Device and method for preparing nanometer ceramic particle-reinforced aluminum-based composite

A technology of nano-ceramic particles and aluminum-based reinforcement, which is applied in the field of devices for preparing metal matrix composite materials, can solve the problems of uneven distribution of nano-ceramic particles, long preparation process routes, and many equipment, so as to eliminate agglomeration defects and improve stirring quality. , the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

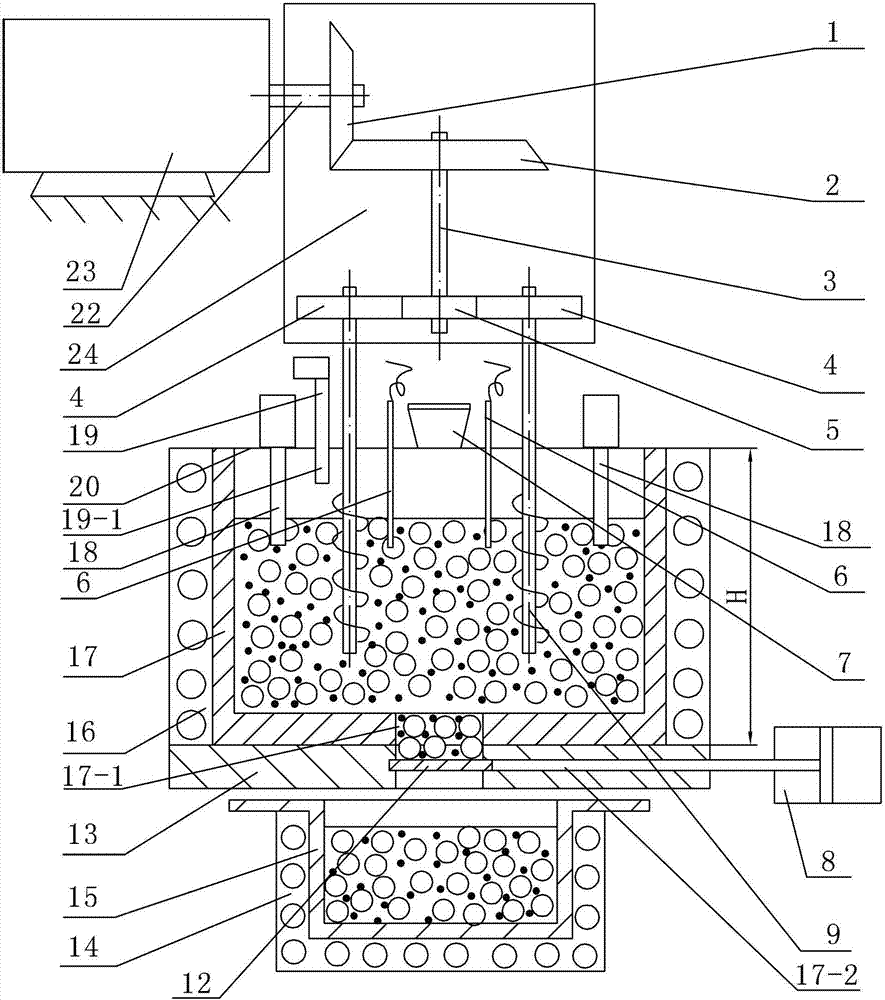

[0018] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a device for preparing nano-ceramic particle-reinforced aluminum matrix composites in this embodiment includes a motor 23, a first gear shaft 22, a gear box 24, a hopper 7, a baffle 12, a heating pad 13, a second A heating device 14, a slurry collection tank 15, a second heating device 16, a crucible 17, a cover plate 20, a hydraulic drive device 8, an argon protection device 19, two temperature measuring elements 6, two screw type stirring paddles 9 and Two ultrasonic devices 18, the crucible 17 is cylindrical, the gear box 24 has an input end and two output ends, the first gear shaft 22 is installed on the input end of the gear box 24, and the output end of the motor 23 Connected with the first gear shaft 22, the two output ends of the gear box 24 are respectively connected with screw-type stirring paddles 9, and the stirring end of the screw-type stirring paddles 9 extends into the cruc...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1Describe this embodiment, the gearbox 24 in this embodiment includes a first bevel gear 1, a second bevel gear 2, a second gear shaft 3, a first spur gear 5 and two second spur gears 4, the first bevel gear 1 is installed on the first gear shaft 22, the first bevel gear 1 meshes with the second bevel gear 2, the second gear shaft 3 is vertically arranged, the second bevel gear 2 is installed on the upper end of the second gear shaft 3, the first bevel gear The gear 5 is installed on the lower end of the second gear shaft 3, and the first spur gear 5 meshes with the two second spur gears 4, and the two second spur gears 4 are respectively equipped with screw-type stirring paddles 9. Such setting has simple structure and reasonable design, which is convenient for stirring by screw-type stirring paddle and has good stirring effect. The motor realizes two-stage deceleration through bevel gear and spur gear, which meets t...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 Describe this embodiment, the hopper 7 described in this embodiment is a truncated cone, the diameter of the lower end of the hopper 7 is smaller than the diameter of the upper end, the intersection angle between the busbar of the hopper 7 and the center line is 22.5°, and the height of the hopper 7 is 180mm. With such setting, the design is reasonable, it is convenient for feeding and pouring, and it meets the design requirements and actual needs. Others are the same as in the first embodiment.

[0022] Specific implementation mode four: combination figure 1 This embodiment will be described. The two temperature measuring elements 6 described in this embodiment are both thermocouples. With this setting, the temperature measurement efficiency is high, the temperature measurement range is large, and materials higher than 200°C can be measured. One thermocouple in this embodiment is used for temperature signal fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Total height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com