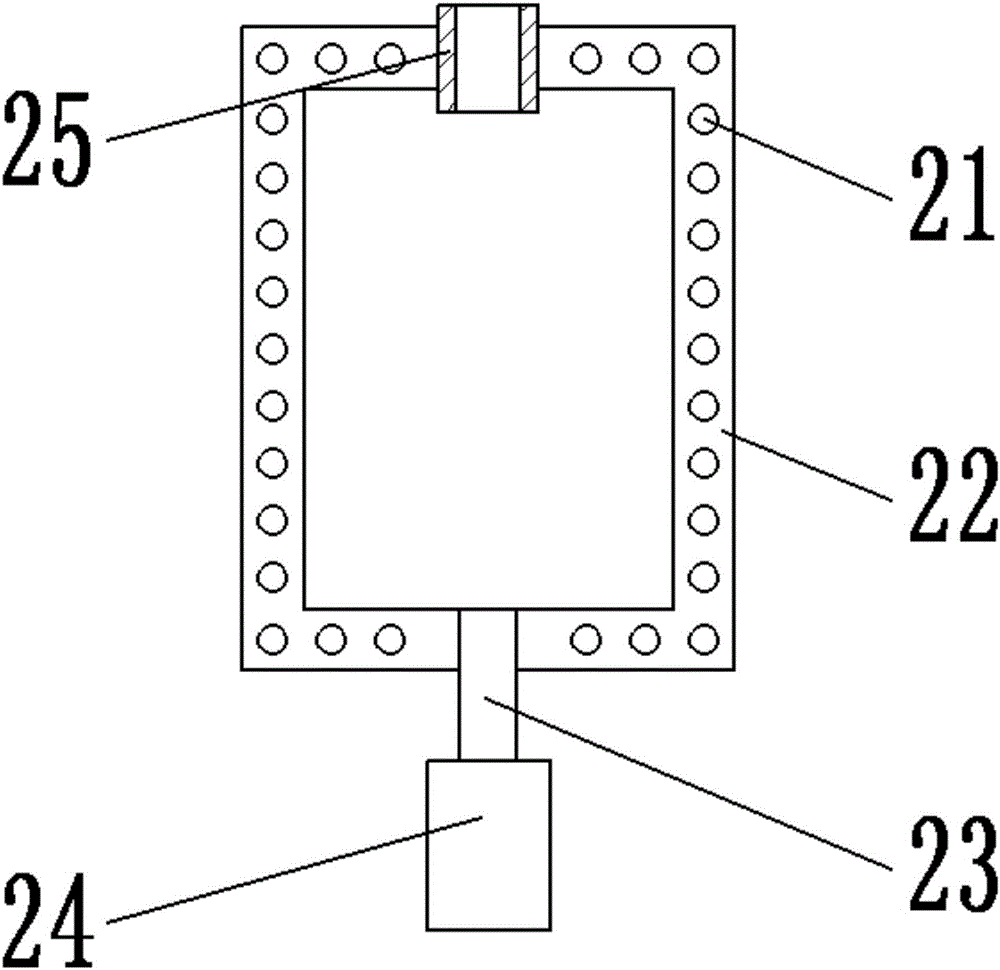

Device and method for preparing nanometer ceramic particle-reinforced aluminum-based composite

A device and a method for preparing a nanometer ceramic particle-reinforced aluminum-based composite relate to a device and a method for preparing a metal matrix composite and aim at solving the problems of long preparing technical path, excessive required equipment and high cost in the existing powder metallurgic method for preparing the nanometer ceramic particle-reinforced aluminum-based composite, as well as the problems of non-uniform distribution, layering and conglobation of nanometer ceramic particles in the existing stirring method. The device comprises a motor, a gearbox, a first gear shaft, a feeding hopper, a baffle, a heating base plate, a first heating device, a slurry collecting groove, a second heating device, a crucible, a cover plate, a hydraulic driving device, an argon protection device, two temperature measuring elements, two screw type stirring impellers and two ultrasonic devices, wherein stirring ends of the screw type stirring impellers extend into the crucible arranged below the gearbox, and probes of the ultrasonic devices penetrate through the cover plate and extend into the crucible. The device and the method, provided by the invention, are used for preparing the nanometer ceramic particle-reinforced aluminum-based composite.

Owner:HARBIN INST OF TECH

Mixed-material discharging apparatus capable of realizing uniform mixing of materials

InactiveCN104289122AReduce frictionReduce loadRotary stirring mixersMixer accessoriesHydraulic cylinderMixed materials

A disclosed mixed-material discharging apparatus capable of realizing uniform mixing of materials comprises a metal housing; the metal housing is inside provided with a discharging cavity, and the center of the discharging cavity is vertically provided with a separation plate dividing the discharging cavity; in the discharging cavity, the metal housing is provided with obliquely-arranged baffle plates respectively at the left side and the right side of the lower end of the separation plate; the two baffle plates both penetrate the metal housing respectively at the right part and the left part and are both connected with a hydraulic cylinder; each hydraulic cylinder is capable of driving the corresponding baffle plate to move, and is fixed via a corresponding fixing plate at the corresponding outer end of the metal housing; the lower end of each baffle plate is provided with a driven roll wheel contacted with the baffle plate; at the center of the lower end of the discharging cavity, the metal housing is provided with a material leakage port; the interior, at the upper end of the material leakage port, of the metal housing is provided with an electric stirring paddle; and the inner lateral sides, at two ends of the material leakage port, of the metal housing are material-integrating inclined planes. The mixed-material discharging apparatus does not contain residual raw materials in the discharging cavity, deformation and vibration of the baffle plates are reduced, and the apparatus is capable of fully mixing the raw materials and improving the mixing quality.

Owner:成都远峰科技发展有限公司

MBR hollow fiber membrane wastewater treatment device

PendingCN112723650AReduce impactPrevent splashSpecific water treatment objectivesTreatment involving filtrationWater processingMechanical engineering

A disclosed MBR hollow fiber membrane wastewater treatment device comprises a purification cylinder, the top of the purification cylinder communicates with a water inlet pipe, the bottom of the side face of the water inlet cylinder communicates with a water outlet pipe, the inner wall of the purification cylinder is fixedly connected with a supporting plate layer, and the supporting plate layer divides an inner cavity of the purification cylinder into two parts; and a valve funnel is installed on the supporting plate layer, the two parts of the inner cavity communicate with each other through the valve funnel, and an MBR membrane layer is fixedly installed on the inner wall of the purification cylinder. According to the MBR hollow fiber membrane wastewater treatment device, in the rotating process of stirring blades, small magnets on the stirring blades can rotate along with the stirring blades, and when the small magnets move to the position below a cleaning ball, due to the fact that magnetic layers on the surface of the cleaning ball and the small magnets have the same polarity, the cleaning ball overcomes gravity and swings upwards and impacts a primary filter screen under the action of repulsive force of the small magnets; and at the moment, the swing rod swings around a fixed column, so that the primary filter screen is vibrated and prevented from being blocked, and the cleaning ball periodically knocks the primary filter screen, so that the anti-blocking effect of the primary filter screen is better.

Owner:江苏龙岱环保集团有限公司

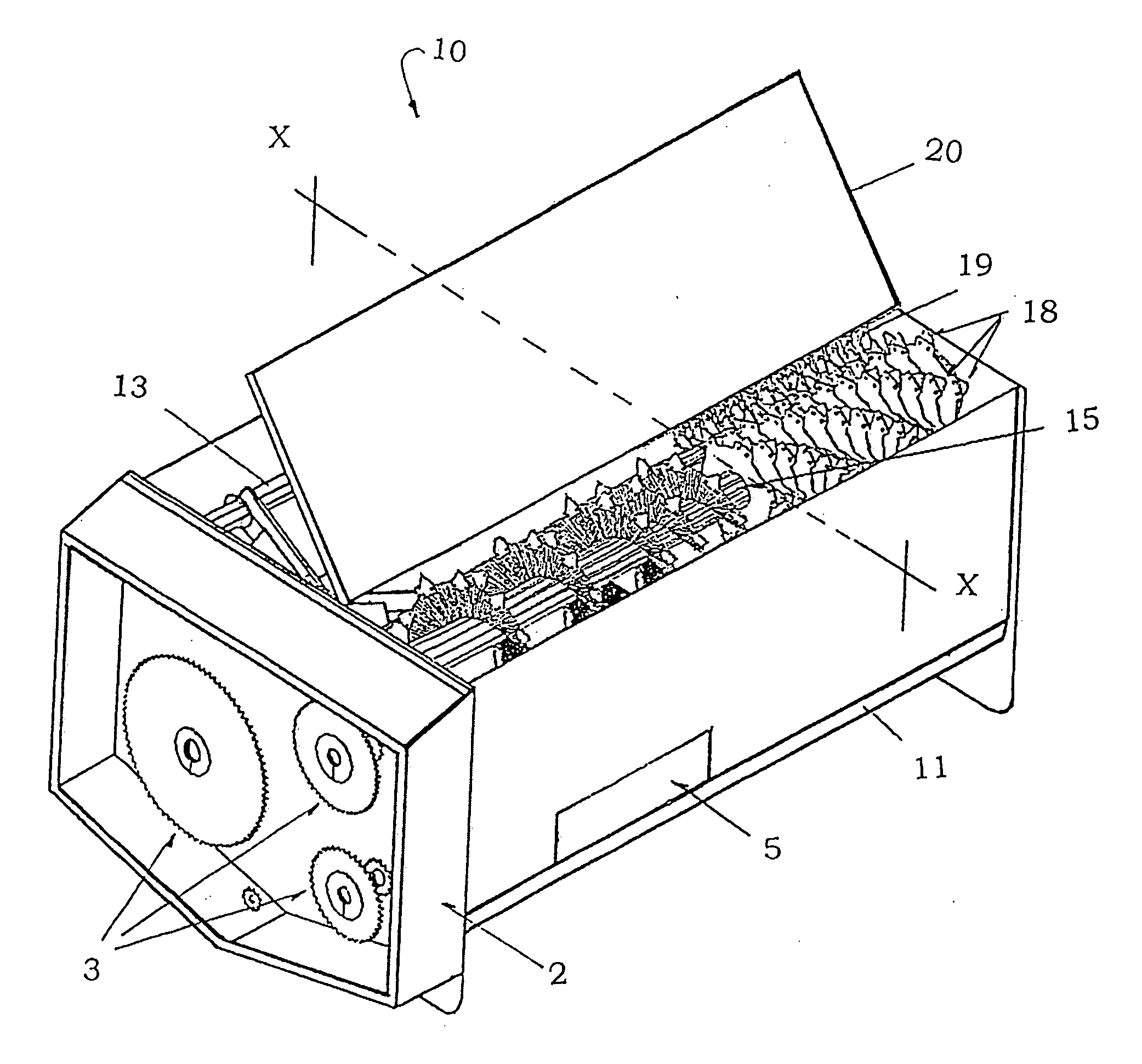

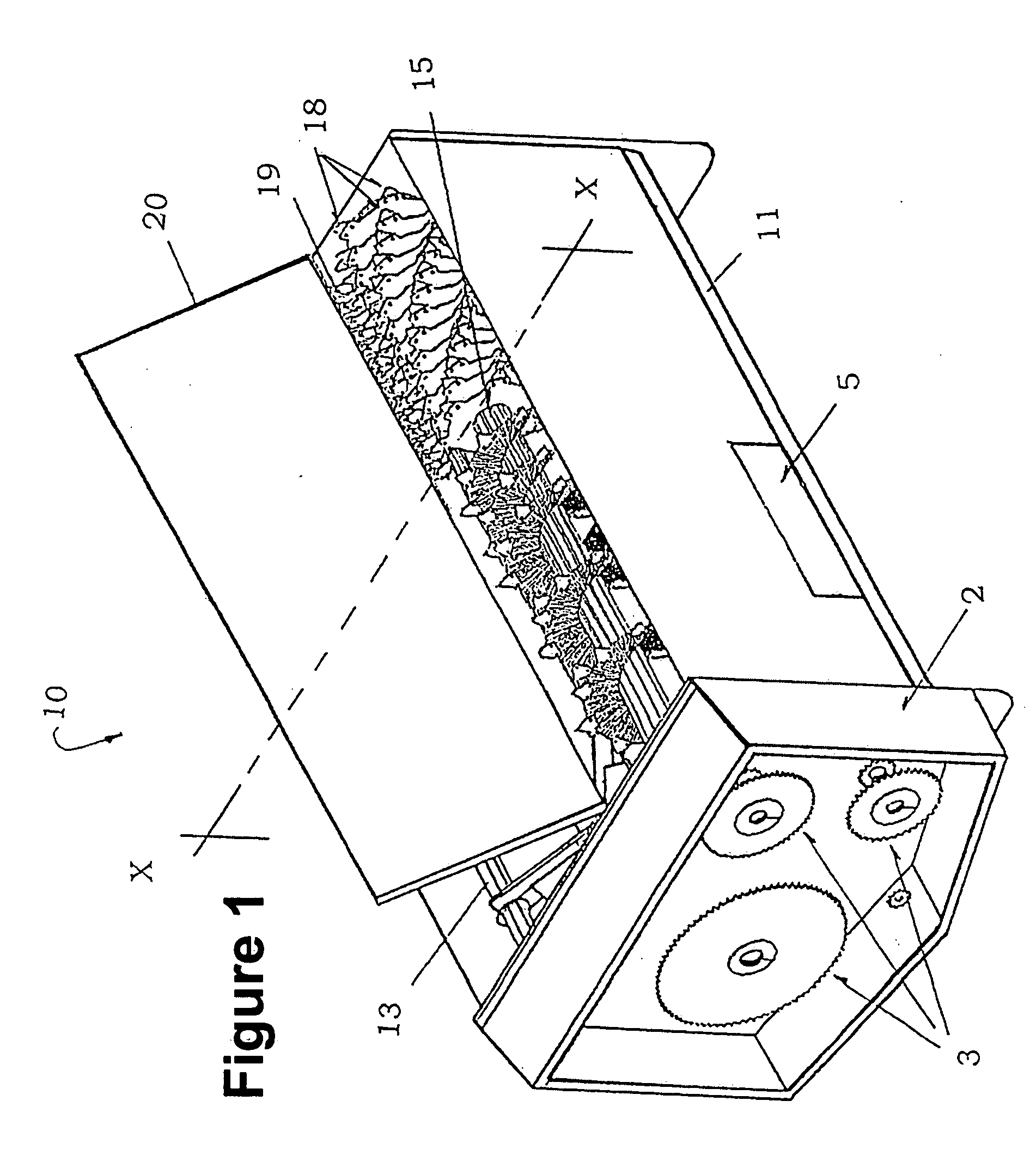

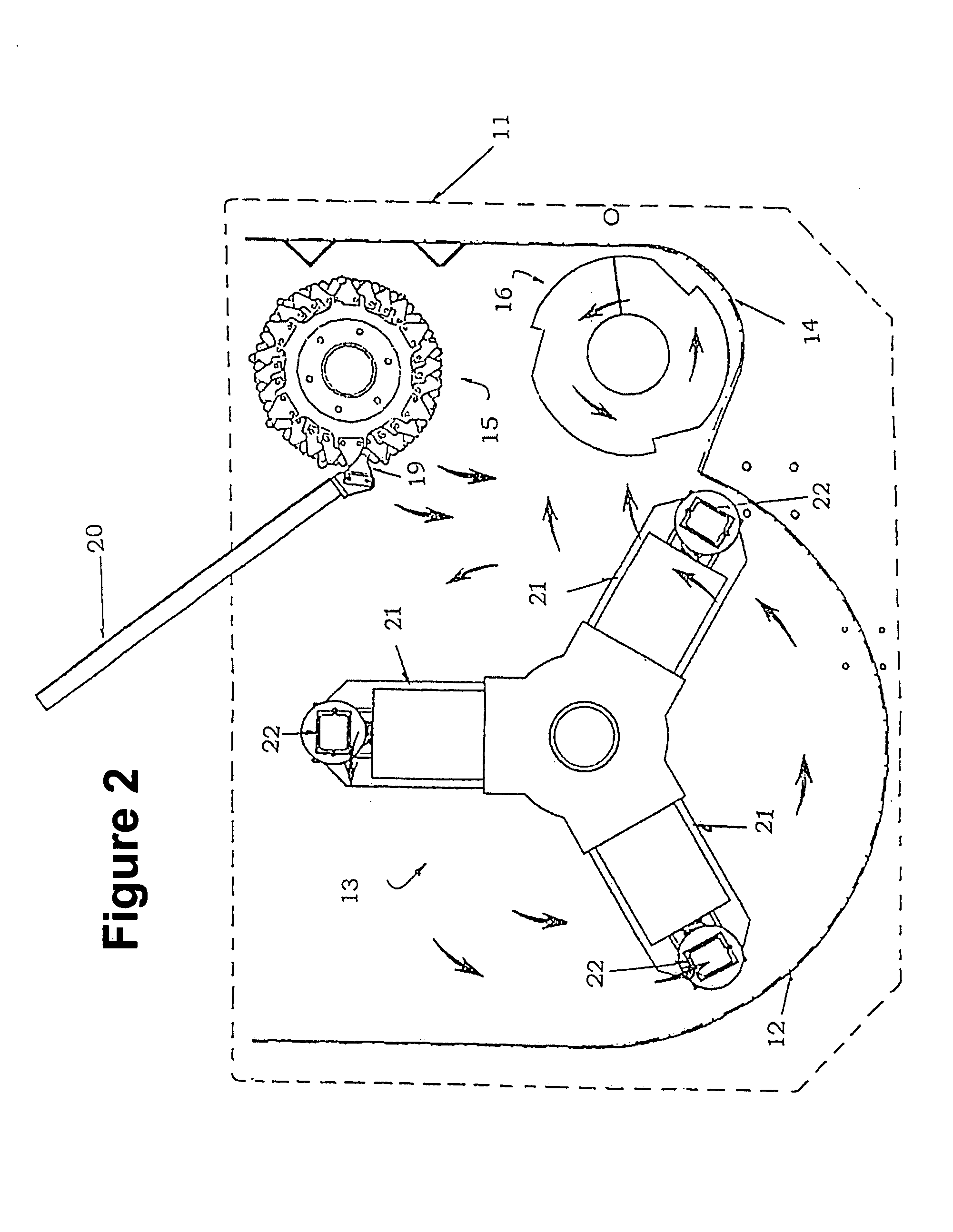

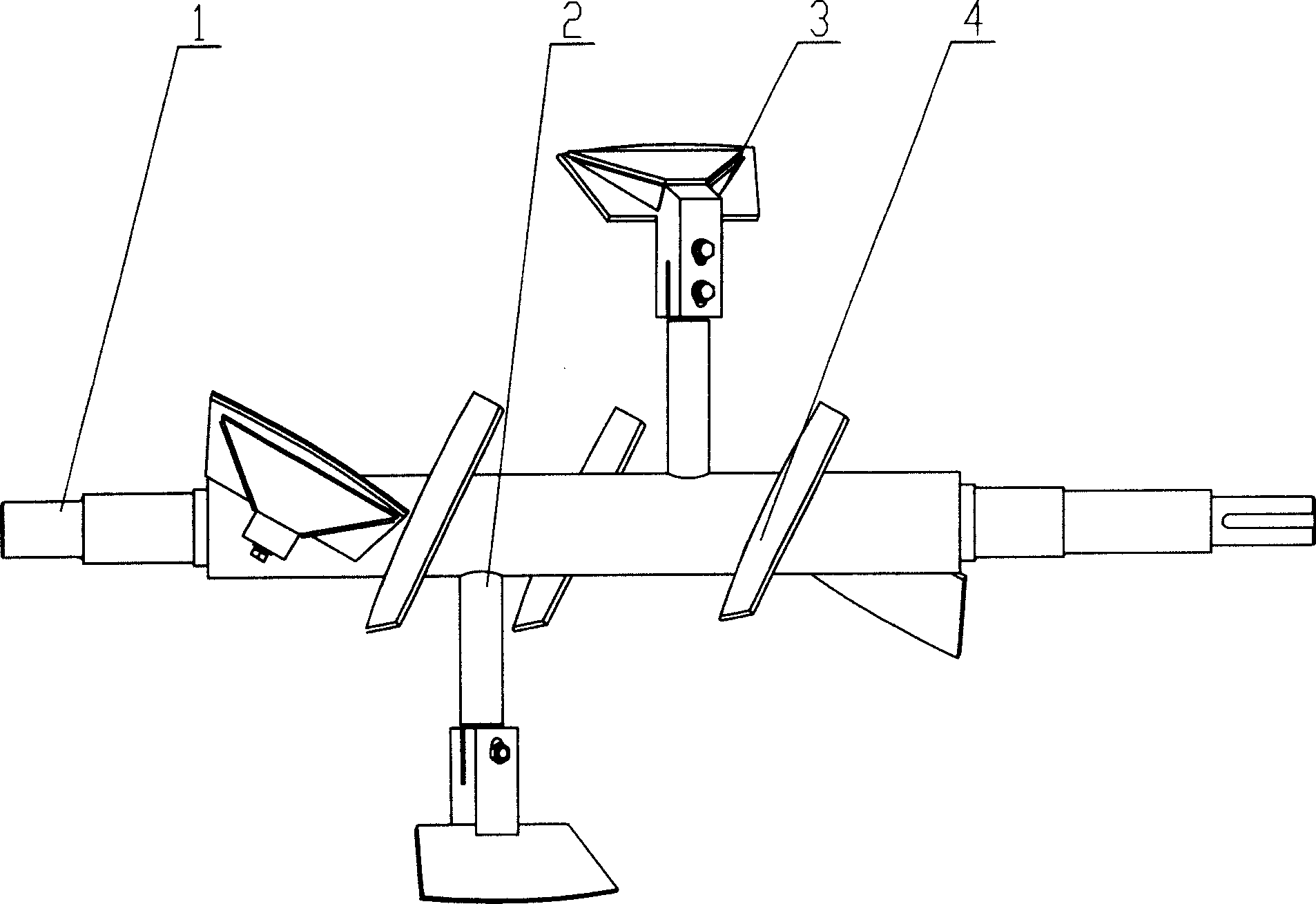

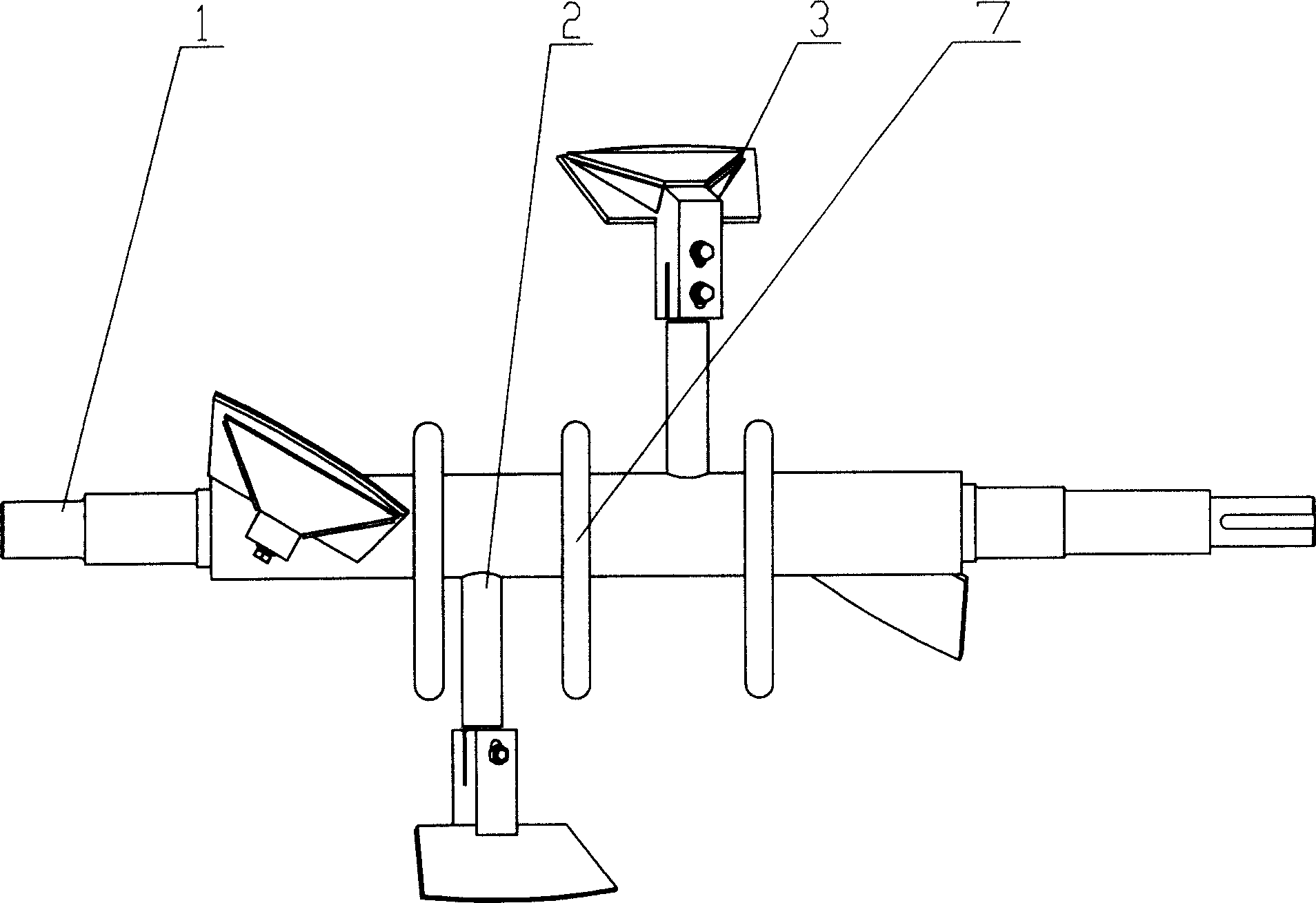

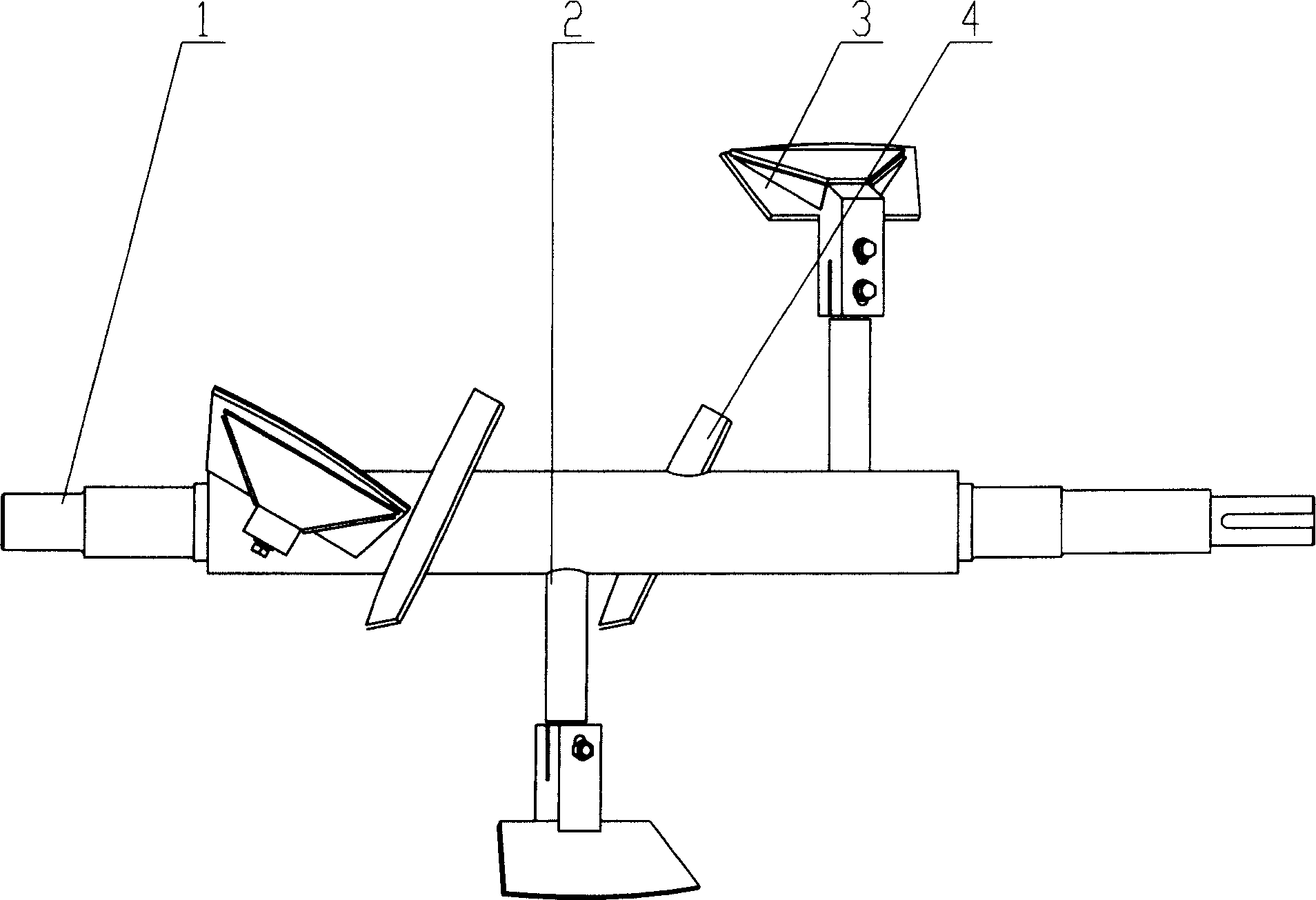

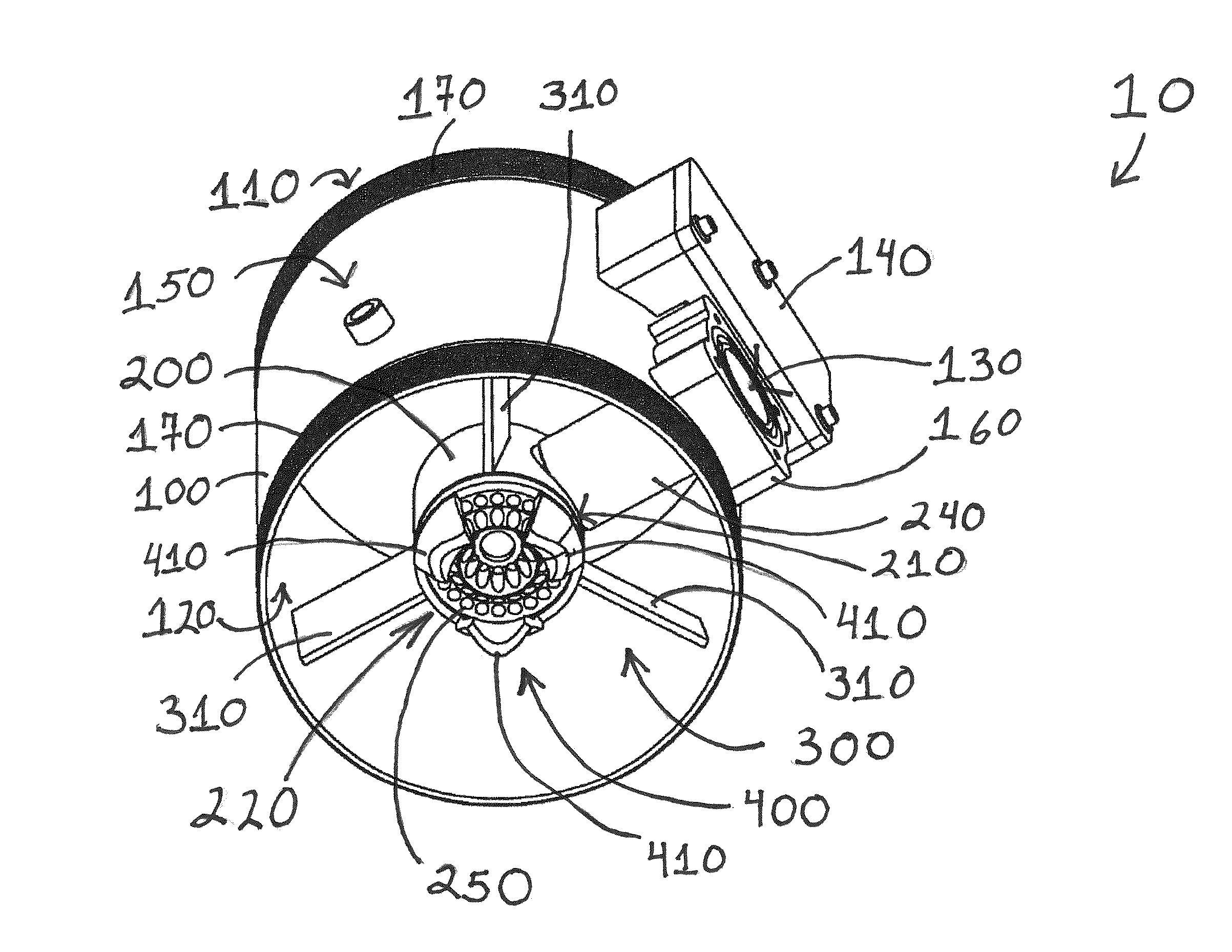

Livestock food processing mixing machine

InactiveUS20050087636A1Quick and efficient mannerCost savingGrain huskingGrain polishingLivestockEngineering

The present invention is related to a mixing machine which basically consists of a hopper, that has a main chamber within its housing, with a rotary member (rotor), where at said rotor ends there are cleaning elements for sweeping the floor and taking up the material, by feeding a secondary chamber, which is located in parallel adjacent to the main chamber, where said secondary chamber has a bottom worm conveying the material from one end of the mixing machine to the other end thereof, until collapsing with a loop found on its front portion and generating a material bubble; an upper worm to remove the material bubble and carrying it up to the middle part of the machine. At the middle part of the machine, the material is forced by a loop system having an upper worm to move towards the rotor area, such that the material is actually moving towards the back portion of the machine, completing a mixing cycle. Said upper worm has from the middle of its axis, a plurality of discs on which peripheral edge of each disc is mounted a series of exchangeable knives placed on a loop arrangement, which are passed through a counterplate, and which shows a series of exchangeable knives placed at the bottom part of the material collector chut, so when the upper worm discs plurality is rotating, it allows both, humid and dry fibers be efficiently crushed and / or ground and besides added to the other several common ingredients a unique and highly qualified mixing is achieved.

Owner:TORMEX IND DE C V

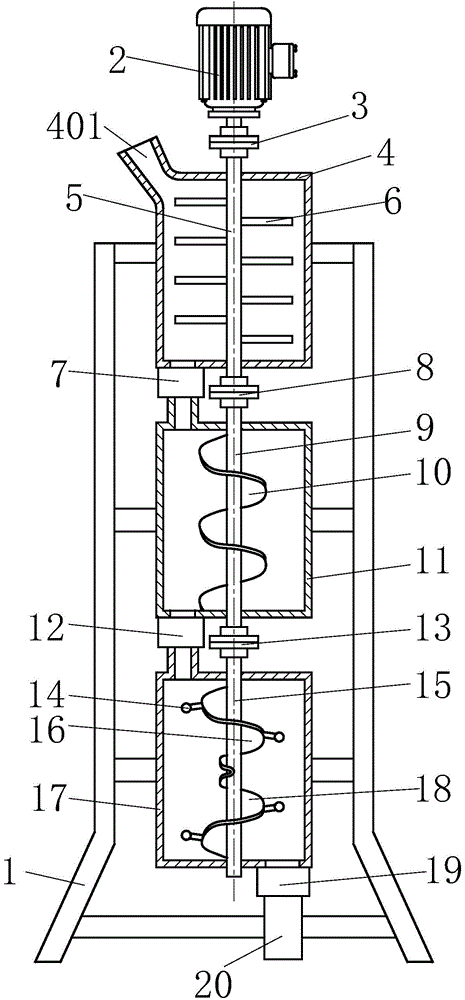

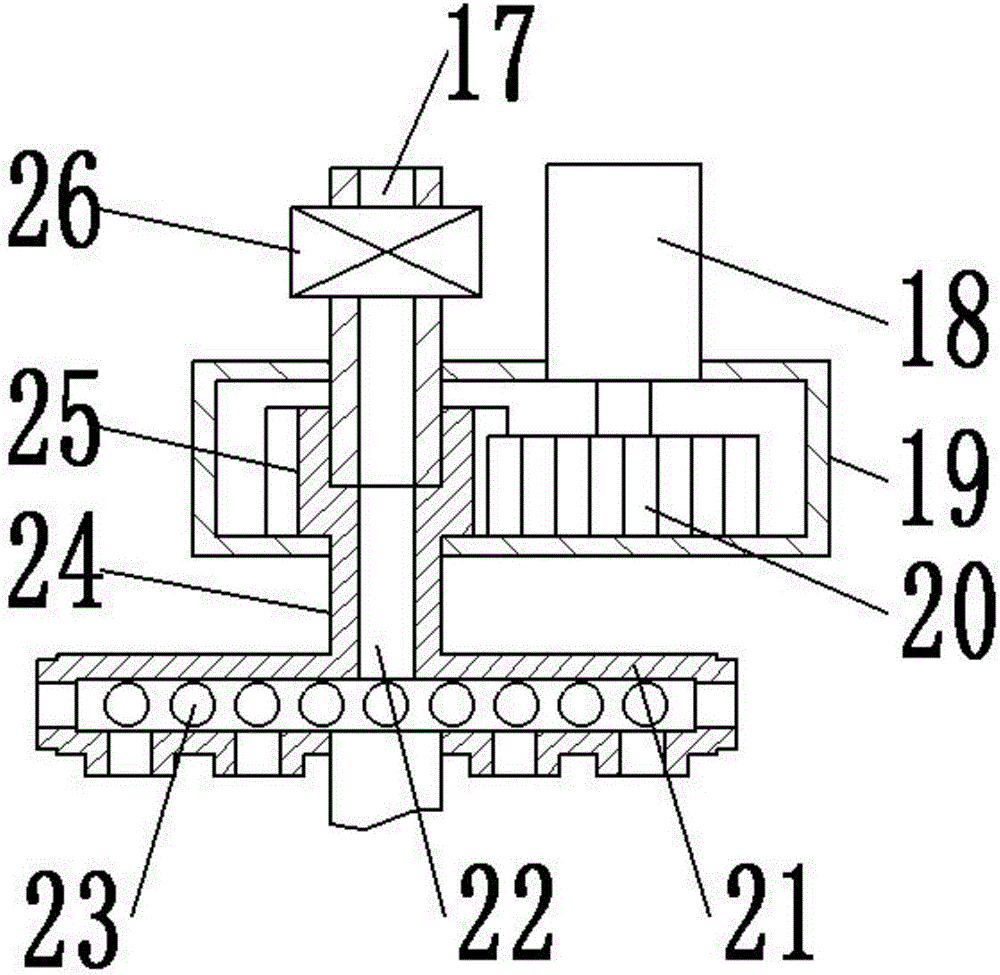

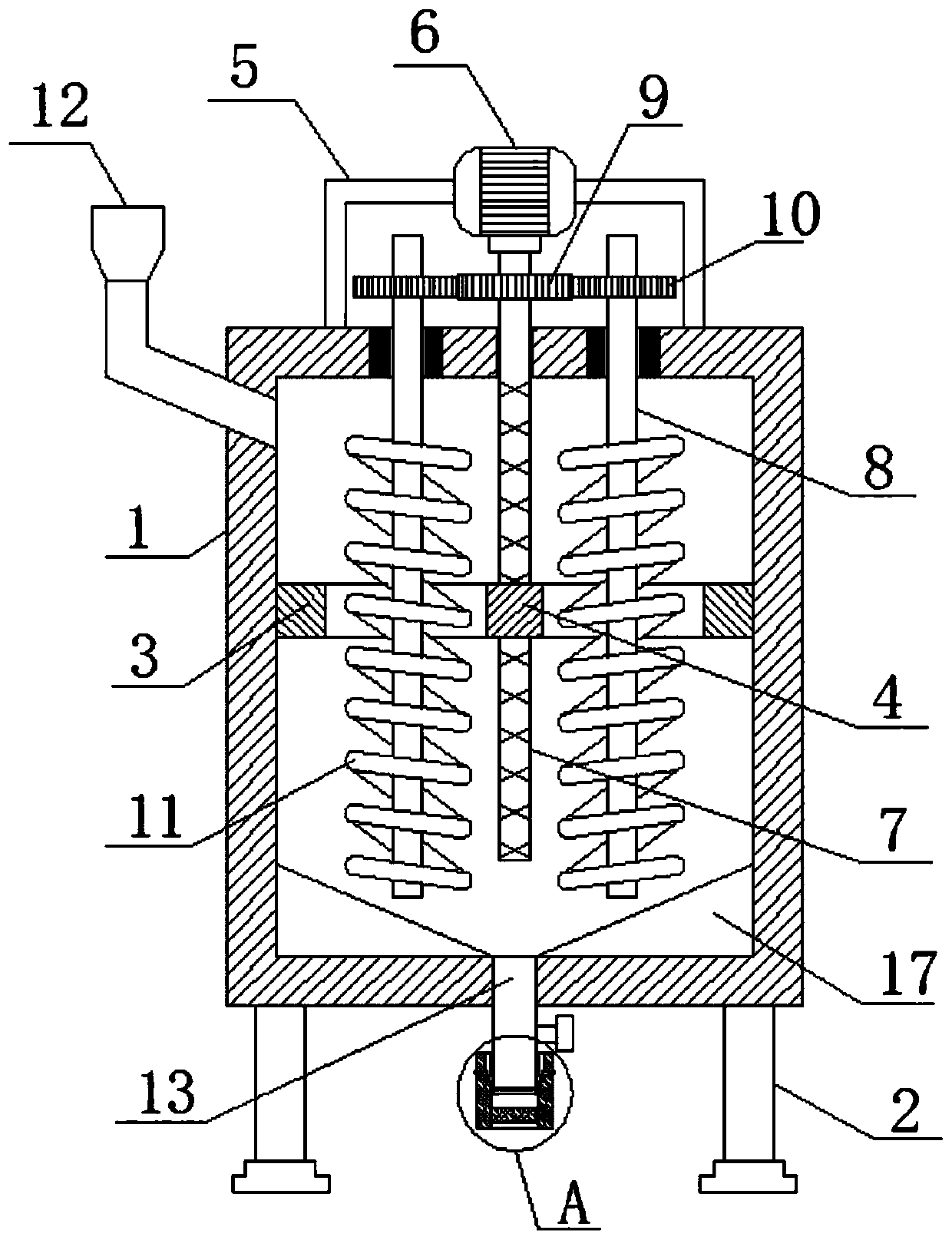

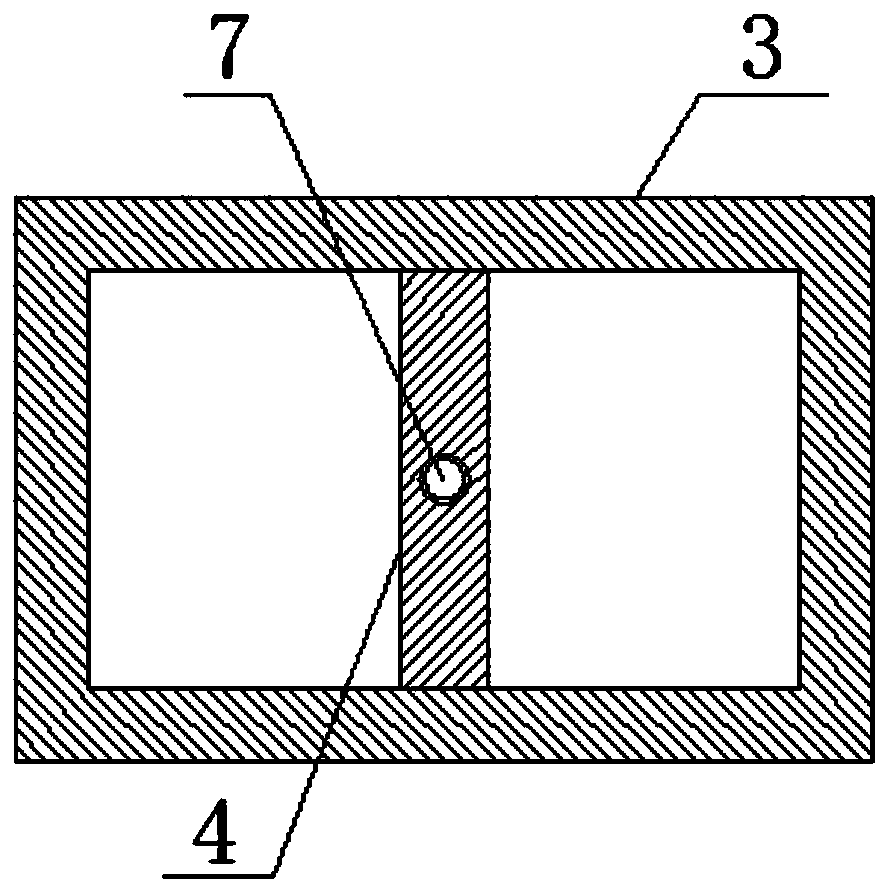

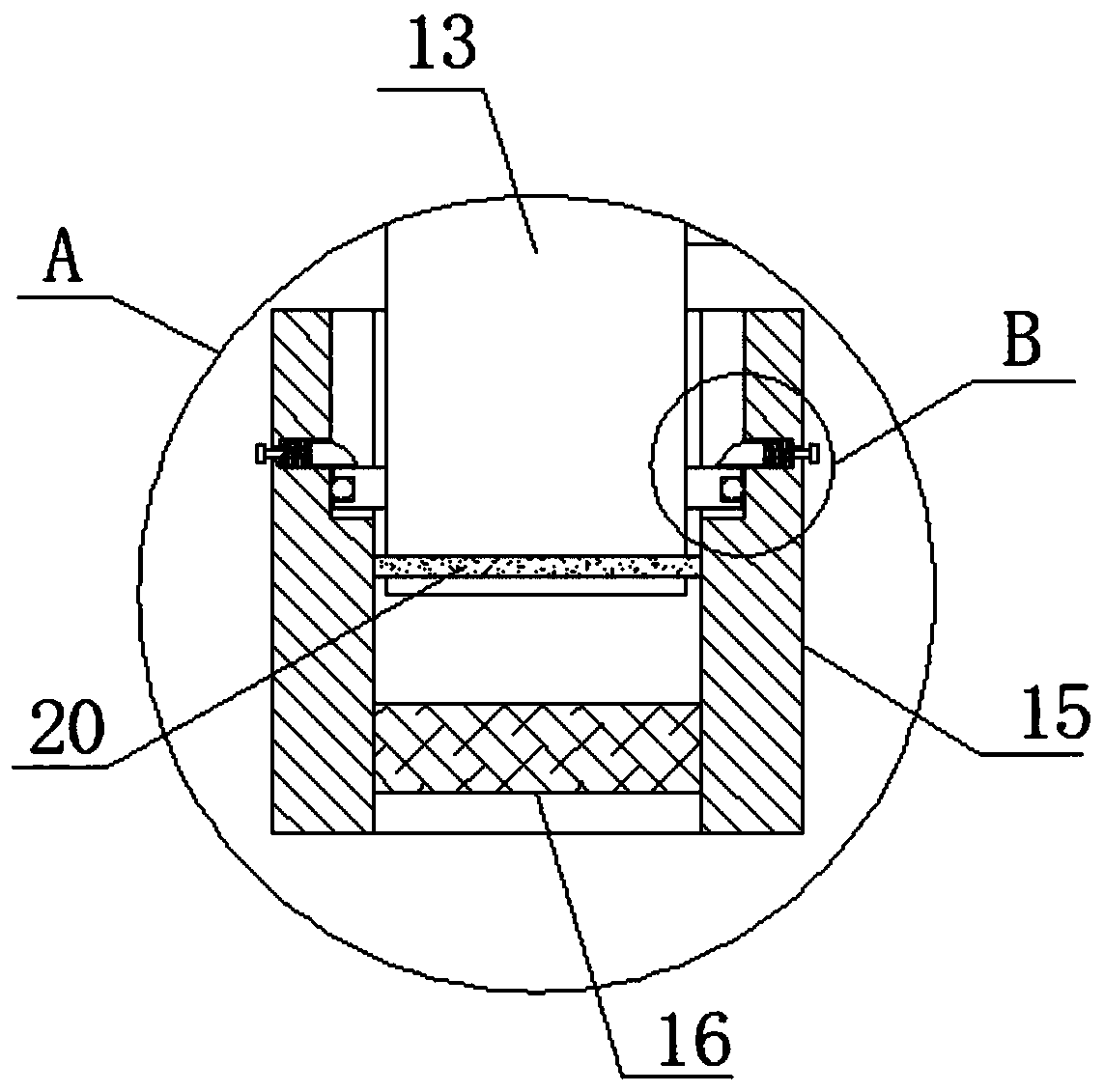

Stirrer

ActiveCN104400903AGuaranteed to mix evenlyImprove mixing qualityCement mixing apparatusThree stageRaw material

The invention relates to a stirrer. The stirrer comprises a supporting rack and a motor, the upper portion, the middle portion and the lower portion of the supporting rack are respectively correspondingly provided with a first-stage stirring device, a second-stage stirring device and a third-stage stirring device, the first-stage stirring device is used for coarse stirring of a concrete raw material, the second-stage stirring device is used for semi-fine stirring of the concrete raw material, and the third-stage stirring device is used for fine stirring of the concrete raw material; and the motor is positioned above the supporting rack. The stirrer adopts a multi-stage stirring mode comprising the coarse stirring, the semi-fine stirring and the fine stirring which do not interfere with each other, realizes the full stirring of the concrete raw material, allows the raw material to be added in the stirring process to realize continuous stirring of the concrete raw material, and provides guarantee for the continuous supply of concrete; and the stirrer uses the three-stage stirring devices to make the concrete raw material have convective flow, ensures the uniform mixing of the concrete raw material, and improves the stirring quality of the concrete.

Owner:平湖市盛泰五金制品有限公司

Efficient stirring and mixing equipment of solid-liquid raw materials for chemical engineering

InactiveCN106582389AEnsure mixing uniformityMixing uniformity does not existRotating receptacle mixersRotary stirring mixersElectric machineryRaw material

The invention provides efficient stirring and mixing equipment of solid-liquid raw materials for chemical engineering. The efficient stirring and mixing equipment comprises a tank body; a stirring cavity is formed in the tank body, an upper cover is installed on an opening formed in the top of the tank body, and four sets of rollers are installed on the lower surface of the tank body; the rollers are installed in a sliding groove formed in a base plate, a support is installed at the end of the base plate, and the vertical portion of the support is fixedly connected with a second motor through a fixing plate; a liquid feeding device is installed on the upper surface of the horizontal portion of the support, the liquid feeding device is composed of a transmission box, a first motor, a liquid feeding pipe, a connecting pillar and a spraying disc, and a first stirring device and a second stirring device are installed in the stirring cavity. According to the efficient stirring and mixing equipment of the solid-liquid raw materials for chemical engineering, through the liquid feeding device, the spraying area and speed of liquid materials are enlarged, so that the liquid materials make sufficient contact with solid materials; through the first stirring device, circulating stirring and mixing of the materials are achieved, so that the spraying speed of the liquid materials is improved; and through arrangement of the second stirring device, the materials are further stirred and mixed.

Owner:郑州吉音动漫科技有限公司

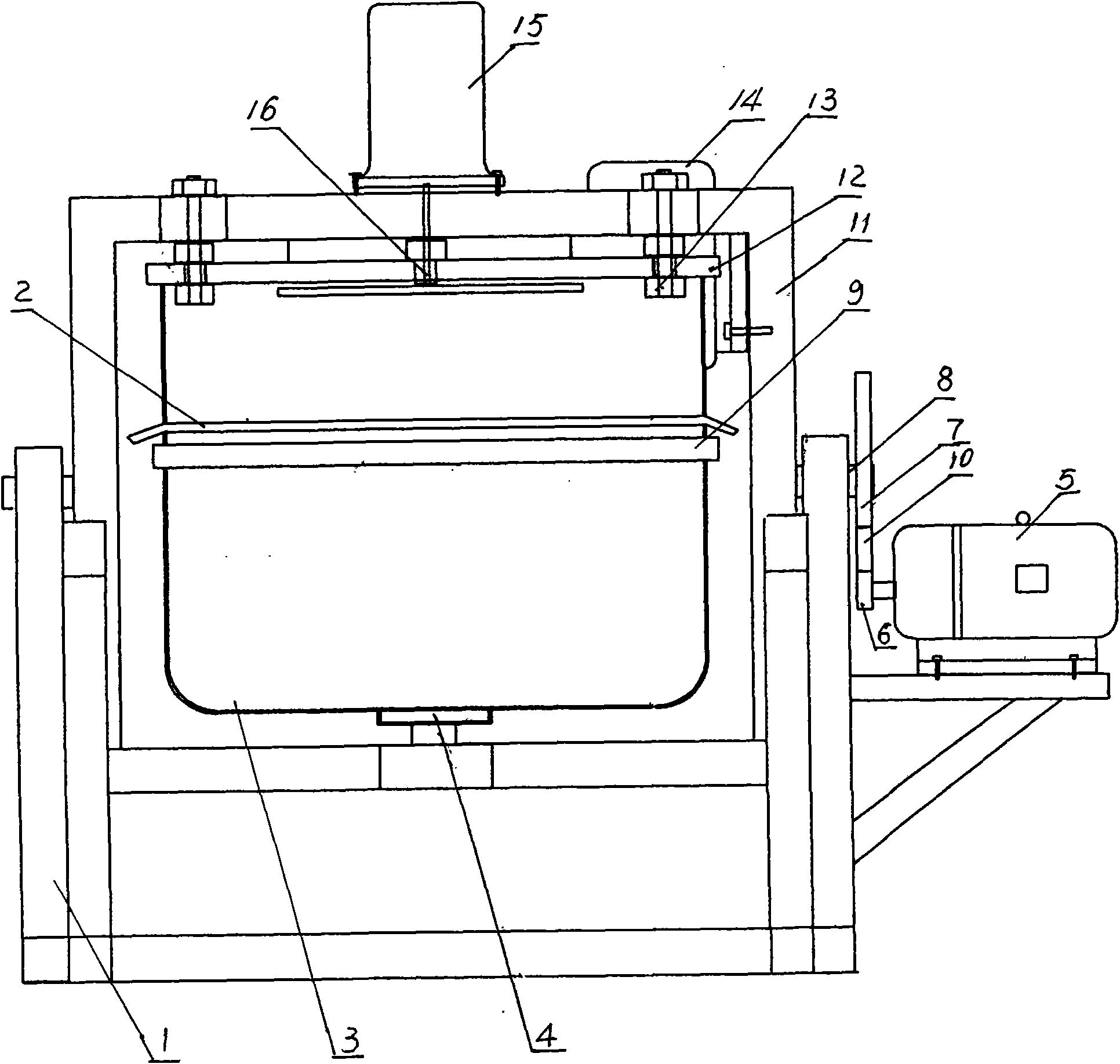

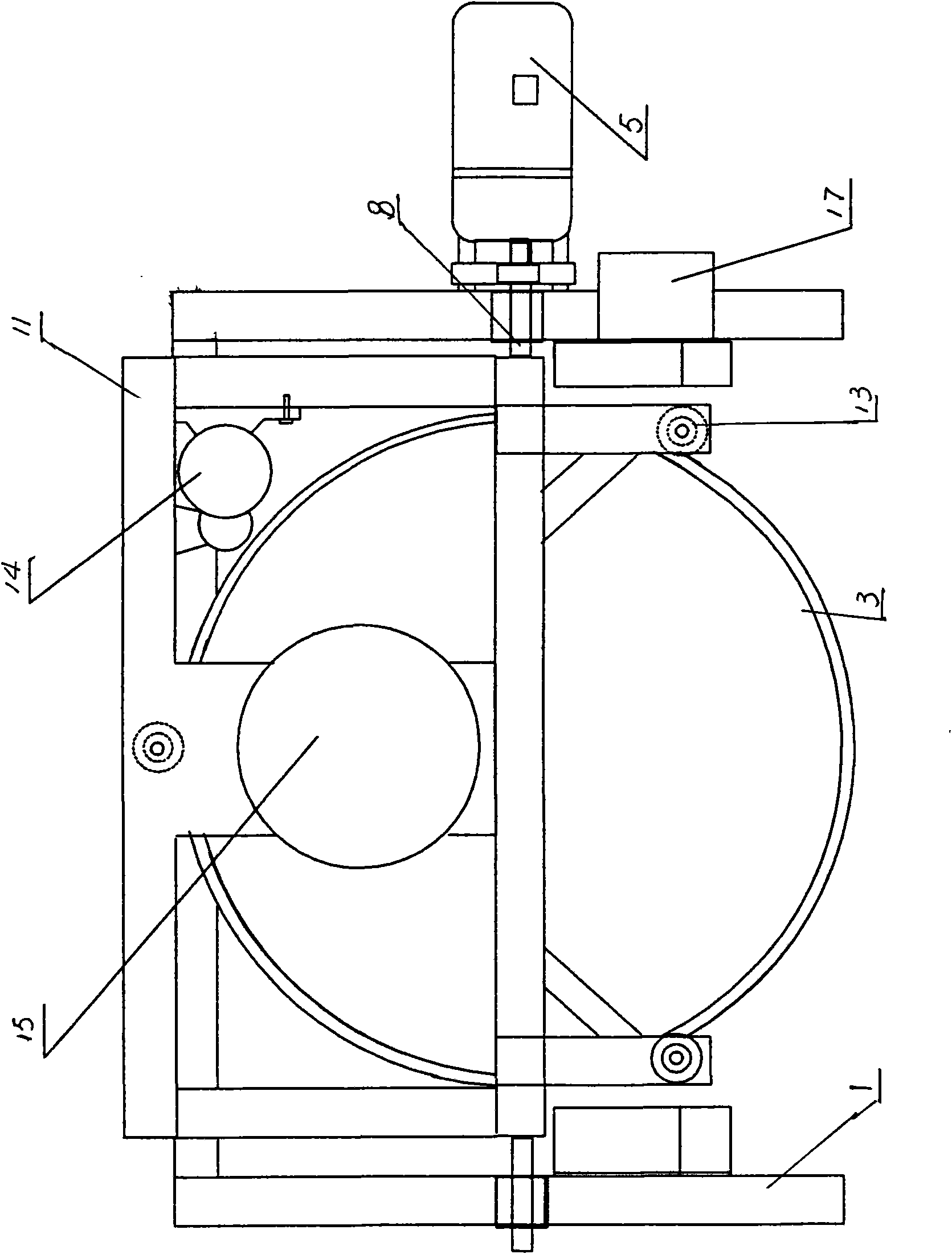

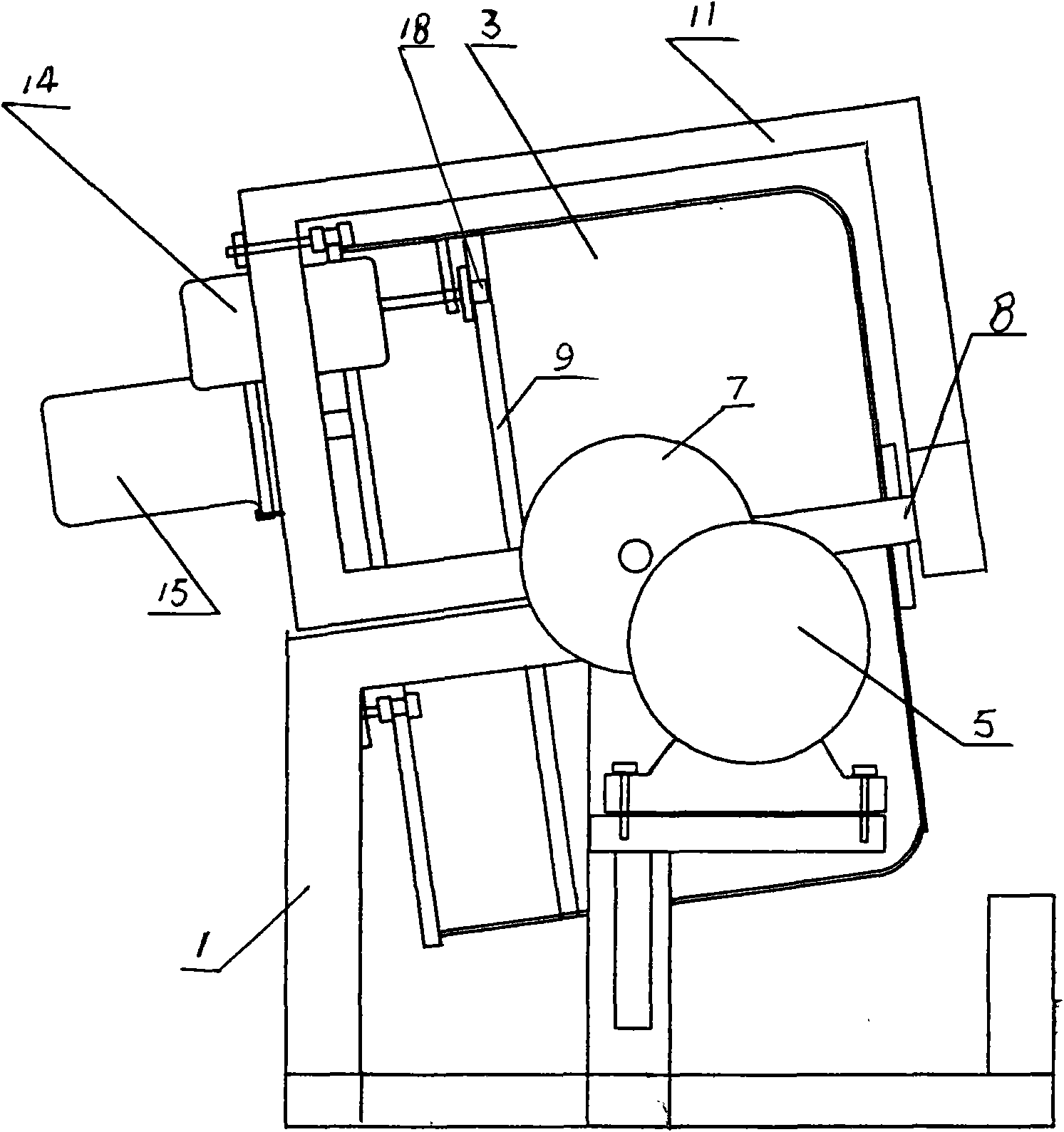

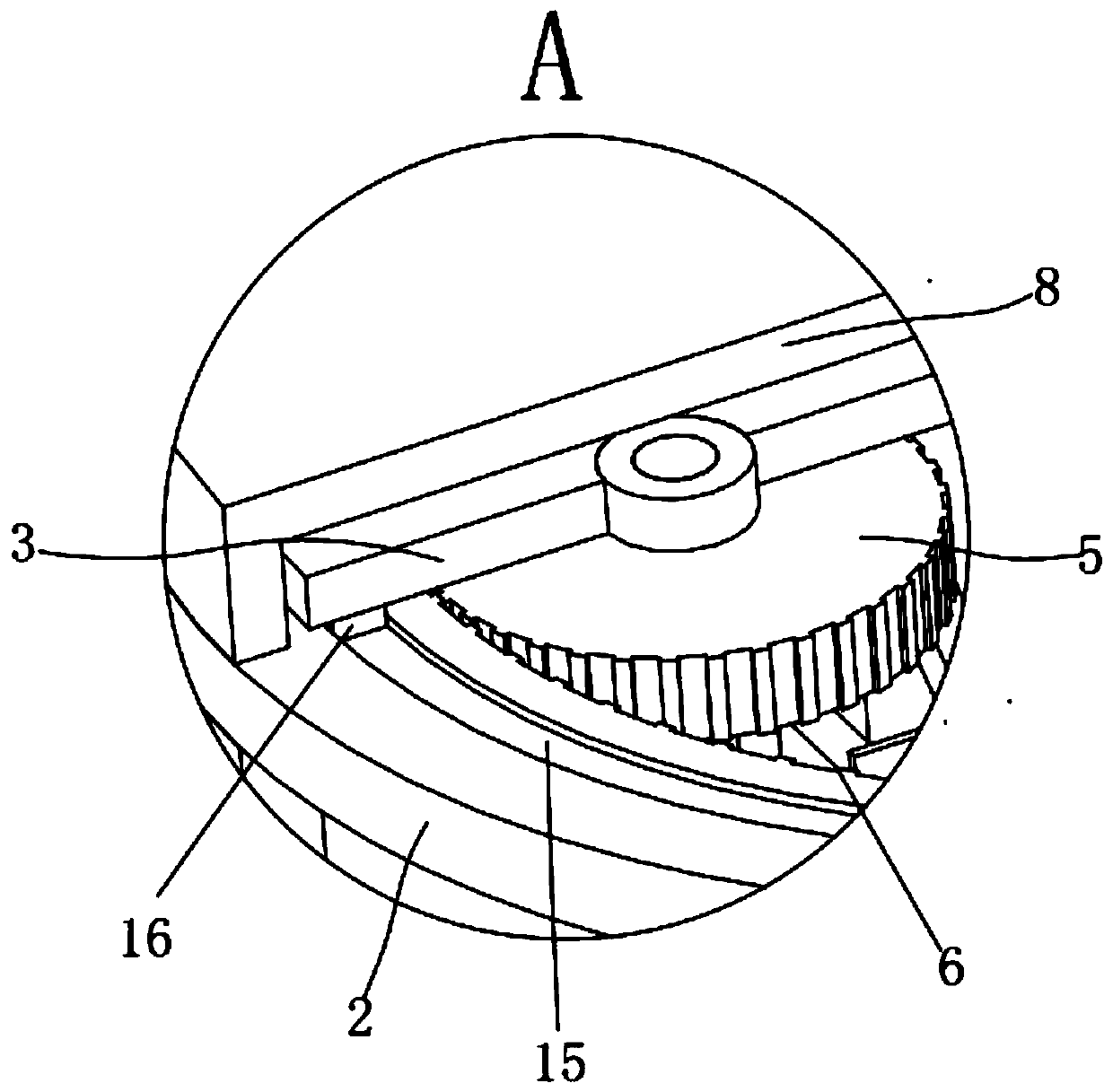

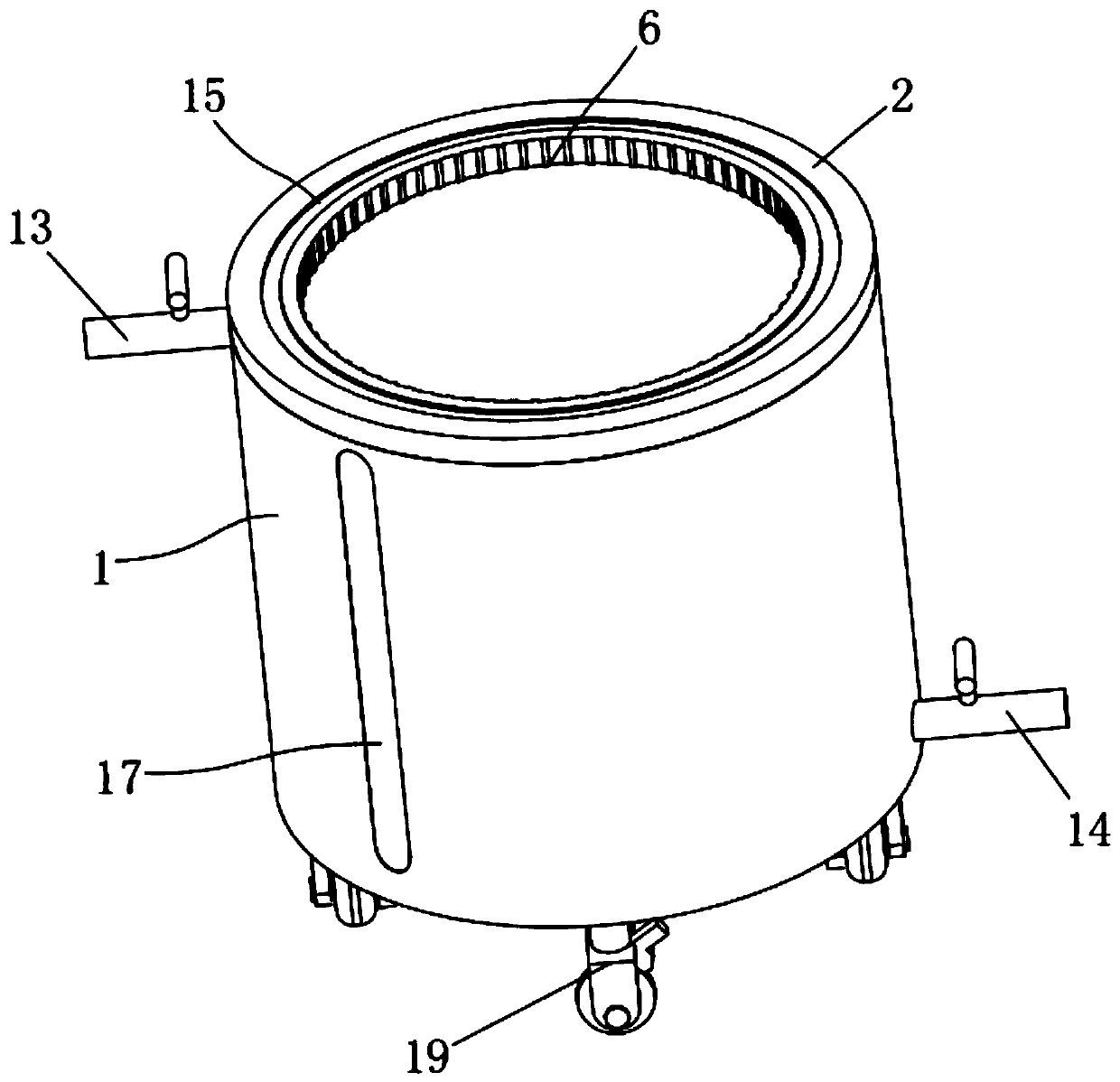

Adhesive cement stirring device

InactiveCN101601981AReasonable designCompact structureRotating receptacle mixersConstruction industryAdhesive cement

The invention relates to high-viscosity adhesive cement stirring device in the chemicals, foods, medicines and construction industries, which is particularly suitable for stirring and mixing cement-base polymer adhesive cement; the device comprises a machine frame, a cylinder body, a cylinder locating idler wheel, a cylinder overturning bracket, a cylinder overturning discharging motor, a cylinder rotating retarding motor, a stirring retarding motor and a stirrer; the cylinder body is arranged on the cylinder overturning bracket by a cylinder supporting bearing base, and a geared ring is arranged on the cylinder body; the two sides of the cylinder overturning bracket are provided with cylinder overturning shafts which are arranged at the upper part of the machine frame, retarding gears are arranged at the end parts of the cylinder overturning shafts, and the cylinder overturning motor is arranged on the machine frame; the cylinder rotating retarding motor is arranged on the cylinder overturning bracket, a cylinder transmission gear is arranged on the output shaft of the cylinder rotating retarding motor, the cylinder transmission gear is meshed with the geared ring outside the cylinder body, and the cylinder body is driven to rotate; the stirring retarding motor is arranged at one side of the upper part of the cylinder overturning bracket eccentrically, and the stirrer is arranged on the output shaft of the stirring retarding motor.

Owner:NANJING JINGYEDA NEW BUILDING MATERIALS

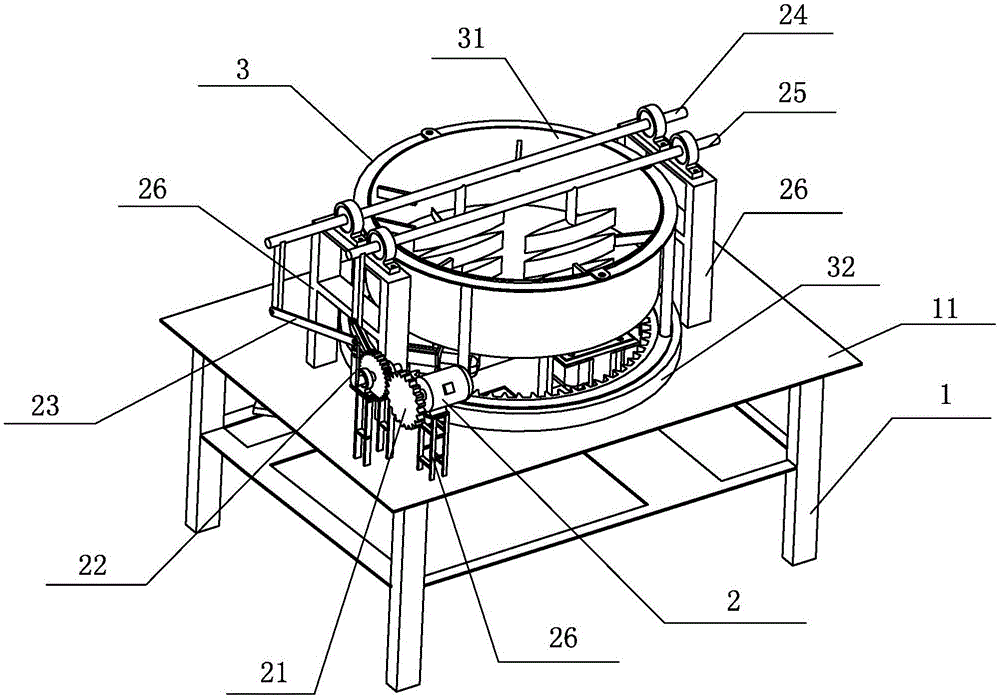

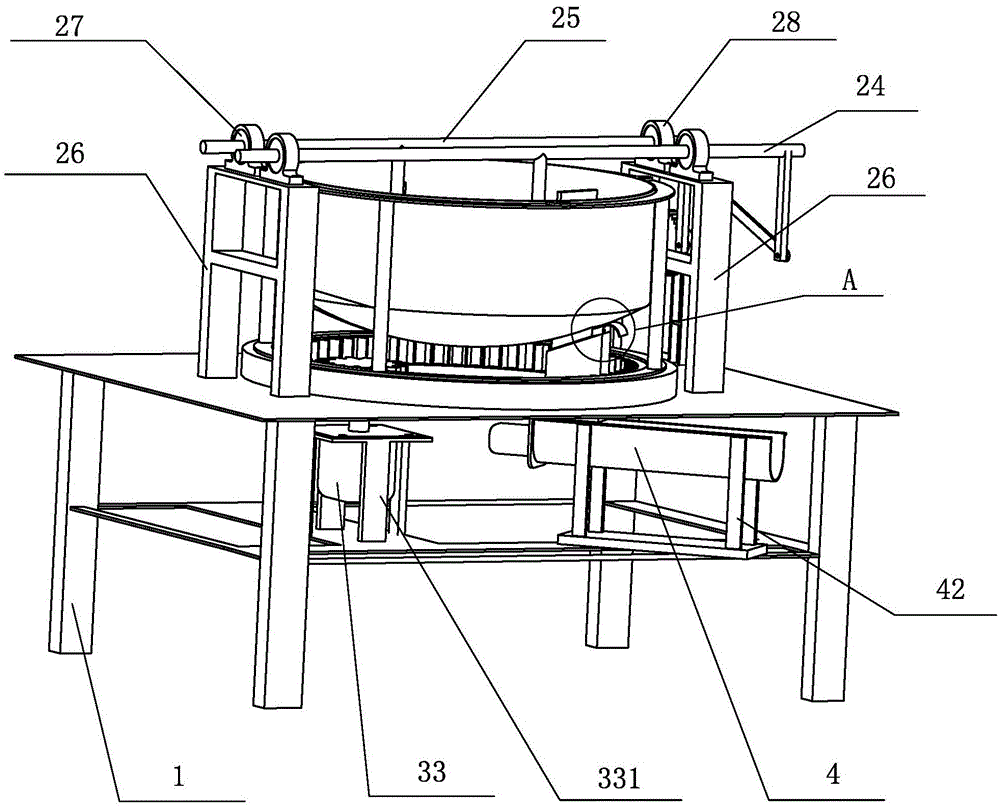

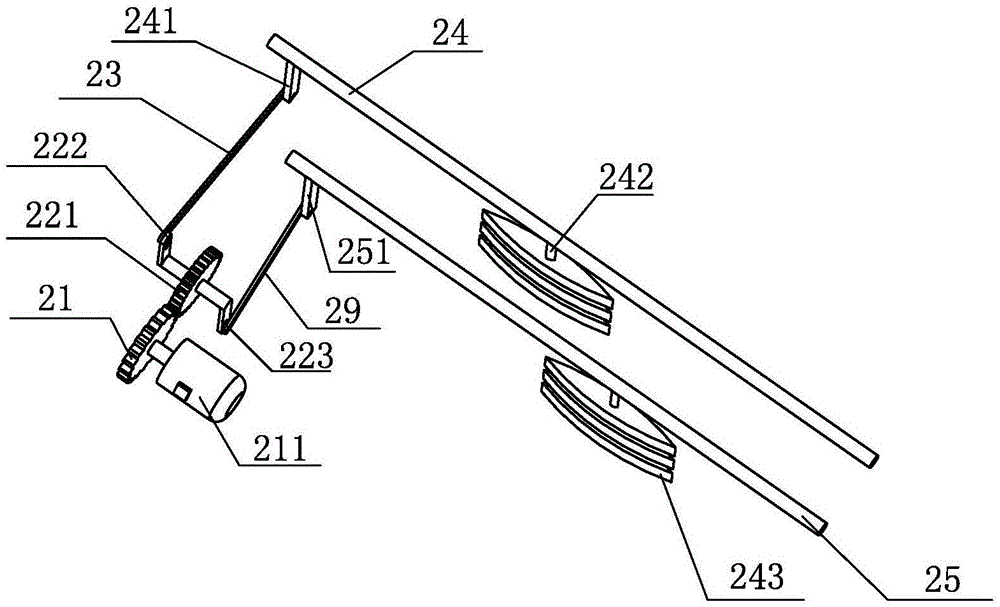

Double-shaft swing type high-thickness material stirrer

ActiveCN105126692AWell mixedAchieving Stirring FrequencyRotating receptacle mixersShaking/oscillating/vibrating mixersElectric machineryMachine

The invention provides a double-shaft swing type high-thickness material stirrer which comprises a stirring barrel, a swing mechanism, a rotating mechanism, a feeding mechanism and a whole machine support. The swing mechanism comprises a swing mechanism motor, a swing conversion mechanism, a swing mechanism support, a first swing rod and a second swing rod. The rotating mechanism comprises a stirring barrel support, a rotating bearing and a rotating mechanism motor, and the stirring barrel is arranged over the rotating bearing through the stirring barrel support. The feeding mechanism comprises a collecting hopper and a spiral conveyor which is arranged in the stirring barrel, and the first swing rod and the second swing rod are connected with the swing conversion mechanism through connecting rods. The swing rods on the stirrer conduct relative swing movement in the stirring process and can rapidly smash block-shaped high-thickness materials, meanwhile, fast and full mixing of the high-thickness materials can be achieved through the rotation movement of the stirring barrel.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

Mixed paint fast proportioning device for building construction

InactiveCN107398216AEasy to scrape offIncrease the mixing areaRotary stirring mixersTransportation and packagingBristleReciprocating motion

The invention discloses a mixed paint fast proportioning device for building construction. The device consists of: proportioning tanks, a mixing tank, piston plates, threaded columns, threaded sleeves, a negative pressure pump, movable sleeves, L-shaped columns and a rotating ring. Stock solutions of different types are injected into the proportioning tanks according to needed capacity, the stock solutions in the proportioning tanks enter the mixing tank to enable proportioning of the stock solution according to a needed ratio, the centrifugal force makes stirring plates stretch outward to increase the stirring area and improve the mixing quality, first bristle and second bristle scrape off the mixed slurry adhered to the mixing tank inner wall to improve the mixing quality, when the mixed slurry adhered to the mixing tank inner wall is difficultly scraped off, the magnetic-south poles and magnetic-north poles of second magnets under a rotational state and first magnets under a stationary state are the same or opposite alternately, a frame body drives the second bristle to do reciprocating motion up and down, thus achieving easy scraping of the adhered mixed slurry, and further improving the mixing quality.

Owner:林红英

Vibration damping type dust-removing and high-efficiency bidirectional stirring equipment

InactiveCN106345342AWell mixedQuality improvementRotary stirring mixersTransportation and packagingBiochemical engineeringWater pipe

The invention provides vibration damping type dust-removing and high-efficiency bidirectional stirring equipment. The vibration damping type dust-removing and high-efficiency bidirectional stirring equipment comprises a tank body, wherein a stirring cavity is formed inside the tank body; a feeding pipe and a water adding and driving device are arranged at the top of the tank body; the water adding and driving device consists of a driving box, a rotating motor, a water inlet pipe and a rotational spraying tray; a first stirring device and a second stirring device are arranged in the stirring cavity; the first stirring device consists of a first stirring shaft, spiral stirring blades and a scraper plate; the second stirring device is arranged at the bottom of the tank body and consists of a stirring motor, a second stirring shaft and stirring blades; a dust remover is arranged on the side wall of the top of the tank body; a discharging pipe is arranged on the side wall of the bottom of the tank body; the bottom surface of the tank body is connected with a base plate through a vibration damping device. According to the vibration damping type dust-removing and high-efficiency bidirectional stirring equipment provided by the invention, the water adding and driving device facilitates the mixing of materials; in addition, after use, the tank body is cleaned; by means of the first stirring device and the second stirring device, sufficient mixing of the materials is facilitated, and the quality of a product is improved.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

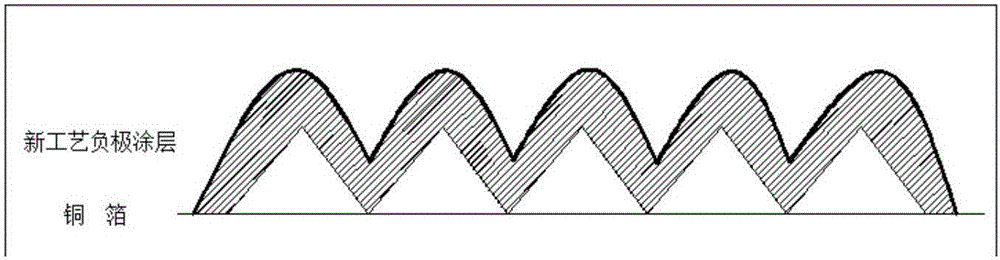

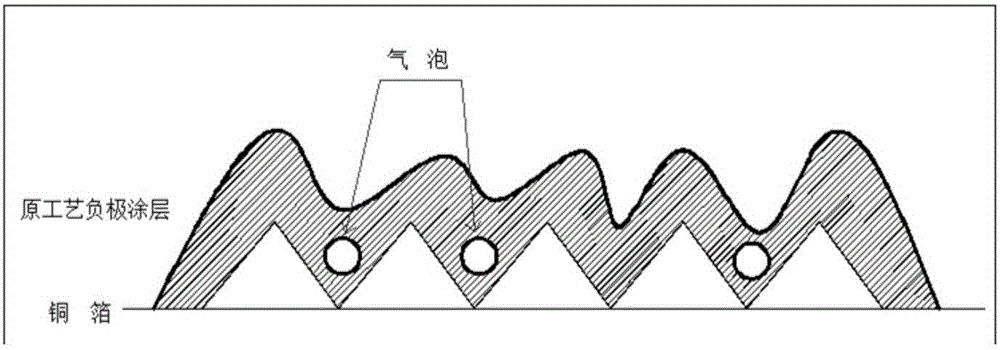

Preparation method of lithium ion power battery cathode

ActiveCN106848205AImproved mixing schemeShorten mixing timeElectrode collector coatingSodium carboxymethylcelluloseButadiene-styrene rubber

The invention relates to the field of power lithium ion batteries, in particular to a preparation method of a lithium ion power battery cathode. The preparation method comprises the following steps: first preparing sodium carboxymethylcellulose glue solution in a number 1 stirring machine, adding conducting carbon black and dry graphite powder in a number 2 stirring machine, uniformly mixing, and then adding the sodium carboxymethylcellulose glue solution in the number 1 stirring machine into the number 2 stirring machine; and adding little alcohol, vacuumizing, defoaming, adding styrene-butadiene latex, mixing, finally vacuum defoaming, and obtaining the lithium ion power battery cathode material. By improving a stirring scheme, the stirring time of the cathode slurry is shortened, the moisturizing coating performance of the cathode slurry is improved, and a bubble-free purpose is achieved.

Owner:HEFEI HENGNENG NEW ENERGY TECH

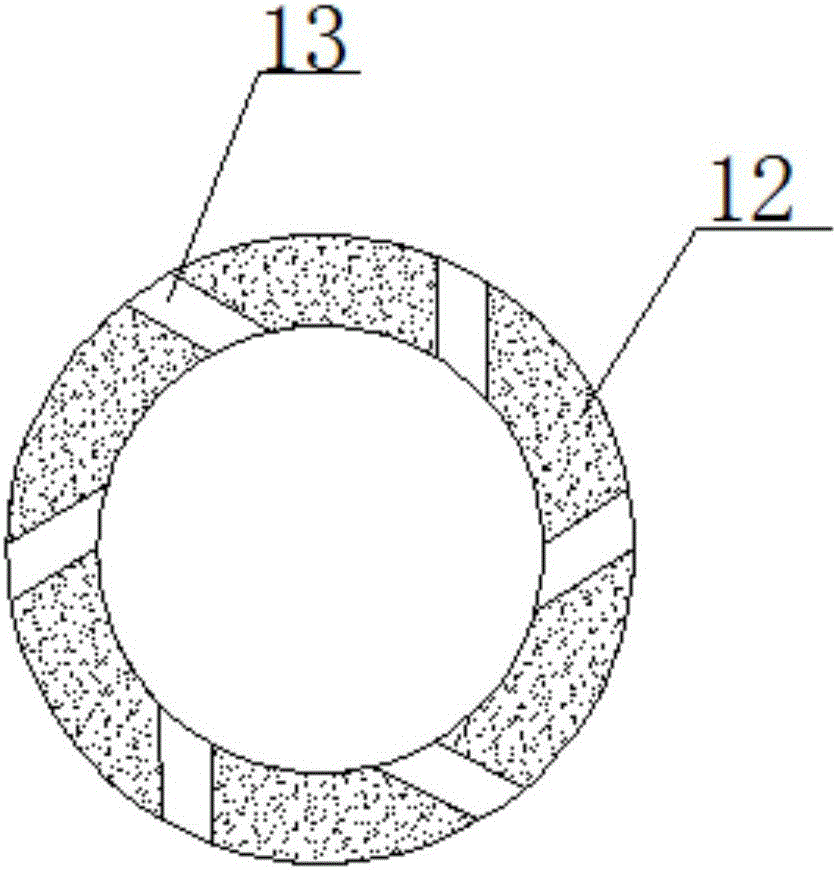

Mixing device for polymer gel raw material production

InactiveCN110681291ASpeed up the mixingImprove mix qualityRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a mixing device for polymer gel raw material production. The device comprises a mixing barrel, wherein a fixed ring is fixed at the upper end of the mixing barrel; a turntableslides at the upper end of the fixed ring; first rotating shafts are mounted on two sides of the turntable; the upper ends of the first rotating shafts are in key connection with an outer gear; the outer side of the outer gear is engaged with an inner gear; the inner gear is embedded in the fixed ring; first stirring blades are welded on the first rotating shafts; a mounting base is fixed at the upper end of the fixed ring; a servo motor is fixedly connected to the upper end of the mounting base; a second rotating shaft is fixed to an output shaft of the servo motor; second stirring blades arewelded to the upper side and the lower side of the second rotating shaft; an inner wall wiping mechanism is fixedly connected to the middle part of the second rotating shaft; a feeding pipe communicates with the upper end of the mixing barrel; and discharging pipes symmetrically communicate with the lower end of the mixing barrel. The stirring directions of the stirring blades in the mixing barrel are different, so different vortexes are generated; and thus, the mixing speed of raw materials is increased, mixing quality is good, working efficiency is high, and the wall of the barrel can be automatically cleaned.

Owner:江山市永安消防材料有限公司 +1

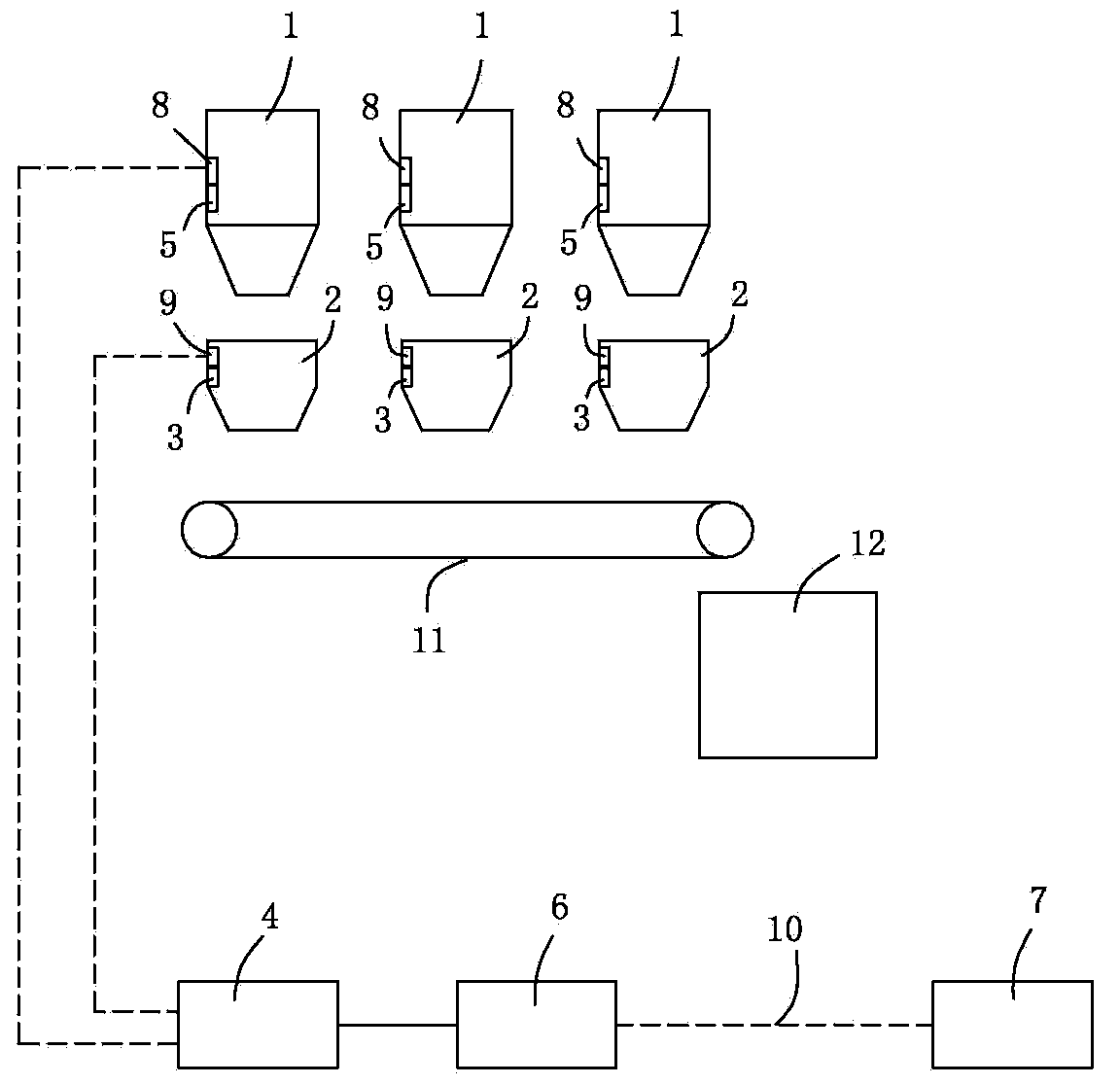

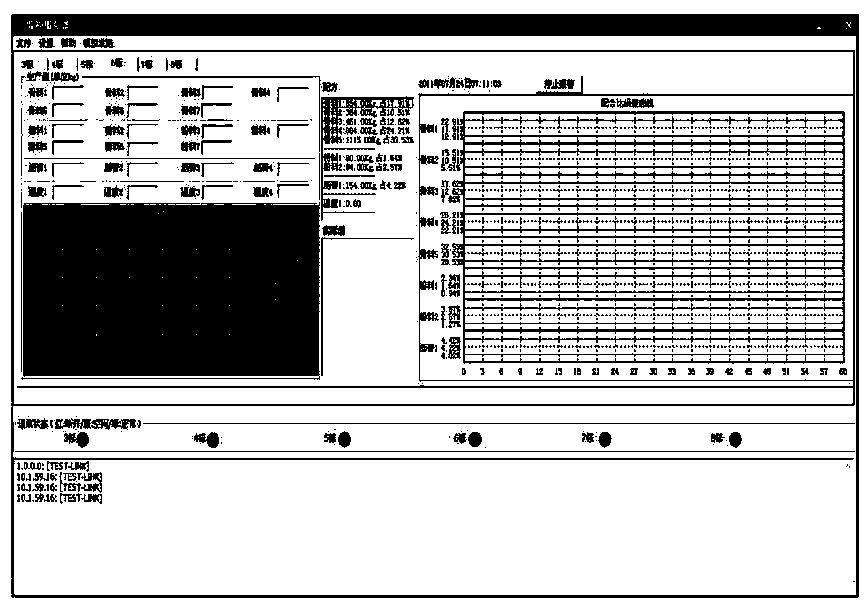

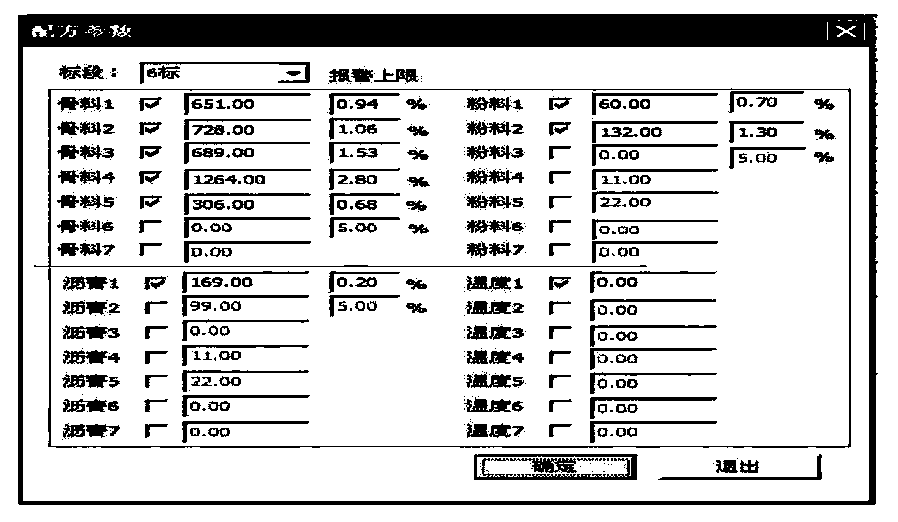

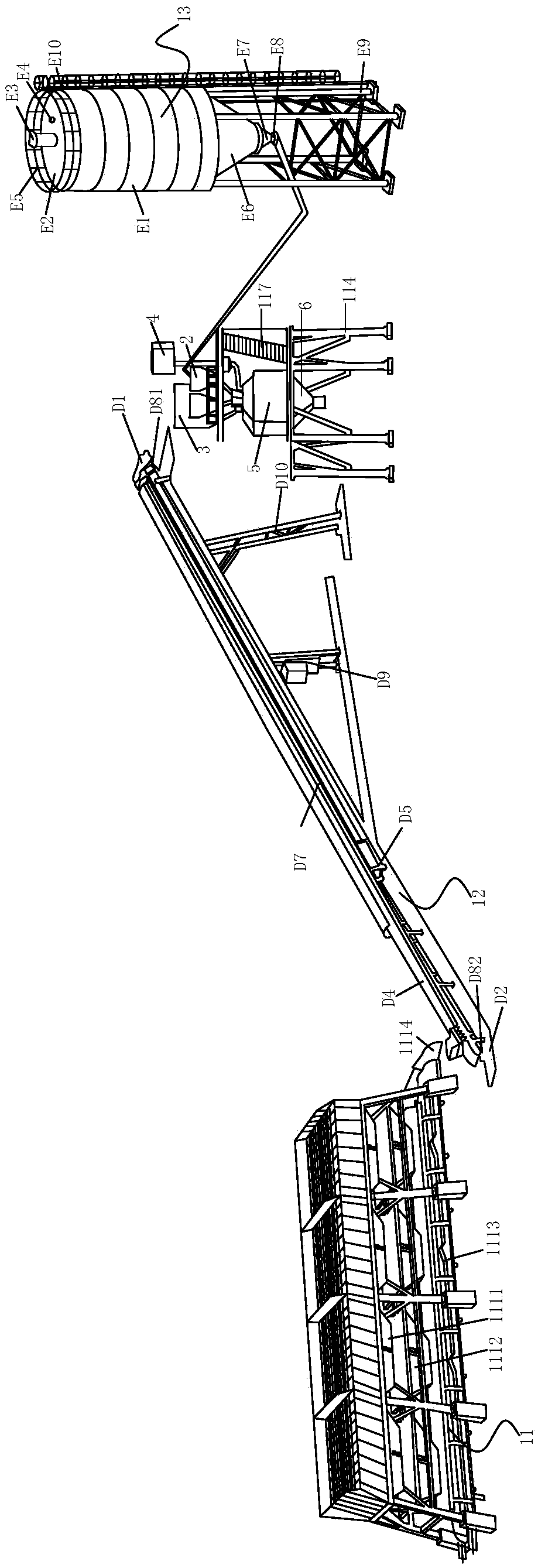

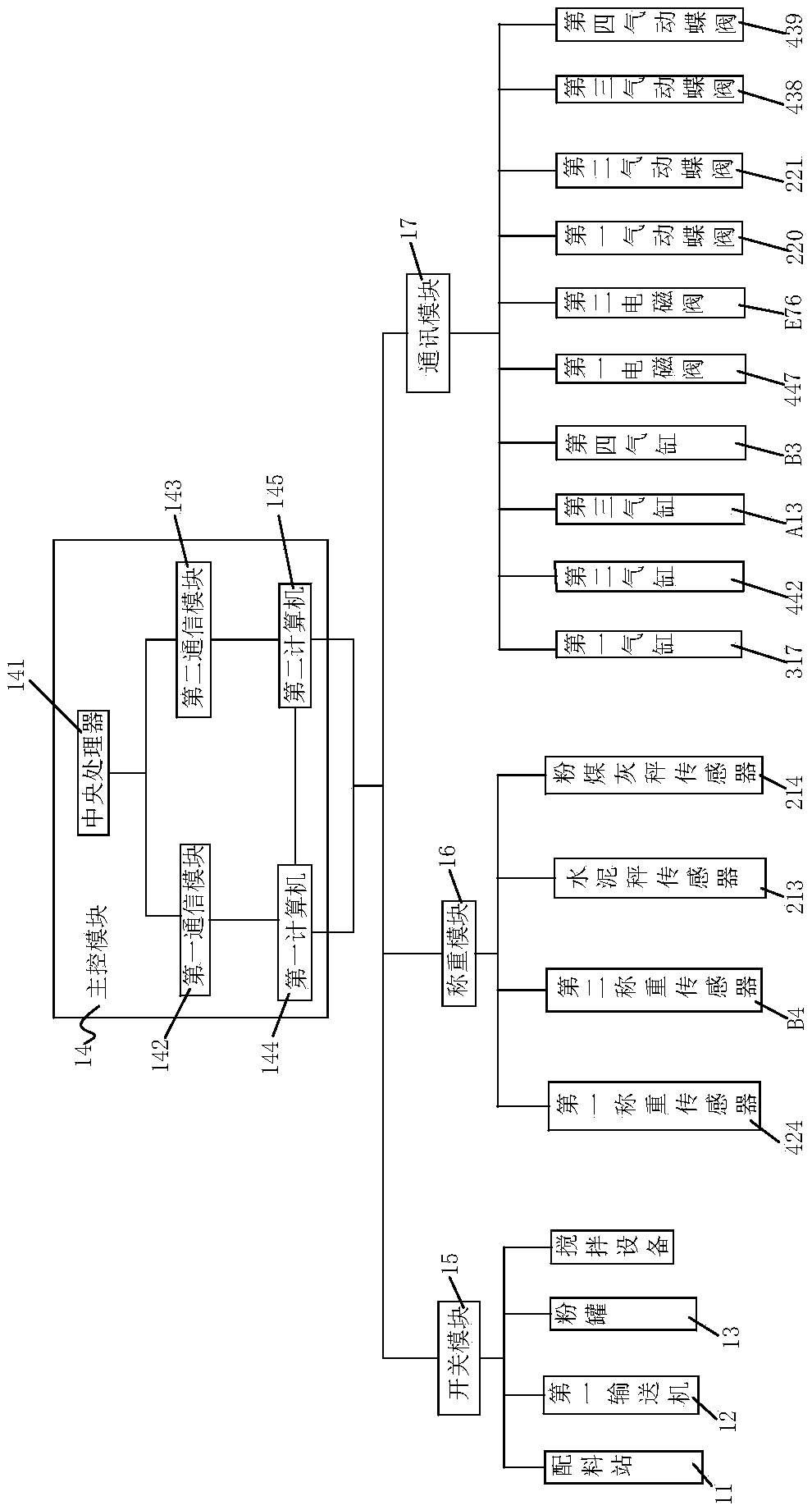

Intermittent production graduation real-time monitoring system and method of hot-mix asphalt mixture

InactiveCN103425115ARealize real-time monitoringImprove mix qualityTransmission systemsTotal factory controlMonitoring systemEngineering

The invention discloses an intermittent production graduation real-time monitoring system and method of a hot-mix asphalt mixture. Real-time detection is carried out on mix proportion of the asphalt mixture and the amount of asphalt on a construction site through a designed data collecting module and a designed data transmitting module. On the basis of real-time detection data, the mix proportion of the asphalt mixture and the amount of the asphalt can be monitored in real time on a mixing site through a designed data processing module and a designed warning system. The method effectively solves the problem of difference between an intermittent mixture production mix proportion and a target mix proportion, makes up for detects of a proportion ratio monitoring technique of an existing cold material bin and achieves real-time monitoring of production graduation in a hot material bin of the hot-mix asphalt mixture.

Owner:CCCC TUNNEL ENG +1

Chemical material mixing device

InactiveCN107583532AExtended service lifeAvoid enteringRotary stirring mixersMixer accessoriesDrive wheelEngineering

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

Thermoplastic mixture with high flexibility and high melting point

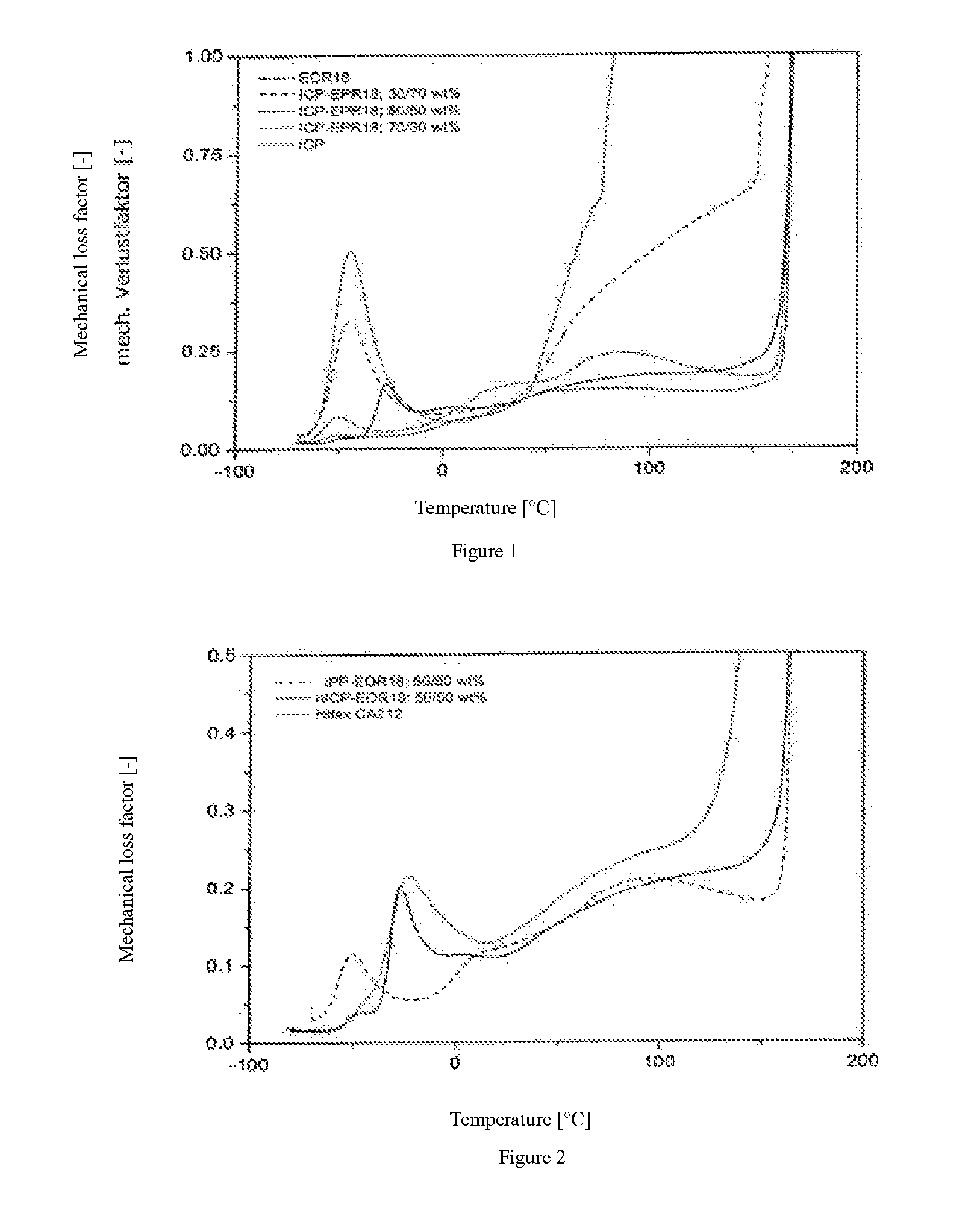

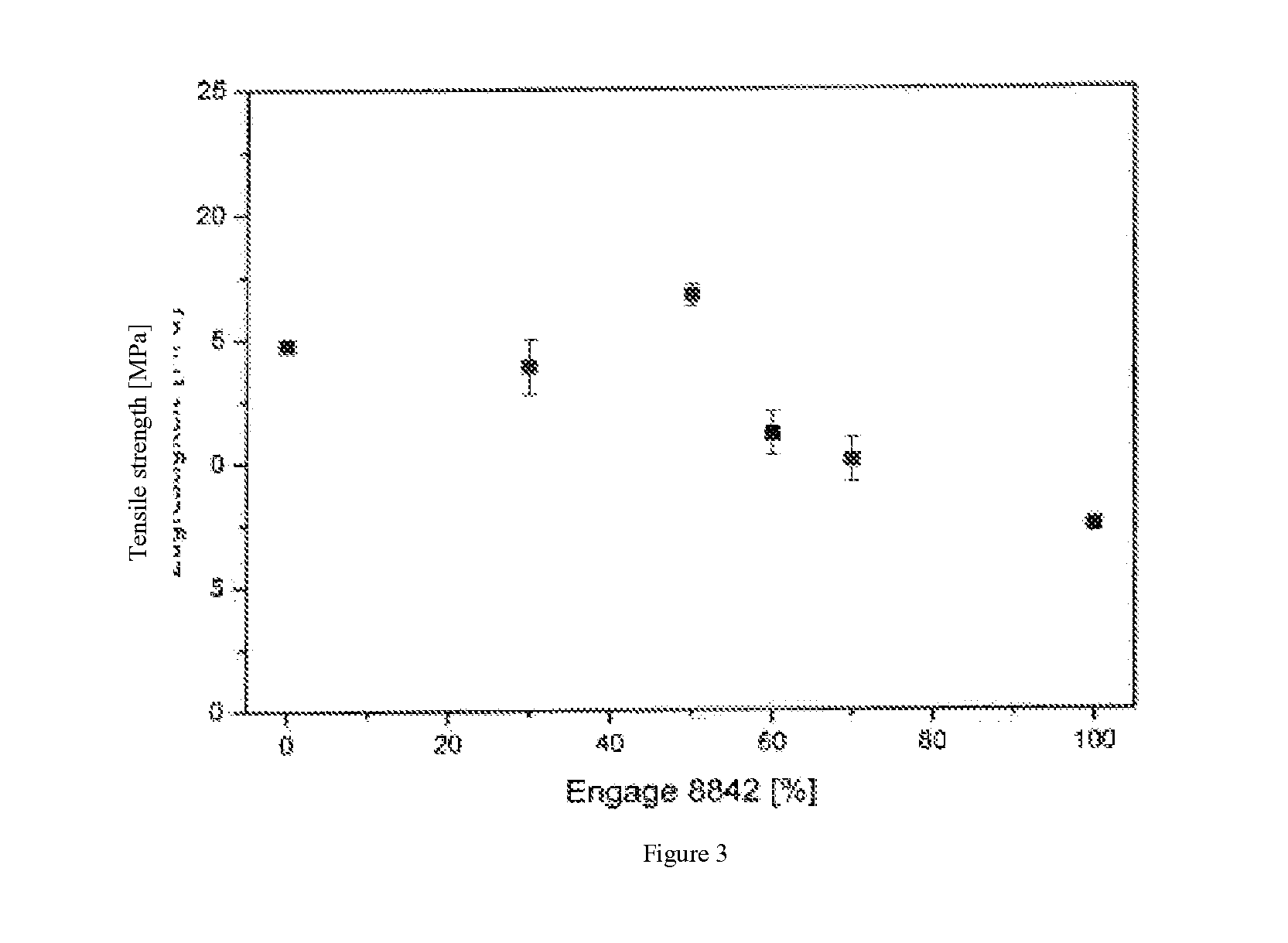

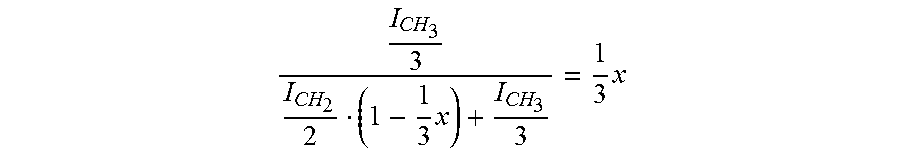

ActiveUS20150232651A1Low modulusRaise the crystallization temperatureAntifouling/underwater paintsPaints with biocides1-OctenePolypropylene

A thermoplastic mixture is described that includes at least one impact-resistant polypropylene copolymer and at least one ethylene-1-octene copolymer. The weight ratio of impact-resistant polypropylene copolymer to ethylene-1-octene copolymer can be in the range of 35:65 to 65:35. The thermoplastic mixture has a high melting point and excellent flexibility. The mixture is suitable in particular for roof membranes and waterproofing membranes.

Owner:SIKA TECH AG

Solid-liquid mixing and stirring device

InactiveCN106621986APrevent twistingExtended service lifeRotary stirring mixersTransportation and packagingAgricultural engineeringWater pipe

The invention discloses a solid-liquid mixing and stirring device. The solid-liquid mixing and stirring device comprises a shell body, wherein a rotary seat is arranged in the middle of the lower end in the shell body; the lower end of a stirring shaft is rotatably connected with the rotary seat; a limiting ring is rotatably connected with the middle of the stirring shaft; fixed rods are arranged at the outer side of the limiting ring; the other ends of the fixed rods are connected with an inner wall of the shell body; a plurality of stirring blades are uniformly connected with the stirring shaft; the outer ends of the stirring blades are connected with mounting bases; supports are arranged at the front sides of the mounting bases; the supports are rotatably connected with sleeve shafts; a plurality of small blades are arranged at the outer sides of the sleeve shafts; a feeding pipe is arranged at the upper end of the left side of the shell body; the feeding pipe comprises an outer pipe and an inner pipe; a cavity is formed between the outer pipe and the inner pipe; a plurality of cyclone inclined holes are uniformly formed in the inner pipe along the circumferential direction; the upper side of the outer pipe is connected with a water inlet pipe; a water pump is arranged on the water inlet pipe; the left end of the inner pipe is connected with a charging pipe and the charging pipe is provided with a charging pump. The solid-liquid mixing and stirring device is simple in structure, convenient to use, good in stirring effect, high in stirring efficiency and long in service life.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

Paddle type mixing machine

InactiveCN1608723AImprove clippingThe structure is novel, reasonable and simpleRotary stirring mixersAgricultural engineeringFast flow

The present invention discloses one kind of paddle type mixing machine in the field of mixing machinery. There are machine body; stirring barrel set on the machine body; rotor comprising rotating shaft inside the stirring barrel, brace bar on the shaft and paddles fixed in the fast flow area; and characterized transition area stirring part set on the shaft and in the slow flow area. The transition area stirring part may be installed directly on the rotating shaft, on the middle section of the brace bar, or on the support column on the rotating shaft. The present invention has novel structure, simple manufacture process and low cost, and is suitable for both single shaft paddle mixing machine and double shaft paddle mixing machine.

Owner:JIANGSU MUYANG GRP CO LTD

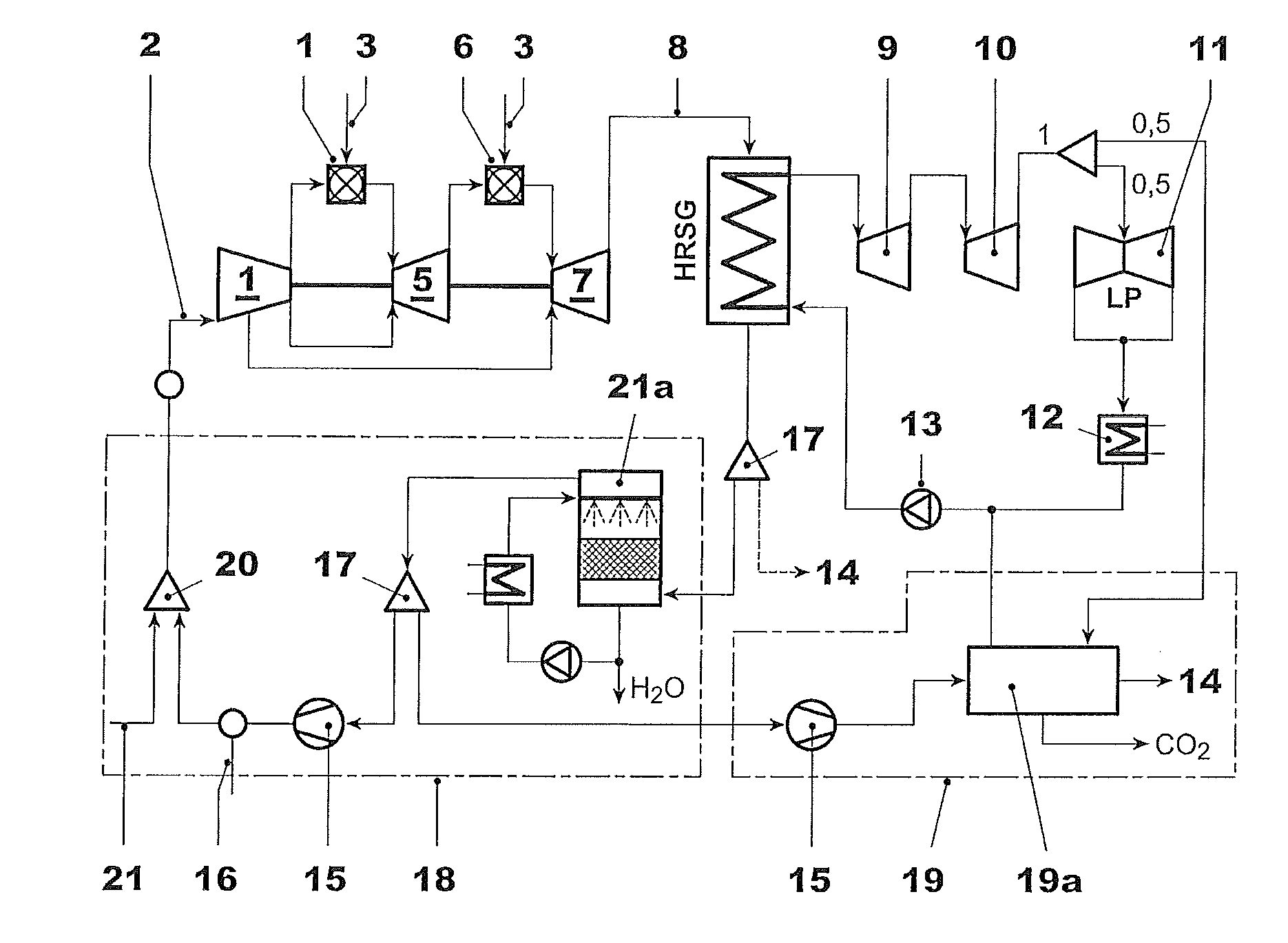

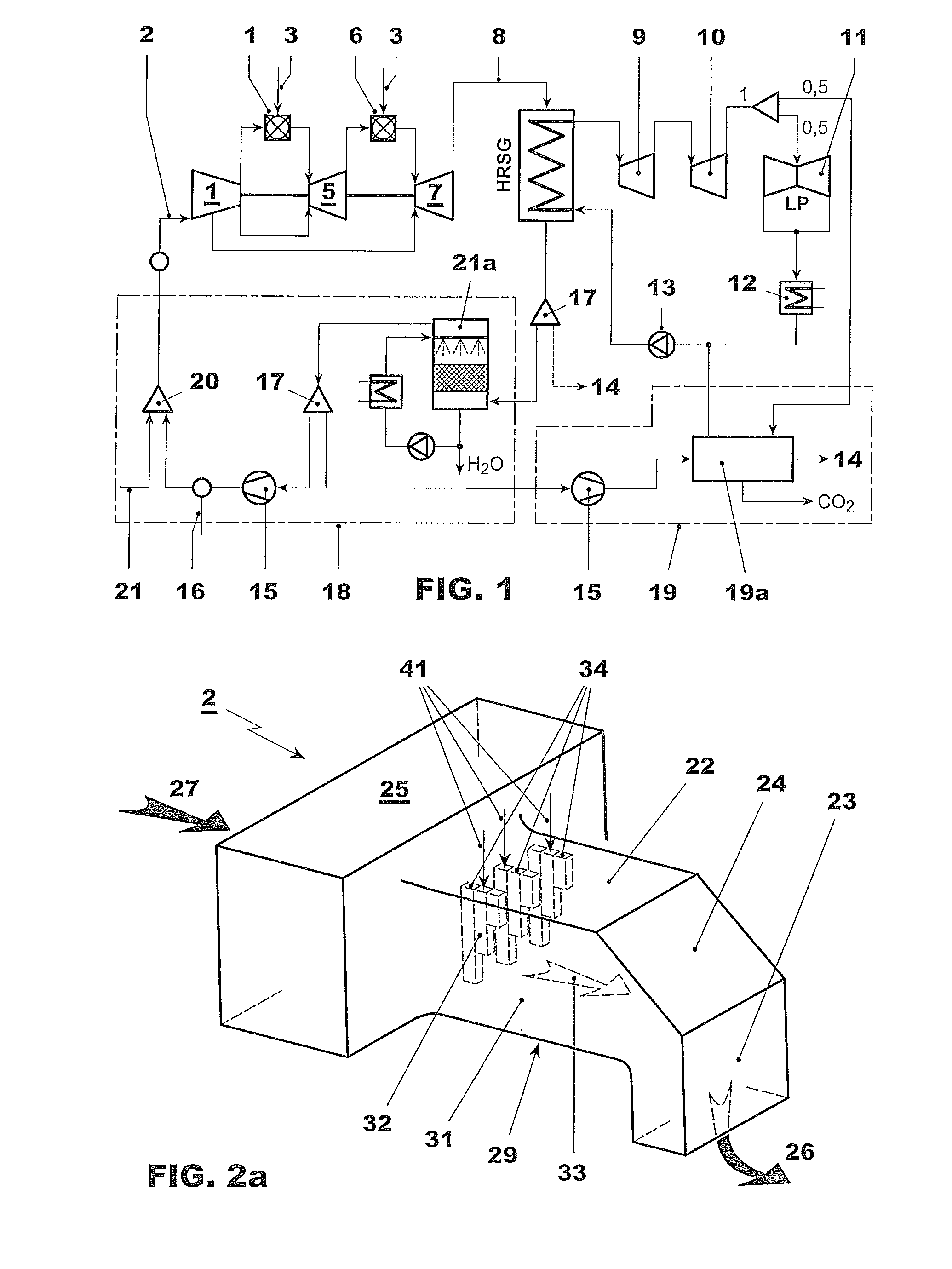

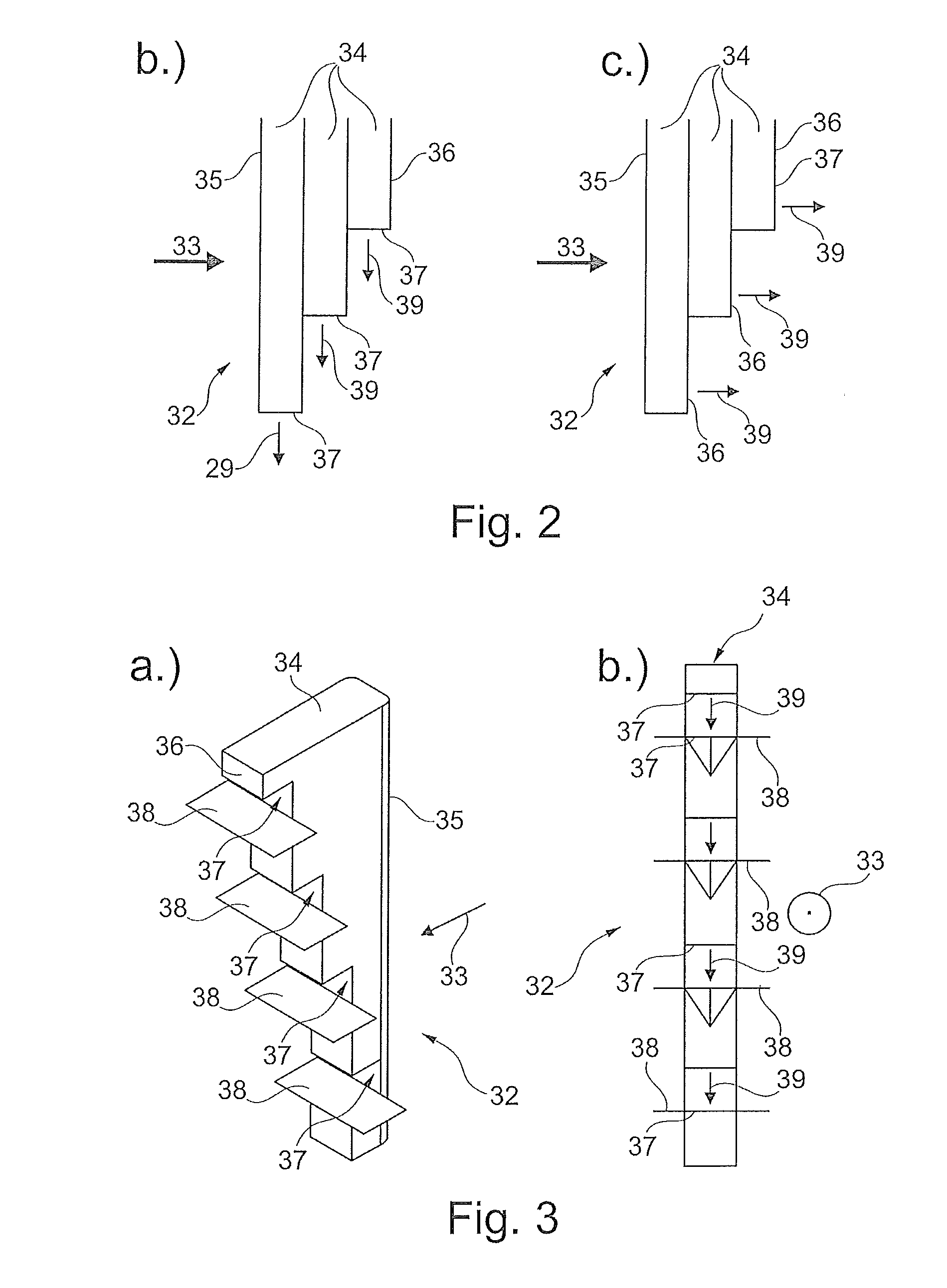

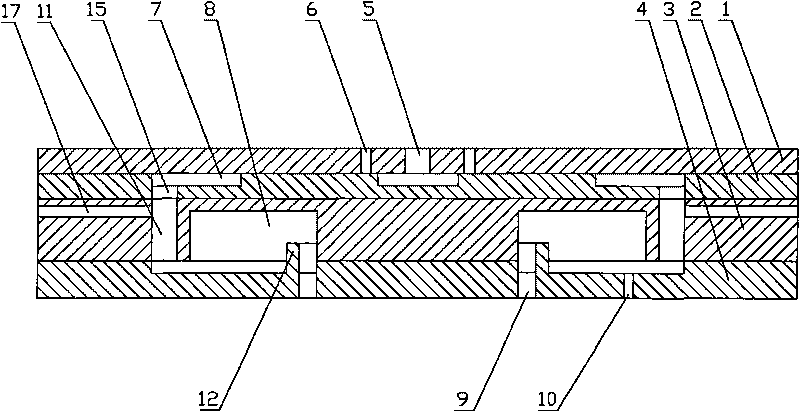

Mixing element for gas turbine units with flue gas recirculation

ActiveUS20130305732A1Improve mix qualitySmall pressure lossFlow mixersTransportation and packagingFlueAirflow

The invention pertains to fluegas recirculation in gas turbines, and specifically to an intake section upstream of the inlet of a compressor of a gas turbine unit with fluegas recirculation. The intake section includes at least one section with a flow path defined by sidewalls in which the fresh airflow of the intake air is flowing along a principal airflow direction, including at least one mixing duct extending into the flow path from at least one sidewall. The mixing duct includes an intake at the at least one sidewall for receiving recirculated fluegas, as well as including at least one outlet opening distanced from said sidewall for blowing recirculated fluegas out of the mixing duct into the airflow.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Magnesia carbon brick and preparation method thereof

The invention relates to a magnesia carbon brick and a preparation method thereof. The magnesia carbon brick is prepared from, by weight, 60%-75% of fused magnesite particles, 10%-30% of fused magnesite fine powder, 5%-10% of carbon, 1%-5% of an antioxidant, 1%-3% of a binding agent and 0.4%-1% of furfural waste liquid. In the preparation process, the fused magnesite particles are placed in a mixing mill to be dry-mixed for 2-15 min, then phenolic resin and the furfural waste liquid are added to continue to be mixed for 5-15 min, then carbon is added to the mixture, mixing is carried out for 5-15 min, finally the fused magnesite fine powder and the antioxidant are added to continue to be mixed for 8-15 min, pug is formed, the rotating speed of the mixing mill is set to range from 950 r / min to 1,000 r / min, mixing time ranges from 10 min to 60 min, and the magnesia carbon brick is prepared after compression moulding and drying solidification. The preparation method is simple, the steps are easy to operate, the uniformity of mixed materials of the magnesia carbon brick is improved, the quality of the mixed materials of the magnesia carbon brick is improved, the labor intensity of workers is lowered, the use amount of phenolic resin is reduced, and due to the addition of the furfural waste liquid, the material mixing process is more even, and phenolic resin is prevented from being caked.

Owner:江苏苏嘉集团新材料有限公司

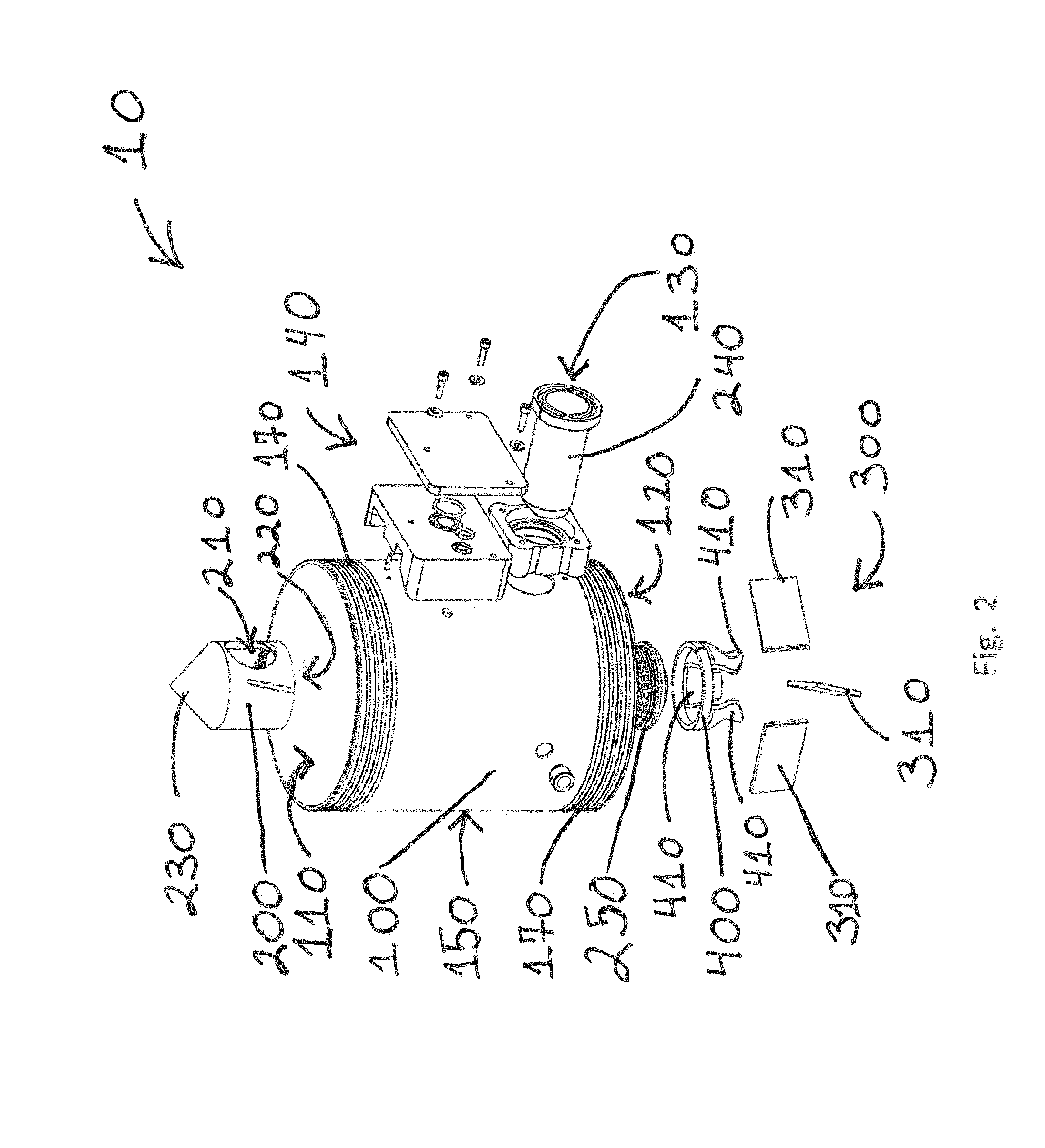

Mixing assembly

InactiveUS20160195050A1Increased turbulenceGood mixing propertiesInternal combustion piston enginesFlow mixersEngineeringInjector

An embodiment of a mixing assembly for mixing at least two fluids, comprises a housing and an injector body disposed concentrically therein, a vorticing element disposed about the injector body, and a compression element disposed about an outlet of the injector body. The housing is disposed for passage of a first fluid therethrough. The injector body being disposed within the housing and further disposed for the introduction of a second fluid within the flow path of the first fluid.

Owner:GREEN JASON E

Hydrocarbon fuel reforming combustion method for micro combustor and micro combustor

InactiveCN101737779AImprove combustion efficiencyImprove mix qualityHydrogenIndirect carbon-dioxide mitigationGaseous hydrocarbonProcess engineering

The invention discloses a hydrocarbon fuel reforming combustion method for a micro combustor, which comprises the following steps: firstly, introducing gaseous hydrocarbon fuel and wet air into a reforming area filled with a gamma-Al2O3 catalyst to produce coupling self-heating reforming reaction so as to generate partial hydrogen; and then introducing the gas after the reaction into a combustion cavity for combusting, wherein the volume ratio of the gaseous hydrocarbon fuel to the wet air is 1: 1.2-1: 1.6. Meanwhile, the invention also discloses a device for implementing the method. The front end of the combustion cavity is provided with the reforming area, the gaseous hydrocarbon fuel and the wet air are introduced into the reforming area, and the gaseous hydrocarbon fuel and the wet air undergo the coupling self-heating reforming reaction (comprising the oxidation reaction of the hydrocarbon fuel and the oxygen and the reforming reaction of the hydrocarbon fuel and the water vapor) under the action of the gamma-Al2O3 catalyst to generate partial hydrogen so as to aid the efficient and stable combustion of the gaseous hydrocarbon fuel and the air in a combustion area.

Owner:CHONGQING UNIV

Emulsion mixing stirrer for preparing nano new material

InactiveCN110124559AWell mixedAvoid stickingTransportation and packagingRotary stirring mixersEmulsionEngineering

The invention relates to the technical field of stirring equipment, and discloses an emulsion mixing stirrer for preparing a nano new material. The emulsion mixing stirrer comprises a stirring box; supporting legs are fixedly connected to four corners of the bottom of the stirring box; a matched scraping frame is slidably connected in the stirring box; a fixing plate is fixedly connected in the scraping frame; the top of the stirring box is fixedly connected with a driving motor through a support; the output end of the driving motor is fixedly connected with a reciprocating screw rod through acoupler; the other end of the reciprocating screw rod sequentially penetrates through the top of the stirring box and the fixing plate extends downwards; the reciprocating screw rod is rotationally connected with the top of the stirring box; the reciprocating screw rod is in threaded connection with the fixing plate; two rotating rods which are symmetrical relative to the position of the reciprocating screw rod are arranged in the stirring box; and the top end of each rotating rod penetrates through the top of the stirring box and extends upwards. According to the invention, mixing and stirring by the emulsion mixing stirrer for preparing the nano new material are more uniform, and the emulsion attached to the inner wall of the stirring box is convenient to clean.

Owner:马鞍山久特新材料科技有限公司

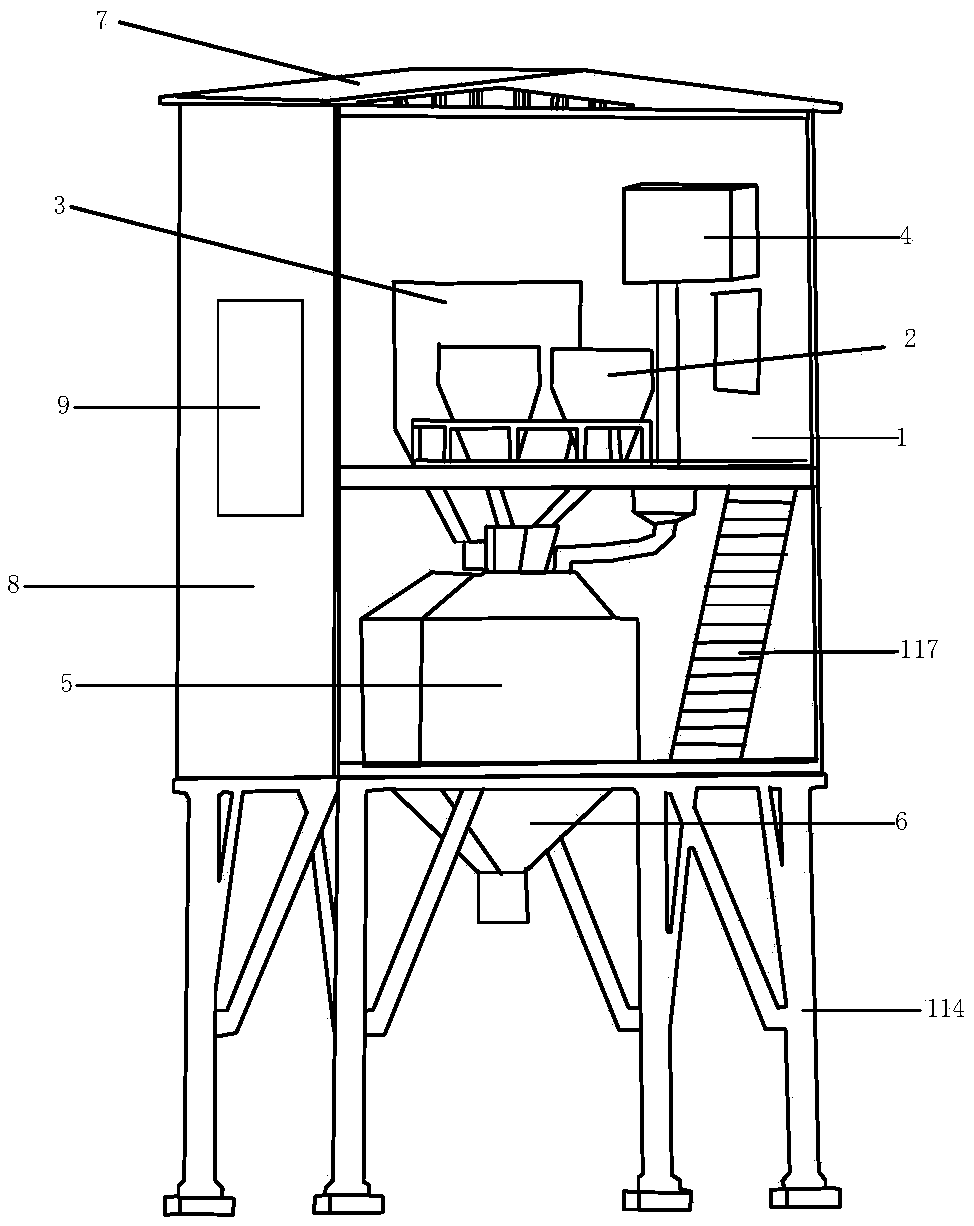

Concrete production equipment

PendingCN109352830APrevent deviationIncrease productivityMixing operation control apparatusIngredients weighing apparatusEquipment useEnergy consumption

The invention discloses concrete production equipment which comprises a concrete mixing station and a control system used for controlling the concrete mixing station. The concrete mixing station comprises a material preparation station used for supplying aggregate, a first conveyor used for transmitting aggregate, a powder tank used for storing powder and mixing equipment used for mixing, one endof the first conveyor is arranged below the material preparation station, the other end of the first conveyor is arranged on the mixing equipment, and the powder tank is connected with the mixing equipment. The control system comprises a master control module and a switch module connected with the master control module and used for controlling the concrete mixing station to be opened or closed, and the switch module is connected with the material preparation station, the first conveyor, the powder tank and the mixing equipment. The concrete production equipment has the advantages of being lowin energy consumption, high in yield, accurate in matching and convenient to control.

Owner:杭州德全建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com