Patents

Literature

55results about How to "Increase the excitation frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient high-speed electric device using low-loss materials

InactiveUS20060208606A1Small increase in core lossImprove efficiencyMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsEngineeringVolumetric Mass Density

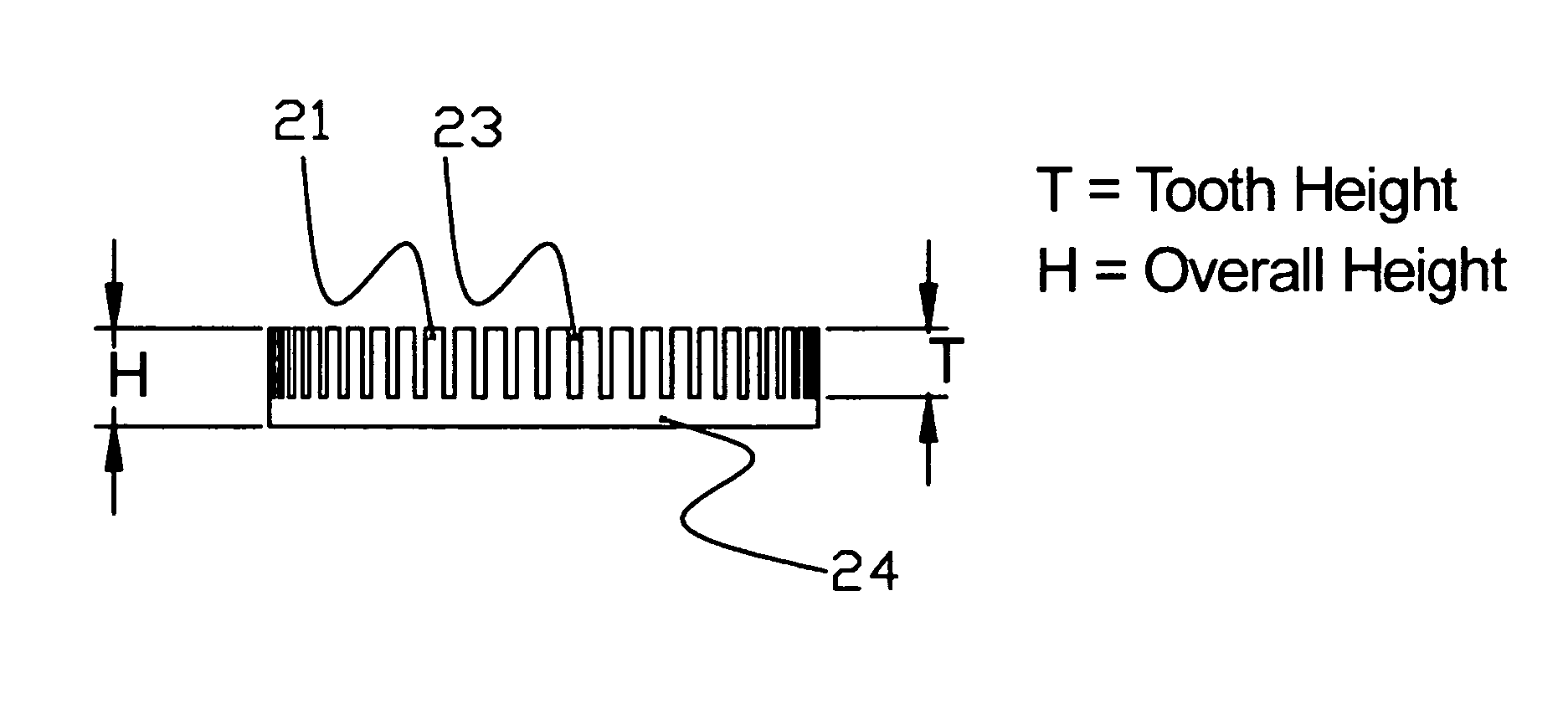

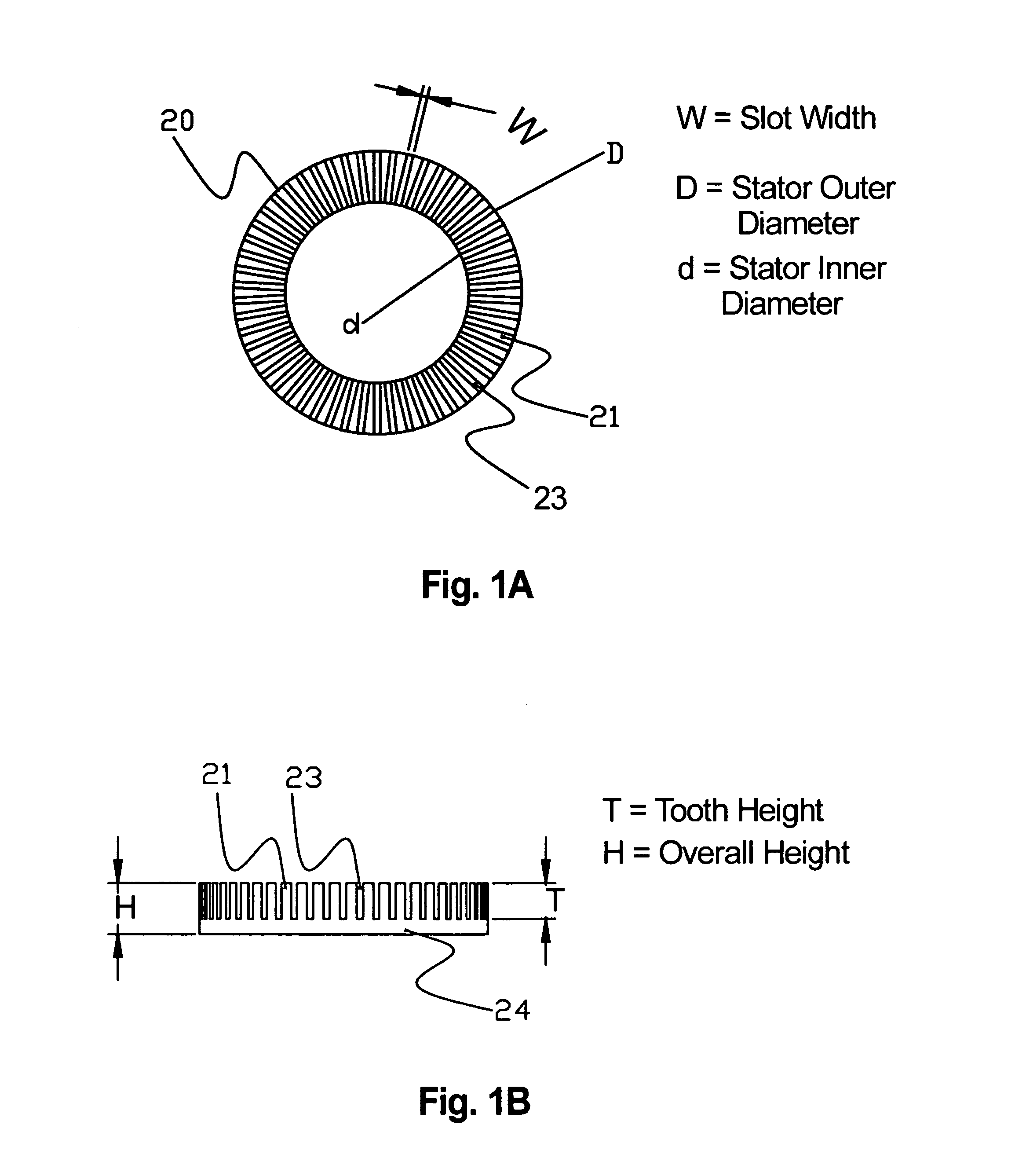

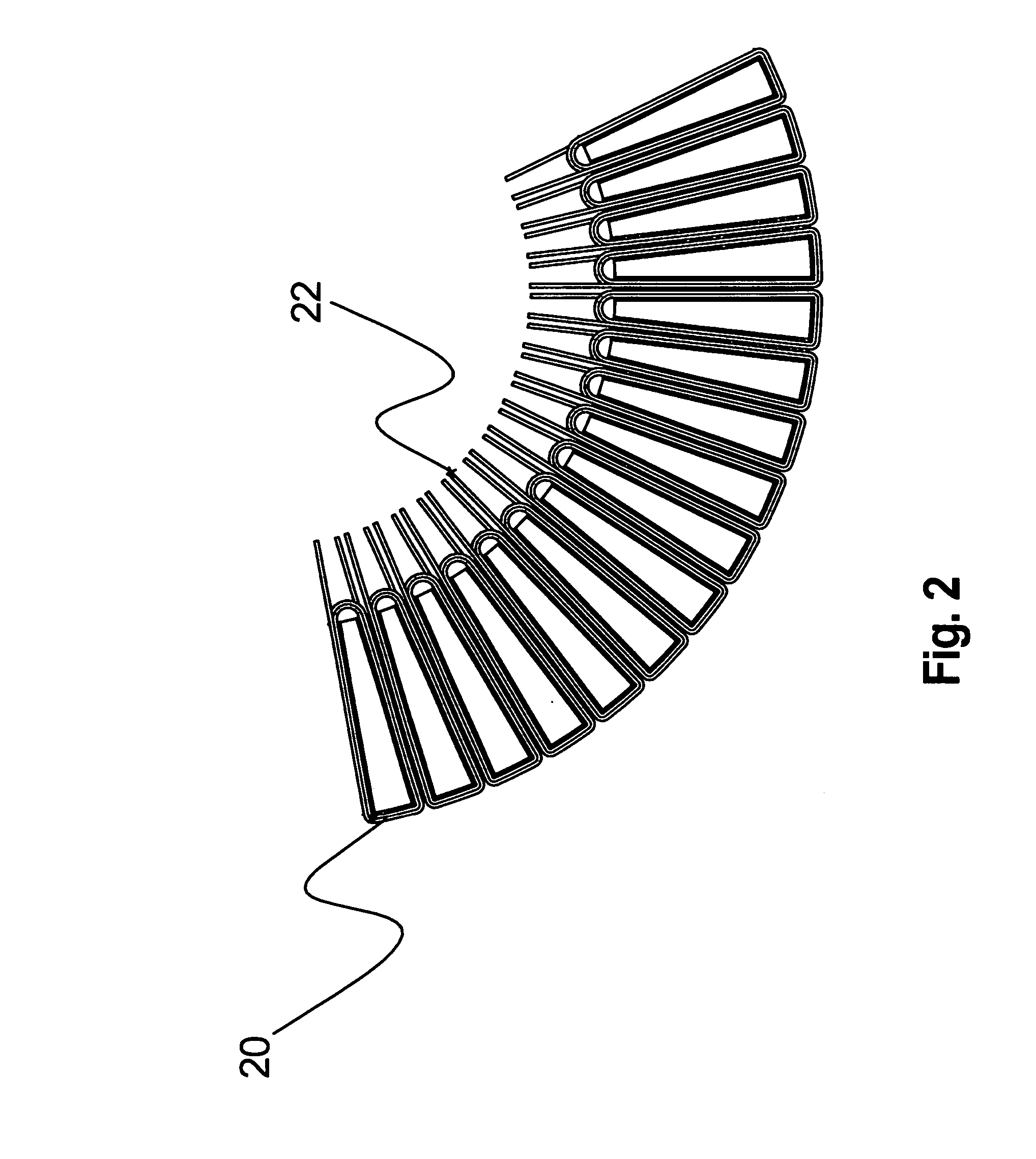

The invention relates generally to an electric device, such as an electric motor, a generator, or a regenerative motor, having a wound stator core made from advanced low-loss material. In preferred embodiments, the electric device is an axial airgap-type configuration. The invention provides an electric device having a high pole count that operates at high commutating frequencies, with high efficiency and high torque and power densities. Advanced low-loss materials exploited by the present invention include amorphous metals, nanocrystalline metals, and optimized Fe-based alloys.

Owner:BERG & BERG ENTERPRISES

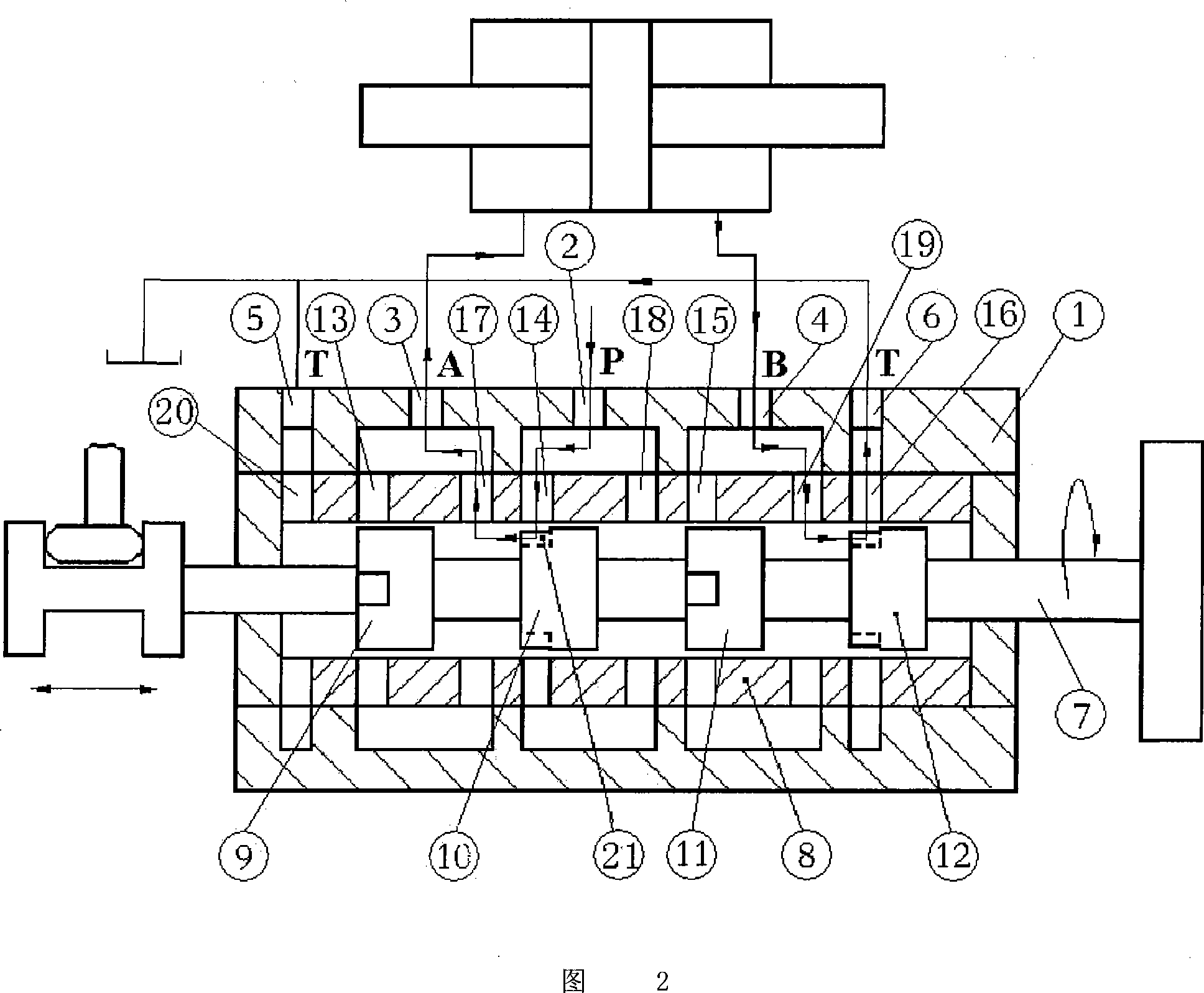

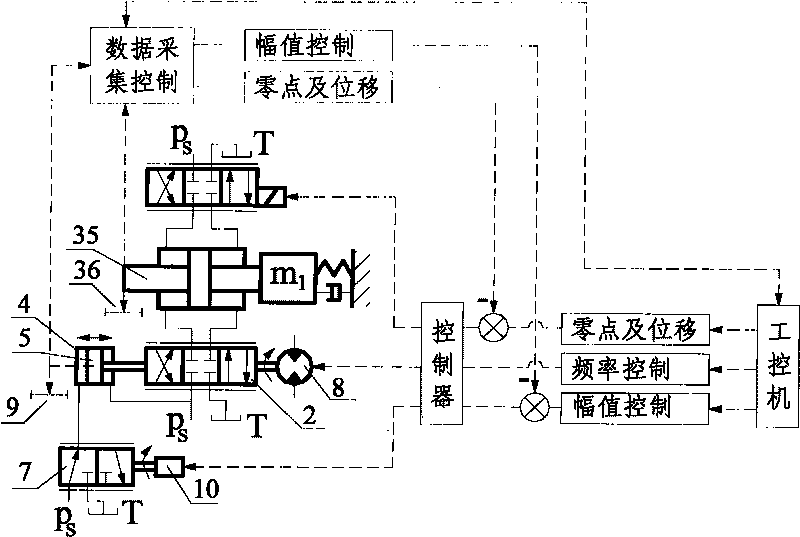

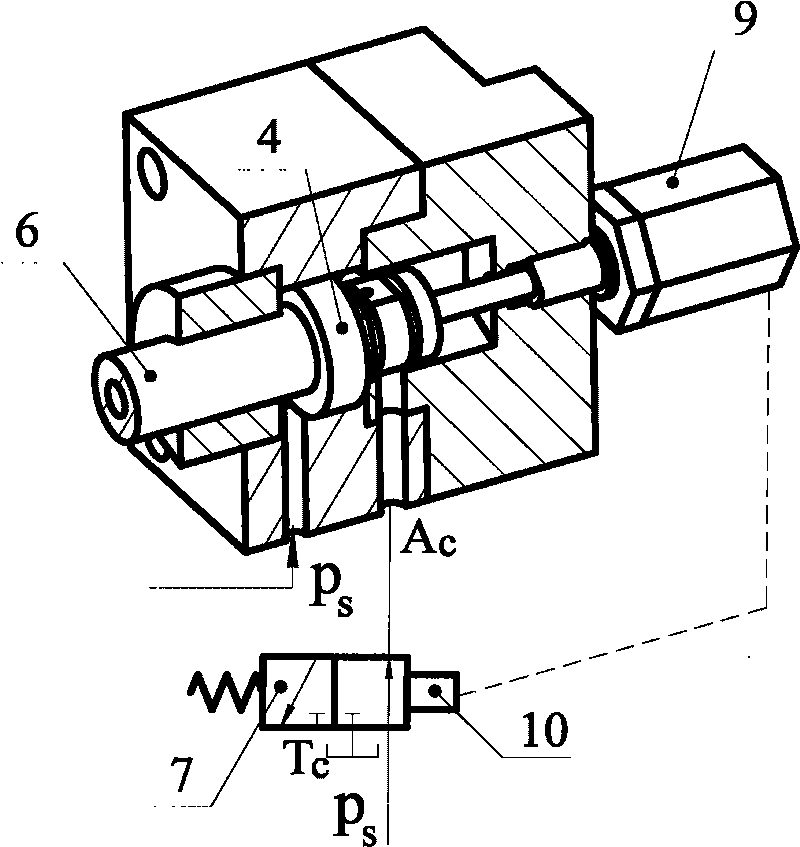

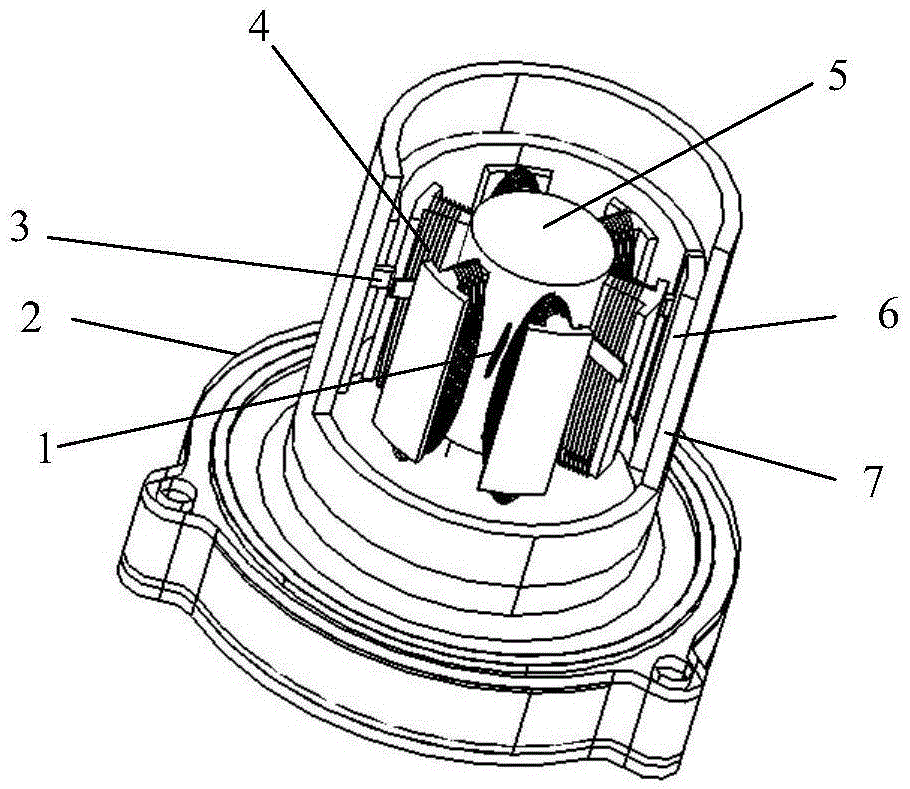

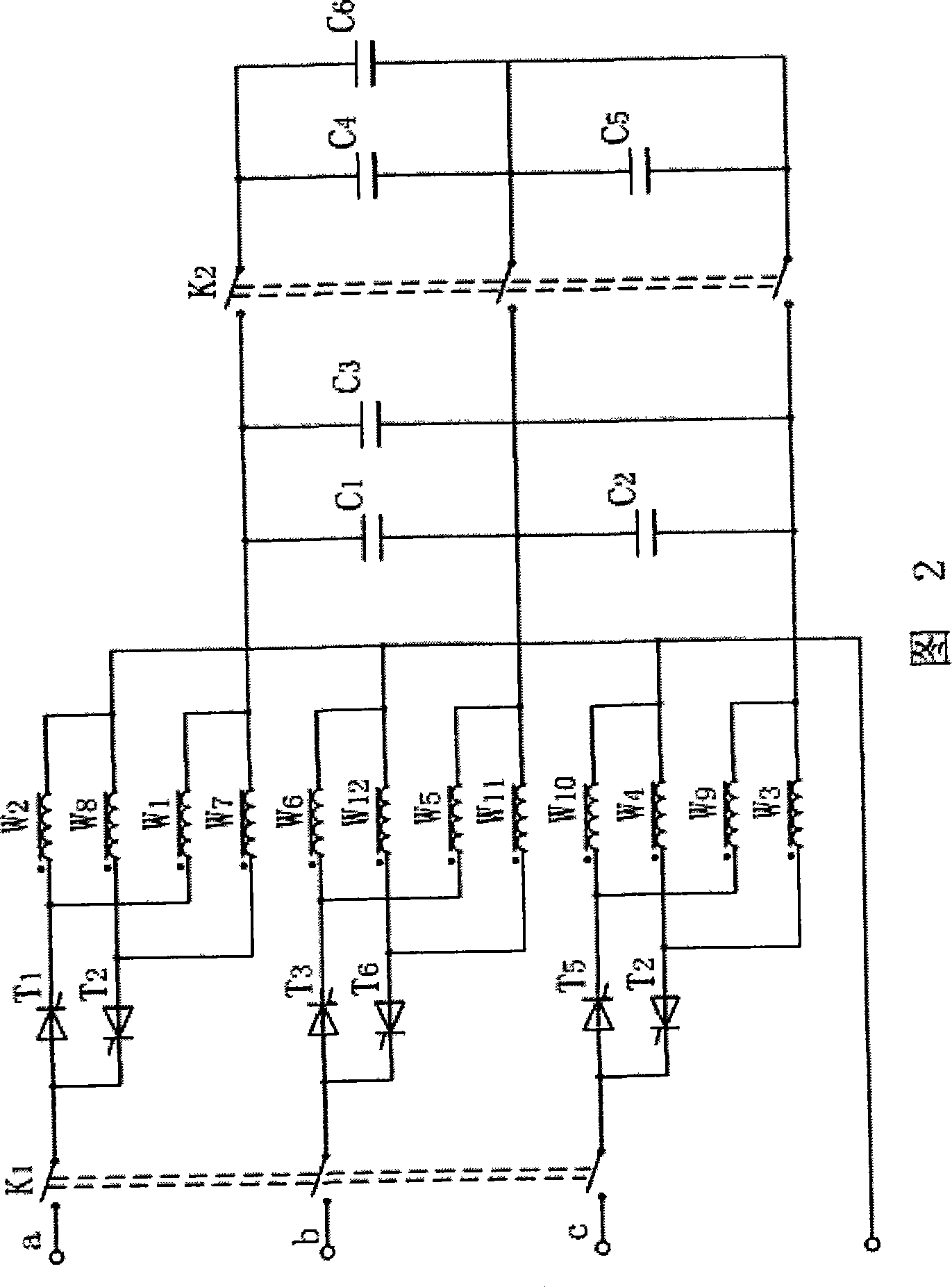

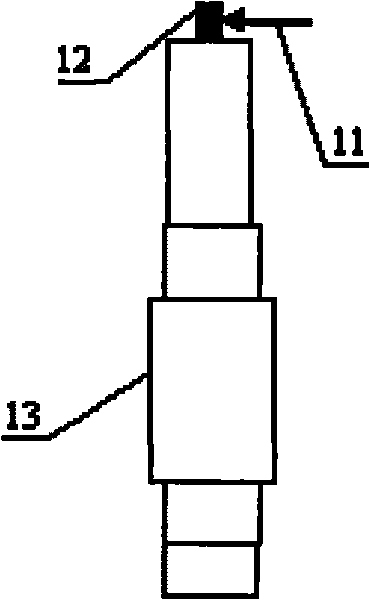

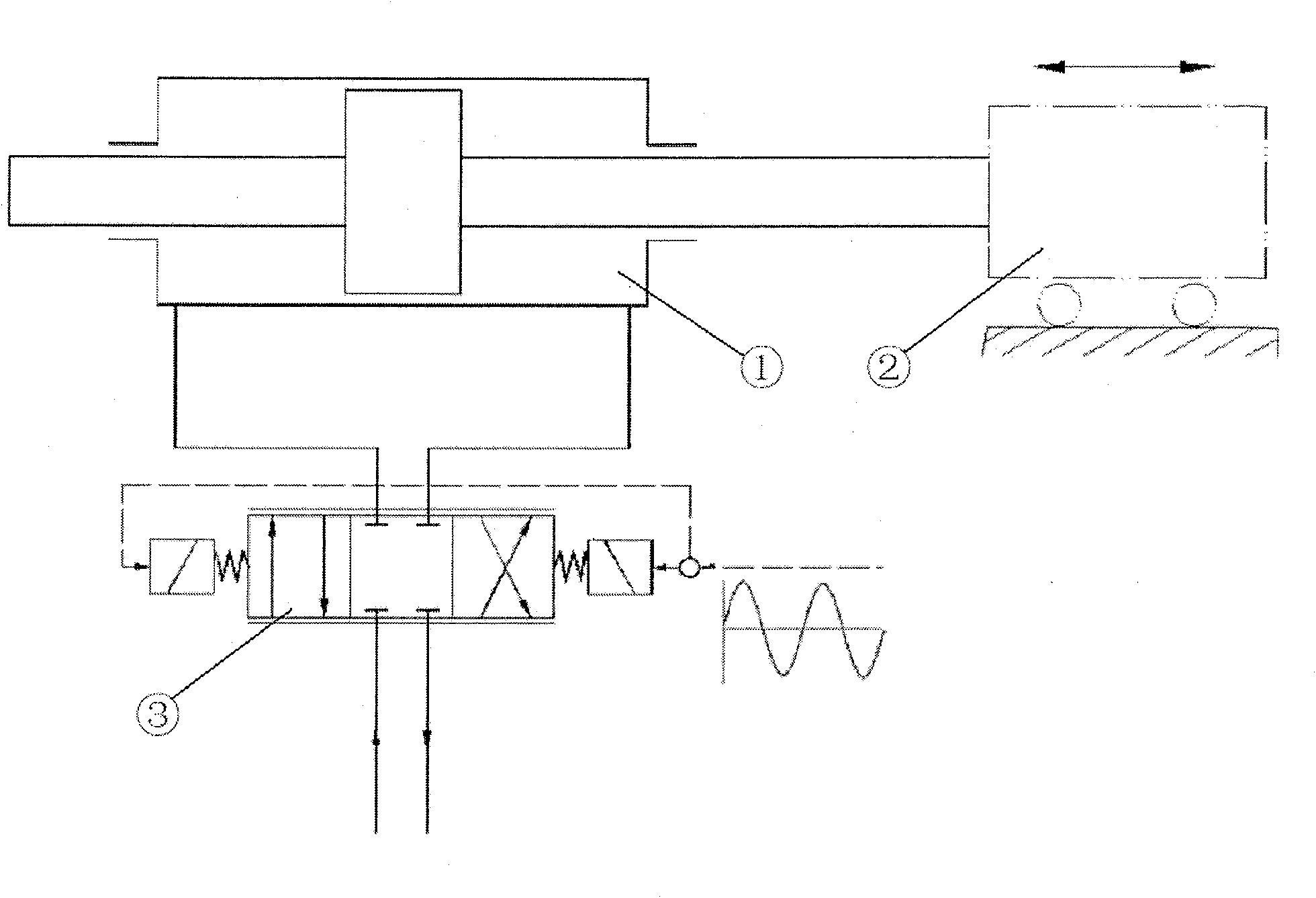

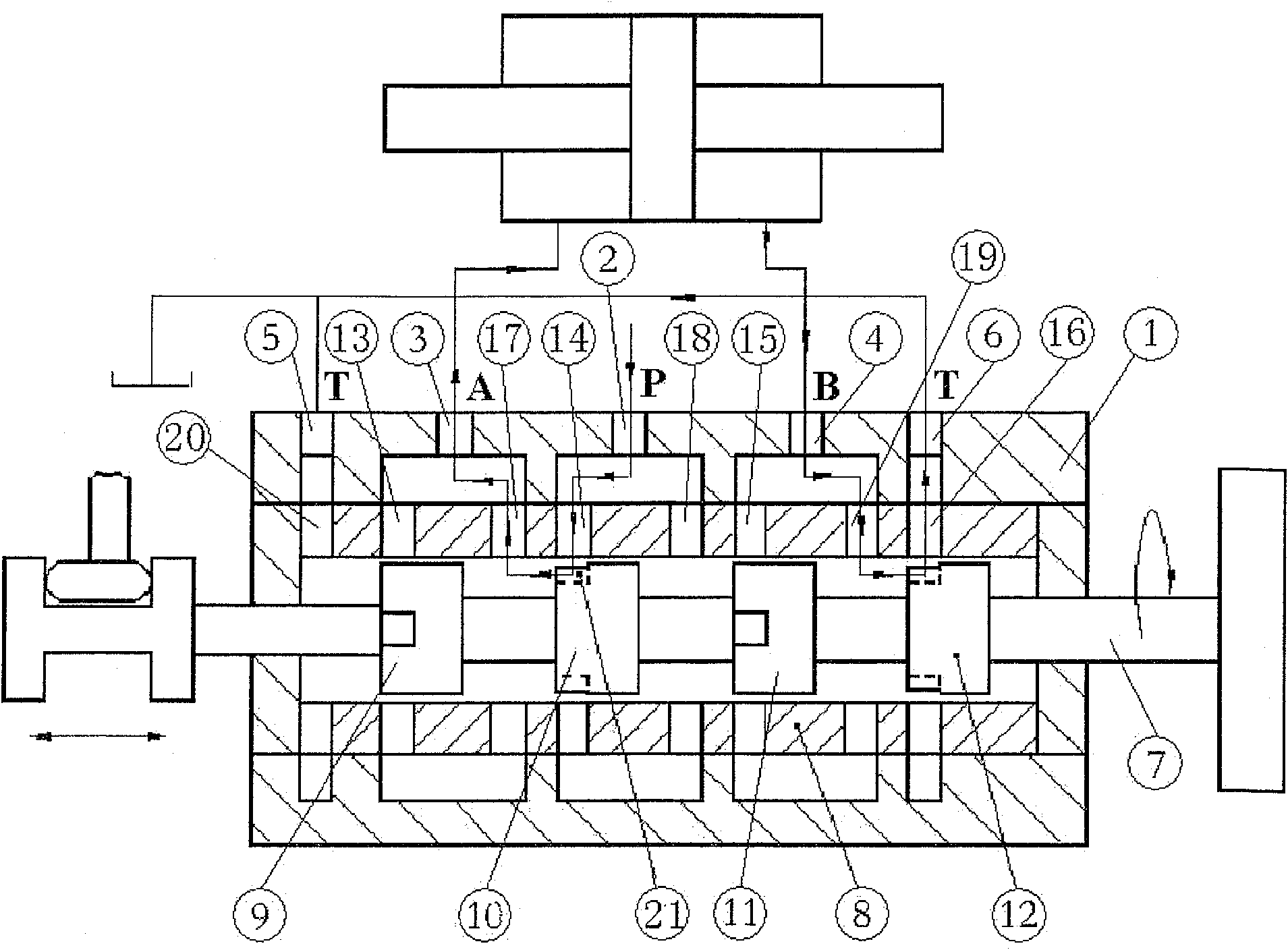

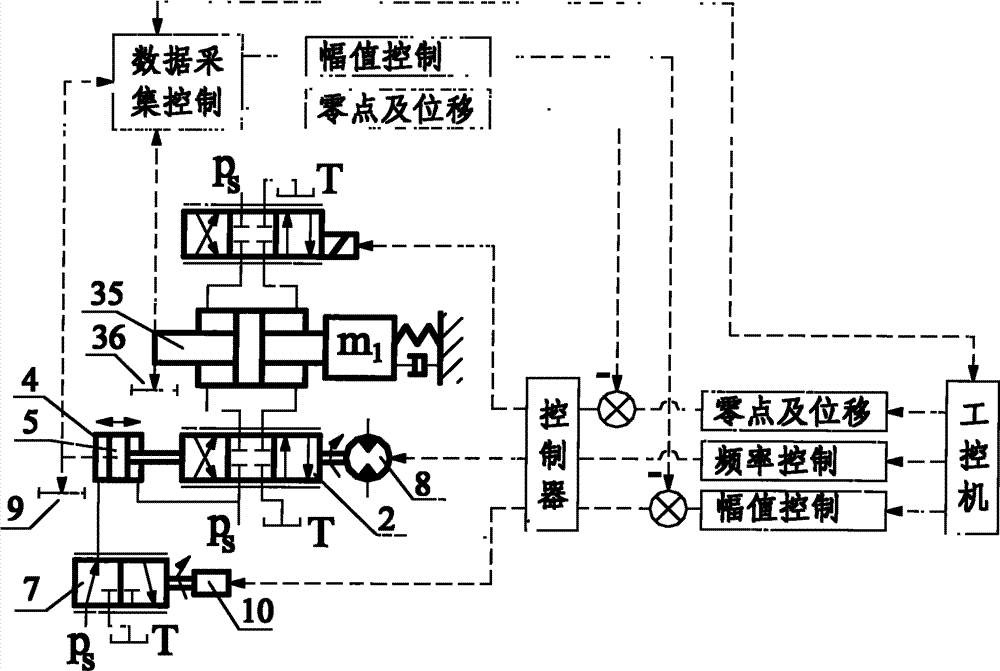

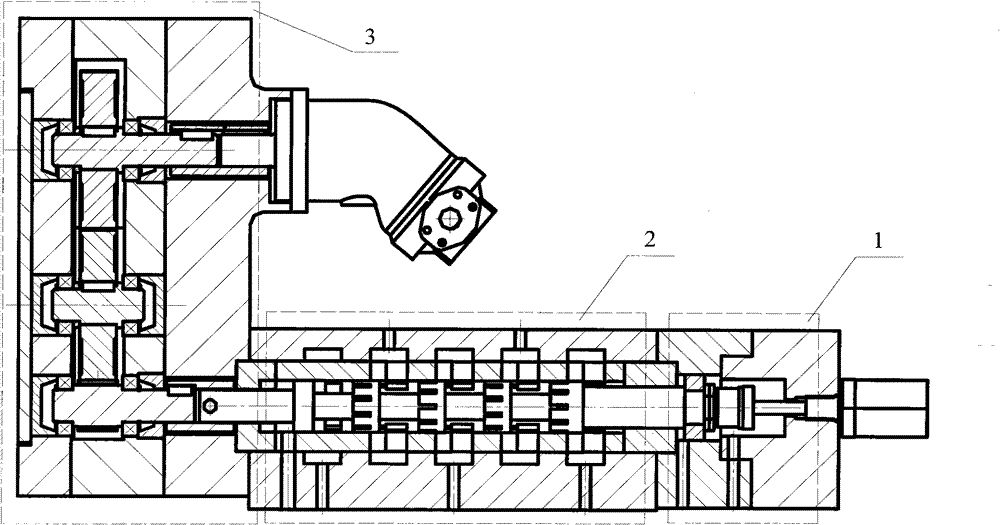

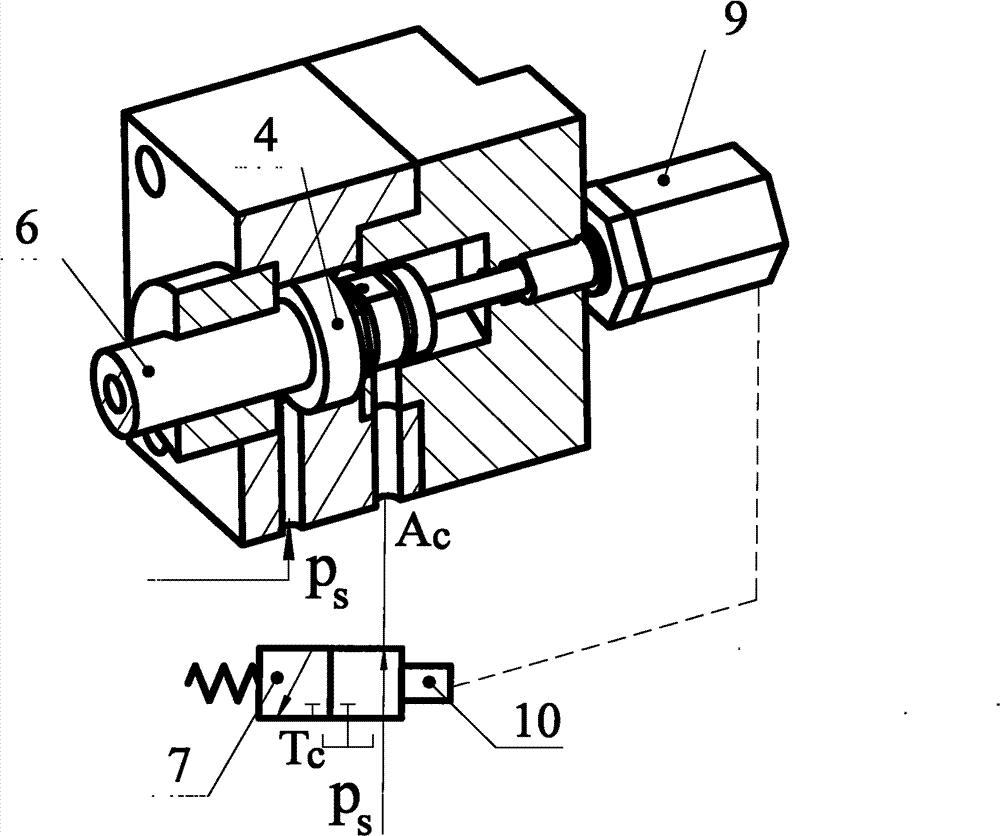

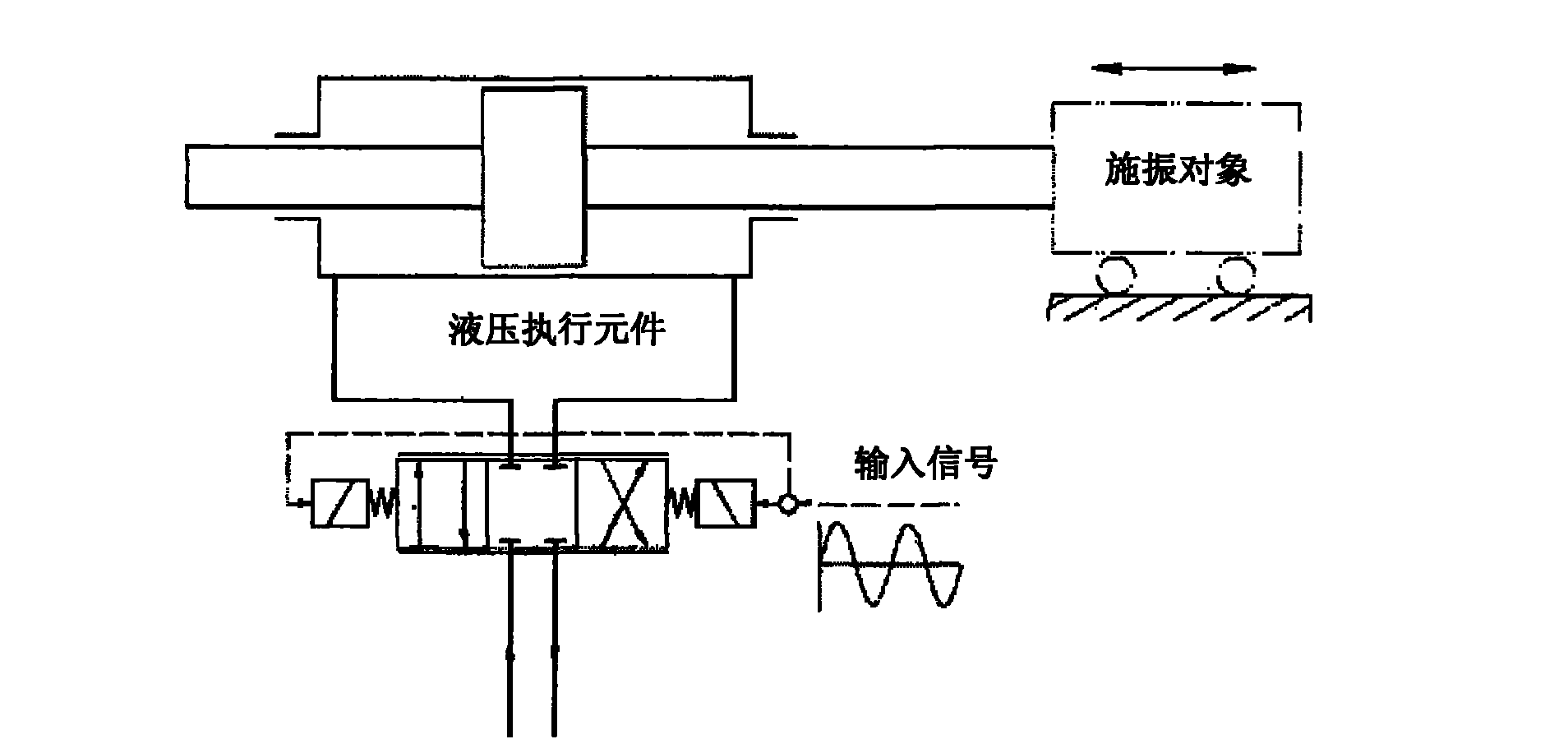

Electrohydraulic excitation controlling valve

InactiveCN101183038AIncrease the excitation frequencyServomotor componentsVibration testingHydraulic cylinderSleeve valve

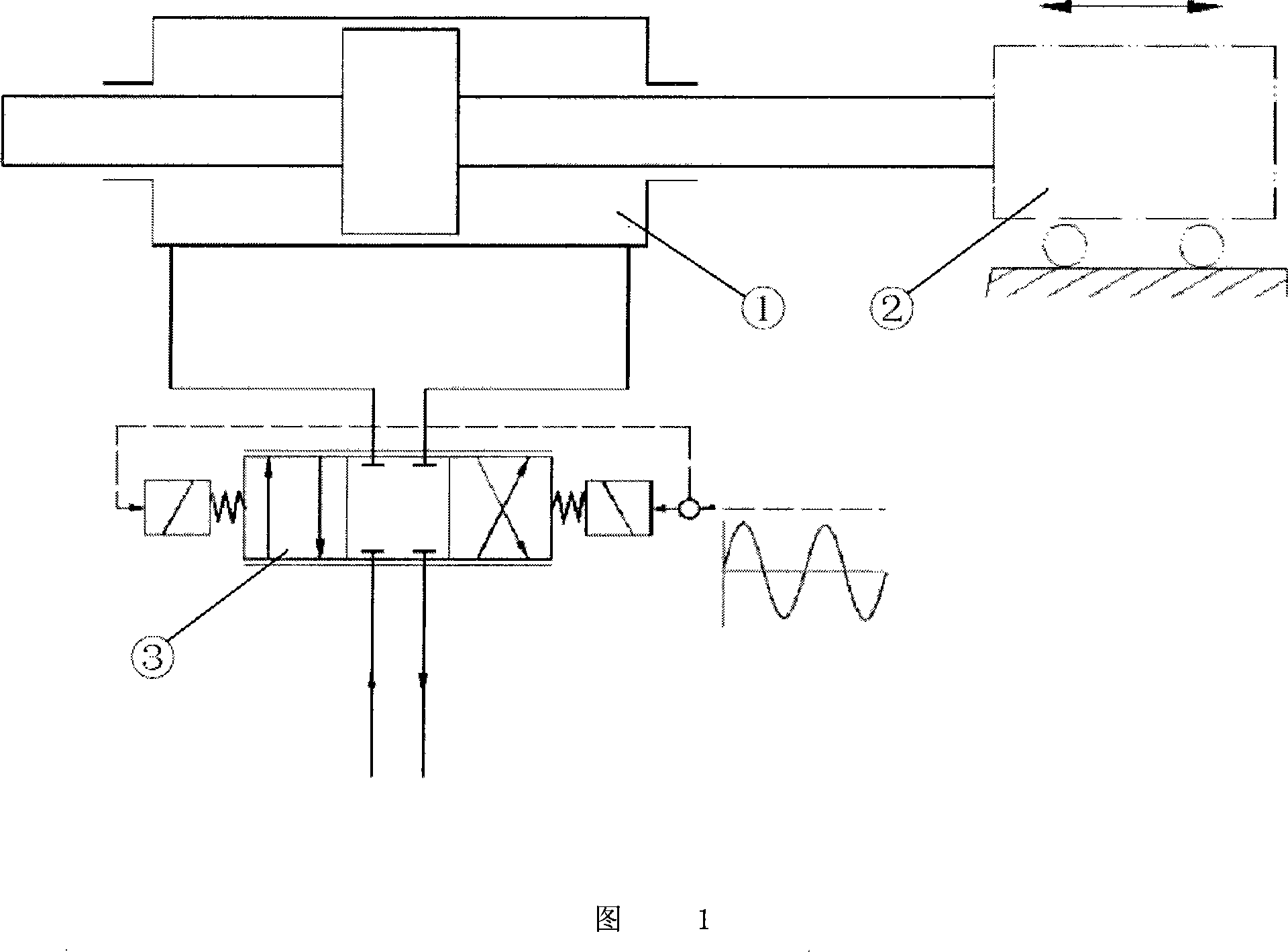

An electro-hydraulic excitation control valve, comprising a valve body, the valve body is provided with an oil inlet connected to a high-pressure oil tank, a first oil inlet and outlet connected to a hydraulic cylinder, a second oil inlet and an outlet, and an oil return port. The first oil outlet and the second oil outlet connected to the oil tank. The electro-hydraulic vibration control valve also includes a valve core and a valve sleeve. The valve sleeve is nested in the inner wall of the valve body, and the valve core passes through the The valve sleeve, the spool is connected to the first servo motor and the second servo motor; at least four shoulders are equidistantly arranged on the spool, and at least two grooves are uniformly opened in the circumferential direction of each shoulder, The grooves on the front and rear adjacent shoulders are misaligned; a ring of valve sleeve windows matching each shoulder is uniformly opened in the circumferential direction of the valve sleeve, and the valve sleeve windows are at least four circles. The valve sleeve between the windows is provided with an auxiliary window, and an additional window is provided at the end of the valve sleeve close to the first valve sleeve window. The invention can greatly increase the electro-hydraulic excitation frequency.

Owner:ZHEJIANG UNIV OF TECH +1

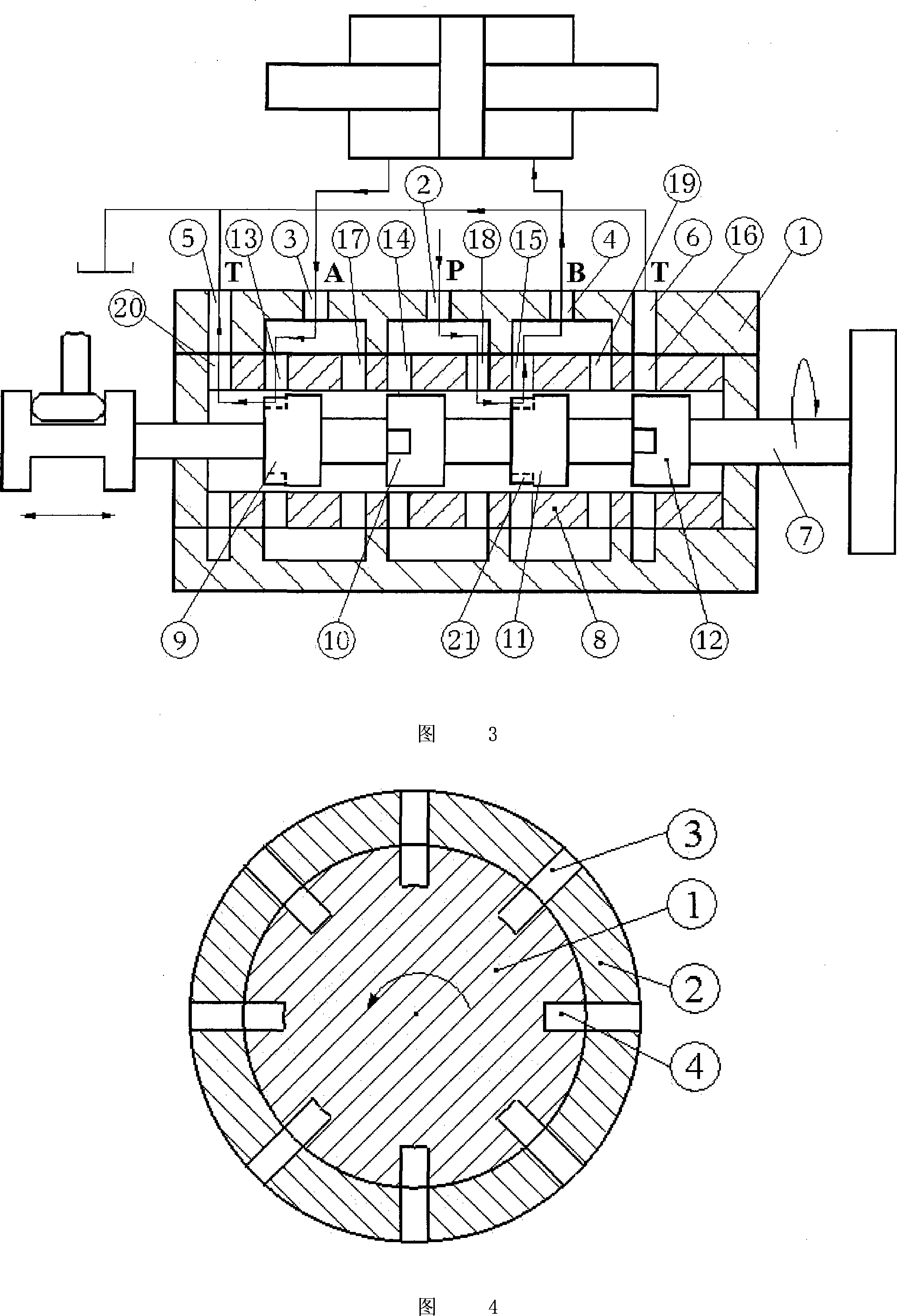

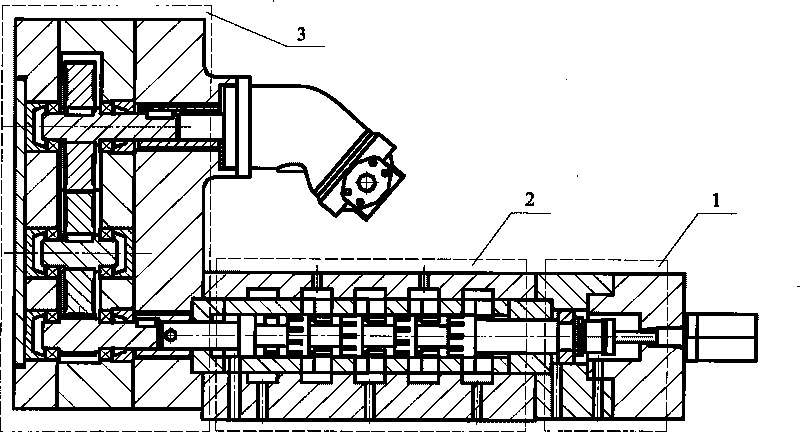

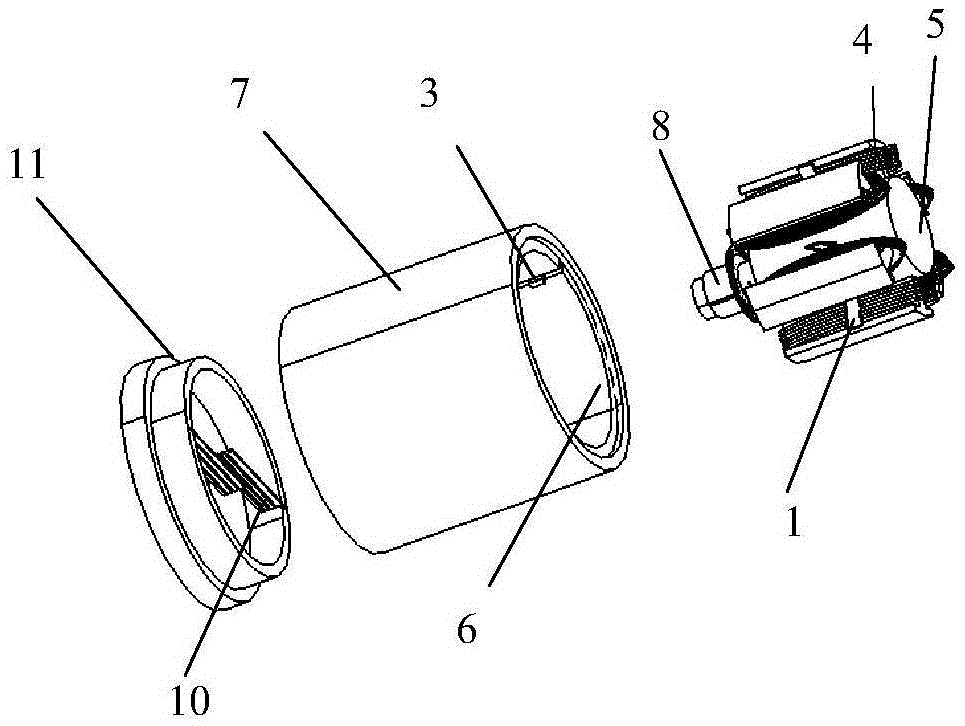

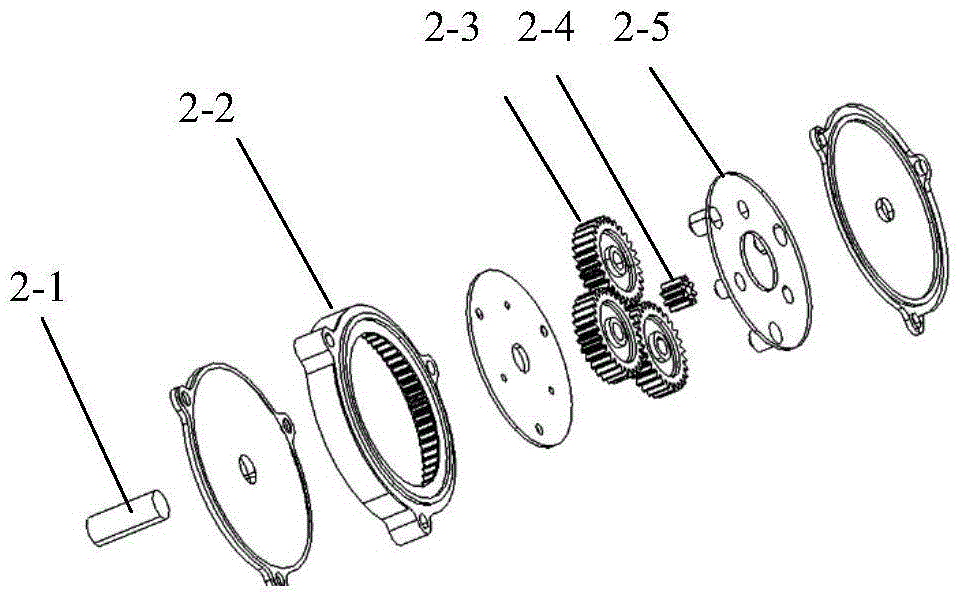

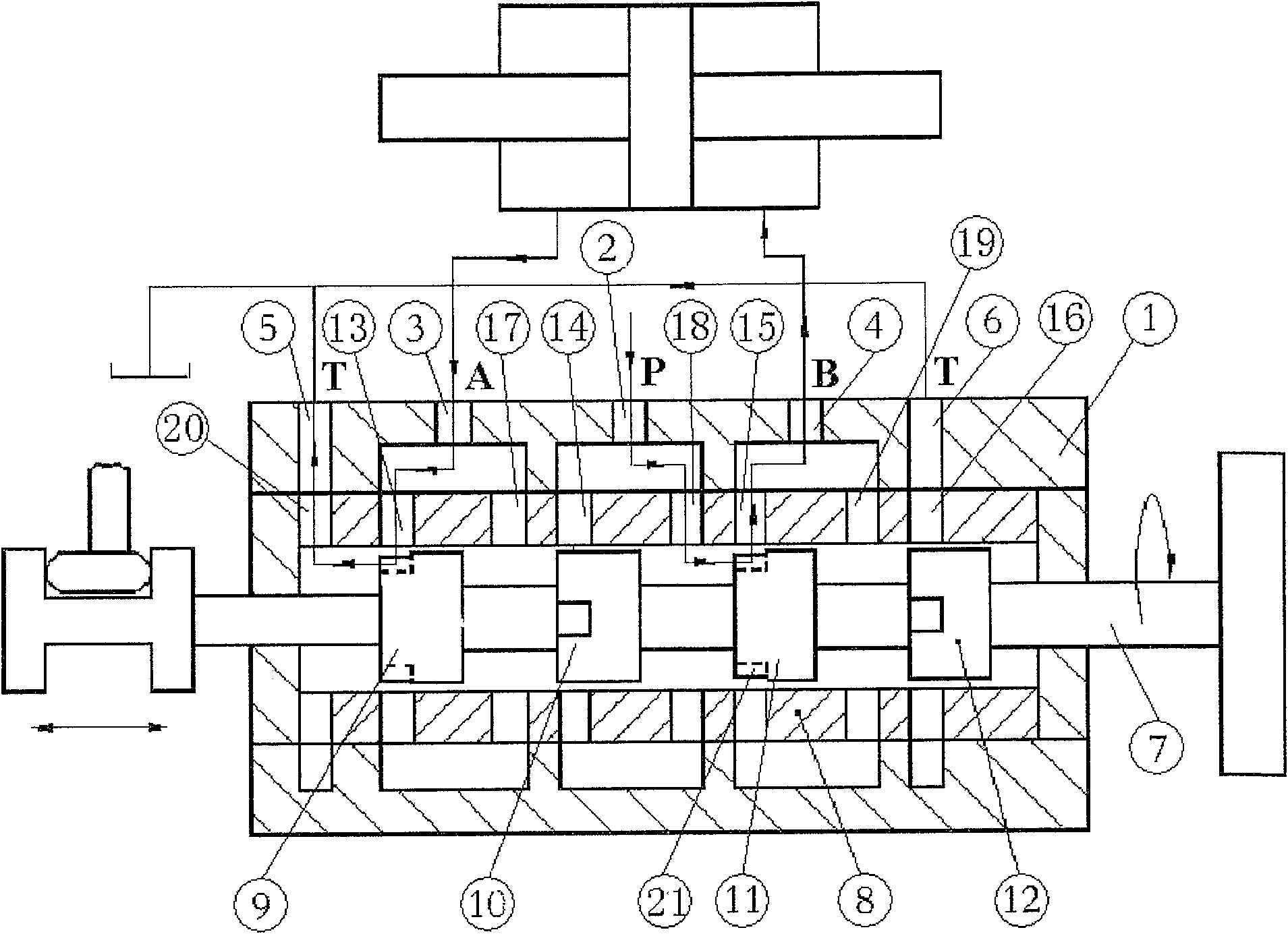

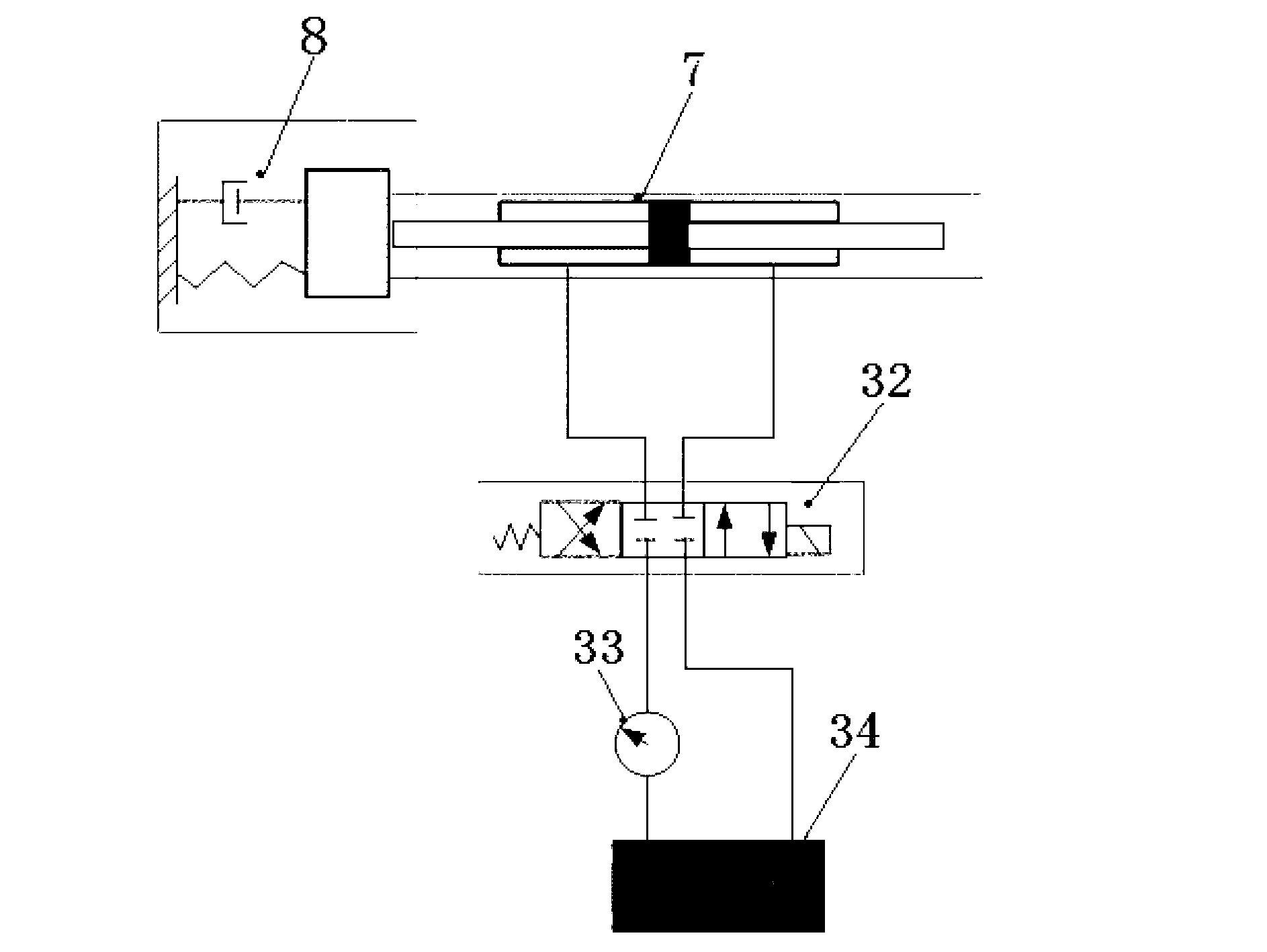

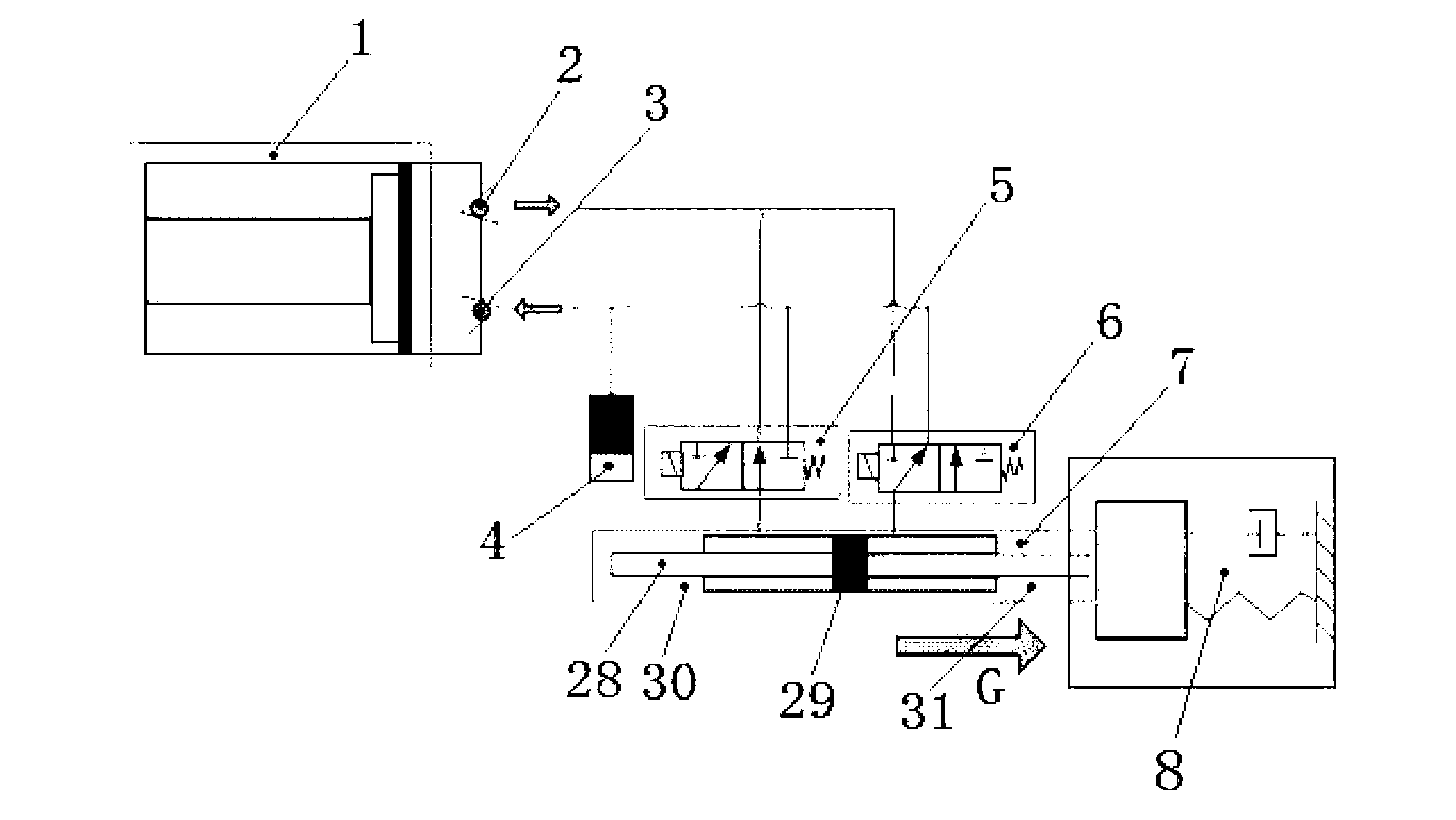

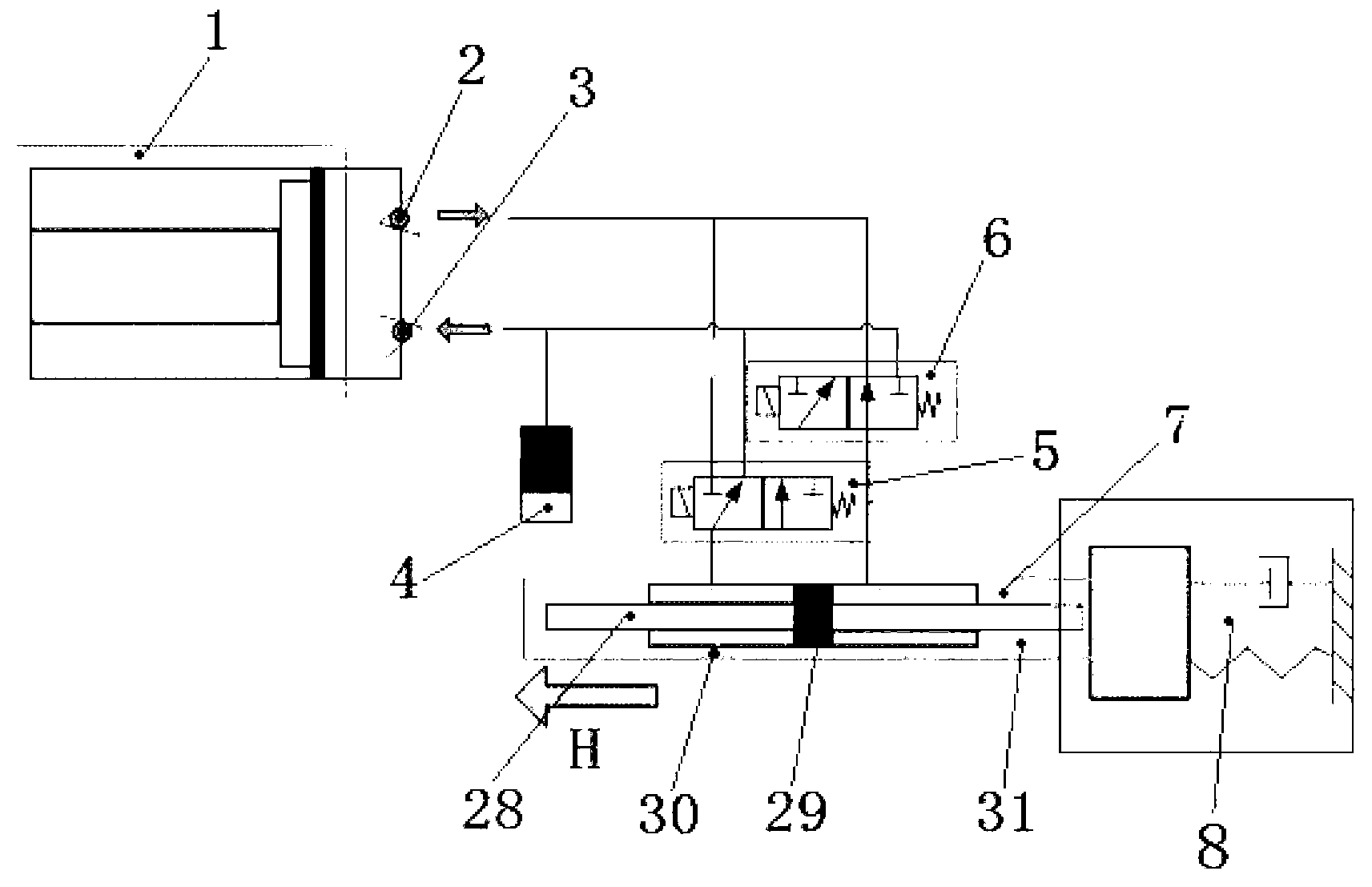

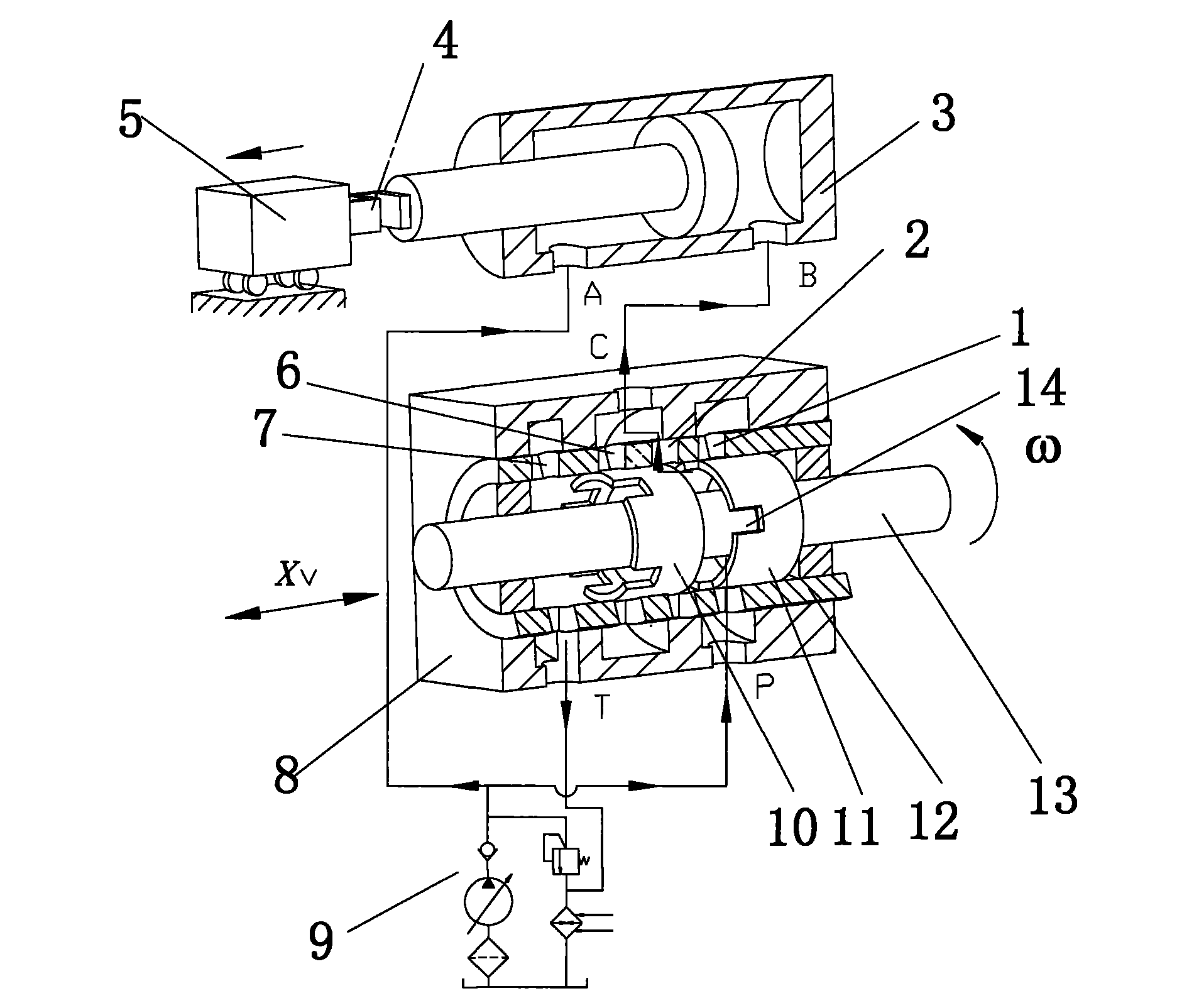

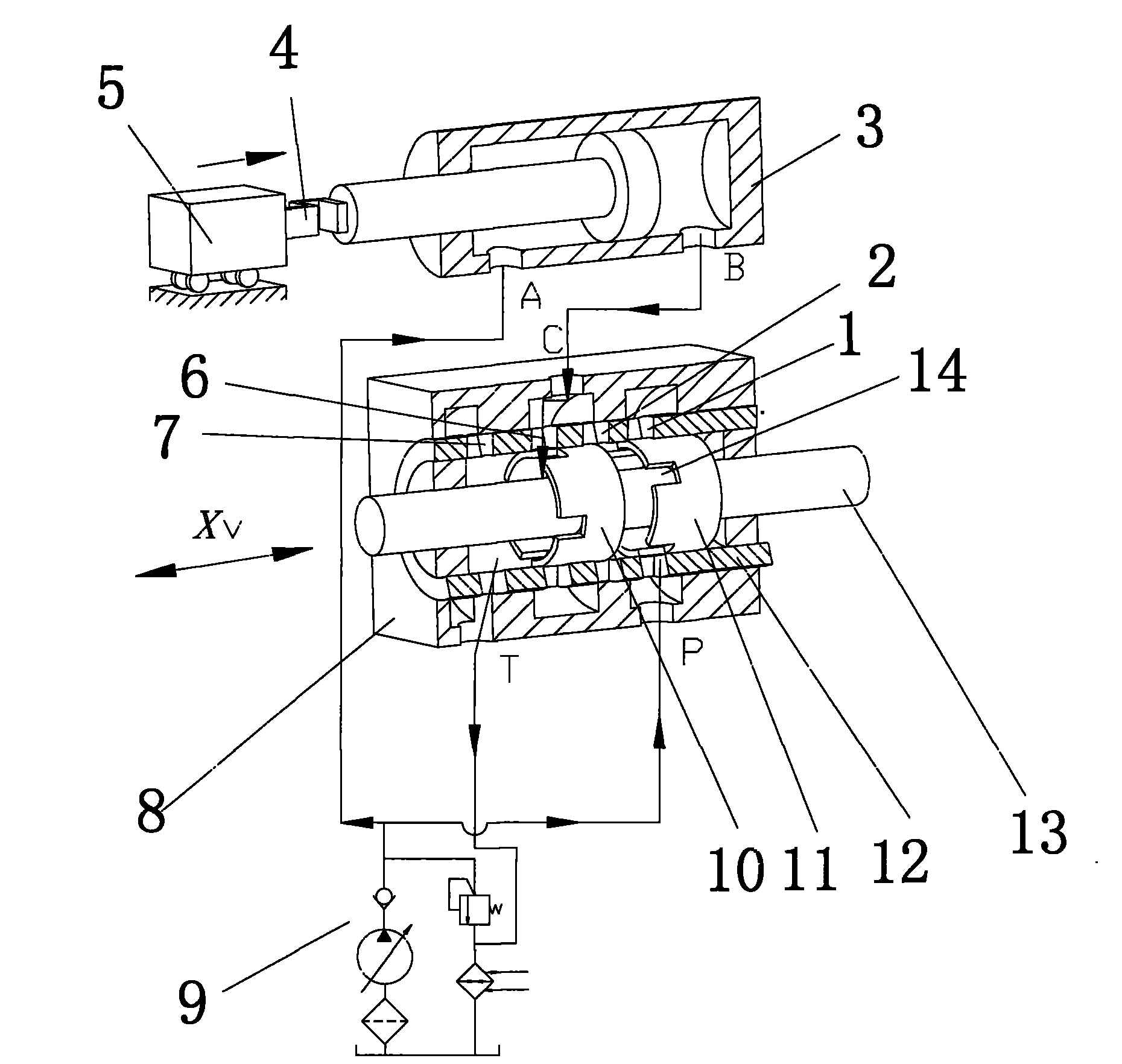

Large-flow high-frequency electrohydraulic exciting shock control valve drive system

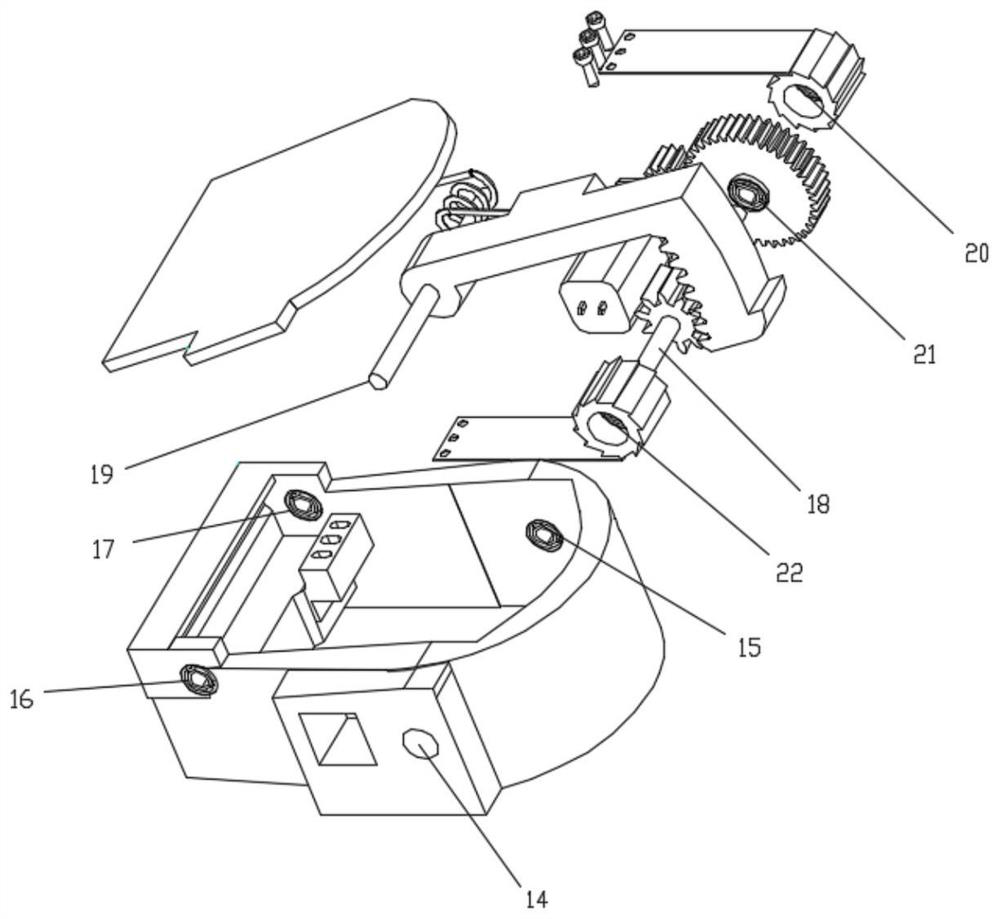

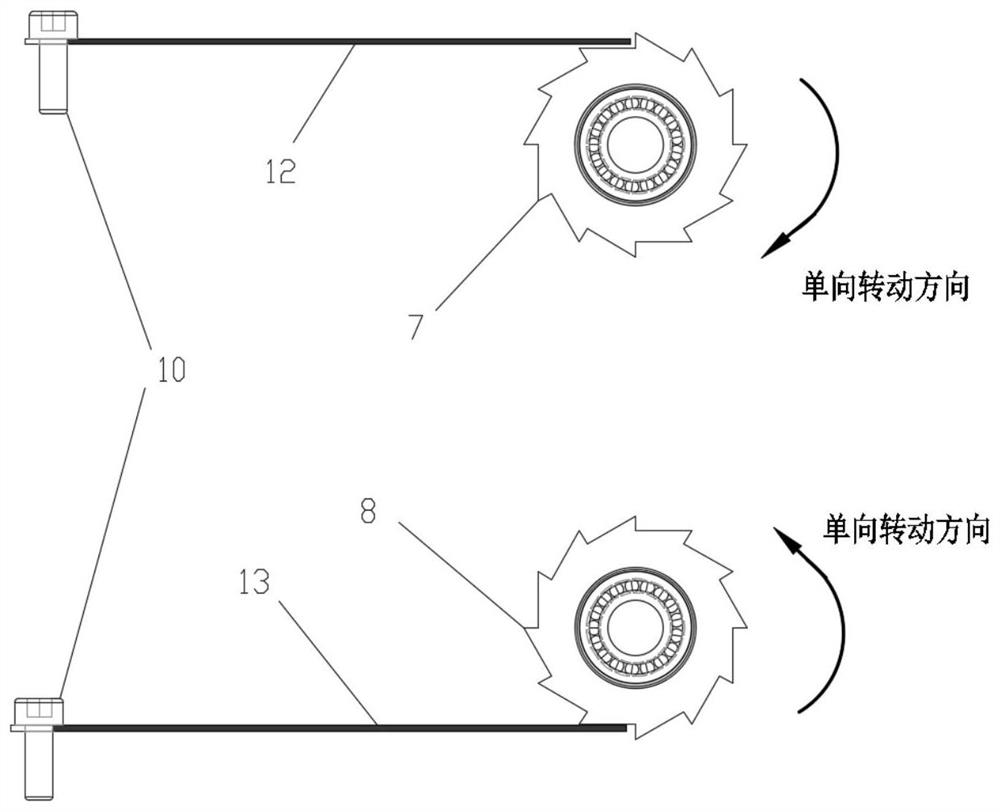

ActiveCN101718291AOvercome frictionOvercome the fluid damping momentFluid-pressure actuator componentsHydraulic cylinderHydraulic motor

The invention relates to a large-flow high-frequency electrohydraulic exciting shock control valve drive system which comprises a large-flow high-frequency electrohydraulic exciting shock valve. The drive system also comprises a main valve end hydraulic cylinder and a transmission, wherein the main valve end hydraulic cylinder is used for driving a valve core to axially slide in a linear way; thetransmission is used for driving the valve core to rotate; the main valve end hydraulic cylinder comprises a cylinder body and a drive piston; the drive piston is fixedly installed at the end part ofthe valve core; the drive piston is used as a boundary in the cylinder body, the cylinder body approaching one side of the valve core is provided with a rod cavity, and the cylinder body at the otherside is provided with a rodless cavity; the rod cavity is communicated with a high-pressure oil box, and the rodless cavity is communicated with the high-pressure oil box by a flow valve; the transmission comprises a hydraulic motor, a drive gear, an idle gear, a driven gear and a gear accelerating mechanism; an output shaft of the hydraulic motor is connected with an input shaft of the gear accelerating mechanism, and an output shaft of the gear accelerating mechanism is connected with the valve core. The invention can increase flows, improve the exciting shock frequency and prevent overloading of a hydraulic system.

Owner:ZHEJIANG UNIV OF TECH

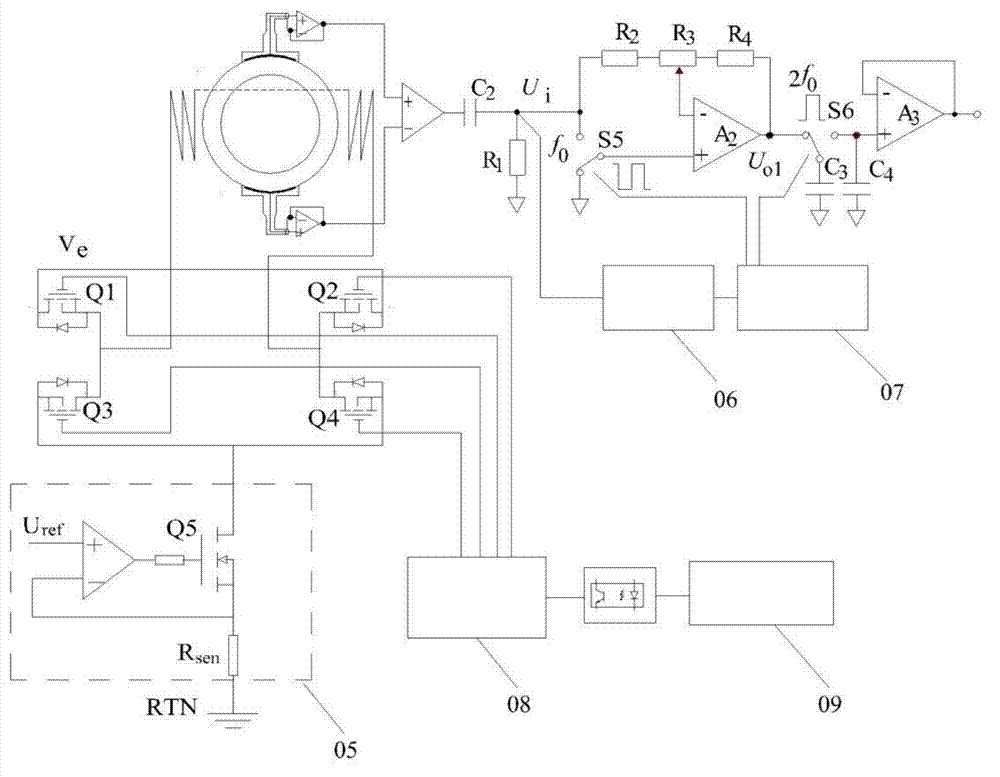

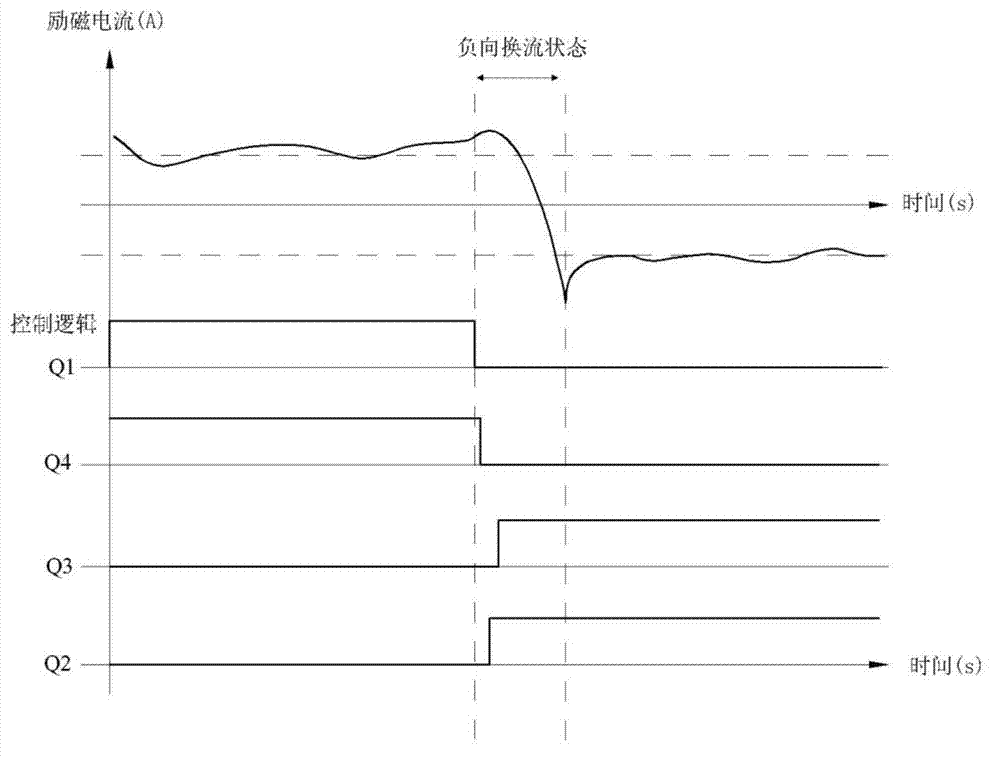

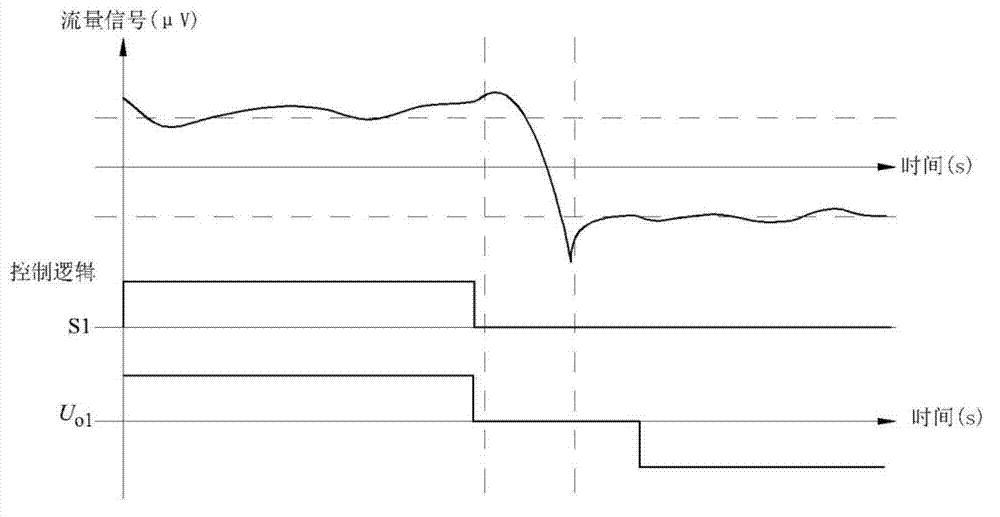

Capacitive electromagnetic flowmeter

ActiveCN103206990AIncrease the excitation voltageReduce distractionsVolume/mass flow by electromagnetic flowmetersSignal processing circuitsHigh dielectric permittivity

The invention relates to a capacitive electromagnetic flowmeter. A sensor of the capacitive electromagnetic flowmeter comprises a high-dielectric-constant industrial ceramic liner and a non-contact plated metal detecting sheet electrode. The sensor is provided with two opposite excitation coils serially connected to excite the inside of the sensor. The metal detecting electrode and a metal shielding electrode are connected to input and output ends of an operational preamplifier respectively to allow for equipotential shielding. A timing control circuit controls a switch of a full-bridge inverter circuit and an analog switch of a flow signal processing circuit according to logic signals of exciting current so as to control the exciting current in the coils and process the flow signals. The full-bridge inverter circuit is capable of enhancing the exciting current to increase the signal-to-noise ratio of the flow signals while inhibiting differential disturbing influence. The full-bridge inverter circuit is used with the timing control circuit to centrally control the power switch of the inverter circuit and the analog switch of the flow signal processing circuit, differential disturbance in the flow signals are removed accurately, and reliable detection on fluid flow is realized finally.

Owner:FUJIAN WIDE PLUS PRECISION INSTR

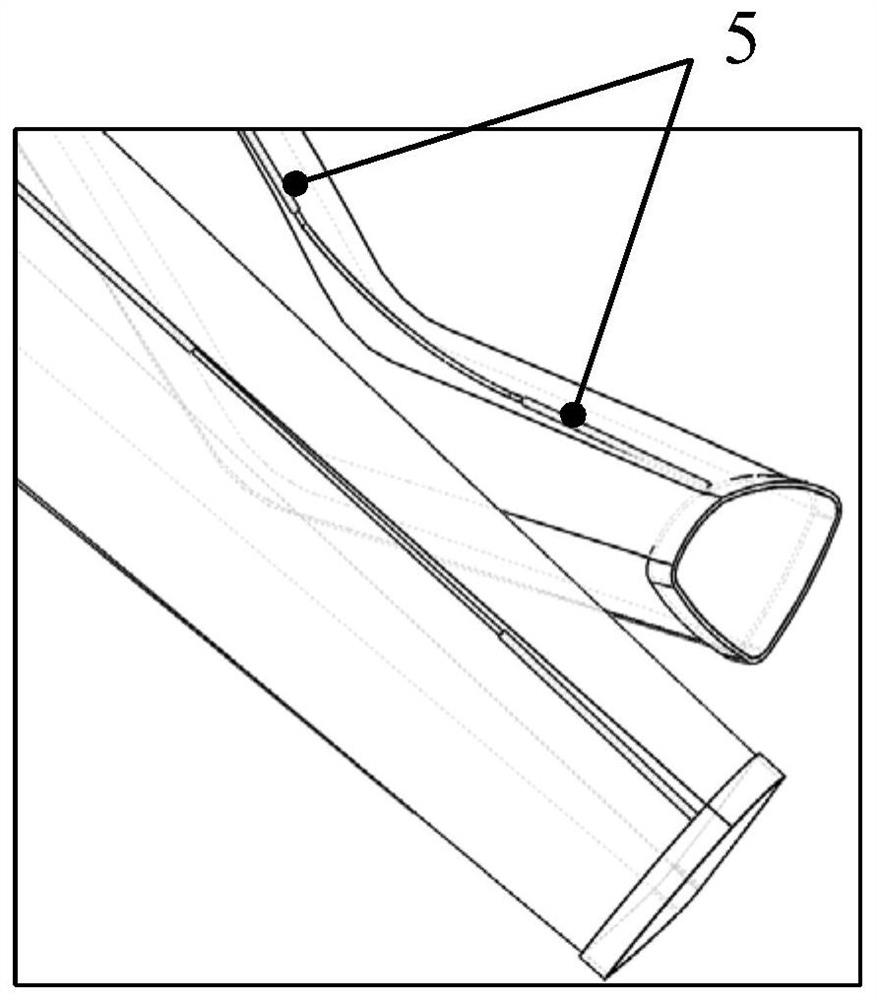

Preparation method of high-rigidity composite material transmission shaft

InactiveCN106523511ACost-effectiveImprove the overall mechanical propertiesYielding couplingShaftsCarbon fiber compositeFunctionalized graphene

The invention discloses a preparation method of a high-rigidity composite material transmission shaft, belongs to the technical field of carbon fiber composite materials, and particularly relates to a composite transmission shaft with functional grapheme modified resin as a base body and adopting different grades of carbon fiber for winding and a preparation method of the composite material transmission shaft. High-strength fiber is adopted for hoop winding, high-modulus fiber is adopted for spiral winding, the strength and rigidity in all directions of the composite material are adjusted and controlled, the performance advantages of the various kinds of fiber are brought into full play, the cost performance is high, and the integral rigidity of the composite material is improved. In addition, by the adoption of the functional grapheme modified resin system, interface combination of the resin and carbon fiber is improved, and the integral rigidity of the composite material is further improved. The composite material transmission shaft prepared through the preparation method has the advantages of being high in rigidity, excellent in torsional property, high in production efficiency, low in cost and the like, and has a wide application prospect in the fields of automobile industry, transmission machines and the like.

Owner:江苏欧亚铂瑞碳复合材料有限公司

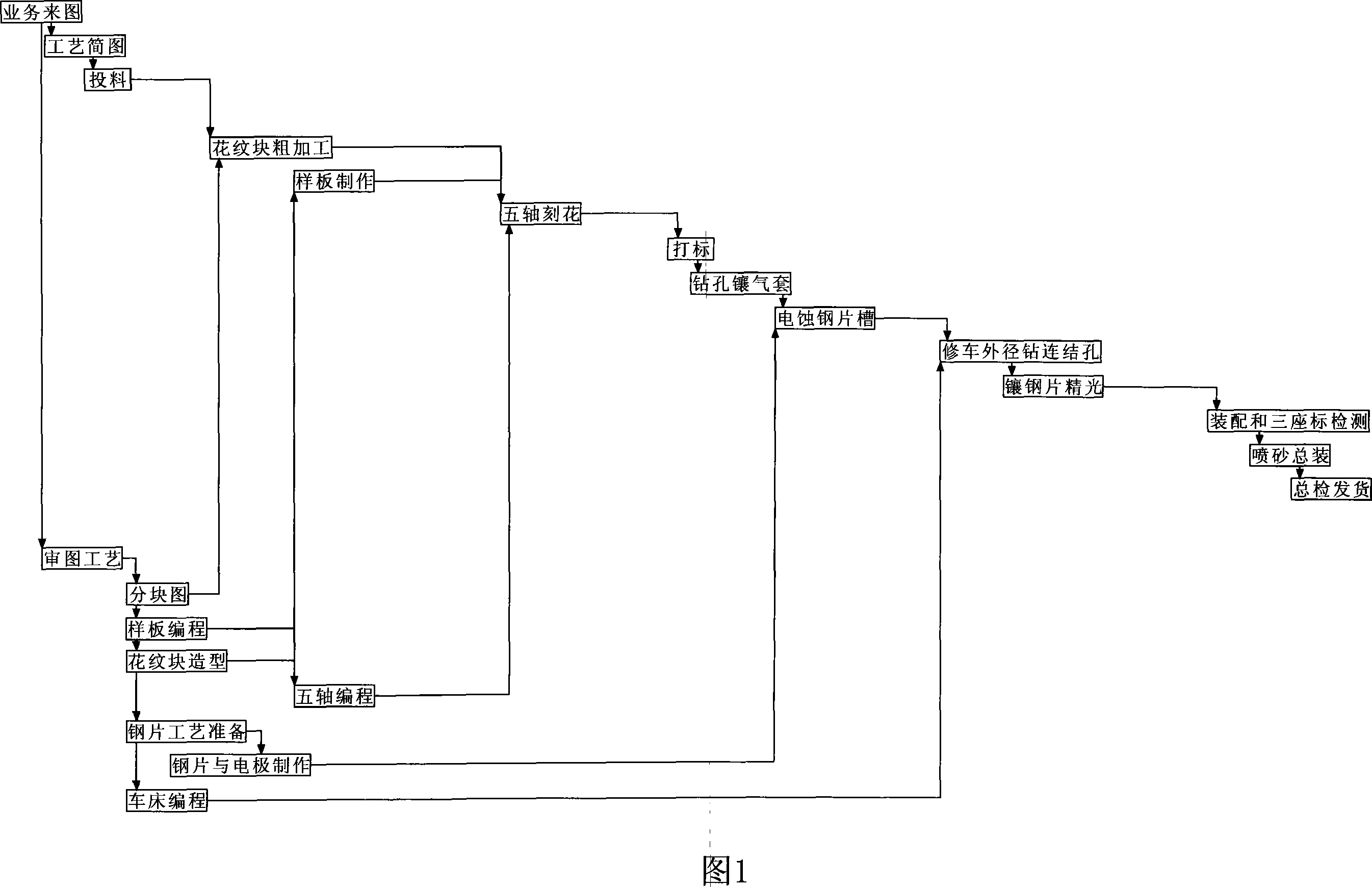

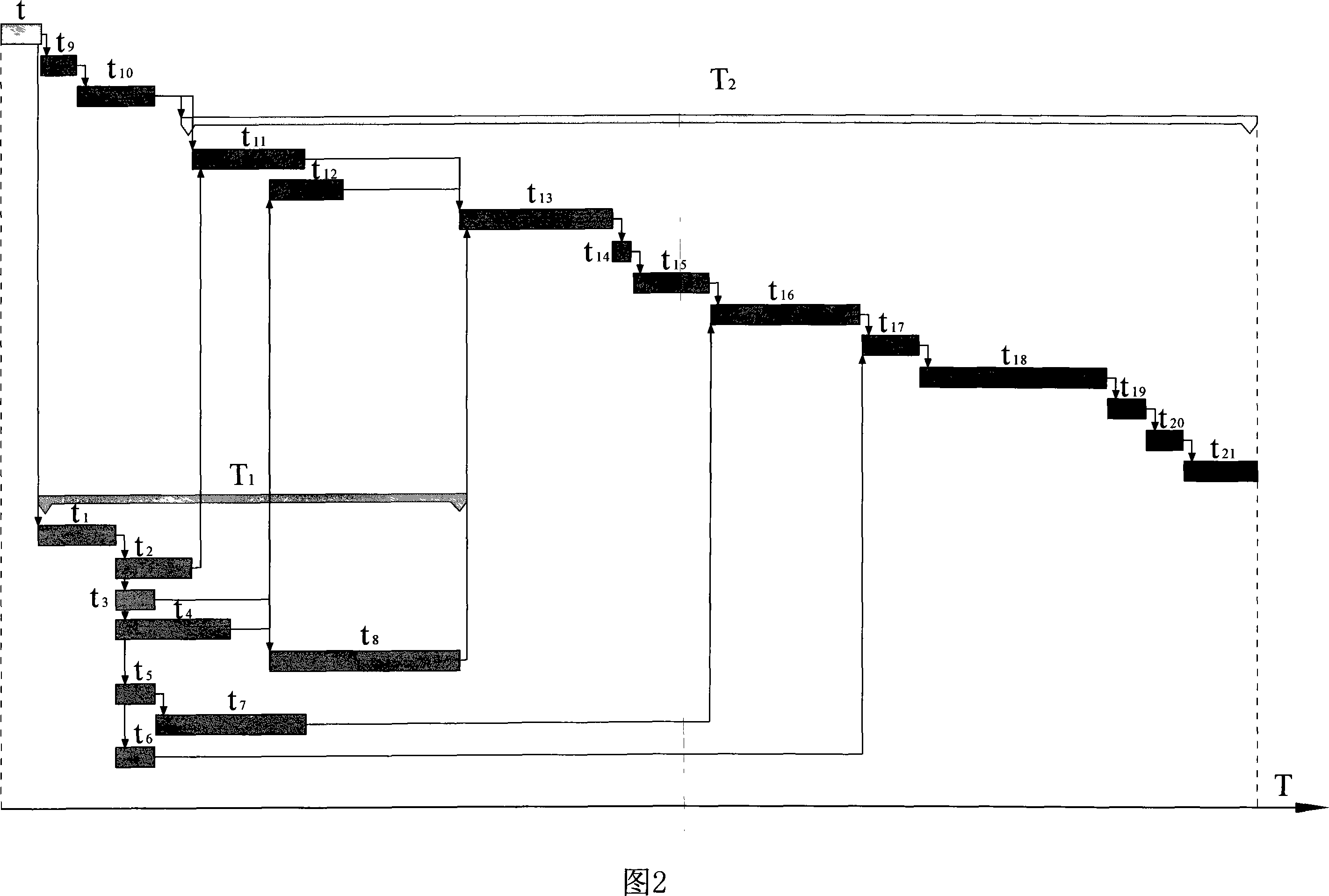

Tire mold high speed high precision parallel machining constitution method

InactiveCN101236416AShorten the design cycleReduce process preparation timeProgramme controlComputer controlNumerical controlEngineering

The invention relates to a high velocity and high precision constituting method for collaterally elaborating a tyre mould, comprising the following steps of a concurrence of designing and manufacture processing; a concurrence of designing and material purchasing; a concurrence of technology planning, rough machining and semifinishing; a concurrence of designing and numerical control process programming; and an elaboration for a single piece with high velocity and high precision. The high velocity and high precision constituting method for collaterally elaborating a tyre mould has the advantages of improving an elaborating precision of a product, shortening a delivery date for the mould and reducing the cost, and is suitable for collaterally elaborating the tyre mould with high velocity and high precision.

Owner:GREATOO INTELLIGENT EQUIP INC

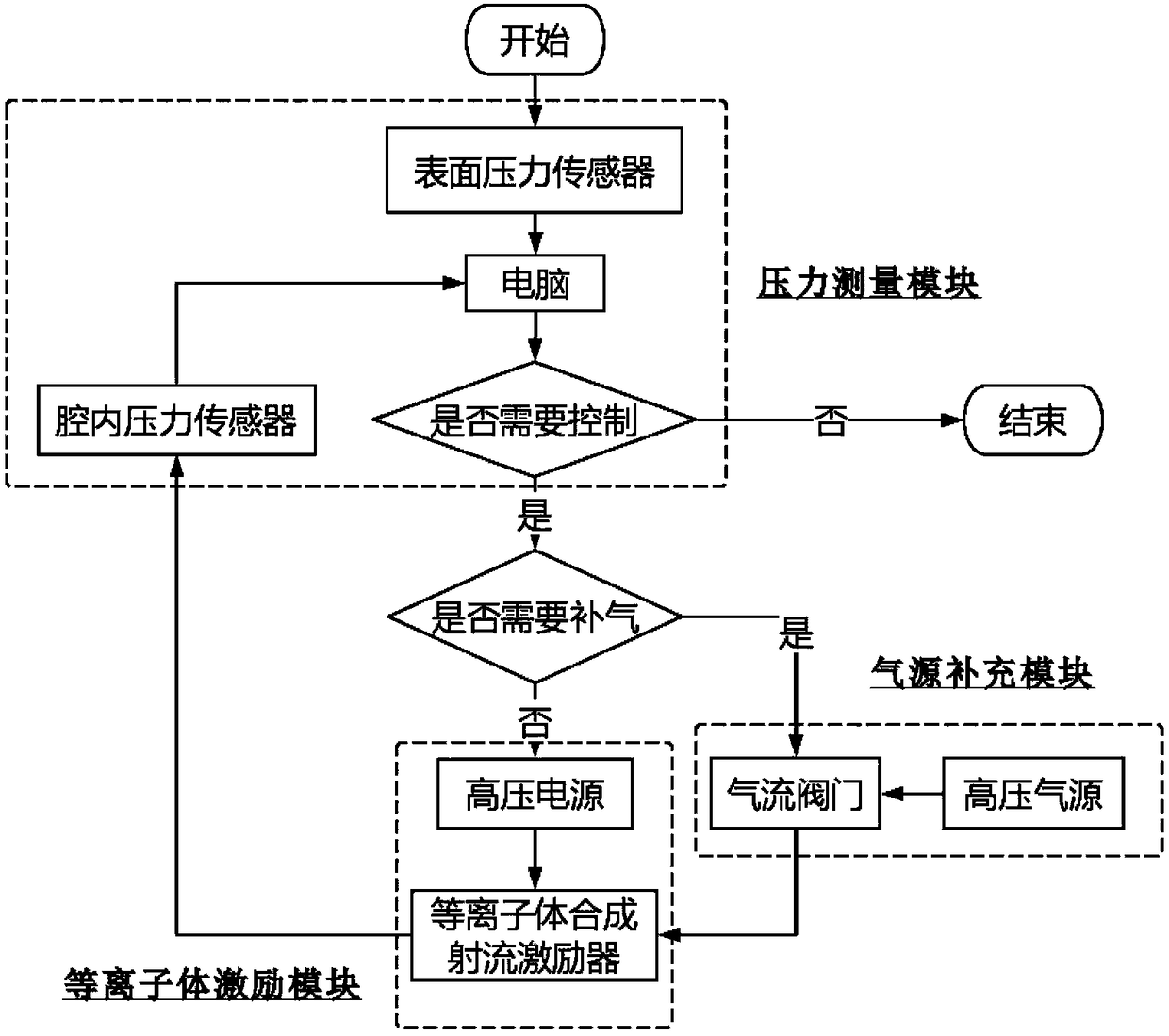

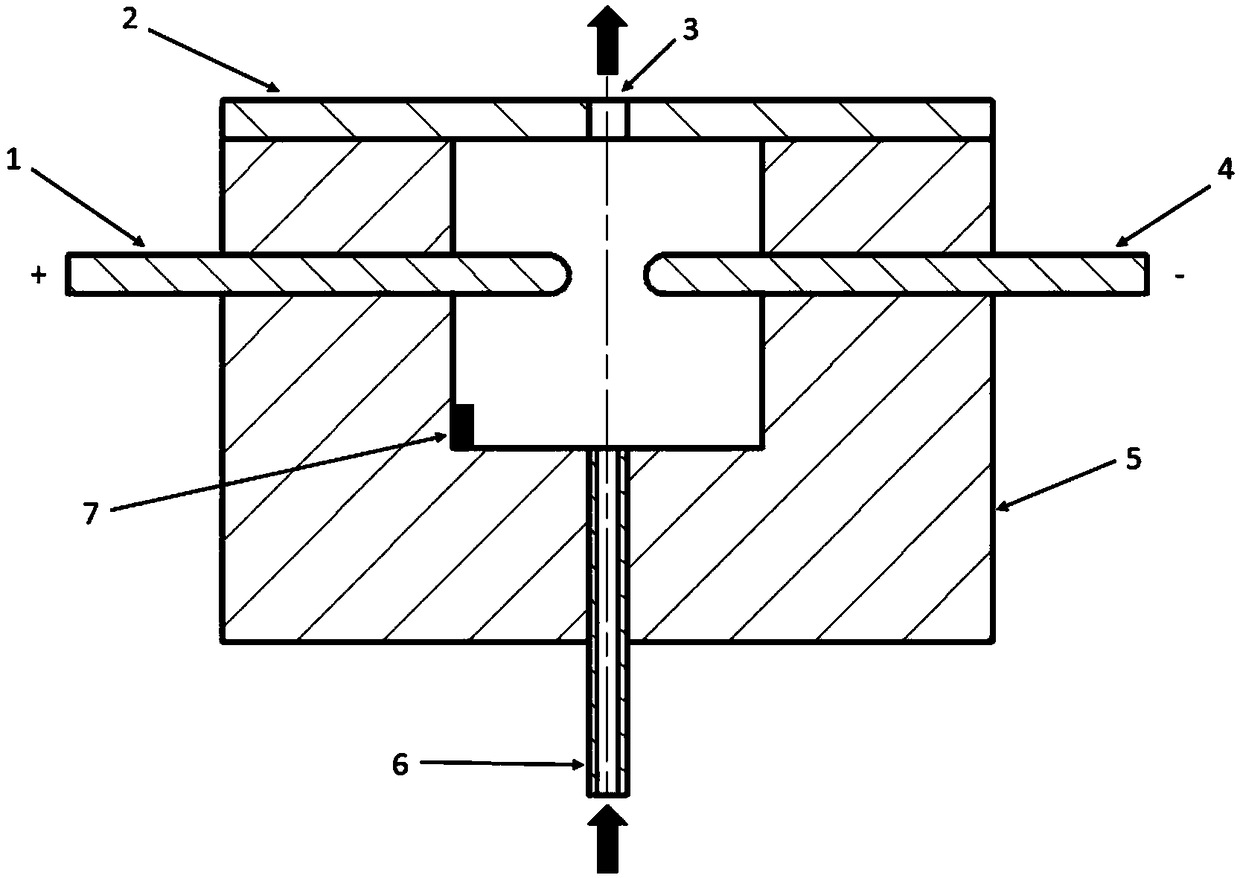

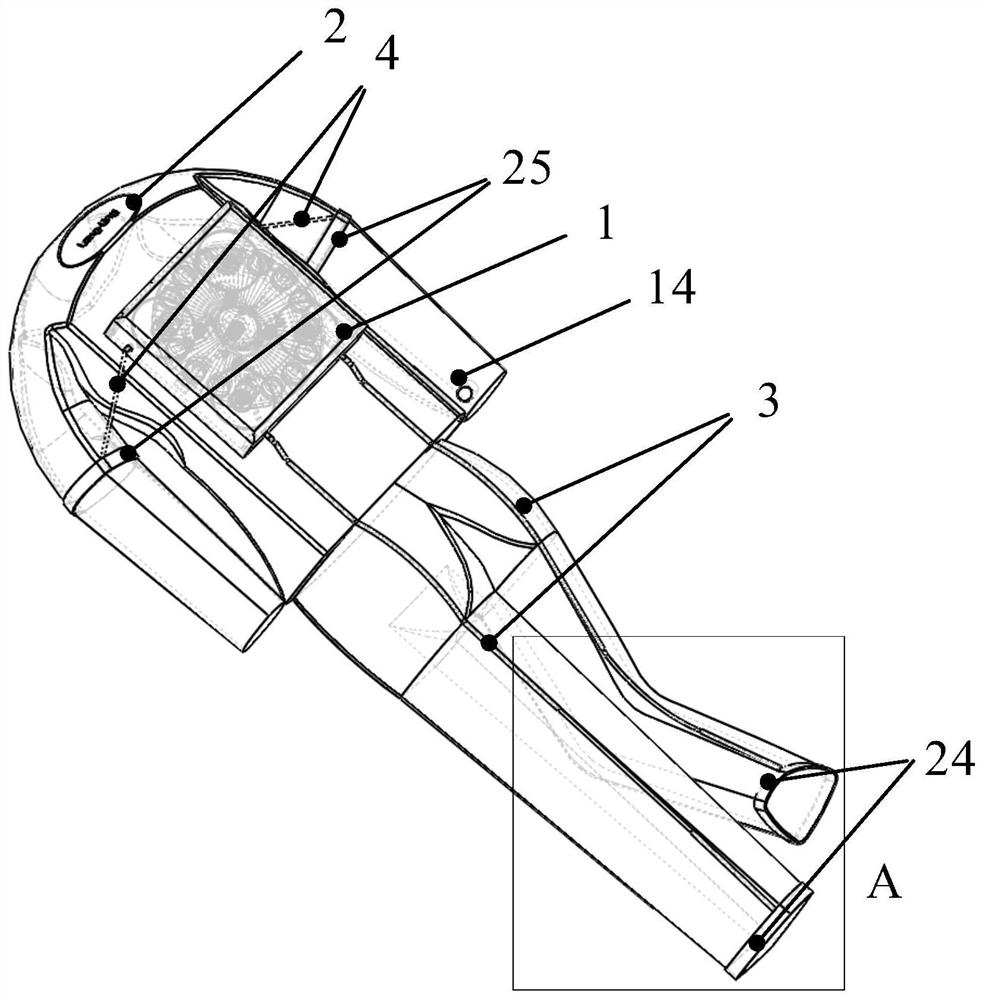

Self-adaptive excitation control system based on plasma synthetic jet actuator

ActiveCN108116664AActive Flow Control ImplementationImprove flight qualityAir-flow influencersPlasma techniqueControl systemHigh pressure

The invention relates to a self-adaptive excitation control system based on a plasma synthetic jet actuator. The system comprises a plasma synthetic jet actuator, an outer wall face pressure sensor, an intracavity pressure sensor, a computer, a high-voltage power supply, a high-pressure gas source and an airflow valve. The system is characterized in that the excitation efficacy of the plasma synthetic jet actuator can be adaptively adjusted according to the situation of an external flow field. The system has wide application range and high response speed, can be used for better mining the excitation efficacy of the plasma synthetic jet actuator, and realizes optimized positive flowing control for the external flow field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

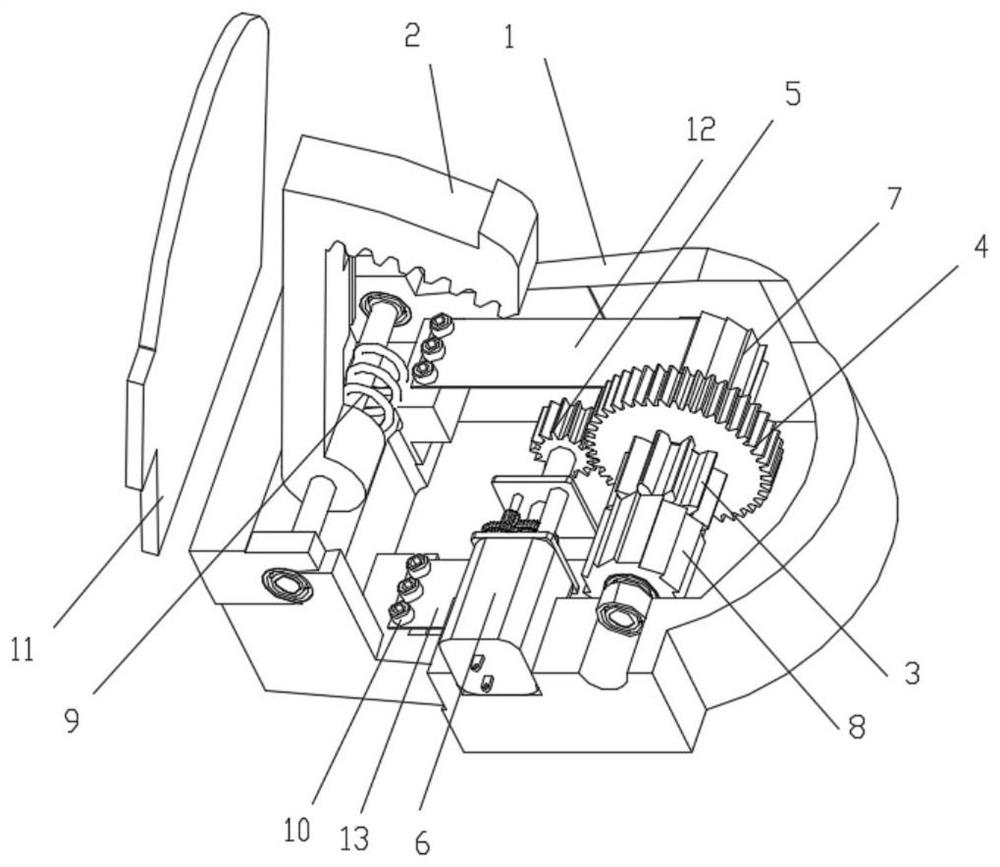

Micro piezoelectric-electromagnetic composite power generation device

InactiveCN105634205ATo achieve the effect of superimposing and magnifyingImprove power generation efficiencyPiezoelectric/electrostriction/magnetostriction machinesMechanical energy handlingElectricityPiezoelectric actuators

The invention discloses a micro piezoelectric-electromagnetic composite power generation device, which comprises an electromagnetic power generation unit, a piezoelectric power generation unit, a planetary gear acceleration mechanism, a housing and a bulge structure, wherein a brushed DC motor structure is adopted by the electromagnetic power generation unit; a cantilever beam-type piezoelectric vibrator structure is adopted by the piezoelectric power generation unit; and the electromagnetic power generation unit and the piezoelectric power generation unit convert external mechanical energy into electric energy. Rotating speed multiplication of a sun gear is achieved by reasonably matching various gear teeth of the planetary gear acceleration mechanism, so that the speed of cutting a magnetic induction line by a coil and the frequency of exciting a piezoelectric vibrator by the bulge structure are improved; and the power generation efficiency is further improved. Two different power generation mechanisms are achieved by the same mechanism, so that the effect of superposing and amplifying output electric energy is achieved; and the power generation efficiency is further improved through ingenious combination with the planetary gear acceleration mechanism.

Owner:JILIN UNIV

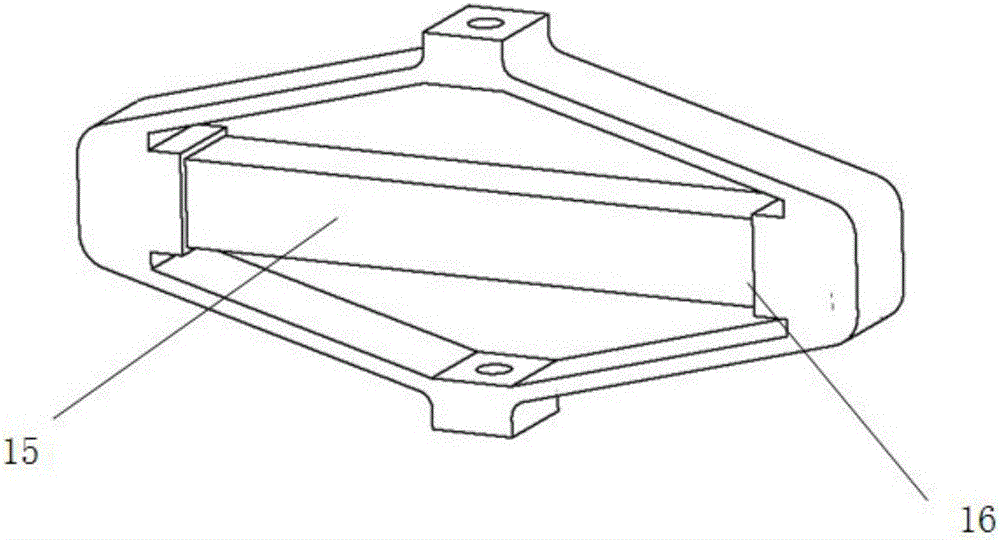

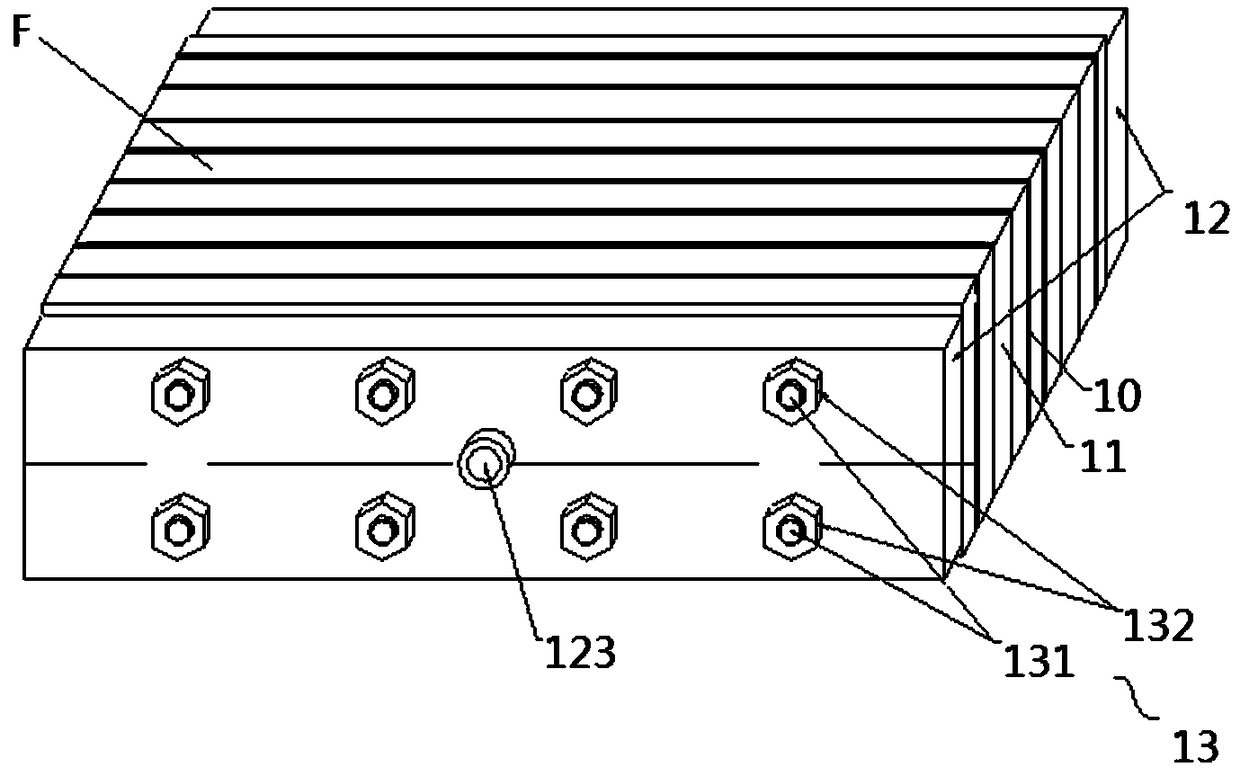

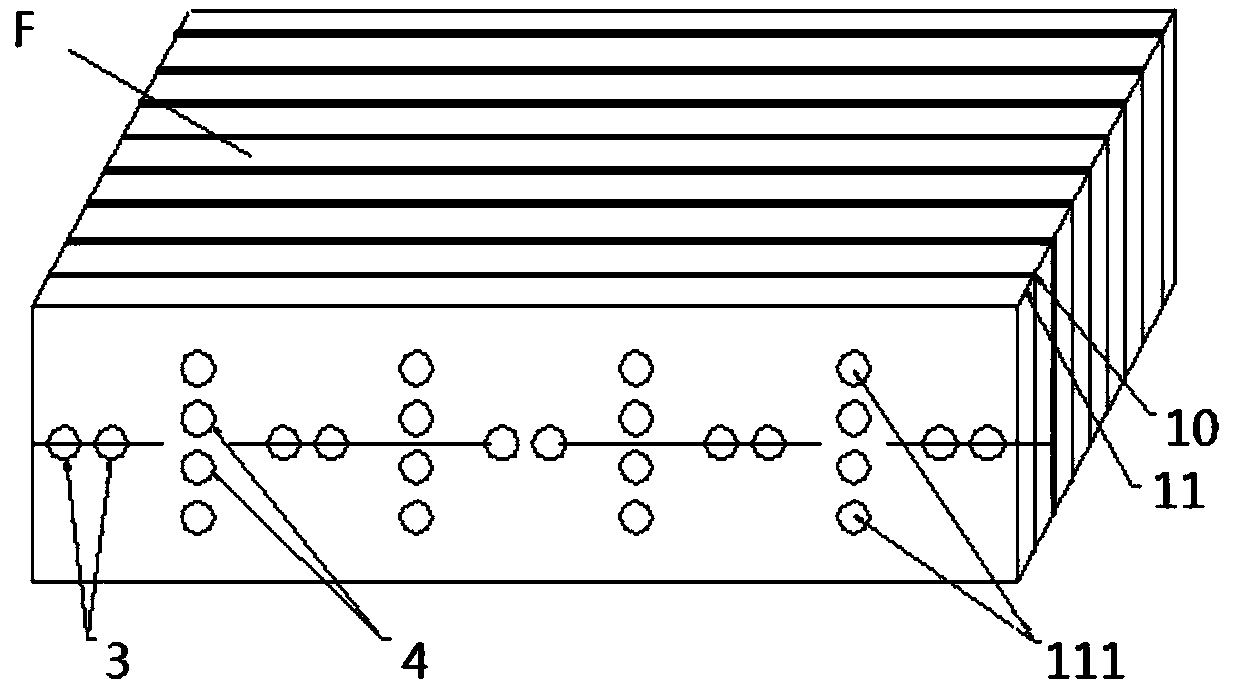

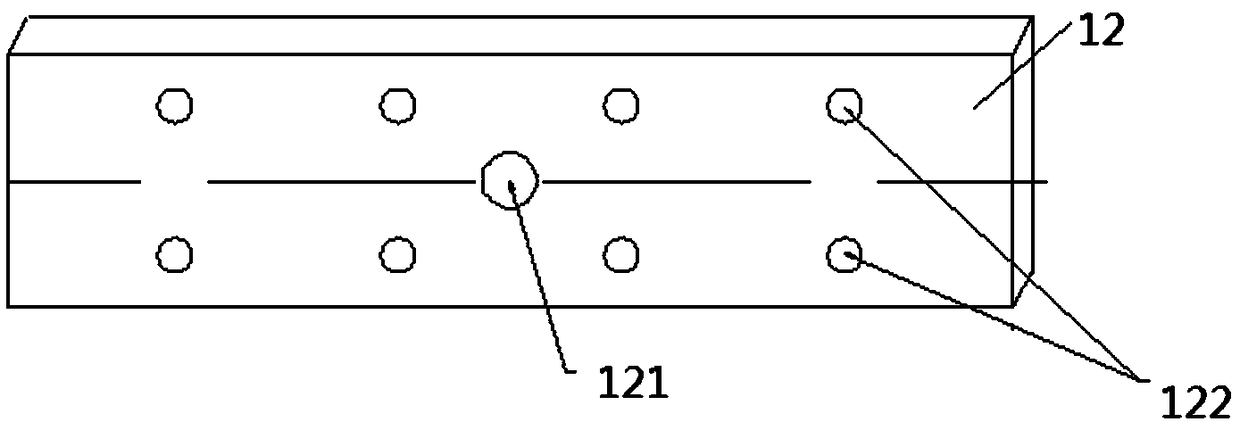

Electromagnetic combined apparatus for synthesizing stone pressure plate

ActiveCN101412245ARealize vibration suppression one by oneSimple structureCeramic shaping apparatusEngineeringQuartz

The invention relates to the field of building material machinery, in particular to an electromagnetic combined synthetic stone pressure plate device. The pressure plate device solves the problem that at present, when the electromagnetic vibration theory is applied to controlling a one-piece pressing tool to achieve integral vibration and pressing, the actual press power applied on part of a material is insufficient, and the pressing requirement on achieving the best compaction effect cannot be satisfied. The device comprises a vacuum cover provided with a supporting plate therein, wherein the supporting plate is provided with electromagnets, and a pressing device is arranged under the supporting plate; the pressing device is provided with a driving rod the end part of which is connected with movable iron cores of the electromagnets through a connecting piece; and a compression spring is arranged between the connecting piece and an electromagnet base. The pressing tool comprises vibrating plates the number of which is in accordance with that of the electromagnets on the supporting plate and which form a rectangular pressing tool through matrix arrangement on the same plane, the vibrating plates are corresponding to the electromagnets on the supporting plate one by one, and each vibrating plate is connected with the movable iron cores of the electromagnets through the driving rod. The pressure plate device has a reasonable and simple structure, good molding effect on pressing artificial quartzes, and high compactness of the finished products.

Owner:STATE GRID CORP OF CHINA +1

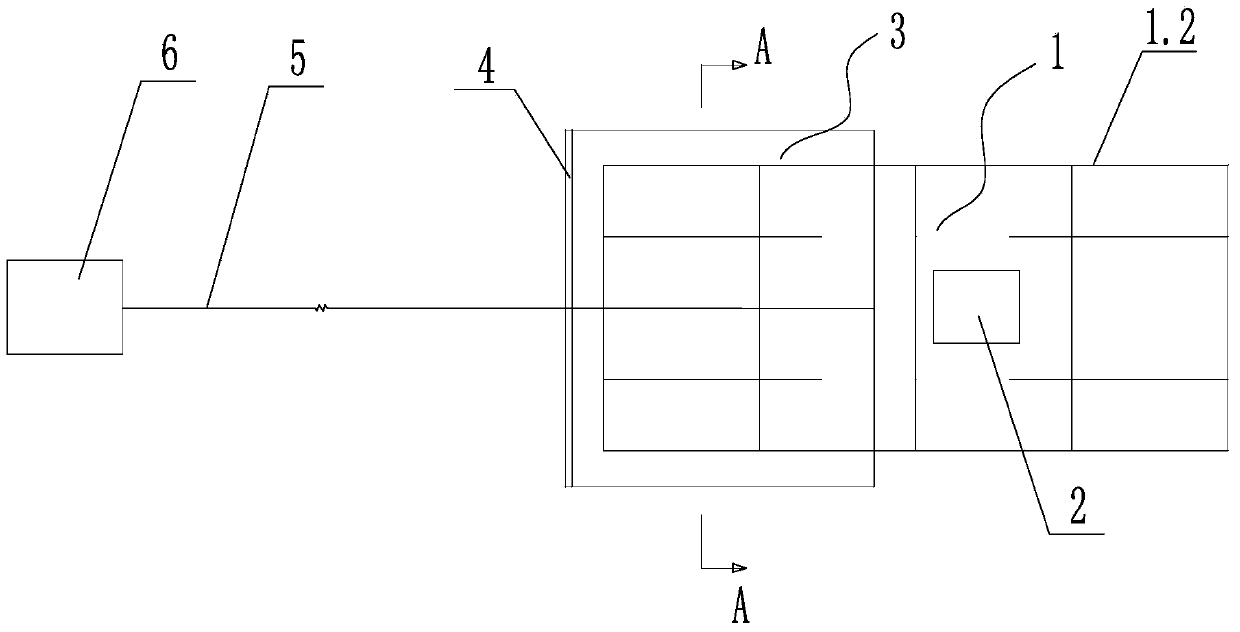

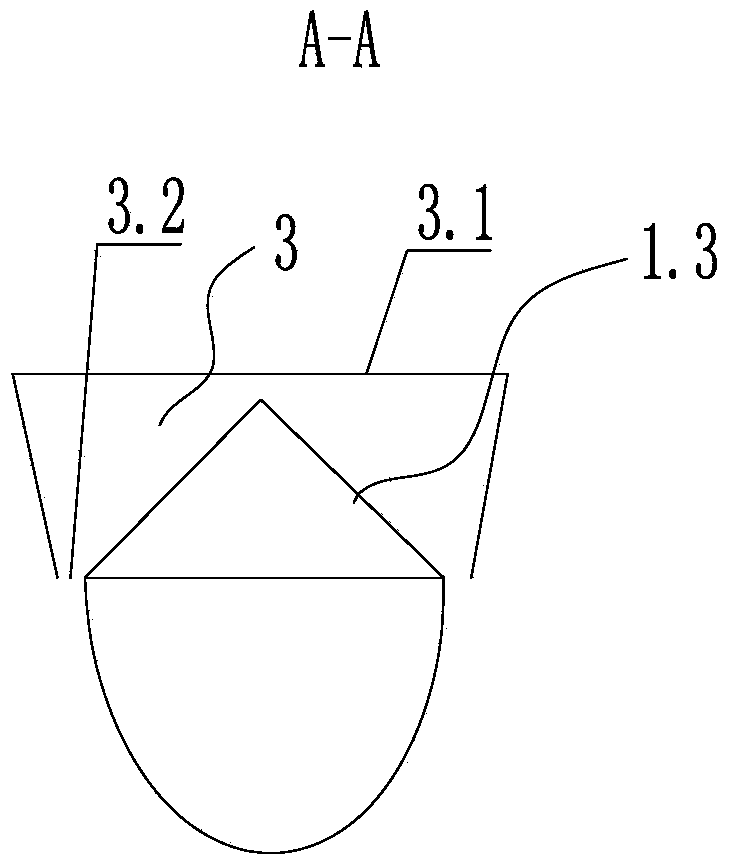

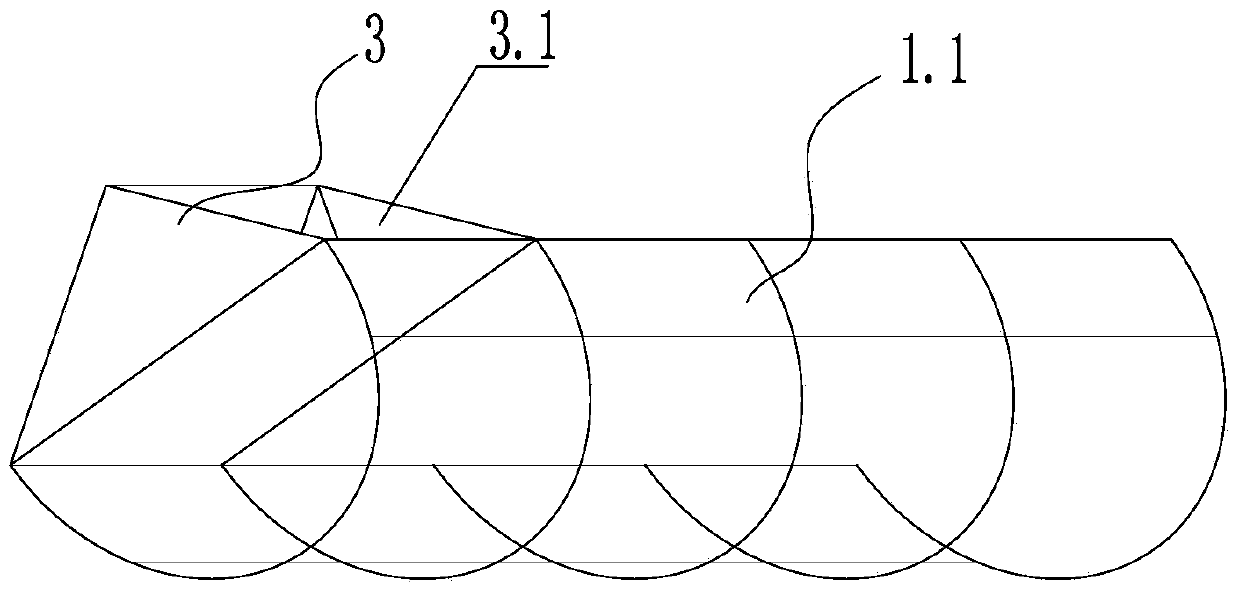

U-shaped channel forming device and forming method

InactiveCN103422472ASimple structureReduce weightIrrigation ditchesArtificial water canalsEngineeringElectrical and Electronics engineering

The invention discloses a U-shaped channel forming device and a forming method. The U-shaped channel forming device comprises a forming mold and a traction driving mechanism, wherein the forming mold is used for casting and forming U-shaped concrete channels in a U-shaped soil mold channel to be cast, and the traction driving mechanism is positioned at the front end of the forming mold, is connected with the forming mold and drags the forming mold to realize the moving casting along the U-shaped soil mold channel to be cast. The U-shaped channel forming device has the advantages that the structure is simple, the cost can be reduced, the casting efficiency can be improved, and the casting quality is ensured. The U-shaped channel forming device is particularly applicable to fields.

Owner:新疆兵团水利水电工程集团有限公司

Heat and vibration composite aging treatment method adopting residual heat of casting billets of cast iron rolls

InactiveCN101705349AHigh efficiency and energy saving effectBest treatment effect and economic benefitFurnace typesHeat treatment furnacesCast ironOptimal treatment

The invention relates to a heat and vibration composite aging treatment method adopting residual heat of casting billets of cast iron rolls, which is characterized by adopting the residual heat and cooling time of the casting billets to carry out vibration aging treatment on the cast iron rolls. As adopting the composite aging treatment method combining heat aging treatment and vibration aging treatment, the invention not only gives play to the advantages of high efficiency and energy saving of vibration aging treatment and the advantage of stable effects of heat aging treatment but also avoids the shortcomings of various aging treatment, thereby obtaining optimal treatment effects and economic benefits. Because the residual heat and cooling time of the casting billets in the lifecycle of the cast iron rolls are fully utilized consciously, the residual stress reduction effect is improved on the basis of not adding energy and time of aging treatment.

Owner:DONGHUA UNIV

Integrated tester and testing method for shock absorption, noise reduction and impact resistance of composite material

ActiveCN111781076AMeet the needs of integrated testingOptimize layoutStrength propertiesMaterials testingTester device

The invention relates to the technical field of material testing, particularly to an integrated tester and testing method for shock absorption, noise reduction and impact resistance of a composite material. The tester comprises a reverberation box, an anechoic box, an upper box body and lower box body supporting and connecting table body, a high-power high-pitch horn, a front power amplifier, a pure post-power amplifier, a plurality of groups of piezoelectric ceramics, a piezoelectric ceramic driving power supply, a projectile centrifugal acceleration ejection device, and a plurality of groupsof projectile sensors, a telescopic support frame, a snake-shaped telescopic thin tube, a laser displacement sensor, a high-speed camera, a plurality of sound pressure sensors, a projectile recoverydevice and a data acquisition instrument. The integrated tester can meet the integrated test requirements for shock absorption, noise reduction and impact resistance of the composite material at the same time, has comprehensive test indexes, has the advantages of high efficiency and mobility, is convenient for on-site test, and objectively evaluates the shock absorption, noise reduction and impactresistance of the composite material.

Owner:沈阳智振科技有限公司

Method of composite thermal and vibratory ageing treatment by utilizing working afterheat of grain roll

InactiveCN101724743AThermally Aged StableAvoid the disadvantages of agingFurnace typesProcess efficiency improvementThermal ageingTreatment effect

The invention relates to a method of composite thermal and vibratory ageing treatment by utilizing the working afterheat of a grain roll, which performs the vibratory ageing treatment on the grain roll by utilizing the working afterheat and the retarded cooling time of the grain roll. By adopting the method of the composite thermal and vibratory ageing treatment which combines the thermal aging treatment and the vibratory ageing treatment, the invention not only has the advantages of high efficiency and energy conservation of the vibratory ageing treatment and the advantage of stable effect of the thermal ageing treatment, but also overcomes the shortcomings of various ageing treatments, thereby achieving best treatment effect and economic benefit. Because the working afterheat and the retarded cooling time of the grain roll are utilized sufficiently and consciously, the effect of reducing residual stress is improved on the premise of not adding the energy and the time for the ageing treatment.

Owner:DONGHUA UNIV

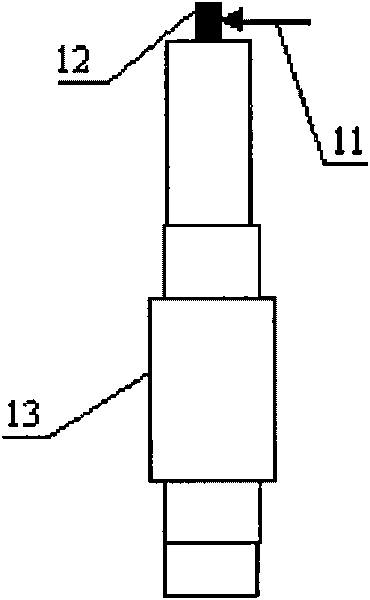

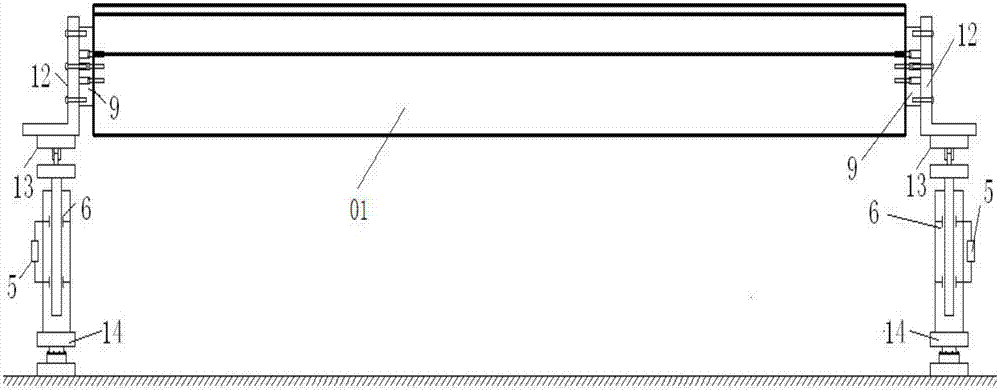

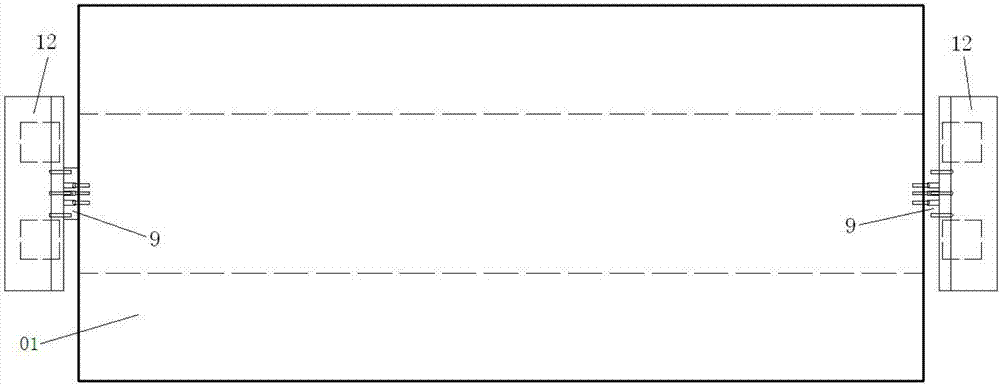

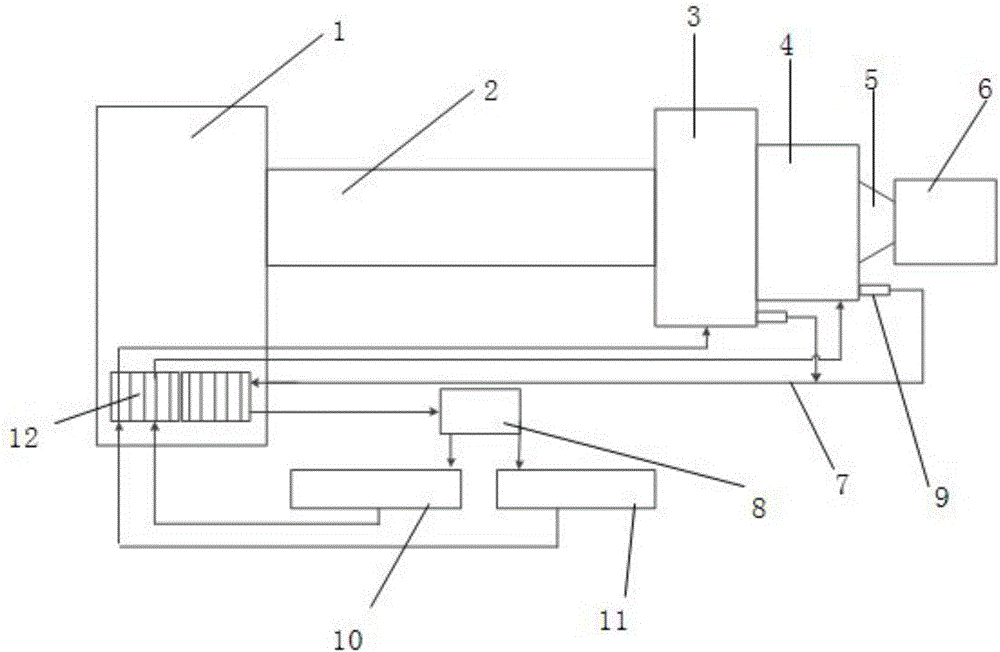

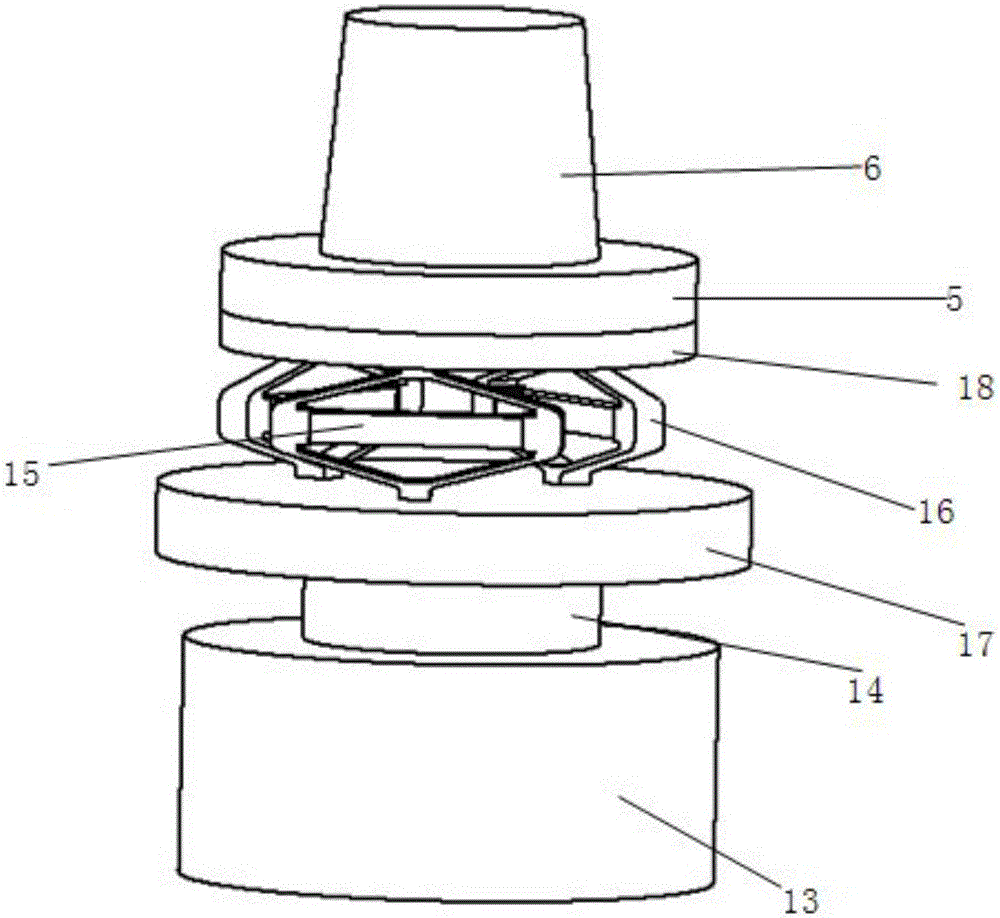

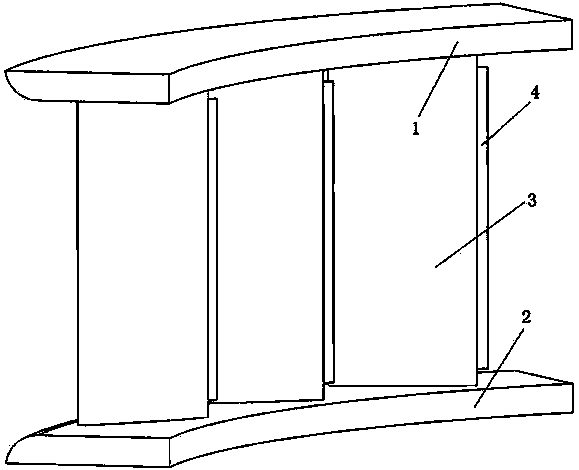

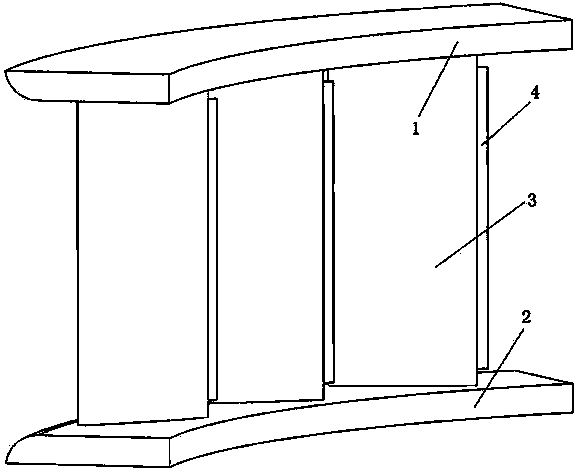

Device for performing forced shock excitation on bridge test model

PendingCN107063625AIncrease the excitation frequencyComprehensive test dataAerodynamic testingReciprocating motionHydraulic ram

The invention provides a device for performing forced shock excitation on a bridge test model. Two ends of the test model in a length direction are respectively provided with a model support, a force measurement sensor is clamped and disposed between each test model and the corresponding model support, hydraulic oil cylinders with piston rods capable of performing up and down reciprocating motions are respectively disposed below four corners of the test model, and the tops of piston rods of the four hydraulic oil cylinders are respectively connected with an upper movable support seat the top of which is connected with the corresponding model support; the two hydraulic oil cylinders locating below one long edge line of the test model are synchronously telescopic, and the bottoms of the two hydraulic oil cylinders locating below the long edge line of the test model are respectively connected with a lower fixed support seat fixedly connected with a test device foundation; and the two hydraulic oil cylinders locating below the other long edge line are also synchronously telescopic, and the bottoms of the two hydraulic oil cylinders locating below the other long edge line are respectively connected with a lower movable support seat fixedly connected with the test device foundation; and the device further comprises a displacement sensor and an acceleration sensor. The device can simulate a single-DOF (degree of freedom) or coupled forced vibration in a vertical direction and a torsion direction, and the device has the advantages of accurate data and the high shock excitation frequency.

Owner:CENT SOUTH UNIV

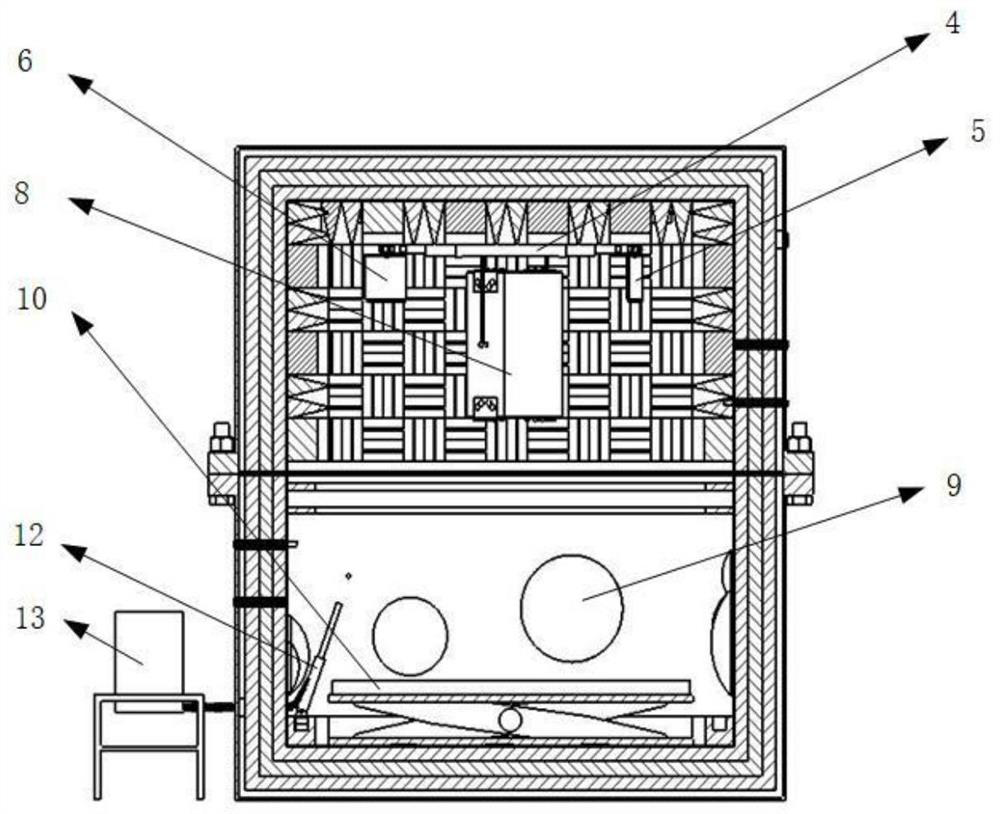

Vibration centrifugation compound environment simulation test apparatus suitable for component product

InactiveCN105910784ASimple excitationSmall weightVibration testingVibration controlVibration acceleration

The invention discloses a vibration centrifugation compound environment simulation test apparatus suitable for a component product. The apparatus comprises a centrifugal machine and a vibration control system. A large arm tail end of the centrifugal machine is provided with a hydraulic shock excitation system, a piezoelectric shock excitation system and a clamp. The hydraulic shock excitation system is fixedly connected to a large arm. A shock excitation direction of the hydraulic shock excitation system is consistent with a large arm axis direction. The piezoelectric shock excitation system is connected rigidly in series. The clamp is fixedly connected to the piezoelectric shock excitation system. The piezoelectric shock excitation system and the hydraulic shock excitation system are provided with acceleration sensors. A signal output terminal of each acceleration sensor is connected to a vibration signal input terminal of a vibration control system through a collecting ring. The vibration control system is electrically connected to a power amplifier and a hydraulic driving system. The power amplifier is electrically connected to the piezoelectric shock excitation system through the collecting ring. A hydraulic driving system is connected to the hydraulic shock excitation system through the collecting ring. By using the apparatus of the invention, composite output of a vibration accelerated speed and an overload accelerated speed from a low frequency to a high frequency can be completed.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

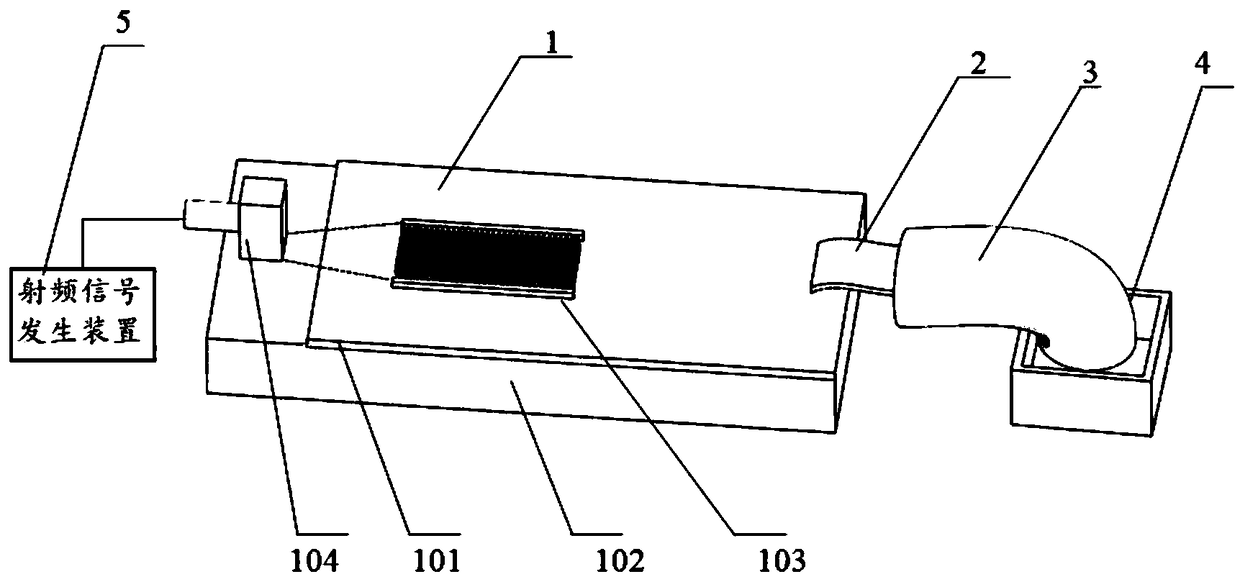

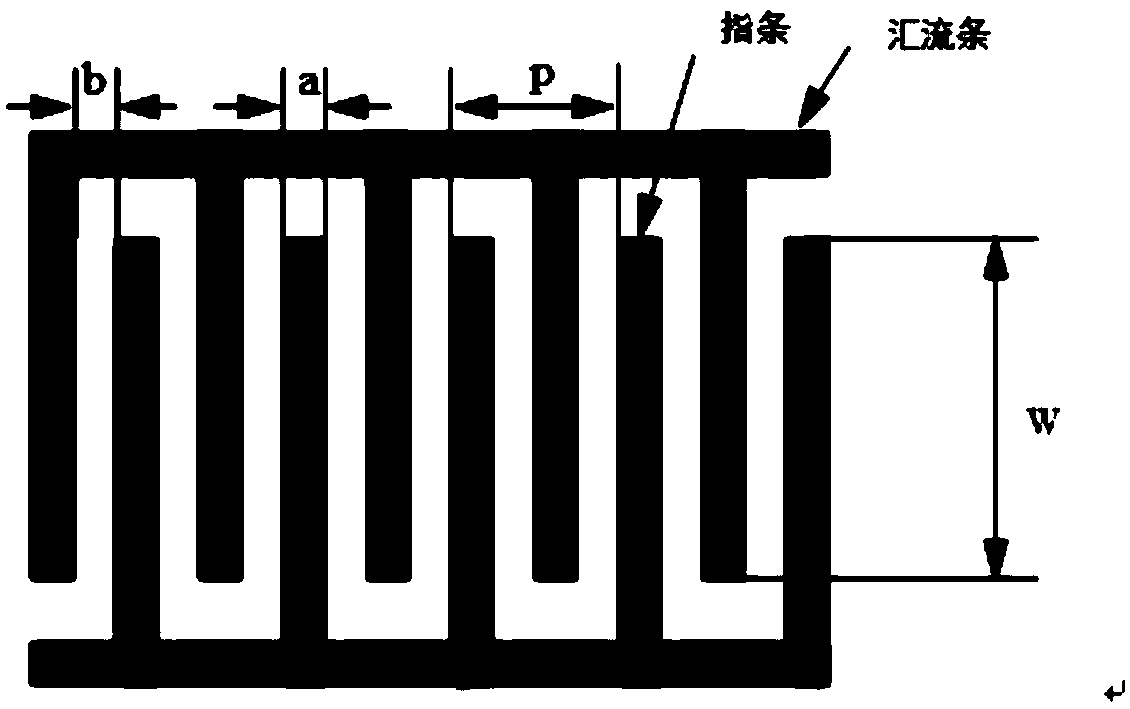

Surface acoustic wave-based atomization device and method

PendingCN109011043ASmall particlesUniform particlesMedical atomisersLiquid spraying apparatusFiberPolyester

The invention discloses a surface acoustic wave-based atomization device, comprising: an atomization chip, polyester fiber paper and a liquid storage tank; the atomization chip comprises a piezoelectric single crystal substrate, and an interdigital energy transducer which is disposed on the piezoelectric single crystal substrate; one end of the polyester fiber paper is attached to the upper surface of the piezoelectric single crystal substrate, and the other end is inserted into the liquid storage tank to suck the liquid in the liquid storage tank onto the upper surface of the piezoelectric single crystal substrate; the interdigital energy transducer generates a surface acoustic wave on the upper surface of the piezoelectric single crystal substrate under the driving of a radio frequency signal to atomize the liquid on the upper surface of the piezoelectric single crystal substrate. The invention also discloses an atomization method. The invention solves the problems of poor liquid atomization effect and large and uneven spray droplet particles in the prior art.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

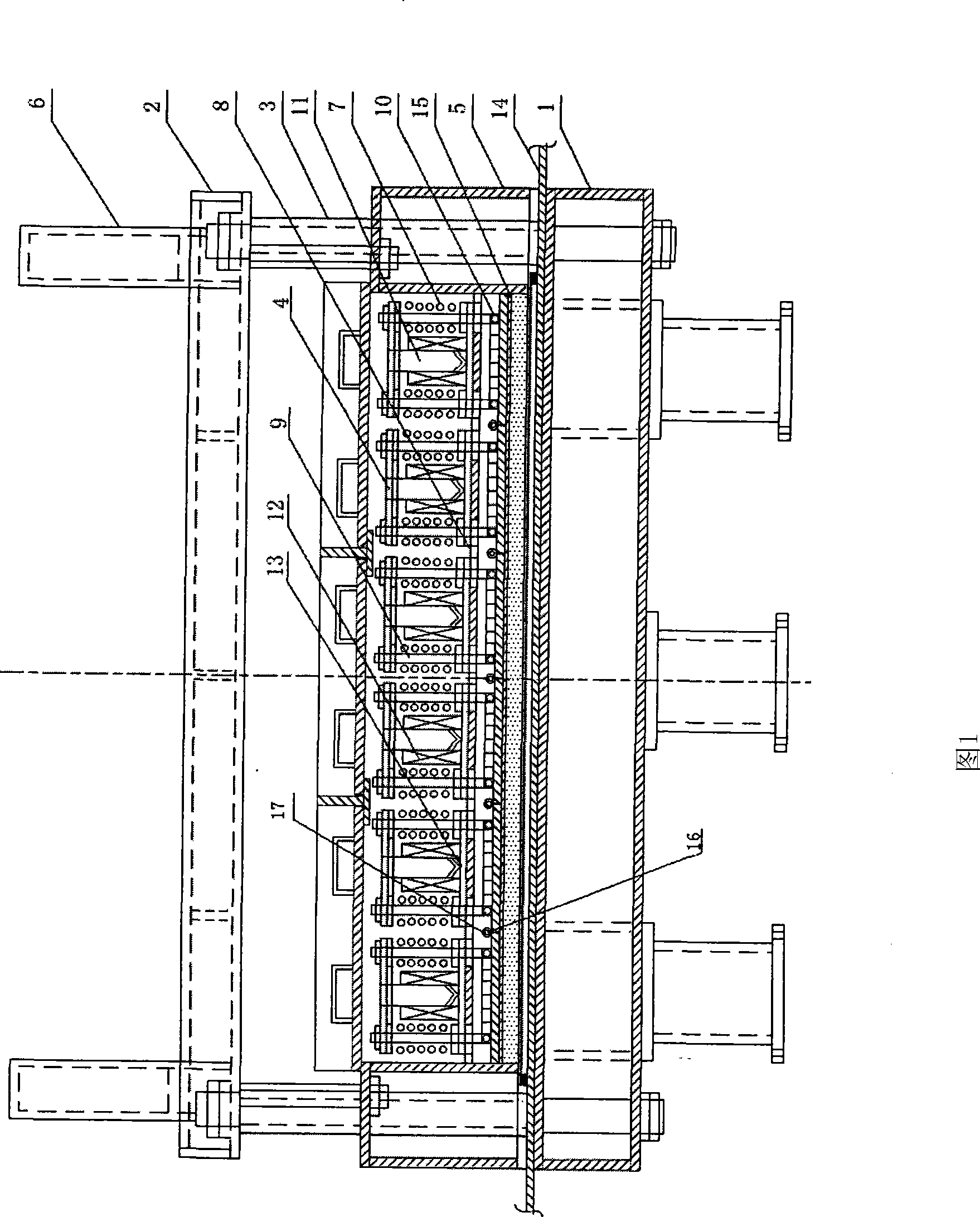

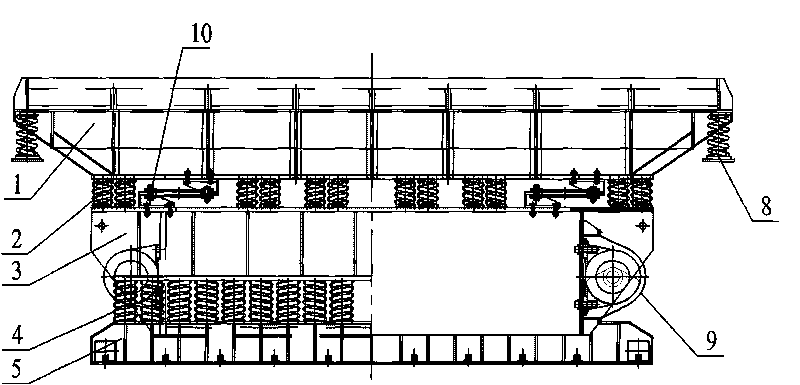

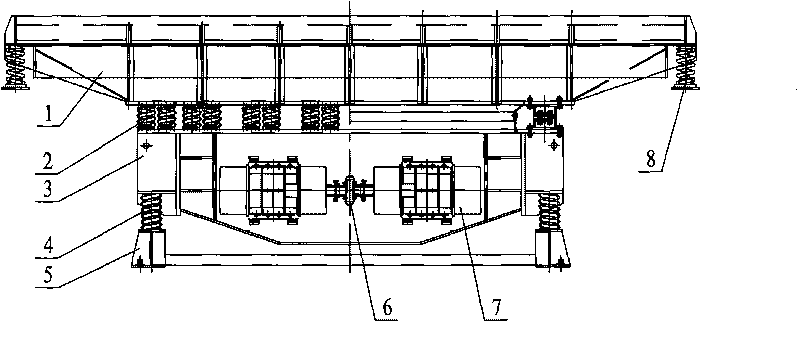

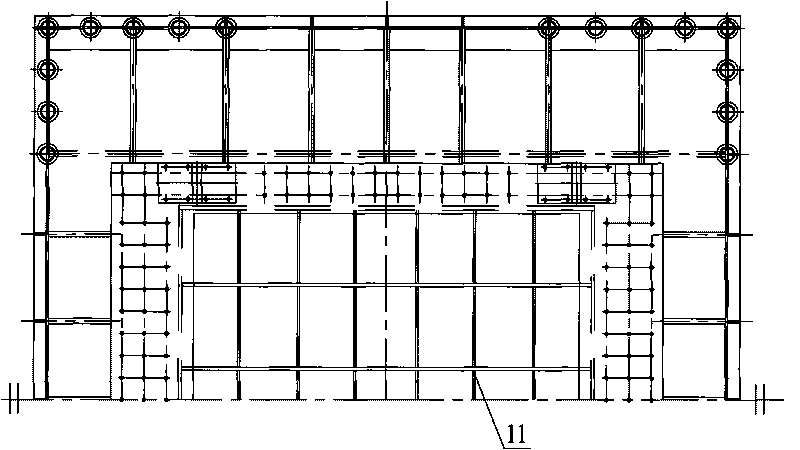

Large vibration table

InactiveCN101758207AEasy sand cleaningImprove the vibration environmentBearing vibrationShock resistance

The invention relates to a large vibration table, comprising a vibration table, a shock excitation spring, a shock excitation body, a base and vibration motors. A shock absorption spring on which the shock excitation body is mounted is arranged on the base. The vibration motors are mounted on both sides of the shock excitation body. The operating vibration motors on both sides rotate in opposite directions. The vibration table is mounted above the shock excitation body and connected with the shock excitation body through the shock excitation spring. The exciting frequency of the invention is higher with good shakeout effect. The invention adopts a design of shock resistance of double-layer of the vibration table and the shock excitation body, thereby improving the vibration environment greatly. The vibration motor conveys vibration to the vibration table through the shock excitation spring so that the amplitude of the vibration table is resonate and amplified, which not only saves energy, but also improves the service life of the vibration motor. Only the vibration table is required to bear vibration and impact of high vibration strength while the shock excitation body only bears vibration of lower strength. The invention adopts the structure of the support spring and the elastic damper, thereby lessening the unbalancedness of vibration of the vibration table effectively.

Owner:WUXI XINAN FOUNDARY MACHINERY

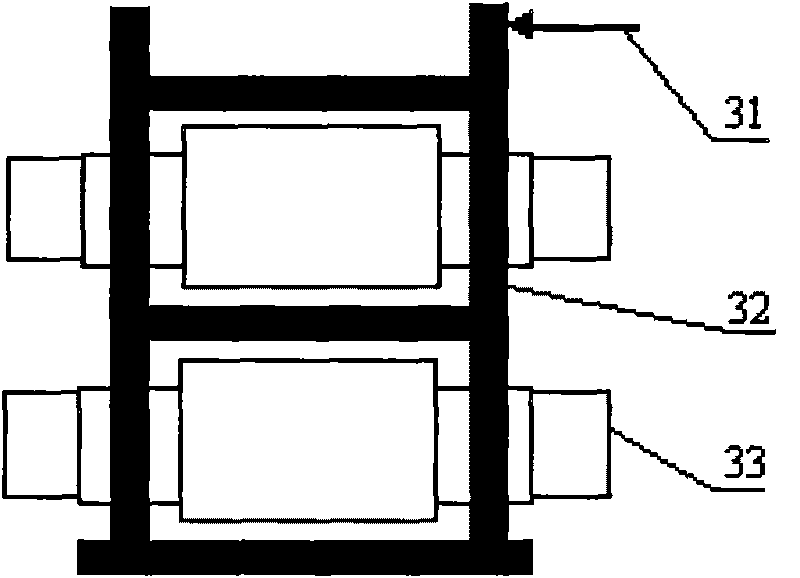

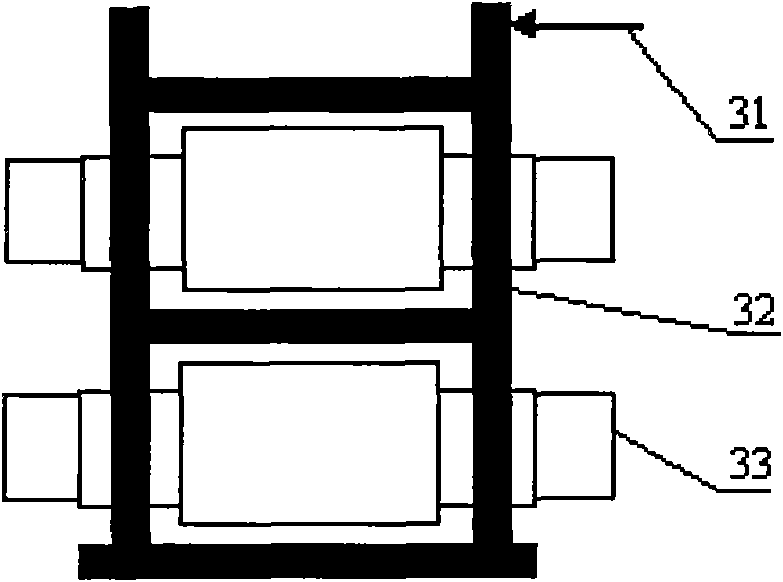

Electrohydraulic excitation controlling valve

InactiveCN100565158CIncrease the excitation frequencyServomotor componentsVibration testingHydraulic cylinderEngineering

The invention provides an electrohydraulic excitation control valve and comprises a valve body. The valve body is provided with an oil inlet communicated with a high pressure oil tank, a first in-and-out oil port communicated with a hydraulic cylinder, a second in-and-out oil port, a first oil outlet communicated with an oil returning tank and a second oil outlet; the electrohydraulic excitation control valve also comprises a valve core and a valve sleeve; the valve sleeve is nested on the inner wall of the valve body; the valve core passes through the valve sleeve; the valve core is connected with a first servo-motor and a second servo-motor; the valve core is provided with at least four shoulders with the same interval; the shoulder is uniformly provided with at least two grooves along the circumferential direction and the grooves on the adjacent shoulders back and forth are mutually mal-positioned; the valve sleeve is uniformly provided with a circle of valve sleeve windows along the circumferential direction and the valve sleeve windows matches with each shoulder; the valve sleeve window has at least four circles and the valve sleeve between the adjacent valve sleeve windows is provided with an auxiliary window; the end of the valve sleeve which is close to the first valve sleeve window is provided with an additional window. The invention can greatly improve electrohydraulic excitation frequency greatly.

Owner:ZHEJIANG UNIV OF TECH +1

Heat and vibration composite aging treatment method adopting preheating quantity of cast iron rolls

InactiveCN101705350AThermally Aged StableAvoid the disadvantages of agingFurnace typesHeat treatment furnacesEconomic benefitsOptimal treatment

The invention relates to a heat and vibration composite aging treatment method adopting preheating quantity of cast iron rolls, which is characterized by adopting the preheating quantity and preheating time of the cast iron rolls to carry out vibration aging treatment on the cast iron rolls. As adopting the composite aging treatment method combining heat aging treatment and vibration aging treatment, the invention not only gives play to the advantages of high efficiency and energy saving of vibration aging treatment and the advantage of stable effects of heat aging treatment but also avoids the shortcomings of various aging treatment, thereby obtaining optimal treatment effects and economic benefits. Because the preheating quantity and preheating time of the cast iron rolls are fully utilized consciously, the residual stress reduction effect is improved on the basis of not adding energy and time of aging treatment.

Owner:DONGHUA UNIV

High-elasticity piezomagnetic body based on piezo-magnetic effect and high-elasticity force cell sensor

ActiveCN108827500AIncrease bearing stressShort response timeForce measurement by measuring magnetic property varationMagnetic effectEngineering

The invention discloses a high-elasticity piezomagnetic body based on a piezo-magnetic effect and a high-elasticity force cell sensor. The piezomagnetic body comprises at least two piezomagnetic material sheets arranged in parallel; any two adjacent piezomagnetic material sheets are connected by a reinforced component with the strength larger than that of the piezomagnetic material sheet to form the piezomagnetic body; and the reinforced component is made of a non-magnetic material; at least two groups of horizontal hole positions and at least two groups of vertical hole positions are arrangedat the piezomagnetic material sheets, wherein the horizontal hole positions are perpendicular to the vertical hole positions. The high-elasticity piezomagnetic body has the following beneficial effects: with the reinforced components, the bearing stress of the piezomagnetic body is enhanced; the applicable range of the high-elasticity piezomagnetic body is extended; compared with the piezomagnetic body made of the piezomagnetic material, the high-elasticity piezomagnetic body disclosed by the invention is suitable for the large tonnage detection environment under the condition of having the same dimensions; and because of the piezomagnetic material sheets, the excitation frequency is improved and thus the response time of the sensor is reduced and the measuring precision is ensured.

Owner:北京中博力科测控技术有限公司

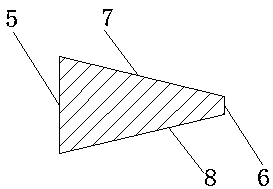

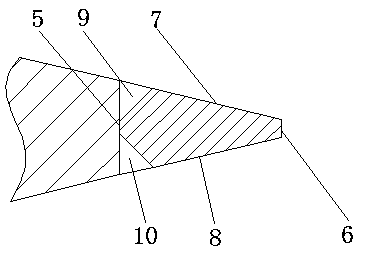

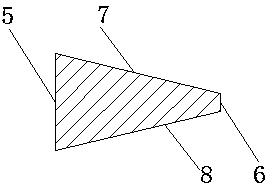

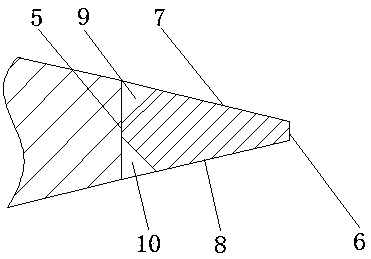

Socket ring of reaction turbine

PendingCN108386304AAvoid howlingGuarantee job stabilityHydro energy generationReaction enginesResonanceHydraulic turbines

The invention discloses a socket ring of a reaction turbine, and belongs to the technical field of turbines. The socket ring comprises an upper ring plate, a lower ring plate and multiple fixed guidevanes fixed between the upper ring plate and the lower ring plate. The socket ring is characterized in that the fixed guide vanes are provided with a tail wing, the tail wing is fixed to the middle ofthe water outlet edge of the fixed guide vanes, the tail wing is in a columnar shape, the cross section of the tail wing is in a trapezoid shape and defined by a tail wing bottom edge, a tail wing water outlet edge, a first tail wing side edge and a second tail wing side edge, the length of the tail wing bottom edge is equal to that of the water outlet edge of the fixed guide vanes, the tail wingbottom edge is parallel to the tail wing water outlet edge, and the length of the tail wing bottom edge is larger than the length of the tail wing water outlet edge. The excitation frequency of a Karman vortex street can be improved, the excitation energy of the Karman vortex street can be reduced, the fixed guide vane outlet Karman vortex street frequency and the fixed guide vane inherent frequency can be staggered, hydroelastic resonance is prevented from being produce, the fixed guide vanes are prevented from being cracked, the turbine is prevented from producing whistles, and working stability of the turbine is ensured.

Owner:DONGFANG ELECTRIC MACHINERY

Reaction water turbine fixed guide vane resonance and crack prevention method

InactiveCN108626055AAvoid howlingGuarantee job stabilityHydro energy generationReaction enginesResonanceWater turbine

The invention discloses a reaction water turbine fixed guide vane resonance and crack prevention method and belongs to the field of water turbines. The method is characterized by comprising the following steps of a, determining tail vanes according to the geometric dimensions of the cross section of fixed guide vanes and machining the tail vanes for standby application; b, reserving a distance h1between the upper ends of the tail vanes and an upper ring plate, and reserving a distance h2 between the lower ends of the tail vanes and a lower ring plate, wherein h1 is 1-5% of the height h of thefixed guide vanes, and h2 is 1-5% of the height h of the fixed guide vanes; and c, installing the tail vanes to the water outlet edges of the fixed guide vanes. According to the method, the tail vanes are mounted on the fixed guide vanes of a water turbine, the excitation frequency of a karman vortex street can be increased, and exciting energy of the karman vortex street can be reduced, and thenthe frequency of the karman vortex street of outlets of the fixed guide vanes and the inherent frequency of the fixed guide vanes are staggered to prevent hydraulic elastic resonance, the fixed guidevanes are protected against cracks, the water turbine is protected again squealing, and the operating stability of the water turbine is guaranteed.

Owner:DONGFANG ELECTRIC MACHINERY

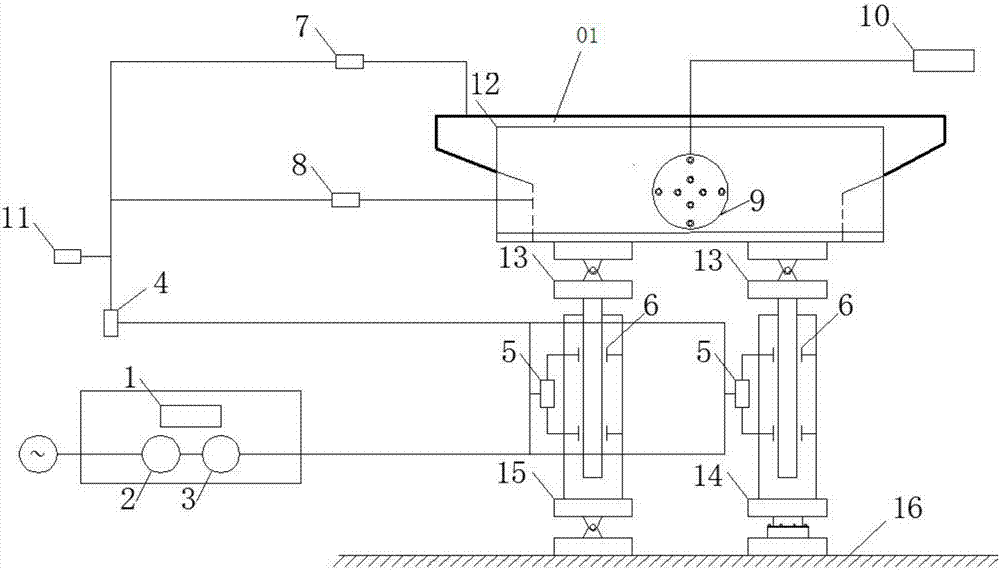

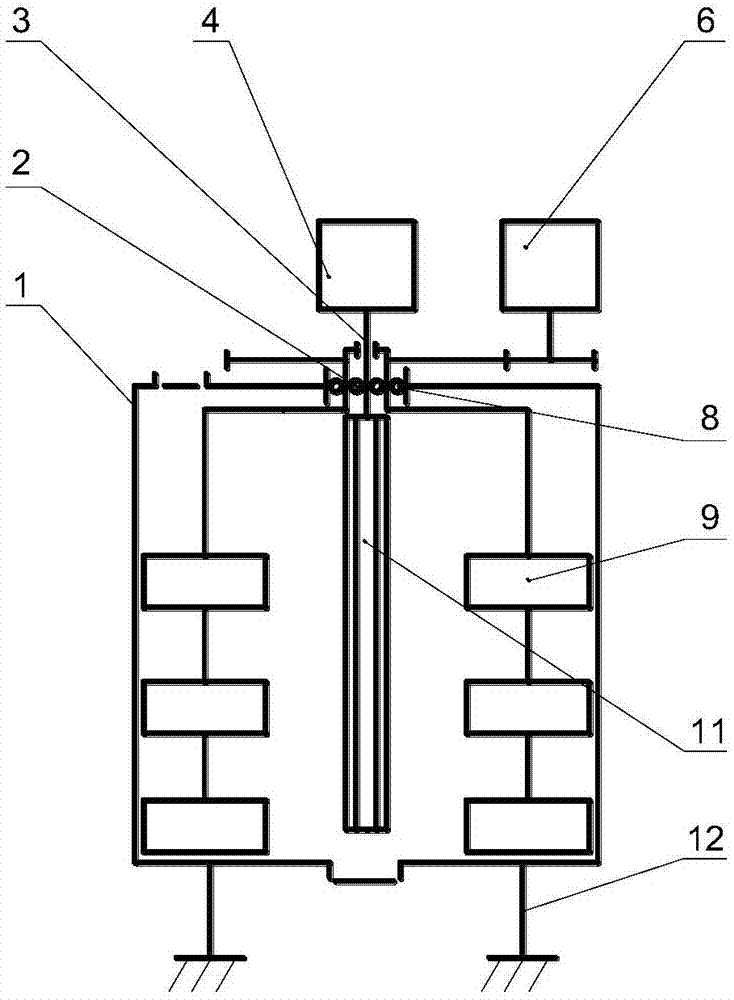

Electric-hydraulic vibration exciter based on magnetostrictive driving

InactiveCN103075395AIncrease the excitation frequencyIncrease cycle frequencyFluid-pressure actuator componentsCeramicElectricity

The invention provides an electric-hydraulic vibration exciter based on magnetostrictive driving, which solves the problem that the excitation frequency of an existing electric-hydraulic vibration exciter is low. The electric-hydraulic vibration exciter comprises a double-rod hydraulic cylinder which is connected with a to-be-excited body through a piston rod, two piezoelectric ceramic driven two-position three-way reversing valves which are respectively connected with a left oil cavity and a right oil cavity of the double-rod hydraulic cylinder, a magnetostrictive driving pump which is connected with the two piezoelectric ceramic driven two-position three-way reversing valves, two one-way valves which have different opening directions and are arranged on the magnetostrictive driving pumps, and an energy accumulator which is arranged between one one-way valve with an inward opening and one piezoelectric ceramic driven two-position three-way reversing valve, wherein the magnetostrictive driving pump comprises an oil cylinder and a magnetostrictive driver; the oil cylinder and the magnetostrictive driver are separated by an elastic mebrane and are packaged into a whole through a shell; and the two one-way valves are connected with the two piezoelectric ceramic driven two-position three-way reversing valves. According to the electric-hydraulic vibration exciter disclosed by the invention, rapid responding can be realized by magnetostriction and piezoelectric ceramics, so that high-frequency excitation output can be realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Large-flow high-frequency electrohydraulic exciting shock control valve drive system

ActiveCN101718291BOvercome frictionPrevent overloadFluid-pressure actuator componentsHydraulic cylinderHydraulic motor

The invention relates to a large-flow high-frequency electrohydraulic exciting shock control valve drive system which comprises a large-flow high-frequency electrohydraulic exciting shock valve. The drive system also comprises a main valve end hydraulic cylinder and a transmission, wherein the main valve end hydraulic cylinder is used for driving a valve core to axially slide in a linear way; thetransmission is used for driving the valve core to rotate; the main valve end hydraulic cylinder comprises a cylinder body and a drive piston; the drive piston is fixedly installed at the end part ofthe valve core; the drive piston is used as a boundary in the cylinder body, the cylinder body approaching one side of the valve core is provided with a rod cavity, and the cylinder body at the otherside is provided with a rodless cavity; the rod cavity is communicated with a high-pressure oil box, and the rodless cavity is communicated with the high-pressure oil box by a flow valve; the transmission comprises a hydraulic motor, a drive gear, an idle gear, a driven gear and a gear accelerating mechanism; an output shaft of the hydraulic motor is connected with an input shaft of the gear accelerating mechanism, and an output shaft of the gear accelerating mechanism is connected with the valve core. The invention can increase flows, improve the exciting shock frequency and prevent overloading of a hydraulic system.

Owner:ZHEJIANG UNIV OF TECH

Method for treating thermal vibration composite ageing of cast iron roll in removing stress

InactiveCN101705344AThermally Aged StableAvoid the disadvantages of agingFurnace typesHeat treatment furnacesThermal ageingStress relieving

The invention relates to a method for processing thermal vibration composite ageing of a cast iron roll in removing stress. After the cast iron roll is heated, the cast iron roll is subject to vibration ageing treatment in a heated state. The composite ageing treatment method which combines thermal ageing treatment with vibration ageing treatment is adopted, so the method has the advantages of high efficiency and energy saving of the vibration ageing treatment and stability of the effect of the thermal ageing treatment, and avoids the disadvantages of various ageing treatment, thereby obtaining optimal treatment effect and economic benefits. The method can be applied in a roll plant and a steel mill so that the method is widely applied.

Owner:DONGHUA UNIV

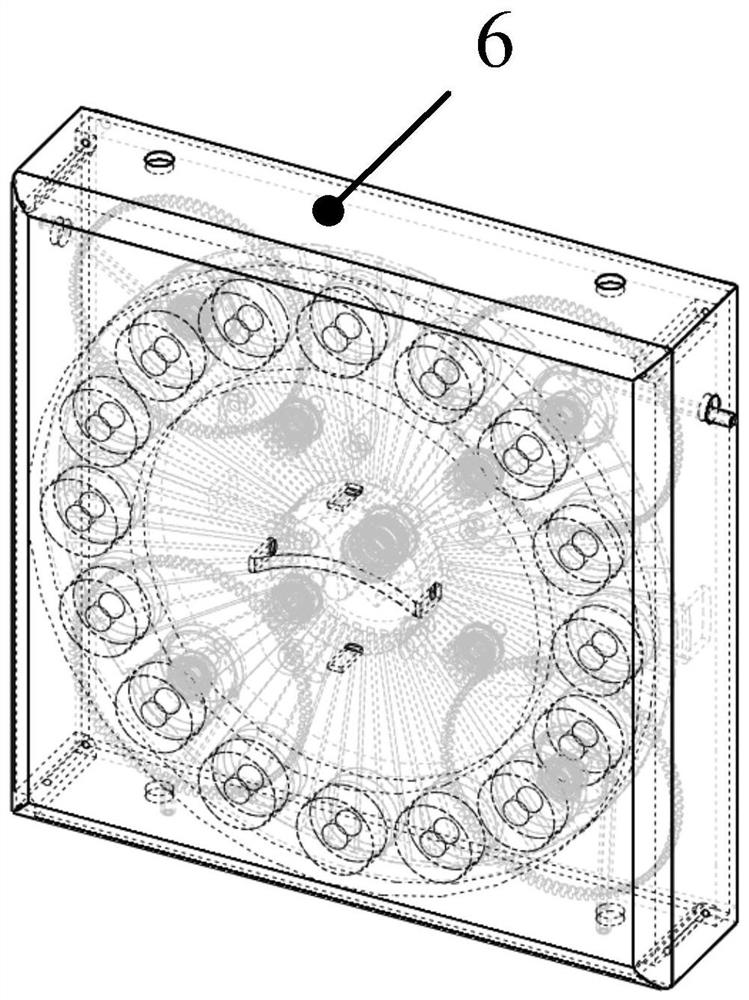

Back-wearing type four-drive human motion energy acquisition device and human body enhancing equipment

PendingCN111894821AImprove exercise energy utilizationAvoid damageFrom muscle energySingle network parallel feeding arrangementsHuman bodyTraction cord

The invention relates to a back-wearing type four-drive human motion energy acquisition device and human body enhancing equipment. The back-wearing type four-drive human motion energy acquisition device comprises a human motion energy power generation device which is fixedly arranged on the back of a human body enhancing suit, wherein the human motion energy power generation device is connected toparts under leg joints and arm parts of the human body enhancing suit through leg traction ropes and arm traction ropes; the human motion energy power generation device comprises an outer cover, a bottom plate, a transmission mechanism and a rotary power generation disc, wherein the bottom plate is fixedly connected to the human body enhancing suit; the transmission mechanism is mounted on the bottom plate; the output end of the transmission mechanism is connected to a rotary power generation disc; a permanent magnet mounting ring is arranged on the rotary power generation disc; a permanent magnet is mounted on the permanent magnet mounting ring; the inner side of the outer cover is equipped with a coil mounting ring corresponding to the rotary power generation disc; and a coil is mountedon the coil mounting ring. The back-wearing type four-drive human motion energy acquisition device can increase a human motion energy utilization rate, reduces influences on human motion, and solvesthe problems that an existing human energy acquisition device is low in output power, is great in influences on human motion, and the like.

Owner:HUNAN INSTITUTE OF ENGINEERING

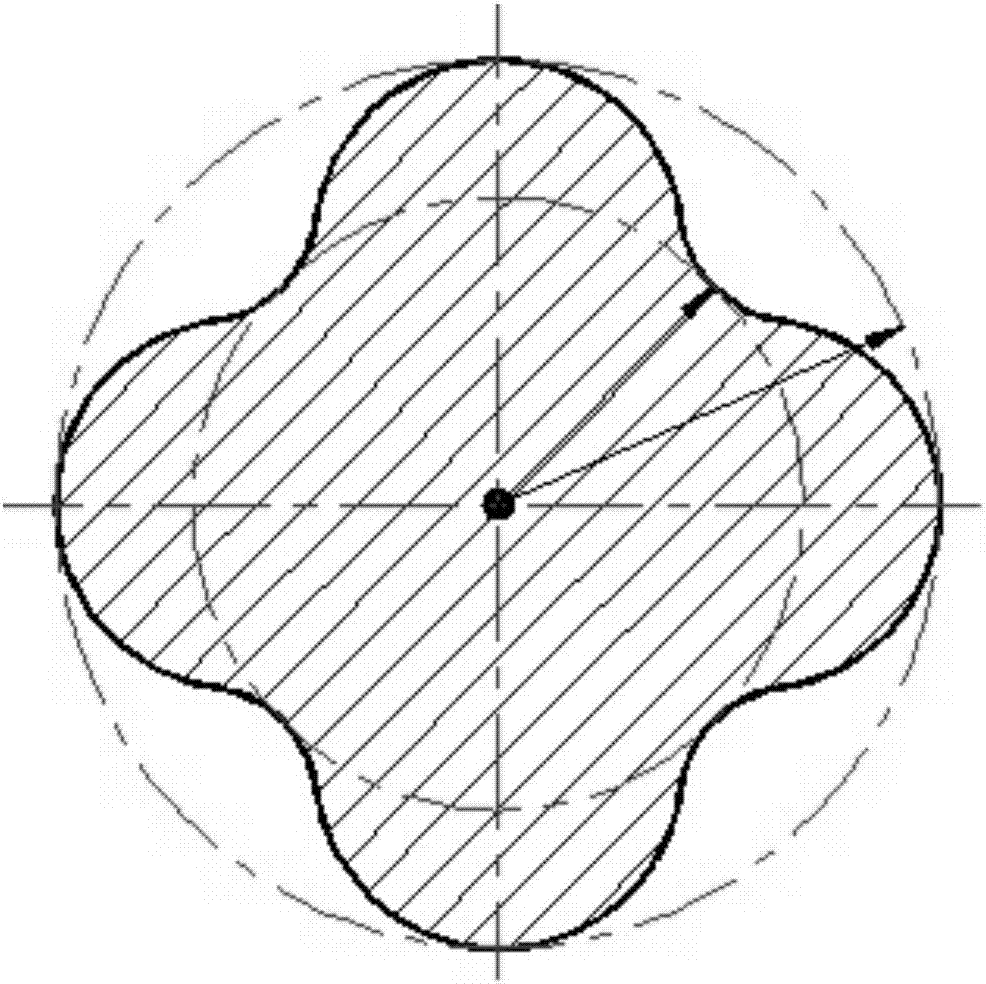

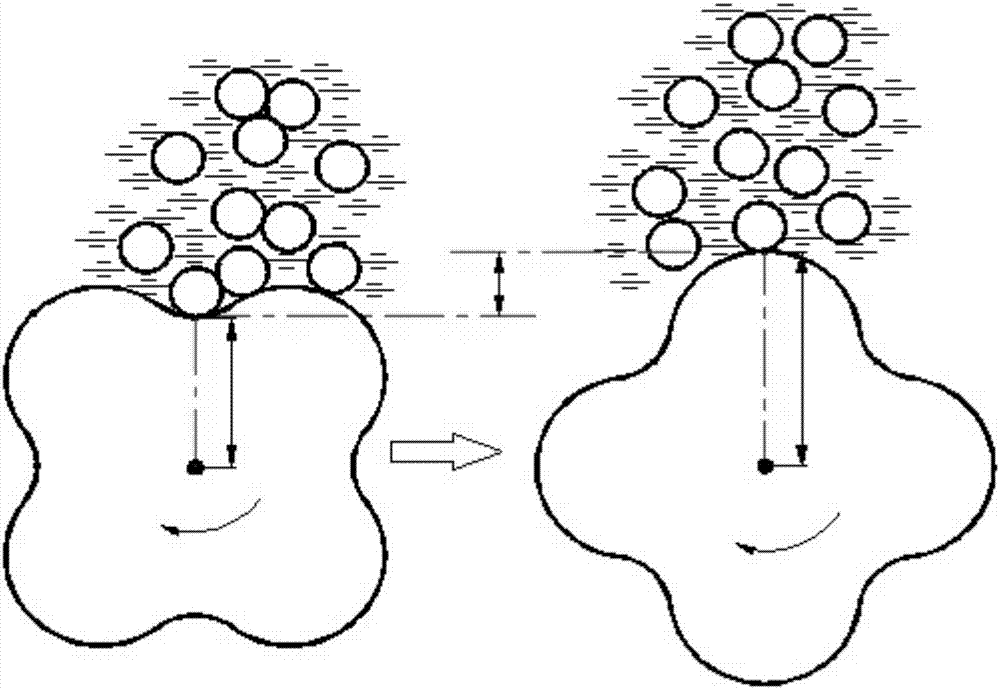

Vertical-axis high-frequency vibration mixer

PendingCN107139337AIncrease the excitation frequencyImprove mix qualityCement mixing apparatusCentre of rotationEngineering

The invention discloses a vertical-axis high-frequency vibration mixer. The vertical-axis high-frequency vibration mixer comprises a vibration driving unit, a mixing driving unit, a mixing cylinder, a mixing device and an exciter; the vibration driving unit and the mixing driving unit are both fixedly arranged above the mixing cylinder; the mixing device is arranged in the mixing cylinder; a hole is formed in the center of an upper cover of the mixing cylinder; the upper end of the mixing device is coaxially arranged in the hole; the exciter is arranged in the mixing cylinder below the hole, and is connected with the vibration driving unit through an exciter connecting shaft; the mixing driving unit is connected with the upper end of the mixing device; the exciter is a polygonal solid shaft or hollow shaft with N smooth projections on the cross section, wherein N is greater than 2, and the centroid is overlapped with a rotating center; the generated excitation frequency is positively correlated to the projection number N linearly; and the heights of the projections are changed to adjust the amplitude of exciting force. The vertical-axis high-frequency vibration mixer breaks through the limit of incapability of improving the excitation frequency of a traditional vibration mixer, further reduces the friction force among molecules, and greatly improves macroscopic and microscopic quality of concrete finally.

Owner:CHANGAN UNIV

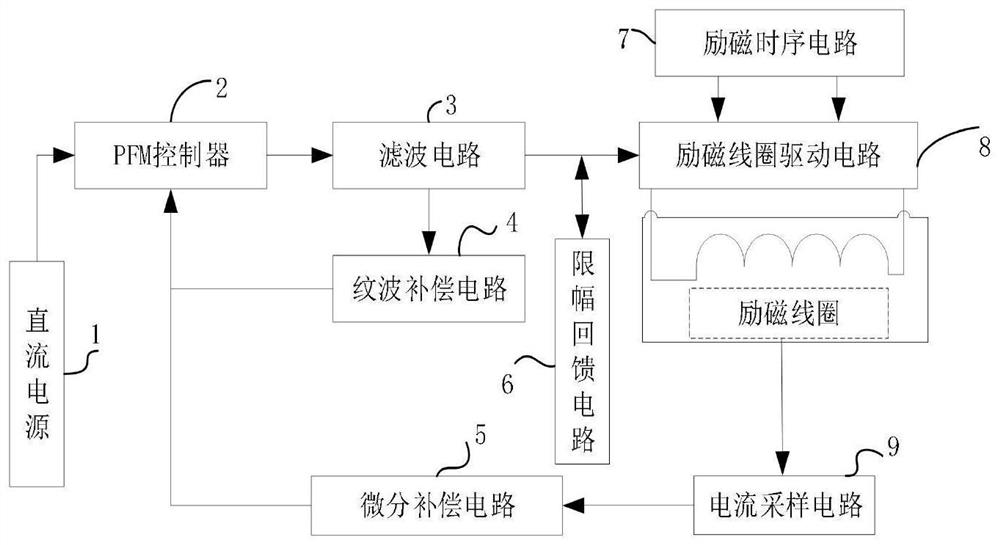

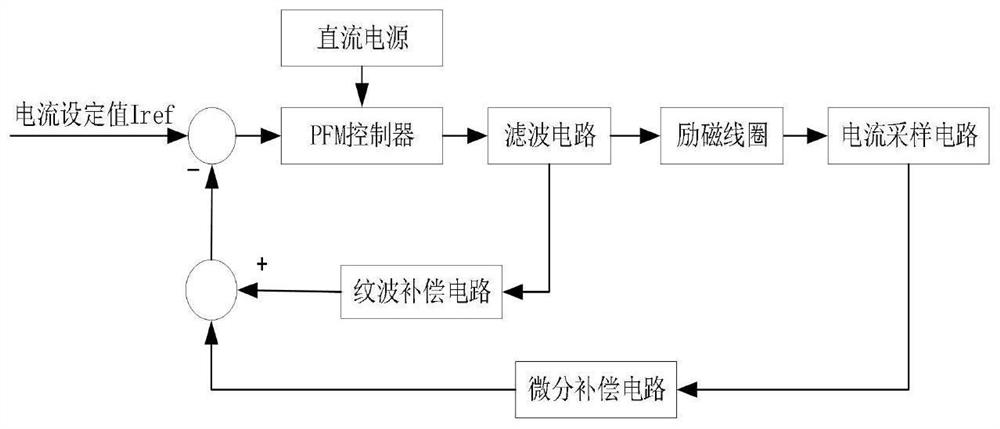

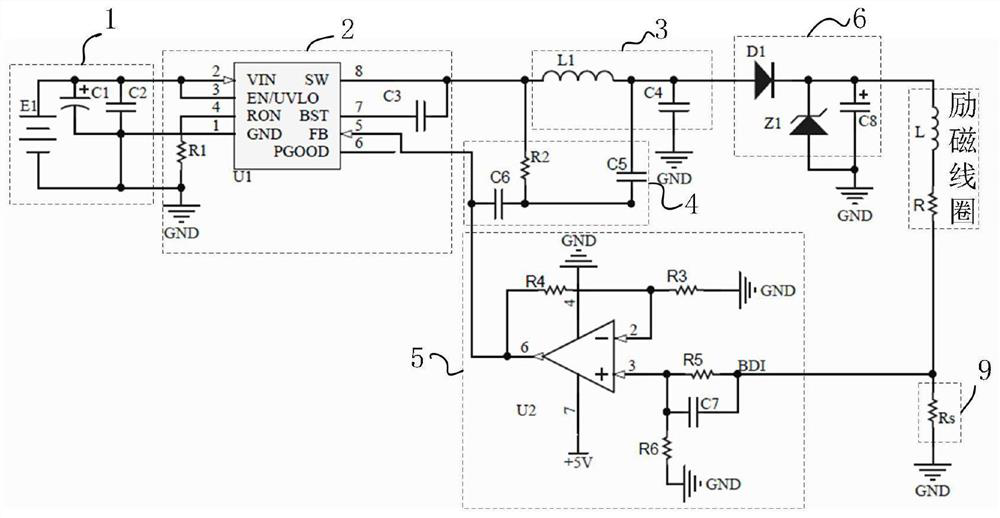

Electromagnetic flowmeter excitation control system based on differential compensation PFM modulation

ActiveCN111765931AFacilitate conductionIncreased shutdown speedVolume/mass flow by electromagnetic flowmetersHemt circuitsEngineering

The invention discloses an electromagnetic flowmeter excitation control system based on differential compensation PFM modulation. The electromagnetic flowmeter excitation control system is composed ofa direct-current power supply, a PFM controller, a filter circuit, a ripple compensation circuit, a differential compensation circuit, an amplitude limiting feedback circuit, an excitation sequentialcircuit, an excitation coil drive circuit and a current sampling circuit. Constant current control is realized by adopting a PFM modulation technology, system efficiency is improved, and system powerconsumption and a system temperature rise are reduced. Excitation current overshoot is suppressed by using the differential compensation circuit so that excitation current overshoot and dynamic adjustment time can be reduced and an excitation frequency can be enhanced. The ripple compensation circuit is used for reducing exciting current ripples and improving exciting current precision. The excitation sequential circuit generates two paths of complementary rectangular wave excitation signals with dead zones and controls an excitation coil driving circuit, an output end of the excitation coildriving circuit is connected with an excitation coil, and excitation current reversing is achieved. According to the excitation control system, the excitation frequency can be improved, the power consumption and the temperature rise of the excitation system are reduced, and the excitation current ripples are reduced.

Owner:HEFEI UNIV OF TECH +1

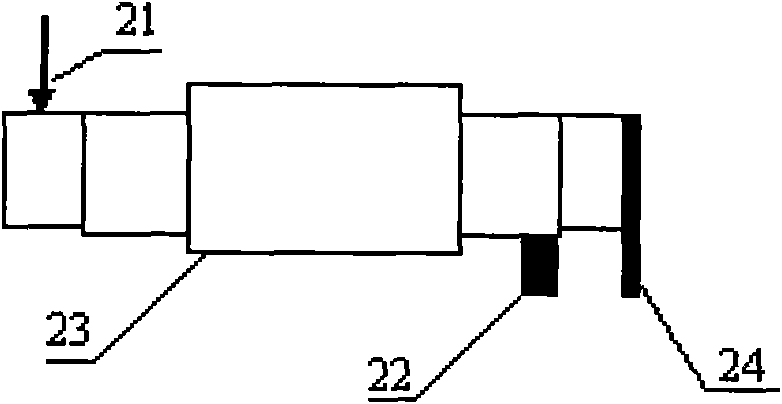

Single-screw hydraulic cylinder electrohydraulic vibration exciter

InactiveCN101608965BIncrease the excitation frequencyImprove energy performanceVibration testingStrength propertiesHydraulic cylinderHigh energy

The invention discloses a single-screw hydraulic cylinder electrohydraulic vibration exciter comprising a 2D electrohydraulic vibration valve, a single-screw hydraulic cylinder and a loading object, wherein, a piston is arranged in the body of the single-screw hydraulic cylinder; one side of the piston is fixedly connected with a piston rod, and one end of the piston rod extends out of the body of the single-screw hydraulic cylinder; the piston rod is connected with the loading object; a hydraulic fluid port of the inner cavity at one side of the piston in the cylinder body is communicated with a high-pressure oil tank, and the hydraulic fluid port of the inner cavity at the other side of the piston in the cylinder body is communicated with the oil inlet and outlet of the 2D electrohydraulic vibration valve; the 2D electrohydraulic vibration valve comprises a valve body, a valve core and a valve cover, wherein, the valve body is provided with an oil inlet communicated with the high-pressure oil tank, the oil inlet and outlet connected with the body of the single-screw hydraulic cylinder and an oil outlet connected with an oil return tank. The invention can effectively improve exciting frequency, reduces valve opening area amplitude attenuation along with the increase of the exciting frequency, has high energy efficiency, and has favourable antipollution performance.

Owner:ZHEJIANG UNIV OF TECH

Up-conversion piezoelectric-electromagnetic energy harvesting device

ActiveCN111628674ARealize power supplyNo pollution in the processPiezoelectric/electrostriction/magnetostriction machinesRatchetGear wheel

The invention discloses an up-conversion piezoelectric-electromagnetic energy harvesting device, and belongs to the technical field of power generation. Mechanical vibration energy can be converted into electric energy to be stored in an up-conversion piezoelectric-electromagnetic energy harvesting mode, power supply to a microelectronic device is achieved, and the device has the advantages of being free of pollution, large in energy density, high in reliability and the like. Energy is recovered when the heel is pressed down and lifted up, a first piezoelectric plate and a generator output energy in the pressing down process, and a second piezoelectric plate outputs energy when the heel is lifted. According to the invention, a ratchet wheel structure is adopted to perform up-conversion onthe piezoelectric plate, the excitation frequency of the piezoelectric plate is improved, and the output power of piezoelectric energy harvesting is improved. The rotating speed of a gear during pressing is increased through a gear speed increasing module, and the power generation efficiency of the electromagnetic energy harvesting module is improved. The adopted one-way bearing can reduce the resistance in the treading process and the return process to the maximum extent, and the friction to a shaft is reduced to the maximum extent when two ratchet wheels and the one-way bearing in the hole of a secondary gear move in the non-working direction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com