Aqueous matt surface finishing agent for PVC (Polyvinyl Chloride) leather and preparation method thereof

A treatment agent and water-based wetting agent technology, applied in the field of surface treatment agents for PVC leather, to achieve good plasticizer resistance, stable performance, and good matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

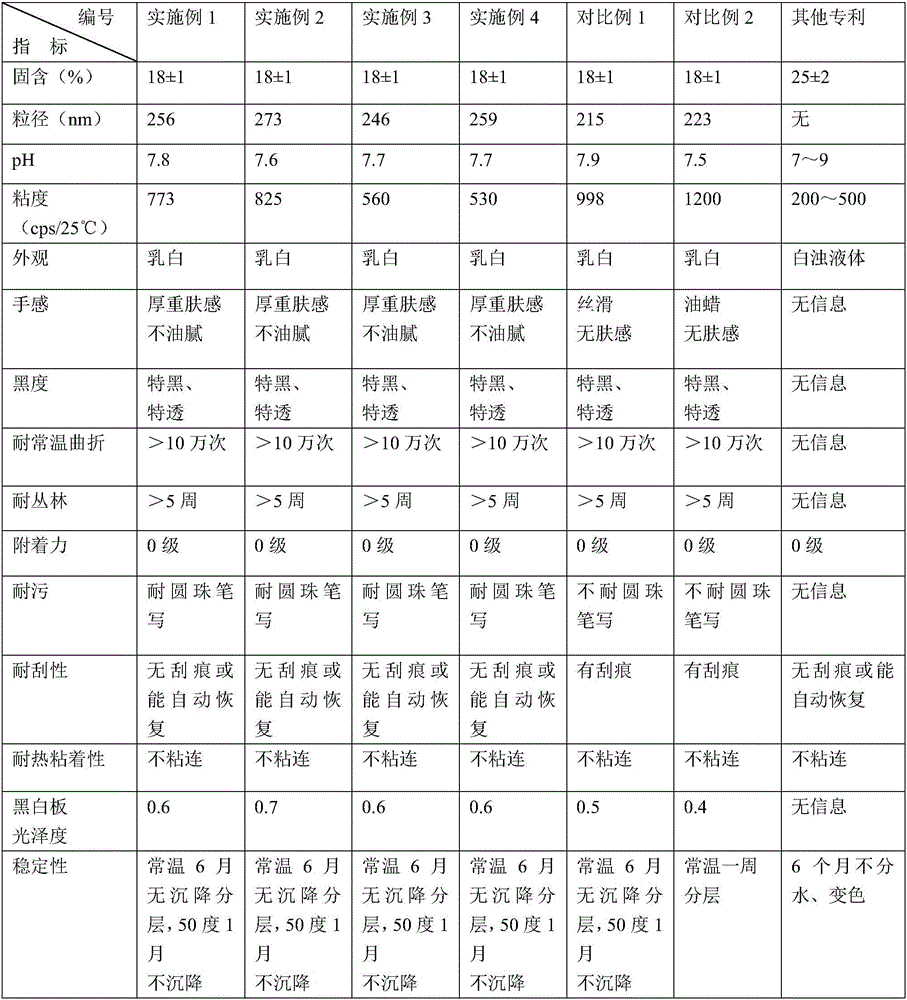

Examples

Embodiment 1

[0057] PVC leather water-based fog surface treatment agent is by IPDI and number-average molecular weight at 2000 polyneopentyl glycol adipate dibasic alcohol synthetic water-based polyurethane resin 31 weight parts, water 44 weight parts, silica matting powder ( ACEMATT 3300) 3.5 parts by weight, polysiloxane aqueous dispersion (Silok 9184) 3.9 parts by weight, water-based wax emulsion (Michem 743) 7.5 parts by weight, water-based wetting agent (Tego 245) 0.2 parts by weight, water-based defoamer ( BYK 024) 0.3 parts by weight and thickener (Vesmody A801) 0.6 parts by weight.

[0058] The preparation method of the above-mentioned water-based matte treatment agent for PVC leather is: 31 parts by weight of water-based polyurethane resin, 3.5 parts by weight of silica matting powder, 0.2 parts by weight of water-based wetting agent, 0.3 parts by weight of water-based defoamer and 44 parts by weight of Mix with water and stir for 1 hour; filter the resulting mixture; finally, add...

Embodiment 2

[0061] Water-based matte treatment agent for PVC leather by H 12 The mass ratio of MDI and HDI is 1: 1 and the aqueous polyurethane resin 35 weight parts that water-based polyurethane resin synthesized by the polycaprolactone diol of number average molecular weight 1000, water 49 weight parts, silica matting powder (ACEMATT TS100) 4.5 weight 4.7 parts by weight of aqueous polysiloxane dispersion (Silok 50), 8.5 parts by weight of aqueous wax emulsion (Michem 270R), 0.4 parts by weight of water-based wetting agent (BYK 346), 0.5 parts by weight of water-based defoamer (Carlant 743) and thickener (Vesmody A 401) 0.5 parts by weight.

[0062] The preparation method of the above-mentioned PVC leather water-based fog surface treatment agent is: 35 parts by weight of water-based polyurethane resin, 4.5 parts by weight of silica matting powder, 0.4 parts by weight of water-based wetting agent, 0.5 parts by weight of water-based defoamer and 49 parts by weight Mix with water and stir...

Embodiment 3

[0065] Water-based matte treatment agent for PVC leather by H 12 Water-based polyurethane resin synthesized by MDI and polyhexamethylene adipate and neopentyl glycol random copolyester diol with a number average molecular weight of 3000 (wherein the mass ratio of hexylene glycol and neopentyl glycol is 3:7) 33 parts by weight, 45 parts by weight of water, 4 parts by weight of silica matting powder (ACEMATT OK520), 4 parts by weight of polysiloxane aqueous dispersion (Silok 9146), 8 parts by weight of water-based wax emulsion (Michem156HS), water-based wetting 0.35 parts by weight of agent (LCN 407), 0.25 parts by weight of water-based defoamer (Tego 815N) and 0.5 parts by weight of thickener (NAT ROSOL 250HBR).

[0066] The preparation method of the above-mentioned PVC leather water-based fog surface treatment agent is: 33 parts by weight of water-based polyurethane resin, 4 parts by weight of silica matting powder, 0.35 parts by weight of water-based wetting agent, 0.25 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com