Multifunctional intelligent clamping jaw and joint robot

A multi-functional and intelligent technology, applied in the direction of chuck, manipulator, program control manipulator, etc., can solve the problems of poor adaptability, high production cost, complex structure, etc., and achieve the effect of adaptability, low production cost, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

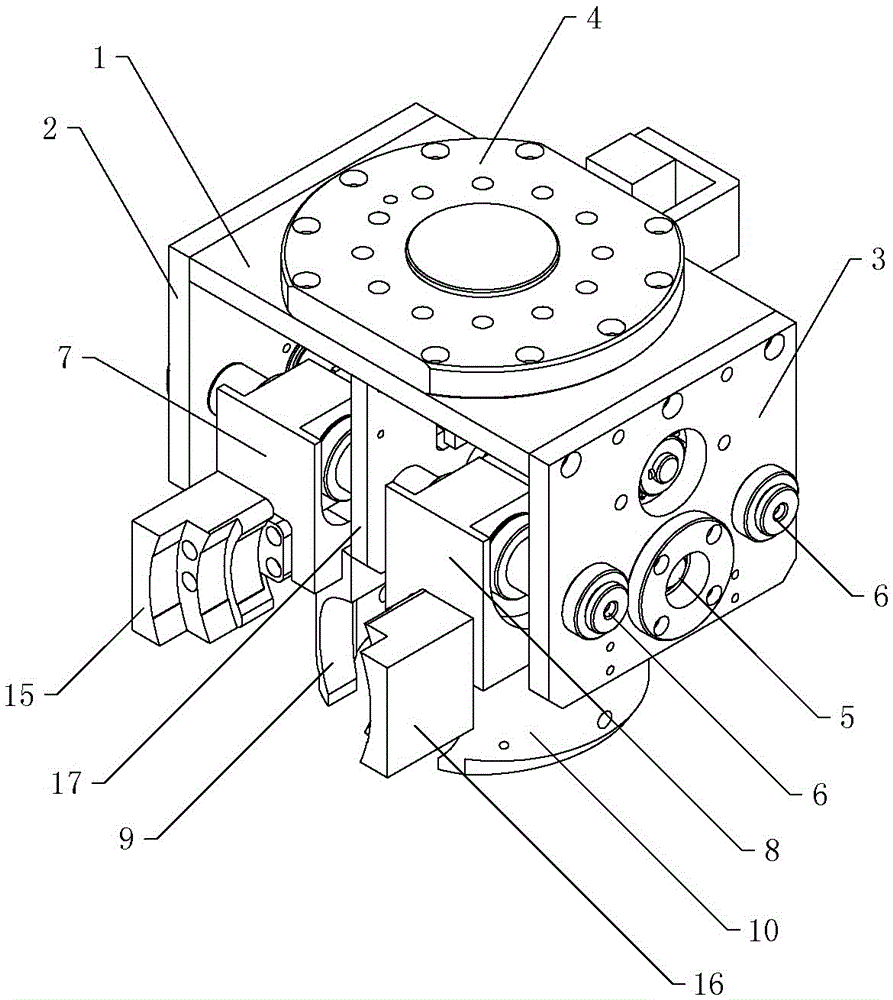

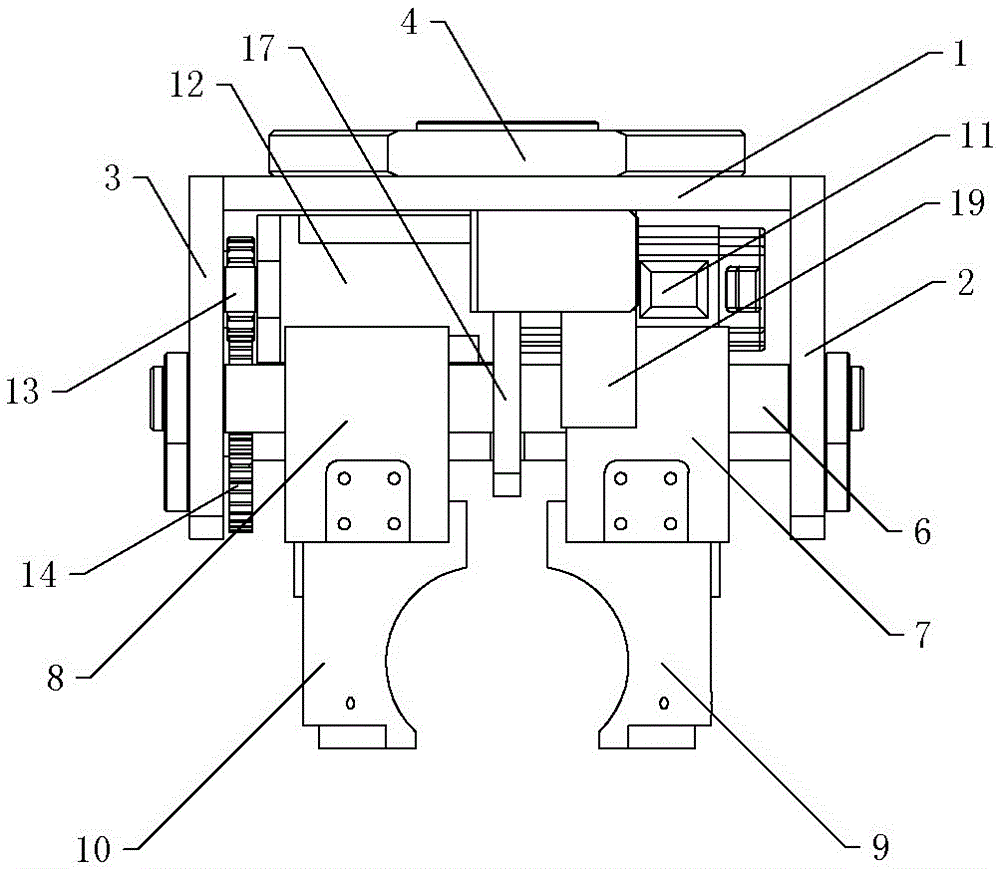

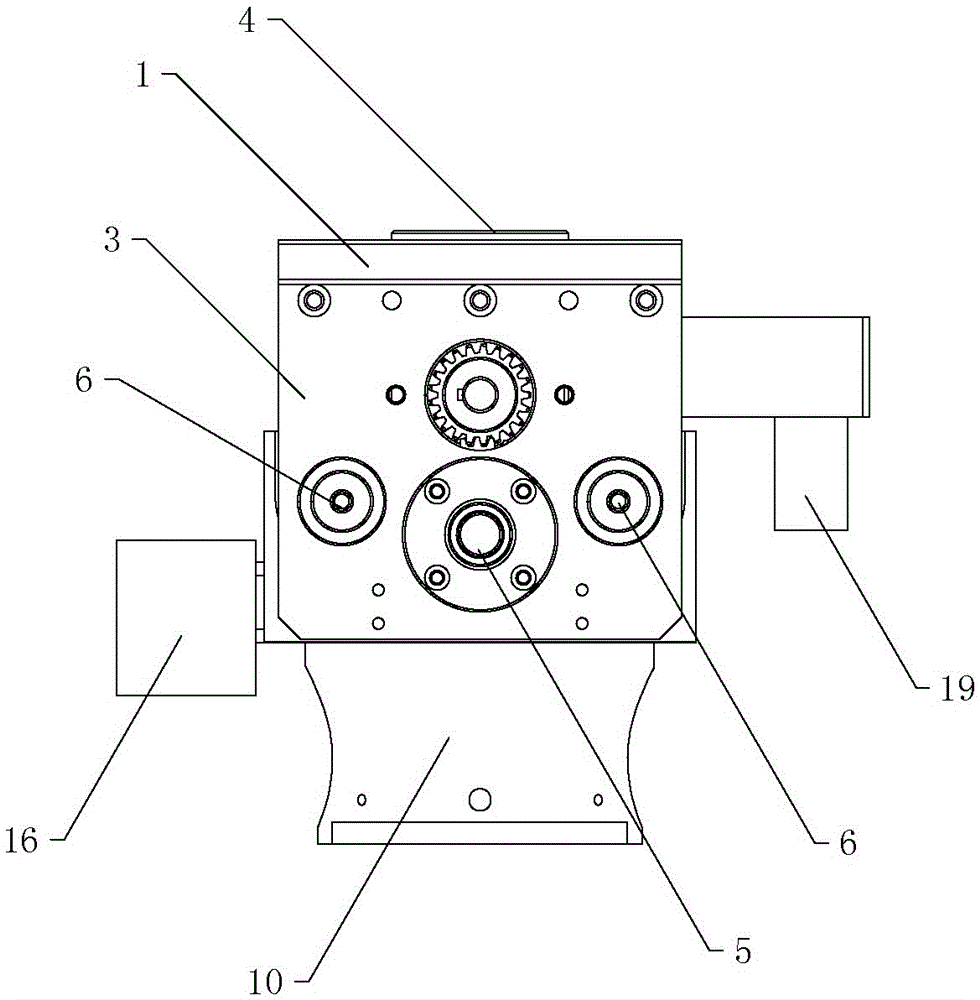

[0059] One of the implementations of the multifunctional smart jaw of the present invention, such as Figure 1~5 Said, wherein: including a bracket, a driving motor, a transmission device and a clamping block; the bracket is provided with an upper fixing plate, a first side plate and a second side plate, and the upper part of the first side plate and the upper part of the second side plate are fixed on top The two sides of the plate are respectively fixedly connected with the upper fixed plate to form a gantry structure; the transmission device is provided with a lead screw, a first lead screw nut, a second lead screw nut, a first guide post slider, and a second guide post slider And the guide post, the lead screw is provided with reverse threads separated on both sides of the axial direction, the first lead screw nut and the second lead screw nut are respectively screwed with the lead screw through the reverse threads on both sides of the lead screw, and the two ends of the le...

Embodiment 2

[0069] One of the implementations of the multifunctional smart jaw of the present invention, such as Figure 1~5 As shown, the main technical solution of this embodiment 2 is basically the same as that of embodiment 1, and the features not explained in this embodiment 2 are explained in embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the clamping block is provided with a first bearing block and a second bearing block, and the first bearing block is fixedly arranged on the first slider and is located in the first clamping block. The side adjacent to or apart from the block corresponds to the second holding block fixedly arranged on the second sliding block and located on the side adjacent to or apart from the second clamping block.

[0070] Specifically, the first bearing block and the second bearing block are provided with stepped arc-shaped steps.

[0071] By setting stepped arc steps, workpieces with different dia...

Embodiment 3

[0073] One of the implementations of the multifunctional smart jaw of the present invention, such as Figure 1~5 As shown, the main technical scheme of this embodiment 3 is basically the same as that of embodiment 1 or embodiment 2, and the features that are not explained in this embodiment 3 adopt the explanations in embodiment 1 or embodiment 2, and are not repeated here to repeat. The difference between this embodiment and Embodiment 1 or Embodiment 2 is that: the bracket is also provided with a middle partition, the middle partition is arranged in parallel with the first side board and the second side board, and is fixedly connected with the upper fixing board to form a The "E" shape of the space, the screw and the guide post all pass through the middle partition. The mechanical structure of the multifunctional intelligent gripper in this embodiment can be made more stable by setting the middle partition, and it is also convenient to install the driving motor and the redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com