Location system for ball screw

A ball screw, positioning system technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of slow screw running speed, difficult to meet modern production, low work efficiency, etc., to achieve high precision, Perfect balance of practicality and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

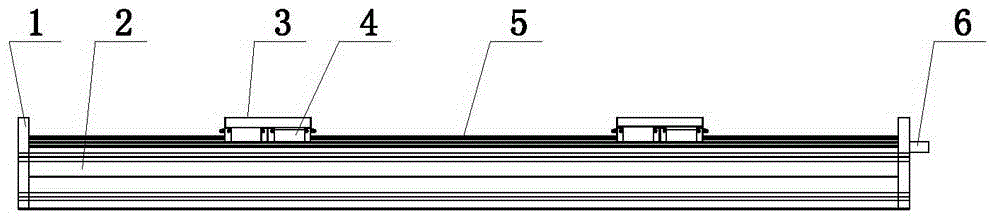

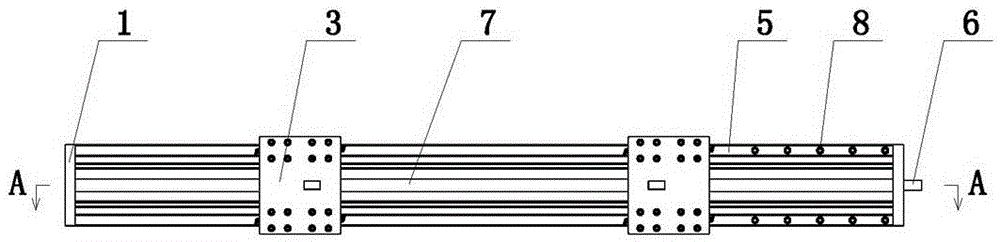

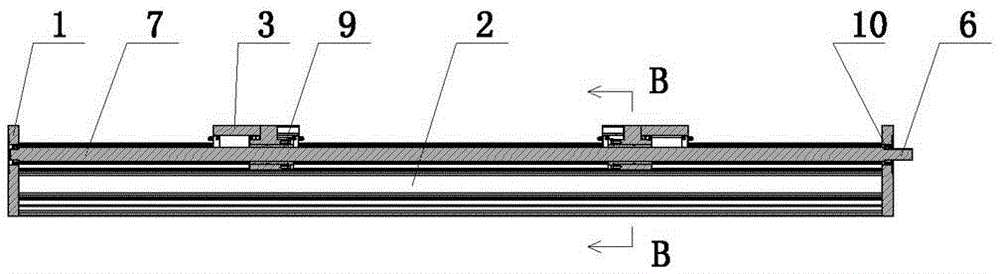

[0015] The present invention includes a load-bearing beam 2, which is characterized in that: a ball screw 7 is arranged inside the load-bearing beam 2, and the two ends of the ball screw 7 are arranged as positive and negative thread structures; A connecting slide 3 is provided.

[0016] As a preferred solution of the present invention, guide rails 5 are provided on both sides of the upper surface of the profile, and sliders 4 that cooperate with the guide rails 5 are provided on the connecting slide 3 .

[0017] Both sides of the upper surface of the load beam 2 are provided with T-shaped grooves 13, and the guide rail 5 is fixed on both sides of the upper surface of the profile through connecting bolts 8 and T-shaped grooves 13, and the upper surface of the load-bearing beam 2 is located between the two T-shaped grooves 13 Screw installation slots 14 are provided, and end plates 1 are provided at both ends of the load beam 2, and support bearings 10 that cooperate with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com