Metal material decorative board and its preparing method

A technology of metal materials and decorative panels, applied in the field of metal panels, can solve problems such as high production costs, polluting the environment, and monotonous decorative patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

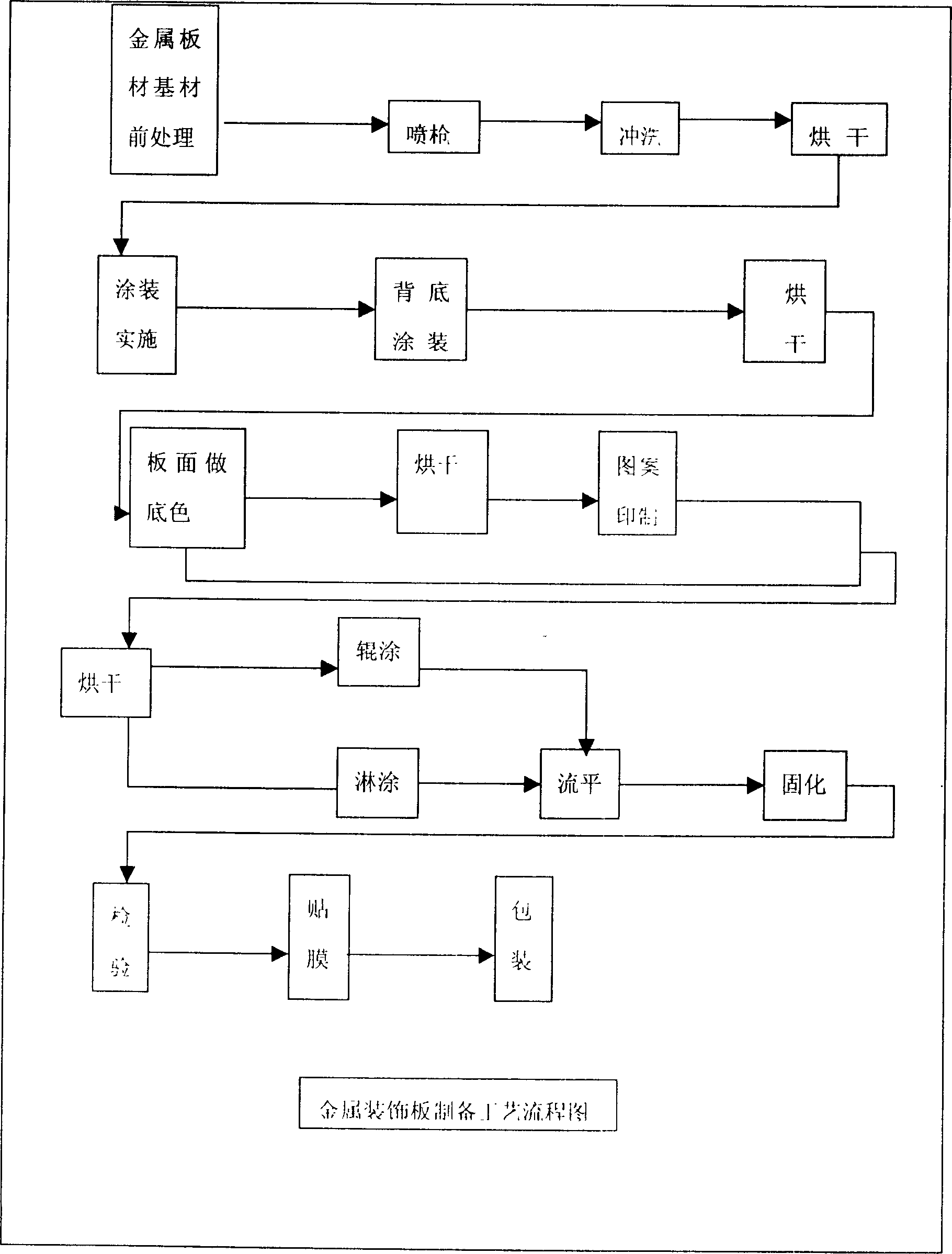

Method used

Image

Examples

Embodiment 1

[0090] The test method used in the embodiment of the present invention (see the table below)

[0091] Test items

specification

Remark

Coating thickness

GB1764-79(89)

Dry Film ASTM Pen D14002-87

pencil hardness

GB / T6739-1996

Mitsubishi UNI hardness 2H pen (NCAA11-12)

Curvature

GB1731-79

(NCAA11-19)

Adhesion

GB / T9286-1998

1mm×1mm grid test (NCAA11-5)

Impact resistance

GB1732-88

500gm×50cm×1 / 2inchO

Boiling water resistance

GB / T9274-1988

Immersion in 102℃ boiling water for 24 hours

Solvent resistance

GB / T9274-1988

MEK and solvent reciprocating wipe more than 70 times

GB / T9274-1988

10% sulfuric acid H2SO4 impregnation for 7 days

Alkali resistance

GB / T9274-1988

10% sulfuric acid NAOH.HCL impregnated for 7 days

GB1865-80(89)

1000 hours accelerated weather resistance, QUV

[009...

Embodiment 2

[0095] Embodiment 2: Preparation of aluminum material, tin iron sheet material, tinplate material galvanized sheet decorative plate

[0096] Substrate: High temperature degreased aluminum plate, thickness 0.48mm, width 70cm, length 70cm

[0097] Tin iron plate thickness 0.30mm width 35cm length 35cm

[0098] Tinplate thickness 0.15mm width 18cm length 40cm

[0099] Galvanized sheet thickness 0.52mm width 38cm length 60cm

[0100] Roll coat the back of the metal plate with perchlorethylene ionic anti-rust coating evenly with a coating thickness of 6um (dry film), bake at 80°C for 15 minutes, and roll coat the metal plate with polyurethane aluminum powder flash coating on the roll coater Surface layer, coating thickness 8um (dry film), bake at 130°C for 15 minutes. Then pour the photocurable resin on the flow coater, the temperature of the feeding tank of the flow coater is 55°C, the transmission speed is 16 m / min, and the thickness of the photocurable resin...

Embodiment 3

[0101] Embodiment 3: the preparation of steel decorative plate

[0102] Base material: thin steel plate thickness 0.25mm width 50cm length 50cm

[0103] 90% degreaser aqueous solution, spray gun with a pressure of 0.7kg evenly on the surface of the steel plate, stay for 3 minutes, rinse with 80°C hot water for 1 minute, then rinse with cold water (normal temperature) for 2 minutes, and dry at 80°C. Use 95% phosphating solution, spray gun with a pressure of 0.8kg to evenly spray on the surface of the board, and bake at 90°C for 10 minutes. Use a silver-gray polyester paint roller to coat the surface layer, the coating thickness is 8um, bake at 150°C for 20 minutes, and then pour light-curing resin on the flow coater. The thickness of the light-cured resin on the silver-gray surface of the steel plate is 56um. Leveling under infrared rays at a temperature of 55°C for 3 minutes, entering a light curing machine equipped with 3 5kw ultraviolet lamps and a transmission speed of 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com