Patents

Literature

57results about How to "Accurate and quick installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

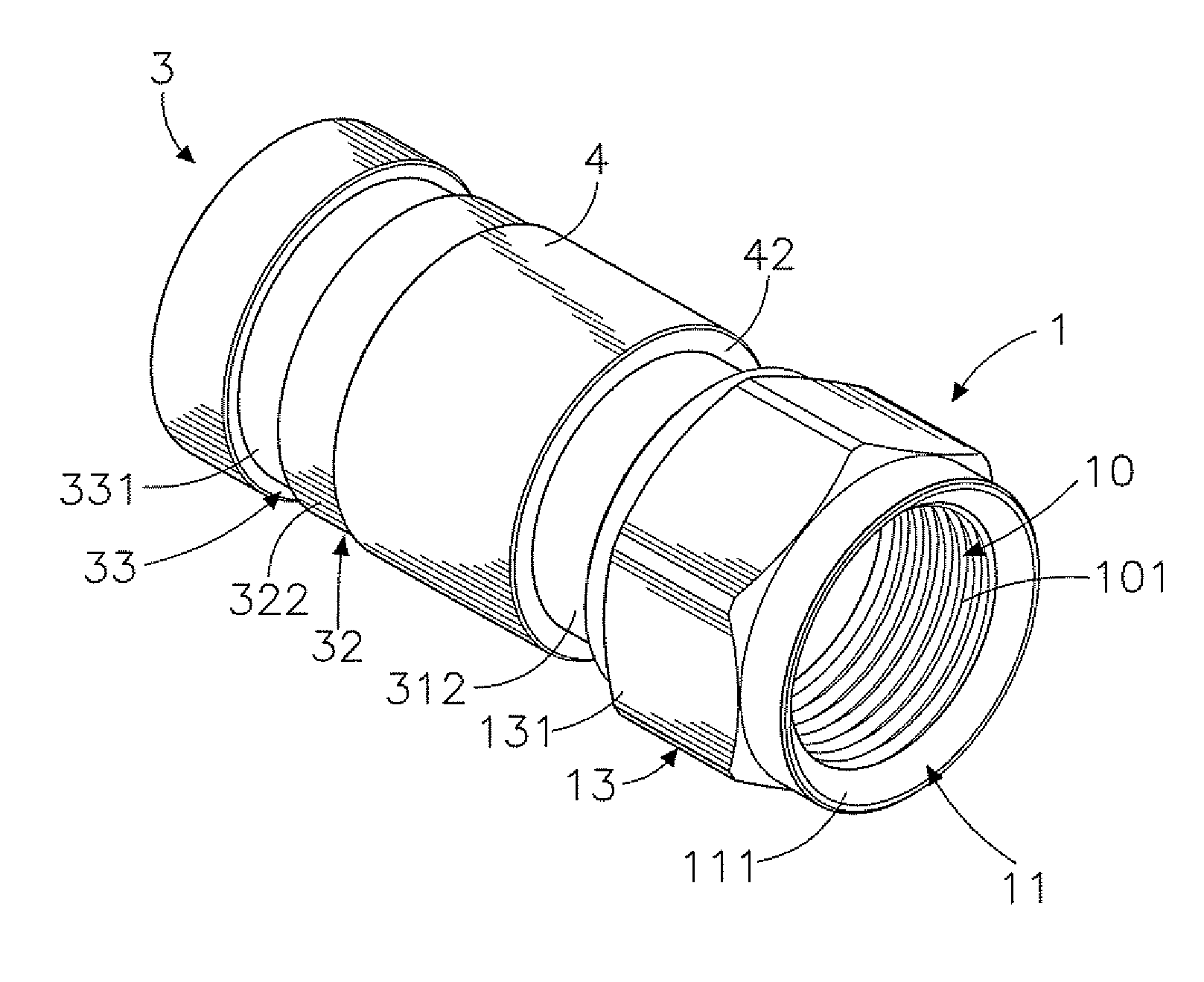

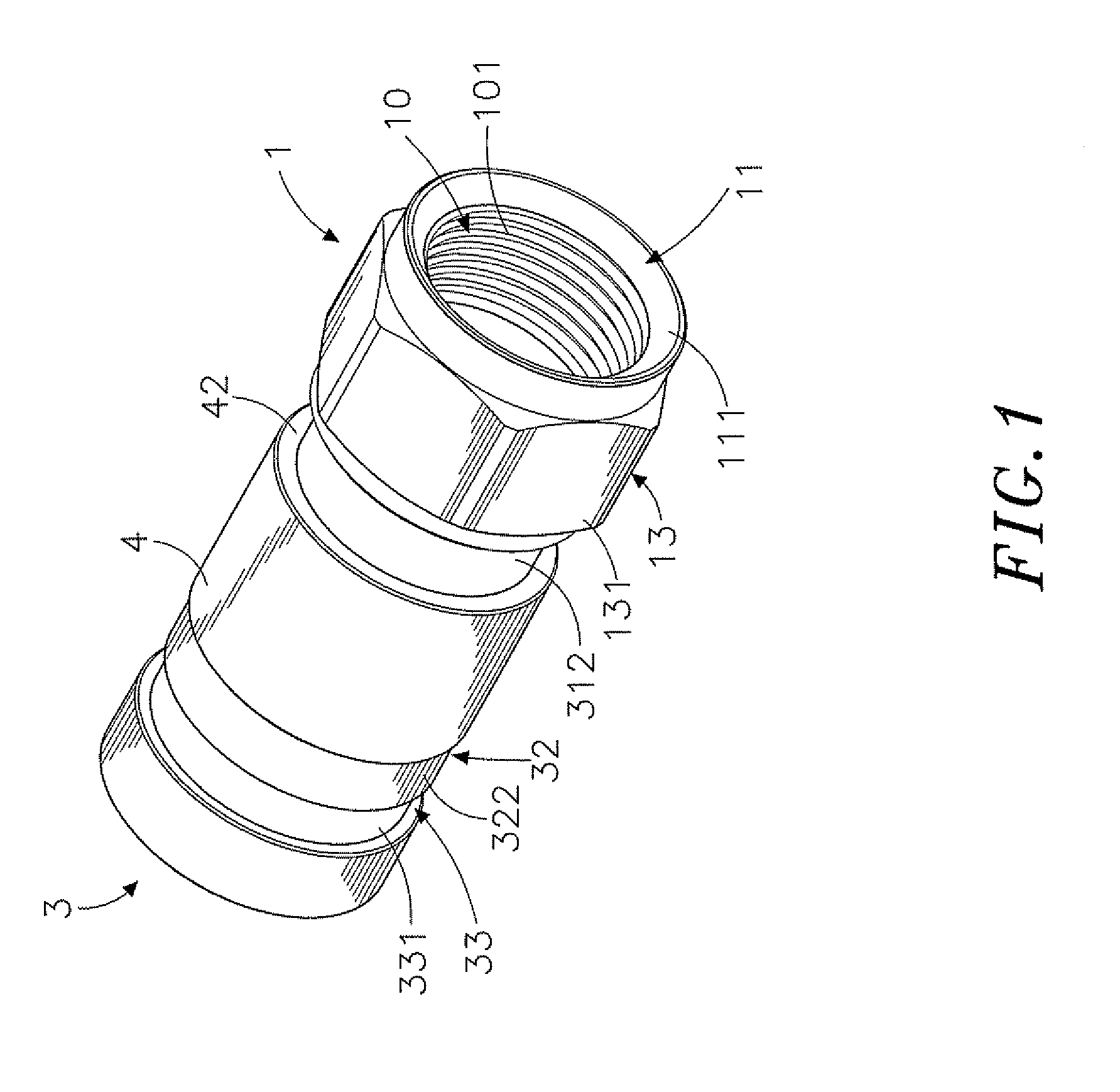

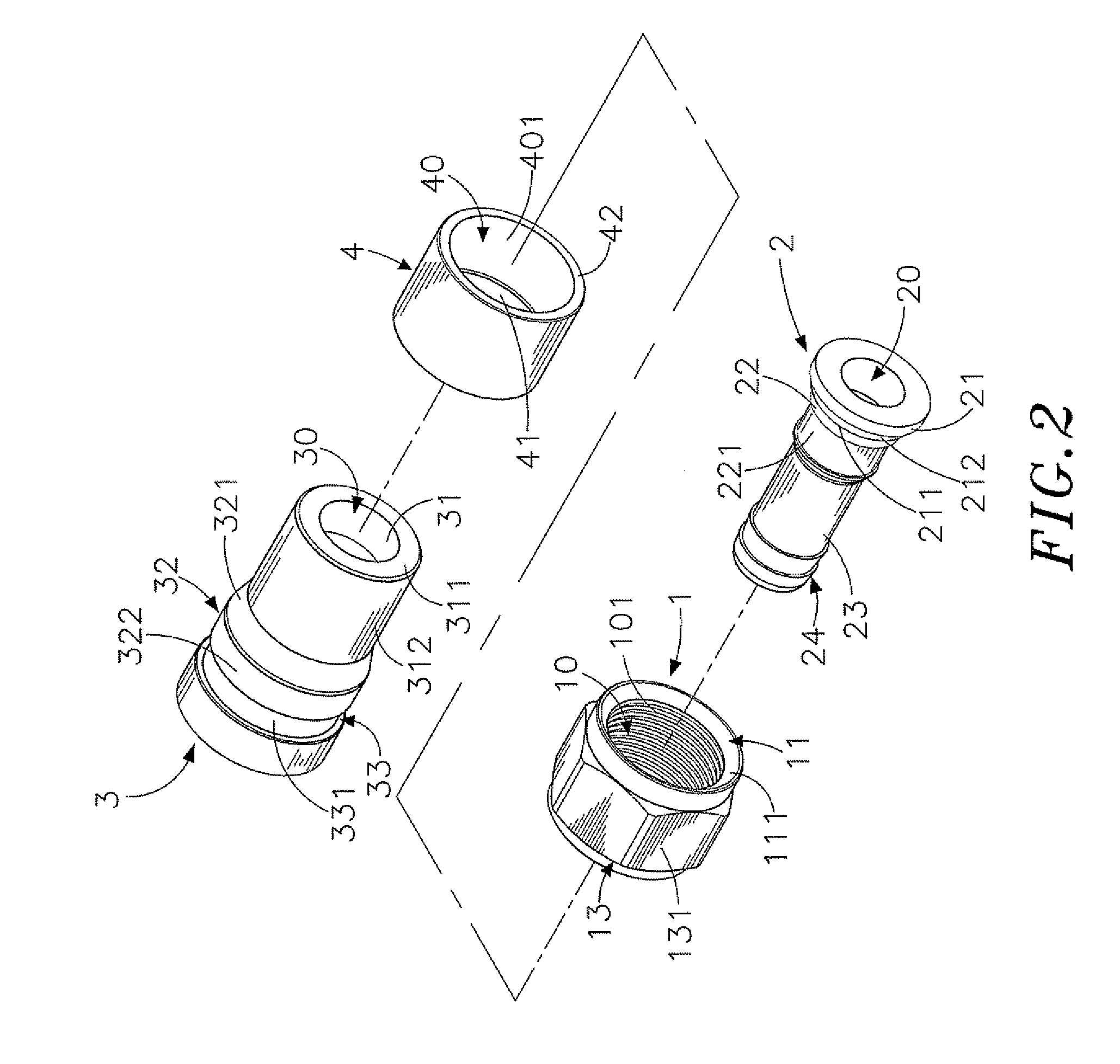

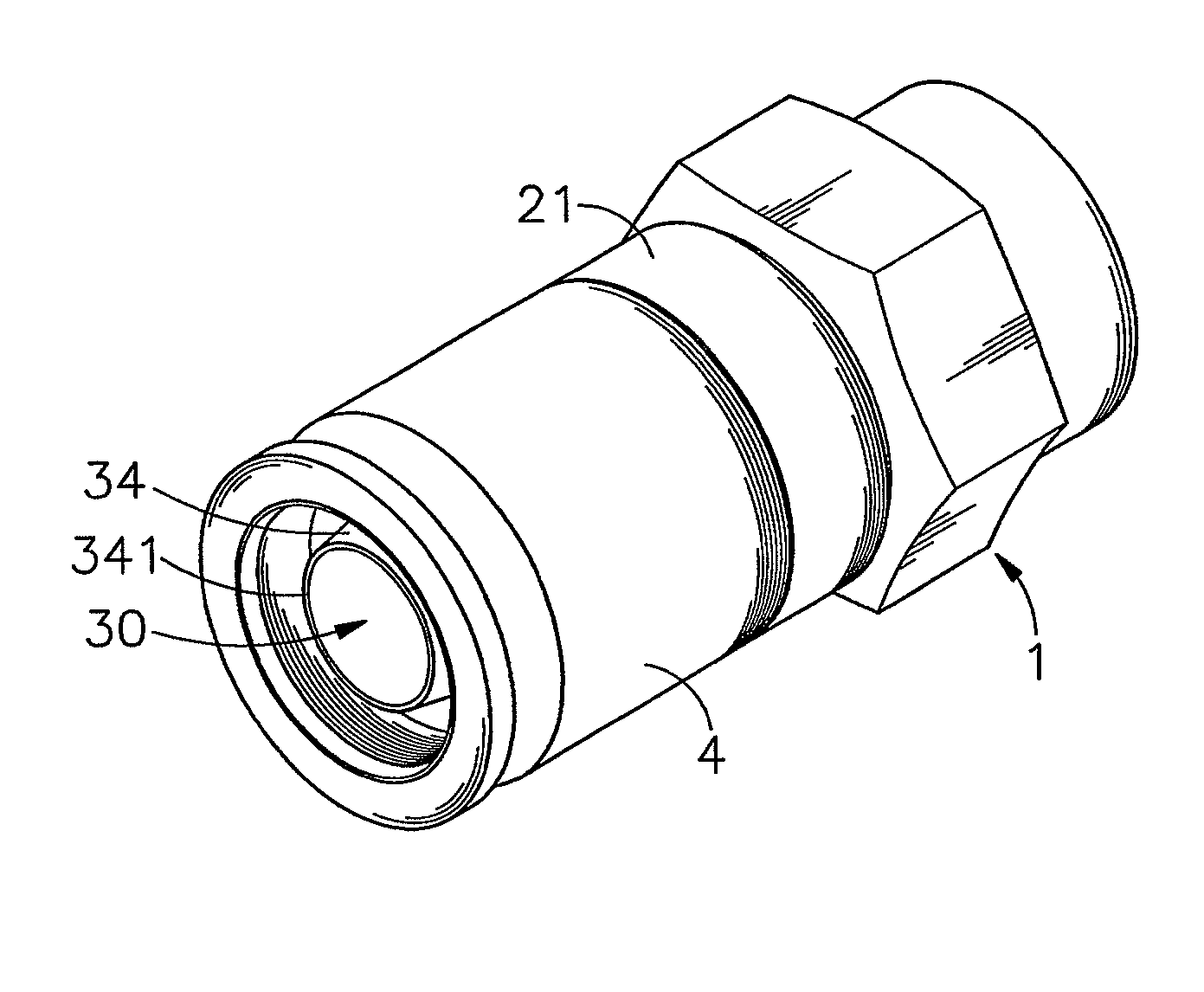

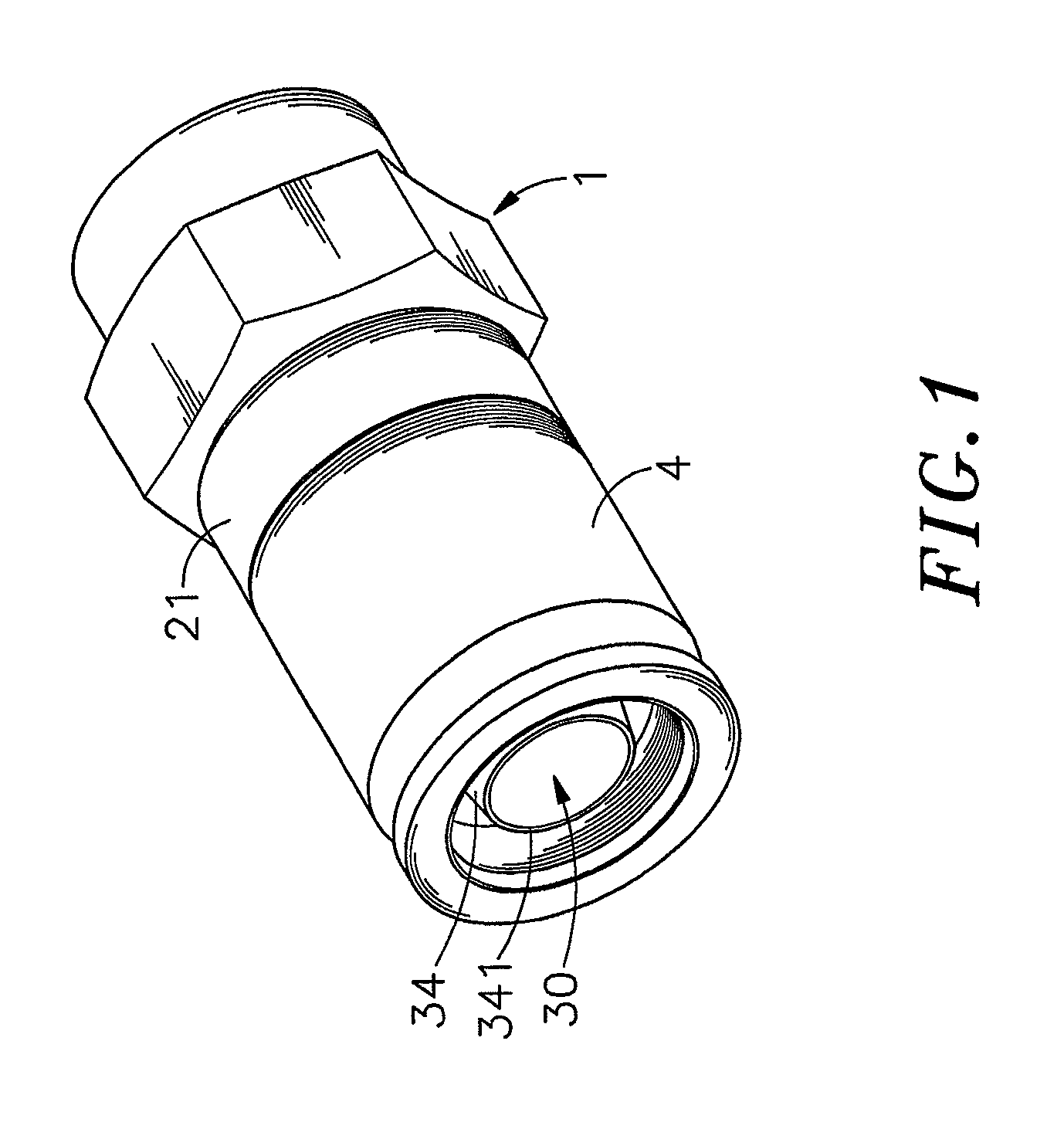

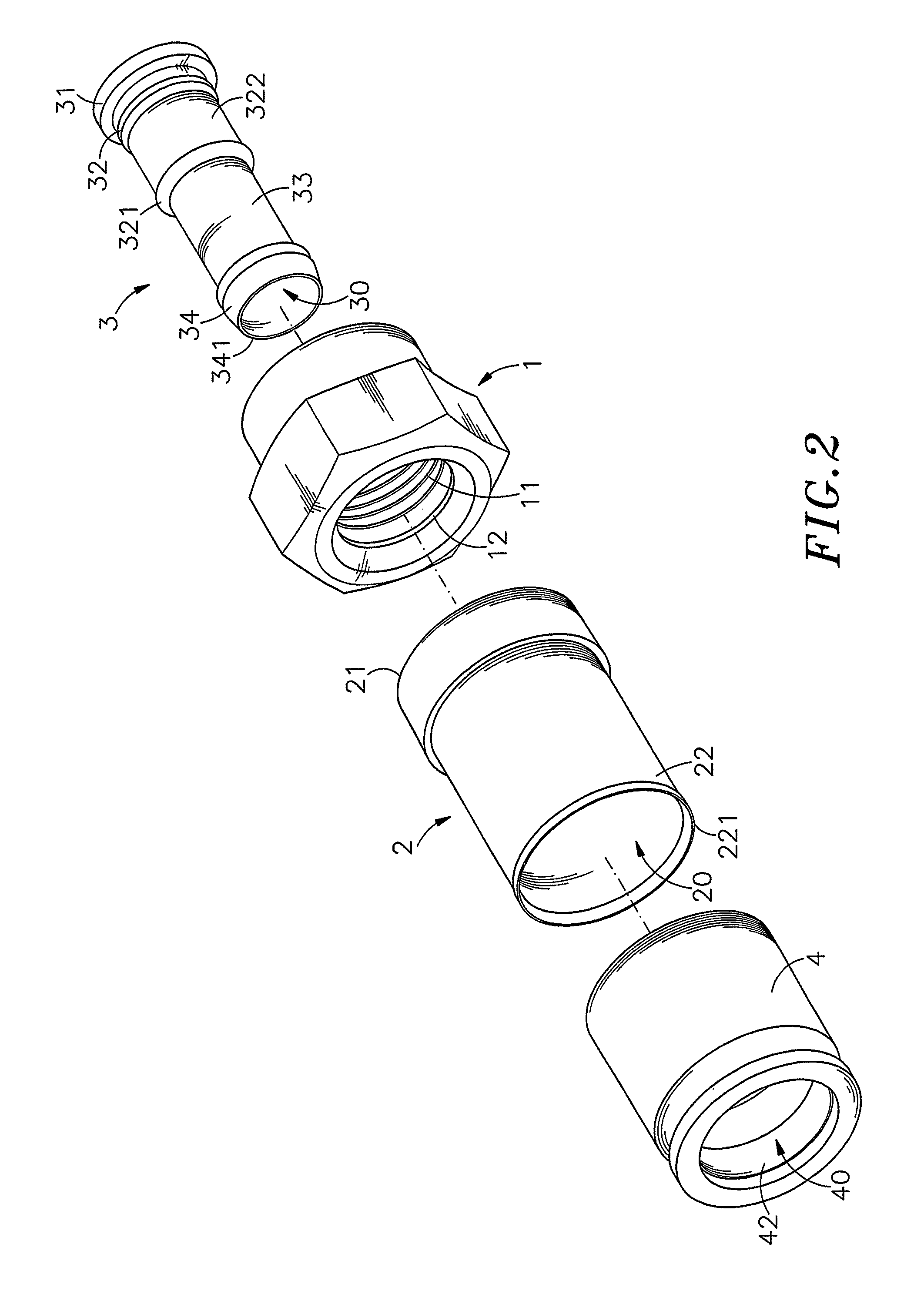

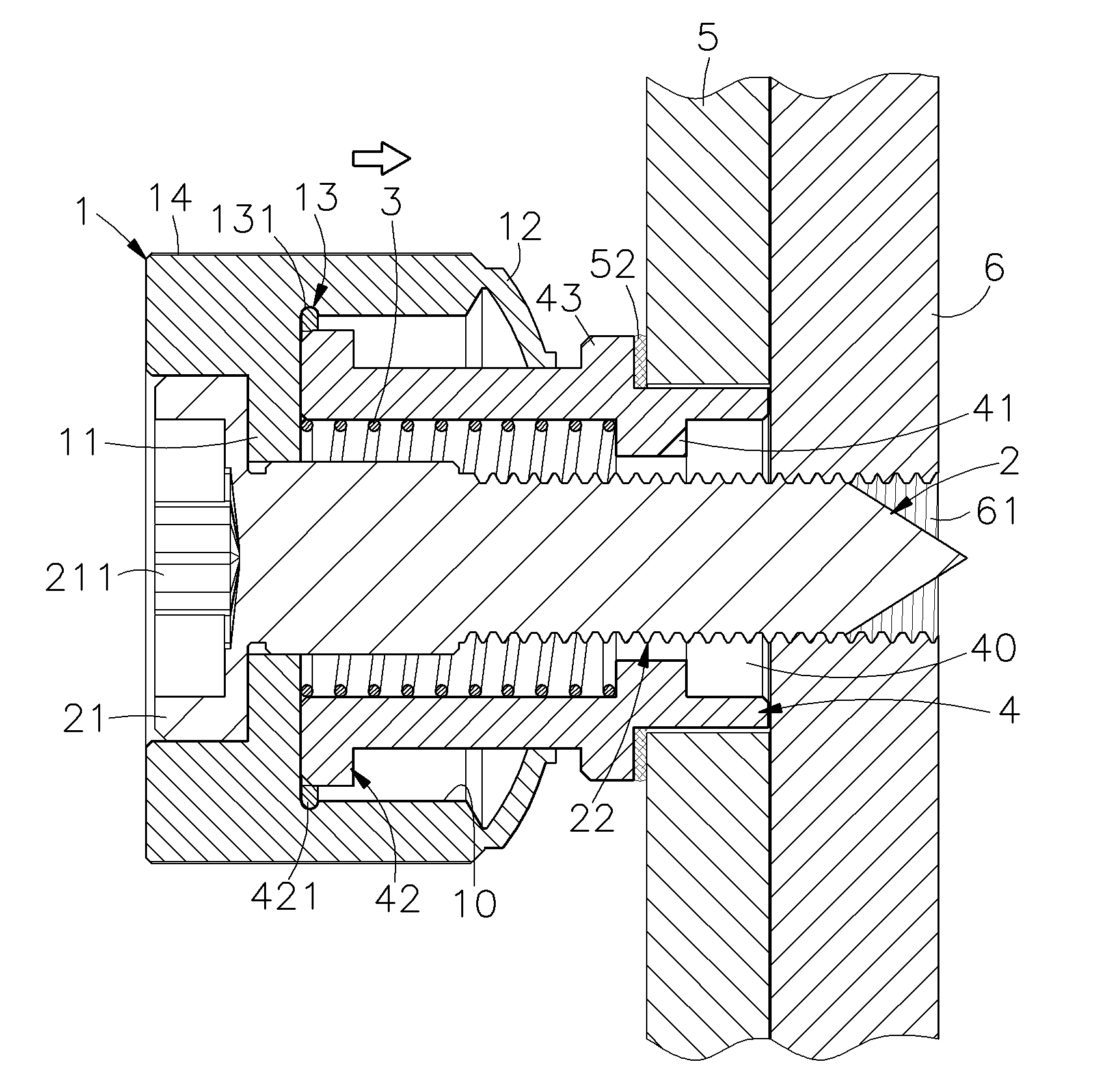

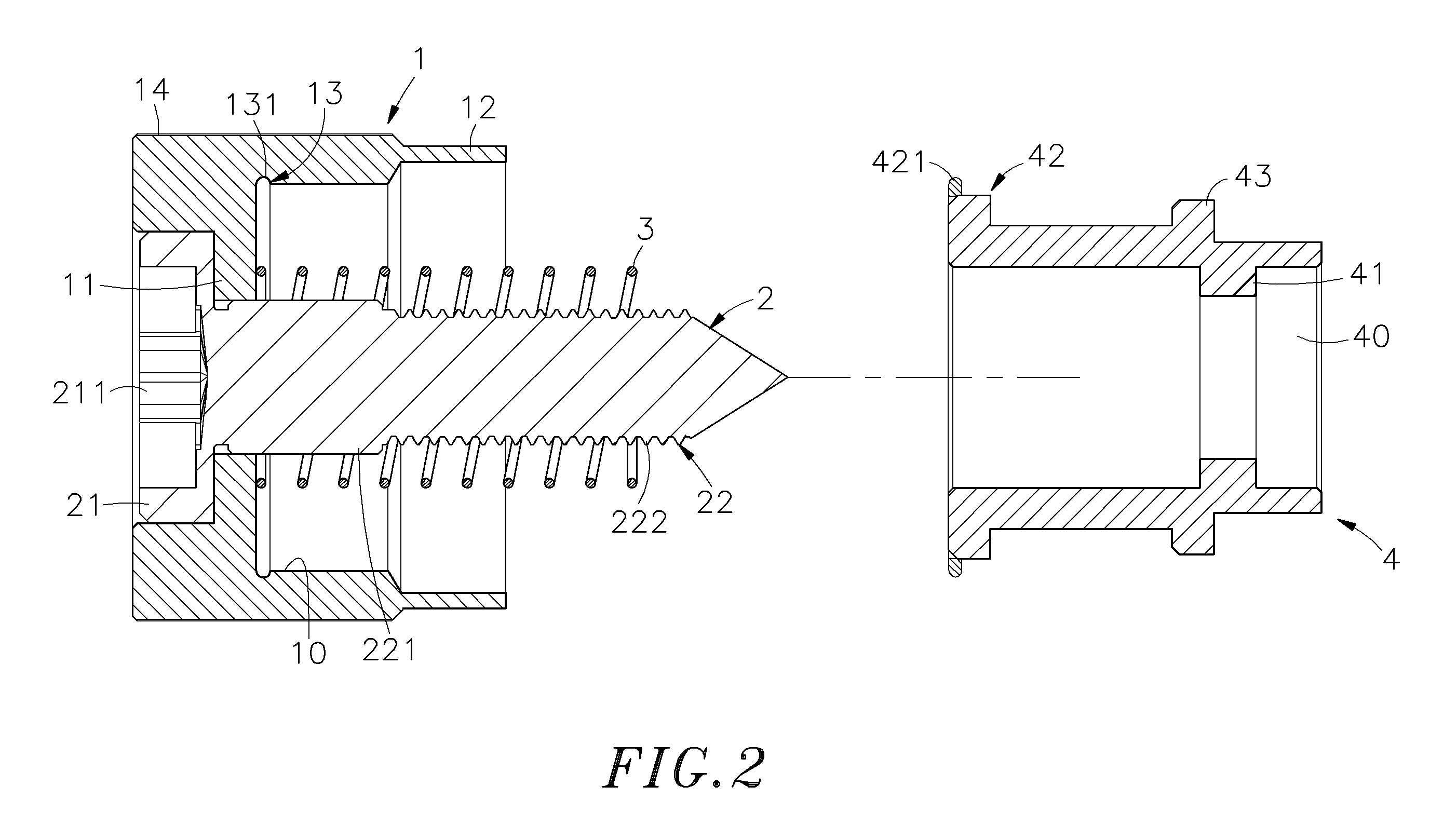

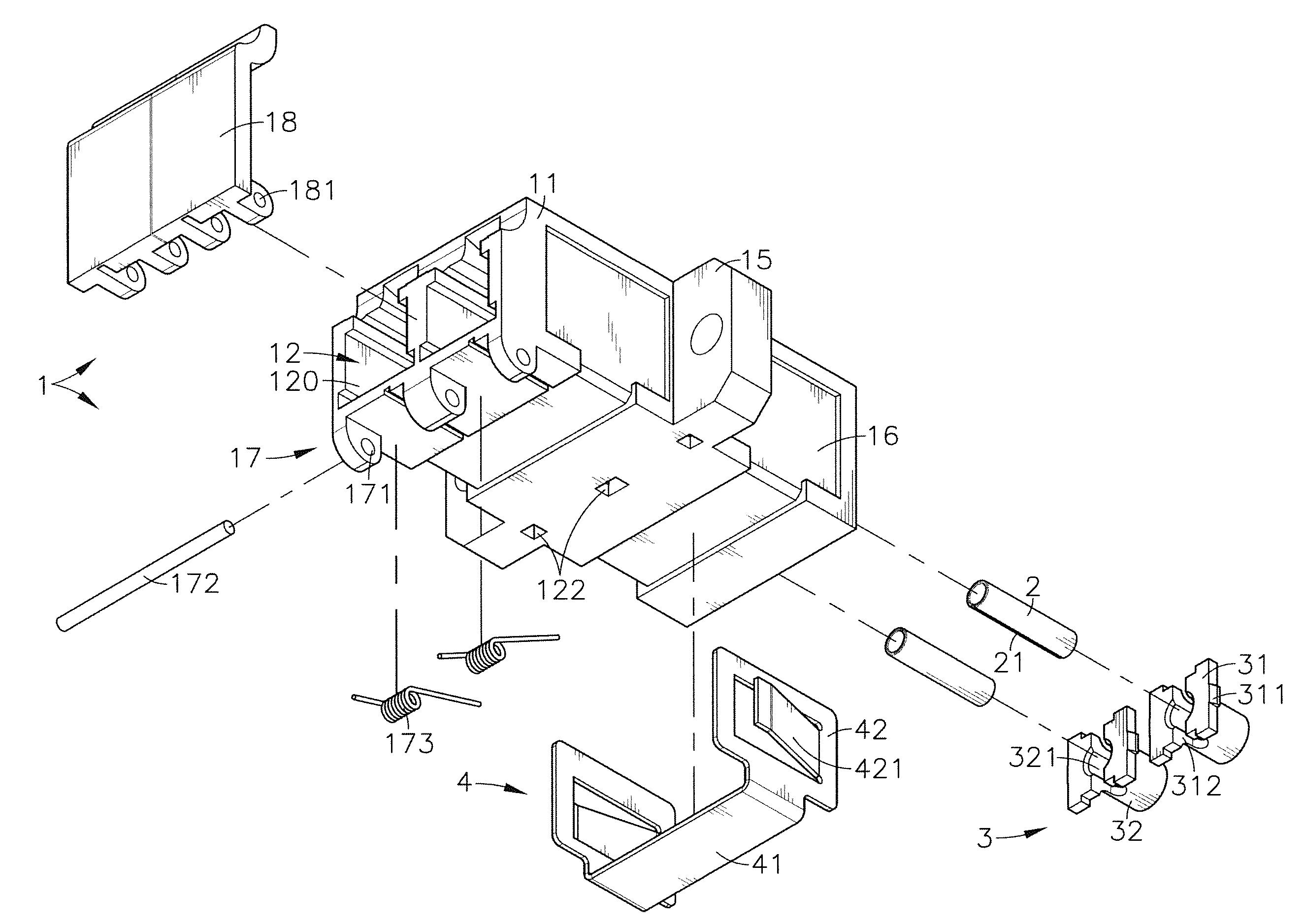

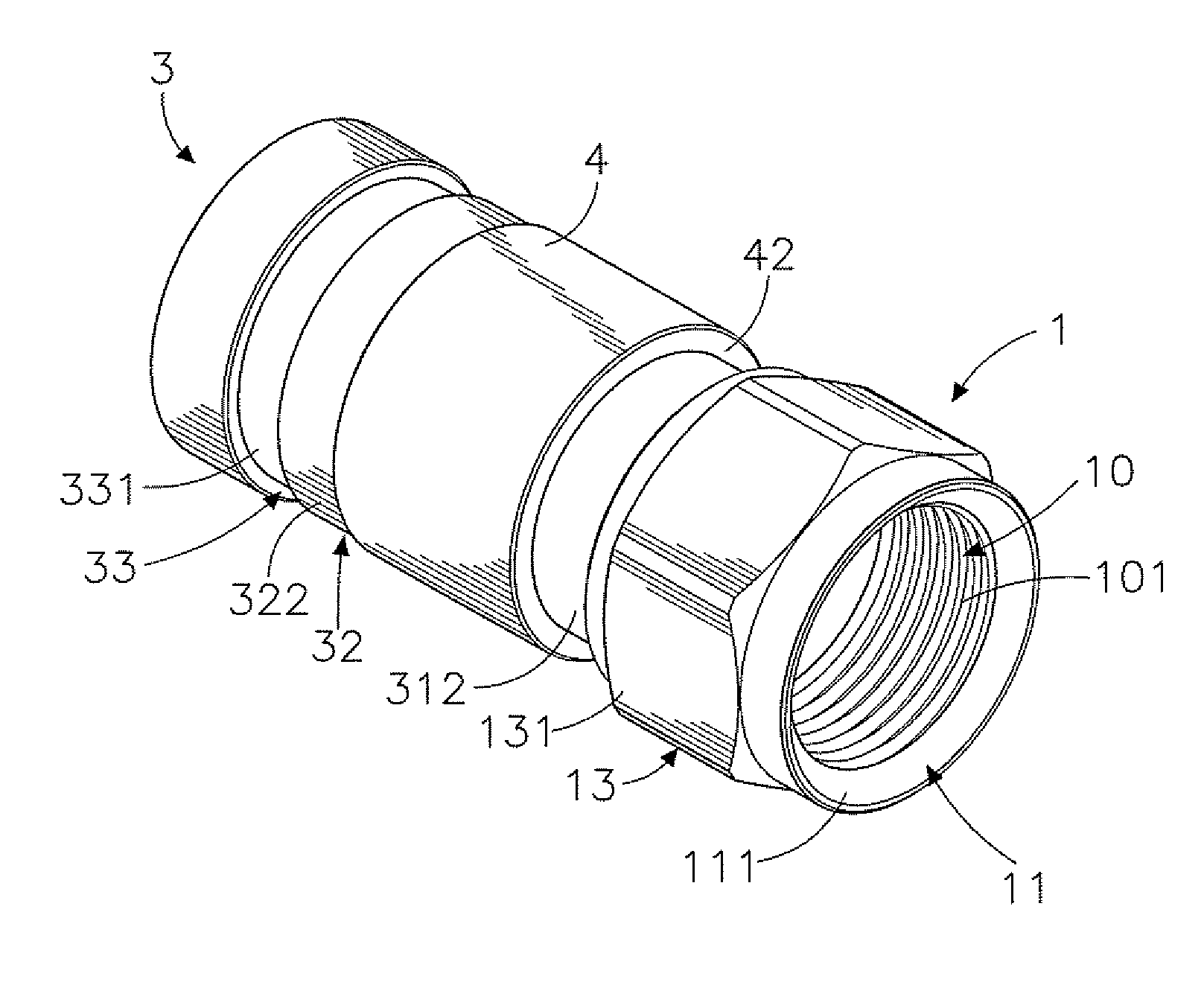

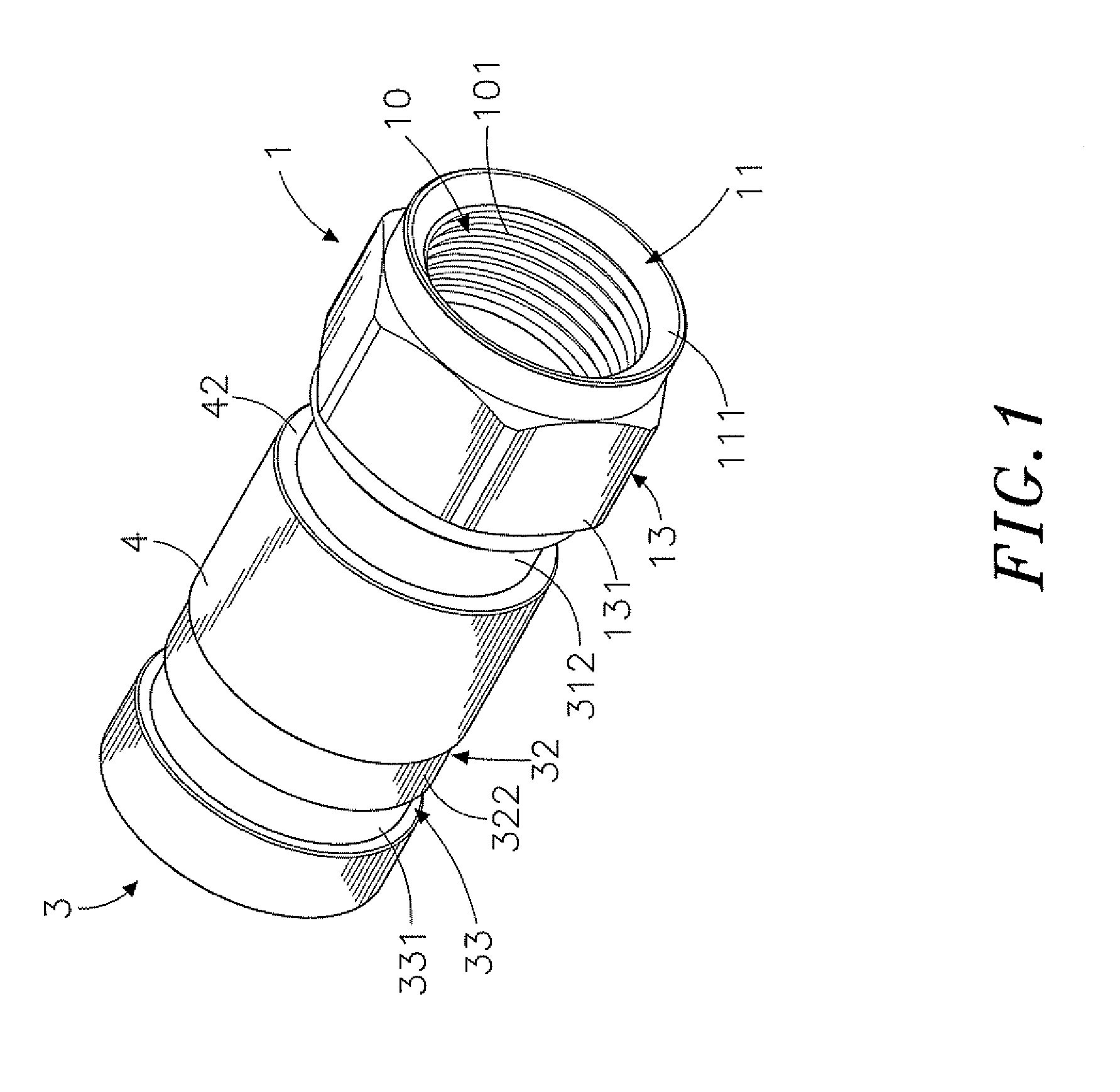

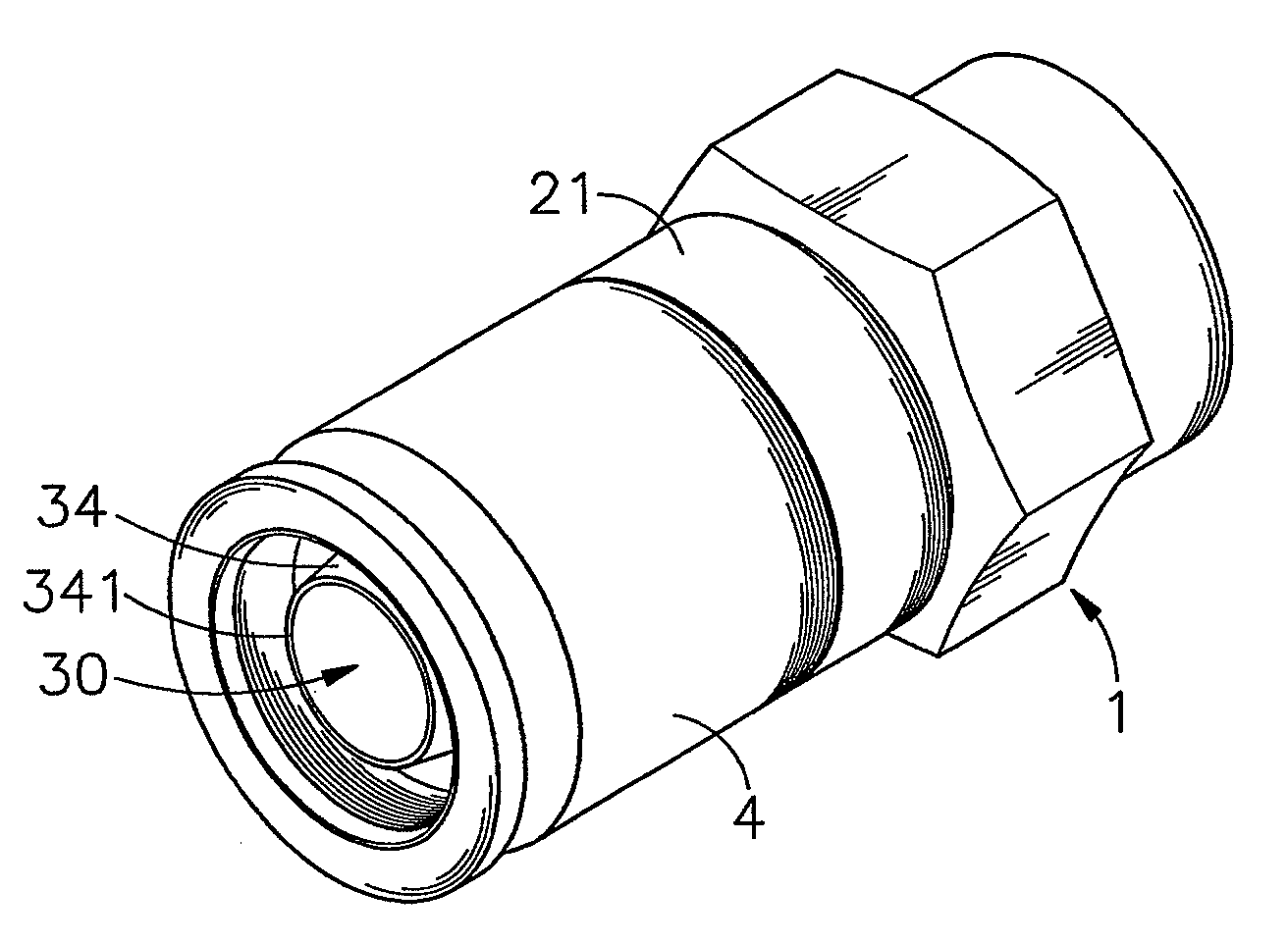

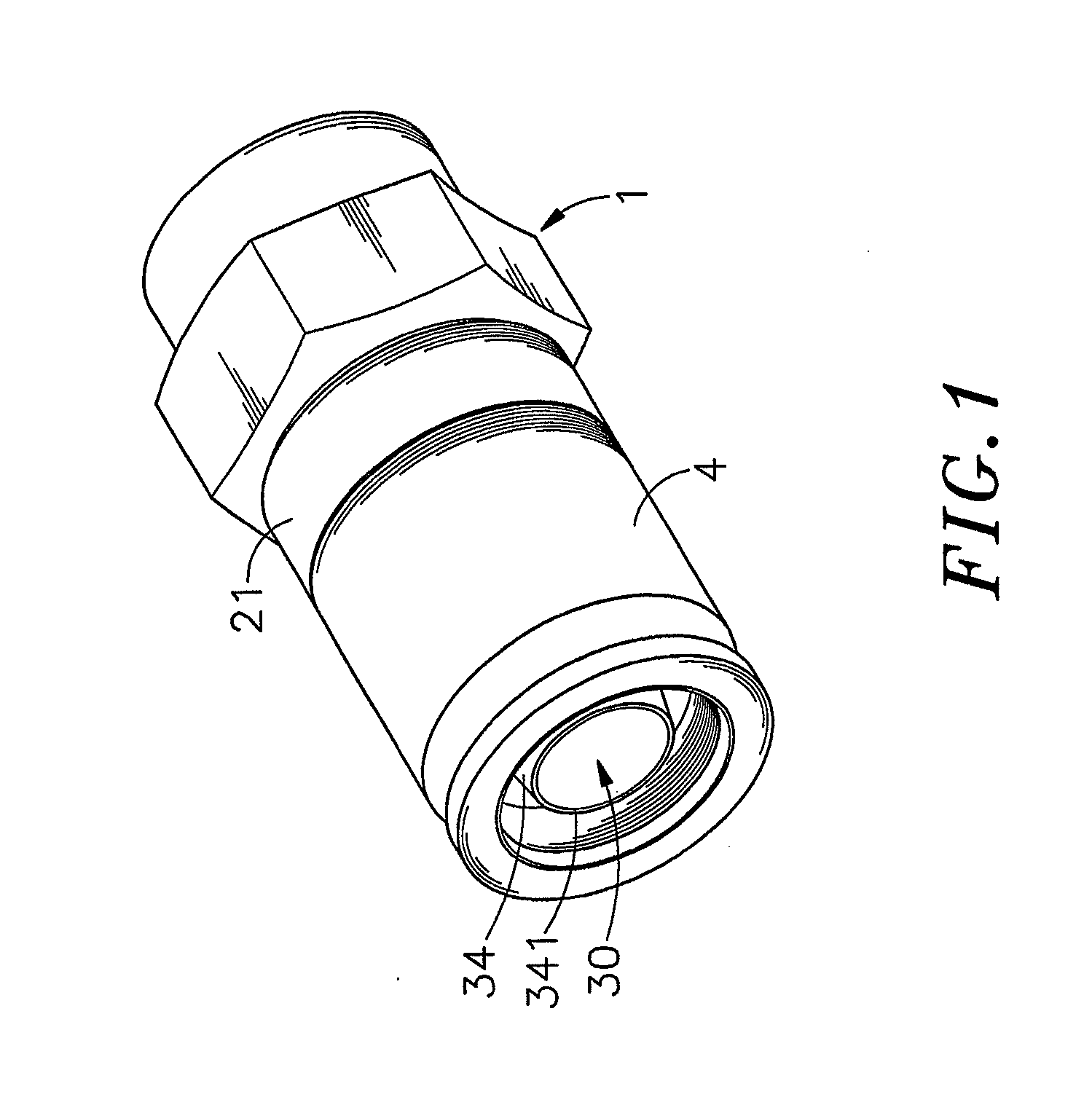

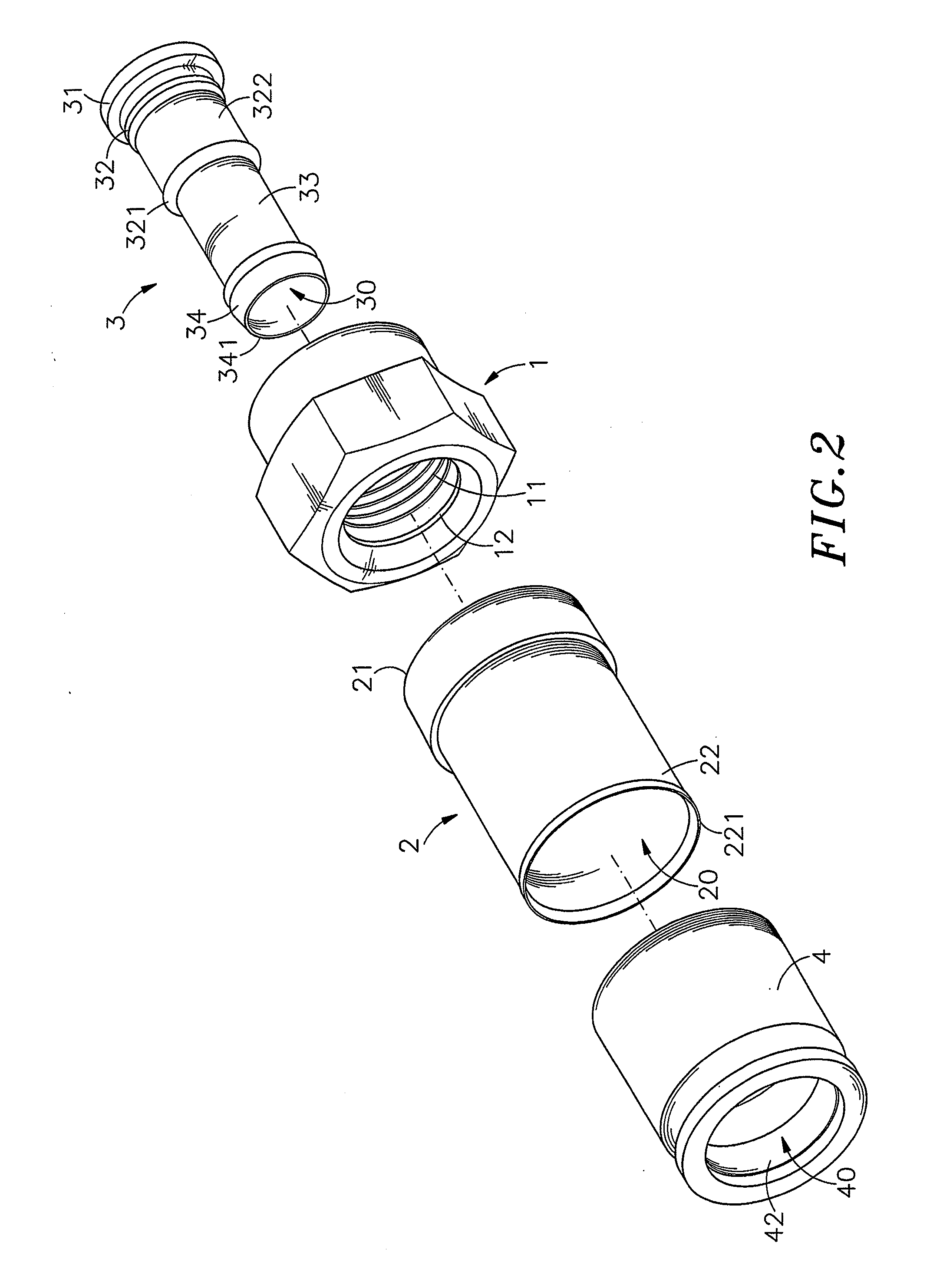

Electrical signal connector having a locknut, core tube, elastic cylindrical casing, and barrel for quick connection with a coaxial cable

ActiveUS8568165B2Accurate and quick installationAvoid damageElectrically conductive connectionsCoupling device detailsCoaxial cableElectrical connector

An electrical connector includes a locknut having an annular locating flange, a core tube for receiving the copper core, inner dielectric insulator and aluminum foil shield of a coaxial cable and supporting the braided metal wrapper and outer plastic sheath of the coaxial cable, a casing surrounding the core tube and having first and second tubular deformable portions and a vertical rear stop edge, and a barrel mounted on the casing between the first tubular deformable portion and the locknut and having a tapered inner surface portion and movable to compress the first and second tubular deformable portions against the coaxial cable and the core tube and an annular front stop edge for stopping a crimping tool used to crimp the casing.

Owner:EZCONN

Electrical signal connector providing a proper installation of a cable

InactiveUS8137132B2Accurate and quick installationImprove waterproof performanceLine/current collector detailsElectrically conductive connectionsElectrical conductorCoaxial cable

Owner:LU YUEH CHIUNG

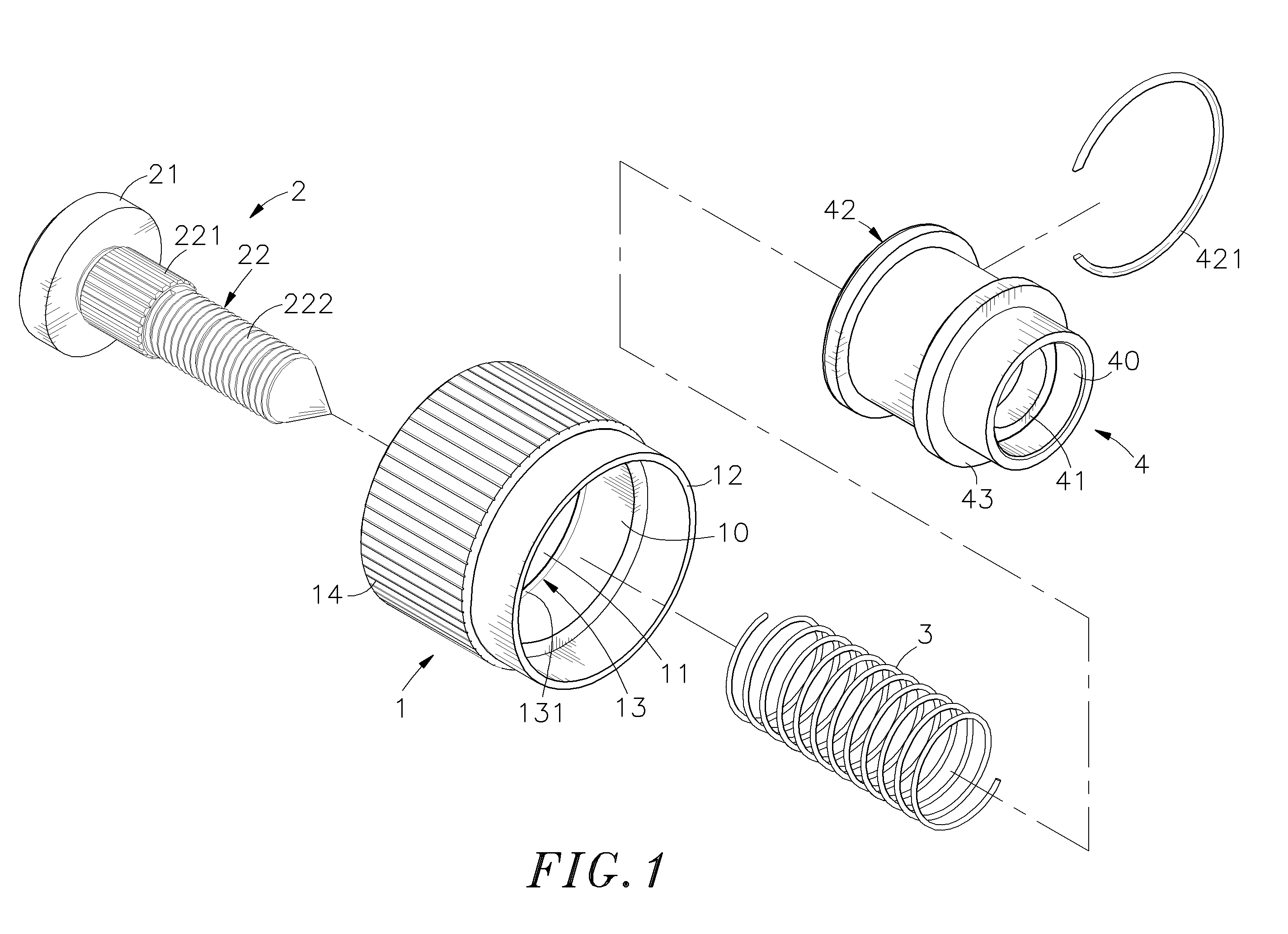

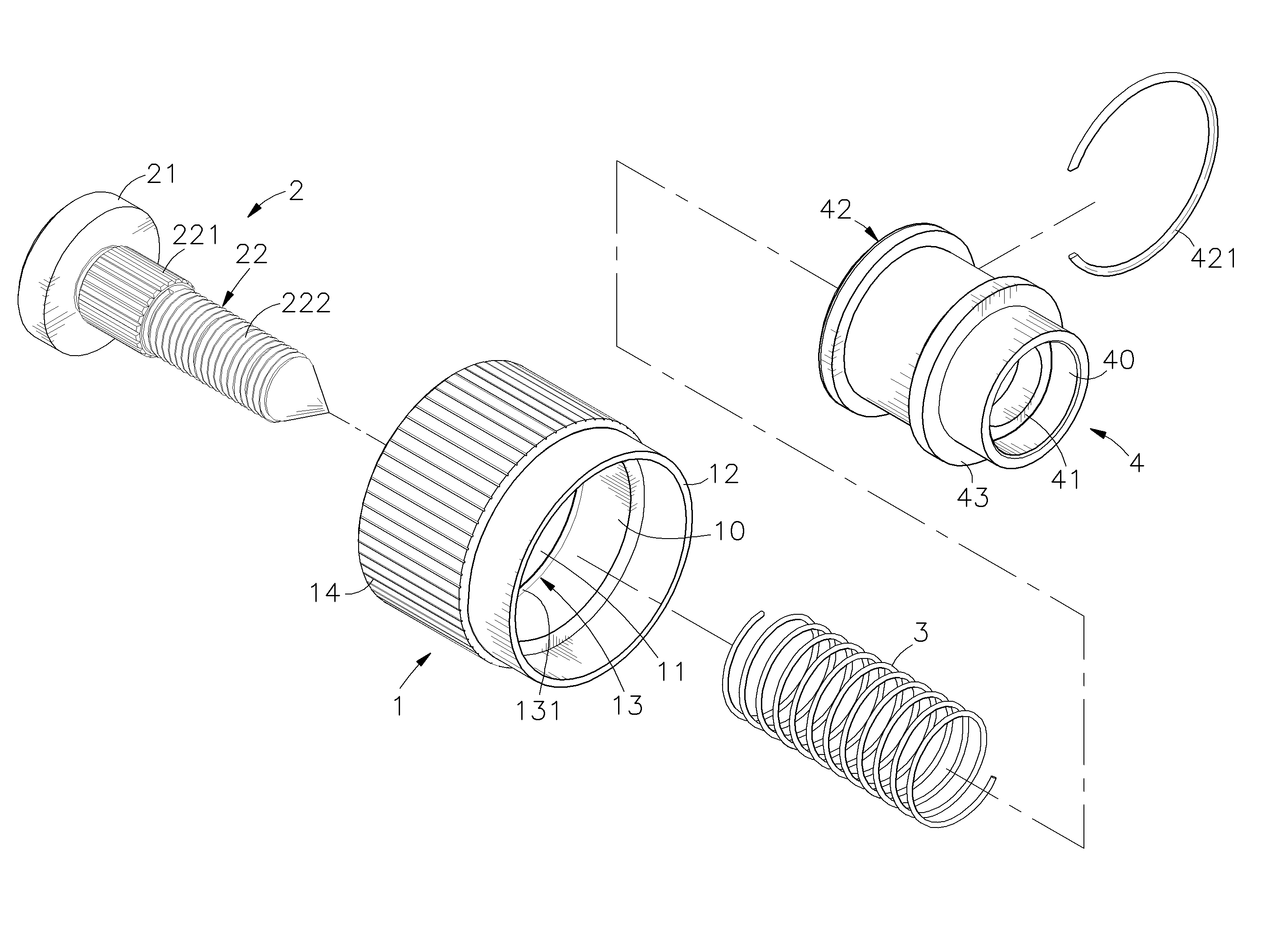

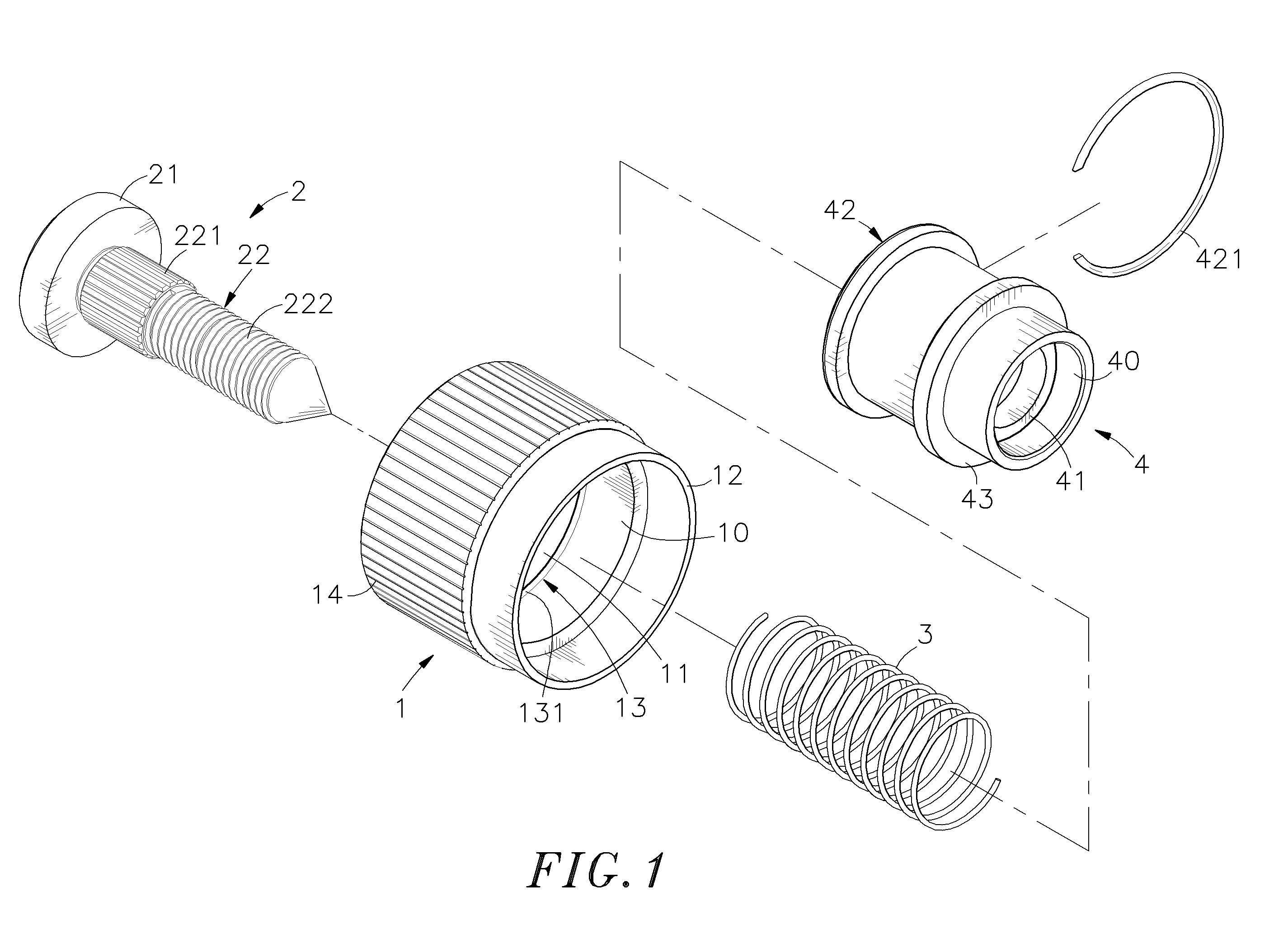

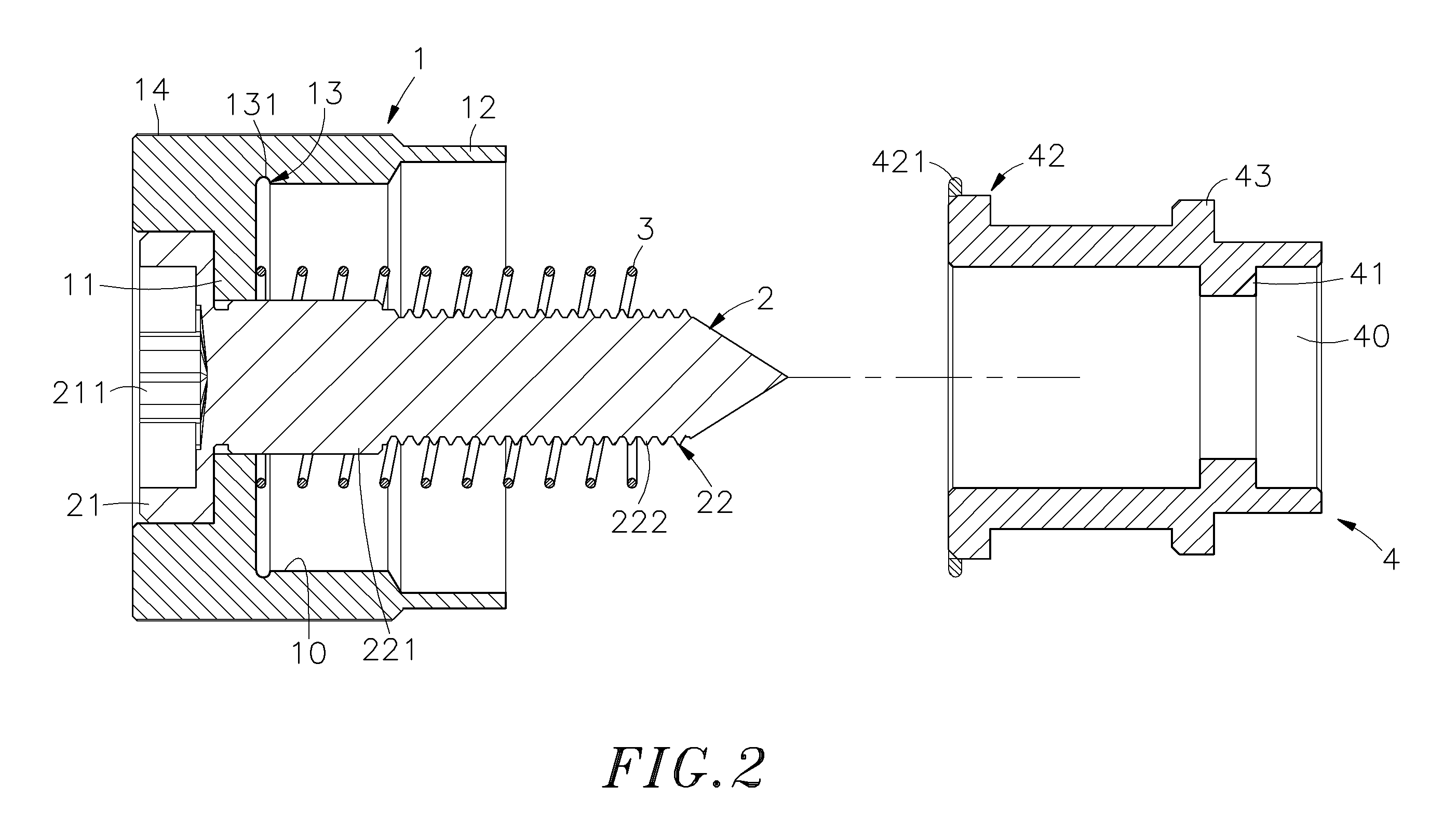

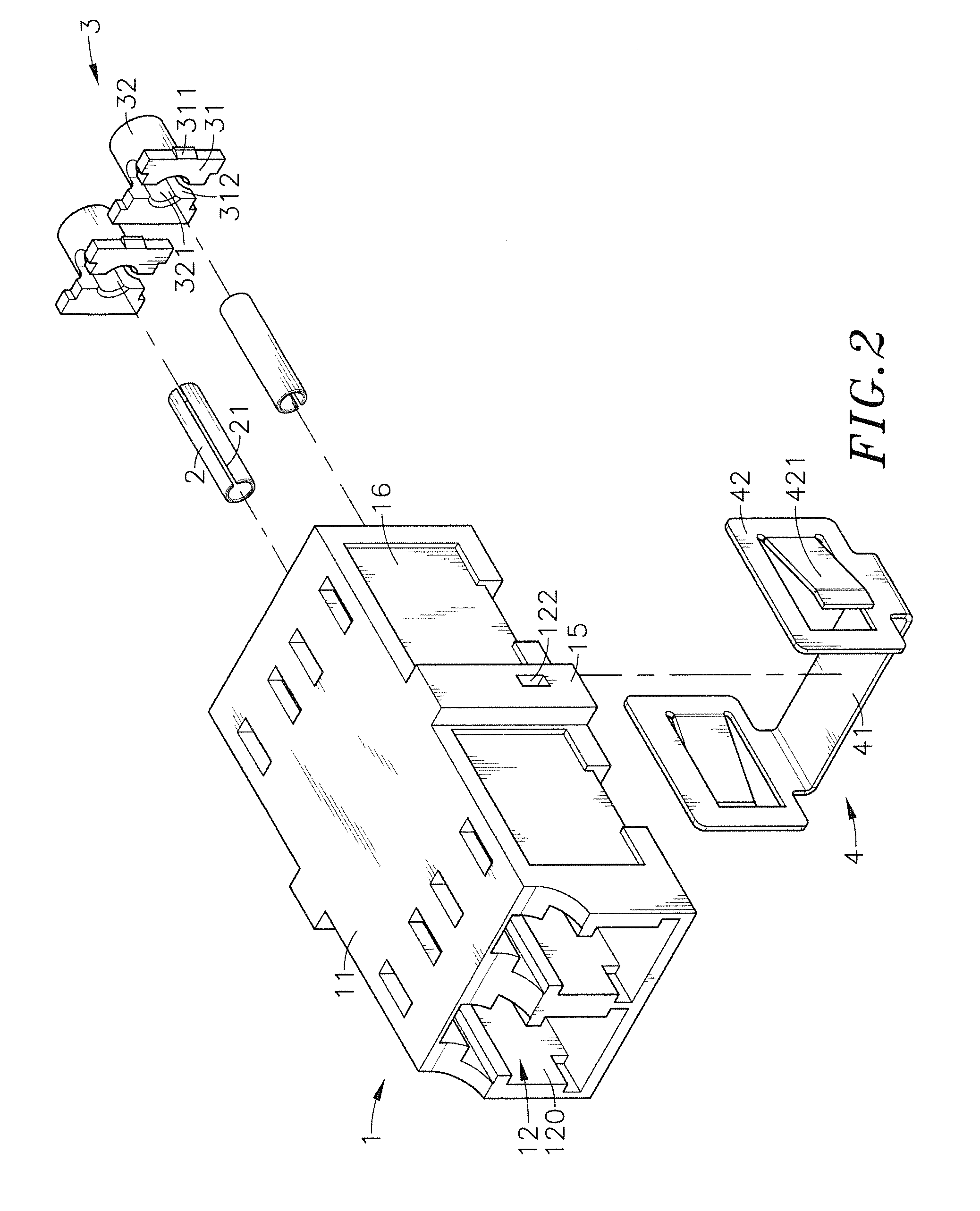

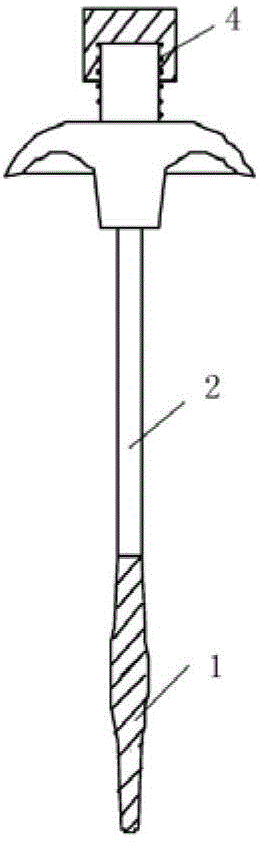

Quick-positioning screw assembly

InactiveUS20100132178A1Quick and accurate installationPrevent fallingNutsBoltsEngineeringScrew press

A quick-positioning screw assembly includes a cap having an inside annular flange and a locating groove or locating rib extending around the inside wall, a mounting socket bonded to a mounting through hole of a first plate member and having a top positioning flange extending around the periphery and detachably forced into engagement with the locating groove or locating rib of the cap, a screw press-fitted into the inner diameter of the inside annular flange of the cap for threading into a screw hole on a second plate member to secure the first plate member to the second plate member, and a compression spring mounted in the cap around the screw and stopped between the inside annular flange of the cap and an inside annular flange of the mounting socket.

Owner:HANWIT PRECISION IND LTD

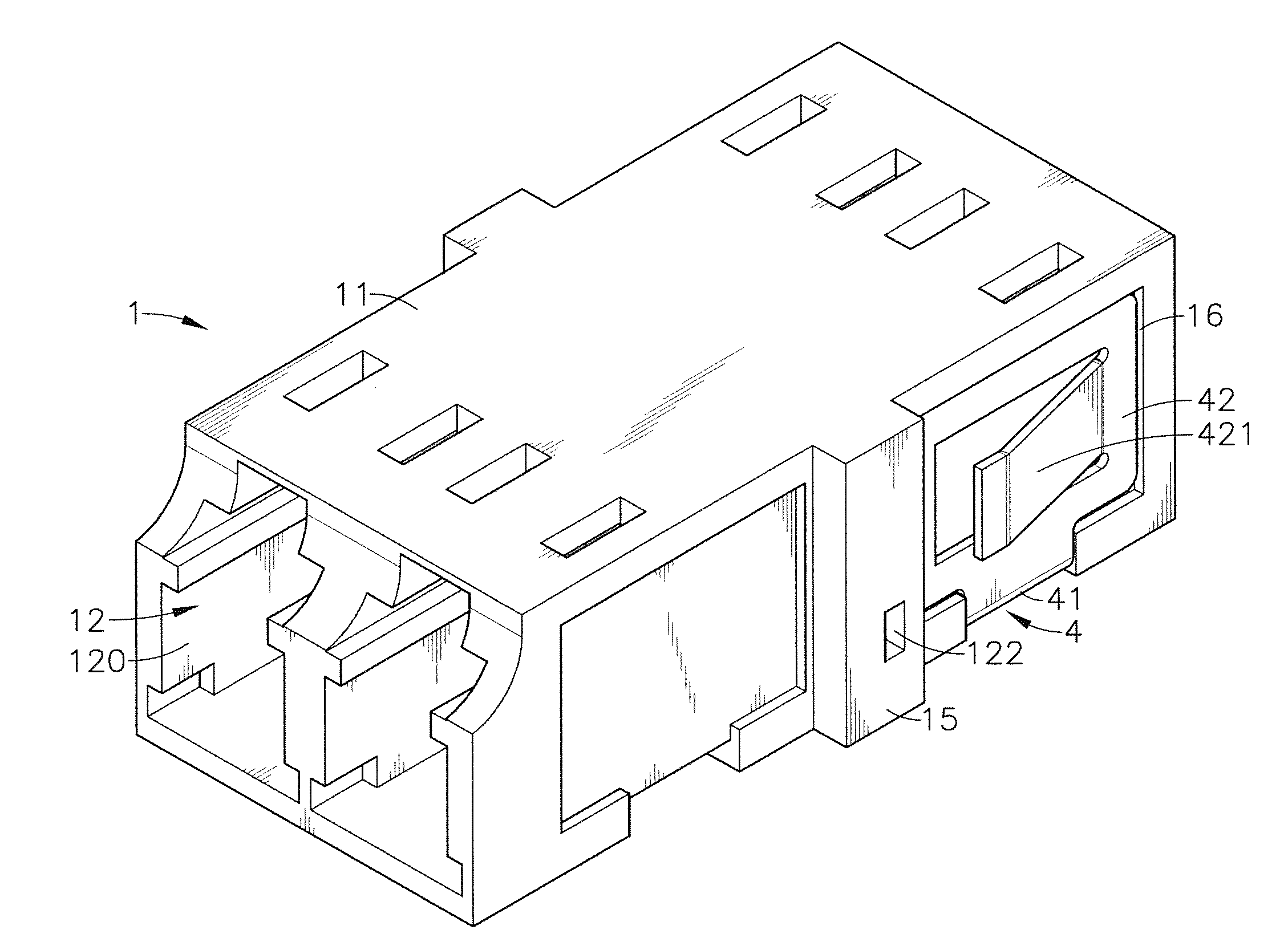

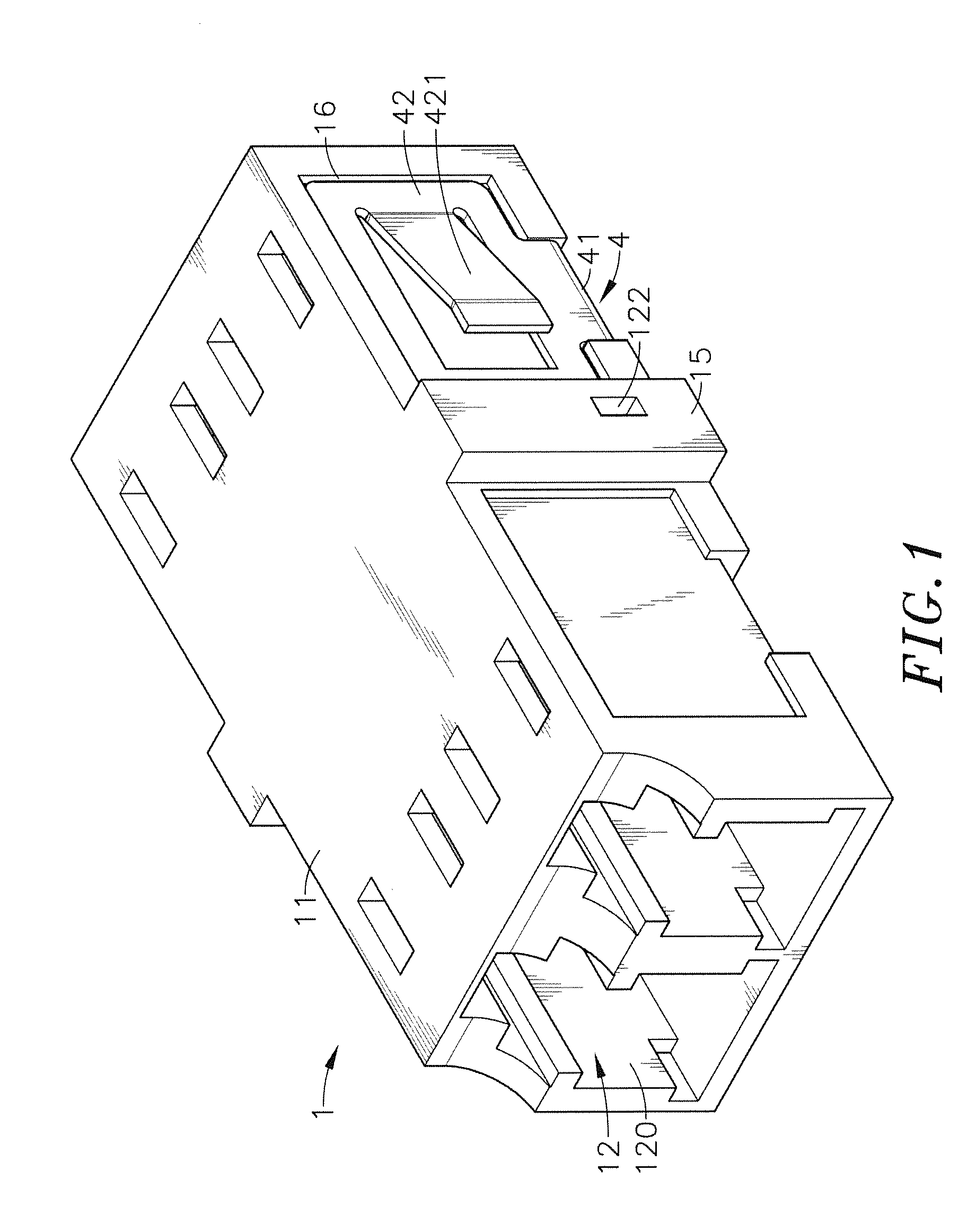

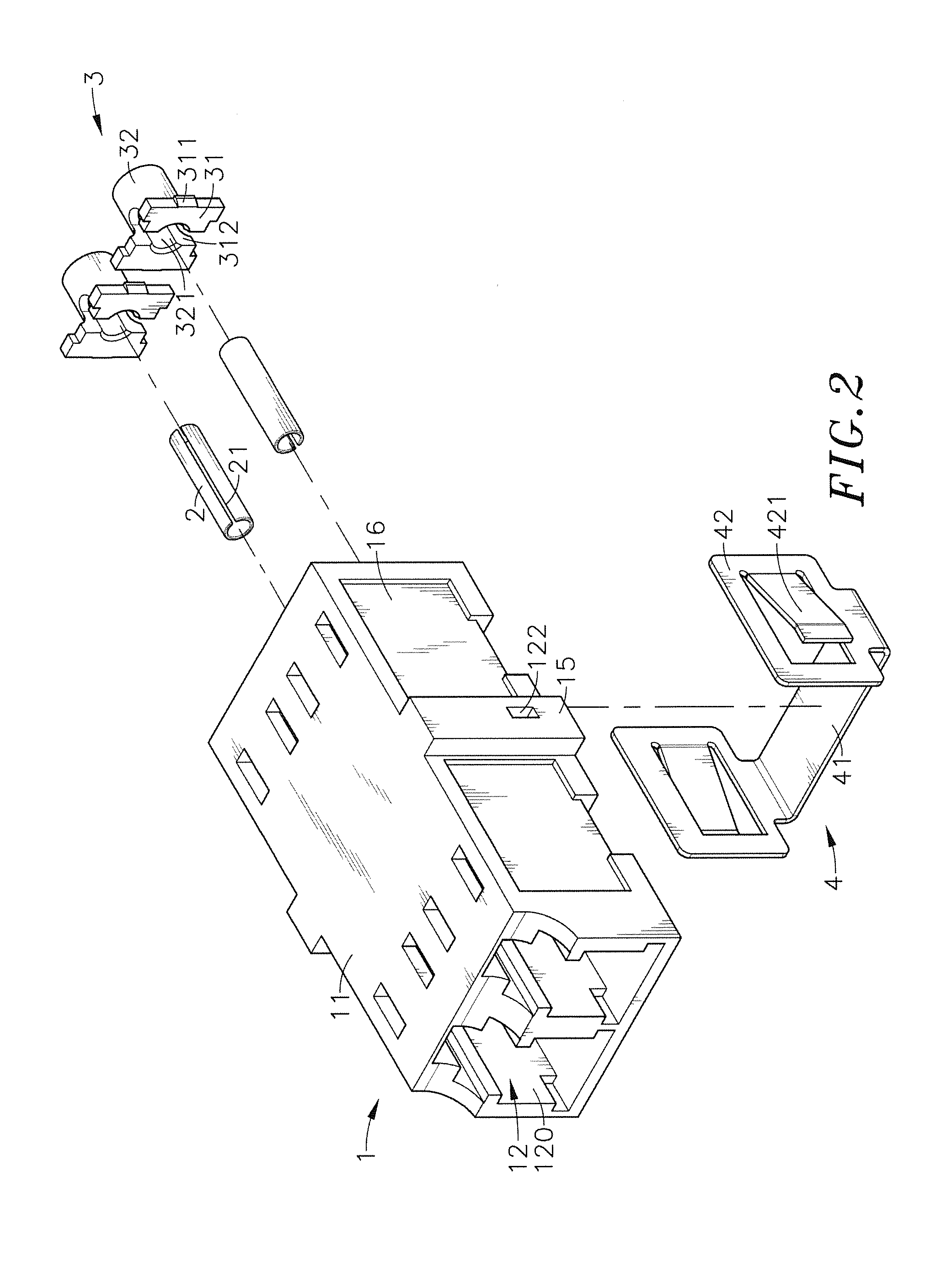

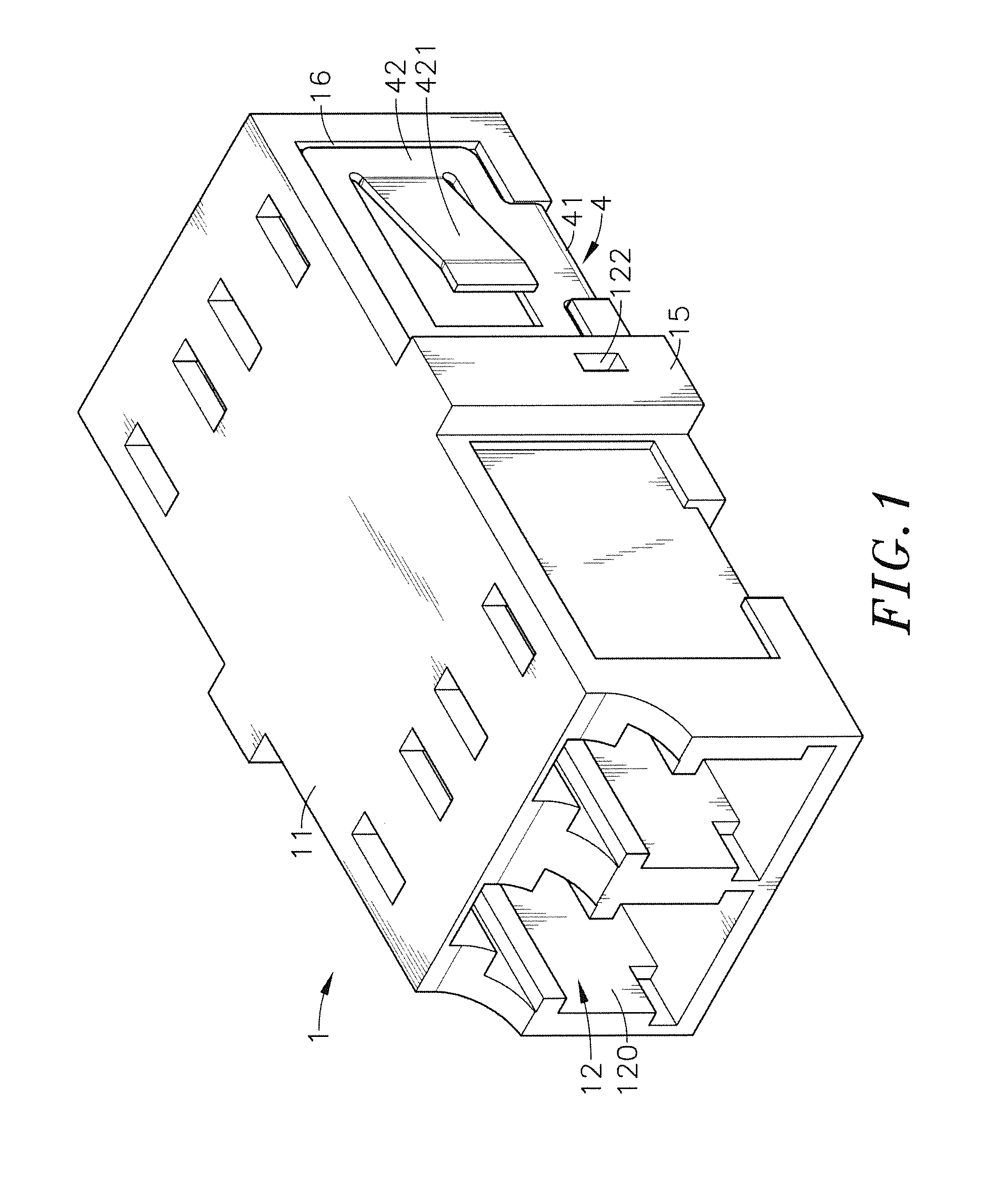

Mono-block type optical fiber adapter

ActiveUS20140147082A1Drawback can be obviatedEffectively eliminates dimensional tolerance and clearance problemCoupling light guidesCouplingEngineering

A mono-block type optical fiber adapter includes an adapter body including a partition wall between each two opposing accommodation chambers and a tubular coupling portion extended from each partition wall toward the inside of one respective front-sided accommodation chamber, a ferrule mounted in each tubular coupling portion and partially suspending in the respective rear-sided accommodation chamber, and a ferrule holder respectively mounted in each rear-sided accommodation chamber and attached to the suspended rear end of the respective ferrule. The one piece design of the adapter body facilitates mass production and effectively eliminates the dimensional tolerance and clearance problems of conventional designs. Further, the matching design between the adapter body and the ferrule holders facilitates quick and accurate installation of the mono-block type optical fiber adapter, saving much installation time and labor and enhancing structural stability and reliability.

Owner:CORNING OPTICAL COMM LLC

Quick-positioning screw assembly

A quick-positioning screw assembly includes a cap having an inside annular flange and a locating groove or locating rib extending around the inside wall, a mounting socket bonded to a mounting through hole of a first plate member and having a top positioning flange extending around the periphery and detachably forced into engagement with the locating groove or locating rib of the cap, a screw press-fitted into the inner diameter of the inside annular flange of the cap for threading into a screw hole on a second plate member to secure the first plate member to the second plate member, and a compression spring mounted in the cap around the screw and stopped between the inside annular flange of the cap and an inside annular flange of the mounting socket.

Owner:HANWIT PRECISION IND LTD

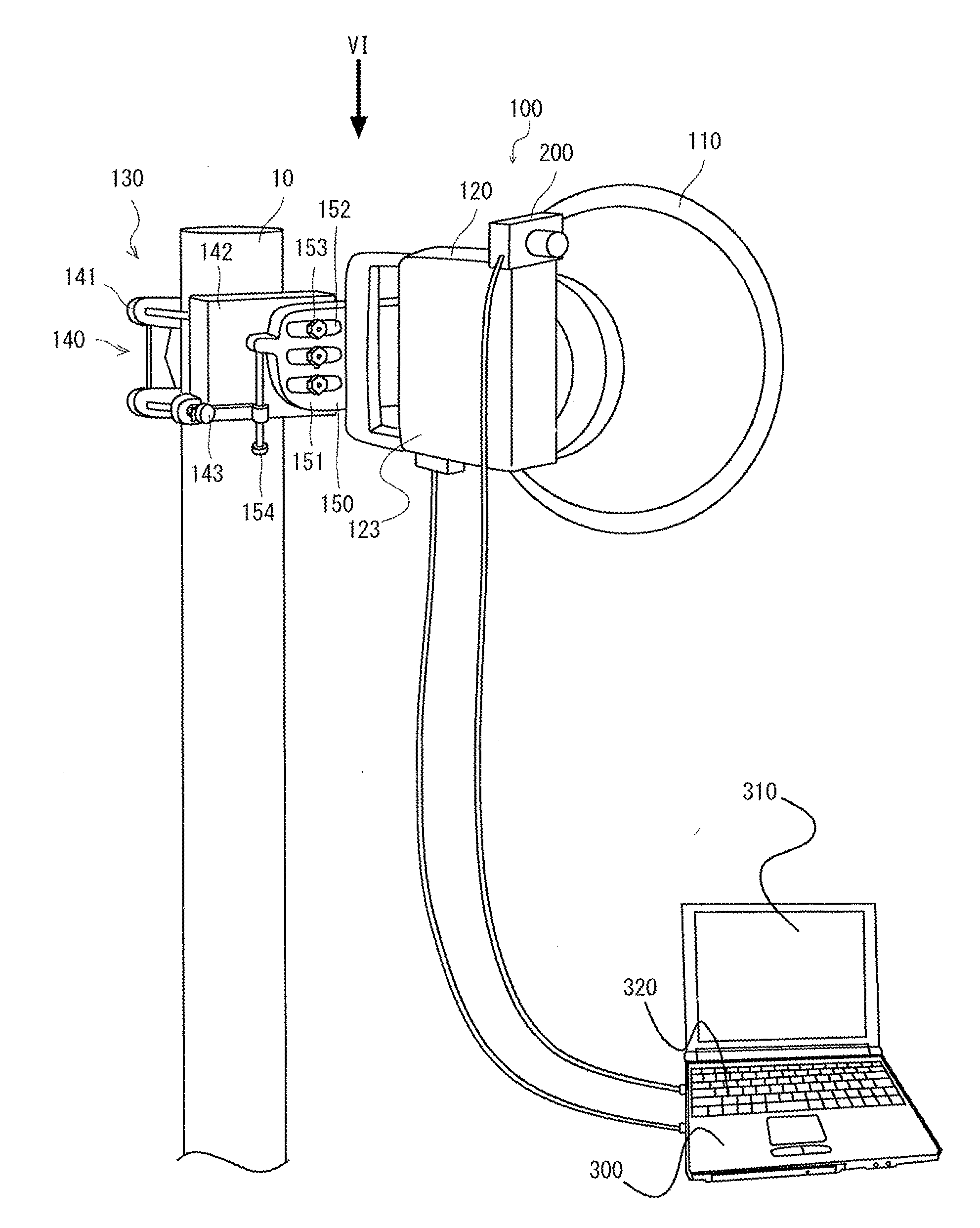

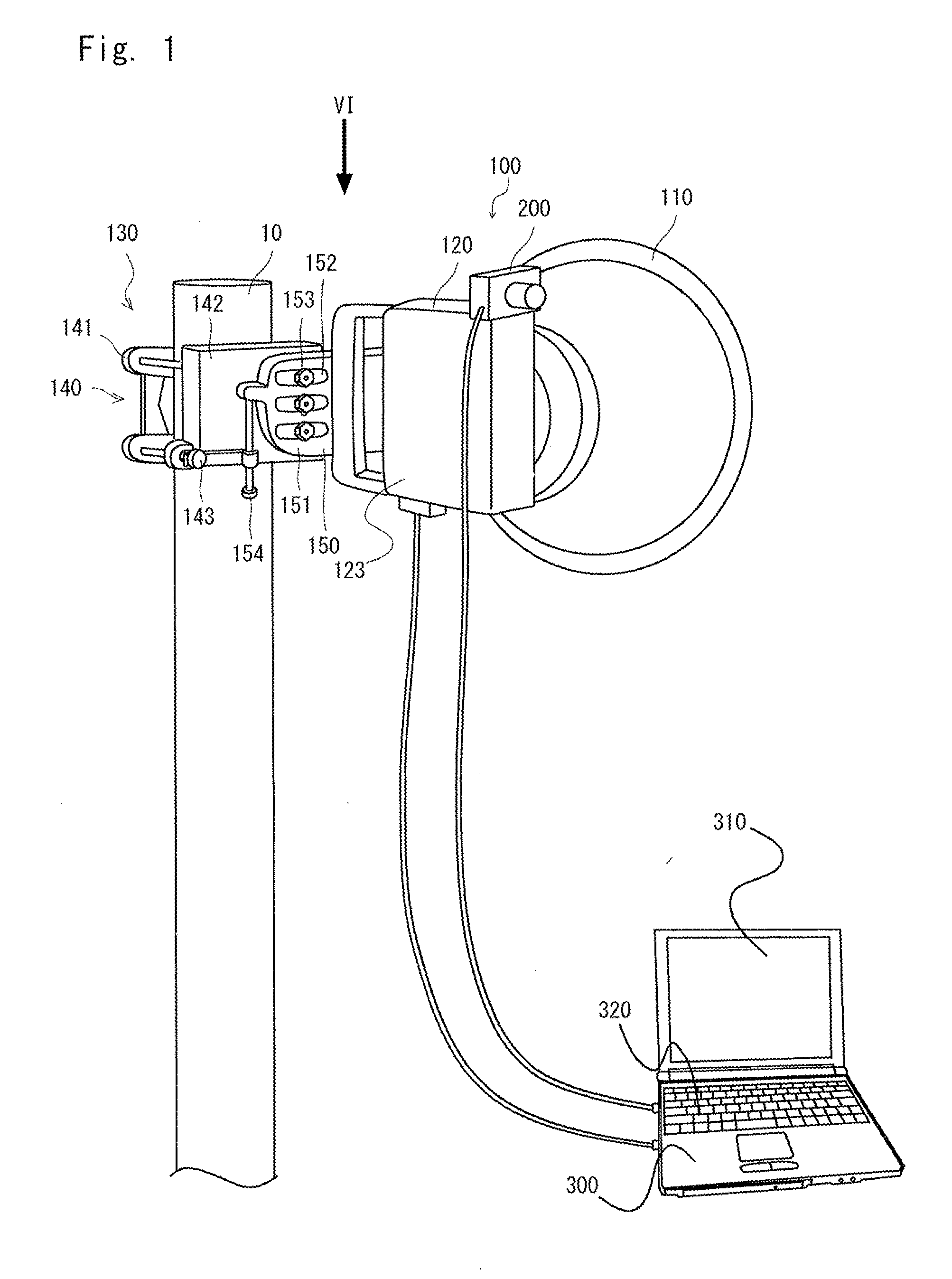

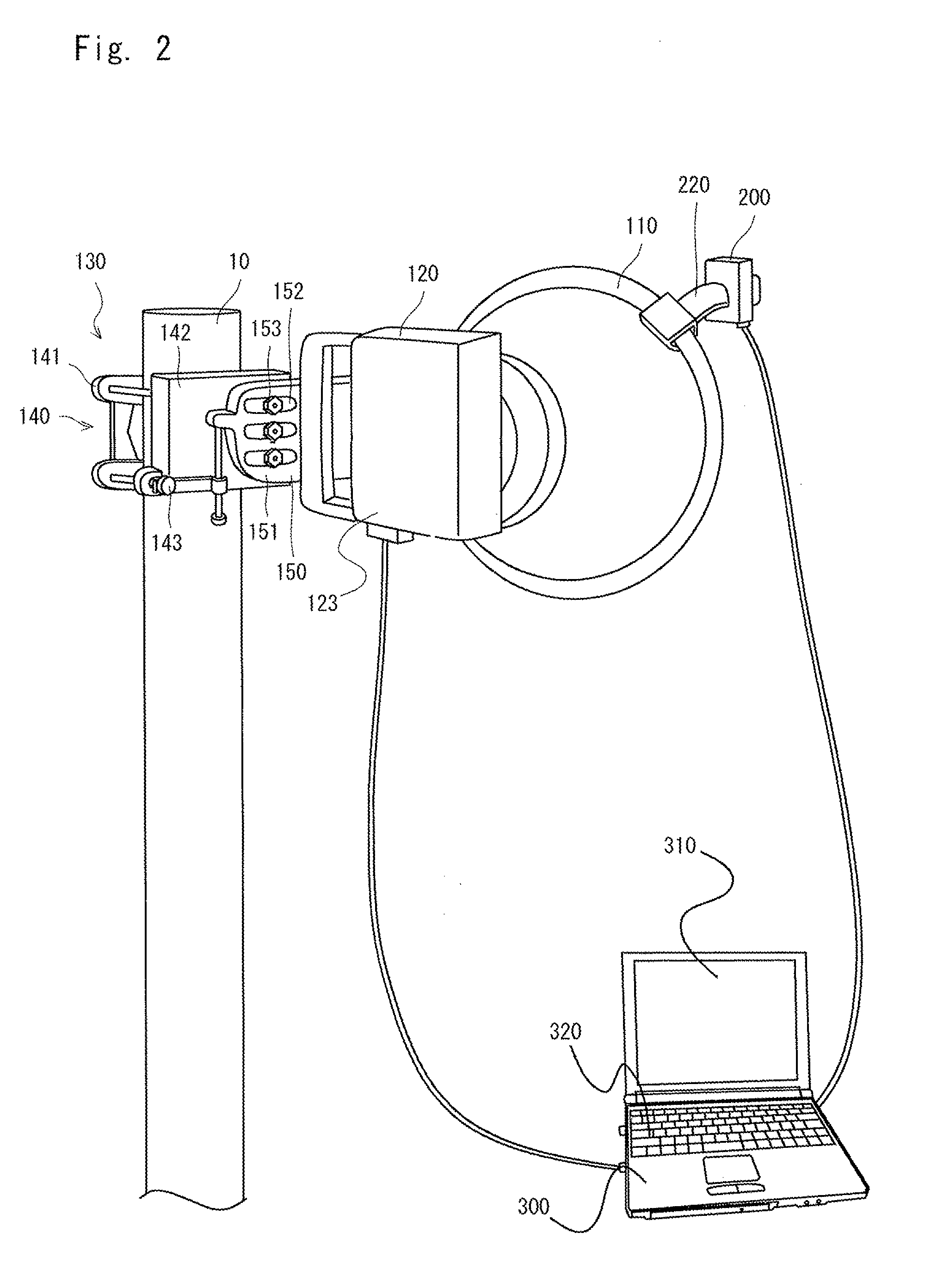

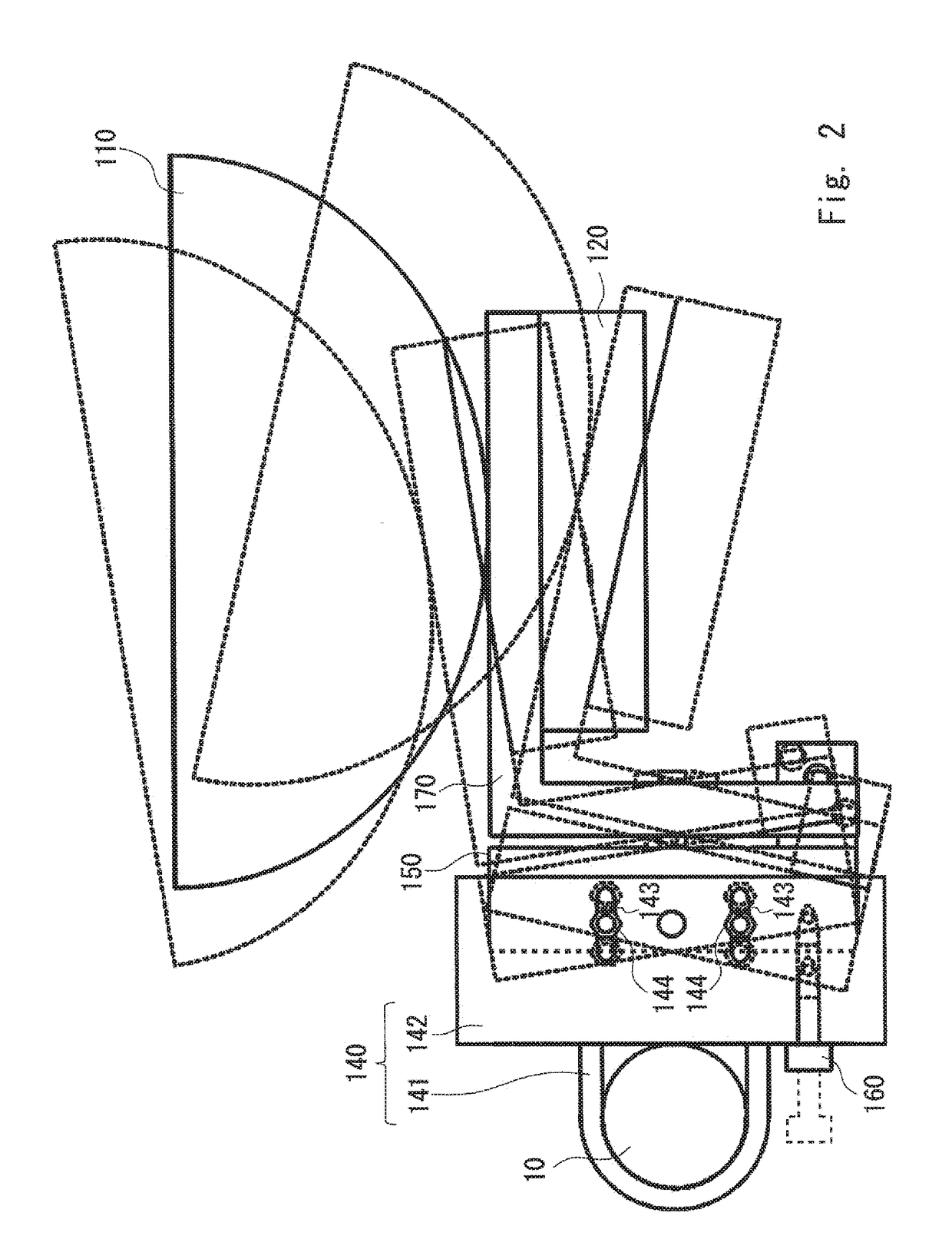

Antenna orientation adjustment assistance device and antenna device installation method

InactiveUS20150263408A1Accurate and quick installationAntenna supports/mountingsElectromagentic field characteristicsRadio wave

An antenna orientation adjustment assistance device that allows any worker to quickly and accurately install an antenna device is provided. An antenna device (100) is temporarily installed. Further, a camera (200) is mounted on the antenna device (100). Then, the antenna orientation adjustment assistance device includes a reception strength detection unit (420) that detects a reception strength of radio waves received by an antenna unit (110), a position calculation unit (414) that calculates a relative angle position of the antenna unit (110) by using an image taken by a camera (200) fixed relative to the antenna unit (110), and a reception strength recording unit (430) that records the relative angle position of the antenna unit (110) and the reception strength at the relative angle position in association with each other.

Owner:NEC CORP

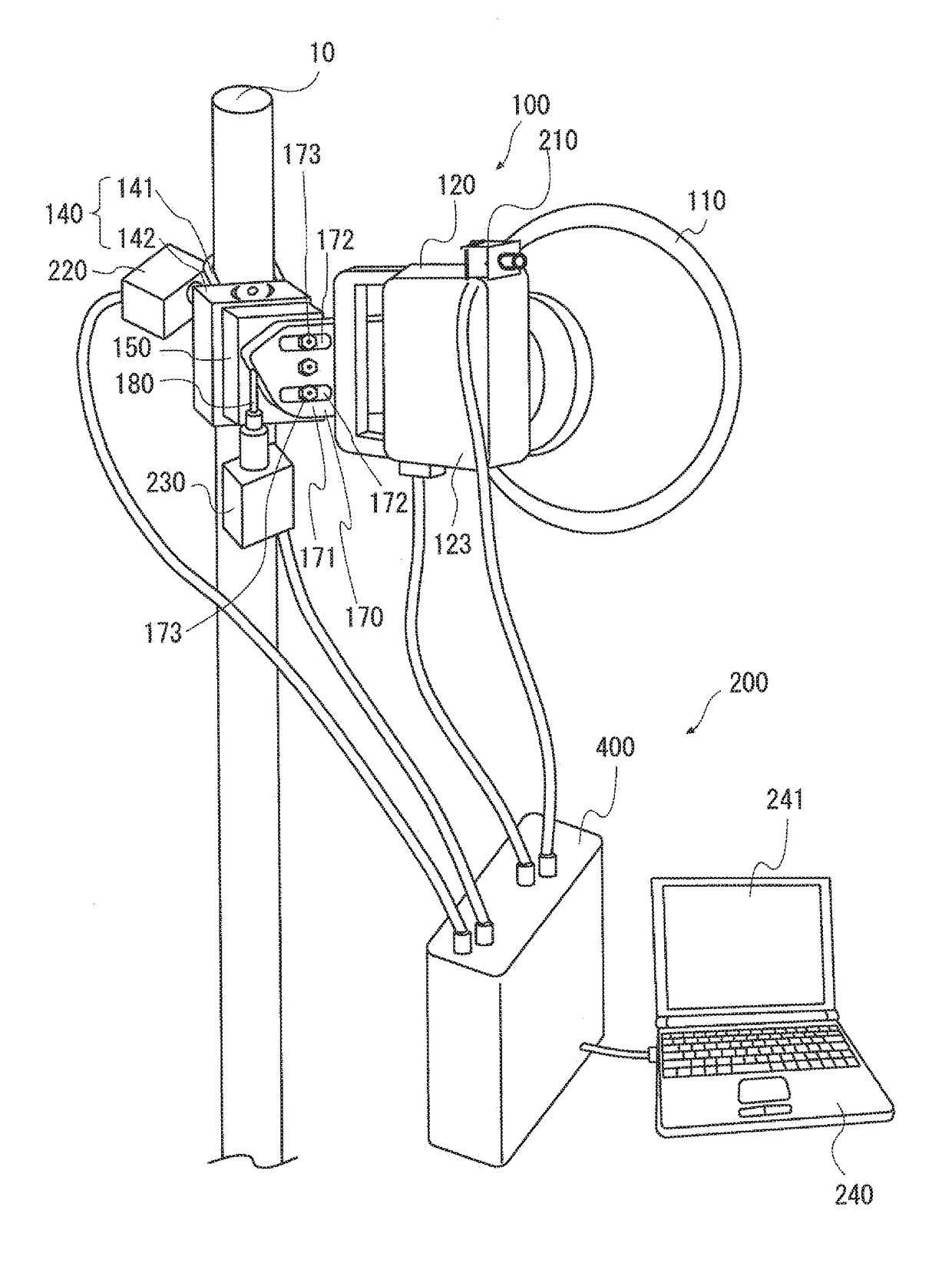

Antenna orientation adjustment device and antenna orientation adjustment method

InactiveUS20170179566A1Accurate and quick installationTransmitters monitoringReceivers monitoringMotion controllerControl theory

An antenna orientation adjustment device (200) include a camera (210), nut runners (220 and 230), and a motion controller (400). The nut runners (220 and 230) can be mounted on an azimuth adjustment bolt (160) and an elevation adjustment bolt (180), respectively. The nut runners (220 and 230) change the orientation of an antenna unit by applying motor power to the azimuth adjustment bolt (160) and the elevation adjustment bolt (180). The motion controller (400) calculates an angle position of the antenna unit (110) where a reception strength is maximum based on an image taken by the camera (210) and a reception strength of radio waves received by the antenna unit (110), and then adjusts the antenna unit (110) to the angle position where the reception strength is maximum by supplying a drive signal to the azimuth adjustment bolt (160) and the elevation adjustment bolt (180).

Owner:NEC CORP

Mono-block type optical fiber adapter

ActiveUS9297962B2Drawback can be obviatedEffectively eliminates dimensional tolerance and clearance problemCoupling light guidesCouplingEngineering

A mono-block type optical fiber adapter includes an adapter body including a partition wall between each two opposing accommodation chambers and a tubular coupling portion extended from each partition wall toward the inside of one respective front-sided accommodation chamber, a ferrule mounted in each tubular coupling portion and partially suspending in the respective rear-sided accommodation chamber, and a ferrule holder respectively mounted in each rear-sided accommodation chamber and attached to the suspended rear end of the respective ferrule. The one piece design of the adapter body facilitates mass production and effectively eliminates the dimensional tolerance and clearance problems of conventional designs. Further, the matching design between the adapter body and the ferrule holders facilitates quick and accurate installation of the mono-block type optical fiber adapter, saving much installation time and labor and enhancing structural stability and reliability.

Owner:CORNING OPTICAL COMM LLC

Electrical signal connector

ActiveUS20130130541A1Alignment accuracyReduce usageElectrically conductive connectionsCoupling device detailsCoaxial cableEngineering

An electrical connector includes a locknut having an annular locating flange, a core tube for receiving the copper core, inner dielectric insulator and aluminum foil shield of a coaxial cable and supporting the braided metal wrapper and outer plastic sheath of the coaxial cable, a casing surrounding the core tube and having first and second tubular deformable portions and a vertical rear stop edge, and a barrel mounted on the casing between the first tubular deformable portion and the locknut and having a tapered inner surface portion and movable to compress the first and second tubular deformable portions against the coaxial cable and the core tube and an annular front stop edge for stopping a crimping tool used to crimp the casing.

Owner:EZCONN

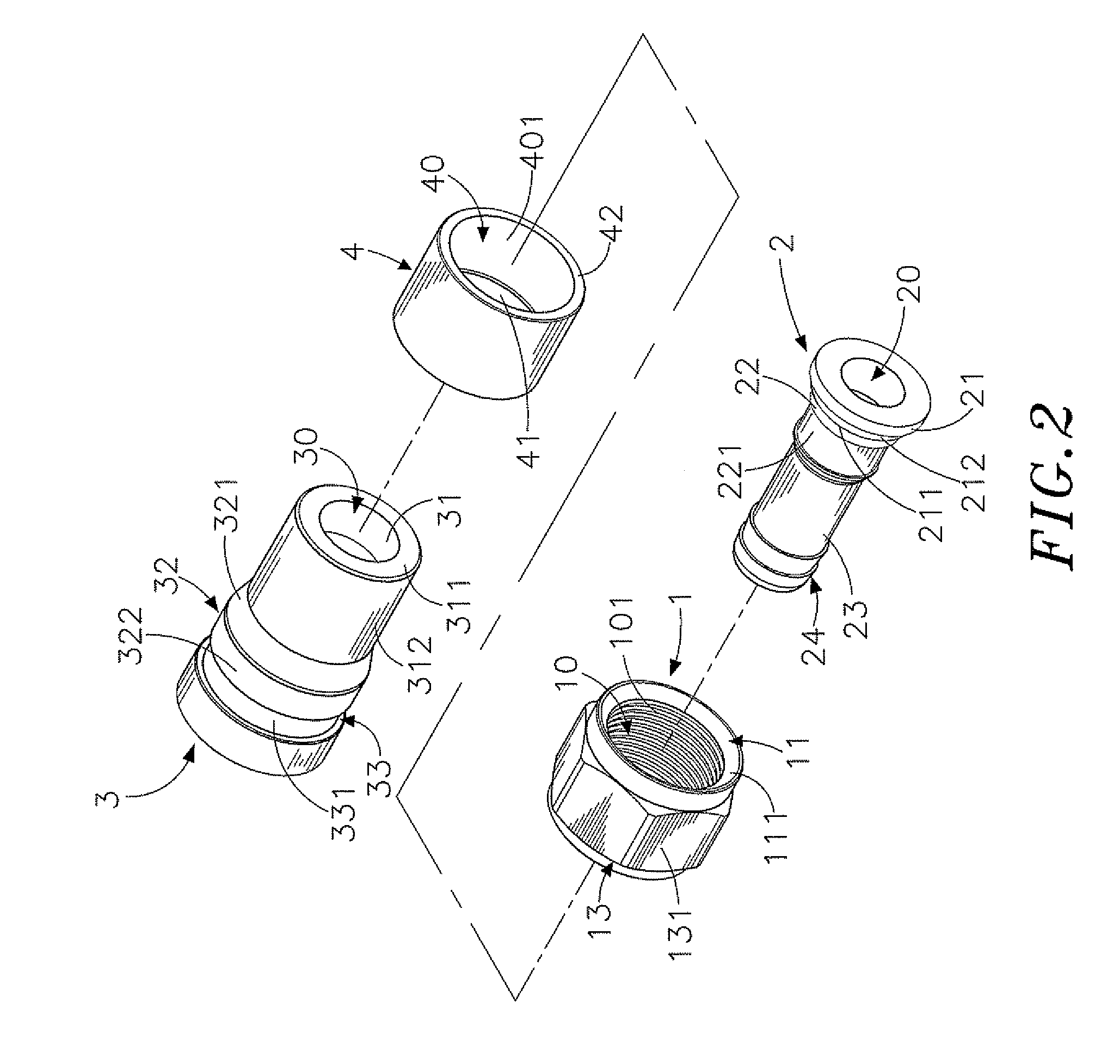

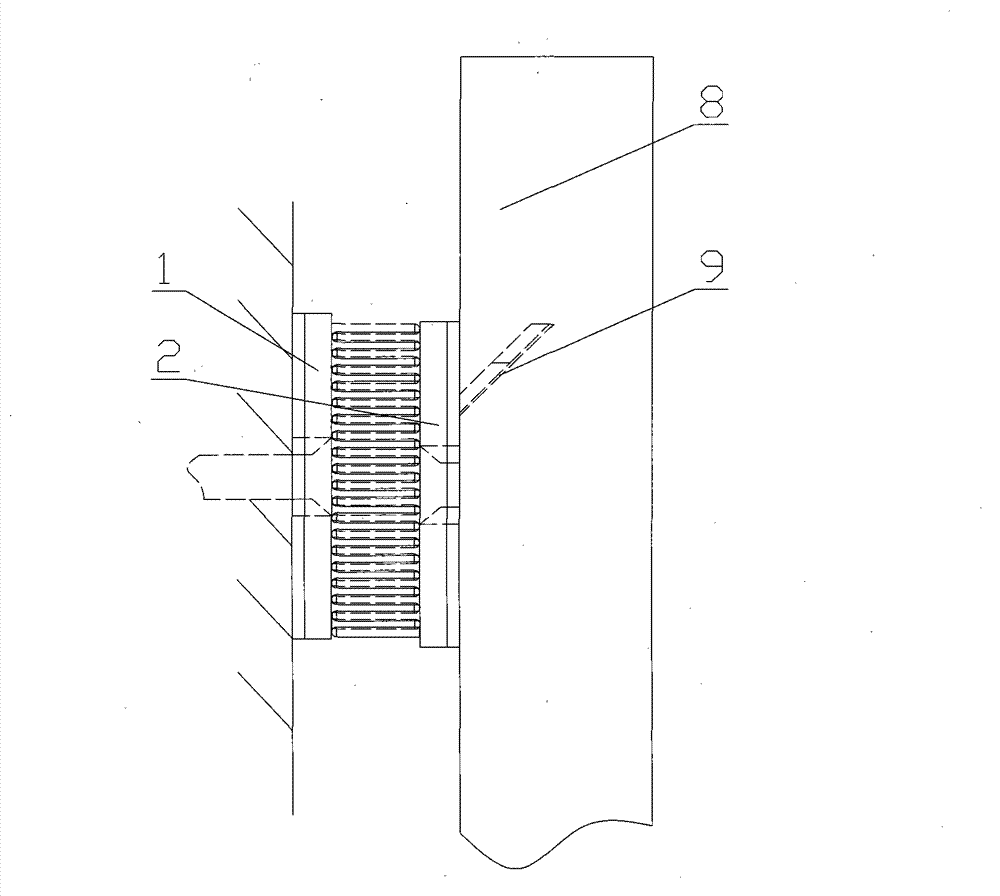

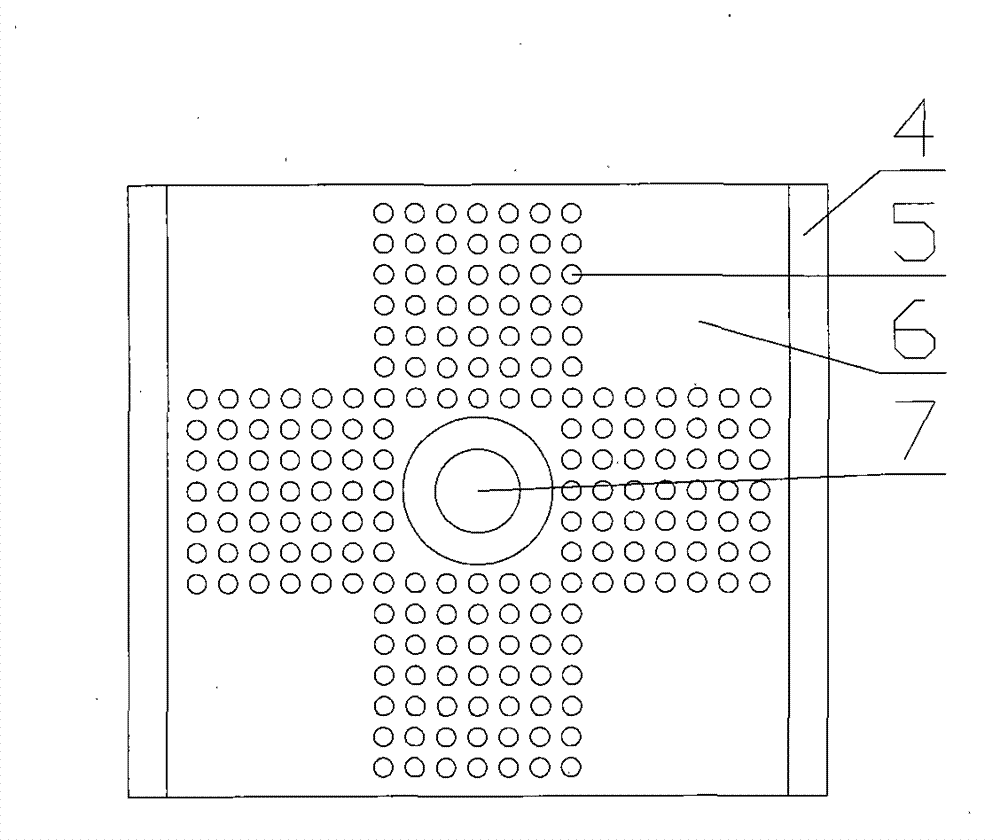

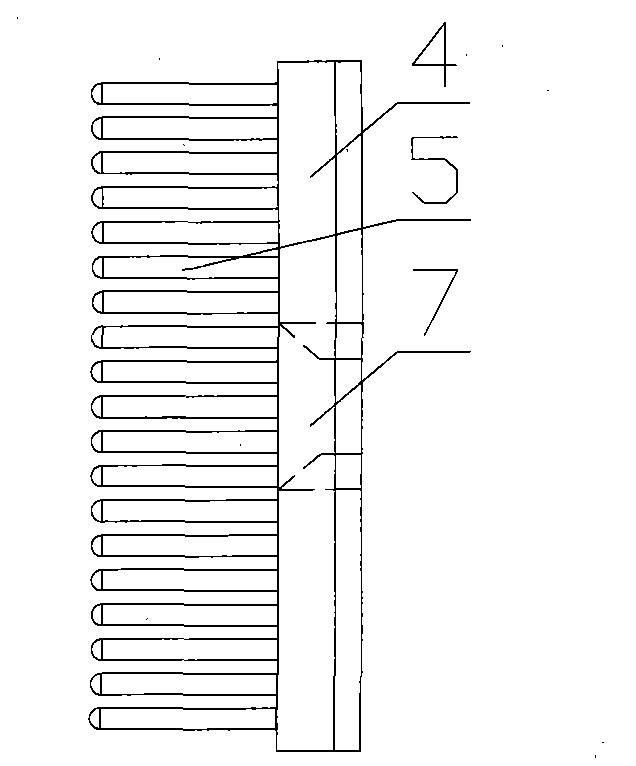

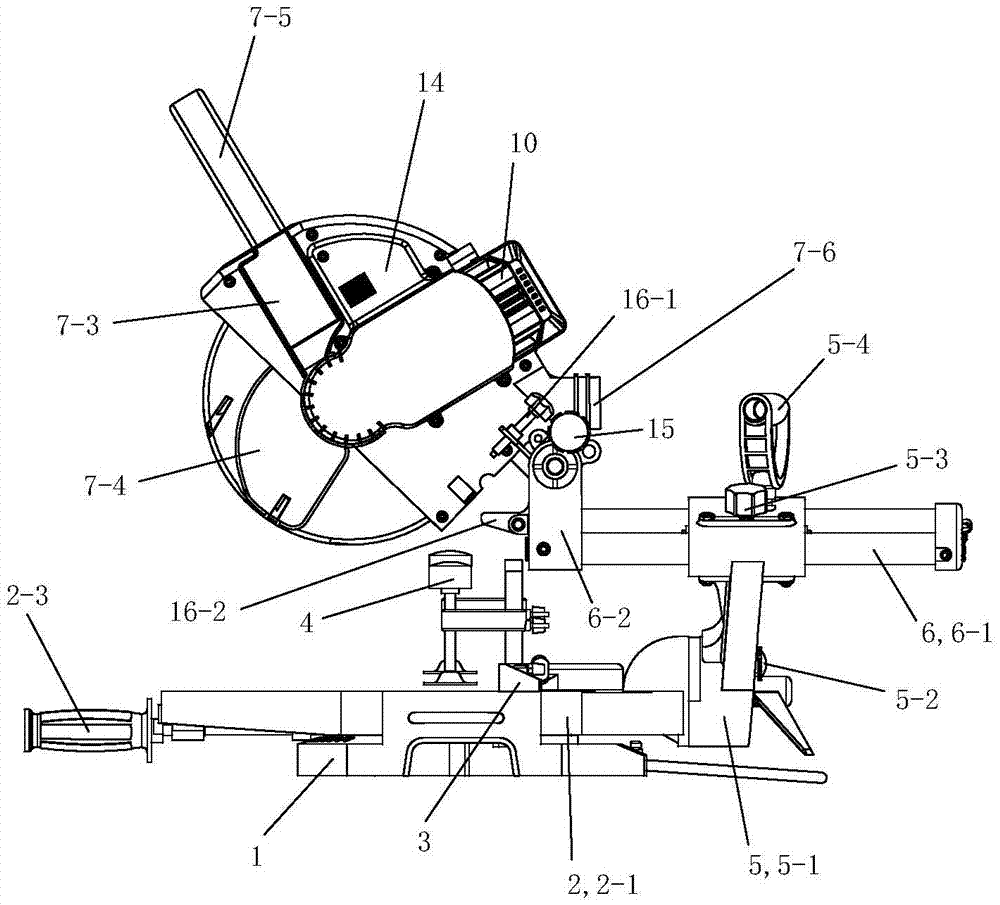

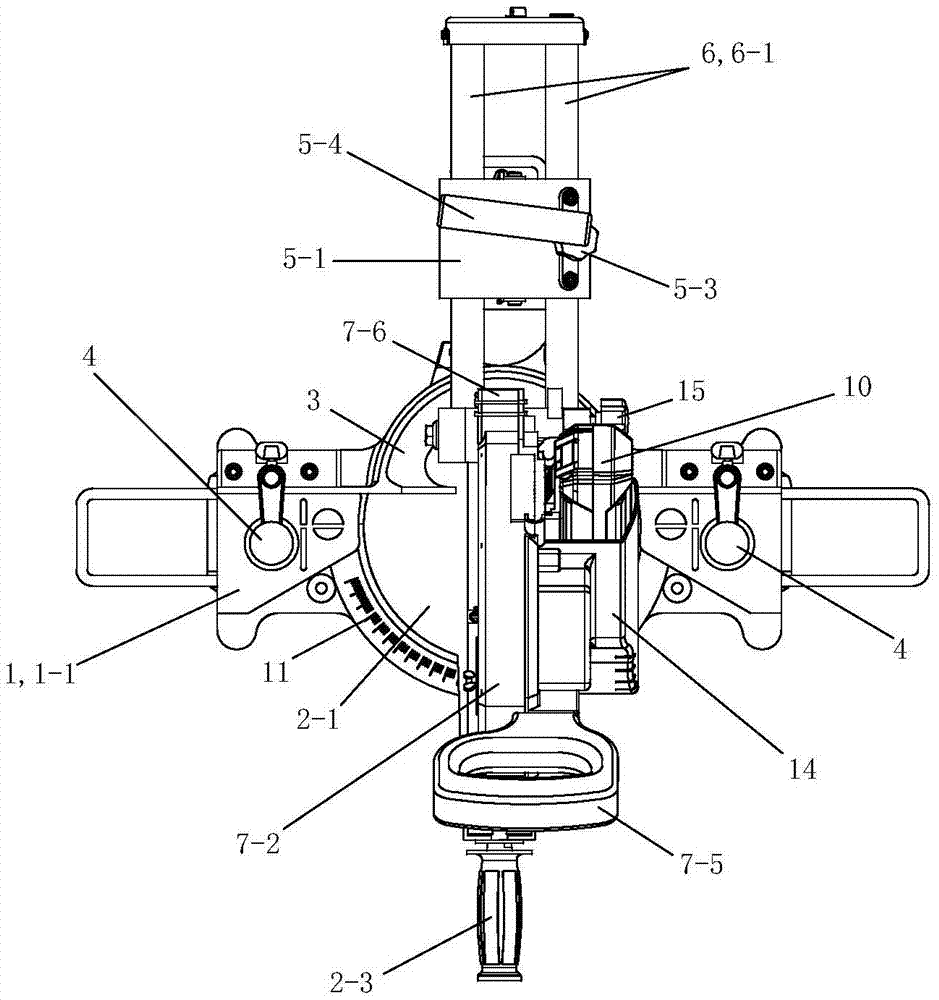

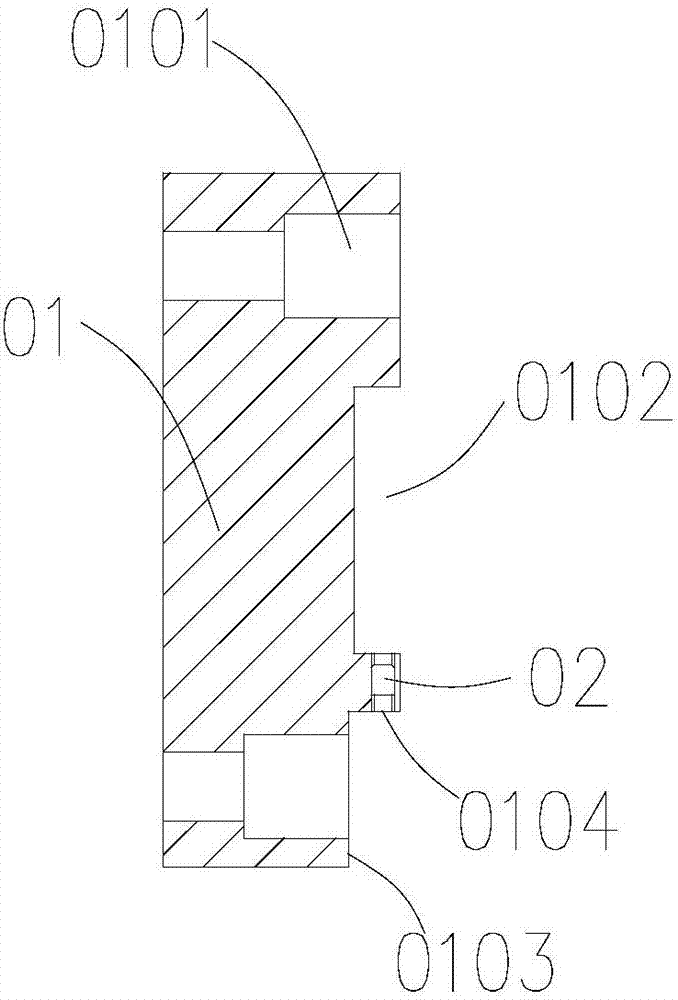

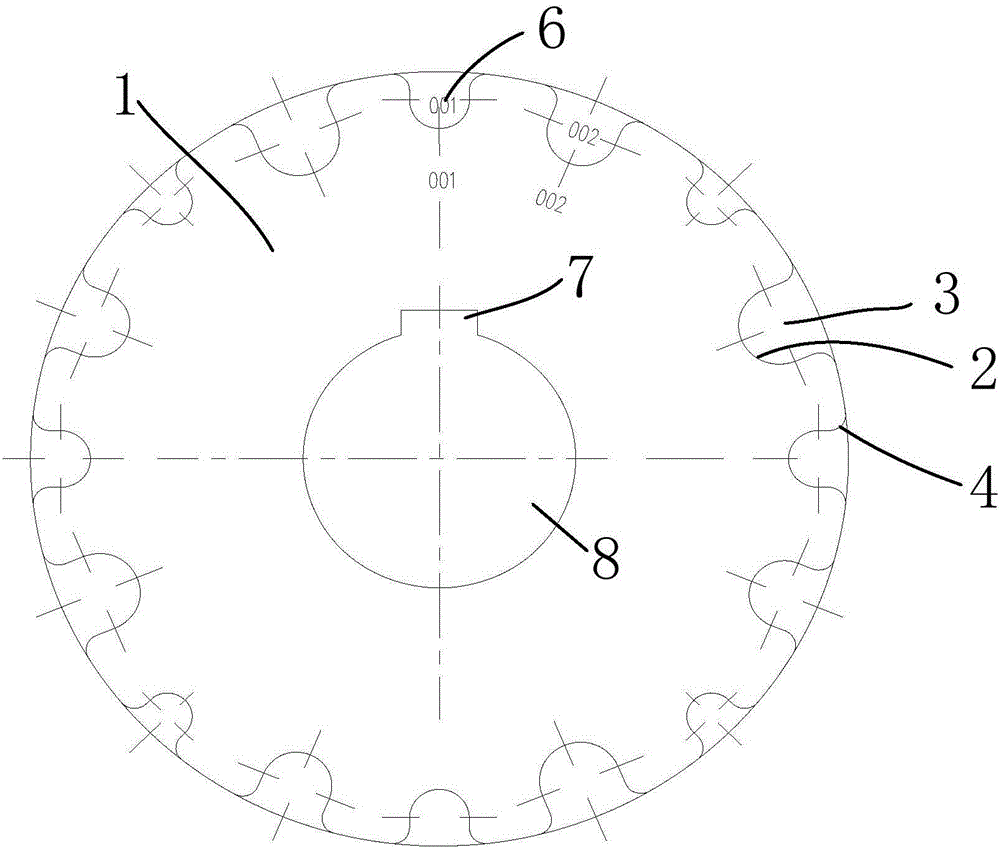

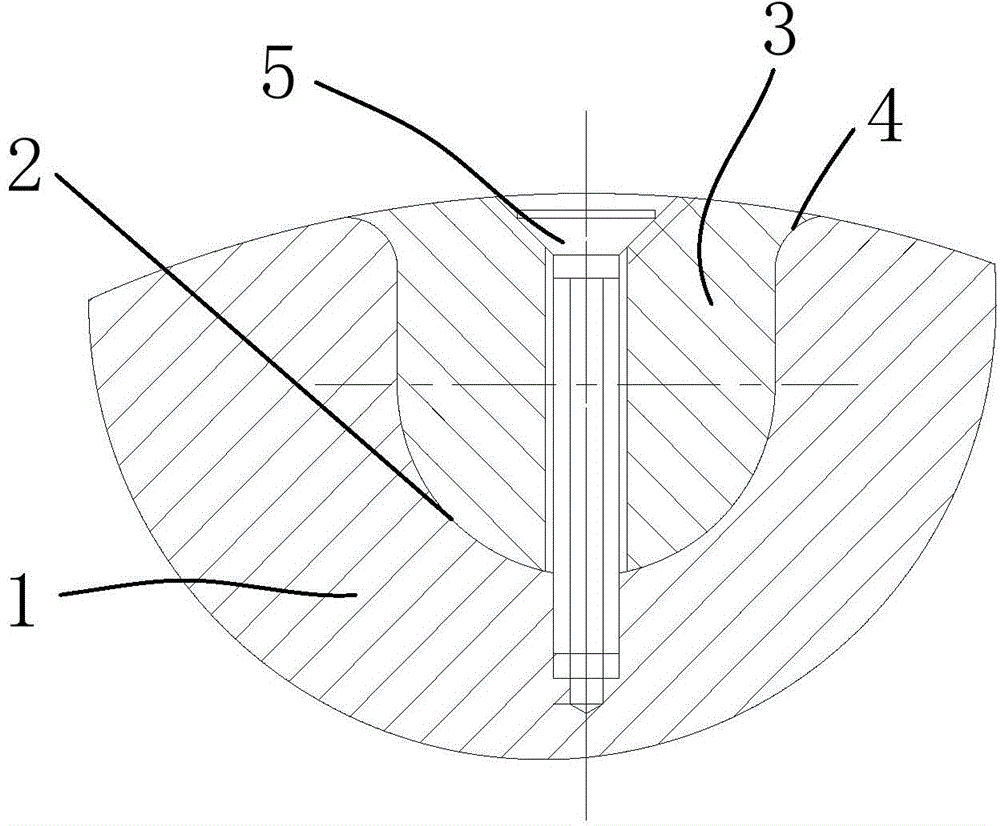

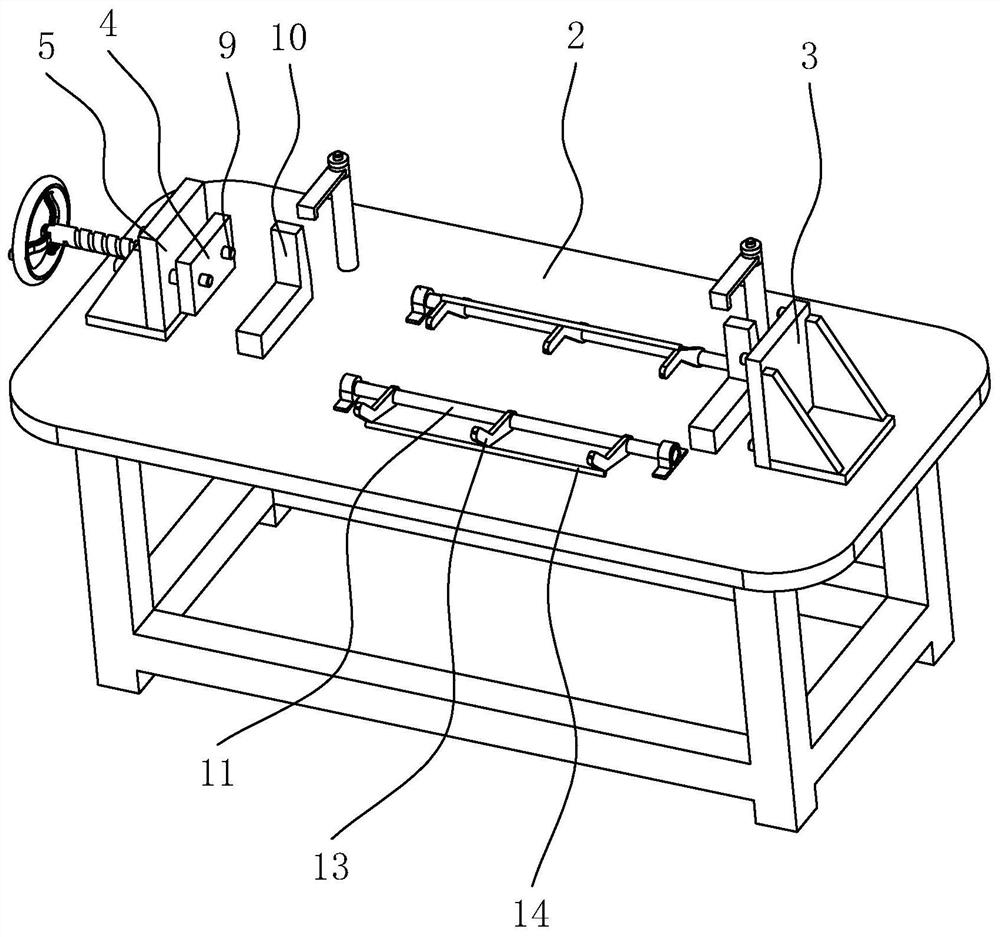

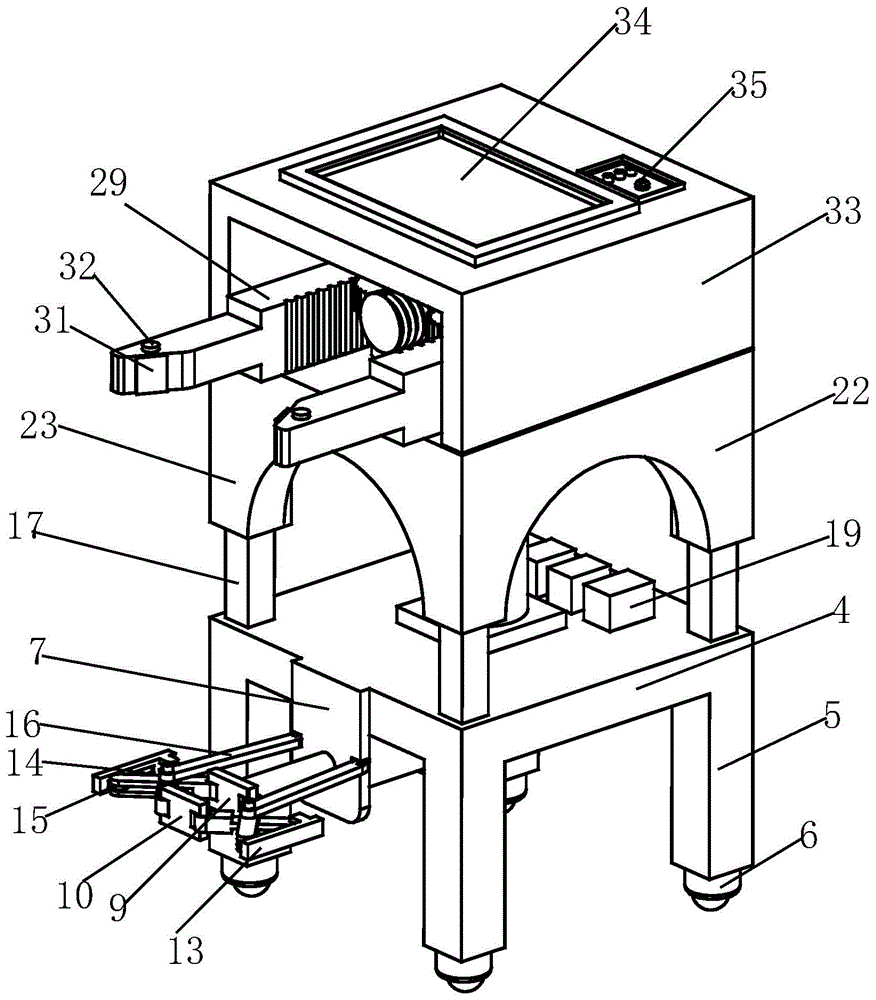

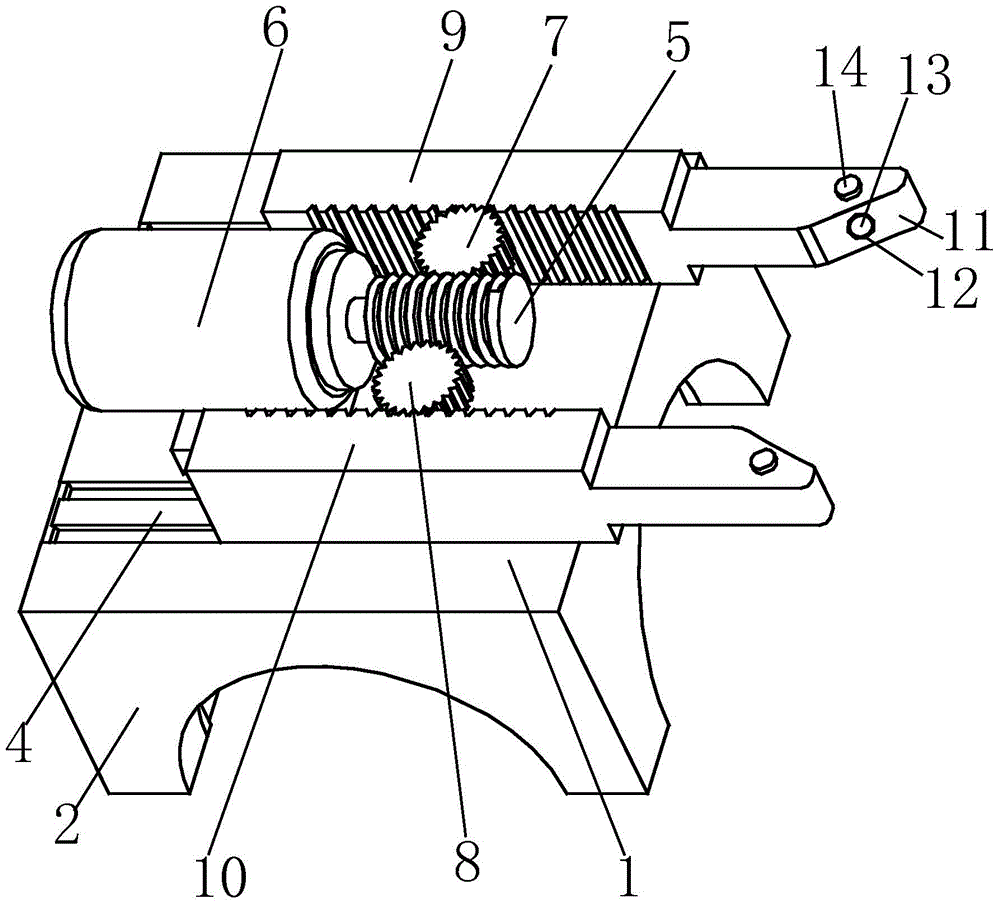

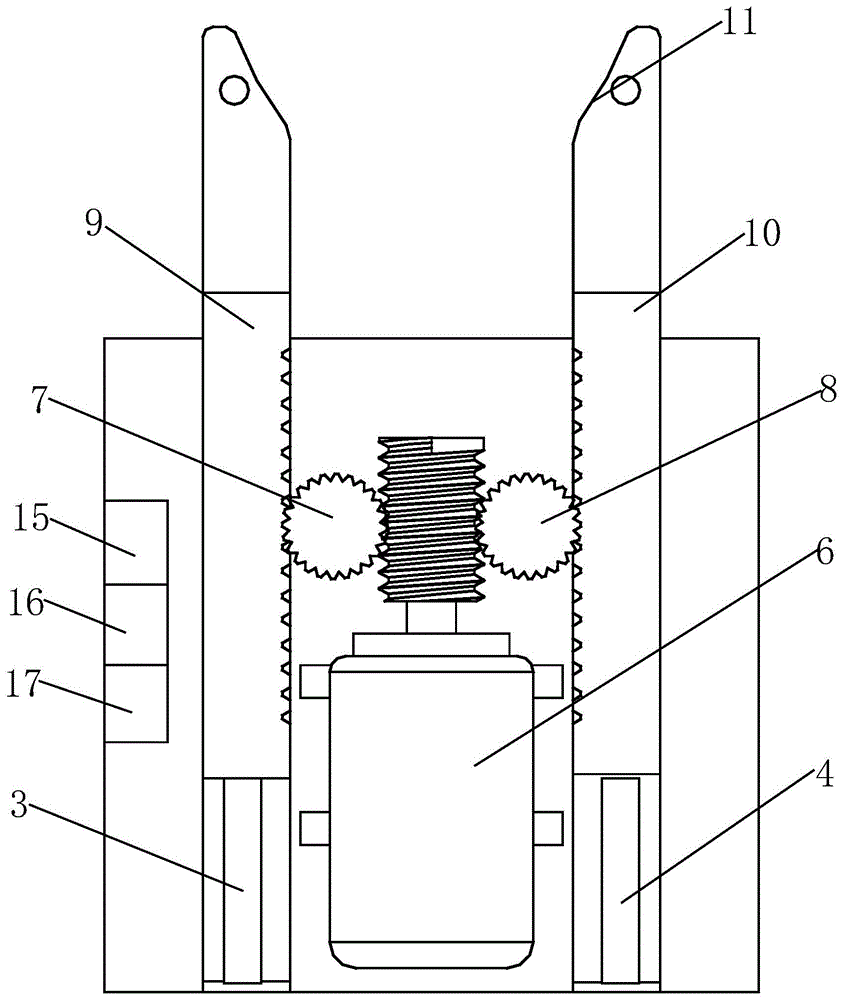

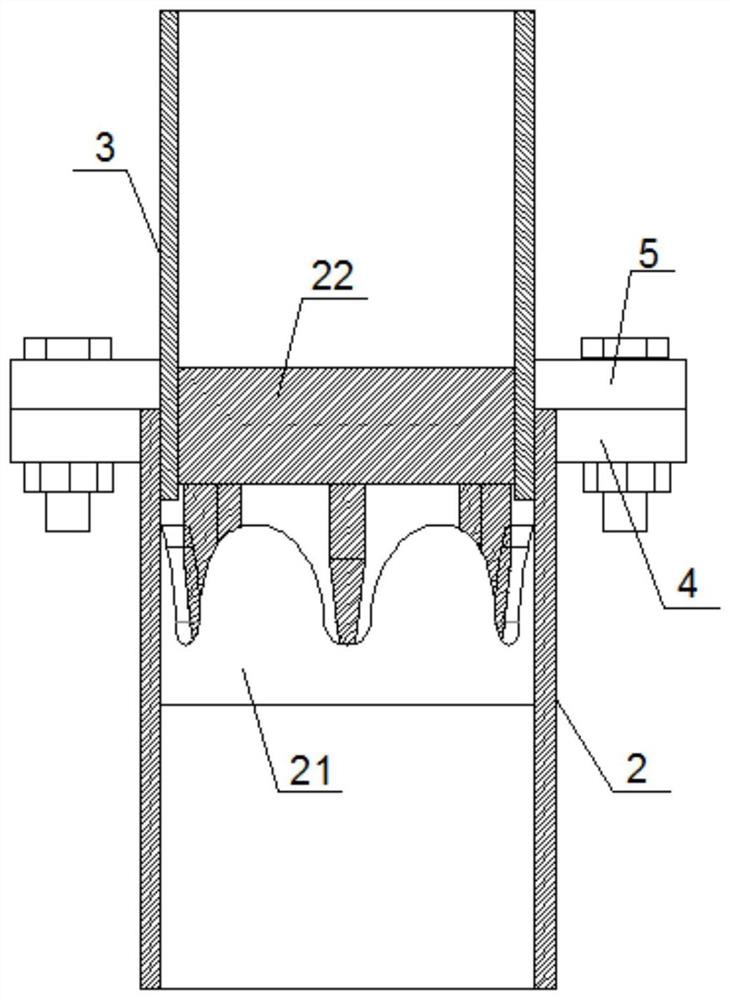

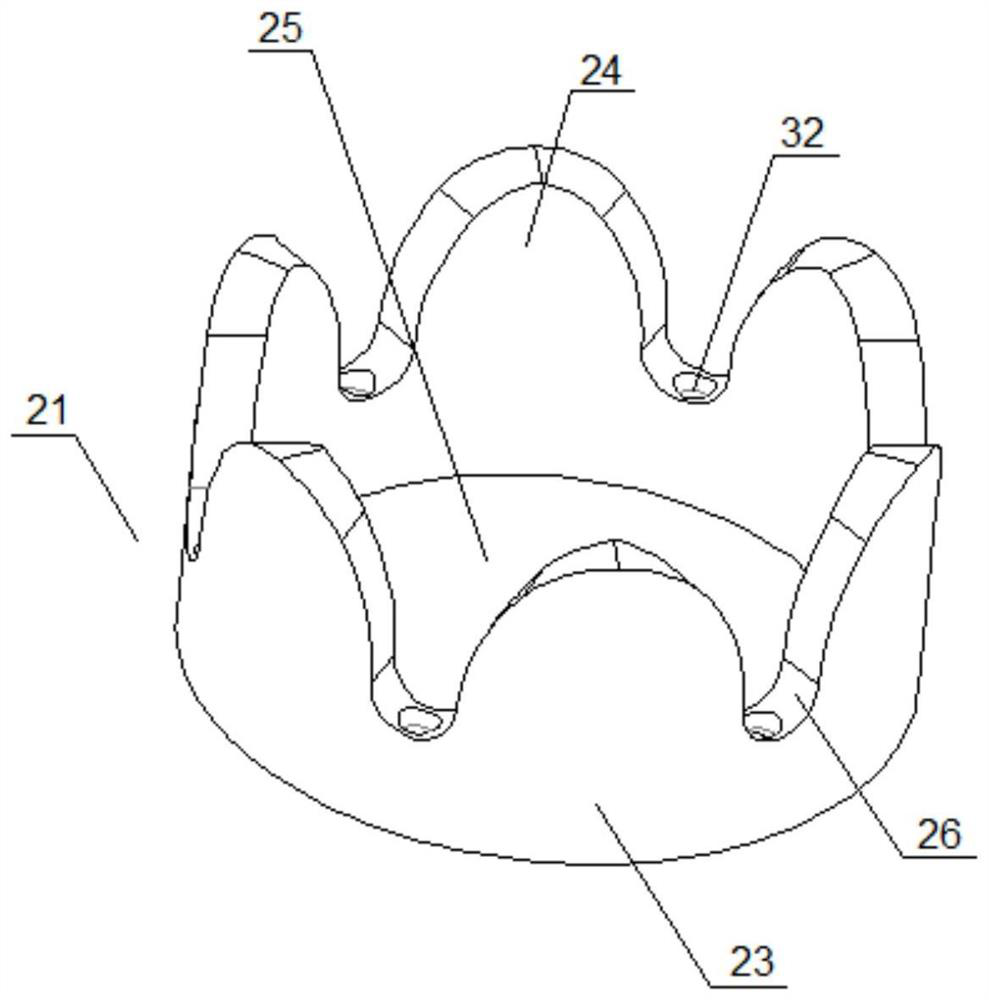

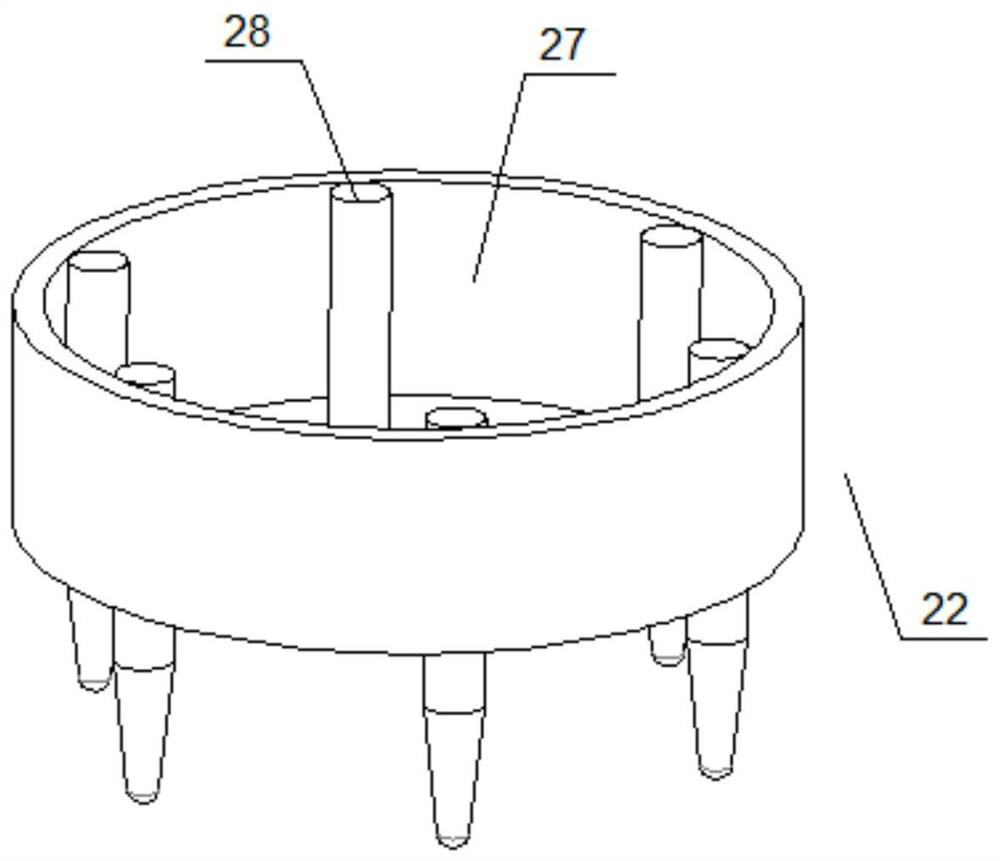

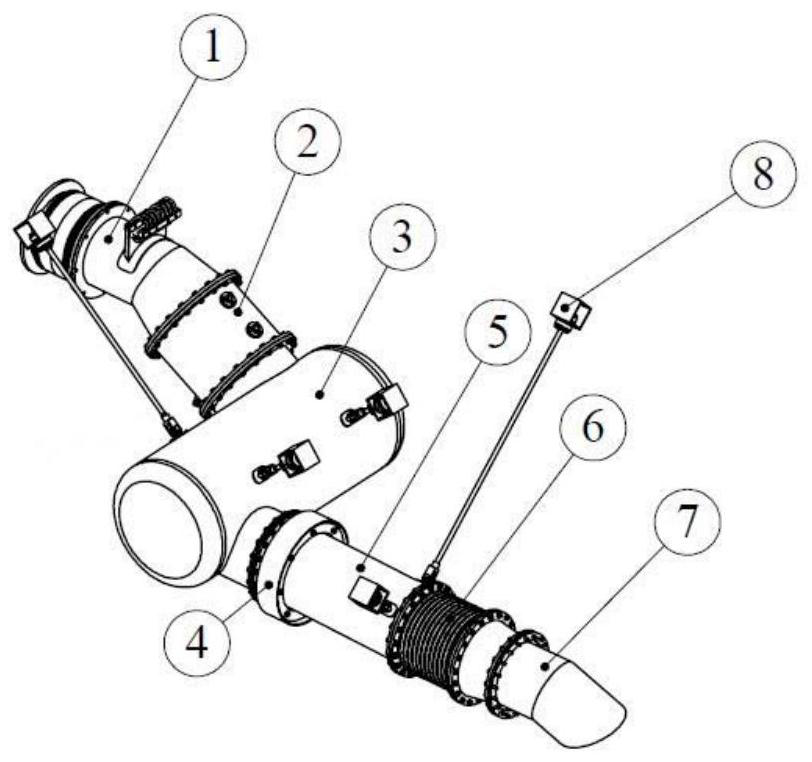

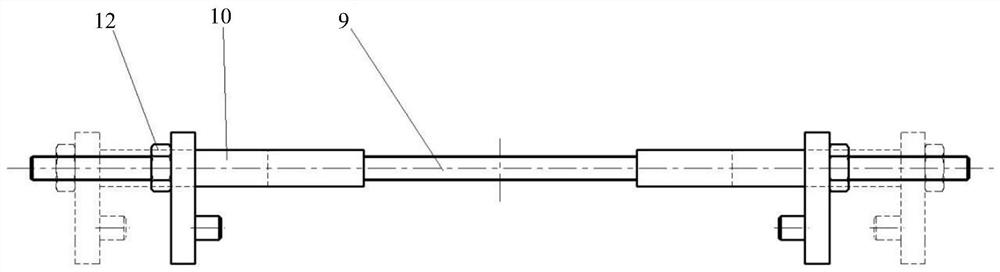

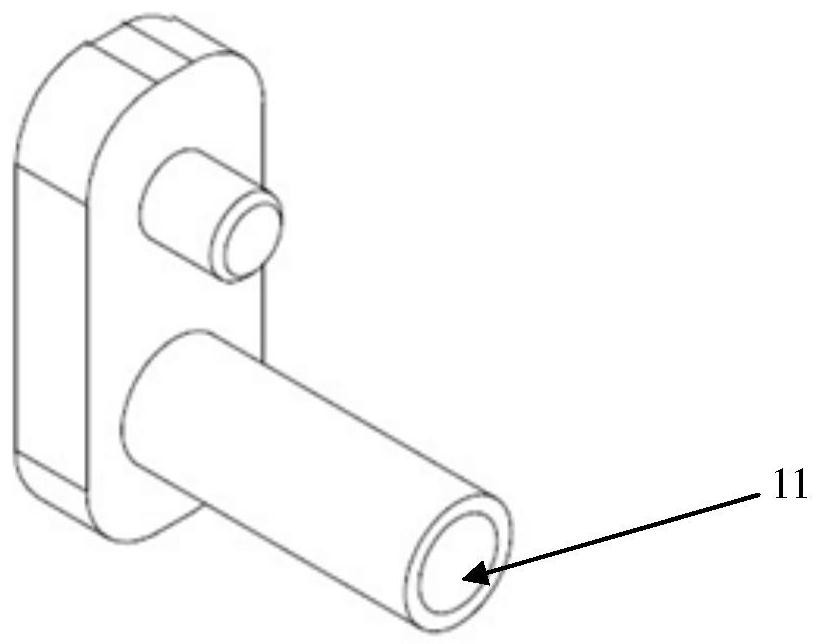

Magnetic pole installing device for surface-mounted permanent magnet motor

ActiveCN104993656ASimplify the pole assembly processImprove installation accuracyMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringElectrical and Electronics engineering

The invention provides a magnetic pole installing device for a surface-mounted permanent magnet motor. The magnetic pole installing device comprises a locating mechanism (10) locating and fixing a rotor core (5), an indexing mechanism (1) driving the rotor core (5) to rotate and setting the angle, a guide mechanism (6) holding magnetic poles (4) and aligning the magnetic poles (4) and magnetic pole grooves of the rotor core (5), and a power pushing mechanism (7) pushing the magnetic poles (4) to install the magnetic poles in the magnetic pole grooves. The indexing mechanism (1) and the rotor core (5) rotate in linkage. The magnetic pole installing device effectively solves such problems as great difficulty in surface-mounted permanent magnet motor magnetic pole installing and low surface-mounted permanent magnet motor magnetic pole installing accuracy.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

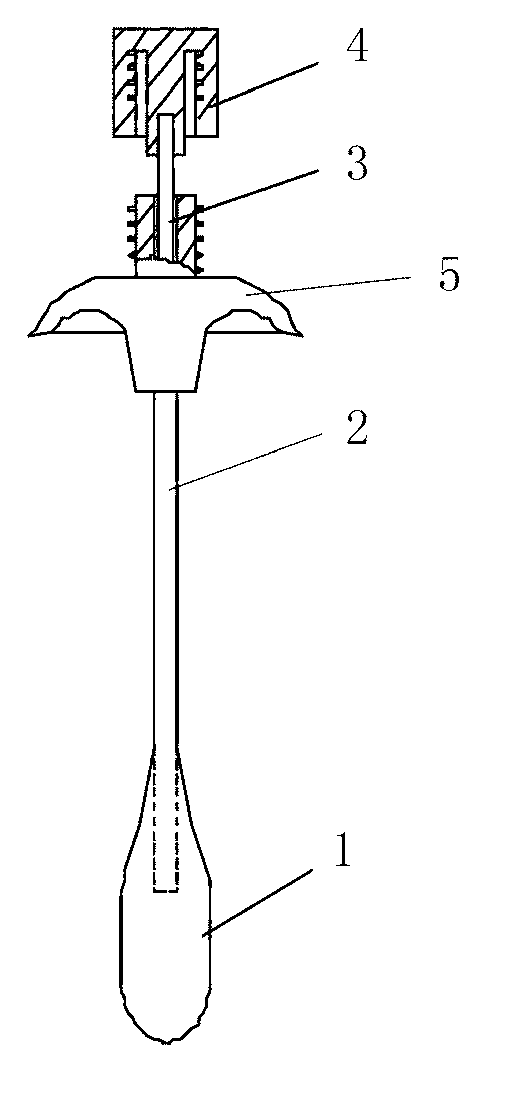

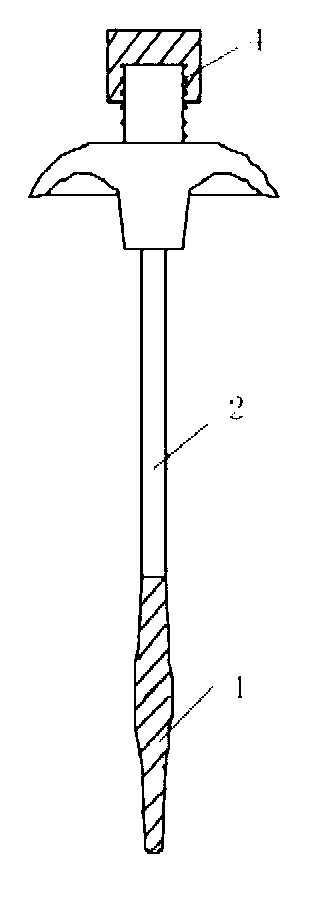

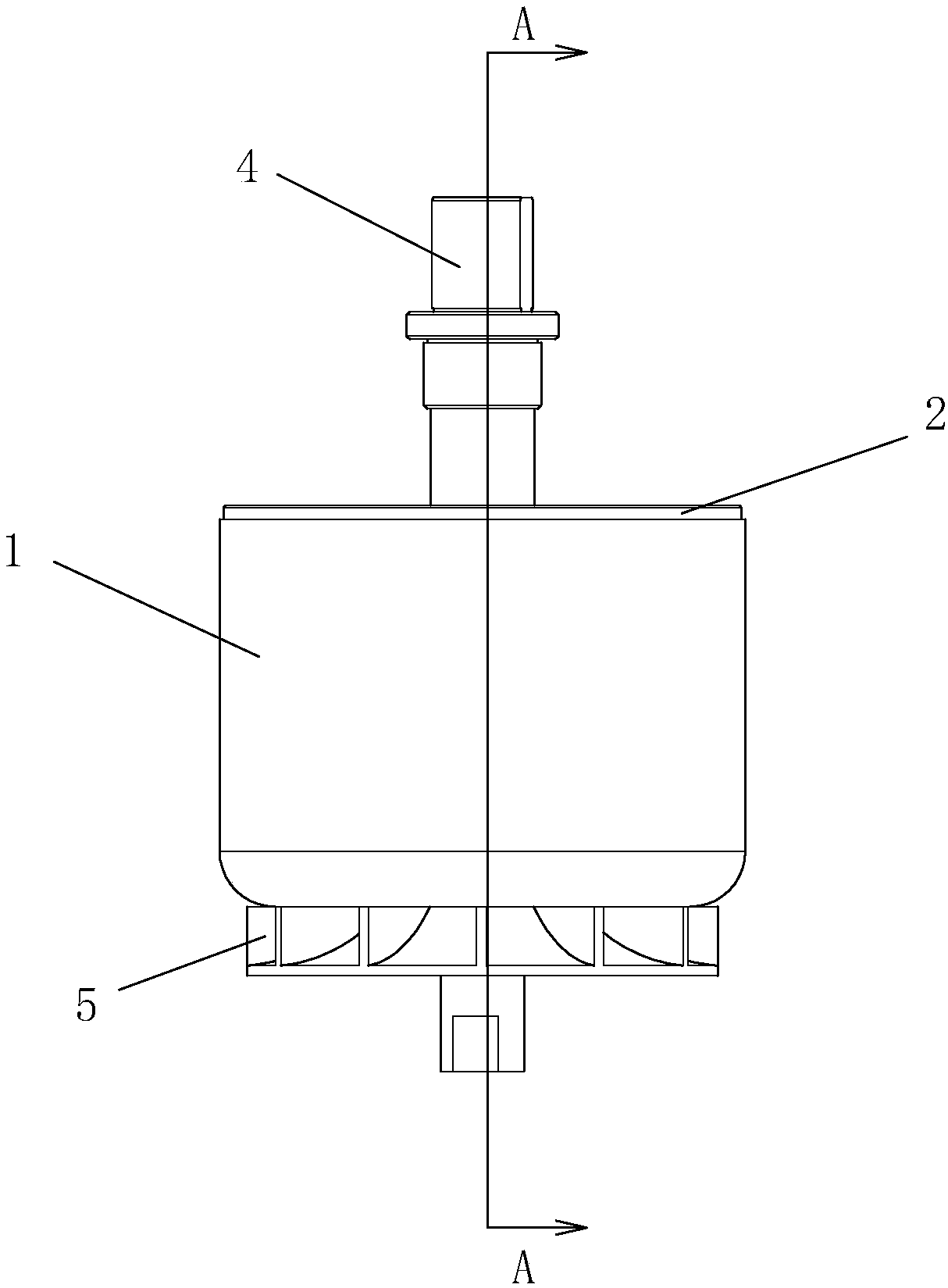

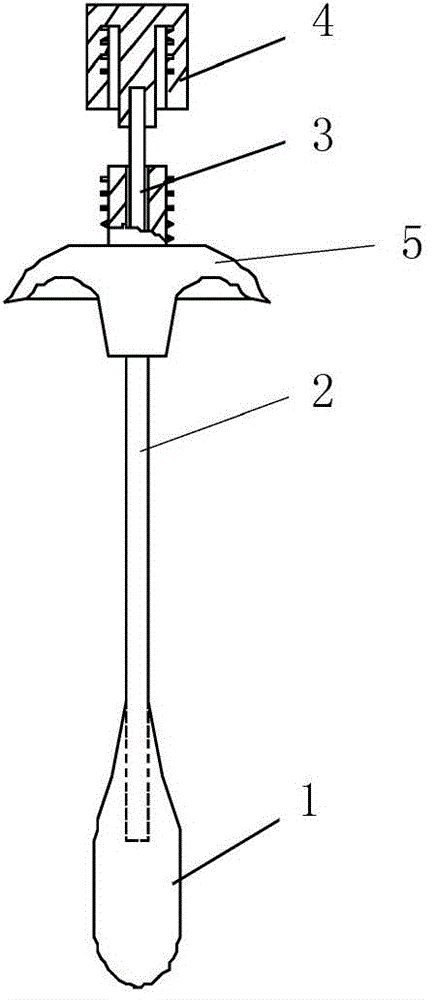

Bone cement filling balloon structure

ActiveCN102835995AHas bone conduction propertiesOsteogenic activitySurgeryPolyethylene glycolAbsorbent material

The invention discloses a bone cement filling balloon structure, which comprises a pipeline-shaped injector, and a balloon connected onto the lower end of the injector, wherein a preassembled rod extending into the balloon is arranged in an inner cavity of the injector; the balloon is made of absorbable materials, such as poly-L-lactic acid, poly-DL-lactic acid, polyglycolic acid, polycaprolactone, polyethylene glycol, poly-di-chalk alkyl ketone, polytrimethylene carbonate, and a copolymer or a polymer blend thereof; and the molecular weight of the absorbable materials is 5,000-1,000,000. The bone cement filling balloon structure disclosed by the invention has the advantages that not only is the distribution of bone cement in a vertebral body be effectively controlled to prevent the bone cement from leaking in quantity, but also the bone cement can be absorbed in the body; and the bone cement filling balloon structure is simple to operate during an operation.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL +1

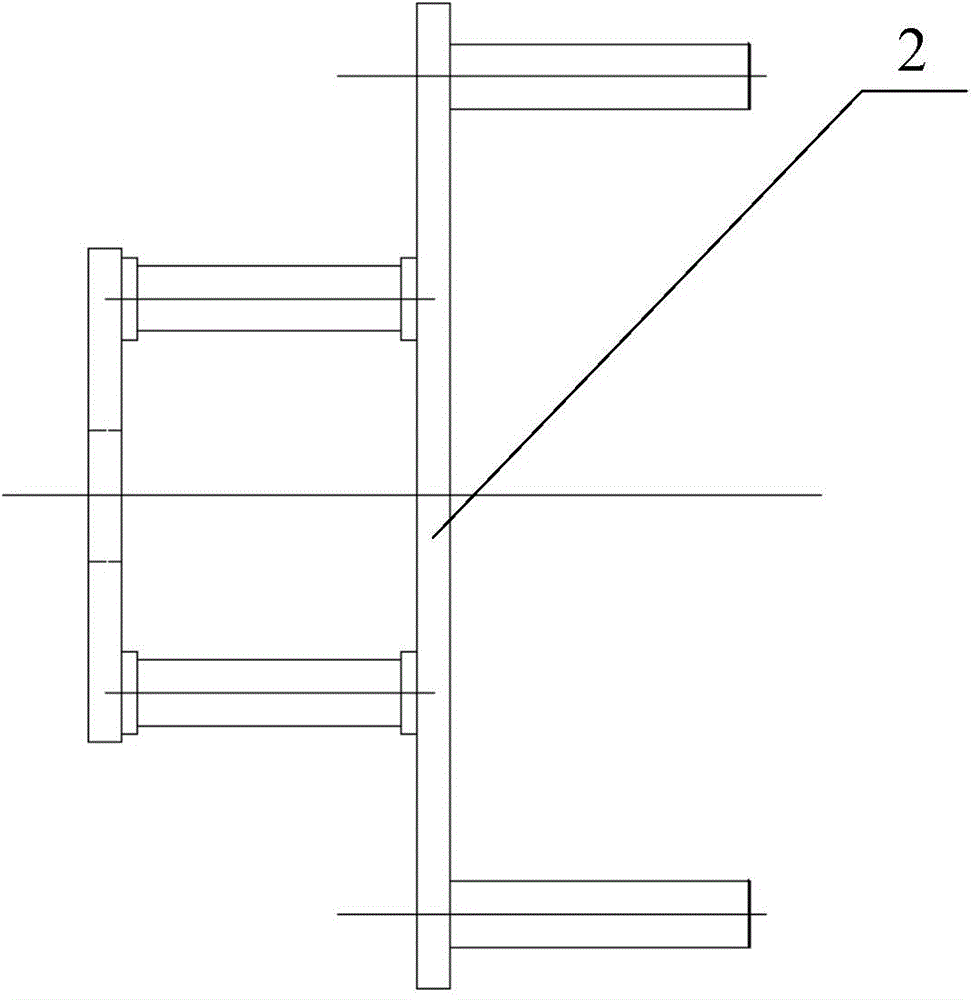

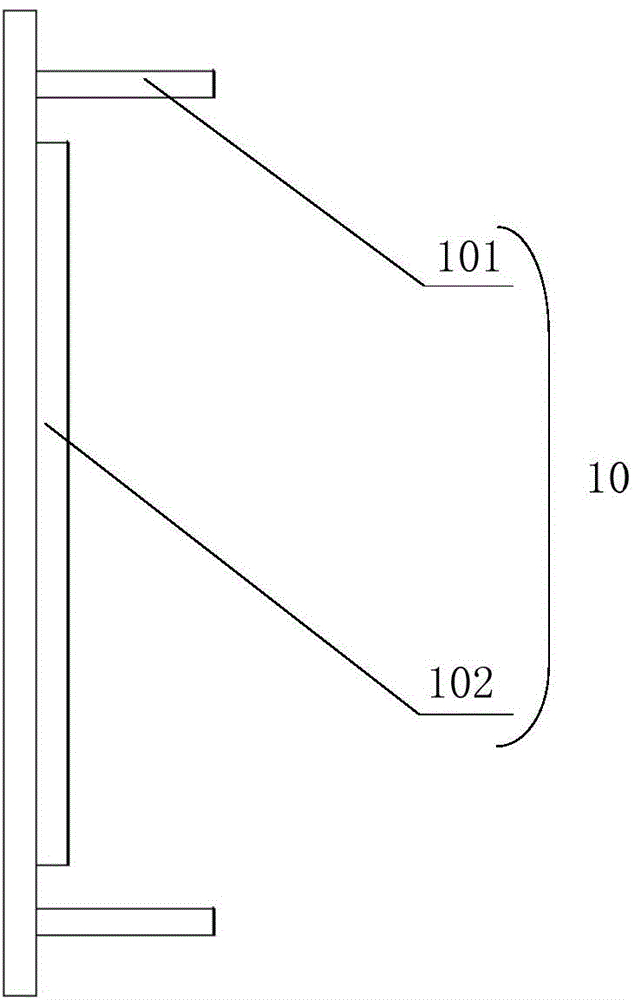

Multi-column-shaped inserting type multipurpose hanging piece

InactiveCN103088987AAccurate and quick installationFirmly connectedCovering/liningsPicture framesBrickKeel

The invention discloses a multi-column-shaped inserting type multipurpose hanging piece, and relates to plate-shaped materials (marble, granite, artificial stones, porcelain plates, vitrified tiles, ceramic plates and glass) of building wall bodies and installation hanging pieces of indoor handiwork hanging pieces (mirror frames and photo frames). The multi-column-shaped inserting type multipurpose hanging piece is structurally composed of wall body hanging pieces and brick body hanging pieces. The brick body hanging pieces are installed on four corner portions of the inner side of a to-be-hanged brick body. The wall body hanging pieces are fixedly arranged on a wall body or a joist. The positions of the wall body hanging pieces correspond to the positions of the brick body hanging pieces on the to-be-hanged brick body. The brick body hanging pieces are inserted into the wall body hanging pieces, and the brick body is hanged on a wall. The multi-column-shaped inserting type multipurpose hanging piece has the advantages of being novel in structure, simple and convenient to process, low in cost, convenient to install, good in stability, easy to adjust, not prone to dropping and the like, thereby being a novel multi-column-shaped inserting type multipurpose hanging piece which integrates economy and practicability.

Owner:王建海

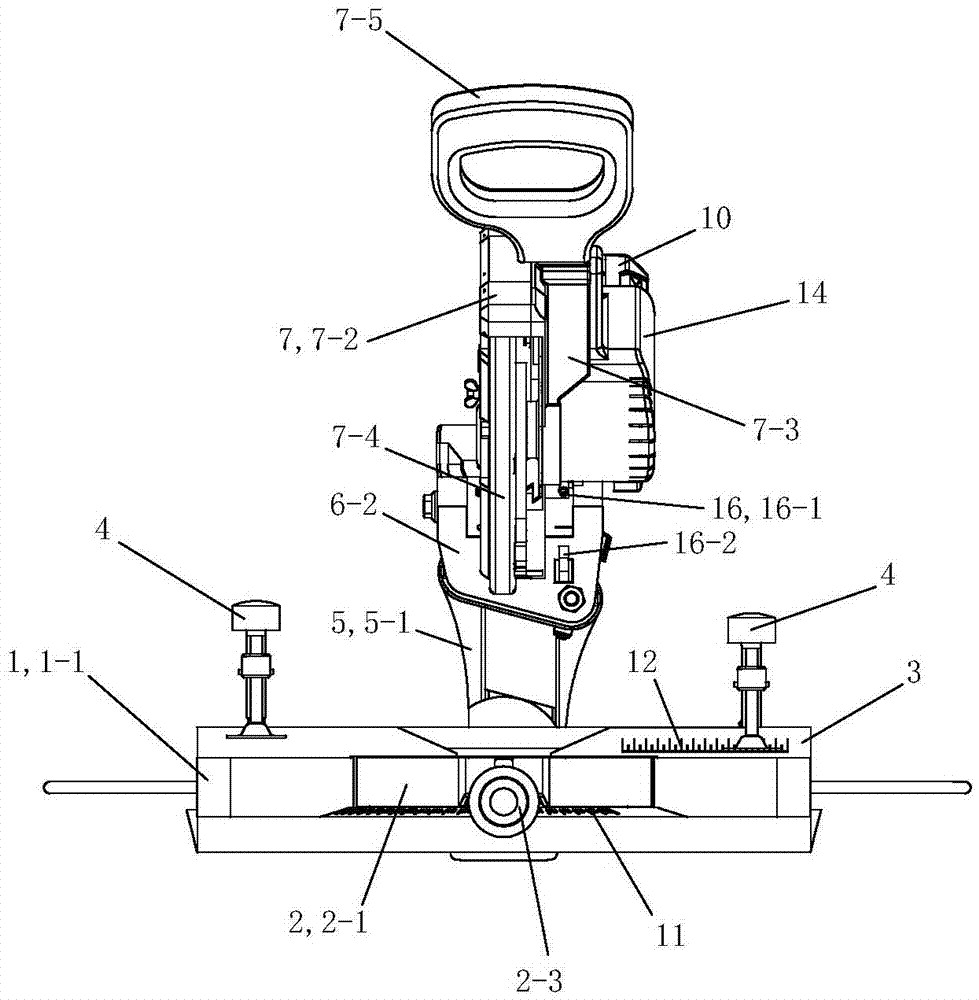

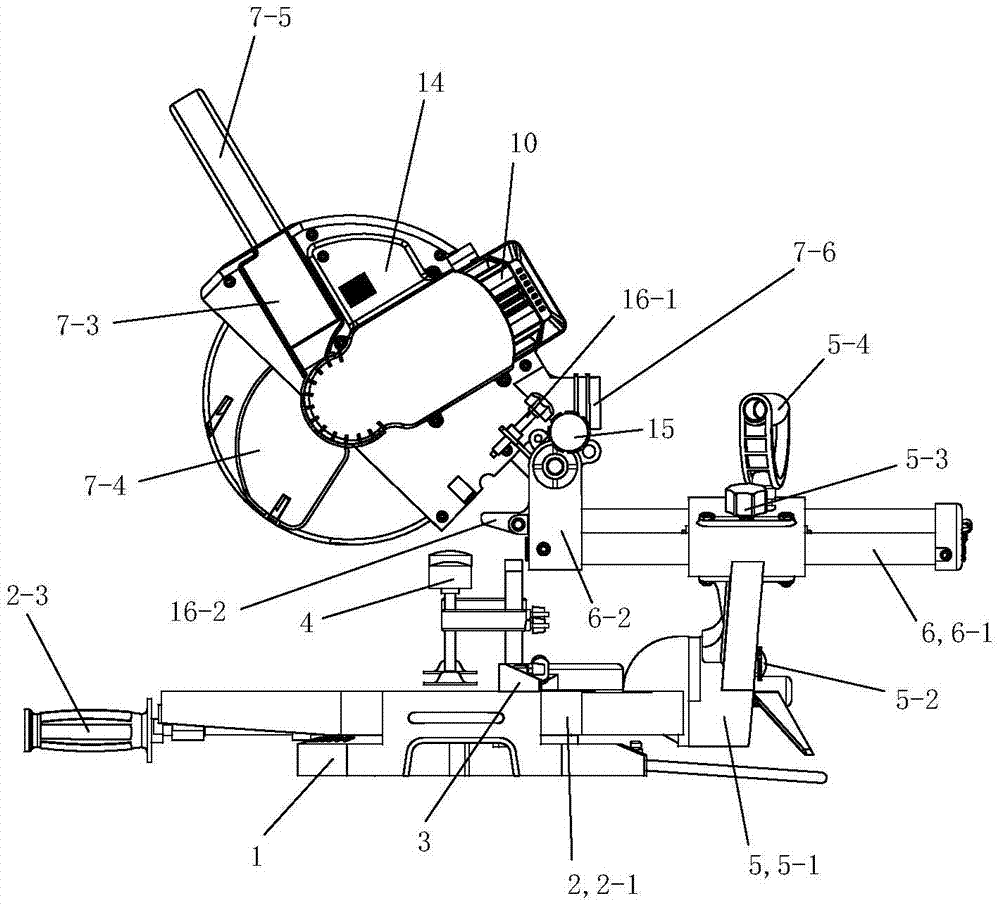

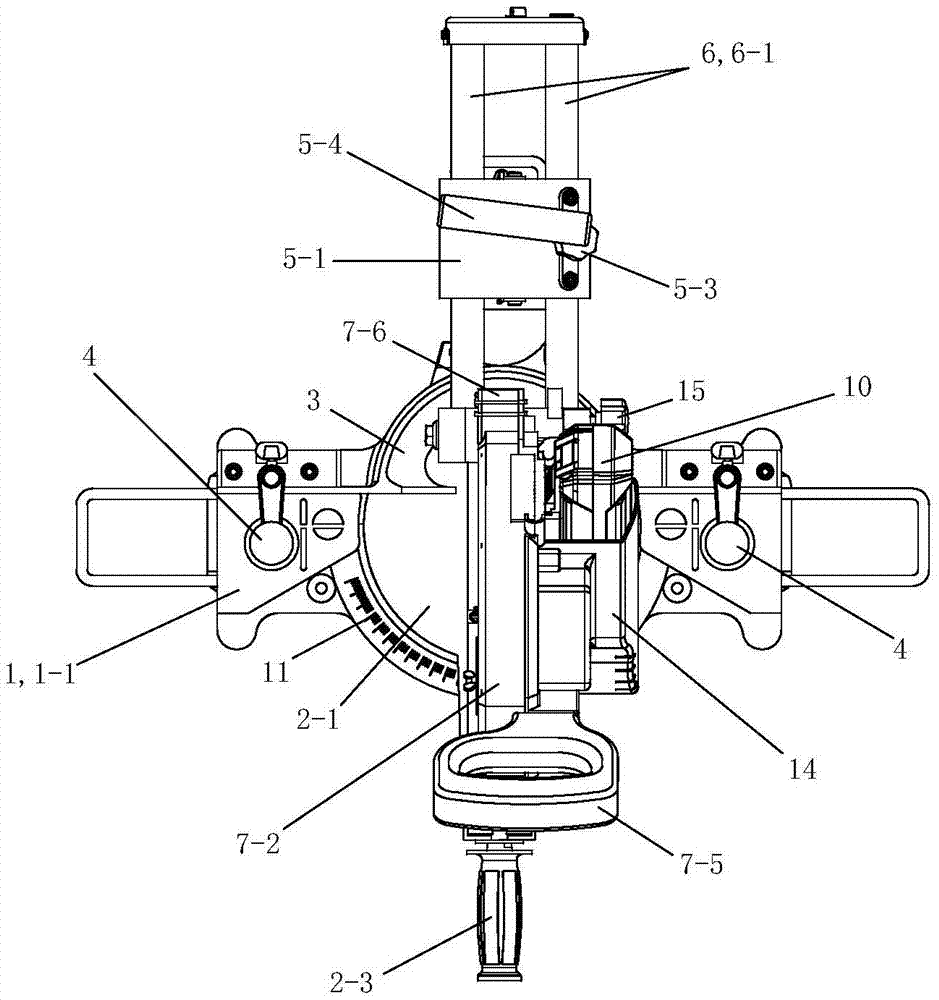

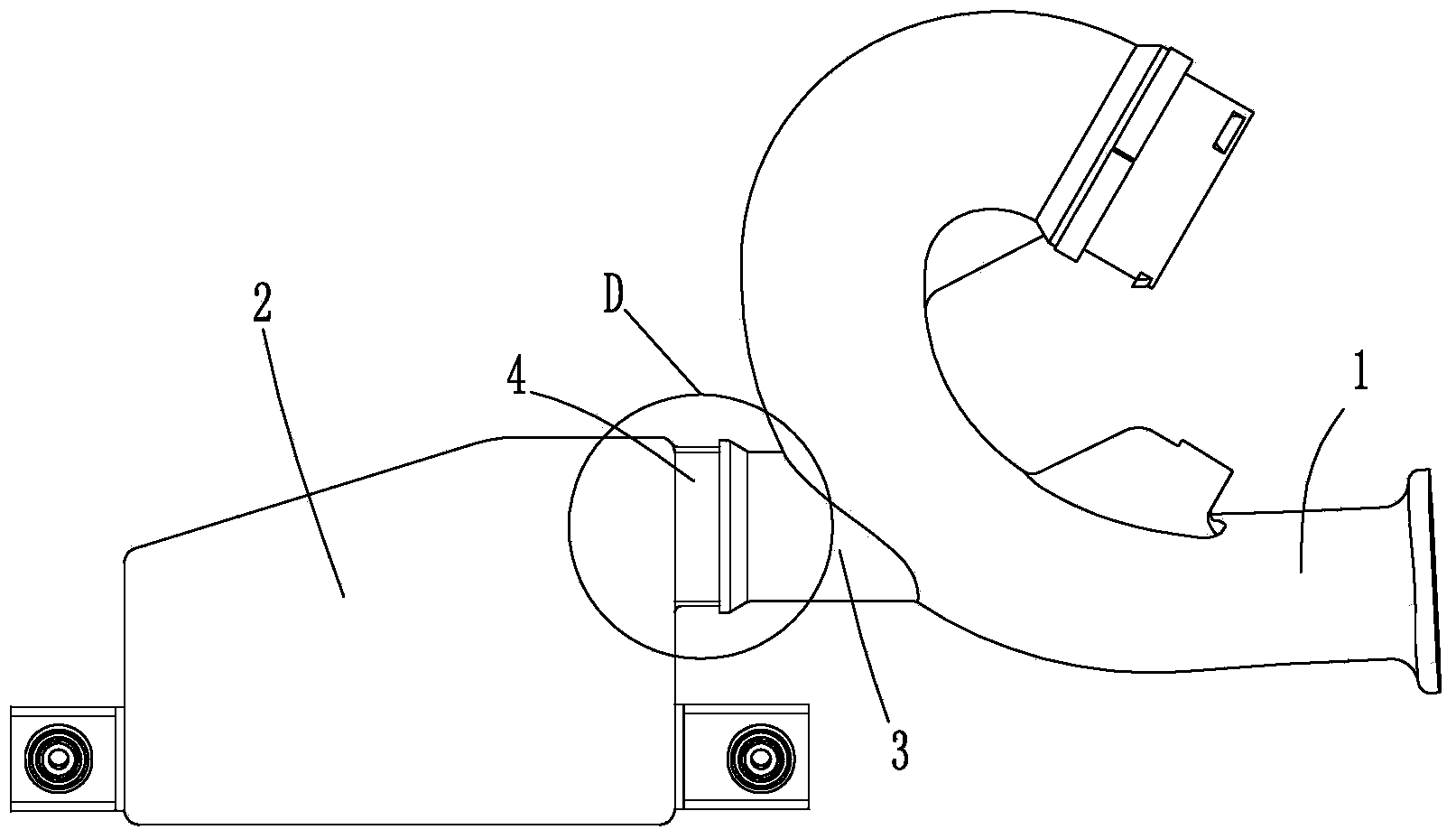

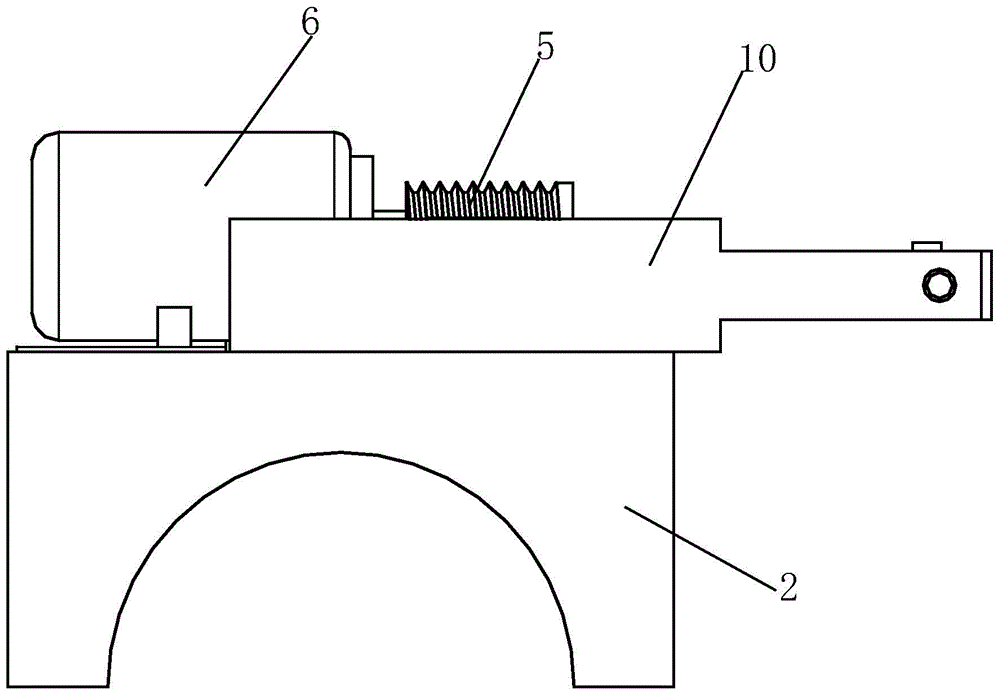

Pull rod type inclined cutting machine convenient to transport

ActiveCN105436606ASimple structureReduce volumeMetal sawing devicesMagnetic circuit rotating partsBrushless motorsElectric machine

Owner:CHANGZHOU CREATE ELECTRIC APPLIANCE

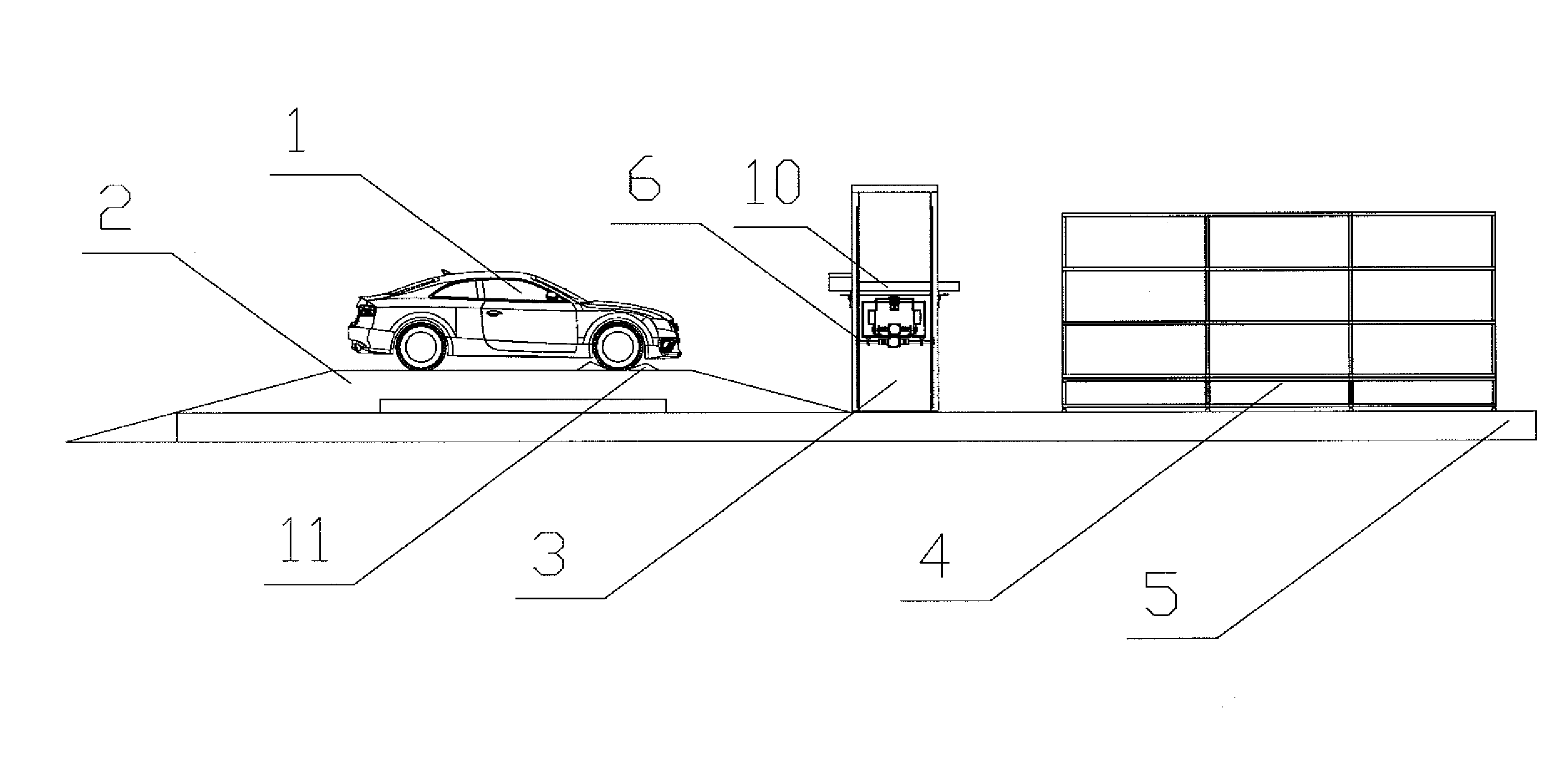

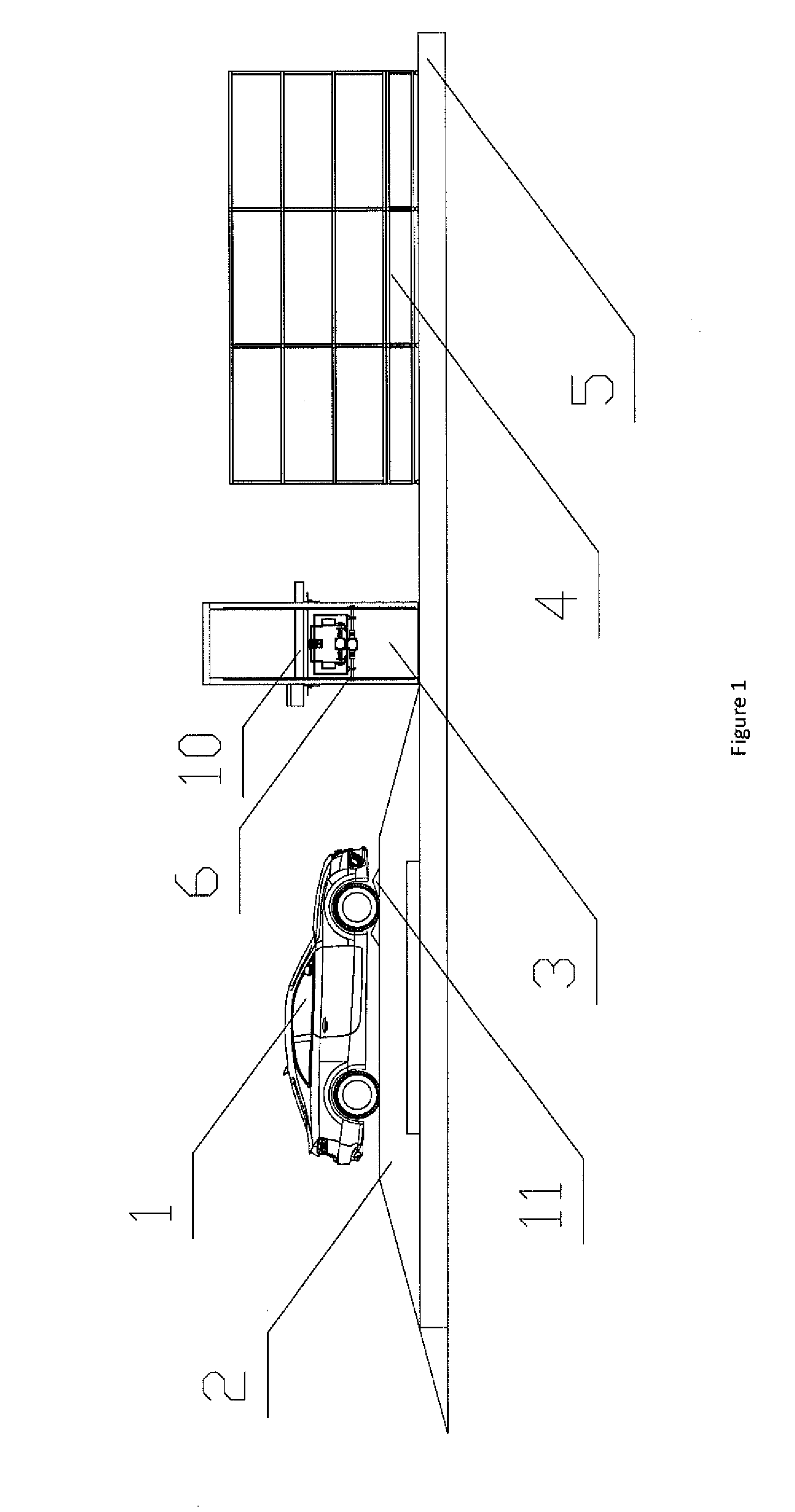

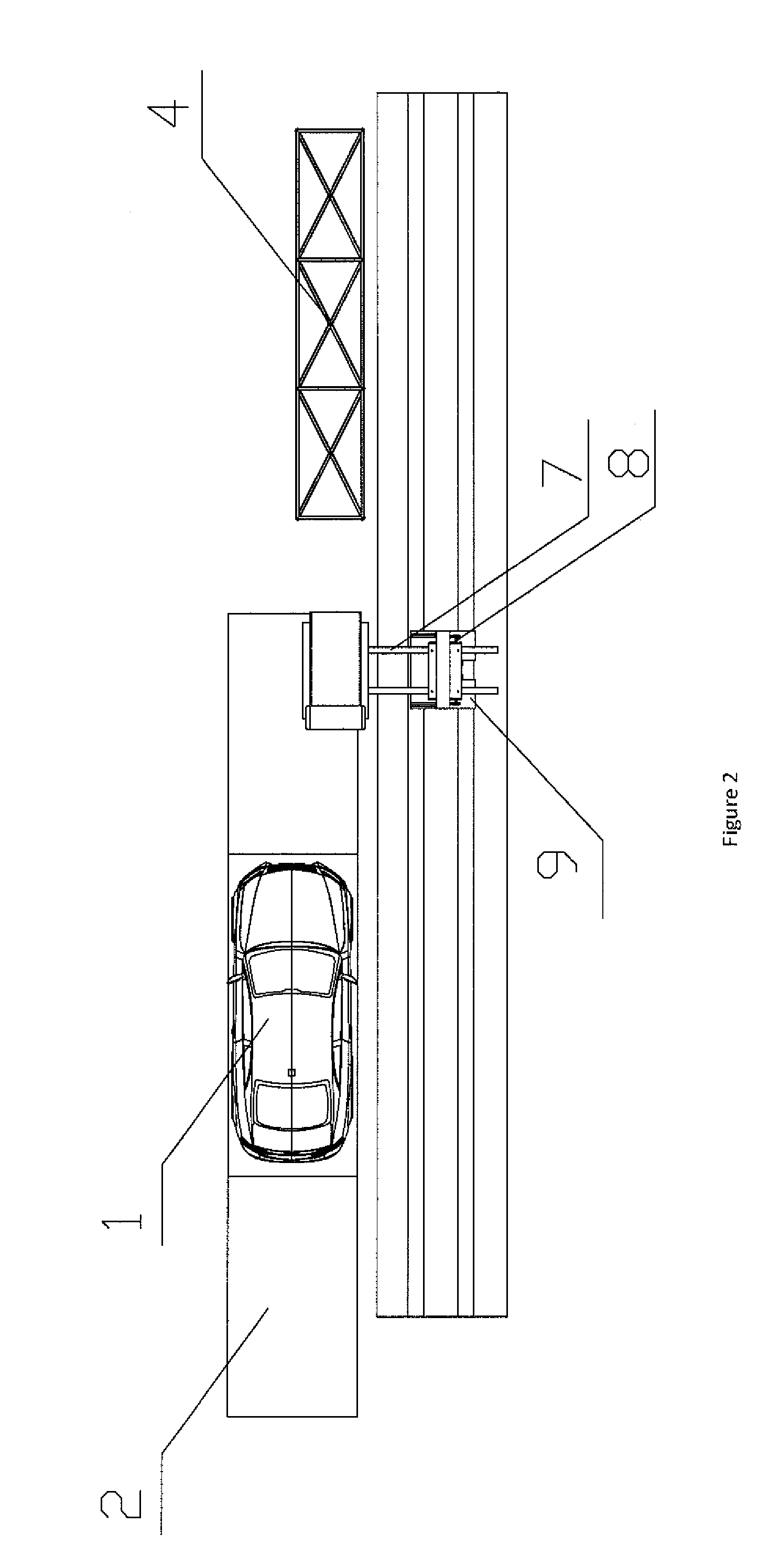

Battery quick-change system for an electric passenger car chassis having a cartesian coordinate robot

InactiveUS8868235B2Achieve and of quickly and accuratelyAccurate and quick installationVehicular energy storageRobotElectric machineControl system

One type of battery quick-change system of electric passenger car chassis based on the Cartesian coordinate robot, including electric changing platform, and this platform, quick-change robot and charging rack along the same straight line; the quick-change robot comprises the battery tray and the Cartesian coordinate robot of four degrees of freedom, the Cartesian coordinate robot is associated with the X-axis driving motor, the Y-axis driving motor, the Z-axis up-down motor, the battery tray is connected with the R-axis driving motor; each of driving motors is connected with the corresponding encoder, and each of encoders is connected to the corresponding drive; there are equipped with a distance measuring sensor on the battery tray, and the corresponding limit switches on the both ends of each two-track rack; the drive, each limit switch and the distance measuring sensor of each driving motor are connected with the control system.

Owner:SHANDONG ELECTRIC POWER RES INST

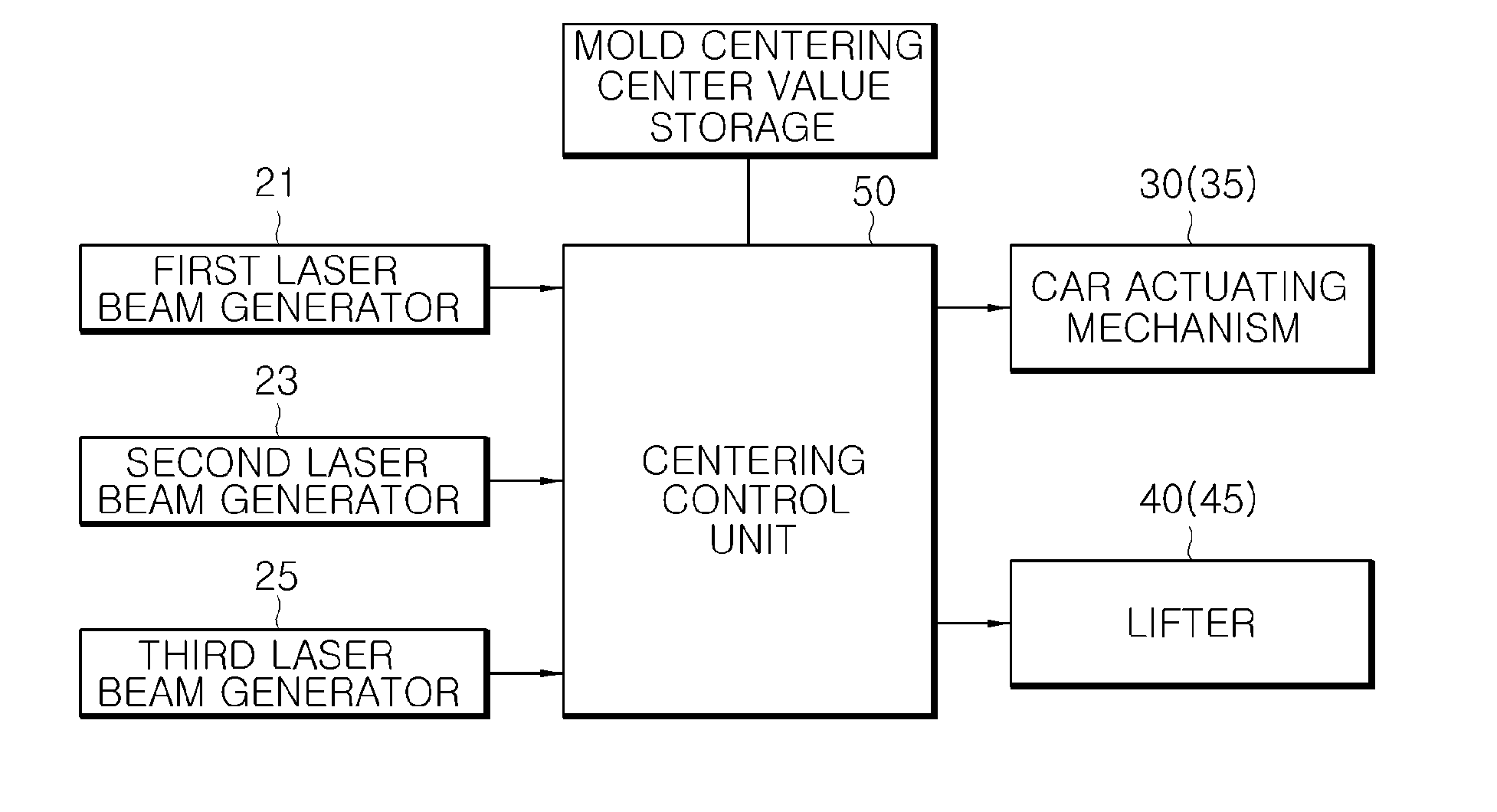

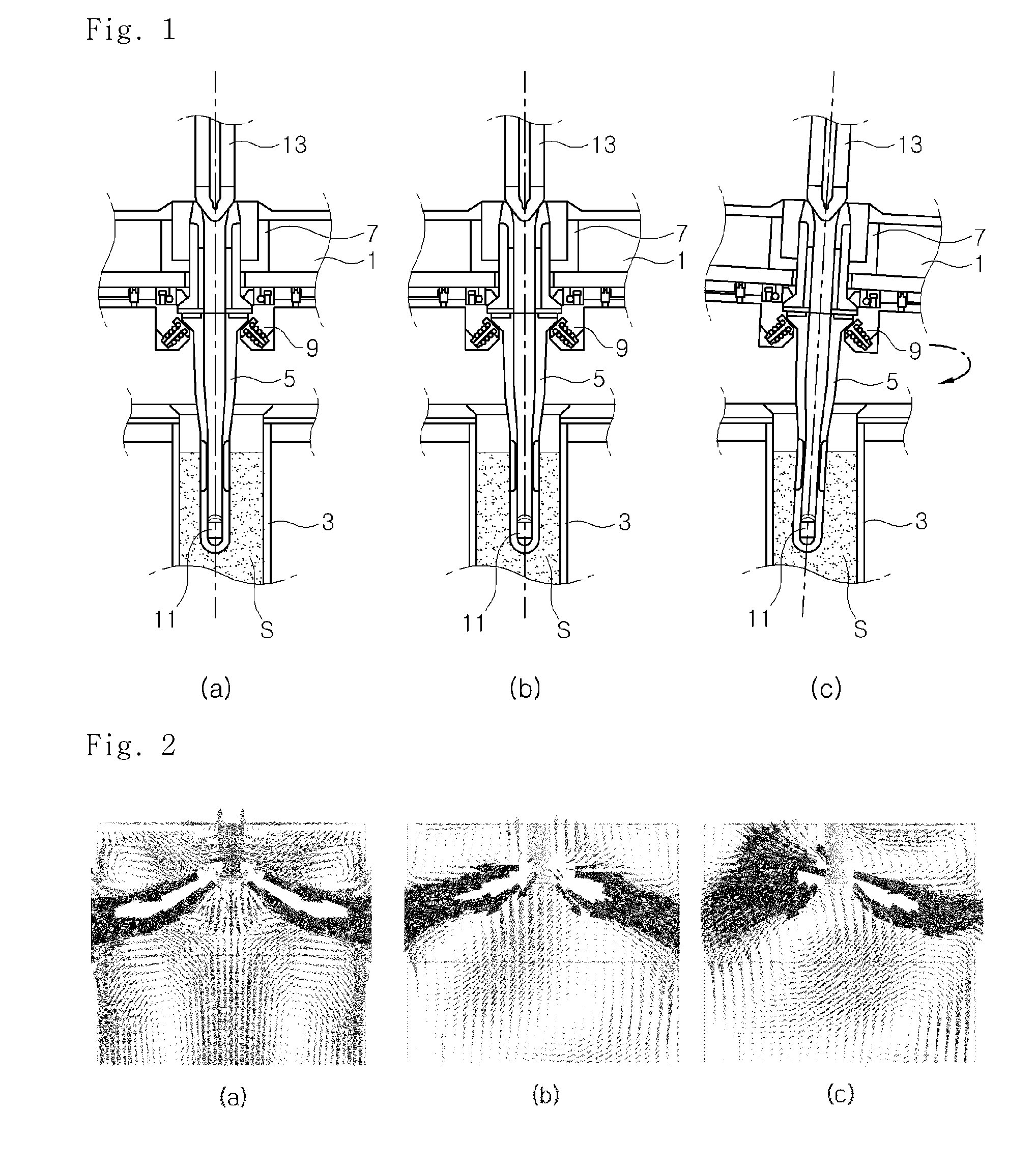

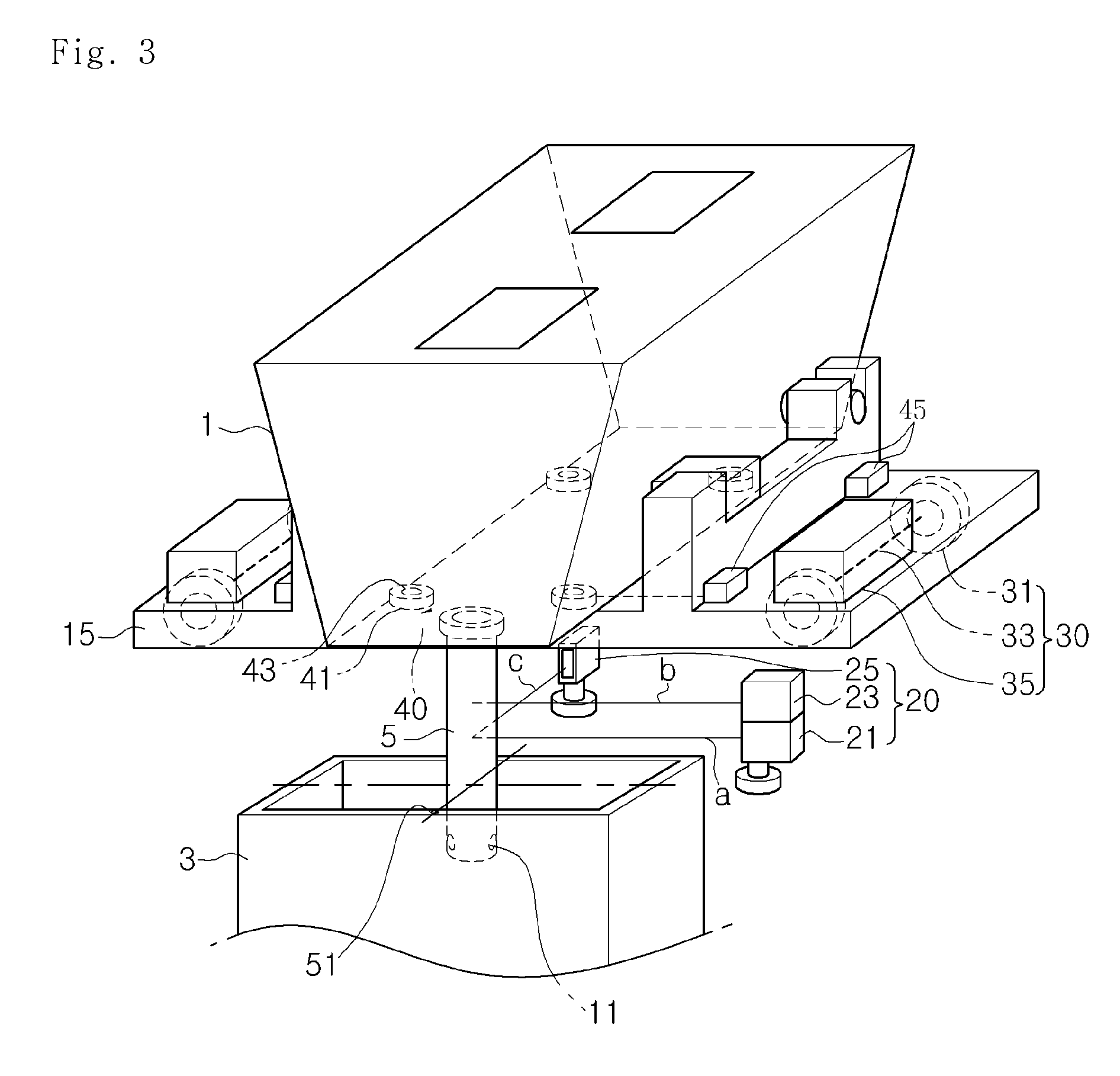

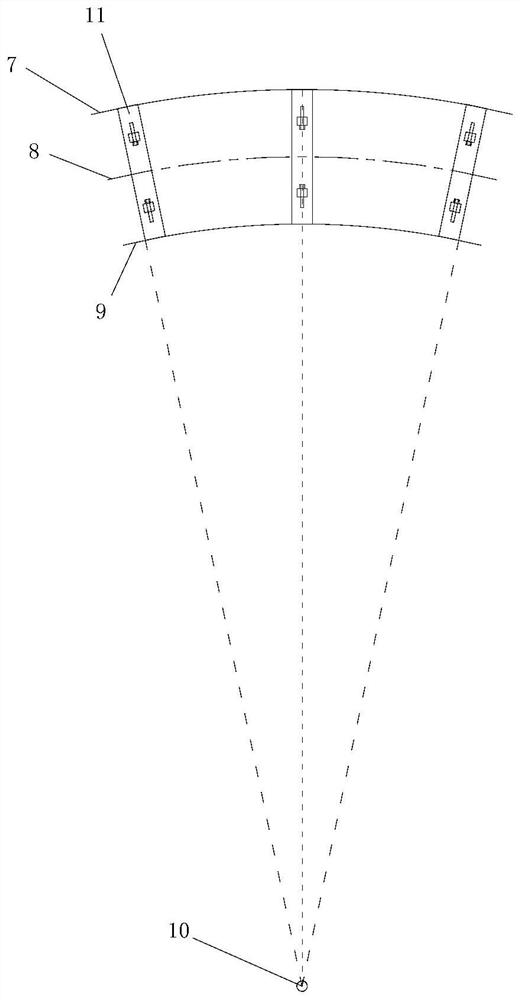

Centering submerged entry nozzle for continuous casting of metal slab

InactiveUS20110127002A1Accurate and quick installationMinimizes channelingMelt-holding vesselsCasting safety devicesTundishEngineering

The present invention relates to an apparatus for centering a submerged entry nozzle. The present invention includes: a plurality of laser beam generators 20 that is disposed above a mold 3 for continuous casting to radiate a laser beam toward the center of the mold; a tundish moving unit 15 that moves a tundish 1 above the mold 3; and a control unit that is linked with the laser beam generators 20 and controls the tundish moving unit 15 to center the installation position of the submerged entry nozzle 5 provided at the lower portion of the tundish, in response to signals transmitted from the laser beam generators 20. According to the present invention, in addition to accurately and quickly centering the submerged entry nozzle 5, it is possible to maintain the submerged entry nozzle that has been centered, such that it is possible to minimize a channeling phenomenon of molten steel. Accordingly, it can be expected to improve the quality of a slab.

Owner:HYUNDAE STEEL CO LTD

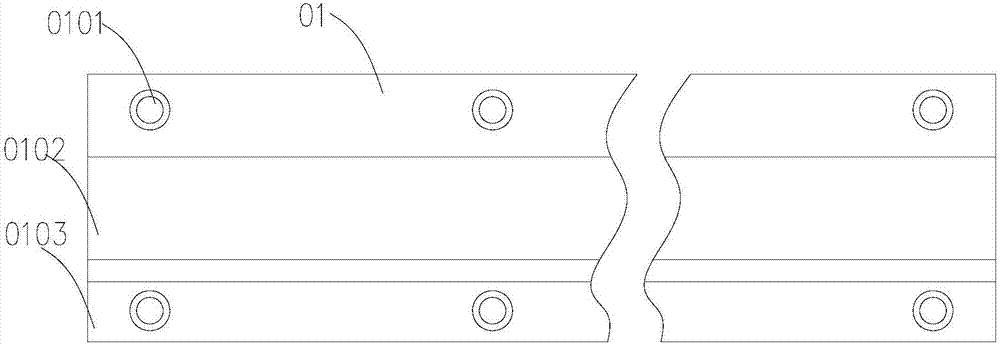

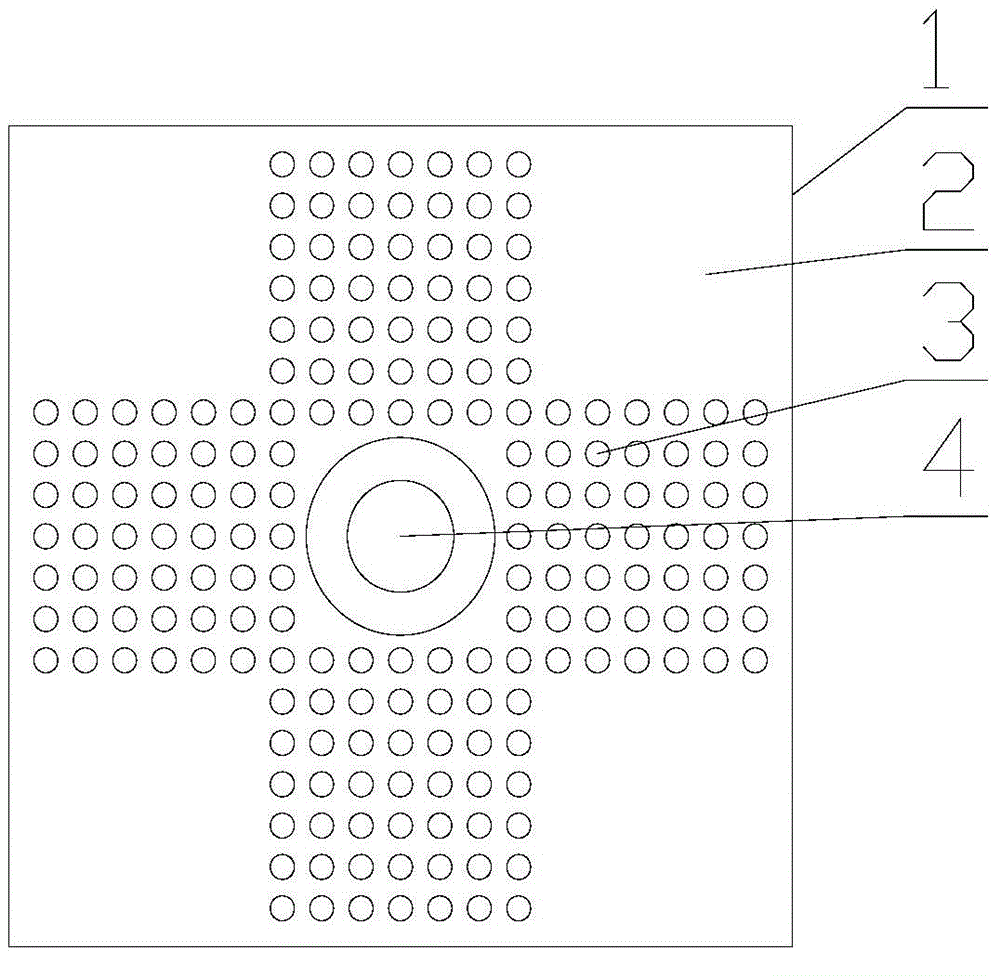

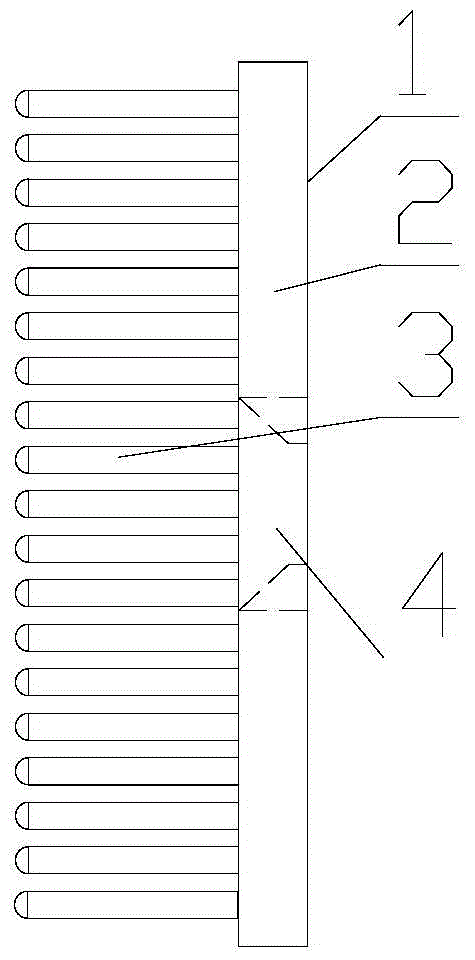

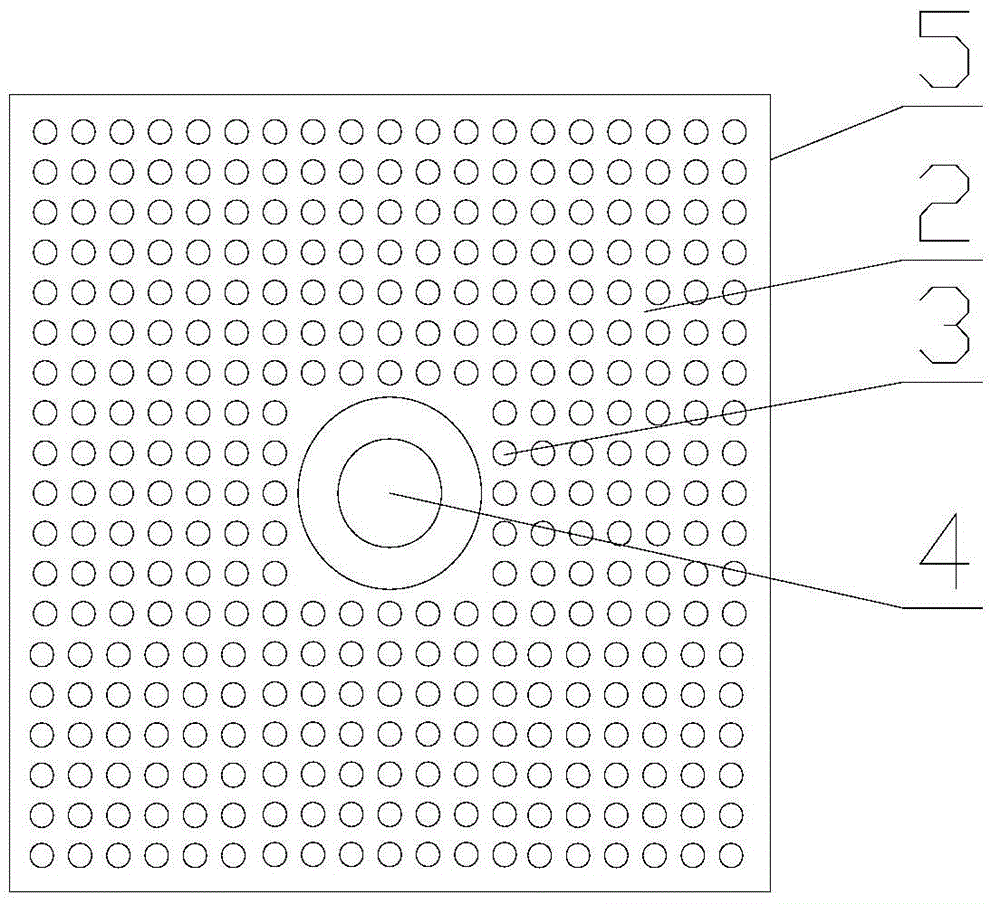

Guide rail fixing device

InactiveCN107143553ASimple structureEasy to obtainLinear bearingsSecuring devicesEngineeringLinearity

The application discloses a guide rail fixing device. The guide rail fixing device includes a guide rail fixing device body, the guide rail fixing device is provided with two rows of counterbore arrays, and one end surface of the guide rail fixing device is provided with guide rail installation grooves. The novel guide rail fixing device has a simple structure, simple materials, and is easy to process. At the same time, the novel guide rail fixing device can install and fix guide rails more accurately and quickly, and can adjust the straightness of the guide rails.

Owner:刘青

Rotary wheel assembly

The invention provides a rotary wheel assembly which comprises a rotary wheel body. At least one set of grooves is formed in the outer circle face of the rotary wheel body in the axial direction, clamping bars matched with the grooves are detachably arranged in the grooves, and the clamping bars are flush with or lower than the outer circle face of the rotary wheel body. According to the rotary wheel assembly, rod-shaped workpieces can be conveyed to machining equipment to be machined fast and orderly through an automatic feeding device with the rotary wheel assembly, the rotary wheel assembly is suitable for conveying the rod-shaped workpieces of different dimensions, the structure is simple, and mounting is convenient.

Owner:江苏兴业铝材有限公司

Drawbar type inclined cutting machine having better heat dissipation effect

ActiveCN105436607ASimple structureReduce volumeMetal sawing devicesMagnetic circuit rotating partsBrushless motorsDrive shaft

The invention discloses a drawbar type inclined cutting machine having a better heat dissipation effect. The drawbar type inclined cutting machine is characterized in that the drawbar type inclined cutting machine comprises a base, a working table, a support, a rocker arm, a sliding bar component, a machine body, a driving device, a control device and a saw blade; a rotating table of the working table is rotationally arranged on the base; the rotating table is provided with a notch groove along the front-back direction; the support is fixedly arranged at the rear part of the upper side of a supporting part of the base; the rocker arm component comprises a rocker arm; the rocker arm is rotationally arranged at the rear end of the rotating table, and can rotate towards the left side and the right side; the machine body is arranged on the rocker arm through the sliding bar component; the driving device is a brushless direct current motor; a stator is fixedly arranged on the machine body; the axis of the stator is arranged horizontally along the left-right direction; a brushless motor outer rotor assembly allows a driving shaft of the brushless motor outer rotor assembly to penetrate through the stator from the right to left, and then is rotationally arranged on the machine body through a corresponding bearing assembly; a corresponding part of the stator is positioned in a motor casing; the saw blade is detachably and fixedly arranged on the driving shaft of the brushless motor outer rotor assembly of the driving device; and the driving device is electrically connected with the control device.

Owner:常州市英杰工具有限公司

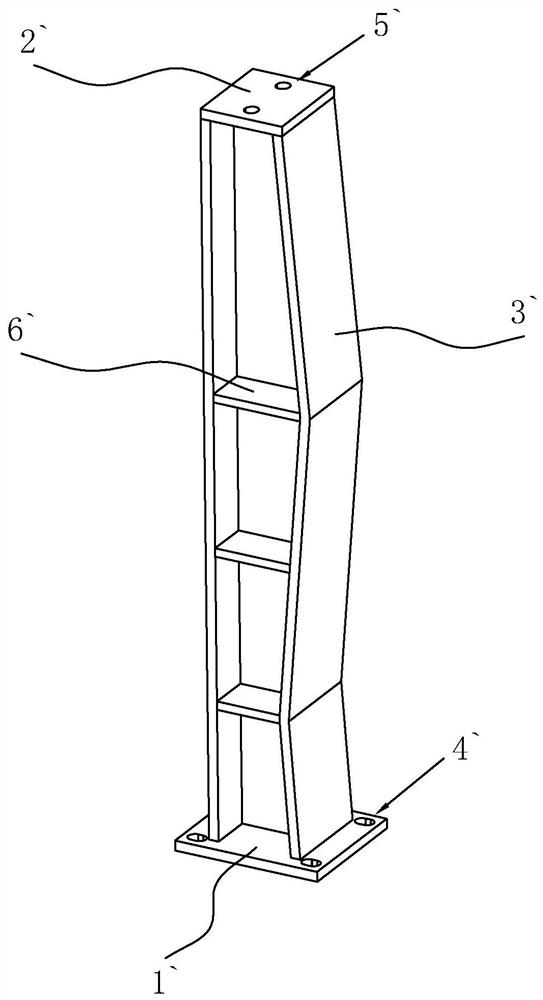

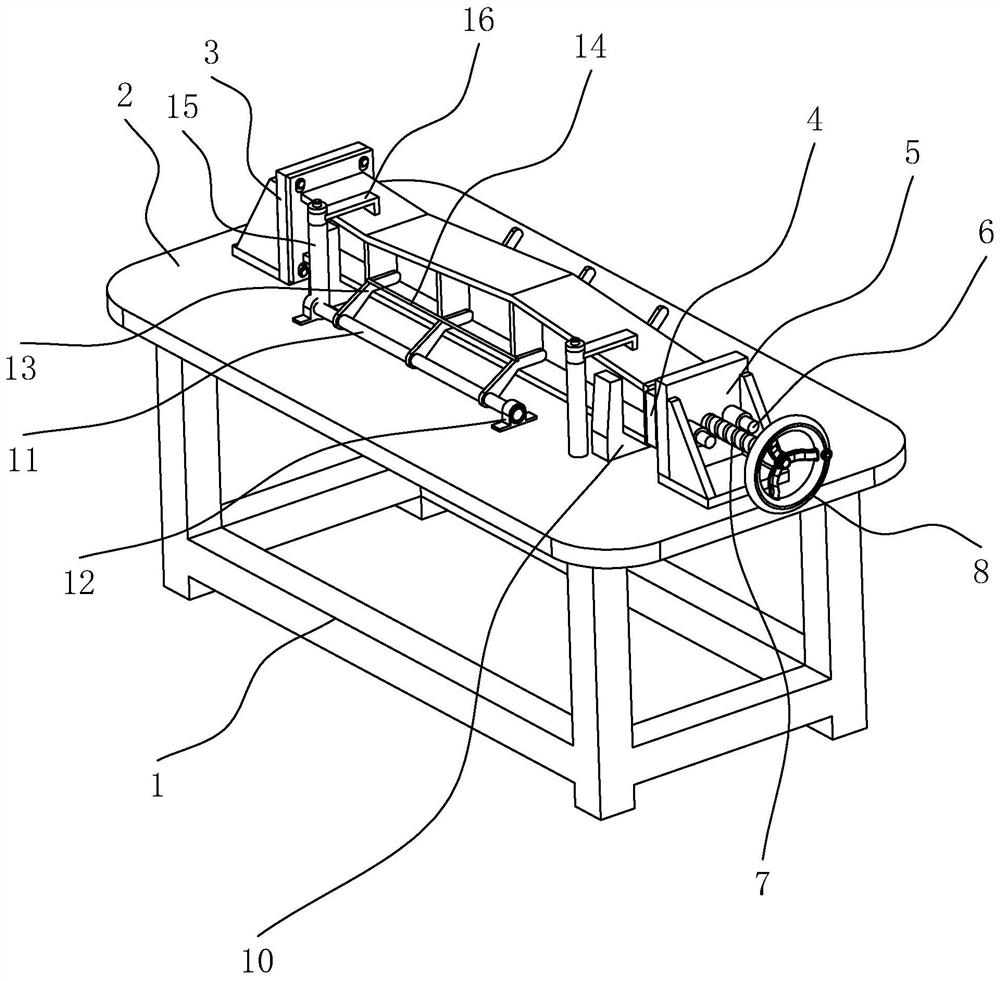

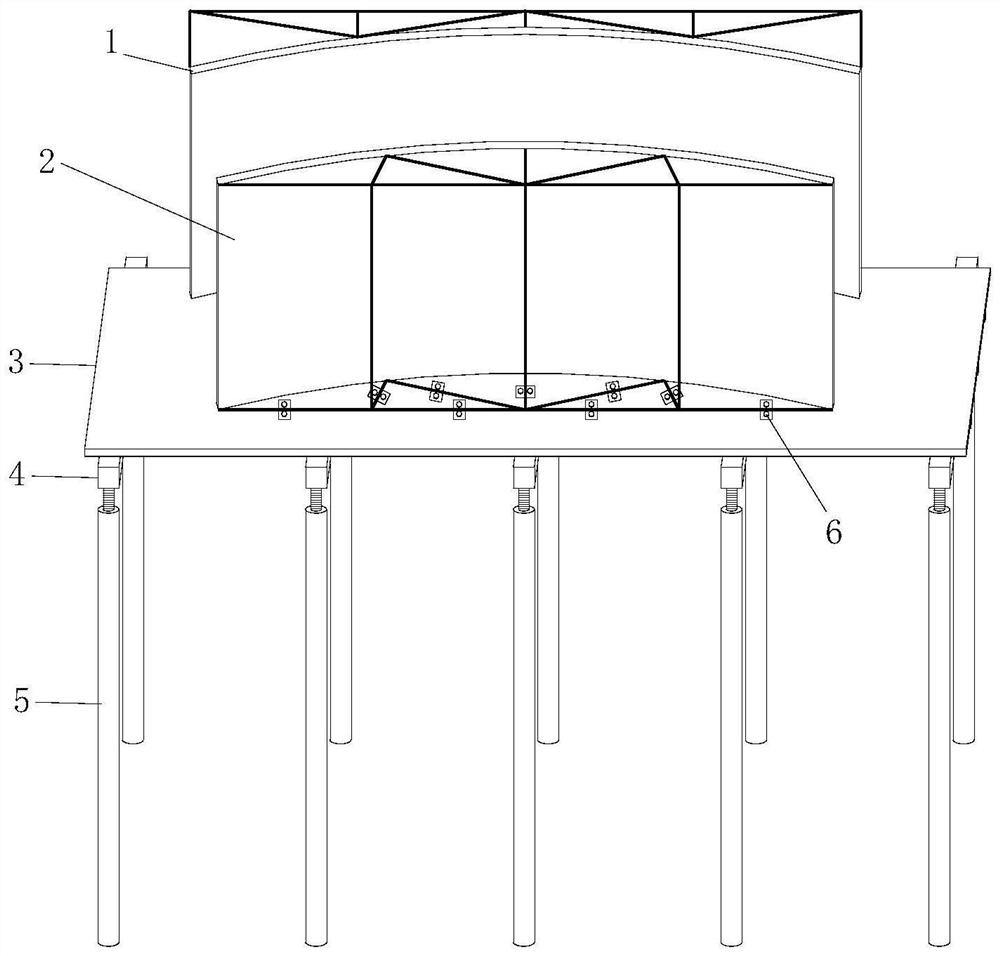

Bridge guardrail column assembling tool and guardrail column processing method

InactiveCN111644799AImprove processing efficiencyAccurate and quick installationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineering

The invention relates to a bridge guardrail column assembling tool and a guardrail column processing method, and solves the problem that in the prior art, a ribbed plate needs to be positioned by artificial marking when being welded onto a guardrail column so as to cause cumbersome operation and time consumption. The invention provides the technical points that the bridge guardrail column assembling tool comprises a frame body and a placement table arranged on the frame body and used for transversely horizontally placing the guardrail column, wherein clamping assemblies for clamping and fixingthe guardrail column are arranged at two ends of the placement table; rotary rods parallel to the length direction of the placed guardrail column are rotatably arranged at the positions, on the placement table, on two sides of the guardrail column; multiple groups of positioning plates for being abutted against the side wall of the guardrail column so as to position the ribbed plate are perpendicularly and fixedly arranged on the rotary rods; and the plate faces of the positioning plates are perpendicular to the axial directions of the rotary rods. Through the scheme, the ribbed plate can bedirectly spot-welded onto the guardrail column through the positioning plates abutted against the guardrail column in the follow-up process, and no marking is needed, so that the processing efficiencyof the guardrail column is greatly improved.

Owner:武汉海腾钢结构工程有限公司

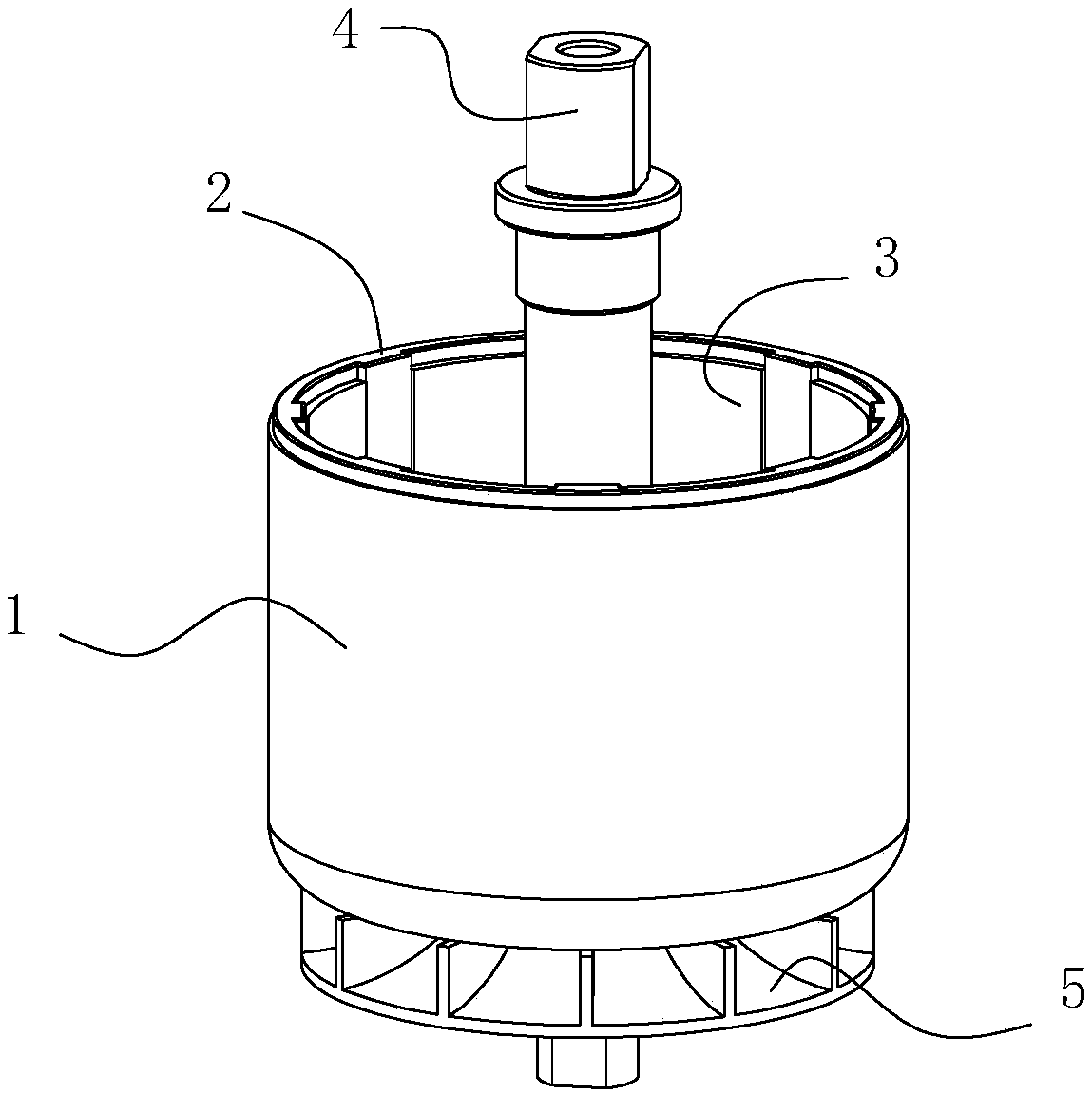

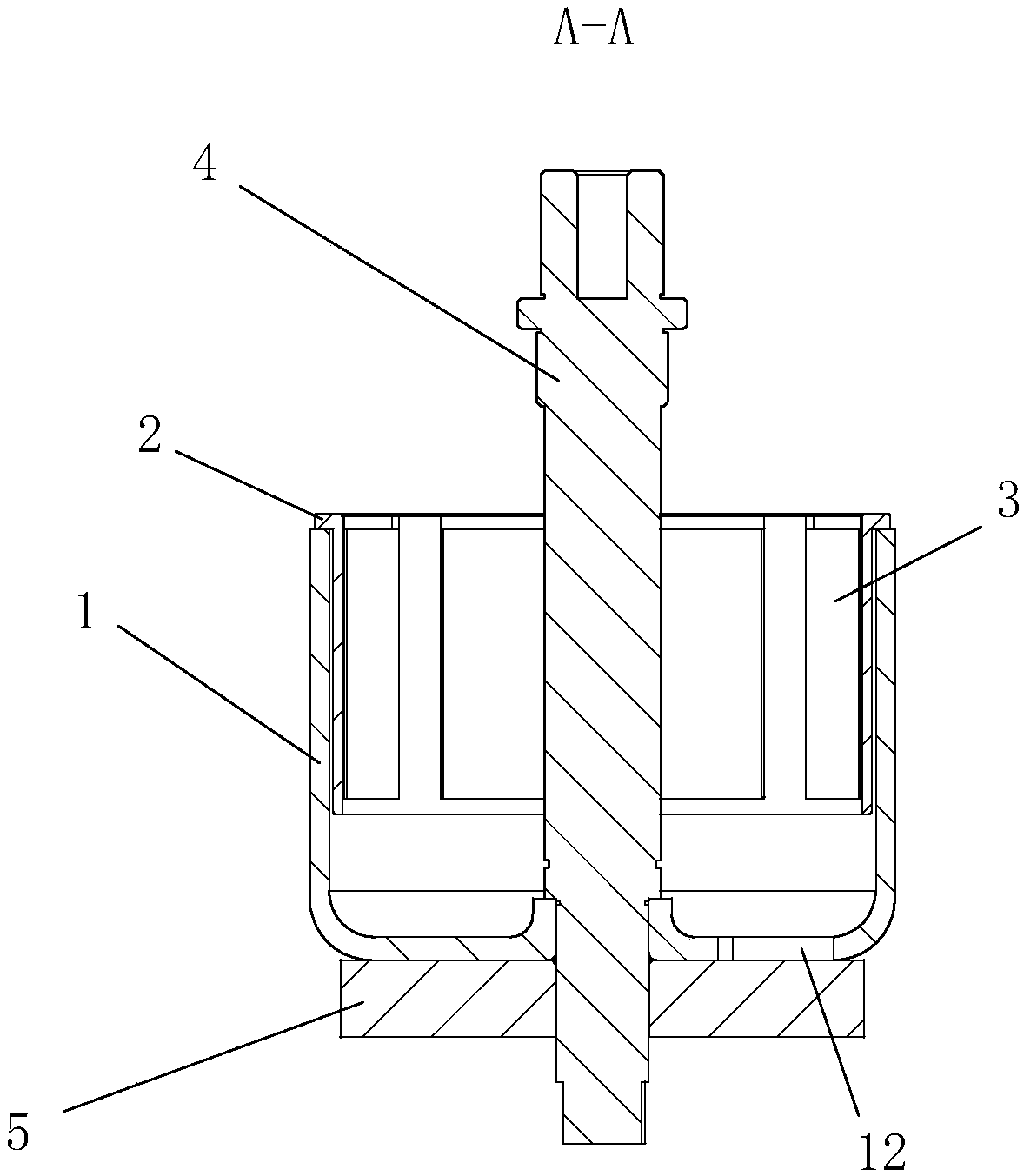

Brushless motor outer rotor assembly with simple structure

InactiveCN108880064ALow costSimple structureMagnetic circuit rotating partsSupports/enclosures/casingsBrushless motorsDrive shaft

The invention discloses a brushless motor outer rotor assembly with a simple structure which comprises a motor shell, a retainer, permanent magnets and a drive shaft. The motor shell is an integral piece of iron or low carbon steel. The opening of the motor shell is upwards, and has a wall thickness with 2 mm to 6 mm. The drive shaft is coaxially and fixedly arranged in the motor shell and extendsout of the motor shell upwards. The retainer is an integral injection molded piece. The retainer comprises a positioning portion and an upper limit portion. The positioning portion has a cylindricalshape as a whole, and has a wall thickness with 1 / 3 to 1 of the thickness of the permanent magnet. An outer diameter of the positioning portion corresponds to an inner diameter of the motor shell. Positioning grooves with the same number as the number of permanent magnets are arranged with the positioning portion at equal intervals in the circumferential direction of the positioning portion, and the shape thereof corresponds to the permanent magnets. The upper limiting portion is arranged on the upper outer circumference of the positioning portion. The retainer is adhesively fixed in the motorshell. The permanent magnets comprise an N permanent magnet and an S permanent magnet sequentially arranged in the positioning grooves of the retainer and adhesively fixed on the motor shell.

Owner:CHANGZHOU CREATE ELECTRIC APPLIANCE

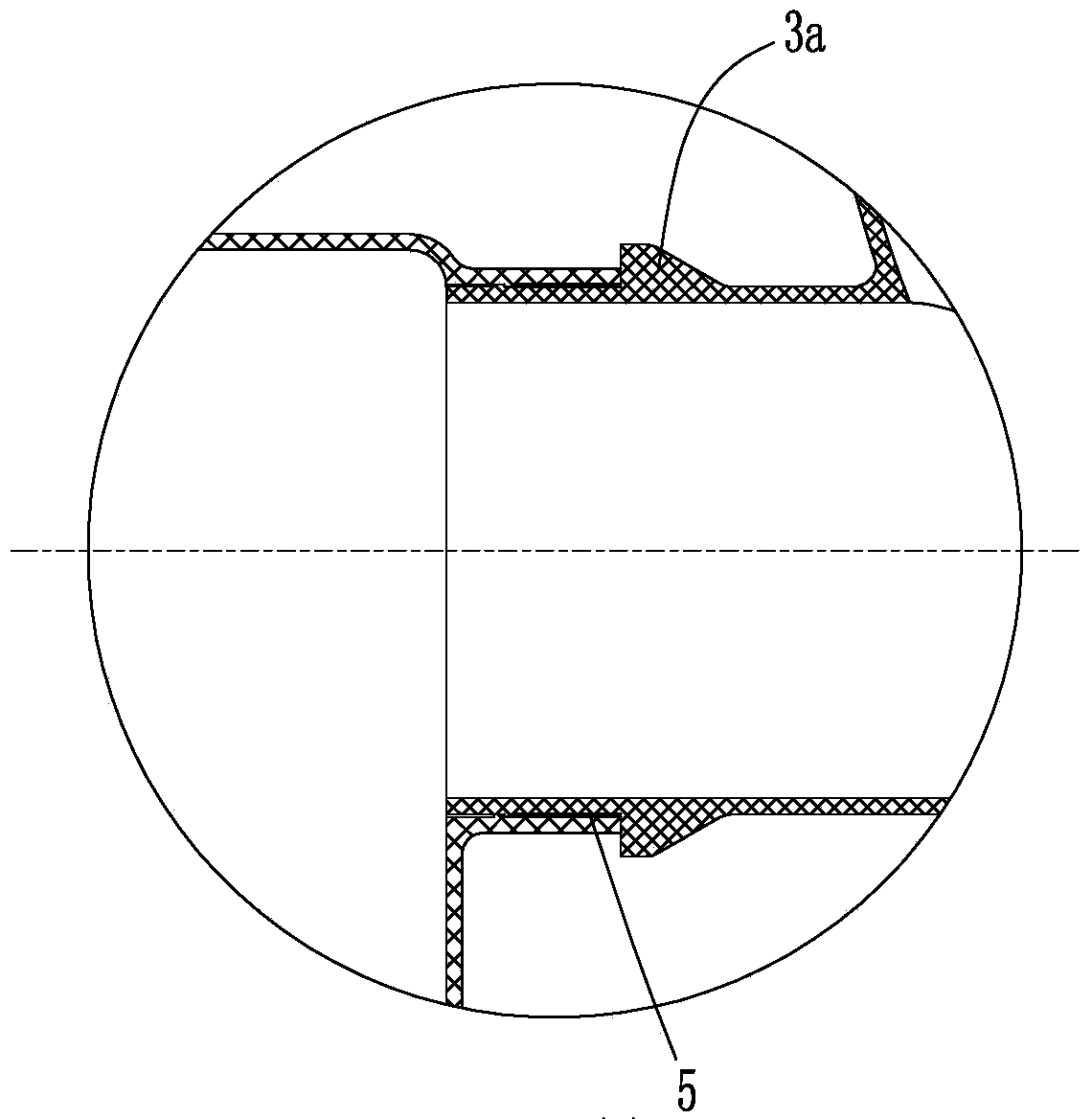

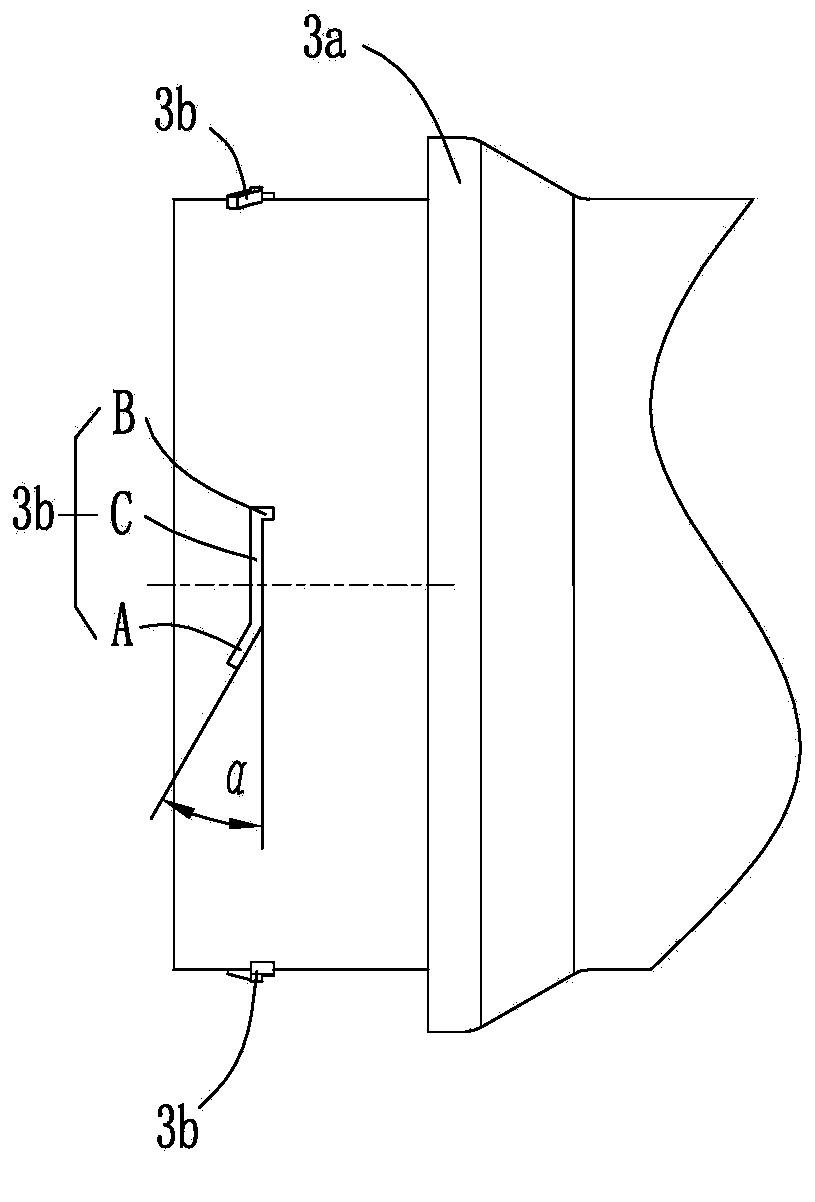

Connecting structure of resonant cavity and air filter air inlet pipe

InactiveCN103410636AGuaranteed smooth assemblyAvoid distortionCombustion-air/fuel-air treatmentMachines/enginesResonant cavityAir filter

The invention discloses a connecting structure of a resonant cavity and an air filter air inlet pipe. The resonant cavity (2) is connected with a first connecting pipe (3) of the air filter air inlet pipe (1) through a second connecting pipe (4), an end socket of the second connecting pipe is sleeved on the outer side of an end socket of the first connecting pipe, first bosses (3b) distributed evenly along the circumference are arranged on the outer wall of the first connecting pipe, and second bosses (4a) distributed evenly along the circumference are arranged on the inner wall of the second connecting pipe. Under the guiding of guiding sections (A) of the first bosses, the second bosses rotate and move towards the air filter air inlet pipe until the second bosses are limited by a rotation stopping section (B) of the next first boss and can not keep rotating. Sponge gaskets (5) are arranged between the second bosses and annular limit steps. Assembling of the resonant cavity and the air filter air inlet pipe can reach a preset angle, conditions of distortion, deformation, obvious seams and the like at the connecting position of two components are avoided, and sealing performance of the resonant cavity is improved.

Owner:力帆科技(集团)股份有限公司

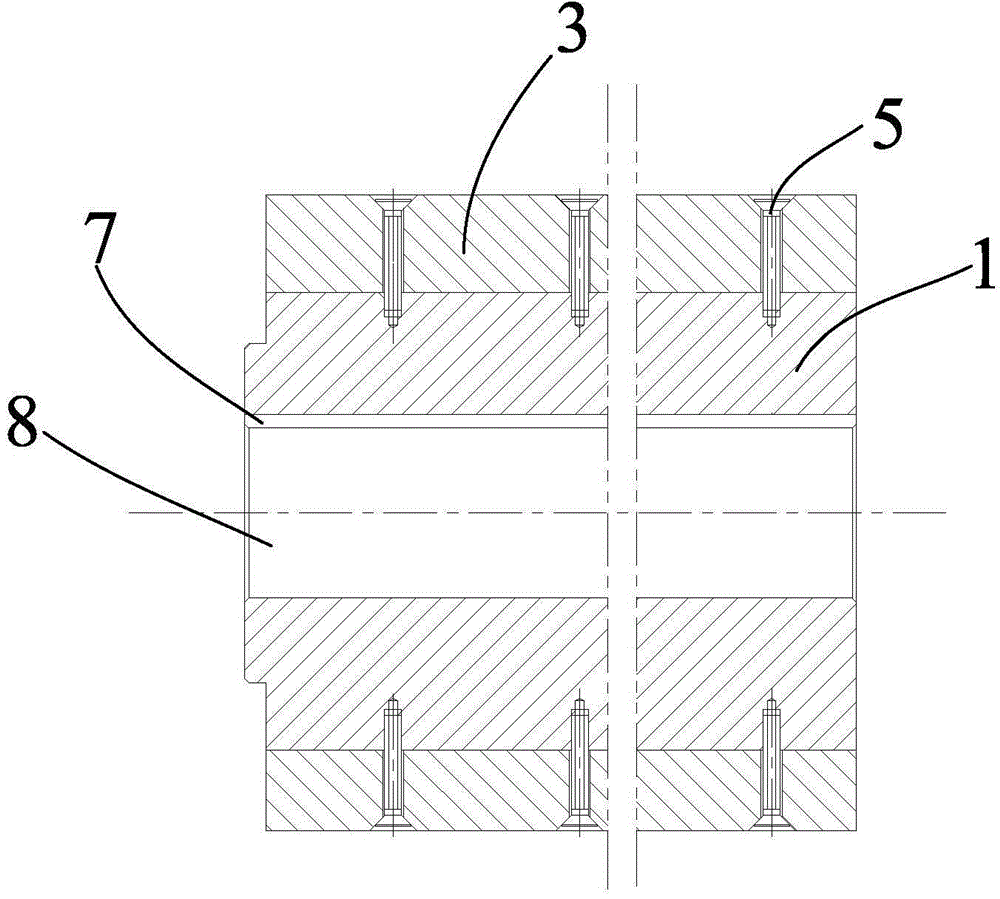

Multi-column plug-in connector for LED (Light Emitting Diode) display screen frame

InactiveCN104582400AAccurate and quick installationFirmly connectedRack/frame constructionIdentification meansLED displayLight-emitting diode

The invention discloses a multi-column plug-in connector for an LED (Light Emitting Diode) display screen frame and relates to an LED display screen frame capable of being hung on a wall easily. The multi-column plug-in connector for the LED display screen frame comprises a simple plug-in connector and a mounting plug-in connector, wherein the simple plug-in connector comprises a back plate, inserting columns and a screw hole; the back plate is a rectangular plate; the inserting columns are processed on one side of the back plate; the screw hole is formed in the middle of the back plate; the simple plug-in connector is mounted on a hanging frame via a bolt; the mounting plug-in connector comprises a back plate, inserting columns, a screw hole and oblique plug-in connectors; the back plate is a rectangular plate; the inserting columns are processed on one side of the back plate; the screw hole is formed in the middle of the back plate; the oblique plug-in connectors are mounted at the other side of the back plate; and the mounting plug-in connector is mounted on a to-be-mounted surface via a bolt. The connector has the characteristics of novel structure, simplicity and convenience in processing, low cost, convenience in mounting, good stability, easiness in adjustment, low possibility of falling and the like.

Owner:DALIAN GONGDE TECH

Electrical signal connector

InactiveUS20110201231A1Accurate and quick installationImprove waterproof performanceLine/current collector detailsElectrically conductive connectionsCoaxial cableElectrical conductor

An electrical connector includes a metal locknut having an inner thread, an orifice defined and a retaining portion, an elastic cylindrical casing having a mounting base for fastening to the retaining portion of the locknut, a core tube inserted into the locknut and the cylindrical casing for receiving the center conductor and inner dielectric insulator of a coaxial cable and having a barbed flange for engaging the braided metal wrapper of the coaxial cable, a first tubular wall and a packing portion connected for engaging into the mounting base of the cylindrical casing, and a barrel mounted on the cylindrical casing and having a contracted inner wall portion adapted for compressing the cylindrical casing.

Owner:LU YUEH CHIUNG

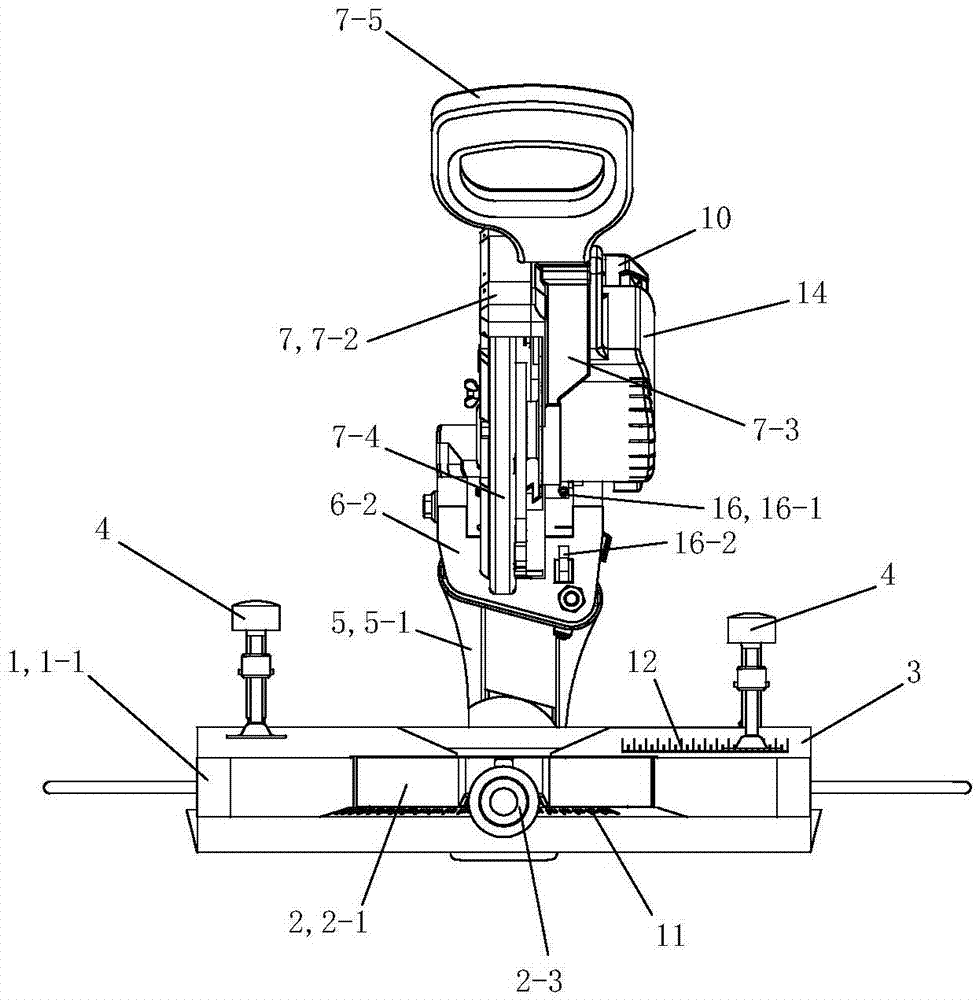

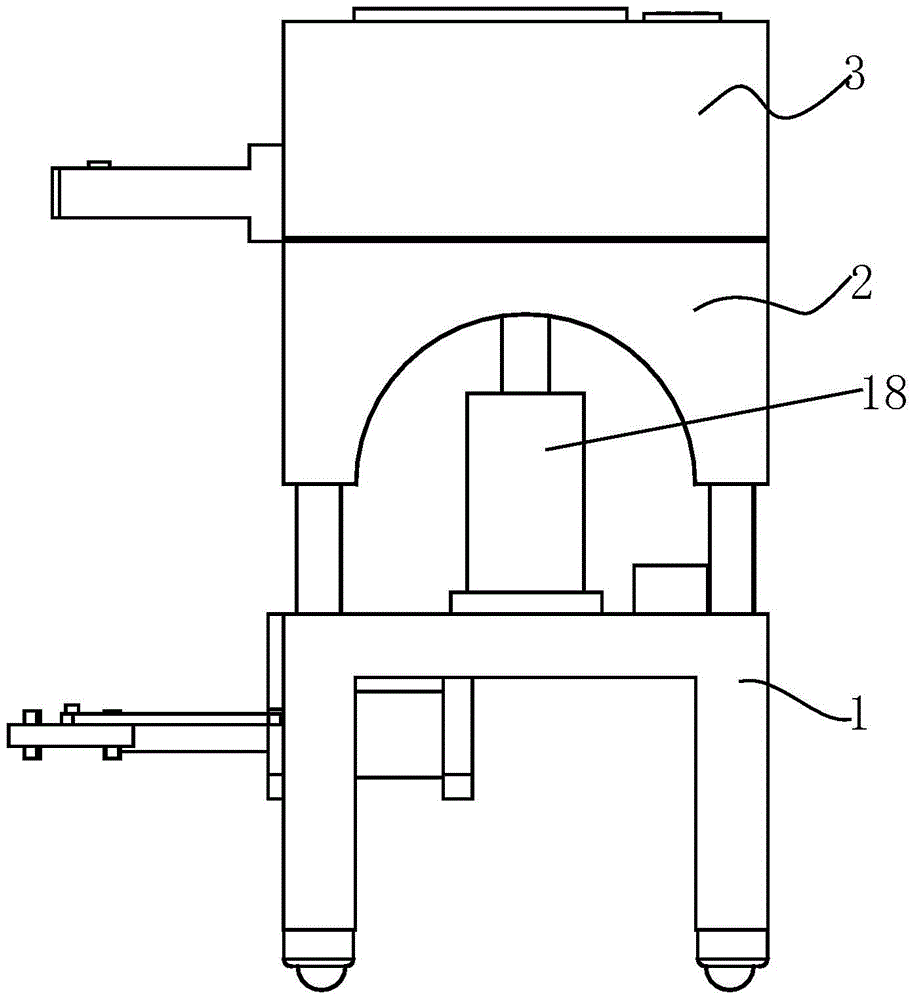

An intelligent auxiliary positioning and indicating vehicle for construction machinery assembly

ActiveCN104589046BAccurate and quick installationAvoid observationMetal working apparatusControl engineeringRolling chassis

The invention relates to an intelligent auxiliary locating indicating car for engineering machinery assembling. The intelligent auxiliary locating indicating car comprises a stretching pressing locating frame, a sensing arm telescopic frame and a moving direction indicating screen. The sensing arm telescopic frame is fixedly connected to the upper end of the stretching pressing locating frame. The moving direction indicating screen is arranged above the sensing arm telescopic frame in a covering mode. The stretching pressing locating frame comprises a base plate. Supporting legs are fixed at the lower end of the base plate. Universal balls are arranged at the lower ends of the supporting legs. An oil cylinder is fixedly arranged in the middle of the upper end face of the base plate. The sensing arm telescopic frame comprises a top plate. The moving direction indicating screen comprises an upper cover. A displaying screen and a keyboard are arranged on the upper end face of the upper cover. Manpower is replaced for detecting the up-load position of engineering machinery, direction guidance is provided for lifting assembling personnel, the problem that assembling personnel observe the position, relative to an engineering machinery bottom disc, of an up-load part of the engineering machinery beside the engineering machinery is avoided, manpower is reduced, the safety coefficient of the assembling personnel is improved, and working efficiency is improved.

Owner:WUHU YINXING AUTO PARTS

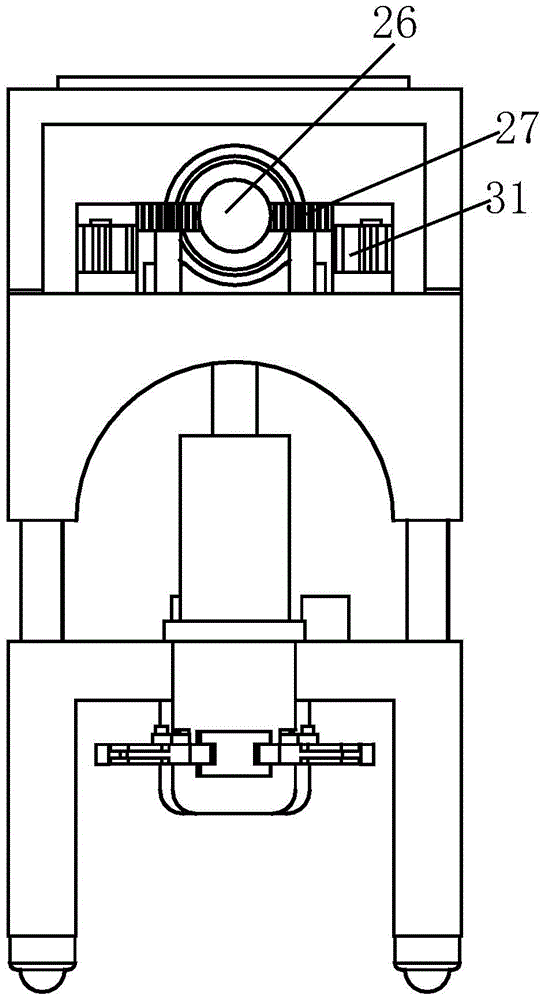

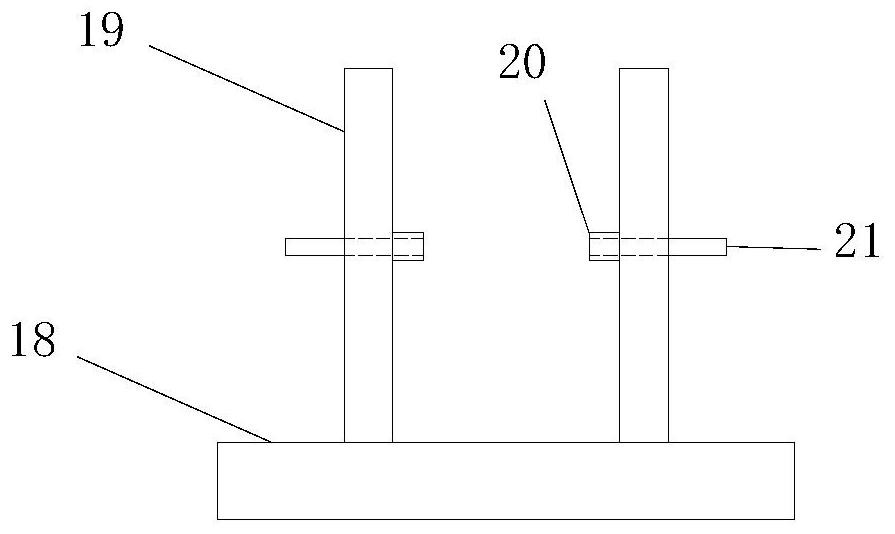

Induction arm telescopic rack of intelligent auxiliary locating and indicating vehicle

ActiveCN104551643AAccurate and quick installationImprove securityMetal working apparatusProximity sensorEngineering

The invention relates to an induction arm telescopic rack of an intelligent auxiliary locating and indicating vehicle. The induction arm telescopic rack comprises a top plate, wherein the lower end surface of the top plate is provided with a guiding sleeve, a left slide way and a right slide way which are parallel to each other are respectively and correspondingly arranged at the left side and the right side of the upper end surface of the top plate, a motor which is provided with a worm on a shaft of the motor and is arranged parallel to the left slide way and the right slide way is arranged at the middle part of the upper end surface of the top plate, a left worm gear which is positioned at the left side of the worm and meshed with the worm and a right worm gear which is positioned at the right side of the worm and meshed with the worm are respectively and correspondingly arranged on the top plate, and a left rack arm and a right rack arm are respectively and correspondingly meshed with the left side of the left worm gear and the right side of the right worm gear. According to the induction arm telescopic rack disclosed by the invention, a distance measurement sensor and a proximity sensor are utilized as signal collecting elements for collecting the distance between a jacket of an engineering machine and a chassis of the engineering machine and the position of the jacket, the position of the jacket of the engineering machine is detected by replacing the manpower, the jacket of the engineering machine is more quickly and accurately arranged on the chassis, the safety coefficient of assembling personnel is increased, and the working efficiency is increased.

Owner:WUHU YINXING AUTO PARTS

A large steel pipe tower

The invention discloses a large-scale steel pipe tower, which comprises a steel pipe main body and a flange alignment assembly. The flange alignment assembly is arranged inside the steel pipe main body. The centering main part and the centering auxiliary part, the centering main part is fixed on the inner wall of the main steel pipe, and the centering auxiliary part is fixed on the inner wall of the supporting steel pipe. The flange alignment assembly makes the supporting steel pipe rotate in the main steel pipe, so that the bolt holes on flange a correspond to the bolt holes on flange b, thus completing the alignment between flange a and flange b It greatly reduces the difficulty of segmented vertical towers, lowers the requirements for the level of lifting operators, reduces the stagnation time of supporting steel pipes, makes the installation of supporting steel pipes faster and more accurate, and reduces safety risks.

Owner:自贡市大西南电力器材制造有限公司

Installation method of low-infrared radiation exhaust system of high-speed assault boat

ActiveCN112253296BImprove securityWeight increaseExhaust apparatusSilencing apparatusOn boardEngineering

The invention discloses a low-infrared radiation exhaust system for a high-speed assault boat, which comprises a first exhaust pipe, an injector, a muffler assembly, a second exhaust pipe, a compensator and an outlet pipe connected in sequence; The wall pipe is composed of the pipe mouth of the double-wall pipe close to the muffler assembly, which is lower than the mouth of the double-wall pipe far away from the muffler assembly. The double-wall pipe is provided with a nozzle socket, and a nozzle holder is installed on the nozzle socket. The invention adopts seawater to cool the exhaust gas, which improves the sound-absorbing performance, reduces the discharge of harmful components in the exhaust gas into the atmosphere, and increases the safety on board. The seawater injection also reduces the exhaust volume flow rate, so the weight and size of the exhaust system can be reduced; the installation method of the system is designed ingeniously to avoid the deformation of the system exhaust pipe and other pipelines during the installation process or the damage during installation.

Owner:JIANGYIN BEIHAI LSA

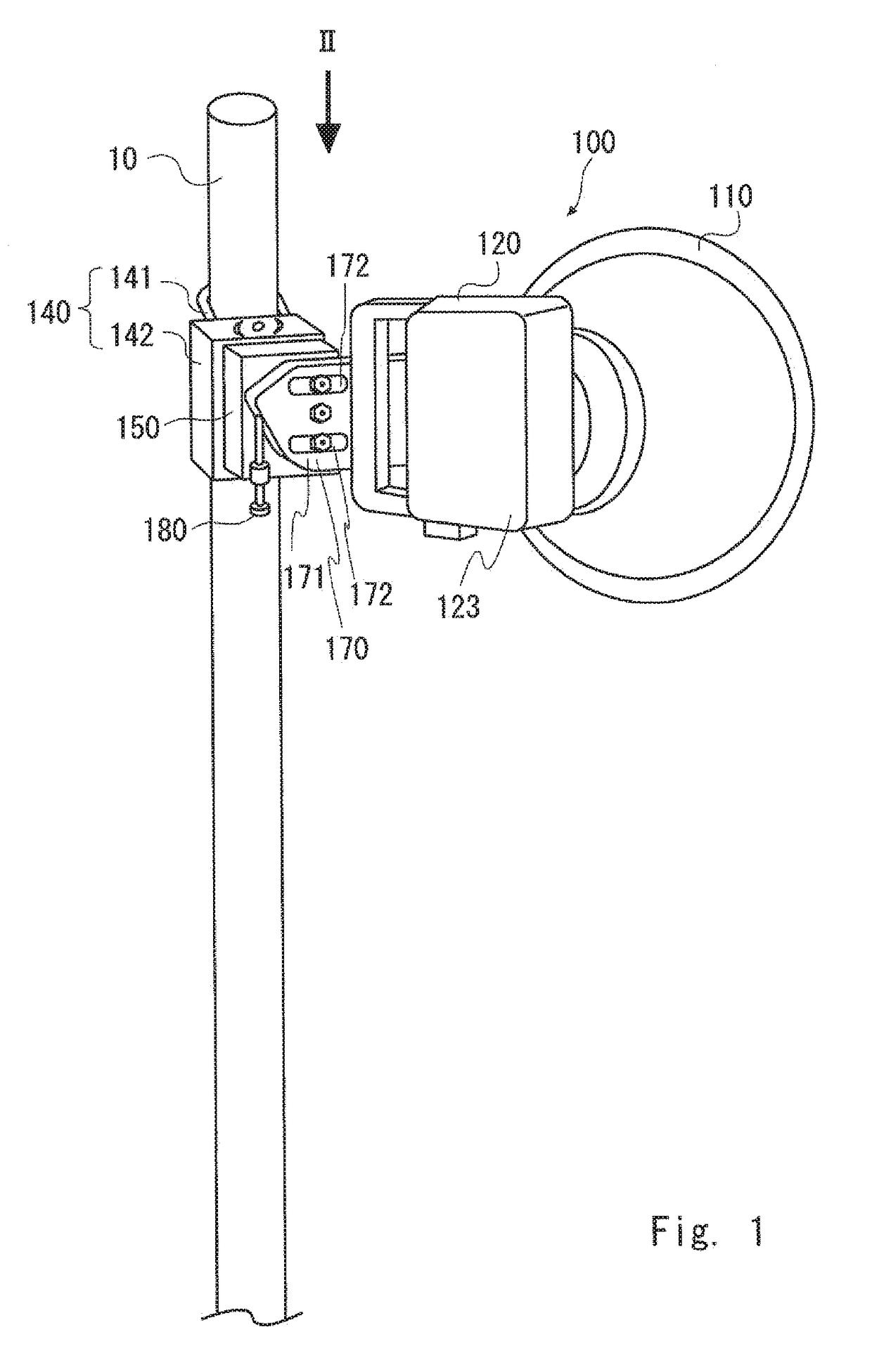

Antenna orientation adjustment device and antenna orientation adjustment method

InactiveUS10044093B2Accurate and quick installationTransmitters monitoringReceivers monitoringMotion controllerControl theory

An antenna orientation adjustment device (200) include a camera (210), nut runners (220 and 230), and a motion controller (400). The nut runners (220 and 230) can be mounted on an azimuth adjustment bolt (160) and an elevation adjustment bolt (180), respectively. The nut runners (220 and 230) change the orientation of an antenna unit by applying motor power to the azimuth adjustment bolt (160) and the elevation adjustment bolt (180). The motion controller (400) calculates an angle position of the antenna unit (110) where a reception strength is maximum based on an image taken by the camera (210) and a reception strength of radio waves received by the antenna unit (110), and then adjusts the antenna unit (110) to the angle position where the reception strength is maximum by supplying a drive signal to the azimuth adjustment bolt (160) and the elevation adjustment bolt (180).

Owner:NEC CORP

Bone cement filling balloon device

ActiveCN102835995BHas bone conduction propertiesOsteogenic activitySurgeryPolyethylene glycolAbsorbent material

The invention discloses a bone cement filling balloon structure, which comprises a pipeline-shaped injector, and a balloon connected onto the lower end of the injector, wherein a preassembled rod extending into the balloon is arranged in an inner cavity of the injector; the balloon is made of absorbable materials, such as poly-L-lactic acid, poly-DL-lactic acid, polyglycolic acid, polycaprolactone, polyethylene glycol, poly-di-chalk alkyl ketone, polytrimethylene carbonate, and a copolymer or a polymer blend thereof; and the molecular weight of the absorbable materials is 5,000-1,000,000. The bone cement filling balloon structure disclosed by the invention has the advantages that not only is the distribution of bone cement in a vertebral body be effectively controlled to prevent the bone cement from leaking in quantity, but also the bone cement can be absorbed in the body; and the bone cement filling balloon structure is simple to operate during an operation.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL +1

Cast-in-place reinforced concrete arc-shaped boundary beam and construction method

The invention relates to the field of building construction, in particular to a cast-in-place reinforced concrete arc-shaped boundary beam and a construction method.During construction, a formwork is manufactured in advance, an arc-shaped boundary beam reinforcement cage is bound through a reinforcement binding jig frame, and then an inner-edge finalization thin steel plate side formwork and an outer-edge finalization thin steel plate side formwork are fixed to a bamboo plywood bottom formwork in a bolting mode; a cast-in-place reinforced concrete arc-shaped boundary beam formwork system is formed, then a manufactured arc-shaped boundary beam reinforcement cage is hoisted into the cast-in-place reinforced concrete arc-shaped boundary beam formwork system, and finally concrete is poured to form a beam; precast concrete arc-shaped boundary beam units are used for controlling the side formwork thin steel plates to be pressed and fixed to form arcs, the radian fixing trusses are used for fixing the radian of the side formwork thin steel plates, the side formwork is fast in arc forming and high in precision, the side formwork is high in overall rigidity, and the bottom face connecting lug plates of the radian fixing trusses are fast connected with the bottom formwork in a bolted mode. The template manufacturing and mounting precision and efficiency are improved, the construction period is shortened, and the pouring forming effect is good.

Owner:浙江恒鸿建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com