Socket ring of reaction turbine

A hydraulic turbine and counterattack technology, applied in the field of hydraulic turbines, can solve problems affecting the working stability of hydraulic turbines, cracks in fixed guide vanes, etc., and achieve the effects of ensuring mechanical strength, reducing workload, and ensuring overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

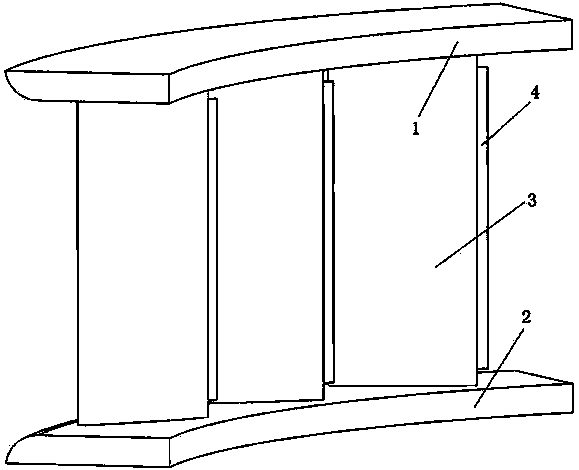

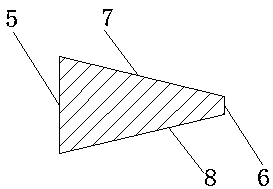

[0034] see figure 1 and figure 2 , the seat ring of the impact turbine, including an upper ring plate 1, a lower ring plate 2 and a plurality of fixed guide vanes 3 fixed between the upper ring plate 1 and the lower ring plate 2, and the fixed guide vanes 3 are provided with empennages 4. The empennage 4 is fixed on the middle part of the water outlet edge of the fixed guide vane 3. The empennage 4 is columnar, and the cross section of the empennage 4 is trapezoidal. Two empennage sides 8 surround, and described empennage base 5 lengths are equal to the water outlet edge length of fixed guide vane 3, and empennage base 5 is fixedly connected with the water outlet edge of fixed guide vane 3, and described empennage base 5 is connected with empennage water outlet The sides 6 are parallel, and the length of the bottom edge 5 of the empennage is greater than the length of the edge 6 of the empennage out of the water.

[0035] This embodiment is the most basic implementation. "T...

Embodiment 2

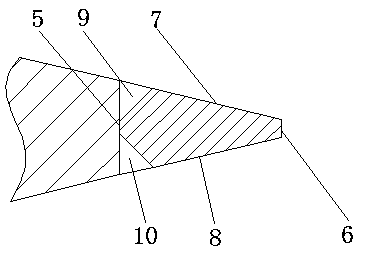

[0037] see figure 1 and image 3 , the seat ring of the impact turbine, including an upper ring plate 1, a lower ring plate 2 and a plurality of fixed guide vanes 3 fixed between the upper ring plate 1 and the lower ring plate 2, and the fixed guide vanes 3 are provided with empennages 4. The empennage 4 is fixed on the middle part of the water outlet edge of the fixed guide vane 3. The empennage 4 is columnar, and the cross section of the empennage 4 is trapezoidal. Two empennage sides 8 surround, and described empennage base 5 lengths are equal to the water outlet edge length of fixed guide vane 3, and empennage base 5 is fixedly connected with the water outlet edge of fixed guide vane 3, and described empennage base 5 is connected with empennage water outlet The sides 6 are parallel, and the length of the bottom edge 5 of the empennage is greater than the length of the edge 6 of the empennage out of the water.

[0038] One side of said empennage base 5 has the first weldi...

Embodiment 3

[0041] see figure 1 and image 3 , the seat ring of the impact turbine, including an upper ring plate 1, a lower ring plate 2 and a plurality of fixed guide vanes 3 fixed between the upper ring plate 1 and the lower ring plate 2, and the fixed guide vanes 3 are provided with empennages 4. The empennage 4 is fixed on the middle part of the water outlet edge of the fixed guide vane 3. The empennage 4 is columnar, and the cross section of the empennage 4 is trapezoidal. Two empennage sides 8 surround, and described empennage base 5 lengths are equal to the water outlet edge length of fixed guide vane 3, and empennage base 5 is fixedly connected with the water outlet edge of fixed guide vane 3, and described empennage base 5 is connected with empennage water outlet The sides 6 are parallel, and the length of the bottom edge 5 of the empennage is greater than the length of the edge 6 of the empennage out of the water.

[0042] One side of said empennage base 5 has the first weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com