Patents

Literature

86 results about "Cartesian coordinate robot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cartesian coordinate robot (also called linear robot) is an industrial robot whose three principal axes of control are linear (i.e. they move in a straight line rather than rotate) and are at right angles to each other.The three sliding joints correspond to moving the wrist up-down,in-out,back-forth. Among other advantages, this mechanical arrangement simplifies the Robot control arm solution. Cartesian coordinate robots with the horizontal member supported at both ends are sometimes called Gantry robots; mechanically, they resemble gantry cranes, although the latter are not generally robots. Gantry robots are often quite large.

Automatization hospital pharmacy

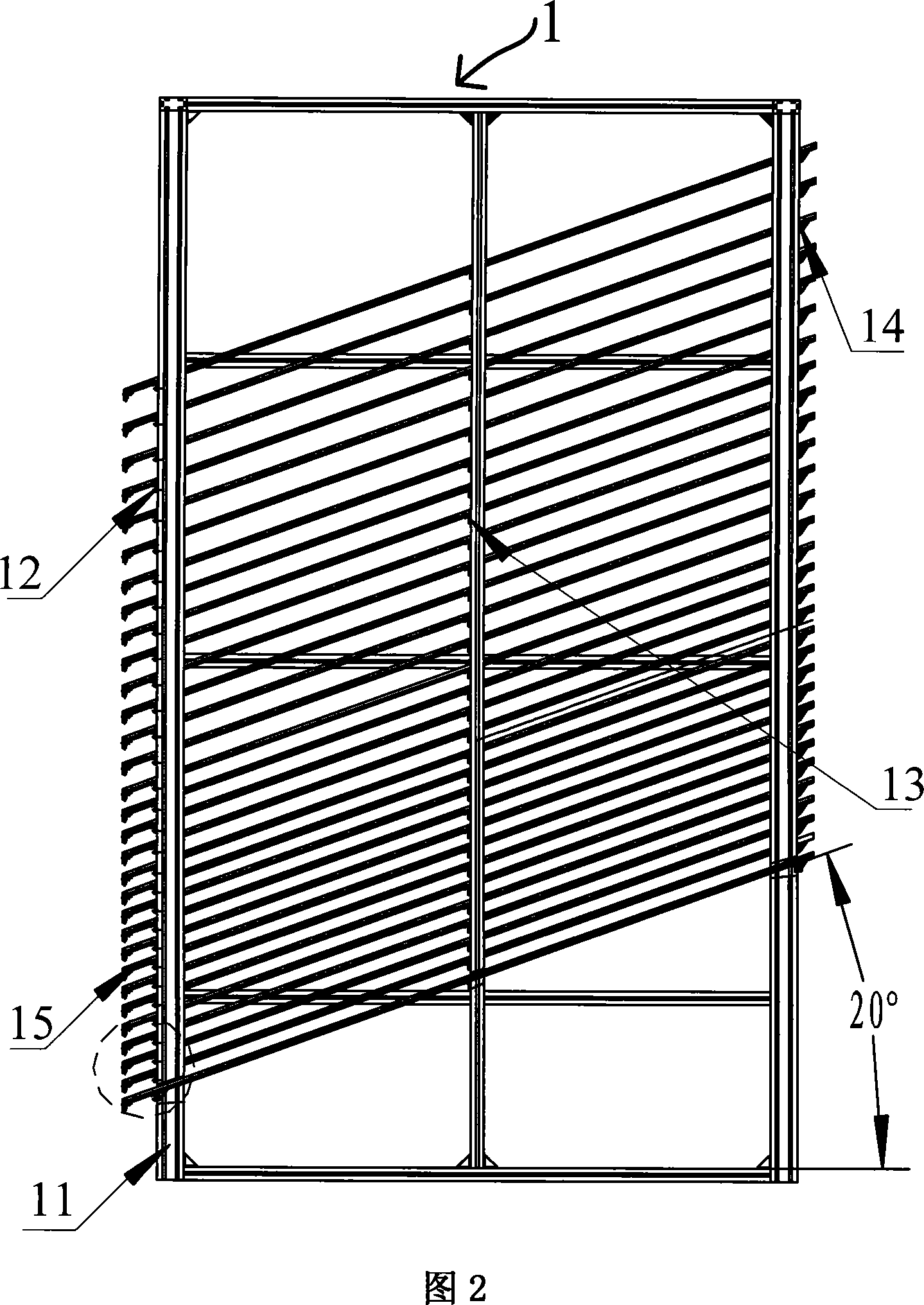

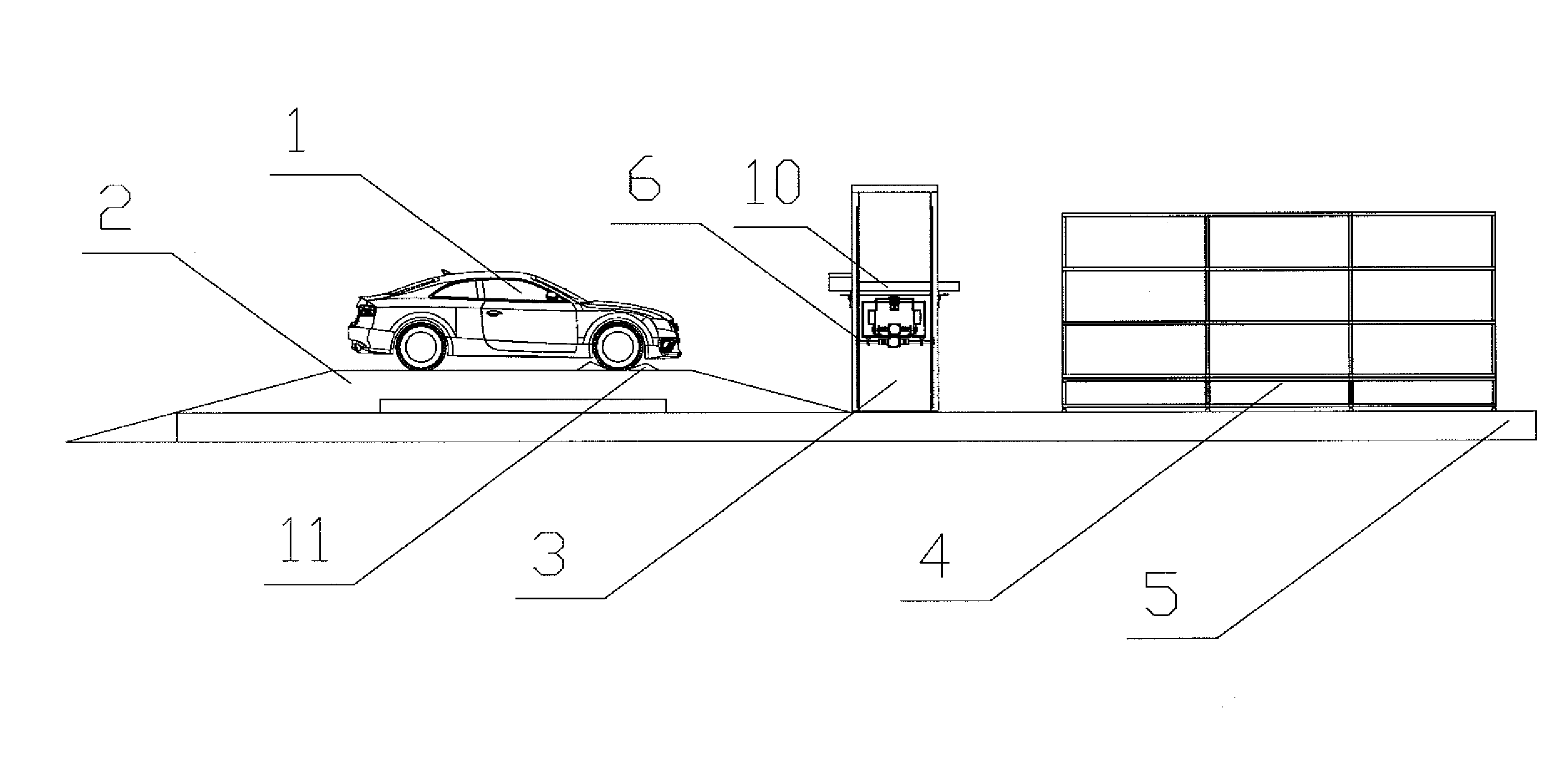

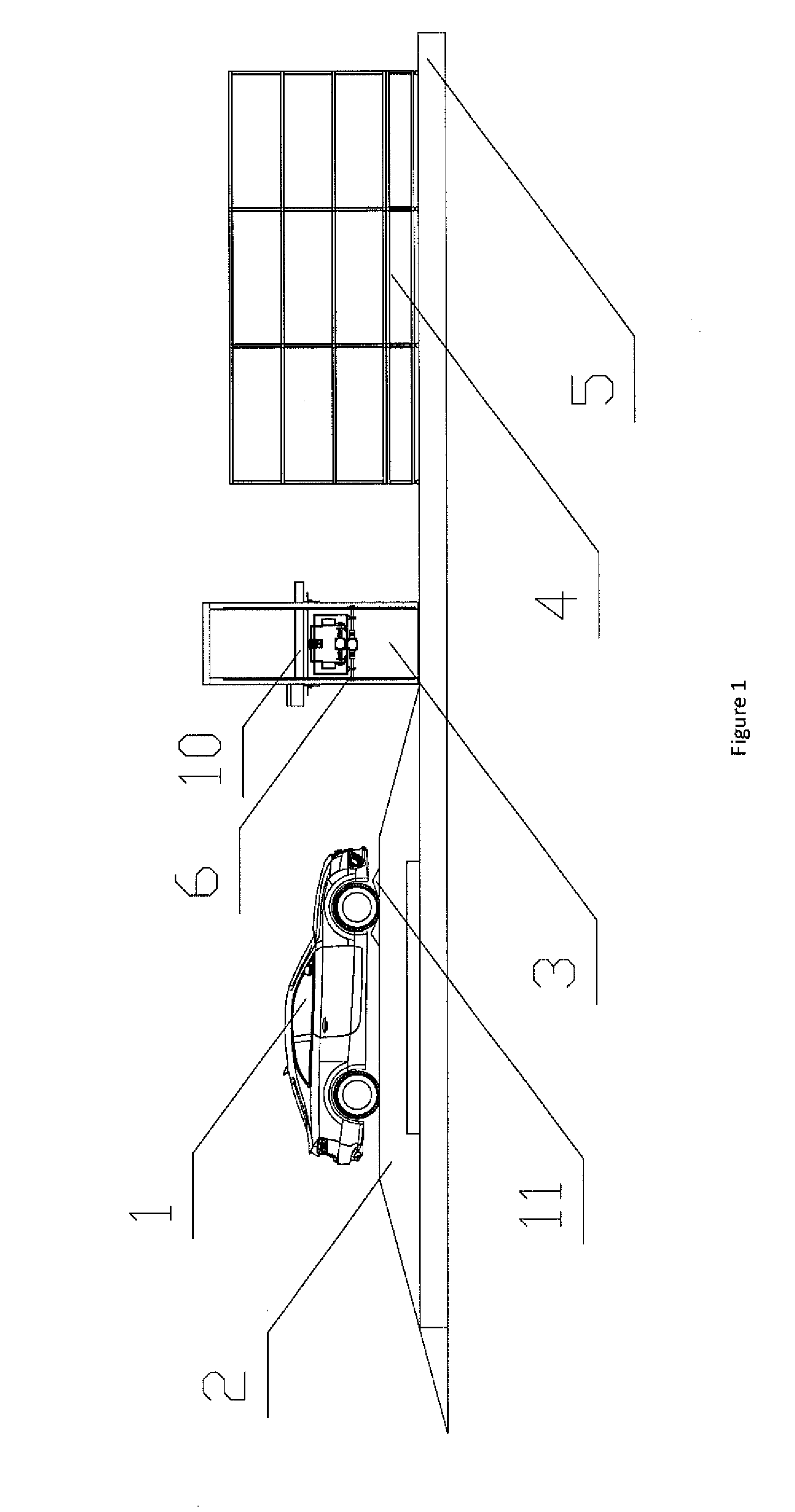

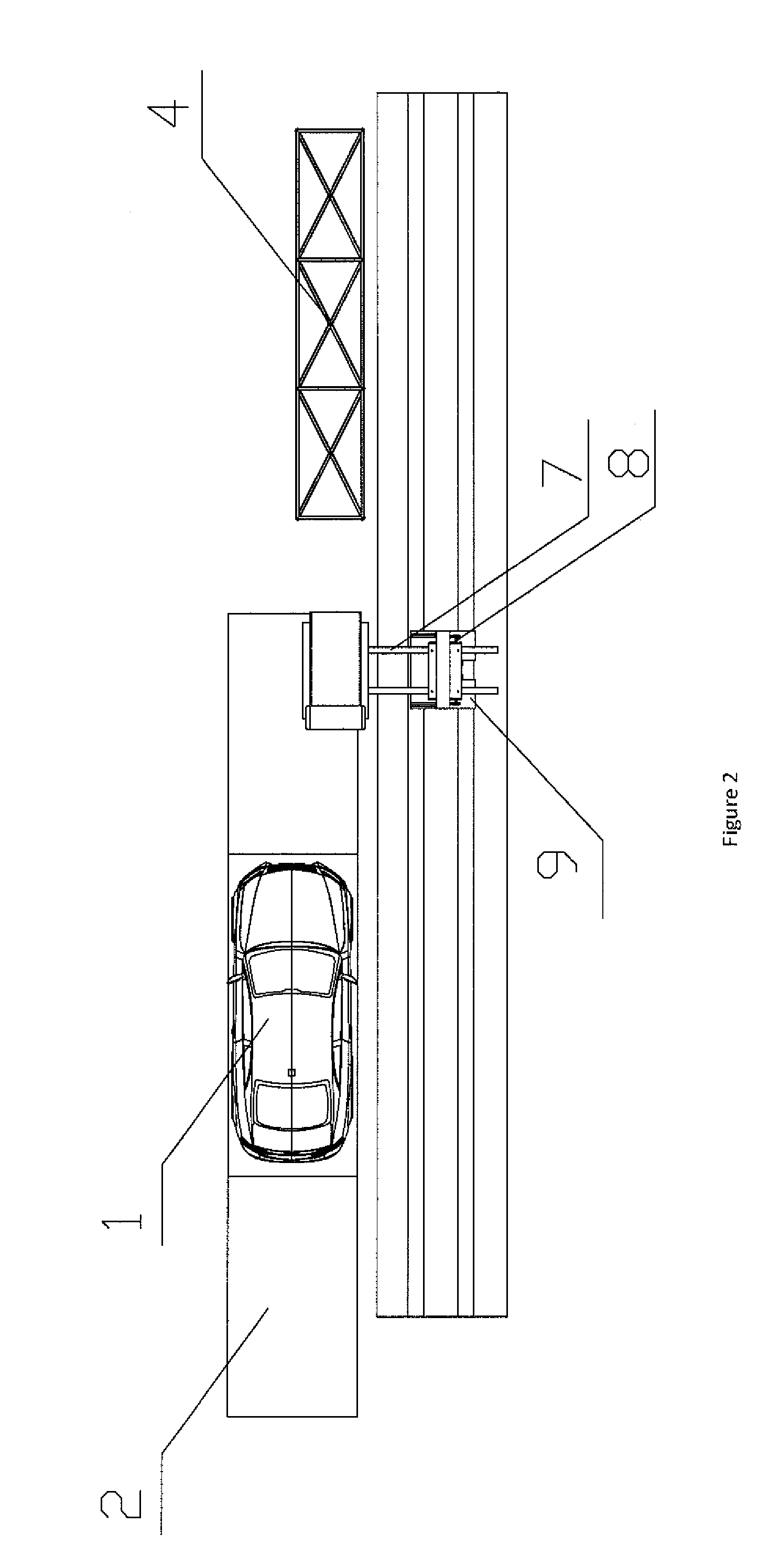

ActiveCN101214107AImprove storage densityImprove distribution efficiencyShow cabinetsProgramme-controlled manipulatorSemi automaticCartesian coordinate robot

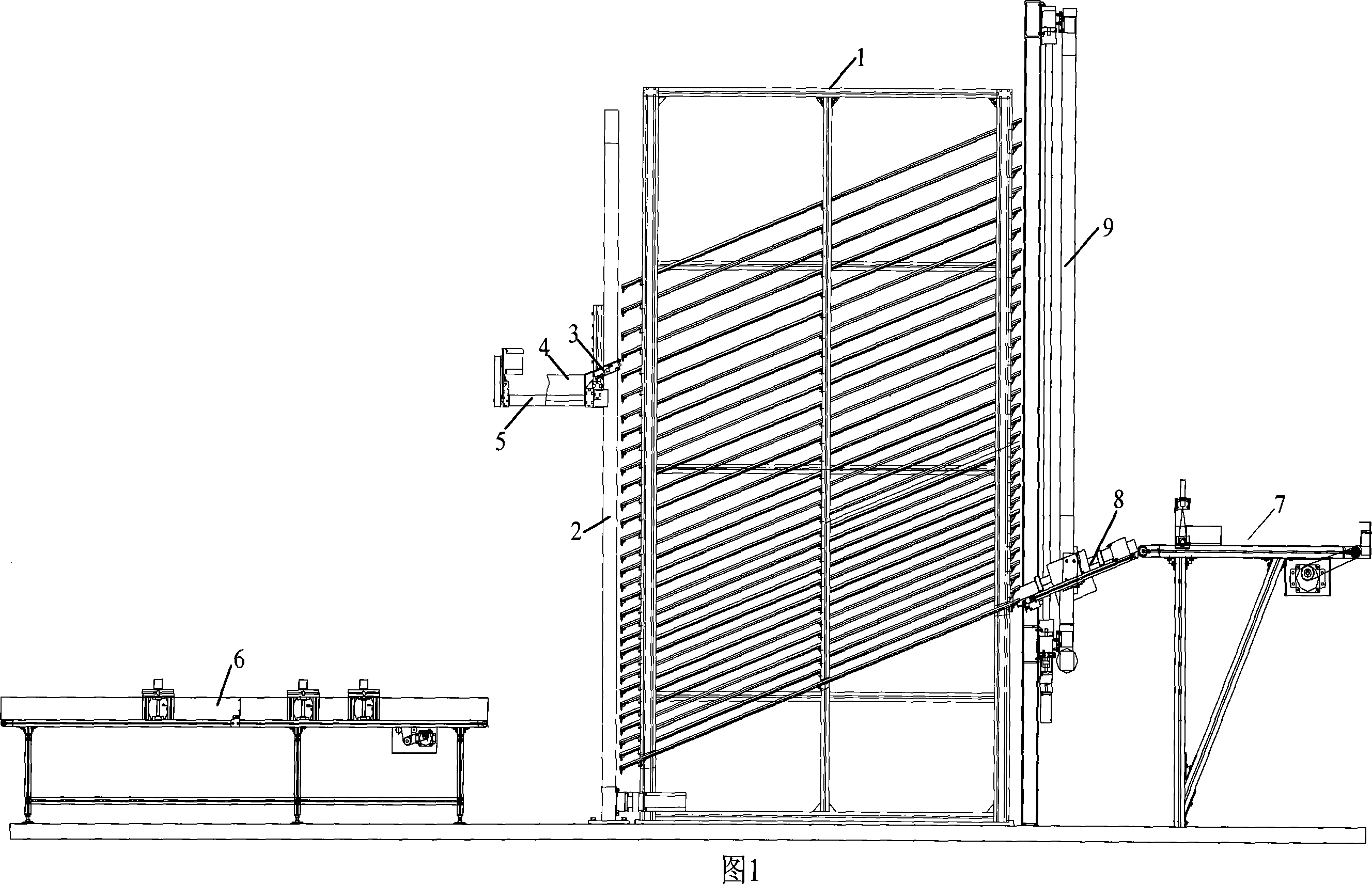

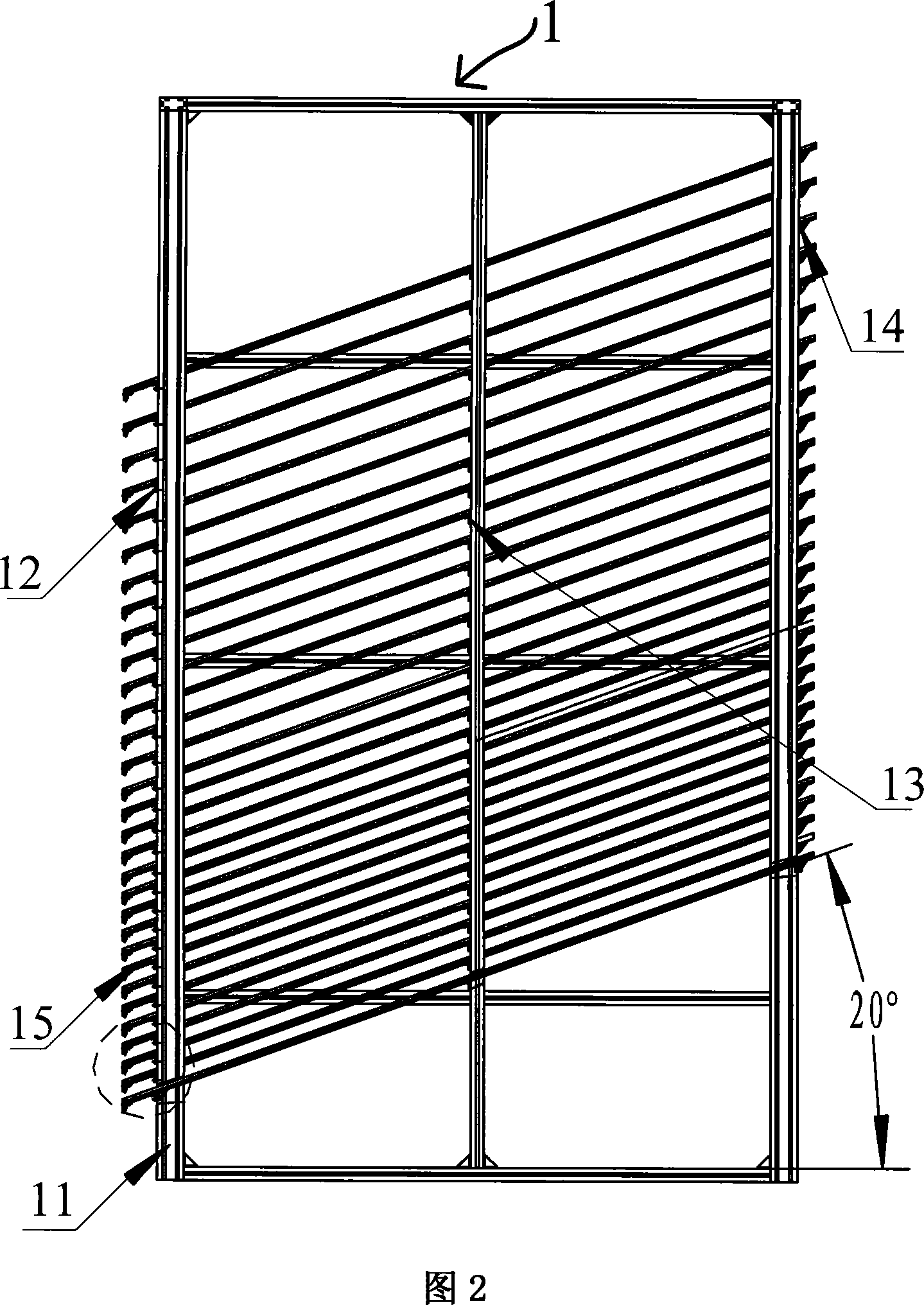

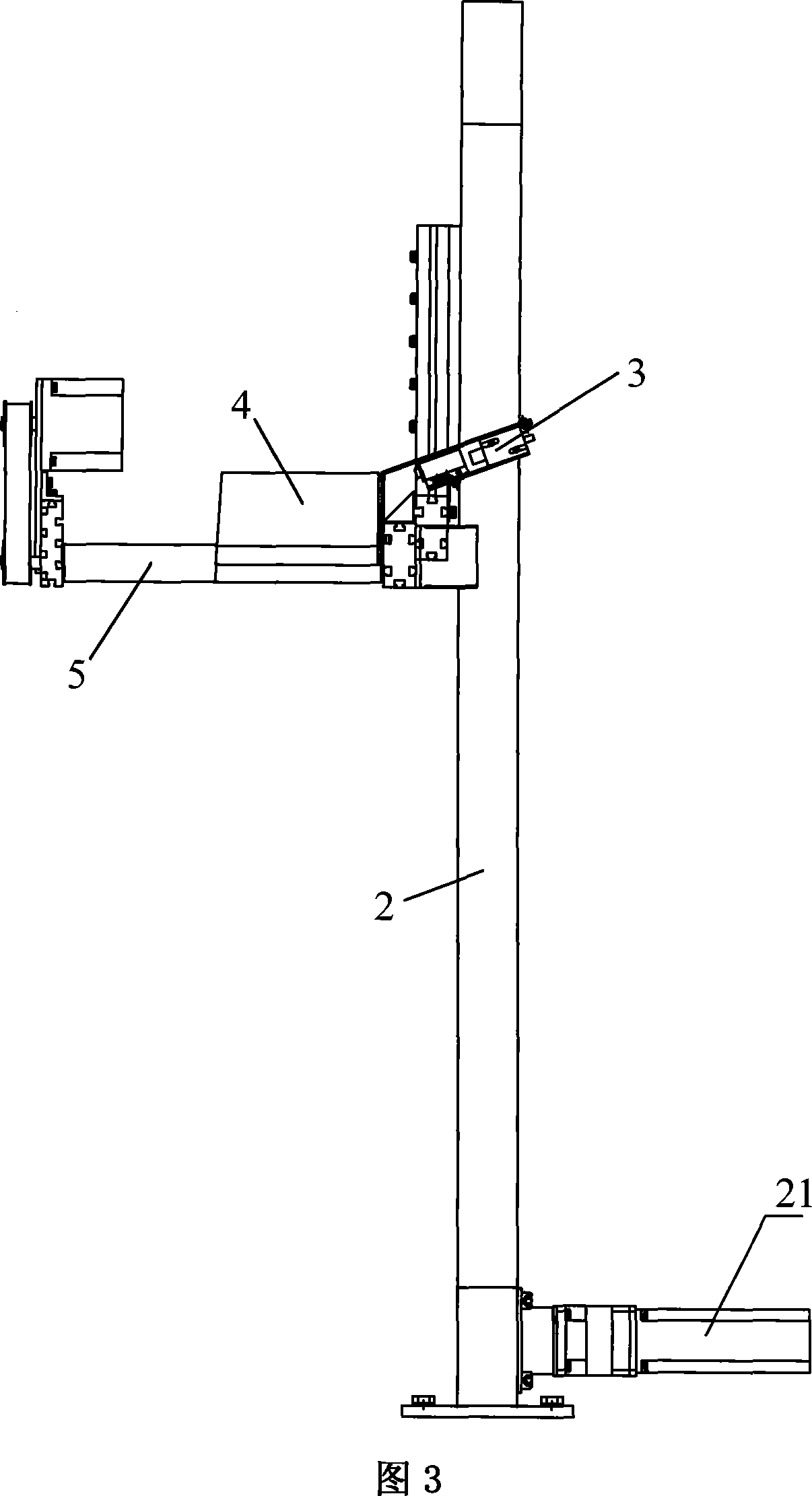

The invention provides an automatic pharmacy, including a slope type medicine storing cabinet, a medicine distributing device, a sorting device, a medication applying device and a control management system. A U-shaped groove of a slope medicine storing holder is fixed to a supporting beam and forms a dip of 20 degrees with the horizontal plane. The medicine distributing device includes an elevator and a medicine output mechanism. A low end medicine outlet port of the U-shaped groove of the slope medicine storing holder is butted with a medicine inlet port of a U-shaped medicine storing groove of the medicine output mechanism. The medicine outlet is connected with a conveyer belt in a way of transiting through a retaining door to form a medicine distributing channel. The medicine outlet end of the medicine distributing device is equipped with the sorting device. A sorting channel is connected with the medicine distributing channel. The medicine outlet port of a medication applying transporting mechanism is butted with a medicine inlet port of a U-shaped groove of a medication applying manipulator which is installed on a Cartesian-coordinate robot. The medicine outlet port of the U-shaped groove of the medication applying manipulator is butted with a high end medicine inlet port of the U-shaped groove of the slope medicine storing holder to form the medication applying channel. Therefore, the functions of semi-automatic batch recharging of boxed medicine, medicine box dense storage and management, automatic medicine distribution according to a prescription and medicine sorting to the determined windows, etc. can be realized.

Owner:SUZHOU IRON TECH

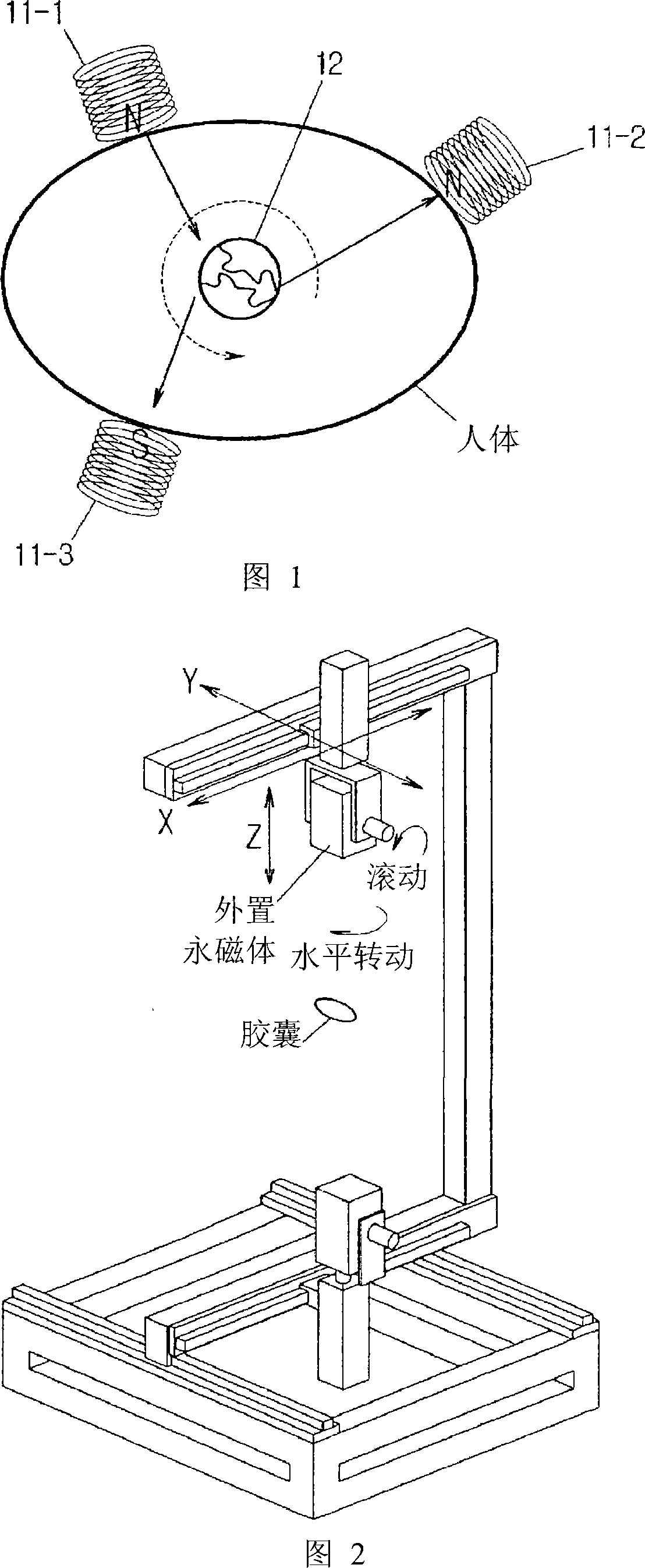

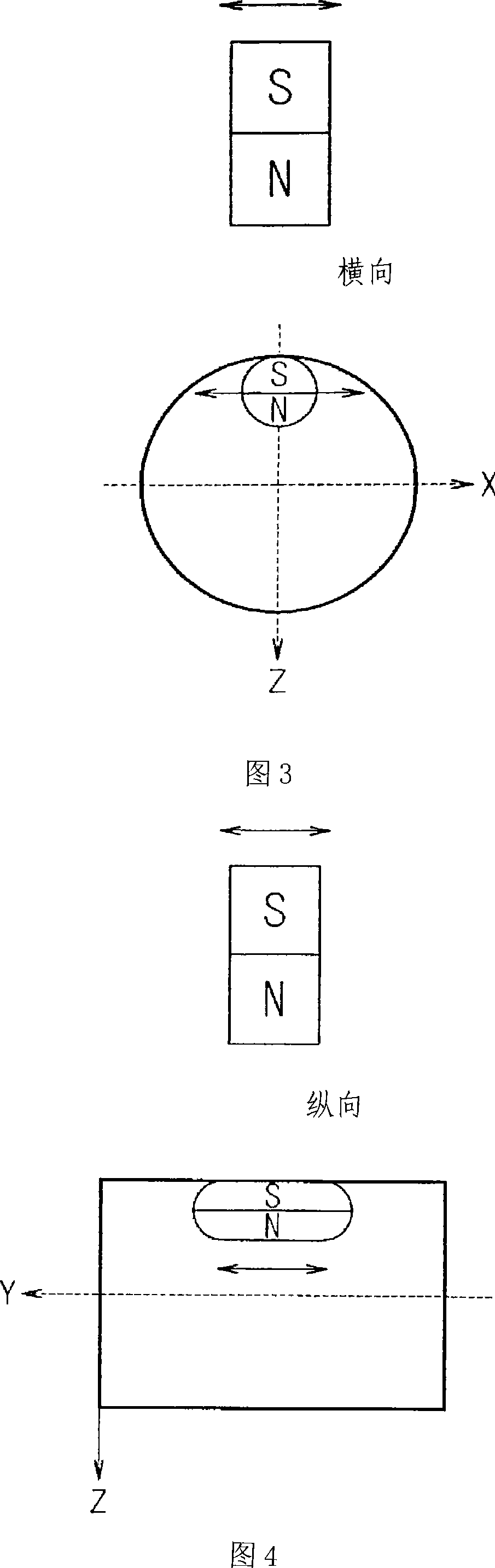

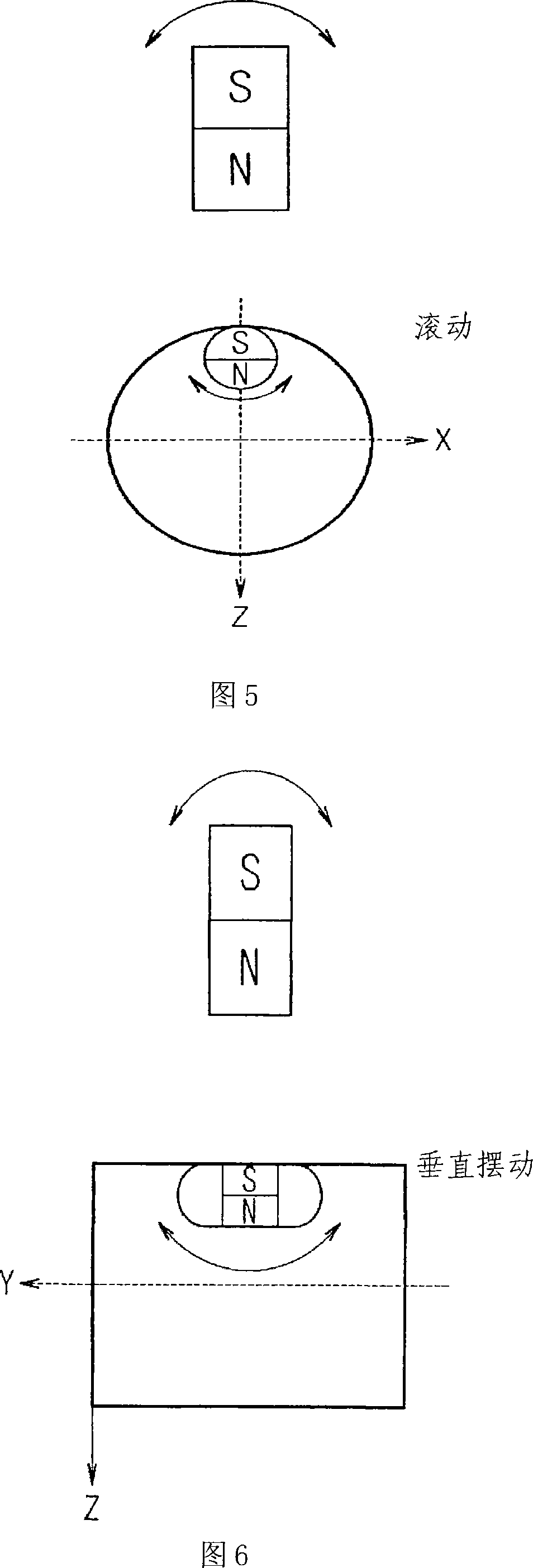

Capsule Type Endoscope Control System

InactiveUS20080300458A1Easy to operateReduce stick-slipEndoscopesDiagnostic recording/measuringMagnetic tension forceWireless transmission

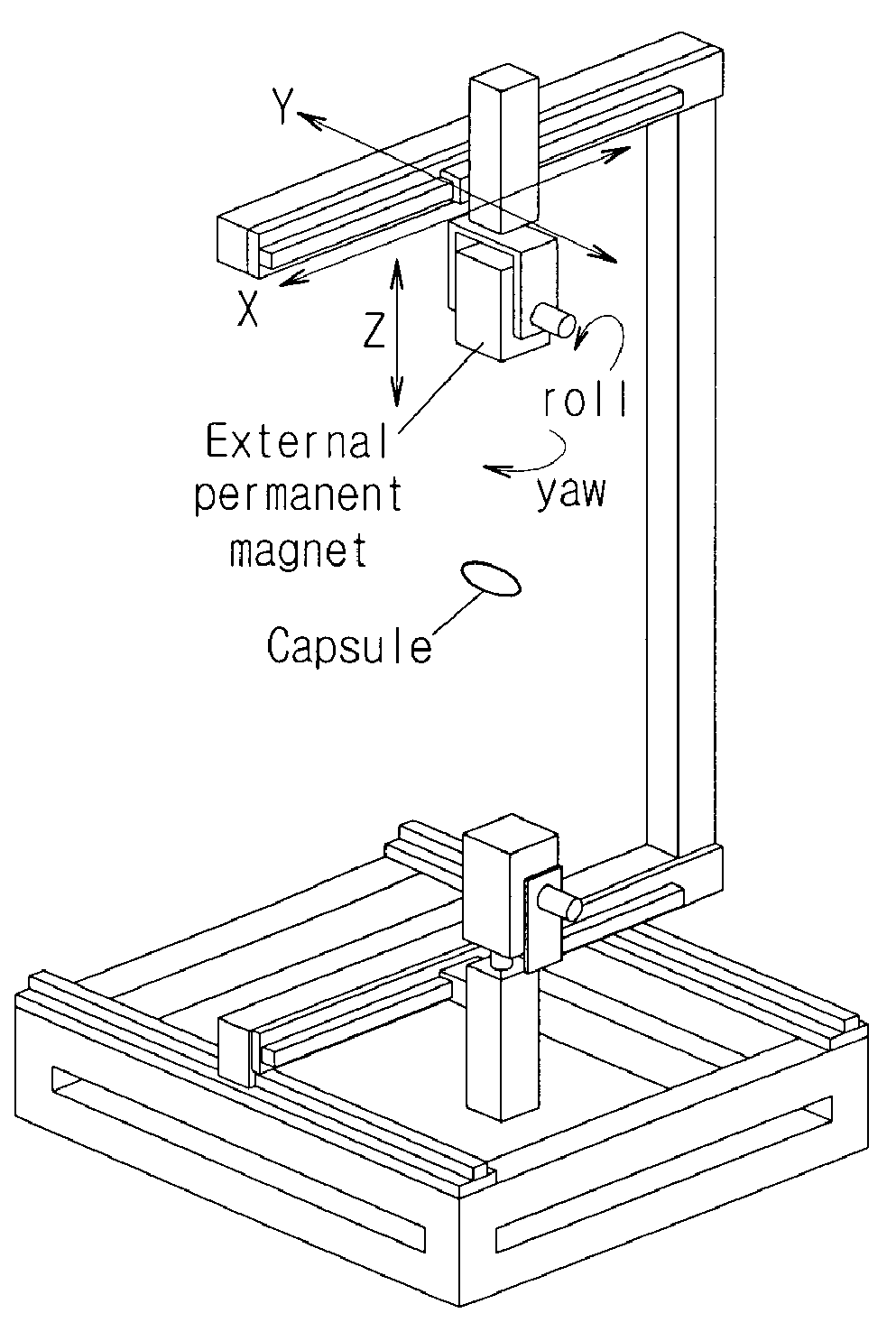

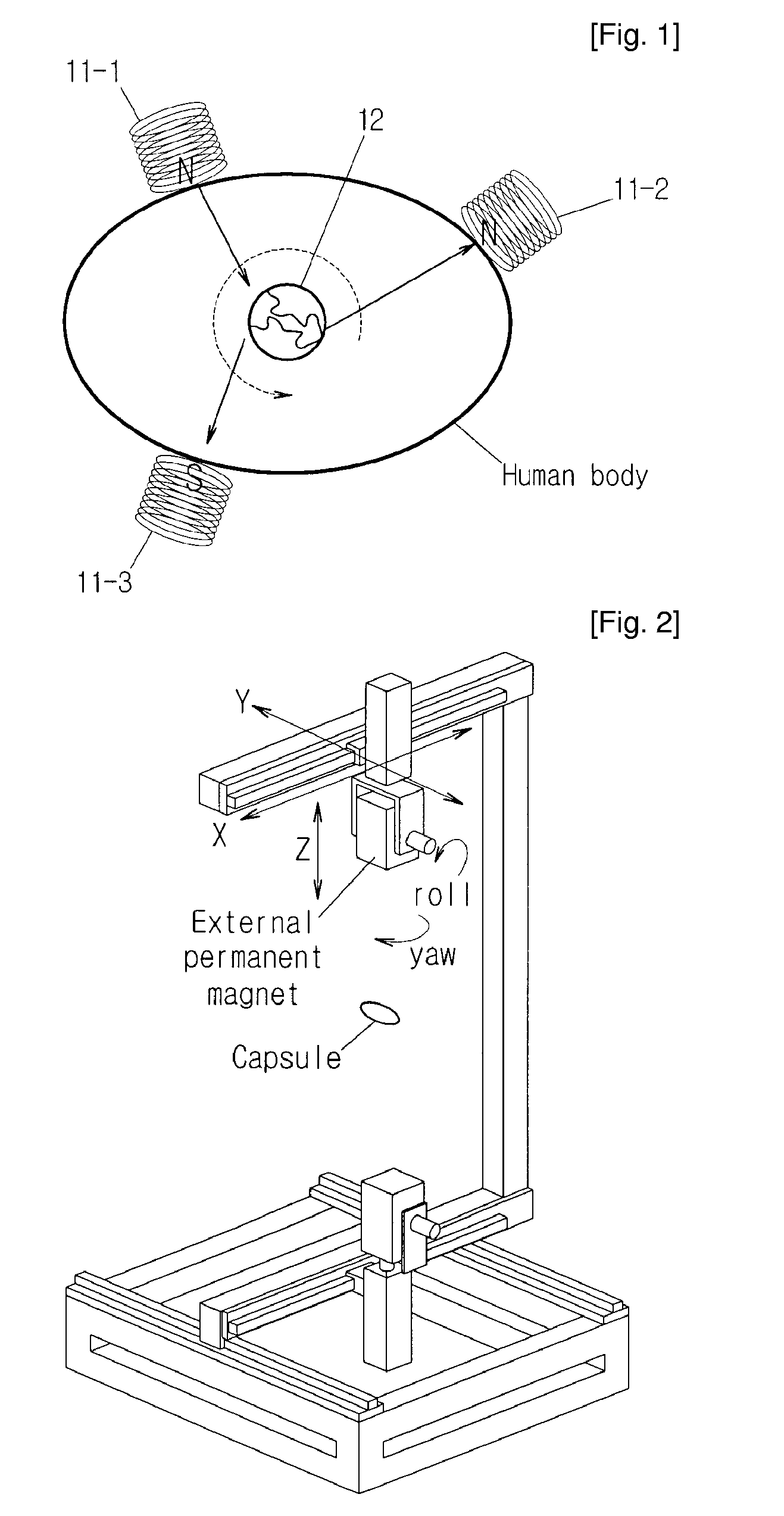

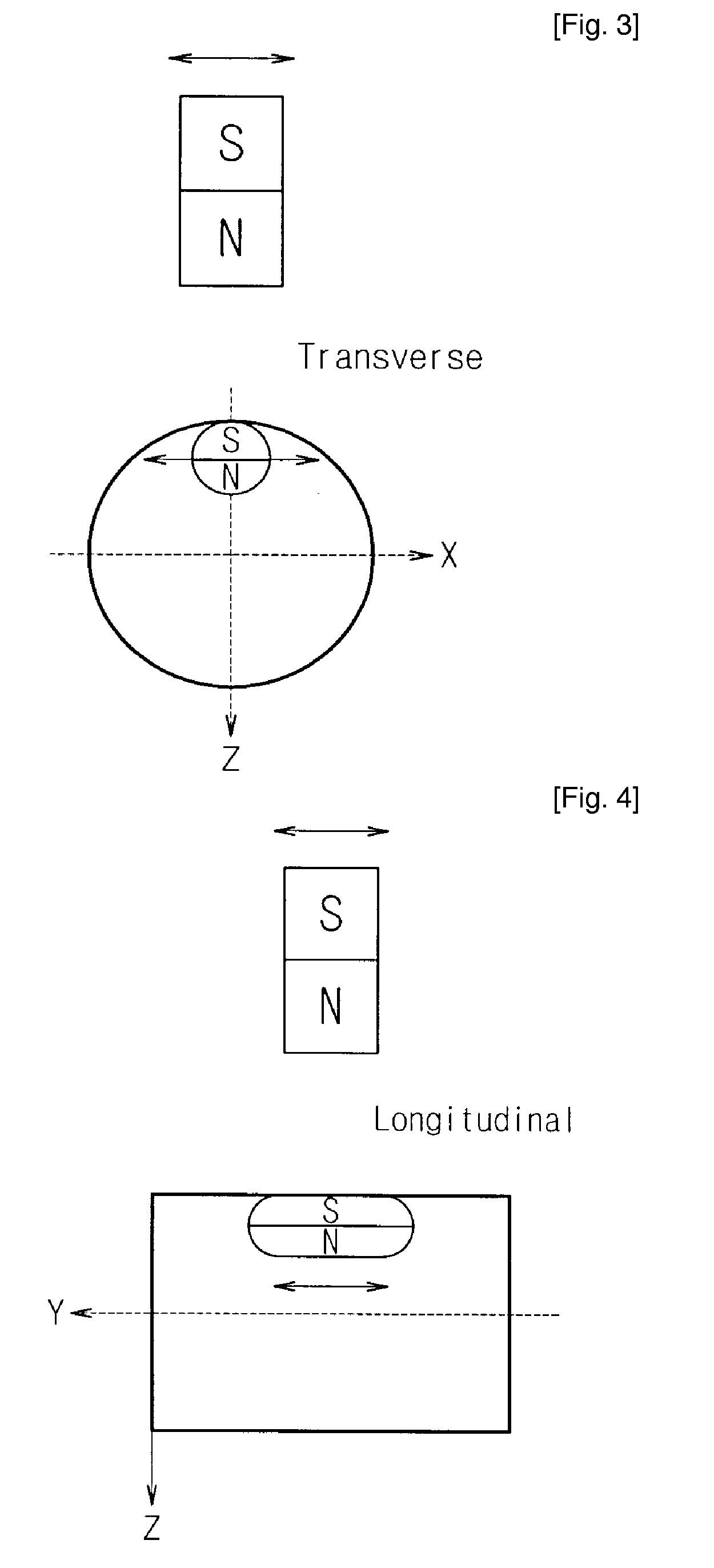

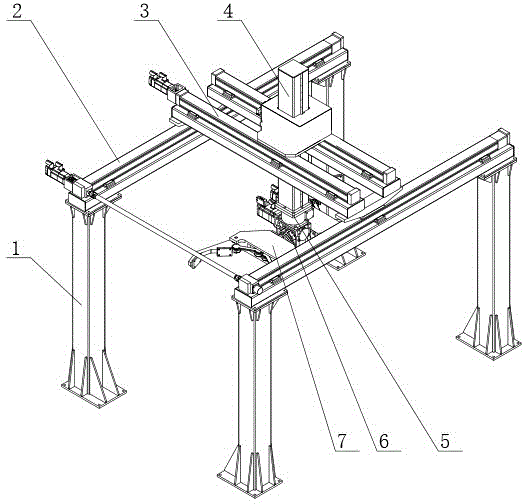

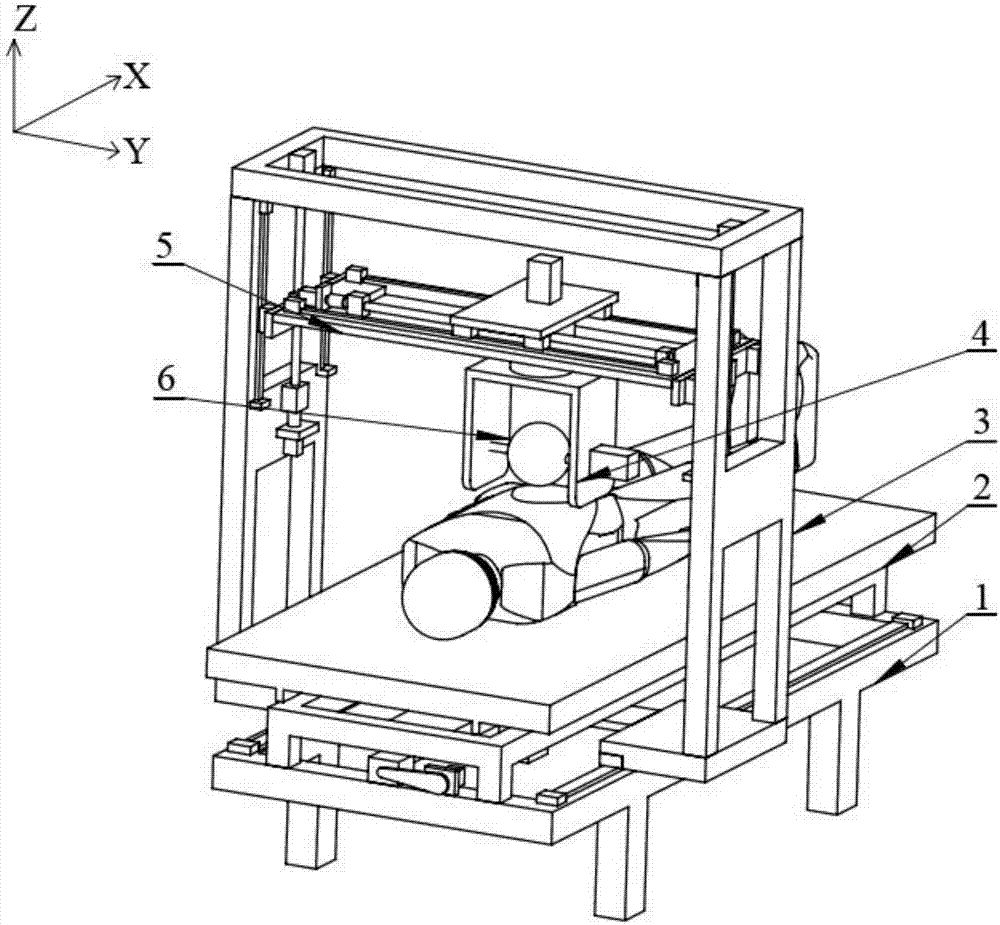

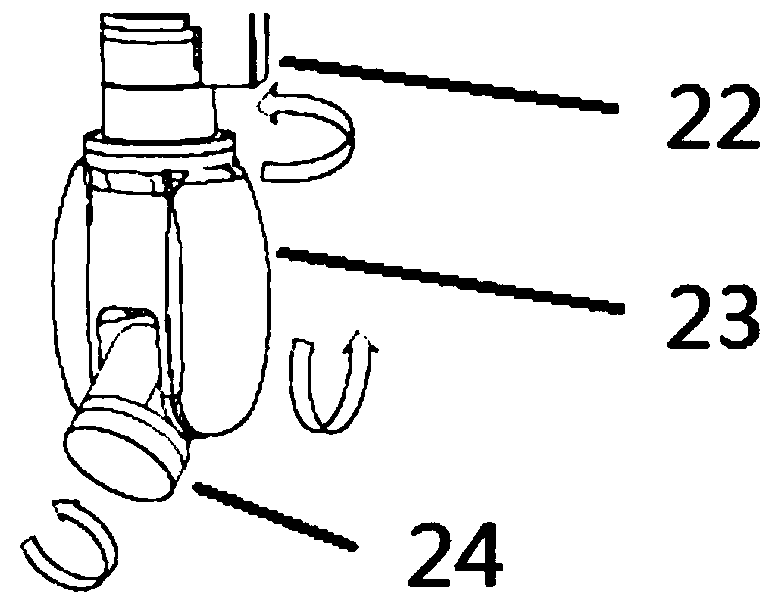

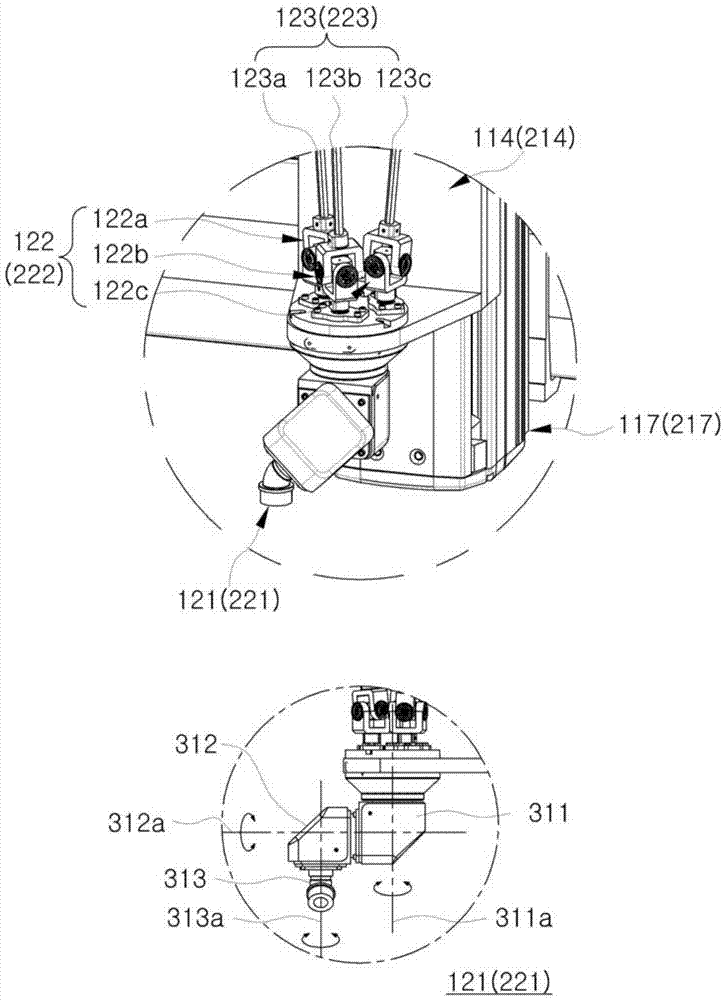

Disclosed is a capsule type endoscope control system which can move to any position, rotate or stop the capsule type endoscope in a human body by a remote control system outside the human body. There is provided a capsule type endoscope control system comprising: a medical capsule equipped with at least one permanent magnet, comprising a wireless transmission circuit for transmitting a series of signals to outside of the body; 2-DOF rotary joint unit for rotating an external permanent magnet in at least two directions, the external permanent magnet applying magnetic magnet forces to the permanent magnets provided in the capsule; a distance sensor for measuring a distance between the external permanent magnet and a surface of the human body; a cartesian coordinate robot for moving the external permanent magnet; a bed for supporting the human body, the bed being able to roll within a certain degree; and a remote control unit outside the human body for controlling operations of the 2-DOF rotary joint unit, the bed and the cartesian coordinate robot.

Owner:KOREA INST OF SCI & TECH

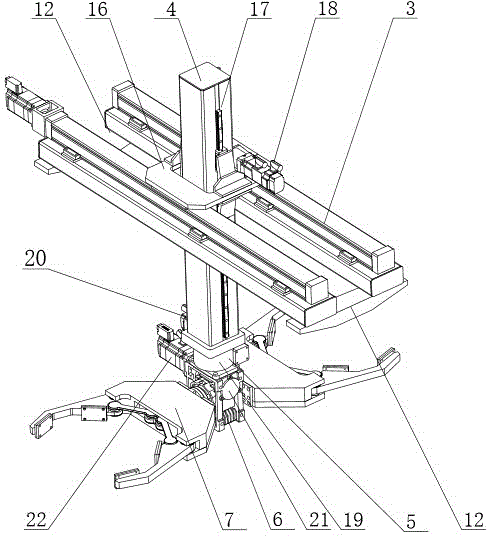

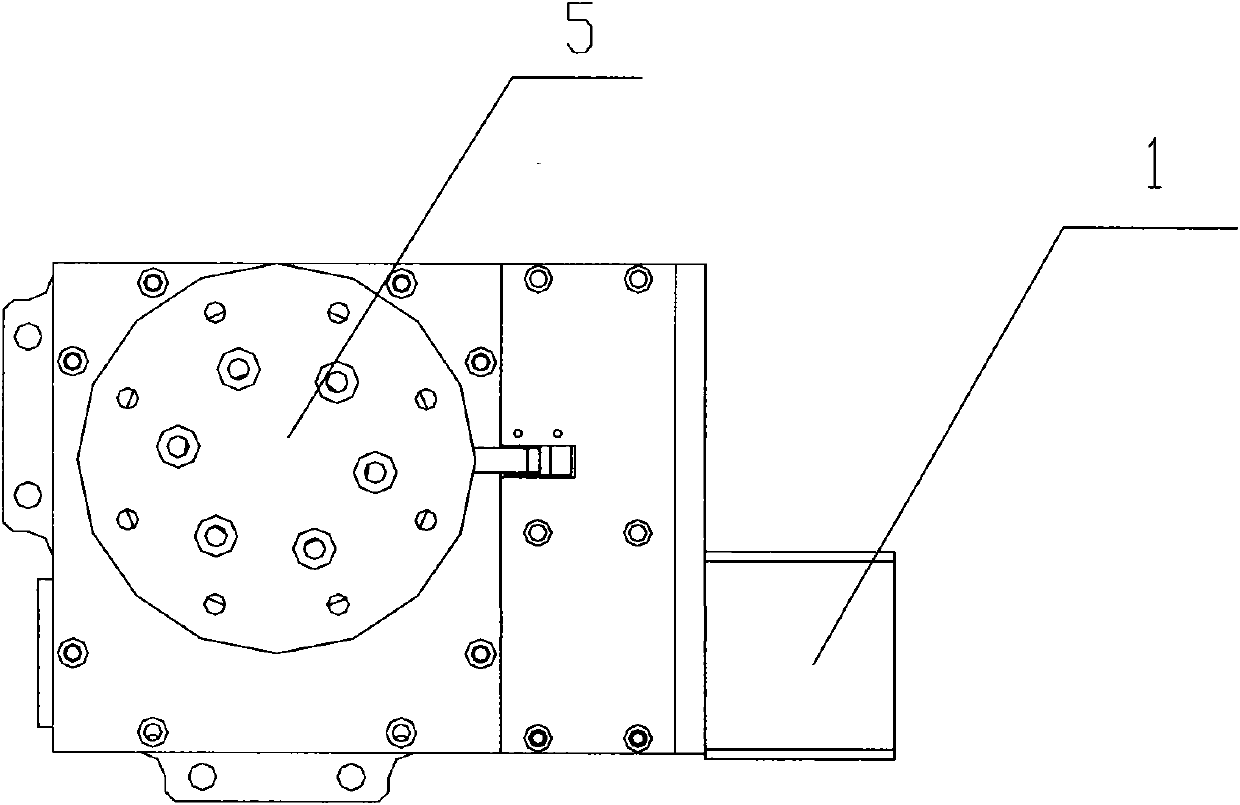

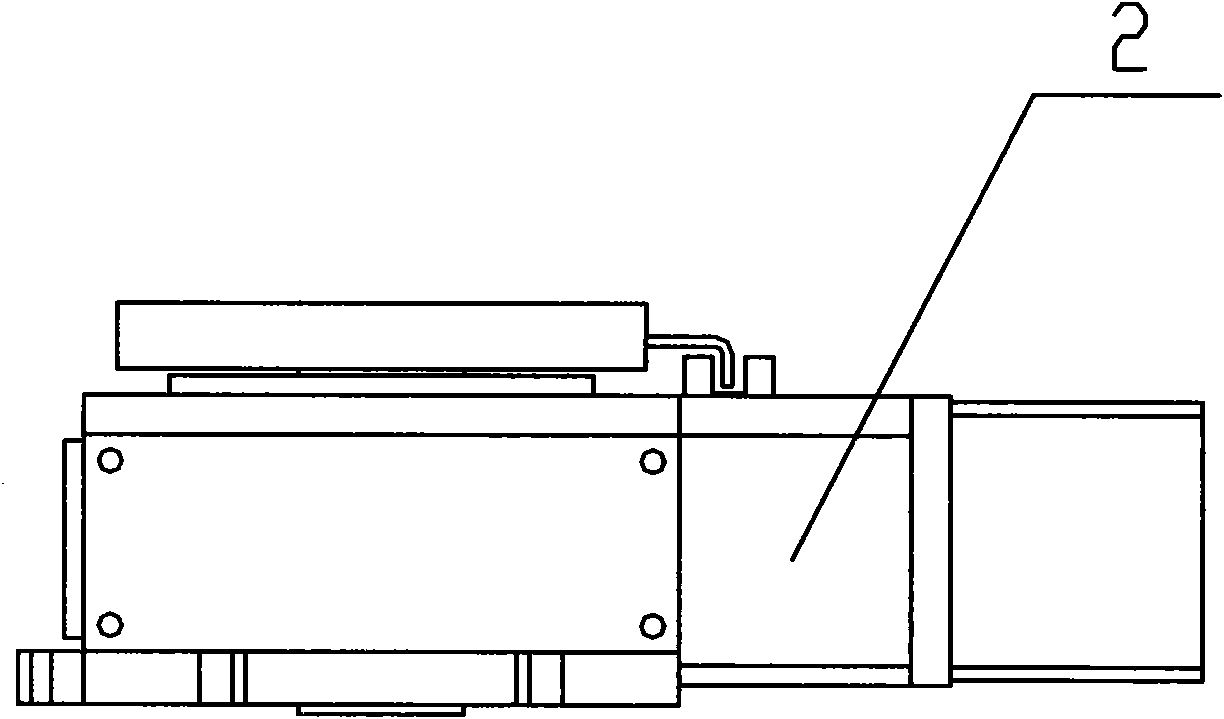

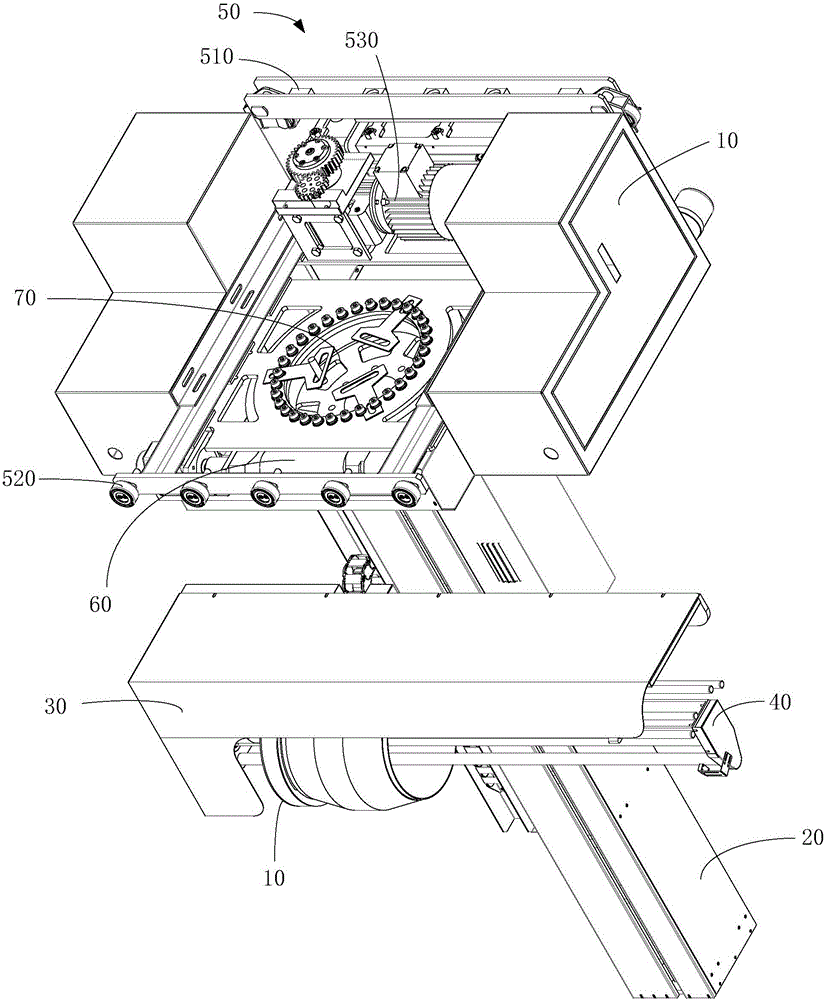

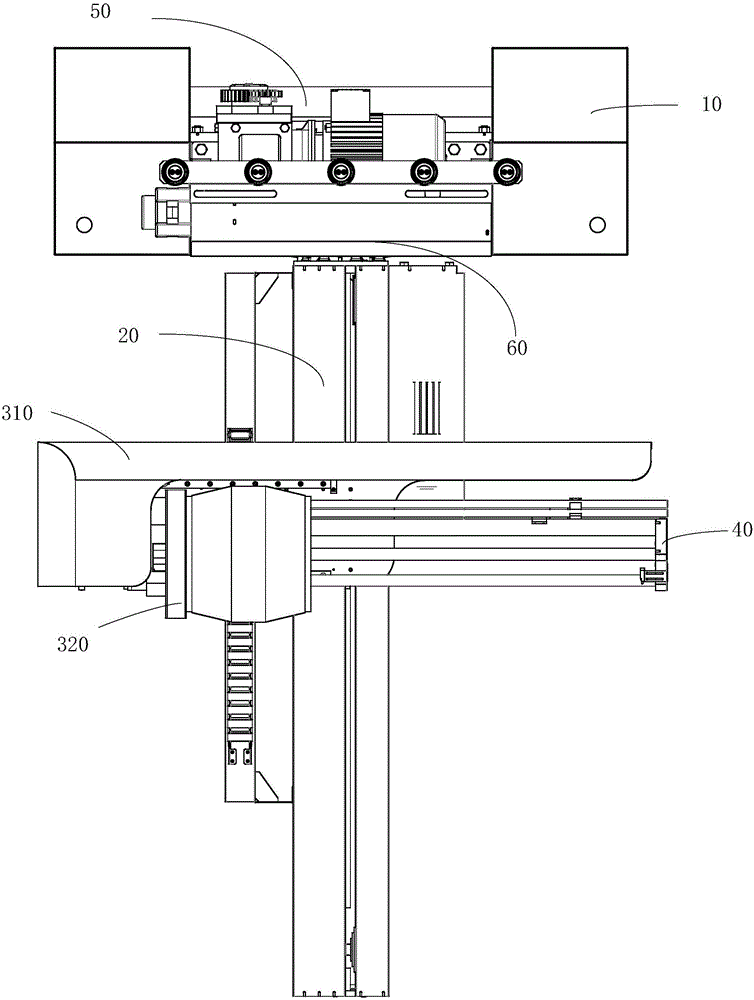

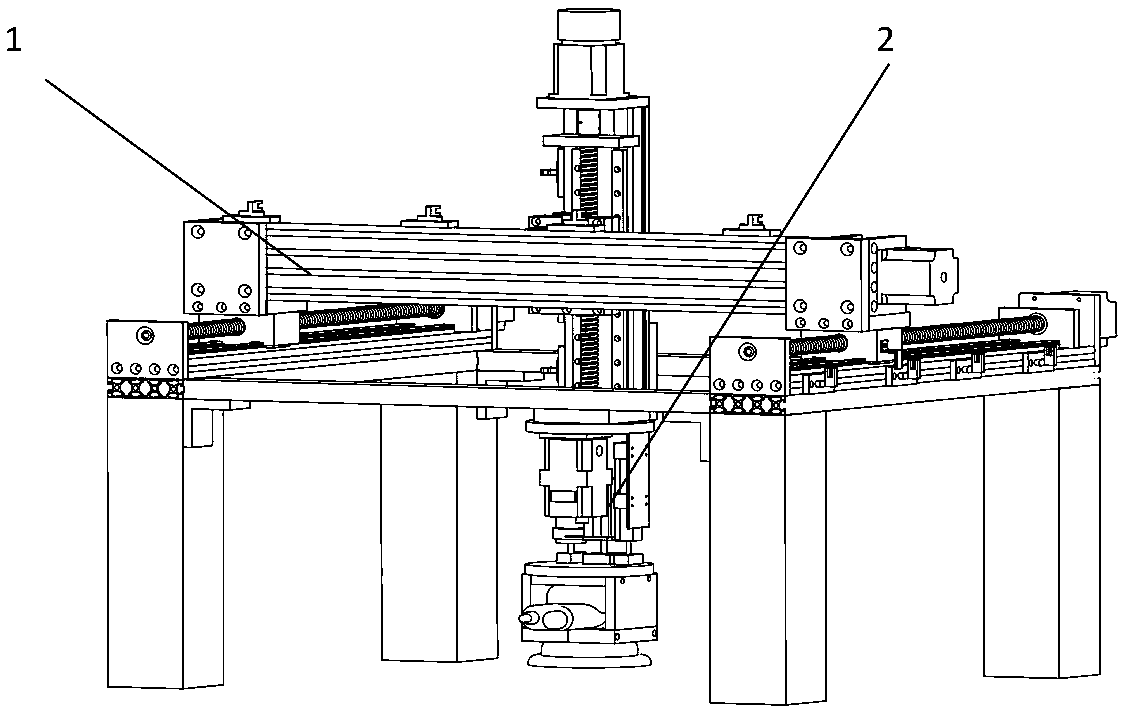

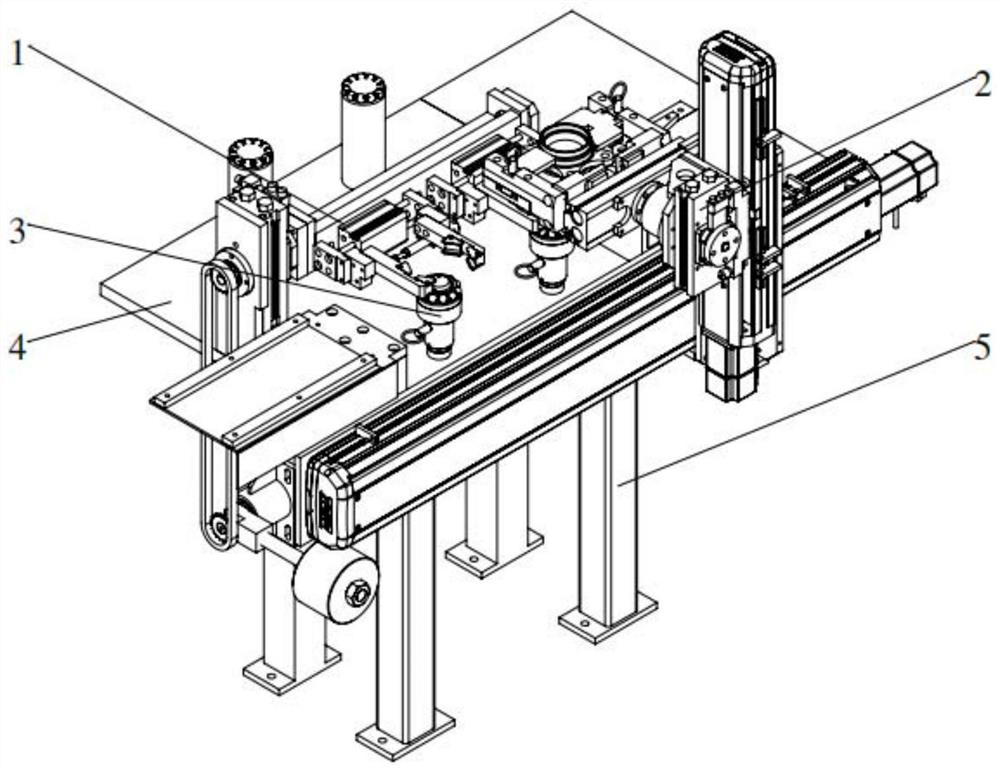

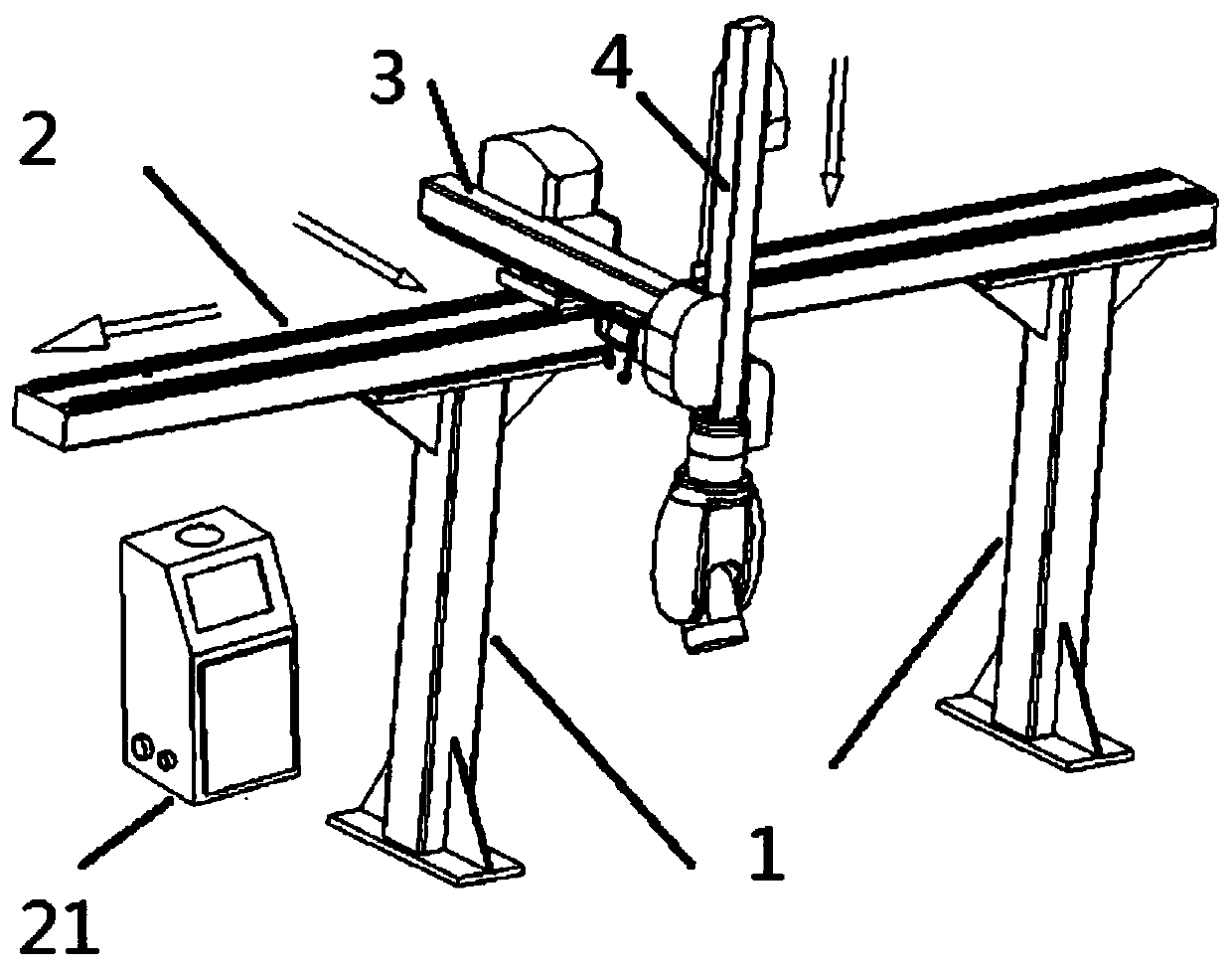

Five-axis hub transfer robot and clamping manipulator

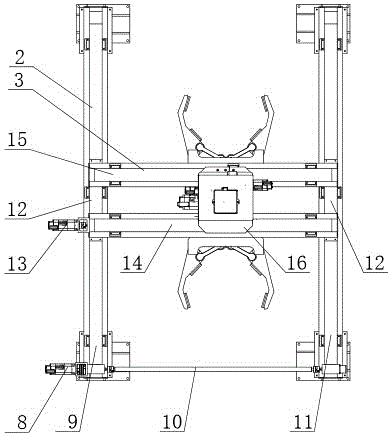

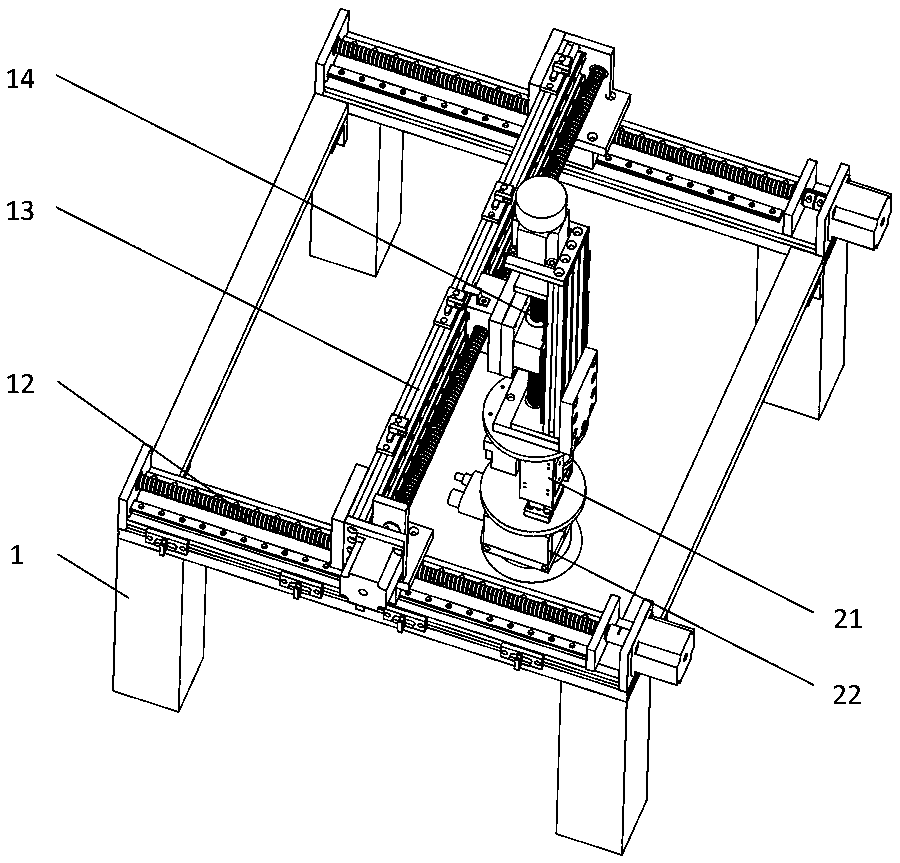

ActiveCN104444360AFlexible handlingReduce material preparation waiting timeConveyor partsRobot handControl engineering

The invention discloses a five-axis hub transfer robot and a clamping manipulator. An X-axis drive system is mounted on a truss. A Y-axis drive system is mounted on the X-axis drive system in a crossing manner through an X-Y-axis connecting plate. A Z-axis drive system is vertically mounted on the Y-axis drive system through a Y-Z-axis connecting plate. The X-axis drive system, the Y-axis drive system and the Z-axis drive system are mutually orthogonal, and an X-Y-Z rectangular-coordinate robot is formed. A C-axis drive system and an A-axis drive system are disposed in order at the bottom of the Z-axis drive system. The C-axis drive system is connected with the A-axis drive system through a C-A-axis connecting flange. An output shaft of the A-axis drive system is connected with the clamping manipulator. The five-axis hub transfer robot and the clamping manipulator have the advantages that operations such as carrying, feeding, discharging, turning and interchanging among different production lines are automated for aluminum alloy hubs, labor intensity is greatly reduced, product quality is ensured, production efficiency is improved, and unattended automated production is achieved for different hub processing units on one hub production line.

Owner:HUST WUXI RES INST

Capsule type endoscope control system

InactiveCN101001563AAvoid damageControl movementEndoscopesDiagnostic recording/measuringMagnetic tension forceWireless transmission

Disclosed is a capsule type endoscope control system which can move to any position, rotate or stop the capsule type endoscope in a human body by a remote control system outside the human body. There is provided a capsule type endoscope control system comprising: a medical capsule equipped with at least one permanent magnet, comprising a wireless transmission circuit for transmitting a series of signals to outside of the body; 2-DOF rotary joint unit for rotating an external permanent magnet in at least two directions, the external permanent magnet applying magnetic forces to the permanent magnets provided in the capsule; a distance sensor for measuring a distance between the external permanent magnet and a surface of the human body; a cartesian coordinate robot for moving the external permanent magnet; a bed for supporting the human body, the bed being able to roll within a certain degree; and a remote control unit outside the human body for controlling operations of the 2-DOF rotary joint unit, the bed and the cartesian coordinate robot.

Owner:KOREA INST OF SCI & TECH

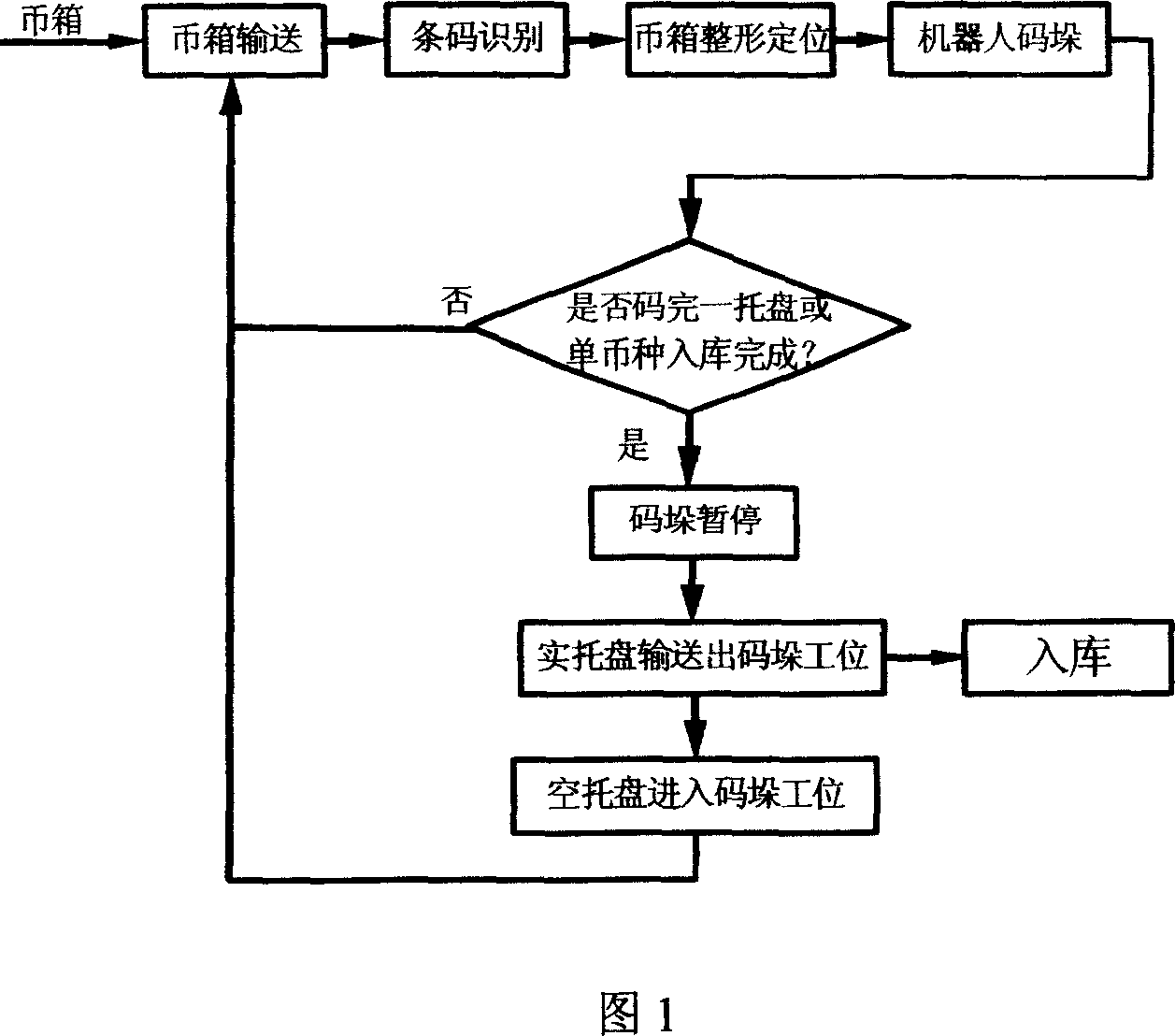

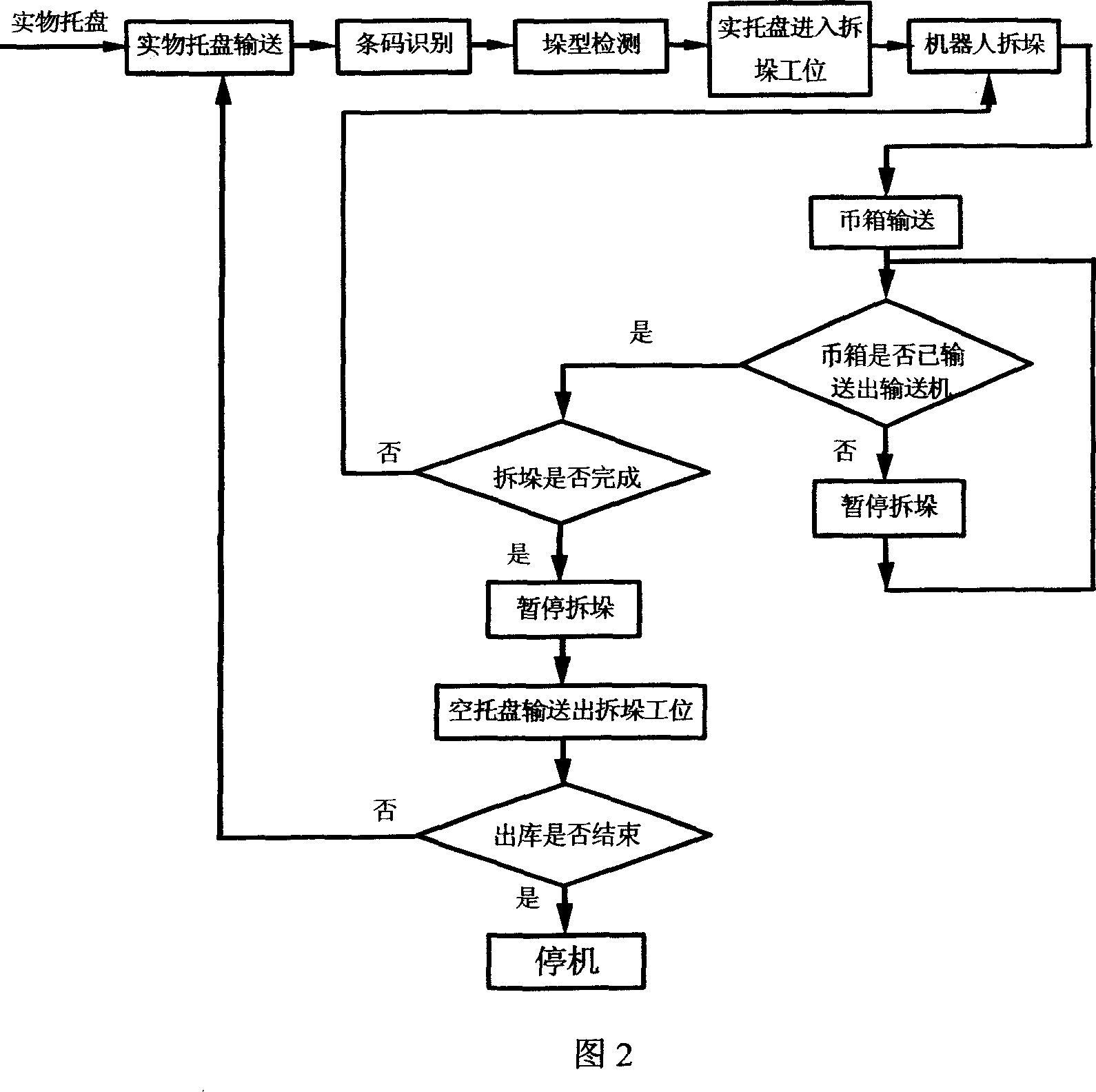

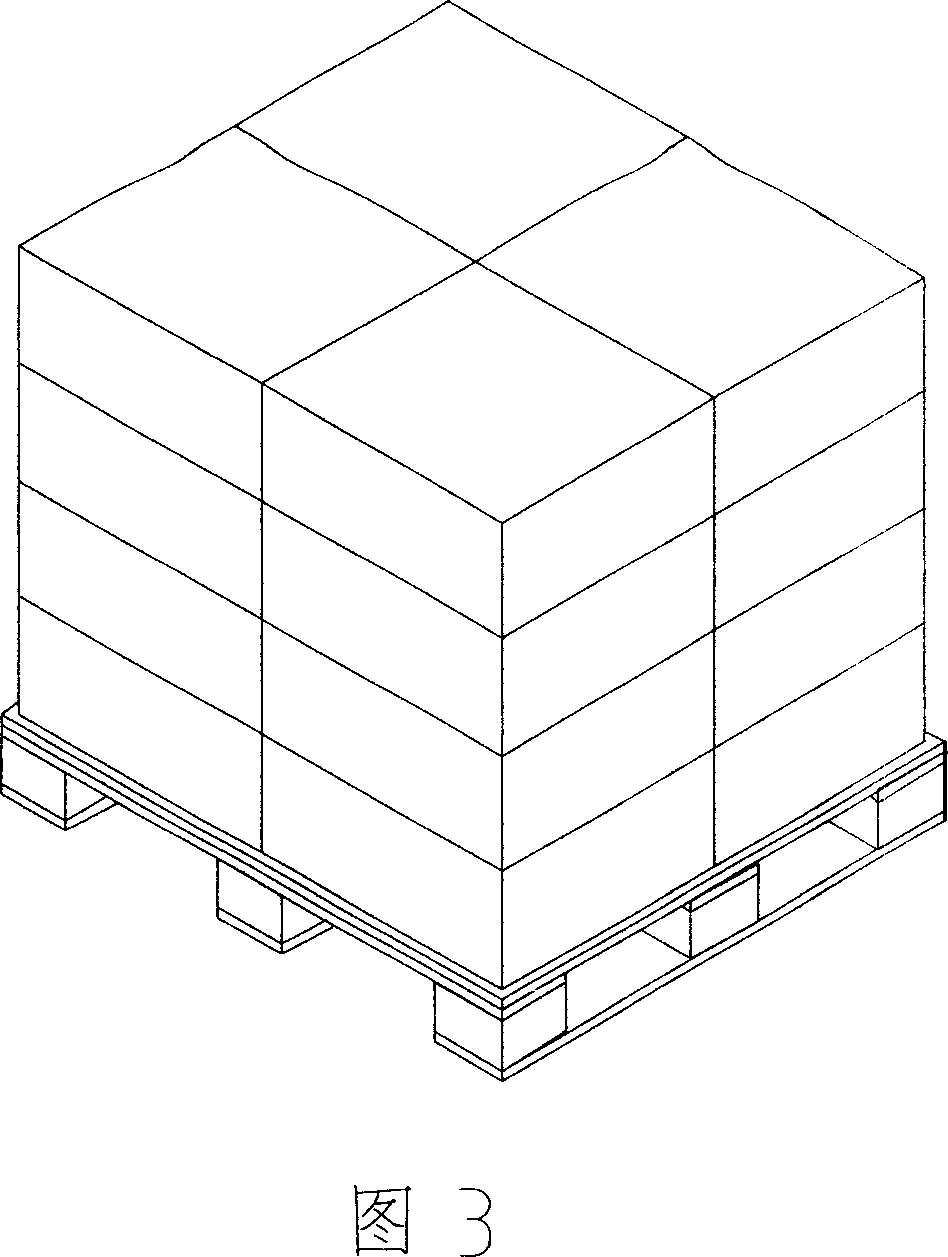

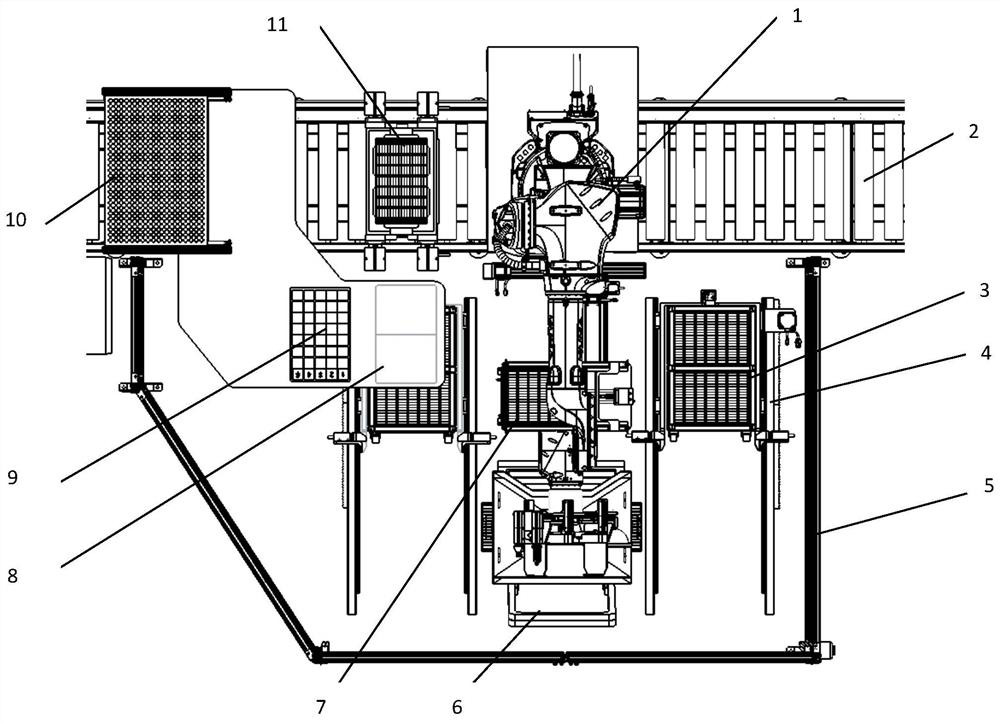

Automatic de-stacking and stacking technology and system for putting currency-box into and out of bank exchequer

ActiveCN1923644AQuick and easy palletizingPalletizing works accuratelyProgramme-controlled manipulatorControl devices for conveyorsStructural engineeringCartesian coordinate robot

The automatic de-stacking and piling process and system for entry and exit of money case in the bank exchequer comprises of the entry piling and exit de-stacking; the system comprises of a Cartesian coordinate robot (5) and the fixture (6) at the bottom, with the transverse conveyer (1) and money box conveyer (10) equipped at the lower part of the robot sequentially. Inside the transverse conveyer and under the robot's piling and de-stacking position, there locates an alighting conveyer (12), whose outlet has an vertical conveyer (14) perpendicular to the transverse conveyer that has an check sensor (29) (19) on it. Above or the side of the transverse conveyer and the money box conveyer, separately locate the bar code scanner (13) (9) and the side of money box conveyer close to the robot has a money box regularizing and positioning device and a check sensor (15), (17). It can use the same system to realize the automatic de-stacking and piling operation of money boxes, automatic hand over of money box's entry and exit of the exchequer with high automation level, small occupant area, and quick and accurate de-stacking and piling.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

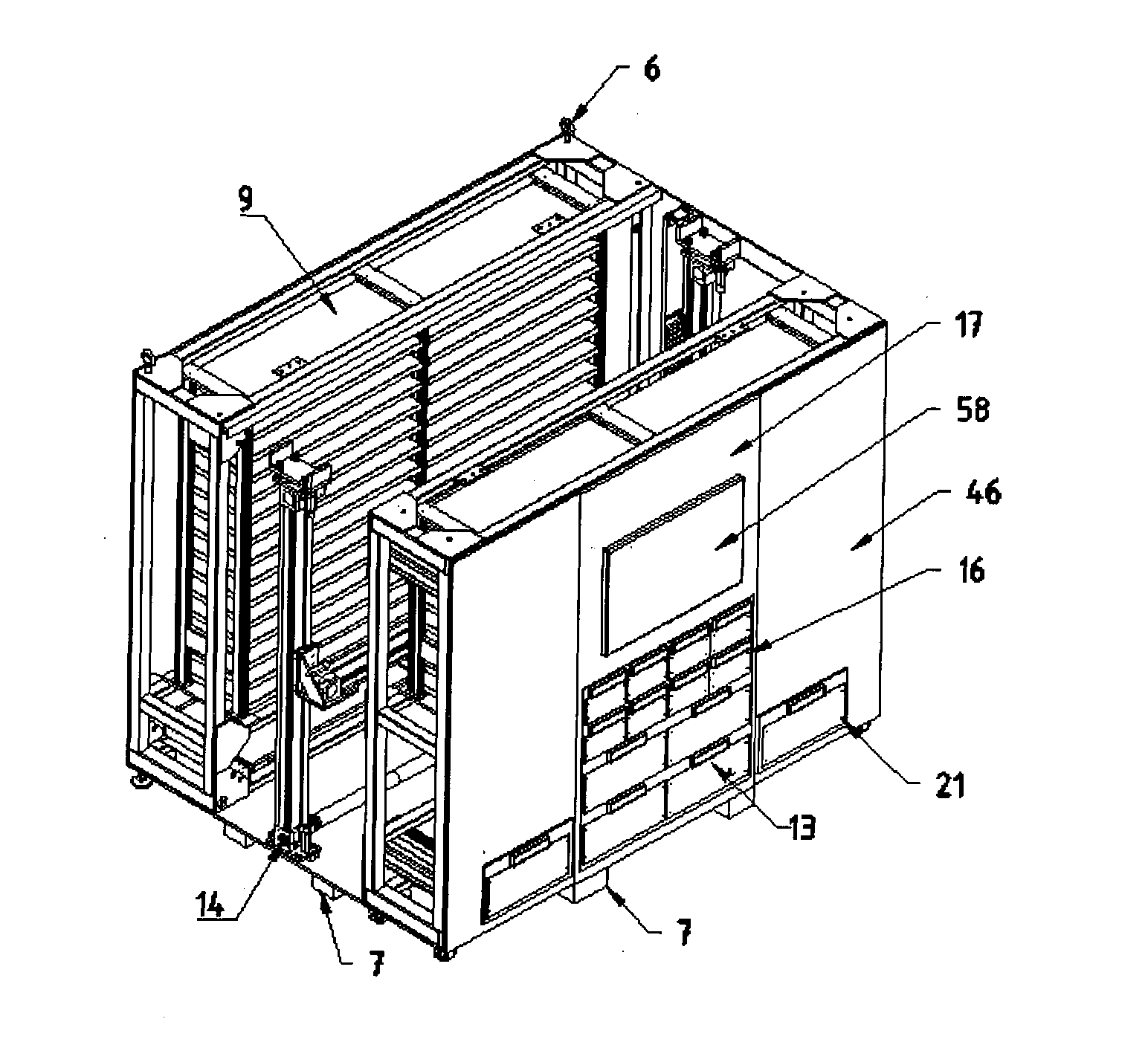

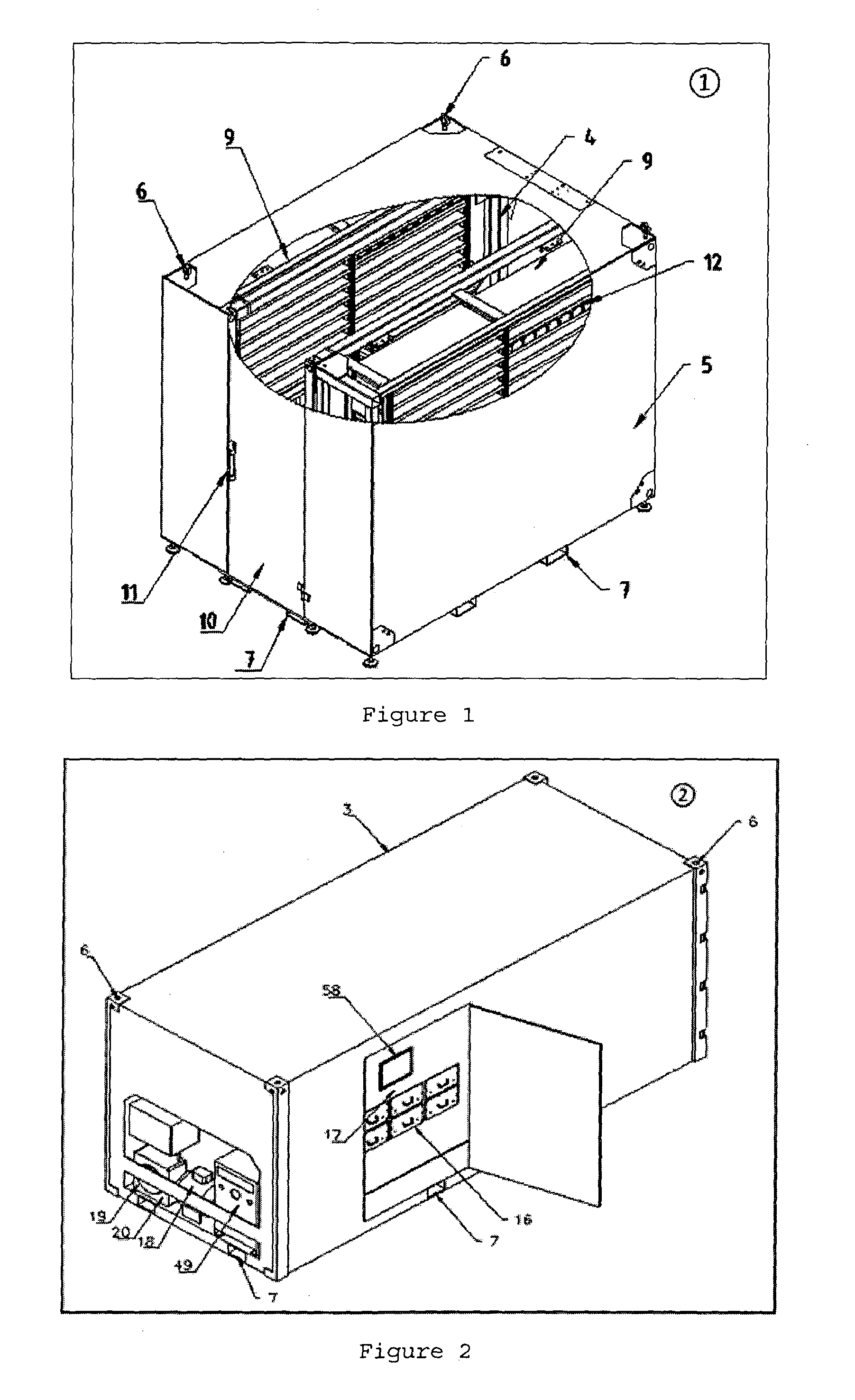

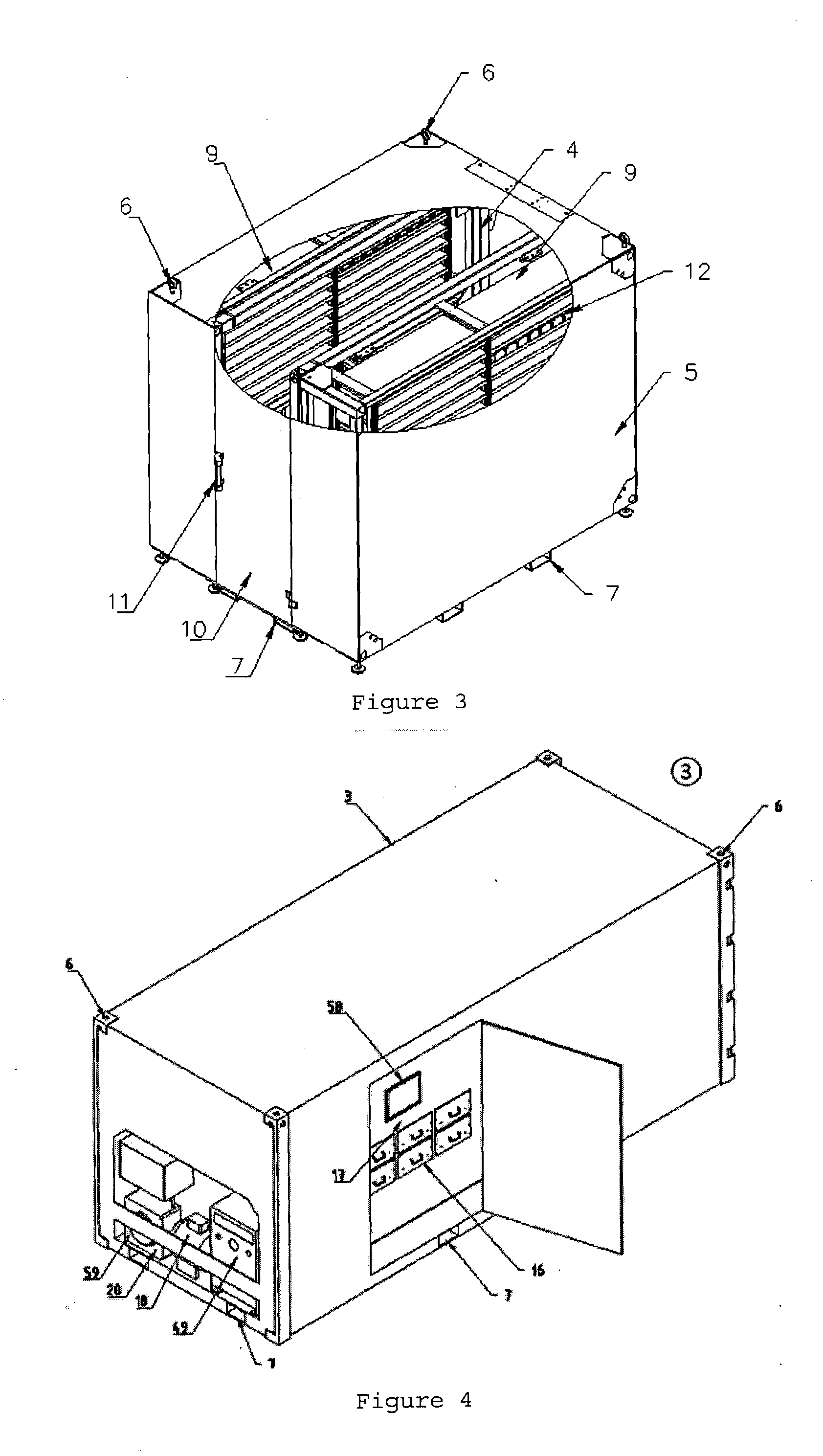

Evolving mobile unit for controlled product storage and dispensing

InactiveUS20170036859A1Improper operationHeavy operationPackagingStorage devicesSoftware systemSemi automatic

An evolving mobile Unit for controlled product storage and dispensing, with modular construction and multiple upgrade possibilities, to the capacity and storing / picking system that can evolve from manual, up to fully automatic operation. The Unit is easy to transport and maneuver, by crane or forklift, using the provided pick up points (6) and pockets (7), either in standard or heavy duty / all-weather form. The Unit can be autonomous, with an integrated power unit (49) and internal climate control (19). The products are stored inside, within Unit Loads (UL) (8) that can hold any kind of materials, either solid or liquid, at ambient or controlled temperature and humidity. The ULs are stored in a modular shelving system (9), adjustable to accommodate mixes of UL sizes. Access control is provided by lock (11), drawer (16) and software systems together with a picking / replenishment method. The software controls the ULs multiple locations (12), and manages the picking method, either in manual, manual assisted, Basic Semi-Automatic, Semi-automatic or Fully-automatic versions, using Cartesian coordinate robots (14) for storing / picking the desired products. These and other features, aspects, and advantages of the present invention will become clearer with the following description, appended claims, and accompanying drawings.

Owner:PICKLOG UNIPESSOAL LDA

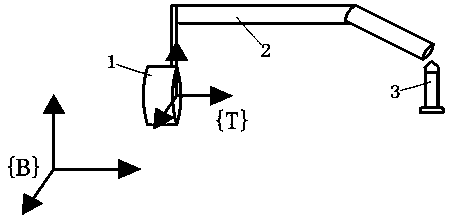

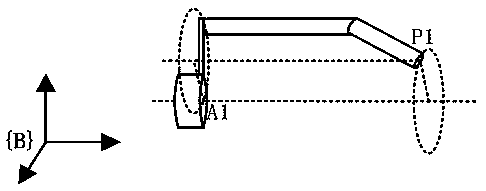

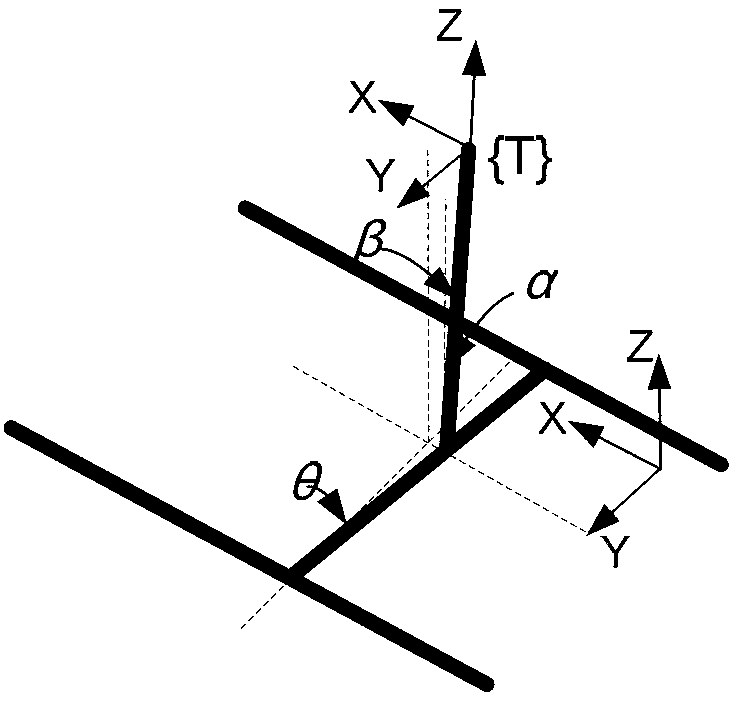

Mechanical arm tool coordinate system self-calibration method

ActiveCN108748159AAvoid getting into weird situationsSimple methodProgramme-controlled manipulatorMultiple pointEngineering

The invention discloses a mechanical arm tool coordinate system self-calibration method, and belongs to the field of correlation technique of robot calibration. The method is applicable to an XYZR cartesian coordinate robot, and comprising the steps of utilizing a self point position of the robot for calibrating a tool center point; and through adjusting multiple points and corresponding multipleposition data of a tool fixedly arranged on a rotary shaft at the tail end of a mechanical arm and a top until the required points are recorded, circle fitting the recorded point position data to obtain a center coordinate, and obtaining a tool coordinate according to a coordinate geometry relationship. According to the mechanical arm tool coordinate system self-calibration method provided by theinvention, no external measurement tool is required, the tool coordinate system can be identified relative to a pose of a terminal coordinate system by utilizing self conditions, so that the method issimple and convenient for field application of the equipment party.

Owner:WUXI XINJIE ELECTRICAL

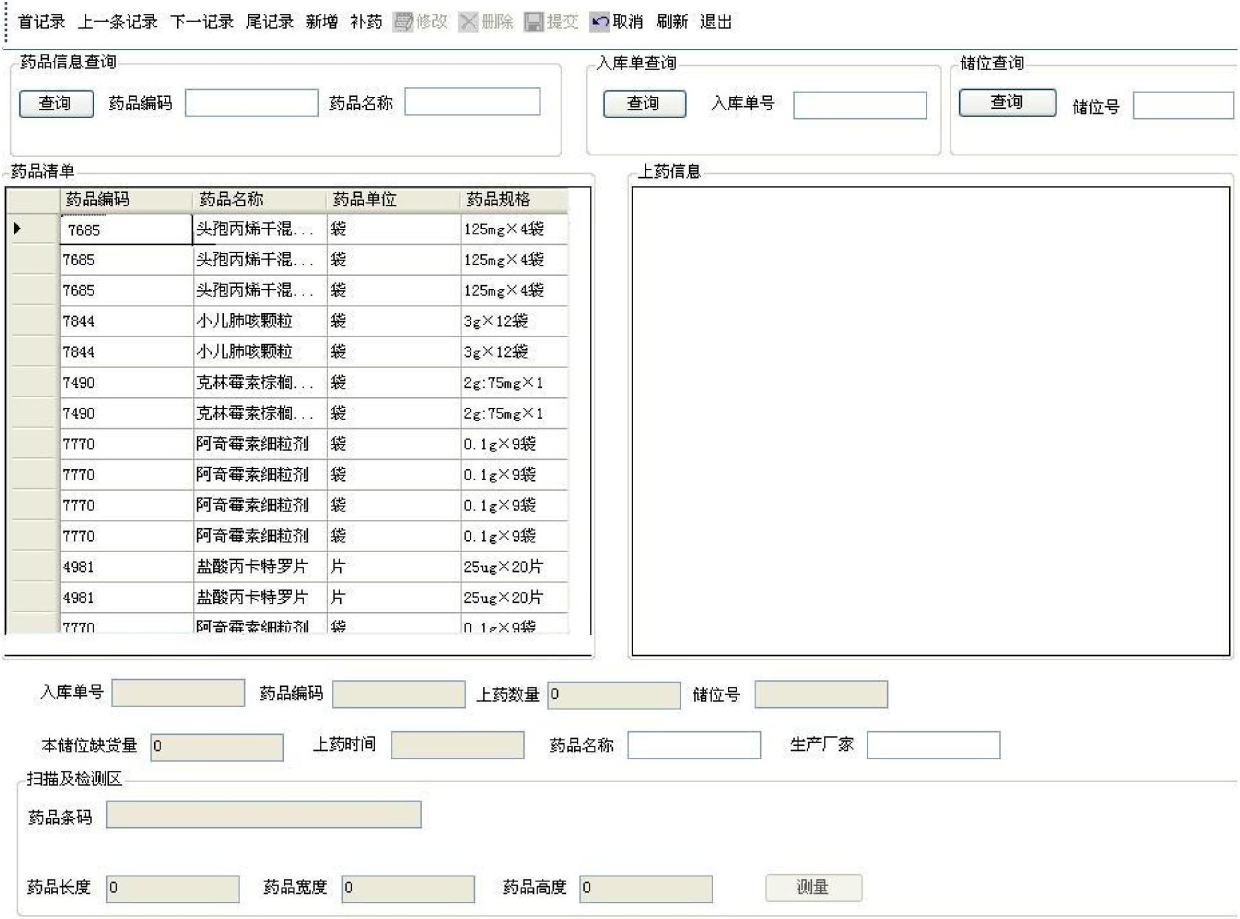

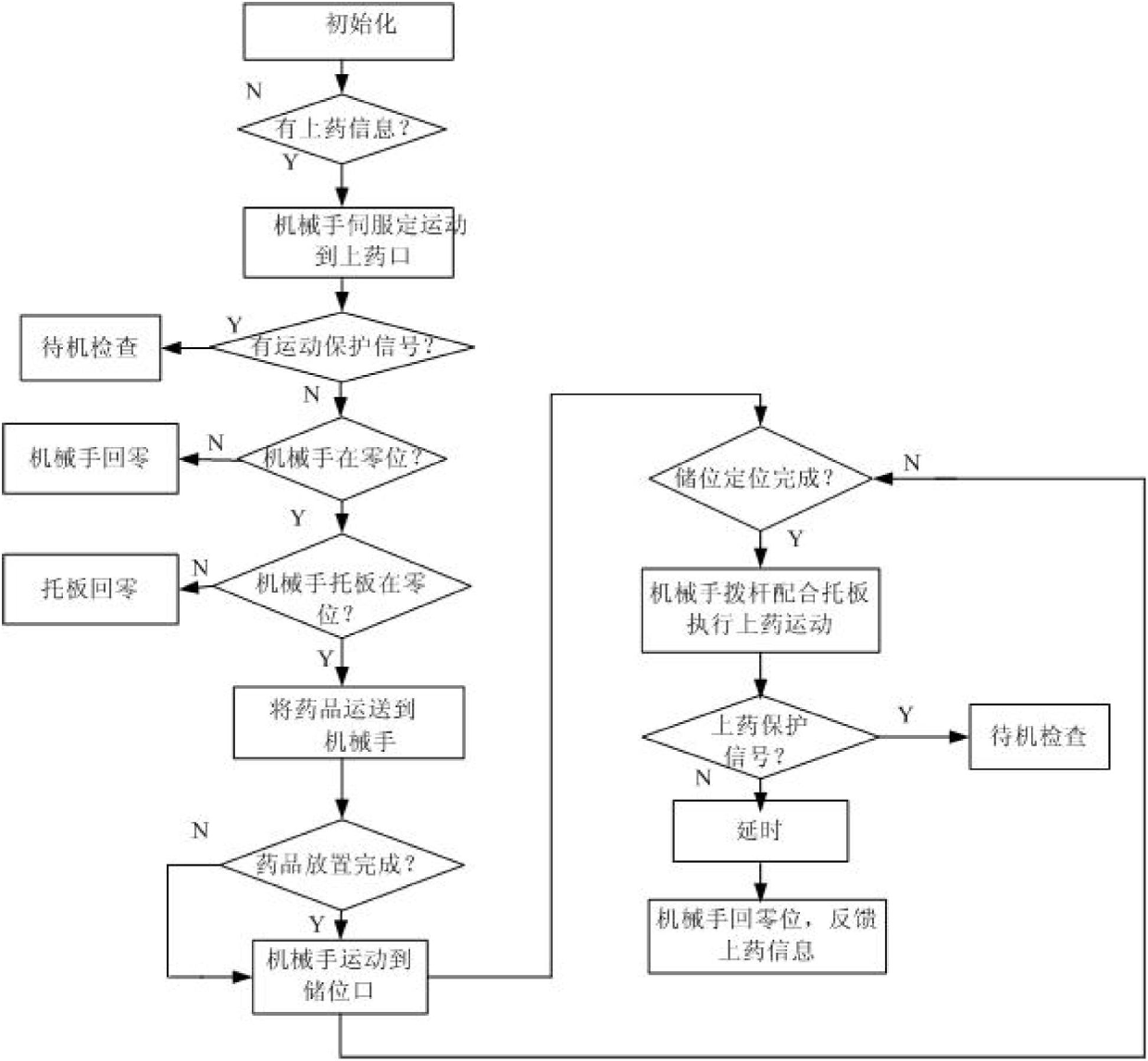

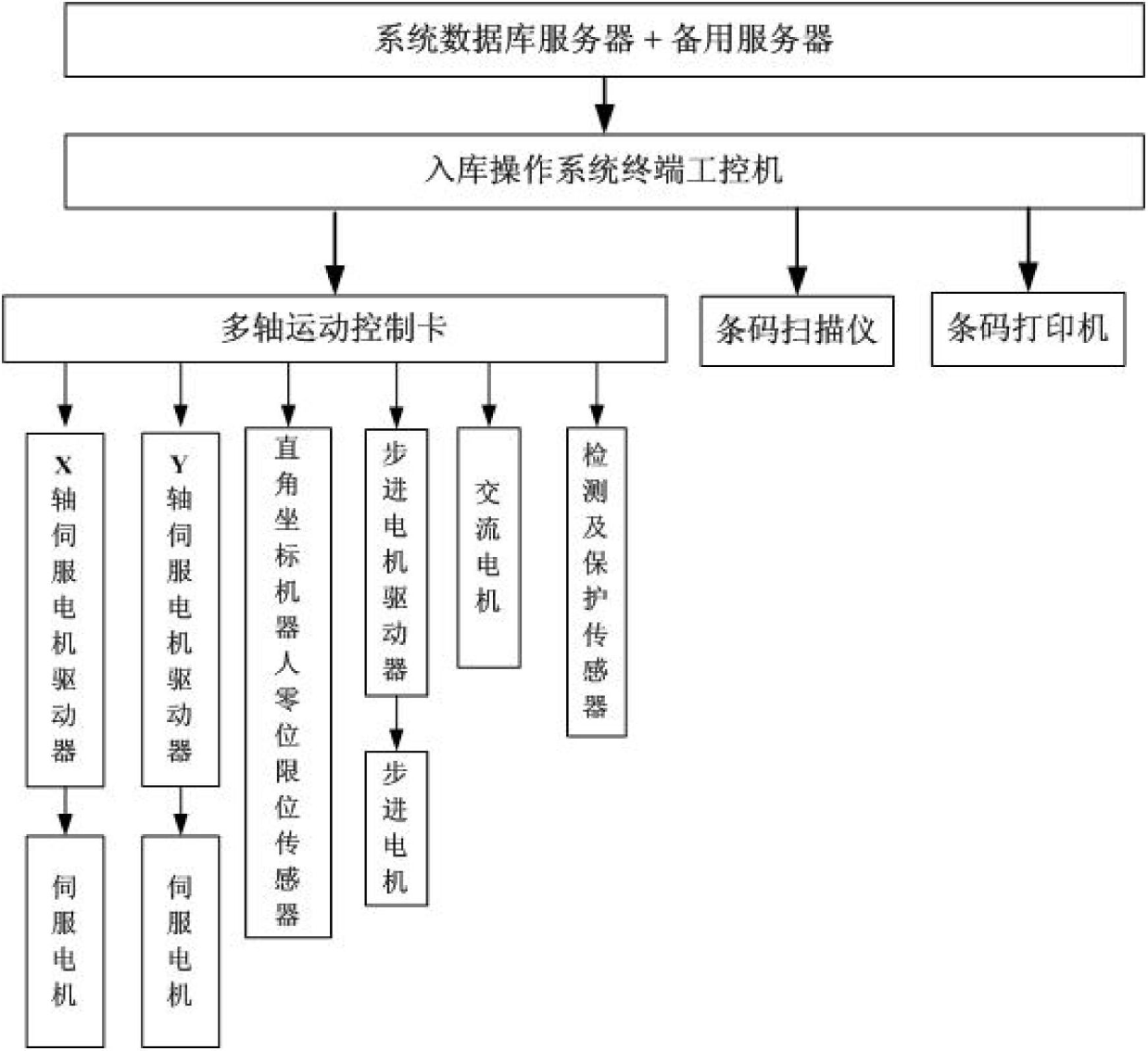

Automated pharmacy drug storage control and management system

InactiveCN102673934AImprove storage efficiencyMeet inventoryStorage devicesCartesian coordinate robotDrug supply

The invention provides an automated pharmacy drug storage control and management system, which comprises a control subsystem and a management subsystem. The storage management subsystem is used for drug storage space distribution and storage space management and has two functions, i.e. a storage space management function and a storage space distribution function. The storage space management function is used for inquiry and modification of the drug storage space state, wherein the storage space state comprises three modes, i.e. occupied, idle and faulty. The storage space distribution function is used for distribution of storage space of newly added drugs and supplemented drugs. The storage control subsystem is used for controlling storage operations of a Cartesian coordinate robot and a cartridge clip type drug supply manipulator. The storage space can be distributed automatically according to drugs to be stored, drugs can be automatically delivered into specified storage tanks, the labor can be saved greatly, the labor intensity of pharmacists in storage operations can be reduced, and the system has good application prospects.

Owner:BEIHANG UNIV

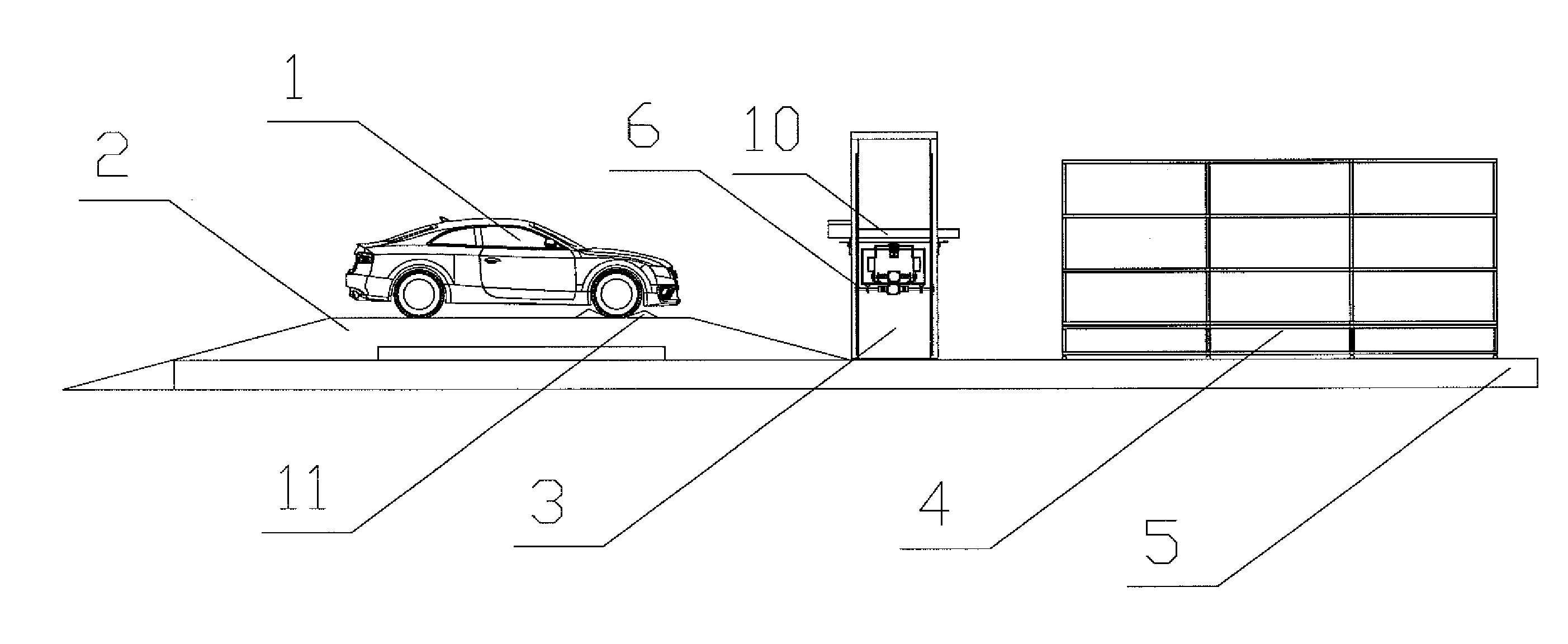

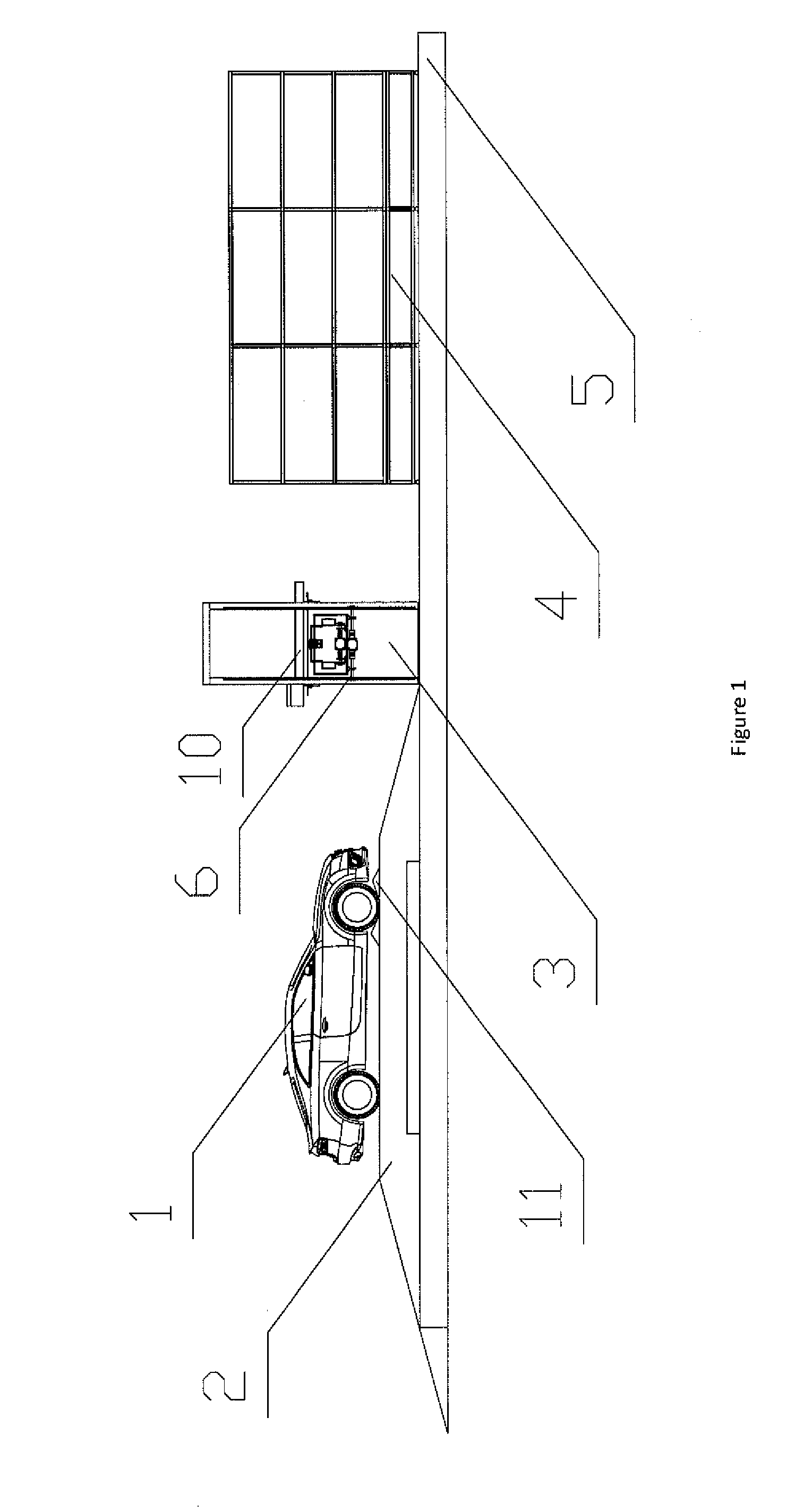

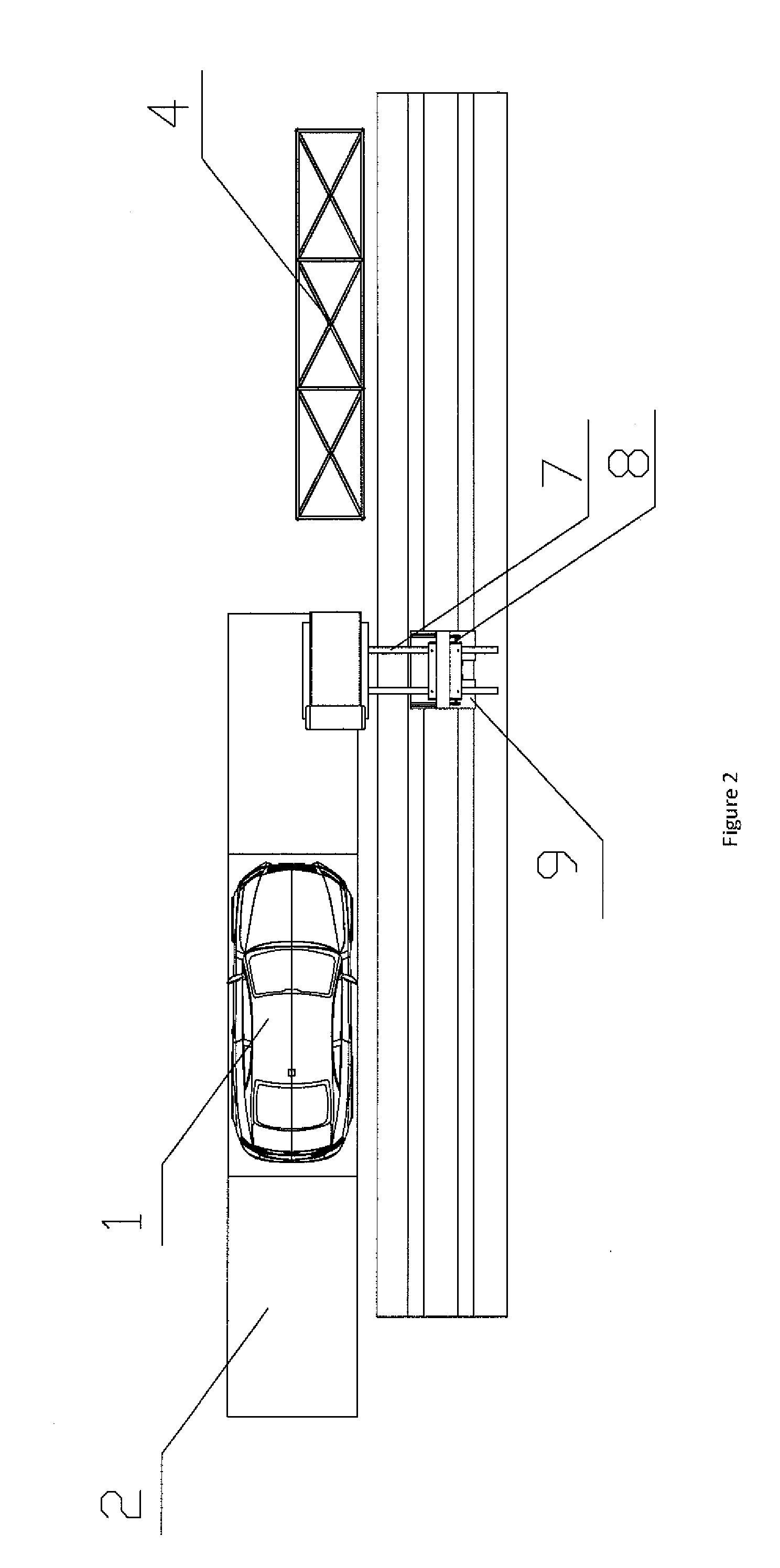

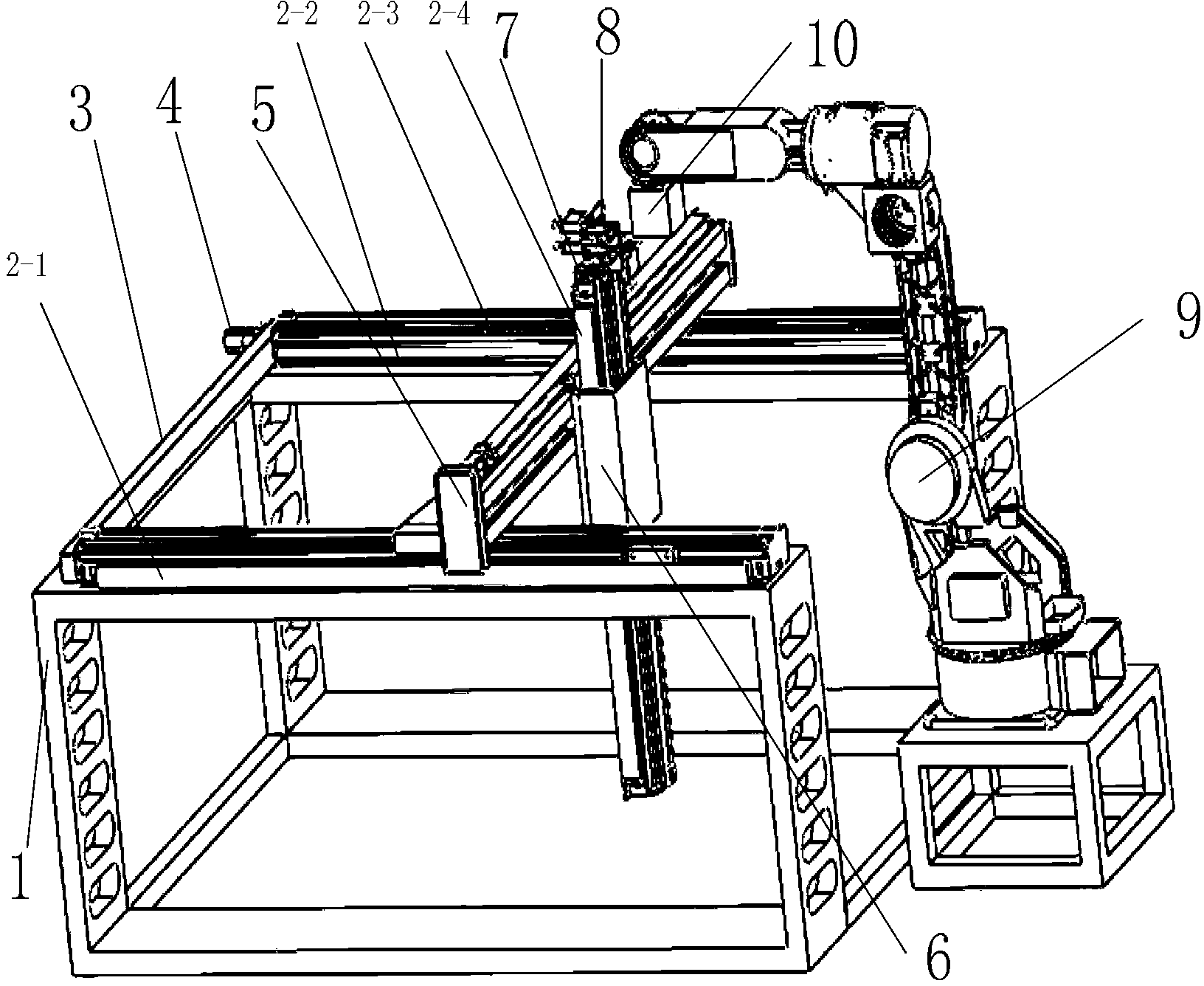

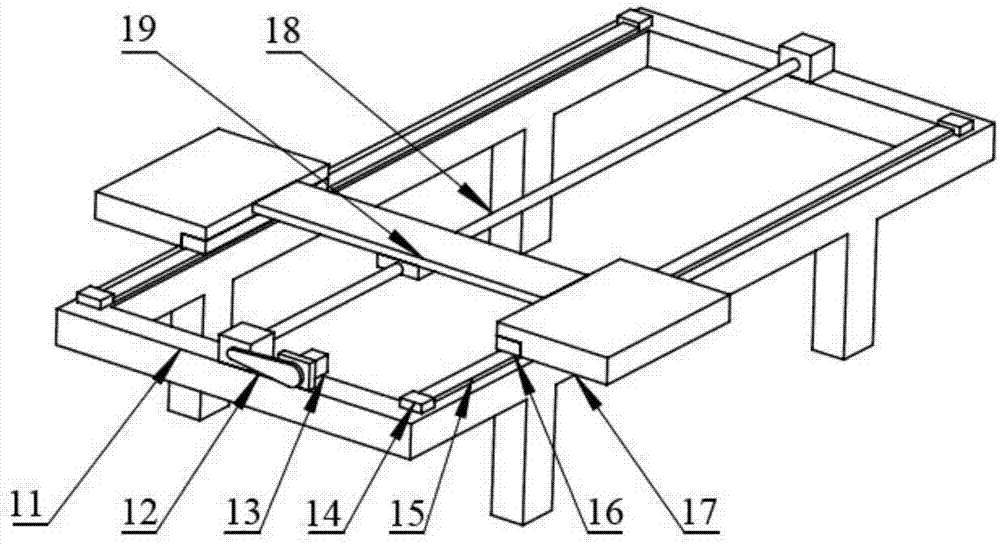

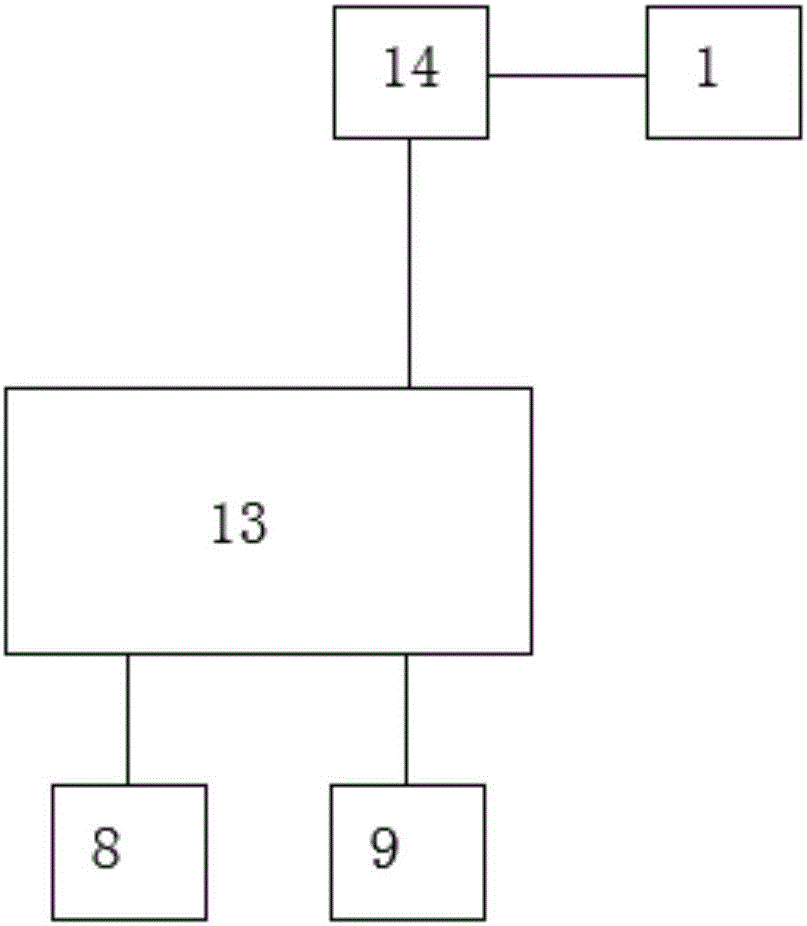

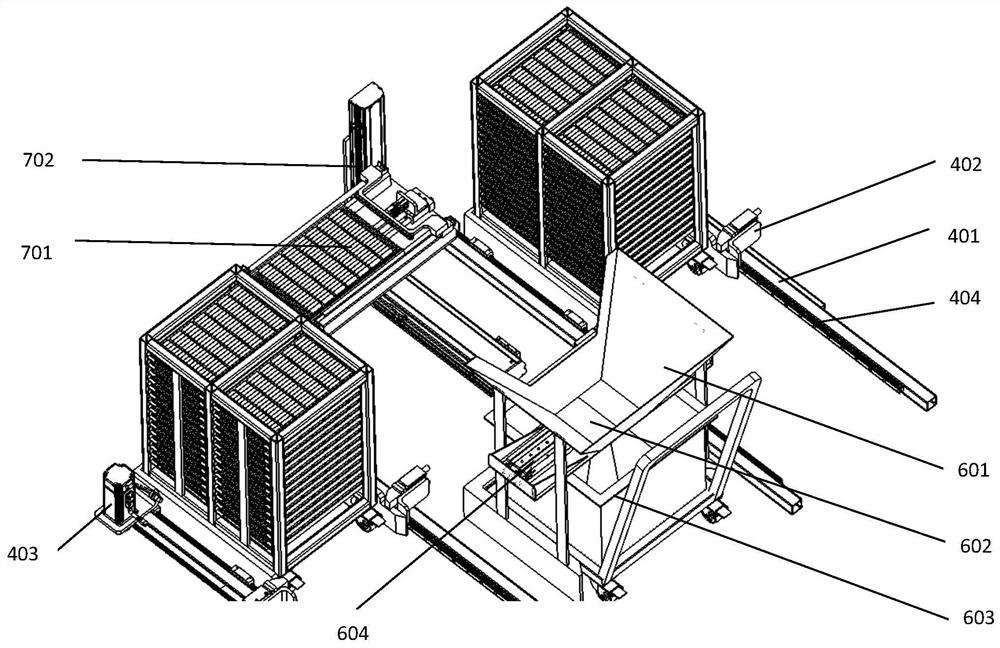

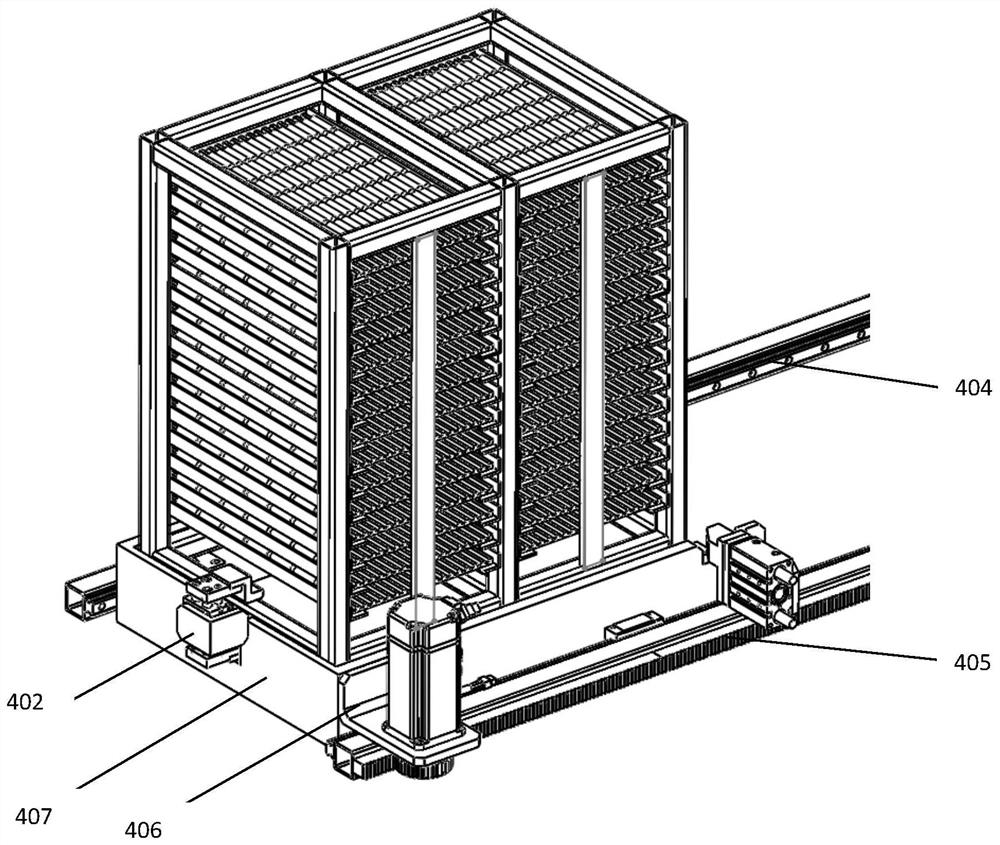

Battery quick-change system of electric passenger car chassis based on the cartesian coordinate robot

InactiveUS20130226345A1Achieve and of quickly and accuratelyAccurate and quick installationVehicular energy storageRobotControl systemDegrees of freedom

One type of battery quick-change system of electric passenger car chassis based on the Cartesian coordinate robot, including electric changing platform, and this platform, quick-change robot and charging rack along the same straight line; the quick-change robot comprises the battery tray and the Cartesian coordinate robot of four degrees of freedom, the Cartesian coordinate robot is associated with the X-axis driving motor, the Y-axis driving motor, the Z-axis up-down motor, the battery tray is connected with the R-axis driving motor; each of driving motors is connected with the corresponding encoder, and each of encoders is connected to the corresponding drive; there are equipped with a distance measuring sensor on the battery tray, and the corresponding limit switches on the both ends of each two-track rack; the drive, each limit switch and the distance measuring sensor of each driving motor are connected with the control system.

Owner:SHANDONG ELECTRIC POWER RES INST

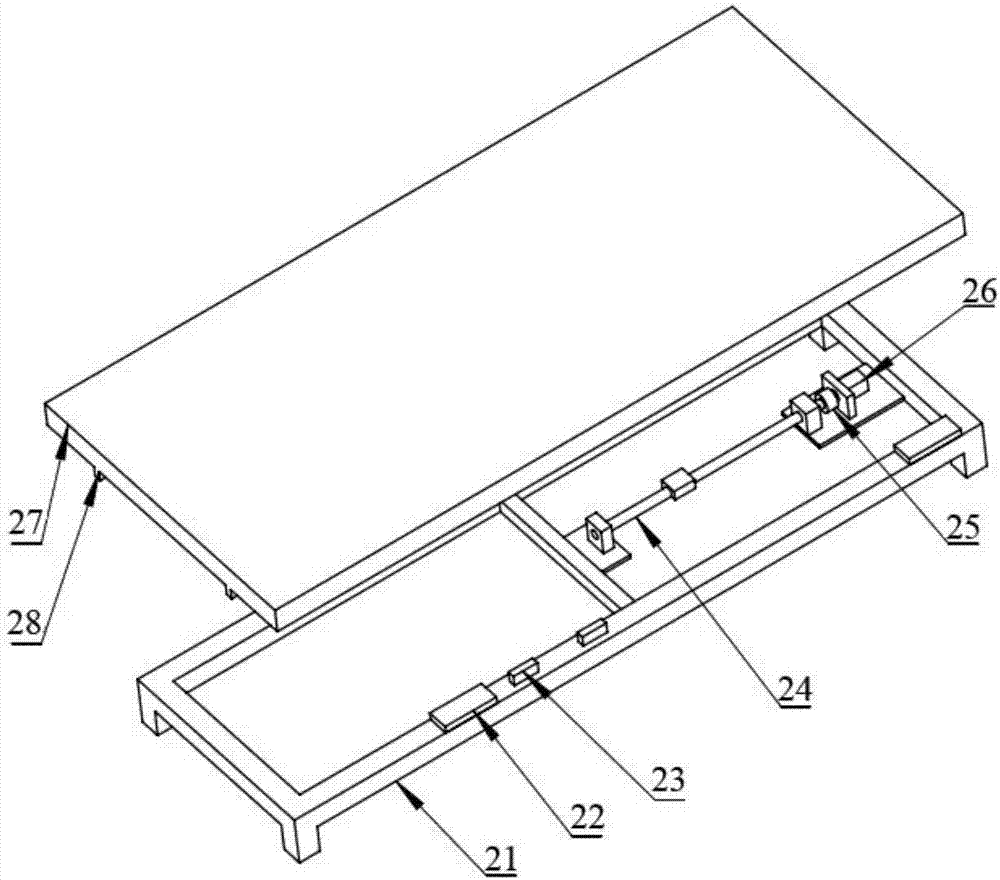

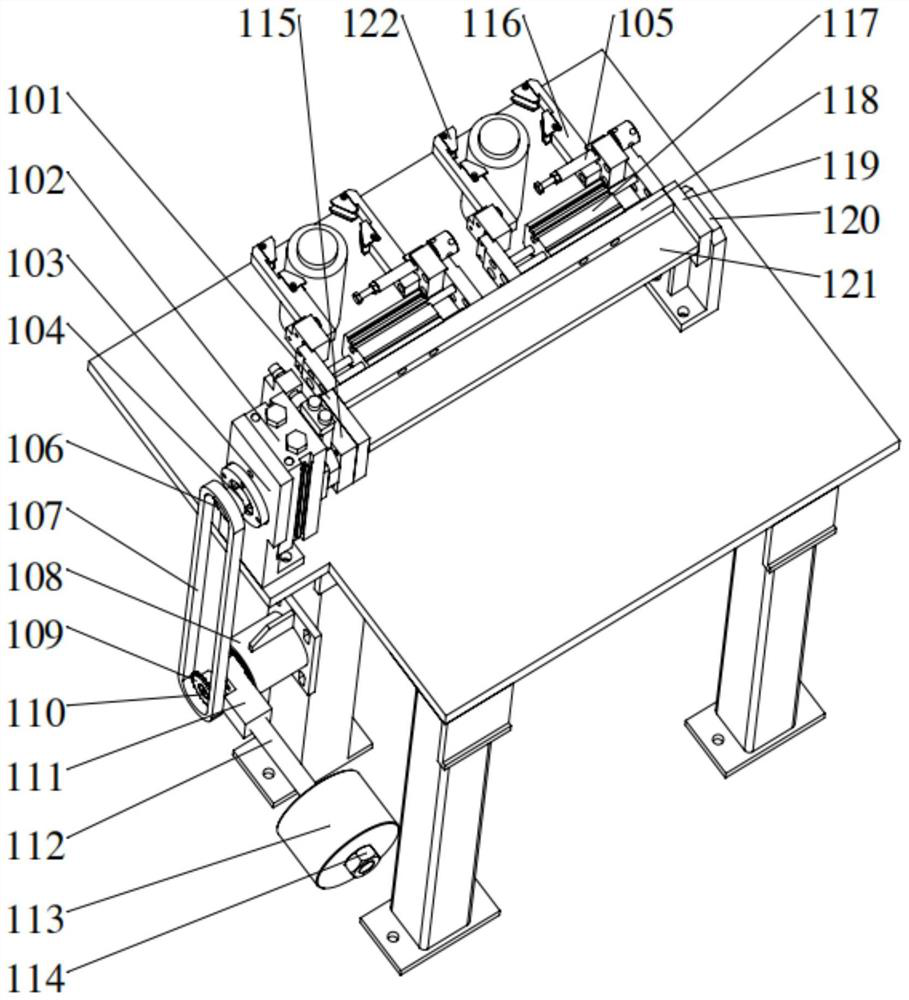

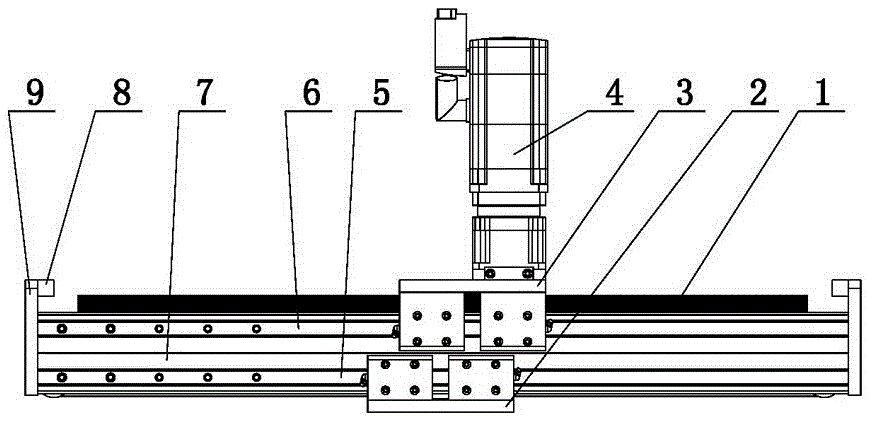

Robot pose error measuring system and method in Cartesian coordinate mode

InactiveCN103017726ARealize automatic collectionEasy maintenanceAngle measurementUsing optical meansEngineeringCartesian coordinate robot

The invention discloses a robot pose error measuring system and a robot pose error measuring method in a Cartesian coordinate mode. The robot pose error measuring system comprises a machine frame, a guiding unit, a driving unit, a measuring unit, a robot and a workpiece, wherein the guiding unit is arranged on the machine frame and is driven by the driving unit; the measuring unit is arranged on the guiding unit; the workpiece is clamped at a tail end of the robot; and the driving unit drives the guiding unit to move to drive the measuring unit to move so as to measure pose parameters of the robot. The problems of complicated data collection, large workload and expensive equipment in the conventional measuring technology are solved.

Owner:SOUTH CHINA UNIV OF TECH

Modularized multi-control Cartesian coordinate robot

InactiveCN101947781ACultivate hands-on abilityCultivate innovation and development capabilitiesProgramme-controlled manipulatorLinear motionBall screw drive

The invention relates to a modularized multi-control Cartesian coordinate robot, which comprises a linear robot and a rotating robot; the linear robot is provided with a linear robot or a rotating robot; the number of the liner robot is at least one; the number of the rotating robot is at least one; the linear robot is provided with a motor which drives a ball screw through a coupler, and a screw nut on the ball screw drives a motion platform to perform linear motion; and the rotating robot is provided with a motor which drives a worm gear through a coupler, and the worm gear drives a rotating platform to rotate. Students can constitute a multi-degree-of-freedom robot through recombining and constructing certain modules by hands, so that the method allows the students to comprehensively grasp the application development and the integration technology of the mechatronics technology, helps the students to recognize constituent parts of a system from the perspective of the whole system so as to grasp the constitution, functions and control principles of an electromechanical control system, and trains the practical ability and the innovation and development ability of the students.

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD

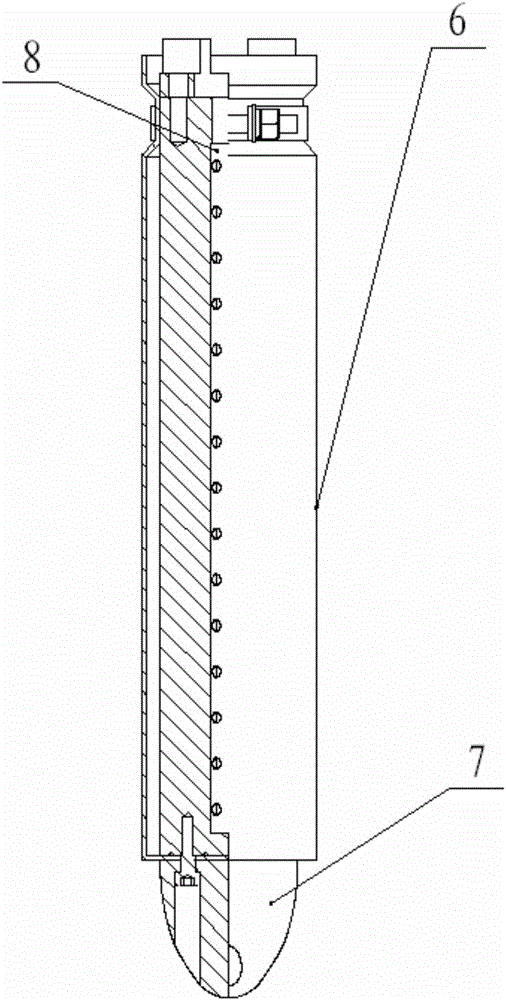

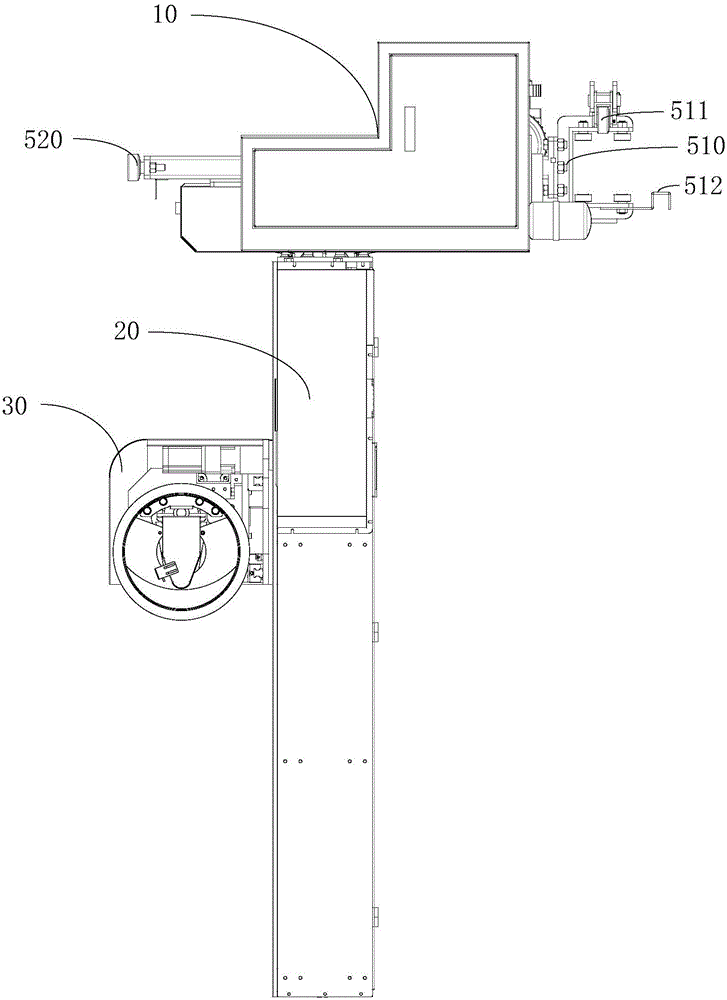

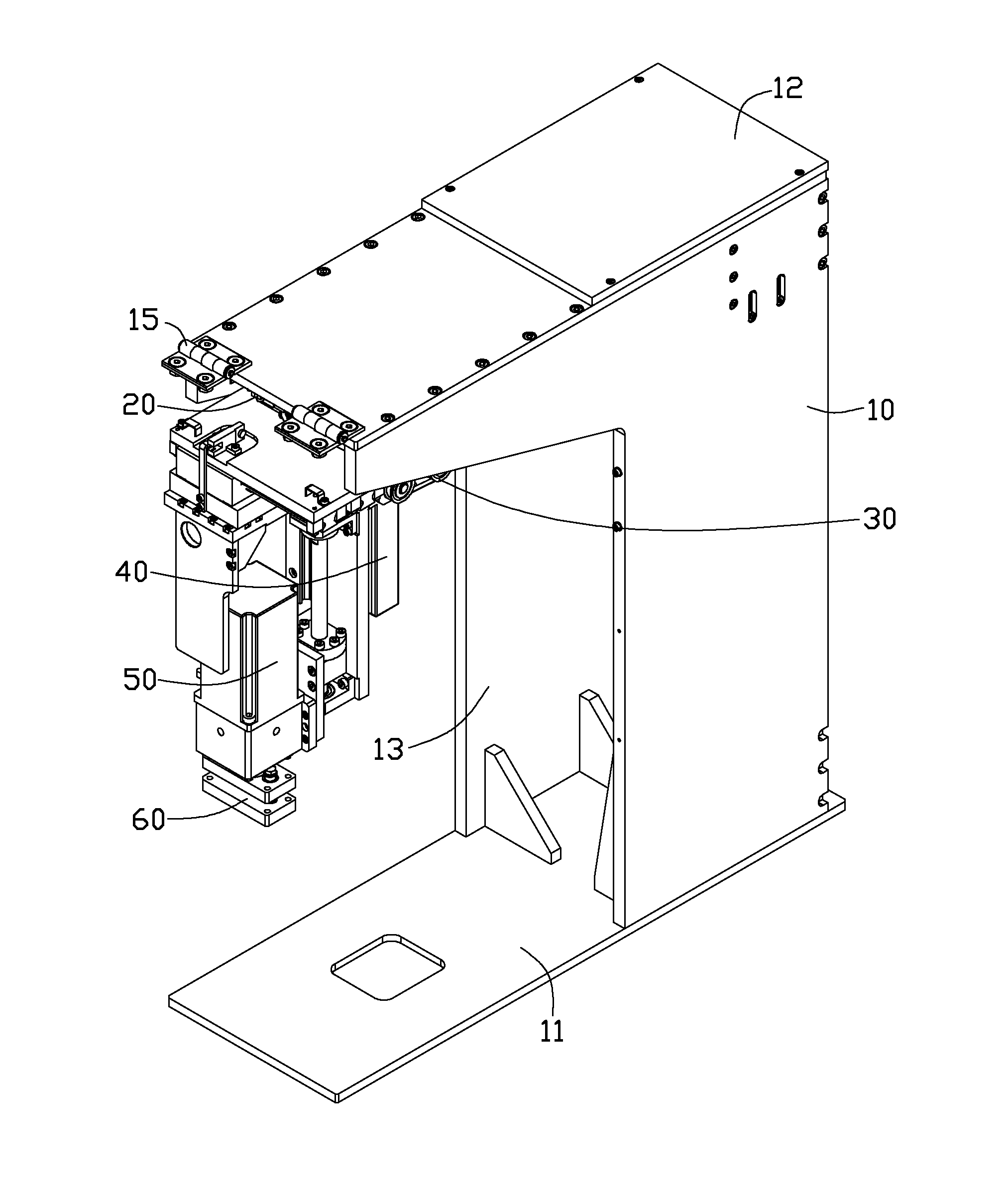

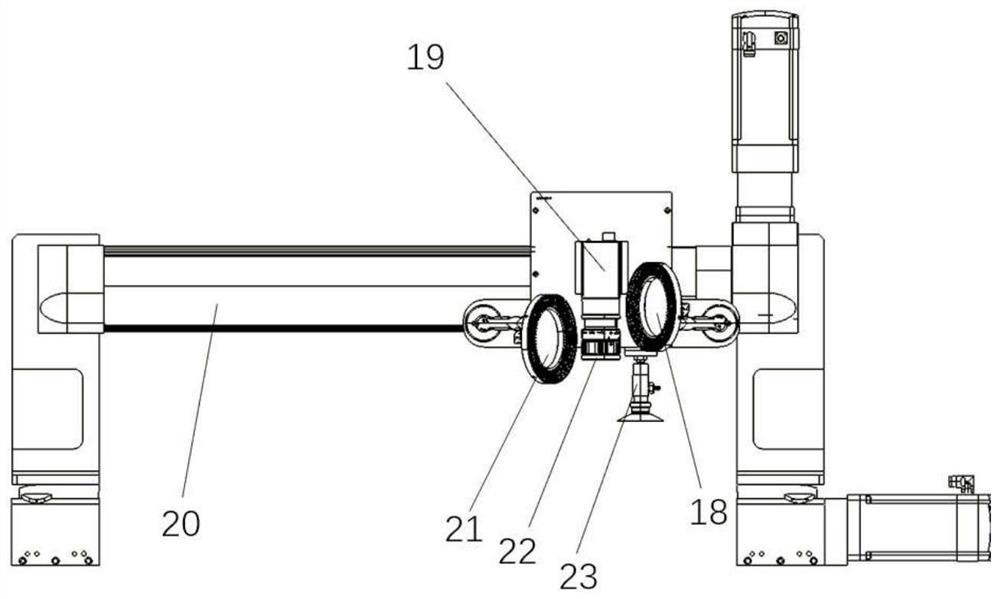

Capsule type endoscope in-vitro navigation device

PendingCN107307839AEasy to controlEasy to understand intuitivelyOperating tablesEndoscopesPhysicsCartesian coordinate robot

The invention provides a capsule type endoscope in-vitro navigation device, and relates to the field of medical apparatus and instruments. The device comprises a base mechanism, a bed body mechanism, a Z-axis frame mechanism, a Y-axis bracket mechanism, a magnet universal rotating mechanism and a magnet; the base mechanism controls the magnet to move in the X-axis direction, the Z-axis frame mechanism controls the magnet to move in the Z-axis direction, the Y-axis bracket mechanism controls the magnet to move in the Y-axis direction, the magnet universal rotating mechanism controls the magnet to rotate in the horizontal axis direction and the vertical direction of the magnet universal rotating mechanism, and the bed body mechanism controls the bed body to move in the X-axis direction. By means of the capsule type endoscope in-vitro navigation device, control over five degrees of freedom of a magnet can be achieved, a gantry type Cartesian coordinate robot structure which is high in reliability and good in stability is adopted, and the structure is simple and convenient to manufacture.

Owner:楠青医疗技术(上海)有限公司

Automatic polyester film roll palletizing system system with pneumatic shaft gripper

ActiveCN106276173AImprove palletizing efficiencyIncrease job securityConveyorsStacking articlesPolyesterCartesian coordinate robot

The invention provides an automatic polyester film roll palletizing system system with a pneumatic shaft gripper. The automatic polyester film roll palletizing system system comprises a tilter, a Cartesian coordinate robot, a conveyor line, a pneumatic shaft gripper, and a depalletizer. The automatic polyester film roll palletizing system system with the pneumatic shaft gripper according to the present invention can allow a great improvement in the polyester film roll palletizing efficiency and an increase in the operating safety factor, and has important technical progress significance and economic value.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

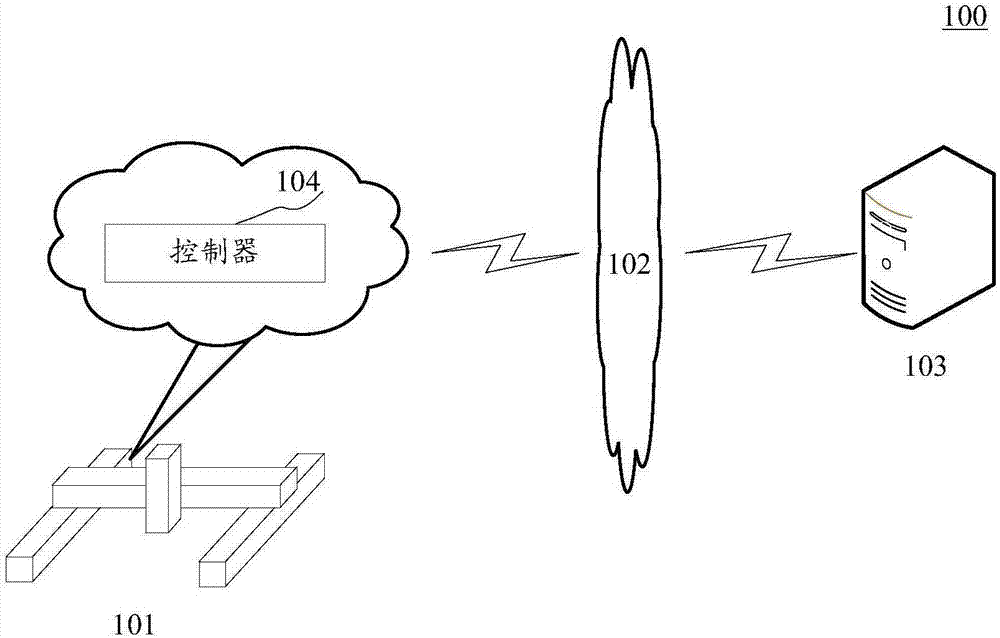

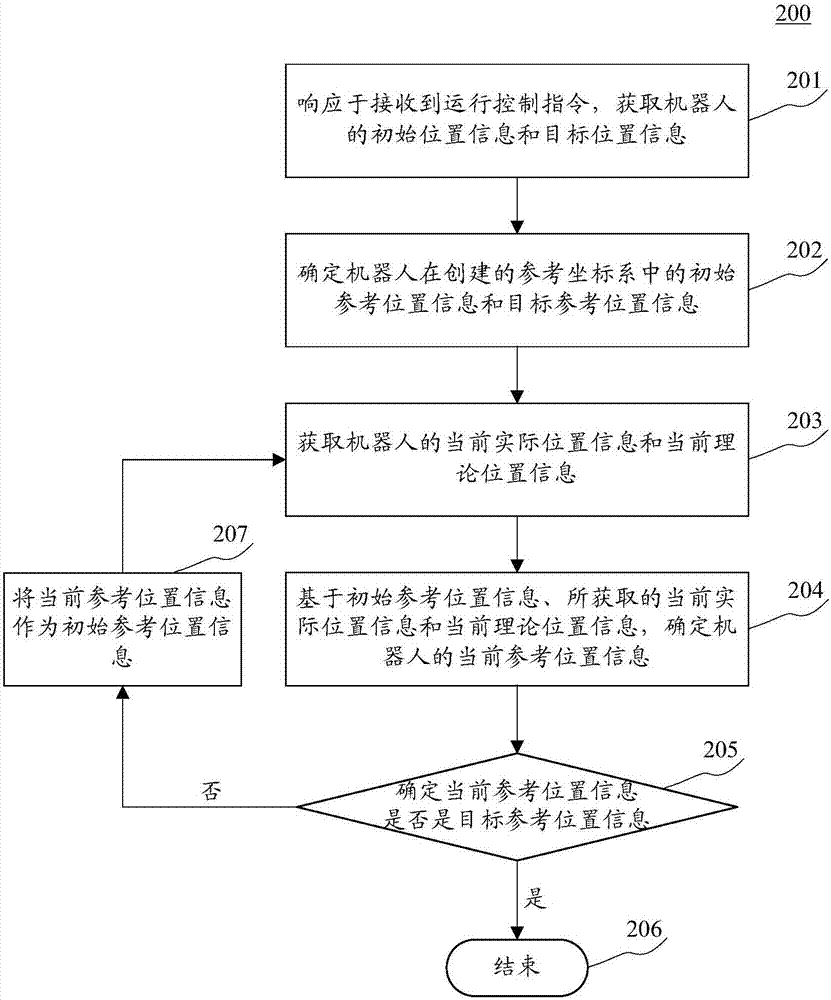

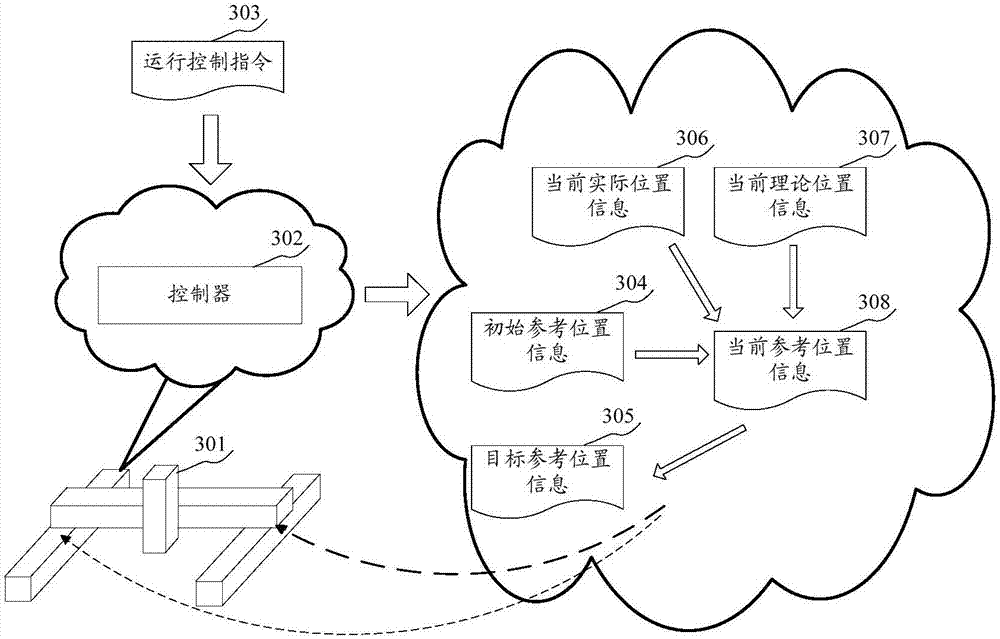

Control method and control device for Cartesian coordinate robot

ActiveCN107443380AGuaranteed uptimeImprove operational efficiencyProgramme-controlled manipulatorSimulationExecution control

The embodiment of the invention discloses a control method and a control device for a Cartesian coordinate robot. One specific implementation mode of the method comprises the following steps: obtaining initial position information and target position information of the robot in response to a received operating control instruction; determining initial reference position information and target reference position information of the robot in an established reference coordinate system; and executing the following control steps: obtaining current actual position information and current theoretical position information of the robot to determine the current reference position information of the robot, and determine whether the current reference position information is the target reference position information in the first coordinate axis direction; and in response to determination that the current reference position information is not the target reference position information, by taking the current reference position information as the initial reference position information, continuously executing a control step. The implementation mode can implement that during operation of the robot, an error produced in the first coordinate axis direction can be dynamically compensated, so that the operation efficiency is improved.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

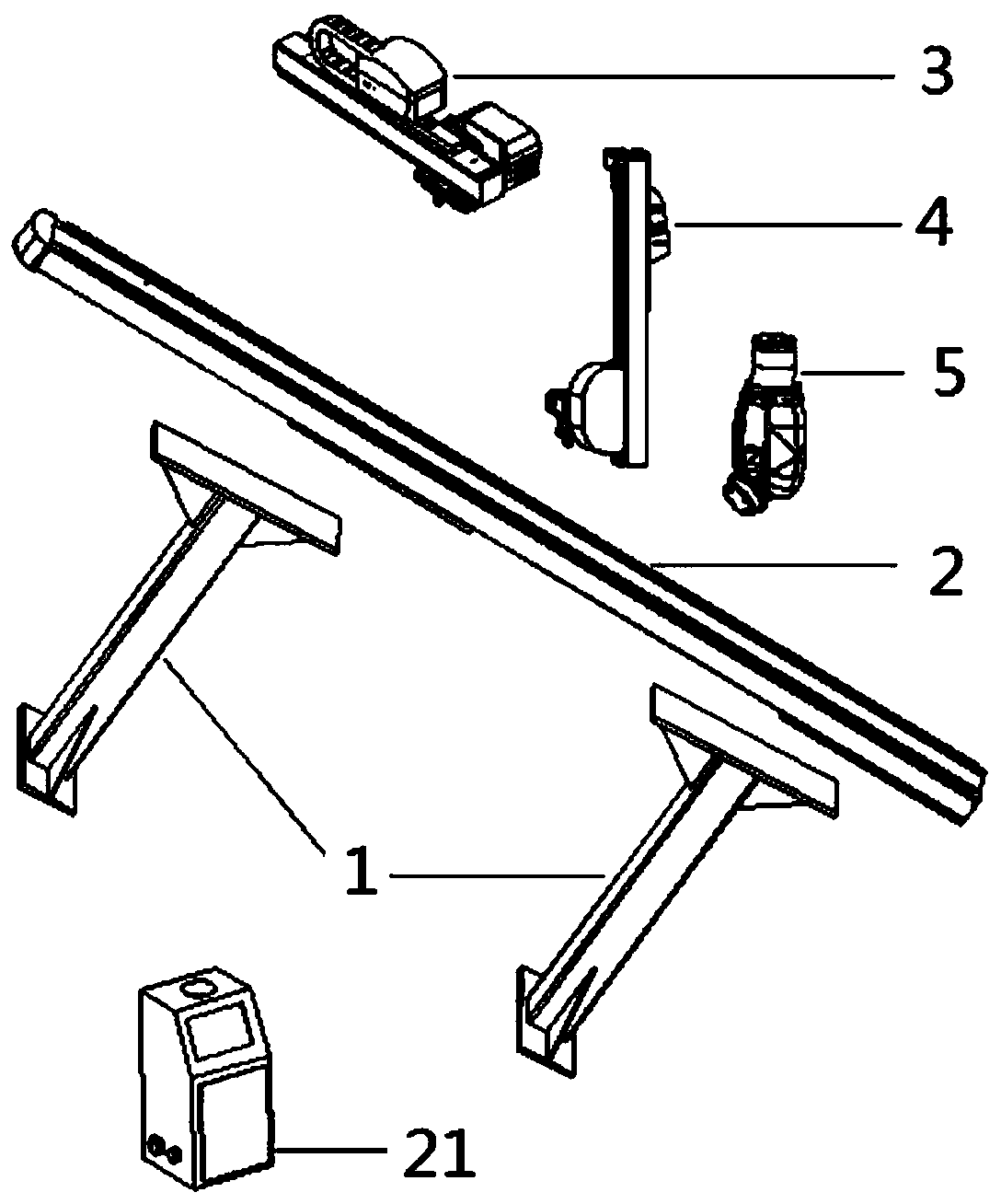

Cartesian coordinate logistics robot

ActiveCN105033989ASave human effortEasy to operateProgramme-controlled manipulatorCartesian coordinate robotEngineering

The invention discloses a Cartesian coordinate logistics robot which comprises a supporting seat, a Y shaft, a cross arm, a weighing bracket, a traveling mechanism and a rotating mechanism, wherein the traveling mechanism is arranged at one side of the supporting seat; the top of the Y shaft is connected with the supporting seat through the rotating mechanism; the cross arm is arranged on the Y shaft; the weighing bracket is arranged in the cross arm. According to the Cartesian coordinate logistics robot disclosed by the invention, the traveling mechanism can directly move at any position on the production line; the weighing bracket is arranged in the cross arm and can be used for directly weighing products on the production line in the transfer process without subsequent actions; besides, the Cartesian coordinate logistics robot disclosed by the invention can be directly docked with the production line and freight trolleys by rotating angles, and labor force for intermediate handling is unnecessary, so that labor force is saved, and the convenience in operation is realized.

Owner:SUZHOU JINPIN LINE MATERIAL

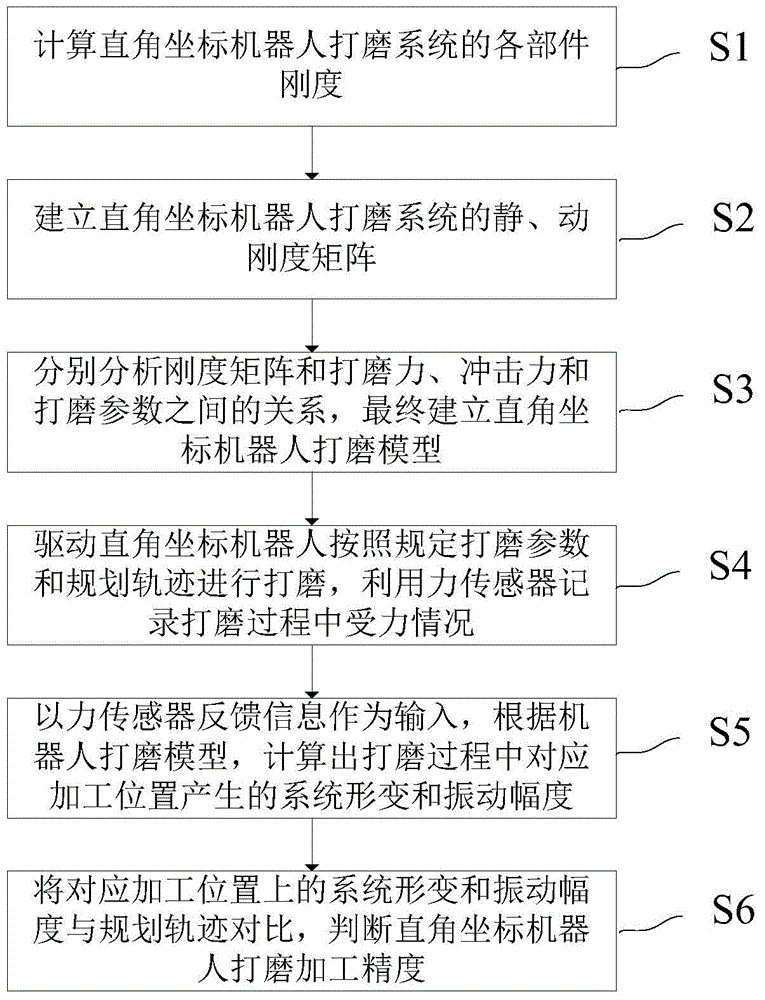

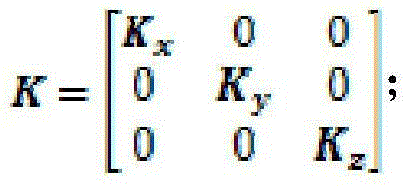

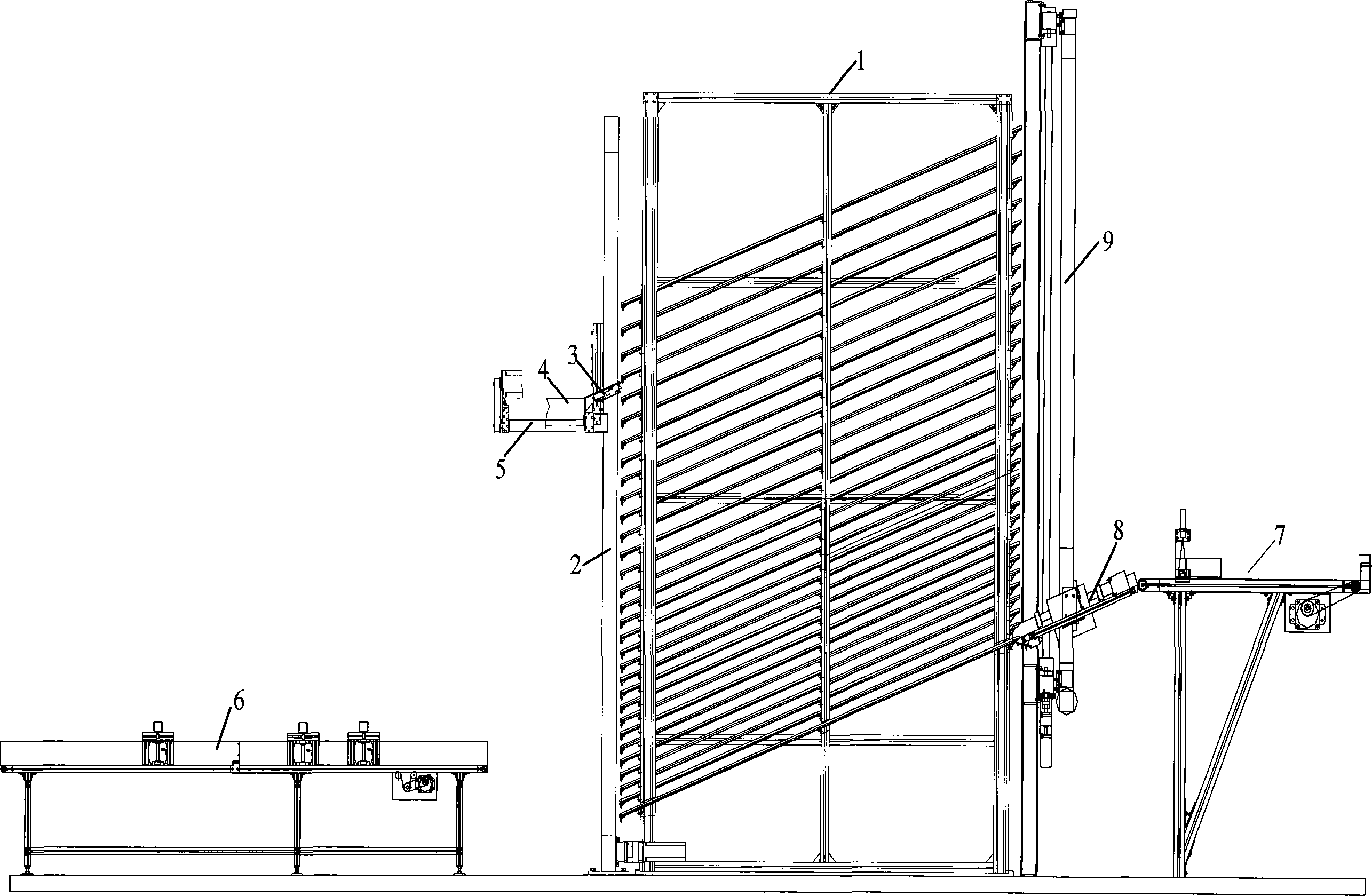

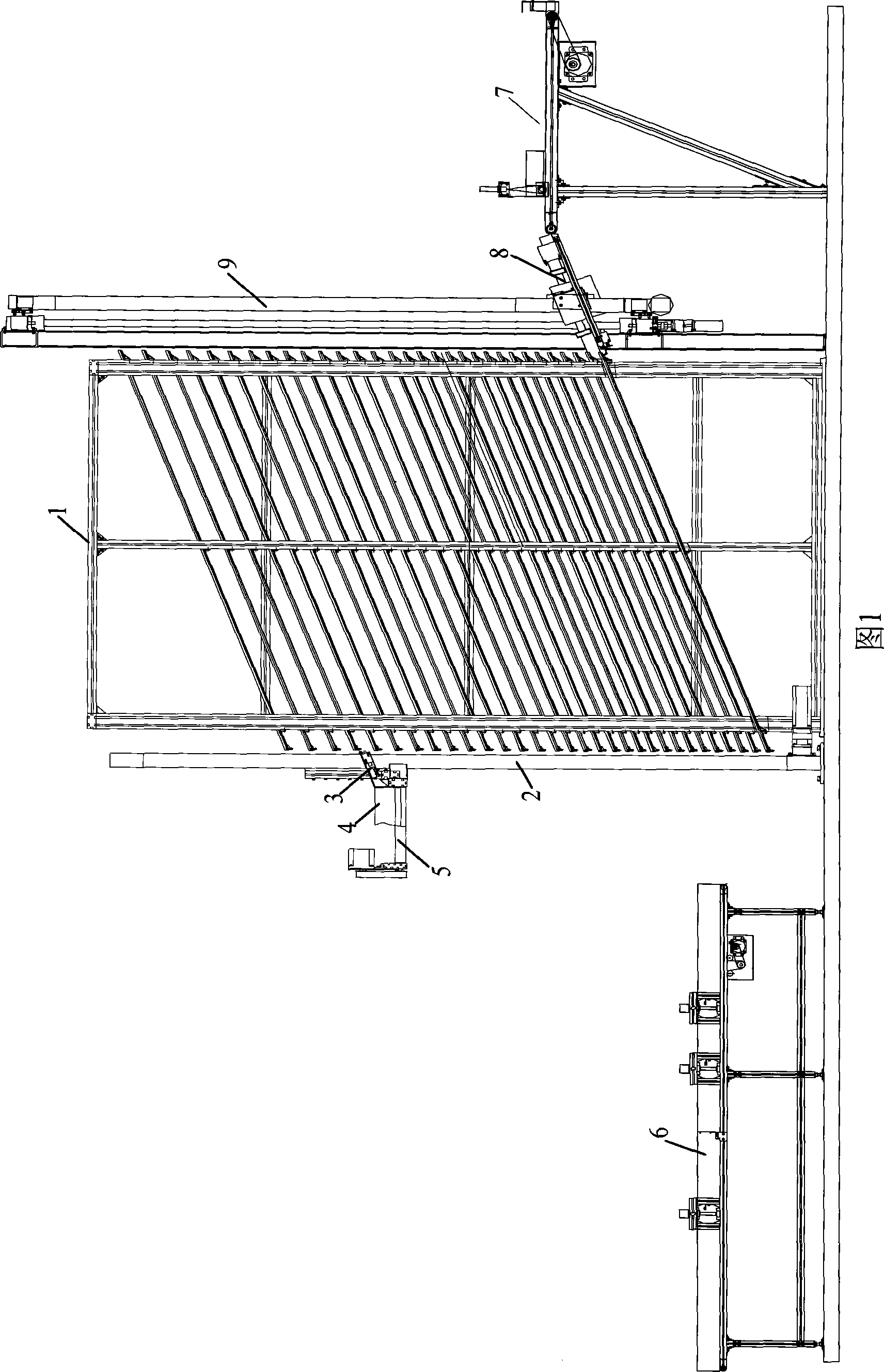

Cartesian coordinate robot polishing method based on stiffness matrix

The invention provides a Cartesian coordinate robot polishing method based on a stiffness matrix. According to the method, as for the structural characteristics of a Cartesian coordinate robot polishing system, a polishing system stiffness matrix is built; on the basis of a traditional polishing model, dynamic and static stiffness matrixes of the Cartesian coordinate robot are introduced, the relation among the polishing force, polishing parameters, deformation and vibration are derived, and a polishing model based on the relation is built; force feedback information produced in the polishing process is used as input, by means of the amplitude, for obtaining system deformation and vibration in the polishing process, in the polishing model and a planning trajectory, the Cartesian coordinate robot polishing precision is judged, and references are provided for follow-up polishing parameter optimization.

Owner:SOUTH CHINA UNIV OF TECH

Automatization hospital pharmacy

ActiveCN101214107BImprove storage densityImprove distribution efficiencyShow cabinetsProgramme-controlled manipulatorCartesian coordinate robotMedical prescription

The invention provides an automatic pharmacy, including a slope type medicine storing cabinet, a medicine distributing device, a sorting device, a medication applying device and a control management system. A U-shaped groove of a slope medicine storing holder is fixed to a supporting beam and forms a dip of 20 degrees with the horizontal plane. The medicine distributing device includes an elevator and a medicine output mechanism. A low end medicine outlet port of the U-shaped groove of the slope medicine storing holder is butted with a medicine inlet port of a U-shaped medicine storing grooveof the medicine output mechanism. The medicine outlet is connected with a conveyer belt in a way of transiting through a retaining door to form a medicine distributing channel. The medicine outlet end of the medicine distributing device is equipped with the sorting device. A sorting channel is connected with the medicine distributing channel. The medicine outlet port of a medication applying transporting mechanism is butted with a medicine inlet port of a U-shaped groove of a medication applying manipulator which is installed on a Cartesian-coordinate robot. The medicine outlet port of the U-shaped groove of the medication applying manipulator is butted with a high end medicine inlet port of the U-shaped groove of the slope medicine storing holder to form the medication applying channel. Therefore, the functions of semi-automatic batch recharging of boxed medicine, medicine box dense storage and management, automatic medicine distribution according to a prescription and medicine sorting to the determined windows, etc. can be realized.

Owner:SUZHOU IRON TECH

Battery quick-change system for an electric passenger car chassis having a cartesian coordinate robot

InactiveUS8868235B2Achieve and of quickly and accuratelyAccurate and quick installationVehicular energy storageRobotElectric machineControl system

One type of battery quick-change system of electric passenger car chassis based on the Cartesian coordinate robot, including electric changing platform, and this platform, quick-change robot and charging rack along the same straight line; the quick-change robot comprises the battery tray and the Cartesian coordinate robot of four degrees of freedom, the Cartesian coordinate robot is associated with the X-axis driving motor, the Y-axis driving motor, the Z-axis up-down motor, the battery tray is connected with the R-axis driving motor; each of driving motors is connected with the corresponding encoder, and each of encoders is connected to the corresponding drive; there are equipped with a distance measuring sensor on the battery tray, and the corresponding limit switches on the both ends of each two-track rack; the drive, each limit switch and the distance measuring sensor of each driving motor are connected with the control system.

Owner:SHANDONG ELECTRIC POWER RES INST

Machine vision system based industrial robot

An industrial robot based on a machine vision system is provided, including a Cartesian coordinate robot and a machine vision system. Vertical lifting mechanism, the grabbing mechanism is installed on the vertical lifting line rail on the vertical sliding seat through the slider; the machine vision system includes a positioning system and a defect detection system, and the positioning system includes a positioning system installed on the front side of the sliding seat cover CCD camera, the defect detection system includes a placement table and a detection CCD camera installed on the outside of the placement table, the positioning CCD camera and the detection CCD camera are connected to the controller, and the controller is connected to the grasping mechanism through a servo driver; The system corrects the deviation of the workpiece, and puts it on the placement table for defect detection through the defect detection system; the placement table designed by the present invention can be driven up and down by the screw rod, and can correspond to workpieces of various sizes.

Owner:SHAANXI LAIFU TECH DEV CO LTD

Passive compliance polishing robot aiming at planar work piece

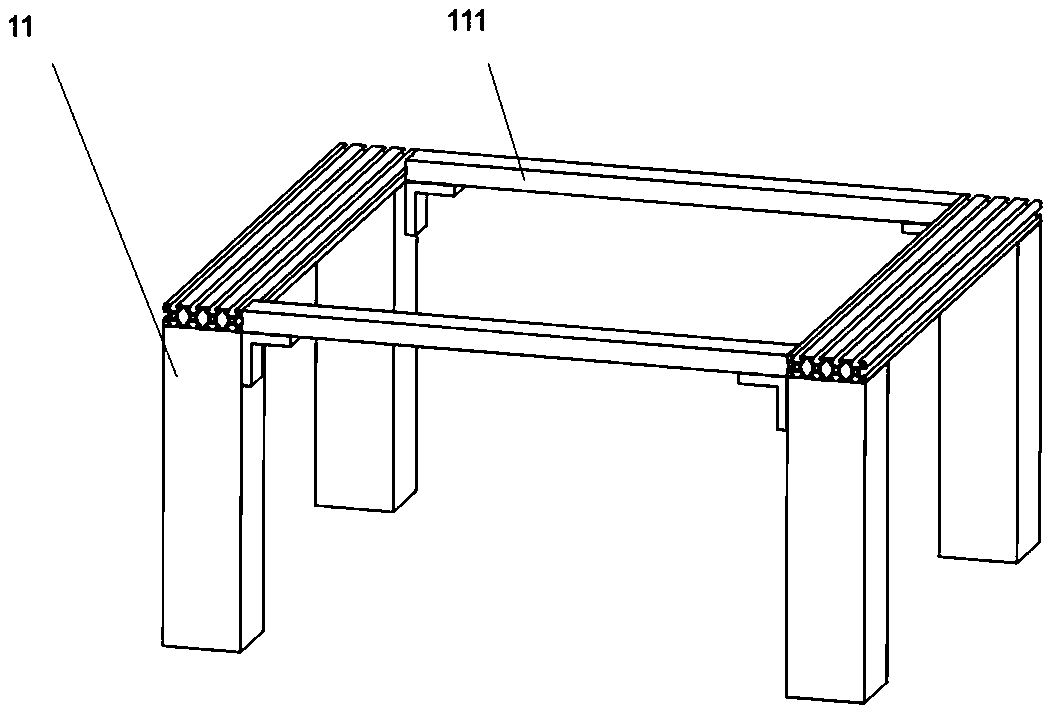

InactiveCN110948305AStructure miniaturizationSimple structural designGrinding drivesGrinding feed controlEngineeringCartesian coordinate robot

The invention belongs to the technical field of robots and especially relates to a passive compliance polishing robot aiming at a planar work piece. The robot comprises a right-angle coordinate robotand a passive compliance device, wherein the right-angle coordinate robot comprises an installation frame, a pair of X-axis linear driving mechanism, a Y-axis linear driving mechanism and a Z-axis linear driving mechanism; the installation frame comprises a horizontal rectangular frame; and the passive compliance device is fixedly installed on the bottom end of the Z-axis linear driving mechanism,so the passive compliance device can move with three freedom degrees in X, Y and Z axes and can make trace motion in three spatial coordinates. Based on design ideas of modularization and light weight, the weight of whole equipment is lower than 30Kg. The passive compliance device adopts a pneumatic driving mode, so responding is quick. Polishing contact force is adjustable between 0N and 200N, and accuracy is lower than 1N. Integral design is used by the passive compliance polishing equipment, wherein maximum compliance displacement is 30mm, and a displacement error is smaller than 2 DEG.

Owner:HEFEI UNIV OF TECH

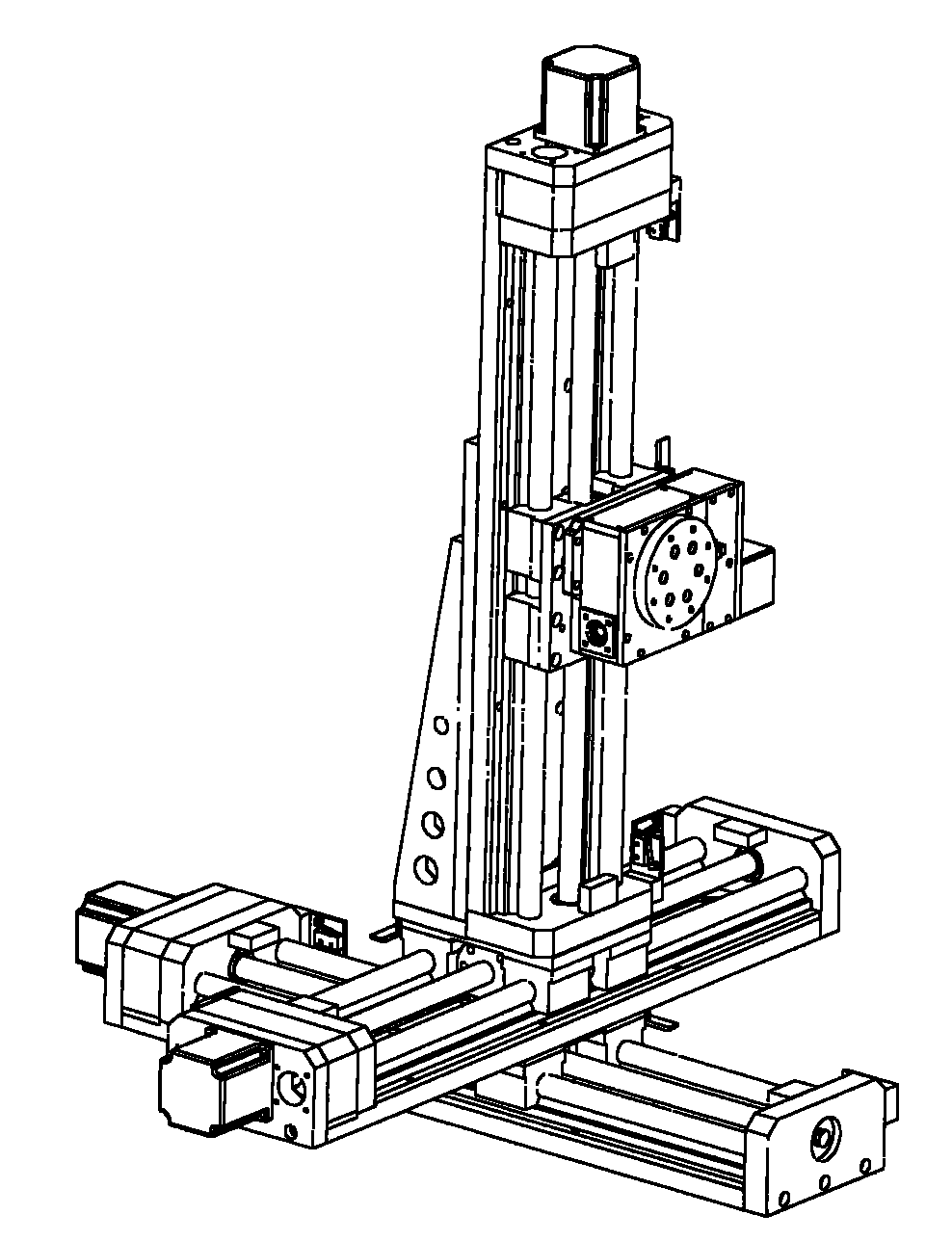

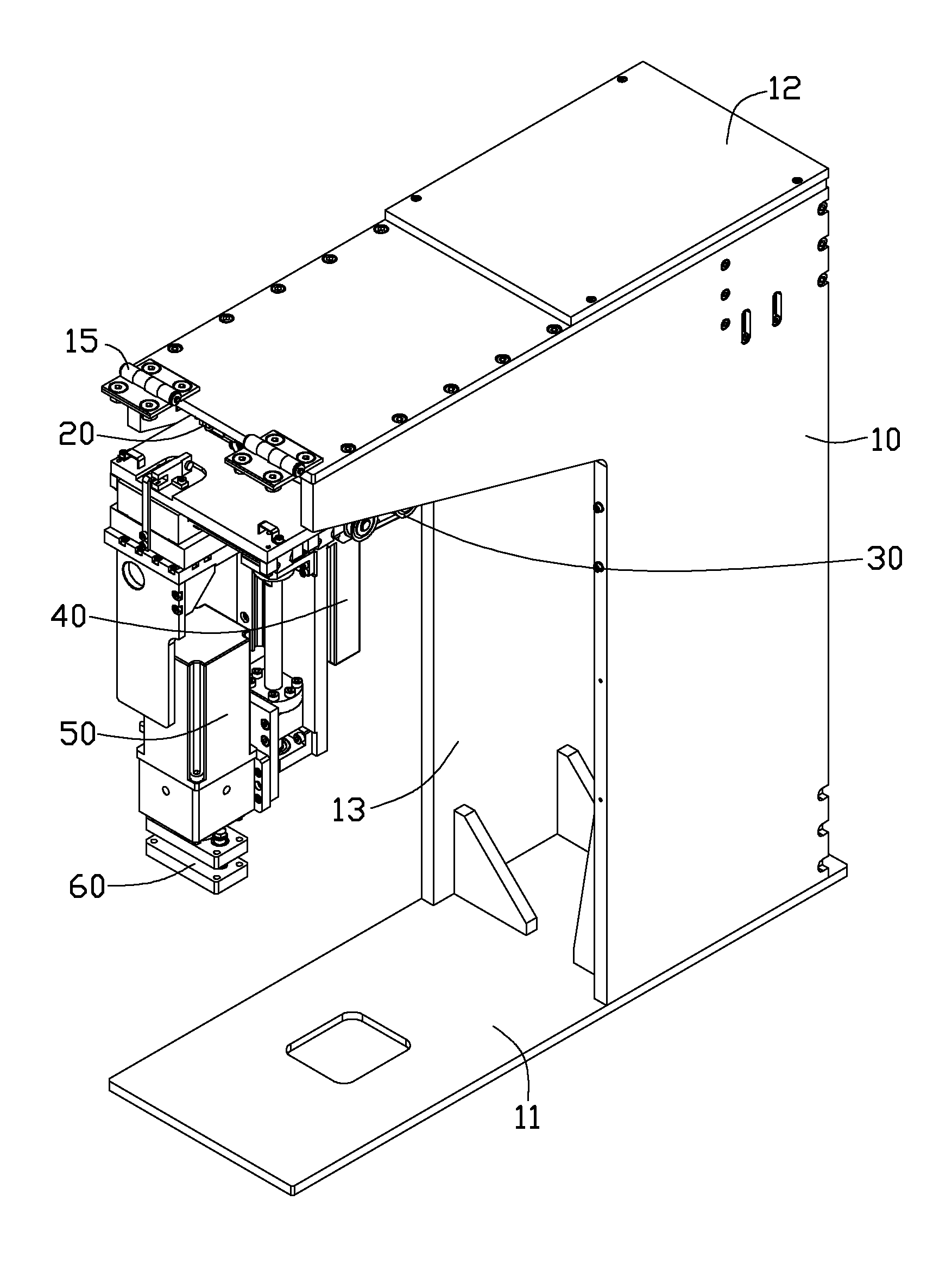

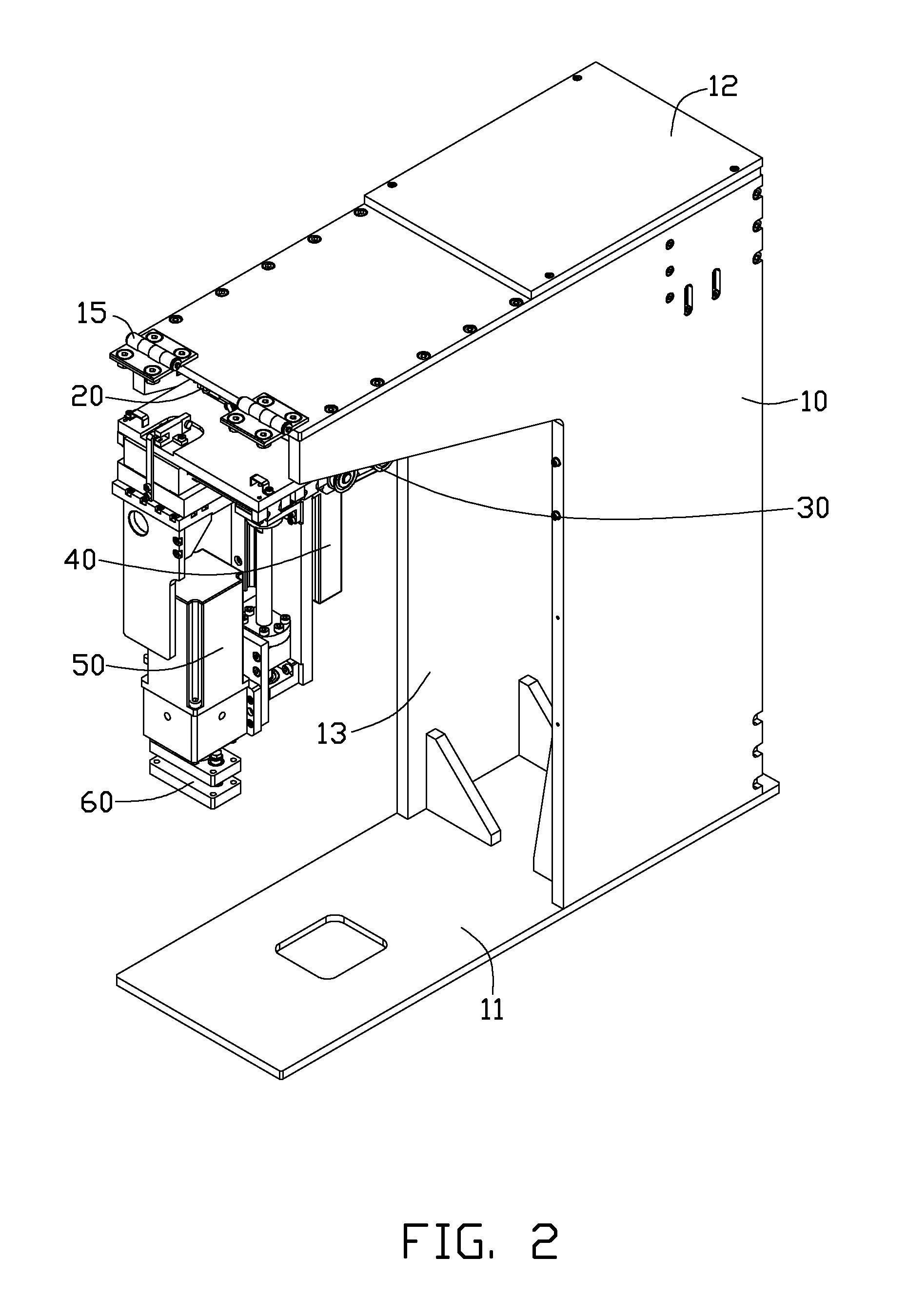

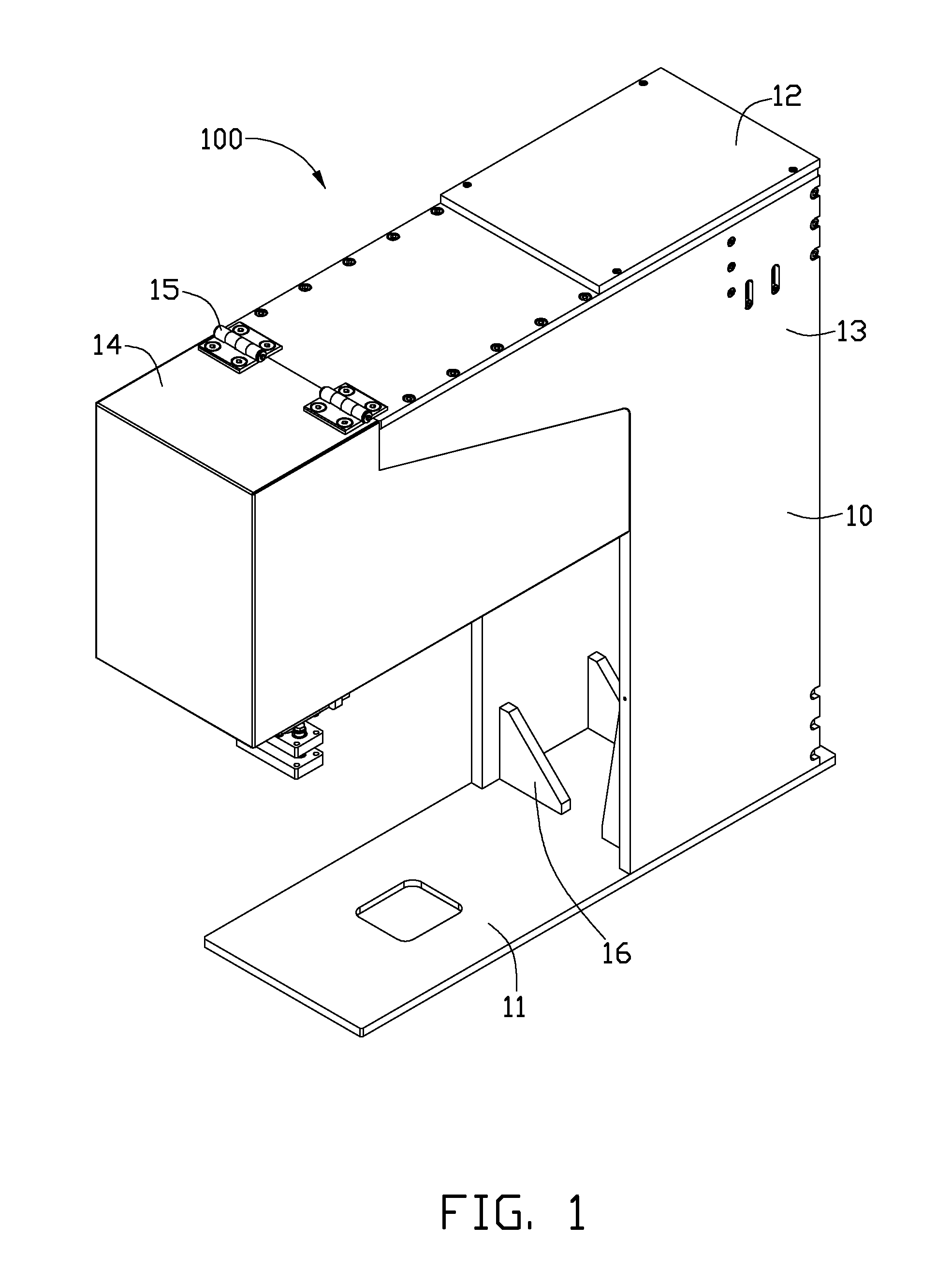

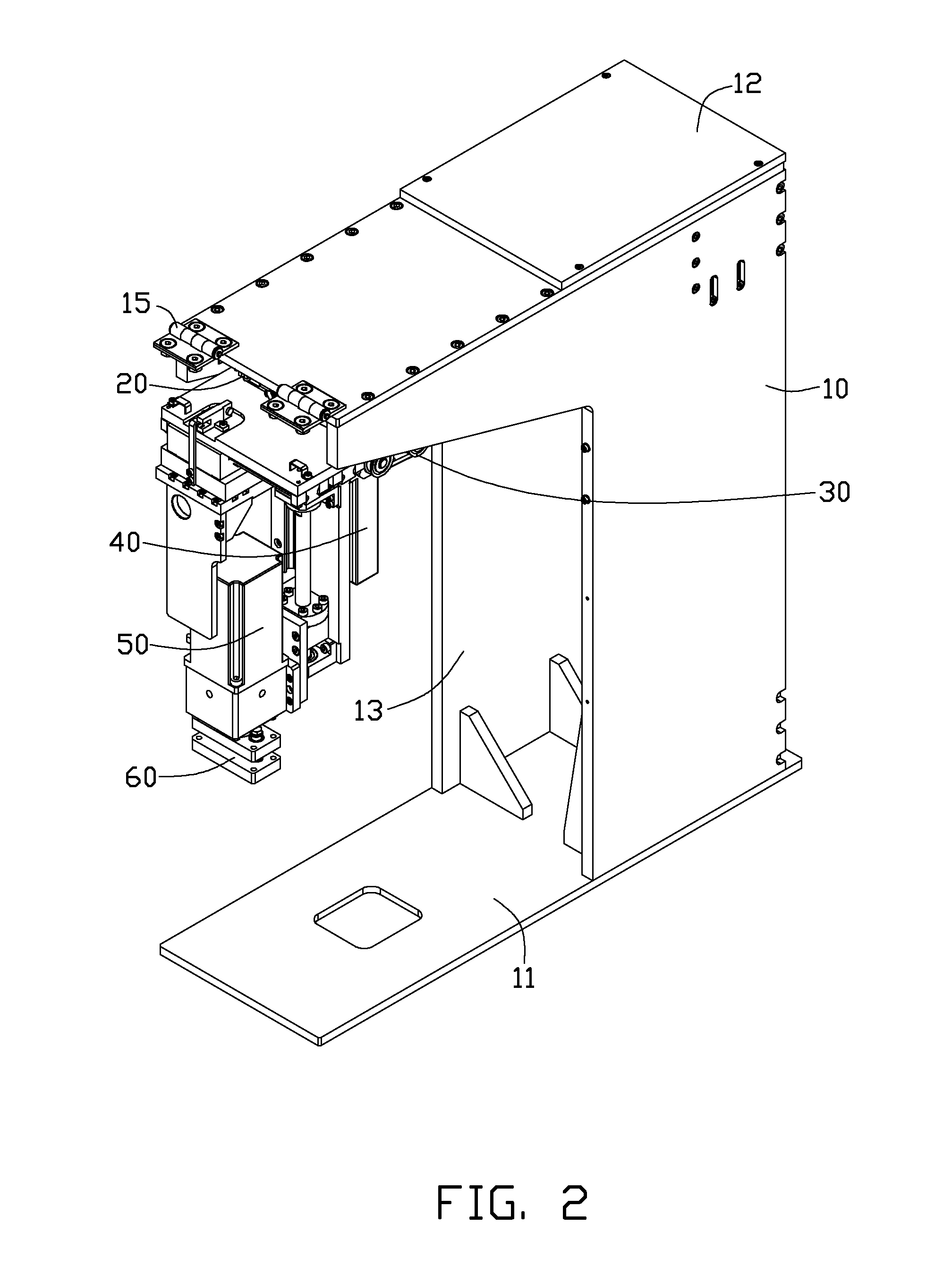

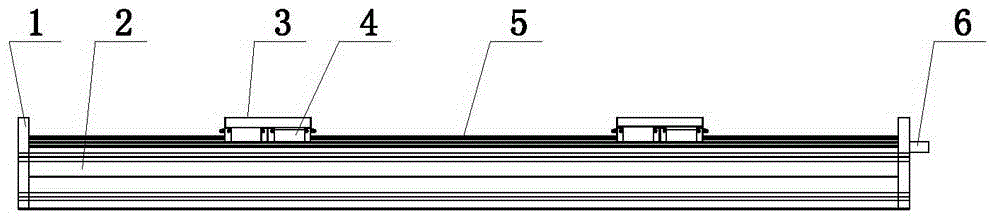

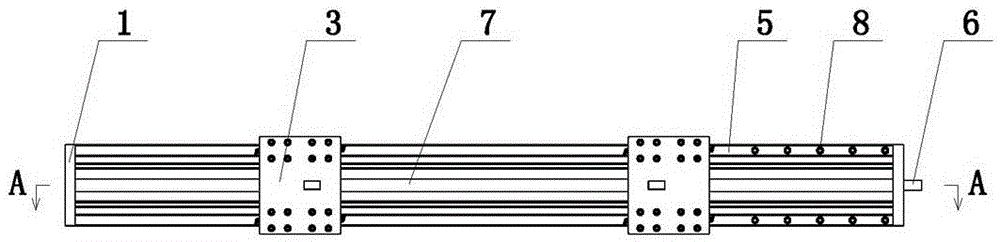

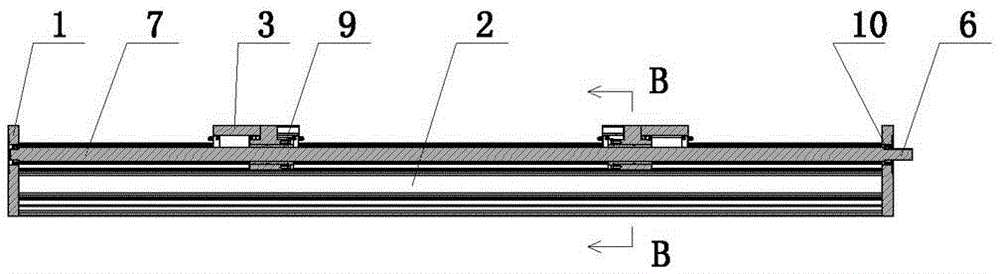

Cartesian coordinate robot

InactiveUS8365632B2High movement precision and reliabilityProgramme-controlled manipulatorMechanical apparatusCartesian coordinate robotElectrical and Electronics engineering

A Cartesian coordinate robot includes a first transmission mechanism slidably connected to a second transmission mechanism, a third transmission mechanism slidably connected to the second transmission mechanism. The first transmission mechanism includes a first guide rail, a first slider slidably connected to the first guide rail, and a first driving module driving the first slider. The second transmission mechanism includes a second guide rail perpendicular to the first guide rail, a second slider slidably connected to the second guide rail, and a second driving module driving the second slider. The third transmission mechanism includes a third guide rail perpendicular to the first guide rail and the second rail, a third slider slidably connected to the third guide rail, and a third driving module driving the third slider.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Automatic feeding and discharging device for cylindrical workpieces

ActiveCN113023350AWon't hurtTake full advantage of degrees of freedomConveyorsLoading/unloadingRobot handEngineering

The invention discloses an automatic feeding and discharging device for cylindrical workpieces, and belongs to the technical field of industrial robot automation equipment. The automatic feeding and discharging device comprises a transfer robot, the transfer robot is used for transferring materials among a circulating conveying line, a tray transfer mechanical arm and a carbon box containing table, and trays loaded with cylindrical workpieces are placed on a tray rack. The tray transfer mechanical arm comprises a three-dimensional rectangular coordinate robot body and a tray transferring gripper, the tray transferring gripper comprises a gripper base plate, a push plate and a tray clamping unit, the gripper base plate is installed at the output end of the three-dimensional rectangular coordinate robot body, guide grooves are formed in the two sides of the gripper base plate, and a channel formed by the guide grooves in the two sides is used for allowing trays to enter. The tray clamping unit is arranged on the sides, away from the tray rack, of the guide grooves, a second moving mechanism is used for driving the tray clamping unit to slide in the extending direction of the guide grooves, the push plate is arranged on the gripper base plate in a sliding manner, and a carbon box bottom plate is placed on the circulating conveying line. The device can realize continuous feeding and discharging carrying in the heat treatment process.

Owner:杭州千岛湖瑞淳机器人研究院有限公司

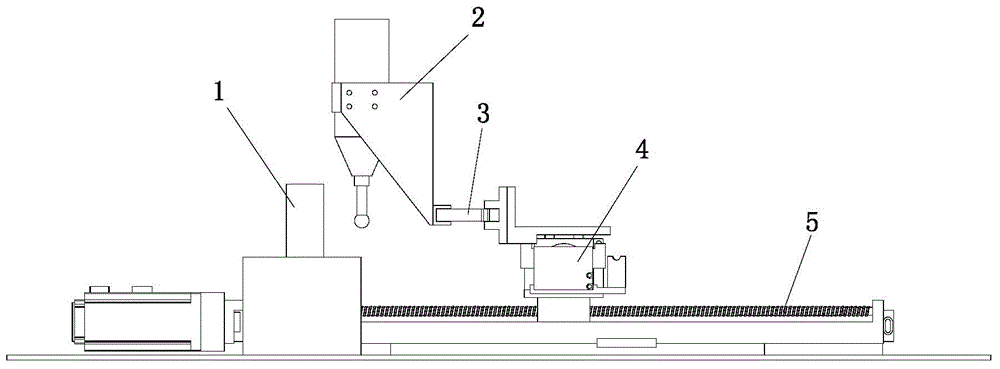

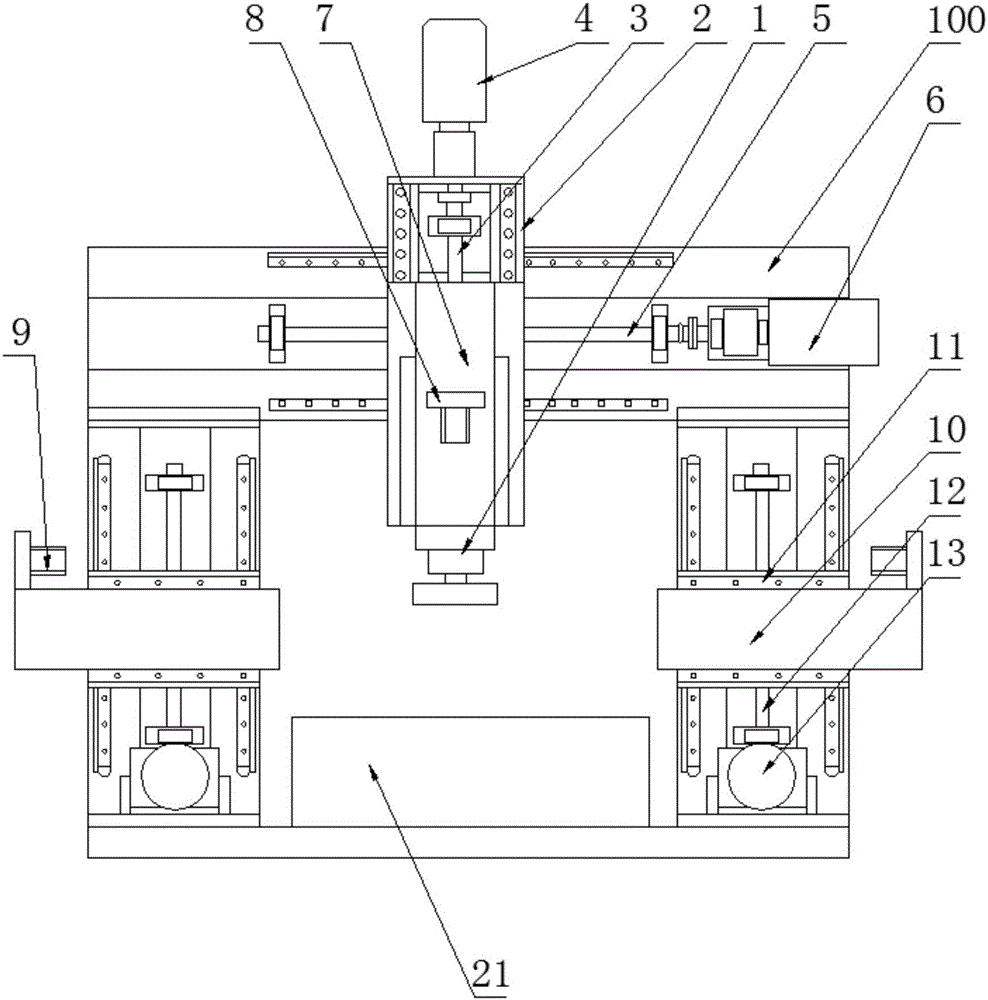

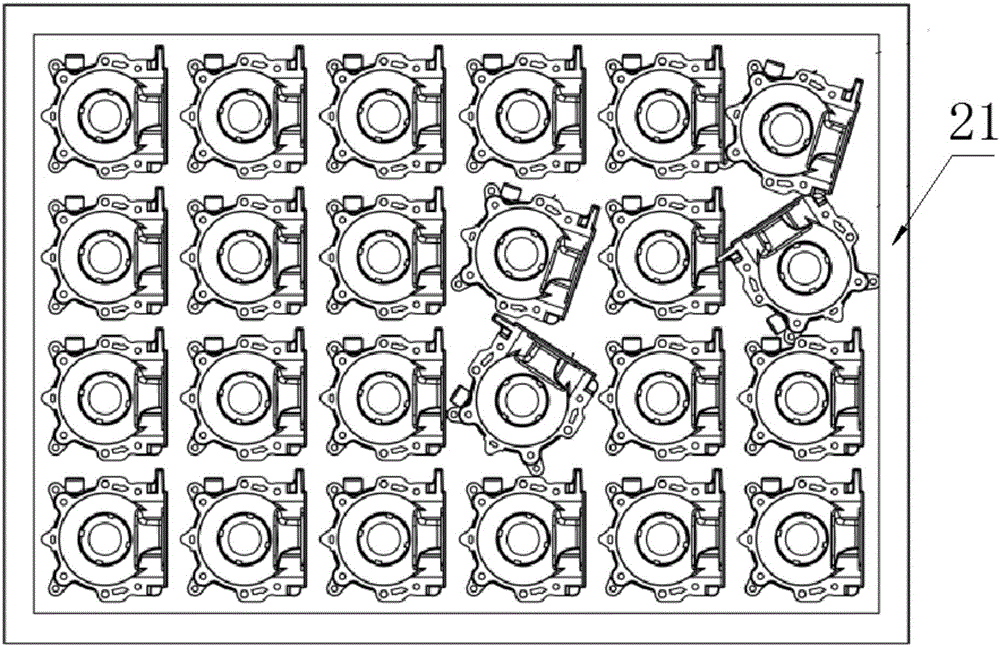

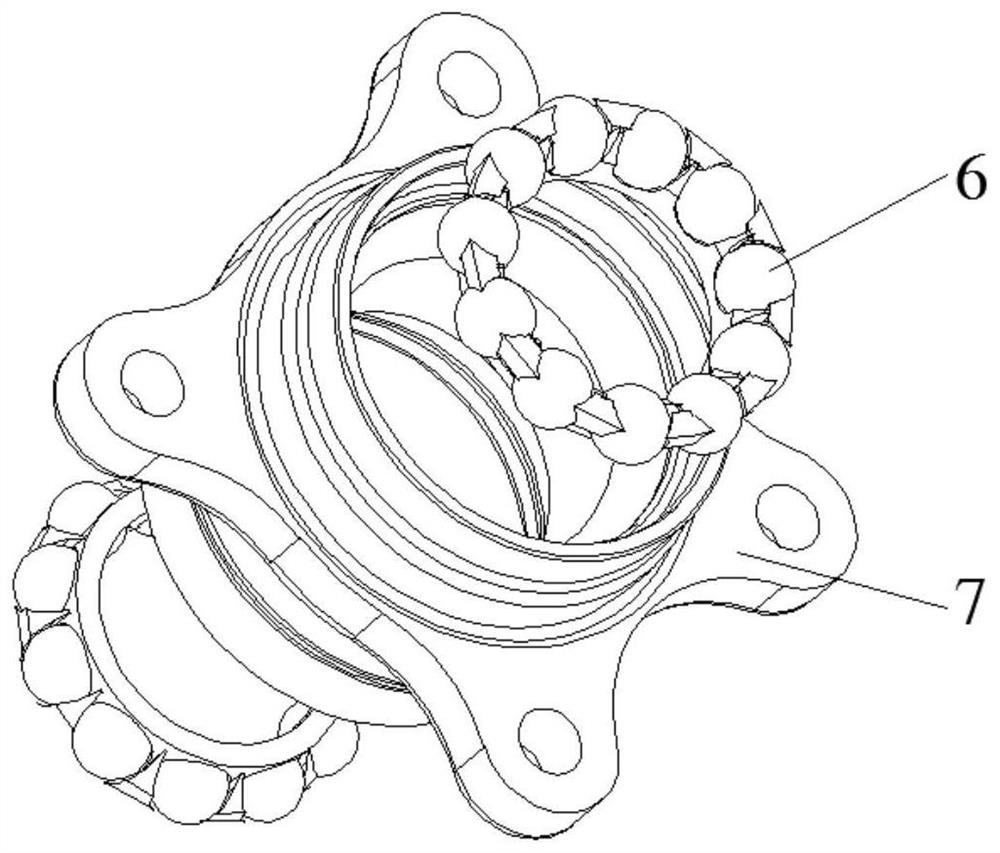

Automatic assembling machine for automobile hub bearing outer ring assembly and assembling method thereof

ActiveCN112324808AEfficient and accurate grippingImprove efficiencyBearing componentsEngineeringStructural engineering

The invention provides an automatic assembling machine for an automobile hub bearing outer ring assembly and an assembling method thereof. The automatic assembling machine comprises a feeding mechanism, an XZ-axis rectangular coordinate robot, an auxiliary assembling table, a workbench and a rack, wherein the executing end of the XZ-axis rectangular coordinate robot is a flat-opening mechanical clamping jaw, and the clamping jaw clamps a hub bearing outer ring and is assembled with two retainers which are placed on the auxiliary assembling table and provided with balls. According to the automatic assembling machine for the automobile hub bearing outer ring assembly and the assembling method thereof, the retainers provided with the balls can be obliquely assembled and squeezed into the automobile hub bearing outer ring under the minimum deformation amount, and assembling is completed.

Owner:DALIAN MARITIME UNIVERSITY

Cartesian coordinate robot

InactiveUS20110132125A1High movement precision and reliabilityProgramme-controlled manipulatorMechanical apparatusEngineeringCartesian coordinate robot

A Cartesian coordinate robot includes a first transmission mechanism slidably connected to a second transmission mechanism, a third transmission mechanism slidably connected to the second transmission mechanism. The first transmission mechanism includes a first guide rail, a first slider slidably connected to the first guide rail, and a first driving module driving the first slider. The second transmission mechanism includes a second guide rail perpendicular to the first guide rail, a second slider slidably connected to the second guide rail, and a second driving module driving the second slider. The third transmission mechanism includes a third guide rail perpendicular to the first guide rail and the second rail, a third slider slidably connected to the third guide rail, and a third driving module driving the third slider.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Long-stroke heavy-load high-precision multi-angle truss hybrid robot

PendingCN111438679AReduce manufacturing costLow running costProgramme-controlled manipulatorJointsRectangular coordinatesCartesian coordinate robot

The invention discloses a truss hybrid robot which comprises a truss base, three rectangular coordinate joints, namely an X shaft, a Y shaft and a Z shaft, and rotary joints A, B and C. The base is supported by two stand columns; the X shaft is a main cross beam and transversely erected on the stand columns; the Y shaft is perpendicularly transversely erected on the X shaft; the Z shaft is overlaid at the tail end of the Y shaft; the X shaft, the Y shaft and the Z shaft are all transmitted by a high-precision linear guide rail, a servo motor and a planetary gear, and three degrees of freedom of translation are achieved; the rotary joints A, B and C are arranged at the tail end of the Z shaft to realize three degrees of freedom of rotation; and each rotary joint is composed of a servo motor, a precision speed reducer, a shaft body and accessories. The truss hybrid robot overcomes the technical defects of a joint robot and a rectangular coordinate robot as a single robot, has the comprehensive parameters similar to or exceeding those of world mainstream robots, is high in reliability, good in universality and low in manufacturing cost, and is suitable for various occasions such as cross-station automatic transportation, welding, and machine tool feeding and discharging.

Owner:中创智造(苏州)智能装备科技有限公司

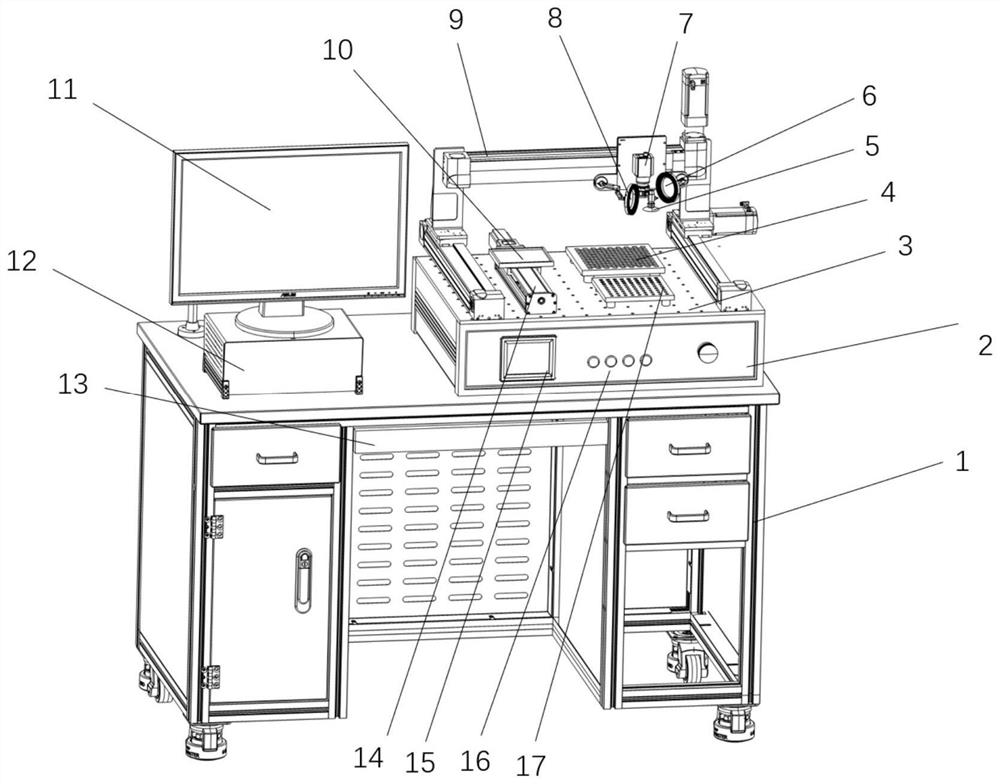

Teaching innovation platform for machine vision

InactiveCN112156992AImplement control learningCosmonautic condition simulationsSortingControl setImage manipulation

The invention relates to a teaching innovation platform for machine vision. The teaching and innovation platform for machine vision comprises a rectangular coordinate robot, a vision detection and execution module, a control integrated module, an electric control module, an electric cylinder sliding table, an optical flat panel and a vision calibration grid module, wherein an industrial camera, alight source and a single suction cup, belonging to the vision detection and execution module, are positioned on an end effector of the rectangular coordinate robot; and to-be-detected objects are sequentially conveyed through the electric cylinder sliding table, are photographed by using the industrial camera, are processed and analyzed through machine vision software, and are sorted through execution of the PLC-controlled suction cup. According to the teaching and innovation platform for machine vision disclosed by the invention, by using the application of detection of the machine vision asa core, combined with the technology of the robot, the machine vision equipment integrating teaching with researching, having functions of positioning, calibration, image processing, measurement, identification and development, can be provided.

Owner:天津博诺智创机器人技术有限公司 +2

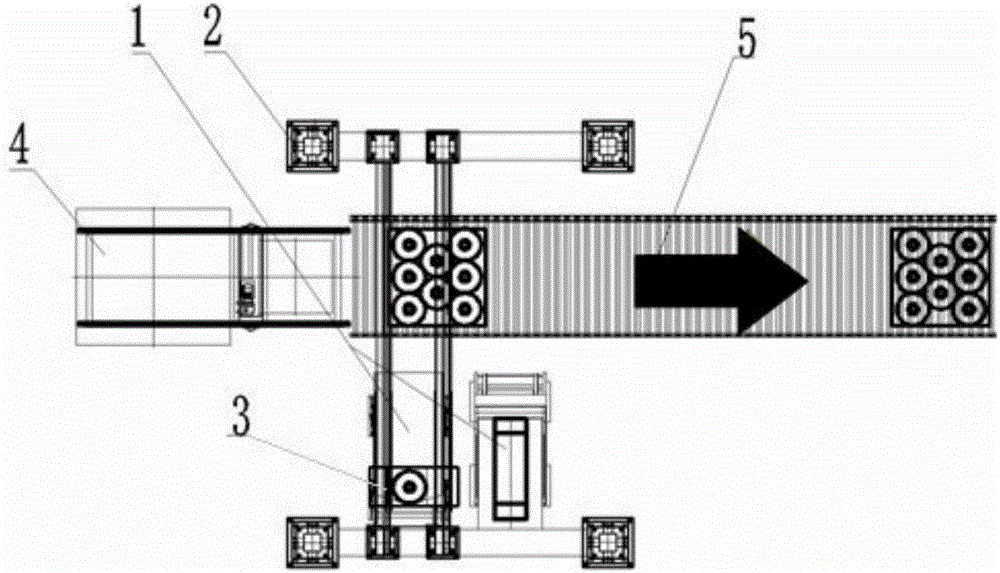

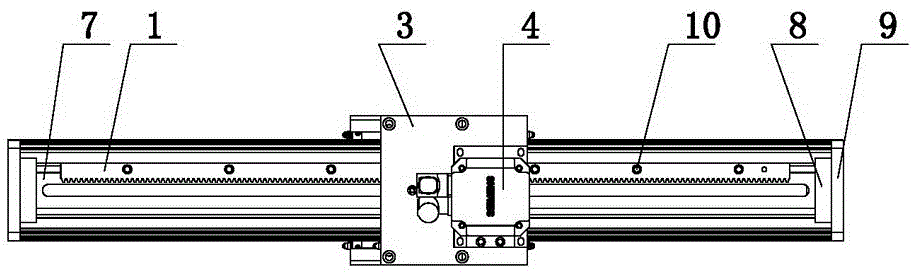

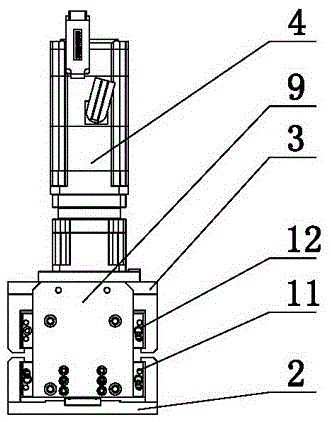

Double-speed retractable positioning system

InactiveCN105772592AAchieve double speed transmissionIncrease productivityMetal-working feeding devicesPositioning devicesCartesian coordinate robotMechanical engineering

The invention belongs to the technical field of Cartesian coordinate robots for automatic feeding and discharging of automobile stamping parts and particularly relates to a double-speed retractable positioning system. The double-speed retractable positioning system is small in occupied space and high in operation efficiency, and comprises a bearing beam. The double-speed retractable positioning system is characterized in that an upper sliding board is arranged on the bearing beam and provided with a drive device; the drive device is engaged with a rack on the bearing beam through a driving gear; a synchronous belt annular mechanism is arranged on the lower portion inside the bearing beam; the upper sliding board is connected with the upper portion of the synchronous belt annular mechanism; the lower portion of the synchronous belt annular mechanism is connected with a lower sliding board; and the bearing beam is 1000 mm long.

Owner:SHENYANG ZHONGTUO ROBOT EQUIP

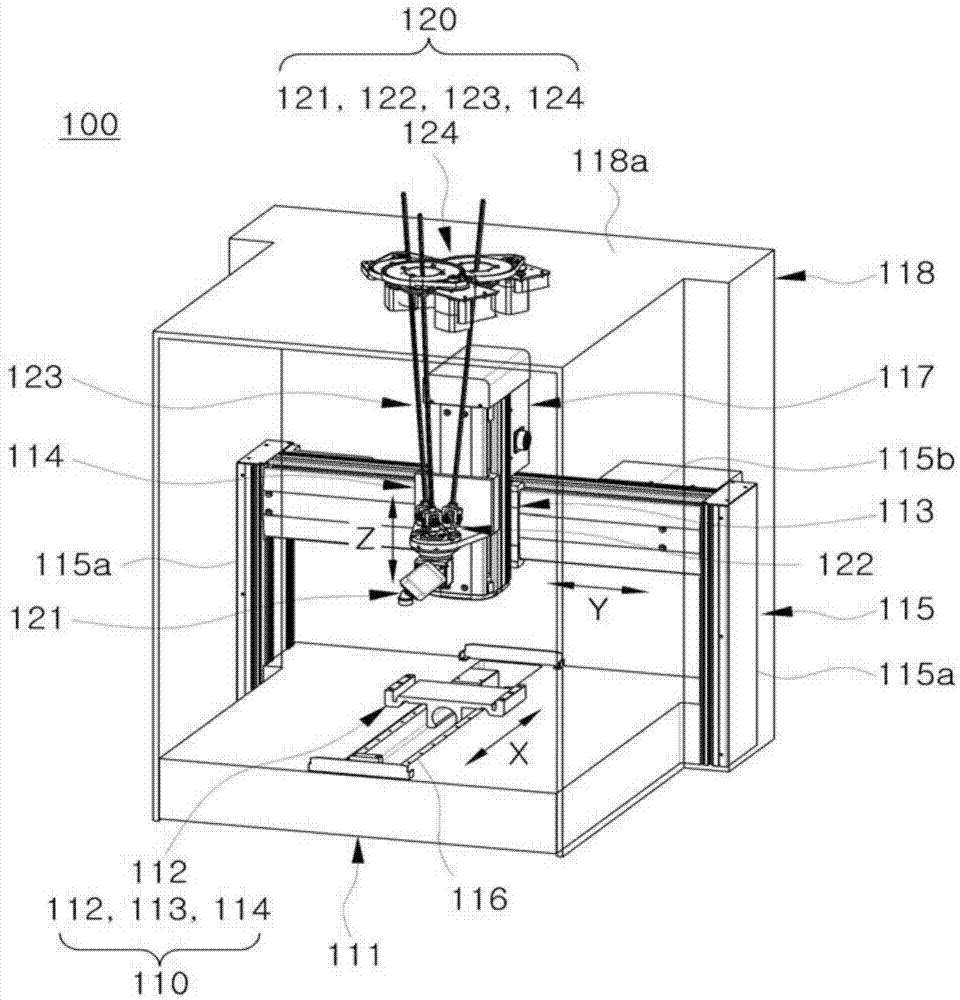

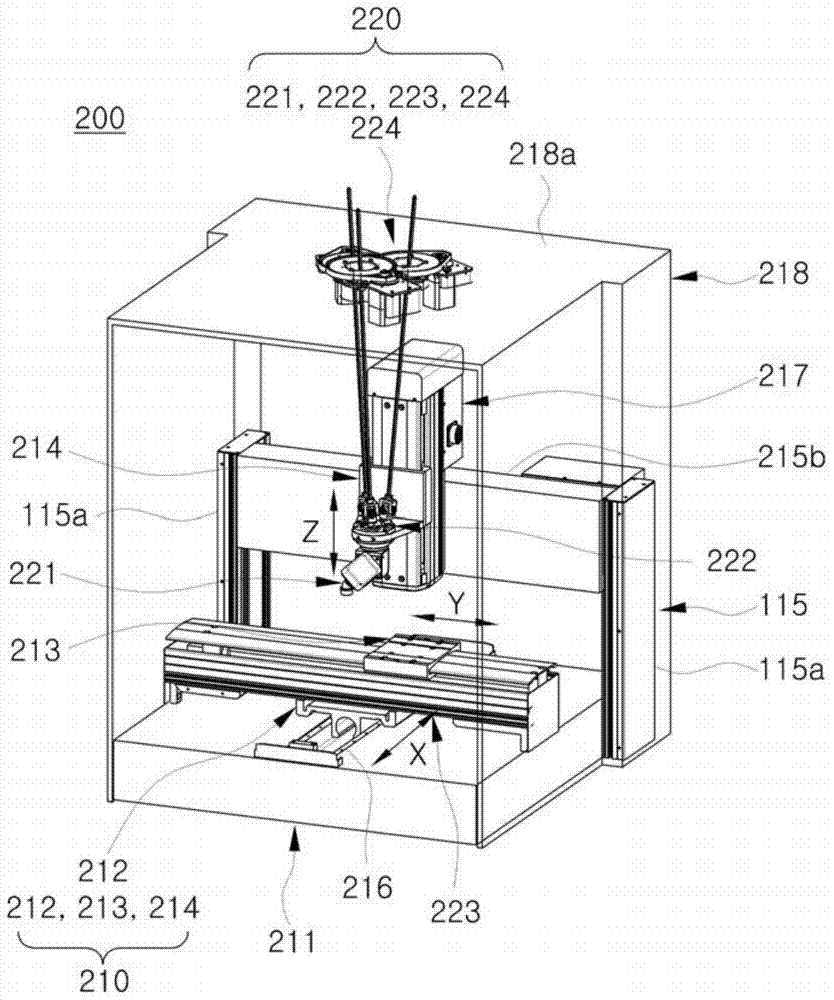

Desktop type cartesian coordinate robot assembled with 3-degree-of-freedom (DOF) wrist device

InactiveCN104842346AAt the same time, the field of work is wideReduce weightProgramme-controlled manipulatorJointsDegrees of freedomCartesian coordinate robot

The present invention relates to a desktop type cartesian coordinate robot assembled with a 3-DOF wrist device. In particular, the tool assembly shaft of the desktop type cartesian coordinate robot is combined with the 3-DOF wrist device to form an industrial robot. The desktop type cartesian coordinate robot assembled with the 3-DOF wrist device comprises a desktop type cartesian coordinate robot capable of conducting the rectilinear movement based on an X-axis drive part, a Y-axis drive part and a Z-axis drive part, wherein the X-axis drive part, the Y-axis drive part and the Z-axis drive part are orthogonal to one another; and a wrist device assembled onto the Z-axis drive part. The wrist device comprises a first rotary member, a second rotary member and a third rotary member, wherein the rotary members are rotated around respectively rotary shafts to realize the 3-DOF movement.

Owner:ROBOSTAR

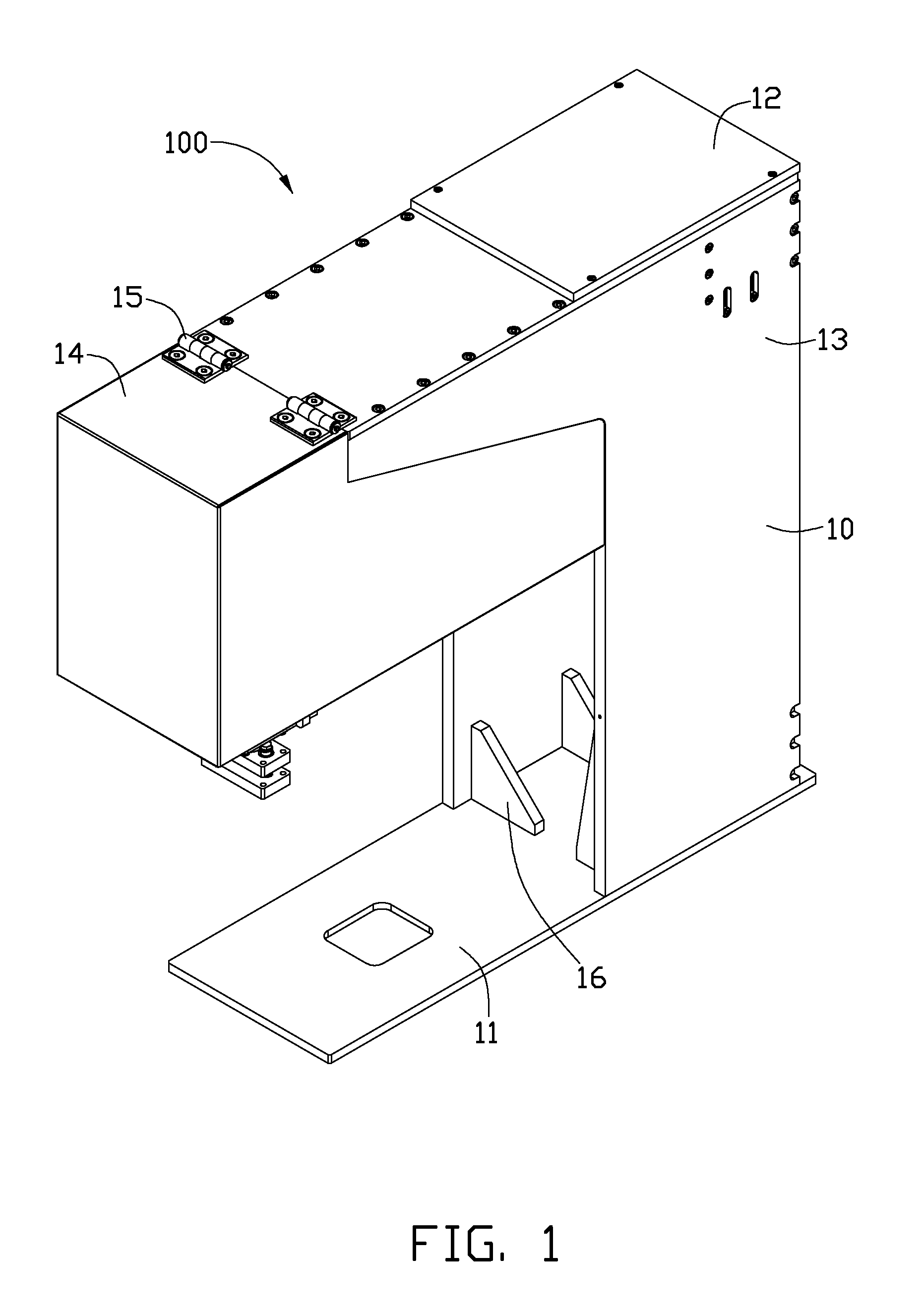

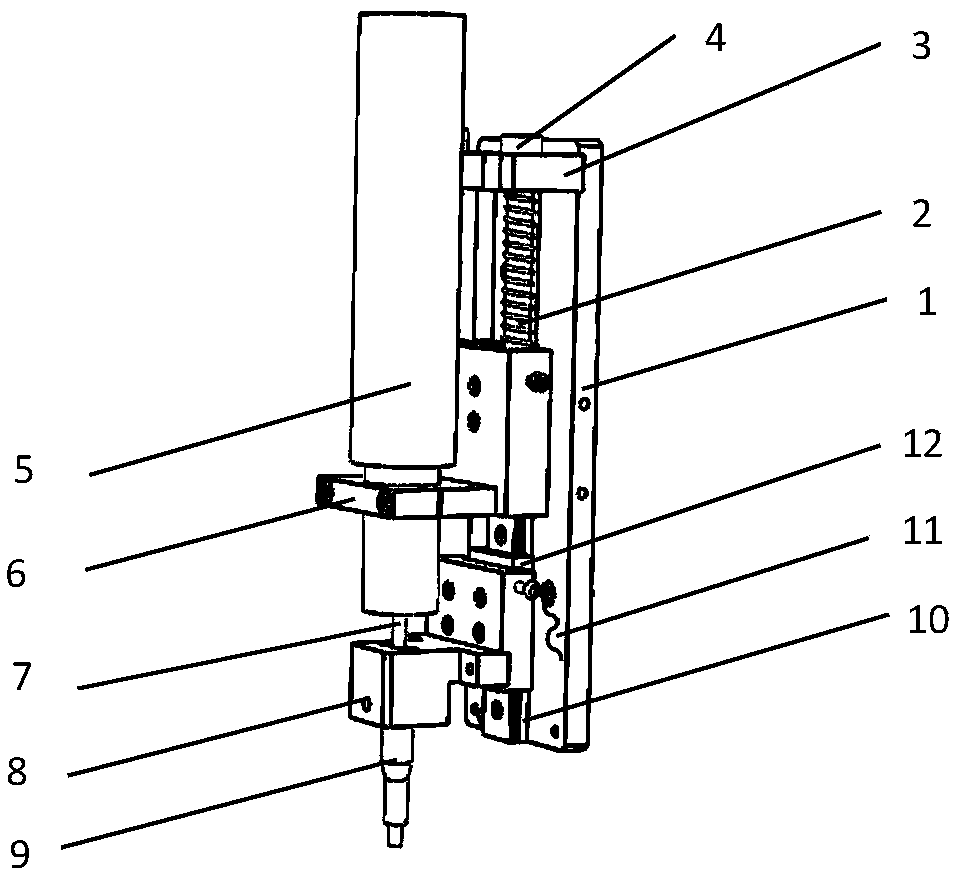

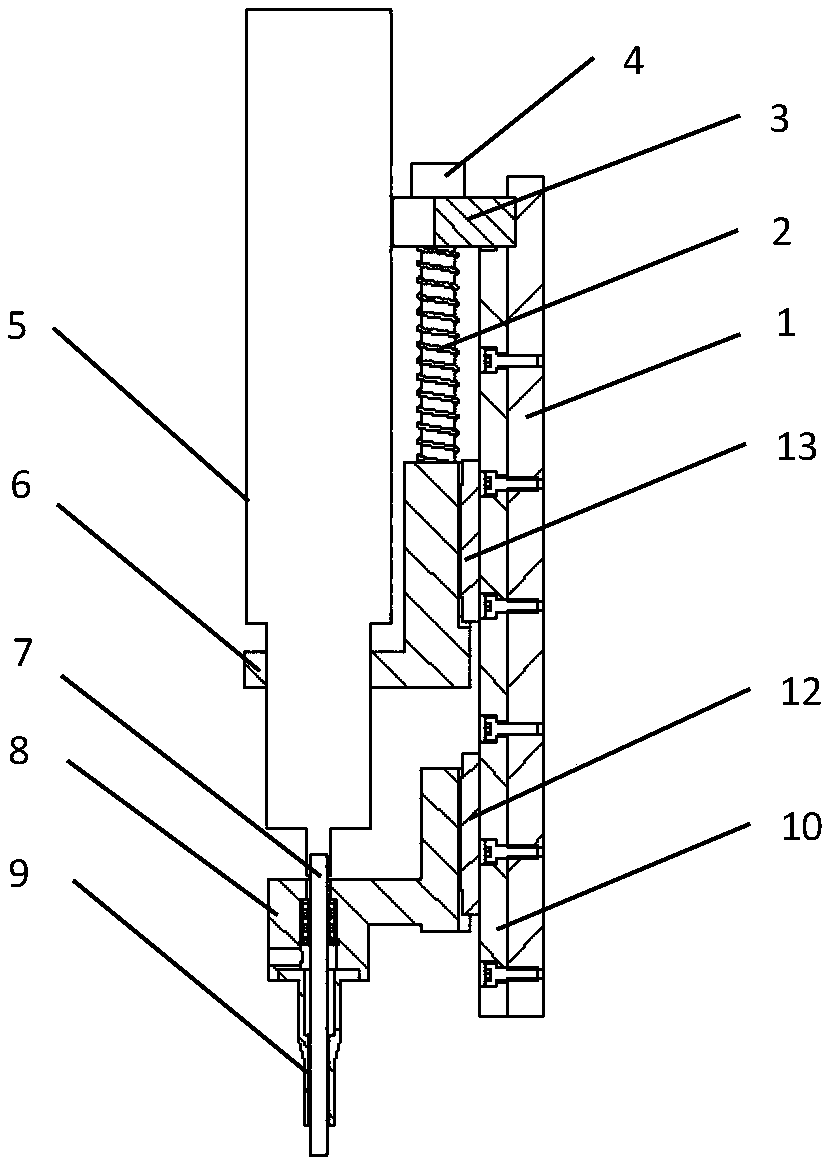

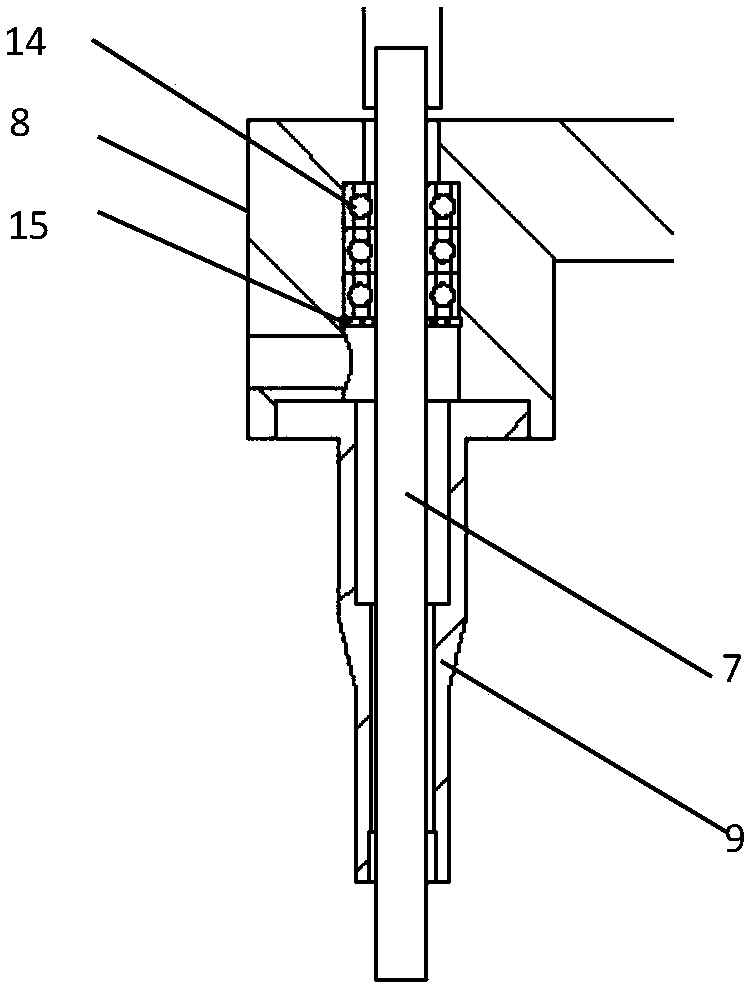

Rectangular coordinate robot screw driving manipulator and rectangular coordinate robot applying same

PendingCN108393682ASimple and reliable initial positioningAccurate screw-in positionMetal working apparatusRectangular coordinatesMechanical equipment

The invention provides a rectangular coordinate robot screw driving manipulator and belongs to the technical field of mechanical equipment. The rectangular coordinate robot screw driving manipulator comprises an output end and a linear sliding rail. An electric screwdriver jig is fixed to the output end and comprises a bottom plate, an electric screwdriver clamping seat and a suction nozzle mounting seat, the linear sliding rail is vertically mounted on the bottom plate, and a first sliding block and the linear sliding rail are matched for using. The electric screwdriver clamping seat is fixedto the first sliding block and used for clamping an electric screwdriver, the two ends of a first spring make contact with the bottom plate and the electric screwdriver clamping seat correspondingly,and a second sliding rail is matched with the linear sliding rail for using. The second sliding rail can slide along the linear sliding rail, a second sliding block is connected with one end of the asecond spring, and the other end of the second spring is fixed to the bottom plate. The suction nozzle mounting seat is fixed to the second sliding block, a suction nozzle is mounted at the bottom ofthe suction nozzle mounting seat, and an air pipe hole is formed in the suction nozzle mounting seat. One end of an air pipe is fixed into the air pipe hole, and the other end of the air pipe is connected with an air pump through an electromagnetic valve. According to the screw driving manipulator, stress during screw driving of the electric screwdriver can be improved.

Owner:ANHUI HISEED ROBOT CO LTD

Location system for ball screw

A ball screw positioning system belongs to the technical field of Cartesian coordinate robots for automatic loading and unloading of automobile stamping parts, and in particular relates to a ball screw positioning system. The invention provides a positioning system which occupies less space and has high working efficiency, in which a lead screw drives a sliding block to move in opposite directions. The present invention includes a load-bearing beam, characterized in that: a ball screw is arranged inside the load-bearing beam, and the two ends of the ball screw are configured as positive and negative thread structures; the two ends of the ball screw are provided with connecting slide plates through screw nuts.

Owner:SHENYANG ZHONGTUO ROBOT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com