Patents

Literature

1020 results about "Automotive transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

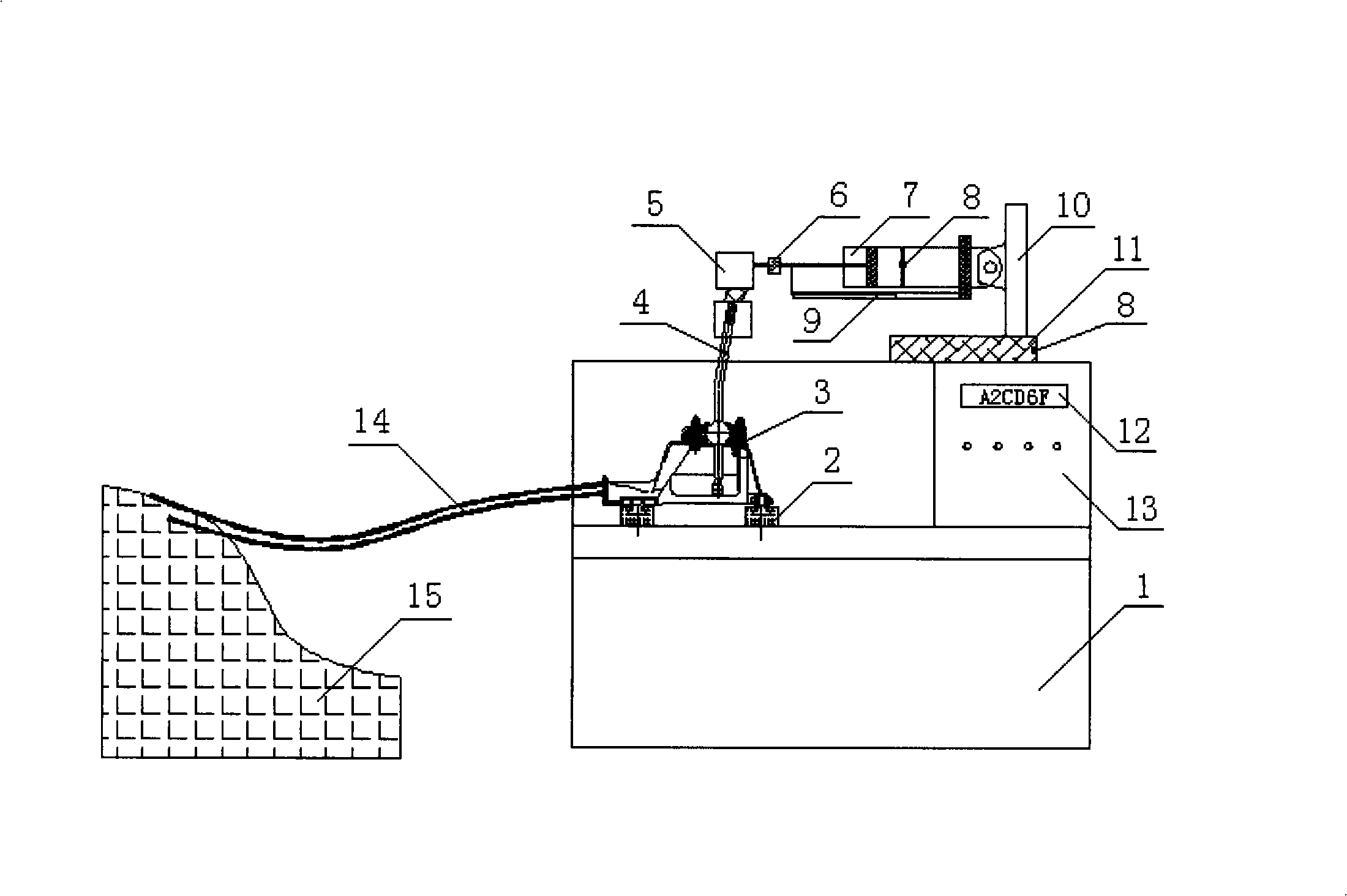

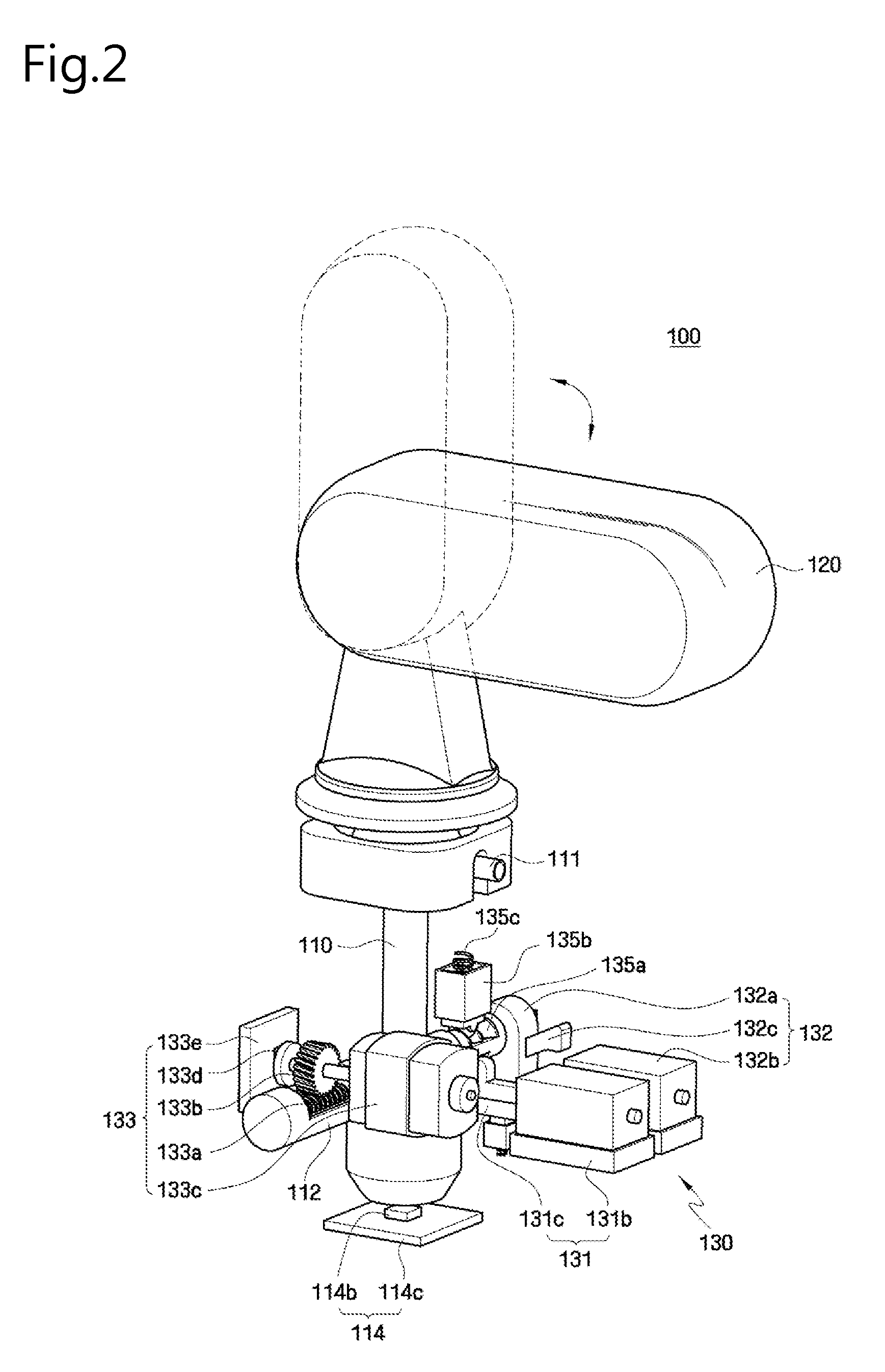

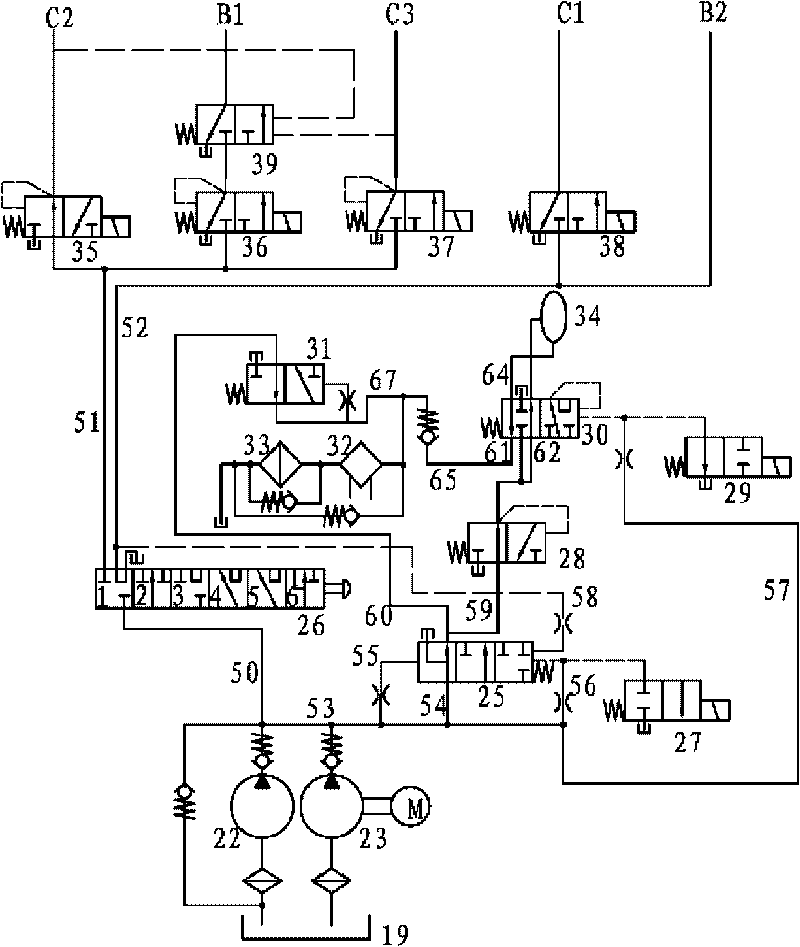

Vehicle transmission control mechanism assembly testing bench

ActiveCN101319964AIt has the function of alarming for excessive gear shiftingSwitch freelyVehicle testingMachine gearing/transmission testingControl systemAutomotive transmission

The invention discloses a test-bed for testing the performances and durability of a shift control mechanism assembly of a vehicle which includes a test-bed body; in the test-bed body, an adjustable mounting adjusting framework with six directions is fixedly arranged at the front end; the shift control mechanism assembly of the vehicle is arranged in the mounting adjusting framework; the output end of the shift control mechanism assembly of the vehicle is connected with a gearbox by selecting and exchanging gearshift lines; the control frame of a PLC control system is arranged on a side wall at the back part in the test-bed body; an air cylinder loading system and a load system are arranged above the test-bed body. The assembly of the test-bed has the following advantages of: 1, being capable of simulating the actual operating condition of the shift control mechanism assembly of the vehicle; 2, being capable of simulating the gear shift and selecting motions on the shift control mechanism assembly of the vehicle; 3, dividing the test-bed controlled by the system into a 'manual' operating mode and an 'automatic' operating mode which can freely and mutually switch; 4, having the function of alarming when the time for gear shift is excessive.

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

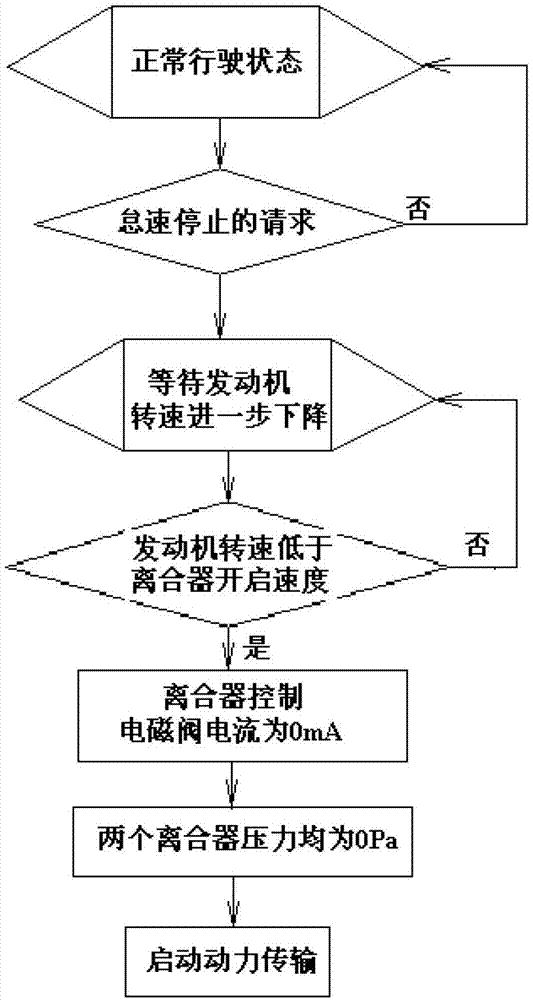

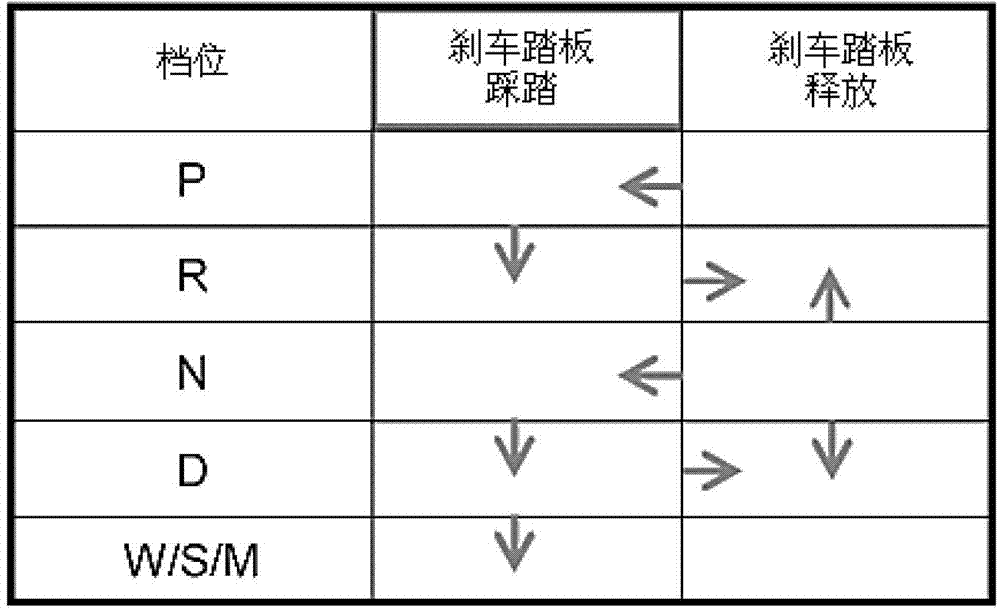

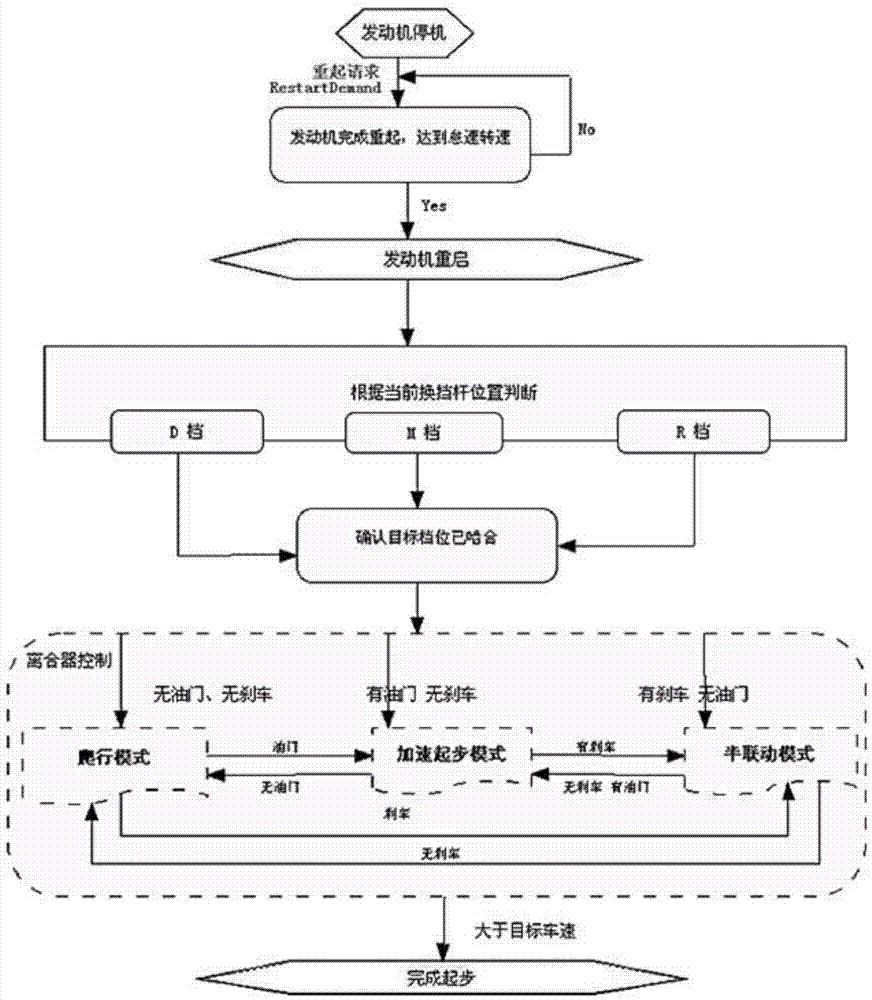

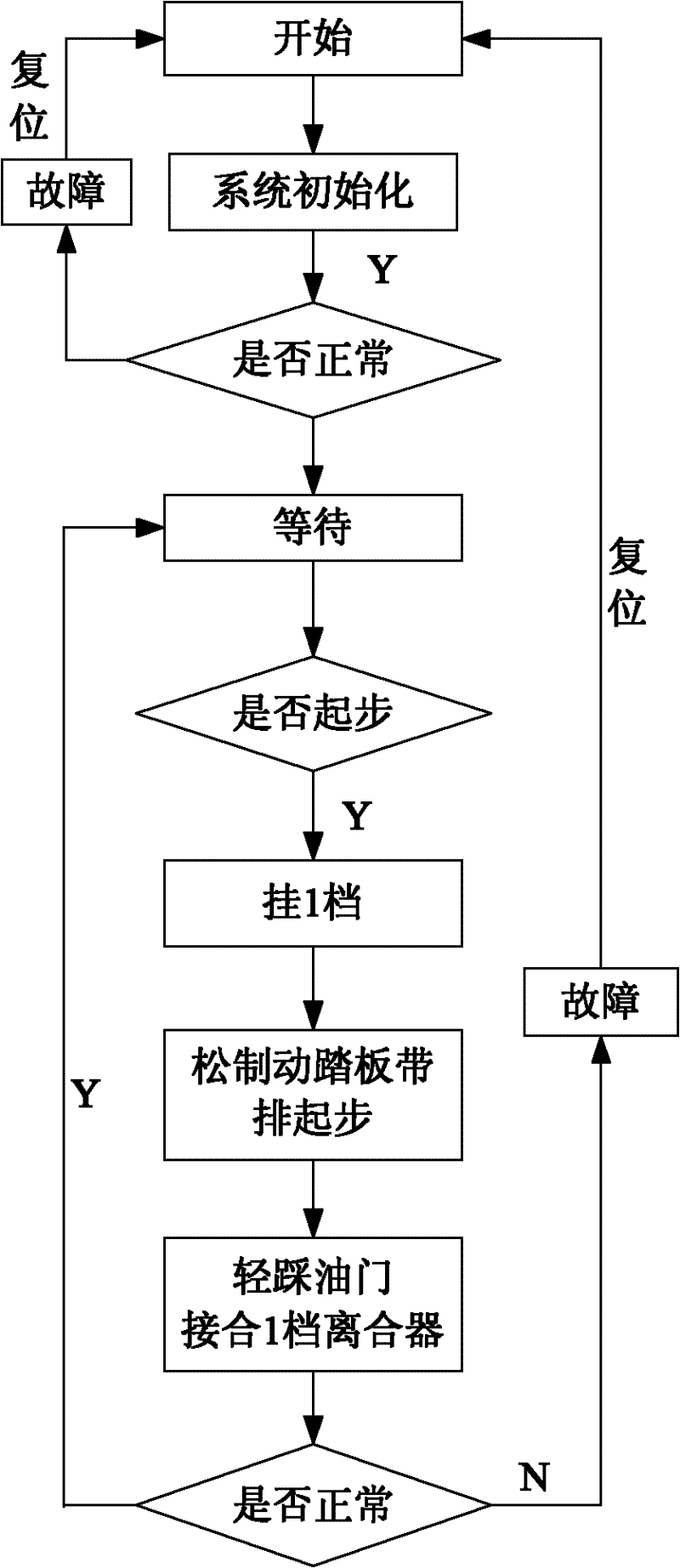

Control method based on engine starting and stopping and system thereof

A control method for a gearbox based on engine starting and stopping and a system thereof belong to the field of automotive transmissions. The judgment and the predictive analysis for an engine state are implemented according to engine control signals acquired by a CAN (Controller Area Network) high-speed bus and gear signals of a gear shift mechanism; and the sliding friction degree of a wet clutch is adjusted by comprehensive judgment and predictive analysis through acquiring gearbox signals and diagnosis results of TCU (Transmission Control Unit) internal logic to present driving working conditions, so that the automobile starting control after engine restarting, the engine stopping time judgment and the start-stop feedback signal sending are realized. The method and the system implement optical control for the working state of the gearbox of the automobile in the mutual change process between movement state and stationary state in the start-stop technology, and solve the problem of wearing the clutch mechanical body caused by needing two clutches for sliding friction starting in the prior art.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

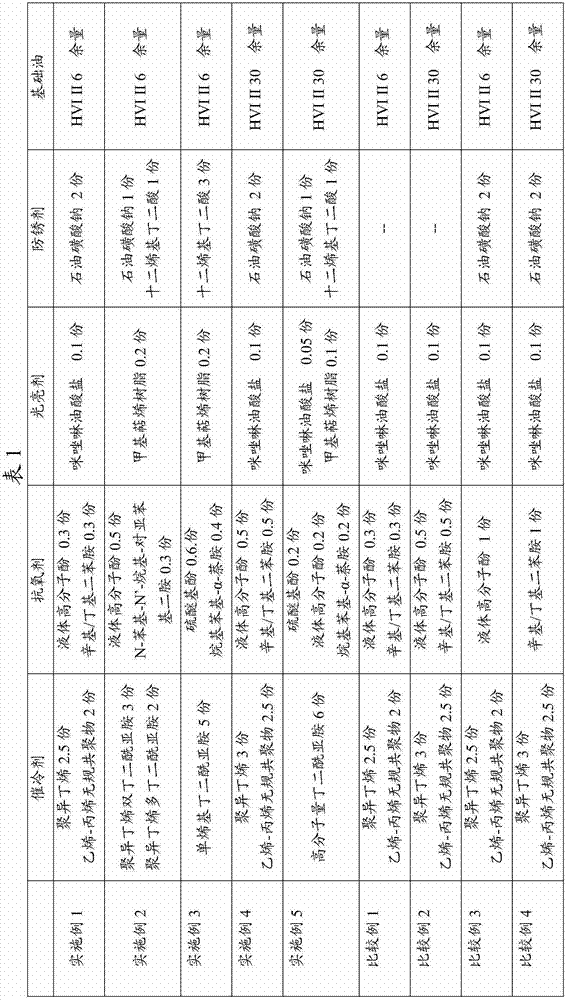

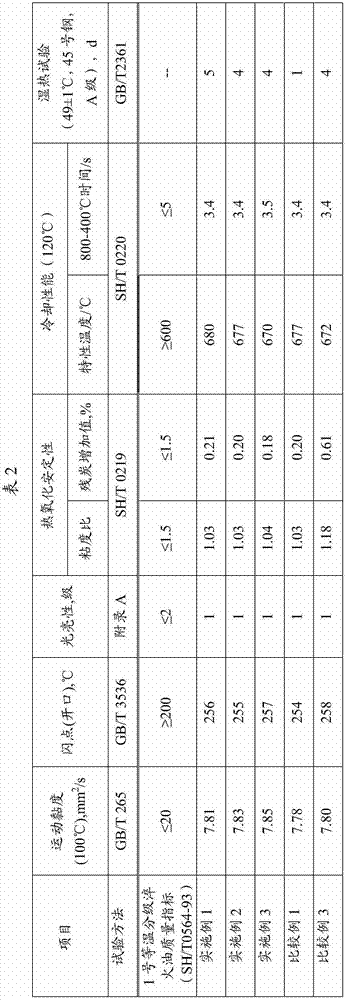

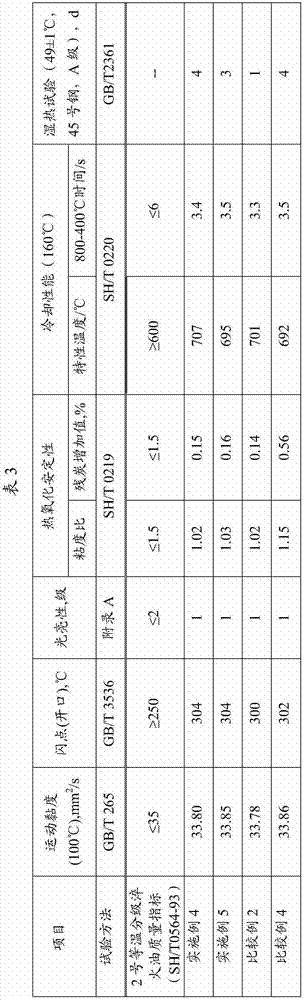

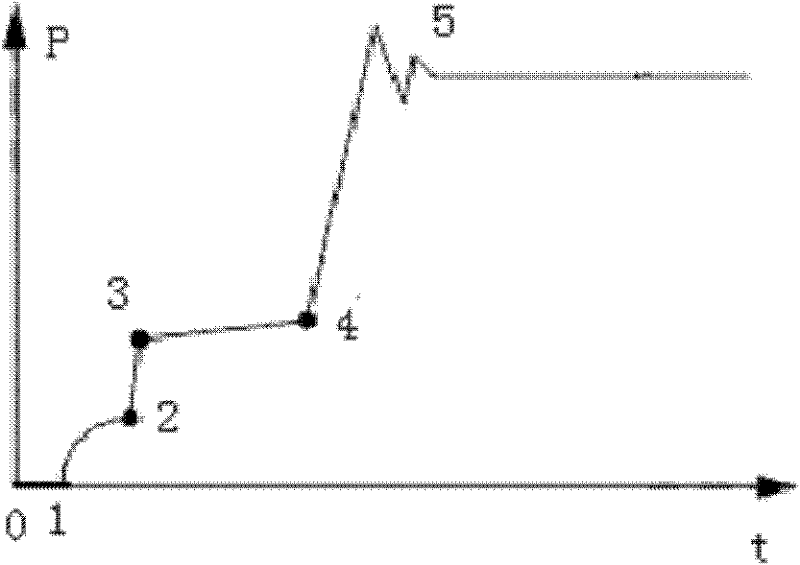

Isothermal graded quenching oil composition and uses thereof

ActiveCN103710083ABright surfaceMeet the requirements of high temperature quenchingQuenching agentsLubricant compositionPhenolic antioxidantSteel ball

The invention relates to an isothermal graded quenching oil composition and uses thereof, mainly aims at further improvement of cooling performances, thermal oxidation stability and brightness of isothermal graded quenching oil in the prior art, and solves the problem that the isothermal graded quenching oil has no corrosion resistant performance on workpieces after quenching. The isothermal graded quenching oil composition comprises the following components: by weight, a) 0.3 to 8 parts of a cooling accelerant; b) 0.1 to 3 parts of an antioxidant; c) 0.001 to 1 part of a brightener; d) 0.03 to 5 parts of an anti rust agent; and e ) 78 to 98 parts of base oil; in the technical scheme, the antioxidant is selected from a phenolic antioxidant or a mixture of amine antioxidants, the technical scheme can well solve the problem, and the isothermal graded quenching oil composition can be used for quenching of wearable steel balls, saw blade, auto gearbox gears, gear rings, gear sleeves, shafts and other precision parts.

Owner:CHINA PETROLEUM & CHEM CORP +1

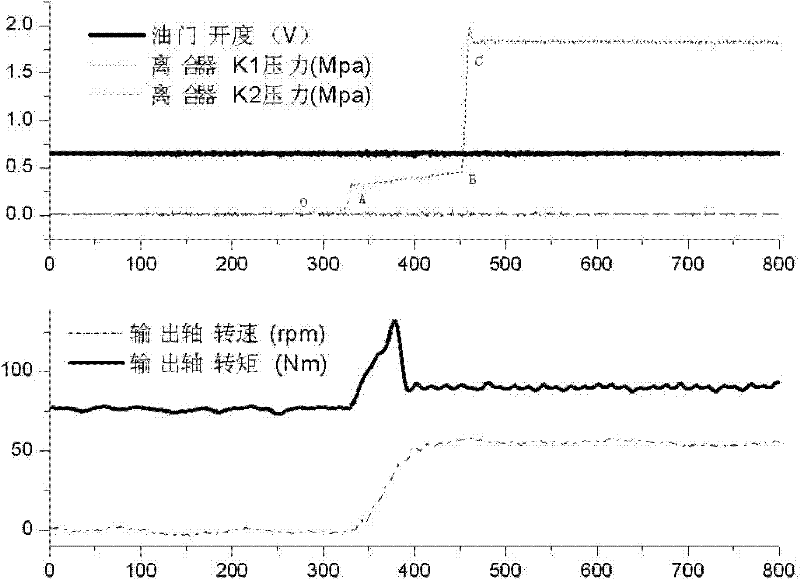

Double-clutch automatic transmission shift control method

ActiveCN102230532AOvercome limitationsSmooth shiftingGearing controlAutomatic transmissionSolenoid valve

The invention belongs to an automotive transmission and in particular discloses a double-clutch automatic transmission shift control method. The method is characterized in that: a duty ratio of a solenoid valve for controlling the engagement and separation of clutches in a double-clutch automatic transmission is adjusted to control a matched timing sequence of two clutches and respective joint speed and joint pressure thereof in the shifting process, so that the sum of transmission torque of a front clutch and a subsequent clutch adapts to the torque of an engine in the shifting process; and a shifting moment and a corresponding shift method are determined according to an accelerator pedal position signal acquired by a sensor, the rotating speed of the engine, the rotating speed and a clutch pressure signal of an input shaft of the front clutch and the rotating speed and a clutch pressure signal of an input shaft of the subsequent clutch. By the method, the shifting process is stable and rapid, the shifting quality is high, and the riding comfort is improved.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

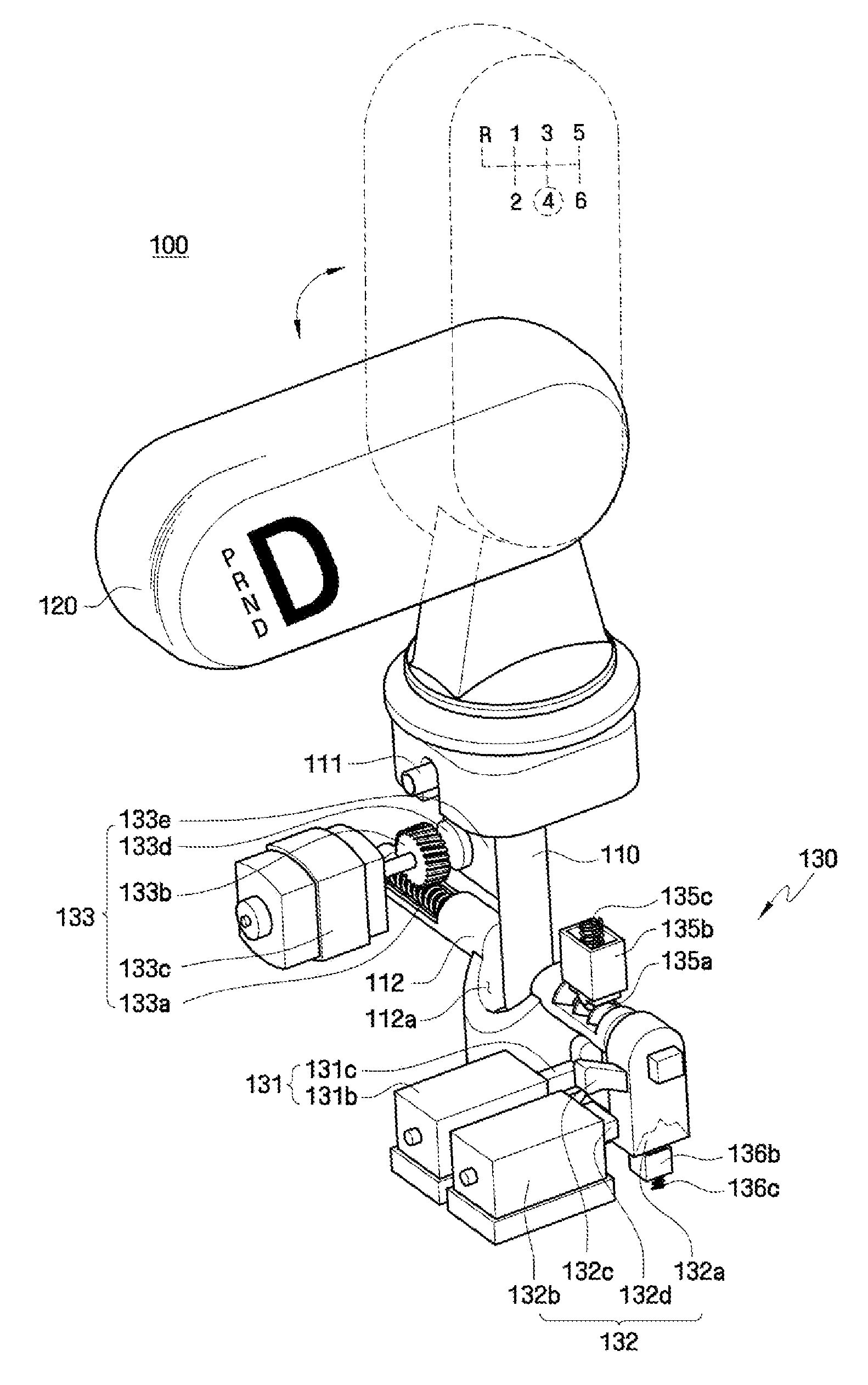

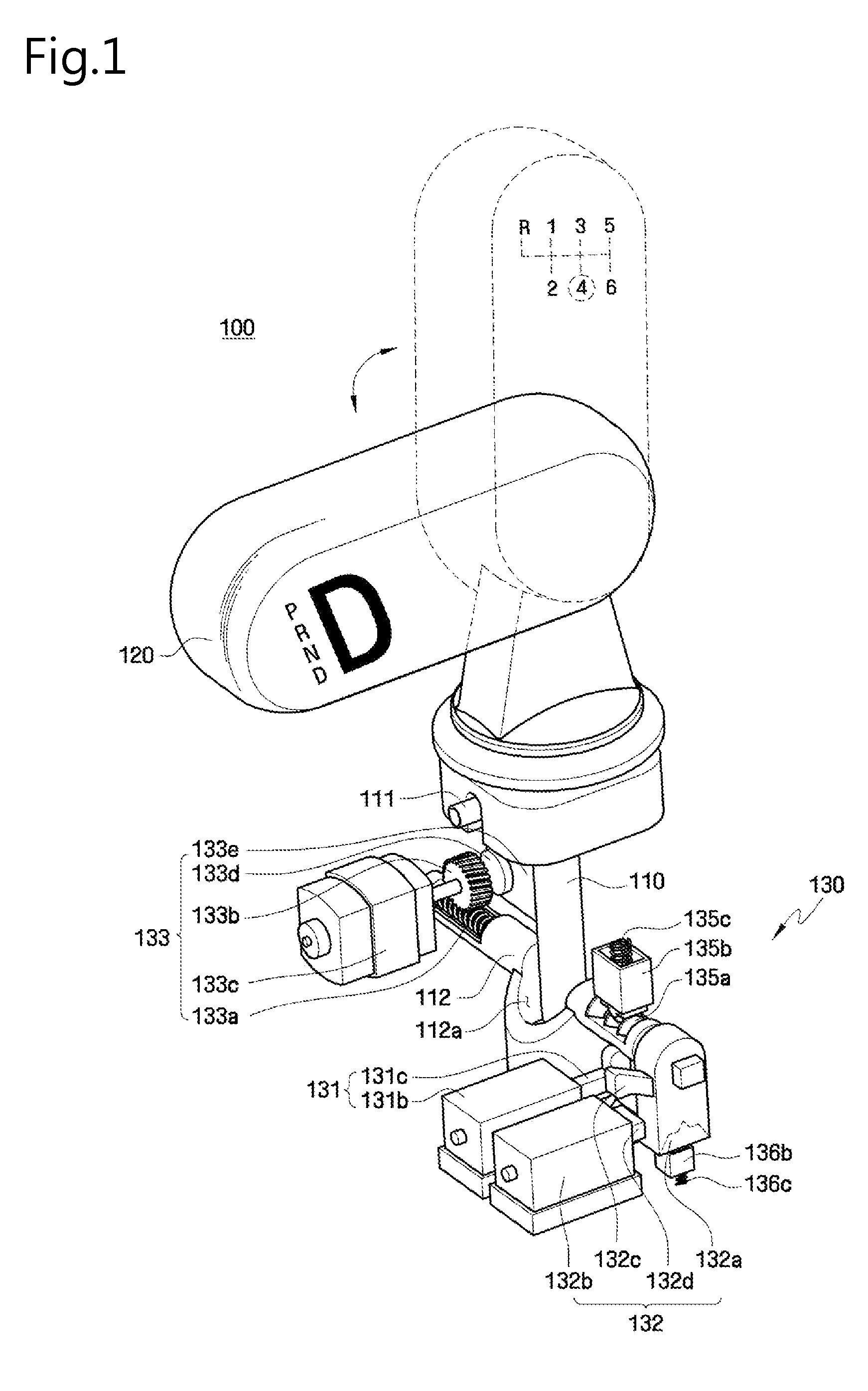

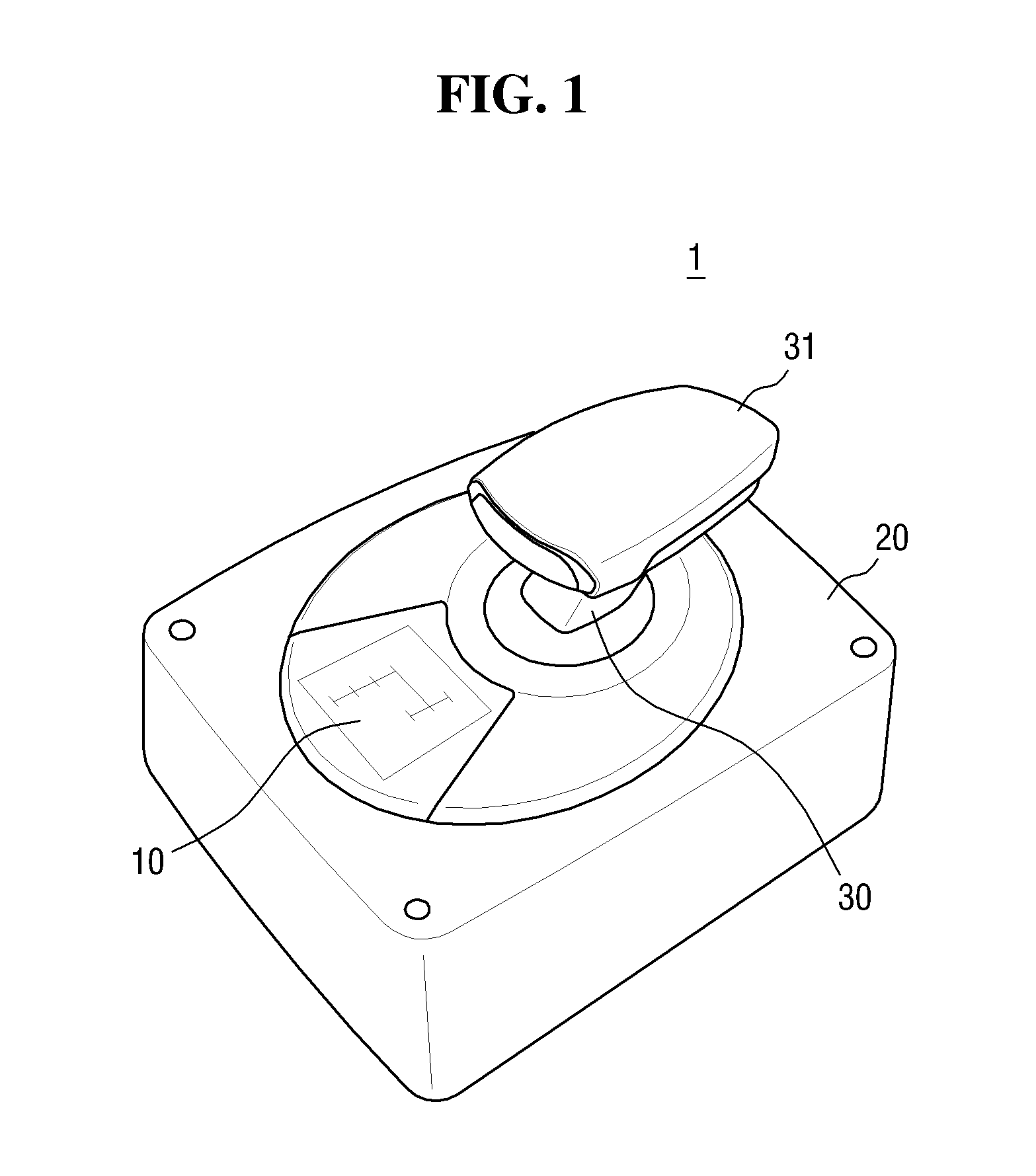

Automotive transmission

ActiveUS20120085193A1Avoid difficult choicesLow costManual control with multiple controlled membersGearing controlEngineeringAutomotive transmission

Disclosed herein is an automotive transmission which includes shift lever which moves in a first direction and a second direction to select a shift position and a shift mode selection unit which is installed at one side of the shift lever to select a shift mode. Additionally, the disclosed automotive transmission also includes a shift blocking unit which selectively blocks movement of the shift lever in the first direction and the second direction such that a shift position of the selected shift mode is selected.

Owner:SL CORP

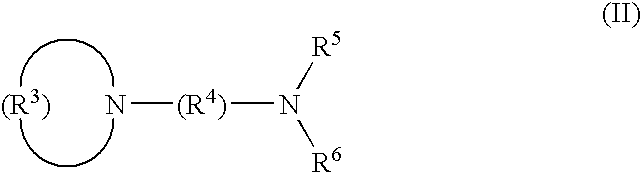

Transmission lubricating compositions with improved performance, containing acid/polyamine condensation product

InactiveUS20050014656A1Improve wear resistanceAppropriate friction durabilityOrganic chemistryLiquid carbonaceous fuelsAutomotive transmissionFatty acid

A lubricating composition containing (a) a hydrocarbyl phosphite; (b) the condensation product of at least one fatty acid with a polyamine; (c) a borate ester; (d) a borated dispersant; and (e) an oil of lubricating viscosity. The invention further relates to the use of the composition in automotive transmissions.

Owner:THE LUBRIZOL CORP

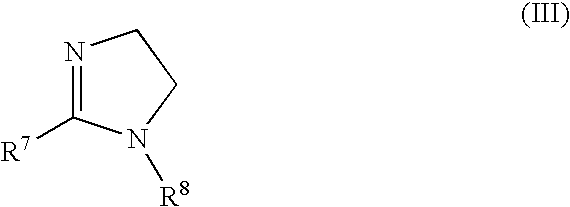

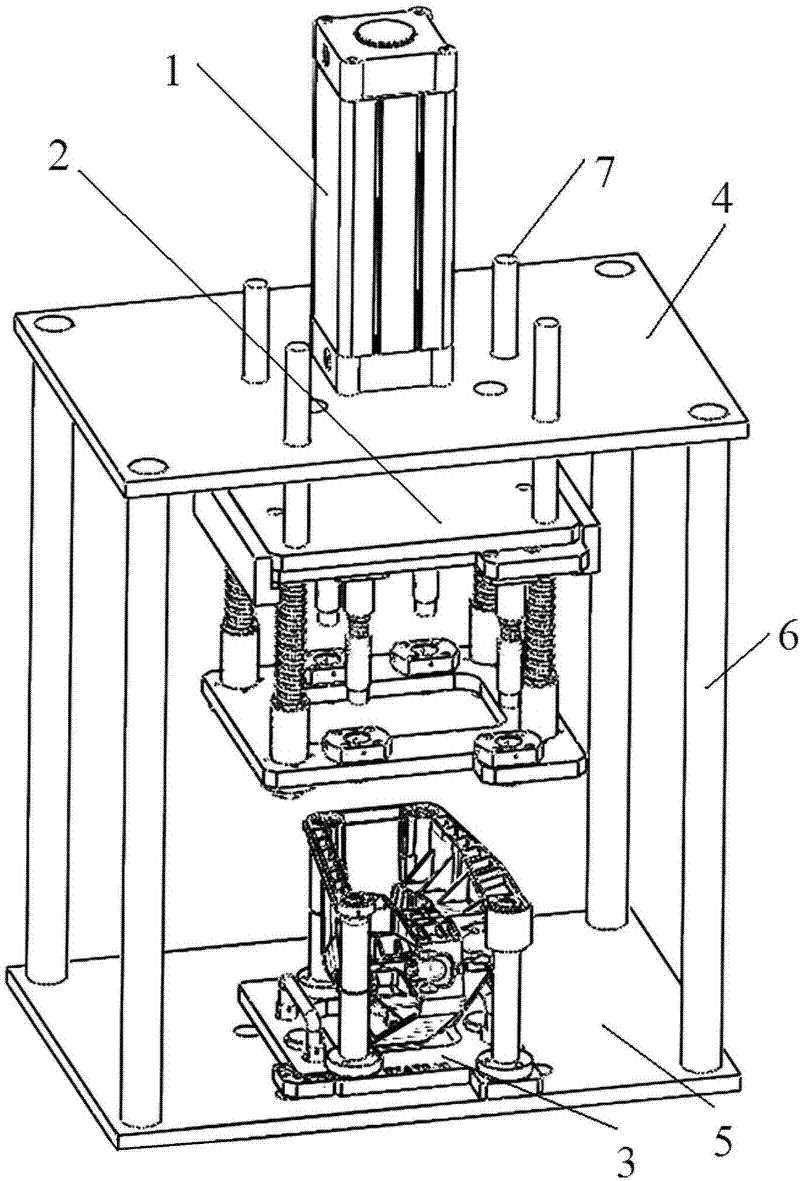

Bush fixing press-mounting machine for automobile gearbox

InactiveCN102528430AFully automatedAccurate and quick installationMetal working apparatusEngineeringAutomotive transmission

The invention discloses a bush fixing press-mounting machine for an automobile gearbox. The bush fixing press-mounting machine comprises an air cylinder and is characterized by also comprising a frame, a multistage press-mounting part and a fixing jig; wherein the frame comprises an upper top plate, a base plate and supporting columns, and the supporting columns are supported between the upper top plate and the base plate in a surrounding way; the cylinder barrel of the air cylinder is fixed above the upper top plate; the piston rod of the air cylinder penetrates through the upper top plate and extends out downward; the multistage press-mounting part is arranged between the upper top plate and the base plate and is fixedly connected with the free end of the piston rod of the air cylinder; the fixing jig is fixed on the upper surface of the base plate; and a press-mounting head is arranged on the multistage press-mounting part. The press-mounting machine has the beneficial effects that the installation automation of a bush can be effectively realized, the installation of the bush is accurate and rapid, and the structure is simple and practical.

Owner:SIP GOLDWAY TECH

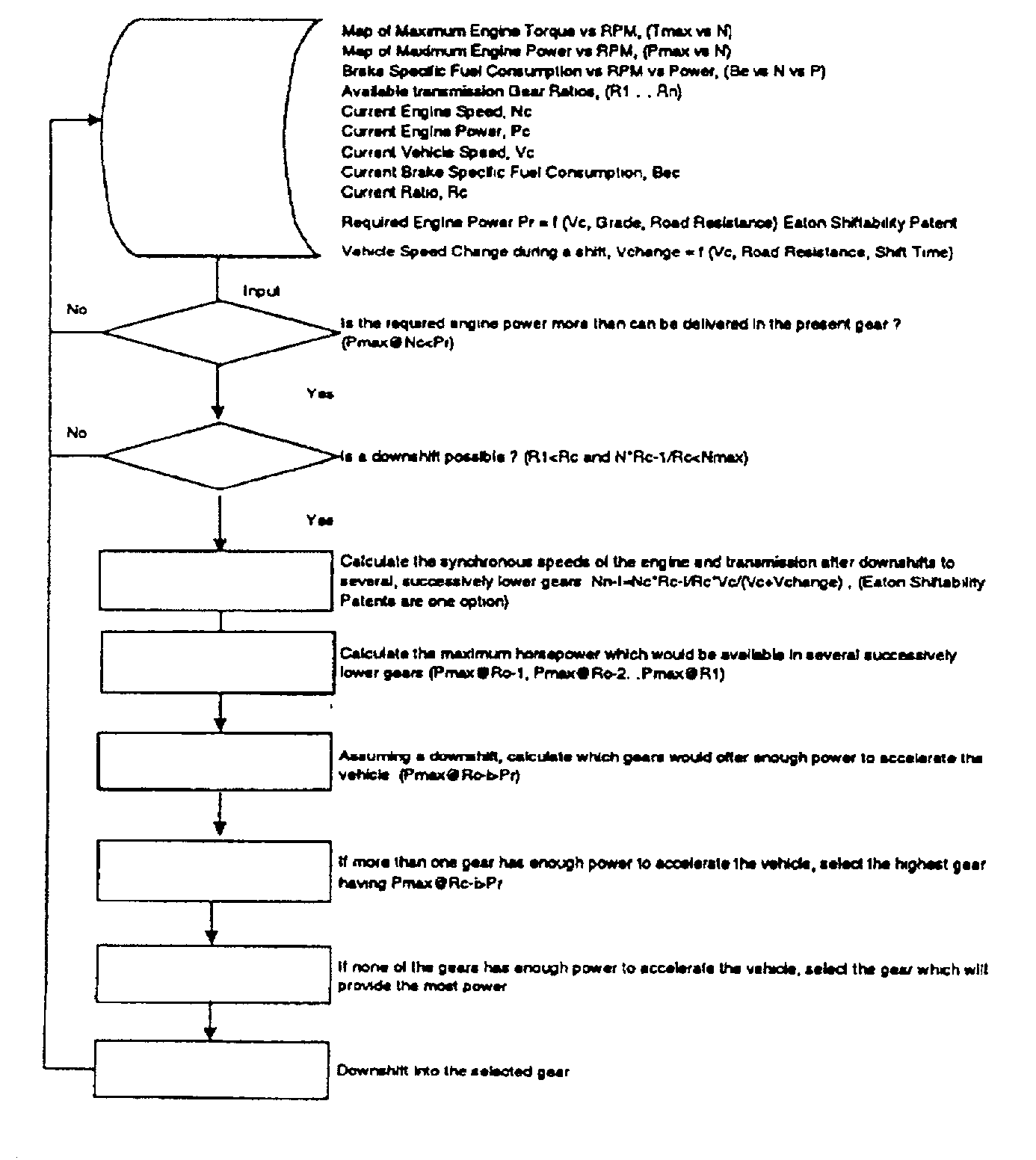

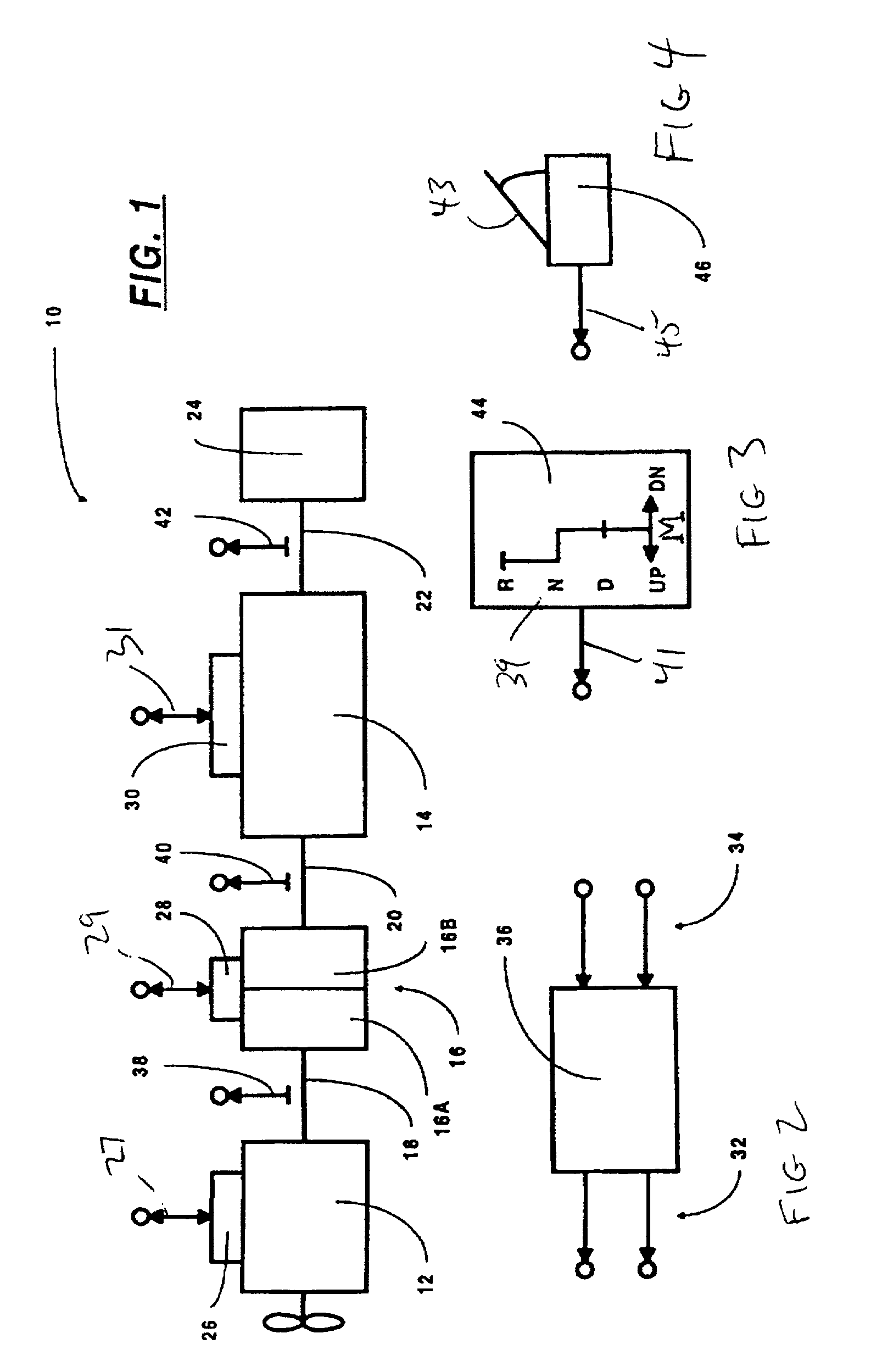

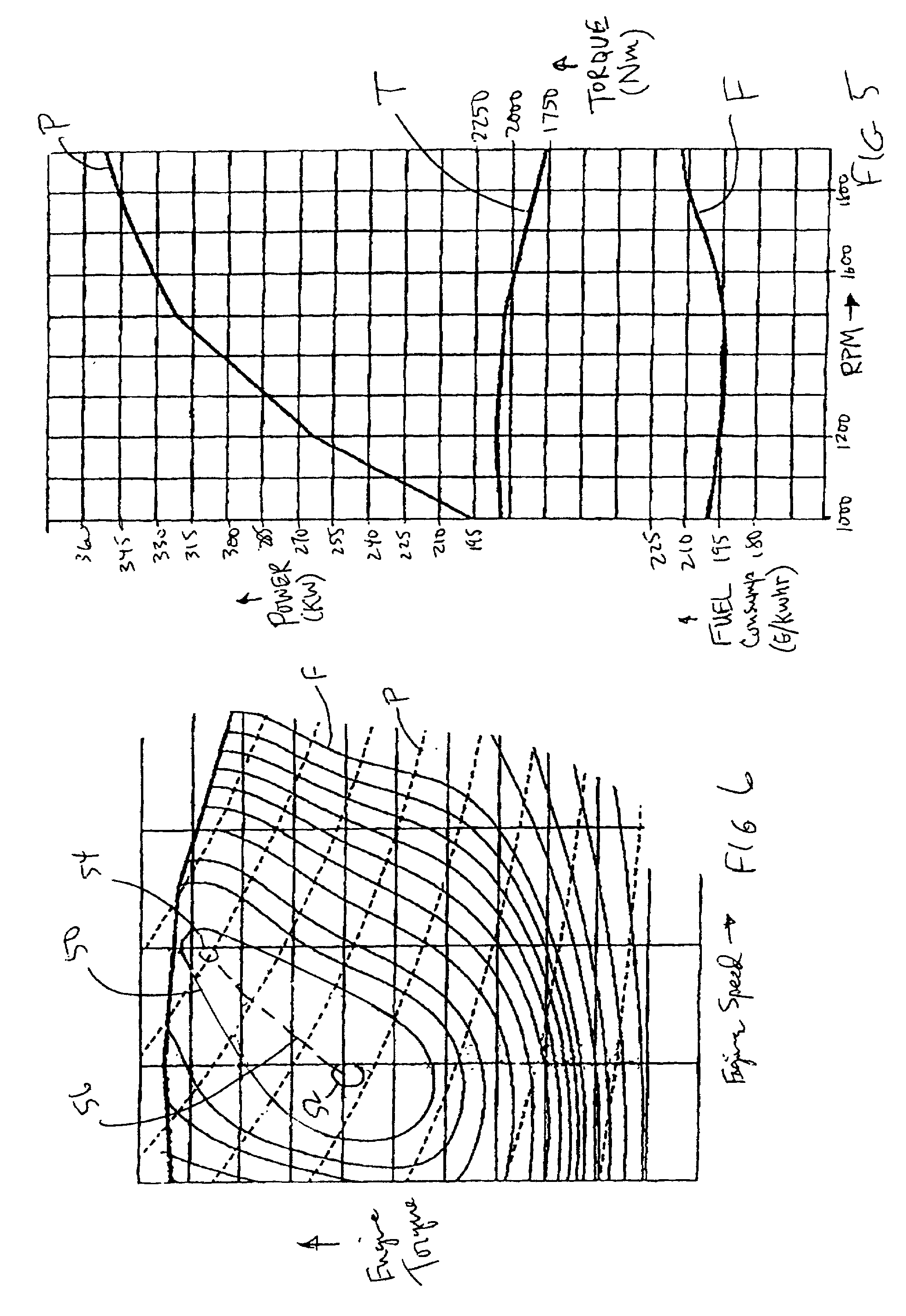

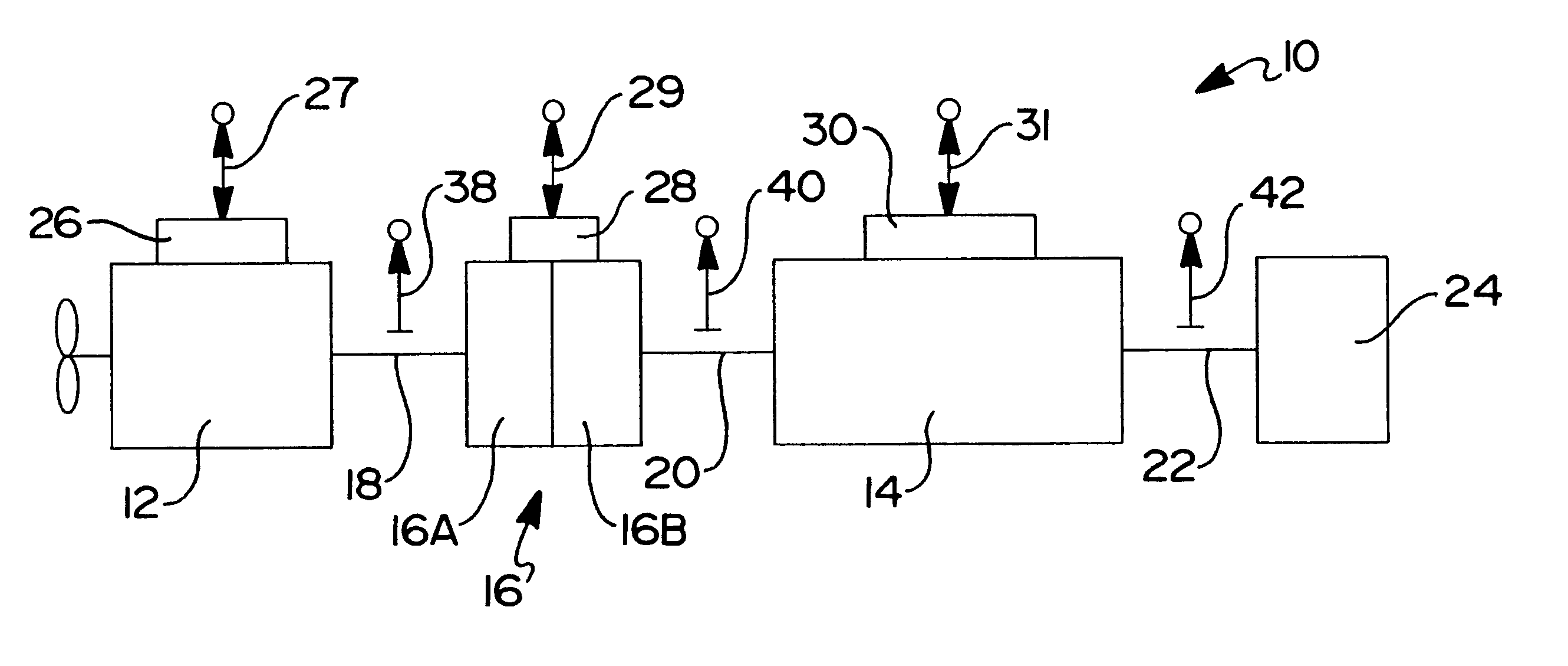

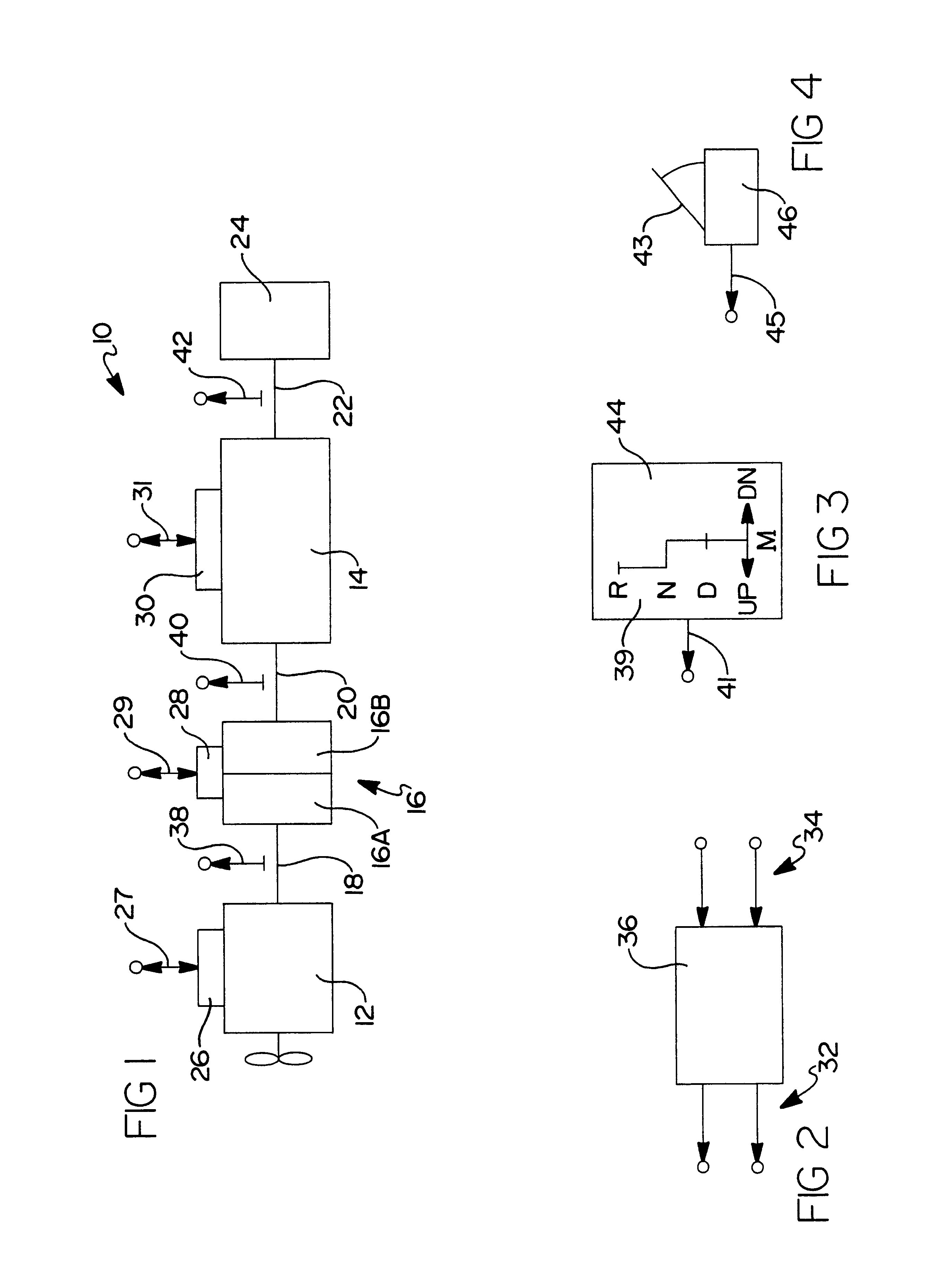

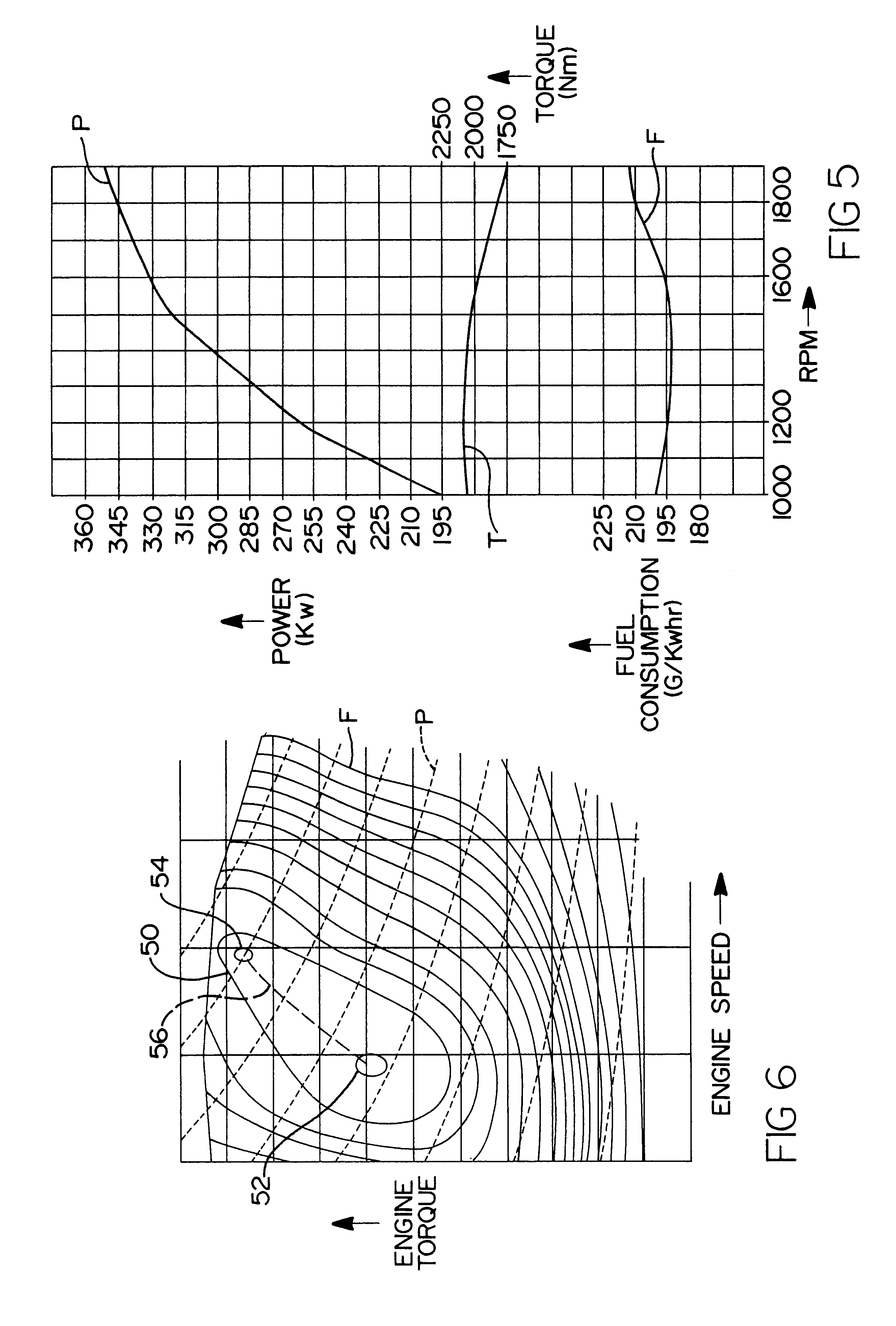

Shift strategies for mock continuously variable transmission

Simulated or "mock" continuously variable transmission shift strategies are used in an electromechanically actuated automotive transmission having reduced ratios steps in its upper ratio ranges. In one described embodiment, a 12-speed truck transmission consists of a five-speed main section and an auxiliary section that includes splitter and range sub-sections to provide the 12 ratios. Separate shift strategies are directed to fuel economy and power optimization modes; driver throttle demand determines the mode. Both strategies are targeted to the upper gear ratios, which represent the ratios subject to approximately ninety percent (90%) of vehicular operation. In the described embodiment, the applicable affected ratios are gears 7-12. In the described embodiments, the shift strategies are carried out by embedded software subject to the command of an electronic power train control module. Both strategies are operated as direct functions of engine torque, transmission input shaft speed, and road speed.

Owner:EATON INTELLIGENT POWER LIMITED

Automobile transmission gear heat treatment method

ActiveCN104894506AAvoid early crackingAlleviate the problem of bulky carbidesSolid state diffusion coatingFatigue IntensityHigh carbon

The invention discloses an automobile transmission gear heat treatment method. The method includes the steps of carburization, carbonitriding, quenching, cleaning, low temperature tempering and air cooling. The carburization technique is combined with the carbonitriding technique, abrasion resistance, fatigue strength and corrosive resistance are improved by a layer of highly hard nitride layer obtained on the carburized layer on the surface of a gear, and comprehensive performance of a product is good; meanwhile, the problems of massive carbide appearing under the high carbon potential state and network carbide appearing in the cooling process are avoided, and early-age cracking of the surface of the gear is avoided; moreover, by the method, the technological process is simplified, heating and cooling links and discharge links are reduced, carburization deformation and quenching deformation are reduced, generation of black structures is reduced as well, and anti-fatigue performance is guaranteed; finally, by the method, production cycle is shortened greatly, energy consumption is lowered, and production efficiency is improved highly.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

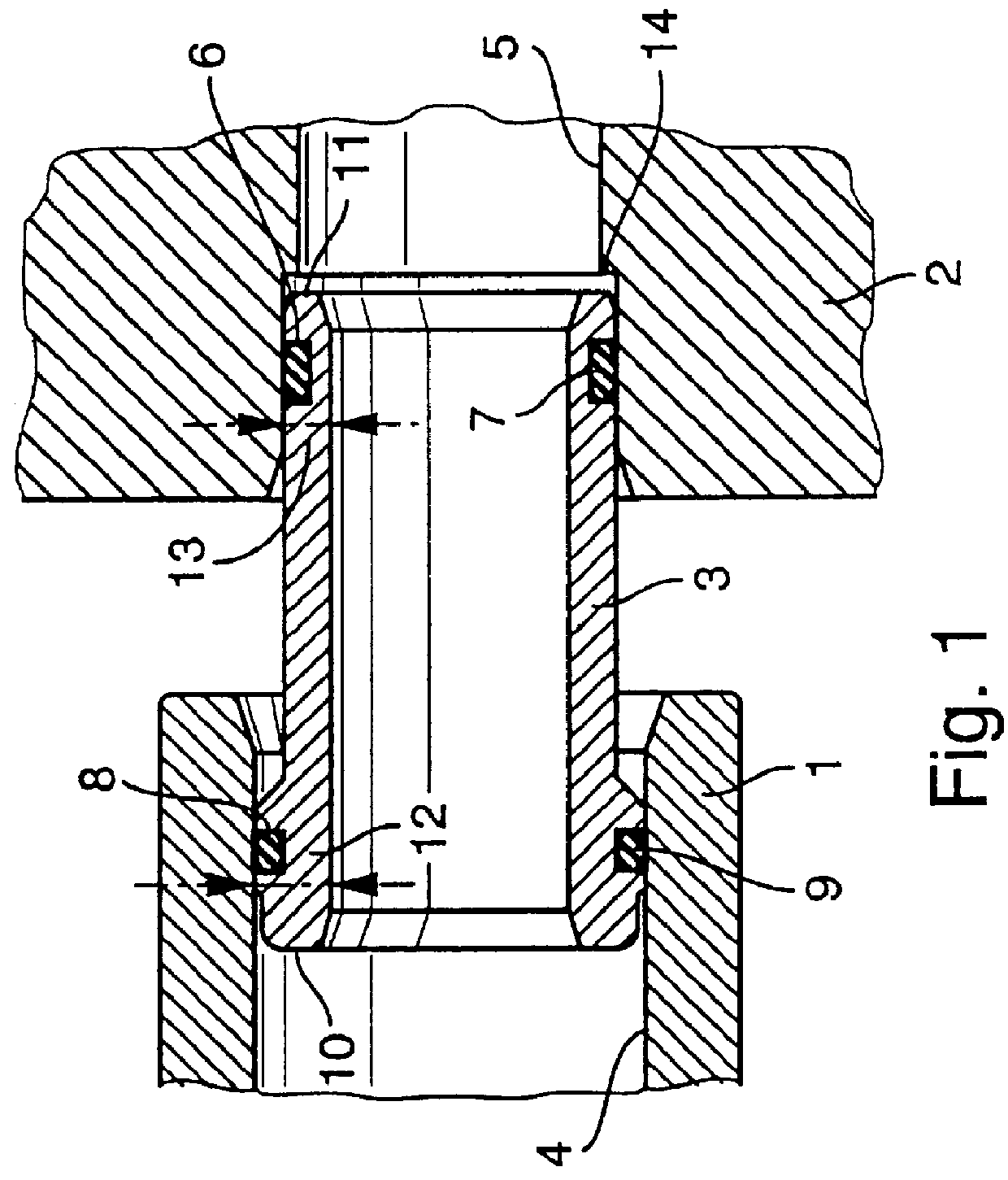

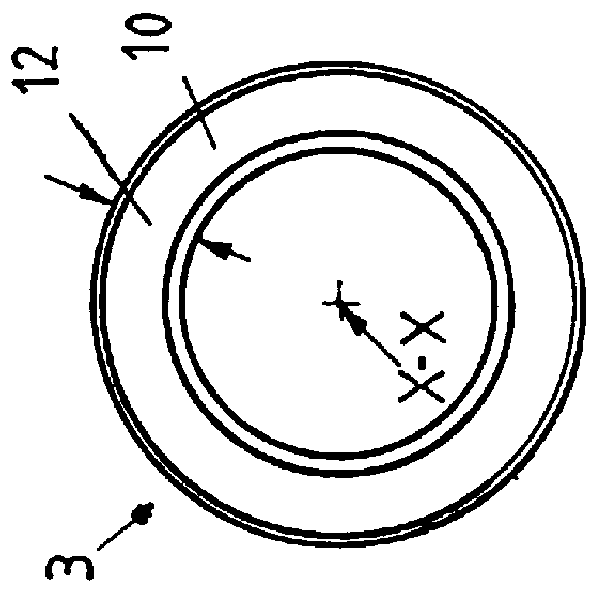

Transmission for motor vehicle

InactiveUS6129188AReduce liquid leakageReduce leakageSleeve/socket jointsFluid actuated clutchesSplit ringEngineering

A transmission for use in the power train of a motor vehicle has a rotary first component (such as a shaft), a second component which may but need not be rotatable, a fluid-conveying conduit having a first end portion extending into a first socket provided in the first component and a second end portion extending into a socket of the second component, a split-ring piston packing located in an external groove of the first end portion, and an O-ring received in an external groove of the second end portion. The O-ring prevents the conduit and the second component from rotating relative to each other. A passage which is defined by the two components and the conduit can receive a stream of pressurized hydraulic fluid from a pump by way of pipes wherein the flow of fluid is controlled by several valves including a manually operated slide valve, at least one preferably adjustable pressure regulating valve, at least one preferably adjustable safety valve, and adjuster for the adjustable valve or valves; such adjuster can employ one or more signal-responsive control valves.

Owner:SCHAEFFLER TECH AG & CO KG

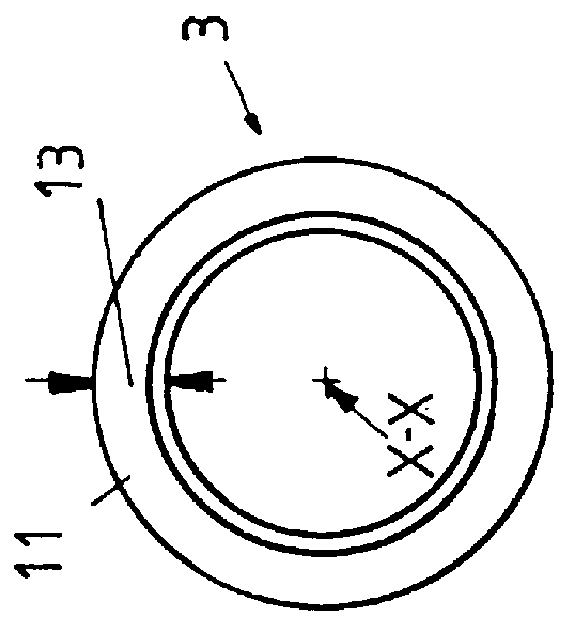

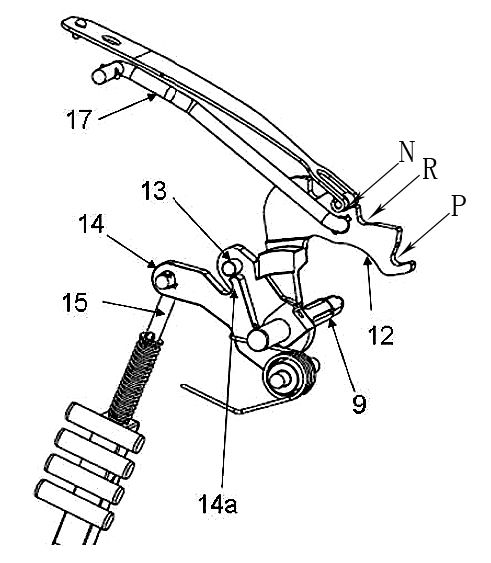

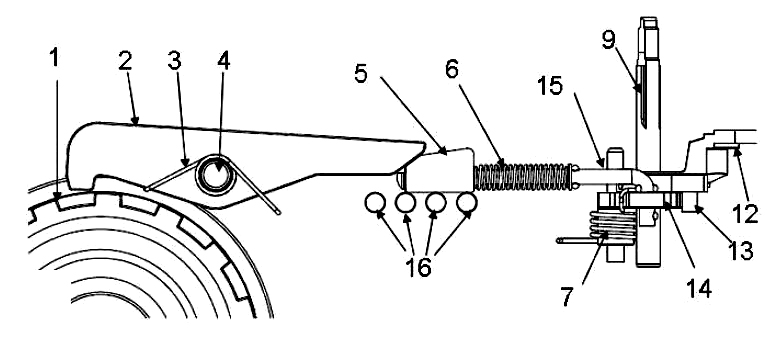

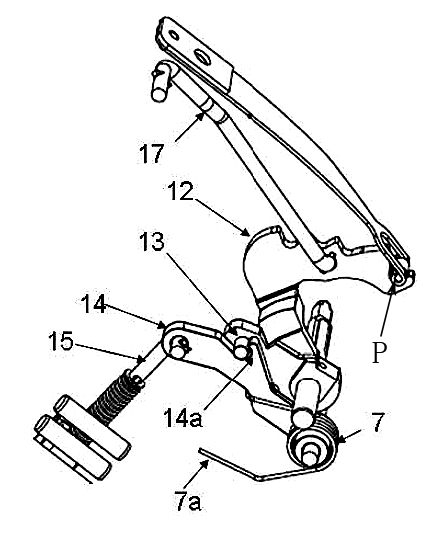

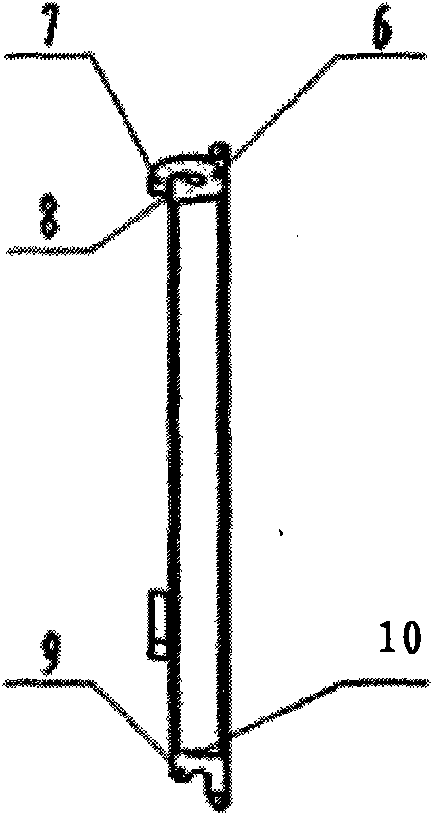

Parking and braking mechanism of automobile gear box

The invention discloses a parking and braking mechanism of an automobile gear box, which mainly comprises a parking gear wheel, a parking ratchet, an actuating rod, a slipping spring, a cam slide block, a plurality of support pins, an intermediate moving rod and a positioning track plate, wherein the cam slide block is connected at the front end of the actuating rod and does slipping connection with the rear end of the parking ratchet under the function of precompression force of the slipping spring; the actuating rod is connected on the intermittent moving rod; and the positioning track plate is connected with the intermittent moving rod when in shift P and shift R, and is disconnected from the intermittent moving rod when in shift N and shift D. When in shift P, the parking ratchet is pushed to the parking gear wheel by the driving pin on the positioning track plate through the intermittent moving rod, the actuating rod, the slipping spring and the cam slide block, and then the gear box is braked. By arranging the support pins and the intermittent moving rod, the slipping speed and control precision of the parking and braking mechanism can be enhanced, and the service life of the braking mechanism is prolonged through the slipping connection of linear contact.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

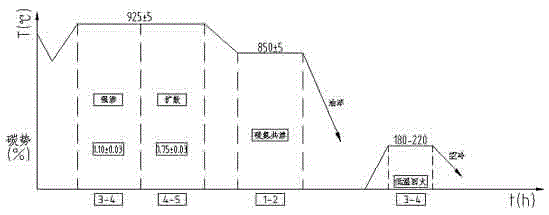

Automobile gearbox gear carburizing and quenching heat treatment method

ActiveCN103710714AHigh surface hardnessImprove wear resistanceSolid state diffusion coatingFurnace typesCarbon potentialRoom temperature

The invention discloses an automobile gearbox gear carburizing and quenching heat treatment method. The method comprises the following steps: 1, carburizing: placing a gear in a heating furnace, and rising temperature of the heating furnace from room temperature to 900+ / -5DEG C for carburizing for 3-4h, wherein the carbon potential CP in a strong carburizing stage is 1.06+ / -0.3C%, and the carbon potential CP in a diffusion stage is 0.85+ / -0.03C%; 2, quenching: cooling the obtained carburized gear to 830+ / -5DEG C, samming for 25-35min, and quenching in 90+ / -10DEG C quenching oil; and 3, tempering: tempering the obtained quenched gear at 165+ / -5DEG C for 2-3h. The proper reduction of the carburizing temperature and the quenching temperature, the rising of the temperature of the quenching oil and the proper rising of the carburizing carbon potential are carried out on the premise of guaranteeing the quality of a carburized layer, so the carburizing time is not prolonged, and the energy consumption is reduced; and the appearance of black microstructures is prevented, so the surface hardness, the wear resistance and the fatigue strength of the gear are obviously improved, deformation is reduced, the driving balance of the gear is improved, noises are reduced, and the service life of the gear is prolonged.

Owner:厦门真冈热处理有限公司

Rubber framework grease seal for automobile gear box and manufacturing method thereof

InactiveCN101319082APrevent leakageSolve the problem of oil leakageEngine sealsDomestic articlesSodium stearateSulfur

The invention provides a rubber framework oil seal used for a gear box of an automobile and a manufacturing method thereof. The rubber framework oil seal comprises the following compositions in weight portion: 100 portions of activated chlorine type acrylate adhesive AR840, 0.5 to 1 portion of a vulcanizing activator stearic acid, 1.5 to 2 portions of a process additive TM-80, 2 to 3 portions of a vulcanizing agent sodium stearate, 0.5 to 0.6 portion of an accelerating agent sulfur and potassium stearate, 1 to 2 portions of an age inhibitor 445, 1 to 2 portions of MB, 4 to 6 portions of a strengthening agent carbon soot and 22 to 28 portions of a siliceous reinforcing agent. The rubber framework oil seal has the characteristics of stable size of hypoid gear oil of the gear box, oil resistance, anti-aging property, and sealing reliability, etc.

Owner:青岛茂林橡胶制品有限公司

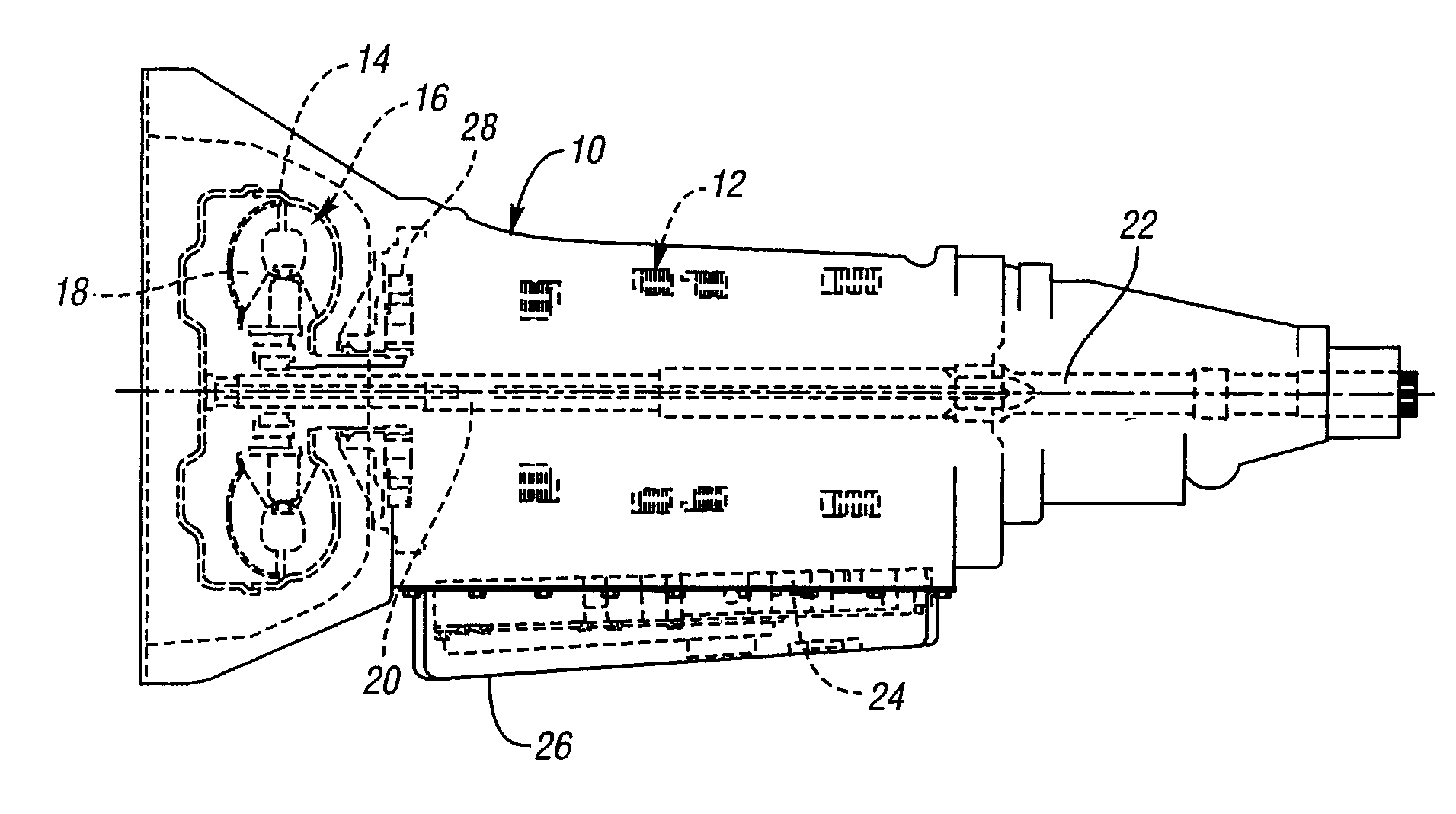

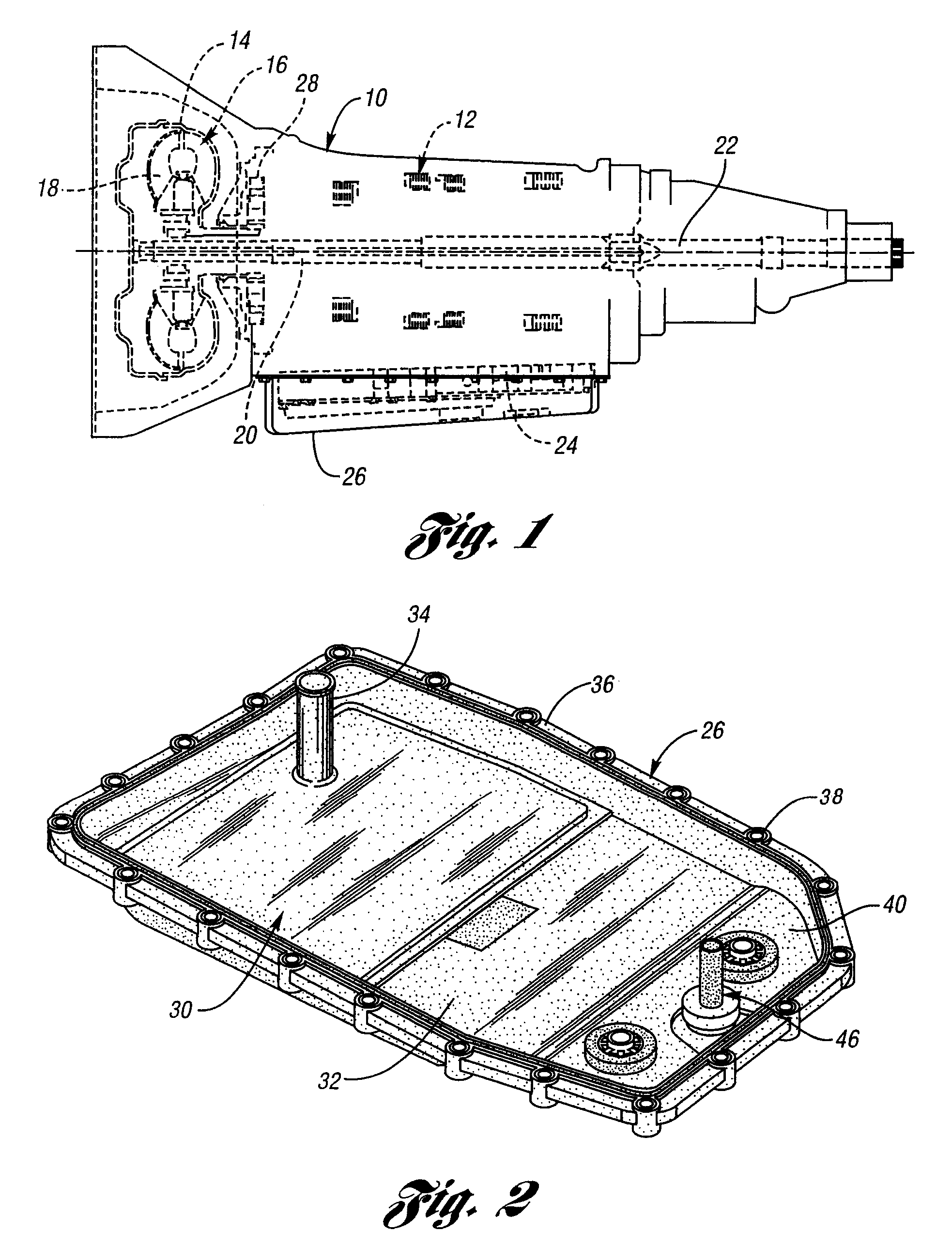

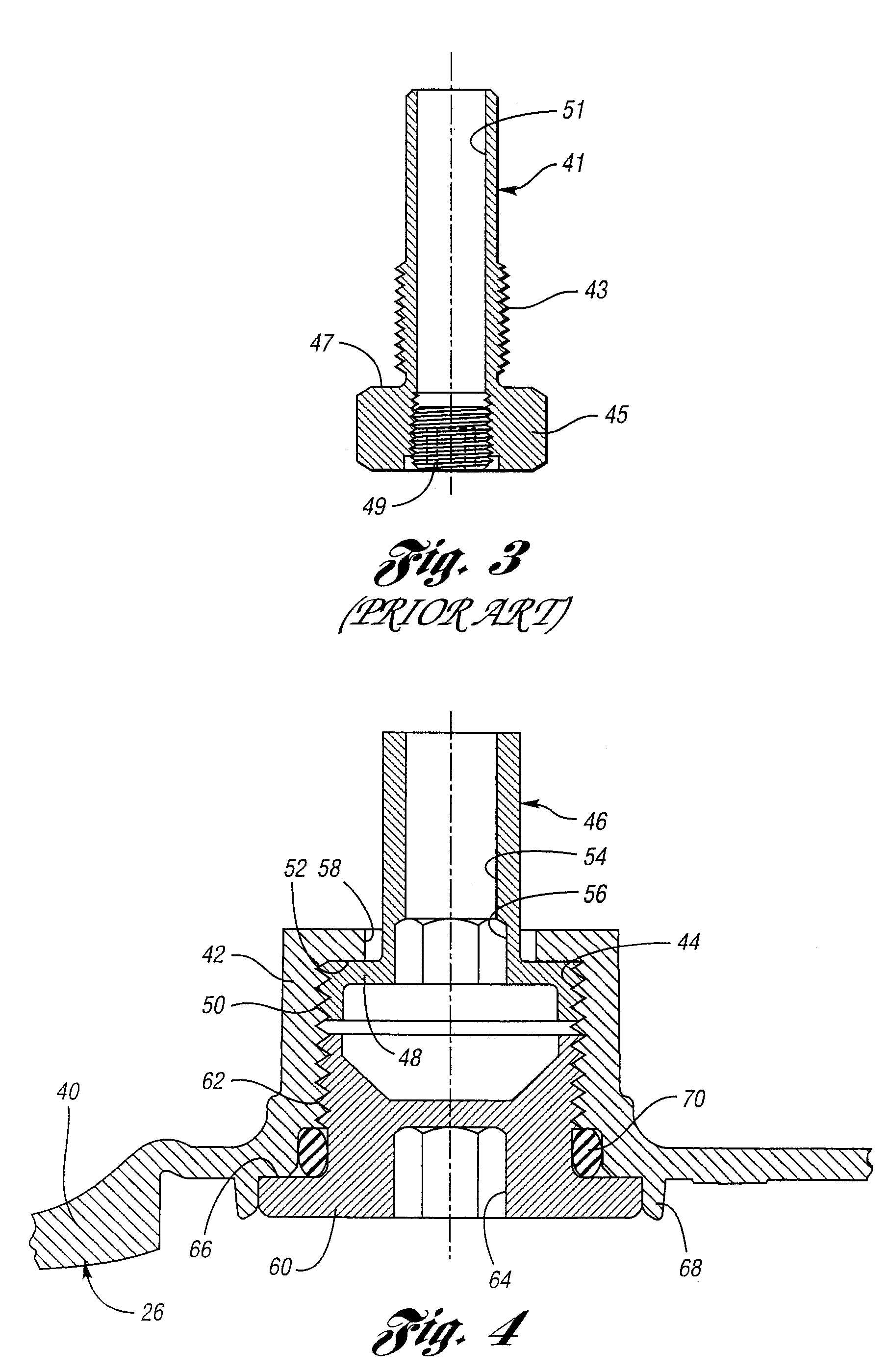

Externally serviceable transmission sump fill pipe and drain port assembly

ActiveUS20060037427A1Leakage problemImprove corrosion resistanceCrankshaftsGearboxesFuel tankAutomotive transmission

A transmission fluid sump for an automotive transmission comprising a reservoir portion, a threaded extension on the reservoir portion and a fill pipe threadably connected to the extension. A closure member seals a central opening in the extension independently of the fill pipe, thereby avoiding overlapping torque windows for the fill pipe and the closure member while providing a single leak flow path for the transmission fluid.

Owner:FORD GLOBAL TECH LLC

Method for manufacturing aluminum automobile gearbox shell

The invention discloses a method for manufacturing an aluminum automobile gearbox shell. The gearbox shell is manufactured from aluminum alloy prepared from, by weight, 7% to 9% of Zn, 12% to 14% of Si, 6% to 8% of Cu, 2% to 4% of Mn, 0.8% to 1.2% of Ti, 0.3% to 0.5% of Re, 3% to 5% of Mg, 1% to 3% of Zr, 0.6% to 0.8% of Ni and the balance Al and inevitable impurities. The manufacturing method comprises the following steps of 1 batching, 2 smelting, 3 mold preparation, 4 die casting, 5 thermal treatment and 6 electroplating. An electroplating method comprises the steps of 1 pretreatment, 2 zinc depositing treatment, 3 electronickelling treatment and 4 surface layer nickel or chromium or copper plating.

Owner:株洲立众精制科技有限公司

Three-dimensionally-woven composite automotive transmission shaft and manufacturing method of three-dimensionally-woven composite automotive transmission shaft

ActiveCN105690793ASmall running vibrationMeet the use requirementsYielding couplingShaftsFiberUniversal joint

The invention discloses a three-dimensionally-woven composite automotive transmission shaft and a manufacturing method of the three-dimensionally-woven composite automotive transmission shaft. A three-dimensionally-woven composite transmission shaft pipe and a universal joint are designed and the sleeve connection and combination manner of the three-dimensionally-woven composite transmission shaft pipe and the universal joint is designed according to the stress characteristic of the transmission process of the automotive transmission shaft. Three-dimensional multi-axial fabric structure combination is conducted through a hybrid fiber multi-direction weaving manner, the structural performance of the specific portion of the transmission shaft is strengthened, and finally integrated weaving of the three-dimensional prefabricated body structure is achieved. After a related three-dimensional fabric prefabricated body workpiece is manufactured, the specific fiber is selected to be subjected to thickness-direction seam laying secondary strengthening treatment so that the strength and rigidity in the thickness direction can be improved; and finally, a thermosetting resin glue solution serves as a base material, resin impregnation recombination and resin curing are conducted on the three-dimensionally-woven prefabricated body fabric by the adoption of continuous forming with vacuum infusion and quick thermocuring combined, and finally a three-dimensionally-woven composite automotive transmission shaft assembly made of the hybrid fiber fabric is formed.

Owner:SHANDONG ZHONGHENG CARBON FIBER TECH DEV CO LTD

Automotive transmission case and manufacturing method thereof

InactiveCN104561858AImprove wear resistanceHigh tensile strengthGearboxesTemperingCryogenic treatment

The invention relates to an automotive transmission case and a manufacturing method thereof. The automotive transmission case with high strength and high tenacity is obtained by preparing a mold for a specific component magnesium alloy; preparing materials, smelting, extruding and casting; quenching, carrying out cryogenic treatment, tempering and carrying out aging treatment.

Owner:邯郸市宝特铸造有限公司

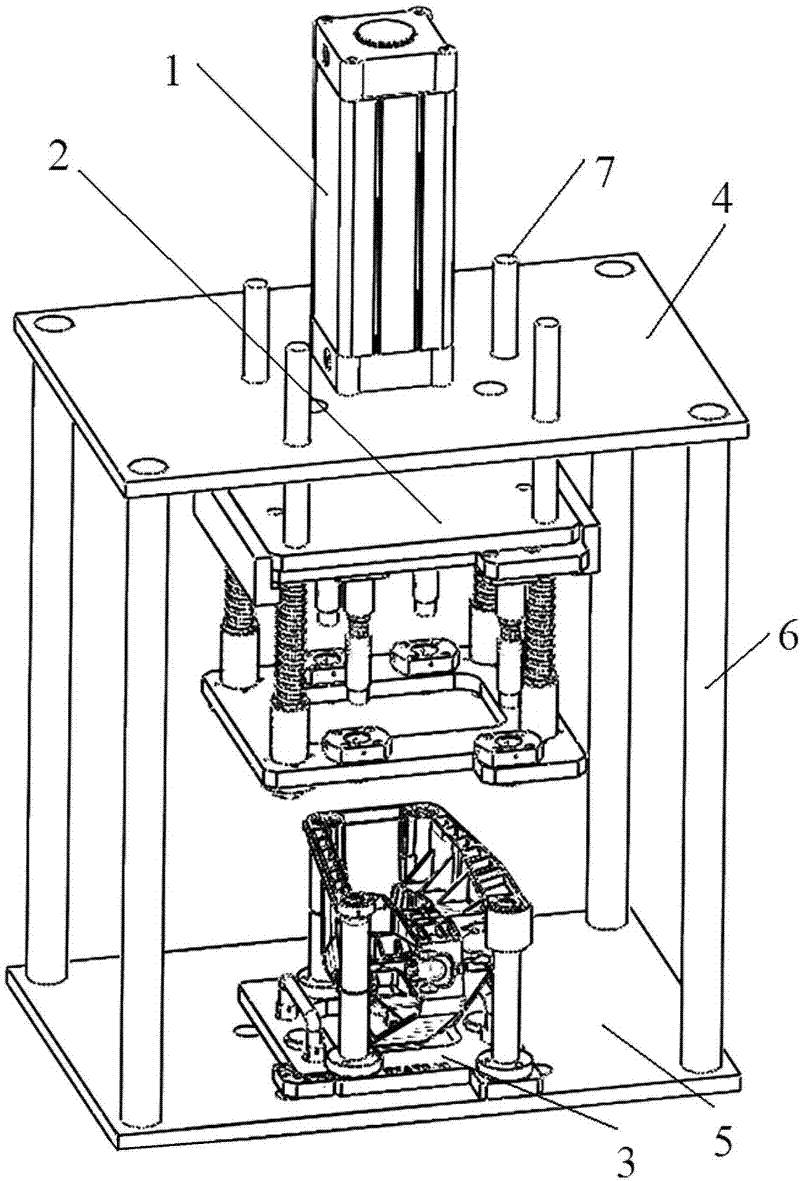

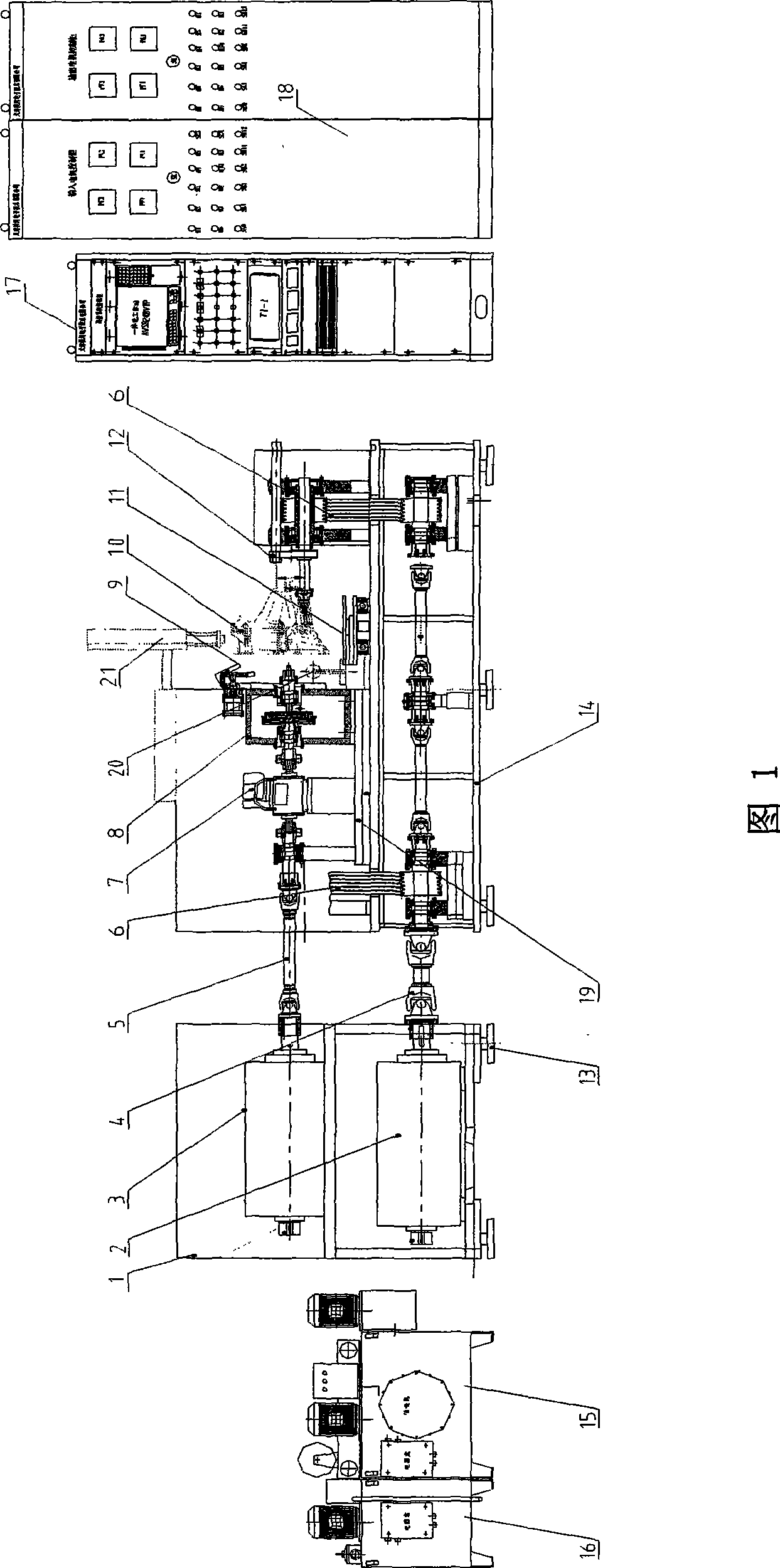

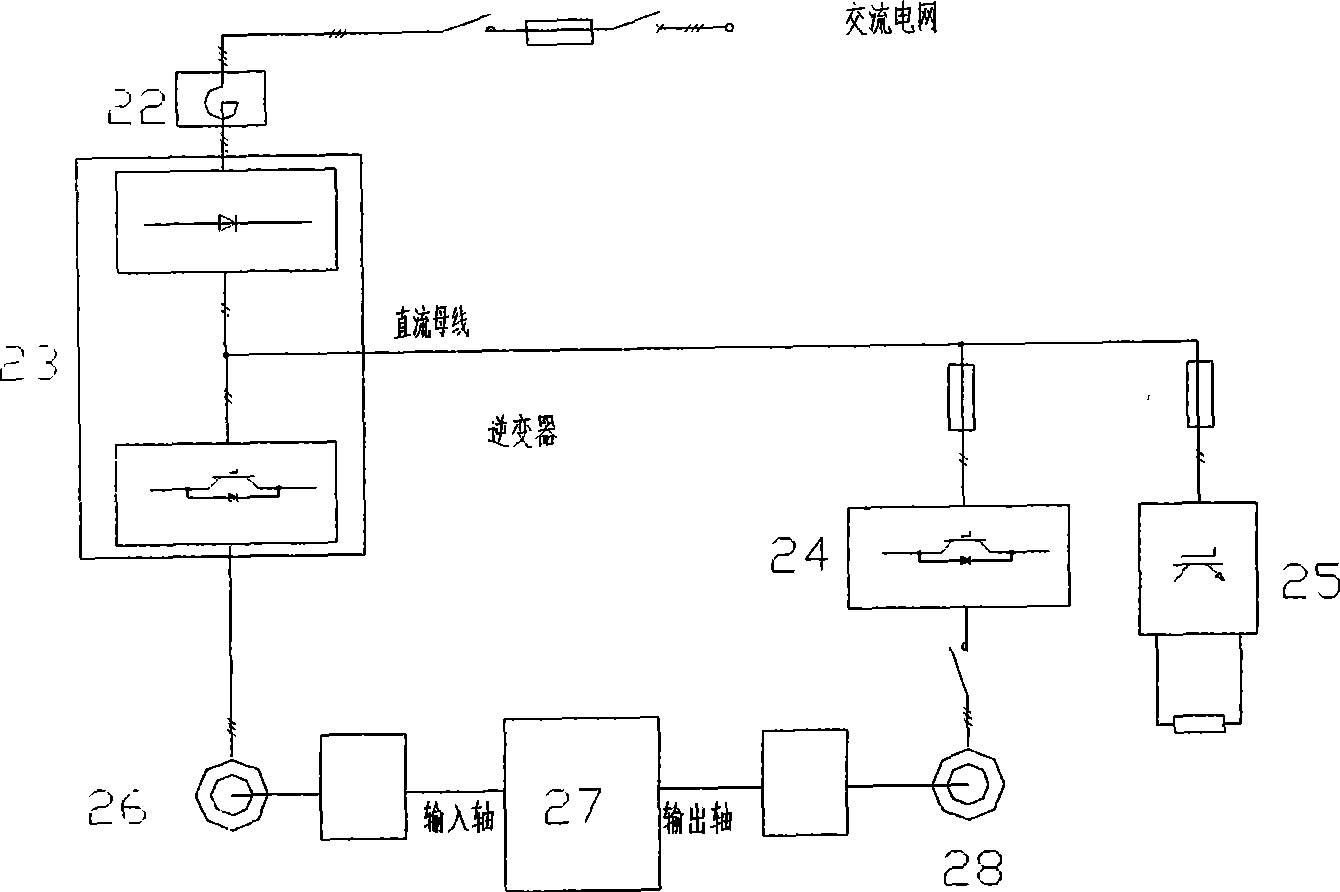

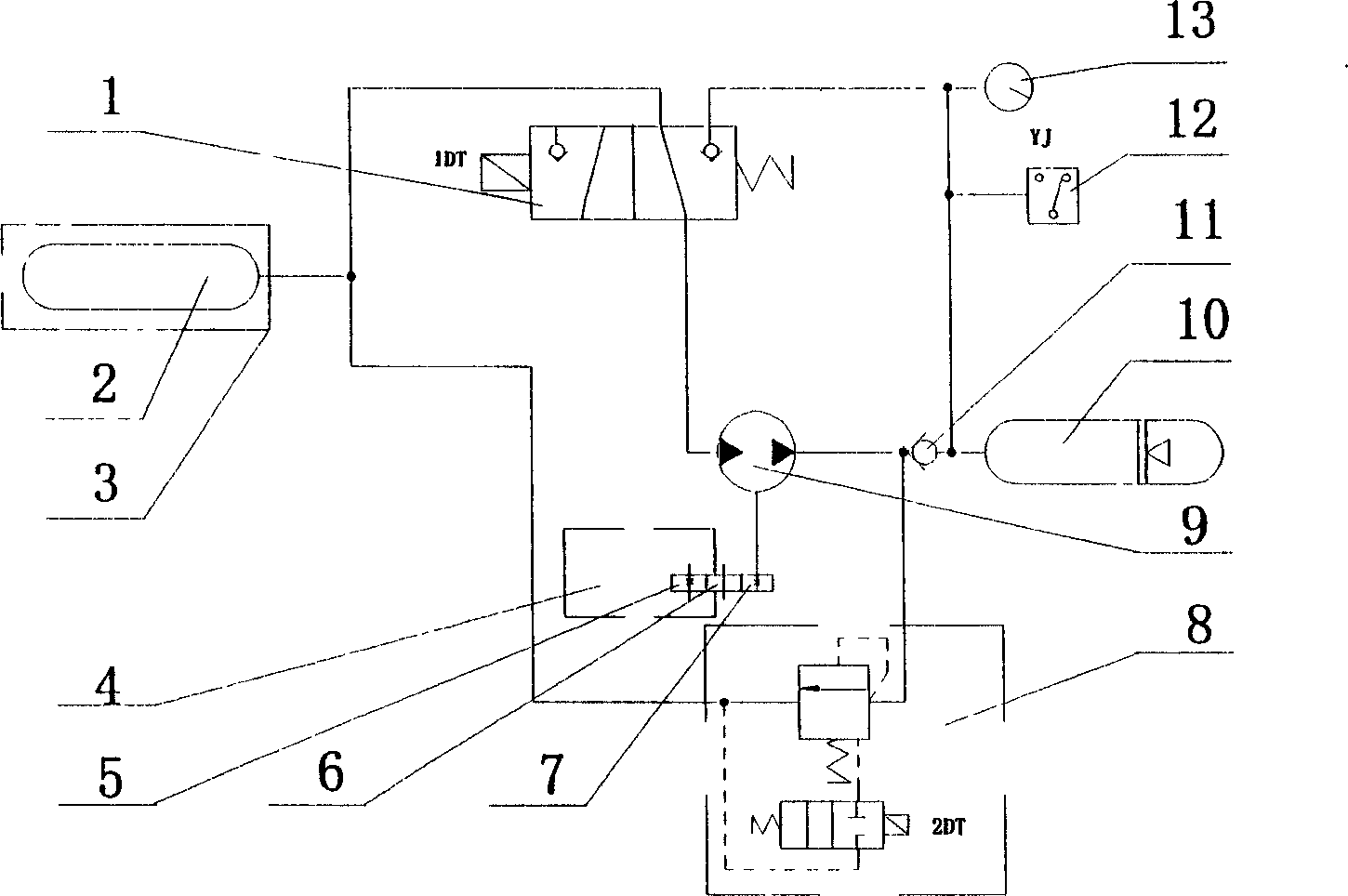

55KW grade electricity loading test stand for automobile gear box low noise energy-conserving type under line detection and working method thereof

InactiveCN101393076AImplement closed loadingAchieve four-quadrant workVehicle testingComputer controlLow noiseAutomatic control

The invention relates to a low-noise energy-saving test bed for the offline detection of 55KW-stage electric loading for an automobile gear-box and an operating method thereof. The test bed comprises a test bed main body, a motor box body, an electric transmission control system, a computer measuring-controlling system and an intensive oil supply hydraulic station, and is characterized in that a noise measuring device is arranged on the tested gear-box and a tray sliding table is arranged under the tested gear-box; and a gear shift device and a handle gear shift force operation measuring device are arranged on the right side of an operator who faces to the test bed. The test bed has the advantages of providing large torque up to 140Nm and meeting requirements on 30 to 100 percent of the factory detection of the loading of the gear-box with multi-specification variety types in the range of between 90 and 350Nm, reducing noise of a machine tool to be lower than 80dB through motor noise isolation and other noise reduction measurements, adjusting center distances and vertical dropping distances of input / output shafts to adapt to positioning and mounting of the gear-box with different variety specifications, adopting electric sealing power to feed back loading for energy conservation, and adopting an industrial control computer system and a measuring instrument to realize automatic control of a testing process.

Owner:天津横河电子技术有限公司

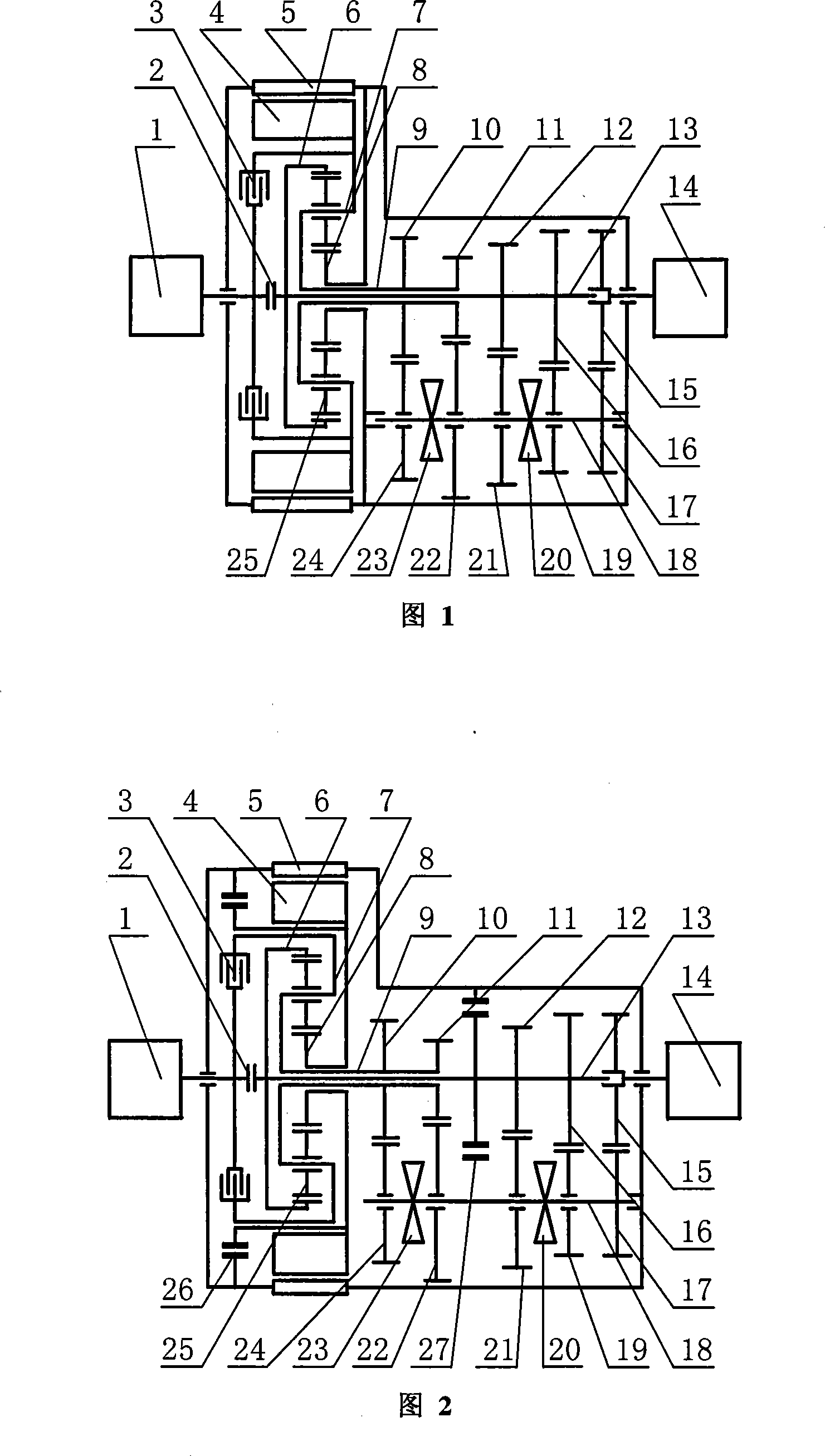

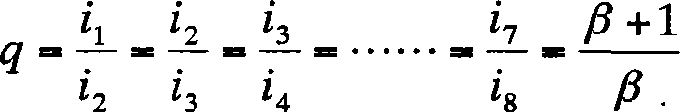

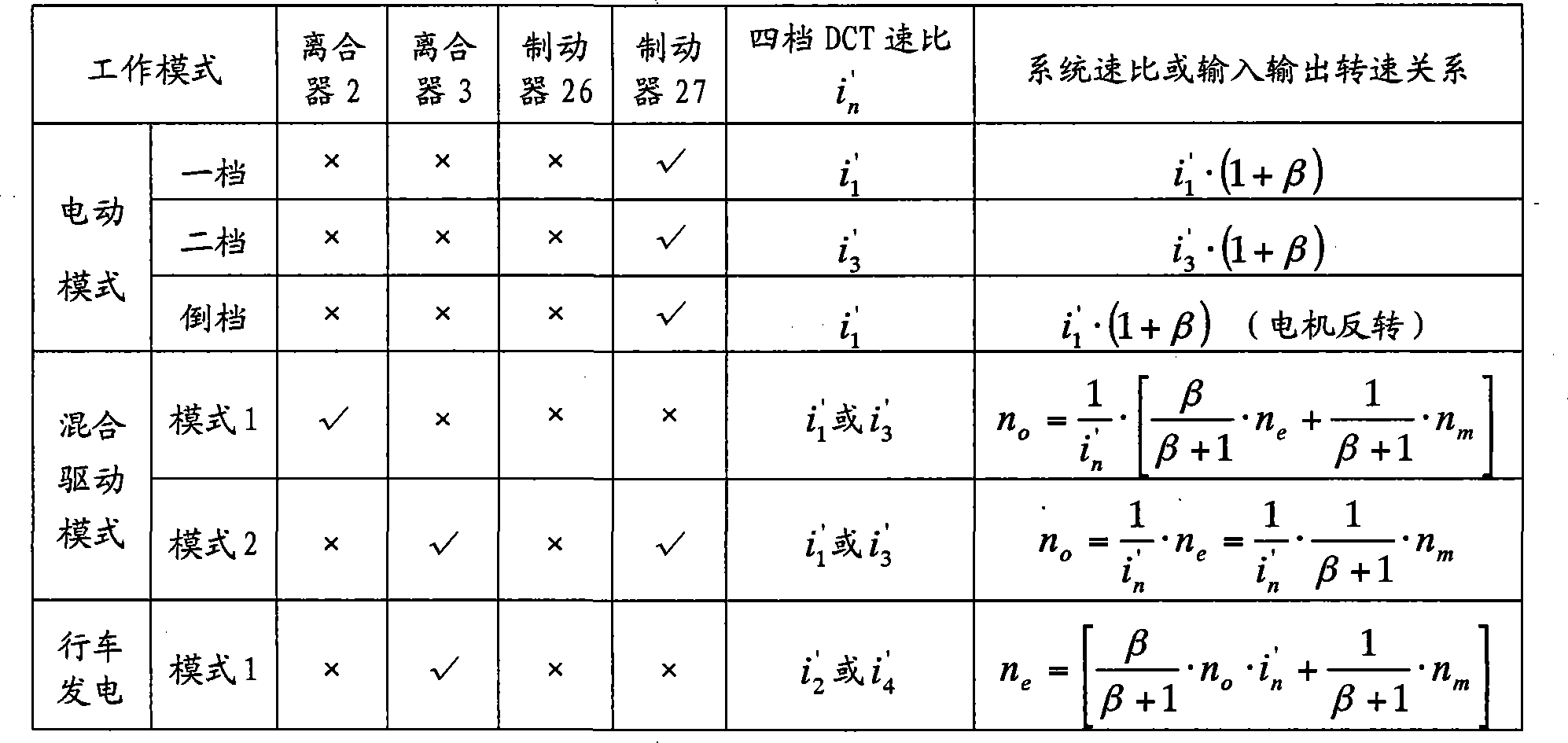

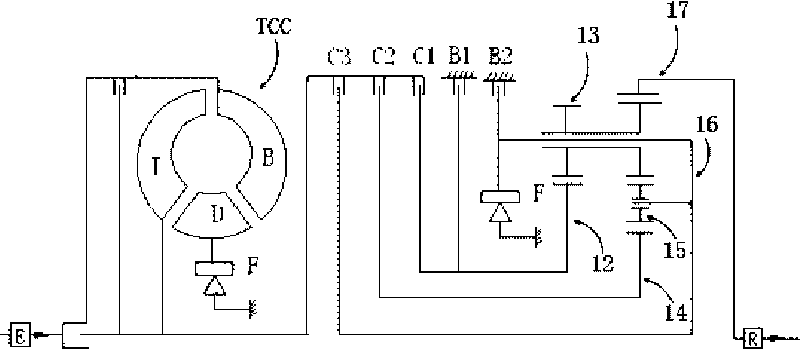

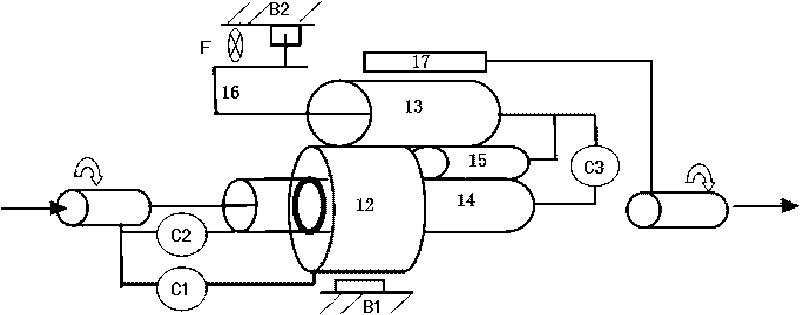

Double-clutch mixed power vehicle driving system

InactiveCN101021244AMeet the requirements of various working conditionsMany forward gearsToothed gearingsGearing controlRegenerative brakeAutomatic transmission

The present invention relates to a double-clutch hybrid power automotive transmission system. It includes the following several portions: internal combustion engine, two clutches, motor rotor, motor stator, four-gear double-clutch automatic speed changer, epicyclic gear train mechanism and output end. Said invention also provides the connection mode of all the above-mentioned portions and working principle of said hybrid power transmission system.

Owner:CHONGQING UNIV

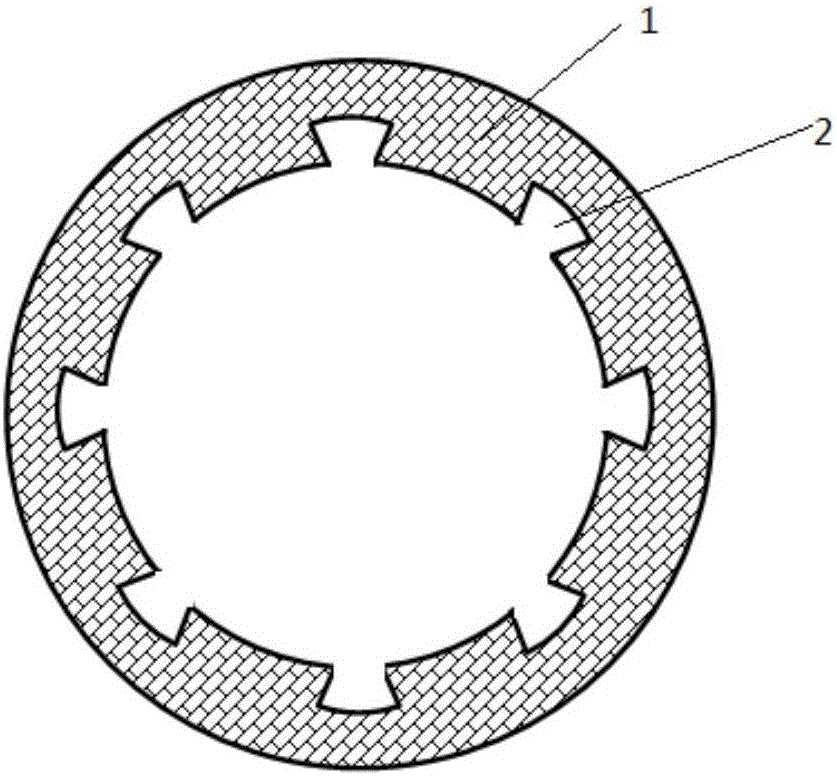

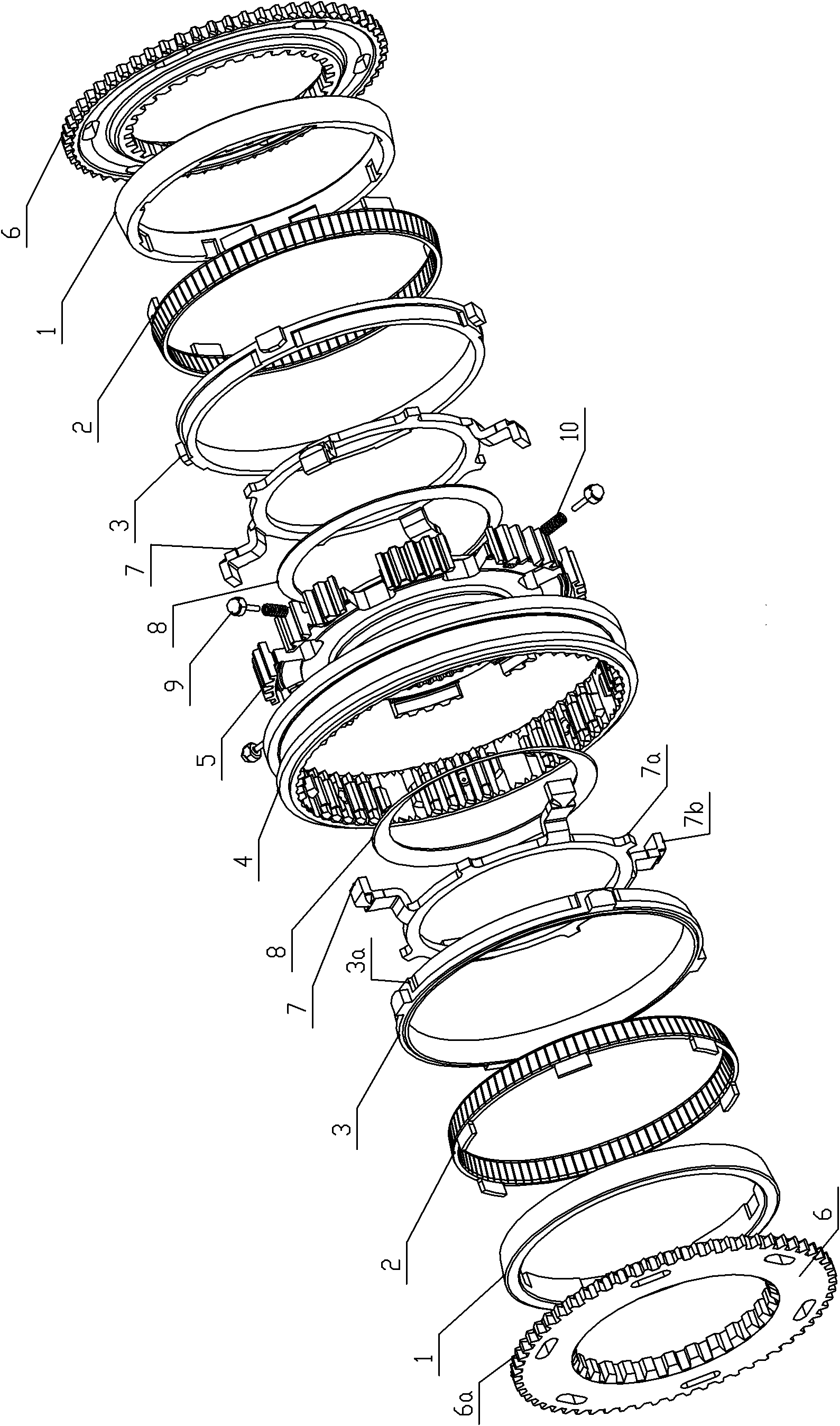

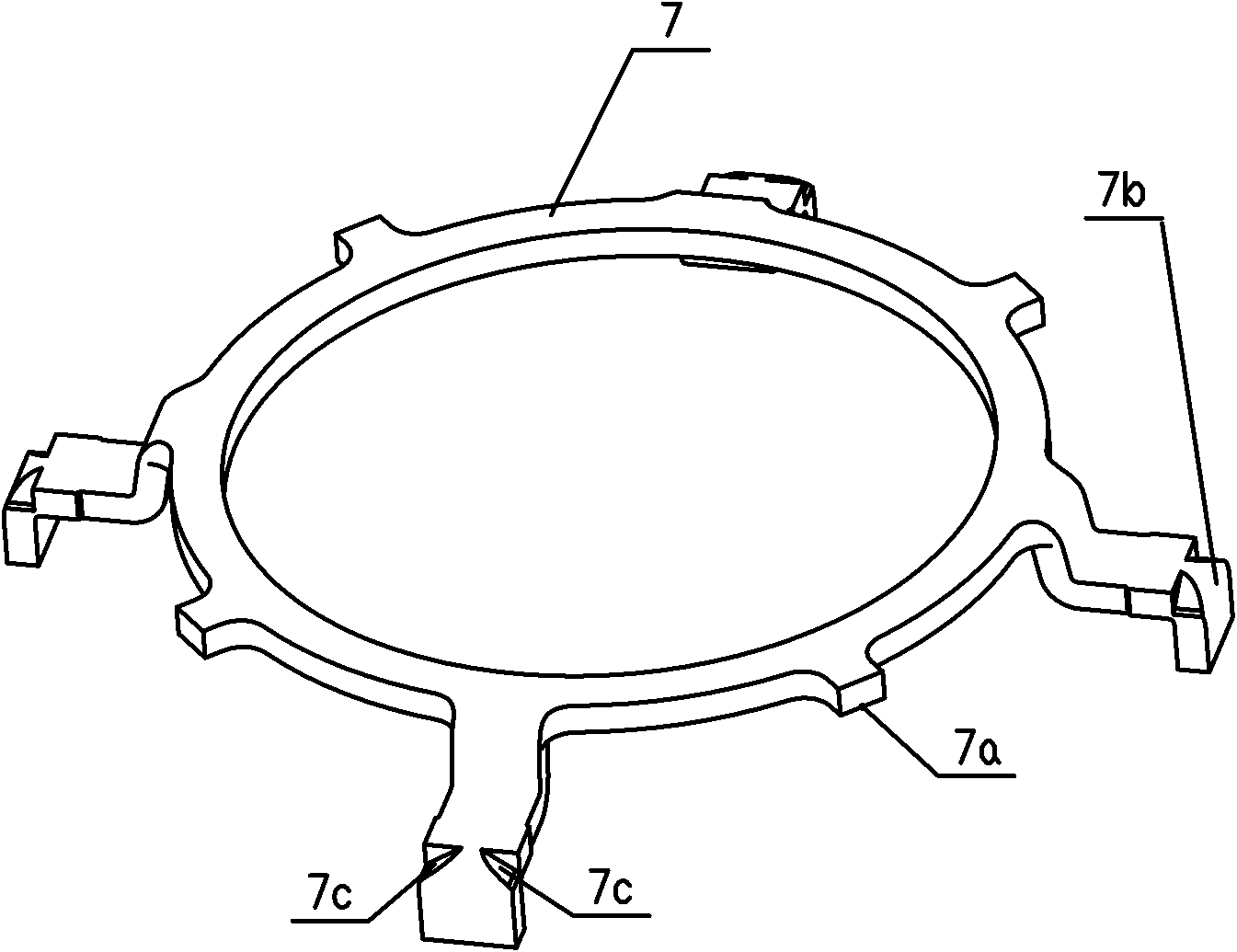

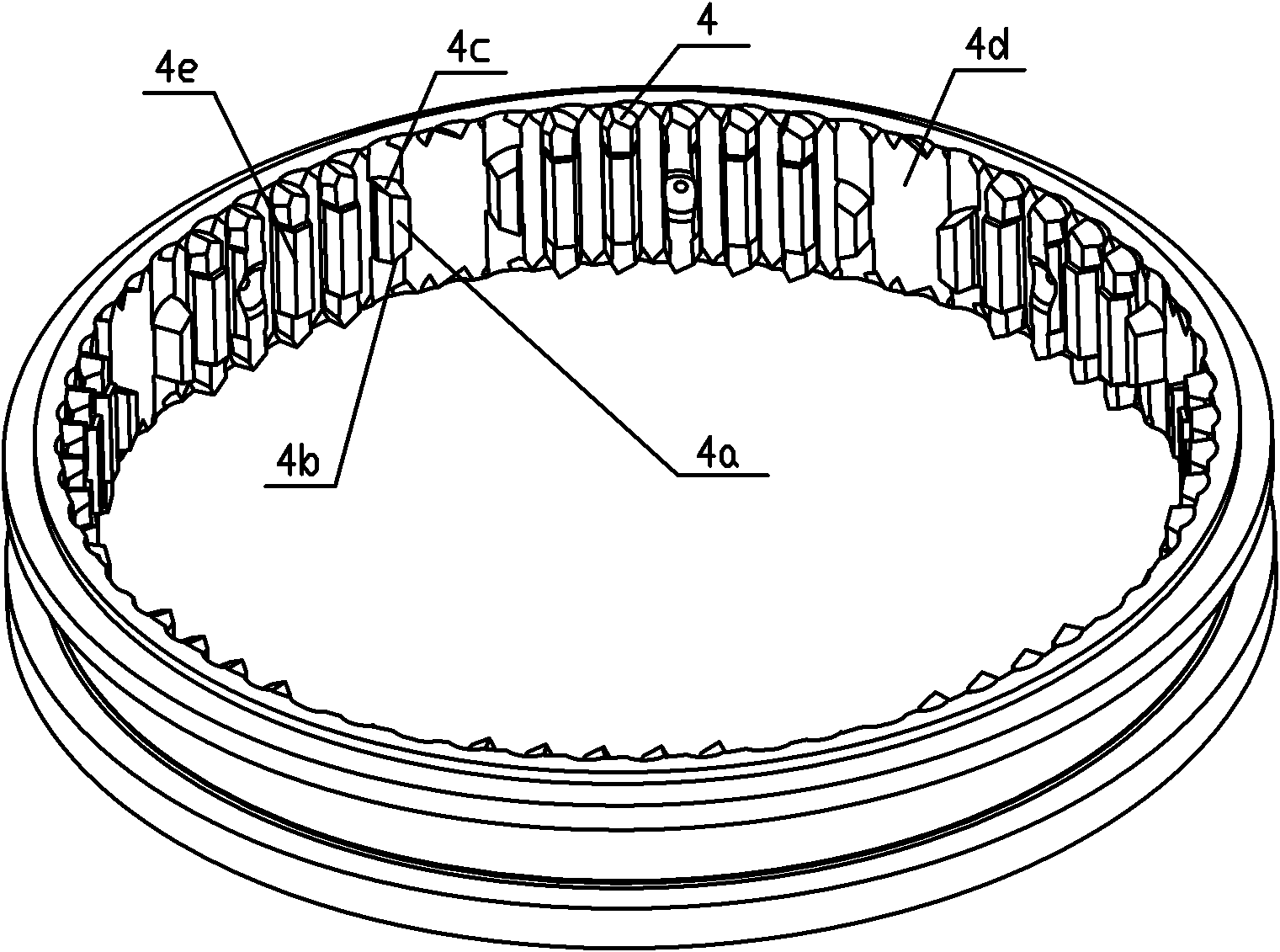

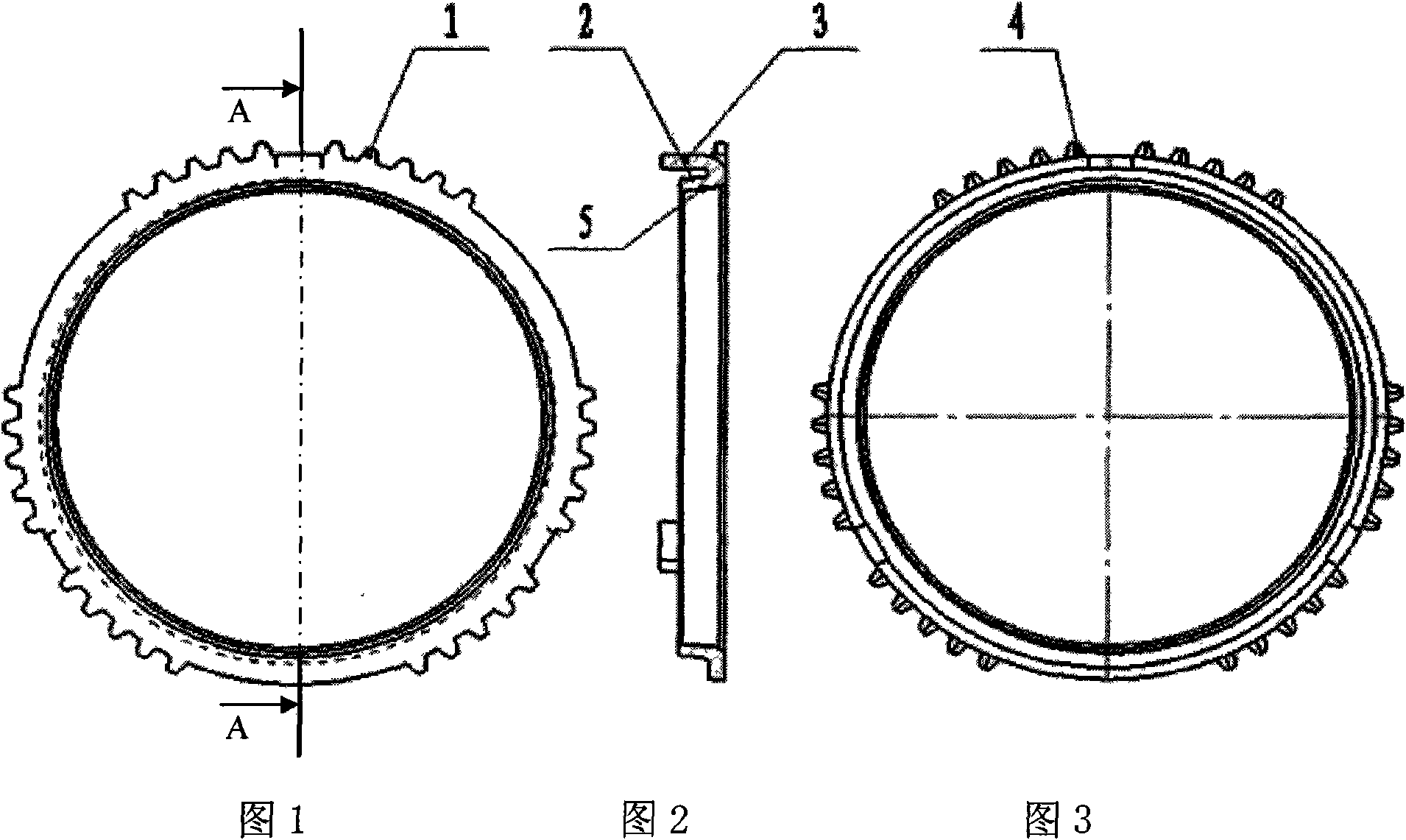

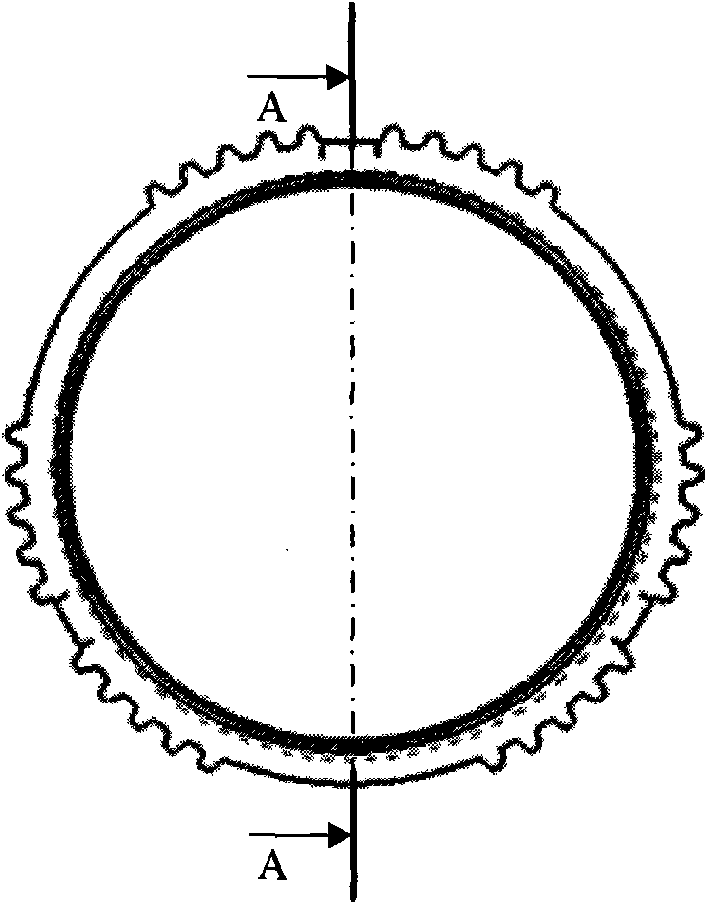

Self-energizing inertia lock key type synchronizer

The invention discloses a self-energizing inertia lock key type synchronizer, which comprises two inner rings, two intermediate rings, two outer rings, a sliding sleeve, gear holders, two connecting gears, pushing blocks and springs, two punched rings and two disc springs, wherein the pushing blocks and the springs are uniformly distributed and in the same number; the sliding sleeve is positionedin the connecting gears and is connected with the gear holders; the disc springs are distributed between the gear holders and the punched rings; the punched rings have a ring structure of which the outer ring is provided with a mounting boss, the outer rings of the punched rings are provided with claws uniformly; first self-energizing inclined planes are arranged on the two sides of the claws, the punched rings are inserted into the gear holders at a certain stagger angle and then arranged in a sliding sleeve, and the inner rings and the punched rings are arranged and connected through the mounting bosses; and the sliding sleeve is provided with a synchronizing gear, a second self-energizing inclined plane matched with the first self-energizing inclined planes is arranged on one side of the synchronizing gear. In the invention, the self energizing is realized by using the punched rings and the disc springs and by arranging the synchronizing gear on the sliding sleeve, the structure issimple, and the requirements on material, heat treatment and manufacturing precision are low. The synchronizer is applicable to synchronous systems for automobile gearboxes.

Owner:SHIYAN TONGCHUANG DRIVE TECH CO LTD

Method for manufacturing alligatoring ring matrix with novel structure

InactiveCN101658888ASimple preparation processIncrease productivityGear wheelsNonferrous metalEngineering

The invention discloses a method for manufacturing an alligatoring ring matrix with a novel structure, relating to the technical field of synchronizers alligatoring rings of automobile gearboxes and aiming at solving the technical problems that the conventional method for manufacturing the synchronizers alligatoring rings has complicated process, low production efficiency, low material utilizationrate, large amount of consumption of expensive nonferrous metals, extremely-high production cost, poor strength of large-diameter alligatoring rings and the like. The method for manufacturing the alligatoring ring matrix with the novel structure comprises the following steps: blanking: annealing, parkerising and saponifying; bending lug bosses: flanging to form an internal conical surface; finelypunching into a tooth shape: annealing, parkerising and saponifying; extruding a locking surface: finely shaping the tooth shaft of involute; fine correction; thermal treatment; shot blast treatment;and finely machining the internal conical surface. The invention is suitable for manufacturing alligatoring ring matrixes with novel structures of the automobile gearboxes.

Owner:CHENGDU HAONENG TECH CO LTD

Shift strategies for mock continuously variable transmission

Simulated or "mock" continuously variable transmission shift strategies are used in an electromechanically actuated automotive transmission having reduced ratios steps in its upper ratio ranges. In one described embodiment, a 12-speed truck transmission consists of a five-speed main section and an auxiliary section that includes splitter and range sub-sections to provide the 12 ratios. Separate shift strategies are directed to fuel economy and power optimization modes; driver throttle demand determines the mode. Both strategies are targeted to the upper gear ratios, which represent the ratios subject to approximately ninety percent (90%) of vehicular operation. In the described embodiment, the applicable affected ratios are gears 7-12. In the described embodiments, the shift strategies are carried out by embedded software subject to the command of an electronic power train control module. Both strategies are operated as direct functions of engine torque, transmission input shaft speed, and road speed.

Owner:EATON INTELLIGENT POWER LTD

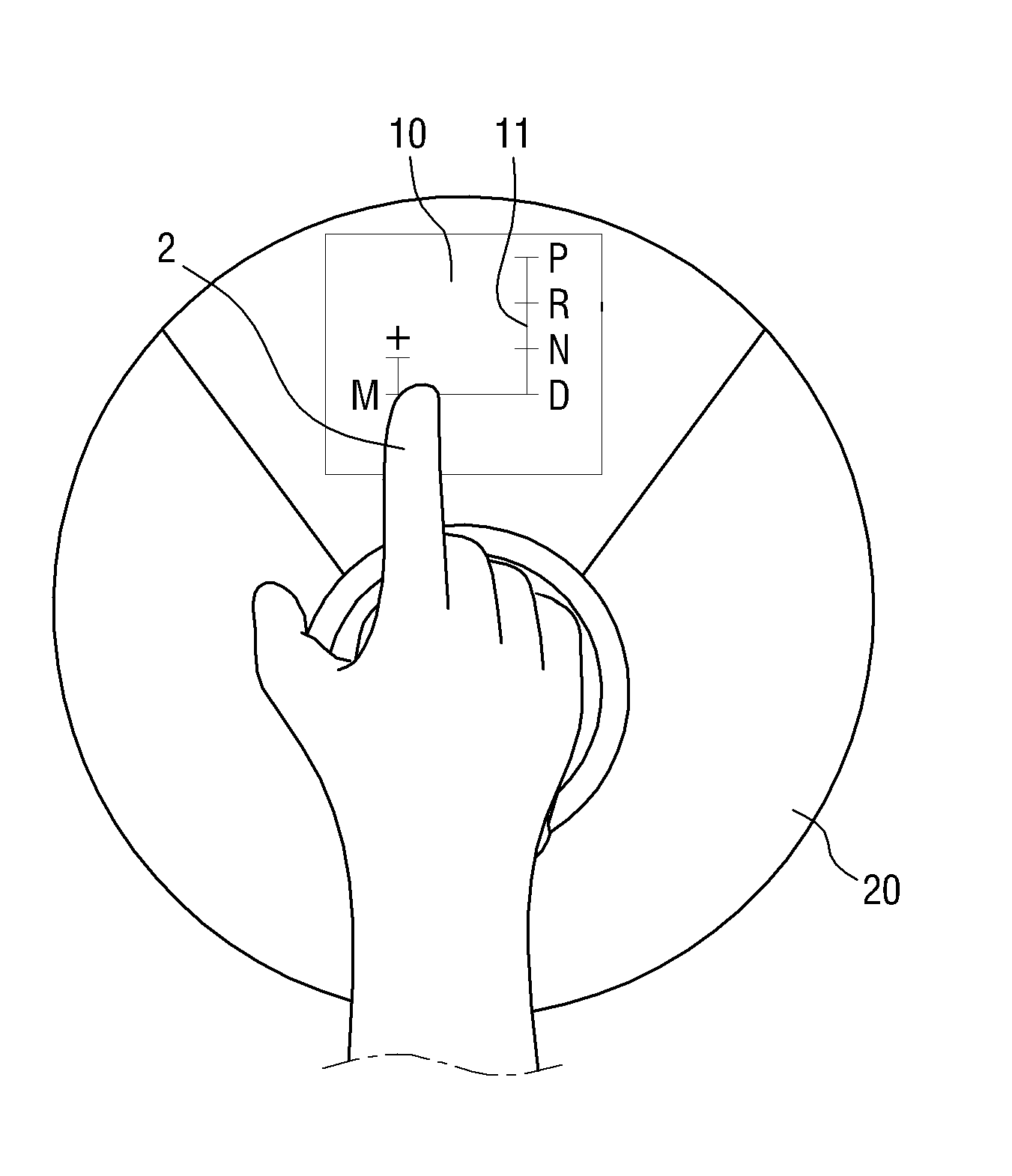

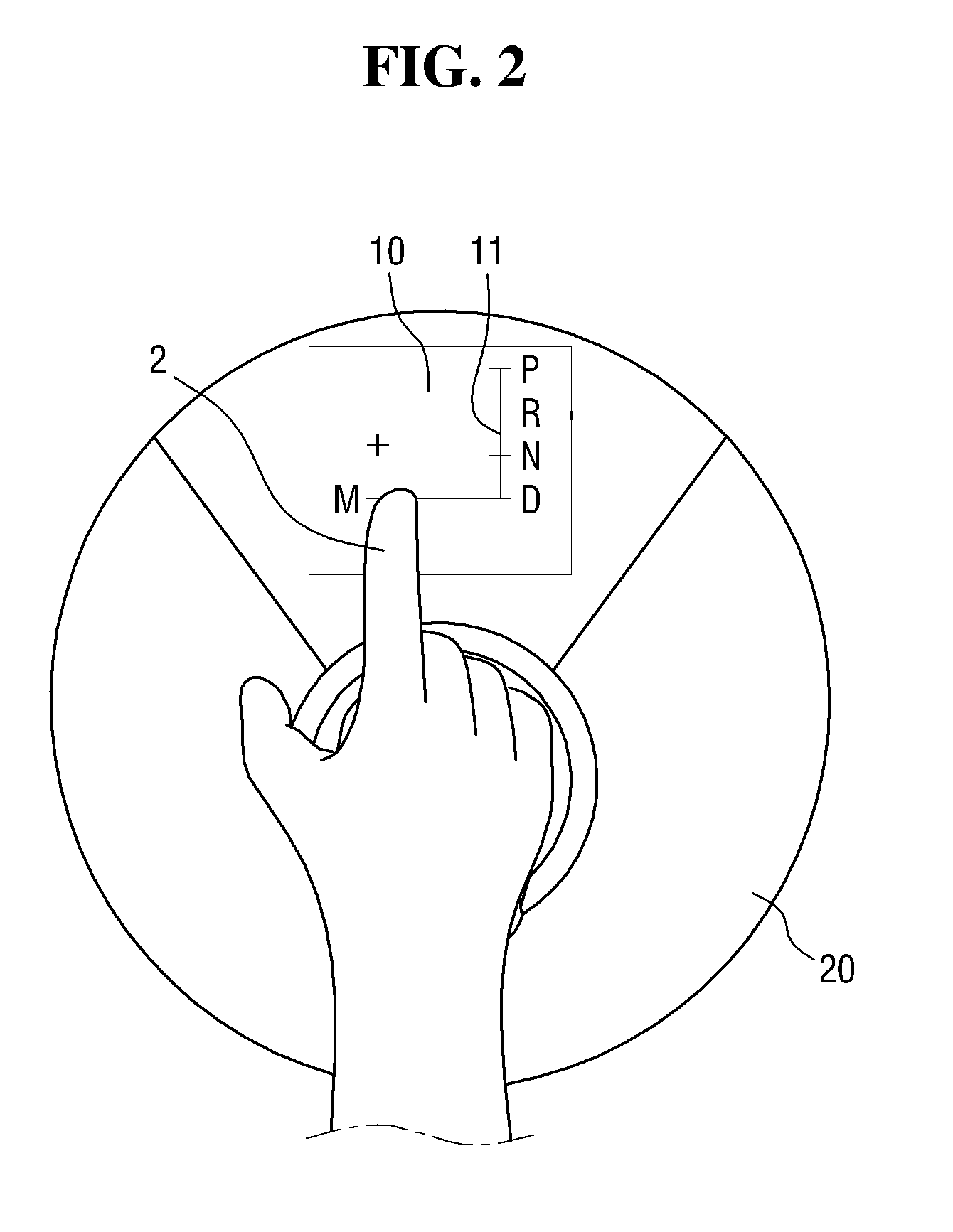

Automotive transmission

An automotive transmission that selects a shift position based on various shift patterns without changing the structure of the automotive transmission. The automotive transmission includes a controller configured to input a selection value based on a shift pattern selected from a plurality of shift patterns and operate a shift lever to move through a moving path based on the selected shift pattern when a shift intention is sensed. When the selection value is input, the shift position is set at an initial position based on the selected shift pattern and actuation power is generating according to the movement of the shift lever. The controller is configured to operate the moving path of the shift pattern based on the selected shift pattern and sense a position of the shift lever using a positing sensing unit.

Owner:SL CORP

Automotive braking force reclaiming economizing and accelerating unit

InactiveCN1833901AImprove economyExtend your lifeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingFuel tankAutomotive transmission

An oil-saving boosting unit able to recover the braked kinetic energy for car features that the additional mechanical structure and simple hydraulic system are additionally installed to the output axle of speed variator or drive axle. When the car is braking, its inertia can drive oil pump to become the pressure energy of fluid and store it in energy accumulator. When the car is driven or accelerated, the energy is released via the same mechanism. An enclosed leather bag type oil tank and a simple hydraulic system are used.

Owner:SHANGHAI SHENZHOU VEHICLE RES & DEV

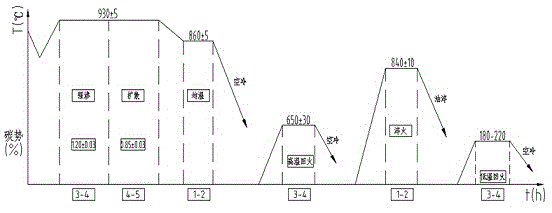

Carburizing and quenching heat treatment process of driven reverse gear used for transmissions

InactiveCN105177492AAdded co-infiltration stepHigh hardnessSolid state diffusion coatingFurnace typesAutomotive transmissionEnergy consumption

The invention provides a carburizing and quenching heat treatment process of a driven reverse gear used for transmissions. The process comprises the following steps: 1) carburizing; 2) carbonitriding; 3) quenching; 4) cleaning; and 5) tempering. The heat treatment process has the beneficial effects that the surface of the driven reverse gear is treated by carbonitriding; and carburizing and nitriding are combined, thus improving the quality of the surface of the driven reverse gear, improving the production efficiency, reducing the energy consumption and saving the production cost.

Owner:JIANGSU BAOJIE FORGING

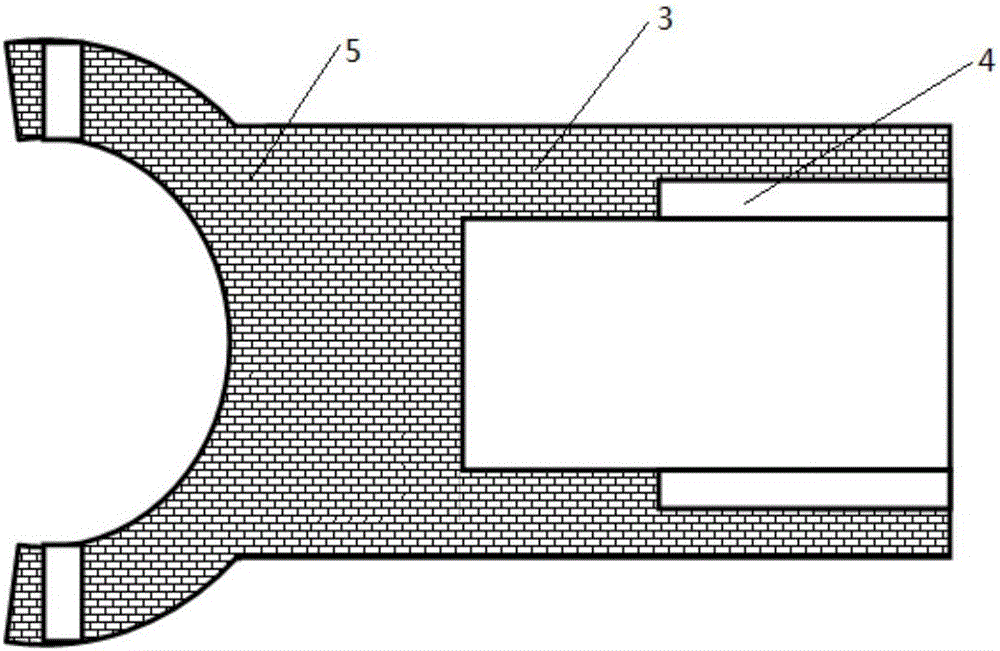

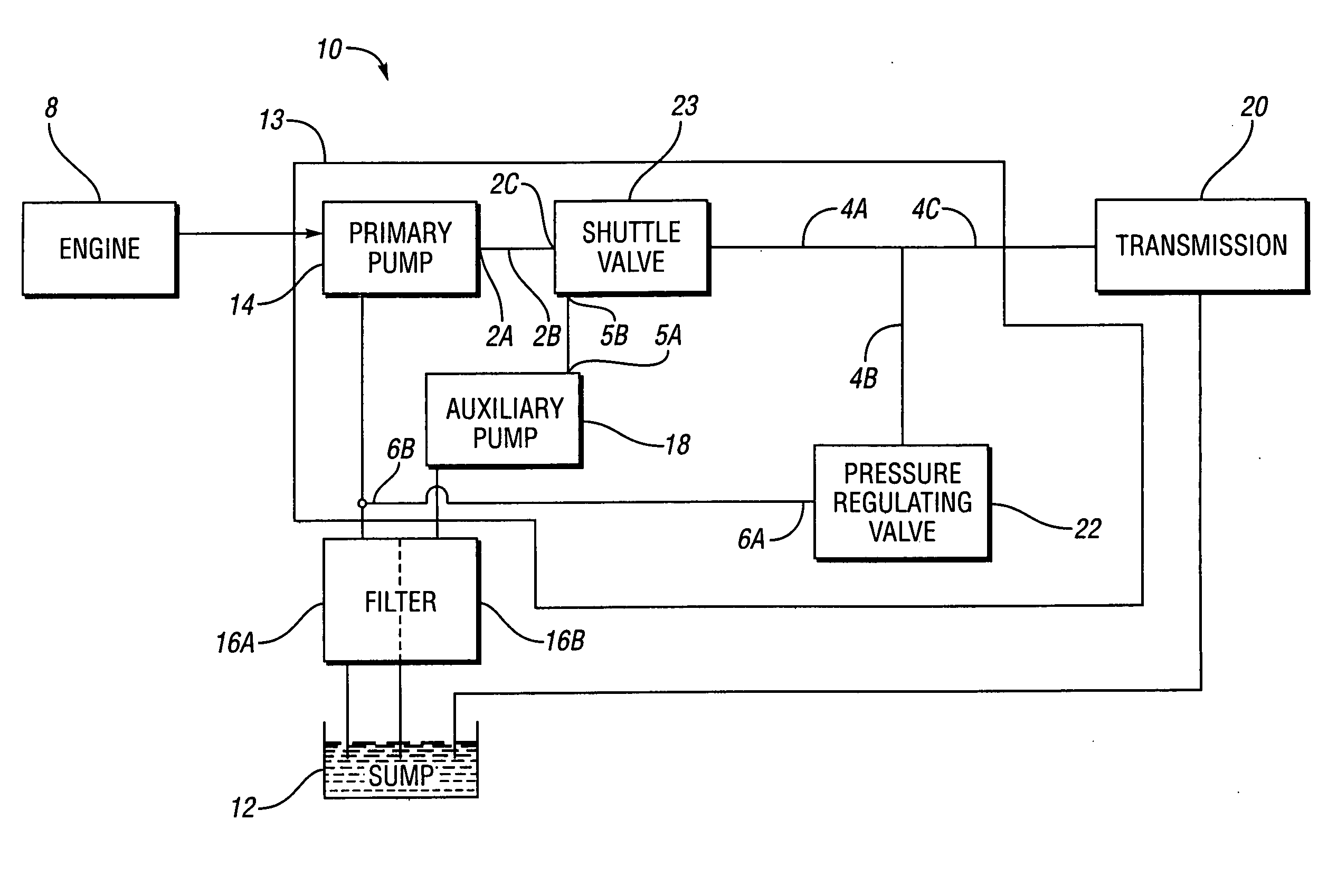

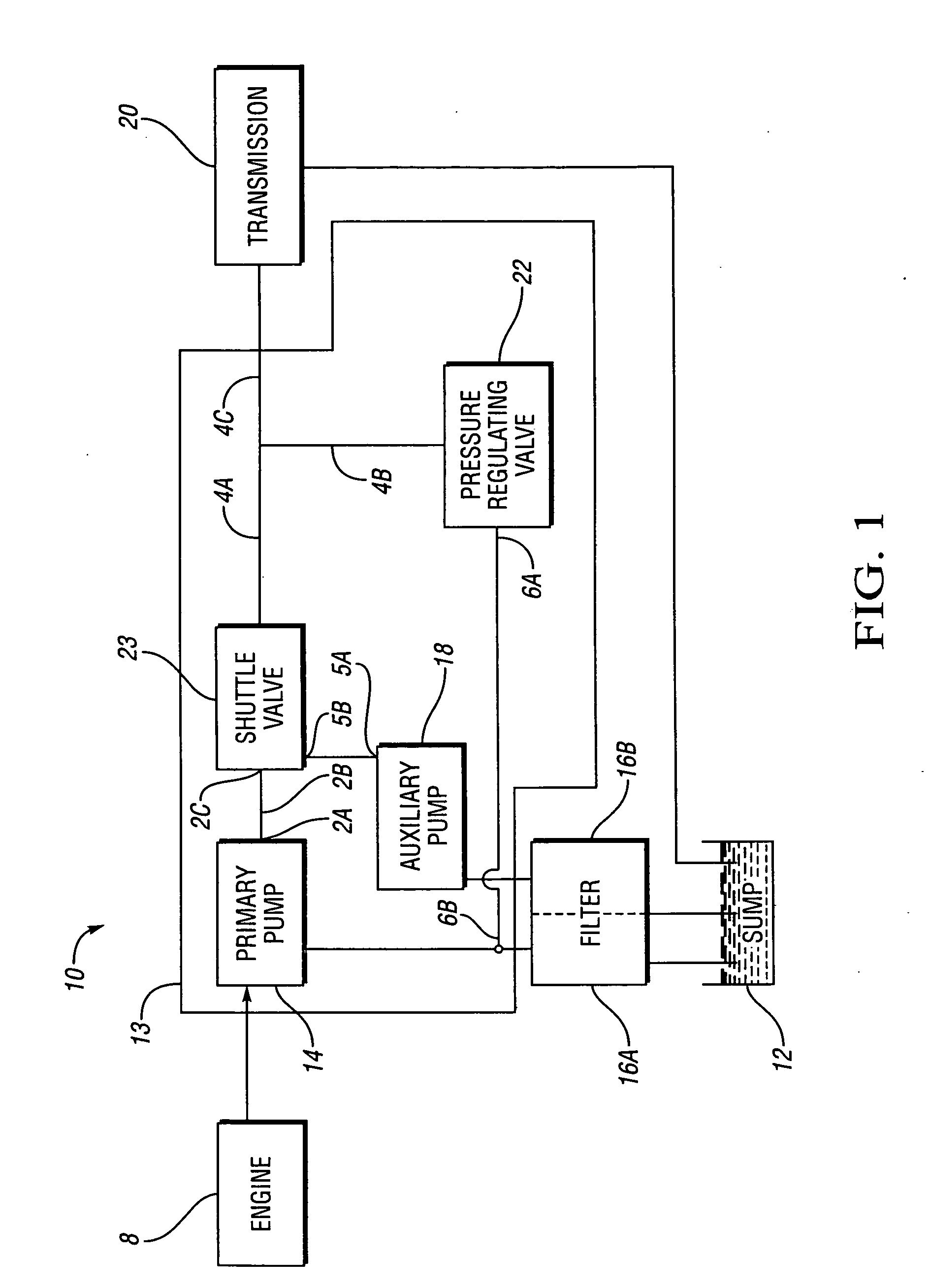

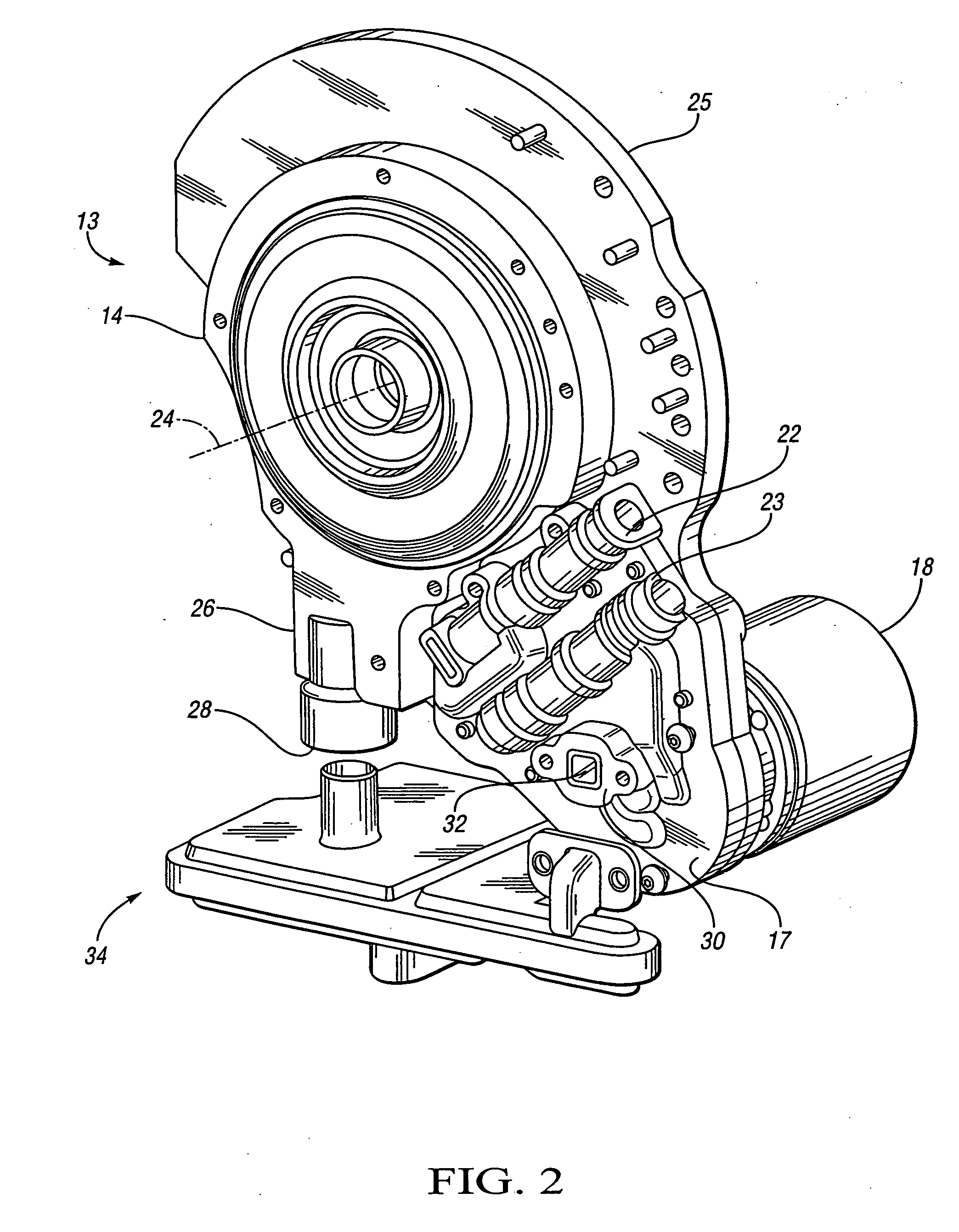

Dual pump assembly

InactiveUS20070098567A1Low costImprove reliabilityRotary/oscillating piston combinationsPiston pumpsShuttle valveAutomotive transmission

The apparatus of the present invention provides a compact dual-pump assembly for an automotive transmission. The dual-pump assembly preferably includes a housing having a valve assembly mounted thereto. The valve assembly includes a shuttle valve disposed in fluid communication with a pressure regulating valve. An on-axis pump is mounted to the housing in fluid communication with the shuttle valve and the pressure regulating valve. An off-axis pump in fluid communication with the shuttle valve is mounted to the housing in close proximity to the on-axis pump such that the dual-pump assembly is compact.

Owner:GM GLOBAL TECH OPERATIONS LLC

Composite fabrication process for tooth blank of automobile gear shifting box combining tooth

The invention is a compound making technique of automobile gear-box combined gear blanks, adopting finely forge-molding processing method. It heats the blank material to 1000-1200 deg.C, premolding the blank material on a hot mold forging press, after constant-temperature normalizing, eliminating oxide debris by impeller cleaning, and surface bonderizing and phosphatization, making cold-refining on tooth form, and finally making cone molding on the tooth by radial extruding method. It instantaneously completes hot mold forging premolding, refining, and cone molding on the press without cutting, saving material, saving labor, low-cost, high-efficiency, long-service life. The combined tooth root has no escrape, it has no stress concentration phenomenon and the tooth has high strength; the extrusion molding of the gear blank does not destroy metallic streamlines, it heightens the synthetic performance, the product quality is stable and can meet use and industrialized production requirements of top-grade autocars.

Owner:夏汉关 +1

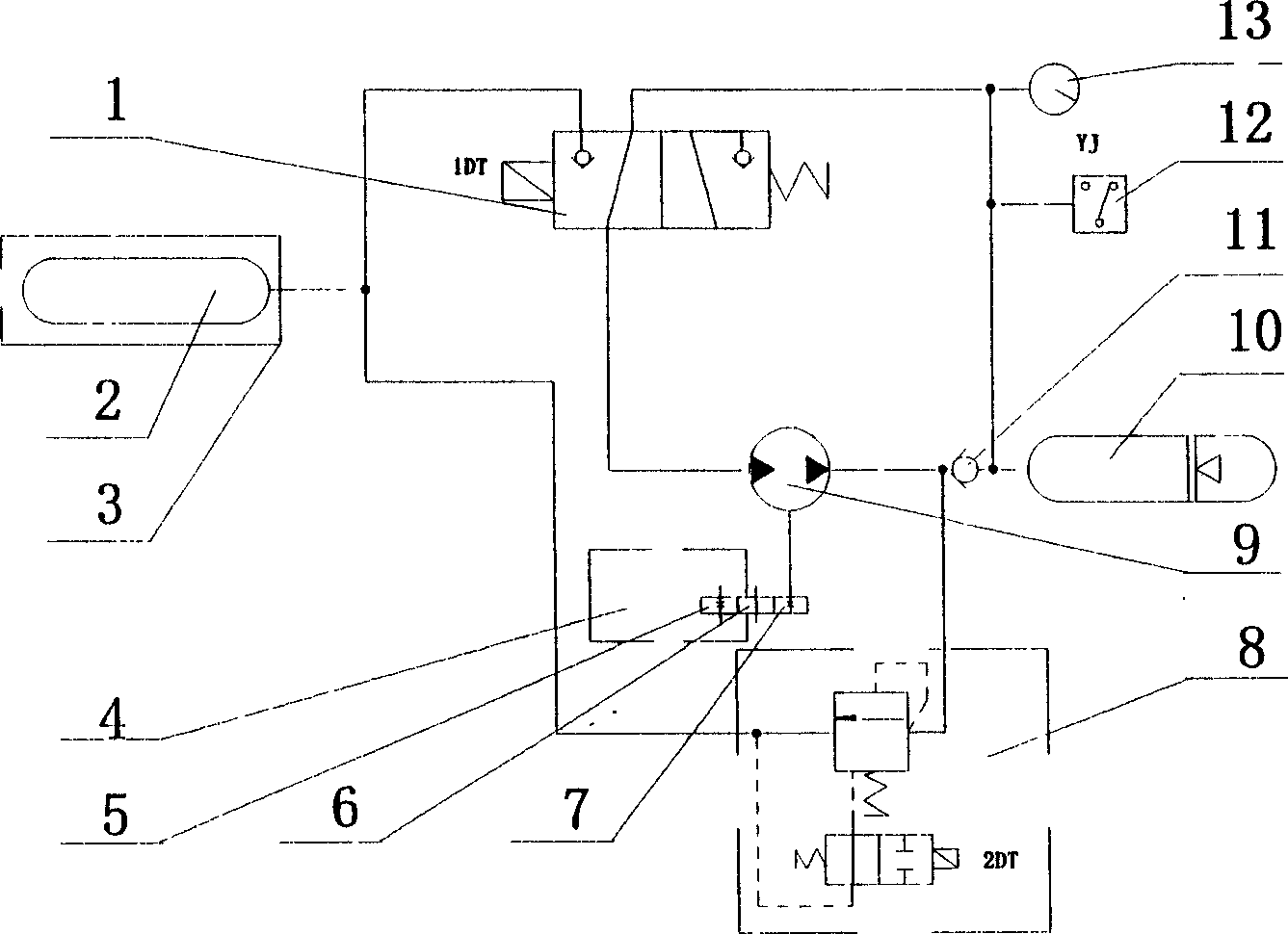

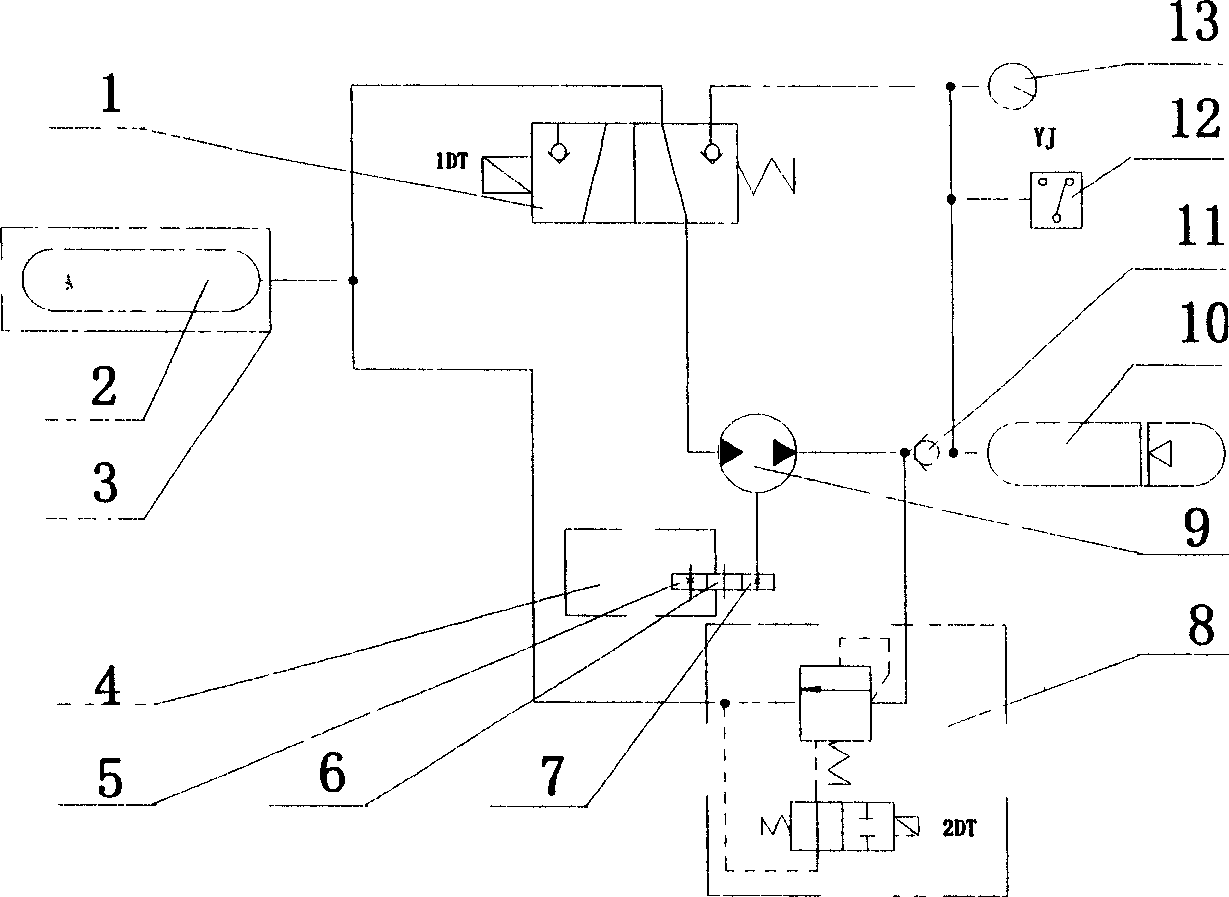

Hydraulic control device of automatic transmission

ActiveCN101705995AReduce consumptionImplement flow controlToothed gearingsGearing controlHydraulic pumpFuel tank

The present invention provides a hydraulic control device of an automatic transmission, and belongs to the technical field of automotive transmission control. The hydraulic control device solves the problems that the conventional hydraulic control device of the transmission has low efficiency, and the oil pump flow is surplus when the rotating speed of the motor is high. The hydraulic control device of the automatic transmission comprises an electronic control system and a hydraulic source connected with the transmission through an oil line, wherein the hydraulic source is used for outputting working oil pressure; the oil line connecting the hydraulic source with the transmission is provided with a manual valve and an electromagnetic valve component in sequence; the electronic control system is connected with the electromagnetic valve component and is used for controlling the switching-on and switching-off of the electromagnetic valve component; the hydraulic source comprises an oil tank, and two or more hydraulic pumps; and an oil inlet of each hydraulic pump is connected with the oil tank, while an oil outlet is communicated with an input port of the manual valve. When the rotating speed of the motor is low, an oil pump and an electric pump can be selected to simultaneously supply oil so as to reduce energy consumption; and when the rotating speed of the motor is high, the electric pump is stopped, and the oil pump separately supplies the oil.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Oil resistant rubber material and preparation method thereof

The invention provides an oil resistant rubber material. The oil resistant rubber material comprises the following components in parts by weight: 60-70 parts of butadiene-acrylonitrile rubber, 25-35 parts of fluororubber, 5-10 parts of dioctyl tin maleate, 2-3 parts of glass fibers, 1-2 parts of stearic acid, 0.5-0.8 part of light calcium carbonate, 3-5 parts of magnesium dimethacrylate, 2-3 parts of drying oil alkyd resin, 1-2 parts of paraffin, 3-5 parts of dilauryl thiodipropionate, 1-2 parts of diacetyl peroxide, 0.8-1.2 parts of zinc oxide, 8-10 parts of aluminium oxide, 6-8 parts of white carbon black, 0.8-1.5 parts of anti-aging agent and 1-3 parts of sulfur. The invention also provides a preparation method of the oil resistant rubber material. The oil resistant rubber material has good sealability, high temperature resistance and oil resistance and is suitable for sealing automobile gearboxes.

Owner:LIUZHOU YINGHANG AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com