Patents

Literature

51results about How to "Eliminate delamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

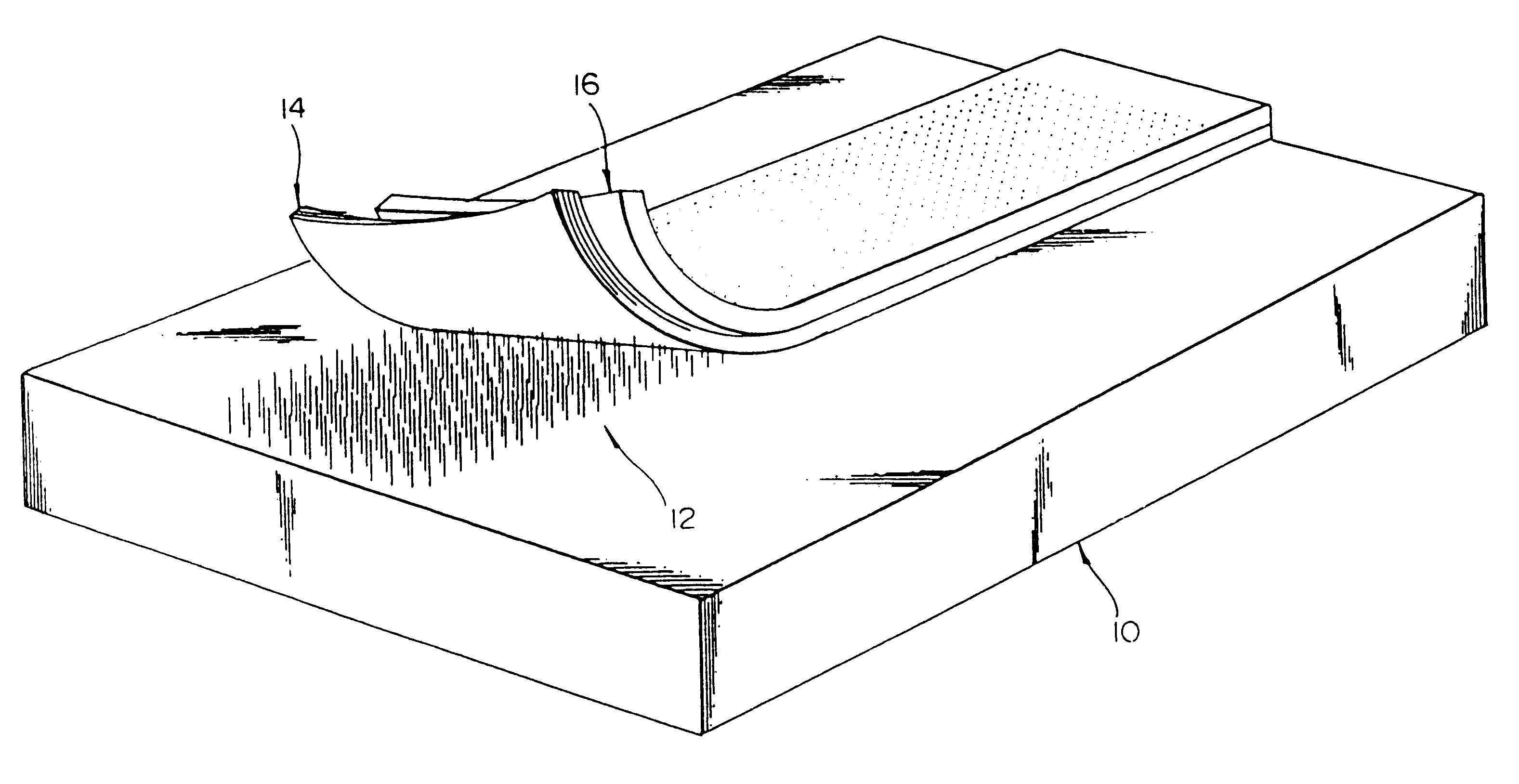

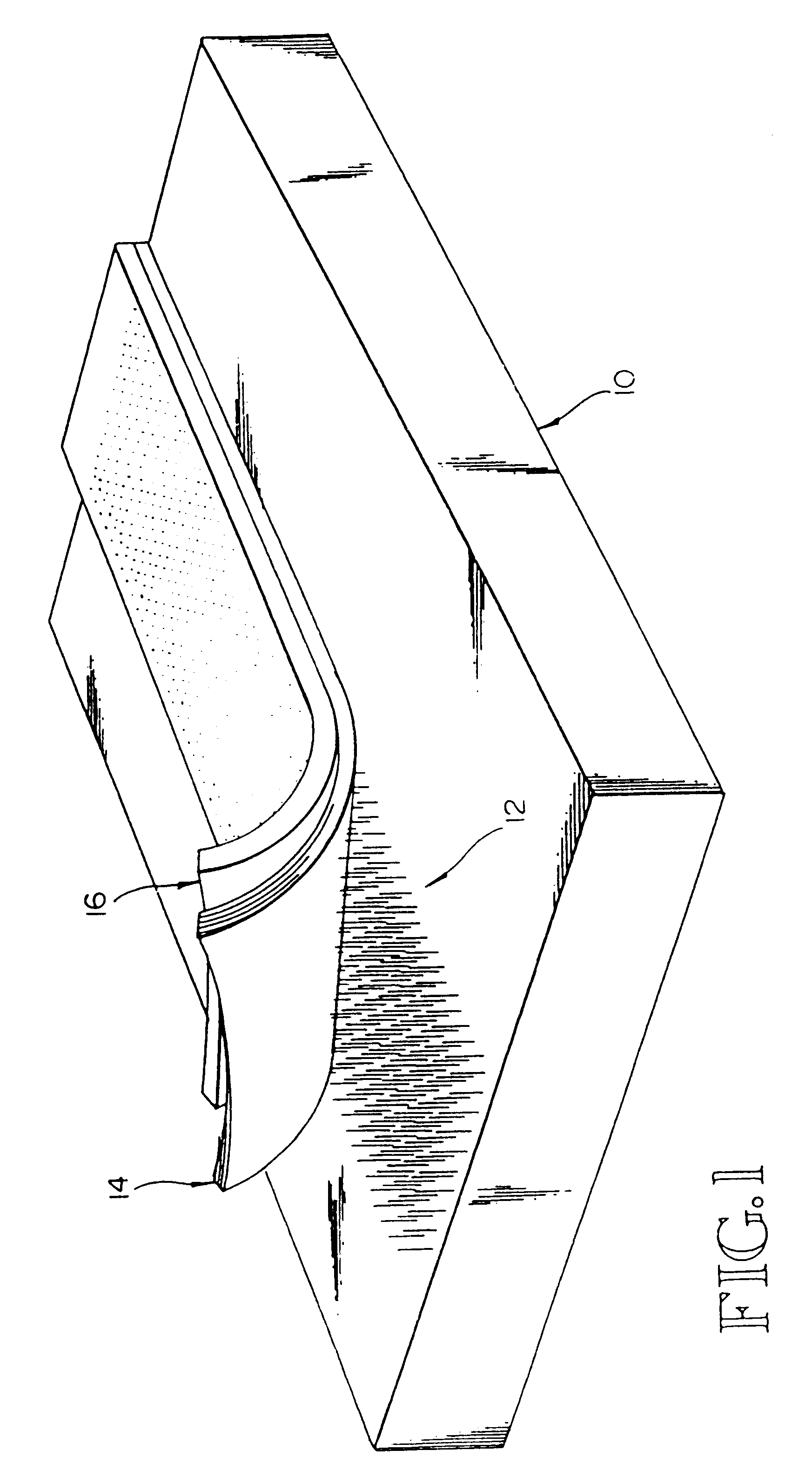

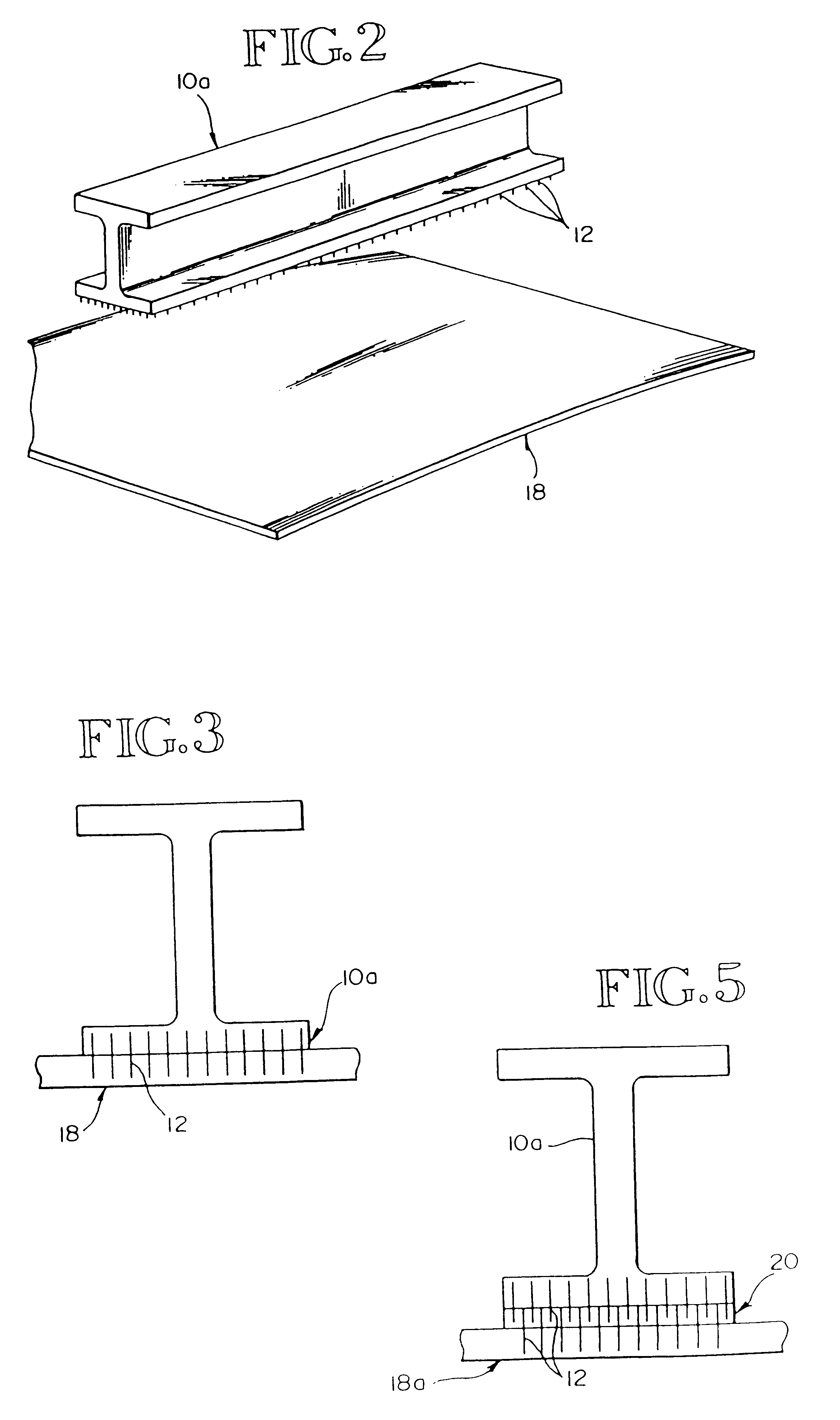

Composites joined with z-pin reinforcement

InactiveUS6436507B1Easy to manufactureLasting shelf-lifeFuselage framesLayered productsEngineeringBond line

Prefabricated composite detail parts use precured strips that include Z-pin reinforcement along the bond line. Each strip has Z-pin stubble protruding from opposed faces so that the pins are embedded into the detail parts when the joint forms.

Owner:THE BOEING CO

Lignosulfonate series air entraining and water reducing admixture for concrete and its prepn process and application

The present invention relates to preparation process of serial lignosulfonate air entraining and water reducing admixtures for concrete. The preparation process includes the following steps: dissolving solid lignosulfonate in water of the same weight, adding catalyst and oxidant, heating after reaction, adding amine and partial aldehyde to aminate, and dropping the rest aldehyde for condensation reaction to obtain the product; adding surfactant and polymer through stirring, and cooling to obtain liquid phase lignosulfonate as air entraining and water reducing admixture. The present invention is used as the admixture for concrete, and has relatively high water reducing rate, capacity of raising the strength of concrete, and certain setting retarding effect to delay the appearance of cement setting heat peak and reduce crack caused by temperature change.

Owner:SOUTH CHINA UNIV OF TECH

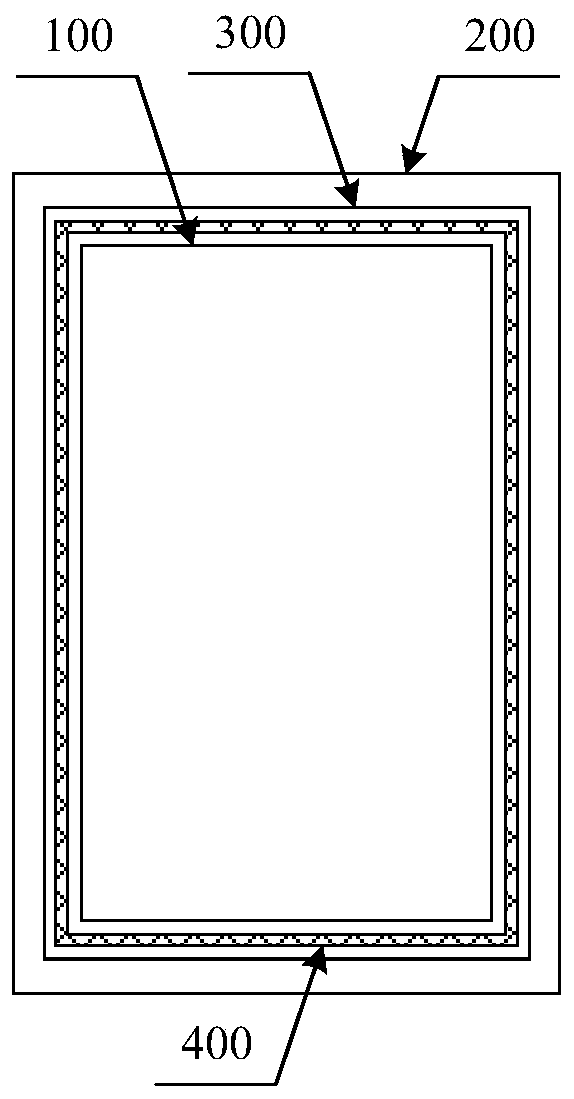

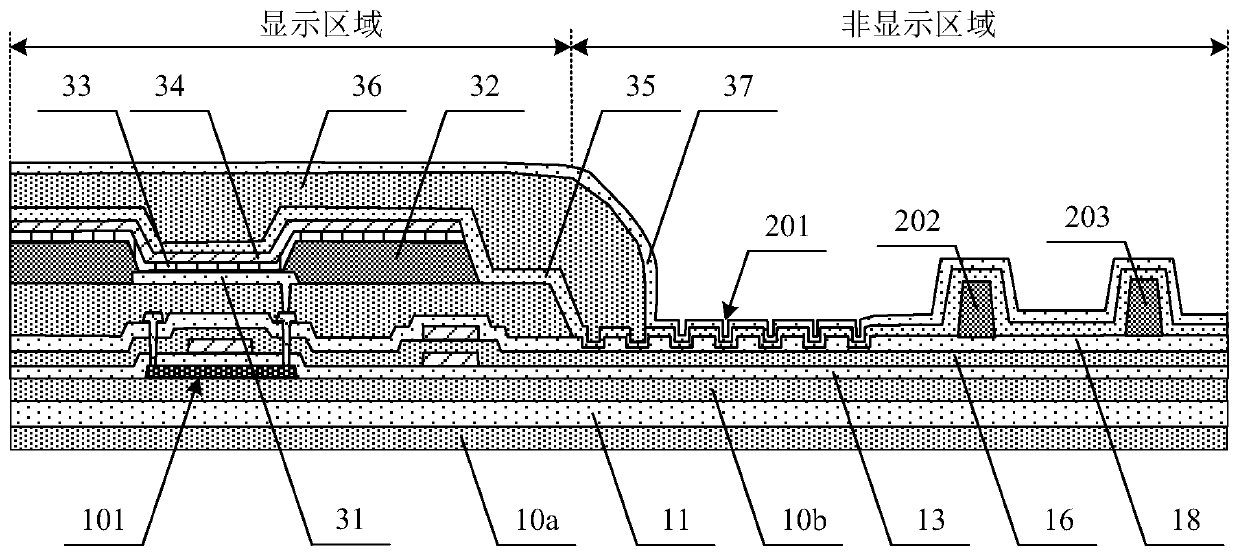

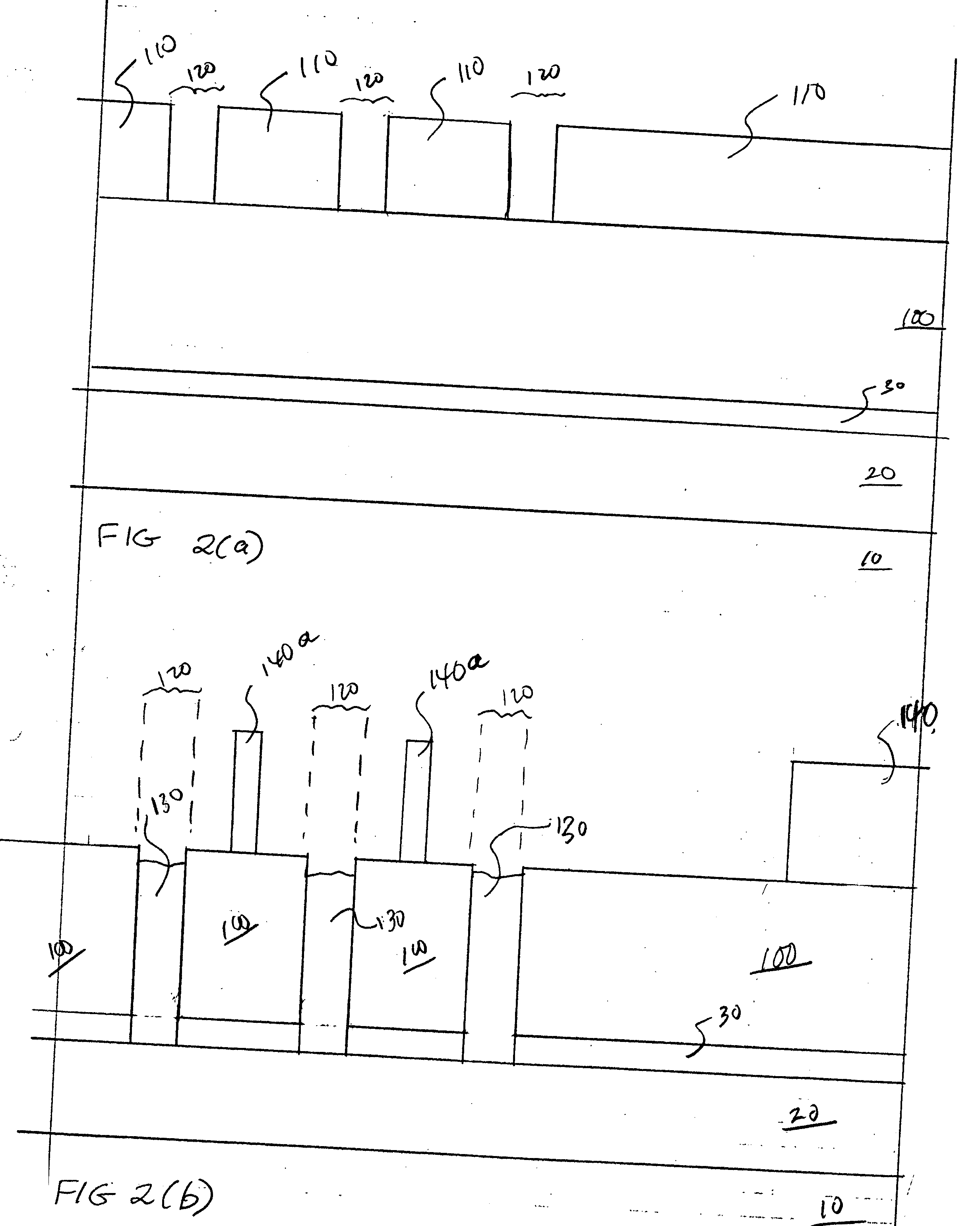

Display substrate, preparation method thereof, and display device

ActiveCN110120463AGuaranteed validityGuaranteed reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingConvex structureDisplay device

The invention provides a display substrate, a preparation method thereof, and a display device. The display substrate comprises a display area and a non-display area. The non-display area comprises afunctional layer, a retaining wall arranged on the functional layer, and an inorganic packaging layer covering the functional layer and the retaining wall. Between the display area and the retaining wall, the functional layer comprises a plurality of grooves arranged at intervals, so that a concave-convex structure is formed on the contact surface of the functional layer and the inorganic packaging layer. According to the invention, the plurality of grooves are formed in the area between the display area and the retaining wall at intervals, so a concave-convex structure is formed on the contact surface of the functional layer and the inorganic packaging layer, thereby increasing the bonding force of the film layer in the area, avoiding the delamination or cracking of an area between the display area and the retaining wall, avoiding a water and oxygen invasion path formed by delamination or cracking, and effectively guaranteeing the effectiveness and reliability of packaging. Moreover,the display substrate is low in manufacturing cost, is easy in process implementation and the like.

Owner:BOE TECH GRP CO LTD +1

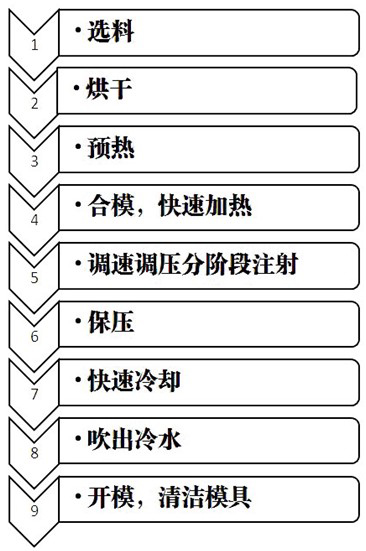

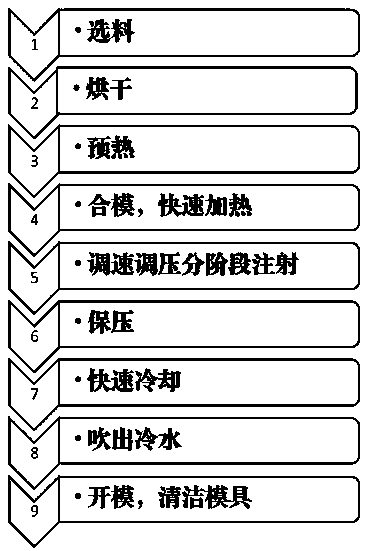

Steam type highlight and traceless injection-molding and forming process for complex precise product

The invention discloses a steam type highlight and traceless injection-molding and forming process for a complex precise product. The process sequentially comprises the following steps of: selecting raw materials, baking, pre-heating, combining a die, then quickly heating, adjusting speed and pressure, injecting in sections, maintaining the pressure, cooling quickly, blowing out cold air, opening the die and cleaning the die. An advanced pressure-regulation and speed-regulation staging injection process and an automatic blowing and impurity-removing technology are adopted in the invention. A special heating and cooling technology is that the shapes, the widths and the arrangement density of water passages are designed according to nonuniform heat and cold of the complex precise product in the injection-molding and forming course and the overall shape variation of the product. The steam type highlight and traceless injection-molding and forming process for the complex precise product has the advantages that the residual stress of the product is effectively decreased, various defects generated in the course of producing the plastic product are greatly reduced, the surface quality and the precision of the product are remarkably improved, and the life of the product is remarkably prolonged at the same time because the special process ensures heating and cooling rates of each part of the complex product in the injection-molding and forming course tend to be consistent.

Owner:海门市创豪工业设计有限公司

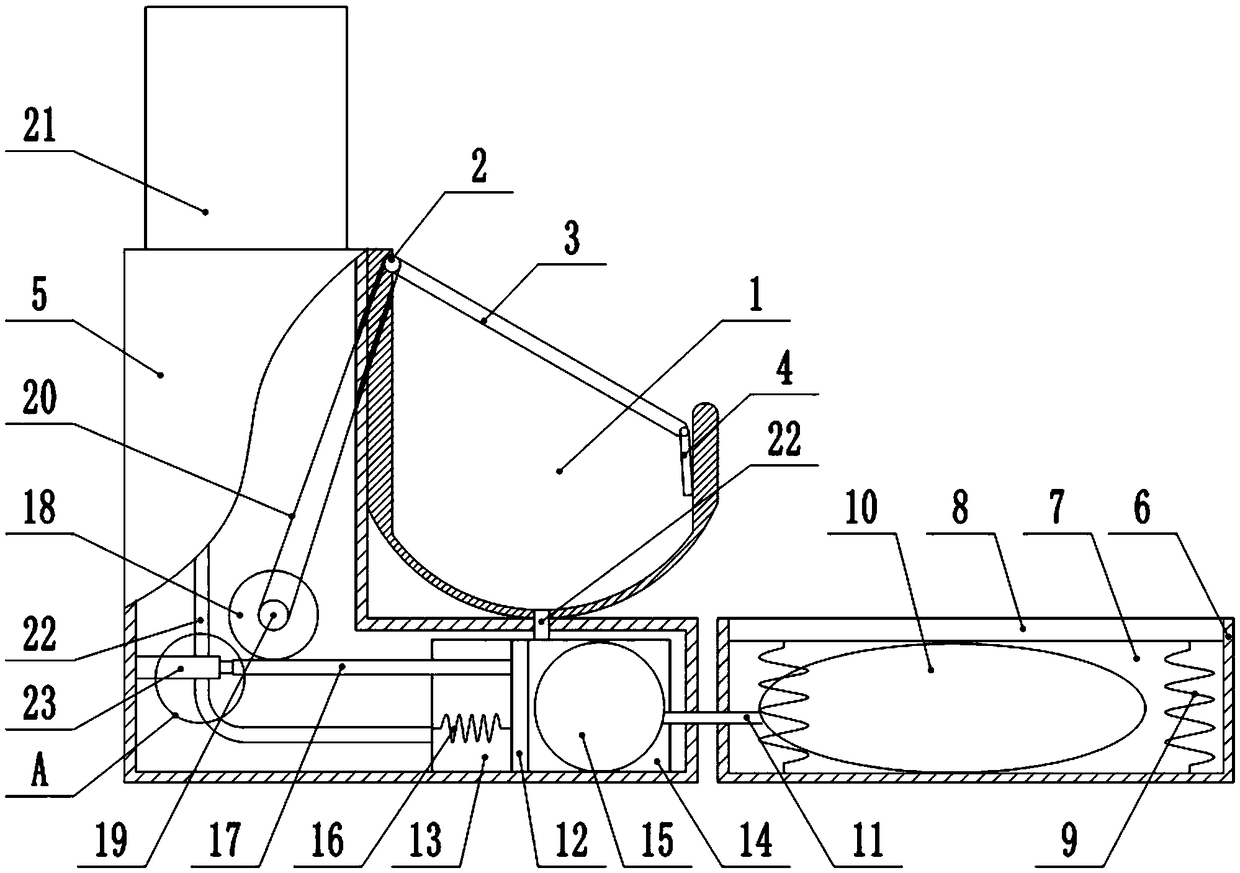

Composite component curing process and composite workpiece

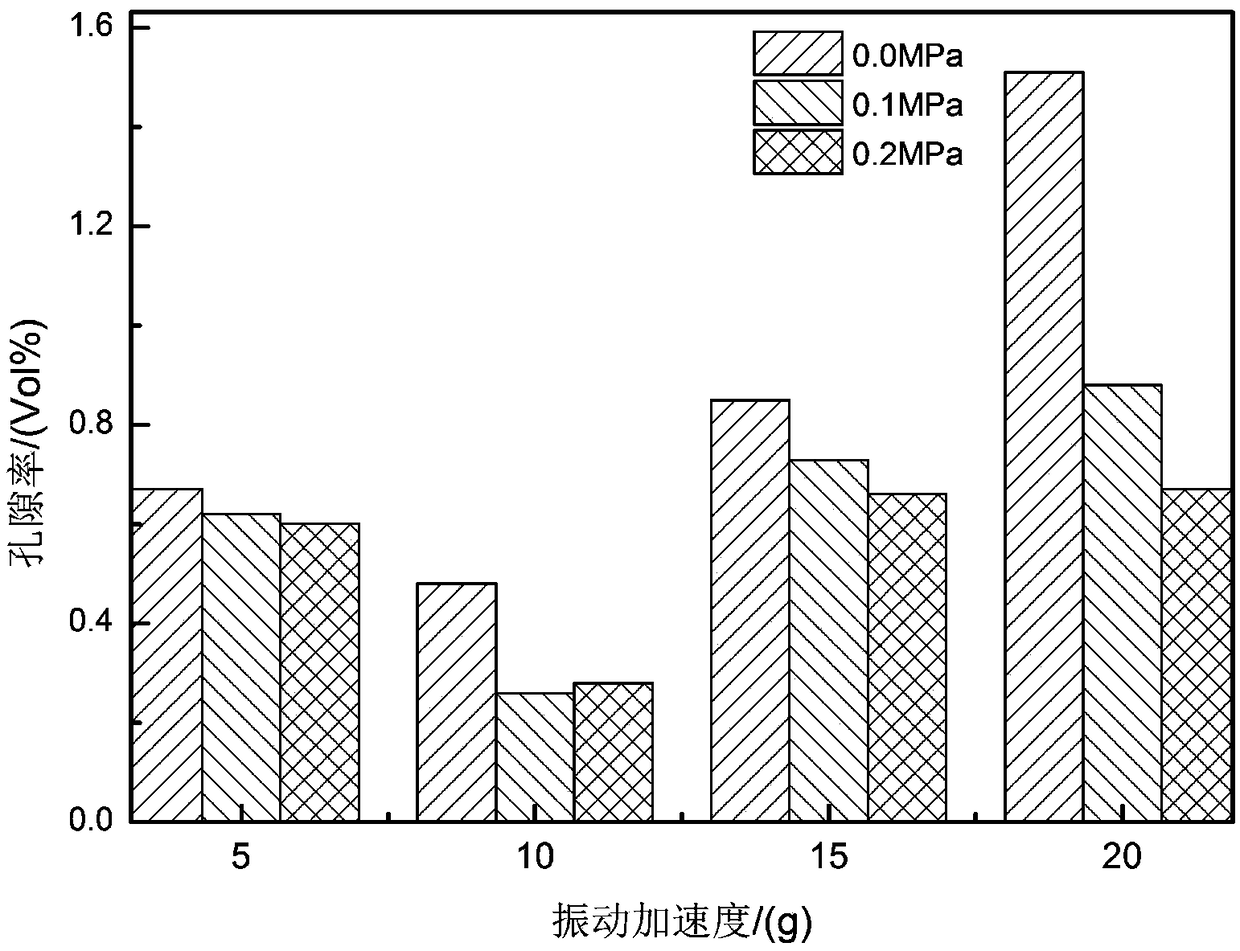

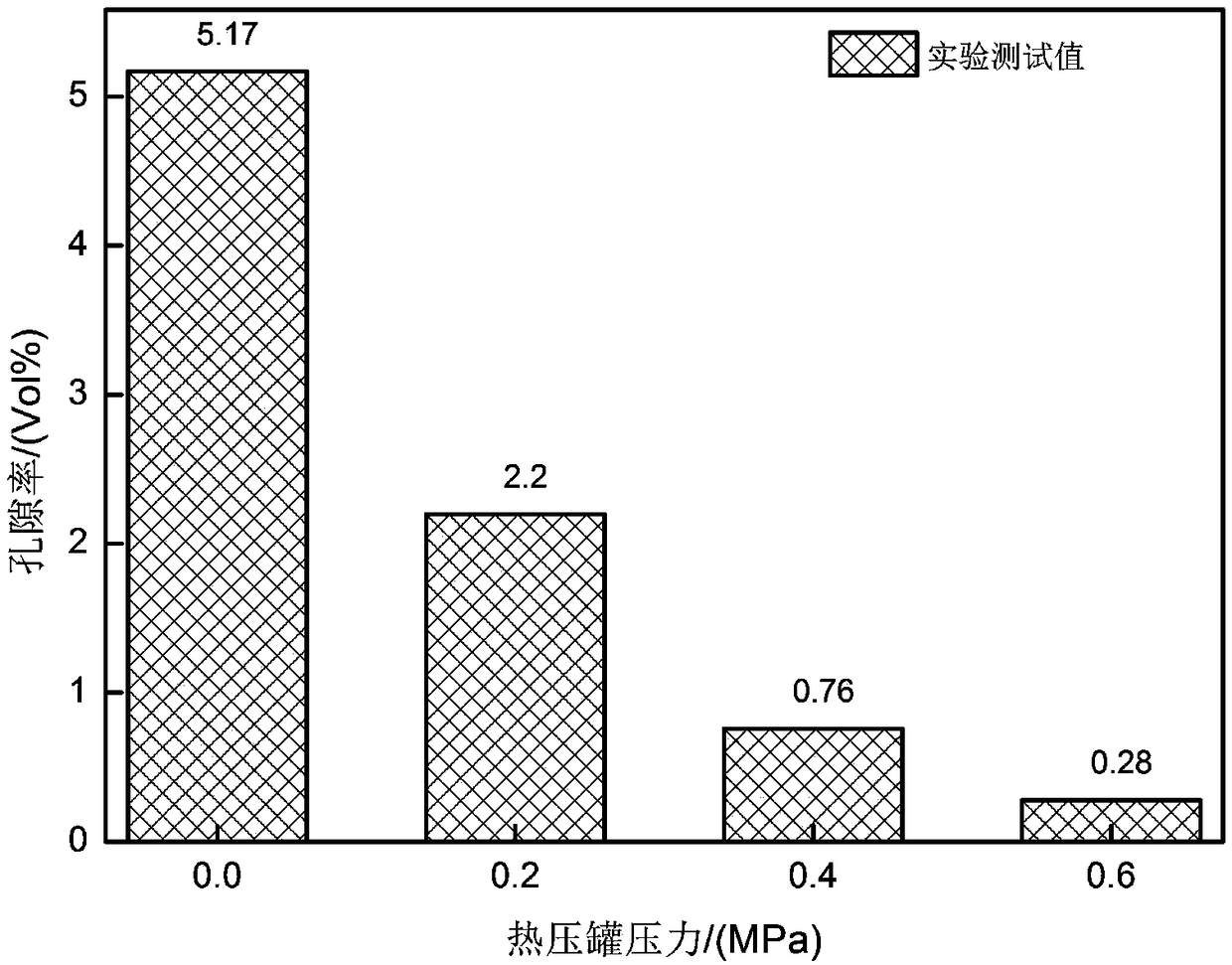

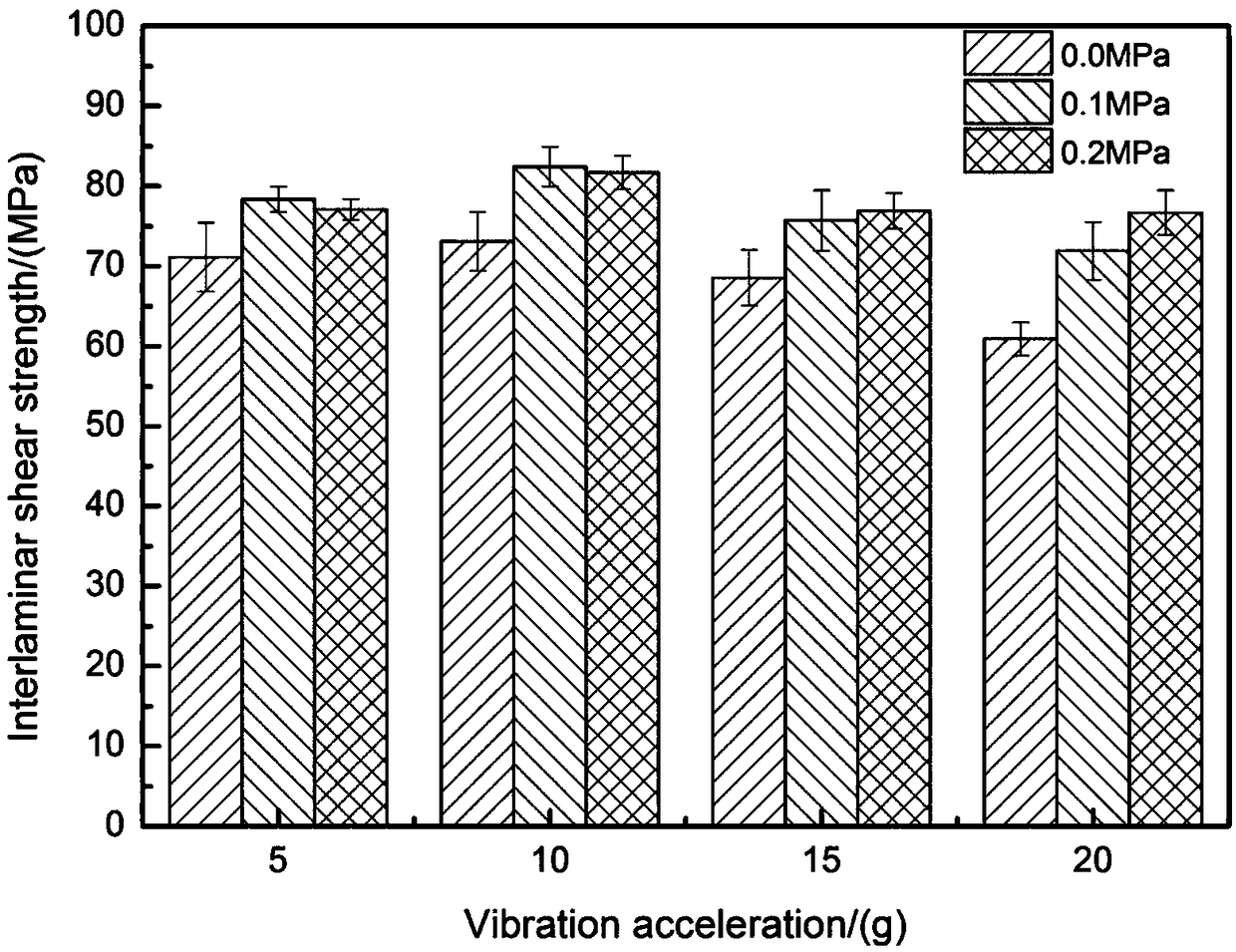

ActiveCN108839359AEliminate delaminationDecreased interlaminar shear performancePorosityEnergy analysis

The invention belongs to the field of materials, and relates to a composite component curing process and a composite workpiece. The composite component curing process comprises the following steps that (1) the to-be-processed composite workpiece is heated and subjected to heat preservation in a vibration experimental platform; (2) in the heating and heat preservation processes, the to-be-processedcomposite workpiece is vibrated through the vibration experimental platform; (3) after vibration is finished, the low pressure is applied to the to-be-processed composite workpiece through the vibration experimental platform; and (4) in the process of applying the low pressure, the to-be-processed composite workpiece is subjected to secondary temperature rise, and subsequent curing of the to-be-processed composite workpiece is completed. According to the composite component curing process, under the low curing pressure, the porosity of the composite workpiece can be significantly decreased, the performance of the composite workpiece can be significantly improved, and safe, efficient and energy-saving forming curing of the large composite workpiece can be achieved.

Owner:CENT SOUTH UNIV

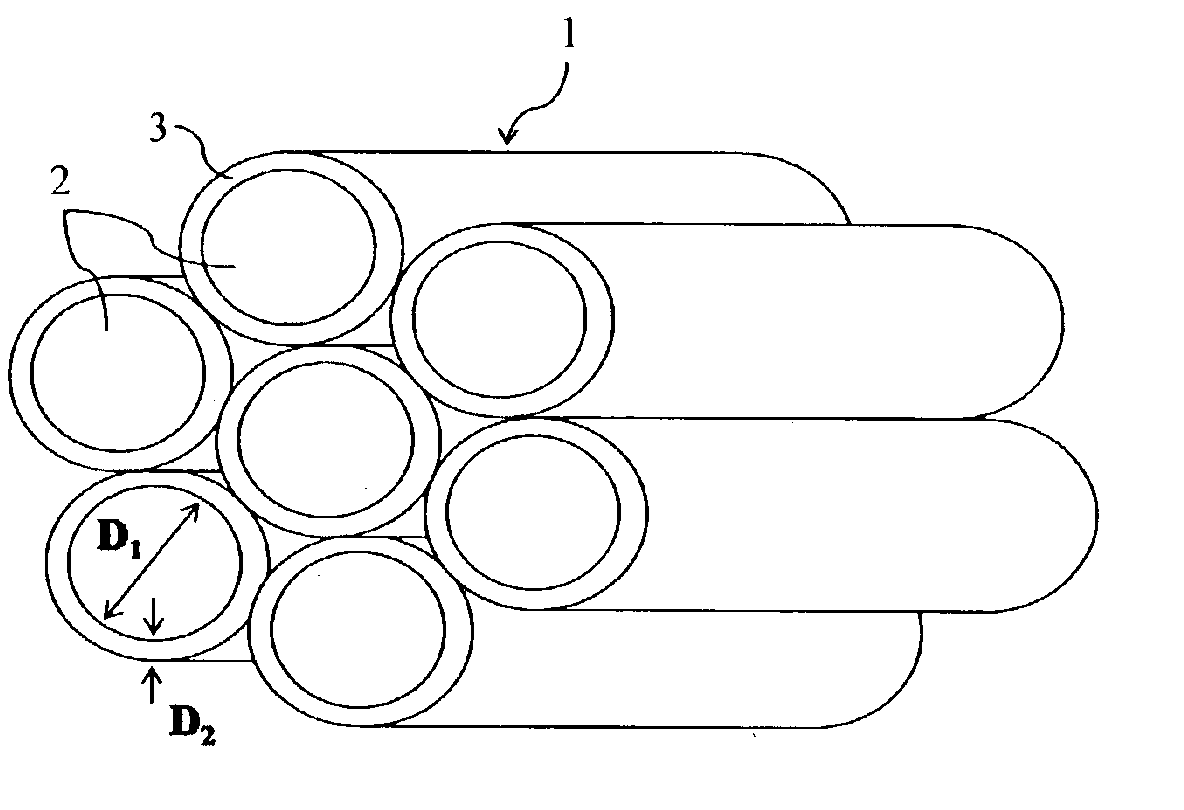

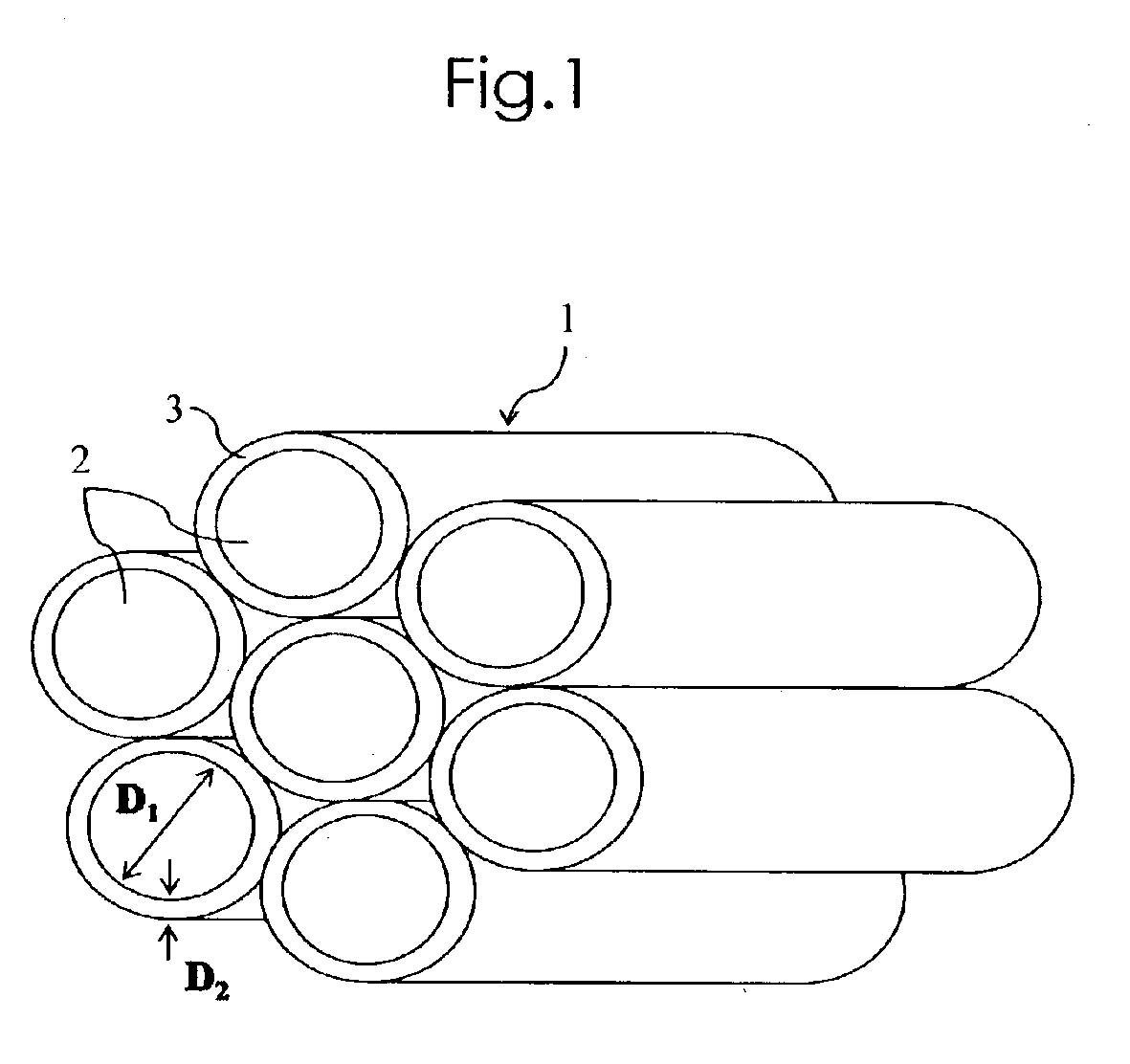

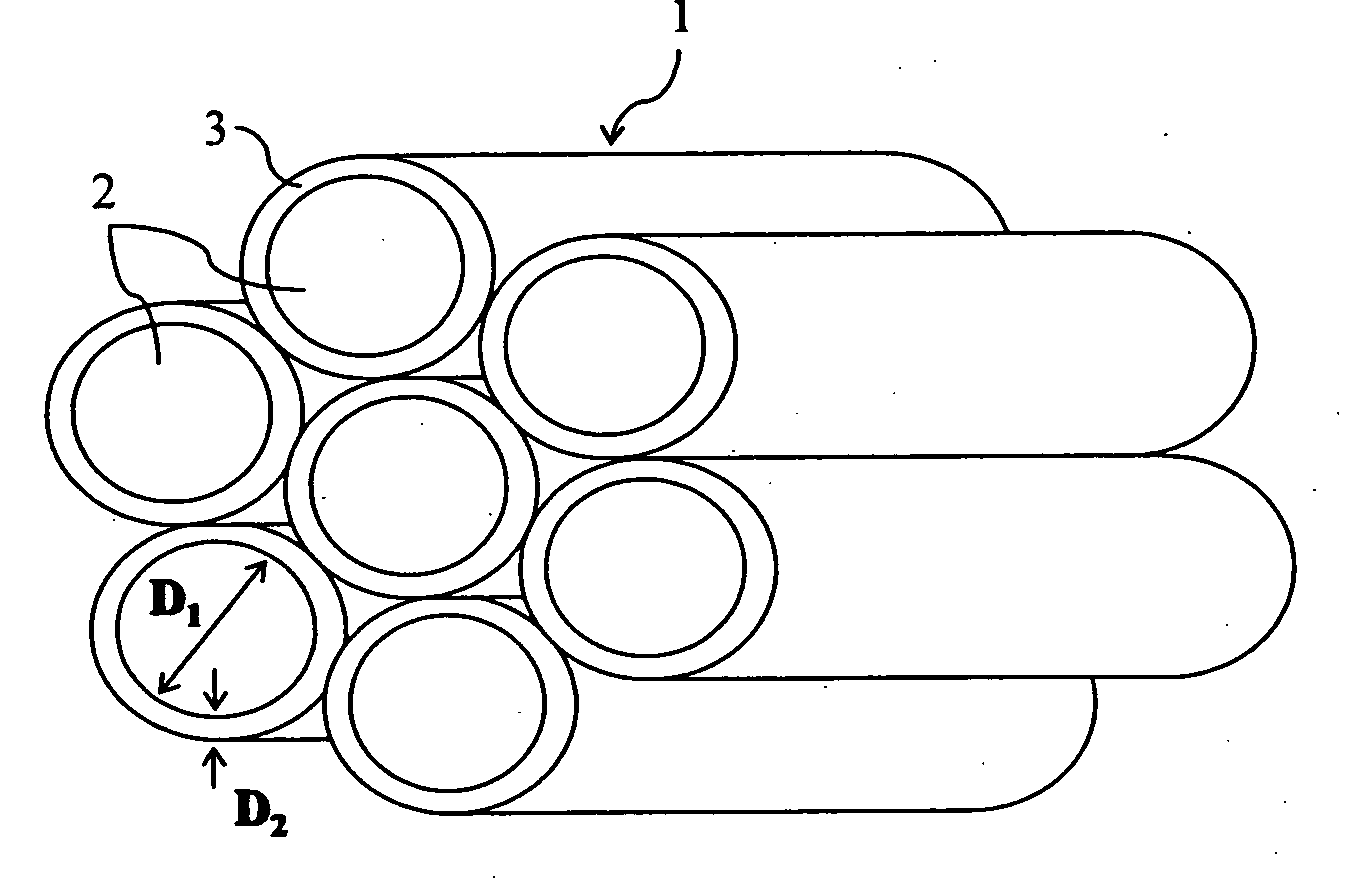

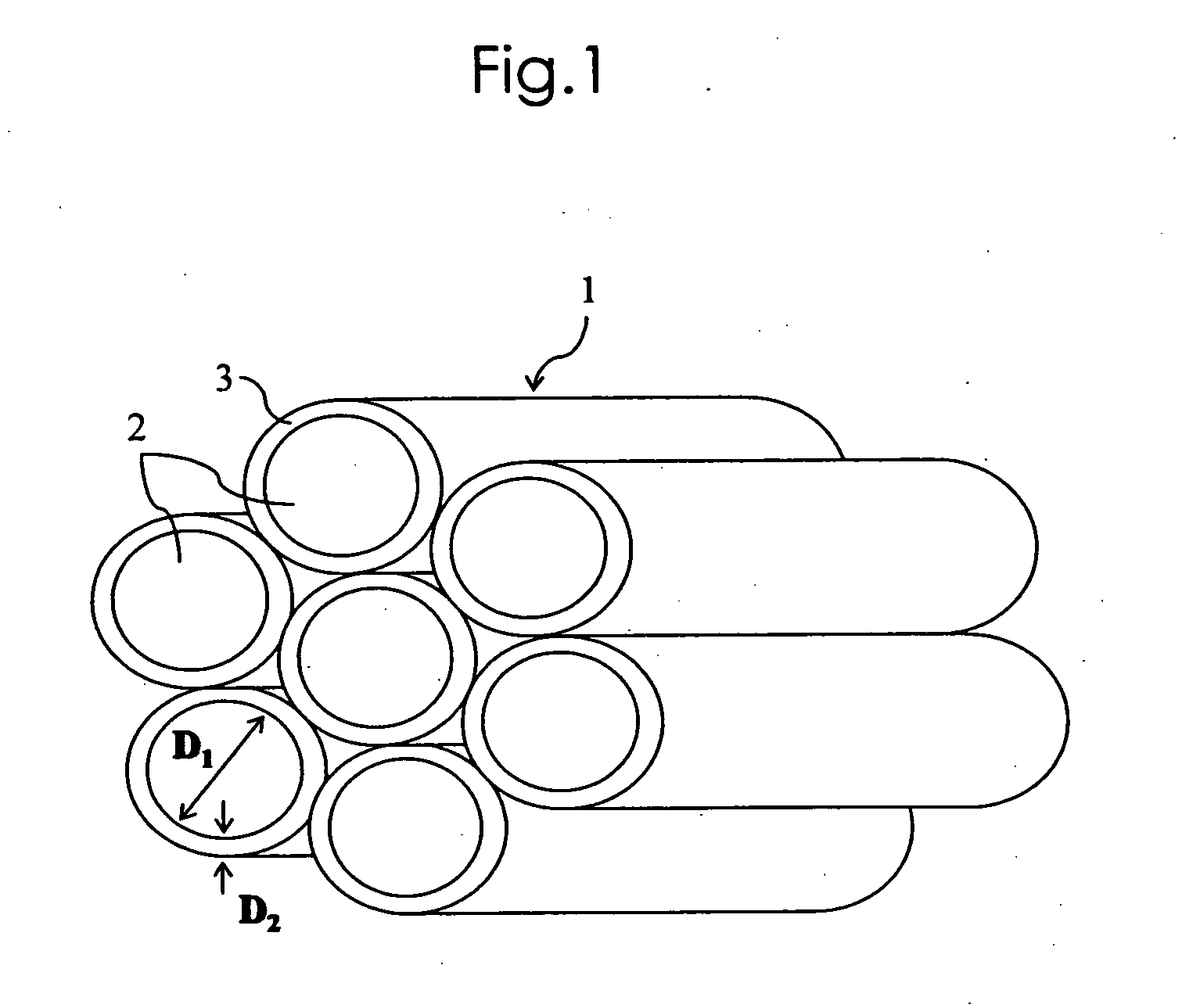

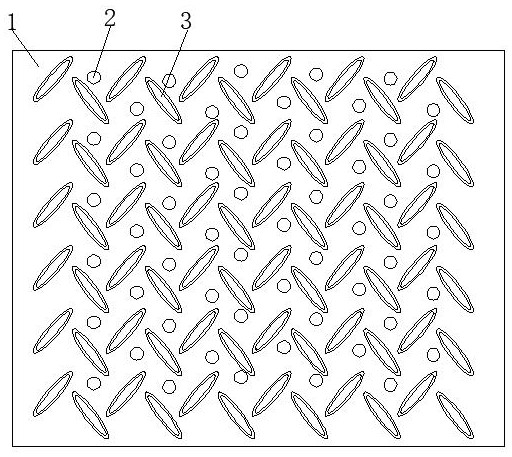

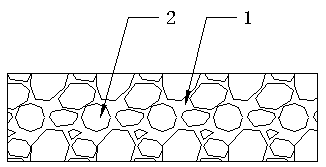

Composite construction and manufacturing method thereof

InactiveUS6878434B2High strengthHigh hardnessCeramic layered productsCoatingsComposite constructionCarbide

A composite construction 1 is obtained by coating the outer periphery of a core material 2 with a shell layer 3. The core material 2 is composed of a first sintered body that is obtained by bonding, with a binder metal, a first hard particle composed of one or more of carbides, nitrides and carbonitrides of metals of Groups 4a, 5a and 6a of the Periodic Table, or a first ceramics obtained by bonding, with a sintering additive, a first ceramic particle composed of at least one of oxides, carbides, nitrides and carbonitrides selected from the group consisting of metals of Groups 4a, 5a and 6a of the Periodic Table, Al, Si and Zn. The shell layer 3 is composed of a second hard sintered body or second ceramics having a different composition from the first hard sintered body. The ratio of the residual free carbon amount Cin in the core material 2 to the residual free carbon amount Cout in the shell layer 3, Cin / Cout, is 0.5 to 2. This prevents shrinkage during the time of sintering and also prevents the strength of the composite construction from lowering due to poor sintering.

Owner:KYOCERA CORP

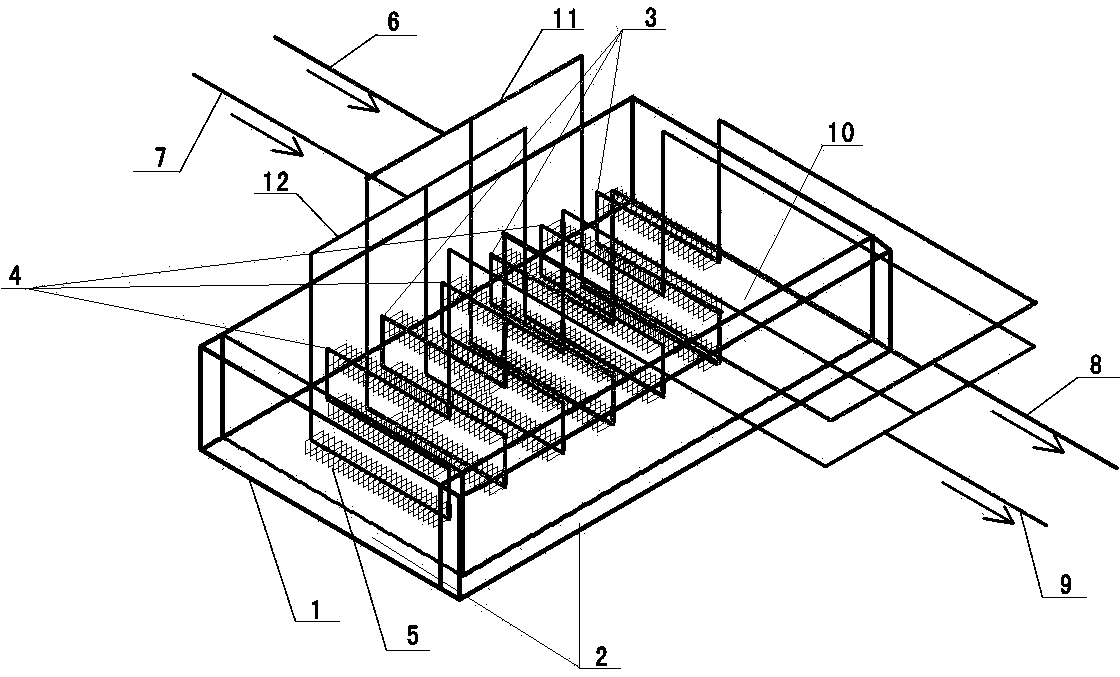

Low-temperature phase-change heat accumulator

InactiveCN103512415ALower phase transition temperatureLarge latent heat of phase changeHeat pumpsHeat storage plantsEvaporationEngineering

The invention provides a low-temperature phase-change heat accumulator which comprises a tank body and a snakelike metal pipe row. The snakelike metal pipe row is arranged in the tank body, metal fins are arranged on the snakelike metal pipe row in a sleeved mode at intervals, the snakelike metal pipe row comprises heat accumulation pipe row bodies and heat releasing pipe row bodies, the heat accumulation pipe row bodies and the heat releasing pipe row bodies are alternatively arranged, the heat accumulation pipe row bodies are connected with a heat accumulation refrigerant loop of a heat accumulation evaporation type air source heat pump through liquid inlet pipes and liquid outlet pipes of the heat accumulation pipe row bodies, the heat releasing pipe row bodies are connected with a heat releasing refrigerant loop of the heat accumulation evaporation type air source heat pump through liquid inlet pipes and liquid outlet pipes of the heat releasing pipe row bodies, the positions between the heat accumulation pipe row bodies and the liquid inlet pipes of the heat releasing pipe row bodies and between the heat accumulation pipe row bodies and the liquid outlet pipes of the heat releasing pipe row bodies are respectively provided with a heat accumulation header, the positions between the heat releasing pipe row bodies and the liquid inlet pipes of the heat releasing pipe row bodies and between the heat releasing pipe row bodies and the liquid outlet pipes of the heat releasing pipe row bodies are respectively provided with a heat releasing header, heat preservation materials are arranged in an interlayer of the tank body, and the interior of the tank body is filled with composite phase-change heat accumulation materials. The low-temperature phase-change heat accumulator is mainly used in an air source heat pump unit technological process, can serve as a heat accumulator or a subcooler or an auxiliary evaporator, and can carry out heat accumulation and heat releasing at the same time. The heat supply coefficients of a heat pump unit can be improved, and the operation performance of the air source heat pump unit in a low-temperature environment is remarkably improved.

Owner:TAIYUAN UNIV OF TECH +2

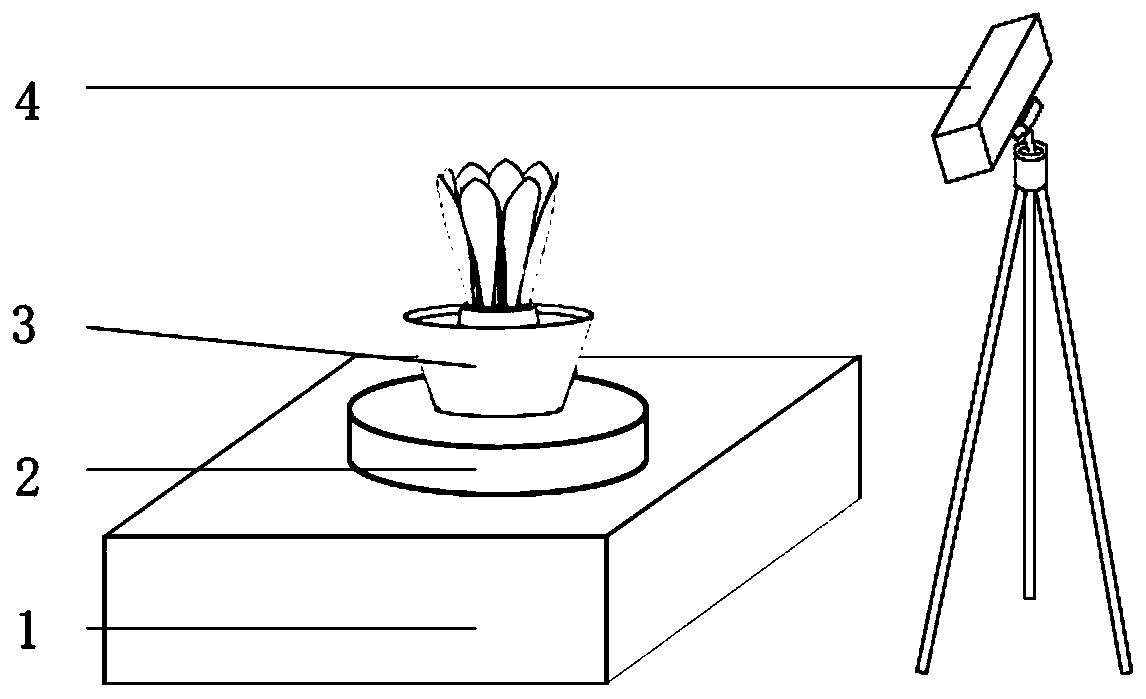

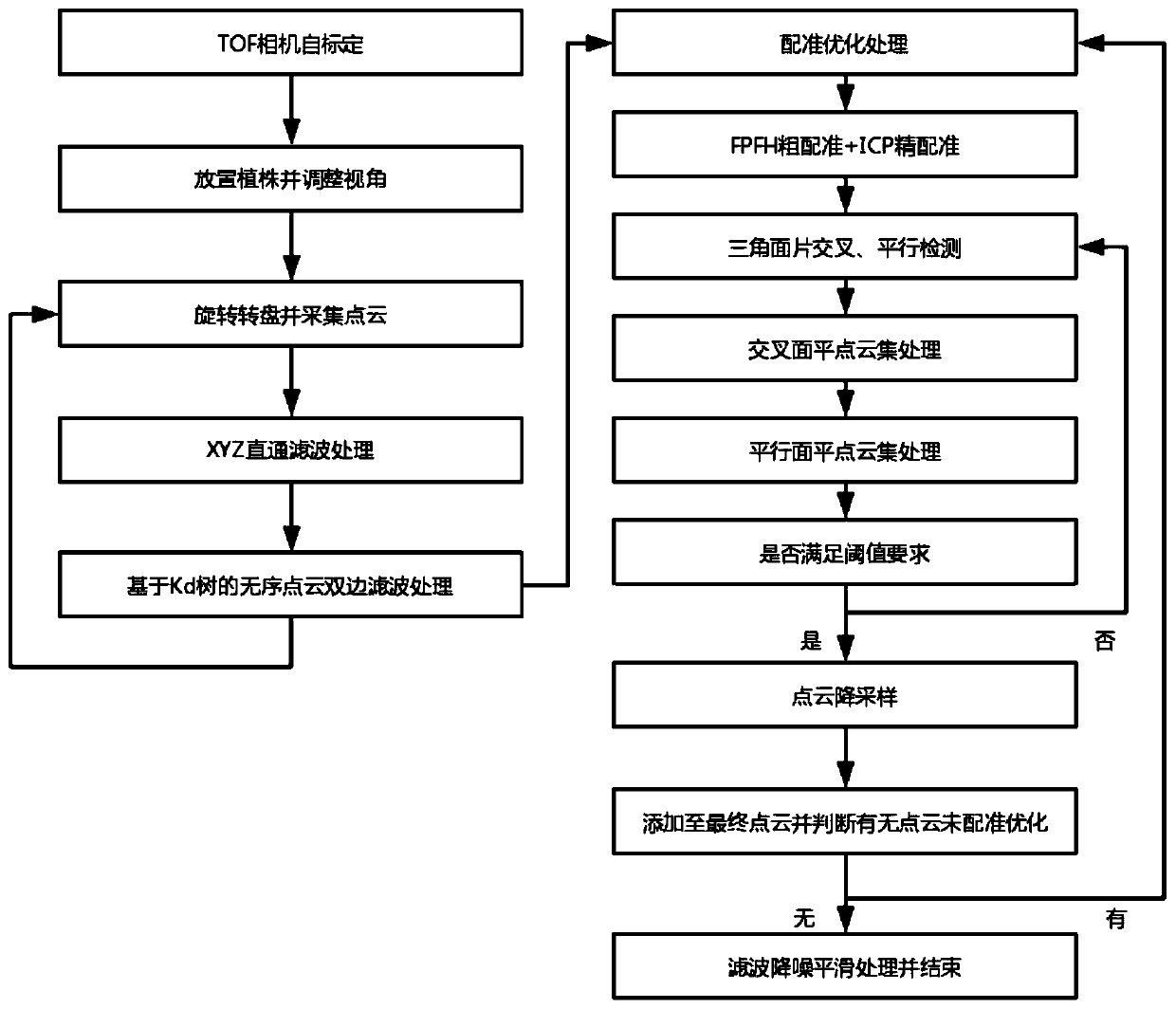

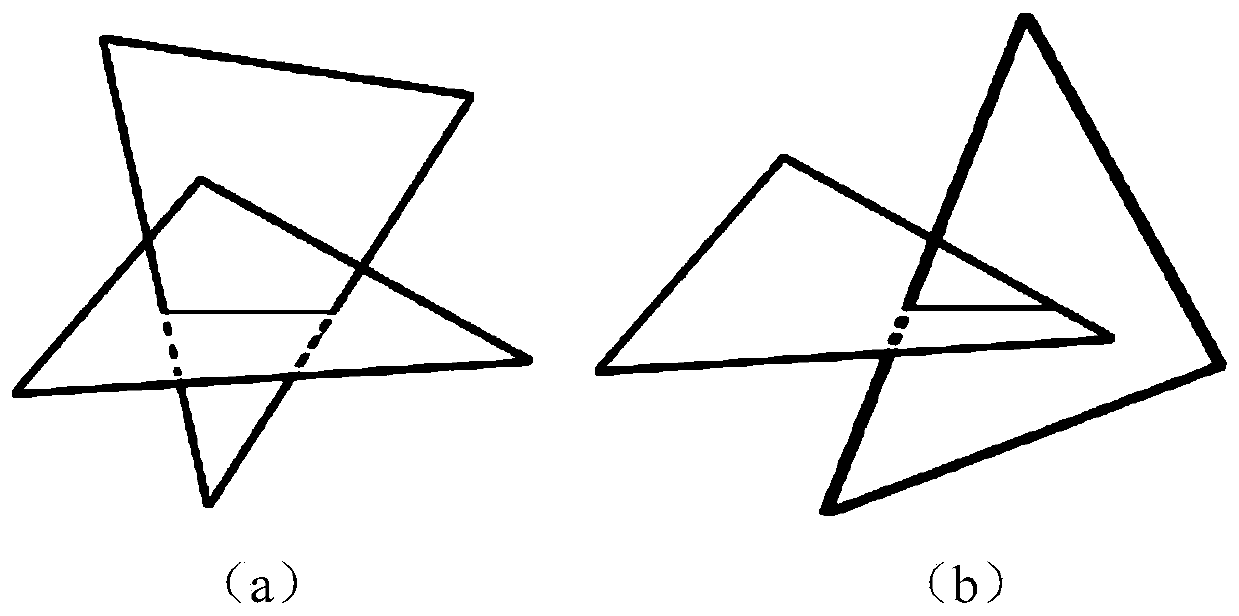

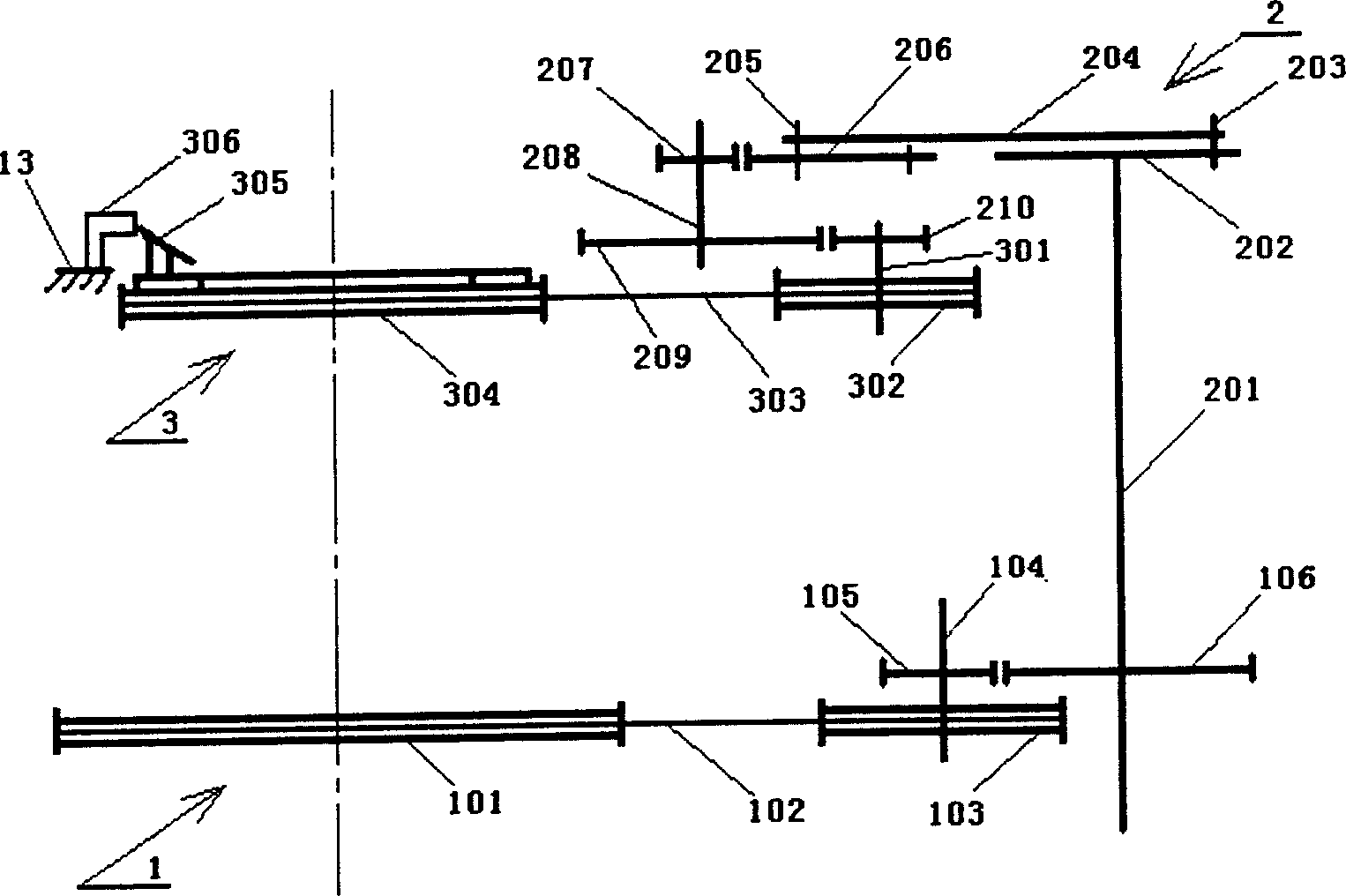

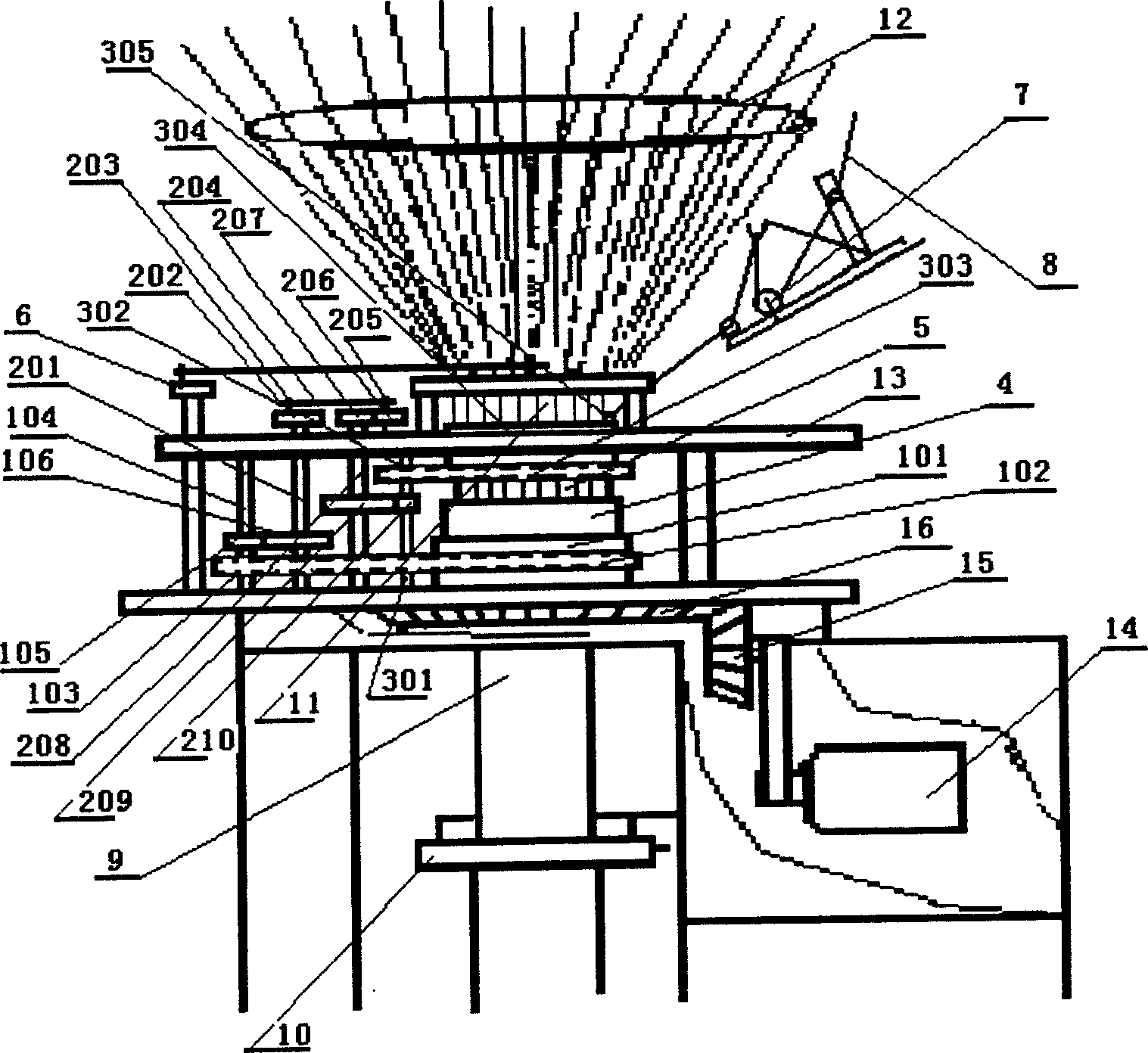

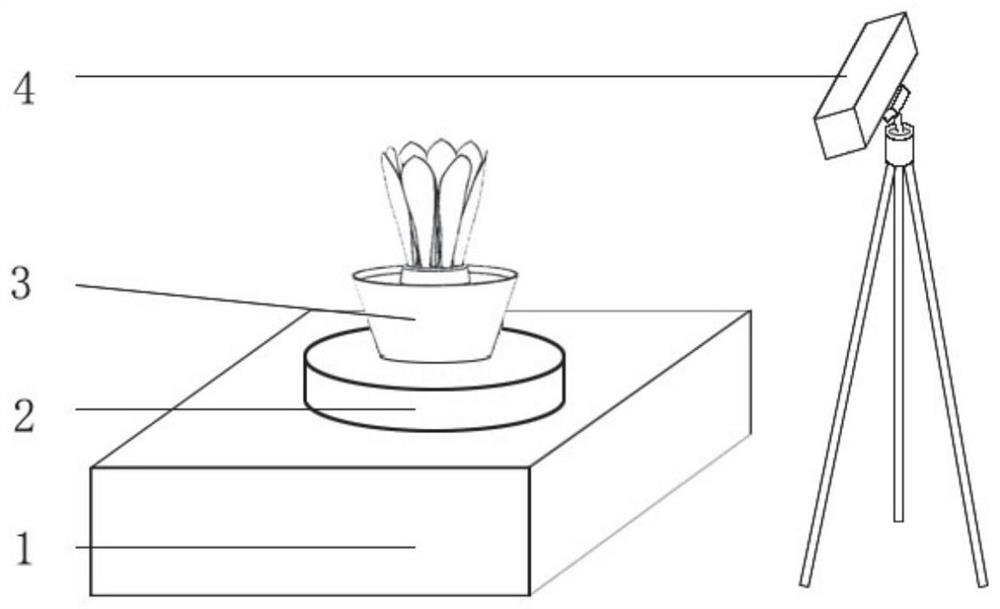

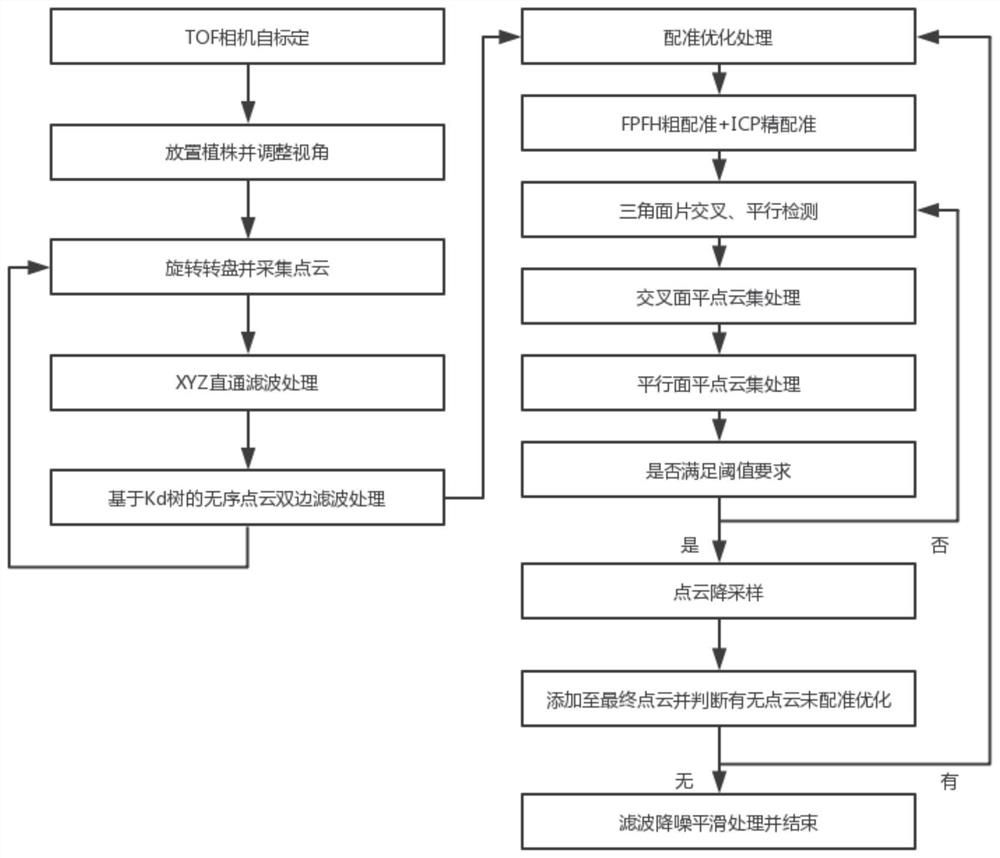

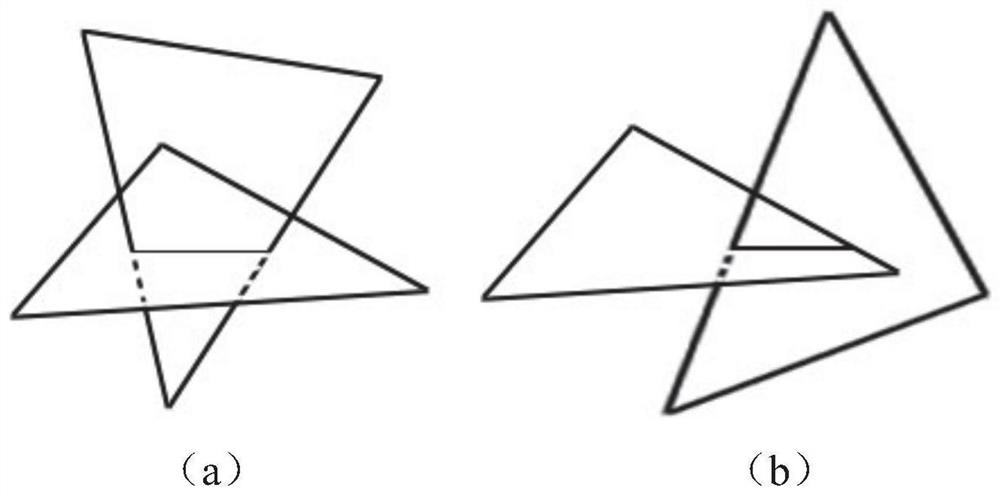

Plant point cloud collection registration and optimization method based on TOF camera

ActiveCN110335295AQuality improvementLow requirements for shooting and acquisition conditionsImage enhancementImage analysisPoint cloudVisual angle

The invention discloses a plant point cloud collection registration and optimization method based on a TOF camera. The plant point cloud collection registration and optimization method comprises the following steps: (1) placing a detected plant on a turntable, adjusting the visual angle of the TOF camera, and enabling the TOF camera to be aligned with the detected plant; (2) starting a rotary table to enable the rotary table to rotate automatically, and collecting point cloud data of a measured plant at intervals by a TOF camera; (3) performing real-time preprocessing on each frame of point cloud data acquired by the TOF camera; (4) performing registration and optimization processing on each two adjacent frames of point cloud data in sequence, and then performing integration to obtain complete plant point cloud data; and (5) eliminating discrete noise in the plant point cloud number obtained by registration and optimization processing by adopting statistical filtering processing to obtain final point cloud data. The plant point cloud collection registration and optimization method provided by the invention can effectively solve the local point cloud layering phenomenon.

Owner:ZHEJIANG UNIV

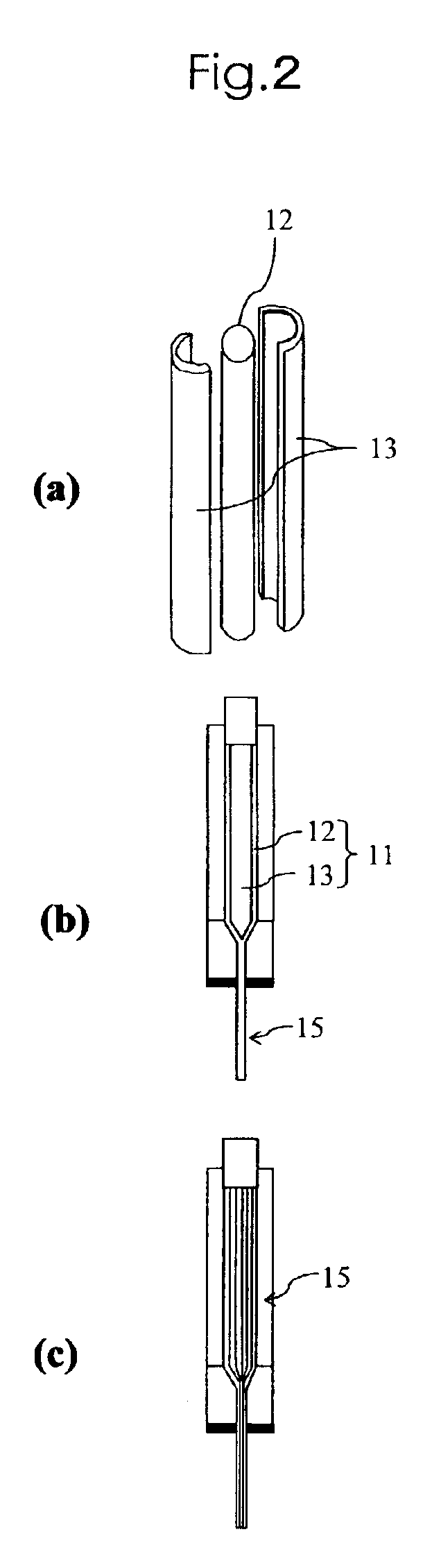

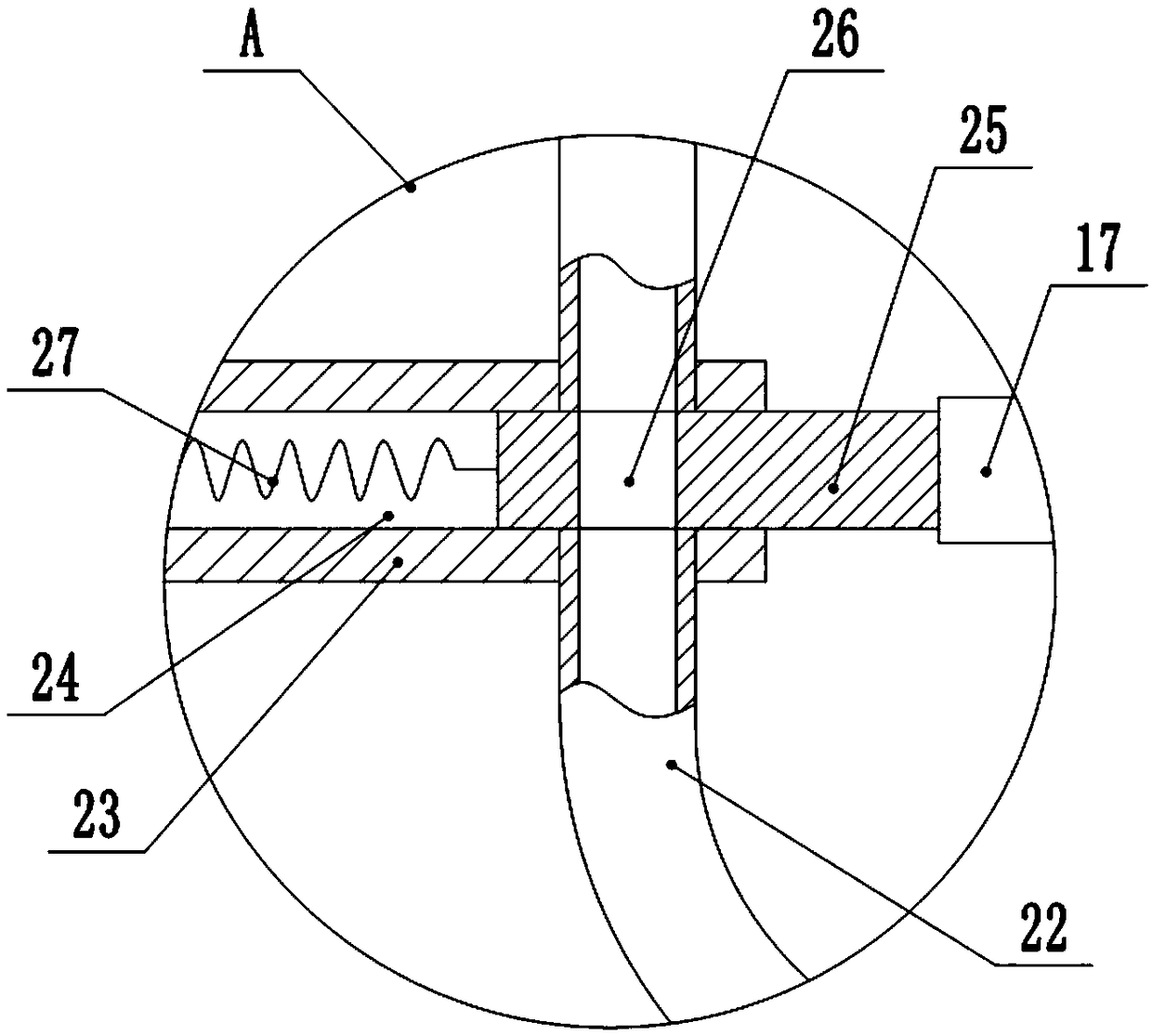

Full width weft insertion device installed on small diameter round warp knitting machine

InactiveCN1693561AImprove molding efficiencyReduce manufacturing costWarp knittingInsertion deviceEngineering

The invention relates to a full-width weft laying-in device to be installed a small diameter round warp knitter, characterized in that it comprises synchronous transmission device, reciprocating conversion and speed change device and full width laying-in yarn leading device, can adds reinforcing yarns that do not take part in weaving, on the basis of weaving tubular fabric, so as to the yarns in the woven seamless tubular fabric run through all the parts of the whole fabric and are interlaced together to form a stable integral structure, thus implementing the function of weaving tubular 3D warp- knitted structure prefab. The fabrics by the invention can be used in tubular warp-knitted composites for decoration, clothing and various industries.

Owner:DONGHUA UNIV

Method for treating phenolic wastewater by using three-dimensional electrode

InactiveCN103626264AEliminate delaminationEasy to handleWater contaminantsWater/sewage treatment by electrochemical methodsChemical oxygen demandRegular type

The invention relates to a method for treating phenolic wastewater by using a three-dimensional electrode. The method comprises the following steps: (2) putting 250ml of a 500mg / L phenolic wastewater sample with the COD (Chemical Oxygen Demand) of 1784mg / L into a three-dimensional electrode reactor; electrifying and treating the phenolic wastewater by using an electrochemical oxidation method; and (2) adding electrolyte with the mass concentration of 1g / L-10g / L into the phenolic wastewater; carrying out aeration treatment to sufficiently mix the phenolic wastewater with the electrolyte, adding sodium carbonate into the phenolic wastewater to adjust the PH (Potential of Hydrogen) value to 2-6, and electrolyzing for 120 minutes under the condition that electrode voltage is 5V-8V. According to the method provided by the invention, a regular type third electrode is adopted so as to eliminate a layering phenomenon of a traditional heaped three-dimensional electrode and reduce short-circuit current; the phenol treatment effect is greatly better than that of the traditional heaped three-dimensional electrode and the method has profound and lasting positive meanings of treating the phenolic wastewater.

Owner:SUZHOU GUOHUAN ENVIRONMENT DETECTION

Fodder trough for fragrant pig breeding

ActiveCN108719097AEasy to eatPrevent trampling on pig foodAnimal feeding devicesAgricultural scienceGear wheel

The invention relates to the technical field of breeding devices and particularly discloses a fodder trough for fragrant pig breeding. The fodder trough for fragrant pig breeding comprises a fodder trough body, wherein partition plates are arranged in the fodder trough body and divide the fodder trough body into a plurality of fodder trough units, a baffle is hinged to the top of each fodder trough unit, and stirring blades are hinged to the baffles. Each fodder trough unit is externally provided with an L-shaped box body and a bearing table, the bearing table is in sliding connection with a pedal, a first spring is connected between the pedal and the bearing table, and a first water bag containing liquid is placed below the pedal. A cylinder body is arranged in the L-shaped box body, theinside of the cylinder body is in sliding connection with a sliding plate, a second water bag is placed on one side of the sliding plate, the other side of the sliding plate is connected with a rack,and a water delivery pipe is communicated between the first water bag and the second water bag. The rack is meshed with a gear, the gear is coaxially connected with a second rotary shaft, and the second rotary shaft is connected with a first rotary shaft through a belt. The fodder trough units are blocked through the baffles, the baffles are automatically opened when fragrant pigs eat, and the fragrant pigs are prevented from treading a pig fodder.

Owner:灵璧县浩翔信息科技有限公司

Treatment technology after production of ultrathin copper foil

InactiveCN108930036AIncrease surface areaIncrease contact areaSuperimposed coating processRough surfaceSurface roughness

The invention discloses a treatment technology after the production of an ultrathin copper foil, and relates to the technical field of production of the copper foils. The treatment technology after the production of the ultrathin copper foil comprises the following steps: copper foil curing treatment, copper foil rough surface galvanizing treatment, copper foil surface passivation treatment, silane coupling agent coating, copper foil drying treatment and copper foil cutting treatment, wherein the copper foil curing treatment is characterized in that a layer of dense metal copper is deposited in tuberculate space gaps of the rough layer to increase the contact surface of the roughen layer and a rough foil substrate in order to reduce the surface roughness of the rough layer. A layer of thetuberculate copper particles is electropalted on the rough surface of the copper foil, so the surface area of the rough surface of the copper foil is increased, and the copper foil is mechanically fastened an insulating resin substrate material; and the curing treatment reduces the roughness, and the increase of the contact area between the rough layer and the rough foil increases the bonding strength between the treated layer and the insulating substrate material, so the layering phenomenon of the treated layer and the rough foil is fundamentally eliminated.

Owner:安徽华创新材料股份有限公司

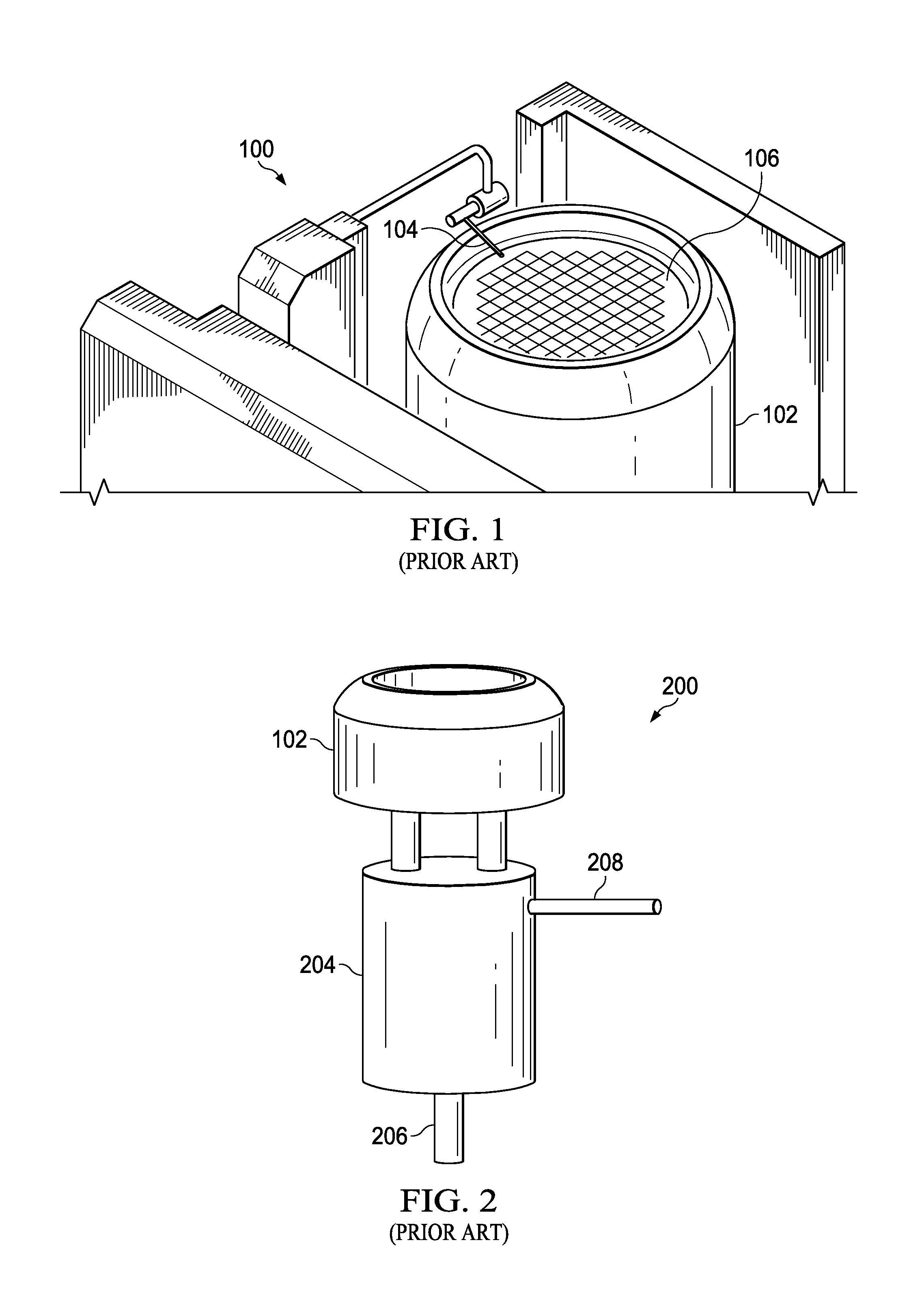

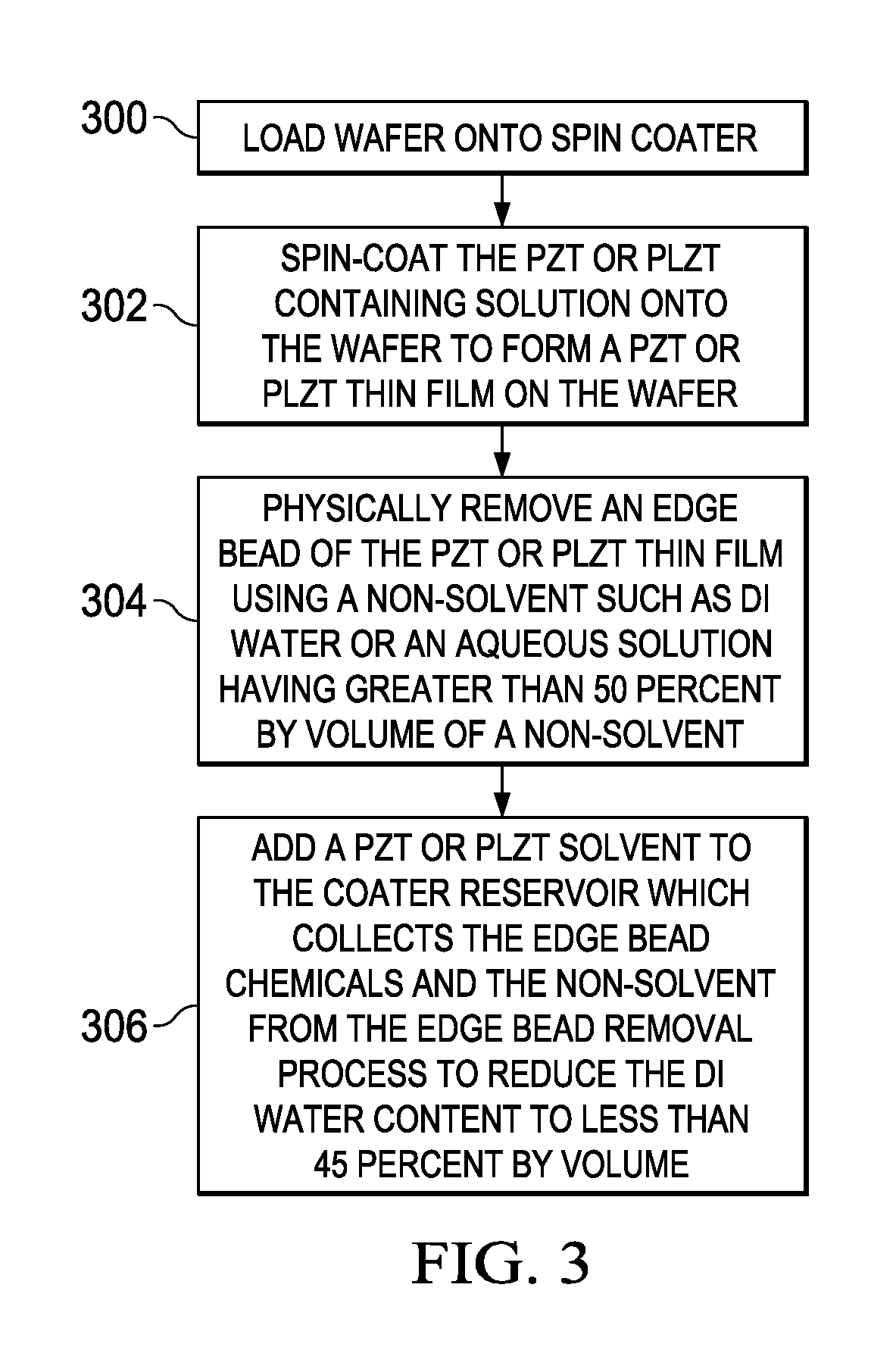

Process for forming PZT or PLZT thinfilms with low defectivity

ActiveUS20150187570A1Reduce yieldEliminates swelling of the exposed edgesLiquid surface applicatorsSemiconductor/solid-state device manufacturingNon solventMaterials science

Use of a non-solvent for the edge bead removal of spin-coated PZT or PLZT thinfilms, eliminates swelling of the exposed edges of the PZT or PLZT thinfilms and eliminates delamination and formation of particle defects in subsequent bake and anneal steps.

Owner:TEXAS INSTR INC

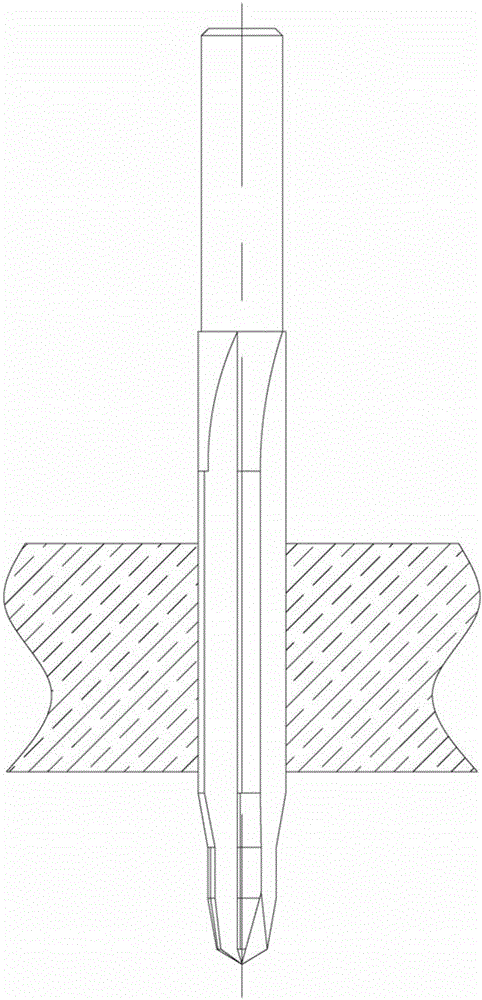

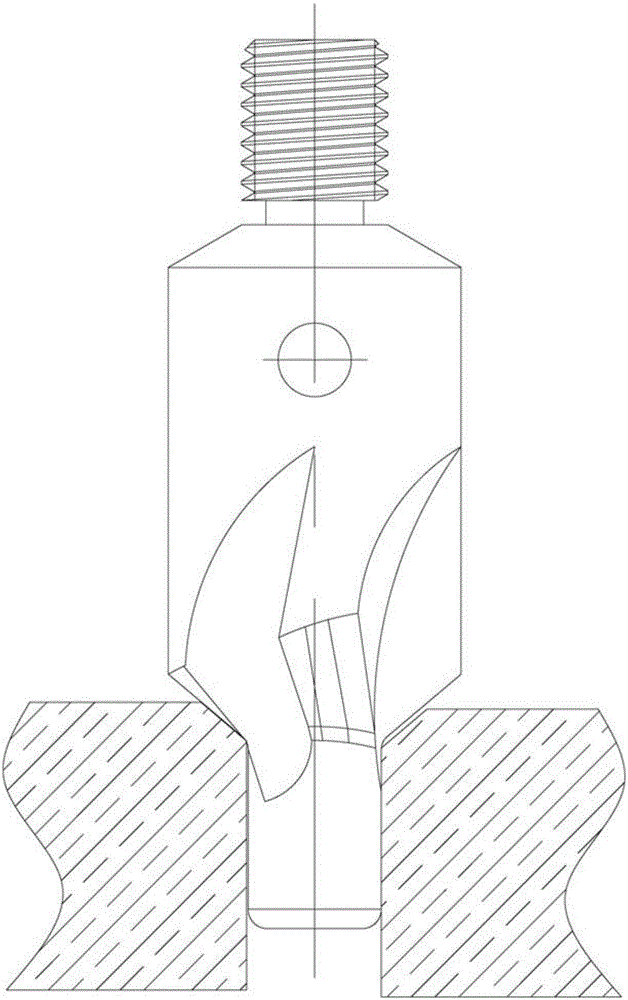

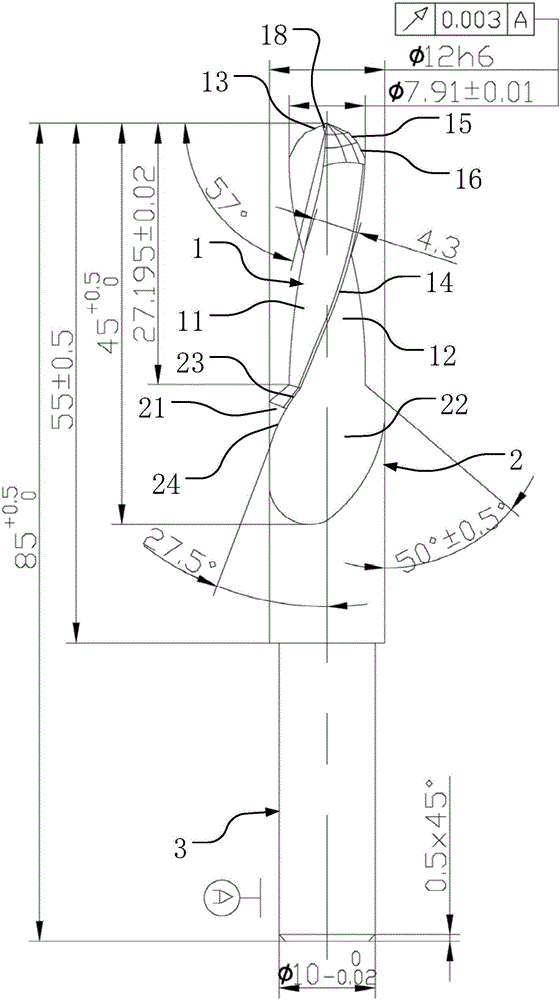

Step molding drill for pore forming on carbon fiber plate

ActiveCN106624075AEasy to processReduce procurement costsTransportation and packagingCutting insertsFiberEngineering

The invention discloses a step molding drill for pore forming on a carbon fiber plate. The step molding drill comprises a drill bit, a chamfering knife and a handle, wherein the drill bit, the chamfering knife and the handle are coaxially connected in sequence; the drill bit comprises two spiral drill blade parts which are arranged in a central symmetry manner; spiral drill hole chip areas are encircled between the corresponding front blade surfaces and blade back surfaces on the two drill blade parts; the drill blade parts comprise drill tip cone edges, spiral peripheral edges as well as second and third cone edges which are sequentially connected between the drill tip cone edges and the spiral peripheral edges; the chamfering knife comprises two spiral chamfering blade parts arranged in a central symmetry manner; spiral chamfering chip areas are encircled between the corresponding front blade surfaces and blade back surfaces on the two chamfering blade parts; the chamfering blade parts comprise chamfering cone edges and circumferential secondary edges; the chamfering cone edges and the spiral circumferential edges are connected to form steps; and the drill hole chip areas are communicated with the chamfering chip areas.

Owner:江西杰浩硬质合金工具有限公司

Composite construction and manufacturing method thereof

InactiveUS20050147851A1High strengthHigh hardnessCeramic layered productsCoatingsComposite constructionCarbide

A composite construction 1 is obtained by coating the outer periphery of a core material 2 with a shell layer 3. The core material 2 is composed of a first sintered body that is obtained by bonding, with a binder metal, a first hard particle composed of one or more of carbides, nitrides and carbonitrides of metals of Groups 4a, 5a and 6a of the Periodic Table, or a first ceramics obtained by bonding, with a sintering additive, a first ceramic particle composed of at least one of oxides, carbides, nitrides and carbonitrides selected from the group consisting of metals of Groups 4a, 5a and 6a of the Periodic Table, Al, Si and Zn. The shell layer 3 is composed of a second hard sintered body or second ceramics having a different composition from the first hard sintered body. The ratio of the residual free carbon amount Cin in the core material 2 to the residual free carbon amount Cout in the shell layer 3, Cin / Cout, is 0.5 to 2. This prevents shrinkage during the time of sintering and also prevents the strength of the composite construction from lowering due to poor sintering.

Owner:KYOCERA CORP

Road surface paving layer construction method

The invention discloses a road surface paving layer construction method which comprises construction on a structure layer and construction on a facing layer. The construction on the facing layer comprises the following steps: performing virtual paving on the facing layer, mixing facing layer materials, and paving the facing layer materials on the structure layer by adopting a round bar with the diameter of 6-26mm; performing initial pressure flattening by adopting a cylindrical roller, performing re-pressing flattening within 15-20 minutes, and performing final pressure flattening within 30-60 minutes. According to the thin-layer construction method for the road surface paving layer, manual operation is replaced by sticks and other equipment, the paving efficiency is high, and the operation is convenient and rapid. Meanwhile, the virtual paving thickness and the compaction thickness are effectively controlled, and accurate and high-quality construction is realized. The facing layer and the structure layer are well adhered, and a layered phenomenon is avoided. The road surface paving layer obtained by adopting the construction method is solid, flat and smooth.

Owner:拉法基豪瑞投资有限公司

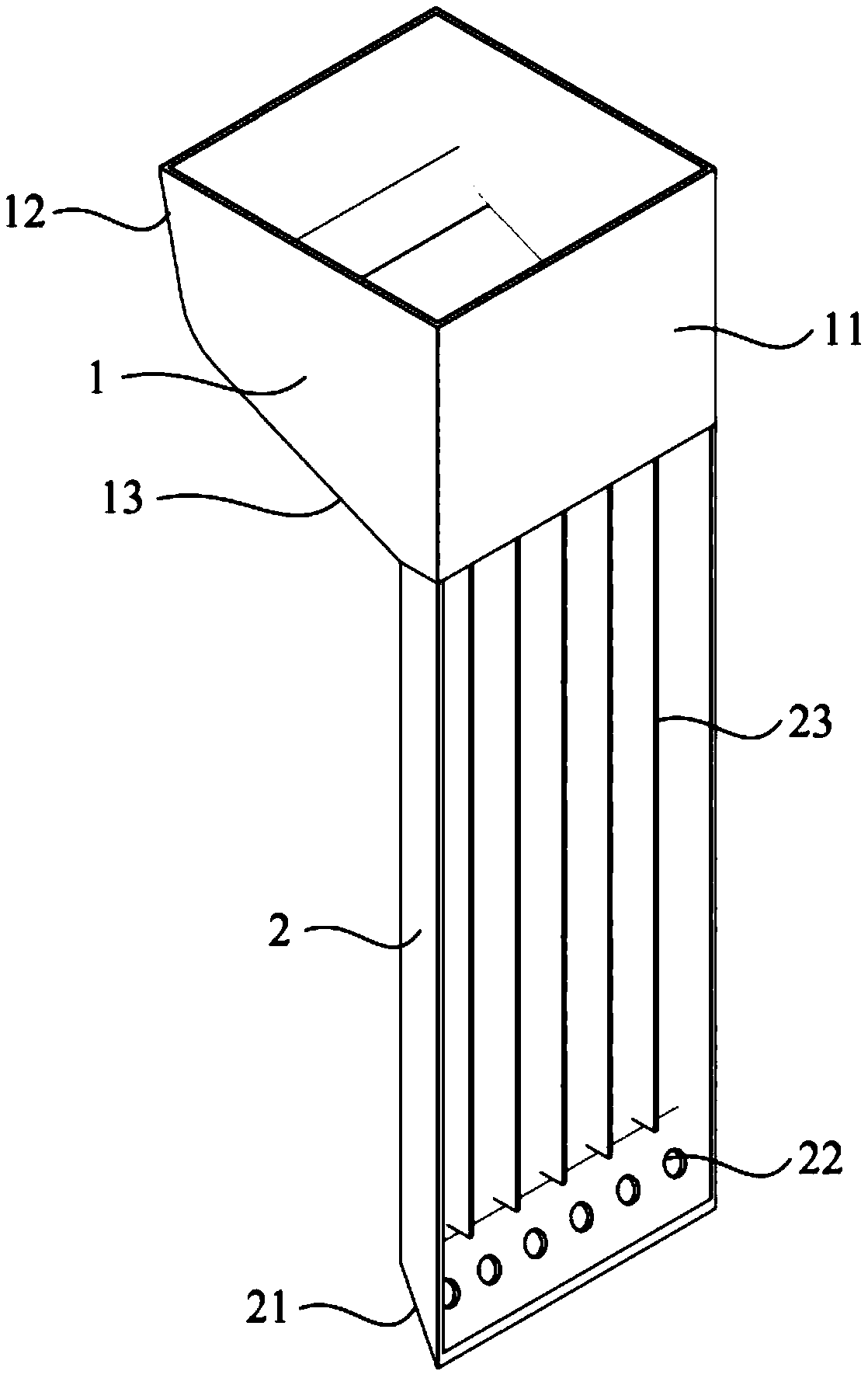

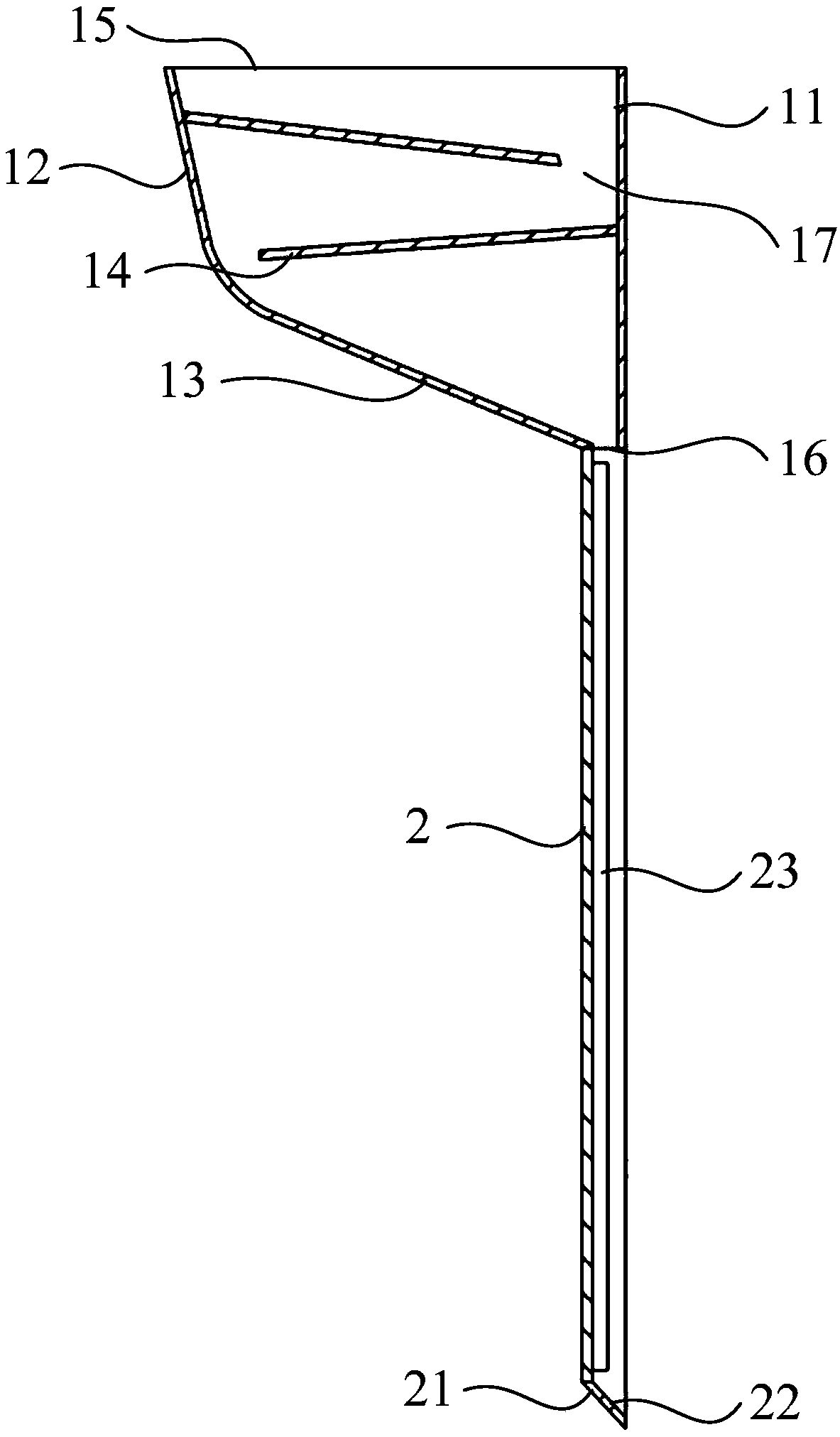

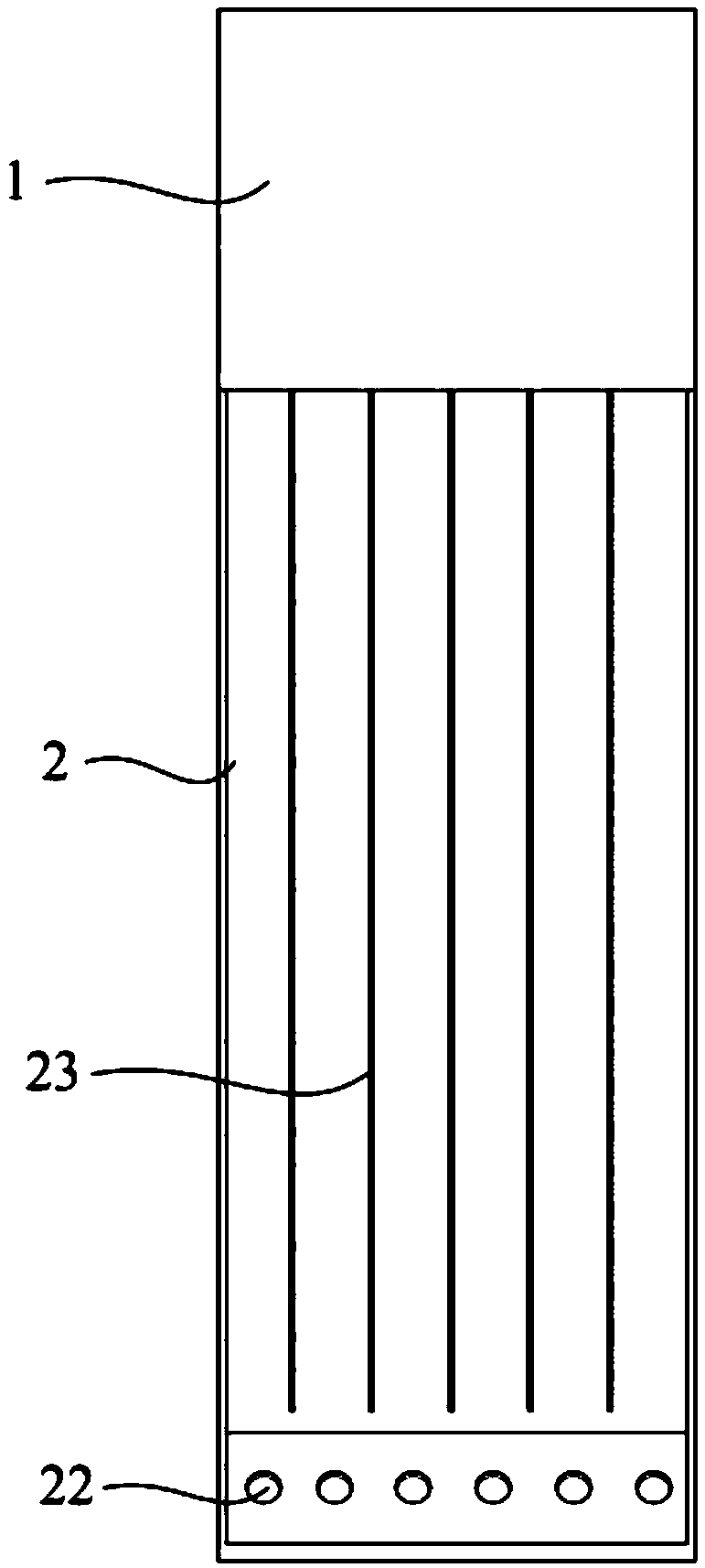

Electrolyte guiding device and storage battery

PendingCN109616609AExtended service lifeImprove the phenomenon of density stratificationElectrolyte moving arrangementsFinal product manufactureElectrical batteryEngineering

The invention relates to the technical field of storage batteries, and in particular to an electrolyte guiding device and a storage battery. The electrolyte guiding device comprises a liquid receivingpart and a guiding part, wherein the liquid receiving part is an open groove; the open end of the open groove is an electrolyte inlet; a low-specific gravity electrolyte flows into the liquid receiving part via the electrolyte inlet; the open groove comprises a first side wall and a bottom wall; a gap is left between the bottom wall and the first side wall to serve as a liquid outlet of the liquid receiving part; one end of the guiding part is communicated with the liquid outlet of the liquid receiving part; and the other end of the guiding part is an electrolyte outlet and can extend into the bottom of a battery container. The device has the beneficial effects that when a car runs on a bumpy road and is accelerated and decelerated, vibration is generated due to the inertia and the low-specific gravity electrolyte in the upper layer of the battery container flows to the downward side of the battery container through the electrolyte guiding device and is mixed with a high-specific gravity electrolyte at the bottom of the battery container, thereby improving the density stratification phenomenon of the electrolyte and prolong the service life of the battery.

Owner:骆驼集团(安徽)蓄电池有限公司

Flavored rose petal jam and preparation method thereof

InactiveCN109007770AReasonable compositionFormulation ScienceFood preservationNatural extract food ingredientsGrape seedPetal

The invention provides flavored rose petal jam. The flavored rose petal jam comprises raw materials in parts by weight as follows: 24-28 parts of rose petals, 30-40 parts of brown sugar, 6-10 parts ofwhite granulated sugar, 4.2-4.8 parts of salt, 5-7 parts of honey, 7-9 parts of aizoon stonecrop herb, 7-9 parts of buckwheat powder, 7-9 parts of lotus root starch, 7-9 parts of soybean flour, 15-20parts of corn starch syrup, 2-4 parts of potassium sorbate, 4-6 parts of grape seeds, 6-8 parts of lemons, 7-9 parts of sweet-scented osmanthus, 1.6-2.0 parts of fruit and vegetable enzyme powder and102-108 parts of water. The invention also provides a preparation method of the flavored rose petal jam. The jam has the advantages as follows: (1) the jam adopts a reasonable and scientific formula,has good taste and flavor and rich and comprehensive nutrients and can provide multiple vitamins, protein for the human body and meet multiple daily function requirements of the human body; and besides, concentrated aizoon stonecrop herb juice is added to components, so that the rose jam can resist bacteria and prevent corrosion and can be placed at the normal temperature for a long time.

Owner:赵南南

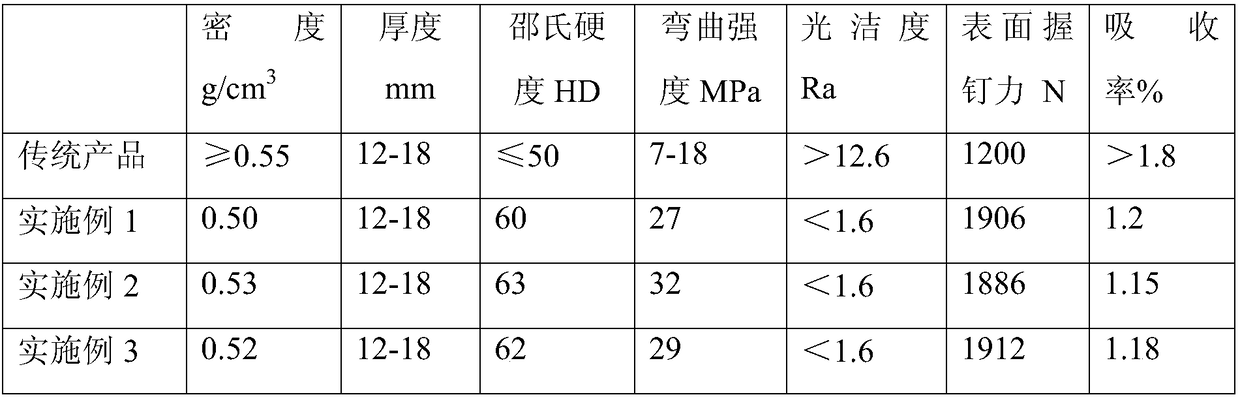

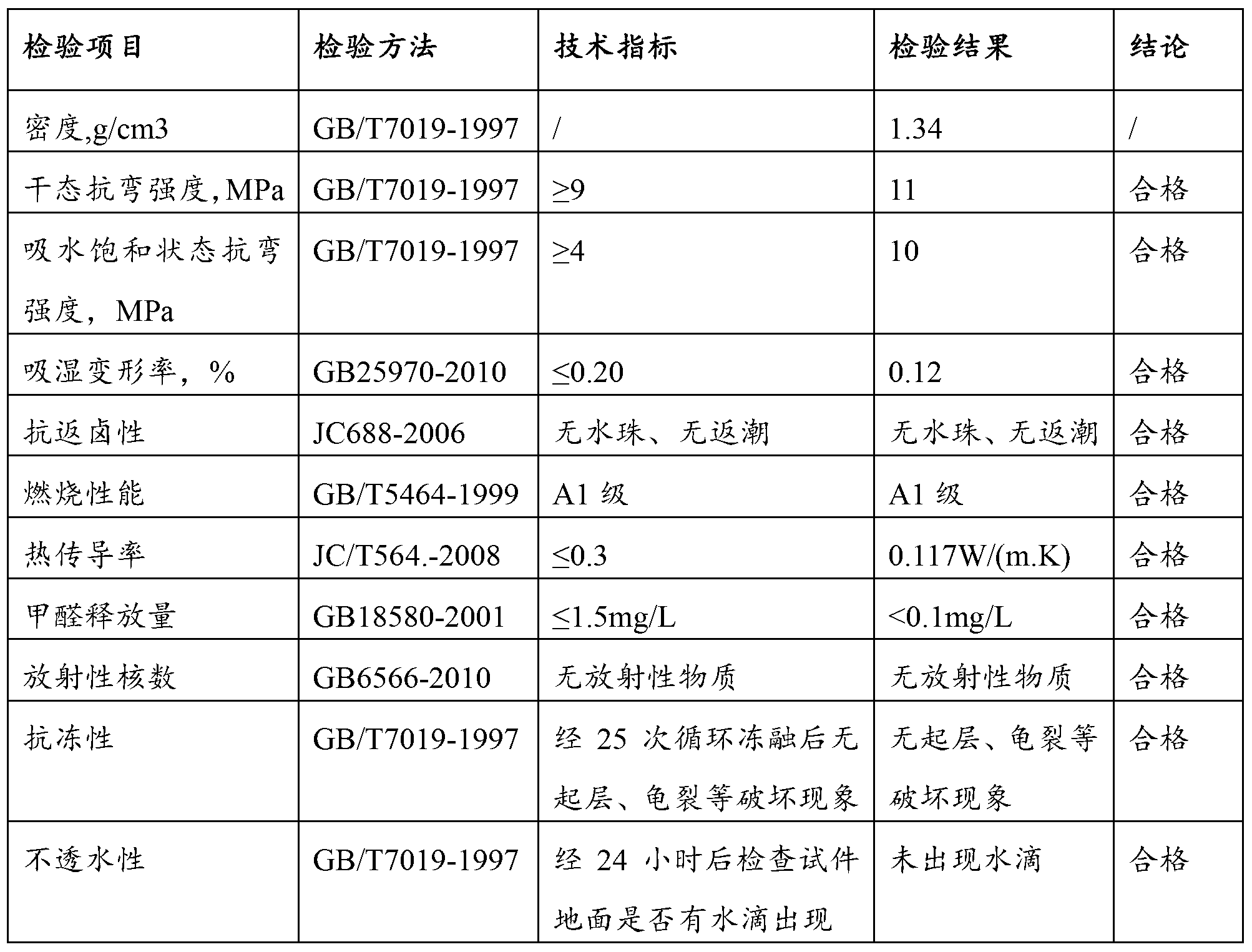

Polyvinyl chloride kitchen and bathroom board and preparation method thereof

The invention discloses a polyvinyl chloride kitchen and bathroom board and a preparation method thereof, belonging to the technical field of polyvinyl chloride plates. The invention solves the problems that hydroscopicity of an existing product is poor, density is low and hardness is poor. The polyvinyl chloride kitchen and bathroom board is prepared from 60-80 parts of polyvinyl chloride SG8 resin, 40-60 parts of ground calcium carbonate, 20-40 parts of reclaimed materials, 7-9 parts of a foaming regulator, 2.7-2.9 parts of a lead salt stabilizer, 0.5-0.6 part of an internal lubricant SP-60,0.2-0.3 part of polyethylene wax, 0.2-0.25 part of micronized polyethylene wax N-14P, 0.1-0.15 part of a plasticizer OA6, 0.5-0.6 part of a heat release type AC foaming agent, 1.2-1.4 parts of a heatabsorption type foaming agent and pigments. The preparation method thereof comprises the following steps: sequentially putting materials into a hot mixing pot, heating and then cooling, and then conveying the cooled materials to an extruding machine, so that the finished product is obtained. The invention is mainly applied to preparation of the polyvinyl chloride kitchen and bathroom board.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

Hyperspectral display frame hyperspectral traceless injection molding technique

InactiveCN108407246AHigh glossImproved surface hardness and qualityInjection molding processEnvironmental resistance

The invention belongs to the technical field of injection molding, and relates to a hyperspectral display frame hyperspectral traceless injection molding technique. A prepared display frame is high insurface glossiness and free of defects such as melted marks, flow marks, bubbles and shrink marks, the product surface hardness and quality are greatly improved, and the product percent of pass is improved by 20-30%; before injection molding, condensation is conducted at first, then drying treatment and microwave treatment are conducted, and residual internal stress in raw materials can be effectively and completely eliminated; pressure adjusting in the injection molding process is conducted in three stages, shrinkage cavities and recesses are avoided, the flow marks, seam lines and the layering phenomenon are eliminated, the internal stress produced in the product injection molding process and various defects caused in the injection molding process are reduced, and the product percent ofpass, quality and strength are improved; rapid temperature increase and rapid temperature decrease during application are achieved, the speed tends to be uniform, heat energy is fully utilized, heatenergy losses and production cost are reduced, and the product percent of pass is increased; and the spraying procedure is not needed, pollution to the environment is greatly reduced, and the requirements of environment protection and energy conservation are met.

Owner:太仓市天丝利塑化有限公司

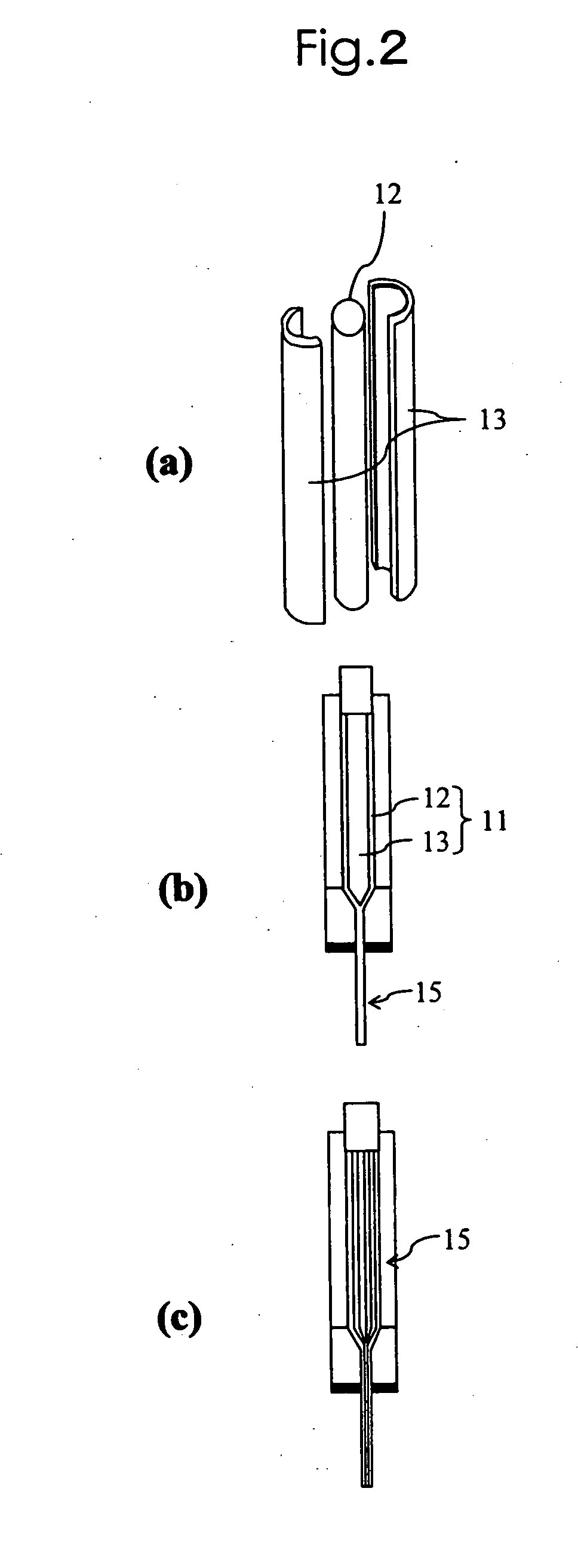

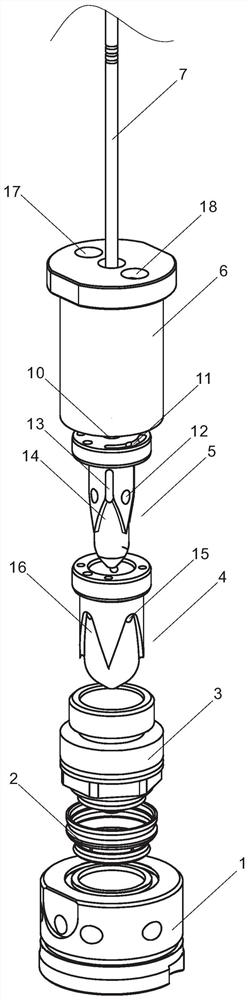

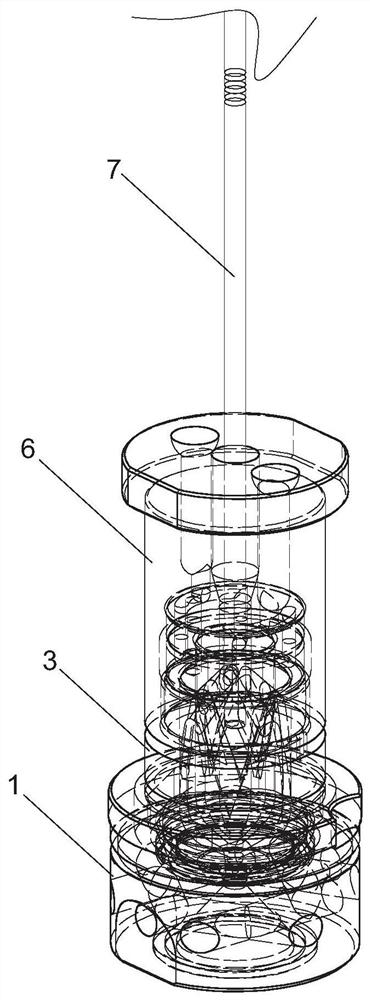

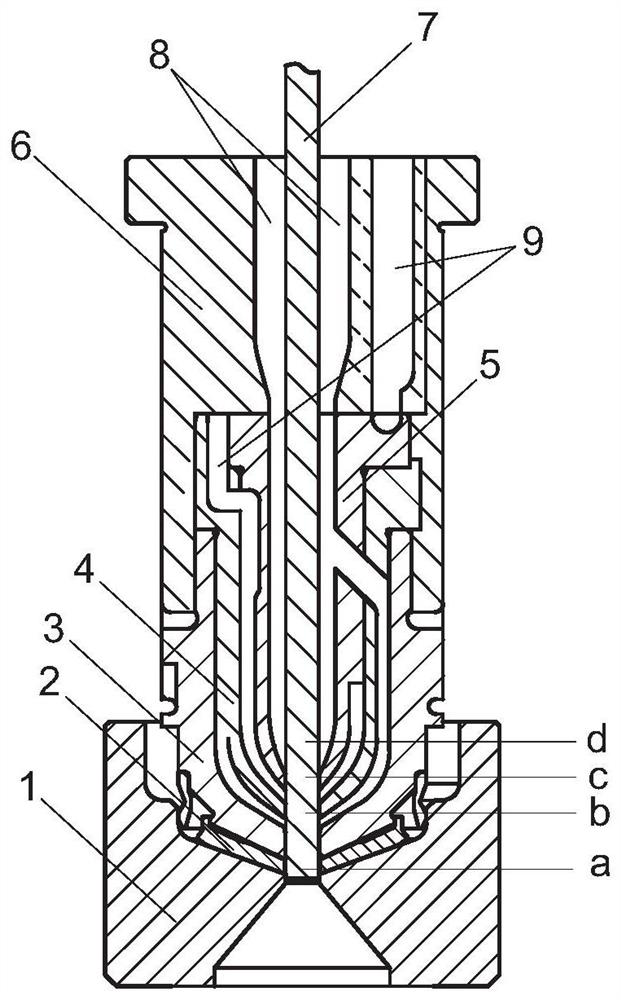

A hot runner nozzle structure for three-layer material injection molding

The invention discloses a three-layer material injection molding hot runner injection nozzle structure. The three-layer material injection molding hot runner injection nozzle structure comprises a cold mold, an injection nozzle, an outer injection nozzle, an inner injection nozzle, an injection nozzle base and a valve needle; the injection nozzle, the outer injection nozzle, the inner injection nozzle and the injection nozzle base are each of a hollow structure, and the bottom centers of the injection nozzle, the outer injection nozzle, the inner injection nozzle and the injection nozzle baseare open; the injection nozzle base, the outer injection nozzle and the inner injection nozzle are sequentially and coaxially matched in an embedded and sleeved mode from outside to inside, and a circumferential positioning structure is arranged among the injection nozzle base, the outer injection nozzle and the inner injection nozzle; the outer injection nozzle is also coaxially matched with theinjection nozzle in an embedded and sleeved mode; the injection nozzle is fixedly connected with the bottom opening end of the injection nozzle base; the bottom of the injection nozzle is embedded into a cavity of the cold mold; the valve needle penetrates through the injection nozzle, the outer injection nozzle, the inner injection nozzle and the injection nozzle base along the axis in a slidingmode; the top end of the valve needle is connected with a valve needle drive device; the injection nozzle base and the inner injection nozzle are provided with matrix material runners and interlayer material runners; an interlayer material runner is arranged inside the outer injection nozzle; a matrix material runner is arranged inside the outer injection nozzle; and outlets of the matrix materialrunners are located in the bottom centers of the injection nozzle and the inner injection nozzle. The three-layer material injection molding hot runner injection nozzle structure can shorten the process procedure and greatly improve the production efficiency.

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

Fiber cement composite plate production process

InactiveCN103223750AStrong fire and water resistanceEliminate delaminationWater-setting substance layered productCement compositesMaterials science

The invention discloses a fiber cement composite plate production process. According to the invention, a well stirred base material is paved through template delivery; a first layer of glass fiber cloth is paved; a middle material is paved; a second layer of glass fiber cloth is paved; the glass fiber cloth is cut, and first constant-temperature maintenance is carried out; de-molding is carried out after 20-30h of maintenance; the plate material is wetted by spraying water, and secondary constant-temperature maintenance is carried out; and after 3-10 days, edge sawing and trimming processes are carried out, such that a finished product is obtained. Compared with prior art, with the fiber cement composite plate production process, the produced fiber cement composite plate has high fireproof performance, high waterproof performance, good safety, and no toxicity. The plate can be directly used in interior or exterior wall decoration. The plate is a durable novel construction plate material.

Owner:广州新绿环阻燃装饰材料有限公司

High heat conductivity and high strength density heterogeneous foamed SiC/Cu material and its preparing method

The present invention relates to heterogeneous foamed ceramic / metal material, and is especially a kind of high strength, high density and high heat conductivity heterogeneous foamed SiC / Cu material and its preparation process. The foamed SiC / Cu material has basic units of closed polygonal ring to form connected 3D network structure, and each of the closed polygonal ring units is heterogeneous foamed ribs comprising SiC in 50-95 vol% and metal Cu in 5-50 vol% and with the relative density not lower than 99 %. The foamed SiC / Cu material is prepared through organic foam soaking, hot pressing to densify, pressure injection filling, thermal decomposition and reaction sintering. The preparation process is simple and low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Steam type highlight and traceless injection-molding and forming process for complex precise product

The invention discloses a steam type highlight and traceless injection-molding and forming process for a complex precise product. The process sequentially comprises the following steps of: selecting raw materials, baking, pre-heating, combining a die, then quickly heating, adjusting speed and pressure, injecting in sections, maintaining the pressure, cooling quickly, blowing out cold air, opening the die and cleaning the die. An advanced pressure-regulation and speed-regulation staging injection process and an automatic blowing and impurity-removing technology are adopted in the invention. A special heating and cooling technology is that the shapes, the widths and the arrangement density of water passages are designed according to nonuniform heat and cold of the complex precise product in the injection-molding and forming course and the overall shape variation of the product. The steam type highlight and traceless injection-molding and forming process for the complex precise product has the advantages that the residual stress of the product is effectively decreased, various defects generated in the course of producing the plastic product are greatly reduced, the surface quality and the precision of the product are remarkably improved, and the life of the product is remarkably prolonged at the same time because the special process ensures heating and cooling rates of each part of the complex product in the injection-molding and forming course tend to be consistent.

Owner:海门市创豪工业设计有限公司

Uniform film-forming fine-grained nickel alloy rotating target and its hot extrusion optimization preparation method

ActiveCN105734507BUniform internal organizationUniform thicknessVacuum evaporation coatingSputtering coatingNickel alloyWork in process

Provided is a hot extrusion optimizing preparation method of a fine grain nickel alloy rotary target capable of achieving even film forming. Nickel with the purity larger than or equal to 99.99% and other element metal with the purity larger than or equal to 99.95% are adopted as alloy raw materials to be molten into a high-purity nickel alloy ingot; and the high-purity nickel alloy ingot is placed in an extrusion die placed in a double-acting backward extrusion machine after being heated by one to two hours, the high-purity nickel alloy ingot is subjected to hot extrusion to form a semi-finished nickel alloy pipe target, the total deformation in the extruding process is larger than 80%, and recrystallization annealing is carried out after cooling. The structure in the nickel alloy is more even, the obvious layering phenomenon is eliminated, the alloy target is high in finished product rate, fine in grain, even in inner structure and more stable in sputtering, film forming is even when the target is used, a high-quality thin film with even thickness can be obtained, and the utilization rate of the target is increased.

Owner:GEMCH MATERIAL TECH SUZHOU

A registration and optimization method for plant point cloud acquisition based on tof camera

ActiveCN110335295BQuality improvementLow requirements for shooting and acquisition conditionsImage enhancementImage analysisPoint cloudComputer graphics (images)

Owner:ZHEJIANG UNIV

Anti-corrosion treatment process for carbon steel plate equipment in environmental protection industry

InactiveCN112718432ALow costPut an end to drum kitsAnti-corrosive paintsSpecial surfacesPunchingCarbon steel

The invention provides an anti-corrosion treatment process for carbon steel plate equipment in an environmental protection industry, and relates to the technical field of corrosion prevention. The anti-corrosion treatment process for the carbon steel plate equipment in the environmental protection industry comprises the following process steps: step 1, selecting a sinter board dust catcher box body substitute material; step 2, punching; and step 3, brushing an anti-corrosion material. An embossed carbon steel plate is used for replacing a carbon steel plate material of an existing sinter board dust catcher box body, holes are punched on the embossed carbon steel plate, resin can be firmly attached to the embossed carbon steel plate, and when the temperature is changed, due to the forced blocking effect of an embossed protruding structure, anti-corrosion resin as a whole can be deformed synchronously with the embossed carbon steel plate, the phenomena of bulging and delaminating are completely eradicated, and meanwhile the cost for maintaining the sinter board dust catcher box body is saved.

Owner:刘莹

A kind of preparation method of airgel composite glass

ActiveCN108623176BSolving Difficult-to-Mix ProblemsImprove featuresGlass rolling apparatusMolten stateSemi solid

The invention provides a preparation method for aerogel composite glass. The aerogel composite glass is composed of an aerogel and a glass phase which is used for bonding the aerogel. The preparationmethod comprises the following steps: (1) mixing: uniformly mixing glass powder with the aerogel; (2) melting: heating the glass powder in a mixture obtained in the step (1) to a molten state so as toobtain semi-solid mixed glass melt; (3) calendaring molding: subjecting the mixed glass melt obtained in the step (2) to calendaring molding between rollers or roller plates, and then carrying out cooling; and (4) annealing. The aerogel composite glass disclosed by the invention has good heat insulation performance, light transmittance, safety performance, sound insulation performance and noise reduction performance, and is applicable to the field of doors and windows, curtain wall glass, lighting roofs and the like of green buildings, ultralow-energy-consumption buildings and near-zero-energy-consumption buildings.

Owner:CHANGSHA XINGNA AEROGEL

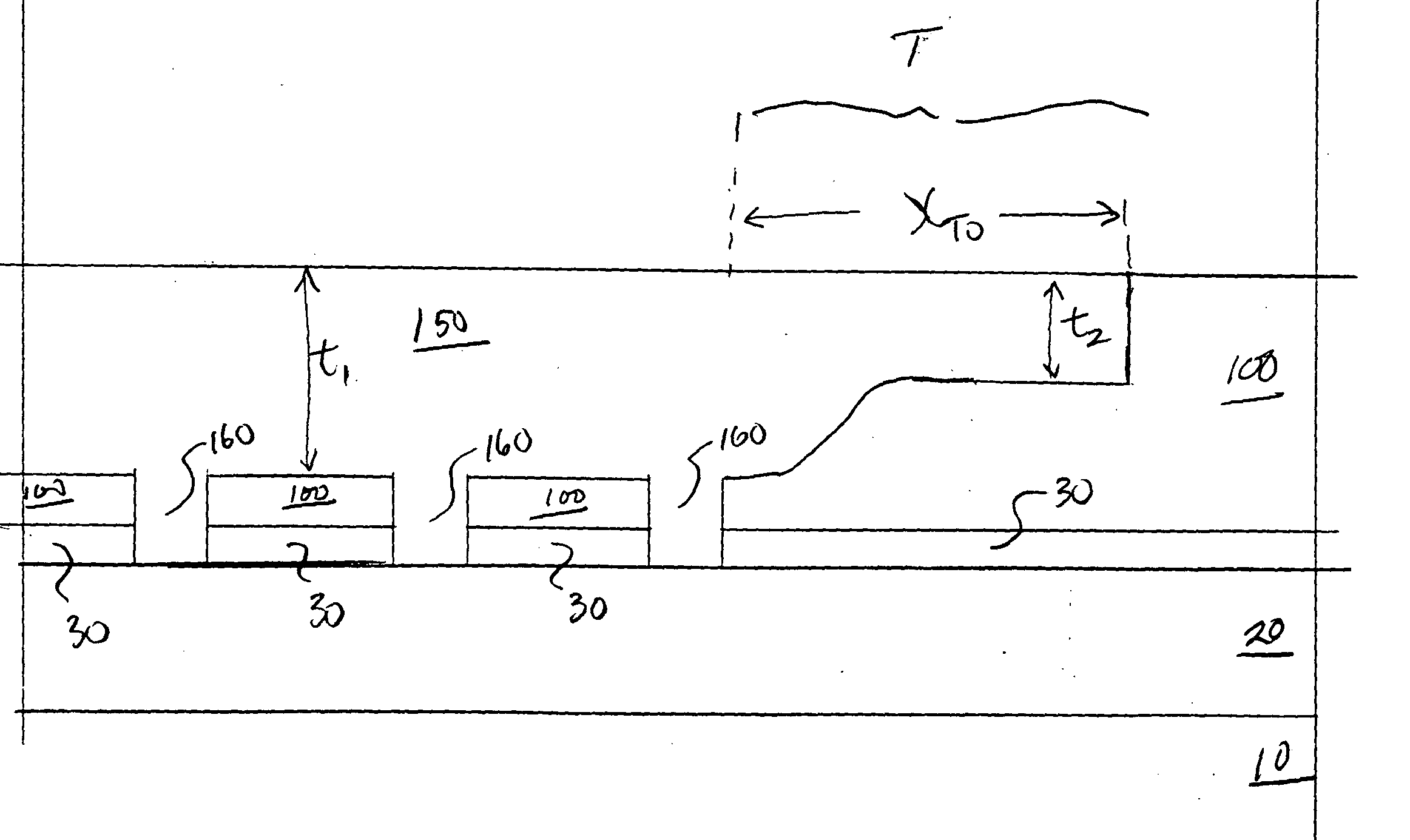

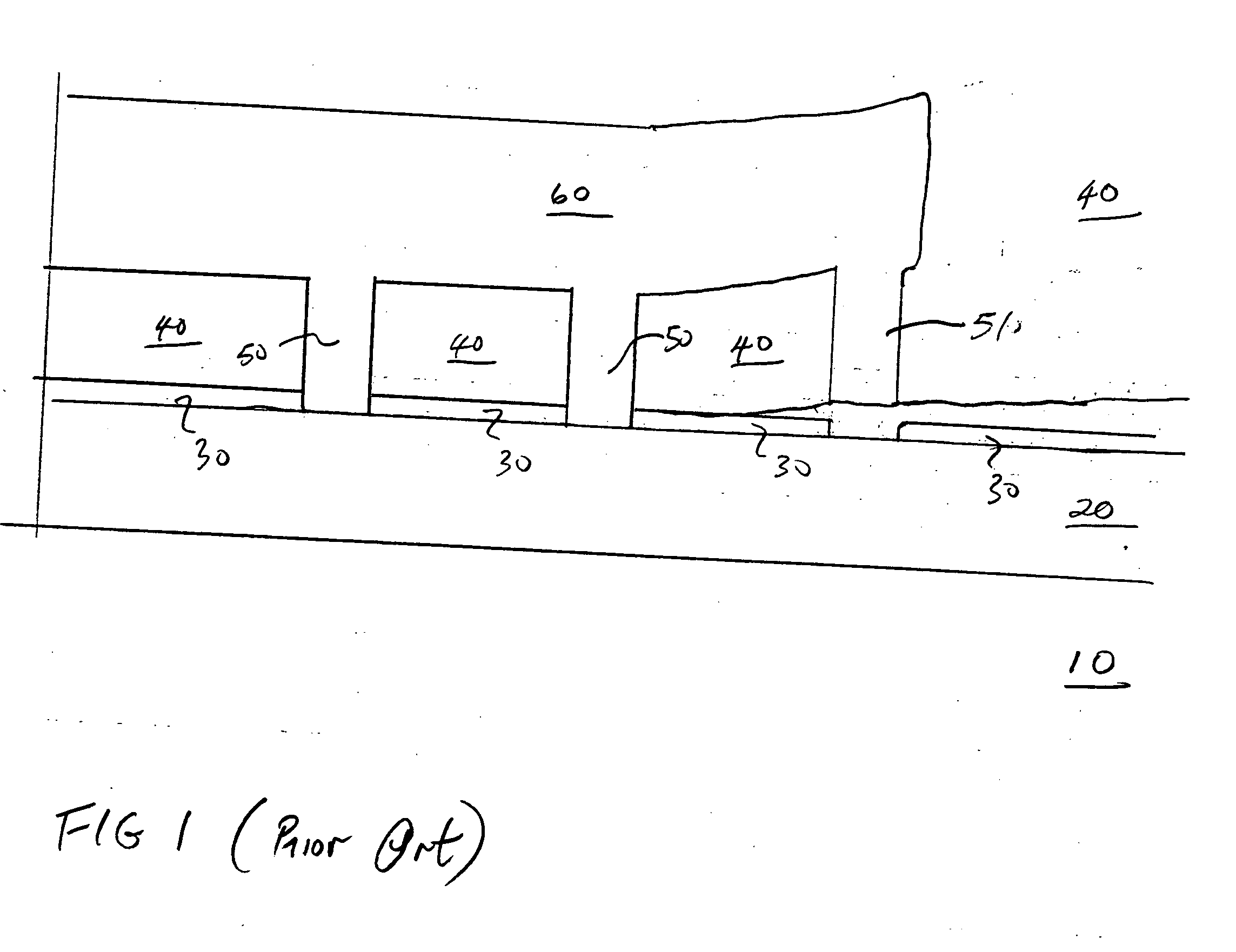

Dual depth trench termination method for improving Cu-based interconnect integrity

ActiveUS20050059189A1Eliminate delaminationMinimum overhang of the copper lineSemiconductor/solid-state device detailsSolid-state devicesLow-k dielectricElectrical and Electronics engineering

A trench is formed in a low K dielectric (100) over a plurality of vias (120) also formed in the low K dielectric layer (100). The vias are separated by a distance of less than XV and the edge of the trench is greater than XTO from the edge α of the via closest to the edge of the trench. The trench and vias are subsequently filled with copper (150), (160) to form the interconnect line.

Owner:TEXAS INSTR INC

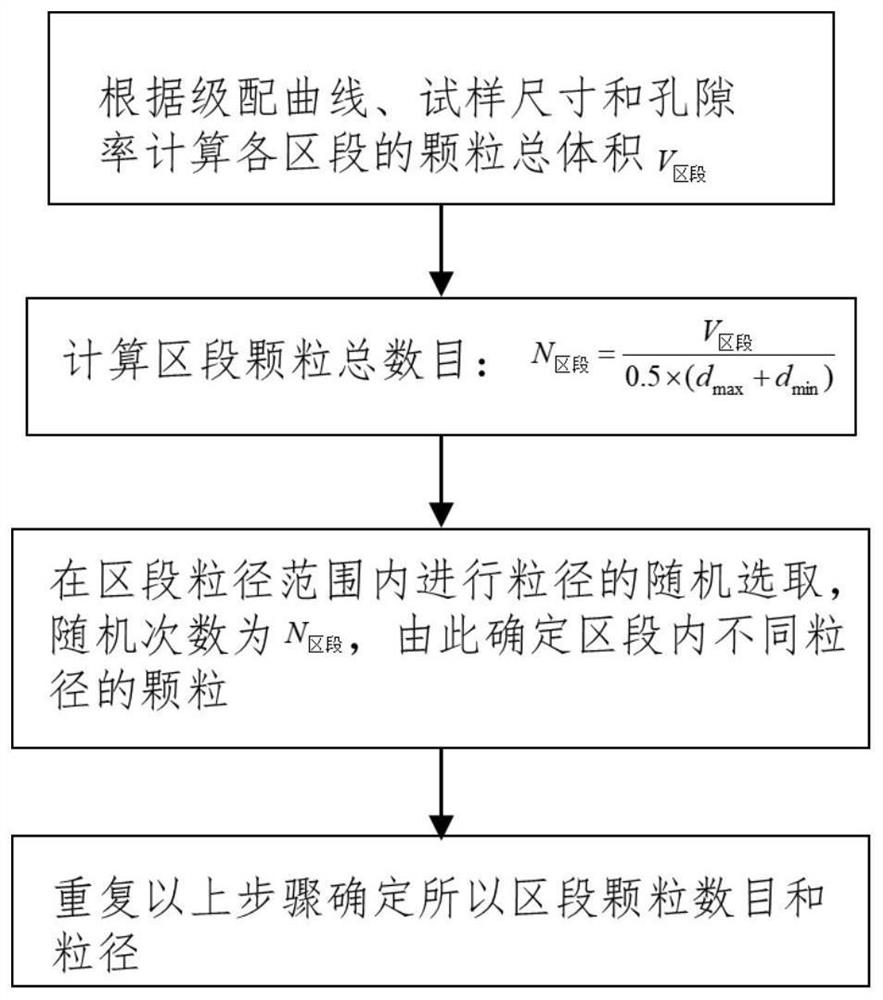

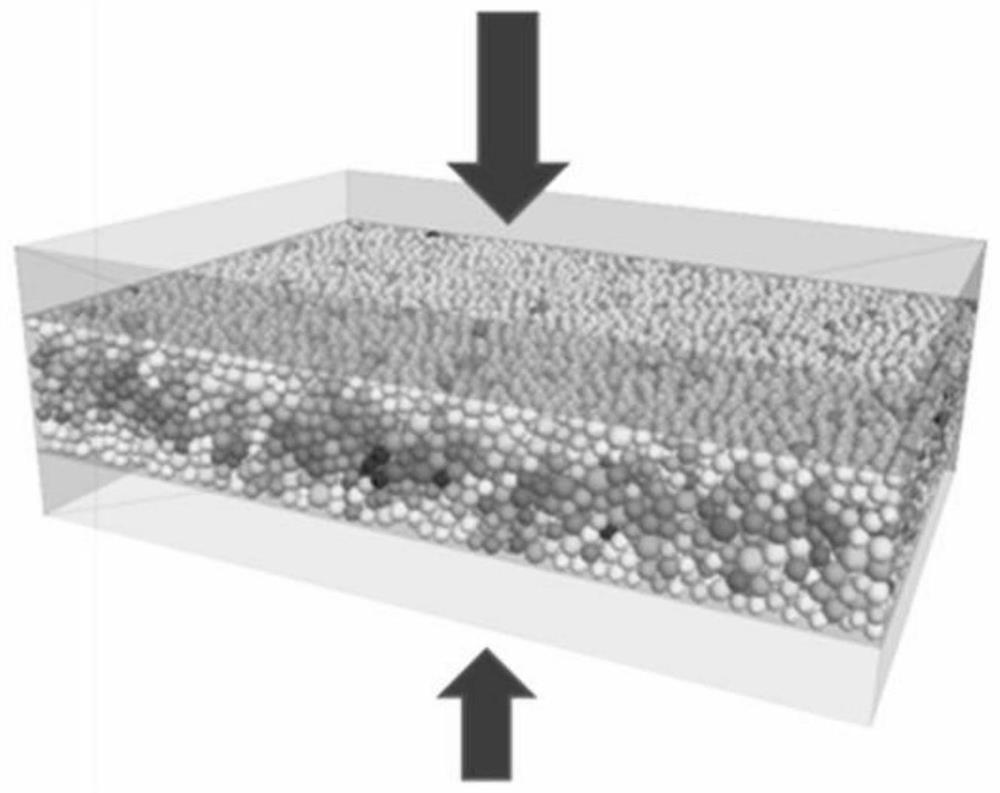

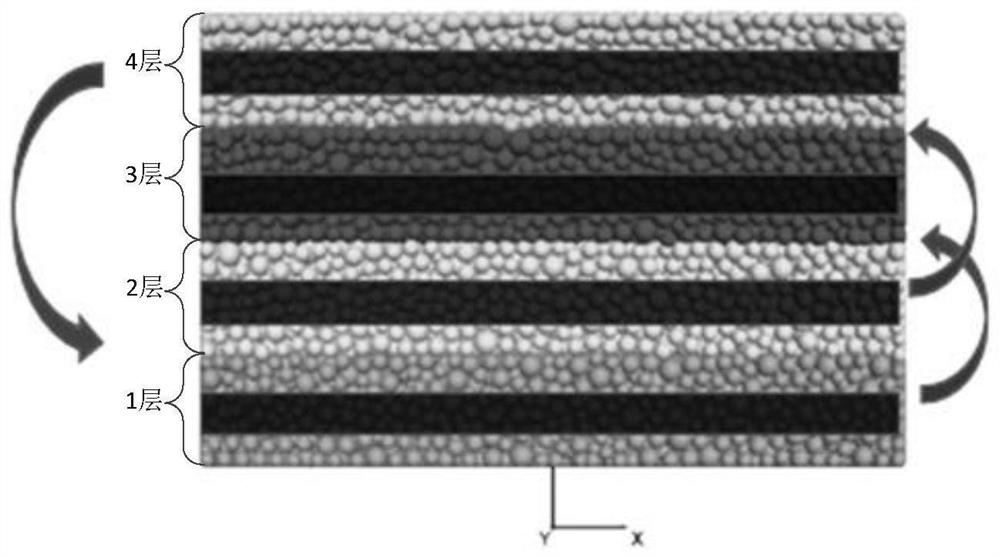

Discrete element soil sample preparation method for generating homogeneous soil sample according to specified grading void ratio

PendingCN113361116AImprove computing efficiencyEliminate delaminationDesign optimisation/simulationSpecial data processing applicationsSoil scienceVoid ratio

A discrete element soil sample preparation method for generating a homogeneous soil sample according to a specified grading void ratio comprises the following steps: 1, determining the number of particles, and determining the number of particles in sections according to control points of a grading curve; 2, conducting single-layer sample preparation: firstly layering samples according to height, determining the number of particles of one layer according to the specified grading and void ratio in the step 1, then generating six walls according to the sizes of two layers, and compacting the particles by moving the upper wall and the lower wall; 3, replacing the particles at the layering position: firstly, assembling the multi-layer samples determined in the step 2, in order to eliminate the layering phenomenon between layers after assembly, deleting the particles between the upper layer and the lower layer, copying the particles in the middle of the lower layer for replacement, and then running enough steps to enable the particles to move in a balanced manner; 4, applying gravity and friction force: after the samples with the required size are obtained in the step 3, finally applying the gravity and the friction force, and running for enough steps to settle and consolidate a soil body under the action of the gravity. According to the method, a homogeneous discrete element soil sample can be rapidly prepared according to the specified grading and void ratio, the calculation efficiency is high, and a real soil body condition can be well simulated.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com