System for mixed flow spraying, cooling and lubricating

A technology of cooling lubrication and mixed spraying, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems that the actual effect of cutting fluid is not necessarily ideal, occupies a large production site, and environmental pollution, etc., and achieves saving The effect of tool change time, saving of production space, and extension of tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

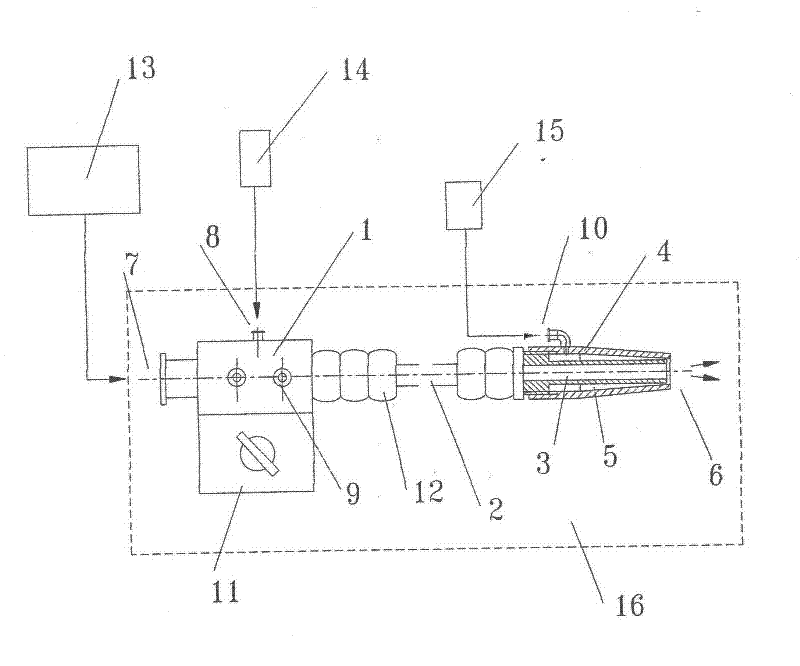

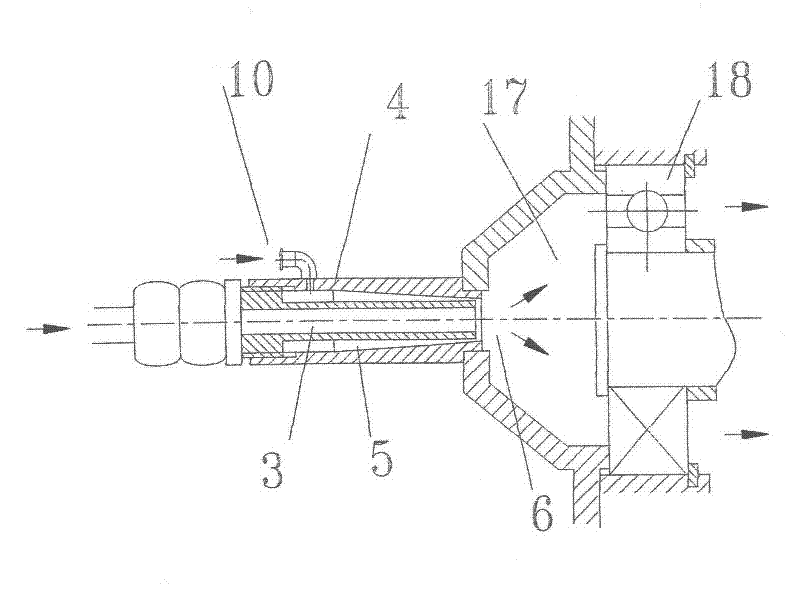

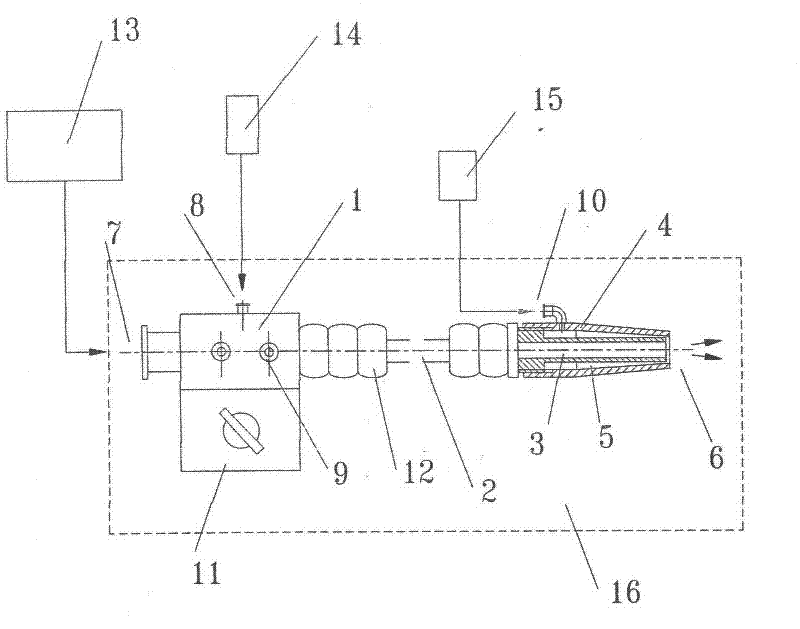

[0021] Below, the present invention is described in further detail in conjunction with accompanying drawing:

[0022] attached figure 1 Among them, the oil-gas mixed flow regulator 1 is a component that can mix a large amount of gas with a small amount of lubricating oil, and it can inject an appropriate amount of lubricating oil into the pressure gas source (the injection volume of oil is usually within 10-100 ml / hour), The amount can be adjusted freely through the oil quantity regulating valve 9, and its function is to make the gas rich in an appropriate amount of lubricating oil components and enter the oil-gas mixed flow channel 2. The oil-gas mixed flow channel 2 is connected with the nozzle 3 of the oil-gas mixed flow channel. On the outer wall of the nozzle 3 of the oil-gas mixed flow channel, an outer spray cover 4 is arranged; the gap between the inner wall of the outer spray cover 4 and the outer wall of the oil-gas mixed flow channel nozzle 3 is a water-based liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com