Motor cooling structure

A motor cooling and motor shaft technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems affecting the physical and mental health of workers, affecting the stability of motors, polluting the working environment, etc., to avoid howling, Reduce working noise and ensure stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manner of the present invention will be further described in detail below by describing the embodiments in conjunction with the accompanying drawings.

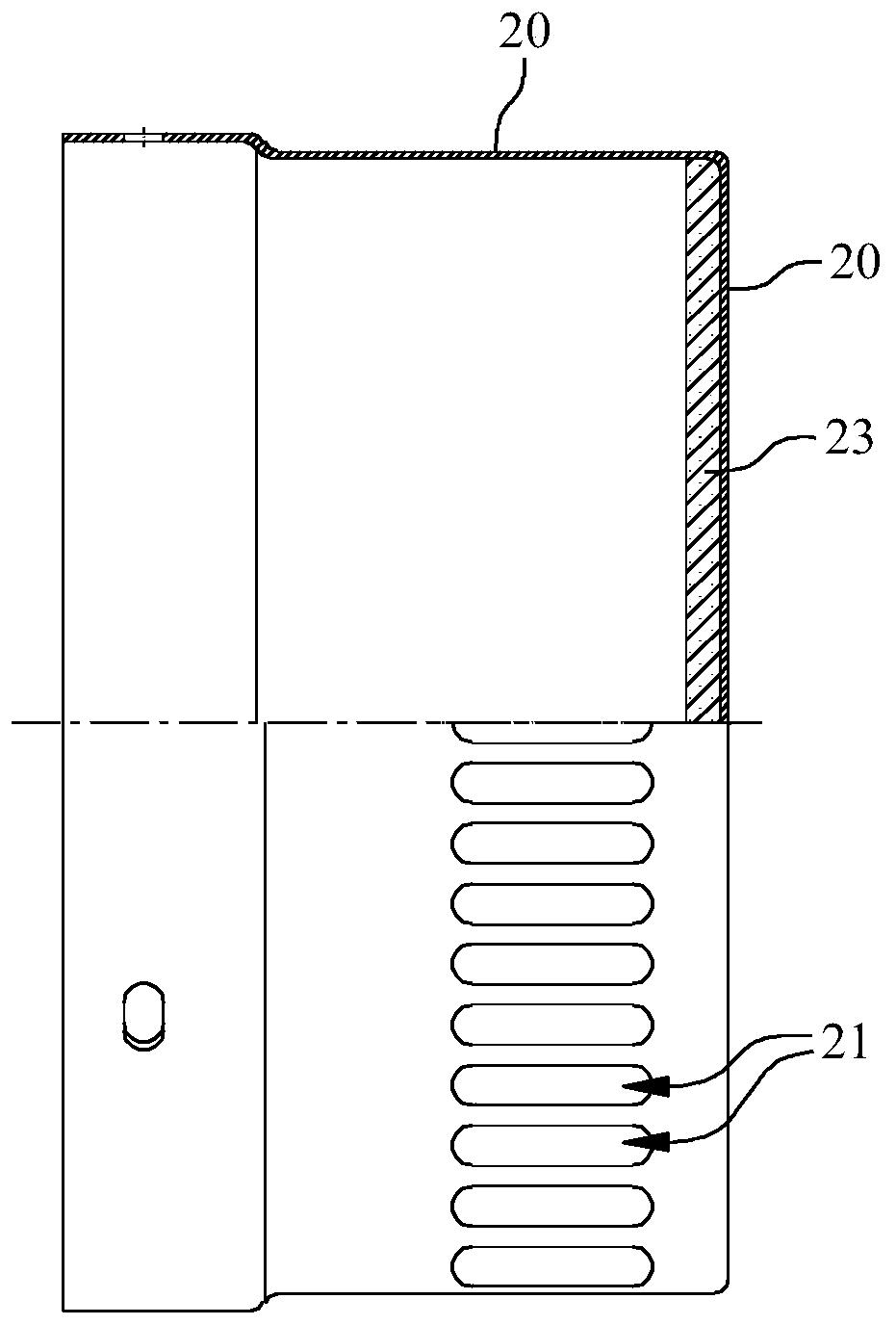

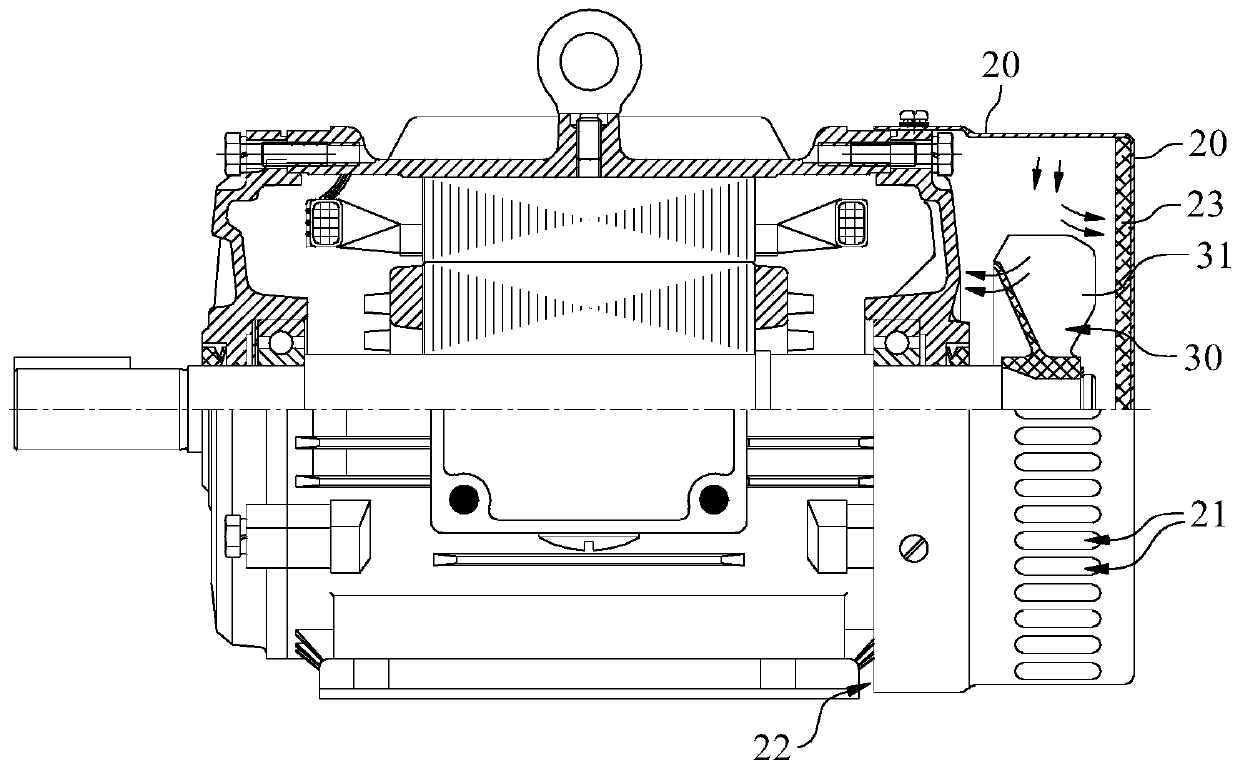

[0011] A motor cooling structure, comprising a motor housing 11, a cylindrical cover 20 is provided at the end of the motor housing 11, and an impeller 30 is arranged in a cavity formed by the cover 20 and the motor housing 11, The side wall of the cover 20 is provided with an air inlet 21 , the gap between the side wall of the cover 20 and the motor housing 11 forms an air outlet 22 , and the inner wall of the bottom wall of the cover 20 is provided with a sound-absorbing layer 23 .

[0012] When in use, the cooling gas enters the inner cavity of the housing from the side wall of the housing 20 , then flows along the axial direction of the housing 20 and is discharged from the air outlet 21 . If the cooling gas is blocked by the motor housing 11 to generate an airflow moving away from the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com