Patents

Literature

73results about How to "Fully hydrated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lignosulfonate series air entraining and water reducing admixture for concrete and its prepn process and application

The present invention relates to preparation process of serial lignosulfonate air entraining and water reducing admixtures for concrete. The preparation process includes the following steps: dissolving solid lignosulfonate in water of the same weight, adding catalyst and oxidant, heating after reaction, adding amine and partial aldehyde to aminate, and dropping the rest aldehyde for condensation reaction to obtain the product; adding surfactant and polymer through stirring, and cooling to obtain liquid phase lignosulfonate as air entraining and water reducing admixture. The present invention is used as the admixture for concrete, and has relatively high water reducing rate, capacity of raising the strength of concrete, and certain setting retarding effect to delay the appearance of cement setting heat peak and reduce crack caused by temperature change.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing composite steel slag carbonized bricks

The invention discloses a method for preparing composite steel slag carbonized bricks, and belongs to the technical field of industrial waste slag utilization. According to the method, steel slags, kerosene and grinding aids are mixed, ball milled, ignited and cooled to obtain combustion slags; the combustion slags are then crushed and sieved to obtain pretreated steel slag powder; aggregates, thepretreated steel slag powder and hydrated lime are stirred and mixed with dispersion liquid to be poured into shape and placed at constant temperature and humidity to obtain unburned bricks; the unburned bricks are subjected to autoclave oxidation and fumigated with vinegar to obtain fumigated bricks; the fumigated bricks are then transferred to a carbonization box and subjected to carbonizationat constant temperature and humidity, and the composite steel slag carbonized bricks are obtained after discharge. The composite steel slag carbonized bricks prepared by adopting the method have excellent strength and stability.

Owner:CHANGZHOU OPTICAL MATERIAL

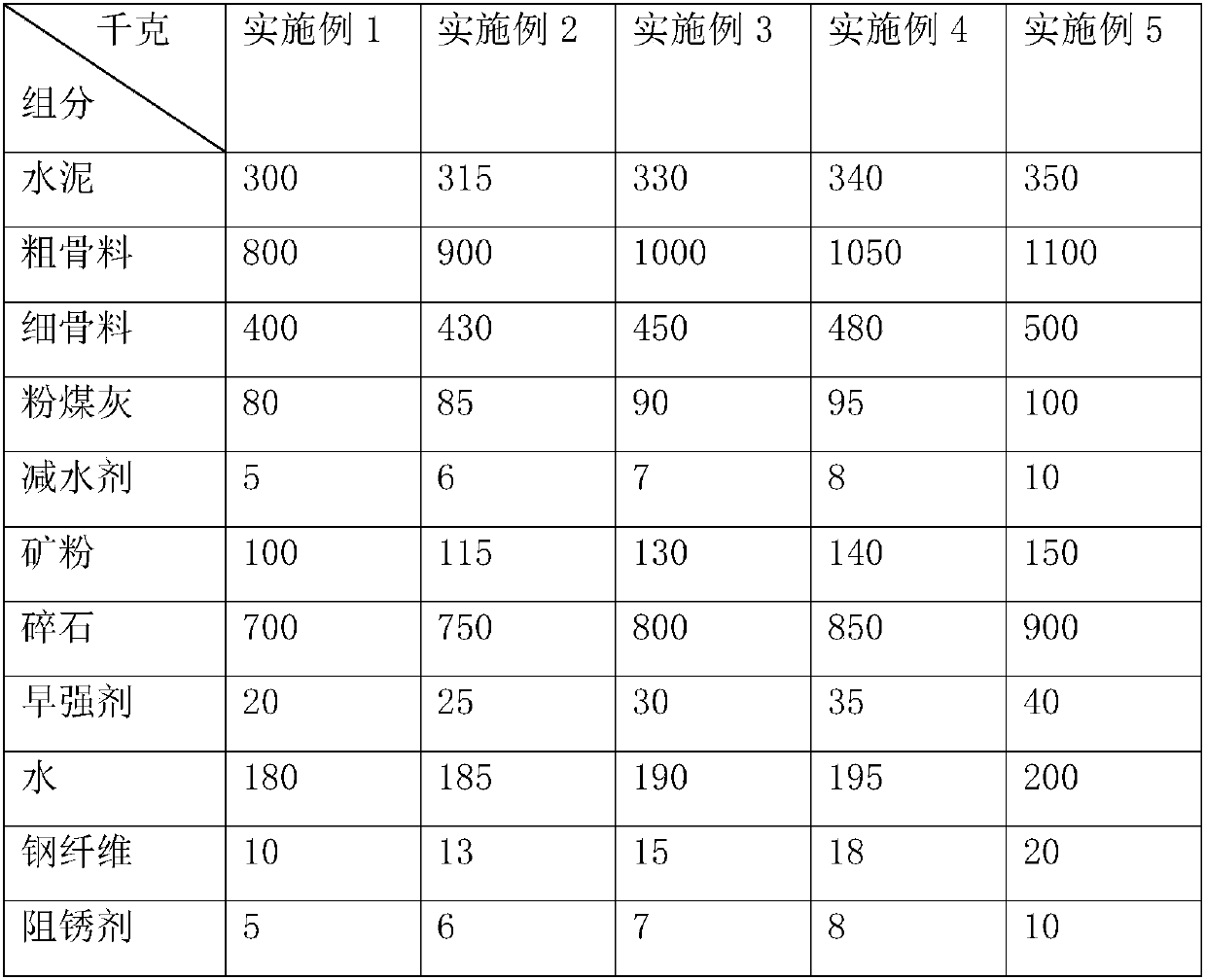

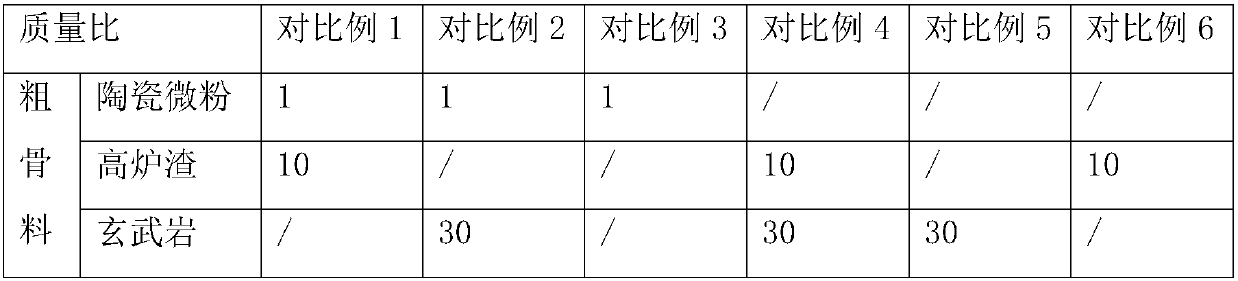

High-strength heat-resistant concrete and preparation method thereof

The invention discloses a high-strength heat-resistant concrete and a preparation method thereof. The high-strength heat-resistant concrete comprises the following components in parts by weight: 300 to 350 parts of cement, 800 to 1100 parts of coarse aggregates, 400 to 500 parts of fine aggregates, 80 to 100 parts of coal ash, 5 to 10 parts of water reduction agent, 100 to 150 parts of mineral powder, 700 to 900 parts of gravels, 20 to 40 parts of early strengthening agent, 180 to 200 parts of water, 10 to 20 parts of steel fibers, and 5 to 10 parts of antirust agent; the coarse aggregates areprepared by mixing ceramic micro powder, blast furnace slag and basalt in a weight ratio of 1: (10 to 15): (30 to 50); and the fine aggregates are prepared by mixing 20 to 40 parts of silica fume, 10to 20 parts of expanded perlite and 15 to 30 parts of sintered magnesite. The high-strength heat-resistant concrete has the advantages of good compactness, high strength, high heat resistance, good workability and pumpability.

Owner:江苏盛达飞建筑材料有限公司

Preparation method of low-grade activated coal ash composite material

InactiveCN102718423ASlow down excessive consumptionLow costCement productionIndustrial wasteAdverse effect

The invention relates to a preparation method of a low-grade activated coal ash composite material applied to cement and concrete. The low-grade activated coal ash composite material is prepared by taking the low-grade coal ash as a main raw material and slag, red mud, and other industrial waste residues, limestone powder and semi-hydrated gypsum as auxiliary materials through the combined action of physical milling and activating and chemical excitation. In the process of mixing concrete materials, 30% by weight of the activated coal ash composite material is used to replace PO52.5, PO42.5 or PO32.5 silicate cement; under the circumstance that other mixing materials remain the same, a great amount of cost can be saved for mixing the concrete per cube meter; the strength of the mixed concrete at all ages is equal to or higher than that of contrast concrete; the newly mixed concrete has the characteristics of high workability, low slump loss, low heat of hydration, good transitive performance of long-term strength, high resistance to sulfate attack, high chemical resistance, high durability, and the like; and the added coal ash composite material has no adverse effect on the performance of the concrete.

Owner:CHINA UNIV OF MINING & TECH

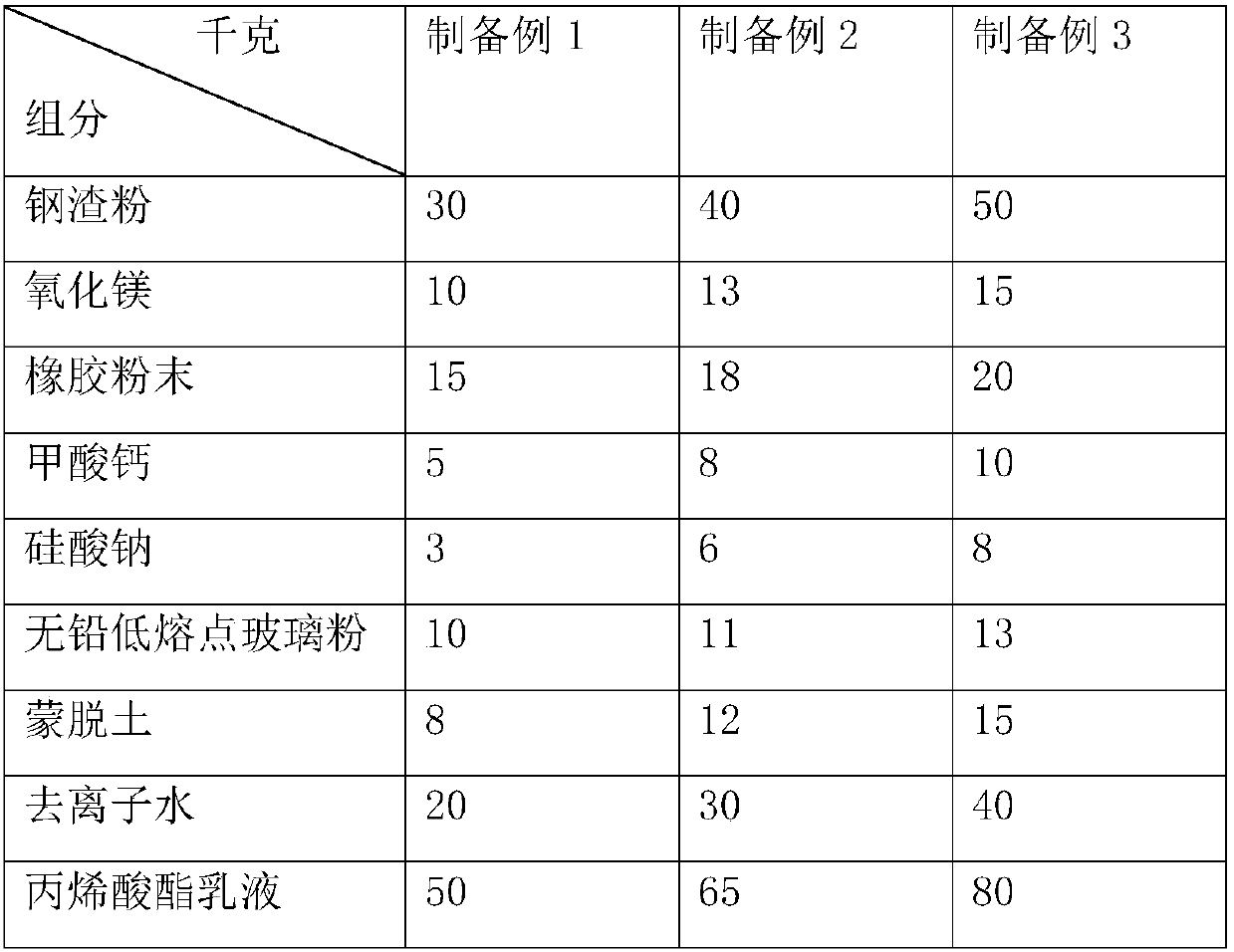

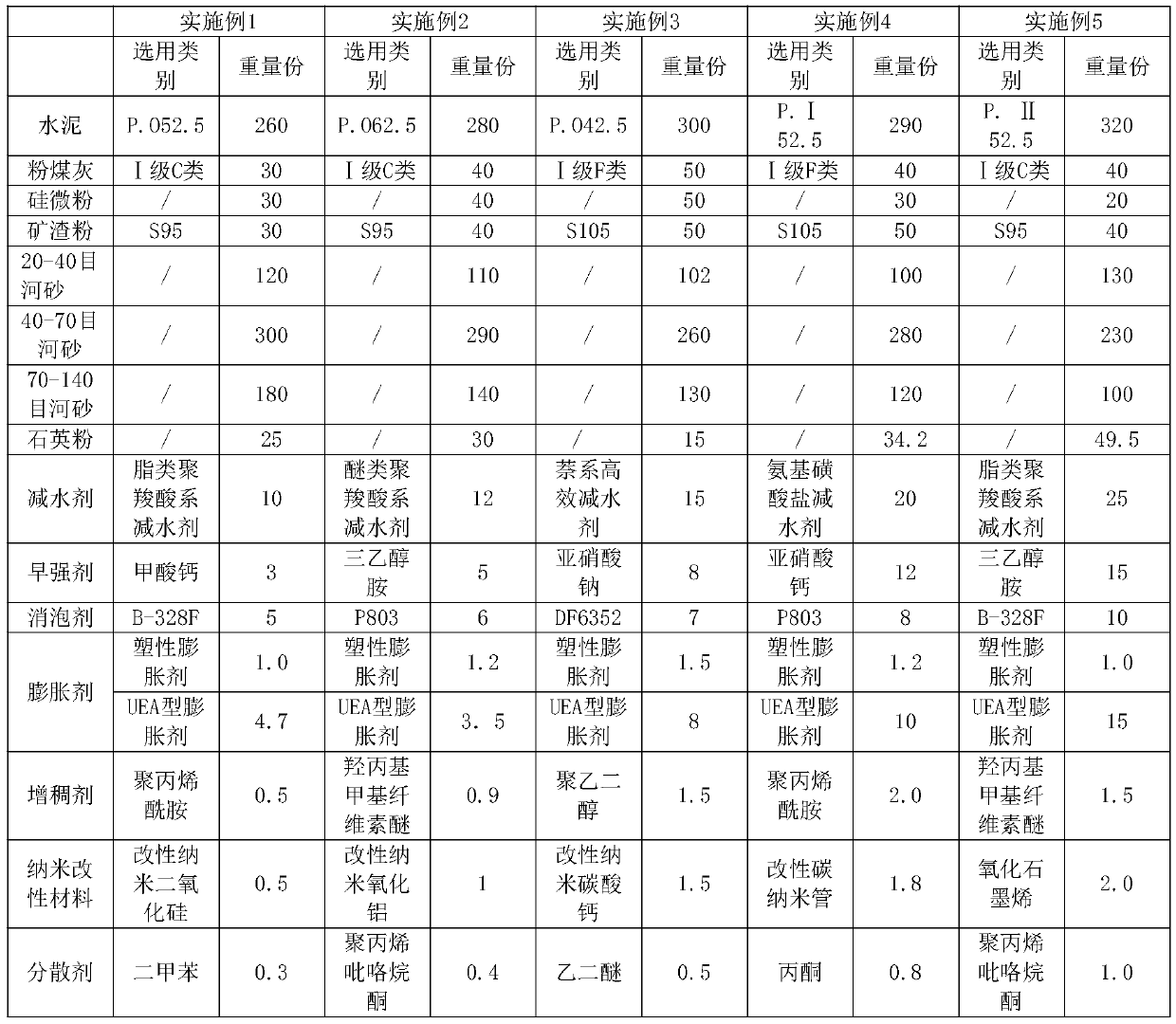

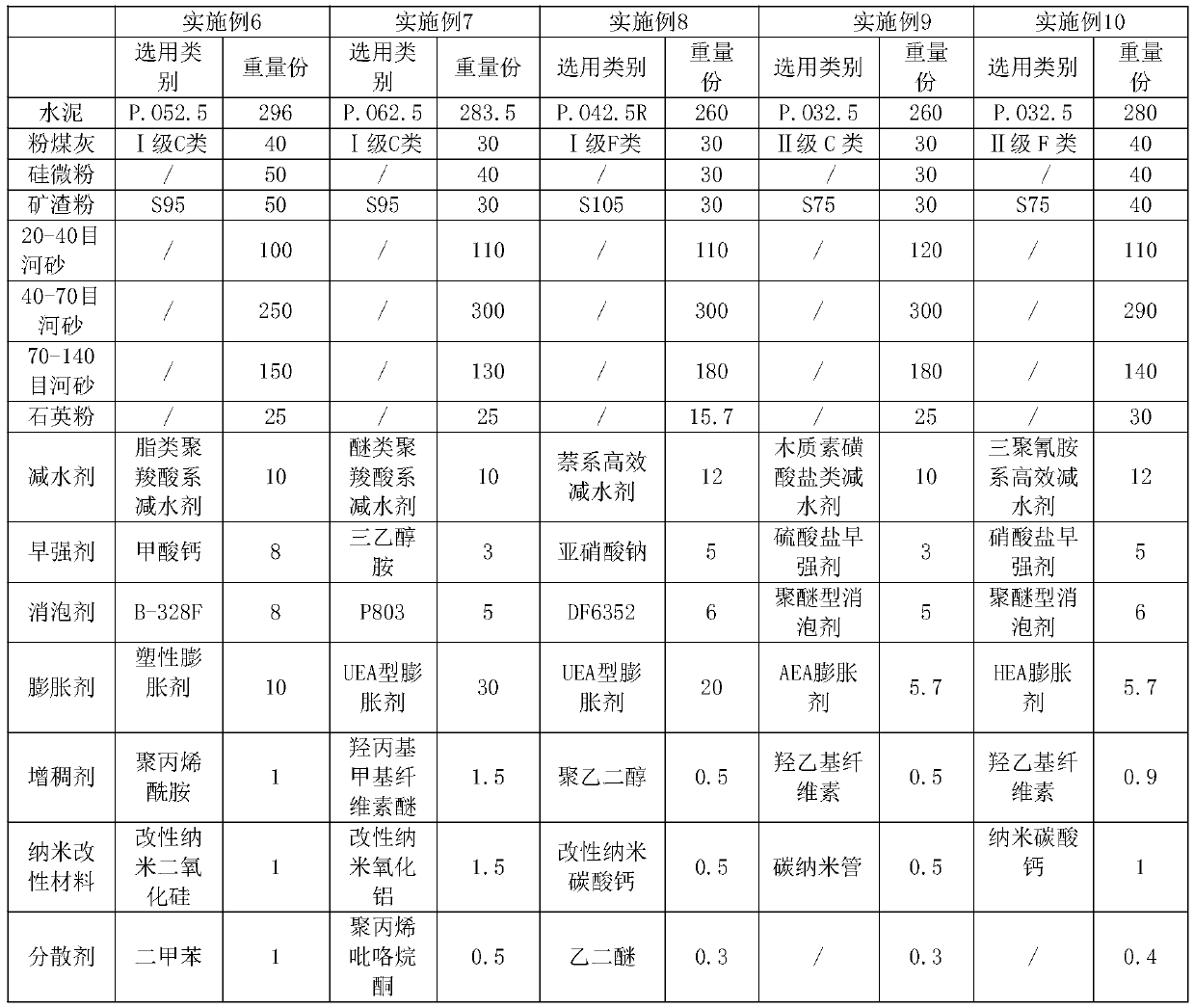

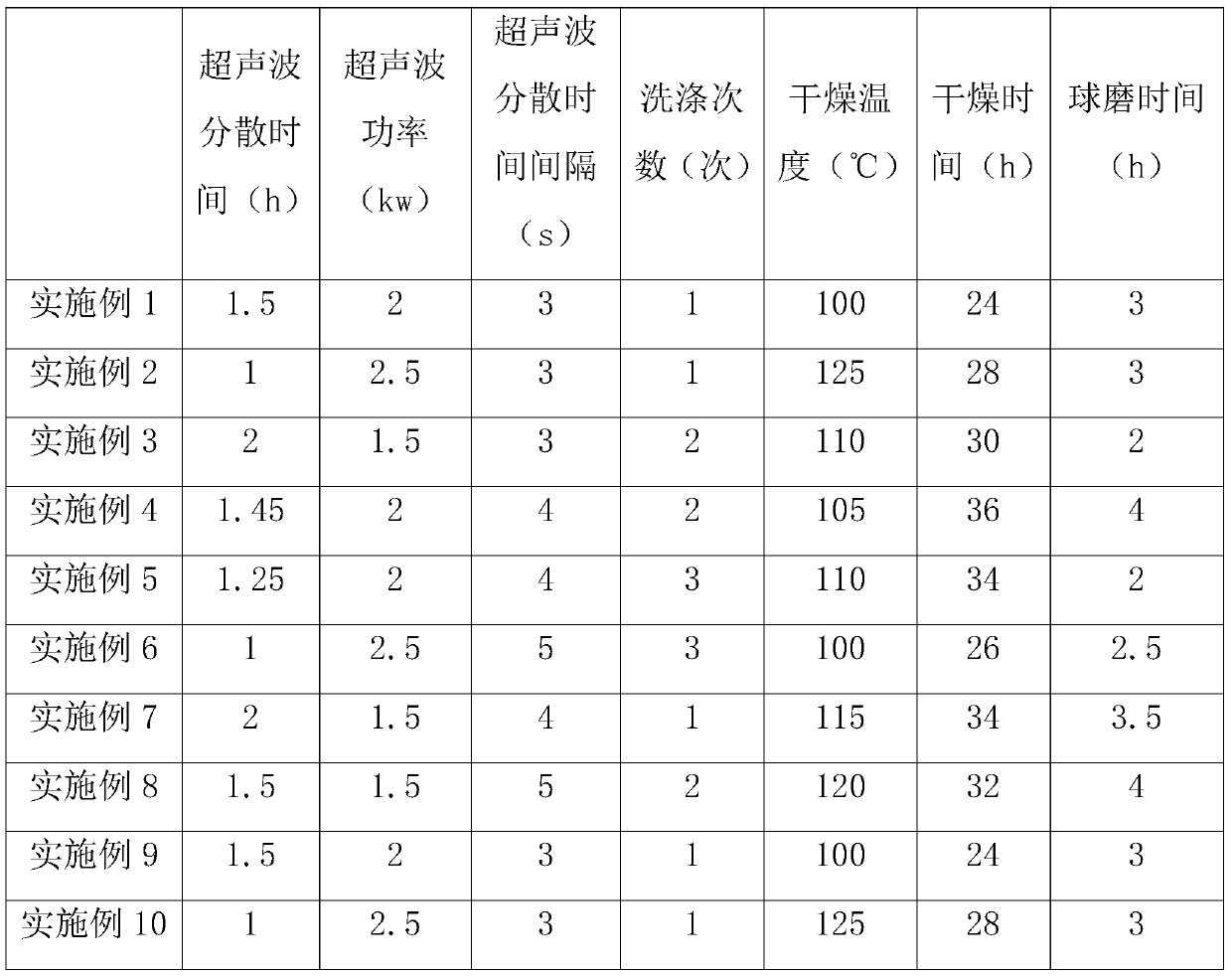

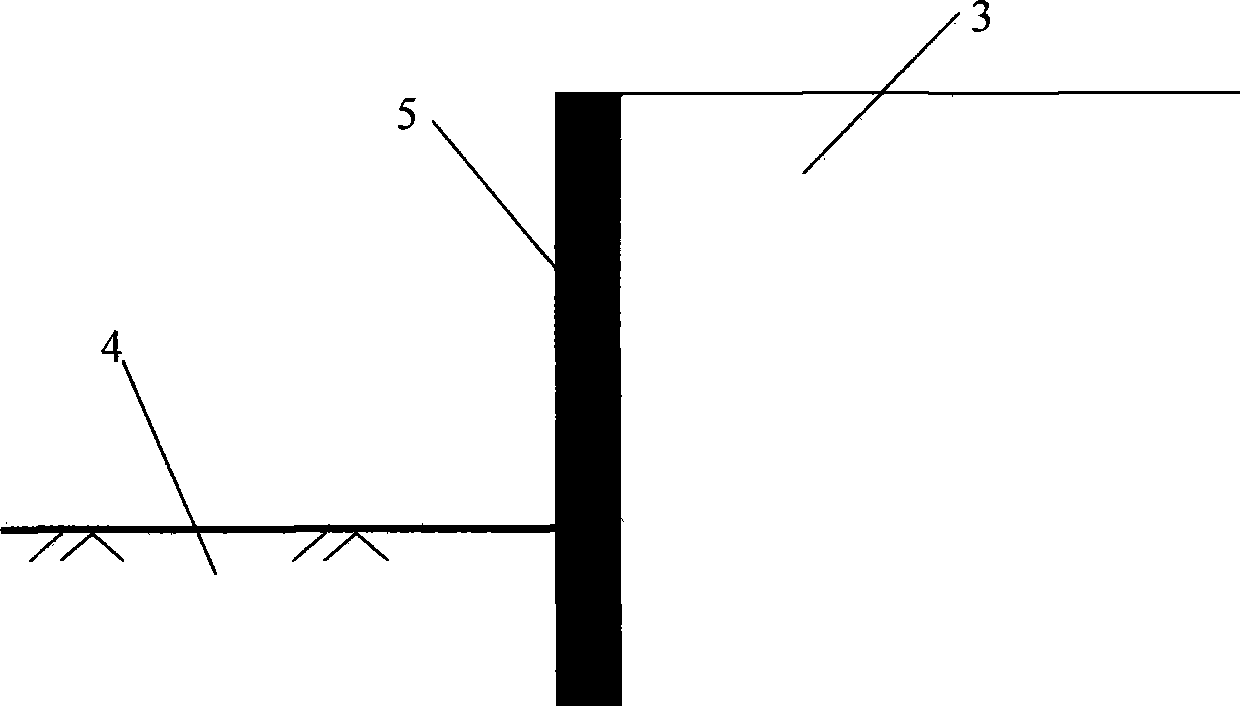

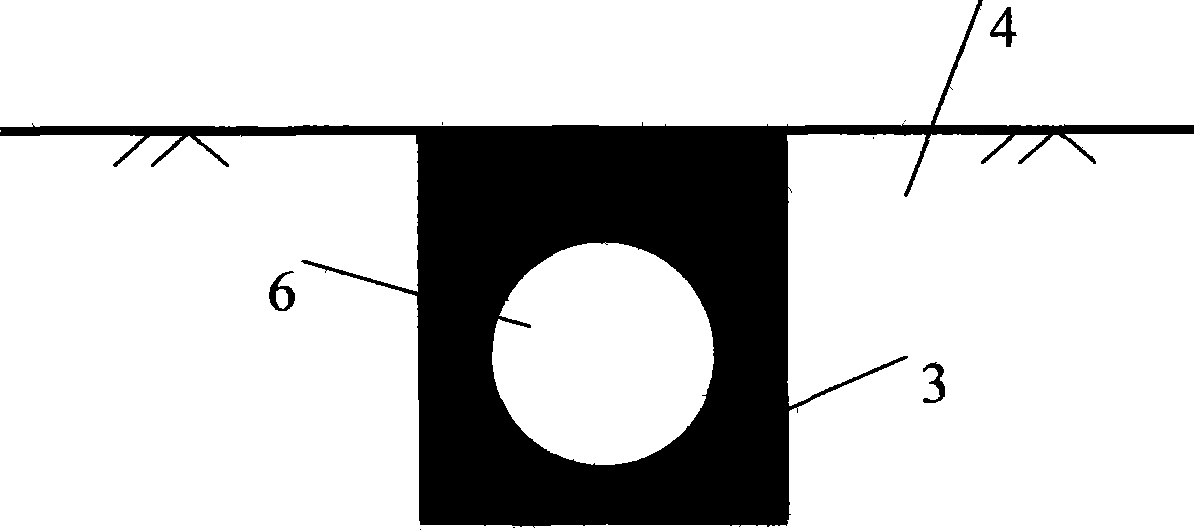

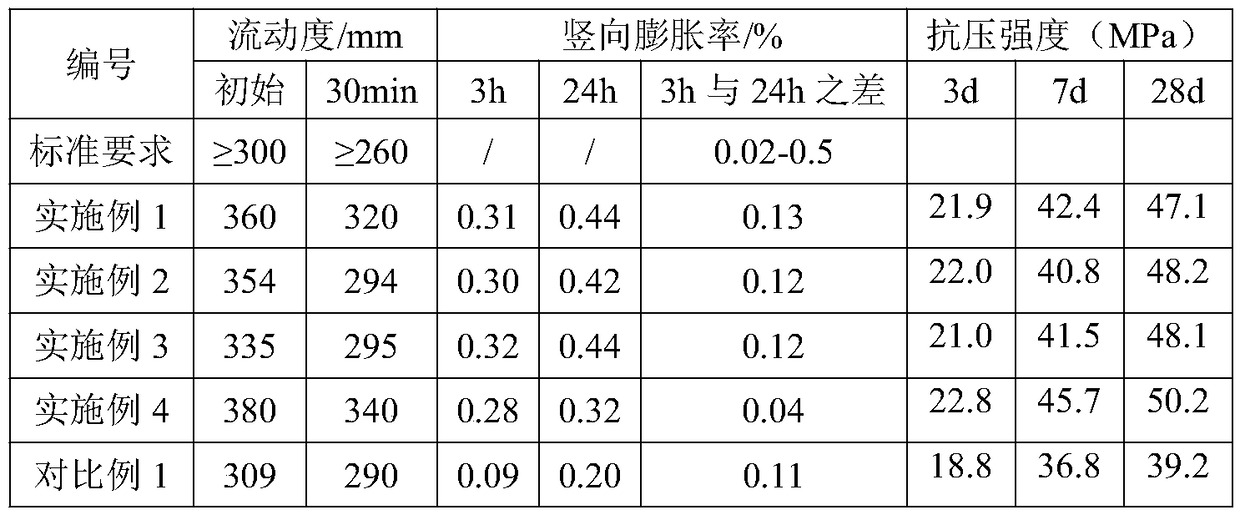

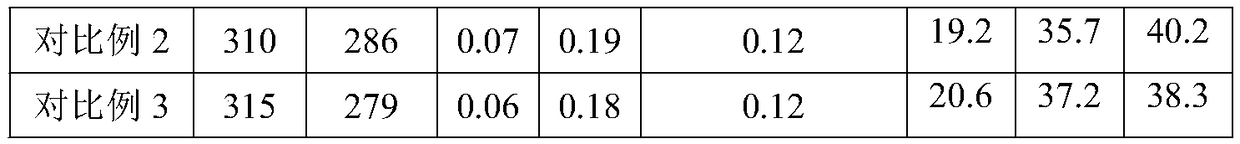

High-performance grouting material for prefabricated buildings and preparation method thereof

InactiveCN111170693AIncrease contact areaAvoid the risk of slow growth or even regression in strengthSlagWater reducer

The invention discloses a high-performance grouting material for prefabricated buildings, which comprises the following raw materials in percentage by weight: a composite cementing material: 26-32% ofcement, 3-5% of fly ash, 2-5% of silica powder and 3-5% of slag powder, graded fine sand: 10%-13% of river sand of 20-40 meshes, 23%-30% of river sand of 40-70 meshes, 10%-18% of river sand of 70-140meshes and 2.5%-4.95% of quartz powder, auxiliary agents: 1%-2.5% of a water reducing agent, 0.3%-1.5% of an early strength agent, 0.5%-1.0% of a defoaming agent, 0.47%-3.0% of an expanding agent and0.05%-0.2% of a thickening agent, and a performance regulator: 0.05%-0.2% of a nano modified material and 0.03%-0.1% of a dispersing agent. The high-performance grouting material for prefabricated buildings has the advantages of early strength, quick hardening, quick and stable strength development, high flowability, micro expansion, no shrinkage, high breaking strength and fracture toughness, low cost and the like.

Owner:CHONGQING ZHONGKE CONSTR GROUP

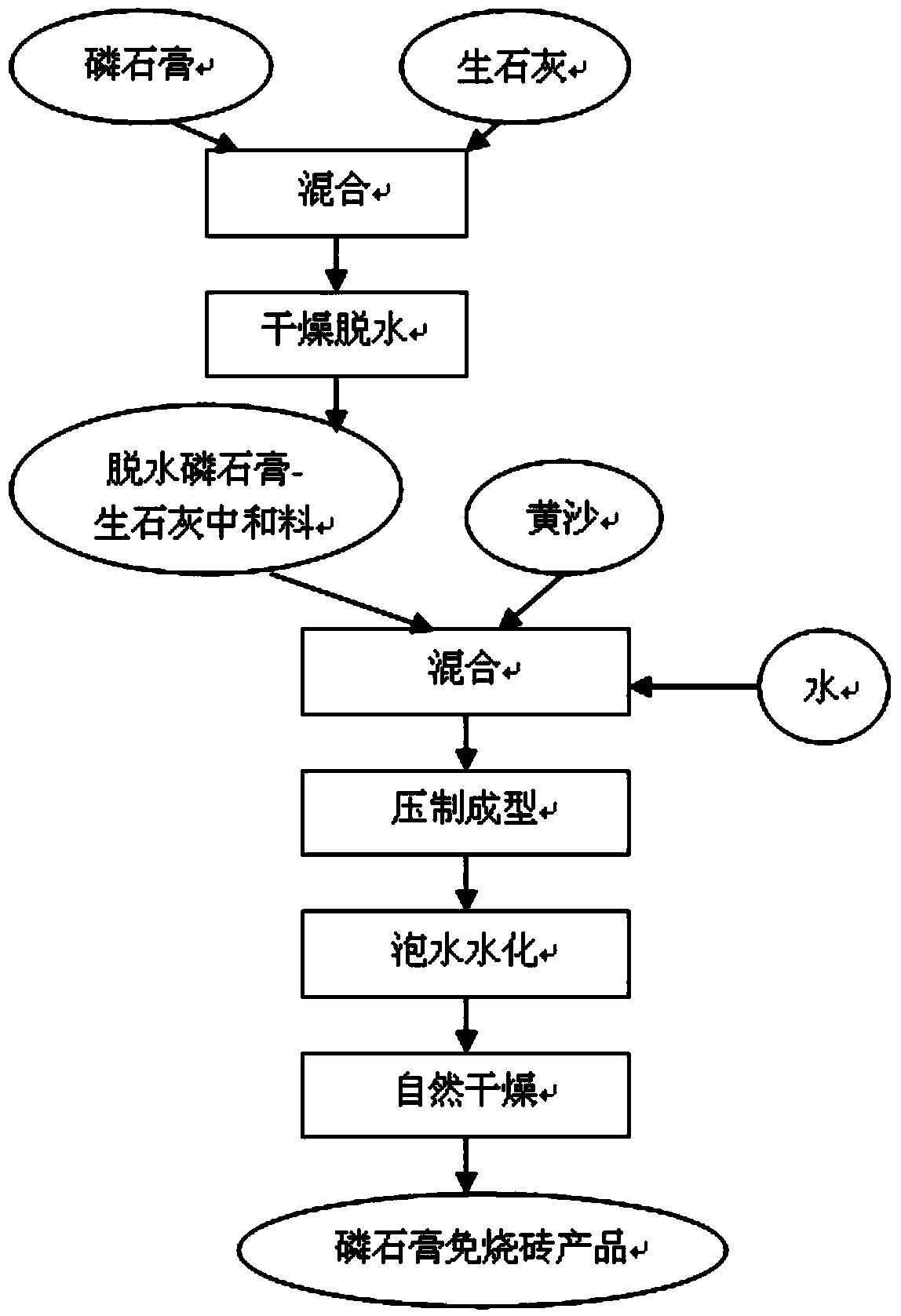

Production process for high-strength high-volume phosphogypsum baking-free brick

The invention relates to a production process for a high-strength high-volume phosphogypsum baking-free brick. The production process comprises the following steps: (1), material pre-treating: mixing phosphogypsum with quick lime to obtain a material mixture, placing the material mixture in drying machinery for drying at 180 DEG C under a normal pressure condition after aging for one day to obtain a dehydrated phosphogypsum-quick lime neutralized material; (2), preparing materials: weighing the dehydrated phosphogypsum-quick lime neutralized material and yellow sand according to a proportion, adding into a stirrer for stirring and uniformly mixing to obtain mixed batch which comprises the following components in percent by weight: 70%-90% of dehydrated phosphogypsum-quick lime neutralized material, and 10%-30% of yellow sand; (3), watering and stirring; (4), pressing and forming; (5), soaking in water and hydrating; and (6), drying. The method provided by the invention is simple in step, not mixed with cement, and low in cost; and moreover, the prepared phosphogypsum baking-free brick is high in strength and suitable for industrial production.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

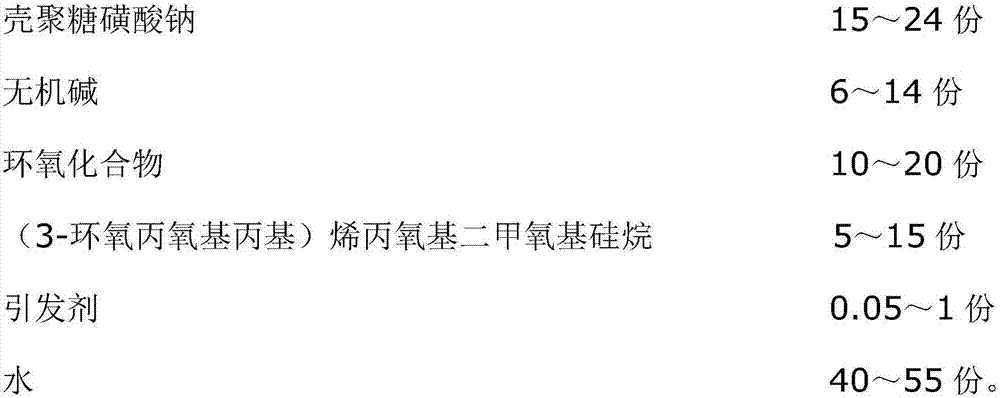

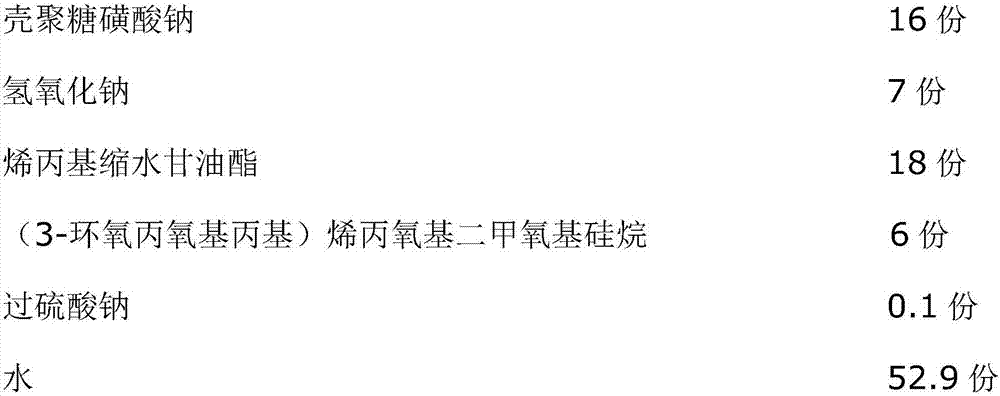

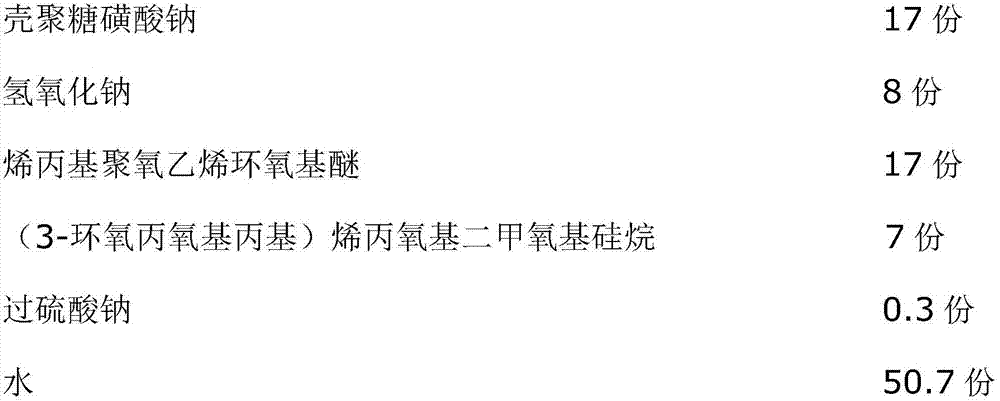

Chitosan sodium sulfonate containing concrete synergist and preparation method thereof

The invention discloses a chitosan sodium sulfonate containing concrete synergist and a preparation method thereof, and belongs to the field of a concrete additive. The synergist comprises chitosan sodium sulfonate, inorganic base, an epoxy compound, (3-epoxy propoxy propyl) allyloxy dimethoxy silicane, an initiator and water, wherein the initiator is a mixture made from one or more than two of sodium persulfate, potassium persulphate or ammonium persulfate. The preparation method comprises: adding weighed chitosan sodium sulfonate, inorganic base and water to a reaction vessel, then adding the epoxy compound and (3-epoxy propoxy propyl) allyloxy dimethoxy silicane to the reaction vessel; and adding the initiator to obtain the concrete synergist. The synergist improves the dispersity of cement particles, stimulates the action of cement, allows the hydration reaction to be fully carried out, improves the comprehensive properties of concrete, raises the strength level of concrete, saves the concrete consumption by about 10%, and reduces the production cost of concrete.

Owner:华海菲菲(河北)混凝土外加剂有限公司

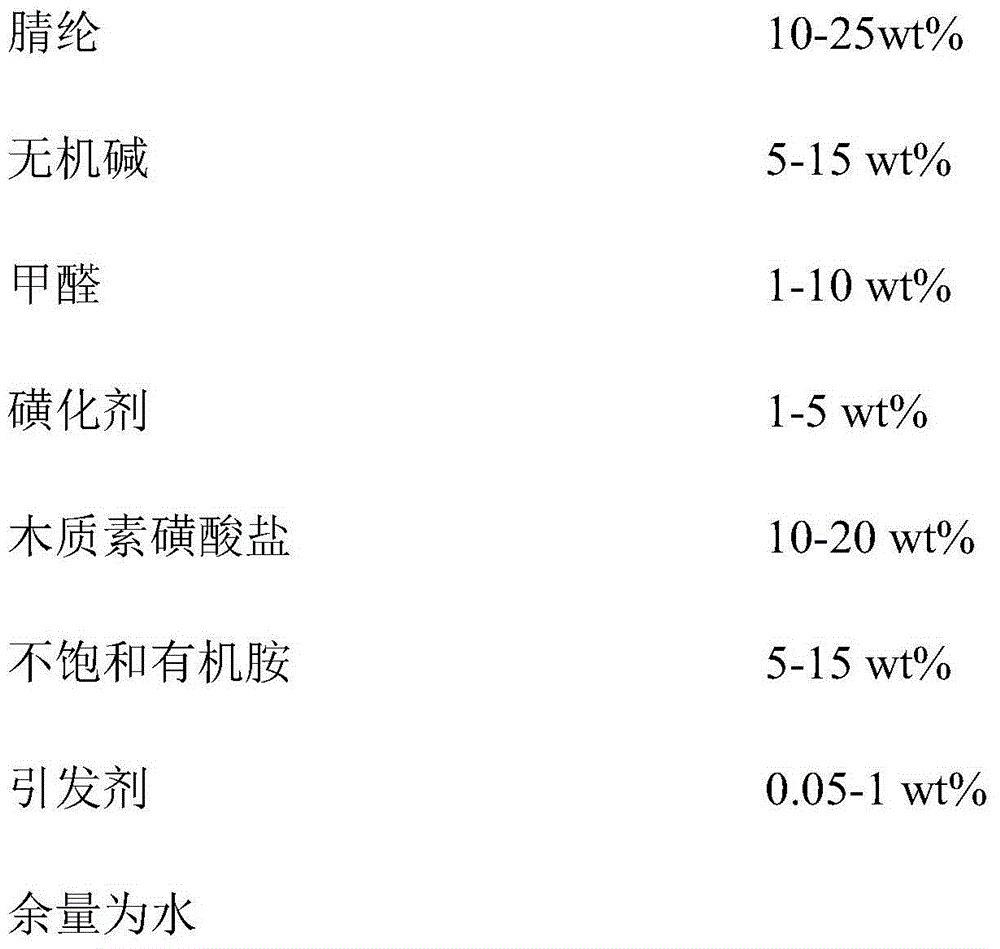

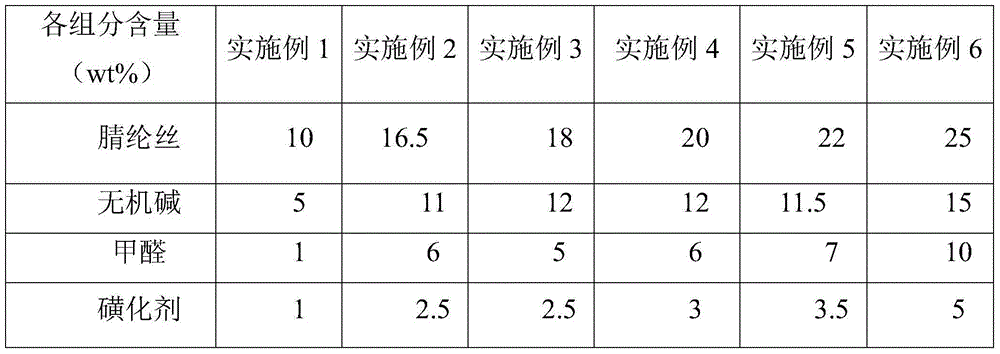

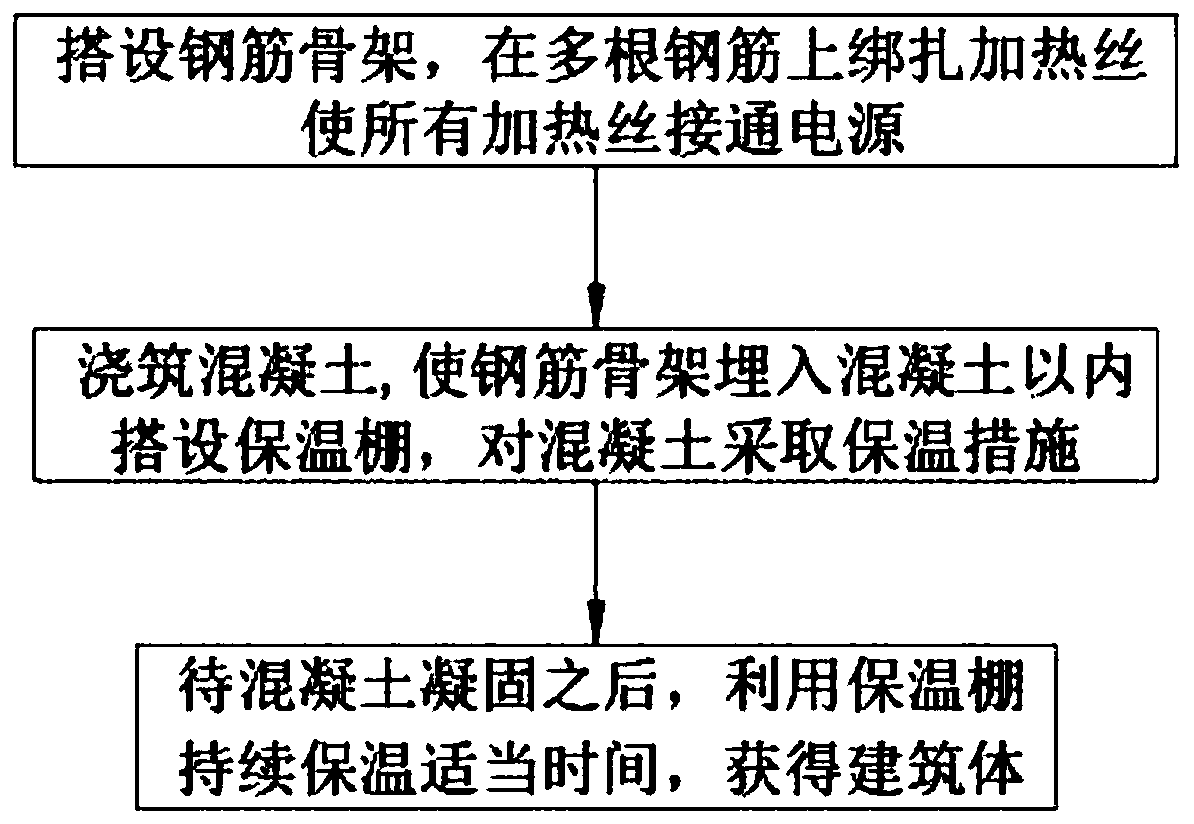

Concrete synergist and preparation method thereof

The invention discloses a concrete synergist and a preparation method thereof. The acrylic fibers in the textile industry are used as the main raw material for preparing the concrete synergist; the concrete synergist prepared by the method is able to improve the strength grade of concrete, about 10% cement of the concrete can be saved, and meanwhile, the working performance and strength of the concrete can be ensured, and the production cost is decreased; the acrylic fibers serving as the main material for preparing the concrete synergist can be waste acrylic fibers obtained from acrylic fibers production and processing or other plants using acrylic fibers as the main raw materials. The method for preparing the concrete synergist has the advantages that the waste acrylic fibers are effectively utilized, so that the environmental burden caused by the waste acrylic fibers can be decreased, and a good application prospect is brought; the concrete synergist aims at improving concrete performances.

Owner:郝旭晖

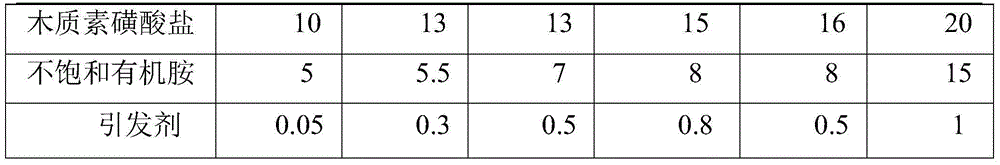

A method for reinforced concrete work construction in cold winter

InactiveCN110230260AFully hydratedComplete hydrationBridge erection/assemblyHydration reactionReinforced concrete

The invention provides a method for reinforced concrete work construction in cold winter. The method comprises the steps of erecting a steel skeleton at a construction site, selecting a plurality of steel bars as heat conductive steel bars, tying heating wires on the heat conductive steel bars, connecting all the heating wires to a power source, pouring concrete to enable the steel skeleton to beembedded in the concrete and obtaining a construction body after the concrete solidifies. According to the technical scheme of the present invention, by tying the heating wires on the plurality of steel bars, when the concrete is poured, the heating wires heat the interior of the concrete, so that the temperature inside the concrete is always maintained within a temperature range suitable for thehydration reaction, thus ensuring that the concrete can be solidified smoothly under cold conditions; and the strength of the concrete structure during solidification continues to grow. According to the invention, heat preservation measures are taken for the concrete by setting up a heat insulation shed, so that the concrete hydration reaction can be carried out more fully and completely, and a foundation is laid for improving the construction quality of the building body.

Owner:SINOHYDRO BUREAU 9

Durable granulated blast furnace slag building block

The invention discloses a durable granulated blast furnace slag building block and belongs to the technical field of a building material. The durable granulated blast furnace slag building block is prepared according to the following steps: crushing granulated blast furnace slag and sieving, thereby acquiring refined granulated blast furnace slag; mixing and stirring the acquired refined granulated blast furnace slag and sulfuric acid, soaking and filtering, thereby acquiring the pretreated granulated blast furnace slag; stirring, mixing and fermenting paper-making black liquor, chitosan solution, soybean protein powder and biogas slurry, thereby acquiring a fermentation liquor; mixing the pretreated granulated blast furnace slag and the fermentation liquor, soaking and filtering, therebyacquiring the modified granulated blast furnace slag; mixing and stirring the modified granulated blast furnace slag, gypsum, quicklime, cement, water, modified charring cocoanut fiber and silane coupling agent, thereby acquiring a mixed slurry; injecting the mixed slurry into a mold, pressing and forming, thereby acquiring a blank; placing the blank into a curing chamber and curing, thereby acquiring the durable granulated blast furnace slag building block. The durable granulated blast furnace slag building block provided by the invention has excellent mechanical properties and durability.

Owner:杨忠华

Preparation method of pressure-resistant aerated brick

The invention discloses a preparation method of a pressure-resistant aerated brick, and belongs to the technical field of building materials. The preparation method comprises the following steps: sequentially weighing fluorite slag powder, cement, gypsum, modified mixed powder, pretreated vitrified micro beads, mixed nano powder, aluminum powder, sepiolite, graphite oxide, talcum powder, calcium stearate, sodium stearate, a dispersing agent and water according to weight parts, calcining the fluorite slag powder to obtain pretreated fluorite slag powder, mixing the pretreated fluorite slag powder with the gypsum, adding water, carrying out stirring and mixing to obtain pretreated mixed slurry, mixing the pretreated mixed slurry with the cement, adding the modified mixed powder, the pretreated vitrified micro beads, the mixed nano powder, the aluminum powder, the sepiolite, the graphite oxide, the talcum powder, the calcium stearate, the sodium stearate and the dispersing agent, carryingout stirring and mixing to obtain mixed slurry, carrying out moulding by casting on the mixed slurry, carrying out pre-curing and demoulding to obtain a blank, and carrying out autoclaved curing on the blank to obtain the pressure-resistant aerated brick. The pressure-resistant aerated brick obtained by the preparation method provided by the invention has excellent pressure resistance.

Owner:嵊州市平隆新型墙体建材股份有限公司

Preparation method of anti-freezing cement mortar with rice husk ash and silica fume

InactiveCN109796164AReduce the amount of solutionHigh strengthSolid waste managementAnti freezingHusk

The invention belongs to the technical field of manufacture of building materials in cold regions, relates to a preparation method of anti-freezing cement mortar with rice husk ash and silica fume, and is intended to solve the problem that existing cement mortar has insufficient anti-freezing capacity and durability. The preparation method comprises the steps of calcining at a high temperature; performing ball milling; proportioning; mixing; vibrating; steam-curing at a high temperature. The preparation method has the advantages that rich husk ash and silica fume as industrial and agriculturalbyproducts contain massive active SiO2 and may be used as mineral admixtures to replace cement so that usage of building cement can be effectively reduced, with emission of CO2 upon cement productionreduced; therefore, waste is turned into wealth, energy is saved, and environment is protected; the rice husk ash is calcined at 800 DEG C, the interior network structure can be broken, and therefore, the finished material has greatly enlarged specific surface area, with the quantity of active SiO2 in the finished material also increased.

Owner:NORTHEAST FORESTRY UNIVERSITY

Waterproof and fireproof thermal insulation wall

ActiveCN110078461AReduce moisture returnImprove water resistanceWallsHeat proofingPorosityThermal insulation

The invention discloses a waterproof and fireproof thermal insulation wall. The thermal insulation wall is prepared from raw materials as follows: 350-400 parts of magnesium oxide, 150-200 parts of magnesium chloride, 4-5 parts of phosphoric acid, 10-15 parts of an organosilicon waterproofing agent and 60-80 parts of expanded perlite. The thermal insulation wall has the advantages as follows: a magnesium oxychloride cement product is a product capable of being recycled and comprehensively utilized and is widely applied in the construction industry due to the characteristics of low price, highmechanical strength, good wear resistance, excellent flame retardation and the like, however, the magnesium-oxy-chloride cement product has the characteristics of poor water resistance, high probability of buckling deformation and the like. After the organosilicon waterproofing agent is added, MgCl2-6H2O in slurry reacts more sufficiently, damping of the product is reduced, besides, a reaction produced product forms hydrophobic capillary channels, external moisture cannot enter the capillary channels, and the water resistance of the magnesium-oxy-chloride cement product is greatly enhanced. Phosphoric acid can improve stability of magnesium oxychloride cement hydrate in water. The expanded perlite has good thermal insulation and flame retardance effects and a good thermal insulation effectdue to the characteristic of porosity.

Owner:浙江卓元建设有限公司

High-strength anti-crack concrete and preparation method thereof

ActiveCN110950603AFully hydratedReduces the effects of early hydrationSuperplasticizerCarboxylic acid

The invention relates to high-strength anti-crack concrete and a preparation method thereof. The high-strength anti-crack concrete comprise, by weight, 450-500 parts of cement, 40-60 parts of fly ash,30-50 parts of silica fume, 1050-1150 parts of coarse aggregate, 580-600 parts of fine aggregate, 140-160 parts of modified waste ABS plastic particles, 40-60 parts of modified zeolite powder, 0.5-0.9 parts of polypropylene fibers and 15.4-17.1 parts of a polycarboxylate superplasticizer, and a water-binder ratio is 0.20 to 0.25. The high-strength anti-cracking concrete provided by the inventionhas the advantages of small internal shrinkage stress, high overall strength, obvious shrinkage reduction effect, excellent anti-cracking performance, simple preparation method, cheap and easily available raw materials, utilization of waste materials and high environmental protection benefit.

Owner:中建商品混凝土江西有限公司 +2

Colored water-permeable concrete and preparation method thereof

InactiveCN112573878AThe ratio is scientific and reasonableHigh compressive strengthSolid waste managementPlant fibreCompressive strength

The invention relates to colored water-permeable concrete and a preparation method thereof, and belongs to the technical field of concrete production, the colored water-permeable concrete comprises the following components in parts by weight: 260-350 parts of cement, 80-90 parts of water, 1200-1300 parts of coarse aggregate, 5-7 parts of hybrid fiber, 3-6 parts of whisker filler, 2-4 parts of silicone acrylic emulsion, 25-35 parts of pigment and 3-5 parts of water reducing agent; wherein the hybrid fibers comprise steel fibers and nano calcium carbonate modified plant fibers; the preparation method comprises the following steps: S1, uniformly mixing and stirring the hybrid fibers and water; and S2, sequentially adding the excess materials into the mixture obtained in the step S1, and uniformly stirring to obtain the colored water-permeable concrete. The colored pervious concrete has the effect of improving the compressive strength of the colored pervious concrete.

Owner:BEIJING JINYU CONCRETE

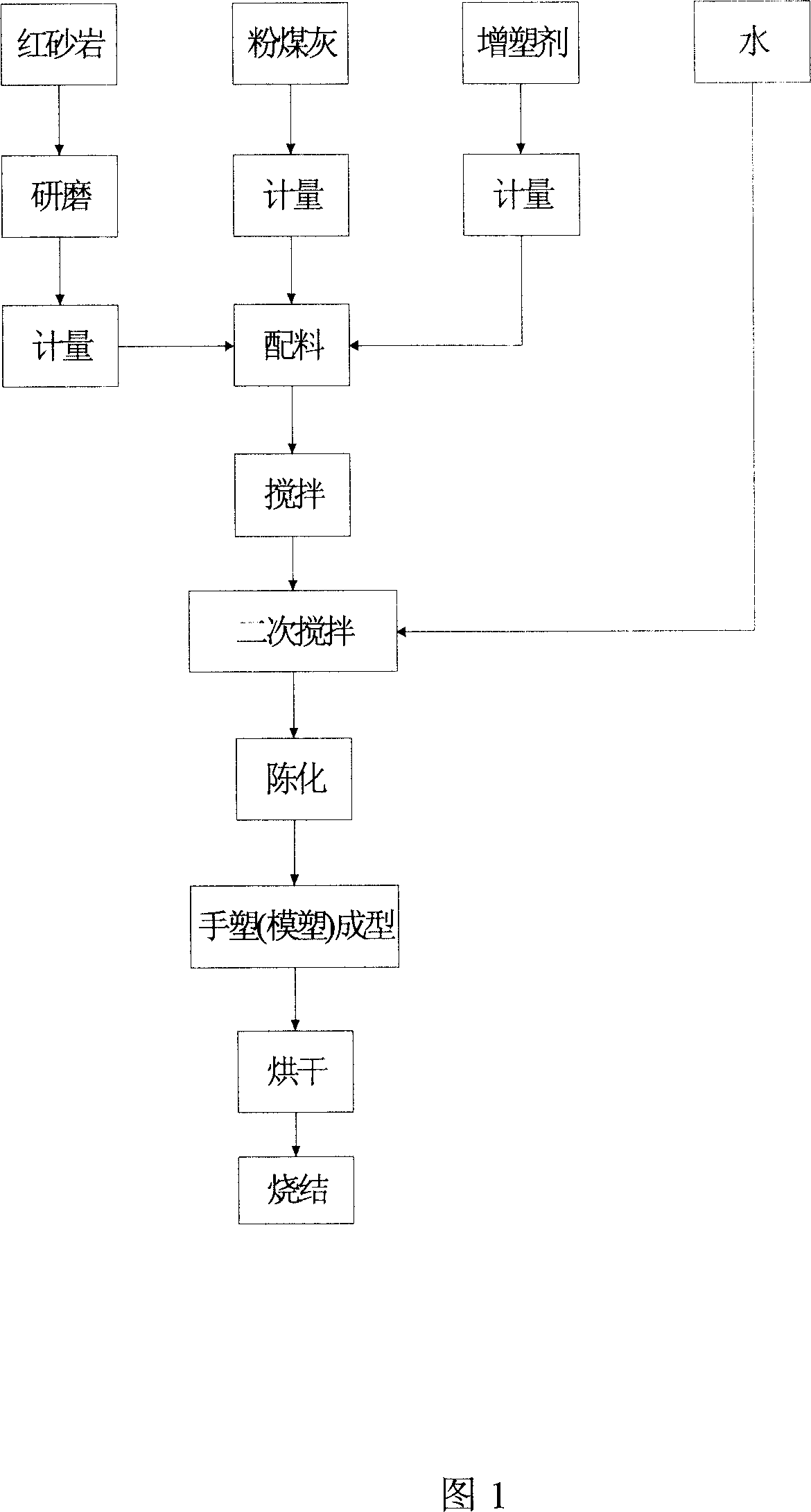

Building bricks sintered from fly ash and red sandstone, and preparation technique

InactiveCN1958508ALarge displacementProne to subsidenceCeramic materials productionClaywaresSodium BentoniteBrick

This invention discloses a method for preparing construction bricks by sintering fly ashes and red sandstone. The raw materials comprise: fly ashes, red sandstone, plasticizer (kaolin or bentonite), and water at a weight ratio of (50-60) :( 40-50) :( 1-5) :( 18-30). The fly ashes are the mass fly ashes from fluidized bed furnace and piled on the material field. The red sandstone is from waste roadbed materials or lost natural resources in mountain areas. The construction bricks can be used for bearing or non-bearing inner and outer walls. The method has such advantages as simple process, easy operation, high efficiency, low sintering temperature, low energy consumption, high performance and wide applications.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Adhesive special for sand aerated concrete boards and preparation method of adhesive

The invention discloses an adhesive special for sand aerated concrete boards and a preparation method of the adhesive. The adhesive comprises, by weight percentage, 25-30% of Portland cement, 50-58% of quartz sand, 15-20% of sand aerated concrete board waste, 1.5-2.0% of redispersible latex powder, 0.1-0.3% of hydroxypropyl methyl cellulose ether, 0.1-0.3% of wood fibers, 0.04-0.08% of starch ether and 0.1-0.2% of polypropylene fibers. The adhesive is good in water-retaining property and adhesive property, small in shrinkage ratio, high in crack resistance and less prone to interface crack generation, the recycled sand aerated concrete board waste is used as the raw material, and consistency with the color of a wall after filling is achieved.

Owner:SHAANXI NITYA NEW MATERIALS TECH CO LTD

Geotechnical filling for use in cold area

InactiveCN101386500AIncrease contact areaIncrease frictionSolid waste managementPolystyrene particlePollution

The invention provides an earthwork filling material for use in cold area, which is formed by waste casting sand, fly ash, cement, polystyrene particles and water according to certain weight percentages. According to the test measurement, the density of the earth work filling material reaches between 0.97 and 1.35x10<3>kg / m<3>, the compression strength reaches between 60 and 292kPa / 7 days, and the compression strength reaches between 116 and 664kPa / 28 days; meanwhile, the earth work filling material also improve the freeze-thaw resistance, the coefficient of thermal conductivity reaches between 0.40 and 0.74W / (m.K) / 7 days, and the coefficient of thermal conductivity reaches between 0.350 and 0.53W / (m.K) / 28 days. The earthwork filling material can reduce the breakdown of an earth filling project caused by frozen expansion in the cold areas and recycle the waste casting sand and fly ash, which cause pollutions on environment, as earthwork filling materials in the earth filling project; moreover, the filling materials, which are secondary industrial wastes, are widely available and low in price, thereby reducing cost.

Owner:HOHAI UNIV

Inner wall putty for architectural decoration project and preparation method of inner wall putty

InactiveCN107177228AImprove deformation abilityIncrease stress distributionFilling pastesSodium BentonitePolyvinyl alcohol

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

Dry-hard concrete applied to parking apron

InactiveCN108892453AEvenly dispersedGood dispersionHelicopter landing platformUltimate tensile strengthFly ash

The invention discloses dry-hard concrete applied to a parking apron, and belongs to the technical field of concrete. The dry-hard concrete is prepared from 375-429 parts of cement, 857-985 parts of sand, 1,200-1,478 parts of broken stone, 57-69 parts of activated fly ash, 85-110 parts of mineral powder, 5-10 parts of plasticizing agent, 2-6 parts of expanding agent and 120-163 parts of water. Thedry-hard concrete has the advantages of being good in liquidity, high in compactibility, high in strength and good in durability.

Owner:北京建工新型建材有限责任公司

Winter maintenance method for concrete component

InactiveCN107877681AQuality assuranceFully hydratedCeramic shaping apparatusEconomic benefitsUltimate tensile strength

The invention discloses a winter maintenance method for a concrete component. The method comprises a static stop stage, a heating stage, a constant temperature stage and a cooling stage which are precisely controlled through programs. The different stages are designed for requirements for concrete strength forming. Concrete early-stage strength is rapidly formed in the static stop stage so as to resist deformation in the concrete heating process. The concrete structure strength is rapidly formed in the heating stage. The hydration extent of cement in concrete is improved in the constant-temperature stage, and the strength is further improved. Concrete meets early-stage from removal and release requirements. By means of the maintenance method, the early-stage strength of concrete is effectively improved, the concrete component is prevented from being cracked in the maintenance process, the template circulation speed is improved, the production efficiency of the concrete component is improved, and therefore economic benefits are improved.

Owner:SHANDONG LINQU SLEEPER +1

Construction method for repairing reinforced concrete wall

ActiveCN108915292ASolve stress concentrationRaise early temperatureBuilding repairsCoatingsRebarRepair material

Provided is a construction method for repairing a reinforced concrete wall. An interface bonding agent is sprayed to a damaged concrete surface, and standing is carried out for 5-8 minutes after evenspraying. The interface bonding agent is composed of, by weight, 100 parts of ethyl acrylate, 5-10 parts of dodecyl alcohol ester, 2-6 parts of 2-(3, 4-cyclohexene oxide) ethyl trimethoxysilane, and 2-4 parts of polyether amine. According to the construction method for repairing the reinforced concrete wall, repairing materials added with antifreeze agents can increase the early temperature of concrete by accelerating the hydration process and heat releasing, the strength and durability of the concrete are improved, cracks and fractures are reduced, the repair materials can be operated at thelow temperature, the hardening can be quickly completed and hydration reaction is sufficient, and damaged concrete parts are effectively filled.

Owner:上海常浦建筑工程有限公司

Fire-resistant pointing material in petroleum industry and construction process of fire-resistant pointing material

The invention discloses a fire-resistant pointing material in petroleum industry, and relates to the field of petrochemical industry. The fire-resistant pointing material comprises the following components by mass percent: 25-40% of silicate cement, 30-45% of powdery refractory mortar, 20-30% of coal ash, 8-12% of alumina micro powder, 0.5-1% of sodium tripolyphosphate or sodium hexametaphosphate or sodium silicate and the balance of water. The strength loss of counter-fire surface of mortar can be effectively reduced, the physical influence caused by high-temperature baking is borne by a protective layer, so that the average strength of the fire-resistant mortar is higher, and the potential quality hazard caused by the reduced strength of the counter-fire surface of the mortar is effectively avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

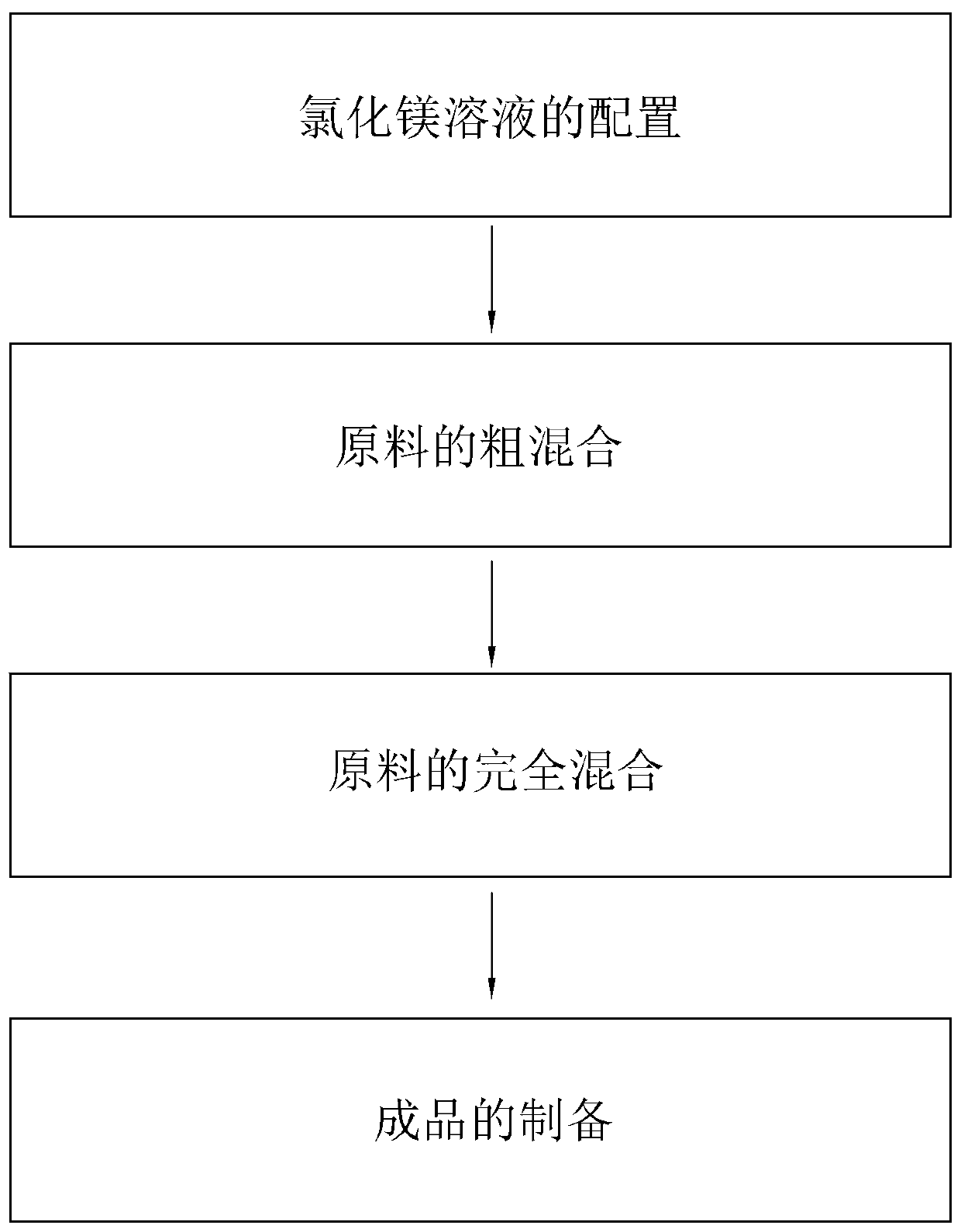

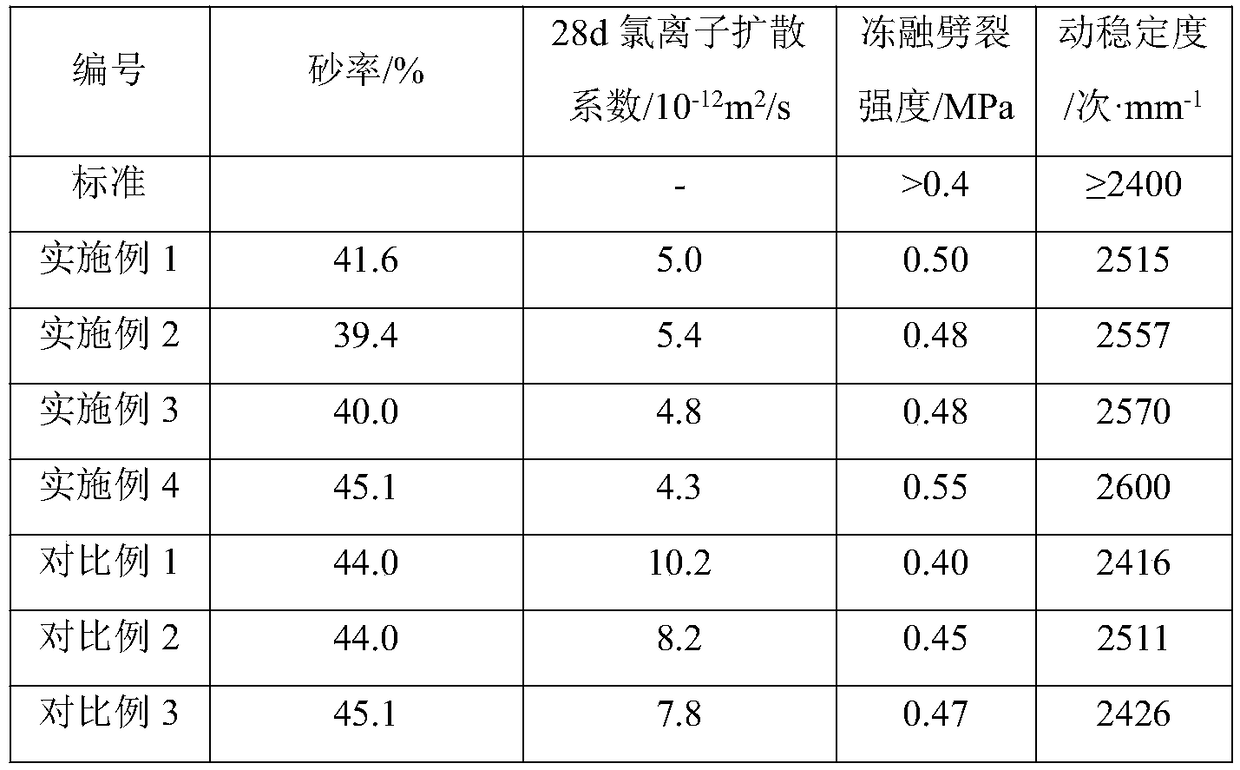

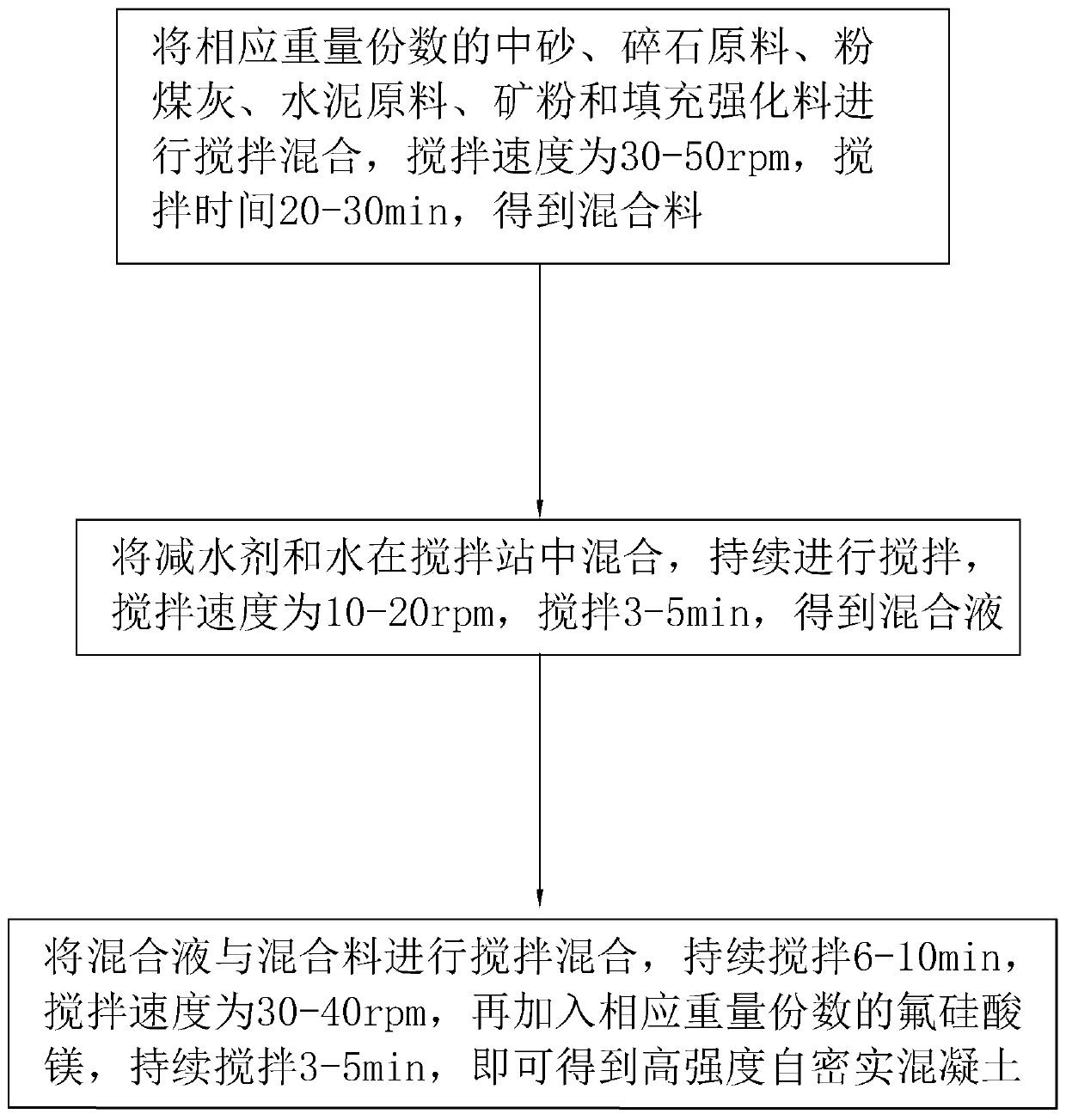

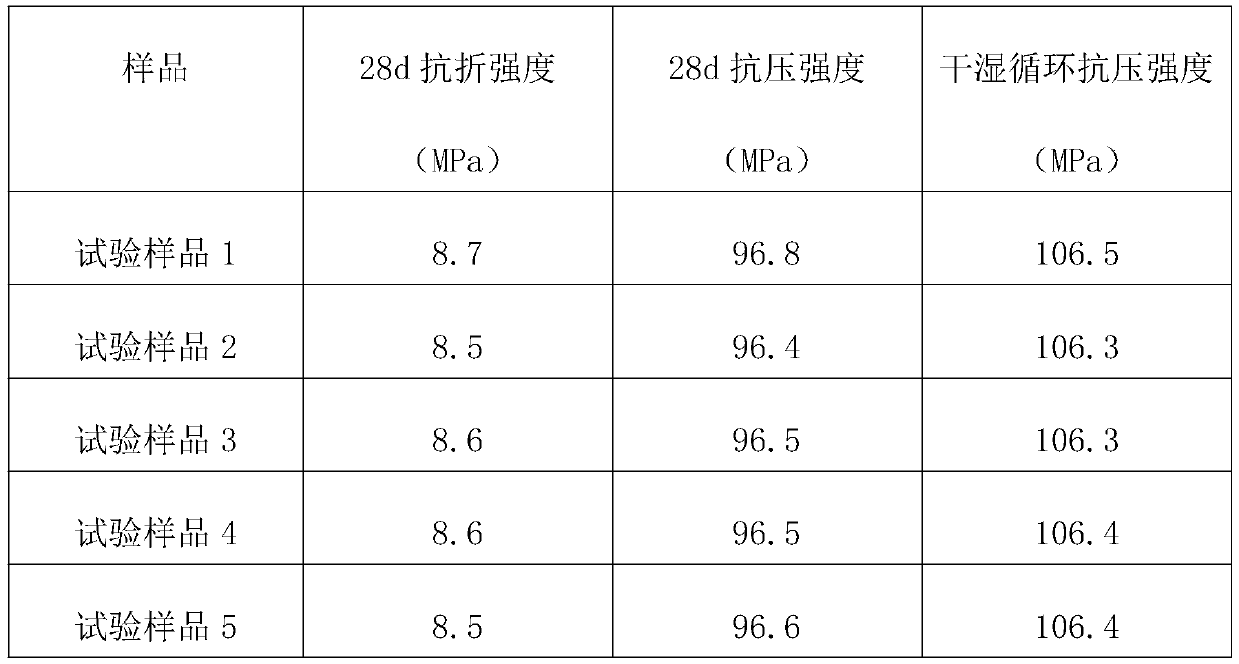

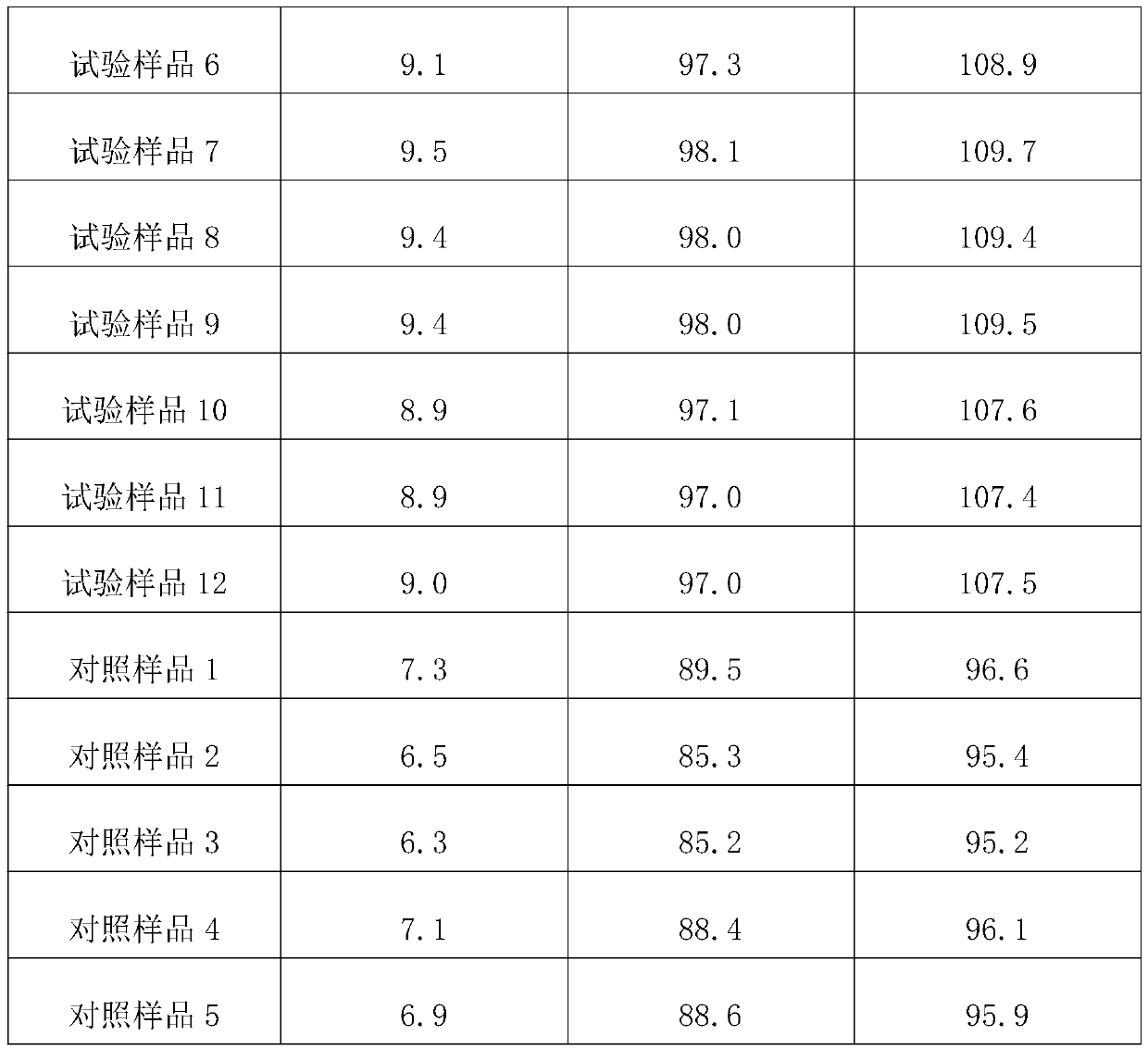

Industrial production process of high-strength self-compacting concrete

The invention discloses an industrial production process of high-strength self-compacting concrete, relates to the technical field of concrete production and processing, and solves the problem that the overall strength of the concrete is greatly reduced due to the fact that cement aggregates exist in a mixture and cannot be fully hydrated in the production process of the concrete. The industrial production process comprises the following steps: 1, preparing raw materials, 2, mixing the slurry, 3, preparing slurry, 4, preparing a mixed material, and step 5, discharging a finished product. According to the process, the mixed material obtained in the step 3 is heated to 50-60 DEG C in 5-10 seconds, then is subjected to heat preservation for 2-5 seconds, and finally is cooled to 20-30 DEG C in5-10 seconds along with continuous stirring to obtain the high-strength self-compacting concrete. In the application process, formation of cement aggregates can be avoided, the diffusion uniformity of cement particles is greatly improved, and the overall strength of concrete is improved.

Owner:上海兆捷实业发展有限公司

Concrete prefabricated bridge deck with plasticizer

A manufacture method of a concrete prefabricated bridge deck with a plasticizer is characterized by comprising the specific steps: weighing concrete materials (by mass) of 40-50 parts of cement, 3-10parts of silica fume, 5-7 parts of carbide slag, 3-5 parts of steel slag, 30-40 parts of sand, 40-50 parts of crushed stone, 10-20 parts of water, and 3-4 parts of the plasticizer; adding the cement,silica fume, carbide slag, steel slag and water into a mixer, mixing, adding sand, crushed stone and the plasticizer, and continuing to mix well to obtain concrete. The concrete prefabricated bridge deck has a water retention rate of 90.4-93.2%, 28-day shrinkage of 0.102-0.116%, initial setting time of 200-210 min, final setting time of 370-390 min, one-day compressive strength of 20.5-22.4 MPa, 7-day compressive strength of 34.5-36.1 MPa, 28-day compressive strength of 47.5-49.2 MPa, and 14-day tensile strength of 1.86-1.93 MPa. The method provides significantly extended initial and final setting time and evidently improved compressive strength and tensile strength for the prior concrete, with shrinkage evidently reduced.

Owner:CITIC CONSTR

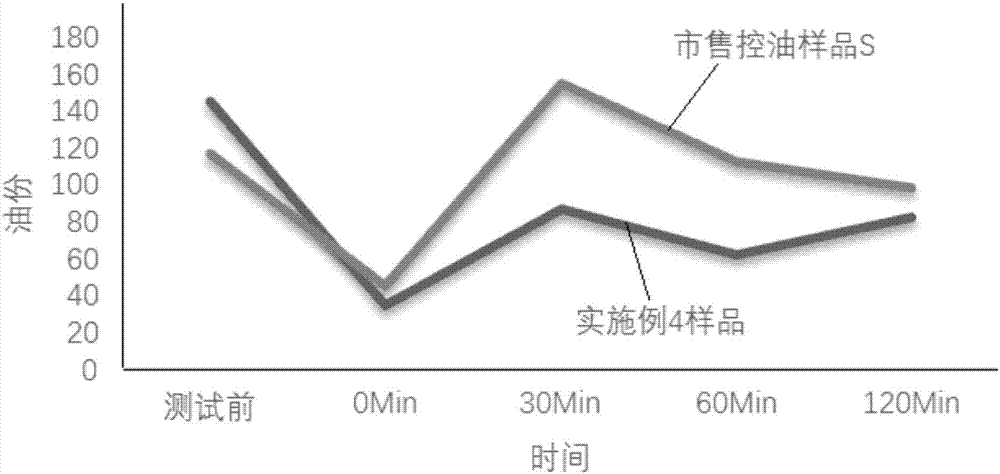

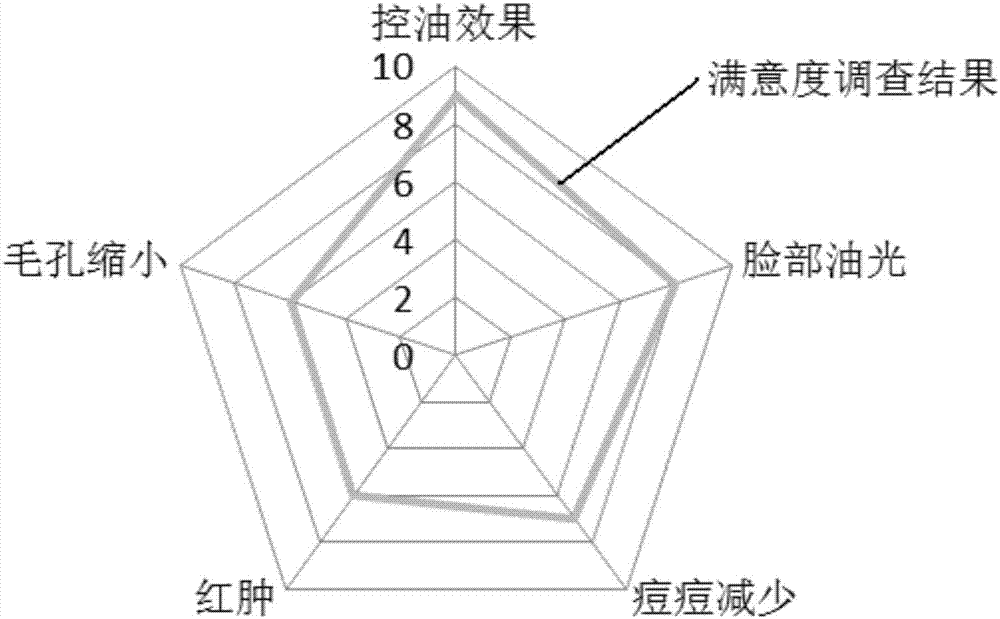

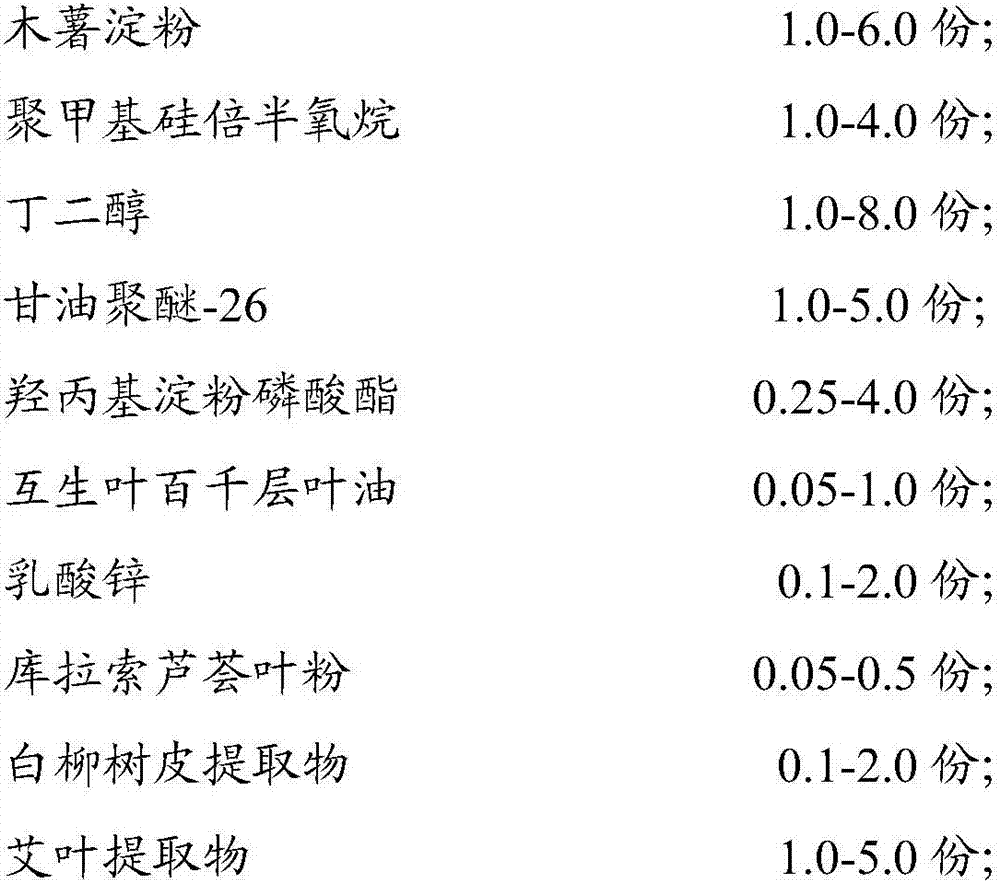

Double-layer water preparation containing oil-controlling starch particles, and preparation method thereof

InactiveCN106983693AGood oil control effectFormulation cost advantageCosmetic preparationsToilet preparationsHydration reactionStarch gelatinization

The invention discloses a double-layer water preparation containing oil-controlling starch particles. According to a preparation method, two kinds of starch particles with different densities and hydrophilic performance are adopted, so that suspension of the oil-controlling starch particles in the double-layer water preparation is realized, deposition of starch is not easily caused, and excellent oil controlling effect is realized. The invention also discloses the preparation method of the double-layer water preparation containing oil-controlling starch particles. According to the preparation method, cassava starch, polymethylsilsesquioxane, and hydroxypropyl starch phosphate are add at last so as to prevent starch gelatinization, control the stirring time of hydroxypropyl starch phosphate, ensure complete powder hydration, and avoid generation of excess foam, and it is convenient for filling in a later period.

Owner:YUNNAN BOTANEE BIO TECH GRP CO LTD +1

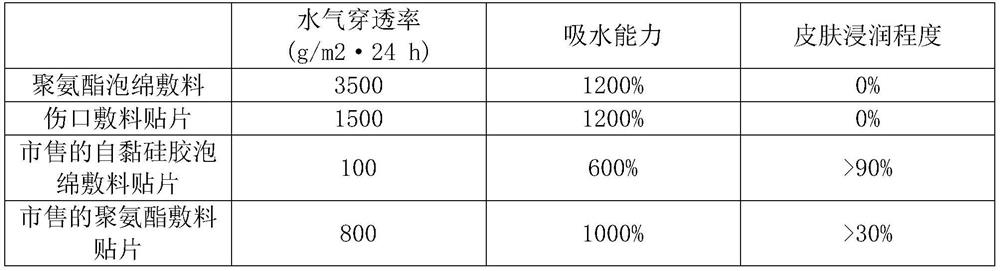

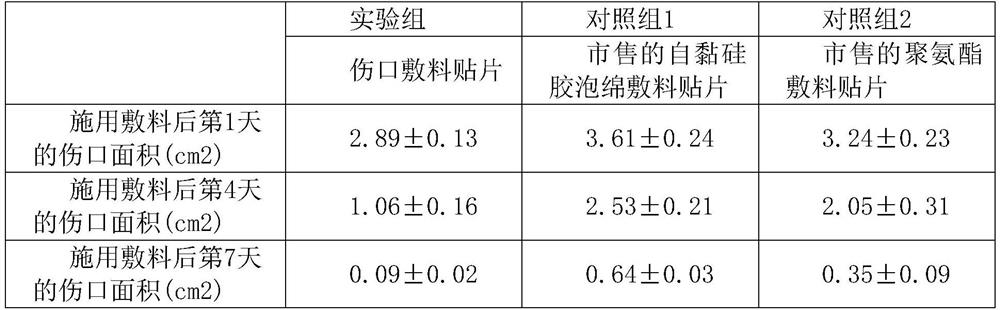

Preparation method of polyurethane foam dressing and wound dressing patch

PendingCN113801285ASpeed up healingFully hydratedPolyureas/polyurethane adhesivesSynthetic resin layered productsPolymer scienceWound dressing

The invention discloses a preparation method of a polyurethane foam dressing and a wound dressing patch, and relates to the medical field. The preparation method of the polyurethane foam dressing comprises the following steps: the step A, mixing and stirring hydrophobic polyol and hydrophilic diisocyanate according to a molar ratio of 1: 3-1: 8, and reacting to obtain a prepolymer containing 3-6 isocyanate groups; and the step B, mixing and stirring the prepolymer obtained in the step A, hydrophilic polyether polyol, a foaming agent, an end-capping reagent, an enhancer and a catalyst according to a molar ratio of 1: (0.5-2): (0.2-0.8): (0.2-0.8): (0.2-0.8), and reacting to form the polyurethane foam dressing. The wound dressing patch comprises a waterproof breathable film, a polyurethane foam dressing and an adhesion layer, and the waterproof breathable film is adhered to the polyurethane foam dressing through the adhesion layer. According to the invention, formation of tiny gaps through which water and gas can penetrate is facilitated, moisture of a wound and normal skin can be fully adjusted, and the wound healing speed is accelerated.

Owner:昆山优瑞森医疗科技有限公司

Concrete doped with multi-component admixture and preparation method of concrete

The invention belongs to the field of preparation of building materials, and particularly relates to concrete doped with a multi-component admixture and a preparation method of the concrete. The concrete comprises cement, the multi-component admixture, an iron tailing sand fine aggregate, natural sand, broken stones, waste stones and a water reducing agent, wherein each cubic meter of the concrete comprises 215 kg to 230 kg of the cement, 200 kg to 215 kg of the multi-component admixture, 260 kg to 300 kg of the iron tailing sand, 260 kg to 300 kg of the natural sand, 320 kg to 360 kg of the broken stones and 840 kg to 880 kg of the iron tailing sand waste stones, the multi-component admixture comprises iron tailings, desulfurized fly ash, slag, fly ash and silica fume in a weight ratio of 5: 2: 1: 0.5: 0.2; The concrete is low in cost and friendly to environment; the structure of the concrete is compact through synergistic matching and defect complementation of multiple solid wastes and aggregate grading optimization; and it is guaranteed that the solid waste mixing amount is large, and meanwhile the early strength and the later strength of the concrete are improved.

Owner:张延年

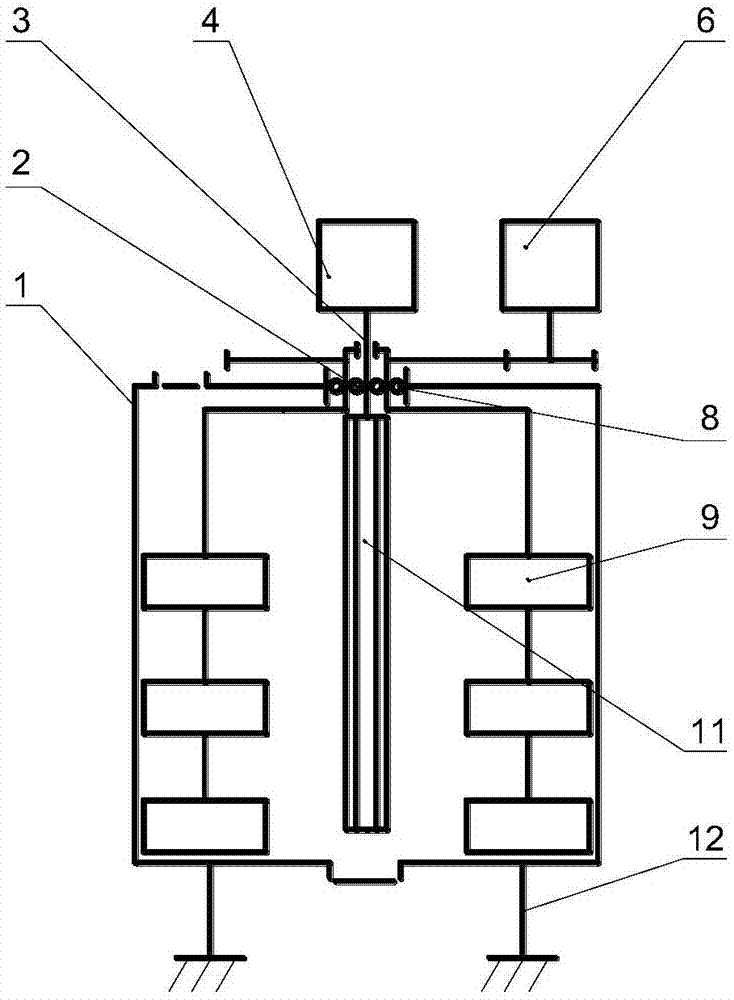

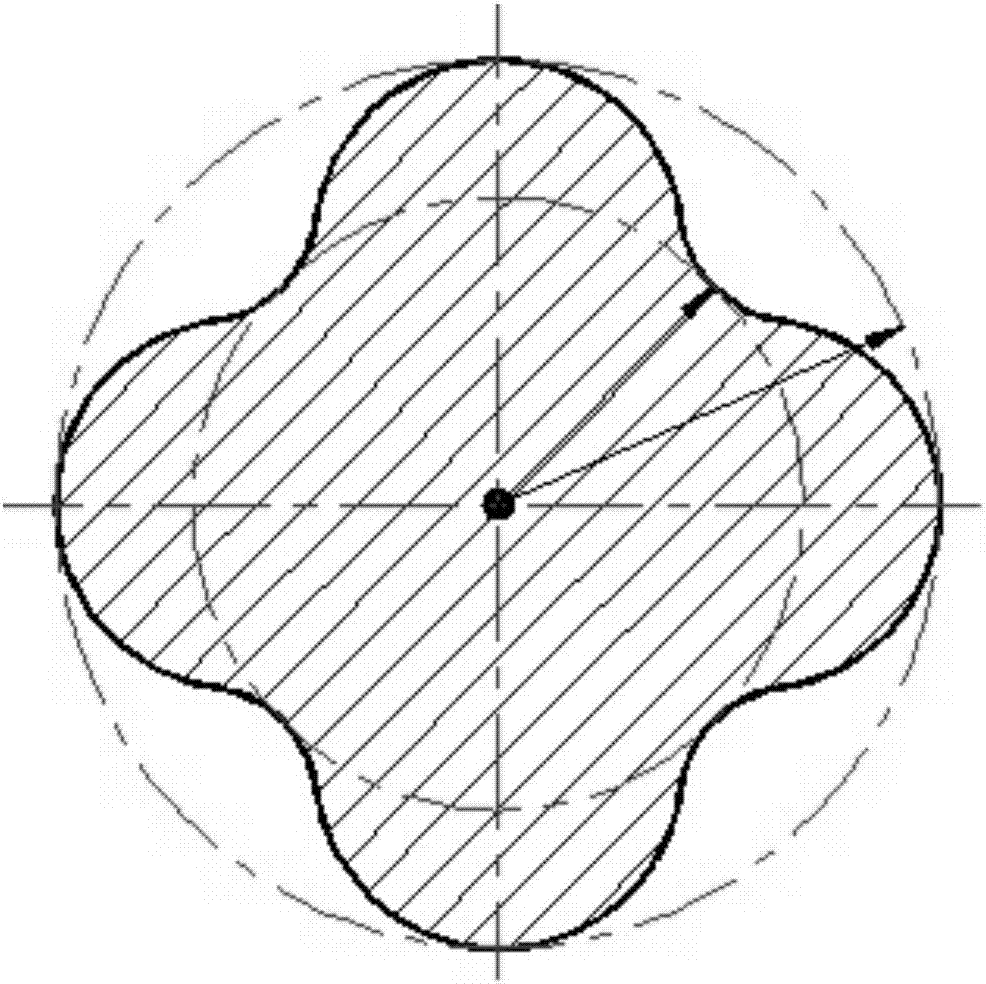

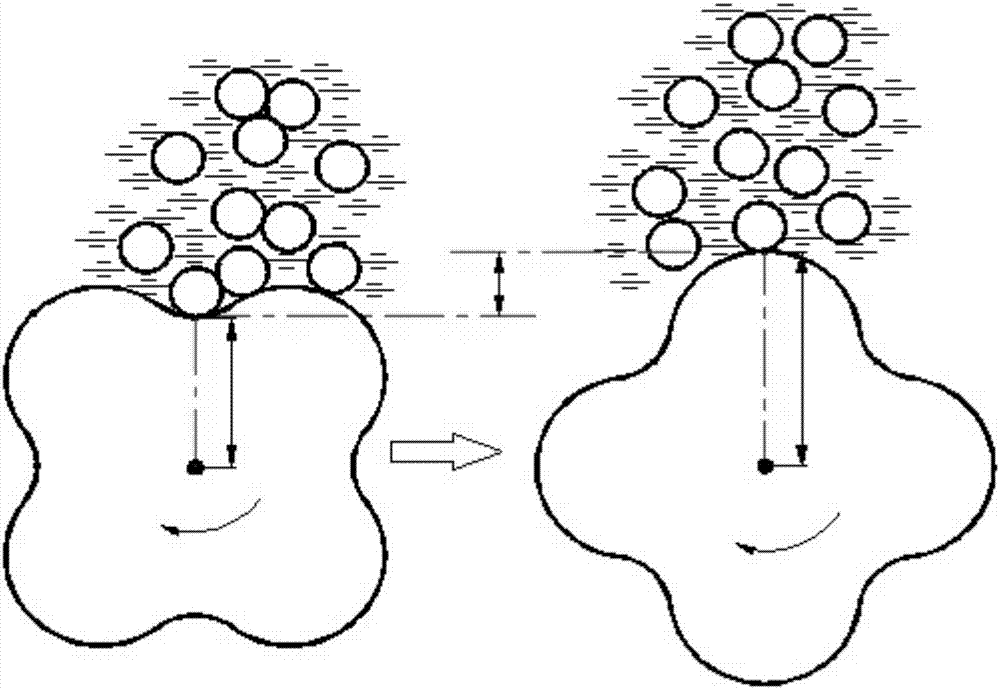

Vertical-axis high-frequency vibration mixer

PendingCN107139337AIncrease the excitation frequencyImprove mix qualityCement mixing apparatusCentre of rotationEngineering

The invention discloses a vertical-axis high-frequency vibration mixer. The vertical-axis high-frequency vibration mixer comprises a vibration driving unit, a mixing driving unit, a mixing cylinder, a mixing device and an exciter; the vibration driving unit and the mixing driving unit are both fixedly arranged above the mixing cylinder; the mixing device is arranged in the mixing cylinder; a hole is formed in the center of an upper cover of the mixing cylinder; the upper end of the mixing device is coaxially arranged in the hole; the exciter is arranged in the mixing cylinder below the hole, and is connected with the vibration driving unit through an exciter connecting shaft; the mixing driving unit is connected with the upper end of the mixing device; the exciter is a polygonal solid shaft or hollow shaft with N smooth projections on the cross section, wherein N is greater than 2, and the centroid is overlapped with a rotating center; the generated excitation frequency is positively correlated to the projection number N linearly; and the heights of the projections are changed to adjust the amplitude of exciting force. The vertical-axis high-frequency vibration mixer breaks through the limit of incapability of improving the excitation frequency of a traditional vibration mixer, further reduces the friction force among molecules, and greatly improves macroscopic and microscopic quality of concrete finally.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com